Page 1

R-410A

This system uses

M00036-V00

Page 2

Installation & service manual

IMPORTANT! Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system so it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local, state, and national electric codes.

• Pay close attention to all danger, warning, and caution notices given in this manual.

WARNING:

This symbol refers to a hazard or unsafe practice, which can result in severe personal injury or death.

CAUTION:

This symbol refers to a hazard or unsafe practice, which can result in personal injury and the potential for product or

property damage.

Caution:

In order to avoid injury, take proper precaution when lifting heavy objects.

Electrical

Safety / alert

Caution:

Sharp sheet metal edges can cause injury. When installing the unit, avoid accidental contact with

sharp edges.

Page 3

Installation & service manual

CONTENTS

Safety considerations 1

Accessories 2

Installation recommendations (indoor unit) 3

Installation recommendations (outdoor unit) 4

Electrical installation 5

Wiring system diagram 6_7

Electrical connections for indoor and outdoor units 8

Refrigerant line connections 9

Refrigerant R410A: special precautions when installing unit 10

Tightening refrigerant piping connections 11

System evacuation 12

Additional charge 13

Gas leak check 14

Checking and testing operation 15

Technical specifications 16

Outline and dimensions 17

Parts diagram (indoor unit) 18

Parts list (indoor unit) 19

Parts diagram (outdoor unit) 20

Parts list (outdoor unit) 21

Page 4

This manual is a guide for properly installing the Williamson-Thermoflo Wall-mounted split air conditioner. Improper

installation can result in unsafe and dangerous conditions that will void the factory warranty. Prior to installation, read

these instructions and any instructions that are packaged with separate pieces of equipment that make up the system.

Please read these instructions thoroughly and carefully before attempting installation or operation. Failure to follow these

instructions may result in improper installation, operation, service, or maintenance, possibly resulting in fire, electrical

shock, property damage, personal injury, or death.

General:

This device must be installed in compliance with national electrical standards.

About the indoor unit

1. There must be no obstacles near the air inlet and outlet.

2. Install the indoor unit on a surface that can support its weight.

3. Choose a position that enables the piping and wiring to be easily connected to the outdoor unit.

4. Leave enough clearance beneath the indoor unit to enable the filters to be removed without hinderance.

5. Maintain sufficient clearance around the indoor unit.

6. Make sure that the water from the drain hose runs away correctly and safely.

7- Install the indoor unit on a strong wall which is not subject to vibration.

8- Do NOT install the unit where it will be exposed to direct sunlight.

About outdoor unit

1. The outdoor unit must NEVER be placed on its side or upside down, as the compressor lubrication oil will run in the

cooling circuit and seriously damage the unit.

3. Choose a location where the noise of the air conditioner when running and the discharged air do not disturb any neighbors.

4. Choose a position that enables the piping and wiring to be easily connected to the indoor unit.

5. Install the outdoor unit on a flat, stable surface that can support its weight and does not generate any unnecessary

noise and vibration.

6. Position the outdoor unit so that the air flow is directed away from exterior walls, as indicated by the arrows on the top

of the unit.

7. Maintain sufficient clearance around the outdoor unit.

8. If the outdoor unit is installed above grade with brackets, ensure that its base is firmly fixed in position.

Installation& service manual _1

SAFETY CONSIDERATIONS

Page 5

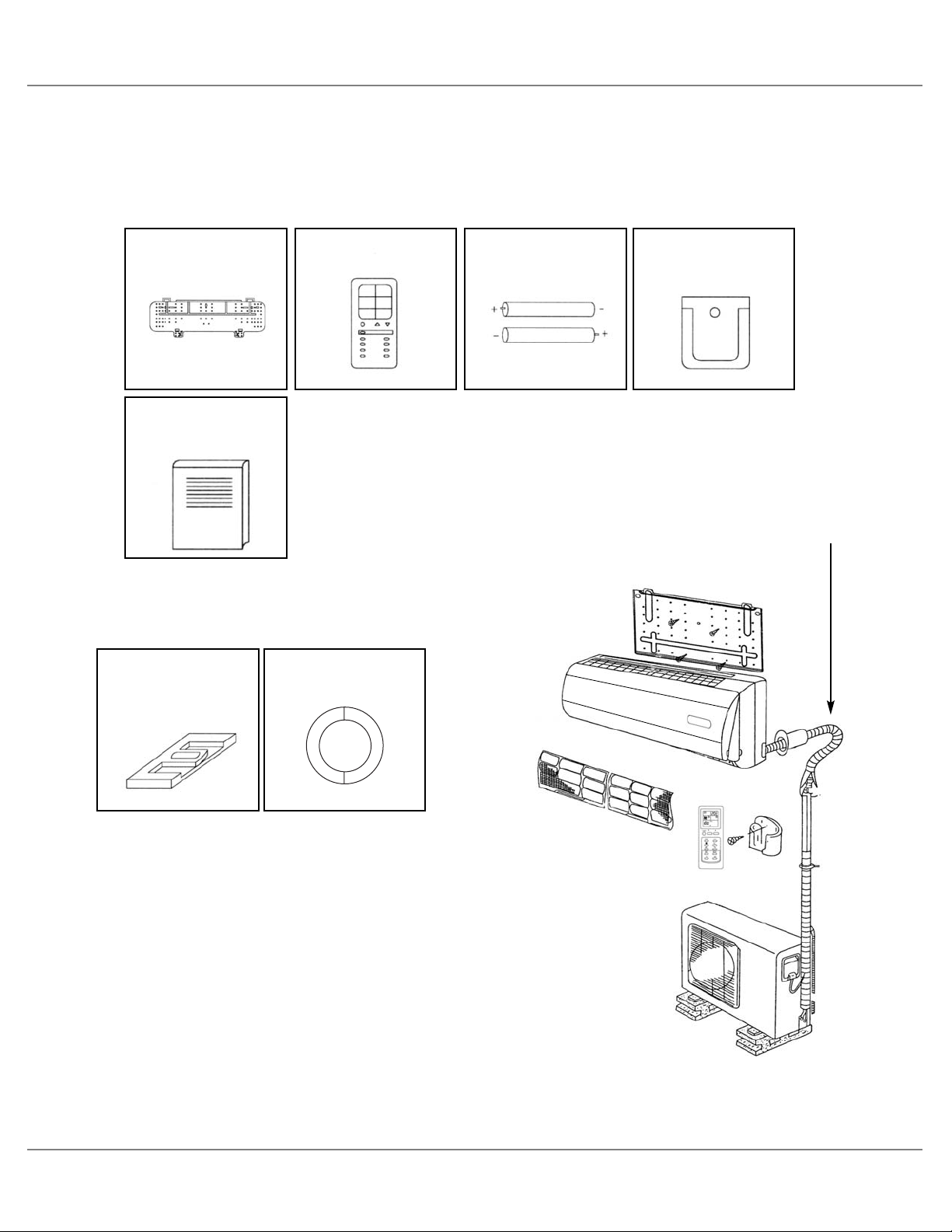

The following accessories are supplied with the air conditioner.

• The quantities are indicated in parenthesi s.

Installation plate (1) Remote control (1)

“AAA” batteries for

remote control (2)

Remote control

holder (1)

Accessories in the Indoor Unit Case

Owner’s manual (1)

Installation manual (1)

Service manual (1)

Warranty (1)

Rubber leg (4)

Interconnecting wiring and conduits

from the outdoor unit to the indoor unit

are not provided with the air conditioner.

Wall plastic sleeve (1)

Accessories in the Outdoor Unit Case

Installation & service manual _2

ACCESSORIES

Page 6

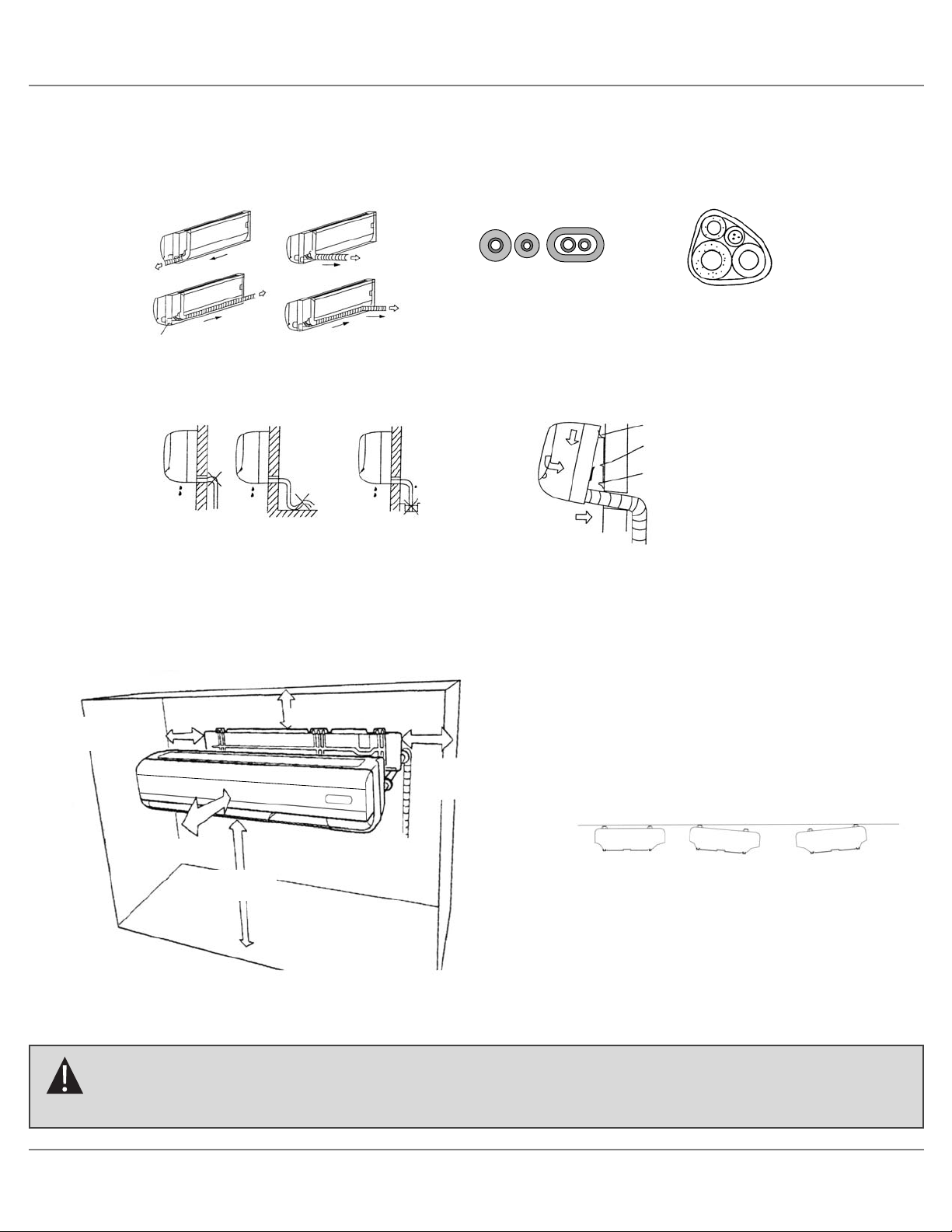

1. Before fixing the installation plate to a wall, you must determine the position of the 2

3

/

4 in (70 mm) hole through which

the conduit, piping and drain hose pass to connect the indoor unit to the outdoor unit. The piping and conduit can be connected from the: Rear, Right or Left side of indoor unit.

2. Determine the position of the pipe and drain hose hole using one of the figures shown, and drill the hole with an inner

diameter of 70 mm (2

3

/

4 inch) so that it slants slightly downwards.

3. The correct mounting of the indoor unit is as shown below.

CORRECT

INCORRECT

POSITION THE MOUNTING PLATE LEVEL

CORRECT

INCORRECT

INCORRECT

Right side 2 in

minimum

Left side 2 in

minimum

59 to 79 in

minimum

59 in minimum

2 3/8 in minimum

Caution:

Take servicing into consideration and leave the spacing shown in the figure above. Also install the unit where

it can be removed.

Installation & service manual _3

INSTALLATION RECOMMENDATIONS (INDOOR UNIT)

Page 7

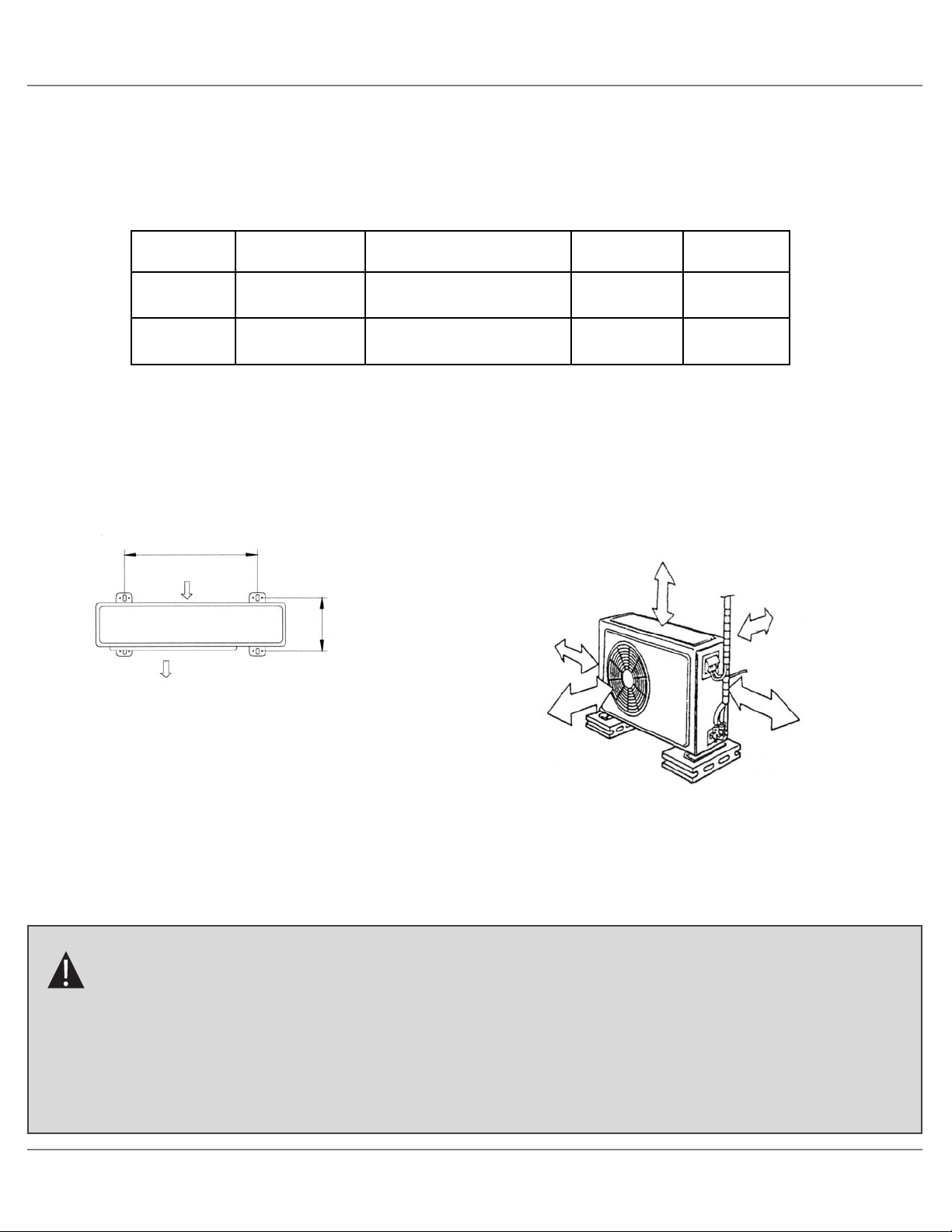

Attach the outdoor unit with 4 anchor bolts and nuts (not supplied) positioned as per dimensions A, B.

9SRAO-HE

Caution:

The outdoor unit should not be exposed to strong winds or where it is very dusty.

- Take your neighbors into consideration so that they will not be disturbed by air blowing into their window

or by noise.

- Provide enough space between the wall and the unit, so that the airflow is not blocked. Also, for efficient

operation, leave enough clearance on both sides and front.

24 in minimum

9 in minimum

16 in minimum

24 in minimum

12 in minimum

Air inlet

Air outlet

A

B

Installation & service manual _4

INSTALLATION RECOMMENDATIONS (OUTDOOR UNIT)

12SRAO-HE | 15SRAO-HE

21 3/8

13

18SRAO-HE

24SRAO-HE

13 3/8

25

24 3/8

15

23

15

A (in)

B (in)

Page 8

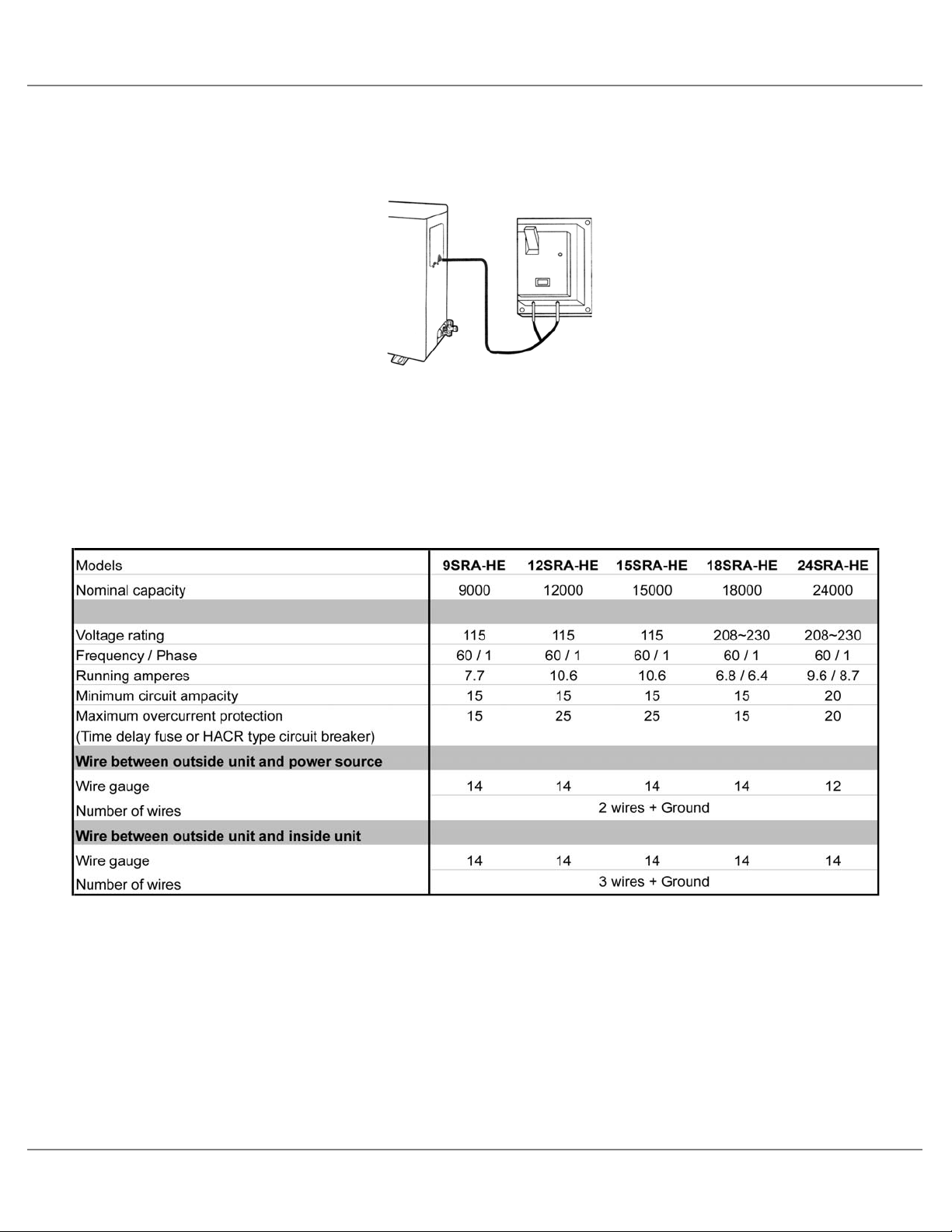

1. The air conditioner shall be installed by a qualified technician in accordance with national and local electrical codes.

2. A disconnect switch shall be installed near the outdoor unit for easy disconnect of power to the air conditioner.

3. An electrical circuit dedicated to the air conditioner shall be used for the power supply to the air conditioner.

4. Interconnecting wiring and conduits from the outdoor unit to the indoor unit are not provided with the air conditioner.

5. The supply voltage, size of over current protective device, and size of supply conductors for the air conditioner are as

shown below.

6. Unit must be installed in accordance with all applicable federal, state and local codes.

7. Check local electrical codes and regulations before obtaining wire.

8. Use copper supply wires only.

9. Each wiring connection must be done tightly and in accordance with the wiring system diagram. Improper wiring may

cause the unit to malfunction or become damaged.

Installation & service manual _5

ELECTRICAL INSTALLATION

BTU

Page 9

3 2 1

Terminal block of indoor unit

3 2 1L1 N

Terminal block

of outdoor unit

Power supply,

1 phase, 60 Hz

INDOOR UNIT OUTDOOR UNIT

Installation & service manual _6

WIRING SYSTEM DIAGRAMS

Ground wire

ACN wire

ACL wire

Communication

wire

9SRA-HE | 12SRA-HE | 15SRA-HE (115V - 60Hz)

INDOOR UNIT

OUTDOOR UNIT

L1

N

3

OUTDOOR UNIT

2

1

INDOOR UNIT WIRING DIAGRAM

3

2

1

ACN

BU

ACL

BN

CMU

OR

INDOOR CONTROL BOARD

FUSE

3.15 A

9

COMPULSIVE SWITCHING

2

PIPE SENSOR

2

TEMP SENSOR

2

5

5

DISPLAY AND

RECEIVE BOARD

IN FAN

STEP

MOTOR

3

2

INDOOR UNIT

1

BN

L1

WH

N

BU

BU

3

BN

ACN

2

OR

1

OUTDOOR UNIT WIRING DIAGRAM

CMU

OUTDOOR CONTROL BOARD

FUSE

3.15 A

COM

NO

CAPACITOR

PROTECTOR

C

5

2

2

RD

R

S

COMPRESSOR

HIGH

PRESSURE

SWITCH

LOW

PRESSURE

SWITCH

OUT

FAN

OUTDOOR TEMP SENSOR

OUTDOOR PIPE SENSOR

Page 10

Installation & service manual _7

WIRING SYSTEM DIAGRAMS

3 2 1

Terminal block of indoor unit

3 2 1L1 L2

Terminal block

of outdoor unit

Power supply,

1 phase, 60 Hz

INDOOR UNIT OUTDOOR UNIT

Ground wire

ACN wire

ACL wire

Communication

wire

18SRA-HE | 24SRA-HE (208-230V - 60Hz)

INDOOR UNIT

OUTDOOR UNIT

L1

L2

3

OUTDOOR UNIT

2

1

INDOOR UNIT WIRING DIAGRAM

3

2

1

ACN

BU

ACL

BN

CMU

OR

INDOOR CONTROL BOARD

FUSE

3.15 A

9

COMPULSIVE SWITCHING

2

PIPE SENSOR

2

TEMP SENSOR

2

5

5

DISPLAY AND

RECEIVE BOARD

IN FAN

STEP

MOTOR

BN

L1

WH

L2

3

2

INDOOR UNIT

1

BU

BU

3

BN

2

OR

1

OUTDOOR UNIT WIRING DIAGRAM

ACN

COM

FUSE

3.15 A

CMU

OUTDOOR CONTROL BOARD

CAPACITOR

PROTECTOR

NO

RD

R

C

COMPRESSOR

HIGH

PRESSURE

SWITCH

LOW

PRESSURE

SWITCH

5

OUT

FAN

OUTDOOR TEMP SENSOR

2

S

Page 11

1. The indoor unit is powered from the outdoor unit. A sufficient length of conduit and wiring shall be used from the

outdoor unit to the indoor unit.

2. To access the terminal block inside the indoor unit, remove the screw on the cover plate. (See Fig. A.)

3. Connect the inter unit conductors to terminals marked 1,2,3, on the indoor unit corresponding to the same numbered

terminals from the outdoor unit. (See Fig.B.)

Figure B

Terminal block of indoor unit

Installation & service manual _8

ELECTRICAL CONNECTIONS FOR INDOOR AND OUTDOOR UNITS

Terminal block

Cover plate

Figure A

INDOOR UNIT

OUTDOOR UNIT

Conduit

Conduit

connectors

Incoming power supply

To indoor unit

1. Two conduit connection openings are provided on the outdoor unit: one for incoming power supply and the second one for

the inter unit wiring.

2. Remove the terminal box cover to access the terminal block.

3. Connect the power supply conductors to terminal marked L1, N or L1, L2, and the grounding wire to terminal

marked .

4. Connect the inter unit conductors to terminals marked , 3, 2, 1.

Conduit

Conduit

connectors

Incoming power supply

To indoor unit

9SRA-HE | 12SRA-HE | 15SRA-HE (115V - 60Hz)

18SRA-HE | 24SRA-HE (208-230V - 60Hz)

Page 12

When connecting the refrigerant tubing

- Keep all tubing runs as short as possible.

- Use the flare method for connecting tubing.

- Apply refrigerant lubricant to the matching surfaces of the flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

- Check carefully for leaks before starting the test run.

Evaporator

Condenser

Compressor

Capillary tube

3-Way valve

2-Way valve

Indoor unit

Outdoor unit

Installation & service manual _9

REFRIGERATION LINE CONNECTIONS

Models 9SRA-HE 12SRA-HE 15SRA-HE 18SRA-HE 24SRA-HE

Refrigeration Tubing

Connection method Flare Flare Flare Flare Flare

Refrigerant tube outer diameter in. Liquid 1/4 1/4 1/4 1/4 3/8

in. Suction 1/2 1/2 1/2 5/8 5/8

Limit of tubing length ft. 49 49 49 49 49

Limit of elevation difference between the two units ft. 20 20 20 20 20

Page 13

Installation & service manual _10

REFRIGERANT R410A: SPECIAL PRECAUTIONS WHEN INSTALLING UNIT

General Information

Systems using R-410A refrigerant run at a pressure of approximately 1.6 times that of similar systems using R-22 and the

energy efficiency is comparable. The R-410A refrigerant is a 50:50 mixture of R-32 and R-125.

When installing equipment using R-410A refrigerant, there are a number of standards that must be met:

• Ester oil is used for R-410A.

• It’s important to work with absolute cleanliness.

• Brazing must be done with the use of Nitrogen.

• The system must always be charged in the liquid state.

When refrigerant R-410A is used, the composition will differ depending on whether or not it is a gaseous state.

Consequently, always charge the refrigerant while it is in a liquid state.

General Precautions – Refrigerant leaking

The composition of refrigerant R-410A changes when it is gaseous state. Thus, when there is a refrigerant leak the basic

performance of the air conditioner may be degraded because of a change in composition of the remaining refrigerant.

Therefore, do not add new refrigerant. Instead, recover the remaining refrigerant with the refrigerant recovery unit. Then,

after evacuation, totally recharge the unit with the specified amount of new refrigerant at it’s normal mixed composition state.

Tubing Precautions

The refrigerant R-410A is less is more easily affected by dust or moisture than R-22 refrigerant. Make sure to temporally

cover the ends of the tubing with caps or tape prior installation.

Never use tubing which is less than 0.03 inch in thickness (Standard Specification ASTM B-280), since air conditioners with

R-410A refrigerant are subject to higher pressures than those using R-22 refrigerant.

Caution:

The compressor POE oil for R-410A units is extremely susceptible to moisture absorption and could cause

compressor failure. Do not leave system open to atmosphere any longer than necessary for installation.

Page 14

Installation & service manual _11

TIGHTENING REFRIGERANT PIPING CONNECTIONS

Caution:

Remove the protection caps on the pipes and connect the assembly piping to each connector. First,

tighten the nuts manually and then with a wrench by applying the tightening torque shown below.

17 x 14 to 18

22 x 34 to 42

26 x 49 to 61

29 x 68 to 82

36 x 100 to 120

Class 2 (for R410A)

Diamètre (mm) x Tightening torque (Nm)

Applicable size

1/4 “

3/8 “

1/2 “

5/8 “

3/4 “

Flare nut size and tightening torque

Page 15

Installation & service manual _12

SYSTEM EVACUATION

Condensing unit liquid and suction valves are closed to contain the charge within the unit. The unit is shipped with the valve

stems closed and caps installed. Do not open the valves until the system is evacuated.

1. Connect the vacuum pump with 250-micron capability to the services valves.

2. Evacuate the system to 250 microns or less using suction and liquid service valves. Using both valves is necessary for some

compressors create a mechanical seal separating the sides of the system.

3. Close pump valve and hold vacuum for 10 minutes. Typically pressure will rise during this period

• If the pressure rises to 1000 microns or less and remains steady the system is considered leak-free; proceed to startup.

• If the pressure rises above 1000 microns but holds steady below 2000 microns, moisture and/or noncondensibles may

be present or the system may have a small leak. Return to step 2: If the same result is encountered, check for leaks as

previously indicated and repair as necessary then repeat evacuation.

• If pressure rises above 2000 microns, a leak is present. Check for a leaks as previously indicated and repair as

necessary then repeat evacuation.

Manifold valve

Low pressure side valve

High pressure side valve

Charging hose

Vacuum pump

A

B

Charging hose

Caution:

Refrigerant must not be discharged into the atmosphere.

After connecting the piping, check the joints for leakage with a gas leak detector.

Page 16

Installation & service manual _13

ADDITIONAL CHARGE AND DISTANCE

Refrigerant suitable for a piping length of 20 ft (6 m) is charged in the outdoor unit at the factory. When the pipe is longer

than 20 ft (6 m), additional charging is necessary. This operation can only be performed by a qualified refrigeration

specialist. Additional amount must be added for each extra 3.3 ft (1 m), see the table below:

Models

Limit of tubing length

ft (m)

Limit of elevation

between the two unit

20 (6)

Models

Additional refrigerant 20 g (0.7 oz)

30 g (1.06 oz)

40 g (1.41 oz)

9SRA-HE

12SRA-HE | 15SRA-HE |

18SRA-HE

24SRA-HE

9SRA-HE | 12SRA-HE | 15SRA-HE | 18SRA-HE | 24SRA-HE

49 (15)

Page 17

Installation & service manual _14

GAS LEAK CHECK

Check that no gas escapes from the connections by using a leak detector or soapy water.

A and B are the liquid and suction valves of the outdoor unit.

C and D are the extremities of the indoor unit flared connections.

Indoor unit check points

B

A

D

Liquid and suction valves

C

Page 18

Installation & service manual _15

CHECKING AND TESTING OPERATIONS

Perform the operation test after completing the gas leak check of the flare nut connections and the electrical connections.

1. To begin the test, turn on the power.

2. Press the auxiliary control button in the indoor unit or use the remote control to start the unit.

3. Check that all air conditioner functions are operating normally. A protection feature prevents the air conditioner from

being started immediately after the unit has been turned off. There is a delay of 3 minutes for the air conditioner to restart

and operate.

4. Press the auxiliary control button to end the operation test.

15 000-18 000-24 000 BTU

9 000-12 000 BTU

Auxiliary control button

Auxiliary control button

Page 19

Installation & service manual _16

TECHNICAL SPECIFICATIONS

SPECIFICATIONS

*Note: Design and specifications are subject to change without notice for product improvement.

Comply with ARI STANDARD 210/240.

Cooling

Cooling

Maximum

Minimum

Maximum

Minimum

Cooling

Liquid

Suction

Width

Height

Depth

Shipping

Net

Width

Height

Depth

Shipping

Net

12SRA-HE

12 000

13.5

R-410A

3.1

441

45-42-34

52

95 (35)

64 (18)

109 (43)

32 (0)

115

60 / 1

10.6

15

25

Flare

1/4

1/2

49

20

31 1/2

10 7/8

8 1/4

22

19

33 7/8

25 5/8

12

101

95

9SRA-HE

9 000

15

R-410A

1.9

382

44-40-33

50

95 (35)

64 (18)

109 (43)

32 (0)

115

60 / 1

7.7

15

15

Flare

1/4

1/2

49

20

31 1/2

10 7/8

8 1/4

22

19

31 3/4

23 1/2

11 1/4

92

88

15SRA-HE

15 000

14

R-410A

3.5

559

47-44-40

55

95 (35)

64 (18)

109 (43)

32 (0)

115

60 / 1

10.7

15

25

Flare

1/4

1/2

49

20

38 3/4

12 5/8

7 1/2

33

29

33 7/8

25 5/8

12

101

95

18SRA-HE

18 000

13.5

R-410A

4.1

647

48-44-40

56

95 (35)

64 (18)

109 (43)

32 (0)

208~230

60 / 1

6.8 / 6.4

15

15

Flare

1/4

5/8

49

20

38 3/4

12 5/8

7 1/2

33

29

37 1/2

33 3/4

13 3/4

139

130

24SRA-HE

24 000

13

R-410A

5.2

765

52-49-45

59

95 (35)

64 (18)

109 (43)

32 (0)

208~230

60 / 1

9.6 / 8.7

20

20

Flare

3/8

5/8

49

20

42 1/2

13

9 1/4

39

35

38 1/4

37 1/2

14 1/4

150

141

BTU/h

BTU/hW

Pt./H

CFM

dB(A)

dB(A)

°F (°C)

°F (°C)

V

Hz / ø

A

A

A

in.

ft.

ft.

in.

lbs

in.

lbs

MODELS

Performance ratings

Nominal capacity

S.E.E.R

Refrigerant type

Dehumidifying capacity

Airflow circulation (High)

Indoor sound rating (High-Medium-Low)

Outdoor sound rating

Temperature Indoor air intake

Outdoor air intake

Electrical data

Voltage rating

Frequency / Phase

Running amperes

Minimum circuit ampacity

Maximum overcurrent protection

(Time delay fuse or HACR type circuit breaker)

Refrigeration tubing

Connection method

Refrigerant tube outer diameter

Limit of tubing length

Limit of elevation difference between the two units

Dimensions & weight

Indoor unit Dimensions

Weight

Outdoor unit Dimensions

Weight

Page 20

In

A

B

C

D

E

F

G

H

I

Models: 9SRA-HE | 12SRA-HE | 15SRA-HE | 18SRA-HE | 24SRA-HE

Indoor unit

Outdoor unit

A

F

B

D

E

H

I

G

C

Installation & service manual _17

OUTLINE AND DIMENSIONS

9SRA-HE

10 7/8

31 1/2

8 1/4

31 3/4

11

23

1/2

11 1/4

14 1/8

12SRA-HE

10 7/8

31 1/2

8 1/4

33 7/8

12

25

5/8

12

14 3/4

15SRA-HE

12 5/8

38 3/4

7 1/2

33 7/8

12

25

5/8

12

14 3/4

18SRA-HE

12 5/8

38 3/4

7 1/2

37 1/2

14

32 1/4

1 1/2

13 3/4

16 1/4

24SRA-HE

13

43 1/2

9 1/4

38 1/4

14 1/2

36

1 1/2

14 1/4

16 1/4

Page 21

Installation & service manual _18

PARTS DIAGRAM (INDOOR UNIT)

INSIDE UNIT

9SRAI-HE

12SRAI-HE

15SRAI-HE

18SRAI-HE

24SRAI-HE

Page 22

Installation & service manual _19

PARTS LIST (INSIDE UNIT)

Inside unit - spare parts

REF.

NO

Faceplate (including display glass) 1

1

Lamp board holder 1

2

Lamp Board (3 lights) + infrared lense 1

3

Lamp board back cover 1

4

5 Control Box Cover 1 P00851 P00851

Terminal block Cover 1

6

Plastic Cover 1

7

8 Filters 2 P00858 P00858

9 Middle Base 1 P00861 P00861

10 Rating plate (WILLIAMSON) 1 L00140 L00141

Wiring circuit diagram 1 L00027 L00027 L00027 L00027 L00027

11

12 Wireless remote control 1

13 Wireless remote control holder 1

Terminal Block 1 P00876 P00876 P00876 P00876 P00876

14

Nameplate (WILLIAMSON) 1 L00138 L00138 L00138 L00138 L00138

15

Control Box 1

16

Controller PCB 1

17

18 Sensors 1

Sensor Bracket 1 P00883 P00883 P00883 P00883 P00883

19

Rubber plug (back drain) 1 P00884 P00884 P00885 P00885 P00885

20

Fan Motor Assembly kit

21

Fan motor cushion 1

21-1

Fan motor

21-2

Evaporator Assembly

22

Cross Flow Fan Assembly

23

Cross Flow Fan

23-1

Cushion - Cross flow fan

23-2

Left Cover (Cross flow fan) 1

24

Drain Hose 1

25

Blade (vertical movement) 1 or 2

26

27 Fan guard metal grid 1

Discharge frame assembly 1

28

Step Motor 1

29

30 Louvers (horizontal movement) 2 P00925 P00925 P00926 P00926 P00927

Base Assembly 1

31

Wall Hook Bracket 1

32

Screw cap 3

33

DESCRIPTION QTY

1

1 P00895 P00895 P00896 P00896 P00897

kit K00090 K00090 K00091 K00091 K00092

1 P00901 P00901 P00902 P00902 P00903

1 P00904 P00904 P00905 P00905 P00906

9SRAI-HE 12SRAI-HE 15SRAI-HE 18SRAI-HE 24SRAI-HE

P00843 P00843

P00846 P00846

P00847 P00847

P00850 P00850

P00854 P00854

P00855 P00855

P00874 P00874 P00874 P00874 P00874

P00875 P00875 P00875 P00875 P00875

P00878 P00878

P00881 P00868 P00869 P00870 P00871

P00882 P00882 P00882 P00882 P00882

K00086 K00086 K00087 K00088 K00089

P00889 P00889 P00890 P00872 P00891

P00892

P00907 P00907 P00908 P00908 P00909

P00910 P00910 P00911 P00911 P00912

P00913 P00913 P00914 P00914 P00915

P00916 P00916 P00917 P00917 P00918

P00919 P00919 P00920 P00920 P00921

P00877 P00877 P00886 P00886 P00924

P00928 P00928 P00929 P00929 P00930

P00931 P00931 P00932 P00932 P00933

P00898 P00898 P00899 P00899 P00900

P00892 P00893 P00873 P00894

P00844 P00844 P00845

P00864 P00864 P00865

P00848 P00848 P00849

P00866 P00866 P00867

P00852 P00852 P00853

P00856 P00856 P00857

N/A N/A N/A

P00859 P00859 P00860

P00862 P00862 P00863

L00142 L00143 L00144

P00879 P00879 P00880

Page 23

Installation & service manual _20

PARTS DIAGRAM (OUTDOOR UNIT)

OUTSIDE UNIT

9SRAO-HE

12SRAO-HE

15SRAO-HE

18SRAO-HE

24SRAO-HE

Page 24

Installation & service manual _21

PARTS LIST (OUTSIDE UNIT)

Outside unit - spare parts

REF.

NO

1 Cabinet | Front L | Painted (including fan cover) 1 P00730 P00731 P00731 P00732 P00733

2 Control box cover 1 P00734 P00734 P00734 P00734 P00734

3 Propeller fan 1 P00738 P00738 P00738 P00739 P00739

4 Motor bracket 1 P00740 P00741 P00741 P00742 P00743

5 Fan motor 1 P00744 P00744 P00744 P00745 P00745

6 Nameplate (WILLIAMSON) 1 L00139 L00139 L00139 L00139 L00139

7 PCB outdoor 1 P00747 P00747 P00747 P00748 P00748

8 Control box 1 P00749 P00735 P00735 P00750 P00751

9 Capacitor | Compressor 1 P00752 P00752 P00752 P00754 P00755

10 Capacitor clamp 1 P00756 P00756 P00756 P00758 P00736

11 Terminal block 1 P00757 P00757 P00757 P00759 P00759

12 Divider wall 1 P00760 P00761 P00761 P00737 P00762

13 Cabinet | top | Painted 1 P00763 P00764 P00764 P00746 P00765

14 Condenser assembly 1 P00766 P00767 P00767 P00768 P00769

15 Cabinet | Front R | Painted 1 include with ref. #1 include with ref. #1 include with ref. #1 P00753 include with ref. #1

16 Base Assembly / Painted 1 P00770 P00771 P00771 P00773 P00774

17 Capillary assembly 1 P00775 P00776 P00776 P00777 P00777

18 Compressor assembly Kit K00082 K00083 K00083 K00084 K00085

18-1 Compressor 1 P00783 P00784 P00784 P00785 P00786

18-2 Special nut | M8 3 P00787 P00787 P00787 P00787 P00787

18-3 Rubber seat 3 P00791 P00791 P00791 P00793 P00794

18-4 Terminal gasket 1 P00795 P00795 P00795 P00797 P00797

18-5 Terminal cover 1 P00799 P00799 P00799 P00801 P00801

19 Noise insulation 1 P00803 P00803 P00803 P00805 P00805

20 Sensor bracket 1 P00807 P00807 P00807 P00807 P00807

21 Rubber caps 2 P00811 P00811 P00811 P00811 P00811

22 Steel Grid 1 P00812 P00813 P00813 P00814 P00815

23 Cabinet | Back R | Painted 1 P00816 P00817 P00817 P00818 P00819

24 Side plastic cover 1 P00820 P00821 P00821 P00823 P00824

25 Electric Diagram 1 L00028 L00028 L00028 L00029 L00029

26 Rating Plate (WILLIAMSON) 1 L00145 L00146 L00147 L00148 L00149

27 Two-Way valve (Liquid) 1 P00831 P00832 P00832 P00830 P00833

28 Three-Way valve (Succion) 1 P00829 P00834 P00834 P00835 P00836

29 Valve panel 1 P00837 P00838 P00838 P00839 P00840

30 Outdoor heat exchanger thermistor 1 P00841 P00841 P00841 P00841 P00841

31 Discharge temperature thermistor 1 P00842 P00842 P00842 P00842 P00842

32 Rubber legs 4 P00772 P00772 P00772 P00772 P00772

33 Low pressure switch 1 P00945 P00945 P00945 P00945 P00945

34 High pressure swicth 1 P00946 P00946 P00946 P00946 P00946

DESCRIPTION QTY

9SRAO-HE 12SRAO-HE 15SRAO-HE 18SRAO-HE 24SRAO-HE

Page 25

Installation & service manual

NOTE

Page 26

8201 W. Calumet Road, Milwaukee, WI 53223 USA

www.williamson-thermoflo.com

Loading...

Loading...