Page 1

2009 Polaris Sportsman 850 EFi/HD/EPS series

Some models may need supplemental manuals which have blue titles. Use

the base manual for everything not contained in the supplement if your

model or year requires a supplement.

If you bought this manual from any other seller, they are reselling my

work.

Please leave them negative feedback & email me at

Our goal is to be one of the BEST sellers on eBay and the internet by

providing you with the BEST customer service and the BEST manuals on the

market.

.

Thank you for choosing us.

Page 2

GENERAL INFORMATION

CHAPTER 1

GENERAL INFORMATION

VEHICLE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

ENGINE DESIGNATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

VEHICLE IDENTIFICATION NUMBER (VIN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

VEHICLE AND ENGINE SERIAL NUMBER LOCATIONS. . . . . . . . . . . . . . . . . . . . . . . .1.2

VEHICLE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

PUBLICATION NUMBERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

REPLACEMENT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

GENERAL: 2009 SPORTSMAN XP 850 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

GENERAL: 2009 SPORTSMAN XP 850 EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

DETAILED: 2009 SPORTSMAN XP 850 / XP 850 EPS. . . . . . . . . . . . . . . . . . . . . . . . . .1.5

MISC. SPECIFICATIONS AND CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

CONVERSION TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6

STANDARD TORQUE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.7

SAE TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 .8

METRIC TAP / DRILL SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8

DECIMAL EQUIVALENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8

GLOSSARY OF TERMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.9

1

1.1

Page 3

GENERAL INFORMATION

VEHICLE IDENTIFICATION

Model Identification

The machine model number must be used with any correspondence regarding warranty or service.

Machine Model Number Identification

Y ear Designation

Engine Designation Number

EH085OLE.............................................................Twin Cylinder, 4-Cycle SOHC, Liquid Cooled, Electric Start

V ehicle Identification Number (VIN)

World

Mfg. ID

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

4 X A Z N 8 5 A * 9 P 0 0 0 0 0 0

Vehicle Descriptor

A 0 9 Z N 8 5 A L

Basic Chassis

Designation

}

}

}

Engine Designation

}

}

Vehicle Identifier

Emissions &

Model Option

}

Body Style

V e hicle and Engine Serial Number Locations

Whenever corresponding about a Polaris ATV, be sure to refer to the vehicle identification number (VIN) and

the engine serial number.

The VIN can be found stamped on the lower frame rail on the front LH side of the ATV (see Figure 1-1).

The engine serial number can be found on top of the engine located on the valve cover (see Figure 1-2).

Figure 1-1

Engine

Powertrain

Emissions

Model

Year

Check Digit

Plant No

Figure 1-2

Individual Serial Number

* This could be either

a number or a letter

VIN

1.2

Engine Serial

Number

Page 4

GENERAL INFORMATION

VEHICLE INFORMATION

Publication Numbers

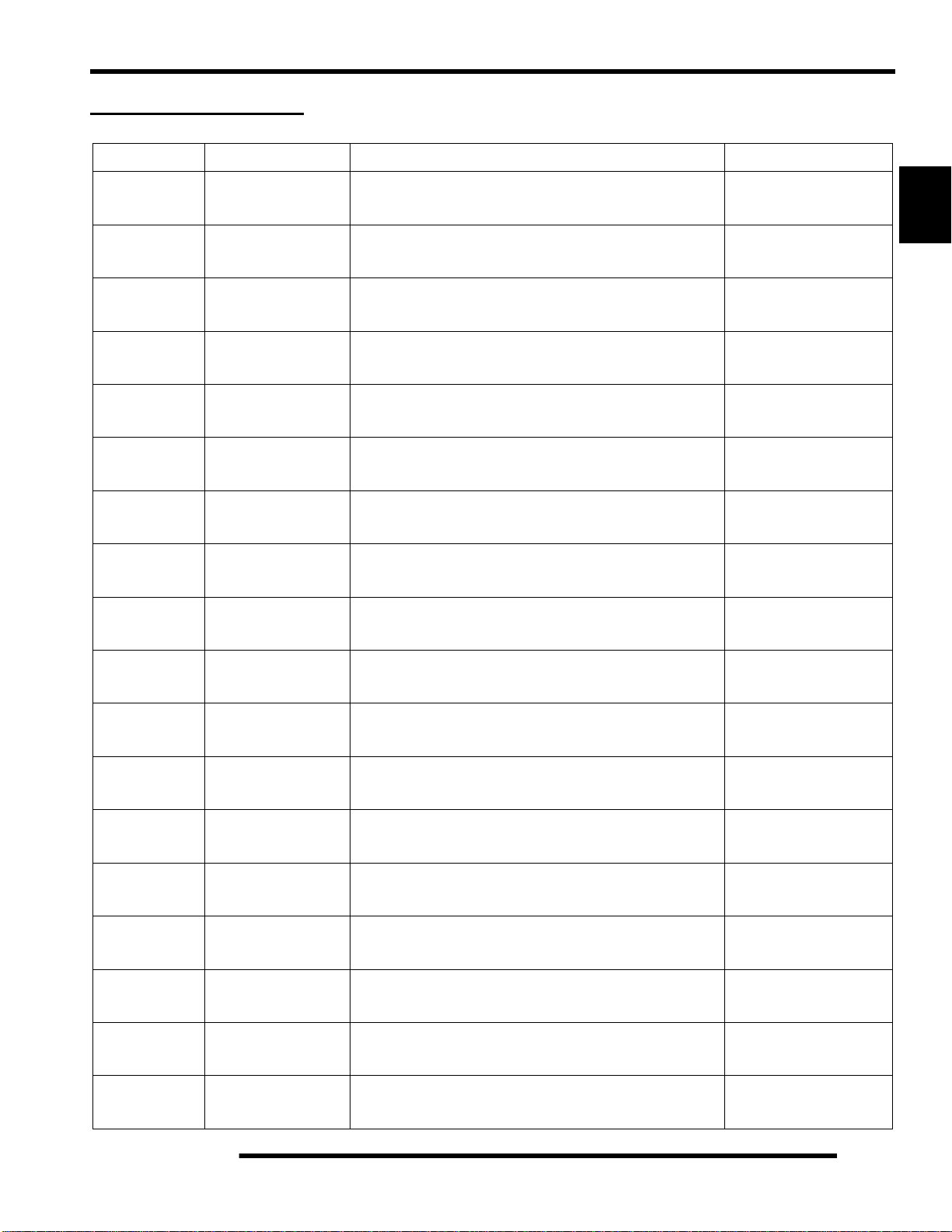

YEAR MODEL MODEL NO. OWNER’S MANUAL PN PARTS MANUAL PN

1

2009 SPORTSMAN XP 850

2009 SPORTSMAN XP 850 EPS

NOTE: Additional Polaris factory publications can be found at www.polarisindustries.com or purchased from

www.purepolaris.com.

A09ZN85AL, AQ,

AS, AT, AX, FL

A09ZX85AG, AL,

AQ, AR, AS, AX, FS

9921854 9921857

9921976 9921977

Replacement Keys

Replacement keys can be made from the original key. T o identify which series the key is, take the first two digits on the original key

and refer to the chart to the right for the proper part number. Should both keys become lost, replacement of the ignition switch

assembly is necessary.

KEY COVER

P/N 5533534

Key Series

Number

Series # Part Number

20 4010278

21 4010278

22 4010321

23 4010321

27 4010321

28 4010321

31 4110141

32 4110148

67 4010278

68 4010278

Special Tools

Special tools may be required while servicing this vehicle. Some of the tools listed or depicted are mandatory, while other tools

maybe substituted with a similar tool, if available. Polaris recommends the use of Polaris Special Tools when servicing any Polaris

product. Dealers may order special tools through Polaris’ official tool supplier, SPX Corporation, by phone at 1-800-328-6657 or

on-line at http://polaris.spx.com/

.

1.3

Page 5

GENERAL INFORMATION

SPECIFICATIONS

MODEL: 2009 SPORTSMAN XP 850

MODEL NUMBER:. . . . . . . . . A09ZN85AL, AQ, AS, AT, AX, FL

ENGINE MODEL:. . . . . . . . . . EH085OLE

Category Dimension

Length 83.25 in. / 211.5 cm

Width 47.6 in. / 121 cm

Height 50.75 in. / 129 cm

Wheel Base 53 in. / 135 cm

Ground Clearance 11.6 in. / 29.5 cm

Turning Radius 84 in. / 213 cm (unloaded)

Dry Weight 784 lbs. / 356 kg

Front Rack Capacity 120 lbs. / 54 kg

Rear Rack Capacity 240 lbs. / 109 kg

Max. Weight Capacity 575 lbs. / 261 kg

Towing Capacity 1500 lbs. / 680 kg

Hitch Tongue Weight 150 lbs. / 68 kg

MODEL: 2009 SPORTSMAN XP 850 EPS

MODEL NUMBER:. . . . . . . . . A09ZX85AG, AL, AQ, AR, AS, AX, FS

ENGINE MODEL:. . . . . . . . . . EH085OLE

Category Dimension

Length 83.25 in. / 211.5 cm

Width 47.6 in. / 121 cm

Height 50.75 in. / 129 cm

Wheel Base 53 in. / 135 cm

Ground Clearance 11.6 in. / 29.5 cm

Turning Radius 84 in. / 213 cm (unloaded)

Dry Weight 796 lbs. / 361 kg

Front Rack Capacity 120 lbs. / 54 kg

Rear Rack Capacity 240 lbs. / 109 kg

Max. Weight Capacity 575 lbs. / 261 kg

Towing Capacity 1500 lbs. / 680 kg

Hitch Tongue Weight 150 lbs. / 68 kg

1.4

Page 6

GENERAL INFORMATION

2009 SPORTSMAN XP 850 / XP 850 EPS

XP MODELS: A09ZN85AL,AQ,AS,AT,AX,FL

XP EPS MODELS: A09ZX85AG,AL,AQ,AR,AS,AX,FS

ENGINE MODEL: EH085OLE

Engine

Platform Domestic Twin Cylinder, 4-Cycle

Engine Model Number EH085OLE011

Engine Displacement 850 cc

Number of Cylinders 2

Bore & Stroke (mm) 87 x 71.5 mm

Compression Ratio 11.0:1

Compression Pressure 210 - 250 psi

Engine Idle Speed 1200

Cooling System / Cap. Liquid Cooled / 2 qt. (1.9 l)

Overheat Warning Instrument Cluster Indicator

Lubrication Pressurized Wet Sump

Engine Oil Requirement PS-4 Plus / 2 qt. (1.9 l)

Exhaust System

Fuel System Type

Throttle Body / Size Mikuni Dual Bore / 40 mm

Fuel Delivery

Fuel Pressure 43 psi

Fuel Capacity

Fuel Requirements 87 Octane (minimum)

Alternator Output 475 W @ 1200 RPM / Peak 575 W

Voltage Regulator 3-Phase / 32 Amp

Head Lights

Brake Light 12V / 27 Watts

Tail Light 12V / 7 Watts

Starting System Electric

Ignition System Bosch EFI (ECU Controlled)

Ignition Timing 6° ± 5° BTDC @ 1200 RPM

Spark plug / Gap REA8MCL / .035 in. (.90 mm)

Battery / Model / AH / CCA Deka / ETX30L / 30 AH / 365

Instrumentation Multifunction Instrument Cluster

DC Outlet Standard

Relays

(Located in Relay/Fuse Box)

Circuit Breaker Fan Motor: 20A

Fuses

(Located in Relay/Fuse Box)

Stainless Steel Dual Header Pipe

w/ Dual Outlet Silencer

Fuel System

Bosch Multi-Port Sequential

Electronic Fuel Injection

Electronic Fuel Pump

XP EPS: 4.5 gal. (17 l)

Electrical

Pod: 12V / 50 Watts

Bumper: 12V / 50 Watts x 2

Chassis / Start Solenoid / Fan /

EFI / Bumper Lights

Lights: 20A / Drive: 20A /

Accessory: 20A / EFI: 20A /

Unswitched: 10A / EPS: 30A

± 50 RPM

(in tank)

XP: 5.25 gal. (20 l)

Drivetrain

Transmission Type

Transmission

Fluid Type / Fluid Capacity

Front Gearcase

Fluid Type / Fluid Capacity

Front Gearcase

ADC Reservoir Fluid Type

Rear Gearcase

Fluid Type / Fluid Capacity

Clutch Type PVT w/EBS

Belt 3211123

Steering / Suspension

Toe Out 0-1/16 in. (0-.159 mm)

Front Suspension Dual A-arm

Front Travel 9.2 in. / 23.4 cm

Rear Suspension Dual A-arm w/Rolled IRS

Rear Travel 10.2 in. / 25.9 cm

Shock Preload Adjustment

Front / Rear

Wheels / Brakes

Front Wheel Size / Bolt Pattern

Tire Model / Size

Rear Wheel Size / Bolt Pattern

Tire Model / Size

Tire Air Pressure

Brakes - Front & Rear

Brake Fluid Polaris DOT 4 Brake Fluid

Automatic PVT

In-Line H-L-N-R-P

Synthetic Sportsman XP

Transmission Fluid /

32 oz. (946 ml)

Premium LT Demand Drive

Fluid / 9.3 oz. (275 ml)

Premium ADC

Front Drive Fluid

ATV Angle Drive Fluid /

7.1 oz. (210 ml)

Cam Adjustable

14 x 6 / 4-156

Carlisle T errathon / 26 x 8 - 14

14 x 8 / 4-156

Carlisle T errathon / 26 x 10 - 14

Front: 7 psi (48 kPa)

Rear: 5 psi (34.5 kPa)

Single Control

Hydraulic 4-Wheel Disc

CLUTCH CHART

Meters

(Feet)

Altitude

0-1800

(0-6000)

1800-3700

(6000 - 12000)

Shift

Weight

24-63

5632215

24-60

5632216

Drive

Spring

Red / Wht

7043349

Red / Wht

7043349

Driven

Spring

Red / Wht

3235621

Red / Wht

3235621

1

1.5

Page 7

GENERAL INFORMATION

MISC. SPECIFICATIONS AND CHARTS

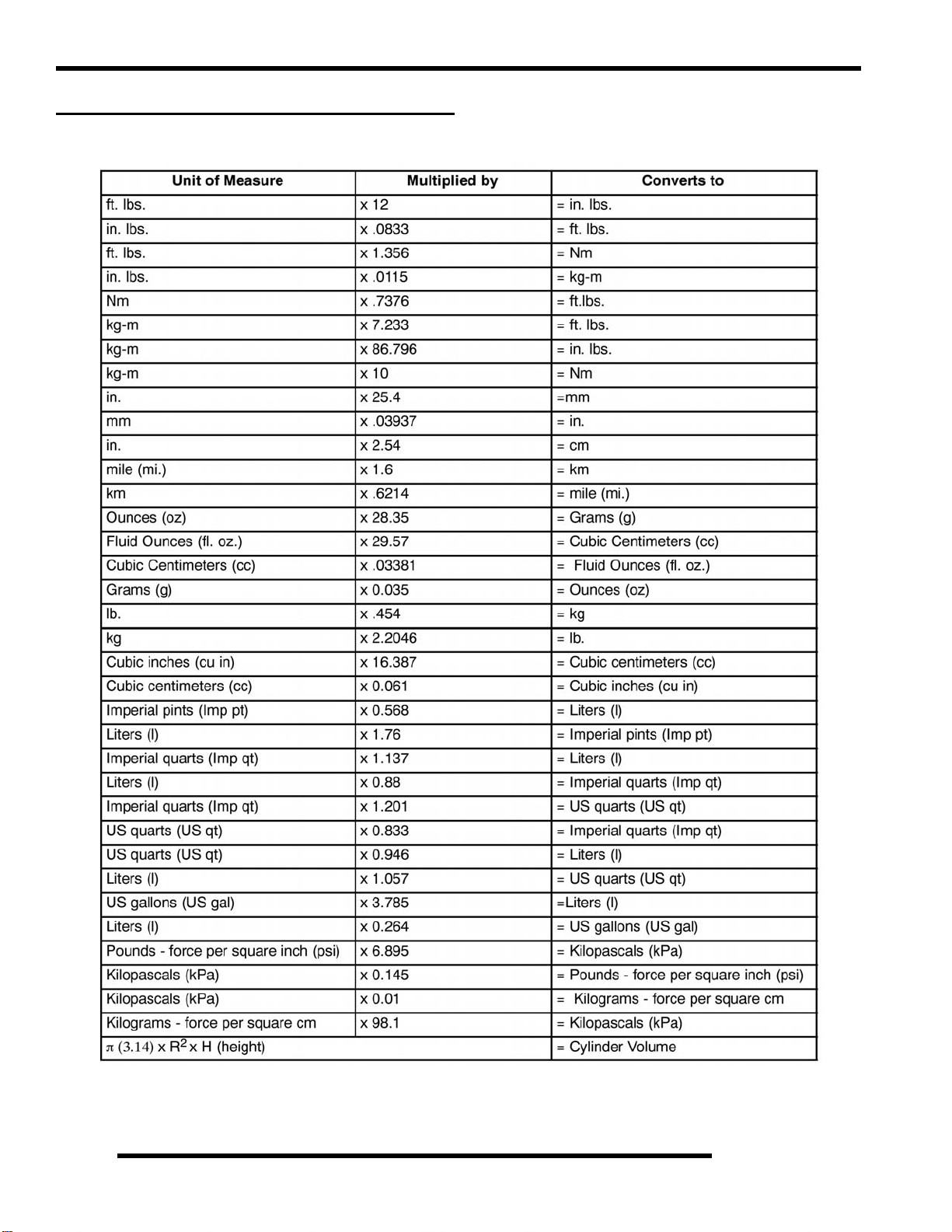

Conversion Table

°C to °F:

9/5

(°C + 32) = °F °F to °C:

1.6

5/9

(°F - 32) = °C

Page 8

GENERAL INFORMATION

Standard Torque Specifications

The following torque specifications are to be used only as a general guideline. There are exceptions in the

steering, suspension, and engine areas. Always consult the exploded views or each manual section for torque

values of fasteners before using standard torque.

1

1.7

Page 9

GENERAL INFORMATION

SAE Tap / Drill Sizes

Decimal Equivalents

Metric Tap / Drill Sizes

1.8

Page 10

GENERAL INFORMATION

Glossary of Terms

ABDC: After bottom dead center.

ACV: Alternating current voltage.

Alternator: Electrical generator producing voltage alternating current.

ATDC: After top dead center.

BBDC: Before bottom dead center.

BDC: Bottom dead center.

BTDC: Before top dead center.

CC: Cubic centimeters.

Center Distance: Distance between center of crankshaft and center of driven clutch shaft.

Chain Pitch: Distance between chain link pins (No. 35 = 3/8" or 1 cm). Polaris measures chain length in number of pitches.

CI: Cubic inches.

Clutch Buttons: Plastic bushings which aid rotation of the movable sheave in the drive and driven clutch.

Clutch Offset: Drive and driven clutches are offset so that drive belt will stay nearly straight as it moves along the clutch face.

Clutch Weights: Three levers in the drive clutch which relative to their weight, profile and engine RPM cause the drive clutch to

close and grip the drive belt.

Crankshaft Run-Out: Run-out or "bend" of crankshaft measured with a dial indicator while crankshaft is supported between centers

on V blocks or resting in crankcase. Measure at various points especially at PTO.

DCV: Direct current voltage

CVT: Centrifugal Variable Transmission (Drive Clutch System)

DCV: Direct current voltage.

Dial Bore Gauge: A cylinder measuring instrument which uses a dial indicator. Good for showing taper and out-of-round in the

cylinder bore.

Electrical Open: Open circuit. An electrical circuit which isn't complete.

Electrical Short: Short circuit. An electrical circuit which is completed before the current reaches the intended load. (i.e. a bare wire

touching the chassis).

End Seals: Rubber seals at each end of the crankshaft.

Engagement RPM: Engine RPM at which the drive clutch engages to make contact with the drive belt.

ft.: Foot/feet.

Foot Pound: Ft. lb. A force of one pound at the end of a lever one foot in length, applied in a rotational direction.

g: Gram. Unit of weight in the metric system.

gal.: Gallon.

ID: Inside diameter.

in.: Inch/inches.

Inch Pound: In. lb. 12 in. lbs. = 1 ft. lb.

kg/cm²: Kilograms per square centimeter.

kg-m: Kilogram meters.

Kilogram/meter: A force of one kilogram at the end of a lever one meter in length, applied in a rotational direction.

l or ltr: Liter.

lbs/in²: Pounds per square inch.

Left or Right Side: Always referred to based on normal operating position of the driver.

m: Meter/meters.

Mag: Magneto.

Magnetic Induction: As a conductor (coil) is moved through a magnetic field, a voltage will be generated in the windings.

Mechanical energy is converted to electrical energy in the stator.

mi.: Mi

mm: Millimeter. Unit of length in the metric system. 1 mm = approximately .040".

Nm: Newton meters.

OD: Outside diameter.

Ohm: The unit of electrical resistance opposing current flow.

oz.: Ounce/ounces.

Piston Clearance: Total distance between piston and cylinder wall.

psi.: Pounds per square inch.

PTO: Power take off.

PVT: Polaris Variable Transmission (Drive Clutch system)

qt.: Quart/quarts.

Regulator: Voltage regulator. Regulates battery charging system output at approx. 14.5 DCV as engine RPM increases.

Reservoir Tank: The fill tank in the liquid cooling system.

Resistance: In the mechanical sense, friction or load. In the electrical sense, ohms, resulting in energy conversion to heat.

RPM: Revolutions per minute.

Seized Piston: Galling of the sides of a piston. Usually there is a transfer of aluminum from the piston onto the cylinder wall.

Possible causes: 1) improper lubrication; 2) excessive temperatures; 3) insufficient piston clearance; 4) stuck piston rings.

Stator Plate: The plate mounted under the flywheel supporting the battery charging coils.

TDC: Top dead center. Piston's most outward travel from crankshaft.

Volt: The unit of measure for electrical pressure of electromotive force. Measured by a voltmeter in parallel with the circuit.

Watt: Unit of electrical power. Watts = amperes x volts.

WOT: Wide open throttle.

le/miles.

1

1.9

Page 11

GENERAL INFORMATION

NOTES

1.10

Page 12

MAINTENANCE

CHAPTER 2

MAINTENANCE

PERIODIC MAINTENANCE CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

BREAK-IN PERIOD / MAINTENANCE CHART KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.2

MAINTENANCE INTERVALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.3

GREASE LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

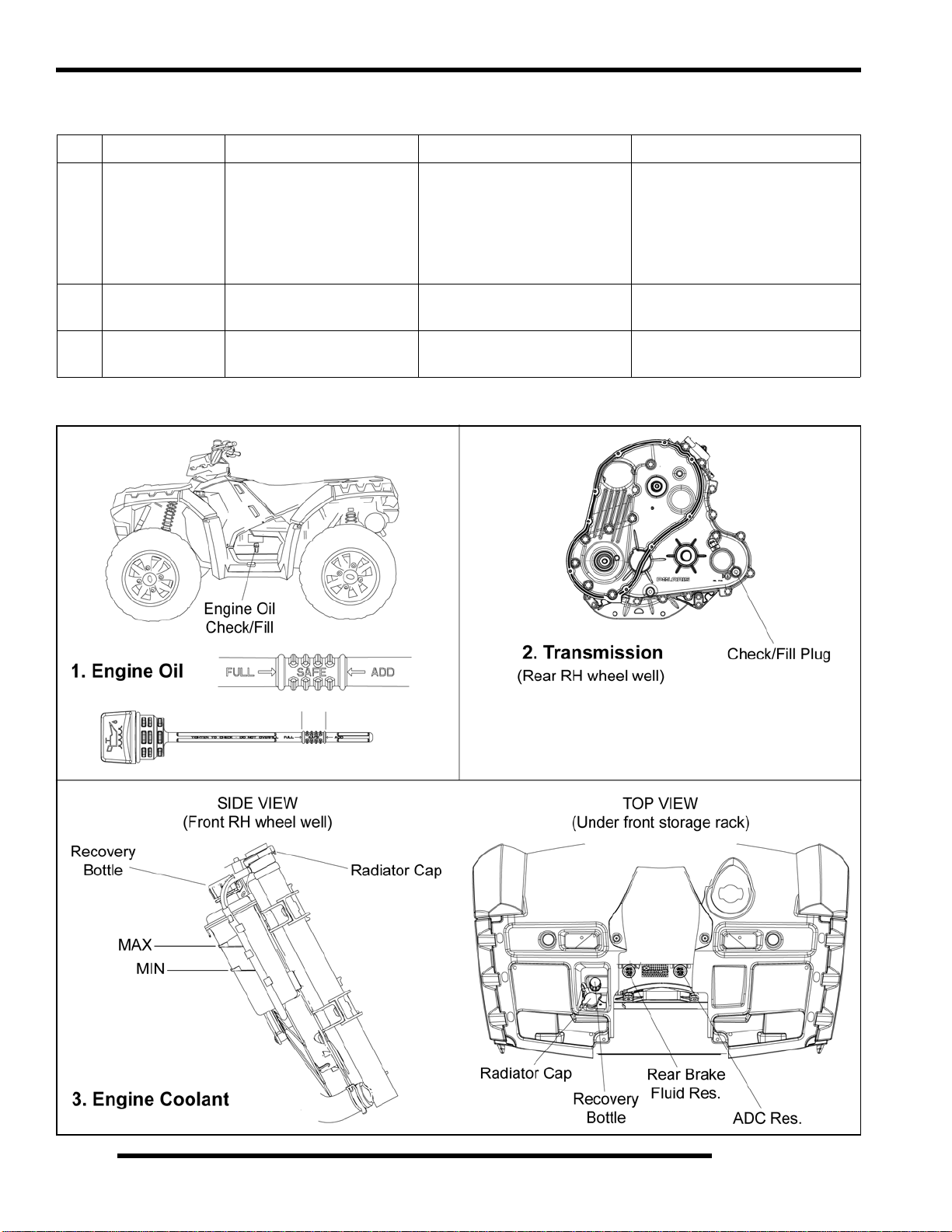

MAINTENANCE QUICK REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.6

MAINTENANCE QUICK REFERENCE, CONTINUED..... . . . . . . . . . . . . . . . . . . . . . . . .2.7

LUBRICANTS / SERVICE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8

GENERAL VEHICLE INSPECTION AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . 2.9

FUEL SYSTEM AND AIR INTAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9

FUEL LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.9

FUEL FILTERS / VENT LINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.10

THROTTLE OPERATION / ETC SWITCH / THROTTLE CABLE ADJUSTMENT . . . . . 2.10

AIR FILTER / PRE-FILTER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

ENGINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

ENGINE OIL LEVEL / OIL AND FILTER CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

ENGINE BREATHER HOSE / BREATHER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . .2.13

VALVE CLEARANCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.14

COMPRESSION AND LEAKDOWN TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.15

EXHAUST SILENCER CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.16

ENGINE MOUNT FASTENER TORQUE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.16

TRANSMISSION AND GEARCASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.17

TRANSMISSION LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.17

FRONT GEARCASE LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.18

FRONT GEARCASE ADC FLUID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.19

REAR GEARCASE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.20

COOLING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21

COOLANT LEVEL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.21

COOLING SYSTEM HOSES / COOLANT STRENGTH / COOLANT TYPE . . . . . . . . .2.22

PVT / FINAL DRIVE / WHEEL AND TIRE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

PVT DRYING / DRIVE BELT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.23

DRIVE SHAFT BOOT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.23

WHEEL AND HUB TORQUE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.24

WHEEL REMOVAL / INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.24

TIRE PRESSURE / TIRE INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.25

ELECTRICAL AND IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

BATTERY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.25

BATTERY REMOVAL / INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.26

SPARK PLUG SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.26

ENGINE / CHASSIS GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.27

STEERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

STEERING INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.28

POWER STEERING UNIT (EPS MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.28

TIE ROD END / STEERING INSPECTION / TOE ALIGNMENT . . . . . . . . . . . . . . . . . .2.29

TOE ALIGNMENT ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.30

SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

SUSPENSION INSPECTION / SUSPENSION SPRING PRE-LOAD ADJUSTMENT . . 2.30

BRAKE SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

BRAKE FLUID / BRAKE PAD / HOSE / FITTING INSPECTION . . . . . . . . . . . . . . . . . .2.31

AUXILIARY BRAKE PEDAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.32

MAINTENANCE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33

2

2.1

Page 13

MAINTENANCE

PERIODIC MAINTENANCE CHART

Periodic Maintenance Overview

Inspection, adjustment and lubrication of important components are explained in the periodic maintenance chart.

Inspect, clean, lubricate, adjust and replace parts as necessary. When inspection reveals the need for replacement parts, use

genuine Pure Polaris parts available from your Polaris dealer.

NOTE: Service and adjustments are critical. If you’re not familiar with safe service and adjustment

procedures, have a qualified dealer perform these operations.

Maintenance intervals in the following chart are based upon average riding conditions and an average vehicle speed of approximately

10 miles per hour. Vehicles subjected to severe use must be inspected and serviced more frequently.

Severe Use Definition

• Frequent immersion in mud, water or sand

• Racing or race-style high RPM use

• Prolonged low speed, heavy load operation

• Extended idle

• Short trip cold weather operation

Pay special attention to the oil level. A rise in oil level during cold weather can indicate contaminants collecting in the oil sump or

crankcase. Change oil immediately if the oil level begins to rise. Monitor the oil level, and if it continues to rise, discontinue use

and determine the cause or see your dealer.

Break-In Period

The break-in period consists of the first 20 hours of operation. Careful treatment of a new engine and drive components will result

in more efficient performance and longer life for these components.

• Drive vehicle slowly at first while varying the throttle position. Do not operate at sustained idle.

• Pull only light loads.

• Perform regular checks on fluid levels and other areas outlined on the daily pre-ride inspection checklist.

• Change both the engine oil and filter after 20 hours or one month.

• See “Owner’s Manual” for additional break-in information.

Maintenance Chart Key

The following symbols denote potential items to be aware of during maintenance:

= CAUTION: Due to the nature of these adjustments, it is recommended this service be performed by an

authorized Polaris dealer.

= SEVERE USE ITEM: See information provided above.

E = Emission Control System Service (California).

NOTE: Inspection may reveal the need for replacement parts. Always use genuine Polaris parts.

WARNING

Improperly performing the procedures marked could result in component failure and lead to serious injury or death.

Have an authorized Polaris dealer perform these services.

2.2

Page 14

Maintenance Intervals

Maintenance Interval

Item

Hours Calendar

Steering - Pre-Ride -

Front Suspension - Pre-Ride -

Rear Suspension - Pre-Ride -

Tires - Pre-Ride Brake Fluid Level - Pre-Ride -

Brake Lever Travel - Pre-Ride -

Brake System - Pre-Ride Wheels / Fasteners - Pre-Ride Frame Fasteners - Pre-Ride Engine Oil Level - Pre-Ride -

Air Filter, Pre-filter - Daily - Inspect;clean often

E

Coolant - Daily -

(whichever comes first)

Miles

(KM)

Inspect and make adjustments as needed.

See Pre-Ride Checklist later in this chapter.

Check level daily, change coolant every two

years

MAINTENANCE

Remarks

2

ADC Fluid - Daily - Check level daily, add as needed

Power Steering Unit

(if equipped)

Head Lights / Tail Lights - Daily -

Air Filter (main element) - Weekly - Inspect; replace as needed

E

Brake Pad Wear 10 H Monthly 100 (160) Inspect periodically

Battery 20 H Monthly 200 (320) Check terminals; clean; test

Engine Oil Change

(Break-in Period)

E

Front Gearcase Fluid 25 H Monthly 250 (400) Inspect level

Rear Gearcase Fluid 25 H Monthly 250 (400) Inspect level

Transmission Fluid 25 H Monthly 250 (400) Inspect level

- Daily - Inspect daily, clean often

Check operation; apply dielectric grease if

replacing

20 H 1 M -

Perform a break-in oil change at one mont h or

20 hours, whichever comes first

Perform these procedures more often for vehicles subjected to severe use.

E Emission Control System Service (California)

Have an authorized Polaris dealer perform these services.

2.3

Page 15

MAINTENANCE

Maintenance Interval

Item

Hours Calendar

General Lubrication 50 H 3 M 500 (800) Lubricate all fittings, pivots, cables, etc.

Throttle Cable /

E

ETC Switch

Throttle Body Intake

E

Duct

Drive belt 50 H 6 M 500 (800) Inspect; replace as needed

Cooling System 50 H 6 M 500 (800)

Radiator 50 H 6 M 500 (800) Inspect; clean external surfaces

Cooling Hoses 50 H 6 M 500 (800) Inspect for leaks

Engine Oil Change 100 H 6 M 1000 (1600)

Oil Filter Change 100 H 6 M 1000 (1600) Replace with oil change

50 H 6 M 500 (800)

50 H 6 M 500 (800) Inspect ducts for proper sealing / air leaks

(whichever comes first)

Miles

Remarks

(KM)

Inspect; adjust; lubricate; replace if

necessary

Inspect coolant strength seasonally;

pressure test system yearly

Perform a break-in oil change at 20 hours or

after one month of operation; change more

frequently during cold weather operation

Front Gearcase Fluid - 12 M 1000 (1600) Change Fluid

Rear Gearcase Fluid - 12 M 1000 (1600) Change Fluid

Transmission Fluid - 12 M 1000 (1600) Change Fluid

Fuel System 100 H 12 M 1000 (1600)

E

Engine Mounts 100 H 12 M 1000 (1600) I nspect

Exhaust Pipe / Silencer 100 H 12 M 1000 (1600) Inspect

Sp ark Plug 100 H 12 M 1000 (1600) Inspect; replace as needed

E

Wiring 100 H 12 M 1000 (1600)

Clutches

(Drive and Driven)

Front Wheel Bearings 100 H 12 M 1000 (1600) Inspect; replace as needed

Brake Fluid 200 H 24 M 2000 (3200) Change every two ye ars

ADC Fluid 200 H 24 M 2000 (3200) Change every two years

Spark Arrestor

(if applicable)

Valve Clearance 1000 H - 10000 (16000) Inspect; adjust

E

Toe Adjustment - Inspect periodically; adjust as needed

Headlight Aim - Adjust as needed

100 H 12 M 1000 (1600) Inspect; clean; replace worn parts

300 H 36 M 3000 (4800) Clean out; or remove clean out plug

Check for leaks at tank cap, fuel lines, fuel

pump; replace lines every two years

Inspect for wear, routing, security; apply

dielectric grease to connectors subjected to

water, mud, etc.

Perform these procedures more often for vehicles subjected to severe use.

E Emission Control System Service (California)

Have an authorized Polaris dealer perform these services.

2.4

Page 16

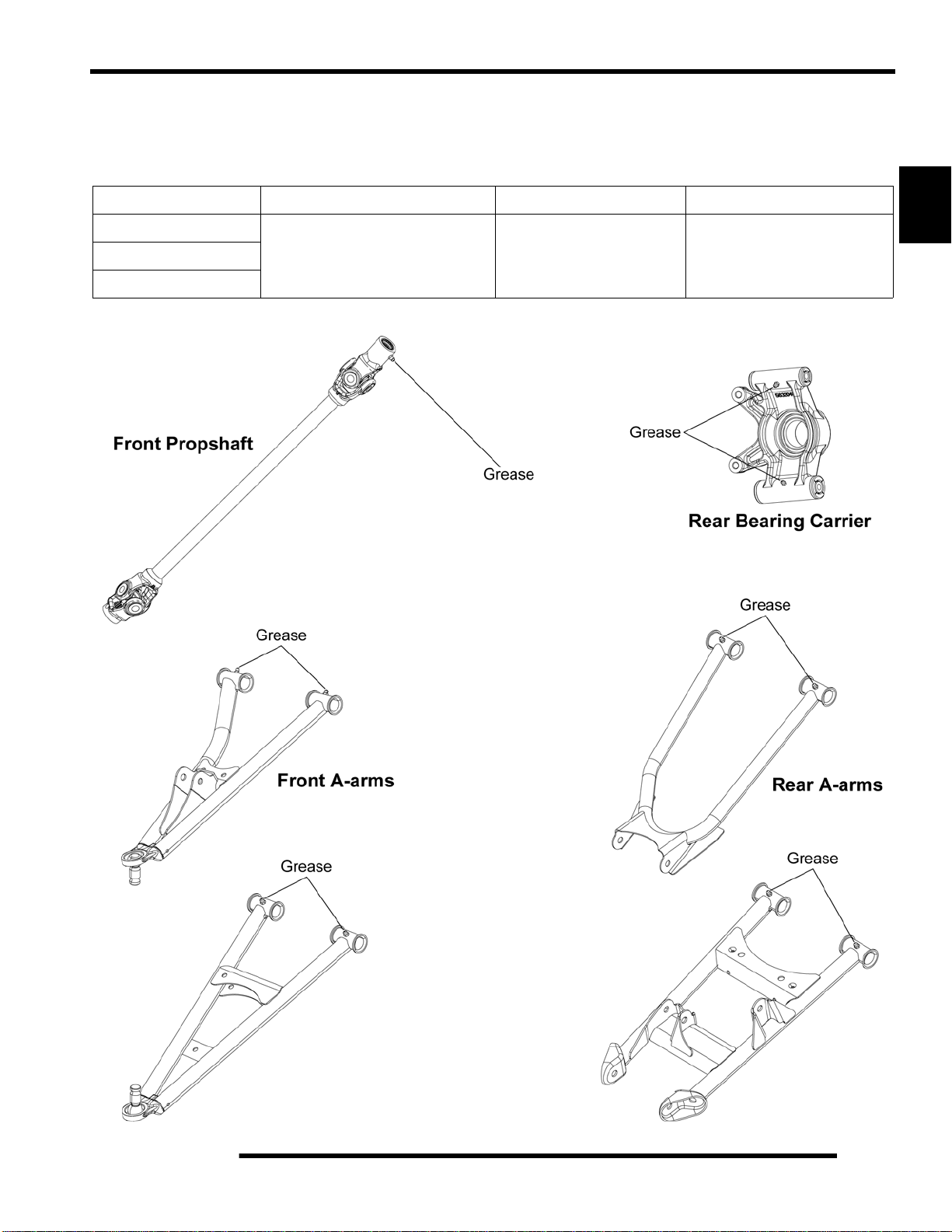

MAINTENANCE

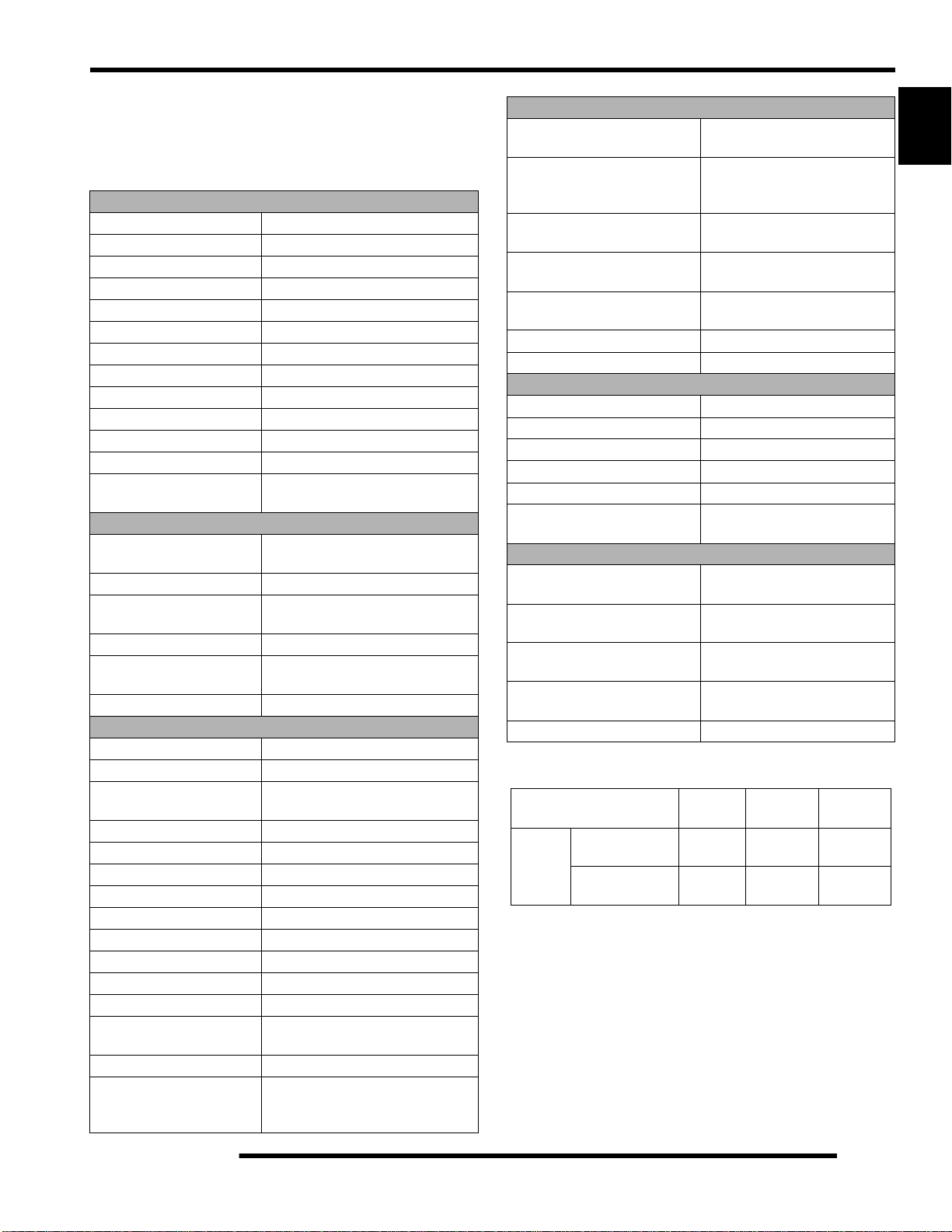

Grease Lubrication Points

There are grease fittings on each upper and lower front and rear A-arms, each rear bearing carrier, and on the front propshaft yoke.

Apply a maximum of 3 pumps of grease at each of these areas.

Item Recommended Lube Method Frequency

Front Propshaft Yoke

Front & Rear A-Arms

Rear Bearing Carrier

Polaris Premium U-Joint Grease

Grease fittings

(3 pumps maximum)

every 500 miles (800 km).

Grease before long periods

2

of storage, and after

pressure washing or

submerging the ATV.

2.5

Page 17

MAINTENANCE

Maintenance Quick Reference

III. # Item Lube Rec. Method Frequency*

Change after 1st month or first

20 hours of operation, 100

Engine Oil Polaris PS-4 PLUS 2W-50

1

Performance Synthetic

Add oil to proper level on

dipstick

hours thereafter; Change more

often (25 hours) in severe duty

conditions or short trip cold

weather operation

2 Transmission

3 Engine Coolant Polaris 60/40 Coolant

* More often under severe use, such as operated in water or under severe loads.

Synthetic Sportsman XP

Transmission Fluid

Add fluid until it is visible at

the fill hole threads

Maintain coolant level in

coolant reservoir bottle.

Check level every 25 hours;

change fluid yearly

Check level daily, change

coolant every 2 years

2.6

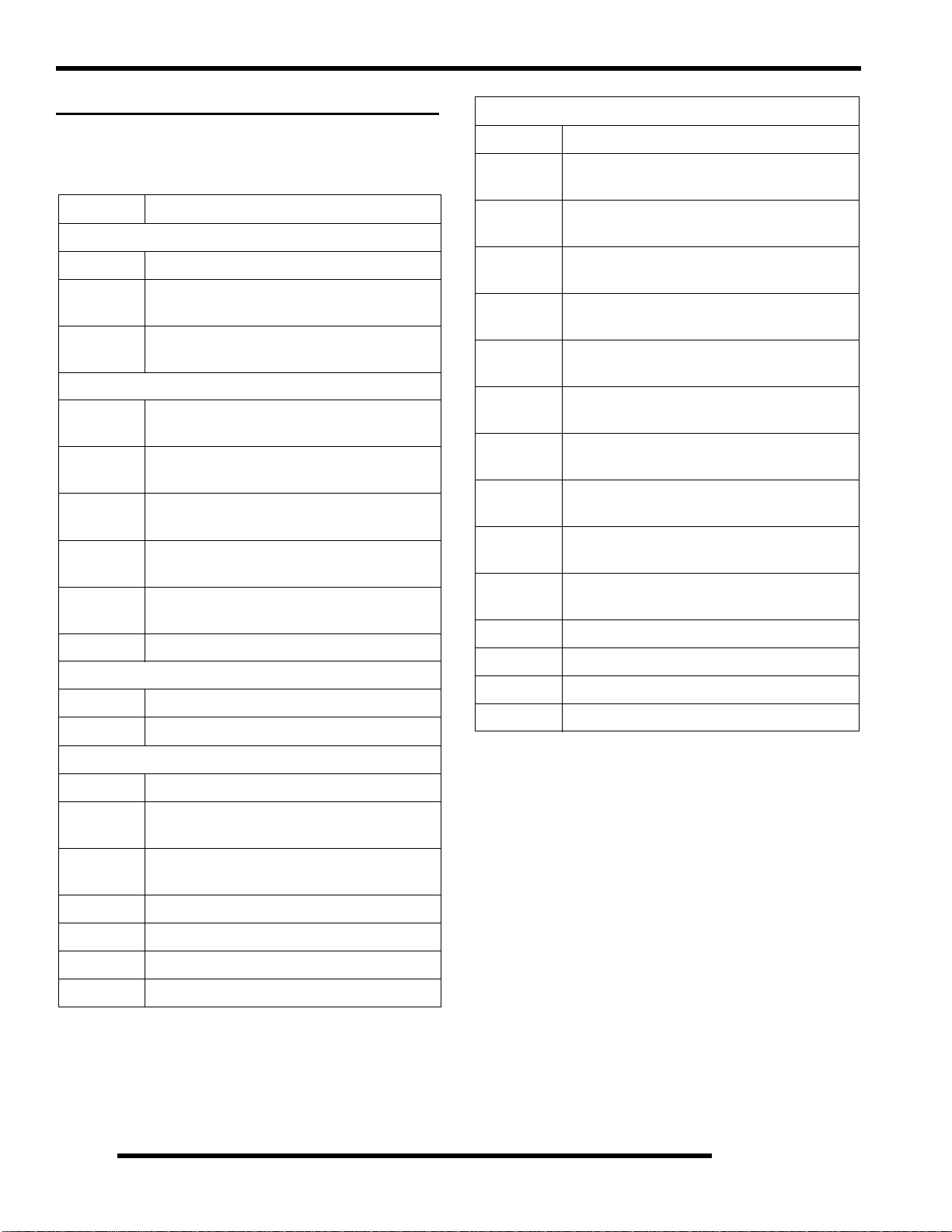

Page 18

MAINTENANCE

Maintenance Quick Reference, Continued.....

III. # Item Lube Rec. Method Frequency*

Front Gearcase

4

ADC Reservoir

5 Front Gearcase

6 Rear Gearcase

7 Brake Fluid Polaris DOT 4 Brake Fluid

* More often under severe use, such as operated in water or under severe loads.

Polaris Premium ADC

Front Drive Fluid

Polaris Premium LT

Demand Drive Fluid

Polaris ATV Angle Drive

Fluid (ADF)

Maintain fluid level in ADC

Reservoir to indicated level

Add fluid until it is visible at

the fill hole threads

Add fluid until it is visible at

the fill hole threads

Maintain fluid level in both

master cylinder reservoirs to

indicated levels

Check level every 25 hours;

change fluid every two years

Check level every 25 hours;

change fluid yearly or 1000 mi.

Check level every 25 hours;

change fluid yearly

Check level during pre-ride

inspection; change fluid every

two years

2

2.7

Page 19

MAINTENANCE

LUBRICANTS / SERVICE PRODUCTS

Polaris Lubricants,Maintenance and Service

Products

Part No. Description

Engine / Transmission Lubricant

2870791 Fogging Oil (12 oz. Aerosol)

2876244

2876245

2877606

2876251

2872277

2876160

2872276

2870465 Pump for Gallon Jug

2871534 60/40 Coolant (Quart) (12 count)

2871323 60/40 Coolant (Gallon) (6 count)

2871312 Grease Gun Kit

2871322

PS-4 PLUS 2W-50 Performance Synthetic

4-Cycle Engine Oil (Quart)

PS-4 PLUS 2W-50 Performance Synthetic

4-Cycle Engine Oil (Gallon)

Gearcase Lubricants

Synthetic Sportsman XP

Transmission Fluid (Quart)

Premium LT Demand Drive Fluid

(Quart) (12 count)

Premium Demand Drive Hub Fluid

(2.5 Gallon) (2 count)

ATV Angle Drive Fluid

(Quart) (12 count)

ATV Angle Drive Fluid

(2.5 Gallon) (2 Count)

Coolant

Grease / Specialized Lubricants

Premium All Season Grease

(3 oz. cartridge) (24 Count)

Additives / Sealants / Thread Locking Agent s / Misc.

2870585 Loctite™ Primer N, Aerosol, 25 g

2871956

2871949

2871950

2871951

2871952

2871953

2871954

2870584

2870587

2871326

2870652 Fuel Stabilizer (16 oz.) (12 Count)

2872189 DOT 4 Brake Fluid (12 Count)

2871557 Crankcase Sealant, 3-Bond 1215 (5oz.)

2872893 Engine Degreaser (12oz.) (12 Count)

NOTE: The number count indicated by each part

number in the table above indicates the number of

units that are shipped with each order.

Loctite™ Thread Sealant 565

(50 ml.) (6 Count)

Loctite™ Threadlock 242

(50 ml.) (10 Count)

Loctite™ Threadlock 242

(6 ml.) (12 Count)

Loctite™ Threadlock 262

(50 ml.) (10 Count)

Loctite™ Threadlock 262

(6 ml.) (12 Count)

Loctite™ Threadlock 271

(6 ml.) (12 Count)

Loctite™ Threadlock 271

(36 ml.) (6 Count)

Loctite™ 680-Retaining Compound

(10 ml.)

Loctite™ 518 Gasket Eliminator / Flange

Sealant (50 ml.) (10 Count)

Premium Carbon Clean

(12 oz.) (12 Count)

2871423

2871460 Starter Drive Grease (12 Count)

2871515 Premium U-Joint Lube (3 oz.) (24 Count)

2871551 Premium U-Joint Lube (14 oz.) (10 Count)

2871329 Dielectric Grease (Nyogel™)

NOTE: Each item can be purchased separately at

your local Polaris dealer.

Premium All Season Grease

(14 oz. cartridge) (10 Count)

2.8

Page 20

MAINTENANCE

GENERAL VEHICLE INSPECTION

AND MAINTENANCE

Pre-ride / Daily Inspection

Perform the following pre-ride inspection daily, and when

servicing the vehicle at each scheduled maintenance.

• Tires - check condition and tire pressure

• Fuel and oil - fill both to their proper level; do not

overfill

• All brakes - check operation (includes auxiliary brake)

• Throttle - check for free operation

• Headlight / Taillight / Brakelight - check operation of

all indicator lights and switches

• Engine stop switch (key switch) - check for proper

function

• Wheels - check for loose wheel nuts

• Air cleaner element - check for dirt or water; clean or

replace

• Steering - check for free operation, noting any unusual

looseness in any area

• Loose parts - visually inspect vehicle for any damaged

or loose nuts, bolts or other fasteners

• Engine coolant - check for proper level at the recovery

bottle

FUEL SYSTEM AND AIR INTAKE

Fuel System

WARNING

2

Gasoline is extremely flammable and explosive

under certain conditions.

• Always stop the engine and refuel outdoors or in a well

ventilated area.

• Do not smoke or allow open flames or sparks in or near

the area where refueling is performed or where gasoline

is stored.

• Do not overfill the tank. Do not fill the tank neck.

• If you get gasoline in your eyes or if you swallow

gasoline, seek medical attention immediately .

• If you spill gasoline on your skin or clothing,

immediately wash it off with soap and water and

change clothing.

• Never start the engine or let it run in an enclosed area.

Engine exhaust fumes are poisonous and can result loss

of consciousness or death in a short time.

• Never drain the fuel when the engine is hot. Severe

burns may result.

Frame, Nuts, Bolts, Fasteners

Periodically inspect the torque of all fasteners in accordance

with the maintenance schedule. Check that all cotter pins are in

place. Refer to specific fastener torques listed in each chapter.

Controls

Check handlebar controls for proper operation, positioning and

adjustment.

Fuel Lines

1. Check fuel lines for signs of wear, deterioration, damage,

or leakage. Replace if necessary.

2. Be sure fuel lines are routed properly and secured with

cable ties where applicable.

CAUTION

Make sure lines are not kinked or pinched

3. Replace all fuel lines every two years.

2.9

Page 21

MAINTENANCE

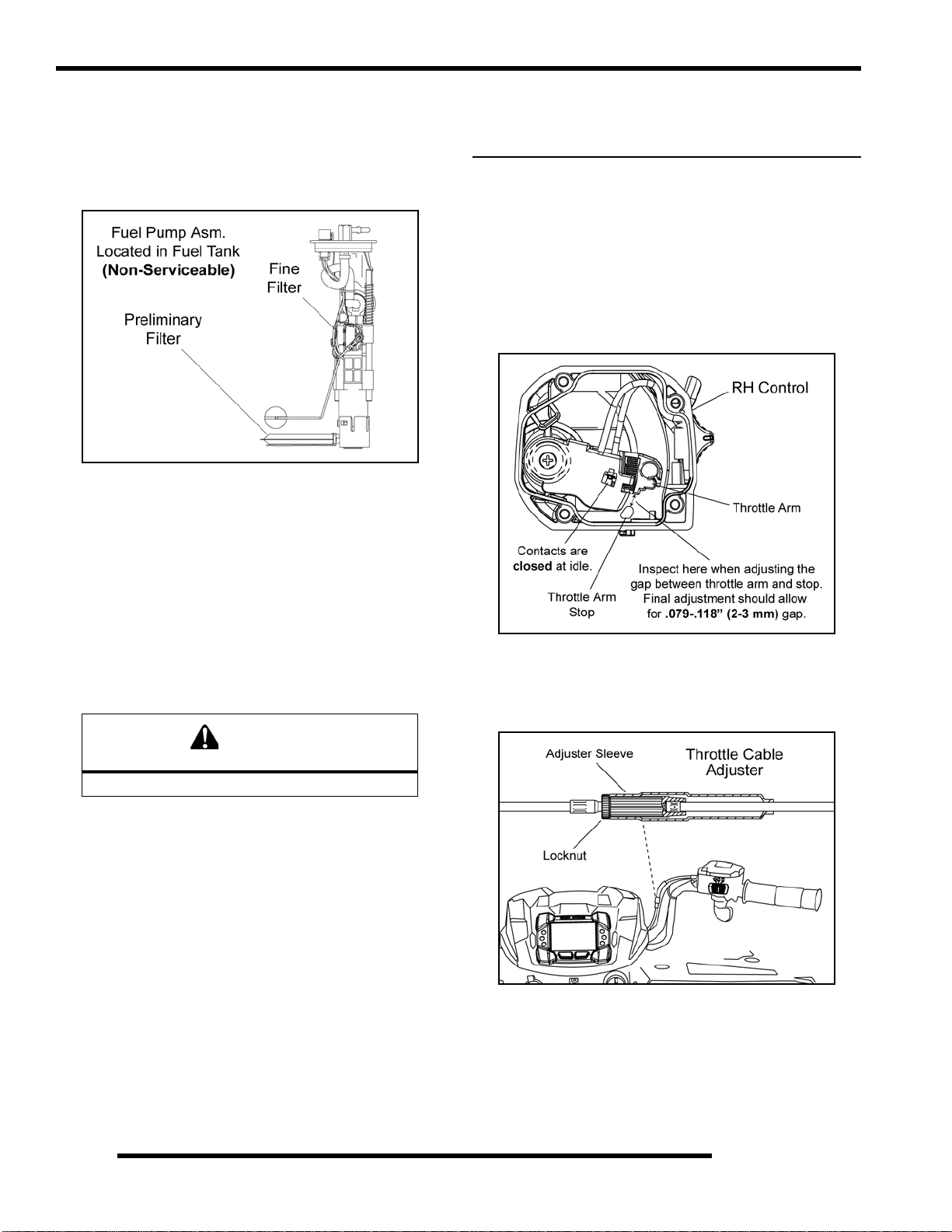

Fuel Filters

There are two fuel filters located within the fuel pump assembly.

The fuel pump is non-serviceable. If the internal fuel pump

filters require service, the fuel pump and fuel tank must be

replaced as an assembly.

NOTE: See the “Electronic Parts Catalog” for more

information. For all other information related to the EFI

System, refer to Chapter 3.

Electronic Throttle Control Switch (ETC) /

Throttle Cable Adjustment

NOTE: Sportsman XP requires a new adjustment procedure.

1. Slide the boot back far enough to expose the inline cab le

adjuster sleeve and loosen the adjuster locknut.

2. Remove the (4) screws and cover from the RH control.

3. With handlebars centered and wheels pointing forward,

slowly turn the adjuster sleeve counter-clockwise (out) just

until the gap is removed between the throttle arm and the

throttle arm stop (see illustration below).

NOTE: While moving the adjuster sleeve, “flip” the

throttle lever slightly to remove slack in the cable.

Vent Line

1. Check the vent line from the fuel tank for signs of wear,

deterioration, damage or leakage. Replace the line every

two years.

2. Verify vent line is routed properly and secured with an

appropriate number of cable ties.

CAUTION

Make sure lines are not kinked or pinched

Throttle Operation

Check for smooth throttle opening and closing in all handlebar

positions. Throttle lever operation should be smooth and lever

must return freely without binding.

1. Place the gear selector in neutral.

2. Set parking brake.

3. Start the engine and let it idle.

4. Turn handlebars from full right to full left. If i dle speed

increases at any point in the turning range, inspect throttle

cable routing and condition. If cable is routed properly and

in good condition, no adjustment is required.

5. Replace the throttle cable if worn, kinked, or damaged.

4. Turn the cable adjuster sleeve clockwise (in) 1.5 - 2 turns;

tighten locknut and reinstall boot. After this adjustment

there should be .079-.118” (2-3 mm) gap between thrott le

arm and throttle arm stop.

5. Reinstall the RH control cover and ensure the O-ring is

properly in place. Securely tighten the (4) screws.

6. Place the vehicle in PARK and start the engine. Turn the

handlebars from full left to full right while listening for any

change in engine speed. If engine speed changes, loosen

the locknut and turn the adjuster sleeve clockwise (in) an

additional 1/2 turn and repeat this step.

2.10

Page 22

MAINTENANCE

Air Filter / Pre-Filter Service

It is advisable to replace the filter when it is dirty . However, in

an emergency, it is permissible to clean the main filter if you

observe the following practices.

• Never immerse the filter in water since dirt can be

transferred to the clean air side of the filter.

• If compressed air is used never exceed a pressure of 40

PSI. Always use a dispersion type nozzle to prevent

filter damage and clean from the inside to the outside.

It is recommended that the air filter and pre filter be replaced

annually. When riding in extremely dusty conditions,

replacement is required more often.

Removal:

1. Remove the seat to access the airbox cover.

Cleaning:

4. Slip the pre-filter screen off of main element. Clean the prefilter with hot soapy water.

5. Rinse and dry thoroughly.

6. Inspect pre-filter screen for tears or damage.

7. Inspect main filter and replace if necessary. If the filter has

been soaked with fuel or oil it must be replaced.

Installation:

8. Inspect airbox cover seal for damage. It should adhere

tightly to the cover and seal all the way around. Replace

seal as needed.

9. Reinstall pre-filter screen over main filter. Be sure the

screen covers entire surface of main filter without folds,

creases, or gaps.

NOTE: Apply a small amount of general purpose grease

to the sealing edges of the filter before reinstalling.

10. Install air filter assembly into the airbox and position it

correctly before closing the airbox cover.

2

2. Unscrew the two knobs retaining the airbox cover and open

the cover.

NOTE: Proper placement of the air filter is important to

prevent air leaks.

11. Close airbox cover and secure cover by tightening the

retaining knobs.

12. Check the intake boot for cracks, deterioration, abrasion, or

leaks. Replace as needed.

3. Remove the air filter assembly from the airbox.

2.11

Page 23

MAINTENANCE

ENGINE

Engine Oil Level

Polaris recommends the use of Polaris PS-4 PLUS synthetic

engine oil. Always use PS-4 PLUS engine oil. Oil may need to

be changed more frequently if Polaris engine oil is not used.

CAUTION

Mixing brands or using a non-recommended

engine oil may cause serious engine damage.

Always use the recommended engine oil. Never

substitute or mix engine oil brands.

1. Locate the engine oil dipstick on the left side of the ATV.

Engine Oil and Filter Change

Always change engine oil and filter at the intervals outlined in

the Periodic Maintenance Chart. Always change the oil filter

whenever changing the engine oil.

1. Position the ATV on a level surface.

2. Place the transmission in park.

3. Start engine and allow it to run for two to three minutes until

the engine is warm.

4. Stop the engine.

5. Clean the area around the drain plug.

2. Position the ATV on a level surface.

3. Stop engine and remove the dipstick. Wipe i t dry with a

clean cloth.

4. Reinstall and tighten the dipstick.

NOTE: The dipstick must be screwed in completely

to ensure an accurate measurement.

5. Remove the dipstick and check the oil level.

6. Maintain the oil level in the safe range. Do not overfill.

6. Place a drain pan beneath the engine crankcase.

7. Using a 6 mm Hex socket, remove the drain plug and allow

the engine oil to drain completely.

WARNING

Hot oil can cause serious burns to skin.

Do not allow hot oil to contact skin.

8. Replace the sealing washer on the drain plug.

2.12

Page 24

MAINTENANCE

NOTE: The sealing surfaces on the drain plug and

crankcase should be clean and free of burrs, nicks

or scratches.

9. Reinstall drain plug and torque to 12 ft. lbs. (16 Nm).

= T

Engine Drain Plug: 12 ft. lbs. (16 Nm)

10. Locate oil filter through access hole in the skid plate. Place

shop towels beneath the oil filter. Using oil filter wrench

(PV-43527) turn oil filter counterclockwise to remove it.

16. Stop the engine and check for leaks.

17. Re-check the oil level on the dipstick and add oil as

necessary to bring the level to the upper mark on the

dipstick.

18. Dispose of used oil and filter properly.

2

Engine Breather Hose

Be sure engine breather hose is routed properly and secured in

place. CAUTION: Make sure line is not kinked or pinched.

Breather

Inspect

Airbox

11. Use a clean dry towel to clean the filter sealing surface on

the crankcase.

12. Check to make sure the O-ring on the new oil filt er is in

good condition. Lubricate O-ring on new filter with a film

of fresh engine oil.

13. Install new oil filter and turn by hand until filter gasket

contacts the sealing surface, then turn it and additional 1/2

turn.

= T

Oil Filter Torque:

Turn by hand until filter gasket contacts sealing

surface, then turn an additional 1/2 turn.

14. Remove dipstick and fill engine with 1.75 qts. (1.66 L) of

the recommended engine oil.

=

Recommended Engine Oil:

Engine Breather Assembly

The engine breather assembly is located on top of the valve

cover. Inspect and service the breather components as required.

PS-4 PLUS Synthetic 4-Cycle Engine Oil

(PN 2876244) (Quart)

15. Start the engine and allow it to idle for one to two minutes.

2.13

Page 25

MAINTENANCE

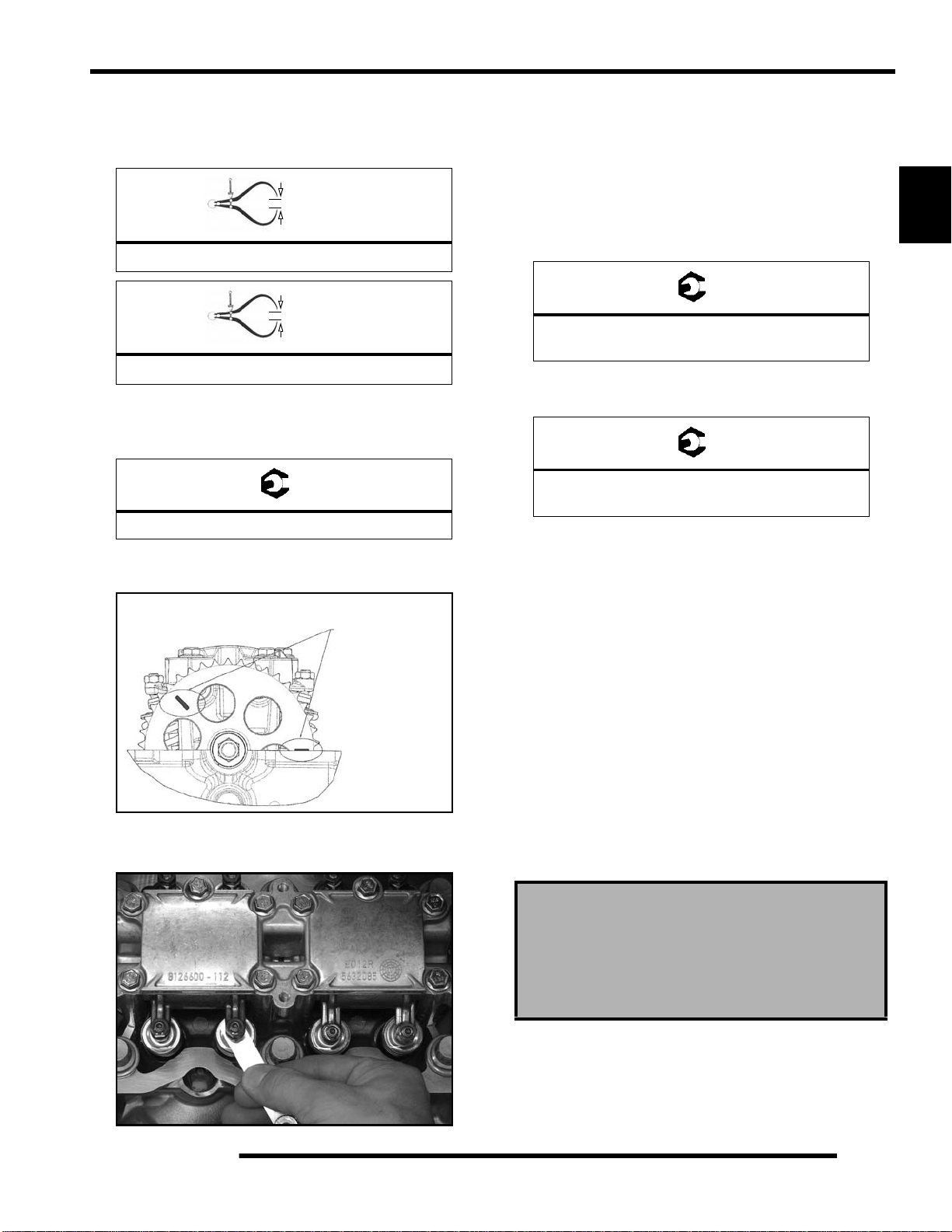

Valve Clearance Adjustment

1. Remove the seat and both upper side panels.

2. Disconnect the shift linkage from the shift lever.

3. Remove the (2) screws retaining the lower portion of the

air box.

4. Remove the hose from the breaker valve located on top of

the valve cover.

5. Remove the push rivets retaining the right-hand portion of

the rear cab to gain access to the bolts retaining the upper

right-hand frame support.

6. Remove the (4) bolts retaining the frame support. Pull the

support forward and down to remove it from the vehicle.

7. Remove the (2) Torx-head screws retaining the upper

portion of the air box to the front cab.

8. Carefully disconnect the ECU by pulling the tab out while

pulling down on the connector.

9. Loosen the hose clamp retaining the intake boot to the

intake plenum and remove the boot.

10. Lift up on the air box and turn it sideways to gain access to

the valve cover bolts.

MAG & PTO ADJUSTMENT PROCEDURE

14. Turn the drive clutch counter-clockwise until the cam

sprocket is in the MAG (#1) Adjustment Position.

MAG (#1)

Adjustment Position

Timing Pin in Vertical Position

TDC #1 (MAG) Cylinder

11. Remove the spark plug wires and spark plugs.

12. Remove the (6) valve cover bolts and valve cover.

13. Remove PVT cover so the engine can be rotated (see “Drive

Belt Removal” procedure within this chapter).

Timing Marks Lined Up With Top of Head

at MAG (#1) Adjustment Position

15. Set the MAG cylinder valve lash by placing the feeler gauge

blade between the lash adjuster and valve as shown.

2.14

MAG (#1)

Page 26

MAINTENANCE

16. Loosen the jam nut and turn the lash adjuster until the valve

lash is correct.

17. Set the intake and exhaust valve lash to specification.

= In. / mm.

Intake Valve Clearance: .006 in. (.15 mm)

= In. / mm.

Exhaust Valve Clearance: .009 in. (.23 mm)

18. Hold adjuster and torque the jam nut using a torque wrench

w/10 mm crow’s foot adaptor. Verify clearance is still

correct after tightening the jam nut.

= T

Rocker Jam Nut: 71-89 in. lbs. (8-10 Nm)

19. Turn the drive clutch counter-clockwise to rotate the cam

sprocket 225° to the PTO (#2) Adjustment Position.

21. Repeat steps 16-18.

22. Clean sealing surfaces of the cylinder head and valve cover.

23. Inspect the condition of the valve cover bolt rubber

isolators. If rubber has become hardened or cracked,

replace them.

24. Install a new valve cover seal and install the valve cover.

Torque the cover bolts to specification.

= T

Valve Cover Bolts:

89 in. lbs. (10 Nm)

25. Install the upper right-hand frame support and torque the

(4) mounting bolts to specification.

= T

Upper Right-Hand Frame Support Bolts:

36 ft. lbs. (49 Nm)

26. Reassemble vehicle by reversing this procedure. Start the

engine to ensure proper valve adjustment was performed.

2

PTO (#2)

Adjustment Position

20. Set the PTO cylinder valve lash by placing the feeler gauge

blade between the lash adjuster and valve as shown.

Timing Marks at PTO (#2)

Adjustment Position

PTO (#2)

Compression and Leakdown Tests

NOTE: This engine does NOT have decompression

components. Compression readings will vary in

proportion to cranking speed during the test.

Smooth idle generally indicates good compression. Low engine

compression is rarely a factor in running condition problems

above idle speed. Abnormally high compression can be caused

by worn or damaged exhaust cam lobes.

A cylinder leak-down test is the best indication of engine

condition. Follow tester manufacturer’s instructions to perform

a cylinder leak-down test. (Never use high pressure leakage

testers as crankshaft seals may dislodge and leak).

Measured Cylinder Compression

210-250 psi (full throttle)

Cylinder Leakage Service Limit: 10%

(Inspect for cause if leakage exceeds 10%)

2.15

Page 27

MAINTENANCE

Exhaust Silencer Cleaning

WARNING

Do not perform clean out immediately after the

engine has been run, as the exhaust system

becomes very hot. Serious burns could result

from contact with exhaust components .

To reduce fire hazard, make sure that there are

no combustible materials in the area when

purging the exhaust silencer.

Wear eye protection.

Do not stand behind or in front of the vehicle

while purging the carbon from the silencer.

Never run the engine in an enclosed area.

Exhaust contains poisonous carbon monoxide.

Do not go under the machine while it is inclined.

Set the hand brake and block the wheels to

prevent roll back.

Failure to heed these warnings could result in

serious personal injury or death.

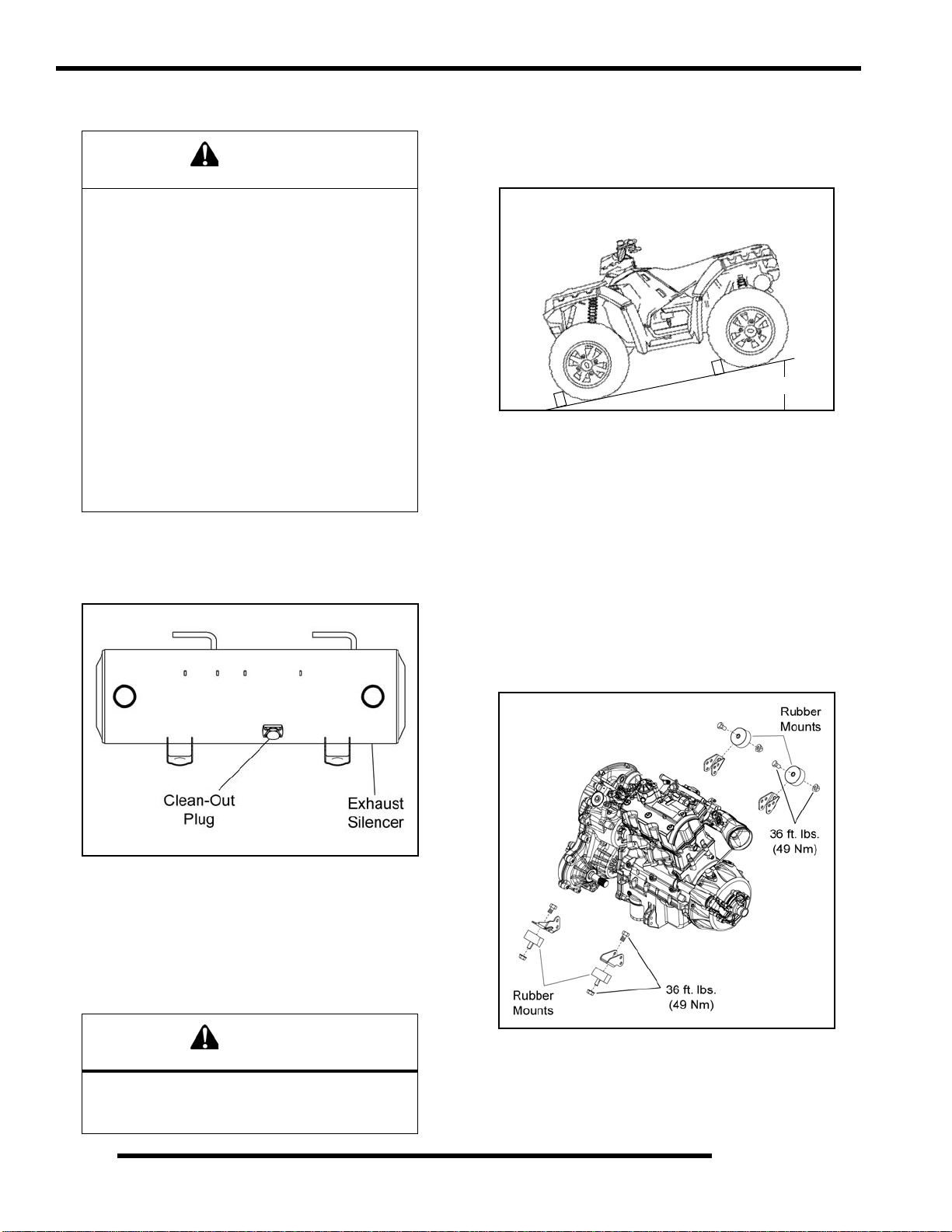

The exhaust silencer must be periodically purged of

accumulated carbon as follows:

5. If particles are still suspected to be in the silencer, back the

machine onto an incline so the rear of the machine is 1 ft.

(30.5 cm) higher than the front. Place the transmission in

park and block the wheels. Repeat steps 3 and 4 (see

WARNING).

1 ft.

6. If particles are still suspected to be in the silencer, drive the

machine onto the incline so the front of the machine is 1 ft.

(30.5 cm) higher than the rear. Place the transmission in

park and block the wheels. Repeat Steps 3 and 4 (see

WARNING).

7. Stop the engine and allow the silencer to cool. Reinstall the

clean out plug.

1. Remove the clean out plug on the bottom of the silencer.

2. Place the transmission in park, and start the engine.

3. Purge accumulated carbon from the exhaust system by

momentarily revving the engine several times.

4. If some carbon is expelled, cover the exhaust outlets and

lightly tap on the silencer around the clean out plug with a

rubber mallet while revving the engine several more times.

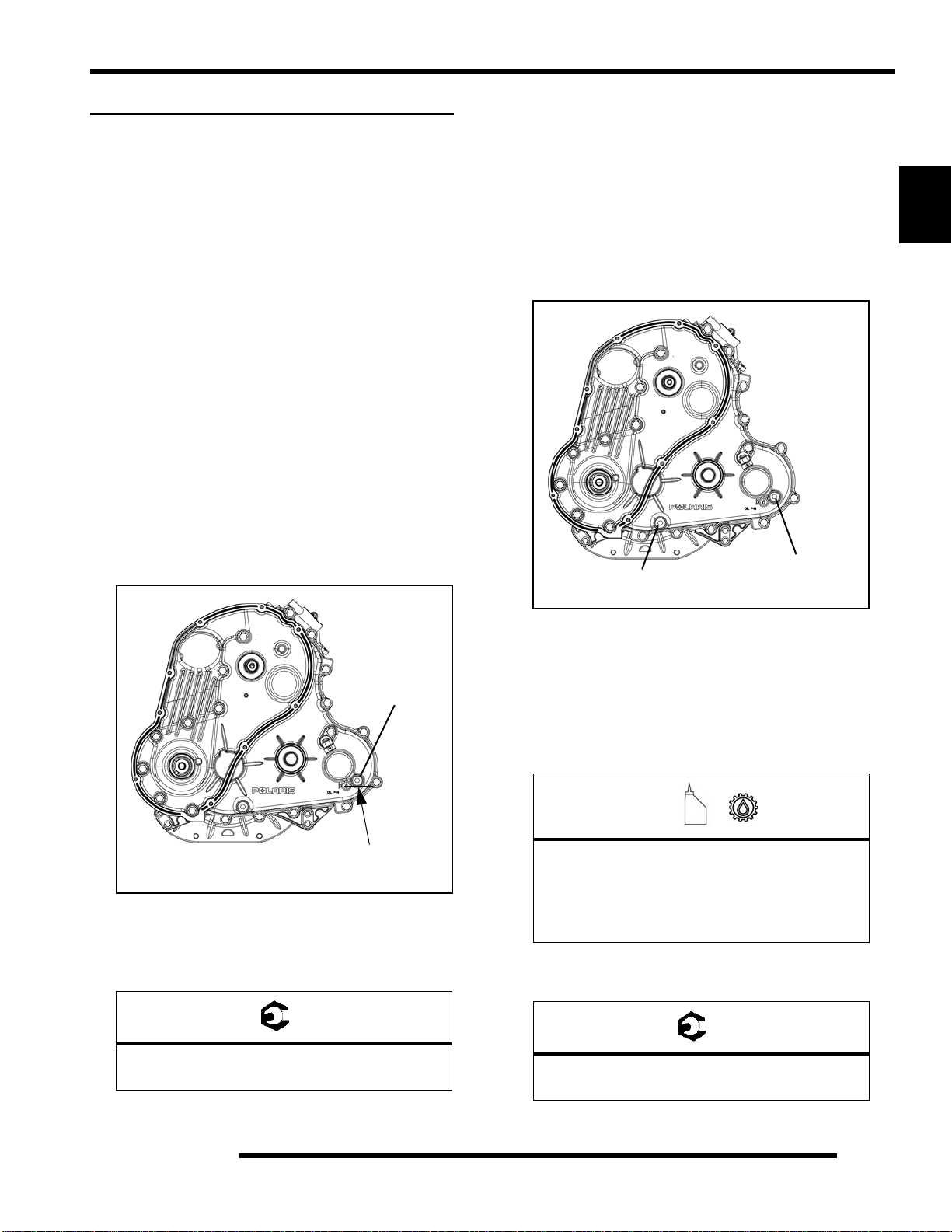

Engine Mount Fastener Torque

Check engine mounting fasteners and ensure they are tight.

Also inspect the condition of the rubber mounts. If rubber

mounts are cracked or show signs of fatigue, replace them.

CAUTION

Wear protective gloves when covering the

exhaust outlets. Serious burns could result from

contact with exhaust components.

2.16

Page 28

MAINTENANCE

TRANSMISSION AND GEARCASES

Transmission Lubrication

NOTE: It is important to follow the transmission

maintenance intervals described in the Periodic

Maintenance Chart. Regular fluid level inspections

should be performed as well.

The transmission fluid leve l should be checked and changed in

accordance with the maintenance schedule.

• Be sure vehicle is positioned on a level surface when

checking or changing the fluid.

• Check vent hose to be sure it is routed properly and

unobstructed.

Transmission Fluid Level Check

The fill plug is located on the right-hand side of the

transmission. Access the fill plug through the rear right-hand

wheel well. Maintain the fluid level even with the bottom

threads of the fill plug hole.

1. Position vehicle on a level surface.

Transmission Fluid Change

Access the drain plug through the rear right-hand wheel well.

The plastic skid plate can be removed for better access to the

drain plug.

1. Remove the fill plug (refer to “Transmission Fl uid Level

Check”).

2. Place a drain pan under the transmission drain plug.

3. Remove the drain plug and allow fluid to drain complete ly.

2

2. Remove the fill plug and check the fluid level.

Fill Plug

10-14 ft. lbs.

(14-19 Nm)

Transmission fluid

flush with the bottom

of thread area.

3. If fluid level is not even with the b ottom threads, add the

recommended fluid as needed. Do not overfill.

4. Reinstall the fill plug and torque to specification.

Drain Plug

10-14 ft. lbs. (14-19 Nm)

4. Clean the drain plug magnetic surface.

5. Reinstall drain plug with a new O-ring and torque to

specification.

6. Add the recommended amount of fluid through the fill plug

hole. Maintain the fluid level at the bottom of the fill plug

hole when filling the transmission. Do not overfill.

Fill Plug

10-14 ft. lbs.

(14-19 Nm)

=

Recommended Transmission Lubricant:

Synthetic Sportsman XP Transmission Fluid

(PN 2877606) (Quart)

Capacity: 32 oz. (946 ml)

7. Reinstall fill plug with a new O-ring and torque to

specification.

= T

Drain/Fill Plug Torque:

10-14 ft. lbs. (14-19 Nm)

= T

Drain/Fill Plug Torque:

10-14 ft. lbs. (14-19 Nm)

8. Check for leaks. Dispose of used fluid properly.

2.17

Page 29

MAINTENANCE

Front Gearcase Lubrication

NOTE: It is important to follow the front gearcase

maintenance intervals described in the Periodic

Maintenance Chart. Regular fluid level inspections

should be performed as well.

The front gearcase fluid level should be checked and changed in

accordance with the maintenance schedule.

• Be sure vehicle is positioned on a level surface when

checking or changing the fluid.

• Check vent hose to be sure it is routed properly and

unobstructed.

Front Gearcase Fluid Level Check

The fill plug is located on the right side of the fron t gearcase.

Access the fill plug through the front right-hand wheel well or

through the front lower bumper. Maintain the fluid level even

with the bottom threads of the fill plug hole.

1. Position vehicle on a level surface.

2. Remove the fill plug and check the fluid level.

Fill Plug

8-10 ft. lbs.

(11-14 Nm)

Front Gearcase Fluid Change:

The drain plug is located on the bottom side of the front

gearcase. Access the drain plug through the access hole in the

front skid plate.

1. Remove the fill plug (refer to “Front Gearcase Fluid Level

Check”).

2. Place a drain pan under the front gearcase drain plug.

3. Remove the drain plug and allow fluid to drain completel y.

Drain Plug

8-10 ft. lbs.

(11-14 Nm)

4. Clean the drain plug magnetic surface.

Fill Plug

8-10 ft. lbs.

(11-14 Nm)

Gearcase fluid

flush with the bottom

of thread area.

3. If fluid level is not even with the b ottom threads, add the

recommended fluid as needed. Do not overfill.

4. Reinstall the fill plug and torque to specification.

= T

Drain / Fill Plug Torque:

8-10 ft. lbs. (11-14 Nm)

5. Reinstall drain plug with a new O-ring and torque to

specification.

6. Add the recommended amount of fluid through the fill hole.

Maintain the fluid level e ven with the bottom threads of the

fill plug hole.

=

Recommended Front Gearcase Fluid:

Premium LT Demand Drive Fluid

(PN 2876251) (Quart)

Capacity: 9.3 oz. (275 ml)

7. Reinstall fill plug with a new O-ring and torque to

specification.

= T

Drain / Fill Plug Torque:

8-10 ft. lbs. (11-14 Nm)

2.18

8. Check for leaks. Dispose of used fluid properly.

Page 30

MAINTENANCE

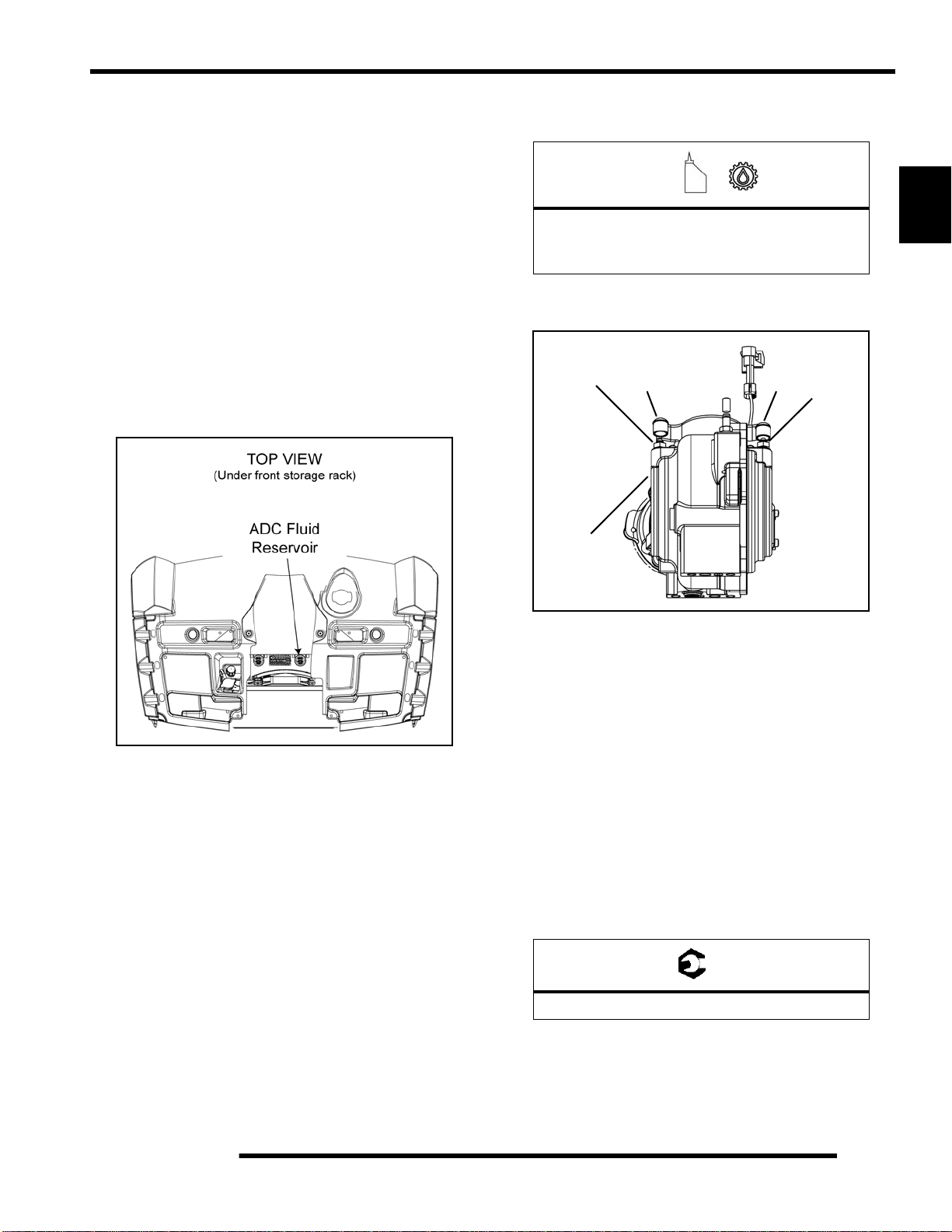

Front Gearcase ADC Fluid

NOTE: It is important to follow the front gearcase

maintenance intervals described in the Periodic

Maintenance Chart. Regular fluid level inspections

should be performed as well.

The front gearcase ADC fluid level should be checked and

changed in accordance with the maintenance schedule.

Front Gearcase ADC Fluid Level Check

The ADC fluid reservoir is located underneath the front rack as

shown below. Maintain the fluid level between the “MIN” and

“MAX” levels indicated on the reservoir.

1. Disengage the anchors and remove front rack assembly.

2. Check the fluid level of the ADC reservoir.

5. Begin the bleeding process by filling reservoir to the

“MAX” level with clean ADC Front Drive Fluid.

=

Recommended ADC Fluid:

Premium ADC Front Drive Fluid

(PN 2876144) (Quart)

6. Locate bleeder valves found on each side of the front

gearcase and remove the protective caps.

Bleeder

Valve

Front

Gearcase

CapCap

Bleeder

Valve

2

3. If fluid level is below the minimum mark on the reservoir,

remove the cap and add the recommended fluid.

4. Reinstall the cap and front rack assembly.

Front Gearcase ADC Fluid Change:

1. Position the vehicle on a level surface and allow the

vehicle to sit for at least 30 minutes.

2. Thoroughly clean the areas around the ADC reservoir and

bleeder valves.

3. Remove the reservoir cap and diaphragm assembly.

4. Make sure the fluid inside the reservoir is free of debris. If

any debris is found, use a clean shop towel or suction device

to remove it from the reservoir.

NOTE: Debris in the reservoir may result in

inadequate bleeding and reduced performance of

the system.

7. Attach a clean clear hose to one of the bleeder valves.

8. Slowly loosen the valve (counter-clockwise) and allow

fluid and trapped air to flow from the fitting.

IMPORTANT: Do not allow ADC fluid in reservoir to

drop below the “MIN” fill line. Close bleeder valve

before the fluid level drops below the “MIN” fill line.

Refilling an empty reservoir will result in air pockets

becoming trapped.

9. Close the valve when clean (bubble-free) fluid begins to

flow from the valve.

10. Repeat steps 7-9 on the remaining bleeder valve.

11. Torque the bleeder valves to specification and reinstall the

protective caps.

= T

Bleeder Valve Torque: 80 in. lbs. (9 Nm)

12. Fill reservoir to a level midway between “MAX” and

“MIN” fill lines. Verify no debris is found in reservoir

fluid.

13. Install the reservoir cap and diaphragm securely and wipe

clean any fluid residue.

2.19

Page 31

MAINTENANCE

Rear Gearcase Lubrication

NOTE: It is important to follow the rear gearcase

maintenance intervals described in the Periodic

Maintenance Chart. Regular fluid level inspections

should be performed as well.

The rear gearcase fluid level should be checked and changed in

accordance with the maintenance schedule.

• Be sure vehicle is positioned on a level surface when

checking or changing the fluid.

• Check vent hose to be sure it is routed properly and

unobstructed.

Rear Gearcase Fluid Level Check:

The fill plug is located on the right side of the rear gearcase.

Maintain the fluid level even with the bottom threads of the fill

plug hole.

1. Position the vehicle on a level surface.

2. Remove the fill plug and check the fluid level.

Rear Gearcase Fluid Change:

The drain plug is located on the bottom right-hand si de of the

rear gearcase. Access the drain plug from the rear right-hand

side of the ATV.

1. Remove the fill plug (refer to “Rear Gearcase Fluid Level

Check”).

2. Place a drain pan under the rear gearcase drain plug.

3. Remove the drain plug and allow the fluid to drain

completely.

Fill Plug

10-14 ft. lbs.

(14-19 Nm)

Fill Plug

10-14 ft. lbs.

(14-19 Nm)

Gearcase fluid

flush with the bottom

of thread area.

3. If fluid level is not even with the b ottom threads, add the

recommended fluid as needed. Do not overfill.

4. Reinstall fill plug and torque to specification.

= T

Drain / Fill Plug Torque:

10-14 ft. lbs. (14-19 Nm)

Gearcase fluid

flush with the bottom

of thread area.

4. Clean the drain plug magnetic surface.

5. Reinstall drain plug with a new O-ring and torque to

specification.

6. Add the recommended amount of fluid through the fill hole.

Maintain the fluid level e ven with the bottom threads of the

fill plug hole.

Drain Plug

10-14 ft. lbs.

(14-19 Nm)

=

Recommended Rear Gearcase Lubricant:

ATV Angle Drive Fluid (PN 2871653)

Capacity: 7.1 oz. (210 ml)

7. Reinstall fill plug with a new O-ring and torque to

specification.

= T

2.20

Drain / Fill Plug Torque:

10-14 ft. lbs. (14-19 Nm)

8. Check for leaks. Dispose of used fluid properly.

Page 32

MAINTENANCE

COOLING SYSTEM

Cooling System Overview

The engine coolant level is controlled, or maintained, by the

recovery system. The recovery system components are the

recovery bottle, radiator filler neck, radiator pressure cap and

connecting hose.

As coolant operating temperature increases, the expanding

(heated) excess coolant is forced out of the radiator past the

pressure cap and into the recovery bottle. As engine coolant

temperature decreases the contracting (cooled) coolant is drawn

back up from the bottle, past the pressure cap, and into the

radiator.

NOTE: Some coolant level drop on new vehicles is

normal as the system is purging itself of trapped air.

Observe coolant level often during the break-in

period.

CAUTION

Overheating of engine could occur if air is not

fully purged from system.

Polaris recommends the use of Polaris Premium 60/40 antifreeze/coolant or a 50/50 mixture of high quality aluminum

compatible anti-freeze/coolant and distilled water.

NOTE: Polaris Premium 60/40 is already premixed

and ready to use. Do not dilute with water.

With the engine at operating temperature, the coolant level

should be between the MAX and MIN marks on the coolant

recovery bottle. If not, perform the following procedure.

1. Position the vehicle on a level surface.

2. View the coolant level in the recovery bottle. The coolant

level can be viewed from inside the front right wheel well.

3. If the coolant level is below the “MIN” line on the bottle,

remove the front rack assembly to access the radiator

pressure cap and recovery bottle cap.

NOTE: If overheating is evident, allow system to

cool completely and check coolant level in the

radiator and inspect for signs of trapped air in

system.

2

Coolant Level Inspection

The pressure cap and recovery bottle are located underneath the

front rack as shown below. Maintain the coolant level between

the “MIN” and “MAX” levels indicated on the recovery bottle.

WARNING

Never remove the pressure cap when the

engine is warm or hot. Escaping steam can

cause severe burns. The engine must be cool

before removing the pressure cap.

4. Remove the pressure cap. Using a funnel, add coolant to

the top of the radiator filler neck.

5. Reinstall the pressure cap.

NOTE: Use of a non-standard pressure cap will not

allow the recovery system to function properly.

6. Remove recovery bottle cap and add coolant using a funnel.

7. Fill recovery bottle to “MAX” level with Polaris Premium

60/40 Anti-Freeze/Coolant or a 50/50 mixture of antifreeze/coolant and distilled water as required for freeze

protection in your area.

8. Reinstall the recovery bottle cap.

2.21

Page 33

MAINTENANCE

9. If coolant was required, start engine and check for leaks.

Make sure radiator fins are clean to prevent overheating.

10. Add coolant as needed. Maintain the coolant level between

the “MIN” and “MAX” marks on the bottle.

11. Reinstall the front rack assembly.

Cooling System Hoses

1. Inspect all hoses for cracks, deterioration, abrasion or

leaks. Replace if necessary.

Coolant Strength / Type

Test the strength of the coolant using an antifreeze hydrometer .

Antifreeze Hydrometer

• A 50/50 or 60/40 mixture of antifreeze and distilled

water will provide the optimum cooling, corrosion

protection, and antifreeze protection.

• Do not use tap water, straight antifreeze, or straight

water in the system. Tap water contains minerals and

impurities which build up in the system.

• Straight water or antifreeze may cause the system to

freeze, corrode, or overheat.

=

Recommended Anti-Freeze/Coolant:

Polaris 60/40 Anti-Freeze/Coolant

(PN 2871534) (Quart)

2. Check tightness of all hose clamps.

CAUTION

Do not over-tighten hose clamps at radiator, or

radiator fitting may distort, causing a restriction

to coolant flow. Radiator hose clamp torque is

36 in. lbs. (4 Nm).

NOTE: For further information on the engine cooling

system, refer to Chapter 4.

2.22

Page 34

MAINTENANCE

PVT / FINAL DRIVE / WHEEL AND TIRE

PVT Drying

NOTE: If operating the ATV through water, be sure

to check the PVT system components for water

ingestion. After operating in water, the ATV should

be checked immediately.

1. Access the PVT drain plug on the bottom of the PVT cover

using a long flat blade screwdriver between the frame and

left-hand lower control arm from the rear of the ATV.

2. Remove the PVT drain plug and O-ring.

Drive Belt Removal

Refer to Chapter 7 “Clutching (PVT)” for more detail.

1. Elevate vehicle and remove the left rear wheel.

2. Remove the lower left-hand frame suppo rt.

3. Remove the (11) screws retaining the outer PVT co ver.

Pull the PVT cover out the LH wheel well.

4. Insert the belt removal tool PN 2877408 into the driven

clutch (tool included with vehicle’s tool kit).

NOTE: Make sure the tool is square with the

moveable sheave surface of the driven clutch.

5. Rotate the tool to open the driven clutch.

6. Walk the belt out of the driven clutch and drive clutch, and

remove the belt from the vehicle.

Drive Shaft Boot Inspection

Inspect the front and rear drive shaft boots for damage, tears,

wear, or leaking grease. If the rubber boots exhibit any of these

symptoms, replace the boot(s). Refer to Chapter 8 for drive

shaft boot replacement.

2

3. Allow the water to drain out completely.

4. Reinstall the drain plug and O-ring.

5. Start the engine and shift into park.

6. Apply varying throttle for 10-15 seconds to expel the

moisture and air-dry the belt and clutches.

NOTE: Do not hold the throttle wide open for more

than 10 seconds.

Rear

NOTE: Remove the CV boot shield from the front

lower A-arms to inspect the front outer CV boots.

Front

7. Allow the engine RPM to return to idle, then shift into low

gear.

8. Test the PVT system for belt slippage. If the belt slips,

repeat the process.

2.23

Page 35

MAINTENANCE

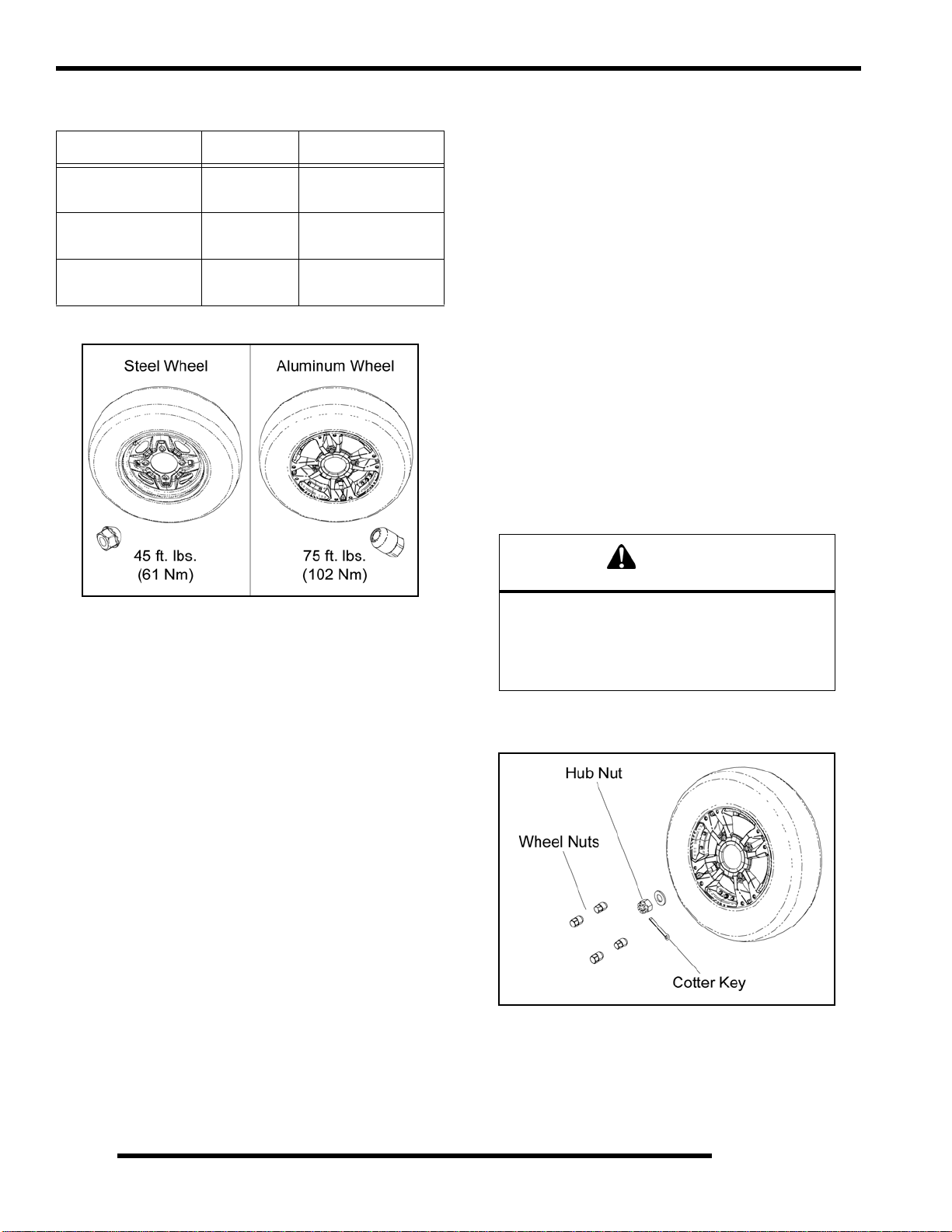

Wheel and Hub Torque Table

Item Nut Type Specification

Aluminum Wheels

Steel Wheels

Hub Retaining Nuts

(Front & Rear)

Tapered Nut

(Long)

Tapered Nut

(Short)

- 80 ft. lbs. (108 Nm)

75 ft. lbs. (102 Nm)

45 ft. lbs. (61 Nm)

Wheel Installation

1. Verify the transmission is still in PARK and the parking

brake is locked.

2. Install the wheel hub, washers, and hub nut, if previously

removed.

3. Place the wheel in the correct position on the wh eel hub.

Be sure the valve stem is toward the outside and rotatio n

arrows on the tire point toward forward rotation.

4. Install the wheel nuts and finger tighten them to align the

center of the wheel holes with the center of the tapered nuts.

IMPORTANT: It is possible to torque the wheel nut on

a steel rim without the nut being centered in the hole.

Be sure to center the wheel nuts before applying

torque to prevent wheel nuts from coming loose.

5. Carefully lower the vehicle to the ground.

6. Torque the wheel nuts and/or hub nut to the proper torque

specification listed in the “Wheel and Hub Torque Table”.

Wheel Removal

1. Position the vehicle on a level surface.

2. Stop the engine, place the transmission in PARK and lock

the parking brake.

3. Loosen the wheel nuts slightly. If wheel hub remov al is

required, remove the cotter key and loosen the hub nut

slightly.

4. Elevate the appropriate side of the vehicle by placing a

suitable stand under the footrest frame.

5. Remove the wheel nuts and remove the wheel.

6. If hub removal is required, remove the hub nut and washers.

CAUTION

Improperly installed wheels could affect vehicle

handling and tire wear. On vehicles with tapered

rear wheel nuts, make sure tapered end of nut

goes into taper on wheel. Be sure to properly

torque and install all wheel nuts.

7. If the hub nut was removed, install a new cotter pin after

the hub nut has been tightened.

2.24

Page 36

MAINTENANCE

Tire Pressure

Tire Pressure Inspection (PSI - Cold)

Front Rear

7 psi (48 kPa) 5 psi (34.5 kPa)

Tire Inspection

WARNING

Operating an ATV with worn tires will increase

the possibility of the vehicle skidding and

possible loss of control.

Worn tires can cause an accident.

Always replace tires when the tread depth

measures 1/8” (.3 cm) or less.

CAUTION

Maintain proper tire pressure.

Refer to the warning tire pressure decal

applied to the vehicle.

Improper tire inflation may affect

ATV maneuverability.

When replacing a tire always use original

equipment size and type.

The use of non-standard size or type tires may

affect ATV handling.

Tire Tread Depth

Always replace tires when tread depth is worn to 1/8” (3 mm) or

less.

Tread

Depth 1/8” (3 mm)

ELECTRICAL AND IGNITION SYSTEM

Battery Maintenance

Keep battery terminals and connections free of corrosion. If

cleaning is necessary, remove the corrosion with a stiff wire

brush. W ash with a solution of one tablespoon baking soda and

one cup water. Rinse well with tap water and dry of f with clean

shop towels. Coat the terminals with dielectric grease or

petroleum jelly.

WARNING

Battery electrolyte is poisonous. It contains sulfuric

acid. Serious burns can result from contact with

skin, eyes or clothing. Antidote:

External: Flush with water.

Internal: Drink large quantities of water or milk.

Follow with milk of magnesia, beaten egg, or

vegetable oil. Call physician immediately.

Eyes: Flush with water for 15 minutes and get

prompt medical attention.

Batteries produce explosive gases. Keep sparks,

flame, cigarettes, etc. away. Ventilate when

charging or using in an enclosed space. Always

shield eyes when working near batteries. KEEP

OUT OF REACH OF CHILDREN.

NOTE: Absorbed Glass Mat (AGM) batteries are

permanently sealed at the time of manufacture.

AGM batteries are designed to minimize gassing and

water loss, but can vent if overcharged.

IMPORTANT: Never attempt to open the battery. If the

seal is broken, the battery will be ruined and will fail

within a few weeks.

2

NOTE: If battery voltage is below 12.6V, fully charge

the battery before putting into service. Charge for 35 hours at a voltage not to exceed 14.6V or 10 Amps.

Voltage should reach at least 14.4V before end of

charge.

2.25

Page 37

MAINTENANCE

Battery Removal

1. Remove the seat to access the battery.

Retaining Screw

2. Disconnect battery negative (-) (black) cable first, followed

by the positive (+) (red) cables.

CAUTION

To reduce the chance of sparks: Whenever

removing the battery, disconnect the negative

(black) cable first.

3. Remove the screw retaining the hold-down strap n ear the

bottom front portion of the battery and remove the strap.

4. Lift the battery out of the ATV.

Battery Installation

IMPORTANT: Using a new battery that is not fully

charged can damage the battery, resulting in a short

battery life and can hinder performance. Follow the

battery charging procedure before installation.

5. Place the spacers on top of the battery terminals. Be sure

they are placed between the battery terminal and cable(s).

Positive

Cables

SpacerSpacer

6. Connect and tighten the positive (+) (red) battery cable first,

followed by the negative (-) (black) battery cable.

Negative

Cable

CAUTION

To reduce the chance of sparks: Whenever

installing the battery, install the

negative (black) cable last.

7. Verify cables are properly routed and fasteners are tight.

NOTE: The cables should be safely tucked away at

the front of the battery.

8. Reinstall the seat.

Spark Plug Service

1. Remove the seat and upper right-hand side panel.

2. Disconnect the shift linkage from the shift lever.

3. Remove the spark plug caps. Clean plug area so no dirt and

debris can fall into engine when plugs are removed.

1. Ensure the battery is fully charged (see Chapter 12).

2. Place the battery into the ATV on its side with the positive

(+) terminal towards the right side of the ATV.

3. Install the hold-down strap and the retaining screw .

4. Coat the battery terminals and bolt threads with Dielectric

Grease (PN 2871329) or petroleum jelly.

2.26

4. Using a 14 mm deep-well socket with an extension, remove

the spark plug.

Page 38

MAINTENANCE

Spark Plug Inspection / Installation

1. Inspect electrodes for wear and carbon buildup. Look for

a sharp outer edge with no rounding or erosion of the

electrodes.

2. Clean with electrical contact cleaner or a glass bead spark

plug cleaner only. CAUTION: A wire brush or coated

abrasive should not be used.

3. Measure gap with a wire gauge. Refer to specifications in

the following illustration for proper spark plug type and

gap. Adjust gap if necessary by carefully bending the side

electrode.

Spark Plug Gap

Gap - .035" (0.90 mm)

4. If necessary, replace spark plug with proper type.

CAUTION: Severe engine damage may occur if the

incorrect spark plug is used.

Engine / Chassis Ground

Periodically inspect the electrical ground cable attachments.

Cables and connections should be tight and corrosion-free.

Inspect the battery-to-chassis connection underneath the seat.

This connection allows the chassis to provide a ground path.

Inspect the chassis-to-engine connection on the left side of the

engine attached to the engine/transmission housing. This

connection allows the engine to provide a ground path.

2

Recommended Spark Plug

Champion REA6MC or REA8MCL

Spark Plug Torque:

18 ± 1.5 ft. lbs. (25 ± 2 Nm)

5. Apply a small amount of anti-seize compound to the spark

plug threads.

6. Install spark plugs and torque to specification.

7. Make sure the high tension leads are retained by the airbox.

8. Reinstall the shift linkage, upper right-hand side panel, and

seat.

2.27

Page 39

MAINTENANCE

STEERING

Steering Inspection

The steering components should be checked periodically for

loose fasteners, worn tie rod ends, and damage. Also check to

make sure all cotter pins are in place. If cotter pins are removed,

they must not be re-used. Always use new cotter pins.

Bolt

Carriage

Bolt

Bracket

Nut

Cotter

Pin

Screw

Bushings

Steering

Post

Nut

Upper Post

PS Unit

Steering

Bracket

Bolt

Drive

Brackets