Page 1

Supervisor Guide

SV 50220, Rev. B

December 1995

Page 2

TRADEMARKS

Mail Center 2000™, PARAGON™, SoftKey™, Weigh on the Way™, W-O-W™,

Para-Text™, Data Trail™ and Postage by Phone

®

ZIP Code

and ZIP+4® are registered trademarks of the U.S. Postal Service.

®

are trademarks of Pitney Bowes Inc.

FCC Compliance - PARAGON™ Mail Processor

"Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense."

"Shielded cables must be used with this unit to insure compliance with the Class A limits."

FCC Compliance - E100 Series Postage Meter

"NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help."

Canadian DOC Compliance

"This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n'emet pas de bruits radioélectriques depassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada."

Page 3

Contents

Overview

Introduction ---------------------------------------------------------------Supervisory Functions ---------------------------------------------------- 1-1

Site Setup

Overview ------------------------------------------------------------------Modify Site Setup --------------------------------------------------------- 2-2

Set Up Operator IDs ------------------------------------------------------ 2-6

Change Operator Info ------------------------------------------------- 2-7

Add Operator----------------------------------------------------------- 2-7

Remove Operator------------------------------------------------------ 2-7

Set Default Class or Acct./Class ---------------------------------------- 2-8

Set Up Preferred Classes ------------------------------------------------- 2-9

Contents

1-1

2-1

Job Presets

Overview -------------------------------------------------------------------

3-1

Saving a Job Preset-------------------------------------------------------- 3-2

Removing a Job Preset --------------------------------------------------- 3-2

Choosing a Job Preset ---------------------------------------------------- 3-3

Job Preset Configuration Table------------------------------------------ 3-3

Troubleshooting. ------------------------------------------------------------- 4-1

Power Up Failure---------------------------------------------------------- 4-1

Troubleshooting Tables -------------------------------------------------- 4-2

Calling for Service ---------------------------------------------------- 4-2

Control Panel Checklist ---------------------------------------------- 4-3

Mail Flow and Paper Handling -------------------------------------- 4-4

Postage Meter ---------------------------------------------------------- 4-5

Postage Printing ------------------------------------------------------- 4-6

Power-on and System Initialization--------------------------------- 4-7

Tape Generation ------------------------------------------------------- 4-8

Weigh-on-the-Weigh

TM

----------------------------------------------------4-8

Glossary . ------------------------------------------------------------------------ 5-1

Options. -------------------------------------------------------------------------- 6-1

Appendix: Operator Skills List ------------------------------------------ A-1

iii

Page 4

Overview

Introduction

This guide shows you how to configure the Mail Center 2000™ PARAGON™ Mail Processor to meet the needs of your mailroom. Before configuring your system, you must familiarize yourself with the operation of the

PARAGON™ by reading the PARAGON ™ Operating Guide (SV50219)

supplied with the system.

After you have read the PARAGON™ Operating Guide, use this

PARAGON ™ Supervisor Guide as a hands-on guide for understanding

how to perform the various configuration procedures.

You may also use this binder to hold the guides for the options you have

purchased with your PARAGON™. Place the guides after section 6,

"Options".

Overview • 1

Supervisory Functions

Because you have a Supervisor level access, you can access the specific

functions which allow you to configure the system. An assigned ID ensures

that no one else can enter the system to configure it.

There are two ways in which you can configure the system. First, you "set up"

the system in a general sense, assigning operator ID's, configuring for scales,

printers, Postage By Phone

section of this guide explains how to do this.

After you perform the Site Setup functions, you may want to create and save

sets of parameters (account ID, class, sealer mode, postage value, etc.), called

"Job Presets", which meet the individual requirements for various runs of

mail. The Job Presets section of this guide explains how to do this.

Note that you may save your Site Setups onto a disk (for later use), but not

your Job Presets. Instructions for saving and restoring your Site Setups are

included in section 8 of the PARAGON Operating Guide.

In addition to configuring the system, you need to be familiar with solutions to

problems that may occur while operating the system. The Troubleshooting

section guides you to a solution for your problem.

®

, setting meter parameters, etc. The Site Setup

Note: Labels, keys and screen titles are printed here as they are in the

PARAGON™ Operating Guide. SoftKey™ labels are placed in single quotes

(for example, 'Change Account'), keyboard keys are placed in angle brackets

(for example, <ENTER>) and screen titles are capitalized (for example, MAIL

RUN).

1-1

Page 5

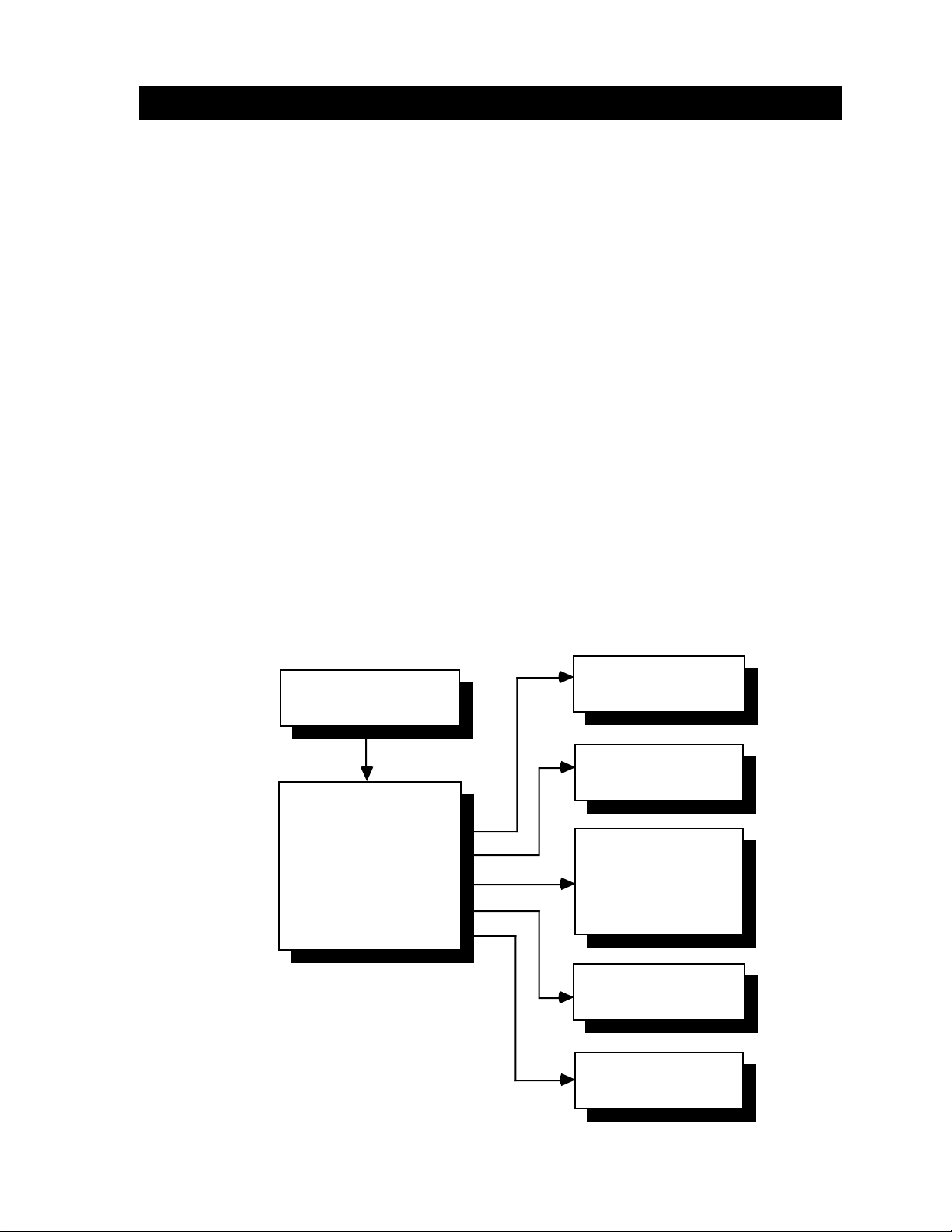

Site Setup

Site Setup Selections

To set up the PARAGONTM to meet your specific mailing demands, access the

MAIL RUN screen, then select 'Site Setup'.

The SITE SETUP SCREEN displays the five selections listed below. For a

description of the selections and procedures, turn to the appropriate section on

one of the following pages.

• 'Modify Site Setup'

• 'Set Up Accounting' (If accounting is installed, see the Data Trail

• 'Set Up Operator IDs' (if you have chosen to require operator log-ons

• 'Set Default Class' or 'Set Default Acct./Class' (if accounting is

Site Setup • 2

Accounting Operating Guide for selections and procedures.)

through the 'Modify Site Setup' screens)

installed)

• 'Set Up Preferred Classes'

The flowchart below shows the sequence of screens and SoftKeysTM used to

make your selection.

MAIL RUN

'Site Setup'

SITE SETUP

'Modify Site Setup'

'Set Up Accounting'

'Set Up Operator IDs'

'Set Default Acct./Class'

'Set Up Preferred Classes'

View or modify the

system parameters

Set up or modify

accounting parameters

Enable/Disable

Operator IDs

If enabled, you can add

or delete operators and

modify operator info

Specify a default

account and/or class

Specify nine commonly

used carrier/class

combinations

2-1

Page 6

Site Setup • 2

Until ID's have been assigned and enabled (see"Set Up Operator IDs") any

user can access all functions, including "Modify Site Setup". After Operator

IDs are assigned and enabled, the screen prompts you for the Supervisor ID.

See the PARAGON

your Diagnostics/Utilities disk.

Modify Site Setup

Use the 'Modify Site Setup' selection to set the system parameters listed below.

After you select 'Modify Site Setup', the screens used to set the parameters

come up in the order listed below.

Each of the following screens offers you choices. You press the desired

SoftKeyTM or, if the system prompts you for data, enter the data using the

keyboard. If you press the wrong key or choose the wrong option, you may fix

it. The changes you make or options you choose do not become effective until

you press <ENTER>. After you press <ENTER>, the change is made effective

and the next screen appears.

TM

Operating Guide to save or restore a site setup using

Time

When this screen displays, you can enter the time (HH:MM). After entering

the time, the screen prompts you to select AM or PM.

Scale Configuration

The Scale Configuration screen presents three modes you must set if you have

an external scale, A300, A305, or Carrier Management System. Select to end

or not end the transaction, have a long or short trip timeout, and to obey or not

obey the disable meter mode, according to which device you have.

SELECTION End Transaction

Mode

DEVICE

A300, A305 DON'T END

TRANSACTION

All Carrier

Management Systems

Scales DON'T END

END TRANSACTION SHORT Not Applicable

TRANSACTION

Trip Timeout Disable Meter Mode

LONG OBEYor DON'T OBEY

(Recommend "OBEY",

but set to your

requirement.)

LONG DON'T OBEY

2-2

Page 7

Site Setup • 2

Printer Configuration

You need to let the system know the type of printer attached to it: None, 80

column or 132 column. If you select 'NONE', the 'View Reports' selection

displays on the MAIL RUN screen; otherwise, the 'Print/Cancel Reports'

selection displays on the MAIL RUN screen.

Manual Postage-by-Phone

®

When this screen displays, you can change the default reset value and the

Postage by Phone

Auto Postage-by-Phone

®

account number.

®

If you have Auto Postage-by-Phone®, when this screen displays you can

change the account number, change the dialing prefix, and choose pulse or

tone dialing.

USPS Intra-BMC Range

When this screen displays, you can change the range of a valid ZIP Code for

your United States Postal Service (USPS) Intra-BMC (Bulk Mailing Center)

area. The codes are initially set up at installation by the Pitney Bowes Customer Service Representative to the codes in effect at that time. If the ZIP

Codes for your Intra-BMC area change, you need to add or delete codes as

required.

ZIP Code ranges are entered as the first three digits of the codes, lowest code

to highest code (for example, 080-087). Leading zeros must be entered. For a

single ZIP Code, enter the three digits twice to complete the range entry (for

example, 127-127).

NOTES

For these changes to become effective, the system power must be turned off

and on again after the completion of site setup.

After selecting any class containing "Inter" and entering a ZIP Code in your

Intra-BMC area, "Inter" automatically changes to "Intra" in the "Class" field.

UPS Intra-state Range

When this screen displays, you can change the range of a valid ZIP Code for

your United Parcel Service (UPS) Intra-state area. In addition, because UPS

Intra-state rates may have a delayed approval/effective date in certain states,

you must enter the proper "Intra-state Code" to assure that the appropriate

rates are applied. The codes are initially set up at installation by the Pitney

Bowes Customer Service Representative to the codes in effect at that time. If

2-3

Page 8

Site Setup • 2

the ZIP Codes for your Intra-state area change, you need to add or delete

codes as required. Also, when UPS rate changes occur, you receive update

rate disks with information on any change to the Intra-state Code.

ZIP Code ranges are entered as the first three digits of the codes, lowest code

to highest code (for example, 080-087). Leading zeros must be entered. For a

single ZIP Code, enter the three digits twice to complete the range entry (for

example, 127-127). The "Intra-state Code" tells the rate manager which UPS

Intra-state rate table to use (0=use latest rates, 1=use previous rates, 2=use

rates two revisions back, etc.).

For these changes to become effective, the system power must be turned off

and on again after the completion of site setup.

After selecting any class containing "Inter" and entering a ZIP Code in your

Intra-state area, "Inter" automatically changes to "Intra" in the "Class" field.

Station ID

The Station ID is used to identify a specific Mail Processor when used as part

of an accounting system. When this screen displays, you can enter a station ID

of one or two digits (0 thru 99). The Station ID initially defaults to a 0.

NOTES

Timeout

A timeout closes the transaction (if accounting is used) and logs off the current operator (if operator log on is enabled). A timeout occurs when there has

been no system activity for a duration greater than the timeout interval.

When this screen displays, you can enable/disable the system timeout. If

enabled, set a timeout value between 0 and 1440 minutes. The timeout is

disabled if the value is set to zero. The timeout interval initially defaults to

three minutes.

Ad definition

When this screen displays, you can enter a definition (up to 20 alphanumeric

characters) for ads B, C and D installed in your postage meter. These definitions appear whenever 'View Ads' is selected. Ad "A" is always a blank.

Inscription definition

When this screen displays, you can enter a definition (up to 20 alphanumeric

characters) for inscriptions B, C and D installed in your postage meter. These

definitions appear whenever 'View Inscriptions' is selected. Inscription "A" is

always a blank.

2-4

Page 9

Site Setup • 2

Low postage warning

When this screen displays, you can enter a low postage warning value.

This value can be any value between zero and the maximum value the

meter is capable of storing. Whenever the amount of postage in the meter

is equal to or below the low postage warning value, a warning message is

displayed on the screen and the postage left field is shown in reverse video

as a reminder to add postage to your meter.

Postage upper limit

When this screen displays, you can enter a postage upper limit. The value

entered sets a cap on how much postage can be spent at one time. If during

an operation, the postage value requested exceeds the postage upper limit,

an error is displayed and the meter postage value is left unchanged.

Dollar unlock limit

When this screen displays, you can enter a dollar unlock limit. This is a

double check to ensure that an operator does not enter too high a postage

value by accident. If during an operation, the postage value equals or

exceeds the dollar unlock limit, the operator is required to confirm that the

postage is correct.

Meter codes

When this screen displays, you can enter a code (up to four alphanumeric

characters) for meter installation, meter removal and meter lock/unlock.

The codes initially default to "3336".

Meter activity log enable/disable

When this screen displays, you can enable or disable the meter activity

log. The meter activity log maintains a history of the meters which have

been installed in the system.

Meter date rollover time

When this screen displays, you can enter the time of day you want the

meter imprint date to change to the next day's date. After entering the time,

you are prompted for AM or PM.

2-5

Page 10

Site Setup • 2

Transaction log printing enable/disable

When this screen displays, you can select whether the user must print the

transaction log before clearing it. If you choose "Yes", the system will stop

processing when the transaction log is full and prompt the user to clear the log

or to print and clear the log. If you choose "No", the system will print and

clear the log without giving the user the option to print or not print.

Set Up Operator IDs

When first delivered, the software assumes anyone using the system is a

Supervisor and has access to all of the functions. In order to restrict the access

to these functions to certain classes of users, you must enable operator IDs and

assign access levels.

With operator IDs enabled, you can limit the functions that individuals are

allowed to access by assigning one of three access levels: Operator, Key

Operator or Supervisor.

The Supervisor has the highest access level, followed by the Key Operator

and Operator (the lowest access level). A user at a higher access level may

perform all the functions available to a user at a lower access level. Thus, on

only the Supervisor can perform the functions in this Supervisor Guide. The

Paragon

TM

Operating Guide indicates which parts of the operation are avail-

able to the Operator and which are available to the Key Operator.

Since each system must have at least one assigned Supervisor, operator

number 1

always has a Supervisor access level. The Supervisor ID code is set

to "9999" when installed but may be changed at anytime.

When you enable operator IDs operators must enter their ID in order to use

the system. You may have up to twenty operator IDs.

When first selected, the Operator ID enable/disable screen displays. If Opera-

tor IDs are disabled, pressing <ENTER> will return you to the SITE SETUP

screen. If Operator IDs are enabled, pressing <ENTER> displays the OPERATOR ID SETUP screen with the list of operators. The following selections are

then available:

• 'Change Operator Info'

• 'Add Operator' (if less than 20 operators are defined)

2-6

• 'Remove Operator' (if there is at least one operator other than #1)

You cannot delete or change the access level (always a Supervisor) of operator #1.

You can, however, change the Name and ID. Operator #1 shall initially default as

follows: ID: 9999, Name: SUPERVISOR, and Access Level: Supervisor.

Page 11

Site Setup • 2

Change Operator Info

Use the following procedure to view or change an operator's information.

TM

1. Press the 'Change Operator Info' SoftKey

. The screen prompts you for an

operator number.

2. Enter the desired number (1 thru 20) and press <ENTER>. The screen

displays the current settings and SoftKeys

TM

which allow you to change the

operator name, ID, and access level. If your system has two languages

installed, you are also able to change the language used.

3. Verify all information and make any desired changes. When you are satisfied with the information, press the <ENTER> key to save the data and

return to the OPERATOR ID SETUP screen which displays the list of

operators.

Add Operator

Use the following procedure to add an operator.

TM

1. Press the 'Add Operator' SoftKey

. The screen prompts you for the opera-

tor name.

2. Enter up to 20 alphanumeric characters and press <ENTER>. The screen

prompts you for the operator ID (password).

3. Enter up to 8 alphanumeric characters and press <ENTER>. This is the code

the new operator will use to log on to the system. The screen now displays

'Operator', 'Key Operator' and 'Supervisor' access level selections.

4. Press the SoftKeyTM for the access level to be assigned to this operator (the

default is Operator), and then press the <ENTER> key. The screen displays

the current settings and SoftKeysTM which allow you to change the operator

name, ID, and access level. If your system has two languages installed, you

are also able to change the language used.

5. Verify all the information and make any desired changes. When you are

satisfied with the information, press the <ENTER> key to save the data and

return to the OPERATOR ID SETUP screen which displays the list of

operators.

Remove Operator

Use the following procedure to remove an operator.

1. Press the 'Remove Operator' SoftKey

TM

. You are prompted for the operator

number.

2. Enter the operator number (1 thru 20) and press <ENTER>. The screen

2-7

Page 12

Site Setup • 2

prompts you to confirm that you want to remove the operator.

3. Press 'Yes' to remove the operator from the system or 'No' to leave the

operator on the system. The OPERATOR ID SETUP screen with the list of

operators displays.

Set Default Class or Set Default Acct./Class

The 'Set Default Acct./Class' selection allows you to specify the account ID

(if accounting is enabled and at least one account is defined) and class type (if

accounting is enabled or rating is used) displayed on the MAIL RUN screen

when a new transaction is started. If only rating is available, the SoftKey

label is 'Set Default Class'. There are three choices for the default account and

class type: None, Previous, or Specific.

If "None" is selected, the operator is required to enter an Account ID or class

when each new transaction is begun.

If "Previous" is selected, the Account ID or class for the new transaction

automatically defaults to the Account ID or class used for the previous transaction.

TM

If "Specific" is selected, the Account ID or class for the new transaction

automatically defaults to the default Account ID or class.

Perform the following procedure to specify the Default Acct./Class:

1. With the DEFAULT ACCOUNT screen displayed, press the desired

SoftKey

TM

to select the default account type: "None", "Previous" or

"Specific".

2. a) If 'Set Default Account to NONE' or 'Use Last Account Selected' is

selected, "None" or "Previous" displays on the screen.

b) If 'Use Specific Account' is selected, you are prompted for the account

ID. Enter the ID and press <ENTER>. The ID displays on the screen.

3. When you are satisfied with the default account selection, press <ENTER>.

The DEFAULT CLASS screen displays.

4. With the DEFAULT CLASS screen displayed, press the desired SoftKey

TM

to select the default class type: "None", "Previous" or "Specific''.

5. a) If 'Set Default Class to NONE' or 'Use Last Class Selected' is selected,

"None" or "Previous" displays on the screen.

TM

b) If 'Use Specific Class' is selected, SoftKeys

displays to allow you to

select a carrier and class. Select the desired carrier and class. The class

then displays on the screen.

2-8

6. When you are satisfied with the default class selection, press <ENTER>.

The SITE SETUP screen displays.

Page 13

Set Up Preferred Classes

This selection allows you to specify/modify nine of your most commonlyused carrier/class combinations ("Preferred Nine"). The Preferred Nine (if

they have been defined) appear first when the 'Change Class' selection (on the

MAIL RUN screen) is made, followed by all other carrier/classes.

Use the following procedure to specify/modify preferred classes:

1. With the SITE SETUP screen displayed, press 'Set Up Preferred Classes'.

The Preferred Classes list displays.

2. Press the 'Modify Preferred Class List' SoftKey

for the Preferred Class number to modify.

3. Enter the number and press <ENTER>. The screen prompts you to choose a

carrier.

4. Press the SoftKey

choose a class.

5. Press the SoftKey

Preferred Classes list.

Site Setup • 2

TM

. The screen prompts you

TM

for the desired carrier. The screen prompts you to

TM

for the desired class. The system returns you to the

6. When you are finished making entries, press the <ENTER> key to return to

the SITE SETUP screen. Otherwise, repeat steps 1-5 until you are finished.

2-9

Page 14

Job Presets

Overview

Using Job Presets you can save specified values for recall at a later time. For

example, if once a week you must run a batch of mail for a specified account/

class, you can set the system to do the job and then you can save this set of

values as a Job Preset. Then, any time you must run the same job, you need

only press the <JOB PRESETS> key and select that Preset to automatically

configure the system for that job.

You can save up to nine Job Presets. The system is automatically set to Job

Preset 1 on power-up or logon (if Operator IDs are used).

You choose values for the following when you make a Job Preset.

Job Presets • 3

• Account ID, if accounting is enabled

• Class, if accounting or rating is enabled

• Feeder Mode (Auto or Single)

• Sealer Mode (Flaps Open/Sealed, Flaps Open/Closed, Seal Only

or Off)

• Sealer wetness setting

• W-O-W

• W-O-W

TM

Mode (On or Off)

TM

weight limit setting

• Date Mode (full date, month/year, no date)

• Date Advance

• Inscription selection (A, B, C or D)

• Ad selection (A, B, C or D)

• Postage value

• Tape Type selection (Wet, Dry or Adhesive)

• Machine speed

• Meter print position

• Ink density setting

• Stacker "Auto" mode (automatically set if a Power Stacker is installed)

• Dark Mail Setting

• Power Stacker Speed

3-1

Page 15

Job Presets • 3

To save the current system state as a Job Preset, remove a Job Preset from the

list, or choose (recalling) a Job Preset, follow the instructions below. These

procedures are available if you are signed in as a supervisor or if Operator IDs

are not used. Note that Key Operators and Operators cannot create Presets, but

they can select Presets which have been saved by a supervisor.

Saving a Job Preset

Use the following procedure to save a Job Preset:

1. Set the system to the desired settings. Be sure all of the items listed on the

previous page are set to the desired selection.

2. With the MAIL RUN screen displayed, press the <JOB PRESETS> key.

The PRESETS screen displays.

3. Press the 'Save Preset' SoftKey

of the Job Preset to use.

4. Enter the number and press <ENTER>. The screen prompts for a name.

TM

. The screen prompts you for the number

5. Enter the name and press <ENTER> to save the state of the system under

that name and number. The PRESETS screen displays.

6. Make another selection or press <BACKTRACK> to return to the MAIL

RUN screen.

Removing a Job Preset

Use the following procedure to remove a Job Preset. (Job Preset 1 can be

modified but not deleted.)

1. With the MAIL RUN screen displayed, press the <JOB PRESETS> key.

The PRESETS screen displays.

2. Press the 'Remove Preset' SoftKey

number of the Job Preset to remove.

3. Enter the number and press <ENTER>. The name of the entered Job Preset

is changed to "Undefined". The PRESETS screen displays.

4. Make another selection or press <BACKTRACK> to return to the MAIL

RUN screen.

TM

. The screen prompts you for the

3-2

Page 16

Choosing a Job Preset

Use the following procedure to choose (recall) a Job Preset.

1. With the MAIL RUN screen displayed, press the <JOB PRESETS> key.

The PRESETS screen displays.

2. Enter the number (1 thru 9) of the desired Preset or press the 'Choose

Preset' SoftKey

TM

. If you entered the number, go to step 4; otherwise, go to

step 3.

3. The screen prompts for the number of the Job Preset to choose. Enter the

desired number.

4. Press <ENTER>. The system is set to the Job Preset and the MAIL RUN

screen displays. If all the conditions of the Job Preset cannot be satisfied,

the system sets up what it can and then displays the PRESET RECALL

ERROR(S) screen with a list of the conditions it could not satisfy.

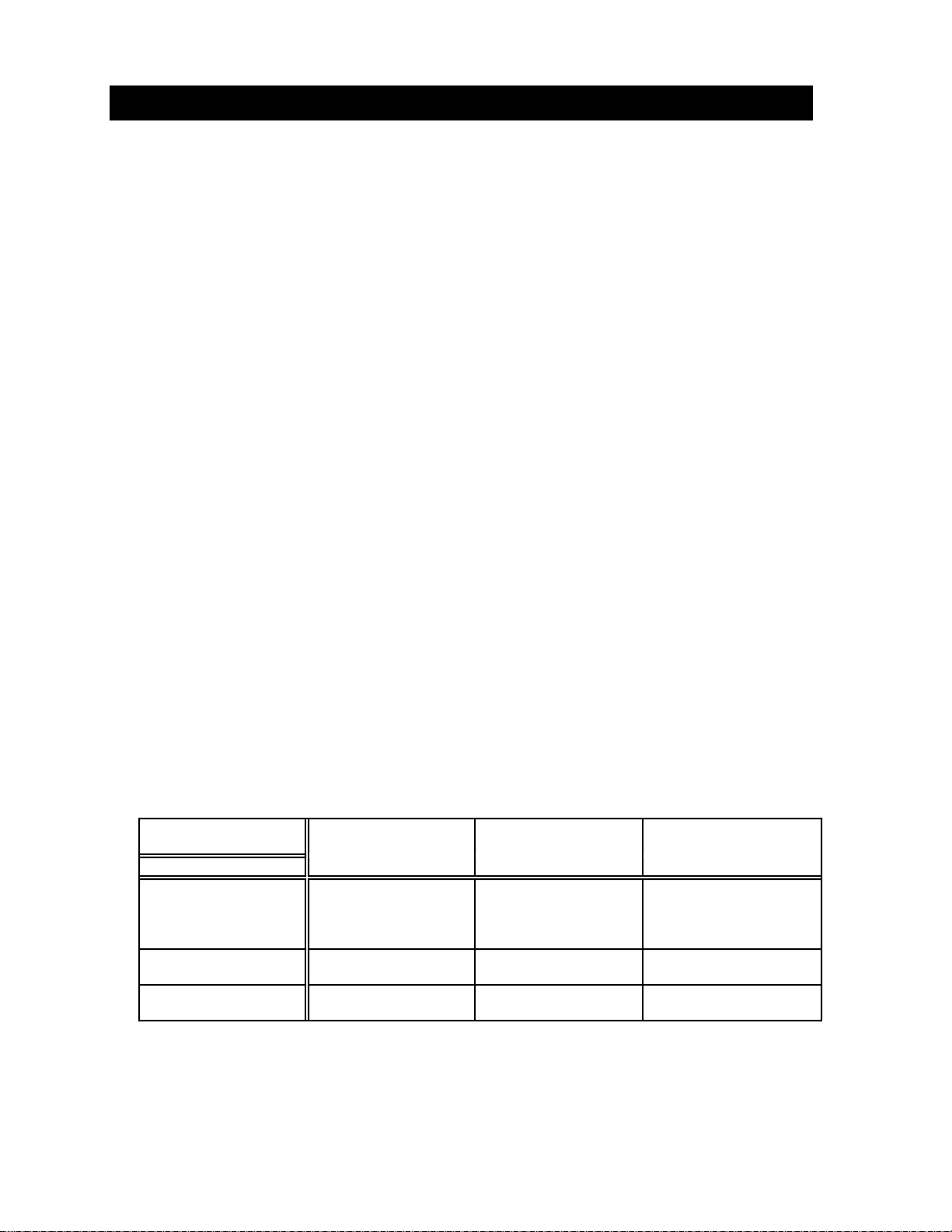

Job Preset Configuration Table

You can use the table on the following page to store the name and values of

the different items for your Job Presets. You should make copies of the following page, complete the required information for each Job Preset, and place

it in a location close to the system.

Job Presets • 3

Remember that whenever the system is powered up it uses the values in Job

Preset 1 to set up the system.

3-3

Page 17

Job Presets • 3

MACHINE IDENTIFICATION:

Item Job Preset Settings

Job Preset # 12345

Preset Name

Account ID

Class

Feeder Mode

Sealer Mode

Sealer Wetness

W-O-W Mode

W-O-W Weight Limit

Date Mode

Date Advance

Inscription

Ad

Postage Value

Tape Type

Machine Speed

Print Position

Ink Density

Power Stacker

(if installed) Auto Auto Auto Auto Auto

Dark Mail

Stacker Speed

Item Job Preset Settings

Job Preset # 6789

Preset Name

Account ID

Class

Feeder Mode

Sealer Mode

Sealer Wetness

W-O-W Mode

W-O-W Weight Limit

Date Mode

Date Advance

Inscription

Ad

Postage Value

Tape Type

Machine Speed

Print Position

Ink Density

Power Stacker

(if installed)

Dark Mail

Stacker Speed

Auto Auto Auto Auto Auto

3-4

Page 18

Troubleshooting

This section contains information you can use in the analysis of problems that

may occur while operating the system.

Power Up Failure

If a failure occurs during the power up sequence after activating the system

display, the POWER UP screen lists the error code(s). You must press any

key to continue operation. The error code format is XXXX/XXXX, where X

is an alphanumeric character. You can use the first four characters of the error

code to determine the area of the machine causing the failure.

0XXX Motor Control or Sensor Controller

1XXX Postage Meter

2XXX Weigh-on-the-Way™

3XXX Accounting software fault

4XXX Mail Processor software fault

5XXX Mail Processor peripheral

6XXX Mail Processor diagnostics

7XXX Disc access error

8XXX MCS communications

9XXX Mail Processor Operating system

DXXX Disk controller/media error

EXXX I/O expansion devices

FXXX Mail Processor software utility

Troubleshooting • 4

Error Code Related area

If the system powers up with the SITE SETUP screen displayed, the battery

for nonvolatile memory has gone bad or something has caused the loss of the

contents of memory. Call Your Pitney Bowes Customer Service Representative.

To use the machine until service arrives, you have to perform a limited site

setup. Enter only the date and time, and press the 'Use Current Settings'

SoftKey

TM

when prompted. This allows you to run mail and tapes until service

arrives.

IMPORTANT: All the accounting information, preferred

nine class list, job presets, and operator IDs you previously

set up are not available.

4-1

Page 19

Troubleshooting • 4

Troubleshooting Tables

The tables on the following pages help you to determine and correct problems in the

indicated areas of the machine. The tables are presented in the following order:

• Control Panel Checklist

• Mail Flow and Paper Handling

• Postage Meter

• Postage Printing

• Power-on and System Initialization

• Tape Generation

• Weigh-on-the-Way™ (W-O-W™)

Calling for Service

Follow the steps in the table to correct your problem. If you still have a problem,

please call Pitney Bowes Customer Service.

4-2

Page 20

Troubleshooting • 4

Control Panel Checklist

Problem Indication Possible Cause Action

Meter Display is not

illuminated - associated keys

are inactive

Machine Status Display is not

illuminated - associated keys

are inactive

System Display is blank 1. Contrast all the way

JOB PRESETS key not

functioning

1. Operator log on screen is

displayed.

2. Machine in "Seal Only". 2. Place the sealer in

3. Nonmeterable rating

class selected.

4. System in diagnostic or

site setup mode.

5. Meter is locked. 5. Unlock the meter.

6. Meter is not installed. 6. Install a meter.

1. Operator log on screen is

displayed.

2. System in diagnostic or

site setup mode.

3. Meter is not installed. 3. Install a meter.

down.

1. Not on MAIL RUN screen. 1. Press <BACKTRACK> to

1. Log on to the system.

another mode.

3. Select a meterable class.

4. Leave diagnostic or site

setup mode.

1. Log on to the system.

2. Leave diagnostic or site

setup mode.

1. Adjust the contrast

control.

go to the MAIL RUN screen.

MAKE TAPES or SINGLE TAPE

key not functioning

POSTAGE or +/= key not

functioning

+DAY key not functioning 1. A portion of date ducked. 1. Press the TODAY key to

START key not functioning 1. Not on MAIL RUN screen. 1. Press <BACKTRACK> to

NEW BATCH key not

functioning

1. Not on MAIL RUN screen. 1. Press <BACKTRACK> to

go to the MAIL RUN screen.

1. Not on MAIL RUN or

TAPE PROCESSING screen.

2. Meter display is not

illuminated.

1. Not on MAIL RUN screen. 1. Press <BACKTRACK> to

1. Go to MAIL RUN or TAPE

PROCESSING screen.

2. Check actions for "Meter

Display is not illuminated"

at top of table.

display the entire date, then

press the +DAY key.

go to the MAIL RUN screen.

go to the MAIL RUN screen.

4-3

Page 21

Troubleshooting • 4

Mail Flow and Paper Handling

Problem Indication Possible Faults Action

System will not start - mail on deck,

‘start’ button pressed

Poor feeding/nudging 1. Mail stack too heavy/too

Double / Stream Feeds 1. Dirty feed deck sensors. 1. Clean all deck sensors with

Envelope flaps not sealing 1. Flaps not stripping properly

Mail jams at stripper blade 1. Flap too deep for stripper to

1. Mail deck sensors dirty. 1. Clean mail deck sensors

with damp cloth.

1. Refer to Operating Guide

high.

2. Mail too thick/too wide. 2. Refer to Operating Guide

- Square flaps.

- Thick inserts.

2. No E-Z Seal® in tank

handle.

2. Only tips of envelopes

sealed.

3. Pre-sealed mail run in

wrong sealer mode.

for stack height and weight

limits.

for stack width and thickness

limits.

a damp cloth.

1a. Run envelopes with flaps

opened.

1b. Slow machine speed.

2. Refill water bottle.

1. Run mail with flaps opened.

2. Sealed mail must be well

sealed on leading edge or will

jam on stripper blade.

3. Select "Open/Sealed" or

"Sealer Off" mode.

4-4

Page 22

Troubleshooting • 4

Postage Meter

Problem Indication Possible Faults Action

Meter won’t latch into

printer

Meter won’t initialize 1. Various Meter fatal

Meter won’t ‘install’ in

system

Meter won’t set postage value 1. Meter internal motor

1. Shutter carriers not

correctly positioned

2. Lead seal on E101 meter

causing interference.

errors - reported on

display.

2. Various Dater fatal

errors - reported on

display.

1. Didn't begin installation. 1. Repeat the "Installing the

2. Started, but didn't

complete installation.

3. Message "Meter not

properly seated" is

displayed.

fatal move error.

2. Value requested exceeds

Postage upper limit.

3. Value requested exceeds

Dollar unlock value.

4. System not in idle. 4. Return to MAIL RUN

1. Power down and turn on

the system again.

2. Reposition seal corectly

and reseat meter.

1. Power down and turn on

the system again.

2. Power down and turn on

the system again.

Meter"procedure in Section

3 of the Operating Guide.

2. Try the "Removing the

Meter" procedure in

Section 3 of the Operating

Guide.

3. Press down on front of

meter to ensure seating.

1. Power down and turn on

the system again.

2. Enter new value or

change Postage upper limit

3. Re-enter value and press

enter key twice.

screen to enter postage.

Meter won’t enable for print 1. Communications error -

reported on display.

2. Meter out of funds reported on display.

Can’t remove meter from

system

1. Load /Latch mechanism

failure - reported on

display.

2. System power failure. 2. Use meter removal tool

1. Repeat operation, if

trouble continues to occur

call Pitney Bowes.

2. Reset meter instructions are in the

Operating Guide and under

the meter keyboard cover.

1. Use meter removal tool

to manually remove meter.

to manually remove meter.

4-5

Page 23

Troubleshooting • 4

Postage Printing

Problem Indication Possible Faults Action

Poor print registration 1. Dirty letter deck sensors. 1. Clean deck sensors in front

of printer.

Prints too light 1. Inking level set too low. 1. Increase the inking level

using the "Changing the Ink

Density " procedure in section

3 of the Operating Guide.

Prints too dark 1. Inking level set too high. 1. Decrease the inking level

using the "Changing the Ink

Density" procedure in section

3 of the Operating Guide

2. Vent cover not removed

from new ink bottle.

No Print - envelope ejected 1. "Seal Only" mode set 1. Set Sealer to another mode.

2. W-O-WTM mode overweight mail-piece.

3. Out of ink. 3. Replace ink bottle.

2. Remove vent cover from ink

bottle.

2. Refer to Operating Guide

for mail-piece weight limits.

Bars printed in postage value 1. Meter dropped rectifiers -

meter fatal error.

Wrong date printed 1. Wrong date set on meter

indicator.

Wrong ad printed 1. Ad titles stored in system

memory do not agree with ads

mounted in meter.

2. Meter ad block out of sync

with system display.

Wrong postal inscription printed 1. Inscription titles stored in

system memory do not agree

with inscriptions mounted in

meter.

2. Meter Inscription Block out

of sync with system display.

1. Power down and turn on the

system again.

1. Press TODAY key to set

current system date.

1. Update ad titles to agree

with the ads mounted in the

meter using the Modify Site

Setup procedure.

2 Power down and turn on the

system again.

1. Update inscription titles to

agree with the inscriptions

mounted in the meter using

the "Modify Site Setup"

procedure.

2. Power down and re-initialize

the system.

4-6

Page 24

Troubleshooting • 4

No Date printed 1. Date ducked

1. Press DATE ON/OFF key

Postage Printing (cont'd)

Problem Indication Possible Faults Action

.

to select proper date mode.

No Ad printed when requested 1. Selected ad location in

meter is empty.

No Inscription printed when

requested

1. Selected inscription

location in meter is empty.

Power-on and System Initialization

Problem Indication Possible Faults Action

System does not power-up

- No initialization

- No control panel

indicators

System powers up but does

not begin initialization.

- No system LCD display

- System indicators

blinking

1. No power to system. 1a. Check that the line cord

1. System power-on

diagnostics failure.

1. Insert proper ad in

meter ad block.

1. Insert proper

inscription in meter

Inscription block.

is plugged into an outlet.

1b. Check that the power

switch is ON.

1c. Call Pitney Bowes for

service.

1. Refer to "Power Up

Failure" in this section.

System powers up but does

not complete initialization.

- Error code on display

System completes

initialization but error code

on system display.

System completes

initialization but warning on

the system display

1. Various fatal

initialization failures - as

indicated on system display.

1. Non-fatal problem

exists. System disables the

indicated function and

displays error.

1. Supply related warning

- Low ink warning.

- Low water warning.

- Out of tape.

1. Call Pitney Bowes for

service.

1a. Recycle the power.

1b. Call Pitney Bowes for

service.

1. Refill indicated supply as

required.

4-7

Page 25

Troubleshooting • 4

Tape Generation

Problem Indication Possible Faults Action

Tape won’t feed off roll 1. Mechanical problem with

tape holder.

2. Jammed tape still in tape

path.

Tape spools off roll 1. Mechanical problem with

tape holder.

2. Clutch broken. 2. Call Pitney Bowes service.

Tape jams in gangplank 1. Jammed tape still in tape

path.

2. Tape not exiting into cutter

assembly.

Tape cutter jams 1. Tape jammed in cutter. 1. Clear tape jam.

Tape carriage movement failure 1. Tape jammed between end

of gangplank and cutter

preventing gangplank

movement.

Tape moistener does not fill 1. Float stuck. 1. Remove and clean tank to

2. Water tube off at moistener

unit.

1. Raise and reseat tape

holder.

2. Check tape path for

obstructions.

1. Raise and reseat tape

holder.

1. Check tape path for

obstructions.

2. Check cutter entrance for

obstructions.

1. Raise tape holder and pull

tape back out of gangplank to

clear jam.

free float.

2. Connect water tube.

Larger tape generated than

expected

Problem Indication Possible Faults Action

W-O-WTM gives wrong weight 1. W-O-WTM out of calibration.

W-O-WTM gives incorrect Postage

value

1. Ad or inscription selected

but not installed in meter.

Weigh on the WayTM

2. Envelope weight poorly

distributed

- Heavy insert on one side of

mail-piece.

- loose or stacked inserts

that can shift easily.

1. Old / Wrong Rate Table

loaded.

2. Wrong class or fees

applied.

3. W-O-WTM out of calibration.

1. Select position "A" for both

ad and inscription.

1. Call Pitney Bowes service.

2. W-O-W will not handle

small, heavy inserts which

grossly distort center of mass weigh these on a platform.

1. Check current revision of

Rate PROMs installed update as required.

2. Check selected class and

attached fees

3. Call Pitney Bowes service.

4-8

4-8

Page 26

Glossary

Glossary • 5

This section gives a brief description of the terms used with the mail processor.

Access Level One of three levels (Operator, Key Operator or

Supervisor) to which features are assigned to

restrict access.

Account A grouping established by a company as a means of

organizing and managing related postal activities,

for example, all mail sent by the Sales Department

would be kept together in such an "Account".

Account ID A company-generated number which IDentifies a

particular account, for example, the Account ID for

the Sales Department may be S100. An Account

ID can consist of an account number and subaccount number, for example, S100-123 where

S100 is the account number and 123 is the

subaccount number.

Ad A feature on the meter which allows printing of a

customer-designed graphic. Up to three ad plates

can be inserted in the meter.

Alphanumeric For the purposes of this document, the term in-

cludes any character which can be entered through

the keyboard, including special characters and

spaces.

Bar Code Wand A hand-held scanner used to read bar code symbols

into the mail processor.

Carrier A company which transports and delivers letters and

packages (United States Postal Service (USPS) or

United Parcel Service (UPS), etc.).

Class A particular type of service or handling for

mail-pieces or parcels.

Date Ducking The inhibiting of the printing of part or all of the

date of the meter imprint.

Dollar Unlock Limit A postage value limit associated with setting the

meter. If an attempt is made to set the meter to a

postage value greater than or equal to the Dollar

Unlock Limit, an additional confirmation is

required from the user before the operation is

completed.

5-1

Page 27

Glossary • 5

Fee A premium paid in return for special carrier

Inscription A graphical or textual mark placed near the meter

Job Preset A "snapshot" of the system configuration. The

Key Operator A user who has access to more features than an

Locked Account An account not currently active (restricted from

services.

imprint which relates to a particular type of mail

service and which is required by the U.S. Postal

Service. Examples include "ZIP+4" and

"ZIP+4 Barcode" inscriptions. Up to three inscrip

tion plates can be inserted in the meter.

system allows nine Job Presets to be saved and

retrieved.

operator and to less features than a supervisor.

use) which may be activated, modified and/or

deleted.

Operator A user with the lowest access level, that is, one

who can access the fewest number of features.

Platform A weighing device used with the mail processor.

Rating class Postal authority or carrier-defined types of service.

Rating classes are provided to the system via the

rating module.

Scale A weighing and rating device which can operate

independently of the mail processor.

SoftKeys

TM

The six keys on the left side of the system display.

The labels and functions of these keys change

depending on the operation being performed.

Subaccount An accounting record which is grouped with other

records under a master account.

Supervisor A user with the highest customer access level.

Surcharge A premium over and above the nominal postage

which is charged to an account when mail for that

account is processed. Note that surcharges can be

negative (rebates).

5-2

Transaction Data about mail and tapes processed (as part of the

same batch) and charged to a given Account ID and

class.

Page 28

Options

Options • 6

In this section, place the operating guides for each option you purchase for

use with your PARAGON™ Mail Processor. Each operating guide contains a

description and procedure (if applicable) for using the specified option.

Data Trail™ Accounting System

Report Printer Interface

Postage by Phone® Auto Meter Resetting Modem

Second Weighing Platform Interface

MMS Interface

Barcode Wand with Interface

Flats Feeder Option

Laser Scanner

Echoplex Interface

6-1

Page 29

Appendix • A

ParagonTM Operator Training Skills List

Listed below are the skills taught to operators in the Paragon™ training class. If you need to

train a new operator, cover all the features below in the order listed. Each operator should be

trained to acknowledge, understand and perform these skills.

1. Operator can locate & identify the following:

Feeder/Sealer Unit (UF30)

[] Mixed mail feeder [] Jetspray™ sealer

[] Tape exit bin [] Serial number & product code

[] Disk drive [] Power Switch

Base Unit (UBF1, UBF0)

[] Para-Text™ control panel [] Present Impression™ meter

[] W-O-W™ [] Serial number & product code

[] Seal ski adjustment

Stacker Unit

[] Drop stacker [] Power stacker

Keypad

[] Numeric entry [] Alpha (letter) entry

[] Postage value entry [] Additional fees entry (+/= key)

[] Start / stop keys [] Backtrack key

[] New batch key [] Make tapes key

[] Job presets key [] Enter key

[] Clear key

Machine Status Display

[] Feeder modes [] Sealing modes & usage

[] W-O-W™ modes [] Stacker modes ( power stacker

only)

[] Tape types and modes [] Jam indicators

[] Water level indicators [] Add water indicator

[] Add ink indicator [] Add tape indicators

Meter Display

[] Postage value [] Date

[] Ad & inscription

System Display

[] Screen title [] Information block

[] Instruction block [] SoftKeys™ & SoftKey™ labels

A-1

Page 30

Appendix • A

2. Operator is able to perform the following:

Basic Set-up

[] Plug in the system to a grounded outlet

[] Turn on system

[] Log on system (if required)

[] Batch Set-up

[] Selecting Account (if installed)

[] Class

[] Fees (use of auto-oversize fee)

[] Set-up meter

[] Enter postage value [] Advance date

[] Duck (OMIT) date [] Select ad & inscription

[] Select feeder mode [] Select sealer mode

[] Select stacker mode [] Select W-O-W

[] Adjust machine settings

[] Machine speed [] Ink density

[] Sealer wetness [] Imprint position

[] WOW weight limit

[] Load mail

[] Mixed sealed & unsealed mail [] Large flap envelopes

[] Mixed size & thickness

TM

mode

Processing Mail

[] Start Batch

[] Stop & Re-start

[] End Batch

[] Make Tapes

[] Single Tapes

[] Multiple Tapes

[] Install supplies

[] Fill E-Z Seal

™ bottle

[] Install new tape roll

[] Ink - remember to remove vent seal

Present Impression™ Postage Meter

[] Install meter [] Lock & unlock meter

[] Remove meter

[] Emergency removal (hand crank)

[] Normal removal

[] Re-set meter

[] Meter receipts

[] Manual meter (Post office reset)

[] Postage-by-Phone

®

meter

[] Through Paragon™ keyboard

[] Through meter keyboard

®

[] Via Postage-by-Phone

modem (If installed)

[] Installing advertisements & inscriptions

A-2

Page 31

Machine Maintenance & Error Correction

[] Daily maintenance

[] Cleaning mail deck sensors

[] Cleaning flap array

[] Clearing Jams

[] Mail jams

[] Tape Jams

[] Calling for service

[] Error codes

3. Supervisor Level Functions

Site Set-up

[] Change system time (standard vs. daylight savings time)

[] Station ID [] Set low postage warning

[] Set system time-out [] Define Ads & Inscriptions

[] Set postage upper limit [] Set dollar lock

[] Set operator IDs

[] Operator ID

[] Access Level

[] Remove operators

[] Preferred classes

[] Set meter date roll-over time

[] Default class & account

[] Intra-state Zip Code ranges (If applicable)

[] Intra- BMC Zip Code ranges (If applicable)

[] Saving & restoring site setup

Appendix • A

Data Trail Accounting

[] No. of Accounts purchased & Acct/Class/Fee combinations

[] Account Template

[] Creating and Deleting Accounts

[] Typical Account [] Basic Account

[] Assigning Speed Codes

[] Use of Bar code

[] Normal Mode [] Account only mode

[] Clearing Data

[] Transaction Log [] Period 1 & 2

[] Accounting Reports

[] Standard Reports [] Report Macros

MMS Interfaced Accounting

[] Setup

[] Station ID [] Account length

[] Job ID & Job type [] Transaction Receipt

[] Surcharge setup

A-3

Page 32

Appendix • A

Defining Job Presets

[] Saving a job preset

[] Using job presets

[] Removing job presets

Customer Diagnostics & Utilities

[] Testing system

[] System event log

[] Meter avtivity log

[] System configuration

System Reports

[] Class / fee list

[] Meter activity report

[] Operator ID list

[] System set-up

Options (As Required)

[] Using 15 lb platform [] Using 100 lb platform

[] Report printer [] Barcode wand / Laser scanner

[] Postage By Phone

®

modem [] Flats feeder kit

I acknowledge the ability to perform the above listed skills.

_____________________________ Paragon™ Operator

Signature

A-4

Loading...

Loading...