Page 1

ModelSmart 250S

User Guide

1

HowP ola

roi dA

reYou .

com

Page 2

CONTENTS

Introduction 3

Safety Instructions 4

Box Contents 5

Printer Set Up 6

Windows Operating System 9

Installing Cartridges 10

Z-Axis Sheets 13

Camera Set Up 14

How to Print 15

Printing via your Polaroid 3D Printer 25

Other LCD functionality 26

Technical Specications 27

Cleaning and Maintenance 28

Manufacturer’s Guarantee 29

Certications and Compliance 30

Troubleshooting 31

Contact Details 35

2

Page 3

INTRODUCTION

The following User Guide provides you

with all of the information you need to

get started printing with your Polaroid

ModelSmart 250S.

It will guide you through the simple

installation of your printer starting with

getting it out of the box, right through

to each of the fantastic features of the

Polaroid Prep printing software and the

easy-to-use touch screen LCD on the

printer itself.

The Polaroid 3D team hope that you have

many happy hours printing with your

new ModelSmart 250S 3D printer, but

if you have any questions at all, please

don’t hesitate in contacting the team via

our online Contact Form.

3

Page 4

SAFETY INSTRUCTIONS

WARNING

(Heated surface)

Whilst in operation, the extruder on your Polaroid 3D printer becomes very hot.

Always allow time for the extruder to cool down before you reach inside the printer.

This product is not to be serviced by anyone other than a Polaroid 3D approved

engineer. Any unapproved servicing will also void your guarantee.

The Polaroid 3D printers include moving parts, which may cause injury if interfered

with whilst in use. Never reach inside your Polaroid 3D printer whilst it is in use.

Never leave your Polaroid 3D printer unattended during operation.

Please ensure that the printer is located in an area that is:

• close to the intended power supply and that the socket is easily accessible

• well ventilated

• clean and dry

• a consistent and stable temperature and humidity

• positioned away from any object that may cover the ventilation holes on the printer

• positioned away from any ammable items

• positioned away from any liquids

• a at and stable surface

(Electrical component)

WARNING

CAUTION

Any damage caused by improper use of the printer or its component and consumable

parts, which is in contradiction with this User Guide becomes the full responsibility of

the user and will void your guarantee.

This printer is not suitable for children. Anyone under the age of 16 must be supervised

by an adult.

Never turn off your Polaroid 3D printer during printing; please wait until the job has

completed and the print bed and extruder have returned to the Home Position before

turning off the power.

Due to the weight of this product, two people are required to remove the printer from

the outer box packaging and onto a suitable surface.

4

Page 5

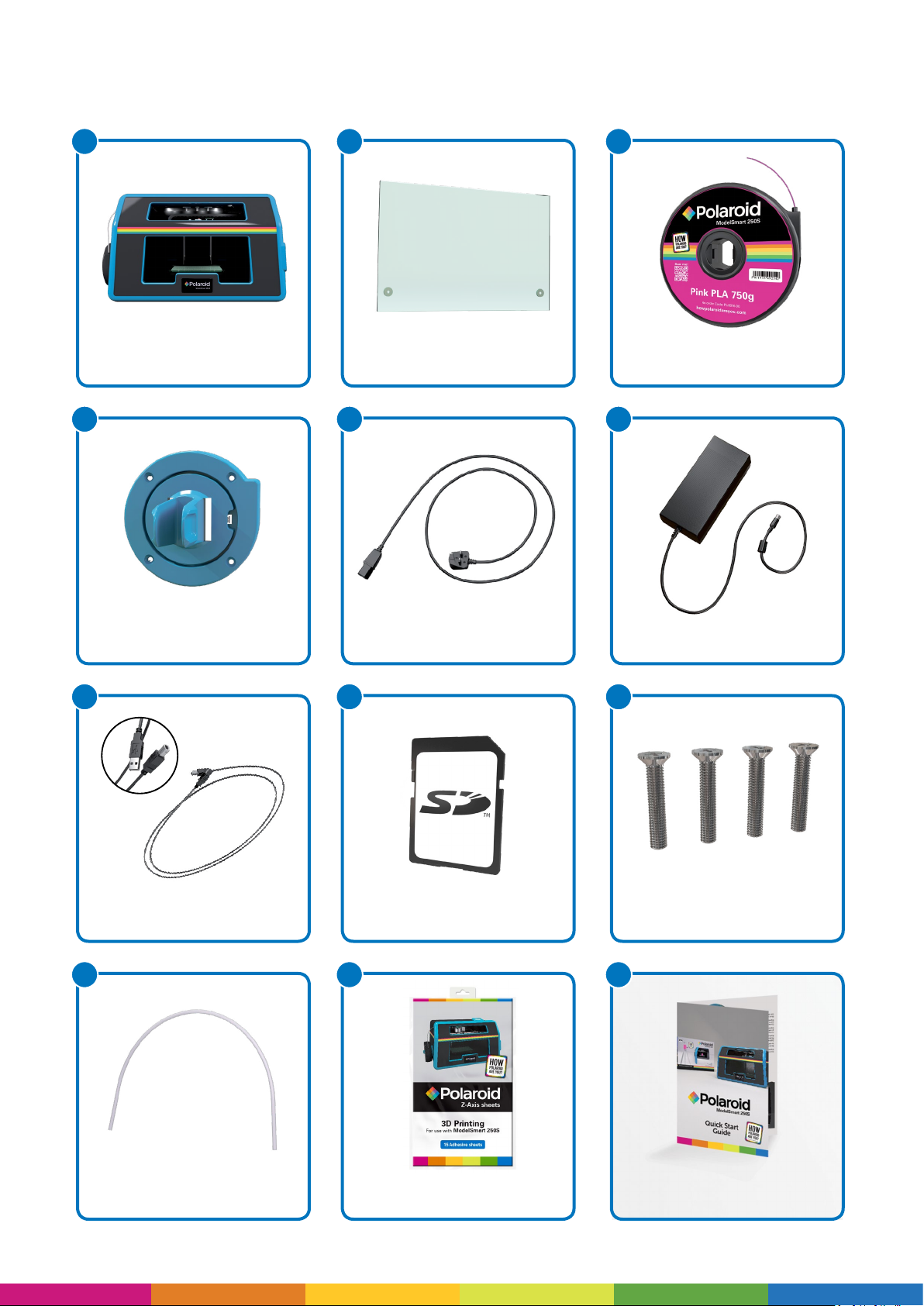

BOX CONTENTS

A B C

Polaroid ModelSmart 250S

Glass bed

D E F

Cartridge lament holder

2m power cable

G H I

Filament cartridge 750g PLA

24v power adapter

Four screws for the lament

Extra long 3m USB Cable

512MB SD Card

cartridge holder

J K L

Filament tube

5

Z-Axis sheets

Quick Start Guide

Page 6

PRINTER SET UP

Please follow the steps below to get your Polaroid 3D printer ready for printing. Before you start,

please note that two people are required to remove the printer from the box. Once removed from

the box please ensure that your printer is positioned on a at and stable surface, this helps to

minimise vibration and produce more accurate prints.

Remove the printer from the double lined box.

1

Please note that two people are required to

remove the printer from the box.

Open the printer door and remove the following

2

items from the box that you nd inside the

printer:

a. Glass bed

b. Filament cartridge

c. Filament cartridge holder

d. 2m Power cable

e. 24V power adapter

f. Extra long 3m USB cable

g. Four screws for the lament holder

h. Filament tube

i. 1x pack of Z-Axis sheets

Set up the lament holder cable:

3

Connect the cable connector to the rear of the

lament cartridge holder. Please refer to the

illustration for details and correct orientation.

With the four screws provided attach the

4

lament cartridge holder to the printer.

Important note: hand tighten only.

6

Page 7

Insert the glass bed onto the print bed area

5

at an angle to ensure it ts underneath the

metal ridge at the back, then lower it onto the

magnets at the front to secure it in place.

An SD card must always be inserted to print

6

whether by computer or via LCD.

8

howpolaroidareyou

www.howpolaroidareyou.com/soware

7

6

Connect the USB cable.

7

Connect the power cable and turn on the

8

printer. Be careful not to damage the cables.

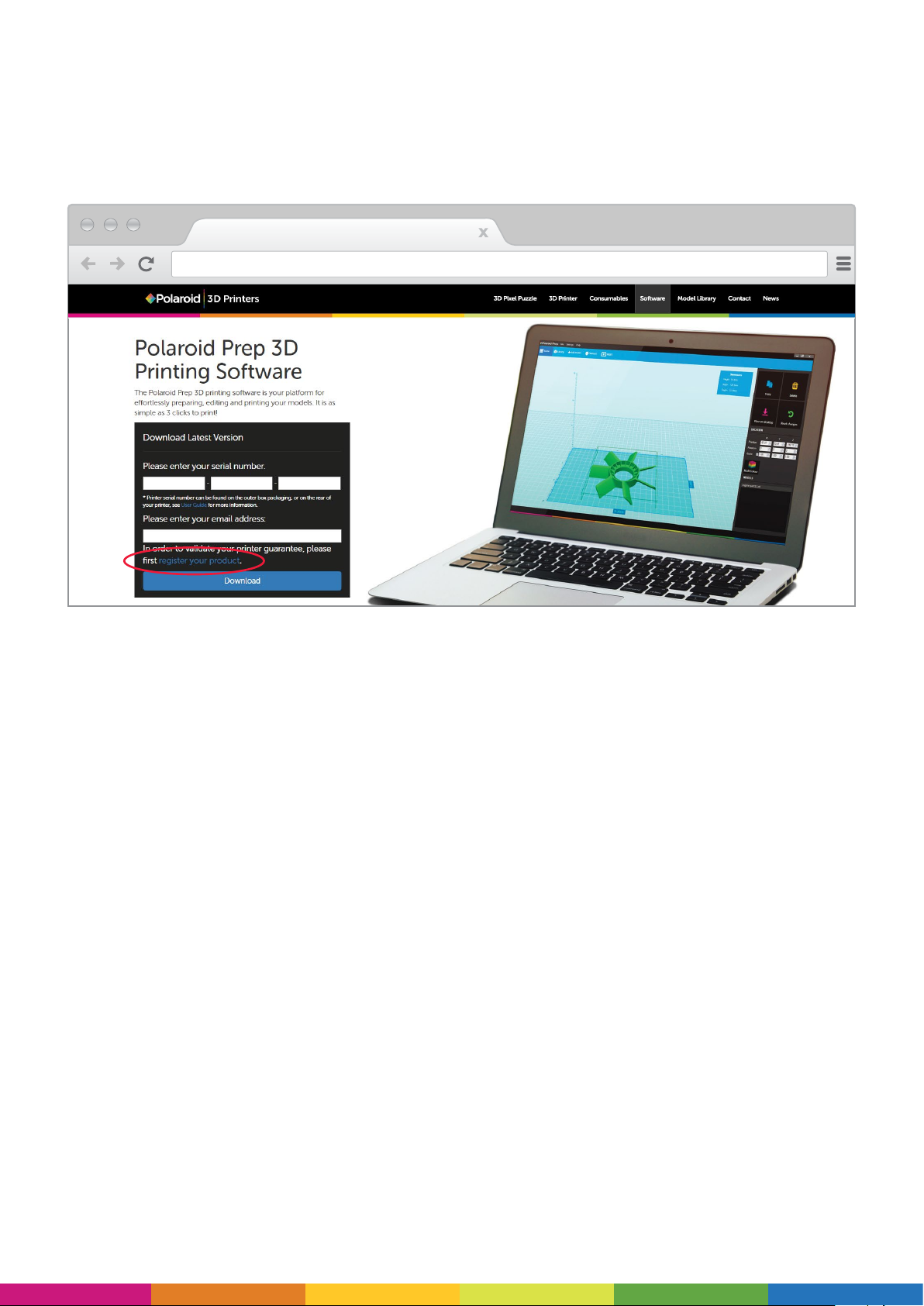

Download and install the Polaroid Prep Software

9

from howpolaroidareyou.com/software

Firstly, please insert your serial number and

email address to download the software.

MODEL:

ModelSmart 250S

howpolaroidareyou.com

MADE IN THE UNITED KINGDOM BY: Environmental Business Products Ltd. 26 Chase Road, London, NW10 6BB

ModelSmart 250S

Serial No. PL-250-18679-12NSJ

100-240V AC;

24V 5A DC;

50-60Hz

7

Your serial number can be found on the outer

box/packaging, or on the rear of your printer.

Page 8

In order to validate your printer guarantee, please click on the link above the download button

“register your product” and then enter your details.

Once you have downloaded the software and double clicked on the installer, the installation process

will then begin.

howpolaroidareyou

www.howpolaroidareyou.com/soware

8

Page 9

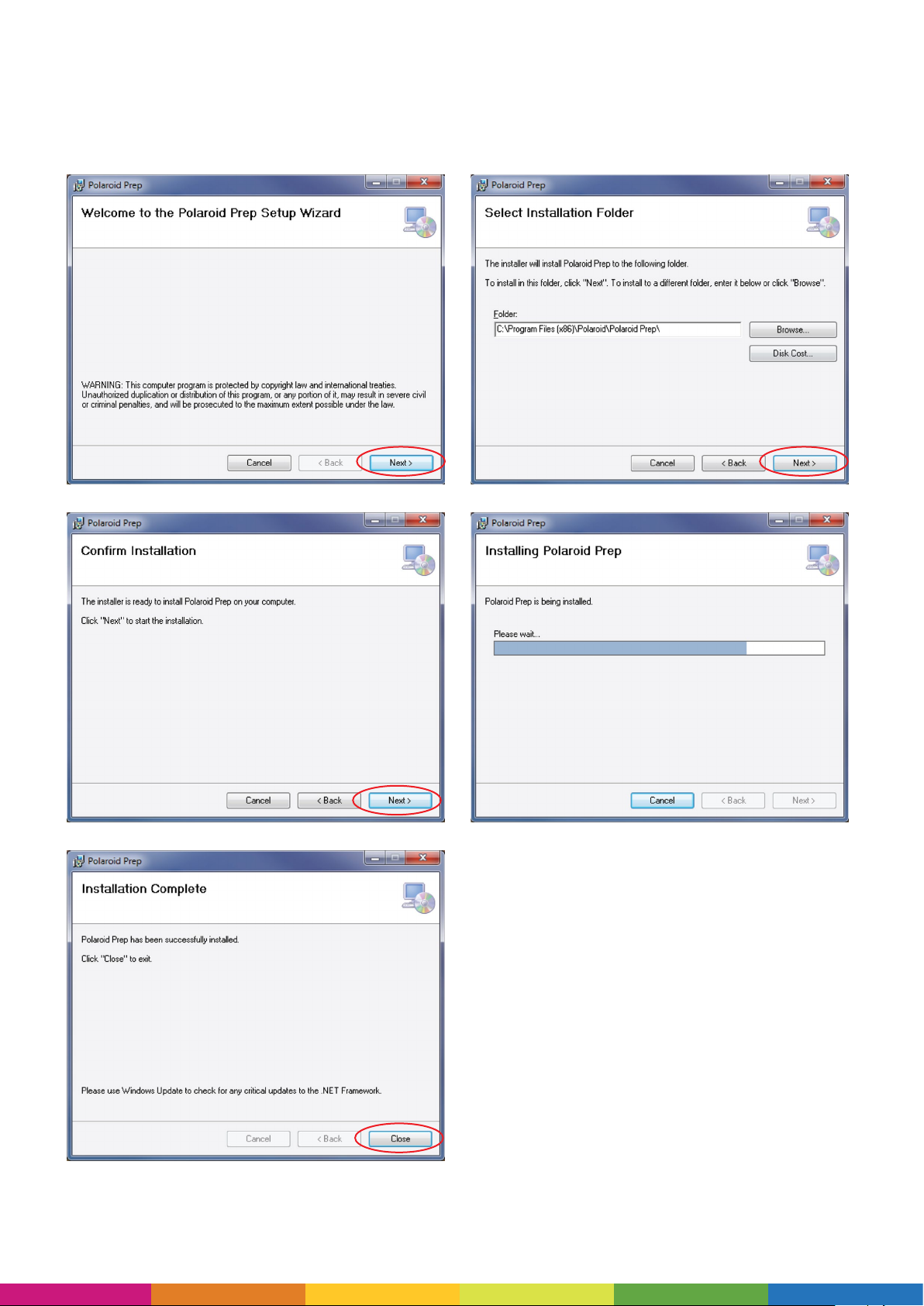

WINDOWS OPERATING SYSTEM

Please follow the on-screen pop-up messages to install the Polaroid Prep software as below:

9

Page 10

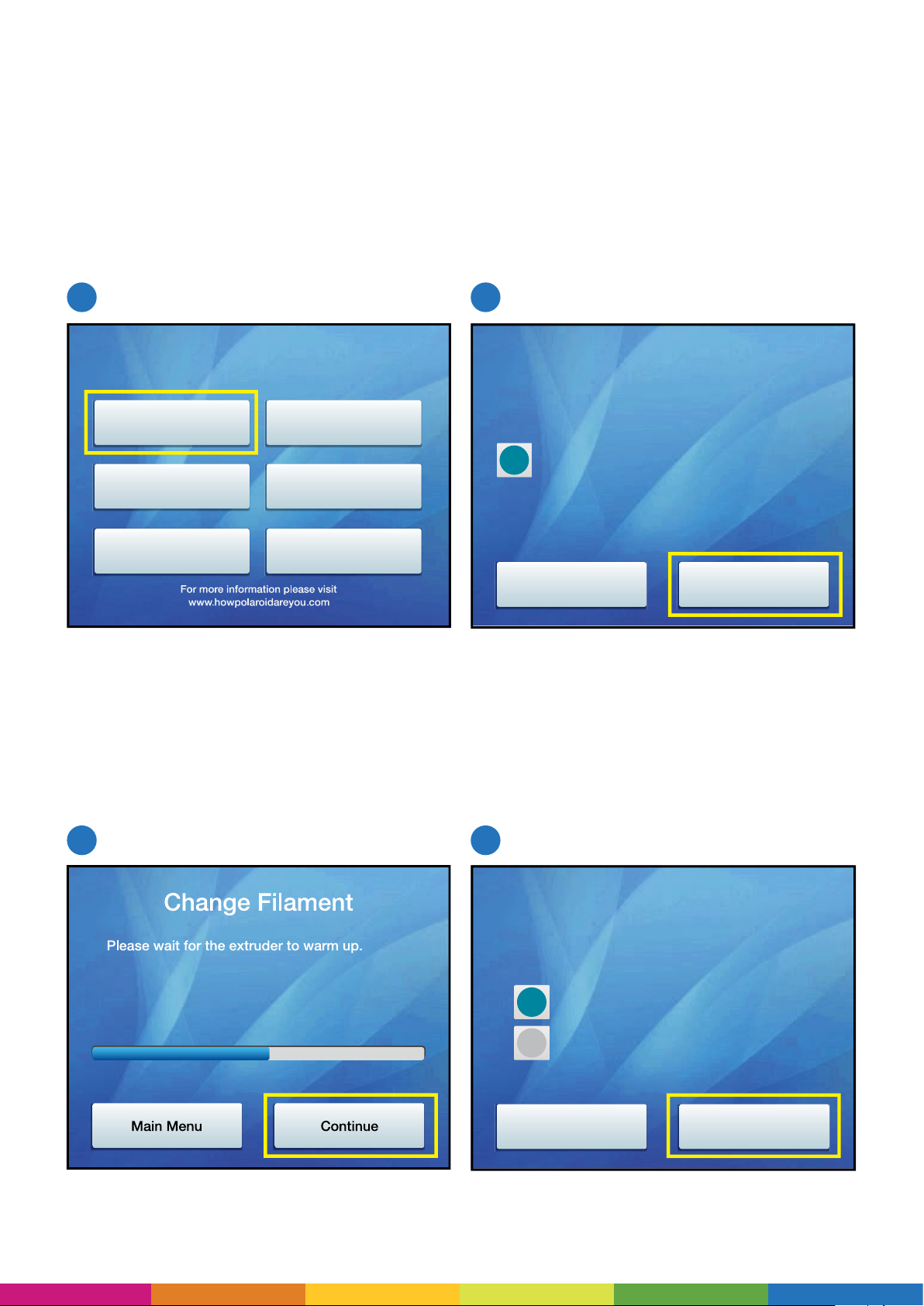

INSTALLING CARTRIDGES

Before you can print you must install a lament cartridge.

In order to do this you must use the menu on the touchscreen LCD on the top of the printer. Please

follow the process below:

From the Main Menu please select ‘Change Filament’

1 2

Main Menu

Change Filament

Preheat

Print

The lament cartridge is already pre-selected so

please press continue.

Settings

Information

Shutdown

Change Filament

Please select the filament to change:

Filament Cartridge

Main Menu

Please then wait a few moments for the selected

extruder to warm up. This is necessary because

in order to successfully load a cartridge a

small amount of material needs to be extruded

through the nozzle. The ‘Continue’ button will

remain inactive until the extruder is warmed to

the correct temperature.

Continue

3 4

10

Change Filament

Is the filament currently loaded?

No

Yes

Cancel

Continue

Page 11

5

You will then be asked if a lament cartridge

Change Filament

Install the cartridge and firmly feed the filament

through the tube until it stops, whilst maintaining

pressure on the filament, press continue to start

the extrusion.

Main Menu Continue

You then need to install the cartridge onto the side of the printer. Firstly, remove the lament

cartridge from the outer packaging and take out the red plug from the side of the cartridge casing.

Slide the cartridge onto the lament holder on the side of the printer and gently push until you hear

it click into place.

is already installed. Initially this will be ‘No’

as this is the rst time a lament cartridge has

been loaded; but when changing a cartridge in

future you will select ‘Yes’. Selecting ‘Yes’ will

uninstall the existing lament before allowing

you to load a new lament.

Next, gently pull out sufcient lament from the cartridge (5cm to 15cm). Cut off the rst 5cm of

the lament and discard (this is to ensure that any previously exposed lament does not enter the

printer as it may have some dirt on it). Then push the lament coming from the cartridge through

the lament tube (item J). Feed the lament through the lament tube into the corresponding

tting on the side of the printer.

Continue feeding the lament into the printer until it you feel it stops. Approximately 30cm of

lament will be required.

11

Page 12

Whilst maintaining gentle pressure (to ensure that the lament has been fed all the way through

correctly), please press the on-screen ‘Continue’ button which will start the extrusion process.

You should then feel the lament being pulled through the printer and see lament being extruded

through the nozzle. When this is complete the ‘Continue’ button will become active and you can

complete the process.

If no lament is extruded, ensure that the lament has been pushed all the way through and whilst

maintaining gentle pressure please push the ‘Repeat Process’ button.

Change Filament

If no filament is extruded after 30 sec, please press

‘Repeat process’.

Repeat Process

Main Menu

Continue

Change of filament is complete.

Change Filament

End

Once the lament has been installed, push the end of the lament tube onto the top of the

cartridge and into the tting on the side of the printer, ensuring that no lament is left exposed.

If removing a part-used lament,

please ensure that you do not push

the end of the lament back into the

cartridge casing as this means that

you will then not be able to attach

this cartridge to the printer again for

printing.

12

Part-used cartridges should be

stored in a cool and dry environment

whilst not in use.

Page 13

Z-AXIS SHEETS

When printing on a 3D printer, the rst layer of the print is all-important. It must adhere to the

print bed to ensure that the subsequent layers sit directly on top of each other and aren’t out of

alignment. Any small movement or imperfection could cause your print to not re-produce correctly.

To ensure this adhesion is secure, the Polaroid 3D printers use a revolutionary product called the

Z-Axis sheets. These are transparent adhesive sheets that are easy to apply to the print bed before

each print. Your model then prints on top and when nished you simply remove the glass bed from

the printer and peel off the Z-Axis sheet. The model then peels from the sheet.

Applying the Z-Axis sheet

for PLA and Wood

1. Before applying the Z-Axis

sheet, ensure the glass bed is

clean.

2. Remove the backing sheet

(clearly labelled this side down)

and apply the revealed adhesive

side to the print bed.

3. Take it slow from one edge

to the other and take care to

minimise air bubbles.

4. Once fully applied remove the

top sheet, leaving the adhesive

layer exposed.

5.You are now ready to print.

6. For best results print within

15 minutes of removing the rst

backing sheet.

13

Page 14

CAMERA SET UP

SWITCH ON YOUR POLAROID 3D PRINTER

1

INSTALL APP

2

Please download the ‘Doby - Smart Camera’ App from Google Play or Apple Store onto your smart

phone or tablet.

SIGN UP AND SIGN IN

3

Open the App and click on ‘Sign Up’ to register.

ADD DEVICE

4

a) Once you have successfully logged in, you will be directed to the Home screen. Click the icon at the

+

bottom right of your screen and then choose the ‘camera’ option.

b) Please make sure that the blue WiFi indicator light is ashing

on the camera. If not, please press and hold the WiFi button for

a few seconds until the blue WiFi indicator light is ashing and

then click on ‘yes’ on the screen. Click icon to view the

!

description of all LED indicator light states.

c) Add device

• Android: on the search page, choose the new device

you want to add. The camera ID number is located on the

camera, which is mounted inside the printer door.

• iPhone: come out of the app and go to ‘Settings > WiFi’ on your iPhone and connect to

‘DOG-00***’ and use the password shown on the screen. Once you have connected come back

to the App and click ‘next’.

Note: If after pressing the WiFi button, the WiFi indicator light does not ash blue, please perform a

factory reset as follows: using a pin, please press and hold the reset button for approx. 5 sec or until the

WiFi indicator turns off. The reset button can be found on the underneath of the camera housing.

d) On the ‘Set Wi’ page, both Android and iPhone, select a network to connect to enter the password

and click ‘next’.

Note: the automatic switching of network is normal during the connection process.

e) Once added successfully click on ‘Done’ and start using.

WATCHING VIDEO

5

a) On the App home page, click on the camera you have added from the list.

b) Click on the play button to watch real-time video. Click on the video to bring up the pause button and

press the pause button to stop the video.

c) Click on the icon on the top right corner of the screen to change the camera settings.

SMART CAMERA DOG-1W

6

PARAMETERS

7

INDICATOR STATE

SpecificationItems

DOG-1W

Microphone

Automatically enable infrared induction

under low illumination

IEEE802.11b, IEEE802.11g

14

DOG-1W

(WiFi)

State

The power light is on Be connected to power supply

WiFi indicator is blue blinking

WiFi indicator is red

blinking slowly

WiFi indicator is blue

all the time

WiFi indicator is flashing

red and blue

Instruction

Be ready to connect with a

mobile device

Fail to connect to a WiFi

Connected to WiFi successfully

System upgrading

Product

Model

Lens

Video

Voice

Night

Vision

WiFi

HD camera, support videoing day and night

H.264 (CODEC), 720*576@15fps (resolution)

Page 15

HOW TO PRINT

Printing in 2 easy steps:

ADD MODEL

1

Open the Polaroid

Prep Software

Select ‘Add model’ at

the top of the screen

and locate your

.stl le within you

computer.

Your model is then

loaded onto the print

bed area.

15

Page 16

2

PRINT

Select ‘Print’ at the

top of the screen

Select to save your

le for printing via SD

card or transfer and

print via USB.

16

If saving your le,

select your SD card

a location on your

computer and click

save.

Page 17

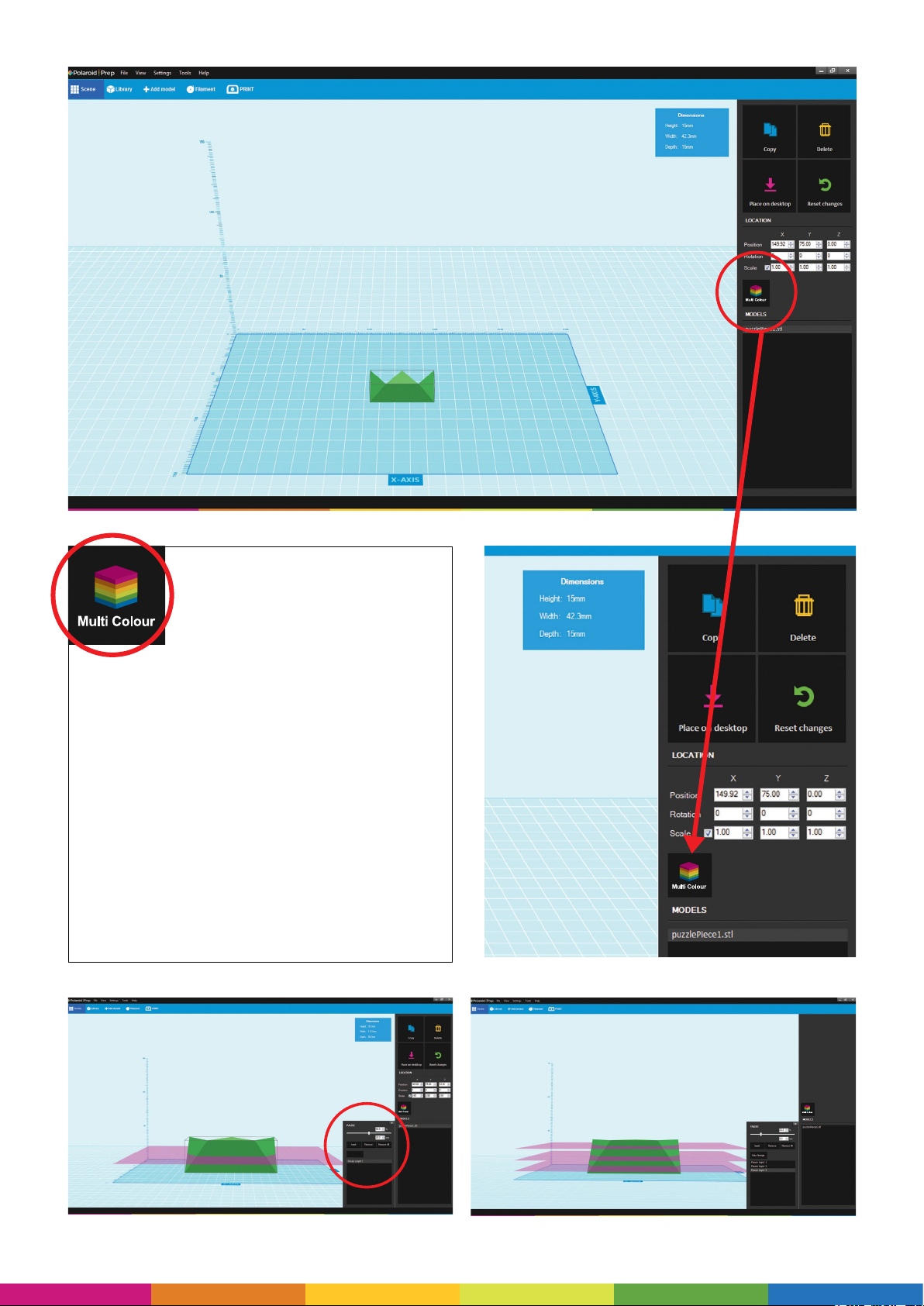

DESKTOP FUNCTIONS

This box provides you with the

height, width and depth dimensions

for the model that you have selected.

This button allows you to make a

copy of the model you currently

have selected. You can make as

many copies as you like.

If you no longer want a model, make

sure it is selected and then press this

button to delete. You can also delete

by pressing delete on your keyboard.

Pressing and holding your delete key

will delete all of the models, one-by-one.

If you re-position your model whilst

editing and it is raised off the print

bed then pressing this button will

place the model back onto the bed.

17

If at any point you want to revert

your models and print area to how it

was before you last saved, then this

button will reset your changes.

Page 18

These boxes provide you with the X, Y and Z position

of the selected model on the print bed area. To adjust

the model position using these boxes you can either

use the arrow buttons, manually type in a new

position, or click into the box where the numbers

are and use the scroll button on your mouse.

Alternatively models can be moved with the mouse

by clicking and dragging within the print bed area.

These boxes provide you with the angle of the

selected model on the print bed area, starting at a

zero position when rst imported. This then allows

you to rotate the position on the bed. To adjust the

angle of the selected model using these boxes you

can either use the arrow buttons, manually type in a

new angle (in degrees), or click into the box where

the numbers are and use the scroll button on your

mouse.

These boxes allow you to adjust the size of your

models. Starting at a scale of 1, you can then scale up

or down in multiples (i.e. 2 would be twice the size).

To adjust the scale of the selected model using these

boxes you can either use the arrow buttons, manually

type in a new scale, or click into the box where

the numbers are and use the scroll button on your

mouse. With a tick in the left hand box you can scale

your model proportionally; unticking this will allow

you to scale along one axis individually.

18

Page 19

Although the Polaroid ModelSmart

250S 3D printer has only one extruder,

you can easily print models in multiple

colours.

By selecting Multi Colour in Polaroid

Prep or opening the door mid-print, the

print will pause. At which point there is an option

on the LCD screen to change your cartridge, this

allowing you to change colour.

Alternatively, if you want to be specic about where

your new colour starts on your print, you can pre-set

the printer to pause. You can do this by pressing the

Multi Colour button in Polaroid Prep; this inserts a

‘pause’ onto your bed (seen as a pink layer). You can

then move this to where you want it on your model,

either by using the slider, or by typing in a position

in millimetres (working from the bottom of your

model upwards) or even a percentage point. You can

set as many pauses in your print as you like. You can

also easily space these equally by clicking the Auto-

Arrange button.

19

Page 20

ADVANCED SETTINGS

All Advanced Settings are set to their default position

for standard printing. This allows you to just go

ahead and print without needing to adjust anything.

If however you want to make changes, you can do

so easily. Any changes you make then allow you to

create a Custom setting. If you are likely to use these

same settings again in the future then you can Save

the Preset for future use.

There are two main things that can affect the quality of your print; one is the layer height (measured in microns)

and the other is print speed (measured in millimetres per second). Using these sliders here you can adjust both

settings. The quality ranges from 50 to 350 microns (0.05mm to 0.35mm) with a default of 200 (0.2mm). The speed

ranges from 20mm/s to 100mm/s with a default of 50mm/s. Note: the smaller the micron number, the ner the print

detail (as you are printing more layers) and the lower the speed, the better quality of print (as there is less vibration

whilst printing).

20

Page 21

Support structures can be important in 3D printing as the method of printing one layer on top of another means

that if there is an overhang within the model (where the layer being printed has nothing underneath to rest on) then

this can cause a print to fail.

To print with supports on the Polaroid ModelSmart 250S is easy; you simply tick the box that says ‘Enable Supports’

when you click Print. This will turn on the default supports, which places them anywhere on your model that has an

overhang that is more than 30° from the vertical.

If you wish to adjust some of the support settings yourself then you can do so under the Advanced Settings. These

include being able to adjust the type of support (default is a line support, or if more support is needed you can

change to a grid structure), and also adjusting what angle the supports will initially be applied from, as well as

other more advanced settings.

21

Under the Advanced Settings you can also adjust the way that your model is printed.

With this form of 3D printing, models are printed with a solid outer wall, surface and base and then a grid inll

(i.e. it isn’t solid throughout). Under the Properties section of the Advanced Settings you can adjust some of these

features.

Shell thickness allows you to adjust how thick the outer walls of your model are in millimetres.

The ll density adjusts the grid inside the model. The default is set to 15% but if you wanted a completely hollow

object you can slide this down to 0%, or for a more solid object simply slide the scale up towards 100%.

The other Properties setting is to adjust the number of layers at the beginning and end of each print. This is default

at 6 layers but can be adjusted up or down accordingly.

Page 22

FILAMENT LEVELS

At any me whilst in Polaroid

Prep you can check the lament

levels of the cartridge you have

connected to the printer. Please

note that the printer and your

computer must be connected

via the USB cable provided in

order to read the cartridge

level informaon from the bidireconal smartchip on the

cartridge. This will tell you the

colour and material of the current

cartridge and how much lament

is remaining (in % and in grams).

Note: when not connected to a

PC you can check your lament

levels via the LCD on the printer

by selecng Sengs, then Other

Sengs, then Printer Status.

When you are running low there

will be a warning sign pop up on

this lament level to let you know.

At this point (or any point), you

can click on the shopping basket

buon and this will take you to a web page idenfying places you can purchase a replacement cartridge from.

You will also see rotang adverts at the boom of the lament level box. These will adverse a variety of items and

services which if you click on will take you direct to the applicable website page.

22

Page 23

MODEL LIBRARY

The Polaroid ModelSmart 250S

3D printer prints .stl le types; .stl

being the industry standard format

for 3D printable models.

To print a model you can either

design it yourself and import into

Polaroid Prep, or download from

one of the many exisng online

model libraries already available

(free of charge). Alternavely you

can download from the Polaroid

Model Library that is built into the

Polaroid Prep Soware.

By clicking on the Model Library

buon at the top of the screen, it

brings up the available models.

Selecng a model will then open

up a new screen that provides you

with a download buon. Once

downloaded you will see the le

name of that model appear in the

model list on the right hand side of

Polaroid Prep. Clicking on Scene in

the top le of the screen will then

take you back to your print area

ready for prinng.

If the model you have selected has mulple parts to it then you will see each of the individual components and can

download all of the parts that you need and then click Scene to return to your print area.

23

Page 24

PREPARING, PRINTING AND SAVING YOUR SCENE

If copying an object when you rst open Polaroid

Prep, it will copy one object behind another (as

show in the rst image), allowing you to arrange

the items on the print bed as you wish. You will

noce that this even keeps copying objects outside

of the print bed area (the model shown in grey).

Alternavely, if you click on Sengs at the top

le of the screen, you will be able to select

Auto Arrange. This will then place objects into

the opmum print posion (to minimise the

movement of the printhead) when copying

objects (as shown in the second image).

If you see an image in grey within your workspace,

it means that it is parally or wholly o the

print bed area. If you choose to print at this

point, the object in grey will simply be ignored.

If you happen to overlap one model with another,

you will see that they turn orange (as seen in the

third image). This is to idenfy to you that they have

overlapped, however the soware will allow you to

connue prinng and the overlapped objects will

print as they appear, i.e. merged into one new model.

If you have mulple objects to print but not all at

one me, then you can simply place the models

you want to print later o the print bed but within

the workspace area (shown in light blue) and then

select File and Save Scene from the headers at the

top le corner of the screen. You can then return

to this scene at any point in the future to connue

prinng the other models from the workspace area.

24

Page 25

PRINTING VIA YOUR POLAROID 3D PRINTER

This process is carried out using the touchscreen LCD on the printer. Please ensure you have an SD

card loaded into the slot on the back of the printer before you start; and that the model you wish

to print is saved on that card.

Please select ‘Print’ from the Main Menu

Main Menu

1

Change Filament

Preheat

Print

Settings

Information

Shutdown

Select the model you wish to print from the

2

list of models that are shown (i.e. the models

that you have saved on your SD card). Please

note that this screen has an eight character

limit for le names; please bear this in mind

when saving models in order to ensure that

you can locate them easily on the SD card

when printing via the LCD.

Once you have selected the correct model,

please press ‘Print’.

Pause Cancel Print

Print

Current Status: Complete.

The on-screen display will then conrm

3

the model selection, the status of print

(initialising, printing or complete), as well the

percentage of printing complete.

At any time during printing you are able to

pause or cancel your print via the LCD.

Once your print is completed this on-screen

message will be displayed.

4

25

Finish

Page 26

OTHER LCD FUNCTIONALITY

PREHEAT

The Preheat functionality allows you to warm up the extruder prior to starting the printing process.

This is not an essential part of the process but will allow faster printing because the printer can be

carrying out this process whilst you prepare your Scene and print le.

If you select ‘Preheat’ the on-screen display

will inform you of the current and optimum

temperatures. When the two temperatures display

the same number then the printer is ready for

printing.

You can turn preheating on or off via the LCD at

any time.

SETTINGS

Under ‘Settings’ you have two further options (excluding returning to the Main Menu).

‘Home Position’ returns the extruder and the print bed to their default position: the extruder to the

rear right-hand corner of the printer, and the print bed being reset to its lowest position.

‘Other Settings’ provides you with two further options; selecting and changing the language of the

LCD, or displaying current Print Status information as shown on the images below:

1 2

Settings

Home Position

Other Settings

Main Menu

Other Settings

Printer Status

Language

Back

26

3 4

Prev Next

English

Italian

French

Dutch

Cancel

Language

OK

Page 27

INFORMATION

Information

The ‘Information’ button will provide you with

manufacturer details as well as conrming

which version of the Firmware you currently

have installed.

SHUTDOWN

The ‘Shutdown’ button informs you that you

should wait until all programs are terminated

and the printer has returned the extruder and the

print bed to their Home Position before turning

the printer off at the main switch.

Product:

Year of manufacture: 2016

Firmware: 1.5.21 / p1.5.9

www.howpolaroidareyou.com

Polaroid ModelSmart 250S

OK

TECHNICAL SPECIFICATIONS

Polaroid ModelSmart 250S

Extruder 1

Resoluon 50-350 microns

Auto Calibraon

Max. Model Size 250(w) x 150(h) x 150(d) mm

PLA

Wood

Filament Size 1.75mm

Z-Axis Sheets

Wi-Fi Camera

Auto Support Generaon

Polaroid Helpful Printer Driver®

Speed (mm/s) 20 - 100 mm/s

Guarantee 12 month manufacturer’s guarantee*

* This may oer by country according to minimum statutory requirements

27

Page 28

CLEANING AND MAINTENANCE

It is important that your Polaroid 3D printer is kept clean at all times in order to ensure continued

consistency in your prints. Please follow the simple points below to help maintain your printer.

Keep the exterior of your printer clean by using a damp cloth to remove any dust

or dirt. Ensure that the printer is switched off before you clean and be careful not

to get water near any of the electrical components. Please take extra care if wiping

down the LCD screen as too much pressure or water in the display could cause

damage to the touchscreen functionality.

It is important to ensure that the extruder remains clean and free from any residual

lament prior to each print otherwise the nozzle could get blocked and the print

may not be successful.

Please ensure that you do not leave any item, model or residual material

underneath or around the print bed, or anywhere inside the printer when printing

as these could obstruct the movement of the extruder and print bed which could

possibly result in an unsuccessful print.

To clean the glass print bed, please remove carefully after each print. Ensure

that your model and any remnants of lament material have been removed,

and then carefully wipe the bed with a clean cloth and warm water or specic

glass cleaning solution. This should remove any residual adhesive left behind

from the Z-Axis sheets. Please then ensure that the bed is dry before applying a

new Z-Axis sheet prior to printing. For how to apply and remove please see our

instructional video.

28

Page 29

POLAROID 3D PRINTER GUARANTEE

12 MONTH GUARANTEE

The manufacturer guarantees this printer against any defects in both material and workmanship

for a period of 12 months (unless minimum statutory requirements otherwise) from the date of

purchase. It does not include wear and tear, and is based on fair use with regular maintenance.

In order to validate this guarantee you must provide your details at the point of downloading the

Polaroid Prep Software.

Should any defect(s) be discovered, please rst visit our online troubleshooting support page at

howpolaroidareyou.com/support. However, if a problem occurs during the 12 month period that

cannot be rectied remotely or on site by the manufacturer’s technical team then you may be

requested to return the printer. The information overleaf outlines the process you must follow in

order to return your printer for repair.

Your serial number and proof of purchase will be required in order to process your claim.

Please ensure you include a copy of your sales receipt when you return the product.

A SIMPLE RETURN PROCESS

Contact the manufacturer’s customer service team Monday to Friday between 8:30-17:30

(GMT) by emailing support@howpolaroidareyou.com . You will be provided with a Returns

Transfer Number (RTN).

Clearly write the RTN on the outside of the box or packaging, next to the shipping label. The

manufacturer will not be responsible for non-traceable packages or packages sent without a

valid RTN on the outside of the packaging.

This guarantee is not valid if the product has been damaged by accident, electrical fault, through

misuse, abuse, or failure to provide reasonable care as outlined within the User Guide. If the product

has been altered without written authorisation from the technical team then the guarantee will not

be valid.

All implied guarantees, including any implied guarantee of tness for any particular purpose, are

limited in duration to 12 months from the date of original purchase. In no event will the manufacturer

be responsible for consequential damages resulting from the use of this product.

The above limitation or exclusion may not apply to you to the extent that applicable law may not

allow the limitation or exclusion of liability for incidental or consequential damages.

Using third party software applications or using non-Polaroid lament may invalidate this guarantee

in the event of damage subsequently being caused to the printer.

Tampering with the printer in any way may invalidate the guarantee. Please contact the the

manufacturer team if you have any technical enquiries.

AFTER SALES SUPPORT: The manufacturer have a dedicated team of 3D printing specialists that

are available to help with any problem or question you may have regarding your 3D printer. Please

contact our team via the contact form on our howpolaroidareyou.com/support.

MAINTENANCE: It is important that your Polaroid 3D printer is kept clean at all times. For best

print output it is recommended to keep the extruder nozzle clean and check regularly for any residual lament build up, as these may cause subsequent unsuccessful prints. Please contact support@

howpolaroidareyou.com for guidance on how to remove any such build up.

29

Page 30

CERTIFICATIONS AND COMPLIANCE

CERTIFICATION

The Polaroid ModelSmart 250S printer is compliant under the following applicable EU certications:

WEEE Directive: As both manufacturer and distributor the Polaroid 3D printer team is WEEE

compliant in all applicable EU countries in which the product is supplied. This ensures that our

responsibilities are fullled in regards to the electronic waste that is generated through the

sale of the Polaroid 3D printers and consumables.

Low Voltage Directive 2006/95/EC: This Directive allows electrical equipment to be

approved by any EU member country, by provision of a set of common broad objectives,

covering safety regulations that the product is tested against. The Polaroid ModelSmart 250S

printers are tested and approved under this Directive.

EMC Directive 2004/108/EEC: This is a Directive that all electronic items must be tested

against. It aims to minimise the side effects that can sometimes be seen when electrical devices

are interconnected or close to each other; e.g. the interference that you sometimes hear when

your mobile phone is near your TV or radio. The Polaroid ModelSmart 250S printers are tested

and approved under this Directive.

RoHS Directive 2011/65/EU: This is the Restriction of Hazardous Substances Directive. Its

purpose is to restrict the use of six hazardous materials in the manufacture of various types

of electronic and electrical equipment. Each individual component of the equipment has been

tested in order to ensure that the Polaroid ModelSmart 250S printers are approved under this

Directive.

Green Dot Packaging Waste Directive - 94/62/EC: This directive ensures that manufacturers

whose products use packaging are responsible for either recovering their own packaging waste,

or contributing to the cost of recovery and recycling of such waste. The Polaroid 3D team is

registered and compliant against this directive across the applicable European countries.

CE Marking: Following all of the above required legislation and certication enables each of

the Polaroid ModelSmart 250S printers to proudly carry the CE Mark which conrms that they

have been approved under each of these Directives.

30

Page 31

TROUBLESHOOTING

We hope that you have happy and trouble-free printing. But should you have any questions

about anything, take a look at our FAQs and Troubleshooting questions below or to our website

howpolaroidareyou.com/support to see if we can help. If you still do not nd a solution, please

feel free to contact our team via our Contact Form.

Question 1. I can’t unload the filament from the extruder

To unload the lament from the printer please follow the ‘Change Filament’ process via the LCD

main menu.

If this does not successfully unload the cartridge, please wait until the nozzle has fully cooled before

carefully reaching inside the printer to remove the plastic tubing from the top of the orange push-

tting for the nozzle.

Once the plastic tubing has been removed, please follow the ‘Change Filament’ process again to

retract the lament, whilst gently pulling the lament (by hand) from the top of the printhead. Try

this process a maximum of two times should the rst time be unsuccessful.

If the second retraction still hasn’t freed the lament, please follow the ‘Change Filament’ process

again, but when asked if lament is currently loaded, select ‘No’. This will start the extrusion process

(rather than retraction) which will hopefully loosen and free the lament.

Once you see lament being extruded (please only try this process a maximum of two times), please

try the retraction process once again. The lament should now be loose and unload successfully.

If the above process is not successful please contact us via our online Contact Form and one of

our customer service team will guide you through a resolution.

Please remember to re-attach the plastic tubing into the orange push-tting before commencing

your next print.

Question 2. I can’t get the printer to extrude any filament

If you are trying to print but no lament is being extruded, please follow the ‘Change Filament’

process via the LCD screen, selecting ‘No’ when asked if a cartridge is already installed. This will start

the extrusion process. You have the option of repeating this process if the rst time is unsuccessful.

Should this not resolve the problem, please carefully reach inside the printer (once completely

cooled) to remove the plastic tubing from the top of the orange push-tting for the corresponding

nozzle that you are trying to extrude.

Please then repeat the extrusion process as above, but this time gently apply pressure by pushing

the lament downwards into the top of the printhead. This should then allow the lament to freeow and extrude correctly.

Should the above process not resolve the problem please contact our team via the online Contact Form.

Question 3. I can’t read my full file name from the LCD

The LCD screen is limited to 8 characters for each le name. Therefore in order to easily locate the

le you require please save your model les with a name that meets this criteria.

31

Page 32

Question 4. I am having problems removing my model from the print bed

Please ensure that you are using the Polaroid Z-Axis sheets when printing with a Polaroid 3D

printer.

These should be applied to the bed by removing the backing sheet (clearly labelled this side down)

and apply the revealed adhesive side to the print bed. Then remove the top sheet, leaving the

adhesive layer exposed.

This will mean that when your model is completed it will be afxed to the bed.

In order to remove the Z-Axis sheet and therefore your model, please start by removing all 4 corners

of the sheet from the bed, leaving it remaining stuck just underneath your model. Then simply take

hold of all four corners and rmly pull away from the glass bed. This will remove both the sheet

and the model.

All you then need to do is peel off the sheet from your model.

You may nd that a small amount of adhesive residue is left on your model from the Z-Axis sheet.

You can easily remove this by using any general purpose household cleaner.

Question 5. I have a filament jam. My printer is printing air, no filament is

being extruded

Firstly please try to unload the lament from the printer using the ‘Change Filament’ process via

the LCD main menu for the cartridge that you wish to unload.

If this does not successfully release the lament jam, please wait until the nozzle has fully cooled

before carefully reaching inside the printer to remove the plastic tubing from the top of the orange

push-tting for the corresponding nozzle that you are trying to unload.

Once the plastic tubing has been removed, please follow the ‘Change Filament’ process again to

retract the lament, whilst gently pulling the lament (by hand) from the top of the printhead. Try

this process a maximum of two times.

If the second retraction still hasn’t freed the lament, please follow the ‘Change Filament’ process

again, but when asked if lament is currently loaded, select ‘No’. This will start the extrusion process

(rather than retraction) which will hopefully loosen and free the lament.

Once you see lament being extruded (please only try this process a maximum of two times), please

try the retraction process once again. The lament should now be loose and unload successfully.

If the above process is not successful please contact us via our online Contact Form and one of

our customer service team will guide you through a resolution.

Please remember to re-attach the plastic tubing into the orange push-tting before commencing

your next print.

Question 6. I have items missing/damaged when unpacking my printer for

the first time

Please get in touch with one of our team via the online Contact Form and let us know what is

missing or damaged. Please note that you will need to provide us with your serial number and a

proof of purchase for the printer so that we can follow this up for you.

32

Page 33

Question 7. I only want to print a small object, why do I have to use a full

size Z-Axis sheet?

At the start of each print, the printer performs an auto-calibration process to ensure that the bed

is level and that the extruder is perfectly positioned to print your model successfully. This requires

a small switch to be lowered to each of the four corners of the bed to measure the exact location

and for printing to begin at the correct position. The height of the Z-Axis sheet plays an important

point in this measurement; as if the bed isn’t calibrated to include this height then the print could

possibly fail. Therefore each of the 4 touch-points need to measure the same height as the central

area where the print itself will take place. In order to achieve this, the Z-Axis sheet needs to cover

not only the central print area, but the 4 corners as well.

Question 8. Why did the printhead extrude a different colour filament from

what is installed on the very first extrusion?

Before the Polaroid 3D printers are despatched to you, they undergo quality control testing to

ensure that they are performing perfectly for you. Part of this test is to print a test model on the

printer to conrm that the quality output matches our pre-determined standard.

If you are seeing a small amount of a different colour lament extruded on the very rst time you

print with your printer it is because a different colour lament was used during this testing phase.

Please follow the ‘Change Filament’ process before printing and select ‘No’ when asked if a cartridge

is already installed. This will extrude a small amount of lament and conrm that the printer is

ready to print. Please repeat this process until the lament that you see extruded is the correct

lament for the cartridge that you have installed. This should happen on the second extrusion, i.e.

you only need to press the ‘repeat process’ button once.

Question 9. My prints are warped across the base

If you are seeing a slight warping across the base of your model when completed, (meaning that

the model you have printed does not sit at) please rstly ensure that you have a Z-Axis sheet

applied to the bed in order for the model to adhere during the rst layers of printing.

If you have a Z-Axis sheet applied and you still have some warping then please double check your

settings when saving your print le. Please ensure that you have selected the correct print material

when saving the le as this will ensure that the extruder is heated as it should be.

If you have conrmed that your settings are correct, you have the Z-Axis sheet applied and you are

still experiencing some warping then please use the ‘brim’ function within the Advanced Settings.

This will print a small amount of lament as a ‘brim’ around the external diameter of your model.

The purpose of this is to retain heat within the area between the brim and the model itself to allow

the lament to adhere to the bed and remain at a temperature that will help it to not contract (which

causes the warping) while the remaining print is completed.

Question 10. I am trying to print a model that is the maximum size of the

print area, with a brim, but it isn’t printing successfully

If printing with a brim, the brim must be included within the maximum print area. This will mean

that your model must be slightly smaller than the print area to allow for the brim.

Please note that the brim itself needs 5mm around the entire perimeter of your model so please

reduce any model that is the maximum print size by this amount on each side.

33

Page 34

Question 11. I am seeing a Windows Error message when connecting the

printer to my PC

When connecting the printer to a Windows PC, upon connection Windows will automatically search

your PC for a hardware device driver that is required in order to install the printer. If it is unable to

locate and install this device driver automatically, Windows will notify you, with this message. In

this instance please follow this link to download the hardware device driver onto your PC. Once

downloaded, please double click the le to begin the installation. This is a simple and straightforward

process and will then allow you to successfully use your Polaroid ModelSmart 250S 3D printer.

Question 12. I am trying to download Polaroid Prep Software but it is not

recognising my serial number

Firstly, please double check that you have entered the serial number correctly.

If you have conrmed this and you are still experiencing problems then please get in touch with one

of our team via the online Contact Form and we will rectify the problem for you or alternatively

provide you with a temporary serial number as an alternative. Please do note however that you will

need to provide us with a proof of purchase for the printer relating to the serial number that you are

experiencing difculties with.

Question 13. If I pause my print why does it carry on printing for a few

seconds after I have opened the door?

The printer will continue printing until it has nished the last command it has received, which may

include several movements of the printhead. Once it has completed this set of commands the

printhead will stop and the bed will lower slightly and the head will move to the front right corner

of the printer. Please do not reach inside the printer until the head and bed have nished moving.

Even then please be aware that the nozzle on the printhead will still be very hot.

Question 14. After uninstalling a cartridge I placed the new cartridge on the

holder as requested but the message for the next step disappeared from the

LCD screen and was replaced by a ‘New Cartridge’ message. How should I

proceed?

If you were in the process of installing a new cartridge and the message that you were following

was replaced with a ‘New Cartridge’ screen please click the ‘OK’ button. This will then take you to

the Main Menu.

From here please follow the ‘Change Filament’ process but this time please select ‘No’ when it asks

if there is already a cartridge installed. This will ensure that it will not uninstall the lament you

have just attached.

After feeding the lament into the printer as instructed you should see the lament extruding. This

means you are ready to print.

34

Page 35

Question 15. I am trying to install a cartridge but it doesn’t seem to be

feeding through and I can hear a knocking sound from the printer

Should you hear a gentle knocking sound when trying to feed through a new lament it means that

the lament hasn’t reached the printhead correctly.

Please follow the ‘Change Filament’ process from the Main Menu and select ‘Yes’ when asked if

a cartridge is already installed. This will retract the lament from the printhead. If you pull on the

lament gently as you do this you should feel this retraction.

This will free the lament from the printhead to allow you to reinstall. To do this, simply continue

following the installation process by feeding the lament through once again. This time the lament

should successfully feed through and extrude.

If you have tried this and are still hearing the same noise, please contact our team via the online

Contact Form and they will guide you through a solution.

CONTACT DETAILS

EBP Group Ltd. (Polaroid 3D Printers)

26 Chase Road

Park Royal

London

NW10 6BB

Sales

enquiries@howpolaroidareyou.com

Support

howpolaroidareyou.com/support

support@howpolaroidareyou.com

Customer Service

+44 (0)20 8838 6888

35

Page 36

ModelSmart 250S

This product is manufactured, distributed and sold by Environmental Business Products Ltd. Polaroid, Polaroid & Pixel, Polaroid Color Spectrum, and Polaroid Classic Border Logo are trademarks

of PLR IP Holdings, LLC, used under license. PLR IP Holdings, LLC does not manufacture this product or provide any Manufacturer’s Warranty or support. ©2015 All Rights Reserved.

36

Loading...

Loading...