Pitco Frialator RP-14, RP-18 Part Manual

SERVICE SECTION

There's Always Something Cooking!

Service, Parts, and Schematics

For Reversible Pump Filter Systems

Covering Models

RP-14 & RP-18

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304

(800) 258-3708 • (603) 225-6684 • FAX (603) 225-8497

R

MTS # PF28-04 Pitco Frialator #L20-091-02 Original Rev. Date 12/27/93

Table of Contents

Section Title Page

Table of Contents (Service) ............................................................................................................. i

List of Tables and Figures ............................................................................................................... ii

Chapter 4: Service ....................................................................................................................4-1

4.1 REPLACEMENT PROCEDURES.......................................................................... 4-1

4.1.1 Pump/Motor Removal.......................................................................................... 4-1

4.2 TROUBLESHOOTING FILTER SYSTEMS ......................................................... 4-2

Chapter 5: Parts .................................................................................................................5-1

ALPHABETICAL PART LIST ............................................................................... 5-5

NUMERICAL PART LIST ......................................................................................5-7

Chapter 6: Schematics..............................................................................................................6-1

i

List of Tables and Figures

Figure Title Page

5-1 Reviersible Pump Filter System ................................................................................. 5-4

Table No. Title Page

5-1 Reversible Pump Filter System .................................................................................. 5-1

ii

Chapter 4: Service

This chapter provides the qualified technician with the replacement and troubleshooting procedures

necessary to service the Pitco filter system.

4.1 REPLACEMENT PROCEDURES

These procedures are provided to the qualified technician as a guide to removal and replacement of

various filter system components. If a test is required to verify component operation after installation,

it will be referenced.

4.1.1 Pump/Motor Removal

1. Remove the screws to the motor cover. (10 total)

2. Remove the cover from the unit.

3. Loosen both unions on each side of the pump head.

4. Remove the hex nuts and washers from the motor base (4 total).

5. Cut and remove the white electrical tape that holds the heat tape to the pump head. (Heater

Option Only)

6. Remove the orange heat tape wrapped around the pump head. (Heater Option Only)

7. Remove the motor electrical door at the rear of the motor.

8. Remove all wirenuts leading to the motor.

9. Remove valve handle by removing the nut on the valve.

10. The pump/motor can be removed by raising the pump/motor straight up over the studs and

twisting out.

11. Replace by reversing above procedures.

4-1

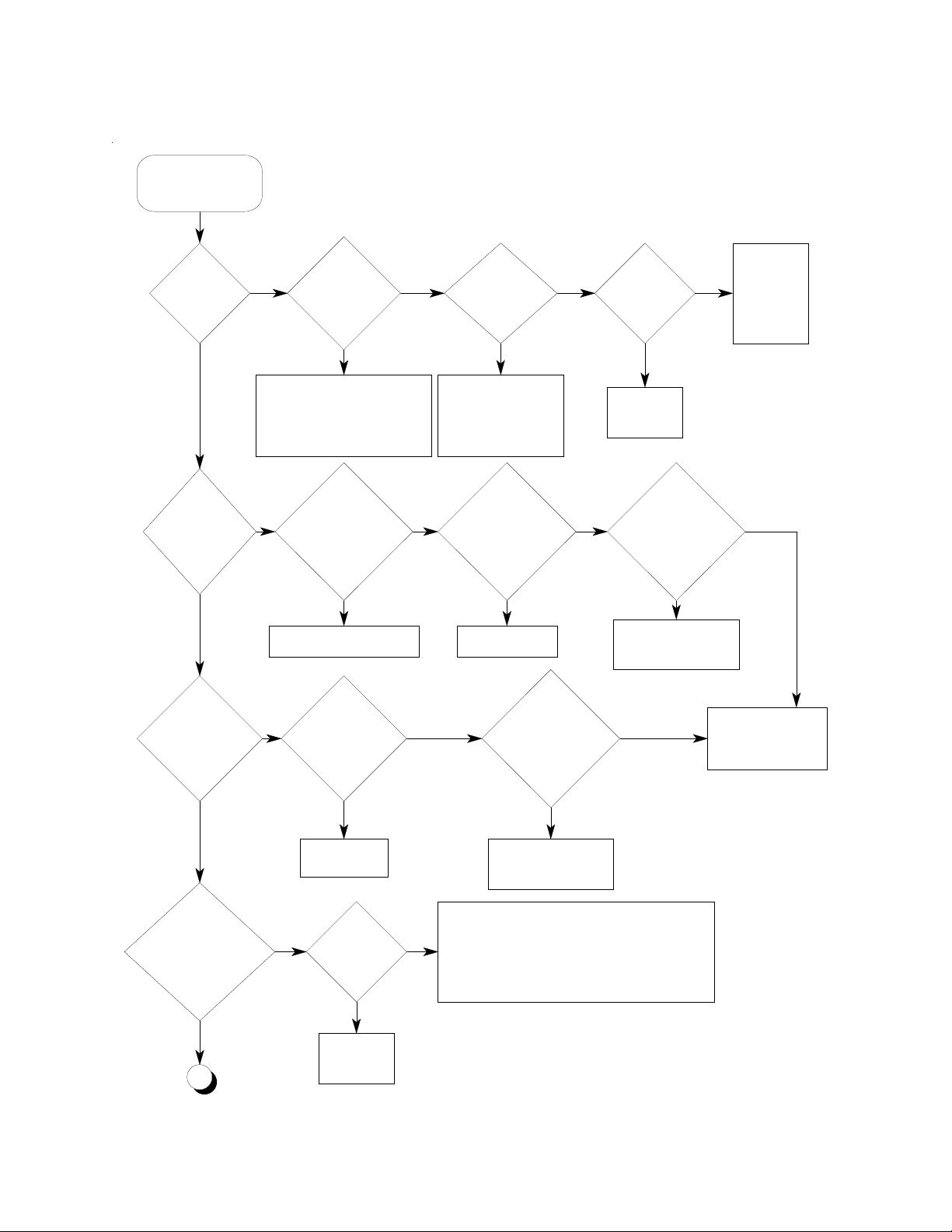

4.2 TROUBLESHOOTING FILTER SYSTEMS

Filter unit is not

working properly.

Is the

pump

running?

YES

Is oil

flowing from filter

to fryer?

YES

NO

Turn the filter power switch

tripping and reset the circuit

NO

Is the filter

circuit breaker

tripped?

YES

off. Correct the cause for

breaker.

Is filter

pickup attached

correctly?

NO

Connect pickup tube.

NO

motor overload

Allow the motor to

cool, reset the

thermal overload on

the motor.

YES

handle in the fully

open position?

Open Valve.

Is filter

tripped

YES

Is valve

NO

NO

YES

Is the

filter plugged

in?

NO

Plug in the

filter.

Is filter paper,

or pickup screens

clogged?

YES

Clean the screen or

replace filter media.

YES

Check the

building

circuit

breaker

NO

Oil pumping

slowly from fryer

to filter?

YES

Does the

Ready light come

on? (Heater

Option Only)

YES

A

Is filter

hose completely

connected?

Connect hose.

NO

Is the

filter plugged

Plug in the

filter.

in?

NO

NO

YESNO

YES

minutes to turn the Ready light on after power is

Is the filter nozzle

screen clogged?

YES

Reverse flow to clear

nozzle.

If the filter has had power removed for more

than 2 hours, it may take the heater 10-12

restored. If the light does not come on call

authorized service and parts distributor.

4-2

NO

service and parts

Call authorized

distributor.

Loading...

Loading...