Page 1

User’s Manual of IGT-90x

User’s Manual

IGT-902 / 902T

IGT-902S / 902TS

IGT-905A

10/100/1000Base-T to 1000Base-SX / LX

Industrial Managed Media Converter

-1-

Page 2

User’s Manual of IGT-90x

Trademarks

Copyright © PLANET Technology Corp. 2010.

Contents subject to which revision without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other trademarks belong to their respective owners.

Disclaimer

PLANET Technology does not warrant that the hardware will work properly in all environments and applications, and

makes no warranty and representation, either implied or expressed, with respect to the quality, performance,

merchantability, or fitness for a particular purpose.

PLANET has made every effort to ensure that this User's Manual is accurate; PLANET disclaims liability for any

inaccuracies or omissions that may have occurred.

Information in this User's Manual is subject to change without notice and does not represent a commitment on the part of

PLANET. PLANET assumes no responsibility for any inaccuracies that may be contained in this User's Manual. PLANET

makes no commitment to update or keep current the information in this User's Manual, and reserves the right to make

improvements to this User's Manual and/or to the products described in this User's Manual, at any time without notice.

If you find information in this manual that is incorrect, misleading, or incomplete, we would appreciate your comments and

suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the Instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at whose own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference, in which case the user

may be required to take adequate measures.

WEEE Warning

To avoid the potential effects on the environment and human health as a result of the presence of

hazardous substances in electrical and electronic equipment, end users of electrical and electronic

equipment should understand the meaning of the crossed-out wheeled bin symbol. Do not dispose of

WEEE as unsorted municipal waste and have to collect such WEEE separately.

Revision

PLANET Industrial Managed Gigabit Ethernet Media Converter User's Manual

FOR MODELS: IGT-902 / IGT-902T / IGT-902S / IGT-902TS / IGT-905A

REVISION: 1.2 (JULY.2010)

Part No.: 2080-AA1130-004

-2-

Page 3

User’s Manual of IGT-90x

TABLE OF CONTENTS

1. INTRODUCTION.............................................................................................................5

1.1 Package Contents.....................................................................................................................................................5

1.2 How to Use This Manual ........................................................................................................................................... 5

1.3 Product Description................................................................................................................................................... 6

1.4 Applications............................................................................................................................................................... 6

1.5 Product Features....................................................................................................................................................... 7

1.6 Product Specification................................................................................................................................................. 8

2. HARDWARE INSTALLATION......................................................................................10

2.1 IGT-90X Front Panel ...............................................................................................................................................10

2.1.1 LED Indicators .................................................................................................................................................. 11

2.1.2 IGT-90X Rear Panel ......................................................................................................................................... 11

2.1.3 Wiring the Power Inputs.................................................................................................................................... 12

2.1.4 Wiring the Fault Alarm Contact......................................................................................................................... 13

2.2 Mounting Installation ...............................................................................................................................................14

2.2.1 DIN-Rail Mounting ............................................................................................................................................ 14

2.2.2 Wall Mount Plate Mounting ............................................................................................................................... 15

2.2.3 Stand-alone Installation .................................................................................................................................... 16

3. INDUSTRIAL MEDIA CONVERTER MANAGEMENT .................................................19

3.1 Overview ................................................................................................................................................................. 19

3.2 Requirements .......................................................................................................................................................... 19

3.3 Management Methods.............................................................................................................................................20

3.3.1 Web Management ............................................................................................................................................20

3.3.2 Login the Industrial Managed Media Converter................................................................................................ 20

3.3.3 SNMP Management .........................................................................................................................................21

3.3.4 PLANET Smart Discovery Utility....................................................................................................................... 21

4. WEB MANAGEMENT................................................................................................... 24

4.1 Main Menu...............................................................................................................................................................24

4.2 System .................................................................................................................................................................... 25

4.2.1 System Information........................................................................................................................................... 25

4.2.2 IP Configuration ................................................................................................................................................26

4.2.3 Password Setting..............................................................................................................................................27

4.2.4 Firmware Upgrade ............................................................................................................................................ 28

4.2.5 SNMP Management .........................................................................................................................................31

-3-

Page 4

User’s Manual of IGT-90x

4.2.6 Factory Default ................................................................................................................................................. 33

4.2.7 System Reboot ................................................................................................................................................. 35

4.3 Port Management.................................................................................................................................................... 37

4.3.1 Port Configuration............................................................................................................................................. 37

4.3.2 Port Status ........................................................................................................................................................40

4.3.3 Port Statistics.................................................................................................................................................... 41

4.4 Converter Configuration ..........................................................................................................................................42

4.5 VLAN....................................................................................................................................................................... 43

4.5.1 VLAN Group ..................................................................................................................................................... 45

4.5.2 VLAN Per Port Setting...................................................................................................................................... 47

4.5.3 Q-in-Q VLAN Setting ........................................................................................................................................48

4.6 Quality of Service .................................................................................................................................................... 49

4.7 OAM Setup.............................................................................................................................................................. 52

4.7.1 Local TS-1000 OAM Setup............................................................................................................................... 52

4.7.2 Remote TS-1000 OAM Setup........................................................................................................................... 53

4.7.3 TS-1000 Loop Back Test.................................................................................................................................. 55

4.7.4 802.3ah Setup ..................................................................................................................................................57

4.7.5 802.3ah Loop Back Test................................................................................................................................... 58

4.8 Security ...................................................................................................................................................................60

4.9 Logout ..................................................................................................................................................................... 61

5. TROUBLE SHOOTING.................................................................................................62

APPENDIX A NETWORKING CONNECTION..................................................................63

A.1 Device‘s RJ-45 Pin Assignments............................................................................................................................ 63

A.2 RJ-45 Cable Pin Assignment..................................................................................................................................63

A.3 Fiber Optical Cable Connection Parameter ............................................................................................................ 64

-4-

Page 5

User’s Manual of IGT-90x

1. INTRODUCTION

1.1 Package Contents

Check the contents of your package for following parts:

● Industrial Managed Gigabit Ethernet Media Converter x1

● CD-ROM User's Manual x1

● Quick Installation Guide x1

● Wall Mount Kit x1

● Rack Mount Kit x1

If any of these are missing or damaged, please contact your dealer immediately, if possible, retain the carton including the

original packing material, and use them against to repack the product in case there is a need to return it to us for repair.

IGT-905A is with one vacant SFP module slot. The 1000Base-SX / LX SFP module is not bundled

with in the package.

1.2 How to Use This Manual

The Industrial Managed Media Converter User’s Manual is structured as followings:

Section 2, Hardware Install a tion

It explains the functions of Industrial Managed Media Converter and how to install the Industrial Managed Media

Converter.

Section 3, Industrial Medi a Converter Management

It contains information about how to manage the Industrial Managed Media Converter.

Section 4, Web Management

It contains information about the Web management function from the Industrial Managed Media Converter.

Section 5, Troubleshooting

It contains troubleshooting guide of Industrial Managed Media Converter.

Appendix A

It contains cable information of Industrial Managed Media Converter.

The term of “Industrial Managed Media Converter” In the following section of this user’s manual means the IGT-90X.

-5-

Page 6

User’s Manual of IGT-90x

1.3 Product Description

The Industrial Managed Media Converter IGT-90X provide conversion between 10/100/1000Base-T and 1000Base-SX

/LX network. There are SC / LC connectors and single-mode / multi-mode media for your needs. Ethernet signal that

allows two type segments connect easily, efficiently and inexpensively.

The Industrial Managed Media Converter equipped with remote Web / SNMP interface. With its built-in Web-based

management, the Industrial Managed Media Converter offers an easy-to-use, platform-independent management and

configuration facility and can be programmed for advanced management functions. Such as IP address Configuration /

DHCP Client function, password setting / firmware upgrade, system reboot / factory default, port configuration that include

TP / Fiber port speed duplex mode setting, flow control setting and Ingress/Egress bandwidth control setting, converter

configuration that include maximum packet length setting, Broadcast / Multicast / Unicast storm control setting, 16 IEEE

802.1Q VLAN groups support and powerful Q-in-Q VLAN function, Quality of Service (QoS), TS-1000 / IEEE 802.3ah

OAM function and TCP & UDP filter function. It supports standard Simple Network Management Protocol (SNMP) and can

be managed via any standard-based management software as well.

With Gigabit mini GBIC interface, the IGT-905A is with high reliability and flexibility to extend the distance from 220m to

120Km. It depends on the Gigabit mini GBIC modules.

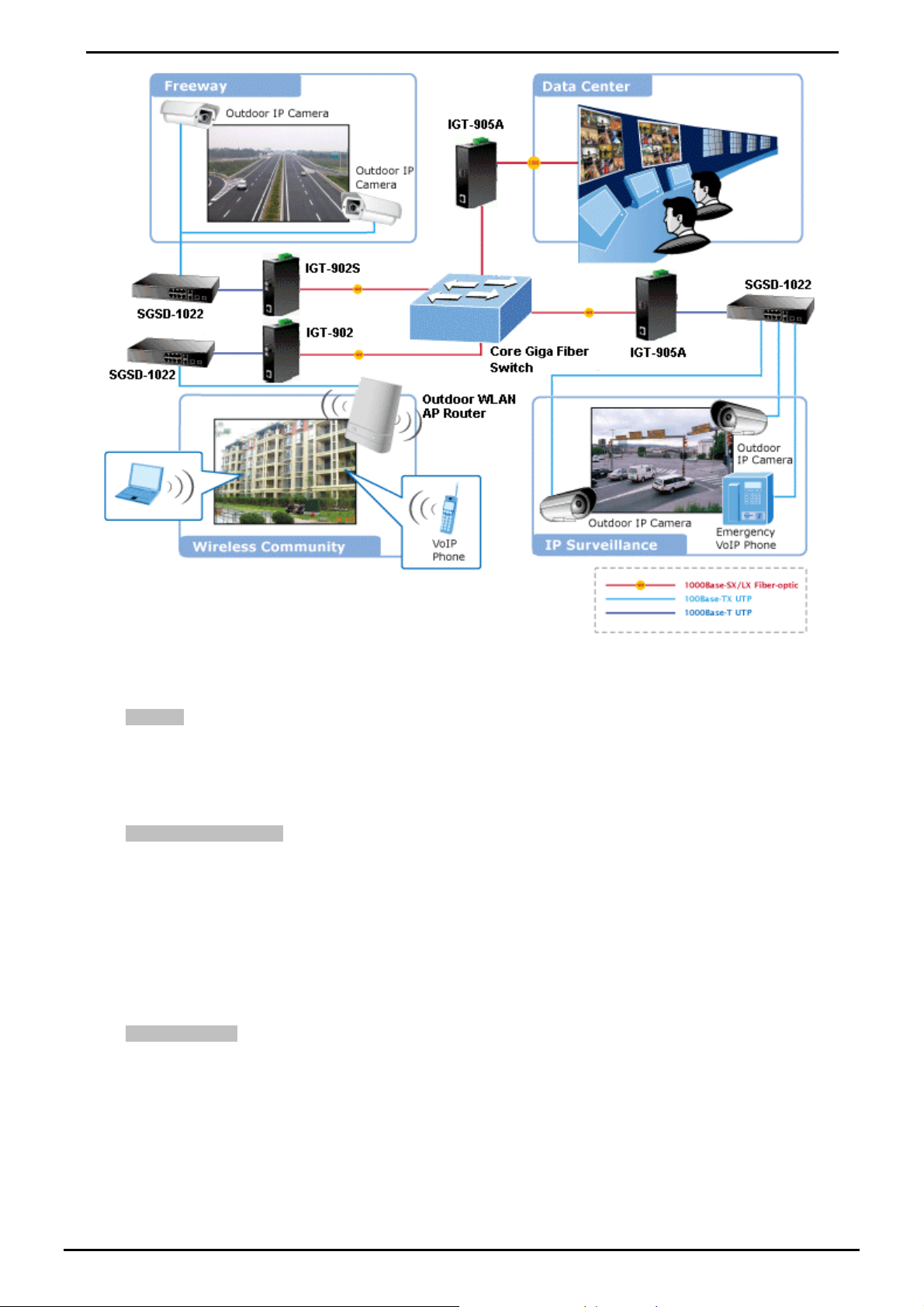

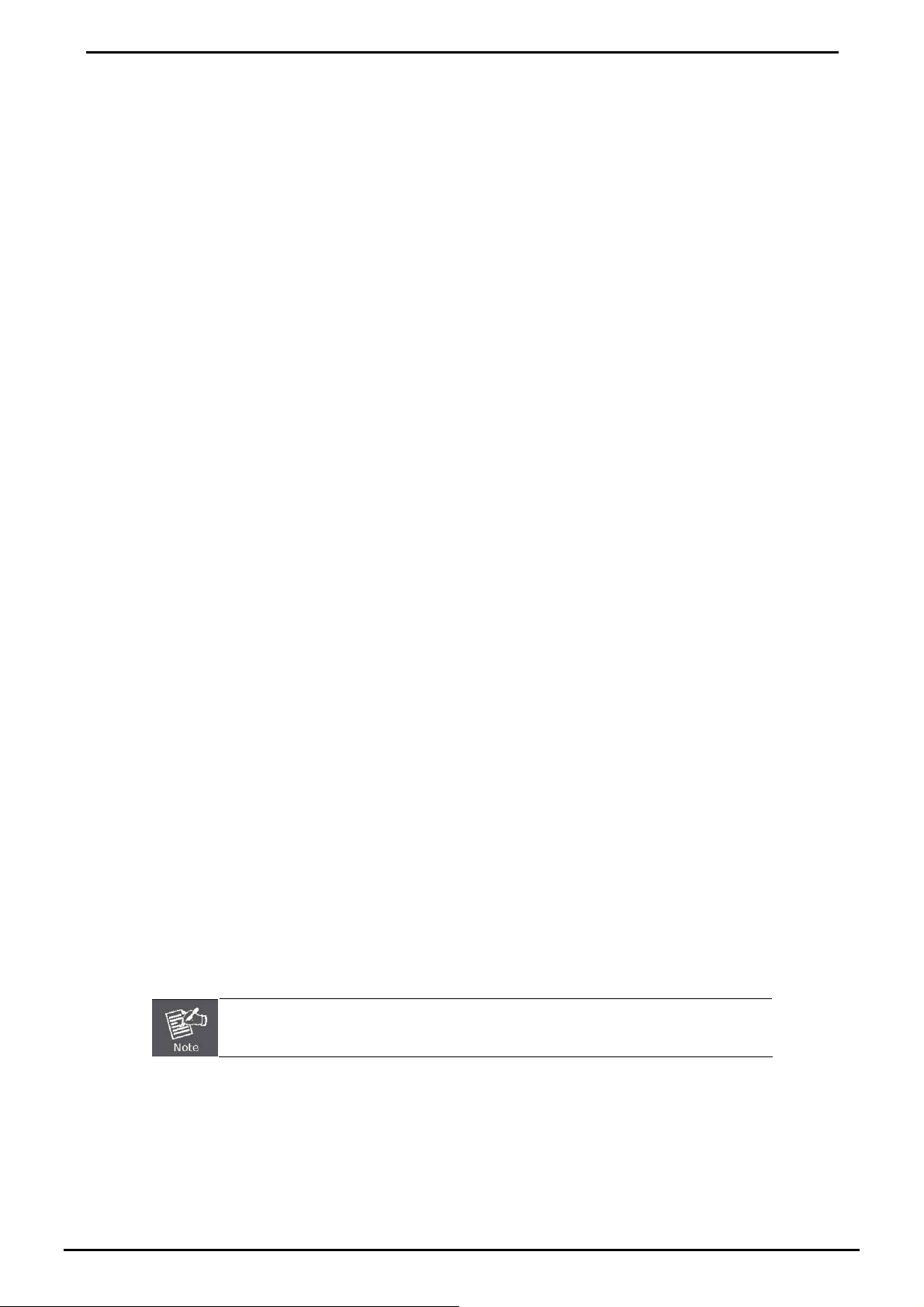

1.4 Applications

Access Control System – Traditional Installation

Industrial area Media Converter for data receive and forwardin g

Most of the enterprises performed centralize manage to remote access machine or other network equipment via Internet

network or Fiber optical network. With connection to IGT-90X which cans extensible distance of network, IGT-90X not only

provides higher speed transfer but also could be managed by remote Web interface. The Fiber extend distance can be up

to 10km on IGT-902S/902TS and 120km on IGT-905A or 550m on IGT-902/902T in a local range.

The Gigabit port supporting 9K jumbo packet can handle large amounts of data transmission in a secure topology linking

to a backbone Switch or high-power servers. The Industrial Managed Media Converter with the slim type IP 30 metal

shape is ideal for most Heavy Industrial demanding environments.

-6-

Page 7

User’s Manual of IGT-90x

1.5 Product Features

¾ Interface

1-Port 10/100/1000Base-T RJ-45 with Auto-negotiation and Auto-MDI/MDI-X function

1 Port 1000Base-SX SC interface, provide long distance up to 220/550m on IGT-902/902T

1 Port 1000Base-LX SC interface, provides long distance for 10km on IGT-902S/902TS

1 Mini-GBIC slot, port provides multi choice of SFP modules on IGT-905A

¾ Industrial Confo rm a nc e

12 to 48V DC, redundant power with polarity reverse protect function

-10 to 60 Degree C operation temperature for IGT-902 / 902S

-30 to 75 Degree C operation temperature for IGT-902T / 902TS / 905A

IP-30 metal case

Relay alarm for port breakdown

Supports 6KVDC Ethernet ESD protection

Free fall, Shock and Vibration Stability

DIN-Rail and Wall-mountable hardware design

¾ Layer 2 Features

Store-and-Forward mechanism

Prevents packet loss with back pressure (Half-Duplex) and IEEE 802.3x PAUSE frame flow control

(Full-Duplex)

Maximum frame size to 9216 Bytes

Loop detection / Broadcast / Multicast / Unicast storm control

Supports VLANs

• IEEE 802.1Q Tagged based VLAN

• Up to 16 VLANs groups, out of 4K VLAN IDs

-7-

Page 8

User’s Manual of IGT-90x

• Management VLAN

¾ Quality of Service

Ingress/Egress Bandwidth control on TP / Fiber port

4 priority queues, strict priority and Weighted Round Robin (WRR)

Traffic classification by:

• IEEE 802.1p Class of Service

• IP DSCP priority

• IP Address priority

¾ Management

Built-in IP-based Web interface for remote management

SNMP v1 / v2c and 4 RMON groups

Event trap and SNMP trap support

Manual IP address setting / DHCP client for IP address assignment

TS-1000 OAM / IEEE 802.3ah OAM / Loop Back Test

16 TCP / UDP Filter groups

Password setting, IP setting and devices description setting through Planet Smart discovery utility

Firmware upgrade via remote Web interface

Reset Button at the front panel for the factory default reset

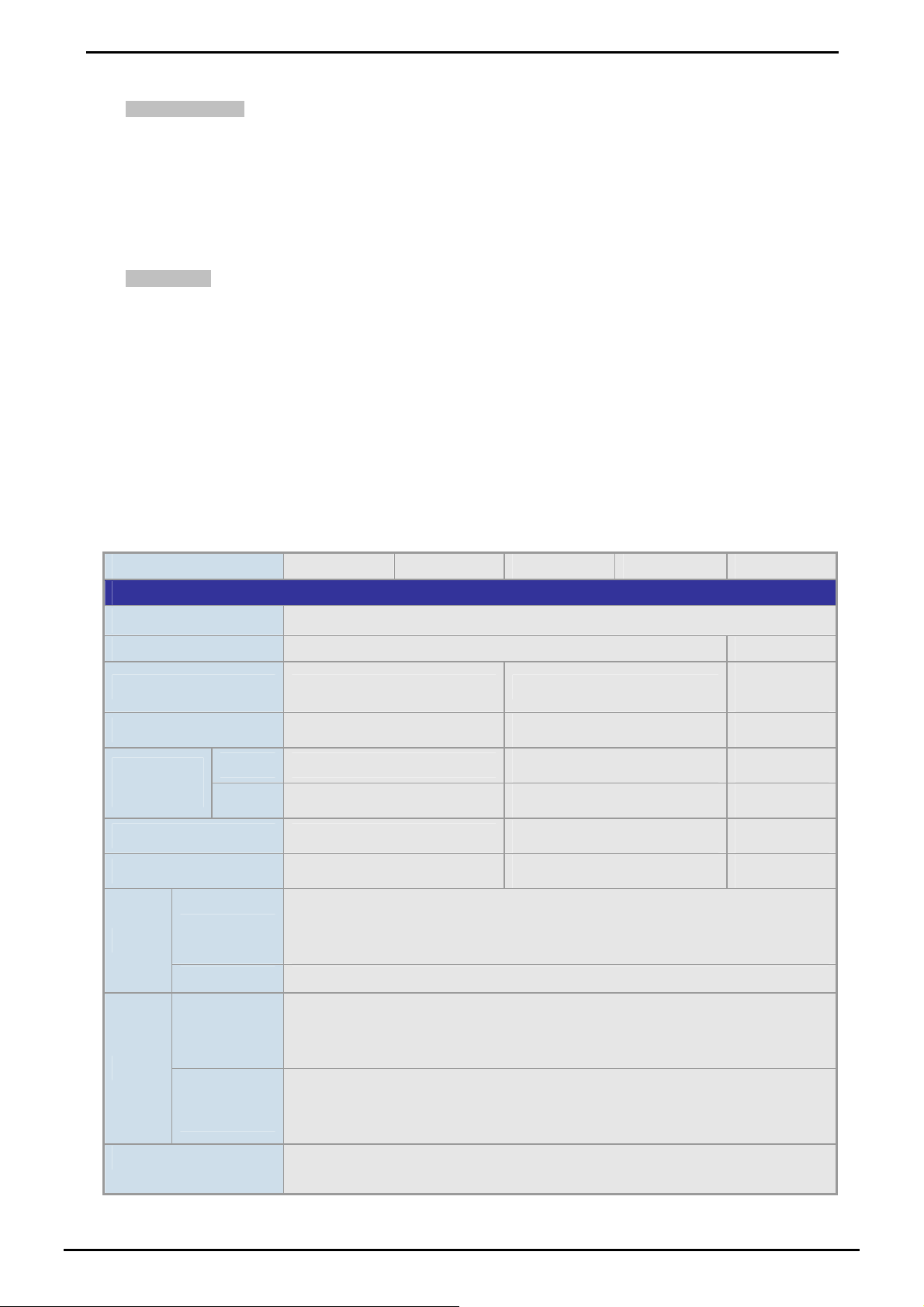

1.6 Product Specification

Product IGT-902 IGT-902T IGT-902S IGT-902TS IGT-905A

Hardware Specification

Copper Interface 1 x 10/100/1000Base-T RJ-45 Auto-MDI/MDI-X ports

Optic Interface SC SFP

Optical Mode Multi-mode Single mode

Optic Wavelength 850nm

Launch

Power(dBm)

Receive Sensitivity -13.5 dBm

Maximum Input power -18 dBm

Speed

MAX. -4 dBm

Min. -9.5 dBm

10/20Mbps for Half / Full-Duplex

Twisted-pair

Fiber-optic 2000Mbps for Full-Duplex

100/200Mbps for Half / Full-Duplex

2000Mbps for Full-Duplex

1310nm -*

-3 dm -*

-9.5dBm -*

-14.4 dBm -*

-20 dBm -*

Vary on

module

Twisted-pair

Cable

Fiber-optic

Cable

LED indicator

10Base-T: 2-pair UTP Cat. 3,4,5, up to 100 m

100Base-TX: 2-pair UTP Cat. 5, up to 100 m

1000Base-T: 4-pair STP Cat 5,6 up to 100m

y 50/125μm or 62.5/125μm multi-mode fiber cable, up to 220/550m.

y 9/125μm single-mode cable, provides long distance for

10/15/20/30/40/50/60/70/120km (very on fiber transceiver or SFP module)

Power: P1, P2, Fault

TP: LNK/ACT, 1000

Fiber: LNK/ACT

-8-

Page 9

User’s Manual of IGT-90x

Power Input

Power Consumption 7.7 Watts/ 26 BTU (maximum)

Operating Temperature

Operating Humidity 5~90% non-condensing

Storage Temperatu r e

Storage Humidity 5~90% non-condensing

Dimension (W x D x H) 13.5 x 8.5 x 3.2 mm

Weight 423g

Installation DIN rail kit and wall mount ear

Management and Layer 2 Features

Management Interface WEB / SNMP v1, v2c

Port Configuration

VLAN

QoS

Bandwidth Control

Standard Conformance

12 to 48V DC

Redundant power with polarity reverse protection function

-10~60

Degree C

-20~85

Degree C

Port disable/enable

Auto-negotiation 10/100/1000Mbps Full and Half duplex mode selection.

Flow Control disable / enable. Bandwidth control on each port.

IEEE 802.1q Tagged Based VLAN , 4K VLAN ID, up to 16 VLAN groups

Q-in-Q VLAN

Traffic classification based on :

• 802.1p priority

• IP DSCP field in IP Packet

• IP Address

Ingress / Egress bandwidth control

• Rate range: 512kbps to 500Mbps

Storm control

• Broadcast / Multicast / Unknown Unicast packet

-30~75

Degree C

-40~85

Degree C

-10~60

Degree C

-20~85

Degree C

-30~75

Degree C

-40~85

Degree C

-30~75

Degree C

-40~85

Degree C

Emissions FCC Class A, CE Class A

IEEE 802.3 10BASE-T

IEEE 802.3u 100BASE-TX

IEEE 802.3z Gigabit SX/LX

Standard

Stability

IEEE 802.3ab Gigabit 1000T

IEEE 802.3x Flow Control and Back pressure

IEEE 802.1p Class of service

IEEE 802.1Q VLAN Tagging

IEEE 802.3ah OAM

IEC60068-2-32 (Free fall)

IEC60068-2-27 (Shock)

IEC60068-2-6 (Vibration)

* =Depend on the various SFP modules

-9-

Page 10

User’s Manual of IGT-90x

2. HARDWARE INSTALLATION

This product provides three different running speeds – 10Mbps, 100Mbps and 1000Mbps in the same Industrial Managed

Media Converter and automatically distinguishes the speed of incoming connection.

This section describes the functionalities of IGT-90X’s components and guides how to install it on the DIN Rail Basic

knowledge of networking is assumed. Please read this chapter completely before continuing.

2.1 IGT-90X Front Panel

The Front Panel of the Industrial Managed Media Converter consists of one 1000Base-SX / 1000Base-LX / mini-GBIC

SFP ports and one Auto-Sensing 10/100/1000Mbps Ethernet RJ-45 Port. Figure 2-1, 2-2, 2-3, 2-4 & 2-5 shows a front

panel of Industrial Managed Media Converter.

Figure 2-1 & 2-2 PLANET

IGT-902 / IGT-902S Front Panel

Figure 2-3 & 2-4 PLANET

IGT-902T / IGT-902TS Front Panel

-10-

Figure2-5 PLANET

IGT-905A Front Panel

Page 11

2.1.1 LED Indicators

LED Color Function

P1 Green Lit Indicate the power 1 has power.

P2

FAULT

Fiber

LNK /ACT

TP 1000 Lights

TP

LNK /ACT

To press and release the RESET button. The IGT-90X will back to the factory default mode. Be sure that you

backup the current configuration of IGT-90X; else the entire configuration will be erased when pressing the

“RESET” button.

Green

Green

Green

Green

Lit Indicate the power 2 has power.

Lit Indicate the either power 1 or power 2 has no power.

Lights

Blinks To indicate the Fiber Optical Port is receiving or sending data.

Lights

Blinks To indicate the Gigabit Ethernet Port is receiving or sending data.

To indicate that the Fiber Optical Port is successfully connecting to the

network at 1000Mbps.

To indicate that the Gigabit Ethernet Port is successfully connecting to the

network at 1000Mbps. OFF indicate the Gigabit Ethernet Port is

successfully connecting to the network at 10/100Mbps.

To indicate that the Gigabit Ethernet Port is successfully connecting to the

network at 10/100/1000Mbps.

User’s Manual of IGT-90x

• Press and release the RESET button shortly, the device will be rebooted.

• Press the RESET button about 10 seconds and release, the device will back to the factory default

mode; the entire configuration will be erased to default setting.

2.1.2 IGT-90X Rear Panel

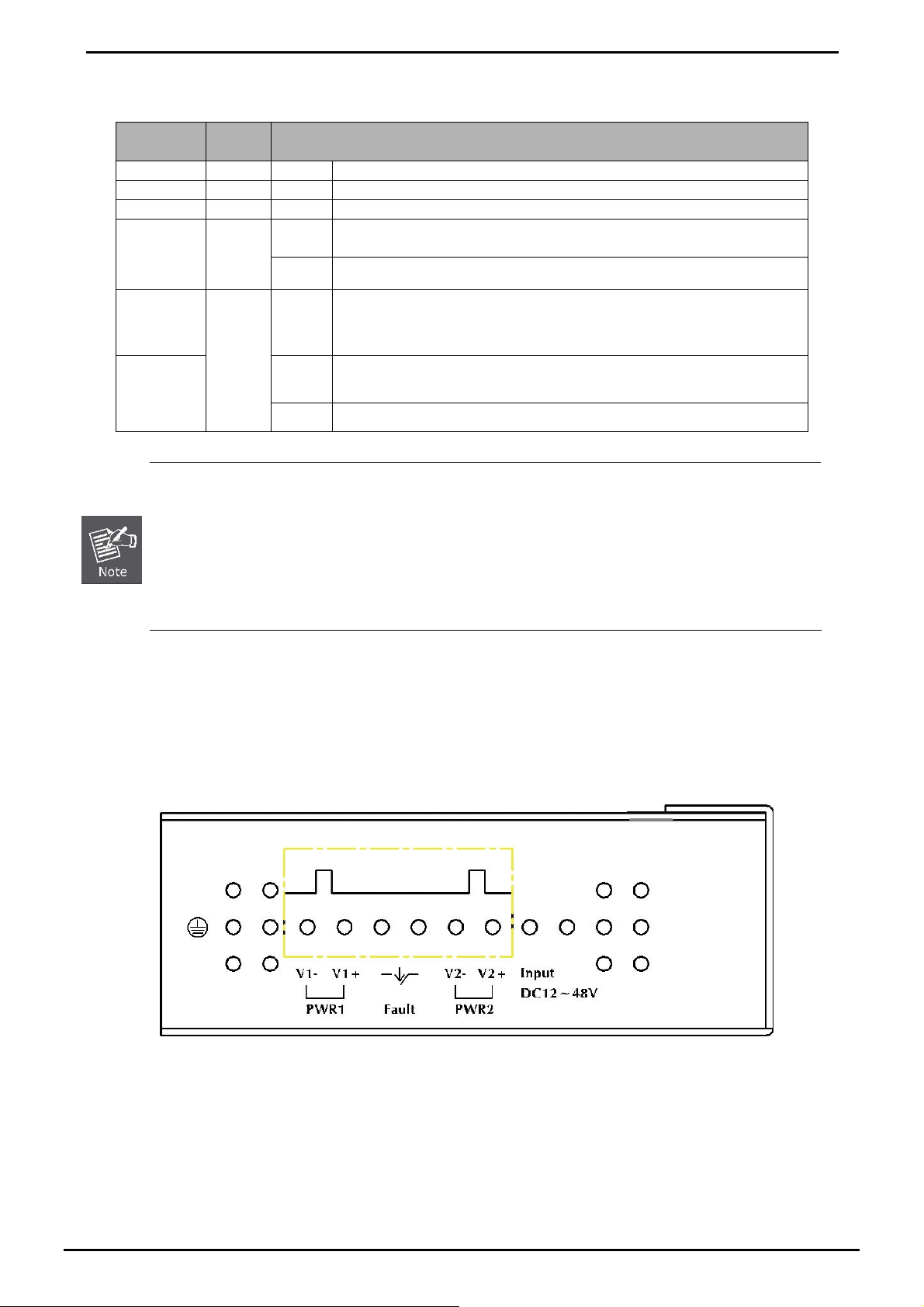

The upper panel of the Industrial Managed Media Converter consist one terminal block connector within two DC power

inputs. Figure 2-6 shows the upper panel of the Industrial Managed Media Converter.

■ IGT-90X series Upper Panel

Figure 2-6 Upper Panel of IGT-90X

-11-

Page 12

User’s Manual of IGT-90x

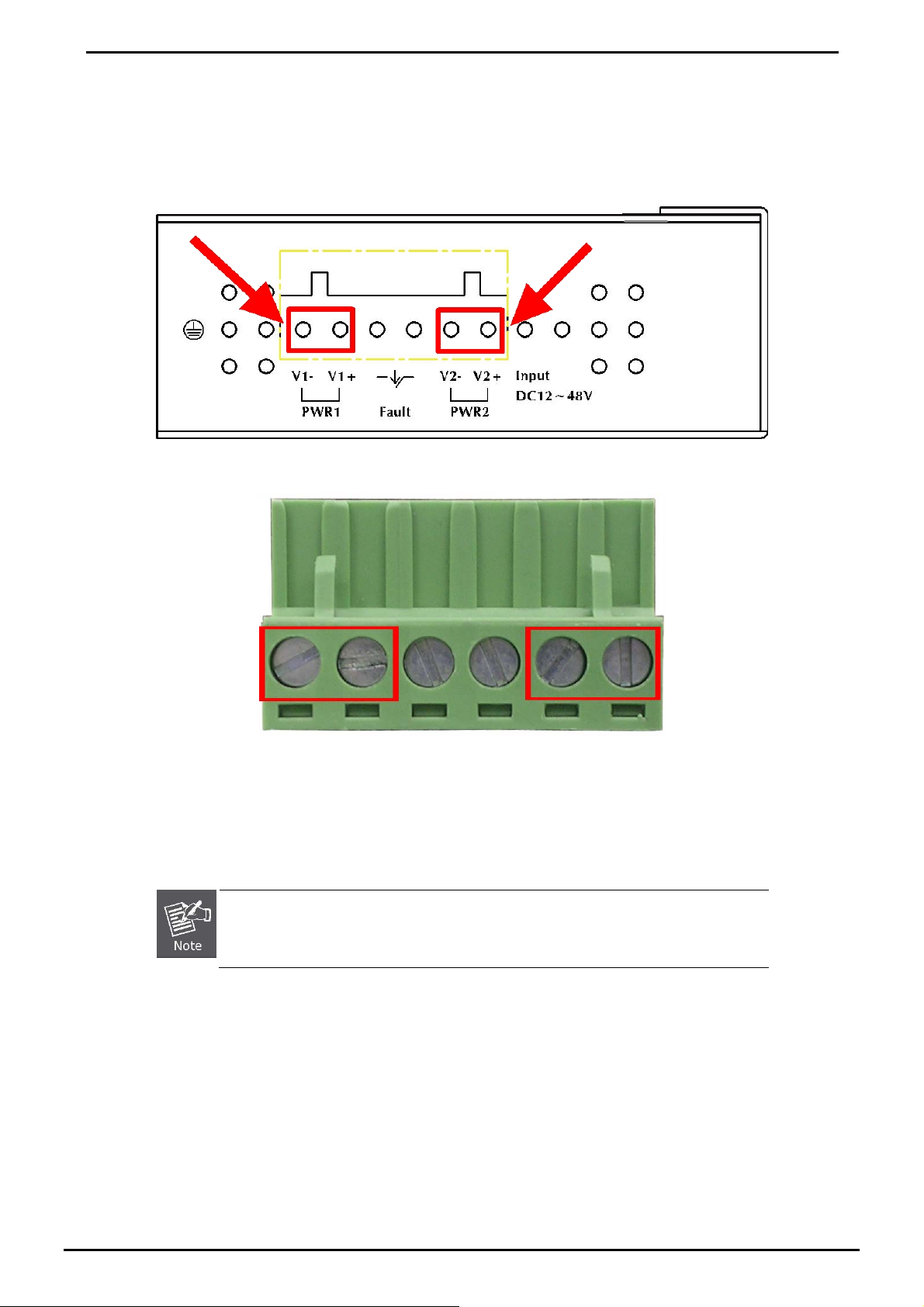

2.1.3 Wiring the Power Inputs

The 6-contact terminal block connector on the top panel of Industrial Media Converter is used for two DC redundant

powers input. Please follow the steps below to insert the power wire.

1. Insert positive / negative DC power wires into the contacts 1 and 2 for POWER 1, or 5 and 6 for POWER 2.

2. Tighten the wire-clamp screws for preventing the wires from loosing.

1 2 3 4 5 6

Power 1 Fault Power 2

- + - +

The wire gauge for the terminal block should be in the range between 12 ~ 24 AWG.

-12-

Page 13

User’s Manual of IGT-90x

2.1.4 Wiring the Fault Alarm Contact

The fault alarm contacts are in the middle of the terminal block connector as the picture shows below. Inserting the wires,

the Industrial Management Media Converter will detect the fault status of the power failure, or port link failure (available for

managed model) and then forms an open circuit. The following illustration shows an application example for wiring the

fault alarm contacts.

1 2 3 4 5 6

Insert the wires into the fault alarm contacts

1. The wire gauge for the terminal block should be in the range between 12 ~ 24 AWG.

2. Alarm relay circuit accepts up to 30V, max. 3A currents.

-13-

Page 14

User’s Manual of IGT-90x

2.2 Mounting Installatio n

This section describes how to install the Industrial Managed Media Converter and make connections to it. Please read the

following topics and perform the procedures in the order being presented.

In the installation steps below, this Manual use IGS-801(PLANET 8 Port Industrial Gigabit Switch) as the

example. However, the steps for PLANET Industrial Switch & Industrial Media / Serial Converter are

similar. Terms of “Industrial Equipment” in following section means the PLANET Industrial devices that

mentioned above.

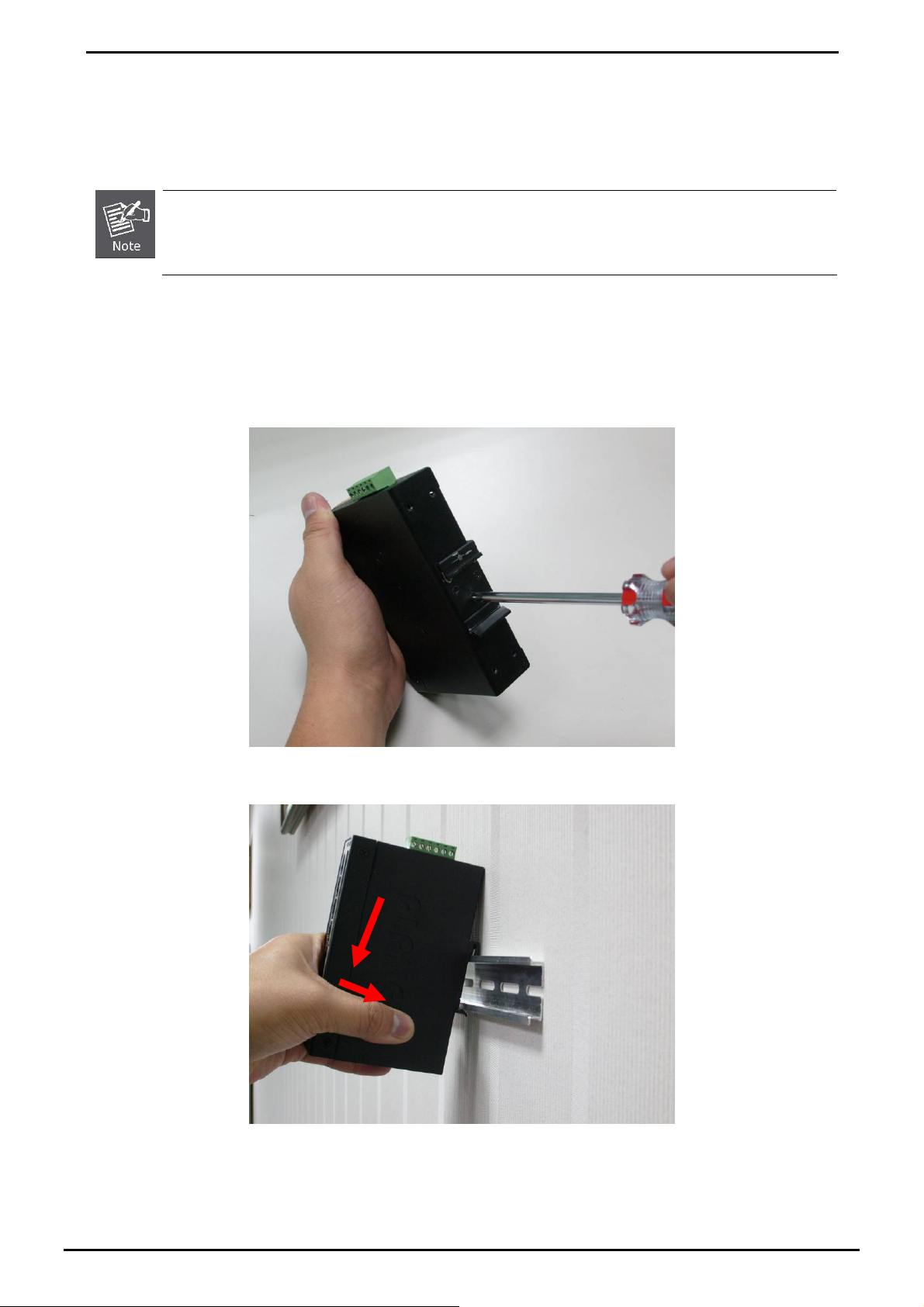

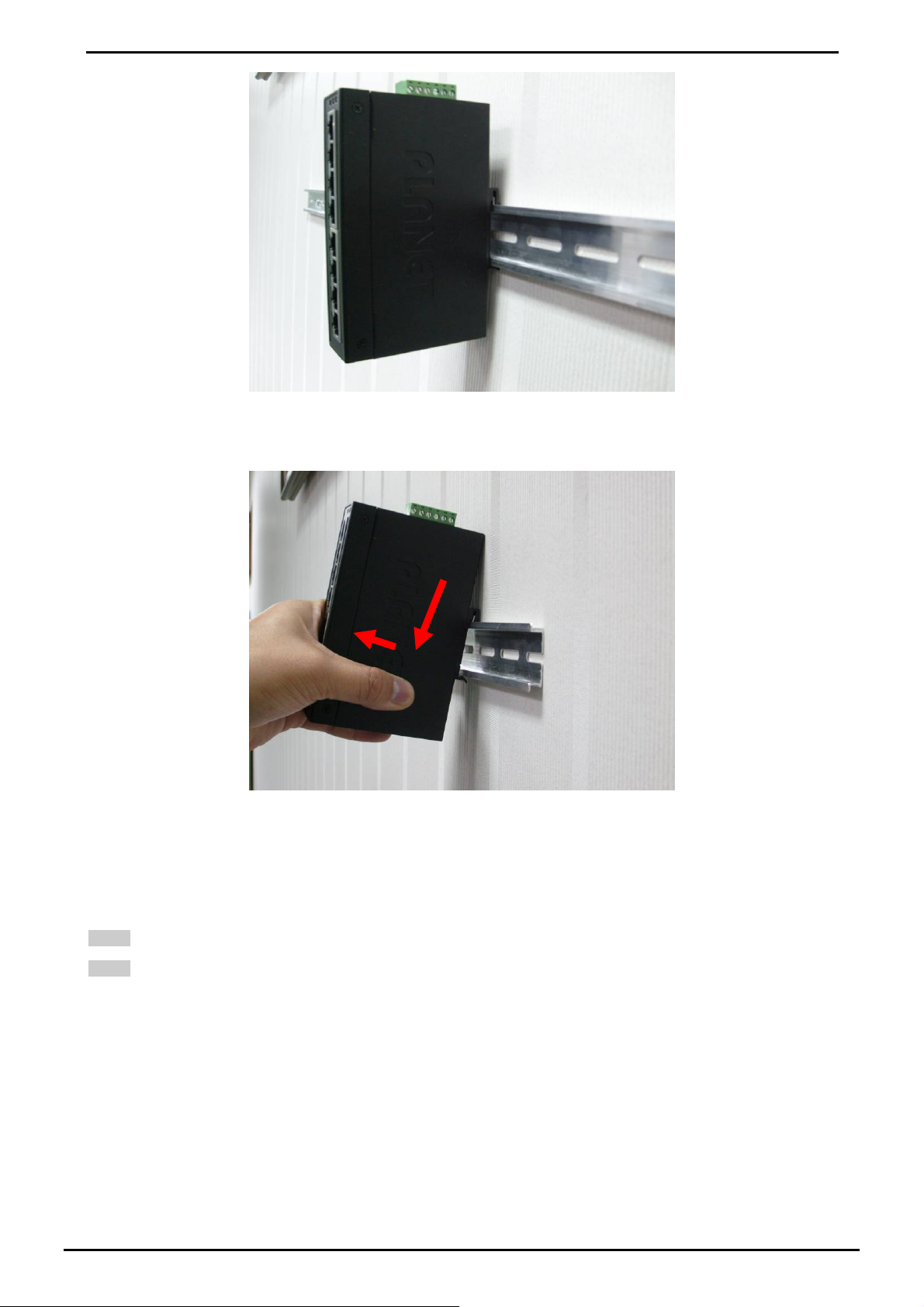

2.2.1 DIN-Rail Mounting

The DIN-Rail is screwed on the Industrial Equipment when out of factory. When need to replace the wall mount application

with DIN-Rail application on Industrial Equipment, please refer to following figures to screw the DIN-Rail on the Industrial

Equipment. To hang the Industrial Equipment, follow the below steps:

Step 1: screw the DIN-Rail on the Industrial Managed Media Converter.

Step 2: Lightly press the button of DIN-Rail into the track.

-14-

Page 15

User’s Manual of IGT-90x

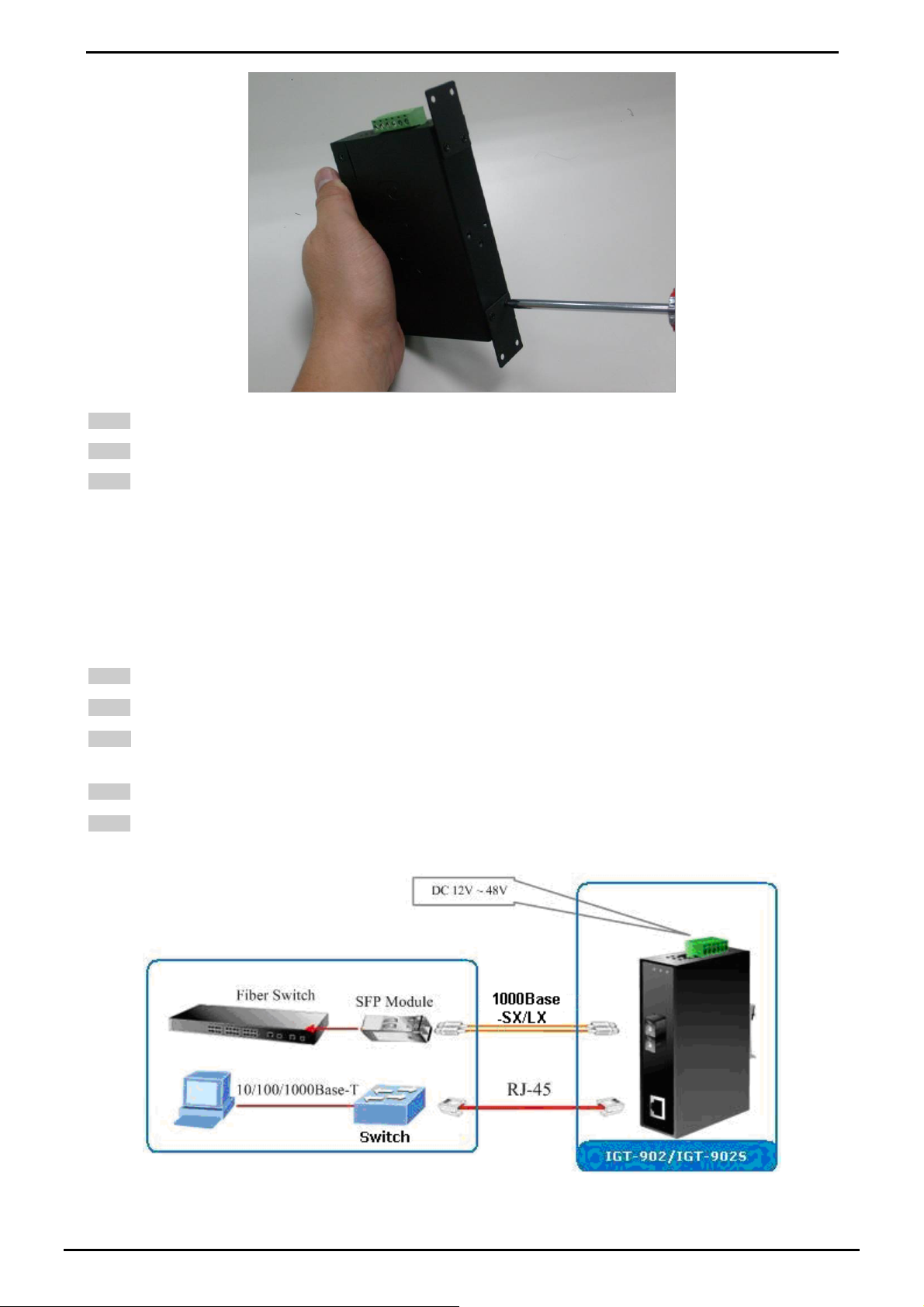

Step 3: Check the DIN-Rail is tightly on the track.

Step 4: Please refer to following procedures to remove the Industrial Gigabit Ethernet Switch from the track.

Step 5: Lightly press the button of DIN-Rail for remove it from the track.

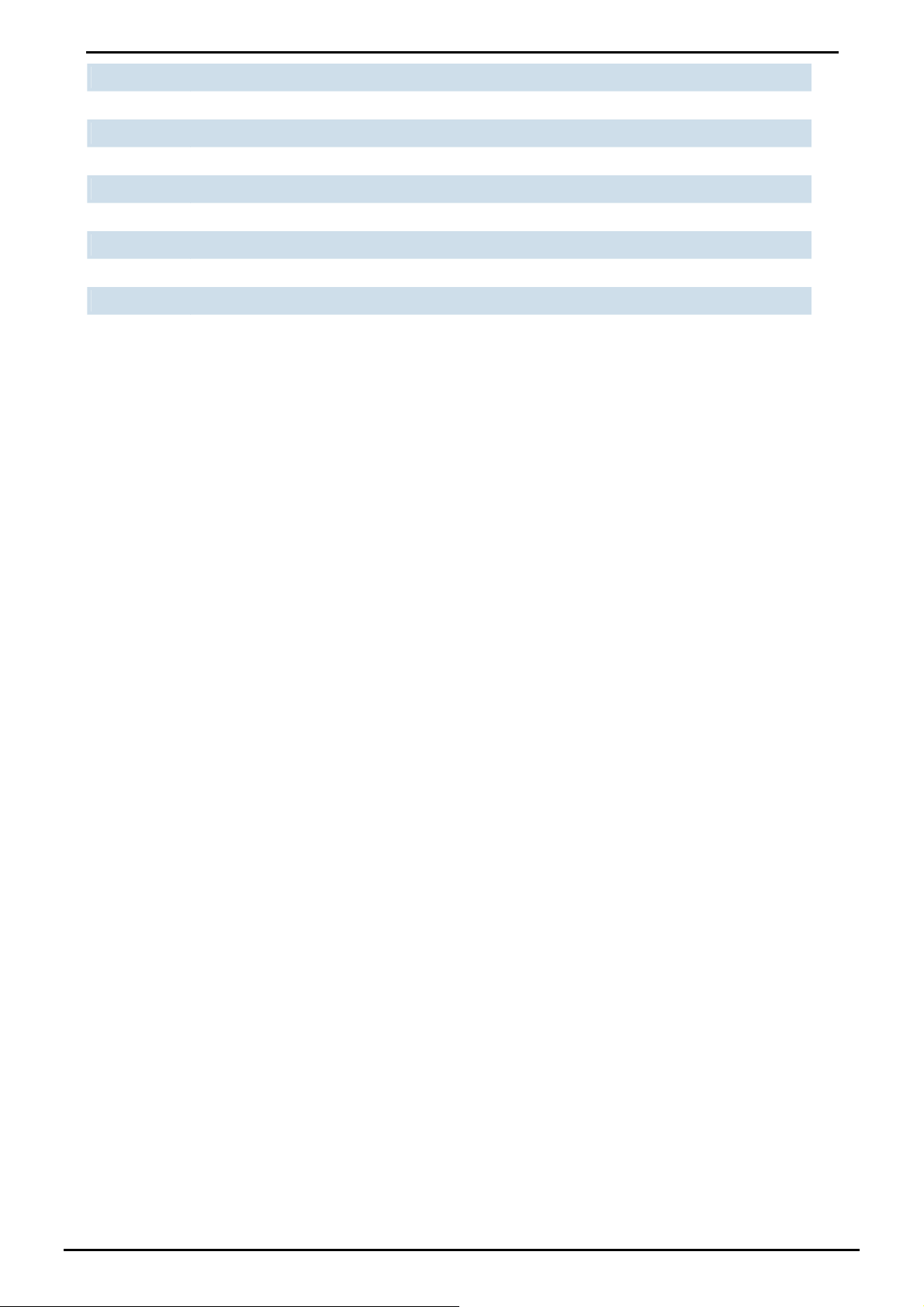

2.2.2 Wall Mount Plate Mounting

To install the Industrial Equipment on the wall, please follows the instructions described below.

Step 1: Remove the DIN-Rail from the Industrial Equipment; loose the screws to remove the DIN-Rail.

Step 2: Place the wall mount plate on the rear panel of the Industrial Equipment.

-15-

Page 16

User’s Manual of IGT-90x

Step 3: Use the screws to screw the wall mount plate on the Industrial Equipment.

Step 4: Use the hook holes at the corners of the wall mount plate to hang the Industrial Equipment on the wall.

Step 5: To remove the wall mount plate, reverse steps above.

2.2.3 Stand-alone Installation

IGT-902 / IGT-902T/ IGT-902S/ IGT-902TS Installation:

To install an Industrial Managed Media Converter stand-alone, on a Track or wall mount, simply complete the following

steps:

Step 1: Turn off the DC power of the device/station in a network to which IGT-90X will be attached.

Step 2: Ensure that there is no activity in the network.

Step 3: Attach fiber cable from the Industrial Managed Media Converter to the fiber network. TX, RX must be paired at

both ends.

Step 4: Connect the DC power to the IGT-90X and verify that the Power LED lights up.

Step 5: Turn on the power of the device/station; the PWR LED (Green) should light when all cables are attached.

Figure 2-7 IGT- 902 / IGT-902T / IGT-902S / IGT-902TS stand-alone installation

-16-

Page 17

User’s Manual of IGT-90x

Please refers to APPENDIX-A for detailed wiring information of the Industrial Managed Media

Converter. To prevent from optic acceptor malfunction, check the both wires / transmitter before

power on the Industrial Managed Media Converter.

IGT-905A Installation:

IGT-905A is with high reliability and flexibility to extend the distance from 220m to 120Km. It depends on the Gigabit mini

GBIC modules. The SFP transceivers are hot-plug and hot-swappable. You can plug-in and out the transceiver to/from

any SFP port without having to power down the Industrial Managed Media Converter.

To install IGT-905A with 1000Base-SX / LX SFP, simply complete the following steps:

Step 1: Precede with the steps 4 and steps 5 of session 2.2.3 Stand-alone In st allation to connect the network cabling

and supply power to your Industrial Managed Media Converter.

Step 2: Slot in the 1000Base-SX / LX SFP. Make sure both side of the SFP transceiver are with the same media type, for

example: 1000Base-SX / 220m & 550m to 1000Base-SX / 220m & 550m, 1000Base-LX / 10km to 1000Base-LX /

10km

Step 3: Connect the fiber cable. Attach the duplex LC connector on the network cable into the SFP transceiver.

Figure 2-8 IGT- 905A stand alone installation

It recommends using PLANET MGB series 1000Base-SX / LX / LX WDM SFP on the IGT-905A. If

you insert a SFP transceiver that is not supported, the IGT-905A will not recognize it.

The following list the available Modules for IGT-905A

MGB-GT SFP-Port 1000Base-T mini-GBIC module

MGB-SX SFP-Port 1000Base-SX mini-GBIC module

MGB-LX SFP-Port 1000Base-LX mini-GBIC module

MGB-L30 SFP-Port 1000Base-LX mini-GBIC module -30KM

MGB-L50 SFP-Port 1000Base-LX mini-GBIC module -50KM

MGB-L70 SF P -Port 1 0 00Bas e - LX mini-GBIC module -7 0 K M

MGB-L120 SFP- P o rt 1000 B ase-LX mini-GBIC module -1 20KM

-17-

Page 18

User’s Manual of IGT-90x

MGB-LA10 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1310nm), SM,10km

MGB-LB10 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1550nm), SM,10km

MGB-LA20 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1310nm), SM,20km

MGB-LB20 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1550nm), SM,20km

MGB-LA40 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1310nm), SM,40km

MGB-LB40 SFP-Port 1000Base-LX mini-GBIC module- LC WDM(TX:1550nm), SM,40km

MGB-TSX SFP-Port 1000Base-SX mini-GBIC module - 550m (-40~75℃)

MGB-TLX SFP-Port 1000Base-LX mini-GBIC module - 10km (-40~75℃)

MGB-TL30 SFP-Port 1000Base-LX mini-GBIC module - 30km (-40~75℃)

MGB-TL70 SFP-Port 1000Base-LX mini-GBIC module - 70km (-40~75℃)

-18-

Page 19

User’s Manual of IGT-90x

3. INDUSTRIAL MEDIA CONVERTER MANAGEMENT

This chapter describes how to manage the Industrial Managed Media Converter. Topics include:

- Overview

- Management methods

- Assigning an IP address to the Industrial Managed Media Converter

- Logging on to the Industrial Managed Media Converter

3.1 Overview

This chapter gives an overview of Industrial Managed Media Converter management. The IGT-90X provides a simply

WEB browser interface. Using this interface, you can perform various Industrial Managed Media Converter configuration

and management activities, including:

System

Port Management

Converter Configu ration

VLAN

Quality of Service

OAM Setup

Security

Logout

Please refer to the following Chapter 4 for more details.

3.2 Requirements

■ Network cables.

For IGT-90x copper interface: Use standard network (UTP) cables with RJ-45 connectors.

For IGT-90x Fiber interface: Use Multi-mode or Single-mode fiber patch cord with SC connectors.

■ Subscriber PC installed with Ethernet NIC (Network Card)

■ Workstations of subscribers running Windows 98/ME, NT4.0, 2000/2003/XP, MAC OS X or later, Linux, UNIX or

other platform compatible with TCP/IP protocols.

■ Above PC installed with WEB Browser, such as Microsoft Internet Explore or Mozilla Firefox

It is recommended to use Internet Explore 7.0 or above to access Industrial Media

Converter.

-19-

Page 20

User’s Manual of IGT-90x

3.3 Management Methods

The way to manage the IGT-90X:

-Web Management via a network or dial-up connection.

-Using SNMP Network Management Station.

3.3.1 Web Management

The PLANET Industrial Managed Media Converter provides a built-in browser interface. You can manage the Industrial

Managed Media Converter remotely by having a remote host with Web browser, such as Microsoft Internet Explorer,

Netscape Navigator or Mozilla Firefox.

Figure 3-1 Web Management over Ethernet

3.3.2 Login the Industrial Managed Media Converter

The following shows how to startup the Web Management of the Industrial Managed Media Converter, please note the

device is configured through an Ethernet connection, make sure the manager PC must be set on the same IP subnet

address.

For example, the default IP address of the Industrial Managed Media Converter is 192.168.0.100 (the factory-default IP

address), then the manager PC should be set at 192.168.0.x (where x is a number between 1 and 254, except 100), and

the default subnet mask is 255.255.255.0.

Use Internet Explorer 7.0 or above Web browser, enter default IP address http://192.168.0.100

After entering the username and password (default user name and password is “admin”) in login screen then the Web

main screen appears.

Default IP Address: 192.168.0.100

Default Account: admin

Default Password: admin

-20-

Page 21

Figure 3-2 Login Web Page screen

User’s Manual of IGT-90x

1. For security reason, please change and memorize the new password after this first setup.

2. Only accept command in lowercase letter under web interface.

3.3.3 SNMP Management

You can manage the Industrial Managed Media Converter across a LAN using an SNMP Network Management Station

with a graphical user interface.

This management method lets you monitor statistical counters and set Industrial Managed Media Converter parameters

from the remote Network Management Station.

Using this management method:

- The network must run the IP protocol.

- The Managed Media Converter must have an IP address.

3.3.4 PLANET Smart Discovery Utility

For easily list the Industrial Managed Media Converter in your Ethernet environment, the Planet Smart Discovery Utility

from user’s manual CD-ROM is an ideal solution.

The following install instructions guiding you for run the Planet Smart Discovery Utility.

1. Deposit the Planet Smart Discovery Utility in administrator PC.

2. Run this utility and the following screen appears.

-21-

Page 22

User’s Manual of IGT-90x

Figure 3-3 Planet Smart Discovery Utility Screen

If there are two LAN cards or above in the same administrator PC, choose different LAN card by

use the “Select Adapter” tool.

3. Press “Refresh” button for list current connected devices in the discovery list, the screen is shown as follow.

Figure 3-4 Planet Smart Discovery Utility Screen

1. This utility show all necessary information from the devices, such as MAC Address, Device Name, firmware version,

Device IP Subnet address, also can assign new password, IP Subnet address and description for the devices.

2. After setup completed, press “Update Device”, “Update Multi” or “Update All” button to take affect. The meaning of

the 3 buttons above are shown as below:

• Update Device: use current setting on one single device.

• Update Multi: use current setting on choose multi-devices.

• Update All: use current setting on whole devices in the list.

The same functions mentioned above also can be finding in “Option” tools bar.

-22-

Page 23

User’s Manual of IGT-90x

3. To click the “Control Packet Force Broadcast” function, it can allow assign new setting value to the Managed Media

Converter under different IP subnet address.

4. Press “Connect to Device” button then the Web login screen appears in Figure 3-2.

5. Press “Exit” button to shutdown the planet Smart Discovery Utility.

-23-

Page 24

User’s Manual of IGT-90x

4. WEB MANAGEMENT

The IGT-90X Industrial Managed Media Converter provide remote Web interface for management function configuration

and make the Industrial Managed Media Converter operate more effectively - They can be configured through the Web

Browser. A network administrator can manage and monitor the Industrial Managed Media Converter from the local LAN.

This section indicates how to configure the Industrial Managed Media Converter to enable its management function.

4.1 Main Menu

After a successful login, the main screen appears, the main screen displays the Industrial Managed Media Converter

Welcome page. The screen in Figure 4-1 appears.

Figure 4-1 Web Main screen

As listed at the left of the main screen, the configurable management functions are shown as below:

◆ System – Provide System configuration of Industrial Managed Media Converter. Explained in section 4.2.

◆ Port Management – Provide Port Management configuration of Industrial Managed Media Converter.

Explained in section 4.3.

◆ Converter Configuration – Provide Converter configuration of Industrial Managed Media Converter. Explained

in section 4.4.

◆ VLAN – Provide VLAN configuration of Industrial Managed Media Converter. Explained in section 4.5.

◆ Quality of Service – Provide Quality of Service (QoS) function of the Industrial Managed Media Converter.

Explained in section 4.6.

◆ OAM Setup – Provide OAM Setup function of the Industrial Managed Media Converter. Explained in section

4.7.

◆ Security – Provide Security function of the Industrial Managed Media Converter. Explained in section 4.8.

◆ Logout– Provide Logout function of the Industrial Managed Media Converter. Explained in section 4.9.

-24-

Page 25

User’s Manual of IGT-90x

4.2 System

4.2.1 System Informatio n

The System Information Web page provides information for the current device. System Information Web page helps

network administrator to identify the firmware versions, IP Subnet Address and etc. The screen in Figure 4-2 appears and

Table 4-1 describes the System Information object of Industrial Managed Media Converter.

Figure 4-2 System Information Web page screen

The System Information Web page screen includes the following fields:

MAC Address

Software Version

IP Address The current IP Address of IGT-90X, the default IP Address is 192.168.0.100.

Subnet Mask The current Subnet Mask of IGT-90X, the default Subnet Mask is 255.255.255.0.

Gateway The current gateway of IGT-90X, the factory default gateway is 192.168.0.254.

Description

Temperature

Power Status

Refresh

Specifies the MAC address of IGT-90X.

The current software version running on the IGT-90X.

The current description of IGT-90X, the factory default description is IGT-90X.

Display current temperature of IGT-90X in Celsius and Fahrenheit.

Display current power supply status of IGT-90X.

Refresh current Web page screen of IGT-90X.

Table 4-1 Descriptions of the System Information Web Page Screen Objects

-25-

Page 26

User’s Manual of IGT-90x

4.2.2 IP Configuration

The IP Configuration includes the DHCP Client, IP Address, Subnet Mask, Gateway and Description. The screen in Figure

4-3 appears and Table 4-2 describes the IP Configuration object of Industrial Managed Media Converter.

Figure 4-3 IP Configuration Web page screen

The IP Configuration Web page screen includes the following configurable data:

DHCP Client

IP Address

Subnet Mask

Gateway

Description Allow to input a new description for the Industrial Managed Media Converter, up to maximum 32

Apply Button

Allow disable or enable the DHCP Client function of the Industrial Managed Media Converter, the

factory default mode is Disable.

Allow assigning a new IP address for the Industrial Managed Media Converter, the factory default IP

address is 192.168.0.100.

Allow assigning a new subnet mask for the Industrial Managed Media Converter, the factory default

subnet mask is 255.255.255.0.

Allow assigning a new gateway for the Industrial Managed Media Converter, the factory default

gateway is 192.168.0.254.

characters allow.

Press “Apply” button for save current configuration of Industrial Managed Media Converter.

Table 4-2 Descriptions of the IP Configuration Web Page Screen Objects

After change the default IP subnet address, if you forget the IP subnet address. Please press the “Reset”

button in the front panel of Managed Media Converter for 10 seconds, the current setting will be lost and

the Industrial Managed Media Converter will restore to factory default mode.

-26-

Page 27

User’s Manual of IGT-90x

4.2.3 Password Setting

This function provides administrator to secure Web login. The screen in Figure 4-4 & 4-5 appears and Table 4-3 describes

the Password Setting object of Industrial Managed Media Converter.

Figure 4-4 Password Setting Web page screen

Figure 4-5 Password Setting Successful Web page screen

-27-

Page 28

The Password Setting Web page includes the following configurable data:

User’s Manual of IGT-90x

Login Name

Old Password

New Password

Confirm

Apply Button

Displays the user name (admin).

Enter the old password is required before entering the new password.

Specifies the new password. The password is not displayed. As it entered an “y” corresponding to

each character is displayed in the field.

(The maximum length is 16 characters)

This confirms the new password. The password entered into this field must be exactly the same

as the password entered in the Password field.

Press “Apply” button for save current configuration of Industrial Managed Media Converter.

Table 4-3 Descriptions of the Password Setting Web Page Screen Objects

4.2.4 Firmware Upgrade

This function provides Firmware Upgrade of the Industrial Managed Media Converter and the screen in Figure 4-6

appears.

Figure 4-6 Firmware Upgrade Web page screen

Press “Browse” button to find the firmware location administrator PC, The screen in Figure 4-7 appears

-28-

Page 29

User’s Manual of IGT-90x

Figure 4-7 Firmware Upgrade Web page screen

After find the firmware location from administrator PC, press “Upgrade” button to start the firmware upgrade process.

The screen in Figure 4-8 & 4-9 appears.

Figure 4-8 Firmware Upgrade Web page screen

Do not power off the converter until the update progress is complete.

Do not quit the Firmware Upgrade page without press the “Upgrade” button - after the image is

loaded. Or the system won’t apply the new firmware. Users have to repeat the firmware

upgrade processes again.

-29-

Page 30

User’s Manual of IGT-90x

Figure 4-9 Firmware Upgrade Web page screen

When firmware upgrade process is completed then the following screen appears, please click “here” to re-login the

IGT-90X with latest firmware and the screen in Figure 4-10 & 4-11 appears.

Figure 4-10 Firmware Upgrade Web page screen

-30-

Page 31

User’s Manual of IGT-90x

Figure 4-11 Login Web page screen

4.2.5 SNMP Management

This function provides SNMP Management and SNMP Trap Receiver Configuration function of the Industrial Managed

Media Converter and the screen in Figure 4-12 & 4-13 appears and Table 4-4 & 4-5 describes the SNMP Management

and SNMP Trap Receiver object of Industrial Managed Media Converter.

Figure 4-12 SNMP Management Web page screen

-31-

Page 32

User’s Manual of IGT-90x

The SNMP Management Web page includes the following configurable data:

SNMP Agent Allow disable or enable the SNMP Agent function, the default mode is “Disable”.

SNMP Read Community Allow input the characters for SNMP Read Community, up to maximum 16 characters

allow.

SNMP Write Community Allow input the characters for SNMP Write Community, up to maximum 16 characters

allow.

System Name Allow input the characters for System Name, up to maximum 16 characters allow.

System Location Allow input the characters for System Location, up to maximum 16 characters allow.

Contact Allow input the characters for Contact person, up to maximum 16 characters allow.

Apply Button

Press “Apply” button for save current configuration of IGT-90X.

Table 4-4 Descriptions of the SNMP Management Web Page Screen Objects

The IGT-90X supports SNMP v1 / v2c protocol.

Figure 4-13 SNMP Trap Receiver Configuration Web page screen

The SNMP Trap Receiver Configuration Web page includes the following configurable data:

SNMP Trap Allow disable or enable the SNMP Trap function, the default mode is “Disable”.

SNMP Trap Destinatio n

Trap Event

Cold Start

Warm Start

Login Fail

Allow input the IP address of SNMP Trap Destination.

When IGT-90X executes Cold Start operation, the administrator PC (SNMP Trap

Destination) will receive a Cold Start Trap.

When IGT-90X executes Warm Start operation, the administrator PC (SNMP

Trap Destination) will receive a Warm Start Trap.

When Web login fail situation appears on IGT-90X, the administrator PC (SNMP

Trap Destination) will receive a Login Fail Trap.

-32-

Page 33

User’s Manual of IGT-90x

Link Up

Link Down

Apply Button

Table 4-5 Descriptions of the SNMP Trap Receiver Configuration Web Page Screen Objects

When TP or Fiber port connection is build up, the administrator PC (SNMP Trap

Destination) will receive a Link Up Trap.

When TP or Fiber port connection is Disconnect, the administrator PC (SNMP

Trap Destination) will receive a Link Down Trap.

Press “Apply” button for save current configuration of IGT-90X

4.2.6 Factory Default

This function provides Factory Default function of the Industrial Managed Media Converter and the screen in Figure 4-14

& 4-15 & 4-16 appears.

Figure 4-14 Factory Default Web page screen

-33-

Page 34

User’s Manual of IGT-90x

Figure 4-15 Factory Default Web page screen

Figure 4-16 Login Web page screen

-34-

Page 35

User’s Manual of IGT-90x

4.2.7 System Reboot

This function provides System Reboot function of the Industrial Managed Media Converter and the screen in Figure 4-17

& 4-18 & 4-19 appears.

Figure 4-17 System Reboot Web page screen

Figure 4-18 System Reboot Web page screen

-35-

Page 36

User’s Manual of IGT-90x

Figure 4-19 Login Web page screen

-36-

Page 37

User’s Manual of IGT-90x

4.3 Port Management

4.3.1 Port Configuration

This function allows displaying TP / Fiber port status. The Link Status in the screen displays the current connection speed

and duplex mode; else this function will show red “Down” when the TP / Fiber port is disconnected. Press the “Refresh”

button to renew the screen. The screen in Figure 4-20 appears and Table 4-6 describes the Port Configuration object of

IGT-90X.

Figure 4-20 Port Configuration Web Page screen

The Port Configuration Web page includes the following configurable data:

Port

Link

Mode

Indicate the TP port and Fiber port.

Displays the current connection speed and duplex mode of TP or Fiber port.

Allow configuring the TP or Fiber port speed and operation mode. Draw the menu

bar to select the mode.

TP Port:

y Auto Speed

y 1000 Full

y 100 Full

y 100 Half

y 10 Full

y 10 Half

Default mode: Auto Speed.

Fiber Port:

y Auto Speed

y 1000 Full

Default mode: Auto Speed.

Setup Auto negotiation

Force sets 1000Mbps Full-Duplex mode

Force sets 100Mbps Full-Duplex mode

Force sets 100Mbps Half-Duplex mode

Force sets 10Mbps Full-Duplex mode

Force sets 10Mbps Half-Duplex mode

Setup Auto negotiation

Force sets 1000Mbps Full-Duplex mode

Flow Control

Allow Disable or Enable Flow Control of TP or Fiber port.

Enable:

IEEE 802.3x Flow Control is enabled on Full-Duplex mode or

Backpressure is enabled on Half-Duplex mode

-37-

Page 38

User’s Manual of IGT-90x

Ingress Rate Limit

Egress Shaping

Disable:

Default mode: Disable

The value of inbound traffic limitation in kilobit-per-second (kbps). The available

options are :

• No Limit

• 512K

• 1M

• 2M

• 4M

• 8M

• 10M

• 50M

• 100M

• 500M

Default mode: No Limit

The Ingress Rate Limit configuration field as show in Figure 4-21.

The value of outbound traffic limitation in kilobit-per-second (kbps). The available

options are :

• No Limit

• 512K

• 1M

• 2M

• 4M

• 8M

• 10M

• 50M

• 100M

• 500M

Default mode: No Limit

No Flow Control or backpressure function on no matter Full-Duplex

or Half-Duplex mode

Apply Button

Refresh Button

The Egress Shaping configuration field as show in Figure 4-22.

Press this button for save current configuration of Industrial Managed Media

Converter.

Press “Refresh” button to refresh current status.

Table 4-6 Descriptions of the Port Configuration Web Page Screen Objects

-38-

Page 39

User’s Manual of IGT-90x

Figure 4-21 Port Configuration-Ingress Rate Limit Web Page screen

Figure 4-22 Port Configuration-Egress Shaping Web Page screen

-39-

Page 40

User’s Manual of IGT-90x

4.3.2 Port Status

This function allows displaying TP / Fiber port detail status, such as Link Status, Duplex Mode, Flow control, Speed and

Auto negotiation. Press the “Refresh” button to renew the screen, the screen in Figure 4-23 appears and Table 4-7

describes the Port Status object of Industrial Managed Media Converter.

Figure 4-23 Port Status Web Page screen

The Port Status Web page includes the following configurable data:

Port

Link Status

Duplex Mode

Flow Control

Speed

Auto Negotiation

Refresh Button

Table 4-7 Descriptions of the Port Status Web Page Screen Objects

Indicate the TP port and Fiber port.

Displays the current link status of TP and Fiber port.

Displays the current duplex mode of TP and Fiber port.

Displays the current Flow Control status of TP and Fiber port.

Displays the current speed mode of TP and Fiber port.

Displays the current Auto negotiation status of TP and Fiber port.

Press “Refresh” button to refresh current status.

-40-

Page 41

User’s Manual of IGT-90x

4.3.3 Port Statistics

This function allows displaying TP / Fiber port detail statistics, press the “Clear” button to clear current counter

information. Press the “Refresh” button to renew the screen, the screen in Figure 4-24 appears.

Figure 4-24 Port Statistics Web Page screen

-41-

Page 42

User’s Manual of IGT-90x

4.4 Converter Configuration

This function provides useful setting for the IGT-90X as Maximum Packet length, Loop detection, storm control and etc.

The screen in Figure 4-25 appears and Table 4-8 describes the Converter Configuration object of Industrial Managed

Media Converter.

Figure 4-25 Converter Configuration Web Page screen

The Converter Configuration Web page includes the following configurable data:

Maximum Packet Length

Loop Detection

Loop Status

Broadcast Storm Control

Multicast Storm Control

Unicast Storm Control

Storm Trigger Counter

Provide maximum packet lengths setting for the IGT-90X, the available options

are 1518 bytes, 2048 bytes and 16K bytes. Default mode is 16K bytes.

Provide Disable or enable the Loop detection function. Default mode is Disable.

Displays the Loop Detection status.

Provide Disable or enable the Broadcast Storm Control function. Default mode is

Disable.

Provide Disable or enable the Multicast Storm Control function. Default mode is

Disable.

Provide Disable or enable the Unicast Storm Control function. Default mode is

Disable.

Provide storm Trigger Counter setting and the available options are:

64 broadcast

32 broadcast

Storm Filter Timer

16 broadcast

8 broadcast

Default mode is 64 broadcast.

Provide storm Filter Timer setting and the available options are:

800ms

400ms

-42-

Page 43

200ms

100ms

Default mode is 800ms.

User’s Manual of IGT-90x

Apply Button

Table 4-8 Descriptions of the Converter Configuration Web Page Screen Objects

Press this button for save current configuration of Managed Media Converter.

4.5 VLAN

A Virtual LAN (VLAN) is a logical network grouping that limits the broadcast domain. It allows you to isolate network traffic

so only members of the VLAN receive traffic from the same VLAN members. Basically, creating a VLAN from a converter

is logically equivalent of reconnecting a group of network devices to another Layer 2 switch. However, all the network

devices are still plug into the same switch physically.

The Industrial Managed Media Converter supports IEEE 802.1Q (tagged-based) VLAN setting in web management page.

In the default configuration, VLAN support is “No VLAN”.

IEEE 802.1Q VLANs

IEEE 802.1Q (tagged) VLAN are implemented on the Industrial Managed Media Converter. 802.1Q VLAN require tagging,

which enables them to span the entire network (assuming all devices on the network are IEEE 802.1Q-compliant).

VLAN allow a network to be segmented in order to reduce the size of broadcast domains. All packets entering a VLAN will

only be forwarded to the stations (over IEEE 802.1Q enabled switches) that are members of that VLAN, and this includes

broadcast, multicast and unicast packets from unknown sources.

VLAN can also provide a level of security to your network. IEEE 802.1Q VLAN will only deliver packets between stations

that are members of the VLAN. Any port can be configured as either tagging or untagging. The untagging feature of IEEE

802.1Q VLAN allows VLAN to work with legacy switches that don't recognize VLAN tags in packet headers. The tagging

feature allows VLAN to span multiple 802.1Q-compliant switches through a single physical connection and allows

Spanning Tree to be enabled on all ports and work normally.

Any port can be configured as either tagging or untagging. The untagging feature of IEEE 802.1Q VLAN allows VLAN to

work with legacy switches that don’t recognize VLAN tags in packet headers. The tagging feature allows VLAN to span

multiple 802.1Q-compliant switches through a single physical connection and allows Spanning Tree to be enabled on all

ports and work normally.

Some relevant terms:

Tag - The act of putting 802.1Q VLAN information into the header of a packet.

Untag - The act of stripping 802.1Q VLAN information out of the packet header.

802.1Q VLAN Tags

The figure below shows the 802.1Q VLAN tag. There are four additional octets inserted after the source MAC address.

Their presence is indicated by a value of 0x8100 in the Ether Type field. When a packet's Ether Type field is equal to

0x8100, the packet carries the IEEE 802.1Q/802.1p tag. The tag is contained in the following two octets and consists of 3

bits of user priority, 1 bit of Canonical Format Identifier (CFI - used for encapsulating Token Ring packets so they can be

carried across Ethernet backbones), and 12 bits of VLAN ID (VID). The 3 bits of user priority are used by 802.1p. The VID

is the VLAN identifier and is used by the 802.1Q standard. Because the VID is 12 bits long, 4094 unique VLAN can be

identified.

The tag is inserted into the packet header making the entire packet longer by 4 octets. All of the information originally

contained in the packet is retained.

-43-

Page 44

802.1Q Tag

User’s Manual of IGT-90x

User Priority CFI VLAN ID (VID)

3 bits 1 bits 12 bits

TPID (Tag Protocol Identifier) TCI (Tag Control Information)

2 bytes 2 bytes

Preamble

Destination

Address

6 bytes 6 bytes 4 bytes 2 bytes 46-1500 bytes 4 bytes

Source

Address

VLAN TAG

Ethernet

Type

Data FCS

The Ether Type and VLAN ID are inserted after the MAC source address, but before the original Ether Type/Length or

Logical Link Control. Because the packet is now a bit longer than it was originally, the Cyclic Redundancy Check (CRC)

must be recalculated.

Adding an IEEE802.1Q Tag

Dest. Addr. Src. Addr. Length/E. type Data Old CRC

Original Ethernet

Dest. Addr. Src. Addr. E. type Tag Length/E. type Data New CRC

Priority CFI VLAN ID

New Tagged Packet

Port VLAN ID

Packets that are tagged (are carrying the 802.1Q VID information) can be transmitted from one 802.1Q compliant network

device to another with the VLAN information intact. This allows 802.1Q VLAN to span network devices (and indeed, the

entire network – if all network devices are 802.1Q compliant).

Every physical port on a switch has a PVID. 802.1Q ports are also assigned a PVID, for use within the switch. If no VLAN

are defined on the switch, all ports are then assigned to a default VLAN with a PVID equal to 1. Untagged packets are

assigned the PVID of the port on which they were received. Forwarding decisions are based upon this PVID, in so far as

VLAN are concerned. Tagged packets are forwarded according to the VID contained within the tag. Tagged packets are

also assigned a PVID, but the PVID is not used to make packet forwarding decisions, the VID is.

Tag-aware switches must keep a table to relate PVID within the switch to VID on the network. The switch will compare the

VID of a packet to be transmitted to the VID of the port that is to transmit the packet. If the two VID are different the switch

will drop the packet. Because of the existence of the PVID for untagged packets and the VID for tagged packets,

tag-aware and tag-unaware network devices can coexist on the same network.

A switch port can have only one PVID, but can have as many VID as the switch has memory in its VLAN table to store

them.

Because some devices on a network may be tag-unaware, a decision must be made at each port on a tag-aware device

before packets are transmitted – should the packet to be transmitted have a tag or not? If the transmitting port is

connected to a tag-unaware device, the packet should be untagged. If the transmitting port is connected to a tag-aware

device, the packet should be tagged.

-44-

Page 45

User’s Manual of IGT-90x

Default VLANs

The Industrial Managed Media Converter initially configures one VLAN, VID = 1, called "default." The factory default

setting assigns all ports on the Industrial Managed Media Converter to the "default". As new VLAN are configured in

Port-based mode, their respective member ports are removed from the "default."

4.5.1 VLAN Group

This function allows disable or enable the IEEE 802.1Q VLAN operation mode. Press the “Apply” button to save the

current configuration of Industrial Managed Media Converter. The screen in Figure 4-26 & 4-27 appears and Table 4-9

describes the VLAN Group object of Industrial Managed Media Converter.

Figure 4-26 VLAN Group Web Page screen

-45-

Page 46

User’s Manual of IGT-90x

Figure 4-27 VLAN Group Web Page screen

The VLAN Group Web page includes the following configurable data:

VLAN Mode

Management VLAN Group

VLAN Group

VID

Member

Apply Button

TP

Fiber

Table 4-9 Descriptions of the VLAN Group Web Page Screen Objects

When change the Management VLAN Group setting, please assure the TP or fiber port that connect to

administrator PC is in the same VLAN Group, otherwise, for further managed is impossible. The only

solution is press the reset button 10 seconds for system reset to default mode.

Provide Disable or enable the IEEE 802.1Q VLAN operation mode. Default mode is

Disable.

Provide define the Management VLAN group. Default mode is VLAN1.

Indicate the VLAN Group from 1 to 16.

Provide define the VLAN Group ID and the available options are 1 to 4094.

Provide assign TP port into VLAN Groups.

Provide assign Fiber port into VLAN Groups.

Press this button for save current configuration of Industrial Managed Media Converter.

-46-

Page 47

User’s Manual of IGT-90x

4.5.2 VLAN Per Port Setting

This function provides IEEE 802.1Q VLAN per port setting for TP and Fiber port of IGT-90X. Press the “Apply” button to

save the current configuration of IGT-90X. The screen in Figure 4-28 appears and Table 4-10 describes the VLAN Per

Port Setting object of Industrial Managed Media Converter.

Figure 4-28 VLAN Per Port Setting Web Page screen

The VLAN Per Port Setting Web page includes the following configurable data:

Port

Egress Link Type

PVID

Accept Frame Type

Ingress Filter Provide disable or enable the Ingress Filter function. Default mode is Enable.

Indicate the TP port and Fiber port.

Provide Egress Link Type options for TP port and Fiber port, the available options are:

• UnTag

• Tag

• ByPass

Default mode is UnTag.

Provide PVID assign for TP port and Fiber port, the available options are 1 to 4094.

Default mode is 1 to 16.

Provide define the Accept Frame Type and the available options are

• All

• Tagged Only

Default mode is All.

Apply Button

Press this button for save current configuration of Industrial Managed Media Converter.

Table 4-10 Descriptions of the VLAN Per Port Setting Web Page Screen Objects

-47-

Page 48

User’s Manual of IGT-90x

4.5.3 Q-in-Q VLAN Setting

When enable Q-in-Q function, IGT-90X can insert or remove 4-bytes Q-in-Q tag in the received 802.3 frames after SA.

User can define Q-in-Q tag value freely. And in default condition, Q-in-Q tag format is same as VLAN tag.

In normal application, enable two port’s Q-in-Q function. UTP Port set to insert Q-in-Q tag and Fiber port set to remove

Q-in-Q Tag. For aggregation layer switch, it will check Q-in-Q tag only, not care about the VLAN tag from the corridor layer

switch. Q-in-Q Tag ether type can be set same as VLAN tag ether type or other values.

This function provides IEEE 802.1Q Q-in-Q VLAN setting of IGT-90X. Press the “Apply” button to save the current

configuration. The screen in Figure 4-29 appears and Table 4-11 describes the Q-in-Q VLAN setting object of IGT-90X.

Figure 4-29 Q-in-Q VLAN setting Web Page screen

The Q-in-Q VLAN setting Web page includes the following configurable data:

Q-in-Q Enable

Q-in-Q Direction

Out Layer VLAN Tag

EtherType (HEX)

Out Layer VLAN VID (DEC)

Apply Button

Table 4-11 Descriptions of the Q-in-Q VLAN setting Web Page Screen Objects

Provide disable or enable the Q-in-Q VLAN function. Default mode is Disable.

Provide two directions for Q-in-Q function, the available options are:

UTP is customer port, Fiber is main port

Fiber is customer port, UTP is main port

Default mode is UTP is customer port, Fiber is main port.

Allow defined the Out Layer VLAN Tag Ether Type and default mode is

0x8100.

Allow defined the Out Layer VLAN VID and default mode is 1.

Press this button for save current configuration of IGT-90X.

-48-

Page 49

User’s Manual of IGT-90x

4.6 Quality of Service

Quality of Service (QoS) is an advanced traffic prioritization feature that allows you to establish control over network traffic.

QoS enables you to assign various grades of network service to different types of traffic, such as multi-media, video,

protocol-specific, time critical, and file-backup traffic.

QoS reduces bandwidth limitations, delay, loss, and jitter. It also provides increased reliability for delivery of your data and

allows you to prioritize certain applications across your network. You can define exactly how you want the switch to treat

selected applications and types of traffic.

You can use QoS on your system to:

。 Control a wide variety of network traffic by:

。 Classifying traffic based on packet attributes.

。 Assigning priorities to traffic (for example, to set higher priorities to time-critical or business-critical applications).

。 Applying security policy through traffic filtering.

。 Provide predictable throughput for multimedia applications such as video conferencing or voice over IP by

minimizing delay and jitter.

。 Improve performance for specific types of traffic and preserve performance as the amount of traffic grows.

。 Reduce the need to constantly add bandwidth to the network.

。 Manage network congestion.

This function provides Quality of Service setting of IGT-90X. Press the “Apply” button to save the current configuration.

The screen in Figure 4-30 appears and Table 4-12 describes the Quality of Service object of IGT-90X.

Figure 4-30 Quality of Service Web Page screen

-49-

Page 50

The Quality of Service Web page includes the following configurable data:

User’s Manual of IGT-90x

QoS Mode

Scheduling

Apply Button

Provide 4 different QoS mode for operation, the available options are:

Disable

802.1p Tag Priority

The 802.1p Tag Priority field as show in Figure 4-31.

IP Address Priority

The IP Address Priority field as show in Figure 4-32.

IP DSCP Priority

The IP DSCP Priority field as show in Figure 4-33.

Default mode is Disable.

Provide two scheduling method for Quality of Service, the available options are:

Strict Priority

Weighted Round Robin (16:8:4:1)

Default mode is Strict Priority.

Press this button for save current configuration of IGT-90X.

Table 4-12 Descriptions of the Quality of Service Web Page Screen Objects

Figure 4-31 802.1p Tag Priority Web Page screen

-50-

Page 51

User’s Manual of IGT-90x

Figure 4-32 IP Address Priority Web Page screen

Figure 4-33 IP DSCP Priority Web Page screen

-51-

Page 52

User’s Manual of IGT-90x

On the top of DSCP Value table have two could be set. The default DSCP value is 63. These two fields

are both for customize DSCP value.

4.7 OAM Setup

4.7.1 Local TS-1000 OAM Setup

This function provides Local TS-1000 OAM Setup of IGT-90X. Press the “Apply” button to save the current configuration

of Industrial Managed Media Converter. The screen in Figure 4-34 appears and Table 4-13 describes the Local TS-1000

OAM Setup object of Industrial Managed Media Converter.

Figure 4-34 Local TS-1000 OAM Setup Web Page screen

The Local TS-1000 OAM Setup Web page includes the following configurable data:

TS-1000 OAM State

TS-1000 Mode

Link Transparent

Link Transparent Result

Apply Button

Table 4-13 Descriptions of the Local TS-1000 OAM Setup Web Page Screen Objects

Provide disable or enable the TS-1000 OAM operation mode. Default mode is Disable.

Provide two TS-1000 modes for operation, the available options are:

Terminal

Center

Default mode is Terminal.

Provide disable or enable the Link Transparent function. Default mode is Disable.

Display the link transparent result.

Press this button for save current configuration of Industrial Managed Media Converter.

-52-

Page 53

User’s Manual of IGT-90x

4.7.2 Remote TS-1000 OAM Se tup

The Remote TS-1000 OAM Setup is an advanced remote device monitor feature that allows you to remote monitor and

automatic notify status indication.

Remote monitor

1. User instructs center Media Converter to issue a status notification request frame defined in TS-1000 to get status of

terminal Media Converter.

2. Terminal Media Converter receives the status notification request frame and sends out status response frame, which

carries its current status.

Autonomous notification

1. Terminal Industrial Media Converter notifies the center Industrial Media Converter autonomously with a status

notification indication, if any change occurs in the status monitored internally by the terminal Industrial Media Converter.

2. Center Industrial Media Converter if support Option A, notifies the terminal Industrial Media Converter autonomously

with a status notification indication, if any change occurs in the status monitored internally by the Industrial center Media

Converter.

This function provides Remote TS-1000 OAM Setup of Industrial Managed Media Converter. Press the “Apply” button to

save the current configuration of Industrial Managed Media Converter. The screen in Figure 4-35 & 4-36 appears.

Figure 4-35 IGT-90x Remote TS-1000 OAM Setup Web Page screen

-53-

Page 54

User’s Manual of IGT-90x

Figure 4-36 IGT-90X Remote TS-1000 OAM Setup Web Page screen

Please use the PLANET GT-80X / GT-90X / IGT-90X as the Remote device.

-54-

Page 55

User’s Manual of IGT-90x

4.7.3 TS-1000 Loop Back Test

The TS-1000 Loop Back Test allows manual run this loop back test to check the interconnection between two Industrial

Media Converter devices. To assure the Remote TS-1000 OAM function can work correctly.

In-band and out-band Loop back

1. Instruct center Industrial Media Converter to issue an OAM frame to request a loop back test. Terminal return start

response OAM frame to center Media Converter.

2. Terminal Media Converter runs at loop back mode.

3. Central Media Converter send test frame and terminal Media Converter loop back the frames. Test frame can be

generated from central Industrial Media Converter’s UTP port (Out-Band) or from central Industrial Media Converter

(In-Band) automatically.

4. Center Industrial Media Converter check the loop back test result after sending all test frames

5. Instruct the central Industrial Media Converter to end loop back test.

This function provides TS-1000 Loop Back Test of Industrial Managed Media Converter. Press the “Apply” button to run

Loop Back Test and see the TS-1000 Loop Back Test Result of Industrial Managed Media Converter, also press the

“Refresh” button to renew the Web screen. The screen in Figure 4-37 appears and Table 4-14 describes the TS-1000

Loop Back Test object of Industrial Managed Media Converter.

-55-

Page 56

User’s Manual of IGT-90x

Figure 4-37 Remote TS-1000 Loop Back Test Web Page screen

The TS-1000 Loop Back Test Web page includes the following configurable data:

TS-1000 Loop Back Test

Send Packet Number

Apply Button

Refresh Button

TS-1000 Loop Back Test Result

Result

Result counter

Table 4-14 Descriptions of the TS-1000 Loop Back Test Web Page Screen Objects

Please use the PLANET GT-80X / GT-90X / IGT-90X as the Remote device.

Allow input the number for packet send and the available options is 1 to 255. Default is

16.

Press this button for save current configuration of Industrial Managed Media

Converter.

Press “Refresh” button to refresh current status.

Display the TS-1000 Loop Back Test Result. Fail or Pass.

Display the value of Counter Result.

-56-

Page 57

User’s Manual of IGT-90x

4.7.4 802.3ah Setup

When enable 802.3ah OAM function, all 802.3ah OAMPDU packets will trap to embedded CPU.

Software will implement auto discovery procedure. With hardware support, software controls the 802.3ah remote loop

back procedure. Hardware can also detect dying gasp even and interrupt CPU to send dying gasp even notification

OAMPDU. All other functions defined by 802.3ah are implemented using embedded CPU.

When remote device is in loop back mode, hardware can support change looped test frame’s DA, SA or both as user

defined. Hardware can also set to don't change looped test frame.

This function provides 802.3ah Setup of Industrial Managed Media Converter. Press the “Apply” button to save the

current configuration of Industrial Managed Media Converter. The screen in Figure 4-38 appears and Table 4-15

describes the 802.3ah Setup object of Industrial Managed Media Converter.

Figure 4-38 802.3ah Setup Web Page screen

The 802.3ah Setup Web page includes the following configurable data:

802.3ah OAM State

802.3ah OAM Mode

Loopback Reply

Remote OAM Configure

Remote OAM Configuration

Result

Apply Button

Table 4-15 Descriptions of the 802.3ah Setup Web Page Screen Objects

1. The 802.3ah function must work with manageable device that supports 802.3ah function.

2. Please use the PLANET GT-80X / GT-90X / IGT-90X as the Remote device.

Provide disable or enable the 802.3ah OAM State function. Default mode is Enable.

Allow to choose “Active” or “Passive” for 802.3ah OAM Mode. Default mode is

Passive.

Provide disable or enable the Loopback Reply function. Default mode is Enable.

Provide disable or enable the Remote OAM Configure function. Default mode is

Enable.

Display the Remote OAM Configuration Result.

Press this button for save current configuration of Managed Media Converter.

-57-

Page 58

User’s Manual of IGT-90x

4.7.5 802.3ah Loop Back Test

The 802.3ah Loop Back Test allows manual run this loop back test to check the interconnection between two Industrial

Media Converter devices. To assure the Remote 802.3ah function can work correctly.

This function provides 802.3ah Loop Back Test of Industrial Managed Media Converter. Press the “Apply” button to run

802.3ah Loop Back Test and see the 802.3ah Loop Back Test Result of Industrial Managed Media Converter, also press

the “Refresh” button to renew the Web screen. The screen in Figure 4-39 appears and Table 4-16 describes the 802.3ah

Loop Back Test object of Industrial Managed Media Converter.

Figure 4-39 802.3ah Loop Back Test Web Page screen

-58-

Page 59

The 802.3ah Loop Back Test Web page includes the following configurable data:

802.3ah Loop Back Test

User’s Manual of IGT-90x

Send Packet Number

Packet Length

(Not include CRC)

Apply Button

Refresh Button

802.3ah Loop Back Test Result

Result

Table 4-16 Descriptions of the 802.3ah Loop Back Test Web Page Screen Objects

1. The 802.3ah function must work with manageable device that supports 802.3ah function.

2. Please use the PLANET GT-80X / GT-90X / IGT-90X as the Remote device.

Allow input the number for packet send and the available options is 1 to 255.

Default is 16.

Allow input the number for Packet Length and the available options is 60 to 1514.

Default is 60.

Press this button for save current configuration of Industrial Managed Media

Converter.

Press “Refresh” button to refresh current status.

Display the 802.3ah Loop Back Test Result. Fail or Pass.

-59-

Page 60

User’s Manual of IGT-90x

4.8 Security

This function provides TCP / UDP Filter setting of Industrial Managed Media Converter. Press the “Apply” button to save