POLARIS RZR User Manual

GENERAL INFORMATION

CHAPTER 1 1

GENERAL INFORMATION

MODEL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 ENGINE DESIGNATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 VIN IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 ENGINE SERIAL NUMBER LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 UNIT SERIAL NUMBER (VIN) LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

VEHICLE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

PUBLICATION NUMBERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 PAINT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 REPLACEMENT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 GENERAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

GENERAL: 2009 RANGER RZR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 GENERAL: 2009 RANGER RZR “S” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 DETAILED: 2009 RANGER RZR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6 DETAILED: 2009 RANGER RZR “S” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

MISC. SPECIFICATIONS AND CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8

CONVERSION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 STANDARD TORQUE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 SAE TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.10 METRIC TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.10 DECIMAL EQUIVALENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.10 GLOSSARY OF TERMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

1.1

GENERAL INFORMATION

MODEL INFORMATION

Model Identification

The machine model number must be used with any correspondence regarding warranty or service.

|

|

|

|

|

|

|

Machine Model Number Identification |

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

R |

0 9 |

|

V H |

7 6 |

A D |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

} } } } |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

Model Year |

|

|

|

|

|

|

|

|

|

|

|

Emissions & |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model Option |

||||||||||||

|

|

|

|

|

|

Designation |

|

|

Basic Chassis |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Designation |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Designation |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Engine Designation Number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

EH076OLE022 ........................................................................ |

|

|

|

|

|

|

|

|

|

|

|

|

|

Twin Cylinder, Liquid Cooled, OHV 4 Stroke, Electric Start (RZR) |

|||||||||||||||

EH076OLE072 ................................................................. |

|

|

|

|

|

|

|

|

|

|

Twin Cylinder, Liquid Cooled, OHV 4 Stroke, Electric Start (RZR “S”) |

||||||||||||||||||

VIN Identification |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

World |

|

Vehicle Description |

|

|

|

|

|

|

Vehicle Identifier |

|

|

|

|

||||||||||||||

|

Mfg. ID |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

10 |

11 |

12 |

13 |

14 |

|

15 |

16 |

17 |

|

||||||||||

|

4 X A |

V H 7 6 A * |

9 P 0 0 0 0 0 0 |

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

} |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Engine |

|

|

|

Year |

|

|

|

|

Individual |

|

Serial No. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

Body Style |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

Emissions |

|

Plant |

No. |

|

|

|

|

|

|

* This could be either |

|||||||||||

|

|

|

|

Powertrain |

|

Check Digit |

|

|

|

|

|

|

|

|

|

|

|

a number or a letter |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

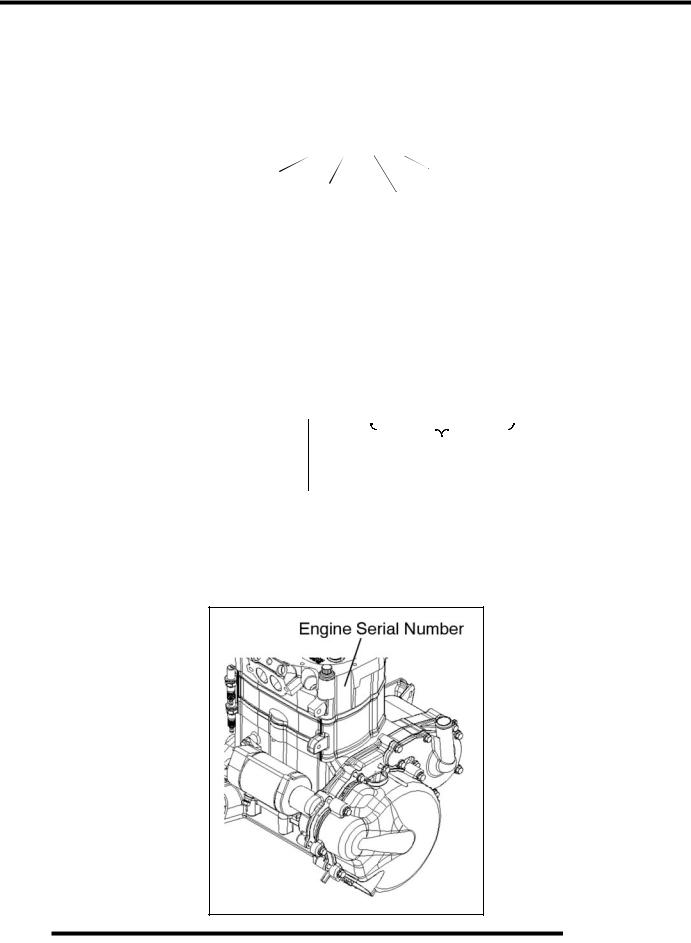

Engine Serial Number Location

Whenever corresponding about an engine, be sure to refer to the engine model number and serial number. This information can be found on the sticker applied to the cylinder head on the side of engine.

1.2

GENERAL INFORMATION

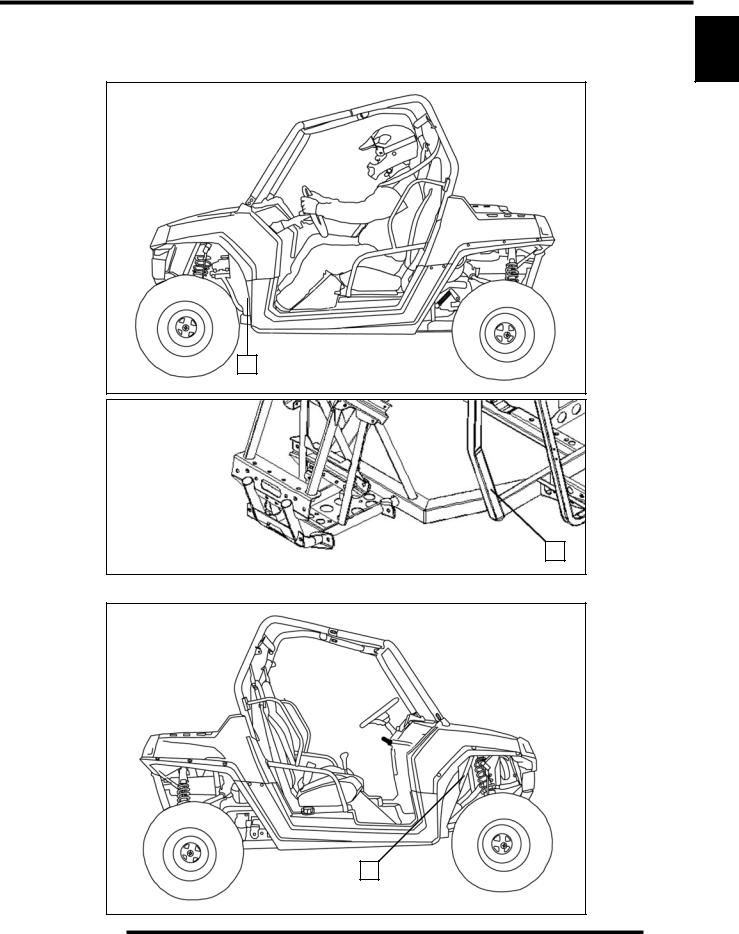

Unit Serial Number (VIN) Location

The machine model number and serial number (VIN) are important for vehicle identification. The VIN number (A) is stamped on a portion of the front left frame rail close to the left front wheel.

A |

A |

1 |

The VIN and model number are also located on a decal (B) attached to the frame support accessible through the front right wheel well.

B |

1.3

GENERAL INFORMATION

VEHICLE INFORMATION

Publication Numbers

Model |

Model No. |

Owner’s Manual PN |

Parts Manual PN |

|

|

|

|

2009 RANGER RZR |

R08VH76AD, AG, AH, AO |

9921878 |

9921879 |

|

|

|

|

2009 RANGER RZR “S” |

R08VH76AX |

9921878 |

9922130 |

|

|

|

|

NOTE: When ordering service parts be sure to use the correct parts manual.

NOTE: Polaris factory publications can be found at www.polarisindustries.com or purchased from www.purepolaris.com.

Paint Codes

Painted Part |

Color Description |

Polaris Number |

|

|

|

Frame / Bumpers / Racks |

Gloss Black |

P-067 |

|

|

|

Frame / Bumpers / Racks |

Matte Black |

P-458 |

|

|

|

Plastic - Hood / Dash / Fenders |

Indy Red |

P-293 |

|

|

|

Plastic - Hood / Dash / Fenders |

Sage Brush Green Metallic |

P-498 |

|

|

|

Replacement Keys

Replacement keys can be made from the original key. To identify which series the key is, take the first two digits on the original key and refer to the chart to the right for the proper part number.

|

|

|

|

KEY COVER |

|

Series# |

Part Number |

|

20 |

4010278 |

|

P/N 5533534 |

|

||

|

21 |

4010278 |

|

|

|

||

|

|

22 |

4010321 |

|

|

23 |

4010321 |

Key Series |

|

27 |

4010321 |

|

28 |

4010321 |

|

Number |

|

||

|

31 |

4110141 |

|

|

|

||

|

|

32 |

4110148 |

|

|

67 |

4010278 |

|

|

68 |

4010278 |

|

|

|

|

SPECIAL TOOLS

Special tools may be required while servicing this vehicle. Some of the tools listed or depicted are mandatory, while other tools maybe substituted with a similar tool, if available. Polaris recommends the use of Polaris Special Tools when servicing any Polaris product. Dealers may order special tools through Polaris’ official tool supplier, SPX Corporation, by phone at 1-800-328-6657 or on-line at http://polaris.spx.com/.

1.4

GENERAL INFORMATION

GENERAL SPECIFICATIONS

MODEL: 2009 RANGER RZR

MODEL NUMBER: R09VH76AD, AG, AH, AO

ENGINE MODEL: EH076OLE022

Category |

Dimension / Capacity |

|

|

|

|

Length |

102 in. / 259 cm |

|

|

|

|

Width |

50 in. / 127 cm |

|

|

|

|

Height |

68.5 in. / 174 cm |

|

|

|

|

Wheel Base |

77 in. / 196 cm |

|

|

|

|

Ground Clearance |

10 in. / 25.4 cm |

|

|

|

|

Dry Weight |

945 lbs. / 429 kg |

|

|

|

|

Gross Vehicle Weight |

1727 lbs. / 783 kg |

|

|

|

|

Front Storage |

25 lbs. / 11.3 kg |

|

Capacity |

||

|

||

Cargo Box Dimension |

42 in. x 22 in. / 107 cm x 56 cm |

|

|

|

|

Cargo Box Capacity |

300 lbs. / 136 kg |

|

|

|

|

Maximum Weight |

740 lbs. / 336.4 kg |

|

(Includes rider(s), cargo, accessories |

||

Capacity (Payload) |

||

and trailer tongue weight) |

||

|

||

|

|

|

Hitch Towing Capacity |

1500 lbs. / 680 kg |

|

|

|

|

Hitch Tongue Capacity |

150 lbs. / 68 kg |

|

|

|

MODEL: 2009 RANGER RZR “S”

MODEL NUMBER: R09VH76AX

ENGINE MODEL: EH076OLE072

Category |

Dimension / Capacity |

|

|

|

|

Length |

106 in. / 269 cm |

|

|

|

|

Width |

60.5 in. / 154 cm |

|

|

|

|

Height |

70.5 in. / 179 cm |

|

|

|

|

Wheel Base |

77 in. / 196 cm |

|

|

|

|

Ground Clearance |

12 in. / 30.5 cm |

|

|

|

|

Dry Weight |

1000 lbs. / 454 kg |

|

|

|

|

Gross Vehicle Weight |

1782 lbs. / 808 kg |

|

|

|

|

Front Storage |

25 lbs. / 11.3 kg |

|

Capacity |

||

|

||

Cargo Box Dimension |

42 in. x 22 in. / 107 cm x 56 cm |

|

|

|

|

Cargo Box Capacity |

300 lbs. / 136 kg |

|

|

|

|

Maximum Weight |

740 lbs. / 336.4 kg |

|

(Includes rider(s), cargo, accessories |

||

Capacity (Payload) |

||

and trailer tongue weight) |

||

|

||

|

|

|

Hitch Towing Capacity |

1500 lbs. / 680 kg |

|

|

|

|

Hitch Tongue Capacity |

150 lbs. / 68 kg |

|

|

|

1 |

1.5

GENERAL INFORMATION

MODEL: 2009 RANGER RZR

MODEL NUMBER: R09VH76AD, AG, AH, AO ENGINE MODEL: EH076OLE022

Engine |

||

Platform |

Polaris Domestic Twin Cylinder, |

|

Liquid Cooled, 4-Stroke |

||

|

||

|

|

|

Engine Model Number |

EH076OLE022 |

|

|

|

|

Engine Displacement |

760cc |

|

|

|

|

Number of Cylinders |

2 |

|

|

|

|

Bore & Stroke (mm) |

80 x 76.5 mm |

|

|

|

|

Compression Ratio |

9.78:1 |

|

|

|

|

Compression Pressure |

150-170 psi |

|

|

|

|

Engine Idle Speed |

1150 ± 100 RPM |

|

|

|

|

Engine Max Operating RPM |

6500 ± 200 RPM |

|

|

|

|

Lubrication |

Pressurized Wet Sump |

|

|

|

|

Oil Requirements |

PS-4 PLUS / 2W-50 Synthetic |

|

|

|

|

Oil Capacity |

2 qts. / 1.9 liters |

|

|

|

|

Coolant Capacity |

4.8 qts. / 4.5 liters |

|

|

|

|

Overheat Warning |

Instrument Cluster Indicator |

|

|

|

|

Exhaust System |

Single Headpipe / Single Silencer |

|

|

|

|

Fuel |

System |

|

Fuel System Type |

Bosch Electronic Fuel Injection |

|

|

|

|

Fuel Delivery |

Electronic Fuel Pump (in tank) |

|

|

|

|

Fuel Pressure |

39 psi |

|

|

|

|

Fuel Filters |

See Chapter 4 |

|

|

|

|

Fuel Capacity / Requirement |

7 gal. (26.5 liters) |

|

87 Octane (minimum) |

||

|

||

|

|

|

Electrical |

||

Alternator Max Output |

500 Watts @ 3000 RPM |

|

|

|

|

Lights: Main Headlights |

2 - Single Beam 55 W / Halogen |

|

|

|

|

Tail / Brake |

2 - 5 Watts / 2 - 5 Watts |

|

|

|

|

Starting System |

Electric Start |

|

|

|

|

Ignition System |

Bosch EFI (ECU Controlled) |

|

|

|

|

Ignition Timing |

13° BTDC @ 1200 RPM |

|

|

|

|

Spark plug / Gap |

Champion RC7YC3 / |

|

.035 in. (0.9 mm) |

||

|

||

|

|

|

Battery |

Yuasa YTX20HL / |

|

18 Amp Hr. / 310 CCA / 12 Volt |

||

|

||

|

|

|

Instrument Type |

Analog Speedometer |

|

with Multifunction LCD |

||

|

||

|

|

|

DC Outlet |

Standard 12 V |

|

|

|

|

Relays |

EFI / Fan |

|

|

|

|

Circuit Breaker |

Fan Motor: 20 Amp |

|

|

|

|

|

Chassis: 20 Amp |

|

|

EFI: 15 Amp |

|

Fuses |

Lights: 15 Amp |

|

|

Accessory: 15 Amp |

|

|

Speedo/ECU: 5 Amp |

|

|

|

|

|

|

|

|

Drivetrain |

|

||

|

Transmission Type |

|

Polaris Automatic PVT |

||||

|

|

|

|

|

|

|

|

|

Gear Ratio: Front / Rear |

|

|

|

|||

|

|

High |

|

|

3.14:1 |

||

|

|

Low |

|

|

8.71:1 |

||

|

|

Rev |

|

|

5.94:1 |

||

|

|

|

|

|

|

|

|

|

Drive Ratio - Front |

|

3.82:1 |

||||

|

|

|

|

|

|

|

|

|

Drive Ratio - Final |

|

3.70:1 |

||||

|

|

|

|

|

|

|

|

|

|

Shift Type |

|

In Line Shift - H / L / N / R / P |

|||

|

|

|

|

|

|

|

|

|

Front Gearcase Oil Requirements |

|

Polaris Demand Drive LT |

||||

|

|

Premium Fluid |

|||||

|

|

|

|

|

|

6.75 oz. (200 ml) |

|

|

|

|

|

|

|

|

|

|

Transmission Oil Requirements |

Polaris High Performance AGL |

|||||

|

|

Main Gearcase |

|

|

24 oz. (710 ml) |

||

|

|

|

|

|

|

|

|

|

Transmission Oil Requirements |

Polaris High Performance AGL |

|||||

|

|

Transfer Case |

|

|

14 oz. (414 ml) |

||

|

|

|

|

|

|

|

|

|

Rear Gearcase Oil Requirements |

|

Polaris Premium ADF |

||||

|

|

26 oz. (769 ml) |

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Belt |

|

|

3211113 |

||

|

|

|

|

|

|

|

|

|

|

Steering / |

Suspension |

|

|||

|

|

Front Suspension |

|

Independent Dual A-arm |

|||

|

|

|

w/Anti-Sway Bar |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Front Travel |

|

|

9 in. / 23 cm |

||

|

|

|

|

|

|

|

|

|

|

Rear Suspension |

Rolled IRS w/Anti-Sway Bar |

||||

|

|

|

|

|

|

|

|

|

|

Rear Travel |

|

|

9.5 in. / 24 cm |

||

|

|

|

|

|

|

|

|

|

Shock Preload Adjustment |

|

Cam Adjustment |

||||

|

|

Front / Rear |

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Toe Out |

|

|

1/8-1/4 in. / 3-6.35 mm |

||

|

|

|

|

|

|

|

|

|

|

|

|

Wheels |

/ Brakes |

|

|

|

|

Front Wheel Size |

|

12 x 6 / 10 gauge |

|||

|

|

Front Tire Size |

|

|

Maxxis / 25 x 8 R12 |

||

|

|

|

|

|

|

|

|

|

|

Rear Wheel Size |

|

12 x 8 / 10 gauge |

|||

|

|

Rear Tire Size |

|

|

Maxxis / 25 x 10 R12 |

||

|

|

|

|

|

|

|

|

|

Tire Air Pressure - Front / Rear |

|

8 psi (55 kPa) |

||||

|

|

|

|

|

|

|

|

|

Brake - Front / Rear |

|

Foot Actuated - 4 Wheel |

||||

|

|

Hydraulic Disc |

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Brake Fluid |

|

|

DOT 4 |

||

|

|

|

|

|

|

|

|

CLUTCH CHART |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Altitude |

|

Shift Weight |

Drive Spring |

Driven |

||

|

|

Spring |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-1500 |

|

20-62 |

|

Blue / Red |

Red or Yellow |

|

Meters |

(0-5000) |

|

(5631700) |

(7043199) |

(3234452) |

|

|

(Feet) |

1500-3700 |

|

20-58 |

|

Blue / Red |

Red or Yellow |

|

|

(5000 - 12000) |

|

(5631216) |

(7043199) |

(3234452) |

|

|

|

|

|

|

|

|

|

1.6

GENERAL INFORMATION

MODEL: 2009 RANGER RZR “S” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drivetrain |

|

1 |

||||

MODEL NUMBER: R09VH76AX |

|

Transmission Type |

|

Polaris Automatic PVT |

||||||

|

|

|

|

|

|

|

|

|||

ENGINE MODEL: EH076OLE072 |

|

Gear Ratio: Front / Rear |

|

|

|

|

||||

|

|

|

|

High |

|

|

3.14:1 |

|

||

Engine |

|

|

|

|

|

|||||

|

|

Low |

|

|

8.71:1 |

|

||||

Platform |

Polaris Domestic Twin Cylinder, |

|

|

Rev |

|

|

5.94:1 |

|

||

Liquid Cooled, 4-Stroke |

|

|

|

|

|

|

|

|

|

|

|

|

Drive Ratio - Front |

|

3.82:1 |

|

|||||

|

|

|

|

|

||||||

Engine Model Number |

EH076OLE072 |

|

|

|

|

|

|

|

|

|

|

Drive Ratio - Final |

|

3.70:1 |

|

||||||

|

|

|

|

|

||||||

Engine Displacement |

760cc HO |

|

|

|

|

|

|

|

|

|

|

|

Shift Type |

|

In Line Shift - H / L / N / R / P |

|

|||||

|

|

|

|

|

|

|||||

Number of Cylinders |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Polaris Demand Drive LT |

|

|||

|

|

|

|

|

|

|

|

|

||

Bore & Stroke (mm) |

80 x 76.5 mm |

|

Front Gearcase Oil Requirements |

|

Premium Fluid |

|

||||

Compression Ratio |

11:1 |

|

|

|

|

|

|

6.75 oz. (200 ml) |

|

|

|

|

|

Transmission Oil Requirements |

Polaris High Performance AGL |

|

|||||

Compression Pressure |

165-185 psi |

|

||||||||

|

|

|

|

Main Gearcase |

|

|

24 oz. (710 ml) |

|

||

Engine Idle Speed |

1250 ± 100 RPM |

|

|

|

|

|

||||

|

|

|

Transmission Oil Requirements |

Polaris High Performance AGL |

|

|||||

Engine Max Operating RPM |

6600 ± 200 RPM |

|

||||||||

|

|

Transfer Case |

|

|

14 oz. (414 ml) |

|

||||

|

|

|

|

|

|

|

||||

Lubrication |

Pressurized Wet Sump |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

Rear Gearcase Oil Requirements |

|

Polaris Premium ADF |

|

||||||

|

|

|

|

|

||||||

Oil Requirements |

PS-4 PLUS / 2W-50 Synthetic |

|

|

|

||||||

|

|

26 oz. (769 ml) |

|

|||||||

|

|

|

|

|

|

|

|

|

||

Oil Capacity |

2 qts. / 1.9 liters |

|

|

|

|

|

|

|

|

|

|

|

Belt |

|

|

3211130 |

|

||||

|

|

|

|

|

|

|

||||

Coolant Capacity |

4.8 qts. / 4.5 liters |

|

|

|

|

|

|

|

|

|

|

|

Steering / Suspension |

|

|

||||||

|

|

|

|

|

|

|||||

Overheat Warning |

Instrument Cluster Indicator |

|

|

|

|

|

|

|

|

|

|

Front Suspension / Shock |

|

Independent Dual A-arm |

|

||||||

|

|

|

|

|

||||||

Exhaust System |

Dual Headpipe / Single Silencer |

|

|

FOX™ PODIUM X |

|

|||||

|

|

|

|

|

|

|

||||

Fuel |

System |

|

|

Front Travel |

|

|

12 in. / 30.5 cm |

|

||

Fuel System Type |

Bosch Electronic Fuel Injection |

|

Rear Suspension / Shock |

Rolled IRS w/Anti-Sway Bar |

|

|||||

|

|

|

|

FOX™ PODIUM X |

|

|||||

Fuel Delivery |

Electronic Fuel Pump (in tank) |

|

|

|||||||

|

|

|

|

|

|

|

||||

|

|

|

|

Rear Travel |

|

|

12 in. / 30.5 cm |

|

||

Fuel Pressure |

39 psi |

|

|

|

|

|

||||

|

|

|

Shock Preload Adjustment |

Threaded Shock Adjustment |

|

|||||

Fuel Filters |

See Chapter 4 |

|

||||||||

|

|

|

|

Front / Rear |

|

|

with Spanner Wrench |

|

||

Fuel Capacity / Requirement |

7 gal. (26.5 liters) |

|

|

|

|

|

||||

87 Octane (minimum) |

|

|

Toe Out |

|

|

1/8-1/4 in. / 3-6.35 mm |

|

|||

|

|

|

|

|

|

|||||

Electrical |

|

|

|

|

Wheels / Brakes |

|

|

|||

Alternator Max Output |

500 Watts @ 3000 RPM |

|

|

Front Wheel Size |

|

12 x 6 / Cast Aluminum |

|

|||

|

|

|

|

Front Tire Size |

|

Maxxis Bighorn / 26 x 9 R12 |

|

|||

Lights: Main Headlights |

2 - Single Beam 55 W / Halogen |

|

|

|

|

|||||

|

|

|

|

Rear Wheel Size |

|

12 x 8 / Cast Aluminum |

|

|||

Tail / Brake |

2 - 5 Watts / 2 - 5 Watts |

|

|

|

|

|||||

|

|

Rear Tire Size |

|

Maxxis Bighorn / 26 x 12 R12 |

|

|||||

|

|

|

|

|

|

|||||

Starting System |

Electric Start |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

Tire Air Pressure - Front / Rear |

|

8 psi (55 kPa) |

|

||||||

|

|

|

|

|

||||||

Ignition System |

Bosch EFI (ECU Controlled) |

|

|

|||||||

|

|

|

|

|

|

|

|

|

||

|

Brake - Front / Rear |

|

Foot Actuated - 4 Wheel |

|

||||||

|

|

|

|

|

||||||

Ignition Timing |

13° BTDC @ 1200 RPM |

|

|

|

||||||

|

|

Hydraulic Disc |

|

|||||||

|

|

|

|

|

|

|

|

|

||

|

Champion RC7YC3 / |

|

|

|

|

|

|

|

|

|

Spark plug / Gap |

|

|

Brake Fluid |

|

|

DOT 4 |

|

|||

.035 in. (0.9 mm) |

|

|

|

|

|

|||||

|

|

CLUTCH CHART |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

Battery |

Yuasa YTX20HL / |

|

|

|

|

|

||||

18 Amp Hr. / 310 CCA / 12 Volt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instrument Type |

Analog Speedometer |

|

Altitude |

|

Shift Weight |

Drive Spring |

Driven |

|

||

|

|

Spring |

|

|||||||

with Multifunction LCD |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-1500 |

|

21-74 |

|

Red / White |

Red or Yellow |

|

DC Outlet |

Standard 12 V |

|

|

|

|

|||||

|

Meters |

(0-5000) |

|

(5632117) |

(7043349) |

(3234452) |

|

|||

|

|

|

|

|

||||||

Relays |

EFI / Fan |

|

||||||||

|

(Feet) |

|

|

|

|

|

|

|

||

|

1500-3700 |

|

21-70 |

|

Red / White |

Red or Yellow |

|

|||

|

|

|

|

|

|

|||||

Circuit Breaker |

Fan Motor: 20 Amp |

|

|

(5000 - 12000) |

|

(5632127) |

(7043349) |

(3234452) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chassis: 20 Amp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EFI: 15 Amp |

|

|

|

|

|

|

|

|

|

Fuses |

Lights: 15 Amp |

|

|

|

|

|

|

|

|

|

|

Accessory: 15 Amp |

|

|

|

|

|

|

|

|

|

|

Speedo/ECU: 5 Amp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.7

GENERAL INFORMATION

MISC. SPECIFICATIONS AND CHARTS

Conversion Table

°C to °F: 9/5(°C + 32) = °F |

°F to °C: 5/9(°F - 32) = °C |

1.8

GENERAL INFORMATION

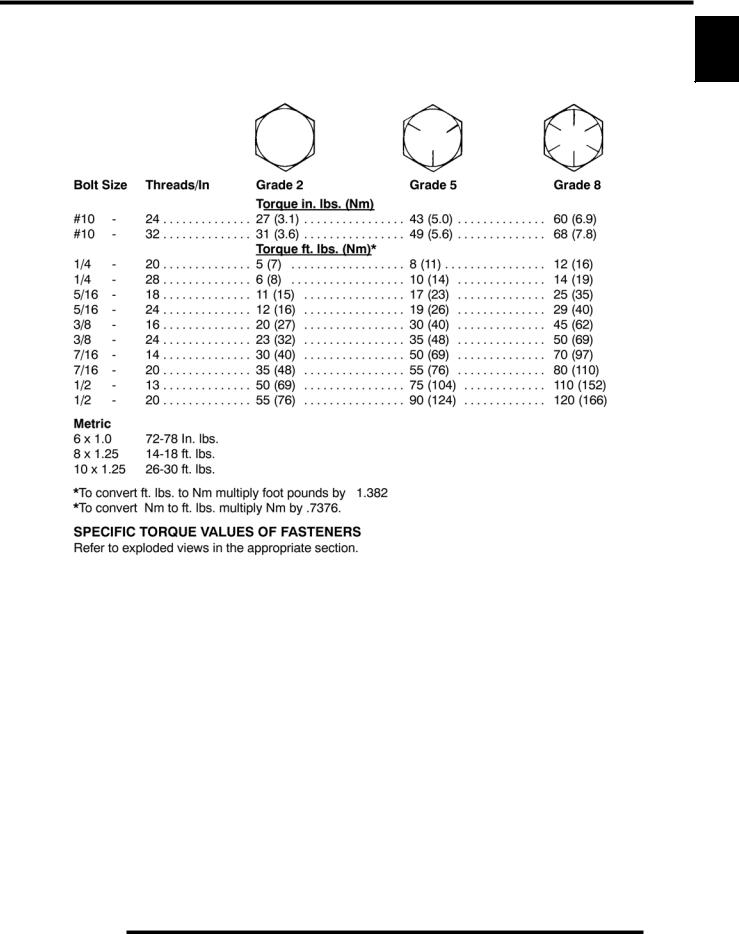

Standard Torque Specifications

The following torque specifications are to be used only as a general guideline. There are exceptions in the steering, suspension, and engine areas. Always consult the exploded views or each manual section for torque values of fasteners before using standard torque.

1 |

1.9

GENERAL INFORMATION

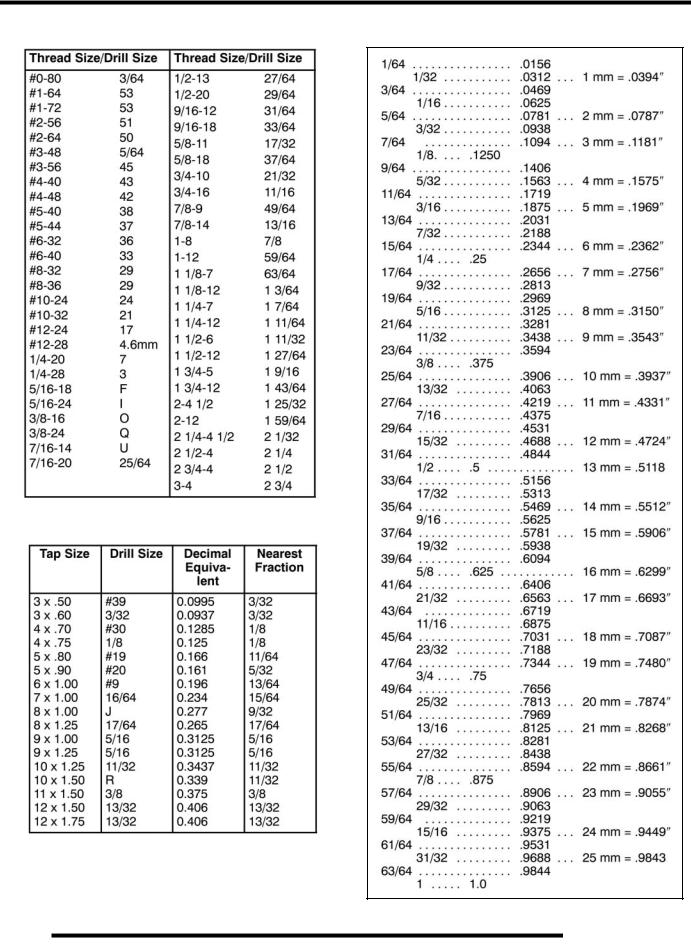

SAE Tap / Drill Sizes |

Decimal Equivalents |

Metric Tap / Drill Sizes

1.10

GENERAL INFORMATION

Glossary of Terms

ABDC: After bottom dead center. ACV: Alternating current voltage.

Alternator: Electrical generator producing voltage alternating current. ATDC: After top dead center.

BBDC: Before bottom dead center. BDC: Bottom dead center. BTDC: Before top dead center. CC: Cubic centimeters.

Center Distance: Distance between center of crankshaft and center of driven clutch shaft.

Chain Pitch: Distance between chain link pins (No. 35 = 3/8" or 1 cm). Polaris measures chain length in number of pitches. CI: Cubic inches.

Clutch Buttons: Plastic bushings which aid rotation of the movable sheave in the drive and driven clutch.

Clutch Offset: Drive and driven clutches are offset so that drive belt will stay nearly straight as it moves along the clutch face. Clutch Weights: Three levers in the drive clutch which relative to their weight, profile and engine RPM cause the drive clutch to close and grip the drive belt.

Crankshaft Run-Out: Run-out or "bend" of crankshaft measured with a dial indicator while crankshaft is supported between centers on V blocks or resting in crankcase. Measure at various points especially at PTO.

DCV: Direct current voltage

CVT: Centrifugal Variable Transmission (Drive Clutch System) DCV: Direct current voltage.

Dial Bore Gauge: A cylinder measuring instrument which uses a dial indicator. Good for showing taper and out-of-round in the cylinder bore.

Electrical Open: Open circuit. An electrical circuit which isn't complete.

Electrical Short: Short circuit. An electrical circuit which is completed before the current reaches the intended load. (i.e. a bare wire touching the chassis).

End Seals: Rubber seals at each end of the crankshaft.

Engagement RPM: Engine RPM at which the drive clutch engages to make contact with the drive belt. ft.: Foot/feet.

Foot Pound: Ft. lb. A force of one pound at the end of a lever one foot in length, applied in a rotational direction. g: Gram. Unit of weight in the metric system.

gal.: Gallon.

ID: Inside diameter. in.: Inch/inches.

Inch Pound: In. lb. 12 in. lbs. = 1 ft. lb. kg/cm²: Kilograms per square centimeter. kg-m: Kilogram meters.

Kilogram/meter: A force of one kilogram at the end of a lever one meter in length, applied in a rotational direction. l or ltr: Liter.

lbs/in²: Pounds per square inch.

Left or Right Side: Always referred to based on normal operating position of the driver. m: Meter/meters.

Mag: Magneto.

Magnetic Induction: As a conductor (coil) is moved through a magnetic field, a voltage will be generated in the windings. Mechanical energy is converted to electrical energy in the stator.

mi.: Mile/miles.

mm: Millimeter. Unit of length in the metric system. 1 mm = approximately .040". Nm: Newton meters.

OD: Outside diameter.

Ohm: The unit of electrical resistance opposing current flow. oz.: Ounce/ounces.

Piston Clearance: Total distance between piston and cylinder wall. psi.: Pounds per square inch.

PTO: Power take off.

PVT: Polaris Variable Transmission (Drive Clutch system) qt.: Quart/quarts.

Regulator: Voltage regulator. Regulates battery charging system output at approx. 14.5 DCV as engine RPM increases. Reservoir Tank: The fill tank in the liquid cooling system.

Resistance: In the mechanical sense, friction or load. In the electrical sense, ohms, resulting in energy conversion to heat. RPM: Revolutions per minute.

Seized Piston: Galling of the sides of a piston. Usually there is a transfer of aluminum from the piston onto the cylinder wall. Possible causes: 1) improper lubrication; 2) excessive temperatures; 3) insufficient piston clearance; 4) stuck piston rings. Stator Plate: The plate mounted under the flywheel supporting the battery charging coils.

TDC: Top dead center. Piston's most outward travel from crankshaft.

Volt: The unit of measure for electrical pressure of electromotive force. Measured by a voltmeter in parallel with the circuit. Watt: Unit of electrical power. Watts = amperes x volts.

WOT: Wide open throttle.

1 |

1.11

GENERAL INFORMATION

NOTES

1.12

MAINTENANCE

CHAPTER 2

MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PERIODIC MAINTENANCE CHART |

. . . . . . . |

2.3 |

2 |

PERIODIC MAINTENANCE OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.3 |

|

|

BREAK-IN PERIOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.3 |

|

|

MAINTENANCE CHART KEY |

2.3 |

|

|

|

|

||

PRE-RIDE - 25 HOUR MAINTENANCE INTERVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.4 |

|

|

50 - 300 HOUR MAINTENANCE INTERVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.5 |

|

|

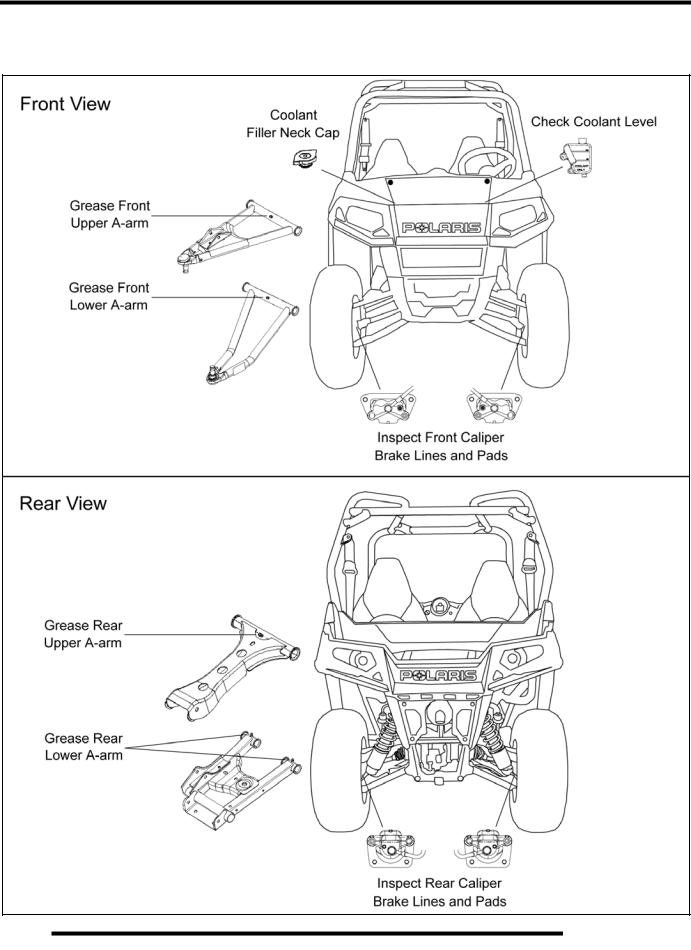

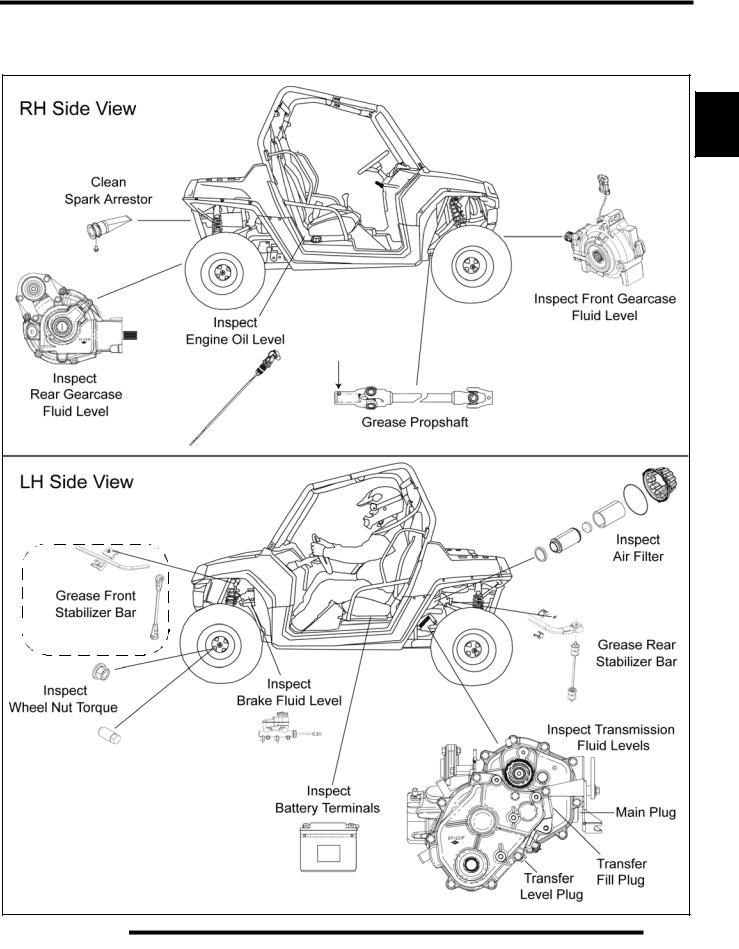

COMPONENT INSPECTION / SERVICE LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

FRONT AND REAR VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6 RH AND LH SIDE VIEWS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

LUBRICANTS / SERVICE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8 MAINTENANCE REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9 GENERAL VEHICLE INSPECTION AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . 2.10

PRE-RIDE / DAILY INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10 FRAME, NUTS, BOLTS, AND FASTENERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10 SHIFT CABLE INSPECTION / ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

FUEL SYSTEM AND AIR INTAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11

FUEL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11 FUEL LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11 FUEL PUMP / FUEL FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11 VENT LINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11 THROTTLE PEDAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12 THROTTLE FREEPLAY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12 THROTTLE CABLE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12 AIR FILTER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.14

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16

ENGINE OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16 ENGINE OIL AND FILTER SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.17 ENGINE BREATHER HOSE INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.18 ENGINE AND TRANSMISSION MOUNT LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2.18 COMPRESSION AND LEAKDOWN TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.18 EXHAUST - SPARK ARRESTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.18

TRANSMISSION AND GEARCASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.19

TRANSMISSION / GEARCASE SPECIFICATION CHART . . . . . . . . . . . . . . . . . . . . . . 2.19 TRANSMISSION LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.19 FRONT GEARCASE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21 REAR GEARCASE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

COOLING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

COOLING SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23 COOLANT LEVEL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23 COOLANT STRENGTH / TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23 COOLING SYSTEM PRESSURE TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24 COOLING SYSTEM HOSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24 RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24 COOLANT DRAIN / RADIATOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

FINAL DRIVE / WHEEL AND TIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

WHEEL, HUB, AND SPINDLE TORQUE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25 WHEEL REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25 WHEEL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25 TIRE INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26 TIRE PRESSURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26 DRIVE SHAFT BOOT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.1

MAINTENANCE

ELECTRICAL AND IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

BATTERY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27 BATTERY REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27 BATTERY INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27 BATTERY OFF SEASON STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28 BATTERY CHARGING (SEALED BATTERY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28 SPARK PLUG SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28 ENGINE TO FRAME GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

STEERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

STEERING INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29 STEERING WHEEL FREEPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29 STEERING INSPECTION / TIE ROD ENDS AND HUBS . . . . . . . . . . . . . . . . . . . . . . . 2.30 TOE ALIGNMENT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30 TOE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

SUSPENSION (RZR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

SPRING PRELOAD ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

SUSPENSION (RZR “S”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.32

SPRING PRELOAD ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.32 SHOCK COMPRESSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.32

BRAKE SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33

BRAKE FLUID INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33 BRAKE PAD / DISC INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33 BRAKE HOSE AND FITTING INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33

2.2

MAINTENANCE

PERIODIC MAINTENANCE CHART

Periodic Maintenance Overview

Inspection, adjustment and lubrication of important components are explained in the periodic maintenance chart.

Inspect, clean, lubricate, adjust and replace parts as necessary. When inspection reveals the need for replacement parts, use genuine Pure Polaris parts available from your Polaris dealer.

NOTE: Service and adjustments are critical. If you’re not familiar with safe service and adjustment procedures, have a qualified dealer perform these operations.

2 |

Maintenance intervals in the following chart are based upon average riding conditions and an average vehicle speed of approximately 10 miles per hour. Vehicles subjected to severe use must be inspected and serviced more frequently.

Severe Use Definition

•Frequent immersion in mud, water or sand

•Racing or race-style high RPM use

•Prolonged low speed, heavy load operation

•Extended idle

•Short trip cold weather operation

Pay special attention to the oil level. A rise in oil level during cold weather can indicate contaminants collecting in the oil sump or crankcase. Change oil immediately if the oil level begins to rise. Monitor the oil level, and if it continues to rise, discontinue use and determine the cause or see your dealer.

Break-In Period

The break-in period consists of the first 25 hours of operation, or the time it takes to use 14 gallons (53 liters) of fuel. Careful treatment of a new engine and drive components will result in more efficient performance and longer life for these components.

•Drive vehicle slowly at first while varying the throttle position. Do not operate at sustained idle.

•Pull only light loads.

•Perform regular checks on fluid levels and other areas outlined on the daily pre-ride inspection checklist.

•Change both the engine oil and filter after 25 hours or one month.

•See “Owner’s Manual” for additional break-in information.

Maintenance Chart Key

The following symbols denote potential items to be aware of during maintenance:

= CAUTION: Due to the nature of these adjustments, it is recommended this service be performed by an authorized Polaris dealer.

= SEVERE USE ITEM: See information provided above.

E = Emission Control System Service (California).

NOTE: Inspection may reveal the need for replacement parts. Always use genuine Polaris parts.

WARNING

WARNING

Improperly performing the procedures marked could result in component failure and lead to serious injury or death. Have an authorized Polaris dealer perform these services.

2.3

MAINTENANCE

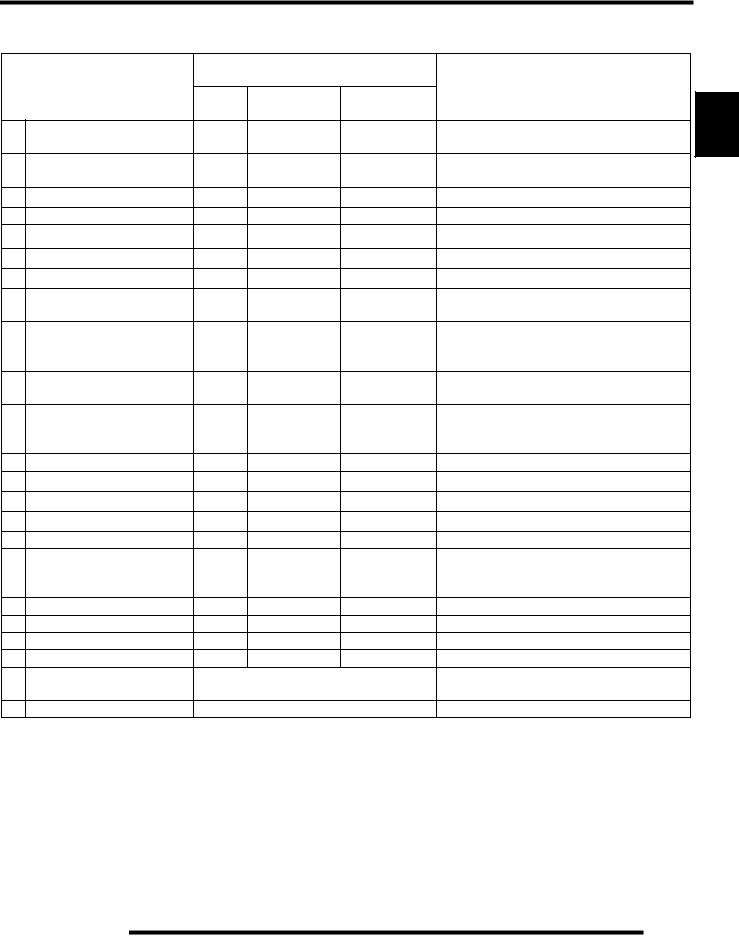

Pre-Ride - 25 Hour Maintenance Interval

|

|

|

Maintenance Interval |

|

||

|

Item |

|

(whichever comes first) |

Remarks |

||

|

Hours |

Calendar |

Miles |

|||

|

|

|

||||

|

|

(KM) |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Steering |

- |

Pre-Ride |

- |

|

|

|

Front Suspension |

- |

Pre-Ride |

- |

|

|

|

|

|

|

|

|

|

|

Rear Suspension |

- |

Pre-Ride |

- |

|

|

|

|

|

|

|

|

|

|

Tires |

- |

Pre-Ride |

- |

|

|

|

Brake Fluid Level |

- |

Pre-Ride |

- |

Make adjustments as needed. |

|

|

|

|

|

|

||

|

Brake Pedal Travel |

- |

Pre-Ride |

- |

||

|

See Pre-Ride Checklist on Page 2.9. |

|||||

|

Brake Systems |

- |

Pre-Ride |

- |

|

|

|

Wheels / Fasteners |

- |

Pre-Ride |

- |

|

|

|

Frame Fasteners |

- |

Pre-Ride |

- |

|

|

E |

Engine Oil Level |

- |

Pre-Ride |

- |

|

|

|

|

|

|

|

|

|

E |

Air Filter / Pre-Filter |

- |

Pre-Ride |

- |

Inspect; clean often; replace as needed |

|

|

|

|

|

|

|

|

|

Coolant Level |

- |

Daily |

- |

Check level daily, change coolant every 2 |

|

|

years |

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Head Lamp / Tail Lamp |

- |

Daily |

- |

Check operation; apply dielectric grease if |

|

|

replacing |

|||||

|

|

|

|

|

||

|

Air Filter, |

- |

Weekly |

- |

Inspect; replace as needed |

|

E |

Main Element |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

|

Brake Pad Wear |

10 H |

Monthly |

100 (160) |

Inspect periodically |

|

|

|

|

|

|

|

|

|

Battery |

25 H |

Monthly |

250 (400) |

Check terminals; clean; test |

|

|

Front Gearcase Oil |

25 H |

Monthly |

250 (400) |

Inspect level; change yearly |

|

|

(Demand Drive Fluid LT) |

|||||

|

|

|

|

|

||

|

Rear Gearcase Oil |

25 H |

Monthly |

250 (400) |

Inspect level; change yearly |

|

|

(ATV Angle Drive Fluid) |

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Transmission - Main |

25 H |

Monthly |

250 (400) |

Inspect level; change yearly |

|

|

(AGL Gearcase Lubricant) |

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Transmission - Transfer |

25 H |

Monthly |

250 (400) |

Inspect level; change yearly |

|

|

(AGL Gearcase Lubricant) |

|||||

|

|

|

|

|

||

|

Engine Breather |

25 H |

Monthly |

250 (400) |

Inspect; replace if necessary |

|

E |

Filter (if equipped) |

|||||

|

|

|

|

|||

|

Engine Oil Change |

25 H |

1 M |

250 (400) |

Perform a break-in oil change at one month |

|

E |

(Break-In Period) |

|||||

|

|

|

|

|||

Perform these procedures more often for vehicles subjected to severe use.

E Emission Control System Service (California)

Have an authorized Polaris dealer perform these services.

2.4

|

|

|

|

|

|

MAINTENANCE |

|

50 - 300 Hour Maintenance Interval |

|

|

|

|

|||

|

|

|

Maintenance Interval |

|

|

||

|

Item |

|

(whichever comes first) |

Remarks |

|

||

|

Hours |

Calendar |

Miles |

|

|||

|

|

|

|

||||

|

|

(KM) |

|

2 |

|||

|

Throttle Cable / Throttle |

|

|

Inspect; adjust; lubricate; replace if |

|||

|

50 H |

6 M |

300 |

(500) |

|||

E |

Pedal |

necessary |

|||||

E |

Throttle Body Air Intake |

50 H |

6 M |

300 |

(500) |

Inspect ducts for proper sealing / air leaks |

|

Ducts / Flange |

|

||||||

|

General Lubrication |

50 H |

3 M |

500 |

(800) Lubricate all fittings, pivots, cables, etc. |

|

|

|

Shift Linkage |

50 H |

6 M |

500 |

(800) |

Inspect, lubricate, adjust |

|

|

Steering |

50 H |

6 M |

500 |

(800) |

Lubricate |

|

|

Front Suspension |

50 H |

6 M |

500 |

(800) |

Lubricate |

|

|

Rear Suspension |

50 H |

6 M |

500 |

(800) |

Lubricate |

|

|

Cooling System |

50 H |

6 M |

500 |

(800) |

Inspect coolant strength seasonally; |

|

|

pressure test system yearly |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check for leaks at tank cap, fuel line, fuel |

|

E |

Fuel System |

100 H |

12 M |

600 (1000) |

pump, and fuel rail. |

|

|

|

|

|

|

|

|

Replace lines every two years. |

|

E |

Spark Plug |

100 H |

12 M |

600 (1000) Inspect; replace as needed |

|

||

|

|

|

|

|

|

Perform a break-in oil change at 25 hours or |

|

E |

Engine Oil & Filter Change |

100 H |

6 M |

1000 |

(1600) |

one month / always replace oil filter when |

|

|

|

|

|

|

|

changing engine oil |

|

|

Drive Belt |

100 H |

12 M |

1000 |

(1600) Inspect; replace as needed |

|

|

|

Radiator |

100 H |

12 M |

1000 |

(1600) Inspect; clean external surfaces |

|

|

|

Cooling Hoses |

100 H |

12 M |

1000 |

(1600) |

Inspect for leaks |

|

|

Engine Assembly Mounts |

100 H |

12 M |

1000 |

(1600) Inspect, torque to specification |

|

|

|

Exhaust Muffler / Pipe |

100 H |

12 M |

1000 |

(1600) |

Inspect |

|

|

|

|

|

|

|

Inspect for wear, routing, security; apply |

|

|

Wiring |

100 H |

12 M |

1000 |

(1600) |

dielectric grease to connectors subjected to |

|

|

|

|

|

|

|

water, mud, etc. |

|

|

Clutches (Drive and Driven) |

100 H |

12 M |

1000 |

(1600) |

Inspect; clean; replace worn parts |

|

|

Front Wheel Bearings |

100 H |

12 M |

1000 |

(1600) Inspect; replace as needed |

|

|

|

Brake Fluid |

200 H |

24 M |

2000 |

(3200) |

Change every two years (DOT 4) |

|

|

Spark Arrestor |

300 H |

36 M |

3000 |

(4800) |

Clean out |

|

|

Toe Adjustment |

|

- |

|

|

Inspect periodically; adjust when parts are |

|

|

|

|

|

replaced |

|

||

|

|

|

|

|

|

|

|

|

Headlight Aim |

|

- |

|

|

Adjust as needed |

|

Perform these procedures more often for vehicles subjected to severe use.

EEmission Control System Service (California)

Have an authorized Polaris dealer perform these services.

2.5

MAINTENANCE

COMPONENT INSPECTION / SERVICE LOCATIONS

Front and Rear View

Standard RZR Shown

Standard RZR Shown

2.6

RH and LH Side Views

Standard RZR Shown

Standard RZR Shown

*Standard RZR Only

MAINTENANCE

2 |

2.7

MAINTENANCE

LUBRICANTS / SERVICE PRODUCTS

Polaris Lubricants, Maintenance and Service

Products

Part No. |

Description |

|

|

|

|

|

Engine Lubricant |

|

|

|

|

2870791 |

Fogging Oil (12 oz. Aerosol) |

|

|

|

|

2876244 |

PS-4 PLUS Performance Synthetic 2W-50 |

|

4-Cycle Engine Oil (Quart) |

||

|

|

|

2876245 |

PS-4 PLUS Performance Synthetic 2W-50 |

|

4-Cycle Engine Oil (Gallon) |

||

|

|

|

Gearcase / Transmission Lubricants |

||

|

|

|

2873602 |

AGL - Synthetic ATV Gearcase Lubricant |

|

(1 Qt.) (12 Count) |

||

|

||

|

|

|

2873603 |

AGL - Synthetic ATV Gearcase Lubricant |

|

(1 Gal.) (4 Count) |

||

|

||

|

|

|

2873604 |

AGL - Synthetic ATV Gearcase Lubricant |

|

(2.5 Gal.) (2 Count) |

||

|

||

|

|

|

2871653 |

ATV Angle Drive Fluid |

|

(8 oz.) (12 Count) |

||

|

||

|

|

|

2872276 |

ATV Angle Drive Fluid |

|

(2.5 Gal) (2 Count) |

||

|

||

|

|

|

2871654 |

Premium Demand Drive Fluid LT |

|

(1 Qt.) (12 Count) |

||

|

||

|

|

|

2870465 |

Oil Pump for 1 Gallon Jug |

|

|

|

|

Grease / Specialized Lubricants

2871312 |

Grease Gun Kit |

|

|

|

|

2871322 |

Premium All Season Grease |

|

(3 oz. cartridge) (24 Count) |

||

|

||

|

|

|

2871423 |

Premium All Season Grease |

|

(14 oz. cartridge) (10 Count) |

||

|

||

|

|

|

2871460 |

Starter Drive Grease (12 Count) |

|

|

|

|

2871515 |

Premium U-Joint Lube (3 oz.) (24 Count) |

|

|

|

|

2871551 |

Premium U-Joint Lube (14 oz.) (10 Count) |

|

|

|

|

2871329 |

Dielectric Grease (Nyogel™) |

|

|

|

|

|

Coolant |

|

|

|

|

2871323 |

60/40 Coolant (Gallon) (6 Count) |

|

|

|

|

2871534 |

60/40 Coolant (Quart) (12 Count) |

|

|

|

NOTE: Each item can be purchased separately at your local Polaris dealer.

Part No. |

Description |

|

|

Additives / Sealants / Thread Locking Agents / Misc.

2870585 |

Loctite™ Primer N, Aerosol, 25 g |

|

|

|

|

2871956 |

Loctite™ Thread Sealant 565 |

|

(50 ml.) (6 Count) |

||

|

||

|

|

|

2871949 |

Loctite™ Threadlock 242 |

|

(50 ml.) (10 Count) |

||

|

||

|

|

|

2871950 |

Loctite™ Threadlock 242 |

|

(6 ml.) (12 Count) |

||

|

||

|

|

|

2871951 |

Loctite™ Threadlock 262 |

|

(50 ml.) (10 Count) |

||

|

||

|

|

|

2871952 |

Loctite™ Threadlock 262 |

|

(6 ml.) (12 Count) |

||

|

||

|

|

|

2871953 |

Loctite™ Threadlock 271 |

|

(6 ml.) (12 Count) |

||

|

||

|

|

|

2871954 |

Loctite™ Threadlock 271 |

|

(36 ml.) (6 Count) |

||

|

||

|

|

|

2870584 |

Loctite™ 680-Retaining Compound |

|

(10 ml.) |

||

|

||

|

|

|

2870587 |

Loctite™ 518 Gasket Eliminator / Flange |

|

Sealant (50 ml.) (10 Count) |

||

|

||

|

|

|

2871326 |

Premium Carbon Clean |

|

(12 oz.) (12 Count) |

||

|

||

|

|

|

2870652 |

Fuel Stabilizer (16 oz.) (12 Count) |

|

|

|

|

2872189 |

DOT 4 Brake Fluid (12 Count) |

|

|

|

|

2871557 |

Crankcase Sealant, 3-Bond 1215 (5oz.) |

|

|

|

|

2872893 |

Engine Degreaser (12oz.) (12 Count) |

|

|

|

NOTE: The number count indicated by each part number in the table above indicates the number of units that are shipped with each order.

2.8

|

|

|

|

MAINTENANCE |

|

|

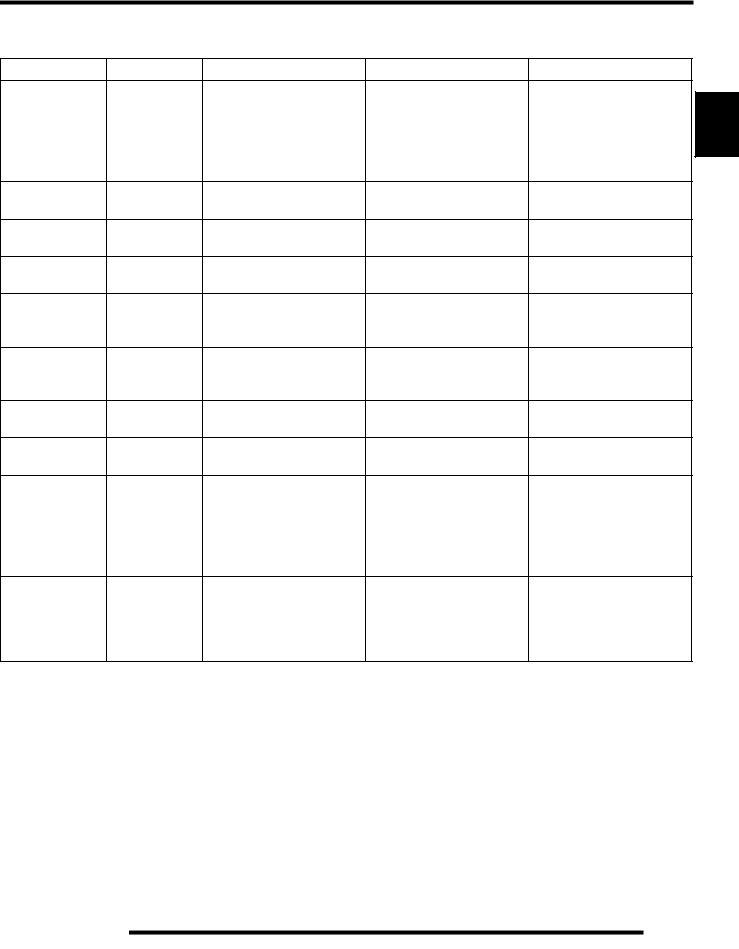

MAINTENANCE REFERENCES |

|

|

|

|||

Item |

Ref. |

Rec. Lube / Fluid |

Method |

Frequency* |

|

|

|

|

|

|

Change after 25 hrs, and then |

|

|

|

|

Polaris PS-4 PLUS |

|

6 months or 100 hours |

2 |

|

|

|

Add oil to proper level on |

thereafter; Change more |

|||

Engine Oil |

Page 2.7 |

Performance Synthetic |

||||

dipstick. |

often in extremely dirty |

|||||

|

|

2W-50 4-Cycle Engine Oil |

||||

|

|

|

conditions, or short trip cold |

|

||

|

|

|

|

|

||

|

|

|

|

weather operation. |

|

|

Engine Coolant |

Page 2.6 |

Polaris Antifreeze 60/40 |

Fill recovery bottle between |

Fill as required. Change |

|

|

(PN 2871534) |

MAX and MIN lines. |

coolant every 2 years. |

|

|||

|

|

|

||||

Brake Fluid |

Page 2.7 |

DOT 4 (PN 2872189) |

Fill reservoir between MAX |

Fill as required. Change |

|

|

and MIN lines. |

brake fluid every 2 years. |

|

||||

|

|

|

|

|||

Transmission |

Page 2.7 |

AGL Synthetic Gearcase |

Add lube to bottom of fill |

Change annually*** |

|

|

(Main Gearcase) |

Lubricant (PN 2873602) |

plug threads. 24 oz. (710 ml) |

|

|||

Transmission |

|

AGL Synthetic Gearcase |

Add lube to bottom of level |

|

|

|

Page 2.7 |

check plug threads. |

Change annually*** |

|

|||

(Transfer Case) |

Lubricant (PN 2873602) |

|

||||

|

14 oz. (414 ml) |

|

|

|||

|

|

|

|

|

||

|

|

Premium Demand Drive |

Add fluid to bottom of fill |

|

|

|

Front Gearcase |

Page 2.7 |

plug threads. |

Change annually*** |

|

||

Fluid LT (PN 2876251) |

|

|||||

|

|

6.75 oz. (200 ml) |

|

|

||

|

|

|

|

|

||

Rear Gearcase |

Page 2.7 |

ATV Angle Drive Fluid |

Add lube to bottom of fill |

Change annually*** |

|

|

(PN 2871653) |

plug threads. 26 oz. (769 ml) |

|

||||

Prop Shaft |

Page 2.7 |

Polaris Premium U-Joint |

Locate fitting and grease with |

Semi-annually** |

|

|

|

|

Lube (PN 2871551) |

grease gun. |

|

|

|

|

|

|

Locate grease fittings on the |

|

|

|

|

|

|

upper and lower A-arms of |

|

|

|

ControlArmPivot |

Page 2.6 |

Polaris Premium All Season |

the front and rear suspension |

Semi-annually** |

|

|

Bushings, FT / RR |

|

Grease (PN 2871423) |

and grease with grease gun. |

|

|

|

|

|

|

(4) Front A-arms |

|

|

|

|

|

|

(6) Rear A-arms |

|

|

|

|

|

|

Locate grease fittings on the |

|

|

|

Stabilizer Bar |

|

Polaris Premium All Season |

front and rear stabilizer bars |

|

|

|

Page 2.7 |

and grease with grease gun. |

Semi-annually** |

|

|||

Bushings, FT / RR |

|

Grease (PN 2871423) |

(2) Front Stabilizer Bar |

|

|

|

|

|

|

|

|

||

|

|

|

(2) Rear Stabilizer Bar |

|

|

|

* More often under severe use, such as operated in water or under severe loads.

**Semi-annually or 50 hours of operation (refer to Maintenance Schedule for additional information)

***Annually or 100 hours of operation (refer to Maintenance Schedule for additional information)

2.9

MAINTENANCE

GENERAL VEHICLE INSPECTION AND MAINTENANCE

Pre-Ride / Daily Inspection

Perform the following pre-ride inspection daily, and when servicing the vehicle at each scheduled maintenance.

•Tires - check condition and pressures

•Fuel tank - fill to proper level

•All brakes - check operation and adjustment

•Throttle - check for free operation and closing

•Headlights/Taillights/Brakelights - also check operation of all indicator lights and switches

•Ignition switch - check for proper function

•Wheels - check for tightness of wheel nuts and axle nuts; check to be sure axle nuts are secured by cotter pins

•Air cleaner element - check for dirt; clean or replace

•Steering - check for free operation noting any unusual looseness in any area

•Loose parts - visually inspect vehicle for any damaged or loose nuts, bolts or fasteners

•Engine coolant - check for proper level at the recovery bottle

•Check all front and rear suspension components for wear or damage.

Frame, Nuts, Bolts, and Fasteners

Periodically inspect the torque of all fasteners in accordance with the maintenance schedule. Check that all cotter pins are in place. Refer to specific fastener torques listed in each chapter.

Shift Cable Inspection / Adjustment

Shift cable adjustment may be necessary if symptoms include:

•No AWD or gear position display on instrument cluster

•Ratcheting noise on deceleration

•Inability to engage into a gear

•Excessive gear clash (noise)

•Gear selector moving out of desired range

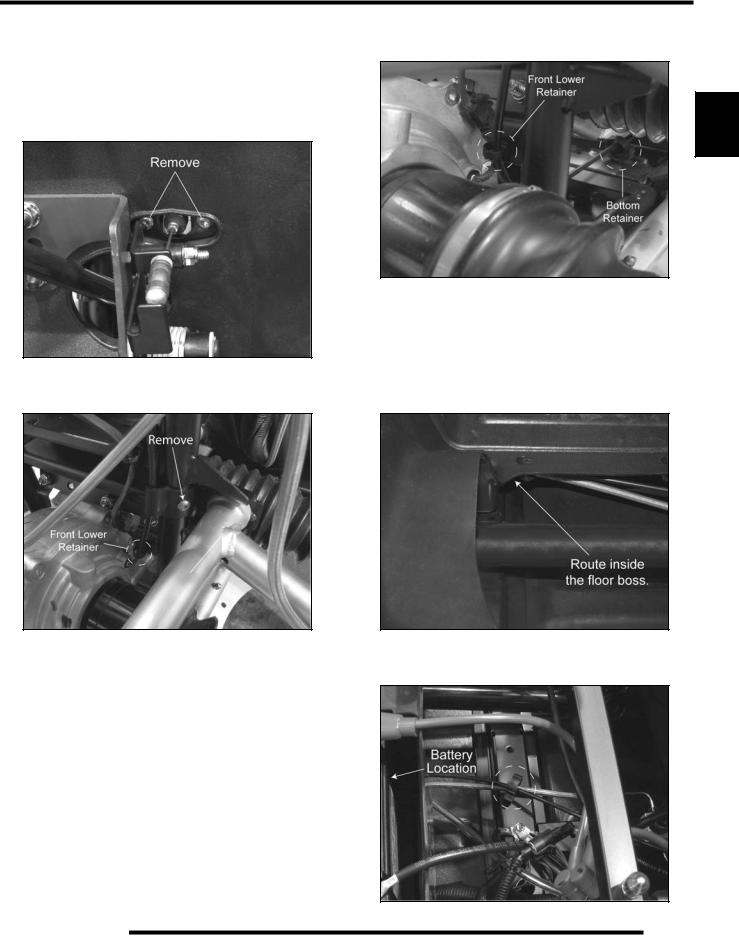

1.Locate the shift cable in the rear LH wheel well area.

Clevis Pin |

Shift  Cable

Cable

Mount

Shift Cable |

|

Dust Boot |

2.Inspect shift cable, clevis pin, pivot bushings, and dust boot. Replace if worn or damaged.

3.If adjustment is required, loosen the lower jam nut and pull the cable out of the mount to move the upper jam nut.

Upper

Jam Nut

Nut

Lower

Jam Nut

4.Adjust the shift cable so there is the same amount of cable travel when shifting slightly past the detents of HIGH (H) gear and PARK (P).

5.Thread the upper or lower jam nut as required to obtain proper cable adjustment.

NOTE: This procedure may require a few attempts to obtain the proper adjustment.

2.10

MAINTENANCE

6.Once the proper adjustment is obtained, place the shift cable and upper jam nut into the mount. Tighten the lower jam nut against the mount.

7.Start engine and shift through all gears to ensure the shift cable is properly adjusted. If transmission still ratchets after cable adjustment, the transmission will require service.

FUEL SYSTEM AND AIR INTAKE

Fuel System

WARNING

WARNING

Gasoline is extremely flammable and explosive under certain conditions.

Always stop the engine and refuel outdoors or in a well ventilated area.

Do not smoke or allow open flames or sparks in or near the area where refueling is performed or where gasoline is stored.

Do not overfill the tank. Do not fill the tank neck. If you get gasoline in your eyes or if you swallow gasoline, seek medical attention immediately.

If you spill gasoline on your skin or clothing, immediately wash it off with soap and water and change clothing.

Never start the engine or let it run in an enclosed area. Engine exhaust fumes are poisonous and can result loss of consciousness or death

in a short time.

Never drain the fuel when the engine is hot. Severe burns may result.

Fuel Line

1.Check the quick-connect fuel line for signs of wear, deterioration, damage or leakage. Replace if necessary.

2.Be sure fuel line is routed properly.

IMPORTANT: Make sure line is not kinked or pinched.

3.Replace fuel line every two years.

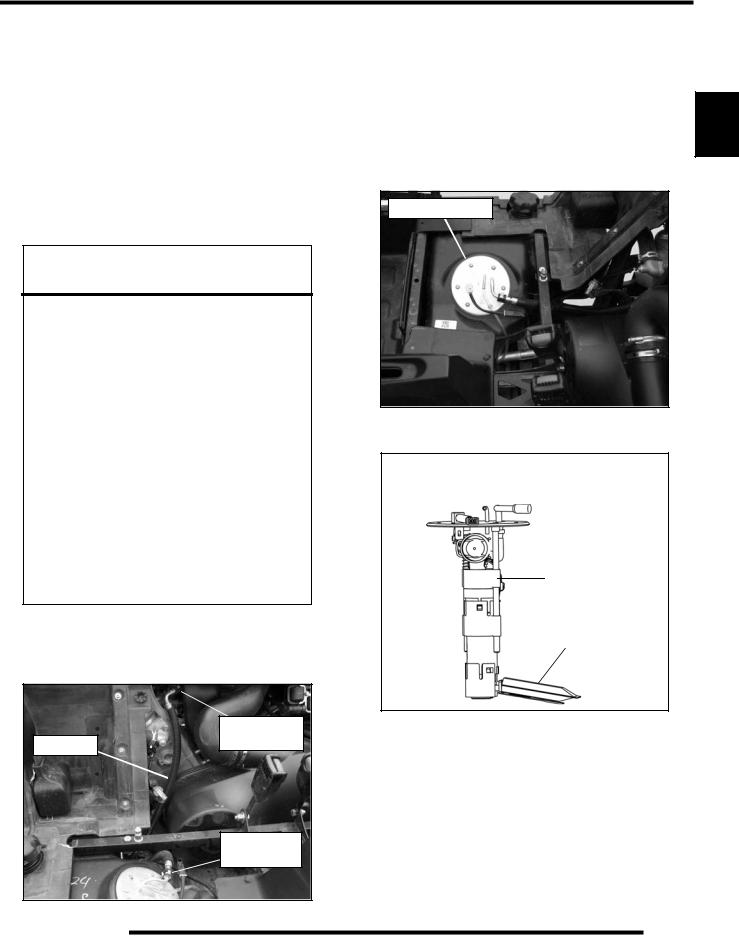

Fuel Pump / Fuel Filters |

2 |

The 800 EFI RZR engine uses a non-serviceable, high-volume, |

|

high-pressure, fuel pump that includes a preliminary filter and |

|

an internal fine filter located before the pump regulator. |

|

Fuel Pump Asm |

|

NOTE: Neither filter is servicable.

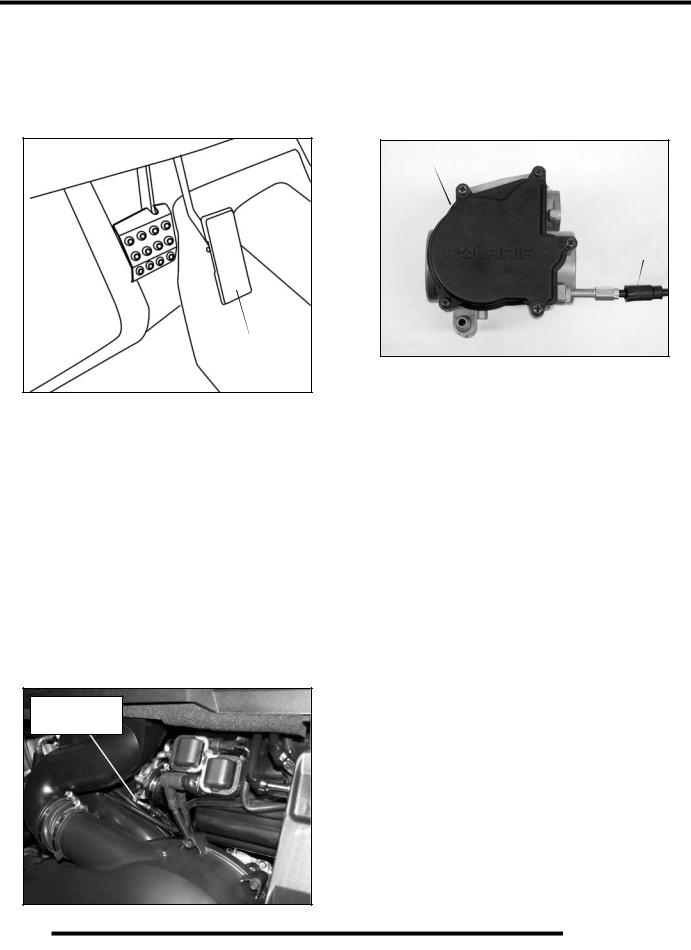

Fuel Pump Asm

Located in Fuel Tank

Fine Filter

Preliminary Filter

|

Injector Rail |

Fuel Line |

Connector |

Fuel Pump

Connector

NOTE: For all other information related to the EFI System, refer to Chapter 4.

Vent Lines

1.Check fuel tank, front gear case, rear gear case and transmission vent lines for signs of wear, deterioration, damage or leakage. Replace every two years.

2.Be sure vent lines are routed properly and secured with cable ties.

IMPORTANT: Ensure lines are not kinked or pinched.

2.11

MAINTENANCE

Throttle Pedal Inspection

If the throttle pedal has excessive play due to cable stretch or cable misadjustment, it will cause a delay in throttle speed. Also, the throttle may not open fully. If the throttle pedal has no play, the throttle may be hard to control, and the idle speed may be erratic.

Throttle Pedal

Check the throttle pedal play periodically in accordance with the Periodic Maintenance Chart and adjust the play if necessary.

Throttle Freeplay Adjustment

Inspection

1.Place the transmission in the P (Park) position.

2.Start the engine, and warm it up thoroughly.

3.Measure the distance the throttle pedal moves before the engine begins to pick up speed. Freeplay should be 1/16” - 1/8” (1.5 - 3 mm).

Adjustment

1.Remove both seats and rear service panel.

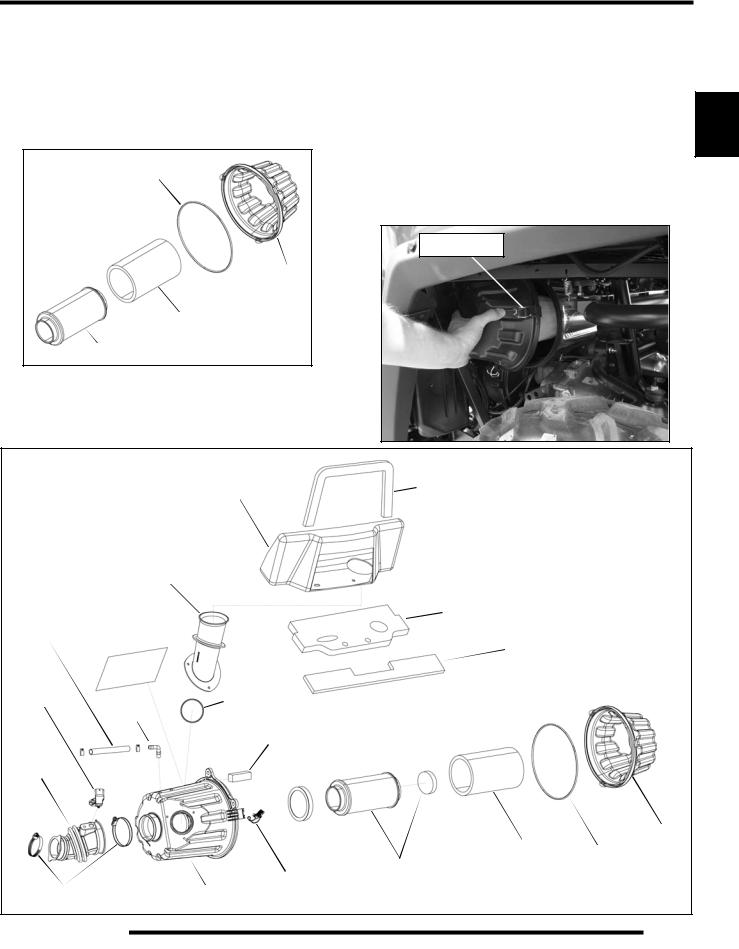

2.Locate the throttle cable adjuster at the throttle body.

Throttle Cable

Adjuster

3.Slide back the cable adjuster boot.

4.Using a 10 mm open-end wrench, loosen the adjustment jam nut.

5.Using an 8 mm open-end wrench, move the cable adjuster until 1/16” to 1/8” (1.5 - 3 mm) of freeplay is achieved at the throttle pedal.

Throttle Body

Adjuster

Boot

Jam Nut

NOTE: While adjusting, lightly move the throttle pedal in and out.

6.Re-tighten the jam nut.

7.Apply a small amount of grease to the inside of the boot and slide it over the cable adjuster to its original position.

Throttle Cable Replacement

1.Place the vehicle in PARK and stop the engine.

2.Remove the seats and rear service panel (see Chapter 5).

3.Remove the shift handle knob and center console (see Chapter 5).

4.Remove the rear cargo box and rear bumper as an assembly (see Chapter 5).

5.Remove the air intake box (see “Air Filter Service”).

6.Remove both PVT outlet and inlet ducts to allow access the throttle body cover (see Chapter 6).

7.Remove the throttle body cover.

NOTE: Upon removing the cable from the throttle plate arm, the brass retainer will become loose or separated from the cable. Take care not to drop brass retainer upon removal.

8.Pull back on the throttle plate arm and remove the throttle cable.

9.Using an 8 mm open-end wrench, remove the throttle cable from the throttle body.

10.Remove the rear floor and rocker panel fasteners to loosen the floor.

2.12

MAINTENANCE

11.Lift up on the floor and remove the panduit strap retaining the throttle cable and brake line to the frame.

12.Remove the cable end and retainer from the throttle foot pedal.

13.Remove the (2) screws retaining the throttle cable bracket to the frame support.

20.Route the cable through the retainer at the bottom of the frame in the floor console opening.

2 |