Page 1

Pressure Cleaner

Booster Pump

Installation and

Operation Manual

ENGLISH | FRANÇAIS

For Polaris PB4-60 Booster Pumps with Serial Numbers beginning with "PB"

and a manufacturing date on or after Dec 1, 2011.

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a contractor who is licensed and qualied

in pool equipment by the jurisdiction in which the product will be installed, where such state or local requirements

exist. In the event no such state or local requirement exists, the maintainer must be a professional with sufcient

experience in pool equipment installation and maintenance, so that all of the instructions in this manual can be

followed exactly. Improper installation and/or operation can create dangerous electrical hazards, which can cause

high voltages to run through the electrical system. Before installing this product, read and follow all warning

notices and instructions that accompany this product. Failure to follow warning notices and instructions may result

in property damage, personal injury, or death. Improper installation and/or operation will void the warranty.

If these instructions are not followed exactly, a re or explosion may result, causing property damage, personal

injury, or death.

ATTENTION INSTALLER: This manual contains important information about the installation,

operation and safe use of this product. This information should be given to the owner/operator of

H0344400 REVD

this equipment.

Page 2

Page 2

ENGLISH

Polaris® PB4-60 Booster Pump | Installation and Operation Manual

Table of Contents

Section 1. IMPORTANT SAFETY INSTRUC-

TIONS ............................................. 3

1.1 Safety Instructions ............................................ 3

1.2 Pool Pump Suction Entrapment

Prevention Guidelines ....................................... 5

Section 2. General Description ...................... 6

2.1 Introduction ....................................................... 6

2.2 Description ........................................................ 6

2.3 Preparation ....................................................... 6

Section 3. Installation ..................................... 6

3.1 Electrical Installation ......................................... 6

3.1.1 Voltage Checks .....................................6

3.1.2 Bonding and Grounding ......................... 6

3.2 Electrical ........................................................... 6

3.2.1 Electrical Wiring ..................................... 7

3.3 Plumbing ........................................................... 7

3.3.1 Requirements ........................................ 7

3.3.2 Pipe Sizing ............................................. 8

3.3.3 Pump Location ....................................... 8

3.3.4 Install the Pump ..................................... 9

3.3.5 Installation Recommendations .............. 9

3.3.6 Check the Water Flow ........................... 9

3.3.7 Conduct Pressure Test .......................... 10

Section 4. Operation ....................................... 10

4.1 Start-up ............................................................. 10

Section 5. Maintenance .................................. 11

5.1 Winterizing the Pump ........................................ 11

Section 6. Troubleshooting and Repair ........ 12

6.1 Troubleshooting ................................................ 12

6.2 Service Technician Maintenance ...................... 13

6.2.1 Blocked Impeller .................................... 13

6.2.2 Impeller Removal ................................... 13

6.2.3 Impeller Replacement ............................ 14

6.2.4 Mechanical Seal Replacement .............. 14

6.2.5 Motor Replacement .............................. 15

Section 7. Product Specications and Techni-

cal Data .......................................... 16

7.1 Replacement Parts List ..................................... 16

7.2 Polaris PB4-60 Booster Pump Exploded View . 16

7.3 Pump Dimensions ............................................. 17

7.4 Visual Identication of the New Polaris PB4-60

Booster Pump ................................................... 18

EQUIPMENT INFORMATION RECORD

DATE OF INSTALLATION

INSTALLER INFORMATION

INITIAL PRESSURE GAUGE READING (WITH CLEAN FILTER)

PUMP MODEL

NOTES:

HORSEPOWER

Page 3

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Page 3

Section 1. IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

1.1 Safety Instructions

All electrical work must be performed by a licensed electrician and conform to all national, state, and local codes.

When installing and using this electrical equipment, basic safety precautions should always be followed, including the

following:

WARNING

To reduce the risk of injury, do not permit children to use this product.

WARNING

To reduce the risk of property damage or injury, do not attempt to change the backwash (multiport, slide, or full

ow) valve position with the pump running.

WARNING

Zodiac® pumps are powered by a high voltage electric motor and must be installed by a licensed or certied

electrician or a qualied swimming pool service technician.

WARNING

RISK OF ELECTRIC SHOCK, FIRE, PERSONAL INJURY, OR DEATH. Connect only to a branch circuit that is

protected by a ground-fault circuit-interrupter (GFCI). Contact a qualied electrician if you cannot verify that the

circuit is protected by a GFCI. Make sure such a GFCI should be provided by the installer and should be tested on

a routine basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push the reset button.

Power should be restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts

power to the pump without the test button being pushed, a ground current is owing, indicating the possibility

of electrical shock. Do not use the pump. Disconnect the pump and have the problem corrected by a qualied

service representative before using.

Due to the potential risk of re, electric shock, or injuries to persons, Zodiac Pumps must be installed in

accordance with the National Electrical Code® (NEC®), all local electrical and safety codes, and the Occupational

Safety and Health Act (OSHA®). Copies of the NEC may be ordered from the National Fire Protection Association®

(NFPA®) online at www.nfpa.org or call 617-770-3000, or contact your local government inspection agency.

WARNING

Incorrectly installed equipment may fail, causing severe injury or property damage.

WARNING

• Do not connect the system to an unregulated city water system or other external source of pressurized water

producing pressures greater than 35 PSI.

• Trapped air in system can cause the lter lid to be blown off, which can result in death, serious personal injury,

or property damage. Be sure all air is out of the system before operating.

Page 4

Page 4

ENGLISH

Polaris® PB4-60 Booster Pump | Installation and Operation Manual

WARNING

To minimize the risk of severe injury or death the lter and/or pump should not be subjected to the piping system

pressurization test.

Local codes may require the pool piping system to be subjected to a pressure test. These requirements are

generally not intended to apply to the pool equipment such as lters or pumps.

Zodiac® pool equipment is pressure tested at the factory.

However, if the WARNING cannot be followed and pressure testing of the piping system must include the lter

and/or pump, BE SURE TO COMPLY WITH THE FOLLOWING SAFETY INSTRUCTIONS:

• Check all clamps, bolts, lids, lock rings and system accessories to ensure they are properly installed and

secured before testing.

• RELEASE ALL AIR in the system before testing.

• Water pressure for test must NOT EXCEED 35 PSI.

• Water temperature for test must NOT EXCEED 100°F (38°C).

• Limit test to 24 hours. After test, visually check system to be sure it is ready for operation.

NOTICE: These parameters apply to Zodiac equipment only. For non-Zodiac equipment, consult equipment

manufacturer.

WARNING

Chemical spills and fumes can weaken pool/spa equipment. Corrosion can cause lters and other equipment to

fail, resulting in severe injury or property damage. Do not store pool chemicals near your equipment.

CAUTION

Do not start pump dry! Running the pump dry for any length of time will cause severe damage and will void the

warranty.

CAUTION

This pump is for use with permanently installed pools and may also be used with hot tubs and spas if so marked.

Do not use with storable pools. A permanently installed pool is constructed in or on the ground or in a building

such that it cannot be readily disassembled for storage. A storable pool is constructed so that it may be readily

disassembled for storage and reassembled to its original integrity.

CAUTION

Do not install within an outdoor enclosure or beneath the skirt of a hot tub or portable spa. The pump requires

adequate ventilation to maintain air temperature at less than the maximum ambient temperature rating listed on

the motor rating plate.

SAVE THESE INSTRUCTIONS

Page 5

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Page 5

1.2 Pool Pump Suction Entrapment Prevention Guidelines

WARNING

Pump suction is hazardous and can trap and drown or disembowel bathers. Do not use or operate

swimming pools, spa, or hot tubs if a suction outlet cover is missing, broken, or loose. The following

guidelines provide information for pump installation that minimizes the risk of injury to users of pools, spas, and

hot tubs:

Entrapment Protection - The pump suction system must provide protection against the hazards of suction

entrapment.

Suction Outlet Covers - All suction outlets must have correctly installed, screw-fastened covers in place. All

suction outlet (drain) covers must be maintained. Drain covers must be listed/certied to the latest version of

®

/ASME® A112.19.8 or its successor standard, ANSI/APSP-16. They must be replaced if cracked, broken, or

ANSI

missing.

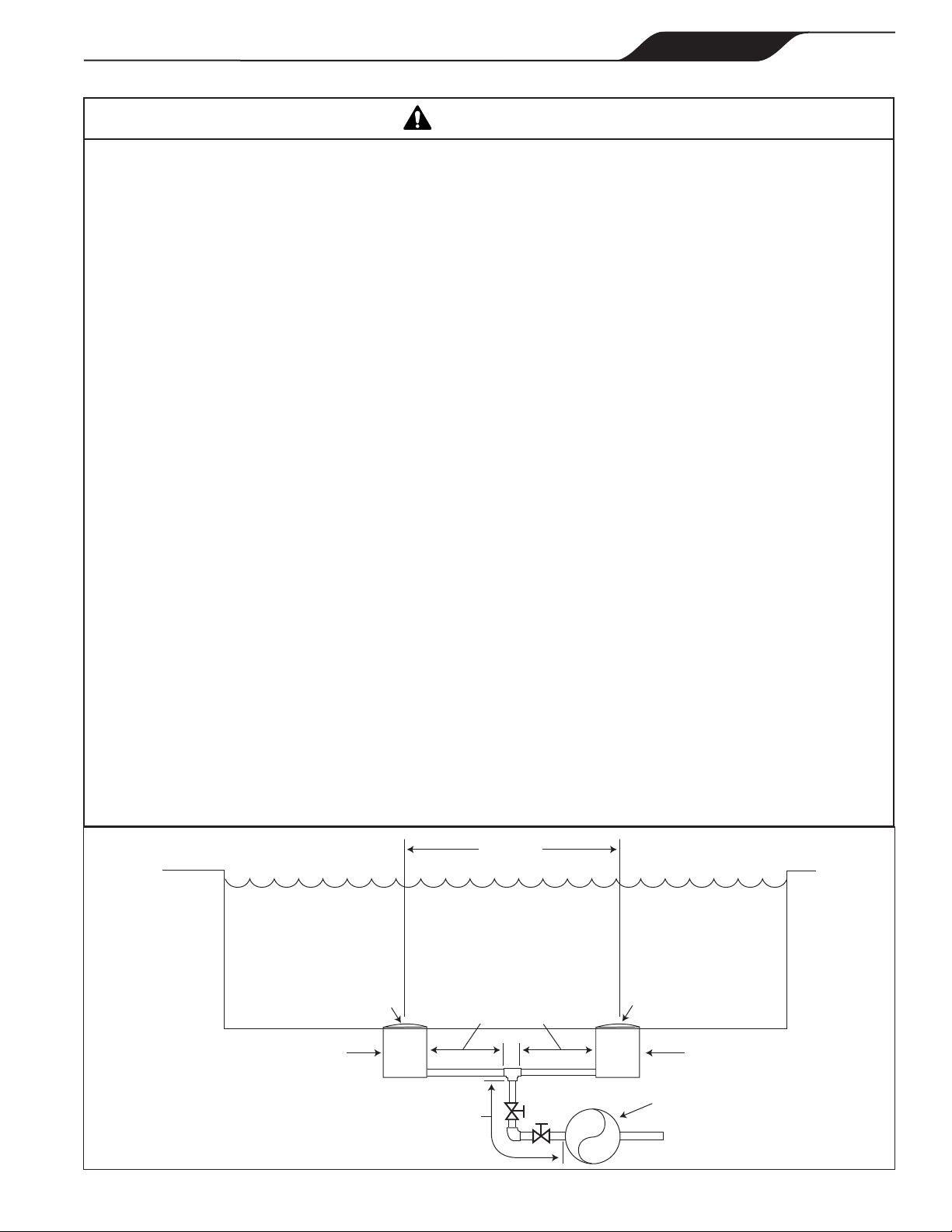

Number of Suction Outlets Per Pump - Provide at least two (2) hydraulically-balanced main drains, with covers,

as suction outlets for each circulating pump suction line. The centers of the main drains (suction outlets) on any

one (1) suction line must be at least three (3) feet apart, center to center. See Figure 1.

The system must be built to include at least two (2) suction outlets (drains) connected to the pump whenever

the pump is running. However, if two (2) main drains run into a single suction line, the single suction line may be

equipped with a valve that will shut off both main drains from the pump. The system shall be constructed such that

it shall not allow for separate or independent shutoff or isolation of each drain. See Figure 1.

More than one (1) pump can be connected to a single suction line as long as the requirements above are met.

Water Velocity - The maximum water velocity through the suction tting or cover for any suction outlet must be

1.5 feet per second unless the outlet complies with the latest version of ANSI/ASME A112.19.8 or its successor

standard, ANSI/APSP-16, the standard for Suction Fittings For Use in Swimming Pools, Wading Pools, Spas, and

Hot Tubs. In any case, do not exceed the suction tting’s maximum designed ow rate.

If 100% of the pump’s ow comes from the main drain system, the maximum water velocity in the pump suction

hydraulic system must be six (6) feet per second or less, even if one (1) main drain (suction outlet) is completely

blocked. The ow through the remaining main drain(s) must comply with the latest version of ANSI/ASME

A112.19.8 or its successor standard, ANSI/APSP-16, the standard for Suction Fittings For Use in Swimming

Pools, Wading Pools, Spas, and Hot Tubs.

Testing and Certication - Suction outlet covers must have been tested by a nationally recognized testing

laboratory and found to comply with the latest version of ANSI/ASME A112.19.8 or its successor standard, ANSI/

APSP-16, the standard for Suction Fittings For Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs.

Fittings - Fittings restrict ow; for best efciency use fewest possible ttings (but at least two (2) suction outlets).

Avoid ttings which could cause an air trap.

Pool cleaner suction ttings must conform to applicable International Association of Plumbing and Mechanical

Ofcials (IAPMO®) standards.

Listed/certified to latest

published version of

ANSI/ASME A112.19.8 - 2007

or its successor,

ANSI/APSP-16

Anti-entrapment

Cover/Grate or Suction

Fitting, screw-fastened

to Main Drain Sump

Suction Outlet

(Main Drain)

Valves OK between

pump and Tee

Figure 1. Number of Suction Outlets Per Pump

At least

three (3) feet

No valves between

Tee and Main Drains

Listed/certified to latest

published version of

ANSI/ASME A112.19.8 - 2007

or its successor,

ANSI/APSP-16

Anti-entrapment

Cover/Grate or Suction Fitting,

screw-fastened

to Main Drain Sump

Suction Outlet

(Main Drain)

Pump

Page 6

Page 6

ENGLISH

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

Section 2. General Description

2.1 Introduction

This manual contains information for the proper

installation, operation and maintenance of the Polaris

PB4-60 pump. Procedures in this manual must be

followed exactly. To obtain additional copies of this

manual contact Zodiac Pool Systems, Inc. ("Zodiac")

at 800.822.7933. For address information, see the back

cover of this manual.

2.2 Description

The Polaris booster pump, PB4-60, supplies high

pressure water to the Polaris pool cleaner to optimize

cleaner efficiency. The pump is not self-priming and

should only be used when the pool filtration pump is on.

CAUTION

Running the booster pump without a ltration pump

will damage the booster pump. Improper operation

of the booster pump will void the warranty.

2.3 Preparation

1. Upon receipt of the pump, check the carton for

damage. Open the carton and check the pump for

concealed damage, such as cracks, dents or a bent

base. If damage is found, contact the shipper or

distributor where you purchased the pump.

2. Inspect the contents of the carton and verify

that all the parts are included. See Section 7.1,

Replacement Parts List.

Section 3. Installation

3.1 Electrical Installation

CAUTION

Failure to provide data plate voltage (within 10%)

during operation will cause the motor to overheat

and void the warranty.

3.1.2 Bonding and Grounding

1. The motor frame must be grounded to a reliable

grounding point using a solid copper conductor,

No. 8 AWG (8.4mm

6 AWG (13.3mm

2

) or larger. In Canada, No.

2

) or larger must be used. If the

pump is installed within five 5 feet (1,5 meter)

of the inside walls of the swimming pool, spa, or

hot tub, the motor frame must be bonded to all

metal parts of the swimming pool, spa, or hot tub

structure and to all electrical equipment, metal

conduit, and metal piping within five (5) feet (1,5

meter) of the inside walls of the swimming pool,

spa, or hot tub.

2. Bond the motor using the provided external lug.

WARNING

To avoid the risk of property damage, severe

personal injury, and/or death, always disconnect

the power source before working on a motor or its

connected load.

WARNING

To avoid the risk of property damage, severe

personal injury, and/or death, make sure that

the control switch or time clock is installed in an

accessible location so that in the event of an

equipment failure or a loose plumbing tting the

equipment can be turned off. This location must not

be in the same area as the pool pump, lter, and

other equipment.

3.1.1 Voltage Checks

The correct voltage, as specified on the pump data

plate, is necessary for proper performance and long

motor life. Incorrect voltage will decrease the pump’s

ability to perform and could cause overheating, reduce

the motor life, and result in higher electric bills.

It is the responsibility of the electrical installer to

provide data plate operating voltage to the pump by

ensuring proper circuit sizes and wire sizes for this

specific application.

The National Electrical Code

®

(NEC®, NFPA-70®)

requires all pool pump circuits be protected with a

Ground Fault Circuit-Interrupter (GFCI). Therefore, it is

also the responsibility of the electrical installer to ensure

that the pump circuit is in compliance with this and all

other applicable requirements of the National Electrical

Code (NEC) and any other applicable installation codes.

CAUTION

The pump must be permanently connected to a

dedicated electrical circuit. No other equipment,

lights, appliances or outlets may be connected to

the pump circuit, with the exception of devices that

may be required to operate simultaneously with the

pump, such as a chlorinating device or heater.

3.2 Electrical

MOTOR RATING

HP S.F RPM VOLTS S.F. AMPS

3/4 1.5 3450 230/115, 60Hz, 1PH 6.4/12.8

Page 7

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Table 1. Maximum Wire Size and Overcurrent Protection

MAXIMUM WIRE SIZE AND MAXIMUM OVERCURRENT PROTECTION*

Distance from Sub-Panel 0-50 feet (15 meters) 50-100 feet (15-30 meters) 100-200 feet (30-60 meters)

Pump

Model

PB4-60 15A 20A

*Assumes three (3) copper conductors in a buried conduit and 3% maximum voltage loss in branch circuit. All National Electrical Code

local codes must be followed. Table shows minimum wire size and branch fuse recommendations for a typical installation per NEC.

Branch Fuse AMPs

Class: CC, G, H, J, K, RK, or T

230 VAC 115 VAC 208-230 VAC 115 VAC 208-230 VAC 115 VAC 208-230 VAC 115 VAC

(2.1mm

Voltage Voltage Voltage

14 AWG

2

)

12 AWG

(3.3mm2)

12 AWG

(3.3mm2)

10 AWG

(5.3mm2)

10 AWG

(5.3mm2)

Page 7

10 AWG

2

(5.3mm

®

(NEC®) and

)

3.2.1 Electrical Wiring

1. The pump motor must be securely and adequately

grounded using the green screw provided. Ground

before attempting to connect to an electrical power

supply. Do not ground to a gas supply line.

2. Wire size must be adequate to minimize voltage

drop during the start-up and operation of the

pump. See Table 1 for wire sizes.

3. Insulate all connections carefully to prevent

grounding or short-circuits. Sharp edges on

terminals require extra protection. To prevent

wire nuts from loosening, tape them using a

suitable, listed (UL

®

, ETL®, CSA®) electrical

insulating tape. For safety, and to prevent entry

of contaminants, reinstall all conduit and terminal

box covers. Do not force connections into the

conduit box.

4. To configure the internal wiring of the pump motor

for the correct voltage, refer to the diagram on the

motor data plate.

5. The starting current of the booster pump motor

may exceed 15 amps on 115 VAC voltage line. It

is recommended that a 20 amp service breaker be

used for the pump connected to 115 VAC.

6. The booster pump motor is factory wired for 230

volts, but can be wired for either 115 or 230 volts.

To rewire to 115 volt, follow the instructions on

the name plate located on the back of the motor or

the sizing plate on the side of the motor.

7. A separate time clock (in addition to the filtration

system time clock) is recommended to control the

On/Off functions of the booster pump. A manual

switch can also be used.

8. If a time clock is used, set it to turn the pump

on at least a half an hour after the pool filtration

pump is turned on, and turn the pump off at least

half an hour before the filtration pump shuts off.

Periodically check the time clock settings to make

sure they are properly synchronized.

3.3 Plumbing

CAUTION

Be careful not to overtighten any pipe tting on the

inlet or outlet of the booster pump. Overtightening

can cause the housing to crack.

3.3.1 Requirements

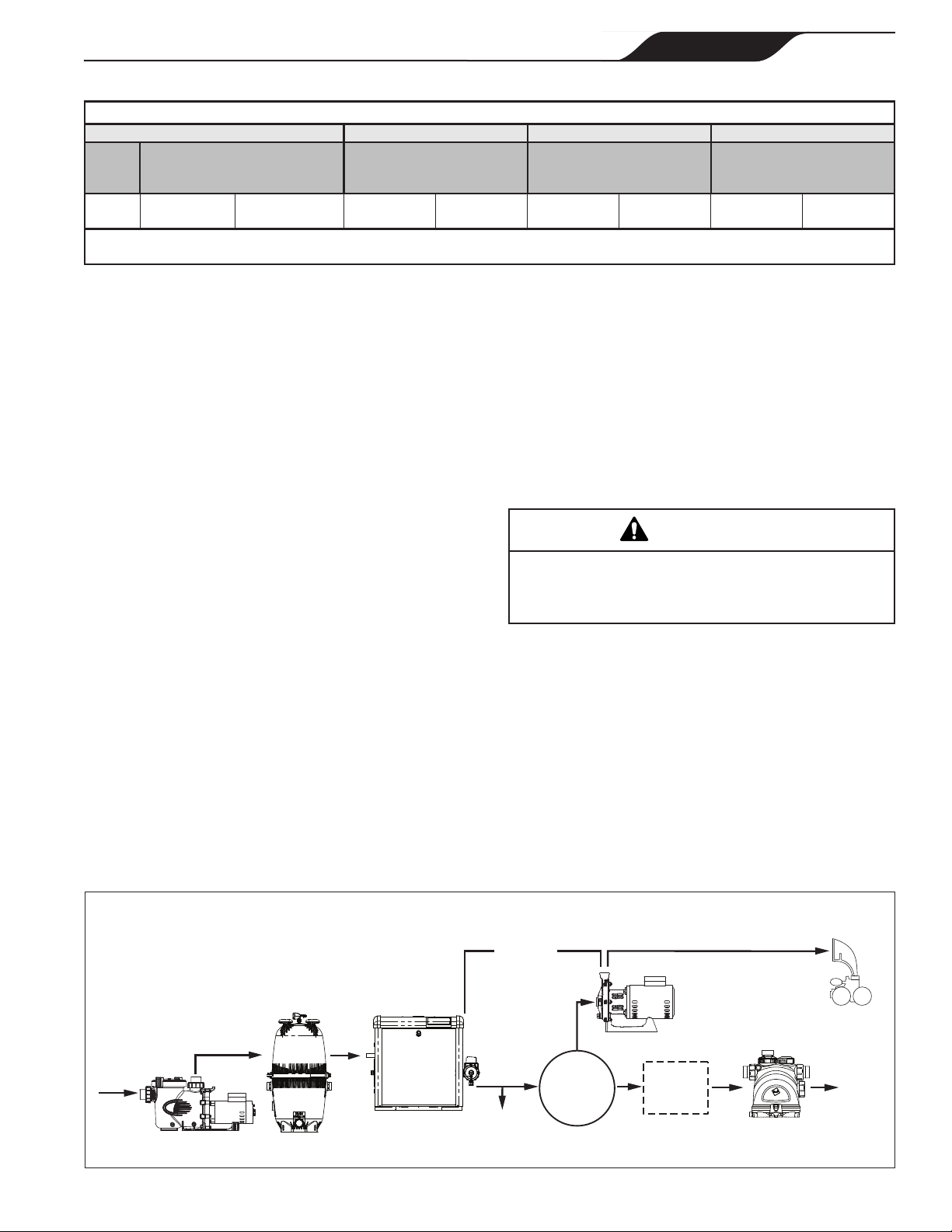

The Polaris Booster Pump requires a dedicated

return line. Plumb the booster pump into the system so

that it always receives flow from the filtration pump.

To ensure proper function of the pump and the cleaner,

refer to Figure 2 and adhere to the following guidelines

for specific equipment.

1. Plumb the dedicated line upstream of all air

inducing equipment.

From

Pool

Filtration Pump

Pool Filter

Figure 2. Typical Equipment Layout

LXiTM Heater

Heater

Minimum

of 3 feet

(1 meter)

To

Spa

NOTE

Plumb the booster pump up-stream

of all air inducing equipment.

Plumbing

Options

1, 2 or 3*

* Refer to Figures 3 and 4

Booster

Pump

Solar

System

Polaris

To

Pool

Chlorinator

Page 8

Page 8

ENGLISH

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

2. If a heater is installed on the system, tap the

inlet for the booster pump into the return line

downstream and at least three (3) feet (1 meter)

from the heater discharge. See Figure 2. Do not

tap the booster pump inlet into the three-foot

(1 meter) section of heat sink pipe that comes

directly out of the heater.

3. Some solar heating systems utilize the entire water

flow when the panels are being purged of air. If the

pump is installed in a non-flow pipe during solar

panel purges, install an automatic override to shut

off the pump.

4. Plumb the booster pump inlet higher, upstream and

as far away as possible from a chlorinator.

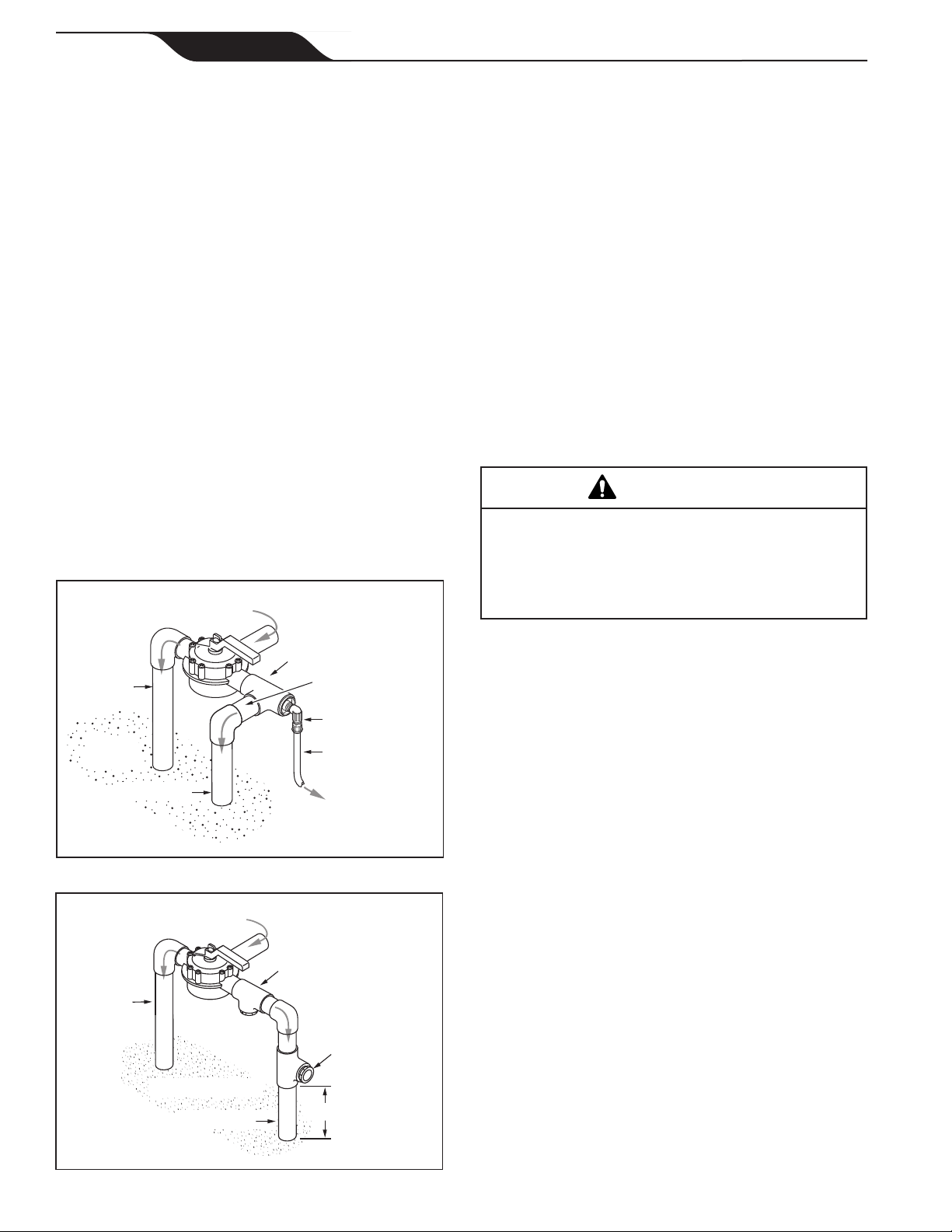

3.3.2 Pipe Sizing

1. Use rigid PVC pipe with a minimum diameter

of 3/4”, 1-1/2” is recommended, for the

dedicated return line. Flexible PVC piping is not

recommended for the dedicated pool return line

underground as it can be damaged by expansion

and movement caused by the surge of pump

pressure. Refer to Figures 3 and 4.

From Filter or Heater

2. The booster pump inlet connection line should be

at least 3/4” pipe. The Softube Quick Connect

fittings are designed to work with the Polaris

reinforced hose (part #P19) only

3. Do not tap into the top of a horizontal line.

4. Use 90° street ells to minimize bends and loops in

the Polaris reinforced hose.

3.3.3 Pump Location

1. Zodiac Pool Systems, Inc. recommends installing

the pump within one 1 foot (30 cm) above the

water level. The pump should not be elevated

more than a few feet above the water level of the

pool.

2. If the pump is located below water level, isolation

valves must be installed on both the suction and

return lines to prevent back flow of pool water

during any routine or required servicing.

WARNING

Some Safety Vacuum Release System (SVRS)

devices are not compatible with installation of check

valves. If the pool has an SVRS device, be sure to

conrm that it will continue to safely operate when

any check valves are installed.

Option #1

To Spa

Ground

Level

Pool Return

Figure 3. Preferred Plumbing Configuration

From Filter or Heater

To Spa

Ground Level

Pool Return

Horizontal

Leg

Street Ell

Polaris

Reinforced

Hose

To Booster

Pump

Option #2

Option #3

Leave 6"

3. The pump and other circulation equipment must

be located more than 5 feet (1,5 meter) from the

water. Choose a location that will minimize turns

in the piping.

NOTE In Canada, the pump must be located a

minimum of 3.0 meters [approximately 10 feet]

from the water (CSA C22.1).

4. The pump must be placed on a solid foundation

that will not vibrate. To further reduce the

possibility of vibration noise, bolt the pump to the

foundation.

NOTE Zodiac® recommends bolting the pump directly

to the foundation.

5. The pump foundation must have adequate drainage

to prevent the motor from getting wet. The pump

needs to be protected from the rain and sun.

6. Proper ventilation is required for the pump to

operate normally. All motors generate heat that

must be removed by providing proper ventilation.

7. Provide access for future service by leaving a

clear area around the pump. Allow plenty of space

above the pump for servicing.

8. If the equipment is under cover, provide adequate

lighting.

Figure 4. Alternate Plumbing Configuration

Page 9

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Page 9

3.3.4 Install the Pump

1. Mount the pump using two (2) concrete expansion

anchors to ensure stability.

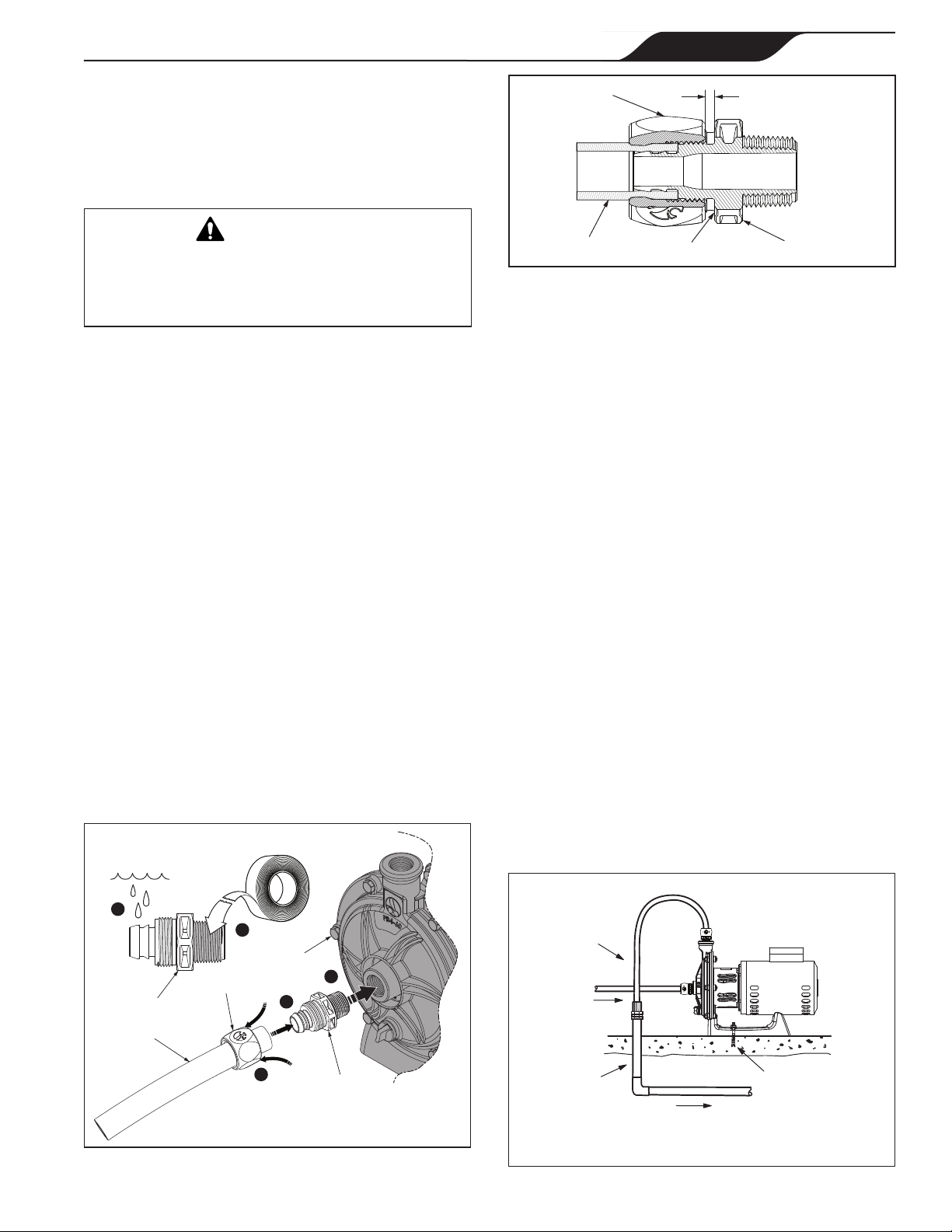

2. Apply four (4) to six (6) wraps of Teflon

®

tape

to the tapered thread of the connecter barb. See

Figure 5 (a).

CAUTION

Pipe dope should NEVER be used on barb threads.

Pipe dope will severely weaken the plastic, causing

leakage and may cause the plastic to fracture. DO

NOT OVERTIGHTEN.

3. Thread and tighten the tapered thread of the

connector barb into the pump port on the pump

body. See Figure 5 (b).

4. Trim reinforced hose to required length. Make sure

cut is clean and square. Avoid unnecessary loops

or bends in the hose.

5. Slide connector nut onto the trimmed end of the

hose with threaded end toward the cut end of the

hose. See Figure 5 (c).

6. Apply water to connector barb to help hose slide

over barbs. Push trimmed edge of hose fully onto

the connector barb. See Figure 5 (d).

7. Slide/Rotate the connector nut to the barb to

engage threads correctly, do not cross thread

connector nut. Tighten the connector nut until

threads are no longer visible (gap about 1/8” or

just less than the width of two dimes), or until it

touches the barb face. See Figure 6.

3.3.5 Installation Recommendations

1. If the pump is located below water level, isolation

valves must be installed on both sides of the pump

to prevent back flow of pool water during any

Connector Nut

Reinforced Hose

Barb Face

Nut Gap

Connector Barb

Figure 6. Tighten Connector Nut to Secure Hose

routine or required servicing.

2. To help prevent difficulty in priming, install the

suction pipe without high points (above inlet of

pump - inverted “U”s in plumbing), which can trap

air.

3. The piping must be well supported and not forced

together where constant stress will be experienced.

4. Always use properly sized valves. Jandy

diverter valves and ball valves typically

Series

®

Pro

have the best flow capabilities.

5. Use the fewest fittings possible. Every additional

fitting has the effect of moving the equipment

farther away from the water.

NOTE If more than 10 suction fittings are needed, the

pipe size must be increased.

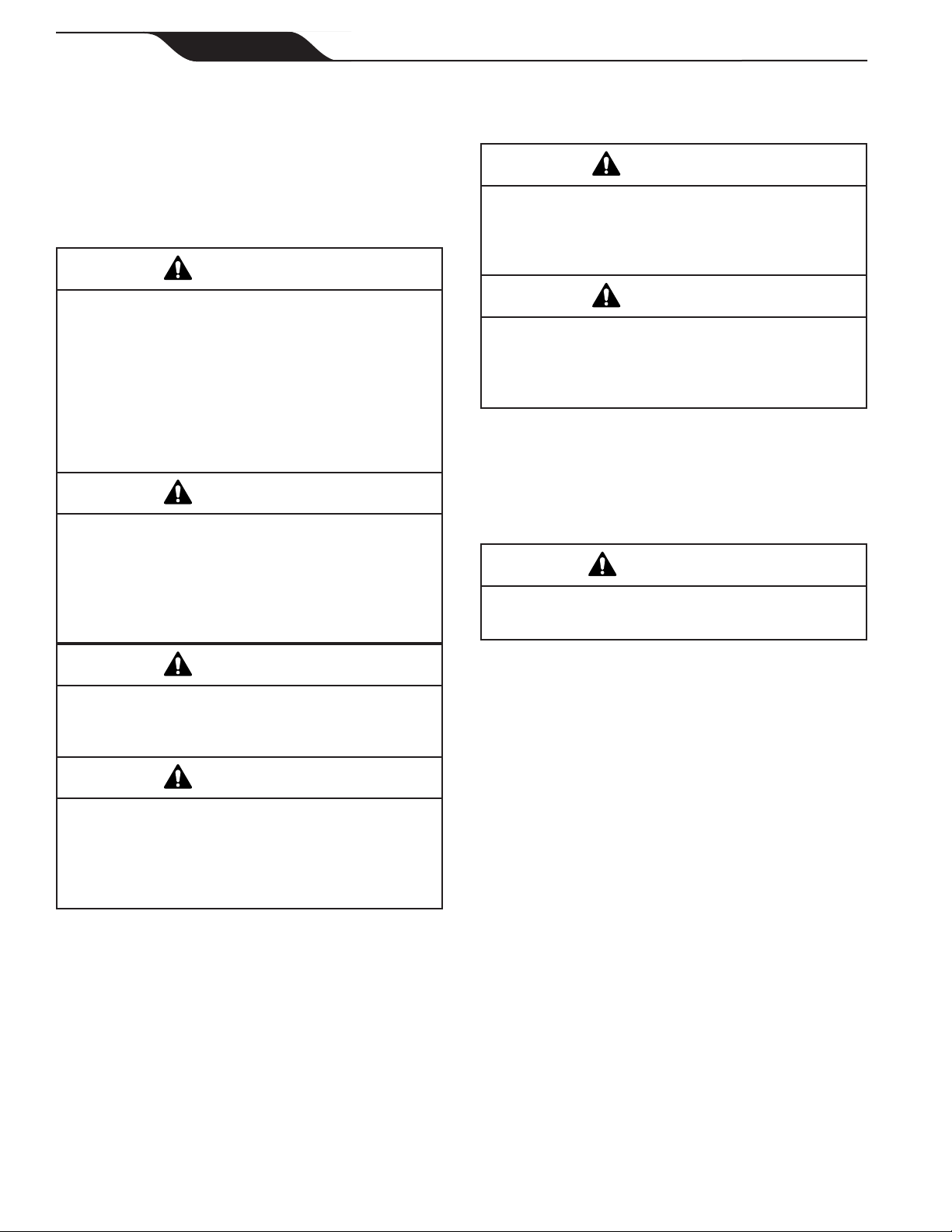

3.3.6 Check the Water Flow

NOTE This pump must have minimum outlet pressure

of 45 psi. Lower pressure may cause an overcurrent motor condition.

After the system is plumbed, verify water flow to

the booster pump by disconnecting the inlet supply line

at the booster pump and then turning on the filtration

pump. Water should flow from the line.

d

a

Pump Body

Connector Nut

Connector Barb

Reinforced Hose

c

b

d

Connector Barb

Figure 5. Prep and install Quick Connect barb and

connector nut

If there is no water flow, check the following:

Polaris

Reinforced

Hose

Inlet

Supply

Line

1-1/2" Rigid

PVC Pipe

Dedicated return

line to pool

Figure 7. Complete Installation

Expansion

Anchor

Page 10

Page 10

ENGLISH

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

1. Verify that the installation is correct. Refer to

Figure 6.

2. Use smaller eyeball fittings in the pool return lines

or plug a return line.

Once flow is established, the pump is ready for

operation.

3.3.7 Conduct Pressure Test

WARNING

When pressure testing a system with water, air

is often trapped in the system during the lling

process. This air will compress when the system is

pressurized. Should the system fail, this trapped air

can propel debris at a high speed and cause injury.

Every effort to remove trapped air must be taken,

including opening the bleed valve on the lter and

loosening the pump basket lid on the lter pump

while lling the pump.

WARNING

Trapped air in system can cause lter lid to be blown

off, which can result in death, serious personal

injury, or property damage. Be sure all air is properly

out of system before operating. DO NOT USE

COMPRESSED AIR TO PRESSURE TEST OR

CHECK FOR LEAKS.

Section 4. Operation

4.1 Start-up

CAUTION

Never run the booster pump without water. Running

the pump “dry” for any length of time can cause

severe damage to both the pump and motor and will

void the warranty.

CAUTION

Never run the booster pump without the cleaner

connected. Running the pump without the cleaner

connected will cause damage to the pump impeller

and will void the warranty.

If this is a new pool installation, make sure all

piping is clear of construction debris and has been

properly pressure tested. The filter should be checked

for proper installation, verifying all connections and

clamps are secure according to the manufacturer's

recommendations.

WARNING

To avoid risk of damage or injury, verify that all

power is turned off before starting this procedure.

WARNING

When pressure testing the system with water, it is

very important to make sure that the pump basket

lid on the lter pump is completely secure.

WARNING

Do not pressure test above 35 PSI. Pressure

testing must be done by a trained pool professional.

Circulation equipment that is not tested properly can

fail, which could result in severe injury or property

damage.

1. Fill the system with water, using care to eliminate

trapped air.

2. Pressurize the system with water to no more than

35 PSI.

3. Close the valve to trap pressurized water in the

system.

4. Observe the system for leaks and/or pressure

decay.

5. For technical support, contact Zodiac

support at 800.822.7933.

®

technical

1. Turn filtration pump ON.

2. Open the filter pressure release to relieve the

system pressure until water comes out.

3. If the filter pump is located below the water level

of the pool, opening the filter pressure release

valve will prime the pump with water.

4. Once all the air has left the filter, close the

pressure release valve.

5. Turn on the power to the booster pump. Then turn

on the booster pump.

6. The booster pump should prime. The time it takes

to prime will depend on the elevation and length of

pipe used on the suction supply pipe. See Section

3.3.6 for proper elevation and pipe size.

7. If the booster pump does not prime and all the

instructions to this point have been followed,

check for a suction leak.

Page 11

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

Section 5. Maintenance

5.1 Winterizing the Pump

CAUTION

The pump must be protected when freezing

temperatures are expected. Allowing the pump

to freeze will cause severe damage and void the

warranty.

CAUTION

Do not use antifreeze solutions in the pool,

spa, or hot tub systems! Antifreeze is highly toxic

and may damage the circulation system. The only

exception to this is Propylene Glycol. For more

information see your local pool/spa supply store or

contact a qualied swimming pool service company.

1. Drain all water from the pump, system equipment,

and piping.

ENGLISH

Page 11

2. Remove the drain plug. Store the drain plug in a

safe location and reinstall it when the cold weather

season is over. Do not lose the o-ring. (Drain Plug

with O-ring Set, R0537000).

3. Keep the motor covered and dry.

NOTE Covering the pump with plastic will create

condensation, and this moisture will damage

the pump. The best way to protect your pump

is to have a qualified service technician or

electrician properly disconnect the electrical

wiring at the switch or junction box. Once the

power is removed, the two (2) quick connect

fittings can be loosened and the pump stored

indoors. For safety, and to prevent entry of

contaminants, reinstall all conduit and terminal

box covers.

4. When the system is reopened for operation, make

sure all piping, valves, wiring, and equipment

are in accordance with the manufacturer's

recommendations. Pay close attention to the filter

and electrical connections.

5. The pump must be primed prior to starting; refer

to Section 4.1, Start-up.

Page 12

Page 12

ENGLISH

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

Section 6. Troubleshooting and Repair

Zodiac® strongly recommends that you call a licensed and qualified service professional in to perform any repairs

on the filter/pump system. To locate an independent service company, check your local yellow pages or visit:

www.zodiacpoolsystems.com.

6.1 Troubleshooting

Symptom Possible Problem/Solution

The cleaning/circulating system is

not operating correctly.

Bubbles present in the filtration

pump basket.

Air leaks are still present. Check the suction side piping union. While the pump is running, try to tighten the union. If

Verify that skimmer baskets, pump basket and other screens are clean. Clean as

necessary.

Check filter and clean as necessary.

Check valve positions. Adjust as necessary.

NOTE Multiple pieces of equipment operating at one time (for example, waterfalls, spa

jets, and surface returns) may prevent the cleaning system from working properly.

Check the cleaning system manually to ensure that the system is adjusted according to the

manufacturer's recommendations.

Air in system. Check the pool or spa water level to ensure it is at the proper level and

that air is not being drawn into the suction piping. If the water is at normal level, turn off

the pump. Remove the lid and check for debris around the lid o-ring seat or improper

installation of the lid seal, as this either of these conditions will cause air to leak into the

system. Clean the lid o-ring and place on the lid. Hand-tighten the lid to make an air tight

seal. Do not use any tools to tighten the lid. Turn the pump back on.

this does not stop the air leak, turn off the pump. Loosen both unions and slide the pump

out of the way. Remove, clean and re-install both union o-rings on the filtration pump.

Reposition the pump next to the piping and secure the union nuts to the pump. With clean

union o-rings, hand-tightening of the unions should create a seal. If the unions still do not

seal, gently tighten with a large pair of tongue-and-groove pliers.

Do not over-tighten.

There is no air in the system, but

the pressure is still low.

There is no debris blocking the

impeller and the pressure is still

low.

The pump is leaking water between

the motor and pump body.

The pump gets hot and shuts off

periodically.

It is possible that debris is caught in the pump impeller. The pump impeller moves the

water, and the vanes in the impeller can become blocked with debris. See Section 6.2,

Service Technician Maintenance, 6.2.1, Blocked Impeller, for more information.

The pump impeller is showing signs of normal wear. Have a qualified service technician

check the impeller and replace as necessary.

If the pump is part of a relatively new installation, it could be an electrical problem. Contact

a qualified service technician. Have the technician check for loose electrical connections

and check the voltage at the pump motor while it is in operation. The voltage must be within

10% of the motor's data plate rating. If the voltage is not within 10%, contact a qualified

electrician and/or the local power service provider.

Pump seal is leaking air. Have a qualified service technician replace the seal.

This is caused by a damaged or failed mechanical seal. Replace the seal. See Section 6.2,

Service Technician Maintenance, 6.2.4, Mechanical Seal Replacement.

Ensure that there is adequate room around the motor to circulate air and keep the motor

cool. Have a qualified electrician check for loose connections and check the voltage at the

pump motor while it is in operation. The voltage must be within 10% of the motor's data

plate rating. If the voltage is not within 10%, contact a qualified electrician and/or the local

power service provider.

Page 13

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Page 13

6.2 Service Technician Maintenance

WARNING

This pump must be serviced by a professional

service technician, qualied in pool/spa installation.

The following procedures must be followed exactly.

Improper installation and/or operation can create

dangerous electrical hazards, which can cause

high voltages to run through the electrical system,

possibly causing property damage, serious injury,

or death. Improper installation and/or operation will

void the warranty.

6.2.1 Blocked Impeller

WARNING

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal

injury or death may occur if the pump starts while

your hand is inside the pump.

1. Turn off the pump. Switch off the circuit breaker

to the pump motor.

2. Look inside the pump for any debris. Remove any

debris found inside.

3. Switch on the circuit breaker to the pump motor.

4. Turn on the pump, and see if the problem is

solved.

5. If the impeller is still blocked with debris and it is

not possible to remove the debris, the pump will

need to be disassembled in order to access the inlet

and outlet of the impeller.

6.2.2 Impeller Removal

WARNING

3. Using a 9/16" wrench, loosen the bolts connecting

the pump volute to the motor backplate. See

Figure 8.

4. Pull the volute from the backplate. The impeller is

connected to the motor shaft.

NOTE At this point you have access to the inlet and

outlet of the impeller to remove any debris.

5. Remove the motor shaft cover on the back of the

motor by twisting the hex-head screw with a 90°

crescent wrench. See Figure 8. The motor shaft

will be exposed.

6. Hold the motor shaft with a ½" wrench while

unscrewing the impeller from the motor shaft with

your hand.

NOTE The impeller is a right-handed thread, therefore

turn the impeller counter-clockwise to unscrew.

7. Inspect the impeller for signs of rubbing and/or

damage.

Motor Body

Backplate

Bolts

(Qty 6)

Volute

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal

injury or death may occur if the pump starts while

your hand is inside the pump.

1. Turn off the pump. Switch off the circuit breaker

to the pump motor. If you are not replacing the

motor, do not disconnect the electrical wiring.

NOTE If you are replacing the motor, Zodiac® strongly

recommends that a qualified service technician

or electrician properly disconnect the electrical

wiring at the pump motor.

2. Turn off any valves to prevent pool water from

reaching the pump. Drain the water from the pump

by loosening the unions or removing the drain

plugs.

Figure 8. Remove the Pump Volute

Page 14

Page 14

• Ceramic Face Seal

• Backplate Seal

• Carbon Face/ Spring

Figure 9. Replace the Mechanical Seal

ENGLISH

Carbon Seal Surface

Side of Seal

• Impeller Side of the

Mechanical Seal

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

Backplate

Mechanical Seal

6.2.3 Impeller Replacement

1. Press the new carbon face seal half (see Figure

9) on the motor shaft using a twisting motion.

Make sure the carbon surface is facing toward the

ceramic ring in the backplate.

VERY IMPORTANT! Grasp the lower portion of the

seal (opposite the carbon face) when installing the

seal, or it will be damaged.

NOTE To assist assembly, only use water and soap

NOTE Exercise great care to keep the seal and mating

2. While holding the motor shaft with a ½" wrench,

thread the impeller onto the motor shaft.

Hand-tighten the impeller until it is secure. Do not

overtighten.

3. Replace the motor shaft cover by inserting the

cover tabs into the slots and rotating the cover 90º

clockwise.

4. Install and tighten the screws lightly in a crossing

“X” pattern using a 9/16" wrench, starting with

the inner (middle) four (4) then the outer (top and

bottom) four (4) to draw the backplate to the body

in an even manner. Once all the screws are snug,

torque in the same order to 18 ft-lbs.

5. Open the pressure release valve on the filter, and

make sure it is clean and ready for operation.

6. Switch on the circuit breaker to the pump motor.

7. Turn on the pump and check the system for normal

operation.

8. Once all the air has left the filter, close the

pressure release valve.

CAUTION

solution as a lubricant. Any other lubricant will

destroy the seal after a short period of time.

parts clean.

Impeller

Figure 10. Backplate, Impeller and Mechanical

Seal Location

6.2.4 Mechanical Seal Replacement

NOTE This is a two (2) part replacement process. The

mechanical seal must be replaced as a set.

NOTE Refer to Figure 10 for an illustration of the

location of the mechanical seal and impeller.

WARNING

Do not damage the ceramic or carbon surfaces of

the seals. If surfaces are damaged, leaks will occur.

1. To access the mechanical seal, follow steps 1

through 6 of Section 6.2.2, Impeller Removal.

2. Remove the carbon face seal half from the motor

shaft. Refer to Figure 9. This is a spring-loaded

seal. Grasp the portion of the seal closest to the

impeller body and pull the seal off using a twisting

motion.

3. Remove the motor from the backplate following

the steps in Section 6.2.5, Motor Replacement.

4. Place the backplate o-ring side down and force the

ceramic seal out using a screwdriver or drift pin.

5. Turn the backplate o-ring side up and insert the

new ceramic seal side into the backplate. Use

great care to press the seal in squarely with your

fingers. The ceramic is easily damaged and must

be pressed in using only your fingers or soft tools.

Do not use any lubricant other than water and soap

solution.

6. Install the motor following the steps in

Section 6.2.5, Motor Replacement.

7. Install the backplate following the steps in

Section 6.2.3, Impeller Replacement.

Page 15

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

ENGLISH

Page 15

6.2.5 Motor Replacement

CAUTION

To ensure continued safety and reliable operation,

Zodiac Pool Systems, Inc. requires that you replace

the motor with a motor that has the identical HP

rating and service factor (Zodiac Pool Systems, Inc.

approved only).

WARNING

To avoid the risk of property damage, severe

personal injury, or death, turn off the pump and

switch off the circuit breaker to the pump motor

before beginning this procedure.

1. Have a qualified service technician or electrician

properly disconnect the electrical wiring at the

pump motor.

2. To disassemble the pump volute from the motor,

follow steps 1 through 6 in Section 6.2.2, Impeller

Removal.

6. To reassemble the pump after replacing the motor,

follow steps 1 through 9 of Section 6.2.3, Impeller

Replacement.

7. Have a qualified service technician or electrician

properly connect the electrical wiring at the pump

motor.

NOTE Zodiac Pool Systems, Inc. recommends that

the mechanical seals be replaced at the same

time the motor is replaced. See Section 6.2.4,

Mechanical Seal Replacement, for details.

3. Remove the four (4) 9/16" screws and remove the

motor.

NOTE Before removing the backplate, note the

alignment of the backplate to the motor. Label is

facing upward. See Figure 11.

4. If installing a new motor, remove the protective

plastic cap from the motor shaft. Place the motor

on the backplate. The label should be facing

upward. The starting capacitor on the motor should

be at the 12 o'clock position.

5. Replace the four (4) bolts and washers holding the

backplate to the motor.

Impeller

Label Location

Backplate

Bolts with

Washers

(Qty 4)

Figure 10. Remove Back Plate

Motor Assembly

Page 16

Page 16

ENGLISH

Polaris® PB4-60 Booster Pump | Installation and Operation Manual

Section 7. Product Specifications and Technical Data

7.1 Replacement Parts List

To order or purchase parts for Polaris pumps, contact your nearest Zodiac® dealer. If they cannot supply you with

what you need, contact Zodiac technical support at 800.822.7933 or www.zodiacpoolsystems.com.

Key

No. Description Qty

1 Replacement Motor for Booster Pump 1 P61

2 O-Ring, Backplate, PB4-60 1 R0536600

3 Seal, Ceramic and Spring 1 R0445500

4 Impeller, PB4-60 1 R0536400

5 Volute, PB4-60 1 R0536300 (Includes Drain Plug with O-Ring)

6 Bolts with Washers and Nuts 6 R0536900

7 Drain Plug with O-Ring, Common 1 R0537000

8 Base, Booster, PB4-60

9 Bolts and Washers, Stainless, Motor, PB4-60

10 Quick Connect Install Kit 1 R0617100

11 Quick Connect Fittings 4 R0621000

12 Pump Hose 6FT Reinforced 1 P19 6' Length

13 Backplate PB4-60 1 R0536700 Includes Seal and Backplate O-ring

1 R0537100

4 R0536800

7.2 Polaris PB4-60 Booster Pump Exploded View

Order Part

No. Comments

Kit includes 1 ea 6' length of

reinforced hose and 4 ea Quick

Connect fittings.

Comes with 4ea Quick Connect

Fittings and Installation Instructions.

9 (Qty 4)

1

13

2

4

3

5

10

6 (Qty 6)

8

12

6 (Qty 6)

11

7

Figure 1. Polaris PB4-60 Booster Pump Exploded View

Page 17

Polaris

7.3 Pump Dimensions

813/16"

22.4 cm

®

PB4-60 Booster Pump | Installation and Operation Manual

9

1

/16"

4 cm

1

/2"

11

29.2 cm

13

/ 16 "

5

14.8 cm

1

/16 "

15

38.3 cm

ENGLISH

Page 17

63/8"

16.2 cm

Bolt Holes,

Center to Center

NOTE When installing pump, leave a minimum of 2.0 feet (60 cm) of clearance above the pump for

service.

Figure 12. Polaris PB4-60 Booster Pump Dimensions

15

/

4 "

16

12.5 cm

Front Edge of Union

to Center of Bolt Holes

Page 18

Page 18

ENGLISH

Polaris® PB4-60 Booster Pump | Installation and Operation Manual

7.4 Visual Identification of the New Polaris PB4-60 Booster Pump

For Polaris PB4-60 Booster Pumps with Serial Numbers beginning with "PB" and a manufacturing date

on or after Dec 1, 2011.

Figure 13. New Polaris PB4-60 Booster Pump

Older models of the PB4-60 Booster Pumps discontinued as of Nov 30, 2011.

Figure 14. Discontinued Older Model of PB4-60 Booster Pump

Page 19

®

Polaris

PB4-60 Booster Pump | Installation and Operation Manual

NOTES

ENGLISH

Page 19

Page 20

Zodiac Pool Systems Canada, Inc.

2115 South Service Road West, Unit 3

Oakville, ON L6L 5W2

1.888.647.4004 | www.ZodiacPoolSystems.ca

Zodiac Pool Systems, Inc.

2620 Commerce Way, Vista, CA 92081

1.800.822.7933 | www.ZodiacPoolSystems.com

ZODIAC® is a registered trademark of Zodiac International, S.A.S.U., used under license.

Polaris® and the Polaris 3-wheeled cleaner design are

registered trademarks of Zodiac Pool Systems, Inc.

All trademarks referenced herein are the property of their respective owners.

©2014 Zodiac Pool Systems, Inc. H0344400 REVD

Page 21

Pompe de

surpression pour

nettoyeur haute

pression

Manuel d’installation et

de fonctionnement

Pour les pompes de surpression Polaris PB4-60 dont les numéros de série

commencent par « PB », fabriquées le 1er décembre 2011 ou postérieurement.

AVERTISSEMENT

POUR VOTRE SÉCURITÉ – L’installation et l’entretien de ce produit doivent être effectués par un technicien autorisé et qualié

pour la réparation des équipements de piscine par les autorités compétentes du territoire dans lequel ledit produit est installé

lorsque de telles exigences locales ou provinciales sont édictées. Si aucune exigence locale, provinciale ou territoriale n’est

disponible, l’agent d’entretien doit être un professionnel avec sufsamment d’expérience dans l’installation et la maintenance

d’équipement de piscine pour appliquer correctement les consignes du présent manuel. Une installation ou utilisation incorrecte

peut causer de dangereux risques électriques pouvant provoquer le passage de courants haute tension dans le système

électrique. Avant d’installer ce produit, veuillez lire et suivre toutes les consignes de mise en garde et les instructions incluses

avec ce produit. Le non-respect des avertissements et des instructions pourrait causer des dommages matériels, des blessures

graves ou même un décès. L’installation ou l’utilisation inappropriée annuleront la garantie.

Si ces consignes ne sont pas suivies à la lettre, un incendie ou une explosion pourrait survenir causant des dommages

matériels, des blessures ou un décès.

À L’ATTENTION DE L’INSTALLATEUR : Le présent manuel contient des renseignements importants sur

l’installation, le fonctionnement et l’utilisation dans risque de ce produit. Ces renseignements doivent être

donnés au propriétaire ou à l’utilisateur de cet appareil.

H0344400 REVD

Page 22

PAGE 22

FRANÇAIS

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

Table des matières

Section 1. Consignes de sécurité

importantes ................................... 23

1.1 Consignes de sécurité ...................................... 23

1.2 Normes de prévention du piégeage par aspiration

de la pompe de piscine. .................................... 25

Section 2. Description générale .................... 26

2.1 Introduction ....................................................... 26

2.2 Description ........................................................ 26

2.3 Préparation ....................................................... 26

Section 3. Installation ..................................... 26

3.1 Installation électrique ........................................ 26

3.1.1 Vérications de la tension ...................... 26

3.1.2 Connexion et mise à la terre .................. 26

3.2 Électrique .......................................................... 26

3.2.1 Câblage électrique ................................. 26

3.3 Plomberie .......................................................... 27

3.3.1 Exigences .............................................. 27

3.3.2 Dimensions des tuyaux ......................... 28

3.3.3 Emplacement de la pompe .................... 28

3.3.4 Installer la pompe .................................. 29

3.3.5 Recommandations relatives

à l’installation. ........................................ 29

3.3.6 Vérier le débit d’eau ............................. 29

3.3.7 Effectuer des tests de pression ............. 30

Section 4. Fonctionnement ............................ 30

4.1 Démarrage ........................................................ 30

Section 5. Entretien ........................................ 31

5.1 Hivernage de la pompe ..................................... 31

Section 6. Dépannage et réparation .............. 32

6.1 Dépannage ....................................................... 32

6.2 Maintenance par un technicien

en entretien et en réparation ............................. 33

6.2.1 Turbine bloquée ..................................... 33

6.2.2 Retrait de la turbine .............................. 33

6.2.3 Remplacement de la turbine .................. 34

6.2.4 Remplacement de

la garniture mécanique ......................... 34

6.2.5 Remplacement du moteur .................... 35

Section 7. Caractéristiques du produit et don-

nées techniques ............................ 36

7.1 Liste des pièces de rechange .......................... 36

7.2 Vue éclatée de la pompe de surpression Polaris

PB4-60. ............................................................. 36

7.3 Dimensions des pompes .................................. 37

7.4 Identication visuelle de la nouvelle pompe de

surpression Polaris PB4-60 .............................. 38

FICHE DE RENSEIGNEMENTS SUR L’ÉQUIPEMENT

DATE D’INSTALLATION

INFORMATION SUR L’INSTALLATEUR

LECTURE INITIALE DU MANOMÈTRE (AVEC FILTRE PROPRE)

MODÈLE DE POMPE

REMARQUES :

CHEVAUX

Page 23

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

FRANÇAIS

PAGE 23

Section 1. Consignes de sécurité importantes

LIRE ET SUIVRE TOUTES LES CONSIGNES

1.1 Consignes de sécurité

Tous les travaux d’électricité doivent être accomplis par un électricien agréé et doivent se conformer aux normes

fédérales, provinciales et locales. Au moment de l’installation et de l’utilisation de cet équipement électrique, des

précautions de base doivent toujours être suivies, entre autres :

AVERTISSEMENT

Pour réduire le risque de blessure, ne pas permettre aux enfants d’utiliser ce produit.

AVERTISSEMENT

An de réduire le risque de dommages matériels ou de blessures, ne pas essayer de changer la position du robinet de lavage

à contre-courant (multivoies, de glissement ou de passage intégral) pendant le fonctionnement de la pompe.

AVERTISSEMENT

Les pompes Zodiac® fonctionnent à l’aide d’un moteur électrique haute tension et doivent être installées par un électricien

agréé ou licencié, ou un technicien en entretien et en réparation de piscines qualié.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE, D’INCENDIE, DE BLESSURES OU DE MORT. Brancher seulement à un circuit qui est

protégé par un disjoncteur de fuite à la terre. En cas de doute, consulter un électricien certié. S’assurer qu’un tel disjoncteur

est fourni par l’installateur et fait l’objet d’essais régulièrement. Pour tester le disjoncteur de fuite à la terre, appuyer sur le

bouton de test. Le disjoncteur de fuite à la terre doit couper l’alimentation électrique. Appuyer sur le bouton de réinitialisation.

L’alimentation électrique devrait être restaurée. Si le disjoncteur de fuite à la terre ne fonctionne pas de cette façon, c’est qu’il

est défectueux. Si le disjoncteur de fuite à la terre coupe l’alimentation à la pompe sans que le bouton de test soit enfoncé, il y

a alors circulation de courant à la terre, ce qui indique la possibilité de choc électrique. Ne pas utiliser la pompe. Débrancher la

pompe et s’assurer que le problème soit résolu par un représentant d’entretien et de réparation qualié avant de l’utiliser.

En raison du risque potentiel d’incendie, de choc électrique ou de blessures corporelles, les pompes Zodiac doivent être

installées conformément au Code national d’électricité (NEC

sur la santé et la sécurité au travail (LSST). Vous pouvez obtenir des exemplaires du Code national d’électricité (NEC) de la

National Fire Protection Association

votre organisme d’inspection gouvernemental local.

®

(NFPA®) en ligne à www.nfpa.org ou en composant le 617 770-3000 ou en contactant

®

), à tous les codes locaux d‘électricité et de sécurité et à la Loi

AVERTISSEMENT

Un équipement mal installé peut être défaillant et causer des blessures graves ou des dommages matériels.

AVERTISSEMENT

• Ne pas raccorder le système à un réseau urbain de distribution d’eau non règlementé ou à une autre source externe d’eau

sous pression générant des pressions supérieures à 2,4 bars (35 psi).

• L’air emprisonné dans le système peut provoquer l’ouverture par soufage du couvercle du ltre et entraîner la mort, de graves

blessures corporelles ou des dommages matériels. Avant d’utiliser le système, s’assurer que tout l’air soit bien expulsé.

Page 24

PAGE 24

FRANÇAIS

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

AVERTISSEMENT

An de réduire les risques de blessures graves ou même la mort, le ltre et/ou la pompe ne devraient pas être soumis à l’essai

de pressurisation de la tuyauterie.

Les codes locaux peuvent exiger l’application d’un essai de pressurisation sur la tuyauterie de la piscine. Ces exigences ne

s’appliquent généralement pas à l’équipement de piscine, tel que les ltres ou les pompes.

®

L’équipement de piscine Zodiac

Si toutefois l’AVERTISSEMENT ne peut être respecté et que l’essai de pressurisation de la tuyauterie doit aussi inclure le ltre

ou la pompe, S’ASSURER DE SE CONFORMER AUX CONSIGNES DE SÉCURITÉ SUIVANTES :

• Vérier que l’ensemble des brides, boulons, couvercles, bagues de retenue et accessoires du système sont correctement

installés et xés solidement avant d’effectuer un test.

• ÉVACUER TOUT L’AIR dans le circuit avant les essais.

• La pression d’eau pour l’essai ne doit PAS DÉPASSER 35 LB/PO² (241 kPa).

• La température de l’eau pour l’essai NE DOIT PAS DÉPASSER 100 °F (38 °C).

• Limiter l’essai à 24 heures. Après l’essai, vérier visuellement le système pour s’assurer qu’il est prêt à fonctionner.

Avis : ces paramètres s’appliquent uniquement à l’équipement Zodiac. Pour l’équipement non fabriqué par Zodiac, consulter le

fabricant.

a fait l’objet d’essais de pressurisation en usine.

AVERTISSEMENT

Des déversements et vapeurs chimiques peuvent affaiblir l’équipement de la piscine ou du spa. La corrosion peut causer la

défaillance des ltres et autre équipement, ce qui peut entraîner des blessures graves ou des dommages matériels. Ne pas

entreposer de produits chimiques de piscine près de votre équipement.

ATTENTION

Ne pas démarrer votre pompe à sec! Faire fonctionner la pompe à sec pendant une durée quelconque causera des dommages

importants et annulera la garantie.

ATTENTION

Cette pompe doit être utilisée avec des piscines installées de manière permanente et, si cela est également mentionné, avec

des cuves thermales et des spas. Ne pas utiliser avec des piscines remisables. Une piscine installée de manière permanente

est construite dans le sol ou sur le sol ou dans un édice de sorte qu’elle ne peut pas être facilement démontée aux ns de

remisage. Une piscine remisable est construite pour être facilement démontée aux ns d’entreposage, puis réassemblée à son

état initial.

ATTENTION

Ne pas installer dans une enceinte extérieure ou sous les bords d’une cuve thermale ou d’un spa portatif. La pompe nécessite

une ventilation adéquate an de maintenir la température de l’air inférieure à la température ambiante maximale indiquée sur

la plaque signalétique du moteur.

CONSERVER CES DIRECTIVES

Page 25

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

FRANÇAIS

PAGE 25

1.2 Normes de prévention du piégeage par aspiration de la pompe de piscine.

AVERTISSEMENT

L’aspiration de la pompe est dangereuse et peut piéger, noyer ou éviscérer les baigneurs. Ne pas utiliser ni faire fonctionner

de piscines, spas ou cuvez thermales si un couvercle de sortie d’aspiration est manquant, brisé ou instable. Les directives

suivantes fournissent l’information d’installation de la pompe an de minimiser le plus possible les risques de blessure aux utilisateurs

de piscines, de spas et de cuves thermales :

Protection contre le piégeage ― Le système d’aspiration de la pompe doit fournir une protection contre les dangers de piégeage par

aspiration.

Couvercles de sorties d’aspiration ― Toutes les sorties d’aspiration doivent être correctement installées, et les couvercles bien

vissés en place. Tous les couvercles de sortie d’aspiration (tuyau d’écoulement) doivent être entretenus. Les couvercles de drain

doivent être listés/certiés dans la dernière version ANSI/ASME A112.19.8 ou la norme remplaçante, ANSI/APSP-16. Ils doivent être

remplacés si ils sont fendus, cassés ou manquants.

Nombre de sorties d’aspiration par pompe ― Fournir au moins deux (2) drains de fond hydrauliquement équilibrés, avec

couvercles, en guise de sorties d’aspiration pour chaque conduite d’aspiration de pompe de circulation. Les centres des drains de

fond (sorties d’aspiration) sur toute conduite d’aspiration doivent être éloignés d’au moins un (1) mètre (3 pi) l’un de l’autre, entr’axe.

Voir la Figure 1.

Le système doit être conçu pour comprendre au moins deux sorties d’aspiration (drains) connectées à la pompe chaque fois que

la pompe fonctionne. Cependant, si deux (2) drains de fond aboutissent à une seule conduite d’aspiration, cette dernière peut être

équipée d’un robinet qui coupera les deux drains de fond de la pompe. Le système doit être conçu de manière à ne pas permettre une

fermeture ou un isolement distinct ou indépendant de chaque drain. Voir la Figure 1.

Plus d’une (1) pompe peut être raccordée à une seule conduite d’aspiration aussi longtemps que les exigences susmentionnées soient

respectées.

Vitesse maximale de l’eau ― La vitesse maximale de l’eau à travers le raccord d’aspiration ou le couvercle de toute prise

d’aspiration doit être de 45 cm/s (1,5 pi/s), à moins que la sortie ne soit conforme à la dernière version ANSI/ASME A112.19.8 publiée

ou la norme remplaçante, ANSI/APSP-16, la norme pour les raccords d’aspiration à utiliser dans les piscines, pataugeoires, spas et

cuves thermales. Dans tous les cas, ne pas dépasser les débits maximaux conçus pour les raccords d’aspiration.

Si 100 % du débit de la pompe provient du système principal de canalisation d’évacuation, la vitesse maximale de l’eau dans

le système hydraulique de la pompe d’aspiration doit être de 1,8 m/s (6 pi/s) ou moins, même lorsqu’un (1) drain de fond (sortie

d’aspiration) est complètement bloqué. Le débit à travers les autres drains de fond doit être conforme à la dernière version ANSI/

ASME A112.19.8 publiée ou la norme remplaçante, ANSI/APSP-16, la norme pour les raccords d’aspiration à utiliser dans les

piscines, pataugeoires, spas et cuves thermales.

Essais et certication - Les couvercles de la prise d’aspiration doivent avoir fait l’objet d’essais de la part d’un laboratoire reconnu à

l’échelle nationale et jugés conformes à la dernière version ANSI/ASME A112.19.8 publiée ou la norme remplaçante, ANSI/APSP-16,

la norme pour les raccords d’aspiration à utiliser dans les piscines, les pataugeoires, les spas et les cuves thermales.

Raccords ― Les raccords limitent le débit, pour une plus grande efcacité, utiliser le moins de raccords possibles (mais au moins

deux (2) sorties d’aspiration).

Éviter les raccords qui pourraient causer l’emprisonnement de l’air.

Les raccords d’aspiration du nettoyeur à piscine doivent être conformes aux normes de l’International Association of Plumbing &

Mechanical Ofcials (IAPMO).

Au moins trois (3)

Listés/certifiés dans la

dernière version publiée

ANSI/ASME

A112.19.8 - 2007

Anti-piégeage

Couvercle/grille anti-piégeage

ou raccord d'aspiration,

visséà la pompe du

drain de fond

T et les drains de fond

Sortie d'aspiration

(Drain de fond)

Les robinets entre la pompe et le

raccord en T sont acceptables

Figure 1. Nombre de sorties d’aspiration par pompe

pieds (91,44 cm)

Aucune soupape

entre le raccord en

Listés/certifiés dans la

dernière version publiée

ANSI/ASME

A112.19.8 - 2007

Anti-piégeage

Couvercle/grille anti-piégeage

ou raccord d'aspiration,

vissé à la pompe

du drain de fond

Sortie d'aspiration

(Drain de fond)

Pompe

Page 26

PAGE 26

FRANÇAIS

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

Section 2. Description générale

2.1 Introduction

Ce manuel comprend des informations nécessaires à

l’installation, le fonctionnement et l’entretien adéquats de

la pompe Polaris PB4-60. Les procédures de ce manuel

doivent être scrupuleusement suivies. Pour obtenir des copies

supplémentaires de ce manuel, communiquer avec Zodiac

Pool Systems, Inc. (« Zodiac ») au 1 800 822-7933. Pour les

coordonnées, voir au verso du présent manuel.

2.2 Description

La pompe de surpression Polaris PB4-60 alimente en eau

haute pression le nettoyeur à piscine Polaris afin de maximiser

le rendement du nettoyeur. La pompe n’a pas de pouvoir

d’aspiration et doit seulement être utilisée lorsque la pompe de

filtration est activée.

ATTENTION

ATTENTION

L’omission de fournir la tension (à 10 % près) gurant sur la

plaque d’identication au cours du fonctionnement causera la

surchauffe du moteur et annulera la garantie.

3.1.2 Connexion et mise à la terre

1. Le châssis du moteur doit être mis à la terre à l’aide d’un

conducteur solide en cuivre no 8 (8,4 mm2) AWG ou plus

grand. Au Canada, le no 6 (13,3 mm2) AWG ou plus grand

doit être utilisé. Si la pompe est installée à moins de cinq

(5) pieds (1,5 m) des parois intérieures de la piscine, du

spa ou du jacuzzi, le châssis du moteur doit être raccordé

à toutes les parties métalliques de la piscine, du spa ou du

jacuzzi et de tous les équipements électriques, les conduits

métalliques, les canalisations métalliques et à moins de

cinq (5) pieds (1,5 m) des parois intérieures de la piscine,

du spa ou du jacuzzi.

2. Faire le raccordement de mise à la terre du moteur à l’aide

de la cosse externe fournie.

L’utilisation de la pompe de surpression sans la pompe de

ltrage endommagera la pompe de surpression. Une utilisation

incorrecte de la pompe de surpression annulerait la garantie.

2.3 Préparation

1. Dès réception de la pompe, vérifier que la boîte

d’expédition n’est pas endommagée. Ouvrir la boîte et

vérifier que la pompe ne cache aucun dommage comme

des fissures, des bosses et que la base n’a pas été pliée.

S’il y a des dommages, contacter l’expéditeur ou le

concessionnaire chez qui la pompe a été acheté.

2. Inspecter le contenu de la boîte et vérifier que toutes les

pièces s’y trouvent. Voir section 7.1, Liste des pièces de

rechange.

Section 3. Installation

3.1 Installation électrique

3.1.1 Vérifications de la tension

La tension adéquate, telle qu’elle est spécifiée sur la plaque

d’identification de la pompe, est nécessaire pour une bonne

performance et une longue durée de vie du moteur. Une tension

inappropriée diminuera le rendement de la pompe et pourrait

causer une surchauffe, réduire la durée de vie du moteur et

entraîner une augmentation de la facture d’électricité.

Il est de la responsabilité de l’installateur de fournir

la tension fonctionnelle de la pompe figurant sur la plaque

d’identification en s’assurant que les bonnes dimensions de

circuit et de câble soient utilisées pour cet usage spécifique.

Le Code national de l’électricité (NEC

que tous les circuits de la pompe d’une piscine soit protégés par

un disjoncteur de fuite à la terre. Par conséquent, il est également

de la responsabilité de l’installateur électrique de s’assurer que

le circuit de la pompe soit conforme aux présentes exigences et à

toute autre exigence applicable du Code national de l’électricité

(NEC) et à tout autre code d’installation applicable.

®

, NFPA-70) exige

AVERTISSEMENT

Pour éviter le risque des dommages matériels, des blessures

graves et/ou de mort, déconnecter toujours la source

d’alimentation avant de travailler sur un moteur ou sur sa

charge branchée.

AVERTISSEMENT

Pour éviter le risque des dommages matériels, des blessures

graves ou de mort, s’assurer que l’interrupteur de commande,

ou l’horodateur, est installé à un endroit accessible an que,

dans l’éventualité d’une défaillance d’équipement ou d’un

raccord de plomberie lâche, l’équipement puisse être mis

hors tension. Cet endroit ne doit pas être dans la même zone

que la pompe de piscine, le ltre et autre équipement.

ATTENTION

Cette pompe doit être connectée en permanence à un

circuit électrique dédié. Aucun autre équipement, lumière,

appareil ou prise de courant ne peut être connecté au

circuit de la pompe à l’exception des dispositifs qui peuvent

devoir fonctionner en même temps que la pompe tel qu’un

chlorateur ou un appareil de chauffage.

3.2 Électrique

Puissance du moteur

HP S.F RPM VOLTS S.F. AMPS

3/4 1.5 3450 230/115, 60Hz, 1PH 6.4/12.8

3.2.1 Câblage électrique

1. Le moteur de la pompe doit être mis à la terre de manière

sécurisée et adéquate en utilisant le tournevis vert fourni.

Mettre à la terre avant d’essayer de connecter à une source

d’alimentation électrique. Ne pas mettre à la terre à un

tuyau d’alimentation en gaz.

2. La dimension du câble doit être appropriée afin de

réduire la chute de tension pendant le démarrage et le

Page 27

Pompe de surpression Polaris® PB4-60 | Manuel d’installation et de fonctionnement

FRANÇAIS

PAGE 27

Tableau 1. Taille maximale des câbles et protection maximale de surintensité

CÂBLAGE DE DIMENSION MAXIMALE ET PROTECTION MAXIMALE CONTRE LES SURINTESITÉS*

Distance du sous-panneau 0 à 50 pieds (15 mètres) 50 à 100 pieds (15 à 30 mètres) 100 à 200 pieds (30 à 60 mètres)

Modèle

de la

pompe

PB4-60 15A 20A

*Suppose trois (3) conducteurs en cuivre dans un conduit enterré et une perte maximale de tension de 3 % dans le circuit branché. Le Code

électrique national (NEC) et les codes locaux doivent être respectés.

fusibles de dérivation pour une installation typique selon le NEC.

Amplicateurs de fusibles de ligne

classe : CC, G, H, J, K, RK, ou T

230 VCA 115 VCA 208 à 230 VCA 115 VCA 208 à 230 VCA 115 VCA 208 à 230 VCA 115 VCA

TENSION TENSION TENSION

14 AWG

(2,1mm2)

12 AWG

(3,3mm2)

Le tableau présente les recommandations de tailles minimales de câbles et de

12 AWG

(3,3mm2)

10 AWG

(5,3mm2)

10 AWG

(5,3mm2)

10 AWG

(5,3mm

2

)

fonctionnement de la pompe. Voir le Tableau 1 pour des

tailles de câbles.

3. Isoler soigneusement toutes les connexions afin

d’empêcher la mise à la terre ou un court-circuit.

Les extrémités tranchantes des bornes nécessitent une

protection supplémentaire. Pour empêcher que les

serre-fils ne se desserrent, les isoler à l’aide du ruban

isolant électrique approprié et homologué (UL

®

). Pour des raisons de sécurité et pour empêcher la

CSA

®

, ETL®,

pénétration de contaminants, replacer tous les couvercles

de boîtes de dérivations et de connexions. Ne pas forcer

les connexions à la boîte de dérivation.

4. Pour configurer le câblage interne du moteur de la pompe

à la tension appropriée, se référer au diagramme sur la

plaque d’identification du moteur.

5. L’intensité du courant au démarrage du moteur de la

pompe de surpression peut dépasser 15 ampères avec

une tension de 115 VCA.

Il est recommendé d’utiliser un

disjoncteur de 20 ampères avec la pompe raccordée à la

source d’alimentation de 115 VCA

.

6. Le moteur de la pompe à surpression est précablé en usine

pour une tension de 230 volts, mais il peut être cablé pour

115 ou 230 volts. Pour recâbler à 115 volts, suivre les

instructions sur la plaque signalétique située au dos du

moteur ou sur la plaque de calibrage située sur le côté du

moteur.

7. Il est recommandé d’utiliser une horloge séparée (en plus

de l’horloge du système de filtration) afin de contrôler

les fonctions de démarrage et d’arrêt de la pompe de

surpression. Il est aussi possible d’utiliser un interrupteur

manuel.

8. Si une horloge est utilisée, la régler afin de démarrer la

pompe au moins 30 minutes avant la mise en marche de

la pompe de filtration, et arrêter la pompe au moins 30

minutes avant l’arrêt de la pompe de filtration. Vérifier

périodiquement les réglages des horloges afin de s’assurer

qu’elles sont bien synchronisées.

3.3 Plomberie

ATTENTION

S’assurer de ne pas trop serrer les raccords des tuyaux

de l’entrée ou de la sortie de la pompe de surpression. Un

serrage trop fort pourrait ssurer le boîtier.

3.3.1 Exigences

La pompe de surpression Polaris requiert une conduite de

retour spéciale. Raccorder la pompe de surpression au système

afin qu’elle reçoive le débit de la pompe de filtration.

Pour s’assurer du bon fonctionnement de la pompe et du

nettoyeur, consulter la

suivantes concernant les équipements spécifiques.

1. Raccorder la conduite dédiée en amont de tous les

équipements qui aspirent l’air.

2. Si un réchauffeur est installé sur le système, installer

l’entrée pour la pompe de surpression dans la conduite de

retour en amont et à au moins trois (3) pieds (1 mètre) du

débit du réchauffeur. Voir la Figure 2. Ne pas installer

l’entrée de la pompe de surpression sur la section du

tuyau du dissipateur de chaleur qui sort directement

du réchauffeur.