Page 1

SERVICE SECTION

L20-055 R12 (06/11)

There's Always Something Cooking!

Service, Parts, and Schematics

For Electric Fryers With Options

Including Options, Built-In and UFM (Spacefighter)

Filter Systems

Covering Models

E7, E7B, E12, E14, E14B, E14X, E18, & E18B

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304

A BLODGETT Company

(800) 258-3708 • (603) 225-6684 • FAX (603) 225-8497

Page 2

MTS # PF05-01 Pitco Frialator #L20-055 Revision 11 Rev. Date 07/18/94

L20-055 R12 (06/11)

Page 3

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for reference.

WARNING

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and

maintenance instructions thoroughly before installing

or servicing this appliance.

WARNING

Installation, maintenance and repairs should be

performed by a Pitco Authorized Service and Parts

(ASAP) company technician or other qualified

personnel. Installation, maintenance or repairs by

unauthorized and unqualified personnel will void the

warranty.

WARNING

Installation and all connections must be made

according to national and local regulations and codes

in force.

WARNING

A country approved all pole circuit breaker with a

minimum open contact gap of 3mm must be used for

proper installation. (CE countries)

WARNING

During the warranty period if a customer elects to use a

non-original part or modifies an original part purchased

from Pitco and/or its Authorized Service and Parts

(ASAP) companies, this warranty will be void. In

addition, Pitco and its affiliates will not be liable for any

claims, damages or expenses incurred by the customer

which arises directly or indirectly, in whole or in part,

due to the installation of any modified part and/or

received from an unauthorized service center.

WARNING

This appliance, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.2, as applicable.

WARNING

DO NOT alter or remove structural material on the

appliance to facilitate storage or for any other reason.

WARNING

This appliance is intended for professional use only

and should be operated by fully trained and qualified

personnel.

WARNING

DO NOT use the electrical cord as a leash to move the

appliance. Series injury and appliance damage can

occur.

WARNING

If the supplied power cord or receptacle is damaged, it

must be replaced by a Pitco Authorized Service and

Parts (ASAP) company technician, or a similarly

qualified person in order to avoid a hazard.

WARNING

The power supply must be disconnected before

servicing, maintaining or cleaning this appliance.

The appliance is NOT jet stream approved. DO NOT

clean the appliance with a water jet.

DO NOT attempt to move this appliance or transfer hot

liquids from one container to another when the unit is

at operating temperature or filled with hot liquids.

Serious personal injury could result if skin comes in

contact with the hot surfaces or liquids.

DO NOT sit or stand on this appliance. The appliance’s

top panel, filter pan, filter carriage, pan cover is not a

step. Serious injury could result from slipping, falling

or contact with hot liquids.

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot liquids.

The filter pan should be dry and free of water droplets

prior to use. Serious injury could result from hot steam

vapors when hot oil/shortening mixes with water.

DO NOT overfill filter pan with hot oil/shortening. Do

not leave appliance unattended while draining or

refilling with oil/shortening. Over filling the appliance

can cause serious injuries and damage the appliance.

The contents of the crumb catch and/or filter pan of

any filter system must be emptied into a fireproof

container at the end of each day. Some food particles

can spontaneously combust if left soaking in certain

types of oil or shortening.

Completely shut the appliance down when the

oil/shortening is being drained from the appliance. This

will prevent the appliance from heating up during the

draining and filling process. Serious injury and

appliance damage can occur.

This appliance is intended for indoor use only.

DO NOT operate appliance unless all panels and

access covers are attached correctly.

It is recommended that this appliance be inspected by

a qualified service technician for proper performance

and operation on a yearly basis

This appliance is designed to operate on a specific

voltage. This information can be found on the data

plate located on the rear of the appliance

.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

2

L20-303 Rev 1. (05/11)

Page 4

Table of Contents (Service)

Section Title Page

Table of Contents (Service)..........................................................................................................i-ii

List of Figures .......................................................................................................................... ii

Chapter 4: Service .....................................................................................................................4-1

4.1 REPLACEMENT PROCEDURES ........................................................................... 4-1

4.1.1 Heating Element Removal and Replacement ...................................................... 4-1

4.1.2 Backup Thermostat Replacement - Computer Models Only............................... 4-2

4.1.3 Calibrating the Thermostat - Computer Models Only.........................................4-3

4.2 TESTING CONTACTORS (RELAYS)....................................................................4-3

4.3 TESTING HEATING ELEMENTS ..........................................................................4-4

4.4 TESTING THE TEMPERATURE SETTING POTENTIOMETERS...................... 4-4

4.5 TESTING THE TEMPERATURE CONTROL MODULES ...................................4-4

4.6 TESTING THE TEMPERATURE PROBE.............................................................. 4-5

4.7 TESTING THE HEATING ELEMENT INTERLOCK............................................ 4-5

4.8 TROUBLESHOOTING FRYERS WITHOUT COMPUTERS................................ 4-7

4.9 TROUBLESHOOTING FRYERS WITH COMPUTERS...................................... 4-14

4.10 TROUBLESHOOTING BASKET LIFT PROBLEMS ..........................................4-16

4.11 TROUBLESHOOTING BUILT-IN FILTER UNITS............................................. 4-18

4.12 TROUBLESHOOTING UFM FILTER UNITS ..................................................... 4-21

Chapter 5: Parts .......................................................................................................................5-1

Fig. No.

5-1 Outside View ............................................................................................................. 5-2

5-2 Entrance Box ............................................................................................................. 5-3

5-3 Inside Fryer Tank Components ................................................................................. 5-4

5-4 Frame-Cabinet / Electrical Assemblies With Components ....................................... 5-7

5-5 UFM Filter, Frame/Electrical Assembly ...................................................................5-9

5-6 UFM Pilter, Pick-Up/Pan Assembly ....................................................................... 5-11

5-7 UFM Filter, Motor / Return Assembly.................................................................... 5-13

5-8 Built-In Filter Pan With Components...................................................................... 5-15

5-9 Filter Piping With Components............................................................................... 5-17

5-10 Built-In Filter With Accessories.............................................................................. 5-19

ALPHABETICAL PART LIST .............................................................................. 5-20

NUMERICAL PART LIST..................................................................................... 5-24

i

Page 5

Table of Contents (Service) Cont.

Section Title Page

Chapter 6: Schematics.............................................................................................................. 6-1

List of Tables and Figures

Table No. Title Page

5-1 Frame-Cabinet / Electrical Assemblies With Components ....................................... 5-6

5-2 UFM Filter, Frame/Electrical Assembly ...................................................................5-8

5-3 UFM Pilter, Pick-Up/Pan Assembly ....................................................................... 5-10

5-4 UFM Filter, Motor / Return Assembly.................................................................... 5-12

5-5 Built-In Filter Pan With Components...................................................................... 5-14

5-6 Built-In Filter Piping With Components ................................................................. 5-16

5-7 Built-In Filter With Accessories.............................................................................. 5-18

Figure No. Title Page

5-1 Outside View ............................................................................................................. 5-2

5-2 Entrance Box ............................................................................................................. 5-3

5-3 Inside Fryer Tank Components ................................................................................. 5-4

5-4 Frame-Cabinet / Electrical Assemblies With Components ....................................... 5-7

5-5 UFM Filter, Frame/Electrical Assembly ...................................................................5-9

5-6 UFM Pilter, Pick-Up/Pan Assembly ....................................................................... 5-11

5-7 UFM Filter, Motor / Return Assembly.................................................................... 5-13

5-8 Built-In Filter Pan With Components...................................................................... 5-15

5-9 Filter Piping With Components............................................................................... 5-17

5-10 Built-In Filter With Accessories.............................................................................. 5-19

ii

Page 6

Chapter 4: Service

This chapter provides the qualified technician with the replacement and troubleshooting procedures

necessary to service the Pitco fryer.

4.1 REPLACEMENT PROCEDURES

These procedures are provided to the qualified technician as a guide to removal and replacement of

various fryer components. If a test is required to verify component operation after installation, it will

be referenced.

WARNING

To prevent burns, always ensure the fryer is completely SHUT DOWN and

COOLED down before working on the fryer. Do not break any fryer gas

connections while the unit is connected to a gas supply line.

WARNING

The power supply must be disconnected before servicing or cleaning the

appliance.

4.1.1 Heating Element Removal and Replacement

Replacing a heating element is a complex and time consuming procedure. Ensure that you have

tested the heating elements to determine that the element is bad and not something else.

a. Move the fryer out to gain access to the rear panels. Remove the upper small access cover

and the large lower access cover.

b. The terminal block for the heating elements is located behind the lower access plate. Tag

the connections with wire markers for easy reinstallation, and remove the wires. The

temperature probe wires are not connected through the terminal board. To disconnect the

temperature probe, remove the small access plate on top of the pivot box (plate opposite

High Limit switch). The connector for the probe is inside the pivot box. Disconnect the

probe at this connector and gently pull the wire out of the pivot box.

c. Disconnect the spring assembly from the pivot box by raising the elements and holding

them in place with a board across the tank. Do not use the element bracket to hold the

elements up.

d. Next remove the pivot box assembly by removing the screws that attach the pivot box

hinges to the fryer. The heating elements will need to be raised to gain access to the screw

heads. Support the heating element assembly before removing the screws. Removing

the hinge screws frees the heating element assembly from the fryer.

4-1

Page 7

e. Once free of the fryer, set the element assembly aside. Remove the access plate on the

back of the pivot box to gain access to the heating element connectors. Disconnect the

wire for the defective element.

f. Loosen the nuts that attach the heating element to the pivot box. Slide the heating element

out of the pivot box.

g. Install the new heating element by reversing this procedure.

4.1.2 Backup Thermostat Replacement - Computer Models Only

Only fryers that have computer controls have this backup thermostat. If your fryer does not have

a computer but does have a thermostat behind the door, this is a thermostat behind the door model.

That means that the knob behind the door controls the solid state temperature module behind the

fryer's control panel (front bezel). The backup thermostat includes the temperature adjustment knob,

temperature sensor inside the fryer tank, and connecting capillary tubing. The high limit controls

also has a temperature sensor in the fryer tank, so ensure you are removing the correct temperature

sensor.

CAUTION

Thermostat capillary tubing is very delicate. Be VERY CAREFUL when

working with the capillary tubing. If the tubing is kinked or broken the

thermostat is no longer usable.

a. Drain the oil from the fryer. The thermostat probe (heat sensor) is clamped to the heating

element assembly inside the tank. Unscrew and remove the two screws in the thermostat

probe clamp.

b. Remove the thermostat probe from the clamp and straighten the capillary tubing.

Unscrew the small hex nut inside the cabinet under the tank for the thermostat control.

c. Unscrew the large connector nut from the fryer tank and pull the thermostat probe and

capillary tubes through the opening.

d. Pull the knob off of the thermostat. Remove the entrance box cover to gain access to the

thermostat.

e. Mark and disconnect he wires from the thermostat terminals.

f. Remove the two screws that hold the thermostat to the inside of the entrance box. Remove

the defective thermostat control unit from the fryer.

g. Install the new thermostat in reverse order. Remember to be careful with the capillary

tubes.

4-2

Page 8

h. Use pipe joint compound on the large fitting before installing to prevent oil leakage. DO

NOT use joint compound on the small nut.

i. Perform the calibration procedures detailed in section 1.5.3.

4.1.3 Calibrating the Thermostat - Computer Models Only

To calibrate this thermostat the dial must be removed from the shaft. The adjustment for the

thermostat is inside the dial shaft.

a. To calibrate the thermostat you must first cause the computer to switch control to the

backup thermostat. To do this, remove the computer from the front panel and disconnect

the connector from the computer. The transfer relay will de-energize and temperature

control will shift to the backup thermostat.

b. Place the tip of a high accuracy thermometer in the shortening approximately 1" above

the temperature sensor.

c. Set the thermostat dial to 325°F and turn the fryer on.

d. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

e. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw

driver to scrape away the sealing compound from the adjustment screw. Turn the

adjustment screw clockwise to lower the temperature setting, and counterclockwise to

raise the temperature. One quarter turn will change the temperature approximately 25°F.

f. Turn the adjustment until the heating elements turn off at 325°F. Replace the knob and

allow the fryer to cycle 4 to 6 times. Check the temperature of the thermometer against

the thermostat dial, if it is greater than 5°F repeat the calibration procedure.

g. When the calibration is correct, remove the thermometer.

4.2 TESTING CONTACTORS (RELAYS)

Contactors and relays use a control voltage to energize the electro magnet and close a set of contacts.

The control voltage is applied to a solenoid-type coil. When measuring a coil's resistance, ensure that

you have disconnected it from the fryer's electrical system. This will ensure that you are measuring

the coil's resistance and not a portion of the fryer's wiring. When measured with an OHM meter these

coils should have a very low resistance, less than 100 ohms. Measure each of the contactors that are

suspect. If any relay or contactor indicates an open circuit or high amount of resistance, replace the

coil.

4-3

Page 9

4.3 TESTING HEATING ELEMENTS

To check a heating element first place the OFF-ON-START switch in OFF. Check the elements by

performing the following:

a. The terminal block that connects the heating elements to the fryer is located behind the

large rear access panel. Move the fryer out and remove the access panel.

b. Using an OHM meter check continuity from one end of the element to the other. The

reading should be very low (a few ohms). If the element indicates an open circuit, replace

the element.

c. Next check from the hot side of the element to ground. It should be infinite, if it is not

replace the element.

4.4 TESTING THE TEMPERATURE SETTING POTENTIOMETERS

The temperature setting potentiometer is a variable resistors. To test the potentiometer ensure that

the OFF-ON-START switch is OFF and perform the following:

a. For thermostat knobs mounted on the front of the fryer, remove the front bezel to gain

access to the back of the potentiometer. If the fryer has the thermostat knob mounted

behind the door (in the entrance box), remove the entrance box cover to gain access to

the back of the potentiometer.

b. Disconnect P10 from J10.

c. Connect an ohm-meter to pin 3 (yellow wire) and pin 1 (violet wire) and rotate the

temperature control knob. The resistance should vary from 0 to 900 ohms.

b. Connect the ohm-meter between pin 3 (yellow wire) and pin 5 (orange wire) and rotate

the knob. The resistance should again vary from 0 to 900 ohms. If the resistance is not

within the ranges specified replace the temperature setting potentiometer.

4.5 TESTING THE TEMPERATURE CONTROL MODULES

The temperature control module receives 24 VAC when the OFF-ON-START switch is ON. To test

the temperature control module perform the following:

a. The temperature control module is located behind the front bezel. Remove the two screws

that hold the bezel in place and move out of the way.

b. Place the OFF-ON-START switch in ON and the Melt switch in OFF. This will apply 24

VAC to pin 1 (black wire) with pin 3 as the common (white wire) of the temperature control

module.

4-4

Page 10

c. Set the temperature setting potentiometer to a temperature above the shortening's current

temperature. This will cause the temperature control module to close and pass 24 VAC to

pin 12 (gray wire) of the control module.

d. Check the temperature probe as described in section 4.6.

e. If the temperature probe test passes and there is not 24 VDC present on pin 12 of the control

module, replace the temperature control module.

4.6 TESTING THE TEMPERATURE PROBE

WARNING

All power supplies must be disconnected before servicing the appliances.

Some appliances have more than one power supply. Make sure they are ALL

disconnected.

The temperature probe is a special type of resistor called a thermistor. Check the temperature probe

by performing the following:

a. Gain access to the temperature probe connection by removing the front panel. Disconnect

P10 and check the resistance of the probe at pins 2 & 4 of P10.

b. Place the OFF-ON-START switch in OFF. Use an ohm-meter to measure the resistance

across the probe. It should be about 100K ohms at room temperature (72°F, 22°C). If the

probe indicates an open or more than 200 ohms away from 100K ohms, replace the probe.

c. Re-install the probe wires and turn on the fryer. Start the fryer and raise the shortening

temperature to normal cooking temperature, approximately 350°F.

d. Unplug the temperature probe and measure the resistance again. It should read approxi-

mately 923.8 ohms ±10 ohms. If the resistance is different by more than 10 ohms, replace

the temperature probe.

4.7 TESTING THE HEATING ELEMENT INTERLOCK

The heating elements are protected from accidental over heating, due to lifting them out of the oil

while unit is ON, by an interlock limit switch. The switch is located on the right side (opposite the

High Limit switch) of the heating element pivot box.

a. This test requires that you gain access to the back of the interlock switch. Remove the four

screws from the small access plate on the top, right of the pivot box. Gently move the wiring

harness to the side to expose the wiring terminal of the interlock switch.

4-5

Page 11

b. Connect an ohm-meter across the switch terminals to measure the resistance across the limit

switch connection.

c. When the elements are down in the tank the interlock switch is closed and the resistance

across the switch will be zero.

d. Lift the element rack up while continuing to measure the resistance across the switch. The

rack only needs to be lifted a short distance to open the switch. A click should be heard when

the switch opens. The resistance will go up significantly when the switch opens. The

resistance will not be infinite unless the switch wires are disconnected. If there is any doubt

about the resistance, remove the wires and check the resistance. With the wires removed the

resistance will be infinite.

4-6

Page 12

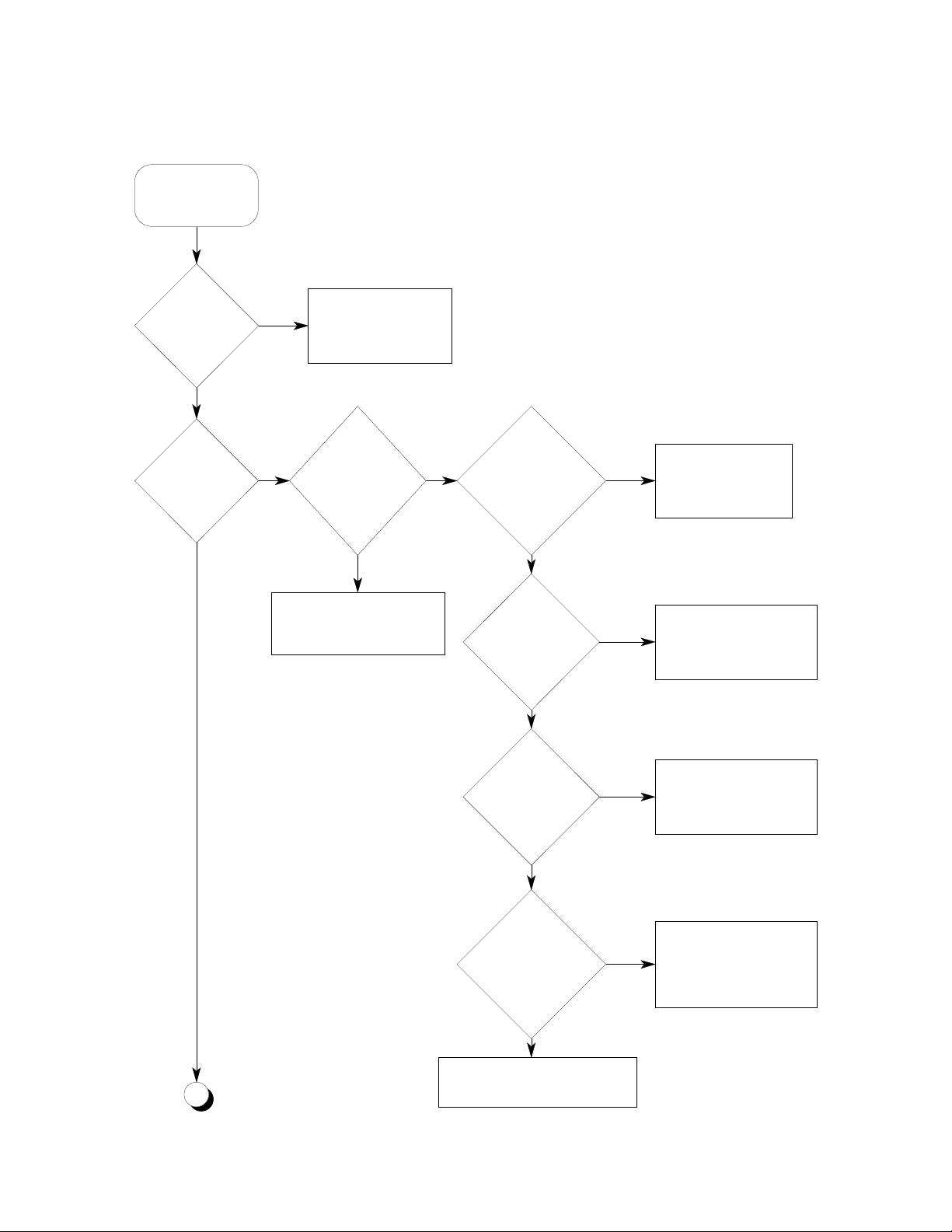

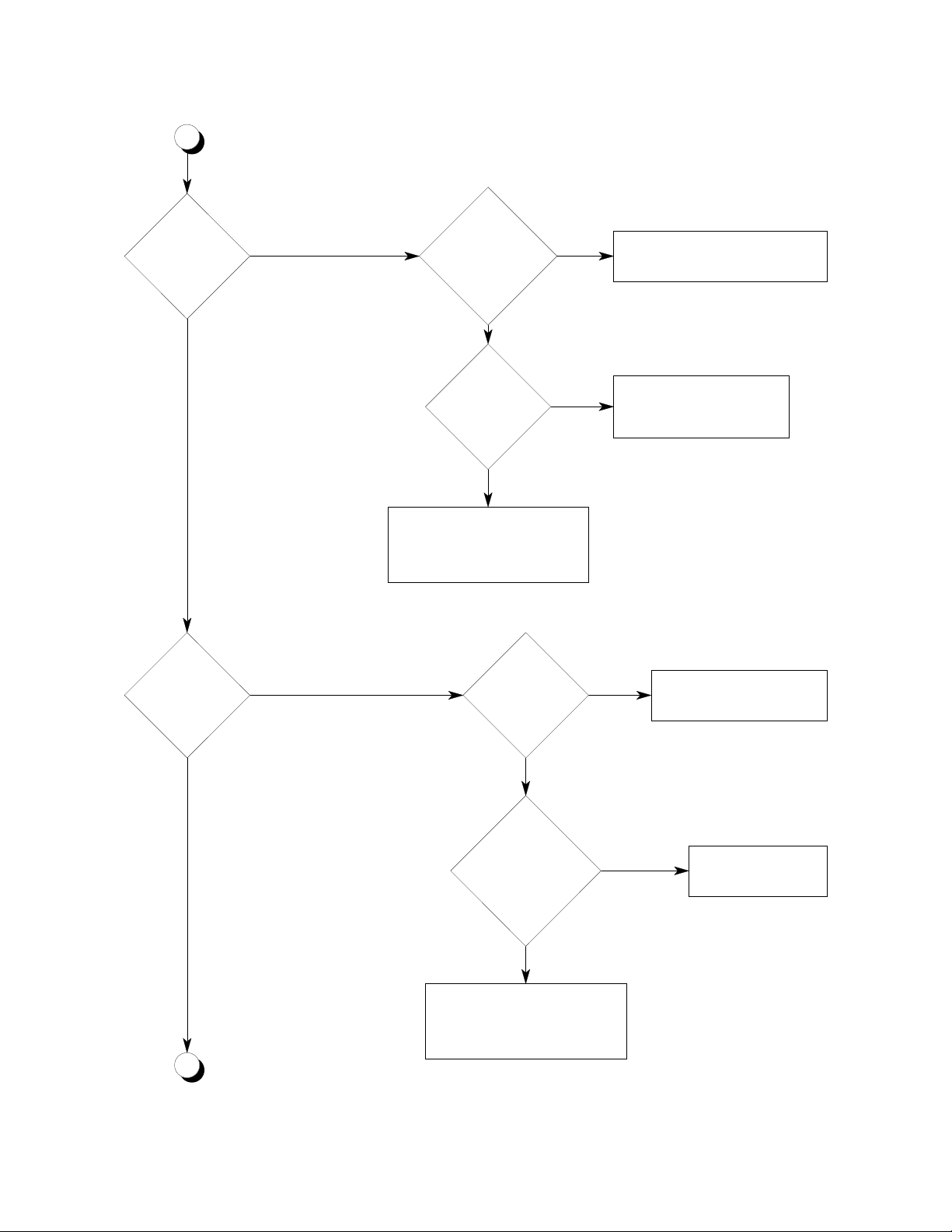

4.8 TROUBLESHOOTING FRYERS WITHOUT COMPUTERS

p

Fryer does no t

operate properly!

Is the fryer

filled with oil?

YES

Does the

POWER ON

indicator light?

YES

NO

NO

Refer to Chapter 2 for

proper filling and

operation of the fryer.

Is the Fryer

connected to building

power su pp l y?

NO

Connect fryer to building

power su pp l y as de sc r i bed i n

Chapter 1.

YES

Is the service

panel circuit

breaker tripped?

NO

Is the fire

protection tie in

system closed?

YES

YES

NO

Determine reason for

tripping. Reset the

circuit breaker.

Ensure that the fire

protection system is closed

or that the fire protection

oint is closed.

tie in

Is the control fuse

(F1) blown?

YES

Are the heating

elements down and is

the interlock

YES

working?

YES

Test the ON/OFF/TEST Switch

A

and repl ace i f ne ce s sa r y

NO

NO

Determine the cause for

blowing. Replace the fuse.

(Refer to 3.6)

Ensure the the heating

elemen t s are down. C h eck

the interlock switch per 4. 7

and replace if necessary.

4-7

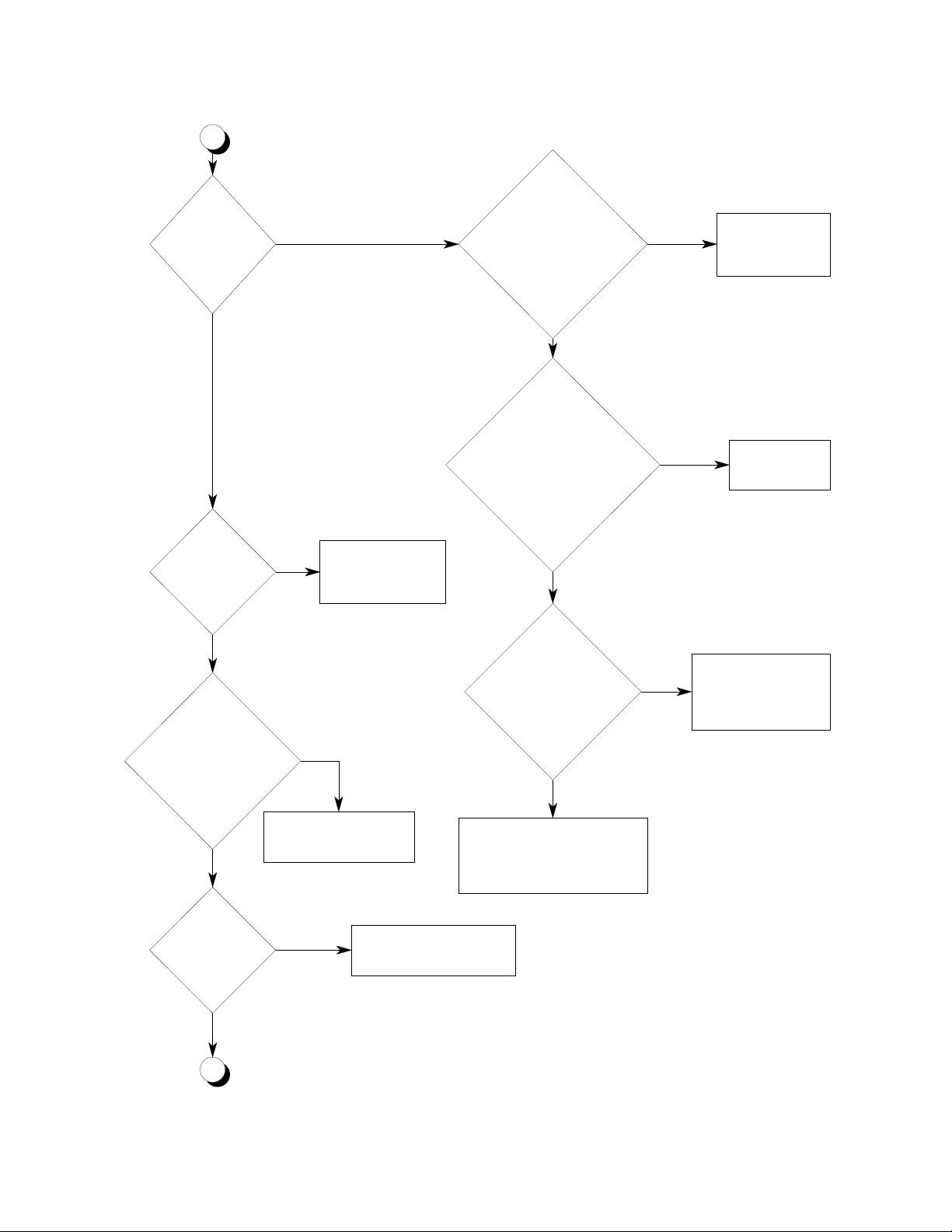

Page 13

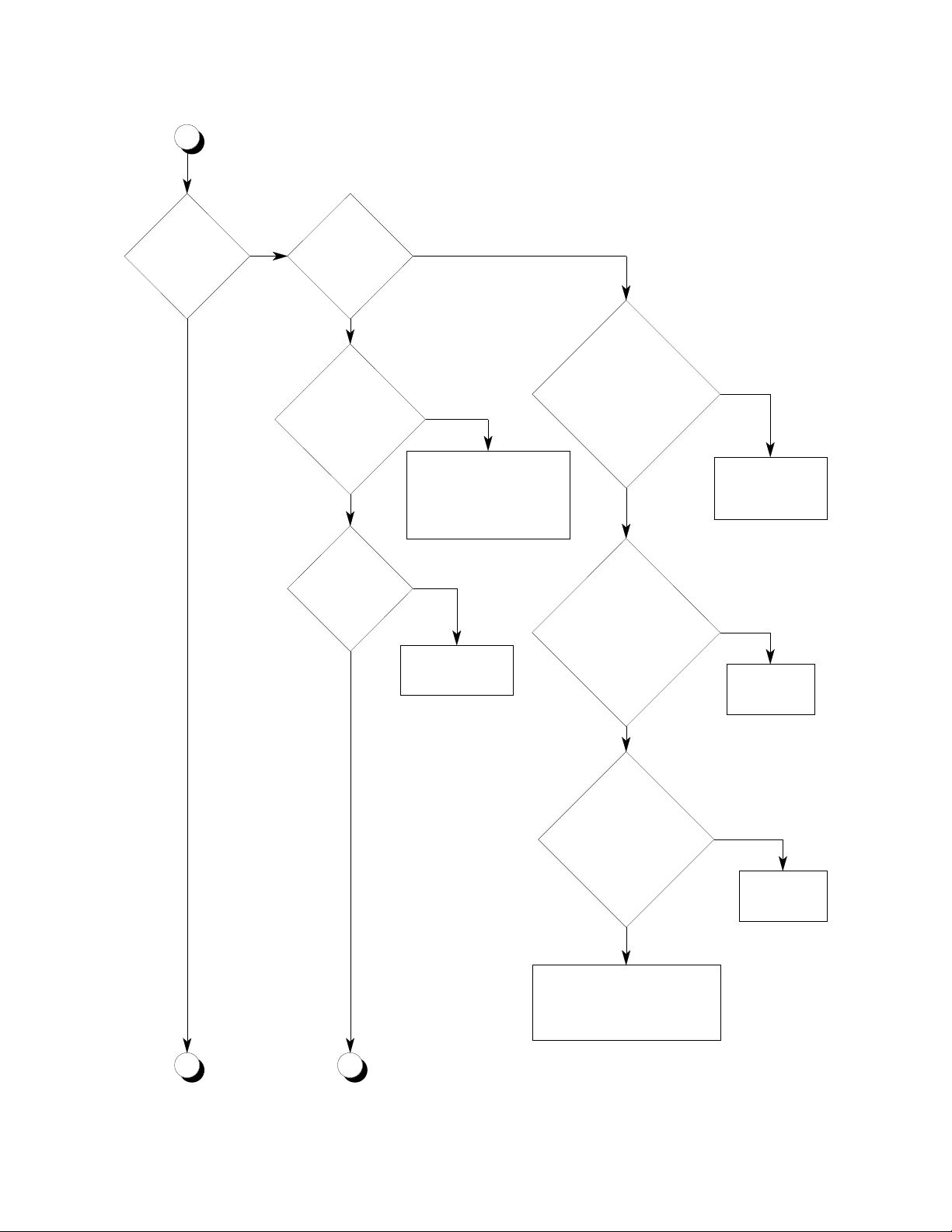

A

p

Does the fr y er

heat up?

YES

NO

Does the

HEATI NG l i ght

come on?

Are the heating

elements down and i s

the interlock

working?

Is the High Li mit

switch open?

YES

YES

NO

NO

Ensure that the heating

elements ar e dow n. C heck

the inter loc k s wi t ch per 4.7

and replace if neces s ary .

YES

Reset swit ch and

check tri p se t t i ng.

Test the temperature

probe as described in 4.6.

Is the temper at ure pr obe

defective?

NO

Test t he

temperature set

potentiom et er as descri bed in

4.4. Is t he potentionmeter

defective?

YES

Replace the

temperature

probe.

YES

Replace the

potentiometer

NO

Test the

NO

B

C

temperat ur e c ont rol

module as descri bed in

4.5. I s t he m odule

defective?

NO

Verify continuity of the leads

which provide 24 VAC pow er ,

and the potent iom eter and

robe signals to t he m odule.

YES

Replace the

module.

4-8

Page 14

B

C

YES

Does HEATING

light go out when

thermostat is set above

oil temperature?

YES

NO

Test the temperature

probe as described in 4.6.

Is the temperature probe

defective?

NO

Test the temperature

set potentiometer

as described in 4.4. Is

the potentionmeter

defective?

YES

Replace the

temperature

probe.

YES

Are heating

element fuses

blown?

NO

Check heating

elements as

described in 4.3.

Are they good?

YES

Check contactors K7 thru K10. Check

wiring for loose connections. Check

continuity between the grey lead on

each contactor and the grey lead to the

HEATING light .

YES

Replace the fuse(s)

and determine the

cause for blowing.

NO

Replace the

defective heating

elements

Replace the

NO

Test the

temperature control

module as described

in 4.5. Is the module

defective?

NO

Verify continuity of the leads

which provide 24 VAC power,

and the potentiometer and probe

D

signals to the module.

potentiometer.

YES

Replace the module.

4-9

Page 15

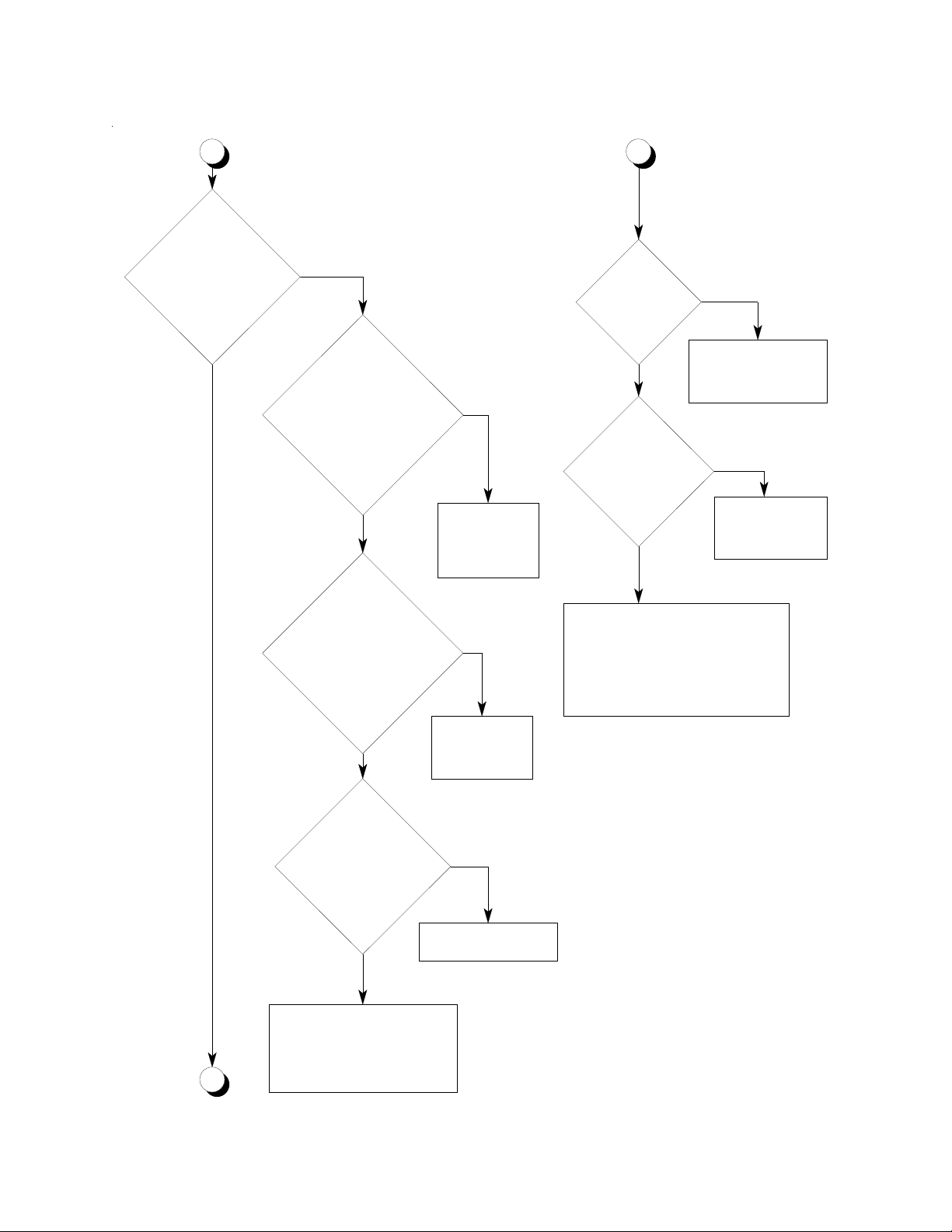

D

NO

Does HIGH LI MIT

switch t r i p dur i ng normal

operation?

NO

YES

Is solid

shortening being

melted?

NO

Is short ening

level too low?

NO

Is High Lim it

capillary tube

touching the heat i ng

elements?

NO

YES

YES

Ensure that short ening is packed

tightly ar ound heating elements !

Make sure t hat t he M el t Cyc le

switch is set to MELT ON.

Ensure that shortening level is f i ll ed

to the level mark.

YES

Gently m ove the capillar y t ube

away from the heating elem ent s

Are the heat i ng

elements dir ty?

NO

Is the t her mostat

set too high?

Test the

Replace the

module.

E

YES

temperature contr ol

module as described

in 4.5. I s the module

NO

defective?

YES

YES

NO

Perfor m a through cleaning of

the fry er as des cribed in 3.2.

Check the setting and

calibrati on of t he thermostat.

If the High Li m it s w it c h can

not be reset of cont i nues to

trip earl y replace the sw it c h.

4-10

Page 16

E

Does the

shortening get t oo

hot?

NO

Does the

shortening not get

hot enough?

YES

YES

Is the shortening

level too low?

NO

Is the t her mostat

set too high?

NO

Test t he temperat ur e pr obe as

described in 4. 6. Repl ace

temperat ure probe if def ec t iv e.

Is the thermost at

set too l ow?

YES

YES

Ensure that shortening level is f i ll ed

to the level mark.

Check the setting and

calibrati on of t he thermostat.

YES

Check the set ting and

calibration of the thermost at .

NO

Check heating

elements as

described in 4. 3. Are

NO

Test t he t emperatur e pr obe as

F

they all good?

YES

described in 4. 6. Replace the

temperature probe if defective.

NO

Replace the def ective

heating element s

4-11

Page 17

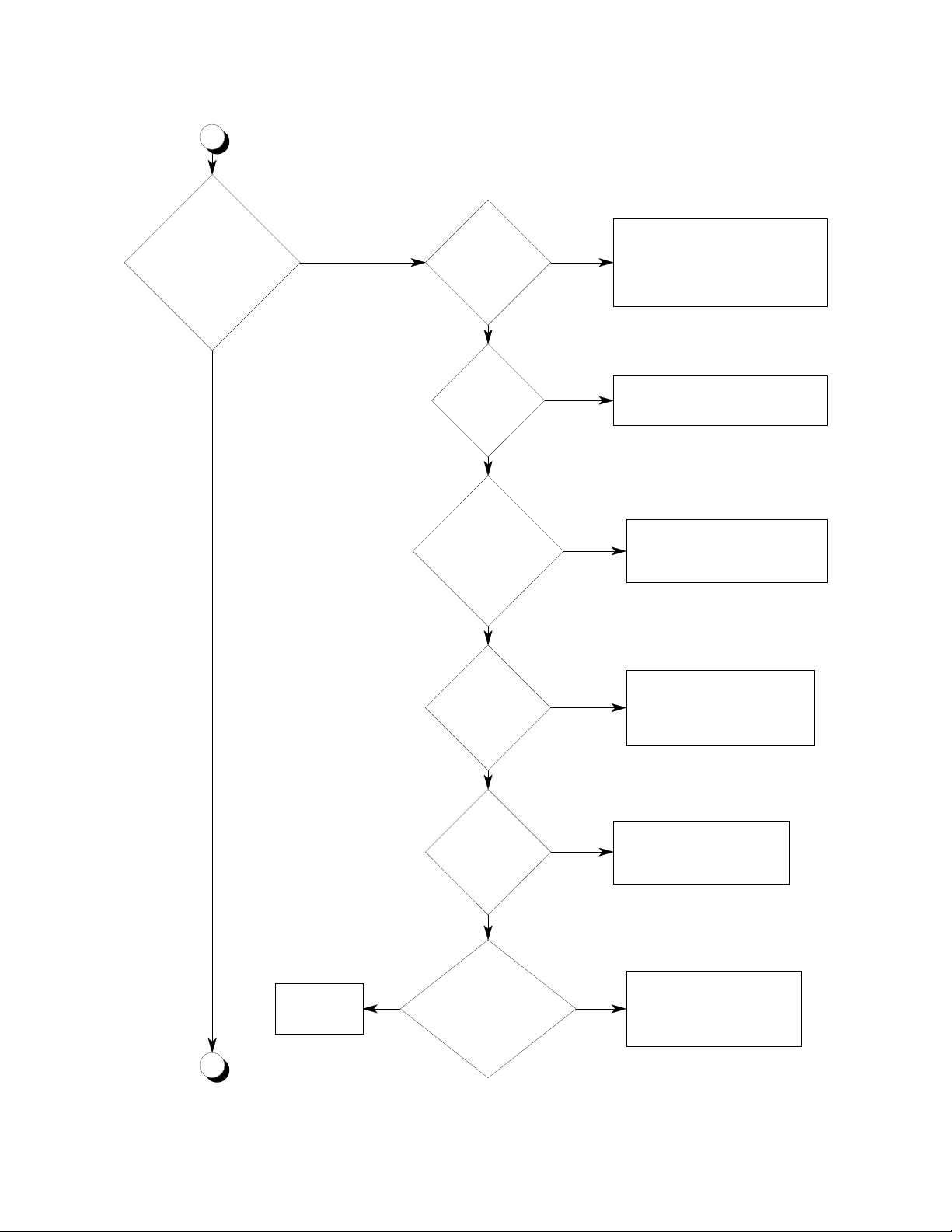

F

Does the f ryer

heat inter mi t t ent ly ?

NO

Does the f ryer

heat slowly ?

YES

Is the fryer

connected t o t he

proper vol tage su pply and

is it connected

properly?

NO

Fryer i s function i ng

NO

YES

properly.

Test the tem per a t ure

probe as described in 4. 6.

Is the temper ature pr obe

defective?

NO

Test the tem per a t ure

set pot ent i o m et e r a s

described in 4. 4. Is the

potentionmeter defecti ve?

NO

Test the

temper at ure contr ol

module as desc ribed in

4.5. I s t he modu le

defective?

NO

YES

YES

Replace the

temperature

probe.

YES

Replace t he

potentiometer.

Replace the

tempera t ure contr ol

module.

YES

Are the heat ing

elements c l ean?

YES

G

Correct t he inst all at ion.

NO

Perfor m a weekly cl eanin g

of the fr yer ( 3.2 )

Check heati ng el em e nt s as

described in 4.3. Rep lac e

heating elements if necessar y.

4-12

Page 18

G

Are any of t h e

heating el ements

fuses blo w n?

NO

Check heat i ng

elements as described

in 4.3. Ar e t hey all

good?

YES

Is the

temper at ur e pr obe l oos e

or in the wrong

location?

YES

NO

Replace the bl own f uses .

Replace the def e ct iv e

heating elem ents

YES

Move or tight en t he

probe.

NO

Check cont a ctors K 7 thru K 10. Check

wiring f or loos e connec t ion s. Check

Continui ty between the g r ey l ead on

each contactor and t he gr ey le ad t o

the HEATIN G light .

4-13

Page 19

4.9 TROUBLESHOOTING FRYERS WITH COMPUTERS

Fryer power is ON, but

the fryer is not functioning

properly.

Is the

computer panel

lit?

YES

Does the

computer display

indicate LOW after

allowing for sufficient time

for the fryer to

warm up?

NO

service panel circuit

breaker for the fryer

Close the breaker.

Is the

ON?

NO

Has temperature

control transfered to the

back-up thermostat? This can

be checked by moving the back-up

thermostat and watching the

heating light cycle

on and off.

YES YES

Check interconnecting wire betw een

computer and computer supply fuse (F3).

Is control fuse

supply fuse (F3)

(F1) open

NO

Is computer

open

NO

NO

YES

Are the

heating elements

properly seated in

the fryer tank?

Replace F1.

Replace F3.

Ensure that

the heating

NOYES

elements are

seated in the

tank.

YES

YES

Temperature control transfers

automatically to the Back-Up

thermostat when there is a problem

with the computer or power is lost to

the transfer relay.

A

Is the High Limit

switch tripped?

NO

CB

Reset the High

Limit Switch. If

YES

the switch will

not reset,

replace the

switch

4-14

Page 20

A CB

Does the

computer displ a y

indicate

PROB?

YES

Is the oil

temperat ure less

than 70°F?

NO

Is the pr obe

resist ance c or r ect?

Refer to 4.6 for pr obe

test proc edur e.

NO

YES

NO

Computer

functioning pr operly

for t em per at ure

control.

Raise the t em perature of

the oil using t he back up

thermostat. T he pr oblem

should correct itself.

Replace the

probe.

Check

element f uses .

Are any of the

fuses open?

NO

Check the

contactor s as

described in 4. 2. A r e

the contactors

defective?

NO

Perform elem ent

resistanc e c heck

asdescribed in 4- 3.

Determi ne why

YES

fuses blew and

replace the blow n

YES

fuses.

Replace the

defective

contactor.

YES

Check

interconnecting

wire.

If t he f y er has a

Blanch Mode Swich

ensure that it is in BLAN CH

OFF. Is the switch in

BLANCH OFF?

NO

But Blanch M ode

switch in BLANCH

OFF.

YES

Check

interconnect ing wi re.

4-15

Page 21

4.10 TROUBLESHOOTING BASKET LIFT PROBLEMS

Fryer works (115 VAC

presen t at fr y er) but

automatic basket lifts do

not function properly.

Does either

basket l ift

work?

YES

NO

Check the basket lift linkage and ensure

that it is not binding. Replace the basket

lift motor if the linkage is OK.

Check the

inter c on ne cting wi re

betwee n the ti mer ( o r

computer) and the basket

lift motors. Are all

connections

good?

YES

NO

Repair as

necessary.

Does

affected basket

lift lower/

raise?

YES

Does

basket lift run

continually?

YES

NO

Check for continuity between

the common and NO terminals

of the timer while pressing the

time start button. Is there

continuity?

YES

Check f or cont i n ui t y

between the NO terminal of

the timer and the NC

terminal of the roller

microswitch. Is there

continuity?

YES

Check continuity between the NC and

common terminal (White) of the microswitch.

There should be continuity when the switch is

released. Does the switch open and close?

YES

NO

NO

Repair wire

connectors.

NO

Replace

the timer.

and/or

Replac e t h e

microswitch.

Check the alignment of the microswit ch. The

switch should be aligned so that it is not

depressed when the basket lift is up and

depressed when the lift is down. If t he

switch cannot be aligned, replace the switch.

A

4-16

Page 22

A

NO

Does

basket lif t m ake

grinding no i ses a s

it cycles?

NO

Basket lift is f un ct i oning

properly.

Check the li nkag e to ens ur e t hat

YES

it is not binding. Level the fryer

and adjust t he bas ket hanger s t o

ensure compl et e cle aran ce.

4-17

Page 23

4.11 TROUBLESHOOTING BUILT-IN FILTER UNITS

Filter unit is not

working proper ly.

Is the

pump

running?

YES

Is oil

flowing?

YES

Oil pumping

slowly?

YES

NO

Turn the filter power switch

tripping and reset the circuit

NO

Is the filter

circuit breaker

tripped?

YES

off. Correct the cause for

breaker.

Is filter

pickup connected to

motor?

NO

Connect hose.

Is filter

pickup completely

connected?

NO

Conect hose.

NO

YES

YESNO

Is filter

motor overload

tripped

YES

Allow the motor to

cool, reset the

thermal overload on

the motor.

Check for solidified

shortening in internal lines.

Use the filter heaters for 5

to 15 minutes to liquify the

solids.

Is filter paper,

bag, or pickup screens

clogged?

Clean the screen or

replace filter media.

YES

NO

power supply wired

NO

Is 120 VAC

YES

in to the TB4

terminal.

NO

Wire in 120

VAC power

supply.

Check the refill time of the

pump with a new filter

installed. It should not exceed

1 minute for each 25 pounds

of shortening. See data plate

on fryer door for rating. The

pump may need replacement

if these times are exceeded

call service.

C

Do the filter

heaters work?

YES

NO

Is HEAT

light on with

heat switch in

HEAT?

YES

BA

NO

Is the

fryer plugged

in?

Plug in the

fryer.

4-18

NO

YES

Turn the filter power switch off.

Correct the cause for tripping

and reset the circuit breaker.

Is the filter

circuit breaker

tripped?

YES

NO

Check the

building

circuit

breaker.

Page 24

A

B

C

enough time for the heaters

resistance at the filter power cord

plug. If the resistance is higher

than 37.5 ohms, a heater has failed

Does the filter

circuit breaker keep

tripping?

Have you allowed

to warm-up?

YES

Use a VOM to measure the

and must be replaced.

Is the filter

correctly connected to

the filter piping?

NO

Allow 1/2 hour for the

filter heaters to

soften hardened

shortening.

YES

Reset the circuit

breaker and check

for a clogged filter

hose.

Replace the

switch.

NOYES

Replace filter

motor.

YES

NO

pump/heater switch when

YES

Is the

building circuit

breaker

open?

NO

Is there

continuity across

in ON

position?

YES

Is 115

VAC present at

the filter motor when

the filter switch

is ON?

NO

Does the filter

motor trip the

overload?

NO

D

Check the filter lines for

clogs.

Is the filter

correctly connected to

the filter piping?

YES

Check the filter lines for

clogs.

Ensure that the filter hose is

correctly connected to the filter unit

and the correct valves are open

NOYES

Ensure that teh filter hose is

correctly connected to the filter unit

and the correct valves are open

4-19

NO

Check switch and

replace if

defective.

Page 25

g

D

Is pu mp runn i n g

slow, taking 4 to 5

minutes to f ill the

tank?

NO

Are the filter

heaters working?

YES

Clean out the filter lines. C heck the

current load on the filter motor. If it is

high replace the defective pum p.

Are a lot of air

bubbles coming out of

the oi l di sc harge

line?

NO

Is PAN HEAT

light ON?

NONO

YES

Is P17

connected?

Check a l l hose c o nn ection s

and the hose itself for leaks.

Correct any leaks or the hose

if damaged.

NO

Connect P 17

(Heater power)

YES

Filter unit is

working properly.

YES

Turn off the heaters and

check the resistance if the

heating element. If t he

resistance is significantly

reater or less than 72 ohms,

replace heater elements.

Check

interconnecting wire

between switch and

heater elements..

YES

4-20

YES

Is the

circuit breaker

open?

NO

Is there

continuity across

pump/heater switch

when in ON

position?

YES

NO

Reset the circuit

breaker and check

for clogged suction

line or quick

disconnect.

Replace the switch.

Page 26

4.12 TROUBLESHOOTING UFM FILTER UNITS

Filter unit is not

working properly.

Is the

pump

running?

YES

Is oil

flowing?

YES

Oil pumping

slowly?

YES

NO

Turn the filter power switch

tripping and reset the circuit

NO

Is the filter

circuit breaker

tripped?

YES

off. Correct the cause for

breaker.

Is filter

pickup attached

correctly?

NO

Connect hose.

Is filter

retun hose

completely connected?

NO

Conect hose.

NO

YES

Ensure return hose is engaged.

YESNO

Is filter

motor overload

tripped

YES

Allow the motor to

cool, reset the

thermal overload on

the motor.

Is the return

hose fully engaged

on filter fitting?

NO

Is filter paper,

bag, or pickup screens

clogged?

YES

Clean the screen or

replace filter media.

NO

supplied to TB4

YES

Is 120 VAC

terminal.

NO

Wire in 120

VAC power

supply.

Check for solidified shortening in

internal lines and check pick up

assembly screen. Wait until the

"PREHEAT FINISHED" light is

on before turning pump switch

"ON"

Check the refill time of the

pump with a new filter

installed. It should not exceed

the times listed in this manual.

NO

If the times are exceed have

the motor replaced. Use filter

aid to prevent fine foods from

blocking paper and causing

premature replacement.

YES

Check the

building

circuit

breaker

Does the

PREHEAT FINISHED

light come on?

YES

A

If the filter has had power removed for

more than 2 hours, it may take the heater

NO

10-12 minutes to turn the PREHEAT

FINISHED light on after power is

restored.

4-21

Page 27

A

Does the

filter leave

excessive oil in

the filter pan?

NO

Does the filter

circuit breaker keep

tripping?

YES

YES

least one system

valve open?

Scrape the filter layer down to the metal

scraping screen. Once the pan is empty,

tight en the pick up tube nut against t h e

sediment screen. Inspect th e filter bag for

tears and change if torn.

Is at

YES

NO

Is the

black hose fully

engaged?

NO

Solid shortening could be

blocking the pump discharge

YES

lines. Wait until the

PREHEAT FINISHED light is

on before turning the pump

switch ON.

NO

Does the filter

motor trip the

overload?

NO

Filt er unit is working

correctly.

Open the desire d valve first, then tur n

on the pump. S tarting t he pump before

opening a valve causes an overload

that opens the circuit breaker.

YES

Open the desired valve first, then

turn on the pump. Starting the

pump before ope ning a valve

causes an overload that opens the

Is at

least one system

valve open?

NO

circuit bre aker .

YES

Ensure that the

hose is fully

engaged on the

filter fitting.

Is the

black hose fully

engaged?

NO

Ensure that the

hose is fully

engaged on the

filter fitting.

Solid shortening could be

blocking the pump dis charge

lines. Wait until the PREHEAT

YES

FINISHED light is on before

turn ing the pump switc h ON. If

the filter has been tr ansfered to

another fryer allow the fryer to

operate for 45 minutes before

filtering.

4-22

Page 28

Chapter 5: Parts

This chapter contains listings of the components used in the different models of universal fryers.

These components are listed in two places, with the illustration and in ordered listings. The

illustrations in this chapter are provided to show relative location of components located in the fryer.

The fryer you have may not be illustrated in this chapter, but the part locations should be the same.

With each illustration there is a table of components in numerical order by illustration number. The

illustration has numbered lines pointing to components which are listed in the table.

At the end of this chapter there are alphabetical and numerical listings of all parts used in the universal

fryers. The alphabetical part list is arranged in alphabetical order according to the part name. Each

part name also has the Pitco Frialator part number. The numerical list is in Pitco Frialator part number

order. A brief description of each component is provided for each part.

5-1

Page 29

4 3

2

5

8

10

1

6

7

9

Index Index

Number Description Number Description

1 Basket Hanger

2 Basket

3 High Limit Cover

4 Interlock Switch Access Cover

5 Computer

6 Door Handle

7 Right Hand Door

8 Left Hand Door

9 Caster Set

10 UFM Filter Module (Optional)

Figure 5-1 Outside View

5-2

Page 30

7

8

6

5

4

3

2

1

Index Index

Number Description Number Description

1 Ground Lug

2 Terminal Block

3 Terminal Block

4 Fuses (6)

5 Fuse Block

6 Contactor, Mercury

7 Transformer

8 Receptacle

9 Contactor, Mechanical

10 Thermostat Knob

9

10

Figure 5-2 Entrance Box

5-3

Page 31

6

5

2

3

1

7

4

Index Index

Number Description Number Description

1 Auxiliary Thermostat Probe

2 Computer Probe Clamp

3 Computer Probe

4 Element Bottom Bar

5 Bracket Screens

6 Element Rack

7 High Limit Probe

8 High Limit Probe Clamp

9 Element

Figure 5-3 Inside Fryer Tank Components

5-4

Page 32

THIS PAGE INTENTIONALLY LEFT BLANK.

5-5

Page 33

Table 5-1 Frame-Cabinet / Electrical Assemblies With Components

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 B7446005 Pan Liner #14 1

B7446006 Pan Liner #18 1

2 A6611401 Stop #14 1

A6611403 Stop #18 1

3 P5046980 Heater Strip 2

4 P6071448 Plug Hole 2" 1

5 A6613101 Cover, Side 1

6 A1819602 Bracket, Door Magnet 1

7 P6071300 Magnet 1

8 B3900101 Leg Set 1

9 B7402238 Bracket, Circuit Breaker 1

10 PP10104 Circuit Breaker 1

11 PP10082 Light, 125V Amber 1

12 PP10195 Screw, Button Head Hex 2

13 A6042801 Overlay 1

14 PP10375 Switch, Rocker 1

15 B3600202 Front Panel Weldment 1

16 B7230202 Hinge, Top Door 1

17 B2301208 Door #14 1

B2301210 Door #18 1

18 P6071516 Handle, Door 1

19 B7230302 Hinge, Bottom Door 1

20 P0075200 Screw, 2 #8 x 1/2 Self Drill 10

21 PP10686 Screw 6-32 x 1/4 2

22 PP10025 Screw 10-32 x 1/4 2

5-6

Revised 5/28/93

Page 34

Figure 5-4 Frame-Cabinet / Electrical Assemblies With Components

5-7

Page 35

Table 5-2 UFM Filter, Frame/Electrical Assembly

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 B6621101 Filter Frame, Weldment 1

2 A6683002 Filter, Cover Motor 1

3 A6685702 Filter, Bracket Mounting Cover 1

4 A6684202 Filter, Cover Tubing 1

5 A6684502 Filter, Cover Tubing Cap 1

6 PP10741 Filter, QD SNP 23 Nipple 1

7 A6683802 Filter, Guard Tubing Channel 1

8 A6683102 Filter, Panel, Switch 1

9 PP10331 Lamp, 125V Green Rectangular 1

10 PP10735 Switch, Rocker DPST 15A, with Breaker 1

11 A6055801 Label, Overlay Filter Module 1

12 A7680402 Plate, Switch Pasta 1

13 A6683302 Filter, Box Electrical Body 1

14 P6071062 Caster, 2" With Top Plate 4

15 P0011300 Screw, 10-24 x 3/8" Indent Hex 16

16 PP10176 Nut, Center Lock 10-24 16

17 PP10147 Clip, Cable 0.375 ID 2

18 PP10107 Bushing, Strain Relief 1

19 B6717901 Wiring, Cord, Filter with Termination 1

20 P0093300 Nut, Hex (KEP) 1/4-20 ZN 5

21 A6682802 Filter, Guide CA 1

22 B6717101 Wiring, Cable Filter Assembly 1

23 PP10192 Bushing, Strain Relief 90 2

24 PP10460 Switch, Rocket Circuit Breaker SPST 8A 125V 1

25 PP10119 Label, Warning Motor Reset 1

26 P6071490 Plug, Hole 7/8" Plated 2

27 PP10692 Screw, 10-24 x 5/16" TH Phillips ZN 5

28 PP10752 Screw, 10-32 x 1/2" Thread Roller 18

29 P0000100 Screw, 6-32 x 7/8" RH ZN 2

30 P009100 Nut, Hex 6-32 ZN (KEP) 2

31 P0075200 Screw, TEK 2 #8 x 1/2" SLF DR 1

32 P6071497 Plug, Hole 3/4" Plated 1

33 B6622301 Hose Assembly With Quick Disconnect 1

5-8

Revised 5/28/93

Page 36

Figure 5-5 UFM Filter, Frame/Electrical Assembly

5-9

Page 37

Table 5-3 UFM Filter, Pick-Up/Pan Assembly

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 B6621001 Filter Pan, Weldment 1

2 B6620001 Filter, Rack 1

3 B6617001 Filter, Screen Clip 1

4 B6621202 Filter, Catch Crumb, Weldment 1

5 A6056001 Label, Filter Instruction - Pan 1

6 B6621301 Filter, Cover Pan, Weldment 1

7 P6071516 Handle, Door, 3" C to C 1

8 A6681802 Filter, Coupling Top 1

9 B6615301 Filter, Screen Inlet 1

10 PP10409 O-Ring Viton 11/16" x .094" W 1

11 B6621601 Filter, Tube Suction, Weldment 1

12 PP10629 Ring, Retaining - Internal .875" 1

13 A6684601 Filter, Insulation Pick-Up 1

14 P0062100 Screw, 1/4-20 x 3/8" Set 2

15 P0007300 Screw, 8-32 x 1/4" Hex & N 2N 2

16 PP10613 Filter Paper, 18-1/2" x 20-1/2" Heavy Duty 1

Revised 5/28/93

5-10

Page 38

Figure 5-6 UFM Filter, Pick-Up/Pan Assembly

5-11

Page 39

Table 5-4 UFM Filter, Motor / Return Assembly

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 PP10101 Pump/Motor 1/3 HP, 115/230V, 50/60Hz 1

2 PP10106 Fitting, Elbow Male 90 .50D x .5 NPT 2

3 A6682702 Filter, Tubing Out SS 1

4 PP10731 Fitting, Elbow Male 90 .50D x .375 NPT 1

5 B6621401 Filter, Tubing Pump - Inlet Weldment 1

6 PP10039 Heat Tape, 1/2" x 79" 110V 165 Watt 1

7 PP10111 O-Ring, Viton .50ID x .688 x .094W 2

8 A6685601 Filter, Insulator O-Ring Fitting 1

9 P0062100 Screw, 1/4-20 x 3/8" Set 1

10 B6717701 Wiring, Motor Harness 1

11 PP10739 Thermostat, Snap Disc 1

12 PP10687 Screw, 6-32 x 5/16" TH Phillips ZN 2

13 P009110 Nut, Hex (KEP) 6-32 ZN 2

14 PP10738 Nut, Retaining Clip 5/16" - 18 1

15 P0144000 Nut, Hex 5/16" - 18 SST 2

16 P0115000 Screw, 5/16" - 18 x 3/4" HHC SSBB 3

Revised 5/28/93

5-12

Page 40

Figure 5-7 UFM Filter, Motor / Return Assembly

5-13

Page 41

Table 5-5 Built-In Filter Pan With Components

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 B6602001 Pan #14 1

B6602101 Pan #18 1

2 B6603001 Paper Retainer #14 1

B6603002 Paper Retainer #18 1

3 B6602401 Hose #14 1

B6602402 Hose #18 1

4 P6071123 Quick Disconnect, Male 1

5 P7037752-1 Elbow 90° 3/8 Street Plated 1

6 A6641802 Handle #14 2

A6641804 Handle #18 2

7 P6072611 Paper Support Rack #14 1

P6072612 Paper Support Rack #18 1

8 P7037316-1 Stand Pipe #14 1

P7037320-1 Stand Pipe #18 1

9 P7037675 Elbow 90° 3/8 Plated 1

Revised 5/28/93

5-14

Page 42

7

9

8

2

1

Figure 5-8 Built-In Filter Pan With Components

5-15

6

3

4

5

Page 43

Table 5-6 Built-In Filter Piping With Components

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 P5046381 Pump and Motor 1

2 P6071530 Pump Only 1

3 P5046384 Motor Only 1

4 B7402241 Quick Disconnect 1

5 P0020600 Bolt 1/4 - 20 x 5/8" 4

6 P0080650 Washer, Flat 8

7 P0093300 Nut, Keep 4

Revised 5/28/93

5-16

Page 44

Figure 5-9 Built-In Filter Piping With Components

5-17

Page 45

Table 5-7 Built-In Filter With Accessories

Item Pitco Frialator Quantity

Number Part Number Description Per Unit

1 P5044768 Food Warmer, Built-In 1

P5044760 Food Warmer, Free Standing 1

2 P6072155 Drain Screen #14 1

P6072156 Drain Screen #18 1

3 A5811202 Pan Liner #14 1

A5811206 Pan Liner #18 1

4 PP10733 Filter Powder, 120, 8oz Packets

5 P6071371 Paper #14 Standard

PP10612 Paper #14 Heavy Duty

P6071373 Paper #18 Standard

PP10606 Paper #18 Heavy Duty

6 A1100802 Basket Hanger #14 1

A1100804 Basket Hanger #18 1

Revised 5/28/93

5-18

Page 46

Figure 5-10 Built-In Filter With Accessories

5-19

Page 47

ALPHABETICAL PART LIST

Models Pitco Frialator

Part Description Used on Part No.

BASKET HANGER, STAINLESS STEEL E14,E14B A1100406

BASKET HANGER, STAINLESS STEEL E18 A1100408

BASKET HANGER, STAINLESS STEEL E18B A1101002

CASTER (4/FILTER) ALL UFM P6071062

CASTER ASSEMBLY 7" WITH LOCKING DEVICE ALL UFM PP10811

CASTER ASSEMBLY 7" WITHOUT LOCKING DEVICE ALL UFM PP10810

CASTER WITH LOCK 6" ALL PP10809

CASTER WITHOUT LOCK 6" ALL PP10808

CHANNEL STRIP #14-2 E14 A1900104

CHANNEL STRIP #18-2 E14 A1900114

CIRCUIT BREAKER, 10 AMP ALL BIF PP10104

CIRCUIT BREAKER, 4 AMP, DOUBLE POLE 240V UFM PP10470

CLAMP, BAND (FILTER) ALL PP10034

CLEAN OUT ROD ALL A3301001

CLIP, SCREEN SF50,SF65 B6603601

CONTACTOR, DEFINITE PURPOSE, 40A, 24 V, 3PST-NO ALL PP10560

CONTACTOR, MERCURY-40AMP 24 VAC 5PST-NO ALL PP10553

CORD, PLUG-RETRACTILE 16-3 SJO E14,E18UFM PP10439

COUNTER BALANCE BEARING ASSEMBLY E14,E14B,

E18,E18B B7361701

COUNTER BALANCE HINGE BRACKET E14 B7361803

COUNTER BALANCE HINGE BRACKET E14B,E18 B7361804

COVER SCREWS ALL P0101200

CRUMB CATCH SF50,SF65 B6601802

CRUMB CATCH BASKET ALL BIF P6072165

CRUMB CATCH RETAINER E14 BIF B6601901

CRUMB CATCH RETAINER E18 BIF B6601902

DOOR HANDLE A LL P6071516

DOOR MAGNET ALL P6071300

DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E14,E14B B2301205

DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E18,E18B B2301206

DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E12 B2301204

DRAIN OUTLET NIPPLE, 1-1/4" E14,E14B,

E18 A2502503

DRAIN VALVE E12 P6071769

DRAIN VALVE, 1-1/2" FULL PORT E18B P6071770

DRAIN VALVE, 1-1/4" STANDARD E14,E14B,

E18,E18B P6071785

ELEMENT HOUSING BOX COVER E14,E14B A2603206

ELEMENT HOUSING BOX COVER E18,E18B A2603208

ELEMENT RACK E12 B2800703-1

ELEMENT RACK E14B,E14 B2800706-1

ELEMENT RACK E18B B2800710-1

ELEMENT RACK E18 B2800708-1

5-20

Page 48

ALPHABETICAL PART LIST (Continued)

Models Pitco Frialator

Part Description Used on Part No.

ELEMENT RACK E14X B2800704-1

ELEMENT WIRES ALL SPECIAL

ORDER

ENTRANCE BOX COVER ALL A2900601

FAT CONTAINER ALL SPECIAL

ORDER

FEMALE QUICK DISCONNECT (BLACK DONUT) SF50,SF65 PP10113

FILTER CATCH, CRUMB, WELDMENT SF50A,SF65A B6621202

FILTER COVER, PAN, WELDMENT SF50A B6621301

FILTER COVER, PAN, WELDMENT SF65A B6621302

FILTER ENVELOPE 18" X 20-1/2" ALL UFM PP10613

FILTER HOSE UFM EXCEPT RPB SF50A,SF65A B6622001

FILTER HOSE UFM FOR RPB SF50A,SF65A B6622002

FILTER INSULATION PICK-UP SF50A,SF65A A6684601

FILTER INSULATOR TOP SF50A,SF65A A6685401

FILTER PAN, WELDMENT SF50A B6621001

FILTER PAN, WELDMENT SF65A B6621002

FILTER PAPER 13-1/2" X 24" E7-E14 BIF P6071371

FILTER PAPER 17-1/2" X 28" E18-E34 BIF P6071373

FILTER PAPER, HEAVY DUTY, 13-1/2" X 24" E7-E14 BIF PP10612

FILTER PAPER, HEAVY DUTY, 17-1/2" X 28" E18-E34 BIF PP10606

FILTER QD SNP 23 NIPPLE SF50A,SF65A PP10741

FILTER QUICK DISCONNECT ADAPTER SF50,SF65 B6603901

FILTER RACK SF50A,SF65A B6620001

FILTER RETURN INSULATION DISCONNECT SF50A,SF65A B6622801

FILTER SCREEN CLIP SF50A,SF65A B6617001

FILTER, TUBE SUCTION, COMPLETE SF50A,SF65A B6621701

FUSE 1 AMP SLOW BLOW GLASS ALL PP10122

FUSE 40 AMP E14,E14B,E18 P5045701

FUSE 50 AMP E18B P5045702

FUSE HOLDER ALL P5045792

GASKET, DRAIN LINE (SLEEVE) ALL PP10032

GASKET, DRAIN LINE (SLEEVE) ALL PP10032

GROUND CLAMP ALL P5045241

HANDLE, VALVE 3/8 BALL, COATED BLUE ALL PP10049

HANDLE, VALVE 3/8 BALL, COATED RED ALL PP10048

HANDLE, VALVE 3/8 BALL, COATED YELLOW A LL PP10050

HEAT TAPE, 1/2" X 79", 110 VAC, 165 W SF50,SF65 PP10039

HEAT TAPE, 110 VAC, 120 W SF50,SF65 PP10194

HEATER, SILICONE, 120 VAC, 250 W SF50,SF65 PP10099

HEATING ELEMENT E12-208V P5046923

HEATING ELEMENT E12-240V P5046924

HEATING ELEMENT E12-480V P5046951

HEATING ELEMENT E18-480V P5046900

5-21

Page 49

ALPHABETICAL PART LIST (Continued)

Models Pitco Frialator

Part Description Used on Part No.

HEATING ELEMENT E18-208V P5046901

HEATING ELEMENT E18-240V P5046902

HEATING ELEMENT E18B-208V P5046903

HEATING ELEMENT E18B-240V P5046904

HEATING ELEMENT E18B-480V P5046952

HEATING ELEMENT E14-208V P5046920

HEATING ELEMENT E14-240V P5046921

HEATING ELEMENT E14-480V P5046919

HEATING ELEMENT E14B,E7-208V P5046915

HEATING ELEMENT E14B,E7-240V P5046916

HEATING ELEMENT E14B,E7-480V P5046960

HIGH LIMIT BULB CLAMP ALL B7370402

HIGH LIMIT CAPILLARY CLAMP ALL A1400902

HIGH LIMIT COVER ALL B7370101

HIGH LIMIT SWITCH ALL P5047216

HINGE, DOOR-BOTTOM LH AL L B7230301

HINGE, DOOR-BOTTOM RH ALL B7230302

HINGE, DOOR-TOP LH ALL B7230201

HINGE, DOOR-TOP, RH ALL B7230202

HOSE ASSEMBLY WITH QUICK DISCONNECT SF50A,SF65A B6622301

INTERLOCK SWITCH ALL P5047170

INTERLOCK SWITCH COVER ALL A2601502

KNOB, 200-400 OFF ELECTRIC ALL PP10539

LAMP, 125 VAC AMBER RECTANGULAR ALL UFM PP10082

LAMP, 125 VAC GREEN RECTANGULAR SF50A,SF65A PP10331

LEG, ADJUSTABLE 6" ALL B3900909

LEG, ADJUSTABLE 8" ALL B7472909

LEG, ADJUSTABLE, 7" ALL B3900408

LOCK ARM TIP ALL P5045161

MODULE 1 PROD 14/18-184 NAT E14,E18 P5044851

MODULE 1 PROD 14/18-184 REBUILT E14,E18 P5044852

MODULE 1 PROD 7-184 NAT E7 P5044856

MODULE 1 PROD 7-184 REBUILT E7 P5044857

MODULE 8 PROD 14/18-884 NAT E14,E18 P5044850

MODULE 8 PROD 14/18-884 REBUILT E14,E18 P5044854

MODULE 8 PROD 7-884 NAT E7 P5044855

MODULE 8 PROD 7-884 REBUILT E7 P5044853

O-RING, VITON .50 ID X .688 X .094W SF50A, SF65A PP10111

PICKUP QUICK DISCONNECT, FEMALE, NO/RING SF50,SF65 P6071122

PICKUP QUICK DISCONNECT, MALE SF50,SF65 P6071123

PLUG - 9 POLE MALE ALL P5045826

PROBE STANDOFF CLAMP AL L B7370403

PUMP/MOTOR ASSEMBLY, 115/230 VAC ALL BIF P5046381

PUMP/MOTOR ASSEMBLY, 115/230 VAC, 60HZ, 1/3 HP ALL UFM PP10101

5-22

Page 50

ALPHABETICAL PART LIST (Continued)

Models Pitco Frialator

Part Description Used on Part No.

RECEPTACLE, 3 PRONG, 15A, 125VAC ALL UFM PP10103

RETURN HOSE NEW STYLE SF50 SF50 B6602803

RETURN HOSE NEW STYLE SF65 SF65 B6602804

SPRING ALL P6071636

SQUARE BASKETS, FINE MESH E12 P6072124

SQUARE BASKETS, FINE MESH E14,E14B P6072144

SQUARE BASKETS, FINE MESH E18 P6072187

SQUARE BASKETS, FINE MESH E12 P6072124

SQUARE BASKETS, REGULAR MESH E12 P6072123

SQUARE BASKETS, REGULAR MESH E14,E14B P6072143

SQUARE BASKETS, REGULAR MESH E18 P6072183

SUCTION TUBE SF50,SF65 B6603801

SUPPORT RACK, TOP SF50,SF65 B6603701

SWITCH , ROCKER, DPDT (ON-OFF-ON) SF50,SF65 PP10098

SWITCH, ROCKER CIRCUIT BREAKER SPST, 8A, 125 VAC SF50A,SF65A PP10460

SWITCH, ROCKER DPST 15A, WITH BREAKER SF50A,SF65A PP10735

TERMINAL BLOCK (TB2) ALL P5047305

TERMINAL BLOCK (TB3) ALL P5047303

THERMOSTAT KNOB ALL P6071270

THERMOSTAT PROBE E12,E14 ALL

E18 P6700602

THERMOSTAT, SNAP DISK SF50A,SF65A PP10739

TWIN BASKETS, FINE MESH E12 P6072126

TWIN BASKETS, FINE MESH E14,E14B P6072146

TWIN BASKETS, FINE MESH E18 P6072188

TWIN BASKETS, REGULAR MESH E12 P6072125

TWIN BASKETS, REGULAR MESH E14,E14B P6072145

TWIN BASKETS, REGULAR MESH E18 P6072184

VALVE, BALL 3/8" PLTD W/O HANDLE ALL P6071780

5-23

Page 51

NUMERICAL PART LIST

Pitco Frialator Models

Part No. Part Description Used on

A1100406 BASKET HANGER, STAINLESS STEEL E14,E14B

A1100408 BASKET HANGER, STAINLESS STEEL E18

A1101002 BASKET HANGER, STAINLESS STEEL E18B

A1400902 HIGH LIMIT CAPILLARY CLAMP ALL

A1900104 CHANNEL STRIP #14-2 E14

A1900114 CHANNEL STRIP #18-2 E14

A2502503 DRAIN OUTLET NIPPLE, 1-1/4" E14,E14B,E18

A2601502 INTERLOCK SWITCH COVER ALL

A2603206 ELEMENT HOUSING BOX COVER E14,E14B

A2603208 ELEMENT HOUSING BOX COVER E18,E18B

A2900601 ENTRANCE BOX COVER ALL

A3301001 CLEAN OUT ROD ALL

A6684601 FILTER INSULATION PICK-UP SF50A,SF65A

A6685401 FILTER INSULATOR TOP SF50A,SF65A

B2301204 DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E12

B2301205 DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E14,E14B

B2301206 DOOR, UNIVERSAL, STAINLESS STEEL OUTSIDE E18,E18B

B2800703-1 ELEMENT RACK E12

B2800704-1 ELEMENT RACK E14X

B2800706-1 ELEMENT RACK E14B,E14

B2800708-1 ELEMENT RACK E18

B2800710-1 ELEMENT RACK E18B

B3900408 LEG, ADJUSTABLE, 7" ALL

B3900909 LEG, ADJUSTABLE 6" ALL

B6601802 CRUMB CATCH SF50,SF65

B6601901 CRUMB CATCH RETAINER E14 BIF

B6601902 CRUMB CATCH RETAINER E18 BIF

B6602803 RETURN HOSE NEW STYLE SF50 SF50

B6602804 RETURN HOSE NEW STYLE SF65 SF65

B6603601 CLIP, SCREEN SF50,SF65

B6603701 SUPPORT RACK, TOP SF50,SF65

B6603801 SUCTION TUBE SF50,SF65

B6603901 FILTER QUICK DISCONNECT ADAPTER SF50,SF65

B6617001 FILTER SCREEN CLIP SF50A,SF65A

B6620001 FILTER RACK SF50A,SF65A

B6621001 FILTER PAN, WELDMENT SF50A

B6621002 FILTER PAN, WELDMENT SF65A

B6621202 FILTER CATCH, CRUMB, WELDMENT SF50A,SF65A

B6621301 FILTER COVER, PAN, WELDMENT SF50A

B6621302 FILTER COVER, PAN, WELDMENT SF65A

B6621701 FILTER, TUBE SUCTION, COMPLETE SF50A,SF65A

B6622001 FILTER HOSE UFM EXCEPT RPB SF50A,SF65A

B6622002 FILTER HOSE UFM FOR RPB SF50A,SF65A

5-24

Page 52

NUMERICAL PART LIST (Continued)

Pitco Frialator Models

Part No. Part Description Used on

B6622301 HOSE ASSEMBLY WITH QUICK DISCONNECT SF50A,SF65A

B6622801 FILTER RETURN INSULATION DISCONNECT SF50A,SF65A

B7230201 HINGE, DOOR-TOP LH ALL

B7230202 HINGE, DOOR-TOP, RH ALL

B7230301 HINGE, DOOR-BOTTOM LH ALL

B7230302 HINGE, DOOR-BOTTOM RH ALL

B7361701 COUNTER BALANCE BEARING ASSEMBLY E14,E14B,

E18,E18B

B7361803 COUNTER BALANCE HINGE BRACKET E14

B7361804 COUNTER BALANCE HINGE BRACKET E14B,E18

B7370101 HIGH LIMIT COVER ALL

B7370402 HIGH LIMIT BULB CLAMP ALL

B7370403 PROBE STANDOFF CLAMP ALL

B7472909 LEG, ADJUSTABLE 8" ALL

P0101200 COVER SCREWS ALL

P5044850 MODULE 8 PROD 14/18-884 NAT E14,E18

P5044851 MODULE 1 PROD 14/18-184 NAT E14,E18

P5044852 MODULE 1 PROD 14/18-184 REBUILT E14,E18

P5044853 MODULE 8 PROD 7-884 REBUILT E7

P5044854 MODULE 8 PROD 14/18-884 REBUILT 14,18

P5044855 MODULE 8 PROD 7-884 NAT E7

P5044856 MODULE 1 PROD 7-184 NAT E7

P5044857 MODULE 1 PROD 7-184 REBUILT E7

P5045161 LOCK ARM TIP ALL

P5045241 GROUND CLAMP ALL

P5045701 FUSE 40 AMP E14,E14B,E18

P5045702 FUSE 50 AMP E18B

P5045792 FUSE HOLDER ALL

P5045826 PLUG - 9 POLE MALE ALL

P5046381 PUMP/MOTOR ASSEMBLY, 115/230 VAC ALL BIF

P5046900 HEATING ELEMENT E18-480V

P5046901 HEATING ELEMENT E18-208V

P5046902 HEATING ELEMENT E18-240V

P5046903 HEATING ELEMENT E18B-208V

P5046904 HEATING ELEMENT E18B-240V

P5046915 HEATING ELEMENT E14B,E7-208V

P5046916 HEATING ELEMENT E14B,E7-240V

P5046919 HEATING ELEMENT E14-480V

P5046920 HEATING ELEMENT E14-208V

P5046921 HEATING ELEMENT E14-240V

P5046923 HEATING ELEMENT E12-208V

P5046924 HEATING ELEMENT E12-240V

P5046951 HEATING ELEMENT E12-480V

P5046952 HEATING ELEMENT E18B-480V

5-25

Page 53

NUMERICAL PART LIST (Continued)

Pitco Frialator Models

Part No. Part Description Used on

P5046960 HEATING ELEMENT E14B,E7-480V

P5047170 INTERLOCK SWITCH ALL

P5047216 HIGH LIMIT SWITCH ALL

P5047303 TERMINAL BLOCK (TB3) ALL

P5047305 TERMINAL BLOCK (TB2) ALL

P6071062 CASTER (4/FILTER) ALL UFM

P6071122 PICKUP QUICK DISCONNECT, FEMALE, NO/RING SF50,SF65

P6071123 PICKUP QUICK DISCONNECT, MALE SF50,SF65

P6071270 THERMOSTAT KNOB ALL

P6071300 DOOR MAGNET ALL

P6071371 FILTER PAPER 13-1/2" X 24" E7-E14 BIF

P6071373 FILTER PAPER 17-1/2" X 28" E18-E34 BIF

P6071516 DOOR HANDLE ALL

P6071636 SPRING ALL

P6071769 DRAIN VALVE E12

P6071770 DRAIN VALVE, 1-1/2" FULL PORT E18B

P6071780 VALVE, BALL 3/8" PLTD W/O HANDLE ALL

P6071785 DRAIN VALVE, 1-1/4" STANDARD E14,E14B,

E18,E18B

P6072123 SQUARE BASKETS, REGULAR MESH E12

P6072124 SQUARE BASKETS, FINE MESH E12

P6072124 SQUARE BASKETS, FINE MESH E12

P6072125 TWIN BASKETS, REGULAR MESH E12

P6072126 TWIN BASKETS, FINE MESH E12

P6072143 SQUARE BASKETS, REGULAR MESH E14,E14B

P6072144 SQUARE BASKETS, FINE MESH E14,E14B

P6072145 TWIN BASKETS, REGULAR MESH E14,E14B

P6072146 TWIN BASKETS, FINE MESH E14,E14B

P6072165 CRUMB CATCH BASKET ALL BIF

P6072183 SQUARE BASKETS, REGULAR MESH E18

P6072184 TWIN BASKETS, REGULAR MESH E18

P6072187 SQUARE BASKETS, FINE MESH E18

P6072188 TWIN BASKETS, FINE MESH E18

P6700602 THERMOSTAT PROBE E12,E14

ALL,E18

PP10032 GASKET, DRAIN LINE (SLEEVE) ALL

PP10032 GASKET, DRAIN LINE (SLEEVE) ALL

PP10034 CLAMP, BAND (FILTER) ALL

PP10039 HEAT TAPE, 1/2" X 79", 110 VAC, 165 W SF50,SF65

PP10048 HANDLE, VALVE 3/8 BALL, COATED RED ALL

PP10049 HANDLE, VALVE 3/8 BALL, COATED BLUE ALL

PP10050 HANDLE, VALVE 3/8 BALL, COATED YELLOW ALL

PP10082 LAMP, 125 VAC AMBER RECTANGULAR ALL UFM

PP10098 SWITCH , ROCKER, DPDT (ON-OFF-ON) SF50,SF65

5-26

Page 54

NUMERICAL PART LIST (Continued)

Pitco Frialator Models

Part No. Part Description Used on

PP10099 HEATER, SILICONE, 120 VAC, 250 W SF50,SF65

PP10101 PUMP/MOTOR ASSEMBLY, 115/230 VAC, 60HZ, 1/3 HP ALL UFM

PP10103 RECEPTACLE, 3 PRONG, 15A, 125VAC ALL UFM

PP10104 CIRCUIT BREAKER, 10 AMP ALL BIF

PP10111 O-RING, VITON .50 ID X .688 X .094W SF50A, SF65A

PP10113 FEMALE QUICK DISCONNECT (BLACK DONUT) SF50,SF65

PP10122 FUSE 1 AMP SLOW BLOW GLASS ALL

PP10194 HEAT TAPE, 110 VAC, 120 W SF50,SF65

PP10331 LAMP, 125 VAC GREEN RECTANGULAR SF50A,SF65A

PP10439 CORD, PLUG-RETRACTILE 16-3 SJO 14,18UFM

PP10460 SWITCH, ROCKER CIRCUIT BREAKER SPST, 8A, 125 VAC SF50A,SF65A

PP10470 CIRCUIT BREAKER, 4 AMP, DOUBLE POLE 240V UFM

PP10539 KNOB, 200-400 OFF ELECTRIC A LL

PP10553 CONTACTOR, MERCURY-40AMP 24 VAC 5PST-NO ALL

PP10560 CONTACTOR, DEFINITE PURPOSE 40AMP 24 VAC 3PST-NO ALL

PP10606 FILTER PAPER, HEAVY DUTY, 17-1/2" X 28" E18-E34 BIF

PP10612 FILTER PAPER, HEAVY DUTY, 13-1/2" X 24" E7-E14 BIF

PP10613 FILTER ENVELOPE 18" X 20-1/2" ALL UFM

PP10735 SWITCH, ROCKER DPST 15A, WITH BREAKER SF50A,SF65A

PP10739 THERMOSTAT, SNAP DISK SF50A,SF65A

PP10741 FILTER QD SNP 23 NIPPLE SF50A,SF65A

PP10808 CASTER WITHOUT LOCK 6" ALL

PP10809 CASTER WITH LOCK 6" ALL

PP10810 CASTER ASSEMBLY 7" WITHOUT LOCKING DEVICE ALL UFM

PP10811 CASTER ASSEMBLY 7" WITH LOCKING DEVICE ALL UFM

SPECIAL ORDER ELEMENT WIRES ALL

SPECIAL ORDER FAT CONTAINER ALL

5-27

Page 55

5-28

Page 56

In the event of problems with or questions about you

order, please contact the Pitco Frialator factory, from

8:00 a.m. - 5:00 p.m., Eastern Standard Time, Monday through Friday:

(603)225-6684 World Wide

L20-055 R12 (06/11)

In the event of problems with or questions about you

equipment, please contact the Pitco Frialator Authorized Service and Parts representative (ASAP) covering your area, through the National Service Network

at: (603)-225-6684 24 hours

Loading...

Loading...