Pitney Bowes DI380 Series, DI425 Series, SI3300, SI3500 Service Manual

DI380/DI425 Series

Document Inserting Systems

(Includes Secap models SI3300/SI3500)

Service Manual

FORM SDT333A (4-06)

The title, copyright and all other proprietary rights in this document are vested in Pitney Bowes Limited and no part of it may be reproduced

in any form without the written permission of Pitney Bowes Limited.

The document is for the exclusive use of the person to whom it is issued; its contents are condential and must not be disclosed to any

third party or used for any purpose other than in the proper conduct of Pitney Bowes Limited's business and it must be returned to Pitney

Bowes Limited immediately upon the person ceasing to be associated with Pitney Bowes Limited.

© Pitney Bowes Limited, 2006

IMPORTANT:

Model and feature availability varies by country. Contact your machine supplier for more information.

This guide covers all models and features. Inclusion within this guide does not guarantee availability of a

particular model or feature within your country.

SDT335A MMI Service Manual & Parts List

i

• Contents

• Contents

Page

SECTION 1

Introduction

1.1 - Purpose ............................................................................................ 1-1

1.2 - Equipment Covered .......................................................................... 1-1

1.3 - Related Publications ......................................................................... 1-1/1-2

1.4 - Contents ........................................................................................... 1-1

1.5 - Safety Summary ............................................................................... 1-2/1-3

1.6 - Equipment Safety ............................................................................. 1-4

SECTION 2

Specications

2.1 - Material Specication ........................................................................ 2-1/2-3

2.2 - Machine Specication ....................................................................... 2-4

SECTION 3

Theory of Operation

3.1 - Introduction- To System Theory ........................................................ 3-1

3.2 - Single Sheet Feeder Mode & Linked Feeder Mode........................... 3-2

Flow Diagram- Single Sheet Feeder Mode ............................. 3-3

3.3 - Insert Feeder Mode ........................................................................... 3-4

Flow Diagram- Insert Feeder Mode ........................................ 3-5

3.4 - Two Sheet Feeder Mode ................................................................... 3-6

Flow Diagram- Two Sheet Feeder Mode ................................ 3-7

3.5 - Single Sheet Feeder Plus an Insert Mode ........................................ 3-8

Flow Diagram- Single Sheet Feeder Plus an Insert Mode ..... 3-9

3.6 - Two Sheet Feeders Plus an Insert Mode .......................................... 3-10

Flow Diagram- Two Sheet Feeders Plus an Insert Mode ....... 3-11

3.7- The Fold Only Mode .......................................................................... 3-12

Flow Diagram- The Fold Only Mode ....................................... 3-13

3.8 - Accumulation From Main Sheet Feeder ............................................ 3-14

Flow Diagram- Accumulation for Sheet Feeder 1 Mode ......... 3-15

3.9- Double Detect Sensors ..................................................................... 3-16

3.10- AC Motor ........................................................................................... 3-17

SECTION 4

Removal & Replacement

4.1 - Removing Covers and P.C.B. ........................................................... 4-1

4.2 - Removal of Jam Access Plate .......................................................... 4-1

4.3 - Removing Sheet Feeder Separator Roller & Pad ............................. 4-2

4.4- Removing Carriage Assembly ........................................................... 4-3

4.5- Removal of Lower Collation Roller .................................................... 4-4

4.6- Removal of Upper Insert Drive Rollers .............................................. 4-5

4.7- Fold Roller Removal/ Replacement ................................................... 4-5/4-6

4.8- Dismantling Insert Feeder (DI380/SI330 Only) .................................. 4-7

4.9- Dismantling Insert Feeder (DI425/SI3500 Only) ................................ 4-8

4.10- Removal of Top Assembly .................................................................. 4-9

4.11- Removal of Envelope Feed Rollers and Separator Pad (DI380/SI330

Only) ................................................................................................... 4-10

ii SDT335A MMI Service Manual & Parts List

• Contents

Page

4.12- Removing Envelope Feeder (DI425/ SI3500 Only) ............................. 4-11

4.13- Removing Envelope Feed Rollers & Separator Pad (DI425/SI3500

Only) .................................................................................................... 4-11

4.14- Removal of Flapper Assembly and Blade ............................................ 4-12

4.15- Removal of the Transport Pivot Plate & Insertion Roller ...................... 4-13

4.16- Removal of Sealer Rollers ................................................................... 4-13

4.17- Removing the Inverter Motor Assembly ............................................... 4-14

4.18- Removal of the Conveyor Transport Belts and Rollers ........................ 4-14/4-15

4.19- Removing Lower Flapper Rollers ......................................................... 4-15/4-16

4.20- Removal of the Lower Envelope Drive Roller ....................................... 4-16

4.21- Removal of the Power Supply Unit and AC Motor ................................ 4-17

SECTION 5

Adjustments

5.1 - Envelope Feed Tray Guides (DI380/SI330 Only) .............................. 5-1

5.2 - Envelope Feeder Offset Adjustment (DI425/SI3500 Only) ................ 5-1

5.3 - Envelope Separator Pad Side to Side Adjustment ............................ 5-2

5.4 - Envelope Separator Pad Height (DI380/SI3300 Only) ...................... 5-2

5.5 - Envelope Separator Pad Height (DI425/SI3500 Only) ...................... 5-3

5.6 - Insertion Flipper Actuation Height/ Hold Down Solenoid Adjustment 5-4

5.7- Insertion Hold Down Finger Rest Position ......................................... 5-5

5.8- Transport Pivot Plate End Float ......................................................... 5-5

5.9- Transport Pivot Plate Setting ............................................................. 5-6

5.10- Fold Plates 1 and 2 Offset ................................................................. 5-7

5.11- Nesting Constant ............................................................................... 5-8

5.12- Q Station Adjustments ....................................................................... 5-8/5-10

5.12.1 Alignment 5-8

5.12.2 Q Station Calibration 5-9

5.12.3 Q Station Height 5-10

5.13- Insert Feeder Adjustments ................................................................. 5-11/5-13

5.13.1 Separator Roller Alignment 5-11

5.13.2 Separator Roller Height 5-11/5-12

5.13.3 Separator Pre-Feed Height (DI380/ SI330 Only) 5-13

5.14- Skew Adjustment ............................................................................... 5-14

5.15- Flapper Adjustment ............................................................................ 5-15

SECTION 6

OMR

6.1 - A Brief Overview of OMR on this system ......................................... 6-1

6.2- OMR Specications .......................................................................... 6-2/6-6

'Standard' OMR Positions Diagram 6-3

'Offset' OMR Positions 6-4

'Swis Offset' OMR Positions 6-5

6.3- OMR Mark Grouping ........................................................................ 6-7

6.3.1 'C' Fold and Double Fold Jobs 6-7

6.3.2 'Z' Fold and Single Fold Jobs 6-7

6.4- Basic OMR ....................................................................................... 6-8

6.5- Benchmark ....................................................................................... 6-8

6.6- Safety ............................................................................................... 6-8

SDT335A MMI Service Manual & Parts List

iii

• Contents

Page

6.7- BOC-(NOT) AND EOC-(NOT) .......................................................... 6-8

6.8- Parity and Other Checks .................................................................. 6-8

6.9- Retime Marks ................................................................................... 6-9

6.10- Allowable Mark Combinations .......................................................... 6-9

6.11- Enhanced OMR ................................................................................ 6-10

6.12- Auto-Batch ........................................................................................ 6-10

6.13- Selective Insertion .......................................................................... 6-10

6.14- Wrap-Around Sequence ................................................................. 6-10

6.15- Wrap Around Sequence Marks ....................................................... 6-11/6-12

6.15.1 Mark Code Interpretation 6-11/6-12

6.16- Enabling the OMR Features ............................................................ 6-12

6.16.1 Basic OMR 6-12

6.16.2 Enhanced OMR 6-12

6.16.3 Switching Off OMR 6-12

6.17- Scanning Template .......................................................................... 6-13

6.18- Procedure for manually setting the sensitivity of the OMR sensors 6-14

SECTION 7

Service Menu & Troubleshooting

7.1- Entering the Service Menu ............................................................. 7-1

7.2- Parameters Menu ........................................................................... 7-1/7-5

7.2.1 Final Assembly Number 7-1

7.2.2 Set Default Job 7-2

7.2.3 Set 50/60Hz 7-2

7.2.4 Serial Interface 7-2

7.2.5 View Error Codes 7-2

7.2.6 Set DDD 7-2

7.2.7 Set Service Counter 7-2

7.2.8 Set Out of Material 7-2

7.2.9 Set Nesting Constant 7-2

7.2.10 Calibrate Q Station 7-3

7.2.11 Set Fold Plate Offsets 7-3

7.2.12 Set Env Stop Count 7-3

7.2.13 Set Serial Number 7-3

7.2.14 View Software Revision 7-3

7.2.15 Select OMR Basic Mode 7-3

7.2.16 Select OMR Enhanced 7-3

7.2.17 Basic Wetter Constant 7-3

7.2.18 OMR/ Acc Wetter Constant 7-4

7.2.19 T1 Clutch Release Time 7-4

7.2.20 T2 Envelope Hold Time 7-4

7.2.21 T3 Table Offset 7-4

7.2.22 OMR Offset Feeder 1 7-4

7.2.23 OMR Offset Feeder 2 7-4

7.2.24 Clear Deck Delay 7-5

7.2.25 MMI Stack Limit 7-5

7.3- Service Diagnostics ......................................................................... 7-6/7-9

7.3.1 Test Sensors 7-6

7.3.2 Test UART 7-7

7.3.3 Test D.C. Motors 7-7

7.3.4 Test Solenoids 7-8

iv SDT335A MMI Service Manual & Parts List

• Contents

Page

7.3.5 Test A.C. Motor 7-8

7.3.6 Run Test Cycle 7-8

7.3.7 Test Display 7-8

7.3.8 Test Clutch and A.C. Motor 7-8

7.3.9 Test OMR Sensors 7-8

7.3.10 Test Service Counter 7-8

7.3.11 Test Interlock Relay 7-8

7.3.12 Test DDD Calibration 7-8

7.3.13 Select Board Type 7-9

7.3.14 Test Memory 7-9

7.4- Troubleshooting Charts .................................................................. 7-9

7.4.1 General Information 7-9

7.4.2 Double Detect 7-9

7.5- Fault Finding Charts ....................................................................... 7-10/7-21

SECTION 8

Preventive Maintenance

8.1- General Information ....................................................................... 8-1

8.2 - The 100k Service ........................................................................... 8-1

8.3- The 200k Service ........................................................................... 8-2

SECTION 9

Installation

9.1- Unpack and Check ......................................................................... 9-1

9.2- Operator Training ............................................................................ 9-2

9.3- Supervisor Training ......................................................................... 9-2

SECTION 10

Diagrams

10.1- Flow Diagrams ...................................................................................... 10-1

10.2- Component Locations ........................................................................... 10-2

10.3- Switches, Sensors, Motors, Solenoids Test Levels ............................... 10-3/10-6

10.4- PCB Layout ........................................................................................... 10-7

10.5- Drive Belt Routing ................................................................................. 10-8

10.6- Schematic- Insertion/ Moistener/ Exit Areas ......................................... 10-9

10.7- Schematic- Sheet Feeders/ Collation Motor ......................................... 10-10

10.8- Schematic- Fold Plates/ Half Fold ......................................................... 10-11

10.9- Schematic- Envelope Feeder/ AC Hand Crank (Manual Advance) ....... 10-12

10.10- Schematic- P40 Envelope Platform Connector (DI425/SI3500) ........... 10-13

10.11- Schematic- P41 Envelope Platform Motor Connector (DI425/SI3500) 10-13

10.12- Schematic- Insert Feeder ...................................................................... 10-14

10.13- Schematic- Display/ PSU ...................................................................... 10-15

SDT3233A DI380/DI425/SI3300/SI3500 Service Manual

1-1

Introduction • 1

1 • Introduction

1.1 PURPOSE

This document provides the information necessary to support the installation and site repair of the

DI380/DI425/SI3300/SI3500 Inserter.

1.2 EQUIPMENT COVERED

This manual applies to the sheet feeder, its accessory equipment and the interface kits required for

table top system operation.

1.3 RELATED PUBLICATIONS

SDC639 DI380 Operating Guide English

SDC640 DI380 Operating Guide German

SDC641 DI380 Operating Guide Italian

SDC642 DI380 Operating Guide Dutch

SDC643 DI380 Operating Guide Norwegian

SDC644 DI380 Operating Guide Finnish

SDC645 DI380 Operating Guide Swedish

SDC646 DI380 Operating Guide Danish

SDC647 DI380 Operating Guide Hungarian

SDC648 DI380 Operating Guide Portuguese

SDC649 DI380 Operating Guide Spanish

SDC650 DI380 Operating Guide French (Pitney Bowes Branded)

SDC1069 DI380 Operating Guide French (Secap Groupe PB Branded)

SDC651 DI380 Operating Guide Polish

SDC730 DI380 Operating Guide Czech

SDC652 DI425 Operating Guide English

SDC653 DI425 Operating Guide German

SDC654 DI425 Operating Guide Italian

SDC655 DI425 Operating Guide Dutch

SDC656 DI425 Operating Guide Norwegian

SDC657 DI425 Operating Guide Finnish

SDC658 DI425 Operating Guide Swedish

SDC659 DI425 Operating Guide Danish

SDC660 DI425 Operating Guide Hungarian

SDC661 DI425 Operating Guide Portuguese

SDC662 DI425 Operating Guide Spanish

SDC663 DI425 Operating Guide French (Pitney Bowes Branded)

SDC1078 DI425 Operating Guide French (Secap Groupe PB Branded)

SDC664 DI425 Operating Guide Polish

SDC731 DI425 Operating Guide Czech

SDC1070 SI3300 Operating Guide Italian

SDC1071 SI3300 Operating Guide Dutch

SDC1072 SI3300 Operating Guide English

SDC1073 SI3300 Operating Guide Danish

SDC1074 SI3300 Operating Guide French

SDC1075 SI3300 Operating Guide German

SDC1076 SI3300 Operating Guide Spanish

SDC1077 SI3300 Operating Guide German (Hefter Branded)

1-2 SDT3233A DI380/DI425/SI3300/SI3500 Service Manual

1 • Introduction

SDC1079 SI3300 Operating Guide Italian

SDC1080 SI3300 Operating Guide Dutch

SDC1081 SI3300 Operating Guide English

SDC1082 SI3300 Operating Guide Danish

SDC1083 SI3300 Operating Guide French

SDC1084 SI3300 Operating Guide German

SDC1085 SI3300 Operating Guide Spanish

SDC1086 SI3300 Operating Guide German (Hefter Branded)

SDT334 DI380/DI425/SI3300/SI3500 Parts List

1.4 CONTENTS

This manual is organised as follows:

● Section 1 – Introduces the manual

● Section 2 – Lists material and equipment specications

● Section 3 – Briey presents the theory of operation

● Section 4 – Presents removal and replacement procedures

● Section 5 – Gives adjustment procedures

● Section 6 – Offers information on the OMR system

● Section 7 – Lists troubleshooting procedures

● Section 7 – Covers preventive maintenance

● Section 8 – Provides installation, setup and check-out instructions

● Section 9 – Contains schematics and other diagrams

1.5 SAFETY SUMMARY

Warning messages are used throughout this manual to alert you to potentially hazardous conditions.

These warnings are explained below.

● WARNING — calls attention to improper practices that could cause injury.

● CAUTION — calls attention to improper practices that could damage the equipment or the material

being run.

● IMPORTANT — calls attention to practices that could adversely affect equipment operation, if

instructions are not followed exactly.

You must familiarise yourself with proper procedures and methods before you install, operate or service

the equipment to avoid personal injury or damage to the equipment. If you are responsible for training

service personnel or equipment operators, it is incumbent on you to explain safety precautions to your

students and encourage safety awareness.

The following is a list of general precautions which cannot be over emphasised:

● HIGH VOLTAGE is present at certain points in the equipment. INJURY or DEATH could result if

you fail to observe safety precautions.

● Know how to turn off power in the work area and how to summon help in case of emergency.

● Do not work on equipment under power unless absolutely necessary.

SDT3233A DI380/DI425/SI3300/SI3500 Service Manual

1-3

Introduction • 1

● When working on a live circuit, use extreme caution. Don’t grasp two sides of a live circuit at the

same time.

● Always use the right tools for the job.

● Treat every circuit like a gun which may be loaded. It may not be “live”, but be sure. Check with a

neon tester, a voltmeter, or simply unplug the machine.

● Use one hand when reaching into a circuit. By keeping one hand free, lethal current is less likely

to pass through vital organs. Observe this rule when connecting or disconnecting plugs or leads,

and when making any adjustments on a live circuit. Don’t underestimate the danger of shock: 1mA

(1/1000 ampere) is uncomfortable; 5 mA (1/200 ampere) is dangerous - the victim may jump back

and be injured; 12 mA (1/83 ampere) causes hand muscles to contract - the victim cannot free

himself; 24 mA (1/40 ampere) has proven fatal; and 100 mA (1/10 ampere) is likely to be fatal.

● Don’t reach into a circuit with metal tools, or while wearing rings or a watch. Even in low voltage

circuits, a metal object can short circuit two terminals.

● Don’t bypass safety devices. Three-wire outlets (220/240 VAC) are designed to ground equipment

to make it safe. If a live wire shorts to a grounded frame, the only result is an open fuse. If a live

wire shorts to an ungrounded frame, the frame itself becomes hot and potentially dangerous. A

fuse is a weak link in a circuit, designed to break down before anything else does. The maximum

safe current in a circuit is determined by the designers. Too large a fuse can pass excessive

current, damaging expensive equipment. Interlock switches are designed to remove power from

a circuit when an access door, cover or panel is opened. When such a switch is “cheated” or

otherwise disabled, a safety device has been bypassed. If you bypass an interlock for service

or diagnostic purposes, use extreme caution.

● If you use air pressure to clean a machine, use low pressure (30 psi or less) and use eye protection

(goggles or face masks).

● When using solvents or cleaning uids, make sure ventilation is adequate.

WARNING!

Always be sure the equipment is unplugged before you make any attempt

to perform the maintenance outlined in this manual. If you must work on a

"live" machine, note that line potential is present at the power panel and the

motherboard.

CAUTION: DO NOT attempt to adjust key timing parameters in the service menu

unless you have been trained and thoroughly understand what you're doing.

Otherwise you could damage the equipment.

1-4 SDT3233A DI380/DI425/SI3300/SI3500 Service Manual

1 • Introduction

1.6 EQUIPMENT SAFETY

Just by walking around, you yourself may carry a threat to the equipment, in the form of a high voltage

electrostatic charge. Your body acts as a giant capacitor which can store large amounts of electricity.

Walking across a rug can charge you with several thousand volts, which can discharge in a spark up

to an inch long.

Digital equipment can be easily damaged or destroyed by static charges. Microprocessors and other

ICs contain tiny transistors not much more than a millionth of an inch across, which operate at 5 to

12 volts. You don’t have to see a spark to ruin an IC — 50 volts is enough. Follow these guidelines to

protect sensitive equipment from static damage:

● Ground yourself before reaching into the equipment, or touching any circuit board or other electrical

component. Just touching a doorknob or metal workbench may be enough, but the best guarantee

is to turn the machine off but leave it plugged in, and ground yourself on the chassis, which is

grounded through the three-wire power cord. If you have access to one, bring a grounding strap

and use it.

● Be careful of rugs — even a few steps can recharge you. Re-ground yourself whenever you’ve

walked away and returned to the machine. Rugs are a major source of static buildup in the

body.

● Take greater precautions as the objects you handle get smaller. A board in the machine is better

protected than one which is not plugged in; a chip on a board is better protected than one in your

hand.

● Stay away from metal conductors. The plastic and resin that chips and boards are made of are

much better insulators than metal. It’s most important to keep your hands away from any metal

which contacts the data. In particular, this means the long connector along the bottom of each

board, and the pins coming out of the chips. These signal and data lines are directly connected to

the fragile inner circuits of the chips. When handling a board, try not to touch the connector; when

handling a chip, try not to touch the pins.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

2-1

2 • Specifications

2 • Specifications

2.1 MATERIAL SPECIFICATIONS

Sheet Feeders

Minimum sheet size: 127mm Width 127mm Length

Maximum sheet size: 229mm Width 406mm Length

Paper weights: 60g/m2 Minimum (non OMR)

70g/m2 Minimum (OMR) 120g/m2 Maximum

Fold congurations: Material length limits before folding

Single fold: 127mm - 315mm

“C” - Letter fold: 150mm - 356mm

“Z” - Accordion fold: 201mm - 356mm

Double fold: 305mm - 406mm

Double Document

Detector Material range: 60g/m2 (16 lb) Min 120g/m2 (32 lb) Max

Feed tray capacity: DI380/SI3300 - Up to a maximum of 325 sheets of 80g/m

2

DI425/SI3500 - Up to a maximum of 325 sheets of 80g/m

2

Manual Feed Mode: Stapled sets up to 5 sheets of 80g/m2 to a maximum total weight of

400g/m2 per set can be processed in the Manual Feed Mode.

Only Sheet Feeder number 1 (plus the Insert Feeder if required),

can be used for Manual Feed applications. The maximum

compressed thickness after folding should not exceed 2mm.

Glossy/coated sheets are not recommended.

Fold Type and Overall Thickness Limits

The table below shows the maximum number of sheets that can be accumulated or collated for each

fold type, based on different weights of paper.

It is important that jobs exceeding these maximums are NOT programmed into the machine

or imposed by OMR code printing and/or OMR selective feed.

The sheet limits above can be used with 1 additional sheet from the Supplementary Feeder plus 1

Insert, only if the total Mail Piece contents are up to a maximum of 2mm total compressed thickness.

For SINGLE Fold ONLY using 60-75g/m2 paper ONLY, up to 10 items can be placed into an envelope.

This 10 item maximum INCLUDES any additional sheet from the Supplementary Feeder and/or Insert.

The overall maximum compressed thickness of 2mm still applies.

Number of

sheets

Paper Weights in g/m

2

60-80 81-100 101-120

1 C,Z,S,D C,Z,S,D C,Z,S,D

2 C,Z,S,D C,Z,S,D C,Z,S

3 C,Z,S,D C,Z,S C,Z,S

4 C,Z,S C,Z,S

5 C,Z,S

Fold Types:

C = C Fold,

Z = Z Fold,

S = Single Fold,

D = Double Fold

2-2 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

2 • Specifications

Insert Feeder

Minimum Insert size: 127mm Width 82mm Length

Maximum Insert size: 230mm Width 152mm Length

Paper Weights: 75g/m2 Minimum (non-folded cut sheet)

180g/m2 Maximum (Single Sheet)

60g/m2 Minimum (folded material)

And Inserts of up to a maximum compressed thickness of 2mm.

Pre-folded or single panel Inserts should be fed from the Insert Feeder.

Double Document

Detector Material range: 60g/m2 Minimum 120g/m2 Maximum

Feed tray capacity: DI380/SI3300 - Up to a maximum of 100 Inserts

DI425/SI3500 - Up to a maximum of 300 Inserts

Sealer

The machine can seal up to a maximum of 1200 envelopes between rells.

Stacker

The envelope Stacker can accommodate up to 150 lled envelopes. (Dependent on size and

contents of the envelope).

Material Requirements

For best performance, use only materials approved by Pitney Bowes.

Materials should be good quality and properly stored.

Recommended storage conditions: 18°C (65°F) to 25°C (77°F)

40% to 60% relative humidity

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

2-3

2 • Specifications

Envelope Feeder

Minimum envelope size: 88mm Depth

220mm Width

Maximum envelope size: 164mm Depth

242mm Width

Envelope weights: 65g/m2 Minimum

100g/m2 Maximum

Envelope tray capacity: DI380/SI3300 - Up to a maximum of 100 90g/m2 envelopes

DI425/SI3500 - Up to a maximum of 300 90g/m2 envelopes

End Clearance: End clearance between the Insert and envelope is a

minimum of 6mm at each side i.e. a minimum of

12mm overall. This measurement should be taken with all

Mail Piece contents placed into the envelope.

Depth Clearance: The Mail Piece Contents must allow a minimum clearance

of 3mm for unfolded inserts, and 6mm for folded material,

below the ap crease after being fully inserted into the

envelope.

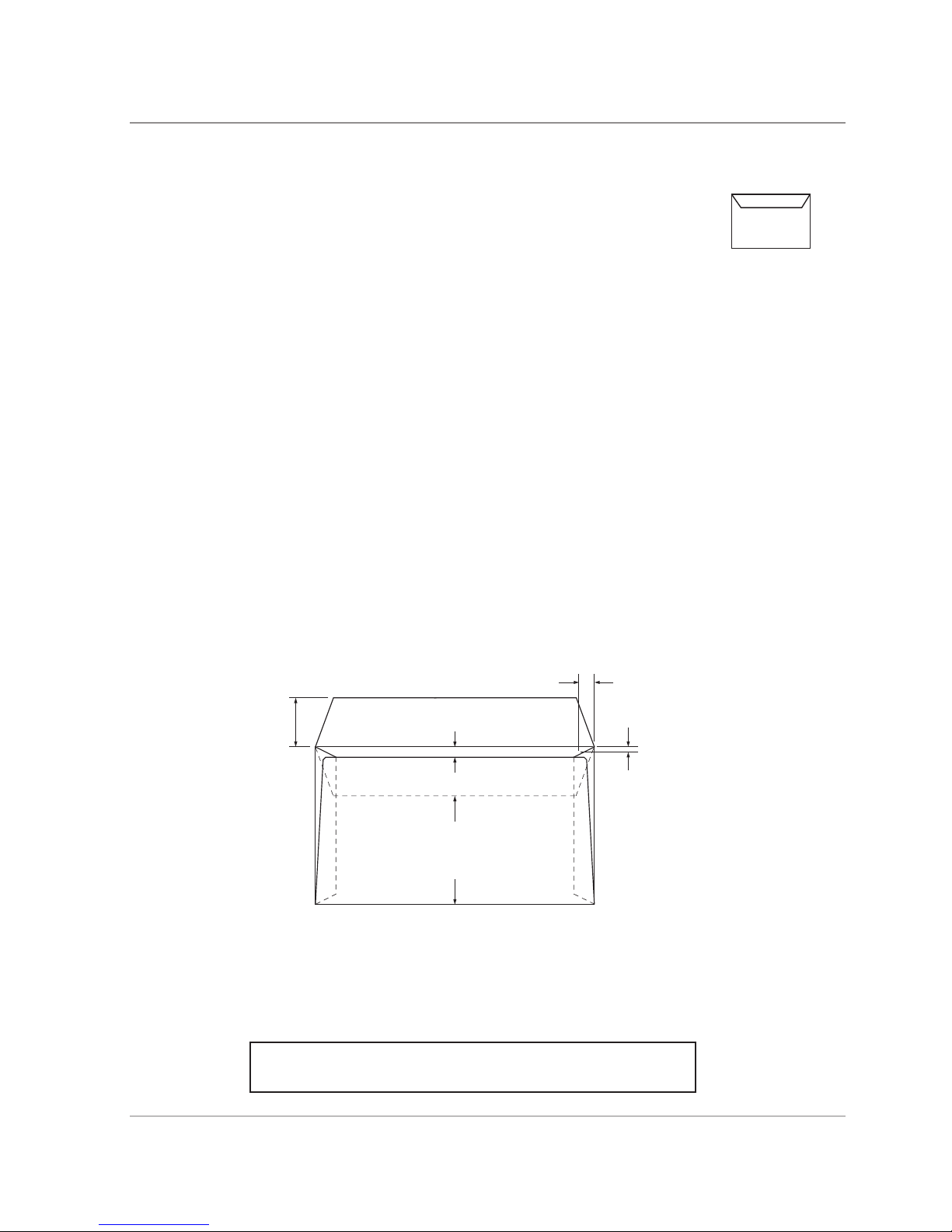

Envelope ap and throat requirements:

DEPTH

WIDTH

Min 25.5mm

Max 63mm

Min 6mm

Max 41mm

19mm

Min 1.6mm

Max 6mm

throat depth

at 19mm in from

edge of envelope

Closed ap tip should not

come closer than

44mm to bottom

of envelope

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTIFICATION AND ARE SUBJECT TO TEST

2-4 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

2 • Specifications

2.2 MACHINE SPECIFICATIONS

Physical Dimensions DI380/SI3300 DI425/SI3500

Length 773mm 1043mm

Depth 568mm 568mm

Height 525mm 525mm

Weight 55kg 65kg

Weight will depend on machine conguration. Weights stated do not include material.

Noise Level

Running 73dBA

Electrical 230VAC, 50Hz, 3A

or 110VAC, 60Hz, 6A

Maximum Speed DI380/SI3300 - Up to a maximum of 3,000 cycles per hour

DI425/SI3500 - Up to a maximum of 3,500 cycles per hour

Depending on model, fold type and material quality.

Compliance It is certied that the Folding/Inserting machine complies with the

requirements of the Low Voltage Directive 73/23/EEC and the EMC

Directive 89/336/EEC. The product was tested in a typical conguration.

For a formal Declaration of Conformity please contact Compliance

Engineering on +44 (0)1279 426731.

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTIFICATION AND ARE SUBJECT TO TEST

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-1

3 • Theory of Operation

3 • Theory of Operation

Note:

Before any job commences, it is assumed that all the appropriate trays are lled to complete

the sequences described below.

Please refer to relevant diagrams in Section 10- Diagrams

3.1 INTRODUCTION TO SYSTEM THEORY

The DI380/SI3300 and DI425/SI3500 are low volume easy to use Folding/Inserting machines, each

available in 3 variants (1, 2 and 3 station machines).

The sheet feeder(s) have self centring guides and automatic separation based on photo copier

technology. Therefore the documents do not require shingling before the they are presented to the

separator roller and pad. The sheet feeders have a sprung lift plate that lifts the weight of the documents

up to the separator roller to ensure only a single document is fed.

The insert feeder has a more traditional type of separation, by means of a manual height adjustment

and a stone/shield setting that is operator settable. This is to enable diverse material to be processed

through the insert feeder.

The envelope feeder will automatically separate a stack of envelopes to ensure only a single envelope

is fed. The separator height is set by the engineer.

When the Start button is pressed, a single sheet is fed into the paper path and driven into fold plate

1. When the sheet reaches the deector stop, the paper is buckled. This buckled edge is then pulled

through fold rollers 2 and 3 which creates the rst fold. It then enters fold plate 2 until it reaches the

deector stop, where the sheet is buckled again. The edge is pulled into fold rollers 3 and 4, creating

the second fold. At this stage, if an insert is programmed as part of the job, the insert will ‘red’ into the

waiting document.

The envelopes are fed aps up and trailing through the apper unit where the envelope ap is peeled

away from the body of the envelope.The envelope then passes through to the Q station area where it

is stopped. The ap of the envelope is held back by the brush. The envelope is opened when the ipper

ngers press down on the back of the envelope and four insertion ngers enter the envelope throat.

The folded sheet (package) at fold rollers 3 and 4, travels through the transport plate rollers and is

driven into the waiting envelope by the insert drive rollers. Once the insert fully enters the envelope,

the Q station ngers lift up and the package then travels along to the sealer rollers where moisture is

applied to the envelope ap. The body of the envelope is forced up into the inverter stop, this in turns

forces the envelope back into the nip of the sealer rollers and presses the ap against the body of the

envelope.

The envelope activates the exit switch as it passes the exit rollers and increments the counter by

one.

3-2 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.2 SINGLE SHEET FEEDER MODE & LINKED FEEDER MODE

When the start button is pressed, the sheet feeder motor (M1) is switched on. This feeds a sheet over

the Double Document Detector (DDD1) sensor and stops it, after a counted delay, in the collation nip.

This results in the sheet being slightly over driven.

At the same time, the envelope motor (M9) is switched on and an envelope is fed through the separator

pad and roller. When the lead edge of the envelope moves forward to the envelope sensor (S1), the

software sends the signal to turn on the collation motor (M5). The transported envelope stops in the

insertion area at a predetermined time according to the size of envelope programmed within the job

setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

The next sheet fed from the sheet feeder is triggered by the previous sheet fed entering the fold plate

2 sensor OP14. When the folded sheet enters onto the pivot plate, this moves the ag out of sensor

(OP5). When the folded sheet is fully inserted, the pivot plate moves backwards returning the ag to

its home position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting the

brush of the sealer by energizing solenoid (L5). It will then de-energize the hold down solenoid (L2),

insertion solenoid (L1), and the shoe horn solenoid (L3).

The envelope is then driven from the insertion area into the sealer area. The next envelope is fed when

the lead edge of the envelope pushes the moistener sensor (S3) forward (the software will increment by

a count of 1 for the EIU). The envelope then enters the inverter area and nally exits into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

In normal run mode, if no material has been detected at the Double Document Detection sensor, the

sheet feeder motor (M1) will time-out after approximately 2 seconds. This is to clean the separator

roller and pad. In 'daily mail' (manual feed) mode, this time is increased to approximately 20 seconds

for operator loading. The manual feed lever opens the gap between the separator roll and pad.

In switchable mode, the software will activate sheet feeder 2 automatically if the tray empty sensor

(OP9) detects that no paper is present in sheet feeder 1 when the document has entered fold plate 2

(OP14).

The software will then switch back to running sheet feeder 1 when the sheet feeder 2 tray empty sensor

(OP10) detects that no paper is present in sheet feeder 2 when the document has entered fold plate

2 (OP14).

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-3

3 • Theory of Operation

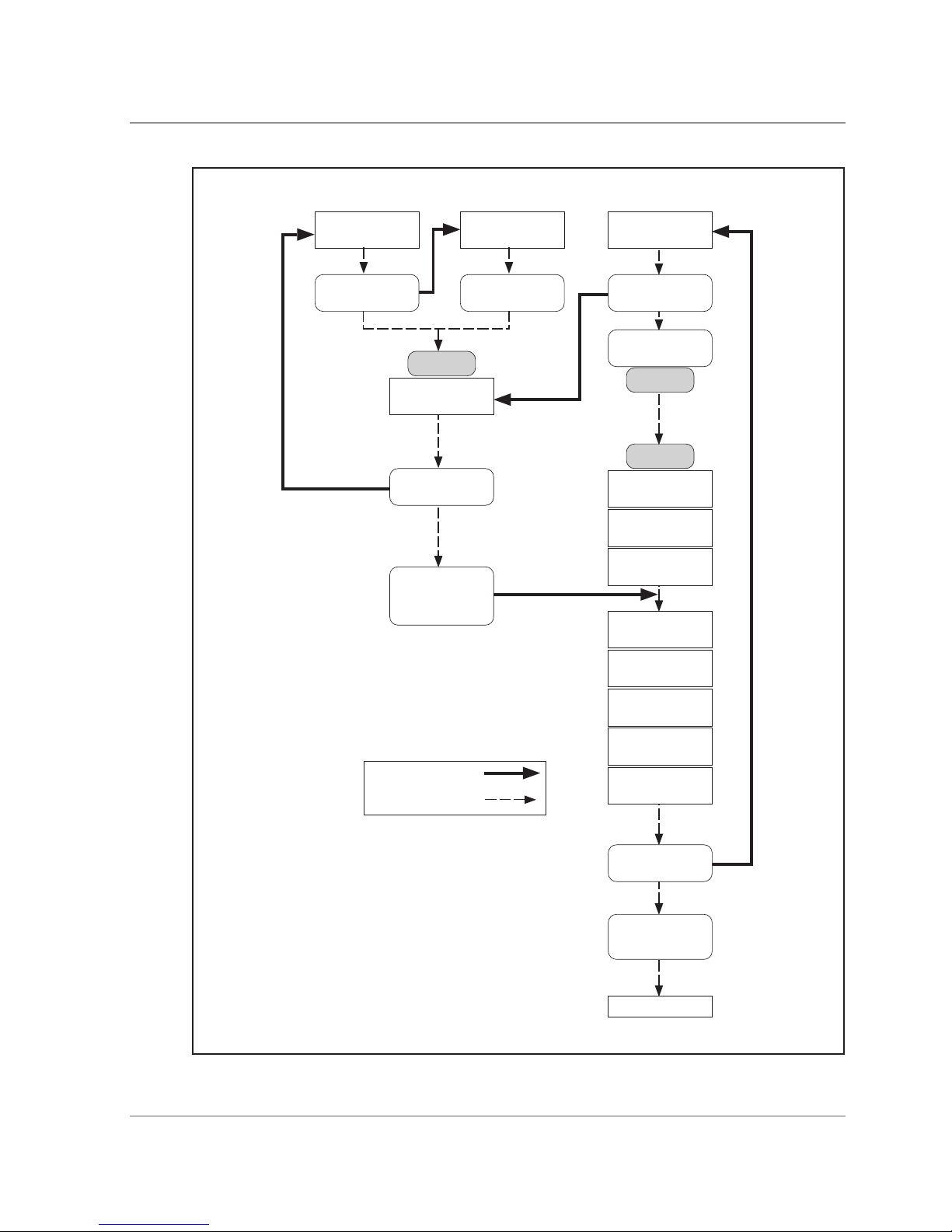

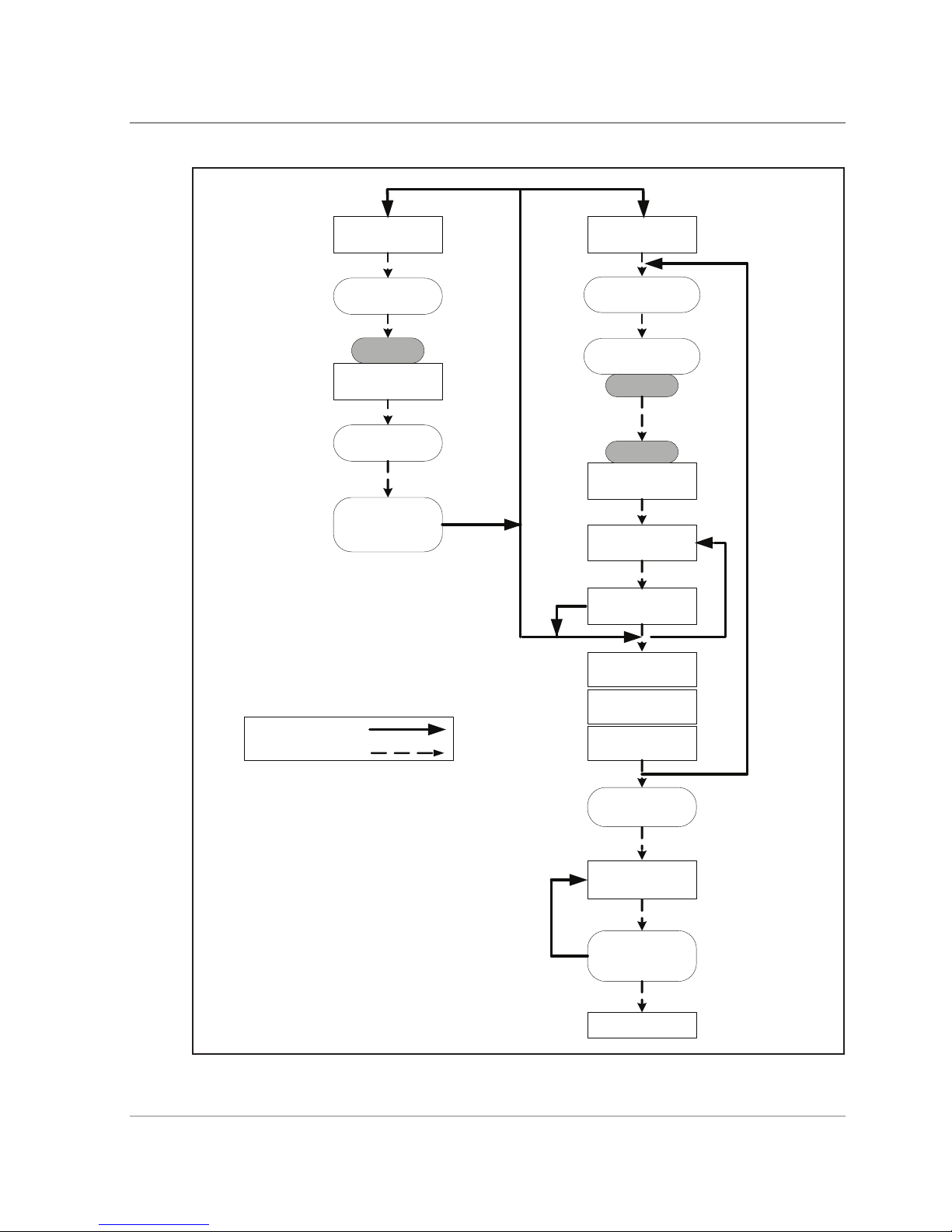

Flow Diagram - Single Sheet Feeder Mode

Sheet Feeder

Motor M1 (OP9)

Sheet Feeder

DDD 1 Sensor

Stop

Collation Motor

M5

Fold Plate 2

Sensor OP14

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Envelope Motor M9

ON

Envelope Sensor S1

ON

Lead Edge Sensor S2

ON

Delay

Stop

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON

Shoe Horn Solenoid

L3 ON

Finger Solenoid L4

ON

Sealer Solenoid L5

ON

Insertion Solenoid L1

OFF

Hold Down Solenoid

L2 OFF

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Mechanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

Shoe Horn Solenoid

L3 OFF

Sheet Feeder

Motor M2 (OP10)

Sheet Feeder

DDD 2 Sensor

3-4 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.3 INSERT FEEDER MODE

When the start button is pressed, two motors control the transport of the insert. The insert pre-feeder

motor (M3) is energized and feeds a single insert past the Double Document Detection (DDD3) sensor.

If a double is detected, the machine will stop and the double insert symbol will be indicated on the

control panel. If no double is detected, the insert will continue to the insert collation area and stop.

At the same time, the envelope motor (M9) is energized. An envelope is fed through the separator pad

and roller.

The transported envelope will stop in the insertion area at a predetermined time according to the size

of envelope programmed within the job setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

When the shoe horn solenoid is energized, the software sends a signal to operate the insert collation

motor (M4). This will trigger the next insert to be fed into the collation insert area.

When the insert enters onto the pivot plate, this moves the ag out of sensor (OP5). When the insert

is fully inserted, the pivot plate moves backwards returning the ag to its home position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting the

brush of the sealer by energizing solenoid (L5). It will then de-energize the hold down solenoid (L2),

insertion solenoid (L1), and the shoe horn solenoid (L3).

The envelope will then be driven from the insertion area into the sealer area. The next envelope will

be fed when the lead edge of the envelope pushes the moistener sensor (S3) forward (the software

will increment by a count of 1 for the EIU). The envelope will then enter the inverter area and then exit

into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-5

3 • Theory of Operation

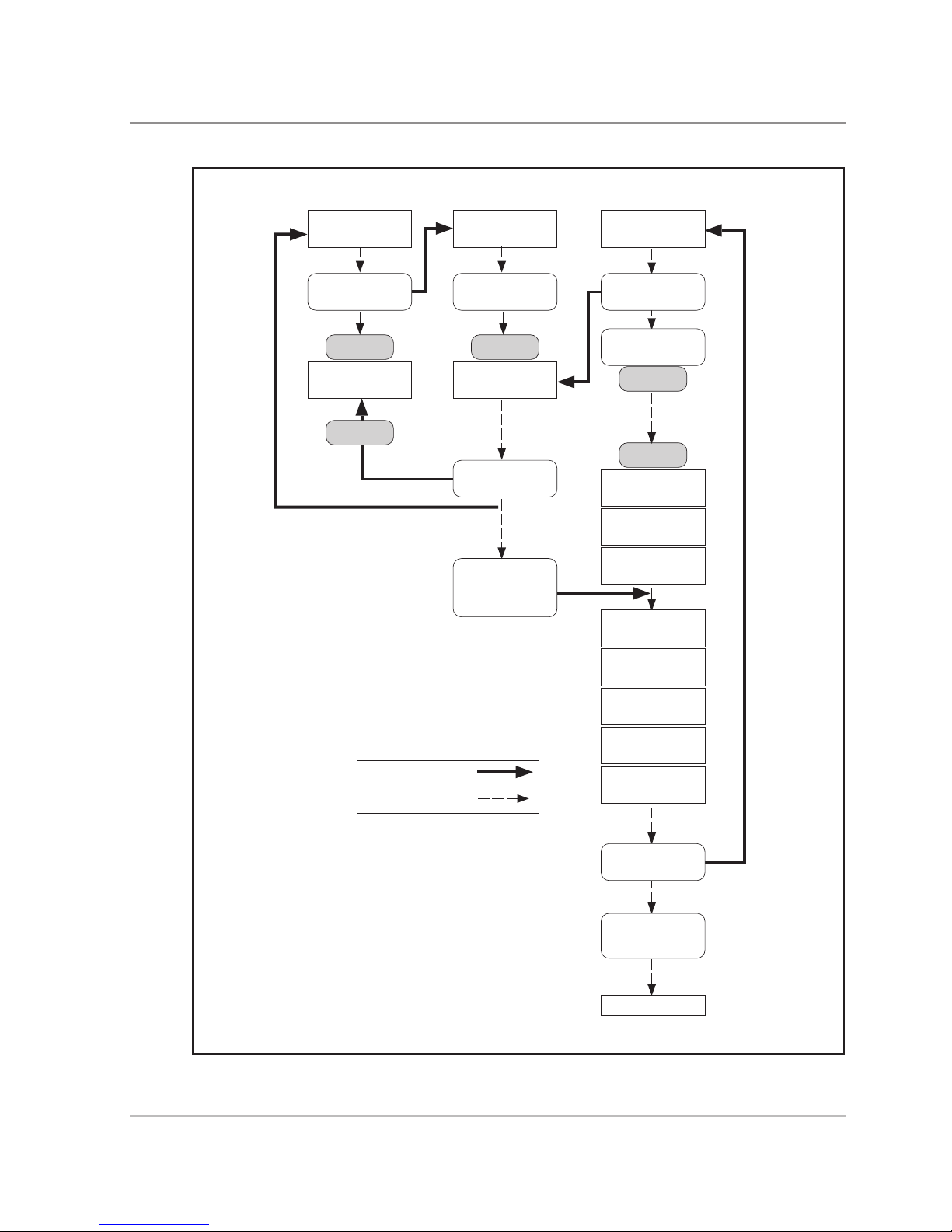

Flow Diagram - Insert Feeder Mode

Insert Pre-Feed

Motor M3

Insert

DDD 3 Sensor

Stop

Insert Collation Motor

M4

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Envelope Motor M9

ON

Envelope Sensor S1

ON

Lead Edge Sensor S2

ON

Delay

Stop

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON

Shoe Horn Solenoid

L3 ON

Hold Down Solenoid

L2 OFF

Insertion Solenoid L1

OFF

Shoe Horn Solenoid

L3 OFF

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Mechanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

Sealer Solenoid L5

ON

Finger Solenoid L4

ON

3-6 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.4 TWO SHEET FEEDER MODE

When the start button is pressed, the sheet feeder motor (M1) is switched on. This feeds a sheet over

the Double Document Detector (DDD1) sensor. This triggers sheet feeder motor (M2) to feed a sheet

up to the Double Document Detector (DDD2). Both sheets stop, after a counted delay, in the collation

nip. This results in the sheets being slightly over driven.

At the same time, the envelope motor (M9) is switched on and an envelope is fed through the separator

pad and roller. When the lead edge of the envelope moves forward to the envelope sensor (S1), the

software sends the signal to turn on the collation motor (M5). The transported envelope will stop in the

insertion area at a predetermined time according to the size of envelope programmed within the job

setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

The next sheet fed from the sheet feeder 1 is triggered by the previous sheet fed entering the fold plate

2 sensor OP14. When the folded sheet enters onto the pivot plate, this moves the ag out of sensor

(OP5). When the folded sheet is fully inserted, the pivot plate moves backwards returning the ag to

its home position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting the

brush of the sealer by energizing solenoid (L5). It will then de-energize the hold down solenoid (L2),

insertion solenoid (L1), and the shoe horn solenoid (L3).

The envelope is then driven from the insertion area into the sealer area. The next envelope is fed when

the lead edge of the envelope pushes the moistener sensor (S3) forward (the software will increment by

a count of 1 for the EIU). The envelope then enters the inverter area and nally exits into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-7

3 • Theory of Operation

Flow Diagram - Two Sheet Feeder Mode

Sheet Feeder

Motor M1

Sheet Feeder

DDD 1 Sensor

Stop

Collation Motor

M5

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Envelope Motor M9

ON

Envelope Sensor S1

ON

Lead Edge Sensor S2

ON

Delay

Stop

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON

Shoe Horn Solenoid

L3 ON

Hold Down Solenoid

L2 OFF

Insertion Solenoid L1

OFF

Shoe Horn Solenoid

L3 OFF

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Mechanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

Sealer Solenoid L5

ON

Sheet Feeder

Motor M2

Sheet Feeder

DDD 2 Sensor

Fold Plate 2

Sensor OP14

Finger Solenoid L4

ON

3-8 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.5 SINGLE SHEET FEEDER PLUS AN INSERT MODE

When the start button is pressed two motors control the transport of the insert. The insert pre-feeder

motor (M3) is energized and feeds a single insert past the Double Document Detection (DDD3) sensor.

If a double is detected, the machine will stop and the double insert symbol will be indicated on the

control panel. If no double is detected, the insert will continue to the insert collation area and stop.

The sheet feeder motor (M1) triggered by the insert passing through the Double Document Detection

and feeds the sheet over the Double Document Detector (DDD1) sensor and stops after a counted

delay in the collation nip. This will result in the sheet being slightly over driven.

At the same time the envelope motor (M9) is energized. An envelope is fed through the separator pad

and roller.

When the lead edge of the envelope moves forward to the envelope sensor (S1), the software sends

the signal to energize the collation motor (M5) to switch on. The transported envelope will stop in the

insertion area at a predetermined time according to the size of the envelope programmed within the

job setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

When the sheet enters fold plate 2, covering sensor OP14, the software switches on the insert motor

(M4) after a timed delay. This delay is the "nesting constant" set in the parameter screen.

The next insert is fed after the rst insert is nested into the folded sheet.

When the folded sheet and insert enter onto the pivot plate, this moves the ag out of sensor (OP5).

When the insert is fully inserted, the pivot plate moves backwards returning the ag to its home

position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting the

brush of the sealer by energizing solenoid (L5). It will then de-energize the hold down solenoid (L2),

insertion solenoid (L1), and the shoe horn solenoid (L3).

The envelope is then driven from the insertion area into the sealer area. The next envelope is fed when

the lead edge of the envelope pushes the moistener sensor (S3) forward (the software will increment by

a count of 1 for the EIU). The envelope then enters the inverter area and nally exits into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-9

3 • Theory of Operation

Flow Diagram - Single Sheet Feeder Plus an Insert Mode

Sheet Feeder

DDD 1 Sensor

Insert Pre-Feed

Motor M3

Insert Feeder

DDD 3 Sensor

Stop

Collation Motor

M5

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Envelope Motor M9

ON

Envelope Sensor S1

ON

Lead Edge Sensor S2

ON

Delay

Stop

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON

Shoe Horn Solenoid

L3 ON

Hold Down Solenoid

L2 OFF

Insertion Solenoid L1

OFF

Shoe Horn Solenoid

L3 OFF

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Mechanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

Sealer Solenoid L5

ON

Sheet Feeder

Motor M1

Fold Plate 2

Sensor OP14

Stop

Insert Motor

M4

Delay

Finger Solenoid L4

ON

3-10 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

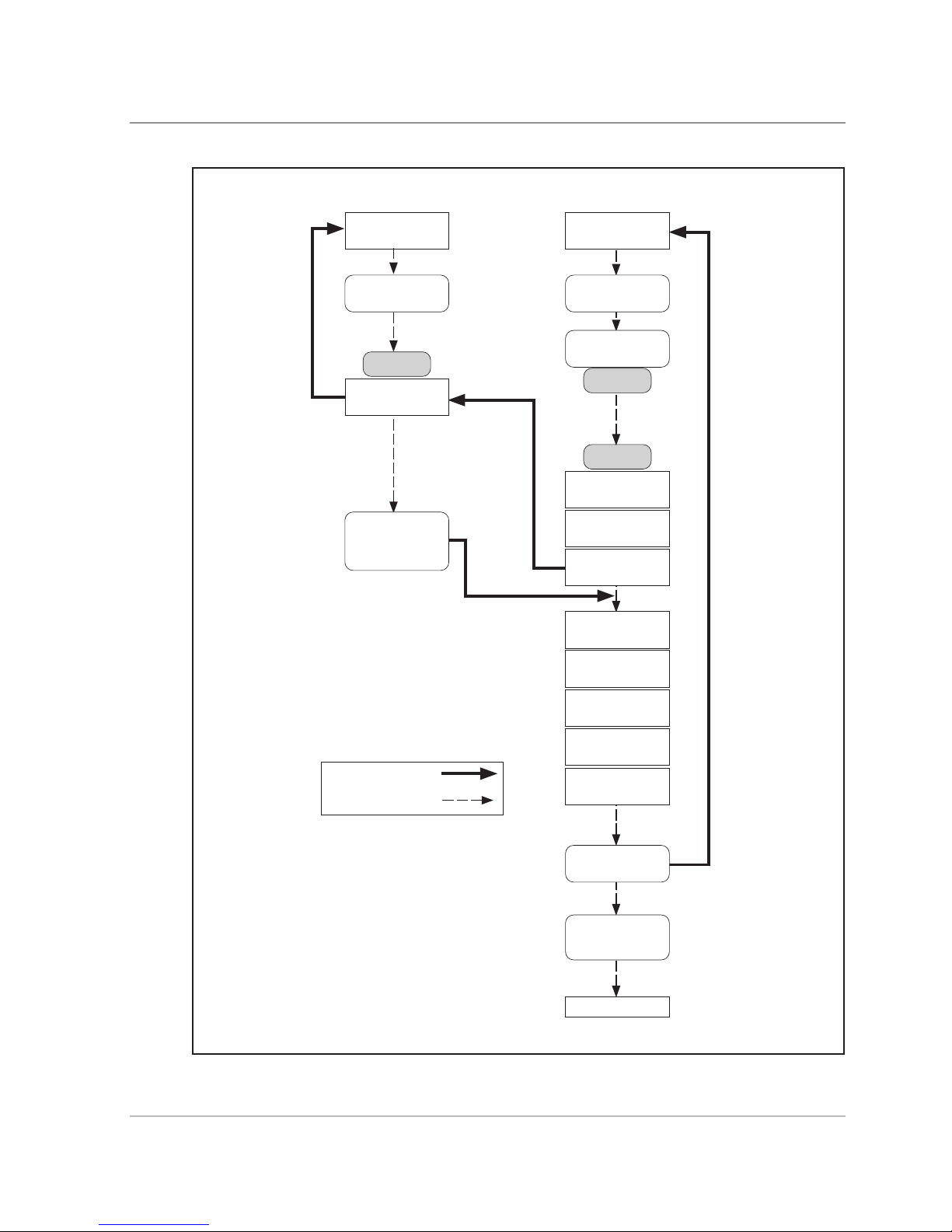

3.6 TWO SHEET FEEDERS PLUS AN INSERT MODE

When the start button is pressed. The insert pre-feeder motor (M3) is energized and feeds a single

insert past the Double Document Detection (DDD3) sensor. If a double is detected, the machine will

stop and the double insert symbol will be indicated on the control panel. If no double is detected, motor

(M4) will energies and will feed the insert into to the insert collation area and stop.

The sheet feeder motor (M1) is triggered by the insert passing through the Double Document Detection

(DDD3), feeds the sheet over the Double Document Detector (DDD1). The Double Document Detector

(DDD1) triggers sheet feeder motor (M2) to feed the sheet through the Double Document Detector

(DDD2), both sheets stop, after a counted delay, in the collation nip. This will result in the sheets being

slightly over driven.

At the same time, the envelope motor (M9) is energized. An envelope is fed through the separator pad

and roller.

When the lead edge of the envelope moves forward to the envelope sensor (S1), the software sends

the signal to energize the collation motor (M5).

The transported envelope will stop in the insertion area at a predetermined time according to the size

of envelope programmed within the job setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

When the sheet enters fold plate 2, covering sensor OP14, the software switches on the insert motor

(M4) after a timed delay. This delay is the "nesting constant" set in the parameter screen.

The next insert is fed after the rst insert is nested into the folded sheets.

When the folded sheets and insert enter onto the pivot plate, this moves the ag out of sensor (OP5).

When the insert is fully inserted, the pivot plate moves backwards returning the ag to its home

position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting the

brush of the sealer by energizing solenoid (L5). It will then de-energize the hold down solenoid (L2),

insertion solenoid (L1), and the shoe horn solenoid (L3).

The envelope is then driven from the insertion area into the sealer area. The next envelope is fed when

the lead edge of the envelope pushes the moistener sensor (S3) forward (the software will increment by

a count of 1 for the EIU). The envelope then enters the inverter area and nally exits into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-11

3 • Theory of Operation

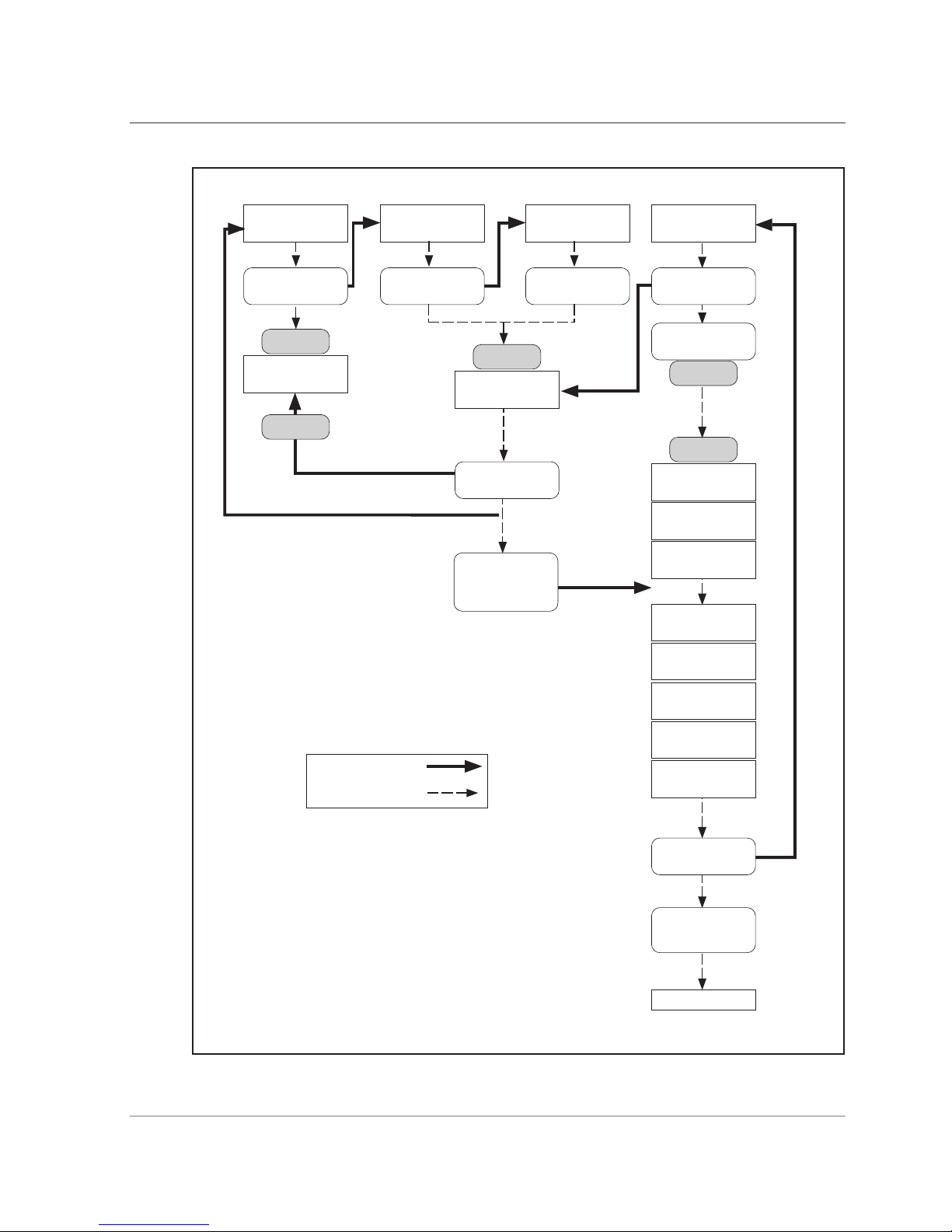

Flow Diagram - Two Sheet Feeders Plus an Insert Mode

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Insert Pre-Feed

Motor M3

Insert Feeder

DDD 3 Sensor

Envelope Motor M9

ON

Envelope Sensor S1

ON

Lead Edge Sensor S2

ON

Delay

Stop

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON

Shoe Horn Solenoid

L3 ON

Hold Down Solenoid

L2 OFF

Insertion Solenoid L1

OFF

Shoe Horn Solenoid

L3 OFF

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Mechanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

Sealer Solenoid L5

ON

Stop

Insert Motor

M4

Delay

Finger Solenoid L4

ON

Sheet Feeder

Motor M1

Sheet Feeder

DDD 1 Sensor

Stop

Collation Motor

M5

Sheet Feeder

Motor M2

Sheet Feeder

DDD 2 Sensor

Fold Plate 2

Sensor OP14

3-12 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.7 THE FOLD ONLY MODE

When the start button is pressed, the sheet feeder motor (M1) is switched on. This feeds a sheet over

the Double Document Detector (DDD1) sensor. The sheet stops, after a counted delay, in the collation

nip. This results in the sheet being slightly over driven.

The software disables the envelope motor (M9) and envelope sensor (S1) and sends the signal to turn

on the collation motor (M5).

The next sheet fed from the sheet feeder will be triggered by the previous sheet fed entering the fold

plate 2 sensor OP14. When the folded sheet enters onto the pivot plate, this moves the ag out of

sensor (OP5). The pivot plate moves backwards and returns the ag to its home position.

This operation triggers the software to energize the nger solenoid (L4), lifting the ngers and lifting

the brush of the sealer by energizing solenoid (L5).

The document is then driven from the insertion area into the sealer area. The next document is fed

when the lead edge of the document pushes the moistener sensor (S3) forward (the software will

increment by a count of 1 for the EIU). The document then enters the inverter area and nally exits

into the stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-13

3 • Theory of Operation

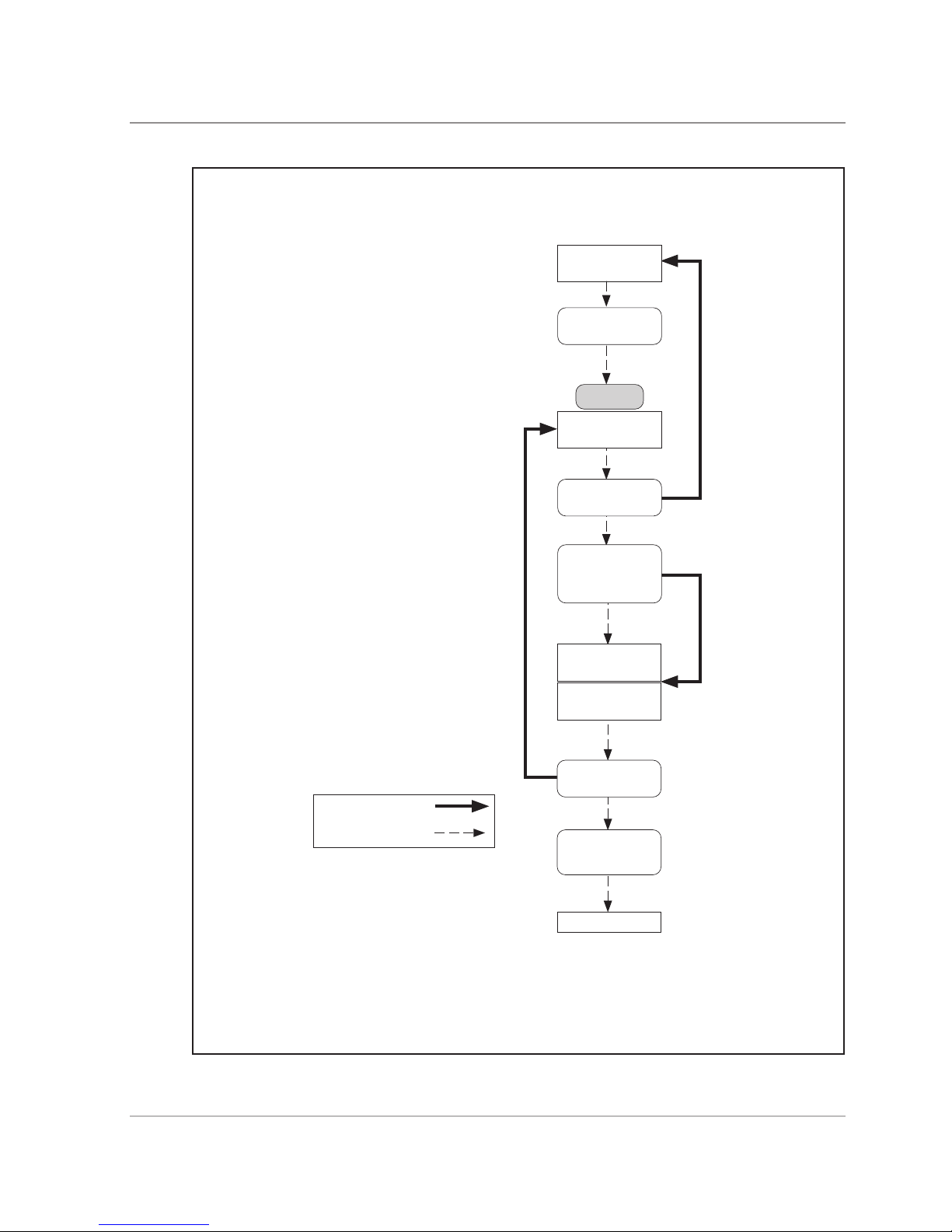

Flow Diagram - The Fold Only Mode

Sheet Feeder

Motor M1

Sheet Feeder

DDD 1 Sensor

Stop

Collation Motor

M5

Fold Plate 2

Sensor OP14

Transport Pivot

Plate

Unblocked/Blocked

Sensor OP5

Finger Solenoid L4

ON

Sealer Solenoid L5

ON

Moistener Sensor

(Software Counter) S3

Exit Sensor

(Machanical Item

Counter) S4

EXIT

SOFTWARE TRIGGER

PAPER PATH

First cycle does not

stop at the collation

motor.

3-14 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

3.8 ACCUMULATION FROM MAIN SHEET FEEDER

After a trial piece has been processed and the start button is pressed, the sheet feeder motor (M1) is

switched on. This feeds a sheet over the Double Document Detector (DD1) sensor and stops it, after

a counted delay, in the collation nip. This results in the sheet being slightly over driven.

At the same time, the envelope motor (M9) is switched on and an envelope is fed through the separator

pad and roller. When the lead edge of the envelope moves forward to the envelope sensor (S1), the

software sends the signal to turn on the collation motor (M5). The transported envelope stops in the

insertion area at a predetermined time according to the size of envelope programmed within the job

setup.

The insertion solenoid (L1) energizes, followed by the hold down solenoid (L2), and nally, by the shoe

horn solenoid (L3).

Depending on fold type the sheet will be fed through the fold rollers and fold plates.

The folded sheet enters onto the pivot plate this moves the ag out of sensor (OP5). When the folded

sheet is fully inserted, the pivot plate moves backwards returning the ag to its home position this de-

energizes the hold down solenoid (L2) and the shoe horn solenoid (L3)

L3 energizes again placing the shoe horn back into the envelope lifting the previous folded documents

up.

The software sends the signal to turn on the collation motor (M5) sending the next sheet down through

the fold rollers and fold plates onto the pivot plate. This happens until the predetermined sheets are

inserted into the envelope. After the last document has entered the envelope the pivot plate moves the

ag out of the sensor (OP5).

This operation then triggers the software to energize the nger solenoid (L4), lifting the ngers and

lifting the brush of the sealer by energizing solenoid (L5) and the insertion solenoid (L1). The shoe horn

at this point stays energized until the package passes the moistener sensor (S3).

The envelope is driven from the insertion area into the sealer area. The next envelope is fed when the

lead edge of the envelope pushes the moistener sensor (S3) forward (the software will be Incremented

by a count of 1 for the EIU). The envelope then enters the inverter area and nally exits into the

stacker.

The exit sensor (S4) will increment the mechanical counter (located behind the manual advance knob

door) by 1.

In normal run mode, if no material has been detected at the Double Document Detection sensor, the

sheet feeder motor (M1) will time-out after approximately 2 seconds. This is to clean the separator

roller and pad. In 'daily mail' (manual feed) mode, this time is increased to approximately 20 seconds

for operator loading. The manual feed lever opens the gap between the separator roll and pad.

This sequence is shown in ow chart form on the following page.

SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3-15

3 • Theory of Operation

Flow Diagram - Accumulation for Sheet Feeder 1 Mode

Envelope Motor M9

ON

Envelope Sensor S1

ON

Stop

Insertion Solenoid L1

Off

Insertion Solenoid L1

ON

Hold Down Solenoid

L2 ON/OFF

Shoe Horn Solenoid

L3 ON/OFF

Finger Solenoid L4

ON

Sealer Solenoid L 5

ON

Shoe Horn Solenoid

L3 OFF

Lead Edge Sensor S2

ON

Transport Pivot Plate

Unblocked/Blocked

Sensor OP5

Moistener Sensor S3

(Software Counter)

Sheet Feeder DDD 1

Sensor

Exit Sensor S 4

(Mechanical Item

Counter)

Stop

Delay

EXIT

Collation Motor M5

SOFTWARE TRIGGER

PAPER PATH

Sheet Feeder Motor

M1 (OP9)

Fold Plate 2 Sensor

OP14

3-16 SDT333A DI380/DI425/SI3300/SI3500 Service Manual

3 • Theory of Operation

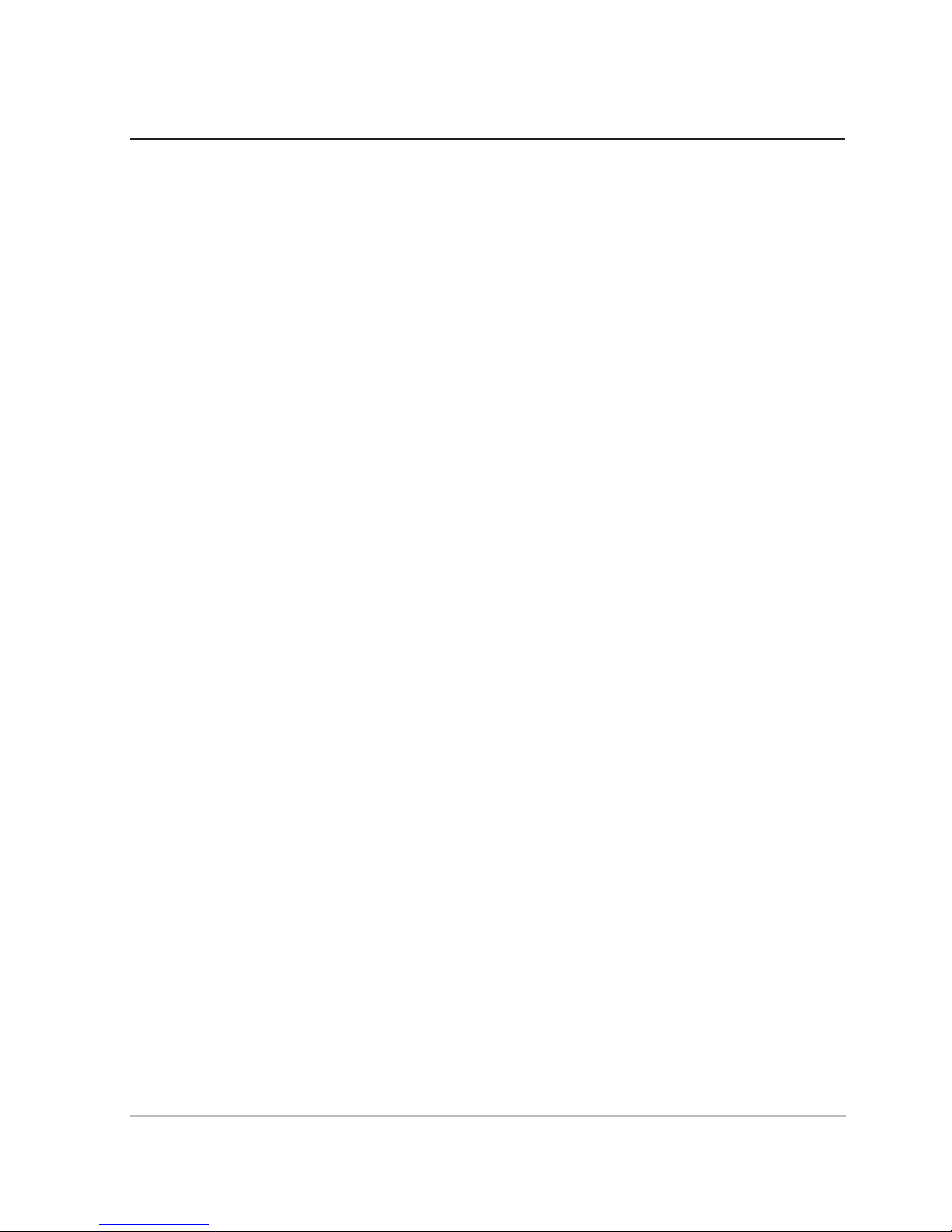

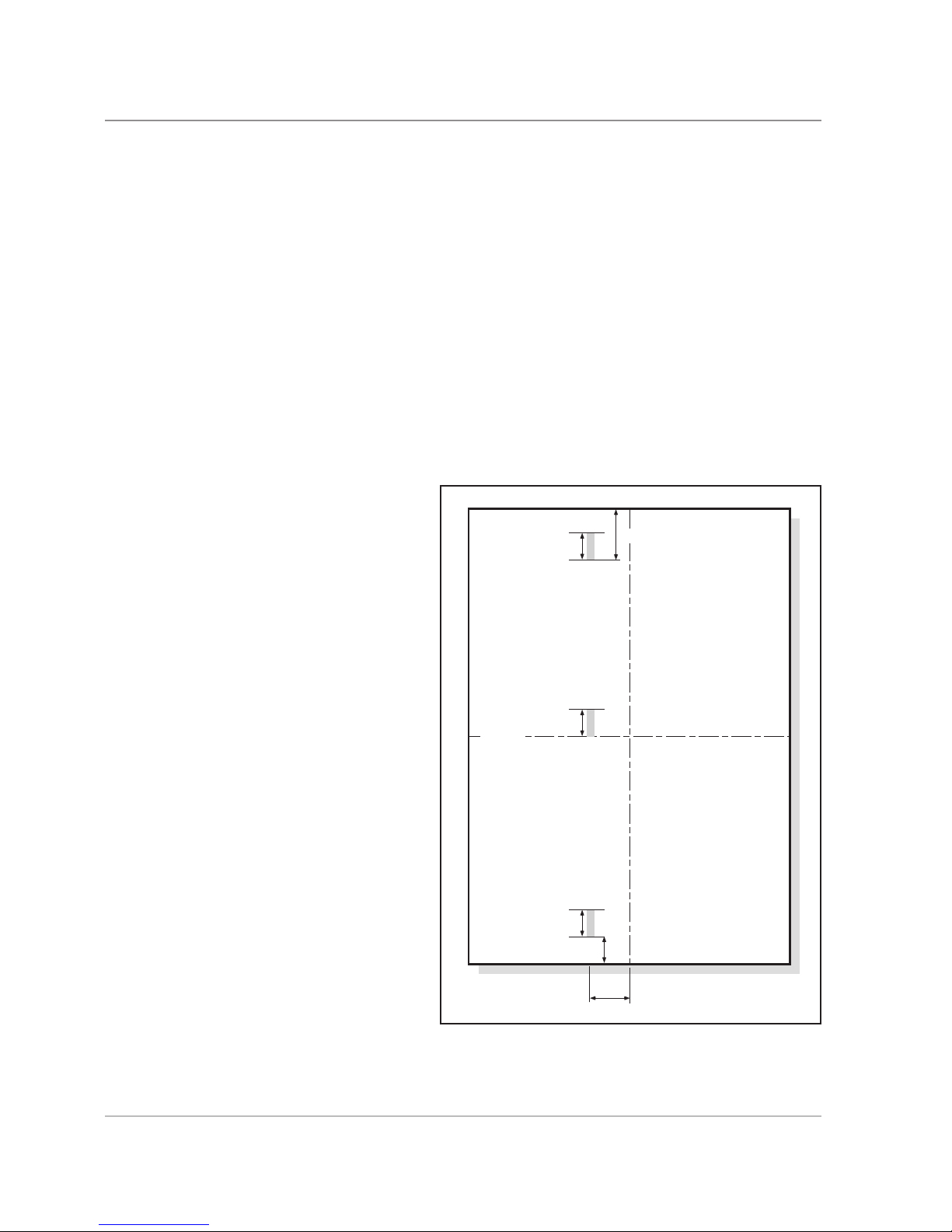

3.9 DOUBLE DETECT SENSORS

only adjustable in the service parameters screen and are not operator selectable. This is to allow the

engineer to choose different detection reference points to suit the customer’s application.

Sheet Feeder 1 and Sheet Feeder 2 have three positions available: LEAD, MIDDLE and TRAIL. The

Insert feeder has only the one option: LEAD.

The Detection sensors work on an LED emmiting through the thickness of the paper onto a Opto

detector. The double detection takes 14 reference points in a 22mm window. There are 7 “High” and 7

“Low”. From these readings, the software will take 7 relevant readings. The sensor is positioned 50mm

to the left of the centre line.

On the LEAD position, the double detection will start reading at approximately 22mm from the lead

edge of the document in the direction of feed. When a double is detected, the machine will stop and

the document will be in the collation nip area. The machine will indicate which feeder the double has

been fed from on the control panel.

On the MIDDLE position (not available

on the inser t feede r) th e dou ble

detection will start halfway down the

document. This is taken from the “length

of paper” entered in the “Job Set Up

Menu”. When a double is detected, the

machine will stop and the document will

be in the insertion area. The machine

will indicate which feeder the double has

been fed from on the control panel.

On the TRAIL position (not available on

the insert feeder) the double detection

will start approximately 45mm from

the trail edge of the document in the

direction of feed. This is taken from the

“length of paper” entered in the “Job Set

Up Menu”. When a double is detected,

the machine will stop with the document

inserted and fed into the stacker area.

The machine will display “Double Check

Stacker” and also indicate which feeder

the double was fed from on the control

panel.

DDD Scan Areas

45mm

TRAIL

22mm

LEAD

50mm

MIDDLE

22mm

22mm

22mm

centre line

centre line

Loading...

Loading...