Page 1

2015-2016 RANGER EV

Service Manual

The information printed within this publication includes the latest product information at time of print. The most recent

version of this Service Manual is available in electronic format at www.polarisdealers.com.

This Service Manual is designed primarily for use by certified Polaris Master Service Dealer

equipped shop and should be kept available for reference. All references to left and right side of the vehicle are from

the operator's perspective when seated in a normal riding position.

Some procedures outlined in this manual require a sound knowledge of mechanical theory, tool use, and shop

procedures in order to perform the work safely and correctly. Technicians should read the text and be familiar with the

service procedures before starting any repair. Certain procedures require the use of special tools. Use only the proper

tools as specified. If you have any doubt as to your ability to perform any of the procedures outlined in this Service

Manual, contact an authorized dealer for service.

We value your input and appreciate any assistance you can provide in helping make these publications more useful.

Please provide any feedback you may have regarding this manual. Authorized dealers can submit feedback using 'Ask

Polaris'. Click on 'Ask Polaris', and then click on 'Service Manual / Service Literature Question'.

Consumers, please provide your feedback in writing to: Polaris Industries Inc. ATTN: Service Publications Department,

2100 Hwy 55, Medina, MN 55340.

FOREWORD

®

technicians in a properly

Publication Printed August 2015 (PN 9926595 R01)

© Copyright 2015 Polaris Industries Inc. All information contained within this publication is based on the latest product information at the time of publication. Due to

constant improvements in the design and quality of production components, some minor discrepancies may result between the actual vehicle and the information

presented in this publication. Depictions and/or procedures in this publication are intended for reference use only. No liability can be accepted for omissions or

inaccuracies. Any reprinting or reuse of the depictions and/or procedures contained within, whether whole or in part, is expressly prohibited. Printed in U.S.A.

Page 2

UNDERSTANDING SAFETY LABELS AND DIRECTIONS

Throughout this manual, important information is brought to your attention by the following symbols:

WARNING

SAFETY ALERT WARNING indicates a potential hazard that may result in severe injury or death to the operator,

bystander or person(s) inspecting or servicing the vehicle.

CAUTION

SAFETY ALERT CAUTION indicates a potential hazard that may result in minor personal injury or damage to the

vehicle.

CAUTION

CAUTION indicates special precautions that must be taken to avoid vehicle damage or property damage.

NOTE

NOTE provides key information by clarifying instructions.

IMPORTANT

IMPORTANT provides key reminders during disassembly, assembly and inspection of components.

Page 3

TRADEMARKS

POLARIS ACKNOWLEDGES THE FOLLOWING PRODUCTS MENTIONED IN THIS MANUAL:

Loctite, Registered Trademark of the Loctite Corporation

Nyogel, Trademark of Wm. F. Nye Co.

Fluke, Registered Trademark of John Fluke Mfg. Co.

Mity-Vac, Registered Trademark of Neward Enterprises, Inc.

Torx, Registered Trademark of Textron

Hilliard, Trademark of the Hilliard Corporation

Warn, Trademark of Warn Industries

FOX, Registered Trademark of FOX RACING SHOX

RydeFX, Registered Trademark of ArvinMeritor

Some Polaris factory publications can be downloaded from www.polarisindustries.com, purchased from

www.purepolaris.com or by contacting the nearest Polaris dealer.

Page 4

Page 5

2015-2016 RANGER EV

Service Manual

Chapter Summary

CHAPTER 1: GENERAL / BATTERY

CHAPTER 2: MAINTENANCE

CHAPTER 3: DRIVE MOTOR

CHAPTER 4: BODY / STEERING / SUSPENSION

CHAPTER 5: FINAL DRIVE

CHAPTER 6: TRANSAXLE / DIFFERENTIAL

CHAPTER 7: BRAKE SYSTEM

CHAPTER 8: ELECTRICAL

Page 6

Page 7

GENERAL / BATTERY

CHAPTER 1

GENERAL / BATTERY

SPECIAL INFORMATION REGARDING THE RANGER EV .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

OPERATING THE RANGER EV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

WORKING ON THE RANGER EV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

VEHICLE TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

VEHICLE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

MODEL NUMBER DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

VEHICLE IDENTIFICATION NUMBER (VIN) DESIGNATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

VEHICLE AND MOTOR SERIAL NUMBER LOCATIONS .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

VEHICLE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

PUBLICATION NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

REPLACEMENT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

GENERAL SPECIFICATIONS ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8

2015 - 2016 RANGER EV.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8

FEATURES AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

CONSOLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

KEY SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

BATTERY DISCHARGE INDICATOR.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.12

CHARGE STATUS INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.13

BATTERY CHARGING CORD / BATTERY CHARGER.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.13

HEADLIGHT SWITCH .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.13

HOUR METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

12 VOLT AUXILIARY POWER OUTLET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

AUXILIARY 12 VOLT TERMINAL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

DIRECTION SELECTOR SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

ALL WHEEL DRIVE (AWD) SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.14

INDICATOR LIGHT PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.16

WINDSHIELD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.17

INDEX TO BATTERY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.17

TROUBLESHOOTING - VEHICLE OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.17

BATTERY SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.18

PROPOSITION 65 WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.18

BATTERY CHARGING WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.18

BATTERY CAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.18

BATTERY COMPARTMENT WARNING LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.19

BATTERY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.20

TO MAXIMIZE BATTERY SERVICE LIFE .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.20

BATTERYACCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.20

MAIN POWER CONNECTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.20

BATTERY TERMINAL FASTENER TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.20

BATTERY CONTACTOR FASTENER TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.21

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.1

Page 8

GENERAL / BATTERY

BATTERY CLEANING (EXTERNAL SURFACES). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.21

BATTERY TERMINAL CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.21

BATTERY CHARGING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.21

BATTERY WATER LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.22

BATTERY TESTING - OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.23

BASIC DISCHARGER INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.24

BATTERY DISCHARGE AND TESTING PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.25

BATTERY SPECIFIC GRAVITY TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.27

BATTERY REMOVAL AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.28

BATTERY TERMINAL ORIENTATION AND CABLE ROUTING.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.29

BATTERY CABLE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.31

BATTERY CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.32

BATTERY STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.33

ACCESSORY INSTALLATION PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.33

BATTERY CHARGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.33

BATTERY CHARGER LED FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.34

BATTERY CHARGER TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.34

SPECIFIC GRAVITY / CHARGE PERCENTAGE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.35

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.36

CONVERSION TABLE.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.36

STANDARD BOLT TORQUE SPECIFICATION .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.37

METRIC BOLT TORQUE SPECIFICATION... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.37

SAE TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.37

METRIC TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.38

DECIMAL EQUIVALENTS ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.38

1.2

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 9

SPECIAL INFORMATION REGARDING THE RANGER EV

OPERATING THE RANGER EV

If you are not familiar with the controls, features, or safe

operation of RANGER EV vehicles, read the Owner’s

Manual thoroughly before you operate the vehicle.

If you are an experienced RANGER EV technician and

have read and become familiar with safe vehicle

operation, a basic description of the switches and

controls unique to the RANGER EV is included in this

manual.

WORKING ON THE RANGER EV

Improper contact between battery terminals can result in

electrical shorts. Electrical shorts can result in burns.

WARNING

Use insulated tools or insulate any tools used within the

battery area to prevent sparks or battery explosion

caused by shorting the battery terminals or wiring.

Remove the batteries or cover the exposed terminals

with an insulating material.

The RANGER EV is equipped with eight 12-volt lead/acid

batteries arranged in two banks of four batteries each.

Each bank of batteries delivers 48 volts to a high

efficiency AC induction motor via the motor controller unit

and a key switch-controlled main contactor. Batteries,

controller, and contactor are located under the seat. Here

are a few key differences to remember when working on

the RANGER EV.

48 VOLT FUSES AND RELAYS

Be aware that some of the fuses and relays on the

RANGER EV are 48 volt; they may look similar to their 12

volt counterparts, but they are not the same and must not

be substituted with other types. The fuse voltage and

current rating is clearly marked on the fuse box label.

Refer to Chapter 8 of this manual (Electrical) for more

information and diagnostics for electrical system

components. Battery information is in this chapter

(Chapter 1).

GENERAL SAFETY REMINDERS

Wear the proper protective gear. Shield your eyes when

working on the RANGER EV.

Working on or around lead-acid batteries can be

dangerous if you do not take precautions and follow

proper handling, charging, and service procedures while

you work. Read the entire BATTERY SAFETY section of

this manual.

Remove all jewelry or metal objects that could come in

contact with battery terminals as you work in or around

the battery compartment; including (but not limited to):

• Rings, chains, wrist watches, bracelets, etc.

If battery access is not required for the task at hand,

keep storage trays and the seat in place to reduce the

chance of a dropped tool or other conductive object

making contact with the battery cables or terminals.

MAIN POWER CONNECTOR / BATTERY CHARGER

Some service procedures require special precautionary

steps to reduce the chance of electrical shorts and avoid

damage to expensive components. Always read and

understand the entire procedure and be sure you have

the proper tools and equipment before you begin. DO

NOT disconnect or work on any electrical component

without first disconnecting the Main Power Connector.

See Main Power Connector, page 1.20. DO NOT work on

the vehicle with the battery charger connected.

“FLOATING” CHASSIS

The RANGER EV frame and other chassis components

ARE NOT used as a conductor (ground path) for

electrical components and therefore not at ground

potential. NEVER connect accessories or other wiring to

the frame or chassis. Accessory Installation Precautions,

page 1.33. NEVER work on the vehicle with the battery

charger connected.

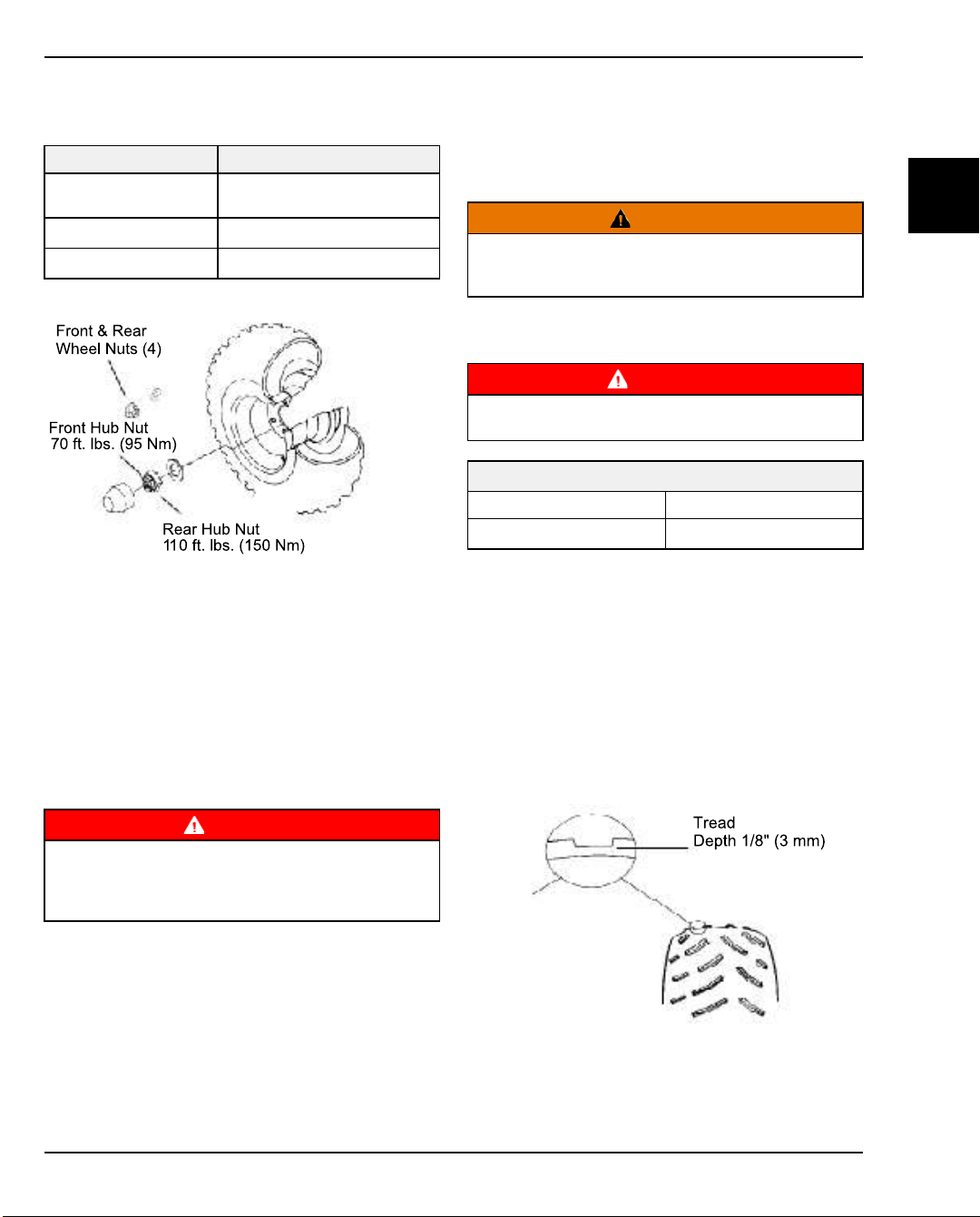

TIRE PRESSURE

Tire pressure for all tires is 20 psi (138 kPa) due to the

tire design used on the RANGER EV.

VEHICLE TOWING

When towing the vehicle, the key MUST be in the OFF

position or severe motor damage will occur.

1. Place direction selector in NEUTRAL

2. Turn key switch OFF.

3. Verify the parking brake is not engaged.

GENERAL / BATTERY

1

CAUTION

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.3

Page 10

GENERAL / BATTERY

VEHICLE IDENTIFICATION

MODEL NUMBER DESIGNATION

Example: A14KA09AD

GROUP

1st 2nd 3rd 4th* 5th* 6th* 7th* 8th* 9th** 10th

A 1 4 K A 0 9 A D

* = digits that would transfer to 17 digit VIN and are used in digits 4-8 respectively

** = 9th digit will be used on color/featured versions of models (not including the base)

First 3 digits and 9th digit are used in model number only. They are not used with the 17 digit VIN.

Digits 1 through 8 determine Digital Wrench calibration.

MODEL

YEAR

CHASSIS

DRIVE-

LINE

ENGINE /

MOTOR CODE

CATEGORY OPTION REGION

VEHICLE IDENTIFICATION NUMBER (VIN) DESIGNATION

Example: 4XAKA09A0E3000000

VEHICLE DESCRIPTORS VEHICLE IDENTIFIERS

WORLD MFG. ID

ENGINE

MODIFIER

ENGINE SIZE

CATEGORY

CHECK DIGIT

MODEL YEAR *

MFG. LOCATION

1 2 3 4

CHASSIS

DRIVELINE

5 6 7 8 9 10 11 12 13 14 15 16 17

4 X A K A 0 9 A 0 E 3 0 0 0 0 0 0

* Model Year: A = 2010; B = 2011; C = 2012; D = 2013; E = 2014; F = 2015; G = 2016

INDIVIDUAL SERIAL NO.

1.4

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 11

GENERAL / BATTERY

VEHICLE AND MOTOR SERIAL NUMBER LOCATIONS

Whenever corresponding about a Polaris utility vehicle, be sure to refer to the vehicle identification number (VIN) and

the motor model and serial number.

The VIN can be found stamped on the lower frame rail on the front LH side of the vehicle and on the dash in front of the

steering wheel (see Figure 1-1).

The drive motor model and serial number can be found on a label (A) applied to the motor (see Figure 1-2).

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.5

Page 12

GENERAL / BATTERY

VEHICLE INFORMATION

PUBLICATION NUMBERS

MODEL MODEL NO.

R15RMAE4EJ 9925678 9925783

2015 RANGER EV

2016 RANGER EV

R15RMAE4GC 9925678 9925783

R15RMAE4GJ 9925678 9925783

R16RMAE4G8 9926456 9926474

R16RMAE4G9 9926456 9926474

NOTE

When ordering service parts be sure to use the correct

Polaris factory publications can be found at www.

polarisindustries.com or purchased from www.

parts manual.

purepolaris.com.

OWNER’S MANUAL

PN

PARTS MANUAL PN

1.6

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 13

REPLACEMENT KEYS

Replacement keys can be made from the original key. To

identify which series the key is, take the first two digits on

the original key and refer to the chart to the right for the

proper part number.

SERIES# PART NUMBER

20 4010278

21 4010278

22 4010321

23 4010321

27 4010321

28 4010321

31 4110141

32 4110148

67 4010278

68 4010278

GENERAL / BATTERY

1

SPECIAL TOOLS

Special tools may be required while servicing this

vehicle. Some of the tools listed or depicted are

mandatory, while other tools maybe substituted with a

similar tool, if available. Polaris recommends the use of

Polaris Special Tools when servicing any Polaris product.

Dealers may order special tools through Polaris’ official

tool supplier, Bosch Automotive Service Solutions, by

phone at 1-800-345-2233 or on-line at http://polaris.

service-solutions. com/. A link to Bosch Automotive

Service Solutions is also provided under the Service &

Warranty tab at www.polarisdealers.com.

WARNING

Use insulated tools or insulate any tools used within the

battery area to prevent sparks or battery explosion

caused by shorting the battery terminals or wiring.

Remove the batteries or cover the exposed terminals

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

with an insulating material.

1.7

Page 14

GENERAL / BATTERY

GENERAL SPECIFICATIONS

2015 - 2016 RANGER EV

MODEL NUMBERS: 2015: R15RMAE4EJ / R15RMAE4GC / R15RMAE4GJ

2016: R16RMAE4G8 / R16RMAE4G9

CATEGORY DIMENSION / CAPACITY

Length

Width 56.5 in. / 143.5 cm

Height

Wheel Base 72 in. / 182.9 cm

Ground Clearance 10 in. / 25.4 cm

Turning Radius

Dry Weight 1750 lbs. / 793.8 kg

Gross Vehicle

Weight

Cargo System

Cargo Box

Dimensions

(Inside dimensions

inches /

centimeters)

Cargo Box Capacity 500 lbs. / 226.8 kg

Vehicle Payload

Towing With The RANGER EV

Hitch Towed Load

Weight (Level

ground)

Hitch Towed Load

Weight (15 degree

grade)

Hitch Vertical

Weight Capacity

Maximum Towing

Speed

108 in. / 274.3 cm

73 in. / 185.4 cm

150 in. / 381 cm

2750 lbs. / 1247 kg

Lock & Ride

Length: 32.0 / 81.3

Width: 42 / 107

Height: 11.5 / 29

1000 lbs. / 454 kg

(Includes weight of operator,

passenger, cargo and accessories)

1250 lbs. / 567 kg

850 lbs. / 386 kg

150 lbs. / 68 kg

10 mph. / 16 kph

®

1.8

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 15

GENERAL / BATTERY

DRIVE MOTOR & ELECTRICAL

Motor Configuration

Motor Peak

Modes

Controller

Battery Pack

Maximum Speed 25 MPH (40 km/h)

Throttle

On-board Charger

Charge Time

Electrical

Charge Indicator

Hour Meter

Indicator Lights

Auxiliary Power 12 volt Accessory Outlet

Lights: Main Headlights

Tail Light / Brake Light

Chassis

Single 48 Volt High Efficiency AC

Induction Motor

30 HP (22.4 kW)

3 Modes:

High for performance

Low for pulling / towing

Max for maximum distance

650 Amp Sevcon Gen 4 controller

with multi-mode driving and

regenerative braking

11.7 kW battery pack at 48Vdc with

(8) 12 volt, US12VXC batteries in

series-parallel configuration.

Redundant, non-contact, inductivesensing pedal

Delta Q 120 volt AC input;

48 volt DC output

8 Hours (dependant on depth of

discharge)

Digital - Indicates Battery

State-of-Charge

Digital - Indicates Cumulative

Hours Of Vehicle Movement

Directional selection, Park Brake,

Motor or Controller Malfunction

Dual 50 Watt

Sealed LED

Floating - no ground connection.

NOTE: When the vehicle batteries

are being charged the chassis is at

ground potential. Do not work on

the vehicle when the battery

charger is connected to an

electrical outlet.

DRIVE TRAIN

Final Drive

Shift Type

Drive System

Drive Ratio - Front 3.81:1

Drive Ratio - Rear 20.56:1

Front Gearcase

Lubricant Requirement

Front Gearcase Fill Plug

Torque

Front Gearcase Drain

Plug Torque

Rear Gearcase

Rear Gearcase

(Transaxle) Lubricant

Rear Gearcase

(Transaxle)

Fill Plug & Drain Plug

Torque

Toe Out

Front Suspension

Front Travel

Rear Suspension Dual A-Arm Independent (IRS)

Rear Travel

Shock Preload

Adjustment

Front Wheel Size / Type

Rear Wheel Size / Type

Front Tire 25 x 9-12 Carlisle All-Trail ll

Rear Tire 25 x 9-12 Carlisle All-Trail ll

Tire Air Pressure

(Front and Rear)

Brake System

Brake Fluid DOT 4

Parking Brake

Direct drive motor-to-transaxle with

low noise gears

N/A

On-Demand True AWD / 2WD /

Versa Trac Turf Mode

Front Gearcase

Demand Drive Plus

6.1 oz. (180 ml)

8-10 ft-lbs (11-13.6 Nm)

11 ft-lbs (15.0 Nm)

ATVAngle Drive Fluid

20.3 oz. (600 ml)

14 ft-lbs (19.4 Nm)

Steering / Suspension

1/8 - 1/4 in. (3.2 - 6.35 mm)

MacPherson Strut / A-arm

8 in. (20.3 cm)

9 in. (22.9 cm)

Cam Adjustment (Rear)

Wheels / Brakes

12 x 6 / Steel

12 x 6 / Steel

20 psi (138 kPa)

4 Wheel Hydraulic Disc With Dual

Bore Front Calipers

Dash Mounted Lever- Activated

Mechanical

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.9

Page 16

GENERAL / BATTERY

Cold Weather Operation

Cold weather operation requires special vigilance in

regard to battery state of charge. Discharged batteries

freeze at a higher temperature than fully charged

batteries (see table for freeze points).

BATTERY FREEZE POINT

Percent

Charged

Freeze Point

(Approximate)

Also keep in mind the following:

• Battery (vehicle) range decreases as the ambient

temperature decreases.

• Maximum range will be attained at an ambient

temperature of 80°F (26.6°C) or higher. This is the

case for all lead-acid battery products. Cold ambient

temperatures can negatively affect the range by up to

30%.

100% 50% 0%

-60° F

(-51° C)0°(-18° C)

+25° F

(-4° C)

1.10

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 17

FEATURES AND CONTROLS

CONSOLE

Console switches and controls are described on the

following pages.

NUMBER DESCRIPTION

q

w

e

r

t

y

u

i

Indicator Lights

Discharge Indicator / Hour Meter

Key Switch

Drive Direction Selector

AWD Switch

Drive Mode Switch

Charge Status Indicator

Headlight Switch

GENERAL / BATTERY

KEY SWITCH

Move the Direction Selector Switch to NEUTRAL then

turn the key to the ON position to activate electrical

circuits.

NOTE

The accelerator will not start the drive motor if the

Direction Selector Switch is in the Forward or Reverse

position when the key is turned ON. Switch to

NEUTRAL, then choose Forward or Reverse.

The key can be removed from the switch when it is in the

OFF position. Turn key OFF when vehicle is not in use.

PARKING BRAKE

To help prevent the vehicle from rolling, set the park

brake when parking the vehicle. When the park brake is

set and the park brake indicator is illuminated, motor

speed is limited. If the accelerator is applied, this limiting

feature prevents operation, which protects the park brake

pads from excessive wear.

This feature will not operate properly if the park brake

connector or switch (under the hood) malfunctions or

becomes disconnected, or if the switch has moved.

Check to be sure the switch is properly connected or test

and repair as required. See Chapter 7 (Brakes) or

Chapter 8 (Electrical) for diagnostic procedure.

Always apply the service brakes before engaging or

releasing the park brake.

Be sure the lever is completely forward when releasing

the park brake.

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Drive Mode Switch

1.11

Page 18

GENERAL / BATTERY

CAUTION

Changing the drive mode switch position while driving

could result in an automatic increase or decrease in

speed without a change to accelerator pedal pressure.

See Table 1.

Use high mode for most trail-riding conditions. The

vehicle will operate at speeds up to 25 MPH (40 km/h).

Low mode is recommended for short-term operation in

extreme load conditions. Use low mode when towing,

hauling loads or maneuvering over obstacles. Speed will

be limited to a maximum of 12 MPH (19 km/h) and

regenerative braking increases to improve control in

aggressive terrain.

Use the Maximum Range mode to operate the vehicle a

greater distance or for a longer time period. This mode

limits both speed and torque to obtain the maximum

driving range.

BATTERY DISCHARGE INDICATOR

The battery discharge indicator displays the amount of

charge removed (used) from fully charged batteries.

When the batteries are fully charged, the right-most bar

illuminates, indicating 0% has been used.

1 - DRIVE MODE CHARACTERISTICS

DECEL

BRAK-

ING

(RE-

GEN.)

Maxi-

mum

MODE

High

Max

Range

Low

MAX

SPEED

25 mph

(40 km/

h)

15 mph

(24 km/

h)

12 mph

(19 km/

h)

TORQUE

(PER-

CENT OF

MAXIMUM

TORQUE)

85% Minimum

60% Minimum

100%

1.12

USE THIS

MODE FOR:

Trail Riding

Maximize

battery range

Towing,

hauling

loads, steep

hills,

As the batteries discharge, the bar moves toward the left.

If batteries are not allowed to recharge fully (solid green

light), the battery discharge indicator may be inaccurate.

When the second bar from the left flashes, battery

discharge is at 70%. The batteries should be recharged

as soon as possible. Avoid discharging the batteries

more than 80%.

If the two left-most bars begin to flash, battery service life

will be significantly reduced with continued operation.

Stop the vehicle and recharge the batteries.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 19

GENERAL / BATTERY

CHARGE STATUS INDICATOR

When charging the batteries, the charge status indicator

light flashes and changes color to indicate the status of

the charge. See Table 2.

2 - Charge Status Indicator

COLOR

Green Solid

Green

Green

Amber

Red

INDICA-

TION CODE DEFINITION

Charge is complete, charger is

in maintenance mode.

Fast

Flash

Slow

Flash

Flashing

Flashing

Less than 80% of charge is

completed.

More than 80% of charge is

completed.

Charge rate is reduced, low

AC voltage or high internal

charger temperature exists;

open hood to improve air flow.

Charger error exists; reset

charger power and refer to

Battery section in this chapter.

BATTERY CHARGING CORD / BATTERY

CHARGER

The battery charging cord (1) is located at the front of the

vehicle, inside the right front bumper. See Battery

Charging, page 1.21 for battery charging procedure. See

Battery Charger Troubleshooting, page 1.34 for battery

charger diagnostics.

HEADLIGHT SWITCH

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.13

Page 20

GENERAL / BATTERY

HOUR METER

The hour meter (2) records and displays the hours of

actual vehicle movement since manufacture (see image

below).

12 VOLT AUXILIARY POWER OUTLET

The 12-volt receptacle (3) can be used to power

accessories, but is limited to 10 amps (the terminal board

and 12-volt outlet are fused together at 10 amps).

DIRECTION SELECTOR SWITCH

When the direction selector is in the center position, the

vehicle is in neutral. The vehicle will not move if the

accelerator is depressed. Place the switch in neutral

before turning the key on.

Always come to a complete stop before reversing

direction.

ALL WHEEL DRIVE (AWD) SWITCH

The AWD switch has three positions: All Wheel Drive

(AWD), Differential Lock/Two Wheel Drive (2WD) and Off

(1WD/Turf Mode).

AUXILIARY 12 VOLT TERMINAL BOARD

The 12-volt terminal board (under hood) contains a

switched 12-voltq, a ground terminalwand a constant

12-volt

accessories. The switched and constant terminals are

fused separately at 10 amps. The 10 amp switched

terminal fuse includes loads connected to both terminal

board and Auxiliary Power Outlet on the dash.

that can be used to power auxiliary lights and

e

AWD MODE - Once enabled, the AWD remains enabled

until the switch is turned off.

1.14

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 21

The AWD switch may be turned on or off while the

vehicle is moving. When the AWD switch is on, the front

gearcase will automatically engage any time the rear

wheels lose traction. When the rear wheels regain

traction, the front gearcase will automatically disengage.

AWD will not engage initially until speed is less than 5

MPH (8 km/h).

Engage the AWD before getting into conditions where

front wheel drive may be needed. If the rear wheels are

spinning, release the accelerator before switching to

AWD.

CAUTION

Switching to AWD while the rear wheels are spinning

may cause severe drive train damage. Always switch to

AWD while the rear wheels have traction or are at rest.

Disengaging AWD - If the AWD switch is turned off

while the front gearcase is moving, it will not disengage

until the rear wheels regain traction.

In some situations, the front gearcase may remain locked

after turning the AWD switch OFF. If this occurs you may

notice increased steering effort and some vehicle speed

restriction. Perform the following procedure to unlock the

front gearcase:

1. Stop the vehicle.

2. Move the direction selector to REVERSE. Operate in

reverse for at least 10 feet (3 meters).

3. Stop completely, then move the direction selector to

FORWARD and drive forward.

4. If the front gearcase remains locked after performing

the above steps, refer to Final Drive (Chapter 5).

2WD MODE - Locking the differential in slippery or

low traction conditions helps improve traction. Move

the rocker switch to the center position (2WD) to lock

the differential and operate in rear wheel drive.

GENERAL / BATTERY

1

CAUTION

Damage to the differential can occur if it is engaged

while the vehicle is traveling at high speeds or while the

rear wheels are spinning. Slow the vehicle to nearly

stopped before engaging the differential.

1WD / TURF MODE - Press the bottom of the switch

to unlock the differential and allow the rear drive

wheels to operate independently. This mode of

operation is well suited to turf driving or whenever

aggressive traction is not required.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.15

Page 22

GENERAL / BATTERY

INDICATOR LIGHT PANEL

The indicator lights can activate only when the key is in the ON position. See Table 3.

3 - Indicator Light Function

NU-

MBE-

INDICATOR STATUS INDICATES

R

Key turned ON with Direction Selector in FORWARD or

REVERSE. Move direction selector switch to neutral, then

back to forward or reverse. NOTE: If accelerator pedal is

depressed when key is turned ON, MIL will illuminate until

pedal is fully released.

Electrical Malfunction Light on Controller will blink a flash

sequence. See Table 4 for description of Blink Codes.

Power delivery terminated to prevent damage from

overheating.

Park brake engaged. Move lever forward to fully released

position or inspect switch (See Chapter 8). Drive motor will

not receive power until park brake light is OFF.

F, N, or R will illuminate depending on position of the

Direction Selector Switch.

1 Malfunction

Motor / Controller High

2

Temperature

3 Park Brake

4 Gear Position - Reverse

5 Gear Position - Neutral

6 Gear Position - Forward

Steady

Flashing

Flashing Reduced performance due to elevated temperature.

Steady

Steady

Steady

4 - Controller Malfunction Blink Codes

NUMBER OF BLINKS CODE DEFINITION NUMBER OF BLINKS CODE DEFINITION

1

2

3 Power fault 12 Communication error

4 Contactor issue 13 Software fault

6

Data or configuration error

Sequence fault

Motor speed or throttle input

error

1.16

7

8

See Chapter 8 for diagnostic procedures.

9926595 R01 - 2015-2016 RANGER EV Service Manual

Voltage protection

Controller or motor out of

temperature range

© Copyright Polaris Industries Inc.

Page 23

GENERAL / BATTERY

WINDSHIELD

The windshield must be removed before transporting the

vehicle. See chapter 4 or refer to Owner’s manual for

cleaning instructions.

INDEX TO BATTERY INFORMATION

NOTICE

Read all BATTERY SAFETY information outlined in this

• Battery Access

• How to Maximize Battery Service life

• Battery Terminal Torque / Cleaning

• Battery Charging

• Battery Water Level

• Battery Testing

• Battery Removal / Installation

• Battery Storage

chapter first.

TROUBLESHOOTING - VEHICLE

OPERATION

Vehicle Will Not Operate

POSSIBLE CAUSE POSSIBLE SOLUTION

Parking Brake Set

Low Battery Voltage Recharge batteries

Battery Connections Dirty

Or Loose

Contactor Connections

Dirty Or Loose

Electronic Controller

Connections Dirty Or

Loose

Main Power Connector

Disconnected For Service

Required Torque Exceeds

Motor Capability

Release parking brake

lever

Clean and re-torque

connections

Clean and re-torque

connections

Remove, inspect, clean if

necessary, and reinstall

Remove seat and storage

tray and re-connect main

power connector (See

Main Power Connector,

page 1.20)

In NEUTRAL, cycle key

switch OFF and ON,

select LOW range, then

select direction.

POSSIBLE CAUSE POSSIBLE SOLUTION

Malfunction Indicator

Displayed On Indicator

Light Panel

Motor / Controller High

Temperature Light

Illuminated On Indicator

Light Panel

Turn key switch OFF. See

Indicator Light Panel,

page 1.16 for further

information.

Turn key switch OFF.

Allow motor or controller

to cool. See Indicator

Light Panel, page 1.16.

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.17

Page 24

GENERAL / BATTERY

BATTERY SAFETY

PROPOSITION 65 WARNING

WARNING

PROPOSITION 65 WARNINGbattery posts, terminals,

and related accessories contain lead and lead

compounds, chemicals known to the state of california

to cause cancer and reproductive harm. wash hands

after handling.battery electrolyte is poisonous. it

contains acid!

serious burns can result from contact with the skin,

eyes, or clothing.ANTIDOTE:EXTERNAL: flush with

water.

INTERNAL: drink large quantities of water or milk.

follow with milk of magnesia, beaten egg, or vegetable

oil. call physician immediately.

EYES: flush with water for 15 minutes and get prompt

medical attention.

batteries produce explosive gases. keep sparks, flame,

cigarettes, etc. away. ventilate when charging or using

in closed space. always shield eyes when working near

batteries.

KEEP OUT OF REACH OF CHILDREN.

BEFORE WORKING IN OR AROUND THE BATTERY

COMPARTMENT

Improper contact between battery terminals can result in

electrical shorts. Electrical shorts can result in burns.

Always use insulated tools in and around the batteries or

battery compartment.

Remove all jewelry or metal objects that could come in

contact with battery terminals as you work in or around

the battery compartment; including (but not limited to):

• Rings, wrist watches, chains, bracelets, etc.

BATTERY CHARGING WARNING

Location: Inside glove box door.

WARNING:

• Explosive gases are released when batteries are

charged. Keep sparks, flames and cigarettes away.

Shield eyes when working near batteries.

• Do not charge batteries in a non-ventilated enclosed

area or near flammable materials.

• Do not attempt to charge frozen, leaking, or damaged

batteries.

• Connect battery charger to properly rated electrical

receptacle with GFCI.

• Do not charge with storage or weather cover on

vehicle or with the cab enclosure doors closed, as fire

and explosion are possible.

• Refer to your Owner’s manual or contact your local

Polaris dealer with any questions.

BATTERY CAUTION

Location: On dashboard above steering column.

• Do not drive through water above the floor of the

vehicle. Battery damage will occur.

• Batteries require regular maintenance.

• Failure to maintain batteries in accordance with the

owners manual can result in battery damage, vehicle

malfunction, fire and/or severe injury or death.

• Do not charge with storage or weather cover on

vehicle or with the cab enclosure doors closed, as fire

and explosion are possible.

• Max towing speed 25 mph (40 km/h). Drivetrain

damage will occur if towed faster than 25 mph (40 km/

h).

• Set parking brake before leaving vehicle.

• Turn key to OFF position and remove when not in use.

• When towing vehicle, place the selector switch in

neutral and turn key to “Off” position.

1.18

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 25

BATTERY COMPARTMENT WARNING

LABEL

Location: Under seat on battery compartment divider.

WARNING:

• SULFURIC ACID in batteries will burn skin, eyes, and

clothing. Do not tip batteries. Keep vent caps tight and

level. In event of injury, flush with water and call

physician immediately.

• HIGH VOLTAGE CABLES and terminals are contained

within this compartment. Improper contact between

battery terminals can result in electrical shorts.

ELECTRICAL SHORTS can result in burns.

• Do not use high pressure water to wash the battery

compartment. Damage to the vented batteries will

result.

• Tampering with or unauthorized modification of this

unit could result in serious personal injury, will void the

warranty, and can result in permanent damage to the

vehicle.

• Refer to your Owner’s manual or contact your local

Polaris dealer with any questions.

GENERAL / BATTERY

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.19

Page 26

GENERAL / BATTERY

BATTERY MAINTENANCE

TO MAXIMIZE BATTERY SERVICE LIFE

The following are key items to ensure maximum service

life from the batteries.

• Always check and maintain water level monthly. Use

only distilled water. Water level should be kept 1/4” (6

mm) below fill well. Do not overfill the battery.

• Always keep batteries fully charged. For maximum life,

charge your vehicle at every opportunity. Use only the

charger supplied with the vehicle. See freeze point

table below.

• Inspect / tighten battery terminal connections monthly

or whenever batteries are serviced.

• Tighten terminals to specified torque.

TORQUE

Battery Cable Terminals: 8.0 ft-lbs (11.0 Nm)Battery

Contactor Terminals: 8.0 ft-lbs (11.0 Nm)

• Always keep battery terminals clean and free of

corrosion at all times.

• Avoid discharging batteries more than 80%. See ,

page 1.12and Battery Charging, page 1.21 for more

details.

• Make sure new batteries are fully charged before

using. New deep cycle batteries need to be cycled

several times before reaching full capacity as shown in

the Battery Conditioning chart below.

• Make sure vent caps are installed properly during

vehicle operation and battery charging.

• Avoid charging at high temperatures. See Battery

Charging, page 1.21.

• Use only genuine Polaris accessories and follow

instructions provided.

MAIN POWER CONNECTOR

WARNING

Use insulated tools or insulate any tools used within the

battery area to prevent sparks or battery explosion

caused by shorting the battery terminals or wiring.

Remove the batteries or cover the exposed terminals

with an insulating material.

Always disconnect the Main Power Connector (A) before

servicing or unplugging any electrical components.

BATTERY CONDITIONING

Number of

Charge Cycles

Percent of Full

Capacity

BATTERY FREEZE POINTS

Percent

Charged

Freeze Point

(Approximate)

NEW 15 30 45

80% 90% 95% 100%

100% 50% 0%

-60° F

(-51° C)

0° F

(-18° C)

+25° F

(-4° C)

BATTERY ACCESS

1. Lift front edge of seat upward to release pins.

2. Slide seat forward to release hinge bracket tabs.

3. Remove storage trays by pulling upward at the rear

edges.

1.20

BATTERY TERMINAL FASTENER TORQUE

Battery terminal fastener torque is one of the most

important maintenance items on the RANGER EV.

Always use a torque wrench when tightening battery

terminal fasteners.

Loose terminals reduce battery performance and

increase the amount of heat present at the battery

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 27

GENERAL / BATTERY

terminal. Permanent battery damage can result from lack

of terminal maintenance.

Over-tightening of terminal fasteners can cause

permanent damage to the battery.

TORQUE

Battery Cable Terminals: 8.0 ft-lbs (11.0 Nm)Battery

Contactor Terminals: 8.0 ft-lbs (11.0 Nm)

BATTERY CONTACTOR FASTENER

TORQUE

Torque contactor fasteners using insulated tools as

described for the battery terminals above.

Loose or over-tightened contactor terminals can

permanently damage the contactor.

3. Disconnect the main electrical connector.

4. Check to be sure battery caps are in place and

securely latched in the closed position. SeeBattery

Water Level, page 1.22 for vent cap operation.

5. Mix a solution of one tablespoon baking soda per

one cup of clean water. Wash battery case with

solution to remove acid residue, dirt, and debris.

CAUTION

Do not allow cleaning solution or tap water to enter the

batteries.

6. Rinse thoroughly with a low pressure stream of water

until batteries are clean. Allow to dry. DO NOT use

pressure washers or compressed air to clean or dry

batteries or contaminants may be forced through the

battery cap vent and contaminate battery cells. Cell

contamination will reduce battery performance and

service life.

BATTERY TERMINAL CLEANING

1. Disconnect the Main Power Connector, page 1.20.

2. Using insulated tools, remove the battery cables for

cleaning (SeeBattery Cable Removal, page 1.31).

3. Clean cables and terminals with a stiff wire brush.

Wash with soda/water solution (proportions

described below).

4. Rinse well with tap water and dry off with clean shop

towels.

5. Reinstall the battery cables (SeeBattery Cable

Installation, page 1.32) in order shown and torque

terminal nuts to 8.0 ft-lbs (10.8 Nm).

6. Coat battery terminals with dielectric grease or

petroleum jelly.

BATTERY CLEANING SOLUTIONS

PARTS BAKING SODA PARTS WATER

1 Teaspoon (15cc) 1 Cup (.25 Liter)

4 Tablespoons (60cc) 1 Quart (1 Liter)

1 Cup (250cc) 1 Gallon (4 Liters)

1

BATTERY CLEANING (EXTERNAL

SURFACES)

1. Turn key OFF.

2. Remove seat and storage trays.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

BATTERY CHARGING

WARNING

Do not work in or around the battery compartment or on

any electrical component on the vehicle while charging

the batteries. The chassis of the vehicle is at ground

potential when the battery charging cord is connected

to an AC outlet. This increases the risk of accidental

short circuits to battery terminals or other wires caused

by tools or other objects.

1.21

Page 28

GENERAL / BATTERY

WARNING

Failure to provide adequate ventilation while charging

batteries can result in an explosion. Volatile hydrogen

gas is emitted during charging and may accumulate in

pockets at the ceiling.

• Always ensure a minimum of 5 air changes per hour in

the charging area.

• Always remove any storage covers from the vehicle

and open cab doors (if equipped) before charging.

• The charging unit produces heat in the charging

process. Open the hood to allow better cooling air flow

over the charger unit.

The battery charging cord (1) is located at the front of the

vehicle through the bumper at the right hand frame rail.

Supply voltage from the wall outlet can be 110-120 or

230-240 AC volts. The charger will recognize a power

source and adjust automatically.

The charge cord is connected to the charger at a flying

lead (2) under the hood.

Battery water level must be above the plates before

charging. Inspect battery water level. If the plates are

exposed in any cell, add distilled water to bring the level

to approximately 1/8² (3mm) above the plates. Cells

should be topped off after charging is complete, not

before, due to a (normal) increase in water level during

the charging cycle. Battery Water Level, page 1.22

DISTILLED WATER ONLY

Be sure all battery cable connections are tight. Do not

work on the vehicle with the charger connected.

1. Position vehicle on a level surface in a well ventilated

area.

2. Turn key switch OFF.

3. Open hood and any door enclosures or zippers.

4. Use an extension cord with a minimum rating of 20

amps.

5. Inspect charging cord and extension cord for cracks,

loose connections and frayed wiring. Replace any

damaged components promptly.

6. Always connect vehicle charging cord to the

extension cord first, then plug in to a 20A GFCI

receptacle.

7. Make sure charger uses a dedicated circuit to

prevent overloading. If charging multiple vehicles,

each vehicle should use a dedicated circuit.

NOTE

When batteries are fully charged, the battery charger

will automatically cycle in and out of trickle charge

mode to maintain the charge. The charge cord can

remain connected indefinitely provided guidelines

above are followed and battery water level is inspected

monthly. Note that if the battery charger does not reach

the end of its cycle (solid green light on Charge Status

Indicator) the Battery Discharge Indicator may be

inaccurate. Always fully charge the batteries if possible.

1.22

8. Disconnect extension cord from the receptacle first,

then disconnect the cord from the vehicle’s charging

cord.

9. Inspect and top off battery water when charge cycle

is complete.

BATTERY WATER LEVEL

NEVER add acid (electrolyte) to batteries. Use clean

distilled water. Tap water contains minerals that are

harmful to a battery.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 29

GENERAL / BATTERY

WARNING

Wear eye protection.

1. Turn key OFF, and remove seat and storage trays.

2. Push lever tabs in direction shown to unlock cell

covers.

3. Remove cell covers and check each cell. Add

distilled water as required to bring level to 1/4 (6mm)

below bottom of fill well (A) in each cell.

BATTERY TESTING - OVERVIEW

The use of a battery discharger is important to accurately

determine overall battery capacity and to identify weak or

faulty cells or batteries in a battery set. Weak or faulty

batteries can be replaced individually; it is not necessary

to replace all batteries at the same time.

After fully charging the batteries, the discharger unit is

connected and a discharge cycle begun. The discharger

applies a resistive load to the batteries (56.25 amps for a

48 volt battery set) and automatically keeps track of the

time elapsed between start and end of the discharge

cycle. A discharge cycle ends when the batteries reach

42 volts, and the discharger shuts off automatically.

When the discharger shuts off, the elapsed time to

discharge (42 volts) is then noted from the discharge unit

display.

A good battery set will take longer to discharge to the 42

volt level than a battery set with a faulty battery or

batteries. If one battery in a set is weak, the other

batteries must make up for the deficiency, and the

discharge time to 42 volts will be less than that of a good

battery set.

Ambient temperature is a factor in the amount of time it

takes to discharge a set of batteries. Therefore, an

adjustment table is provided in the test procedure to

make it easy to calculate an accurate temperatureadjusted discharge time. Note that temperatures above

80° F require no adjustment, and actual discharge time is

taken directly from the display of the discharger.

If the adjusted discharge time is 175 minutes or more, no

further testing is required, as all batteries are in good to

excellent condition.

If discharge time took less than 175 minutes, the

discharger is re-started and the voltage of each battery

tested under load and recorded. A weak or faulty battery

or batteries will be identified by a noticeably lower

voltage reading than other “healthy” batteries in the set.

NOTE: When the discharger is re-started for battery

testing, it will load the batteries for a 3-minute period,

allowing ample time to test the voltage of each of the

eight batteries in the set.

Batteries that fall below the service limit under load must

be replaced.

See Battery Testing Procedure to perform the discharge

cycle and test each battery.

Read discharger unit instructions for complete

information on features, operation, and program settings

prior to connecting the unit. Only basic instructions for

technicians familiar with the Lester Discharge Unit are

provided in this manual.

1

4. Inspect O-rings on cell caps and replace if damaged.

5. Install caps and slide levers to the locked position.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Equipment required:

Battery Discharger - Lester 36/48 is recommended.

(Available through Bosch Automotive Service Solutions

and Commercially Available).

1.23

Page 30

GENERAL / BATTERY

Fluke 73 Digital Multimeter (PV-43546) or Fluke 77

Digital Multimeter (PV-43568) or equivalent.

BASIC DISCHARGER INSTRUCTIONS

The following are brief instructions to program the Lester

36/48 Discharger Unit for use on RANGER EV 48 volt

battery systems. These instructions are for basic set-up

only. Refer to instructions provided with the discharger

unit for a complete guide to other features and

information. The following applies only to the Lester 36/

48 model discharger unit which is the recommended

discharger for the RANGER EV.

PROGRAMMING INSTRUCTIONS

The following list of functions and what they represent is

printed on the front panel of the discharger unit.

Display Functions

Func1

Func2

Func3

Func4

Func5

The two functions that must be verified or reset are:

• Maximum Discharge Time

• Shut-off Voltage

NOTE: Values for the above variables can be

changed at any time, even while a discharge cycle is

running.

Changing The Maximum Timer

The default discharge time is 240 minutes. This value is

the maximum amount of time the discharge unit allows to

discharge a set of batteries. Do not set the Maximum

Timer below 200 minutes.

To INCREASE the maximum timer (if it has been

decreased from the 240 minute default value to a value

below 200 minutes):

1. Press and release the DISPLAY button until Func1 is

2. Continue to hold in the DISPLAY button while you

3. Press and release the DISPLAY button until you see

Present Battery Voltage

Discharge time in minutes and seconds.

(Minutes are displayed on the left and

seconds to the right of the decimal point).

Lowest battery voltage reached during

discharge

Battery voltage sensed (36 or 48)

Discharge data printout interval.

(Number of seconds)

displayed.

press and release the START/STOP button. Every

time you press and release START/STOP the

maximum timer will increase by 5 minutes. When the

setting is at least 200 minutes, release the DISPLAY

button.

Changing The Shut-off Voltage

When the discharge unit is powered up it will

automatically decide whether to discharge at the 36

or the 48 volt rate. If the discharger senses a voltage

above 42 volts, a 48 volt discharge will begin (56.25

amp rate) and the shut-off voltage will default to its

lowest programmable value of 42 volts.

The time and voltage minimums specified in this

manual are for a 42 volts shut-off. Do not change this

setting to a different value.

To check which type of battery set the discharger has

sensed:

the value of Func4 before you press the START/

STOP button. The voltage sensed by the discharger

should be 48 volts, and the shut-off voltage will be 42

volts.

1.24

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 31

GENERAL / BATTERY

BATTERY DISCHARGE AND TESTING

PROCEDURE

1. Remove seat and storage trays and open the cargo

box.

2. Torque all battery terminal nuts to specification

TORQUE

Battery Terminal Nuts: 8.0 ft-lbs (11.0 Nm)

3. Torque contactor nuts to specification.

TORQUE

Battery Contactor Nuts: 8.0 ft-lbs (11.0 Nm)

4. Fully charge the batteries. The dashboard indicator

light should be solid green.

5. Place the discharge unit on a foundation of concrete,

brick, stone, or grounded metal. Be sure area around

discharge unit is well ventilated for proper cooling air

flow, and the unit is at least 18 inches (46 cm) away

from walls or equipment.

6. Connect the RED (+) cable of the discharger unit to

the positive terminal of the rear-most battery in the

LEFT bank (driver side) with the cable that leads to

the top terminal of Contactor).

7. Connect the BLACK (-) cable of the discharger unit

to the negative terminal of the rear-most battery in

the RIGHT bank (passenger side) with the cable that

leads to the negative (-) terminal of the Controller.

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.25

Page 32

GENERAL / BATTERY

TOP VIEW OF DISCHARGER CONNECTION

8. With cables securely connected, the discharger unit

will display the voltage of the battery set.

NOTE

Depending on battery condition and state of charge, the

battery voltage may be considerably higher than 48

volts.

WARNING

Do not touch the back or sides of the case during or just

after operation of the discharge unit. A large amount of

energy is being dissipated by the unit and the case will

become hot. To reduce the risk of fire, do not use the

discharger near flammable materials or vapors.

Never disconnect the discharge unit from the batteries

while the unit is operating. The large amount of energy

being dissipated by the resistive element could cause

damage to the discharge unit if the fan is not running.

11. The discharger will stop when one of the following

conditions occurs:

• START / STOP button is pressed.

• Shut-off voltage (42 volts) has been reached.

• Maximum time shut-off. This is programmable from 5

to 240 minutes, but should be set to a minimum of 200

minutes.

• Over temperature shut-off.

12. When a discharge cycle has been terminated (the

discharger shuts off, and OFF is displayed on the

screen) the cooling fan may continue to run for a

certain amount of time to cool the internal coils.

13. Check to see which type of shut-off has occurred by

pressing and releasing the DISPLAY button.

• If the value in Func2 is the value programmed for

maximum timer, then the terminating method was by

maximum time shut-off.

• If the value in Function 3 is the value programmed for

the shut-off voltage, then the terminating method was

by shut-off voltage.

• If NEITHER maximum time or shut-off voltage caused

the termination, then it was caused by overtemperature or by someone pressing the START/

STOP button.

• If overheat was the cause, make sure nothing is

obstructing the ventilation area around the discharge

unit and that the unit is at least 18 inches from walls or

equipment. Be sure cooling fan is operating (see

discharger instructions).

14. Press the DISPLAY button to view Func2 (discharge

time) and record the time in minutes from the display.

9. Press the START/STOP button to begin a discharge

cycle. The cooling fan on the discharge unit should

start running.

10. Note the time of day and the ambient (room)

temperature for reference at end of discharge cycle.

NOTE: Although the discharger unit monitors total

discharge time, it is advisable to note the time of day

to compare with the logged data in the discharger

unit at the end of the discharge cycle. The temperature is required for calculation of Adjusted Discharge

Time later.

1.26

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 33

GENERAL / BATTERY

15. Refer to Table 5. If ambient temperature recorded

earlier was below 80° F, multiply discharge time in

minutes by the multiplier value in Table 5 that

corresponds to that temperature. Record Adjusted

Discharge Time.

At peak capacity, the discharge cycle time will be

about 220 minutes (3 hours and 40 minutes). If the

Adjusted Discharge Time is greater than 175 minutes

(2 hours and 55 minutes) the battery pack is in good

to excellent condition, and no further testing is required. If the adjusted discharge time is LESS than

175 minutes, proceed to the next step - Battery

Testing.

TABLE 5:

Time Adjustment For Temperature

TEMP,

F

60 15.5 1.15

62 17 1.13

64 18 1.11

66 19 1.10

68 20 1.08

70 21 1.07

72 22 1.05

74 23 1.04

76 24.5 1.03

78 25.5 1.01

80-100

Adjusted Discharge Time = Multiplier x Discharge

Minutes

BATTERY VOLTAGE TESTING (LOADED)

16. Have a digital voltmeter ready and set to Volts DC.

17. Press START/STOP to re-start the discharger and

test battery voltages under load. A 3-minute test

cycle will begin, allowing ample time to test all (8)

batteries.

18. Connect red meter lead to positive and black meter

lead to negative terminal post of each individual

battery. Record voltage reading in the table below.

19. Replace any battery with a voltage less than 9 volts.

TEMP,

C

26.5-

38.0

MULTIPLIER

1.00

ADJUSTED

DISCHARGE TIME

20. Press START/STOP to end test. DO NOT disconnect

the discharger until cooling fan stops!

BATTERY VOLTAGE UNDER LOAD

LEFT (DRIVER’S SIDE)

BATTERIES

Outside battery (Bat 1)

Front battery (Bat 2)

Center battery (Bat 3)

Rear battery (Bat 4)

VOLTAGE

MEASUREMENT

BATTERY VOLTAGE UNDER LOAD

RIGHT (PASSENGER SIDE)

BATTERIES

Outside battery (Bat 5)

Front battery (Bat 6)

Center battery (Bat 7)

Rear battery (Bat 8)

VOLTAGE

MEASUREMENT

BATTERY SPECIFIC GRAVITY TEST

A Specific Gravity test measures the density of battery

electrolyte in relation to water (water = 0). Specific gravity

is the best indicator of battery condition and can identify

a weak cell or cells in an individual battery.

A temperature-compensated digital or a numerically

graduated hydrometer is required for this test. Floating

ball types cannot be used.

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.27

Page 34

GENERAL / BATTERY

1. Fully charge the batteries. Be sure terminals and

cables are clean and tight before charging.

2. Remove cell caps on the battery to be tested. Do not

add distilled water at this time.

3. Insert hydrometer draw tube into the cell to be

tested. Fill and drain the hydrometer 2-4 times to mix

the fluid for a more accurate reading before pulling a

sample and record the reading. Be sure enough fluid

is drawn in the sample to fully support the float.

4. Repeat steps above for each cell in the battery (5).

5. Check the state of charge compared to Specific

Gravity Table 6 on Specific Gravity / Charge

Percentage Table, page 1.35.

BATTERY SPECIFIC GRAVITY

LEFT SIDE

BATTERIES

(DRIVER SIDE)

CELL #: C1 C2 C3 C4 C5 C6

Outside battery

(Bat 1)

Front battery (Bat

2)

Center battery

(Bat 3)

Rear battery (Bat

4)

SPECIFIC GRAVITY

MEASUREMENT

BATTERY SPECIFIC GRAVITY

RIGHT SIDE

BATTERIES

(PASSENGER

SIDE)

CELL #: C1 C2 C3 C4 C5 C6

Outside battery

(Bat 5)

Front battery (Bat

6)

Center battery

(Bat 7)

Rear battery (Bat

8)

SPECIFIC GRAVITY

MEASUREMENT

1.28

BATTERY REMOVAL AND INSTALLATION

Review all Battery Safety information.

See Fig. 1 for proper orientation of battery terminals and

cable routing for reference.

1. Turn key switch OFF.

2. Set parking brake.

3. Remove seat and storage trays.

4. DISCONNECT the battery charging cord from the

AC outlet and then from the vehicle charge cord.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 35

GENERAL / BATTERY

5. DISCONNECT the main power connector.

Always disconnect the Main Power Connector (A)

before servicing or unplugging any electrical

components.

6. FRONT - Remove the lower T27 Torx-head screws

retaining the foot pads.

10. Remove the three T27 Torx-head screws retaining

the foot pads.

11. Remove the three T27 Torx-head screws retaining

the rear panel.

12. Repeat this procedure to remove the other rear

fender.

13. Remove battery cables in order shown on Battery

Cable Removal, page 1.31 using an insulated

ratchet, extension, and socket.

14. Remove battery retaining bracket bolts. Place bolts

at a safe distance from battery compartment so they

cannot fall and make contact with battery terminals.

15. Remove batteries.

16. Clean battery tub

baking soda and water solution then rinse with clear

water and dry with clean shop towels.

and lower battery trayewith a

w

1

17. Clean battery retainer bolt threads thoroughly and

dry with compressed air. Apply anti-seize compound

to threaded holes with a small brush.

18. Install battery tub with retainer bolt holes aligned.

19. Install batteries with terminals oriented as shown on

Battery Terminal Orientation And Cable Routing,

page 1.29.

20. Apply anti seize compound liberally to threads of

7. Remove the two push rivets retaining the front fender

and remove the fender from the vehicle.

8. Repeat this procedure to remove the other front

fender.

9. REAR - Remove the lowTorx-head screws retaining

the foot pads.

retainer bolts.

21. Battery Cable Installation, page 1.32 in order shown.

22. Assemble parts removed for access and re-connect

Main Power Connector.

BATTERY TERMINAL ORIENTATION AND

CABLE ROUTING

The following illustration depicts general cable orientation and routing. See following pages for cable removal and

installation sequence.

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.29

Page 36

GENERAL / BATTERY

WARNING

Do not work in or around the battery compartment or on any electrical component on the vehicle while charging

batteries. The chassis of the vehicle is at ground potential when the battery charging cord is connected to an AC

outlet. This increases the risk of accidental short circuits to battery terminals or wires caused by tools or other objects.

1.30

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 37

BATTERY CABLE REMOVAL

GENERAL / BATTERY

1

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

1.31

Page 38

GENERAL / BATTERY

BATTERY CABLE INSTALLATION

Battery Retainer Bracket Nut: 8 ft-lbs (11 Nm)Battery Terminal Nut: 8 ft-lbs (11 Nm)

TORQUE

1.32

9926595 R01 - 2015-2016 RANGER EV Service Manual

© Copyright Polaris Industries Inc.

Page 39

GENERAL / BATTERY

BATTERY STORAGE

The battery charger can be connected during extended

storage periods provided all battery charging precautions

and guidelines are followed. Battery Charging, page

1.21.

The storage area must be well ventilated. Always remove

any storage covers from the vehicle and open any cab

doors (if equipped) and hood before charging.

Clean batteries, torque terminal nuts Battery Contactor

Fastener Torque, page 1.21and inspect fluid level Battery

Water Level, page 1.22 prior to storage.

If the storage area, conditions, or circumstances do not

allow the charger to be plugged in continuously, fully

charge the batteries initially, and then recharge once

every 2-3 months following all charging guidelines. The

main power connector should be disconnected if the unit

is stored for longer than a month without the charger

being plugged in. The main power connector must be

reconnected to charge the batteries.

Review all Battery Charging Warning, page 1.18. The

charger will maintain batteries at their peak condition

automatically.

ACCESSORY INSTALLATION

PRECAUTIONS

Follow these guidelines when installing accessories on

the RANGER EV:

• USE ONLY GENUINE RANGER EVAPPROVED

ACCESSORIES and follow the instructions provided.

• ALWAYS make sure that all electrical accessories are

grounded directly to the negative (-) battery post (of

the auxiliary accessory battery) or to the accessory

terminal block GROUND as indicated in the

instructions.

• NEVER use the chassis or body as a ground

connection.

• NEVER connect an auxiliary battery to the factoryinstalled DC-to-DC converter. If more than 10 amps

are needed for accessories, always install the polaris

approved auxiliary accessory battery kit.

• NEVER connect a 12 volt accessory directly to the

drive system batteries. Battery damage will occur.

ALWAYS connect any powered accessory to a 12 volt

auxiliary power outlet or to the accessory terminal

board.

BATTERY CHARGER

The battery charger unit is located under the hood. A

display of 10 LEDs on the right side of the charger unit

function as outlined below.

q

1