Page 1

Installation and Operation Manual

For Electric Fryers

Covering Models

SE, SEH Series

ENGLISH

Pitco Frialator, Inc., P.O. Box 501, Jct I-89 & I-93 Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304

(800) 258-3708 • (603) 225-6684 • FAX (603) 225-8497

L20-246 Rev 0 (01/03)

Page 2

WARNING! FIRE HAZARD

THE OIL LEVEL SHOULD NOT FALL BELOW THE MINIMUM INDICATED LEVEL AT ANY

TIME. THE USE OF OLD OIL CAN BE DANGEROUS AS IT WILL HAVE A REDUCED FLASH-

POINT AND BE MORE PRONE TO SURGE BOILING.

WARNING

INSTALLATION AND ALL CONNECTIONS MUST BE MADE ACCORDING TO NATIONAL

AND LOCAL REGULATIONS AND CODES IN FORCE.

WARNING

A COUNTRY APPROVED ALL POLE CIRCUIT BREAKER WITH A MINIMUM OPEN CON-

TACT GAP OF 3mm MUST BE USED FOR PROPER INSTALLATION.

WARNING

THE FRYER IS NOT JET STREAM APPROVED. DO NOT CLEAN THE APPLIANCE WITH A

WATER JET.

NOTICE

INSTALLATION SHOULD ONLY BE DONE BY A COMPETENT SERVICE TECHNICIAN. THE

MODEL & SERIAL NUMBER, AND ELECTRICAL REQUIREMENTS STAMPED INTO THE

DATA PLATE, LOCATED ON THE INSIDE PANEL OF THE DOOR.

NOTICE

THIS APPLIANCE IS INTENDED FOR PROFESSIONAL USE ONLY, AND AS SUCH,

SHOULD BE OPERATED BY FULLY TRAINED PERSONNEL.

NOTICE

IT IS RECOMMENDED THAT THIS MACHINE BE INSPECTED BY A QUALIFIED TECHNI-

CIAN ON A YEARLY BASIS.

WARNING

THE POWER SUPPLY MUST BE DISCONNECTED SERVICING OR CLEANING THE UNIT.

WARNING

SHORTENING, WHEN IT IS AT OPERATING TEMPERATURES, IS VERY HOT AND

DANGEROUS! USE EXTREME CAUTION WHEN HANDLING! USE PROPER PROTEC-

TIVE GEAR SUCH AS INSULATED GLOVES, APRONS, FACE SHIELD, AND SLEEVES

WHEN HANDLING HOT SHORTENING. DO NOT ATTEMPT TO MOVE MACHINE THAT

HAS HOT OIL IN IT. ALLOW TO COOL TO ROOM TEMPERATURE OR DRAIN THE OIL

INTO A SUITABLE CONTAINER BEFORE MOVING THE FRYER.

L20-246 Rev 0 (12/02)

Page 3

WARRANTY STATEMENT

Pitco Frialator, Inc. makes the following limited warranties to the original purchaser only for this equipment and replacement parts:

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

1. WARRANTY PROVISIONS - FRYERS

A. Pitco Frialator, Inc. warrants all parts, with

the exception of the frypot, elements and

computer for 1 year after the date of installation of the fryer.

B. If any parts become defective during the first

year after the installation date, Pitco Frialator will also pay for the labor, freight and

travel costs involved in replacing said part.

2. WARRANTY PROVISIONS - FRYPOTS

A. If a frypot develops a leak due to a defect in

material or workmanship within the first 10

years after installation, Pitco Frialator, Inc.

will either weld or replace, at its discretion,

the frypot.

B. The customer will be responsible for all

freight, labor and travel charges for this repair.

3. WARRANTY PROVISIONS - COMPUTER

A. Pitco Frialator, Inc. will warrant the Intelli-

fry Computer from defects in material or

workmanship for a period of two years.

B. If the computer is found to be defective dur-

ing the first 2 years after the installation date,

Pitco Frialator Inc. will also pay for the labor, freight and travel costs involved in replacing said part.

WARNING:

IMPROPER INSTALLATION, ADJUST-

MENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND

MAINTENANCE MANUALS THOR-

OUGHLY BEFORE INSTALLING OR SER-

VICING THIS EQUIPMENT.

WARNING:

This machine is intended to be hard wired

when installed in its final location.

WARNING:

If a manufacturer supplied cord is damaged, it

must be replaced by the manufacturer or its

service agent or a similarly qualified person in

order to avoid a hazard.

Retain this manual for future reference.

ENGLISH

4. WARRANTY PROVISIONS - ELEMENTS

A. Pitco Frialator, Inc. will warrant the Electric

Elements from defects in material or workmanship for a period of 3 years.

B. The customer will be responsible for all

freight, labor and travel charges for this repair.

L20-246 Rev 0 (12/01)

Page 4

INSTALLATION INSTRUCTIONS

tion, maintenance and servicing.

CAUTION:

This equipment is manufactured for the use on a

particular voltage and phase which is specified on

the rating plate located on the inside of the door.

When your fryers arrive, inspect carefully

noting any damage on the freight bill. If concealed

damage is found after you have accepted the

equipment, report it to the carrier immediately as

all claims must be filled within 15 days of the

receipt of the shipment. Also, be sure to keep all

packing materials as these will be necessary to

make any claim.

Follow these installation instructions carefully. A proper installation is important for the

operation of the fryers.

All installations must conform to all local and

national codes.

Wiring diagram(s) are located in the back of

the service manual and inside the fryers.

Regular cleaning of this equipment, as well as

the hood, is an important part of proper maintenance.

Once the fryers are in place:

Leveling the fryers will help ensure proper

operation. To level the fryers loosen the two set

screws on the caster stem. Rotate the collar of the

caster to raise or lower the height of the unit.

Tighten set screws to lock the adjustment. Casters

should be adjusted so that the fryers are level and

at the correct height under the hood system.

Do not block the area around the casters and

under the fryers. Contact the Authorized Pitco

Frialator representative for any service related

problems. Routine maintenance may be performed

by qualified personnel.

The duct system, the hood system and the

fryers must be cleaned on a regular basis and must

be kept clear of any grease build up.

Ventilation:

A proper ventilation system is also an important part of the installation.

Clearances:

Minimum clearance of 6" (15cm) must be

maintained from combustible construction on each

side and the rear of the equipment. This equipment

may be installed on combustible floors.

Maintain a minimum of 24"(61cm) clearance

in front of the fryer to provide for proper opera-

1

L20-246 Rev 0 (12/02)

Page 5

EQUIPMENT SET UP AND SHUT DOWN

PROCEDURES

NOTE: Should you experience a power failure, your

fryers will shut off automatically. Once the power

has been restored, press the

key to turn the fryer

NOTE: It is recommended that melt cycle be used

. This will extend the shortening life. In melt cycle

the shortening turns from solid to liquid gradually

through short, controlled bursts of heat. Once the

predetermined temperature has been reached, the unit

will exit the melt cycle and go to normal operation.

back ON. If the machine is being filtered, close the

RED return valve so that the filter does not run if the

machine is left unattended. Do not attempt to restart

the fryers until the power is restored.

Filling the fryer with oil:

It is very important to make sure the oil level

is correct before attempting to heat shortening in

your Pitco fryer.

Liquid shortening can be poured directly into

the fry tank until the correct level has been

reached. This is indicated by a line on the right

hand side of the inside of the tank.

NOTE: The “COLD” level is considered to be the

“MINIMUM” oil level and the “HOT” level is considered to be the “MAXIMUM” oil level.

For solid shortening, the shortening must be

cut into small blocks about 1" (2.54 Cm) in size.

These small blocks must be placed under and

around the heating elements.

The fryer can now be turned ON.

Make sure that the shortening is at the proper

level after cooking temperature has been reached.

It may be necessary to add shortening to maintain

the proper level.

NOTE: When adding solid shortening to an empty

fry tank, first remove the baskets and support racks

and fill the bottom of the tank with shortening, continue to pack the remaining shortening into the tank.

Place the basket support rack on top of the shortening before turning the unit ON.

For liquid shortening fill to the level lines indicated

on the side of the tank.

NOTE: Maximum cooking load is not to exceed

3lbs (6.6kg) per basket.

CAUTION:

Excessive loading or loading of over-wet food can

cause surge boiling.

Shut Down:

Press the corresponding key to turn the

fryer OFF. The Computer display will go blank

and all heating functions will cease.

ENGLISH

Set-Up:

NOTE: Please read the Operating instructions thor-

oughly before attempting to operate this equipment.

Press the

computer, or the right key for the right side

and the left key for the left side of a split vat

computer to turn the unit ON.

The computer display will light and the

heating elements will begin to heat and will be

controlled by the computer/controller.

key on either side of the full vat

2

NOTE: When the fryer is not being used, place the

cover over the fry tank. (The covers are optional and

do not come with fryer unless ordered)

L20-246 Rev 0 (12/01)

Page 6

FILTER PROCEDURES FOR

FLAT PAPER FILTER SYSTEMS

return valve to the tank you are filtering.

This will start the pump and return the oil to

the bottom of the fry tank.

NOTE

When working with hot oil ALWAYS wear oil

proof, insulated gloves.

WARNING

NEVER - Run the filter system without a filter

bag/paper.

NEVER - Empty the oil from the fryer before

turning OFF the fryer burners.

NEVER - Store the Filter Unit anywhere other

than in the fryer filter cavity.

a. Slide the filter pan out. Carefully remove

filtered residue off the filter media. Examine

the filter media for clogged or torn areas.

Refer to filter media replacement instructions

following this section. Reinstall the pan.

b. Turn the fryer that is to be filtered OFF (See

Standby Shutdown). Remove the baskets

from the fryer tank(s). Use the clean out

brush to lift out the tube screens.

c. Check the pickup tube screen by unscrewing

the cap counterclockwise. Any debris should

be cleaned from the screen before using the

filter system. Reinstall the screen by scewing

the cap back on clockwise. Do not overtighten.

f. When bubbles are seen coming out of the oil

return spout, close the red handled valve to

turn the pump off.

If necessary add more oil to the tank to return

the oil level to the fill mark. The fryer is

now ready for use.

DRAINING A TANK

The filter system is also used to drain the fryers. You

0

will need a container capable of holding 400

F oil and

protective gloves.

a. Rotate the drain down spout so that it ex-

tends in the container that you want to drain

the shortening into.

b. Open the green handled drain valve for the

tank to be drained. The oil will drain into the

container you have chosen. When the container is full or the fry tank is empty, close

the green handled drain valve. If the container was full repeat this step until fryer tank

is empty.

c. Once tank is completely empty add new

shortenning and follow fryer start up procedures.

WARNING

The power supply must be disconnected before

servicing or cleaning the appliance.

c. Slowly open the green handled drain valve

for the tank being filtered. If necessary use

the clean-brush to clear the crumbs from the

drain. Use the brush to clean the sides of the

tank as the oil drains.

WARNING

This filter pan is only large enough to hold the

contents of one (1) tank at once, during the

filter process.

e. When the tank is empty, close the green

handled drain valve. Open the red handled

L20-246 Rev 0 (12/02)

Preparing the filter for use:

· Slide drawer forward until it stops.

· Grasp the Left and Right handles of the Paper

Retaining Frame and lift upward to remove it.

· Remove the filter paper or pad by folding the edges

inward so that the debris is collected.

· Lift the Paper Support Screen out of the pan.

· The Pan, Paper Support Screen and Paper Retaining Frame can now be cleaned.

NOTE: Be sure that the filter pan is free of any debris

which could cause the paper and hold down ring not

to seat properly.

3

Page 7

· Place the Paper Support Screen in the bottom of the

pan.

· Place filter Paper or Pad over screen making sure

that there is an equal amount of excess paper on

each side.

· Place the Retaining Frame on the paper or pad

making sure that all edges are being pressed down

evenly.

· Slide filter drawer back under fryer making sure

that the oil return pipe locates into its mating

connection.

CAUTION:

Be careful when using the clean out rod.

Damage to the drain valve may result.

WARNING:

Hot shortening can cause severe injury.

Take care when filtering or disposing of

hot shortening. Protective gear such as

gloves, apron, face shield and sleeves

should be worn.

ENGLISH

Allow all of the shortening to return to the tank.

Bubbles will be produced in the vat when all the

shortening has been returned. This means that

the return lines have been cleared.

· Close the RED Return Valve, by pushing upward

on the Red Return Valve Handle. This will turn

the pump off.

· Press the key and the Display will show

“OFF”.

· Allow the Drain and Return lines to drain for at

least 5 minutes before removing filter pan to reduce dripping.

Your machine is now ready to use.

4

L20-246 Rev 0 (12/01)

Page 8

FILTER PROCEDURES FOR

ENVELOPE PAPER FILTER SYSTEMS

NOTE

When working with hot oil ALWAYS wear

oil-proof, insulated gloves.

WARNING

NEVER • Run the filter system without a

filter bag/paper.

WARNING

This filter pan is only large enough to hold the

contents of one (1) tank at once, during the

filter process.

g. When the tank is empty, close the green handled

drain valve. Open the red handled return valve

to the tank you are filtering. This will start the

pump and return the oil to the bottom of the fry

tank.

NEVER • Empty the oil from the fryer

before turning OFF the fryer burners.

NEVER • Store the UFM Filter Unit

anywhere other than in the fryer filter

cavity.

a. Slide the filter pan out. Carefully remove

filtered residue off the filter media. Examine

the filter media for clogged or torn areas.

Refer to filter media replacement instructions

following this section. Reinstall the pan.

b. Turn the fryer that is to be filtered OFF (See

Standby Shutdown). Remove the baskets

from the fryer tank(s). Use the clean out

brush to lift out the tube screens. If there are

excess crumbs in the fryer tank, remove them

with the crumb scoop.

c. If you have replaced the filter media or

remove crumbs and debris, sprinkle Precoat

Filter Aid on the filter paper.

d. Check the drain spout to ensure that it is in

the drain tower and over the filter pan opening.

e. Slowly open the green handled drain valve

for the tank being filtered. If necessary use

the clean-brush to clear the crumbs from the

drain. Use the brush to clean the sides of the

tank as the oil drains.

f. Slowly open the green handled drain valve

for the tank being filtered. If necessary use

the clean-brush to clear the crumbs from the

drain. Use the brush to clean the sides of the

tank as the oil drains.

h. When bubbles are seen coming out of the oil

return spout, close the red handled valve to turn

the pump off.

If necessary add more oil to the tank to return

the oil level to the fill mark. The fryer is now

ready for use.

DRAINING A TANK

The filter system is also used to drain the fryers. You will

need a container capable of holding 4000F oil and protective gloves.

a. Rotate the drain down spout so that it extends in

the container that you want to drain the shortening into.

b. Open the green handled drain valve for the tank

to be drained. The oil will drain into the container you have chosen. When the container is

full or the fry tank is empty, close the green

handled drain valve. If the container was full

repeat this step until fryer tank is empty.

c. Once tank is completely empty add new

shortenning and follow fryer start up procedures.

WARNING

The power supply

must be disconnected

before servicing or

cleaning the appliance.

FILTER MEDIA REPLACEMENT

The filter module stores neatly under the fryer when not

in use. The unit is very easy to use and allows for quick

installation and filtration, even under the busiest conditions. Follow the procedures below to change the filter

media.

L20-246 Rev 0 (12/02)

Page 9

WARNING

At operating temperature, the shortening in

the fryer may be hotter than 375°F (190°C).

This hot, melted shortening will cause severe

burns. Do not let the hot shortening touch

your skin or clothing. Always wear insulated oil-proof gloves when working on the

filter system. It will be easier and safer if

the filter assembly has cooled to room temperature before handling any filter parts.

a. With the filter pan empty of oil, remove the

filter media by grasping the filter pan handle

and gently pull the assembly toward the front

of the fryer.

b. Separate the filter pickup tube from the filter

pickup screen assembly by pulling up on the

pickup tube just above where it connects to

the pickup screen assembly. Lift pickup tube

and swing it to the left, until it rests on the left

hand side of the filter pan.

h. Fold the open end of the bag in two folds.

The first fold should be approximately 1

inch from the end and the second should be

over the edge of the rack assembly.

i. Slide the clip screen over the folded end of

the filter paper. Ensure the opening of the

clip screen goes over the pick up tube

connection. Screw the suction tube connection onto the threaded connection.

ENGLISH

j. Place the filter pickup assembly into the

filter pan and slide the filter pan assembly

back into the fryer cabinet.

k. Filter unit is now ready for use.

c. Grab filter screen pickup assembly lift

handles and carry it to a trash barrel and

shake off heavy discard any debris that may

be built upon the top of the assembly.

d. Unscrew the filter paper clip bracket from

the filter paper support screen and slide the

filter paper support screen out of the filter

paper clip bracket.

e. Remove filter paper support screen from the

filter envelope.

f. All of the filter pick up assembly parts can be

washed in a dish washer or a pot sink. Flush

out the suction tube assembly with hot water.

After cleaning, it is very important to thoroughly dry the parts before reassembling.

Water and oil do not mix. Water in hot oil

will cause the oil to splatter.

g. Start reassembling the filter pick up assembly

by sliding the new filter paper on to the filter

paper support rack. Ensure that the hole in

the filter paper goes over the pick up tube

assembly threaded connector.

L20-246 Rev 0 (12/01)

Page 10

MULTIPLE LEVEL

CO

MPUTER

PROGRAMMING INSTRUCTIONS

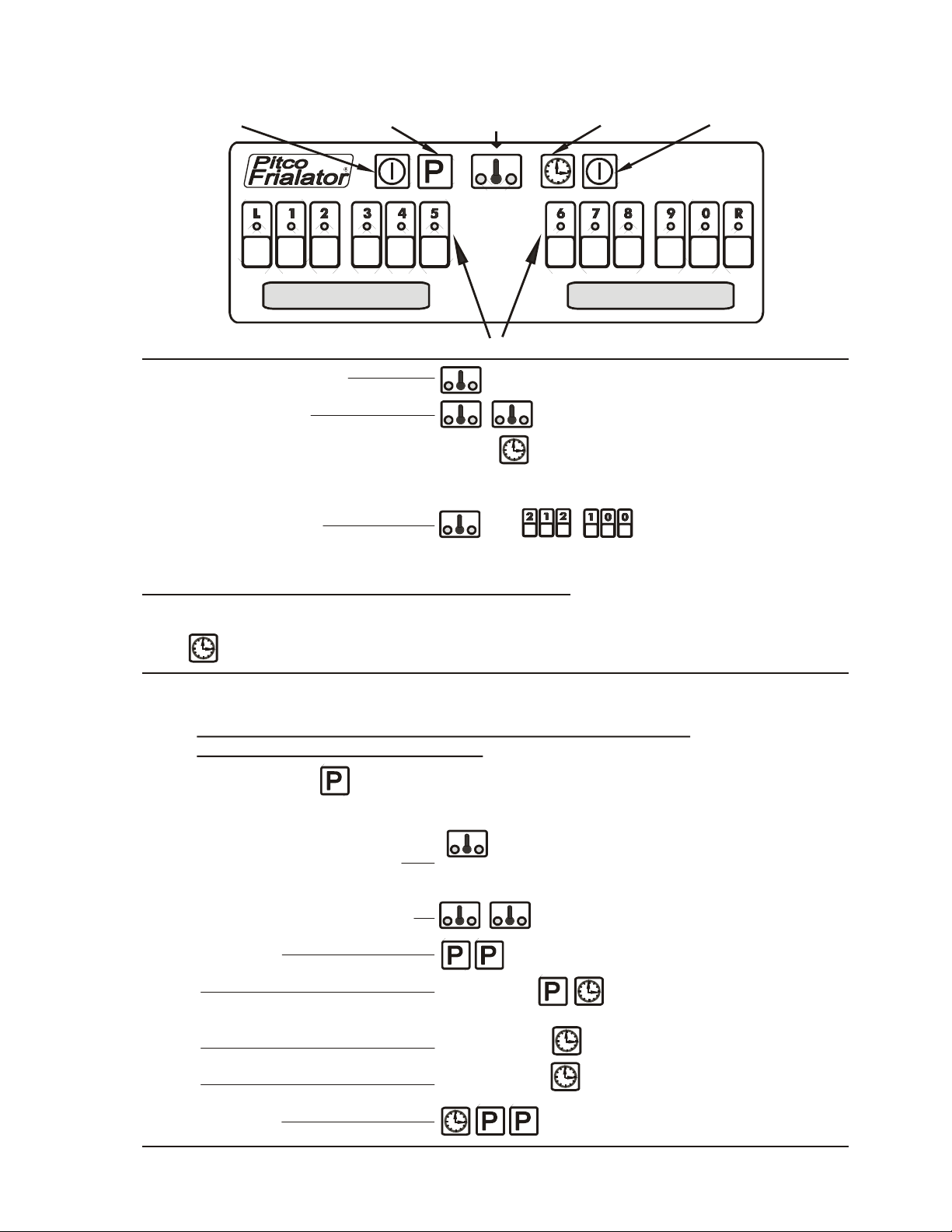

POWER ON/OFF KEY POWER ON/OFF KEY

PROGRAM KEY

TIME KEYTEMPERATURE KEY

PRODUCT KEYS

TO CHECK ACTUAL TEMP.

TO CHECK SET TEMP.

TO CHECK COOK, SHAKE, AND HOLD TIMES THEN THE PRODUCT KEY DESIRED

NOTE: THE TIMES WILL BE DISPLAYED IN SEQUENCE PAUSING MOMENTARILY ON EACH TIME AND THEN RETURN TO COOK MODE.

TO ENTER BOIL MODE

CHECKING THE REMAINING TIME WHEN USING MULTIPLE TIMERS

TO VIEW REMAINING TIME ON ANY FUNCTION KEYS WHEN MULTIPLE TIMERS ARE COUNTING IS AS FOLLOWS:

PRESS THEN PRESS FUNCTION KEY OF ANY NON DISPLAYED ACTIVE TIMERS YOU WANT TO VIEW

enter ( if using ºC mode) when last digit of

temperature is entered, boil mode will start automatically. You

must turn off both fryers to exit Boil mode.

After 5 secs. machine will return to run mode.

After 5 secs. machine will return to run mode.

FIRST LEVEL PROGRAMMING

USING AND ENTERING FIRST LEVEL PROGRAMMING AND

PROGRAMMING FUNCTION KEYS

Press the key (display shows ), then enter pass word if needed.

"PROGRAM"

If you are unable to remember the set pass word use (6684).

TO PROGRAM SINGLE OR DUAL TANK

COMPUTER SET TEMP LEFT SIDE

TO PROGRAM DUAL TANK

COMPUTER SET TEMP RIGHT SIDE

TO SAVE OR EXIT

TO SET

TO SET

TO SET

TO SAVE OR EXIT

L20-246 Rev 0 (12/02)

ENTER DESIRED TEMP.

COOK TIME AND A PRODUCT KEY THEN

ENTER TIME

SHAKE TIME ENTER TIME

HOLD TIME ENTER TIME AND

5

Page 11

ENGLISH

6

L20-246 Rev 0 (12/01)

Page 12

L20-246 Rev 0 (12/02)

7

Page 13

ENGLISH

8

L20-246 Rev 0 (12/01)

Page 14

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Computer does not come on A. Main circuit breaker is A. Locate the correct building circuit breaker

nothing shows in either display turned off and turn OFF and back ON again.

B. Fryer fuse is blown B. Call an Authorized Service Technician

Computer heat light comes on A. If the oil is hot the A. Allow the oil to cool, reset the Hi Limit and

but elements do not heat Hi - Limit may be tripped turn the computer OFF and back ON

again.

Computer display shows A. Bad computer A. Locate the correct building circuit breaker and

"OFF" and cannot be turned turn OFF and back ON again. If this does not

"ON". reset the computer call an Authorized Service

Technician.

RED return valve is open no A. RED return valve not fully A. Pull slightly on the RED return valve handle

pump sound can be heard open

B. Filter circuit breaker may be B. Locate the filter circuit breaker behind the door

tripped of the left hand fryer and reset it.

C. Filter motor Thermal Over- C. Push RED reset button located on end of filter

load may be tripped motor, behind the door of left hand fryer.

D. Sensor switch may be loose D. If the mounting screws are loose try to tighten

them, if this is not possible call an Authorized

Service Agency.

Drain valve is closed and A. GREEN drain valve is not A. Apply a little more pressure to close the valve

the computer has been fully closed

reset but still shows B. Sensor switch may be loose B. If the mounting screws are loose try to tighten

"DRAINING" or them, if this is not possible call an Authorized

"TURN OFF" Service Agency.

Drain valve is open, the oil is A. GREEN drain valve is not A. Apply a little more pressure to open the valve

draining slowly or not at all. fully open

B. Drain is plugged with debris B. Use the clean out rod to clear the drain valve

from inside the fry vat. If this does not clear the

blockage, CLOSE the GREEN drain valve and

follow the instructions for clearing the main

drain line.

CAUTION:

Some HOT oil may come out when the cap is

removed.

Remove the two wing nuts from the end cap

(do NOT lose these.) Use the clean out rod to

clear the main drain tube. Install the end cap

along with its gasket and four screws. Do not

overtighten these screws or remove drain "T"

cleanout access covers, by removing thumb

screws (do not loose screws). Then clean drain,

replace access cover and thumb screws.

L20-246 Rev 0 (12/02)

9

Page 15

ENGLISH

10

L20-246 Rev 0 (12/01)

Page 16

In the event of problems with or questions about

your order, please contact the Pitco Frialator factory at:

(800)258-3708 US and Canada only or

(603)225-6684 World Wide

L20-246 Rev 0 (12/02)

In the event of problems with or questions about

your equipment, please contact the Pitco Frialator

Authorized Service and Parts representative

(ASAP) covering you area, or contact Pitco at the

numbers listed to the left.

Page 17

Installations - Und Bedienungsanleitung

Elektrsche Friteuse

SE, SEH Serie

DEUTSCH

Pitco Frialator, Inc., P.O. Box 501, Jct I-89 & I-93 Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304

(800) 258-3708 • (603) 225-6684 • FAX (603) 225-8497

L20-246 Über. 0 (12/02)

Page 18

WARNUNG! BRANDGEFAHR

DER ÖLSTAND SOLLTE NIEMALS UNTER DIE ANGEGEBENE UNTERGRENZE SINKEN.

WARNUNG

INSTALLATION UND ALLE ANSCHLÜSSE MÜSSEN DEN JEWEILS GELTENDEN

LANDESWEITEN BZW. ÖRTLICHEN VORSCHRIFTEN ENTSPRECHEN.

WARNUNG

DIESE FRITEUSE DARF NICHT MIT WASSER ABGESPRITZT ODER ÜBERGOSSEN WERDEN.

WARNUNG

ZUR KORREKTEN INSTALLIERUNG MUSS EIN VOM LAND GELIEFERTER, ALLPOLIGER

AUSSCHALTER MIT OFFENER KONTAKTLÜCKE VON MINDESTENS 3MM VERWENDET WERDEN.

HINWEIS

DIE INSTALLATION SOLLTE VON EINER KOMPETENTEN SERVICEFACHKRAFT

DURCHGEFÜHRT WERDEN. MODELL- UND SERIENNUMMER SOWIE

ELEKTRISCHE ANSCHLUSSDATEN BEFINDEN SICH AUF DEM DATENSCHILD

AN DER INNENSEITE DER TÜR.

HINWEIS

DIESE MASCHINE DIENT AUSSCHLIESSLICH KOMMERZIELLEN ZWECKEN UND SOLLTE

DAHER NUR VON FACHLICH AUSGEBILDETEM PERSONAL VERWENDET WERDEN.

HINWEIS

ES WIRD EMPFOHLEN, DIESE MASCHINE EINMAL JÄHRLICH VON EINER

QUALIFIZIERTEN FACHKRAFT ÜBERPRÜFEN ZU LASSEN.

WARNUNG

VOR JEDER WARTUNG ODER REINIGUNG DES GERÄTES MUSS DER STROMANSCHLUSS

UNTERBROCHEN WERDEN.

WARNUNG

ÖL AUF BETRIEBSTEMPERATUR IST SEHR HEISS UND GEFÄHRLICH! BEI DER

HANDHABUNG IST ÄUSSERSTE VORSICHT GEBOTEN! ES SOLLTE UNBEDINGT

SCHUTZKLEIDUNG GETRAGEN WERDEN, WIE Z.B. ISOLIERTE HANDSCHUHE,

SCHÜRZE, AUGENSCHUTZ UND LANGE ÄRMEL. NIEMALS DIE MIT HEISSEM ÖL

GEFÜLLTE MASCHINE BEWEGEN. AUF ZIMMERTEMPERATUR ABKÜHLEN LASSEN ODER

DAS ÖL VOR DEM BEWEGEN DER FRITEUSE IN EINEN ENTSPRECHENDEN BEHÄLTER

ABLAUFEN LASSEN.

L20-246 Über. 0 (12/02)

Page 19

GARANTIEERKLÄRUNG

Pitco Frialator, Inc. gewährt dem Erstkäufer

ausschließlich für dieses Gerät und Ersatzteile die

folgende beschränkte Garantie:

elektrischen Elemente für die Dauer von 3

Jahren.

B. Für diese Reparatur trägt der Kunde die

Kosten für Versand, Arbeit und Anreise.

1. GARANTIEBEDINGUNGEN - FRITEUSE

A. Pitco Frialator, Inc. leistet Garantie auf alle

Teile mit Ausnahme der Wanne, der

elektrischen Elemente und des Computers für

die Dauer von 1 Jahr ab dem Datum der Installation der Friteuse..

B. Für jegliche während des ersten Jahres ab dem

Installationsdatum schadhaft werdende Teile

übernimmt Pitco Frialator auch die mit dem

Austauschen jenes Teiles verbundenen Kosten

für Arbeit, Versand und Anreise.

2. GARANTIEBEDINGUNGEN -

FRITEUSENWANNE

A. Sollte in der Friteusenwanne während der

ersten 10 Jahre ab Installation aufgrund

schadhaften

Materials oder mangelhafter Verarbeitung ein

Leck auftreten, wird Pitco Frialator, Inc. nach

eigenem Ermessen die Wanne entweder

schweißen oder austauschen.

B. Für diese Reparatur trägt der unde die Kosten

für Versand, Arbeit und Anreise.

3. GARANTIEBEDINGUNGEN -COM-

PUTER

A. Pitco Frialator, Inc. leistet Garantie auf

Schäden bei Material oder Verarbeitung des

Intellifry

Computers für die Dauer von 2 Jahren.

B. Sollte sich der Computer während der ersten

2 Jahre ab dem Installationsdatum als

schadhaft erweisen, übernimmt Pitco Frialator

Inc. auch die mit dem Austauschen jenes

Teiles verbundenen Kosten für Arbeit,

Versand und Anreise.

FÜR IHRE SICHERHEIT:

NIEMALS BENZIN ODER ANDERE

BRENNBARE GASE ODER

FLÜSSIGKEITEN IN DER NÄHE DIESES

ODER ANDERER HAUSHALTSGERÄTE

LAGERN ODER VERWENDEN.

WARNUNG:

UNSACHGEMÄSSE INSTALLATION,

ÄNDERUNGEN, SERVICE- ODER

WARTUNGSARBEITEN KÖNNEN ZU

BESCHÄDIGUNGEN, VERLETZUNGEN

UND TODESFÄLLEN FÜHREN. VOR DER

INSTALLATION ODER WARTUNG DIESES

GERÄTS IMMER DIE INSTALLATIONS-,

BETRIEBS- UND

WARTUNGSANLEITUNGEN SORGFÄLTIG

DURCHLESEN.

WARNUNG:

FALLS EIN VOM HERSTELLER

GELIEFERTES KABEL BESCHÄDIGT IST,

MUß DIESES VOM HERSTELLER ODER

SEINEM SERVICEVERTRETER ODER

EINER ÄHNLICH QUALIFIZIERTEN PER-

SON ERSETZT WERDEN, UM GEFAHREN

ZU VERHINDERN.

WARNUNG:

Diese Maschine muss für die Installation auf

ihrem endgültigen Standort fix montiert

werden.

Diese Anleitung für zukünftiges

DEUTSCH

4. GARANTIEBEDINGUNGEN -

ELEMENTE

A. Pitco Frialator, Inc. leistet Garantie auf

Schäden bei Material oder Verarbeitung der

Nachschlagen aufbewahren.

L20-246 Über. 0 (12/02)

Page 20

INSTALLATIONSANLEITUNGEN

VORSICHT:

Diese Maschine eignet sich nur für eine bestimmte

Spannung. Diese Information befindet sich auf dem

Datenschild auf der Innenseite der Tür.

Dieses Gerät kann auf nicht feuerfestem Fußboden

installiert werden.

Vor der Friteuse sollte ein Mindestfreiraum von 61

cm eingehalten werden, um ordnungsgemäßen

Betrieb, Wartung und Service zu gewährleisten.

Überprüfen Sie Ihre Friteusen bei Erhalt und

vermerken Sie jegliche Beschädigungen auf dem

Frachtbrief. Versteckte Mängel, die nach der

Annahme des Gerätes entdeckt werden, sind

unverzüglich dem Spediteur zu melden, da alle

Ansprüche innerhalb von 15 Tagen ab Erhalt der

Lieferung eingereicht werden müssen. Es wird

unbedingt empfohlen, auch das Verpackungsmaterial

aufzuheben, da dies zur Geltendmachung eines

Anspruches erforderlich ist.

Diese Anleitungen gewissenhaft befolgen. Die

richtige Installation ist für den korrekten Betrieb der

Friteusen unerlässlich.

Alle Installationsarbeiten müssen in

Übereinstimmung mit den örtlichen und

landesweiten Vorschriften vorgenommen werden.

Niemals den Bereich um die Gleitrollen und unter

den Friteusen blockieren. Wenden Sie sich zwecks

servicebezogener Probleme bitte an den autorisierten

Vertreter von Pitco Frialator. Routinemäßige

Wartungsarbeiten können von qualifiziertem

Fachpersonal vorgenommen werden.

Der Schaltplan befindet sich am Ende der

Serviceanleitungen und in den Friteusen.

Regelmäßige Reinigung dieses Gerätes und der

Abzugshaube ist ein wichtiger Teil ordnungsgemäßer

Wartung.

Friteusen waagrecht aufstellen:

Waagrechtes Aufstellen der Friteusen ist für den

richtigen Betrieb unerlässlich. Zu diesem Zweck

müssen die zwei Stellschrauben an den Gleitrollen

gelockert werden. Den Ring der Gleitrollen drehen,

um die Höhe des Gerätes zu verändern. Die

Stellschrauben nach Erreichen der gewünschten

Einstellung festziehen. Die Gleitrollen müssen

eingestellt werden, um die Friteusen in waagrechte

Lage und die richtige Höhe unter dem Abzugssystem

zu bringen.

Die Rohrleitungen, das Abzugssystem und

die Friteusen müssen regelmäßig gereinigt und

jegliche Anhäufung von Fett vermieden werden.

Ventilation:

Ein ordnungsgemäß funktionierendes

Ventilationssystem ist ebenfalls ein wichtiger Teil

der Installation.

Einbaumaße:

Ein Mindestfreiraum von 15 cm muss bei

nicht feuerfester Konstruktion an jeder Seite,

einschließlich Rückseite, eingehalten werden.

L20-227 Über. 1 12/2001

15

Page 21

VORBEREITUNG UND AUSSCHALTEN DES

GERÄTES

HINWEIS: Bei Stromausfall schalten sich die

Friteusen automatisch aus. Nach Wiedereinschalten

des Stroms die Taste drücken, um die Friteuse

wieder einzuschalten. Wird die Maschine gefiltert,

muss das ROTE Rücklaufventil geschlossen werden,

damit der Filter nicht läuft, wenn die Maschine

unbeaufsichtigt ist. Niemals versuchen, die Friteusen

während des Stromausfalls wieder einzuschalten.

Die Friteuse mit flüssigem Öl anfüllen:

Es ist sehr wichtig, den richtigen Ölstand

einzuhalten, bevor das Öl in Ihrer Pitco-Friteuse

erhitzt wird.

Flüssiges Öl kann direkt in die Friteusenwanne

geleert werden, bis der richtige Ölstand erreicht

ist. Dieser ist durch eine Linie an der rechten

Innenseite der Wanne markiert.

HINWEIS: “COLD” (KALT) zeigt die erforderliche

Mindesteinfüllgrenze und “HOT” (HEISS) die

“MAXIMALE” Einfüllgrenze an.

HINWEIS: Es wird empfohlen, den Schmelzzyklus

zu verwenden. Dadurch wird die Verwendbarkeit des

Öls verlängert. Im Schmelzzyklus wird das feste

Bratfett allmählich durch kurze gesteuerte

Hitzeimpulse verflüssigt. Sobald die vorbestimmte

Temperatur erreicht ist, schaltet das Gerät vom

Schmelzzyklus auf den Normalbetrieb um.

Nach Erreichen der Kochtemperatur den Ölstand

überprüfen. Es muss möglicherweise zusätzlich Öl

nachgefüllt werden, um den richtigen Ölstand zu

erreichen.

HINWEIS: Wenn festes Bratfett in die leere Wanne

hinzugefügt wird, müssen zuerst die Körbe und

Haltegitter entfernt werden, bevor der Boden der

Wanne mit Bratfett gefüllt wird. Danach Korb mit

Haltegitter wieder einsetzen und das Gerät

einschalten.

Bei flüssigem Öl muss die Wanne bis zu den

Markierungslinien auf der Seite der Wanne angefüllt

werden.

HINWEIS: Die empfohlene, maximale Kochmenge

pro Korb beträgt 6,6kg.

Festes Bratfett in kleine Stücke von etwa 2,5 cm

schneiden und unter sowie rund um die

Heizelemente plazieren.

Nun kann die Friteuse eingeschaltet werden.

Vorbereitung :

HINWEIS: Vor Inbetriebnahme dieses Gerätes

unbedingt die Betriebsanleitungen sorgfältig

durchlesen.

Die Taste auf einer Seite des Computers für die

gefüllte Wanne drücken, oder die rechte Taste

für die rechte Seite bzw. die linke Taste für die

linke Seite am Computer für Doppelwanne drücken,

um das Gerät einzuschalten. Die Computeranzeige

leuchtet auf, die Heizelemente erhitzen sich und

werden vom Computer / Controller gesteuert.

Ausschalten:

Die entsprechende Taste drücken, um die Friteuse auszuschalten. Die Computeranzeige schaltet

sich aus und alle Heizfunktionen werden beendet.

HINWEIS: Die Abdeckung über die

Friteusenwanne plazieren, wenn die Friteuse nicht

verwendet wird. (Die Abdeckungen sind als Option

erhältlich und werden nur auf Bestellung mit der

Friteuse mitgeliefert.)

DEUTSCH

16

L20-227 Über. 1 12/2001

Page 22

FILTERUNGSANLEITUNGEN

WARNUNG:

Öl auf Betriebstemperatur ist sehr HEISS und

GEFÄHRLICH! Bei der Handhabung ist äußerste

Vorsicht geboten! Es sollte unbedingt

Schutzkleidung getragen werden, wie z.B. isolierte

Handschuhe, Schürze, Augenschutz und lange

Ärmel. Für die Entfernung von gebrauchtem Öl die

Friteuse in einen entsprechenden Auffangbehälter

ablaufen lassen. Danach das ausgeschiedene Öl vom

Aufangbehälter in das Ölbehältnis pumpen.

WARNUNG:

Niemals mehr als eine Wanne ablaufen lassen. Das

Ablaufen von mehr als einer Wanne könnte die

Filterpfanne zum Überlaufen bringen und schwere

Verletzungen und Beschädigungen am Gerät

verursachen.

Vorbereitung des Filters:

Pfanne plazieren, wobei sich das Gitter auf den

beiden Haltestiften am Boden der Pfanne

befinden muss.

· Filterpapier so auf das Gitter legen, dass auf

jeder Seite gleich viel Papier übersteht.

· Den Halterahmen auf dem Papier oder Kissen

plazieren, wobei alle Seiten gleichmäßig

niedergedrückt werden müssen.

· Falls Pulver verwendet wird, dieses gemäß den

Anleitungen auf der Packung hinzufügen.

· Die Abdeckung anbringen, indem die hintere

Kante über die Rückseite der Pfanne gedrückt

wird. Nun die Abdeckung auf die Pfanne legen

und nach vorne ziehen. Damit sollte sich die

Abdeckung in die Pfannenkanten einpassen.

· Das Filterfach zurück unter die Friteuse schieben

und sicherstellen, dass das Ölrückflaufrohr mit

dem richtigen Anschluss verbunden wird. Nun

müssen beide Seiten korrekt eingeklinkt werden,

damit sich die Filterpfanne unter der Friteuse

nicht bewegen kann.

· Die Filterfachriegel lösen, indem der Griff an der

Vorderseite der Pfanne nach oben gezogen und

die Pfanne herausgezogen wird.

· Das Fach bis zum Anschlag nach vorne ziehen.

· Die Pfannenabdeckung durch Halten des Griffes

an der vorderen rechten Seite entfernen. Die

Abdeckung etwa 2,5 cm nach hinten schieben

und die Rückseite der Abdeckung von der Pfanne

lösen. (Die Abdeckung muss dabei

möglicherweise etwas geschüttelt werden.)

· Mit dem linken und rechten Griff des

Papierhalterahmens diesen nach oben heben und

entfernen.

· Das Filterpapier oder Filterkissen entfernen,

indem die Ränder nach innen gefaltet werden,

um jeglichen Schmutz einzusammeln.

· Das Papierhaltegitter aus der Pfanne heben.

· Pfanne, Papierhaltegitter und -halterahmen

können nun gereinigt werden.

HINWEIS: Sicherstellen, dass die Pfanne von

jeglichem Schmutz befreit wird, da sonst Papier und

Haltering nicht fest eingesetzt werden können.

· Das Papierhaltegitter auf dem Boden der

VORSICHT:

Vorsicht bei der Verwendung der Reinigungsbürste.

Das Ablaufventil könnte sonst beschädigt werden

WARNUNG:

Heißes Öl kann schwere Verletzungen verursachen.

Vorsicht bei der Filterung oder Entsorgung von

heissem Öl. Es sollte unbedingt Schutzkleidung

getragen werden, wie z.B. Handschuhe, Schürze,

Augenschutz und lange Ärmel.

Betriebsanleitungen für den Filter

VORSICHT

Nur Filtern, wenn das Öl auf Kochtemperatur ist.

· Das Ablaufventil öffnen, indem der grüne

Ventilhebel nach unten gezogen wird. Es wird

“DRAINING TURN OFF” (ABLAUFEN

ABDREHEN) angezeigt.

· Das Öl bis zur Höhe der Heizelemente

ablaufen lassen.

· Das Ablaufventil schließen, indem der grüne

Hebel nach oben gezogen wird. Es wird

L20-227 Über. 1 12/2001

17

Page 23

weiterhin “TURN OFF” (ABDREHEN)

angezeigt.

· Die Wände der Wanne und die Heizelemente

mit der mitgelieferten Reinigungsbürste

reinigen. Unbedingt Schutzhandschuhe,

Schürze und Augenschutz tragen.

· Das GRÜNE Ablaufventil öffnen.

· Das ROTE Rücklaufventil öffnen, indem der

rote Hebel nach unten gezogen wird, bis das

Betriebsgeräusch der Pumpe hörbar ist.

· Den verbliebenen Schmutz am Boden der

Wanne in den Abfluss bürsten. (Weiterhin

Schutzkleidung tragen.) Bei übermäßiger

Verschmutzung des Wannenbodens die

mitgelieferte Krümelkelle zur Entfernung von

Schmutzanhäufungen verwenden.

· Das GRÜNE Ablaufventil schließen. Es wird

weiterhin “TURN OFF” (ABDREHEN)

angezeigt, und die Wanne wird sich wieder

anfüllen. Das gesamte Öl wieder in die Wanne

fließen lassen. Blasenbildung in der Wanne

zeigt an, dass das gesamte Öl zurückgeflossen

ist. Das bedeutet, dass die Rücklaufleitungen

leer sind.

· Das ROTE Rücklaufventil schließen, indem

der rote Hebel nach oben gedrückt wird. Damit

wird die Pumpe ausgeschaltet.

· Die Taste drücken. “OFF” (AUS) wird

angezeigt.

· Vor dem Entfernen der Filterpfanne sollten die

Ablauf- und Rücklaufleitungen mindestens 5

Minuten ablaufen, um die Möglichkeit des

Tropfens zu verringern.

Ihre Maschine ist nun betriebsbereit.

DEUTSCH

18

L20-227 Über. 1 12/2001

Page 24

ANLEITUNGEN FÜR COMPUTERPROGRAMMIERUNG -

MEHRERE EBENEN

PROGRAMMIERTASTE ZEITTASTE

EIN/AUSSCHALTER

ÜBERPRÜFEN DER drücken. Nach 5 Sekunden kehrt die Maschine in den

TATSÄCHLICHEN TEMPERATUR Betriebsmodus zurück.

TEMPERATURTASTE

EIN/AUSSCHALTER

PRODUKTTASTEN

ÜBERPRÜFEN DER

PROGRAMMIERTEN TEMPERATUR Betriebsmodus zurück.

UM DIE ZEITEN FÜR KOCHEN, DRÜCKEN UND DANN DIE GEWÜNSCHTE

PRODUKTTASTE SCHÜTTELN UND RUHEZEIT DRÜCKEN.

ZU ÜBERPRÜFEN

HINWEIS: DIE ZEITEN WERDEN SEQUENTIELL MIT JEWEILS EINER KURZEN PAUSE

ANGEZEIGT. DANACH KEHRT DIE ANZEIGE IN DEN KOCHMODUS ZURÜCK.

AUSKOCHMODUS drücken und eingeben (oder im Celsius-Modus).

Nachdem EINGEBEN die letzte Ziffer der Temperatur eingegeben wurde, wird der

Auskochmodus automatisch begonnen. Beide Friteusen müssen ausgeschaltet werden,

um denAuskochmodus zu verlassen.

DIE VERBLEIBENDE ZEIT BEI VERWENDUNG MEHRERER TIMER ÜBERPRÜFEN

DIE VERBLEIBENDE ZEIT FÜR EINE BELIEBIGE FUNKTIONSTASTE BEI VERWENDUNG

MEHRERER TIMER KANN FOLGENDERMASSEN ABGELESEN WERDEN:

UND DANACH DIE GEWÜNSCHTE FUNKTIONSTASTE DRÜCKEN, DEREN AKTIVER TIMER

NICHT ANGEZEIGT WIRD.

PROGRAMMIERUNG - ERSTE EBENE

VERWENDUNG UND EINGABE DER PROGRAMMIERUNG - ERSTE EBENE - SOWIE

PROGRAMMIERUNGSFUNKTIONSTASTEN

Die Taste drücken (“PROGRAM” wird angezeigt). Danach Passwort eingeben, falls erforderlich. Wenn Sie

das programmierte Passwort vergessen haben, “6684” eingeben.

drücken. Nach 5 Sekunden kehrt die Maschine in den

UM DIE TEMPERATUR FÜR EINE EINZELWANNE ODER DIE LINKE SEITE EINER DOPPELWANNE ZU

PROGRAMMIEREN DRÜCKEN.

UM DIE TEMPERATUR FÜR DIE RECHTE SEITE EINER DOPPELWANNE ZU

PROGRAMMIEREN, DRÜCKEN.

SPEICHERN ODER VERLASSEN: DRÜCKEN.

KOCHZEIT PROGRAMMIEREN: UND EINE PRODUKTTASTE DRÜCKEN.

DANACH ZEIT EINGEBEN.

SCHÜTTELZEIT PROGRAMMIEREN: DRÜCKEN UND ZEIT EINGEBEN.

RUHEZEIT PROGRAMMIEREN: DRÜCKEN UND ZEIT EINGEBEN.

UM ZU SPEICHERN ODER VERLASSEN:

L20-227 Über. 1 12/2001

19

Page 25

PROGRAMMIEREN - ZWEITE EBENE

EINGABE FÜR PROGRAMMIERUNG - ZWEITE EBENE

Die Taste

haben das programmierte Passwort vergessen, “6684” eingeben. Danach

in der zweiten Programmierungsebene. Alle verwendbaren Tasten leuchten auf und “SELECT OPTIONS”

(OPTIONEN WÄHLEN) wird angezeigt.

HINWEIS: Immer wenn

zu “Select Option” zurückzukehren.

FUNKTIONSPROGRAMMIERUNG

FAHRENHEIT-/ CELSIUSSKALA - Schaltet durch Drücken der Taste zwischen Fahrenheit und Celsius

hin und her. Änderungen können durch Drücken der Taste gespeichert werden.

PASSWORT EINGEBEN - Schaltet die Passwort-Funktion ein und aus. Es kann auch ein numerisches

Passwort eingegeben werden. Passwort ein- oder ausschalten. , wählt zwischen “PASS REQ”

(PASSWORT ERFORDERLICH) oder “NO PASS” (KEIN PASSWORT). Wurde ein Passwort gewählt,

drücken, und das Passwort wird angezeigt. Mit den Nummerntasten kann ein neues Passwort

eingegeben werden und durch Drücken der Taste gespeichert werden.

SIGNALLAUTSTÄRKE - Damit kann die Lautstärke des Alarmsignals eingestellt werden. drücken und

aus Lautstärke 1, 2 und 3 wählen. drücken, um zu speichern.

drücken (“PROGRAM” wird angezeigt). IST EIN PASSWORT ERFORDERLICH, und Sie

verwendet wird, um eine Einstellung zu speichern, muß gedrückt werden, um

. drücken. Sie befinden sich nun

SPRACHE - Zwischen Englisch, Spanisch, Französisch, Deutsch und Holländisch wählen. drücken und

eine der Sprachoptionen wählen. drücken, um zu speichern.

SCHMELZZYKLUS - Es stehen 3 Zyklen zur Wahl: NO MELT (Schmelzzyklus ist deaktiviert), MELT S

(Schmelzzyklus für festes Bratfett), MELT L (Schmelzzyklus für flüssiges Bratfett). drücken, um zu

speichern.

TESTZEIT FÜR TEMPERATURANSTIEG - Zeigt die voreingestellte sowie die tatsächliche Testzeit des

Temperaturanstiegs von 104° auf 138°C (220°F auf 280°F) Can. Die voreingestellte Testzeit ist nicht

relevant. Die tatsächliche Testzeit vor Ort verwenden, um etwaige Probleme beim Temperaturanstieg bzw.

-steuerung festzustellen. HINWEIS: Der Ölstand beeinflußt diese Testzeit. drücken. Es wird “F065

LXXX” angezeigt, wobei die angezeigte Zeit 065 beträgt und die zuletzt gemessene Testzeit “LXXX”

beträgt.

STEUERUNG / TIMER - Schaltet den Computer von Steuerung aller Friteusenfunktionen auf

ausschließliche Steuerung des Timers bei einem Computer für nur eine Wanne bzw. für die linke Wanne

einer Doppelwannenfriteuse um. drücken, um zwischen Steuerung und Timer hin- und herzuschalten.

drücken, um zu speichern.

STEUERUNG / TIMER - Schaltet den Computer von Steuerung aller Friteusenfunktionen auf

ausschließliche Steuerung des Timers für die rechte Seite eines Computers für Doppelwanne um.

drücken, um zwischen Steuerung und Timer hin- und herzuschalten. drücken, um zu speichern.

DEUTSCH

UM DIE ZWEITE EBENE DES PROGRAMMIERUNGSMODUS ZU VERLASSEN,

FUNKTIONSTASTE DRÜCKEN

20

L20-227 Über. 1 12/2001

Page 26

STEUERUNGSANZEIGE

EIN/AUS-SCHALTER

LINKER TIMER/

LEUCHTANZEIGE EIN

LINKE TIMER-TASTE

PROGRAMMIERANLEITUNG FÜR DIGITAL STEUERUNG

PROGRAMMIERTASTE

RECHTER TIMER/

LEUCHTANZEIGE EIN

RECHTE TIMER-TASTE

TEMPERATURTASTE

STEUERFUNKTIONEN

DRÜCKEN, UM STEUERUNG EINZUSCHALTEN

PROGRAMMIERANLEITUNGEN - ERSTE EBENE

HINWEIS: SIND DIE TIMER AKTIVIERT, KANN NICHT PROGRAMMIERT WERDEN

SCHRITT 1

PROGRAMM EINGEBEN

SCHRITT 2

PASSWORTMODUS

DRÜCKEN UND FÜR 3 SEKUNDEN HALTEN. UM STEUERUNG

DRÜCKEN, UM TATSÄCHLICHE TEMPERATUR ANZUZEIGEN

ZWEIMAL DRÜCKEN, UM EINGESTELLTE TEMPERATUR ANZUZEIGEN

DRÜCKEN, UM TIMER FÜR LINKEN KORB EINZUSCHALTEN

DRÜCKEN, UM TIMER FÜR RECHTEN KORB EINZUSCHALTEN

DRÜCKEN, UM PROGRAMMIERMODUS ZU AKTIVIEREN

DRÜCKEN. Erscheint

AUSZUSCHALTEN

ZEIGT AN, OB PROGRAMMIERMODUS DURCH PASSWORT

GESICHERT IST

auf der Anzeige, mit SCHRITT 2 fortsetzen. Leuchtet

die LEUCHTANZEIGE für den LINKEN TIMER AUF und die ANZEIGE zeigt die für den

linken Timer eingestellte Zeit an (die angezeigte Zeit zählt nicht rückwärts), befinden

Sie sich im PROGRAMMIERMODUS. Mit SCHRITT 3 fortsetzen.

Wird

angezeigt, die Tasten

(Passwort) drücken, um den

Programmiermodus zu erreichen. HINWEIS: Beginnt der Timer mit dem Countdown,

wurde das Passwort nicht schnell genug eingegeben. Die Steuerung muß aus- und

wieder eingeschaltet und SCHRITT 1 wiederholt werden.

PROGRAMMIEROPTIONEN DER STEUERUNG

UM EINGABEN ZU SPEICHERN UND DEN PROGRAMMIERMODUS ZU VERLASSEN,

DRÜCKEN UND 5 SEKUNDEN HALTEN

SCHRITT 3

LINKE TIMER-TASTE

PROGRAMMIEREN

Wenn die LEUCHTANZEIGE für den LINKEN TIMER aufleuchtet und die für den

linken Timer programmierte Kochzeit auf der ANZEIGE erscheint,

drücken, um die programmierte linke Kochzeit zu ändern. ZUM SPEICHERN VON

EINGABEN SIEHE ANLEITUNG OBEN.

SCHRITT 4

RECHTE TIMER-TASTE

PROGRAMMIEREN

DRÜCKEN. Die LEUCHTANZEIGE für den RECHTEN TIMER leuchtet auf und

die programmierte Zeit für den RECHTEN TIMER erscheint auf der ANZEIGE.

oder drücken, um die programmierte rechte Kochzeit zu ändern. ZUM

SPEICHERN VON EINGABEN SIEHE ANLEITUNG OBEN.

SCHRITT 5

PROGRAMMIEREN DER

TEMPERATUR

DRÜCKEN. Auf der ANZEIGE erscheint die VORPROGRAMMIERTE

TEMPERATUR. oder drücken, um die vorprogrammierte TEMPERATUR zu

ändern. ZUM SPEICHERN VON EINGABEN SIEHE ANLEITUNG OBEN.

L20-227 Über. 1 12/2001

21

oder

Page 27

PROGRAMMIEROPTIONEN - ERSTE EBENE - FORTSETZUNG

HINWEIS: SIND DIE TIMER AKTIVIERT, KANN NICHT PROGRAMMIERT WERDEN

UM EINGABEN ZU SPEICHERN UND DEN PROGRAMMIERMODUS ZU VERLASSEN,

UND 5 SEKUNDEN HALTEN

DRÜCKEN

SCHRITT 6

SCHMELZZYKLUS

PROGRAMMIEREN

SCHRITT 7

/ PASSWORT

PROGRAMMIEREN

SCHRITT 8

CELSIUS / FAHRENHEIT

PROGRAMMIEREN

SCHRITT 9

SCHRITT 1

SCHRITT 2

KORB ANHEBEN,

EINFACHE BZW.

DOPPELHEBEOPTION

SCHRITT 3

ANZEIGE DER

TATSÄCHLICHEN

TEMPERATUR

DRÜCKEN.

vorprogrammierte “SCHMELZ”-Einstellung zu ändern. ( = Schmelzzyklus festes

Bratfett,

ZUM SPEICHERN VON EINGABEN SIEHE ANLEITUNG OBEN.

DRÜCKEN. oder RECHTS wird angezeigt.

Passwort zu aktivieren (ON) bzw. deaktivieren (OFF).

EINGABEN SIEHE ANLEITUNG OBEN.

DRÜCKEN. [C] oder [F] (Celsius oder Fahrenheit) wird angezeigt.

DRÜCKEN, um die programmierte Temperaturskala zu ändern. ZUM SPEICHERN VON

EINGABEN SIEHE ANLEITUNG OBEN.

DRÜCKEN. Der Programmierzyklus ist nun zu SCHRITT 3 oder zum Beginn

zurückgekehrt.

PROGRAMMIERANLEITUNGEN - ZWEITE EBENE

SCHRITT 1 und SCHRITT 2 der PROGRAMMIERANLEITUNGEN - ERSTE EBENE

folgen.

DRÜCKEN und HALTEN. Während die Taste. gedrückt gehalten wird drücken.

oder

Hebefunktionen in der Friteuse zu ändern. ZUM SPEICHERN VON EINGABEN SIEHE

ANLEITUNG OBEN.

DRÜCKEN.

programmierte Einstellung zu ändern ( = tatsächliche Temperatur wird nur

angezeigt, wenn die Taste gedrückt wird, tatsächliche Temperatur wird ständig

angezeigt).

ZUM SPEICHERN VON EINGABEN SIEHE ANLEITUNG OBEN.

= Schmelzzyklus flüssiges Bratfett, und = kein Schmelzzyklus.)

,

wird angezeigt. oder DRÜCKEN, um die Anzahl der

oder wird angezeigt. oder DRÜCKEN, um die

oder

wird angezeigt.

oder DRÜCKEN, um die

oder DRÜCKEN, um

ZUM SPEICHERN VON

oder

ERKLÄRUNG DER STEUERUNGSANZEIGEN

DIE FRITEUSE BEFINDET SICH IN EINEM SCHMELZZYKLUS.

DIE TEMPERATUR DER FRITEUSE IST NIEDRIGER ALS DIE PROGRAMMIERTE

TEMPERATUR UND FRITEUSE IST IM AUFHEIZEN BEGRIFFEN.

DIE FRITEUSE HAT DIE PROGRAMMIERTE TEMPERATUR ERREICHT UND IST

BETRIEBSBEREIT

WENN DER PUNKT AUFLEUCHTET, IST DAS HEIZSYSTEM AKTIVIERT.

22

L20-227 Über. 1 12/2001

Page 28

FEHLERSUCHE

PROBLEM WAHRSCHEINLICHE URSACHE MASSNAHME

A.

Computer schaltet sich

nicht ein, die beiden

Anzeigen bleiben leer.

Die Heizanzeige auf dem

Computer leucht auf, aber die

Heizelemente erwärmen sich

nicht.

Computer zeigt “OFF” (AUS)

und kann nicht eingeschaltet

werden.

Das ROTE Rücklaufventil ist

offen aber kein

Pumpengeräusch hörbar.

Ablaufventil ist geschlossen

und der Computer wurde neu

gestartet (Reset), zeigt aber

weiter “DRAINING”

(ABLAUFEN) oder “TURN

OFF” (ABDREHEN) an.

Ablaufventil ist offen, das Öl

äuft nur langsam oder

überhaupt nicht ab.

A. Hauptschalter ist ausgeschaltet.

B. Durchgebrannte

Friteusensicherung.

A. Ist das Öl heiss, wurde

möglicherweise der

Begrenzungsresetschalter

ausgelöst.

A. Fehlerhafter Computer

A. Das ROTE Rücklaufventil ist

nicht völlig offen.

B. Der Filter-Überlastschalter

wurde ausgelöst.

C. Überlastschalter des

Filtermotors wurde ausgelöst.

D. Fühlerschalter könnte locker sein.

A. Das GRÜNE Ablaufventil ist nicht

völlig geschlossen.

B. Fühlerschalter könnte locker

sein.

A.Das GRÜNE Ablaufventil ist nicht

völlig offen.

B.Abfluss ist verstopft.

Den entsprechenden Hauptschalter im

Gebäude AUS- und wieder

EINSCHALTEN.

B. Einen autorisierten Servicetechniker

kontaktieren.

A. Öl abkühlen lassen, Reset auf dem

Begrenzungschalter drücken und

den Computer AUS- und wieder

EINSCHALTEN.

A. Den Überlastschalter im Gebäude

AUS- und wieder EINSCHALTEN.

Schaltet sich der Computer nicht ein,

muss ein autorisierter

Servicetechniker kontaktiert werden.

A. Vorsichtig am Hebel des ROTEN

Rücklaufventils ziehen.

B. Reset drücken auf dem hinter der Tür

der linken Friteuse befindlichen FilterÜberlastschalter.

C. Den ROTEN Reset-Knopf am Ende

des Filtermotors hinter der Tür der

linken Friteuse drücken.

D. Versuchen, die lockeren

Befestigungsschrauben, festzuziehen.

Sollte dies nicht möglich sein, muss

ein autorisiertes Serviceunternehmen

kontaktiert werden.

A. Versuchen, mit leichtem Druck das

Ventil zu schließen.

B. Versuchen, die lockeren

Befestigungsschrauben,

festzuziehen. Sollte dies nicht

möglich sein, muss ein autorisiertes

Serviceunternehmen kontaktiert

werden.

A. Versuchen, mit leichtem Druck das

Ventil zu öffnen.

B. Mit Hilfe der Reinigungsbürste das

Ablaufventil von der Innenseite der

Wanne aus reinigen. Wird dadurch

die Verstopfung nicht gelöst, das

GRÜNE Ablaufventil SCHLIESSEN

und den Anleitungen zur Reinigung

der Hauptabflussleitung folgen.

L20-227 Über. 1 12/2001

VORSICHT:

Beim Entfernen des Deckels könnte

HEISSES Öl austreten. Die beiden

Flügelmuttern vom Deckel entfernen

(NICHT verlieren). Mit der

Reinigungsbürste die

Hauptabflussleitung reinigen. Den

Deckel mit Dichtungsring und vier

Schrauben wieder anbringen. Diese

Schrauben nicht zu fest anziehen, und

das T-Stück nicht entfernen.

Flügelschrauben (nicht verlieren)

entfernen undAbdeckungen reinigen.

Abfluss reinigen, Abdeckung und

Flügelschrauben wieder anbringen.

23

Page 29

24

L20-227 Über. 1 12/2001

Page 30

Page 31

Page 32

Bei Problemen oder Fragen zu Ihrer Bestellung

wenden Sie sich bitte von Montag bis Freitag

zwischen 8.00 und 17.00 Uhr Ortzeit (Ostküste)

gebührenfrei an das Pitco Frialator Werk unter der

Ruf-Nr.:

Bei Problemen oder Fragen zu Ihren Geräten

wenden Sie sich bitte an den für Ihren Bereich

zuständigen ASAP-Vertreter (Authorized Service

and Parts) von Pitco Frialator über das National

Service Network unter der Ruf-Nr.:

(800) 258-3708 für USA und Kanada oder

(603) 225-6684 weltweit

L20-227 Über. 1 12/2001

(800) 298-1862 nur für USA, 24 Stunden täglich

Loading...

Loading...