Page 1

400 Series Chamber Vacuum Sealer

Quick Start Guide

Page 2

Setting Up

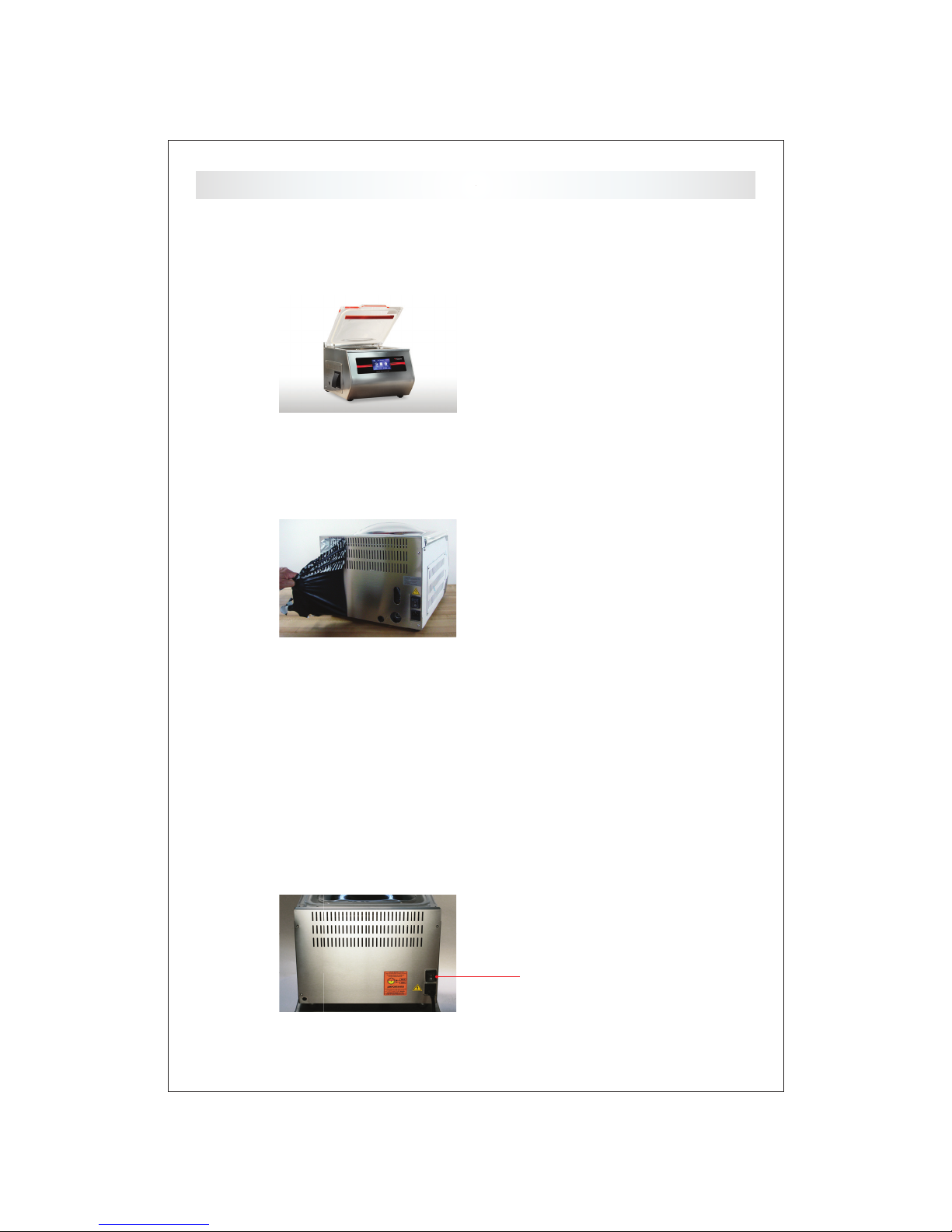

1 Machine Placement

Caution: Machine is heavy, do not lift alone!

2 Protective Skin Covering

Place machine on a secure

level table and adujst the leveling

feet if needed.

Remove white protective

covering exposing

304 stainless steel.

3 AC Power

For 120V models supply 120V/20A circuit. All others consult an electrician.

Caution: Do not use extension cords or surge protectors.

Do not share the line with motors or compressors.

4 Power Switches & Resets

400 Series (back)

Main Power Switch

- 2 -

Page 3

Setting Up

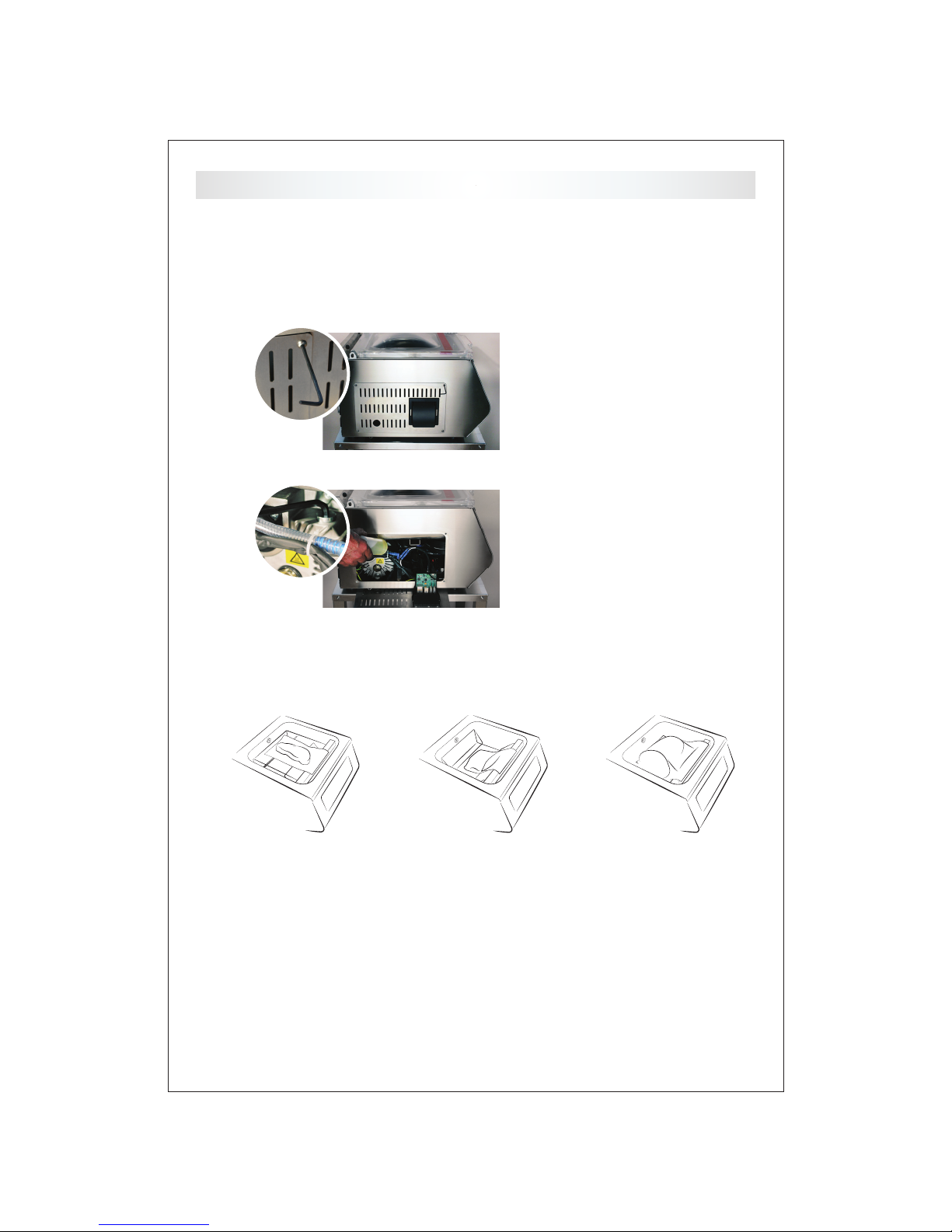

5 Adding Oil

Caution: Add oil before starting machine.

Mind the oil fi ll line, see label instructions on machine.

400 Series

Use 2.5mm hex wrench

supplied and remove cover,

location may vary.

Use wrench supplied

to remove top oil plug and

add oil, location may vary.

6 Flippin' Tray

POSITION 1

Pint - ideal for

steaks & llets

Quart - Angled for

marinades & soups

POSITION 2

POSITION 3

Gallon - Bulk food,

rib roast, etc.

7 Tips

Never tilt or lay vacuum machine on its side.

Pump oil may move into the lter & sensor creating numerous issues.

Change oil frequently, especially when vacuum sealing liquids.

Food products release moisture which over time will contaminate the oil.

Maintain a low sealing time.

A low sealing time will extend the life of the Te on tape, seal wire and cushion.

- 3 -

Page 4

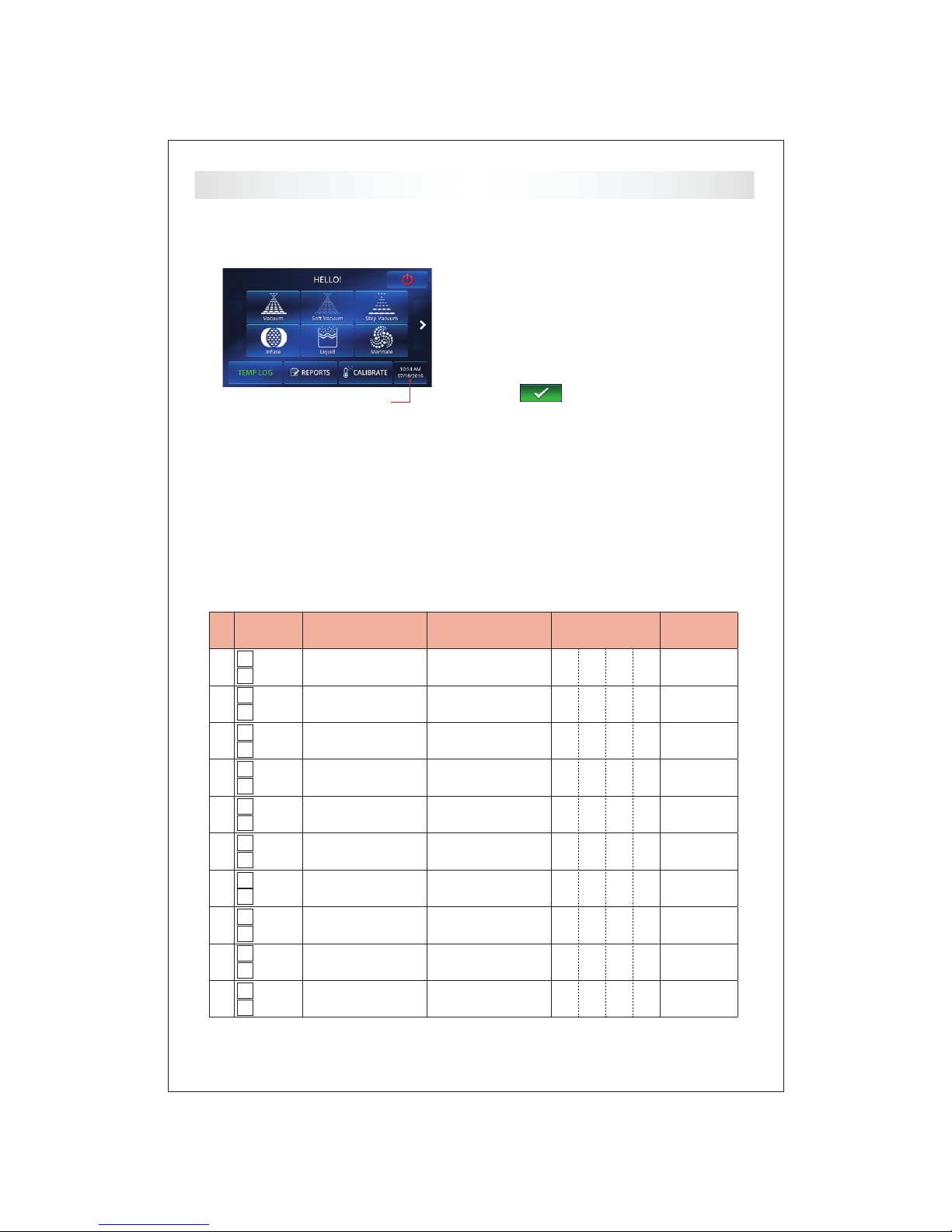

1 Date & Time

Powering Up

Home Screen

When powering up the machine for the rst time,

please check the date & time. If it needs to be

changed, navigate to the Date & Time settings:

Home > Settings > Date & Time

Once you have set the date/time, touch the green

Check the date & time

check mark and the machine will restart.

2 Users & Passcodes

When setting up users, you can choose between Operator and Manager user types. An operator can

start programs and download reports. A manager has full access to all settings, including adding/

deleting products, users, logs, and reports.

Before setting up users on your machine, we recommend to write them down rst:

User Type First Name Last Name or Initials 4-Digit PIN Today’s Date

Manager

1

Operator

Manager

2

Operator

Manager

3

Operator

Manager

4

Operator

Manager

5

Operator

Manager

6

Operator

Manager

7

Operator

Manager

8

Operator

Manager

9

Operator

Manager

10

Operator

MM/DD/YY

- 4 -

Page 5

2 Users & Passcodes

Powering Up

To set up users on the machien go to

Home > Settings > Users and touch the Add User

button .

Once you are done adding users, you have to

activate the PIN prompt - go to Home > Settings >

Screens and turn “On” Passcodes. Type in your PIN

and it will take you back to the Home screen.

After restarting the machine, you will notice the

Logout button on the Home screen. Touch

it to switch between users.

OPERATOR

Edit / Delete a User

Log in as a Manager, go to Home > Settings > Users

and touch the user name you want to edit/delete.

To delete, touch the Delete button in the

top left corner. To edit, toggle through the screens

by touching the Next button .

MANAGER

- 5 -

Page 6

Getting Started

1 Presets

Your 400 Series machine comes with 6 most commonly used Presets to get you started. The preset

buttons are listed on the Home screen. Below is a description of their vacuum settings and how they

are being used.

VACUUM

Vacuum seal in a bag/pouch for

chilled storage or low temperature

cooking. The preset removes

99.9% of the atmosphere from

the chamber.

INFUSE

Infuse avors in a hotel pan or

Vac-Box to create dramatic avor

& aroma to drinks. The preset

preserves avor, color & fruit

crispness. Enhance the avor

of Spa Water, create Sangria in

minutes.

SOFT VACUUM

S

oft Vacuum seals sausage and

patties in a bag/pouch for chilled

storage or low temperature cooking. The preset removes 97% of

the atmosphere then returning

the air slowly preventing damage.

Step Vacuum seals sh llets, and

hams in a bag/pouch for chilled

storage or low temperature cooking.

The preset removes atmosphere in

increments, preventing boiling

which may harm the product.

LIQUID

Liquid seals in a bag/pouch for

chilled storage, retherming or

low temperature cooking. The

preset allows the user to vacuum

seal at temperatures below

150ºF (65ºC).

Note: food safety logging is being skipped for Presets

Marinate in minutes not hours

to create that special avor. The

preset opens and closes the pro-

tein bers allowing liquid marinade

to penetrate. Use a hotel pan or

Vac-Box to instantly marinate.

After touching the desired Preset button, place your

food product in the bag, lay the open side over the

sealing bar (see Flippin’ Tray on page 3), close the lid

and touch the green start button to start the vacuuming

process.

STEP VACUUM

MARINATE

Repeat with all products from the same batch. When

you are done, touch the Home button to get

back to the home screen.

- 6 -

Page 7

Getting Started

2 Product Groups/Logs

Grouping food products organizes and speeds up the product look up process (PLU) as well as aids

in HACCP planning. Select up to 6 groups that best de ne the food products you plan to place under

vacuum. Each group stores up to 99+ unique food products, their vacuum settings and all information

related to that unique product.

On the Home screen you can display either Presets or Groups. To show the Groups, go to the Home

screen, and scroll to the right side and touch the Presets button - it will turn into Groups.

Now you can see 6 groups on your Home screen:

Factory pre-selected groups

DELI MEAT

FISH

VEGETABLES

1. To change a group, go to Home >

Logs and touch the group name you

want to change.

Each group has pre-set food safety questions. You will be asked these questions prior to vacuum

packaging a batch of the product. You can turn on/off as well as change the wording of each ques-

tion. Your answers are being logged and saved to a food safety report le (more details on page 9).

SMOKED

POULTRY

INFUSED WATER

MEAT

PORK

CUT FRUIT

MARINATED

BEEF

WHOLE FRUIT

All available groups

SEASONED

SAUCE - SOUP

INFUSION

2. Touch the Edit button in

the top right corner, and select a

different group.

AGED

COOK-CHILL

LOW TEMP COOK

SAUSAGE

RETHERM

OTHER

GROUND

CHEESE

VAC-BOX

- 7 -

Page 8

Getting Started

3 Save New Product

To add a new product you must be logged in as a Manager user.

Go to Home > Products and touch the Add Product

button in the top right corner of the screen.

Choose a Product Number (up to 5 digits long).

Tip: Keep products from the same group within the same range,

for example: Fresh Meat 100-199, Poultry 200-299, etc.

Select a Group/Log for your product.

Air Out

Select how much air you want to take out - you can choose

between mbar and %. Set a Hold time to keep your product at the

set vacuum before releasing the air back into the chamber.

Pulse9™

Pulse lets you run up to 9 cycles in a

row. This feature gives you superior

results for Infusion and Marination.

Air Return de nes how much air to let

back in before the next Pulse begins.

VACUUM SETTINGS

Turn on/off each individual Pulse

Navigate between the Pulses

Seal

We recommend to use Bar Up = 0.2s, Seal = 1.4s, Cure = 0.2s.

If you are using thicker/tinner bags than the common 3mil bags,

you might have to increase/decrese the Seal slightly.

SofAir

We recommend to use Air Return = 100%, Pause = OFF.

If you are packaging sausges, burger patties, or bone-in

products, please read SofAir on page 9.

Type in a Product Name and touch the green checkmark

to save the product. It is now saved in the selected group.

- 8 -

Page 9

Getting Started

4 Edit/Delete a Product

Log in as a Manager user, go to Home > Products and touch

the Edit button - it will turn green color. Now touch

the product name you want to edit/delete.

To delete, touch the Delete button in the top left

corner. To edit toggle through the product by touching the

Next button .

Food Safety

1 Food Safety Log (Questions)

You can set speci c food safety log questions for each

group. Go to Home > Logs and touch the log you want to

manage the questions for.

A log cosists of 3 categories:

BQs = Before Questions - asked before packaging

AQs = After Questions - asked after packaging

Msg = Messages - CCPs listed on the nal report le

2 Save/Delete Reports

Note: Your USB ash drive must be

formatted in FAT32 le system and

the volume name must be one single

word. For detailed instructions on how

to format your USB ash drive, go to

www.minipack.us/usb-format.pdf

Touch the on/off button next to each question to turn it on

or off.

Note: the machine is already pre-programmed with the

most common questions for each group. You can edit the

questions as well as turn them on/off.

Plug in your USB ash drive into one of the two USB ports

on the side of the machine, and go to: Home > Reports.

Select which reports you want to save: Food Safety or

Probes. Touch the Save to USB button to save the

report as a PDF le.

To delete a report from the machine, login as a Manager

user and go to: Home > Reports and touch the Delete

button next to the report's name.

Operator users cannot delete reports.

- 9 -

Page 10

Settings

Settings on the y by touching the icons at the bottom

1 Freestyle Mode

This mode is useful for experimenting or trying to nd the

right vacuum settings before saving it as a product.

To access Freestyle Mode login as a Manager user and

go to Home > Freestyle. You can change all Vacuum

.

To reset the settings back to factory default, touch the

Refresh button .

Note: food safety logging is being skipped in Freestyle

2 AirOut - Hold vs. Plus

When AirOut = 98.9% or lower, you can de ne a Hold time.

The Hold timer will start once the AirOut value has been

reached.

When AirOut = 99%, you can de ne a Plus time. Plus will

keep the vacuum pump running for the set time to achieve

the maximal vacuum possible, having the tiniest air pockets

being pulled out of your product.

3 SofAir

4 Default Seal

Use the SofAir settings when vacuum packaging formed

products, beef patties, product with bones, shell sh in the

shell, and sausages.

We recommend the settings Air Return = 10%, and Pause =

1.0s, however you may adjust these settings to t your needs.

This setting will let the air return to the chamber in 10% steps

preventing ruptured sausage casings, squished product, and

holes in the bag from bones.

To change the seal time for the Presets and the default

seal time in the Freestyle Mode (when touching the Refresh

button), go to Home > Settings > General and change the seal

time under Default Seal. Restart the machine to take effect.

We recommend 1.4 seconds for the 400 Series.

- 10 -

Page 11

HACCP Portal Registration

HACCP Portal provides you with an easy way

to create a thorough HACCP plan for

Reduced Oxygen Packaging (ROP) and

Sous Vide Cooking.

To get started with your HACCP plan,

HACCP Portal is included with

your 400 Series and your machine’s

serial number is your free ticket:

www.haccp-portal.com/400series

visit the website below.

Page 12

1 Temperature Probe

2 Label Printer

Accessories

Sous Vide Probe, K-Type (3”, dull tip)

#ST200045

Product Probe, K-Type (4”, sharp tip)

#ST200040

Direct Thermal

Label Printer (USB)

#ST200009

3 Keyboard

Water-Resistant Silicone

Keyboard (USB)

#ST200012

4 Inkjet Report Printer

Canon Pixma MG2550 (USB)

#ST200015

5 USB Flash Drive

Pre-formatted (4GB)

#ST200062

6 Cart

2x3” Labels - Case

(425 labels/roll, 12 rolls/case)

#ST200060

7 Leg Extensions

To order accessories call: +1-714-283-4200

Stainless Steel

#ST200025

Stainless Steel

#ST200020

Page 13

Important Product Information

One-Year Limited Warranty

*This warranty ONLY applies to the Original

Purchaser and Owner of the new equipment and

ONLY applies to manufacturer’s defects.

This warranty will ONLY be honored if minipack

america, inc. determines by EVALUATION that

damage is not due to Non-Warranty Items listed

below.

WARRANTY

Machines manufactured by minipack are warranted

to be free of defects in parts and craftsmanship

under normal use and with recommended service.

The warranty period for non-wearable parts is (1)

year from the date of installation. minipack america,

inc.’s exclusive obligation under this warranty is

limited to repairing or, at its option, replacing any

minipack part that is determined by minipack

america, inc. to be defective.

NON-WARRANTY

• Wearable parts such as Teon tape, sealing wires,

rubber components, lters, oil, etc.

• Damage from freight, installation, improper

electrical connection, moisture damage, accident,

neglect, misuse, improper maintenance, alteration,

modication, or repair by anyone other than a minipack america, inc. authorized re-seller.

• In the event of highly corrosive or high moisture

applications, special protective coating or stainless

steel construction might be needed.

authorized distributors/dealers), which are inconsistent with the terms herein shall not constitute a

term of the minipack-torre and minipack america,

inc express warranty, and shall not be binding to

minipack-torre or minipack america, inc.

EXCLUSION

THE LIMITED WARRANTY SET FORTH ABOVE IS THE

SOLE AND ENTIRE WARRANTY PERTAINING TO THE

PRODUCT, AND IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES OF ANY NATURE WHATSOEVER, WHETHER EXPRESSED, IMPLIED OR ARISING BY

OPERATION OF LAW, INCLUDING, BUT NOT LIMITED

TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. THIS

WARRANTY DOES NOT COVER OR PROVIDE FOR

THE REIMBURSEMENT OR PAYMENT OF INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY TYPE,

MANNER, OR DEGREE, AND ANY LIABILITY BY

MINIPACK-TORRE OR MINIPACK AMERICA, INC FOR

SUCH INCIDENTAL OR CONSEQUENTIAL DAMAGES

HEREBY DISCLAIMED.

Some states do not allow this exclusion or limitation

of warranties and/or damages, so the above limitations and/or exclusions might not be applicable to

you. This warranty gives you specic legal rights, and

you might also have other rights that vary from state

to state.

SERVICE WITHIN WARRANTY PERIOD

• For Repair or Service please contact the entity

from whom you purchased the machine from.

Component subsystems manufactured by minipack

carry the warranty as stated herein. The warranty

does not apply to subsystem component parts which

are not manufactured by minipack. Subsystem component parts not manufactured by minipack, shall

be subject to any warranty of their manufacturer.

minipack-torre and minipack america, inc. shall not

be liable if minipack-torre equipment or components

are used with accessory equipment not manufactured by minipack.

Representations and/or warranties, by whomever

made (even if made by minipack america, inc.

Sanitation

Approved

• The Original Purchaser must contact minipack

america, inc. for an RMA Request Form to request

the return or repair of the machine or part. The

Original Purchaser or Owner of the equipment is

responsible for all shipping charges, including outbound and inbound freight charges. In the case that

our minipack america, inc. evaluation determines

there is a manufacturer’s defect, no shipping charges

will apply and the outbound freight charges initially

paid by the customer, will be reimbursed by minipack

america, inc. Freight reimbursement applies only to

standard shipping charges.

Electrical

Approved

- 13 -

Loading...

Loading...