Page 1

4-Port 10/100Mbps +1/2 100FX Fiber Port

Industrial Fast Ethernet Switch

ISW-511 / ISW-621Series

User's Manual

Page 2

Trademarks

Copyright © PLANET Technology Corp. 2009.

Contents subject to revision without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other

trademarks belong to their respective owners.

Disclaimer

PLANET Technology does not warrant that the hardware will work

properly in all environments and applications, and makes no warranty

and representation, either implied or expressed, with respect to

the quality, performance, merchantability, or tness for a particular

purpose.

PLANET has made every effort to ensure that this User’s Manual is

accurate; PLANET disclaims liability for any inaccuracies or omissions

that may have occurred.

Information in this User’s Manual is subject to change without notice

and does not represent a commitment on the part of PLANET. PLANET

assumes no responsibility for any inaccuracies that may be contained in

this User’s Manual. PLANET makes no commitment to update or keep

current the information in this User’s Manual, and reserves the right

to make improvements to this User’s Manual and/or to the products

described in this User’s Manual, at any time without notice.

If you nd information in this manual that is incorrect, misleading, or

incomplete, we would appreciate your comments and suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the Instruction manual, may cause harmful interference to radio

Page 3

communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may

cause radio interference, in which case the user may be required to

take adequate measures.

WEEE Warning

To avoid the potential effects on the environment and human

health as a result of the presence of hazardous substances in

electrical and electronic equipment, end users of electrical

and electronic equipment should understand the meaning of

the crossed-out wheeled bin symbol. Do not dispose of WEEE as

unsorted municipal waste and have to collect such WEEE separately.

Revision

PLANET 4-Port 10/100Mbps +1/2 100FX Fiber Port Industrial Fast

Ethernet Switch User’s Manual

For Models: ISW-511 / ISW-621 Series

Revision: 1.0 (February, 2009)

Part No: EM-ISW-511_621_v1.0 (2350-AH0150-000)

Page 4

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................ 6

1.1 Package Contents ............................................................... 6

1.2 How to Use This Manual ..................................................... 6

1.3 Product Features ................................................................. 7

Physical Port ....................................................................... 7

Layer 2 Features ................................................................. 7

Industrial Case / Installation ................................................ 8

1.4 Product Specications ......................................................... 9

2. INSTALLATION .........................................................................

2.1 Product Description .............................................................13

2.1.1 Switch Front Panel ....................................................14

2.1.2 LED Indicators ..........................................................16

2.1.3 Switch Upper Panel ...................................................16

2.1.4 Wiring the Power Inputs ............................................17

2.1.5 Wiring the Fault Alarm Contact ...................................18

2.2 Mounting Installation ..........................................................19

2.2.1 Install DIN-Rail Mounting ...........................................19

2.2.2 Wall Mount Plate Mounting .........................................21

APPLICATION ...........................................................................22

3

Installation Steps ...............................................................23

13

Page 5

4. SWITCH OPERATION .................................................................24

4.1 Address Table ....................................................................24

4.2 Learning ...........................................................................24

4.3 Forwarding & Filtering ........................................................24

4.4 Store-and-Forward .............................................................24

4.5 Auto-negotiation ................................................................25

5. TROUBLESHOOTING .................................................................

APPENDIX A: NETWORKING CONNECTION .......................................27

A.1 Switch’s RJ-45 Pin Assignments ..........................................27

A.2 RJ-45 cable Pin Assignments ..............................................27

26

Page 6

6

1. INTRODUCTION

1.1 Package Contents

Check the contents of your package for following parts:

● Industrial Fast Ethernet Switch x 1

● User's Manual x 1

● DIN Rail Kit x 1

● Wall Mount Kit x 1

If any of these are missing or damaged, please contact your dealer

immediately, if possible, retain the carton including the original packing

material, and use them against to repack the product in case there is a

need to return it to us for repair.

1.2 How to Use This Manual

This Industrial Fast Ethernet Switch User Manual is structured as

follows:

Chapter 2 Installation

The chapter explains the feature, functionality and the physical

installation of the Industrial Fast Ethernet Switch.

Chapter 3 Application

The chapter explains the Industrial Fast Ethernet Switch application.

Chapter 4 Switch operation

The chapter explains the Industrial Fast Ethernet Switch transmit

operation.

Chapter 5 Troubleshooting

The chapter explains the troubleshooting of the Industrial Fast Ethernet

Switch.

Appendix A

This chapter contains cable information of the Industrial Fast Ethernet

Switch.

Page 7

1.3 Product Features

Physical Port

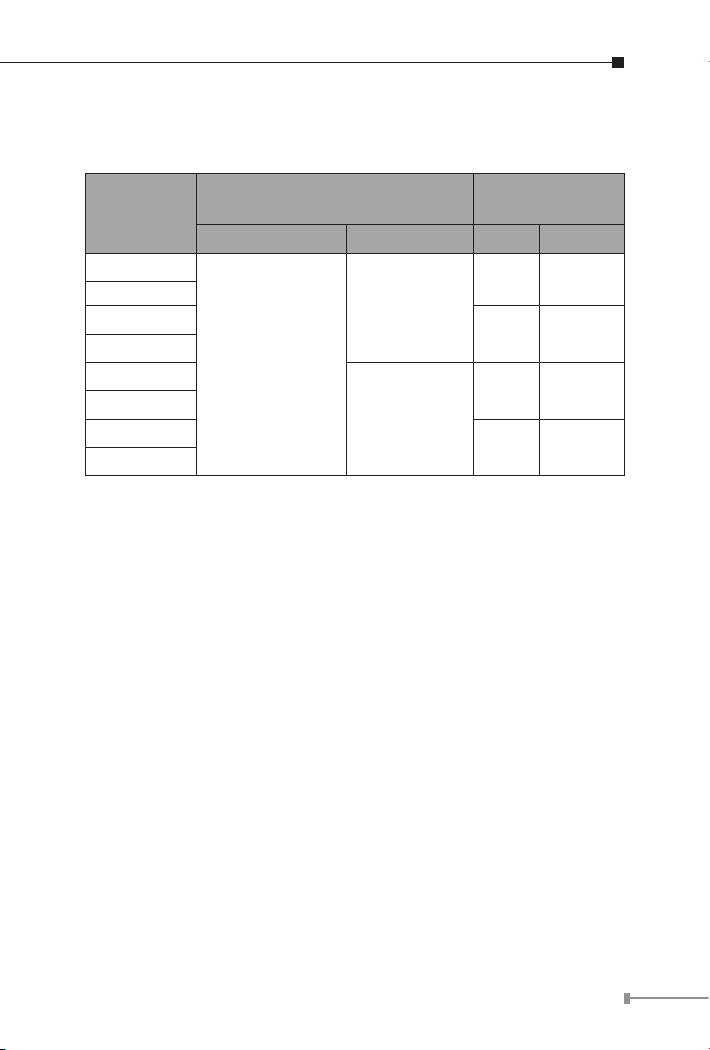

Model

Name

ISW-511

ISW-511T

ISW-511S15

ISW-511TS15

ISW-621

ISW-621T

ISW-621S15

ISW-621TS15

Ports

Copper Optical Mode Distance

1 x 100Base-FX

4 x 10/100Base-TX

2 x 100Base-FX

Fiber Optical

Interface

Multimode

Singlemode

Multimode

Singlemode

2km

15km

2km

15km

Layer 2 Features

□ Complies with IEEE 802.3, IEEE 802.3u 10/100Base-TX, 100Base-FX

□ Supports Auto-negotiation and 10/100Mbps half / full duplex mode

for each copper port

□ High performance store and forward architecture, broadcast storm

control, runt/CRC ltering eliminates erroneous packets to optimize

the network bandwidth

□ Prevents packet loss with back pressure (Half-Duplex) and IEEE

802.3x PAUSE frame ow control (Full-Duplex)

□ Backplane (Switching Fabric): ISW-511 Series: 1Gbps, ISW-621

Series: 1.2Gbps

□ Integrated address look-up engine, support 2K absolute MAC

addresses

□ 1Mbit on-chip frame buffer on ISW-511 / ISW-621 Series

□ Automatic address learning and address aging

7

Page 8

8

□ CSMA/CD Protocol

Industrial Case / Installation

□ IP-30 Metal case / Protection

□ DIN Rail and Wall Mount Design

□ 12 to 48V DC, redundant power with polarity reverse protect function

and connective removable terminal block for master and slave power

□ -10 to 60 Degree C operation temperature on ISW-511 / ISW-

511S15 / ISW-621 / ISW-621S15

□ -40 to 75 Degree C operation temperature on ISW-511T / ISW-

511TS15 / ISW-621T / ISW-621TS15

Page 9

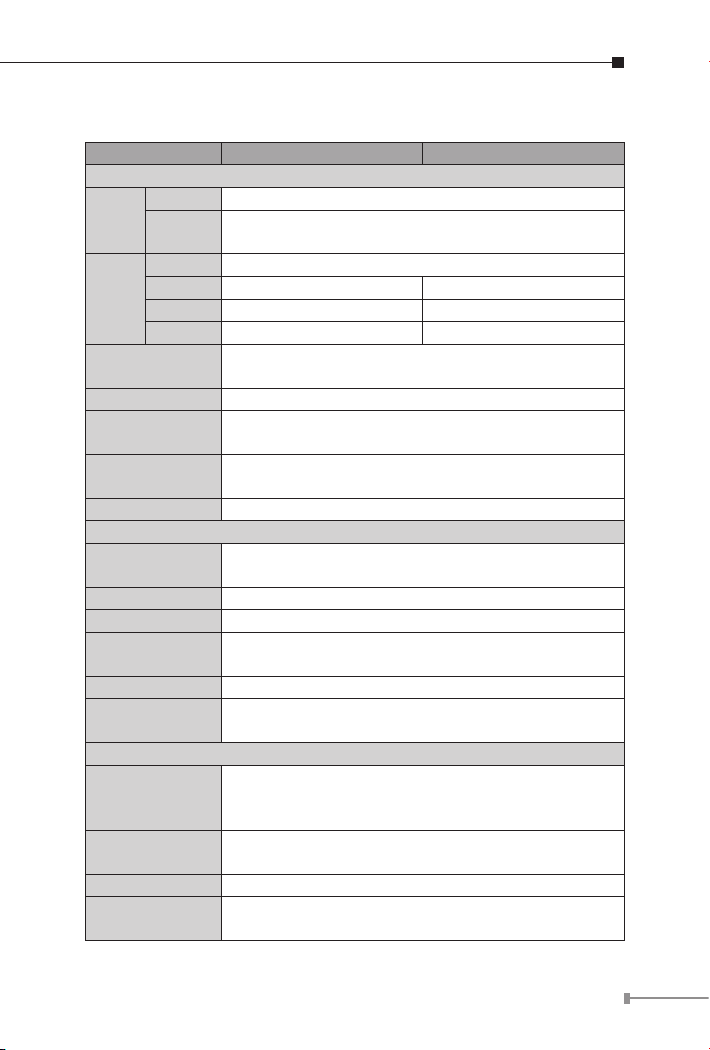

1.4 Product Specications

Model ISW-511 ISW-511S15

Hardware Specication

Ports 4 x 10/100Base-TX, Auto-negotiation, Auto-MDI/MDI-X

Copper

Cable

Port 1 x 100Base-FX

Cable 50/125μm or 62.5/125μm ber 9/125μm ber

Fiber

Optical

Mode Multi-mode Single-mode

Distance 2km 15km

Dimensions

(W x D x H)

Weight 436g

Power Requirement

Power Consumption

/ Dissipation

Installation DIN rail kit and wall mount ear

Switch Specication

Switch Processing

Scheme

Address Table 2K entries

Buffer 1Mbit

Flow Control

Switch Fabric 1Gbps

Throughput

(Packet Per Second)

Standards Conformance

Standards

Compliance

Temperature

Humidity Operating Operating: 5% to 90%, Storage: 5% to 90% (Non-condensing)

Regulation

Compliance

10Base-T: 2-pair UTP Cat. 3, 4, 5 cable (100meters, max.)

100Base-TX: 2-pair UTP Cat. 5 cable (100meters, max.)

135mm x 97mm x 32mm

12~48 VDC,

Redundant power with polarity reverse protection function

9.1 Watts / 31BTU

Store-and-Forward

Back pressure for half duplex,

IEEE 802.3x Pause Frame for full duplex

0.74Mpps @ 64Bytes

IEEE 802.3 Ethernet, 10Base-T

IEEE 802.3u Fast Ethernet, 100Base-TX, 100Base-FX

IEEE 802.3x Full-duplex ow control

Operating: -10~60 Degree C

Storage: -40~85 Degree C

FCC Part 15 Class A, CE

9

Page 10

10

Model ISW-511T ISW-511TS15

Hardware Specication

Ports 4 x 10/100Base-TX, Auto-negotiation, Auto-MDI/MDI-X

Copper

Cable

Port 1 x 100Base-FX

Cable 50/125μm or 62.5/125μm ber 9/125μm ber

Fiber

Optical

Mode Multi-mode Single-mode

Distance 2km 15km

Dimensions

(W x D x H)

Weight 436g

Power Requirement

Power Consumption

/ Dissipation

Installation DIN rail kit and wall mount ear

Switch Specication

Switch Processing

Scheme

Address Table 2K entries

Buffer 1Mbit

Flow Control

Switch Fabric 1Gbps

Throughput

(Packet Per Second)

Standards Conformance

Standards

Compliance

Temperature

Humidity Operating Operating: 5% to 90%, Storage: 5% to 90% (Non-condensing)

Regulation

Compliance

10Base-T: 2-pair UTP Cat. 3, 4, 5 cable (100meters, max.)

100Base-TX: 2-pair UTP Cat. 5 cable (100meters, max.)

135mm x 97mm x 32mm

12~48 VDC,

Redundant power with polarity reverse protection function

9.1 Watts / 31BTU

Store-and-Forward

Back pressure for half duplex,

IEEE 802.3x Pause Frame for full duplex

0.74Mpps @ 64Bytes

IEEE 802.3 Ethernet, 10Base-T

IEEE 802.3u Fast Ethernet, 100Base-TX, 100Base-FX

IEEE 802.3x Full-duplex ow control

Operating: -40~75 Degree C

Storage: -40~85 Degree C

FCC Part 15 Class A, CE

Page 11

Model ISW-621 ISW-621S15

Hardware Specication

Ports 4 x 10/100Base-TX, Auto-negotiation, Auto-MDI/MDI-X

Copper

Cable

Port 2 x 100Base-FX

Cable 50/125μm or 62.5/125μm ber 9/125μm ber

Fiber

Optical

Mode Multi-mode Single-mode

Distance 2km 15km

Dimensions

(W x D x H)

Weight 442g

Power Requirement

Power Consumption

/ Dissipation

Installation DIN rail kit and wall mount ear

Switch Specication

Switch Processing

Scheme

Address Table 2K entries

Buffer 1Mbit

Flow Control

Switch Fabric 1.2Gbps

Throughput

(Packet Per Second)

Standards Conformance

Standards

Compliance

Temperature

Humidity Operating Operating: 5% to 90%, Storage: 5% to 90% (Non-condensing)

Regulation

Compliance

10Base-T: 2-pair UTP Cat. 3, 4, 5 cable (100meters, max.)

100Base-TX: 2-pair UTP Cat. 5 cable (100meters, max.)

135mm x 97mm x 32mm

12~48 VDC,

Redundant power with polarity reverse protection function

11.6 Watts / 40BTU

Store-and-Forward

Back pressure for half duplex,

IEEE 802.3x Pause Frame for full duplex

0.89Mpps @ 64Bytes

IEEE 802.3 Ethernet, 10Base-T

IEEE 802.3u Fast Ethernet, 100Base-TX, 100Base-FX

IEEE 802.3x Full-duplex ow control

Operating: -10~60 Degree C

Storage: -40~85 Degree C

FCC Part 15 Class A, CE

11

Page 12

12

Model ISW-621T ISW-621TS15

Hardware Specication

Ports 4 x 10/100Base-TX, Auto-negotiation, Auto-MDI/MDI-X

Copper

Cable

Port 2 x 100Base-FX

Cable 50/125μm or 62.5/125μm ber 9/125μm ber

Fiber

Optical

Mode Multi-mode Single-mode

Distance 2km 15km

Dimensions

(W x D x H)

Weight 442g

Power Requirement

Power Consumption

/ Dissipation

Installation DIN rail kit and wall mount ear

Switch Specication

Switch Processing

Scheme

Address Table 2K entries

Buffer 1Mbit

Flow Control

Switch Fabric 1.2Gbps

Throughput

(Packet Per Second)

Standards Conformance

Standards

Compliance

Temperature

Humidity Operating Operating: 5% to 90%, Storage: 5% to 90% (Non-condensing)

Regulation

Compliance

10Base-T : 2-pair UTP Cat. 3, 4, 5 cable (100meters, max.)

100Base-TX : 2-pair UTP Cat. 5 cable (100meters, max.)

135mm x 97mm x 32mm

12~48 VDC,

Redundant power with polarity reverse protection function

11.6 Watts / 40BTU

Store-and-Forward

Back pressure for half duplex,

IEEE 802.3x Pause Frame for full duplex

0.89Mpps @ 64Bytes

IEEE 802.3 Ethernet, 10Base-T

IEEE 802.3u Fast Ethernet, 100Base-TX, 100Base-FX

IEEE 802.3x Full-duplex ow control

Operating: -40~75 Degree C

Storage: -40~85 Degree C

FCC Part 15 Class A, CE

Page 13

2. INSTALLATION

This section describes the functionalities of the Industrial Fast Ethernet

Switch’s components and guides how to install it on the desktop.

Basic knowledge of networking is assumed. Please read this chapter

completely before continuing.

In the following section, the term “Industrial Fast Ethernet Switch”

means the ISW-511 / ISW-621 series.

2.1 Product Description

The PLANET ISW-511 / ISW-621 series is 4-Port 10/100Mbps + 1/2

100FX Fiber Port Industrial Fast Ethernet Switch with non-blocking wirespeed performance and new slim type with IP 30 metal shape for easily

deployment in Heavy Industrial demanding environments.

With a 1/1.2Gbps internal switching fabric, the Industrial Fast Ethernet

Switch can handle extremely large amounts of data in a secure

topology linking to a backbone or high capacity servers.

The Industrial Fast Ethernet Switch has 2K MAC address table and

offers wire-speed packets transfer performance without risk of packet

loss. The stable throughput of the device makes it ideal for most

Ethernet environments.

All RJ-45 copper interfaces support 10/100Mbps Auto-negotiation for

optimal speed detection through RJ-45 Category 5, 4 or 3 cables.

Support standard for Auto-MDI/MDI-X that can detect the type of

connection to any Ethernet device without requiring special straight or

crossover cables.

The ow control function allows Industrial Fast Ethernet Switch

supported routers and servers to directly connect to this device for fast,

reliable data transfer.

13

Page 14

14

2.1.1 Switch Front Panel

Figure 2-1 & 2-2 & 2-3 & 2-4 shows a front panel of Industrial Fast

Ethernet Switch.

Figure 2-1 ISW-511 / ISW-511S15 front panel Figure 2-2 ISW-621 / ISW-621S15 front panel

Page 15

Figure 2-3 ISW-511T / ISW-511TS15 front panel Figure 2-4 ISW-621T / ISW-621TS15 front panel

15

Page 16

16

2.1.2 LED Indicators

LED Color Function

P1 Green Lit: indicate the power 1 has power.

P2 Green Lit: indicate the power 2 has power.

FAULT Green

100 Green

10/100 Green Copper

Lit: indicate the either power 1 or power 2 has no

power.

Fiber

Optical

Lit: indicate the Fiber port is successfully

connecting to the network at

100Mbps.

Lit: indicate the Switch is successfully

connecting to the network at

100Mbps.

Off: indicate that the Switch is

successfully connecting to the

network at 10Mbps.

Fiber

Optical

LNK/ACT Green

Copper

Lit: indicate the link through that port is

successfully established.

Blink: indicate that the Switch is actively

sending or receiving data over that

port.

2.1.3 Switch Upper Panel

The upper panel of the Industrial Fast Ethernet Switch consist one

terminal block connector within two DC power inputs. Figure 2-5 shows

the upper panel of the Industrial Fast Ethernet Switch.

Figure 2-5 Industrial Fast Ethernet Switch upper Panel.

Page 17

2.1.4 Wiring the Power Inputs

Note

The 6-contact terminal block connector on the top panel of Industrial

Fast Ethernet Switch is used for two DC redundant powers input. Please

follow the steps below to insert the power wire.

1. Insert positive / negative DC power wires into the contacts 1 and 2

for POWER 1, or 5 and 6 for POWER 2.

2. Tighten the wire-clamp screws for preventing the wires from

loosing.3.

V1- V1 + V2 - V2 +

1 2 3 4 5 6

Power 1 Fault Power 2

- + - +

The wire gauge for the terminal block should be in the

range between 12 ~ 24 AWG.

17

Page 18

18

2.1.5 Wiring the Fault Alarm Contact

Note

The fault alarm contacts are in the middle of the terminal block

connector as the picture shows below. Inserting the wires, the Industrial

Fast Ethernet Switch will detect the fault status of the power failure,

or port link failure (available for managed model) and then forms an

open circuit. The following illustration shows an application example for

wiring the fault alarm contacts.

1 2 3 4 5 6

Insert the wires into the fault alarm contacts

1. The wire gauge for the terminal block should be in

the range between 12 ~ 24 AWG.

2. Alarm relay circuit accepts up to 30V, max. 3A

currents.

Page 19

2.2 Mounting Installation

Note

This section describes how to install the Industrial Fast Ethernet Switch

and make connections to it. Please read the following topics and

perform the procedures in the order being presented.

In the installation steps below, this Manual use IGS801 (PLANET 8 Port Industrial Gigabit Switch) as the

example. However, the steps for PLANET Industrial

Switch & Industrial Media Converter are similar.

2.2.1 Install DIN-Rail Mounting

The DIN-Rail is screwed on the Industrial Fast Ethernet Switch when

out of factory. When need to replace the wall mount application with

DIN-Rail application on Industrial Fast Ethernet Switch , please refer to

following gures to screw the DIN-Rail on the Industrial Fast Ethernet

Switch. To hang the Industrial Fast Ethernet Switch, follow the below

steps:

Step 1: screw the DIN-Rail on the Industrial Fast Ethernet Switch.

19

Page 20

20

1

2

Step 2: Lightly press the button of DIN-Rail into the track.

Step 3: Check the DIN-Rail is tightly on the track.

Step 4: Please refer to following procedures to remove the Industrial

Fast Ethernet Switch from the track.

1

2

Step 5: Lightly press the button of DIN-Rail for remove it from the

track.

Page 21

2.2.2 Wall Mount Plate Mounting

To install the Industrial Fast Ethernet Switch on the wall, please follows

the instructions described below.

Step 1: Remove the DIN-Rail from the Industrial Fast Ethernet

Switch; loose the screws to remove the DIN-Rail.

Step 2: Place the wall mount plate on the rear panel of the Industrial

Fast Ethernet Switch.

Step 3: Use the screws to screw the wall mount plate on the

Industrial Fast Ethernet Switch.

Step 4: Use the hook holes at the corners of the wall mount plate to

hang the Industrial Fast Ethernet Switch on the wall.

Step 5: To remove the wall mount plate, reverse steps above.

21

Page 22

22

3. AppLICATION

Control Center

Harbor

Factory

Warehouse

Robot

Robot

Fiber Switch

100Base-TX UTP

100Base-FX Fiber-optic

100

I/O

DI/DO

15km

ISW-511S15

ICA-651 ICA-350

ISW-511S15

ICS-2100

PLC

ICA-310

ISW-511S15

ICS-2100

PLC

Serial Device

Server

ICA-525

ROBOT

ROBOT

I/O

100

100

100

I/O

I/O

I/O

15km

15km

Control Center

Subway 2

Subway 1

Maintenance Shop

ICA-525

ISW-621S15

ICA-310

ISW-621S15

ISW-621S15

I/O Device

PLC

ICS-2100

ICA-601

ICS-2100

PLC

Robot

Robot

I/O

I/O

ROBOT

ROBOT

Fiber Switch

100Base-TX UTP

100Base-FX Fiber-optic

100

I/O

DI/DO

100 100

100

I/O

I/O

I/O

15km

15km

15km

I/O

I/O

Serial over Ethernet

device

In this paragraph, we will describe how to install Industrial Fast

Ethernet Switch and the installation points for the attention.

Page 23

Installation Steps

Note

Step 1: Unpack the Industrial Fast Ethernet Switch.

Step 2: Check the DIN-Rail is screwed on the Industrial Fast Ethernet

Switch. (Please refer to DIN-Rail Mounting section for DINRail installation. If the DIN-Rail is not screwed on the

Industrial Fast Ethernet Switch.). If you want to wall mount

the Industrial Fast Ethernet Switch, then please refer to

Wall Mount Plate Mounting section for wall mount plate

installation.

Step 3: To hang the Industrial Fast Ethernet Switch on the DIN-

Rail track or wall, please refer to the Mounting Installation

section.

Step 4: Power on the Industrial Fast Ethernet Switch. (Please refer

to the Wiring the Power Inputs section for power input) The

power LED on the Industrial Fast Ethernet Switch will light

up. Please refer to the LED Indicators section for meaning of

LED lights.

Step 5: Prepare the twisted-pair, straight through Category 5 cable

for Ethernet connection.

Step 6: Insert one side of Category 5 cables into the Industrial Fast

Ethernet Switch Ethernet port (RJ-45 port) and another side

of category 5 cables to the network devices’ Ethernet port

(RJ-45 port), ex: Switch, PC or Server. The UTP port (RJ-45)

LED on the Industrial Fast Ethernet Switch will light up when

the cable connected with the network device. Please refer to

the LED Indicators section for LED light meaning.

Be sure the connected network devices support MDI/

MDI-X. If it does not support then use the crossover

category 5 Cable.

Step 7: Insert ber cable from the ISW-511/621 series to the ber

network. TX, RX must be paired at both ends. The optical

port LED on the Industrial Fast Ethernet Switch will light up

when the cable connected with the network device. Please

refer to the LED Indicators section for LED light meaning.

Step 8: When all connections are all set and LED lights all show in

normal, the installation is complete.

23

Page 24

24

4. SwITCh OpeRATION

4.1 Address Table

The Industrial Fast Ethernet Switch is implemented with an address

table. This address table composed of many entries. Each entry is used

to store the address information of some node in network, including

MAC address, port no, etc. This information comes from the learning

process of Industrial Fast Ethernet Switch.

4.2 Learning

When one packet comes in from any port. The Industrial Fast Ethernet

Switch will record the source address, port no. And the other related

information in address table. This information will be used to decide

either forwarding or ltering for future packets.

4.3 Forwarding & Filtering

When one packet comes from some port of the Industrial Fast Ethernet

Switch, it will also check the destination address besides the source

address learning. The Industrial Fast Ethernet Switch will lookup the

address-table for the destination address. If not found, this packet will

be forwarded to all the other ports except the port which this packet

comes in. And these ports will transmit this packet to the network it

connected. If found, and the destination address is located at different

port from this packet comes in, the Industrial Fast Ethernet Switch will

forward this packet to the port where this destination address is located

according to the information from address table. But, if the destination

address is located at the same port with this packet comes in, then

this packet will be ltered. Thereby increasing the network throughput

and availability.

4.4 Store-and-Forward

Store-and-Forward is one type of packet-forwarding techniques. A

Store-and-Forward Industrial Switch stores the incoming frame in an

internal buffer, do the complete error checking before transmission.

Page 25

Therefore, no error packets occurrence, it is the best choice when a

network needs efciency and stability.

The Industrial Fast Ethernet Switch scans the destination address from

the packet-header, searches the routing table provided for the incoming

port and forwards the packet, only if required. The fast forwarding

makes the switch attractive for connecting servers directly to the

network, thereby increasing throughput and availability. However, the

switch is most commonly used to segment existing hubs, which nearly

always improves overall performance. An Ethernet Switching can be

easily congured in any Ethernet network environment to signicantly

boost bandwidth using conventional cabling and adapters.

Due to the learning function of the Industrial Fast Ethernet Switch,

the source address and corresponding port number of each incoming

and outgoing packet are stored in a routing table. This information is

subsequently used to lter packets whose destination address is on the

same segment as the source address. This connes network trafc to

its respective domain, reducing the overall load on the network.

The Industrial Fast Ethernet Switch performs “Store-and-Forward"

therefore, no error packets occur. More reliably, it reduces the retransmission rate. No packet loss will occur.

4.5 Auto-negotiation

The STP ports on the Industrial Fast Ethernet Switch have builtin “Auto-negotiation”. This technology automatically sets the best

possible bandwidth when a connection is established with another

network device (usually at Power On or Reset). This is done by detect

the modes and speeds at the second of both device is connected and

capable of, both 10Base-T and 100Base-TX devices can connect with

the port in either Half- or Full-Duplex mode.

25

Page 26

26

5. TROUBLeShOOTING

This chapter contains information to help you solve issues. If the

Industrial Fast Ethernet Switch is not functioning properly, make sure

the Industrial Fast Ethernet Switch was set up according to instructions

in this manual.

The per port LED is not lit

Solution:

Check the cable connection of the Industrial Fast Ethernet Switch.

Performance is bad

Solution:

Check the speed duplex mode of the partner device. The Industrial Fast

Ethernet Switch is run at Auto-negotiation mode and if the partner is

set to half duplex, then the performance will be poor.

Per port LED is lit, but the trafc is irregular

Solution:

Check that the attached device is not set to dedicate full duplex. Some

devices use a physical or software switch to change duplex modes.

Auto-negotiation may not recognize this type of full-duplex setting.

Why the Industrial Fast Ethernet Switch doesn’t connect to the

network

Solution:

Check per port LED on the Industrial Fast Ethernet Switch. Try another

port on the Industrial Fast Ethernet Switch Make sure the cable is

installed properly Make sure the cable is the right type Turn off the

power. After a while, turn on power again.

Why the Industrial Fast Ethernet Switch doesn’t connect to the

network

Solution:

Check per port LED on the Industrial Fast Ethernet Switch. Try another

port on the Industrial Fast Ethernet Switch Make sure the cable is

installed properly Make sure the cable is the right type Turn off the

power. After a while, turn on power again.

Page 27

AppeNDIX A: NeTwORKING CONNeCTION

A.1 Switch’s RJ-45 Pin Assignments

10/100Mbps, 10/100Base-TX

RJ-45 Connector pin assignment

Contact

1 Tx + (transmit) Rx + (receive)

2 Tx - (transmit) Rx - (receive)

3 Rx + (receive) Tx + (transmit)

4, 5 Not used

6 Rx - (receive) Tx - (transmit)

7, 8 Not used

Media Dependant Interface

MDI

Media Dependant Interface

A.2 RJ-45 cable Pin Assignments

MDI-X

-Cross

The standard RJ-45 receptacle/connector

There are 8 wires on a standard UTP/STP cable and each wire is colorcoded. The following shows the pin allocation and color of straight cable

and crossover cable connection:

27

Page 28

Straight Cable

Cross Over Cable

SIDE 1

SIDE 1

SIDE 2

SIDE 1

SIDE 2

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

SIDE 2

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

SIDE 1 SIDE 2

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

1 = White/Green

2 = Green

3 = White/Orange

4 = Blue

5 = White/Blue

6 = Orange

7 = White/Brown

8 = Brown

Figure A-1: Straight-Through and Crossover Cable

Please make sure your connected cables are with same pin assignment

and color as above picture before deploying the cables into your

network.

28

Loading...

Loading...