Planmed Sophie TM11 Service Manual

PLANMED SOPHIE

MAMMOGRAPHY X-RAY UNIT

8

TECHNICAL MANUAL

En |

788405/11 |

|

|

|

TABLE OF CONTENTS |

|

|

|

|

|

Chapter A GENERAL & TECHNICAL DATA |

|

|

1 |

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . A-1 |

|

2 |

MANUAL VERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . A-2 |

|

3 |

UNIT MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . A-2 |

|

4 |

SOFTWARE REVISIONS & COMPATIBILITY . . . . . . . . . . . . |

. . . . . . . . A-3 |

|

5 |

HOW TO FIND INFORMATION IN THIS MANUAL . . . . . . . . . |

. . . . . . . . A-4 |

|

6TECHNICAL SPECIFICATIONS (TOSHIBA E7272 X-RAY TUBE) . . . . A-5

7USER’S STATEMENT FOR PLANMED SOPHIE

(TOSHIBA E7272 X-RAY TUBE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

7.1 Definition of measurement criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7 7.2 Toshiba E7272 x-ray tube ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9 7.3 Cooling curves for x-ray tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

8TECHNICAL SPECIFICATIONS (TOSHIBA E7290 X-RAY TUBE) . . . A-11

9USER’S STATEMENT FOR PLANMED SOPHIE

(TOSHIBA E7290 X-RAY TUBE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

9.1 Toshiba E7290 x-ray tube ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15 9.2 Cooling curves for x-ray tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Chapter B UNPACKING & INSTALLATION

1 PRE-INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

|

1.1 |

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-1 |

1.2 |

Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

1.3 |

Space requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

1.4 |

Radiation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

1.5 |

Power requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

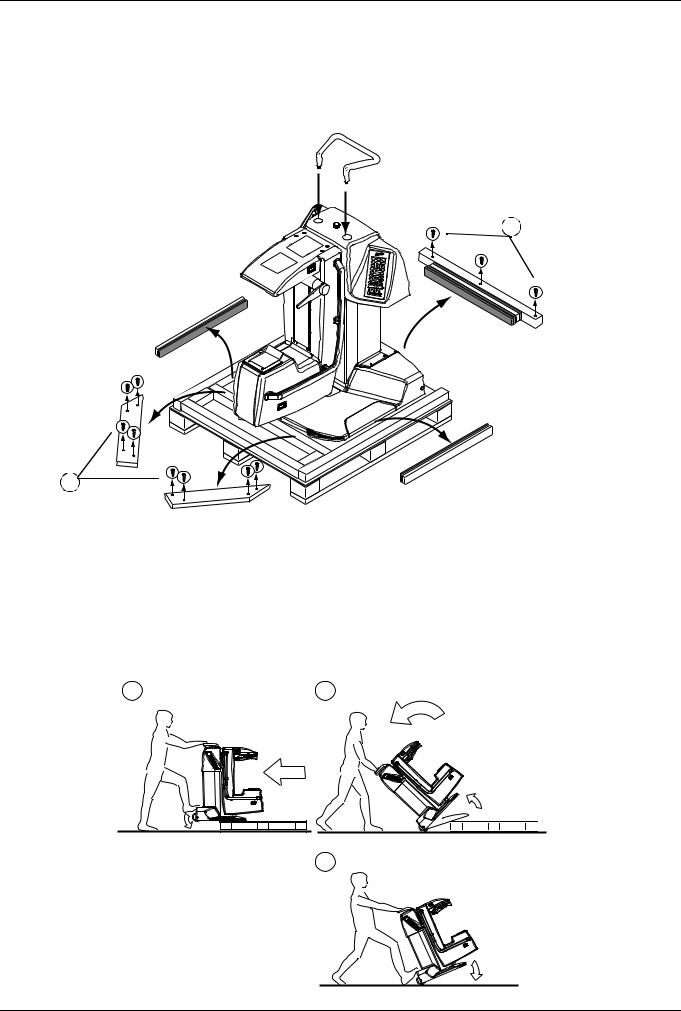

2 UNPACKING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

|

2.1 |

General about unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-3 |

2.2 |

Step-by-step unpacking instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

2.3 |

Driving the unit out of the transportation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

2.4 |

Attaching the unit to the floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-6 |

2.5 |

Unpacking the accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-7 |

3 |

ATTACHMENT OF ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

|

|

3.1 |

Compression paddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . B-8 |

|

3.2 |

Remote control attachment (optional for the mobile unit) . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

|

3.3 |

Mobile Sophie special accessories attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

|

3.4 |

Exposure warning light (option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

|

3.5 |

Printer (option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

|

3.6 |

ADMARK darkroom film-marking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. B-8 |

4 |

SETUPS AND CHECKS PRIOR TO USE . . . . . . . . . . . . . . . . . . . . . . . |

B-9 |

|

5 |

RE-PACKING & TRANSPORTATION OF THE SOPHIE UNIT . . . . . . . |

B-10 |

|

|

5.1 |

Driving the unit into the transportation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-10 |

|

5.2 |

Transporting the unit on its own wheels (non-mobile unit). . . . . . . . . . . . . . . . . . . . . |

B-10 |

6 MOBILE SOPHIE HANDLING & TRANSPORTATION . . . . . . . . . . . . . B-11

6.1 Preparing the mobile unit for use after transportation . . . . . . . . . . . . . . . . . . . . . . . . B-11 6.2 Preparing the mobile unit for transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Chapter C KEYBOARD FUNCTIONS & MODES

1 |

KEYBOARD OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

C-1 |

|

2 |

USER MODE FUNCTIONS SHORT-FORM . . . . . . . . . . . . . . . . . . . . . . |

C-2 |

|

|

2.1 |

Normal user functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. C-2 |

|

2.2 |

Special user settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. C-2 |

3 SERVICE MODE FUNCTIONS SHORT-FORM . . . . . . . . . . . . . . . . . . . C-4

3.1 How to enter / exit the service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Technical Manual |

Sophie Mammography X-ray unit TOC-1 |

TABLE OF CONTENTS

3.2 Meaning of displays in the service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4 3.3 Service mode settings & special displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

4 SERVICE MODE FUNCTION DETAILS . . . . . . . . . . . . . . . . . . . . . . . . . C-7

4.1 Transport position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7 4.2 Display of internal temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7 4.3 Displaying the real density value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8 4.4 Displaying the exposure counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8 4.5 Displaying the recent 49 error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8 4.6 Print a list of the recent 49 errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9 4.7 Ignore errors temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9 4.8 Diagnostic display of internal signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Chapter D HELP AND ERROR MESSAGES

1 GENERAL ABOUT ERROR DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . D-1

1.1 Stop-message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1 1.2 Help messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1 1.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

2 HELP MESSAGES SHORTFORM TABLE . . . . . . . . . . . . . . . . . . . . . . . D-2

3 ERROR MESSAGES SHORTFORM TABLE . . . . . . . . . . . . . . . . . . . . . D-4

4 DETAILED ERROR MESSAGE EXPLANATIONS . . . . . . . . . . . . . . . . . D-8

4.1 ERRORS 00-09 (User related, not stored in internal error list) . . . . . . . . . . . . . . . . . . D-8 4.2 ERRORS 10-16 (X-ray safety and AEC-sensor related) . . . . . . . . . . . . . . . . . . . . . . . D-9 4.3 ERRORS 20-29 (motion and compression related) . . . . . . . . . . . . . . . . . . . . . . . . . D-10 4.4 ERRORS 30-38 (tube head and power supply related) . . . . . . . . . . . . . . . . . . . . . . D-12 4.5 ERRORS 40-49 (sensor & switch related) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13 4.6 ERRORS 50-59 (temperature & special sensor related). . . . . . . . . . . . . . . . . . . . . . D-15 4.7 ERRORS 60-68 (serial communication & CPU voltage related) . . . . . . . . . . . . . . . . D-16 4.8 ERRORS 71-78 (CPU software related) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-16 4.9 ERRORS 80-87 (CPU hardware related) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17 4.10 ERRORS 90-97 (Erroneous sensor signals) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18

Chapter E PREVENTIVE MAINTENANCE

1 SYSTEM MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1 1.2 Operator’s maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

2 PREVENTIVE MAINTENANCE CHECKS . . . . . . . . . . . . . . . . . . . . . . . E-2

2.1 Preventive maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2 2.2 Calibration and verification of the instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2 2.3 Determining half value layer (HVL / beam quality) . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3 2.4 Checking X-ray tube efficiency (radiation output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4 2.5 Focal spot size measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4 2.6 Image quality evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5 2.7 Verifying AEC-system control limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

3 OTHER PREVENTIVE CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

3.1 Verifying compression force measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6 3.2 Verifying filament pre-heating voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6 3.3 Verifying the anode voltage (kV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6 3.4 Verifying the tube current (mA) and the exposure time (Toshiba E7272 x-ray tube) . . E-8 3.5 Verifying the tube current (mA) and the exposure time (Toshiba E7290 x-ray tube) . . E-9 3.6 Verifying x-ray beam alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-10 3.7 Verifying light-field beam illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-10 3.8 Verifying visually defined x-ray fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-11 3.9 Verifying electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-11

Chapter F ADJUSTMENT & CALIBRATION

1 SPECIAL REGIONAL & INITIAL SETUPS . . . . . . . . . . . . . . . . . . . . . . |

F-1 |

|

1.1 |

Regional setups before using the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

F-1 |

1.2 |

Other setups before using the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

F-1 |

TOC-2 Sophie Mammography X-ray unit |

Technical Manual |

TABLE OF CONTENTS

2 KEYBOARD-CONTROLLED (in normal mode) . . . . . . . . . . . . . . . . . . F-3

2.1 Automatic kV mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3 2.2 Automatic rhodium/molybdenum filter selection mode . . . . . . . . . . . . . . . . . . . . . . . . F-3 2.3 Default magnification factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4 2.4 Automatic release of compression after exposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4 2.5 Initial descent speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4 2.6 Compression speed decrease rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5 2.7 Intermediate compression stopping force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5 2.8 Twincomp compression on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5 2.9 Lift motor crawling speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5 2.10 Setting correct time and date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6 2.11 Density offset adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6 2.12 AAEC contrast adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6 2.13 Automatic film labeling (on/off). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6 2.14 Disabling bucky grid movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7 2.15 Alarm sound frequency (loudness) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7 2.16 Dimming the displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7 2.17 mA limit (on/off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

3 KEYBOARD-CONTROLLED (in service mode) . . . . . . . . . . . . . . . . . . F-8

3.1 How to enter the service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8 3.2 Factory preset (recalling settings for all parameters). . . . . . . . . . . . . . . . . . . . . . . . . . F-9 3.3 C-arm upright position calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12 3.4 Breast thickness measurement calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12 3.5 Compression force measurement calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-13 3.6 X- ray tube filament preheating voltage calibration . . . . . . . . . . . . . . . . . . . . . . . . . . F-14 3.7 AEC-sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-15 3.8 kV-value fine-adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-16 3.9 Special system parameters setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-17

4 FINE TUNING SOPHIE AEC FOR NONSTANDARD FILM/SCREEN COMBINATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-24

4.1 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-24 4.2 Testing the AEC for proper tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-24 4.3 Adjusting the thickness, tube potential and time compensations . . . . . . . . . . . . . . . F-24 4.4 Adjusting the filter and imaging mode adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . F-26

5 MECHANICAL ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-28

5.1 MAG/LOAD mechanism positional calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-28 5.2 UP/DOWN mechanism positional calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-28 5.3 X-ray beam adjustment (Toshiba E7272 X-ray tube). . . . . . . . . . . . . . . . . . . . . . . . . F-29 5.4 X-ray beam adjustment (Toshiba E7290 X-ray tube). . . . . . . . . . . . . . . . . . . . . . . . . F-35 5.5 Light field beam adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-42 5.6 Filter position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-43 5.7 Twincomp paddle damper adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-43 5.8 Gas spring tension adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-43

6 ADJUSTING SENSORS & SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . F-44

6.1 Collimator mechanism limit sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-44 6.2 Compression mechanism limit sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-49 6.3 MAG/LOAD mechanism limit sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-52 6.4 Labeling head disk position sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-54 6.5 C-arm rotation sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-54 6.6 UP/DOWN mechanism sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-58 6.7 Cassette table size identification switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-61 6.8 Lower paddle identification switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-64

Chapter G TROUBLESHOOTING & FAULTFINDING

1 DISPLAYING INTERNAL SENSOR SIGNALS . . . . . . . . . . . . . . . . . . . . G-1

2 ELECTRICAL PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

2.1 Unit completely dead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

3 MOTOR & MOTION RELATED PROBLEMS . . . . . . . . . . . . . . . . . . . . . G-2

3.1 DC motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2 3.2 Stepper motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Technical Manual |

Sophie Mammography X-ray unit TOC-3 |

TABLE OF CONTENTS

4 MECHANICAL PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

4.1 Paddle holder related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

5 BEFORE CALLING FOR ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . G-8

5.1 General required information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8 5.2 How to report image quality problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8 5.3 How to contact Planmed head office. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Chapter H PARTS REPLACEMENT & REPAIR

1 REMOVING & REPLACING COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-1 |

|

1.1 |

Base covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. H-2 |

1.2 |

Telescopic column covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-2 |

1.3 |

Stationary column covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-3 |

1.4 |

C-arm covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-4 |

1.5 |

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-6 |

1.6 |

Cassette table cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-7 |

1.7 |

Collimator cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-7 |

2 |

SOFTWARE VERSION UPDATING . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. H-8 |

|

|

2.1 |

Replacing software chips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . H-8 |

3 |

REPLACING FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-10 |

|

|

3.1 |

Mains fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. H-10 |

|

3.2 |

Power supply fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-10 |

4 |

LIGHTFIELD BULB REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . |

H-12 |

|

5 |

REPLACING THE X-RAY TUBEHEAD . . . . . . . . . . . . . . . . . . . . . . . . . |

H-13 |

|

|

5.1 |

Preparations before changing the tubehead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-14 |

|

5.2 |

Removal of the tubehead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-17 |

6 |

REPLACING THE POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-18 |

|

7 |

REPLACING CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-19 |

|

|

7.1 |

Location of PC-boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-19 |

|

7.2 |

Boards in the base & column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-20 |

|

7.3 |

C-arm pc-boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-20 |

|

7.4 |

Tubehead assembly boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-22 |

|

7.5 |

Keyboards & displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-22 |

8 REPLACING SENSORS & SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . H-23

8.1 Placement of sensors & switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-23 8.2 Limit sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-24 8.3 Lift motor rotation sensor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-24 8.4 C-arm motor rotation sensor replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-25 8.5 MAG-motor rotation sensor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-25

9 MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-26

9.1 Lift motor replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-26 9.2 C-arm rotation motor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-28 9.3 Compression motor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-34 9.4 Magnification motor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-35

10 REPLACING THE LABELING HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . H-37

11 GAS SPRING REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-38

11.1 C-arm is functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-38 11.2 C-arm is not rotating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-38 11.3 Replacing the gas-spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-38

12 REPLACING PARTS IN COMPRESSION MECHANISM . . . . . . . . . . . H-39

12.1 Replacing the twin-comp damper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-39

Chapter I SCHEMATICS & DIAGRAMS

COPYRIGHT PLANMED 2000-10

PUBLICATION NUMBER 788405 revision 11

TOC-4 Sophie Mammography X-ray unit |

Technical Manual |

Chapter

A GENERAL & TECHNICAL DATA

1 WARNINGS

WARNING

THE FOLLOWING WARNINGS, CAUTIONS AND NOTES MUST ALWAYS BE CONSIDERED WHILE SERVICING, IN ORDER TO AVOID EITHER PERSONAL INJURY OR DAMAGE TO THE UNIT.

CAUTION RADIATION SAFETY RULES

Some procedures described in this manual produces X-ray radiation. Always follow rules for radiation safety.

Never touch or scratch the surface of the x-ray tube radiation window. The window is made of beryllium that can be harmful if inhaled or swallowed.

Never attempt to open the TUBE-HEAD. It does not contain any serviceable parts and this would make it inoperable and void the warranty.

Never make any exposures without the Mo/Al filter in the beam, or without the beam limiting device (collimator) in place. Otherwise the radiation safety cannot be guaranteed.

CAUTION ELECTRICAL SAFETY RULES

The unit contains hazardous voltages. While servicing internal parts, always disconnect the unit from the mains (if possible) by removing the plug from the wall outlet, and wait for 2 minutes before touching any electrical parts.

Always replace the fuses with ones of the same type and rating. Otherwise patient, operator or equipment safety cannot be guaranteed.

The circuit boards can be damaged due to static discharges and requires careful handling and storage.

CAUTION GENERAL SAFETY RULES

The unit must be serviced only by qualified personnel, trained by PLANMED Repairs and parts replaced by unqualified personnel carry no warranty.

Periodical maintenance as described in this manual must be performed on a regular basis, to ensure the safety and image quality of the unit.

Some procedures described in the unit could jeopardize the function of the unit, if not followed as stated.

Technical Manual |

Sophie Mammography X-ray unit A-1 |

Chapter A - GENERAL & TECHNICAL DATA |

MANUAL VERSIONS |

2 MANUAL VERSIONS

PLANMED pursues a policy of continuous product development. Although every effort is made to produce up-to-date product documentation this manual should not be regarded as an infallible guide to current production specifications. Planmed reserves the right to make changes to specifications without prior notice. This manual is valid for all versions of the Sophie Mammography X-ray units with SID 650mm. In case you have the unit with SID 600mm, you need a technical manual revision 9.

NOTE |

THIS TECHNICAL MANUAL IS VALID FOR SOFTWARE REVISIONS: TUBE CPU 2.41 |

|

(OR LATER) AND REAR CPU 4.41 (OR LATER). |

|

If you find that your SOPHIE doesn’t have some keyboard functions, or its keyboard |

|

functions differs from procedures described in this manual, then either the software |

|

must be replaced with at least the above mentioned revision, or you have to relate to |

|

an older version of this manual. The former procedure is recommended. |

|

|

3 UNIT MODELS

All Sophie Mammography X-ray unit models are electrically and mechanically identical, except for some minor details. This manual is valid for all versions since the differences are small.

The darkroom versus daylight differs only in the size and dimensions of the cassette table and film marking device.

The mobile versus the stationary units differs only in the base wheel system and the X-ray tube locking system (for transportation).

Daylight units can be converted to darkroom units (and vice versa), please contact PLANMED for details.

A-2 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA |

SOFTWARE REVISIONS & COMPATIBILITY |

4 SOFTWARE REVISIONS & COMPATIBILITY

Background

Since this unit is fully microprocessor controlled, its operation is controlled by the currently installed software. PLANMED reserves the right to improve functionality or to add new features to the product by modifying the software and/or hardware. Manuals are updated accordingly and technical bulletins published in order to inform about these changes or additions.

Hardware compatibility

As a general rule; new software releases are compatible with all existing hardware. New software releases (or possible upgrading kits containing new software) are normally directly compatible with existing hardware, but not necessarily without some re-calibration procedures.

Software numbering & compatibility

Since the unit contains two communicating microprocessors, these must be able to “understand” each other.

Incompatible software versions should never be used together, the unit would either be totally non-functional, produce continuous error codes, or some important features or functions could be missing. However, no damage or safety hazard would result if two non-compatible software chips are accidentally used together.

The following table contains information about compatible software versions. Use versions together only as listed in this table.

Table 1: SOFTWARE COMPATIBILITY LIST

REAR CPU |

TUBE CPU |

|

|

|

|

1.20 - 1.28 |

1.20 - 1.28 |

|

1.59 |

1.59 |

|

1.60 |

1.60 |

|

1.63 |

1.63 |

|

1.64 |

1.64 |

|

1.65 |

1.64 |

|

1.66 |

1.64 |

|

1.67 |

1.64 |

|

1.68 |

1.64 |

|

1.69 |

1.69 |

|

1.70 |

1.69 |

|

1.71 |

1.69 |

|

1.72 |

1.69 |

|

1.73 |

1.69 |

|

1.74 |

1.69 |

|

1.75 |

1.69, 1.70 |

|

1.76 |

1.75, 1.76 |

|

1.77 |

1.77, |

1.78, |

|

1.79 |

|

REAR CPU |

TUBE CPU |

|

|

1.80 |

1.80, 2.00 |

1.81 |

1.81, 2.01 |

4.00 |

2.01 |

4.01/2.01 |

2.04 |

4.02/2.02 |

2.04 |

4.06/2.06 |

2.04 |

4.20 |

2.20 |

4.21 |

2.22 |

4.22 |

2.23 |

4.23 |

2.25 |

4.30 |

2.31 |

4.40 |

2.40 |

4.41 |

2.41 |

|

|

|

|

|

|

|

|

|

|

Technical Manual |

Sophie Mammography X-ray unit A-3 |

Chapter A - GENERAL & TECHNICAL DATA |

HOW TO FIND INFORMATION IN THIS MANUAL |

5 HOW TO FIND INFORMATION IN THIS MANUAL

For normal operating instructions, please refer to the “SOPHIE USER’S MANUAL”. However, this manual contains also full explanations of all user accessible adjustments that can be done with the keyboards.

For navigation, please refer to the table of contents in the beginning of this manual. The following is a brief description of the chapters in this manual.

“GENERAL & TECHNICAL DATA” on page A-1 (this chapter)

This chapter contains general information as well detailed technical specifications of the unit. Here you can find answers to all questions related to the unit specifications. Full technical specification details can be found here.

“UNPACKING & INSTALLATION” on page B-1

This chapter contains complete instructions how to unpack and install the unit, with information about installation requirements. Also information about transportation and handling is included.

“KEYBOARD FUNCTIONS & MODES” on page C-1

This chapter contains a complete short-form presentation of all available special keyboard functions. For explanation of normal user operation. Please refer to the “SOPHIE USER’S MANUAL”. The special display modes are also described here.

The detailed descriptions of all adjustments performed with the help of the keyboards can be found in the chapter “ADJUSTMENT & CALIBRATION” on page F-1.

“HELP AND ERROR MESSAGES” on page D-1

This chapter contains general information as well as a complete short-form presentation of all available special messages (STOP, HELP, ERROR) that can appear on the displays. A detailed description of the error messages and their reasons is also included.

“PREVENTIVE MAINTENANCE” on page E-1

This chapter describes the operators maintenance. Complete step-by-step instructions how to check the performance of the unit are also included. Some of these checks must be performed annually and before using the unit.

“ADJUSTMENT & CALIBRATION” on page F-1

This chapter contains detailed instructions of how to perform keyboard-controlled adjustments and calibrations, mechanical adjustments and sensor & switch adjustments.

“GENERAL & TECHNICAL DATA” on page A-1

For help and guidance with general troubleshooting and faultfinding, please refer to this chapter. It contains information of how to proceed in possible problematic situations.

“PARTS REPLACEMENT & REPAIR” on page H-1

This chapter contains detailed instructions how to replace both mechanical and electrical parts. It also reminds of what possible calibrations or adjustments must be performed after replacing particular parts.

“SCHEMATICS & DIAGRAMS” on page I-1

This chapter contains electrical wiring diagrams and schematics.

A-4 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA TECHNICAL SPECIFICATIONS (TOSHIBA E7272 X-RAY

6 TECHNICAL SPECIFICATIONS (TOSHIBA E7272 X-RAY TUBE) |

|

ORIGINAL MANUFACTURER |

|

PLANMED Oy, Asentajankatu 6, 00810 Helsinki, FINLAND |

|

phone: +358-9-7590 5300, fax: +358-9-7590 5555 |

|

MODEL AND APPROVALS |

|

MODELS: |

PLANMED SOPHIE, PLANMED SOPHIE MOBILE |

APPROVALS: |

IEC safety class: I, IEC degree of protection: B, IEC enclosure class: IP20 |

|

Complies with IEC 601-1 safety and IEC 601-2-7 radiation regulations |

X-RAY TUBE ASSEMBLY

X-ray tube |

Toshiba E7272 |

Anode type |

rotating anode (3000 rpm at 50 Hz) |

Anode braking |

Automatic, electrical |

Anode thermal capacity |

300 000 HU |

Anode target material |

Molybdenum |

Anode target angle |

16 degrees |

Tube port material |

Beryllium |

Focal spot sizes |

0.3mm / 0.1 x 0.07 mm |

Filtration |

30µm Mo and 0.5mm Al or |

|

30µm Mo and 25µm Rh |

GENERATOR ASSEMBLY (for both tube types if not otherwise specified)

Generator |

constant potential, high frequency |

|

Anode voltage range |

20 |

- 35kV ± 2kV, virtually DC |

Anode current range/0.3mm focus |

70 |

- 110mA (70 - 120 mA @ 60Hz) ± 5mA |

Anode current range/0.1mm focus |

10 |

- 22mA (12 - 22 mA @ 60Hz) ± 1mA |

mAs range/0.3mm focus |

10 |

- 500mAs (optional 600mAs in GB) ± 4mAs |

|

or ±10% (whichever is larger) |

|

mAs range/ 0.1mm focus |

10 |

- 200 mAs |

Exposure time /0.3mm focus |

0.1 - 5 seconds (optional 6 seconds) ±5% |

|

Exposure time / 0.1mm focus |

0.1 - 9.9 seconds ±5% |

|

Cooling |

automatically controlled (internal fan) |

|

Line voltage |

208 - 240V~, 50 or 60Hz - single phase |

|

Line voltage compensation |

automatic ±10% |

|

Line voltage regulation |

±10% (absolute minimum/maximum 187V~/265V~) |

|

Fuses |

2 x 15AT / 250V |

|

Total power consumption |

max. 100VA idle, 4000VA max. for 5 seconds |

|

Power factor |

> 0.95 |

|

Mode of operation |

intermittent |

|

Maximum mains resistance |

Ω 1 ¾ |

|

Maximum continuous |

|

|

heat dissipation |

< 250W |

|

BUCKY GRID SPECIFICATION

Grid manufacturer |

Gilardoni |

Grid type |

GRIDGIL HT; Fiber interspaced vertical |

Grid movement |

Variable amplitude oscillation |

Grid ratio |

r5 |

Grid lines per cm |

N36 |

Focusing distance |

f065 |

Application limits |

18x24: f150 f291 |

|

24x30: f153 f282 |

Material of absorbing strips |

Pb |

Contrast improvement ratio |

K1.47 |

Selectivity |

Σ6.04 |

Grid exposure factor |

B1.69 |

Transmission of primary radiation |

Tp 0.75 |

Max. deviation between the central |

|

line indication and the true |

∆2 |

central line |

Technical Manual |

Sophie Mammography X-ray unit A-5 |

Chapter A - GENERAL & TECHNICAL DATA |

TECHNICAL SPECIFICATIONS (TOSHIBA E7272 X-RAY |

AUTOMATIC EXPOSURE CONTROL (AEC) |

|

Sensors |

three selectable large area solid-state sensors |

Density adjustment |

15 density steps (13% change in OD per step) |

|

plus fine adjustment ± 5 steps (0,05 OD per step) |

Function modes |

Normal AEC, Advanced AEC (AAEC) |

C-ARM |

|

Rotation |

motorized, range -135° to +180° |

Vertical movement |

motorized, range 795mm to 1350mm (31.3in to 53.1in) |

SID |

650mm |

Compression |

fully motorized, variable speed, variable angle (twincomp) |

Cassette sizes |

18 x 24cm and 24 x 30cm |

Magnification |

motorized, variable range from 1.3 to 1.8 |

MECHANICAL DATA |

|

Dimensions |

(H x D x W) 1000 x 900 x 755 (mm) minimum |

|

(36.6 x 35.0 x 29.7 inch minimum) |

Weight |

160kg (352lbs), unpacked |

Color |

RAL 9016 |

A-6 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

7 USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA E7272 X-RAY TUBE)

Radiation leakage technique factors

The maximum-rated peak tube potential is 35 kVp and the maximum rated continuous tube current is 3.5mA for the maximum-rated peak tube voltage.

Minimum filtration

The Beam-limiting device contains three different filtrations 30µm molybdenum, 25µm rhodium and 0.50mm aluminum. The measured half-value layers are 0.343mmAl, 0.373mmAl and 0.377mmAl at 30kVp. These measured values correspond to aluminum equivalents of 0.55 - 0.65mmAl.

Rate line voltage

208 - 240V~ ±10%. Line voltage regulation 10%.

Maximum line current

Maximum 22 Amperes at absolute minimum stated mains voltage (187V~)

Technique factors that constitute the maximum line current condition

27kV / 110mA

Generator rating and duty cycle

3kW. The duty cycle and wait period can be calculated using the following formulas:

•Wait period = Tw = kV* mA* exp. Time / 500W

•Duty Cycle = 1 / (1 + kV* mA / 500W)

Maximum deviation of peak tube potential from indicated value

±2kV

Maximum deviation of tube current from indicated value

±5mA large focal spot, ±1mA small focal spot

Maximum deviation of exposure time tube current product from indicated value

±4mAs or ±10%, whichever is larger

Maximum deviation of exposure time from indicated value

±5%

7.1Definition of measurement criteria

Exposure time

The beginning and end points of the exposure time are defined at 70% of the peak radiation waveform measured with a calibrated x-ray monitor.

Peak tube potential

Is defined as the measured high voltage mean value measured with a calibrated non-invasive kVp meter.

Tube current

Is defined using the resistance and voltage over the feedback resistor measured with a calibrated multimeter. The mA value is then the voltage divided by the resistance.

mAs product

Is defined as the product of the exposure time and the tube current measurements.

The nominal x-ray voltage together with the highest x-ray tube current obtainable from the high-voltage generator when operated at its nominal x-ray tube voltage

35kV 80mA / 60Hz - large focal spot, 35kV 70mA / 50Hz - large focal spot 35kV 16mA / 60Hz - small focal spot, 35kV 14mA / 50Hz - small focal spot

Technical Manual |

Sophie Mammography X-ray unit A-7 |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

The highest x-ray tube current together with the highest x-ray tube voltage obtainable from the high-voltage generator when operated at its highest x-ray tube current

120mA 24kV / 60Hz - large focal spot, 110mA 24kV / 50Hz - large focal spot 22mA 26kV / 60Hz - small focal spot, 22mA 24kV / 50Hz - small focal spot

The x-ray tube voltage and x-ray tube current which result in the highest electric output power

27kV 110mA / 60Hz - large focal spot, 34kV 80mA / 50Hz - large focal spot 26kV 22mA / 60Hz - small focal spot, 24kV 22mA / 50Hz - small focal spot

The nominal electric power for a load time of 0.1s and at the nominal x-ray tube voltage

35kV 80mA / 60Hz - 2800W large focal spot, 35kV 70mA / 50Hz - 2450W large focal spot 35kV 16mA / 60Hz - 560W small focal spot, 35kV 14mA / 50Hz - 490W small focal spot

Reference current time product

large focal spot: for all kV values |

40mA / 0.1s / 4mAs |

small focal spot: for all kV values |

10mA / 0.1s / 1mAs |

The lowest current time product within the specified range of compliance

large focal spot: |

30mA / 0.1s / 3mAs |

small focal spot: |

10mA / 0.1s / 1mAs |

The nominal shortest irradiation time in the AEC-mode

20ms

A-8 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

7.2Toshiba E7272 x-ray tube ratings

Manual exposures

With manual exposures the tube kV, mAs and focal spot can be selected by the user. The mA value is automatically determined by the selected kV value, and the exposure time is determined by the selected mAs value. The mA value used is always the highest possible value, that depends on the kV value, focal spot, exposure time and line frequency (see following table on the next page). The maximum exposure time is 6.0 sec. for the large focal spot, and 9.9 sec. for the small focal spot. The minimum mAs value is 10 mAs and it can be increased in approx. 20% steps to the maximum (see values below). The maximum mAs value for the large focal spot is either 300, 500, 550 or 600 mAs, depending on the value of the service mode parameter 6. The maximum mAs value for the small focal spot is 200 mAs.

The possible mAs values are: 10, 12, 14, 16, 18, 20, 25, 30, 35, 40, 50, 60, 70, 85, 100, 120, 140, 160, 180, 200, 225, 260, 300, 350, 400, 450, 500, 550, 600.

Automatic exposures

Automatic exposures are terminated when the radiation detector indicates that the required dose has been reached. In this mode the kV is selected by the operator and mA is chosen to be the maximum allowed mA for the selected kV and Hz (line frequency).

If the exposure time is longer than 1 sec (5 sec for the small focal spot) then a falling load technique is used. The exposure is started at the mA as specified in the following tables. The accumulated dose is checked at 0.45 sec (2.45 sec for the small focal spot) and if it has reached more than half of the required dose, the exposure can be continued at the same mA level, and will be terminated within 1 second (5 seconds for the small focal spot) - well before the tube is overloaded.

If the accumulated dose is detected to be less than half of the required, a longer exposure time than the one specified for the tube current can be expected. Therefore the tube current is reduced at this time (after 0.45 or 2.45 sec exposure) to a lower mA that, when added to the already produced tube loading, will not exceed the maximum tube rating. The falling load current levels are listed in the two following tables.

Thermal ratings

Two separate methods are used to protect the tube from overload. One is measuring the tube head enclosure temperature and if it exceeds 60 °C no further exposures are allowed until it falls below 60 °C.

The other method keeps the average input power into the tube below or equal to 500W. The exposure parameters are limited as indicated by the following tables, but this feature forces a waiting time between the exposures to ensure that the average power into the tube never can exceed this limit. For example if an exposure of 24 kV, 100 mA, 1 sec is performed a wait period of 5 seconds is calculated and no further exposures are allowed until this time has elapsed.

There is no way to bypass these safety feature under any circumstances, and it is thus virtually impossible to overload the X-ray tube.

Technical Manual |

Sophie Mammography X-ray unit A-9 |

Chapter A - GENERAL & TECHNICAL DATA |

|

|

|

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

||||||||||||||||||

|

|

|

Table 2: Maximum mA for Tube E7272 vs. different modes and line frequencies |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MANUAL EXPOSURE MODE |

|

|

|

|

AUTOMATIC (AEC) EXPOSURE MODE |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Large focal spot |

|

Small focal spot |

|

Large focal spot |

|

Small focal spot |

|

|||||||||||||

|

|

|

(0.3 mm) |

|

|

|

(0.1 mm) |

|

|

|

(0.3 mm) |

|

|

|

(0.1 mm) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 - 1 |

1 - 5 |

1 - 6 |

0 - 5 |

> 5 |

|

0 - 1 |

0.45 - 5 |

0.45 - 6 |

0 - 5 |

2.45 -10 |

|

||||||||||

|

sec |

sec |

sec |

sec |

sec |

sec |

sec |

sec |

sec |

sec |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

kV |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

|

60 |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

60 |

|

|

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

|

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

70 |

70 |

70 |

70 |

80 |

80 |

20 |

20 |

20 |

|

20 |

70 |

70 |

70 |

70 |

80 |

85 |

20 |

20 |

18 |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

80 |

80 |

80 |

80 |

90 |

90 |

20 |

20 |

18 |

|

20 |

80 |

80 |

80 |

80 |

90 |

95 |

20 |

20 |

18 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

90 |

90 |

90 |

90 |

100 |

100 |

22 |

22 |

18 |

|

18 |

90 |

90 |

90 |

90 |

100 |

105 |

22 |

22 |

16 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

100 |

100 |

100 |

100 |

100 |

100 |

22 |

22 |

18 |

|

18 |

100 |

100 |

98 |

100 |

98 |

108 |

22 |

22 |

16 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

110 |

110 |

100 |

100 |

90 |

90 |

22 |

22 |

16 |

|

18 |

110 |

110 |

98 |

108 |

93 |

103 |

22 |

22 |

16 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

100 |

110 |

90 |

100 |

90 |

90 |

20 |

22 |

16 |

|

16 |

100 |

110 |

95 |

97 |

90 |

92 |

20 |

22 |

14 |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26 |

100 |

110 |

90 |

90 |

90 |

90 |

20 |

22 |

16 |

|

16 |

100 |

110 |

91 |

98 |

89 |

96 |

20 |

22 |

14 |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |

100 |

110 |

80 |

90 |

80 |

80 |

18 |

20 |

14 |

|

16 |

100 |

110 |

87 |

87 |

83 |

83 |

18 |

20 |

14 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

90 |

100 |

80 |

90 |

80 |

80 |

18 |

20 |

14 |

|

14 |

90 |

100 |

85 |

88 |

79 |

82 |

18 |

20 |

12 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 |

90 |

100 |

80 |

80 |

80 |

80 |

18 |

20 |

14 |

|

14 |

90 |

100 |

82 |

88 |

78 |

84 |

18 |

20 |

12 |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

90 |

90 |

80 |

80 |

70 |

70 |

16 |

18 |

12 |

|

14 |

90 |

90 |

80 |

77 |

79 |

72 |

16 |

18 |

13 |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

31 |

80 |

90 |

70 |

80 |

70 |

70 |

16 |

18 |

12 |

|

14 |

80 |

90 |

77 |

78 |

73 |

72 |

16 |

18 |

10 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 |

80 |

90 |

70 |

80 |

70 |

70 |

16 |

18 |

12 |

|

12 |

80 |

90 |

75 |

78 |

69 |

72 |

16 |

18 |

10 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

33 |

80 |

90 |

70 |

70 |

60 |

60 |

16 |

16 |

12 |

|

12 |

80 |

90 |

72 |

78 |

67 |

73 |

16 |

16 |

10 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34 |

80 |

80 |

70 |

70 |

60 |

60 |

14 |

16 |

12 |

|

12 |

80 |

80 |

70 |

68 |

65 |

65 |

14 |

16 |

11 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

35 |

70 |

80 |

60 |

70 |

60 |

60 |

14 |

16 |

10 |

|

12 |

70 |

80 |

67 |

68 |

64 |

65 |

14 |

16 |

11 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.3Cooling curves for x-ray tube

ANODE THERMAL CHARACTERISTICS

|

210 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 |

|

|

|

|

|

COOLING |

|

|

|

|

|

|

|

|

|

|

|

|

707W |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kJ) |

140 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

565W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STORAGE |

120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

424W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

HEAT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

283W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

141W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

||||||||||||

TIME (min)

HEAT STORAGE (kHU)

700

TUBE HOUSING

HEAT DISSIPATION CAPACITY

600

500

400

300

200

100

0

0 |

50 |

100 |

150 |

200 |

250 |

TIME (min)

A-10 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA TECHNICAL SPECIFICATIONS (TOSHIBA E7290 X-RAY

8 |

TECHNICAL SPECIFICATIONS (TOSHIBA E7290 X-RAY TUBE) |

||

|

ORIGINAL MANUFACTURER |

|

|

|

PLANMED Oy, Asentajankatu 6, 00810 Helsinki, FINLAND |

||

|

phone: +358-9-7590 5300, fax: +358-9-7590 5555 |

||

|

MODEL AND APPROVALS |

|

|

|

MODELS: |

PLANMED SOPHIE, PLANMED SOPHIE MOBILE |

|

|

APPROVALS: |

IEC safety class: I, IEC degree of protection: B, IEC enclosure class: IP20 |

|

|

|

Complies with IEC 601-1 safety and IEC 601-2-7 radiation regulations |

|

|

X-RAY TUBE ASSEMBLY |

|

|

|

X-ray tube |

|

Toshiba E7290 |

|

Anode type |

|

rotating anode (9700 rpm at 180 Hz) |

|

Anode braking |

|

Automatic, electrical |

|

Anode thermal capacity |

300 000 HU |

|

|

Anode target material |

Molybdenum |

|

|

Anode target angle |

|

16 degrees (large focal spot) / 10 degrees (small focal spot) |

|

Tube port material |

|

Beryllium |

|

Focal spot sizes |

|

0.3mm / 0.1 mm |

|

Filtration |

|

30µm Mo and 0.5mm Al or |

|

|

|

30µm Mo and 25µm Rh |

|

GENERATOR ASSEMBLY |

|

|

|

Generator |

|

constant potential, high frequency |

|

Anode voltage range |

|

20 - 35kV ± 2kV, virtually DC |

|

Anode current range/0.3mm focus |

80 - 110mA ± 5mA |

|

|

Anode current range/0.1mm focus |

21 - 35mA ± 1mA |

|

|

mAs range/0.3mm focus |

10 - 500mAs (optional 600mAs in GB) ± 4mAs |

|

|

|

|

or ±10% (whichever is larger) |

|

mAs range/ 0.1mm focus |

10 - 310 mAs |

|

|

Exposure time /0.3mm focus |

0.1 - 5 seconds (optional 6 seconds) ±5% |

|

|

Exposure time / 0.1mm focus |

0.1 - 9.9 seconds ±5% |

|

|

Cooling |

|

automatically controlled (internal fan) |

|

Line voltage |

|

208 - 240V~, 50 or 60Hz - single phase |

|

Line voltage compensation |

automatic ±10% |

|

|

Line voltage regulation |

±10% (absolute minimum/maximum 187V~/265V~) |

|

|

Fuses |

|

2 x 15AT / 250V |

|

Total power consumption |

max. 100VA idle, 4000VA max. for 5 seconds |

|

|

Power factor |

|

> 0.95 |

|

Mode of operation |

|

intermittent |

|

Maximum mains resistance |

≤ 1Ω |

|

|

Maximum continuous |

|

|

|

heat dissipation |

|

< 250W |

|

BUCKY GRID SPECIFICATION |

|

|

|

Grid manufacturer |

|

Gilardoni |

|

Grid type |

|

GRIDGIL HT; Fiber interspaced vertical |

|

Grid movement |

|

Variable amplitude oscillation |

|

Grid ratio |

|

r5 |

|

Grid lines per cm |

|

N36 |

|

Focusing distance |

|

f065 |

|

Application limits |

|

18x24: f150 f291 |

|

|

|

24x30: f153 f282 |

|

Material of absorbing strips |

Pb |

|

|

Contrast improvement ratio |

K1.47 |

|

|

Selectivity |

|

Σ6.04 |

|

Grid exposure factor |

|

B1.69 |

|

Transmission of primary radiation |

Tp 0.75 |

|

|

Max. deviation between the central |

|

|

|

line indication and the true |

∆2 |

|

|

central line |

|

|

Technical Manual |

Sophie Mammography X-ray unit A-11 |

Chapter A - GENERAL & TECHNICAL DATA |

TECHNICAL SPECIFICATIONS (TOSHIBA E7290 X-RAY |

AUTOMATIC EXPOSURE CONTROL (AEC) |

|

Sensors |

three selectable large area solid-state sensors |

Density adjustment |

15 density steps (13% change in OD per step) |

|

plus fine adjustment ± 5 steps (0,05 OD per step) |

Function modes |

Normal AEC, Advanced AEC (AAEC) |

C-ARM |

|

Rotation |

motorized, range -135° to +180° |

Vertical movement |

motorized, range 795mm to 1350mm (31.3in to 53.1in) |

SID |

650mm |

Compression |

fully motorized, variable speed, variable angle (twincomp) |

Cassette sizes |

18 x 24cm and 24 x 30cm |

Magnification |

motorized, variable range from 1.3 to 1.8 |

MECHANICAL DATA |

|

Dimensions |

(H x D x W) 1000 x 900 x 755 (mm) minimum |

|

(36.6 x 35.0 x 29.7 inch minimum) |

Weight |

160kg (352lbs), unpacked |

Color |

RAL 9016 |

A-12 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

9 USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA E7290 X-RAY TUBE)

Radiation leakage technique factors

The maximum-rated peak tube potential is 35 kVp and the maximum rated continuous tube current is 3.5mA for the maximum-rated peak tube voltage.

Minimum filtration

The Beam-limiting device contains three different filtrations 30µm molybdenum, 25µm rhodium and 0.50mm aluminum. The measured half-value layers are 0.343mmAl, 0.373mmAl and 0.377mmAl at 30kVp. These measured values correspond to aluminum equivalents of 0.55 - 0.65mmAl.

Rate line voltage

208 - 240V~ ±10%. Line voltage regulation 10%.

Maximum line current

Maximum 22 Amperes at absolute minimum stated mains voltage (187V~)

Technique factors that constitute the maximum line current condition

33kV / 97mA

Generator rating and duty cycle

3.2kW. The duty cycle and wait period can be calculated using the following formulas:

•Wait period = Tw = kV* mA* exp. Time / 500W

•Duty Cycle = 1 / (1 + kV* mA / 500W)

Maximum deviation of peak tube potential from indicated value

±2kV

Maximum deviation of tube current from indicated value

±5mA large focal spot, ±1mA small focal spot

Maximum deviation of exposure time tube current product from indicated value

±4mAs or ±10%, whichever is larger

Maximum deviation of exposure time from indicated value

±5%

Definition of measurement criteria

Exposure time

The beginning and end points of the exposure time are defined at 70% of the peak radiation waveform measured with a calibrated x-ray monitor.

Peak tube potential

Is defined as the measured high voltage mean value measured with a calibrated non-invasive kVp meter.

Tube current

Is defined using the resistance and voltage over the feedback resistor measured with a calibrated multimeter. The mA value is then the voltage divided by the resistance.

mAs product

Is defined as the product of the exposure time and the tube current measurements.

Technical Manual |

Sophie Mammography X-ray unit A-13 |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

The nominal x-ray voltage together with the highest x-ray tube current obtainable from the high-voltage generator when operated at its nominal x-ray tube voltage

35kV 91mA - large focal spot 35kV 28mA - small focal spot

The highest x-ray tube current together with the highest x-ray tube voltage obtainable from the high-voltage generator when operated at its highest x-ray tube current

110mA 29kV - large focal spot 35mA 28kV - small focal spot

The x-ray tube voltage and x-ray tube current which result in the highest electric output power

33kV 97mA - large focal spot 31kV 32mA - small focal spot

The nominal electric power for a load time of 0.1s and at the nominal x-ray tube voltage

35kV 91mA - 3185W large focal spot 35kV 28mA 980W small focal spot

Reference current time product

large focal spot: for all kV values |

40mA / 0.1s / 4mAs |

small focal spot: for all kV values |

10mA / 0.1s / 1mAs |

The lowest current time product within the specified range of compliance

large focal spot: |

30mA / 0.1s / 3mAs |

small focal spot: |

10mA / 0.1s / 1mAs |

The nominal shortest irradiation time in the AEC-mode

20ms

A-14 Sophie Mammography X-ray unit |

Technical Manual |

Chapter A - GENERAL & TECHNICAL DATA |

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

9.1Toshiba E7290 x-ray tube ratings

Manual exposures

With manual exposures the tube kV and mAs can be selected by the user. In order to keep the exposure times at minimum the required mAs is always achieved at highest possible tube current for the kV selected. The parameters are listed in the following table.

Automatic exposures

Automatic exposures are terminated when the radiation detector indicates that the required dose has been reached. In this mode the kV is selected by the operator and mA is chosen to be the maximum allowed mA for the selected kV.

If the exposure time is longer than 1 sec (5 sec for the small focal spot) then a falling load technique is used. The exposure is started at the mA as specified in the following table. The accumulated dose is checked at 0.45 sec (2.45 sec for the small focal spot) and if it has reached more than half of the required dose, the exposure can be continued at the same mA level, and will be terminated within 1 second (5 seconds for the small focal spot) - well before the tube is overloaded.

If the accumulated dose is detected to be less than half of the required, a longer exposure time than the one specified for the tube current can be expected. Therefore the tube current is reduced at this time (after 0.45 or 2.45 sec exposure) to a lower mA that, when added to the already produced tube loading, will not exceed the maximum tube rating. The falling load current levels are listed in the following table.

Thermal ratings

Two separate methods are used to protect the tube from overload. One is measuring the tube head enclosure temperature and if it exceeds 60 °C no further exposures are allowed until it falls below 60 °C.

The other method keeps the average input power into the tube below or equal to 500W. The exposure parameters are limited as indicated by the following table, but this feature forces a waiting time between the exposures to ensure that the average power into the tube never can exceed this limit. For example if an exposure of 24 kV, 100 mAs is performed a wait period of 5 seconds is calculated and no further exposures are allowed until this time has elapsed.

There is no way to bypass these safety feature under any circumstances, and it is thus virtually impossible to overload the X-ray tube.

Technical Manual |

Sophie Mammography X-ray unit A-15 |

Chapter A - GENERAL & TECHNICAL DATA |

|

USER’S STATEMENT FOR PLANMED SOPHIE (TOSHIBA |

|||||||||||||

|

|

|

|

|

Table 3: Maximum mA for Tube E7290 vs. different modes |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MANUAL EXPOSURE MODE |

|

|

AUTOMATIC (AEC) EXPOSURE MODE |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Large focal spot |

Small focal spot |

|

Large focal spot |

|

Small focal spot |

|

||||||

|

|

|

|

(0.3 mm) |

|

(0.1 mm) |

|

|

(0.3 mm) |

|

(0.1 mm) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 - 1 |

|

1 - 5 |

1 - 6 |

0 - 5 |

> 5 |

0 - 1 |

|

0.45 - 5 |

0.45 - 6 |

0 - 5 |

2.45 -10 |

|

|

|

kV |

sec. |

|

sec. |

sec. |

sec. |

sec. |

sec. |

|

sec. |

|

sec. |

sec. |

sec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

80 |

|

80 |

80 |

20 |

20 |

80 |

|

80 |

|

80 |

20 |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

84 |

|

84 |

84 |

21 |

21 |

84 |

|

84 |

|

84 |

21 |

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

88 |

|

88 |

88 |

23 |

23 |

88 |

|

88 |

|

88 |

23 |

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

92 |

|

92 |

92 |

25 |

25 |

92 |

|

92 |

|

92 |

25 |

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

96 |

|

96 |

96 |

27 |

27 |

96 |

|

96 |

|

96 |

27 |

27 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

100 |

|

100 |

100 |

29 |

29 |

100 |

|

100 |

|

100 |

29 |

29 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26 |

104 |

|

104 |

104 |

31 |

31 |

104 |

|

104 |

|

104 |

31 |

31 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |