Page 1

There's Always Something Cooking!

Installation, Operation, and Maintenance Manual

For Food, Donut, Chicken, and Fish Fryers

Covering Models

20, 24, 26, and 34

R

R

APPR OVE D

R

Page 2

MTS # PF17-01 Pitco Frialator #L20-078 Revision 3 Rev. Date 09/09/96

Page 3

NOTICES

There are three different types of notices that you should be familiar with, a NOTICE, CAUTION,

and WARNING. A NOTICE is a special note used to call attention to a particularly important point.

CAUTION is used to point out a procedure or operation which may cause equipment damage. The

WARNING notice is the most important of the three because it warns of an operation that may cause

personal injury. Please familiarize yourself with your new cooker before operating it and heed the

notices throughout this manual. The WARNINGS are listed below and on the following page for

your review prior to operating the unit.

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this equipment.

TO THE PURCHASER

POST IN A PROMINENT LOCATION INSTRUCTIONS TO

BE FOLLOWED IN THE EVENT THAT AN OPERATOR

SMELLS GAS. OBTAIN THIS INFORMATION FROM YOUR

LOCAL GAS SUPPLIER.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

Page 4

SAFETY SAFETY SAFETY SAFETY SAFETY

WARNING

The fryer may be equipped with an oil proof, electrical supply cord with a

three prong safety plug. This is to protect operators from electrical shock

hazard in the event of an equipment malfunction. DO NOT cut or remove the

grounding (third) prong from this plug.

WARNING

There is an open flame inside the fryer. The unit may get hot enough to set

near by materials on fire. Keep the area around the fryer free from combustibles.

WARNING

NEVER supply the fryer with a gas that is not indicated on the data plate.

Using the incorrect gas type will cause improper operation. If you need to

convert the fryer to another type of fuel, contact your dealer.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

Wait 5 minutes before attempting to relight the pilot to allow for any gas in

the fryer to dissipate.

WARNING

Never melt blocks of shortening on top of the burner tubes. This will cause

a fire, and void your warranty.

WARNING

Water and shortening DO NOT mix. Keep liquids away from hot shortening.

Dropping liquid frozen food into the hot shortening will cause violent boiling.

WARNING

At operating temperature the shortening temperature will be greater than

300°F. Do not attempt to move the appliance when the oil is at operating

temperature. The hot oil WILL cause injury to you when it comes in contact

with your skin.

SAFETY SAFETY SAFETY SAFETY SAFETY

Page 5

SAFETY SAFETY SAFETY SAFETY SAFETY

WARNING

Ensure that the fryer can get enough air to keep the flame burning correctly.

If the flame is starved for air it can give of a dangerous carbon monoxide gas.

Carbon Monoxide is a clear odorless gas that can cause suffocation.

WARNING

If your appliance operates on line voltage, the power supply must be

disconnected before servicing or cleaning the appliance.

WARNING

The fryer must be properly restrained to prevent movement or tipping. This

restraint must prevent the fryer from movements that would splash hot liquids

on personnel. This restraint may be by any means (alcove installation,

adequate ties, or battery installation).

SAFETY SAFETY SAFETY SAFETY SAFETY

Page 6

Table of Contents

Section Title Page

Safety Notice

Table of Contents ........................................................................................................................ i-ii

List of Tables and Figures .............................................................................................................. iii

Chapter 1: General Information and Installation .................................................................. 1-1

1.1 WHICH FRYER DO I HAVE? ................................................................................ 1-1

1.2 CHECKING YOUR NEW FRYER ......................................................................... 1-1

1.3 ASSEMBLY AND LEVELING .............................................................................. 1-2

1.3.1 Leg Installation and Adjustment ........................................................................... 1-2

1.3.2 Heat Deflector Installation .................................................................................... 1-2

1.3.3 Splashback Installation ......................................................................................... 1-3

1.3.4 Flue Installation .................................................................................................... 1-3

1.3.5 Drainboard Installation ......................................................................................... 1-3

1.4 INSTALLATION ..................................................................................................... 1-3

1.4.1 Installation Clearances .......................................................................................... 1-4

1.4.2 Gas Connection .................................................................................................... 1-4

1.4.2.1 Fuel Types ..................................................................................................... 1-4

1.4.2.2 Fuel Supply Line Leak and Pressure Testing ................................................. 1-5

1.4.2.3 Gas Line Connection ..................................................................................... 1-5

1.4.3 Electrical Connection ........................................................................................... 1-5

1.4.4 Ventilation and Fire Safety Systems ..................................................................... 1-6

1.5 INITIAL ADJUSTMENTS ...................................................................................... 1-7

1.5.1 Visual Checks ...................................................................................................... 1-7

1.5.2 Burner Ignition Systems ....................................................................................... 1-8

1.5.2.1 Lighting Instructions for Manual Pilot Lights ................................................. 1-8

1.5.2.1.1 Pilot Flame Adjustment ............................................................................ 1-9

1.5.2.2 Electronic Ignition Pilot Systems .................................................................. 1-10

1.5.2.2.1 Electronic Ignition Pilot Flame Adjustment ............................................ 1-10

1.5.3 Main Burner System .......................................................................................... 1-11

1.5.3.1 Gas Line Requirements ................................................................................ 1-12

1.5.3.2 Burner Adjustment ....................................................................................... 1-12

1.5.4 Initial Cleaning ................................................................................................... 1-13

1.5.5 Thermostat Calibration Check (Standard) .......................................................... 1-14

1.5.6 Thermostat Calibration ....................................................................................... 1-15

1.5.7 Thermostat Calibration (Solid State) .................................................................. 1-15

i

Page 7

Table of Contents (Continued)

Section Title Page

Chapter 2: Operating Instructions .......................................................................................... 2-1

2.1 FILLING THE FRYER ............................................................................................ 2-1

2.1.1 Filling the Fryer With Liquid Shortening ............................................................. 2-1

2.1.2 Filling the Fryer With Solid Shortening ............................................................... 2-1

2.2 OPERATING INSTRUCTIONS ............................................................................. 2-2

2.2.1 Fryer Start-Up ...................................................................................................... 2-2

2.2.2 Fryer Shutdown ................................................................................................... 2-2

2.2.3 Power Failure ....................................................................................................... 2-3

2.3 DAILY CLEANING ................................................................................................ 2-3

CHAPTER 3: Owner Maintenance and Adjustments .......................................................... 3-1

3.1 WEEKLY FRYER CLEANING (BOIL OUT) ....................................................... 3-1

3.2 FRYER TROUBLESHOOTING ............................................................................. 3-3

ii

Page 8

List of Tables and Figures

Table Title Page

1-1 Ventilation and Fire Safety References ...................................................................... 1-6

Figure Title Page

1-1 Pilot Assembly, Flame Adjustment ............................................................................ 1-9

1-2 Main Burner Conditions ........................................................................................... 1-11

1-3 Typical Gas Valve Showing Location of Pressure Regulator and Pilot Adjusters ... 1-12

1-4 Air Collar ............................................................................................................... 1-13

iii

Page 9

iv

Page 10

Chapter 1: General Information and Installation

Congratulations on the purchase of your new Pitco Frialator universal fryer. This unit will give you

many years of reliable service if you follow the simple operation and maintenance procedures in this

manual. Contained in this manual are the general installation, operation, and maintenance

procedures for the universal fryer Models 20, 24, 26 & 34.

1.1 WHICH FRYER DO I HAVE?

There are many models and options available for the gas fryer, each with its own model number. To

find out which model you have, look inside the door at the equipment identification plate. This plate

has a lot of useful information. The model number identifies which fryer and what features you have.

A brief description of each model and its features in Table 1-1.

Table 1-1 Fryer Model Information

Model

Number

20 These large capacity fryers are designed to provide

large amounts of fried foods, fish, chicken, etc.

These fryers give top quality batch after batch

because they incorporate exclusive features that

eliminate product damage or sogginess. Each

model can be equipped with a varity of options

24 Frying Area: 24" X 24"

26 Frying Area: 18" X 26"

Description Features

Frying Area: 20" X 20"

Oil Capacity: 100 Lbs

48.8 Liters

Gas Consumption:

60,000 BTU

15,120 KCal

Oil Capacity: 150 Lbs

73.4 Liters

Gas Consumption:

120,000 BTU

30,240 KCal

Oil Capacity: 120 Lbs

58.7 Liters

Gas Consumption:

80,000 BTU

20,160 KCal

34 Frying Area:24" X 34"

Oil Capacity: 210 Lbs

102.6 Liters

Gas Consumption:

110,000 BTU

27,720 KCal

1-1

Page 11

1.2 CHECKING YOUR NEW FRYER

Your new fryer has been carefully packed into a crate. Every effort has been made to ensure that your

fryer will be delivered to you in perfect condition. As you unpack your new fryer, inspect each of

the pieces for damage. If something is damaged, DO NOT sign the bill of lading. Contact the shipper

immediately, because the shipper is only responsible for 15 days after delivery. Check the packing

list enclosed with your fryer to ensure that you have received all of the parts to the fryer. If you are

missing any parts, contact the dealer from whom the fryer was purchased. As you unpack the fryer

and it's accessories be careful to keep the weight of the fryer evenly distributed.

Flue Vents

CAUTION

To prevent equipment damage, don't tilt the fryer onto

any two of it's legs or pull the unit by the flue vents.

XX

Locate your Pitco Frialator warranty and fill in the serial number of the fryer and the date received.

You will find the serial number on the plate inside the door. Put your warranty sheet in a safe place

for future reference. DO NOT return the sheet to Pitco Frialator.

1.3 ASSEMBLY AND LEVELING

When you receive your fryer it is completely assembled with the exception of the legs, flue,

splashback, and the heat shield. If the unit comes with a drainboard, it will need to be assembled.

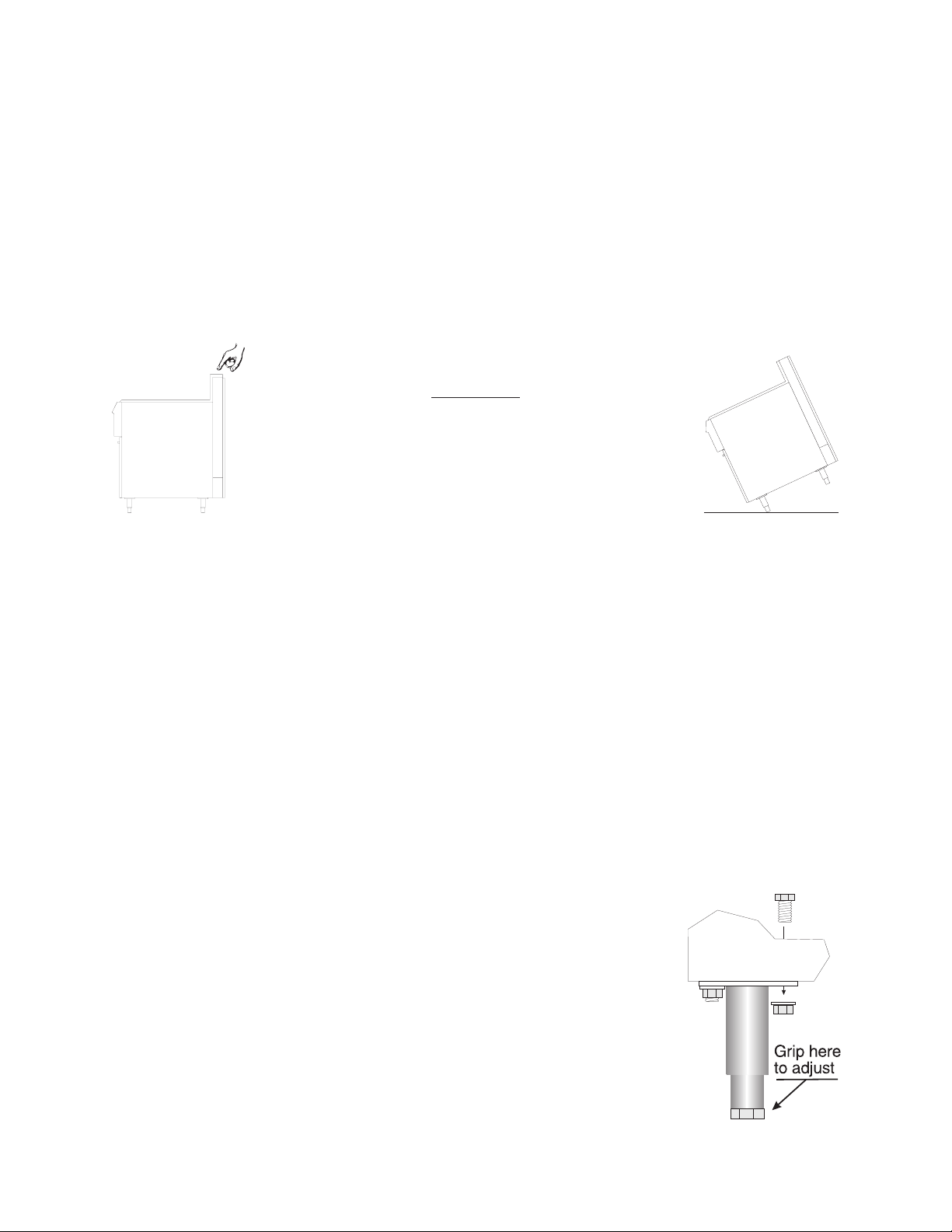

1.3.1 Leg Installation and Adjustment

Installing the legs and leveling the fryer is done with a 7/16" wrench, socket, and a large pair of water

pump pliers. The legs must be installed before connecting the unit to the gas supply. The legs provide

the necessary height to meet sanitation requirements and assure adequate air supply to the burner.

Attach the legs by performing the following procedure.

a. Lay the fryer on its back being careful not to damage the flue by

pulling on it. Protect the outside of the fryer with cardboard or a

drop cloth when laying it down.

b. Attach each leg with the hex head cap screws supplied with the

fryer. Each leg requires four 1/4-20 x 5/8" cap screws.

c. Mount the screws from the inside of the fryer with the nut on the

outside of the cooker. The nuts have lock washers attached to

them, therefore it is not necessary to use lock washers.

1-2

Page 12

d. When all four legs are mounted, stand the unit up being careful not to put too much weight

on any one leg. Adjust the height and level the fryer by adjusting the leveling devices on

the leg with the water pump pliers.

1.3.2 Heat Deflector Installation

If the fryer requires a heat deflector, you will find a removable label at the rear top edge of the unit.

This label has instructions for positioning and installation of the heat deflector. Refer to the label and

the instructions below to install the deflector.

a. Remove the two self-drilling screws from the top, back area of the cooker.

b. Position the heat deflector so that the angled portion of the deflector is facing toward the

front of the fryer. Secure the heat deflector to the back of the unit using the sheet metal

screws previously removed.

WARNING

DO NOT obstruct the flow of combustion/ventilation or air openings around

the fryer. Adequate clearance around the fryer is necessary for servicing and

proper burner operation. Ensure that you meet the minimum clearances

specified in the installation instructions.

c. When properly installed the angled section of the heat deflector will extend over the flue

opening to redirect the heat. It SHOULD NOT cover the flue opening. Nothing should

block the flue opening as this will cause the fryer to overheat and produce dangerous

gases.

1.3.3 Splashback Installation

a. Lift the splashback assembly and place over the opening at the back of the tank. Make

sure the front of the splashback faces forward.

b. Using the four supplied countersink screws, attach the splashback to the cabinet sides.

1.3.4 Flue Installation

Insert the flue through the hole in the top of the splashback. Make sure it rests on the flue opening

at the back of the tank.

1.3.5 Drainboard Installation

While the drainboard is being held in place, slide the pivot rod through the holes in the bottom end

of the drainboard. The end of the rod should locate in the hole in the backsplash. The front end is

attached to the top of the tank using a bolt and washer.

1-3

Page 13

1.4 INSTALLATION

WARNING

The fryer must be properly restrained to prevent movement or tipping. This

restraint must prevent the fryer from movements that would splash hot liquids

on personnel. This restraint may be by any means (alcove installation,

adequate ties, or battery installation).

Although it is possible for you to install and set up your new fryer, it is STRONGLY recommended

that you have it done by qualified professionals. The professionals that install your new fryer will

know the local building codes and ensure that your installation is safe.

1.4.1 Installation Clearances

The fryer needs clearance around it for proper operation. Adequate clearances allow for servicing

and proper burner operation. The clearances shown below are for cooker installation in combustible

and non-combustible construction.

Combustible Non-Combustible

Construction Construction

Back 6" 0"

Sides 6" 0"

Floor - Combustible 4-3/4" 4-3/4"

In addition to the clearances required for proper fryer operation, there must be at least 28 inches of

isle space in front of the fryer.

1.4.2 Gas Connection

Your fryer will give you peak performance when the gas supply line is of sufficient size to provide

the correct gas flow. The fryer must be installed to meet the local building codes or National Fuel

Gas Code ANSI Z223.1 Latest Edition. In Canada, install the fryer in accordance with CAN/CGAB149.1 or .2 and local codes. Gas line sizing requirements can be determined by your local gas

company by referring to National Fuel Gas Code, Appendix C, Table C-4 (natural gas) and Table C16 (propane). The gas line needs to be large enough to supply the necessary amount of fuel to all

appliances without losing pressure to any appliance. Other factors that are used to determine the

piping requirements are BTU requirements of the appliances being connected and the length of pipe

between the meter and the appliances.

WARNING

NEVER supply the fryer with a gas that is not indicated on the data plate.

Using the incorrect gas type will cause improper operation. If you need to

convert the fryer to another type of fuel, contact your dealer.

1-4

Page 14

1.4.2.1 Fuel Types - Each fryer is equipped to work with one type of fuel. The type of fuel with

which the appliance is intended to operate is stamped on the data plate attached to the inside of the

door.

WARNING

DO NOT use an open flame to check for gas leaks!

1.4.2.2

before the fryer is used. If the fuel line is going to be tested at a pressure greater than (>)1/2 PSIG

(3.45 kPa), make sure that the fryer is disconnected from the fuel line. If the fuel line is to be tested

at a pressure equal to or less than (

gas valve must be shut. Test all gas line connections for leaks with a solution of soap and water when

pressure is applied.

1.4.2.3 Gas Line Connection - Connect the fryer to the gas supply line with a connector that

complies with the Standard for Connectors for Movable Gas Appliances (ANSI Z21.69 or CAN/

CGA-6.16).

Fuel Supply Line Leak and Pressure Testing - The fuel supply system must be tested

<) 1/2 PSIG (3.45 kPa), the fryer can be connected but the unit's

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the cooker

connection. This may not allow proper gas flow for optimum burner

operation, resulting in poor cooker performance. NEVER supply the cooker

with any fuel other than the type indicated on the data plate. Using the

incorrect gas type will cause improper operation.

1-5

Page 15

1.4.3 Electrical Connection

The electrical service used by the fryer must comply with local codes. If there are no local codes that

apply, refer to the National Electrical Code (NEC) to install the service. In Canada refer to CSA

Standard C22.1 Canadian Electrical Code Part 1 & 2, and local codes. Wiring diagrams are provided

inside the fryer control box. The power requirements for the fryer are shown below.

North America International

Input Voltage 120 VAC, 60Hz 220 (or 240) VAC, 50Hz

Current per fryer 0.5 Amps 0.5 Amps

WARNING

The fryer is equipped with an oil proof, electrical supply cord with a three

prong safety plug. This is to protect operators from electrical shock hazard

in the event of an equipment malfunction. DO NOT cut or remove the

grounding (third) prong from this plug.

If your fryer uses line current (electric power), a supply cord will be furnished

with a three prong (grounding) plug. This plug provides protection against

shock hazards in the event of equipment malfunction. The plug should be

plugged into a properly grounded three prong receptacle.

The fryer has one power supply which supplies power to the fryer controls. The fryer must be

grounded in accordance with local code; if there is not a local code, comply with NEC ANSI/NFPA

No. 70-1990. It is advised that this power supply be plugged into a wall receptacle that is controlled

by the ventilation control. This will prevent the fryer from being operated without the ventilator on.

1.4.4 Ventilation and Fire Safety Systems

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas

temperatures can reach as high as 1200°F. Therefore, it is very important to install a fire safety

system. Your ventilation system should be designed to allow for easy cleaning. Frequent cleaning

of the ventilation system and the fryer will reduce the chances of fire. Table 1-2 provides a list of

reference documents that provide guidance on ventilation and fire safety systems. This table is not

necessarily complete. Additional information can be obtained from the American Gas Association,

8501 East Pleasant Valley Road, Cleveland, OH 44131.

1-6

Page 16

Table 1-2 Ventilation and Fire Safety References

Topic

Underwriters Laboratory

Document

National Fuel Gas Code

Document

Grease Extractor ANSI/UL 710-1981 ANSI/NFPA 96-1987

Ventilation Hood ANSI/UL 705-1984 ANSI/NFPA 96-1987

Filter Unit ANSI/UL 586-1985

ANSI/NFPA 96-1987

ANSI/UL 900-1987

Types of Fire Extingushers

and Detection Equipment

CO

2

ANSI/UL 154-1983 ANSI/NFPA 12-1989

Dry Chemical ANSI/UL 299-1984 ANSI/NFPA 17-1985

Water ANSI/UL 626-1984 ANSI/NFPA 13-1989

Foam ANSI/NFPA 11-1988

Sprinklers ANSI/UL 199-1982 ANSI/NFPA 13-1989

ANSI/NFPA 13-1989

Smoke Detectors ANSI/UL 268-1981 ANSI/FPA 72B-1986

Fire Detection Thermostats ANSI/UL 521-1987 ANSI/FPA 72B-1986

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the

burner. Leave at least 18 inches of open space between the fryer's flue vent opening and the intake

of the exhaust hood.

CAUTION

Ensure that your ventilation system does not cause a back draft (down draft)

at the fryer's flue opening. Back drafts will not allow the fryer to exhaust

properly and will cause overheating which may cause permanent damage.

Damage caused by backdrafts will not be covered under equipment warranty.

NEVER allow anything to obstruct the flow of combustibles or ventilation

exiting from the fryer flue. DO NOT put anything on top of the flue area.

NOTICE

NEVER connect the ventilation blower directly to the flue openings. The

direct flow of air will cause poor temperature recovery, poor ignition,

inefficient operation of the fryer, and could extinguish the pilot.

1-7

Page 17

1.5 INITIAL ADJUSTMENTS

After your fryer has been installed as described in section 1.4, it needs to be adjusted to ensure that

it will perform as designed. These adjustments must be performed by a qualified person. To perform

these adjustment the following tools will be needed:

• Manometer (low pressure gauge) • Digital Thermometer (Temperature probe)

• DC Millivolt Meter

1.5.1 Visual Checks

Before you begin filling and adjusting the fryer, perform the following

visual checks:

a. After the fryer is in its permanent location check the level-

ness. Any additional leveling that is necessary can be

performed as described in section 1.3.

b. Check the temperature bulb (high-limit), located in the fryer

tank to ensure that the mounting screws are tight. The figure

shows the probe location. Look down inside the fryer tanks

to see the probes.

Ensure that these parts

are not loose.

1.5.2 Burner Ignition Systems

Before going any further, fill the fryer with WATER. Water is used for the

installation adjustments because the temperature will never exceed 212°F

(100°C) thereby allowing plenty of adjustment time. Never let the water level

go below the MIN LEVEL mark on the rear of the tank.

There is an open flame inside the fryer. The unit may get hot enough to set

near by materials on fire. Keep the area around the fryer free from combustibles.

CAUTION

WARNING

1-8

Page 18

1.5.2.1 Lighting Instructions for Manual Pilot Lights - To light the pilot light refer to the

following instructions.

WARNING

Wait 5 minutes before attempting to relight the pilot to allow for any gas in

the fryer to dissipate.

a. Open the gas supply valves to the fryer.

b. Turn the thermostat control knob counterclockwise to the OFF position.

c. Turn the gas valve knob to the PILOT position and push in on the knob.

ON

OFF

P

I

L

O

T

Hold the knob in for approximately one minute to purge the air out of

the line. Hold a flame to the pilot light until the pilot ignites. This may

take a little while the first time you light the fryer because of air in the

lines. Once lit, hold the knob in for approximately 60 seconds and then

release.

d. If the pilot goes out wait 5 minutes and repeat step c. If after three tries the pilot will not

remain lit, refer to the operator troubleshooting section of this manual.

T

e. Turn the gas valve knob counterclockwise to the ON position.

O

L

I

P

OFF

ON

f. Set the thermostat control knob to the desired temperature setting.

g. The main burner will light and be controlled by the thermostat.

1.5.2.1.1 Pilot Flame Adjustment - The pilot flame should be adjusted to produce the proper

millivolt output from the pilot sensing device. Millivolt output for the thermopile should be between

300 and 500 millivolts. This procedure is only necessary on the manual pilot ignition system. Figure

1-1 shows the pilot assembly with examples of the incorrect and correct pilot size. Example A

illustrates a pilot flame size that is too small to produce sufficient millivolt output. Example B is the

correct size for proper millivolt output.

1-9

Page 19

AB

Figure 1-1 Pilot Assembly, Flame Adjustment

a. This test requires a DC millivolt meter set to a scale of 0-1000mv. Using test leads with

sharp probes will help in taking the required reading.

b. Locate the thermopile wires coming from the thermostat/limit box going to the gas valve.

The wire insulation size decreases near the gas valve connections.

c. Using the positive (+) test probe, connect the probe to High Limit wire terminal. On UFM

systems pierce High Limit wire insulation at the gas valve safety magnet connection.

d. Connect the negative (-) test probe to pilot tubing.

e. Remove the pilot flame adjustment cover.

f. Turning the flame adjusting screw clockwise lowers the flame and the millivolt output.

Turning the screw counterclockwise increases flame size and millivolt output.

g. Rotate the screw in the direction to achieve a reading of 400 ±50 mv.

NOTICE

Allow 3 to 5 minutes between flame adjustments to allow the reading to settle.

h. Replace the pilot flame adjusting screw cover.

1.5.2.2 Electronic Ignition Pilot Systems - There is nothing to manually light on the electronic

ignition systems. Pilot ignition is controlled by the electronic pilot system.

a. Open the gas supply valves to the fryer.

b. Turn the thermostat control knob counterclockwise to the OFF position.

1-10

Page 20

c. Turn the gas valve knob to the ON position.

d. Turn the fryer ON/OFF/TEST switch to the ON position. If the fryer is equipped with

the optional melt cycle, place the switch in the MELT ON position.

e. Turn the thermostat to the desired temperature setting.

f. The main burner will light and be controlled by the thermostat.

g. The POWER ON light will come on and remain on as long as the power switch is in the

ON position. The HEATING light will be lit when the main burners are on.

1.5.2.2.1 Electronic Ignition Pilot Flame Adjustment - Figure 1-3 illustrates the pilot adjusting

screw location

a. This test requires that a DC milliammeter be connected between the flame sensor terminal

and the flame sensor lead. Observe correct polarity, if the meter needle goes below 0

milliamps reverse the leads. The current reading must be 0.15 milliamps or greater.

b. Adjust the current reading to the required level by adjusting the pilot flame. Remove the

pilot flame adjustment cover to expose the adjusting screw.

c. Turning the flame adjusting screw clockwise lowers the flame and current. Turning the

screw counterclockwise increases flame size and current.

d. Rotate the screw in the direction to achieve a reading of 0.15 mA or greater.

NOTICE

Allow 3 to 5 minutes between flame adjustments to allow the reading to settle.

e. Once the pilot flame is set, replace the pilot flame adjusting screw cover and remove the

ammeter.

1-11

Page 21

1.5.3 Main Burner System

For the burners to work the gas supply valve must be open and the main power switch must be on.

The main burner receives gas from the main gas supply through the thermostatically controlled valve.

When the thermostat is turned up the gas control valve opens. If you have a pilot light system, the

pilot will ignite the burners. The electronic ignition system will create a spark to ignite the gas. After

the burner system is operating, perform the burner adjustments in the following procedure. Figure

1-2 illustrates the different conditions possible for the main burner.

The tubes and baffles are

badly carbonized. Check

vent and adjust if necessary.

Check for heat tube or flue

blockage.

INSUFFICIENT FLOW EXCESSIVE FLOW

Have gas company check

incoming gas pressure.

Adjust manifold pressure as

described in 1.5.3.2.

The flame seems to "lift off"

the face of the burner.

To correct adjust main

burner as described in

1.5.3.2.

A soft, steady blue flame

should enter the heat tube

without touching the front

outside rim of the tube.

INSUFFICIENT GAS PRESSURE NORMAL FLOW

Figure 1-2 Main Burner Conditions

1-12

Page 22

1.5.3.1 Gas Line Requirements - A properly installed gas supply system will deliver 7.0 ±2.0"

w.c. natural gas (12.0 ±2.0" w.c. LP) to all appliances connected to the line, operating at full demand.

1.5.3.2

Burner Adjustment - The burners must be adjusted to deliver optimum flame. Adjust the

burner flame using the following procedure.

a. Ensure that the main gas valve is shut off, remove the manifold pressure tap plug and

connect an accurate pressure gauge (range of 0-16" w.c. in 0.1" increments) or

manometer.

IN

Figure 1-3 Typical Gas Valve Showing Location of Pressure Regulator and Pilot Adjusters

b. Turn on all appliances connected to the gas supply line and light their main burners. The

pressure reading of the installed pressure gauge should not drop from the required

installation pressure. Any loss of pressure indicates inadequate supply line installation

which will cause poor performance of all appliances during peak usage.

c. The installed pressure gauge reading should be the same, ±0.1", as that marked on the data

plate inside the door. If the pressure is correct go to step e, if not, adjust the pressure.

d. To adjust the pressure, remove the regulator adjustment screw cover (see Figure 1-3). Use

a flat tip screwdriver to adjust the screw until the proper pressure is reached. Turning the

screw clockwise will increase the pressure, counterclockwise will decrease the pressure.

e. When the pressure is correct, install the regulator adjustment screw cover.

f. To remove the pressure gauge, turn off fryer and shut the main gas valve. Remove the

gauge and install the pressure tap plug.

1-13

Page 23

Figure 1-4 Air Collar

g. Now that the pressure is set for proper operation, set the main burner flame. Unlock the

air collars by loosening the set screw for the collars. Open the main gas valve, (light the

pilot if fryer has manual pilot), and turn thermostat to light the main burners.

h. Adjust the shape and size by raising or lowering the air collars to achieve a soft blue flame

with well defined inner cones.

i. When the flames have been properly adjusted, lock the collars in place with the set screw.

1.5.4 INITIAL CLEANING

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before

the fryer is ready for cooking it must be cleaned. This will remove the oil coating and any foreign

matter that may have accumulated during storage and shipment. Perform the cleaning as described

below.

a. Fill the fryer with water. Turn the fryer on and set the thermostat to 200°F.

b. Allow the fryer to heat for 15 minutes. Add Pitco cleaner, stirring with the fryer cleaning

brush to ensure cleaner has dissolved thoroughly.

NOTICE

Do not leave the fryer unattended during cleaning. Never let the water level

go below the "Min Level" mark on the back of the tank.

1-14

Page 24

c. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

d. When cleaning is complete, turn off the fryer by turning the gas valve knob to the PILOT

position. Drain the water into a container suitable for hot water and dispose of it.

e. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank

until the cleaner has been rinsed, thoroughly from the tank.

f. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water,

because any residual water will cause hot oil to splatter out of the fryer.

CAUTION

Mild steel tanks must be wiped down/coated with oil to keep the tank from

rusting.

g. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to 2.1 for

instructions on adding shortening to the fryer.

1.5.5 Thermostat Calibration Check (Standard)

NOTICE

Thermostat calibration requires that the temperature of the fryer be raised

above boiling. Therefore, you will need to drain the water from the fryer and

fill it with oil. Before removing the water, perform the initial cleaning of the

fryer. Cleaning the fryer now will prevent you from having to drain the oil and

refill with water later.

Filling the fryer with oil is described in 2.1. To perform the calibration check detailed below you will

need a digital thermometer.

a. Place the tip of the thermometer in the shortening approximately 1" above the temperature

sensors.

b. Set the thermostat at 325°F and wait for the temperature reading on the thermometer to

rise. As the temperature rises toward 325°F watch the thermometer closely.

c. If the shortening temperature reaches 350°F and the burners DO NOT turn off, turn the

thermostat down. Keep lowering the thermostat setting until the burners go out.

CAUTION

If the burners do not turn off at the lowest thermostat setting, the thermostat

could be defective. Contact your ASAP representative.

1-15

Page 25

d. Let the fryer cycle 4 to 6 times before checking the temperature. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

apart, calibrate the thermostat using the appropriate calibration procedure in this manual.

1.5.6 Thermostat Calibration

There are two types of thermostats that can be calibrated, a Robertshaw electric and a gas operated

manual mechanical. Both thermostats are calibrated by following the procedures below.

a. Place the tip of the thermometer in the shortening approximately 1" above the temperature

sensors.

b. Set the Thermostat to 325°F and wait for the temperature reading on the thermometer to

rise.

c. Let the fryer cycle 4 to 6 times to ensure that the temperature has stabilized. Compare the

thermometer temperature against the thermostat setting.

d. Remove the thermometer dial by pulling the knob straight out. DO NOT rotate the dial.

e. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw driver

to scrape away the sealing compound from the adjustment screw.

f. Turn the adjustment screw clockwise to lower the temperature setting and counterclock-

wise to raise the temperature. One quarter turn changes the temperature approximately

25°F.

g. Turn the adjustment until the burners turn on at 325°F. Replace the knob and allow the

fryer to cycle 4 to 6 times. Check the temperature of the thermometer against the

thermostat dial, if it is greater than 5°F difference repeat the calibration procedure.

h. When the calibration is correct, remove the thermometer and replace the tube screen.

1.5.7 Thermostat Calibration (Solid State)

The solid state thermostat knob has the temperature settings imprinted in the panel behind the dia.

a. Place the tip of the thermometer in the shortening approximately 1" above the temperature

sensors.

b. Set the Thermostat to 325°F and wait for the temperature reading on the thermometer to

rise.

1-16

Page 26

c. Let the fryer cycle 4 to 6 times to ensure that the temperature has stabilized. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

apart, go to step d. If the values are within 5°F, the thermostat is operating correctly.

d. Loosen the set screw that holds the thermostat knob to its shaft.

e. Rotate the thermostat dial, without moving the shaft, to the temperature indicated on the

thermometer. Tighten the set screw on the thermostat dial to lock the dial in place.

f. Adjust the thermostat to a new setting and allow the fryer to cycle 4 to 6 times at the new

setting. Check the thermometer temperature against the dial setting. If the temperature

is ±5°F of the thermostat dial setting, remove the thermometer and replace the tube screen.

If the temperature is greater than ±5°F away from the dial setting, perform the above

procedure again.

1-17

Page 27

1-18

Page 28

Chapter 2: Operating Instructions

This chapter describes how to operate your fryer to obtain the best performance. Included in this

chapter are filling, operating, and cleaning instructions for gas fryers.

2.1 FILLING THE FRYER

Both liquid and solid shortening can be used in the fryer, but liquid is preferred. If solid shortening

is used, it is recommended that you melt the shortening before adding it to the fryer. You can melt

solid shortening in the fryer, but you must carefully not to scorch the shortening.

2.1.1 Filling the Fryer With Liquid Shortening

a. Make sure the drain valve is completely closed.

b. Fill the fryer with oil to the "Oil Level" line marked on

the back of the tank.

2.1.2 Filling the Fryer With Solid Shortening

WARNING

Solid

Shortening

Solid

Shortening

Never melt blocks of solid shortening on top of the burner

tubes. This will cause a fire, and will void your warranty.

Temp . P rob e

Tube s

a. Make sure the drain valve is completely closed.

b. Remove the screen covering the tubes.

c. Cut the shortening into cubes no larger than 1". ALWAYS

pack the shortening below, between, and on top of the

burner tubes. DO NOT leave any large air gaps. Use care

when packing the solid shortening in the tank. DO NOT

bend or break the temperature sensor probes. If these are

damaged the fryer will not function properly.

o

l

i

O

r

S

h

o

r

t

e

n

Burner Tubes

g

n

i

Temp . Prob e

Tube s

Shortening

Blocks

d. Once the fryer is packed with shortening, the shortening

must be melted. Melt the shortening by cycling the main

burners on for 4 seconds and leaving the burners off for 30

seconds.

2-1

Temp . P rob e

Excessive Air Gaps

Tube s

Page 29

2.2 OPERATING INSTRUCTIONS

To ensure the food always comes out the very best, follow the preparation instructions for the food

you are cooking. Using the best shortening makes the best fried foods. The best shortening will last

longer than lower grade shortening and save you money. When not in use the shortening should be

cooled and covered to prevent contamination.

CAUTION

This fryer has been installed using restraining devices to prevent accidental

tipping or movement. Do not attempt to move the fryer when it has hot liquid

in it. Splashing hot liquids can cause severe burns.

WARNING

Water and shortening DO NOT mix. Keep liquids away from hot shortening.

Dropping liquid frozen food into the hot shortening will cause violent boiling.

2.2.1 Fryer Start-Up

DO NOT START FRYER WITHOUT FILLING WITH OIL!

a. Light the pilot light as described in section 1.5.2.

b. Turn the temperature control knob (thermostat) to the desired temperature setting. This

knob is located behind the front doors or on the front control panel.

c. The main burners will light and raise the temperature of the fryer.

2.2.2 Fryer Shut-Down

There are two shutdown modes of fryer operation, STANDBY and COMPLETE. The standby mode

removes the ability for the fryer's main burners to cycle. Complete shutdown turns off the gas supply

to the fryer. Shut down the fryer by:

ON

OFF

P

I

L

O

T

STANDBY Turn the thermostat to OFF. Turn the gas valve clockwise to the

PILOT position. The cooker is now in Standby and can remain this

way for only brief periods of time. NEVER leave the cooker in

standby overnight.

COMPLETE To completely shut down the cooker, depress and turn the gas valve

counterclockwise to the OFF. The fryer is now completely shut

down and can be cleaned and filtered.

ON

T

OFF

P

I

L

O

2-2

Page 30

2.2.3 Power Failure

NOTICE

No attempts should be made to operate the fryer during power outages.

If your fryer is supplied with AC power and, it is removed from the unit for any reason during

operation, the fryer will shut down. Wait five minutes after power is restored before restarting the

fryer. This will give any gas fumes in the burner time to dissipate. To restart the fryer, follow the

Fryer Start-Up procedures as you normally would.

2.3 DAILY CLEANING

Your fryer should be cleaned every day to maintain peak performance and appearance. Perform the

procedures below every day.

a. Wipe up any shortening that spills onto the exterior of the fryer. This should be done with

a clean soft cloth while the oil is still warm.

b. Use warm water with a mild detergent to clean surfaces. Be careful not to get water in

the shortening and to remove any detergent from the fry tank.

c. Use a non-abrasive scouring powder or pad to clean stains if necessary.

d. Perform the weekly boil out cleaning of your fryer described in section 3.1.

2-3

Page 31

2-4

Page 32

Chapter 3: Owner Maintenance and Adjustments

This chapter provides you with the information and procedures necessary to perform basic fryer

maintenance and adjustments. If after performing maintenance on your fryer it does not perform

properly, contact your authorized service center.

WARNING

The power supply must be disconnected before servicing or cleaning the

appliance.

WARNING

At operating temperature, the shortening in the fryer may be hotter than 375°F

(190°C). This hot, melted shortening can cause severe burns. Do not let the

hot shortening touch your skin or clothing. Always wear insulated oil-proof

gloves when working on hot fryers

3.1 WEEKLY FRYER CLEANING (BOIL OUT)

The fryer should be thoroughly cleaned once a week. This cleaning should include a complete

draining of the fryer and a boil out.

a. You will need a container large enough to hold 1 1/2 times the oil in one tank. This

container must also be able to withstand operating temperature oil.

CAUTION

Completely shut down the fryer when the oil is being replaced by water. This

will prevent the main burners from coming on during the oil draining and

water filling procedure.

b. Drain the oil from the fryer and discard or save for reuse. Remove the tube cover screens.

Close the drain valve and fill the tank with warm water and non-caustic detergent. For

best results use Pitco Fryer Cleaner part number P6071397 (sample packet included with

your new fryer).

c. Restart your fryer as described in 2.3 and set the thermostat to 200°F and bring the water

to a slow boil. DO NOT allow water to boil because excessive foaming will occur.

d. Allow the fryer to soak for 20 minutes to soften shortening deposits. Use fryer brush to

remove any residue from tank, tubes, and side walls. Perform the daily cleaning

procedure described in section 2.7.

3-1

Page 33

e. Wipe the tank dry with soft clean cloth. Close the drain valve and remove the large

container.

f. Replace the tube screens and refer to section 2.1 to refill the fryer.

3-2

Page 34

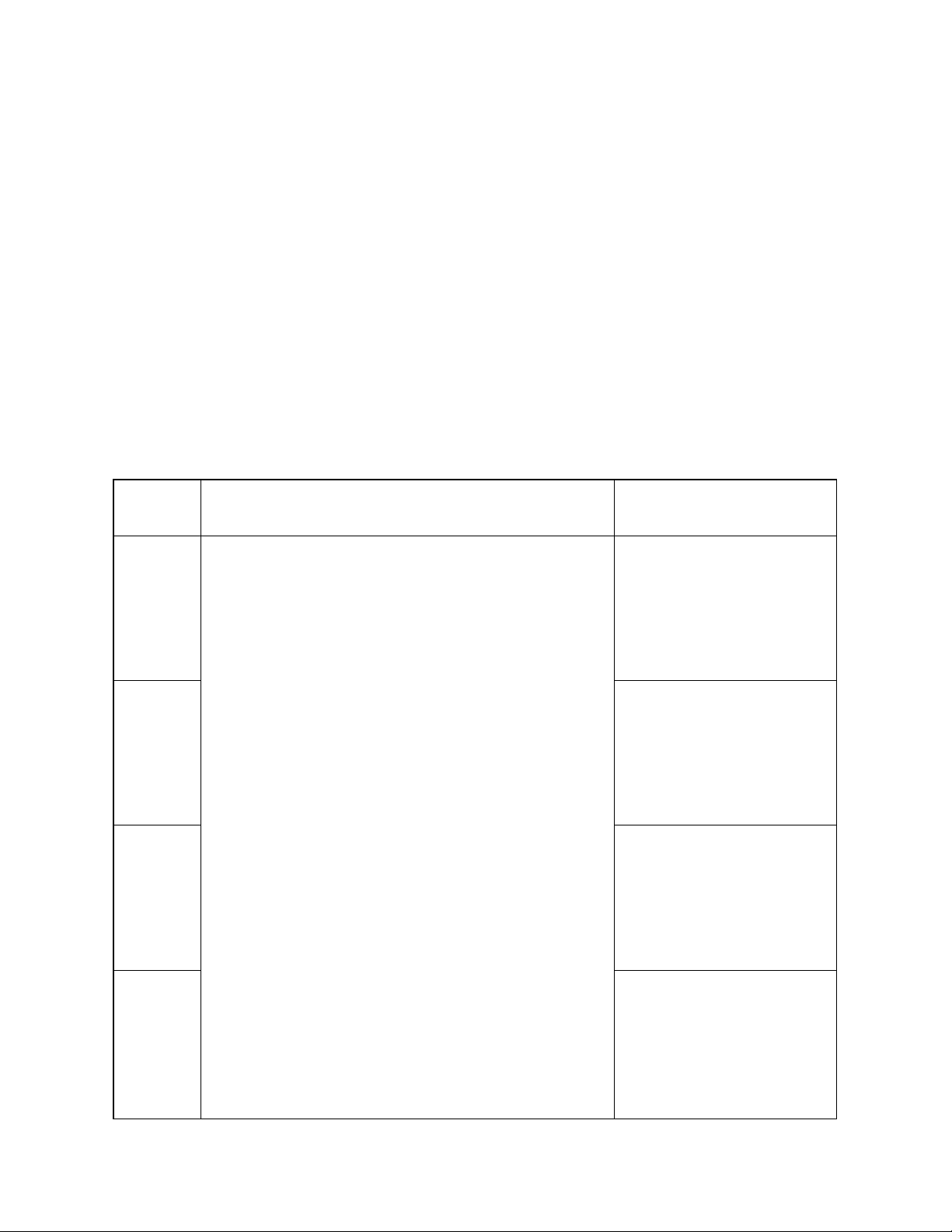

3.2 FRYER TROUBLESHOOTING

Refer to this section to correct common problems that may be encountered in equipment operation.

Fryer does not

work.

Will the

pilot light?

YES

Does pilot

remain lit after

Unitrol Knob is

released?

YES

Does pilot

go out when the

temperature

increases?

NO

NO

YES

Is the gas

supply

valve open?

YES

Purge air from gas

line (1.5.2)

Is all the air

purged from the

gas line?

YES

Purge air from gas line by

placing the Unitrol Valve

knob in PILOT and holding

in for approx. 1 minute.

Contact a Qualified

Technician.

NO

NO

Open the gas valve

and light pilot (1.5.2)

Is High Limit

Switch open?

Contact a

Qualified

Technician.

YES

NO

Will Limit

switch reset?

YES

Reset &

Light Pilot

NO

Contact a

Qualified

Technician.

NO

Does the Main

burner light?

YES

If the main burner is lighting but not

performing properly refer to Chapter

1 to verify proper installation or

contact a qualified technician.

NO

Is the Unitrol gas

valve knob in the ON

position?

NO

Turn Unitrol gas

knob to ON.

3-3

YES

knob in the OFF

Turn Thermostat to a

temperature setting.

Is the

Thermostat

position?

YES

NO

Contact a Qualified

Technician.

Page 35

3-4

Loading...

Loading...