Planet Technology ISW-800M User Manual

8-Port Managed Industrial Ethernet Switch

ISW-800M

User's Manual

Trademarks

Copyright ○

Contents subject to which revision without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other trademarks belong to their

respective owners.

c

PLANET Technology Corp. 2006.

Disclaimer

PLANET Technology does not warrant that the hardware will work properly in all environments and

applications, and makes no warranty and representation, either implied or expressed, with respect to the

quality, performance, merchantability, or fitness for a particular purpose.

PLANET has made every effort to ensure that this User's Manual is accurate; PLANET disclaims liability

for any inaccuracies or omissions that may have occurred.

Information in this User's Manual is subject to change without notice and does not represent a

commitment on the part of PLANET. PLANET assumes no responsibility for any inaccuracies that may be

contained in this User's Manual. PLANET makes no commitment to update or keep current the

information in this User's Manual, and reserves the right to make improvements to this User's Manual

and/or to the products described in this User's Manual, at any time without notice.

If you find information in this manual that is incorrect, misleading, or incomplete, we would appreciate

your comments and suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

Instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at whose own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference, in which

case the user may be required to take adequate measures.

WEEE Warning

To avoid the potential effects on the environment and human health as a result of the

presence of hazardous substances in electrical and electronic equipment, end users

of electrical and electronic equipment should understand the meaning of the

crossed-out wheeled bin symbol. Do not dispose of WEEE as unsorted municipal

waste and have to collect such WEEE separately.

Revision

PLANET Managed Industrial Ethernet Switch User's Manual

FOR MODELS: ISW-800M

Part No. EM_ISW800Mv2 (2081-AH0010-000)

Table of Contents

1. INTRODUCTION................................................................................................................... 5

1.1 Packet Contents.............................................................................................................. 5

1.2 How to Use This Manual ................................................................................................. 5

1.3 Product Feature............................................................................................................... 5

1.4 Product Specification....................................................................................................... 6

2. HARDWARE INSTALLATION .............................................................................................. 9

2.1 Product Description......................................................................................................... 9

2.2 Mounting Installation ..................................................................................................... 14

3. NETWORK INSTALLATION............................................................................................... 17

3.1 Hardware Installation..................................................................................................... 17

3.2 Network Application....................................................................................................... 17

3.3 Redundant Ring Application.......................................................................................... 18

3.4 Coulping Ring Application ............................................................................................. 19

3.5 Dual Homing Application ............................................................................................... 20

4. WEB MANAGEMENT......................................................................................................... 21

4.1 About Web-based Management.................................................................................... 21

4.2 Preparing for Web Management................................................................................... 21

4.3 System Login................................................................................................................. 21

4.4 Port Status..................................................................................................................... 22

4.5 Single port information .................................................................................................. 23

4.6 Port Statistics................................................................................................................. 23

4.7 Port Control ................................................................................................................... 24

4.8 Switch Settings.............................................................................................................. 25

4.9 Port Mirroring................................................................................................................. 26

4.10 VLAN configuration ..................................................................................................... 27

4.11 Alert.............................................................................................................................. 32

4.12 IP Configuration........................................................................................................... 35

4.13 SNTP Configuration .................................................................................................... 36

4.14 IP Security ................................................................................................................... 38

4.15 RSTP Configuration .................................................................................................... 39

4.16 Redundant Ring .......................................................................................................... 41

4.17 QoS Configuration....................................................................................................... 43

4.18 IGMP ........................................................................................................................... 44

4.19 SNMP Configuration.................................................................................................... 45

4.20 Security Manager ........................................................................................................ 46

4.21 Configuration Backup.................................................................................................. 47

4.22 Factory Default............................................................................................................ 49

4.23 Save Configuration...................................................................................................... 50

4.24 System Reboot............................................................................................................ 51

4.25 Rate Control ................................................................................................................ 51

4.26 System Log ................................................................................................................. 52

5. TROUBLESHOOTING........................................................................................................ 55

5.1 Incorrect connections.................................................................................................... 55

5.2 Diagnosing LED Indicators............................................................................................ 55

6. APPENDIX .......................................................................................................................... 57

6.1 100BASE-TX/10BASE-T Pin Assignments ................................................................... 57

1. INTRODUCTION

The 8-Port 10/100TX with redundant ring Web management industrial switch is a cost- effective solution

and meets the high reliability requirements demanded by industrial applications. The switch can be easily

managed through the Web GUI. It also provides the redundant ring function that can prevent the network

connection failure.

1.1 Packet Contents

Check the contents of your package for following parts:

▫ Industrial Fast Ethernet Switch x1

▫ DIN-Rail kit (screwed on the switch)

▫ Wall-mount kit (wall-mount plate with 6 screws)

▫ CD-ROM user's manual x1

If any of these are missing or damaged, please contact your dealer immediately, if possible, retain the

carton including the original packing material, and use them against to repack the product in case there is

a need to return it to us for repair.

1.2 How to Use This Manual

This User Manual is structured as follows:

Chapter 2, HARDWARE INSTALLATION

The chapter explains the functions of the Switch and how to physically install the Switch.

Chapter 3, NETWORK INSTALLATION

The chapter explains how to install the Switch in the Network.

Chapter 4, WEB MANAGEMENT

The chapter explains how to configure the switch by the web interface.

Chapter 5, TROUBLE SHOOTING

The chapter explains how to trouble shooting of the Switch.

Chapter 6, APPENDIX

The chapter contains cable information of the Switch.

1.3 Product Feature

Hardware Feature

▫ Comply with IEEE 802.3, IEEE 802.3u

▫ CSMA/CD Protocol

▫ RJ-45 Port support auto MDI/MDI-X function

▫ 2K MAC address table

▫ 1Mbit memory buffer

▫ 2.0Gbps back-plane

▫ Wide-range redundant power design

▫ Store and forward switch architecture

▫ DIN rail and 3-way wall mount design

Industrial Conformance

▫ 12~48V DC, redundant power with polarity reverse protect function

▫ 0 to 60 Degree C operation temperature

▫ IP-30 Aluminum case

▫ Relay alarm for port breakdown, power failure

▫ FCC Class A, CE compatibility

▫ Free fall, Shock and Vibration Stability

Switching Feature

▫ Ring function data redundant, 300ms data recovery

▫ 802.1q Tagged VLAN/Port-based VLAN

▫ IEEE 802.1p class of service, 4 priority queues

▫ IGMP v1 and Query mode

▫ 802.1d STP/802.1w Rapid STP

▫ Ingress/Egress bandwidth control

System

▫ Web/SNMP management

▫ System event log support

▫ Configuration backup/restore

▫ E-mail event alert

▫ IP security for illegal access prevention

▫ TFTP firmware upgrade

▫ Port mirror transmission monitoring

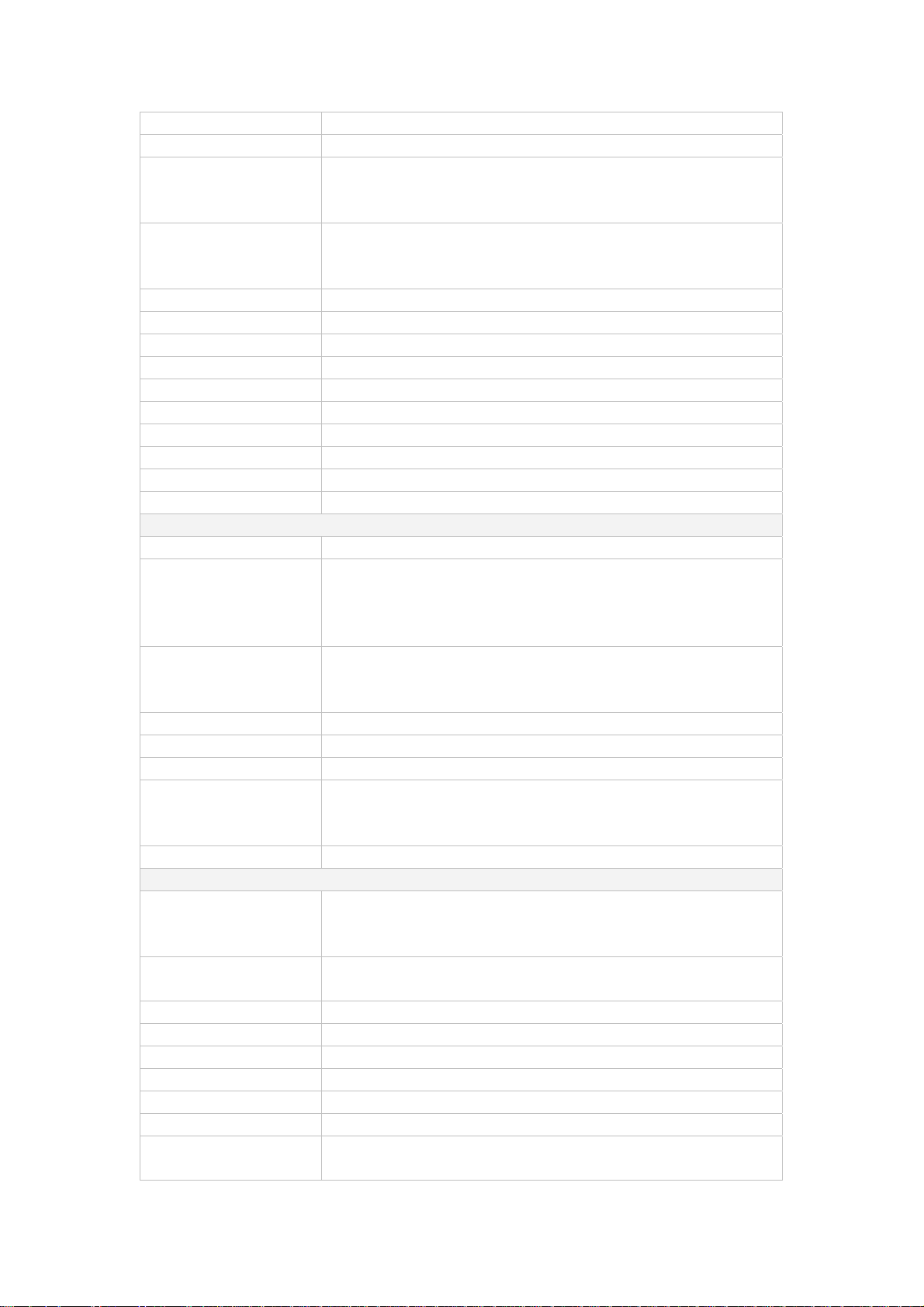

1.4 Product Specification

Model ISW-800M

Hardware

Standard IEEE 802.3af, IEEE 802.3, IEEE802.3u, 10/100Base-TX

10/100Mbps TP 8

Protocol CSMA/CD

Switching Architecture Store and forward

Transfer Rate 144,880 pps for Ethernet port and 1448,800 pps for Fast Ethernet port

MAC address 2K

Memory Buffer 1Mbit

Network Cable 10Base-T : 2-pair UTP/STP Cat 3, 4, 5 cable

100Base-TX: 2-pair UTP/STP Cat. 5 cable

10Base-T: EIA/TIA-568 100-ohm (100m)

LED Per port: Link/Activity (Green), Full duplex/Collision (Yellow)

Per unit: Power (Green), Power 1 (Green), Power 2 (Green), Fault (Yellow),

Master (Green)

Back-plane 1.6Gbps

Packet throughput ability 1.19Mpps@64bytes (8TX)

Power Supply 12 to 48 VDC, Redundant power with polarity reverse protection function

Power Consumption 8-Port TX: 4.6 Watts

Installation Provide DIN rail kit and wall mount plate for 3-way installation

Operating environment 0 to 60 Degree C, 5% to 90%RH (Non-condensing)

Storage environment -40 to 85 Degree C, 5% to 90%RH (Non-condensing)

Dimension (W x D x H) 54 × 105 × 155 mm

Emission FCC Class A, CE mark

Stability testing IEC60068-2-32(Free fall), IEC60068-2-27(Shock), IEC60068-2-6(Vibration)

Management

Management Interface Web, SNMP v1,v2c, v3

SNMP MIB RFC 1213 MIBII, RFC 1493 Bridge MIB, RMON RFC 1757, RFC 2674 VLAN

MIB, RFC 1643 Ethernet like MIB, RFC1215 Trap MIB, IGMP MIB.

Private MIB for switch information, super ring, port alarm, TFTP firmware

upgrade, reset, port mirror, IP security.

SNMP Trap Up to 3 Trap stations.

Cold start, Port link Up, Port link down, Authentication Failure, Private Trap for

power status, Port Alarm configuration, Fault alarm, super ring.

Management IP security Support IP address security to prevent unauthorized intruder.

Firmware update Support TFTP firmware update, TFTP configuration backup and restore.

System event log Provides 1000 event log entries.

Alarm Provides one relay output for port breakdown, power fail and provide DIP switch

to mask link down port.

Alarm Relay current carry ability: 1A @ DC24V

DHCP client Provide DHCP client function to obtain IP address from DHCP serve.

Switching

Redundant ring 2 ports for super ring to provide redundant backup feature and the recovery time

below 300ms. It also supports coupling ring function. Ring and coupling port

configure by web interface and ringmaster by hardware DIP switch.

VLAN Supports port-based VLAN and IEEE802.1Q Tag VLAN.

Both of port based and Tag based VLAN group up to 64 VLANs.

Class of service IEEE802.1p class of service support, per port provides 4 priority queues.

Quality of service The quality of service support port based, Tag based and IPv4 Type of service.

IGMP Support IGMP v1 and Query mode. Up to 256 groups.

Spanning tree IEEE802.1d spanning tree and IEEE802.1w rapid spanning tree.

SNTP Support simple network time protocol.

SMTP Support simple mail transfer protocol.

Bandwidth control Support ingress packet filter and egress packet limit.

The egress rate control supports all of packet type and the limit rates are

128kbps, 256Kbps, 512Kbps, 1MB, 2MB, 4MB, and 8MB.

Ingress filter packet type combination rules are Broadcast/Multicast/Unknown

Unicast packet, Broadcast/Multicast packet, Broadcast packet only and all of

packet. The packet filter rate can be set follow as:1Mbps、2Mbps、4Mbps、

8Mbps、16Mbps、32Mbps、64Mbps.

Port mirror Support TX packet only or both of TX and RX packet.

Packet filter

4 selection rules for different type of packet combination:

1. All of packet

2. Broadcast/ multicast/ unknown unicast packet

3. Broadcast/ multicast packet

4. Broadcast packet only

IEEE 802.3 10Base-T Ethernet

IEEE 802.3u 100Base-TX Fast Ethernet

Network Standard

IEEE802.3x Flow Control and Back-pressure

IEEE802.1d spanning tree / IEEE802.1w rapid spanning tree

IEEE802.1p class of service

IEEE802.1Q VLAN Tag

2. HARDWARE INSTALLATION

This section describes the functionalities of the Switch's components and guides how to install it on the

rack or mount to the wall. Basic knowledge of networking is assumed. Please read this chapter

completely before continuing.

2.1 Product Description

The PLANET Management Industrial Ethernet Switch provides substation hardened, fully managed,

Ethernet switches specifically designed to operate reliably in electrically and environmentally harsh

environments. It provides IEEE 1613 Class 2 error-free communications performance under EMI stress.

An operating temperature range of 0 to 60 Degree C allows the switch be placed in almost any location.

The Switch also provides a wide range of power supply options suitable for multiple industries and for

worldwide operability.

2.1.1 Product Overview

The management switch models offer advanced Layer 2 networking features and network management

via the Web interface. The feature of the switching is the performance of its IEEE 802.1w Rapid Spanning

Tree Protocol (RSTP) used for implementing fault tolerant ring and mesh network architectures. The

protocol has been optimized to support ring and fault recovery times in the order of less than 300ms.

The management function provides improved system reliability and advanced networking features

making it ideally suited for creating Ethernet networks for mission-critical, real-time, control applications.

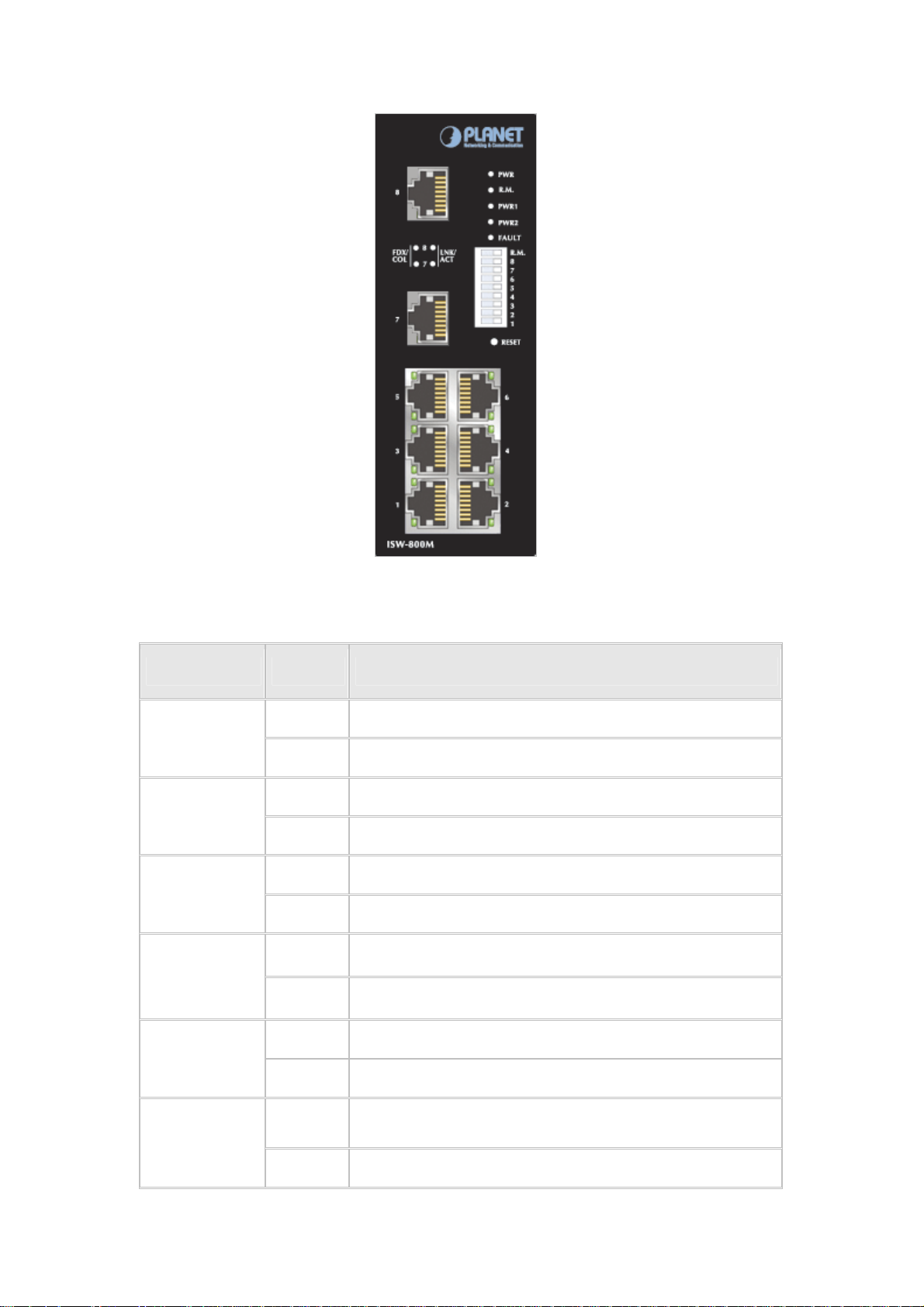

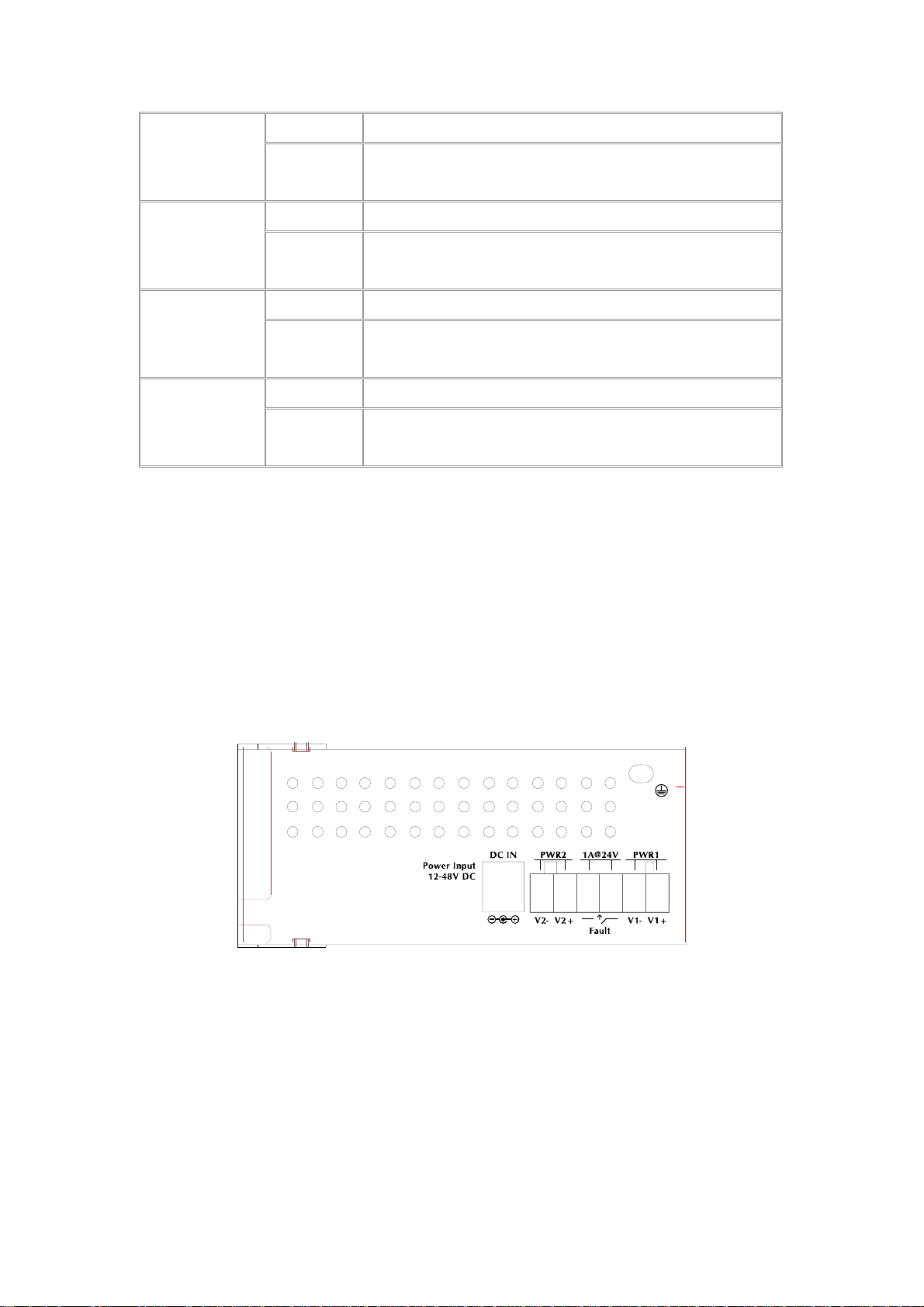

2.1.2 Switch Front Panel

Figure 2-1 shows the front panel of the switch.

Figure 2-1 ISW-800M Front Panel

2.1.3 LED Indications

LED Status Meaning

Green The switch unit is power on.

Power

Off The switch unit is no power input.

Green Power on

Power 1

Off No power inputs

Green Power on

Power 2

Off No power inputs

Yellow Power failure or UTP port failure or Fiber port failure

Fault

Off No Power failure or UTP port failure or Fiber port failure occurs

R. M.

(Ring Master)

LNK/ACT

(Port 7 & 8)

Green The industrial switch is the master of redundant ring group.

Off The industrial switch is not a ring master in redundant ring group.

Green The port is linking.

Blinks The port is transmitting or receiving packets from the TX device.

Off No device attached

Yellow The port is operating in full-duplex mode.

FDX/COL

(Port 7 & 8)

Blinks Collision of Packets occurs in the port.

Off The port in half-duplex mode or no device attached

2.1.4 Reset Button

The reset button provides user a quick and easy way to restart and set the configuration back to default

value.

。 Restart: press the button for 2 seconds and release.

。 Set to factory default value: press the button for 5 seconds and release. The switch

will set all configurations back to default setting.

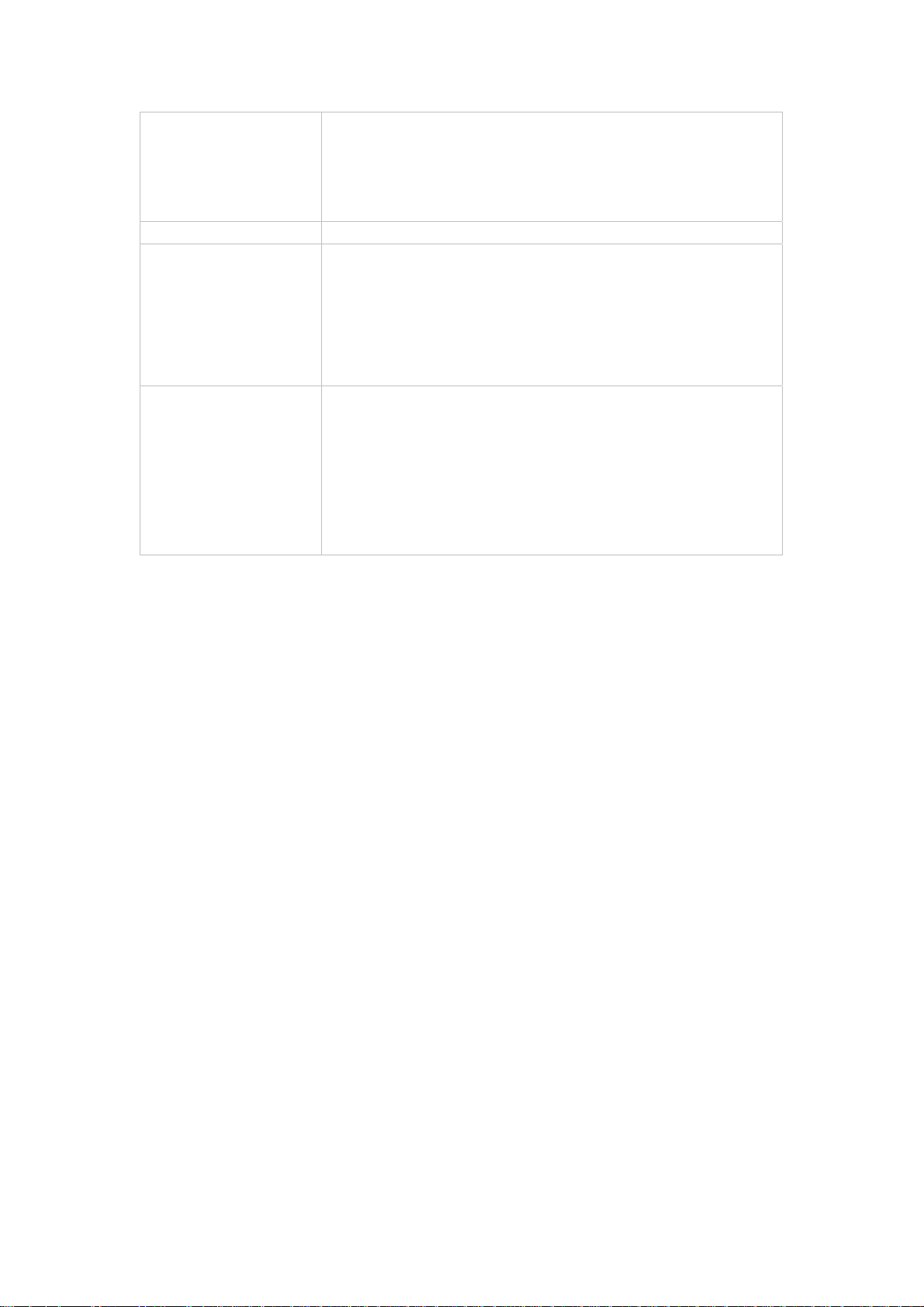

2.1.5 DIP Switches

The switch provides the 9 DIP-switch for configuring the relay alarm operation mode and the ring master

operation mode. The default value of Dipswitch is OFF.

DIP Switch No

1

2

3

4

5

Status Description

OFF Disable port 1 Alarm

Enable port 1 Alarm. If the port’s link fails, the fault LED will

ON

light up.

OFF Disable port 2 Alarm

Enable port 2 Alarm. If the port’s link fails, the fault LED will

ON

light up.

OFF Disable port 3 Alarm

Enable por 3 t Alarm. If the port’s link fails, the fault LED will

ON

light up.

OFF Disable port 4 Alarm

Enable port 4 Alarm. If the port’s link fails, the fault LED will

ON

light up.

OFF Disable port 5 Alarm

Enable port 5 Alarm. If the port’s link fails, the fault LED will

ON

light up.

OFF Disable port 6 Alarm

6

ON

OFF Disable port 7 Alarm

7

ON

OFF Disable port 8 Alarm

8

ON

OFF Disable the ring master function.

9

ON

[NOTE]

1. When port alarm function is enabled, the fault LED will on and Alarm relay will activity when port failure

occurs.

2. Please restart the switch after the Redundant ring DIPswitch is set.

Enable port 6 Alarm. If the port’s link fails, the fault LED will

light up.

Enable port 7 Alarm. If the port’s link fails, the fault LED will

light up.

Enable port 8 Alarm. If the port’s link fails, the fault LED will

light up.

Enable the switch as the ring master in the redundant ring

group.

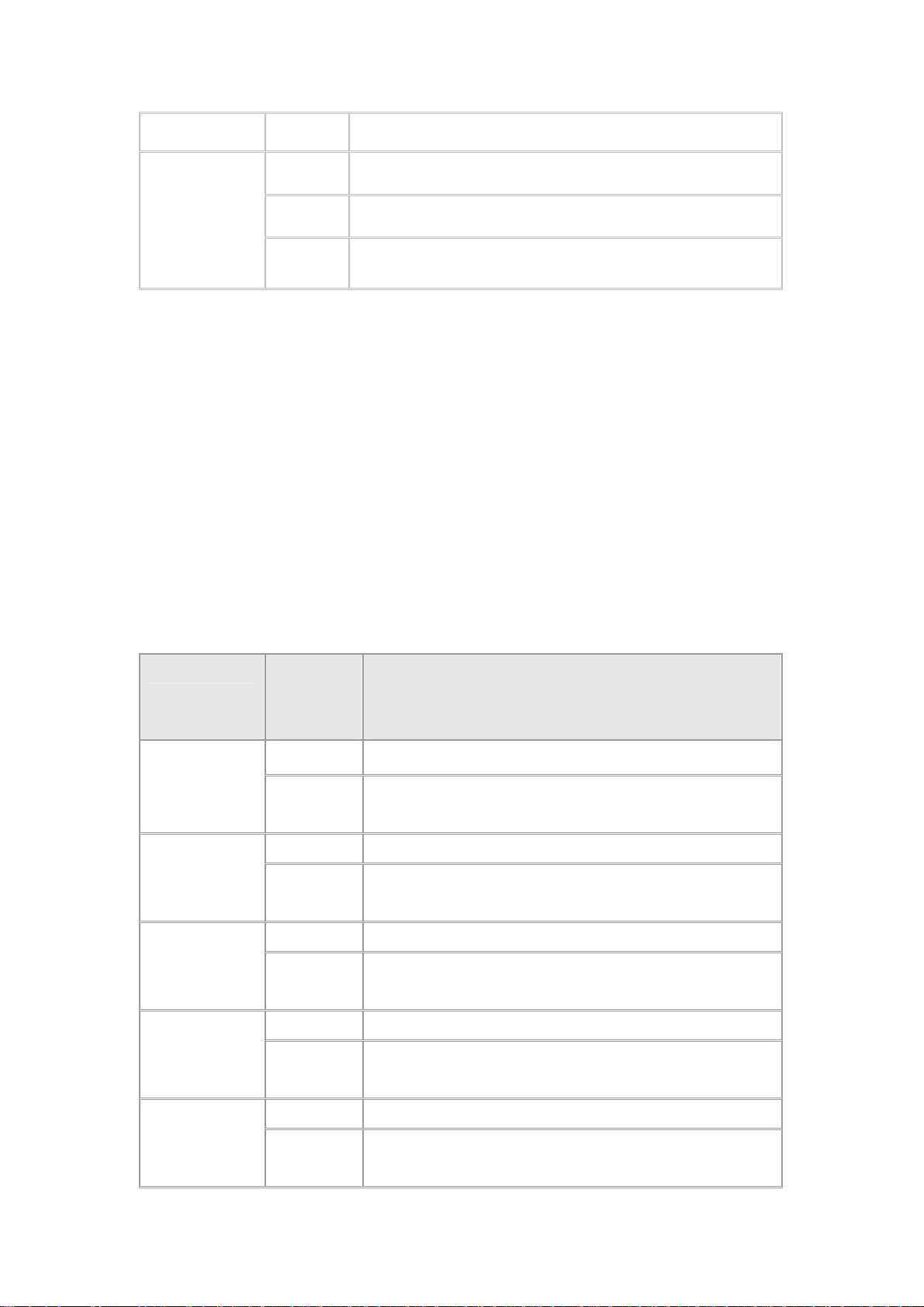

2.1.6 Switch Bottom Panel

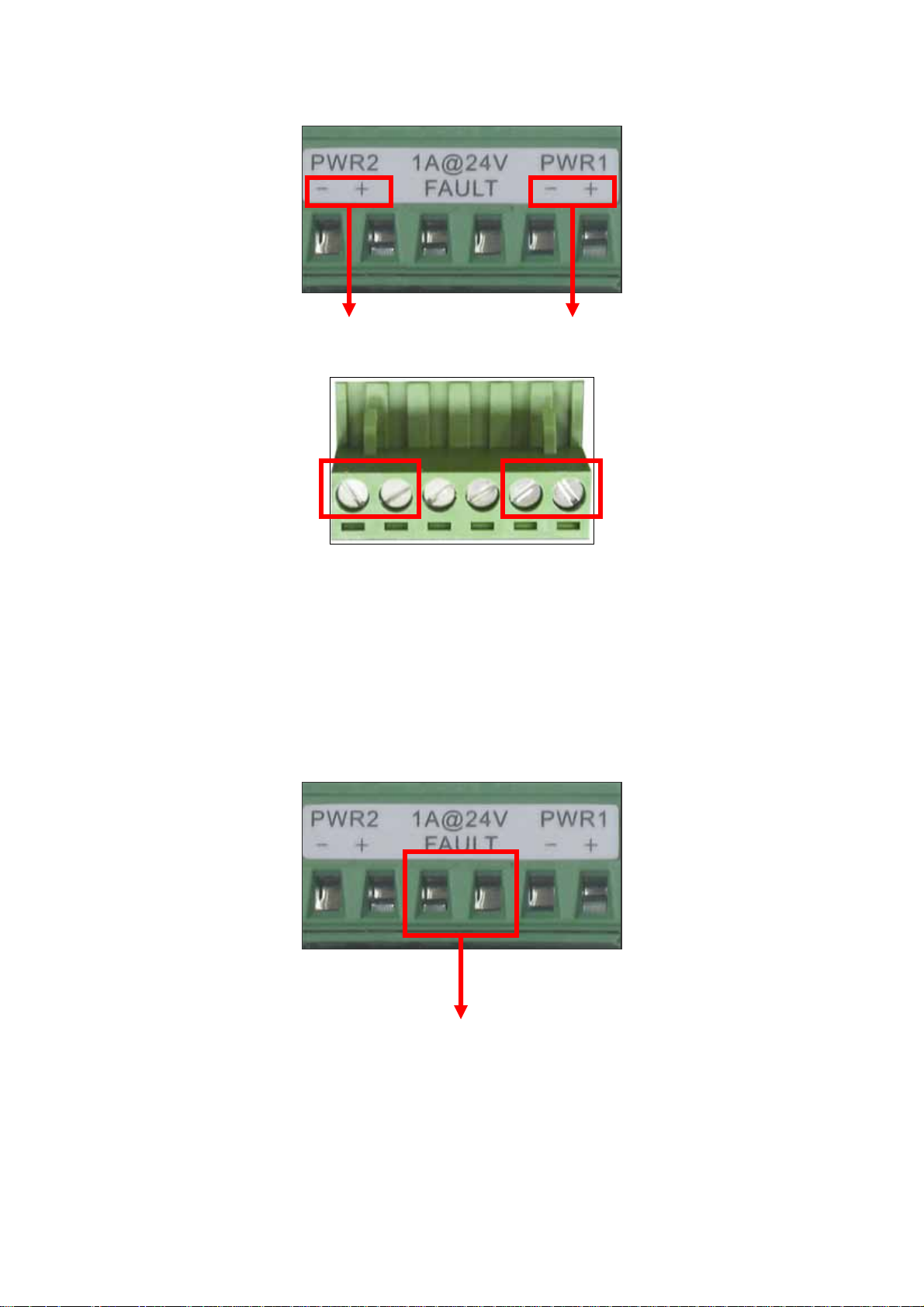

The bottom panel of the ISW-800M consists one terminal block connector within two DC power inputs

and one DC IN power jack for extra AC/DC power adapter.

Figure 2-2 shows the bottom panel of the switch

Figure 2-2 ISW-800M Bottom Panel.

2.1.7 Wiring the Power Inputs

Please follow below steps to insert the power wire.

V - V + V - V +

1. Insert the positive and negative wires into the V+ and V- connector on the terminal block connector.

2. To tighten the wire-clamp screws for preventing the DC wires to loose.

Power Notice:

The wire range of terminal block is from 12~ 24 AWG.

2.1.8 Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of terminal block connector as below figure shows. By inserting

the wires and set the DIPswitch at "ON" status, it will detect when power is failure or port link failure and

form an open circuit. And, the following figure shows an application example for the fault alarm contact.

Inset the wires into the falult alarm contact

Fault Alarm Contact

The open circuit will form

when the power failure or

port link failure.

24V DC Buzzer 24V Battery

The fault alarm device will

send a warning signal t

warn the user, ex: alarm

sound or flash light.

2.2 Mounting Installation

This section describes how to install the Ethernet Switch and make connections to it. Please read the

following topics and perform the procedures in the order being presented.

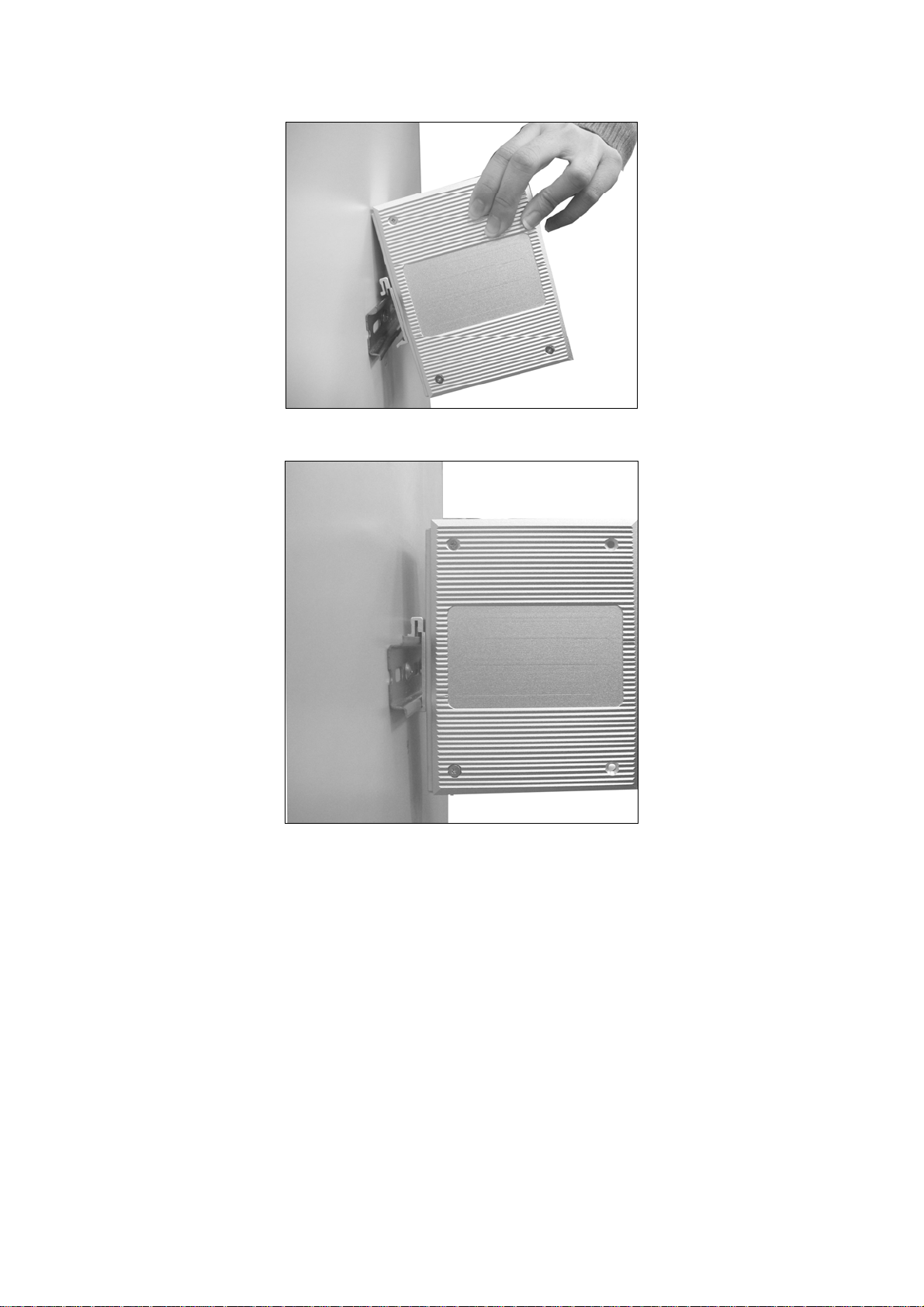

2.2.1 DIN-Rail mounting

The DIN-Rail is screwed on the industrial switch when out of factory. If the DIN-Rail is not screwed on the

industrial switch, please see the following figure to screw the DIN-Rail on the switch. To hang the

industrial switch, follow the below steps:

Step1: Insert the top of DIN-Rail into the track.

Step2: Lightly push the button of DIN-Rail into the track.

Step3: Check the DIN-Rail is tightly on the track.

Step4: To remove the industrial switch from the track, reverse steps above.

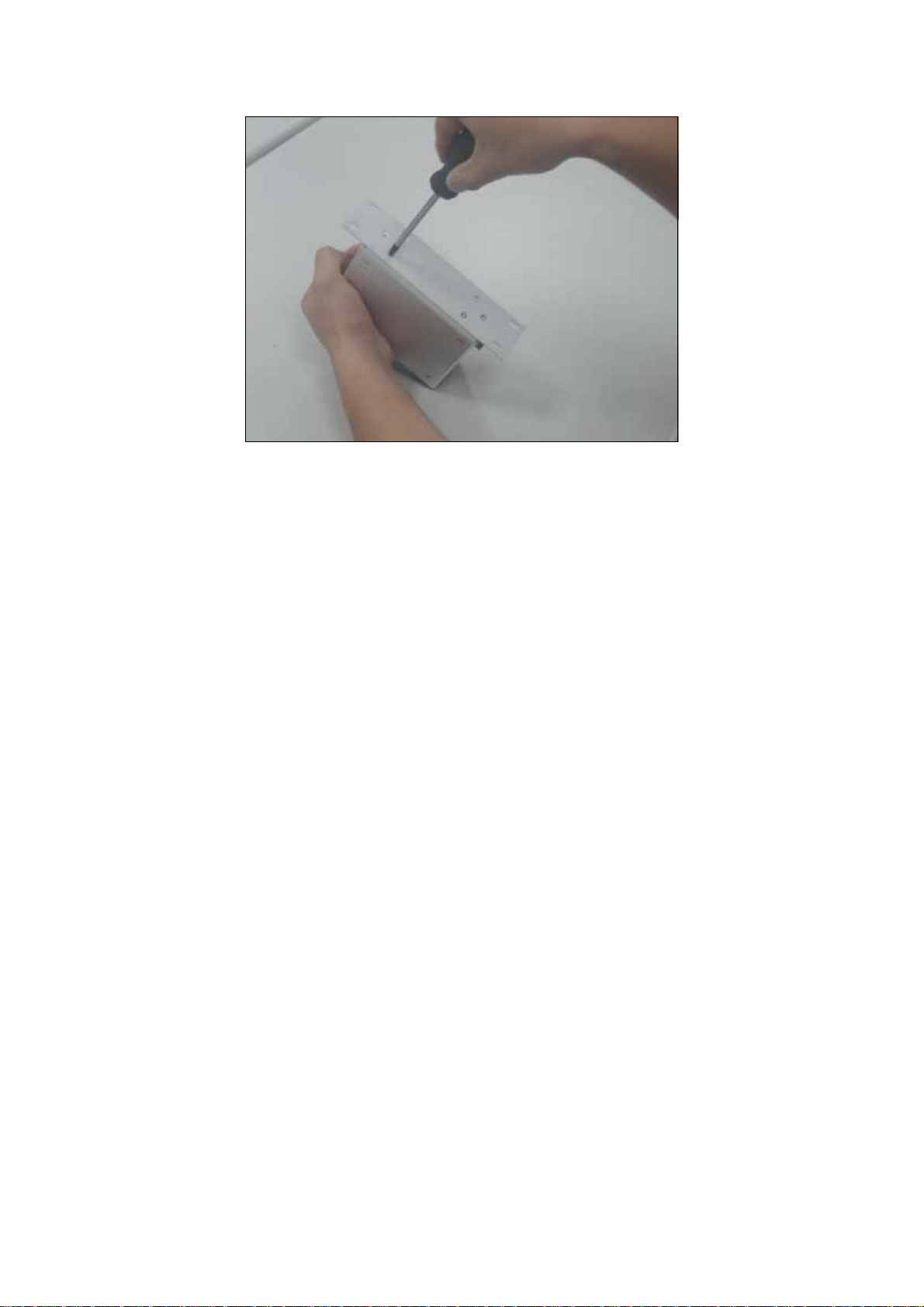

2.2.2 Wall Mount Plate Mounting

To install the switch on the wall, please follows the instructions described below.

Step1: Remove the DIN-Rail from the industrial switch; loose the screws to remove the DIN-Rail.

Step2: Place the wall mount plate on the rear panel of the industrial switch.

Step3: Use the screws to screw the wall mount plate on the industrial switch.

Step4: Use the hook holes at the corners of the wall mount plate to hang the industrial switch on the wall.

Step5: To remove the wall mount plate, reverse steps above.

3. NETWORK INSTALLATION

3.1 Hardware Installation

In this paragraph, we will describe how to install the 8-Port 10/100TX with redundant ring Web

management industrial switch and the installation points for attention.

1. Unpacked the Industrial switch.

2. Check the DIN-Rail is screwed on the Industrial switch. If the DIN-Rail is not screwed on the

Industrial switch. Please refer to DIN-Rail Mounting section for DIN-Rail installation. If you want to

wall mount the Industrial switch, then please refer to Wall Mount Plate Mounting section for wall

mount plate installation.

3. To hang the Industrial switch on the DIN-Rail track or wall, please refer to the Mounting Installation

section.

4. Power on the Industrial switch. How to wire the power; please refer to the Wiring the Power Inputs

section. The power LED on the Industrial switch will light up. Please refer to the LED Indicators

section for meaning of LED lights.

5. Prepare the twisted-pair, straight through Category 5 cable for Ethernet connection.

6. Insert one side of Category 5 cables into the Industrial switch Ethernet port (RJ-45 port) and

another side of category 5 cables to the network devices' Ethernet port (RJ-45 port), ex: switch, PC

or Server. The UTP port (RJ-45) LED on the Industrial switch will light up when the cable connected

with the network device. Please refer to the LED Indicators section for LED light meaning.

[NOTE] Be sure the connected network devices support MDI/MDI-X. If it does not support then use the

crossover category 5 Cable.

7. When all connections are all set and LED lights all show in normal, the installation is complete.

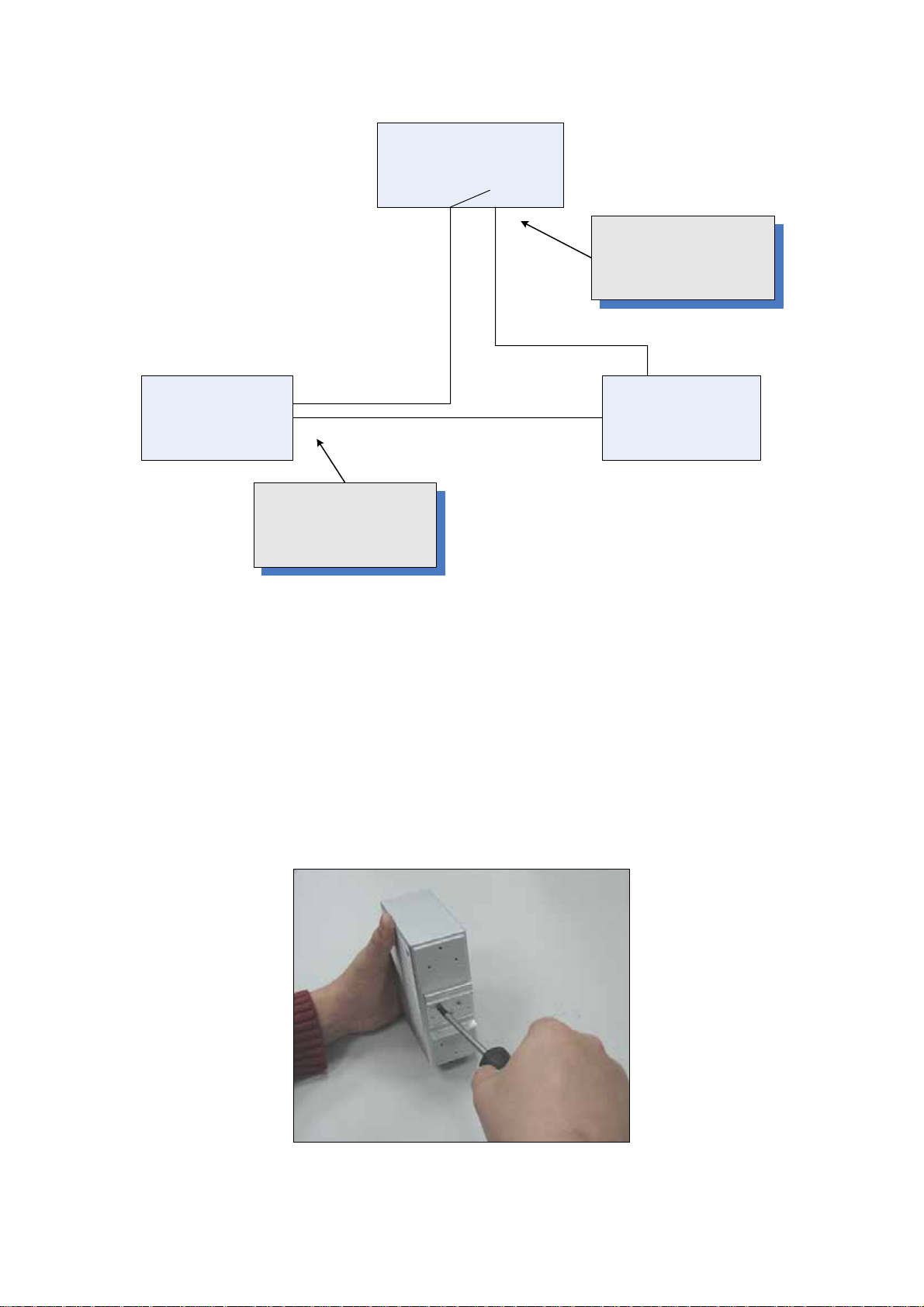

3.2 Network Application

This chapter provides some sample applications to help user to have more actual idea of

industrial switch function application. The following figure is a sample application of the

industrial switch.

3.3 Redundant Ring Application

The industrial switch supports the redundant ring protocol that can help your network system to recovery

from network connection failure within 300ms or less, and make your network system more reliable. The

redundant ring algorithm is like as spanning tree protocol (STP) algorithm but it has faster recovery time

than STP. The following figure is a sample redundant ring application.

Loading...

Loading...