Page 1

PMS 419

Failure to properly follow the instructions and precautions in

POLARIS POWER™

P1000i

P2000i

Operator’s Manual

(Australian models)

this manual can result in property damage, serious injury or

For your nearest Polaris supplier,

call 0393945610

or visit www.polarispower.com.au

Polaris Sales Australia Pty Ltd.,

(ABN 62088081949) of Locked Bag 2006,

Sunshine Post Shop,

Sunshine, Victoria, 3020

Australia

Part No. 9925471 Rev 02

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls and features . . . . . . . . . . . . . . . . . . . 16

First Use Instructions . . . . . . . . . . . . . . . . . . . 22

Pre-Operation Inspection . . . . . . . . . . . . . . . . 25

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Transportation and Storage . . . . . . . . . . . . . . 56

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 62

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . 64

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 66

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . 76

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1

Page 3

INTRODUCTION

Welcome

Thank you for purchasing a POLARIS POWERTM Generator, and

welcome to our world-wide family of POLARIS owners.

Here at POLARIS we proudly produce an exciting line of utility and

recreational products.

• Snowmobiles

• All-terrain vehicles (ATVs)

• RANGER

•RZR

•VICTORY

• INDIAN

•GEM

• POLARIS POWER

We believe POLARIS sets a standard of excellence for all utility

vehicles, recreational vehicles, and power equipment manufactured in

the world today. Many years of experience have gone into the

engineering, design, and development of your POLARIS machine.

For safe and enjoyable operation of your generator, be sure to follow the

instructions and recommendations in this owner’s manual. Your manual

contains instructions for minor maintenance, but information about

major repairs is outlined in the POLARIS Service Manual and should be

performed only by a factory certified technician.

For all technical questions visit www.polarispower.com.au.

®

utility vehicles

®

sport vehicles

®

Motorcycles

®

Motorcycle

®

electric vehicles

TM

Generator

2

Page 4

INTRODUCTION

Intended Use

The POLARIS Power Generator is intended to supply power for

appliances. Such items include, but are not limited to:

• Furnace fans

• Sump pumps

• Dishwashers

• Hotplates / Stoves

•Lamps

•Fans

• Washing machines

• Garage door openers

• Water heaters

• Televisions

• Refrigerators

• Computers

Appliances that use more than recommended amount (see page 62) of

combined power consumption should not be connected to this generator.

3

Page 5

INTRODUCTION

Safety Precautions

Failure to follow recommended precautions and procedures could result

in severe injury or death. Always heed all safety precautions and follow all

operation, inspection, and maintenance procedures outlined in this

manual.

Please read the POLARIS P1000i/P2000i Generator Owner’s Manual.

This manual contains information essential to safe operation and proper

maintenance of the generator. Anyone who operates the generator must

read the owner’s manual before operating the generator.

Read and understand the information found in the safety section, and

have manual on hand when operating the generator. Following the

safety precautions and procedures will ensure a safe operating

experience.

Understand and follow all inspection and maintenance procedures

outlined in this manual. Following these procedures will ensure that the

generator remains in safe operating conditions at all times.

4

Page 6

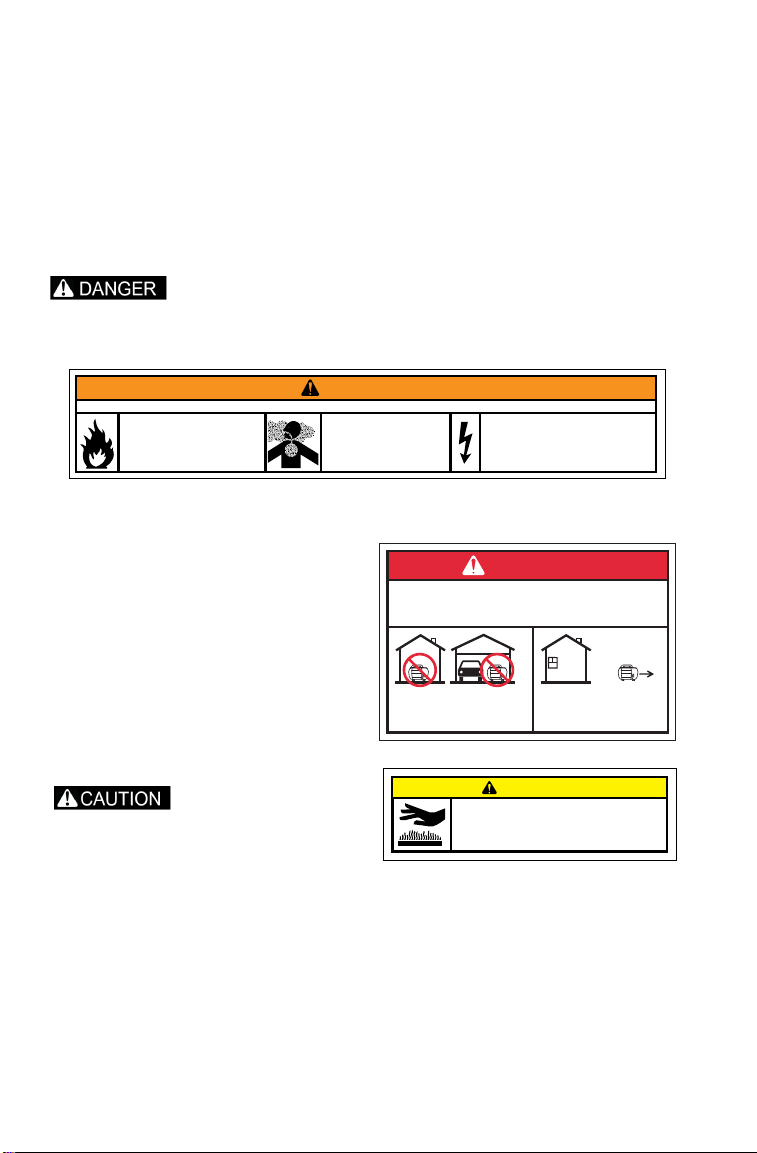

INTRODUCTION

Warnings, Cautions and Notices

Signal Words and Safety Terms

The following signal words and symbols appear throughout this manual.

Your safety, and the safety of others, is involved when these words and

symbols are used. Become familiar with their meaning before reading

the manual.

A safety alert warning indicates a hazardous situation which, if not

avoided, may result in death or serious injury.

A safety alert caution indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury.

A notice is used to address practices not related to physical injury.

IMPORTANT: Key reminders during assembly, disassembly, and inspection

of components.

Note: Key information to clarify instructions.

ALCOHOL OR DRUG USE

Operating the generator after consuming alcohol or drugs could adversely

affect operator judgement. Never consume alcohol or drugs before or

while operating the generator.

5

Page 7

INTRODUCTION

Serial Number

P1000i

P2000i

Identification Numbers and Locations

Record your generator’s identification numbers in the space provided.

The model and serial number decal is located inside the service door.

MODEL NUMBER: ______________________________________________________

SERIAL NUMBER: ______________________________________________________

PURCHASE DATE: ______________________________________________________

PURCAHSE LOCATION:__________________________________________________

6

Page 8

SAFETY

Safety Warnings and Precautions

IMPORTANT SAFEY INSTRUCTIONS. SAVE THESE

INSTRUCTIONS.

Failure to follow recommended precautions and procedures could result

in severe injury or death. Always read all safety precautions and follow all

operation, inspection, and maintenance procedures outlined in this

manual.

General

• Read and understand all of the safety and operating information in

this manual and on the product before using the machine. Use the

generator only as described in this manual.

• Understand and follow all inspection and maintenance procedures

outlined in this manual. Following these procedures will ensure that

the generator remains in safe operating condition.

• Turn off the petrol valve and close the fuel cap vent when the

generator is not in use.

It is the responsibility of the owner to ensure that all users of this

generator are fully informed of the safety and operating information prior

to use.

Before and During Operation

• Preform all Pre-Inspection activities as shown on page 25 of this

manual. Inspect and tighten all parts regularly. Ensure the generator

does not have any damaged, loose, or missing parts before use. All

defects should be corrected before use. Do not operate the generator if

it has been dropped or damaged until all defective parts have been

repaired.

• Do not place any flammable materials near the generator.

• Never start the generator or let it run in an enclosed area. Exhaust

vapors are poisonous and can cause loss of consciousness or death in

a short time. Keep the generator away from buildings and other

equipment during operation.

7

Page 9

SAFETY

Safety Warnings and Precautions

Before and During Operation

• Do not operate the generator in exposed locations where it will be

subjected to wet conditions.

• Do not touch the generator with wet hands, as this may cause severe

electric shocks.

• Do not pour water directly over the generator or wash it.

• Do not use or store the generator in the rain or snow.

• Do not cover the generator when in use.

• Always operate the generator on a firm, flat, and level surface, as the

generator will vibrate on an irregular surface. If the generator is tilted,

fuel may spill or the generator may tip over, causing a hazardous

situation.

• Do not connect the generator to another power supply source.

• The engine becomes extremely hot during and immediately after it

has been in use. Be careful not to touch any parts of the hot engine,

especially the muffler or muffler cover, or serious burns may result.

• Do not connect external equipment to the generator before starting

the engine.

• Do not use for life support, or life sustaining systems.

• The output of this generating set is potentially lethal. The set should

not be connected to a fixed electrical installation except by an

appropriately licensed person.

• Do not operate in a hazardous location, e.g. where there may be a risk

of explosion of petrol fumes, leaking gas or explosive dusts.

• Do not operate in a confined area where exhaust gases, smoke or

fumes could reach dangerous concentrations.

• Do not refuel while engine is running.

Fire Safety

Generator exhaust system gets hot enough to ignite some materials and

burn skin if touched.

• Keep the generator away from buildings, other equipment, and

combustible materials during operation.

• Do not enclose the generator in any structure.

8

Page 10

SAFETY

Safety Warnings and Precautions

Fire Safety

• Keep the generator away from buildings, other equipment, and

combustible materials during operation.

• Do not enclose the generator in any structure.

• Keep children and pets away from generator.

• Exhaust system components are very hot during and after use. Hot

components can cause burns and fire. Do not touch the hot exhaust

system components. Always keep combustible materials away from

the exhaust system.

• Ensure that any spilled fuel is properly wiped up prior to using the

generator as fuel vapors are flammable.

Operator Safety

Operating the generator with worn, damaged, or malfunctioning

components could result in serious injury or death. Never start the engine

without checking all of the generator components to be sure of proper

operation.

• Read and understand all of the safety and operating information in

this manual and on all warning labels before using the generator. Use

the generator only as described in this manual.

• Know how to stop the generator quickly in case of emergency, see

page 30 for information on stopping the unit quickly.

• Keep children, pets, and bystanders at a safe distance from the

generator.

• Review and understand the use of all generator controls.

• Be sure that anyone who operates the generator receives proper

instruction. Do not let children operate the generator.

• Use the generator only for intended purposes.

• Turn off the generator immediately if the unit begins to operate

abnormally. After the generator has cooled, disconnect the generator

and call your authorized POLARIS supplier.

• While operating the generator, if you experience headache, fatigue,

nausea / vomiting, confusion, or seizures, immediately get to fresh

air. Do not delay and do not attempt to shut down the unit.

• Run the generator on flat, dry surfaces only. The generator can only

be run while stationary. Do not run the generator on any moving

vehicle or objects.

9

Page 11

SAFETY

Safety Warnings and Precautions

Fuel Safety

Petrol is highly flammable and explosive under certain conditions. Always

use caution when handling petrol.

• Petrol is extremely flammable, and petrol vapor can explode. Before

refueling allow the engine to cool completely if the generator has

been in operation.

• Always store petrol in an approved container.

• Always refuel outdoors or in a well-ventilated area away from any

combustible materials.

• Do not smoke or allow open flames or sparks in or near the area

where refueling is performed or where petrol is stored.

• Never permit children to handle petrol.

• Never refuel around bystanders, pets, and flammable objects.

• Loosen the fuel cap slowly to relieve pressure in the tank.

• Take care not to overfull or spill any fuel on the generator or muffler

when refueling.

• If petrol spills on skin or clothing, immediately wash it off with soap

and water and change clothing.

• Do not use the generator if you observe leaking petrol. Have the

generator serviced immediately and before using it again.

• When operating or transporting the generator, be sure it is kept

upright. If it tilts, fuel may leak. Be sure the fuel tank cap is tightened

when transporting the generator.

• Do not refuel using petrol station pumps.

• Remove fuel from the generator before transporting in a vehicle.

Do not swallow petrol, inhale petrol vapors, or spill petrol. If you swallow

petrol, inhale more than a few breaths of petrol vapor, or splash petrol in

your eyes, see a physician immediately. If petrol spills on skin or clothing,

immediately wash it off with soap and water and change clothing.

10

Page 12

SAFETY

Safety Warnings and Precautions

Carbon Monoxide Safety

Generator exhaust contains Carbon Monoxide (CO) vapors. Exposure to

Carbon Monoxide by people or pets can result in SEVERE INURY or

DEATH. ALWAYS operate generate according to guidelines in labels and

this manual.

• This portable generator runs on petrol. The generator exhaust vapor

contains carbon monoxide (CO).

• Carbon monoxide is odorless. You cannot smell it.

• Carbon monoxide is colorless. You cannot see it.

• Never run an engine in an enclosed area. Exhaust contains poisonous

carbon monoxide vapor that can cause loss of consciousness or death.

Operate the engine in an open area, and well ventilated. The generator

is for outdoor use only.

• Do not use the generator indoors in garages, basements, crawl spaces,

sheds, portable buildings, or similar areas even if doors and / or

windows are open or if ventilating fans are used to circulate air.

• Do not use the generator near windows, doors, vents or any other

building openings even if they are closed. Poor seals on a door, as just

one example, could still permit high levels of carbon monoxide to

infiltrate the living area of a home.

• Be sure to install approved carbon monoxide detectors in your home

that have battery back-up systems that will continue to detect the

presence of carbon monoxide during electric-power outages. Test

these devices and replace batteries as recommended by their

respective manufacturers.

• If you experience headache, fatigue, nausea / vomiting, confusion, or

seizures, immediately get to fresh air and away from the unit. Do not

delay for any reason.

• Do not run the generator directly on grass or with the exhaust pipe

close to plants or grass. Exhaust gas temperature will be high.

11

Page 13

SAFETY

Safety Warnings and Precautions

Electrical Safety

This generator produces high voltage electricity.

• The generator produces enough electric power to cause serious shock

or electrocution if misused.

• Always connect the generator to a suitable ground circuit.

• When servicing the generator, disconnect the spark plug wire and

place it where it cannot contact the plug. Turn the engine switch to the

OFF position.

• Do not check for a spark with the plug removed. Use only approved

spark plug testers.

• Using a generator or electrical appliance in wet conditions, such as

rain or snow, or near a pool or sprinkler system, or when your hands

are wet, could result in electrocution. Keep the generator dry and

away from all sources of moisture.

• Do not store the generator outdoors unprotected from the weather.

• If the Generator has been subjected to water, moisture, or ice check

all of the electrical components on the control panel before each use.

Moisture or ice can cause a malfunction or short circuit in electrical

components that could result in electrocution.

• Do not connect the generator to a building’s electrical system unless

an isolation switch has been installed that meets applicable electrical

codes and regulations.

• To avoid overloading the generator, ensure that the load is kept within

the rating stated on the generator. Overloading will damage the unit

and / or shorten its operating lifespan.

• Both the P1000i and P2000i can be paralleled with another P1000i or

P2000i using the POLARIS parallel kit.

• Do not over charge a battery with the DC receptacle, over charging

the battery may result in battery damage and potential ignite if a spark

is introduced.

12

Page 14

SAFETY

Safety Warnings and Precautions

Extension Cord Information

• Read the manufacturer starting and running wattage details and

operating instructions for the device(s) and appliance(s) that will be

used. Often this information can be found in the owner's manual or on

specification decals on the device or appliance.

• POLARIS recommends using only U.L. (Underwriters Laboratories,

Inc.) approved extension cords labeled with the use, size, and wattage

rating. Only use heavy-duty extension cords with a three-prong

(grounded) plug for your safety. Decide on what length extension

cord is required as cord length determines the extension cord gauge.

Remember, as the cord gets longer, the current capacity of the cord

decreases.

• Never use an extension cord designated as “indoor use only”

outdoors.

• Store all extension cords indoors when not in use. Outdoor conditions

can deteriorate a cord over time.

• Never keep an extension cord plugged in when not in use. The cord

will still conduct electricity until it is unplugged from the outlet.

• Before plugging an extension cord or power cord into the generator,

check the cord for any signs of damage.

Equipment Modifications

Modifying the generator by adding or removing any equipment not

approved by POLARIS may void the warranty. Such modifications may

make the generator unsafe to operate and could result in severe injury to

operators and / or bystanders, as well as damage to the generator. Some

modifications may not be legal in your area. If in doubt, contact your

authorized POLARIS supplier.

13

Page 15

SAFETY

WARNING

Improper Generator use can result in SEVER E INJURY or DEATH. Read the Owner’s Manual. Follow all instructions and Warnings.

Generatorexhaust contains poisonous

Carbon Monoxide (CO) vapors. ALWAYS

operate in a well-v entilated area.

NEVER operate in a home, garage, enclosed

area or near windows, doors, or people.

NEVER operate near ammable objects.

Petrol is ammable and explosive. Severe

burns can result. ALWAYS stop engine and let

cool bef

ore refueling. ALWAYS checkfor fuel

leaks and wipe up any spills. ALWAYS turn fuelto

OFF when not in use. NEV ER handle petrol

indoors. NEVER overll fuel tank.

Electrocution can result from using generator inrain,

snow, nearwater, withwet hands, or with improper

connections. ALWAYS keep generator and surrounding

area dry. NEVERconnect generator to any building

without electrical-isolation protection that meets

applicable

codes and regulat ions.

DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside a home

or garage. EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

CAUTION

Contacting a hot exhau st system

can cause serious burns.

Do not touch if generator is or has

been running.

Safety Labels and Locations

Safety and warning decals have been placed on the generator for your

protection. Read and follow the instructions of the decals and warnings

on the generator carefully. If any of the decals depicted in this manual

differ from the decals on your generator, always read and follow the

instructions of the decals on the generator.

Carbon Monoxide Warning

Using a generator indoors CAN KILL YOU IN MINUTES.

The carbon monoxide warning is located on top of the generator.

Outdoor Use ONLY Danger Label

Generator Exhaust contains carbon

monoxide. This is a poison you

cannot see or smell.

NEVER use inside a home or

garage, EVEN IF doors and

windows are open.

Only use OUTSIDE and far away

from windows, doors, and vents.

Hot Exhaust Caution

The hot exhaust caution is located

on the muffler cover.

Contacting a hot exhaust system

can cause serious burns.

Do not touch if generator is or has been running.

14

Page 16

SAFETY

Safety Labels and Locations

Improper Generator use can result in SEVERE INJURY or DEATH. Read the

OWNER’S MANUAL. Follow all Instructions and Warnings.

Petrol is flammable and explosive. Severe burns can result. ALWAYS stop

the engine and let cool down before refueling. ALWAYS check for fuel

leaks and wipe up any spills. ALWAYS turn the fuel to OFF when not in

use. NEVER handle petrol indoors. NEVER overfill the fuel tank.

Generator exhaust contains poisonous Carbon Monoxide (CO) vapors.

ALWAYS operate in a well-ventilated area. NEVER operate in a home,

garage, enclosed area or near windows, doors, or people. NEVER operate

near flammable objects.

Electrocution can result from using generator in rain, snow, near water,

with wet hands, or with improper connections. ALWAYS keep generator

and surrounding area dry. NEVER connect generator to any building

without electrical-isolation protection that meets applicable codes and

regulations.

15

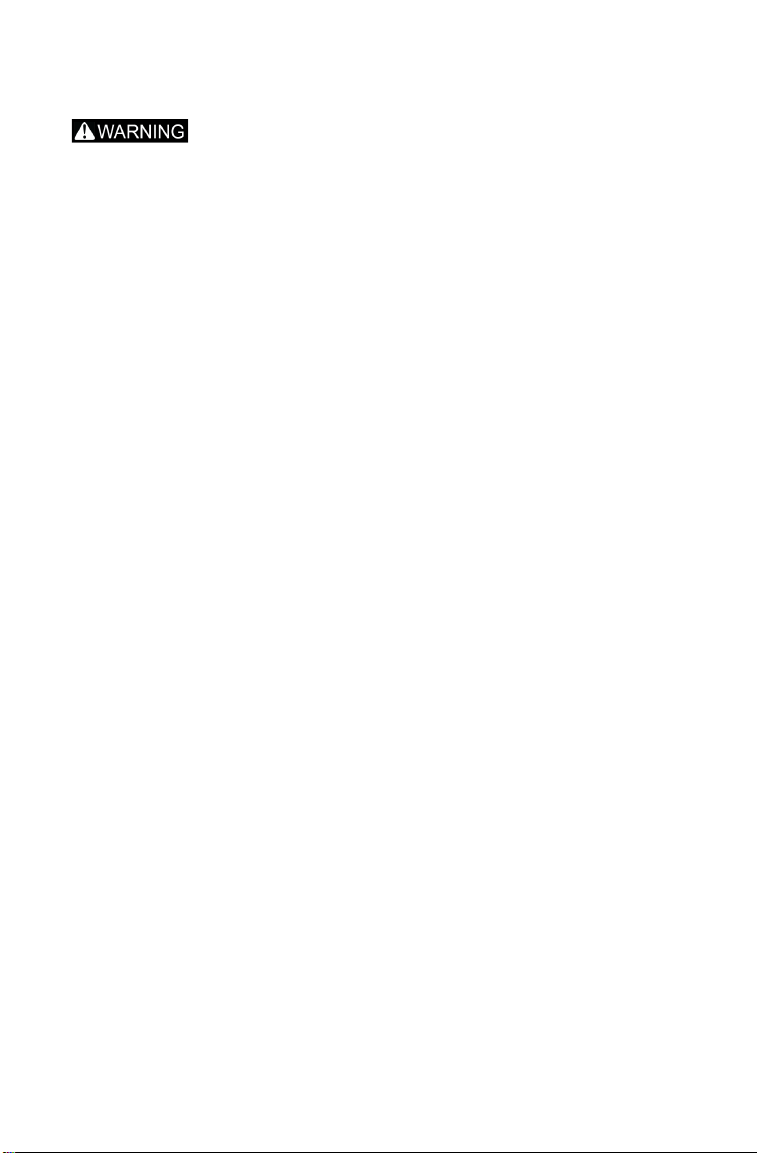

Page 17

CONTROLS AND FEATURES

A

B

C

D

E

F

G

H

I

J

Generator Components:

ITEM NOMENCLATURE DESCRIPTION

A Spark Plug Cap Remove the top to access the spark plug

B Control Panel Generator controls

C Air Filter

D Oil Dipstick Measures oil level in the engine

E Carburetor Vent Hose Atmospheric vent

F Carburetor Drain Hose Drains fuel from the carburetor

G Starter Recoil Grip

H Choke Lever

I Fuel Tank Cap Accesses fuel tank

J Engine / Fuel Switch

Protects the air flow to the carburetor from

becoming obstructed with debris

Causes the recoil starter to crank the engine

when pulled

Provides proper starting mixture when

engine is cold

Controls the ignition system and the fuel

valve

16

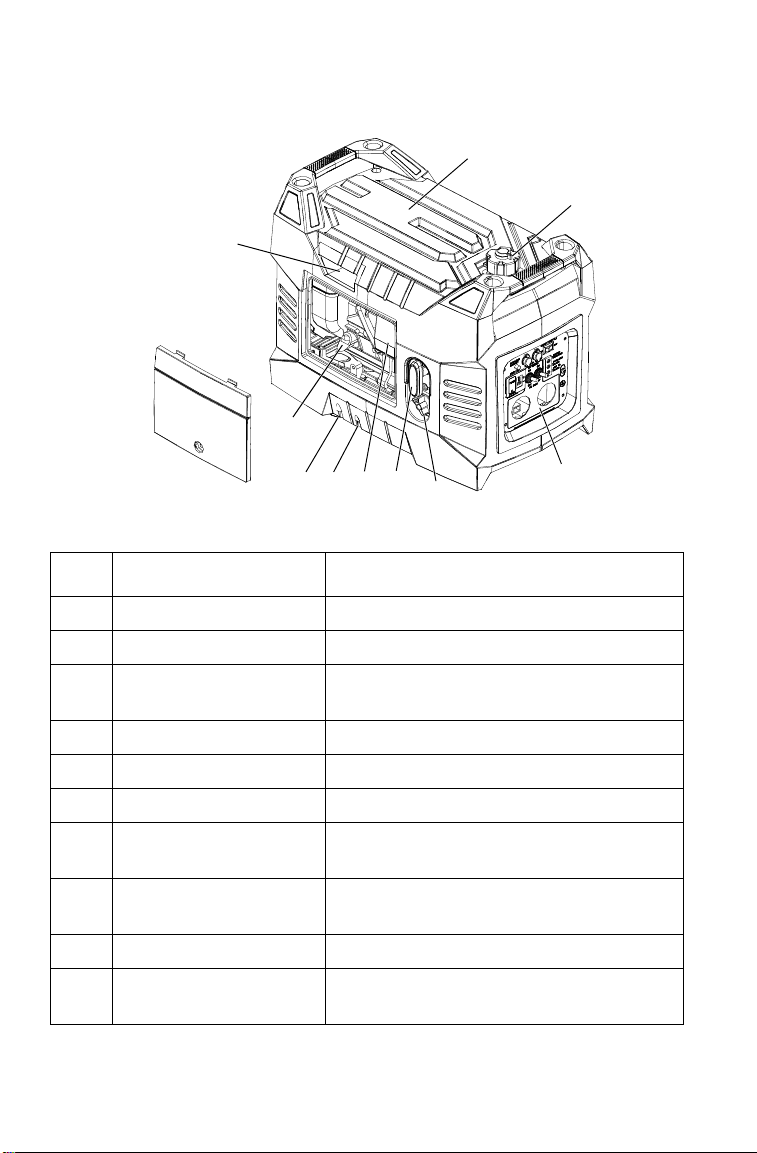

Page 18

CONTROLS AND FEATURES

K

Q

R

S

U

O

P

U

K

Q

R

O

S

P

N

M

T

T

N

M

P1000i

P2000i

Control Panel Components:

ITEM NOMENCLATURE DESCRIPTION

K SMART Throttle Switch

M DC Fuse Protector Protects DC charging circuit from overloads

N 12V DC Receptacle Charges 12V DC batteries

O Ground Terminal

P 240V AC Receptacles

Q Output Indicator

R Overload Indicator

S Low Oil Indicator

T Overload Reset Switch Resets the circuit after an AC overload

U Parallel Receptacles For use with proper POLARIS Parallel kits

Automatically reduces engine speed when

loads are shut off or disconnected

Provides ground for non-conductive metal

parts and receptacle ground terminals

Provides two connections for properly rated

AC appliances

Illuminates GREEN when the generator is

operating normally

Illuminates RED for appliance short circuits

or overloads

Illuminates RED prior to the oil level falling

below a safe limit

17

Page 19

CONTROLS AND FEATURES

OFF

ON

ON

OFF

G

J

Choke Lever

Move the choke lever (H) to the START

position when starting a cold engine.

Slowly move the choke lever to the RUN

position as the engine RPM stabilizes.

Fuel Tank Cap Vent Lever

When the engine is well-cooled and not

in use, the fuel tank cap vent lever (I)

must be placed in the OFF position to

reduce the possibility of fuel leakage.

The vent lever must be in the ON

position to allow the engine to operate.

Engine Fuel Switch

The engine switch (J) controls the

ignition system and the fuel valve. ON:

opens the fuel valve and allows the

engine to be started. OFF: closes the fuel

valve and shuts off the engine.

Starter Recoil Grip

Do not allow starter grip to snap back against the generator. Return it

gently to prevent damage to the starter.

The starter recoil grip (G) causes the recoil starter to crank the engine

when pulled.

18

Page 20

CONTROLS AND FEATURES

M

N

SMART Throttle Switch

The SMART throttle switch (K)

automatically reduces engine speed

when loads are shut off or disconnected.

The engine returns to the proper speed to

power the electrical load when

appliances are turned ON or reconnected.

Press the SMART throttle switch to the

OFF position to reduce voltage changes

when high electrical loads are

simultaneously connected or when using

the DC output.

DC Receptacle and Fuse

The DC receptacle (N) is protected

from an overload with a fuse. If the

DC circuit is overloaded, the 5 amp

fuse (M) will blow and power to the

DC receptacle will cease. The red

light on the DC panel will illuminate.

The fuse is located to the left of the

receptacle and is accessed by

snapping open the access door. See

details on page 35. Replace the fuse

with one of the same capacity. Using

a higher rated fuse may cause damage

to the generator alternator.

The DC receptacle charges 12V DC automotive-type batteries. The DC

charging output is not regulated. The 12V DC receptacle has no battery

overcharge protection function. Do not overcharge the battery.

19

Page 21

CONTROLS AND FEATURES

P1000i P2000i

Q

R

S

Ground Terminal

The ground terminal (O) connects to the frame of the

generator, metal parts that do not conduct current, and

ground terminals of each receptacle. Consult a qualified

electrician, electrical inspector, or local agency having

jurisdiction for local codes or ordinances for the

intended use of the generator before using the ground

terminal.

AC Receptacles

The AC receptacles (P)

provide connections for

properly rated AC appliances,

see page 62 for specifications.

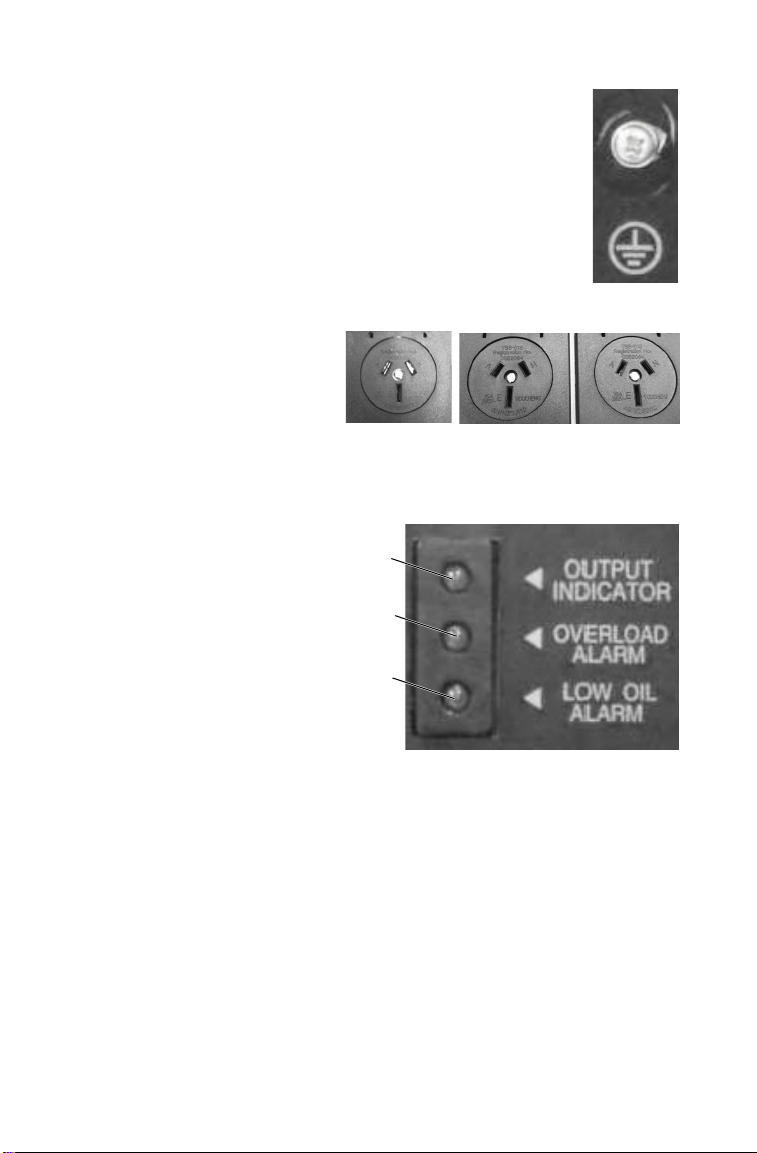

Indicator Panel

Output Indicator

The output indicator (Q)

illuminates GREEN when the

generator is in normal operation

and producing electrical power at

the receptacles.

Overload Indicator

The overload indicator (R)

illuminates RED if there is a short

circuit in the connected

appliance(s), or if the generator is

overloaded. The light remains

illuminated for 5 seconds, then the

current to the connected appliance

is shut off and the output indicator

light (GREEN) extinguishes.

Low Oil Indicator

The low oil indicator (S) illuminates RED before the oil level falls

below a safe limit and the detection system automatically stops the

engine. When there is a low engine oil level at startup, the engine will be

prevented from starting.

20

Page 22

CONTROLS AND FEATURES

Overload Protector Reset Switch

Should the generator overload, AC power will be cut

off but the engine will stay running. Correct the

overload condition and then press the overload reset

switch (T) on the front panel. AC power will be

restored immediately.

Parallel Receptacles

Two POLARIS parallel ready generators can be

connected together to increase the total power

available to a load, using the parallel receptacles (U).

The system seamlessly matches frequency and

automatically evenly distributes the load to each

generator so one is not overloaded. Contact your

supplier for the proper kit for your particular application. Only

POLARIS parallel kit (PN 3410252) can be used for POLARIS

generator parallel power output.

21

Page 23

FIRST USE INSTRUCTIONS

A

Upper Level

B

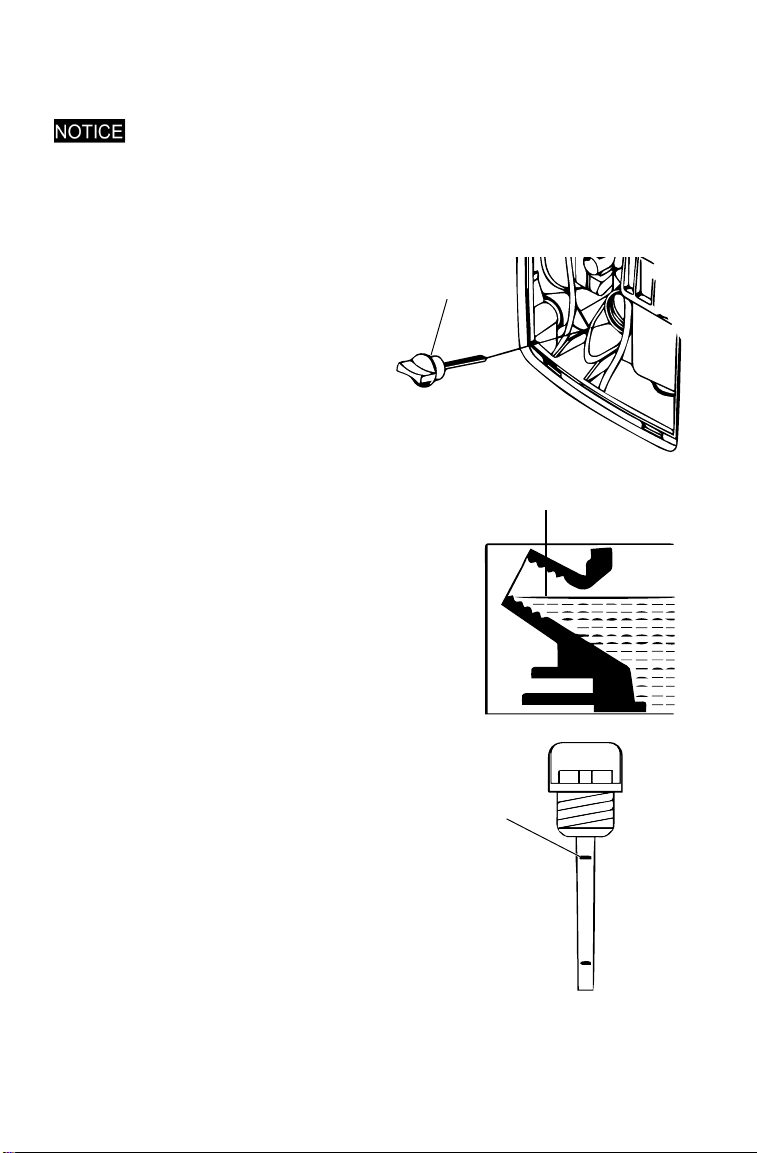

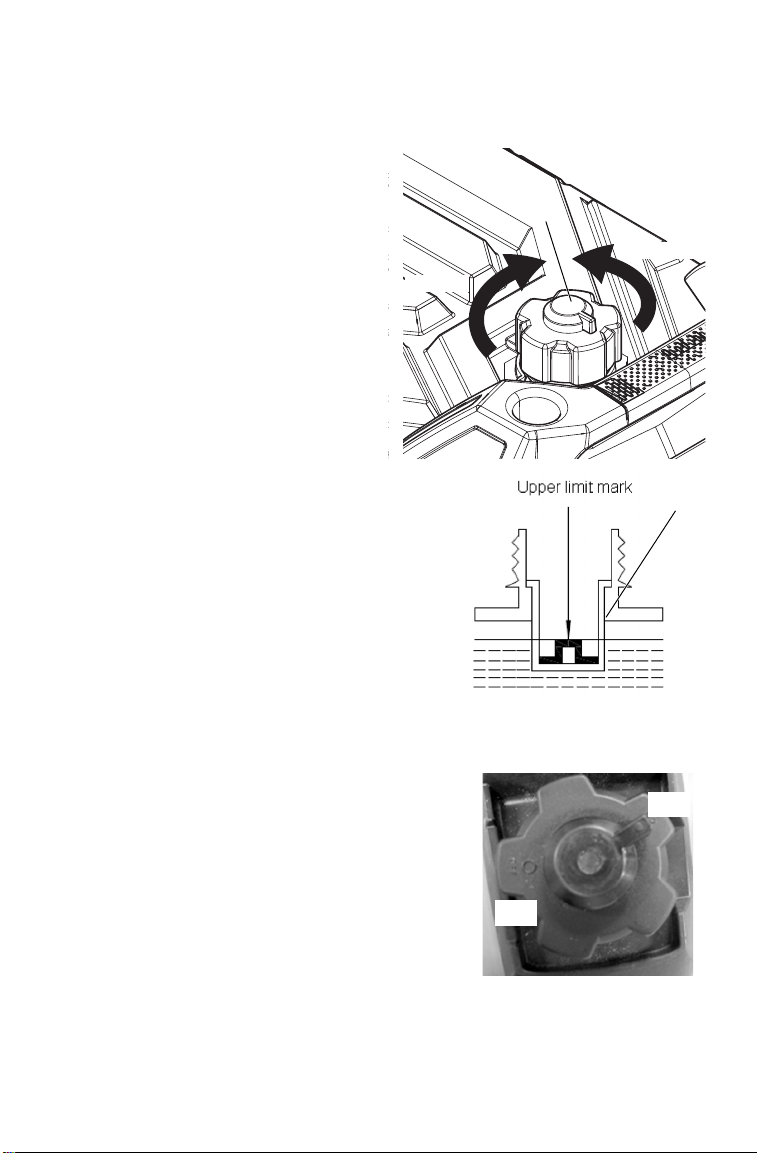

Adding Engine Oil

Failure to use the recommended 4-stroke engine oil may result in engine

damage, see page 62 for recommended oil and capacity.

1. Place generator on flat, level surface. Open the service door. See

page 46.

2. Remove the oil filler cap /

dipstick (A).

3. Fill the engine crankcase with the

specified amount of engine oil. See

page 62.

4. Insert the dipstick into the filler

neck, without screwing it in.

5. Remove the dipstick and verify that

the oil level is at the upper limit (B).

Add additional oil and inspect the

level as needed until the upper limit

has been reached.

6. Re-install the dipstick (A). Use a

clean shop rag to clean any spilled

oil.

7. Re-install the service door.

22

Page 24

FIRST USE INSTRUCTIONS

Fuel Recommendation

POLARIS recommends the use of 91 octane fuel or higher. Do not use

fuel containing more than 10% ethanol. Do not use petrol containing

methanol.

IMPORTANT: Operating the generator with an obstructed fuel system will

result in serious engine damage. Perform maintenance as recommended.

IMPORTANT: Thoroughly read “Safety” section and all safety information

when handling fuel.

IMPORTANT: In order to insure the optimum output and the maximum

service life of the generator, the generator should run at a 50% load for the

first 20 hours.

Petrol is highly flammable and explosive and can cause serious injury.

Stop the engine and keep heat, sparks, and flame away. Handle fuel only

outdoors. Wipe up spills immediately.

Do not spill fuel when filling the fuel tank. Damage caused by spilled fuel

is not covered under warranty. Spilled fuel is a fire hazard, causes

environmental damage, and can damage paint and plastic. Wipe up spills

immediately. Do not fill above bottom of strainer.

Refuel in a well ventilated area before starting the engine. If the engine has

been running, allow it to cool.

Never refuel the engine inside a building where vapors may reach flames

or sparks. Keep fuel vapors away from electrical appliances.

23

Page 25

FIRST USE INSTRUCTIONS

Loosen

Tighten

A

C

B

Adding Fuel

1. Remove the fuel tank cap (A).

2. Fill carefully to avoid spilling fuel on

the fuel tank strainer (B). Do not

overfill the fuel tank (there should be

no fuel above the upper limit mark).

3. Securely tighten the fuel tank cap (A).

4. Position the fuel tank vent lever (C) OFF for storage or transport, or

ON to operate the generator.

5. Move generator away from the fueling source and site before

starting the engine.

After refueling, securely reinstall the fuel tank cap (A).

24

Page 26

PRE-OPERATION INSPECTION

Note: Always perform the recommended pre-operation inspections before each

use. Always perform the inspections at the beginning of a project and

when removing the generator from storage.

Failure to perform the recommended pre-operation inspections could

result in minor or moderate injury or property damage. When inspection

reveals the need for adjustment, replacement, or repair, perform service

promptly.

Pre-Operation Checklist

Open the service door to expose the generator inner components. See

page 46.

Engine Oil

Perform “Oil Level Inspection” (see page 49). Add oil as needed.

Fuel Line

Petrol is highly flammable and explosive and can cause serious injury.

Stop the engine and keep heat, sparks, and flame away. Handle fuel only

outdoors. Wipe up spills immediately.

Inspect the fuel hose for cracks or damage. Replace as needed.

Fuel Level

Check the fuel level and refuel as needed. See page 26.

Exhaust System

If the engine has been running, the muffler will be very hot. Allow the

muffler to cool before servicing.

Inspect the exhaust system for leakage. Tighten or replace the gasket as

needed.

Carburetor

Inspect the choke lever operation.

Starting System

Inspect the recoil starter operation. Verify the starter recoil grip

functions properly.

Air Filters

Inspect the air filters. Clean or replace as needed. See page 25.

25

Page 27

OPERATION

Safe Operating Precautions

Fuel Recommendations

The generator engine is certified to operate on regular unleaded petrol

with a pump octane rating of 91 or higher.

Never use stale or contaminated petrol or an oil /petrol mixture. Avoid

getting dirt or water in the fuel tank.

The use of regular unleaded petrol containing no more than 10% ethanol

(E10) by volume is permitted. Do not use petrol containing methanol. If

the content of ethanol or methanol exceeds the specified limits, it may

cause starting or performance problems. It may also damage metal,

rubber, and plastic parts of the fuel system. Damage due to ethanol or

methanol is not covered under warranty.

Refueling

IMPORTANT: Thoroughly read the “Safety” section and all warnings and

cautions when handling fuel.

Petrol is highly flammable and explosive and can cause serious injury.

Stop the engine and keep heat, sparks, and flame away. Handle fuel only

outdoors. Wipe up spills immediately.

Do not spill fuel when filling the fuel tank. Damage caused by spilled fuel

is not covered under warranty. Spilled fuel is a fire hazard, caused

environmental damage, and can damage paint and plastic. Wipe up spills

immediately. Do not fill above bottom of strainer.

Refuel in a well ventilated area before starting the engine. If the engine has

been running, allow it to cool.

Never refuel the engine inside a building where vapors may reach flames

or sparks. Keep fuel vapors away from electrical appliances.

26

Page 28

Safe Operating Precautions

Loosen

Tighten

A

B

OFF

ON

Refueling

1. Remove the fuel tank cap (A).

2. Fill carefully to avoid spilling

fuel or exceeding the bottom of the

fuel tank strainer (B).

OPERATION

3. Securely tighten the fuel tank cap

(A) until it clicks.

4. Position the fuel tank vent lever OFF

for storage or transport, or ON to

operate the generator, if equipped.

5. Move generator at least 10 feet (3

meters) away from the fueling source

and site before starting the engine.

27

Page 29

OPERATION

DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside a home

or garage. EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

Safe Operating Precautions

Before Starting the Engine

Read, understand, and follow the

Safety Section of this manual.

1. Ensure the generator is away

from the fueling source.

2. The generator will vibrate

during operation. Place the

generator in a dry location and

on a flat, level surface.

3. Unplug all power cords and

extension cords from the

generator.

Starting the Engine

1. Position the fuel tank cap vent lever to ON.

2. Position the SMART throttle switch

to OFF.

3. For a cold engine start, position the

choke lever to START. To restart a

warm engine, leave the choke lever

in the RUN position.

28

Page 30

OPERATION

ON

OFF

AC

Switch

Safe Operating Precautions

Starting the Engine

4. Position the engine switch to ON.

5. Lightly pull the starter recoil grip until resistance is felt. Then,

firmly pull straight out.

Do not allow starter grip to snap back

against the generator. Return it gently

to prevent damage to the starter.

6. If the choke lever was positioned to START the engine, gradually

move it to RUN as the engine warms up.

7. After a 2 to 3-minute warm up, select ON or OFF on the SMART

throttle switch as desired.

8. If connecting loads to generator, reference “AC Operation” or “DC

Operation” as outlined later in this section.

9. Make sure to turn the AC switch

to "ON" position. Otherwise,

there will be no AC power

output from AC receptacles.

29

Page 31

OPERATION

ON

OFF

OFF

ON

Safe Operating Precautions

Stopping the Engine

In case of emergency, position the engine switch to OFF to stop the

engine. Under normal conditions, perform the following procedure.

1. Shut off or disconnect all appliances connected to the generator.

2. Position the engine switch to

OFF.

3. Allow the engine to cool and

position the fuel tank cap vent

lever to OFF.

30

Page 32

OPERATION

A

B

Safe Operating Precautions

AC Operation

Before connecting a device or power cord to the generator, ensure it is in

good condition. Faulty appliances or power cords can create a potential

for electrical shock.

If an appliance begins to operate abnormally, becomes sluggish, or

suddenly stops, immediately shut it off. Disconnect the appliance and

determine whether the problem is the appliance or if the rated load

capacity of the generator has been exceeded.

Ensure the combined electrical rating of the device or appliance does not

exceed the maximum allowed by the generator. Never exceed the

maximum power rating of the generator. Power levels between rated and

maximum may be used for no more than 30 minutes.

Note: When the electric motor starts, the overload indicator (middle light) may

illuminate (RED) and extinguish within 4 seconds. If the overload indicator

remains illuminated, consult the generator supplier.

Note: In order to insure the optimum output and the maximum service life of the

generator, the generator should run at a 50% load for the first 20 hours

1. Start the engine and ensure that

the output indicator (A)

illuminates (GREEN).

2. Plug the device or extension cord

into one of the AC receptacles

(B).

3. Turn on the device.

Note: If the generator is overloaded or if

there is a short circuit in a

connected appliance, the overload

indicator (RED) will illuminate. The

overload indicator will remain

illuminated and, after about 4

seconds, current to the connected

appliance(s) will shut off but the

engine will stay running. The output

indicator (GREEN) will extinguish.

4. If overloaded or short circuit in a connected device occurs, stop the

engine and refer to the “Troubleshooting” section. Determine if the

cause is a short circuit in the connected device or an overload.

Correct the problem and restart the generator.

5. After determining the cause of the overload and when it is safe to

resume using the AC power in order to correct the overload

condition and then press the overload reset switch on the front

panel. AC power will be restored immediately.

31

Page 33

OPERATION

Safe Operating Precautions

AC Capacity

In case of substantial overloading, the electronic circuit protector will

activate. Slightly overloading the generator or running at maximum

power operation (30 minutes) may not switch the circuit ON, but will

shorten the service life of the generator.

Maximum power is:

(see page 62)

For continuous operation, do not exceed rated power:

(see page 62)

Consider the total power requirements of all connected devices.

Appliance and power-tool manufacturers usually list the rating

information near the model or serial number. After plugging in a device,

allow the generator to stabilize before plugging in additional items.

Always consider the generator capacity before plugging in any device.

32

Page 34

OPERATION

Safe Operating Precautions

AC Capacity

Note: Typical wattages are listed in the table below. Before plugging any device

into the generator, verify the manufacturer-listed wattage on the device.

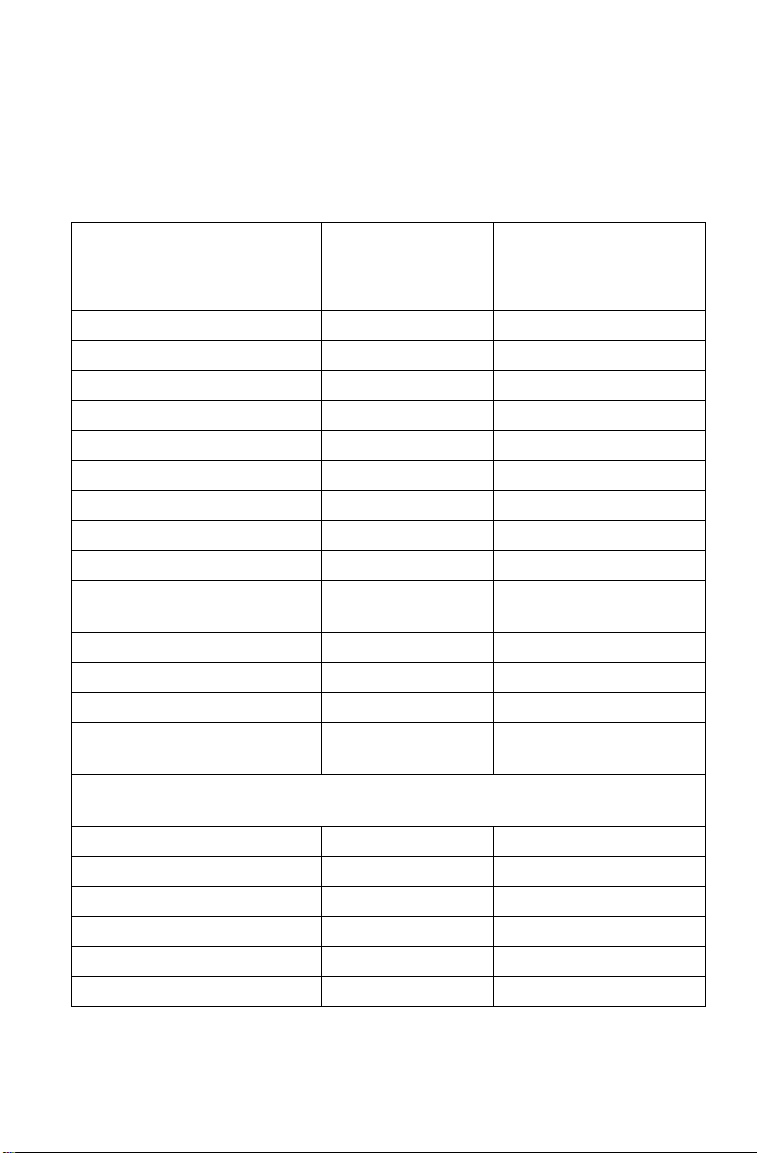

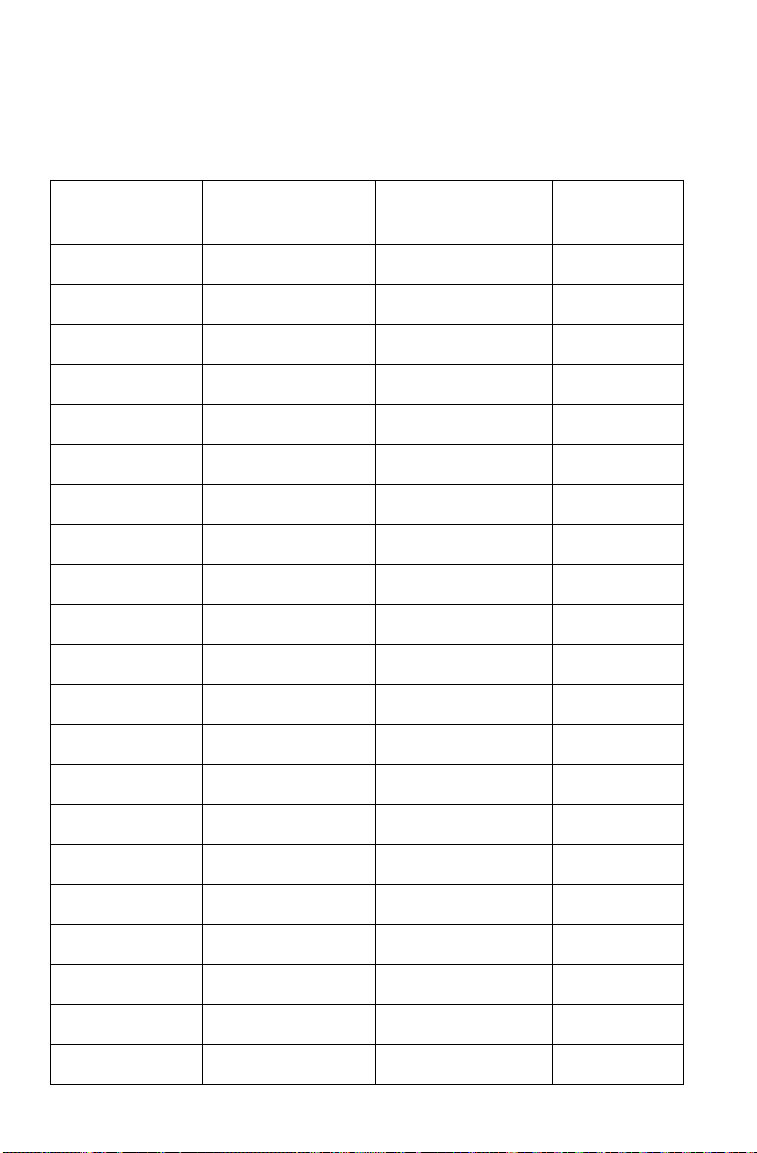

Wattage Reference Table

DEVICE

Circular Saw - 7 1/4” 1400 2300

Coffee Maker 1000 0

Dehumidifier 650 800

Electric Drill - 3/8”, 4 Amps 440 600

Hair Dryer 300 - 1200 0

Light Bulb (75-Watt) 75 0

Microwave Oven1000-Watt 1000 1400

Paint Sprayer 360 1080

Heat Pump 4700 4500

Personal Computer with 17”

Monitor

Radio 300 300

Refrigerator 400 - 800 2200

Space / Wall Heater 1800 0

Table Saw / Radial Arm Saw 10”

Do not use or only use with the POLARIS Parallel Kit, see page 38 for more

information

High-Pressure Washer-1 HP 1200 3600

Garage Door Opener 1/2 HP 875 2350

Sump Pump - 1/2 HP 1050 2200

Central AC Unit48,000 BTU 6000 7800

Television (Color) - 27” 500 0

Air Compressor - 1 HP 1600 4500

RUNNING

(RATED) WATTS

800 0

2000 2000

ADDITIONAL

STARTING (SURGE)

WATTS

33

Page 35

OPERATION

Safe Operating Precautions

Power Management

DEVICE

Paint Sprayer 360 1080

Radio 300 300

RUNNING

(RATED) WATTS

ADDITIONAL

STARTING (SURGE)

WATTS

Total Running (Rated) Watts = 660

Additional Starting Surge Watts = 1380

Total Generator Output Required = 2040

Ensure the combined electrical rating of the powered device(s) do not

exceed the maximum allowed by the generator. Never exceed the

maximum power rating of the generator. Power levels between rated and

maximum may be used for no more than 30 minutes.

DC Operation

Connecting the Battery Charging Cable (included)

The battery emits explosive hydrogen gas during normal operation. A

spark or flame can cause the battery to explode with enough force to kill

or cause serious injury. Wear protective clothing and eye protection when

charging a battery.

Battery posts, terminals, and related accessories contain lead and lead

components. Wash hands after handling.

The DC charging output is not regulated. The DC receptacle should only

be used for charging 12V DC batteries.The 12V DC receptacle has no

battery overcharge protection function. Do not overcharge the battery.

When using the DC output, position the SMART throttle switch to OFF.

The DC receptacle may be used while the AC power is in use.

34

Page 36

OPERATION

Safe Operating Precautions

DC Operation

Connecting the Battery Charging Cable (included)

1. Position the SMART throttle switch

to OFF.

2. Disconnect the vehicle ground cable

from the negative (-) battery

terminal.

3. Plug the battery charging cable into

the DC receptacle. See page 19.

4. Connect the red lead of the battery charging cable to the positive (+)

battery terminal and then the black lead to negative (-) battery

terminal.

Start the generator

Do not start the vehicle while the battery charging cable is connected and

the generator is running. The vehicle’s charging system or the generator

may be damaged.

An overloaded DC circuit, excessive current draw by the battery, or a

wiring problem will trip the DC circuit fuse. If this happens, The fuse must

be replaced before the DC receptacle is operative. Replace the fuse with

one of the same size and rating (5 amp). Exceeding the current rating may

lead to alternator damage. If the DC circuit protector fuse continues to trip,

discontinue charging and see your authorized POLARIS generator

supplier.

The circuit protector does not prevent

overcharging the battery. Over charging

the battery may result in battery damage

and potential ignite if a spark is

introduced.

35

Page 37

OPERATION

Safe Operating Precautions

DC Operation

Disconnecting the Battery Charging Cable:

1. Stop the generator.

2. Disconnect the black lead of the battery charging cable from the

negative (-) battery terminal and then the lead from the positive (+)

battery terminal.

3. Unplug the battery charging cable from the DC receptacle. See page

19.

4. Connect the vehicle battery ground cable to the negative (-) battery

terminal.

SMART Throttle System

With the SMART throttle switch in the ON position, engine speed is

automatically lowered when loads are reduced, turned off, or

disconnected. When devices are turned on or connected, the engine

returns to the proper speed to power the electrical load. When the smart

throttle is in the OFF position, the engine runs at rated load RPM

Appliances with large start-up power demands may not allow the engine

to reach normal operating RPM when they are connected to the

generator. Position the SMART throttle switch to OFF and connect the

device to the generator. If the engine still will not reach normal

operating speed, ensure the device does not exceed the rated load

capacity of the generator.

If high electrical loads are simultaneously connected, position the

SMART throttle switch to OFF to reduce voltage changes.

The SMART throttle system is not

effective for use with devices or

appliances requiring only momentary

power. If the device or appliance will be

quickly turned on and off, the SMART

throttle switch should be in the OFF

position. When using the DC output,

position the SMART throttle switch to

OFF.

36

Page 38

OPERATION

Safe Operating Precautions

Standby Power

Improper connection to a building electrical system can allow current from

the generator to back feed into the utility lines. Such back feed may

electrocute utility company workers or others who contact the lines during

a power outage. Additionally, the generator may explode, burn, or cause

fires when utility power is restored. Consult the utility company or a

qualified electrician prior to making any power connections.

Connections to a Building Electrical System

Connections for standby power to a building's electrical system must be

made by a qualified electrician and must comply with all applicable

laws and electrical codes. Improper connections can allow electrical

current from the generator to back feed into the utility lines. Such back

feed may electrocute utility company workers or others who contact the

lines during a power outage; when utility power is restored, the

generator may explode, burn, or cause fires in the building's electrical

system. Do not connect this generator to an automatic transfer switch.

Serious damage to the engine and inverter module may result.

In some areas, generators are lawfully required to be registered with

local utility companies. Check local regulations for proper registration

and usage procedures.

System Ground

To prevent electrical shock from faulty appliances, the generator should

be grounded. Connect a length of heavy cable between the generator's

ground terminal and an external ground source.

System Requirements

There may be federal or state regulations, local codes, or ordinances that

apply to the intended use of the generator. Please consult a qualified

electrician, electrical inspector, or the local agency having jurisdiction.

If the generator is used at a construction site, there may be additional

regulatory requirements.

37

Page 39

OPERATION

A

B

Parallel Generator Operation

Parallel operation features, kits sold separately.

Two POLARIS parallel ready generators can be connected together to

increase the total power available to a load. The system seamlessly

matches frequency and automatically evenly distributes the load to each

generator so one is not overloaded.

Operating the generators in parallel has 0.9 power de-rate factor. For

example, connecting a 1kw and 2kw together in parallel operation, the

continuous rated combined output will equal 0.9x (900w + 1600w) =

2250W.

Any combination of two POLARIS parallel ready generators can be

connected such as a P2000i and a P1000i, two P2000i models, etc.

There are two different parallel connection kits. One kit has a 30A

receptacle ideal for connecting two P2000i models or a P2000i and a

P1000i.

Parallel operation procedure

1. Turn off both generators and disconnect all the electrical devices

from the generators

2. Prepare two parallel ready generators for operation. Place them on a

hard and level surface.

3. Connect the parallel kit to each

generator by inserting one pair of

leads from the parallel box to the

parallel receptacles (A) on the

panel

4. Ground the generators (B).

5. Start both generators and confirm

that both green "RUN" lights are

illuminated. The Smart throttle

system may be used as long as the

Smart throttle setting of both

generators is the same.

6. Securely plug the electrical

appliance plug into parallel cable

receptacle and switch on the

electrical appliance power supply.

38

Page 40

OPERATION

Parallel Generator Operation

Parallel operation procedure

While operating in parallel, the only AC output is through the receptacle

on the parallel cable box.

Do not use the receptacles on the control panel of the generator.

The required output of the electrical appliance cannot exceed the rated

output of parallel generators.

Shutting off the generators

1. Turn off the power of electrical appliance then, pull out the

receptacle plug.

2. Turn off the two generators.

3. Disconnect the parallel kits from the generators.

• The parallel cable connectors can only be used with POLARIS parallel ready

generators.

• While connecting the generator and electrical appliance with the parallel

output cable, do so carefully and safely insert the plug into the receptacle.

• While operating in parallel, the only AC output is through the receptacle on

the parallel cable box. Do not use the receptacles on the control panel of

either generator.

• Do not disconnect the parallel cables during operation

39

Page 41

OPERATION

High Altitude Use

Carburetor Modification

When carburetor has been modified for high altitude operation, the airfuel mixture will be too lean for low altitude use and may cause engine

damage.

At high altitude, the standard carburetor air-fuel mixture will be

excessively rich. Performance will decrease and fuel consumption will

increase. A very rich mixture will also foul the spark plug and cause

hard starting. Operation at an altitude different than that which this

engine was certified, for extended periods of time, may increase

emissions.

High altitude operation can be improved by specific modifications to the

carburetor. If always operating the generator at altitudes above 5000 feet

(1500 meters), have an authorized POLARIS servicing supplier perform

the carburetor modification. The engine will meet each emission

standard throughout its life when operated at high altitude with the

carburetor modifications for high altitude operation.

With the carburetor modification, engine horsepower will decrease by

about 3.5% for every 1000 feet (300 meters) increase in altitude. The

effect of altitude on horsepower will be greater if no carburetor

modification is made.

Operation of the generator at an altitude lower than the carburetor is

jetted for may result in reduced performance, overheating, and serious

engine damage caused by an excessively lean air/fuel mixture. Be sure

to have any modification reversed at lower altitudes.

40

Page 42

OPERATION

Emission Control System Information

Source of Emissions

Exhaust gas contains carbon monoxide, nitrous oxide (NOx), and

hydrocarbons. It is very important to control the emissions of NOx and

hydrocarbons as they are a major contributor to air pollution. Carbon

monoxide is a poisonous gas. The generator engine utilizes a precise airfuel ratio and emission control system to reduce the emissions of carbon

monoxide, NOx, hydrocarbons.

POLARIS utilizes appropriate air-fuel ratios and other emissions control

systems to reduce the emissions of carbon monoxide, oxides of

nitrogen, and hydrocarbons. In addition, POLARIS fuel systems utilize

components and control technologies to reduce evaporative emissions.

To keep the engine emissions within the emission standards, the

following procedures must be followed:

Alterations

Altering the emission control system may increase emissions beyond

the legal limit. Some possible alterations are as follows:

• Removal or alteration of any part of the intake, fuel, or exhaust

systems

• Altering or defeating the governor linkage or speed-adjusting

mechanism to cause the engine to operate outside its design

parameters

41

Page 43

OPERATION

Emission Control System Information

Problems Affecting Emissions

If aware of any of the following, have the engine inspected and repaired

by an authorized POLARIS supplier:

• Hard starting or stalling after starting

• Rough idle

• Shut down or backfire after applying an electrical load

• Afterburning (backfiring)

• Black exhaust smoke or high fuel consumption

Replacement Parts

The emission control system on the engine was designed, built, and

certified to conform to applicable emission regulations. We recommend

the use of POLARIS Genuine parts whenever maintenance is

performed. These original design replacement parts are manufactured to

the same standards as the original parts. The use of replacement parts

that are not of the original design and quality may impair the

effectiveness of the emission control system.

Aftermarket part manufacturers assume the responsibility that the part

will not adversely affect emission performance. The manufacturer or rebuilder of the part must certify that use of the part will not result in a

failure of the engine to comply with emission regulations.

42

Page 44

MAINTENANCE

Importance of Maintenance

Good maintenance is essential for safe and economical operation.

Proper maintenance will also help reduce air pollution.

To ensure the longevity of the generator, the following pages include a

periodic maintenance schedule and inspection and maintenance

procedures. Other, more difficult tasks, require special tools and

expertise provided by a POLARIS technician or other qualified

mechanic.

The maintenance schedule applies to normal operating conditions. If the

generator is operated under unusual conditions, such as sustained high

load or high temperature, or dusty conditions, consult the servicing

supplier for applicable recommendations.

To ensure the best quality and reliability, use only new, POLARIS

Genuine parts or their equivalents for repair and replacement.

All necessary replacement parts and labor incurred, with the exception

of authorized warranty repairs, become the responsibility of the

registered owner. If, during the course of the warranty period, part

failures occur as a result of owner neglect in performing recommended

regular maintenance, the cost of repairs are the responsibility of the

owner.

43

Page 45

MAINTENANCE

Maintenance Safety

Personal safety is critical when attempting to service the generator.

Improperly installed or adjusted components can make the generator

unstable or dangerous. Improperly installed electrical components can

cause engine or electrical systems failure. In either event, damage or

serious injury could result. If you do not have the time, tools, and/or

expertise necessary to complete a procedure properly, please see your

POLARIS supplier for service.

Failure to correct a problem before operation and improper maintenance

can cause a malfunction resulting in injury or death. Always follow the

inspection and maintenance schedules and requirements in this manual.

The following important safety precautions cannot warn of every

possible hazard from maintenance. The decision to perform a given task

must be evaluated by the individual performing it.

Safety Precautions

Read the safety section of this manual.

Ensure the engine is off before performing any maintenance or repairs.

This should minimize the potential for exposure to the following

hazards:

• Fuel and fire - Avoid flames, sparks, and smoking during service.

• Carbon monoxide poisoning - Avoid indoor operation of engine and

stay away from open windows and doors.

• Burns - Allow the engine and exhaust system to cool before

touching. Exercise caution when working around hazardous

materials.

• Injury from moving parts - Avoid running the engine unless

specifically instructed.

Follow the instructions and ensure the required tools are used.

Exercise caution when working around petrol to reduce the possibility

of fire or explosion. Use only non-flammable solvents to clean parts.

Keep cigarettes, sparks, and flames away from all fuel-related

components.

44

Page 46

MAINTENANCE

Periodic Maintenance

• Always stop the engine before servicing. Disconnect all devices and

extension cords to avoid receiving an electrical shock.

• Periodic checks and maintenance are very important for keeping the

generator in good condition.

• Inspect, clean, lubricate, adjust, and replace parts as necessary. When

inspection reveals the need for replacement parts, use POLARIS

Genuine parts available from your POLARIS supplier.

• Before beginning any maintenance procedure, read the instructions

for the entire procedure. During some procedures, potentially

hazardous products may be used. Always follow the instructions and

warnings on the product packaging.

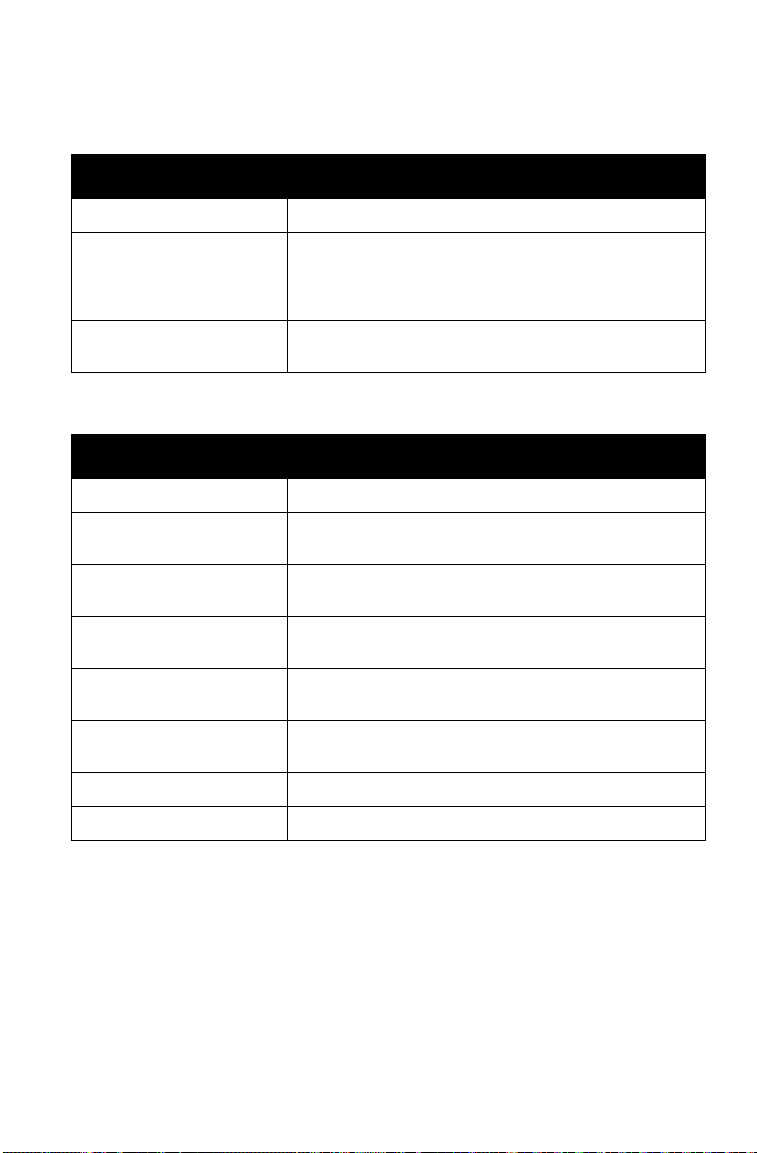

Periodic Maintenance Chart

Pre-

Item Remarks

Check condition.

Spark plug

Spark

arrester

Engine oil

Air filter

Combustion

chamber

Fuel tank

and filter

Val ve

clearance

Fuel line

(1) Log hours of operation to determine proper maintenance.

(2) Service more frequently when used in dusty conditions.

(3) These items should be serviced by an authorized POLARIS supplier unless the owner

has the proper tools and is mechanically proficient. Refer to the POLARIS Service manuals.

Adjust gap and clean.

Replace

Clean the carbon

deposits.

Check the oil level. X

Replace X X

Check X

Clean. Replace as

needed.

Clean

Clean

Check and adjust

when engine is cold.

Check fuel line for

twists, cracks, or

damage. Replace as

needed.

Operation

Check

(daily)

Initial 1

month or

20 hrs

X

Every 2 years (Replace as necessary)

Every 3

months or

50 hrs

Every 300 Hours

Every 6

months or

100 hrs

X

(2)

(2)

Every 12

months

or 200

hrs

X

X

X

(3)

X

(3)

(3)

45

Page 47

MAINTENANCE

A

D

C

B

ON

OFF

Opening the Service Door

Use the following steps to open the generator service door and gain

access to the inner components. Before performing any maintenance,

the fuel tank cap vent lever and engine switch should be positioned to

OFF. See page 18.

1. Position the fuel tank cap vent

lever (A) to OFF, if equipped.

See page 18.

2. Position the engine switch (B)

to OFF. See page 18.

3. Loosen the service door screw

(C).

4. Open the service door (D).

5. Expose the generator inner

components.

6. Upon completion of

maintenance, return the fuel

tank cap vent lever (A), and the

engine switch (B) to the ON

position to allow engine

operation.

46

Page 48

MAINTENANCE

Loosen

Tighten

A

C

Initial Maintenance

20-Hour Initial Break-In

In order to insure the optimum output and the maximum service life of

the generator, the generator should run at a 50% load for the first 20

hours

1. Perform “Oil Change”.

2. Perform “Air Filter Inspection”. Replace as needed.

Fuel System

Petrol is highly flammable and explosive, and can cause serious injury or

death. Stop the engine and keep heat, sparks, and flame away. Handle fuel

only outdoors. Wipe up spills immediately.

Fuel Line Inspection

Inspect the fuel line to ensure absence of twists, cracks, and / or damage.

Replace as needed.

Fuel Tank Strainer Inspection

1. Remove the fuel tank cap (A).

47

Page 49

MAINTENANCE

B

ON

OFF

Fuel System

2. Remove the fuel tank strainer (B)

from the fuel tank.

3. Remove any foreign objects or

debris from the fuel tank strainer (B).

4. Inspect the fuel tank strainer (B) for

damage. Replace as needed.

5. Install the fuel tank strainer (B) into

the fuel tank.

6. Securely tighten the fuel tank cap

(A) until it clicks.

7. Position the fuel tank cap vent lever

(C) OFF for storage or transport, or

ON to run the generator.

48

Page 50

MAINTENANCE

A

B

Engine Oil

Oil Recommendation

Oil directly affects performance and service life. Use a 4-stroke

automotive detergent oil. POLARIS 5W-30 Engine Oil is recommended

for this generator.

The SAE oil viscosity and service category are in the API label on the

oil container. POLARIS recommends the use of API service category

“SJ” or later, equivalent oil.

Oil Level Inspection

Failure to use the proper 4-stroke engine oil may result in engine

damage.

Using non-recommended oil may cause serious engine damage. Never

substitute or mix oil brands.

Note: Inspect the oil level before each use with the engine stopped and the

generator on a level surface.

1. Open the service door.

2. Remove the oil filler cap /

dipstick (A) and wipe it clean.

3. Insert the dipstick (A) into

filler neck, without screwing it

in, to inspect the oil level.

4. Remove the dipstick and

verify that the oil is at the

upper limit (B). Add

additional oil and inspect the

level as needed until the upper

limit has been reached.

5. Re-install the dipstick (A).

6. Re-install the service door.

49

Page 51

MAINTENANCE

ON

OFF

A

Engine Oil

Oil Change Procedure

Oil may be hot. Do not allow hot oil to come into contact with skin, as

serious burns may result.

Note: Drain the oil while the engine is warm to assure rapid and complete

draining.

1. Start the engine and allow it to run for a few minutes. Stop the

engine.

2. Position engine switch and fuel cap

vent lever to OFF.

3. Open the service door. See page 46.

4. Place a drain pan beneath the generator for used oil.

5. Remove the oil filler cap /

dipstick (A), tip the generator

toward the oil filler neck, and

drain the oil into a drain pan.

Note: Improper disposal of engine oil

can be harmful to the

environment and is unlawful.

Properly dispose of used oil.

6. Drain the used oil into a

sealed container and take it to

a recycling center. Do not

discard the oil into a rubbish

bin, dump it on the ground,

or pour it down the drain.

50

Page 52

MAINTENANCE

B

Engine Oil

Oil Change Procedure

7. Fill the oil to the high limit mark (B)

on the dipstick (A).

8. Start the engine and let it run for 1 or

2 minutes. Stop the engine and look

for leaks.

9. Re-check the oil level on the

dipstick (A) and add oil as needed to

bring the level to the upper mark (B)

on the dipstick.

10. Re-install the dipstick (A).

11. Re-install the service door.

12. Wash hands with soap and water after handling used oil.

51

Page 53

MAINTENANCE

A

B

C

Air Filters

Operating the engine without air filters or with a damaged air filters will

allow debris to enter the engine, causing rapid wear.

Air Filter Inspection

Note: An obstructed air filter restricts air flow to the carburetor. To prevent

carburetor malfunction, regularly service the air filter. Service more

frequently when operating the generator in extremely dusty areas.

1. Open the service door. See page 46.

2. Loosen the cover screw (A)

and remove the air filter cover

(B).

3. Remove the two air filters (C).

4. Inspect the air filters (C) to

ensure both are clean and in

good condition. If obstructed,

perform “Air Filter Cleaning”.

If damaged, perform “Air

Filter Replacement”.

5. Ensure the rubber seal is set in

to the groove of air filter cover

(B).

6. When the maintenance complete, re-install the air filter cover and

service door.

52

Page 54

MAINTENANCE

Air Filters

Air Filter Cleaning

Note: If operating the generator in a very dust area, clean the air filters more

frequently than specified in the Periodic Maintenance Chart.

1. Wash the air filters (C) in warm water and detergent, rinse, and

allow to completely dry; or clean with a high flash point solvent and

allow to completely dry.

2. Soak the elements in clean engine oil and squeeze out the excess oil.

3. Wipe debris from the air filter housing and air filter cover (B) using

a moist towel.

4. Re-install the cleaned filter(s) (C).

Air Filter Replacement

1. Remove the air filters (C).

2. Install new air filters.

53

Page 55

MAINTENANCE

A

Spark Plug

Spark Plug Inspection and Replacement

Using a non-recommended spark plug can result in serious engine

damage. Always use recommended spark plugs.

Note: In order to service the spark plug, a commercially available spark plug

wrench is required.

Refer to the “Specification” (page 62) for the recommended spark plug

type. Always torque the spark plug to specification.

Note: To ensure proper engine operation, the spark plug must be free of

deposits and properly gapped. If the engine has been running, allow it to

cool before servicing.

Normal Spark Plug

The normal insulator tip is gray, tan, or light brown. There will be few

combustion deposits. The electrodes are not burned or eroded. This

indicates the proper type and heat range for the engine and the service.

Note: The tip should not be white. A white insulator tip indicates overheating,

caused by use of an improper spark plug, fuel, or incorrect carburetor

adjustments.

Wet Fouled Spark Plug

The wet fouled insulator tip is black. A damp oil film covers the firing

end. There may be a carbon layer over the entire nose. Generally, the

electrodes are not worn. Fouling may be caused by excessive oil or by

frequent short trips, especially in cold weather.

1. Remove the top of the generator by

removing the 4 bolts (A) in the top

through the handles.

54

Page 56

MAINTENANCE

B

Inspect electrode

for wear and

buildup

Spark plug gap

Spark Plug

Spark Plug Inspection and Replacement

2. Remove the spark plug cap (B).

3. Clean any dirt from around the

base of the spark plug.

4. Using a spark plug wrench,

remove the spark plug.

5. Inspect the electrode for wear and

carbon buildup. Look for a sharp

outer edge with no rounding or

erosion of the electrode.

6. Inspect spark plug. Replace if electrode is worn or if the insulator is

cracked, chipped, or fouled.

7. Using a wire-type feeler gauge,

measure the spark plug

electrode gap. If necessary,

correct the gap by carefully

bending the side electrode. The

gap should be 0.6 - 0.7 mm

(0.024 - 0.028 in).

8. Ensure the spark plug sealing washer is in good condition and

thread the spark plug in by hand to prevent cross-threading.

A loose spark plug can overheat and damage the engine. Over tightening

the spark plug can damage the plug threads.

9. After a new spark plug has been seated by hand, it should be

tightened 1/2 turn with a wrench to compress its washer. If a used

plug is being reinstalled, it should only require 1/8 to 1/4 turn after

being seated.

10. Re-install the spark plug cap (B).

11. Re-install the top of the generator by inserting and tightening the 4

bolts (A) through the handles.

55

Page 57

TRANSPORTATION AND STORAGE

A

B

ON

OFF

Transportation

Transporting the Generator

A hot engine or exhaust system can cause severe burns and ignite

flammable material. Ensure adequate time for cooling before storage or

transportation.

When operating or transporting the generator, be sure it is kept upright. If

the generator tilts, fuel may leak. Be sure the fuel tank cap is tight during

transportation.

Do not operate the generator while transporting or while it is in a vehicle.

Do not transport the generator with fuel in the fuel tank.

IMPORTANT: Take care not to drop or strike the generator when

transporting. Do not place heavy objects on the generator.

1. If the generator has been used, allow it to cool for at least 15

minutes before loading it on the transport vehicle.

2. Drain the fuel prior to transportation. See page 59.

3. Position the engine switch (A)

and the fuel tank vent lever (B) to

OFF (see page 18), and keep

generator level to reduce

possibility of fuel leakage.

56

Page 58

TRANSPORTATION AND STORAGE

Storage

Storage Preparation

Petrol is highly flammable and explosive and can cause serious injury.

Stop the engine and keep heat, sparks, and flame away. Handle fuel only

outdoors. Wipe up spills immediately.

Note: Long-term storage of the generator will require some additional

preventative measures to guard against deterioration. If fuel is kept in the

generator, ensure that the engine is run for at least 30 minutes per month

in order to ensure an easy start in emergencies.

1. If the generator will be stored with fuel, perform “Adding Fuel

Stabilizer”.

2. If the generator will be stored dry of fuel, perform the “Draining

Fuel” and “Fogging the Engine procedures.

3. Perform “Oil Change”. See page 50.

4. Clean the exterior of the generator with a clean cloth and apply a

rust inhibitor.

Do not pour water directly on to the generator or wash it with water.

57

Page 59

TRANSPORTATION AND STORAGE

Loosen

Tighten

A

B

C

Storage

Accessing the Fuel Tank

1. Position the fuel tank vent

lever (A) to OFF (see page 18)

to reduce leakage possibilities.

Remove the fuel tank cap (B).

2. Remove the fuel tank strainer

(C) from the fuel tank. Remove

debris as needed.

3. When maintenance is complete, re-

install the fuel tank strainer (C) into

the fuel tank.

4. Securely tighten the fuel tank cap (B)

until it clicks.

58

Page 60

TRANSPORTATION AND STORAGE

A

B

Screw driver

Storage

Draining Fuel from the Fuel Tank and Carburetor

Petrol is highly flammable and explosive and can cause serious injury.

Stop the engine and keep heat, sparks, and flame away. Handle fuel only

outdoors. Wipe up spills immediately.

Do not spill fuel when draining the fuel tank. Spilled fuel is a fire hazard,

causes environmental damage, and can cause damage to paint and

plastic. Wipe up spills immediately.

Note: This procedure applies if fuel will NOT be kept in the fuel tank during

storage.

1. Access the fuel tank. See page 58.

2. Empty the fuel tank into an approved petrol container. POLARIS

recommends using a commercially available petrol hand pump to

empty the tank. Do not use an electric pump.

3. Re-install the fuel tank strainer into the fuel tank.

4. Securely tighten fuel tank cap until it clicks.

5. Open the service door. See page 46.

6. Position engine switch to ON (see

18). Loosen the carburetor drain

screw (A).

7. Drain the petrol from the carburetor

through the attached drain hose (B)

and into a suitable container.

8. Remove the top of the unit to access

the spark plug. See page 54.

59

Page 61

TRANSPORTATION AND STORAGE

C

ON

OFF

D

E

A

Storage

9. Remove spark plug cap (C).

10. Pull starter grip (D) three to four

times to drain the petrol from the

fuel pump and into a suitable

container.

11. Position engine switch (E) to

OFF (see page 18) and tighten the

carburetor drain screw.

12. Re-install spark plug cap on the

spark plug securely.

13. Re-install the top of the unit and

the service door.

Fogging the Engine

1. Remove the top of the unit to access the spark plug, see page 54.

2. Remove the spark plug cap (A).

3. Using a spark plug wrench, remove spark plug.

4. Pour about a tablespoon of clean engine oil into the cylinder. Crank

the engine several revolutions to distribute the oil and then reinstall

the spark plug.

60

Page 62

TRANSPORTATION AND STORAGE

Storage

Fogging the Engine

5. Ensure that the spark plug sealing washer is in good condition and

hand-tighten the spark plug to prevent cross-threading. Torque to

specification on page 62.

6. Re-install the spark plug cap (A) and the top of the unit.

Storage Precautions

Do not store the generator outdoors in the cold weather when not in use.

• Select a well-ventilated storage area away from any flame-operated

appliance (i.e., furnace, water heater, or clothes dryer). Also avoid