Page 1

Polaris 9300/9300xi Diagnostic Instructions

WARN ING

FOR YOUR SAFETY - This product must be serviced by a contractor who is licensed and qualified in pool equipment by the

jurisdiction in which the product will be installed where such state or local requirements exists. In the event no such state or local

requirement exists, the installer or maintainer must be a professional with sufficient experience in pool equipment installation and

maintenance so that all of the instructions in this manual can be followed exactly. Before installing this product, read and follow

all warning notices and instructions that accompany this product. Failure to follow warning notices and instructions may result in

property damage, personal injury, or death. Improper installation and/or operation will void the warranty.

Improper installation and/or operation can create unwanted electrical hazard which can cause serious injury, property damage, or

death.

Connect unit to receptacle protected by a ground fault circuit interrupter (GFCI). Such a GFCI receptacle should be provided by

a qualified installer and should be tested on a routine basis. To test the GFCI, push the test button. The GFCI should interrupt

power. Push the reset button. Power should be restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the

GFCI interrupts power to the pump without the test button being pushed, a ground current is flowing, indicating the possibility

of an electric shock. Do not use this product. Disconnect the cleaner and have the problem corrected by a qualified service

representative before using.

KEEP OUT OF REACH OF CHILDREN

1. Introduction

This document gives diagnostic testing instructions

for the 9300/9300xi Sport.

The instructions were written with safety as the

priority and must be followed exactly. Not following

the written procedure or taking shortcuts may

increase the risk of personal injury. Read through

the instructions completely before starting the

procedure.

2. Diagnostic Instructions

The customer must provide the following items to

perform the diagnostic testing:

• Control Unit

• Cleaner Head with Floating Cable

H0359300 Rev -

Future

Use

Press to

STOP the test

Figure 1. Polaris Quick Diagnostic Test Box

Press to START

9300 or 9300xi test

Page 2

Page 2

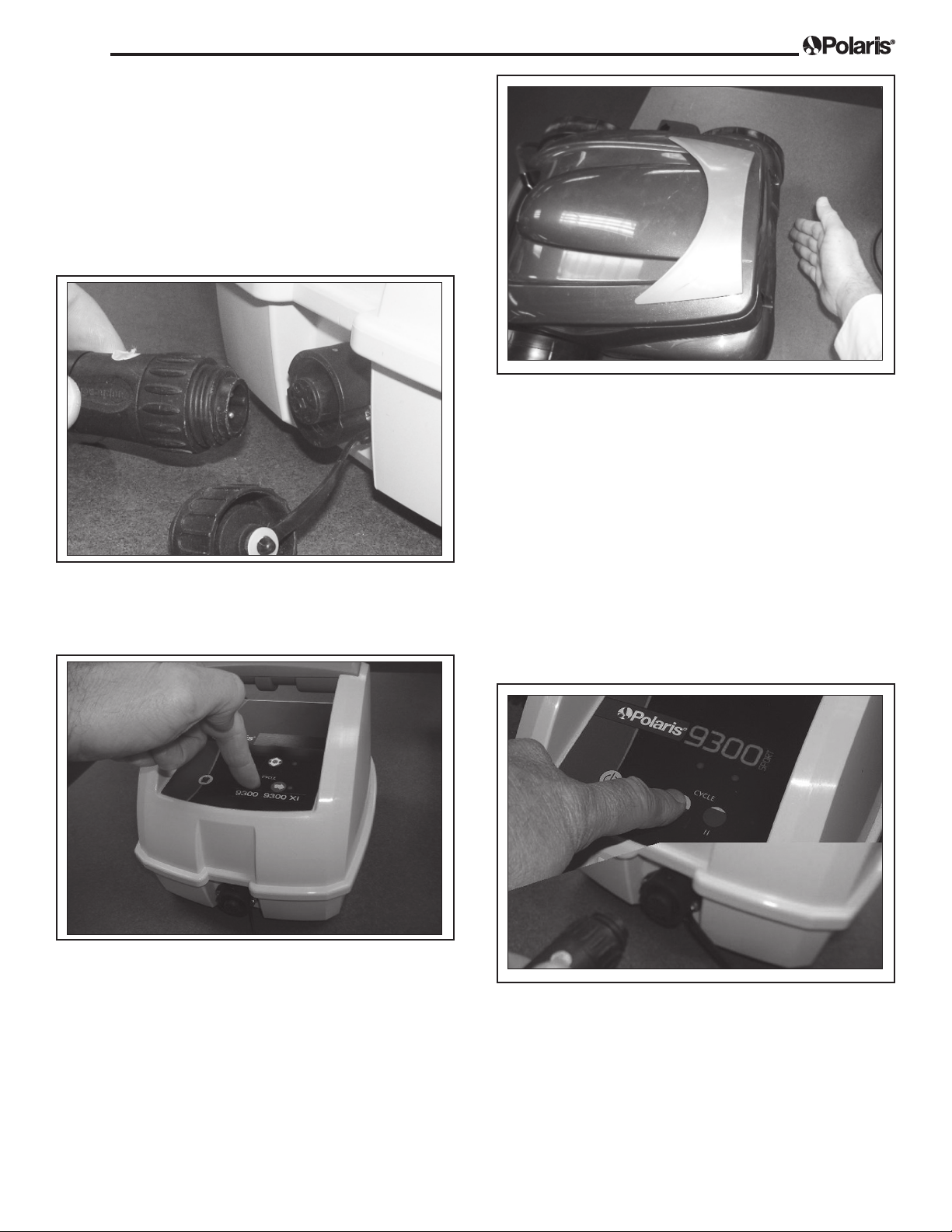

A. Testing Cleaner Head and Floating Cable

1. Set the cleaner head on a block of wood or some

object that allows the cleaner wheels to be elevated

from the surface.

2. Plug the Polaris Quick Diagnostic Test Box into a

GFCI protected outlet.

3. Connect the fl oating cable from the cleaner to the

test box (see Figure 2).

Figure 4. Checking for Air Flow

7. If the cycle completes without fl ashing lights, the

fl oating cable and cleaner head have successfully

passed the test.

Figure 2. Connect Floating Cable to Test Box

4. Determine the corresponding button for the model

being diagnosed (9300 or 9300xi). Press the button

to start the test (see Figure 3).

Figure 3. Select the Cleaner Model

8. If the diagnostic box fl ashes red lights at any

time during the test or the cleaner head does

not activate, proceed to Section C: Diagnosing a

Defective Motor Block or Floating Cable.

B. Testing the Control Unit

1. Reconnect the cleaner to the customer’s control

unit. Press the Cycle I button. (see Figure 5).

5. The pump motor should start fi rst. Check for air

fl owing from the exhaust on the back end of the

cleaner (see Figure 4).

6. Next, the drive motors should start within fi ve (5)

seconds after the pump motor starts. Take note

which direction the drive motors are rotating. The

drive motors drive the two (2) front wheels. Verify

that the two (2) front drive wheels move forward

then in reverse. After ten (10) seconds, all motors

should stop.

Figure 5. Testing the Control Unit

2. The drive cycle will turn on and will last for

approximately fi ve (5) seconds.

3. The cleaner will then drive forward for approximately

fi ve (5) seconds. If the cleaner does not drive

forward for approximately fi ve (5) seconds, then the

control unit is defective and must be replaced.

Page 3

Page 3

4. If the pump and drive motors drive, the control unit

has passed the test successfully. Turn off the power

to the control unit.

NOTE The control unit is programmed to shut down

power to the cleaner head within ten (10) seconds in order to protect the motor from damage.

C. Diagnosing a Defective Motor Block or

Floating Cable

1. Open the cleaner top and remove the fi lter canister.

Unthread the screw securing the prop guard in place

and remove the propeller guard (see Figure 6).

3. Close the cover and turn the cleaner over so that it’s

resting on its top.

4. Remove the four (4) screws from the bottom of the

cleaner. Remove the bottom plate/motor block

(see Figure 8).

Figure 8. Remove the Propeller Guard

Figure 6. Remove the Propeller Guard

2. Remove the propeller and the fl ow director

(see Figure 7).

5. Disconnect the fl oating power cable from the motor

block by removing the two screws connecting the

cable to the block, then pulling the plug away from

the block (see Figure 9).

Figure 9. Remove the Floating Cable

Figure 7. Remove the Propeller and Flow Director

Page 4

Page 4

6. Using the short test cable, connect the motor block to

the Polaris Quick Diagnostic Test Box (see Figure 10).

Figure 10. Motor Block Connected to Test Box

7. Once secured, start the diagnostic test (see Figure 11).

Figure 11. Testing the Motor Block

8. If the test completes without fl ashing red lights, then

the cable is defective. Replace the fl oating cable.

9. If the test ends with fl ashing red lights on the

diagnostic panel, then the motor block is defective.

Replace the motor block and return old motor to

Zodiac.

Zodiac Pool Systems, Inc.

2620 Commerce Way, Vista, CA 92081

1.800.822.7933 | www.ZodiacPoolSystems.com

All trademarks referenced herein are the property of their respective owners.

®

ZODIAC

is a registered trademark of Zodiac International, S.A.S.U., used under license.

©2011 Zodiac Pool Systems, Inc. H0359300 Rev - 1101

Loading...

Loading...