Page 1

Installation & Operation Manual

CRTE: Electric Counter Top Rethermalizer

ENGLISH

L20-259, rev. 3 (1/06)

Page 2

Page 3

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for reference.

WARNING

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and

maintenance instructions thoroughly before installing

or servicing this appliance.

WARNING

Installation, maintenance and repairs should be

performed by a Pitco Authorized Service and Parts

(ASAP) company technician or other qualified

personnel. Installation, maintenance or repairs by an

unauthorized and unqualified personnel will void the

warranty.

WARNING

Installation and all connections must be made

according to national and local regulations and codes

in force.

WARNING

A country approved all pole circuit breaker with a

minimum open contact gap of 3mm must be used for

proper installation. (CE countries)

WARNING

During the warranty period if a customer elects to use

a non-original part or modifies an original part

purchased from Pitco and/or its Authorized Service

and Parts (ASAP) companies, this warranty will be

void. In addition, Pitco and its affiliates will not be

liable for any claims, damages or expenses incurred

by the customer which arises directly or indirectly, in

whole or in part, due to the installation of any

modified part and/or received from an unauthorized

service center.

WARNING

This appliance, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.2, as applicable.

WARNING

Adequate means must be provided to LIMIT the

movement or this appliance without depending on the

electrical cord connection. Single appliances

equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with casters

must be stabilized by installing restraining chains.

WARNING

DO NOT alter or remove structural material on the

appliance to accommodate placement under a

ventilation hood.

WARNING

This appliance is intended for professional use only

and should be operated by fully trained and qualified

personnel.

WARNING

If the supplied power cord is damaged, it must be

replaced by a Pitco Authorized Service and Parts

(ASAP) company technician, or a similarly qualified

person in order to avoid a hazard.

WARNING

The power supply must be disconnected before

servicing, maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT

clean the applaince with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from one container to another when the unit is

at operating temperature or filled with hot liquids.

Serious personal injury could result if skin comes in

contact with the hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The

appliance’s front panel, tank, splash back, tank cover,

workshelf, drain board is not a step. Serious injury

could result from slipping, falling or contact with hot

liquids.

WARNING

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot liquids.

WARNING

The water level should be maintained at the level line.

DO NOT turn the appliance on until the heating

elements are fully covered with water at all times.

Serious injury could result from hot steam vapors off

the heating element.

WARNING

If overflow drain is not equipped or if overflow drain

stop is used, do not leave appliance unattended while

filling with water. Over filling the appliance can cause

serious injuries and damage the equipment.

WARNING

Completely shut the appliance down when the water is

being drained from the appliance. This will prevent the

appliance from heating up during the draining and

filling process. Serious injury and heating element

damage can occur.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and

access covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by

a qualified service technician for proper performance

and operation on a yearly basis.

i L20-259, rev. 3 (1/06)

Page 4

CRTE COUNTER TOP RETHERMAILZER TABLE OF CONTENTS

1. INSTALLATION ....................................................................................1

1.1. CHECKING YOUR NEW APPLIANCE..........................................................................................1

1.2. INSTALLATION CLEARANCES ...................................................................................................2

1.3. INSTALLATION TO COUNTER ....................................................................................................2

1.4. DRAINAGE CONNECTIONS .........................................................................................................2

1.5. ELECTRICAL CONNECTIONS .....................................................................................................3

1.6. VENTILATION AND FIRE SAFETY SYSTEMS ............................................................................5

1.7. INSPECTION..................................................................................................................................5

1.8. INITIAL CLEANING .......................................................................................................................6

2. OPERATION .........................................................................................7

2.1. FILLING THE APPLIANCE............................................................................................................7

2.1.1. FILLING THE COOKER TANK ............................................................................................... 7

2.2. APPLIANCE START UP ................................................................................................................7

2.3. COOKING.......................................................................................................................................8

2.3.1. ADDITIONAL CONTROLLER FUNCTIONS ...........................................................................8

2.3.2. COOKING TIPS....................................................................................................................... 8

2.4. APPLIANCE SHUTDOWN.............................................................................................................8

3. PREVENTATIVE MAINTENANCE ........................................................9

3.1. DAILY PREVENTATIVE MAINTENANCE.....................................................................................9

3.1.1. APPLIANCE INSPECTION .....................................................................................................9

3.1.2. CLEANING THE COOK TANK................................................................................................9

3.1.3. CLEANING THE CABINET .....................................................................................................9

3.2. MONTHLY PREVENTATIVE MAINTENANCE..............................................................................9

3.2.1. DELIMING ...............................................................................................................................9

3.3. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION............................ 10

3.3.1. HEATING ELEMENT ............................................................................................................ 10

3.3.2. TEMPERATURE PROBE & HIGH LIMIT PROBE ................................................................10

3.3.3. CONTROLLER ......................................................................................................................10

3.3.4. CONTROL BOX & ELECTRICAL COMPONENTS...............................................................10

3.3.5. TANK .....................................................................................................................................10

3.3.6. DRAIN SYSTEM.................................................................................................................... 10

4. TROUBLESHOOTING ........................................................................11

4.1. POWER FAILURE........................................................................................................................11

4.2. HIGH TEMPERATURE LIMIT ......................................................................................................11

4.3. TROUBLESHOOTING CHART ...................................................................................................11

ii

Page 5

INSTALLATION

WARNING

WARNING

1. INSTALLATION

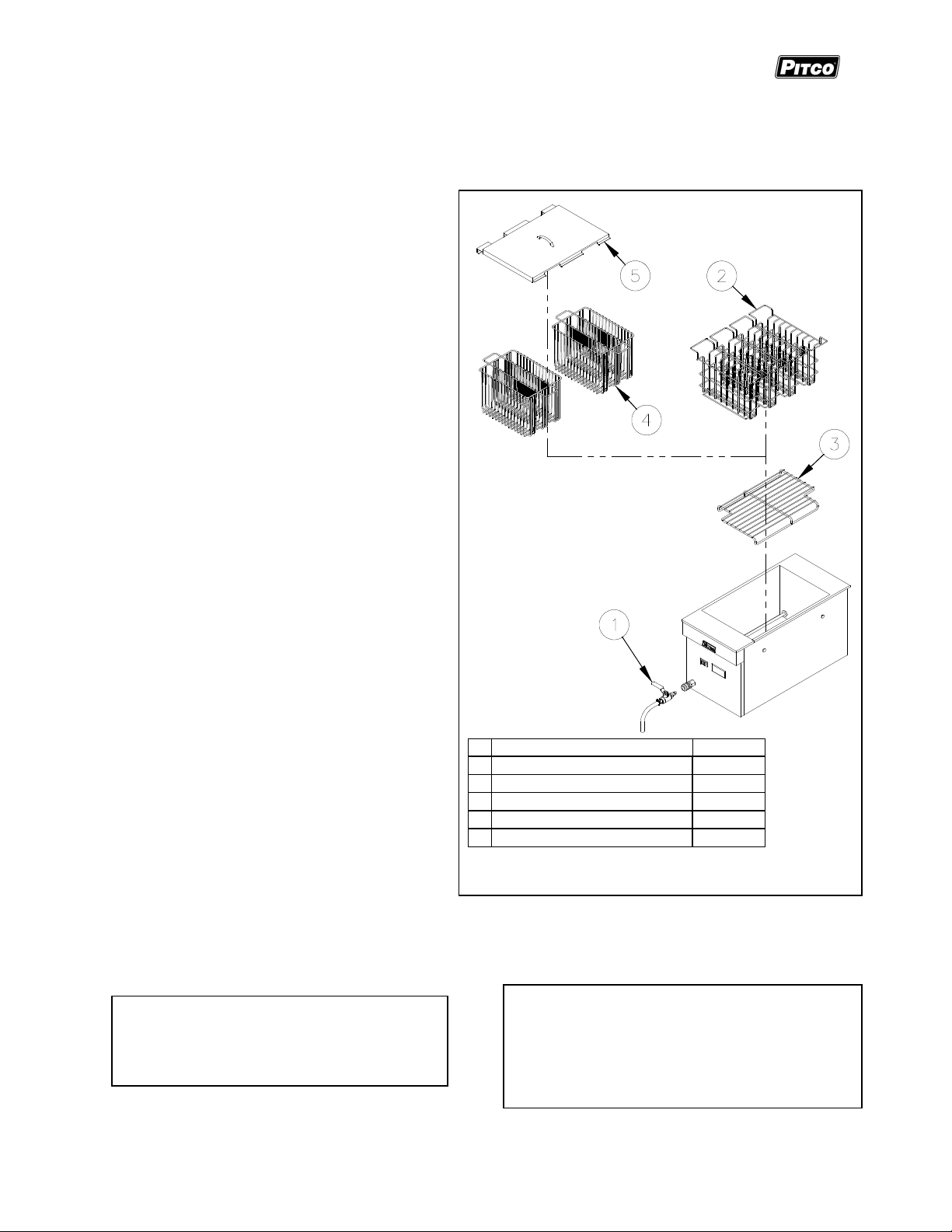

1.1. CHECKING YOUR NEW APPLIANCE

Your new Pitco appliance has been

carefully packed into one crate. Every effort

has been made to ensure that it is delivered

to you in perfect condition. As you unpack

your new appliance, inspect each of the

pieces for damage. If something is

damaged, DO NOT sign the bill of lading.

Contact the shipper immediately; the

shipper is only responsible for 15 days after

delivery. Check the packing list enclosed

with your appliance to ensure that you have

received all the parts to the appliance. If

you are missing any parts, contact the

dealer from whom the appliance was

purchased. As you unpack the appliance

and its accessories be careful to keep the

weight of the appliance evenly distributed.

Refer to the table below to identify which

accessories should be included with your

appliance.

Locate your Pitco model number and serial

number on the inner door of the appliance

and the find the date purchased. Write this

information on the front cover of this manual

for future reference.

If you have completed the above steps that

are applicable to the appliance you

purchased, the appliance is now ready to

be installed. Although it may be possible for

you to install and set up your new

appliance, it is STRONGLY recommended

that you have this done by qualified

professionals. A qualified professional will

ensure that the installation is safe and

meets local building and fire codes.

Description CRTE

#

1 Drain Hose Standard

2 Soup Rack (Quantity 4) Standard

3 Element Rack Optional

4 3 Product Rack (Quantity 2) Optional

5 Tank Cover for 3 Product Rack Optional

Accessories

DO NOT install this appliance next to a

deep fat fryer. A splash over of water into

the hot oil may cause a flash fire.

1 L20-259, rev. 3 (1/06)

DO NOT sit or stand on this appliance. The

appliance’s front panel, tank, tank cover,

workshelf, drain board is not a step. Serious

injury could result from slipping, falling or

contact with hot liquids.

Page 6

CRTE COUNTER TOP RETHERMAILZER INSTALLATION

WARNING

WARNING

WARNING

1.2. INSTALLATION CLEARANCES

The clearances shown below are for combustible and non-combustible installations and will allow for

safe and proper operation of your appliance.

Combustible Construction Non Combustible Construction

Inches (centimeters) Inches (centimeters)

Back

Sides

Counter

In addition to the above clearances there must also be at least 16 inches (40.64cm) of aisle space in

front of the unit.

DO NOT obstruct the flow of ventilation, or air openings around the appliance. Adequate

clearance around the appliance is necessary for servicing and proper component ventilation.

Ensure that you meet the minimum clearance requirements specified in this manual.

The appliance should be secured to the counter top to prevent accidental

moving of the appliance and the splashing of hot liquid on the operator.

1.3. INSTALLATION TO COUNTER

After the appliance is in its permanent location, check the levelness. Level the counter as needed.

6.0" (15.24cm) 0.0" (0.0cm)

6.0" (15.24cm) 0.0" (0.0cm)

4.75" (12.07cm) 0.0" (0.0cm)

DO NOT perform leveling procedure when appliance is in

operation or full of hot liquids. Serious injury could result.

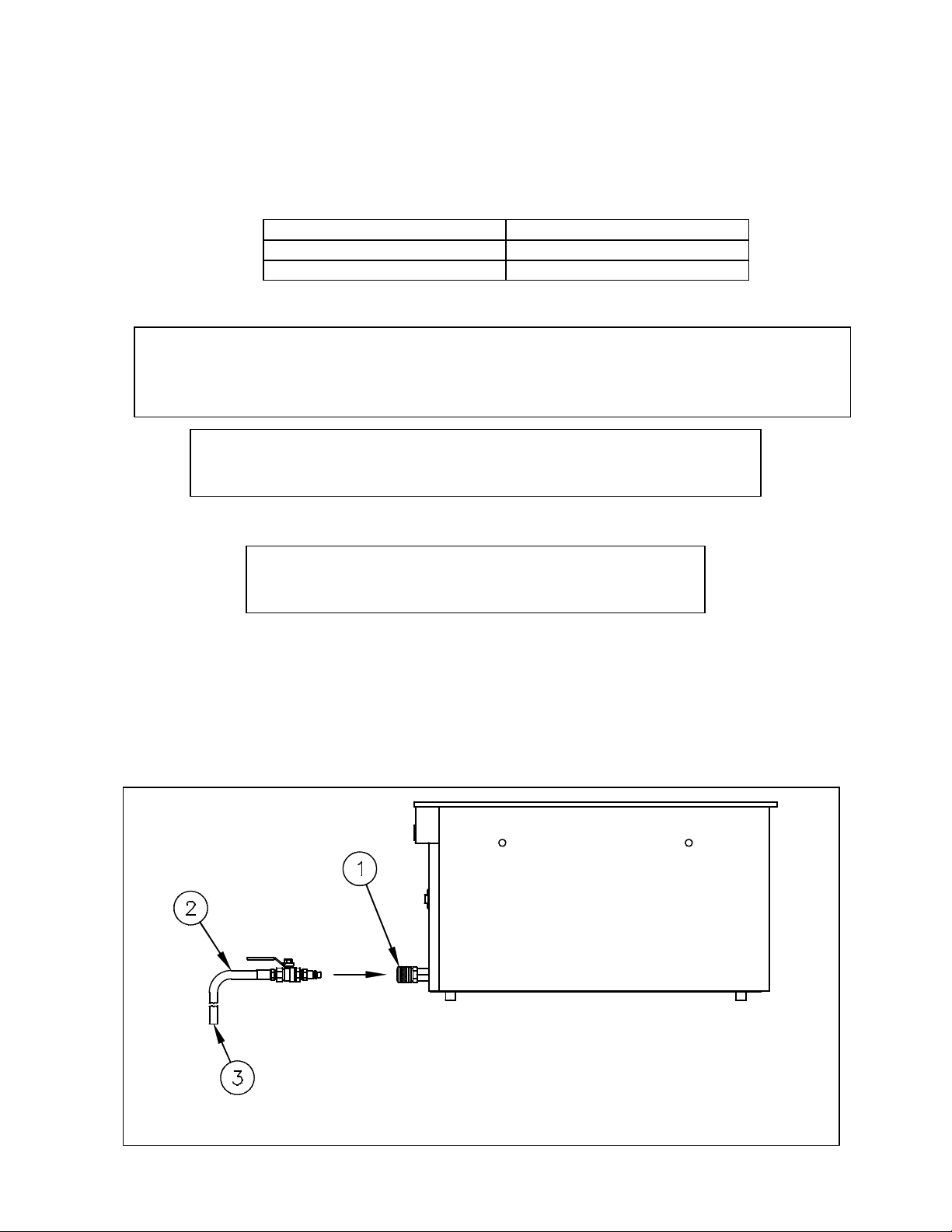

1.4. DRAINAGE CONNECTIONS

The plumbing installation should be done by a licensed plumber and must comply with local and

national codes.

This appliance has a drain that can be inserted into a drainage system. The drain hose must be

inserted into the tank quick disconnect fitting before the appliance can drain correctly. Drain

connections for this appliance are to be made at the end of the 36” (91.44 cm.) long drain hose (3/8”

(0.95 cm.) ID tubing).

1) Tank Quick Disconnect Fitting 2) Drain Hose 3) Drainage outlet

2

Page 7

INSTALLATION

CAUTION

WARNING

WARNING

WARNING

cases, refer to local and national codes and regulations.

WARNING

WARNING

WARNING

WARNING

WARNING

1.5. ELECTRICAL CONNECTIONS

It is advised that this power supply be plugged into a wall receptacle that is controlled by the

ventilation control. This will prevent the appliance from being operated without the ventilator on. If

your appliance requires an electrical connection, the power requirements are listed below.

Voltage/Phase KW Amps

200VAC, single phase 5.5 28

208VAC, single phase 6 29

220VAC, single phase 5 23

230VAC, single phase 5.5 24

240VAC, single phase 6 25

Connecting the appliance to the wrong power supply may damage the appliance and void

the warranty.

This appliance must be connected to a power supply having the same voltage and phase as

specified on the data plate located on the inside of the appliance door.

DO NOT attempt to connect the appliance to an electrical supply other then that indicated

on the data plate. Electrical connection should be performed by qualified personnel.

The electrical connection used by this appliance must comply with local codes. If there are

no local codes that apply, refer to the National Electrical Code (NEC), ANSI/NFPA 70 for

installation in the US. In Canada, refer to CSA Standard C22.2 and local codes. In all other

The appliance must be grounded in accordance with local code; if there is no local code,

comply with the NEC and ANSI/NFPA No. 70 latest edition (for US and Canadian

installations). In all other cases, refer to local and national codes and regulations. To

comply with European requirements, European models are equipped with an equalizationbonding clamp. An equalization bonding lead must be connected to this clamp to provide

sufficient protection against potential difference. This clamp, located on the rear of the

appliance is marked with the following universal symbol.

A country approved all pole circuit breaker with a minimum open contact gap of 3mm must

be used for proper installation. (CE countries)

This equipment must be installed so that the plug is accessible unless other means for

disconnection from the power supply (e.g. a circuit breaker) is provided.

If this appliance is permanently connected to fixed wiring, it must be connected by means

of copper wires having a temperature rating of not less then 167°F (75°C).

All copper wiring for this appliance must be made in accordance with the wiring diagram(s)

located on the appliance.

3 L20-259, rev. 3 (1/06)

Page 8

CRTE COUNTER TOP RETHERMAILZER INSTALLATION

Available Power Cords

# Description Standard Hubbell # Mates to

1 Twist Lock NEMA L6-30P HBL2621 HBL2620

2 Shrouded Twist Lock NEMA L6-30P HBL2621S HBL2626

3 Right Angle Straight Blade NEMA 6-30P HBL9331 HBL9330

4 Pin & Sleeve IEC 309-1 or

IEC 309-2

HBL330P6W HBL330C6W or

HBL330R6W

Appliance will be shipped with only one power cord from the listing above.

4

Page 9

INSTALLATION

1.6. VENTILATION AND FIRE SAFETY SYSTEMS

Your new appliance must have proper ventilation to function safely and properly. It is very important

to install a fire safety system. Your ventilation system should be designed to allow for easy cleaning.

Frequent cleaning and proper maintenance of the ventilation system and the appliance will reduce the

chances of fire. Ventilation and fire safety systems must comply to local and national codes. Refer to

ANSI 83.11 for a list of reference documents that will provide guidance on ventilation and fire safety

systems.

1.7. INSPECTION

Before you begin filling and operating the appliance, perform the following visual checks:

After the appliance is in its permanent location, check the levelness. Any additional leveling that

is necessary can be performed as previously described.

Ensure that the probe, heating element and high temperature limit is in place and secure. Check

the high limit bulb mounting screws to ensure that they are tight.

Review the installation portion of this manual and ensure that all steps have been followed and

executed properly.

1) Probe

2) High Temperature Limit

3) Heating Element

5 L20-259, rev. 3 (1/06)

Page 10

CRTE COUNTER TOP RETHERMAILZER INSTALLATION

CAUTION

WARNING

CAUTION

WARNING

time the cleaner remains on the food contact surfaces.

Be careful not to disturb the probe and high temperature

limit during operation and cleaning of this appliance.

1.8. INITIAL CLEANING

When your appliance is shipped, many of its parts are covered with a thin coat of oil for protection.

Before the appliance is ready for cooking it must be cleaned. This will remove the oil coating and any

foreign matter that may have accumulated during storage and shipment. Refer to the following

procedure to clean the appliance.

Wear protective gloves and clothing when cleaning and draining the appliance and

when disposing of water. The water is extremely hot and can cause severe injuries.

DO NOT leave the appliance unattended during cleaning. Never let the water level

go below the heating element.

1. Read the “operation” section of this manual prior to filling or operating the appliance.

2. The following steps should be followed using a grease dissolving commercial cleaner.

Use a commercial grade cleaner formulated to effectively clean and sanitize food

contact surfaces. Read the directions and precautionary statements before use.

Particular attention must be paid to the concentration of cleaner and the length of

3. Following the manufacturer’s directions, clean the tank interior and all other food contact

surfaces.

4. When cleaning is complete, rinse the inside of the tank thoroughly with cool water. Continue to

rinse the tank until the cleaner has been completely and thoroughly rinsed from the tank.

5. Using a clean dry cloth, wipe out all of the water.

6

Page 11

OPERATION

Tank Capacity

CAUTION

WARNING

WARNING

WARNING

2. OPERATION

An operator’s manual for your appliance’s specific control type should be included with this manual.

Refer to that manual prior to operating this appliance.

2.1. FILLING THE APPLIANCE

2.1.1. FILLING THE COOKER TANK

It is recommended that the cooker tank is filled with hot water. This will greatly decrease the time

it takes for the appliance to reach operating temperature. Refer to the following procedure to fill

the cook tank prior to operation.

This appliance is not designed for cooking

with oil. Fill with potable water only.

DRAIN VALVE CLOSED

1. Ensure that the drain valve is closed.

2. Fill the tank with water until the water reaches the water level line(s).

Model Capacity

CRTE 6 Gal. (22.7 Liters)

Water must completely cover the heating elements at all times while appliance is on.

2.2. APPLIANCE START UP

Refer to the following procedure to start the appliance prior to operation.

1. Ensure that the drain valve is closed.

2. Fill the cook tank with water. (See section 2.1 “Filling the Appliance”)

3. Press the power switch to the

NEVER operate the appliance with an empty cook tank. It may void the warranty.

Adding water after the elements have been heated may cause injuries from hot

splattering liquids and steam.

4. The appliance is now on and heating the water in the cook tank.

position.

Water must completely cover the heating elements at all times while appliance is on.

7 L20-259, rev. 3 (1/06)

Page 12

CRTE COUNTER TOP RETHERMAILZER OPERATION

Typical

Retherm Times

WARNING

2.3. COOKING

It is important to keep the cook tank full of water to minimize the chance of boiling the appliance dry

and to keep the water at a level that will provide optimum cooking performance. To ensure the quality

of the food you cook in this appliance, follow the preparation instructions from the food manufacturer.

Dry fired elements are extremely hot, will shorten its service life and may void your warranty.

2.3.1. ADDITIONAL CONTROLLER FUNCTIONS

Some controllers have additional functions not described in this manual. If your appliance’s

controller has additional functions, refer to the controller’s operation manual to access these

functions.

2.3.2. COOKING TIPS

Always follow the food manufacturer’s directions and only use vacuum-sealed products in this

appliance.

Some products can be reheated and held at the same temperature. If this is the case, the

product may be held in this appliance while still in its vacuum-sealed bag. No separate

holding device required.

Product bag size can be important in reaching the shortest retherm times. Thin bags typically

retherm faster then thicker ones.

Always allow a gap between product bags. This will allow the hot water to circulate around

the entire surface of the product bag, creating good heat transfer and ultimately shorter

retherm times.

Do NOT retherm in boiling water. Boiling water increases your energy and water

consumption and furthermore this appliance is NOT recommended for boiling.

Always follow proper food safety. Refer to FDA and the food manufacturer’s guidelines for

proper handling of the vacuum-sealed product.

Appliance Temperature

Product 140F 200F

Frozen 40 min. 9-10 min.

Thawed 30 min. 7-8 min.

This table is for reference only.

Please refer to the product

manufacturer’s specifications to

determine exact cook times.

2.4. APPLIANCE SHUTDOWN

Press the I/0 (ON/OFF) switch, to the 0 (OFF) position to shutdown the appliance.

8

Page 13

PREVENTATIVE MAINTENANCE

WARNING

WARNING

extremely hot and can cause severe injuries.

WARNING

WARNING

3. PREVENTATIVE MAINTENANCE

3.1. DAILY PREVENTATIVE MAINTENANCE

Performing the preventative maintenance steps below on a daily basis will keep your equipment safe

and at peak performance.

3.1.1. APPLIANCE INSPECTION

Check that the high temperature limit,

temperature probe and elements are

in the correct position and secured in place.

Check that wires and cords are not frayed or loose in and out of the cabinet.

Check around the appliance for loose parts or accessories that need to be secured or other

foreign items (ex: Aerosol cans) that should be removed from the area.

Check for water leaks around the drain lines and water supply in and out of the cabinet and

around the appliance.

3.1.2. CLEANING THE COOK TANK

1. Turn the appliance off.

2. Scrub the tank, basket hanger,

baskets, heating element and

temperature probe using a Scotchbrite™

or other abrasive pad with a commercial

type cleaner specifically designed for

cleaning and sanitizing food contact

surfaces. Follow the directions and

familiarize yourself with the safe use of this cleaner

prior to using it to clean the appliance. Care must be

taken to remove all the foreign material on the tank and

on components in the tank.

The power supply must be disconnected

before cleaning and servicing this appliance!

Wear protective gloves and clothing when

cleaning and draining the appliance and

when disposing of water. The water is

Read the operation section of this manual

prior to filling or operating the appliance.

DO NOT leave the appliance

unattended during cleaning.

3. When cleaning is complete, rinse the inside of the tank

and its components thoroughly with cool water. Continue to rinse at least twice or until the

cleaner has been completely and thoroughly rinsed from the tank.

3.1.3. CLEANING THE CABINET

1. The outside of the cabinet should be cleaned with a wetted cloth and mild detergent to

remove oil, dust, dirt and debris. Be careful not to introduce the detergent into the tank and

food zone regions of the appliance.

3.2. MONTHLY PREVENTATIVE MAINTENANCE

Water can leave mineral deposits inside the tank. Performing the monthly preventative maintenance

steps below will keep your equipment safe and at peak performance. It may be necessary to clean

these components more then once a month.

3.2.1. DELIMING

1. Read the “operation” section of this manual prior to filling or operating the appliance.

2. Following the manufacturer’s deliming instructions, remove deposits from the tank’s interior.

3. When cleaning is complete, rinse the inside of the tank and its components thoroughly with

cool water. Continue to rinse at least twice or until the cleaner has been completely and

thoroughly rinsed from the tank.

4. Using a clean dry cloth, wipe out all of the water.

9 L20-259, rev. 3 (1/06)

Page 14

CRTE COUNTER TOP RETHERMAILZER PREVENTATIVE MAINTENANCE

WARNING

The power supply must be disconnected before cleaning and servicing this appliance!

3.3. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION

This section should ONLY be performed by a qualified service technician as part of a regular kitchen

maintenance program. This inspection should take place a minimum of once a year by an Authorized

Service Technician recommended by Pitco.

3.3.1. HEATING ELEMENT

Check if the element is mechanically strong and in good condition. Look for scale build up

and inspect for signs of repeated dry firing.

Verify element wires are in good working condition. Look for damage to wires or frayed

insulation. Check that the insulation is dry.

Verify that bulkhead connections/nut is tight and leak free. Look for water stains and wet

surfaces.

Verify amp-draw is within range as compared to the information on the data plate.

3.3.2. TEMPERATURE PROBE & HIGH LIMIT PROBE

Verify probes are in good working condition. Check for damage and that the fasteners are

tightly secured to the tank.

Verify compression fittings are leak free.

Check wiring for loose electrical connections.

3.3.3. CONTROLLER

Perform the following inspection if the appliance is equipped with a temperature controller.

Verify that the controller is in good mechanical condition. Check all lights, displays and

switches to assure that they are working properly. Examine overlay for damage that could

allow moisture to enter.

Check for loose electrical connections.

Verify simmer temperature. Check temperature 1” above controller probe, if necessary check

probe resistance.

3.3.4. CONTROL BOX & ELECTRICAL COMPONENTS

Verify that heating contactors are in good condition. Check for worn or pitted contacts. Verify

that wires are tight and in good condition.

Verify that all components (transformer, terminal block, relays, drain switches, etc…) are in

good condition. Verify that wires are tight and in good condition.

Verify enclosures are free of leaks. Check for water stains and wet surfaces.

Verify that the covers and panels are in tact and provide a safe condition. Check for loose

parts.

Verify power cord is in good condition. Check for frayed or exposed wires. Verify that the

insulation is in good condition and the attachment to the appliance is tight.

3.3.5. TANK

Verify that the tank is in good condition. Check for scale build up and inspect for signs of

corrosion. Verify that tank is leak free. Check drain overflow (if equipped) for scale build up

and debris blockage.

3.3.6. DRAIN SYSTEM

Verify that drain valve is in good condition. Check for leaks in the seal area and fitting region.

Verify that drain lines are leak free, kink free and in good condition. Check for scale build up

and debris blockage. Verify that the clamps and connections are securely tightened.

10

Page 15

TROUBLESHOOTING

CAUTION

WARNING

4. TROUBLESHOOTING

4.1. POWER FAILURE

If electric power is removed for any reason, the appliance will shut down. To restart the appliance,

follow the appliance start up procedure in section 2.2.

DO NOT attempt to operate this appliance during a power outage.

4.2. HIGH TEMPERATURE LIMIT

This appliance is equipped with a high temperature limit switch. The high temperature limit switch will

stop the appliance from functioning if the internal cook tank reaches an unsafe temperature. In the

event that the high temperature limit has tripped, Please refer to the following procedure to reset the

switch.

1. Turn the appliance off.

2. Allow the appliance ample time to cool to room temperature.

3. Add water to the cook tank as needed.

4. The high limit switch is now reset and the appliance is ready for start up.

DO NOT add water to the tank until it has been given ample time to cool down. Failure

to do so may result in damage to the appliance and/or injury to the operator.

4.3. TROUBLESHOOTING CHART

Problem Probable Causes Corrective Actions

No power to appliance. Check main building power supply.

Circuit Breaker tripped. Reset circuit breaker.

Controller does not

activate.

I/0 Switch in 0 position.

Power Cord loose or not connected. Connect power cord.

High temperature limit has tripped

Press the power switch to the

position.

Allow appliance to cool and reset

High temperature limit.

11 L20-259, rev. 3 (1/06)

Page 16

CRTE COUNTER TOP RETHERMAILZER TROUBLESHOOTING

This Page intentionally left blank.

12

Page 17

In the event of problems with or

questions about your order, please

contact the Pitco Frialator factory at:

(800) 258-3708 US and Canada only or

(603) 225-6684 World Wide

Website Address: www.pitco.com

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

L20-259, rev. 3 (1/06)

In the event of problems with or questions

about your equipment, please contact the

Pitco Frialator Authorized Service and Parts

representative (ASAP) covering your area, or

contact Pitco at the numbers listed to the left.

Loading...

Loading...