Polymetron 9210 User Manual

221=192=010

POLYMETRON Model 9210

Silica Analyzer

USER MANUAL

May 2009, Revision K

Table of Contents

Section 1 General Information.........................................................................................................5

1.1 Disclaimer .................................................................................................................................... 5

1.2 Safety information ........................................................................................................................ 5

1.2.1 Use of hazard information................................................................................................... 5

1.2.2 Safety recommendations ....................................................................................................5

1.2.3 Service and repairs .............................................................................................................6

1.2.4 Precautionary labels............................................................................................................6

1.3 Product recycling information....................................................................................................... 7

1.4 Product disposal .......................................................................................................................... 9

1.5 Restriction of hazardous substances (RoHS) ............................................................................10

Section 2 Specifications..................................................................................................................11

2.1 Technical specifications.............................................................................................................11

Section 3 Analyzer Overview ......................................................................................................... 13

3.1 Operation ................................................................................................................................... 13

3.2 Calibration..................................................................................................................................14

3.3 Analyzer outputs ........................................................................................................................ 14

3.4 Maintenance ..............................................................................................................................14

3.5 Presentation...............................................................................................................................15

3.5.1 Front panel........................................................................................................................ 15

3.5.2 Rear panel......................................................................................................................... 16

Section 4 Installation........................................................................................................................17

4.1 Analyzer inspection and unpacking ........................................................................................... 17

4.2 Analyzer preparation..................................................................................................................17

4.3 Installation checklist ...................................................................................................................17

4.4 Mounting the analyzer................................................................................................................18

4.4.1 Panel version ....................................................................................................................18

4.4.2 Cabinet version................................................................................................................. 19

4.5 Installing the canister holder ...................................................................................................... 20

4.6 Connecting the sample .............................................................................................................. 21

4.7 Connecting the drain tube..........................................................................................................22

4.8 Mains power connection ............................................................................................................ 22

4.9 External communications connection ........................................................................................26

4.10 Input/Output connections ......................................................................................................... 27

4.11 Reagent preparation ................................................................................................................ 29

4.11.1 Reagent 1M - Molybdate (2 liters)...................................................................................29

4.11.2 Reagent 1A - Nitric acid (2 liters) .................................................................................... 29

4.11.3 Reagent 2 - Oxalic acid...................................................................................................29

4.11.4 Reagent 3 - Reducing reagent........................................................................................ 30

4.11.5 Calibration solution.......................................................................................................... 30

4.12 Connecting the canisters .........................................................................................................31

4.13 Analyzer startup ....................................................................................................................... 32

4.13.1 Reagents volume declaration..........................................................................................32

4.13.2 Flow rate adjustment....................................................................................................... 32

4.13.3 System and user setup procedures ................................................................................32

Section 5 Operating Instructions..................................................................................................33

5.1 Data Entry .................................................................................................................................. 33

5.1.1 Function Keys ...................................................................................................................33

5.1.2 Modification of a value ...................................................................................................... 33

5.2 Measurement screens ...............................................................................................................33

5.2.1 Main screen....................................................................................................................... 33

5.2.2 Display screen 2 - Measurement history...........................................................................34

5.2.3 Display screen 3 - Alarms .................................................................................................34

5.2.4 Display screen 4 - Graph ..................................................................................................34

5.3 Main menu ................................................................................................................................. 35

1

Table of Contents

5.4 Analyzer menu overview ............................................................................................................36

Section 6 System Setup...................................................................................................................37

6.1 Menu overview ...........................................................................................................................37

6.1.1 Time ..................................................................................................................................37

6.1.2 Display...............................................................................................................................38

6.1.3 Code..................................................................................................................................38

6.1.4 Soft issues.........................................................................................................................39

6.1.5 Default values....................................................................................................................39

6.1.6 mA adjustments.................................................................................................................39

6.1.7 Factory ..............................................................................................................................40

Section 7 User Setup........................................................................................................................41

7.1 Measure menu overview ............................................................................................................41

7.1.1 Measuring mode................................................................................................................41

7.1.2 Grab sample......................................................................................................................42

7.1.3 Historic ..............................................................................................................................42

7.1.4 ADC values .......................................................................................................................43

7.2 Alarms menu overview...............................................................................................................43

7.2.1 Alarms 1 to 6 .....................................................................................................................44

7.2.2 Warning alarm ...................................................................................................................45

7.2.3 System alarm ....................................................................................................................45

7.2.4 Alarm conditions................................................................................................................46

7.3 mA outputs menu overview........................................................................................................47

7.3.1 Affect .................................................................................................................................47

7.3.2 Special programming ........................................................................................................48

7.3.3 Test ...................................................................................................................................49

7.4 RS485 ........................................................................................................................................49

7.5 Sequence ...................................................................................................................................50

7.5.1 Channel activation.............................................................................................................50

7.5.2 Sequence ..........................................................................................................................50

Section 8 Calibration........................................................................................................................51

8.1 Menu overview ...........................................................................................................................51

8.1.1 Programming (automatic calibration) ................................................................................52

8.1.2 Execution primary calibration ............................................................................................53

8.1.3 Execution manual calibration ............................................................................................53

8.1.4 Parameters........................................................................................................................54

8.1.5 Historic ..............................................................................................................................54

8.1.6 Calibration results..............................................................................................................55

Section 9 M aintenance.....................................................................................................................57

9.1 General.......................................................................................................................................57

9.2 Cleaning overview......................................................................................................................57

9.2.1 General cleaning process..................................................................................................57

9.2.2 Chemical cleaning procedure............................................................................................58

9.3 Battery replacement ...................................................................................................................59

9.4 Fuse replacement.......................................................................................................................59

9.5 Yearly maintenance....................................................................................................................60

9.6 Maintenance menu overview......................................................................................................63

9.7 Startup........................................................................................................................................64

9.8 Reagents refill ............................................................................................................................64

9.9 Extended stop ............................................................................................................................65

9.10 Tube cleaning...........................................................................................................................65

9.11 Photometer test........................................................................................................................66

9.12 Pumps - others.........................................................................................................................66

9.13 Pumps flowrate.........................................................................................................................66

2

Table of Contents

9.14 Solenoid valves........................................................................................................................67

9.15 Relays ...................................................................................................................................... 67

9.16 Logical inputs ........................................................................................................................... 67

9.17 Preparation of the tubes for insertion in the fast connectors.................................................... 68

Section 10 Troubleshooting........................................................................................................... 69

10.1 Possible sources of the problem..............................................................................................69

10.2 Possible solutions .................................................................................................................... 69

10.3 Typical measurement values during calibration....................................................................... 70

Section 11 Spare Parts.....................................................................................................................71

Section 12 Default Configuration..................................................................................................73

Section 13 Material Safety Data Sheets (MSDS)........................................................................ 77

13.1 Oxalic acid ............................................................................................................................... 77

13.2 Sulfuric acid (98%)...................................................................................................................78

13.3 Nitric acid (50-70%) ................................................................................................................. 80

13.4 Ammonium hydroxide (10-35% NH3) ......................................................................................84

13.5 Sodium hexafluorosilicate ........................................................................................................88

13.6 Ferrous ammonium sulfate hexahydrate ................................................................................. 89

13.7 Sodium molybdate dihydrate ................................................................................................... 91

13.8 Reagent R1A ...........................................................................................................................92

13.9 Reagent R1M...........................................................................................................................94

13.10 Reagent R2............................................................................................................................96

13.11 Reagent R3............................................................................................................................98

13.12 Lithium battery safety precautions .......................................................................................100

3

Table of Contents

4

Section 1 General Information

1.1 Disclaimer

The information in this manual has been carefully checked and is believed to be accurate.

However, Hach Lange assumes no responsibility for any inaccuracies that may be contained in

this manual. In no event will Hach Lange be liable for direct, indirect, special, incidental, or

consequential damages resulting from any defect or omission in this manual, even if advised of

the possibility of such damages. In the interest of continued product development, Hach Lange

reserves the right to make improvements in this manual and the products it describes at any

time, without notice or obligation.

Copyright © 2009 by Hach Lange. All rights reserved. No part of the contents of this manual

may be reproduced or transmitted in any form or by any means without the written permission of

Hach Lange.

1.2 Safety information

Read this entire manual before unpacking, setting up or operating this equipment. Pay attention

to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

To make sure that the protection provided by this equipment is not impaired, do not use or install

this equipment in any manner other than that specified in this manual.

Note: This equipment has been tested and found to comply with the limits for Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

1.2.1 Use of hazard information

WARNING

A warning is used to indicate a condition which, if not met, could cause serious personal

injury and/or death. Do not move beyond a warning until all conditions have been met

CAUTION

A caution is used to indicate a condition which, if not met, could cause minor or

moderate personal injury and/or damage to the equipment. Do not move beyond a

caution until all conditions have been met.

Note: A note is used to indicate important information or instructions that should be considered

before operating the equipment.

1.2.2 Safety recommendations

For safe operation, it is imperative that these service instructions be read before use and that

the safety recommendations mentioned herein be scrupulously respected. If repairs or

adjustments are necessary, the analyzer should be returned to an authorized Hach Lange

service center.

If danger warnings are not heeded to, serious material or bodily injury could occur.

WARNING

In accordance with safety standards, it must be possible to disconnect the power supply

of the analyzer in its immediate vicinity.

WARNING

The installation of the analyzer should be performed exclusively by personnel

specialized and authorized to work on electrica l installa tions, in a ccordance with re levan t

local regulations.

5

General Information

1.2.3 Service and repairs

None of the analyzer’s components can be serviced by the user. Only personnel from Hach

Lange or its approved representative(s) is (are) authorized to attempt repairs to the system and

only components formally approved by the manufacturer should be used. Any attempt at

repairing the analyzer in contravention of these principles could cause damage to the analyzer

and corporal injury to the person carrying out the repair. It renders the warranty null and void

and could compromise the correct working of the analyzer and the electrical integrity or the CE

compliance of the analyzer.

If you have any problems with installation, starting, or using the analyzer please contact the

company that sold it to you. If this is not possible, or if the results of this approach are not

satisfactory, please contact the manufacturer’s Customer Service.

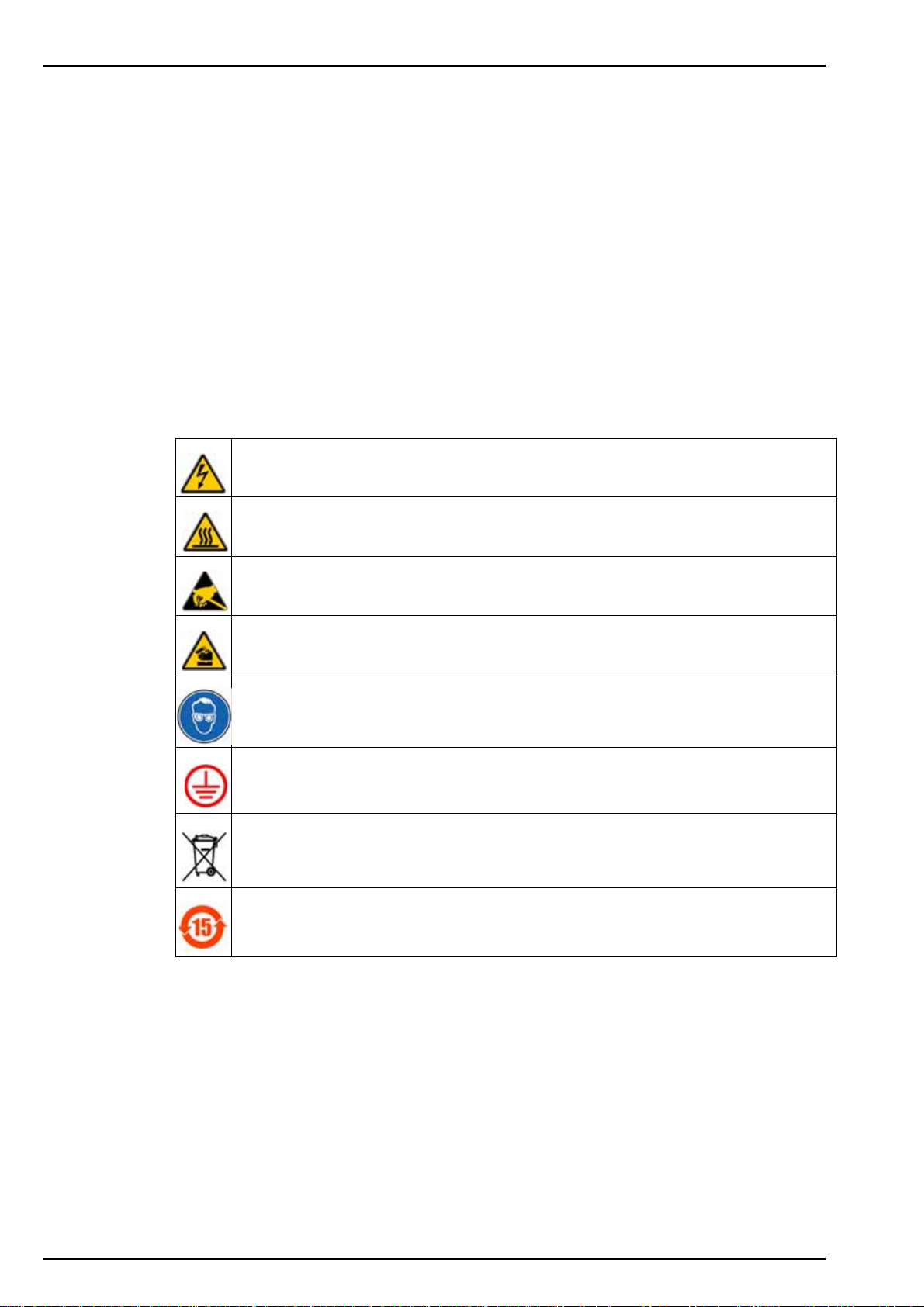

1.2.4 Precautionary labels

Read all labels and tags attached to the analyzer. Personal injury or damage to the analyzer

could occur if not observed.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical

shock and/or electrocution exists and indicates that only individuals qualified to work with

hazardous voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates that the marked item can be hot and should

not be touched without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to

electrostatic discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that

only individuals qualified and trained to work with chemicals should handle chemicals or perform

maintenance on chemical delivery systems associated with the equipment.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for protective

earth (ground).

Electrical equipment marked with this symbol may not be disposed of in European public

disposal systems. In conformity with European local and national regulations, European

electrical equipment users must now return old or end-of-life equipment to the manufacturer for

disposal at no charge to the user.

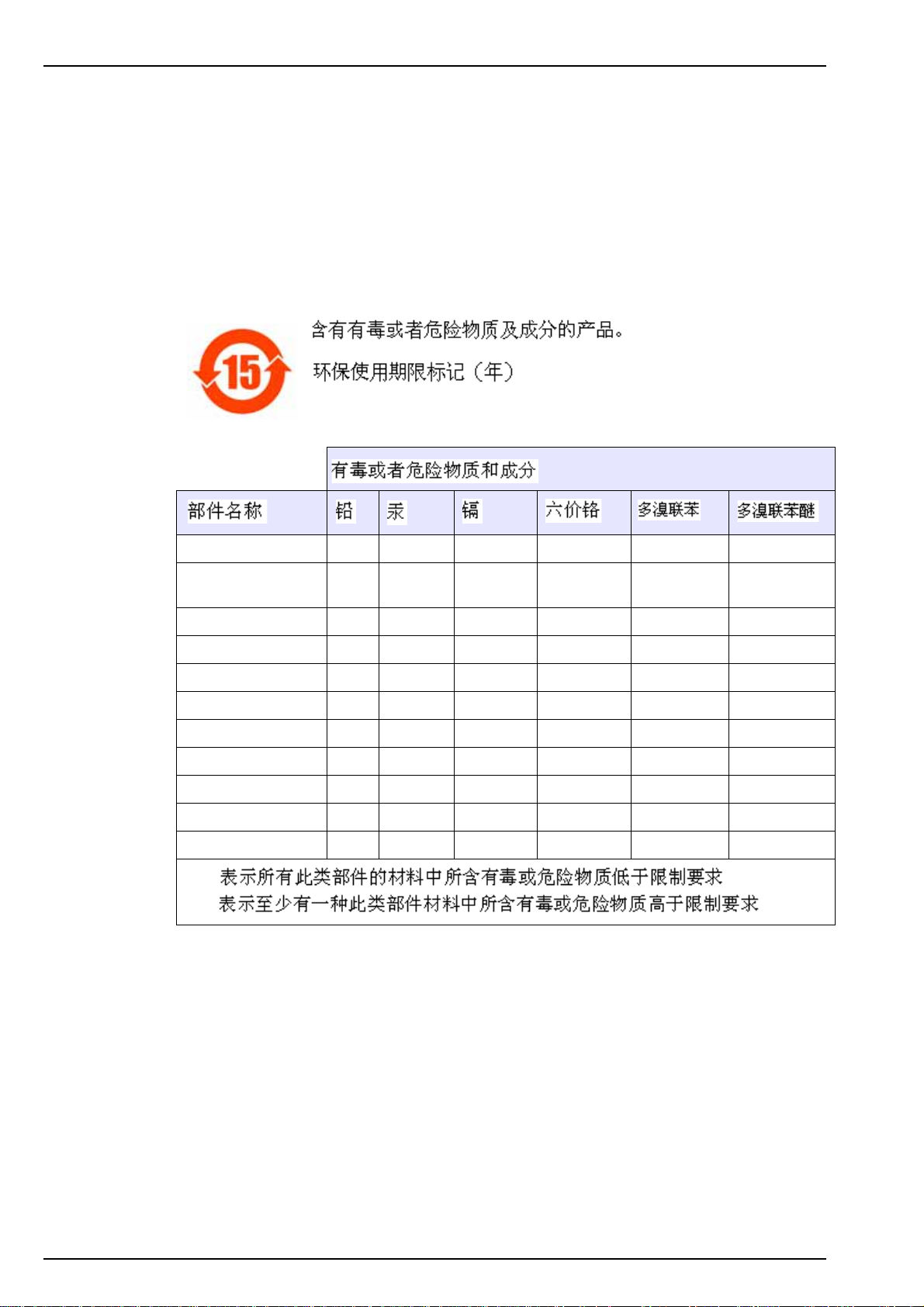

Products marked with this symbol indicates that the product contains toxic or hazardous

substances or elements. The number inside the symbol indicates the environmental protection

use period in years.

6

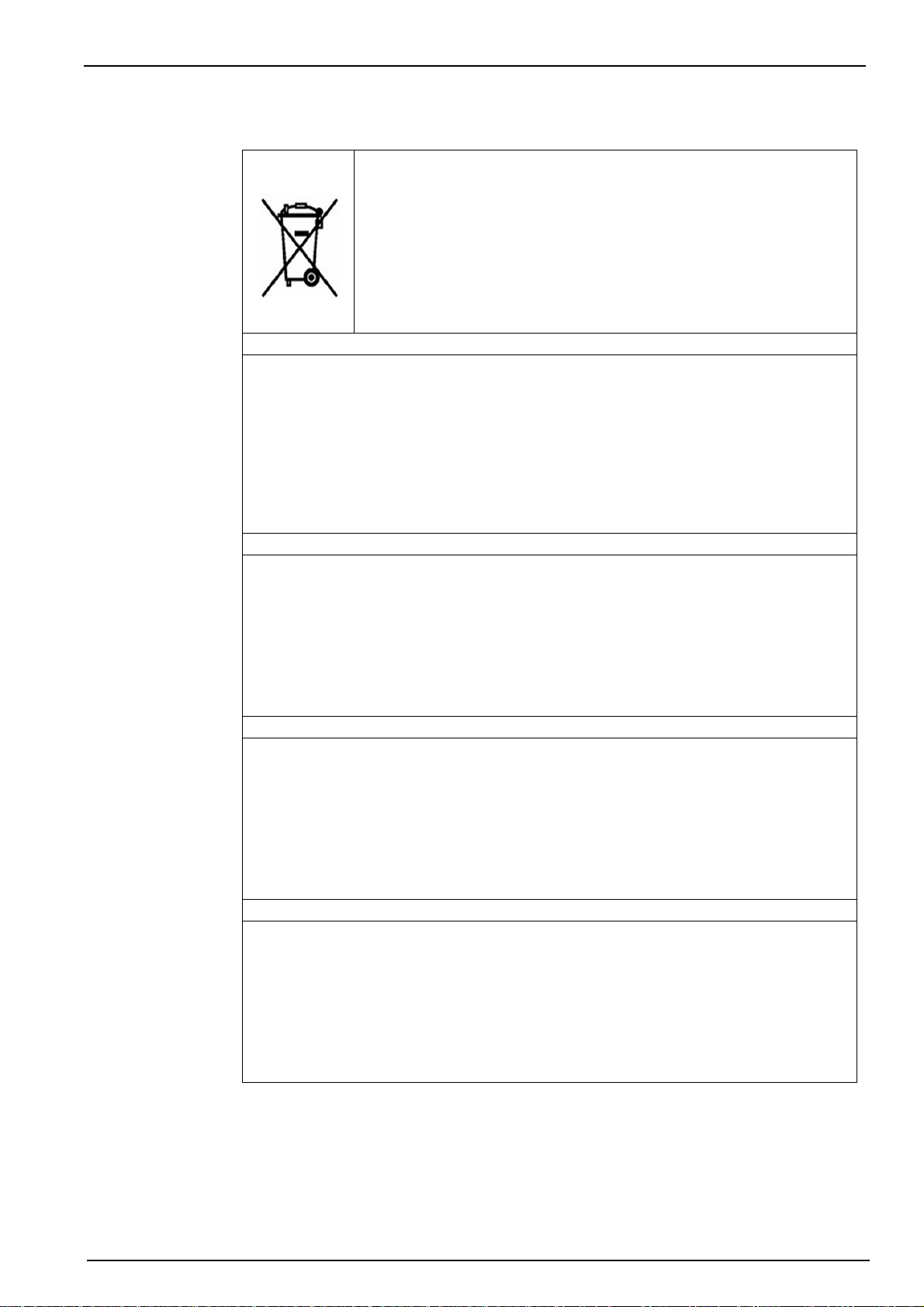

1.3 Product recycling information

ENGLISH

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of-life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment

manufacturer or supplier for instructions on how to return end-of-life

equipment for proper disposal.

DEUTSCH

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in Europa nach dem 12.

August 2005 nicht mehr über die öffentliche Abfallentsorgung entsorgt werden. In

Übereinstimmung mit lokalen und nationalen europäischen Bestimmungen (EU-Richtlinie

2002/96/EC), müssen Benutzer von Elektrogeräten in Europa ab diesem Zeitpunkt alte bzw. zu

verschrottende Geräte zur Entsorgung kostenfrei an den Hersteller zurückgeben.

Hinweis: Bitte wenden Sie sich an den Hersteller bzw. an den Händler, von dem Sie das Gerät

bezogen haben, um Informationen zur Rückgabe des Altgeräts zur ordnungsgemäßen

Entsorgung zu erhalten.

General Information

FRANCAIS

A partir du 12 août 2005, il est interdit de mettre au rebut le matériel électrique marqué de ce

symbole par les voies habituelles de déchetterie publique. Conformément à la réglementation

européenne (directive UE 2002/96/EC), les utilisateurs de matériel électrique en Europe doivent

désormais retourner le matériel usé ou périmé au fabricant pour élimination, sans frais pour

l'utilisateur.

Remarque: Veuillez vous adresser au fabricant ou au fournisseur du matériel pour les

instructions de retour du matériel usé ou périmé aux fins d'élimination conforme.

ITALIANO

Le apparecchiature elettriche con apposto questo simbolo non possono essere smaltite nelle

discariche pubbliche europee successivamente al 12 agosto 2005. In conformità alle normative

europee locali e nazionali (Direttiva UE 2002/96/EC), gli utilizzatori europei di apparecchiature

elettriche devono restituire al produttore le apparecchiature vecchie o a fine vita per lo

smaltimento senza alcun costo a carico dell’utilizzatore.

Nota: Per conoscere le modalità di restituzione delle apparecchiature a fine vita da riciclare,

contattare il produttore o il fornitore dell’apparecchiatura per un corretto smaltimento.

DANSK

Elektriske apparater, der er mærket med dette symbol, må ikke bortskaffes i europæiske offentlige

affaldssystemer efter den 12. august 2005. I henhold til europæiske lokale og nationale regler

(EU-direktiv 2002/96/EF) skal europæiske brugere af elektriske apparater nu returnere gamle eller

udtjente apparater til producenten med henblik på bortskaffelse uden omkostninger for brugeren.

Bemærk: I forbindelse med returnering til genbrug skal du kontakte producenten eller

leverandøren af apparatet for at få instruktioner om, hvordan udtjente apparater bortskaffes

korrekt.

7

General Information

SVENSKA

Elektronikutrustning som är märkt med denna symbol kanske inte kan lämnas in på europeiska

offentliga sopstationer efter 2005-08-12. Enligt europeiska lokala och nationella föreskrifter

(EU-direktiv 2002/96/EC) måste användare av elektronikutrustning i Europa nu återlämna gammal

eller utrangerad utrustning till tillverkaren för kassering utan kostnad för användaren.

Obs! Om du ska återlämna utrustning för återvinning ska du kontakta tillverkaren av utrustningen

eller återförsäljaren för att få anvisningar om hur du återlämnar kasserad utrustning för att den ska

bortskaffas på rätt sätt.

ESPANOL

A partir del 12 de agosto de 2005, los equipos eléctricos que lleven este símbolo no deberán ser

desechados en los puntos limpios europeos. De conformidad con las normativas europeas

locales y nacionales (Directiva de la UE 2002/96/EC), a partir de esa fecha, los usuarios

europeos de equipos eléctricos deberán devolver los equipos usados u obsoletos al fabricante de

los mismos para su reciclado, sin coste alguno para el usuario.

Nota: Sírvase ponerse en contacto con el fabricante o proveedor de los equipos para solicitar

instrucciones sobre cómo devolver los equipos obsoletos para su correcto reciclado.

NEDERLANDS

Elektrische apparatuur die is voorzien van dit symbool mag na 12 augustus 2005 niet meer

worden afgevoerd naar Europese openbare afvalsystemen. Conform Europese lokale en

nationale wetgegeving (EU-richtlijn 2002/96/EC) dienen gebruikers van elektrische apparaten

voortaan hun oude of afgedankte apparatuur kosteloos voor recycling of vernietiging naar de

producent terug te brengen.

Nota: Als u apparatuur voor recycling terugbrengt, moet u contact opnemen met de producent of

leverancier voor instructies voor het terugbrengen van de afgedankte apparatuur voor een juiste

verwerking.

POLSKI

Sprzęt elektryczny oznaczony takim symbolem nie może być likwidowany w europejskich

systemach utylizacji po dniu 12 sierpnia 2005. Zgodnie z europejskimi, lokalnymi i państwowymi

przepisami prawa (Dyrektywa Unii Europejskiej 2002/96/EC), użytkownicy sprzętu elektrycznego

w Europie muszą obecie przekazywać Producentowi stary sprzęt lub sprzęt po okresie

użytkowania do bezpłatnej utylizacji.

Uwaga: Aby przekazać sprzęt do recyklingu, należy zwrócić się do producenta lub dostawcy

sprzętu w celu uzyskania instrukcji dotyczących procedur przekazywania do utylizacji sprzętu po

okresie użytkownia.

PORTUGUES

Qualquer equipamento eléctrico que ostente este símbolo não poderá ser eliminado através dos

sistemas públicos europeus de tratamento de resíduos sólidos a partir de 12 de Agosto de 2005.

De acordo com as normas locais e europeias (Directiva Europeia 2002/96/EC), os utilizadores

europeus de equipamentos eléctricos deverão agora devolver os seus equipamentos velhos ou

em fim de vida ao produtor para o respectivo tratamento sem quaisquer custos para o utilizador.

Nota: No que toca à devolução para reciclagem, por favor, contacte o produtor ou fornecedor do

equipamento para instruções de devolução de equipamento em fim de vida para a sua correcta

eliminação.

8

1.4 Product disposal

Note: The following only applies to European customers.

Hach Lange is committed to ensuring that the risk of any environmental damage or pollution

caused by any of its products is minimized as far as possible. The European Waste Electrical

and Electronic Equipment (WEEE) Directive (2002/96/EC) that came into force on August 13

2005 aims to reduce the waste arising from electrical and electronic equipment; and improve the

environmental performance of all those involved in the life cycle of electrical and electronic

equipment.

In conformity with European local and national regulations (EU Directive 2002/96/EC stated

above), electrical equipment marked with the above symbol may not be disposed of in

European public disposal systems after 12 August 2005.

Hach Lange will offer to take back (free of charge to the customer) any old, unserviceable or

redundant analyzers and systems which carry the above symbol, and which were originally

supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

General Information

In addition, Hach Lange will offer to take back (at cost to the customer) any old, unserviceable

or redundant analyzers and systems which do not carry the above symbol, but which were

originally supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

Should you wish to arrange for the disposal of any piece of equipment originally supplied by

Hach Lange, please contact your supplier or our After Sales Service department in Geneva for

instructions on how to return this equipment for proper disposal.

9

General Information

1.5 Restriction of hazardous substances (RoHS)

The European Union RoHS Directive and subsequent regulations introduced in member states

and other countries limits the use of six hazardous substances used in the manufacturing of

electrical and electronic equipment.

Currently, monitoring and control instruments do not fall within the scope of the RoHS Directive,

however Hach Lange has taken the decision to adopt the recommendations in the Directive as

the target for all future product design and component purchasing.

Note: The following only applies to exports of this product into the People’s Republic of China.

Transmitter box X

CPU PCB

(with battery)

Power PCB O O

RS 485 O

Profibus O

PCB CAN O

PCB Local controller O

PCB Measure O

PCB Pumps O

PCB Mixer O

PCB Channel O

OO

O:

X:

10

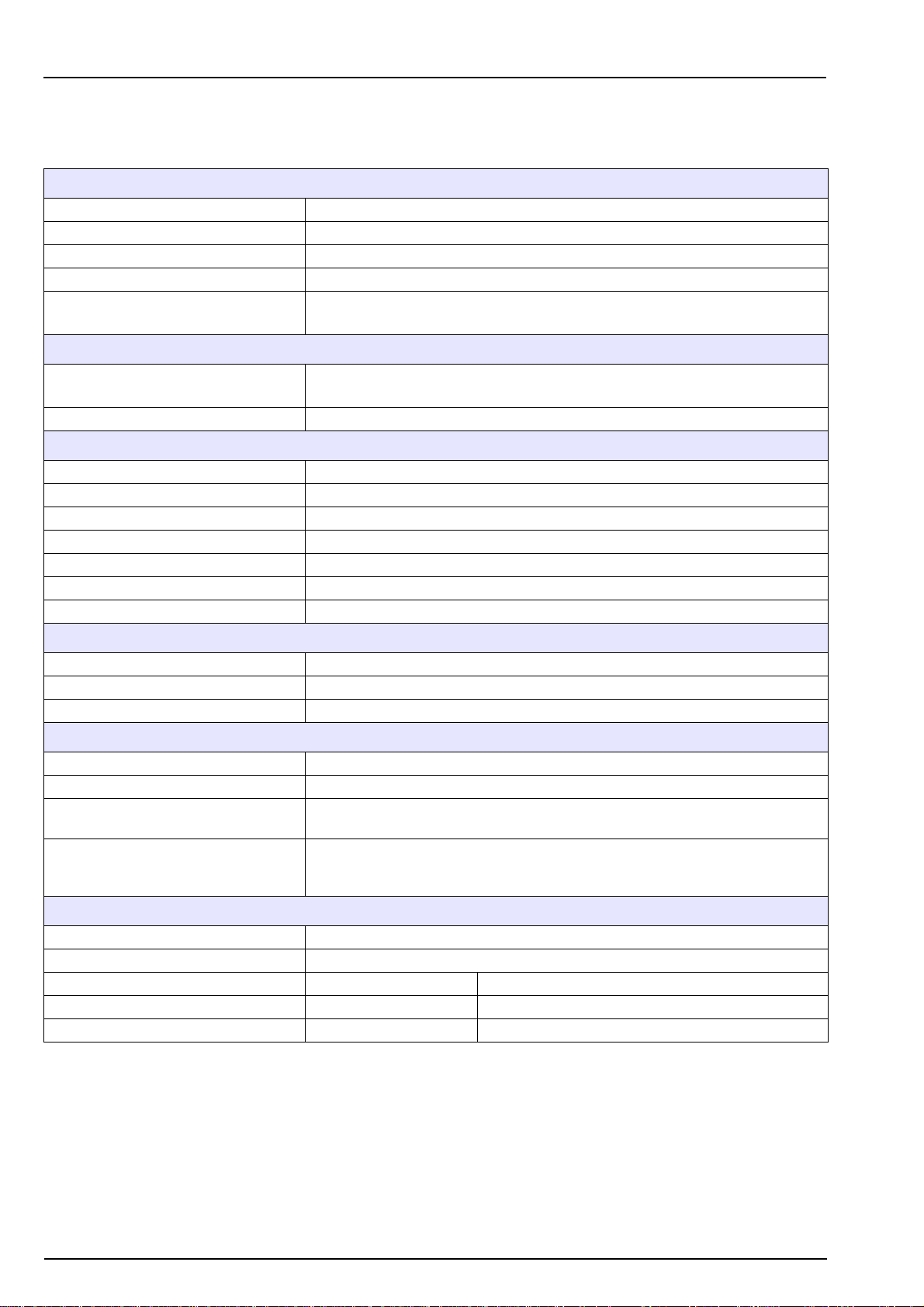

Section 2 Specifications

2.1 Technical specifications

Specifications are subject to change without notice.

Sample

Number of channels 1 - 6

Measurement cycle < 10 min / channel

Sample pressure 0.2 to 6 bar (3 to 87 psi)

Temperature 5 - 50°C (41 - 122°F)

Sample flow

Connections

Sample input

Sample output Barbed stem for 12 mm (½" I.D.) hose

Conditions of use

Ambient temperature 5 to + 45°C (41 to 113°F)

Power supply voltage fluctuation ± 10%

Overvoltage category 2 (according to standard EN 61010-1)

Degree of pollution 2 (according to CEI 664)

Altitude ≤ 2000 m

Relative humidity 10 to 80%

Measurement category Cat II, Class 1 (overvoltage < 1500V)

Weight

Panel analyzer without canister 13 kg

Cabinet analyzer without canister 65 kg

Full canisters 8 kg

Minimum 5L / hour

Maximum 30L / hour

Simple fittings for 6 mm O.D. tubing or ¼" O.D. in PE-low density.

¼" OD in PHED-PTFE-SS as option

Standards

EMC EN 61326-1 (1997) & A1 (1998) & A2 (2001) & A3 (2004)

European safety standards IEC 61010-1 (2001) & EN 61010-1 (2001)

UL & CSA agreement

UL & CSA standards

Analysis

Value measured Dissolved SiO

Cycle time Approximately 10 minutes per channel

Measurement range (2 versions) 0 - 1000 ppb 0 - 5000 ppb

Repeatability ± 2% or ± 0.5 ppb ± 2% or ± 2 ppb

Detection limit 0.5 ppb 2 ppb

Certified to UL & CSA safety standards, with cETLus mark

(Control Number: 3164002)

Safety of Electrical Equipment for Measurement, Control and Laboratory use;

UL61010-1, Issued: 2004/07/12, Ed.2 Rev: 2005/07/22 and CAN/CSA C22.2

No. 61010-1, Issued: 2004/07/12

2

11

Specifications

Inputs / Outputs

Number 8

Functions 6 threshold alarms / lack of sample / active channel

Alarms

Cut-off power 30 VDC, 0.5 A maximum

Number 12

Logical inputs

Serial input interface RS 485, Modbus communication protocol

Outputs 4 / 20 mA

Materials and protection

Transmitter Aluminium with polyester paint

Panels and other boxes Polystyrene

Protection transmitter box IP 65

Protection cabinet (optional) IP 54

Cabinet front door Plexiglas

Maintenance

Remote alarm clearance

By-pass measurement for a channel

Number 8

4/20 mA or 0/20 mA programmable

Galvanically insulated

Maximum charge of 800 ohms

1 system alarm

1 warning alarms

Calibration Chemical zero, slope with calibration solution

Maintenance

Reagent consumption Approximately 1L per month and per reagent

Calibration solution consumption Approximately 200 ml / calibration

Time safeguard lithium battery CR 1220 (3 V)

Transmitter

Display

Mains power supply

Mains

No particular maintenance is necessary

Cleaning can be done with a soft non-aggressive cloth

Programming by menu

Concentration of 6 samples

Analyzer status

Alarms

Trend curves

Concentration historic

Calibration parameters historic (date, slope and offset)

100 - 240 VAC 50 - 60 Hz

Automatic switching

Max. consumption: 80 VA

12

Section 3 Analyzer Overview

3.1 Operation

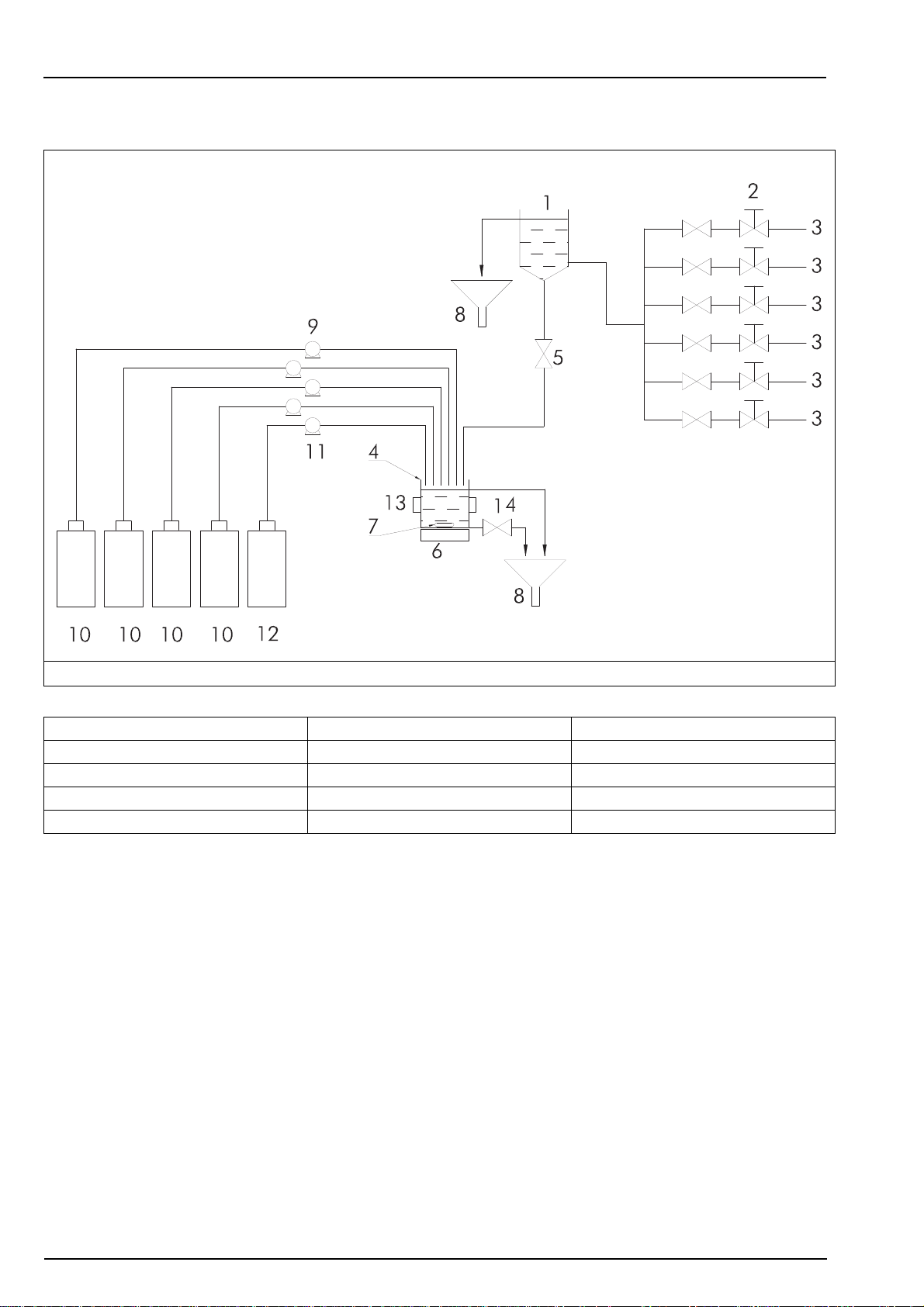

Figure 1 Working principal

1 - Overflow tank with level detector 6 - Mixing motor 11 - Calibration pump

2 - Flow adjustment valves (1 to 6) 7 - Magnetic bar 12 - Calibration solution canister

3 - Sample input (1 to 6) 8 - Drain 13 - Photometer

4 - Photometric measuring cell 9 - Reagent pumps (x4) 14 - Drain pump of measuring cell

5 - Measuring solenoid valve 10 - Reagent canisters (x4)

The 9210 can analyze up to six different samples. The sample to be analyzed circulates in a

fast loop permitting rapid renewal of the sample. Adjustment of the flow is carried out with the

help of a needle valve (2). At the beginning of the analysis, the sample is introduced into the

measuring cell (4) with the use of a solenoid valve (5).

The reagents R1M and R1A are first added using two of the reagent pumps (9). The silica

contained in the sample then reacts with the molybdate and forms the silicomolybdic complex.

The reaction will take up to 5 minutes.

Oxalic acid is then added using a reagent pump (9) to avoid phosphate interference and to

intensify the color.

The silicomolybdic complex is reduced to a blue molybdenum complex by means of ferrous

ions. A photometric measurement is carried out at the end of the reaction.

13

Analyzer Overview

3.2 Calibration

In order to ensure accurate measurements, the analyzer should be calibrated periodically. The

zero is achieved chemically and internally in the analyzer. The system slope is controlled by

comparison to a standard solution of known concentration. Further information regarding

calibrations can be found in the section entitled Calibration on page 51.

3.3 Analyzer outputs

The instrument can measure silica concentration from three different sources:

• the process sample during a normal measuring cycle

• the calibration solution during an automatic calibration

• an external sample during the grab sample operation

Whatever the sample source, the measurement cycle structure is identical and all analyzer

outputs (e.g. 4/20 mA outputs, screen display, RS485 data, alarm status, etc.) are refreshed

during the last minute of the measurement.

3.4 Maintenance

To ensure a high degree of accuracy is maintained by the analyzer, it is recommended to

perform a specific maintenance procedure once a year. All replacement parts and fittings are

available by purchasing the maintenance kit 09120=A=8000 which contains enough parts and

fittings for two years.

Full details on this procedure and the contents of the maintenance kit can be found in Yearly

maintenance on page 60.

14

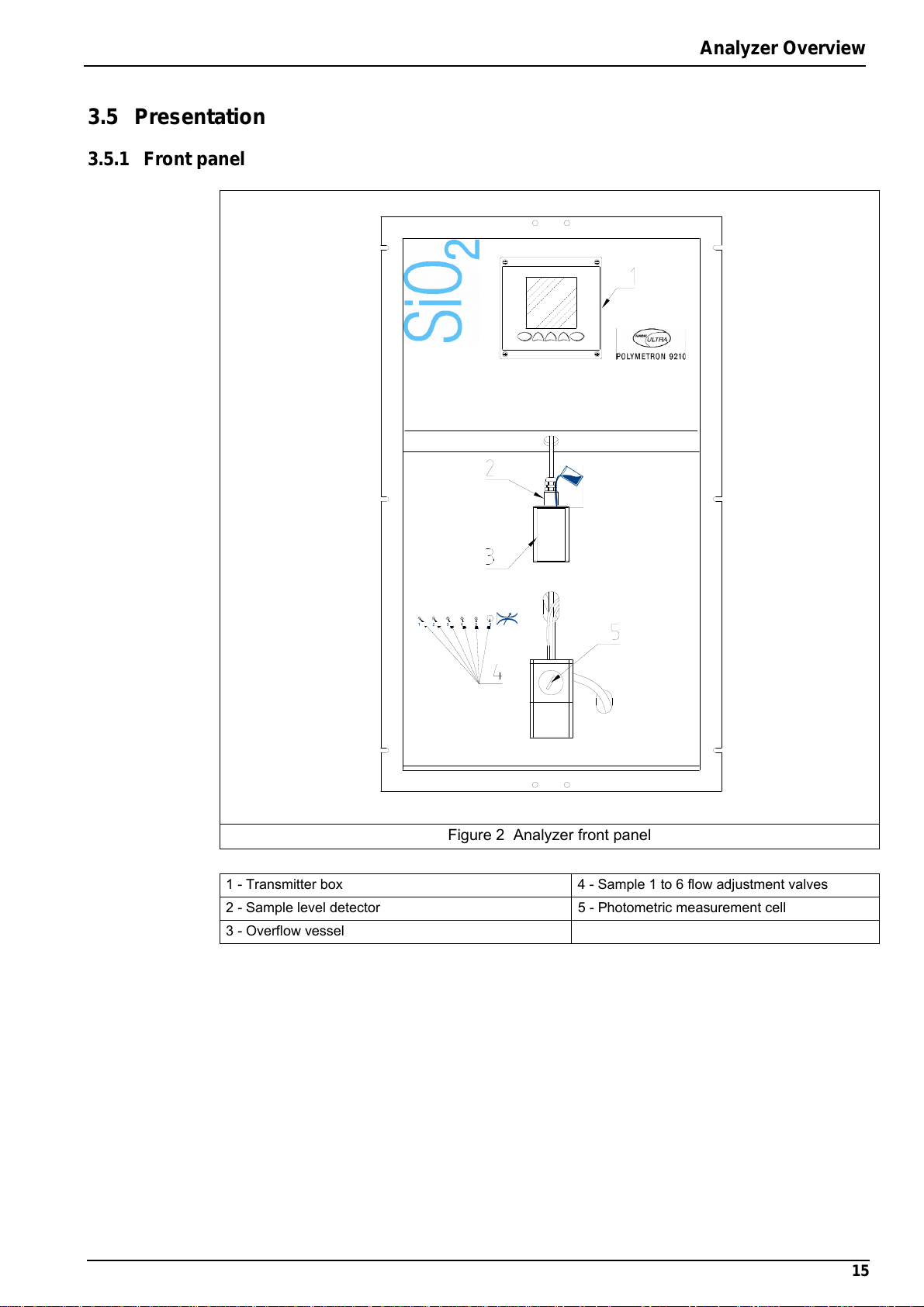

3.5 Presentation

3.5.1 Front panel

Analyzer Overview

Figure 2 Analyzer front panel

1 - Transmitter box 4 - Sample 1 to 6 flow adjustment valves

2 - Sample level detector 5 - Photometric measurement cell

3 - Overflow vessel

15

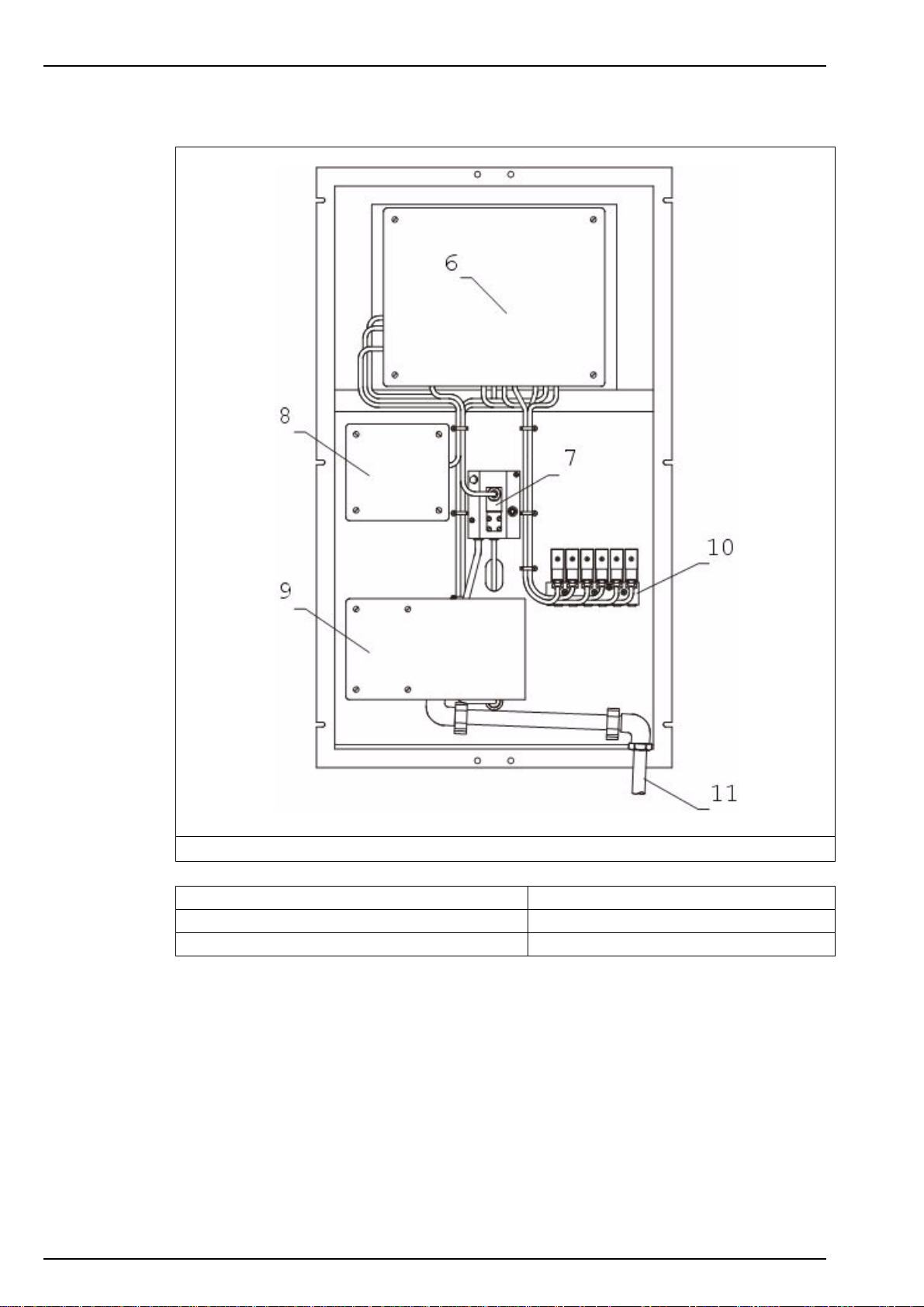

Analyzer Overview

3.5.2 Rear panel

16

Figure 3 Analyzer rear panel

6 - Local controller box 9 - Measurement box

7 - Measurement solenoid valve 10 - Sample inlet valves

8 - Pumps box 11 - Drain

Section 4 Installation

WARNING

The analyzer should only be assembled by qualified staff. Mains power should only be

connected once installation has been completed and checked.

4.1 Analyzer inspection and unpacking

The analyzer has been factory tested and checked prior to shipping. We nevertheless

recommend that you perform a visual inspection in order to ensure that it has not been

damaged. Any marked packaging is a potential sign of damage that may not be immediately

visible. Keep all packaging in the event of claims.

Open the box. Take the packing list from the box and check the presence of all the items

selected. If any parts or accessories are missing, refer to your distributor or to Hach Lange.

4.2 Analyzer preparation

Before installing the analyzer, think about the following:

• Place the analyzer close to the sample point. This will allow the response time to be reduced.

• The sample should be homogenous and representative.

• The temperature of the sample should be between 5 and 50°C.

• The pressure of the sample should be between 0.2 and 6 bar and remain relatively stable.

• The solution should be free of particles.

• Sample lines should be in PE/PTFE/FEP (4 x 6 mm).

• Avoid any location with a corrosive atmosphere or subject to liquid spills.

• Chose a dry and dust-free location.

• The ambient temperature of the analyzer should not exceed 45°C. If the temperature is

below 5°C, the analyzer should be installed in a heated cabinet (not provided by Hach

Lange).

4.3 Installation checklist

For a complete installation, perform the following actions in the order specified, following the

instructions very carefully:

1. Mount the analyzer - section 4.4 on page 18

2. Install the canister holder - section 4.5 on page 20

3. Connect the sample lines - section 4.6 on page 21

4. Connect the drain tube - section 4.7 on page 22

5. Connect the mains power - section 4.8 on page 22

6. Connect the external communications - section 4.9 on page 26

7. Input/Output connections - section 4.10 on page 27

8. Reagent preparation - section 4.11 on page 29

9. Connect reagent canisters - section 4.12 on page 31

10. Analyzer stabilization and startup - section 4.13 on page 32

17

Installation

4.4 Mounting the analyzer

CAUTION

Wherever the analyzer is to be mounted, it is important to note that it must be placed in

an upright position with the transmitter at the top. It is recommended to use a spirit level

to ensure that the analyzer is correctly positioned and not leaning to one side or forward.

This is essential to guarantee the accuracy of the analyzer.

4.4.1 Panel version

For the panel version, the dimensions of the analyzer and fixation holes are shown in Figure 4.

18

Figure 4 Panel version dimensions - mm [ins]

A. Mains power supply cable gland, drilled ∅ 11 (5 to 10mm), 100…240V, 50-60Hz, 25VA

B. Field bus cable gland, drilled ∅ 13 (6 to 12mm)

C. 5 to 7 mm cable gland

• Alarm signals: 30V, 0.5A max.

• Logic inputs: Cutoff on channels 1 to 6, acknowledgement of alarm signals

• Analog outputs: 0-20 mA or 4-20 mA

D. Sample inlets, (channels 1 to 6), QR coupling for semi-rigid tubing ∅ 6mm, 5 to 50°C

(40° to 120°F), P 0.2 to 6 bar (3 to 87 PSI)

E. Drain tube: silicon tubing ∅ 12 x 17mm, at atmospheric pressure

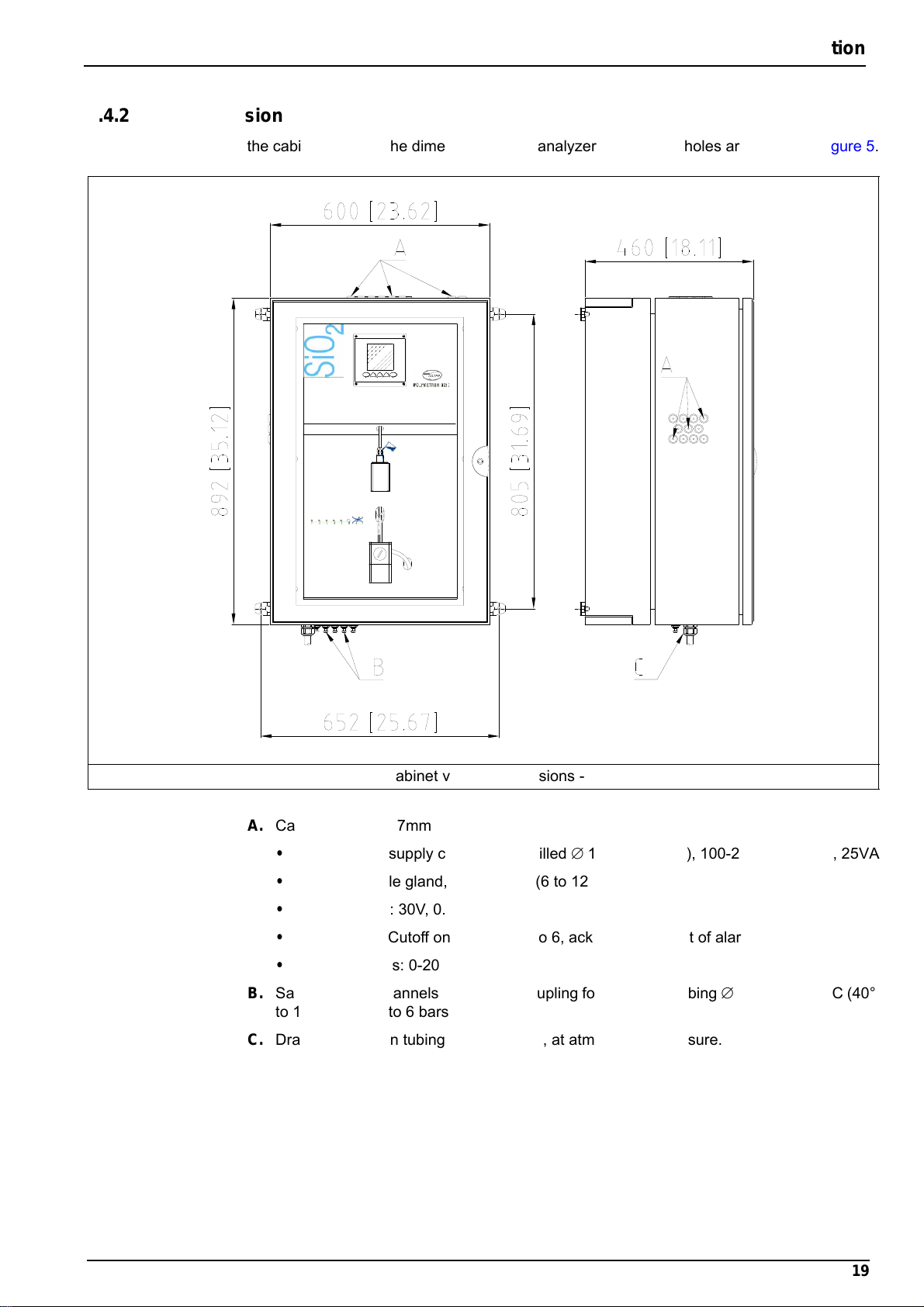

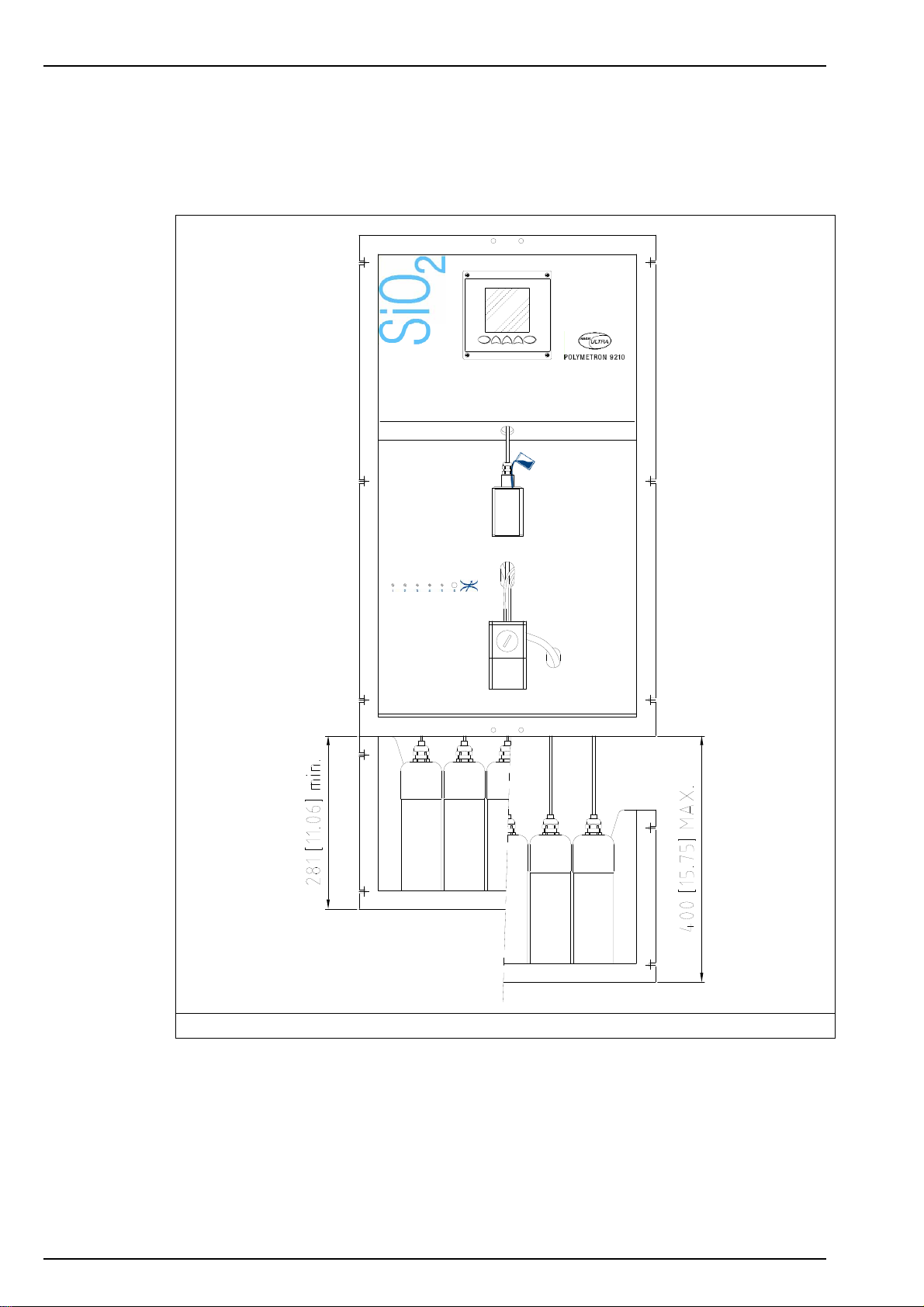

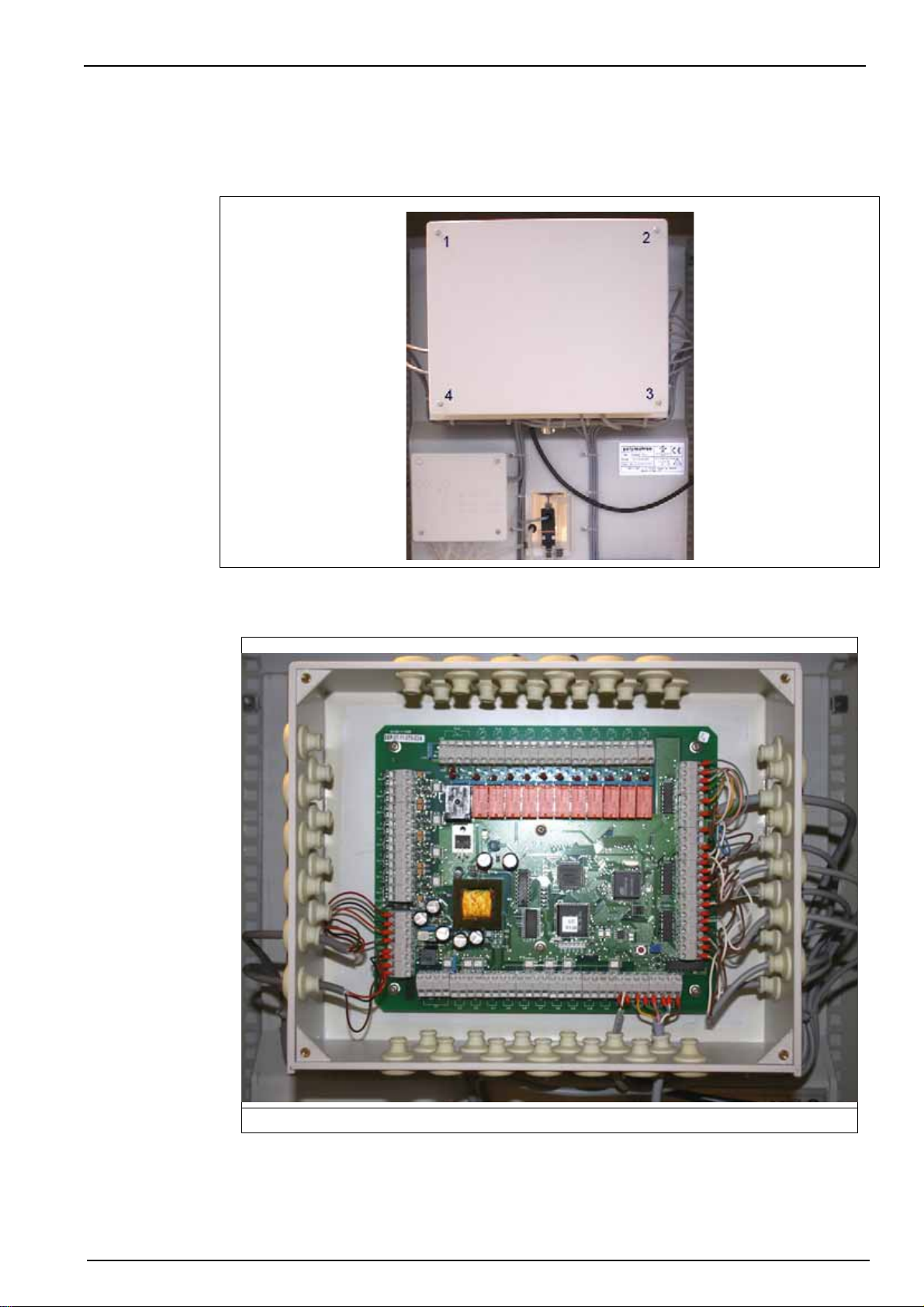

4.4.2 Cabinet version

For the cabinet version, the dimensions of the analyzer and fixation holes are shown in Figure 5.

Installation

Figure 5 Cabinet version dimensions - mm [ins]

A. Cable gland, 5 to 7mm

• Mains power supply cable gland, drilled ∅ 11 (5 to 10mm), 100-240V, 50-60Hz, 25VA

• Field bus cable gland, drilled ∅ 13 (6 to 12mm)

• Alarm signals: 30V, 0.5A max.

• Logic inputs: Cutoff on channels 1 to 6, acknowledgement of alarm signals

• Analog outputs: 0-20mA or 4-20mA

B. Sample inlets (channels 1 to 6), QR coupling for semi-rigid tubing ∅ 6mm, 5 to 50°C (40°

to 120°F), P 0.2 to 6 bars (3 to 87 PSI)

C. Drain tube: silicon tubing ∅ 12 x 17mm, at atmospheric pressure.

19

Installation

4.5 Installing the canister holder

For cabinet versions, a canister holder is pre-mounted in the rear of the cabinet. For the panel

version, a canister holder is supplied separately and must be installed under the analyzer as

illustrated in Figure 6 below.

20

Figure 6 Canister holders

Ensure the position of the canister holder does not exceed the maximum and minimum

distances from the bottom of the analyzer that are given in Figure 6 above.

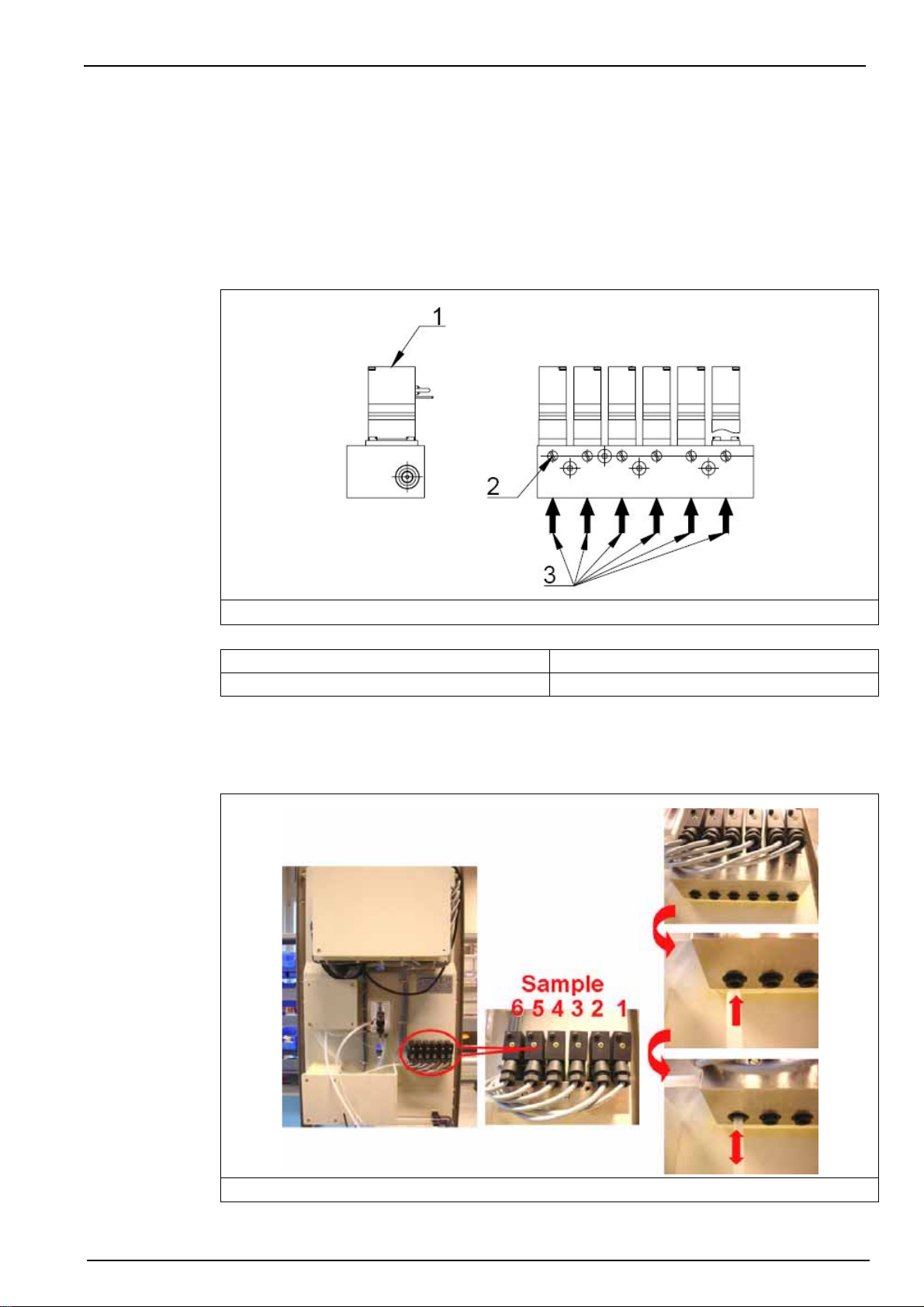

4.6 Connecting the sample

Use new tubes for connections during installation

• Exterior ∅: 6 mm exactly (or ¼'')

• Material: polyethylene or PTFE or FEP

• Pressure: 0.2 to 6 bar

• Temperature: 5 to 50°C

Installation

Figure 7 Sample connections schematic

1 - Solenoid valve 3 - Sample input 1 to 6

2 - Solenoid valve flow adjustment screw

At this stage of the installation, make sure that the flow valves (2) are all closed.

Connect the tubes by inserting into the quick release connections found under the sampling

block as illustrated in Figure 8 below.

Figure 8 Sample connections

21

Installation

4.7 Connecting the drain tube

The drain outlet is located on the bottom of the analyzer. A 12 x 17 mm pipe is delivered with

the analyzer and should be connected to the drain outlet at one end and the other fed to a drain

for sample evacuation.

Note: Evacuation should be free of any mechanical constraints, and any counter-pressure.

4.8 Mains power connection

WARNING

No intervention should be carried out on the analyzer without first switching off the

power.

The electrical installation should be carried out by duly qualified personnel. A supply voltage of

100-240 VAC is acceptable without changing the configuration. The power supply terminals can

be removed from their housing to make connection easier.

For safety reasons, it is imperative to respect the following:

• Use a three-wire power lead (live + neutral + earth) for supplying the required power.

• The analyzer should be connected to the mains via a circuit-breaker or fuse whose value

should be less or equal to 20 A. It should be located in the proximity and be identified.

This connection should cut-off the live and neutral when electrical problems occur or

when the user wishes to intervene inside the analyzer. However, the earth conductor

should always be connected.

Figure 9 Drain connection

22

Installation

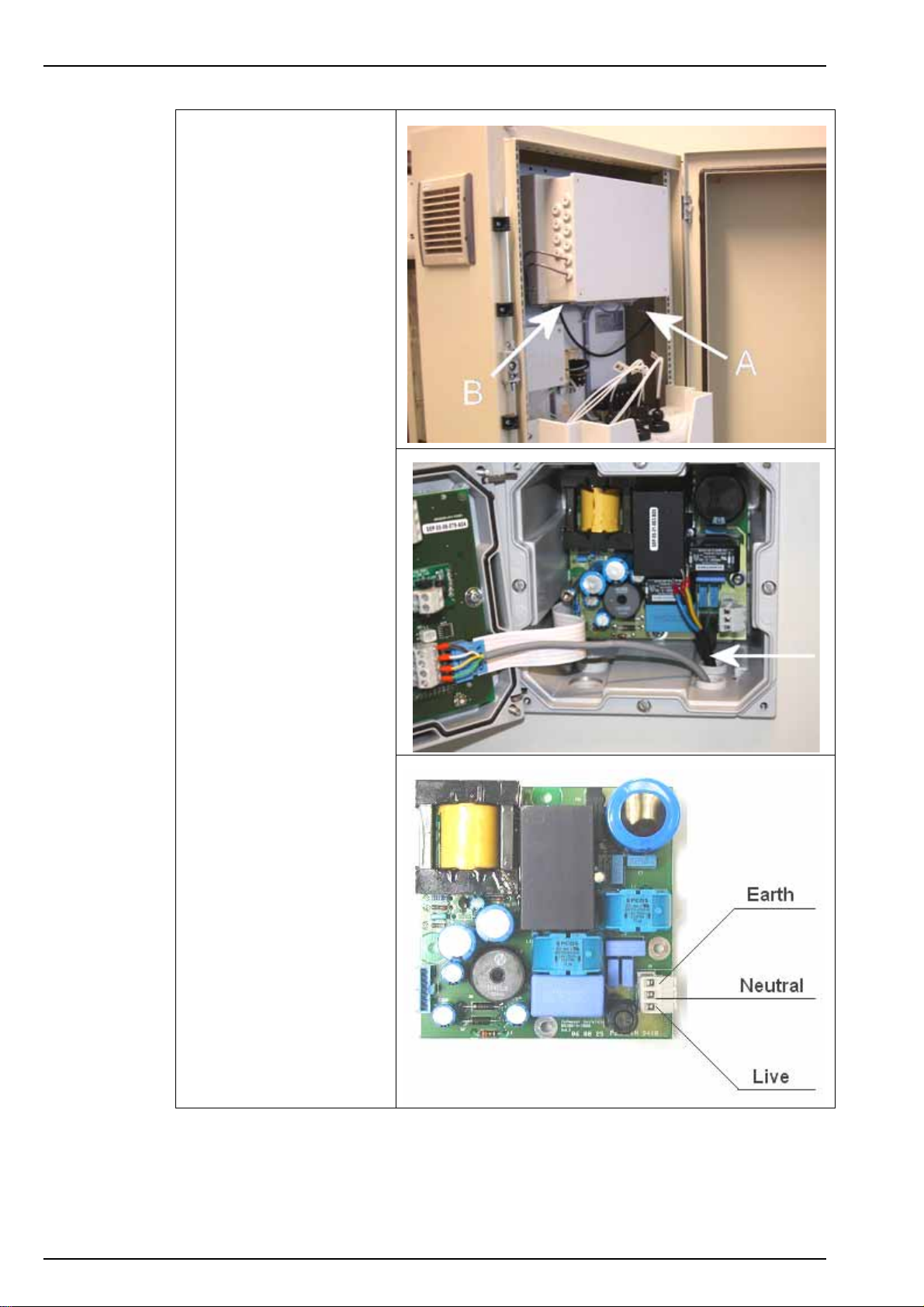

The following procedure outlines the steps required to connect power to the analyzer. The main

cabinet should be open with access to the interior:

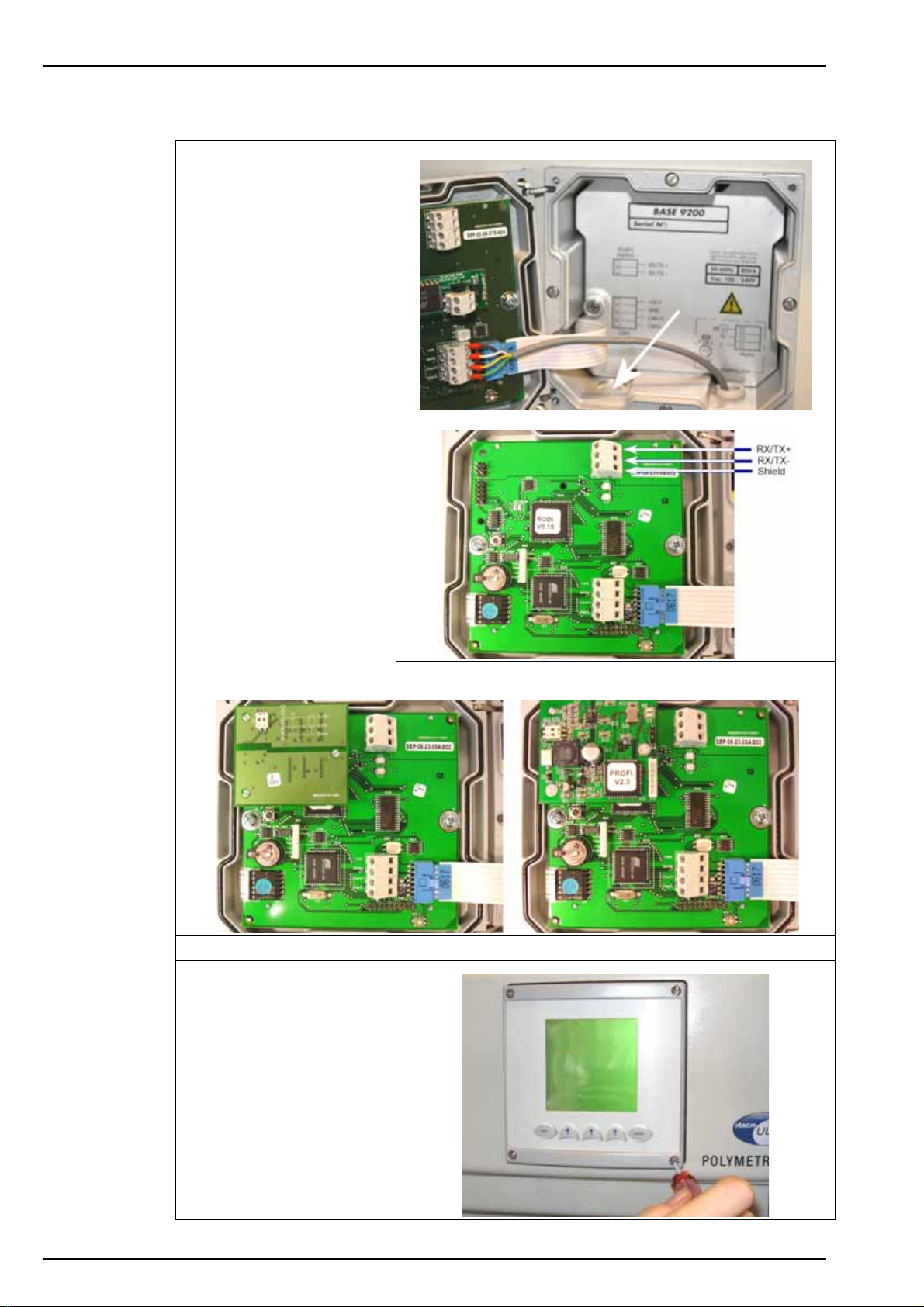

1. Open the transmitter front

door by unscrewing the

four holding screws.

2. Swing open the door (it is

hinged to the left) to

reveal the inside of the

transmitter.

3. Remove the metallic

shielding plate protecting

access to the main board.

4. Once the shielding plate

is removed, the location

of the power cable gland

can be seen (indicated

with the arrow).

23

Installation

5. Next, run the power

supply cable through one

of the external cable

glands located on the left

outside of the cabinet (A),

and into the analyzer.

6. Put your hand behind the

local controller box and

you will locate two cable

glands to the left and two

to the right on the bottom

of the transmitter (B). The

cable gland for the power

cable is located left and

nearest to you.

7. Unscrew the cable gland

nut, pass the power cable

through it, and then up

through the cable gland

and into the transmitter.

8. Screw back the cable

gland nut to secure the

power cable.

9. Remove the power supply

connector and note where

the earth, live and neutral

must be connected.

24

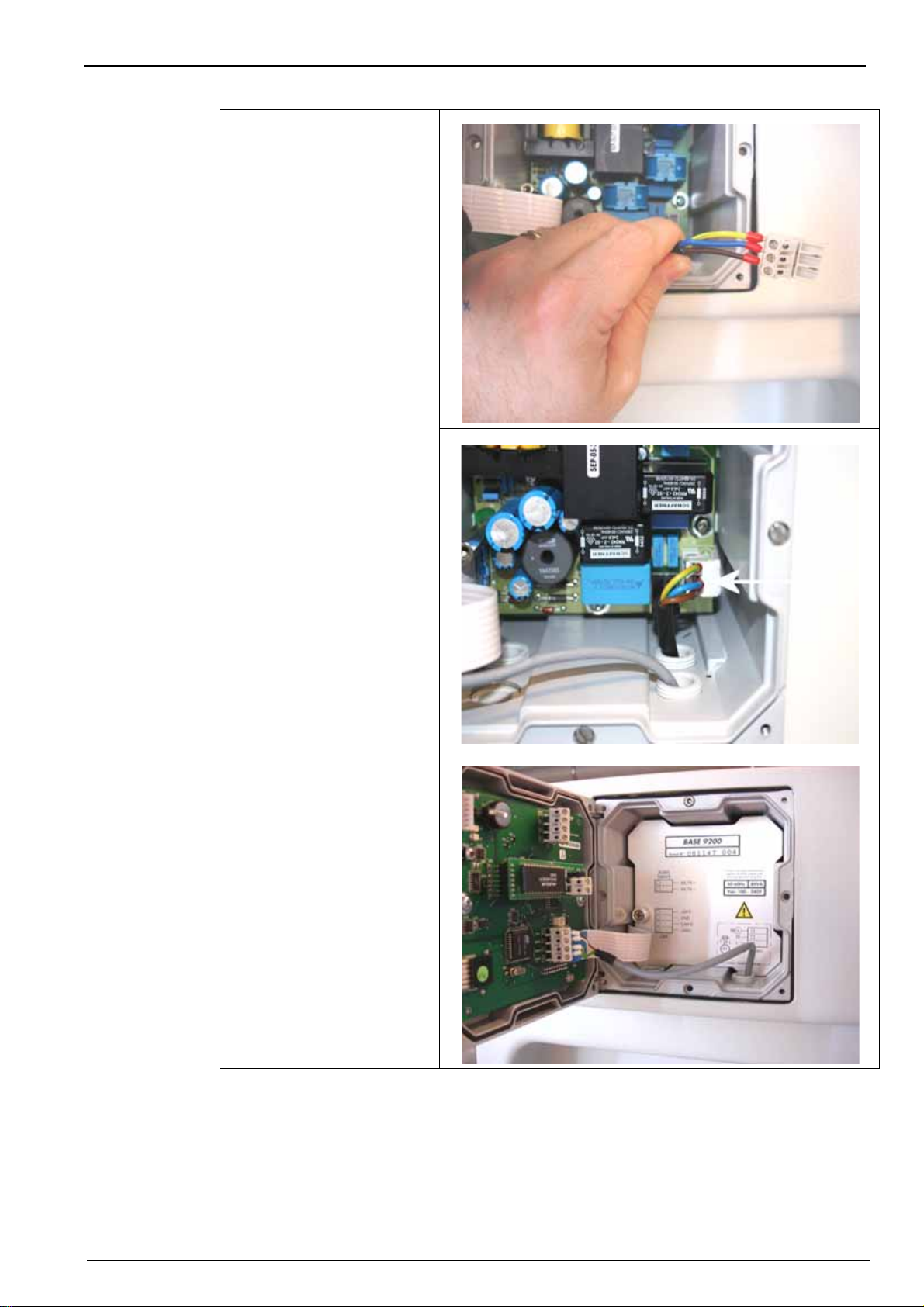

10. Connect the power supply

cables to the connector.

Installation

11. Put the connector back in

place.

12. Replace the metallic

shielding plate, ensuring it

is in front of the power

cable just installed.

25

Installation

4.9 External communications connection

1. As with the power cable,

run the communications

cable through an external

cable gland on the left

side of the cabinet, and

into the analyzer.

2. Pass it through the cable

gland located right and

farthest from you on the

base of the transmitter, so

it appears inside the

transmitter through the

left front cable gland (as

indicated).

3. Depending on the type of

board installed in the

analyzer, connect the

communication cable as

indicated.

Note: Connection is the same on

the CPU board for both the

JBUS/MODBUS and PROFIBUS

options.

CPU board without RS485 option

CPU board with JBUS/MODBUS option - - - - - CPU board with PROFIBUS option

26

4. Close the transmitter door

and screw securely back

in place.

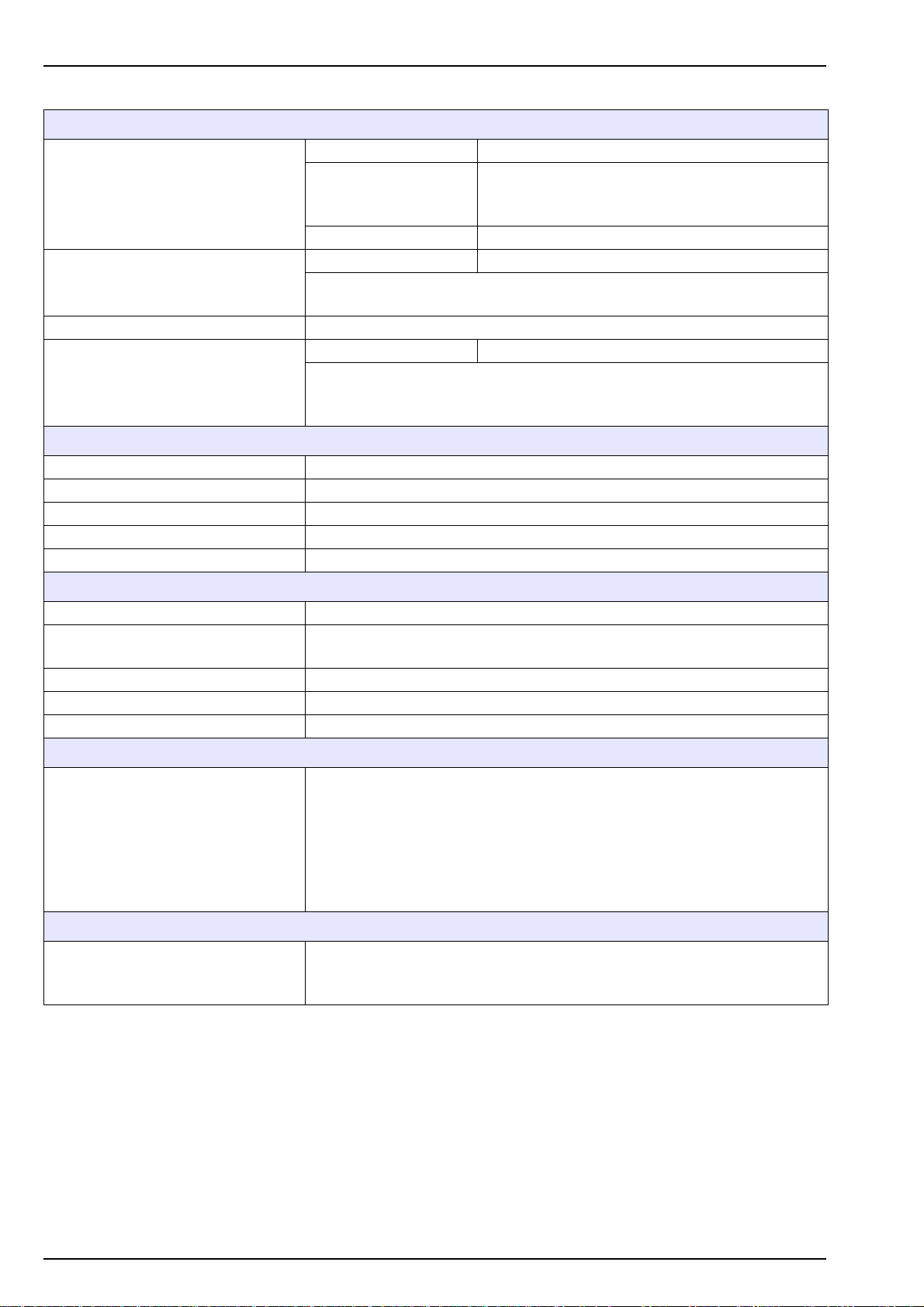

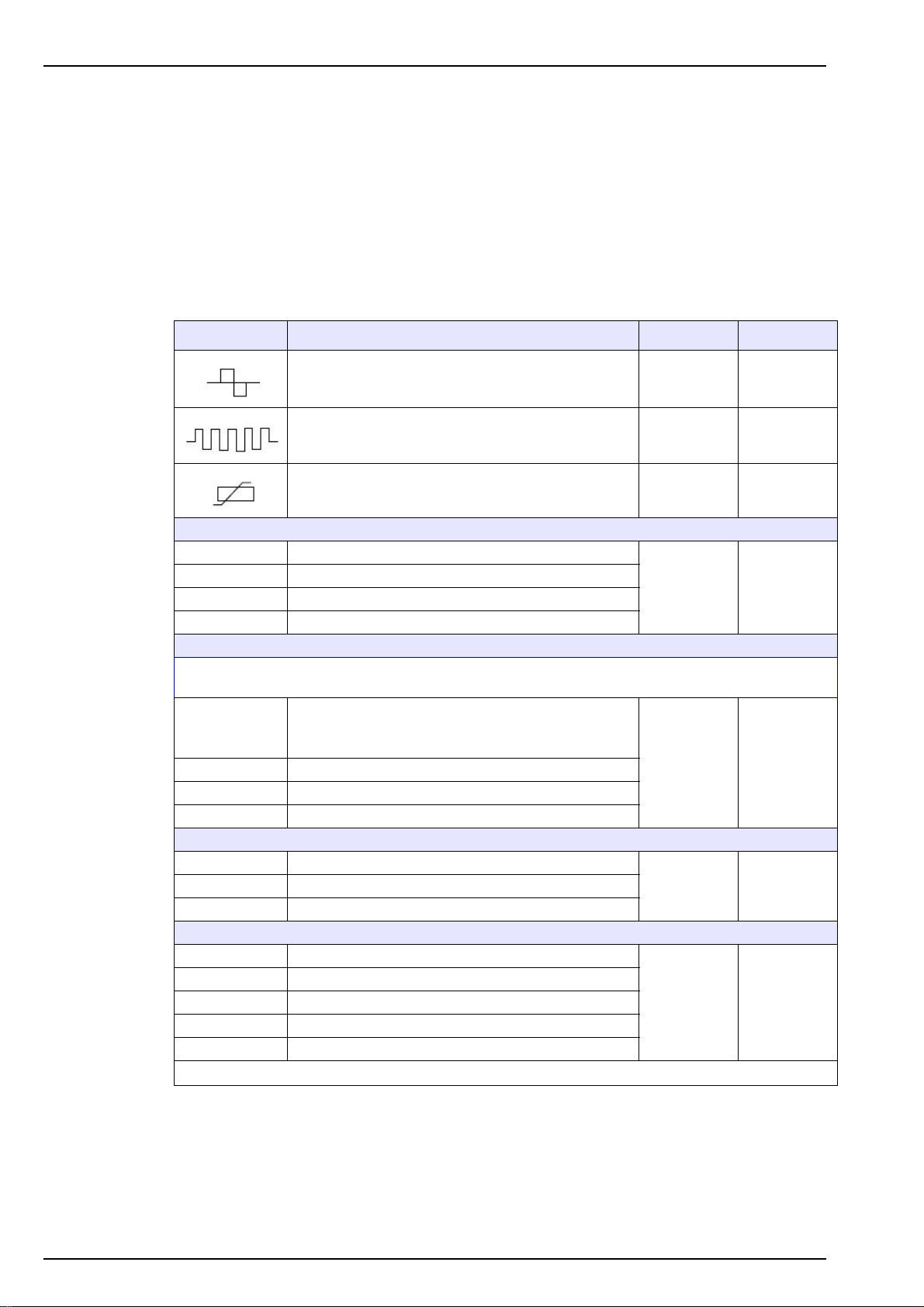

4.10Input/Output connections

To gain access to the I/O connections, open the back of the local controller box by unscrewing

the 4 corner screws.

Installation

This will reveal the I/O board as illustrated in Figure 10 (which shows connections already in

place).

Figure 10 Local controller connections

27

Installation

Before using any of the cable glands, perforate first with a screwdriver. To ensure a good seal,

the external diameter of the cables should be between 5 and 7 mm.

For information on the connections available refer to Table 1.

CAUTION

The relay outputs can only supply power in very low safety voltage (30 VAC or 42.4 VDC

maximum) and limited to 0.5 A.

The nomenclature given in the connections column of Table 1 below, refers to the same

nomenclature that is printed on the I/O board against each available connection.

Connections Function Max. voltage Max. current

Mixer control 24 VAC 1 A

Heater control 24 VDC 1 A

Cell temperature measurement 5 VDC 1 mA

Re1 to Re6 User relay of thresholds 1 - 6

Re7 to Re10 Not used

Re11 Warning alarm

Re12 System alarm (NO and NC switches are available)

Note: Dry relays are used for all the following logical inputs. At best, provide 1 dry circuit (no voltage)

which will be closed to launch an action.

By-pass sample measurement (channels 1 - 6)

In1 to In6

In7 to In10 Not used

In11 Remote acknowledgment of alarms

In12 Level sample detector

Iout1 to Iout6 Analog output 0-20 or 4-20 mA (channels 1 - 6)

Iout8 Not used

Vout1 Sample electrovalve control

Vout2 to Vout7 Sample selection electrovalve controls (channels 1 - 6)

Vout8 Calibration pump

Vout9 to Vout11 Reagent pumps

Vout12 Drain pump

For input In1, use terminals " in " and " - "

Terminals " + " and " out " are not used

30 Veff or

42.4 VDC

5 VDC 5 mA

24 VDC 23 mAIout7 Analyzer status

30 VDC 1 A

0.5 A

resistive

charge

Table 1 Relay functions

28

When all I/O connections have been made, put the cover back on the local controller box and

secure in place with the 4 screws.

Loading...

Loading...