Page 1

DA50S/DA55S and DA70S/DA75S

AddressRight™ Shuttlehead Printers

DA50S (WS51) - Black

DA55S (WS56) - Black & Color

DA70S (WS71) - Black

DA75S (WS76) - Black & Color

Service Manual

Page 2

FCC Compliance

This equipment had been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if not installed and used in accordance

with the users manuals, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Shielded cables must be used with this unit to insure compliance with Class A limits.

Canadian DOC Compliance

This digital apparatus does not exceed in the Class A limits for radio noise emissions from digital ap-

paratus set out in the Interference-causing Equipment Regulations (Standard ICES-003) of the Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la class A prescrites dans le Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.

NOTE: This equipment has been tested and found to comply with the U.S. Standard for Safety

UL1950, Third Edition, Safety of Information Technology Equipment including Electrical Business

Equipment and Canadian Standards C22.2 No 950-95, Third Edition, Safety of Information Technology Equipment including Electrical Business Equipment

First Edition, March 2007

SV61831 Rev. A

©2007 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or stored in a

retrieval system of any type or transmitted by any means, electronically or mechanically, without the

express written permission of Pitney Bowes Inc.

We have made every reasonable effort to assure the accuracy and usefulness of this manual, however, we cannot assume responsibility for errors or omissions or liability for the misuse or misapplication of our products.

Page 3

Table of Contents

Chapter 1 – Introduction

1.1 Purpose of this Manual .............................................................. 1-1

1.2 Related Publications .................................................................. 1-1

1.3 Book Organization ..................................................................... 1-2

1.4 Safety ........................................................................................ 1-2

Chapter 2 – Specifi cations

2.1 Product Description ................................................................... 2-1

2.2 System Requirements ............................................................... 2-1

2.3 Physical Equipment Specifications ............................................ 2-2

2.4 Print Specifications .................................................................... 2-3

2.5 Material Specifications............................................................... 2-7

Chapter 3 - Theory

3.1 Changes From Earlier Models .................................................. 3-1

3.2 Printer Architecture .................................................................... 3-2

3.3 Operating Sequence.................................................................. 3-5

Chapter 4 - Troubleshooting/Diagnostics

4.1 Block Diagrams ......................................................................... 4-1

4.2 Main Controller Board Diagnostics ............................................ 4-3

4.3 Troubleshooting Tables .............................................................. 4-7

4.4 Printer Error Codes.................................................................. 4-14

4.5 Print Samples for Troubleshooting .......................................... 4-15

Chapter 5 - Removal & Replacement

5.1 List of Procedures...................................................................... 5-1

DA50S/DA55S (WS51/WS56) Parts Removal

5.2 Covers ...................................................................................... 5-2

5.3 Display/Keyboard ..................................................................... 5-3

5.4 Main Processor Board/Grounding Sheet Assembly ................. 5-3

5.5 USB/Ethernet Input Board ........................................................ 5-4

5.6 Power Supply ........................................................................... 5-5

5.7 Paper Transport Motor/Belt ...................................................... 5-7

5.8 Sensor ...................................................................................... 5-9

5.9 Feed Roller Assembly ..............................................................5-11

5.10 Encoder and Operator Side Drive Belt ................................. 5-13

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

iii

Page 4

Table of Contents

Chapter 5 - Removal & Replacement (continued)

DA70S/DA75S (WS71/WS76) Parts Removal

5.11 Covers .................................................................................. 5-15

5.12 Display/Keyboard ................................................................. 5-17

5.13 Main Processor Board/Grounding Sheet Assem. ................. 5-17

5.14 USB/Ethernet Input Board .................................................... 5-18

5.15 Power Supply ....................................................................... 5-18

5.16 Feed Roller Assembly............................................................ 5-19

5.17 Motor Drive Belts and Main Motor ........................................ 5-21

5.18 Exit Roller ............................................................................. 5-23

5.19 Sensor .................................................................................. 5-23

5.20 Shuttle Head Motor, Print Head, Shuttle Drive ..................... 5-24

5.21 H-Block Tip ........................................................................... 5-25

Chapter 6 - Adjustments

6.1 List of Adjustments .................................................................... 6-1

Adjustments for All Models

6.2 LCD Display .............................................................................. 6-2

6.3 Paper Sensor Test and Calibration ........................................... 6-2

DA50S/DA55S (WS51/WS56) Adjustments

6.4 Main Brake ............................................................................... 6-3

6.5 Printhead Clearance .................................................................. 6-5

6.6 Adjusting Exit Roller Idler Assembly .......................................... 6-6

6.7 Printhead Drive Belt .................................................................. 6-7

6.8 Main Drive Belt .......................................................................... 6-8

6.9 Adjusting Service Station Assembly .......................................... 6-9

DA70S/DA75S (WS71/WS76) Adjustments

6.10 Main Brake ............................................................................ 6-10

6.11 Print Head Drive Belt ............................................................. 6-10

6.12 Timing Belt .............................................................................6-11

6.13 Main Drive Belt .......................................................................6-11

6.14 Print Head Home Position ..................................................... 6-12

iv SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 5

Table of Contents

Chapter 7 - Maintenance Procedures

7.1 General ...................................................................................... 7-1

7.2 Specific Maintenance ................................................................ 7-2

Appendix A – Printer Control Panel Menus and Utilities

A.1 Control Panel Menus for the Printer ..........................................A-1

A.2 LCD Control Panel Menu .........................................................A-3

A.2 LCD Main Menu .......................................................................A-4

A.3 LCD Setup Menu.......................................................................A-9

A.4 LCD Service Menu .................................................................. A-19

A.5 Setting Factory Defaults (from LCD Menu) ............................. A-24

A.6 Updating Firmware ..................................................................A-26

Appendix B – Printer Communications

B.1 Communication Scenarios ........................................................B-1

B.2 Troubleshooting Tables .............................................................B-4

B.3 Testing Printer Communications Within a Network ...................B-7

Appendix C – Schematics

Main Processor Board Schematic ....................................................C-2

LCD/Keypad .....................................................................................C-3

USB/Ethernet LAN Function .............................................................C-4

Black & White Printer Head ..............................................................C-5

Color Print Head ...............................................................................C-6

Index (not ready at time of publishing) ........................ I-1

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

v

Page 6

Table of Contents

vi SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 7

1 • Introduction

1.1 Purpose of

this Manual

This book contains instructions for troubleshooting and site repair of DA50S/

DA55S and DA70S/DA75S AddressRight™ shuttlehead printers. It also includes

complete product specifications and a section on theory for training purposes.

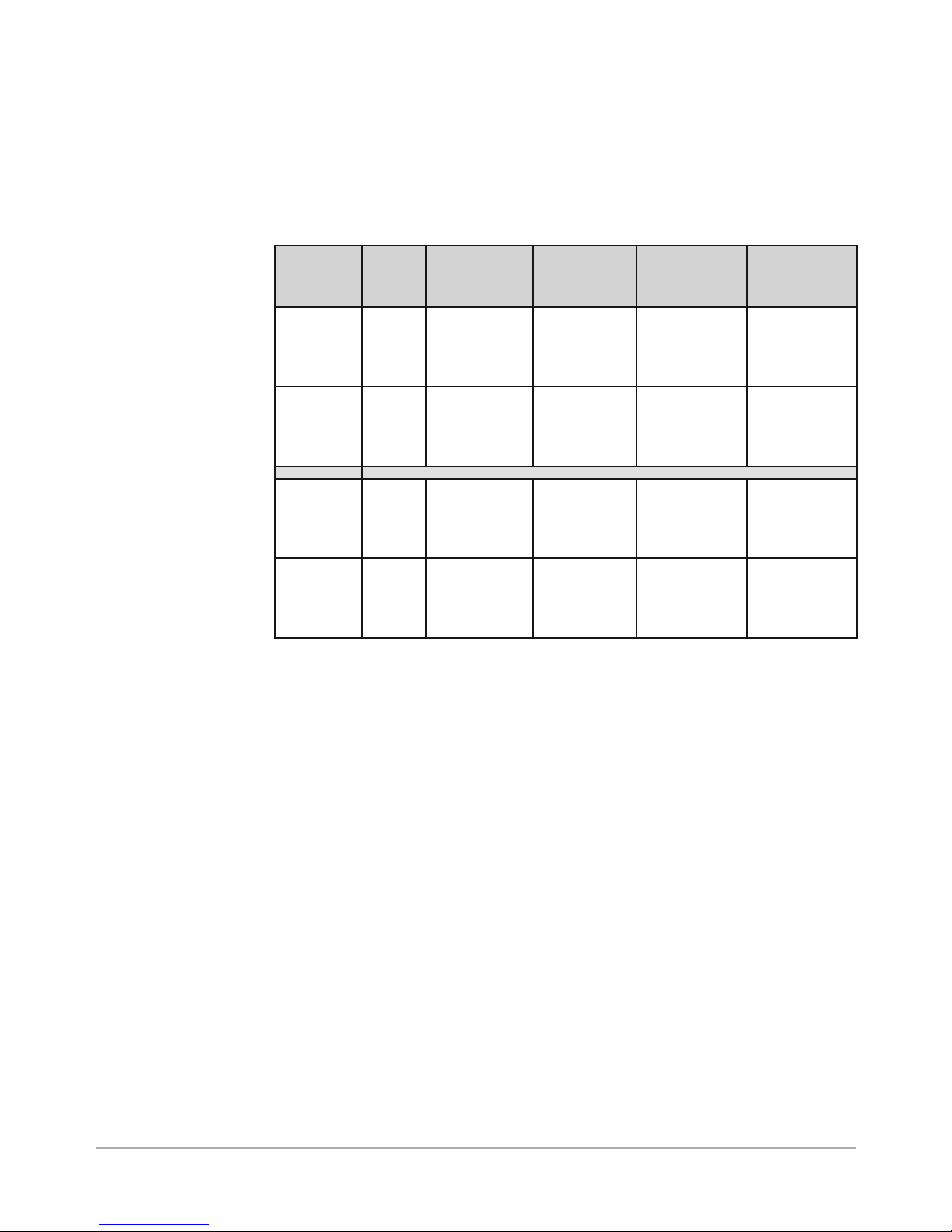

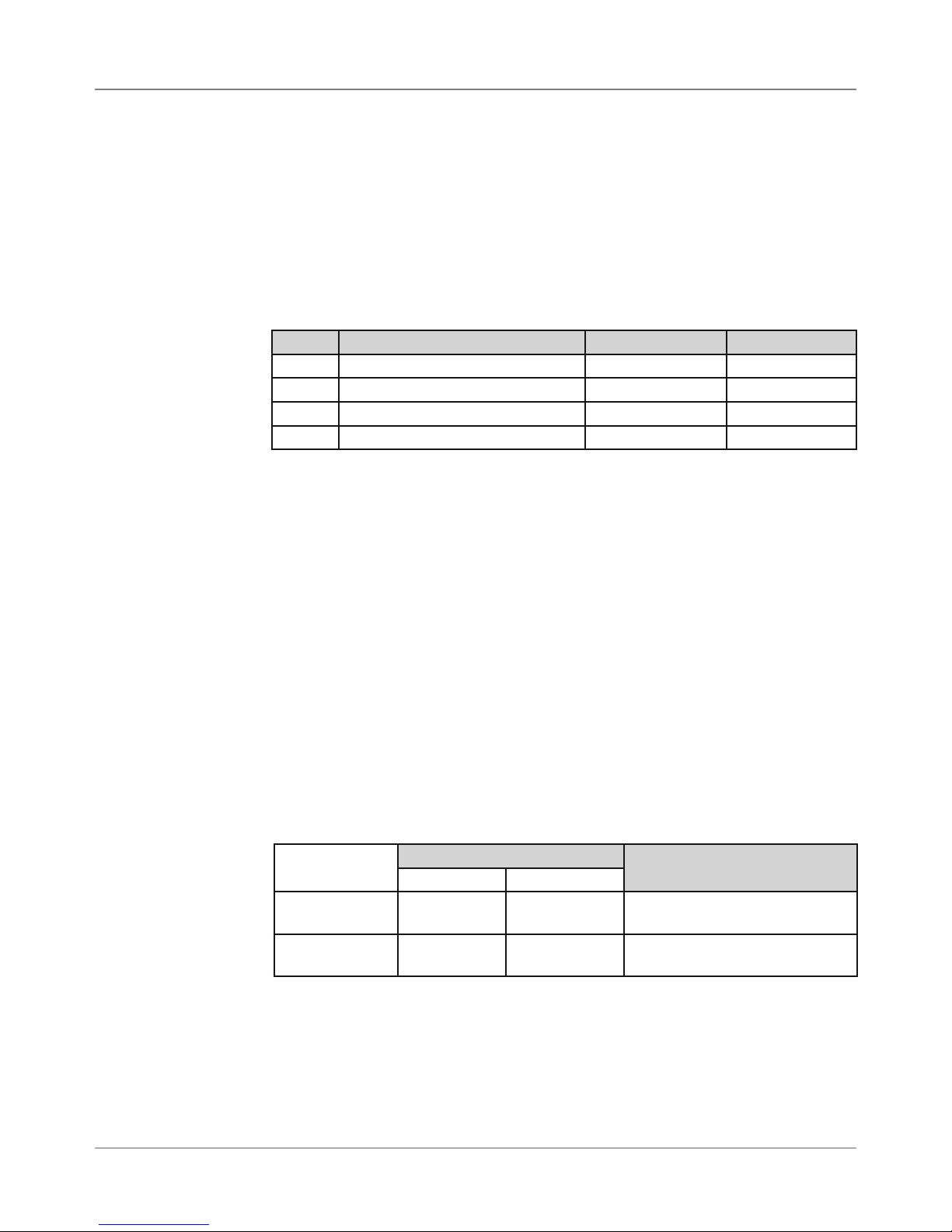

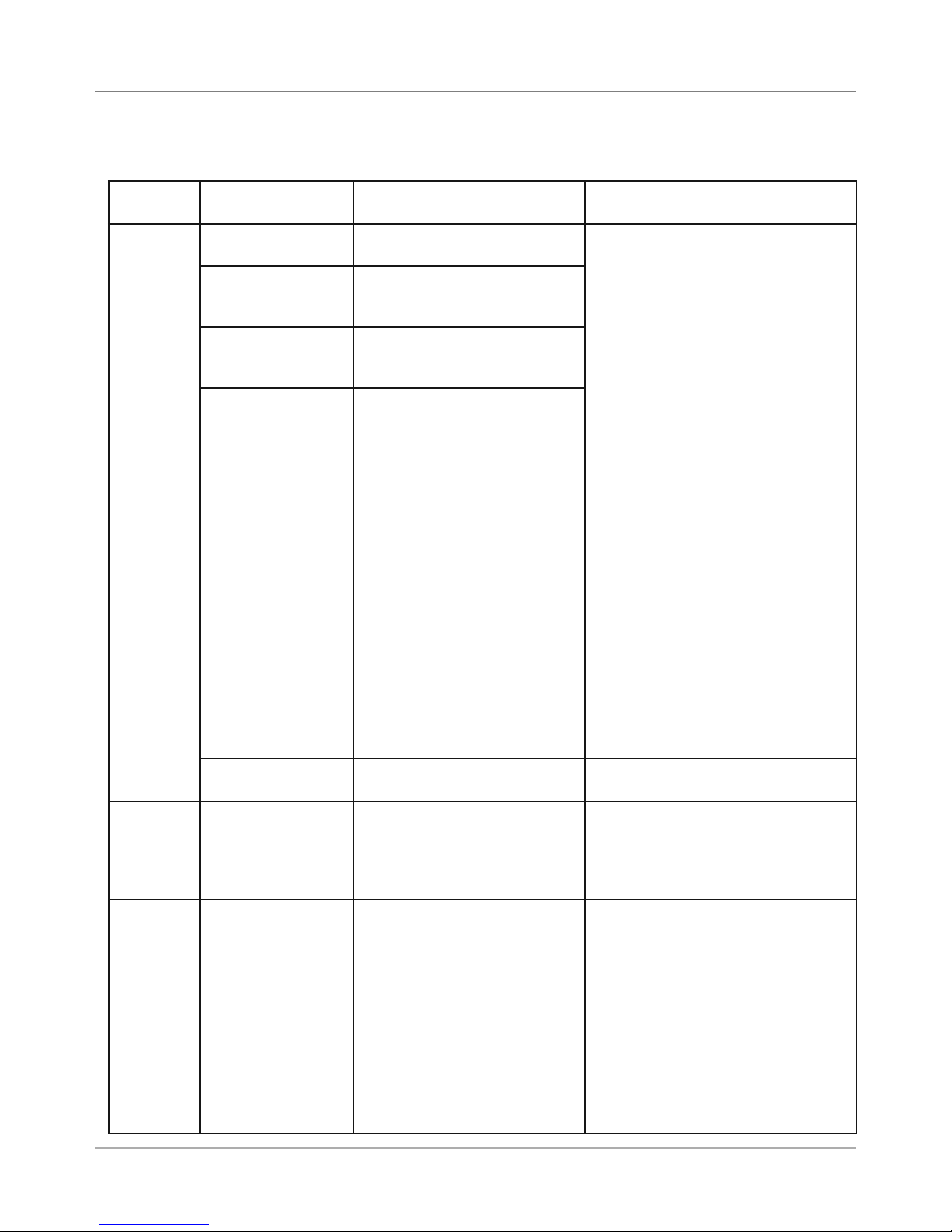

For reference, the table below shows the predecessor shuttle head models.

New

Marketing

Model

DA50S WS51 Black Up to 10,000

DA55S WS56 Black & Pro-

DA70S WS71 Black Up to 14,000

DA75S WS76 Black & Pro-

New

PCN

Printing

Capability

cess Color

(CYMK)

cess Color

(CYMK)

Speed Predecessor

Marketing

Model

DA500 W660

#10 or DL

envelopes

per hour

Up to 10,000

#10 or DL

envelopes

per hour

#10 or DL

envelopes

per hour

Up to 14,000

#10 or DL

envelopes

per hour

DA550 W680

DA700 W707

DA750 W790

Predecessor

PCN

1.2 Related

Publications/

Information

DA50S/DA55S Operator Guide SV61663

DA50S/DA55S Quick Setup Instructions (customer) SV61933

DA50S/DA55S Install SV61664

DA50S/DA55S Parts List SV61832

DA70S/DA75S Operator Guide SV61665

DA70S/DA75S Quick Setup Instructions (customer) SV61934

DA70S/DA75S Install SV61666

DA70S/DA75S Parts List SV61919

For other information on the printers, refer to these sources:

• Software Control Panel Application (on the host PC) - see the help sys-

tem on the software.

• FAQs document - see the Customer Service website under the product

page for AddressRight™ printers.

• Training - see Enhanced AddressRight™ Shuttle Head Printers Self-Directed Course (GMS-MC-03246) at My Portfolio on the Pitney Bowes intranet.

• Training Job Aids - print the job aids for the software control panel appli-

cation (GMS-MC-03246JA) at My Portfolio on the Pitney Bowes intranet.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

1-1

Page 8

1 • Introduction

1.3 Book

Organization

1.4 Safety

Chapter 1: Introductory and safety information

Chapter 2: Product specifications

Chapter 3: Theory of operation

Chapter 4: Troubleshooting and Diagnostics

Chapter 5: Removal and replacement procedures

Chapter 5: Adjustment procedures

Chapter 7: Maintenance procedures

Appendix A: Printer Control Panel Menus

Appendix B: Printer Communications

Appendix C: Schematics/Diagrams

Warning messages appear throughout this manual to alert you to potentially

hazardous con di tions. Two designations indicate their relative seriousness:

WARNING! Calls attention to improper practices that

could result in a potentially serious, even lethal injury to

you or the customer.

CAUTION! Calls attention to practices that could

cause minor injury to you or a customer or that could

damage equipment or material.

Familiarize yourself with proper procedures and methods before you install,

operate or re pair the equipment to avoid personal injury or damage to the

equipment. If you train service peo ple or equip ment operators, it is important to

explain safety precautions to your students and en cour age safety awareness.

Personal Safety

Follow these precautions for your own safety:

• Treat every circuit like a gun that may be loaded. It may not be “live,” but

be sure. Check with a neon tester or voltmeter, or simply unplug the machine.

• Know how to turn off the power in the work area and get help in an emer gen cy.

• Don’t work on equipment under power unless it’s absolutely necessary.

If you must, use extreme cau tion. Don’t grasp two sides of a live circuit

at the same time—use one hand when reach ing into a cir cuit, touching

a ground ed case or chas sis with that wrist or el bow if pos si ble. This pre vents cur rent from passing through vital organs. Observe this rule when

con nect ing or dis con nect ing plugs or leads, or mak ing any adjustments

on a live cir cuit.

1-2 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 9

Introduction • 1

1.4 Safety

Personal Safety (continued)

• Don’t un der es ti mate the danger of shock: 1 mA (1/1000 amp) is un com fort able; 5 mA is dan ger ous —you may jump back and be injured; 12 mA

causes hand muscles to con tract, so you can not free your self; 24 mA has

proven fatal; and 100 mA (1/10 amp) is likely to be fa tal.

• Use the right tools for the job. A tool which slips can cause a short—or a

shock. Don’t reach into a circuit with metal tools, or while wearing rings or

a watch. Even in low voltage cir cuits, a metal object can short circuit two

terminals. When work ing on live cir cuits, use tools with in su lat ed handles

and try to keep your tool hand grounded.

• Don’t bypass safety devices, particularly fuses. Three-wire outlets (120

Vac) are designed to ground equipment to make it safe. If a hot wire

shorts to a grounded frame, the only result is an open fuse. If a hot wire

shorts to an ungrounded frame, the frame itself be comes hot and po ten tial ly dangerous. A fuse is a weak link in a circuit, de signed to break down

before any thing else does. The maximum safe cur rent in a circuit is de ter mined by the de sign ers. Too large a fuse can pass excessive current,

dam ag ing expensive equipment.

• For electrical fires, use Type C, BC or ABC extinguishers only. Don’t use

soda acid or other liq uid stream extinguishers. They will damage elec tri cal equipment and present a shock hazard to the user.

• Digital equipment can be easily damaged or destroyed by static charges.

Mi cro pro ces sors and other integrated circuits con tain tiny transistors not

much more than a mil lionth of an inch across, which operate at 5 to 12

volts.

• Be extremely careful when lifting heavy equipment. Follow the guidelines

below:

a. Squat to lift and lower. DO NOT bend at the waist.

b. Keep your low back bowed in while bending over.

c. Keep the weight as close to you as possible.

d. Bow your back in and raise up with your head first.

e. If you must turn, turn with your feet, not your body.

f. Never jerk or twist!

g. Put the weight down by keeping your low back bowed in.

h. Keep your feet apart, staggered if possible.

i. Wear shoes with non-slip soles.

j. Get help if you need it.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

1-3

Page 10

1 • Introduction

1.4 Safety

Electrostatic Discharge ( ESD) Procedures

Follow these guidelines to protect sen si tive equipment from static damage:

• Always use a wrist grounding strap and anti-static mat when working on

equipment sensitive to electrostatic discharge. These items are furnished

in the ESD Field Service Kit, L-8351.

• Ground yourself before reaching into the equip ment, or touch ing any

circuit board or other electrical component. Just touch ing a doorknob or

metal work bench may be enough, but the best guarantee is to turn the

machine off but leave it plugged in, and ground your self on the chassis,

which is grounded through the three-wire power cord.

• Be careful of rugs—even a few steps can recharge you. Re-ground yourself whenever you’ve walked away and re turned to the ma chine. Rugs

are a major source of static build up in the body.

• Take greater precautions as the objects you handle get smaller. A board

in the machine is better protected than one that is not plugged in; a chip

on a board is better protected than one in your hand.

• Stay away from metal conductors. The plastic and resin that chips and

boards are made of are much better insulators than metal. It’s most important to keep your hands away from any metal which contacts the data.

In particular, this means the long connector along the bottom of each

board, and the pins coming out of the chips. These signal and data lines

are directly connected to the fragile inner circuits of the chips. When handling a board, try not to touch the connector; when handling a chip, try

not to touch the pins.

1-4 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 11

2 • Specifications

2.1 Product

Description

2.2 System

Requirements

The DA50S/DA55S and DA70S/DA75S ink jet printers are shuttle type desktop models used to print addresses, graphics and other information, in black

(DA50S & DA70S), or black and color (DA55S & DA75S); on a wide range of

material sizes, construction and composition. The operator can define the font,

placement, print quality and bar code characteristics for the printed addresses.

Customer PCs must meet the following minimum requirements:

• CPU: Pentium III 500MHz. or greater, 500MB RAM or more preferred

• Operating System: Windows 2000/2003 Server/XP (not yet tested on Vista)

• USB Cable or Ethernet Cable: A USB cable is supplied with the printer. If

the customer chooses to use another cable, it must be no longer than 15

feet (5m).

For the Control Panel software, the following is required:

• Win2K SP4, WinXP Pro SP2, Win Server 2003 SP1 w/ latest Service

Pack (not yet tested on Vista)

• Dot Net v1.1

• 5MB Disk space

• Administrative rights to install software

2.3 Physical

Equipment

Specifications

Physical Dimensions

DA50S/DA55S:

14.7” (37.3 cm) high; 16.2” (41.2 cm) wide; 21.7” (55.1 cm) deep (without

input guide).

DA70S/DA75S:

13” (33 cm) high; 19” (48 cm) wide; 17” (43 cm) deep (without input guide).

Weight

DA50S/DA55S:

44.11 lbs. (20 kg), including print cartridges (B & C) and catch bin.

DA70S/DA75S:

50 lbs. (23 kg), including high-capacity print cartridges and catch bin.

Electrical

Domestic: 120VAC, 60Hz, 1A; International: 220-240VAC, 50Hz, 0.5A

Fuse Type: 1 Amp Slo-Blo 250VAC (on Main Circuit Board)

Power Consumption: 126 Watts, 430 BTU/hr.

Agency Approvals

UL/cUL/VDE-GS - Refer to the FCC and CE statements at the front of this

manual for more information.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

2-1

Page 12

2 • Specifications

2.3 Physical

Equipment

Specifications

Interface

USB, Ethernet

Control Language

PCL5, modified

Address Recovery

Memory buffer holds a maximum of 99 addresses

Environmental Limits

Operating Conditions

• Temperature: 55 to 95°F (12 to 35°C)

• Humidity: 8 to 80%

• Maximum Wet Bulb Temperature: 80°F (27°C)

Storage Conditions

• Temperature (Printer): 42° to 100°F (5 to 40°C)

• Humidity (Supplies): 10 to 90% (5 to 95%)

• Maximum Wet Bulb Temperature: 85°F (29°C)

Shipment Conditions

• Temperature (Printer): -40 to 140°F

• Humidity (Supplies): 5 to 100%

• Maximum Wet Bulb Temperature: 85°F (29°C)

Noise Level

DA50S/DA55S

The sound pressure level at the operator’s position for this equipment as

measured in any mode using ANSI and ISO Standards is less than 68 dB(A).

DA70S/DA75S

The sound pressure level at the operator’s position for this equipment as

measured in any mode using ANSI and ISO Standards is less than 72 dB(A).

2-2 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 13

Specifications • 2

2.4 Print

Specifications

*The Light Mode

printing feature is not

functional at the time

of this writing but is

planned for a future

release.

Print Modes (Print Resolution)

The printers each have three print resolutions. They are Executive (600),

Letter (300), and Draft (150), which represent the horizontal density. Additionally, there are two Light Mode* settings (ON and OFF), which represent

the vertical density. When Light Mode* is "ON", the vertical density setting is

300 DPI; when Light Mode* is "OFF" the vertical density setting is 600 DPI.

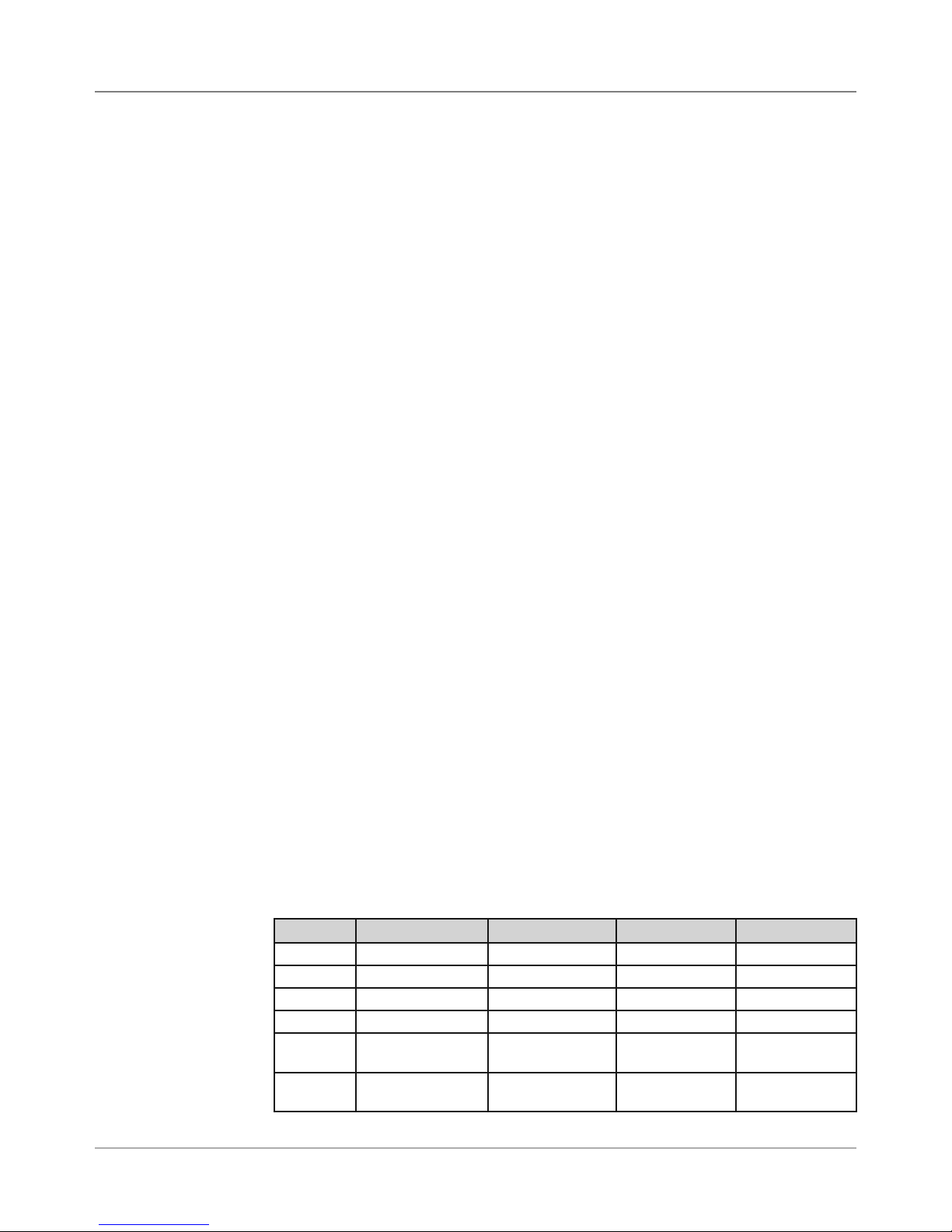

Refer to the table below.

Print Quality With Light Mode* set to

"ON"

Executive 600 x 300 DPI 600 x 600 DPI

Letter 300 x 300 DPI 300 x 600 DPI

Draft 150 x 300 DPI 150 x 600 DPI

With Light Mode* set to

"OFF"

Fonts

Resident Fonts

Arial, Comic Sans MS, Courier New, Georgia, Impact, Kino, MSLogo, Symbol, Tahoma, Times New Roman, Trebuchet MS, Verdana, Webdings, Wingding. All fonts are scalable from 4 to 144 point size.

Resident Font Enhancements

Bold, Italic

Downloadable Fonts

Supports bitmapped, downloadable fonts.

Cartridge Fonts

Not Required. Fonts are downloaded with addresses.

User-Definable Parameters

• Font Characteristics

• Address Placement

• Barcode Characteristics

• Print Quality

Barcode Printing Position

The printer can print a barcode in one of three positions:

• Lower right of the envelope (normal printing orientation only- not inverted)

• Above the address block

• Below the address block

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

2-3

Page 14

2 • Specifications

2.4 Print

Specifications

Barcode Printing Types Position

All the printers in the DA Series can print the following barcodes:

1-Dimensional

• USPS Certified POSTNET barcode. All types of barcodes can be printable including FIM, 3 of 9, 4 state barcode (UK, Canadian, Euro, Australia, etc.) and others.

• 5-, 9-, or 11- digit POSTNET barcodes. 5-digit barcode printing may be

disabled through menu selection. NOTE: 5-digit barcode not accessible

from the control panel menu on the printer.

• Delivery point barcode is generated by transmitting the three digits.

• Planet barcode for delivery confirmation services. The printer is also capable of printing any barcode rendered by a Windows® True Type font.

2-Dimensional

The printers are capable of printing a USPS Certified IBIP barcode as well

as all types of 2-D barcodes defined for the countries (UK, Canadian, Euro,

Australia etc.) and others to the defined standards. Reference applicable

Postal Standards.

Special Note on FIM Barcode

FIM (Face Identification Marking) barcode was developed by the USPS as

part of their POSTNET barcoding system. It is normally used by high-volume

mailers to put on return envelopes for their customers’ invoices.

When the invoices are mailed back in their return envelope, the USPS sorts

and processes this mail according to what version of FIM barcode is used on

the envelope: FIM A (Postage required, POSTNET bar code included), FIM

C (Postage prepaid, POSTNET bar code included), and FIM D (Postage required, POSTNET bar code not included).

One of the requirements of the FIM barcode is that it needs to be printed

on the edge of the envelope (typically printed in the top right corner). This

is difficult to support by our printers, especially on the trail edge. Inverted

mode may supply a better print for the FIM, but any attempt to print to the

exact edge of the envelope is liable to "miss" the edge occasionally. Because

of these issues, we cannot guarantee full USPS compliance for print-

ing FIM barcode. As a result, some of our high-volume customers used

pre-printed envelopes containing the FIM barcode that meet USPS printing

specifications.

However, if you want to try printing the FIM using our printers, the Pitney

Bowes Envelope Designer Plus software allows you to place a FIM graphic

on the envelope. You can obtain photo-ready graphics directly from the

USPS (the Envelope Designer software itself can not create the FIM barcode

graphic). When printing, use the inverted orientation since the printer is more

accurate at printing items near the leading edge.

2-4 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 15

Specifications • 2

2.4 Print

Specifications

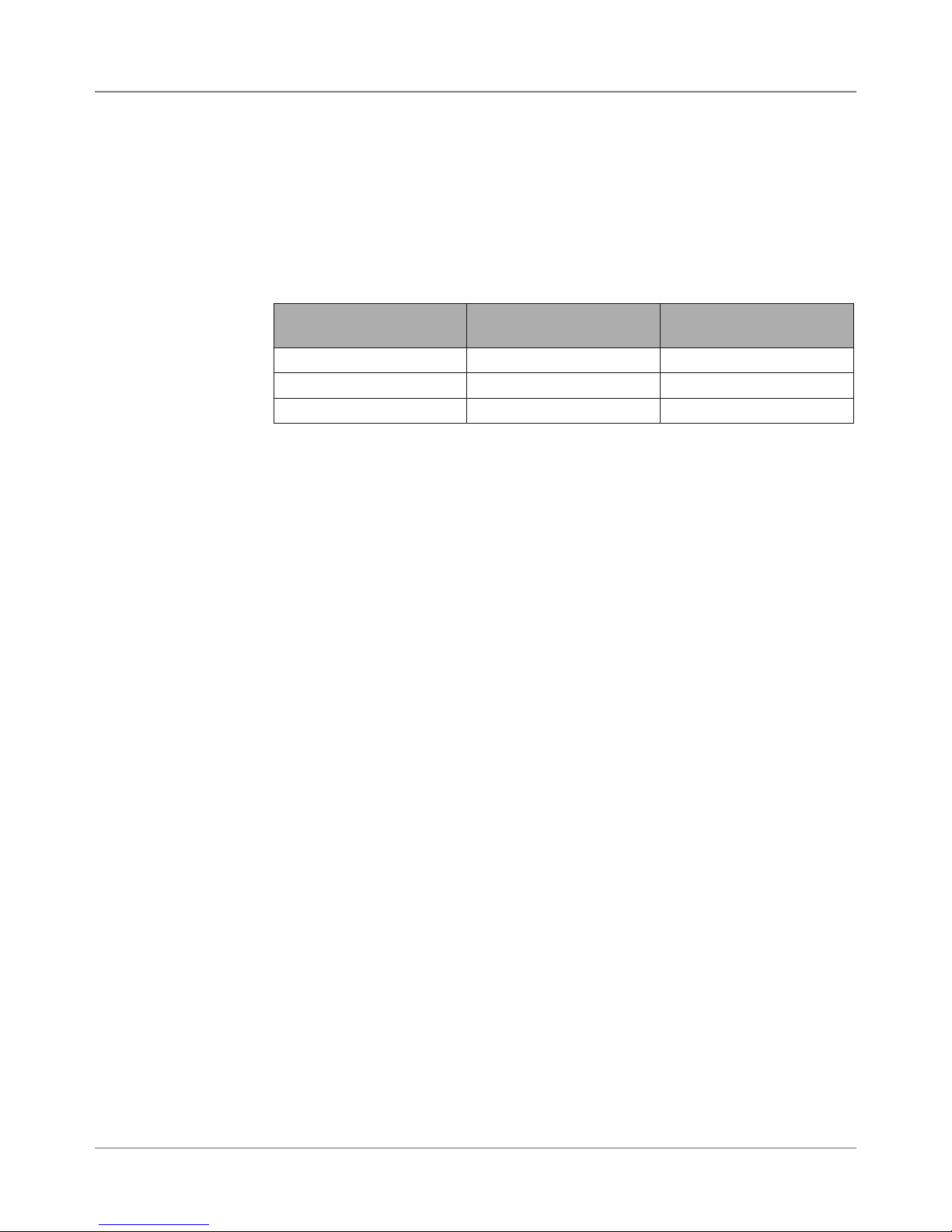

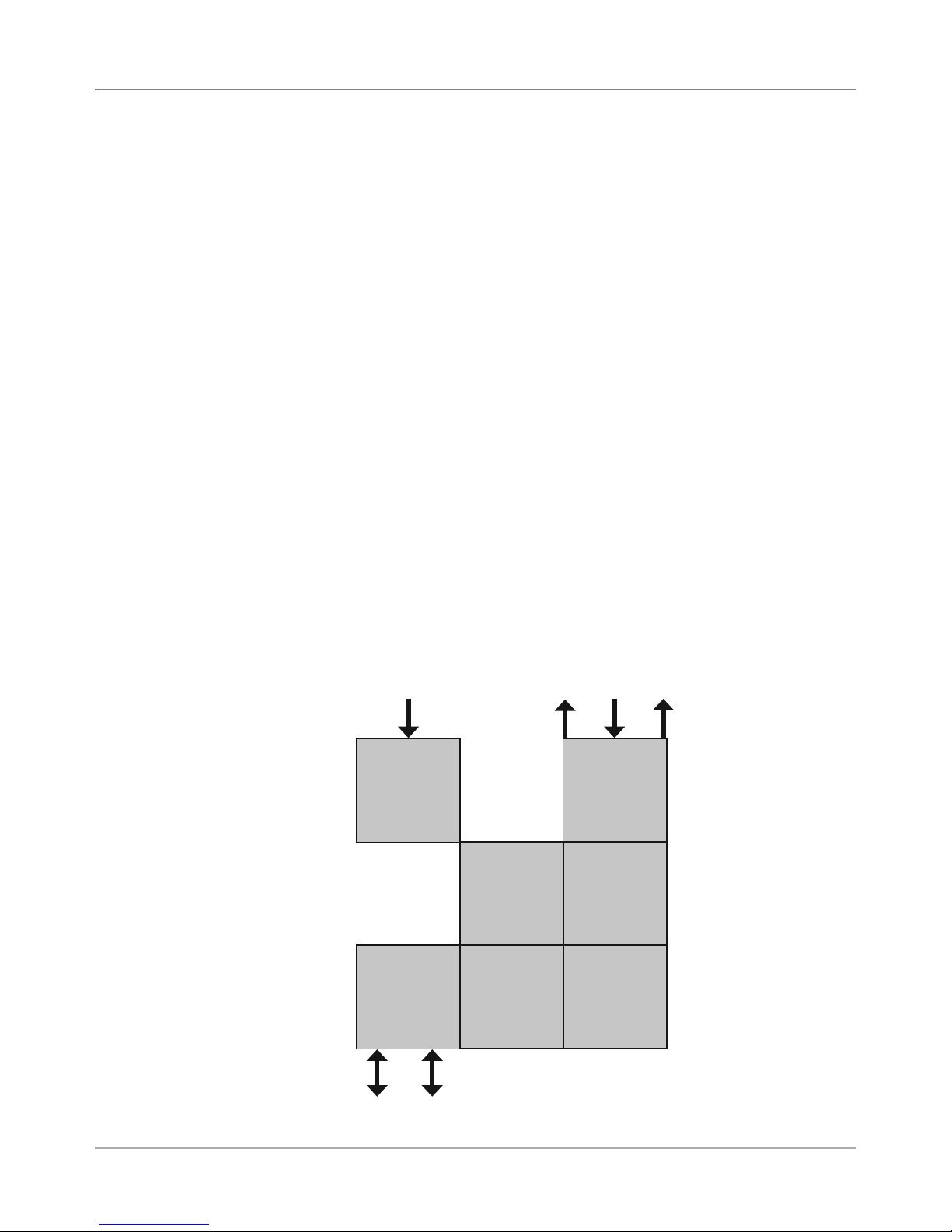

Effective Print Area

The printable width is 9.4" (24cm) measured from the right side of the piece

of mail. The printable height is 15" (38cm) measured from the bottom edge

of the piece of mail. See the figure below.

Flap on Opposite

Trailing Edge (Top)

Feed Direction

Left

Leading Edge (Bottom)

Feed Direction and Print Area

NOTES:

Side

Right

• All edges are viewed from the front surface of the material.

• Two clear zones, each 0.3" (7.6mm) wide, are required on the piece of

mail to allow clearance for the exit rollers.

• Printing is allowed to the top edge of the media, however print quality will

be degraded.

• The lower 5/8" (16mm) of the material is reserved for the lower right barcode when it is used.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

2-5

Page 16

2 • Specifications

2.4 Print

Specifications

Inkjet Cartridges

Cartridges are operator replaceable. The ink supply cartridges for the

DA50S/DA55S and DA70S/DA75S are the same ones used on their predecessor models (see table on page 1-1). The table below lists some common

order numbers for replacement cartridges. For a complete list of ink cartridges, go to http://www.pb.com/supplies. In the Find Your Supplies field on the

left panel, select “AddressRight” from the dropdown list provided. Follow the

links for the model of your printer from the web page that displays.

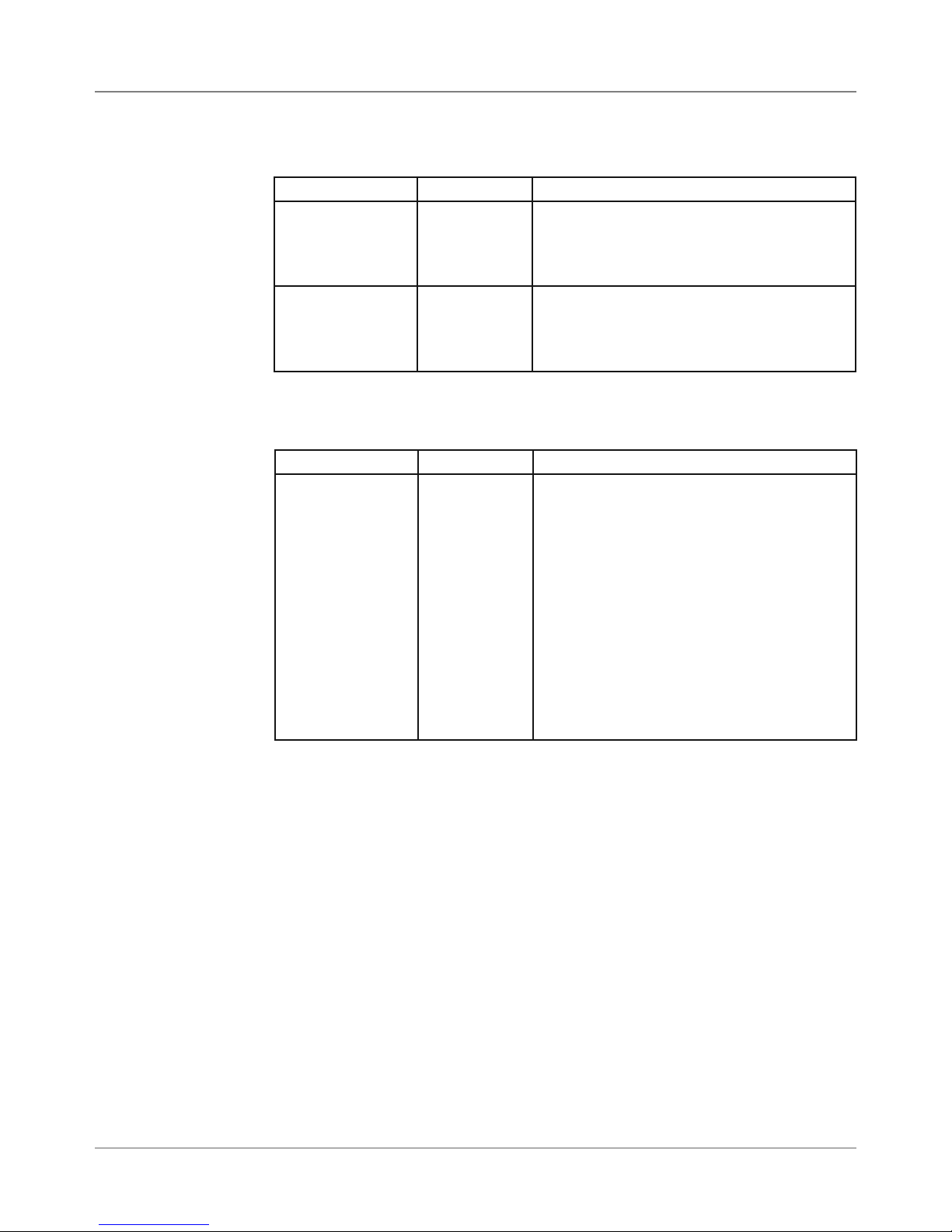

Model Printing Capability Black Cartridge Color Cartridge

DA50S Black 51645A n/a

DA55S Black & Process Color (CYMK) 51645A 51641A

DA70S Black 51645A n/a

DA75S Black & Process Color (CYMK) 51645A 51641A

Print Position Accuracy

For a #10 or DL envelope (Acclaim #10 WW Commercial, Regular):

• Horizontal: within +/- 1.5 mm

• Vertical: within +/- 1.5 mm

• Skew: within +/- 1 degree

For other media:

• Horizontal: within +/- 3.0 mm

• Vertical: within +/- 3.0 mm

• Skew: within +/- 2-1/2 degrees

Recommended Usage

The printers have been tested under many different conditions. Use of the

printer should fall within these piece usage recommendations:

Monthly Piece Usage Product Life

Typical Maximum

DA50S/DA55S 36,000 77,000 5 years or 4,620,000 cycles

(whichever comes first)

DA70S/DA75S 104,000 250,000 5 years or 15,000,000 cycles

(whichever comes first)

NOTE: Usage beyond the maximum monthly pieces is not covered by the

Equipment Maintenance Agreement (EMA).

2-6 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 17

Specifications • 2

2.2 Print

Specifications

2.5 Material

Specifications

Throughput

DA50S/DA55S: 10,000 letters per hour (lph)

DA70S/DA75S: 14,000 letters per hour (lph)

Based on:

• Print quality - Draft mode

• 3-line destination address

• 18 characters per line

• 12-point character size

• Time New Roman font

• Bidirectional printing of text

NOTE: Adding graphics and/or printing at a higher resolution (e.g., Letter or

Executive mode) will decrease throughput.

For envelope addressing purposes, the printer is compatible with any word

processor or database application that can print a mailing label.

The paper types listed below are approved for use with the printer. Please note

that the dimensional limits above apply in all cases, and that all media (enve-

lopes, postcards, flats, etc.) must be without windows, unstuffed and unsealed.

• White Wove

• Bond paper

• Recycled paper

• Coated paper

• Card stock

• Brown kraft

• Manila

• Perforations

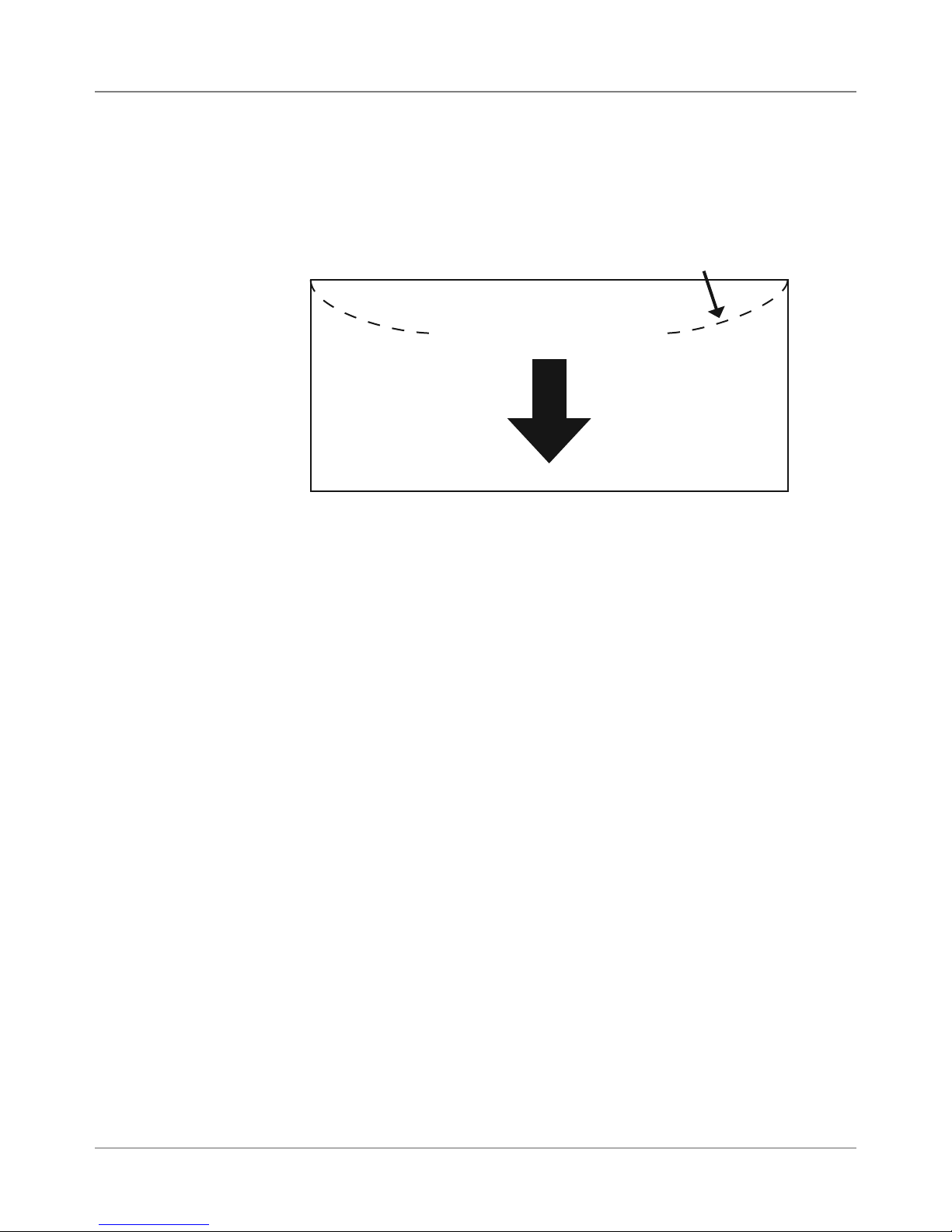

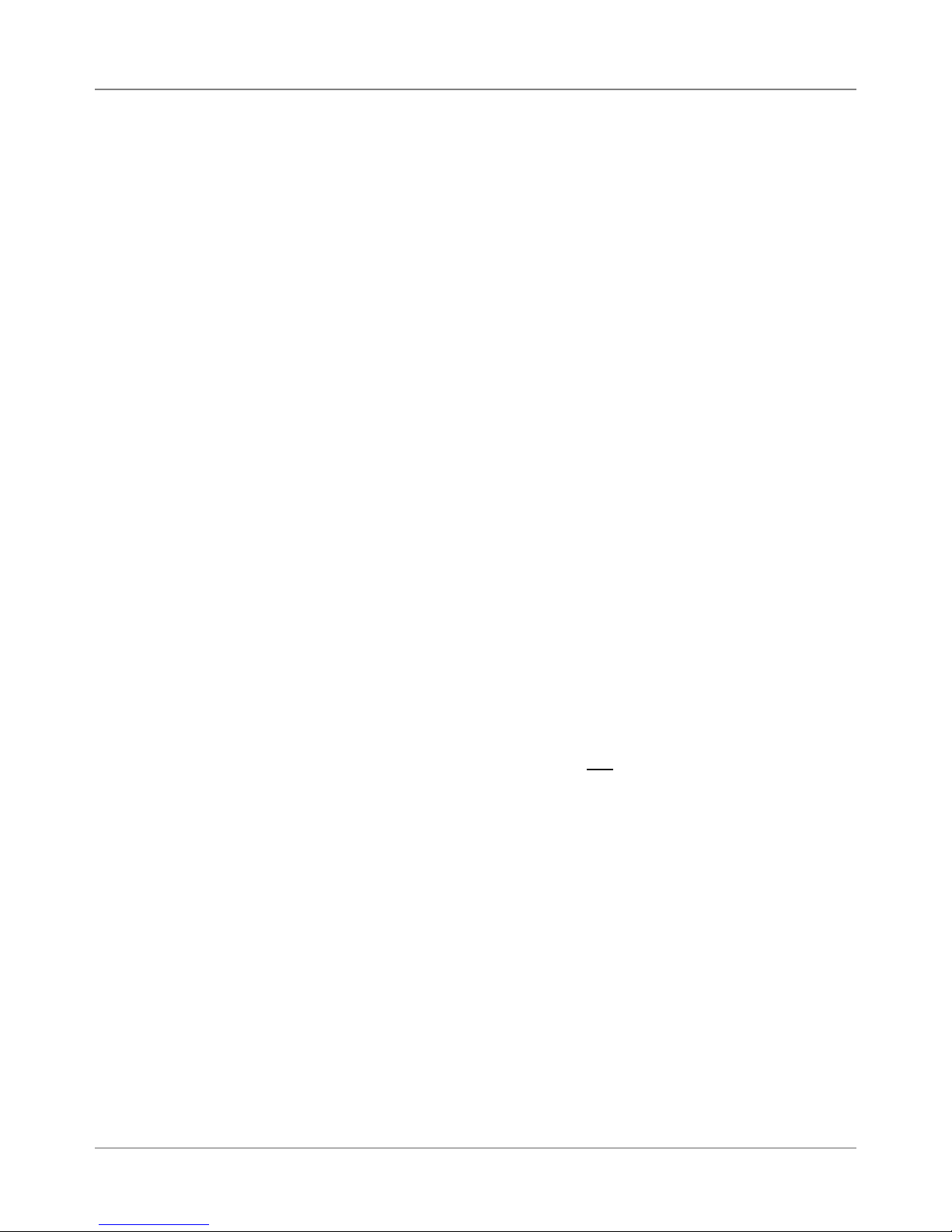

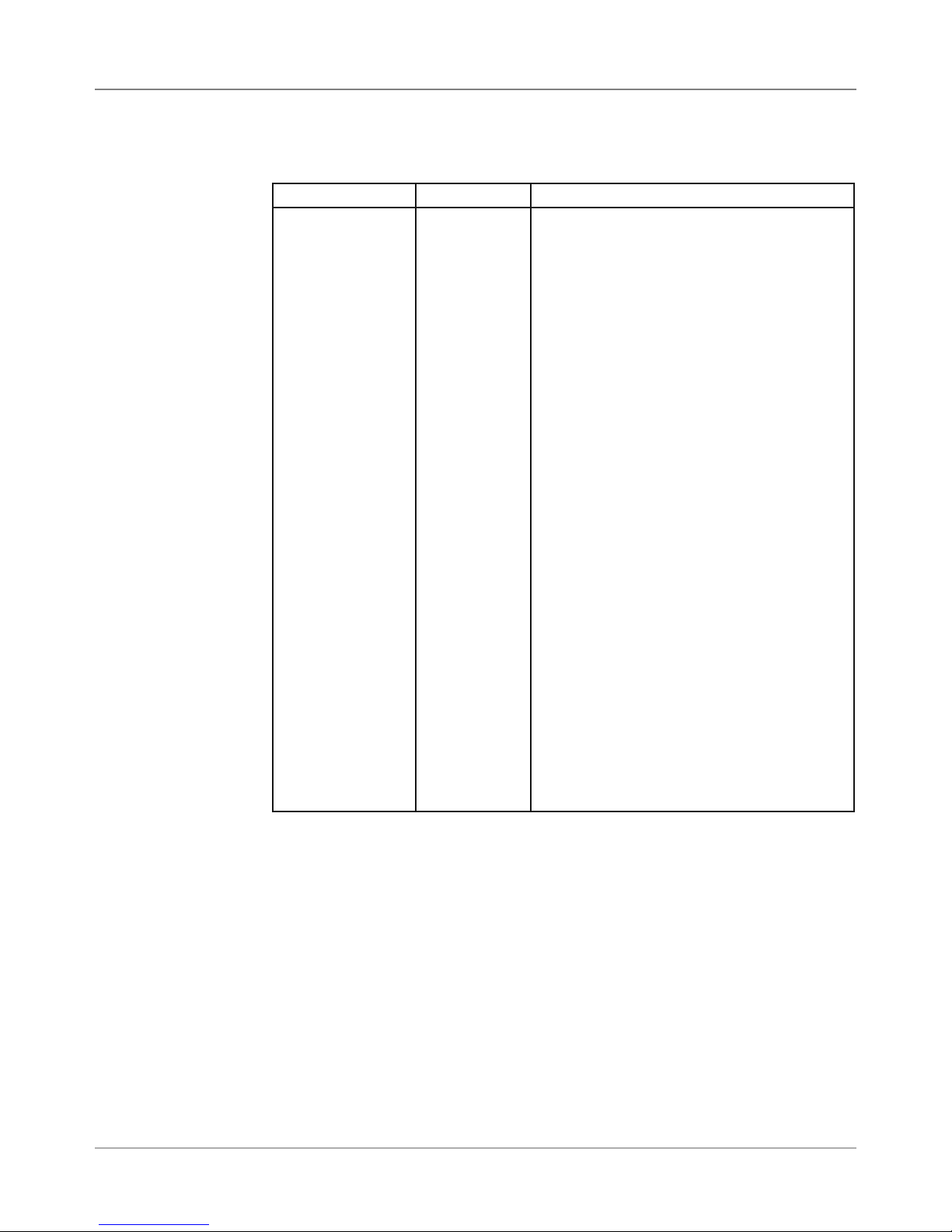

Refer to the table below for media size specifications.

Media Sizes

DA50S DA55S DA70S DA75S

Min length 3.5" (89 mm) 3.5" (89 mm) 3.5" (89 mm) 3.5" (89 mm)

Max length 13.5" (343 mm) 13.5" (343 mm) 15.5" (394mm) 15.5" (394mm)

Min width 4.5" (114 mm) 4.5" (114 mm) 3.5" (89 mm) 3.5" (89 mm)

Max width 12.75" (324 mm) 12.75" (324 mm) 15" (381mm) 15" (381mm)

Min

thickness

Max

thickness

0.003" (0.08 mm) 0.003" (0.08 mm) 0.003" (0.08 mm) 0.003" (0.08 mm)

0.125" (3.175 mm) 0.125" (3.175 mm) 0.250" (6.35 mm) 0.250" (6.35 mm)

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

2-7

Page 18

2 • Specifications

2.5 Material

Specifications

Stacker Capacity

Input Stacker — DA50S/DA55S: 200 #10 or DL Envelopes; DA70S/DA75S:

600 #10 or DL Envelopes with Bin extension, or 250 without extension installed.

Output Stacker — DA50S/DA55S/DA70S/DA75S: 150 #10 or DL Envelopes

Approved Media

• Envelopes have a flap along the long edge and are processed by the

printer non-flap edge first. Envelopes may have either a diagonal or

straight edge along the envelope flap.

• Booklets are defined as media having physical dimensions 6 x 9”

(1523mm x 230mm) or larger. Booklets have an opening along their long

edge which is covered by a flap with an adhesive seal.

• Catalog envelopes have an opening along their short edge which is

closed by a flap with an adhesive seal.

• Postcards have no folds or bends. The printable side may have a higher

surface roughness than the non-printable side.

• Self-mailers may be of “C,” “Z,” or half-folded construction. They may not

exceed the maximum allowable thickness as specified on the previous

page and must be tabbed per postal regulations.

• A catalog may consist of multiple pages bound by adhesive or tabs on

the feed edge or at 90 degrees with respect to the feed edge.

2

• Sheet stock may consist of 16 to 28 lb. (60 to 105g/m

60 to 80 lb. (220 to 300g/m2) coated stock. The size and thickness constraints specified above apply.

NOTE: The following materials should not be used:

• Contaminants – material with visible material loss (loose powder, ink, sur-

face glaze, etc.) when hung free over a clean surface and struck sharply

with a standard wood ruler

• NCR paper

• Special Materials – materials that are sensitive to heat such as thermal

papers, any pressure-sensitive materials, and materials that are sensitive

to minor magnetic fields.

) bond as well as

2-8 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 19

Specifications • 2

2.5 Material

Specifications

Supported Envelope/Paper Sizes

Paper Name Displayed in List Size (Width) Size (Height)

US/Canada Envelope/Paper Sizes

ENV_9 Envelope #9 8⅞"3⅞"

ENV_10 Envelope #10 9½" 4⅛"

ENV_11 Envelope #11 10⅜" 4½"

ENV_12 Envelope #12 11" 4¾"

PPR_Booklet_9_12 Booklet 9 x 12 12" 9"

ENV_MONARCH Envelope Monarch 7½" 3⅞"

PPR_Card_4_6 Card 6 x 4 6" 4"

PPR_Card_5_7 Card 7 x 5 7" 5"

LETTER Letter 8½" 11"

LEGAL Legal 8½" 14"

EXECUTIVE Executive 7¼" 10½ in

European Envelope/Paper Sizes

ENV_B4 Envelope B4 353mm 250mm

ENV_B5 Envelope B5 250mm 176mm

ENV_B6 Envelope B6 176mm 125mm

ENV_C4 Envelope C4 324mm 229mm

ENV_C5 Envelope C5 229mm 162mm

ENV_C6 Envelope C6 162mm 114mm

ENV_C65 Envelope C65 229mm 114mm

PG_ENV_C76 Envelope C76 162mm 81mm

PG_ENV_C7 Envelope C7 114mm 81mm

ENV_DL Envelope DL 220mm 110mm

ENV_DLX Envelope DLX 235mm 120mm

ENV_DLE Envelope DLE 225mm 114mm

A4 A4 210mm 297mm

A5 A5 148mm 210mm

Asian Envelope/Paper Sizes

Envelope 12JE 140mm 265mm

Envelope 9JE 190mm 265mm

Envelope 6JE 215mm 305mm

Envelope ZL [China] 230mm 120mm

Chou #3 Yoko 120mm 235mm

Chou #4 Tate 90mm 205mm

Hagaki 100mm 148mm

Postcard #3 165mm 102mm

Postcard #4 183mm 100mm

Maximum Paper Size 9.4" 15"

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

2-9

Page 20

2 • Specifications

2-10 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 21

3 • Theory

3.1 Changes

From Earlier

Models

The DA50S/DA55S (WS51/WS56) and DA70S/DA75S (WS71/WS76) series

of printers are based on the previous Pitney Bowes shuttle head printers

(W660/W680 and W707/W790). For those familiar with the older models, the

changes implemented include:

• Updated Main Board, LCD/Keyboard Board/Print Head Driver Board and

added Ethernet/USB Interface Board. Now 100% RoHS compliant.

• Removed large transformer and replaced with heavier duty power supply (allows a graceful shutdown of the printer to allow the print head to go

back to its maintenance station and the software to be saved)

• New DC motor and high-resolution encoder (replaces stepper motor) for

greater paper control and less RFI

• Elimination of plug-in memory card to store fonts (now stored on SDRAM)

• Elimination of Centronics (parallel) and serial connectors (replaced by USB

and Ethernet board/connectors)

• Improved paper sensor calibration now accessible via LCD menu

• Keyboard/LCD display changed on DA70S/DA75S to match the former

W660/W680 (now DA50S/DA55S) 6-button style

• Added new second belt pass with spring-loaded tensioner

• New options on the control panel menus for greater flexibility and control

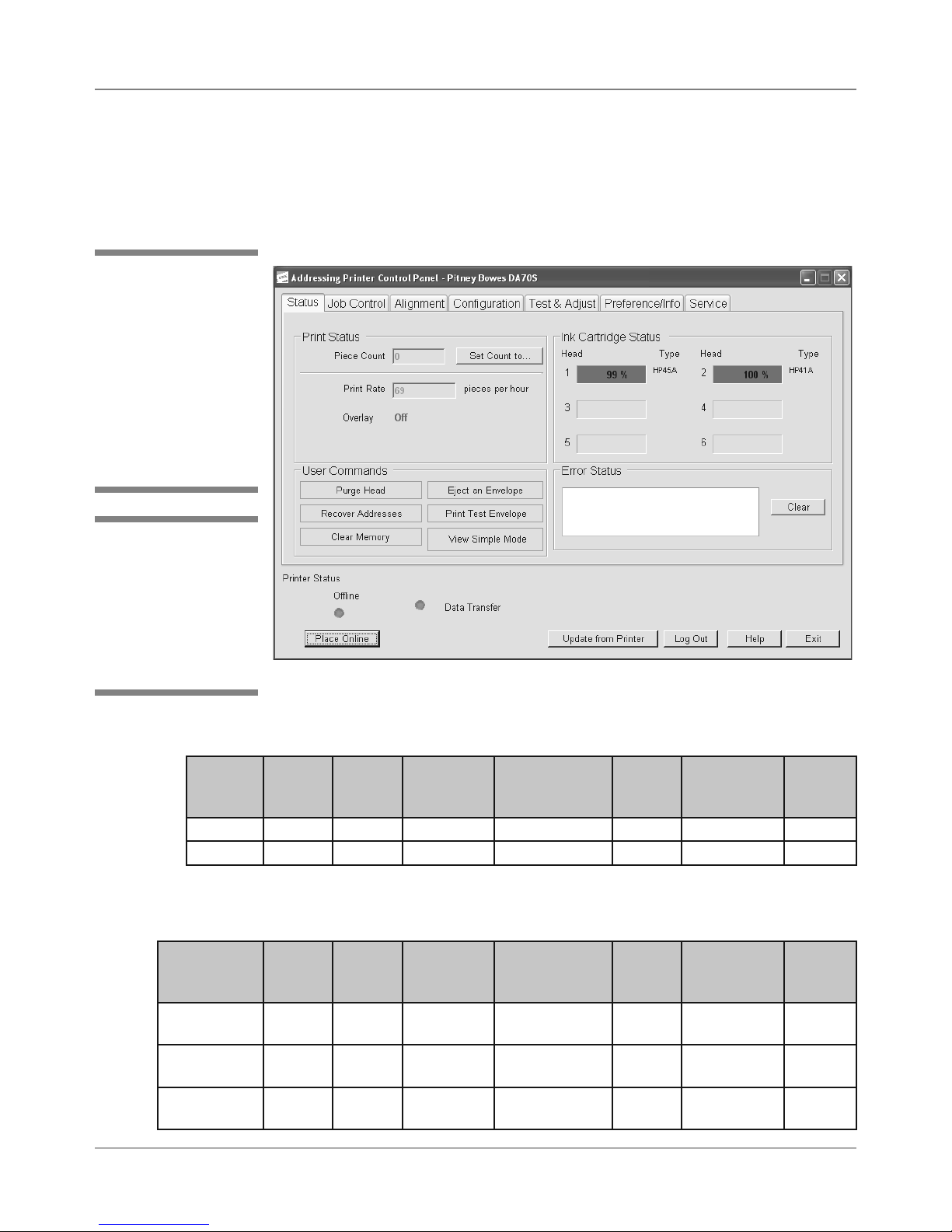

• Introduction of a “soft control panel” (running under Windows on a separate PC) which mimics the features of the printer’s control panel while

also adding more diagnostic and administrative features

• Standardize most screws to square-head

• Easier to disassemble:

DA50S/DA55S – mounting screws are accessible after removing covers,

top assembly can be removed from base, cables are routed along base

DA70S/DA75S – new access holes or areas on side, end, and bottom for

quicker access to inside of unit

• Support for 18 languages in the documentation, soft control panel, and

labelling

• New cover colors and styling

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

3-1

Page 22

3 • Theory

3.2 Printer

Architecture

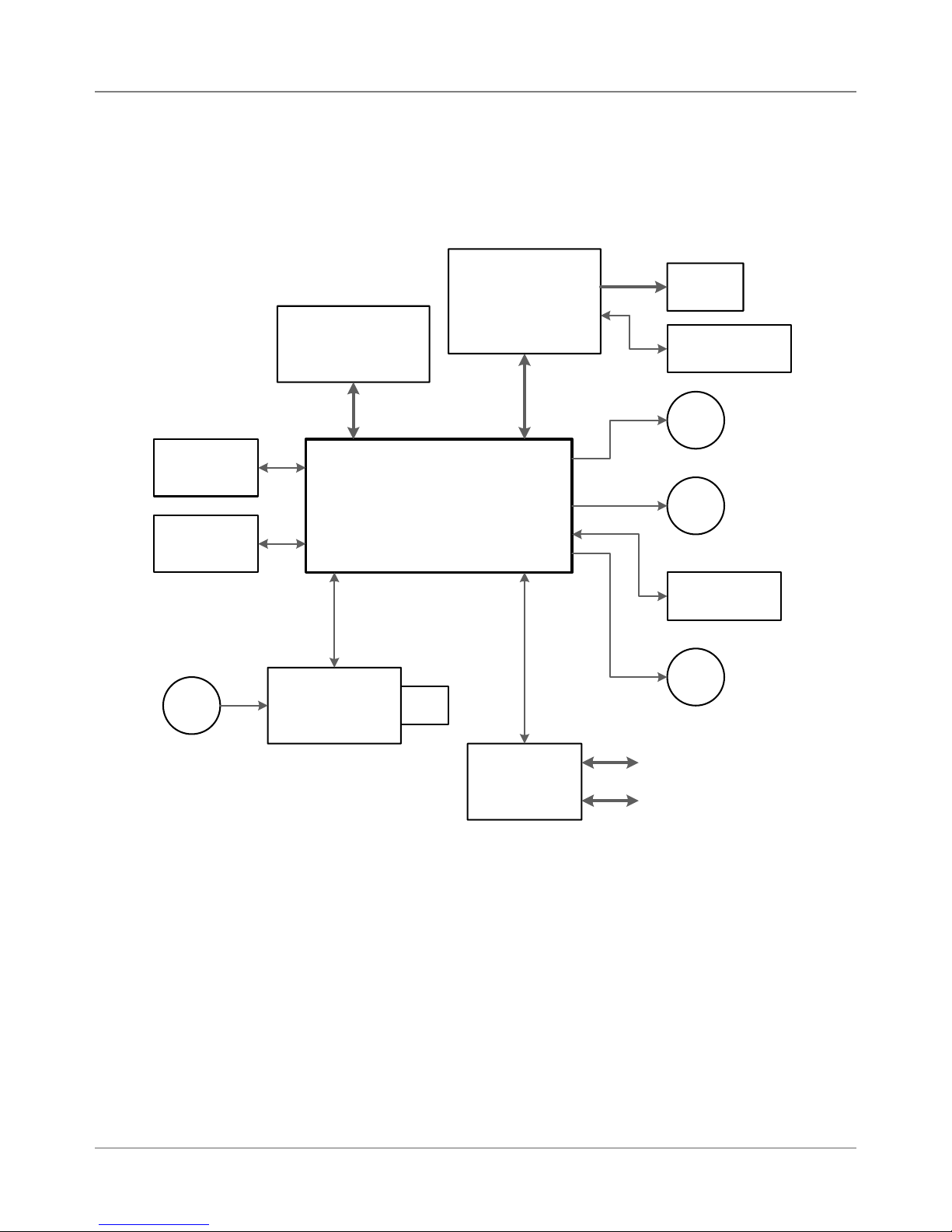

The printer system is made up of several sub-systems (see Figures 3-1 and 3-2):

• Universal Power Supply - The universal power supply has auto sensing/

switching for input voltage and intelligent shutdown capability. It ensures

proper parking of the cartridges in the maintenance station and proper

shutdown of the software. (It is the same supply used in the midrange

DM series mailing machines.)

• System Controller - The system controller is comprised of the overall op-

erating system in the firmware that controls the behavior of the system

and coordinates activities between the other sections.

• User Interface - The user interface is the LCD display, the buttons, and

the software to drive it within the firmware.

• Feeder and Transport Motion Control - The feeder and transport motion

control is responsible for feeding and positioning the envelope beneath

the printer for printing. All material motion is controlled by the transport

motor and firmware.

• Head Motion Control (Head Management) - The head motion is a combi-

nation of shuttle motion control and head management result in printing

1/2” swaths across the envelope as required. These work in conjunction

with the transport motion control for proper positioning of the printed material on the envelope.

• Communications - The communications hardware and firmware are re-

sponsible for the interface to the host PC through which print streams are

received and passed to the system controller for parsing and rendering.

Operator

Te xt

User Interface

Feeder

Transport

Motion Control

Management

Input

and

Head

LED

Power

Universal Power

Supply

Communications

USB Ethernet

Display

System

Controller

Head

Motion Control

3-2 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Busy/Error

Figure 3-1 Printer System Functional Architecture

Page 23

3.2 Printer

Architecture

Theory • 3

&RQWURO3DQHO

'LVSOD\%RDUG

:6

(PLWWHU

6HQVRU

0DLQ&RQWUROOHU%RDUG

5HFHLYHU

6HQVRU

8QLYHUVDO

$& )DQ

3RZHU6XSSO\

:6

:6

3ULQW+HDG

'ULYHU%RDUG

:6>&@

:6>%:@

3ULQW

+HDG

6KXWWOH0RWRU

(QFRGHU

0

6KXWWOH0RWRU

0

7UDQVSRUW0RWRU

6KDIW

(QFRGHU

0

0DLQWHQDQFH0RWRU

3RZHU,QSXW

Figure 3-2 Printer Block Diagram

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

,QWHUIDFH

%RDUG

:6

/$1

86%

3-3

Page 24

3 • Theory

3.2 Printer

Architecture

/NLINE3WITCH

6ALID!DDRESS

4RANSPORT-OTOR

&EED2OLLERS

0HOTO3ENSOR

3HUTTLE-OTOR

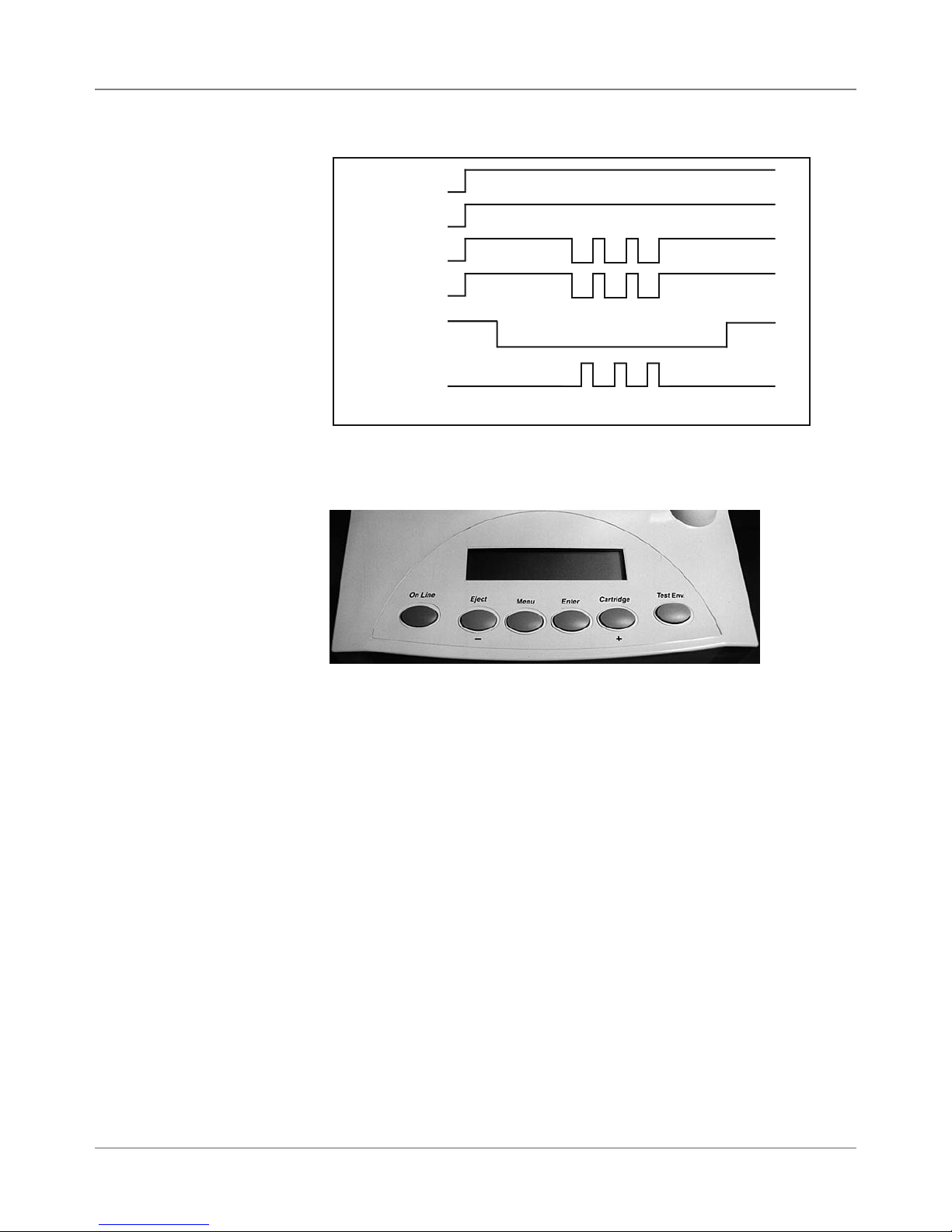

Figure 3-3 Printer Timing Diagram

1

Figure 3-4 User Interface (Control Panel) on Printer

/.

#LUTCH/.

3ENSOR"LOCKED

0RINTING/&&

2

34

5

6

1. On Line — Press to toggle between On Line (communicates with host

PC) and Off Line (no communications).

2. Eject - — Press to scroll through menu options from bottom to top. When

printer is off-line, press the minus key to eject an envelope.

3. Menu — Press to exit or enter a menu when printer is off-line.

4. Enter — While in a menu, press to enable an option.

5. Cartridge + — Press to scroll through menu options from top to bottom.

When printer is off line, press the plus key to bring the print head to the

center of its travel for cartridge replacement.

6. Test Env.— Press to print an internally generated test address.

NOTE: See Appendix A, Printer Control Panel Menus for a full explanation of

all the menu options.

3-4 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 25

Theory • 3

3.3 Operating

Sequence

The timing diagram (Figure 3-3) depicts the sequence of events during a

print cycle. The media to be addressed or printed upon is loaded into the

input bin. Whenever a valid address is received from the computer while the

printer is in the “on line” mode, the micro processor signals the transport motor to rotate.

The transport motor drives the main feed, intermediate and exit rollers via the

two-stage serpentine timing belts. As the main feed roller turns, it drives the

bottom piece between the “H” block separator tabs and the main feed roller.

The separator tabs retard all but the bottom piece in the stack.

The transport motor timing belt connects the upper and lower transport and

the exit rollers via the drive belt on the front plate assembly. The upper transport rollers are connected to the main feed roller by way of the timing belt on

the center plate assembly.

The main feed roller assembly (with integrated slip clutches) consists of six

rollers mounted on a shaft. Each roller has a replaceable “tire” that provides

the friction surface to drive the material through the printer. The roller assembly is driven by the main drive motor through two stages of serpentine timing

belts. The separators are designed to frictionally restrain all but the bottom

piece of media (the DA70S/DA75S has a second set of transport rollers

which help securely transport the printed media).

The feed roller moves the piece of media between the upper idler and the

upper transport rollers. The speed differential between upper / lower transport rollers and the main feed roller creates a gap between the moving pieces of media.

The lower transport rollers move the leading edge of the media into the path

of the sensor assembly.

The main feed rollers drive the leading edge of the piece into the path of the

through-beam sensor assembly. The sensor pair is mounted above the paper

guide and below the feed deck just above the shaft of the intermediate roller.

The transiting piece interrupts the infrared path between the lower (receiver)

and upper sensor (emitter/LED). The processor board sensor voltage changes, alerting the microprocessor to the location of the piece's lead edge.

The transport motor (with high-resolution encoder) continues to turn the lower transport rollers, moving the media ahead. At a predetermined measurement (bottom margin), the micro processor signals the print head shuttle DC

motor to move the print head holder assembly from the park position onto the

media surface. The encoder strip, passing through the encoder reader on the

print head drive board, keeps track of the movement of the print head. The

shuttle motor drives the print head assembly via a timing belt.

As the print head sweeps across the media, the processor signals the transport main drive DC motor to stop the feeding cycle.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

3-5

Page 26

3 • Theory

3.3 Operating

Sequence

The processor then sends data to the print head driver circuitry to print a

swath of information onto the media along the X axis (horizontally). After the

swath prints, the transport motor cycles on, again moving the media ahead

along the Y axis (vertically). If there is more data in the buffer, the X-Y cycle

continues until the buffer is empty.

The piece of media is then fed between the right and left hand exit idler rollers and the exit roller assembly. The lower transport and exit rollers move

the media until the trailing edge is past the infrared sensor path and ejects

the media. The sensor voltage changes and the processor registers the end

of the media. The feed rollers then push the next piece of media under the

separators for the printing cycle to begin again. The process repeats again

until all the addresses in the job are printed.

3-6 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 27

4 • Troubleshooting/Diagnostics

4.1 Block

Diagrams

✍

TIP: See Appendix B

- Printer Communications, for troubleshoot-

ing problems relating to

networking and printer

communications.

(PLWWHU

6HQVRU

5HFHLYHU

6HQVRU

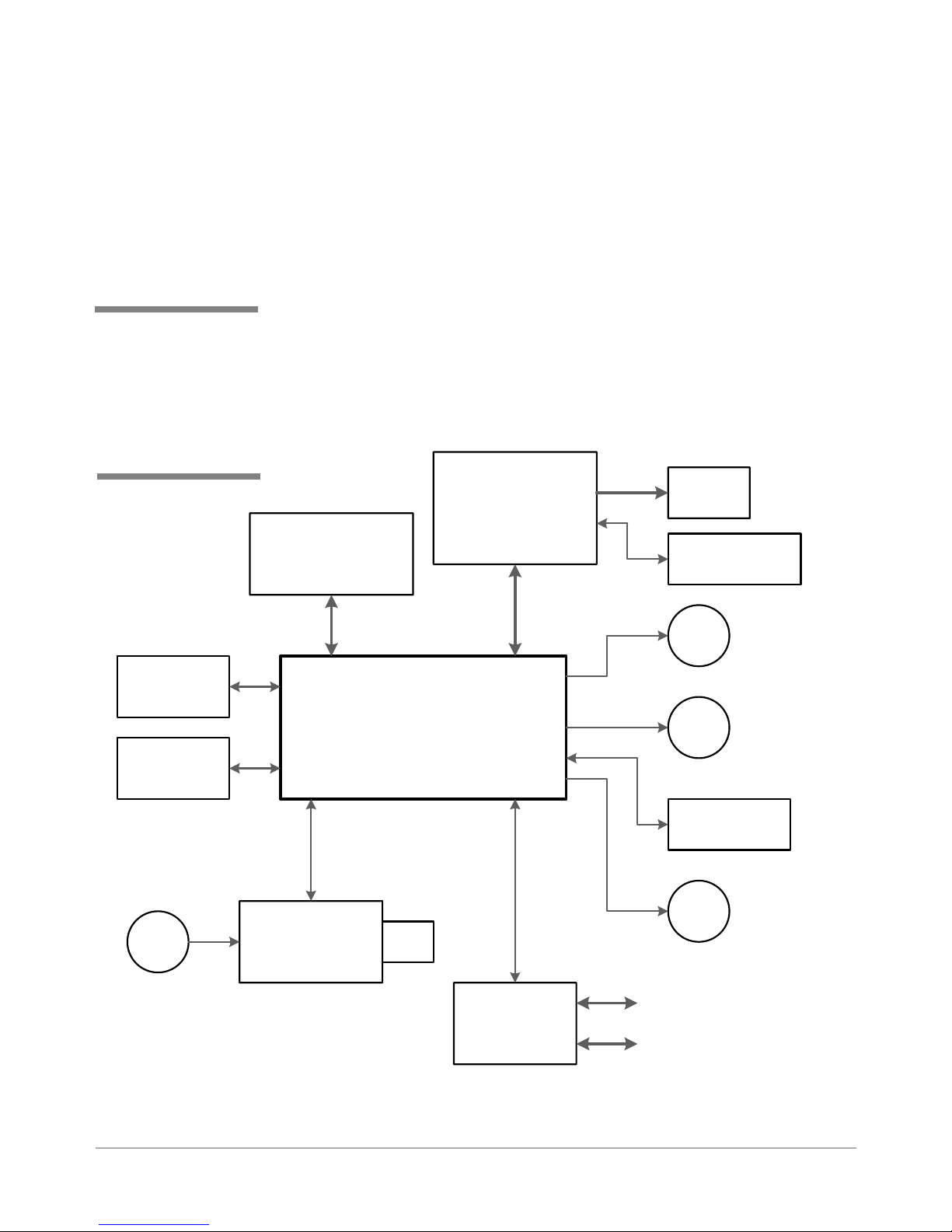

This chapter discusses diagnostics for the DA50S/DA55S (WS51/WS56)

and DA70S/DA75S (WS71/WS76) shuttle head printers.

&RQWURO3DQHO

'LVSOD\%RDUG

:6

3ULQW+HDG

'ULYHU%RDUG

:6>&@

:6>%:@

3ULQW

+HDG

6KXWWOH0RWRU

(QFRGHU

0

6KXWWOH0RWRU

0DLQ&RQWUROOHU%RDUG

0

:6

7UDQVSRUW0RWRU

8QLYHUVDO

$& )DQ

3RZHU,QSXW

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

3RZHU6XSSO\

:6

Figure 4-1 Shuttle Head Printer Block Diagram

,QWHUIDFH

%RDUG

:6

6KDIW

(QFRGHU

0

0DLQWHQDQFH0RWRU

/$1

86%

4-1

Page 28

4 • Troubleshooting/Diagnostics

4.1 Block

Diagrams

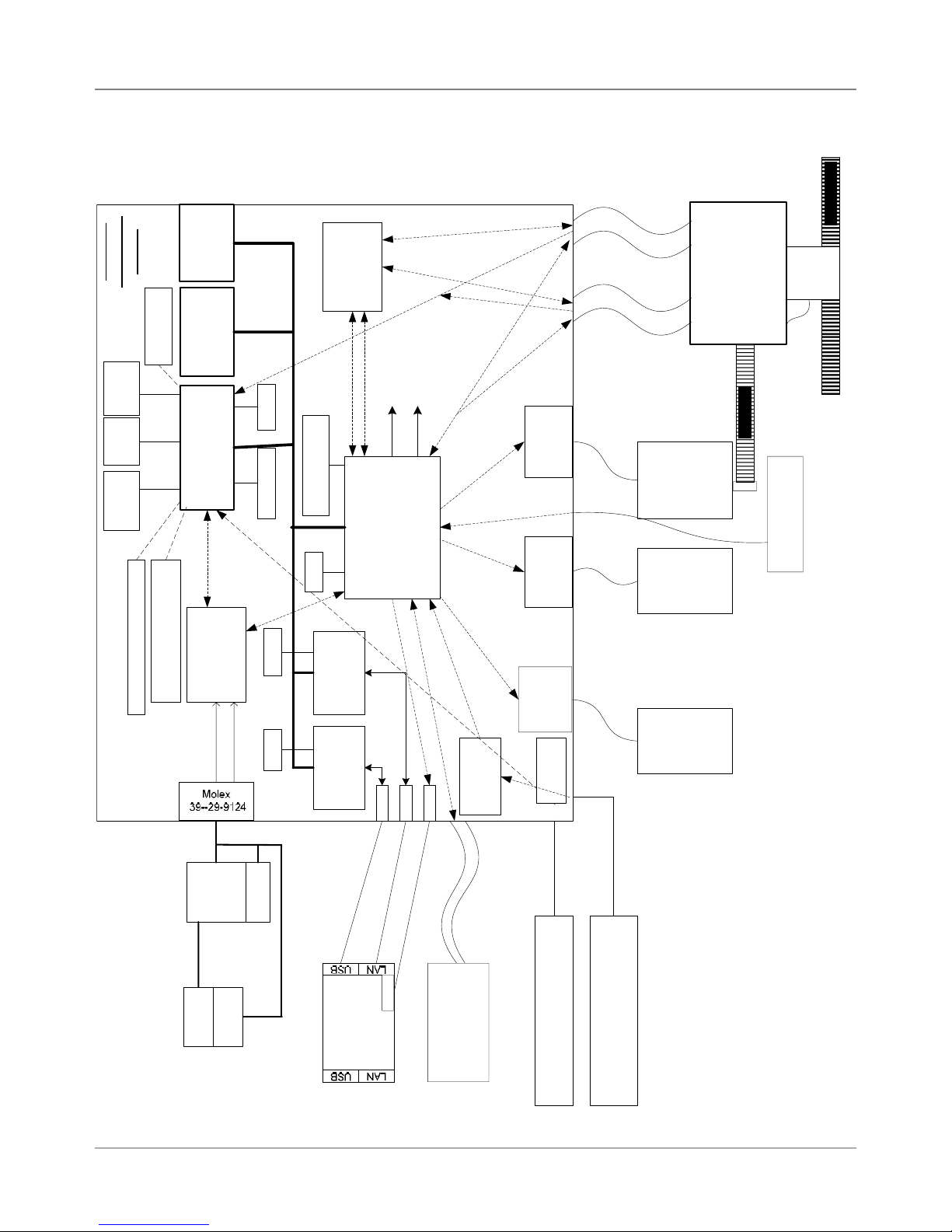

0DLQ%RDUG

:6

..

*UHHQ/('

5HG/('

&LUFXLWU\

5(6(7

6ZLWFK

',3

WHVWRQO\

56

'ULYHU

&RQILJ3LQIRU6:9HUFRQWURO

DQG%&WKUX3DSHUVHQVRU

&RQILJ3LQIRU..

0%,QWHO

0%0LFURQ

+'%3$'9

()-&

)/$6+

07/&0

6'5$0

5HQHVDV6+

&38 6+

(QFRGHU6WULS

2QEDFNRIKHDGFDUULDJH

- - - - - - -

3+'ULYHU

'$7$

ELW

'$7$

ELW

-7$*

0+]

Q7U

&

((3520

-7$*

&3+'

3+'

;&6;/34

$'&LQ

&38

,54

,5/

+%ULGJH

/

'ULYHU

'&%UXVK

:6

0RWRU

6SDUWDQ;/VHULHV

;LOLQ[)3*$

+%ULGJH

6,

'ULYHU

'&%UXVK

:6

0RWRU

3ULQW+HDG'ULYH%RDUG

(QFRGHU

6WULS

7LPLQJ%HOW

6KXWWOH

7UDQVSRUW

+3+('0-

(QFRGHUDWVKDIW

-

)XVH

&RQQHFWRU

99

,(&

5HJXODWLRQIRU

999

/$1&

(WKHUQHW

606&

8/1%

+%ULGJH

'ULYHU

9$

9$

0+]0+]

ELW'DWDELW'DWD

0LG-HW

VXSSO\

3RZHU

)$1

6ZLWFK

3RZHU

,63$

3KLOLSV

86%

86%)XQFWLRQ

(WKHUQHW

%RDUG

86%

-

/('

,QWHUIDFH

$'&6

&K$'

/$1

/('

-

-

)(0$%DFNOLJKW/&'

-

IURP.0DFKLQH

/&'%XWWRQV

8VHU,QWHUIDFH

0$;

-

(PLWWHU237(.23%

,&WR'$

5HFHLYHU237(.23

3DSHU6HQVRU

:6

6WHSSHU

0RWRU

0DLQW

%/2&.',$*5$0

..6<67(0

</HH

3DSHU6HQVRU

Figure 4-2 Shuttle Head Printer Detailed Block Diagram

4-2 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 29

4.2 Main

Controller

Board

Diagnostics

Troubleshooting/Diagnostics • 4

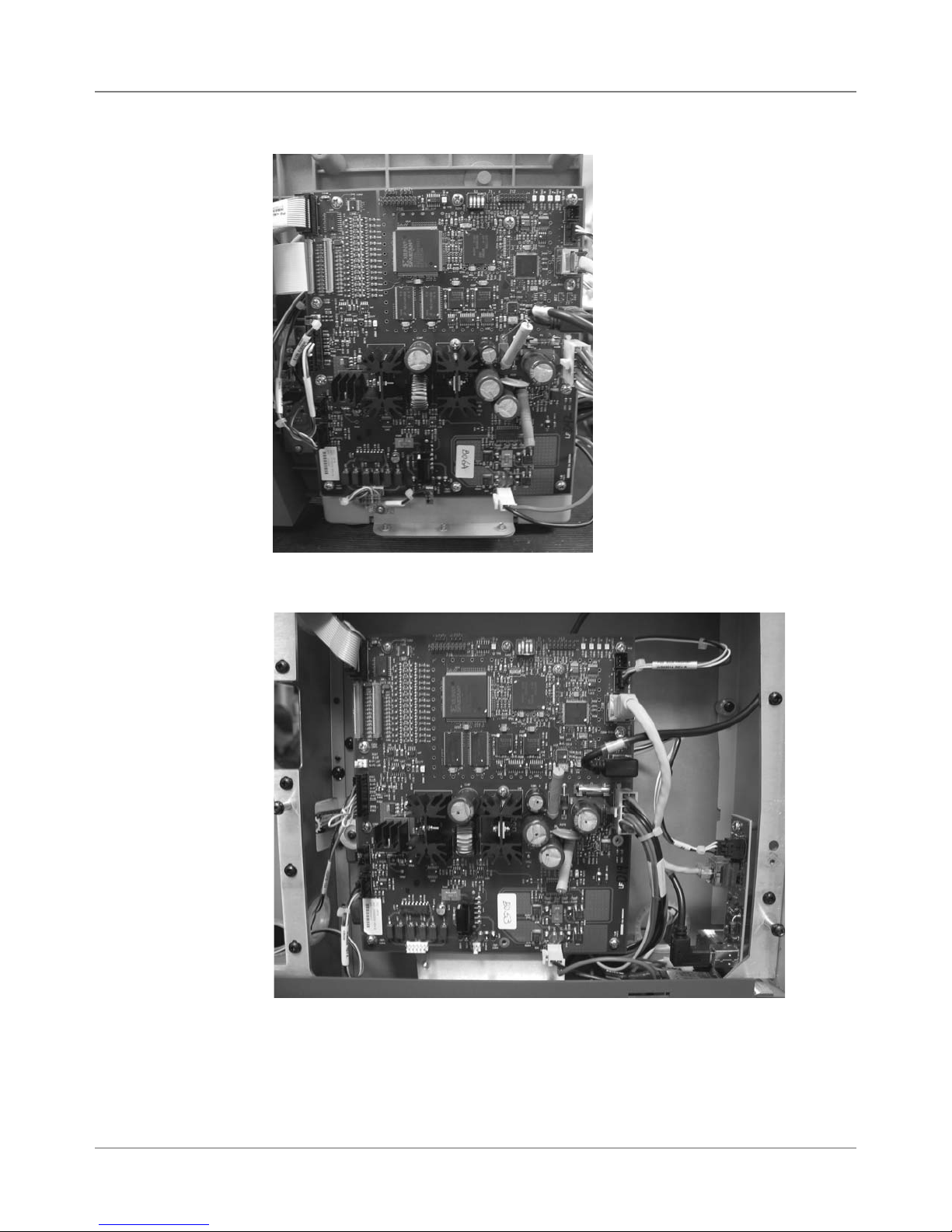

Figure 4-3 Main Controller Board Mounted in DA50S/DA55S Printers

Figure 4-4 Main Controller Board Mounted in DA70S/DA75S Printers

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4-3

Page 30

4 • Troubleshooting/Diagnostics

4.2 Main

Controller

Board

Diagnostics

✍

TIP: Device name

is unique to each

printer’s main board.

Therefore, replacing

an existing main board

in the printer gives that

printer a new device

name.

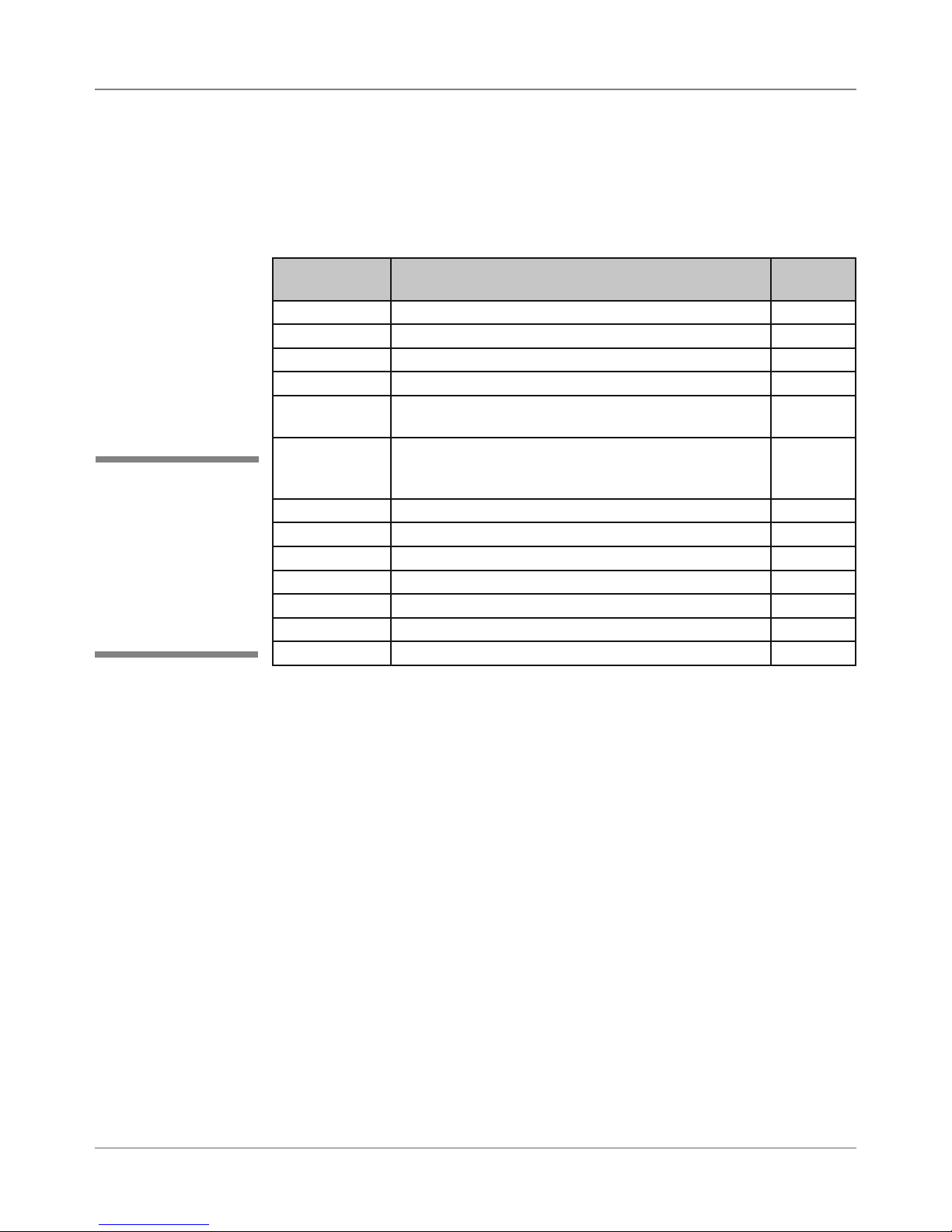

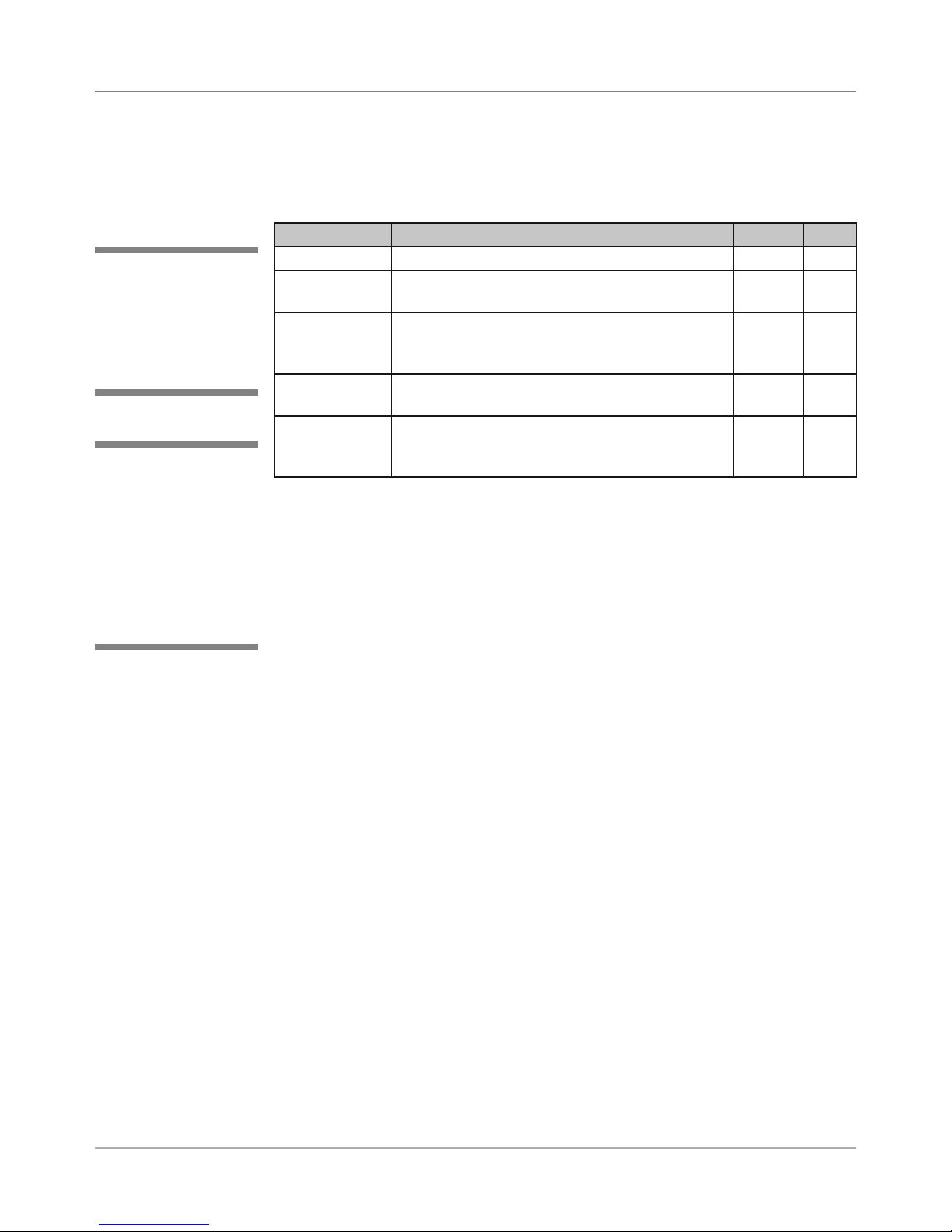

Main Controller Board Voltage Checks

To help your troubleshooting, measure the voltages on the Main Controller

Board (with power applied) using a digital voltmeter (see tables below).

Table 4-1 Main Board Test Points With Voltage Ranges

Voltage With

Normal Range

1.5V ±5% Generated from main board TP32

3.3V ±5% Generated from main board TP31

5V ±5% Generated from main board TP54

6.5V ±5% Input from power supply TP57

12V ±5% Generated from main board (voltage occurs during

15V ±5% Generated from main board (voltage occurs when

40V ±5% Input from power supply TP55

16V ±1.5V Generated from main board (U20) for Transport Motor U20, pin 1

13V ±1.5V Generated from main board (U24) for Shuttle Motor U24, pin 9

Ground Ground for 3.3V measurement TP29

Ground Ground for 1.5V measurement TP30

Ground Ground for 12V, 15V, 40V measurement TP52

Ground Ground for 5V, 6.5V measurement TP53

Where It Comes From/Going Location

TP56

printing or when stopped)

TP56

print heads are moving into maintenance station;

maintenance motor is running)

4-4 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 31

Troubleshooting/Diagnostics • 4

4.2 Main

Controller

Board

Diagnostics

✍

TIP: See Appendix B

- Printer Communications, for troubleshoot-

ing problems relating to

networking and printer

communications.

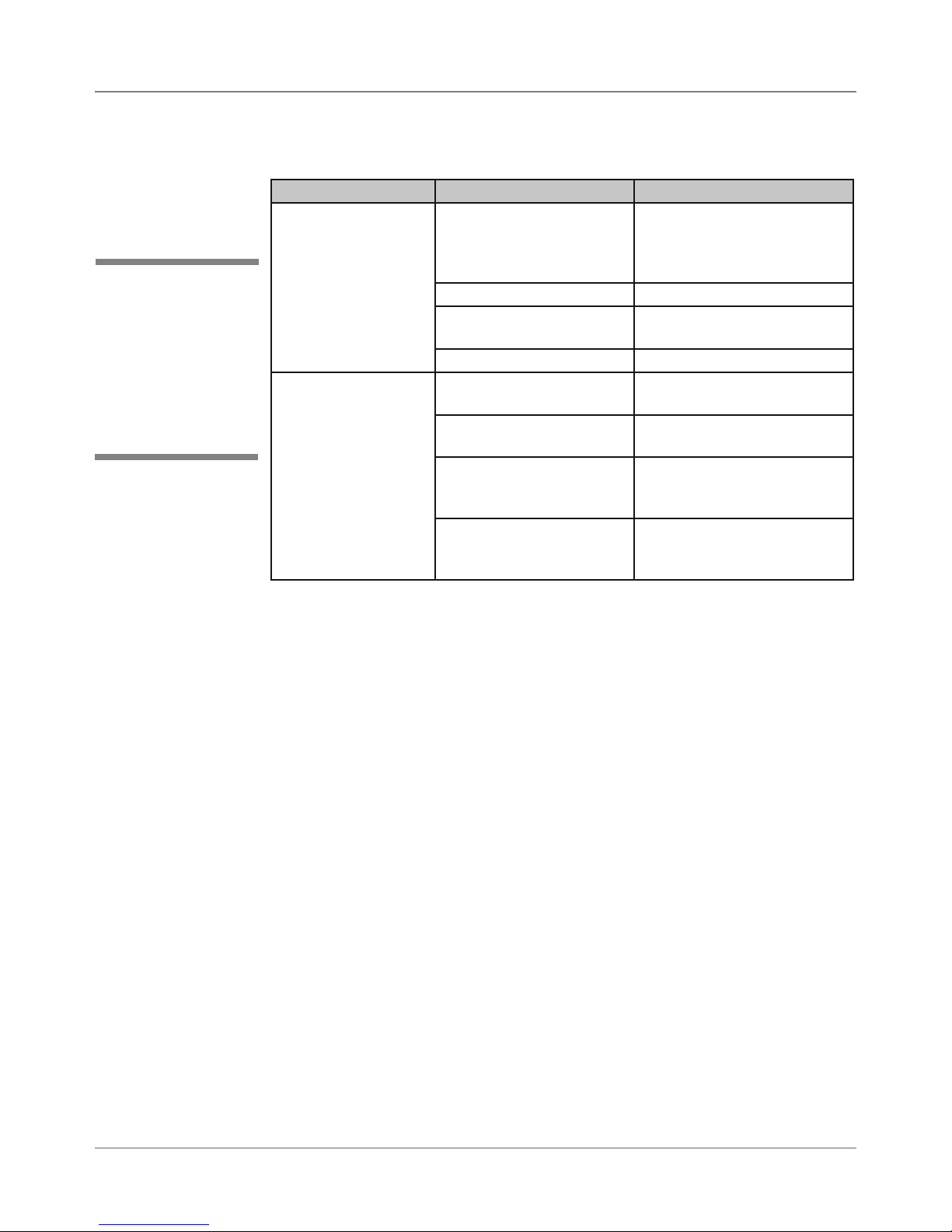

Table 4-2 Main Board LED Designations

LED Color

When

Lit

CR1 Red General purpose software

CR2 Red General purpose software

CR3 Green General purpose software

CR4 Green General purpose software

CR10 Red Transport Motor Current

CR12 Green USB connection detected LED is lit when

CR13 Green Configuration Complete for

CR22 Red Paper Sensor LED lit when

Description Normal State Error State

LED is lit if either

programing (during booting

blinks once)

programing (during booting

blinks once)

programming (during booting blinks once)

programming (during booting blinks once, then three

times, then stays ON)

Limit

the FPGA (Field Programmable Gate Array - U14).

The FPGA receives its

configuration program from

the processor and must

be programmed on every

power up.

the transport mo-

tor or the shuttle

motor is running

LED is lit when

printer is printing

LED not lit LED stays lit

LED is lit LED stays off

LED is lit from

time-to-time

when printer is

printing

USB connection

is detected; blinks

when USB is

active

LED is lit (FPGA

programming is

complete)

sensor is blocked

LED stays lit

(indicates a

board/software

problem)

LED stays

lit under ALL

printer states

(indicates a

board/software

problem)

(indicates a

board/software

problem)

(indicates a

board/software

problem)

LED stays lit (indicates shuttle

motor over-current detected)

LED stays off

after connecting

a USB device

(indicates a bad

USB connection; may be

interface board

in printer, cable

or USB device

on other end)

LED stays off

(indicates a

board/software

problem)

LED not lit

when sensor is

blocked

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4-5

Page 32

4 • Troubleshooting/Diagnostics

4.2 Main

Controller

Board

Diagnostics

J9 (User

Interface)

J3 (Print Head

Driver Board)

J4 (Print Head

Driver Board)

J18 (Paper

Sensor, Emitter)

CR22

CR13

CR1, CR2, CR3, CR4

J22 (LED

for LAN)

J10 (LAN)

CR12

J7 (USB)

J23 (Paper

Sensor, Receiver)

J11 (Encoder

on Shaft)

J6 (Maintenance

Stepper Motor)

U24,

Pin 9

(Shuttle

Motor)

J5 (Shuttle

Motor)

Fuse (1A

Slo-Blo

250VAC)

J13 (Power)

CR10

U20, Pin 1

(Transport

Motor)

J2 (Transport Motor)

Figure 4-5 Main Controller Board With Service-Related Components Called Out

4-6 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 33

Troubleshooting/Diagnostics • 4

4.3

Troubleshooting

Tables

✍

TIP: See Appendix B

- Printer Communications, for troubleshoot-

ing problems relating to

networking and printer

communications.

Table 4-3 Feed/Jam Problems

Symptom Possible Cause Solution

Feed Problems

(intermittent)

Multiple feeds Brake misadjusted Check that brake gap is in

Fails to feed Feed gap incorrect Adjust “H” blocks to thickness

Motor on; main

feed roller doesn’t

turn

Input bin setup incorrect/

Feed Ramp not used

Main feed roller dirty; paper

dust (yellow residue) present

Lead/trail edge sensor dirty Clean sensor and/or run sen-

Severely worn separator tips Replace the separator tips

“H” block separators improperly set

Loose encoder Make sure encoder is attached

Lead/trail edge sensors dirty

or bad

Material out of spec

Loose setscrew on drive train Tighten screw

Drive belt (s) Check for loose or broken belt,

One way bearing bad Rotate drive belt in both direc-

Mechanical clutch broken Manually rotate Feed Rollers

Check side guide, feed angle

and position of material prop.

Adjust the media on the incline

plane of the Feed Ramp.

Check “H” block gap and if tip

of the “H” block is damaged or

misinstalled. Adjust the Wire

Form to the correct height and

to the center of the media.

Clean feed rollers with denatured alcohol

sor calibration

spec.

Adjust separators to thickness

of material

to printer properly

Blow sensors with clean with

air (replace if necessary)

of material

Minimum thickness is 0.003”;

Maximum is 0.150” (DA50/

55S) Maximum is 0.250”

(DA70/75S)

No staples, paper clips, etc., on

media

adjust spring tensioner screw

tions; check that feed roller

turns in one direction. If not,

replace one way bearing.

in both directions. Verify belts

turn only in one direction. Replace Feed Pulley.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4-7

Page 34

4 • Troubleshooting/Diagnostics

4.3

Troubleshooting

Tables

✍

TIP: When working

with skew issues, you

can run the “7. Print

Head Skew” test pattern from the Service

Menu (see Appendix

A - Printer Control

Panel Menus) to

verify the problem has

been fixed (all lines in

test pattern should be

lined up).

Table 4-3 Feed/Jam Problems (continued)

Symptom Possible Cause Solution

Paper out or

Paper jam

Shuttle jam Shuttle hitting material Adjust lever so head height is

Input bin empty Refill

“H” Block separators improp-

erly adjusted

Paper jam Paper path obstructed; clear

Damaged transport shaft

encoder

Print head shaft dirty Clean shaft with alcohol and

Print head holder bushing

clogged with paper dust

Damaged flex cable connecting the print head board and

the main board

Adjust to thickness of material

jam

Replace the transport shaft

encoder

above media.

soft cotton cloth

Remove print head holder and

clean with soft cotton cloth

Replace the flex cable

4-8 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 35

Troubleshooting/Diagnostics • 4

4.3

Troubleshooting

Tables

Table 4-3 Feed/Jam Problems (continued)

Symptom Possible Cause Solution

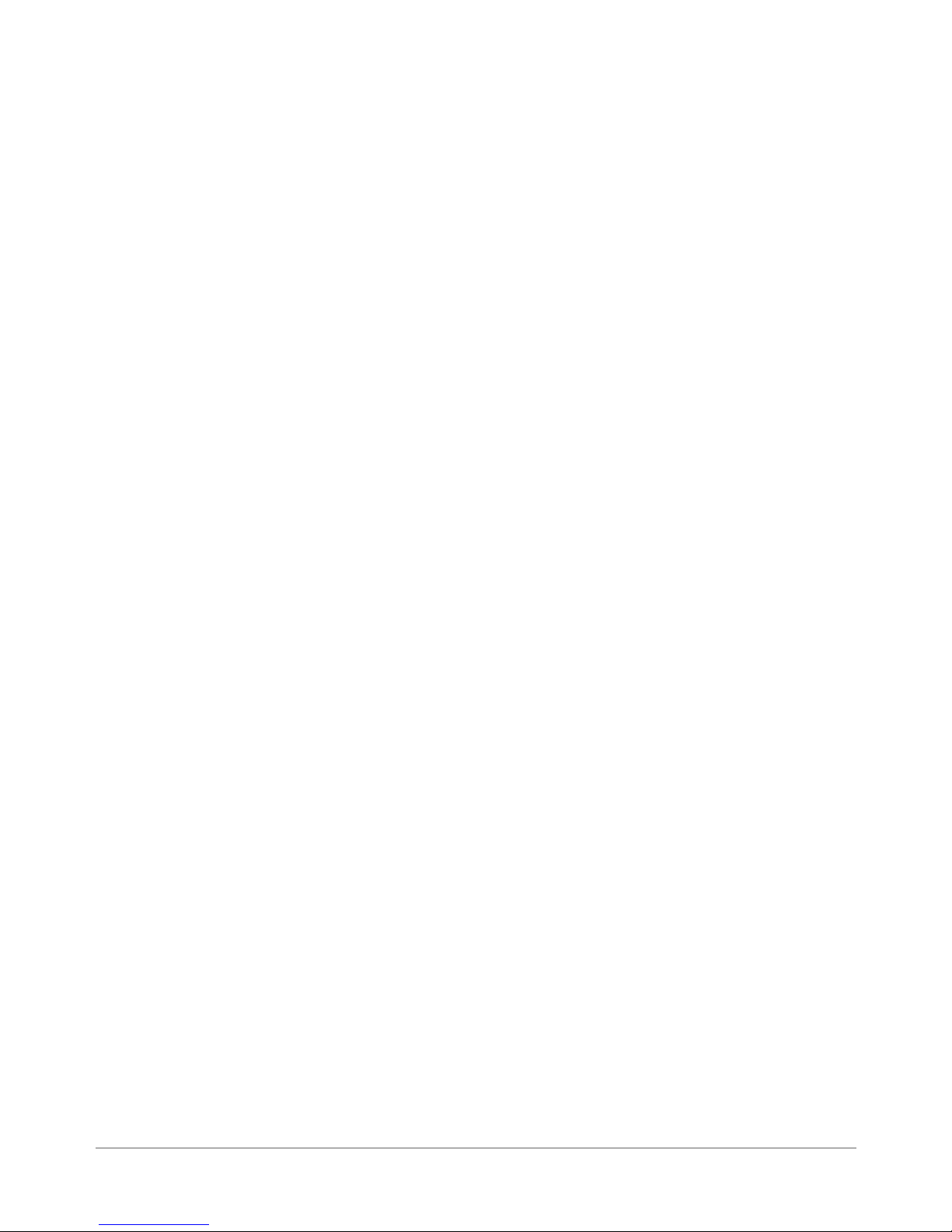

Shuttle head

doesn’t move or

moves slightly/

slowly/erractically,

but the motor

sounds like it is

trying to perform

normal operation.

Damaged flex cable connecting the print head board and

the main board

Set screws on the motor pulley driving the shuttle head

drive belt have come loose

Replace the flex cable

Tighten or replace the set

screws (two per pulley) that

are on the motor collar (see

photos below). To gain access:

1. On DA50S/DA55S, remove

non-operator access cover.

On DA70S/DA75S, open back

plexigalss cover.

2. From back of machine,

move maintenance capping

station (under motor on right)

towards front with a screwdriver or other long object.

3. Slide print head toward center of machine.

4. Locate and tighten set

screws on metal collar.

5. Return print head and capping station to original position

and reassemble cover.

Shuttlehead Motor in

DA50S/DA55S Printers

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Set

screws

Set

screws

Shuttlehead Motor in

DA70S/DA75S Printers

4-9

Page 36

4 • Troubleshooting/Diagnostics

4.3

Troubleshooting

Tables

Table 4-4 Print Quality Problems

Symptom Possible Cause Solution

Ink Print Quality not Sharp

Ink streaking

on Media

Non-Uniform

Print

Quality

Envelope thickness adjustment incorrect

Material out of spec Change to typical white wove bonded

Contaminated mainte-

nance station

Envelope thickness ad-

justment incorrect

Exit idler rollers dirty Clean rollers with water to remove ink

Print head needs purging Run “Purge Print Head” from Setup

The print cartridge is dirty Clean the cartridge

Print Head Holder broken Check the print head holder for

Print head holder Check that flex circuit dimples are not

Multiple print nozzles not

working

Print Head If gap appears in test pattern, replace

Adjust lever to lower print head

Clean the caps and wipe with damp

cloth or paper towel

Adjust lever to raise print head

Menu

broken pins. Replace print head

drive board if pins are broken. NOTE:

When trying to decide if print head

driver board should be replace or

not, run “Test Print Head” from Setup

Menu, replace the ink cartridge with

a new one, then run the print head

test again. If the gaps are consistent

with different ink cartridge, then the

print head driver board needs to be

replaced (when there is no physical

sign that the print head driver board

is damaged).

crushed

Run “Purge Print Head“ from Setup

Menu, then run “Test Print Head”. If

not helpful, swap ink cartridge with

known good one. If the same nozzles

are out, check the ribbon cable going

to print head cartridge (it may have

lost power to nozzles). If cable is fine,

check print head board.

print head.

4-10 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 37

Troubleshooting/Diagnostics • 4

4.3

Troubleshooting

Tables

✍

TIP: See Appendix B

- Printer Communications, for troubleshoot-

ing problems relating to

networking and printer

communications.

Table 4-4 Print Quality Problems (continued)

Symptom Possible Cause Solution

Print is Skewed

(Skew specification +/- 2-1/2

degrees from

bottom edge)

Address Walking (main frame

applications

only)

Gray Print Ink Jet Cartridge empty Ink supply too low, replace ink jet

No Print Ink Jet Cartridge prob-

Unwanted

BOLD type

(main frame

applications

only)

Wiper Assembly bent or

Idler Assembly set wrong

Wire frame (input bin) Adjust wire frame so it is centered

Fence Adjust fence to within 1/16” of mate-

Exit idler rollers Adjust exit idler rollers to within 1/4”

Left Justify Run left justify function in the service

Number of lines of address varies. No Form

Feed used for address

termination

Incorrect address setup Count carriage returns and line feeds

lems

Sensor dirty or bad Blow sensor clean; recalibrate sen-

Power supply voltage out

of spec

Print Head Holder broken Check for crimped or torn flex circuit

Printer Service Station

broken or unplugged

Press TEST button Standard Pitney Bowes address

Do a HEX dump of problem address

Replace wiper assembly when bent.

Level the idler or wiper assembly if

necessary.

with respect to material

rial. Check that fence is square with

re-spect to material.

of the outside edges of the material

menu

Check Line Termination CR-

CR,LF=LF. Address Termination

should be Form Feed.

of address field; should match address setup

cartridge

Purge ink jet cartridge. Clean car-

tridge with soft cotton cloth and

water.

Change to a known good cartridge

sor via Test Paper Sensor on Service

Menu on LCD (see section A.4);

replace if necessary

Check voltages on main board (see

section 4.2)

Check service station connector.

Verify that the service station moves

when printer is first switched on

should print

Examine address for ESC sequence

(1B) before the start of the line.

Turn off bolding in software and/or

turn bold selection in printer menu

OFF

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4-11

Page 38

4 • Troubleshooting/Diagnostics

4.3

Troubleshooting

Tables

Table 4-5 Address/Barcode Printing Problems

Symptom Possible Cause Solution

Address too high

error

Address too low Software margin; lead

Barcode (lower

right) wandering up

and down

No barcode No clear zone (5/8”

Software margin; lead

edge sensor “seeing

through” paper

Paper size used

doesn’t match the

layout size

Sensor is dirty or bad Blow sensor clean; recalibrate

The sensor may

misread if during the

printing process the

envelope trail edge

covers the paper sensor half-way.

edge sensor “seeing

through” paper

Paper size used

doesn’t match the

layout size

Sensor is dirty or bad Blow sensor clean; recalibrate

Belt tension not set

properly

minimum distance)

Invalid ZIP Code Check ZIP Code

Top line of address is above edge

of material. Move address location

down. Adjust lead edge sensor.

Adjust the layout size in the control

panel menu

sensor via Test Paper Sensor on

Service Menu on LCD (see section

A.4); replace if necessary

By printing something when the

paper sensor is half-covered, it

causes the sensor reading to flicker

during the process. Move the text

or graphics that is close to the trail

edge of the envelope up or down

slightly so that the sensor is either

covered or uncovered, not half covered when the content is printed.

The address is below the bottom

edge of the material. Increase the

bottom edge margin. Adjust lead

edge sensor.

Adjust the layout size in the control

panel menu

sensor via Test Paper Sensor on

Service Menu on LCD (see section

A.4); replace if necessary

Check main drive belt tension adjustment (see Adjustments section)

5/8” required between last line of

address and bottom edge of material

4-12 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 39

Troubleshooting/Diagnostics • 4

4.3

Troubleshooting

Tables

✍

TIP: Device name

is unique to each

printer’s main board.

Therefore, replacing

an existing main board

in the printer gives that

printer a new device

name.

Table 4-6 Miscellaneous Problems

Symptom Possible Cause Solution

LCD display shows

solid line of erroneous

characters

Nothing happens

when power is

switched on

Power supply problem Check J13 (provides power

to board from power supply).

Replace Power Supply if

necessary.

Bad Main Board Replace main board

Cable loose at the display

or motherboard

Bad LCD display board Replace the display board

No power to AC inlet of

printer

J13 on Main Board discon-

nected

Fuse is blown on Main

Board

Fuse blown in Power Supply

Check P9 cable to LCD dis-

play is secured at both ends

Check power cord and AC

outlet to which it is plugged in

Connect J13 (provides power

to board from power supply)

Replace fuse (Slo Blo 1A

250V) on the mainboard right

next to J13

Replace power supply (no

service replaceable parts

inside)

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4-13

Page 40

4 • Troubleshooting/Diagnostics

4.4 Printer

Error Codes

✍

TIP: Error codes are

internal to the firmware

and not displayed on

the LCD. Only the textual description of the

error is displayed.

✍

TIP: The printer firmware

errors are categorized

into different system error types:

• Unknown error (0)

• Paper transport error (1)

• Shuttle error (2)

• EEPROM failure (3)

• Out of memory error (4)

• Color ink out (5)

• Black ink out (6)

Table 4-7 Printer Error Codes

Error Text System

Error

Unknown Error 0 Restart the printer

Paper Jam 1 1 Clear the jam and put

Out of Paper 1 2 Load the feeder with

Address too

High

Paper Sensor

Failure

Sensor Blocked 1 6 Sensor is dirty or media

Sensor Dirt 1 7 Sensor is dirty

Shuttle Error 2 0 Make sure shuttle can

Shuttle Jam 2 1 Clear jam and put the

Over Current 2 2 Clear the jam and put

EEPROM

Failure

File Print Error Not being displayed

Eject Error Not being displayed

Out of Memory 4 Restart the printer

No Color Ink

(Color printer

only)

No Black Ink 6 Com-

System Shutdown

1 3 Load the bigger media

1 5 Clean the sensor and

3 Put the printer back on-

5 Com-

Error

Code

posite

posite

N/A Not an error

Possible Resolution Comments

the printer back online

paper and put the printer

back online

This is due to the

size

run sensor calibration

is blocking the sensor.

Clear the sensor and put

the printer back online

move freely by hand

and put the printer back

online

printer back online

the printer back online

line to see if printer continues to run properly. If

not, EEPROM hardware

problem. Service call

Change the ink cartridge

Change the black ink

image printed on

paper is bigger than

media it is printed

on

Detected as shuttle

jam

currently

currently

4-14 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 41

Troubleshooting/Diagnostics • 4

4.5 Print

Samples for

Troubleshooting

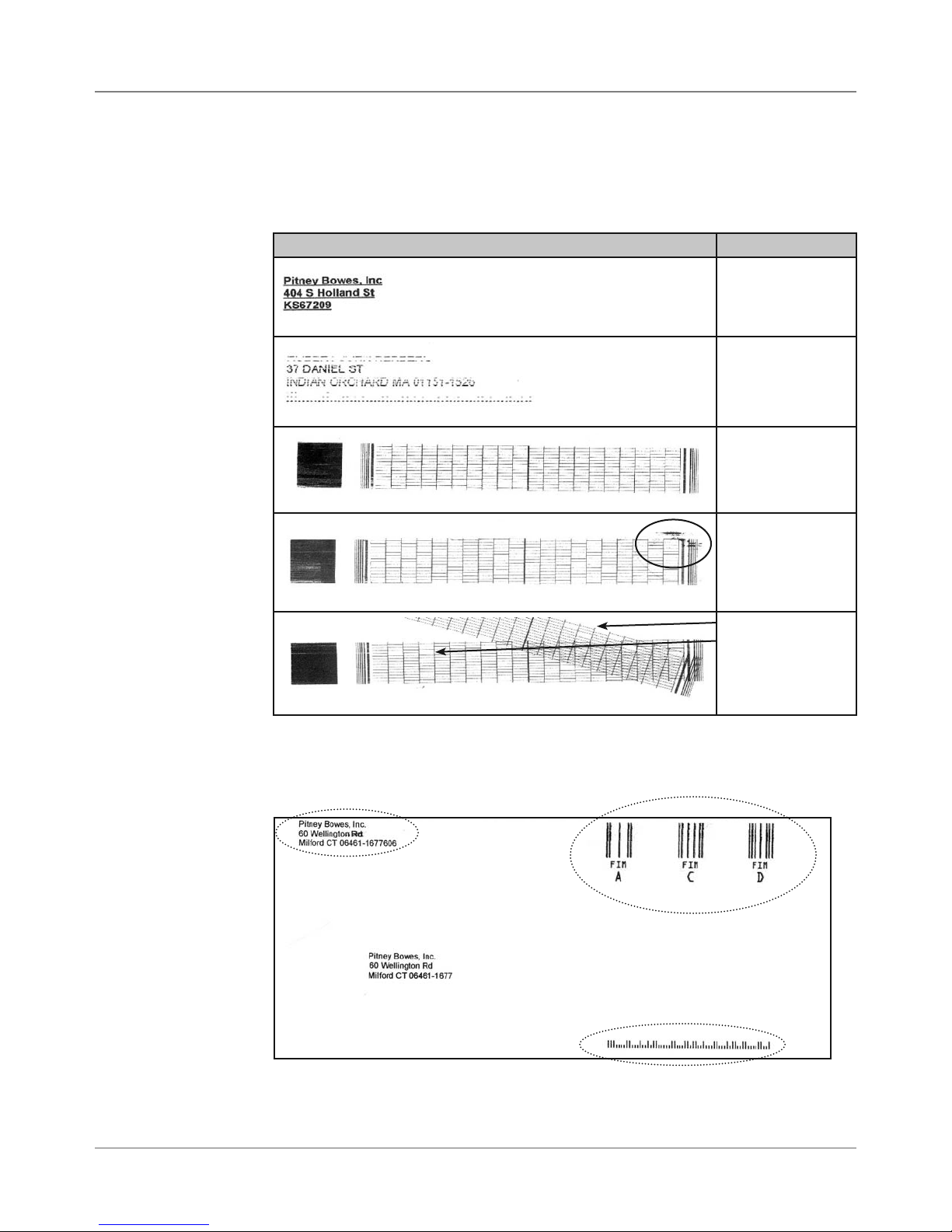

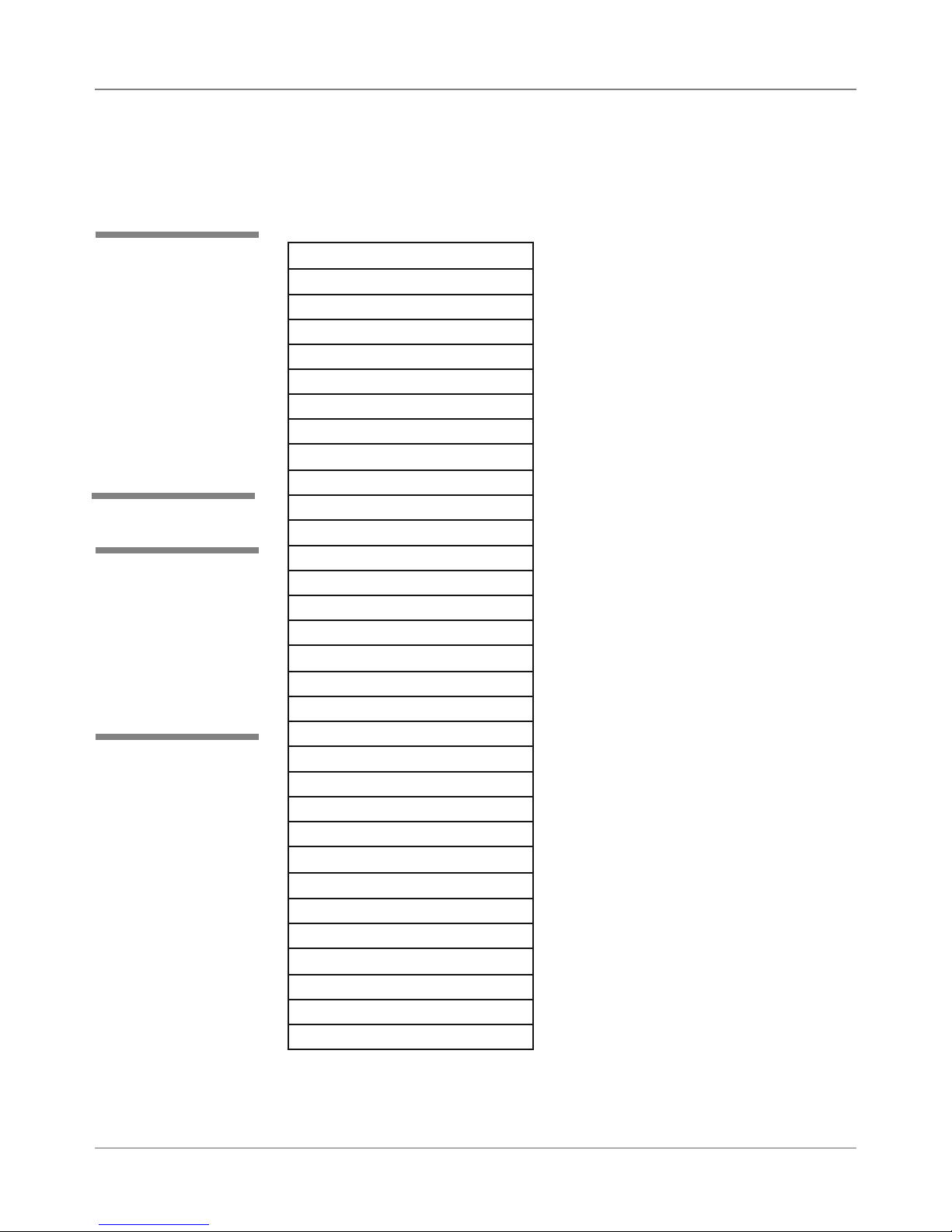

The print samples below are provided to help troubleshoot printing problems

you may encounter.

Table 4-8 Sample Prints

Sample Print What It Indicates

Good printing

Poor printing due

to low ink (replace

ink cartridge)

Good test print

Smudging (need

to purge print

head)

Return Address

A. Skew

B. Misfiring head

(missing points,

do purge print

head)

All 3 versions of FIM

Barcode (USPS)

Figure 4-6 Sample Envelope Printed with a Variety of Options

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Postnet Barcode (USPS)

4-15

Page 42

4 • Troubleshooting/Diagnostics

4-16 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 43

5 • Removal & Replacement

5.1 List of

Procedures

This chapter contains parts removal instructions and is divided into two sections; one for the DA50S/DA55S and one for the DA70S/DA75S printers.

Tools Required

• Ball end square drives. Sizes used:

#0 for 4-40 screws

#1 for 6-32 screws

#2 for 8-32 screws

NOTE: Phillips head screwdrivers of the same size work but not as well if

you are at an angle.

• Allen wrenches (imperial standard sizes). NOTE: The extra small encoder Allen (.050 inch) is taped inside each printer.

DA50S/DA55S (WS51/WS56) Parts Removal

5.2 Covers ...................................................................................... 5-2

5.3 Display/Keyboard ..................................................................... 5-3

5.4 Main Processor Board/Grounding Sheet Assembly ................. 5-3

5.5 USB/Ethernet Input Board ........................................................ 5-4

5.6 Power Supply ........................................................................... 5-5

5.7 Paper Transport Motor/Belt ...................................................... 5-7

5.8 Sensor ...................................................................................... 5-9

5.9 Feed Roller Assembly ..............................................................5-11

5.10 Encoder and Operator Side Drive Belt ................................. 5-13

DA70S/DA75S (WS71/WS76) Parts Removal

5.11 Covers .................................................................................. 5-15

5.12 Display/Keyboard ................................................................. 5-17

5.13 Main Processor Board/Grounding Sheet Assem. ................. 5-17

5.14 USB/Ethernet Input Board .................................................... 5-18

5.15 Power Supply ....................................................................... 5-18

5.16 Feed Roller Assembly............................................................ 5-19

5.17 Motor Drive Belts and Main Motor ........................................ 5-21

5.18 Exit Roller ............................................................................. 5-23

5.19 Sensor .................................................................................. 5-23

5.20 Shuttle Head Motor, Print Head, Shuttle Drive ..................... 5-24

5.21 H-Block Tip ........................................................................... 5-25

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

5-1

Page 44

5 • Removal & Replacement

DA50S/DA55S (WS51/WS56) Parts Removal

5.2 Covers

1. Remove chrome paper stand and metal side guide.

2. Lift up smoked plastic output cover. Unfasten two phillips screws from

non-operator side cover (see photo below). Smoked output cover comes

off with side cover. Lift up printer slightly to completely remove side cover

(one printer foot is captured by the cover).

3. Unfasten two phillips screws from operator side cover (see left photo below). Lift up printer slightly to completely remove side cover (two printer

feet are captured by the cover). Unfasten display/keyboard cable (gray

P9) and the green grounding cable (see right photo below) that attaches to

board mounted on cover.

Green

Ground

P9

5-2 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 45

Removal & Replacement • 5

DA50S/DA55S (WS51/WS56) Parts Removal

5.3 Display/

Keyboard

5.4 Main

Processor

Board/

Grounding

Sheet

Assembly

1. Unfasten operator side cover (two phillips screws). Lift up printer slightly

to completely remove cover (two printer feet are captured by the cover)

2. From behind cover, unfasten display/keyboard cable (gray P9) and the

green grounding cable (see photo below).

3. Carefully peel back display overlay (from corner) on front of display.

4. Remove three phillips head screws (circled below) from underneath and

remove board from cover.

Display/Keyboard Board

(screw locations in circles)

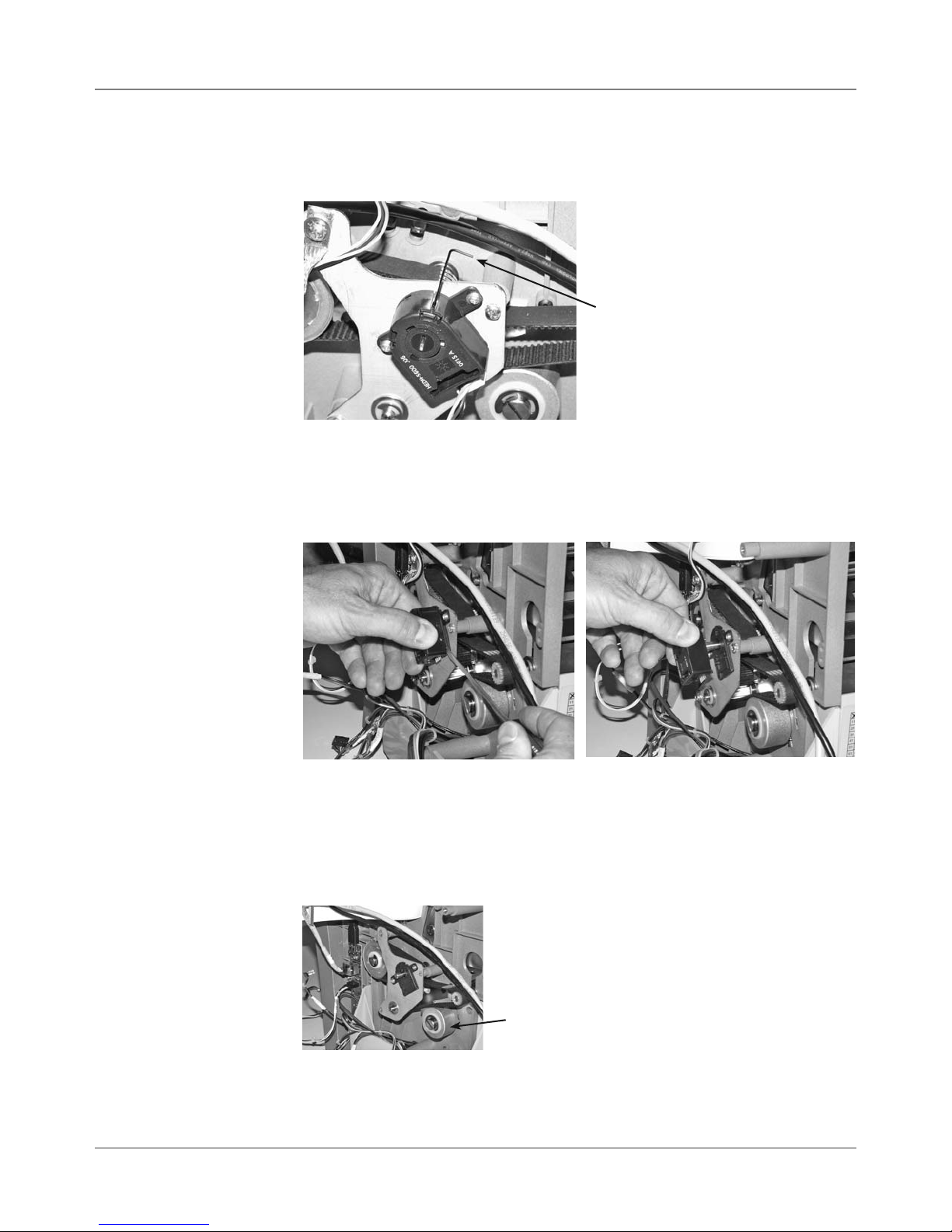

1. Remove operator side cover (see section 5.2).

2. Remove all cables. Starting clockwise from top right: P22, P10 (LAN),

P7 (USB), P13, P2 (red/white motor cable), P5, P6, P11, P23, P18, P3

(white ribbon cable), P4 (2nd white ribbon cable if color printer), and P9.

3. Remove 11 phlllips screws (circled in left photo below) holding board to

shield and remove board.

4. Remove grounding strap from bottom left corner and three bottom

screws (circled in right photo below) to remove grounding sheet.

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Main Processor Board

(screw locations in circles)

Grounding Sheet Under

Main Processor Board

(screw locations in circles)

5-3

Page 46

5 • Removal & Replacement

DA50S/DA55S (WS51/WS56) Parts Removal

5.5 USB/

Ethernet Input

Board

1. Remove operator side cover (see section 5.2).

2. Remove P3, P4, P5 from USB/Ethernet board.

3. Remove two phillips screws fastening board to chassis.

USB/Ethernet Board

(screw locations in circles)

5-4 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 47

Removal & Replacement • 5

DA50S/DA55S (WS51/WS56) Parts Removal

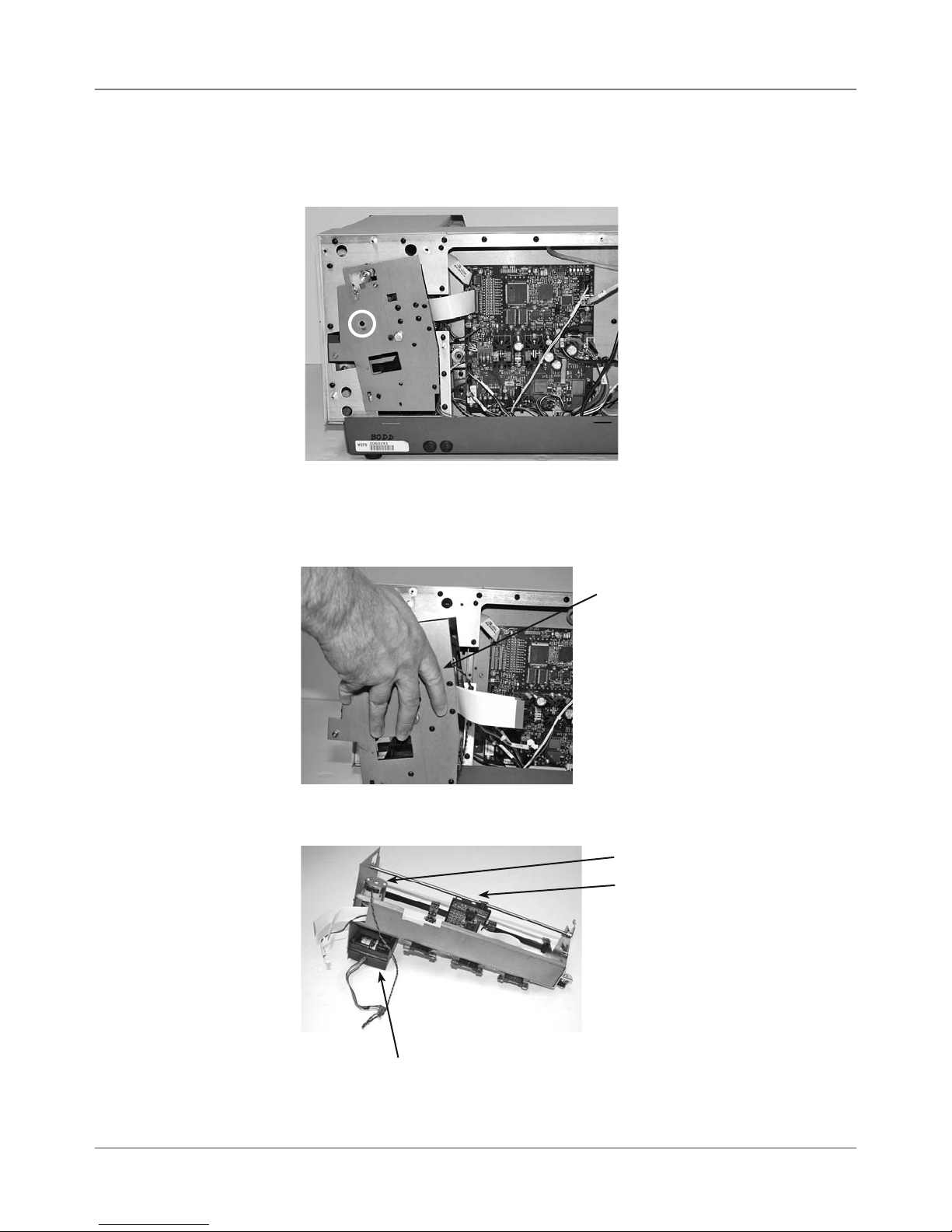

5.6 Power

Supply

1. Remove operator and non-operator side covers (see section 5.2).

2. Remove main processor board/grounding sheet assembly (see section

5.43A).

3. On non-operator side, remove P18, P5, and P6 junction connectors.

4. Remove ground strap (furthest on the right with black sleeve), see photo.

Ground

Strap

5. Remove three main power cables to AC inlet. Use screwdriver or needle

nose pliers to pry off each (see photo below).

Using Screwdriver

to Pry Cables from

Spade Lugs (3)

Spade Lug

6. Remove two phillips screws holding blue side chassis to bottom gray tray

(see photo below). Do for both sides of machine (four screws total).

Side Chassis Attachment

to Gray Tray (screw locations in circles)

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

5-5

Page 48

5 • Removal & Replacement

DA50S/DA55S (WS51/WS56) Parts Removal

5.6 Power

Supply

(continued)

7. Lift and remove top chassis assembly from bottom gray tray.(photo)

Top Chassis

Bottom Tray

8. Remove the four screws holding captive the power supply feet.

Close-up of One

Screw Holding

Power Supply

Feet (in circle)

9. Remove power supply assembly (includes fan, housing and cables).

Power Supply

Assembly

5-6 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

Page 49

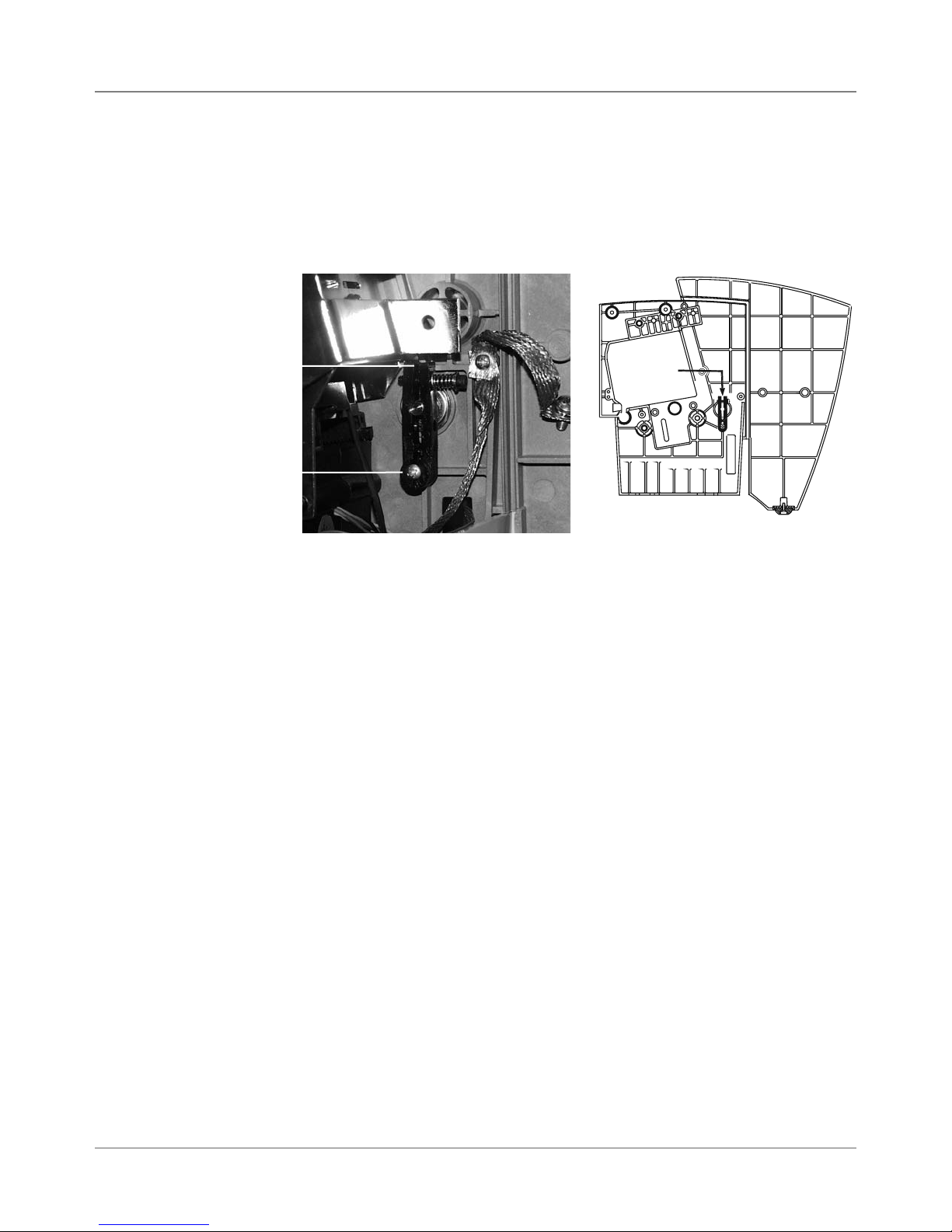

Removal & Replacement • 5

DA50S/DA55S (WS51/WS56) Parts Removal

5.7 Paper

Transport

Motor/Belt

1. Remove operator and non-operator side covers (see section 5.2).

2. Remove main processor board/grounding sheet assembly (see section

5.4).

3. On non-operator side, remove P18, P5, and P6 junction connectors.

4. Remove ground strap (furthest on the right with black sleeve), see photo.

Ground

Strap

5. Remove three main power cables to AC inlet. Use screwdriver or needle

nose pliers to pry off from each spade lug (see photo below).

Using Screwdriver

to Pry Cables from

Spade Lugs (3)

Spade Lug

6. Remove two phillips screws holding blue side chassis to bottom gray tray

(see photo below). Do for both sides of machine (four screws total).

Side Chassis Attachment

to Gray Tray (screw locations in circles)

DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

5-7

Page 50