Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

Installation and Operation Manual

Covering Model Series

35, 45 and 65

AUSTRALIA

The Australian

Gas Association

L20-290 Rev 3, (5/12)

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance. Do not spray aerosols in the vicinity of this appliance while

it is in operation.

Improper installation, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

TO THE PURCHASER

Post in a prominent location the instructions

to be followed in the event that an operator

smells gas. Obtain this information from

your local gas supplier.

WARNING

There is an open flame inside this appliance.

The unit may get hot enough to set nearby

materials on fire. Keep the area around the

appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas

that is not indicated on the data plate. If you

need to convert the appliance to another

type of fuel, contact your dealer.

WARNING

DO NOT use an open flame to check for

gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots

extinguish, wait 5 minutes before attempting to

relight the pilot to allow any residual gas in

appliance to dissipate.

WARNING

Ensure that the appliance can get enough air to

keep the flame burning correctly. If the flame is

starved for air, it can give off a dangerous carbon

monoxide gas. Carbon monoxide is a clear

odorless gas that can cause suffocation.

WARNING

Adequate means must be provided to limit the

movement of this appliance without depending on

the gas line connection. Single appliances

equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with

WARNING

casters must be stabilized by installing restraining

chains. If a flexible gas line is used, an additional

restraining cable must be connected at all times

when the appliance is in use.

An appliance equipped with casters and a flexible

gas line must be connected to the gas supply with

a quick disconnect device. This quick disconnect

must comply with AS4627. To limit the movement

of the appliance without depending on the

connector or quick disconnect, a restraining cable

must also be installed. The length of the

restraining cable must not exceed 80% of the

length of the flexible gas line.

Installation of this appliance should be done by a

qualified professional. This appliance should be

inspected by a qualified professional on an annual

basis to insure safe and proper operation.

This appliance must be installed in compliance

with AS/NZS 5601 (current revision) or local codes,

as applicable.

The power supply must be disconnected before

servicing or cleaning this appliance.

Do not attempt to move this appliance when the

unit is at operating temperature. Serious personal

injury could result if skin comes in contact with the

hot surfaces.

DO NOT sit or stand on this appliance. Serious

injury could result from falling or contact with hot

shortening/oil.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

L20-290 Rev 3, (5/12)

Page 3

Table of Contents

Section Page

Installation

Assembly and Leveling

Leg and Caster Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Heat Deflector Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Quick Disconnect Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel Supply Line Leak and Pressure Testing . . . . . . . . . . . . . . . . . . . 3

Ventilation and Fire Safety Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Initial Adjustments

Burner Ignition Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pilot Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main Burner System Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Initial Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation

Filling the Tank

Filling the Tank with Liquid Shortening/oil . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Filling the Tank with Solid Shortening/oil . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Instructions

Appliance Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Appliance Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance and Adjustments

Thermostat Calibration

Thermostat Calibration Check (Standard) . . . . . . . . . . . . . . . . . . . . . . . . 9

Thermostat Calibration (Gas and Electric Thermostat Models) . . . . . . . . 9

Weekly Cleaning

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Weekly Boil Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ventilation Hood Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Oil Temperature Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting

Basic Troubleshooting Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Checking your new Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

L20-290 Rev 3 (5/12)

Page 4

INSTALLATION

CHECKING YOUR NEW APPLIANCE

Your new appliance has been carefully packed into one crate. Every effort has been made to ensure that you it

is delivered to you in perfect condition. As you unpack your new appliance, inspect each of the pieces for

damage. If something is damaged, DO NOT sign the bill of lading. Contact the shipper immediately; the shipper

is only responsible for 15 days after delivery. Check the packing list enclosed with your appliance to ensure that

you have received all the parts to the appliance. If you are missing any parts, contact the dealer from whom the

appliance was purchased. As you unpack the appliance and its accessories be careful to keep the weight of the

appliance evenly distributed.

CAUTION

To prevent equipment damage and/or personal injury, do not tilt the appliance onto any

two of its casters or legs, or pull the appliance by the flue vent.

ASSEMBLY

When you receive your appliance it is completely assembled with the possible exception of the legs (or casters)

and heat deflector.

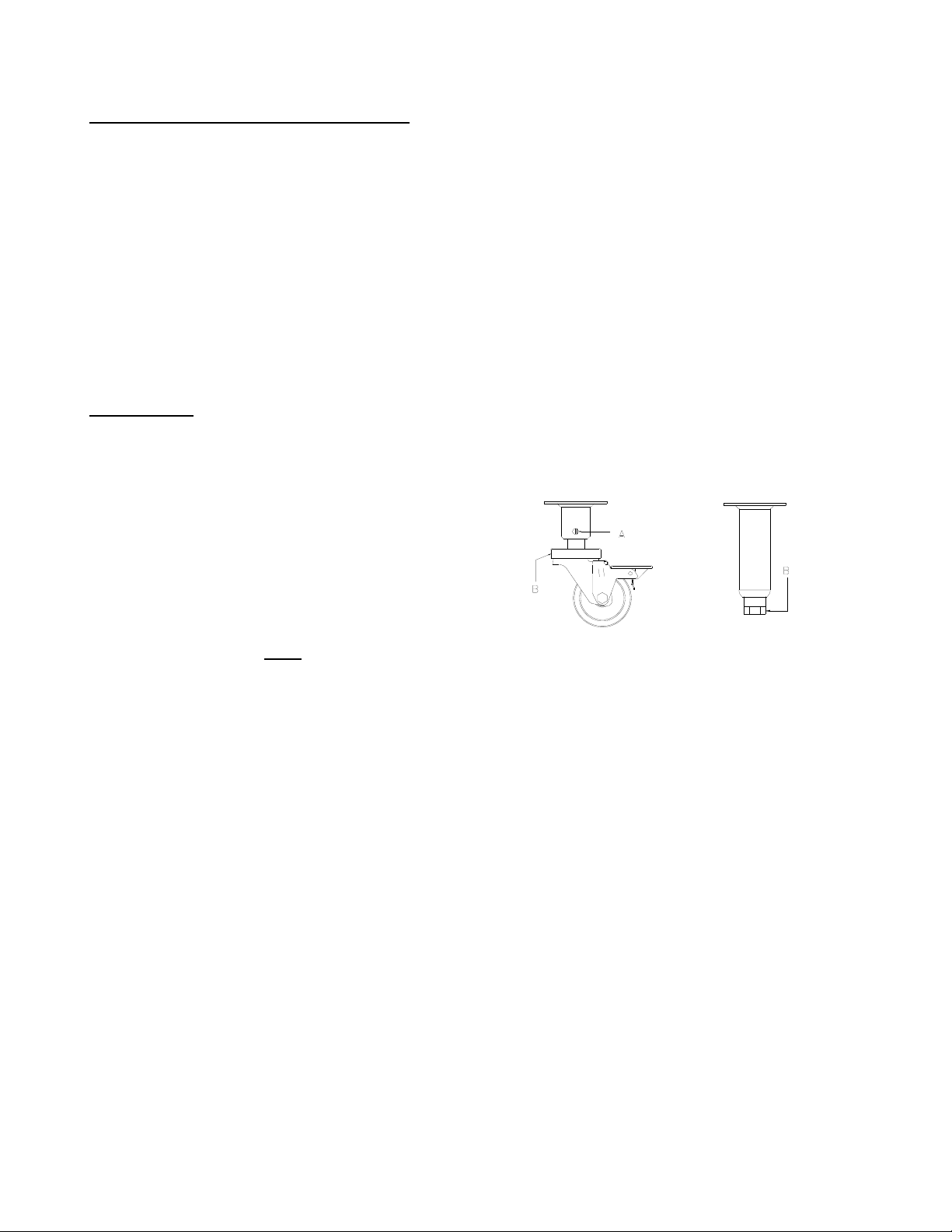

Leg/Caster Installation and Leveling

This appliance must be installed with legs or casters; it

cannot be curb mounted. Curb mounting will seriously inhibit

this appliances ability to effect proper combustion.

WARNING

This appliance must

casters provided by the manufacturer.

Do not install legs or casters, or perform leveling procedure when unit is in operation or

Required tools: 7/16 “ wrench and socket and a large pair of water pump pliers. The legs/casters must be

installed before connecting the appliance to the gas supply. The legs provide the necessary height to meet

sanitation requirements and assure adequate air supply to the combustion system. Use the following procedure.

a. Lay the appliance on its back, being careful not to damage the flue area by pulling on it. Protect

the outside of the appliance with cardboard or a drop cloth when laying it down.

b. Attach each leg/caster with the hex head screws and nuts supplied. Each leg/caster requires

four ¼-20 x 5/8” hex head screws and nuts. Insure that all screws are tight.

c. Mount the screws from the inside of the appliance with the nut on the outside (bottom) of the

appliance. The nuts have lock washers attached to them, therefore it is not necessary to use

lock washers

d. When all four legs/casters are securely mounted, stand the unit up, being careful not to put too

much weight on any one leg. Adjust the height and level the appliance by adjusting the leveling

devices (B) with water pump pliers. On casters, loosen 2 screws (A) before leveling, then

retighten.

be installed with the legs or

WARNING

full of cooking medium. Serious injury could result.

L20-290 Rev 3, (5/12) 1

Page 5

INSTALLATION

Heat Deflector Installation

If the appliance requires a heat deflector, you will find a removable label at the rear top edge of the unit. This

label has instructions for positioning and installation of the heat deflector. Refer to the label and the instructions

below to install the deflector.

a. Remove the two self-drilling screws from the top, back area of the appliance.

b. Position the heat deflector so that the angled portion of the deflector is facing toward the front of

appliance. Secure the heat deflector to the back of the unit using the two previously removed

fasteners.

c. When properly installed the angled section of the heat deflector will extend over the flue

opening to redirect the heat. It SHOULD NOT cover the flue opening. Never allow anything to

block the flue opening; this will cause the appliance to over heat and inhibit proper combustion,

which could produce dangerous gases

INSTALLATION

If you have completed the above steps that are applicable to the appliance you purchased, the appliance is now

ready to be installed. Although it may be possible for you to install and set up your new appliance, it is

STRONGLY recommended that you have this done by qualified professionals. A qualified professional will

ensure that the installation is safe and meets local building and fire codes.

WARNING

DO NOT obstruct the flow of combustion, ventilation or air openings around the appliance.

Adequate clearance around the appliance is necessary for servicing and proper burner

operation. Ensure that you meet the minimum clearance requirements specified in this

manual.

Installation Clearances

The clearances shown below are for combustible and non-combustible installations and will allow for safe and

proper operation of your appliance.

Back 6 in. (15 cm) 0

Sides 6 in. (15 cm) 0

Floor 4 ¾ (11.5 c,) 4 ¾ (11.5 cm)

In addition to the above clearances there must also be at least 28 inches (71 cm) of aisle space in front of the

appliance.

Combustible

Construction

Gas Connection

Your appliance will give you peak performance when the gas supply line is of sufficient size to provide the

correct gas flow. The gas line must be installed to meet the in accordance with AS/NZS 5601 or local codes, as

applicable. Gas line sizing requirements can be determined by a qualified installation professional, your local

gas company or by the Technical Regulator. The gas line needs to be large enough to supply the necessa ry

amount of fuel to all appliances without losing pressure to any appliance. A properly sized and installed gas line

will deliver a minimum supply pressure of 7.0 ± 2.0 inches w.c. (1.75 ± 0.5 kPa) for natural gas and 12.0 ± 2.0

inches (3.0 ± 0.5 kPa) for propane to all appliances connected to the supply line, operating simultaneously a t full

demand. Each appliance is equipped to operate on one certain fuel type. The type of fuel with which the

appliance is intended to operate is stamped on the data plate, which is attached to the inside of the door.

NonCombustible

Construction

2 L20-290 Rev 3, (5/12))

Page 6

INSTALLATION

WARNING

NEVER supply the appliance with a gas other than the one that is indicated on the data

plate. Using the incorrect gas type will cause improper operation and could result in

serious injury or death. If you need to convert the appliance to another type of fuel,

contact the dealer you purchased it from.

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the appliance connection.

This may not allow proper gas flow for optimum burner operation, resulting in poor

performance and improper operation.

Quick Disconnect Gas Connection

Gas appliances equipped with casters must be installed in compliance with the applicable clauses of The

Standard for Gas Installations, AS/NZS 5601(latest edition). This connection should include a quick disconnect

device that complies with the Standard for Limited Flexibility Connectors, AS4631 (latest edition). When

installing a quick disconnect you must also install adequate means for limiting the movement of the appliance

without depending on the connector and quick-disconnect device or its associated piping to limit the movement

of the appliance. The restraining device should be attached to the appliance on the back panel.

Fuel Supply Line Leak and Pressure Testing

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be tested at a

pressure greater than ½ PSIG (3.45 kPa), insure that that appliance is disconnected from the fuel line. If the fuel

line is to be tested at a pressure equal to or less than ½ PSIG (3.45 kPa), the appliance can be connected

during the test, but the unit’s gas valve must be shut. Test all gas line connections for leaks with a solution of

soap and water when pressure is applied.

Ventilation and Fire Safety Systems

Your new appliance must have proper ventilation to function safely and properly. Exhaust gas temperatures can

reach as high as 1100 °F (593 °C). Therefore, it is very important to install a fire safety system. Your ventilation

system should be designed to allow for easy cleaning. Frequent cleaning and proper maintenance of the

ventilation system and the appliance will reduce the chances of fire.

It is essential that the appliance be operated only when adequate ventilation is provided. Your ventilation hood

should be properly maintained. A qualified installation professional should ensure that the hood is operating

properly in conjunction with the appliance. Inadequate ventilation may not properly evacuate appliance all

emissions. Excessive or unbalanced ventilation may cause drafts, which could interfere with proper operation of

the pilot and burners. Leave at least 18 inches (45.7 cm) of open space between the flue of the appliance and

the intake of the exhaust hood.

CAUTION

Ensure that your ventilation system does not cause a down draft at the appliance’s flue

opening. A down draft will not allow the appliance to exhaust properly and will cause

overheating, which may cause permanent damage. NEVER point a fan or similar device at

or toward the flue opening of this appliance. Damage caused by down drafts will not be

covered by the warranty. NEVER allow anything to obstruct the flow of combustibles or

ventilation exiting the appliance. NEVER place anything on top of the flue area, or block

the flue in any way.

NOTICE

NEVER connect the ventilation blower or hood directly to the flue of this appliance. The

resulting increased flow of air through the combustion system will cause improper

operation, poor temperature recovery, poor ignition and could extinguish the pilot.

L20-290 Rev 3, (5/12) 3

Page 7

INSTALLATION

INITIAL ADJUSTMENTS

It is necessary to test the operation of your appliance after your appliance has been properly installed as

described in the installation section of this manual. It will most likely need to be adjusted to ensure that it will

perform as designed. These adjustments must be performed by a qualified person. To perform these

adjustments the following tools will be needed:

• Manometer • Digital Thermometer (Temperature Probe)

• DC Millivolt Meter • DC Milliameter

Before you begin filling and adjusting the appliance, perform the

following visual checks:

a. After the appliance is in its permanent location,

check the levelness. Any additional leveling that is

necessary can be performed as previously

described.

b. Check the temperature probe and high limit bulb (in

the tank) to ensure that the mounting screws are

tight.

c. Review the installation portion of this manual and

ensure that all steps have been followed and

executed properly.

Burner Ignition Systems

Before proceeding any further, fill the tank with WATER. Water is used for the installation

adjustments because the temperature will never exceed 212°F (100°C), thereby allowing

plenty of adjustment time. Never let the water level go below the MIN LEVEL mark stamped

During operation there is an open flame inside this appliance. The unit may get hot

enough to set near by materials on fire. Keep the area around the appliance free from

Lighting Instructions

For manual pilots

If pilot extinguishes, wait 5 minutes before attempting to relight the pilot to allow any built

a. Open gas supply valves to the appliance.

b. Turn the thermostat control knob counterclockwise to the OFF po sition.

c. Turn the gas valve knob to the PILOT position and push in on the knob.

, refer to the following instructions.

Hold the knob in for approximately one minute to purge the air out of the

line. Hold a flame to the pilot until the pilot ignites; this may take a little

while the first time you light the pilot because of the air in the lines. Once

lit, hold the knob in for approximately one minute and then release.

CAUTION

on the tank.

WARNING

combustibles.

WARNING

up gas to dissipate.

Ensure that these

parts are not loose

6 L20-290 Rev 3 (5/12)

Page 8

INSTALLATION

Lighting Instructions (continued)

d. If the pilot goes out, wait 5 minutes and repeat step C. If after three tries

the pilot will not remain lit, refer to the operator troubleshooting section of

this manual.

e. Once a pilot flame has been established, turn the gas valve knob

counterclockwise to the ON position.

f. Set the thermostat control knob to the desired temperature setting.

The main burners will ignite and be controlled by the thermostat.

Pilot Flame Adjustment

For manual pilots

NOTE: This procedure requires a DC millivolt meter set to a scale of 0-1000 mV.

Using test leads with sharp probes will help in taking the required readings.

a. Locate the thermopile wires coming from the thermostat/limit

b. Using the positive (+) test probe, connect the probe to the high

c. Connect the negative (-) test probe to the pilot tubing.

d. Remove the cap screw located below the pilot tubing on the

e. While monitoring the DC millivolt meter, rotate the pilot flame adjustment screw in the

Note: Allow 3 to 5 minutes between flame adjustments to allow the reading to stabilize.

f. Replace the cap screw.

Main Burner System Adjustment

For the main burners to operate the gas supply valve must be open and the thermostat must be turned

on. For models with electric controls, the main power switch must be on. The main burners receive gas

from the main gas supply through the thermostatically controlled valve. When the thermostat is turned up

the gas control valve opens.

The main burner pressure must be adjusted to deliver optimum flame. Refer to the following procedure to

adjust the main burners.

, refer to the following instructions. Perform this procedure once the pilot is lit.

REGULATOR ADJUSTOR

(UNDER CAP SCREW)

box going to the gas valve. The wire size decreases near the

gas valve connections.

limit wire terminal. On UFM systems, pierce the high limit wire

insulation, with the tip of the test lead probe, at the gas valve

safety magnet connection.

PILOT ADJUSTOR

gas valve. The pilot flame adjustment screw is recessed

behind this. Turning the pilot flame adjustment screw clockwise

lowers the pilot flame and millivolt output. Turning the pilot flame

adjustment screw counter- clockwise increases the pilot flame size

and millivolt output.

direction necessary to achieve a reading of 25 ± 5 mV.

(UNDER CAP SCREW)

L20-290 Rev 3, (5/12) 5

Page 9

INSTALLATION

CAUTION

Before proceeding any further, fill the tank with WATER. Water is used for the installation

adjustments because the temperature will never exceed 212°F (100°C), thereby allowing plenty of

adjustment time. Never let the water level go below the MIN LEVEL mark stamped on the tank.

a. Ensure that the main gas valve is shut off; remove the manifold pressure tap plug and

connect an accurate pressure gauge having a range from 0 to 16 “ w.c. in 0.1”

increments (0 to 4 kPa in .025 kPa increments) or manometer with similar resolution.

b. Turn on this and all appliances connected to the

gas supply line and light their main burners. The

pressure reading of the installed pressure gauge

should not drop from the required installation

pressure. Any loss of pressure indicates

inadequate supply line installation, which will

cause poor performance of all appliances during

peak usage.

c. The installed pressure gauge should be the

same, ±0.1” w.c. (.025 kPa), as that marked on

the data plate on the inside door of the appliance.

If the pressure is correct, go to step e, if it is not,

adjust the pressure as outlined in step d.

d. To adjust the pressure, remove the regulator

adjustment screw cap and, with a flat head screwdriver, adjust the regulator screw until the

proper burner pressure is reached. Turning the screw clockwise will increase the burn er

pressure. Turning the screw counterclockwise will decrease the burner pressure.

e. When the pressure is correct, replace the regulator adjustment screw cover.

f. Turn off the ALL appliances, shut the main gas valve to your appliance and remove the

pressure gauge. Apply pipe joint compound to the manifold pressure tap plug and reinstall it.

Initial Cleaning

When your appliance is shipped, many of its parts are covered with a thin coat of shortening/oil for protecti on.

Before the appliance is ready for cooking it must be cleaned. This will remove the shortening/oil coating and any

foreign matter that may have accumulated during storage and shipment. Refer to the following proced ure to

clean the appliance.

a. Fill the tank with water. Light the pilot, turn the appliance on and set the thermostat to

200°F (93°C).

b. Allow the appliance to hear for 15 minutes. Add cleaner to the water, stirring with the cleaning

brush to ensure that the cleaner dissolves thoroughly.

CAUTION

DO NOT leave the appliance unattended during cleaning. Never let the water level go below the

“Min Level” mark stamped on the tank.

c. Using the cleaning brush, scrub the inside of the tank to remove the protective coating.

d. When cleaning is complete turn the appliance off and drain the water into a container suitable

for hot water and dispose of it.

MAIN BURNER

MAIN BURNER ORIFICE

AIR COLLAR

SET SCREW

BURNER FITTING

GAS PRESSURE

TEST PLUG

6 L20-290 Rev 3 (5/12)

Page 10

OPERATION

WARNING

Wear protective gloves and clothing when cleaning and draining the appliance and when

disposing of water. The water is extremely hot and can cause severe injuries.

e. When the tank has cooled, rinse thoroughly with cool water. Continue to rinse the tank

until the cleaner has been completely and thoroughly rinsed from the tank.

f. Using a clean dry cloth, wipe out all of the water. Be very thorough when removing the

water, as any residual water will cause hot shortening/oil to splatter out of the appliance.

NOTICE

Mild steel tanks must be wiped down/coated thoroughly with shortening/oil to keep the tank

from rusting

FILLING THE TANK

Both liquid and solid shortening/oil can be used in this appliance, but liquid is preferred. If solid

shortening/oil is used it is recommended that you melt the shortening/oil before adding it to the appliance.

You can melt solid shortening/oil in the appliance, but you must be very careful not to scorch the

shortening/oil.

Filling the tank with liquid shortening/oil

To fill the tank with liquid shortening/oil refer to the following procedure.

a. Ensure that the drain valve is completely closed and that there

is no residual moisture in the tank.

b. Fill the tank with shortening/oil. You may fill the tank to the “MIN

LEVEL” mark or slightly below the nominal level mark: the

shortening/oil will expand slightly when it heats up, raising the

level slightly.

Filling the tank with solid shortening/oil

To fill the tank with solid shortening/oil refer to the following procedure.

WARNING

NEVER melt blocks of solid shortening/oil on top of the burner

tubes. This will cause a fire and could result in personal injury.

a. Remove the screen covering the tubes (tube screen).

b. Cut the solid shortening/oil into cubes no larger than one inch

(2.54 cm). ALWAYS pack the shortening/oil below, between, and

on top of the burner tubes. DO NOT leave any large air gaps. Use

care when packing the solid shortening/oil into the tank.

DO NOT bend or break the temperature or high limit sensor

probes.

If these are damaged the appliance will not function properly.

c. Once the appliance tank is firmly packed with shortening/oil, the

shortening/oil must be melted. Melt the shortening/oil by cycling

the main burners on for 4 seconds and off for 30 seconds

repeatedly, using the thermostat knob.

L20-290 Rev 3, (5/12) 7

Page 11

OPERATION

OPERATING INSTRUCTIONS

To ensure the quality of the food you cook in this appliance, follow the preparation instructions from the

food manufacturer. Using the best shortening/oil makes the best fried foods. The best shortening/oil will

last longer than lower grade shortening/oil and save you money. When not in use, the shortening/oil

should be cooled and covered to prevent contamination.

WARNING

This appliance has been installed using restraining devices to prevent accidental tipping or

movement. DO NOT attempt to move the appliance when it is in use or has hot liquid in it.

Splashing hot liquids can cause severe burns.

WARNING

Water and shortening/oil DO NOT mix. Keep liquids away from hot shortening/oil.

Dropping liquid frozen foods into the hot shortening/oil will cause violent boiling.

Appliance Start-Up

WARNING

DO NOT start the appliance without filling the tank with shortening/oil first!

To start up the appliance refer to the following instructions.

a. Light the pilot as previously described in this manual

b. Turn the temperature control knob (thermostat) to the desired temperature setting. This

knob is located behind the front doors or on the front control panel.

c. The main burners will light and raise the shortening/oil temperature to the desired setting.

Appliance Shutdown

There are two shutdown modes of appliance operation: STANDBY and COMPLETE. The standby mode

removes the ability of the appliances main burners to operate. Complete shutdown turns off the gas

supply to the appliance.

STANDBY Turn the thermostat to the OFF position. Turn the Pilot knob clockwise to the PILOT

position. The cooker is now in Standby and can remain this way for only brief periods of

time. NEVER leave the appliance in standby mode for prolonged periods or overnight.

COMPLETE Turn the thermostat to the OFF position. Depress and turn the Pilot knob counter clock-

wise to the OFF position. The appliance is now completely shut down and can be

cleaned and filtered if desired.

Power Failure

CAUTION

DO NOT attempt to operate this appliance during a power outage.

Wait five minutes after the power is restored before attempting to restart the appliance. This will allow time for

any gas that may have accumulated in the burner or tubes to dissipate. To restart the appliance, follow the

appliance start up procedure in this manual.

8 L20-290 Rev 3 (5/12)

Page 12

MAINTENANCE AND ADJUSTMENTS

DAILY CLEANING

Your appliance should be cleaned every day to maintain peak performance, proper sanitation and appearance.

Perform the following procedures daily.

a. Wipe up any shortening/oil that spills onto the exterior of the appliance. This should be done with

a clean soft cloth while the shortening/oil is still warm.

b. Use warm water with a mild detergent to clean surfaces. Be careful not to get water into the

shortening/oil and be sure to completely remove any detergent from the fry tank. Use a non-

abrasive scouring powder or pad to clean stains if necessary.

NOTICE

Maintenance and repairs should be performed by qualified personnel. If you are

unsure, contact the factory, factory representative to locate the nearest qualified

Service Company.

Thermostat Calibration

Thermostat Calibration Check (Standard)

Thermostat calibration requires that the temperature of the appliance be raised above

boiling. If you have water in the tank you will need to drain it, dry it and fill it with

To check the calibration of your appliance, refer to the following procedure.

a. Remove the tube screen from the tank.

b. Place the tip of a digital thermometer probe in the shortening/oil approximately one inch

above the temperature sensor.

c. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow

the shortening/oil to come up to temperature. Watch the thermometer closely as the

temperature rises.

d. If the shortening/oil temperature reaches 350°F (167 °C) and the burners do not turn off,

turn the thermostat down. Keep lowering the thermostat setting until the burners go out.

If the burners do not shut off at the LOWEST thermostat setting, the thermostat may be

e. Let the appliance cycle 4 to 6 times before checking the temperature. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

(3 °C) apart, calibrate the thermostat using procedure in this manual.

Thermostat Calibration

For Gas Operated and Electric Thermostats

a. Remove the tube screen from the tank and place the tip of a digital thermometer in the

shortening/oil approximately one inch above the temperature sensor.

b. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow the

shortening/oil to come up to temperature; let the appliance cycle 4-6 times to insure that the

shortening/oil temperature has stabilized. Compare the thermostat setting of 325°F (163 °C) to

the digital thermometer reading.

NOTICE

shortening/oil. Follow the filling instructions in this manual.

CAUTION

defective. Contact your local service company.

refer to the following procedure.

L20-290 Rev 3, (5/12) 9

Page 13

MAINTENANCE AND ADJUSTMENTS

c. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

d. Holding the outside of the shaft so that it DOES NOT MOVE, scrape away the sealing

compound in the center of the shaft with a small flat blade screwdriver.

e. Turn the adjustment screw clockwise to lower the thermostat’s temperature setting or counter-

clockwise to raise it.

NOTE

One-quarter turn of the adjustment screw changes the temperature setting

approximately 24°F (13 °C).

f. Turn the adjustment screw until the burners come on at 325°F (163 °F).

g. Replace the knob and allow the appliance to cycle 4 to 6 times. Check the temperatu re of the

digital thermometer against the thermostat dial setting; if there is greater than a 5°F

(3 °C) difference, repeat the calibration procedure.

Weekly Cleaning

The appliance should be thoroughly cleaned AT LEAST once a week. This should include a thorough wipe down

of the entire appliance with a rag and mild detergent.

WARNING

The power supply must be disconnected before cleaning and servicing this appliance!

WARNING

NEVER spray cleaner into the main burners or pilot. This could act as a magnet for dust and

other debris, causing it to accumulate and inhibit the proper operation of your appliance.

Boil Out Procedure

The appliance should be boiled out AT LEAST once a week to remove food debris and shortening/oil build up.

You will need a container large enough to hold 1 ½ times the shortening/oil in the tank. Refer to the following

procedure for weekly boil out.

WARNING

Completely shut the appliance down when the shortening/oil is being drained and

replaced with water. This will prevent the main burners from coming on during the

draining and filling procedure.

WARNING

At operating temperatures, the shortening/oil in the appliance is VERY HOT and can cause

severe burns. Do not let the hot shortening/oil touch your skin or clothing. ALWAYS wear

insulated, oil proof gloves, protective clothing and eyewear when working on a hot

appliance.

a. Drain the shortening/oil from the appliance and discard or save for reuse. Remove the tube

screen. Close the drain valve and fill the tank with warm water and non-caustic detergent

b. Restart the appliance as described in this manual and set the thermostat to 200°F (93 °C). Bring

the water to a slow boil. DO NOT allow the water to boil excessively as this will cause excessive

foaming and boil over.

c. Allow the appliance to soak for 20 minutes to soften shortening/oil deposits. Use the cleaning

brush to scrub and remove any residue from the tank, tubes and side walls.

d. When finished drain the water and wipe the tank dry with a soft clean cloth.

10 L20-290 Rev 3 (5/12)

Page 14

MAINTENANCE AND ADJUSTMENTS

e. Ensure that the drain valve is closed and replace the tube screen.

f. You may now refill the tank with shortening/oil per the filling instructions in this manual.

Ventilation Hood Maintenance

Proper ventilation hood operation is very important for the correct operation of this appliance and the safety of

personnel. The ventilation hood should be inspected at the time of installation of this appliance to insure that it

will operate properly in conjunction with the appliance. A regular schedule of examination and maintenance, to

ensure operation in accordance with AS 4566 latest edition and/or applicable local codes, must be followed.

OIL TEMPERATURE

Keep the oil temperature in the fryer to a maximum of 190°C. Higher temperatures will cause rapid

breakdown of the oil and give you no faster cooking. At 205°C to 210°C the life of the oil is only one third

of its life at 190°C. In addition, increased decomposition causes the oil to smoke badly even if the

temperature is lowered to 190°C again. High oil temperatures give you no advantage, cost you money

and increase the fire danger.

TEMPERATURA DELL’OLIO

Mantenere la temperatura dell’olio nella friggitrice fino a un massimo di 190°C. Temperature maggiori causano un

rapido degrado dell’olio, senza tuttavia eseguire una cottura più rapida. Da 205°C a 210°C la durata dell’oli o è

inferiore di un terzo rispetto a quella a 190°C. Inoltre, l’accresciuta decomposizione comporta una forte emi s sione di

fumo, anche se la temperatura viene riportata di nuovo a 190°C. Le alte temperature non prevedono vantaggi, sono

antieconomiche e aumentano il rischio d’incendio.

ΘΕΡΜΟΚΡΑΣΙΑ ΛΑΔΙΟΥ

Διατηρείτε τη θερμοκρασία λαδιού στη φριτέζα μέχρι 190 βαθμούς Κελσίου. Υψηλότερες θερμοκρασίες θα

αλλάξουν τη σύνθεση του λαδιού πολύ σύντομα και δεν ψήνετε γρηγορότερα. Η δυναμικότητα του λαδιού

στους 205-210 βαθμούς Κελσίου είναι μόνο το ένα τρίτο (33%) της δυναμικότητάς του στους 190 βαθμούς

Κελσίου. Επιπλέον η αυξημένη αποσύνθεση του λαδιού, σε θερμοκρασίες πάνω από

κάνει το λάδι να καπνίζει άσχημα κι αν ακόμη κατεβάσετε τη θερμοκρασία κατόπιν πάλι στους 190

βαθμούς Κελσίου. Οι υψηλές θερμοκρασίες δε σας παρέχουν κανένα πλεονέκτημα, σας κοστίζει

περισσότερα χρήματα και αυξάνουν τον κίνδυνο πυρκαγιάς.

190 βαθμούς Κελσίου,

L20-290 Rev 3, (5/12) 11

Page 15

TROUBLESHOOTING

p

p

p

Refer to this section to correct common problems that may be encountered during the course of normal

operation. If applicable, a schematic is provided behind the panel containing the electrical components.

Appliance does not

work.

Will the

pilot

light?

YES

Does pilot

stay lit after

pilot knob is

released?

YES

Does pilot go

out when the

temperature

increases?

NO

Do the main

burners

light?

If the main burners are

lighting, but not performing

properly refer to the

INSTALLATION section of

this manual to verify proper

installation.

NO

NO

NO

Is the gas

supply

valve

en?

o

YES

Purge air from

gas line

Is all the

air purged

from the

pilot gas

NO

Purge air from pilot line by

turning pilot knob to the

"PILOT" position and

holding it in for approx. 1

minute.

YES

Is the gas

valve knob in

the "ON"

position?

NO

Turn the gas

valve knob to

the "ON"

position.

NO

YES

Open the gas

valve and light

NO

YES

ilot

Is high

limit

switch

open?

Contact a

qualified service

technician

NO

Is the

thermostat

knob in the

position?

OFF

YES

Turn the

thermostat knob

to a

erature

tem

Reset switch

and light pilot.

Will high

limit switch

reset?

NO

YES

12 L20-290 Rev 3 (5/12)

Page 16

Model 35 45 65

Total Gas Consumption 95 Mj/h 129 Mj/h 145 Mj/h

Burner Pressure Natural Gas 1.0 kPa 0.9 kPa 1.0 kPa

Burner Pressure ULPG 2.50 kPa 2.50 kPa 2.50 kPa

Injector Size: Main Burners 3 of 4 of 5 of

Natural Gas 2.53 mm (#39) 2.58 mm (#38) 2.38 mm (#42)

ULPG 1.59 mm (1/16") 1.59 mm (1/16") 1.51 mm (#53)

Injector Size: Pilot 1 of 1 of 1 of

Natural Gas 0.56 mm (N22) 0.56 mm (N22) 0.56 mm (N22)

ULPG 0.41 mm (LP16) 0.41 mm (LP16) 0.41 mm (LP16)

Minimum Tank Capacity 15.9 kg 19.7 kg 24.9 kg

Cooking Area Length 356 mm 356 mm 457 mm

Cooking Area Width 356 mm 356 mm 457 mm

Cooking Area Depth 70 mm 127 mm 127 mm

Overall Height 1201 mm 1201 mm 1204 mm

Overall Width 384 mm 384 mm 512 mm

Overall Depth 769 mm 769 mm 875 mm

Shipping Weight 73 kg 95 kg 103 kg

In the event of problems with or questions about

your order, please contact the Pitco Frialator

factory at:

(603) 225-6684 World Wide

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

L20-290 R3 (05/12)

In the event of problems with or questions about

your equipment, please contact the Pitco Frialator

Authorized Service and Parts representative

(ASAP) covering your area, or contact Pitco at the

numbers listed to the left.

Loading...

Loading...