Polaris PC 130-50 2NV, PC 150-50 2NV, PC 175-50 3NV, PC 130-34 2NV, PC 199-50 3NV User Manual

...Page 1

This manual covers model numbers:

Canada

PC 100-34 2NV or 2PV

PC 130-34 2NV or 2PV

PC 130-50 2NV or 2PV

PC 150-34 2NV or 2PV

PC 150-50 2NV or 2PV

PC 175-50 3NV or 3PV

PC 199-50 3NV or 3PV

Note:

The manufacturer of this water heater recommends that it

be professionally installed by trained and qualified service

professionals.

Polaris®

Commercial Gas

Water Heater

Installation

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any telephone in your

building.

• Immediately call your gas supplier

from a neighbor’s telephone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

PRINTED IN U.S.A. 0112

Instructions and

Use & Care Guide

To obtain technical, warranty or service assistance during or

after the installation of this water heater, visit our website at:

http://www.gsw-wh.com

or call toll free:

1-888-479-8324

When calling for assistance, please have the following

information ready:

1. Model number

2. 7 Digit product number

3. Serial number

4. Date of installation

5. Place of Purchase

Table of Contents........................................................... 2

INSTALLER:

• Affix these instructions to or adjacent to the water

heater.

OWNER:

• Retain these instructions and warranty for future

reference. Retain the original receipt as proof of

purchase.

322761-000

1

Page 2

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

Important Instructions

• Do not use this water heater if any part has been under water. Immediately call a qualified service technician.

Water heaters subjected to flood conditions or anytime the gas controls, main burner or ignition control have been

submerged in water require replacement of the entire water heater.

• Hydrogen gas can be produced in a hot water system that has not been used for a long period of time (generally

two weeks or more). Hydrogen gas is extremely flammable and can ignite when exposed to a spark or flame. To

prevent the possibility of injury under these conditions, we recommend the hot water faucet be opened for several

minutes at the kitchen sink before using any electrical appliance which is connected to the hot water system. If

hydrogen is present, there will probably be an unusual sound such as air escaping through the faucet as water

begins to flow. Do not smoke or have any open flame near the faucet at the time it is open.

Table of Contents Page

Water Heater Safety ............................................................................ 1-2

Installation Instructions ...................................................................... 3-22

Unpacking the Water Heater ............................................................ 3

Location Requirements ..................................................................... 4

Condensate Line ........................................................................... 5-6

Intergrated Filter Installation ............................................................ 7

Vent Pipe System ........................................................................ 8-11

Vent Terminations ........................................................................ 9-12

Gas Input Rate ................................................................................ 13

Water System Piping ................................................................. 13-16

Gas Supply and Piping ............................................................. 17-18

Electrical Connections/Wiring Diagram ..................................... 19-20

Installation Checklist ....................................................................... 21

Operating Your Water Heater .......................................................... 22-24

Polaris® Operating Instructions ........................................................... 23

Maintenance of Your Water Heater ................................................. 24-25

Troubleshooting .................................................................................... 26

Software Operation Sequence ............................................................. 27

Parts List and Diagram ......................................................................... 28

Polaris® Models and Dimensions .......................................................... 29

2

Page 3

INSTALLATION INSTRUCTIONS

Consumer Information

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

This water heater is design-certified by CSA International

as a Category IV, direct vented water heater which takes

its combustion air from the outside of the structure and

exhausts all products of combustion to the outside of the

structure.

This water heater must be installed according to all local

and state codes or in the absence of local and state codes

with the “National Fuel Gas Code”, ANSI Z223.1(NFPA

54)- current edition. Canadian installations must be performed in accordance with CAN/CSA-B149.1-current edition. This is available from the following:

CSA America, Inc.

8501 East Pleasant Valley Road

Cleveland, OH 44131

National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02169-7471

Canadian Standards Association

178 Rexdale Boulevard

Toronto, ON M9W 1R3

Check the phone listings for the local authorities having

jurisdiction over this installation.

Installer and Owner Responsibilities

This manual has been prepared to acquaint you with the

installation, operation, and maintenance of your gas water

heater and provide important safety information in these

areas.

Read all of the instructions thoroughly before attempting

the installation or operation of this water heater.

Do not discard this manual. You or future users of this

water heater will need it for future reference.

Service to the water heater should only be performed

by a qualified service technician.

Examples of qualified service technicians include:

those trained in the plumbing and heating industry,

local gas utility personnel, or an authorized service

person.

The manufacturer and seller of this water heater will

not be liable for any damages, injuries, or deaths

caused by failure to comply with the installation and

operating instructions outlined in this manual.

A data plate identifying your water heater can be found on

the front of the heater. When referring to your water heater,

always have the information listed on the data plate readily

available.

Keep combustibles such as boxes, magazines, clothes,

etc., away from water heater area.

Retain your original receipt as proof of purchase.

Unpacking the Water Heater

Excessive Weight Hazard

Use two or more people to move and

install water heater unless proper

handling equipment is utilized.

Failure to do so can result in back or

other injury.

Removing Packaging Materials

Important: Do not remove any permanent instructions,

labels, or the data plate from outside of the water heater or

on the inside of panels.

• Remove exterior packaging and place installation

components aside.

• Inspect all parts for damage prior to installation and

start-up.

• Completely read all instructions before attempting to

assemble and install this product.

• After installation, dispose of packaging material in the

proper manner.

If you lack the necessary skills required to properly install

this water heater, or you have difficulty following the

instructions, you should not proceed but have a qualified

service technician perform the installation of this water

heater.

3

Page 4

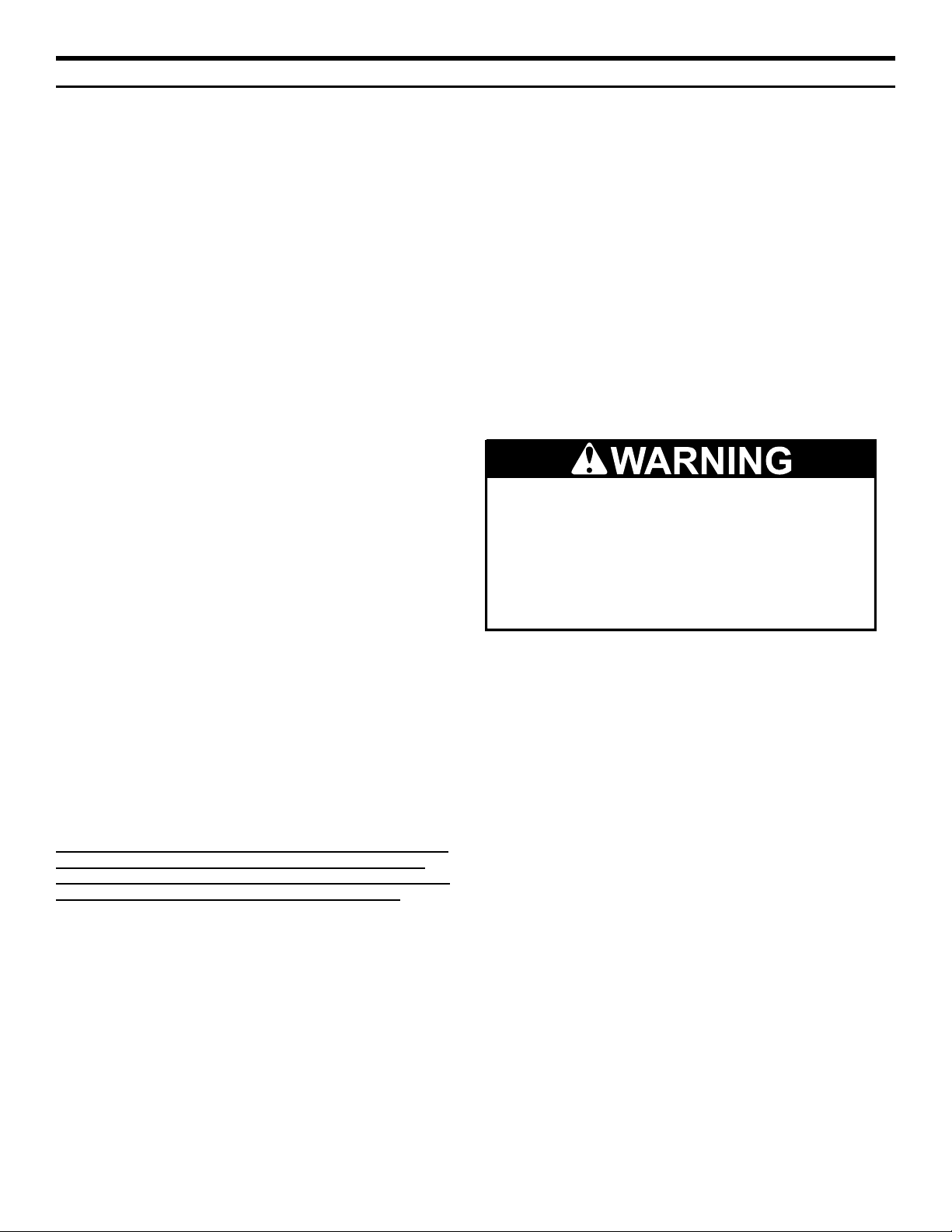

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

the termination with a minimal length and number of

elbows. Input rates are reduced as vent system length

increases. The venting system must comply with the

requirements set forth in the venting section of this

manual.

• Locate the water heater near the existing gas piping.

If installing a new gas line, locate the water heater to

minimize the pipe length and elbows.

Important: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to corrosive elements in the atmosphere is excluded from warranty coverage.

Note: The water heater must be installed according to all

state and local/provincial codes or in absence of the state

and local/provincial codes with the “National Fuel Gas

Code”, ANSI Z223.1 (NFPA 54)-current edition. Canadian

installations must be performed in accordance with CAN/

CSA-B149.1-current edition.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance. Storage of or

use of gasoline or other flammable vapors

or liquids in the vicinity of this or any other

appliance can result in serious injury or death.

Location Requirements

The water heater design has been tested by CSA

International and complies with ANSI Z21.10.1, Section

2.35 Flammable Vapors Resistance. In garage installation

avoid damage to your water heater by installing a vehicle

stop as shown in figure below. Check state and local/

provincial codes for requirements prior to installation.

Figure 1: Garage Installation

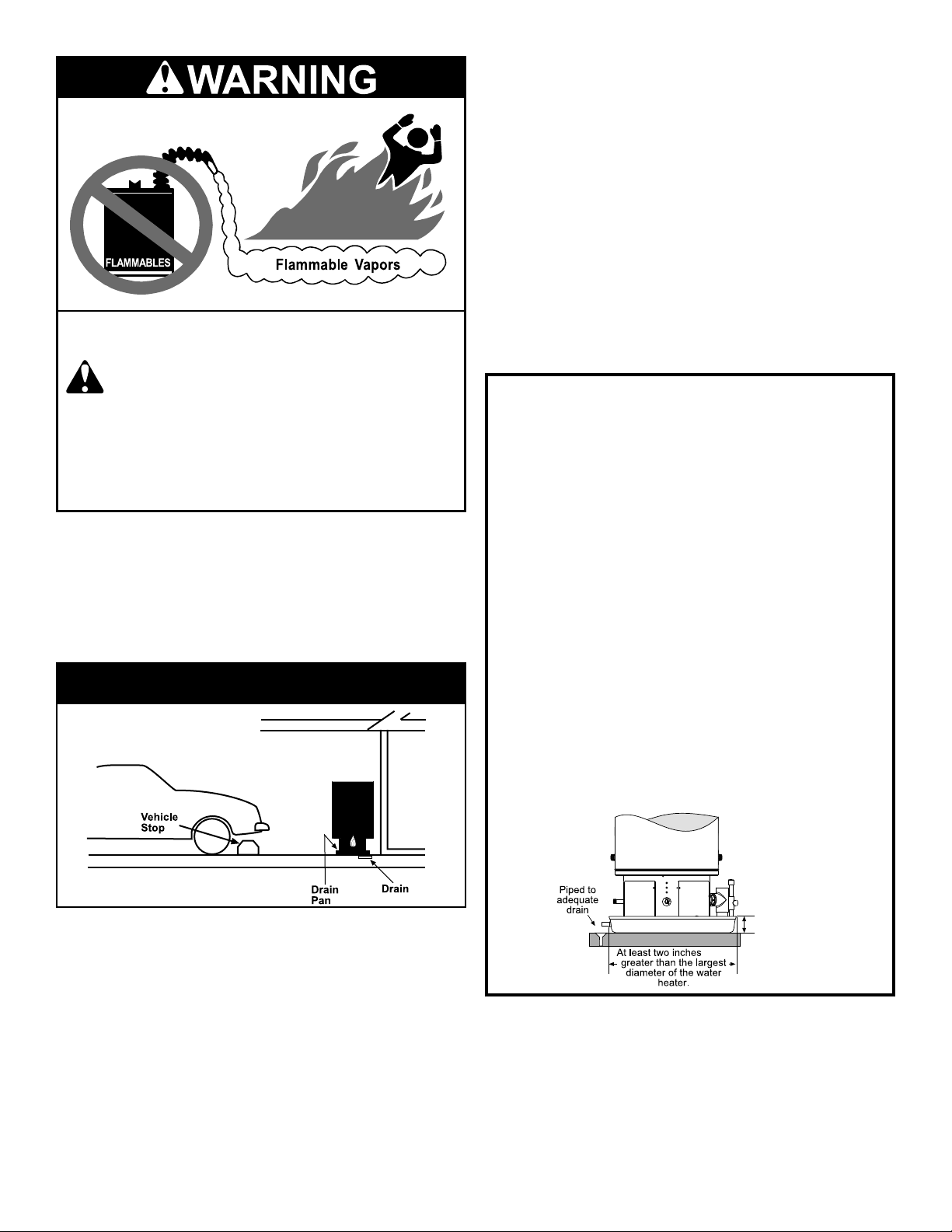

Important: The water heater should be located in

an area where leakage of the tank or connections will

not result in damage to the area adjacent to the water

heater or to lower floors of the structure. Due to the

normal corrosive action of the water, the tank will

eventually leak after an extended period of time.

Also any external plumbing leak, including those

from improper installation, may cause early failure

of the water tank due to corrosion if not repaired.

A qualified service technician should be contacted

for repairs. A suitable metal drain pan should be

installed under the water heater as shown below, to

help protect the property from damage which may

occur from condensate formation or leaks in the piping

connections or tank. The pan must limit the water level

to a maximum depth of 1-3/4” (4.45 cm) and be at least

two inches (5 cm) wider than the heater and piped to an

adequate drain. Locate the water heater near a suitable

indoor drain. Outside drains are subject to freezing

temperatures which can obstruct the drain line. The

piping should be at least 3/4” (1.91 cm) ID and pitched

for proper drainage. Under no circumstances will the

manufacturer or seller of this water heater be held liable

for any water damage which is caused by your failure to

follow these instructions.

This water heater is not certified for installation in mobile

homes.

Site Location

• Select a location near the center of the water piping

system. The water heater must be installed indoors

and in a vertical position on a level surface. DO NOT

install in bathrooms, bedrooms, or any occupied room

normally kept closed. Note: The water heater may be

installed in a closet with a door off a bedroom or bathroom providing the units are installed and vented per

the manufacturer’s instructions.

• Consider the inlet and exhaust vent system piping

when selecting the water heater location. The venting

system must be able to run from the water heater to

4

1-3/4” (4.45 cm) Max.

(5 cm)

Figure 1A

• The water heater should be located in an area not sub-

ject to freezing temperatures. Water heaters located in

unconditioned spaces (i.e., attics, basements, etc) may

require insulation of the water piping and drain piping

to protect against freezing. The drain and controls must

be easily accessible for operation and service. Maintain

proper clearances as specified on the data plate.

Page 5

Clearances and Accessibility

Notice: Minimum clearances from combustible materi-

als are stated on the data plate located on the front of the

water heater.

• The water heater is certified for installation on a

combustible floor.

Important: If installing over carpeting, the carpeting must

be protected by a metal or wood panel beneath the water

heater. The protective panel must extend beyond the full

width and depth of the water heater by at least 3 inches

(7.62 cm) in any direction or if in a alcove or closet installation, the entire floor must be covered by the panel. The

panel must be strong enough to carry the weight of the

heater when full of water.

Figure 2 may be used as a reference guide to locate the

specific clearance locations. A minimum of 24 inches

(61 cm) of front clearance and 4 inches (10.2 cm) on each

side should be provided for inspection and service.

Figure 2: Minimum Clearance Locations

Back 0” (0 cm)

Sides: 4” (10.2 cm)

Min. for service

Front: 24”

(61 cm )

Min. for service

Top: 0” (0 cm)

Vent: 0”

(0 cm)

CONDENSATE LINE

Important: Do not run the condensate drain in areas

that are likely to freeze. Frozen condensate will block the

drain line and result in property damage or water heater

malfunction.

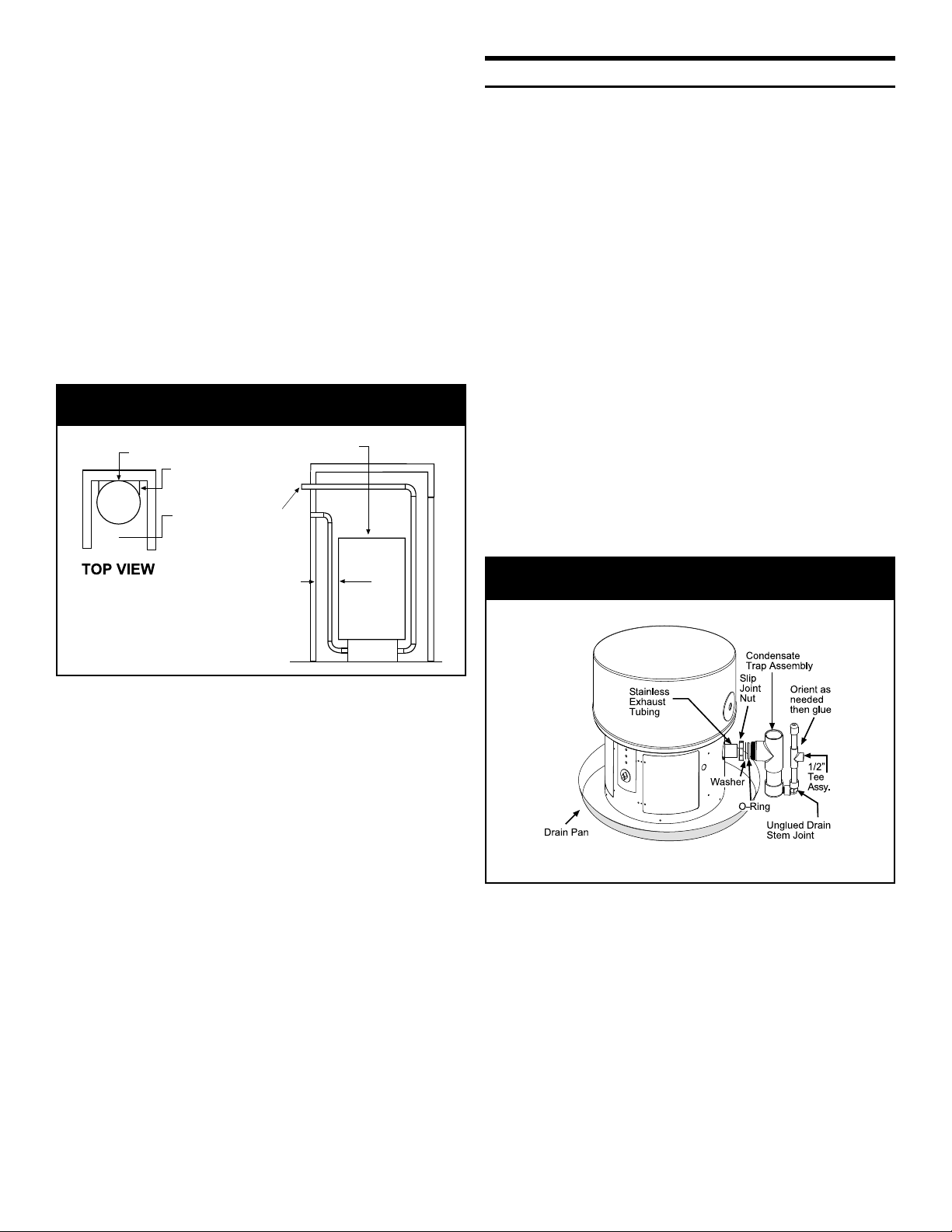

Condensate Trap Assembly

A condensate trap/drain stem assembly has been supplied

with the water heater and is located behind the access door

inside the base of the water heater. This assembly must be

installed between the water heater and the exhaust outlet

piping to ensure proper operation of the water heater. To

install, remove the slip-joint nut, stainless steel washer, and

O-ring from the trap assembly. Slip the nut, washer and

O-ring (in that order) over the stainless exhaust tubing and

slide them back near the base of the heater. Insert the trap

assembly over the tubing (see figure 3A accordingly) and

firmly hand-tighten (using a wrench will cause the O-ring to

seal improperly) the nut to form a water-tight seal between

the O-ring and the stainless exhaust tubing. When

tightened, the nut to heater base clearance should be 3/4”

(+/- 1/8”) tolerance (1.9 cm +/- 0.31 cm tolerance).

Note: The trap should be aligned so that the exhaust pipe

is in a vertical position close to the surface of the water

heater.

Sides: 4” (10.2 cm)

Min. for service

Figure 3A: 2” Condensation Trap Installation

5

Page 6

Figure 3B: Condensate Drain

Condensate Drain Line

All parts of the condensate trap are glued except for the

1/2” CPVC drain stem joint at the elbow (see figure 3A).

This assembly can be turned with the outlet of the tee

oriented as needed.

Once orientation direction is decided, remove the unglued

joint from the elbow at the bottom and apply a suitable

cement to joint. Re-insert the joint fully and quickly into

the elbow making sure to orient it before the cement sets.

Connect the remaining piping and run the condensate drain

line to a suitable drain.

Important: Be sure the drain stem joint is inserted against

the stop in the elbow. Failure to do so may result in

improper water heater operation.

If required by local codes, install a condensate neutralizer

cartridge on the drain line (see figure 3B).

The condensate drain line must be routed to a suitable

drain. If no floor drain is available or the drain is above

the level of the condensate line, install a condensate pump

that is resistant to the acidic condensate. These pumps are

available from local distributors. If the pump is not resistant

to acidic water, a condensate neutralizer must be used

ahead of the pump.

When installing the drain line, note the following:

• Plastic pipe or tubing must be used to connect the

condensate drain to a suitable drain or condensate

pump. Do not use copper tubing, iron, or steel pipe for

the condensate drain line.

• Condensate drain lines should be installed in conditioned areas only. Drain lines installed in areas that are

subject to freezing temperatures should be wrapped

with a nationally recognized/listed heat tape and/or

approved insulation for freeze protection. Install per

manufacturer’s instructions.

• Do not common drain with the temperature and pressure relief valve or the condensate line from an air

conditioner evaporator coil.

• Slope the condensate drain toward the inside floor

drain or condensate pump.

• The condensate drain line and connection to the drain

piping must comply with all local codes.

• Do not run the condensate line into the metal drain

pan.

VENT PIPE SYSTEM

Carbon Monoxide Hazard

Follow all instructions to locate and install

the vent pipe system.

Instructions can be found in this manual, in

state or local codes (or the authority having

jurisdiction), or in the absence of such, the

National Fuel Gas Code, ANSI Z223.1, NFPA

54, Current Edition. Canadian installations

must be performed in accordance with

CAN/CSA-B149.1, Current Edition.

Failure to properly locate and install the

vent pipe system can result in death or

carbon monoxide poisoning.

Venting

This water heater has a direct vent system in which all air

for combustion is taken from the outside atmosphere and

all combustion products are discharged to the outdoors.

This water heater must be properly vented for removal

of exhaust gases to the outside atmosphere. Correct

installation of the vent pipe system is mandatory for the

safe and efficient operation of this water heater and is an

important factor in the life of the unit.

Vent pipe installation must be performed in accordance

with state and local codes, or in the absence of such, the

National Fuel Gas Code, NFPA 54, ANSI Z223.1-current

edition. Canadian installations must be performed in

accordance with CAN/CSA-B149.1-current edition.

When replacing an existing Polaris® unit, it is recommended

that the venting system be reviewed for compliance with

the requirements contained in this installation manual. If the

venting is not in compliance, it is recommended that the

appropriate changes be made to bring it into compliance.

Note: It is important that the factory-installed air inlet

filter be inspected at least twice each year and cleaned if

necessary. See “Integrated Filter Installation, Preventive

Maintenance”. Note: if the vent system is not in compliance

with the current installation manual, the manufacturer

reserves the right to evaluate the installation prior to

granting any warranty on service claims.

Important: Check to make sure the vent pipe is not

blocked in any way.

Note: Do not common vent this water heater with any

other appliance. Do not install in the same chase or

chimney with a metal or high-temperature plastic from

another gas or fuel burning appliance.

6

Page 7

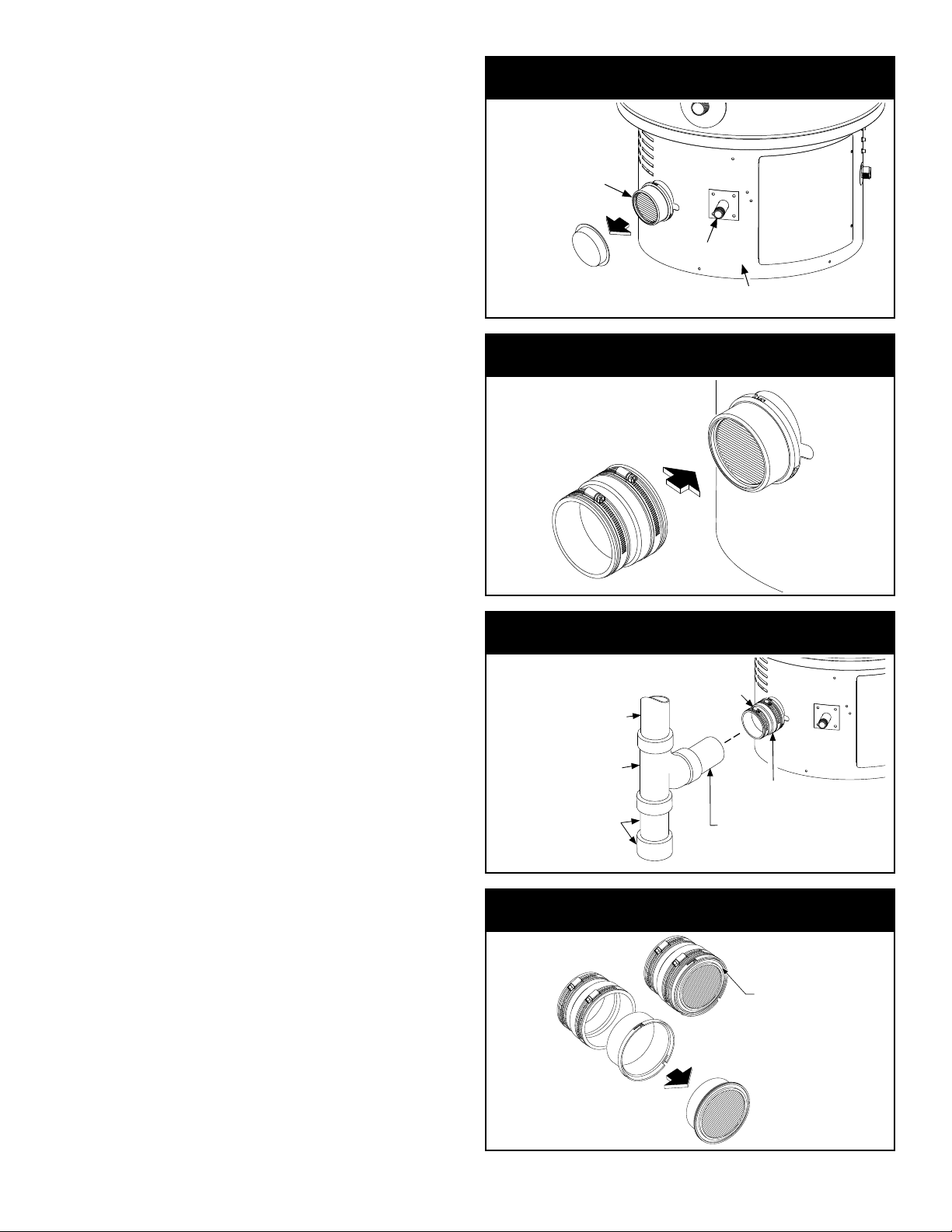

Integrated Filter Installation

When installing the adaptor rubber boot, note the following:

• Remove and discard the plastic cap from the outer

clamshell housing (see figure 4A).

• To connect the heater to the air inlet, use the vent

adaptor rubber boot provided in the base skirt. The

adaptor rubber boot is designed for 3” venting (see

figure 4B). Note: If there is a need for 2” venting, then

use plastic pipe and fittings to transition down.

• Loosen the hose clamp at the adaptor rubber boot and

slide the plastic piping into the adaptor rubber boot.

With piping in place, tighten the hose clamp. Install a

3” x 3” x 3” TY drain/waste/vent fitting to trap airborne

particulates (see figure 4C). Note: If piping has been

previously cut with a saw, be sure to remove all burrs

and plastic shavings from the piping before installing.

Preventive Maintenance

Figure 4A: Remove Plastic Cap

Outer Clamshell

Housing With Filter

Gas Piping

Remove

Plastic Cap

Base Skirt

Figure 4B: Adaptor Rubber Boot

The heater is designed to shut down if the pressure

switch senses that the air inlet vent or the exhaust vent

is restricted. In this case, the pressure switch will open

and the heater will generate a 2-flash code (see the

troubleshooting section). If troubleshooting section of

this manual indicates that there is a blockage, note the

following:

• Turn off the gas supply to the water heater at the

manual gas shut-off valve, and disconnect power to the

water heater.

• To inspect the filter, loosen the hose clamp at the adaptor rubber boot and slide the plastic pipe out and away

from the adaptor rubber boot (see figure 4C).

• Remove the adaptor rubber boot containing the outer

clamshell housing by turning clockwise approximately

1/2” (30.5 cm) and pulling off of the internal clamshell

housing (see figure 4C).

• Using your fingers or a small flat blade screwdriver,

remove the filter media from the outer clamshell housing, handle carefully (see figure 4D).

• To clean filter, lightly tap the back of the filter support

to dislodge any large debris. Smaller debris may be removed by using a vacuum cleaner. the filter media may

be cleaned by dipping the filter media into a solution of

warm soapy water and rinsing in clean water. Do not

scrub, allow to air dry before reinstalling. Filter media

may be cleaned on an average 2 to 3 times before

replacing with a new filter media is required.

• Reinstall the filter media by doing the above steps in

reverse order.

• Turn on the gas supply and reconnect power, refer to

the operating instructions on front of the water heater.

Verify proper operation of the water heater before

leaving.

Note: The heater must never be operated without the

filter media installed.

Adaptor Rubber

Boot

Figure 4C: Air Inlet Piping

Piped To

External Air

Supply

3” x 3” x 3” TY DWV Fitting

(Position Cure Slope Upward)

Install A Small Portion

Of Pipe And A Pipe Cap

To Rest On Floor.

Figure 4D: Filter Media

Filter Media shown inside

the Outer Clamshell Housing

Adaptor

Rubber Boot

Outer Clamshell

Housing

Push On &

Tighten Clamp

grease to the surface of the black rubber

Remove

Filter Media

Outer Clamshell

Housing

Hose Clamp

Adaptor Rubber Boot

Outer Clamshell Housing

3” Plastic Pipe

NOTE: if found difficult to

reattach the outer clamshell

housing to the internal clamshell

housing - apply a thin layer of silicone

support of the Filter Media.

7

Page 8

Vent Pipe Material

Combustion Air Inlet Piping; The following plastic

materials may be used for combustion air inlet piping.

IMPORTANT: Follow all local codes or, in the absence

of local codes, CSA B149.1, Natural Gas and Propane

Installation Code - current edition to properly install air inlet

piping.

• Schedule 40 PVC

• Schedule 40 or 80 CPVC

• DWV Pipe and Foam Core Piping is

acceptable as intake pipe only.

Exhaust Piping; Exhaust PVC or CPVC plastic piping

shall be certified and marked as complying to Standard

for Type BH Gas Venting System ULC-S636. In addition

plastic piping, plastic components, primers, and glues must

be from a single source manufacturer and not mixed with

other listed or unlisted systems. IMPORTANT: Follow all

local codes or, in the absence of local codes, CSA B149.1,

Natural Gas and Propane Installation Code - current

edition to properly install exhaust piping.

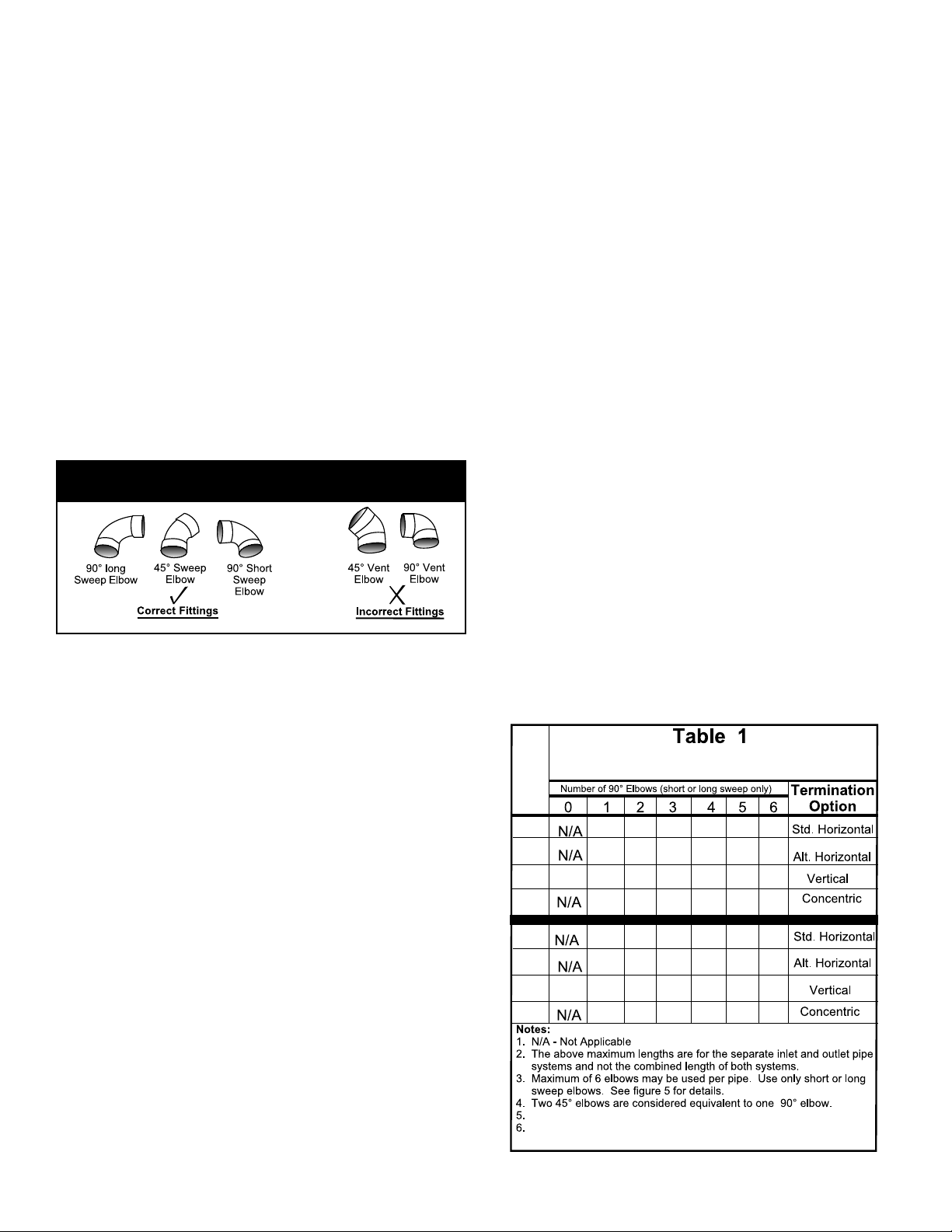

Important: Do not use vent elbows in this vent pipe installation (see figure 5 below).

Figure 5: Correct and Incorrect Pipe Fittings

Vent Pipe Installation

The following guidelines should be followed when installing

the air inlet and exhaust outlet piping:

• Venting should be as direct as possible with a minimum

number of pipe fittings.

• Vent diameter must not be reduced unless specifically

noted in the installation instructions.

• All 2” horizontal vent piping must be sloped upward

1/4 inch per foot (21 mm per meter); (3” Piping must

slope upward at 1/8” per foot) (10.5 mm per meter).

This will allow condensate to run back to the heater

and exit through the condensate trap.

• Support all horizontal pipe runs every four feet (1.2 m)

and all vertical pipe runs every six feet (1.8 m) or

according to local codes.

• Vents run through unconditioned spaces where below

freezing temperatures are expected should be properly

insulated to prevent freezing. For horizontal runs, wrap

the vent pipe with nationally recognized/listed heat tape

and/or approved insulation for freeze protection. Install

per the manufacturer’s instructions.

• An air intake filter is included with the unit and must be

installed according to the installation instructions

supplied with the filter.

The combustion air inlet and exhaust outlet piping and

termination may be installed in one of the following type

terminations:

1. Standard Horizontal (2 Pipe)

2. Alternate Horizontal (2 Pipe)

3. Vertical (2 Pipe)

4. Concentric Vent - Through the Wall

5. Concentric Vent - Through the Roof

8

All pipe, fittings, pipe cement, primers and procedures

must conform to American National Standard Institute and

American Society for Testing and Materials (ANSI/ASTM)

standards in the United States. This water heater has been

design certified by the Canadian Standards Association for

use with the specified (CSA) listed plastic vent pipe.

All joints in the inlet and outlet piping must be properly

cemented. Size and cut all piping before cementing.

1. Cut the pipe end square and remove all ragged edges

and burrs. Make sure the inside of the pipe is clean

and free of cuttings and loose dirt. Chamfer the end

and apply primer to the fitting and pipe.

2. Using a suitable grade of pipe cement, apply a moderate, even coat inside the fitting. Apply a liberal amount

of cement to the outside of the pipe to socket depth.

Note: It is important to select the proper pipe cement for

the type of plastic pipe being used.

3. Assemble the parts quickly while the cement is

still wet. Twist the pipe 1/4 turn during insertion

and hold for 30 seconds.

Vent Pipe Length

Size the exhaust outlet and combustion air inlet pipes as

specified in Table 1. This table lists the maximum allowable length in feet of the exhaust outlet and combustion air

inlet pipes as related to the number of required elbows and

the termination. The specified maximum lengths are for

the separate inlet and exhaust pipe systems and not the

combined length of both systems. Minimum pipe length is

6 feet (1.8 m) with one elbow per side.

1. Determine termination type and pipe size.

2. Determine number of elbows in exhaust pipe. Do not

include the elbows in the termination or the condensate

trap. Corresponding number Indicates the maximum

length of exhaust pipe.

3. Determine number of elbows in inlet pipe. Do not

include the elbows in the termination. The corresponding number indicates the maximum length of inlet pipe.

Maximim allowable Length in Feet (Meters) of Exhaust and Air Inlet Pipe

Pipe

Size in

Inches

*2

*2

*2

*2

3

3

3

3

Minimum length is 6 feet (1.8 m) per pipe with 1 elbow per side.

2 Inch pipe may be used with 100,000, 130,000 & 150,000

BTU/HR (29.3, 38, & 43.9 kW) input models only.

* 3” pipe must be used for 175,000 BTU/Hr (51.29 kW) input and above.

For Schedule 40 CPVC, OR PVC Pipe and Fittings

52

48

(15.8)

(14.6)

44

(13.4)40(12.2)36(11)32(9.7)28(8.5)24(7.3)

48

52

(15.8)

130

(39.6)

44

(14.6)

(13.4)40(12.2)36(11)32(9.7)28(8.5)

52

48

(15.8)

(14.6)44(13.4)40(12.2)36(11)32(9.7)

120

125

(36.6)

(38.1)

115

110

(35)

(33.5)

120

115

(36.6)

(35)

125

120

(38.1)

(36.6)

44

(13.4)

115

(35)

105

(32)

110

(33.5)

115

(35)

40

(12.2)

110

(33.5)

100

(30.5)

105

(32)

110

(33.5)

(28.9)

(30.5)95(28.9)

(11)

105

(32)

95

100

105

(32)

36

32

(9.7)

100

(30.5)

90

(27.4)

100

(30.5)

Page 9

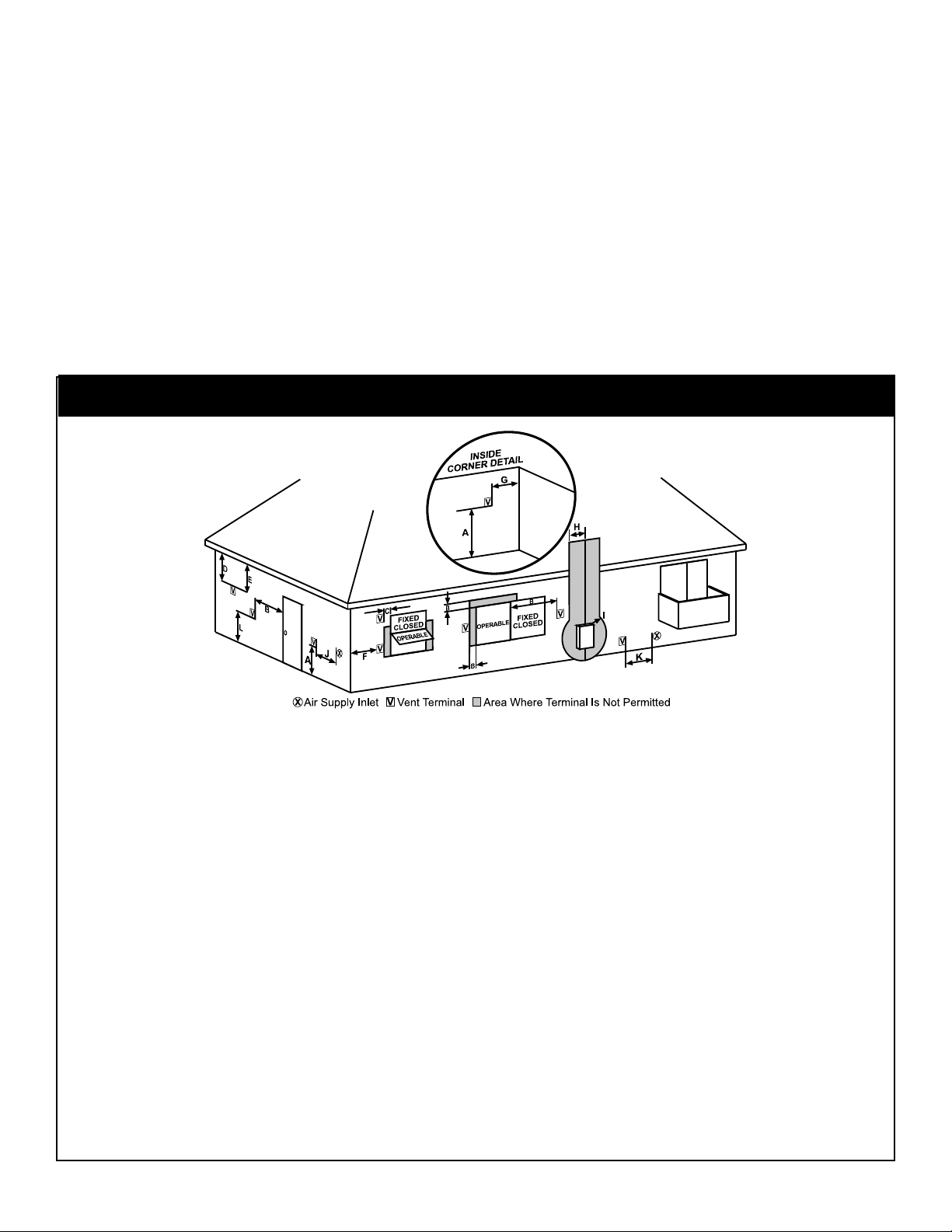

Vent Termination Locations

The air inlet and exhaust outlet must be installed with the

following minimum clearances (see figure 6):

• Twelve inches (30 cm) above grade or maximum antici-

pated snow level.

• Twelve inches (30 cm) from any opening through which

flue gases could enter the structure.

• Four feet (122 cm) horizontally and vertically from gas

or electric meters, gas regulators, dryer vents, vent

hoods, bathroom fan exhaust, attic fans and turbines.

• Two feet (61 cm) from an inside corner formed by two

exterior walls.

• Two feet from porches, decks, overhangs and other

obstructions.

In addition to maintaining the minimum clearances , the

vent should terminate according to the following guidelines:

Figure 6: Minimum Clearances for Inlet/Outlet and Concentric Vent

1. Use only 2 inch pipe or a 2 inch concentric vent

on the vent termination for 100,000 - 150,000 BTU/

Hr models. Do not expose any 3” X 2” reducers or

bushings to outdoor ambient temperatures.

CAN/CSA B149.1 Section 8.14.8:

2. When terminating a vent under a veranda, porch or

deck, venting must be installed in accordance to all local and provincial codes or in the absence of local and

provincial codes, please refer to the CAN/CSA B149.1.

3. A vent shall not terminate less than 7 ft. (2.1 m) above

a paved sidewalk or paved driveway that is located on

public property.

4. A vent shall not terminate in an area where children or

animals could block pipes.

5. A vent shall not terminate in a location that is too close

to shrubs or bushes.

6. Caulk all cracks, seams and joints within 6 feet (1.83 m)

horizontally above and below the vent.

7. Combustion air inlet termination and exhaust air termination must be located in the same pressure zone.

US Installations Canadian Installations

A. 12 in (30 cm) min. clearance above grade,

veranda, porch, deck, balcony, or maximum

anticipated snow level.

B. 12 in (30 cm) min. clearance on top and side of

window or door that may be opened. Maintain a

36 in (91 cm) minimum clearance below a window

or door that may be opened.

C. Clearance to permanently closed window.**

D. 12 in (30 cm) min vertical clearance to ventilated

soffit located above the terminal within a horizontal

distance of 2 ft (61 cm) from the center line of the

terminal.

E. 12 in (30 cm) min. clearance to unventilated soffit.

F. Clearance to outside corner **

G. 2 ft (61 cm) clearance to inside corner formed by

two exterior walls.

H. 4 ft (122 cm) clearance to each side of center line

extending above meter/regulator assembly.

I. 4 ft (122 cm) clearance to service regulator vent

outlet.

J. 12 in (30 cm) clearance to nonmechanical air

supply inlet to building or the combustion air inlet

to any other appliance.

K. 3 ft (91 cm) above if within 10 ft (3 m) horizontally of

mechanical air supply inlet.

**Clearance in accordance with local installation codes and the requirements of the gas supplier.

A. 12 in (30 cm) min. clearance above grade,

veranda, porch, deck, balcony, or maximum

anticipated snow level.

B. 12 in (30 cm) min. clearance on top and side of

window or door that may be opened. Maintain

a 36 in (91 cm) minimum clearance below a

window or door that may be opened.

C. Clearance to permanently closed window.**

D. 12 in (30 cm) min vertical clearance to ventilated

soffit located above the terminal within a horizontal

distance of 2 ft (61 cm) from the center line of the

terminal.

E. 12 in (30 cm) min. clearance to unventilated soffit.

F. Clearance to outside corner. **

G. 2 ft (61 cm) clearance to inside corner formed by

two exterior walls.

H. 3 ft (91 cm) within a height 15 ft (4.57 m) above the

meter/regulator assembly.

I. 4 ft (122 cm) clearance to service regulator vent outlet.

J. 12 in (30 cm) clearance to nonmechanical air

supply inlet to building or the combustion air inlet to

any other appliance.

K. 6 ft (1.83 m) clearance to mechanical air supply inlet.

9

Page 10

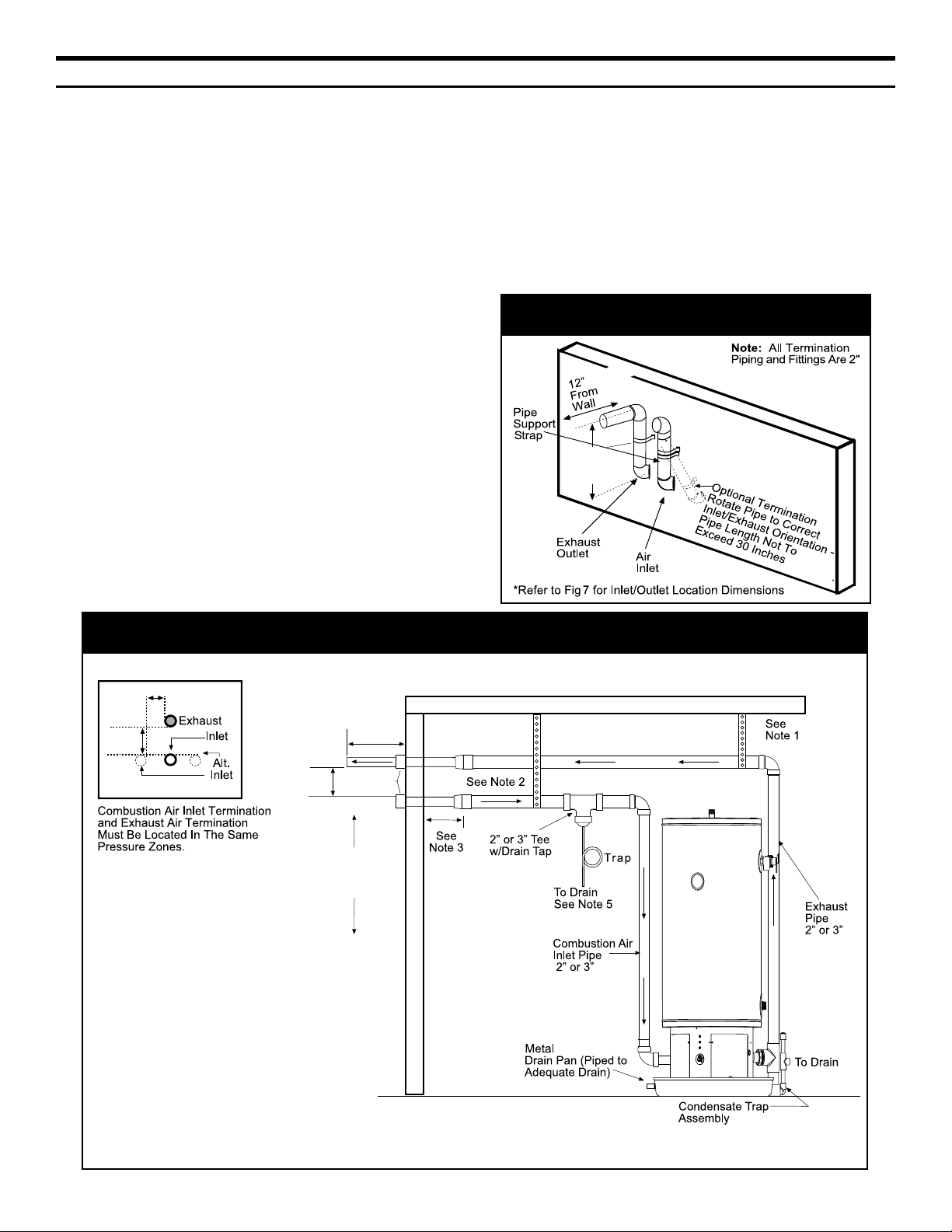

INLET/OUTLET VENT TERMINATIONS

Standard Horizontal Termination

When 3 inch pipe is used between the water heater and the

outside wall, reduce it to 2 inch pipe before penetrating the

wall. A maximum of 18 inches (45.7 cm) of 2 inch pipe may

be used between the 3 inch transition and the inside of the

wall (see figure 7).

The standard horizontal air inlet termination is a 2 inch

pipe which terminates at the exterior wall and utilizes a

coupling to prevent the pipe from being pushed back into the

structure. The standard horizontal exhaust outlet termination

is a 2 inch pipe which terminates 12 inches (30.5 cm) from

the outside wall. The air inlet must be located with respect to

the exhaust outlet as shown in figure 7 (bottom).

Install a drain tee assembly and trap in the inlet vent as close

to the water heater as possible. This is to drain any water

that may be in the combustion air pipe and prevent it from

entering the blower. Connect the trap drain line to a suitable

drain or downstream of the condensate trap of the water

heater.

®

Note: See “Venting Additional Polaris

for correct terminations if installing more than one Polaris®

gas water heater.

Units” on Page 11

Alternative Horizontal Termination

The combustion air and exhaust terminations may be

raised up to 24 inches (61 cm) above the wall penetrations

if required for anticipated snow levels (see figure 8). The

two elbows shown in figure 8 are considered part of the

termination and should not be included when determining

the maximum allowable vent pipe length.

®

Note: See “Venting Additional Polaris

for correct terminations if installing more than one Polaris®

gas water heater.

Figure 8: Alternate Horizontal Termination

(30.5 cm)

24”

(61 cm)

Max.

Units” on Page 11

Figure 7: Standard Horizontal Termination

3” (7.6cm) Max.

Note 4.

12” (30.5 cm)

2”

Coupling

4” (10 cm)

Max.

4” (10 cm)

Max.

12” (30.5cm) Min. Above

Grade or Anticipated

Notes:

1. Support Horizontal Pipe Every

Four Feet (1.2 m). Support Vertical

Pipe Every Six Feet (1.8 m).

2. When Using 3 Inch Pipe, Reduce To 2 Inches Before

Penetrating The Outside Wall.

3. 18 Inch (45.7 cm) Maximum When Using 3 Inch Pipe.

4. Increase The 12 Inch (30.5 cm) Minimum Above

Grade To Keep Terminal Openings Above Anticipated

Snow Levels.

5. Slope All Piping Down Toward the Water Heater as

Follows:

´3LSLQJVORSH´3HU)RRWPPSHUPHWHU

´3LSLQJVORSH´3HU)RRWPPSHUPHWHU

Snow Level. See

(76.2 cm)

*

*

*

10

Page 11

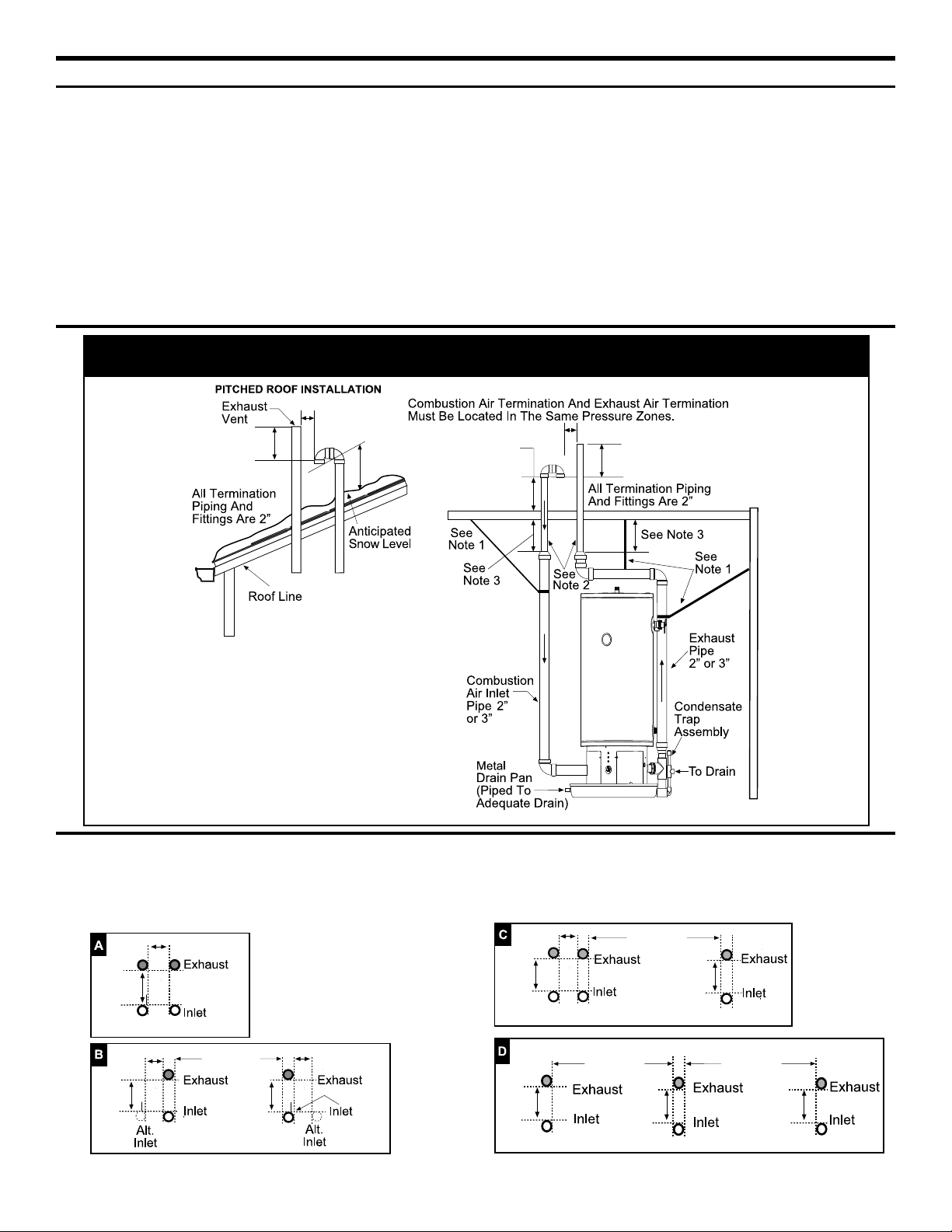

VERTICAL TERMINATIONS

When 3 inch pipe is used between the water heater and the

roof, reduce it to 2 inch pipe before penetrating the roof.

A maximum of 18 inches (45.7 cm) of 2 inch pipe may be

used between the 3 inch transition and the inside of the

roof.

The vertical inlet air termination requires a return bend

or two short or long sweep radius 90 elbows to keep the

inlet downward and prevent entry of rain. These elbows

are considered part of the termination and should not be

included when calculating the maximum allowable vent

pipe length. Refer to figure 9 for the proper location of the

air inlet with respect to the exhaust outlet termination. The

vertical exhaust outlet termination is a 2 inch (30.5 cm) pipe

Figure 9: Vertical Termination

4” (10 cm)

12” (30.5 cm)

Min.

Max.

12”

(30.5 cm)

Min.

12” (30.5cm) Min.

Above Roof or

Anticipated Snow

Level. See Note 4.

which terminates at least 12 inches (30.5 cm) above the

inlet air termination.

The air inlet and exhaust outlet terminations must be at

least 12 inches (30.5 cm) above the roof line or anticipated

snow levels. See figure 9 below.

®

Note: See “Venting Additional Polaris

Units” below if

installing more than one Polaris® gas water heater.

4” (10 cm) Max.

12” (30.5 cm) Min.

Notes:

1. Support Horizontal Pipe Every

Four Feet (1.2 m). Support Vertical

Pipe Every Six Feet (1.8 m).

2. When Using 3 Inch Pipe, Reduce To

2 Inches Before Penetrating The

Roof.

3. 18 Inch (45.7 cm) Maximum When

Using 2 Inch Pipe.

4. Increase The 12 Inch (30.5 cm)

Minimum Above Grade To Keep

Terminal Openings Above Anticipated

Snow Levels.

Venting Additional Polaris® Units

When using two (2) Polaris® units, install vent terminations

using either Method A or Method B below:

Figure 9A, 9B

3” (7.6cm) Max.

4” (10cm)

Max.

(7.6 cm)

Max.

4”

(10cm)

Max.

3”

36” (91.4 cm)

Minimum

4”

(10cm)

Max.

3” (7.6 cm) Max.

*

*

When using three or more Polaris® units, install vent

terminations per Method C or Method D:

Figure 9C, 9D

(7.6 cm)

4”

(10cm)

Max.

4”

(10cm)

Max.

3”

Max.

36” (91.4 cm)

Minimum

36” (91.4 cm)

Minimum

(10cm)

4”

Max.

4”

(10cm)

Max.

36” (91.4 cm)

Minimum

(10cm)

Max.

4”

11

Page 12

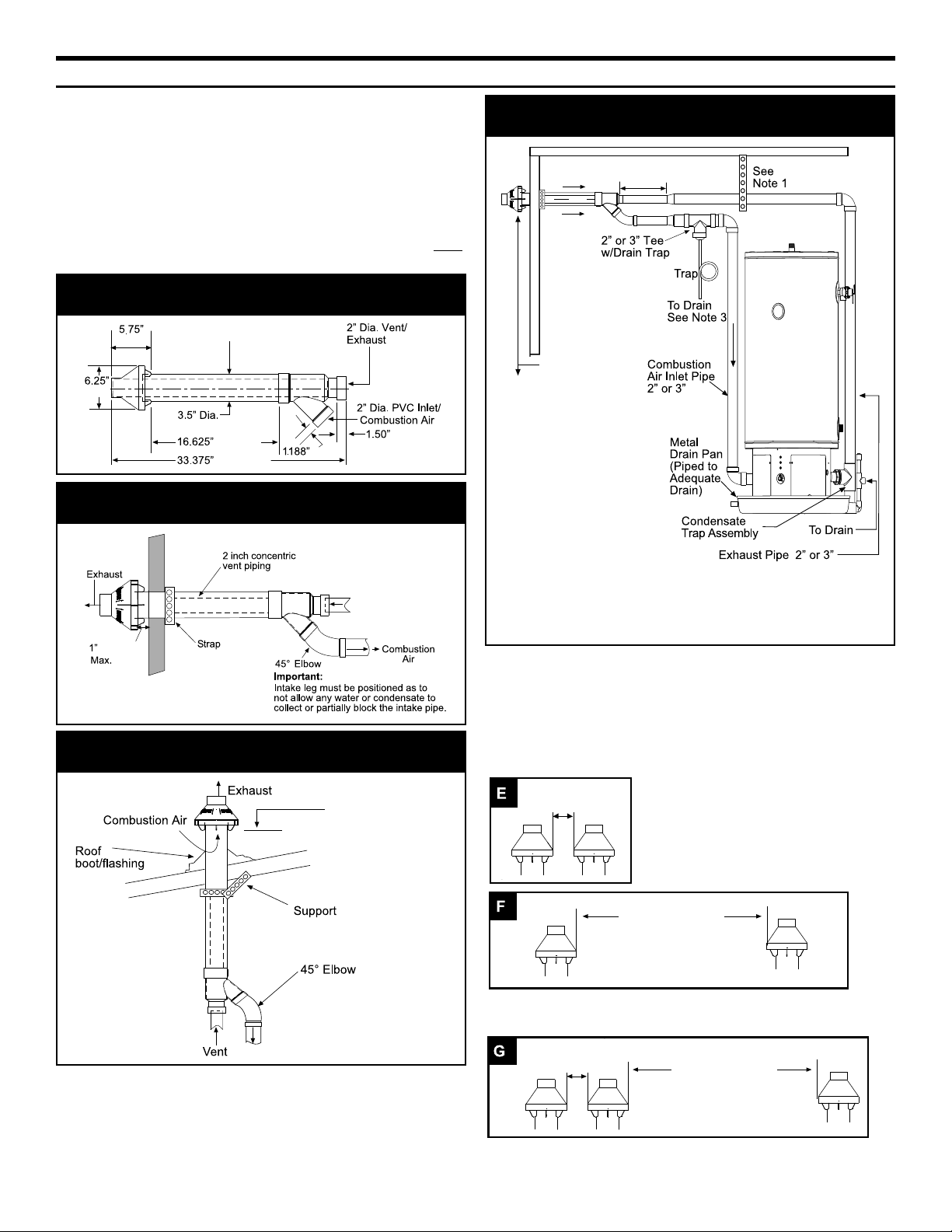

CONCENTRIC VENT TERMINATIONS

For new installations, install 2” or 3” ULC S636 certified PVC or

CPVC concentric vent terminations may be used. See the vent

termination manufacturer’s instructions for complete installation

information or contact customer service at 1-888-479-8324

or techsupport@hotwater.com. For planning purposes, see

figures 10-13 below for vent terminal specifications.

Note: For replacement installations, previously installed

American Water Heater Company supplied concentric vent kits

are acceptable for use on 100,000-130,000 BTU/Hr models only.

Figure 10: 2 Inch Concentric Vent

Figure 13: Through the Wall Termination

18”

See Note 4

(45.7cm)

Max.

*

(14.6cm)

(15.7cm)

(8.9cm Dia.)

(42.2cm)

(84.77cm)

(4.8cm)

Figure 11: Through the Wall Termination

(2.54cm)

Figure 12: Through the Roof Termination

(3.8cm)

12” (30.5cm)

Minimum Above

Grade or

Anticipated

Snow Level.

(See Note 2.)

Notes:

1. Support Horizontal Pipe Every

Four Feet (1.2 m). Support

Vertical Pipe Every Six ft. (1.8 m).

2. Increase The 12 Inch (30.5 cm)

Minimum Above Grade To Keep

Inlet Opening Above Anticipated

Snow Levels.

3. Slope All Piping Down Toward

the Water Heater as follows:

´3LSLQJVORSH

´3HU)RRWPPSHUPHWHU

´3LSLQJVORSH

´3HU)RRWPPSHUPHWHU

´FPPD[LPXPZKHQXVLQJ

´SLSH

For clarity, T&P discharge line not shown. See the Temperature

and Pressure Relief Valve section for requirements.

*

*

Concentric Venting Multiple Water

Heaters (All Models)

When using two Polaris® units, install vent terminations

using either Method E or Method F below:

12

12” (30.5cm) Minimum

clearance above

anticipated snow level.

24” (61cm) Max.

2” (5.08 cm)

Max.

Figure 13E, 13F, 13G

36” (.9144 m) Min.

Note: For installation of more than two Polaris® units,

follow the pattern established in Method G.

2” (5.08 cm)

Max.

36” (.9144 m) Min.

Page 13

Gas Input Rate

The gas input rate of this water heater is affected by

several environmental factors such as:

• The heating value of the gas

• The air and gas densities (which vary widely due to baro-

metric pressure and temperature changes)

• Venting installations (pipe diameter, length and fittings)

• Altitude

When measuring the input rate these factors should be

incorporated into the calculations. Also measure the gas

consumption over a sufficiently long time to obtain an

accurate gas consumption rate (e.g. 3-5 minutes, not one

revolution of the meter needle).

Long vents and each additional elbow, inherently reduce

the gas input rate due to increased resistance to moving

combustion air and flue gases. The approximate maximum/

minimum input for the 100k, 130k, and 150k models is

shown in figure 14.

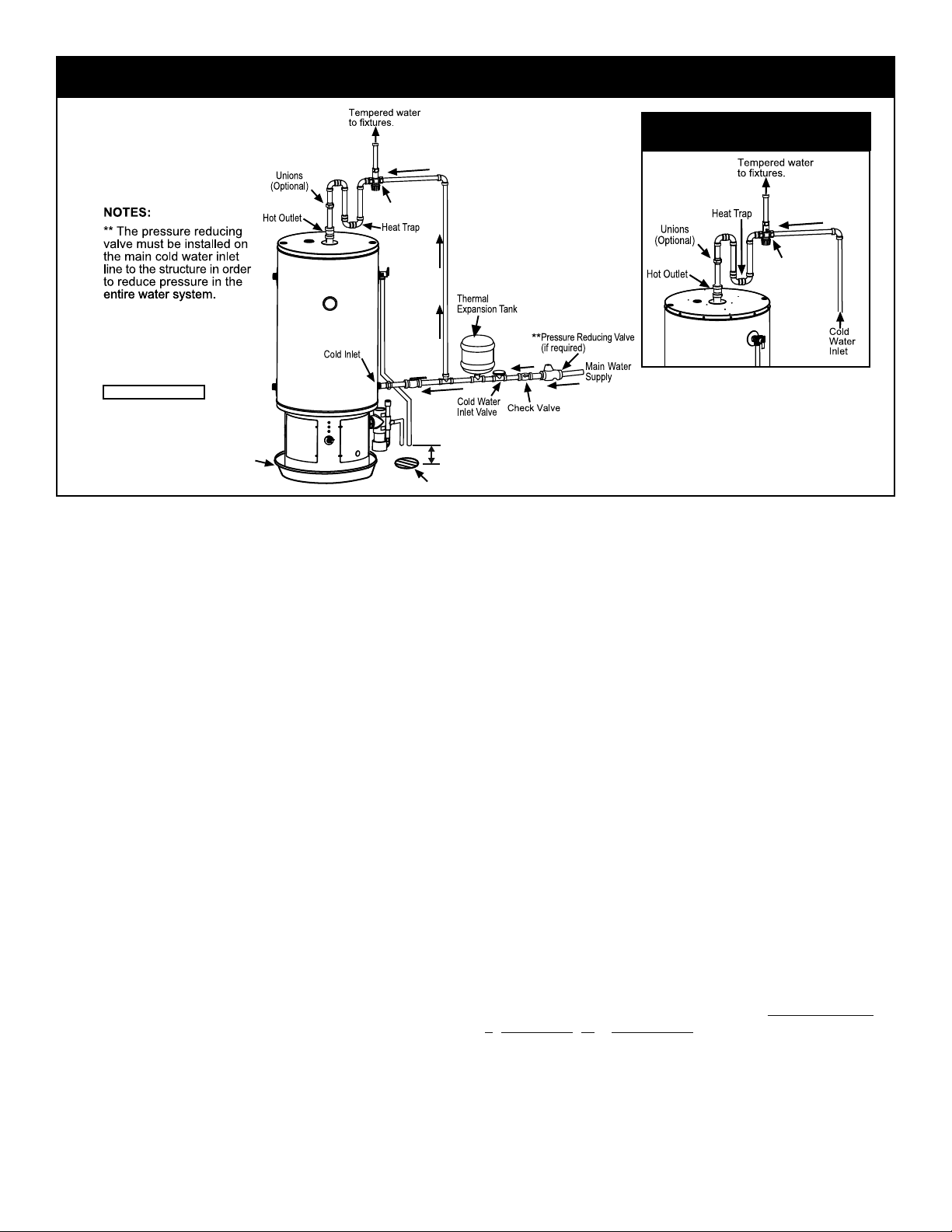

WATER PIPING SYSTEM

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (figure 15). If the indoor installation

area is subject to freezing temperatures, the water piping

must be protected by insulation.

The water supply pressure should not exceed 80 psi

(551.5 kPa). If this occurs, a pressure reducing valve with a

bypass should be installed in the cold water inlet line. This

should be placed on the supply to the entire house in order

to maintain equal hot and cold water pressures.

Important: Heat cannot be applied to the water fittings

on the heater as they may contain nonmetallic parts.

If solder connections are used, solder the pipe to the

adapter before attaching the adapter to the hot and

cold water fittings.

Important: Do not install this water heater with iron or

galvanized piping. Use brass caps on all unused inlet/

outlet connections.

1. Install the water piping and fittings as shown in figure

15. Note: If state or local codes require, install a vacuum relief valve per the manufactures instructions in the

cold water supply line. Connect the cold water supply

(use 1” NPT) to the fitting marked “COLD INLET”.

Do not turn the cold water nipple. The mark should

remain along the top side of the nipple. Connect the

hot water supply (use 1” NPT) to the fitting marked

“HOT OUTLET”.

2. Always use a suitable grade of joint compound and be

certain that all fittings are tightened properly.

3. The installation of unions in both the hot and cold water

supply lines is recommended for ease of removing the

water heater for service or replacement.

4. If installing the water heater in a closed water system,

install an expansion tank in the cold water line as specified under “Closed System/Thermal Expansion” (Page

14).

5. Install a shut-off valve in the cold water inlet line. It

should be located close to the water heater and be

easily accessible. Know the location of this valve and

how to shut off the water to the heater.

Figure 14: Input Graph

6. The Polaris® gas water heater is shipped with a factoryinstalled Temperature and Pressure Relief Valve.

Install a discharge line in the opening in the T & P valve

(see instructions on Page 16).

7. After piping has been properly connected to the water

heater, remove the aerator at the nearest hot water

faucet. Open the hot water faucet and allow the tank

to completely fill with water. (To prevent damage to

the unit, DO NOT connect power until the tank is

COMPLETELY FILLED). To purge the lines of any

excess air, keep the hot water faucet open for 3 minutes after a constant flow of water is obtained. Close

the faucet and check all connections for leaks.

Corrosion and Water Quality

Water quality will vary from location to location and may

contain contaminates that may reduce the life or performance of the water heater. To test for contaminates a

water quality test kit is available, reference part number

6903791.

Contaminates which can reduce the life or performance

of the water heater if present in high quantities include

those which contribute to hardness (dissolved minerals

such as sodium, calcium and magnesium); plus chlorides

and sulfates. Additionally, water that is too acidic or basic

(measured as pH) can reduce the life of the water heater.

Water treatment systems (such as water softeners for

hardness) should be used and maintained properly if the

contaminate levels exceed the following:

Warranty is void in applications which exceed the

water quality requirements listed below.

Table 2:

Total Hardness: 12 grains per gal. (205 mg/liter) max.

Chloride: 200 mg/liter max.

pH: 6.5-8.0

Alkalinity: 200 mg/liter max.

13

Page 14

Check local codes.

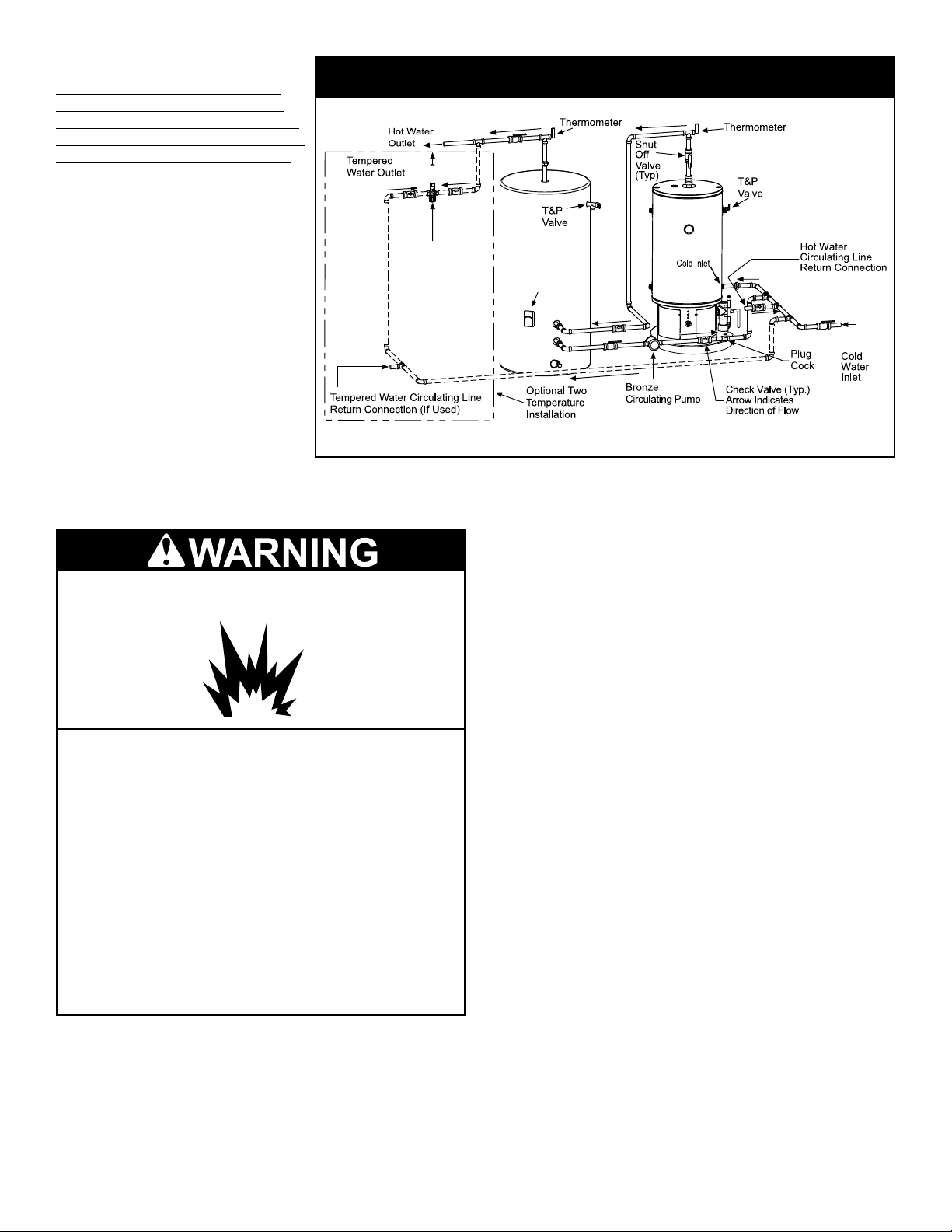

Figure 15: Typical One-Temperature System Piping Installation

Figure 16: Sample Mixing

Valve Installation

Mixing Valve

Mixing Valve

(set to 120° F

[48.8° C] or lower)

Metal Drain Pan

6” (15.2cm)

Air Gap Max.

Adequate Drain

Mixing Valve Installation

A mixing valve has been provided for use with the

Polaris

manufacturer’s instructions, in the domestic hot water line.

See Figure 16 for a sample tempering valve installation.

®

Gas water heater and must be installed, per the

General Information

Water piping, fittings, and valves must be properly installed

for the correct and safe operation of this water heater.

Please note the following:

• The system should be installed only with piping that is

suitable for potable (drinking) water such as copper,

CPVC, or polybutylene. PVC water piping may be used

on the cold water inlet supply but not within 18 inches

(45.7 cm) of the cold water connection on the water

heater.

• Do not use PVC piping on the hot water outlet,

space heating supply, or space heating return.

• Do not use any pumps, valves, or fittings that are

not compatible with potable water.

• Do not use valves that may cause excessive

restriction to water flow. Use full flow ball or gate

valves only.

• Do not use 50/50 tin-lead solder (or any lead based

solder) in potable water lines. Use 95/5 solder or

other equivalent material.

• Do not tamper with the thermostat, gas valve,

blower, electrical components, or temperature and

pressure relief valve. Tampering with any of the

components is dangerous and can result in death,

severe injury, or property damage. Tampering voids

all warranties. Only qualified technicians should

service these components.

• Do not use this water heater as a replacement for an

existing boiler installation.

• Do not use with piping that has been treated with

chromates, boiler seal, or other chemicals.

• Do not add any chemicals to the system piping

which will contaminate the potable water supply.

Closed System/Thermal Expansion

As water is heated, it expands (thermal expansion). In a

closed system, the volume of water will increase. As the

volume of water increases, there will be a corresponding increase in water pressure due to thermal expansion.

Thermal expansion can cause premature tank failure (leakage). This type of failure is not covered under the limited

warranty. Thermal expansion can also cause intermittent

temperature-pressure relief valve operation; water discharged from the valve due to excessive pressure build up.

The temperature-pressure relief valve is not intended for

the constant relief of thermal expansion. This condition is

not covered under the limited warranty.

A properly-sized thermal expansion tank should be

installed on all closed systems to control the harmful

effects of thermal expansion. Contact a plumbing service

agency or your retail supplier regarding the installation of a

thermal expansion tank. The manufacturer of this water

heater will void the warranty if there is a failure to

install a properly sized expansion tank.

Combination Space Heating/Potable

Water System

Some water heater models are equipped with inlet/

outlet connections for use in space heating applications.

Note: this water heater, “Suitable for combination water

(potable) heating and space heating and not suitable for

space heating applications only.” If this water heater is to be

used to supply both space heating and potable (drinking)

water, the instructions listed below must be followed (see

figure 17).

• Be sure to follow the manual(s) shipped with the air

handler or other type heating system.

• This water heater is not to be used as a replacement

for an existing boiler installation.

14

Page 15

Figure 17: Air Handler Piping Installation

Mixing Valve

Metal Drain Pan

• Do not use with piping that has been treated with

chromates, boiler seal or other chemicals and do not

add any chemicals to the water heater piping.

• If the space heating system requires water temperatures

in excess of 120°F (48.9°C), a mixing valve (provided)

must be installed per the manufacturer’s instructions

in the potable hot water supply to limit the risk of scald

injury.

• Pumps, valves, piping and fittings must be compatible

with potable water.

• A properly installed flow control valve is required to pre-

vent thermosiphoning. Thermosiphoning is the result

of a continuous flow of water through the air handler

circuit during the off cycle. Weeping (blow off) of the

temperature and pressure relief valve (T & P) or higher

than normal water temperatures are the first signs of

thermosiphoning.

• The hot water line from the water heater should be ver-

tical past any mixing valve or supply line to the heating

system to remove air bubbles from the system.

• Do not connect the water heater to any system or

components previously used with non-potable water

heating appliances when used to supply potable water.

6” (15.2cm)

Air Gap Max.

Adequate Drain

Storage Tank Installation

When installing the Polaris® with a storage tank, see figure

18 for piping suggestions.

Solar Installation

If this water heater is used as a solar storage heater or as

a backup for the solar system, the water supply temperatures to the water heater tank may be in excess of 120°F

(48.9°C). A mixing valve must be installed in the water supply line to limit the supply temperature to 120°F (48.9°C).

Note: Solar water heating systems can often supply water

with temperatures exceeding 180°F (82.2°C) and may

result in water heater malfunction.

15

Page 16

Notes on Figure 18:

If tank temperature is set above

120°F (48.9°C) and water is supplied for domestic use (hand washing, showering, etc.) a mixing valve

must be installed in the hot water

line to domestic fixtures.

Installation must conform to local

code requirements. If a check valve

is installed in the cold water supply line, an expansion tank must be

installed between the check valve

and the water heater’s cold water

inlet. Set storage tank temperature

five degrees lower than the water

heater’s temperature setting. Using

the plug valve in the recirculating

line, adjust the flow in the recirculating line to five gallons per minute.

Figure 18: Polaris® with Auxillary Storage Tank - One or Two

Temperature System (With or Without Building Recirculation)

Mixing

Valve

Tank

Temperature

Control

(170°F [76.6°C] Max.)

(If Used)

Temperature and Pressure

Relief Valve

Explosion Hazard

• Temperature-pressure relief valve must

comply with ANSI Z21.22-CSA 4.4 and

ASME code.

• A properly-sized temperature-pressure

relief valve must be installed in the

opening provided.

• Do not plug, block, or cap the discharge

line.

• Failure to follow this warning can result in

excessive tank pressure, serious injury

or death.

For protection against excessive pressures and temperatures, a temperature and pressure relief valve must be

installed in the opening marked “T & P RELIEF VALVE”.

This valve must be design certified by a nationally recognized testing laboratory that maintains periodic inspection

of the production of listed equipment or materials as meeting the requirements for Relief Valves and Automatic Shut-

off Devices for Hot Water Supply Systems, ANSI Z21.22.

The function of the temperature and pressure relief valve is

to discharge water in large quantities in the event of excessive temperature or pressure developing in the water heater. The valve’s relief pressure must not exceed the working

pressure of the water heater as stated on the data plate.

Important: Only a new temperature and pressure relief

valve should be used with this water heater. Do not use

an old or existing valve as it may be damaged or not adequate for the working pressure of the new water heater. Do

not place any valve or piping between the relief valve and

the tank.

The Temperature & Pressure Relief Valve:

• Must not be in contact with any electrical part.

• Must be connected to an adequate discharge line.

• Must not be rated higher than the working pressure

shown on the data plate of the water heater.

• The BTUH rating of the T & P valve must be greater

than, or equal to, the input rating of the water heater

The Discharge Line:

• Must not be smaller than the pipe size of the relief

valve or have any reducing coupling installed in the

discharge line.

• Must not be capped, blocked, plugged or contain any

valve between the relief valve and the end of the discharge line.

• Must terminate a maximum of 6 inches (15.2 cm)

above a floor drain or external to the building.

• Must be capable of withstanding 250°F (121°C) without

distortion.

• Must be installed to allow complete drainage of both

the valve and discharge line.

16

Page 17

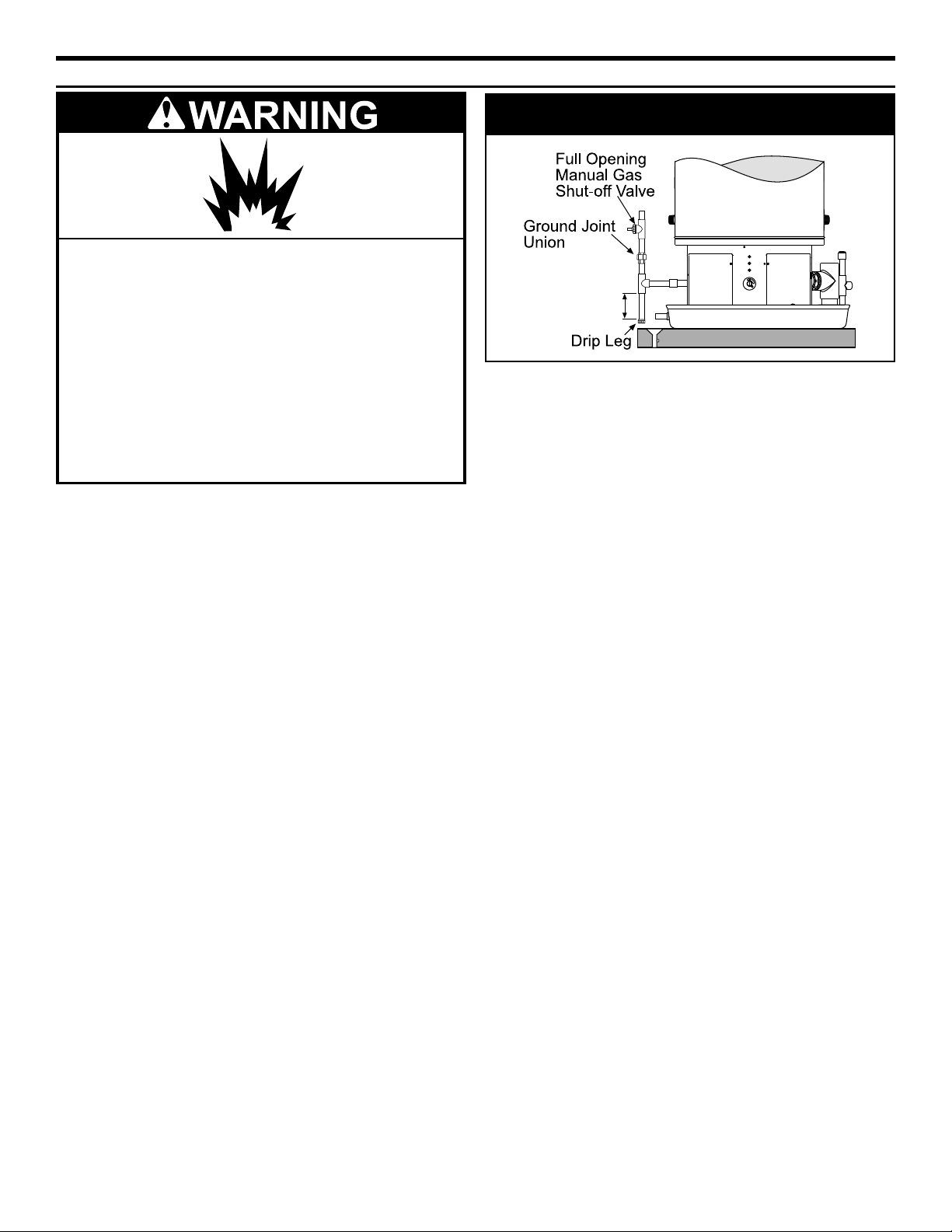

GAS SUPPLY AND PIPING

Explosion Hazard

Use a new AGA or CSA approved gas

supply line.

Install a shut-off valve.

Do not connect a natural gas water

heater to a L.P. Gas Supply.

Do not connect an L.P. gas water heater

to a Natural Gas Supply.

Failure to follow these instructions can

result in death, explosion, or carbon

monoxide poisoning.

Gas Requirements

Read the data plate to be sure the water heater is made

for the type of gas being used. This information will be

found on the data plate located on the front of the water

heater. If the information does not agree with the type of

gas available, do not install or operate the water heater.

Call your dealer.

Note: An odorant may be added by the gas supplier to

the gas used by this water heater. This odorant may fade

over an extended period of time. Do not depend upon this

odorant as an indication of leaking gas.

Gas Piping

The gas piping must be installed according to all local and

state codes or in absence of local and state codes with the

“National Fuel Gas Code”, ANSI Z223.1 (NFPA 54)-current

edition. Canadian installations must be performed in

accordance with CAN/CSA-B149.1-current edition.

Note: If using a flexible gas connector, make sure its rating

tag matches or exceeds the input of the water heater.

Follow the instructions below and reference figure 19 for

gas piping installation.

1. Install a readily accessible manual shut-off valve in the

gas supply line as recommended by the local utility.

Know the location of this valve and how to turn off the

gas to this unit.

2. Install a drip leg as shown. The drip leg must be no

less than 3 inches (7.62 cm) long for the accumulation

of dirt, foreign material and water droplets.

3. Install a ground joint union between the water heater

and the manual shut-off valve. This is to allow easy

servicing.

4. Turn the gas supply on and check for leaks. Use a

chloride-free soap and water solution (bubbles forming

indicate a leak) or other approved method.

Figure 19: Gas Piping Installation

3” (7.62 cm)

Minimum

Gas Pressure

Important: The gas supply pressure must not exceed the

maximum supply pressure as stated on the water heater’s

data plate. Minimum supply pressure should also be

maintained per the data plate.

17

Page 18

Gas Pressure Testing

Important: This water heater and its gas connection must

be leak tested before placing the appliance in operation.

• If the code requires the gas lines to be tested at a

pressure of 14” W.C. (3.486 kPa) or greater, the water

heater and its manual shut-off valve must be discon-

nected from the gas supply piping system and the line

capped.

• If the gas lines are to be tested at a pressure less

than 14” W.C. (3.486 kPa), the water heater must be

isolated from the gas supply piping system by closing

its manual shut-off valve.

Nationally listed/recognized fuel gas and carbon

monoxide(CO) detectors are recommended in

all applications and should be installed using the

manufacturer’s instructions and local codes, rules, or

regulations.

Note: Air may be present in the gas lines and could prevent

the burner from lighting on initial start-up. The gas lines

should be purged of air by a qualified service technician

after installation of the gas piping system.

Explosion Hazard

Have a qualified person make sure that

the L.P. gas operating pressure does not

exceed 13” water column (3.237 kPa).

Examples of a qualified person include

licensed heating personnel, authorized

gas company personnel, and authorized

service personnel.

Failure to do so can result in death,

explosion, or fire.

18

Page 19

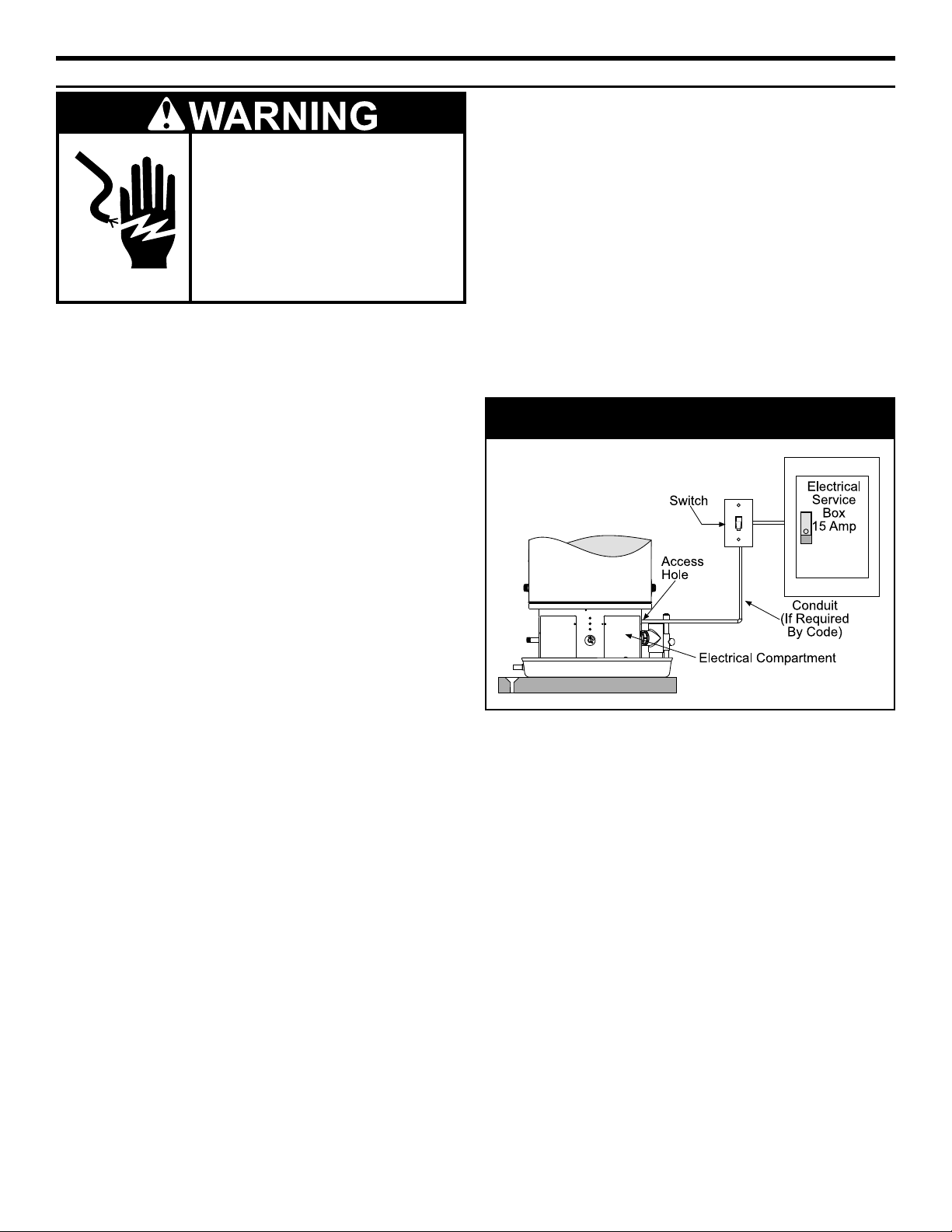

ELECTRICAL CONNECTIONS

Electrical Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electrical shock.

If you lack the necessary skills required to properly install

the electrical wiring to this water heater, do not proceed but

have a qualified electrician perform the installation.

When making the electrical connections, always make

sure:

• The voltage and frequency correspond to that specified

on the water heater data plate on the front of the water

heater.

• The electrical supply has the proper overload fuse

or breaker protection. The heater draws less than 7

amps.

• Wire sizes and connections comply with all applicable

codes.

• Wiring enclosed in approved conduit (if required by local codes).

• The water heater and electrical supply are properly

grounded.

• This water heater must be “hard-wired” - do not use an

extension cord to supply electrical power to this water

heater.

4. Connect this circuit (directly from the electrical service

box) to an electrical disconnect switch.

5. Ground the water heater by connecting the electrical

service ground wire to the green ground wire (provided).

Note: The power supply to this water heater must be

properly polarized, [120 volts from the hot lead (black) to

ground and 0 volts from the neutral lead (white) to ground]

otherwise, the unit will not operate.

6. After making all electrical connections, completely fill

the tank with water and check all connections for leaks.

Open the nearest hot water faucet and let it run for 3

minutes to purge the water lines of air and sediment

and to ensure complete filling of the tank. The electrical power may then be turned on. See figure 20 for

completed installation.

Figure 20: Electrical Connections

Note:

The wiring diagram can be found on Page 20. Always

reference the wiring diagram(s) for the correct electrical

connections.

When installing the electrical wiring to the water heater:

1. Shut off the power at the electrical service box.

2. Loosen the screws securing the access panel to the

electrical compartment. (The electrical wiring diagram.

models can be found on the inside of the access panel

at the base of the water heater.) Set the access panel

aside.

3. Connect the electrical supply to the water heater in

accordance with local utility requirements and codes.

Use only a dedicated electrical circuit containing a

properly sized fuse or circuit breaker. Maximum overload protection should not exceed 15 amperes.

19

Page 20

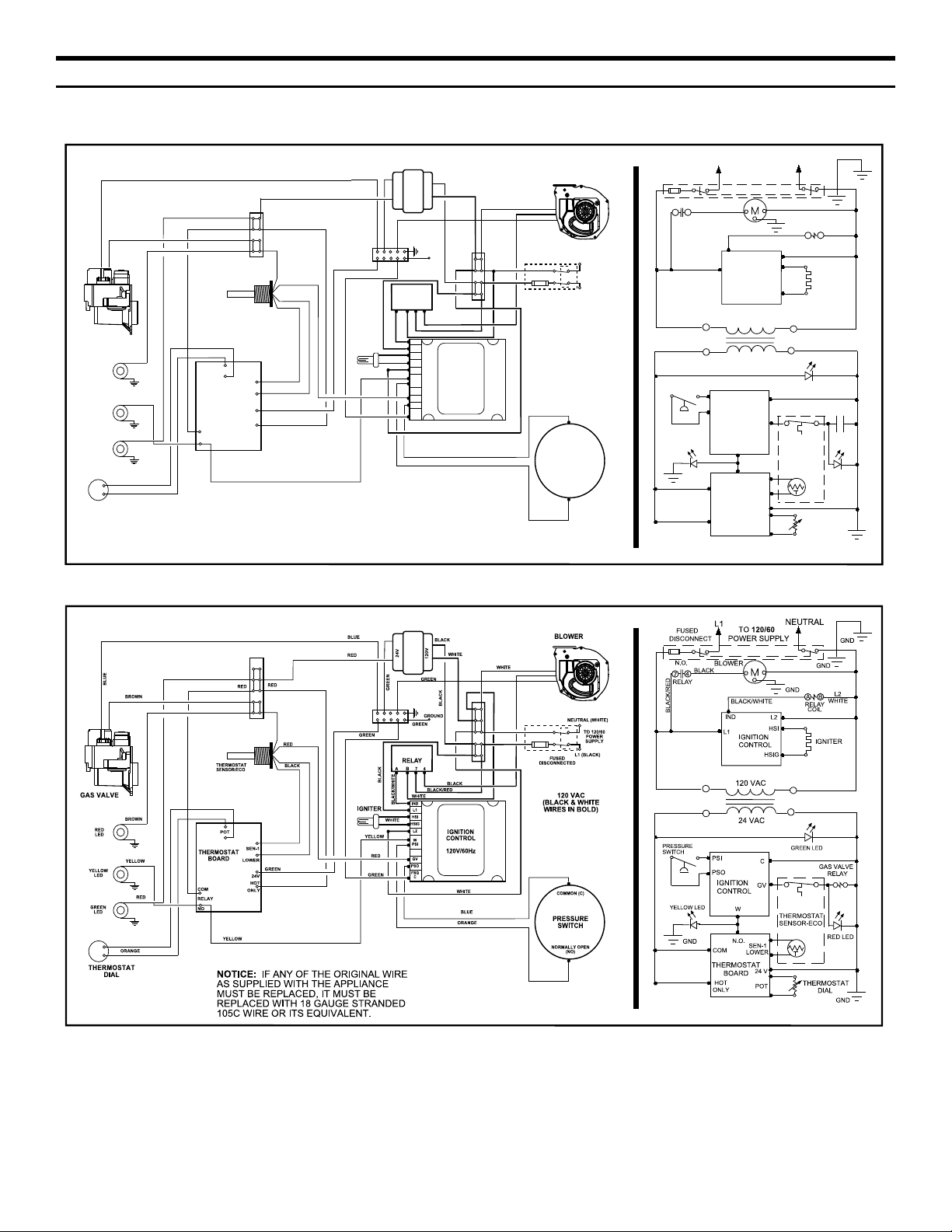

WIRING DIAGRAM

HEATER SUPPLIED WITH T92 SERIES RELAY

Figure 20A

BLUE

GAS VALVE

RED

LED

YELLOW

LED

GREEN

LED

THERMOSTAT

DIAL

BROWN

BROWN

YELLOW

ORANGE

BLUE

RED

RED

RED

RED

THERMOSTAT

SENSOR/ECO

POT

THERMOSTAT

BOARD

RED

COM

RELAY

NO

YELLOW

NOTICE: IF ANY OF THE ORIGINAL WIRE

AS SUPPLIED WITH THE APPLIANCE

MUST BE REPLACED, IT MUST BE

REPLACED WITH 18 GAUGE STRANDED

105C WIRE OR ITS EQUIVALENT.

LOWER

SEN-1

ONLY

BLACK

GREEN

24V

HOT

GREEN

IGNITER

YELLOW

GREEN

BLACK

WHITE

RED

24V

GREEN

RELAY

BLACK/WHITE

TRANSFORMER

GREEN

1

8

WHITE

IND

L1

HSI

HSIG

L2

W

PSI

GV

PSO

FSG

C

120V

GREEN

GROUND

60

BLACK/RED

BLACK

BLACK

BLACK

IGNITION

CONTROL

120V/60Hz

WHITE

ORANGE

WHITE

BLUE

HEATER SUPPLIED WITH KUHP SERIES RELAY

WHITE

BLOWER

NEUTRAL (WHITE)

L1 (BLACK)

FUSED

DISCONNECTED

120 VAC

(BLACK & WHITE

WIRES IN BOLD)

COMMON (C)

PRESSURE

SWITCH

NORMALLY OPEN

(NO)

TO 120/60

POWER

SUPPLY

FUSED

DISCONNECT

N.O.

6

8

RELAY

BLACK/RED

PRESSURE

SWITCH

YELLOW LED

GND

BLACK

PSI

PSO

COM

THERMOSTAT

BOARD

HOT

ONLY

L1

TO 120/60

POWER SUPPLY

BLOWER

BLACK/WHITE

IND

L1

IGNITION

CONTROL

120 VAC

24 VAC

IGNITION

CONTROL

W

N.O.

SEN-1

LOWER

C

GV

24 V

POT

L2

HSI

HSIG

THERMOSTAT

SENSOR-ECO

NEUTRAL

GND

0

RELAY

COIL

GREEN LED

THERMOSTAT

DIAL

GND

1

WHITE

IGNITER

GAS VALVE

RELAY

RED LED

GND

L2

GND

Figure 20B

20

Page 21

INSTALLATION CHECKLIST

Water Heater Location

Requirements

Centrally located with the water piping system. Located

as close to the gas piping and vent pipe system as possible.

Located indoors and in a vertical position. Protected

from freezing temperatures.

Proper clearances from combustible surfaces main-

tained and not installed directly on a carpeted floor.

Sufficient room to service the water heater.

Provisions made to protect the area from water dam-

age. Properly sized metal drain pan installed and piped

to an adequate drain.

Installation area free of corrosive elements and

flammable materials.

Condensate Line

Drain stem is fully inserted in the elbow and glued

properly.

Trap aligned so that the exhaust pipe is in a vertical

position close to the surface of the water heater.

Line properly sloped to adequate drain or approved

condensate pump.

Properly vented.

Protected from freezing (if required).

Vent Pipe System

Vent pipe and fittings of approved material.

Acceptable size, length, and number of elbows on air

inlet pipe.

Acceptable size, length, and number of elbows on

exhaust outlet pipe.

Add the air inlet filter per the manufacturer’s instruction.

Installed in accordance with prevailing provisions of

Local codes, or in the absence of such, National Fuel

Gas Code, NFPA 54, ANSI Z223.1-Current Edition.

Canadian Installations must be performed in accordance with CAN/CSA-B149.1-Current Edition.

All 2” horizontal piping sloped down toward the water

heater at 1/4” per foot (21 mm per meter). 3” piping

sloped down towards the heater at 1/8” per foot (10.5

mm per meter).

Not obstructed in any way.

Vent Termination

Alternate Horizontal

Correct relationship - outlet to inlet.

12” Min. (30.5 cm) above anticipated snow level.

2” exhaust outlet/air inlet pipe sloped down towards

water heater at 1/4” per foot (21 mm per meter). 3”

piping sloped down towards the heater at 1/8” per foot

(10.5 mm per meter).

Away from corners, other vents, windows, etc.

Vertical

Inlet - 12” Min. (30.5 cm) above roof/snow level.

Correct relationship - outlet to inlet.

Away from corners, other vents, windows, etc.

Concentric

12” Min. (30.5 cm) above grade/snow level.

2” exhaust outlet/air inlet pipe sloped down towards

water heater at 1/4” per foot (21 mm per meter). 3”

piping sloped down towards the heater at 1/8” per foot

(10.5 mm per meter).

Away from corners, other vents, windows, etc.

Water System Piping

Temperature and pressure relief valve properly

installed with a discharge line run to an open drain and

protected from freezing.

All piping properly installed and free of leaks.

Heater completely filled with water.

A properly sized expansion tank must be installed on all

closed systems.

A mixing valve must be installed per the manufacturer’s

instructions.

Gas Supply and Piping

If using a flexible gas connector, make sure its rating

tag matches or exceeds the input of the water heater.

Adequate pipe size and of approved material.

Gas supply is the same type as listed on the water

heater data plate.

Gas line equipped with full opening shut-off valve,

union and drip leg.

Approved pipe joint compound used.

Chloride-free soap and water solution or other ap-

proved means used to check all connections and fittings for possible gas leaks.

Horizontal

Correct relationship - outlet to inlet.

12” Min. (30.5 cm) above grade/snow level.

2” exhaust outlet/air inlet pipe sloped down towards

water heater at 1/4” per foot (21 mm per meter). 3”

piping sloped down towards the heater at 1/8” per foot

(10.5 mm per meter).

Away from corners, other vents, windows, etc.

Electrical Connections

Unit connected to a dedicated power supply.

Unit connected to a 120V electrical supply.

Proper polarity.

Water heater properly grounded.

Installed in accordance with prevailing provisions of

local codes, or in the absence of such, National Fuel

Gas Code, NFPA 54, ANSI Z223.1-Current Edition.

Canadian installations must be performed in accordance with CAN/CSA-B149.1-Current Edition.

21

Page 22

OPERATING YOUR WATER HEATER

Read and understand these directions thoroughly before

attempting to operate the water heater (see Operating

Instructions on Page 23). Check the data plate on the

front of the water heater for the correct gas. Do not use this

water heater with any gas other than the one listed on the

data plate. If you have any questions or doubts, consult

your gas supplier or gas utility company.

L.P. (Propane) Models

Propane gas is heavier than air and in the occurrence of

a leak in the system, the gas will settle on the floor level.

Basements, crawl spaces, skirted areas under mobile

homes (even when ventilated), closets and areas below

ground level will serve as pockets for the accumulation of

gas. Before lighting a propane gas water heater, smell all

around the appliance at floor level. If you smell gas, follow

the instructions as given in the warning on the front page.

When your propane tank runs out of fuel, turn off the gas

at all gas appliances including pilot lights. After the tank

is refilled, all appliances must be re-lit according to their

manufacturer’s instructions.

Water Heater Operation

This water heater does not have a pilot light. It is equipped

with an electronic ignition that automatically lights the

burner. There are three lights to indicate the various stages

of operation; Green = Electrical power is on, Yellow =

Thermostat is calling for heat, which signals the beginning

of the ignition sequence (see figure 21), and Red = Ignition

control is signaling the gas valve to open.

Figure 21: Sequence of Operation

When the thermostat calls for heat, the blower will run for

6 seconds to purge the system of any accumulated gas or

air. The hot surface igniter will heat up for 35 seconds. The

blower will turn on and the gas valve open, forcing the air

and gas mixture across the hot surface igniter, causing the

burner to light. The hot surface igniter will turn off and act

as an electronic flame sensor to determine if burner ignition

has been accomplished. If it detects any loss of flame, it

will shut off the gas supply to the burner.

The ignition control will try to light the burner three times.

If the ignition control does not detect a flame after three

tries, it will temporarily lock out, but then auto restart and go

through three additional tries for ignition after 60 minutes.

It will repeat until ignition occurs or the system locks out

requiring service. Refer to Troubleshooting Guide on Page 26.

Thermostat Sensor

The sensor is a 10K ohm [at 77°F (25°C)] thermistor. Read

resistance through the black wires that run to the sensor.

Remove wires from circuit board before checking. An open

or short circuit indicates sensor failure. Check reading

against the values listed in Table 3. The resistance should

correspond with the temperature in the tank:

Table 3:

Temperature I Resistance

60°F 16°C 15,300 ohms

80°F 27°C 9,300 ohms

100°F 38°C 5,800 ohms

120°F 49°C 3,800 ohms

140°F 60°C 2,500 ohms

160°F 71°C 1,700 ohms

185°F 85°C 1,100 ohms

22

Page 23

(48.9°C)*

(54.4°C)*

(60°C)*

* Temperatures shown are approximates

and may vary.

(48.9°C)*

(54.4°C)*

(60°C)*

Stacking

Stacking occurs when a series of short draws of hot water

(3 gallons [11.3 liters] or less) are taken from the water

heater tank. This causes increased cycling of the burner

and can result in increased water temperatures at the hot

water outlet. A mixing valve must be installed in the hot

water supply line to reduce the risk of scald injury.

Water Temperature Regulation

Water temperature over 125°F (51.6°C) can cause

severe burns instantly or death from scalds.

Children, disabled and elderly are at highest risk

of being scalded.

See instruction manual before setting

temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are available.

The thermostat is adjusted to its lowest temperature setting

when it is shipped from the factory. Water temperature

can be regulated by moving the temperature dial to the

preferred setting. The preferred starting point is 130°F

(54.4°C); however, in some instances, setting the water

heater higher than 130°F (54.4°C) can reduce the

occurrence of igniter failure due to excessive condensate.

Important: A mixing valve (provided) must be installed in

the hot water outlet to reduce the risk of scald injury when

setting the thermostat in excess of 120°F (48.9°C).

Many home heating systems

used with this water heater are

Figure 22:

Temperature Dial

designed for temperatures higher

than 130°F (54.4°C). Refer to

the manufacturer’s instruction

manuals supplied with this type

of equipment for recommended

temperature settings.

(48.9

(60

(54.4

°

C)

°

C)

°

C)

Important: Adjusting the

thermostat past the 120°F

(48.9°C) setting on the

temperature dial (see figure 22) will increase the risk of scald

injury. Hot water can produce first degree burns within:

Table 4

Water

Temperature

°F (°C)

110 (43.3)

116 (46.7)

116 (46.7)

122 (50)

131 (55)

140 (60)

149 (65)

154 (67.8)

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15,1978)

Time for 1st

Degree Burn

(Less Severe Burns)

(normal shower temp.)

(pain threshold)

35 minutes 45 minutes

1 minute 5 minutes

5 seconds 25 seconds

2 seconds 5 seconds

1 second 2 seconds