PORTAMATIC 421 User guide

PORTA

PORTA----NAI LS, I NC

PORTAPORTA

NAILS, INC....

NAILS, INCNAILS, INC

!!!!

!!!!

PO BOX

PO BO X 1257

PO BOXPO BOX

1257

1257 1257

HOM E PAGE:

HOME PAGE: www.p o r ta

HOM E PAGE: HOM E PAGE:

WILMINGTON, NC 28402

WILMINGTON, NC 28402

WILMINGTON, NC 28402 WILMINGTON, NC 28402

www.porta----nails.com

www.portawww.porta

nails.com E

nails.comnails.com

!!!!

910

910----762

762----6334

910910

762762

E----MAIL: info@porta

MAIL: info@porta----nails.com

E E

MAIL: info@portaMAIL: info@porta

6334

63346334

!!!!

800

800----634

800800

nails.com

nails.comnails.com

634----9281

9281

634634

92819281

!!!!

FAX 910

FAX 910----763

FAX 910FAX 910

763----8650

763763

OWNER’S MANUAL

®

PORTAMATIC

Pneumatic Nailer

For Tongue and Groove Solid Wood & Hardwood Laminate

8650

86508650

Flooring, Roof Decking and Wood Sub Flooring

CAUTION - Read important safety instructions AND operation instructions BEFORE operating

your PORTAMATIC® Pneumatic Nailer.

Your new

performance throughout its lifetime. To take full advantage of these capabilities you should thoroughly

understand the proper method and technique of its operation. Therefore, we suggest you read this manual

before operating and that you save it for future reference.

PORT AMATIC

®

Pneumatic Nailer

is a quality-built machine, capable of dependable

FORM P/N 750048 (6/1/2002)

ETL Listed:

US Patent Numbers:

Fastener Type:

Operating Pressure:

Firing Mode:

Jam Clearance:

Dimensions:

Weight:

Use only

90 P.S.I.

Hammer Actuated

Hinged Lever Type, Quick Release Gate

19” High x 20” Long x 3” Wide

Approximately 13 LBS.

PORTAMATIC

CAT. NO. 421

SPECIFICATIONS

Control Number 9801577

6,095,392 & D419,048

*

*

Porta-Nails

Porta-Nails

(See Operating Instructions Pg. 7)

Must Be Purchased Separately

®

(See Clearing a Jam Pg. 9)

PNI’s LIMITED TWO YEAR WARRANTY

PNI is proud of the products that it manufactures and warrants them to be free from

defects in materials and workmanship for 2 years. In the unlikely event that a problem

occurs, return the product to our plant freight prepaid and allowed, so that a

determination of the fault can be made. If the fault is determined to be defective

materials or workmanship, a no-charge replacement or repair will be made, at our

discretion. The product will be returned to you freight prepaid and allowed. This

warranty does not cover accidents, abuse or misuse and in no case will PNI be liable for

incidental or consequential damages. No other warranty written or verbal is authorized.

Returns for warranty service should be sent to:

Porta-Nails, Inc.

4235 US Hwy. 421 N.

Currie, NC 28435

2

Safety Instructions

1. KNOW YOUR POWER TOOL

Read the owner's manual carefully. Learn its

applications and limitations as well as the potential

hazards specific to this tool.

2. THE OPERATOR AND ALL OTHER

PERSONNEL MUST WEAR PROPER EYE AND

EAR PROTECTION IN THE WORK AREA.

Wear safety goggles at all times. (Must comply with

ANSI Z87.1). Everyday eyeglasses have impact

resistant lenses only. They are NOT safety glasses.

Also, wear ear protectors (plugs or muffs) during

extended periods of operation

3. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to sawdust.

4. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

5. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) that could get caught in

moving parts. Wear non-slip footwear. Wear

protective hair covering to contain long hair. Roll

long sleeves above the elbow.

6. SECURE WORK

Be sure the tongue and groove of the flooring strips

are properly interlocked and secured in place before

nailing.

7. STAY ALERT

Watch what you are doing. Use common sense. Do

not operate tool when you are tired or while under the

influence of medication, alcohol or drugs.

8. ALWAYS INSPECT TOOL BEFORE

OPERATING.

Tool must be inspected prior to use to insure proper

use of power supply. Tool must be inspected to insure

proper working order. An improperly functioning tool

must not be used

9. KEEP HANDS, FEET AND OTHER BODY

PARTS AWAY FROM NAIL EJECTION AREA.

Serious injury could occur if body parts are not kept

away from nail ejection area.

10. ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS.

Do not activate the tool unless the tool is placed firmly

against the work piece.

11. NO HORSEPLAY.

Do not point the tool toward yourself or anyone

whether it contains fasteners or not.

12. NEVER TRANSPORT TOOL WHILE

DEPRESSING THE TRIGGER.

13. DISCONNECT TOOL FROM AIR SUPPLY

WHEN:

Moving the tool to a new location, performing any

maintenance or repair, clearing a jam or tool is

unattended.

14. NEVER SERVICE WHILE ATTACHED TO AIR

SUPPLY.

Always disconnect the tool from the power source

when servicing, or replacing parts.

15. DO NOT USE TOOL IF OPERATING

CONTROLS ARE INOPERABLE.

Do not remove, tamper with, or otherwise cause the

tool operating controls or safety controls to become

inoperable.

16. DO NOT OPERATE TOOL IF SAFETY

FEATURES NOT WORKING PROPERLY.

Disconnect tool from power source if safety trigger or

operating controls are not working properly.

17. USE ONLY PORTA-NAIL FASTENERS.

Only use fasteners recommended by the manufacturer.

Use of other fasteners may cause serious injury,

jamming of tool or improper operation.

18. USE ONLY PRESSURE-REGULATED POWER

SOURCE.

Use only a pressure regulated power source set

at 125 psi maximum. The power source must have a

safety relief valve set at 135 psi maximum.

19. THE TOOL SHOULD NOT BE OPERATED AT

THE MAXIMUM AIR PRESSURE.

The tool air-line should be connected to the power

source through an airline pressure Regulator and an

airline Filter. The air line Regulator should never be

set higher than 110 psi as marked on the tool. Lower

pressures may be used as recommended by the

manufacturer.

20. HAZARDOUS POWER SOURCES SHALL NOT

BE USED.

Hazardous power sources including, but not limited

to, Oxygen, Combustible gases, sources whose

pressure can exceed 200 psi if the pressure Regulator

fails, bottled gases, including air should never be used.

3

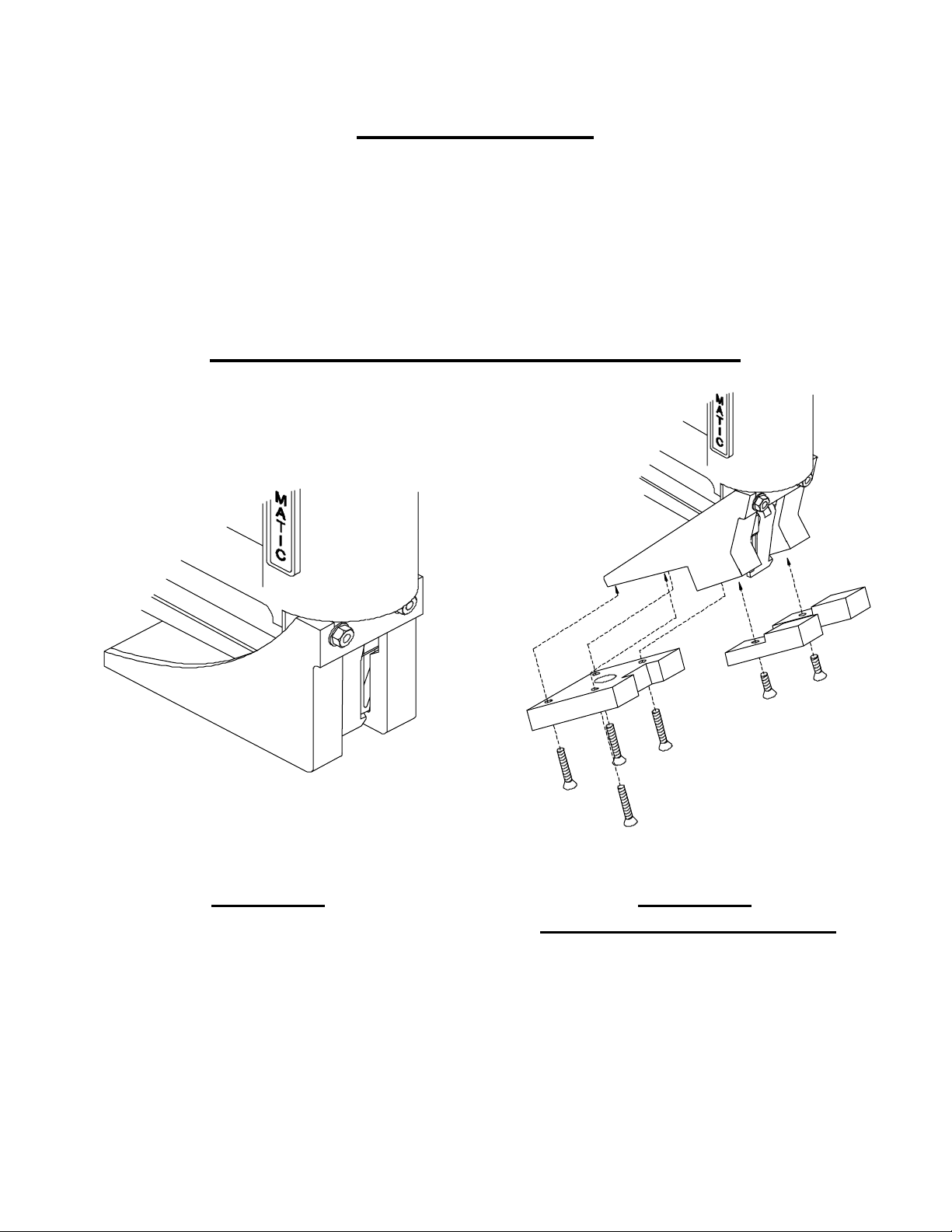

APPLI CATIONS

Your model 421

Nailing 9/16”, 25/32”, and 33/32” Hardwood Tongue and Groove Flooring. (See

Accessory Applications

PORTAMATIC

section)

®

Nailer is designed for Face Nailing and Angle

Shoe

PORTAMATIC

®

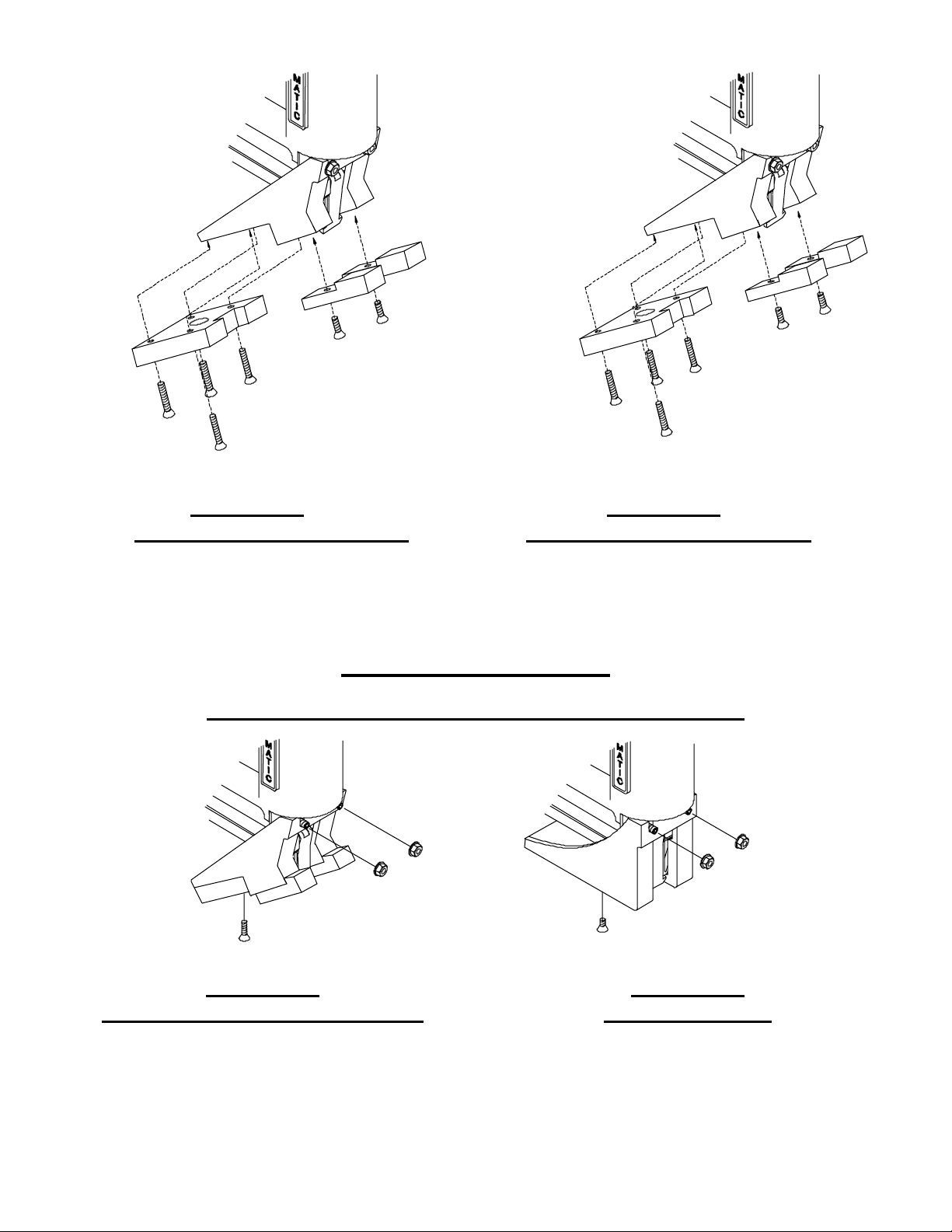

ACCESSORY SHOE APPLICATIONS

FIGURE 1

Face Nailing

Accessory Shoe Cat. No. 50113

FIGURE 2

Tongue Nailing 33/32” Flooring

Shoe P/N 50125

Shoe Base and Pads

Accessory P/N 50250

4

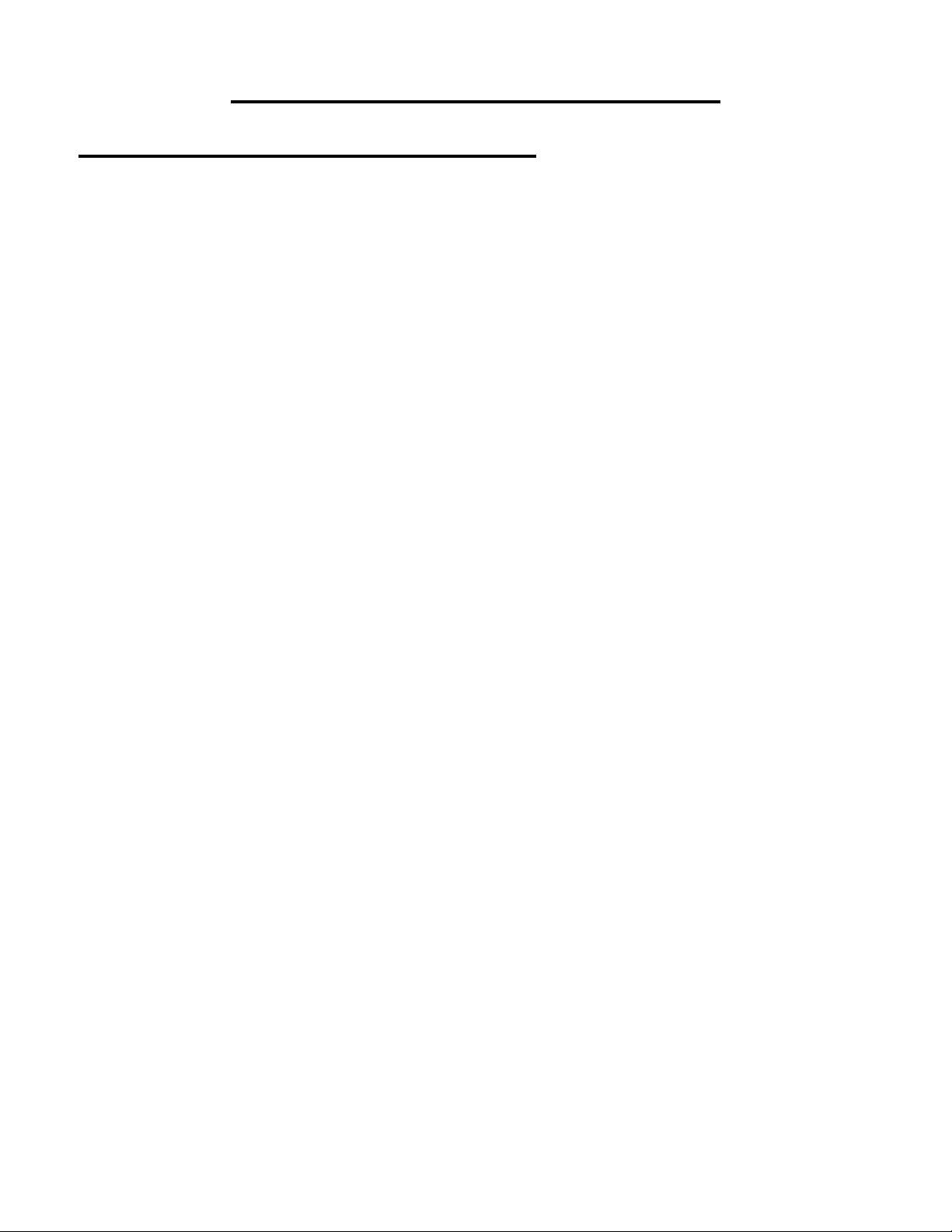

FIGURE 3

FIGURE 4

Tongue Nailing 3/4” Flooring Tongue Nailing 9/16” Flooring

Shoe P/N 50125 Shoe P/N 50125

Shoe Base P/N 50115 Shoe Base and Pad

Shoe Pad P/N 50114 Accessory P/N 50246

SHOE CHANGING

CONVERSION TO AND FROM FACE NAILING

FIGURE 5

Tongue and Groove Flooring Shoe

Cat. No. 50111

Loosen or remove Flange Nuts (Ref. No. 33) with Wrench and Shoe Screw (Ref.

No. 50) to remove and change over from Tongue Nailing to Face Nailing Applications.

Change from Face Nailing to Tongue Nailing by loosening or removing Flange Nuts (Ref.

No. 33) with Wrench and Face Shoe Screw (Ref. No. 42).

5

FIGURE 6

Face Nailing Shoe

Cat. No. 50113

Nailing Tongue And Groove Flooring

Using the PORTAMATIC® Nailer

Install the Face Nailing Shoe on the

1.

Section Pg. 5 Figure 6).

After squaring the Floor and allowing for expansion as recommended by the Wood

2.

PORTAMATIC

Flooring Industry (NWFA, NOFMA and MFMA), place the grooved edge of the first

row of Flooring towards the wall on the side of the room from which you are starting.

Be careful to use the Brown Cap of the Hammer to hit the Ram Head of the

3.

®

PORTAMATIC

Nailer and the Gray Cap on the Flooring. Using the Brown Cap to

hit the Flooring will destroy the Cap.

Depress Safety Trigger, and strike Ram Head of the

4.

Face Nailing Shoe installed.

After striking the Ram Head, the actuating cycle of the

5.

drives one nail into the Flooring.

When the nail has been completely driven, the

6.

PORTAMATIC

automatically reset, and is ready to be moved to the next position and drive another

nail.

Be careful not to drive one nail on top of another. Damage to the Nailer might result or

7.

injury from sparks or a sliver of metal that might break away if this should occur.

If a nail is driven on top of another or a jam occurs, refer to the “Clearing a Jam”

8.

section of the manual on page 9.

Slide the

9.

PORTAMATIC

®

Nailer along the Flooring to the location at which you

desire to drive the next nail.

Continue until four (4) rows of Flooring have been Face Nailed.

10.

Remove the Face Nailing Shoe Accessory from the

11.

install the Tongue and Groove Nailing Shoe

Place the groove of the fifth row of Flooring over the tongue of the fourth row of

12.

(See

Flooring and tighten using the Hammer. Depress Safety Trigger, and strike Ram Head

of the

Slide the

13.

PORTAMATIC

PORTAMATIC®

®

Nailer with the Tongue and Groove Nailing Shoe installed.

Nailer along the tongue of the Flooring to the location at

which you desire to drive the next nail.

Continue Step 11 until you have completely nailed all but the last five (5) rows of

14.

Flooring.

Remove the Tongue and Groove Nailing Shoe from the PORTAMATIC Nailer and

15.

install the Face Nailing Shoe (See

Install and nail in place the remaining five (5) rows of Flooring using the

16.

®

PORTAMATIC

Nailer with the Face Nailing Shoe installed.

Shoe Changing

®

Nailer

PORTAMATIC

(See

Shoe Changing

®

PORTAMATIC

®

Nailer will

PORTAMATIC

Shoe Changing

Section Pg. 5 Figure 5).

®

Section Pg. 5 Figure 6).

Nailer with the

®

Nailer

Nailer and

6

Loading...

Loading...