Page 1

Film Data Sheet

T-85

Black & White Pack Film

3URIHVVLRQDOB&W3DFN)LOP

[

LQFK

[FP

7\SH

85

Film Speed

ISO 80/DIN 20

Format

1

3

/4 x 33/8 in. (8.3 x 8.6 cm)

Pack Film

Image Area

3

2

/4 x 27/8

Finish

Glossy

Exposures per Unit

10 exposures per pack

Development Time

30 seconds at 65°F (18°C) and above

in. (6.9 x 7.2 cm)

ILOP

Description

Medium-speed, medium-contrast, fine-grain film which produces

high quality black and white prints and negatives suitable for

enlarging.

Key Applications

• Old time photography

• Portraits

• Professional photography proofing

Compatible Hardware

• Cameras or instruments with CB-1034 or CB-80 camera backs

• MiniPortrait Camera models M484, M485b, M486V , and M488V

• ProPack Camera

Special Treatment

Requires print coating the positive and clearing the negative to

prevent fading and discoloration. T o clear the negative for reuse,

immerse it in a sodium sulfite clearing bath within 3 minutes after

development. Sodium sulfite powder is readily available from

professional photographic supply dealers and chemical supply

houses.

Mix in the following proportions:

Warm water: 2 liter or 70 fl. oz.

Sodium sulfite powder:440 grams or 16 oz. (weight)

(anhydrous/desiccated)

Slowly add the powder to the water; stir continuously until all

powder is dissolved. Allow to cool to approximately 700F(210C)

before using. Store the solution in brown, well-stoppered

bottles or in a tank with a floating lid.

T o prevent scratches:

Negative scratch resistance can be improved by treating the

processed negative (after clearing in water and sodium sulfite) in

a solution of Kodak Rapid Fix with Hardener (parts A & B) for

two minutes. This solution should be made up and used in

accordance with Kodak’s recommended mix procedures,

chemical caution statements, wash times and temperatures.

Caution

This film uses a small amount of caustic paste. If any paste appears, avoid contact with skin, eyes and mouth

and keep away from children and animals. If you get some paste on your skin, wipe it off immediately, then

wash with water to avoid an alkali burn. If eye contact occurs, quickly wash the area with plenty of water and

see a doctor. Keep discarded materials away from children, animals, clothing and furniture.

Limited Warranty

See information on the film box.

“Polaroid” and “ProPack” are trademarks of Polaroid Corporation, Waltham, MA 02451 USA.

All other product names may be the property of their respective owners.

Page 2

Film Data Sheet

Technical Data

T-85, T-665 (positive/negative)

Instant B&W Peel-Apart Pack Film

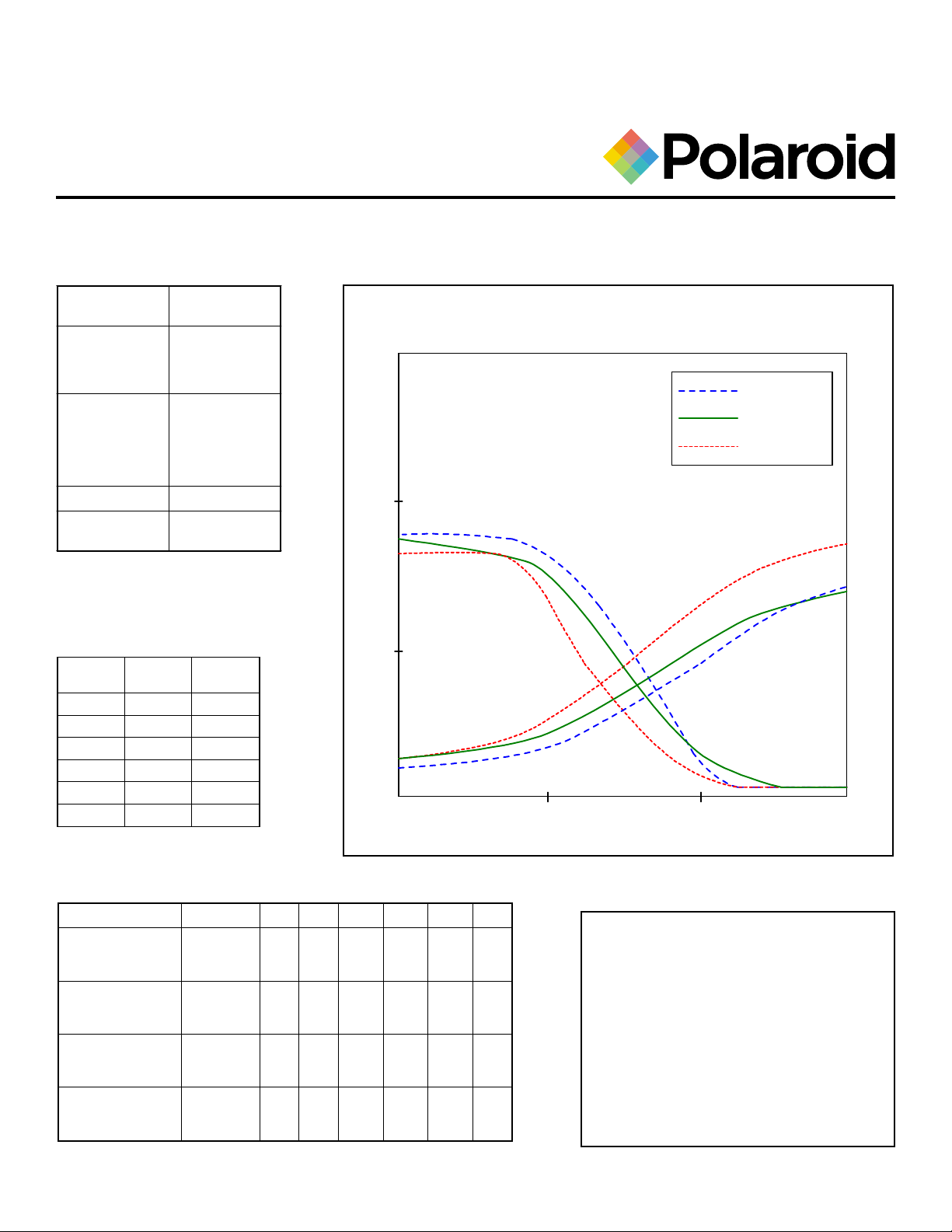

The information below represents the typical performance of Polaroid’s T-85 and T-665 black and white peel-apart film.

Specific film lots may vary.

o

Recommended

speed (ISO)

Recommended

processing time

and

temperature

Resolution

(1000:1)

Contrast

Spectral

sensitivity

80 / 20

30 sec. at

o

F/21oC

70

13 - 16 line

pairs/mm (print)

160 - 180 line

pairs/mm

(negative)

Medium

Panchromatic

Characteristic H&D curve for normal,

hot and cold development

3

o

o

55

F/13

C

o

70

F/21oC

o

F/35oC

95

2

Processing time and temperature

For best results process at temperatures

above 60oF(16oC).

o

F

85+ 29+ 30

75 24 30

70 21 30

65 18 30

60 15 40

50 10 60

o

C

Tim e in

seconds

Filter factors

Filter no. 6 8 15 25 47 58

Light source at

o

3200

K - Tungsten

Light source at

o

5500

K - Daylight

Aperture

adjustment

(f-stops)

Filter factor

(exposure

multiplier)

Aperture

adjustment

(f-stops)

Filter factor

(exposure

multiplier)

Pos.

Sample Density

1

0

At 70oF/21oC: D-Max = 1.90(P) D-Min = .10(P) Slope = 1.40(P)

1.42(N) .23(N) .70(N)

1/2 2/3 1 2 1/2 3 2/3 3

1.4 1.6 2 5.6 12.6 8

1 1 1 1/3 3 1/2 3 3

2 2.5 2.8 11.2 8 8

Neg.

-2 -1-3 -0

Relative Log Exposure

D-Max:

The density value for the film’s darkest

black.

D-Min:

The lowest density value that a film

exhibits. In prints, the whiteness of the brightest

highlight, relative to the unprocessed print.

Slope:

The positive ratio of the log E increments

of the straight line region of the curve, as

determined by the 1/4-3/4 increment method.

The slope of an H&D curve indicates the overall

contrast of a film: low contrast slopes less than

1.10; medium contrast slopes from 1.10 to 1.70;

high contrast slopes greater than 1.70.

Page 3

Film Data Sheet

Technical Data

T-85 (positive/negative)

Instant B&W Peel-Apart Pack Film

Reciprocity law failure

A wide range of shutter speeds can be used without loss of film speed.

For longer exposure times, some exposure compensation is suggested.

Filter Factors

Reciprocity Law Failure

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

Spped Change (f-stops)

-3.0

-3.5

.001" .01" .1" 1" 10" 100"

Exposure Time (seconds)

Spectral Sensitivity

1000

100

10

Spectral Sensitivity

1

Modulation Transfer Function

100

80

60

40

% Modulation

20

0

134

Spatial Frequency (cycles/mm)

Processing the reusable negative

In order to remove the reagent layer and the anti-halation

dyes, the processed negative needs to be washed in an

18% sodium sulfite solution. The salts within the solution

minimize swelling in the negative’s gelatin layer that would

be caused by washing in water only. Swelling can cause

reticulation which would remain after the negative dries.

To prevent scratches:

Negative scratch resistance can be improved by treating

the processed negative (after clearing in water and

sodium sulfite) in a solution of Kodak Rapid Fix with

Hardener (parts A & B) for two minutes. This solution

should be made up and used in accordance with Kodak’s

recommended mix procedures, chemical caution

statements, wash times and temperatures.

2

0

350 450 550 650 750

Wavelength (nm)

Reciprocity:

The ability of the film to respond in a constant manner

to a constant exposure (light intensity x time). Reciprocity failure

occurs during very long or very short exposures, requiring the

photographer to increase exposure.

Spectral Sensitivity:

Shows the equivalent energy needed at each

wavelength in order to activate the emulsion so that it produces a

neutral density of .75.

Ingredients

Warm Water

Sodium sulfite

(anhydrous)

Metric

2.0 liters

440 grams

U.S.

70 fl. oz.

16 oz. (avdp)

Page 4

Type 85

Polaroid Positive/Negative

Black & White Instant Pack Film

First prepare the negative-clearing solution

Do this before the film is exposed and developed. Immediately after

development (within 3 minutes) the negative must be immersed in

an 18% sodium sulfite clearing bath.

Preparation of the 18% sodium sulfite solution

Sodium sulfite powder is readily available from professional

photographic supply dealers and chemical supply houses.

Mix in the following proportion:

- Warm water 2 liters 70 oz. (fluid)

- Sodium sulfite powder 440 grams 16 oz. (avdp.)

(anhydrous/desiccated)

Slowly add the powder to the water; stir continuously until all

powder is dissolved. Allow the solution to cool to approx. 70°F

(21°C) before using. Store the solution in brown, well-stoppered

bottles or in a tank with a floating lid.

Loading, exposing and processing film

See instructions supplied with your camera or film holder for

detailed information.

Important:

negative, separating the negative and preparing it for printing

should be done in dim light. If that is not possible, extend the

development time. (Such extended development will improve the

minimum density areas of the negative and assist in negative

clearing, but may reduce the quality of the accompaning Polaroid print.)

For best results in the minimum density areas of the

Separating the negative and print:

At the end of the full recommended development time, peel the print

away from the negative using a swift unhesitating motion. Be careful

not to touch or scratch the image surface of the negative or the print.

Coat the print immediately (see Coating and care of prints.)

Temperature is important

Pictures may be exposed at any temperature, but the temperature of

the film during development is important. Below 65°F (18°C),

develop longer, as shown in the chart. At the lower temperatures,

the speed of the negative will be reduced. Thus, a correctly exposed

positive may be accompanied by a negative that is too thin. To get

the best possible negative at these temperatures, give more

exposure, so that you get a positive that is somewhat lighter than

normal. Development below 50°F (10°C) is not recommended.

Temperature Processing time

65°F+ 18°C+ 30 sec.

60°F 15°C 40 sec.

50°F 10°C 60 sec.

Preparation of the negative for printing

Important: To avoid film damage, all solutions and wash water

should be nearly the same temperature, ideally 65–75°F (18–24°C),

when in use.

Clear negative: Immerse negative in sulfite solution and agitate

gently for 30–60 seconds or longer, if desired. The solution can be

used in trays (with emulsion side up), or in deep film tanks. Put each

negative through individually or use clip-type film hangers such as

the Kodak #6 hanger. Insert each negative carefully and keep the

negatives from touching each other. Remove tabs and back coat

material. Negative must be cleared of residual developer layer and

opaque backcoat. Negative may remain in solution up to 72 hours.

Note:

Do not use conventional fixer as a substitute for sodium sulfite

as it will not remove the opacity layer from the negative. For

information on treatment of the negative in the field, contact the

Polaroid office nearest you.

Temporary storage in water:

sodium sulfite, you can safely store developed negatives in water

(about 70°F/21°C) for a short time. While negatives are in water,

handle them carefully and do not attempt to rub off the developer

layer. As soon as you can do so, treat the negatives in a sodium

sulfite bath in the normal way.

Wash negative:

30 seconds will do; rewash later for permanence. Avoid scratching

the negatives, by keeping them away from each other and from the

sides of the container. Excessive washing may weaken the emulsion.

Wash for 5 minutes in running water. For urgent use,

Dip negative in wetting agent:

agent (such as Kodak Photo-Flo diluted at least 1:600). Follow

manufacturer’s instructions for use.

Dry negative:

hangers, clothespins, etc. Do not dry with excessive heat. Avoid

dusty areas.

Hang up with commercially available film clips,

Printing and retouching:

necessary, and enlarged by conventional techniques.

Coating and care of prints

Prints must be coated immediately after development to protect

them against scratching and fading. Use the print coater packed in

the plastic tube. Keep freshly coated prints separate from each other

until they are thoroughly dry. Keep the coater fluid away from skin,

clothing, furniture.

If you do not have immediate access to

To avoid drying marks, use a wetting

When dry, the negative can be retouched, if

Page 5

Type 85

Polaroid Positive/Negative

Black & White Instant Pack Film

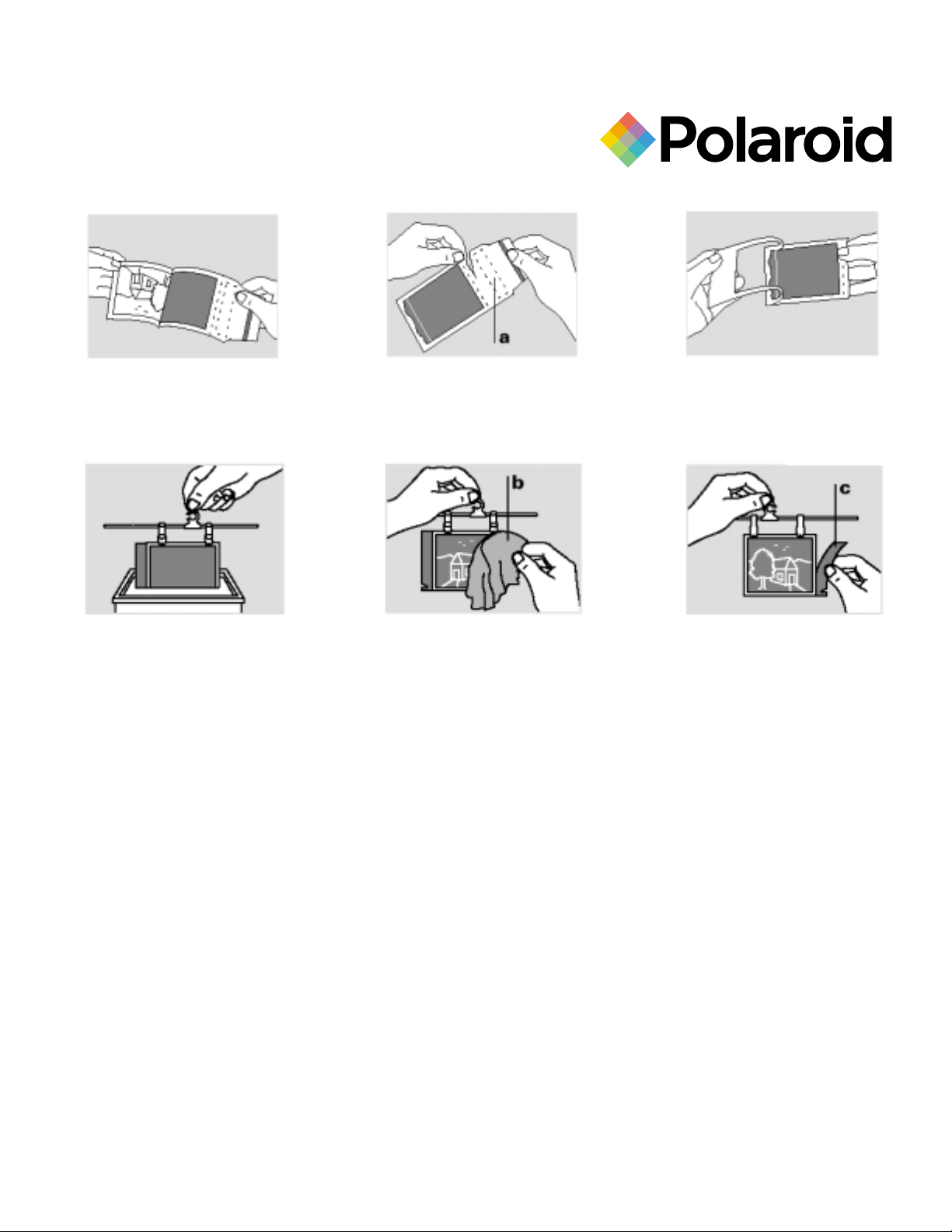

1

Peel print off in a swift,

continuous motion.

4

Agitate negative gently in

sulfite 30-60 sec., or store

in solution.

2

Holding negative top tab,

tear off leader just below

pod (a) and discard.

5

Remove from sulfite, pull

off top tab and black backcoat (b); inspect negative.

3

Holding negative by top

tab, remove paper mask

from negative and discard.

6

Pull off bottom tab (c);

store negative in sulfite or

go to finishing process.

Loading...

Loading...