Page 1

C316 ORP Controller

with pH Display, 24 Volt

O WNER’S MANUAL

Page 2

Table of Contents

I. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

III. Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

IV. Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A. Timed Feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

B. Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . .5

V. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

A. Feeding Systems . . . . . . . . . . . . . . . . . . . . . . . . . .6

B. Controller Installation . . . . . . . . . . . . . . . . . . . . . . .6

C. Flow Cell Installation . . . . . . . . . . . . . . . . . . . . . . .7

D. Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . .11

E. Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

F. Start-up Operations . . . . . . . . . . . . . . . . . . . . . . .11

G. Sanitizer Settings . . . . . . . . . . . . . . . . . . . . . . . . .12

H. pH Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .13

VI. Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

VII. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A. Setting Feed and Delay Times . . . . . . . . . . . . . . .15

B. Feed Light Activation . . . . . . . . . . . . . . . . . . . . . .15

C. Out-of-range Indicator . . . . . . . . . . . . . . . . . . . . .16

D. Manual Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

E. Winterizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

VIII. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

A. Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B. Cleaning the Sensor Tips . . . . . . . . . . . . . . . . . . .17

C. Checking the ORP Sensor . . . . . . . . . . . . . . . . . .18

D. Checking the pH Sensor . . . . . . . . . . . . . . . . . . .18

IX. Erosion Feeder Operating Tips . . . . . . . . . . . . . . . . .19

X. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

XI. Guidelines for Using ORP for Water Maintenance . . .22

XII. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Page 3

POWER

ON

OFF

MAINTAIN

PROPER pH

FEED

MANUAL

pH

ADJ.

FEED

C-316 ORP Controller w/pH Display, 24 V

6

.

6

6

.

8

7

.

0

7

.

2

7

.

4

7

.

6

7

.

8

8

.

0

8

.

2

8

.

4

¥

2

0

0

¥

3

0

0

¥

4

0

0

¥

5

0

0

¥

6

0

0

¥

7

0

0

¥

8

0

0

¥

9

0

0

¥

1

0

0

0

¥

1

0

0

D

E

C

R

E

A

S

E

¥

I

N

C

R

E

A

S

E

O

R

P

p

H

2

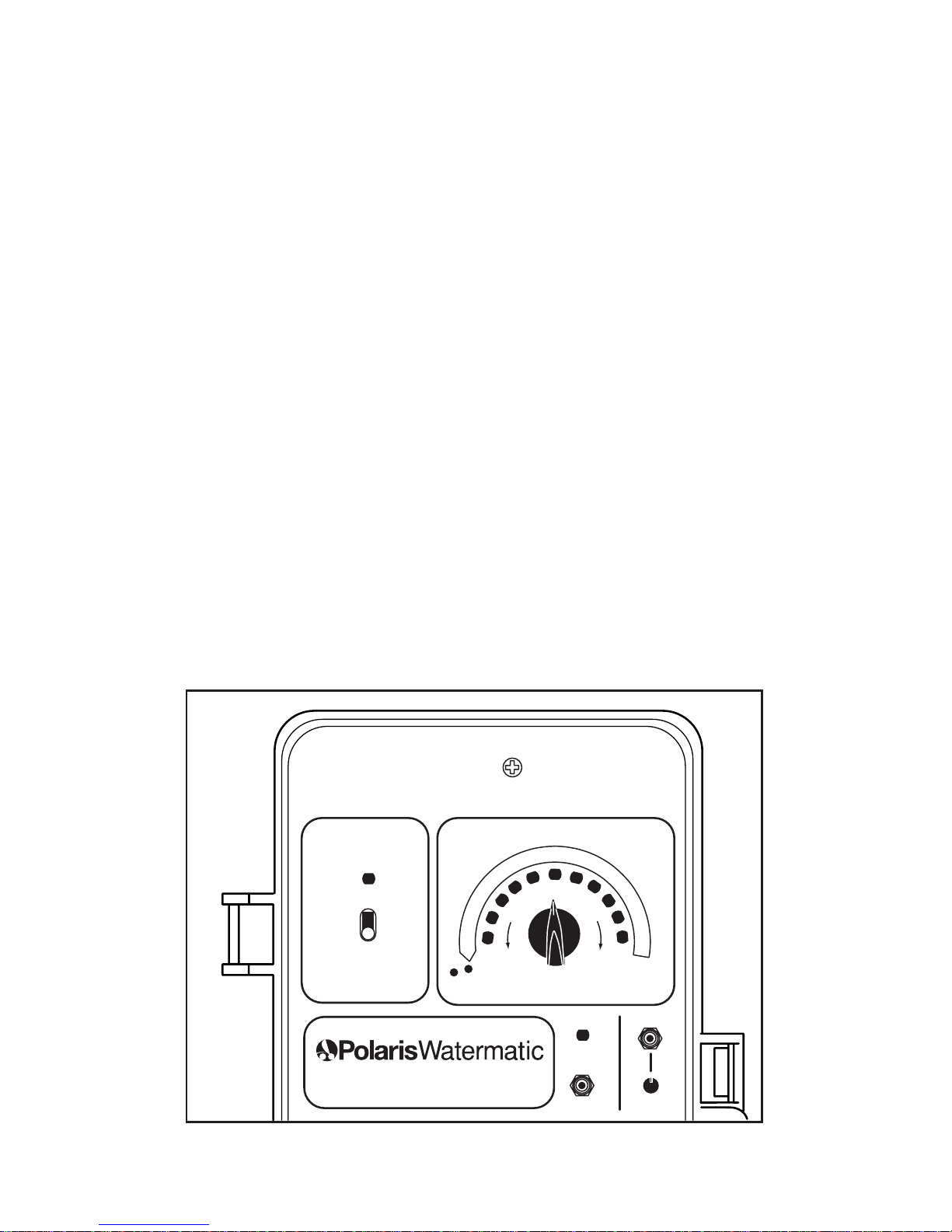

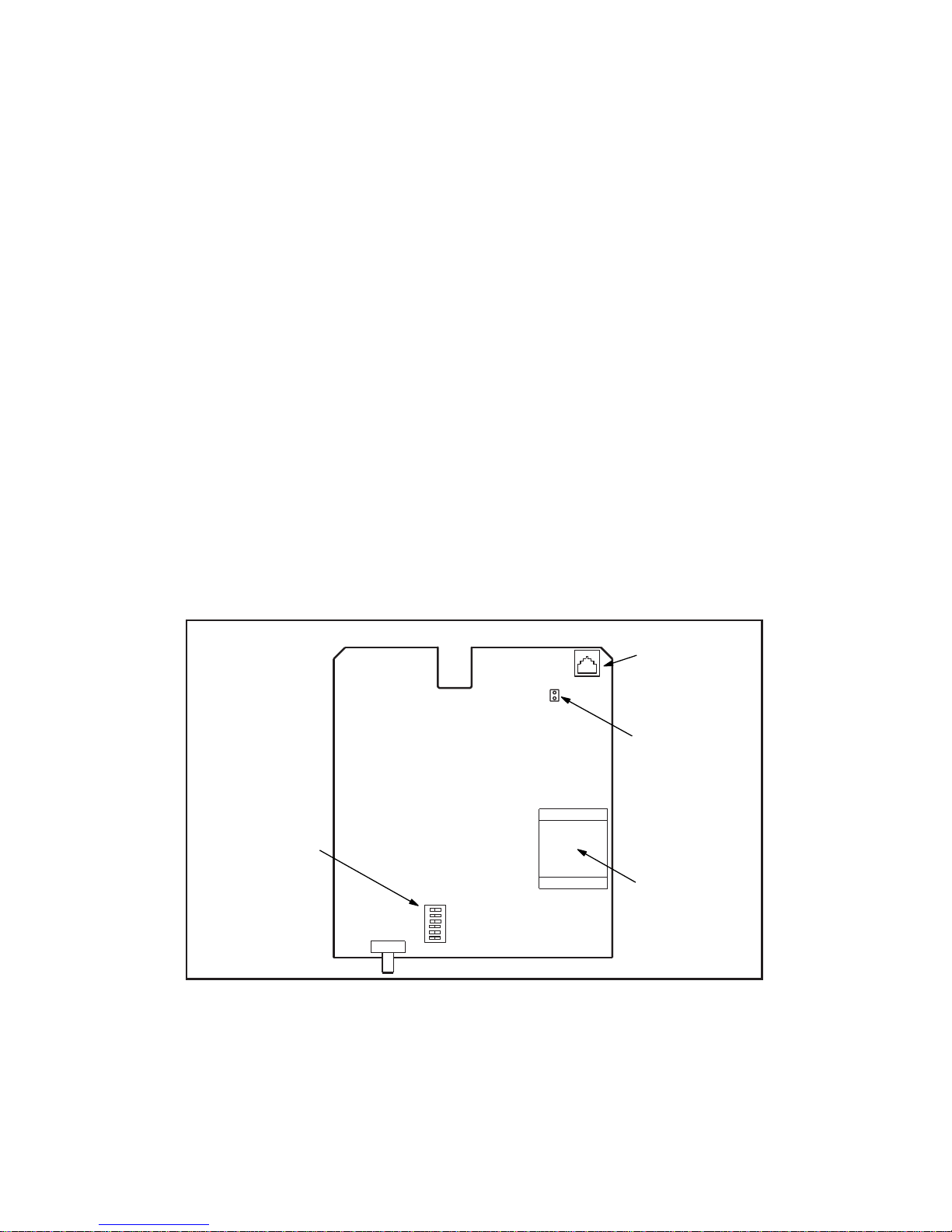

I. Introduction

For your protection, read all instructions carefully before

installing or operating this automatic controller.

The Polaris Watermatic®C316 24-Volt Controller is designed to

automatically monitor and maintain the sanitizer level and pH

balance in swimming pools, spas and any circulating water system that requires water chemistry management.This controller

is designed for easy installation and simple operation, and is

used with tablet erosion feeders.

During the filtration cycle of the pool or spa, the sanitizer level

and pH balance are maintained by a constant measurement of

the ORP (Oxidation-Reduction-Potential) and pH balance of

the water. Levels are displayed on the controller’s ORP and pH

light bar arrays (see Figure 1).If the sanitizer level (ORP) falls

below a predetermined set point, the controller activates the

chemical feeder until the preset level is reached.The pH is

maintained in a similar manner.

Figure 1

Page 4

3

II. Specifications

pH Range: 7.0 - 8.2

ORP Range: 100 mV to 1000 mV

Input Power: 24 VAC 50/60 Hz, 40 Volt Amp

(transformer included)

Controller Power: Less than .5 Amp internally fused

Output Power: 24 VAC 50/60 Hz, 5 Amp fuse

Display: Light Bar Array — Yellow for ORP,

Green for pH

Operating

Temperature: 40°-120° F

Sensors: ORP: platinum combination with 10'

cable; pH: glass combination

with 10' cable

Selectable Features:

• Desired ORP settings

• pH calibration

• Safety lockouts for low or high (out of range) ORP levels

• Visual alert and optional audible aler t for self-correcting and

non-correcting conditions

III. Components

The C316 Controller box contains:

• C316 Controller

• ORP Sensor (part #3-270)

• pH Sensor (part #3-260)

•110 V to 24V Plug-in Transformer (part #9-620)

• 1/2" Jaco Compression Fittings (part #2-260)

Recommended (optional) components include:

• Flow Cell Assembly (part #9-700)

Page 5

4

IV. Pre-installation

Before installing the controller, it is impor tant to do a site

assessment and consider where and how you will mount the

unit.The controller should be mounted on a wall or other surface at least ten feet away from the edge of the water and less

than six feet from the GFCI power source.

Once the best site is selected, obtain all necessary mounting

screws or anchors (no mounting screws are provided with

controller). Seal-tight or strain relief connectors for the electrical

access holes in the control box and electrical wire will also

be needed.

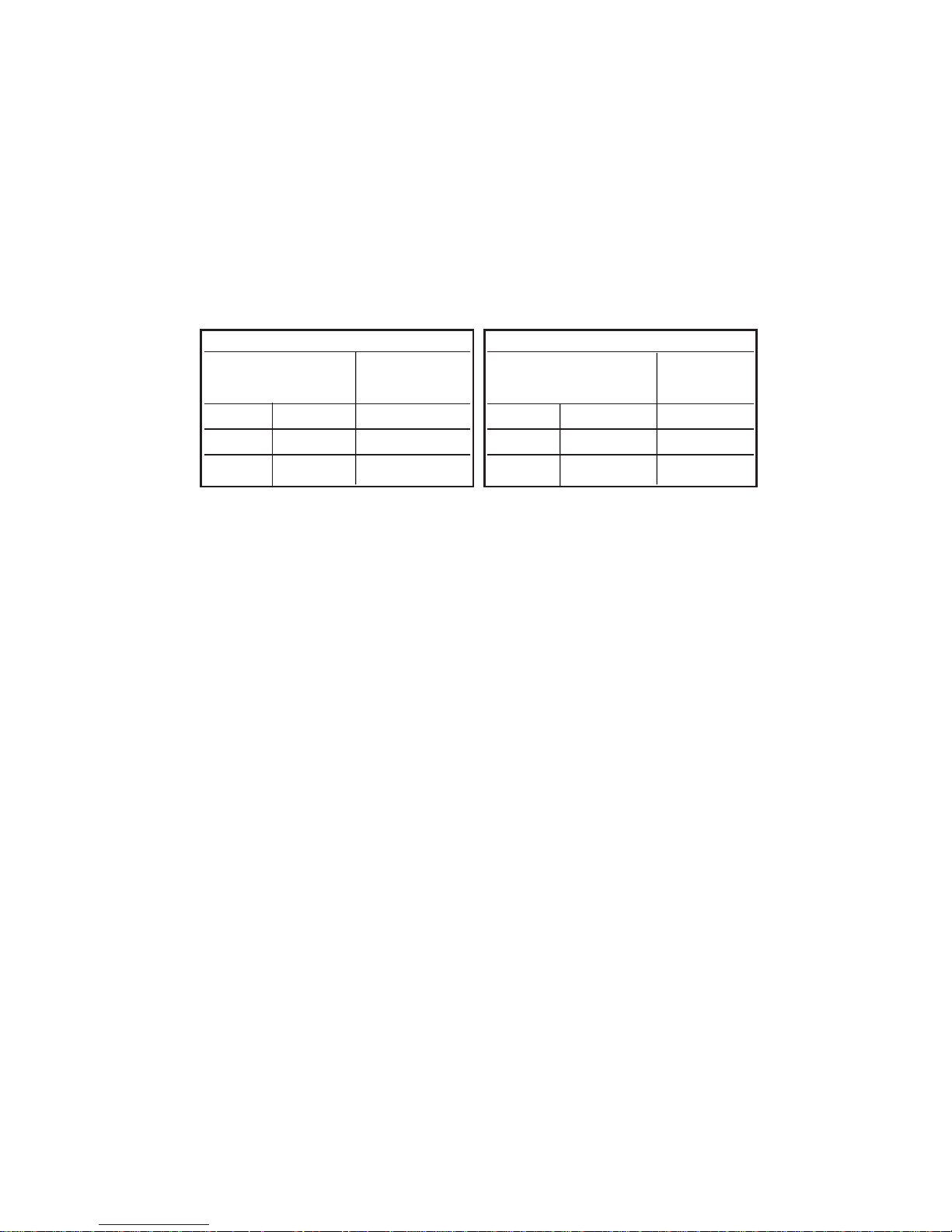

A. Timed Feeds

The controller was designed with the flexibility to be adjusted

to meet individual user applications. Feed times and aler ts can

be adjusted through optional dip switch settings.To access and

adjust the dip switches, located on the back of the board (see

Figure 2), disconnect the controller from the power source and

remove the three mounting screws.

The timed feed and delay option allows the use of erosion feeders on spas and small bodies of water without spiking. An automatic shut down feature that can be adjusted for small pool/spa

applications. Additionally, the timed feed allows the injection of

sanitizer before the ORP/pH sensors.

Pool Spa

For Remote

Monitoring

Flow Jumper

Transformer

OFF ON

1

2

3

4

5

6

Dip Switches

Figure 2

Page 6

5

B. Switch Settings

1. Dip switches #1 and #2 control the feed times. Feed times

vary depending on whether the controller is in the pool or

spa mode.

Note: Once the settings have been modified, move the

Pool/Spa Switch on the front of the controller to the appropriate mode to activate the changes. Refer to Figure 4.

2. Dip switch #3 controls the delay time between feeds.

OFF 30 sec.

ON 7 min.

3. Dip switch #4 must be in the OFF position.

4. Dip switch #5 controls the low ORP shutoff.

The controller is set to shut down when the ORP level drops

below 100 mV.This prevents overfeeding if there is an ORP

sensor failure.

Moving switch #5 to the OFF position will override this

function.This override might be required in extremely small

bodies of water where sudden organic loads dissipate the

sanitizer in a very short time.

5. Dip switch #6 has no assigned function.

Pool Position

Dip Switch Feed

12 Time

OFF ON 1 min.

ON ON 5 min.

OFF OFF 10 min.

Spa Position

Dip Switch Feed

12 Time

OFF OFF 1 sec.

ON OFF 5 sec.

OFF ON 10 sec.

Page 7

6

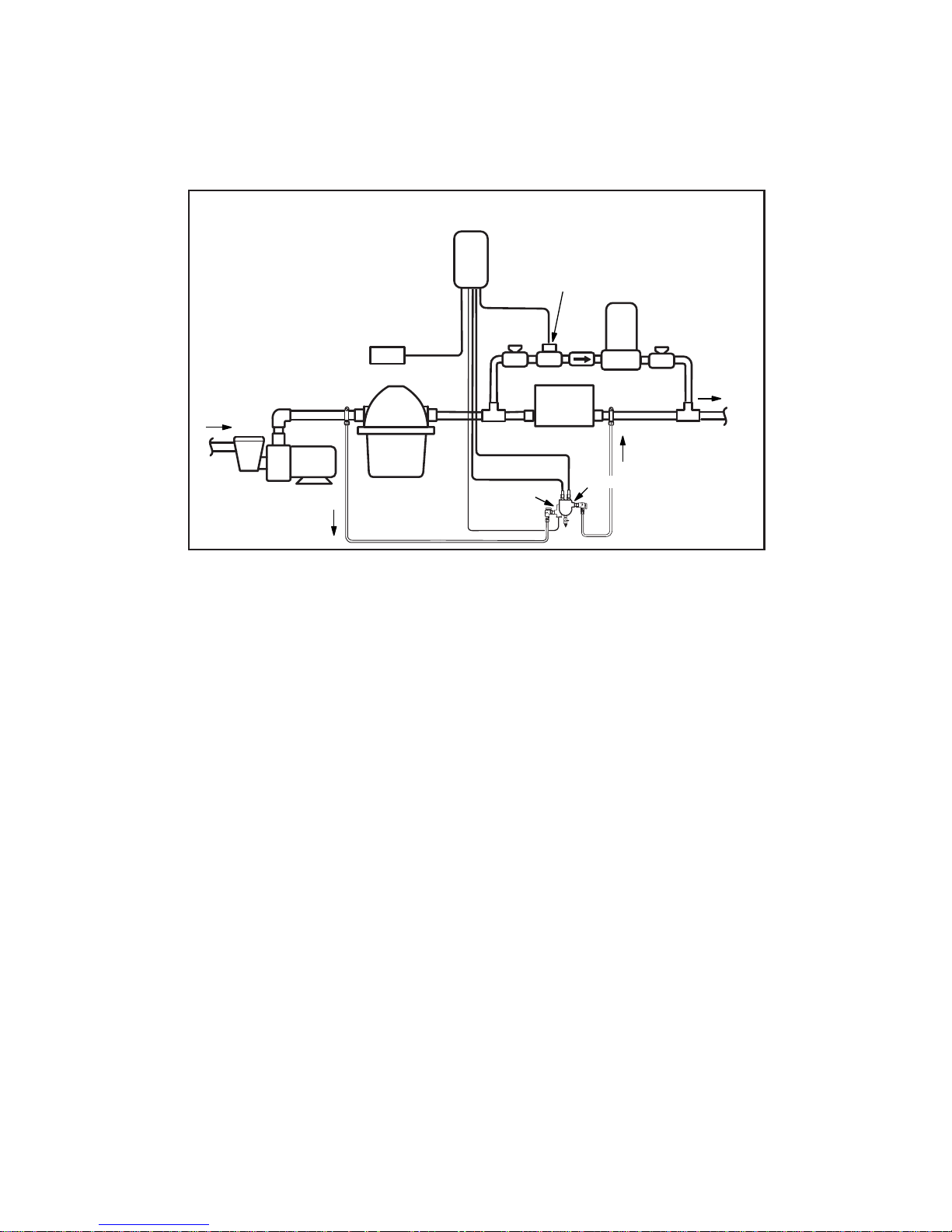

V. Installation

The feeder should be installed before the controller.

A. Feeding System

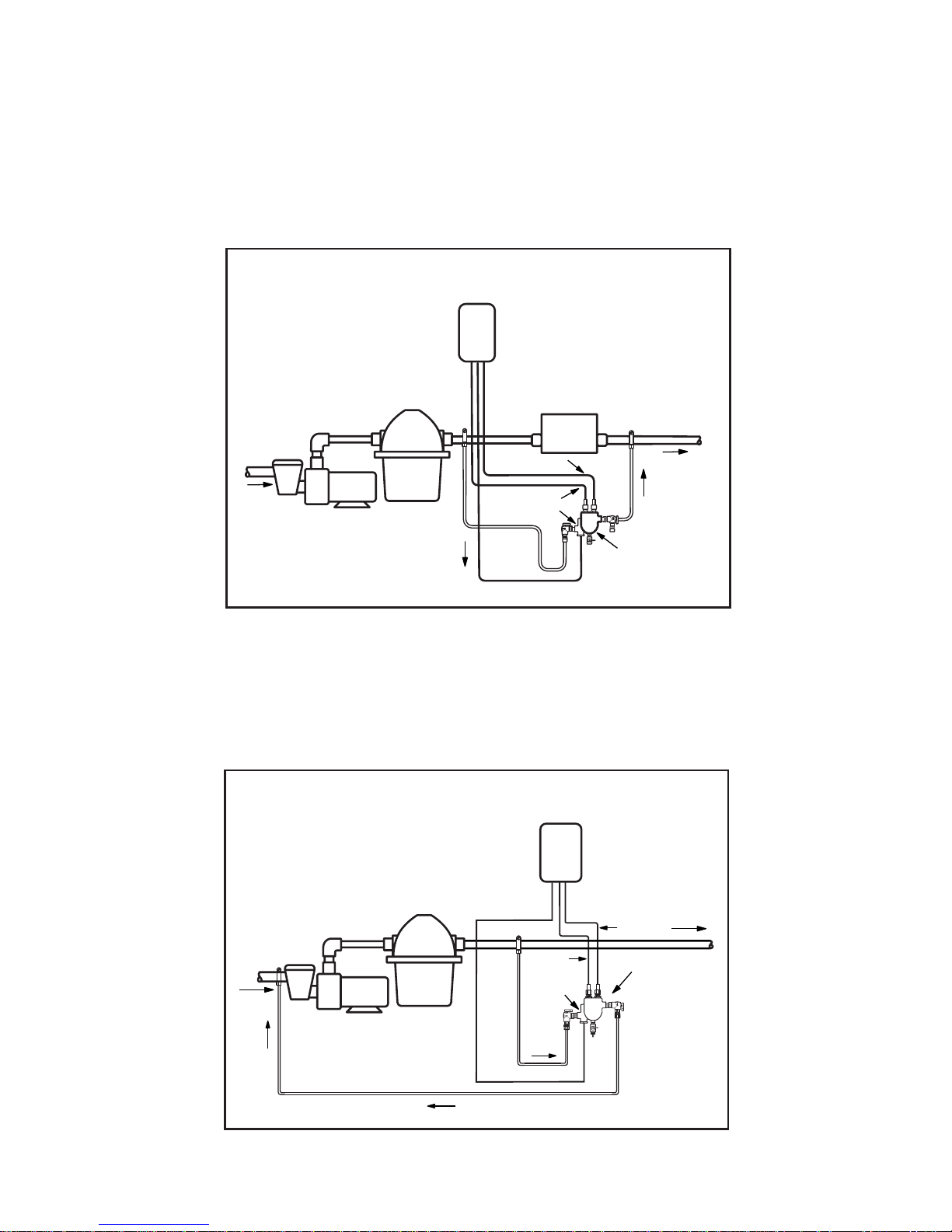

Install the feeding system as shown in Figure 3 or in accordance with the installation instructions that were provided with

the feeder.

B. Controller Installation

The voltage on the feeder solenoid valve must match the output

voltage of the controller. The C316 Controller must be matched

with a 24V solenoid valve.

1. Turn off the power to the filter pump at the breaker box.

2. Remove the Caution Plate at the bottom of the controller by

removing the two screws.

3. To avoid damage, remove the controller module from the

controller box by removing the BNC connector(s) and the

faceplate screws.

4. Drill or cut out the electrical access holes that are best

suited for your installation (using a hammer can damage the

controller). Install seal-tight or strain relief connectors in the

access holes and replace the module.

5. Mount the controller on a wall or surface within eight feet of

the feeder.

316

Controller

110V to 24V Plug-in

Transformer

To Pool

Heater

pH Sensor

Filter

Pump

From Pool

Flow

Flow

Switch

Flow Cell

Check

Valve

24V Solenoid

Valve

Figure 3

Page 8

7

6. A plug-in 110v to 24v transformer (part #22-3190) is

provided with the controller. Locate the nearest 110V

standard outlet. Using a minimum of 20 to 22 gauge PVC

jacketed wire, connect the controller to the transformer that

will plug into the 110V outlet.Thread the wire through the

controller seal-tight or strain relief connecter and hook it to

the line side of the terminal strip and transformer.

6. Connect the controller output using a minimum of 20 to 22

gauge wire through the compression fitting to the solenoid.

7. Replace the Caution Plate at the bottom of the controller.

8. We recommend that the sensor be installed in the Flow Cell

Assembly (part #9-700), available from Polaris.

If you do not use the flow cell assembly, you can install the

sensor using the compression fitting that comes with the

controller.The fitting should be installed in a vertical position

on the pressure side of the pool circulation system. It should

be located after the filter and before the heater, and it can

be installed using a tee, saddle tee or a 1/2” NPT tap.

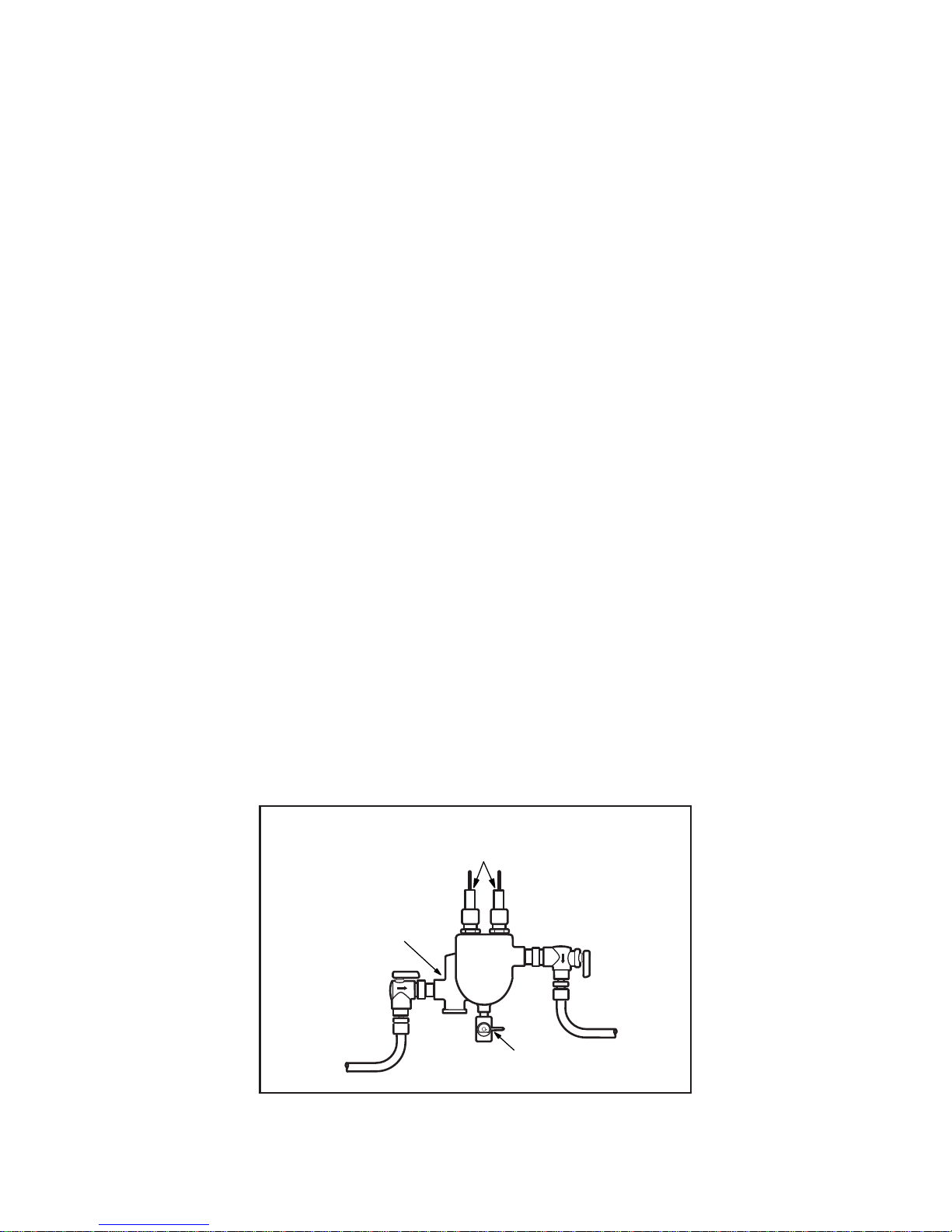

C. Flow Cell Assembly Installation (Optional)

If using the flow cell assembly, locate the assembly within eight

feet of the controller and mount it using the brackets provided.

The flow cell must be plumbed so the pressure difference

between the inlet and outlet is sufficient to ensure flow through

the flow cell. It is also desirable to have filtered water pass over

the sensors to minimize cleaning.

Flow Switch/

Flow Indicator

Sample

Port

Inlet

Ball

Valve

Outlet

Compression Fittings

with Sensors

Flow Cell

Assembly

Page 9

8

There are three suggested methods to install the flow cell.

1. Plumb the inlet to the flow cell after the filter and plumb the

outlet of the flow cell after the heater using the saddle

clamps provided. See the Pressure Differential Installation

diagram. Fittings for 1/4" NPT taps are included.

2. Plumb from after the filter to before the pump. This ensures

excellent flow but the flow will need to be adjusted so the

sensors are not subjected to a suction environment. See the

Pressure Suction Installation diagram. Open the sample

port (see Flow Cell Assembly drawing) to verify that the

water is flowing freely.

To Pool

From Pool

Flow

Flow

Cell

pH Sensor

ORP Sensor

Filter

Heater

Pump

Controller

Flow Switch

pH

Controller

To Pool

Flow

Flow

Switch

ORP

Flow Cell

From Pool

Flow

Filter

Pump

Pressure Differential

Installation

Pressure Suction

Method

Page 10

9

3. Plumb from before the filter to after the heater, using an

inline filter to minimize debris coming into contact with the

sensors. See the Pressure Differential Alternative

Installation diagram.

Note: Solar systems and other factors can alter pressure

differentials in a system, adversely impacting flow through the

flow cell.

Controller

To Pool

Heater

pH Sensor

Filter

Pump

From Pool

Flow

Flow

Switch

Flow Cell

1/8

NPT

Strainer Assembly #8-110

Pressure Differential

Alternative Installation

Page 11

10

The flow cell comes fully assembled in the box. It is setup to

use with the 3/8" tubing provided; however, other sized tubing or

1/2" hard plumbing can be used.To use alternative tubing,

remove the 90° on/off valves and plumb according to the application.

1. If using a saddle clamp, drill a 7/16" hole in the pipe on

the pressure side of the pump.Thread the 1/8" Jaco fitting

(#2 in diagram below) through the clamp (#3) and place the

nylon jam nut (#4) onto the Jaco fitting.Slide the pipe seal

washer (#5) onto the end of the Jaco fitting.Inser t the completed assembly into the hole in the pipe and tighten the

clamp. Test for leaks.

If the pipe is larger than 2" in diameter, two clamps joined

together will be required per each hole.

If using a pipe tap, drill a 7/16" hole and tap a 1/4" NPT

hole. Apply RTV silicone, teflon stick or teflon paste to the

threads on the Jaco fitting and screw securely into the pipe.

Test for leaks.

2.. Cut the tubing (#1) to the appropriate length. Slightly loosen

the Jaco fitting in the pipe and insert the tubing into it. Take

the free end of the tubing and insert it into the Jaco fitting

on the flow switch side of the flow cell.

3. Complete these steps for the return side of the flow cell.

Use the appropriate remaining par ts to complete this task.

Take the free end of the tubing and insert it into the Jaco

fitting on the outlet side of the flow cell.

1

5

3

2

4

Page 12

11

D. Sensor Installation

Carefully unpack the ORP and pH

sensors and remove the plastic protective cap(s) from the sensor tip(s).

Store the protective cap(s) inside

the controller enclosure for future

use when winterizing or reshipping.

Slide the sensor inside the compression fitting on the flow cell assembly

or the main pool line so that the

sensor tip is below the water line in

the pipe.Tighten the nut of the compression fitting until it is finger tight.

DO NOT USE A WRENCH.

Attach the sensor connector(s) to

the proper fittings on the controller

box. (see Figure 4, #7 and #14).

E. Electrical

Use the plug-in transformer provided to attach to the 110V outlet. Low voltage (24V) wiring can be run from the transformer

output to the controller input. Low voltage wiring can then be

run from the controller output to the 24V solenoid valve.

F. Start-up Operations

1. Determine the free sanitizer level of your swimming pool or

spa using a DPD test kit. It should be between 1.0 and 3.0

ppm—adjust if required.

The controller will not operate if the sanitizer level is below

0.2 ppm (below 100 mV).

2. Check the pH level of your pool or spa with a test kit. The

pH should be maintained between 7.2 and 7.6 to maximize

sanitizer efficiency and ensure the accuracy of the controller.A pH level above or below this range will cause

inaccurate sensor readings. High or low pH levels can also

cause irritation to swimmers as well as other problems

associated with the pool and equipment.

Coil Extra

Sensor Cable

Externally

Controller

Sensor

Compression

Fitting

PVC Tee

Sensor Tip

Page 13

12

3. Make sure the power switch (Figure 4, #2) is off and the

ORP selection knob (Figure 4, #9) is rotated counterclockwise to the lowest setting.

4. Turn on the filter pump and then the controller power switch.

The red power light (Figure 4, #1) and indicator lights on the

controller light bar array (Figure 4, #8) will come on.

5. Leave the system running for approximately five minutes so

the sensors can get an accurate reading from the pool.

6. Check for leaks and correct as necessary.

G. Sanitizer Settings

Be careful when adjusting the ORP set knob.The dial is

extremely sensitive in the 600 to 800 mV range and an adjustment of 50 mV could change the sanitizer level by several parts

per million.

1. The average pool should have a sanitizer level between

1.0 and 3.0 ppm.This equates to approximately 650 mV on

the controller’s ORP light bar array. If the pool has been

balanced correctly, the lights illuminated on the ORP light

bar array should be near 650 mV. Adjust the ORP selection

knob to point at the illuminated light on the ORP light bar

array. If more than one light is illuminated, set the knob to

point in between the two lights.

To maintain a higher sanitizer level, set the selection knob

above the light shown on the light bar array.To maintain a

lower sanitizer level, set the selection knob below the light

shown on the light bar array.

2. Allow the system to operate for 24 hours.

3. With the filtration system running, retest the sanitizer level

using a test kit and adjust the sanitizer selection knob if

necessary. It may require two to three days to accurately set

the controller to maintain the ideal sanitizer level.

4. If the chemistry of the pool or spa water changes (e.g. refill-

ing, significant changes in pH, build-up of total dissolved

solids, additions of other chemicals, etc.), the sanitizer

selection knob may have to be adjusted.

Page 14

13

H. pH Calibration

1. Take a clean sample of pool water and place the pH sensor

into the water sample.

2. Push the pH display button (Figure 4, #10).The yellow ORP

lights on the scale indicator light (Figure 4, #3) will go out

and the green pH scale indicator lights will come on.The

lights on the light bar array now correspond to the readings

on the pH scale.

When the button is pushed, the controller will monitor the

pH for approximately 5 seconds, or for as long as the pH

button is held down, before retur ning to the ORP scale.

3. The pH can be calibrated to match the reading taken by

the test kit by simultaneously holding down the pH display

button and turning the pH calibration set knob (Figure 4,

#11) until the lights on the light bar array indicate the pH

reading of the test kit.

Sanitizer can now be added to the feeder.See the feeder

owner’s manual for instructions.

Page 15

14

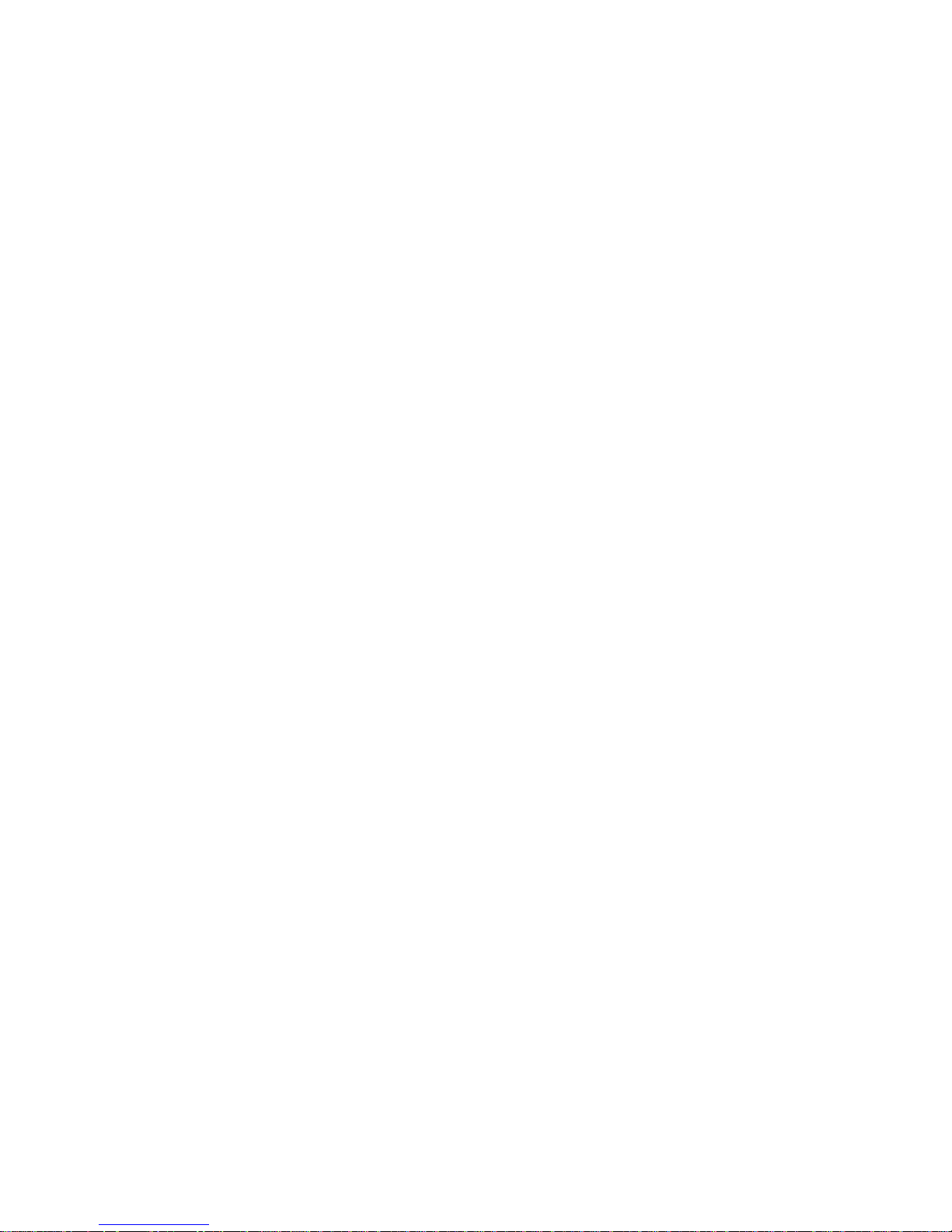

VI. Panel Features

# DESCRIPTION FUNCTION

1Power On Light Indicates controller is on

2Power On/Off Switch Turns on the controller

3 Scale Indicators Indicates which scale is being displayed

4Feed Light Flashes during feed cycle; lit during delay

5 Manual Feed Button Instantly feeds sanitizer

6Terminal Strip 24 volt input/output

7 ORP Sensor Connector BNC jack

8 Light Bar Array Displays the ORP or pH sensor readings

9 ORP Set Knob Selects the desired ORP level of the water

10 pH Display Button Displays the pH reading for 10 seconds

11 pH Adjustment Knob Calibrates pH sensor

12 Pool/Spa Switch Selects applicable delay cycles

13 Fuse Adjust to match feeder solenoid

14 pH Sensor Connector BNC jack

15. Output 24V to solenoid valve

16 Input 24V to controller

SPA

POOL

LINE

OUTPUT

POWER

ON

OFF

MAINTAIN

PROPER pH

FEED

MANUAL

pH

ADJ.

FEED

C-316 ORP Controller w/pH Display, 24 V

1.5 AMP SLO-BLO

HOT COM. GND HOT COM. GND

F

U

S

E

F

U

S

E

F

U

S

E

6

.

6

6

.

8

7

.

0

7

.

2

7

.

4

7

.

6

7

.

8

8

.

0

8

.

2

8

.

4

¥

2

0

0

¥

3

0

0

¥

4

0

0

¥

5

0

0

¥

6

0

0

¥

7

0

0

¥

8

0

0

¥

9

0

0

¥

1

0

0

0

¥

1

0

0

D

E

C

R

E

A

S

E

¥

I

N

C

R

E

A

S

E

O

R

P

p

H

12

6

1

2

3

8

9

10

11

4

5

13

14

7

15

16

Figure 4

Page 16

15

VII. Operation

The controller will only operate during the filtration cycle.

A. Setting Feed and Delay Times

1. The controller is preset at the factory with the following feed

and delay times:

Pool Setting:Feed = 1 minute, Delay = 30 second

Spa Setting:Feed = 10 seconds, Delay = 30 seconds

These settings can be adjusted as needed to maintain the

pool balance. To modify the factory settings see PreInstallation, section B.

2. Delays are built into the system to prevent the feeder from

oversanitizing the pool. Once the feeder has dispensed a

dose of sanitizer, the feeder is unable to dispense again for

either 30 seconds or seven minutes.This delay allows the

sanitizer to be circulated through the pool or spa and

returned through the filtration system where the sensors can

test the sanitizer level. After the delay period, another dose

of sanitizer will be dispensed if needed.

B. Feed Light Activation

1. The yellow feed light (Figure 4, #4) flashes to indicate that

the feeder is active and sanitizer is being dispensed. During

feed delays, although no sanitizer is being dispensed. the

feeder is still technically active, so the feed light remains

constantly lit.

2. Do not adjust the set knob while the feed light is on.When

the feed light is on, the lights on the light bar array may

register an inaccurate sanitizer level since the system is still

circulating a dose of sanitizer.

Page 17

16

C. Out-of-range Alert

When the ORP is out-of-range (less than 100 mV) for ten consecutive minutes, the lowest red light on the light bar array will

flash and the controller will not activate the feeder.Depending

on the level of ORP, the manual feed button may be used to

raise the ORP level.

D. Manual Feed

The manual feed button is mainly used to restart the feed cycle

when the system shuts down because the ORP level dropped

below 100 mV (commonly due to an empty feeder or dirty sensor). It can also be used to test the solenoid. It cannot be used

while the feed light is on, i.e.the feeder is active or in delay.

E. Winterizing

If the system is subject to extended shutdowns or is located in

colder climates, it is important to winterize the system.

1. Turn off the main power to the controller.

2. Remove the sensors from the compression fittings.The

sensor tips must be stored in a protective cap or bottle

filled with a liquid solution of one teaspoon salt and

three teaspoons water. Mix the solution thoroughly and

make sure the solution completely covers the sensor tips.

STORE SENSORS IN A WARM PLACE - DO NOT

SUBJECT SENSORS TO FREEZING TEMPERATURES.

3. Empty the system of all water.

4. If the pool or spa has a flow cell assembly installed, drain

the water from the assembly.

5. Remove all material from the feeder and clean all

feeder parts.

Page 18

17

VIII. Maintenance

A. Testing

1. Test the sanitizer and pH levels with a test kit weekly or

more frequently as required by local health codes.

2. Adjust the pH in the pool or spa as needed to maintain a

level between 7.4 and 7.6.

B. Cleaning the Sensor Tips

1. It is important to keep the sensor tips clean to ensure

accurate sanitizer level readings.When the sensor tips

become dirty, the sensors may read lower than actual

sanitizer levels and cause the controller to oversanitize.

Note:A sensor tip coated with scale or oil will not look

visibly dirty.

2. As a general rule, the sensor tips should be cleaned every

two to four weeks for commercial pools and spas, and once

a month for residential pools and spas.Cleaning frequency,

however, can vary from one body of water to another.To

determine the appropriate frequency for your pool or spa,

note the light bar reading prior to cleaning. After cleaning

the sensor, allow a stabilizing per iod of approximately ten

minutes. If the light bar reading is identical to the reading

prior to cleaning, the sensor was not dirty and the time

between sensor cleanings can be increased.

3. To clean the sensor tip, turn off the controller and gently

remove the sensor from the compression fitting.Swirl the tip

for five seconds in muriatic acid (diluted 5 to 1) or white

vinegar, and rinse it in water. DO NOT TOUCH, WIPE OR

BRUSH THE END OF THE SENSOR. For commercial pools

and spas, ever y third cleaning, swirl the sensor tip in a

solution of liquid soap and warm water. Rinse with water.

4. Gently replace the sensors and turn on the controller.

5. Allow the controller to operate for a few minutes to get an

accurate reading. Adjust the selection knob if necessary.

Page 19

18

C. Checking the ORP Sensor

1. The ORP sensor should be checked every six months or

anytime the feeder oversanitizes the water.

2. Clean the sensor tip as noted previously.

3. Place the sensor in a clean glass of tap water. This should

give a reading between 200 and 400 mV. Adding a small

amount of chlorine should cause the ORP level to jump to

between 700 and 800 mV.

If the sensor has been sitting in a high concentration of

chlorine for more than 20 hours, it may pick up a ‘memor y’.

that will not allow it to read below the 500 to 600 mV level.

If this is the case, adjust your controller setting accordingly.

The sensor should return to normal after a week or two

of normal operation.To return it to nor mal functioning more

quickly, place the sensor in a glass of tap water for

72 hours.

4. If the sensor does not respond as indicated, the sensor

should be replaced.

D. Checking the pH Sensor

1. The pH sensor should be checked every six months or

anytime the pH goes out of range or cannot be calibrated to

the test kit.

2. Place the sensor in a clean glass of tap water. Add a small

amount of acid to the glass.The pH reading should drop to

the lowest red light.Then place the sensor in any solution

with a pH above 7.5.The pH reading should move up.

3. If the sensor does not respond as indicated, the sensor

should be replaced.

Page 20

19

IX. Erosion Feeder Operating Tips

•Feeders must be sized properly. When automating an

existing system, multiple feeder may be required.The feeder should be able to attain desired levels in short operating

cycles. Automation becomes ineffective if the feeder must

run for prolonged periods.

• The output of erosion feeders is dependent on the erosion

rate of the tablets.This erosion rate is dependent on the

water flow, contact area on the tabs, and temperature of

the water. Also, bromine tends to erode more slowly

than chlorine.

To maximize output:

1. Fully open all valves into and out of the feeder,.

2. Keep the feeder full at all times.

3. If possible, use small tablets, not large pucks.

• Erosion feeders are designed to maintain levels, not to balance the pool's chemistry. Erosion feeders should not be

used to bring a pool up to the desired levels. Use liquid or

Cal Hypo to raise levels to the desired point. Once the

desired level is reached, the erosion feeder can be used to

maintain these levels.

•Feeders must be located on a separate bypass line with a

check valve between the solenoid valve and the feeder. It

is recommended that a flow indicator be placed in this

bypass line.

• The coil/plunger on the solenoid valve should be

checked periodically for corrosive buildup that could affect

its operation.

• The bypass loop for the feeder may be hooked up from

before the filter to after the heater. If it is, an inline

filter located before the solenoid valve is desirable to prevent debris from entering the solenoid valve.

• Erosion feeders are subject to potting (continued tablet

dissolution when the flow is off). As a result, the sanitizer

concentration in the feeder can be extremely high. When

Page 21

20

the solenoid valve opens, the initial flow from the feeder

may significantly increase (spike) the sanitizer level in a

small body of water. For this reason, it may be desirable to

use the timed-feed feature, which opens the solenoid for a

short per iod, then delays the next feed cycle until the initial

feed is distributed throughout the pool/spa system.

Page 22

21

X.Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

SANITIZER LEVEL Set knob set too low Adjust knob clockwise until the

TOO LOW proper sanitizer level is reached

pH level too low (less than 7.2) Check pH level with a test kit

and adjust as required

Chemical feeder empty Refill chemical feeder

Chemical feeder is clogged Clean and dry feeder measuring

cup assembly

Defective sensor Replace sensor

SANITIZER LEVEL Set knob set too high Adjust knob counterclockwise

TOO HIGH until the proper sanitizer level

is reached

pH level too high (above 7.8) Check pH level with a test kit and

adjust as necessary

Sensor tip is dirty Clean sensor tip

Defective sensor Replace sensor

DISPLAY LIGHTS No power supply Check circuit breaker

OFF

Page 23

22

XI. Guidelines for Using ORP for

Water Maintenance

Q. Why should I maintain a pH level between 7.4 and 7.6?

A. pH levels below 7.4 can cause eye irritation, metal cor-

rosion, etching of plaster, stains, damage to vinyl liners,

and loss of sanitizer. In addition to eye irritation, pH levels above 7.6 can cause cloudy water, scale for mation

and loss of sanitizer efficiency (low ORP).

Q. How do I increase the pH level?

A. Small amounts of basic (alkaline) chemicals such as pH

Plus or pH Up can be added.

Q. How do I lower the pH level?

A. Small amounts of liquid acid (muriatic) or dry acid (sodi-

um bisulfate) such as pH Minus or pH Down can

be added.

Q. How does 650 mV relate to the ppm of chlorine?

A. Pure water, without conditioner, at a pH level of 7.5 cor-

responds to approximately 1.5 ppm of chlorine. Actual

pool or spa water usually takes at least 1-2 ppm of chlo-

rine to generate 650 mV ORP, although the Total

Dissolved Solids and pH can affect the activity of the

chlorine and thus change the level of ORP.

Q. Does an ORP of 650 mV stop algae?

A. No.Because algae is a living organism that adapts

genetically to a constant level of sanitizer, the periodic

addition of an algicide or shocking may be necessary.

Please note that the addition of some chemicals can

change the ORP readings for up to several days.

Q. What causes a low ORP?

A. A low sanitizer level, a pH level above 7.6, a conditioner

level above 200 ppm or a TDS (Total Dissolved Solids)

above 3,000 ppm can all cause a low ORP.

Page 24

23

Q. How do I make sure the ORP sensor is

working properly?

A. Watch the sensor reading when adding sanitizer.If it

does not respond properly, follow the recommended

cleaning procedures, see Maintenance. If cleaning does

not solve the problem, check the sensor as outlined in

the Maintenance section.

Q. How should the ORP sensor respond to adding acid?

A. Adding acid decreases the pH level thus increasing

the ORP.

Q. How should the ORP sensor respond to adding base?

A. Adding base increases the pH level thus decreasing

the ORP.

Q. How should the ORP sensor respond to adding sanitizer?

A. Depending upon the type of sanitizer used, the ORP

should increase. A sanitizer high in base, such as liquid

chlorine (sodium hypochlorite) or a dry chlorine powder

(calcium hypochlorite), however, can cause the pH level

to rise and the ORP to decrease.The pH level must be

in the ideal range to maintain the proper ORP level.

Q. Can ORP be used with ozone?

A. Even though ozone is an excellent oxidizer, it has a

very short lifetime.Therefore, a chlorine or bromine

residual will still be needed in order to maintain the

proper ORP level.When using ozone, the ozone must

be introduced into the system downstream from

the sensors.

Q. Can ORP be used with UV or metal ions?

A. Only if the proper chlorine or bromine residual

is maintained.

Page 25

24

XII.WARRANTY

Polaris Watermatic C316 Controller

This limited warranty is extended to the original consumer

purchaser of this Polaris Watermatic C316 Controller

manufactured by Polaris Pool Systems, Inc., 2620 Commerce

Way, Vista, CA 92083-8438, USA.

Polaris Pool Systems warrants the Water matic Controller it

manufactures, including all parts and components thereof, to be

free of defects in material and workmanship.For questions

regarding your Polar is Watermatic Controller, please feel free to

call or write us. Be sure to provide the serial number of

your unit.

The warranty commences on the date of installation of the controller and shall remain in effect for a period of one (1) year, but

in no event shall it be in effect for more than two (2) years from

the date of manufacture of the controller as established by the

serial number.

This limited warranty does not apply if the failure is caused or

contributed by any of the following: improper handling, improper

storage, abuse, unsuitable application of the unit, lack of reasonable and necessary maintenance, winter freezing or repairs

made or attempted by other than Polar is Pool Systems or one

of its authorized service centers. Polaris will repair or replace, at

its option, a unit or part proved to be defective within the warranty period and under the conditions of the warranty.

Unless local repair is authorized, the consumer must deliver or

ship the unit or the warranty parts, freight prepaid to the nearest

Polaris Author ized Ser vice Center or return it freight prepaid

(after proper authorization) to the plant of manufacture.

Authorization to return a unit to the plant of manufacture must

be obtained from the Polaris Customer Service Department.

For your convenience, please check with your dealer for the

local procedure before exercising this warranty. If fur ther directions or instructions should be required, contact the Customer

Service Depar tment at 1-800-VAC-SWEEP (USA and Canada

only) or 760-599-9600. Be sure to insure your shipments

against loss or damage during transit.

Page 26

25

Polaris is not responsible for the cost of removal of the unit,

damages due to removal, any other expenses incurred in shipping the unit or parts to or from the factory or its author ized

service centers, the installation of the repaired or replacement

unit.The consumer must bear these expenses.

This warranty does not cover repair or replacement of a unit

except at our factory or a Polaris Authorized Service Center.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE DISCLAIMED EXCEPT TO THE EXTENT ANY

IMPLIED WARRANTY MAY BE IMPOSED BY STATE CONSUMER LAW. ANY SUCH IMPLIED WARRANTY IMPOSED

BY STATE CONSUMER LAW IS LIMITED IN DURATION TO

ONE (1) YEAR FROM DATE OF PURCHASE.

IN NO EVENT SHALL POLARIS POOL SYSTEMS BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

NATURE OR KIND OR FOR DAMAGES TO PERSONS OR

PROPERTY, INCLUDING ANY DAMAGE RESULTING FROM

THE USE OF THE POLARIS WATERMATIC CONTROLLER.

Some states do not allow limitations on how long an implied

warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations may not apply

to you.

This limited warranty is valid only in the United States of

America and Canada, and it does not apply to Polaris

Watermatic Controllers sold or installed in any other country.

Page 27

© 2003 Polaris Pool Systems, Inc. All rights reserved TL-413 1/03

Loading...

Loading...