Operator’s Manual

Liquid-to-Air Recirculator

Original Instructions

110-368 09.02.15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table of Contents

Introduction .............................................................................................................................................................. 2

General Information ................................................................................................................................................. 2

General Safety Information .................................................................................................................................... 2

Safety Recommendations ...................................................................................................................................... 3

Regulatory Compliance and Testing ...................................................................................................................... 3

Unpacking Your Recirculator ................................................................................................................................. 3

Contents ................................................................................................................................................................. 3

Controls and Components ..................................................................................................................................... 4

Installation and Startup ........................................................................................................................................... 5

Site Requirements ................................................................................................................................................. 5

Ambient Temperature and Relative Humidity .................................................................................................... 5

Location .............................................................................................................................................................. 5

Clearance ........................................................................................................................................................... 5

Electrical Power ..................................................................................................................................................... 5

Plumbing ................................................................................................................................................................ 6

Process Piping ................................................................................................................................................... 6

Reservoir Drain .................................................................................................................................................. 6

Startup .................................................................................................................................................................... 6

Process Coolant ................................................................................................................................................. 6

Electrical Power .................................................................................................................................................. 7

Starting Process Fluid Flow ................................................................................................................................ 7

Safety By-Pass Pressure Regulator Adjustment ................................................................................................... 7

Positive Displacement Pump .............................................................................................................................. 7

Turbine Pump ..................................................................................................................................................... 8

Normal Operation .............................................................................................................. ...................................... 9

Routine Maintenance & Troubleshooting ............................................................................................................. 9

Draining Reservoir (Preparing for Transportation or Storage) ............................................................................... 9

Periodic Inspection ................................................................................................................................................. 9

Cleaning Exterior Surfaces .................................................................................................................................... 9

Condenser, Air Vents and Reusable Filter .......................................................................................................... 10

Fluid Filter ............................................................................................................................................................ 10

Fluid Level ............................................................................................................................................................ 10

Troubleshooting ................................................................................................................................................... 10

Technical Information ........................................................................................................................................... 11

Performance Specifications ................................................................................................................................. 11

Replacement Parts ................................................................................................................................................ 12

Wiring Diagram ...................................................................................................................................................... 12

Equipment Disposal (WEEE Directive) ................................................................................................................ 13

Service and Technical Support ............................................................................................................................ 13

Warranty ................................................................................................................................................................. 14

110-368 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Introduction

This Liquid-to-Air Recirculator continuously pumps near-ambient temperature water from a reservoir to an

external heat source, through a cooling radiator, and then returns cooled water to the reservoir. By blowing

ambient air over the radiator, water flowing inside is cooled and the heat is exhausted into the atmosphere.

General Information

General Safety Information

When installed, operated, and maintained according to the directions in this manual and common safety

procedures, your Recirculator should provide safe and reliable heat removal. Please ensure that all individuals

involved in the installation, operation, or maintenance of this unit read this manual thoroughly prior to working with

the unit.

This symbol alerts you to a wide range of potential dangers.

This symbol advises you of danger from electricity or electric shock.

This symbol marks information that is particularly important.

This symbol indicates alternating current.

/

These symbols on the Power Switch / Circuit Breaker indicate that they place the main power supply ON / OFF.

This symbol on the Power Switch indicates that it places the unit in a standby mode. It DOES NOT fully

disconnect the unit from the power supply.

This symbol indicates a protective conductor terminal.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation and maintenance is the user’s responsibility.

Protection can be impaired if the equipment is used in a manner not specified by the

manufacturer.

110-368 2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Safety Recommendations

To prevent injury to personnel and/or damage to property, always follow your workplace’s safety procedures when

operating this equipment. You should also comply with the following safety recommendations :

WARNING:

Always connect the power cord on this unit to a grounded (3-prong) power outlet. Make

certain that the outlet is the same voltage and frequency as your unit.

Never operate the unit with a damaged power cord.

Always turn the unit OFF and disconnect Mains power before performing any maintenance

or service.

Regulatory Compliance and Testing

Canada USA (60Hz units)

CAN/CSA C22.2 No. 61010-1-12 — Safety Requirements for Electrical Equipment for Measurement, Control

and Laboratory Use, Part I: General Requirements

UL Std. No. 61010-1 (2012) — Electrical Equipment for Laboratory Use, Part I: General Requirements

CE (50 Hz units)

Machinery Directive 2006/42/EC

EC Electromagnetic Compatibility Directive 2014/30/EU

RoHS Directive 2011/65/EU

IEC 61010-1 / EN 61010-1:2010

Highly Accelerated Life Test (HALT) and Vibration Tests per ASTM D4169-8 (all units)

A-Weighted Emission Sound Pressure Level: Does not exceed 70 db(A)

Unpacking Your Recirculator

Your Recirculator is shipped in a special carton. Retain the carton and all packing materials until the unit is

completely assembled and working properly. Set up and run the unit immediately to confirm proper operation.

Beyond one week, your unit may be warranty repaired, but not replaced. If the unit is damaged or does not

operate properly, contact the transportation company, file a damage claim and immediately contact the company

where your unit was purchased.

WARNING: Keep unit upright when moving. Be sure to follow your company’s procedures and practices

regarding the safe lifting and relocation of heav y object s. For items weighing 18kg or more, safe practice lifting

should be performed by at least two people.

Contents

The following items have been included with your Recirculator:

Operator’s Manual

IEC Power Cord

Two sets of nylon Inlet/Outlet adapters:

½ inch male NPT to ½ inch barb 90° elbow

½ inch male NPT to 5/8 inch barb 90° elbow

110-368 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

r

/

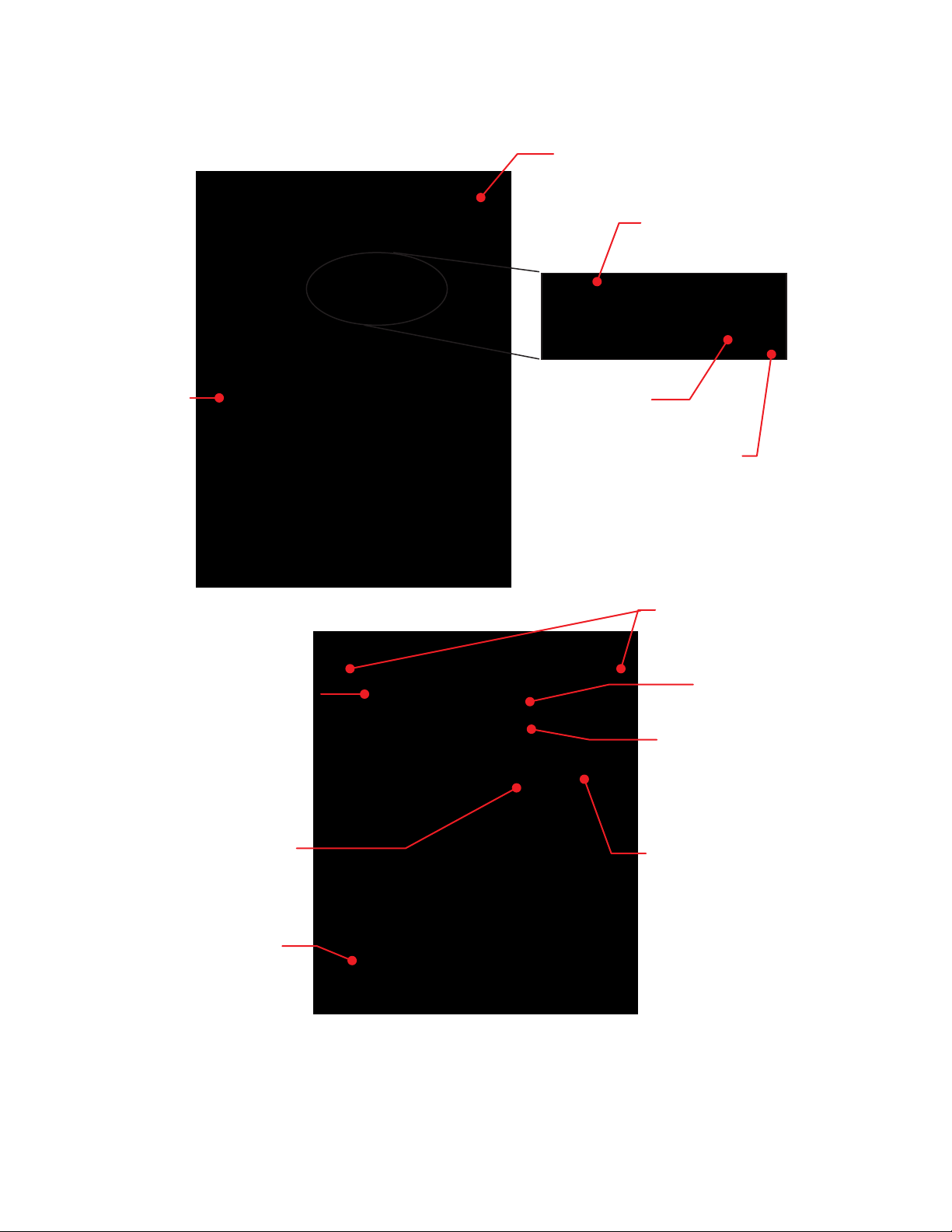

Controls and Components

Reservoir Cap

Pressure Gauge

Air Filter Access

Reservoir Liquid

Level Indicator

Fluid Inlet

Low Liquid Level

Warning Indicato

Power Switch

Top Panel Access Screws

Circuit Breaker

Power Switch

IEC Power Inlet

Fluid Outlet

Drain

110-368 4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Installation and Startup

WARNING: Be sure all power is off before proceeding.

Site Requirements

Ambient Temperature and Relative Humidity

The Recirculator is designed for indoor installation in ambient temperatures between 5° and 35°C (41° and 95°F);

relative humidity should not exceed 80% (non-condensing).

Location

The Recirculator should be installed on a strong, level surface. It should be located as close to possible to the

process requiring cooling. It should not be installed closer than 4 feet (1.2 meters) to a heat-generating source,

such as heating pipes, boilers, etc. If possible, the Recirculator should be located near a suitable drain to prevent

flooding in the event of leaks. Do not place it where corrosive fumes, excessive moisture, excessive dust, or high

room temperatures are present.

For ease of positioning and maneuverability, the Recirculator is supplied with ca sters. The front wheels can be

locked to keep the Recirculator in place while in use.

To help prevent voltage drops, position the Recirculator as close as possible to the power distribution panel.

Avoid voltage drops by using a properly grounded power outlet wired with 14 gauge or larger diameter wire. The

use of an extension cord is not recommended.

CAUTION: The Recirculator may be located at a level below that of the equipm ent being cooled. As long as

the process remains closed, overflow will not occur when adding coolin g fluid to the Recirculator reservoir.

Clearance

Adequate clearance should be allowed on the front, sides, and rear of the Recirculator for access to connections

and components. The front and rear vents of the Recirculator must be a minimum of 24 inches (61 cm) away from

walls or vertical surfaces so air flow is not restricted.

Electrical Power

An IEC power cord is provided with the Recirculator. It should be attached to the receptacle on the rear of the

enclosure. Make sure that the power outlet used for the Recirculator is properly grounded and matches the

voltage and frequency indicated on the identification label on the back of the Recirculator.

The use of an extension cord is not recommended. However, if one is necessary, it must be properly grounded

and capable of handling the total wattage of the unit. The extension cord must not cause more than a 10% drop in

voltage to the Recirculator.

WARNING: DO NOT plug the Recirculator into the electrical outlet until the unit is ready for startup (see

Startup).

110-368 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Plumbing

Process Piping

The Recirculator has two internally threaded (1/2 inch NPT) fittings on the rear

of the instrument housing for the process water connections. The outlet of the

heat source should be connected to the inlet of the Recirculator and the inlet of

the heat source connected to the outlet of the Recirculator. Use heavy wall

tubing, preferably reinforced, to make the connections. Minimize bends in the

tubing as well as the length of tubing from the Recirculator to the heat source.

Do not run the connecting tubing near any type of heat source. Be sure all connections are secure and clamped

before filling with water.

Reservoir Drain

A ½ inch NPT connection is provided for the reservoir’s gravity drain. It should be piped to a drain or receptacle

positioned below the bottom of the reservoir. If a receptacle is used, be sure it is of sufficient volume to hold all

the water in the reservoir, process, and process lines.

Startup

Process Coolant

Distilled water is recommended. To prevent algae growth in the system, shield tubing from light. Insulation around

the tubing will suffice. Use an algaecide (such as polyclean CLARIFIER, 004-300040) in the cooling water to

minimize algae growth.

Wetted components of this Recirculator are copper, brass, PVC, polyethylene, nylon, and stainless steel. Any

fluids used in the circulating system must be compatible with these materials.

WARNING: Do NOT use chlorine bleach as an algaecide.

WARNING: Do not use the following fluids:

Automotive antifreeze with additives

Hard tap water

Deionized water with a specific resistance > 1 meg ohm (except units with DI water compatible

plumbing)

Any flammable fluids

Concentrations of acids or bases

Solutions with halides: chlorides, fluorides, bromides, iodides or sulfur

Bleach (Sodium Hypochlorite)

Solutions with chromates or chromium salts

Glycerin

Syltherm fluids

WARNING: Do not use a flammable liquid as a fire hazard may result.

Filling the Reservoir

Remove the filler cap from the reservoir and, using a funnel, add fluid until it reaches the MAX line on the

reservoir’s fluid level gauge. Once the reservoir is full, remove the funnel but do not replace the cap at this time.

110-368 6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Electrical Power

Plug the Recirculator’s power cord into an appropriate electrical outlet.

Place the Circuit Breaker/Power Switch on the rear of the instrument enclosure in the ON position.

Starting Process Fluid Flow

Press the Power Button on the front panel. The system startup sequence will begin and proceed as follows:

1. The cooling fan and pump will turn on and fluid will begin circulating through the system.

2. With the pum p running, the reservoir’s fluid level will drop as the process and/or process cooling lines fill

with fluid. Slowly add fluid to the reservoir until the liquid level remains stable.

3. Check all plumbing connections for leaks. If leaks are found, do not continue to operate the Recirculator

until all connections are secure.

CAUTION: Never let the Recirculator pump run dry.

Safety By-Pass Pressure Regulator Adjustment

Positive Displacement Pump

Cover Nut

To protect the pump in case of blockage or shut off of fluid flow, a Safety By-Pass Relief Valve is built into the

pump head. This permits fluid to continue flowing within the pump and minimizes the possibility of damage due to

a dry pump.

Adjustment of the Safety By-Pass Pressure Relief Valve (factory set at 50 psi / 3.44 bar):

1. Attach a fluid-filled pressure gauge (not supplied) with a range of 0 to 150 psi ( 0 to 10.3 bar) to the

Recirculator outlet fitting to prevent fluid flow.

110-368 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2. Fill the reservoir as indicated in the Startup section.

3. To access the pressure by-pass valve, remove the two screws at the upper left and right corners of the

Recirculator’s rear panel, slide the top panel back about 2-3 inches (5 to 7.6 cm) and lift off. Remove the right

side panel by lifting it straight up from the frame. The valve is located in the bottom right rear corner of the unit

(when facing the unit).

4. Turn the unit ON and check for leaks. Be sure pressure gauge is not leaking. The gauge should display

approximately 50 psi (3.44 bar).

5. Remove the Cover Nut on the pump head to access the Adjustment Screw.

6. To INCREASE the Safety By-Pass Relief pressure setting, use a flat head screwdriver to turn the Adjustment

Screw clockwise; to DECREASE the pressure setting, turn the pressure Adjustment Screw counter-clockwise.

While reading the pressure gauge, continue turning the Adjustment Screw until the desired setting is

achieved.

CAUTION: Maximum pressure is 100 psi (6.88 bar). Care must be taken to limit adjustment of Safety ByPass Relief Valve setting to 100 psi (6.88 bar) or less. Damage may occur at settings exceeding 100 psi

(6.88 bar) and will void the warranty.

Turbine Pump

To protect the pump in case of blockage or shut off of fluid flow, a Safety By-Pass Relief Valve is built into the

unit. This permits fluid to continue flowing within the pump and minimizes the possibility of damage due to a dry

pump.

Adjustment of the Safety By-Pass Relief Valve (factory set at 50 psi / 3.44 bar):

1. Attach a fluid-filled pressure gauge (not supplied) with a range of 0 to 150 psi ( 0

to 10.3 bar) to the Recirculator outlet fitting to prevent fluid flow.

2. Fill the reservoir as indicated in the Startup section.

3. To access the pressure by-pass valve, remove the two screws at the upper left

and right corners of the Recirculator’s rear panel, slide the top panel back about

2-3 inches (5 to 7.6 cm) and lift off. The valve is located in the top left rear corner

of the unit (when facing the unit).

4. Turn the unit ON and check for leaks. Be sure pressure gauge is not leaking.

The gauge should display approximately 50 psi (3.44 bar).

Cover lock nut

5. Loosen the Cover Lock Nut on the by-pass valve.

6. To INCREASE the Safety By-Pass Relief pressure setting, turn the Adjustment Handle clockwise; to

DECREASE the pressure setting, turn the pressure Adjustment Handle counter-clockwise. While reading the

pressure gauge, continue turning the Adjustment Handle until the desired setting is achieved.

7. Tighten the Cover Lock Nut.

CAUTION: Maximum pressure is 100 psi (6.88 bar). Care must be taken to limit adjustment of Safety ByPass Relief Valve setting to 100 psi (6.88 bar) or less. Damage may occur at settings exceeding 100 psi

(6.88 bar) and will void the warranty.

110-368 8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Normal Operation

NOTE: Recirculating Coolers operate at maximum cooling performance. Actual coolin g

performance will vary based on ambient temperature.

1. Place the Power Switch / Circuit Breaker on the rear of the Recirculator in the ON position.

2. Press the Power Switch on the front panel. The cooling fan and pump will begin running and fluid will

begin circulating through the system. The pressure gauge on the front of the unit indicates fluid pressure

at the outlet of the Recirculator.

Routine Maintenance & Troubleshooting

WARNING: Refer servicing to qualified service personnel.

WARNING: When electrical power is ON, dangerous voltages exist within chassis com ponents. Use extreme

care when measuring voltages on live circuits.

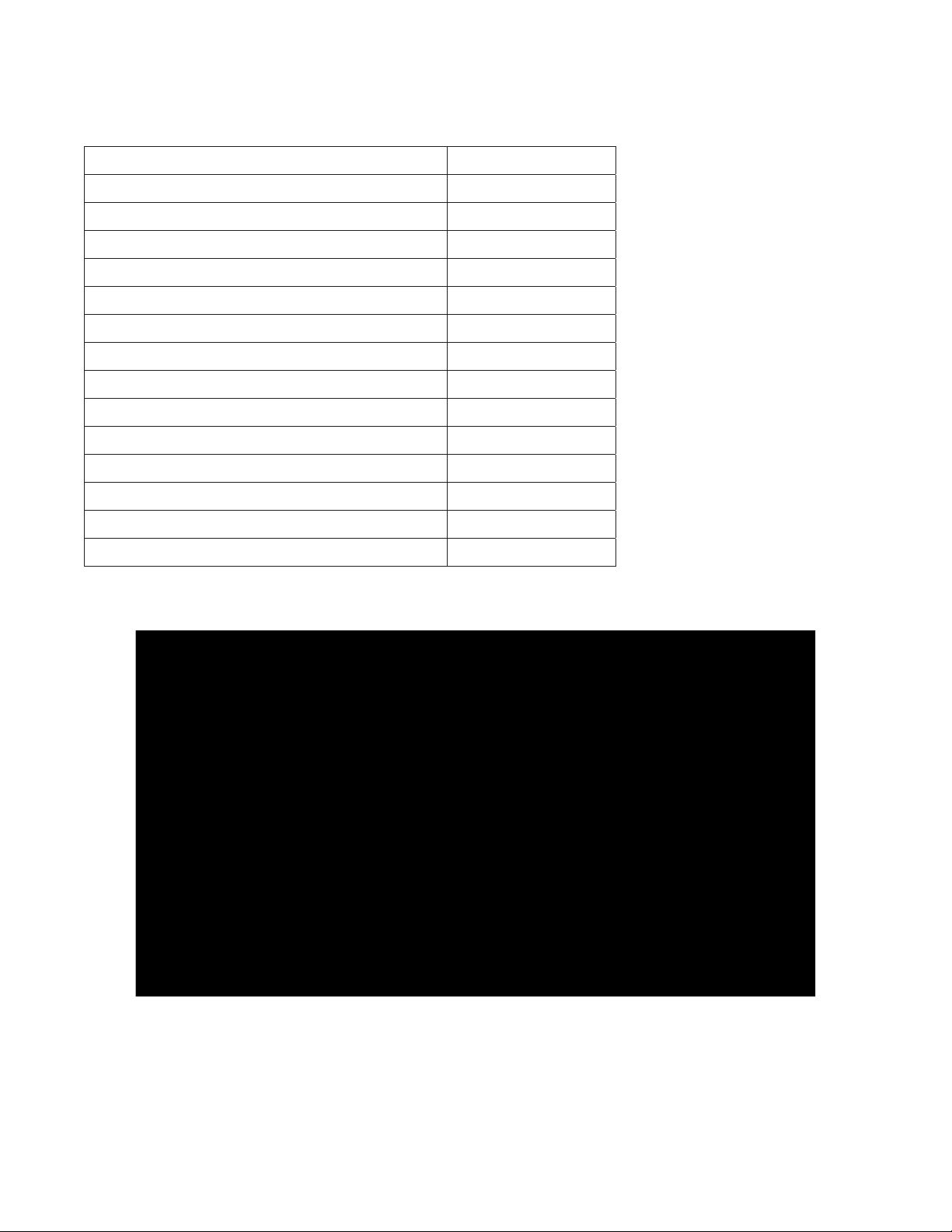

Draining Reservoir (Preparing for Transportation or Storage)

Due to potential exposure to freezing temperatures, the following

procedure is recommended for use when transporting or storing the unit.

Follow this procedure to evacuate fluid from the Heat Exchanger Coil and

reduce the potential for damage to coil copper lines.

Reservoir fluids should be piped to a drain or receptacle positioned below

the bottom of the reservoir. If a receptacle is used, be sure it is of

sufficient volume to hold all the water in the reservoir, process, and

process lines. Removing the drain plug will allow fluid to exit the unit. Make sure to replace the plug when done.

Factory-installed

Drain

drain plug

Periodic Inspection

All components should be inspected at least once a month or more frequently if the Recirculator is used

continuously. Examine all fittings for leaks and also check the fluid level. If the level is low, check the heat source

as well as the Recirculator for leaks. Replace the recirculating fluid every three months. If algae growth is noted,

replace more frequently.

Cleaning Exterior Surfaces

Only mild detergents and water or an approved cleaner should be used on the painted surfaces of your

Recirculator.

110-368 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Condenser, Air Vents and Reusable Filter

To keep the system operating at optimum cooling capacity, the condenser, the air vents, and

reusable filter should be kept free of dust and dirt. They should be checked on a regular basis

and cleaned as required.

The reusable filter is easily accessed from either the left or right side of the unit. Use a mild

detergent and water solution to wash off any accumulated dust and dirt. Rinse and dry

thoroughly before reinstalling.

Fluid Filter

A removable, highly efficient fluid filter is integrated into the fluid reservoir. To remove it for cleaning, simply

remove the reservoir cap and lift the filter out of the reservoir. Rinse off accumulated particulate matter and

reinstall.

Fluid Level

The fluid level gauge on the rear of the Recirculator should be periodically checked to determine if the fluid level

needs to be topped off. Generally, fluid should be added whenever the level in the reservoir is at or near the “Low”

gauge mark.

Troubleshooting

WARNING: Always turn the Power Switch / Circuit Breaker OFF and disconnect the electrical cord from the

power source before servicing the unit.

Problem Cause Corrective Action

Unit does not run

No cooling or

insufficient cooling

No power to unit

Rear Power Switch / Circuit

Breaker in OFF position

Front Power Switch OFF

No power to unit

Blocked airflow

Ambient air temperature too

high

Fluid too hot for unit to

continuously cool

Heat exchanger fan not

operating

Check that electrical cord is plugged into an operating

electrical outlet.

Place Power Switch / Circuit Breaker in ON position.

Place Power Switch in ON position.

Check that rear Power Switch / Circuit Breaker and/or

front Power Switch is ON.

Check heat exchanger fins and air vents for blockages.

Check ambient air temperature.

Check heat removal specifications; heat loss to room may

be excessive.

Check fan for operation (listen for fan noise, check for

airflow through unit).

110-368 10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Technical Information

Performance Specifications

Positive Displacement Pump

Turbine Pump

500 watts based on 2°C ǻT

1000 watts based on 4°C ǻT

Cooling Capacity @ 20°C

2000 watts based on 8°C ǻT

3000 watts based on 10°C ǻT

4000 watts based on 11°C ǻT

Dimensions (L x W x H) 20.5 x 15 x 22.3 in. (52 x 38.1 x 56.6 cm)

External Fluid Connections Inlet & Outlet, 1/2 in. female NPT

Reservoir Capacity 1.1 gallons (4.2L)

Maximum Liquid Temperature 170°F (77°C)

Electrical Requirements

Maximum Fluid Flow Rate

By-Pass Pressure Regulator

Shipping Weight 118 Lbs (53.5 kg) 132 Lbs (59.9 kg)

Recommended Coolant Distilled Water

ǻT = Process water temperature – ambient air temperature

Environmental Conditions Indoor use only

Maximum Altitude: 2000 meters

Operating Ambient: 5° to 35°C (41° to 95°F

Relative Humidity: 80% for temperatures to 30°C

Installation Category II

Pollution Degree: 2

120VAC, 60Hz,

1 ph, 7A

2.4 gpm (9.1 lpm) 2 gpm (7.6 lpm)

240VAC, 50Hz,

1 ph, 3.75A

Adjustable 20 to 100 psi / 1.4 to 6.9 bar

(Factory pre-set to 50 psi / 3.44 bar)

120VAC, 60Hz,

1 ph, 7A

5.4 gpm

(15.2 lpm)

240VAC, 50-60Hz,

4.5 gpm (17.1 lpm)

1 ph, 4.75A

110-368 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Replacement Parts

Description Part Number

Positive Displacement Pump Motor 215-217

Pump Head (2.3 gpm) 215-218

Turbine Pump T31E-4GPM 215-328

Air Filter, Reusable 750-855

Reservoir Cap 300-460

Reservoir Strainer 565-102

Fan Motor, 35W, 120VAC 525-306

Fan Motor, 35W, 240VAC 525-311

Fan Blade (35W motor), 115VAC and 240VAC 215-076

Fan Motor, 50W, 240VAC 525-710

Fan Blade (50W motor), 240VAC 215-309

Fan Blade Collar (50W motor), 240VAC 400-533

Gauge, Pressure 750-076

polyclean CLARIFIER 004-300040

Wiring Diagram

110-368 12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Equipment Disposal (WEEE Directive)

or

This equipment is marked with the crossed out wheeled bin symbol to indicate it is covered by the Waste

Electrical and Electronic Equipment (WEEE) Directive and is not to be disposed of as unsorted municipal waste.

Any products marked with this symbol must be collected separately, according to the regulatory

guidelines in your area.

It is your responsibility to correctly dispose of this equipment at lifecycle-end by handing it over to an authorized

facility for separate collection and recycling. It is also your responsibility to decontaminate the equipment in case

of biological, chemical and/or radiological contamination, so as to protect the persons involved in the dispo sal an d

recycling of the equipment from health hazards. By doing so, you will help to conserve natural a nd environmental

resources and you will ensure that your equipment is recycled in a manner that protects human health.

Requirements for waste collection, reuse, recycling, and recovery programs vary by regulatory authority at your

location. Contact your local responsible body (e.g., your laboratory manager) or authorized representative for

information regarding applicable disposal regulations.

Service and Technical Support

If you have followed the troubleshooting steps and your Recirculator fails to operate properly, contact the supplier

from whom the unit was purchased. Have the following information available for the customer service pe rson:

Model, Serial Number, and Voltage (from back panel)

Date of purchase and your purchase order number

Suppliers' order number or invoice number

A summary of your problem

110-368 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Warranty

The manufacturer agrees to correct for the original user of the product, either by repair (using new or refurbished

parts), or at the manufacturer’s election, by replacement (with a new or refurbished product), any defects in

material or workmanship which develop during the warranty period. The standard warranty is twenty-four (24)

months after delivery of the product. In the event of replacement, the replacement unit will be warranted for the

remainder of the original warranty period or ninety (90) days, whichever is longer. For purposes of this limited

warranty, “refurbished” means a product or part that has been returned to its original specifications. In the event of

a defect, these are your exclusive remedies.

If the product should require service, contact the manufacturer’s/supplier’s office for instructions. When return of

the product is necessary, a return authorization number is assigned and the product should be shipped,

transportation charges pre-paid, in either its original packaging or packaging affording an equal degree of

protection to the indicated service center. To insure prompt handling, the return authorization number must be

placed on the outside of the package. A detailed explanation of the defect should be enclosed with the item.

The warranty shall not apply if the defect or malfunction was caused by accident, neglect, unreasonable use,

improper service, acts of God, modification by any party other than PolyScience, or other causes not arising out of

defects in material or workmanship.

EXCLUSION OF IMPLIED WARRANTIES. THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION AND PERIOD AS STATED IN THE OPERATOR’S

MANUAL INCLUDED WITH EACH PRODUCT.

LIMITATION ON DAMAGES. THE MANUFACTURER’S SOLE OBLIGATION UNDER THE WARRANTY IS

LIMITED TO THE REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT AND POLYSCIENCE SHALL

NOT, IN ANY EVENT, BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND

RESULTING FROM USE OR POSSESSION OF THIS PRODUCT.

Some states do not allow: (A) limitations on how long an implied warranty lasts; or (B) the exclusion or limitation

of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may have other rights that vary from state to state.

110-368 14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...