Page 1

Palmse Mehaanikakoda, Võsupere küla, Vihula vald, Lääne-Virumaa 45202, Estonia

tel. +3723255375 fax +3723255378 e-mail: palms@palms.eu http://www.palms.eu

USER MANUAL

FOREST TRAILER PALMS 81

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ...................................................................................................... 2

2. SAFETY.................................................................................................................... 3

3. BASIC COMPONENTS............................................................................................ 5

4. ACCESSORY ........................................................................................................... 6

5. TECHNICAL DATA .................................................................................................. 7

6. HYDRAULIC SYSTEM............................................................................................. 9

7. ASSEMBLY AND MOUNTING................................................................................. 9

8. OPERATING INSTRUCTIONS............................................................................... 10

9. STORAGE INSTRUCTIONS .................................................................................. 11

10. MAINTENANCE ..................................................................................................... 12

11. SPARE PARTS ...................................................................................................... 13

12. WARRANTY........................................................................................................... 17

Page 3

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 2

1. INTRODUCTION

This manual gives you detailed overview about forest trailer Palms 81. Read the manual

carefully before you start using this machine. The manual contains essential directions

for efficient and safe use of forest trailer. These instructions should always be followed.

This forest trailer is constructed to transport raw wood material from forest as well for

transportation treated wood. Forest trailer is build for use with agricultural tractors. It

has an unified connection junction for mounting Palms forest cranes. This machine

meets all technical standards and safety regulations of valid EU Machinery Directive

and its amendments. Forest trailer is fitted out with CE marking.

User of forest trailer is obliged to be aware of and strictly follow all safety precautions

and instructions described in this manual. In addition to this, instructions of local

occupational safety authorities, as well national laws, regulations and highway codes,

must be followed. Using the machine for other tasks, than those for which it is intended

or exceeding its performance, is not allowed. The manufacturer/dealer is not respon-

sible for damage caused by misuse of the forest trailer.

Pay attention to regular maintenance. In case there will occur problems during use of

forest trailer, which are not covered in this manual, contact authorized dealer or

manufacturer.

Page 4

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 3

2. SAFETY

2.1 General

Read the manual carefully before you start using forest trailer. Use forest trailer only for

purposes, what it is made for. Driver must have proper valid licence to drive tractor in

connection with trailer and has sufficient training for that. Notice, avoid and prevent all

potentially hazardous situations.

IT IS STRONGLY FORBIDDEN:

• to use forest trailer in state of intoxication by alcohol, drugs or other

psychoactive substances

• to exceed maximum loading values

• to use forest trailer for transporting people

• to rebuild forest trailer

• to use repairing materials without the producer’s permission

BEFORE YOU START LOADING, MAKE SURE THAT:

• forest trailer is fully in working condition

• you have full visibility over all the working area

• forest trailer is placed on even ground

• parking brake is engaged

2.2 Safety distances

General safety distance for working with forest trailer is 20 metres!

Follow special safety distance when working close to live electrical conductors:

Rated voltage, kV Safety area, m

Up to 0,5 2

Up to 20 10

35 – 110 25

220 – 330 40

Table 1. Safety area

Page 5

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 4

2.3 Hydraulic system

• Hydraulic system must be serviced by qualified and experienced hydraulics

mechanic only

• Continually inspect the condition of hydraulic system. Repair all safety en-

dangering defects immediately

• Before starting repair work or maintenance make sure, there is no pressure in

hydraulic system

• Use safety goggles and gloves during repair work and maintenance

• Use original spare parts or parts recommended by the manufacturer

• Prevent oil dripping to the ground to avoid environment pollution

• In ecologically sensitive areas use bio-oil

2.4 Operation

• Ensure, that forest trailer is in good working condition

• Operating with damaged or defective machine is prohibited

• Ensure, that you have control over all the working area

• Prevent entering unauthorized persons to the working area

• Support legs must be used while forest trailer is being loaded

• Be sure not to endanger anyone while lowering the support legs

• Use parking brake while loading

• Do not load over the upper edge of safety screen

• Loading short logs be shure they are supported at least with two pairs of

bolsters

• Follow strictly load limits stated by the manufacturer for certain trailer

• Pull the support legs up before moving forest trailer

• Release parking brake

• Pay extra attention driving with unlocked drawbar

• Prevent any hoses between trailer and tractor to be squashed on sharp turns

• For driving on roads lock drawbar in straight position with locking shaft

• Make shure signal lights are unfolded and working for driving on public roads

• Follow traffic regulations

• Max speed by manufacturer for certain forest trailer is 40 km/h

• Manufacturer is not responsible for damage or loss, caused by misuse or

incorrect, careless and inappropriate use of the machine

Page 6

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 5

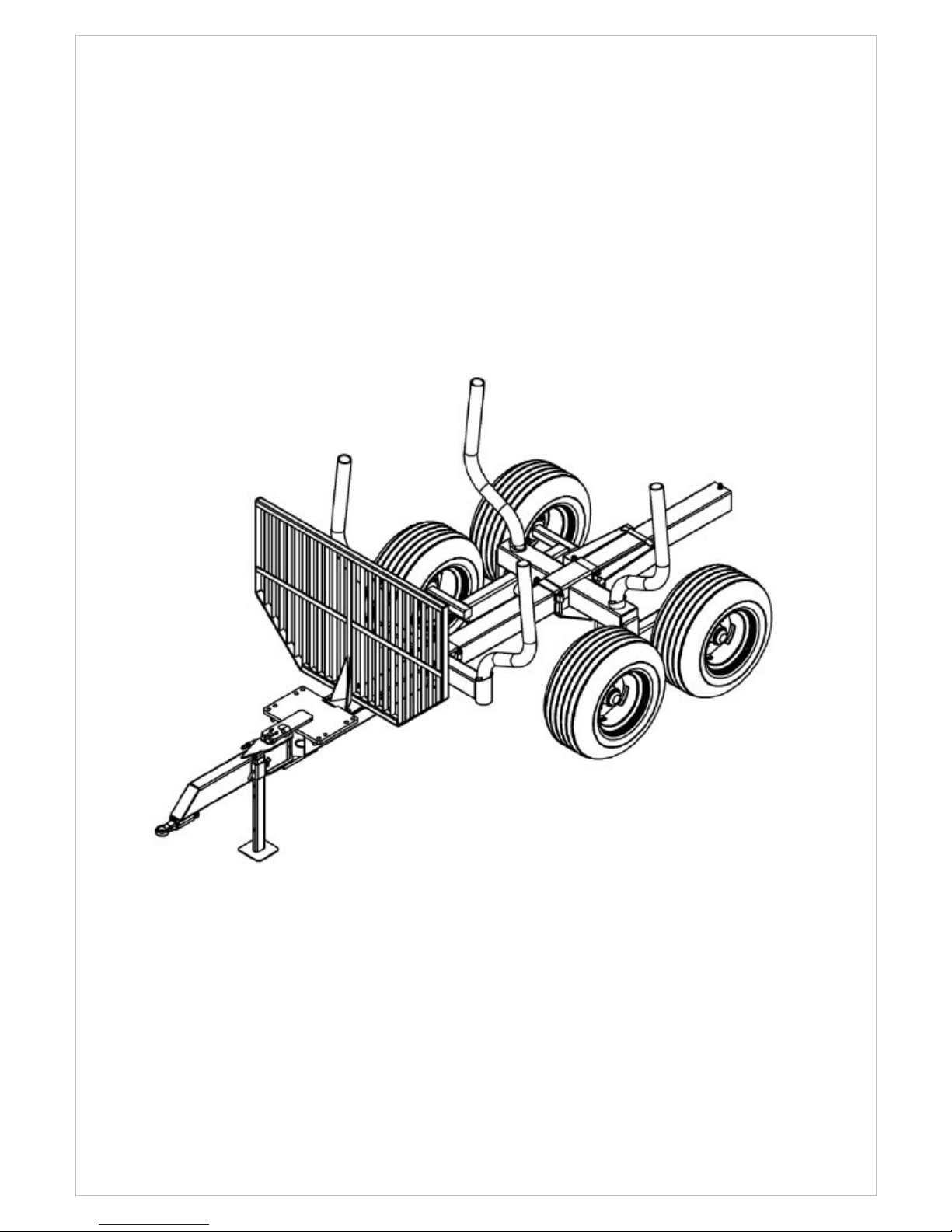

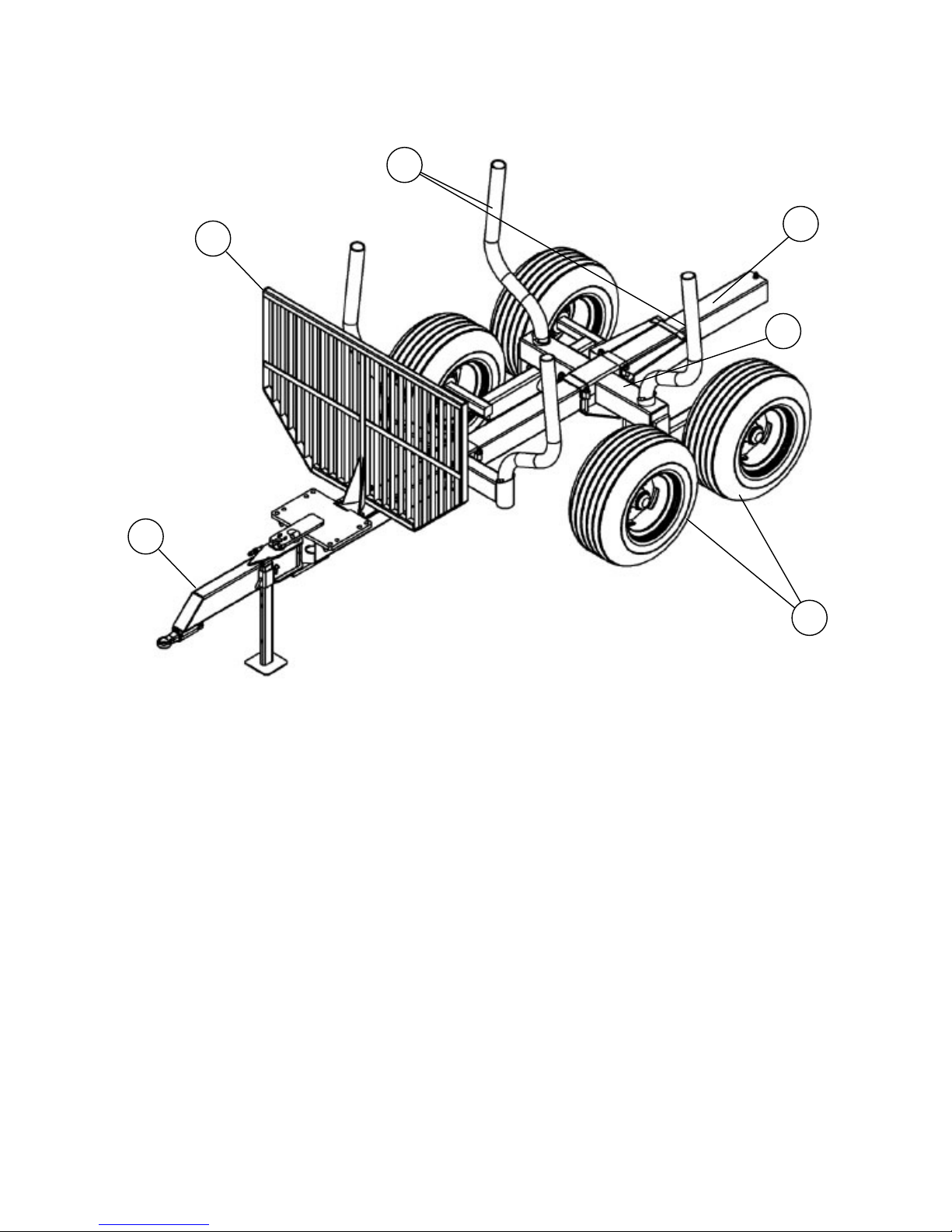

3. BASIC COMPONENTS

Figure 1. Basic components of Palms 81 forest trailer

1. Drawbar 2. Chassis 3. Safety screen

4. Bolsters 5. Boggie 6. Wheels, standard 11,5/80-11,3

1

3

2

6

5

4

Page 7

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 6

4. ACCESSORY

4.1 Brakes

Figure 2. Brakes on on axle Figure 3. Brakes on two axles

4.2 Frame extension and signal lights

Figure 4. Frame extension Figure 5. Signal lights

Page 8

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 7

5. TECHNICAL DATA

5.1 Technical data

Load capacity ≤40 km/h 8000 kg

Axles 60x60-6

Chassis 160x160

Loading area 1,8 m2

Length of loading area, mm 3400

Total length, mm 5330

Clearance

Brakes

Width with standard wheels, mm 1920

Standard wheels 11,5/80-11,3

Drawbar cylinders 1

Drawbar turning angle to sides, ° ±40

Net weight, kg 950

Max torque of installed crane, kNm ≤45

Table 2. Forest trailer Palms 81 technical data

Manufacturer reserves the right to change specifications without prior notice.

Page 9

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 8

5.2 Dimensions

Figure 6. Dimentions of Palms 81 forest trailer

Page 10

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 9

6. HYDRAULIC SYSTEM

6.1 Connection

Connect trailer’s hydraulic hoses to one of sections of tractor’s control valve. Be sure all

connections are properly locked. Unlock drawbar by removing locking shaft. Using lever

of control valve section, where you connected forest trailer’s hydraulic hoses, work

carefully thru extreme positions of drawbar to both sides until turning cylinder is working

smoothly.

7. ASSEMBLY AND MOUNTING

Read these instructions before starting any assembly or mounting work. Improper

mounting can cause hazards during use of the forest trailer. Mounting, carried out in a

manner other than specified in this manual, can expose the user to danger and will void

the manufacturer’s warranty.

7.1 Mounting forest crane to Palms trailer

Mounting of forest crane should be performed at the dealer service center or by person

authorized by the manufacturer or dealer. Mounting/detaching the crane can also be

made by end user, if professional equipment is used, all safety regulations are followed

and at least one qualified mechanic is in present during all the mounting/detaching

process.

Strength class for mounting bolts of support legs - trailer (pos. 1, fig. 5) has to be 12.9

(DIN912). Use self-locking nuts M24. Tightening torque for the mounting bolts is 1220

Nm.

Retighten bolts after test run and after first 8 hours of use! Check after 40

working hours, tighten if needed. Later on do visual check.

Figure 7. Connection junction on A- support legs

1

Page 11

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 10

8. OPERATING INSTRUCTIONS

8.1 Connecting forest trailer to tractor

Before you hook up trailer with tractor ensure, that:

• tractor is enough powerful for this trailer

• tractor’s hitch is in perfect working condition

• trailer is on even ground and fixed with wheel chocks

• trailer is in perfect working condition

• all hydraulic hoses on trailer are proparly connected

Before you start transport forest trailer ensure, that:

• forest trailer is hooked up and locked to tractor properly

• hydraulic hoses between trailer and tractor are connected properly

• trailer’s brakes are released

• wheel chocks have been removed

• there is right air pressure in trailer’s tyres

• drawbar is locked in straight position while driving on roads

• signal lights cable is connected to the tractor and lights are working properly

Adjust speed according to the road and weather conditions. Do not exceed

the speed limit! Driving with the load be especially careful on turns!

Page 12

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 11

9. STORAGE INSTRUCTIONS

Always switch the pump off before disconnecting hydraulic hoses from

tractor’s hydraulic system!

• Clean forest trailer and if necessary, touch up any points, where paint has peeled off

• Lubricate forest trailer thoroughly (see lubricating instructions)

• Release pressure from the cylinders

• Protect draw bar turning cylinder’s piston rods with grease

• Store forest trailer in a sheltered area(under the roof), avoid direct contact with ground

Page 13

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 12

10. MAINTENANCE

10.1 Lubrication

Using the appropriate lubricants like Beacon EP2, Multipurpose GR Moly, Mobilux EP2,

Mobil Grease MP Special, Energrease LS-EP2 or similar. Right lubricants guarantee

troublefree operation of the machine.

Figure 8. Lubrication points of Palms 81 forest trailer

Lubrication point Pcs Lubricant

Interval,

working hour

Additional information

1. Drawbar eyelet, A 1 Grease 8 2% molybdensulfide

2. Shaft of the drawbar, B 1 Grease 8

3. Turning cylinder eyelet, C 2 Grease 8

4. Rollerbearings of wheels, D 4 Grease Once a year

5. Shaft of the boggie, E 2 Grease 8

Table 3. Lubrication

A

B

E

D

C

D

D

E

Page 14

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 13

11. SPARE PARTS

11.1 Basic parts

Figure 9. Spare parts of Palms 81 forest trailer

Page 15

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 14

Pos Qty Part № Part name

1 1

1080000101 Palms 81 frame with drawbar

2 1

1080000201 Palms 81 boggie bunk

3 1

1080000301 Palms 81 front safety barrier

4 1

1080000401 Palms 81 bunk

5 2

1080000501 Palms 81 boggie

6 4

2080000601 Palms 81 clamp

7 2

2080000701 Palms 81 boggie pin

8 4

2080000801 Palms 81 post

9 1

2112001001 Parking leg

10 1

2112000801 Drawbar locking pin

11 2

2112001201 Sylinder pin

12 1

2112001301 Parking leg locking pin

13 4

* Wheel

14 1

3703202030 Drawbar turning cylinder

15 4

5800606065 Bearing bush 60-65X60 WB800

16 2

5030038000 3/8 L-union

17 2

4380127260 Hydraulic hose 3/8 - 1/2 TR L - 2600

18 2

5080012000 1/2 quickcoupling

19 1

7933160300 Screw M16 x 30 DIN 933

20 4

7933160500 Screw M16 x 50 DIN 933

21 8

7931201800 Screw M20 x 180 DIN 931

22 5

7985160000 Nut M16 DIN 985

23 8

7985200000 Nut M20 DIN 985

24 24

7000018015 Wheel nut M18 x 1,5

25 5

7125160000 Washer 16 DIN 125

26 12

7125200000 Washer 20 DIN 125

27 1

7110244075 Cotter pin 4 x 75 DIN 11024

28 2

7148110050 Pin 10 x 50 DIN 1481

29 5

7714120600 Grease nipple M6 DIN 71412

Table 4. Spare parts list of Palms 81 forest trailer

Page 16

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 15

11.2 Hydraulic brakes on one(front) axle

Figure 10. Brakes on front axle

Pos Qty Part № Part name

1 1 11220101 Boggie

2 1 11220201 Boggie

3 1 11220301 hydraulic hose 1/4 - 1/4 L -

4 2 11220401 hydraulic hose 1/4 - 1/4 90 L -

5 1 11220501 1/4 T-union

6 1 11220601 1/2 - 1/4 nipple

7 1 11220701 1/2 usit-seal

8 1 11220801 1/2 quickcoupling

9 2 11220901 1/4 double nipple

10 2 11221001 1/4 usit-seal

11 1 11221101 1/2 cover

Table 5. Spare parts list of hydraulic brakes on one axle

Page 17

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 16

11.3 Hydraulic brakes on two(front and rear) axles

Figure 11. Brakes on both axles

Pos Qty Part № Part name

1 1 11230101 Boggie

2 1 11230201 Boggie

3 1 11230301 hydraulic hose 1/4 - 1/4 L -

4 2 11230401 hydraulic hose 1/4 - 1/4 90 L -

5 2 11230501 hydraulic hose 1/4 - 1/4 90 L -

6 2 11230601 hydraulic hose 1/4 - 1/4 90 L -

7 1 11230701 1/4 T-union

8 1 11230801 1/2 - 1/4 nipple

9 2 11230901 1/4 double nipple

10 1 11231001 1/2 quickcoupling

11 1 11231101 1/2 cover

12 1 11231201 1/2 usit-seal

13 2 11231301 1/4 usit-seal

Table 6. Spare parts list of hydraulic brakes on both axles

Page 18

FOREST TRAILER PALMS 81

Ver 1.00 EN © 2010 Palmse MK 17

12. WARRANTY

Product warranty is valid for one year starting from the date of delivery or issuing an

invoice. Product warranty is valid only if:

• all instructions in this manual were followed

• during the maintenance original spare parts were used

• maintenance work was performed by the qualified specialist

• forest trailer was not overloaded

• proper pressure was used in the hydraulic system

Product warranty is NOT VALID in case of user’s incompetence and/or irrespective

handling of the equipment. Warranty does not cover transportation cost or loss of profit

due to normal abrasion or product failure.

Producer:

Palmse Mehaanikakoda LLC

Võsupere

Lääne-Virumaa

45 202 Estonia

Tel +372 32 55 375

Fax +372 32 55 378

info@palms.eu

www.palms.eu

Loading...

Loading...