Page 1

REPAIR MANUAL

ProPalette 8K Series

Color Film Recorders

Includes models 8035, 8045, 8067

May 24, 2000

© Copyright Polaroid Corporation, 2000. All rights reserved.

“Polaroid” and “ProPalette” are trademarks of Polaroid Corporation, Cambridge, MA, U.S.A.

All other product names may be trademarks of their respective owners.

Americas Business Center

Technical Services

201 Burlington Road

Bedford MA 01730

TEL: 1.781.386.5309

FAX: 1.781.386.5988

Page 2

Polaroid 8K Series ProPalette Film Recorders

Repair Manual

Contents

Introduction...............................................................................................9

Purpose of This Manual.......................................................................... 9

Manual Organization.............................................................................. 9

Other Service Documents.....................................................................10

Important Safety Instructions ............................................................... 10

Electrostatic Discharge Warning.......................................................... 10

Note, Caution and Warning Conventions............................................. 10

1 8K Series ProPalette Description ......................................................11

Model 8035 Description....................................................................... 11

Model 8045 Description....................................................................... 12

Model 8067 Description....................................................................... 13

8K Series ProPalette Factory Optimization.......................................... 13

Film Recorder Optics............................................................................ 13

Electronics ............................................................................................14

System Status LCD Panel..................................................................... 14

Ports......................................................................................................15

Software and Interface Accessory Kits................................................. 15

Palette for Windows Kit ....................................................................16

RasterPlus for Macintosh Kit............................................................. 16

Palette for Macintosh Kit................................................................... 16

Accessory Kit PID Numbers ............................................................. 17

8K Series ProPalette Feature Summary................................................ 18

System Specifications........................................................................... 20

2 Hardware Operating Information ....................................................22

Installation Quickstart........................................................................... 22

Unpack the Box .................................................................................22

Position the Film Recorder................................................................22

Connect the Film Recorder................................................................ 23

Connection Tips.................................................................................26

Install the Software............................................................................26

Configure RasterPlus for Macintosh ................................................. 27

Configure RasterPlus for Windows...................................................27

2

Page 3

8K Series ProPalette Repair Manual Contents

2 Hardware Operating Information (continued)

Terminating the ProPalette Internally................................................... 28

Changing the ProPalette SCSI ID......................................................... 29

Controls, Indicators and Connectors.....................................................30

Front (Without Camera) .................................................................... 30

Keypad............................................................................................... 31

Using the 35mm Camera Back.............................................................31

35mm Camera Back Description....................................................... 31

Loading 35 mm Film......................................................................... 32

Using the 4x5 Camera Back .................................................................33

Loading 4x5 Film .............................................................................. 34

Using the 6x7 Camera Back .................................................................35

Loading 6x7 Film .............................................................................. 35

Locking the Film Type Via the Keypad ...............................................40

Locking the Camera Type via the Keypad ...........................................41

Bulk Camera Support ........................................................................... 41

Leaving a Film Leader.......................................................................... 41

Making Exposures................................................................................ 42

Removing Exposed Film ......................................................................43

Rewinding a Partially Exposed Roll.....................................................43

Advancing Film.................................................................................... 43

Removing and Replacing the 35mm Camera Back.............................. 43

Enhanced Information Display............................................................. 44

Artifact Warning Indicators.................................................................. 44

Hardware Configuration Display.......................................................... 45

High Density Grids............................................................................... 45

Protecting the CRT and Camera from Dust.......................................... 45

Cleaning the CRT Face......................................................................... 45

Cleaning the Camera Lens.................................................................... 46

Testing the Hardware Installation......................................................... 46

Troubleshooting Hardware and Film Problems.................................... 47

Color Balance and Exposure for Negative Film................................ 47

Running a Self-Test........................................................................... 48

Redisplaying an Error Message.........................................................48

LCD Panel Messages............................................................................ 48

Setup Menu Reference.......................................................................... 50

Activating Monitor Mode.....................................................................51

Activating Monitor Mode Via Front Panel Buttons.......................... 51

Activating Monitor Mode Via Digital Board ....................................51

Activating Monitor Mode Via LCD Menu........................................ 52

3

Page 4

8K Series ProPalette Repair Manual Contents

2 Hardware Operating Information (continued)

Displaying or Changing the Stored Serial Number.............................. 52

Viewing the Stored Serial Number and Board Versions................... 52

Serial Number Syntax........................................................................ 53

Changing the Stored Serial Number..................................................54

Viewing and Interpreting the Error Log...............................................54

Enabling and Disabling the Watchdog Timer.......................................54

3 Theory of Operation...........................................................................55

Design Objectives................................................................................. 55

Image Quality Objectives .................................................................. 55

Manufacturability and Serviceability.................................................55

CPU....................................................................................................56

Deflection and Geometry Control ..................................................... 56

Sharpness Control.............................................................................. 56

Exposure Control...............................................................................56

ProPalette Major Systems.....................................................................57

Exposure System .................................................................................. 59

Exposure Sequence............................................................................ 59

Exposure System Components.......................................................... 59

Power Supply.....................................................................................60

Digital Board ........................................................................................ 62

Digital Board Circuits........................................................................62

Digital Board Components................................................................ 62

Digital Board Functional Groups....................................................... 64

Group 1 Functions .............................................................................65

Group 2 Functions .............................................................................65

Group 3 Functions .............................................................................65

Group 4 Functions .............................................................................66

Analog Board ........................................................................................ 67

Slowscan Description and Imaging Sequence...................................... 68

Grid for Deflection ............................................................................ 69

Video DAC Data Generation............................................................. 69

Exposure Summary............................................................................ 70

Flash Description..................................................................................70

Flash Data Organization.................................................................... 70

Programs for Reading and Writing the Flash .................................... 71

Autoluma Process................................................................................. 72

Firmware Description........................................................................... 73

Downloading New Firmware.............................................................73

General Description...........................................................................73

Camera Back Interface ......................................................................... 73

4

Page 5

8K Series ProPalette Repair Manual Contents

3 Theory of Operation (continued)

Keypad/LCD Interface.......................................................................... 75

LCD Menus ....................................................................................... 76

Exiting from Menus........................................................................... 76

Startup Messages............................................................................... 76

Status Messages.................................................................................76

Film Tables........................................................................................77

Pacing Commands................................................................................ 77

4 Troubleshooting and Diagnostics......................................................78

Recommended Diagnostic Sequence.................................................... 78

Utility Program Summary.....................................................................78

Connecting to the Service FTP Site......................................................78

Inspection and Cleaning ....................................................................... 79

Firmware Upgrade................................................................................79

Purpose .............................................................................................. 79

Obtaining the Latest Firmware.......................................................... 79

Required Tools and Equipment ......................................................... 80

Upgrade Procedure with Parallel Cable.............................................81

Upgrade Procedure with SCSI Cable.................................................81

ProPalette Startup Diagnostics and Tests............................................. 83

Test Image Exposure Sequence............................................................85

Monitor Mode....................................................................................... 85

Error Message Redisplay...................................................................... 85

Serial Communication Cable................................................................ 86

Purpose .............................................................................................. 86

Required Equipment.......................................................................... 86

Wiring Diagram.................................................................................86

Digital Board Diagnostics (FPDIAG) via Host Computer...................86

Purpose .............................................................................................. 86

Required Tools and Equipment ......................................................... 87

Test Procedure ................................................................................... 87

PCPLUS Configuration........................................................................ 88

Uploading and Running a Hex File...................................................... 89

Purpose .............................................................................................. 89

Required Tools and Equipment ......................................................... 89

Procedure........................................................................................... 89

Digital Board Interface Test .................................................................93

Purpose .............................................................................................. 93

Required Tools and Equipment ......................................................... 93

Test Procedure ................................................................................... 93

5

Page 6

8K Series ProPalette Repair Manual Contents

4 Troubleshooting and Diagnostics (continued)

Analog Board Voltage Test .................................................................. 95

Purpose .............................................................................................. 95

Required Tools and Equipment ......................................................... 95

Test Procedure ................................................................................... 95

Analog Board Functional Test via Host Computer ..............................96

Purpose .............................................................................................. 96

Required Tools and Equipment ......................................................... 96

Test Procedure ................................................................................... 96

Analog Board Functional Test Troubleshooting ...............................98

Parallel Port Hardware Test............................................................... 98

SCSI Interface Hardware Test........................................................... 98

Image Evaluation..................................................................................98

Purpose .............................................................................................. 98

Required Tools and Equipment ......................................................... 98

Printing the Test Images.................................................................... 98

Error Logging (ERRSTAT.EXE).........................................................99

Error Classes and Messages............................................................. 100

Error Log Data................................................................................. 101

Running ERRSTAT.EXE................................................................ 102

Sample Report ................................................................................. 102

Board Versions ................................................................................103

Error Message and Symptom Tables..................................................104

LCD Panel Error Messages ............................................................. 105

Host System Error Messages...........................................................107

Host System Plug-In Symptoms...................................................... 109

Operation and Performance Symptoms...........................................111

Image Quality Symptoms................................................................ 115

Diagnostic (FPDIAG) Error Message Tables.................................. 116

5 Parts Replacement............................................................................121

Removal of the Front Bezel Assembly............................................... 122

Installation of the Front Bezel Assembly ...........................................122

Removal of the LCD Keypad Assembly ............................................123

Installation of the LCD Keypad Assembly......................................... 123

Removal of the LCD Panel................................................................. 124

Installation of the LCD Panel............................................................. 124

Removal of the Front Bezel Door....................................................... 125

Installation of the Front Bezel Door................................................... 125

Removal of the Power Switch ............................................................126

Installation of the Power Switch.........................................................126

Removal of the Camera Plate Assembly ............................................ 127

Installation of the Camera Plate Assembly......................................... 128

6

Page 7

8K Series ProPalette Repair Manual Contents

5 Parts Replacement (continued)

Removal of the Camera Connector/Cable Assembly......................... 128

Installation of the Camera Connector/Cable Assembly...................... 129

Removal of the Top Cover and Rear Panel Assembly .......................129

Installation of the Top Cover and Rear Panel Assembly....................130

Removal of the Stepper Motor ........................................................... 131

Installation of the Stepper Motor........................................................ 132

Removal of the Autoluma Board Assembly....................................... 133

Installation of the Autoluma Board Assembly ...................................134

Removal of the Wheel Position Sensor (Photo Interrupter)............... 134

Installation of the Wheel Position Sensor (Photo Interrupter)............ 136

Removal/Installation of the LCD Interface Cable..............................137

Removal/Installation of the Camera Cable Assembly........................ 137

Removal of the Electronics Drawer....................................................139

Installation of the Electronics Drawer................................................ 140

Removal of the Digital PC Board Assembly...................................... 140

Installation of the Digital PC Board Assembly ..................................141

Replacement of the Camera Power Fuse............................................ 141

Removal of the Analog PC Board ...................................................... 141

Installation of the Analog PC Board................................................... 142

Removal of the Low Voltage Power Supply...................................... 142

Installation of the Low Voltage Power Supply...................................143

Removal of the Light Box Assembly .................................................143

Installation of the Light Box Assembly..............................................146

Disassembly of the CRT..................................................................... 149

Reassembly of the CRT......................................................................149

Removal of the Front Plate Assembly................................................150

Installation of the Front Plate Assembly.............................................150

Removal of the Filter Wheel............................................................... 151

Installation of the Filter Wheel...........................................................151

Removal of the High Voltage Power Supply......................................152

Installation of the High Voltage Power Supply.................................. 152

7

Page 8

8K Series ProPalette Repair Manual Contents

6 Using the Flash Manager Utility .....................................................153

ProPalette Flash Device Description ..................................................153

Flash Manager Description................................................................. 153

Running Flash Manager...................................................................... 154

Requirements................................................................................... 154

Starting and Using Flash Manager...................................................155

Reloading Firmware ........................................................................155

Switching Between Virtual Flash Devices ......................................156

Erasing the Entire Virtual Flash ...................................................... 156

Erasing a Single Code Block........................................................... 157

FLASHMAN Menu Options ...........................................................158

FLASHMAN Common Code Blocks.............................................. 158

VFO Code Blocks............................................................................ 158

VF1 Code Blocks............................................................................. 159

7 Schematic Drawings .........................................................................160

Digital Board Schematics................................................................... 161

Analog Board Schematics...................................................................170

Autoluma Board Schematic................................................................ 178

Keypad Board Schematic ...................................................................179

Power Fail Fix Schematic................................................................... 180

Interconnection Diagram .................................................................... 181

Index.......................................................................................................182

8

Page 9

8K Series ProPalette Repair Manual Introduction

Introduction

Purpose of This Manual

This manual is intended to be a reference and training guide for authorized service

technicians who install, troubleshoot and repair the following Polaroid 8K Series

ProPalette Color Film Recorders:

• ProPalette 8035

• ProPalette 8045

• ProPalette 8067

Manual Organization

This manual is organized into seven sections:

1 ProPalette Description Describes the 8K Series ProPalette Color

Film Recorders, along with their features, components and

specifications.

2 Hardware Operating Information This section includes the setup,

operating and troubleshooting instructions provided to users in the 8K

Series ProPalette Hardware Manual (reproduced in this manual for

the convenience of service technicians).

3 Theory of Operation Detailed explanations of 8K Series ProPalette

system and component functions; for use in diagnosing problems and

performing other service.

4 Troubleshooting and Diagnostics Instructions for diagnosing image

defects, errors and other malfunctions, along with likely causes and

suggested corrective action.

5 Parts Replacement Instructions for replacing individual 8K Series

ProPalette components.

6 Using the Flash Manager Utility Description of the Flash Manager

utility program and instructions for using it to view and program 8K

Series ProPalette flash devices.

7 Schematic Drawings Major circuit board and interconnection

diagrams for use in troubleshooting.

9

Page 10

8K Series ProPalette Repair Manual Introduction

Other Service Documents

In addition to this manual, ProPalette service personnel should have access to the

following documents:

8K Series ProPalette Parts Catalog

8K Series ProPalette Hardware Manual

Palette Export Software User Guide

RasterPlus Software Manual

ProPalette Test Stand Manual (locations with appropriate equipment only)

Important Safety Instructions

When servicing a ProPalette film recorder, always take the following safety precautions:

• Read and understand all applicable service procedures before proceeding.

• Turn off and unplug the unit before servicing.

• When service procedures require the unit to be plugged in with the cover

off, take special care to avoid contact with high voltage connections, wires

and components.

Warning: The ProPalette Color Film Recorder has

hazardous internal voltages. Maintenance

operations, especially those performed with the

printer cover removed, should be performed

only by qualified service personnel.

Electrostatic Discharge Warning

ProPalette circuitry can be easily damaged by small, unnoticeable static discharges.

Always use an anti-static mat and wrist strap when removing the ProPalette cover or

when servicing the unit with the cover removed.

Note, Caution and Warning Conventions

The use of notes, cautions and warnings in this manual follows these conventions:

Note - Information that is essential to highlight.

Caution - Procedure or other information that, if not strictly observed, could result

in equipment damage.

Warning - Procedure or other information that, if not strictly observed, could result

in personal injury or loss of life

10

Page 11

1 8K Series ProPalett e Des crip tio n

The Polaroid 8K Series ProPalette models are a family of digital, photographic-quality

printers designed for the mid-range/professional color film recorder market. Operating

with either Windows or Macintosh platforms, they are ideal for mini-labs, audio-visual

departments, professional photographers and anyone else requiring detailed output,

faithfully rendered by a reliable, easy-to-operate film recorder.

The 8K Series ProPalette models include the following:

• Model 8035

• Model 8045

• Model 8067

Model 8035 Description

As implied by its designation, the Model 8035 uses a 35mm camera. The camera is

manufactured to Polaroid specifications by Ricoh. It produces 35mm format positive

(chrome) and negative (print) images.

The Model 8035 (Figure 1-1) provides professional quality, continuous-tone 35mm color

negatives and transparencies with up to 8192 horizontal and 5460 vertical pixels

resolution. The Model 8035 uses a 35mm camera which has a 43.53mm, f/6, six element

lens. Positive, negative and instant 35mm film can be used and a bulk roll film adapter is

available for high-volume applications.

Figure 1-1. 8K Series ProPalette Model 8035

11

Page 12

8K Series ProPalette Repair Manual Description

The standard 35mm camera back automatically loads, counts exposures, and rewinds at

the end of each roll of film. (There is an option for early rewind.) System setup and status

is indicated via the 20-character, 2-line LCD panel.

Model 8035 can be expanded to produce 4x5 or 6x7 images through the purchase of

accessory camera backs. (Adding the camera backs also requires factory realignment.)

Model 8045 Description

The 8K Series ProPalette Model 8045 (Figure 1-2) produces professional quality,

continuous-tone 4 x 5 images with up to 8192 horizontal and 6370 vertical pixels

resolution. The Model 8045 uses a 4x5 camera which has a 101mm, f/6.7, six element

lens. Positive, negative and instant 4 x 5 film can be used. System setup and status is

indicated via the 20-character, 2-line LCD panel.

Figure 1-2. 8K Series ProPalette Model 8045

Model 8045 includes a 35mm camera back which can replace the 4 x 5 camera back to

produce 35mm images. Additionally, Model 8045 can be expanded to produce 6 x 7

images through the purchase of the accessory 6 x 7 camera back. (Adding the camera

back also requires factory realignment.)

12

Page 13

8K Series ProPalette Repair Manual Description

Model 8067 Description

The Model 8067 (Figure 1-3) offers professional quality, continuous-tone 6 x 7 cm

images with up to 8182 horizontal and 6702 vertical pixels resolution. The Model 8067

uses a 6x7 camera which has a 74mm, f/5.5, six element lens. Positive and negative 6 x 7

film can be used. System setup and status is indicated via the 20-character, 2-line LCD

panel.

Figure 1-3. 8K Series ProPalette Model 8067

Model 8067 includes a 35mm camera back which can replace the 6 x 7 camera back to

produce 35mm images. Additionally, Model 8067 can be expanded to produce 4 x 5

images through the purchase of the accessory 4 x 5 camera back. (Adding the camera

back also requires factory realignment.)

8K Series ProPalette Factory Optimization

All 8K Series ProPalette film recorder models (8035, 8045, 8067) are factory-optimized

and matched to a specific camera during manufacture. Using a Polaroid Digital

Alignment Station at the factory assures that image quality, sizing, sharpness, location,

geometry and color saturation are all at peak level. These critical alignments result in

ideal match-ups between recorder and camera.

This process results in a film recorder with the highest level of precision which achieves

unprecedented image quality right out of the box. Each ProPalette model produces higher

resolution images than other film recorders in its product category.

Film Recorder Optics

The 8K Series ProPalette film recorders have a high-resolution, precision 7-inch CRT

with a proprietary anti-reflection and anti-static coating to render superb image sharpness

and purity. They also utilize custom optics with six element glass lenses and glass

dichroic filters to minimize spot size and maximize color saturation.

13

Page 14

8K Series ProPalette Repair Manual Description

Electronics

Auto-Luma /Auto-Chroma digital circuits automatically adjust brightness, luminance and

color balance. Digital geometry correction provides exacting straight lines and perfect

circles and eliminates pin cushioning, barreling and keystoning. Dynamic focus circuits

adjust the focus of the electron beam to assure consistent sharpness and clarity over the

entire image area. The system’s electronics adjust the focus of each image on the CRT

and use custom lookup tables for horizontal and vertical planes.

The 8K Series ProPalette provides 8000-line, continuously variable resolution for

recording images in their native, scanned resolution. This eliminates the image

degradation exhibited at lower resolutions and the need for time-consuming image

interpolation and decimation. The 8K Series ProPalette models are also designed for fast

printing: exposing a 35mm image at 4096 dpi requires less than 60 seconds.

The finished product is a 24-bit image with 36-bit color depth per pixel and 16.8 million

colors drawn from a palette of 68 billion colors. This results in smooth, ramped

backgrounds and accurate colors.

System Status LCD Panel

A 20-character, two line interactive LCD panel on the film recorder guides the user

through setup and also provides system status information during operation. A control

panel with a push-button menu system allows the user to send commands to the recorder.

Status/command functions are provided in choice of five languages and include:

• Storage of all setups in permanent

memory

• Image pixel dimensions displayed during

green exposure

• Firmware version and update status

• Automatic load/unload film status

• Detection of film jams/mis-thread

• Frames counted and frames available for

exposure

• Red/green/blue pass in progress

• Rewind film/advance film/remove

film/abort exposure

• Pacing indicators and waiting for host

warnings

• Previous error storage and information

retrieval

• Circuit board version information

• Unit serial number

• Calibration in progress

• SCSI ID, SCSI terminate settings

• Leader/no-leader selection

• Out-of film detection by end of roll or

frame count

14

Page 15

8K Series ProPalette Repair Manual Description

Ports

The 8K Series ProPalette models have four ports (Figure 1-4):

• Centronics parallel

• Synchronization IEEE 1284 style

• SCSI-1

• RJ-11 serial (available to service personnel only)

Figure 1-4. ProPalette Ports

Software and Interface Accessory Kits

The software provided in the Windows and Macintosh accessory kits is designed

specifically for ProPalette film recorders. Accessory kits are purchased separately.

ColorTune software matches the image seen on the computer monitor to the final image

created by the Propalette. This allows the user to perform more accurate previewing when

making adjustments to color and tone scale. ColorTune also enables the user to customize

film look-up tables to their individual workstation to obtain specific results.

Palette Export, an Adobe Photoshop export plug-in module allows printing directly from

Photoshop to produce continuous tone images quickly and simply.

The recorders can be networked with Palette for Windows (including Windows 95,

Windows 98, and Windows NT) and Palette for Macintosh. These software kits include

RasterPlus drivers.

All 8K ProPalette software has been tested for year-2000 compliance.

Accessory kits also include the appropriate cables for connecting the ProPalette film

recorder to Windows or Macintosh platforms.

The accessory kits are described in more detail in the following sections. For the PID

number associated with each kit, see Table 1-1 on page 17.

15

Page 16

8K Series ProPalette Repair Manual Description

Palette for Windows Kit

The Palette for Windows kit (for Windows 95, 98 and NT) consists of the following:

•••• RasterPlus for Windows. A print manager, including a queue feature for unattended

printing.

•••• ColorTune2 for Windows. Matches the film recorder output to the monitor image.

(This software is not included with the initial product release, but is available from the

Polaroid Web site. ColorTune2 for Windows will be included with later releases.)

•••• Polaroid Palette Export. Plug-in module compatible with Adobe Photoshop and

other popular image processing applications

•••• Parallel cable. Allows ProPalette to be connected to the PC via a parallel port.

RasterPlus for Macintosh Kit

The Raster Plus for Macintosh accessory kit is for use with G3 PowerMac systems, and it

provides Postscript compatibility. This kit includes the following:

•••• RasterPlus for Macintosh. A file-print and Postscript-compatible driver.

•••• Scheduler. A print-spooling utility allowing deferred printing.

•••• Palette Export for Macintosh. A plug-in for exporting images directly from

Photoshop.

•••• SCSI cable and terminator. Allows ProPalette to be connected to a Macintosh or

added to an existing SCSI chain.

Palette ColorTune for Macintosh is under development and currently not included in the

Raster Plus for Macintosh kit.

Palette for Macintosh Kit

The Palette for Macintosh accessory kit is for use with older 68K-based Macintosh

systems and does not provide Postscript compatibility. This kit includes the following:

•••• Palette for Macintosh. A chooser-level printer driver for all Macintosh computers

•••• SiPrint Assistant. A spooling utility for unattended printing.

•••• Palette Export for Macintosh. A plug-in for exporting images directly from

Photoshop

•••• SCSI cable and terminator. Allows ProPalette to be connected to a Macintosh or

added to an existing SCSI chain.

Palette ColorTune for Macintosh is under development and currently not included in the

Raster Plus for Macintosh kit.

16

Page 17

8K Series ProPalette Repair Manual Description

Accessory Kit PID Numbers

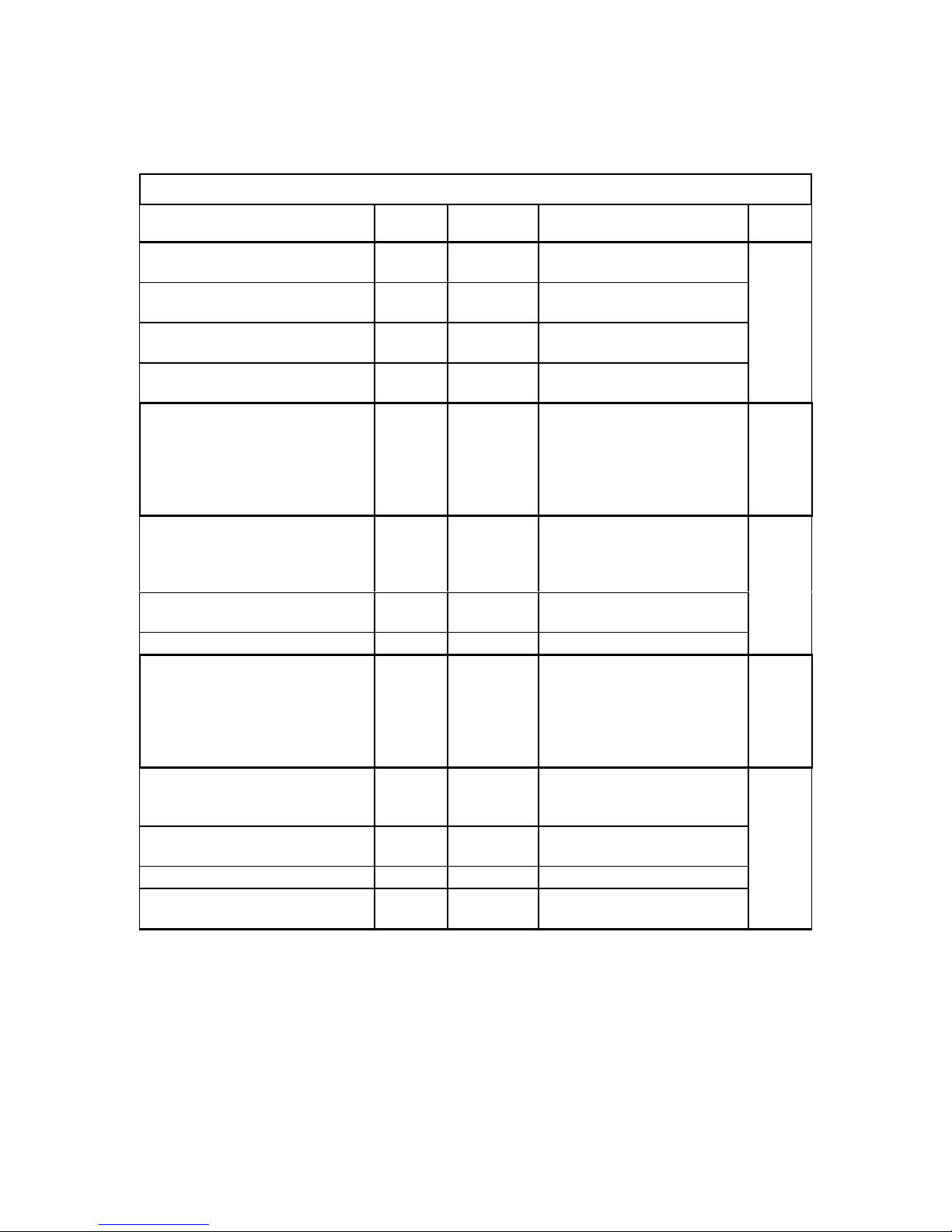

ProPalette software/interface components are summarized in Table 1-1.

Table 1-1. ProPalette Software/Interface Matrix

Operating

Name Vendor

Palette for Windows Kit

(includes the three items below)

RasterPlus for Windows Graphx Windows File-Print manager. Provides

Polaroid Palette Export for

Windows

Palette ColorTune2 for Windows

(not included with initial release)

Palette for Windows Upgrade

RasterPlus for Macintosh Kit

(includes the two items below)

RasterPlus for Macintosh &

Scheduler

Palette Export for Macintosh Polaroid Macintosh Photoshop export plug-in

RasterPlus for Macintosh

Upgrade

Palette for Macintosh Kit

(includes the three items below)

Palette for Macintosh & SiPrint

Assistant

Palette Export for Macintosh Polaroid Macintosh Photoshop plug-in utility

Palette ColorTune for Macintosh Polaroid Macintosh

Polaroid Windows Driver kit; includes parallel

Polaroid Windows Photoshop export plug in

Polaroid Windows Matches output to monitor by

Polaroid Windows

Polaroid Macintosh

Graphx Macintosh Driver and batching utility

Graphx Macintosh

Polaroid

System Description or Comments PID No.

101333

cable

PostScript & Queue capability

adjusting film tables

Intended fo r owners upgrading

to Windows 95 / 98 / NT;

includes all software in Palette

for Windows Kit above, but

does

requires RasterPlus 1.x or later

Driver kit for Power PC. (OS

7.5 or later, excluding 8.0);

includes SCSI cable and

terminator

Driver upgrade for owners

moving to RasterPlus for

Macintosh; includes all software

in the RasterPlus for Macintosh

Kit above, but does

SCSI cable or terminator.

Macintosh

V7.6 or later

Macintosh Drive r and batching utilit y

Driver kit for older 68K-based

Macintosh; no t Postscriptcompatible.

Film table tuner (matches output

to monitor)

include parallel cable;

not

not

include

101330

100197

101332

623879

This table is subject to change without notice.

17

Page 18

8K Series ProPalette Repair Manual Description

8K Series ProPalette Feature Summary

Feature Description Benefit

Custom optics Custom 6 element glass lenses;

35mm - 43.53mm, f/6; 4x5 101mm, f6.7; 6x7 - 74mm,

f/5.5; dichroic filters which

combine high transmittance

with sharp color cut-off; custom

CRT faceplate optics

Automatic exposure

and color balance

control

Electronics for automatically

setting optimum brightness and

color balance before exposure

of each image

Geometry correction Automatic digital correction of

geometry and linearity to

eliminate pincushion, barrel and

keystoning

Dynamic focus

adjustment

Automatic electronic focus of

the image on the CRT using a

lookup table customized for that

unit

Minimized spot size and

maximized color saturation

Bright images and accurate

colors

Distortion-free images with

straight lines and round

circles

Consistent clarity and

sharpness over entire image

area

High-resolution, 7in. CRT

Precision CRT with proprietary

anti-reflection / anti-static

coating

8K resolution Variable resolution with up to :

8192 horizontal and 5460

vertical pixels (35mm camera);

8192 horizontal and 6370

vertical pixels (4 x 5 camera);

8192 horizontal and 6702

vertical pixels ( 6 x 7 camera)

36-bit color depth 24-bit images with precision of

36 bits per pixel

Consistent clarity and

sharpness

Clearly defined details and

text

Printing in 16.8 million

colors, from a palette of 68

billion colors

18

Page 19

8K Series ProPalette Repair Manual Description

Feature Description Benefit

LCD display on

front panel

20-character x two-line

interactive display provides

setup and status information

Flash memory 4-megabyte DRAM, 512-

kilobyte flash memory

Multiple film

formats

Software and hardware support

for 35mm, 4x5, 6x7 and 35mm

bulk camera backs; cameraspecific film tables for multiple

E6, C-41, and Polaroid instant

films are included

Film tables Custom film tables for over 50

different 35mm, 120/220, and

4x5 films

Self diagnostics Unit performs a self-diagnostics

routine at startup. Routine can

also be initiated via the keypad

or host computer, if necessary

Easy to learn operation and

immediate understanding of

current status for efficiency

and productivity

Fast, simple upgrading of

firmware and product

enhancements

Flexibility to handle

expanding or changing

imaging needs

Provide maximum flexibility

for wide variety of film while

maintaining color and

exposure accuracy

Helps isolate problems

quickly and without special

tools or software

CRT access door Access to internal CRT from

beneath recorder

No potentiometer

adjustments

Operating and

service history

stored in memory

Manual optimization

unnecessary

Total exposures, film type used

for each, service history

information recorded in

nonvolatile memory for

reference

19

Allows easy cleaning of CRT

face

Fast, automated, accurate

calibration of individual units

Up-to-date operating and

service history available to

service technicians

Page 20

8K Series ProPalette Repair Manual Description

System Specifications

CRT

Optics

Image precision

Image quality

Color depth

LCD Display/Controls

Hardware

requirements

High resolution 7" CRT with anti-reflection & anti-static coating

All models - custom 6-element glass lenses:

35mm - 43.53mm, f/6

4x5 - 101mm, f/6.7

6x7 - 74mm, f/5.5

Glass dichroic filters

Custom CRT face plate optics

Automatic exposure and color balance control

Geometry correction

Dynamic focus circuitry

Any resolution up to a maximum resolution of 8192 horizontal x 5460

vertical lines (35mm); 8192 horizontal x 6370 vertical lines (4 x 5); 8182

horizontal x 6702 vertical lines (6 x 7)

36 bits per pixel (12 bits per color)

16.8 million colors per image from of a 68 billion color palette

20 character by 2 line interactive LCD display, 4-button command keys

PC environment:

•

Pentium class 150 mHz or faster processor

•

32 MB of RAM (64 MB for Windows NT)

•

15 MB program and 30 MB swap disk space

•

Windows 95; Windows 98; or Windows NT

•

DOS required for firmware upgrade utility

•

Parallel port or SCSI adapter card required

Memory

Macintosh environment: (Non-Power PC)

•

Palette for Macintosh

•

68K based Macintosh computer

•

System 7.6 or higher

•

SCSI interface

Macintosh environment (Power PC)

•

RasterPlus for Macintosh

•

Mac OS 7.5 or later (excluding OS 8.0)

•

PowerPC class processor

•

40 MB of RAM

•

10 MB of program and 30 MB of hard drive space

Unix environment:

Supported through third party manufacturer

4 MB DRAM for printer memory, 512 KB flash memory for firmware and

camera optimization data storage

20

Page 21

8K Series ProPalette Repair Manual Description

System Specifications (continued)

Postscript

compatibility

Network printing

Hardware interface

Available Supported

Cameras (all factory

matched to film

recorder)

Power source

Power consumption

Environment

Dimensions

RasterPlus for Widows software provides Level II PostScript compatibility

RasterPlus for Macintosh software provides Level III PostScript

compatibility

Palette for Macintosh software does not provide Postscript support.

Supported via software drivers on Windows and Macintosh systems

Parallel and SCSI (adapter required for Windows systems)

35mm camera

4 x 5 inch camera

6 x 7 centimeter camera

Bulk film 35mm camera

90-240 Vac, 50-60 Hz

Under 45 watts

Temperature: 50 to 100 degrees Fahrenheit (18 to 38 degrees Centigrade)

Storage Temperature: -20 to 160 degrees F (-29 to 71 degrees C)

Relative Humidity: 5 to 90 % non-condensing

11" x 28" x 8.5", (28 x 71 x 21.6 cm)

Weight

Certifications

Warranty

34 lb. (15.4 kg) (with 35mm camera)

UL, FCC, TUV, C-UL, CE, C-TICK, and EN55022 certification

One year parts and labor

Extended warranties available

21

Page 22

2 Hardware Operating Information

For the convenience of repair technicians, information in this chapter is excerpted from

the Polaroid ProPalette Installation Quickstart and Quickreference instruction guides

provided to ProPalette purchasers.

Installation Quickstart

Unpack the Box

Make sure you have all the following components. Contact your dealer if any is missing

or damaged.

1

2

3

Figure 2-1. Unpacking

1. Film recorder (Figure 2-1)

2. Power cord

3. 35 mm camera back (mounted on film recorder) (Also, as applicable, 4x5

camera back and/or 6x7 camera back)

Also included but not shown in Figure 2-1 are a Quick Start, quick reference and

registration cards.

8K Series ProPalette software and connecting cables must be purchased and are in a

separate box. Model 8045 includes a 4x5 camera back; model 8067 includes a 6x7

camera back.

Position the Film Recorder

Place the film recorder at a convenient working height on a flat, vibration-free surface.

Make sure that all four rubber feet are in contact with the surface, and that the ventilation

holes are not obstructed. Position the film recorder away from any electro-magnetic fields

such as computer monitors or electric motors.

22

Page 23

8K Series ProPalette Repair Manual Hardware Operating Information

Connect the Film Recorder

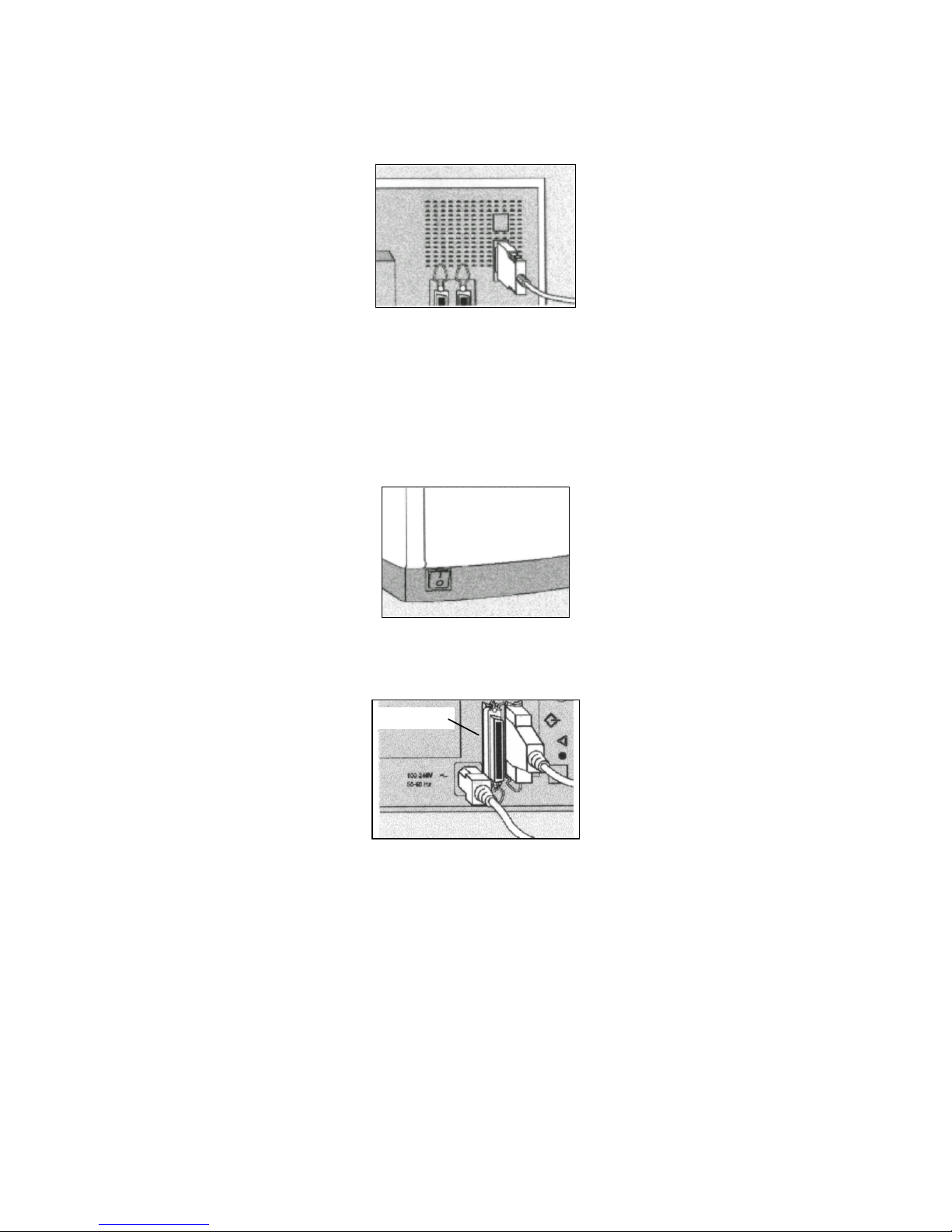

ProPalette film recorders have a parallel port (1 in Figure 2-2) for connection to a

Windows 95 or 98 computer, and a SCSI port (2 in Figure 2-2) for connection to either a

Macintosh computer or to a Windows 95, 98 or NT computer with a SCSI host adapter

installed. (The parallel connection cannot be used with Windows NT systems.) The

power cord connects at 4 in Figure 2-2, and item 3 is the reset button.

1

2

3

4

Figure 2-2. Rear panel of film recorder

The software kit for Windows systems includes a parallel cable, but you can connect your

system to the SCSI port if you have a SCSI host adapter installed and a SCSI connection

cable (not included).

If you install a SCSI host adapter, follow the instructions provided by the adapter

manufacturer. (Host adapters may not be available for some iMac computers.)

Parallel Connection (PC with Windows 95 or 98)

Note: The parallel port must be configured as ECP in the PC

BIOS.

1. Turn off the PC and the ProPalette (Figure 2-3).

Figure 2-3. Film recorder On/Off switch

2. Connect the power cable to the ProPalette (Figure 2-4) and plug the cable into

AC power.

Figure 2-4. Connecting to power

23

Page 24

8K Series ProPalette Repair Manual Hardware Operating Information

3. Connect the parallel cable to the parallel port on the ProPalette and to the

parallel port on the computer.

Figure 2-5. Connecting cable to ProPalette parallel port

4. Turn on ProPalette and wait for it to complete initialization; (READY shows

on the display).

SCSI Connection (PC or Mac)

1. Turn off both your computer and the ProPalette.

Figure 2-6. Turn off ProPalette

2. Plug in a power cable to connect the ProPalette to power.

SCSI port

Figure 2-7. Connecting power cable and SCSI cable

3. Plug the 50-pin end of the SCSI cable into one of the SCSI ports on the rear

panel of the ProPalette and secure the connection.

4. Plug the 25-pin end of the SCSI cable into the SCSI port on your computer

and secure the connection.

5. Turn on ProPalette and wait for it to complete initialization (READY shows

on the display).

24

Page 25

8K Series ProPalette Repair Manual Hardware Operating Information

Note: SCSI device chains must be terminated once at each end of

the chain. The host adapter terminates one end. You must

terminate the other end. The following figures show three

typical connections.

In Figure 2-8, ProPalette is the only SCSI device and must be terminated. This

example shows external termination using a separate terminator (not

included). The ProPalette may be terminated internally instead (see below).

Connect the SCSI terminator either between the SCSI cable and the ProPalette

or to the second SCSI connector on the ProPalette rear panel.

Figure 2-8. SCSI connection #1

In Figure 2-9, ProPalette is the last device in the SCSI chain and must be

terminated. Figure 2-9 shows external termination using a separate terminator

(not included).

Figure 2-9. SCSI connection #2

The ProPalette may be terminated internally instead. (See “Terminating the

ProPalette Internally” on page 28.) Connect the SCSI terminator either

between the SCSI cable and the ProPalette or to the second SCSI connector on

the ProPalette rear panel.

Note: Do not terminate ProPalette both internally and externally.

In Figure 2-10 ProPalette is in the middle of the SCSI chain and must not be

terminated.

Figure 2-10. SCSI conection #3

25

Page 26

8K Series ProPalette Repair Manual Hardware Operating Information

Connection Tips

• When you connect or disconnect a SCSI device, make sure all SCSI devices have their

AC power switched OFF.

• Always make SCSI connections firmly, connecting the clips or tightening the screws

that secure cables and terminators. Most problems with SCSI devices are connection

problems along the SCSI chain.

• Some devices, such as the ProPalette, have two SCSI ports. The cable can be connected

to either port without affecting the performance of your equipment.

• Each device on a SCSI chain must have a unique SCSI ID number. These numbers are

described in the following section.

• Wherever a 50-to-50 pin cable is required, be sure to use a cable which meets the

SCSI-2 specification, such as an Apple cable.

• If you are using a PC, the ProPalette can be connected to two host computers at once;

one via the parallel connector and one via the SCSI connector. The recorder will image

in the order the signal is received.

Install the Software

1 Turn on your computer.

2 Insert the Polaroid Palette Software CD-ROM into the drive.

3 Follow the appropriate instructions for your platform:

Power MAC or Power PC Windows 95, 98, or NT

a Select Polaroid 8K Series

ProPalette Installer.

a Wait for the 8K Series ProPalette

program to start. If it does not start, select

Run from the Windows Start menu.

b Follow instructions on the screen.

b Click Browse and select

POLAROID.EXE on the CD-ROM, then

click OK.

c Follow instructions on the screen.

4 Remove the CD.

5 Configure the RasterPlus software for the appropriate platform as described in

the following sections.

26

Page 27

8K Series ProPalette Repair Manual Hardware Operating Information

Configure RasterPlus for Macintosh

For Power Macintosh and PowerPC systems, use the following steps to configure

RasterPlus for Macintosh software:

1 On the first launch of RasterPlus for Macintosh, personalize RasterPlus by

filling in the fields on the personalization screen and clicking OK.

2 Select your film recorder model and click OK.

3 Enter your desktop printer model (not the film recorder) and click OK.

4 Click Interface on the film recorder menu (the menu name matches the film

recorder selected in step 2) to confirm communication with the film recorder.

5 Click Camera Options on the film recorder menu and select the appropriate

camera back and film type.

6 Click Application Preferences on the Edit menu and set preferences for

schedule, files, previews, output log, network and miscellaneous items.

Configure RasterPlus for Windows

For Windows 95, 98 or NT systems, configure RasterPlus95 with the following steps:

1 Start the PC and the RasterPlus software.

2 Add the print driver and set device properties as follows:

a In Graphx RasterPlus95, click Global Properties on the Tools menu.

b Click the Device Manager tab.

c Select your film recorder under Available Devices and click Install.

Note: Graphx RasterPlus95 drivers are based on the Microsoft/ Adobe

PostScript core driver (PSCRIPT.DRV). If you have not yet installed

any other PostScript printer on your system, the software may

prompt you to insert and/ or specify a path which points to your

Microsoft Windows 95 installation CD so that it can copy

Microsoft’s PostScript driver files to your hard disk

d Select your film recorder under Devices installed in Microsoft Windows and

click Connect.

e Select the printer port to which your printer is connected in the Select Printer

Connection dialog box and click OK.

f Click Properties.

27

Page 28

8K Series ProPalette Repair Manual Hardware Operating Information

g On the Paper tab, select the appropriate page size.

For example, select PowerPoint if you are using the Microsoft PowerPoint

application, or select 35mm if you are using a 35mm camera back in another

application.

h Click the Device Options tab and select the appropriate film type from the

Change Setting for: Film Type list.

i Click the Graphics tab and select a resolution from the Resolution list.

j Click OK to save your properties settings.

k Click Close to close the Global Properties dialog box.

3 Select the queue properties as follows:

a Click Queue Properties on the Edit menu and click the Device tab if

necessary.

b Select the recorder you are using from the Device list.

c Select the port to which the film recorder is connected from the

Connection list (LPT or SCSI port).

d Click the Options button.

e Click the Info button in the [Device] Options dialog box.

4 Wait for film recorder information to appear on the screen, indicating that the

software is communicating with the ProPalette.

If an error message states that the recorder is not connected or is turned off,

the software cannot communicate with the ProPalette. If this happens, make

sure the ProPalette is properly connected (see “Connect the Film Recorder” on

page 23), turned on, and the correct port is selected on the Device tab of

Queue Properties.

Terminating the ProPalette Internally

1. Turn off the computer and all other SCSI devices.

2. Turn on the ProPalette and wait for it to complete initialization; (READY

shows on the display).

3. Press to display the Change Setup? menu on the message panel.

4. Press

until SCSI Terminated? appears.

28

Page 29

8K Series ProPalette Repair Manual Hardware Operating Information

5. Press , then press or to highlight Yes (terminate) or No (turn off

termination).

6. Press

, then press twice.

7. Press the Reset button on the back of ProPalette.

Changing the ProPalette SCSI ID

Caution: If two devices on a SCSI chain have the same SCSI ID

number, neither will work correctly, and data may be

damaged when you turn on the devices.

The preset ProPalette SCSI ID is 4. If the SCSI ID of

any other device is 4, either change the SCSI ID of that

device (consult the device documentation) or of

ProPalette.

1. Turn off the computer and all other SCSI devices.

2. Turn on 8K Series ProPalette.

3. Press to display the Change Setup? menu on the message panel.

4. Press until SCSI ID? appears, then press to display the current SCSI ID

number.

5. Press to select an unused SCSI ID number.

Note: The SCSI host adapter is usually ID 0, and most internal

SCSI hard drives are ID 1. An internal SCSI CD-ROM

drive may be ID 3.

6. Press , then press twice.

7. Press the Reset button on the back of 8K Series ProPalette.

29

Page 30

8K Series ProPalette Repair Manual Hardware Operating Information

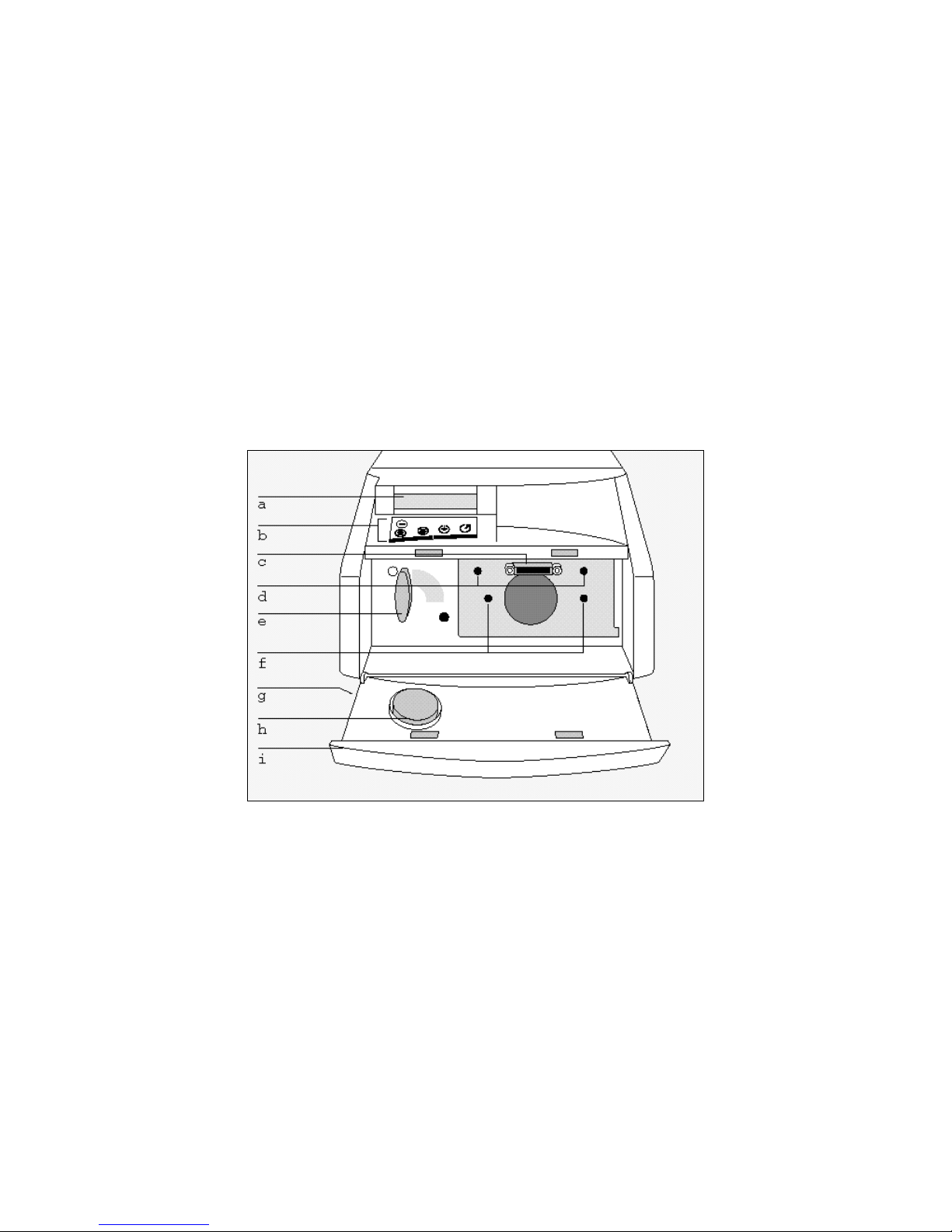

Controls, Indicators and Connectors

Front (Without Camera)

The following controls, indicators and connectors on the front of the 8K Series ProPalette

unit are shown in Figure 2-11:

a. Message panel

b. Keypad

c. Camera connector

d. Attachment holes for optional camera backs

e. Camera locking lever

f. 35mm Camera positioning holes

g. Power OFF/ON (0/1) switch (beneath door)

h. Lens cap holder and lens cap

i. Front cover

Figure 2-11. Front controls, indicators, features

30

Page 31

8K Series ProPalette Repair Manual Hardware Operating Information

Keypad

The 8K Series ProPalette keypad controls and indicators are identified in Figure 2-12.

Figure 2-12. Keypad controls and indicators

Using the 35mm Camera Back

35mm Camera Back Description

The 35mm camera back provided with the recorder features automatic film loading,

advancing and rewinding for maximum convenience. The camera can detect the length of

the film, and counts frames as exposures are made. This information is displayed on the

message panel for reference.

Refer to Figure 2-13 for the location of the following camera back components:

a. Film door button

b. Film ID window

c. Film door

d. Edge connector

e. Lens

f. Positioning pins

Figure 2-13. 35mm camera back

31

Page 32

8K Series ProPalette Repair Manual Hardware Operating Information

Loading 35 mm Film

1. Verify that the 35 mm camera back is properly attached, and turn the film

recorder on (Figure 2-14).

Figure 2-14. Turn on film recorder

2. Slide the film door button on the camera back down (Figure 2-15) and open

the door.

Figure 2-15. Open camera back door

3. Insert the film cassette at an angle into the chamber (Figure 2-16). Push the

cassette in fully, so that the film lies flat against the track.

Figure 2-16. Insert film cassette into camera

Note: Do not touch the shutter when loading the film.

32

Page 33

8K Series ProPalette Repair Manual Hardware Operating Information

4. Pull the end of the film gently to the right (Figure 2-17) until the end reaches

1/2-inch past the white triangle at the lower right. (If you pull the end of the

film too far, remove the cassette, turn the black knob at the top of the cassette

to wind the end back in, and reinsert the cassette into the chamber.)

Figure 2-17. Pull film to right

5. Close the film door until you hear a click. The message panel (Figure 2-18)

displays Loading Film, the film advances, then the message panel displays

the number of exposures available.

Message

panel

Figure 2-18. Film recorder message panel

6. Close the front door.

Using the 4x5 Camera Back

The 4x5 camera back is shown in Figure 2-19.

Figure 2-19. 4x5 camera back

33

Page 34

8K Series ProPalette Repair Manual Hardware Operating Information

Loading 4x5 Film

1. Verify that the 4x5 camera back is properly attached and secured, and turn the

film recorder on (Figure 2-20).

Figure 2-20. Turn on film recorder

2. In a darkroom, load the 4x5 film holder with film. Orient the film with the

notch positioned as shown in Figure 2-21.

Notch

Figure 2-21. Orienting film in holder

Note: Some 4x5 films are available in Ready-load packages.

When used with the Polaroid 545 or the Kodak Readyload

Packet filmholder, you can load the film holder outside of a

darkroom.

3. Pull open the outer section of the camera back enough, but no more than 2

inches, to slide the film holder in (Figure 2-22).

Figure 2-22. Inserting film holder into camera back

Caution: Do not pull the outer section too far. This can cause the

camera back to pop out of the springs and require

Service Center repair.

34

Page 35

8K Series ProPalette Repair Manual Hardware Operating Information

4. Insert the 4x5 film holder into the camera back from the right.

Note: To avoid light leak, make sure that the left side of the film

holder lies snugly against the left side of the outer section

of the camera back.

5. Wait for the message panel to display a message directing you to pull out the

dark slide.

6. Pull out the dark slide (Figure 2-23) before exposure.

Figure 2-23. Pull out dark slide

Note: Remember to reinsert the dark slide after exposure.

7. Gently push any button on the keypad to confirm dark slide removal.

Using the 6x7 Camera Back

The 6x7 camera back is shown in Figure 2-24.

Figure 2-24. 6x7 camera back

Loading 6x7 Film

1. Verify that the 6x7 camera back is properly attached and secured, and turn the

film recorder on (Figure 2-25).

Figure 2-25. Turn on film recorder

35

Page 36

8K Series ProPalette Repair Manual Hardware Operating Information

2. Steady the camera insert with your left hand, and pull the top latch on the film

door up and the bottom latch down with your right hand. Remove the camera

insert (Figure 2-26).

Figure 2-26. Removing camera insert

3. Note the pressure plate dial setting (Figure 2-27). If the black arrow is

pointing to the type of film (120 or 220 length) you are loading, proceed to

step 5.

Dial

Figure 2-27. Check the dial setting

If the black arrow is not pointing to the correct film type:

a Hold the camera insert in your left hand. Do not set it down on a flat

surface.

Note: Make sure you’re fingers are not touching the pressure

plate on the back of the camera insert.

b Push in the pressure plate dial (Figure 2-28) and turn it clockwise until

the arrow points to the film you are loading (as printed on the film

package).

Figure 2-28. Resetting the pressure plate dial

36

Page 37

8K Series ProPalette Repair Manual Hardware Operating Information

4. Turn the camera insert around, verify that the film type appears in the display

window (Figure 2-29), and check that the plate is locked into position.

Figure 2-29. Check film type in window

If the plate is not locked into position, turn the pressure plate dial slightly until

it snaps into position.

5. Turn the camera insert so that the OFF/ON switch is on the bottom. If the

empty spool is on the right (take-up) side, proceed to step 6.

If the empty spool is on the left side:

Figure 2-30. Swing out spool

a. swing out the left spool retainer, remove the empty spool, and swing in the

left spool retainer.

If the empty spool is on the right side:

b. swing out the right spool retainer, insert the empty spool, and swing in

the right spool retainer.

6. Turn the film roll so that the film feeds toward the back of the camera insert

(Figure 2-31).

Figure 2-31. Load film so it feeds to back of insert

37

Page 38

8K Series ProPalette Repair Manual Hardware Operating Information

7. Swing out the left spool retainer. Insert the film roll (Figure 2-32). Swing in

the left spool retainer.

Figure 2-32. Load film onto spool

8. Pull out and wrap the film around the back of the pressure plate until the end

reaches the take-up spool (Figure 2-33).

Figure 2-33. Wrap film around pressure plate to take-up spool

Caution: Do not pull the film out too far. Doing so will fog part

of the film and reduce the number of available

exposures.

9. Insert the end of the film into the take-up spool slot. Turn the film advance

knob counterclockwise (Figure 2-34) until the arrows on the film roll line up

with the red arrow on the left spool retainer.

Figure 2-34. Insert film into take-up spool

Note: If the film does not wind evenly. remove the spool, take out

the film. and reinsert the end of the film into the take-up

spool slot and restart rewinding.

38

Page 39

8K Series ProPalette Repair Manual Hardware Operating Information

10. Open the camera back. Check that the top and bottom latches are fully open.

Seat the camera insert tightly onto the camera back (Figure 2-35).

Figure 2-35. Open camera door to check latches

11. While holding the camera insert onto the camera back, close the film door

(Figure 2-36). Hold the door shut while pushing the top latch down and the

bottom latch up.

Figure 2-36. Close film door

Note: If the door does not shut and latch easily, reseat the camera

insert tightly onto the camera back.

12. Check the control lever positions on the top of the camera back (Figure 2-37).

If the control levers do not point to the white squares, turn the levers until they

point to the white squares.

Figure 2-37. Check control lever position

13. Turn the camera back OFF/ON switch to ON (Figure 2-38).

Figure 2-38. Turn camera switch to ON

39

Page 40

8K Series ProPalette Repair Manual Hardware Operating Information

14. Press the START button on top of the camera back (Figure 2-39) to advance

the film to the first exposure.

Figure 2-39. Press START button

15. Pull out the dark slide (Figure 2-40) before exposure.

Figure 2-40. Pull out dark slide

Locking the Film Type Via the Keypad

The film type must always be selected in the software and it must match the film loaded

into the recorder to ensure proper color balance and exposure. If the recorder is on a

network, it may be inconvenient for remote users to confirm which film type is currently

loaded into the recorder. If so, you can “lock in” the film type you have just loaded using

the keypad. Doing so will prevent users from making exposures on the incorrect film type

(an error message will alert the user).

When the film type is “unlocked” (not selected via the keypad), no error message is sent.

In this case, remote users should check which film is loaded before imaging.

To lock the film type:

1. Press the Escape key to reach the Change Setup menu.

2. Press the Down key until “Lock Film Type?” is displayed. Press the Select

key. “*Unlocked” or the name of the currently locked film is displayed.

3. Press the Down (or Up ) key to display the film type that is currently loaded.

Or, select Unlocked to allow any film type to be selected in the software.

4. Press the Select key to enter the selection. An asterisk (*) will appear next to

your selection to indicate it has been selected. Press Escape twice to return to

the Ready message.

40

Page 41

8K Series ProPalette Repair Manual Hardware Operating Information

Locking the Camera Type via the Keypad

A camera-locking function has been added to the 8K Series ProPalette LCD/keypad

menu. This function allows the operator to bypass the camera auto-sense and manually

select the camera installed on the system.

The available menu options are:

• Auto Sense (default)

• 35 mm

• 4 x 5

• 6 x 7

• 6 x 8

• Bulk 35 mm (see the following section, “Bulk Camera Support”)

To lock the camera type:

1. Press the Escape key to reach the Change Setup menu.

2. Press the Down key until “Lock Camera Type?” is displayed. Press the Select

key. The name of the current selection is displayed.

3. Press the Up or Down key to display the desired camera type.

4. Press the Select key to enter the selection.

5. Press Escape twice to return to the Ready message.

Bulk Camera Support

The 8K Series ProPalette models (8035, 8045, 8067) support the bulk camera back

manufactured by Double M. The ProPalette automatically detects the bulk back and

displays “35-mm bulk” when it is attached. To expose bulk images, use the standard

35mm drivers and film tables.

The bulk camera can also be selected by manually setting the camera type to “Bulk 35

mm” as described in the previous section.

Leaving a Film Leader

It is more convenient to process Polaroid Polachrome HC instant 35mm film if a short

length of film (a “leader”) remains extended from the cartridge after the roll is exposed

and rewound. To set the camera back to leave a leader after rewinding, do the following:

1. Press the Escape key to reach the Change Setup menu.

41

Page 42

8K Series ProPalette Repair Manual Hardware Operating Information

2. Press the Down key until “Leave Leader?” is displayed.

3. Press the Select key, then press the Down key to display “Yes.”

4. Press the Select key to enter the selection. Press Escape twice to return to the

Ready message.

Note: Select No under “Leave Leader?” when reloading

conventional 35mm film to rewind the film completely into

the cartridge.

Making Exposures

Once you have loaded the film, the Ready status message will be displayed on the

message panel. You are now ready to begin initiating exposures from the software. (Be

sure to select the correct film type in the software.)

Before an exposure is started, "READY" appears on the first line of the LCD display.

When a 35 mm camera is mounted, the second line of the LCD display alternates

between the camera name with its serial number and the frame count status. If any other

camera is mounted, the camera name and its serial number appears on the second line.

Note: The displayed camera serial number was stored in flash

memory at the factory when the camera was matched to the

ProPalette. The ProPalette does not read the camera serial

number from the camera.

When you begin your first exposure, the unit may do a brief calibration routine first (the

message panel will display “Calibrating.”).

During the exposure, the message panel displays information about the process. The top

line indicates the color is being exposed and the line count being exposed. The second

line of the display changes and depends on the color is being exposed. During the RED

exposure, the second line displays the selected film type. During the GREEN exposure,

the second line displays the image resolution. During the BLUE exposure, the second line

displays the current frame count.

After each exposure, the panel will count down the frames available (for example, “23

Frames Left of 24”). When the last exposure is finished, the message panel will display

“Out of Film.” Remove the exposed film as described in the following section.

Note: When you turn off the recorder with a partially exposed roll

loaded, the recorder keeps the status information in

memory and will redisplay the correct frame count when

you turn on the recorder again.

42

Page 43

8K Series ProPalette Repair Manual Hardware Operating Information

Removing Exposed Film

When you are finished exposing a roll of 35mm film, the camera will automatically

rewind the film. The message panel will then display “Out of Film.” Open the front door

of the recorder, open the film door, and remove the film cassette. The film should be

completely rewound into the cassette unless the film leader option has been selected as

described on page 41.

Rewinding a Partially Exposed Roll

To rewind a partially exposed roll of film, press the Escape key to display the Change

Setup menu. Press the Down key until “Rewind Film” is displayed. Press the Select key.

The film will rewind, and the message panel will display “Out of Film” when done.

Remove the film.

Note: Do not try to reinstall a partially exposed roll of film.

Advancing Film

If you need to advance film (leave unexposed frames) during a session, press the Escape

key to display the Change Setup menu. Press the Down key until “Advance Film?” is

displayed. Press the Select key; the film will advance one frame. To advance the film by

more than one frame, repeat this sequence the desired number of times.

Note: This option is useful if a power failure occurs during an exposure.

Advance the film by one frame, then reshoot the image on the next frame.

Or, if you accidentally opened the film door when a partially exposed roll

was loaded, advance the film by a few frames to bypass the light-fogged

area of film.

Removing and Replacing the 35mm Camera Back

To remove the 35mm camera back:

1. Open the front cover of the recorder.

2. Move the locking lever to the unlocked ({) position (Figure 2-41, left).

3. Carefully pull the camera back straight off (Figure 2-41, right). Replace the

lens cap, which is stored in the front cover, while the camera is not in use.

Figure 2-41. Removing and replacing the camera back

43

Page 44

8K Series ProPalette Repair Manual Hardware Operating Information

To replace the camera back:

1. Remove the lens cap and store it in the holder in the front door.

2. Be sure the locking lever is set to the unlocked ({) position.

3. Push the 35mm camera back gently but firmly onto the mounting plate so the