Page 1

Installation and Operation Manual

Covering Models

VF35, VF65 Fryers

L20-418 Rev 2 (5/16)

Page 2

TO THE PURCHASER, OWNER AND STORE MANAGER

TO THE PURCHASER

supplier.

FOR YOUR PROTECTION

this equipment when it is in operation.

WARNING

equipment.

Please review these warnings prior to posting them in a prominent location for re ference.

WARNING

Post in a prominent location the

instructions to be followed in the event

that an operator smells gas. Obtain this

information from your local gas

DO NOT store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other equipment.

Do not spray aerosols in the vicinity of

Improper installation, adjustment,

operation, alteration, service or

maintenance can cause property

damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before

installing, operation, servicing this

WARNING

Installation, maintenance and repairs

should be performed by a Pitco

Authorized Service and Parts (ASAP)

company technician or other qualified

personnel. Installation, maintenance or

repairs by an unauthorized and

unqualified personnel will void the

warranty.

WARNING

Installation and all connections must be

made according to local codes in force.

In the absence of local codes in North

America, the installation must conform

with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or the Natural Gas and

Propane Installation Code CSA B149.1

as applicable. In Australia, the appliance

must be installed in compliance with

AS/NZS 5601.

During the warranty period if a customer

elects to use a non-original part or

modifies an original part purchased from

Pitco and/or its Authorized Service and

Parts (ASAP) companies, this warranty

will be void. In addition, Pitco and its

affiliates will not be liable for any claims,

damages or expenses incurred by the

customer which arises directly or

indirectly, in whole or in part, due to the

installation of any modified part and/or

received from an unauthorized service

center.

WARNING

This appliance, when installed, must be

electrically grounded in accordance with

local codes, or in the absence of local

codes, with the National Electrical Code,

ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2, as

applicable and the hose must comply

with AS/NZS 1869 and be class B or D.

WARNING

Adequate means must be provided to

LIMIT the movement or this appliance

without depending on the gas or

electrical cord connection. Single

appliances with legs must be stabilized

by installing anchor straps. All

appliances equipped with casters must

be stabilized by installing restraining

chains.

WARNING

An appliance equipped with casters and

a flexible gas line must be connected to

the gas supply with a quick disconnect

device. In North America, this quick

disconnect must comply with ANSI

Z24.41. In Australia, the quick

disconnect must comply with AS 4627.

ii L20-418 Rev 2 (5/16)

Page 3

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for re ference.

WARNING

DO NOT alter or remove structural

material on the appliance to

accommodate placement under a

ventilation hood.

WARNING

If the appliance is equipped with a power

cord and it is damaged, it must be

replaced by a Pitco Authorized Service

and Parts (ASAP) company technician,

or a similarly qualified person in order to

avoid a hazard.

WARNING

The power supply must be disconnected

before servicing, maintaining or

cleaning this appliance.

WARNING

The appliance is NOT jet stream

approved. DO NOT clean the appliance

with a water jet.

WARNING

DO NOT attempt to move this appliance

or transfer hot liquids from one

container to another when the unit is at

operating temperature or filled with hot

liquids. Serious personal injury could

result if skin comes in contact with the

hot surfaces or liquids.

WARNING

DO NOT use an open flame to check for

gas leaks!

WARNING

DO NOT sit or stand on this appliance.

The appliance’s front panel, tank, splash

back, tank cover, workshelf, drain board

is not a step. Serious injury could result

from slipping, falling or contact with hot

liquids.

WARNING

NEVER use the appliance as a step for

cleaning or accessing the ventilation

hood. Serious injury could result from

slips, trips or from contacting hot

liquids.

WARNING

The oil/shortening level should NOT fall

below the minimum indicated level line

at any time. The use of old shortening

can be dangerous as it will have a

reduced flash point and be more prone

to surge boiling.

WARNING

The contents of the crumb catch and/or

filter pan of any filter system must be

emptied into a fireproof container at the

end of the frying operation each day.

Some food particles can spontaneously

combust into flames if left soaking in

certain oil/shortening materials.

WARNING

Completely shut the appliance down

when oil/shortening is being drained

from the appliance. This will prevent the

appliance from heating up during the

draining and filling process. Serious

injury can occur.

WARNING

This appliance is intended for indoor

use only.

WARNING

DO NOT operate appliance unless all

panels and access cov ers are att ach ed

correctly.

WARNING

It is recommended that this appliance be

inspected by a qualified service

technician for proper performance and

operation on a yearly basis.

L20-418 Rev 2 (5/16) iii

Page 4

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for re ference.

WARNING

There is an open flame inside this

appliance. The unit may get hot enough

to set nearby materials on fire. Keep the

area around the appliance free from

combustibles.

WARNING

DO NOT supply the appliance with a gas

that is not indicated on the data plate. If

you need to convert the appliance to

another type of fuel, contact your dealer.

WARNING

If gas flow to appliance is interrupted, or

pilots extinguish, wait 5 minutes before

attempting to relight the pilot to allow

any residual gas in appliance to

dissipate.

WARNING

Ensure that the appliance can get

enough air to keep the flame burning

correctly. If the flame is starved for air, it

can give off a dangerous carbon

monoxide gas. Carbon monoxide is a

clear odorless gas that can cause

suffocation.

WARNING

Never add oil to the appliance when it is

at operating temperature. Splashing hot

oil can cause severe injuries.

WARNING

Never add water to hot oil. Violent

boiling can occur causing severe injury.

WARNING

This appliance is intended for

professional use only and should be

operated by fully trained and qualified

personnel.

WARNING

To avoid splashing of hot liquid when

installed, this fryer must be restrained

either in the manner of installation, or

with adequate ties to prevent tipping.

WARNING

In North America, gas appliances

equipped with casters must be

installed with connectors that comply

with the Standard for Connectors for

Movable Gas Appliances, ANSI

Z21.69.CSA 6.16 Latest Edition. This

connection should include a quick

disconnect device that complies with

the Standard for Quick Disconnect

Devices for Use with Gas Fuel ANSI

Z21.41.CSA 6.9 Latest Edition.

WARNING

In Australia, an appliance equipped

with casters and a flexible gas line

must be connected to the gas supply

with a quick disconnect device that

complies with AS 4627 Latest Edition

and a restraining cable. The restraining

cable must not exceed 80% of the

length of the flexible gas line.

WARNING

This appliance is not intended for use by

a person (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning

use of the appliance by a person

responsible for their safety. Children

should be supervised to ensure that

they do not play with the appliance.

WARNING

Children should not be in the vicinity of

this appliance when it is being operated,

cleaned, maintained or serviced nor

allowed to play on and/or with the

appliance at any time.

iv L20-418 Rev 2 (5/16)

Page 5

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

INSTALLATION .................................................................................................................................................. 6

GAS CONNECTION ............................................................................................................................................ 9

FILLING THE APPLIANCE ................................................................................................................. 11

LIGHTING INSTRUCTIONS ............................................................................................................... 12

PILOT FLAME ADJUSTMENT ........................................................................................................... 13

BURNER SYSTEM ADJUSTMENT ..................................................................................................... 13

OPERATION .................................................................................................................................................... 15

APPLIANCE START UP ..................................................................................................................................... 17

APPLIANCE SHUTDOWN ................................................................................................................................. 18

PREVENTATIVE MAINTENANCE ...................................................................................................................... 18

APPLIANCE INSPECTION ................................................................................................................. 19

CLEANING THE COOK TANK ............................................................................................................ 19

CLEANING THE CABINET ................................................................................................................. 19

BOIL OUT PROCEDURE ................................................................................................................... 20

SAFETY EVALUATION ..................................................................................................................... 21

MECHANICAL INSPECTION ............................................................................................................. 21

TEMPERATURE CONTROL SYSTEM ................................................................................................. 21

GAS COMBUSTION SYSTEM ........................................................................................................... 21

TROUBLESHOOTING ....................................................................................................................................... 23

L20-418 Rev 2 (5/16) 5

Page 6

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

Combustible Construction

Non-Combustible Construction

Inches (centimeters)

Inches (centimeters)

Back

6.0" (15.2 cm)

0.0" (0.0 cm)

Sides

6.0" (15.2 cm)

0.0" (0.0 cm)

Floor

9” (22.86 cm)

9” (22.86 cm)

WARNING

WARNING

WARNING

INSTALLATION

Your new Pitco appliance has been carefully packed into one crate. Every effort has been made to ensure

that it is delivered to you in perfect condition. Pitco does not assume responsibility for damage or loss

incurred in transit. If something is damaged, DO NOT sign the bill of lading.

1. Upon Delivery, inspect for visible shipping damage in the presence of the trucking operator. If

something appears damaged, file a claim for damages regardless of extent.

2. Unpack and inspect unit for damage. Contact the shipper within 15 days and file a concealed damage

claim; the shipper is only responsible for concealed damage for 15 days after delivery.

3. Remove the unit from the shipping pallet:

4. Do not allow the full weight of the unit to rest on the legs or caster (if installed) when removing the

appliance from the shipping pallet. The casters can be bent or damaged if too much weight or force is

applied to them from improper handling.

5. Check the packing list enclosed with your appliance to ensure that you have received all the parts to the

appliance. If you are missing any parts, contact the dealer from whom the appliance was purchased.

6. Using the front cover of this manual, record the following for warranty service or future reference:

1. Your Pitco m odel number.

2. Fryer serial numbers (Found on the inner door of each fryer).

3. The date purchased from your dealer invoice.

Once you have completed the above, the fryer is ready to be installed.

The clearances shown below are for combustible and non-combustible installations and will allow for safe

and proper operation of your fryer.

In addition to the above clearances there must also be at least 30 inches (76.2 cm) of aisle space in front

of the fryer.

Leave at least 18 inches (47 cm) of open space between the flue of the appliance and the

intake of the exhaust hood. Failure to do so could result in improper operation of the

appliance.

DO NOT obstruct the flow of ventilation air openings around the appliance. Adequate

clearance around the appliance is necessary for servicing and proper component ventilati o n.

Ensure that you meet the minimum clearance requirements specified in this manual.

DO NOT install this appliance next to a water cooker, or use it in any way in which water can

come in contact with the hot oil. Splash over of water into hot oil may result in a steam

eruption, potentially causing hot oil to be ejected from the fryer, and creating a burn hazard.

6 L20-418 Rev 2 (5/16)

Page 7

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

CAUTION

WARNING

WARNING

To prevent appliance damage and/or personal injury, do not tilt the appliance onto any two of its

casters or legs, or pull the appliance by the splash back.

This appliance must be installed with the legs or caster s provided by the manufacturer.

DO NOT perform leveling procedure when appliance i s in operation or full of hot liquids. Serious

injury could result.

When you receive your appliance, it is completely assembled with the possible exception of legs or

optional casters and heat deflector.

This appliance must be installed with legs or casters; it cannot be curb mounted, or sealed to a base.

Curb mounting will seriously inhibi t th is appliance’s ability to effect proper component ventilation. The

supplied legs or casters provide the necessary height to meet sanitation requirements and assure

adequate air supply for electrical com p on ent ventilation. To level the appliance, use the following

procedure.

Required tools: Large pair of water pump pliers, Medium flat blade screwdriver, level 12” (30.5 cm) long

max.

1 Position appliance in final installed location.

2 Apply level across front, and then the left and right side of unit, determine lowest point, and distance to

level.

3 Add the distance determined in step 2 to caster or leg on the lowest corner of appliance.

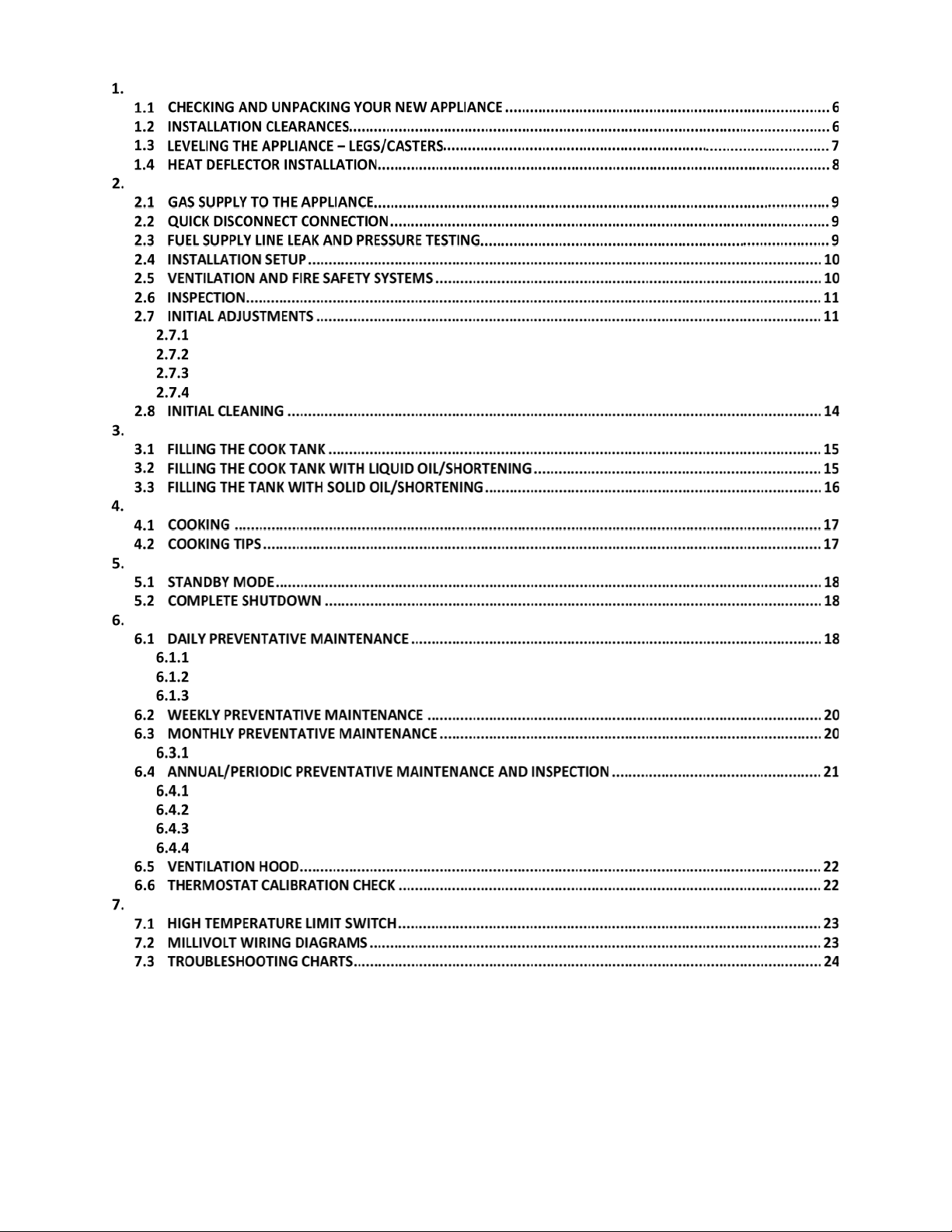

1. Swivel casters- loosen 2 set screws (A)

2. Legs and swivel casters-. Adjust the height of the leg / caster by turning adjustment collar/ foot (B)

with water pump pliers until desired change in height is achieved.

Swivel casters only: Retighten set screws (A).

3. Fixed casters- Adjust hei gh t by moving wheel and axle to alternate holes (D) in wheel bracket

higher or lower as needed. Refer to “FIXED” type caster in Figure 3.

4 Adjust remaining casters or legs as needed to ensure the appliance is supported evenly at each

caster/leg contact point.

L20-418 Rev 2 (5/16) 7

Figure 3 Caster and leg types

Page 8

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

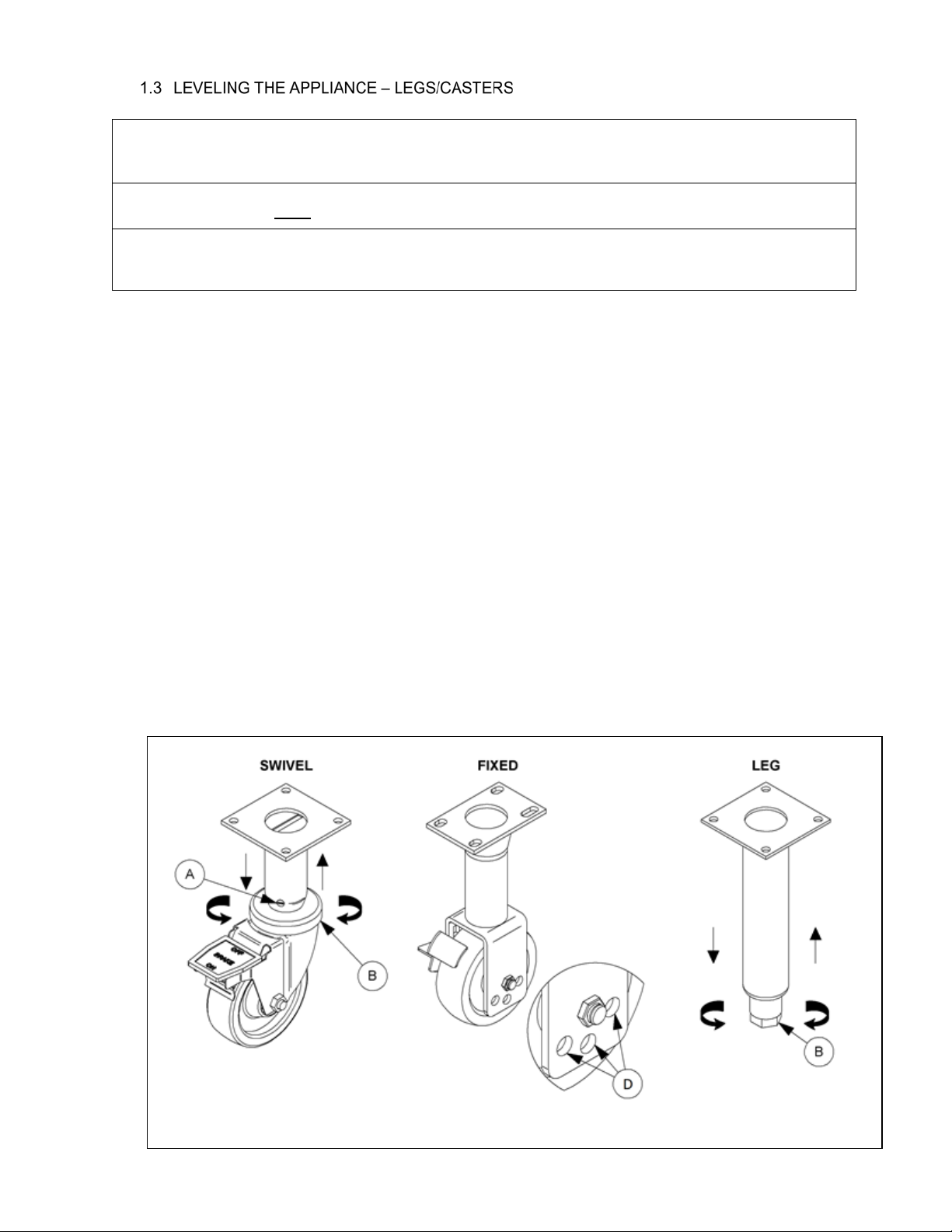

A T, BG, CH, CZ, DK, EE, FI, GB, GR, HU, IE, IT, LT, LV, NO,

PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ES I

2.2 mm / 2. 38 m m

BE

I

2E+

2.2 mm NO

DE

I

2EL L

2.2 mm / 2. 38 m m

NL

G25-G25.3 I

2L

- I

2EK

25 2.38 mm 2.3/2.2

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HU, HR, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31

I

3P

37/50 37 #54 0.8

A T, BG, CY, CH, CZ, DK, EE, FI, FR, DE, GR, HU, IE, IT, LT,

LU, MT, NL, NO, PL, RO, SI, SE, SK, TR

BU G30

I

3B/P

30/50 25.4 #55 0.6

A T, BG, CH, CZ, DK, EE, FI, GB, GR, HU, IE, IT, LT, LV, NO,

PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ES I

2.2 mm / 2. 38 m m

BE

I

2E+

2.2 mm NO

DE

I

2EL L

2.2 mm / 2. 38 m m

NL

G25-G25.3 I

2L

- I

2EK

25 2.38 mm 2.9

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HU, HR, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31

I

3P

37/50 25.4 #54 1.0

A T, BG, CY, CH, CZ, DK, EE, FI, FR, DE, GR, HU, IE, IT, LT,

LU, MT, NL, NO, PL, RO, SI, SE, SK, TR

BU G30

I

3B/P

30/50 25.4 #55 0.8

VF655

VF35

19.0

LP16

LP16

Nat

G20/G25

G20/G25

G20

G20

20.5

26.5

24.5

10.8

18.5

20/25

20/25

20

20

10

Applicable

Countries

Nat

Nominal Gas

Rate (m3/hr)

Model

Fuel Type

Net

Input ( kW )

Supply

Pressure (mbar)

Burner

Pressure (mbar)

Governor

Gas

Appliance

Category

Gross

Input ( kW )

YES

N22

Burner

Orifice

Pilot

Orif i ce ( code)

2.5/2.9

2.0/2.3

2.0

2.5

2.2 mm

2.2 mm

N22

YES

YES

YES

Model

Fuel Type

Gross

Input

BTUs (kW)

Net Input

kW

Supply

Pressure

(mbar)

Burner

Pressure

(mbar)

Burner

Orifice

Pilot

Orifice

(code)

Natural 18 7" W. C. (17. 4) 4" W. C. (10) 2.2 m m N22

Propane 19 11" W. C. (27. 4) 10 W.C. (25) #54 LP16

Natural 25 7" W.C. (17.4) 4" W. C. (10) #43 N22

Propane 26 11" W. C. (27. 4) 10 W.C. (25) 1.45 LP16

Natural 1.74 k Pa 1.0 k Pa 2.2 m m 0. 56 m m (N22)

ULPG 2.74 k Pa 2.5 k Pa 1.40 m m (#54) 0.41 m m (LP 16)

Natural 1.74 k Pa 1.0 k Pa 2.2 m m 0. 56 m m (N22)

ULPG 2.74 k Pa 2.5 k Pa 1.40 m m (#54) 0.41 m m (LP 16)

NON-CE GAS TA BLE

VF35

VF65

95 Mj/ h

VF35

70,000 (20. 5)

95,000 (27. 8)

VF65

74 Mj/ h

67 Mj/ h

86 Mj/ h

AUSTRALIAN GAS TABLE

the Netherlands Only - Natural Gas

CE GAS TABLE

Refer to the following table for gas specifications for the country of use. If the country of use is NOT listed, refer

to the information printed on the data plate.

Belgium – Natural gas units require a restrictor orifice on the supply line for proper operation.

Dit toestel is afgesteld voor de toestelcategorie K (I2K) en is geschikt voor het gebruik van G en G+

distributiegassen volgens de specificaties zoals die zijn weergegeven in de NTA 8837:2012 Annex D met

een Wobbe-index van 43,46 – 45,3 MJ/m3 (droog, 0 °C, bovenwaarde) of 41,23 – 42,98 (droog, 15 °C ,

bovenwaarde). Dit toestel kan daarnaast worden omgebouwd en/of opnieuw worden afgeregeld voor de

toestelcategorie E (I

) Dit houdt derhalve in dat het toestel: “geschikt is voor G+-gas en H-gas, dan wel

2E

aantoonbaar geschikt is voor G+-gas en aantoonbaar geschikt is te maken voor H-gas” in de zin van het

“Besluit van 10 mei 2016 tot wijziging van het Besluit gastoestellen….”

If the appliance requires a heat deflector, you will find a removable label at the rear top edge of the unit. This

label has instructions for pos itionin g and ins ta llati on of the h eat def lector . Refer to the label and the

instructions below to install the deflector.

1. Remove the two self-drilling screws from the top, back area of the appliance.

2. Position the heat deflector so that the angled portion of the deflector is facing toward the front of

8 L20-418 Rev 2 (5/16)

appliance. Secure the heat deflector to the back of the unit using the two previously rem oved

fasteners.

Page 9

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

dealer you purchased it from.

NOTICE

3. When properly installed the angled section of the heat deflector will extend over the flue opening to

redirect the heat. It SHOULD NOT cover the flue opening. Never allow anything to block the flue

opening; this will cause the appliance to overheat and inhibit prop er com bus tion, whic h could pr od uc e

dangerous gases

GAS CONNE CTION

Your gas appliance will give you peak performance when the gas supply line is of sufficient size to provide

the correct gas pressure. The gas line must be installed to meet the local building codes or North America

National Fuel Gas Code ANSI Z223.1 Latest Edition. In Canada, install the appliance in accordance with

CAN/CGA-B149.1 or .2 and local codes. In Australia, install the appliance in accordance with AS/NZS 5601

Latest Edition. Gas line sizing requirements can be determined by your local gas company or, in North

America, by referring to the National Fuel Gas Code, Appendix C, Table C-4 (for natural gas) and Table C16 (for propane). The gas line needs to be large enough to supply the necessary amount of fuel to all

appliances without losing pressure to any appliance.

A properly sized and installed gas line will deliver a supply pressure between 7.0” W.C.

(17.4mbars, 1.74kPa) and 10.0” W.C. (24.9mbars, 2.49kPa) natural gas or between 11.0” W.C.

(27.4mbars, 2.74kPa) and 13.0” W.C. (32.4mbars, 3.25kPa) for propane to all appliances

connected to the supply line, operating simultaneously at full demand.

THE PRESSURE AT THE GAS CONTROL VALVE SHALL NOT EXCEED ½ PSI (13.84 “WC, 34.5 mbar,

3.45 kPa).

The gas supply connection to this appliance is located in the rear of the appliance approximately 10-1/2”

(26.7 cm) from the floor of the appliance when legs are used.

Each appliance is equipped to operate on one certain fuel type. The type of fuel with which the

appliance is intended to operate is printed on the data plate, which is attached to the inside of the door.

NEVER supply the appliance with a gas other than the one that is indicated on the data

plate. Using the incorrect gas type will cause improper operation and could result in seriou s

injury or death. If you need to convert the appliance to another type of fuel, contact the

NEVER use an adapter to make a smaller gas supply line fit the appliance connection. This

may not allow proper gas flow for optimum burner operation, resulting in poor performance

and improper operation.

In North America, gas appliances equipped with casters must be installed with connectors that comply with

the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69.CSA 6.16 Latest Edition. This

connection should include a quick disconnect device that complies with the Standard for Quick Disconnect

Devices for Use with Gas Fuel Appliances ANSI Z21.41.CSA 6.9 Latest Edition. In Australia, an appliance

equipped with casters and a flexible gas line must be connected to the gas supply with a quick disconnect

device that complies with AS 4627 Latest Edit ion and a restraining cable. The restraining cable must not

exceed 80% of the length of the flexible gas line. The restraining device should be attached to the appliance

at the back panel.

For Australia, the appliance must be installed in accordance with AS/NZS 5601 Latest Edition, local

authority and any other relevant statutory regulations. Flexible hose (if used) must comply with AS/NZS

1869 Class B or D, be of appropriate internal diameter, be kept as short as possible (not exceed 1.2

meters), must not be kinked and not be in contact with a hot surface. A chain must be fitted to restrict the

appliance movement to no more than 80% of the hose length.

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be tested at a

pressure greater than ½ PISG (3.45 kPa, 34.5 mbar), ensure that that appliance is disconnected from the

fuel line. If the fuel line is to be tested at a pressure equal to or less than ½ PSIG (3.45 kPa, 34.5 mbar), the

L20-418 Rev 2 (5/16) 9

Page 10

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

WARNING

WARNING

adequately protected.

appliance can be connected during the test, but the unit’s gas control valve must be turned OFF. Test all

gas line connections for leaks with a solution of soap and water when pressure applied.

The installation of this appliance MUST conform to local codes. In the absence of local codes in North

America, the installation must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 Latest

Edition or the Natural Gas and Propane Installation Code CSA B149.1 Latest Edition as applicable. In

Australia, the appliance must be installed in compliance with AS/NZS 5601 Latest Edition

Your new appliance must have proper ventilation to function safely and properly. Exhaust gas temperatures

can reach as high as 1100 °F (593 °C). Therefore, it is very important to install a fire safety system. Your

ventilation system should be designed to allow for easy cleaning. Frequent cleaning and proper

maintenance of the ventilation system and the appliance will reduce the chances of fire. Ventilation and fire

safety systems must comply to local and national codes for US and Canada. Refer to ANSI 83.11 for a list

of reference documents that will provide guidance on ventilation and fire safety systems. For installations in

U.S. and Canada, additional information can be obtained from CSA International, 8501 East Pleasant Valley

Road, Cleveland, OH, 44131 or visit their website at www.csa-international.org

system must comply with AS/NZS 5601.0.

It is essential that the appliance be operated only when adequate ventilation is provided. Your ventilation

hood should be properly maintained. A qualified installation professional should ensure that the hood is

operating properly in conjunction with the appliance. Inadequate ventilation may not properl y evacuate all

appliance emissions. Excessive or unbalanced ventilation may cause drafts, which could interfere with

proper operation of the pilot and burners. Leave at least 18 inches (47 cm) of open space between the flue of

the appliance and the intake of the exhaust hood.

. In Australia, the ven ti lation

Ensure that your ventilation system does not cause a down draft at the appliance’s flue opening. A

down draft will not allow the appliance to exhaust properly and will cause overheating, which may

cause permanent damage. Damage caused by down drafts will not be covered by the warranty.

NEVER allow anything to obstruct the flow of combustibles or ventilation exiting the appliance.

NEVER place anything on top of the flue area, or block the flue in any way. Never place a grease

condensing drip pan over the flue opening.

NEVER connect the ventilation blower or hood directly to the flue of this appliance. The resulting

increased flow of air through the combustion system will cause improper operation, poor

temperature recovery, poor ignition and could extinguish the pilot.

Replacing or adding appliances under a pre-existing fire safety system may require modifications to

the system. ALWAYS contact a professional who is qualified in installing, designing and main taining

your fire safety system to assure that any appliance located under the fire safety system are

10 L20-418 Rev 2 (5/16)

Page 11

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

Before you begin filling and adjusting the appliance, perform the following visual c hec ks :

After the appliance is in its permanent location, check the levelness. Any additional leveling that is

necessary can be performed as previously described.

Ensure that the sensing probe and high temperature limit bulb are in place and secure. Check the

high limit bulb mounting screws to ensure that they are tight.

Review the installation portion of this manual and ensure that all steps have been followed and

executed properly.

1) Probe

2) High Temperature Limit

After your appliance has been properly installed as described in the INSTALLATION section of this manual,

it will need to be adjusted to ensure that it will perform as designed. A qualified person must perform these

adjustments.

To perform these adjustments the followi ng too ls will be needed:

Manometer

Digital Thermometer (Temperature Probe)

DC Voltmeter (capable of reading millivolts)

FILLING THE APPLIANCE

Refer to the following procedure to fill the cook tank prior to making adjustments.

1. Ensure that the drain valve is closed.

2. Fill the tank with WATER. Water is used for the installation adjustments because the

temperature will never exceed 212°F (100°C), thereby allowing plenty of adjustment time.

Never let the water level go below the MIN LEVEL mark stamped on the tank.

Oil/shortening must completely cover the heat tubes at all times while th e appliance is ON.

CAUTION

This appliance is not designed for cooking with water. Fill with oil/shortening only for cooking.

L20-418 Rev 2 (5/16) 11

Page 12

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

set nearby materials on fire. Keep the area arou n d th e appliance free from combustibles.

WARNING

gas to dissipate.

PILOT

WARNING

ON

Thermostat Control Knob

Gas Control Valve Knobs

During operation, there is an open flame in side this appliance. The unit may get hot enough to

If pilot extinguishes, wait 5 minutes before attempting to relight the pilot to allow any built-up

LIGHTING INSTRUCTIONS

Refer to the following instructions to light the appliance.

1. Verify that all clearanc es , g as connect ions , ve nti latio n r equirements and

gas pressures have been properly implemented, tested, adjusted and

checked for compliance in accordance with the instruc tions and

requirements in the INSTALLATION section of this document prior to

proceeding.

2. Open the gas supply valves to the appliance.

3. Turn the thermostat control knob counterclockwise to the OFF

position.

4. Turn the gas control valve knob to the PILOT position and push in on the knob.

Hold the knob in for approximately one minute to purge the air out of the line.

5. While keeping the knob on the gas control valve depressed, hold a flame to the

pilot until the pilot ignites.

6. Keep the knob on the gas control valve pressed for approximately 30 seconds

or until the pilot remains lit without the knob being pressed.

7. If the pilot goes out, wait 5 minutes and repeat step 4. If after three tries the

pilot will not remain lit, refer to the TROUBLESHOOTING section of this

manual.

8. Once a pilot flame has been established, turn the gas control valve knob

counterclockwise to the ON position.

9. Set the thermostat control knob to the desired temperature setting, the burners

will ignite and be controlled by the thermostat.

Do not store flammable materials in or near this appliance. Do not spray aerosols in the vicinity

of this appliance while it is in operation. Contact a qualified service person or the factory,

using the information on the back of this manual, if the appliance produces unusual odor,

yellow tipping flames or is not performing as per the original installation.

12 L20-418 Rev 2 (5/16)

Page 13

PILOT FLAME ADJUSTMENT

Gas Control Valve / Millivolt

Gas Control Valve / Millivolt

Perform this procedure with the pilot lit.

Note: This procedure requires a DC millivolt meter set to a scale of 0-1000 mV. Using test leads

with sharp probes will help in taking the required readings. Using test leads with sharp probes

will help in taking the required readings

1. Locate the thermopile wires coming from the pilot to the

gas control valve.

2. Connect the positive (+) test probe to the terminal with the

red wire. Then connect the negative (-) test probe to the

terminal with th e wh ite wire.

3. Adjust the current reading to the required level by

adjusting the pilot flame. Remove the pilot adjustment cap

screw to expose the pilot adjustment screw. Turning the pilot

adjustment screw clockwise will decrease the size of the pilot

flame and flame sense current. Turning the pilot adjustment

screw counterclockwise will increase the pilot flame size and

the flame sense current.

4. Turn the screw in or out as needed to achieve a reading

of 550 mV ± 50 mV.

Note: Allow 3 to 5 minutes between flame adjustments to

allow the reading to stabilize.

Once the pilot flame has been adjusted properly, remove

the millivolt meter and replace the pilot adjustment cap

screw.

BURNER SYSTEM ADJUSTMENT

For the burners to operate the gas control valve must be open and

the thermostat must be turned ON. The burners receive gas from

the main gas supply through the thermostatically controlled gas

control valve. When the oil temperature drops below the preset

temperature the gas control valve opens.

The burners must be adjusted to deliver optimum flame. Refer to the following procedure to adjust the

burners.

1. Ensure that the gas control valve is shut OFF, remove the burner

2. Turn on this and all appliances connected to the gas supp l y line and

3. The installed pressure gauge should be the same, ±0.1” W.C.

4. Turn off ALL appliances, turn OFF the gas control valve on your Pitco appliance and remove the

5. Check for leaks at the burner pressure tap.

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

1. Pressure Regulator Cap

Screw

2. Pilot Adjustment Cap Screw

1. Pressure Regulator Cap

Screw

2. Pilot Adjustment Cap Screw

pressure tap plug and connect an accurate pressure gauge (range of

0-16 “W.C. (39.85mbar, 3.98kPa) in 0.1” (.25mbar, .02kPa)

increments) or manometer.

light their burners. The pressure reading of the installed pressure

gauge should not drop from the required installation pressure. Any

loss of pressure indicates inadequate supply line installation, which

will cause poor performance of all appliances during peak usage.

(.25mbar, .02kPa), as that marked on the data plate on the inside

door of the appliance. If the pressure is correct, go to step 6, if it is

not, adjust the pressure as outlined in step 4. To adjust the pressure,

remove the pressure regulator cap screw and, with a flat head

screwdriver, adjust the regulator screw until the proper burner

pressure is reached. Turning the screw clockwise will increase the

Burner Pressure Tap

burner pressure. Turning the screw counterclockwise will decrease

the burner pressure. When the pressure is correct, replace the pressure regulator cap screw.

IF the pressure cannot be set to within these limits of the pressure stated on the data plate,

DO NOT operate the appliance. Contact an Authorized Service Company.

pressure gauge. Apply pipe joint compound to the burner pressure tap plug and reinstall it.

L20-418 Rev 2 (5/16) 13

Page 14

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

CAUTION

operation and cleaning of this appliance.

CAUTION

WARNING

means of securing the appliance in place are not used.

WARNING

Opening the drain valve will lead to the outflow of the hot contents of the appliance.

NOTICE

butcheries, etc., but not for continuous mass production of food.

WARNING

disposing of water. The water is extremely hot and can cause severe injuries.

CAUTION

the heat tubes.

WARNING

Be careful not to disturb the probe and high temperature limit bulb and capillary during

When your appliance is shipped, many of its parts are covered with a thin coat of oil for protection. Before

the appliance is ready for cooking all transit materials must be removed and the appliance must be cleaned.

This will remove the oil coating and any foreign matter that may have accumulated during storage and

shipment. Refer to the following procedure to clean the appliance.

Wear protective gloves and clothing when clea ning and draining the appliance and when

DO NOT leave the appliance unattended during cleaning. Never let the liquid level go below

1. Read the OPERATION section of this manual prior to filling or operating the appliance.

2. The following steps should be followed using a food grade cleaner.

Use a commercial grade cleaner formulated to effectively clean and sanitize food contact

surfaces. Read the directions and precautionary statements before use. Particular attention

must be paid to the concentration of cleaner and the length of time the cleaner remains on the

food contact surfaces.

3. Following the cleaning directions in this manual to clean the tank interior and all other food contact

surfaces. (6.3.1 Boil Out Procedure, page 20)

4. When cleaning is complete, rinse the inside of the tank thoroughly with cool water. Continue to rinse

the tank until the cleaner has been completely and thoroughly rinsed from the tank.

5. Using a clean dry cloth, wipe out all of the water in the fry tank.

If the appliance can’t be adjusted to operate properly contact a qualified service per son or

contact the factory using the contact information on the back of this manual.

Before operating the appliance, check that tipping restraints or other features to prevent

tipping are installed and mechanically s o u nd . Splashing of hot liquid may occur if adequate

This appliance is intended to be used for commercial applications, for example in the kitchens

of restaurants, canteens, hospitals and in commercial enterprises such as bakeries,

14 L20-418 Rev 2 (5/16)

Page 15

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

Lbs.

kg

liter

VF35

35

15.9

17.5

VF65

65

29.5

32.4

CAUTION

OPERATION

Both liquid and solid oil/shortening can be used in this appliance, but liquid is preferred. If solid

oil/shortening is used it is recommended that you melt the oil/shortening before adding it to the appliance.

You can melt solid oil/shortening in the appliance, but you must be very careful not to scorch the

oil/shortening.

This appliance is NOT designed for cooking with water. Cook with oil or shortening only.

To fill the tank with liquid shortening, refer to the following procedure.

OIL CAPACITIES

APPLIANCE

MODEL

It is recommended that high quality liquid frying oils be used for longest oil life.

1. Verify that the tank interior is clean and free of any construction debris and moisture.

2. Rinse the tank and drain line with a small amount of clean cooking oil.

3. Ensure that the drain valve is closed.

4. Fill the tank to about the MIN oil level mark. The oil will expand when heated up, raising the level to

OIL LEVEL line.

5. After the cooking oil is at operating temperature, add oil to the frypots as needed to obtain the desired

operating level.

Illustration of liquid oil/shortening fill.

TANK

OIL CAPACITY*

L20-418 Rev 2 (5/16) 15

Page 16

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

WARNING

WARNING

CAUTION

To fill the tank with solid oil/shortening refer to the following procedure

1. Remove the screen covering the heat tubes (tube screen).

2. Cut the solid oil/shortening into cubes no larger than one inch (2.54 cm). ALWAYS pack the

oil/shortening below, between, and on top of the heat tubes.

DO NOT leave any large air gaps. Use care when packing the solid oil/shortening into the

tank.

DO NOT bend or break the temperature or high limit sensor probes. If these are damaged

the appliance will not function pro perly.

3. Once the appliance tank is firmly packed with solid oil/shortening, the oil/shortening must be

melted. Melt the oil/shortening by cycling the burners ON for 4 seconds and OFF for 30 seconds

repeatedly, using the thermostat knob.

AVOID these conditions.

Very Hazardous Excessive and large spaces

16 L20-418 Rev 2 (5/16)

NEVER melt blocks of solid shortening on top of the heat tubes. This can cause a fire and

could result in personal injury

Oil must completely cover the heat tubes at all times while appliance is on.

Do not overload the fry baskets, or allow the oil level to exceed the MAX line while cooking.

Wet product, or too much oil in the frypot can lead to surge boiling, and over topping the

frypot. Overtopping may create hazards such as burns or slippery floors.

This appliance is NOT designed for cooking with water. Severe appliance damage will occur if

a fryer is used as a water bath for rethermalizi n g foods. Damage of this type is not covered

under the warranty.

Page 17

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

Maximum Allowable Load per Tank Size (W x L)

7 x 14 in

(17.8 x 35.6 cm)

14 x 14 in

(35.6 x 35.6 cm)

18 x 18 in

(45.7 x 45.7 cm)

14 x 18 in

(35.6 x 45.7 cm)

18 x 14 in

(45.7 x 35.6 cm)

Typical French Fry Cook Times (m/s)

Temperature

350°F

360°F

370°F

Fry Thickness

(177°C)

(182°C)

(188°C)

Thin

2:45

2:30

2:15

Medium

3:45

3:30

3:15

Thick

4:15

4:00

3:45

determine exact cook temperatures and times.

WARNING

WARNING

WARNING

WARNING

APPLIANCE START UP

Refer to the following procedure to start the appliance prior to operation.

1. Fill the cook tank with oil/shortening (See Section 2.1 FILLING THE COOK TANK). Never operate the

appliance unless the cook tank is properly filled.

2. Light the pilot as previously described in this manual.

3. Turn the temperature control knob (thermostat) to the desired temperature setting. This knob is

located behind the door.

4. The appliance is now on and heating the oil/shortening in the cook tank.

NEVER operate the appliance with an empty fry tank. It will void the warranty.

Oil/shortening level should NOT be allowed to fall below the indicated level line at any time. Dry

firing of the fry tank will shorten tank service life and will void your warranty.

Oil level should NOT be allowed to fall below the indicated level line at any time. Dry fir ing of the

tank may cause a fire, and can shorten tank service life. Evidence of dry firing will void your

warranty.

To ensure the quality of the food you cook in this appliance, follow the preparation instructions from the food

manufacturer. When the appliance is not in use, the oil should be cooled and covered to prevent

contamination.

1.5 lbs. (0.68kg) 3 lbs. (1.36 kg) 5 lbs. (2.27 kg) 3 lbs. (1.36 kg) 5 lbs. (2.27 kg)

Always follow the food manufacturer’s directions.

The lower the oil temperature, the longer the

cooking time and the greater the fat absorption.

NEVER ov er fill appliance baskets. Overfilling

can result in soggy, greasy product.

When removing baskets from the cook tank,

shake gently to remove excess oil.

Never leave a basket over the appliance. The

heat from the cook tank will continue to cook the

product.

Oil/shortening quality can affect product quality.

Keep salt and water away from the oil/shortening

to maintain its life. Oil/shortening filtration

removes crumbs from the oil which will also

extend its life.

This table is for reference only. Please refer to

the product manufacturer’s specifications to

Dry fired heat tubes are extremely hot, will shorten the tank service life and will void your warranty.

L20-418 Rev 2 (5/16) 17

Page 18

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

OIL TEMPERATURE

you money and increase the fire danger.

TEMPERATURA DELL’OLIO

temperature non prevedono vantaggi, sono antieconomiche e aumentano il rischio d’incendio.

ΘΕΡΜΟΚΡΑΣΙΑ ΛΑΔΙΟΥ

χρήματα και αυξάνουν τον κίνδυνο πυρκαγιάς.

WARNING

apron, heat resistant gloves for ski n p rotection and goggles for eye protection.

Keep the oil temperature in the fryer to a maximum of 190°C (374°F). Higher temperatures will cause rapid

breakdown of the oil and give you no faster cooking. At 205°C (401°F) to 210°C (410°F) the life of the oil is

only one third of its life at 190°C (374°F). In addition, increased decomposition causes the oil to smoke badly

even if the temperature is lowered to 190°C (374°F) again. High temperatures give you no advantage, cost

Mantenere la temperatura dell’olio nella friggitrice fino a un massimo di 190°C. Temperature maggiori

causano un rapido degrado dell’olio, senza tuttavia eseguire una cottura più rapida. Da 205°C a 210°C la

durata dell’olio è inferiore di un terzo rispetto a quella a 190°C. Inoltre, l’accresciuta decomposizione

comporta una forte emissione di fumo, anche se la temperatura viene riportata di nuovo a 190°C. Le alte

Διατηρείτε τη θερμοκρασία λαδιού στη φριτέζα μέχρι 190 βαθμούς Κελσίου. Υψηλότερες θερμοκρασίες θα

αλλάξουν τη σύνθεση του λαδιού πολύ σύντομα και δεν ψήνετε γρηγορότερα. Η δυναμικότητα του λαδιού

στους 205-210 βαθμούς Κελσίου είναι μόνο το ένα τρίτο της δυναμικότητάς του στους 190 βαθμούς

Κελσίου. Επιπλέον η αυξημένη αποσύνθεση του λαδιού, σε θερμοκρασίες πάνω από 190 βαθμούς Κελσίου,

κάνει το λάδι να καπνίζει άσχημα κι αν ακόμη κατεβάσετε τη θερμοκρασία κατόπιν πάλι στους 190 βαθμούς

Κελσίου. Οι υψηλές θερμοκρασίες δε σας παρέχουν κανένα πλεονέκτημα, σας κοστίζει περισσότερα

APPLIANCE SHUTDOWN

There are two shutdown modes of appliance operation: STANDBY and COMPLETE. The standby mode

removes the ability of the appliances burners to operate. COMPLETE shutdown turns off the gas supply to

the appliance. A STANDBY shutdown can be used during slow business periods. ALWAYS perform a

COMPLETE shut down when the appliance will not be in use and unsupervised for an extended period of

time. Refer to the following procedures to enter the appropriate shutdown mode.

1. Turn the thermostat to the OFF position. Turn the Pilot knob clockwise to the PILOT position.

The cooker is now in Standby and can remain this way for only brief periods of time. NEVER

leave the appliance in standby mode for prolonged periods or overnight.

1. Turn the thermostat knob to the OFF position.

2. Depress and turn the Pilot knob counter clock-wise to the OFF position.

3. The appliance is now completely shut down and can be cleaned and filtered if desired.

PREVENTATIVE MAINTENANCE

Performing the preventative maintenance steps below daily will keep your appliance safe and at peak

performance. During the cooking process, oil/shortening may spill and splatter and requires immediate

attention. Furthermore, during the cooking process, particles, crumbs and crackling collect inside the fry

tank reducing product quality and decreasing oil/shortening life. If you are producing high quantities of fried

food and/or frying heavily battered food, it will be necessary to perform these steps more than once a day.

Serious injury could result from direct contact with hot surfaces and/or oil. Always wear

18 L20-418 Rev 2 (5/16)

Page 19

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

wear apron, heat resistant gloves for skin protection and goggles for eye protection

WARNING

WARNING

DAILY CLEANING

At least daily, filtering the oil is required. Make sure a clean filter is used every day.

Using the cleaning brush, crumb scoop and clean out rod, remove all the loose debris

APPLIANCE INSPECTION

Check that the high temperature limit and temperature probe are in the correct position and secured

in place. (Refer to illustration on page 11 of this manual).

Check around the appliance for loose parts or accessories that need to be secured or other foreign

items (ex: Aerosol cans) that should be removed from the area.

Check for oil/shortening leaks around the inside and o utside of the cabinet and around the

appliance.

Serious injury could result from direct contact with hot surfaces and/or oil. Always

Read the OPERATION section of this manual prior to filling or operating the appliance.

DO NOT leave the appliance unattended during cleaning.

CLEANING THE COOK TANK

Recommended at least once a week.

1. Follow the procedure from 4.2. (COMPLETE SHUTDOWN) turn OFF and drain the oil/shortening.

Allow the unit to cool, then perform the following procedure for cleaning.

2. Remove baskets, tank rack and basket hanger for cleaning in pot sink, power soak sink or

dishwasher.

3. Using the cleaning brush, crumb scoop and clean out rod, remove all the loose debris and scrub

all tank surfaces.

4. For tougher carbonized oil/shortening and carbon buildup scrub tank using a Scotchbrite or other

abrasive pad. DO NOT use steel wool.

5. Wipe residue with a clean water dampened cloth. Carefully dry and REMOVE ALL MOISTURE

from the tank before returning oil/shortening into the tank.

6. Clean and dry baskets, tank rack and basket hanger before reinstalling.

7. Refill tank with oil/shortening.

CLEANING THE CABINET

1. Wipe any spilled oil/shortening, dust and lint from the cabinet exterior with a clean damp cloth and

a mild food grade detergent. Be careful not to get any water or detergent in the oil/shortening. Use

a nonabrasive pad for tougher stains if needed.

2. Remove detergent from all surfaces.

3. Cleaning the interior cabinet requires a clean cloth to remove any oil/shortening, dust, lint or filter

powder (i.e.: Magnesol) from the interior of the cabinet.

L20-418 Rev 2 (5/16) 19

Page 20

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

Performing the preventative maintenance steps above on a daily basis will keep your appliance clean and

safe. On a weekly basis, these additional steps should be performed. Wear personal protective gear when

performing preventative maintenance!

1. Turn the appliance OFF. Allow the oil/shortening to cool to room temperature before pulling the

appliance away from the hood. Hint: This maintenance may be ideal to perform on the day the

oil/shortening is being changed so no oil/shortening is present in the tank.

2. Disconnect the gas hose and rete nti on la n yard.

3. Wearing your protective gear, pull the appliance away from the hood.

4. Check that vent hood drip cup is empty and not dripping oil/shortening into the flue.

5. Check that the hood baffles are clean and not dripping oil/shortening into the flue.

6. Clean the appliance sides, back and the flue area, it may be necessary to use a non-abrasive pad to

scour and a putty knife to scrape the oil/shortening buildup. With a clean damp cloth and food grade

detergent wipe the area clean.

7. Wipe up any excessive oil/shortening on the gas hose with a dry cloth.

8. Check flue pipe for any foreign debris/object and remove if found.

9. Reattach gas hose and retenti on lanyard then push appliance back under the hood.

Food debris and oil/shortening can build up inside the tank. Performing the monthly preventative

maintenance steps below will keep your appliance safe and at peak performance. If you are producing high

quantities of fried food and/or frying heavily battered food, it may be necessary to clean these components

more than once a month.

BOIL OUT PROCEDURE

Wear protective gloves and clothing when cleaning and draining the appliance. Oil/shortening, water or

steam may spatter and will cause injury to personnel.

1. Read the “OPERATION” section of this manual prior to filling or operating the appliance.

2. Turn the appliance OFF. Drain al l the oil/shortening from the tank into a container and allow it to

cool. The container must be large enough to hold the entire contents of the tank and must also be

able to withstand 400°F (205°C) temperatures.

3. To drain the tank, open the drain valve.

4. Remove baskets, tank rack and basket hanger for cleaning in pot sink, power soak sink or

dishwasher.

5. Remove and discard any large debris inside the tank.

6. Close the drain valve.

7. Fill the tank with water and set the thermostat for 200°F (93°C.)

8. Once the water reaches a simmer, follow the directions of the boil out product that you are using.

9. Scrub the inside of the tank using a cleaning brush safe for hot water. Care must be taken to

remove all the foreign material on the tank, heat tubes, sidewalls and other components in the tank.

Be careful not to loosen or damage the high limit or temperature probe during when scrubbing.

10. Drain the water from the tank into a container that is large enough to hold the contents of the tank

and is suitable for use with 212°F(100°C) water .

11. Once the tank has cooled, rinse it thoroughly with clean, potab le water.

12. Remove all remaining water and residue with a clean dry cloth.

13. Clean and dry baskets, tube rack and basket hanger before reinstalling

14. Close the drain valve and fill the cooker tank with oil/shortening. See Section 2.1. FILLING THE COOK

TANK.

20 L20-418 Rev 2 (5/16)

Page 21

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

This section should ONLY be performed by a qualified service technician as part of a regular kitchen

maintenance program. This inspection should take place a minimum of once a year by an Authorized

Service Technician recommended by Pitco. It may be necessary perform this inspection more than once a

year.

SAFETY EVALUATIO N

Check legs, casters, wheels, plate welds and ensure all nuts and bolts are secured.

Check conditions of flexible gas line and verify appliance retention / lanyard system is in place.

MECHANICAL INSPECTION

Check frypot for shortening leaks and excessive oil build up

Check for oil migration (Clean as required)

Check hood drain cup, ensure it is empty and not dripping into the flue.

Check hood baffle for clean surface, oil/water condensate can drip on and into the flue.

Check flue for foreign debris and hood down draft currents.

Check drain/filtration system (if equipped) for leaks

Check for missing appliance parts, i.e.: cover strips

Check for missing fasteners

TEMPERATURE CONTROL SYSTEM

Check temperature probes and limits for carbon build up and plating. Clean as required

Check proper mounting of probes and sensors and all fasteners are secure.

Check thermistor probe resistances for stability.

Check Controller/thermostat features to ensure they are functioning.

Check Temperature Calibration

GAS COMBUSTION SYSTEM

Check for gas leaks.

Check and clean vent tube on gas control valve pressure regulator.

Check burners, clean debris and grease from pilot and pilot orifice tips.

Check and adjust the burner pressure to nameplate reading.

Check incoming gas pressure to the appliance under static and dynamic conditions.

Check ignition system and adjust pilot flame as required.

Check flame sensor reading.

Check gap spacing and clean igniter.

Recheck for gas leaks after inspection.

L20-418 Rev 2 (5/16) 21

Page 22

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

CAUTION

defective. Turn OFF the gas control valve. Contact an Authorized Service Company.

Proper ventilation hood operation is very important for the correct operation of this appliance and the safety

of personnel. The ventilation hood should be inspected at the time of installation of this appliance to ensure

that it will operate properly in conjunction with the appliance. A regular schedule of examination in

accordance with ANSI/NFPA 96 latest edition and/or local codes must be followed.

This MUST be performed with oil/shortening in the tank.

1. Use a high-grade pyrometer or digital thermometer suitable for temperature up to 380°F (193°C).

Place the thermometer in the oil, above the tip of the appliance’s temperature probe and within 1”

(2.54 cm). Be sure not to touch the heat tubes since this will measure incorrect temperatures.

Allow several minutes for the thermometer to equalize with the oi l temper atur e.

2. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow the

oil/shortening to come up to temperature. Watch the thermometer closely as the temperature

rises.

3. If the oil/shortening temperature reaches 350°F (177°C) and the burners do not turn off, turn the

thermostat down. Keep lowering the thermostat setting until the burners go out.

If the burners do not shut off at the LOWEST thermostat setting, the thermostat may be

4. Let the appliance cycle 4 to 6 times before checking the temperature. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

(3°C) apart, contact an Authorized Service Company for further assistance.

22 L20-418 Rev 2 (5/16)

Page 23

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

WARNING

TROUBLESHOOTING

This appliance is equipped with a high temperature limit switch. The high temperature limit switch will stop

the appliance from functioning if the oil temperature in the cook tank reaches an unsafe temperature. In the

event that the high temperature limit has tripped, please refer to the following procedure to reset the switch.

Turn the appliance OFF.

a. Allow the appliance ample time to cool to room temperature.

b. Add oil/shortening to the cook tank as needed.

c. Press the high temperature reset button.

d. The high limit switch is now reset and the appliance is ready for startup.

DO NOT add oil/shortening to the tank until it has been given ample time to cool down.

Failure to do so may result in damage to the appliance and/or injury to the operator.

L20-418 Rev 2 (5/16) 23

Page 24

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

NO

Is the gas control

“PILOT” position?

NO

Turn the gas control valve knob to the

"PILOT" position and light pilot.

Purge air from pilot line.

stay lit after

pilot knob is

YES

YES

NO

line?

YES

NO

Is high

open?

YES

Did high

reset?

YES

NO

NO

go out when

temperature

YES

NO

Purge air from pilot line by turning gas

Light pilot.

NO

Is the gas

control valve

position?

YES

Is the

position?

NO

YES

YES

Turn the gas control

"ON" positi on.

NO

Turn the thermostat

temperature setting.

YES

Fryer does not work.

Does pilot

released?

Does pilot

increases?

If the burners are lighting, but not

performing properly refer to the

INSTALLATION section of this

manual to verify proper installation.

Will the

pilot

light?

Do the

burners

light?

valve in the

Is all the air

purged from

the pilot gas

control valve knob to the "PILOT" position

and holding it in for approx. 1 minute.

knob in the

"ON"

valve knob to the

limit

switch

Contact a qualified

service technician.

thermostat

knob in the

OFF

knob to the required

With the gas control

valve knob in the

"PILOT" position, hold

the knob in for approx.

1 minute. Light pilot.

Light the pilot.

limit

switch

24 L20-418 Rev 2 (5/16)

Page 25

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

Model

Cooking Area

Length

Cooking Area

Width

Cooking Area Depth Overall Height Overall Wi dth Overall Depth

Shipping

Weight

VF35 14" (35.6 cm) 14" (35.6 c m )

2.0' - 3.5"

(5.1 - 8. 9 cm)

47.3" (120.1 cm ) 15.6" (39. 6 cm) 32" (81.3 c m ) 161 lbs. (73 kg)

VF65 18" (45.7 cm) 17.3" (44 c m )

4" - 6"

(10.2 - 15. 2 cm)

47.3" (120.1 cm )

19.6" (49.8 cm ) 34" (86.4 c m ) 181 lbs. (82 k g)

L20-418 Rev 2 (5/16) 25

Page 26

PITCO VF SERIES INSTALLATION & OPERATIONAL MANUAL

In the event of problems wi th or quest ions

In the event of problems wi th or quest ions

Annual service to this appliance by an authorized person is recommended. Do not modify this appliance:

servicing must only be carried out by an authorized person. For service and parts, minor adjustments, fault

finding, or if this appliance cannot be adjusted to operate correctly, contact:

about your order, please contac t the P it co

factory at

+1 (603) 225-6684 World Wide

Website Address: www.pit co.c om

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 39 SHEEP DAVIS RD., PEMBROKE, NH 03275

Original instructions.

about your appliance, please contact the Pitco

Authorized Service and Parts repr es entati ve

(ASAP) covering your area, or con tact Pitco at

the numbers li s ted to the left.

26 L20-418 Rev 2 (5/16)

Loading...

Loading...