Page 1

2"

File Here

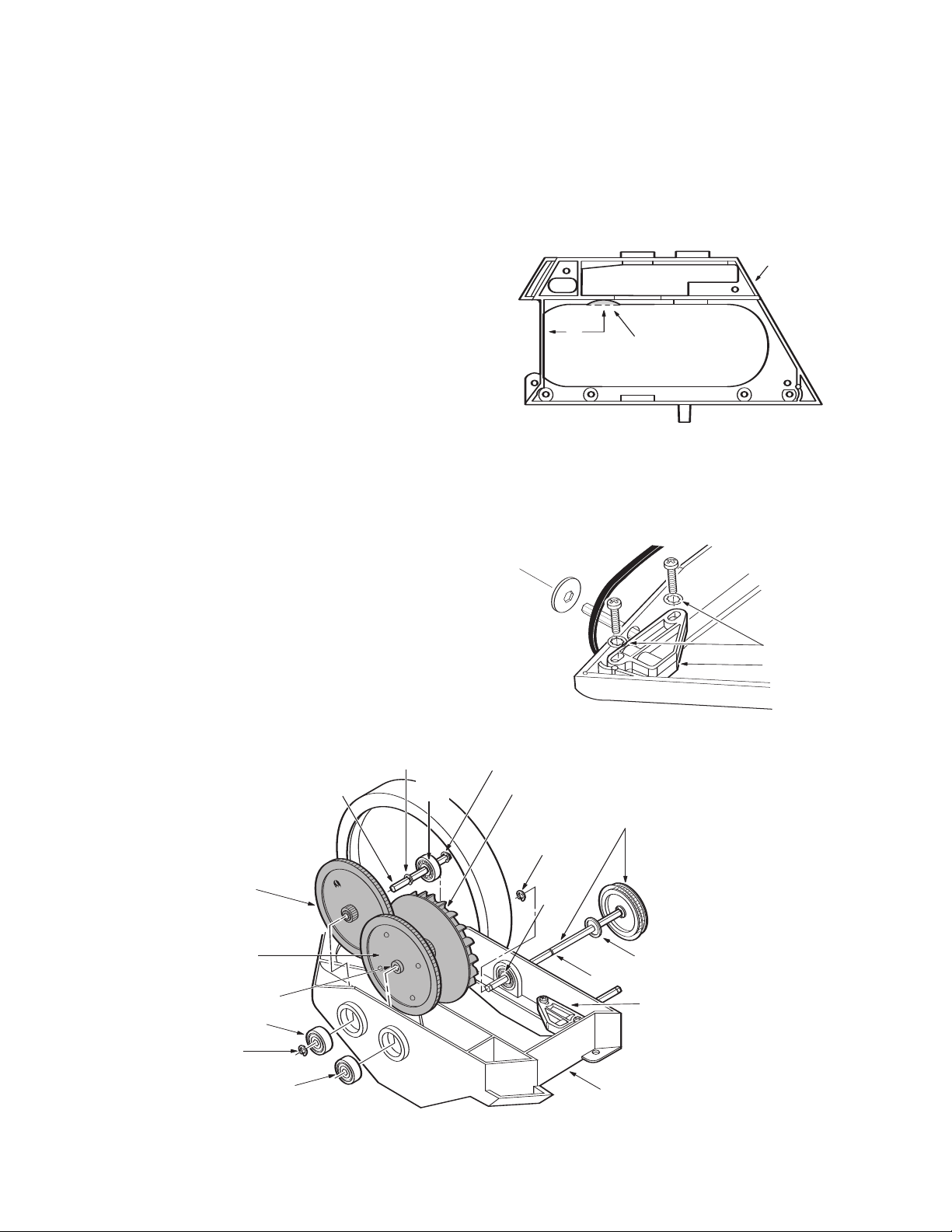

Frame

Lock

Washers

Axle Block

Assembly

Frame

Turbine Wheel

with Bearing

Bearing Shield

Bearing #1

(Shield side out)

Transfer Pulley/Drive

Shaft Assembly

Drive Gear

E-clip #2

Compound

Gear

E-clip #1

Notch for E-clip #1

Hub (Shortest)

Compound Gear Shaft

Bearing #2 (Shield side out)

E-clip #3

E-clip #4

Inner

Bearing

Axle Block

Bearing

Polaris 380 Factory Rebuild Kit

Tools Needed:

• Phillips screwdriver

• Needle nose pliers

• Small flathead screwdriver

Disassembly

1. Remove and discard the all-purpose bag,

head float, top cover(s), feed pipe/timer

blank assembly and sweep hose assembly.

2. Remove the four screws that secure the

frame to the base. Lift the frame off the base

at a 45-deg

Discard the base

pre-assembled base unit, so all items still

attached to the base can be discarded.

3. Familiarize yourself with the gears, bearings

and e-clips, and note their location on the

shafts before dismantling the frame (see

diagram below). Disengage the front and rear

belts by pushing the belt off the pulley while

turning the wheel.

4. Remove the hub caps, e-clips, wheels,

belts, axle blocks, transfer pulley/drive shaft

assembly, gears, bearings and turbine wheel.

These parts can be discarded.

ree angle, pull back and lift off.

. The rebuild kit contains a

5. If the frame has not already been notched,

file the fr

ame to provide proper clearance for

the feed pipe/timer blank assembly.

Assembly

1. Install the new axle blocks using lock washers

with screws. Tighten screws loosely to keep

them in place.

Page 2

2. Install bearings, shield side out. Insert

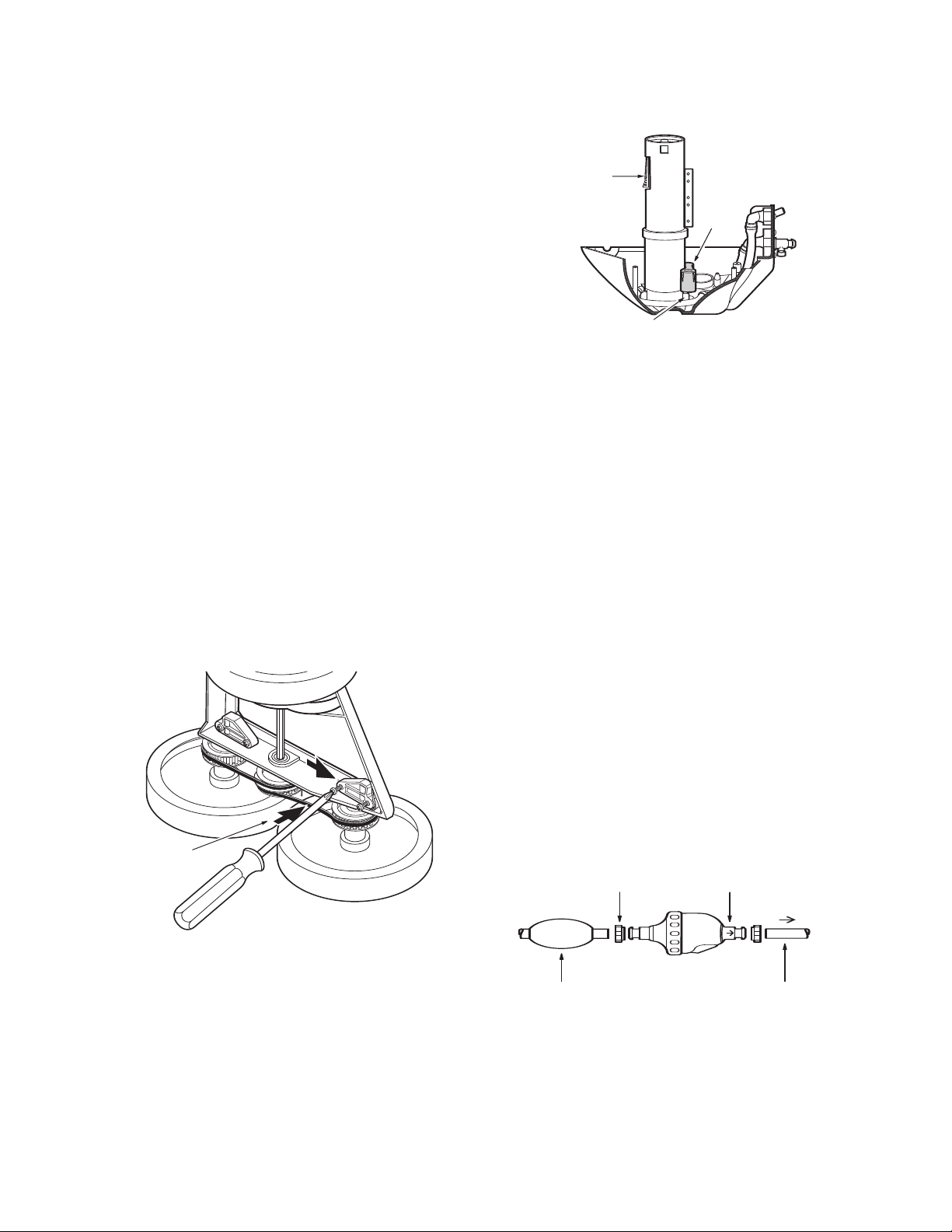

1/4"

Deflection

Base

Weight

Rear Jet Retainer

Vacuum Tube

Latch

30" Section

Polaris

Add Float

Flow ArrowMender Nut

compound gear shaft with inner bear

ing.

Install new compound gear. Note: Gear

y seem tight.

ma

3. Once gear is installed attach e-clip. Push the

compound gear shaft through, secure it to

the other side with another e-clip. E-clips

should snap into place.

4. Place the longest hub of the new drive gear

into the new turbine wheel.

5. Push the drive shaft through the new turbine

bearing, turbine wheel, drive gear and install

single-wheel side wheel with bearing. Secure

with e-clip.

6. Lay the frame on the single-wheel side and

place the drive belts over the axle block

shafts. Install the new bearing shields.

7. Install the new double-wheel side wheels with

bearings, e-clips and the hub caps. Engage

each belt by pushing the belt onto the pulley

while turning the wheel. The small belt should

be on the inside of the transfer pulley and the

large belt on the outside with the belt divider

separating them.

8. Place the frame on the double-wheel side.

Push the axle blocks toward the outside

edge of the Polaris until the belts have 1/4"

tension and tighten the axle block screws.

12. Install feed pipe and o-ring. Reinstall the

eed pipe screws.

three f

13. From the back, slide top in and over vacuum

tube. Align top and base and snap into place.

IMPORTANT: Top should be secured by

the vacuum tube latch.

14. Slide on back plate and reinstall screws to

secure the thrust jet. You may have to create

tension on the thrust jet to line up the holes.

15. Attach new head float. pushing it forward as

close to the Polaris as possible.

16. Attach the new bag.

17. Attach sweep hose using the new

attachment clamp.

Replacement of In-line Back-up Valve

1. Remove any existing in-line back-up valve.

The replacement Polaris in-line back-up

valve and float should be installed 30” from

the cleaner.

9. Remove two back screws from new preassembled new body. Lift off back plate.

Push in vacuum tube latch to remove top.

10. Place lower turbine housing into base. Place

w base w

ne

against the v

Slide fr

11.

of the 3/4” screws into frame. Place upper

turbine housing cover on, then screw in the

th and final 3/4”

our

f

eight on rear jet retainer flush

acuum tube

ame onto ne

.

w base

w.

scre

Reinstall three

.

2. Install the new float as shown below. It may

be helpful to tr

im the end of the hose at an

angle so the hose can be pulled through the

float with needle nose pliers. Once the float

is installed, tr

im the hose square.

3. Attach the back-up valve to the hose with the

flow arrow pointing toward the cleaner.

Push the ne

4.

alve as possible.

v

w float as close to the bac

k-up

Page 3

Serial Number

Upper Turbine

Housing

Hub Cap

MaxTrax

Tires (2)

Back Plate

Lower Turbine

Housing

Feed Pipe/Timer

Blank Assembly

Double Side

Wheels (2)

Single

Side Wheel

Small and Large

Belt Kit

Base Weight

Tr a

nsfer

Pulley/Drive

Shaft Assembly

To p Assembly

Base Assembly

Bearing

Shields

MaxTrax

Tire

Thrust

Jet

O-Ring

®

Head Float

All-Purpose Bag

and Collar Tie

Hub Caps

Stainless

Steel E-clips (3)

Bearings

Bearings

Bearing

In-line Back-up V alve

Sweep Hose

Assembly

Sweep Hose Barb

Page 4

Polaris 380 Factory Rebuild Kit Limited Warranty

This limited warranty is extended to the original consumer purchaser of this Polaris 380 Rebuild Kit

manufactured by Polaris Pool Systems, Inc., 2620 Commerce Way, California 92081-8438, USA.

Polaris warrants the parts in this kit to be free of defects in material and workmanship. We do not cover

tires, bottom plates, belts, or bearings which have been worn out by use. These are normal replacement items.

We do not cover damage caused by improper installation of the parts in the Rebuild Kit. If you have a question

regarding your Polaris 380 Rebuild Kit or your Polaris 380 Automatic Swimming Pool Cleaner, please feel free

to call or wr

frame of your unit, when you contact us.

of purchase.

improper handling, improper usage, improper storage, winter freezing, abuse, improper installation, unsuitable

application of the unit, improper maintenance, lack of reasonable and necessary maintenance, damage in

transit or during installation, or damage from repairs/alterations made or attempted by anyone other than

Polaris or one of its Authorized Service Centers. Polaris will repair or replace, at its option, a part proved to be

defective within the warranty period and under the conditions of the warranty.

freight prepaid to the nearest Polaris Authorized Service Center or return it freight prepaid (after proper

authorization) to the plant of manufacture. Authorization to return a unit or parts to the plant of manufacture

must be obtained from the Polaris Customer Service Department. Check with your dealer for the local

procedure before exercising this warranty. If further directions or instructions should be required, contact the

Customer Service Department at 1-800-822-7933 (USA and Canada only) or (760) 599-9600. Be sure you

insure your shipments against loss or damage in transit.

any other expenses incurred in shipping the unit or parts to or from the factory or its Authorized Service

Centers, or damages during the installation of the repaired or replacement unit. The consumer must bear

these expenses.

Polaris Authorized Service Center. This warranty does not cover pattern removal, abrasion or markings on a

vinyl liner.

INCLUDING

PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE DISCLAIMED EXCEPT TO THE EXTENT ANY

IMPLIED WARRANTY MAY BE IMPOSED BY STATE CONSUMER LAW. ANY SUCH IMPLIED WARRANTY

IMPOSED BY STATE CONSUMER LAW IS LIMITED IN DURATION TO ONE (1) YEAR FROM DATE OF

PURCHASE.

D

AMA

ANY DAMAGE RESULTING FROM THE USE OF THE POLARIS 380 AUTOMATIC SWIMMING POOL

CLEANER WITH A SUBSTANDARD POOL CIRCULATION SYSTEM.

incidental or consequential damages, so the above limitations may not apply.

apply to Polaris 380 Factory Rebuild Kits sold or installed in any other country.

ite us. Please provide the serial number, which can be located under the handle on the rear of the

The Polaris 380 Factory Rebuild Kit is warranted for a period of one year from date of purchase with proof

This limited warranty does not apply if the failure is caused or contributed to by any of the following:

In order to make a claim under this warranty, the consumer must deliver or ship the unit or warranty parts

Polaris is not responsible for the cost of removal of the unit or parts, damages during or due to removal,

This warranty does not cover repair or replacement of a unit or part except at our plant of manufacture or

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

ARRANTIES OF MERCHANT

THE IMPLIED

IN NO EVENT SHALL POLARIS BE LIABLE FOR INCIDENT

GES OF ANY NATURE OR KIND OR FOR DAMAGES TO PERSONS OR PROPERTY, INCLUDING

Some states do not allo

This limited warranty is valid only in the United States of America, Canada and Australia, and it does not

W

w limitations on ho

w long an implied w

ABILITY AND FITNESS FOR A PARTICULAR

AL OR CONSEQ

arranty lasts, or the exclusion or limitation of

UENTIAL

©

olaris Pools Systems, Inc. All rights reserved. TL-864 5/05

2005 P

Loading...

Loading...