Page 1

Page 2

NOTICES

TO THE PURCHASER

There are three different types of notices that you should be familiar with, a NOTICE, CAUTION, and

WARNING. A NOTICE is a special note used to call attention to a particularly important point. CAUTION

is used to point out a procedure or operation which may cause equipment damage. The WARNING notice is

the most important of the three because it warns of an operation that may cause personal injury. Please

familiarize yourself with your new cooker before operating it and heed the notices throughout this manual.

The WARNINGS are listed below and on the following page for your review prior to operating the unit.

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property dam age, injury or

death. Read the installation, operating and maintenance

thoroughly before installing or servicing this equipment.

POST IN A PROMINENT LOCATION INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THAT AN OPERATOR SMELLS

GAS. OBTAIN THIS INFORMATION FROM YOUR LOCAL GAS

SUPPLIER.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

Page 3

SAFETY SAFETY SAFETY SAFETY SAFETY

There is an open flame inside the fryer. The unit may get hot enough to set near by materials on

fire. Keep the area around the fryer free from combustibles.

DO NOT supply the fryer with a gas that is not indicated on the data plate. If you need to

convert the fryer to another type of fuel, contact your dealer.

DO NOT use an open flame to check for gas leaks!

Wait 5 minutes before attempting to relight the pilot to allow for any gas in the fryer to

dissipate.

Never melt blocks of shortening on top of the burner tubes. This will cause a fire, and void your

warranty.

Water and shortening DO NOT mix. Keep liquids away from hot shortening. Dropping liquid

frozen food into the hot shortening will cause violent boiling.

At operating temperature the shortening temperature will be greater than 300'F. Extreme care

should be exercise when working with hot shortening to avoid personnel injury.

Ensure that the fryer can get enough air to keep the flame burning correctly. If the flame is

starved for air it can give off a dangerous carbon monoxide gas. Carbon Monoxide is a clear

odorless gas that can cause suffocation.

In the event of a oil fire in the fryer, use ONLY a dry chemical extinguisher. The exti nguisher

should be a B/C or A/B/C type extinguisher that contains sodium bicarbonate or potassium

bicarbonate.

SAFETY SAFETY SAFETY SAFETY SAFETY

Page 4

Table of Contents

1.3.2

Gas Connection

1-4

1.3.2.2

Gas Line Connection

1-4

1.3.3

Electrical Connection

1-5

1.4

INITIAL ADJUSTMENTS

1-7

1.4.3

Pilot Flame Adjustment

1-10

2.2

FRYER OPERATING INSTRUCTIONS

2-2

Section Title Page

Safety Notice

Table of Contents

List of Tables and Figures iv

CHAPTER 1: GENERAL INFORMATION AND INSTALLATION 1-1

1.1 FRYER SPECIFICATIONS 1-1

1.2 CHECKING YOUR NEW FRYER 1-2

1.2.1 Check Your Order 1-2

1.3 INSTALLATION 1-3

1.3.1 Installation Clearances 1-3

1.3.1.1 Leveling 1-3

1.3.2.1 Fuel Types 1-4

1.3.2.3 Quick Disconnect Gas Connection 1-5

1.3.2.4 Fuel Supply Line Leak and Pressure Testing 1-5

1.3.3.1 Electrical System with UFM Filter System 1-6

1.3.4 Ventilation and Fire Safety Systems 1-6

1.4.1 Visual Checks 1-7

1.4.2 Burner Ignition Systems 1-8

1.4.2.1 Lighting Instructions/or Manual Pilot Lights 1-8

i-ii

1.4.4 Main Burner System 1-12

1.4.4.1 Gas Line Requirements 1-13

1.4.4.2 Burner Adjustment 1-13

1.5 INITIAL CLEANING 1-14

CHAPTER 2: OPERATING INSTRUCTIONS 2-1

2.1 FILLING THE FRYER 2-1

2.1.1 Filling the Fryer With Liquid Shortening 2-1

2.1.2 Filling the Fryer With Solid Shortening 2-1

2.2.1 Fryer Start-up 2-2

2.2.2 Displaying Temperatures 2-3

2.2.2.1 Shortening Actual Temperature 2-3

2.2.2.2 Cooking Setpoint 2-4

2.2.3 Display Product Times 2-4

Page 5

Table of Contents (Continued)

Section Title Page

2.2.3.1 Viewing Product Times 2-4

2.2.4 Cooking Product 2-4

2.2.5 Shutdown 2-5

2.2.4 Power Failure 2-5

2.3 PROGRAMMING THE INTELLIFRY COMPUTER 2-6

2.3.1 Basic Programming 2-6

2.3.1.1 Programming Shortening Temperature 2-6

2.3.1.2 Programming Product Times 2-7

2.3.2 Low Level Programming 2-8

2.3.2.1 Temperature display 2-8

2.3.2.2 Password 2-8

2.3.2.3 Beeper Volume 2-9

2.3.2.4 Languages 2-10

2.3.2.5 MeAC^cfc 2-10

2.3.2.6 Recovery Test 2-11

2.3.2.7 Computer Control Mode 2-11

2.4 SHORTENING FILTER PROCEDURES 2-13

2.4.1 General Filter Hints 2-15

2.4.2 Filter Procedures 2-16

2.4.3

Draining a Tank

2-17

CHAPTER 3: OWNER MAINTENANCE AND ADJUSTMENTS 3-1

3.1 FILTER MEDIA REPLACEMENT 3-1

3.2 FRYER CLEANING 3-3

3.2.1 Daily 3-3

3.2.2 Weekly (Boilout) 3-3

3.3 FLUE AND BAFFLE INSPECTION 3-4

3.4 SERVICE 3-4

3.4.1 Replacement Procedures 3-4

3.4.1.1 Main Burner Removal and Replacement 3-5

3.4.1.2 Changing the Main Burner Orifice 3-5

3.4.1.3 Replacing the Heat Baffles 3-5

3.4.1.4 Pilot Burner Removal and Replacement 3-5

3.4.1.5 Pilot Orifice Replacement 3-5

3.4.1.6 Thermopile Replacement 3-6

3.4.1.7 Limit Control Replacement 3-6

3.5 TROUBLESHOOTING 3-8

3.5.1 Fryer Troubleshooting 3-8

3.5.2

Pilot Troubleshooting

ii

3-9

Page 6

Table of Contents (Continued)

Section Title Page

3.5.3 Filter Troubleshooting 3-10

CHAPTER 4: PARTS 4-1

ALPHABETICAL PART LIST 4-5

NUMERICAL PART LIST 4-7

CHAPTER 5: SCHEMATICS 5-1

iii

Page 7

List of Tables and Figures

Table Title Page

1-1 Fryer Characteristics............................................................................................….... 1-1

1-2 Ventilation and Fire Safety References................................................................…... 1-7

4-1 Wendy's Model W14-3UFM Exploded View (Index)............................…...........…. 4-2

Figure Title Page

1-1 Inside View of Fryer.........................................................................................…..…1-9

1-2 Pilot Assembly, Flame Adjustment..............................................................….….... 1-10

1-3 Gas Valve Showing Location of Pressure Regulator and Pilot Adjusters ......…...... 1-10

1-4 Main Burner Conditions ....................................................................................…... 1-12

1-5 Air Collar ..........................................................................................................….... 1-13

2-1 Intellifry Computer..............................................................................................….. 2-2

2-2 Fryer Illustrating Filter Components ..................................................................…...2-13

4-1 Wendy's Model W14-3UFM Exploded View...............................................…….... 4-3/4-4

iv

Page 8

CHAPTER 1: GENERAL INFORMATION AND INSTALLATION

Congratulations on the purchase of your new Pitco Model W1 4S-3 WF gas fryer. This unit has been

specially designed to suit the needs of your establishment and will give you many years of reliable service if

you follow the simple operation and maintenance procedures in this manual. Contained in this manual are

the general installation, operation, and maintenance procedures for the Model Wl 4-3 WF gas fryer.

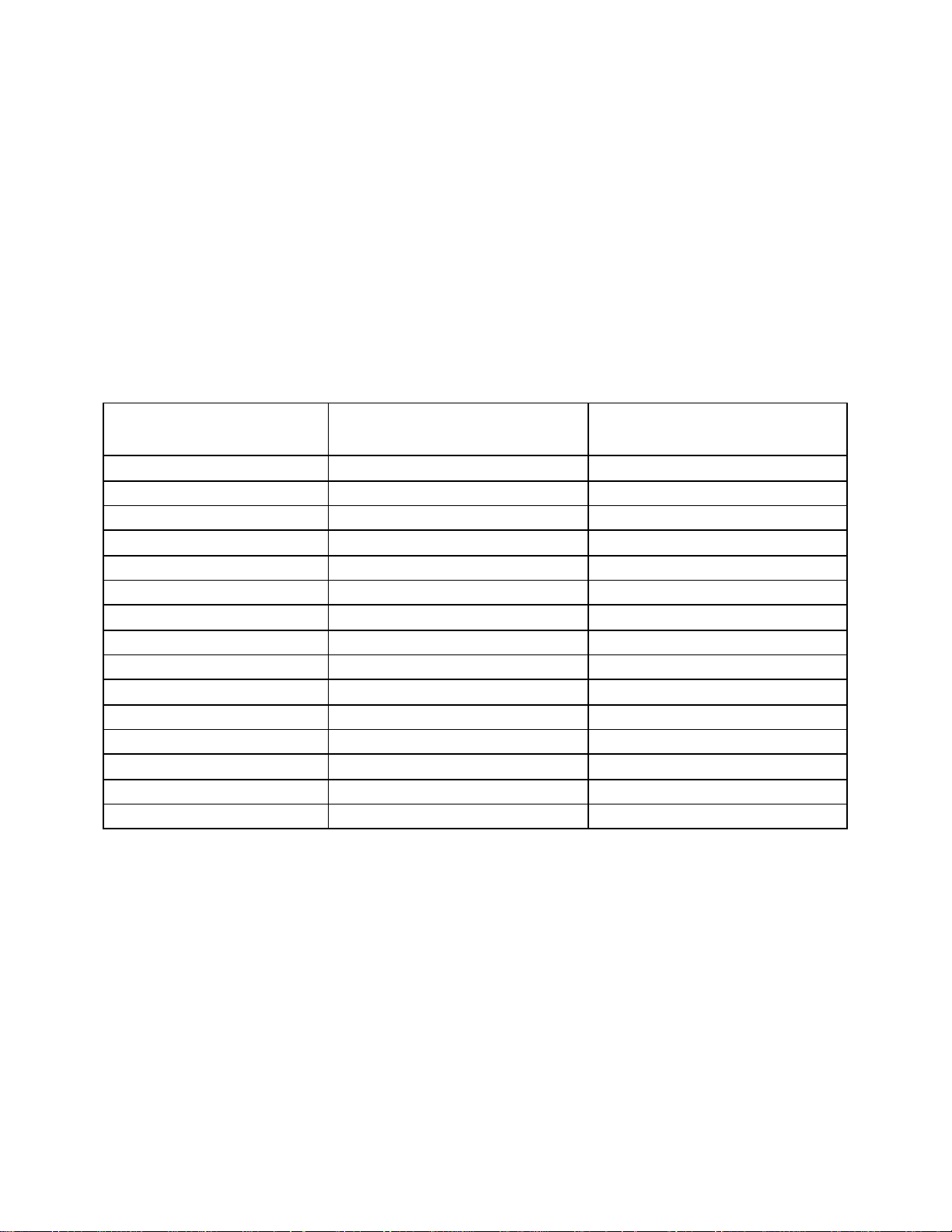

1.1 FRYER SPECIFICATIONS

This unit has been designed to fit the need of the Wendy's chain of stores. The table below lists the

characteristics and specifications associated with this unit:

Table 1-1 Fryer Characteristics

Description Specification (US) Specification (Metric)

Height, Overall 48" 121.9cm

Height, Working 35" 88.9 cm

Width (Unit) 48-3/8 122.9cm

Depth (Unit) 34" 86.4 cm

Number of Tanks/Unit 3 3

Frying Area/Tank 14"x 14" 35.6 x 35.6 cm

Frying Depth 4" 10.2 cm

Aisle space (minimum) 21" 53.3 cm

Oil Capacity/Tank 40 - 42 Lbs 18.1 -19.1 Kg

Input/Tank (BTU/Hr) 122,000 (per tank) 30,744KCal

Gas Type LP or Natural LP or Natural

Input Voltage 120 VAC Single Phase 120 VAC Single Phase

Current Requirements/Unit 9 Amps 6 Amps

Filter Media Filter Paper Filter Paper

Pump Rate 5.0 GPM 18.9LPM

1-1

Page 9

1.2 CHECKING YOUR NEW FRYER

Your new fryer and it's filter components have been carefully packed into one crate. Every effort has been

made to ensure that your fryer will be delivered to you in perfect condition. As you unpack your new fryer,

inspect each of the pieces for damage. If something is damaged, DO NOT sign the bill of lading. Contact the

shipper immediately, the shipper is only responsible for 15 days after delivery. Check the packing list

enclosed with your fryer to ensure that you have receiv ed all of the parts to the fryer. If you are missing any

parts, contact the dealer from whom the fryer was purchased. As you unpack the fryer and it's accessories be

careful to keep the weight of the fryer evenly

distributed.

Flue Vents

CAUTION

To prevent equipment damage, don't tilt the fryer onto any two of

it's casters or pull the unit by the flue vents.

You will find the model and serial numbers on the plate inside the doors. Make note of these numbers

for future reference

1.2.1 Check Your Order

The crate containing the fryer unit will also contain the following:

(2) Fry baskets per fryer

(1) Fry Basket Hanger per fryer

(2) Pitco Cleaner Sample

(1) Drain Clean Out Rod

The filter tools and components are very important and MUST be retained for future use. A complete

description of each component is contained in the Oil Filter Procedure in Chapter 2.

(1) Precoat Filter Aid

(1) Filter Screen

(1) Cleaning Brush (Fryer)

(1) Fryer Crumb Scoop

(1) Filter Crumb Scoop

1-2

Page 10

1.3 INSTALLATION

Although it is possible for you to install and set up your new fryer, it is STRONGLY recommended that you

have it done by qualified professionals. The professionals that install your new fryer will know the local

building codes and ensure that your installation is safe.

The fryer must be properly restrained to prevent movement or tipping. This

restraint must prevent the fryer from movements that would splash hot

liquids on personnel. This restraint may be any means (alcove installation,

adequate ties, or battery installation).

DO NOT obstruct the flow of combustion/ventilation or air openings around

the fryer. Adequate clearance around the fryer is necessary for servicing and

proper burner operation. Ensure that you meet the minimum clearances

specified in the installation instructions.

1.3.1 Installation Clearances

The fryer needs clearance around it for proper operation. Adequate clearances allow for servicing and proper

burner operation. The clearances shown below are for cooker installation in combustible and noncombustible construction.

Combustible Non-Combustible

Construction Construction

Back 6" 6"

Sides 6" 6"

Floor – Combustible -- --

In addition to the clearances required for proper fryer operation, there must be at least 21 inches of aisle

space in front of the fryer to remove/install the filter pan/module.

1.3.1.1 Leveling

When you receive your fryer it is completely assembled. The fryer will need to be leveled once it is in place.

Leveling the fryer is done with a large pair of water pump pliers. The casters provide the necessary height to

meet sanitation requirements and assure adequate air supply to the burner.

a. Adjust the height and level the fryer by adjusting the leveling devices on the caster with the water pump

pliers.

1-3

Page 11

b. Move the fryer to the desired location and lock the wheels using the locking devices on the sides of the

WARNING

casters.

c. Once the unit is in place, check and readjust the levelness as necessary.

1.3.2 Gas Connection

Your fryer will give you peak performance whe n the gas supply line is of sufficient size to provide the

correct gas flow. The gas line must be installed to meet the local building codes or National Fuel Gas Code

(NFPA 54-1984) and ANSI Z223. 1-1988 Latest Edition. In Canada, install the fryer in accordance with

CAN/CGA-B 149.1 or .2 and local codes. Gas line sizing requirements can be determined by your local gas

company by referring to National Fuel Gas Code, Appendix C, Table C-4 (natural gas) and Table C-16

(propane). The gas line needs to be large enough to supply the necessary amount of fuel to all appliances

without losing pressure to any appliance. Other factors that are used to determine the piping requirements

are BTU requirements of the appliances being connected and the length of pipe between the meter (main

shut off) and the appliances.

NEVER supply the fryer with a gas that is not indicated on the data plate. Using

the incorrect gas type will cause improper operation. If you need to convert the

fryer to another type of fuel, contact your dealer.

1.3.2.1 Fuel Types

Each fryer is equipped to work with one type of fuel. The type of fuel with which the appliance is intended

to operate is stamped on the data plate attached to the inside of the door.

DO NOT use an open flame to check for gas leaks!

1.3.2.2 Gas Line Connection

Connect the fryer to the gas supply line with a connector that complies with the Standard for Connectors for

Movable Gas Appliances (ANSI Z21.69-1987). If you are installing a fryer with casters using a quick

disco nnect refer to the Quick Disconnect installation instruction, 1.3.2.3. Connect the gas line to the fryer

using a pipe joint sealant that is resistant to liquefied petroleum. If the fryer was disconnected during the fuel

line testing, use a solution of soap and water to leak test the new connection.

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the cooker

connection. This may not allow proper gas flow for optimum burner operation,

resulting in poor cooker performance.

1-4

Page 12

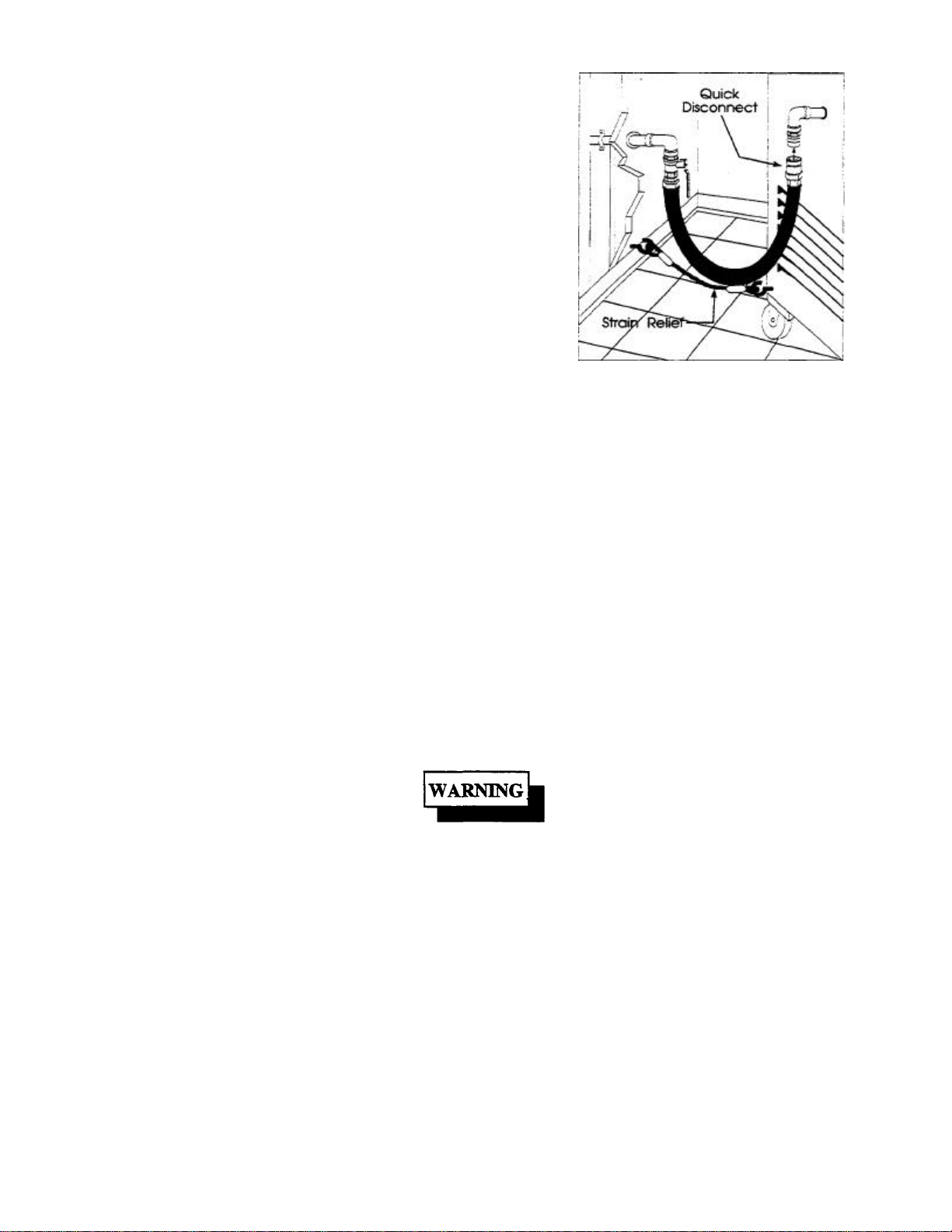

1.3.2.3 Quick Disconnect Gas Connection

International

Gas fryers equipped with casters must be installed with connectors

that comply with the Standard for Connectors for Movable Gas

Appliances, ANSI Z21.69-1987, and Addenda Z21.69A -1989. This

connection should include a quick disconnect device that complies

with the Standard for Quick Disconnect Devices for Use With Gas

Fuel, ANSI Z21.41-1989. When installing a quick disconnect you

must also install a means for limiting the movement of the fryer.

This device will preve nt the gas line or the quick disconnect from

being strained. The restraining device should be attached to the

cooker on the back panel as shown in the illustration. The quick

disconnect, hose, and restraining device can be obtained from your

dealer.

1.3.2.4 Fuel Supply Line Leak and Pressure Testing

The fuel supply system must be tested before the fryer is used. If the fuel line is going to be tested at a

pressure greater than (>)1/2 PSIG (3.45 kPa), make sure that the fryer is disconnected from the fuel line. If

the fuel line is to be tested at a pressure equal to or less than (<) 1/2 PSIG (3.45 kPa), the fryer can be

connected but the unit's gas valve must be shut. Test all gas line connections for leaks with a solution of

soap and water when pressure is applied.

1.3.3 Electrical Connection

The electrical service used by the fryer must comply with local codes. If there are no local codes that apply,

refer to the National Electrical Code (NEC) to install the service. In Canada refer to CSA Standard C22.1

and local codes. Wiring diagrams are provided inside the fryer control box. The power requirements for the

fryer are shown below.

North America

Input Voltage

Current per fryer

UFM Filter System

120VAC,60Hz

0.5 Amps

7.0 Amps

220 (or 240) VAC, 50Hz

0.5 Amps

4.0 Amps

The fryer is equipped with an oil proof, three prong (grounding) plug for your

protection against electrical shock hazard in the event of equipment

malfunction. DO NOT cut or remove the grounding (third) prong from this

plug. This plug must be plugged into a properly grounded three prong

receptacle.

1-5

Page 13

The fryer must be grounded in accordance with local code; if there is not a local code, comply with

NECANSI/NFPANo. 70-1990. It is advised that this power supply be plugged into a wall receptacle that is

controlled by the ventilation control. This will prevent the fryer from being operated without the ventilator

on.

1.3.3.1 Electrical System with UFM Filter System

The fryer has one power supply for the controls and the filter module.

1.3.4 Ventilation and Fire Safety Systems

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas temperatures can

reach as high as 1200°F. Therefore, it is very important to install a fire safety system. Your ventilation

system should be designed to allow for easy cleaning. Frequent cleaning of the ventilation system and the

fryer will reduce the chances of fire. Table 1-2 provides a list of reference documents that provide guidance

on ventilation and fire safety systems. This table is not necessarily complete. Additional information can be

obtained from the American Gas Association, 8501 East Pleasant Valley Road, Cleveland, OH 44131.

Table 1 -2 Ventilation and Fire Safety References

Topic Underwriters Laboratory Document

Grease Extractor ANSI/UL710-1981 ANSI/NFPA 96-1987

Ventilation Hood ANSI/UL 705-1984 ANSI/NFPA 96-1987

Filter Unit

Types of Fire Extinguishers

and Detection Equipment

CO2 ANSI/UL 154-1983 ANSI/NFPA 12-1989

Dry Chemical ANSI/UL 299-1984 ANSI/NFPA 17-1985

Water ANSI/UL 626-1984 ANSI/NFPA 13-1989

Foam

Sprinklers ANSI/UL 199-1982

Smoke Detectors ANSI/UL 268-1981 ANSI/FPA72B-1986

ANSI/UL 586-1985

ANSI/UL 900-1987

National Fuel Gas Code

Document

ANSI/NFPA 96-1987

ANSI/NFPA 11-1988

ANSI/NFPA 13-1989

ANSI/NFPA 13-1989

Fire Detection Thermostats ANSI/UL 521-1987 ANSI/FPA72B-1986

1-6

Page 14

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the burner.

Leave at least 18 inches of open space between the fryer's flue vent opening and the intake of the exhaust

hood.

In the event of an oil fire in the fryer, use ONLY a dry chemical extinguisher. The

extinguisher should be a B/C or A/B/C type extinguisher that contains sodium

bicarbonate or potassium bicarbonate.

Ensure that your ventilation system does not cause a down draft at the fryer's flue

opening. Down drafts will not allow the fryer to exhaust properly and will cause

overheating which may cause permanent damage. Damage caused by down drafts

will not be covered under equipment warranty. NEVER allow anything to obstruct

the flow of combustibles or ventilation exiting from the fryer flue. DO NOT put

anything on top of the flue area.

NEVER connect the blower directly to the flue openings. The direct flow of air will

cause poor temperature recovery, poor ignition, inefficient operation of the fryer,

and could extinguish the pilot.

1.4 INITIAL ADJUSTMENTS

CAUTION

NOTICE

After your fryer has been installed as described in section 1.4, it needs to be adjusted to ensure that it will

perform as designed. These adjustments must be performed by a qualified person. To perform these

adjustment the following tools will be needed:

• Manometer (low pressure gauge)

• DC Millivolt Meter

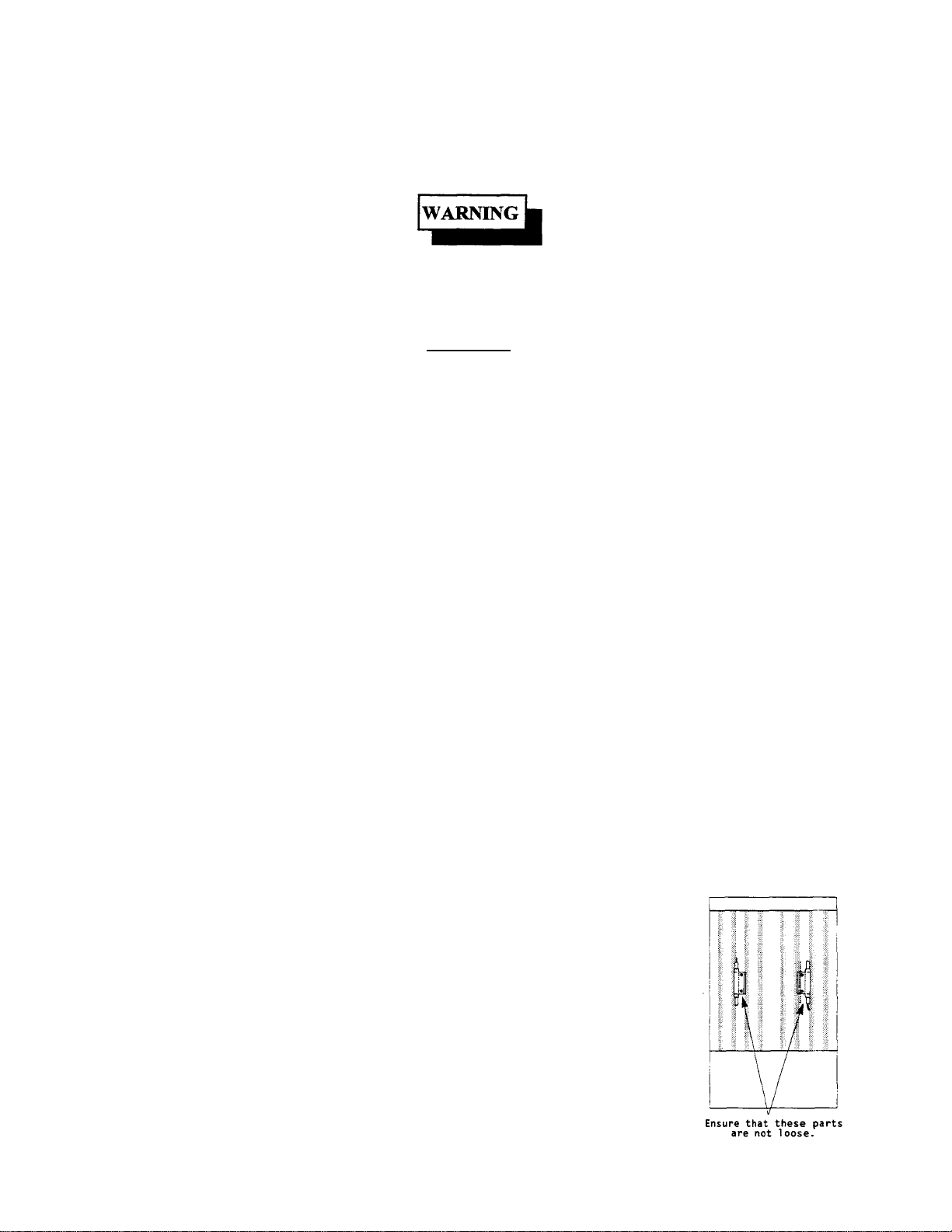

1.4.1 Visual Checks

Before you begin filling and adjusting the fryer, perform the following visual checks:

a. After the fryer is in its permanent location, lock the casters and check for

levelness. Any additional leveling that is necessary can be performed as

described in section 1.3.

b. Check the temperature bulb s (computer/high-limit), located in the fryer tank to

ensure that the mounting screws are tight. The figure shows the probe typical

location. Look down inside each fryer tank to see the probes.

• Digital Thermometer (Temperature probe)

1-7

Page 15

1.4.2 Burner Ignition Systems

The unit has a manual (standing flame) pilot ignition system. The pilot light must be lit manually before

fryer operation.

CAUTION

Before going any further, fill the fryer with WATER. Water is used for the

installation adjustments because the temperature will never exceed 212°F (100°C)

thereby allowing plenty of adjustment time. Never let the water level go below the

MIN LEVEL mark on the rear of the tank.

There is an open flame inside the fryer. The unit may get hot enough to set near by

materials on fire. Keep the area around the fryer free from combustibles.

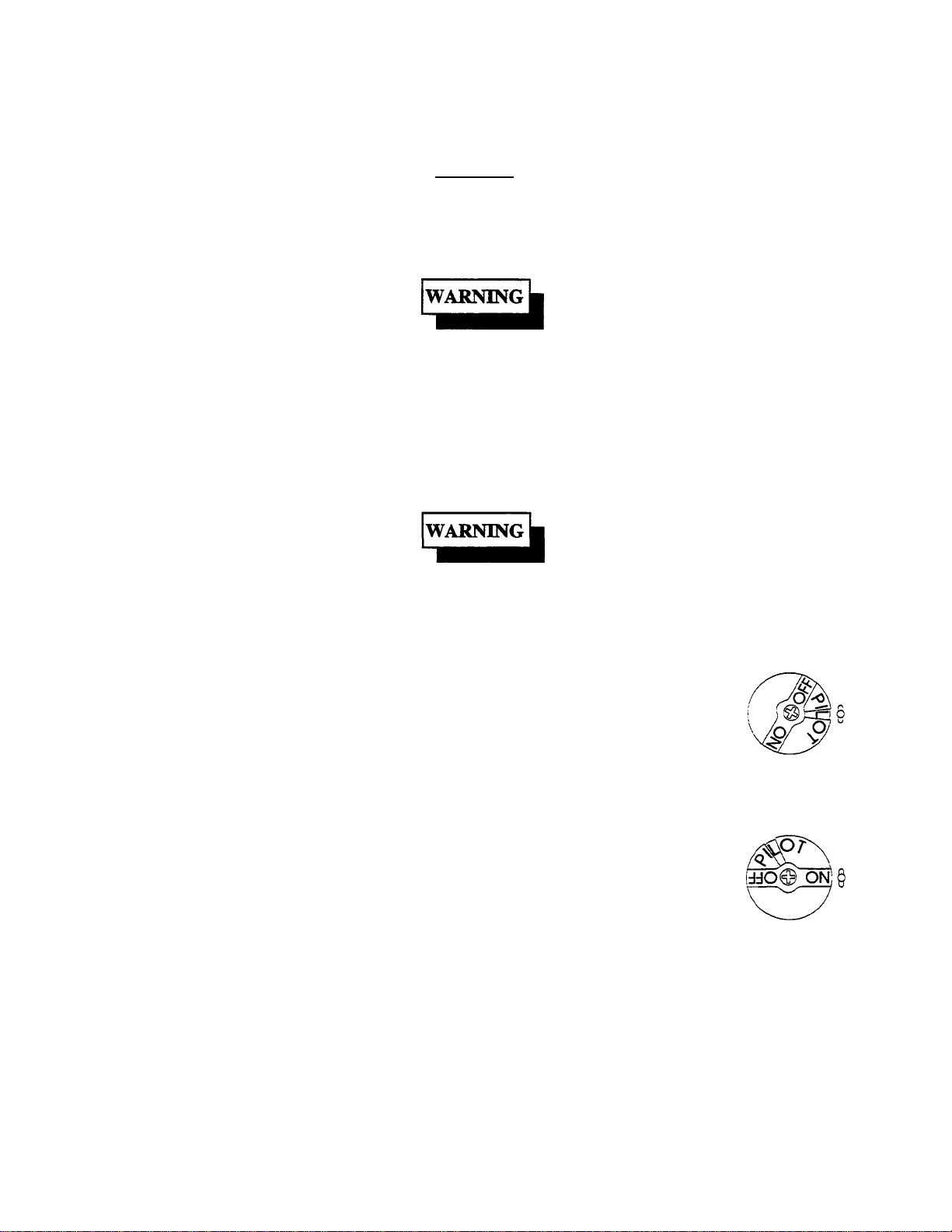

7.4.2.1 Lighting Instructions for Manual Pilot Lights

To light the pilot light refer to these instructions and. The numbers in parenthesis refer to Figure 1-2

callouts.

Wait 5 minutes before attempting to relight the pilot to allow for any gas in the fryer to

dissipate.

a. Open the gas supply valves to the fryer.

b. Open the fryer's door (1) to gain access to the controls.

c. Turn the Unitrol valve knob (2) to the PILOT position for the fryer being started, and

push in on the knob. Hold the knob in for approximately one minute to purge the air

out of the line. Hold a flame to the pilot light (3) until the pilot ignites. This may take a

little while the first time you light the fryer because of air in the lines. Once lit, hold

the knob in for approximately 60 seconds and then release.

d. If the pilot goes out wait 5 minutes and repeat step c. If after three tries the pilot will

not remain lit, refer to the operator troubleshooting section of this manual.

e. Turn the Unitrol valve knob counterclockwise to the ON position.

1-8

Page 16

f. Turn the fryer OFF/ON switch (4) to the ON position. The computer display will change from OFF to

MELT (the display may indicate a different condition of the fryer depending on fryer temperature).

g. The main burner (5) will light and be controlled by the computer. The pilot burner will remain lit

regardless of the switch position or computer operation.

h. Refer to the computer operation section for fryer control information.

1-9

Figure 1-1 Inside View of Fryer

Page 17

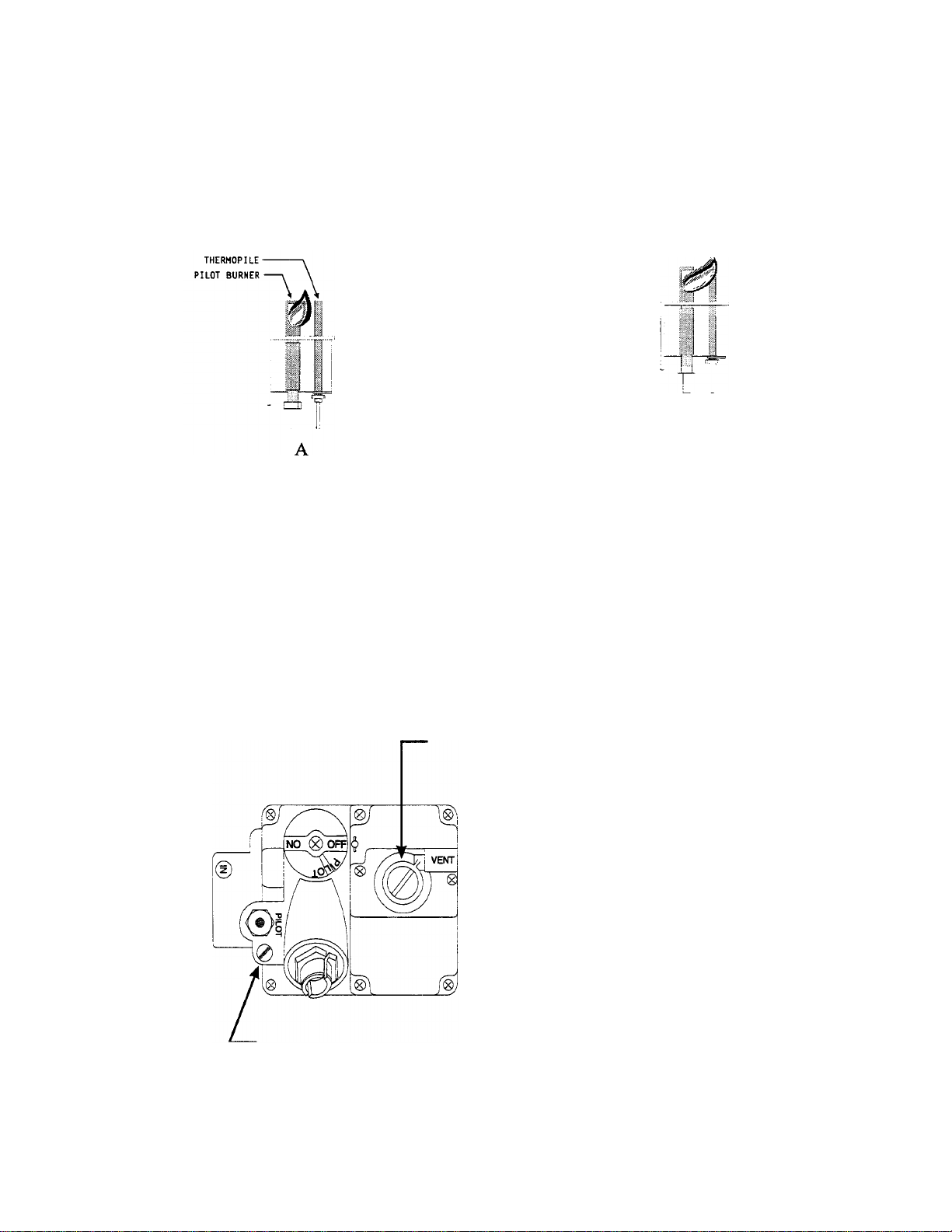

1.4.3 Pilot Flame Adjustment

The pilot flame should be adjusted to produce the proper millivolt output from the pilot sensing device.

Millivolt output for the thermopile should be between 300 and 500 millivolts. Figure 1-3 shows the pilot

assembly with exa mples of the incorrect and correct pilot size. Example A illustrates a pilot flame size that

is too small to produce sufficient millivolt output. Example B is the correct size for proper millivolt output.

B

Figure 1 -2 Pilot Assembly , Flame Adjustment

This test requires a DC millivolt meter set to a scale of 0-1000mv.

a.

Locate the thermopile wires coming from the thermostat/High Limit box

b.

going to the gas shut off valve. The wire insulation size decreases near the

gas valve connections .

c.

Connect the negative (-) test probe to pilot bracket.

Connect the positive (+) test probe to one of the High Limit terminal

d.

connections

PRESSURE REGULATOR LOCATION

(UNDER CAP SCREW)

PILOT ADJUSTER LOCATION (UNDER CAP SCREW)

Figure 1-3 Gas Valve Showing Location of the Pressure Regulator and Pilot Adjusters

1-10

Page 18

e. Light the pilot.

f. Remove the pilot flame adjustment cover.

g. Turning the flame adjusting screw clockwise lowers the flame and the millivolt output.

Turning the screw counterclockwise increases flame size and millivolt output.

h. Rotate the screw in the direction to achieve a reading of 400 ±50 mv for thermopiles.

NOTE

Allow 3 to 5 minutes between flame adjustments to allow the reading to settle.

i. Replace the pilot flame adjusting screw cover.

1-11

Page 19

1.4.4 Main Burner System

For the burners to work the gas supply valve must be open and the main power switch must be on. The main

burner receives gas from the main gas supply through the thermostatically controlled valve. When the

computer calls for flame the gas control valve opens and the pilot light ignites the burners. After the burner

system is operating, perform the burner adjustments in the following procedure. Figure 1-5 illustrates the

different conditions possible for the main burner.

The tubes and baffles are badly

carbonized. Check vent and

adjust if necessary. Check for

heat tube or flue blockage.

The flame seems to "lift off"

the face of the burner. To

correct adjust main burner as

described in

1.4.3.2.

INSUFFICIENT FLOW

Have gas company check

incoming gas pressure. Adjust

manifold pressure as described

in 1.4.3.2.

EXCESSIVE FLOW

A soft, steady blue flame

should enter the heat tube

without touching the front

outside rim of the tube.

INSUFFICIENT GAS PRESSURE

NORMAL FLOW

Figure 1-4 Main Burner Conditions

1-12

Page 20

1.4.4.1 Gas Line Requirements

A properly installed gas supply system will deliver 7.0 ±2.0" w.c. natural gas (11.0 ±2.0" w.c. LP) to all

appliances connected to the line, operating at full demand.

1.4.4.2 Burner Adjustment

The burners must be adjusted to deliver optimum flame. Adjust the burner flame using the following

procedure.

a. Ensure that the gas control valve is in the OFF position. Remove the manifold pressure tap plug and

connect an accurate pressure gauge (range of 0-16" w.c. in 0.1" increments) or manometer.

b. Light the pilot burner (see 1.4.2) for the unit being tested and adjust the thermostat to light the main

burners.

c. The installed pressure gauge reading should be the same, ±0.1", as that marked on the data plate inside

the door. If the pressure is correct go to step e, if not, adjust the pressure.

d. To adjust the pressure, remove the regulator adjustment screw cover. Use a flat tip screwdriver to adjust

the screw until the proper pressure is reached. Turning the screw clockwise will increase the pressure,

counterclockwise will decrease the pressure.

e. When the pressure is correct, install the regulator adjustment screw cover.

f. To remove the pressure gauge, turn gas control valve to OFF. Remove the gauge and install the pressure

tap plug.

Figure 1-5 Air Collar

1-13

Page 21

g. Now that the pressure is set for proper operation, set the main burner flame. Unlock the air collars (see

Figure 1 -5) by loosening the set screw for the collars. Turn the gas control valve to ON and set the

computer to light the main bur ners.

h. Adjust the shape and size by raising or lowering the air collars to achieve a soft blue flame with well

defined inner cones (see Figure 1-4).

i. When the flames have been properly adjusted, lock the collars in place with the set screw provided.

1.5 INITIAL CLEANING

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before the fryer

is ready for cooking it must be cleaned. This will remove the oil coating and any foreign matter that may have

accumulated during storage and shipment. Perform the cleaning as described below.

a. Fill the tank with water and add one packet of Pitco fryer cleaner or a mild detergent.

b. Turn the fryer on and allow the computer to bring the water to a boil automatically. Allow the fryer to

heat for 15 minutes.

NOTE

Do not leave the fryer unattended during cleaning. Never let the water level go

below the "Min Level" mark on the back of the tank.

c. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

d. When cleaning is complete, turn off the fryer main burners and turn gas valve knob to the PILOT

position. Drain the water into a container suitable for hot water and dispose of it.

e. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank until the cleaner

has been rinsed, thoroughly from the tank.

f. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water, | because any

residual water will cause hot oil to splatter out of the fryer.

CAUTION

Mild steel tanks must be wiped down/coated with oil to keep the tank from

rusting.

g. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to 2.1 for instructions on

adding shortening to the fryer.

1-14

Page 22

CHAPTER 2: OPERATING INSTRUCTIONS

This chapter describes how to operate your fryer to obtain the best performance. Included in this chapter are

filling, operating, and cleaning instructions for gas fryers.

2.1 FILLING THE FRYER

Both liquid and solid shorte ning can be used in the fryer, but liquid is preferred. If solid shortening is used, it

is recommended that you use the solid melt cycle feature built into the computer to melt the shortening.

2.1.1 Filling the Fryer With Liquid Shortening

a. Make sure the drain valve is completely closed.

b. Fill the fryer with oil to the "Oil Level" line marked on the back of the

tank.

2.1.2 Filling the Fryer With Solid Shortening

Never melt blocks of solid shortening on top of the burner

tubes. This will cause a fire, and will void your warranty.

a. Make sure the drain valve is completely closed.

b. Remove the screen covering the tubes.

c. Cut the shortening into cubes no larger than 1". ALWAYS pack the

shortening below, between, and on top of the burner tubes. DO NOT

leave any large air gaps. Use care when packing the solid shortening

in the tank. DO NOT bend or break the temperature sensor probes. If

these are damaged the fryer will not function properly.

d. Once the fryer is packed with shortening, the shortening must be

melted. Shortening melt cycles are controlled completely by the

Intellifry computer. Refer to Fryer Operating procedures for

computer operation.

.

2-1

Page 23

2.2 FRYER OPERATING INSTRUCTIONS

Always observe the safety precautions described in the front of this manual before operating this fryer.

Because fryer operation is controlled by the computer, start-up and operation is very easy. The instructions

below describe how to operate the fryer to perform daily fryer operation. Detailed programming instructions

are provided later in this chapter in section 2.3. Figure 2-1 illustrates the Intellifry computer.

Figure 2-1 Intellifry Computer

2.2.1 Fryer Start -up

Start up the fryer as described in Chapter 1. The computer will come on and display the status of the fryer. If

the shortening temperature is below the set point of the melt cycle the computer will go into one of the preset

melt cycles. When the main burners are on the LEDs in the temperature key will light. If the fryer is operating

in the melt cycle, the temperature key lights will cycle on and off at the preset times. Below is a sequence of

displays that will occur when the fryer is started up with the shortening at room temperature:

1. Turn the fryer on. If a melt cycle is programmed to run, the display will show Melt L or Melt S.

Refer to the programming section 2.3 for selection details.

2-2

Page 24

Melt L indicates that you have the liquid melt cycle programmed to run. Although you do not need to

"melt" liquid shortening, it is a very good idea to heat up all shortening slowly. This will prolong the

life of the shortening and lessen the thermal stress on the fryer tank.

Melt S indicates that the solid shortening melt cycle has been programmed to run. This program will

melt solid shortening and bring the liquefied shortening up to cooking temperature without scorching

the shortening. Refer to the fryer operation manual for solid shortening loading information.

2. When the shortening is above the melt range but below the cooking range the

display will read "Heating". This indicates that the main burners are on steady

and heating the shortening.

3. Once the shortening has reached the cook temperature (Setpoint) the main burners

will turn off and the display will indicate Ready. Ready will be displayed, even

when the main burners are on, as long as the fryer remains in the cooking

temperature range.

* OVER TEMPERATURE - If the temperature of the shortening exceeds the cooking setpoint by 40°F the

display will flash "Hi-Temp" and the alarm will be sounding. Shut down the fryer and allow it to cool down.

2.2.2 Displaying Temperatures

There are two temperatures that the user can select from the computer. Actual and Set. The actual

temperature is the temperature of the shortening and the set temperature is the setpoint that the fryer will

cook at. To display these temperatures perform the followin g:

2.2.2.1 Shortening Actual Temperature:

1. Press and release the "Temperature" key once to display the temperature of the

shortening.

2. The display will show the shortening temperature for three seconds

then return to displaying the fryer status.

3. To continuously display the shortening temperature, press and hold the temperature key. Computers

controlling a single fryer will display the shortening temperature as long as the key is pressed.

2-3

Page 25

2.2.2.2 Cooking Setpoint:

To view the cooking setpoint of the fryer press the Temperature key

twice within one second. The display will change to show the cooking

setpoint for the fryer. The display will hold the setpoint for three seconds

then return to displaying the fryer status.

2.2.3 Display Product Times

Each product button has three times associated with it, cook, shake, and hold. Cook time is the total time the

product is to be cooked. The shake time is the length of time before the end of the cook cycle that the beeper

will sound to indicate you should shake the product. After the product has finished cooking it can be held for

a certain amount of time before it should be replaced with fresh product. This time is called the hold time. To

view the times associated with each product key perform the following:

NOTE

You can only perform this procedure when the product key is not in

a cook or hold cycle.

2.2.3.1 Viewing Product Times:

1. View the product times by first pressing the Time key and then the

product key you want to check.

2. The display will change to show the time for each of the three

changeable times. The illustrations show how the product times

will be displayed. Each time setting will be displayed for three

seconds before changing to the next one. After the last time is

displayed for three seconds the display will return to fryer status

display.

CK Indicates Cook Time (Product key LED blinks rapidly during cook cycle)

SH Indicates Shake Time

HD Indicates Hold Time

2.2.4 Cooking Product

Cooking with the computer is very easy. Select the product button to use and press it. The computer does the

rest. The discussion below shows each step in the cooking process.

1. Press the product key for the product bein g cooked. The product key

LED will blink rapidly and the display will show the product cook

time and start counting down.

2-4

Page 26

2. When the shake time is reached the buzzer will sound and the display will display shake. The buzzer

(beeps slowly) will sound for a short time and then cancel itself.

3. The product will continue to cook until the cook time has run out. When the cook time is up the buzzer

will sound again (rapid beeping) and the product key LED will blink slower to indicate that the product is

finished cooking. Press the product key to silence the buzzer and lift the product out of the shortening.

4. The product key LED blinks slowly during the hold time and the display will show the remaining hold

time.

5. When the Hold time is up the buzzer will sound again (beep very slowly) . After a short time the product

key light will go out and the buzzer will stop.

2.2.5 Shutdown

There are two shutdown modes of fryer operation, STANDBY and COMPLETE. The standby mode removes

the ability for the fryer's main burners to cycle. Complete shutdown turns off the gas supply to the fryer. Shut

down the fryer by:

STANDBY Turn fryer switch to OFF. The computer display will indicate OFF. Turn the

gas valve knob clockwise to the PILOT position. The fryer is now in

Standby and can remain this way for only brief periods of time. NEVER

leave the cooker in standby overnig ht.

COMPLETE To completely shut down the cooker, turn the gas valve knob clockwise to

the PILOT position. Depress the knob slightly and turn it to the OFF

position. The fryer is now completely shut down and can be cleaned and

filtered.

2.2.4 Power Failure

NOTE

No Attempts should be made to operate the fryer during power outages.

If power is removed from the fryer for any reason during operation, the unit will shutdown. Wait five minutes

after power is restored before restarting the fryer. This will give any gas fumes in the burner time to dissipate.

To restart the unit, follow the Start-up procedure as you normally would.

2-5

Page 27

2.3 PROGRAMMING THE INTELLIFRY COMPUTER

1. Press the Program key

If no password is programmed the display will indicate

There are three levels of programming for the new computer, user, service, and factory. Each level allows

for different degrees of computer control. Only the user level of programming is discussed in detail in this

section. The service and factory levels of programming deal with the configuration of the computer and

require an additional password to enter. The user programming section is broken down into two section

basic and infrequent.

2.3.1 Basic Programming

There are only two items that will be changed on a routine basis, shortening temperature and product times.

If a password is programmed you must enter the password to change the program in the computer.

2.3.1.1 Programming Shortening Temperature

NOTE

Skip step one if you are still in the program mode from a previous procedure. By remaining in

the program mode you will not need to reenter the password.

PROGRAM. If a password is required the display will change to PASS_ _ _ _indicating that you

must enter the password. Enter the password to access the user level programming mode.

2. Press the Temperature key . The current set temperature

will be displayed. If the current temperature setting is correct

press the Program key return to the programming mode.

3. Enter the new shortening temperature by pressing the product number keys for the desired

temperature. For instance if you want the new te mperature to be 350°F, you would press the 3, 5,

and 0 product keys.

4. The new temperature will be shown in the display. To exit the temperature program and save the new

setting press the Program key You will still be in the user programming mode.

You can go to the next item to be changed or exit the programming mode. To exit the programming

mode press the Program key again.

2-6

Page 28

2.3.1.2 Programming Product Times

NOTE

Skip step one if you are still in the program mode from a previous procedure.

By remaining in the program mode you will not need to reenter the

password.

1. Press the Program key. The display will change to PASS_ _ _ _indicating that you must enter

the password. Enter the password to access the user level programming mode.

NOTE

You can review the set times without making changes by pressing the

time key to advance through the settings after a product key is

selected. You can return to the programming mode any time by

pressing the Program key

2. Press the Time key . All of the product key LEDs will light up. Press the product key

that is to be changed and the display will show the cook time for the product. Enter the new cook time

using the product number keys. A maximum of 99:99 can be entered. After entering the desired time

press the Time key to accept the new setting. To set the shake

time go to step 3. To exit the time set program press the Program key to return to the program

mode.

3. Press the Time key to set the shake time. The display will change to show the current shake

time. Enter the new shake time using the product number keys. A maximum of 99:99 can be entered.

After entering the desired time press the Time key to accept the new setting. To set the

hold time go to step 4. To exit the time set program press the Program key to return to the

program mode .

4. Press the Time key to set the hold time. The display will change to show the current hold

time. Enter the new hold time using the product number keys. A maximum of 99:99 can be entered.

After entering the desired time press the Time ke y to accept the new setting. When

the Time key is pressed you will be returned to the beginning of the time set program.

To set another product key repeat steps 1 through 4. To exit the time set program press the Program

key to return to the program mode.

2-7

Page 29

2.3.2 Low Level Programming

In addition to the basic programs there are a number of low level programs. These functions are used to set

the features of the computer that do not need to be changed often. These functions are:

• Temperature System °C or °F

• Password

• Volume

• Language

• Melt Cycle Setting

• Recovery Test

• Computer Control Mode

To enter the lower level programming level and change the desired function, use the procedure for the

function to be changed.

2.3.2.1 Temperature display

To toggle between °C and °F use the following procedure:

1. Press the Program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to enter the

password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the one (1) product key to enter the temperature program. The display will indicate the current

temperature units "DEGREE F" (DEGREE C).

4. To change the temperature units press the zero (0) product key. The display will alternate between

"DEGREE F" and "DEGREE C" each time the zero (0) key is pressed.

5. To exit the temperature display setting program press the Program key to return to the

program mode. To exit programming mode press the Program key again.

2.3.2.2 Password

To set a new password or remove the password follow the procedure below:

1. Press the Program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to enter the

password.

2-8

Page 30

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the two (2) product key. The display will indicate "SET PASS".

4. To turn the password requirement on or off press the zero (0) product. When the display

indicates "NO PASS" a password is not required to enter the program mode. A display of

"PASS RERQ" indicates that a password is required to enter the programming mode.

5. To enter a new password (or display the current password), press the Program key . The

display will change to display the current password "PASS####" where the current password

would display in the place of the ####.

6. While the "PASS####" is being displayed you can change the password. Use the key pad

to enter any four numbers. After the new password has been entered (or to exit viewing

the current password) press the program key to return to the program mode.

7. To exit the programming mode press the program key again.

2.3.2.3 Beeper Volume

To set beeper volume, follow the procedure below:

1. Press the program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to

enter the password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the three (3) product key. The display will change to indicate "VOLUME #". The

# will be replaced with the current setting for the beeper. There are three settings for beeper

volume, one (1) being the softest and three (3) the loudest.

4. To toggle through the beeper volumes press the zero (0) product key. Each of the volume

settings will be displayed as the zero (0) key is pressed and the beeper will sound to provide

an example the volume.

5. After selecting the desired volume, (or to exit viewing the current volume setting) press the

program key to return to the program mode.

5. To exit the programming mode press the program key again.

2-9

Page 31

2.3.2.4 Languages

To set the language that will be displayed follow the procedure below:

1. Press the program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to

enter the password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the four (4) product key to enter the language program. The display will change

to indicate "ENGLISH" or the current language.

4. To toggle through the available language settings press the zero (0) product key.

5. To exit the language setting program press the program key once. To exit the low level

programming menu press the program key again.

2.3.2.5 Melt Cycle

To select the melt cycle desired follow the procedure below:

1. Press the program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to

enter the password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the five (5) product key to enter the melt cycle program. The display will change

to indicate "SOLID" or the current melt setting.

4. To toggle through the three available melt cycle settings press the zero (0) product key. Each

of the settings (NO MELT, LIQUID, or SOLID) will be displayed as the zero (0) key is

pressed.

5. After selecting the desired melt cycle, (or to exit viewing the current setting) press the

program key to return to the program mode.

6. To exit the programming mode press the program key again.

2-10

Page 32

2.3.2.6 Recovery Test

To view the recovery test data follow the procedure below:

1. Press the program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to

enter the password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the six (6) product key to enter the recovery test program. The display will

change to indicate "RECOVERY".

4. To display the recovery test data press the six (6) key again. The display will change to

display the recovery test data (F###L###).

5. The display indicates the time it took the fryer to heat up from 250°F to 300°F at the factory

and the last time the recovery test was performed. The F### portion of the display

indicates the time in seconds that the fryer took to heat up at the factory. The L###

indicates the heat up time in seconds the fryer took the last time the test was performed.

6. After viewing the recovery test data press the program key to return to the program

mode.

7. To exit the programming mode press the program key again.

2.3.2.7 Computer Control Mode

The computer can be switched from control mode to timer mode. In timer mode the computer

does not control the fryer. To change the computer mode from control to timer follow the

procedure below:

1. Press the program key and enter the password (if a password is programmed). If you

are still in the low level programming mode from a previous procedure you will not need to

enter the password.

2. Press the zero (0) product key. The display will change to show "SELECT".

3. Next press the seven (7) product key to enter the computer control program. The display will

change to indicate "CONTROL" or "TIMER".

4. To toggle between the two modes of control press the zero (0) product key. Each of the

settings (CONTROL or TIMER) will be displayed as the zero (0) key is pressed.

2-11

Page 33

5. When "CONTROL" is displayed the computer has complete control of the fryer. When

"TIMER" is displayed, the computer acts only as a timer.

NOTE

When the computer is in TIMER mode the display will indicate "TIMER"

during normal operation of the fryer.

5. After selecting the desired control mode, (or to exit viewing the current setting) press the

program key to return to the program mode.

6. To exit the programming mode press the program key again.

2-12

Page 34

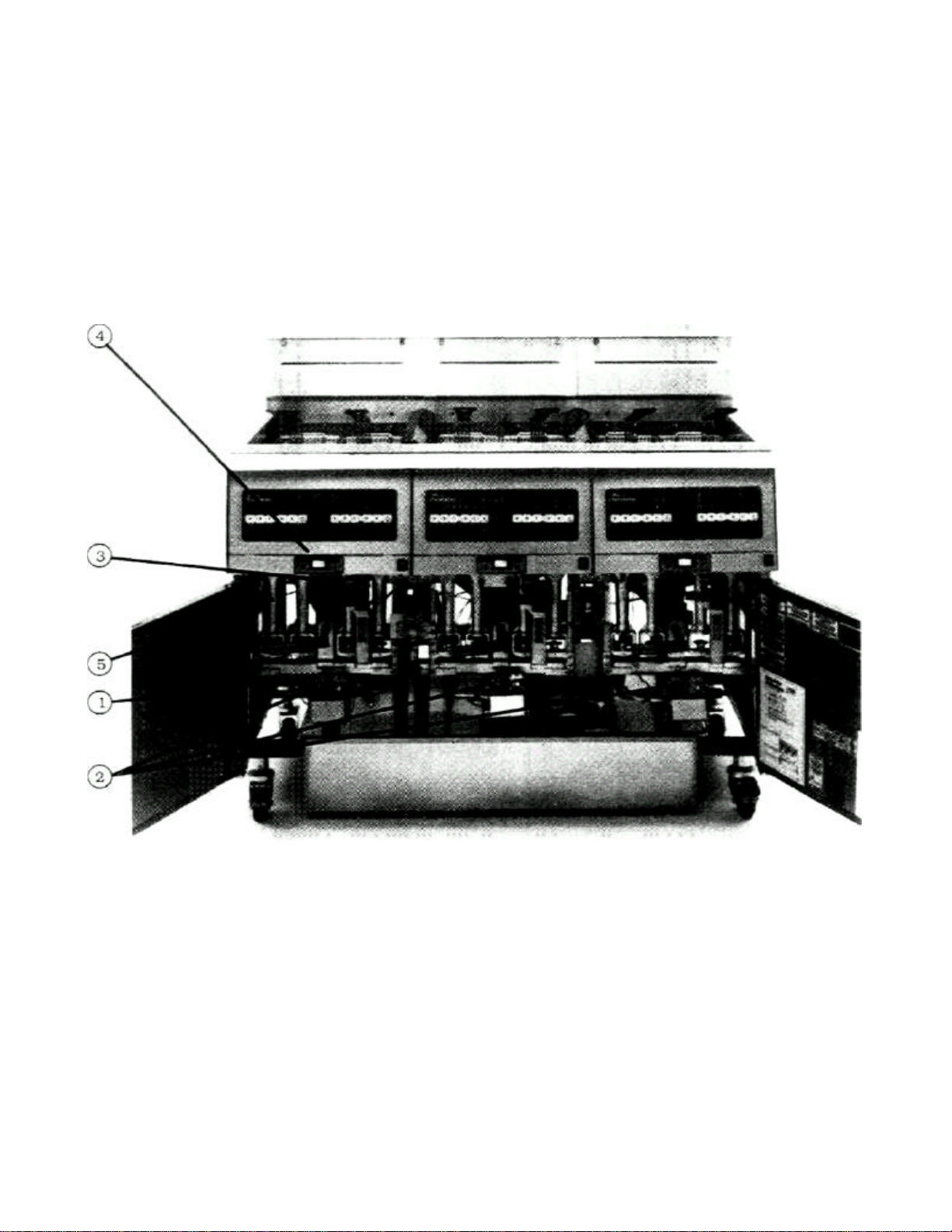

2.4 SHORTENING FILTER PROCEDURES

This section describes the procedures used to filter the fryer. Figure 2-2 shows the

locations of the components used in the filter process. The filter accessories and

tools you should have to perform normal filtering operations are described after

Figure 2-2. The illustrations used with the filter procedures are provided to show

where the oil is going and which valves are open. Frequent filtering of your

shortening will prolong the shortening's usable life. Daily shortening filtering is

strongly recommended.

NOTE

See Maintenance Section for Filter Operational

Information.

Figure 2-2 Fryer Illustrating Filter Components

2-13

Page 35

(1) Return Valve(s) RED - When open, with the filter pump on, allows the shortening to return to

the fryer tank.

(2) Unit Drain Connection YELLOW - Quick disconnect and valve for optional flush hose.

(3) Drain Valve(s) GREEN - Drain the oil from the fryer tanks to the filter pan.

(4) Oil Return Connection - Quick disconnect for return oil from the filter unit to the fryer.

Simply push down on fitting to connect. Lift up lower black collar to disconnect.

(5) Filter Media - Long lasting filter media. Filter paper envelopes.

(6) Filter Crumb Scoop - Short handle wide pan design, this scoop is used to remove the debris

from the filter pan.

(7) Cleaner - Used during fryer boil-out cleaning.

(8) Drain Clean Out Rod - Long handled design, this tool is used to clean out the drain openings.

(9) Precoat Filter Aid - Coarse Diatomaceous earth used to enhance the filter ability of the filter

media.

(10) Cleaning Brush - This long handled stiff bristle brush is used to brush down the crumbs

inside the fryer tank during shortening filtering.

(11) Fryer Crumb Scoop - A specially designed long handle scoop for scooping out the fryer. The

scoop section is narrow enough to fit down between the fryer burner tubes.

(12) Precoat Measuring Cup - Marked in ounces for correctly measuring precoat to be added to

the shortening prior to filtering.

At operating temperature the shortening temperature will be greater than

3OOF. Extreme care should be used when filtering operating temperature

shortening to avoid personal injury.

2-14

Page 36

2.4.1 General Filter Hints

1. Ensure that all oil in the filter pan is returned before it cools and hardens. This is very

important if you are using solid shortening.

2. Always use Pitco Precoat® for fastest filtrations, maximum labor saving, and cleanest/

clearest shortening possible. Impaired filter performance will result without the use of a filter

aid.

3. The longevity of your oil is related to how clean you keep it. With a Pitco built in system, it is

easy to do a quick drain/refill anytime. By removing suspended particles often, it prevents

them from burning.

4. When the time it takes to refill the fryer after filtering exceeds 3:00 minutes per tank, scrape

the filter media. If scraping does not bring the refill time back down to less than 3:00 minutes,

thoroughly clean the filter media and replace as necessary.

5. The filter pump is protected from clogging by a special screen in

the pickup tub. Clean this screen thoroughly each time the filter is

cleaned or new filter media is installed (see Chapter 3).

6. If you have filter system problems refer to section 3.7.3.

7. Always check to ensure that the oil return line is connected securely

before filtering.

2-15

Page 37

2.4.2 Filter Procedures

Numbers in parenthesis refer to Figures 2-1 and associated text.

NOTE

• When working with hot oil ALWAYS wear oil-proof, insulated gloves.

NEVER

• Run the filter system without a filter bag/paper.

• Empty the oil from the fryer before turning OFF the fryer burners.

• Store the UFM Filter Unit anywhere other than in the fryer filter cavity.

a. Disconnect the filter pan, slide it out. Scrape previously filtered residue off the filter media.

Examine the filter media for clogged or torn areas. Refer to 3.1.1 for filter media replacement

instructions. Reinstall the pan.

b. Turn the fryer that is to be filtered OFF (See Standby Shutdown). Remove the baskets from

the fryer tank(s). Use the clean out rod (8) to lift out the tube screens. If there are excess

crumbs in the fryer tank, remove them with the crumb scoop(l 1).

c. If you have replaced or scraped the filter media, stir in Precoat Filter Aid (9) to the oil in fryer

(2 packets per fry tank being filtered). After cleaning out the excess debris with the fryer

scoop (11) sprinkle the powder into the first fry tank to be filtered and stir the powder into the

oil.

d. Check the drain spout to ensure that it is over the filter cover opening. Adjust the cover or

slide the filter pan as necessary to line up the drain and the cover opening.

e. Slowly open the green handled drain valve (2) for the tank being filtered. If necessary use the

clean -out rod (8) to clear the crumbs from the drain. Use the long handled brush (10) to clean

the sides of the tank as the oil drains.

NOTE

This filter pan is large enough to filter all three tanks at once.

f. When the tank is empty, close the green handled drain valve. Open the red handled return

valve (1) to the tank you are filtering. This will start the pump and return the oil to the bottom

of the fry tank. As the tank fills, brush the inside of the tank to remove crumbs.

g. When bubbles are seen coming out of the oil return spout, close the red handled valve to turn

the pump off. Open the green handled drain valve (2) and allow the tank to drain again. Repeat

steps b through d until the tank is clean.

2-16

Page 38

h. When the tank is clean, drain the shortening by opening the green handled drain valve (2).

With the drain valve open, open the red handled return valve (1) and allow the shortening to

circulate for approximately 2 minutes. This ensures that all impurities are removed from the

shortening.

i. Close the red handled return valve to turn off the pump. Close the green handled drain valve

and replace the tube screen in the fry tank.

j. Open the red handled return valve (1) and turn on the pump to refill the fryer with the filtered

oil. Continue to run the filter pump until bubbles come out the oil return opening. Close the

red handled valve to mm the pump off. If necessary add more oil to the tank to return the oil

level to the fill mark. The fryer is now ready for use.

2.4.3 Draining a Tank

The filter system is also used to drain the fryers. You will need the Shortening Shuttle® that came

with the fryer to perform this procedure. This procedure can be used in conjunction with the filter

procedure (2.6.2). Instead of performing step (j) of the filter procedure perform the procedures

below.

The Shortening Shuttle® only hold enough oil to accommodate one fry

tank at a time.

a. Move the Shortening Shuttle® to the front of the fryer close enough to connect the hose to

the drain outlet.

b. Connect the male quick disconnect fitting of the Shortening Shuttle® to the female quick

disconnect of the fryer. There is a yellow handled valve associated with the fryer drain quick

disconnect. Ensure that the hose is firmly connect to the fryer.

c. Open the green handled drain valve for the tank to be drained. The oil will drain to the filter

pan. When the fry tank is empty close the green handled drain valve.

d. Open the yellow handled discharge valve. This will start the pump and pump the oil from the

filter pan to the Shortening Shuttle®.

e. When the filter pan has been pumped out, close the yellow handled discharge valve.

Disconnect the Shortening Shuttle® hose from the fryer. Fill the fry tank with fresh oil and

restart the fryer.

2-17

Page 39

CHAPTER 3: OWNER MAINTENANCE AND ADJUSTMENTS

This chapter provides you with the information and procedures necessary to perform maintenance,

adjustments, and service on the Wendy's W 14S-3 WF fryer. If after performing maintenance on your

fryer it does not perform properly, contact your authorized service center.

The power supply must be disconnected before servicing or cleaning the

appliance.

3.1 FILTER MEDIA REPLACEMENT

The filter module stores neatly under the fryer when not in use. The unit is very easy to use and

allows for quick installation and filtration, even under the busiest conditions. Follow the procedures

below to change the filter media.

At operating temperature, the shortening in the fryer may be hotter

than 375°F (190°C). This hot, melted shortening will cause severe

bums. Do not let the hot shortening touch your skin or clothing.

Always wear insulated oil-proof gloves when working on the filter

system. It will be easier and safer if the filter assembly has cooled to

room temperature before handling any filter parts.

a. To remove the filter media, disconnect the filter tube pick-up from the fryer. This is done by

unscrewing the pick-up tube connector from the fryer connector.

b. Grasp the filter pan handle and gently pull the assembly toward the front of the fryer. When

the pan is clear of the fryer, remove the filter pan cover.

c. Discard any debris that may be in the crumb

catch.

d. Lift up on the filter paper assembly and

remove from the filter pan. Unscrew the

suction tube from the filter paper support

rack. Remove the clip screen and slide the

filter paper support rack assembly out of the

filter bag.

3-1

Page 40

e. All of the filter pick up assembly parts can be washed in a dish washer or

a pot sink. Flush out the suction tube assembly with hot water. The pick

up tube screen keeps grit and solid material from binding the pump. After

flushing the pick up tube screen check to ensure that the screen is free of

debris. After cleaning, it is very important to thoroughly dry the parts

before re-assembling. Water and oil do not mix. Water in hot oil will

cause the oil to splatter.

f. Start re-assembling the filter pick up assembly by sliding the new filter

paper on to the filter paper support rack. Ensure that the hole in the filter paper goes

over the pick up tube assembly threaded connector.

g. Fol d the open end of the bag in two folds. The

first fold should be approximately 1 inch from

the end and the second should be over the edge

of the rack assembly. Approx. One Inch

h. Slide the clip screen over the folded

end of the filter paper. Ensure the opening of the

clip screen goes over the pick up tube connection.

Screw the suction tube assembly onto the threaded

connection.

i. Slide the filter pan assembly back into the filter unit and attach the pick up tube

connector to the filter unit connection.

3-2

Page 41

3.2 FRYER CLEANING

3.2.1 Daily

Your fryer should be clean every day to maintain peak performance and appearance. Perform the

procedures below every day.

a. Wipe up any shortening that spills onto the exterior of the fryer. This should be done with a

clean soft cloth while the oil is still warm.

b. Use warm water with a mild detergent to clean surfaces. Be careful not to get water in the

shortening and to remove any detergent from the fry tank.

c. Use a nonabrasive scouring powder or pad to clean stains if necessary.

3.2.2 Weekly (Boilout)

The fryer should be thoroughly cleaned once a week. This cleaning should include a complete

draining of the fryer and a boil out. This would also be a good time to check the filter media for

damage.

CAUTION

Completely shut down the fryer when the oil is to be replaced by

water, and when the heating portion of the cleaning is complete. This

will prevent the heating system from coming on during the oil draining

and water filling procedure.

a. Drain the oil from the fryer using the fryer drain procedures in chapter 2. When the oil has been

pumped into the oil shuttle, disconnect the filter pan and remove from the fryer.

Do not use the filter pan to drain cleaning water into. The only way to

remove liquid from the filter pan is via the filter pump. Do not use the

filter pump to pump water. Water can remain in the filter lines and mix

with hot oil during filter procedures creating a problem.

b. Remove tube rack/mesh tube screens and remove any large debris from the bottom of the fry

tank. Close the drain valve and fill the fry tank with water and noncaustic detergent. For best

results use Pitco Fryer Cleaner part number P6071397.

c. Place a large pan under the drain. This pan will be used to catch the cleaning water. The pan

must be of sufficient size to hold all of the water.

3-3

Page 42

d. Restart your fryer as described in 2.3. When the water temperature reaches 212°F the computer

will automatically go into Boil mode. To get the fryer out of BOIL mode you must turn the

fryer power off.

e. After the water has reached a slow boil, turn the fryer off. Allow the fryer to soak for 20

minutes to soften shortening deposits and carbon. Use fryer brush to remove any residue from

tank, heating tubes, and side walls. Perform the daily cleaning procedure described in section

2.5.

f. Drain the water into the pan by slowly opening the green handled drain valve.

g. Wipe the tank dry with clean cloth wipes. Close the drain valve and remove the large container.

h. Refer to section 2.1 to refill the fryer.

3.3 FLUE AND BAFFLE INSPECTION

It is recommended that once every six months, with the cooker cooled down, you examine the flue

area. Check for corrosion or blockage of the flue. Ensure that the cooker is shutdown and do not

turn it on during the examination. Examination of the flue area during cooking may cause bodily

i njury.

3.4 SERVICE

This chapter provides the qualified technician with the replacement and troubleshooting procedures

necessary to service the Pitco fryer.

3.4.1 Replacement Procedures

These procedures are provided to the qualified technician as a guide to removal and replacement of

various fryer components. If a test is required to verify component operation after installation, it

will be referenced.

To prevent bums, always ensure the fryer is completely SHUT DOWN and

COOLED down before working on the fryer. Do not break any fryer gas

connections while the unit is connected to a gas supply line.

The power supply must be disconnected before servicing or cleaning the

appliance.

3-4

Page 43

3.4.1.1 Main Burner Removal and Replacement

a. Loosen the set screw in the base of the burner casing.

b. Unscrew and remove the two hex head screws at the top of the burner.

c. Loosen the set screw on the air collar. Lift the burner and air collar up to clear the top of the

burner fitting. Remove the burner from the fryer.

d. To re-install the burner, reverse the procedure.

3.4.1.2 Changing the Main Burner Orifice

a. Unscrew the orifice with a 3/8" wrench and remove the orifice.

b. Insert the new orifice and tighten with the 3/8" wrench. Ensure the orifice is tight enough to

prevent gas leakage around the orifice.

3.4.1.3 Replacing the Heat Baffles

a. Remove the Main Burner as described in 3.4.1.1.

b. The heat baffles are located inside the heat tubes. They are attached to the rear of the baffle

supported by tack welds. Using a chisel, break away the baffle support and remove the old

baffles. Be careful not to puncture the heat tubes because this will require complete tank

replacement.

c. Insert the new baffles in the tubes in the original position. The new baffles sit in position and

do not require welding.

d. Install the main burners.

3.4.1.4 Pilot Burner Removal and Replacement

a. Unscrew the tubing nut from the pilot tubing connection at the gas valve. Disconnect the

thermopile from the connection on the gas valve.

b. Unscrew and remove the two screws that attach the pilot assembly to the fryer tank. Lift the

entire pilot assembly out of the fryer.

c. To replace the pilot assembly, reverse the procedure.

3.4.1.5 Pilot Orifice Replacement

a. Remove the pilot assembly as described in 3.4.1.4.

3-5

Page 44

b. Unscrew the tubing nut from the pilot tubing connection at base of the pilot burner. The pilot

orifice is located inside the tubing connection.

c. Remove the orifice and replace with the new orifice. Ensure the orifice is tight enough to

prevent gas leakage around the orifice.

d. Replace the tubing nut in the pilot tubing connection and tighten enough to prevent gas

leakage.

e. Replace the pilot assembly and adjust the pilot flame as described in 1.5.2.

3.4.1.6 Thermopile Replacement

a. Remove the pilot assembly as described in 3.4.1.4.

b. Unscrew and remove the thermopile from the pilot assembly.

c. Remove from gas valve magnet.

d. Insert the new thermopile in the pilot assembly.

e. Replace the pilot assembly and adjust the pilot flame as described in 1.5.2.

3.4.1.7 Limit Control Replacement

The limit control includes a temperature sensor inside the fryer tank, control unit inside the fryer

cabinet, and connecting capillary tubing. The high limit control temperature sensor looks like the

thermostat temperature sensor, so ensure you are removing the correct temperature sensor clamp.

CAUTION

The limit control capillary tubing is very delicate. Be VERY

CAREFUL when working with the capillary tubing. If the tubing is

kinked or broken the limit control is no longer usable.

a. Drain the oil from the fryer and remove the heat tube screens.

b. The limit control probe (heat sensor) is clamped to the heat tube inside the tank. Unscrew and

remove the two screws in the probe clamp.

c. Remove the probe from the clamp and straighten the capillary tubing. Unscrew the small hex

nut inside the cabinet at the bottom of the tank for the limit control.

d. Unscrew the large connector nut from the tank and pull the probe and capillary tubes through

the opening.

3-6

Page 45

3.5 TROUBLESHOOTING

This section is provided to aid you in the event of fryer or filter troubles. If these troubleshooting

procedures do not correct your problem contact a qualified technician or the factory. The

troubleshooting procedures are in a flowchart format.

3.5.1 Fryer Troubleshooting

Refer to this section to correct common problems that may be encountered in equipment operation.

3-7

Page 46

3.5 TROUBLESHOOTING

This section is provided to aid you in the event of fryer or filter troubles. If these troubleshooting

procedures do not correct your problem contact a qualified technician or the factory. The

troubleshooting procedures are in a flowchart format.

3.5.1 Fryer Troubleshooting

Refer to this section to correct common problems that may be encountered in equipment

operation.

3-8

Page 47

Page 48

Page 49

Page 50

CHAPTER 4: PARTS

This chapter contains listings of the components used in the Wendy's model W14S-3 WF fryer.

These components are listed in two places, with the illustration and in ordered part lists. The

illustrations in this chapter are provided to show relative location of component of the fryer. With

each illustration there is a table of components in numerical order by illustration number. The

illustration has numbered lines pointing to components which are listed in the table.

At the end of this chapter there are alphabetical and numerical listings of all parts used in the fryer.

The alphabetical part list is arranged in alphabetical order according to the part name. Each part

name also has the Pitco Frialator part number. The numerical list is in Pitco Frialator part number

order. A brief description of each component is provided for each part.

4-1

Page 51

Table 4-1 Wendy's Model W14-3UFM Exploded View (Index)

Index Number

1 Tank, Weldment W/RR NIP 52 Handle, Valve Weldment

2 Clamp, Probe Temperature 53 Aces, Switch Drain Valve Interlock

3 Clamp, Bulb Limit Pasta 54 PG, Bracket Manifold Sprt 14

4 Tank Fitting, NIP Drain Ext 55 Screw, 10-24 x 1/2 HHC SS

5 Tank, Bracket Spacer Overflow 56 Washer, Flat #10

6 Valve, Ball 1-1/4" Drain Full Port 57 Screw, 10-24 x 1/2 Thumb W/S

7 Tank, Overflow Tubing Weldment 58 Connector, Thermocouple SS

8 Clamp, U-Bolt 1/4 -20 x 1-1/8 59 PG, Cir Air, 7,12,12D,14,14C+,14R,18

9 Probe, Thermistor Gas 60 Switch, Rocket SPST W/BK (1-1)

10 FL, Weldment 14 HRPO 61 Handle, Drain Spacer

11 Tank, BK SPLH Weldment 62 Cabinet Bk, Bracket Relief Valve

12 Cabinet, Frame Weldment 63 Entrance Box, Assy Left

13 Cabinet, Side, Right Hand 64 Entrance Box, Assy Middle

14 Cabinet, Side, Left Hand 65 Entrance Box, Assy Right

15 Cabinet, Back, Top 66 Label, Sheet Gas 7,14,18,14R,14C+

16 Cabinet, DR Bumper Assy 67 Label, Overlay Pump Circuit Breaker

17 Front Panel, Rail Bottom 68 Label, Drain Handle

18 Front Panel, Cap End Left Hand 69 Label, Discharge Valve

19 Front Panel, Cap End Right Hand 70 Label, Return Valve Handle

20 Front Panel, Intermediate SPRT Weldment 71 Label, Quick Filter Instruction

21 Front Panel, Bezel Weldment 72 Label, Switch ON-OFF

22 Cabinet, DK Front Weldment 73 Label, A-F

23 Computer, EP 3600 14 Single (TDI) 74 Schem, Label

24 DR, Assy, Right Hand 75 Handle, Valve 24R.18WKS, E147UFM

25 DR, Assy, Left Hand 76 Pin, Clevis 1/4 x 2-1/4

26 Hinge, Pivot Vertical Bracket Top RH 77 Pin Cotter 1/16 x 3/4 ZN

27 Hinge, Pivot Vertical Bracket Bottom LH 78 Grommet 0-19 ID x 1.13 OD x 0.88 GRV

28 Hinge, Pivot Vertical Bracket Top LH 79 Screw, 1/4 -20 x 1 HHC SS Full Thread

29 Hinge, Pivot Vertical Bracket Bottom RH 80 Nut, Hex (KEP) 1/4 -20 ZN

30 Caster, Swivel, 7" Locking Polyu 81 Electric Assy, Power Cord

31 Caster, Swivel, 7" Nonlocking Polyu 82 Clip, U, Spring Steel 0.10-0.16

32 Burner, Pitco 4" 83 Screw, 10-32 x 1/2 PHN ZN TF

33 PG, Manifold Assy, Nat 84 Box, Electrical 4 x 2-1/8 x 1-7/8

34 PG, Pilot Assy Nat 85 Cover, Box, 4x2

35 PG, Sprt Flush Hose 86 Screw, 1/4 -20 x 2-1/4 HHC ZN

36 PG, Sply Gas RR 87 Screw, 1/4-20 x 1/2 HHC SS

37 PG, Brkt Sprt Gas Manifold 88 Screw, 5/16-18 x 3/4 HHC SSBB

38 Filter, Handle Return Assembly 89 Washer, Lock 5/16 ZN (Split)

39 Filter, Bracket Handle Actuator 90 Screw, 10-32 x 1/4 Set SH Cup Pt

40 Filter, PG Return Assy 91 Wrg, Valve 24V GBB Non-EI

41 PG, Out Discharge Assy 92 Nut, Hex (KEP) 10-24 ZN

42 Hi-Limit Switch Assy 93 Screw, 10-24 x 5/8 RDH Phillips SS

43 Gasket, Drain Line (Sleeve) 94 Nutsert 10-24 (AVDEL)

44 Filter, Pan Weldment 95 Label, Overlay P/Matic 14 Clear Prot

45 Filter, Lid Weldment 96 Tank, Shield, Burner Bracket, Heat 14 L

46 Filter, Bracket SW 97 Tank, Shield, Burner, Bracket Heat 14 R

47 Front Panel, Intrmed Sprt Weldment L 98 Label, Caution Yellow

48 Filter, Tube Suction Assy 99 Label, Reset Button Horizontal

49 Filter, Rack Weldment 100 Ship Kit, W1'4-3UFM Wendy's (N/S)

50 Filter, Screen, Clip 101 Filter Envelope 20.5 x 14.344 Center Hole

51 Filter, Air RLF Assy

Description Index Number Description

Page 52

NOTES.

1. ITEMS NOT SHOWN FOR CLARITY:

#58 P5045047 - CONN, THERMOCOUPLE SS QTY 3.

#59 A8001001 - COLLAR, AIR QTY 12.

ALL LABELS, REFER TO DWG B60-OS9 FOR LOCATIONS AND PART NUMBERS.

ALL HARDWARE.

Figure 4-1 Wendy's Model W14S-3WF Exploded View 4-3

Page 53

4-4

Page 54

ALPHABETICAL PART LIST

Part Description

BRUSH, FRYER CLEANING PP10056

BURNER, MAIN "A" 4" P6071050

CASTER, 7" LOCKING PP10883

CASTER, 7" NON-LOCKING PP10884

CLAMP, U-BOLT PP10891

CLEANER, FRYER SAMPLE PACKET P6071400

COLLAR, AIR - SET SCREW TYPE A8001001

COMPUTER, EPS 600, 14 SINGLE (TDI) PP10804

DOOR ASSEMBLY - LH B2301902

DOOR ASSEMBLY - RH B2301902

DRAIN VALVE HANDLE B4000801

FILTER PAN B6632701

FILTER PAN LID B6632801

FILTER RACK ASSEMBLY B6620002

FILTER SCREEN CLIP B6617002

FILTER TUBE SUCTION ASSEMBLY B6633801

FLUE HEAT DEFLECTOR 14/14B/14R/P14/PR14/RTG14 A3 519905

FLUE HEAT DEFLECTOR 14/14B/14R/P14/PR14/RTG14 - SS A3519906

FUSE, 15 AMP, 125V P5045727

HANGER, BASKET #14/14R/PM14/PR14 C/R A1100107

HANGER, BASKET #14/14R/PM14/PR14 S/S A1100108

HI-LIMIT SWITCH ASSEMBLY B7550401

HIGH LIMIT BULB CLAMP A1402202

HINGE, DOOR - BOTTOM LEFT PP10894

HINGE, DOOR - BOTTOM RIGHT PP10893

HINGE, DOOR - TOP LEFT PP10895

HINGE, DOOR - TOP RIGHT PP10896

KNOB, UNITROL P6071267

MAGNET, DOOR - ALL MODELS P6071300

PILOT ASSY, W/ HEAT SHIELD B3302501

PROBE, THERMOSTAT PP10882

RETURN VALVE HANDLE (RED) B6634101

ROD, FRYER CLEAN OUT A3301001

SCOOP, FILTER CRUMB B7404801

SCOOP, FRYER CRUMB B7490701

TANK BACKSPLASH B3312801

TANK BRACKET, OVERFLOW A3322002

TANK FITTING, DRAIN A2511501

TANK, STAINLESS STEEL B3312902

Pitco Frialator

Part Number

TEMPERATURE PROBE CLAMP A1402302

4-5

Page 55

ALPHABETICAL PART LIST

Part Description Pitco Frialator

Part Number

TEMPERATURE PROBE CLAMP Al402202

VALVE, DRAIN 1-1/4" P6071785

4-6

Page 56

NUMERICAL PART LIST

Pitco Frialator

Part Number

Al100107 HANGER, BASKET #14/14R/PM14/PR14 C/R

Al100108 HANGER, BASKET #14/14R/PM14/PR14 S/S

A1402202 HIGH LIMIT BULB CLAMP

A1402202 TEMPERATURE PROBE CLAMP