Page 1

Service Manual

GAS FRYER

with

FILTER

Model Number

AG14S

PITCO FRIALATOR, INC.

P.O.BOX 501 CONCORD, NH 03302-0501

Phone: 1(603)225-6684

Toll Free: 1(800)258-3708

Fax: 1(603)225-8497

Pitco Frialator

Literature # L20-157 Rev 2 Rev Date 29 April 1997 Made in the United States of America

Page 2

FOR YOUR SAFETY:

Do not store gasoline or other flammable

vapors or liquids in the vicinity of this or

any other appliance.

TO THE PURCHASER

POST IN A PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THAT AN OPERATOR SMELLS GAS.

OBTAIN THIS INFORMATION FROM YOUR

LOCAL GAS SUPPLIER.

can give off a dangerous carbon monoxide gas. Carbon

Monoxide is a clear odorless gas that can cause suffocation.

WARNING

Carbon Monoxide gas can build up if you obstruct the

flue. Blocking the flue will also cause the unit to overheat. DO NOT obstruct the flow of combustion/ventilation or air opening around the machine. Ensure that

you meet the minimum clearances specified in the installation instructions. Adequate clearance around the

unit is necessary for servicing and proper burner operation.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE MANUALS

THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

WARNING

This appliance is equipped with a grounding plug. This

is for your protection against shock hazard in the event

of equipment malfunction. Always plug the unit into a

properly grounded receptacle. DO NOT cut or remove

the grounding prong.

WARNING

DO NOT use an open flame to check for gas leaks!

Keep all open flames away from the machine at all

times.

WARNING

Machines equipped with casters and a flexible power

cord, must be connected to a gas supply with a QuickDisconnect device. This quick disconnect must comply with ANSI Z24.41. To limit the movement of the

unit without depending on the connector or quick disconnect, a restraining device must also be installed.

WARNING

There is an open flame inside the machine. The unit

may get hot enough to set nearby materials on fire. Keep

the area around the unit free from combustibles.

WARNING

If the machine should shut down unexpectedly wait 5

minutes before attempting to restart it. This will allow

time for any excess gas in the unit to dissipate.

WARNING

The power supply must be disconnected before servicing or cleaning the unit.

WARNING

DO NOT supply the fryer with a gas that is not identified on the data plate, located on the inside of one of

the doors of the machine. If you need to convert the

machine to another type of fuel, contact your dealer or

Authorized Pitco Service Agency.

WARNING

If your Pitco Frialator fryer is equipped with a Gas Hose,

Quick Disconnect and restraining device, when the fryer

is in its operating location, lock the casters and reattach

the restraining device to the rear of the machine.

WARNING

Shortening, when it is at cooking temperatures, is very

HOT and DANGEROUS! Use extreme caution when

handling! Use the proper protective gear such as insulated gloves, aprons, face shield and sleeves when handling hot shortening. DO NOT attempt to move any

machine that has hot oil in it. Allow the oil to cool to

room temperature or drain the oil into a suitable container before moving the fryer.

Retain this manual for future reference.

WARNING

Ensure that the machine can get enough air to keep the

flame burning correctly. If the flame is starved of air it

Page 3

ORIGINAL EQUIPMENT LIMITED WARRANTY - ADVANCED FRYERS

General Warranty

Pitco Frialator, Inc. warrants to the original user of its Advanced Fryer cooking appliance that said appliances and related equipment will be free

from defects in material and workmanship under normal use for a period of one (1) year from the date of installation, with appropriate documentation,

subject to the following additions, exceptions, exclusions and limitations.

What is covered

This warranty is limited to the repair or replacement at the Company’s option, without charge, of any part found to be defective within the warranty

period and reasonable expenses incurred for freight and material for the installation of such part; in addition, the Company’s obligation shall be limited to

reimbursement for normal labor on such parts.

Pitco Frialator, Inc. agrees to pay the G.S. Blodgett Corporation Authorized Service and Parts Distributor, for any labor and material required to

repair or replace, at the Company’s option, any part which may fail due to defects in material or workmanship during the above general warranty period.

Fry Tanks

In addition, the Company warrants to the original user of any fry tank to be free from defects for a period of ten (10) years from the date of

manufacture. Labor and freight shall be the responsibility of the user. This shall only obligate the Company to repair or replace, at its option, any fry tank

which it determines to be defective. Claims under this item shall be supported by a statement detailing the defect, and the Company may require the return

of the fry tank claimed to be defective.

Computer or Digital Cooking Controller

In addition, the Company warrants to the original user of any Cooking Computer or Digital Controller to be free from defects for a period of two (2)

years,from the date of manufacture. During the two (2) year period all charges involved in the replacement of a Pitco Computer or Digital Controller will

be the responsibility of Pitco Frialator Inc.

Burner

In addition, Company warrants to the original user of any Advanced Fryer Burner to be free from defects for a period of five (5) years from the date

of manufacture. Labor and freight shall be the responsibility of the user.

How to Keep Your Warranty in Force

€ Make sure any shipping damages are reported immediately. Damages of this nature are the responsibility of the carrier.

€ Install the unit properly. This is the responsibility of the installer and the procedures are outlined in the manual. Do not install it in a home

or residence.

€ Maintain the unit properly. This is the responsibility of the user, the procedures are outlined in the manual.

What is NOT covered under this Warranty

€ Adjustments, such as calibration, leveling, tightening of fasteners or plumbing or electrical connections normally associated with initial

installation are not covered under this warranty. These procedures are outlined in the installation manual.

€ Damaged due to flood, fire or other acts of Nature are not covered under this warranty.

€ If the unit is used for a purpose other than for which it was intended or designed, resulting damages are not covered under the warranty.

€ Failures due to erratic voltage or gas supplies are not covered under the warranty.

€ Material alterations or modifications from the condition in which the unit left the factory are not covered under the warranty.

€ Units with unreadable, obliterated or removed serial number rating plates are not covered by the warranty.

€ Any parts other than Genuine OEM parts from Pitco Frialator, Inc. or its Authorized Parts and Service Distributors are not covered by the

warranty.

€ Any other failure which is not attributable to a defect in materials or workmanship is not covered bt the warranty.

This warranty specifically excludes parts which wear or would be replaced under normal usage, including, but not limited to, electric lamps, fuses,

interior or exterior finishes and gaskets.

Limits to the Warranty

Outside the United States of America and Canada, this warranty is limited to the replacement of parts and Pitco Frialator, Inc. will not bear any other

expense be it labor, mileage, freight or travel.

Charges for mileage over one hundred (100) miles, travel time over two (2) hours, overtime, and holiday charges are not covered under this warranty.

These charges are the responsibility of the individual or firm requesting these services.

If any oral statements have been made regarding the appliance, these statements do not constitute warranties and are not part of the contract of sale.

This limited warranty constitutes the complete, final and exclusive statement with regard to warranties.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES WHETHER WRITTEN, ORAL OR IM-

PLIED, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

WARRANTY AGAINST LATENT DEFECTS.

Limitations of Liability

In the event of a warranty or other claim, the sole obligation of Pitco Frialator, Inc. will be the repair or replacement, at the Company’s option, of the

appliance or the component part. This repair or replacement will be at the expense of Pitco Frialator, Inc. except as limited by this warranty statement. Any

repair or replacement under this warranty does not constitute an extension in time to the original warranty. Parts covered under this warranty will be

repaired or replaced, at the Company’s option, with new or functionally operative parts. The liability of Pitco Frialator, Inc. on any claim of any kind,

including claims based on warranty, express or implied contract, negligence, strict liability or any other legal theories will be exclusively the repair or

replacement of the appliance. This liability will not include, and the purchaser specifically renounces any right to recover special, incidental, consequential or other damages of any kind, including, but not limited to, injuries to persons, damage to property, loss of profits or anticipated loss of the use of this

appliance.

If any provision of this warranty is unenforceable under the law of any jurisdiction, that provision only will be inapplicable there, and the remainder

of the warranty will remain unaffected. The maximum exclusion or limitation allowed by law will be substituted for the unenforceable provision.

How to Obtain Warranty Service

First direct your claim to the G.S. Blodgett Corporation Authorized Service and Parts Distributor closest to you giving complete model, serial and

code numbers, voltage, gas type, and description of the problem. Proof of the date of installation and/or the sales slip may also be required. If this

procedure fails to be satisfactory, write the National Service Manager, Pitco Frialator, Inc., P. O. Box 501, Concord, NH. 03302-0501. USA

This warranty gives you certain specific legal rights; you may have other rights which vary from state to state.

i

Page 4

ii

Page 5

Table of Contents

WARRANTY STATEMENT................................................................................................ i

TABLE OF CONTENTS ...................................................................................................... iii

INSTALLATION INSTRUCTIONS..................................................................................... 1

Ventilation ...................................................................................................................... 1

Quick Disconnect Gas Connection ................................................................................ 1

Fuel Supply Line Leak and Pressure Testing ................................................................. 1

Clearances ......................................................................................................................1

Leveling the fryers.......................................................................................................... 1

Filling the fryer with oil ................................................................................................. 2

HOW DOES IT WORK? ...................................................................................................... 3

Heating System ............................................................................................................... 3

Hi - Limit System ........................................................................................................... 3

Filter System...................................................................................................................3

LADDER DIAGRAMS ........................................................................................................ 4

COMPONENT TROUBLESHOOTING .............................................................................. 5

Probe ............................................................................................................................... 5

Relays ............................................................................................................................. 5

Hi Limits......................................................................................................................... 5

Drain Valve & Return Valve Switches ........................................................................... 5

Transformer .................................................................................................................... 6

Blower ............................................................................................................................ 6

Pressure Switch .............................................................................................................. 6

Gas Valve........................................................................................................................ 6

Ignition Control Module ................................................................................................. 6

TROUBLESHOOTING GUIDE .......................................................................................... 7

Fryers .............................................................................................................................. 7

Filters .............................................................................................................................. 8

COMPONENT CHANGEOUT ............................................................................................ 9

Probes ............................................................................................................................. 9

Hi Limits......................................................................................................................... 9

Computers ...................................................................................................................... 9

Components mounted in the front panel ........................................................................ 10

Filter Relays ...................................................................................................................10

Control Relays ................................................................................................................ 10

Circuit Breaker ............................................................................................................... 10

Gas Valves ......................................................................................................................11

Burners and Spark Ignitors ............................................................................................. 11

Proximity Switches......................................................................................................... 11

Blowers ........................................................................................................................... 12

Pressure Switches ........................................................................................................... 12

Fry Tanks ........................................................................................................................ 13

Parts ...................................................................................................................................... 15

Operational Components ................................................................................................ 15

Filter ............................................................................................................................... 15

Miscellaneous ................................................................................................................. 15

Wiring Harnesses ........................................................................................................... 16

Parts Identification ................................................................................................................ 17

Schematics ............................................................................................................................ 18

iii

Page 6

iv

Page 7

INSTALLATION INSTRUCTIONS

CAUTION:

This equipment is manufactured for the use

on a particular type of gas and electrical voltage which is specified on the rating plate located on the inside of the door.

When your fryers arrive, look them over carefully noting any damage on the freight bill. If concealed damage is found after you have accepted

the equipment, report it to the carrier immediately, as all claims must be filled within 15 days

of the receipt of the shipment. Also, be sure to

keep any packing materials as these will be necessary to make a claim.

Follow these installation instructions carefully.

A proper installation is important for the operation of the fryers.

Note: It is recommended that the ventilation

system be cleaned and maintained on a regular basis.

Quick Disconnect Gas Connection:

Units equipped with casters must be installed

with connectors that comply with the standards

for connectors for Movable Gas Appliances,

ANSI Z21.69-1987, and Addenda Z21.69A-

1989. (CAN/CGA - 6.16 and CAN/CGA - 6.9.)

This connection should include a quick disconnect device that complies with the Standard for

Quick Disconnect Devices for use with Gas Fuel,

ANSI Z21.41-1989. When installing a quick disconnect you must also install a means of limiting the

movement of the fryer. This device will prevent the

gas line or quick disconnect from being strained.

Fuel Supply Line Leak and Pressure Testing:

In the United States, all installations must conform to all local and state codes and well as the

National Fuel Gas Code (ANSI 223.1 1992). In

Canada, installations must be made in accordance to Canadian Standard CAN 1-B149.1 or

.2 “Installation Codes for Gas Burning Appliances & Equipment.”

Electrically operated appliances must be electrically grounded in accordance with local codes;

or in the absence of local codes, with the National Electric Code ANSI/NFPA No. 70-1996;

in CANADA, with CSA C22-1 Canadian Electrical Code Part 1.

Ventilation:

A proper ventilation system is also an important part of the installation. For information on

the construction and installation of ventilating

hoods, please see “Standard for the Installation of Equipment for the Removal of Smoke

and Grease Laden Vapors from Commercial

Cooking Equipment”, N.F.P.A. No. 96-1987.

Copies can be obtained by writing to the National Fire Protection Association, Battery March

Park, Quincy, MA 02269.

The fuel supply system must be tested before the machine can be used. If the fuel line is going to be tested

at a pressure greater than (>) 1/2 PSI (3.45 kPa), make

sure that the unit is disconnected from the fuel line.

If the fuel line is going to be tested at a pressure

equal to or less than (≤) 1/2 PSI (3.45 kPa), the machine can be connected to the supply but the gas valve

must be shut.

Clearances:

Minimum clearance of 6" (15cm) must be maintained from combustible construction on each

side and the rear of the equipment. This equipment may be installed on combustible floors.

Maintain a minimum of 24" (61cm) clearance in

front of the fryer to provide for proper operation,

maintenance and servicing.

NOTE: Do not block the area around the bottom or underneath the fryer. The air required to

support the gas combustion is drawn from the

underneath and sides of the fryer.

Leveling the fryers:

Leveling the fryers will help ensure proper opera-

1

Page 8

tion. To level the fryers loosen the two set screws on

the caster/leg stem. Rotate the collar of the caster/

leg to raise or lower the height of the unit. Tighten

the set screws to lock the adjustment in place.

Filling the fryer with oil:

CAUTION:

Never operate this equipment empty. Always

make sure there is the correct amount of shortening or in the case of cleaning, water in the

fry tank before turning the unit ON.

It is very important to make sure the oil level is correct before attempting to heat shortening in your Pitco

fryer.

Liquid shortening can be poured directly into the fry

tank until the correct level has been reached. This is

indicated by a line on the right or left hand sides of

the inside of the fry tank. "C" is the level for Cold

shortening and "H" is the level for Hot shortening.

For solid shortening, the shortening must be cut

into small blocks about 1" (2.54 Cm) in size.

These small blocks must be placed under and

around the heat tubes.

Regular cleaning of this equipment, as well as

the hood, is an important part of proper maintenance. Clean the fry tanks using the Boil Out

procedure described in the operating manual.

A wiring diagram is located in the back of this

manual and inside the fryers.

Retain this manual for future reference.

2

Page 9

HOW DOES IT WORK?

The Advanced Gas Fryer will have certain reactions to what is happening, knowing what

these reactions are and knowing what the machine is trying to do will enable us to diagnose

most of the problems likely to be encountered.

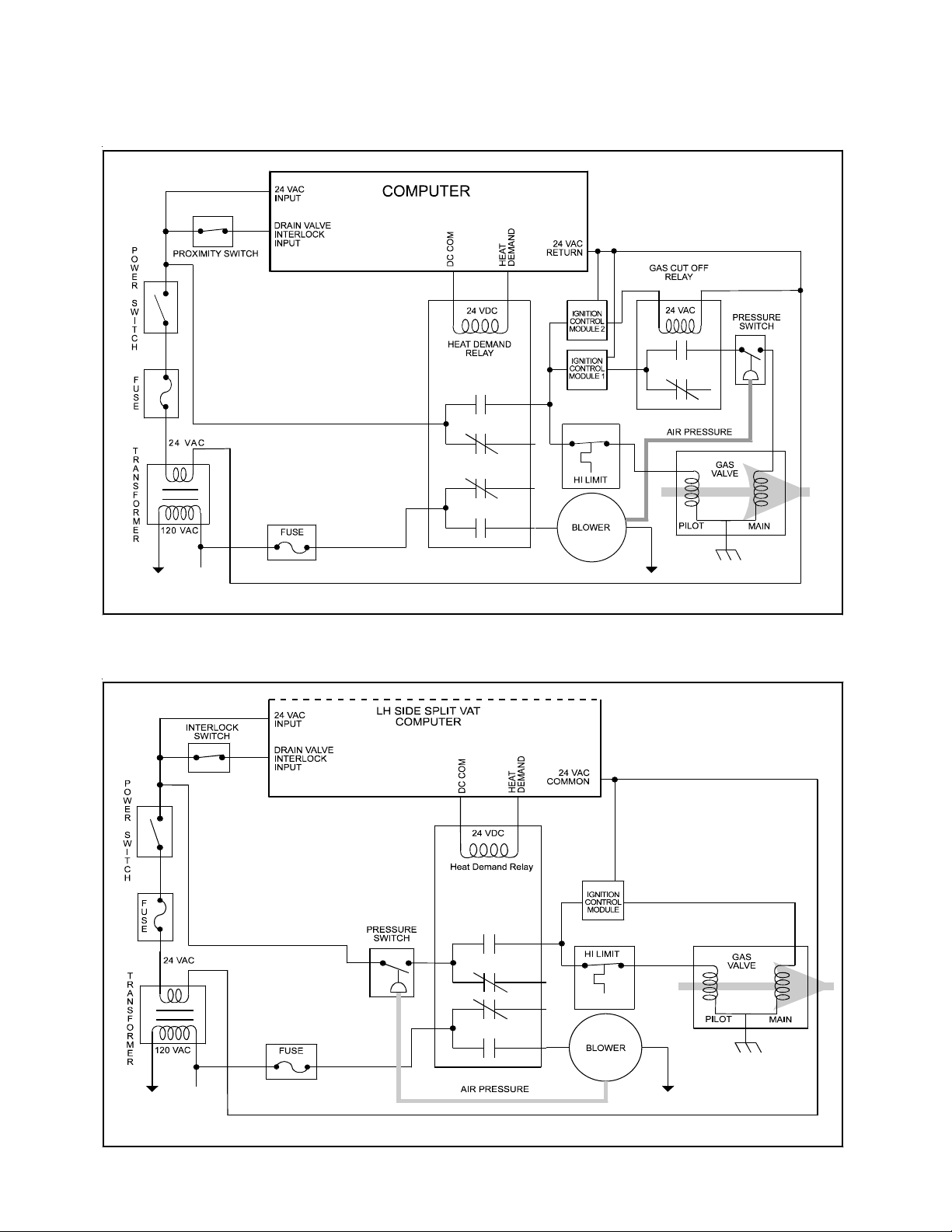

Heating System

• Power to the machine is turned ON.

• The computer is supplied with 24VAC and, if

the Drain Valve Handle is closed, the Proximity

Switch will supply 24 VAC to the DVI (Drain Valve

Interlock) Input at the computer. As soon as the computer is powered up it will show something on the

display.

• Computer calls for heat.

• Full Tank - The Heat Demand Relay will energize, supplying the Blower, the Pilot Solenoid on the

Gas Valve and the Ignition Control Modules with

power. Both Ignition Control Modules supply power

to the Spark Ignitors. At the same time one of the

Ignition Control Modules supplies power to the Gas

Cut Off Relay. The Gas Cut Off Relay energizes allowing the second Ignition Control Module to supply power to the normally open Pressure Switch.

When the Blower comes up to speed, which should

take a couple of seconds, the Pressure Switch will

close allowing 24 VAC to the Main Solenoid of the

Gas Valve. This will also supply the computer with

a heat feedback signal. Since there are two burners

in a full vat machine each of the Ignition Control

Modules alternately sends a spark signal to the Ignitor and tests for a flame sense signal from the same

Ignitor. When a flame sense signal is received it will

cease to send the spark signal and continue to sense

flame. If, after 10 seconds, a flame sense signal has

not been established the Ignition Control Module will

"Lock Out" and cease to run until reenergized.

• Split Vat - The same power that supplies the computer also supplies 24 VAC to the normally open

Pressure Switch. When the computer energizes the

Heat Demand Relay the Blower will be supplied with

power and come up to speed. At this time the air

pressure from the blower will close the Pressure

Switch and allow 24 VAC to go to the second set of

contacts within the Heat Demand Relay. Since the

Heat Demand Relay is now closed the Ignition Control Module and Hi Limit Switch will receive 24

VAC. If the Hi Limit Switch is NOT tripped it will

allow 24 VAC to be supplied to the Pilot Solenoid of

the Gas Valve. The Ignition Control Module supplies 24VAC to the Main Solenoid of the Gas valve.

The Ignition Control Module alternately sends a

spark signal to the Ignitor and tests for a flame sense

signal from the same Ignitor. When a flame sense

signal is received it will cease to send the spark signal and continue to sense flame. If, after 10 seconds,

a flame sense signal has not been established the Ignition Control Module will "Lock Out" and cease to

run until it re-energizes.

Hi - Limit System:

When the Hi Limit trips it causes the power to

the Pilot Solenoid to stop and gas will cease to

flow through the gas valve. This will cause a

Lock Out condition and the burners will not light.

The Hi Limit Switch should be manually reset by

pressing the Power Switch to the OFF position and

pressing it back to the ON position.

Filter System:

With the Filter Circuit Breaker in the ON position,

opening the RED Return Valve Handle will cause

the Pump On Relay to be energized and the pump

will begin to operate. Closing the Return Valve

Handle will de-energize the Relay and the Pump will

stop running.

Heat Tape:

All Advanced fryers are equipped with Heat Tape

which has an indicator light that will illuminate when

the piping is up to operating temperature, do not attempt to pump unless the Filter Ready Light has illuminated.

3

Page 10

Full Vat Fryers:

LADDER DIAGRAMS

Split Vat Fryers:

4

Page 11

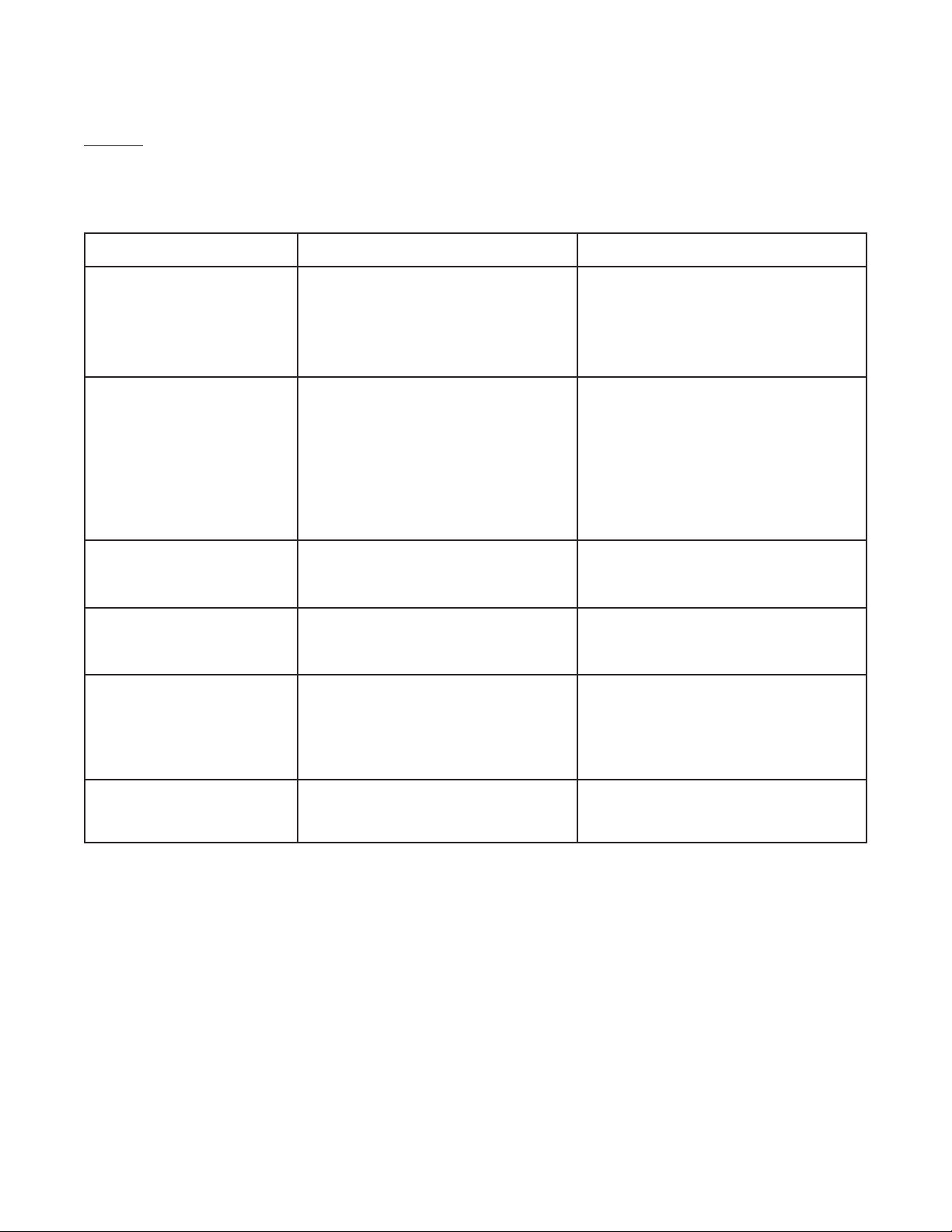

COMPONENT TROUBLESHOOTING

Temperature Probe:

plied to the coil. When energizing, the relay Switching Contacts will close, thus connecting the Common and Normally Open terminals.

The resistance of the probe decreases as the temperature rises. The lower the temperature the greater

the resistance change will be per degree of temperature change, as the temperature approaches the working range of the probe, the resistance change will

slow and become more linear. If the probe is suspect, check its resistance and the oil/air temperature

at which it was taken. Compare these values on the

chart below.

TEMP RESISTANCE TEMP RESISTANCE

ºF Ohms Ω ºF Ohms Ω

60° 139055 Ω 330° 1192 Ω

80° 84644 Ω 335° 1123 Ω

100° 53146 Ω 340° 1058 Ω

120° 34328 Ω 345° 998 Ω

140° 22755 Ω 350° 942 Ω

160° 15446 Ω 355° 890 Ω

180° 10716 Ω 360° 841 Ω

200° 7586 Ω 365° 795 Ω

210° 6427 Ω 370° 752 Ω

220° 5470 Ω 375° 712 Ω

240° 4013 Ω 380° 675 Ω

260° 2991 Ω 385° 640 Ω

280° 2262 Ω 390° 607 Ω

300° 1734 Ω 395° 576 Ω

320° 1347 Ω 400° 547 Ω

325° 1267 Ω

If the probe returns an open circuit or 0 Ohms reading it should be replaced. If the resistance varies more

than 20 Ohms from the above chart when being

checked between 325-375°F (162ºC - 190ºC) the

probe will give a false temperature reading on the

computer and should be replaced. However, it will

continue to operate at a slightly higher or lower temperature. Allow the oil to cool and check the probe

resistance at a lower temperature. As can be seen

from the chart a greater degree of offset can be allowed at a lower temperature.

Relays:

Hi Limits:

A Hi - Limit switch is a normally closed switch until

the temperature at its probe reaches 435ºF ± 15°

(225ºC ± 15º). In order to test this switch it will be

necessary to bypass the Heat Demand Relay.

This will cause the fryer to heat until the temperature of the oil reaches the necessary temperature to trip the Hi Limit.

WARNING

Do NOT leave the machine during this test. This

test will cause the oil to heat past the normal operating temperature and can cause damage to the

machine and its operator. Always use an external

temperature probe to observe the oil tempersature

during this procedure

In order to cause the oil to reach a temperature where

the Hi Limit will trip it will be necessary to bypass

the Heat Demand Relay. To do this, use a small

jumper wire and join the Normally Open (Terminal

#5) and Common (Terminal #3) terminals on the

switch section of the relay

If the switch does not trip between the prescribed

limits it is defective and should be replaced. Once

tripped, the switch cannot be reset until the oil

has cooled to approximately 400°F (204ºC). If

the switch cannot be reset it is defective.

Drain Valve & Return Valve Switches:

These switches are magnetically operated Reed

switches. When the Drain Valve handle is moved to

the open position, the Actuator will move away from

the switch causing the Reed switch to open. When

the Drain Valve is closed the Reed switch will close.

This switch can also be checked with an Ohm meter.

The normal gap between the Actuator and the Sensor switch on the Drain Valve handle is 1/8" - 1/4" (3 6 mm).

Relays will energize when the correct voltage is sup-

5

Page 12

Transformer:

Ignitors:

Transformers are multiple input voltage, 24 volt output voltage and can be checked by reading the input

and output voltages.

Blower:

Check the voltage between the wires going to the

Blower. If 120 VAC is found and the Blower is NOT

turning it is defective.

Pressure Switch:

As the blower speed rises the amount of vacuum on

the suction side of the pressure switch rises past approximately 1.3" WC (0.325 kPa) the Presssure

Switch will close. When the vacuum falls below approximately 0.8" WC (0.2 kPa) the Pressure Switch

will open. With the Blower running, check the IN

and OUT voltage of the Switch. If 24VAC can be

found on one side but NOT the other the Pressure

Switch is defective.

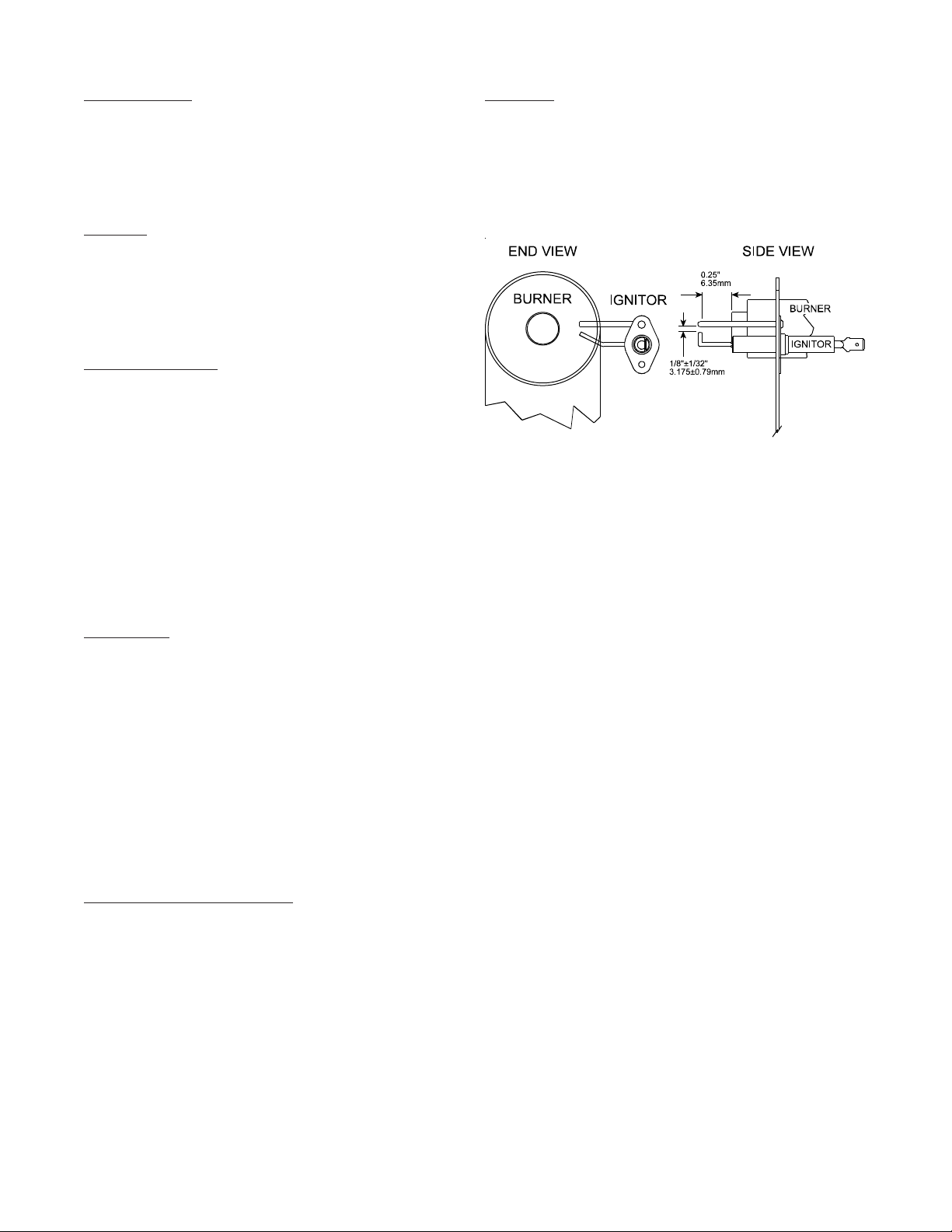

When an Ignitor is supplied with power and does

NOT spark the Spark Gap should be checked.The

distance between the Ignitor and the Ground post

should be approximately 1/8" ± 1/32".

If the Ignitor is sparking but the Burner does not light,

check for a gas supply and make sure the Ignitor is

located in the correct position as shown in the drawing.

Gas Valve:

The Knob should be in the ON position. Check for

24VAC between the terminals marked MV and MV/

PV and between PV and MV/PV. If voltage IS found

between both of these connections and the Gas Valve

does not open the Gas Valve is defective. If voltage

is NOT present at both of the coils on the Gas Valve,

troubleshoot and repair the machine until voltage IS

present at both coils, retest the Gas Valve as previously described.

Ignition Control Modules:

When the Ignition Control Module is supplied with

24 VAC from the temperature control system at the

TH terminal it will send a signal to the Ignitor which

will begin to spark. At the same time the Ignition

Control Module will also have a 24 VAC output signal on the MV terminal. The Ignition Control Module will cause the Ignitor to spark for 10 seconds and

and then look for a flame sense signal, if it does not

receive a flame sense within 10 seconds signal it will

"Lock Out".

6

Page 13

TROUBLESHOOTING GUIDE

Fryers:

It is assumed that, before starting any troubleshooting, the power is turned on and the gas lines are connected correctly.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Computer does not come on A. Power Switch is NOT turned ON A. Press switch to the ON position.

nothing shows in either display B. Main circuit breaker is turned off B. Locate the correct circuit breaker and

C. Fryer fuse is blown turn OFF and back ON again.

D. Transformer C. Check and Replace as needed

D. Check Transformer

Computer heat light comes on A If the oil is hot the Hi Limit may be A. Allow the oil to cool, the Hi Limit will

but burners do not tripped reset itself. Turn the computer OFF and

B. Ignition Lockout back ON again to reset the computer.

B. Check gas supply, Flame Sensor,

Hi Limit, Gas Valve, Ignition Control

Module/s, Pressure Switch (Full Tank),

Gas Cut Off Relay (Full Tank), Blower

(Full Tank)

No Spark heard, blower IS A. Heat Demand Relay A. Check and replace where needed.

running B. Ignition Control Module B. Check and replace where needed.

C. Spark Ignitor C. Check / adjust / replace where needed.

Spark sound can be heard, A. F2 fuse blown A. Check and replace where needed.

Blower NOT running B. Blower B. Check and replace where needed.

C. Heat Demand Relay C. Check and replace where needed.

Spark sound can be heard, A. Ignition Control Module A. Check and replace where needed.

Blower IS running but main B. Gas Valve Relay (Full Tank Only) B. Check and replace where needed.

burners do not run C. Defective Pressure Switch C. Check and replace where needed.

D. Tripped or defective Hi limit D. Check and replace where needed.

E. Gas Valve E. Check and replace where needed.

Burner comes ON for short A. Flame Sensor A. Check / adjust / replace where needed.

time, does not come back on B. Ignition Control Module B. Check and replace where needed.

C. Gas Valve C. Check and replace where needed.

7

Page 14

Filters:

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Red Return Valve is open but no A. Red Return Valve NOT fully open A. Pull slightly on the Red handle to check

pump sound can be heard B. Filter Circuit Breaker may be tripped that it is fully open.

C. Filter Motor Thermal Overload may B. Locate the circuit breaker and reset.

be tripped C. Push Red reset button located on end of

D. Sensor switch may be loose or bad filter motor.

D. Check that the switch is tight in its

mounting. If switch is bad replace it.

Drain valve is closed and the A. Green Drain Valve is NOT fully A. Apply a little more pressure to the

computer has been reset but Closed Green Handle to check that it is

still shows "DRAINING" or B. Sensor switch may be loose or bad fully closed.

"TURN OFF" B. Check that the switch is tight in its

mounting. If switch is bad replace it.

Drain Valve is OPEN, the oil A. Green Drain Valve is NOT fully open A. Apply a little more pressure to the

is draining slowly or not at all. B. Drain is plugged with debris Green Handle to check that it is fully

closed.

B. Use the Clean Out Rod from inside the

Fry Vat to clear the Drain Valve. If this

NOT clear the blockage, CLOSE the

Green Drain Valve and follow these

instructions for clearing the main drain

line.

CAUTION:

Some HOT oil may still come out when

the cap is removed.

Remove the two screw from the end

cap (Do NOT lose these.) Use the

Clean Out Rod to clear the main drain

tube. Install the end cap along with its

gasket and two screws. Do not

overtighten these screws.

8

Page 15

COMPONENT CHANGEOUT

Computers:

It is assumed that for all (except where noted) of these

component changeout instructions the fryer has been

shut down and disconnected from the power and gas

supplies, cooled and drained of oil.

Probes:

1. Unplug the wiring connector.

2. Unscrew the small nut on the probe seal.

3. Slide the probe from the seal.

Install in the reverse order using the new ferrule

supplied with the new probe.

CAUTION:

Take care not to drop any of the components from

the front panel as this will damage them.

1. Remove the two screws from the upper mount

of the front panel.

2. Unplug the wiring connection at the rear of the

computer.

NOTE: On split tank machines you will find 2 wiring connections to unplug.

Hi Limits:

1. Unplug the wiring connector.

2. Unscrew the Hi Limit from the front of the fry

tank.

Install in the reverse order.

Install in the reverse order.

9

Page 16

Components mounted in the front panel:

To access all of the components mounted in the front

panel follow the instructions below:

1. Remove the computer as described previously.

The components within the front panel area can

now be accessed.

Filter Relays:

This relay is wired in the following manner -

Filter Pumps:

1. From the front of the machine, pull the ring back

on each of the 2 quick disconnects and release

the couplings.

2. Remove the 2 screws, and the front of the Pump/

Motor assembly will drop. The assembly can be

removed from the machine by lifting the rear

slightly and pushing back. The front of the mount

can be lowered until the assembly can be removed from the machine.

Control Relays:

Control relays are always wired in the following manner -

Install in the reverse order.

Circuit Breaker:

1. Remove the 2 mounting

screws on either side of

the door magnet catch.

Remove the door magnet

catch.

2. Remove the 2 mounting

screws from the top and

bottom of the cover.

3. Depress the 4 catches that

hold the circuit breaker in the cover.

10

Page 17

Install of the reverse order.

Gas Valves:

1. Unscrew the fittings to the gas outlet tubes at the

top of the gas valve.

1. Unscrew the fitting for the gas supply tubing on

the bottom of the burner.

2. Unplug the wire to the spark ignitor.

3. Remove the 2 screws that hold the spark ignitor

and burner in place.

2. Unscrew the pipe union, located behind the gas

valve.

3. Unplug the 3 wires that plug into the gas valve.

Install in the reverse order.

Burners and Spark Ignitors:

NOTE: If the ignitor is to be removed without the

burner start the proceedure at step 2.

The burner and spark ignitor may be removed together. Install in the reverse order.

Proximity Switches:

1. The actuator can be removed by removing the 2

mounting screws.

11

Page 18

2. The sensor may be removed by disconnecting

the wiring harness and by removing the 2 mounting screws.

Install in the reverse order.

NOTE: The new blower will be shipped with the

blower housing attached. Remove the motor from

the blower housing in the above manner. Clean the

sealant from the new motor and the old housing (still

attached to the machine). Apply a small amount of

high temperature silicone sealant to the motor mounting flange.

Install the motor in the reverse order of removal.

Pressure Switches:

1. Unscrew the plastic fitting from the air connection on the pressure switch.

2. Unplug the 2 wires from the switch.

Blowers:

1. Unplug the wiring connector.

2. Remove the 3 screws from the mounting flange.

3. Using a flat screwdriver, break the seal at the

motor flange.

4. The motor can now be lowered out of the machine.

3. Remove the 2 screws from the mounting bracket.

Install in the reverse order.

Fry Tanks:

Full Fry Tanks-

1. Remove ALL of the computer/controllers from

the machine.

2. Remove the burners and ignitors from the tank

to be removed.

3. Disconnect the drain valve switch wires.

4. Disconnect the return valve switch wires.

5. Disconnect the blower wires.

6. Remove the drain line from the left and right ends

of the drain valve tee.

7. Disconnect the filter return piping at the rear of

the Fry Tank.

8. Remove the 3 screws from the front of each unit.

12

Page 19

9. Remove all of the nuts and washers holding the

splash deck in place.

10. Remove the front deck from the machine.

12. Remove the brackets located inside the splash

back.

11. Remove all of the screws holding the front of

the tank.

13. Remove the upper rear cover.

14. Remove the complete splash back assembly.

13

Page 20

15. Remove the lower rear back cover.

16. Unscrew the compression fitting at the rear of

the tank.

17. Remove the air tube from the air box (the blower

is mounted to this box).

18. Grasp the tank by the middle tube and remove it

from the rear of the cabinet.

NOTE: To disconnect the filter return piping (as in

step # 15) unscrew the union connecting the return

piping to the tanks.

Install in the reverse order.

Split Fry Tanks-

Split Fry Tanks should be removed and installed as

pairs in the same manner as Full Fry Tanks. There

are 3 sets of clamps that hold the two Split Fry Tanks

together:

1. On the rear of the tank.

2. On the bottom of the tank accessed by first removing the blower.

3. On the bottom of the tank at the front.

14

Page 21

Parts

Operational Components:

Part Schematic Description

Number Nomenclature

PP11254 A1 Computer

PP11286 A1 Computer

PP11144 A2/A3 Ignition Control Module

PP11067 M1 Blower

PP11131 Ignitor/Flame Sensor

PP11065 RT1 Probe

PP11140 V1 Gas Valve, NAT

PP11141 V1 Gas Valve, LP

PP11064 S2 Hi Limit

PP11068 K1 Relay, Heat Demand

PP11068 K2 Relay, Gas Valve

PP11033 K3 Relay, Hood System

PP10210 T1 Transformer

PP11066 S4 Pressure switch

PP10262 S3 Proximity Switch, Sensor

PP10263 S3 Proximity Switch, Actuator

P5045717 F1 Fuse, 2 Amp Slow Blow

P5045720 F2 Fuse, 4 Amp Slow Blow

Filter:

PP11042 Power Cord

Part Number Description

PP10101 Motor

PP10416 Motor Only

PP10417 Pump Only

PP10262 Proximity Switch, Sensor

PP10263 Proximity Switch, Actuator

PP10058 Relay, Filter

PP10460 Circuit Breaker

PP11138 Gasket, Drain Line End

PP11172 Clamp, Band

PP10032 Gasket

B6641101 Filter Pan Assembly

B6640801 Filter Drawer Assembly

B6641001 Lid, filter (Front)

A7013502 Lid, filter (Rear)

P6071516 Handle, Lid

B6640901 Retainer, Paper

A7001202 Support, Paper

PP10409 O-Ring

A7001701 Bracket, Drawer Roller Mount

B4002001 Handle, Return Valve LH

B4002002 Handle, Return Valve RH

P6071780 Valve, Ball 3/8"

PP11181 Gasket, Drain End

PP11182 Gasket, Tee Clean Out

A7004401 Cover, Tee Clean Out

A6643701 Thumb Screw

Miscellaneous:

Call Factory Tank, Full Tank

Call Factory Tank - LT Split Tank, w/ Gaskets

Call Factory Tank - RT Split Tank, w/ Gaskets

B1003001 Baffle, Heat Tube

B3502301 Flue

PP10814 Caster, 9" Non Lock

PP Caster, 9" Locking

Part Number Description

15

Page 22

B2302301 Door, LH

B2302302 Door, RH

A3802901 Hinge, Top

A3802903 Hinge, Bottom

B3801301 Hinge Rod

PP11006 Handle, Door

P6071305 Magnet Catch

PP10368 Drain Valve, Full Tank

P6071769 Drain Valve, Split Tank

A1401202 Clamp, Hi Limit Bulb

PP11130 Burner, Main

B4001601 Handle, Drain Valve, Full Tank

B4001701 Handle, Drain Valve, Split Tank LH

B4001702 Handle, Drain Valve, Split Tank RH

A4015801 Handle, Lever Stop Release

PP11059 Plunger

PP11132 Orifice, #31 Nat Gas

PP11170 Orifice, #49 LP Gas

B2100904 Cover, Full Tank

B2100901 Cover, Split Tank

P6071516 Handle, cover

A8022301 Bracket, LH Ignitor

A8022303 Bracket, RH Ignitor

P6073148 Rack Tube, Full Vat

B4510401 Rack Tube, Split Vat

Wiring Harnesses:

B6728001 Harness, Filter Pump

B6730801 Harness, Full Tank

B6730701 Harness, Split Tank

B6731101 Harness, Control Cable

B6731201 Harness, Filter Option

PP11128 Wire, Ignitor

16

Page 23

Parts Identification

Computer/Controller

PP11254

Ignition Control Module

PP11144

Blower

PP11067

Ignitor/Flame sensor

PP11131

Probe

PP11065

Proximity switch, Sensor

PP10262

Proximity Switch, Actuator

PP10263

Motor, Filter

PP10101

Relay, Filter

PP10058

Circuit Breaker

PP10460

Gas Valve

PP11140 - Nat Gas

PP11141 - LP

Hi Limit Switch

PP11064

Relay, Heat Demand & Gas Valve

PP11068

Relay, Hood System

PP11033

Transformer

PP10210

Gasket, Clean Out Port

PP11182

Gasket, Drain Line

PP10032

Clamp, Band

PP11172

Valve, Ball 3/8"

P6071780

Pressure Switch

PP11066

17

Page 24

18

Page 25

19

Page 26

In the event of problems with or questions about your order, please contact the Pitco Frialator factory,

from 8:00 a.m. - 5:00 p.m., Eastern Standard Time, Monday through Friday, toll-free at:

(800)258-3708 US and Canada only or

(603)225-6684 World Wide

Page 27

AG14 FRYER PARTS BREAKDOWN

1

Page 28

AG14 FRYER FRONT

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... PP10752 ......................................... 10-32 X 1/2” SCREW

2 ...................................................... A1830901 ...................................... MAGNET STRIKER PLATE

........................................................ A1835001 ...................................... MAGNET STRIKER PLATE COVER

3 ...................................................... A1837501 ...................................... SWITCH MOUNTING PLATE

4 ...................................................... A3802901 ...................................... TOP RIGHT & LEFT DOOR HINGE

5 ...................................................... B3801301-C .................................. DOOR HINGE PIN

6 ...................................................... A3802903 ...................................... BOTTOM RIGHT & LEFT DOOR HINGE

7 ...................................................... B2302301-C .................................. LEFT DOOR ASSEMBLY

8 ...................................................... B2302302-C .................................. RIGHT DOOR ASSEMBLY

9 ...................................................... B3626803-C .................................. CE COMPUTER BEZLE ASSEMBLY FULL

B3626804-C .................................. CE COMPUTER BEZLE ASSEMBLY SPLIT

10 .................................................... P0092300 ....................................... 10-24 HEX NUT

11 .................................................... P0080601 ....................................... #10 FLAT WASHER

12 .................................................... PP11370 ......................................... I-12 COMPUTER (SINGLE)

PP11372 ........................................ I-12 COMPUTER (DUAL)

13 .................................................... B362601-C .................................... COMPUTER BEZLE

14 .................................................... PP11068 ......................................... HEAT DEMAND RELAY

P5046688....................................... MAIN GAS VALVE RELAY

15 .................................................... A5059102 ...................................... TERMINAL STRIP COVER

16 .................................................... P5045282 ....................................... WIRE TERMINAL STRIP

17 .................................................... PP11058 ......................................... FILTER PUMP RELAY

18 .................................................... PP10429 ......................................... TRANSFORMER CE

PP10210 ........................................ TRANSFORMER DOMESTIC

19 .................................................... PP11225 ......................................... SPARK IGNITION MODULE DOMESTIC

PP11145......................................... SPARK IGNITION MODULE CE

2

Page 29

3

Page 30

AG14 FRYER CABINET

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... A1834301 ...................................... DUAL FRYER CABINET COVER (STAND-

(For fryers without capping piece). A1834101 ..................................... TRIPLE FRYER CABINET COVER OFF)

A1834301+ A1834301 .................. QUAD FRYER CABINET COVER

A1834301+ A1834101 .................. QUINT FRYER CABINET COVER

2 ...................................................... A4106302 ...................................... SINGLE BACK SPLASH SEAL ANGLE

(For fryers without capping piece) A4105502....................................... DUAL BACK SPLASH SEAL ANGLE

A4105602 ...................................... TRIPLE BACK SPLASH SEAL ANGLE

A4105702 ...................................... QUAD BACK SPLASH SEAL ANGLE

A4105802 ...................................... QUINT BACK SPLASH SEAL ANGLE

3 ...................................................... B4101601-C .................................. SINGLE FRYER BACK SPLASH

B4101001-C .................................. DUAL FRYER BACK SPLASH

B4101101-C .................................. TRIPLE FRYER BACK SPLASH

B4101201-C .................................. QUAD FRYER BACK SPLASH

B4101701-C .................................. QUINT FRYER BACK SPLASH

4 ...................................................... PP10752 ......................................... 10-32 X 1/2” SCREW

5 ...................................................... A1623901 ...................................... REAR CABINET ACCESS PLATE (STEEL)

A1623902 ...................................... REAR CABINET ACCESS PLATE (SS)

6 ...................................................... A1623501+A1623502 ................... SINGLE FRYER CABINET BACK

(1st #galvinized, 2

A1623701+A1623702 ................... TRIPLE FRYER CABINET BACK

A1623801+A1623802 ................... TRIPLE FRYER CABINET BACK TOP

USE DUAL TWICE ........................ QUAD FRYER CABINET BACK

USE DUAL & TRIPLE ................... QUINT FRYER CABINET BACK

7 ...................................................... P0020600 ....................................... 1/4” X 5/8” BOLT

8 ...................................................... PP10815 ......................................... 9” LOCKING CASTER

8 ...................................................... PP10814 ......................................... 9” NON-LOCKING CASTER

9 ...................................................... P0093300 ....................................... 1/4” X 20 NUT

10 .................................................... B3622401-C .................................. SINGLE FRONT PANEL TOP DECK

B3627001-C .................................. DUAL FRONT PANEL TOP DECK

B3627201-C .................................. TRIPLE FRONT PANEL TOP DECK

B3627401-C .................................. QUAD FRONT PANEL TOP DECK

B3628201-C .................................. QUINT FRONT PANEL TOP DECK

11 .................................................... P0080650 ....................................... 1/4” FLAT WASHER

12 .................................................... P0093300 ....................................... 1/4” X 20 NUT

13 .................................................... A1838101 ...................................... SINGLE CABINET BOTTOM PLATE

A1834501 ...................................... CABINET BOTTOM PLATE LEFT HAND

(Non-filter).......... A1839301 ...................................... DUAL CABINET BOTTOM PLATE

(Non filter) ..........A1839303 ...................................... TRIPLE CABINET BOTTOM

(Filter) ................. A1839401 ...................................... TRIPLE CABINET BOTTOM RIGHT H.

A1839501 ...................................... PUMP BOTTOM COVER

nd

# stainless) A1623601+A1623502 ................... DUAL FRYER CABINET BACK

4

Page 31

10

11

13

13

7

8

9

2

3

4

5

6

1

5

Page 32

AG14 FRYER FILTER

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... B4003203-C .................................. OIL RETURN HANDLE FULL & RH SPLIT

B4003204-C .................................. OIL RETURN HANDLE LH SPLIT

2 ...................................................... P0079500 ....................................... 10-24 X 1/2” SCREW

3 ...................................................... A7004401 ...................................... DRAIN LINE CLEAN OUT COVER

4 ...................................................... PP11182 ......................................... CLEAN OUT COVER GASKET

5 ...................................................... PP10568 ......................................... 10-24 WING NUT

6 ...................................................... B6643101-C .................................. FILTER DRAIN LINE END CAP

7 ...................................................... PP11181 ......................................... DRAIN LINE END CAP GASKET

8 ...................................................... PP10696 ......................................... 10-24 X 1/2” SCREW

9 ...................................................... PP11241 ......................................... FLEX TUBING WITH FITTINGS 18”

10 .................................................... B6638601-C .................................. PUMP & MOTOR ASSEMBLY 115VAC

(Including tubing & heat tape) ... B6638602-C .................................. PUMP & MOTOR ASSEMBLY 240VAC

(Including tubing & heat tape) ... B6638603-C .................................. PUMP & MOTOR ASSEMBLY 220VAC

(Pump & motor only) ...... PP10101 ......................................... PUMP & MOTOR ASSEMBLY 115-230VAC

PP10416 ........................................ MOTOR ONLY 115-230VAC

(Pump & motor only) ...... PP10171 ......................................... PUMP AND MOTOR ASSEMBLY

PP10417 ........................................ PUMP ONLY

11 .................................................... PP11242 ......................................... FLEX TUBING WITH FITTINGS 20”

12 .................................................... P0020600 ....................................... 1/4-20 X 5/8 BOLT

13 .................................................... P0080650 ....................................... 1/4 FLAT WASHER

14 .................................................... B6652601-C .................................. FILTER RETURN RECEPTICLE ASSY.

15 .................................................... PP10039 ......................................... HEAT TAPE 165 WATT 110VAC 79”

PP10080 ........................................ HEAT TAPE 165 WATT 240VAC 79”

PP10194 ........................................ HEAT TAPE 96 WATT 110VAC 48”

PP10598 ........................................ HEAT TAPE 96 WATT 240VAC 48”

6

Page 33

SEE DETAIL A

13

12

11

10

9

14

15

SEE DETAIL A

1

8

7

6

5

2

4

3

7

Page 34

AG14 FRYER FILTER DRAWER

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... B6640901-C .................................. PAPER RETAINING RACK

2 ...................................................... B6647701-C .................................. OIL DRAIN CATCH TOWER

3 ...................................................... PP10409 ......................................... FILTER COUPLING “O” RING

4 ...................................................... B6661601-C .................................. FILTER PICK-UP ASSEMBLY

5 ......................................................P0020900 ....................................... 1/4-20 HEX HEAD SCREW

P6071020....................................... 1/4” NYLON BUSHING

P0080650....................................... 1/4” FLAT WASHER

P0093300....................................... 1/4-20 NUT

6 ...................................................... PP10177 ......................................... VINYL PROTECTIVE COVER

P0093300....................................... 1/4-20 NUT

P0080650....................................... 1/4” FLAT WASHER

P0020900....................................... 1/4-20 HEX HEAD SCREW

7 ...................................................... B6640701-C .................................. FILTER DRAWER HANDLE

8 ...................................................... B6640601-C .................................. FILTER DRAWER WELDMENT

9 ...................................................... PP11152 ......................................... ROLLER WHEEL KIT

10 .................................................... B6656801-C .................................. FILTER DRAWER EXTENSION RAIL (RH)

B6656802-C .................................. FILTER DRAWER EXTENSION RAIL (LH)

11 .................................................... A7008302 ...................................... PAPER SUPPORT RACK

12 .................................................... B6661501-C .................................. FILTER PAN

13 .................................................... P0007300 ....................................... 8-32 X 1/4” SCREW

14 .................................................... PP10900 ......................................... FLAT WASHER

15 .................................................... B6641001-C .................................. FRONT FILTER PAN COVER W/HANDLE

A7001102 ...................................... FRONT FILTER PAN COVER NO HANDLE

16 .................................................... P6071516 ....................................... FILTER PAN COVER HANDLE

17 .................................................... A7013502 ...................................... REAR FILTER PAN COVER

18 .................................................... B6654101-C .................................. CRUMB CATCH BASKET

8

Page 35

9

Page 36

AG14 FRYER DRAIN VALVE HANDLE

PARTS ASSEMBLY

I.D. # PART # PART DESCRIPTION

1 ...................................................... PP11302 ......................................... VINYL DRAIN VALVE HANDLE COVER

2 ...................................................... PP10263 ......................................... DRAIN PROXIMITY SWITCH ACTUATOR

3 ...................................................... B4002902-C .................................. DRAIN VALVE HANDLE FULL, RH SPLIT

B4002901-C .................................. DRAIN VALVE HANDLE LH SPLIT VAT

4 ...................................................... PP10266......................................... 4-40 X 1/4” SCREW

5 ...................................................... PP10647 ......................................... 1/2-13 NUT

6 ...................................................... PP11059 ......................................... PLUNGER ASSEMBLY

7 ...................................................... A4015801 ...................................... DRAIN HANDLE RELEASE LEVER

8 ...................................................... PP11303 ......................................... RELEASE LEVER VINYL COVER

9 ...................................................... B4003001-C .................................. FULL VAT HANDLE ASSEMBLY

(Complete drain valve handle assy) B4003003-C .................................. LH SPLIT VAT HANDLE ASSEMBLY

B4003005-C .................................. RH SPLIT VAT HANDLE ASSEMBLY

10

Page 37

11

Page 38

AG14 GAS & BURNER SYSTEM

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... B3317701-C .................................. FULL VAT BURNER BOX ASSEMBLY

B3321101-C .................................. FULL VAT BURNER BOX INSULATION

KIT

2 ...................................................... PP11064 ......................................... HI LIMIT SWITCH

3 ...................................................... A8027301 ...................................... IGNITOR MOUNTING BRACKET

4 ...................................................... B8022301-C .................................. BURNER (DOMESTIC)

B8027001-C .................................. BURNER (CE GERMANY)(CE LP)

5 ...................................................... PP11131 ......................................... IGNITOR (DOMESTIC)

PP11193......................................... IGNITOR (CE)

6 ...................................................... PP11193 ......................................... FLAME SENSOR (CE)

7 ...................................................... CALL SERVICE AGENT FOR # BURNER ORIFICE

8 ...................................................... PP10958 ......................................... CE GAS VALVE (NAT)

PP11112 ......................................... CE GAS VALVE (PROPANE)

9 ...................................................... B3316801-C .................................. TEMPERATURE PROBE ASSEMBLY

10 .................................................... B3314801-C .................................. SPLIT VAT BURNER BOX ASSEMBLY LH

B3314802-C .................................. SPLIT VAT BURNER BOX ASSEMBLY RH

B3321201-C .................................. SPLIT VAT BURNER BOX INSULATION

KIT

11 .................................................... B8021602-C .................................. COMBUSTION TUBE (FULL & SPLIT

VAT )

12 .................................................... B3316601-C .................................. SPLIT VAT TANK

13 .................................................... B3316501-C .................................. FULL VAT TANK

12

Page 39

13

12

1

2

3

4

5

6

7

11

10

8

9

13

Page 40

AG14 FRYER ACCESSORIES

PARTS LISTS

I.D. # PART # PART DESCRIPTION

1 ...................................................... B2100903-C .................................. COVER ASSEMBLY (SPLIT VAT)

2 ...................................................... PP11332 ......................................... FRYER COVER HANDLE

3 ...................................................... P0082400 .......................................

4 ...................................................... PP10693 .........................................

5 ...................................................... A1103202 ....................................... BASKET HANGER

6 ...................................................... A1907504 ...................................... CHANNEL STRIP INTERIOR OF A SPLIT

A1906804 ...................................... CHANNEL STRIP (SPLIT TO SPLIT VAT)

7 ...................................................... A1906804 ...................................... CHANNEL STRIP (SPLIT TO FULL, FULL

TO FULL VAT)

8 ...................................................... P6073148 ....................................... TUBE RACK (FULL VAT)

B4510401-C .................................. TUBE RACK (SPLIT VAT)

9 ...................................................... B2100904-C .................................. COVER ASSEMBLY (FULL VAT)

14

Page 41

15

Loading...

Loading...