Page 1

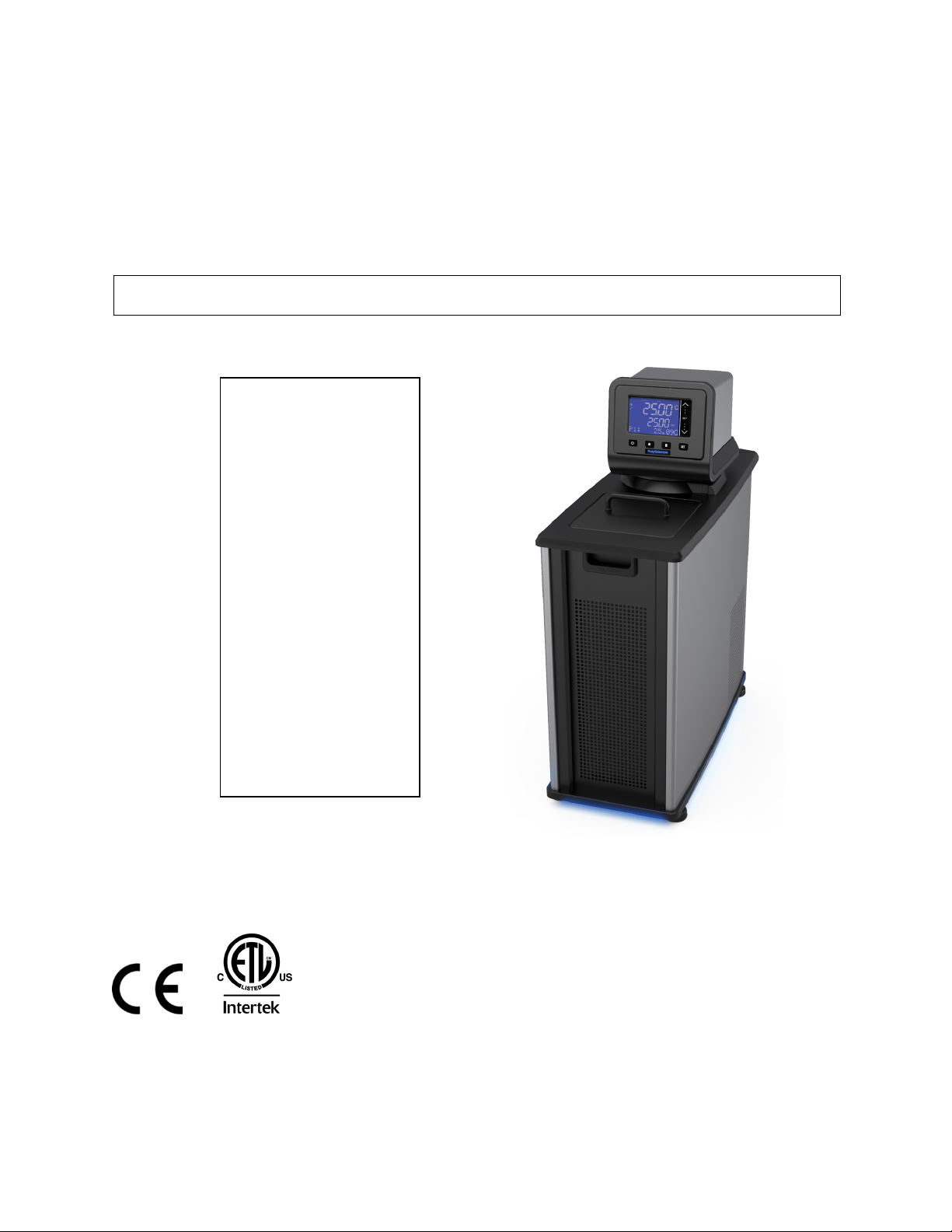

Circulating Baths with

Models:

Advanced Digital Temperature

Controller

Operator’s Manual

AD07R-20

AD07R-40

AD7LR-20

AD15R-30

AD15R-40

AD20R-30

AD28R-30

AD45R-20

AD07H200

AD15H200

AD20H200

AD28H200

AD06S150

AD10S150

AD28S150

AD29VB3S

AD29VB5R

110-513 PSC/EN 17 November 2014

Page 2

Table of Contents

Introduction ................................................................................................................................................. 4

PolyScience Circulating Baths with the Advanced Digital Temperature Controller ................................. 4

General Safety Information ....................................................................................................................... 5

Safety Recommendations......................................................................................................................... 6

Regulatory Compliance & Testing ............................................................................................................ 7

Unpacking Your Circulator ........................................................................................................................ 8

Contents ................................................................................................................................................... 8

Controls & Components............................................................................................................................ 9

Advanced Digital Controller .................................................................................................................. 9

Refrigerating/Heating Baths ............................................................................................................... 10

Heating Only Baths............................................................................................................................. 11

Open Bath Systems (Stainless Steel) ................................................................................................ 12

Viscosity Bath (Polycarbonate) .......................................................................................................... 12

Quick-Start ................................................................................................................................................. 13

Installation & Startup ................................................................................................................................ 15

General Site Requirements .................................................................................................................... 15

Adding Liquid to the Bath Reservoir ....................................................................................................... 15

Pump Inlet and Outlet Connections ........................................................................................................ 16

External Closed Loop Circulation ........................................................................................................... 17

Open Loop Circulation ............................................................................................................................ 17

Refrigeration Control Connections (Refrigerating/Heating Circulators only) .......................................... 18

Electrical Power ...................................................................................................................................... 18

Refrigerating/Heating Circulators ....................................................................................................... 18

Heat Only Circulators and Open Bath Systems ................................................................................. 19

Communication ....................................................................................................................................... 20

USB Communication .......................................................................................................................... 21

Ethernet .............................................................................................................................................. 21

RS232 / RS485 Serial Communication .............................................................................................. 21

External (P2) Temperature Probe .......................................................................................................... 21

Controller Setup ...................................................................................................................................... 22

Power ................................................................................................................................................. 22

Safety Set Temperature ..................................................................................................................... 23

Normal Operation ...................................................................................................................................... 24

Keys and Controls .................................................................................................................................. 24

Turning Your Circulator ON .................................................................................................................... 24

Main Operational Display........................................................................................................................ 25

Set-Up Sub-Menus ................................................................................................................................. 27

Adjusting the Temperature Set Point ...................................................................................................... 28

Selecting the Temperature Unit .............................................................................................................. 29

Selecting the Pump Speed ..................................................................................................................... 30

Setting the High Limit Temperature ........................................................................................................ 31

Setting the Low Limit Temperature ......................................................................................................... 32

Setting the Differential Temperature ....................................................................................................... 33

Setting the Auto Cool Temperature ........................................................................................................ 34

Setting the Specific Heat Capacity (SHC) .............................................................................................. 35

Selecting Internal or External Control ..................................................................................................... 36

Calibrating Your Circulator (Offset) ........................................................................................................ 37

Displaying the Safety Set Temperature .................................................................................................. 38

Selecting a Remote Communication and Control Protocol .................................................................... 39

Using the Timer ...................................................................................................................................... 40

Entering a Password ............................................................................................................................... 41

Enabling / Disabling Data Logging ......................................................................................................... 42

110-513 PSC/EN 2

Page 3

Selecting the Operational Language ...................................................................................................... 43

Setting Auto Restart ................................................................................................................................ 44

Resetting the Factory Default Values ..................................................................................................... 44

Changing Your Circulator's Viewing Angle ............................................................................................. 45

Inert Gas Purge ...................................................................................................................................... 45

Tap Water Cooling .................................................................................................................................. 45

Reservoir Cover Storage ........................................................................................................................ 46

Display Messages and Alarms ................................................................................................................ 47

Routine Maintenance & Troubleshooting ............................................................................................... 48

Maintaining Clear Bath Water ................................................................................................................. 48

Draining the Bath Reservoir ................................................................................................................... 48

Refrigerated / Heating and Heat only Circulating Baths..................................................................... 48

Polycarbonate Viscosity Baths ........................................................................................................... 49

Checking the Over-Temperature / Low Liquid Level Safety Systems .................................................... 50

Over-Temperature Protection ............................................................................................................. 50

Low Liquid-Level Protection ............................................................................................................... 50

Cleaning Your Circulator......................................................................................................................... 51

Temperature Controller ...................................................................................................................... 51

Bath Reservoir .................................................................................................................................... 51

Pump Impeller .................................................................................................................................... 51

Condenser, Air Vents, and Reusable Filter (Refrigerating / Heating Circulators only) ...................... 51

Temperature Controller Removal and Re-Installation ............................................................................ 52

Removal ............................................................................................................................................. 52

Re-Installation ..................................................................................................................................... 53

Viewing Component Operating Time ...................................................................................................... 54

Troubleshooting Chart ............................................................................................................................ 55

Technical Information ............................................................................................................................... 57

Performance Specifications .................................................................................................................... 57

Reservoir Fluids ...................................................................................................................................... 58

Application Notes .................................................................................................................................... 60

Tubing and Fitting Temperature Ranges ................................................................................................ 60

Fluid Compatibility .................................................................................................................................. 60

RS232/RS485 Configuration .................................................................................................................. 61

RS232/RS485 Communications ............................................................................................................. 63

USB Data Logging .................................................................................................................................. 65

USB B Setup, Monitoring, and Control ................................................................................................... 65

Initial Setup ......................................................................................................................................... 65

Monitoring and Control ....................................................................................................................... 66

Configuring the Ethernet Connection ..................................................................................................... 66

Direct Computer to Controller Configuration ...................................................................................... 66

Wired or Wireless Network Configuration .......................................................................................... 66

Equipment Disposal (WEEE Directive) ................................................................................................... 70

Replacement Parts & Accessories .......................................................................................................... 71

PolyScience Circulating Bath Fluids ...................................................................................................... 73

Service & Technical Support ................................................................................................................... 73

Warranty ..................................................................................................................................................... 74

110-513 PSC/EN 3

Page 4

Introduction

(1)

(1)

(1)

(1)

(1)

(1)

(2)

(2)

Thank you for choosing a PolyScience Circulating Bath. It is intended for the precise temperature control

of suitable liquids in a reservoir. Extremely easy to use and maintain, your Circulating Bath combines

design innovation with highly intuitive operation to deliver convenient and reliable liquid temperature

control for a wide range of applications.

WARNING: PolyScience Circulating Baths are not intended for directly controlling the temperature of

foods, pharmaceuticals, medicines, or other objects which may be ingested by or injected in humans

or animals. Any such objects must be isolated from contact with the bath fluid and bath surfaces.

Here are some of the features that make your Circulating Bath so user-friendly:

• Simple, intuitive operation

• Extra-large digital readout that displays actual and set point temperature simultaneously

• Powerful variable speed duplex pump with open- and closed-loop external circulation

capability

• 180° viewing radius (Swivel 180™ rotating control head)

• DuraTop™ heat and chemical resistant top plate

• LidDock™ self-storing reservoir cover (integrated baths only)

• Built-in temperature protection

• Suitable for use with Class III flammable fluids per DIN 12876-1

It will take you very little time to get your new Circulating Bath installed and running. This Operator’s

Manual is designed to guide you quickly through the process. We recommend that you read it thoroughly

before you begin.

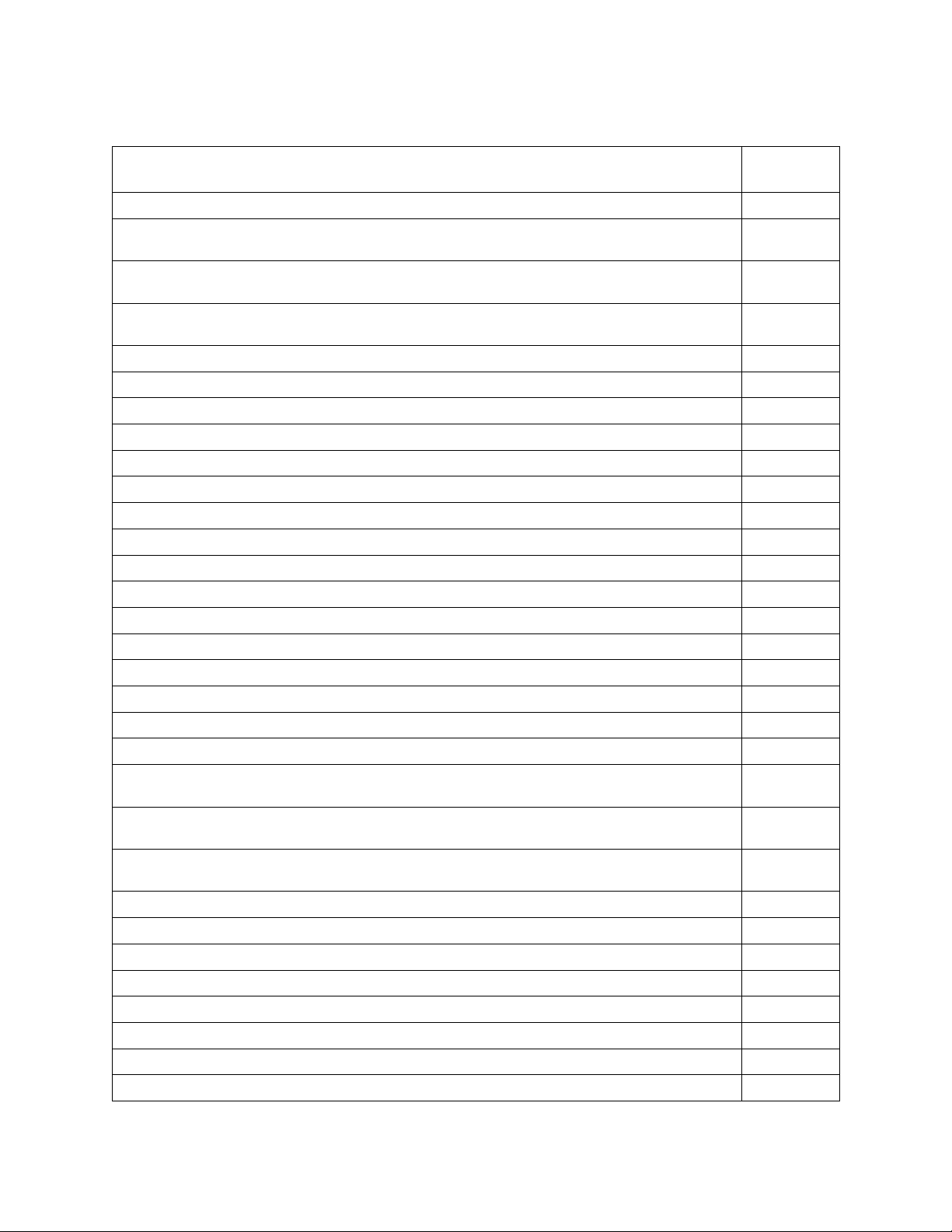

PolyScience Circulating Baths with the Advanced Digital Temperature Controller

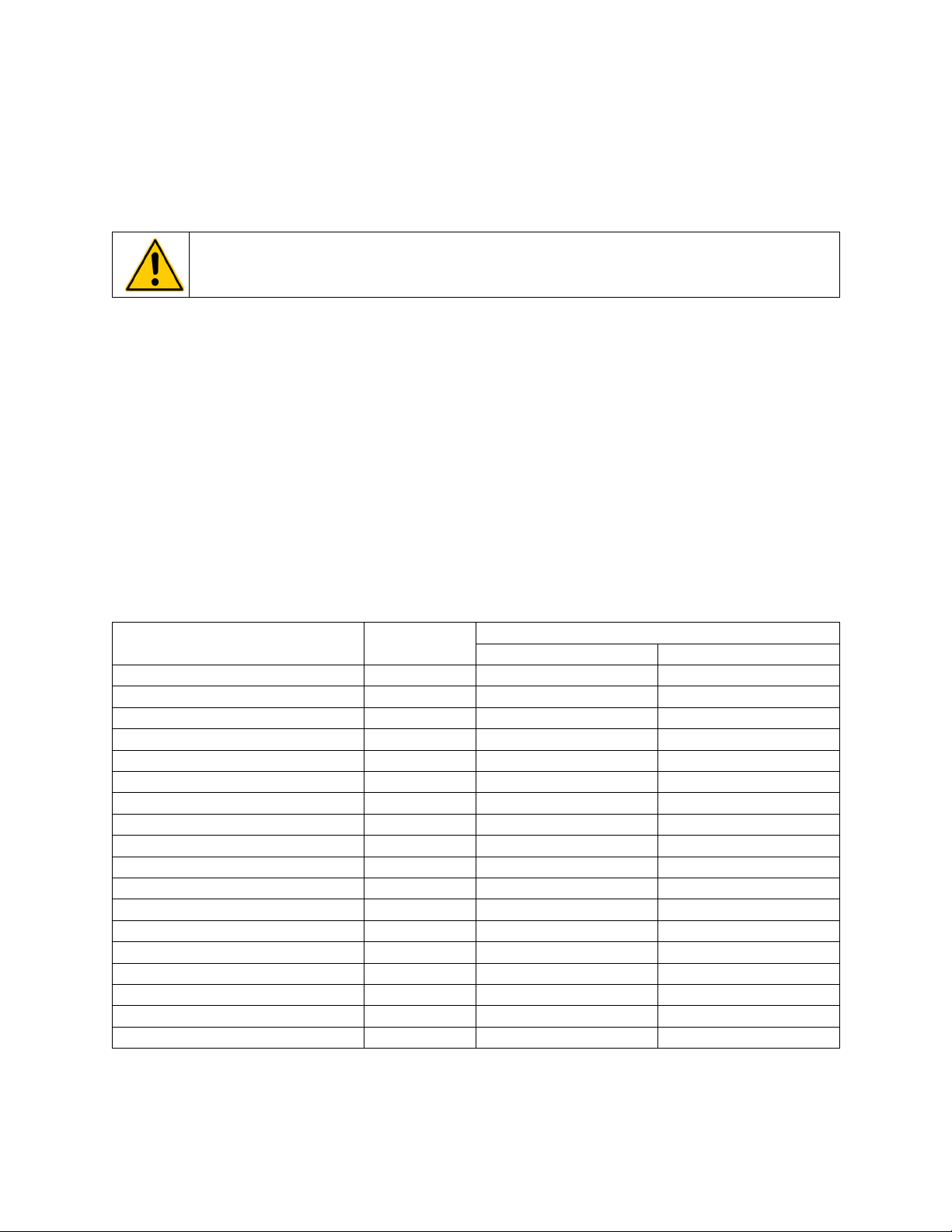

Model Type

AD07R-20 Refrigerating / Heating Bath 7 liters -20° to 200°C -4° to 392°F

AD07R-40 Refrigerating / Heating Bath 7 liters -40° to 200°C -40° to 392°F

AD7LR-20 Refrigerating / Heating Bath 7 liters -20° to 200°C -4° to 392°F

AD15R-30 Refrigerating / Heating Bath 15 liters -30° to 200°C -22° to 392°F

AD15R-40 Refrigerating / Heating Bath 15 liters -40° to 200°C -40° to 392°F

AD20R-30 Refrigerating / Heating Bath 20 liters -30° to 200°C -22° to 392°F

AD28R-30 Refrigerating / Heating Bath 28 liters -30° to 200°C -22° to 392°F

AD45R-20 Refrigerating / Heating Bath 45 liters -25° to 135°C -13° to 275°F

AD07H200 Heating Only Bath 7 liters Ambient +10° to 200°C Ambient +20° to 392°F

AD15H200 Heating Only Bath 15 liters Ambient +10° to 200°C Ambient +20° to 392°F

AD20H200 Heating Only Bath 20 liters Ambient +10° to 200°C Ambient +20° to 392°F

AD28H200 Heating Only Bath 28 liters Ambient +10° to 200°C Ambient +20° to 392°F

AD06S150 Open Bath System 6 liters Ambient +10° to 150°C

AD10S150 Open Bath System 10 liters Ambient +10° to 150°C

AD20S150 Open Bath System 20 liters Ambient +10° to 150°C

AD28S150 Open Bath System 28 liters Ambient +10° to 150°C

AD29VB5R Polycarbonate Viscosity 29 liters Ambient +10° to 85°C

AD29VB3S Polycarbonate Viscosity 29 liters Ambient +10° to 85°C

1. Maximum operating temperature at which ±0.01°C temperature stability can be maintained; Advanced Digital Controller is

capable of higher temperatures.

2. Maximum operating temperature for polycarbonate tank. Advanced Digital Controller is capable of higher temperatures.

Reservoir

Capacity

Temperature Range

°C °F

Ambient +20° to 302°F

Ambient +20° to 302°F

(1)

Ambient +20° to 302°F

Ambient +20° to 302°F

Ambient +20° to 185°F

(2)

Ambient +20° to 185°F

(1)

(2)

110-513 PSC/EN 4

Page 5

General Safety Information

When installed, operated, and maintained according to the directions in this manual and common safety

procedures, your Circulating Bath should provide safe and reliable temperature control. Please ensure

that all individuals involved in the installation, operation, or maintenance of this Circulating Bath read this

manual thoroughly prior to working with the unit.

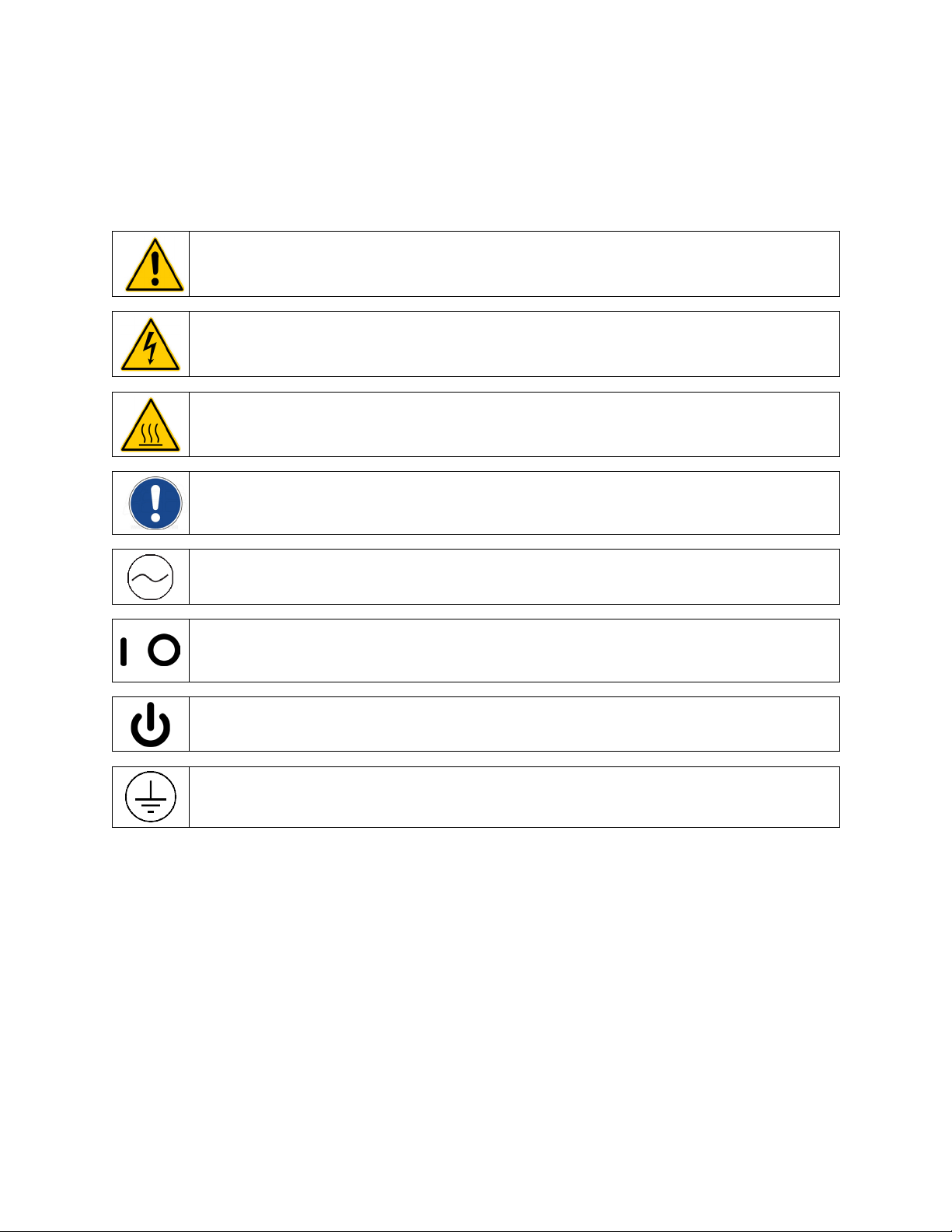

This symbol alerts you to a wide range of potential dangers.

This symbol advises you of danger from electricity or electric shock.

This symbol indicates that a hot surface may be present.

This symbol marks information that is particularly important.

/

This symbol indicates alternating current.

These symbols on the Power Switch / Circuit Breaker indicate that they place the main power supply

ON / OFF.

This symbol on the Power Key indicates that it places the unit in a standby mode. It DOES NOT fully

disconnect the unit from the power supply.

This symbol indicates a protective conductor terminal.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation and maintenance is the user’s responsibility.

110-513 PSC/EN 5

Page 6

Safety Recommendations

To prevent injury to personnel and/or damage to property, always follow your workplace’s safety

procedures when operating this equipment. You should also comply with the following safety

recommendations:

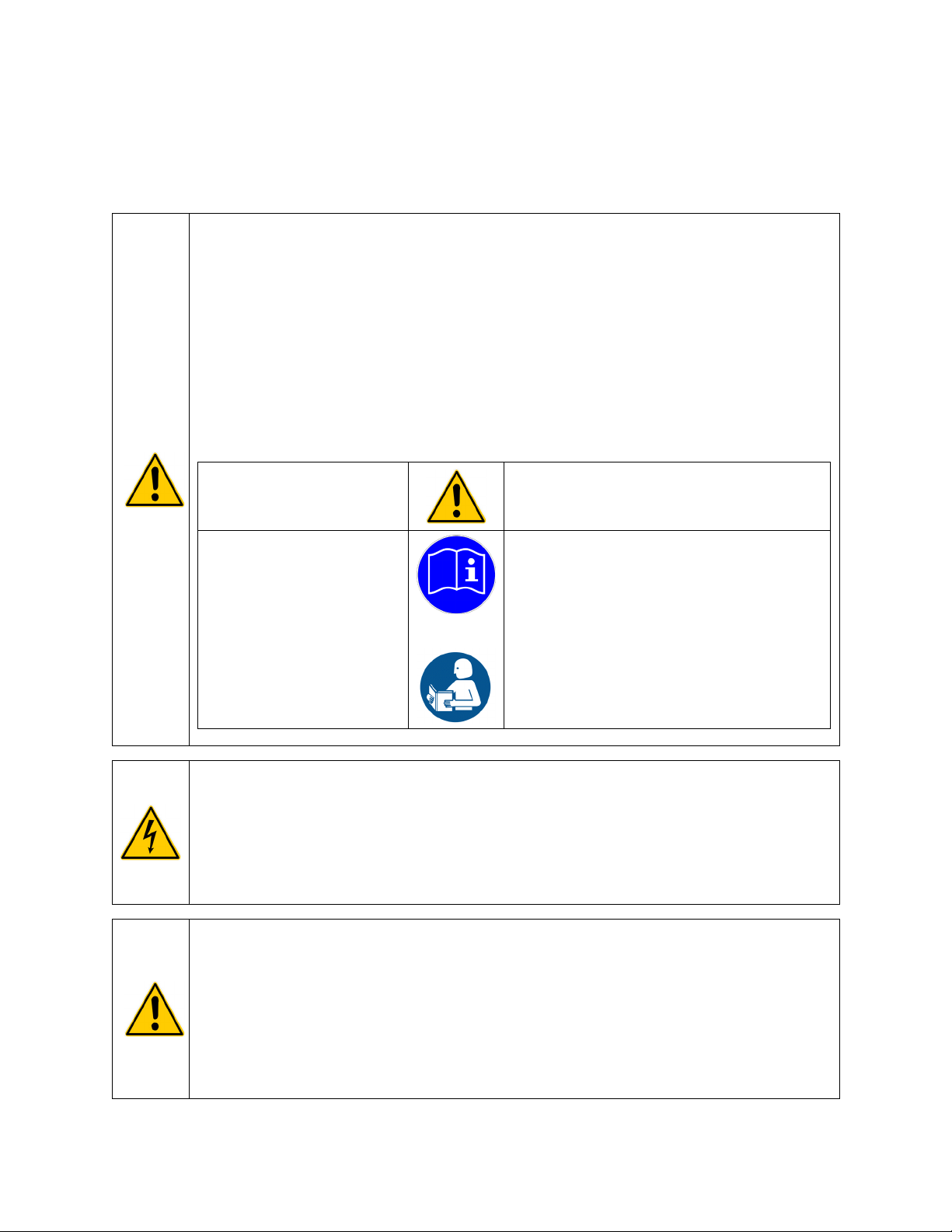

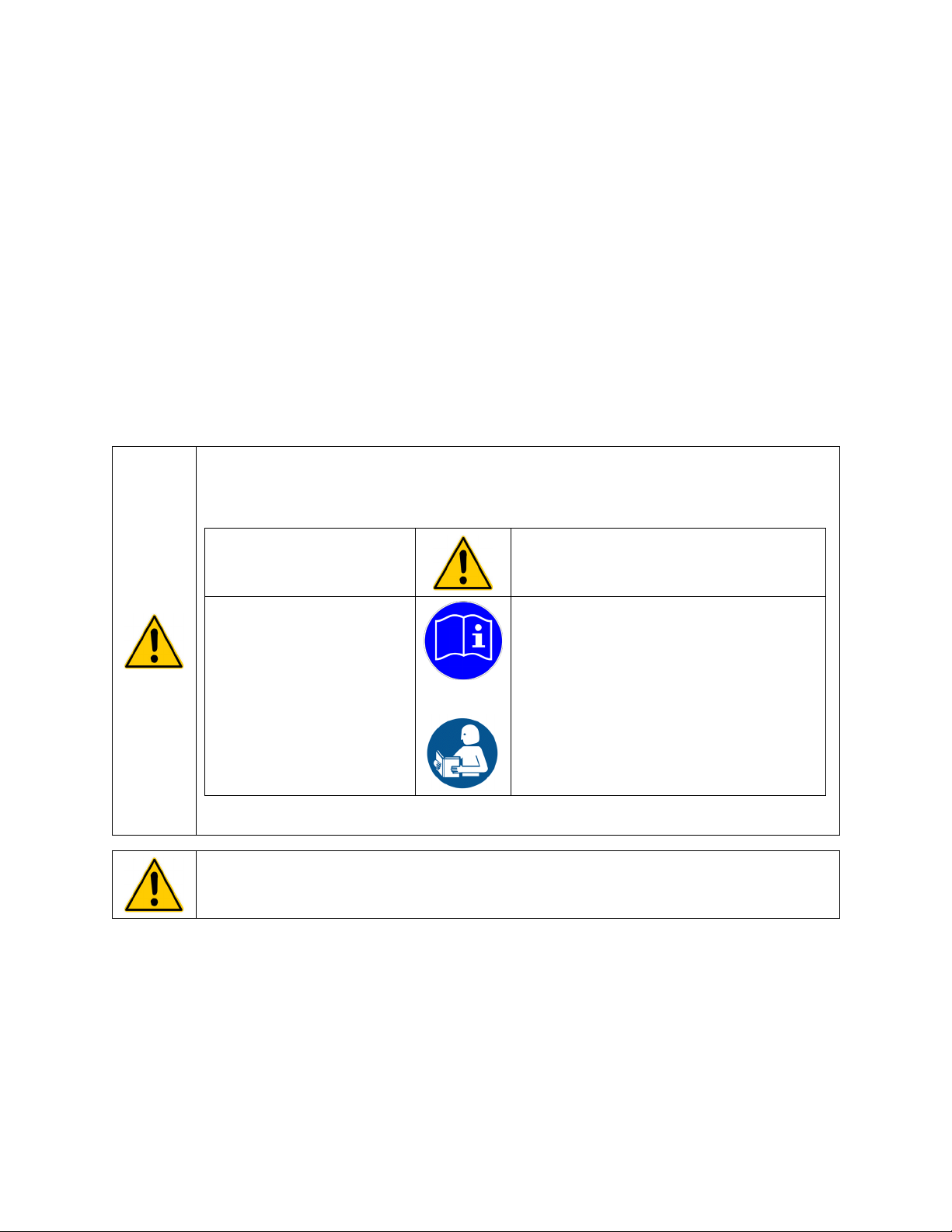

WARNING:

• This Circulating Bath is suitable for use with Class III flammable fluids per DIN 12876-1. A fire

hazard may be present.

• Be aware of the chemical hazards that may be associated with the bath fluid used. Observe all

safety warnings for the fluids used as well as those contained in the material safety data sheet.

• Explosive gas mixtures may accumulate if used with insufficient ventilation. Use this Circulating

Bath in a well ventilated area or beneath a suitable fume hood only.

• Use only recommended bath fluids; see Technical Information in the rear of this manual for

recommended fluids.

• Use only non-acid bath fluids.

WARNING: When using Class III flammable fluids per DIN 12876-1, the user must attach the

following warning labels to the front of the unit so that they are well visible:

Warning Label

W09

Colors: Yellow/black

Mandatory Label

M018

Colors: Blue/white

or

Semi S1-0701

Table A1-2 #9

Colors: Blue/white

WARNING:

Danger Area.

Attention! Observe instructions

(operating manual, safety data sheet)

Carefully read the user information prior to

beginning operation.

Scope: EU

Carefully read the user information prior to

beginning operation.

Scope: NAFTA

• Always connect the power cord on this Circulator to a grounded (3-prong) power outlet. Make

certain that the outlet is the same voltage and frequency as your unit.

• Never operate the Circulator with a damaged power cord.

• Always turn the Circulator OFF and disconnect mains power before performing any maintenance or

service.

WARNING:

• Never operate the Circulator without bath fluid in the reservoir. Periodically check the reservoir to

ensure that the liquid depth is within acceptable levels. Always refill the reservoir using the same

bath fluid type that is already in the reservoir. Bath oil must not contain any water contaminants

and should be preheated to the actual bath temperature before adding as there is an explosion

hazard at high temperatures.

• Always drain all fluid from the reservoir before moving or lifting your Circulator. Be sure to follow

your organization’s procedures and practices regarding the safe lifting and relocation of heavy

objects.

110-513 PSC/EN 6

Page 7

WARNING:

• Always allow the bath fluid to cool to ambient temperature before draining.

• The reservoir cover, top deck, and/or external pump connections may become hot with continuous

use. Exercise caution when touching these parts.

• Always keep within the 85°C maximum operating temperature limit if using a polycarbonate tank.

WARNING: It is the user’s responsibility to properly decontaminate the unit in the event hazardous

materials are spilled on exterior or interior surfaces. Consult manufacturer if there is any doubt

regarding the compatibility of decontamination or cleaning agents.

Regulatory Compliance and Testing

This equipment is compliant with the European Directive 2002/95/EC and its latest amendments on

Restrictions on Hazardous Substances (RoHS) and below the given limits of hazardous substances.

ETL Intertek (60 Hz units)

UL 61010-1 / CSA C22.2 No. 61010-1 — Safety Requirements for Measurement, Control, and

Laboratory Use; Part 1: General Requirements

UL 61010A-2-010 / CSA C22.2 No. 61010-2-010:04 — Safety Requirements for Measurement, Control,

and Laboratory Use; Part 2-010: Particular Requirements for Laboratory Equipment for the Heating of

Materials

UL 61010A-2-051 / CSA C22.2 No. 61010-2-051:04 — Safety Requirements for Measurement, Control,

and Laboratory Use; Part 2-051: Particular Requirements for Laboratory Equipment for the Mixing and

Stirring

CE (all units)

EC Low Voltage Directive 2006/95/EC

EC Electromagnetic Compatibility Directive 2004/108/EC

IEC 61010-1-2001

IEC 61010-2-2001

IEC 61326:2005 / EN 61326 : 2006

110-513 PSC/EN 7

Page 8

Unpacking Your Circulator

● ●

●

Your Circulator was packed in a special carton or cartons. You should keep the packaging, along with all

packing materials, until the unit has been installed and you are certain it is working properly.

CAUTION: Remove any loose packing material that may have fallen into the heater/pump housing

during shipping. Before powering up, check that nothing remains around the heater or Circulator

pump.

We recommend that you begin using your Circulator immediately to confirm proper operation, since

beyond one week you may be eligible for warranty repair only (rather than replacement). You’ll find

complete warranty information in the back of this manual.

In the unlikely event that the unit was damaged or does not operate properly, contact the transportation

company, file a damage claim, and contact the company where your Circulator was purchased.

Contents

The items included with your Circulator will vary depending on which model Circulating Bath you

purchased.

Resource Disk with

Operator’s Manual

Reservoir Lid

3-ft / 0.91 m IEC to

IEC Power Cord

6-ft / 1.82 m IEC to

Mains Power Cord

Refrigeration Control

Cable

Fittings 1/4 in. NPT to 3/16 in. barbed adapter

Cooling Coil N/A Integral Optional ●

Certificate of

Compliance

Quick-Start Guide ●

1. 60Hz and 50Hz models

2. 50Hz models only

Refrigerating /

Heating Bath

●

● ● ●

●

● N/A N/A N/A

●

●

● N/A N/A N/A

1/4 in. NPT to 1/4 in. barbed adapter

1/4 in. NPT to 3/8 in. barbed adapter

1/4 in. NPT to M16 barbed adapter

●

●

Heating Only

Bath

Open Bath

System

● ●

(1)

(1)

(1)

(2)

● ●

● ●

Viscosity

Bath

N/A

110-513 PSC/EN 8

Page 9

Controls and Components

3.75” (9.5 cm)

Color LCD

Touch Scroll Bar

Set Key

Menu Key

Power Key

Home Key

Swivel 180

Latch

IEC Power Cord

Power Switch /

Circuit Breaker

(located on Refrigeration

Power Module on

Refrigerating/Heating

Circulators)

Safety Set

Thermostat

Refrigeration Control

Connection (functional on

Refrigerating/Heating

Circulat

Fluid Inlet Connection

RS232/RS485 Serial Port

Fluid Outlet Connection

Inert Gas Injection Port

IEC Electrical

ection

Bypass Hose

External (P2)

Temperature Probe

Connection

USB B Connection

USB A Connection

Ethernet Connection

Advanced Digital Controller

Release

Conn

ors only)

110-513 PSC/EN 9

Page 10

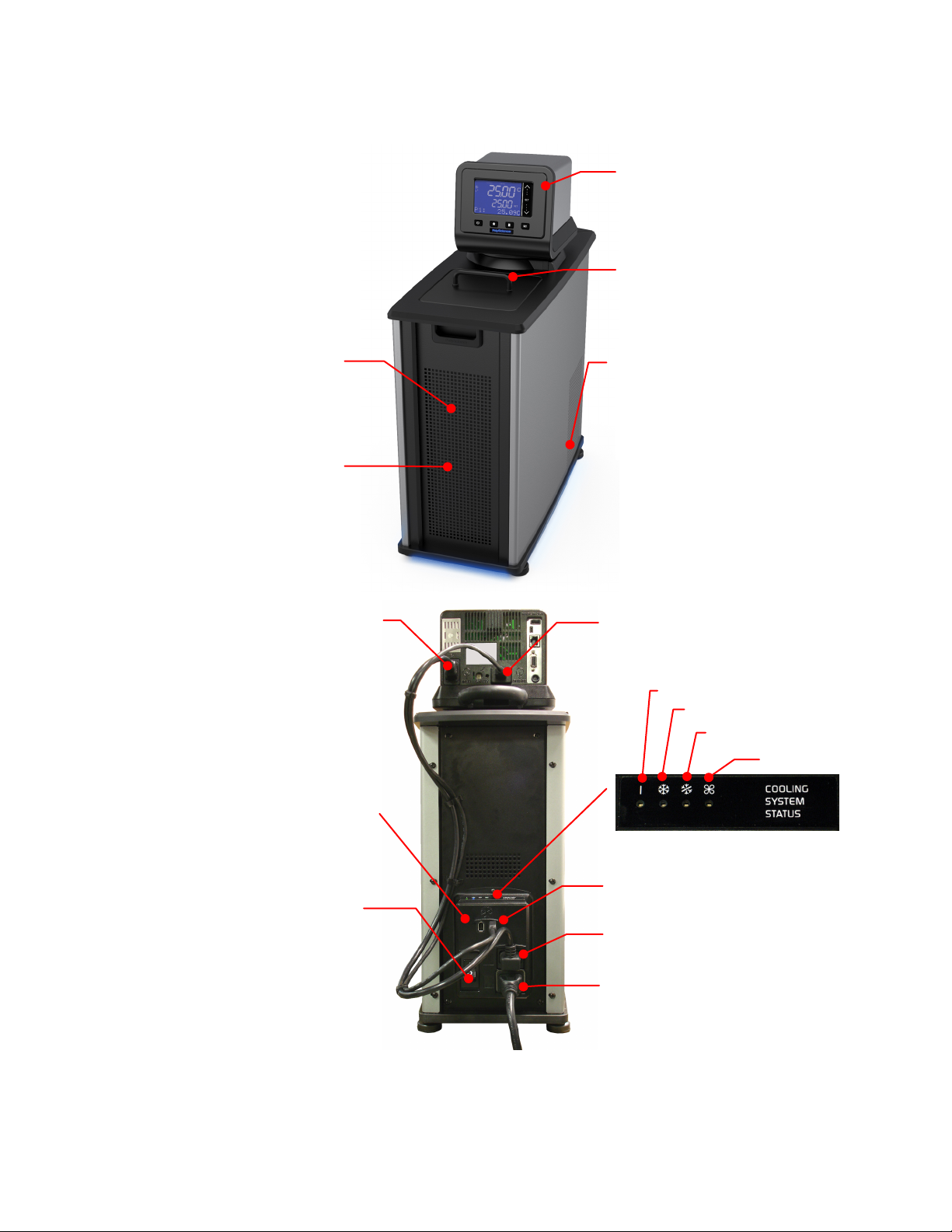

Refrigerating/Heating Baths

Advanced Digital

Temperature Controller

Reservoir Cover

Reservoir Drain Valve and Port

(behind access panel)

20)

Drain Valve and Port

(right side on

Washable Air Filter

(behind access panel)

IEC Power Connection to

Refrigeration Power Module

IEC Power Connection to Mains

Refrigeration Power Module

IEC Power Connection to Controller

Power Switch / Circuit Breaker

Refrigeration Control Connection

Cooling System Status Display

Refrigeration Control

Connection

Power

Cooling

Fan

Cooling Fault

Side access on AD7LR-

AD7LR-20 only)

110-513 PSC/EN 10

Page 11

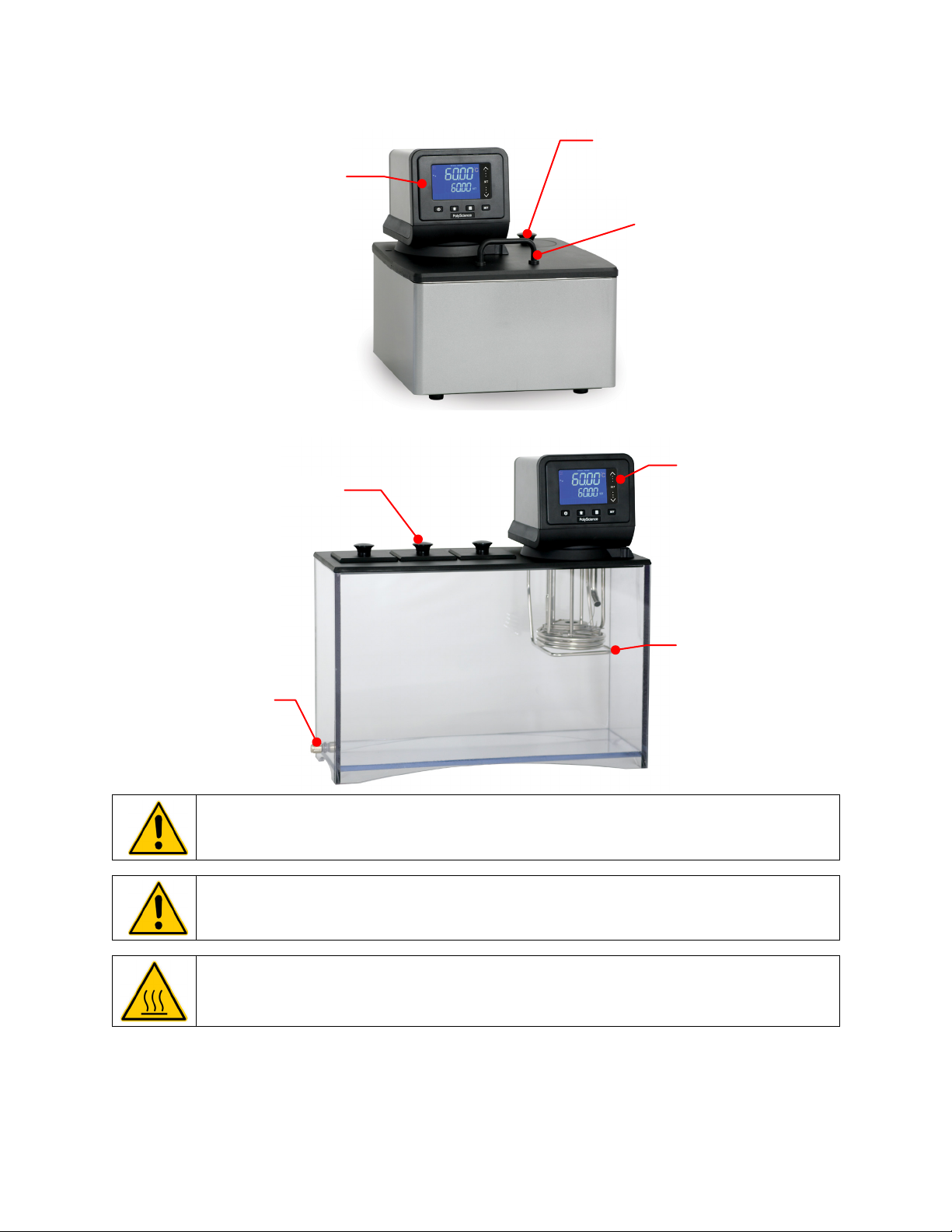

Heating Only Baths

Advanced Digital

Temperature Controller

Reservoir Cover

Reservoir Drain Valve and Port

access panel)

Tap Water Cooling Connection

(outlet)

Tap Water Cooling Connection

(inlet)

Power Switch / Circuit Breaker

IEC Connection to Mains

(behind

110-513 PSC/EN 11

Page 12

Open Bath Systems (Stainless Steel)

Advanced Digital

Temperature Controller

Cooling Coil Opening with Cover

(10L, 20L, and 28L models)

Reservoir Cover

Advanced Digital

Temperature

Controller

Tap Water Cooling

Coil

Lidded Viscometer Openings

Reservoir Drain Port

Viscosity Bath (Polycarbonate)

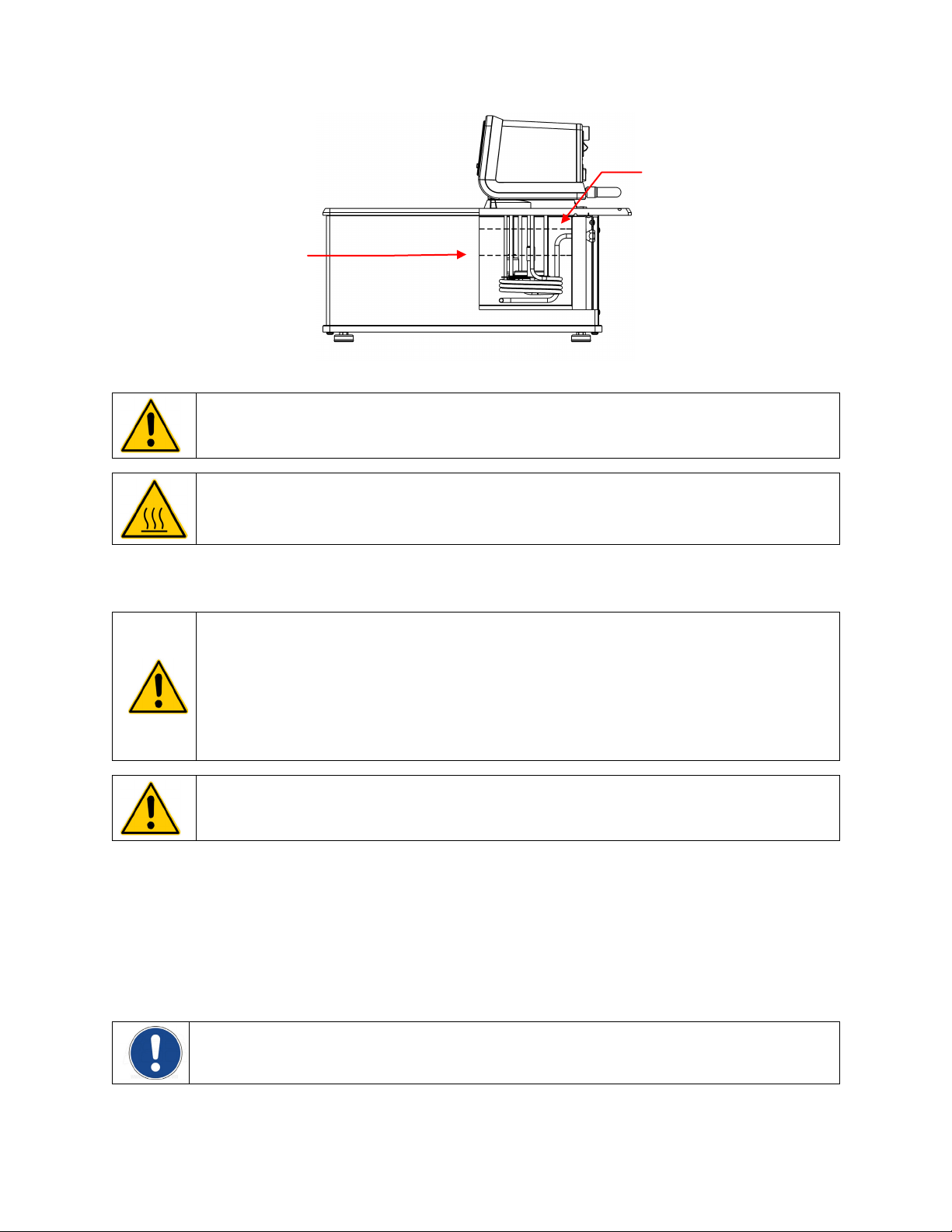

WARNING: The top deck on Open Bath Systems and Viscosity Baths is not attached. Do not remove

deck while Circulator is operating. Do not lift bath by grasping the Temperature Controller or top

deck. Always disconnect electrical power and drain fluid from bath before moving.

WARNING: The PolyScience Advanced Digital Temperature Controller is designed for use with

Class III flammable liquids per DIN 12876-1; however, we strongly recommend that Open Bath

Systems and Viscosity Baths be used only with non-flammable fluids.

WARNING: To avoid the potential for burns, allow the Circulator to cool completely before cleaning

or performing any maintenance.

110-513 PSC/EN 12

Page 13

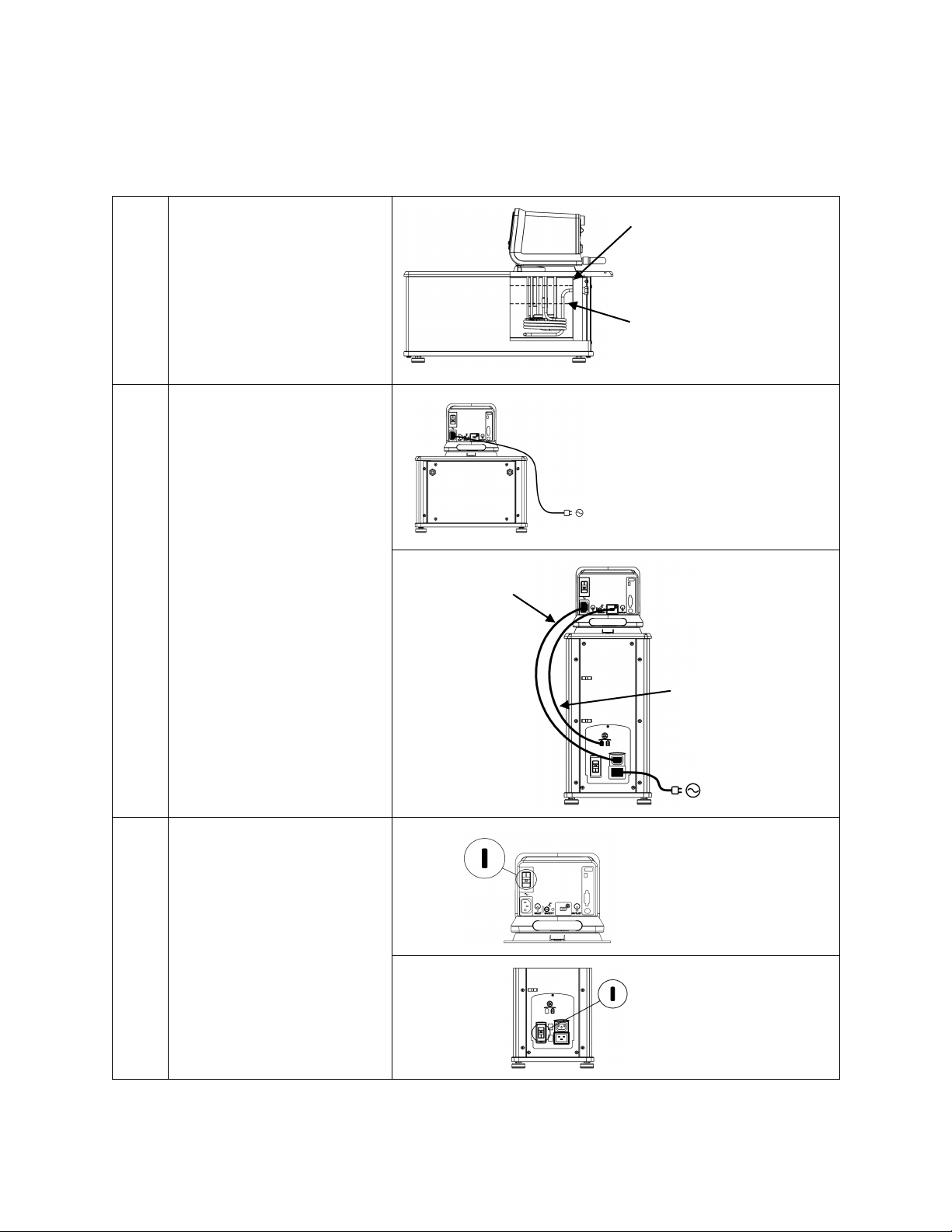

Quick-Start

Maximum: 1 in. / 2.54 cm

below underside of top deck

Minimum: 3.0 in. / 7.6 cm

below underside of top deck

Heating only models

Refrigerating / Heating

IEC power cord

from Controller

to Refrigeration

Power Module

Refrigeration control

cable

Heating only models

Refrigerating / Heating

Unless otherwise specified, quick-start instructions apply to all models. See Installation and Startup for

additional information.

1

Fill reservoir with fluid

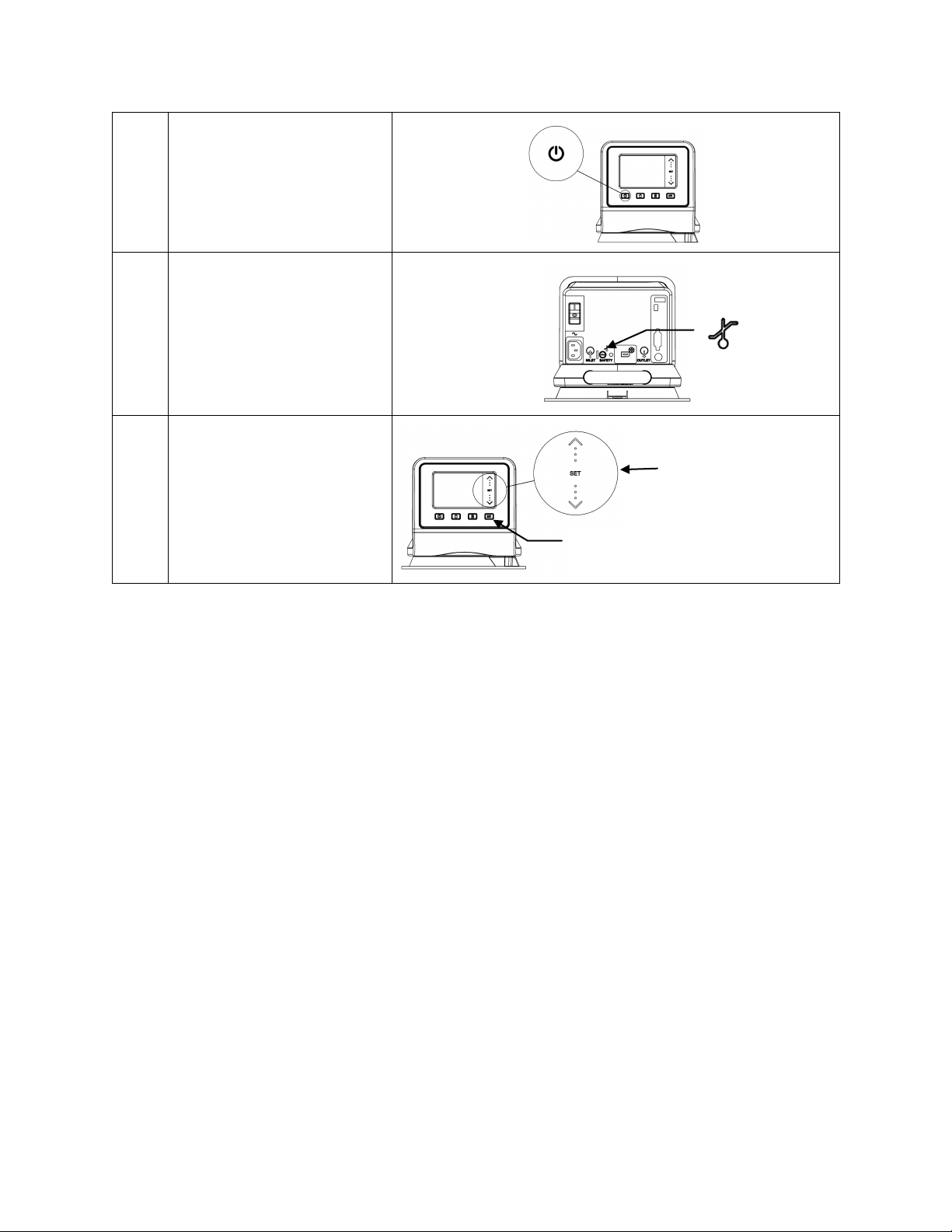

Connect all power cords and

2

control cables

models

3

110-513 PSC/EN 13

Place Power Switch / Circuit

Breaker in ON position

models

Page 14

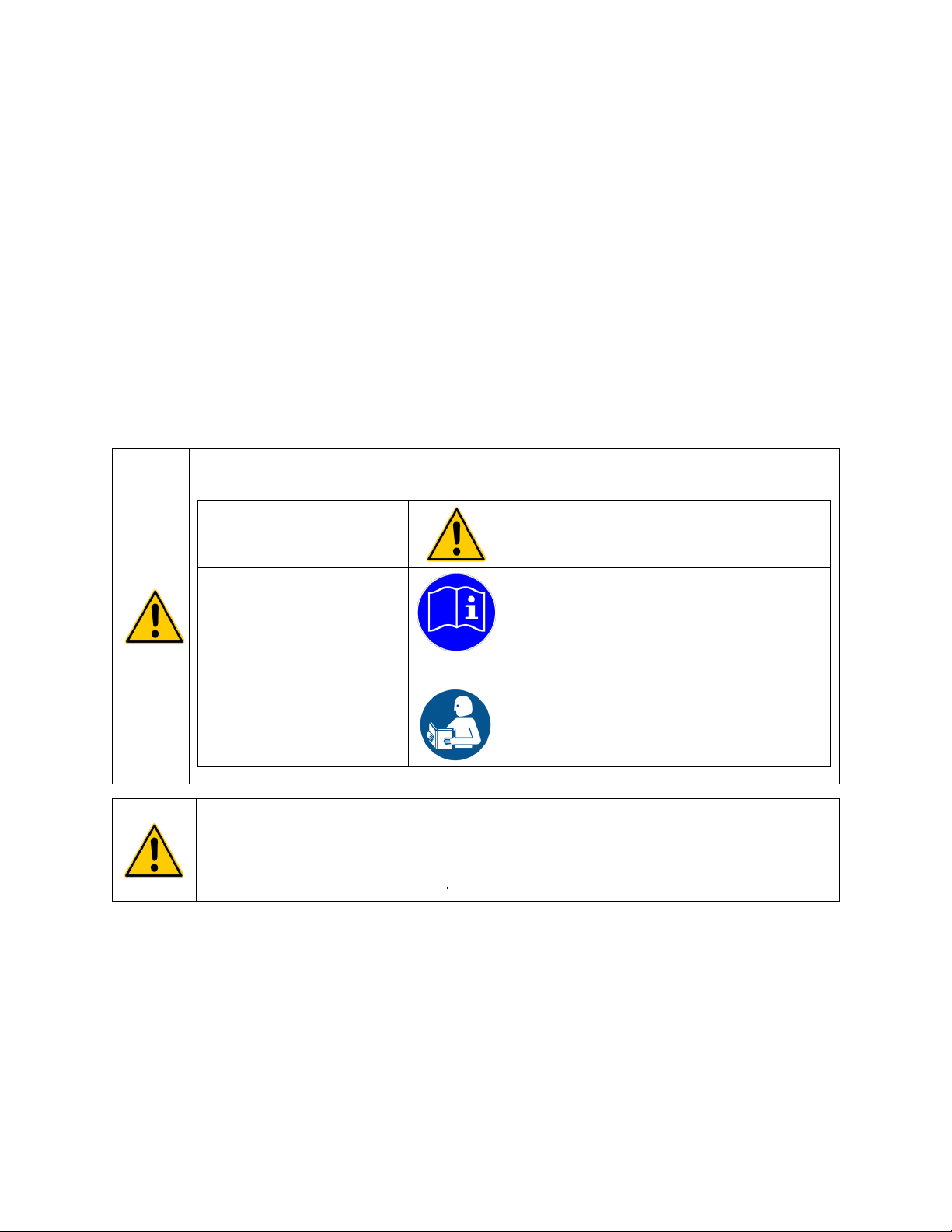

4

6A.

Press SET

6B.

Touch and hold or slide

finger up/down scroll bar

Turn Controller “ON”

5

Set safety thermostat

Enter temperature

6

set point

110-513 PSC/EN 14

Page 15

Installation and Startup

Your Circulating Bath with Advanced Digital Temperature Controller is designed to be simple to set-up

and install. The only tools required are a No.1 Phillips-head screwdriver and a container for adding water

or other suitable fluid to the bath reservoir.

General Site Requirements

Locate your Circulator on a level surface free from drafts and direct sunlight. Do not place it where there

are corrosive fumes, excessive moisture, high room temperatures, or in excessively dusty areas.

Refrigerating / Heating Circulators must be 10.2 cm / 4 inches or more away from walls or vertical

surfaces so that airflow is not restricted.

Avoid voltage drops by using properly grounded power outlets wired with 14 gauge or larger diameter

wire and if possible, be close to the power distribution panel. The use of extension cords is not

recommended; this will reduce the potential for problems caused by low line voltage.

Adding Liquid to the Bath Reservoir

WARNING: When using Class III flammable fluids per DIN 12876-1, the user must attach the

following warning labels to the front of the unit so that they are well visible:

Warning Label

W09

Colors: Yellow/black

Mandatory Label

M018

Colors: Blue/white

or

Semi S1-0701

Table A1-2 #9

Colors: Blue/white

WARNING: See Technical Information in the rear of this manual for a list of compatible liquids.

WARNING: Read the safety data sheet for the bath fluid being used carefully before filling reservoir.

WARNING: If the proper fluid level is not maintained, the heater coil may become exposed and

possibly damaged (fluid level too low) or the bath may overflow (fluid level too high).

Danger Area.

Attention! Observe instructions

(operating manual, safety data sheet)

Carefully read the user information prior to

beginning operation.

Scope: EU

Carefully read the user information prior to

beginning operation.

Scope: NAFTA

The liquid in the reservoir should be maintained at a depth between 1 inch / 2.54 cm and 3.0 inches / 7.6

cm below the underside of the bath’s top deck. Upon start up, it may be necessary to add fluid to the bath

to compensate for the fluid required for external circulation. Likewise, be sure to compensate for fluid

displacement when placing samples or other materials in the Circulator’s reservoir.

110-513 PSC/EN 15

Page 16

Maximum Fluid Level =

1 inch / 2.54 cm below

underside of top deck

Minimum Fluid Level =

3.0 inches / 7.6 cm

below underside of top

deck

WARNING: Always drain all fluid from the reservoir before moving or lifting your Circulator. Be sure

to follow your organization’s procedures and practices regarding the safe lifting and relocation of

heavy objects.

WARNING: To avoid the potential for burns, allow the Circulator to cool completely before cleaning

or performing any maintenance.

Pump Inlet and Outlet Connections

WARNING: When connecting tubing to an external application, it is the user’s responsibility to make

sure that the tubing and fittings connected to the Circulator are suitable for the fluid being used and

the temperature range of operation.

CAUTION: The Circulator’s bypass tubing is secured to the fluid inlet and outlet connections by high

temperature nylon hose clamps, which can be removed by carefully cutting them with diagonal

cutters.

CAUTION: Secure the tubing to the inlet and outlet fittings using hose clamps with a minimum ID of

7/8 inch (22 mm). Do not operate the unit without hose clamps.

The pump inlet and outlet ports are female ¼ inch NPT connections that permit use of barbed tubing

adapters or hard plumbing fittings. ½ inch (13 mm) ID tubing may also be slid over these connections and

held in place with a hose clamp (minimum 7/8 inch / 22 mm ID).

If the pump inlet and outlet are not used for external circulation, the Bypass Tubing provided with the unit

should be left in place in order to optimize fluid mixing within the reservoir.

The nylon barbed tubing adapter fittings supplied with the unit are intended for applications from

-40° to 93°C. For applications above 93°C, brass, stainless steel, or Teflon

inch NPT to M16 stainless steel male adapter fittings are provided with all 50Hz models.

110-513 PSC/EN 16

WARNING: If the Circulating Bath will not be used for external circulation, the inlet and outlet ports

should remain connected using the Buna N bypass tubing provided with the unit.

®

fittings are recommended. ¼

NOTE: The use of quick-connect fittings is not recommended as they typically restrict flow rate.

Page 17

External Closed Loop Circulation

Connect the pump inlet and outlet to the external apparatus. To maintain adequate flow, avoid restrictions

in the tubing. When connecting the Circulator to more than two closed loops, the use of a manifold made

of “Y” adapters to divide the fluid into multiple banks is recommended. After setting up multiple closed

loops, check for adequate flow at the return manifold of each loop and check that the bath fluid is at an

adequate level. A booster pump may be added to closed loops without damaging the Circulator’s pump.

The temperature control stability of a closed loop system is better at the external apparatus than in the

Circulator reservoir (provided the control point of the apparatus represents a constant load and is well

insulated). For example, if you circulate fluid through a viscometer at 50°C, the temperature variation

observed in the Circulator reservoir may be ±0.1°C while the temperature variation in the viscometer may

be only ±0.05°C.

Although temperature stability is generally better at the external apparatus control point, depending on the

length of tubing used and the efficiency of the insulation, the actual temperature reading at the external

apparatus may be slightly different than the temperature reading at the Circulator reservoir.

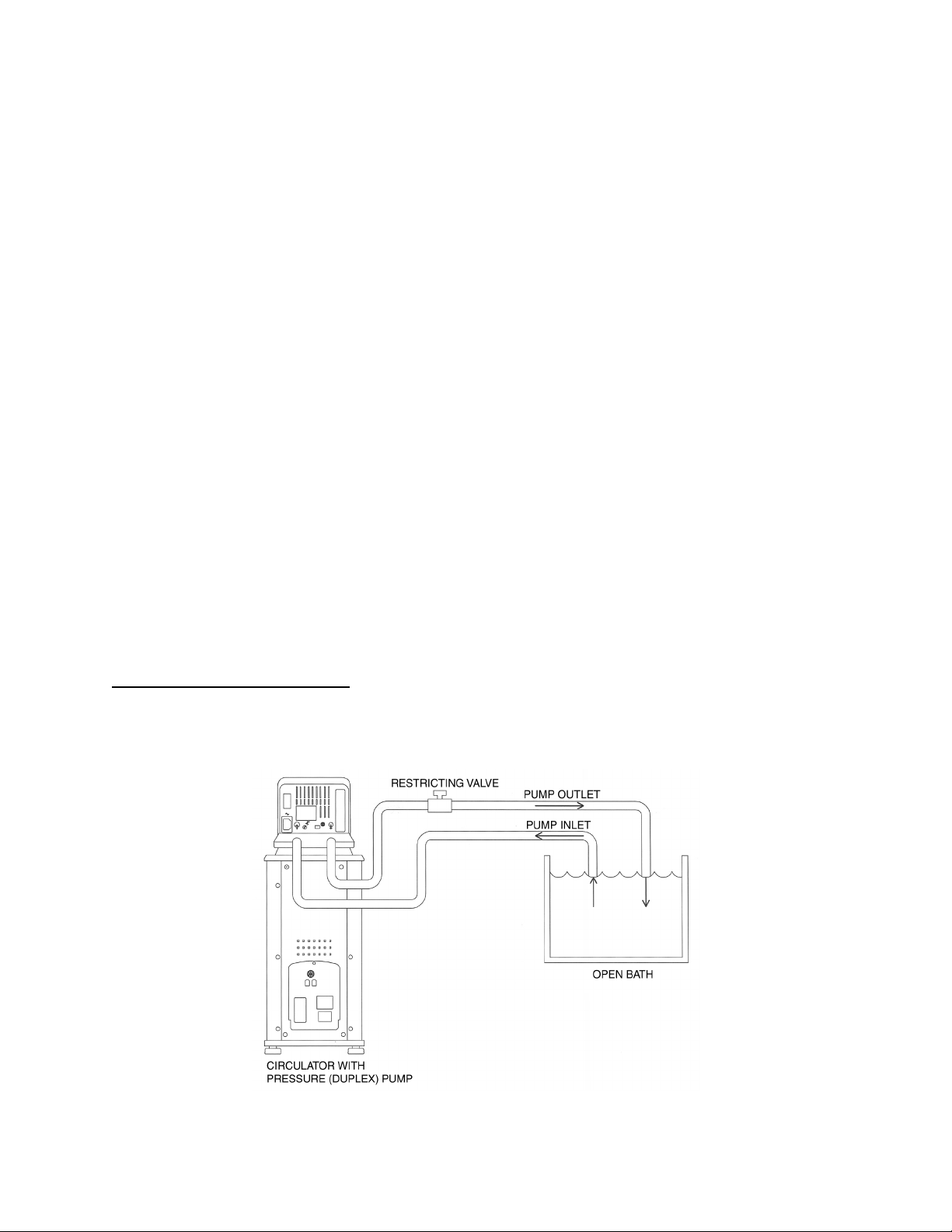

Open Loop Circulation

The duplex (pressure/suction) pump permits circulation to and from an external open bath. To prevent

siphoning when the Circulating Bath is turned off, position both baths so that the two fluid levels are at the

same elevation.

Connect the pump inlet and outlet to the external bath using tubing of the same diameter and length. The

same size fittings should also be used on both the inlet (suction) and outlet (pressure). This helps ensure

a balanced flow. A restricting valve or pinch clip should be installed in the pressure (outlet) tubing and

adjusted to match the return suction (inlet) flow rate. Cut the external end of the suction tube into a “V”

shape so that the tube will not seal itself against the wall of the external tank. Both the pressure and

suction tubing should be securely fastened to the external tank to prevent movement during use.

When using flexible tubing, the suction tubing must have a wall thickness that will not collapse under

vacuum, particularly when going around bends.

Circulating Bath Height Regulation — Position the ends of the pressure and suction tubes at the desired

maximum fluid level in the external bath and fill the bath to that level. Fill the Circulating Bath to a height

one inch (25mm) below the top of the reservoir. Start the pump and adjust the restricting valve/pinch clip

on the pressure tubing until the liquid height in both baths remains constant. Add fluid to the baths as

needed to compensate for the fluid in the inlet and outlet lines.

110-513 PSC/EN 17

Page 18

Refrigeration Control Connections (Refrigerating/Heating Circulators only)

Refrigeration Control Connection

Refrigeration Control Connection

Refrigeration Control Cable

Electrical Power

WARNING: The Circulator’s power cord must be connected to a properly grounded electrical

receptacle. Make certain that this electrical outlet is the same voltage and frequency as your

Circulator. The correct voltage and frequency for your Circulator are indicated on the identification

label on the back of the Controller.

CAUTION: The use of an extension cord is not recommended. If one is necessary, it must be

properly grounded and capable of handling the total wattage of the unit. The extension cord must not

cause more than a 10% drop in voltage to the unit.

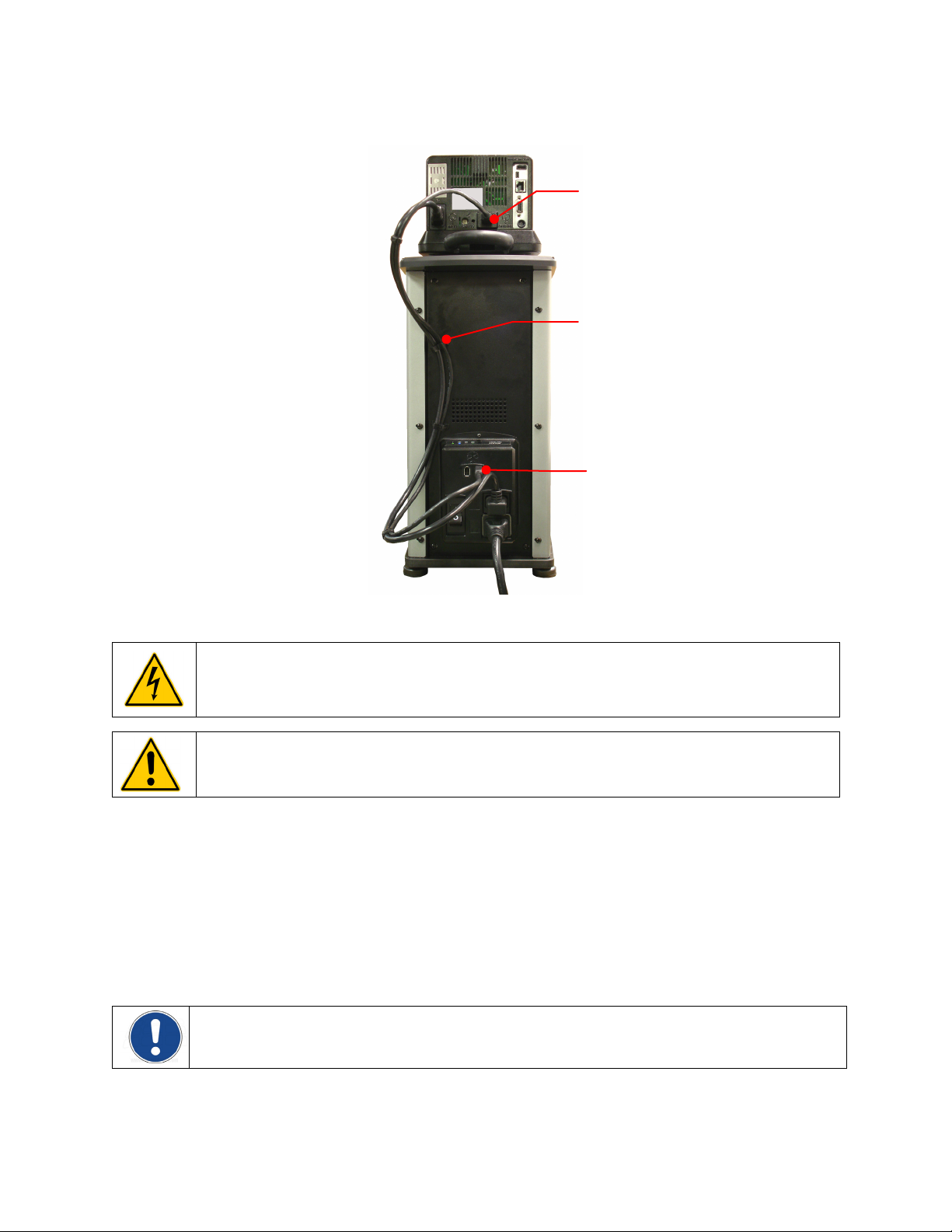

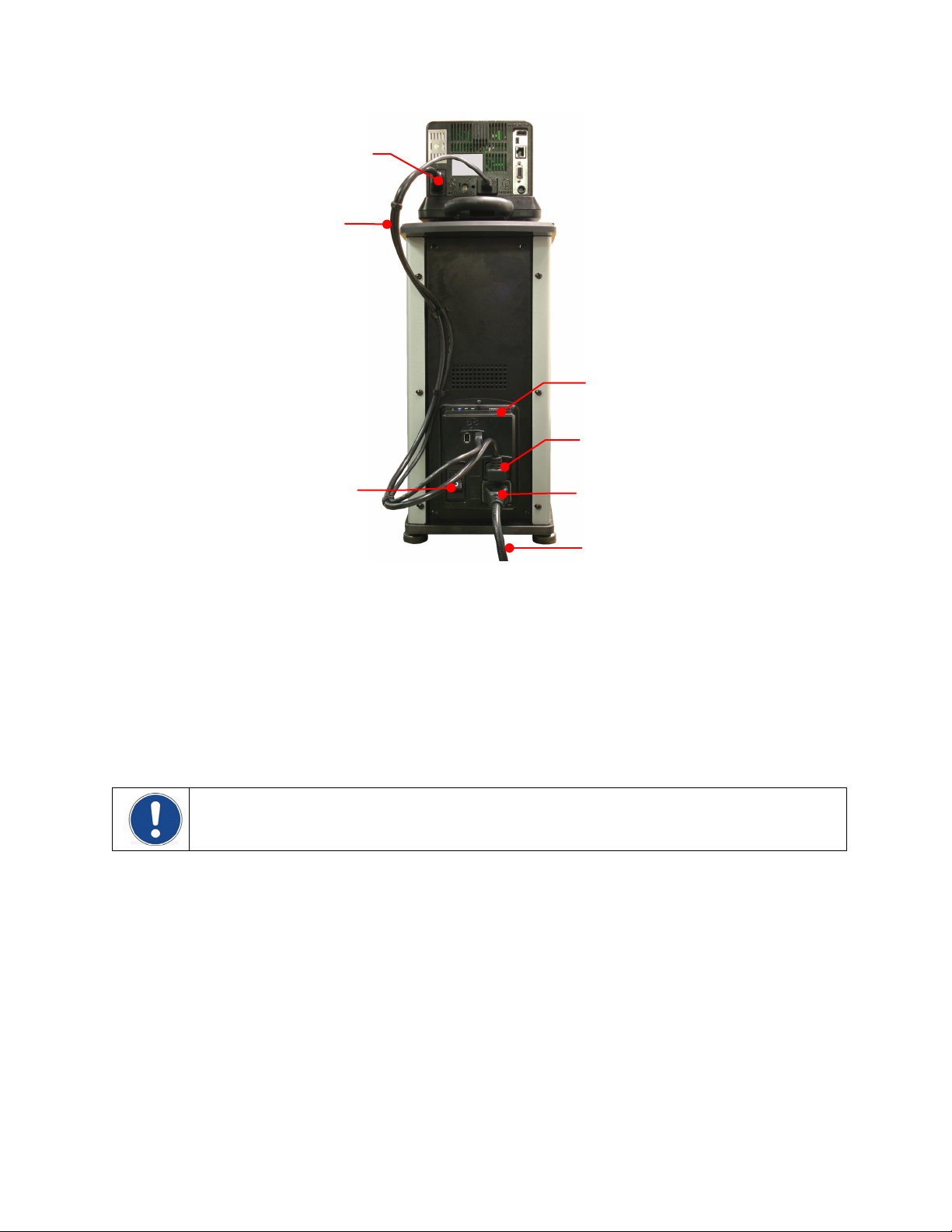

Refrigerating / Heating Circulators

Attach the 3-ft / 0.91 m power cord to the IEC electrical connectors on the Temperature Controller (male)

and the Refrigeration Power Module (female).

Attach the 6-ft / 1.8 m power cord to the IEC electrical connection on the Refrigeration Power Module and

then plug the male connector into the Mains electrical outlet.

Place the Power Switch / Circuit Breaker on the Refrigeration Power Module in the ON position. The LCD

on the Controller will light and “Standby” will appear on the display; the PolyScience logo and the Power

Key will also light.

NOTE: To conserve power when not in use, the LCD’s backlighting will go out about 5 seconds after

“Standby” appears. The Power Key and PolyScience logo will remain lit to indicate that the Controller is

energized and ready to use.

110-513 PSC/EN 18

Page 19

IEC Power Connection to

Refrigeration Power Module

IEC Power Connection to Mains

IEC to IEC Power Cord

Refrigeration Power Module

IEC Power Connection to Controller

IEC to Mains Power Cord

Power Switch / Circuit Breaker

Heat Only Circulators and Open Bath Systems

Attach the 6-ft / 1.8 m power cord to the IEC electrical connection on the Temperature Controller and then

plug the male connector into the Mains electrical outlet.

Place the Power Switch / Circuit Breaker on the Temperature Controller in the ON position. The LCD on

the Controller will light and “Standby” will appear on the display; the PolyScience logo and the Power Key

will also light.

NOTE: To conserve power when not in use, the LCD will go black about 5 seconds after “Standby”

appears. The Power Key and PolyScience logo will remain lit to indicate that the Controller is energized

and ready to use.

110-513 PSC/EN 19

Page 20

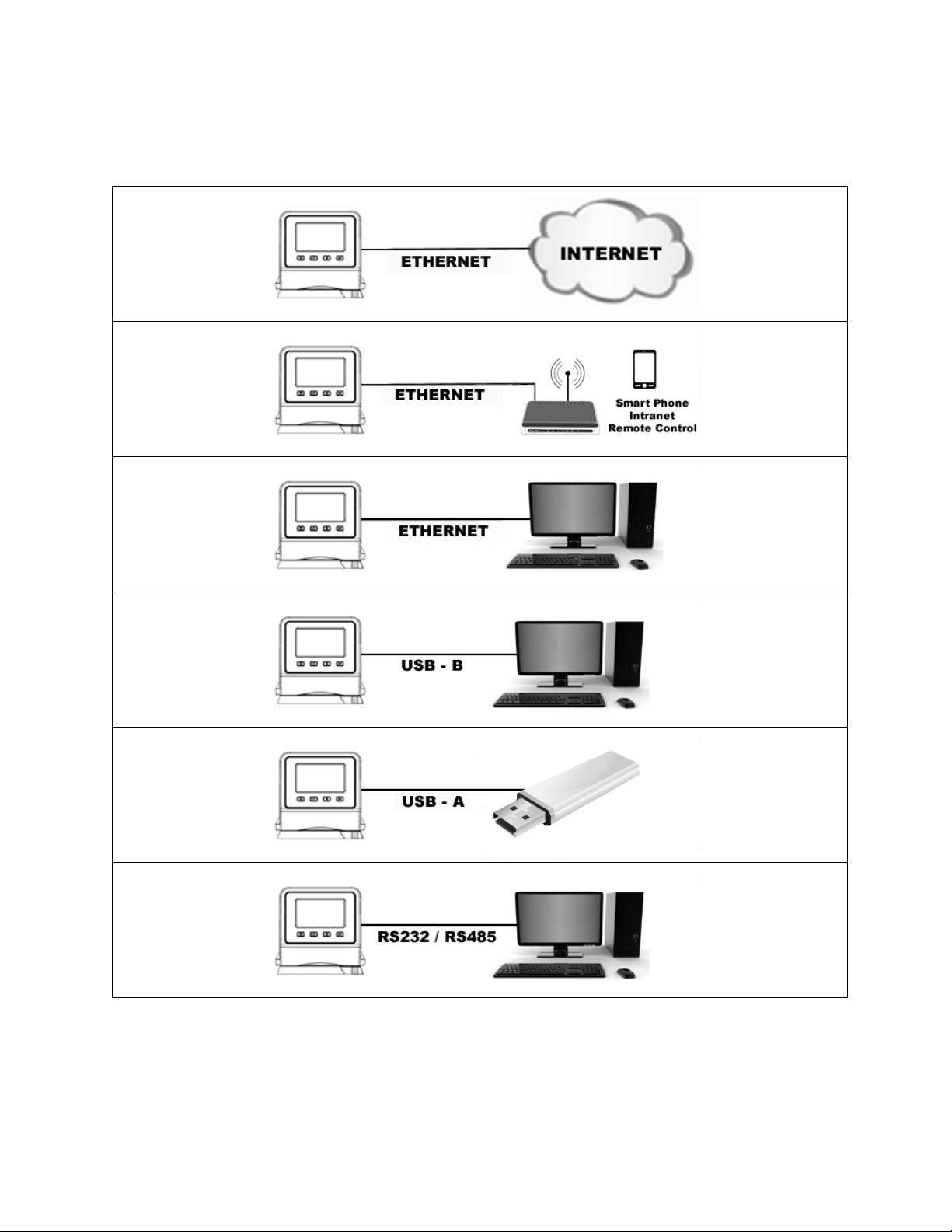

Communication

The Advanced Digital Controller features a variety of connectivity options. Following are some typical

ways you can use them to monitor and control the operation of your Circulator.

110-513 PSC/EN 20

Page 21

USB Communication

Two USB ports (A and B) are provided on the rear of the Temperature Controller. USB A is intended for

use with a flash drive and allows you to easily log temperature data. USB B allows you to remotely

monitor and control your Circulator using a computer. See Normal Operation, Selecting a Remote

Communication and Control Protocol and the Technical Information section of this manual for additional

information.

Ethernet

An Ethernet port is provided on the back of the Temperature Controller to enable you to connect your

Circulator to a computer network. See Normal Operation, Selecting a Remote Communication and

Control Protocol and the Technical Information section of this manual for additional information,

RS232 / RS485 Serial Communication

CAUTION: Always turn electrical power to the Circulator OFF before making a connection to the

serial (DB9) port.

Your Circulator features RS232 / RS485 serial communication for remote data logging and control

capability. A DB9 connector is provided on the rear of the Temperature Controller for this purpose. See

Normal Operation, Selecting a Remote Communication and Control Protocol and the Technical

Information section of this manual for additional information.

The serial interface should be connected to a serial communication port on a remote PC using an

appropriate cable. Information on the RS232 / RS485 command and communication protocol can be

found in the Technical Information section of this manual.

External (P2) Temperature Probe

Your Circulator is capable of controlling temperature based on either the temperature of the internal bath

or that of an external vessel or device. The connection for the optional external temperature probe is on

the rear of the Temperature Controller. The Temperature Controller automatically detects the external

temperature probe when it is connected. See Replacement Parts & Accessories for available lengths and

part numbers.

Pin Out Diagrams — External (P2) Temperature Probe Connection

MAXIMUM OPERATING TEMPERATURE @ 200 C, CLASS A 0.003850 OHMS/DEGREES C.

110-513 PSC/EN 21

RTD SENSOR: 4 WIRE CIRCUIT, 100 OHMS @ 0 DEGREES C,

Page 22

Controller Setup

Heating symbol

Circulating symbol

Refrigerating symbol

Control probe

Actual bath

temperature

Set point

temperature

Power

Press

. The Circulator will begin running, actual and set point temperatures will be displayed, and the

word “SET” will be continuously lit. The pump symbol will also be lit and the heating or refrigerating

symbol may be lit or flashing.

Internal (P1) control only – external probe (P2) not connected

110-513 PSC/EN 22

Page 23

Safety Set Temperature

Current Safety

Set Temperature

Safety Set

menu

Safety Set Thermostat

This is a “Do Not Exceed” temperature setting for your Circulator and is the temperature at which the

heater will be turned OFF should the liquid level in the bath drop too low or the heater malfunctions. It is

normally set about 5° higher than the desired operating temperature. Setting the Safety Set temperature

is a simple 3-step procedure.

WARNING: The Safety Thermostat is user-adjustable from approximately 100° to 220°C / 312° to

428°F. Do not force the indicator dial beyond the stops at either end of the dial’s range.

1. Press the

sub-

2. Using a No.1 Philips head screwdriver, rotate the Safety Thermostat on the rear of the Temperature

Controller until the desired Safety Set Temperature is displayed (clockwise to increase; counterclockwise to decrease).

key until SAFETY appears.

3. Press

110-513 PSC/EN 23

to return to the main operational screen.

Page 24

Normal Operation

Keys and Controls

Power

Home

Menu

SET

Touch Scroll

Bar

Turns the Circulator’s Temperature Controller ON.

Returns the LCD to the Main Operational Display (from any screen).

Accesses the Temperature Controller’s set-up sub-menus. The items in

these sub-menus are used to configure the Controller’s general

operational parameters (temperature unit, pump speed, upper and low

temperature limits, etc. (see Set-up Sub-Menus, below).

Used in conjunction with the Touch Scroll Bar to change the set point

temperature and some operational parameters.

Used to make temperature set point and other operational changes. Slide finger

up / down scroll bar or touch upper / lower sections to make minor adjustments;

hold your finger on the scroll bar to make large adjustments.

Turning Your Circulator ON

Press the key.

When the Circulator begins running, the actual and set point temperatures will be displayed and the

circulating symbol will be lit. If the optional external temperature probe is connected, a temperature value

will also be displayed along the bottom of the screen. This is the bath temperature measured by the noncontrolling (monitor) probe.

If the actual bath temperature is lower than the set point temperature, the heating symbol will also be lit.

Refrigerating/Heating Models: If the actual bath temperature is higher than the set point temperature, the

refrigerating symbol will be lit. It is normal for both the heating and refrigerating symbols to be lit

simultaneously when nearing or maintaining the set point temperature.

110-513 PSC/EN 24

Page 25

Main Operational Display (Home)

Heating symbol

Control probe (internal or external)

Circulating symbol

Refrigerating symbol

Actual fluid temperature

as measured by control

probe

Set point

temperature

Monitoring probe ID

P2 = External

Bath temperature

as measured by

monitoring probe

This is the Circulators main operational display. You can return to this screen at any time by pressing the

key.

Internal (P1) control only – external probe (P2) not connected

Internal (P1) control – external probe (P2) connected

110-513 PSC/EN 25

Page 26

External (P2) control

Bath temperature

as measured by

monitoring probe

Monitoring probe ID

P1 = Internal

110-513 PSC/EN 26

Page 27

Set-Up Sub-Menus

Pressing the

key accesses and scrolls through the Temperature Controller’s set-up sub-menus. The

Touch Scroll Bar is used to change the current setting / value in the sub-menus.

Sub-Menu Description Selection / Range

UNIT

PUMP Pump speed Variable – 5 to 100 40

HI LIM High limit temperature

LO LIM Low limit temperature

SET DIFF

AUTOCOOL

SHC

CONTROL Internal or external temperature control

OFFSET / CALIBRATION

SAFETY Safety Set Temperature ~40° to 240°C N/A

COM Remote communication and control

TIMER Count down timer with audible signal

PASSWORD

USB LOG Turns data logging ON and OFF No (OFF) or Yes (ON) No (OFF)

ENGLISH

pODO Operational hours on pump Display only N/A

cODO Operational hours on compressor Display only N/A

AUTO-ON

Unit in which temperature is set and

displayed

Maximum allowable difference between

the measured internal and external

temperatures

Temperature at which refrigeration is

activated

The specific heat capacity of the bath

fluid

Calibration or display offset value

Password required

Permits access to Calibration and

Diagnostic screens

Language in which information will be

displayed

Determines how unit will restart after a

disruption in electrical power

°C or °F °C

25° to 202°C /

80° to 395°F

-52° to 20°C /

-65° to 65°F

2° to 20°C 10°C

1° to 150°C 45°C

0.10 to 2.00 1.00

P1 (Internal) or

P2 (External)

-3.0°C to +3.0°C 0.0°C

RS232, RS485, USB,

Ethernet

1 second to

999 minutes, 59

seconds

10 = Diagnostic

screen

12 = Access Calibrate

English, French,

German, Spanish

ON or OFF OFF

Factory

Default

202°C / 395°F

-52°C / -65°F

P1

RS232

000:00

0

English

To accept a value in a sub-menu, press

, , or allow the LCD to return to the main

,

operational display ( approximately 10 seconds).

110-513 PSC/EN 27

Page 28

Adjusting the Temperature Set Point

Press SET once to change

whole degree values

Press

changes of less than a degree

(decimal point will flash)

Touch and hold up/down

arrows to make large changes

Touch and release arrows

slide finger up/down scroll bar

to make small changes

This is the temperature at which the fluid in your Circulating Bath will be maintained. It may be set to onehundredth of a degree over a range of -50.00° to +200.00°C / -60.00° to +390°F. The factory default set

point is +20.0°C / +68.0°F.

or

SET twice to make

To Change: Press . The arrow around the word “SET” will begin flashing. To make

changes of one degree or more, touch the scroll bar until the desired set point

temperature is displayed. To make changes of less than a degree, (e.g.,0.50°C), press

a second time. The decimal point will begin flashing. Touch the scroll bar until the

desired value is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

NOTE: An audible alarm and the words Low Limit or High Limit flashing on the display indicate that the

temperature set point value is outside the Low Limit or High Limit value. The Circulator will continue to

heat/cool until the actual bath temperature reaches the Limit value, at which point operation will stop.

110-513 PSC/EN 28

Page 29

Selecting the Temperature Unit

Touch top for degrees C

Touch bottom for degrees F

The temperature units sub-menu (°C / °F) allows you to select the temperature unit in which the actual

bath temperature and set point temperature are displayed. The factory default is °C.

To Access: Press the

key until UNIT is displayed.

To Change: To select °F, touch the bottom portion of the scroll bar; to select °C, touch

the top portion of the scroll bar.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 29

Page 30

Selecting the Pump Speed

Touch and hold up/down

arrows

Touch and release to make

minor changes

This sub-menu allows you to set your Circulator’s pump speed. The pump speed range is 5 to 100; the

factory default is 40.

to make large changes

To Access: Press the

key until PUMP is displayed.

To Change: Touch the scroll bar until the desired pump speed is displayed (5 minimum,

100 maximum).

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 30

Page 31

Setting the High Limit Temperature

Touch and hold up/down

arrows

changes

Touch and release to make

minor changes

This sub-menu allows you to limit how high the temperature set point may be set. It also serves as a high

limit safety, alerting you if bath temperature rises above the high limit temperature setting. The High Limit

value may be set from +25° to +202°C / +80° to +395°F; the factory default is 202°C.

To avoid an unwanted shutdown during regular operation, the High Limit value should be set at least 5°

higher than the selected control temperature.

to make large

To Access: Press the

key until HI LIMIT is displayed.

To Change: Touch the scroll bar until the desired high limit temperature is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 31

Page 32

Setting the Low Limit Temperature

Touch and hold up/down

arrows

changes

Touch and release to make

minor changes

This sub-menu allows you to limit how low the temperature set point may be set. It also serves as a low

limit safety, alerting you if bath temperature falls below the low limit temperature setting. The Low Limit

value may be set from -52° to +20°C / -65° to +65°F; the factory default is -52°C.

To avoid an unwanted alarms or shutdown during regular operation, the Low Limit value should be set at

least 5° lower than the selected control temperature.

to make large

To Access: Press the

key until LO LIMIT is displayed.

To Change: Touch the scroll bar until the desired low limit temperature is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 32

Page 33

Setting the Differential Temperature

Touch and hold up/down

arrows

changes

Touch and release to make

minor changes

This sub-menu is for use when external temperature control (P2) is being used. It establishes the

maximum allowable differential between the external and internal measured temperatures and is intended

prevent uncontrolled heating or cooling should the external temperature probe be dislodged or fail. The

differential temperature may be set from 2° to 20°C; the factory default is 10°C.

to make large

To Access: Press the

To Change: Touch the scroll bar until the desired P2 - P1 (external – internal )

temperature differential displayed.

key until SET DIFF is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

CAUTION: The Differential Temperature value is always shown in degrees C, even if degrees F is

selected as the temperature unit in which the control and actual bath temperatures are displayed.

110-513 PSC/EN 33

Page 34

Setting the Auto Cool Temperature

Touch and hold up/down

arrows

changes

Touch and release to make

minor cha

This sub-menu is displayed only on Refrigerating / Heating Circulators. It determines the set point

temperature at which refrigeration will be activated and permits more precise control when operating at

high temperatures as well as more rapid cool downs. For most applications, a set point that is 15°C above

room temperature is recommended. The Auto Cool control range is from +1°C to 150°C. The refrigeration

system will turn on when the bath temperature set point (150°C maximum) is below the Auto-Cool set

point. The factory default is 45°C.

Cool Command™ Refrigeration — -40°C 7 liter Refrigerating/Heating Circulators and 15 liter and larger

Refrigerating/Heating Circulators feature the Cool Command™ modulating refrigeration control system.

Cool Command allows the refrigeration system to turn on at a fluid temperature up to 150°C when the

temperature set point is changed to or below the Auto Cool set point (150°C maximum). As a result, bath

fluid cools more quickly.

Conventional Refrigeration — -20°C 7 liter Refrigerating/Heating Circulators use a conventional

refrigeration system. The refrigeration system will turn on when the bath fluid temperature and set point

are below the Auto Cool set point (70°C maximum).

to make large

nges

To Access: Press the

until AUTOCOOL is displayed.

To Change: Touch the touch scroll bar or touch the arrow symbols until the desired auto

cool temperature is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 34

Page 35

Setting the Specific Heat Capacity (SHC)

Touch and hold up/down

arrows to make large changes

Touch and release to make

minor changes

This sub-menu allows you to tune the Circulator’s control algorithm for the specific heat capacity

(SHC) of the fluid you are using. The factory default is 1.00.

To Access: Press the

key until SHC is displayed.

To Change: Touch the touch scroll bar or touch the arrow symbols until the desired

specific heat capacity value is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 35

Page 36

Selecting Internal or External Temperature Control

Touch top for P1 (internal)

Touch bottom for P2 (external)

This sub-menu lets you determine whether temperature control will be based on the fluid temperature

within the Circulator’s reservoir or the fluid temperature at an external device.

To Access: Press the

key until CONTROL is displayed.

To Change: Touch the scroll bar until the desired temperature probe is displayed. P1 =

Internal; P2 = External.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

If P2 is selected but an external temperature probe is not connected to the Temperature Controller, P2

UNPLUGGED will appear on the display.

110-513 PSC/EN 36

Page 37

Calibrating Your Circulator (Offset)

Touch top arrow to

increase offset

Touch bottom arrow to

decrease offset

These two sub-menus allow you to match the Circulator’s internal and/or external temperature probe to

an external reference thermometer. A value from -3.0°C to +3.0°C may be entered; the factory default is

0.0°C.

CAUTION: The Offset Calibration value is always shown in degrees C, even if degrees F is selected as

the temperature unit in which the control and actual bath temperatures are displayed. Your Circulator

will automatically convert the °C offset calibration value to the correct °F display offset value.

NOTE: If you attempt to calibrate the Circulator when OFFSET is displayed, Password! will appear at

the bottom of the screen. To proceed, advance to the PASSWORD sub-menu, enter 12, and then

return to this sub-menu.

Protected – Password Required

Unlocked

To Access: Press the

key until the calibration sub-menu for the temperature probe

you wish to calibrate (P1 or P2) is displayed. If this function has been locked, OFFSET

will appear and must be unlocked before changes can be made; if this function has been

unlocked, CALIBRATE will appear.

To Change: Touch the scroll bar or touch the arrow symbols until the desired calibration

temperature displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 37

Page 38

Displaying the Safety Set Temperature

This display shows the current Safety Set Temperature.

NOTE: If you attempt to set the Safety Set temperature using the scroll bar, Rear Adjust will appear at

the bottom of the screen. Use the Safety thermostat on the rear of the Temperature Controller to adjust

the Safety Set temperature.

To Access: Press the

key until SAFETY is displayed.

To Change: This is a display only. The Safety Set Temperature is changed using the

Safety thermostat on the rear of the temperature controller. The temperature value shown

on the display will change as the thermostat is adjusted.

To Exit: Press

, , or allow the LCD to return to the main operational display

,

(approximately 10 seconds).

110-513 PSC/EN 38

Page 39

Selecting a Remote Communication and Control Protocol

Touch top arrow for Ethernet

Touch areas between the

arrows for USB and RS485

Touch bottom arrow RS232

This sub-menu allows you to select the protocol you want to use for remote communication and control.

The choices are RS232, addressable RS485, USB, and Ethernet; the factory default is RS232.

To Access: Press the

key until COM and the currently selected protocol appears on

the display.

To Change: To select RS232, touch the down arrow; to select Ethernet, touch the top

arrow. RS485 and USB protocols are selected by touching areas on the scroll bar that lie

between the two arrows.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

CAUTION: Although you can accept the displayed protocol by pressing either the Home, Menu, or

SET keys, we recommend using the Menu key the first time a protocol is selected as there are

additional parameters that must be configured when RS232, RS485, or Ethernet is selected. This will

ensure that you are prompted to configure those parameters. See Technical Information,

RS232/RS485 Configuration and Technical Information, Ethernet Configuration for additional

information.

NOTE: See Technical Information, USB Setup, Monitoring, and Control for information on controlling

your Circulator via the USB-B port.

110-513 PSC/EN 39

Page 40

Using the Timer

Touch and hold up/down

arrows to set long

durations

Touch and release

short durations

This sub-menu allows you to set and activate the Temperature Controller’s count-down timer. Any time

duration from 1 second to 999 minutes, 59 seconds can be entered.

set

changes

To Access: Press the

key until TIMER is displayed.

To Change: Touch the scroll bar until the desired time duration is displayed.

To Start the Timer: Press

To Pause the Timer: Press

To restart the timer, return to the Timer sub-menu and press

, The timer will begin counting down.

. The display will revert to the main operational display.

.

The timer counts down in one second increments until it reaches 000:00. At this point, the time display

flashes and an audible signal is activated. Press

NOTE: You can access other menu functions while the timer is running without affecting the count

down.

to acknowledge and deactivate.

110-513 PSC/EN 40

Page 41

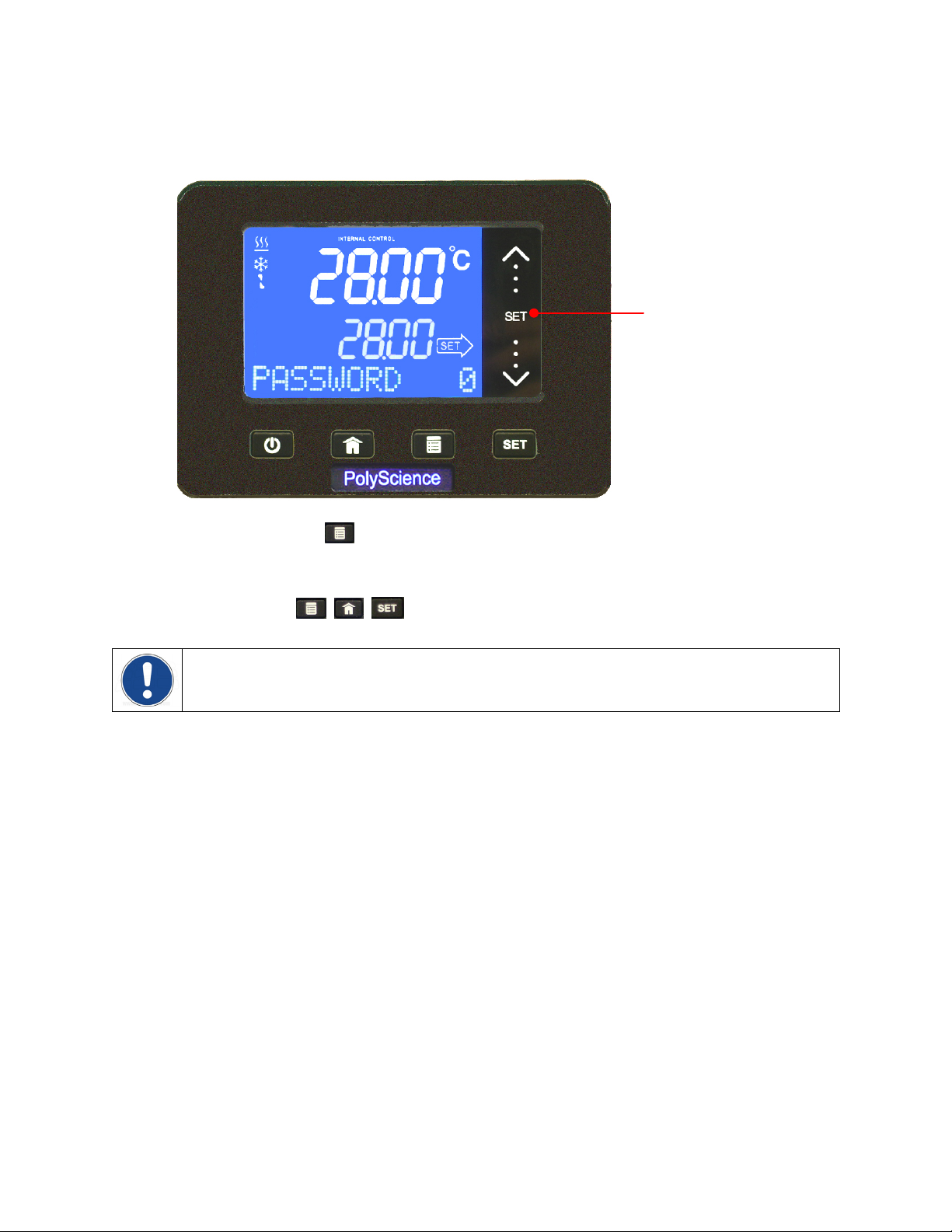

Entering a Password

Touch arrows to enter

the

This sub-menu allows access to the Calibration and Diagnostic sub-menus.

numeric password

To Access: Press the

key until PASSWORD is displayed.

To Change: Touch the scroll bar until the password needed to access the desired submenu is displayed. Calibration = 12; Diagnostic = 10)

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

IMPORTANT: Once a password has been entered and accepted, the function it enables stays

unlocked until either a new password is entered or the Circulator is turned OFF.

110-513 PSC/EN 41

Page 42

Enabling / Disabling Data Logging

Touch top arrow to turn

data logging ON

Touch bottom arrow to

turn data logging OFF

(No)

This sub-menu allows you to turn data logging ON and OFF.

IMPORTANT: This Advanced Digital Temperature Controller has both USB A and USB B ports. USB A

is used for data logging; USB B is used for remote monitoring and control. Data is stored in a CSV file

that can be read in spreadsheet programs such as Microsoft Excel

flash drive into the USB A port and then set USB LOG to YES.

®

. To begin data logging, plug a

(Yes)

To Access: Press the

key until USB LOG is displayed.

To Change: Touch the scroll bar until the desired status is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

NOTE: See the Technical Information for complete information regarding data logging file formats and

content.

110-513 PSC/EN 42

Page 43

Selecting the Operational Language

Touch top arrow to scroll up

through language list

Touch bottom arrow to scroll

down through language list

This sub-menu allows you select the language in which information will be displayed. The choices are

English, Spanish, French, and German; the factory default is English.

To Access: Press the

key until the current language is displayed.

To Change: Touch the scroll bar until the desired language is displayed.

To Accept: Press

, , or allow the LCD to return to the main operational

,

display (approximately 10 seconds).

110-513 PSC/EN 43

Page 44

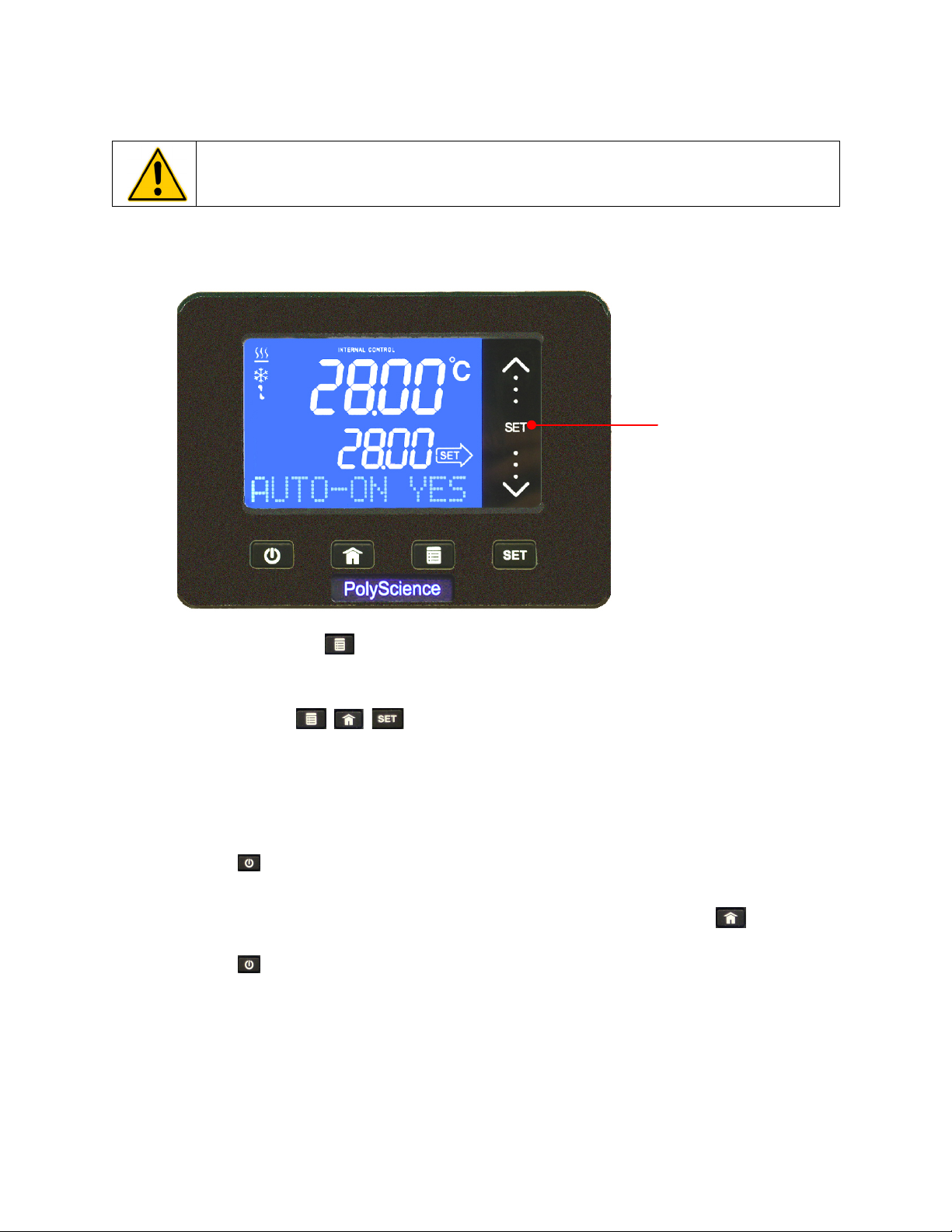

Setting Auto Restart

Touch top arrow to

turn Auto

(

Touch bottom arrow to

turn OFF (NO)

WARNING: The unit may start automatically after a disruption in electrical power.

This sub-menu allows you to select how the unit will begin operating after a disruption in electrical power.

When Yes is selected, the Circulator will begin running automatically when power is restored. When No is

selected, the Circulator will power up in the Standby mode.

-On ON

YES)

To Access: Press the

To Change: Touch the top of the scroll bar to select Yes (ON); touch the bottom of the

scroll bar to select No (OFF).

To Accept: Press

display (approximately 10 seconds).

key until AUTO-ON is displayed.

, , or allow the LCD to return to the main operational

,

Resetting the Factory Default Values

To reset your Circulator to its original factory default values, proceed as follows:

1. Press the

key to place the unit in Standby.

2. Place the Power Switch / Circuit Breaker in the OFF position.

3. Return the Power Switch / Circuit Breaker to the ON position while pressing the

“STANDBY” appears on the display.

4. Press the

key.

key until

110-513 PSC/EN 44

Page 45

Changing Your Circulator’s Viewing Angle

Swivel 180™ latch release

Your Circulator is equipped with Swivel 180™, an innovative feature which permits viewing of the

temperature display from anywhere within a 180° radius.

NOTE: There are positive stops at 45° intervals; however, the viewing angle may be set

anywhere within a 180° radius.

To change the viewing angle, slide the release latch to the right and rotate the

Temperature Controller to the desired angle. The latch release will

automatically return to the locked position at every 45° positive stop.

Inert Gas Purge

A 0.125 in. / 3 mm port on the rear of the Temperature Controller is provided to allow you to blanket the

surface of the liquid in the bath reservoir with nitrogen or another inert gas to help prevent condensation

and dilution of the bath fluid.

Tap Water Cooling

Tap water cooling allows for more rapid bath cool down from high temperatures and/or more precise

operation at temperatures near ambient.

Heat only Circulating Baths feature an integrated cooling coil as standard equipment. The tap water

connections are made on the rear of the unit. Two 0.25 inch / 6.4 mm female NPT fittings are provided for

these connections.

Polycarbonate Viscosity Baths feature a cooling coil with two 0.375 inch / 9.5 mm OD straight barb

fittings at which the fluid inlet and outlet connections can be made. Either connection may serve as the

fluid inlet or outlet. Be sure to secure the tubing with the appropriate size hose clamps.

An optional cooling coil is available for use on Stainless Steel Open Bath systems. This cooling coil has

two 0.375 inch / 9.5 mm OD straight barb fittings at which the fluid inlet and outlet connections can be

made. Either connection may serve as the fluid inlet or outlet. Be sure to secure the tubing with the

appropriate size hose clamps.

WARNING: The fluid outlet must be connected and flow to a suitable drain or vessel located at a

level below that of the inlet.

110-513 PSC/EN 45

Page 46

Reservoir Cover Storage

Lid Positioning

Notch

Lid Positioning

Notch

Refrigerating/Heating and Heat Only Circulating Baths feature the LidDock® system to eliminate mess

when adding fluid or samples to the reservoir. Specially positioned notches in the inner lip of the top deck

allow you to stand the reservoir cover up upright over the bath opening, allowing condensate to flow back

into the bath.

110-513 PSC/EN 46

Page 47

Display Messages and Alarms

Message and/or

Symbol

POWER FAILED

WARNING!

LOW LIMIT!

WARNING!

HIGH LIMIT!

FAULT!

LOW LIMIT!

FAULT!

HIGH LIMIT!

Description Corrective Action

Informational: Indicates that electrical

power was lost during operation;

appears only when Auto-On is set to

Yes.

Warning: The fluid temperature or

temperature set point is below the Low

Limit value.

(Message flashes, audible beep)

Warning: The fluid temperature or

temperature set point is above the High

Limit value.

(Message flashes, audible beep)

Fault: The bath temperature has fallen

below the Low Limit temperature value.

Power to the compressor and pump will

remain OFF until the problem is

corrected.

(Message flashes, continuous tone)

Fault: The bath temperature risen has

above the High Limit temperature value.

Power to the heater and pump will

remain OFF until the problem is

corrected.

(Message flashes, continuous tone)

Press key to clear the message.

Decrease the Low Limit temperature value or

increase the temperature set point.

If problem is not corrected within about 30

seconds, the Circulator will go into a Low Limit

Fault condition and operation will cease.

Increase the High Limit temperature value or

decrease the set point temperature.

If problem is not corrected within about 30

seconds, the Circulator will go into a High Limit

Fault condition and operation will cease.

Press

then decrease the Low Limit temperature value

or increase the temperature set point.

Controller failure; consult factory.

Press

then increase the High Limit temperature value

or decrease the temperature set point.

Controller failure; consult factory.

to turn power OFF. Restore power and

to turn power OFF. Restore power and

Fluid level in reservoir has fallen below minimum

level; add fluid as required.

Fluid temperature is higher than Safety Set

temperature; increase Safety Set temperature

setting.

Controller failure; consult factory.

Reconnect external probe, turn power OFF and

then back ON.

If problem persists, replace external probe or

operate using Internal Control.

FAULT!

EXT PROBE 2

Fault: The liquid in the bath has

dropped too low or the temperature of

the bath fluid has exceeded the Safety

Set temperature. Power to the heater

will remain OFF until the problem is

corrected.

Fault: The external temperature probe

has been disconnected. Appears only

when using External Control.

(Message flashes, continuous tone)

Informational Messages — Do not disrupt normal operation. Clear by pressing the key.

Warnings — Circulator operation continues unless left uncorrected for approximately 35 seconds. Press

the

key to silence the audible signal. Correct problem and press the key a second time to clear

Warning.

Faults — Circulator operation is halted (heater, pump, and compressor turn OFF). Press the

silence the audible signal. Press

110-513 PSC/EN 47

to turn power OFF and then restore power and correct the problem.

key to

Page 48

Routine Maintenance and Troubleshooting

Drain Valve

Drain Port

WARNING: Always turn your Circulator OFF and disconnect it from the electrical power outlet before

performing any maintenance or service.

WARNING: To avoid the potential for burns, allow the Circulator to cool completely before cleaning

or performing any maintenance.

Maintaining Clear Bath Water

Optimum temperature and moisture conditions for algae growth exist when using water as a bath fluid. To

prevent algae contamination and minimize the frequency of draining the reservoir, an algaecide such as

Polyclean Bath Algaecide (004-300040) should be used.

WARNING: Do not use chlorine bleach.

Draining the Bath Reservoir

WARNING: Bath fluids should be stored and disposed of according to applicable laws and

regulations.

Refrigerated / Heating and Heat only Circulating Baths

Refrigerated / Heating and Heat only Circulating Baths are equipped with a drain valve and port located

either beneath the front access panel or on the right hand side of the unit.

To drain fluid from the bath, attach a short length of suitable 0.45 inch / 11.5 mm ID tubing to the drain

port and secure it using a hose clamp with a minimum ID of 0.7 inch / 18 mm. Open the drain valve using

a flat blade screwdriver. When closing the valve, do not over tighten.

WARNING: Be sure to close the drain valve before refilling the bath reservoir. Do not over tighten.

110-513 PSC/EN 48

Page 49

Polycarbonate Viscosity Baths

Polycarbonate Viscosity Baths are equipped with a drain port. To drain fluid from these baths, remove the

knurled cap.

WARNING: Be sure to replace and tighten knurled cap before refilling the bath reservoir. Do not over

tighten.

110-513 PSC/EN 49

Page 50

Checking the Over-Temperature / Low Liquid Level Safety Systems

Safety Set Temperature

Safety Set

Thermostat

Your Circulator incorporates over-temperature and low liquid level protection according to IEC 61010-2-

010. For optimum safety, these systems should be checked at least every six months for proper

operation. These checks must be performed with the unit running.

Over-Temperature Protection

1. Press

until the Safety sub-menu is displayed.

2. Using a No.1 Philips head screwdriver, rotate the Safety Set

Thermostat on the rear of the Temperature Controller until the unit

shuts down. The Safety Set temperature at this point should be the

same as the actual bath temperature.

3. Return the Safety Set temperature to the desired over-temperature

value.

4. Press the

Low Liquid-Level Protection

1. Set the temperature set point to ambient and allow the Circulator to stabilize at that temperature.

2. Increase the temperature set point to about 5°C above ambient and slowly drain fluid from the bath.

3. Continue draining fluid until the unit shuts down. The fluid level at this point should be approximately

3.75 in. / 9.5 cm below the underside of the Circulator’s top deck.

4. Replace the bath fluid and return to normal operation.

key to return to the Main Operational Display.

110-513 PSC/EN 50

Page 51

Cleaning Your Circulator

Reusable

ilter

WARNING: It is the user’s responsibility to properly decontaminate the unit in the event hazardous

materials are spilled on exterior or interior surfaces. Consult the manufacturer if there is any doubt

regarding the compatibility of decontamination or cleaning agents.

Temperature Controller

Turn the Temperature Controller OFF by pressing

and unplug power cord from the electrical outlet.

Wipe the housing with a clean cloth dampened with a mild detergent and water or mild all-purpose

cleaner.

CAUTION: Do not spray cleaning liquids directly onto the Temperature Controller or allow them to

enter the Controller’s vents. Do not use abrasives as these could scratch the housing or the digital

display.

Bath Reservoir

Bath Reservoir and Wetted Components — A concentrated bath cleaner (polyclean Bath Cleaner, part

number 004-300050) is available to remove mineral deposits from the stainless steel reservoir and the