Page 1

Operator’s Manual

Model 4100 and 4200 Series Liquid-to-Liquid

Coolers

110-497 09 March 2020

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Table of Contents

Introduction ...............................................................................................................................................................3

General Safety Information .....................................................................................................................................3

Safety Recommendations .......................................................................................................................................4

Unpacking Your Liquid-to-Liquid Cooler .................................................................................................................4

Regulatory and Compliance Testing .......................................................................................................................4

Contents ..................................................................................................................................................................4

Controls and Components ......................................................................................................................................5

Front Control Panel .................................................................................................................................................5

Rear Panel ..............................................................................................................................................................5

Installation and Startup ............................................................................................................................................6

Site Requirements ..................................................................................................................................................6

Ambient Temperature and Relative Humidity .....................................................................................................6

Location ...............................................................................................................................................................6

Clearance ............................................................................................................................................................6

External Piping ........................................................................................................................................................6

General Considerations .......................................................................................................................................6

Process Fluid Connections ..................................................................................................................................7

Facility Water Connections ..................................................................................................................................7

Process Coolant ......................................................................................................................................................7

Electrical Power ......................................................................................................................................................8

Main Power Connection ......................................................................................................................................8

Optional Serial Output (RS-232) .............................................................................................................................8

Optional Dry Contact Remote ON/OFF ..................................................................................................................8

Startup .....................................................................................................................................................................9

Normal Operation .................................................................................................................................................. 10

Electrical Power ................................................................................................................................................... 10

Selecting the Temperature Unit ........................................................................................................................... 10

Displaying and Adjusting the Set Point ................................................................................................................ 10

Setting Operational Parameters ........................................................................................................................... 11

High Temperature Limit (HL) ............................................................................................................................ 11

Low Temperature Limit (LL) ............................................................................................................................. 11

High Ambient Temperature Limit (HA) ............................................................................................................. 12

Maximum Fluid Pressure (FP) .......................................................................................................................... 12

Minimum Flow Rate (FL) .................................................................................................................................. 12

Calibration Offset (°C) ...................................................................................................................................... 13

Flow Calibration (Fc) ........................................................................................................................................ 13

Baud Rate (PC) ................................................................................................................................................ 14

Adjusting the High Pressure Bypass Setting ..................................................................................................... 14

Display, Alarm and Error Messages .................................................................................................................... 15

Enabling / Disabling the Local Lockout .............................................................................................................. 17

Routine Maintenance and Troubleshooting ....................................................................................................... 18

Routine Maintenance ........................................................................................................................................... 18

Air Vents ........................................................................................................................................................... 18

Process and Facility Line Strainers .................................................................................................................. 18

In-Line Fluid Filter ............................................................................................................................................. 18

Fluid Level ........................................................................................................................................................ 18

Software Version .............................................................................................................................................. 18

Draining the Unit .................................................................................................................................................. 19

Troubleshooting Chart ......................................................................................................................................... 19

Technical Information ........................................................................................................................................... 20

Performance Specifications ................................................................................................................................. 20

Cooling Capacity vs. Facility Water Flow Rate .................................................................................................... 21

Wiring and Flow Diagram ..................................................................................................................................... 22

110-497 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Reservoir Fluids ................................................................................................................................................... 23

Replacement Parts ................................................................................................................................................ 24

PolyScience Fluids ................................................................................................................................................ 24

Optional Serial Output (RS-232) ........................................................................................................................... 25

Equipment Disposal (WEEE Directive) ................................................................................................................ 26

Service and Technical Support ............................................................................................................................ 26

Warranty ................................................................................................................................................................. 27

110-497 2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Introduction

This symbol alerts you to wide range of potential dangers. When attached to the unit, this symbol draws

attention to the relevant section of the operator’s manual.

This symbol advises

This symbol marks information that is particularly important

This symbol indicates alternating current.

/

These symbols on the Power Sw

This symbol on the Power Switch indicates that it places the unit in a standby mode. It DOES NOT fully disconnect the unit

from the power supply.

This symbol indicates a protective conductor terminal.

Your Liquid-to-Liquid Cooler is a quiet and efficient heat removal system. Process cooling is provided by pumping

facility water (or other liquid cooling medium) through a liquid-to-liquid brazed plate heat exchanger to cool the

process fluid loop. Heat is rejected to the facility fluid and temperature controlled by a proportional valve that

bypasses a portion of the process fluid around the heat exchanger. Because the facility water and process fluid

remain separate, there is no risk of equipment damage due to facility water contamination.

Key features:

• Powerful liquid-to-liquid coolin g

• Quiet, energy-efficient operation

• Microprocessor control

• Digital set and read (°C or °F)

It will take you very little time to get your Liquid-to-Liquid Cooler installed and running. This manual is designed to

guide you quickly through the process. We recommend that you read it thoroughly before you begin.

General Safety Information

When installed, operated, and maintained according to the directions in this manual and common safety

procedures, your Liquid-to-Liquid Cooler should provide safe and reliable heat removal. Please ensure that all

individuals involved in the installation, operation, or m aintenance of this unit read this manual thoroughly prior to

working with the unit.

you of danger from electricity or electric shock.

.

itch / Circuit Breaker indicate that they place the main power supply ON / OFF.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation and maintenance is the user’s responsibility.

110-497 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Safety Recommendations

WARNING:

• Always connect the power cord on this unit to a grounded (3-prong) power outlet. Make certain that the

outlet is the same voltage and frequency as your unit.

• Never operate the unit with a damaged power cord.

• Always turn the unit OFF and disconnect Mains power before performing any maintenance or service.

CAUTION: To ensure that internal damage does not occur during shipping or storage, water must be drained

from all parts of the system or an antifreeze solution added

CAUTION

regarding the safe lifting and relocation of heavy objects.

To prevent injury to personnel and/or damage to property, always follow your workplace’s safety procedures when

operating this equipment. You should also comply with the following safety recommendations:

.

Unpacking Your Liquid-to-Liquid Cooler

Your Liquid-to-Liquid Cooler is shipped in a special carton. Retain the cart on and all packing materials until the

unit is completely assembled and working properly. Set up and run the unit immediately to confirm proper

operation. Beyond one wee k, y our un it may b e warra nty re paired, but not replaced. If the uni t is damaged or does

not operate properly, contact the transportation company, file a damage cl aim and contact the c ompany where

your unit was purchased immediately.

: Keep unit upright when moving. Be sure to follow your company’s procedures and practices

Regulatory and Compliance Testing

Canada USA (60Hz units)

CAN/CSA C22.2 No. 61010-1-12 — Safety Requirements for Electrical Equipment for Measurement, Control

and Laboratory Use, Part I: General Requirements.

UL Std No. 61010-1 (2012) — Safety Requirements for Electrical Equip ment for Measurement, Control and

Laboratory Use - Part I: General Requirements.

CE (50Hz units)

Machinery Directive 2006/42/EC

EC Electromagnetic Compatibility Directive 2014/30/EU

IEC 61010-1 / EN 61010-1:2010

IEC 61326:2012 / EN 61326:2013

RoHS Directive 2011/65/EU

Highly Accelerated Life Test (HALT) and Vibration Tests per ASTM D4169-8 (All units )

Contents

The following items have been included with your Liquid-to-Liquid Cooler:

• Liquid-to-Liquid Cooler

• Operator’s Manual

• IEC Power Cord

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 4

www.GlobalTestSupply.com

Page 6

Controls and Components

Temperature Display

Select/Set Knob

Power Button

Pressure / Flow Rate Display

Units / Menu Select Button

Reservoir Cap and Fluid Filter Port

(top rear)

Process Water In

Facility Water In

Circuit Breaker /

Power Switch

IEC Power Connection

Pressure / Flow Rate Units

Facility Water Out

Process Water Out

Temperature Units

Communication Port

(optional Remote

ON/OFF)

RS-232 Connection

(optional)

Front Control Panel

Rear Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 5

www.GlobalTestSupply.com

Page 7

Installation and Startup

WARNING:

NOTE:

evel below that of the equipment being cooled. As

long as the process remains closed, overflow will not occur when adding cooling f

Liquid

Cooler reservoir.

WARNING:

Be sure all power is off before proceeding.

Site Requirements

Ambient Temperature and Relative Humidity

The Liquid-to-Liquid Cooler is designed for indoor installation in ambient temperatures between 5° and 35°C (41°

and 95°F); relative humidity should not exceed 80% (non-condensing).

Location

The Liquid-to-Liquid Cooler should be installed on a strong, level surface. Do not place it where corrosive fumes,

excessive moisture, excessive dust, or high room temperatures are present.

For ease of positioning and maneuverability, the unit is supplied with casters. The front wheels can be locked to

keep it in place while in use.

To help prevent voltage drops, position the Liquid-to-Liquid Cooler as close as possible to the power distribution

panel. Avoid voltage drops by using a properly grounded power outlet wired with 14 gauge or larger diameter

wire. The use of an extension cord is not recommended.

The Liquid-to-Liquid Cooler may be located at a l

luid to the Liquid-to-

Clearance

Adequate clearance should be allowed on the front, sides, and rear of the Liquid-to-Liquid Cooler for access to

the reservoir tank, electrical cabinet, and external piping connections.

External Piping

All facility water connections must be made by a licensed plumber.

General Considerations

• Take care when selecting hoses and connections for the Liquid-to-Liquid Cooler. All external piping, tubing,

or hoses should be run full size to limit the potential for external pressure drops. Quick-connect fittings may

be used, but they can cause substantial pressure drops.

• Materials of construction should be compatible with the fluid being used as well as the temperature and

pressure at which the unit will operate.

• Where applicable, always use a back-up wrench when making piping connections to the Liquid-to-Liquid

Cooler.

• Pressure Ratings – Hoses should be able to withstand the greatest pressure they will encounter. 150 psi

(344.7 kPa) is recommended. Unit will alarm if default value of 80 psi (551.6 kPa) is exceeded; maximum

setting is 100 psi (689.5 kPa).

• Flexible Tubing – Avo id tubing that will expan d and increase fluid volume when operating at the desired

pressure.

• Hose Diameter – The fittings on the Liquid-to-Liquid Cooler’s process and facility water fluid inlets and

outlets are female 0.5 inch NPT.

• Facility Water – Should be clean and well maintained. Ideally, the facility water should be tested monthly to

ensure a pH level between 7.2 and 7.8. Add algaecide if algae growth is present.

110-497 6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Process Fluid Connections

WARNING: The incoming cooling water pressure should be limited to 125 psi (861.8 kPa) maximum.

NOTE:

whenever the unit is tur

WARNING:

equirements. Caustic,

corrosive, or flammable fluids should never be used. Read the safety data sheet for the process fluid being

used carefully before filling reservoir.

WARNING:

DO NOT use automotive

antifreeze as the additives may be harmful to the Liquid

stainless steel, EPDM rubber, nylon, and PVC).

Connect the process fluid inlet on the equipment to be cooled to the process fluid outlet on the Liquid-to-Liquid

Cooler. Connect the process fluid outlet on the equipment to be cooled to the process fluid inlet on the Liquid

Temperature.

Facility Water Connections

The cooling water supply may be from a chiller, city tap water, or a cooling tower. The cooling water supply should

be connected to the facil ity water inlet on the Liquid-to-Liquid Co oler. The facility water outlet on the Liquid-toLiquid Cooler should be connected to t he appropriate return or drain, as require d. The incoming water pressure

should be limited to 125 psi (861.8 kPa) .

A solenoid valve inside the Liquid-to-Liquid Cooler shuts off facility water fluid flow

ned OFF or if an alarm condition is detected that turns the pump OFF.

Process Coolant

See Technical Information, Reservoir Fluids (page 23) for additional information.

Suitable Fluids

Only use fluids that satisfy safety, health, and equipment compatibility r

Operation below 15°C (59°F) requires antifreeze in the circulation fluid.

-to-Liquid Cooler’s wetted parts (brass, bronze,

The Liquid-to-Liquid Cooler is designed to accommodate a variety of coolant fluids (water, glycol mixtures, etc).

For most applications above 15°C (59°F), distilled water is satisfactory. For operation at or below 15°C (59°F), the

unit must be protected with an antifreeze solution. Ethylene glycol (laboratory grade) and distilled water in a 50/50

mixture is satisfactory from +15° to -15°C (59° to 5°F). Select a fluid that is compatible with the Liquid-to-Liquid

Cooler’s wetted parts (brass, bronze, stainless steel, EPDM rubber, nylon, and PVC).

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 7

www.GlobalTestSupply.com

Page 9

Electrical Power

WARNING: Be sure that the electrical power supply is the same voltage and frequency as specified on the

identific

WARNING:

Liquid Cooler into the electrical outlet until the unit is ready for startup

(see

WARNING: All electrical connections should be made by a qualified, licensed electrician. Proper building

co

WARNING:

WARNING: Make sure the equipment’s main power switch is in the OFF position before connecting or

disc

CAUTION

een filled.

When Controller power is turned ON, the pump automatically begins pumping. If the reservoir has not been

filled, the pump could be damaged.

des and safety regulations should be followed.

onnecting electrical power.

ation label.

DO NOT plug the Liquid-to-

Startup).

Follow all applicable electrical and safety codes when connecting power to this equipment.

: DO NOT turn Controller power ON until the Liquid-to-Liquid Cooler’s reservoir has b

Main Power Connection

Verify that the Power Switch / Circuit Breaker on the rear of the unit is in the OFF position. Attach the IEC power

cord provided with the Liquid-to-Liquid Cooler to the receptacle on the rear of the enclosure. Make sure that the

power outlet used for the Liquid-to-Liquid Cooler is properly grounded and matches the voltage and frequency

indicated on the identification label on the back of the Liquid-to-Liquid Cooler.

The use of an extension cord is not recommended. However, if one is necessary, it must be properly grounded

and capable of handling the total wattage of the unit. The extension cord must not cause more than a 10% drop in

voltage to the Liquid-to-Liquid Cooler.

Optional Serial Output (RS-232)

This option allows you to remotely control the Liquid-to-Liquid Cooler and/or output temperature readings to an

external recorder or other auxiliary device. The maximum communications distance for units equipped with the

RS-232 option is 50 feet (15 meters). A 9-pin D-connector is provided on the rear of the instrument enclosure for

this connection.

Optional Dry Contact Remote ON/OFF

If the unit is equipped with this option, a 15-pin sub D-connector will be provided on the rear panel. Connect pins

1 and 2 to turn the unit OFF, open to turn the unit ON. When unit has been turned OFF by remote control, EC

appears on the right hand display.

110-497 8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Startup

. .

. . .

1. Process Fluid

• Connect the Liquid-to-Liquid Cooler to the process to be cooled with hoses or pipes.

• Check hoses and fittings for tightness and make sure there are no crimps or bends in the hoses.

2. Facility Water Fluid

• Connect the Liquid-to-Liquid Cooler to the facility water supply.

• Open the valves to the facility water supply and return.

• Check hoses and fittings for leaks and make sure there are not bends or crimps in the hoses.

3. Filling the Reservoir

• Remove the filler cap from the reservoir and, using a funnel, add fluid until the reservoir is about two-thirds

full.

• Once the reservoir is two-thirds full, remove the funnel but do not replace the cap at this time.

4. Electrical Power

• Plug the Liquid-to-Liquid Cooler’s power cord into an appropriate electrical outlet.

• Place the Circuit Breaker/Power Switch on the rear of the instrument enclosure in the “ON” position. Three

decimal points will appear on the Temperature display; two decimal points will appear on the pressure/flow

rate display. This signifies that the Controller is in “Standby” and ready for power up.

5. Starting Process Fluid Flow

• Press the Power Button on the front panel. The pump wil l turn on and fluid wi ll be gin circulatin g through the

system. The set point temperature will appear briefly on the Temperature display; after a few seconds, it will

be replaced by the actual fluid temperature.

• Check for leaks.

• With the pump running, the reservoir’s fluid level will dr op as the process and/or process cooling lines

fill with fluid. Slowly add fluid to the reservoir until the liquid level remains stable at about two-thirds full.

This means that the system is filled and the air has been purged from it.

• Replace the reservoir cap and turn it clockwise to lock.

110-497 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Normal Operation

. .

. . .

CAUTION:

when the temperature unit is changed. The Liquid

ous alarm

settings should be reset to the desired values.

Electrical Power

Place the Circuit Breaker/Power Switch on the rear of the instrument enclosure in the “ON” position. Three

decimal points will appear on the Temperature display; two decimal points will appear on the Pressure/Flow Rate

display.

Press the Power Button on the Controller’s front panel. 888 will appear on the Temperature display; 88 wil appear

on the Pressure/Flow Rate display. The pump will turn on and fluid will begin circulating through the system. The

set point temperature will appear briefly on the temperature display; after a few seconds, it will be replaced by the

actual fluid temperature.

Selecting the Temperature Unit (°C or °F)

The LEDs adjacent to the Temperature Display indicate the unit (°C or °F) used for temperature displays.

To change from °C to °F or vice versa, proceed as follows:

To change to °F — Place the Circuit Breaker/Power Switch on the rear of the instrument in the “OFF”

position. Press and hold the Units/Menu Select Button while returning the Circuit Breaker/Power Switch

to the “ON” position.

To change to °C — Place the Circuit Breaker/Power Switch on the rear of the instrument in the “OFF”

position. Press and hold the Power Button on the front panel while returning the Circuit Breaker/Power

Switch to the “ON” position.

All user settings, except baud rate and calibration offset, return to the original factory defaults

-to-Liquid Cooler’s temperature set point and vari

Displaying and Adjusting the Set Point

Press the Select/Set Knob on the front panel. The current set point temperature will be displayed and the decimal

point at the bottom right of the display will flash, indicating that the temperature can be changed.

Rotate the Select/Set Knob until the desired set point temperature is displayed. The setting is accepted after the

Select/Set Knob is pressed a second time or automatically after a few seconds of inactivity.

Allow sufficient time for the unit to stabilize at the desired temperature.

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 10

www.GlobalTestSupply.com

Page 12

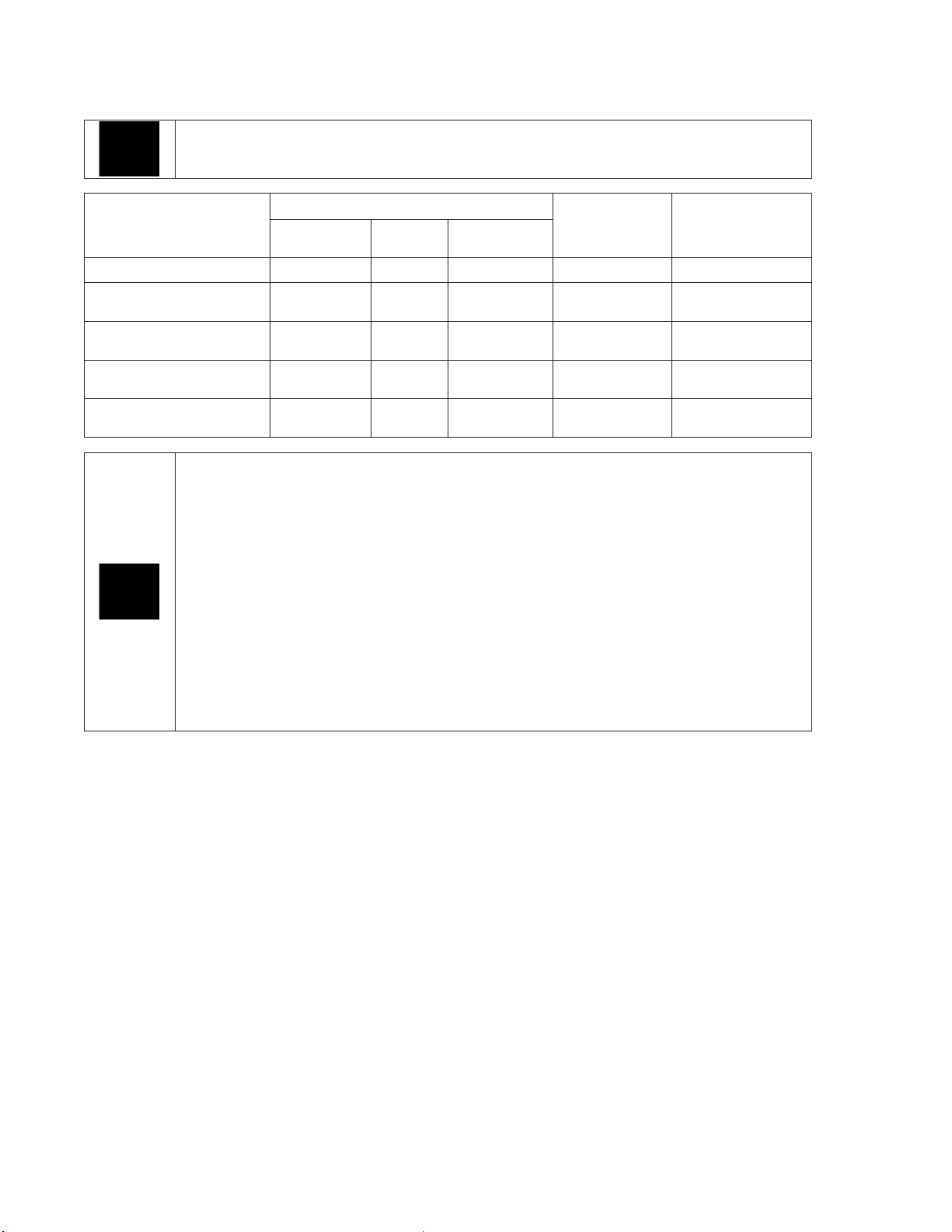

Setting Operational Parameters

Description

Choice/Ranges / Comme

Default

Setting

High Temperature Limit Alarm Set

Point

+21° to 60°C / 69° to 140°F

35°C

95°F

Low Temperature Limit Alarm Set Point

+3° to 20°C / 37° to 68°F

10°C

50°F

Front Panel High Ambient Temperature

Alarm Set Point

+30° to 50°C.

Always displayed and set in °C.

40ºC

FP w/psi

LED lit

Maximum Fluid Pressure Alarm Set

Point

40 to 100 PSI

80 PSI

FP w/kPa LED lit

Maximum Fluid Pressure Alarm Set

Point

2.7 to 6.8 (x 100) kPa

5.5 kPa

(x 100)

LED lit

Minimum Flow Rate Alarm Set Point

0

2.0

GPM

LPM LED lit

Minimum Flow Rate Alarm Set Point

0 or 7.0 to 30.0 LPM

7.0 LPM

AP

Ambient Probe (not available on this model)

nAP

Calibration Offset

±2.9°C (always displayed in °C). Special access

procedure required; see Calibration Offset (°C).

0.0°C

Flow Calibration

0.01 to 50.0 (gain setting)

Nominal

Flow

RS

0, 24, 48, 96, 192.

Represents baud rates of 0 (no

communication), 2400, 4800, 9600, and 19200.

9600

HL 35.

LL 10.

The Liquid-to-Liquid Cooler’s operational parameters can be accessed by pressing and holding the Units/Menu

Button until HL appears on the pressure/ flow rate display. Pressing and releasing the Units/Menu Button once HL

appears allows you to scroll through the various parameters.

The displayed parameter is changed by rotating the Select/Set Knob until the desired value is displayed. You can

accept the displayed value by either pressing the Select/Set Knob or allowing the display to timeout.

Menu Item

HL

LL

HA

GPM

°C

Fc

PC

-232 Baud Rate

nts

or 2.0 to 8.0 GPM

High Temperature Limit (HL)

This menu item serves two functions. First, it establishes the maximum allowable set point temperature and thus

helps prevent an operator from inadvertently selecting a temperature set point above a pre-established value.

Secondly, it serves as a high temperature alarm, automatically activating both audio and visual alarm indicators if

the measured fluid temperature reaches the HL setting.

Low Temperature Limit (LL)

This menu item also serves a dual function. First, it establishes the minimum allowable set point temperature and

thus helps prevent an operator from inadvertently selecting a temperature set point below a pre-established value.

Secondly, it serves as a low temperature alarm, automatically activating both audio and visual alarm indicators if

the measured fluid temperature drops to the LL setting.

110-497 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

High Ambient Temperature Limit (HA)

NO

HA 40.

NOTE:

But

FP

x

80

FP

kPa x 100

5.5

NOTE:

. To view the FL value

in

LED will light up.

FL

Option E

2.0

FL

●

Option M

7.0

TE: This value is always set in °C.

This menu item protects the unit from overheating due to a high ambient temperature. Should the ambient

temperature rise above the limit value, the audio and visual alarms will activate and the pump will turn OFF.

To change the high ambient temperature value, rotate the Select/Set Knob until the desired value is displayed on

the temperature readout.

Maximum Fluid Pressure (FP)

This is the maximum allowabl e f luid pres sure a nd c a n be s et in either PS I or kPa (the LED adjacent to the d is play

indicates the active unit of measure). Shou ld the flu id pressure rise above the maximum fluid pressure valu e, the

audio and visual alarms will activate and the pump will turn OFF.

To change the fluid pressure limit v alue, rotate the Select/Set Knob until the des ired value is displayed on t he

temperature readout.

When FP first appears, the PSI LED will be lit. To view the FP value in kPa, press the Units/Menu

ton again. The FP will remain on the display, and the kPa LED will light up.

PSI

x

Minimum Flow Rate (FL)

This is the minimum allowable flow rate and can be set in either GPM or LPM (the LED adjacent to the display

indicates the active unit of measure). Should the fluid flow rate drop below the minimum value, the audio and

visual alarms will activate and the pump will turn OFF.

To change the minimum flow rate value, rotate the Select/Set Knob until the desired flow rate value is displayed

on the temperature readout.

With FL set to “0”, the flow alarm is disabled, and the unit will continue to operate with the output flow blocked.

When FL first appears, the GPM LED will be lit, indicating the FL value is GPM

LPM, press the Units/Menu Button again. The FL will remain on the display and the LPM

●

110-497 12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Calibration Offset (°C)

CAUTION:

sequence is required to access this func

NOTE:

°C

0.0

Fc

0.0

To prevent the operator from accidentally changing the calibration offset, a special keystroke

tion.

This menu item allows you to adjust th e Liqu id-to-Liquid Cooler’s temper ature re a ding to match that of a traceable

standard. It allows you to offset the displayed temperature value by as much as ±2.9°C.

Calibration offset values are always set and displaye d in °C.

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until AP appears on the display.

3. Press and hold the Units/Menu Button.

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL appears on the temperature readout, release the Units/Menu Button. The current calibration

offset value will appear on the temperature readout and alternate with the fluid temperature reading

(enabling you to simultaneously adjust the offset and see the effect on the temperature).

6. Rotate the Select/Set Knob until the desired calibration offset is displayed. Press the Select/Set Knob or

simply allow the display to time out to accept the displayed value.

Flow Calibration (Fc)

This menu item allows you to calibrate (single point) the flow rate in GPM. Flow rate is calibrated at the factory at

the nominal flow rate for this unit; further adjustment should not be necessary. However, if you wish to calibrate

the unit’s flow rate against a known standard, the calibration is performed as follows:

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until °C appears on the display.

3. Press and hold the Units/Menu Button; Fc will appear on the display.

4. While holding the Units/Menu Button, press and release the Select/Set Kn ob.

5. Release the Units/Menu Button and rotate the Select/Set Knob to change the flow reading on the left hand

display (GPM); the reading on the right hand display is the gain value and is for factory reference only.

6. When the flow rate is calibrated, press the Select/Set Knob to return to normal operation.

110-497 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Baud Rate (PC)

WARNING: There are exposed fan blades inside the housing. Exercise extreme care when accessing or

adjusting any interior components.

WARNING:

PC 96

This menu item allows you to establish the baud rate for serial communication. Allowable settings are 0 (no serial

communication), 24 (2400 baud), 48 (4800 baud), 96 (9600 baud), 192 (19200 baud).

To change the displayed setting, rotate the Select/Set Knob until the desired baud rate is displayed.

Press the Select/Set Knob or allow the display to time out to accept the displayed value.

Adjusting the High Pressure Bypass Setting

4100 and 4200 Series Liquid-to-Liquid Coolers with positive displacement or turbine pumps incorporate an

automatic safety to maintain outlet pressure below a valve-regulated pressure. This valve is adjustable and is

located inside the unit’s housing.

Hazardous voltages are present.

To access the high-pressure bypass valve, remove the two screws at the upper left and right corners of the

Cooler’s rear panel, slide the top panel back about 2-3 inches, and lift off. The regulator valve is located in the left

rear corner of the unit.

The high-pressure bypass is adjusted as follows:

1. Set the low flow rate alarm value to zero (see Setting Operationa l Parameters, Minimum Flow Rate, page

12). This will prevent the unit from activating the flow alarm while you are adjusting the maximum

pressure setting.

2. Completely block the Cooler’s outlet flow. This should cause the outlet pressure to rise.

3. Set the Pressure/Flow Rate display to read either PSI or kPa.

4. Rotate the handle on the pressure valve until the desired maximum pressure setting is shown on the

Pressure/Flow Rate display.

5. Reset the flow alarm value to the previous setting.

6. Return the Pressure/Flow Rate disp lay to the pre vio us setting.

7. Replace the top panel of the Cooler, being sure to secure the bayonet-style prongs on the front of the

panel in the openings at the front of the unit. Reinsert the two screws that secure the top panel to the rear

panel of the unit.

110-497 14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Display, Alarm and Error Messages

Message Code

Insufficient or no flow

through heat exchanger

Warning / Alarm — Insufficient flow to heat exchanger. An alarm will

sound once every 8 seconds for 5 occurrences. If the flow is still low

after 40 seconds, the unit will shut down

Increase flow.

Front panel high ambient

temperature warning

Warning

emperature is higher than the set ambient

limit.

Lower ambient temperature or raise temperature limit.

High temperature set point

warning

Warning

temperature limit value. If not corrected, the high temperature limit

alarm will be activated when the fluid temperature rises above the

established HL value

Lower temperature set point or increase high temperature limit value.

Low temperature set point

warning

Warning

temperature limit value. If not corrected, the low temperature limit

alarm will be activated when the fluid temperature falls below the

established LL value.

Increase temperature set point or decrease low temperature limit

value.

L

Normal

Appears momentarily when Select/Set

view/change set point value. See

Lockout

Cancel Loc

Normal

disabled. Appears momentarily when the Local Lockout status is

changed from enabled (LLO) to disabled.

When certain conditions are detected, a message code flashes on the display and the local audio alarm sounds.

Depending on the nature of the condition, power to various system components, such as the heater and pump, is

removed. When the condition is rectified, push the front panel power button or turn the circuit breaker OFF and

then back ON to clear the fault or error.

During an alarm condition, the Pressure/Flow Rate display will alternate between “°C” and “Ft”. The Temperature

Display will alternate between the current process temperature and a fault code (see below).

Description Action Required

EFL

EHA

EHL

ELL

LLO

CAn

ocal Lockout

al Lockout

- The ambient t

— The temperature set point is higher than the high

.

— The temperature set point is lower than the low

— Indicates that the Local Lockout feature is enabled.

(page 17).

— Indicates that the Local Lockout feature has been

.

Knob is pressed to

Enabling/Disabling the Local

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 15

www.GlobalTestSupply.com

Page 17

Fault Code

Low temperature alarm

(signaled

6°C / 60.8°F

for 5 seconds)

Alarm

Process fluid temperature has dropped to low temperature

limit value. Pump is turned OFF.

Increase heat load or decrease low temperature limit value.

High limit temperature

alarm

Alarm

temperature limit value. Pump is turned OFF.

Decrease heat load or increase high temperature limit value.

Low liquid level alarm

(optional)

Delayed Alarm — Activated when the liquid level in the reservoir falls

below an acceptable level for 30 seconds or longer. Pump is turned

OFF.

Add fluid to reservoir.

High bath temperature

alarm

Alarm

turned OFF.

Lower fluid temperature.

Low flow alarm

Alarm

Pump is turned OFF.

Note: Disabled during first 2 minutes of operation.

Correct cause of low flow rate or decrease minimum flow rate setting.

High pressure alarm

Delayed Alarm

ressure

limit value for 30 seconds. Pump is turned OFF.

Decrease outlet pressure by removing blockage or increase high

pressure limit value.

Internal software fault

Fault

Default unit to °C or °F to reset operational parameters (

Se

persist,

Electronic power

component fault (Triac)

Fault

Default unit to °C or °F to reset operational paramet

Se

persist,

Internal probe fault

Fault

temperature control PCB is having a p

signal. Pump is turned OFF.

Contact supplier.

Communications fault

Fault

Default unit to °C or °F to reset operational parameters (see

Selecting

persist,

ADC fault, internal probe

Fault

temperature control PCB is having a problem reading the probe

signal. Pump is turned OFF.

Contact supplier.

Front panel high ambient

temperature alarm

Warning — The ambient temperature is higher than the set ambient

limit.

Lower ambient temperature or increase ambient temperature limit.

02

03

Description Action Required

—

if <1

— Process fluid temperature has reached the high

05

06

07

08

09

10

— Fluid temperature has exceeded 82°C (180°F). Pump is

— Flow rate has dropped below minimum flow rate setting.

— Fluid outlet pressure has exceeded high-p

-

— Pump is turned OFF.

see

lecting the Temperature Unit (°C or °F), page 10. If problem

replace Control PCB.

— Pump is turned OFF.

ers (see

lecting the Temperature Unit (°C or °F), page 10. If problem

replace Control PCB.

— The internal RTD platinum probe has failed or the

11

13

14

16

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 16

— Pump is turned OFF.

the Temperature Unit (°C or °F), page 10. If problem

replace Control PCB.

— The internal RTD platinum probe has failed or the

Pump is turned OFF.

www.GlobalTestSupply.com

roblem reading the probe

Page 18

Enabling / Disabling the Local Lockout

CAUTION:

interface.

This feature is used to prevent unauthorized or accidental changes to set point and other operational values.

When enabled, these values can be viewed but not changed.

To enable the local lockout, press and hold the Select/Set Knob until LLO is displayed (approximately 5 seconds).

Once enabled, LLO will appear momentarily when the Select/Set Knob is pressed to display the set point.

To disable the local lockout, press and hold the Select/Set Knob until CAn appears momentarily as local lockout

status changes from enabled (LLO) to disabled (approximately 5 seconds).

The Local Lockout feature does not prevent set point changes entered via the RS-232

110-497 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Routine Maintenance and Troubleshooting

WARNING: Hazardous voltages are present. Turn all power to the unit OFF and unplug the power cord from

the electrical outlet when servicing unit. If electrical power is required (such as when m

across a live circuit), use extreme care when servicing the unit.

WARNING:

easuring voltages

Refer servicing to qualified service personnel.

Routine Maintenance

The Liquid-to-Liquid Cooler is designed to require a minimum of periodic maintenance.

Air Vents

To keep the system operating at optimum cooling capacity, the air vents should be kept free of dust and dirt. They

should be checked on a regular basis and cleaned as required.

Process and Facility Line Strainers

To optimize flow and prevent pump and heat exchanger damage due to scale or foreign particles, “Y” strainers

are installed on the inlets of both the process and facility lines. These strainers should be inspected on a regular

basis and cleaned as required. How frequently filter cleaning will be necessary will depend on the environment,

use of the unit, and the cleanliness of the process fluid and facility water.

In-Line Fluid Filter

A removable, highly efficient fluid filter is integrated into the fluid reservoir. To remove it for cleaning, simply

remove the reservoir cap and lift the filter out of the reservoir. Rinse off accumulated particulate matter and

reinstall. How frequently this strainer requires cleaning will depend on how and where the Liquid-to-Liquid Cooler

is being used.

Fluid Level

The Liquid-to-Liquid Cooler’s fluid level should be periodically checked to determine if fluid needs to be added.

Generally, fluid should be added whenever the reservoir is less than two-thirds full.

Software Version

To check the version of the software program installed in the unit:

1. Turn the unit to Standby by pressing the Power Button.

2. Press and hold the Power Button until the software version code appears.

To return to normal operation, release the Power Button. The unit will turn ON.

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 18

www.GlobalTestSupply.com

Page 20

Draining the Unit

CAUTION: To ensure that internal damage does not occur during shipping or storage, water must be drained

from all parts of the system and an antifreeze solution of technical grade ethylene glycol or propylene glycol

added.

WAR

disposing of spent coolant

Problem

Cause

Corrective Action

Unit does not run

(digital displays blank)

No pow

Check that the electrical cord is secure and

connected to an operating electrical outlet.

Check that Power Switch / Circuit Breaker on rear of

unit is ON.

Default the unit (see Selecting the Temperature Unit,

page

Unit does not run

(three decimal points

appear on temperature

display, two decimal

points on pressure/flow

rate display)

Unit in Standby mode

Press Power Button on front panel.

No fluid circulation

Insufficie

Blockage in circulating system

Pump is not operating

Add fluid to reservoir.

Remove blockage.

Replace pump.

Insufficient circulation

Fluid viscosity too high

External tubing diameter too small

Restrictions in fluid lines

Low line vo

Replace with lower viscosity fluid.

Replace with larger diameter tubing.

Check and correct as required.

Check and correct as required.

Unit does not cool or

cooling is insufficient

Facility water line turned off

Facility water line blocked or

conta

Excessive heat load

Low or high line voltage

Check and correct as required.

Remove blockages as required.

Check that heat load does not exceed capacity of

unit

Check and correct as required.

EFL error code displayed

Liquid level in reservoir is low

Add fluid to reservoir.

NING: Be sure to follow all appropriate safety and environmental guidelines when collecting and

.

Press the Power Button to turn the unit OFF and disconnect the power cord from the electrical outlet.

Disconnect the process in and process out lines at the rear panel of the Cooler.

Disconnect the facility water in and facility water out lines at the rear panel of the Cooler.

Remove the reservoir cap and siphon as much coolant as possible from the unit’s reservoir.

Insert a compressed air hose into the opening on the inside bottom of the reservoir. Any coolant remaining in the

Cooler’s internal process lines will be blown out the process inlet and outlet.

Attach a compressed air hose to the facility water inlet or outlet. Any facility water remaining in the Cooler’s

internal facility w ater li nes will be blown out the opposite connection.

Troubleshooting Chart

er to unit

nt fluid in reservoir

ltage

minated (algae growth)

10); contact factory if problem persists.

; correct as required.

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 19

www.GlobalTestSupply.com

Page 21

Technical Inf ormation

4200 Series Models

Operating T

Temperature Stability :

Temperat

Cooling Capacity @ 30°C:

Reservoir Size:

Standard Pump:

Typical Flow Rate:

5 GPM / 18.9 LPM

4.7 GPM / 17.8 LPM

Pump Bypass Pressure Setting:

Facility Water In @ 20°C:

Piping Connection

Overall Dimensions (L x W x H):

Shipping Weight:

Electrical Requirements:

240V, 50/60Hz, 4.0A

208-240V, 50/60Hz, 7.0A

Performance Specifications

emperature: 5° to 50°C / 41° to 122°F

±0.4°C / ±0.7°F

ure Units: °C or °F

4100 Series Models

10,000 watts

34,100 BTU/hr

1.1 gal / 4.16 liters

0.33 HP turbine 0.75 HP turbine

60 Hz Units

50 Hz Units

3 GPM / 10 LPM

2.5 GPM / 9.4 LPM

50 PSI / 344.7 kPa

2.64 GPM / 10 LPM minimum

s: 0.5 inch NPT

27.6 x 14.5 x 22.6 inches / 70.1 x 36.8 x 57.4 cm

168 lbs / 76 kg

208-

Notes: Refer to the serial number plate on the rear of unit for model and electrical data.

Environmental Conditions Indoor use only

Performance specifications determined at ambient temperature of 20°C / 68°F

Maximum Altitude: 2000 meters

Operating Ambient: 5° to 35°C

Relative Humidity: 80% for temperatures to 30°C

Over Voltage Category II

Pollution Degree: 2

Class 1: Residential, commercial, light industrial

Class 2: Heavy industrial

20,000 watts

68,200 BTU/hr

110-497 20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Cooling Capacity vs. Facility W ater Flow Rate

The following graph is applicable to both 4100 and 4200 Series Liquid-to-Liquid Coolers.

NOTE: Graph shows performance with full flow to process (no bypass).

Facility water pressure drop through unit is 5 psi / 34.5 kPa at 16 GPM / 60.8 LPM.

Facility water supply temperature is shown at 5°C, 10°C and 15°C below process temperature.

110-497 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

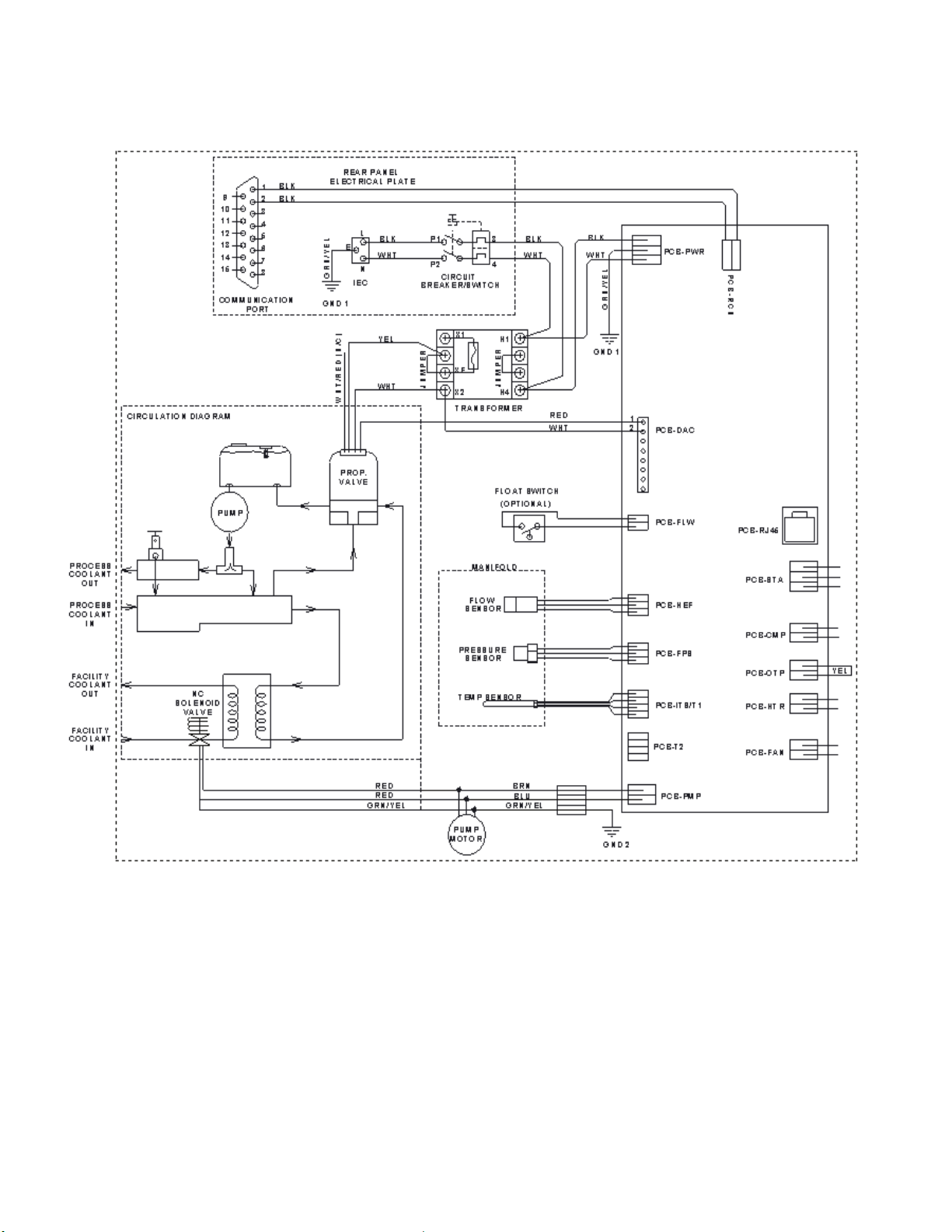

Wiring and Flow Diagram

110-497 22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Reservoir Fluids

WWAARRNNIINNGG:: DDoo nnoott ooppeerraattee uunniitt wwiitthh aannyy ppootteennttiiaallllyy ffllaammmmaabbllee mmaatteerriiaallss,, aass aa ffiirree hhaazzaarrdd mmaayy

rreessuulltt.

.

Specific Heat

Temperature

Temperature

Temperature

BTU/lb°F

Distilled water

Ethylene glycol

(5

O)

Ethylene glycol

(30/70 mix with distilled H2O)

Propylene glycol

(50/50 mix with distilled H2O)

Propylene glycol

(30/70 mix with distilled H2O)

WARNING:

•

•

•

•

•

•

•

•

•

•

**

ives or mineral deposits may develop. If deposits are allowed to build up,

deposit build up.

Fluid Description

@ Fluid

KJ/Kg°C

Normal

Range

Extreme

Range

50°C 1.00

0/50 mix with distilled H

Automotive antifreeze with additives**

Hard tap water**

Deionized water with a specific resistance > 1 meg ohm

Any flammable fluids

Concentrations of acids or bases

Solutions with halides: chlorides, fluorides, bromides, iodides or sulfur

Bleach (Sodium Hypochlorite)

Solutions with chromates or ch romiu m salt s

Glycerine

Syltherm fluids

At temperatures above 40°C, addit

the unit may overheat and fail. Higher temperatures and higher concentrations of additives will hasten

2

-20°C 0.78

0°C 0.89

-10°C 0.83

5°C 0.92

DO NOT USE THE FOLLOWING LIQUIDS

4.18 10° to 90°C

3.26 -25° to 100°C

3.72 0° to 95°C -15° to 107°C

3.47 -20° to 100°C

3.85 5° to 90°C -10° to 107°C

2° to 100°C

-30° to 115°C

-30° to 115°C

Find Quality Products Online at: sales@GlobalTestSupply.com

110-497 23

www.GlobalTestSupply.com

Page 25

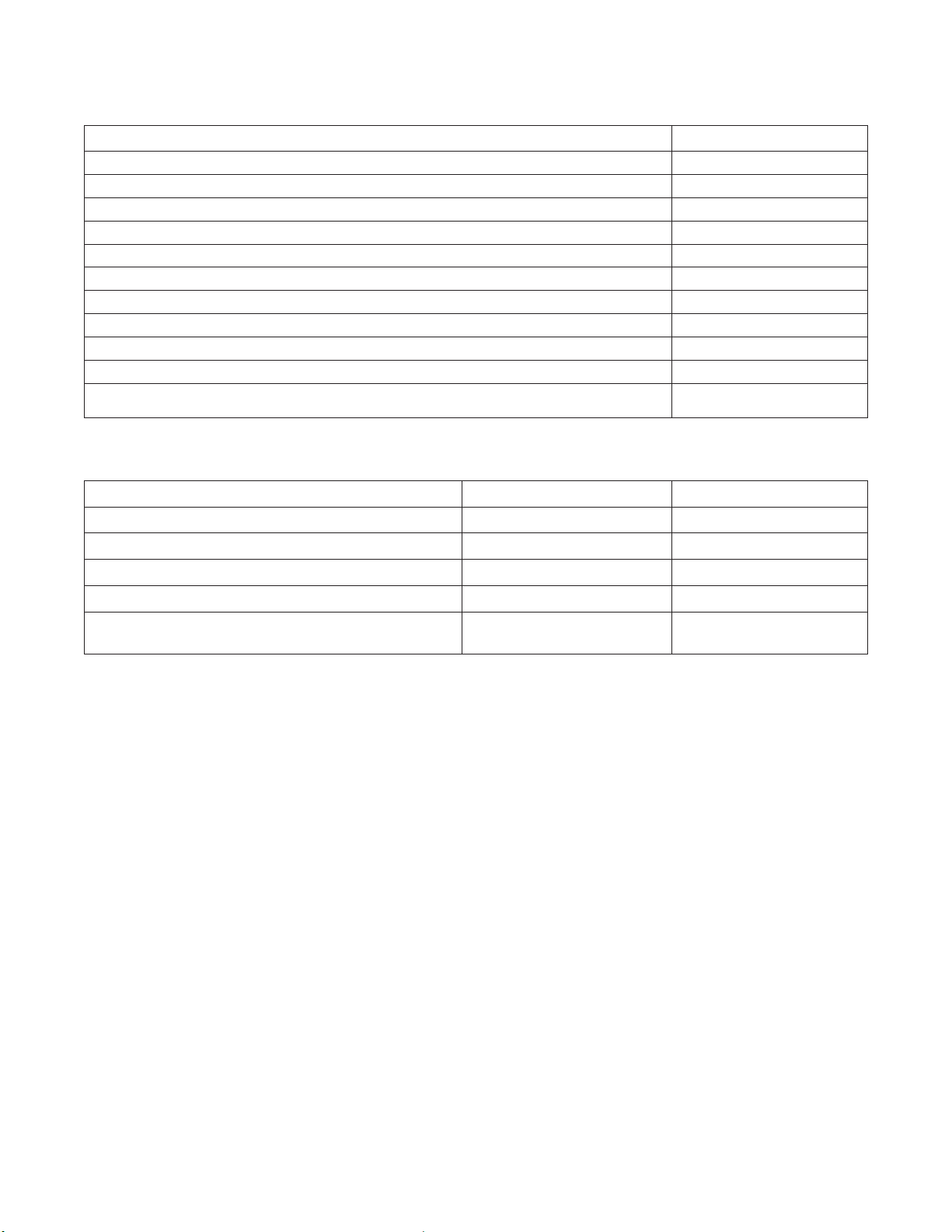

Replacement Parts

Description

Part Number

Operator’s Manual

110-497

0.33 HP Turbine Pump, bronze

215-305

0.75 HP Turbine Pump, bronze

215-499

Circuit Breaker, 15 amp

215-330

Line cord, IEC-320-19 female/NEMA 6-15P

225-230

Fluid Filter

565-102

Tank Assembly, stainless steel (no insulation)

540-504

Reservoir Low Liquid Level Switch

525-550

Bypass Valve

750-175

3-way Proportional Valve

775-513

Heat Exchanger

Circulating Bath Fluids

Quantity

Part Number

polyclean

polyclean

Twelve 8 oz / 236 ml bottles

polycool EG

polycool PG

polycool

O plus

polyclean

750-193

PolyScience Fluids

CLARIFIER 8 oz / 236 ml 004-300040

CLARIFIER

-25 (ethylene glycol) 1 gal / 4.5 liter 060340

-20 (propylene glycol) 1 gal / 4.5 liter 060320

MIX -25 (50/50 blend polycool EG -25 / H

CLARIFIER)

004-300041

2

0.5 gal / 2.27 liter bottles

Five

004-300060

110-497 24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Optional Serial Output (RS-232)

Command

Format

Set command echo ON

SE1[CR]

1

![CR]

Set command echo OFF

SE0[CR]

0

![CR]

Turn unit ON

SO1[CR]

1

![CR]

Turn unit OFF

SO0[CR]

0

![CR]

Set set point

SSxxx[CR]

5-50°C (41° to 122°F)

![CR]

Read set point temperature

RS[CR]

----

xx.x[CR]

Read temperature

RT[CR]

----

xx.x[CR]

Read temperature units

RU[CR]

C or F

C[CR] or F[CR]

Read status

RW[CR]

1 = Run

0 = Standby

1[CR] or 0[CR]

Read pump pressure in PSI

RP[CR]

----

xx.x[CR]

Read pressure in kPa

RK[CR]

----

xx.x[CR]

Read flow in GPM

RG[CR]

----

xx.x[CR]

Read flow in LPM

RL[CR]

----

xx.x[CR]

Read ambient temperature on

Control PCB

RA[CR]

---- xx.x[CR]

Read fault status (see

Alarm and Error Messages, page

14)

RF [CR]

00 = system OK

02

![CR]

Serial Connector — A 9-pin D-connector (optional) is provided on the back panel of the Liquid-to-Liquid Cooler for

RS-232 data communication. A serial cable that uses only the following pins should be used to connect the unit to

the computer:

Pin #2 — data read (data from computer)

Pin #3 — data transmit (data to computer)

Pin #5 — signal ground

RS-232 Protocol — The controller uses the following RS-232 protocol:

Data bits — 8

Parity — none

Stop bits — 1

Flow control — none

Baud rate — selectable (Liquid-to-Liquid Cooler and PC baud rates must match).

Communications Commands — Commands must be entered in the exact format shown. Do not send a [LF] (line

feed) after the [CR] (carriage return). Be sure to follow character case exactly. A response followed by an

exclamation point (!) indicates that a command was executed correctly. A question mark (?) indicates that the

Cooler could not execute the command (either because it was in an improper format or the values were outside

the allowable range). A response must be received from the Liquid-to-Liquid Cooler before another command can

be sent. All responses are terminated with a single [CR].

Command Description

Display,

Values Return Message

-16 = Fault

110-497 25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Equipment Disposal (WEEE Directive)

or

This equipment is marked with the crossed out wheeled bin symbol to indicate it is covered by the Waste

Electrical and Electronic Equipment (WEEE) Directive and is not to be disposed of as unsorted municipal waste.

Any products marked with this symbol must be collected separately, according to the regulatory

guidelines in your area.

It is your responsibility to correctly dispose of this equipment at lifecycle-end by handing it over to an authorized

facility for separate collection and recycling. It is also your responsibility to decontaminate the equipment in case

of biological, chemical and/or radiological contamination, so as to protect the persons involved in the disposal and

recycling of the equipment from health hazards. By doing so, you will help to conserve natural and environmental

resources and you will ensure that your equipment is recycled in a manner that protects human health.

Requirements for waste collection, reuse, recycling, and recovery programs vary by regulatory authority at your

location. Contact your local responsible body (e.g., your laboratory manager) or authorized representative for

information regarding applicable disposal regulations.

Service and Technical Support

If you have followed the troubleshooting steps and your Liquid-to-Liquid Cooler fails to operate properly, contact

the supplier from whom the unit was purchased. Have the following information available for the customer service

person:

• Model, Serial Number, and Voltage (from back panel)

• Date of purchase and your purchase order number

• Suppliers' order number or invoice number

• A summary of your problem

110-497 26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Warranty

The manufacturer agrees to correct for the original user of the product, either by repair (using new or refurbished

parts), or at the manufacturer’s election, by replacement (with a new or refurbished product), any defects in

material or workmanship which develop during the warranty period. The standard warranty is twenty-four (24)

months after delivery of the product. In the event of replacement, the replacement unit will be warranted for the

remainder of the original warranty period or ninety (90) days, whichever is longer. For purposes of this limited

warranty, “refurbished” means a product or part that has been returned to its original specifications. In the event of

a defect, these are your exclusive remedies.

If the product should require service, contact the manufacturer’s/supplier’s office for instructions. When return of

the product is necessary, a return authorization number is assigned and the product should be shipped,

transportation charges pre-paid, in either its original packaging or packaging affording an equal degree of

protection to the indicated service center. To insure prompt handling, the return authorization number must be

placed on the outside of the package. A detailed explanation of the defect should be enclosed with the item.

The warranty shall not apply if the defect or malfunction was caused by accident, neglect, unreasonable use,

improper service, acts of God, modification by any party other than the manufacturer, or other causes not arising

out of defects in material or workmanship.

EXCLUSION OF IMPLIED WARRANTIES. THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION AND PERIOD AS STATED IN THE OPERATOR’S

MANUAL INCLUDED WITH EACH PRODUCT.

LIMITATION ON DAMAGES. THE MANUFACTURER’S SOLE OBLIGATION UNDER THE WARRANTY IS

LIMITED TO THE REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT AND THE MANUFACTURER

SHALL NOT, IN ANY EVENT, BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

KIND RESULTING FROM USE OR POSSESSION OF THIS PRODUCT.

Some states do not allow: (A) limitations on how long an implied warranty lasts; or (B) the exclusion or limitation

of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may have other rights that vary from state to state.

110-497 27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...