Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

ENGLISH

Exploded Parts Manual

VF35 Gas Fryer Models

L22-382 Rev 1 (8/14)

Page 2

TO THE PURCHASER, OWNER AND

STORE MANAGER

Please review these warnings prior to

posting them in a prominent location for

reference

Post in a prominent location the instructions to be

followed in the event that an operator smells gas.

Obtain this information from your local gas supplier.

WARNING

DO NOT store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

WARNING

Improper installation, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this

appliance.

WARNING

Installation, maintenance and repairs should be performed by a Pitco

Authorized Service and Parts (ASAP) company technician or other

qualified personnel. Installation, maintenance or repairs by an

unauthorized and unqualified personnel will void the warranty.

WARNING

Installation and all connections must be made according to local codes

in force. In the absence of local codes in North America, the installation

must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or

the Natural Gas and Propane Installation Code CSA B149.1 as

applicable. In Australia, the appliance must be installed in compliance

with AS/NZS 5601.

WARNING

During the warranty period if a customer elects to use a non-original part

or modifies an original part purchased from Pitco and/or its Authorized

Service and Parts (ASAP) companies, this warranty will be void. In

addition, Pitco and its affiliates will not be liable for any claims, damages

or expenses incurred by the customer which arises directly or indirectly,

in whole or in part, due to the installation of any modified part and/or

received from an unauthorized service center.

WARNING

This appliance, when installed, must be electrically grounded in

accordance with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.2, as applicable

WARNING

Adequate means must be provided to LIMIT the movement or this

appliance without depending on the gas or electrical cord connection.

Single appliances equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with casters must be stabilized by

installing restraining chains.

WARNING

DO NOT alter or remove structural material on the appliance to

accommodate placement under a ventilation hood.

WARNING

If the appliance is equipped with a power cord and it is damaged, it must

be replaced by a Pitco Authorized Service and Parts (ASAP) company

technician, or a similarly qualified person in order to avoid a hazard.

WARNING

The power supply must be disconnected before servicing, maintaining or

cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT clean the appliance

with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot liquids from one

container to another when the unit is at operating temperature or filled

with hot liquids. Serious personal injury could result if skin comes in

contact with the hot surfaces or liquids.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

DO NOT sit or stand on this appliance. The appliance’s front panel, tank,

splash back, tank cover, work shelf, drain board is not a step. Serious

injury could result from slipping, falling or contact with hot liquids.

Exploded Parts-VF35 Gas Model

WARNING

NEVER use the appliance as a step for cleaning or accessing the

ventilation hood. Serious injury could result from slips, trips or from

contacting hot liquids.

WARNING

The oil/shortening level should NOT fall below the minimum indicated level

line at any time. The use of old shortening can be dangerous as it will

have a reduced flash point and be more prone to surge boiling.

WARNING

The contents of the crumb catch and/or filter pan of any filter system must

be emptied into a fireproof container at the end of the frying operation

each day. Some food particles can spontaneously combust into flames if

left soaking in certain oil/shortening materials.

WARNING

Completely shut the appliance down when shortening/oil is being drained

from the appliance. This will prevent the appliance from heating up during

the draining and filling process. Serious injury can occur.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and access covers are

attached correctly.

WARNING

It is recommended that this appliance be inspected by a qualified service

technician for proper performance and operation on a yearly basis.

WARNING

There is an open flame inside this appliance. The unit may get hot enough

to set nearby materials on fire. Keep the area around the appliance free

from combustibles.

WARNING

DO NOT supply the appliance with a gas that is not indicated on the data

plate. If you need to convert the appliance to another type of fuel, contact

your dealer.

WARNING

If gas flow to appliance is interrupted, or pilots extinguish, wait 5 minutes

before attempting to relight the pilot to allow any residual gas in appliance

to dissipate.

WARNING

Ensure that the appliance can get enough air to keep the flame burning

correctly. If the flame is starved for air, it can give off a dangerous carbon

monoxide gas. Carbon monoxide is a clear odorless gas that can cause

suffocation.

WARNING

Never add oil to the appliance when it is at operating temperature.

Splashing hot oil can cause severe injuries.

WARNING

Never add water to hot oil. Violent boiling can occur causing severe

injury.

WARNING

This appliance is intended for professional use only and should be

operated by fully trained and qualified personnel.

WARNING

To avoid splashing of hot liquid when installed, this fryer must be

restrained either by the manner of installation, or with adequate ties to

prevent tipping.

WARNING

An appliance equipped with casters and a flexible gas line must be

connected to the gas supply with a quick disconnect device. In North

America, gas appliances equipped with casters must be installed with

connectors that comply with the Standard for Connectors for Movable Gas

Appliances, ANSI Z21.69.CSA 6.16 Latest Edition. This connection should

include a quick disconnect device that complie s w ith the Standard for Quick

Disconnect Devices for Use With Gas Fuel ANSI Z221.41.CSA 6.9 Latest

Edition. In Australia, an appliance equipped with casters and a flexible gas

line must be connected to the gas supply with a quick disconnect device that

complies with AS 4627. The hose must comply with AS/NZS 1869 and be

class B or D and have a restraining cable. The restraining cable must not

exceed 80% of the length of the flexible gas line.

L22-382 Rev 1 (08/14)

Page 3

Exploded Parts-VF35 Gas Model

NOTICE

In the event of problems or questions about your order, contact the Pitco Frialator factory at (603) 225-6684.

In the event of problems or questions about your equipment, contact the Pitco Frialator Authorized Service and Parts

representative (ASAP) covering your area, or contact Pitco at the number listed above.

Mailing Address

Pitco Frialator

P. O. Box 501

Concord, NH 03302-0501

Shipping Address

Pitco Frialator

10 Ferry Street

Concord, NH 03301

L22-382 Rev 1 (8/14)

3

Page 4

Exploded Parts-VF35 Gas Model

TABLE OF CONTENTS

A) FRYER EXPLODED VIEWS .......................................................................................................................... 5

FRYER EXPLODED PARTS LIST/VIEW ..................................................................................................................................... 5

B) TANK & FLUE ................................................................................................................................................ 6

TANK & FLUE EXPLODED PARTS LIST/VIEW ........................................................................................................................... 6

C) BURNER ASSEMBLY ................................................................................................................................... 7

BURNER ASSEMBLY EXPLODED PARTS LIST/VIEW .................................................................................................................. 7

D) GAS TRAIN.................................................................................................................................................... 8

GAS TRAIN DRAWING PARTS LIST ......................................................................................................................................... 8

GAS TRAIN DRAWING VIEW ................................................................................................................................................... 9

E) GAS CONVERSION KITS ........................................................................................................................... 10

GAS CONVERSION KITS QUICK REFERENCE ........................................................................................................................ 10

GAS CONVERSION KITS QUICK REFERENCE DRAWING ......................................................................................................... 11

F) STANDARD CABINET DRAWING ............................................................................................................... 12

STANDARD CABINET DRAWING LIST .................................................................................................................................... 12

STANDARD CABINET PARTS DRAWING ................................................................................................................................. 13

G) ACCESSORIES ........................................................................................................................................... 14

ACCESSORIES DRAWING PARTS .......................................................................................................................................... 14

ACCESSORIES DRAWING PARTS LIST .................................................................................................................................. 15

4

L22-382 Rev 1 (8/14)

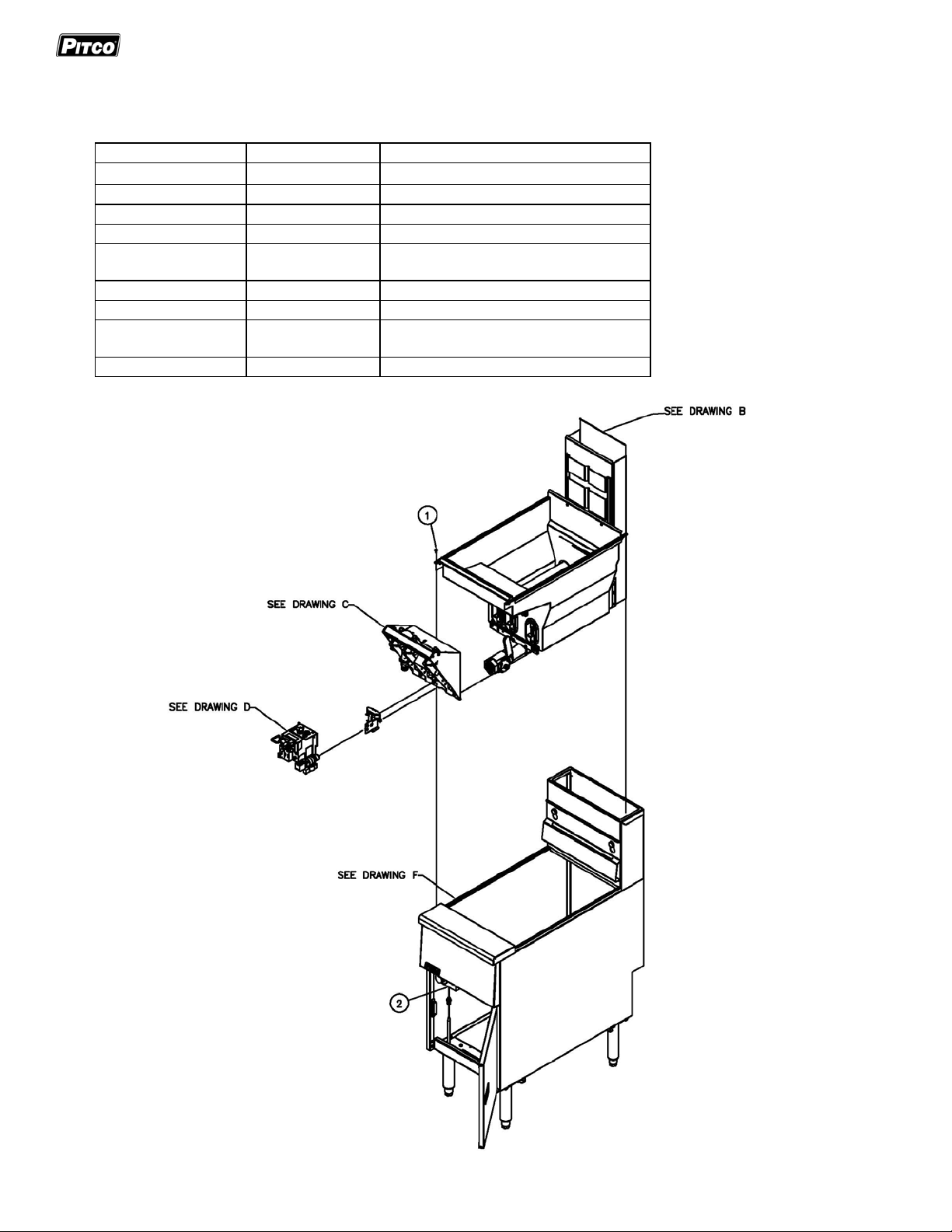

Page 5

Exploded Parts-VF35 Gas Model

A) FRYER EXPLODED VIEWS

Fryer Exploded Parts List/View

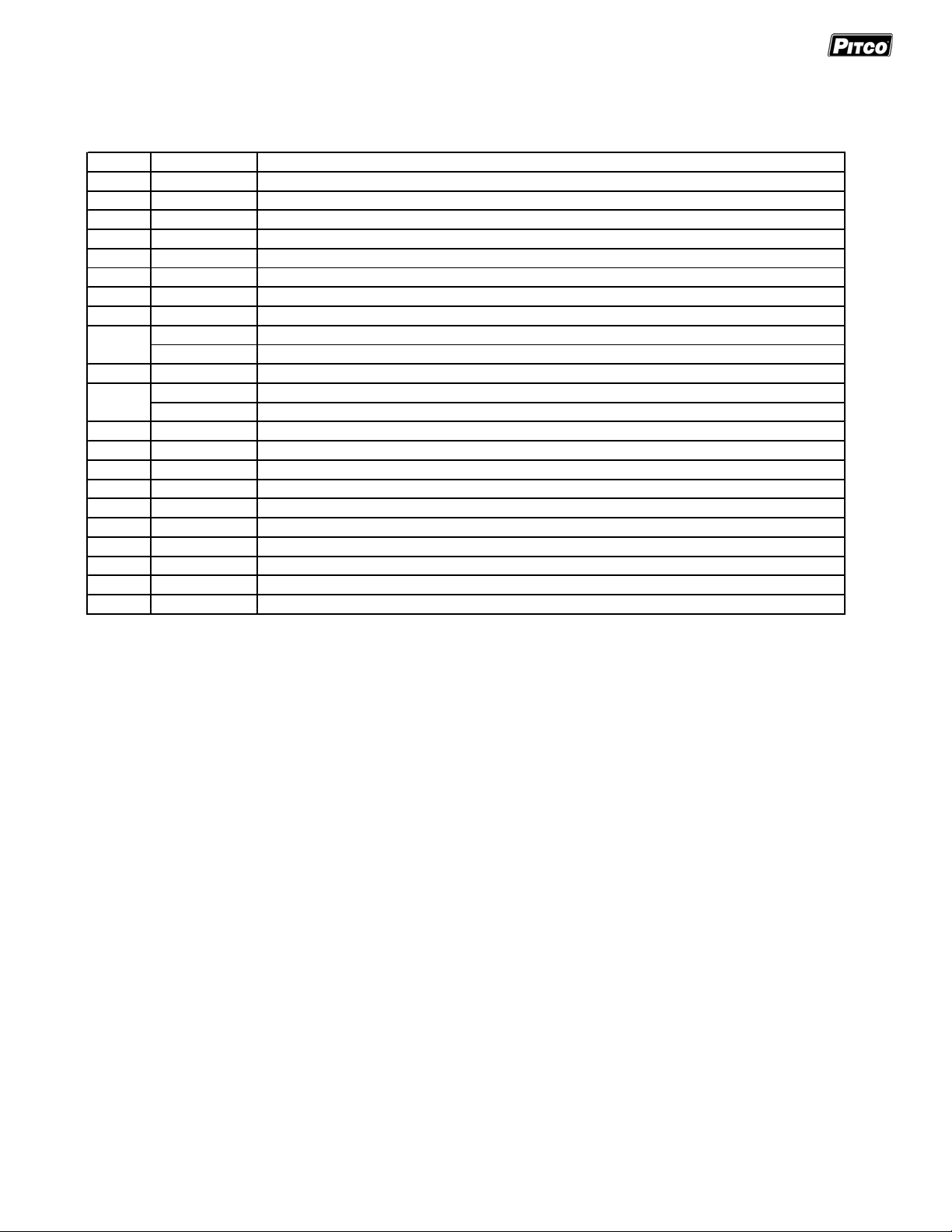

ITEM # PART PART DESCRIPTION

1 PP10023 SCR,10-24 X 3/8 SLF TAP

2 B8030101 PG,ASSY HI-LIM & TSTAT SG14

See Drawing B Tank & Flue Page 6

See Drawing C Burner

See Drawing D Gas Train Page 8-9

See Drawing E Gas Conversion Page 10-11

See Drawing F Cabinet

See Drawing G Accessories Page 14/15

Assembly

Assembly

Page 7

Page 12/13

L22-382 Rev 1 (8/14)

5

Page 6

Exploded Parts-VF35 Gas Model

B) TANK & FLUE

Tank & Flue Exploded Parts List/View

ITEM # PART PART DESCRIPTION

1 B3333301 TK,WLDMT VF35

2 PP10368 VLV,BALL 1-1/4INCH NONLOCKING

3 P0092300 NUT, HEX 10-24 KEP ZN

4 P0075400

5 B3506301 FL,WLDMT VF35

6 PP11326 SCR,#14 X 1-1/2 HEX WH TAP

7 A1406702 CLP,LIM/TSTAT

SCR,10-24 X 1/2 SELF TAP

6

L22-382 Rev 1 (8/14)

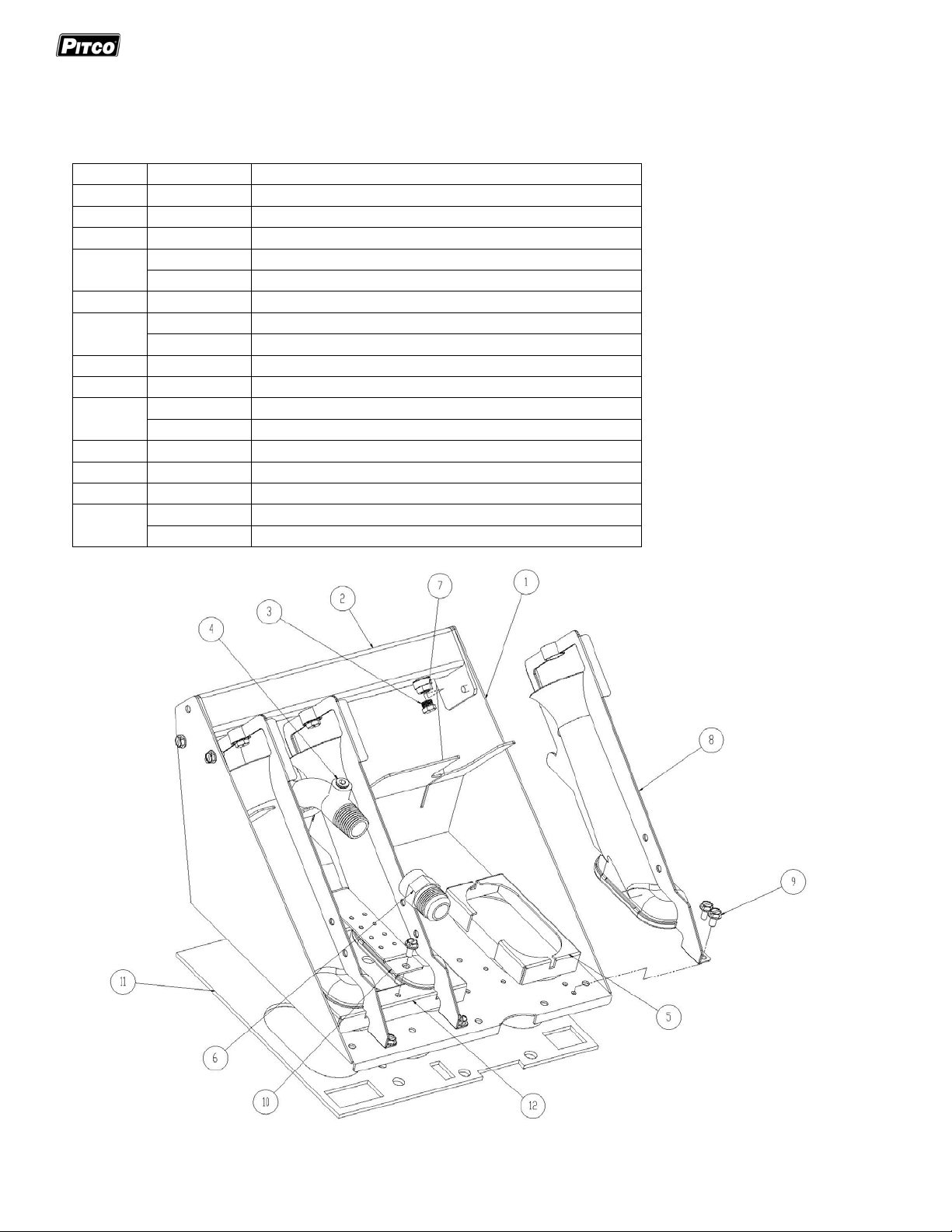

Page 7

Exploded Parts-VF35 Gas Model

C) BURNER ASSEMBLY

Burner Assembly Exploded Parts List/View

ITEM # PART PART DESCRIPTION

1 A8033201 PIPING, BURNER BRACKET SGC

2 B8035301 PIPING, MANIFOLD WELDMENT

3 A7513706 ORIFICE, 2.2MM NAT

P6071354 PG,BNR VF35 #54 ORF LP

4 N/A PLUG, STEEL .125 MNPT RECESSED

5 A8031701 PIPING, BURNER SHIELD-NAT

A8034901 PIPING, BURNER SHIELD-LP

6 60127501 FITTING, ADAPTER MALE FLARE X .500 FPT

7 60129701 FITTING, BURNER

8 B8041901 PIPING, BURNER INCONEL 601 SCREEN SG-NAT

B8046101 PIPING, BURNER INCONEL 601 SCREEN SG-LP

9 N/A SCREW, 10-24 X .375 SELF TAPPING

10 A8031601 PIPING, CROSSOVER

11 A8047601 PG,GSKT BNR BRKT SGC,VF35

12 A8031701 PIPING, BURNER SHIELD, LH -NAT

A8034901 PIPING, BURNER SHIELD, LH - LP

L22-382 Rev 1 (8/14)

7

Page 8

Exploded Parts-VF35 Gas Model

D) GAS TRAIN

Gas Train Drawing Parts List

ITEM# PART# PART DESCRIPTION

1 60125901 TUBE, VENT GAS V A LVE

2 60127601 FITTING, A DA P TER FE M ALE SWIVEL X 1/2 MPT

3 A8029001-C PIPING, VALVE SHIELD

4 60127401 FITTING, ELBOW M ALE FLARE X MPT

5 P0007300 SCREW , 8-32 X 1/ 4 HE X HEAD SLO TTED ZN

6 A8029105 COUPLING, GAS SUPPLY SHORT SG, MKG

7 60128101 VA LVE, GA S SUPP LY SHUTOFF

8 60128015 TUBING, FLEXIBLE WITH FITTINGS 22 GAS

9

10 A 8035302 PIPING, P ILOT BRACK ET SG14 S G14R

11

12 60119001 TUBE, FLEXIBLE WITHOUT FITTINGS 18 X 1/4 OD

13 60088001 SCREW , 10-32 X 1/4 HE X HEA D S ST

14 PP 10084 SWITCH, HI-LIMIT LCM05030

15 A8028601-C PIP ING, BRACKET HI-LIMIT-THERMOS TAT SG MILLIVOLT

16 60125501 THERMOP ILE , MILLIVOLT

17 P 0190700 CLIP, CANOE FA S TEX

18 PP 10539 KNOB , THERMOS TAT WITH OFF, 200-400F & 100-200C

19 PP 10687 SCRE W, 6-32 X 313 THRUSS HEAD PHILLIPS ZN

20 B 6744401 WIRING, MILLIVOLT HI-LIMIT & THERMOS TAT SG

21 60125401 THERMOS TAT, RX MILLIVOLT 200-400F

60125201-C VALVE , GAS VS820 NAT

60125202-C VALVE , GAS VS820 LP

60128801 PILOT, REVERSE STANDING NAT SG

60128802 PILOT, REVERSE STANDING LP SG

8

L22-382 Rev 1 (8/14)

Page 9

Exploded Parts-VF35 Gas Model

Gas Train Drawing View

L22-382 Rev 1 (8/14)

9

Page 10

Exploded Parts-VF35 Gas Model

E) GAS CONVERSION KITS

Gas Conversion Kits Quick Reference

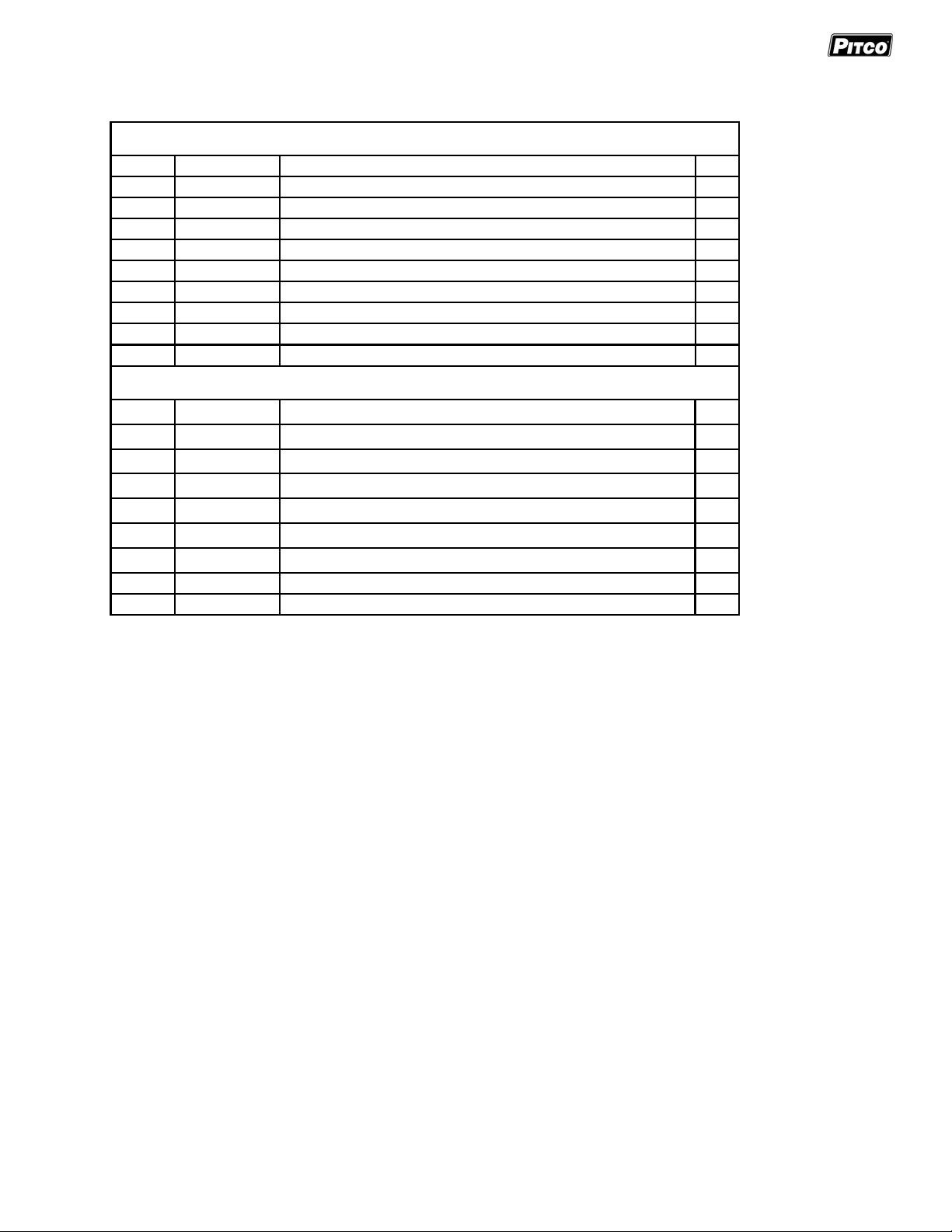

ITEM # PART # PART DESCRIPTION QTY

1 B8043267-C P G,CONV VF35 NAT TO LP

1A P6071354 ORIFICE TIP #54 DIA 3

1B 60126502 GAS VA LVE CONV K IT VS820 NAT TO LP 1

1C P 6071665 ORFICE P ILOT SPUD LP . 016 DIA 1

1D PP10426 GAS CONV NOTICE LAB E L NA T TO LP 1

1E B8046101 PG,BNR INC 600,20X20 SCRN 3

1F A8034905 PG, COLLA R B NR LP S T MG, SGH 1

1G A8034901 PG, COLLA R B NR LP F T LH MG, S GH 1

ITEM # PART # PART DESCRIPTION QTY

1 B8043266-C

1A A7513706

1B 60126501

1C P 6071666 ORFICE P ILOT SPUD NAT .022 DIA 1

1D PP10427 GAS CONV NOTICE LAB E L LP TO NAT 1

1E - - -

1F A8031801 PG, BNR SHLD S G14T* 1

1G A8031701 PG, B NR S HLD LH DG14 1

NATURAL TO LP

LP TO NATURAL

PG,CONV VF35 LP TO NAT

ORIFICE TIP 2 .2M M

GAS VALVE CONV KIT VS820 LP TO NAT

3

1

10

L22-382 Rev 1 (8/14)

Page 11

Exploded Parts-VF35 Gas Model

Gas Conversion Kits Quick Reference Drawing

L22-382 Rev 1 (8/14)

11

Page 12

Exploded Parts-VF35 Gas Model

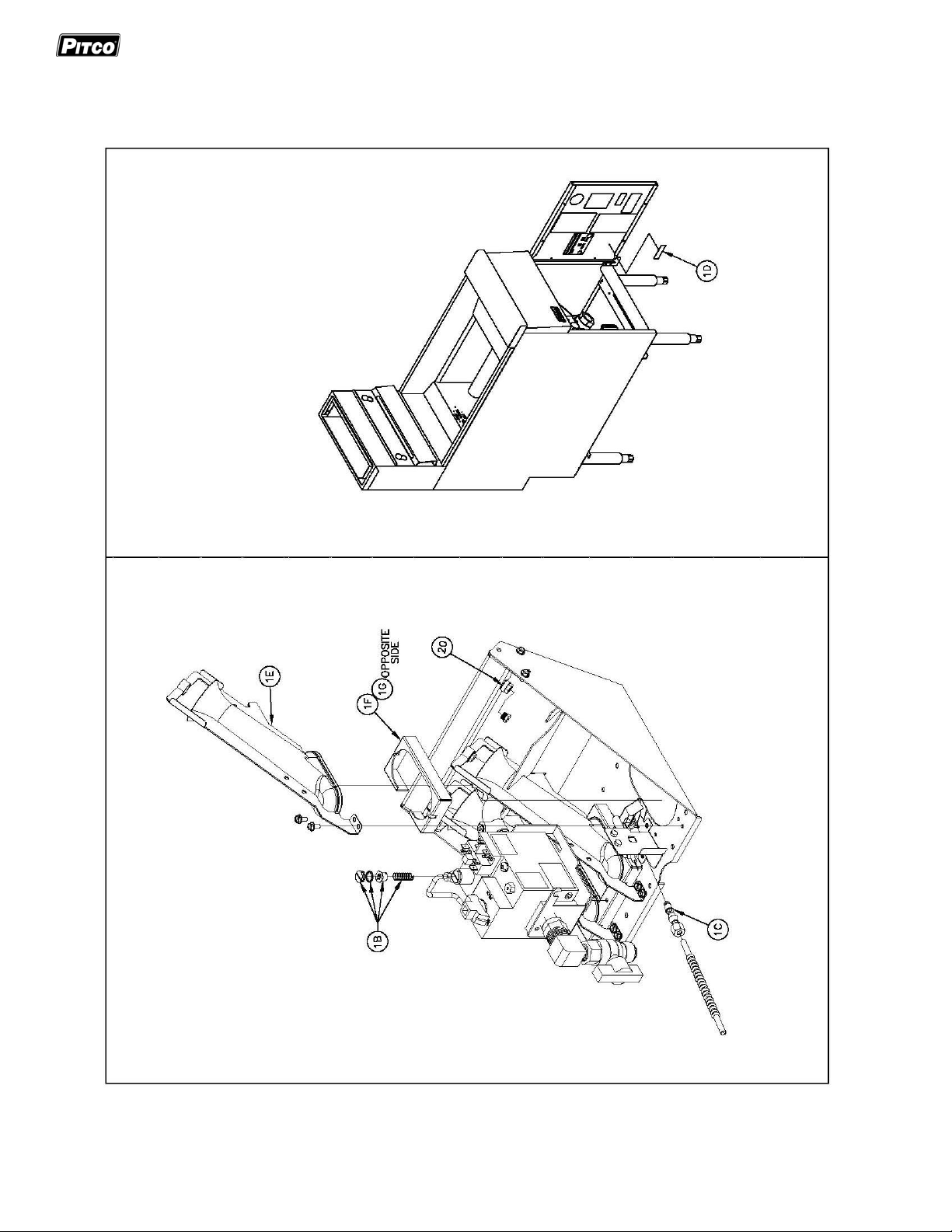

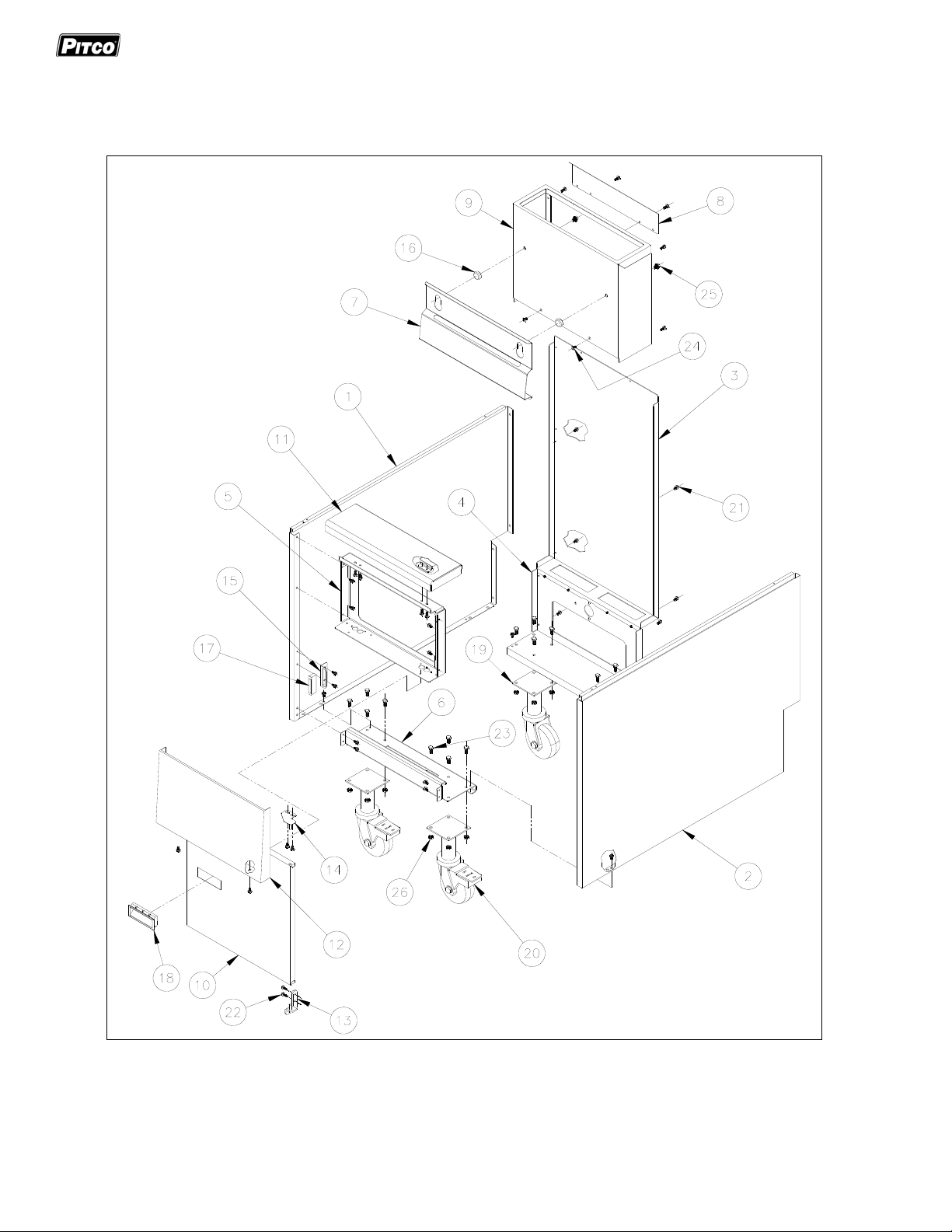

F) Standard Cabinet Drawing

Standard Cabinet Drawing List

IT EM # PART # PART DES CRIPTION

1 A1512002-C CAB INET SIDE LEF T-HAND

2 A1512004-C CAB INET SIDE RIGHT-HAND

3 A1635101-C CAB INET BA CK S G14, S G 14R, S G14T

4 A1635201-C CAB INET BA CK B OTTOM SG14,SG14R,SG14T

5 A1849601-C CAB INET FRONT SPACER SG14,SG14R,SG14T

6 A1235201-C CAB INET FRONT BOTTOM BRACE S G 14, S G14R, SG14T

7 A1105402-C BASKET HANGER SG14,SG14R,SG14T

8 A3526002-C FLUE RE AR HEAT DEFLECTOR SG14

9 A4106902-C SP LASH BA CK S G 14, S G14R, SG14T

10 B2304101-C DOOR ASSEMBLY SG14,SG14R,SG14T

11 B3630901-C FRONT PANE L TOP DECK WELDMENT SG14, S G14R, SG14T

12 B3632301-C FRONT PANE L ASSEMBLY SG14,SG14R,SG14T

13 B3801801 HINGE W E LDME NT LOW E R RIGHT HAND SG*

14 B3802401 HINGE W E LDM E NT UPPER RIGHT HAND SG*

15 A1847002 BRA CK E T MAGNE TIC CATCH

16 60132001 S TUD SPLA S H B A CK S CRE W ON

17 P6071300 MA GNE TIC CATCH STANDARD

18 PP 11006 HA NDLE DOOR RECESSED PLASTIC

19 SEE DRAWING G CASTER SWIVEL 9" NON-LOCKING

20 SEE DRAWING G CASTER SWIVEL 9" LOCKING

N/A SEE DRAWING G LEG SET W/HARDWARE 9" (4-PACK)

21 PP 10023 SCREW 10-24 X 3/8 SELF TAPPING

22 P0075400 SCREW 10-24 X 1/2 SELF TAPPING

23 P0020600 SCREW 1/4-20 X 5/8 HE X HEAD CAP ZN

24 60125801 S CREW 10-24 X 3/8 TRUSS HE A D SLOTTED LOCKING SST

25 60118201 B OLT 1/4-20 X 3/8 HEX FLANGE HEAD

26 P0093300 NUT HEX (KEP) 10-24 ZN

27

NOT SHOWN

(INCLUDES

ITEMS: 1-6 & 21)

B1822302-C CABINET ASSEMBLY STAND ALONE SG14,SG14R,SG14T

12

L22-382 Rev 1 (8/14)

Page 13

Exploded Parts-VF35 Gas Model

Standard Cabinet Parts Drawing

L22-382 Rev 1 (8/14)

13

Page 14

Exploded Parts-VF35 Gas Model

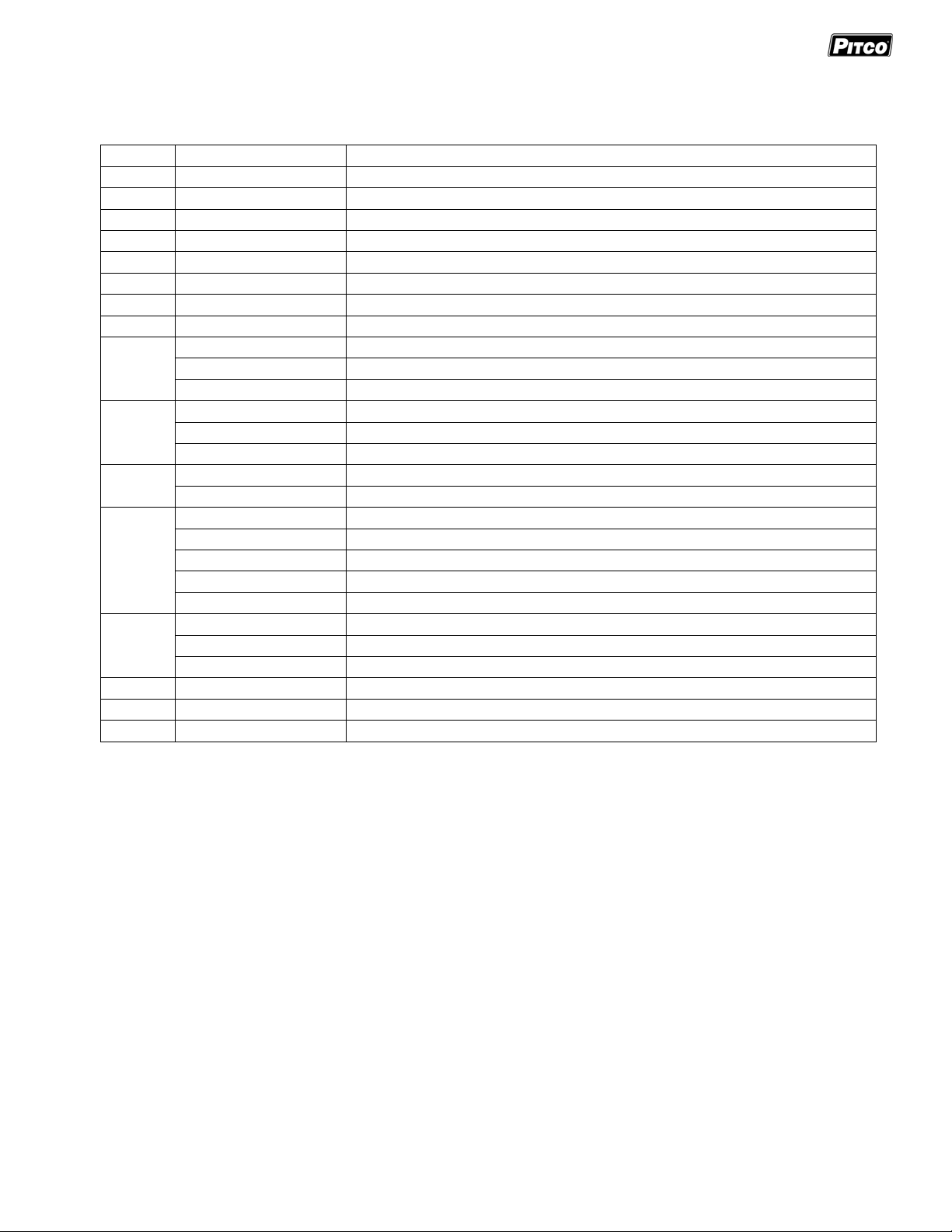

G) ACCESSORIES

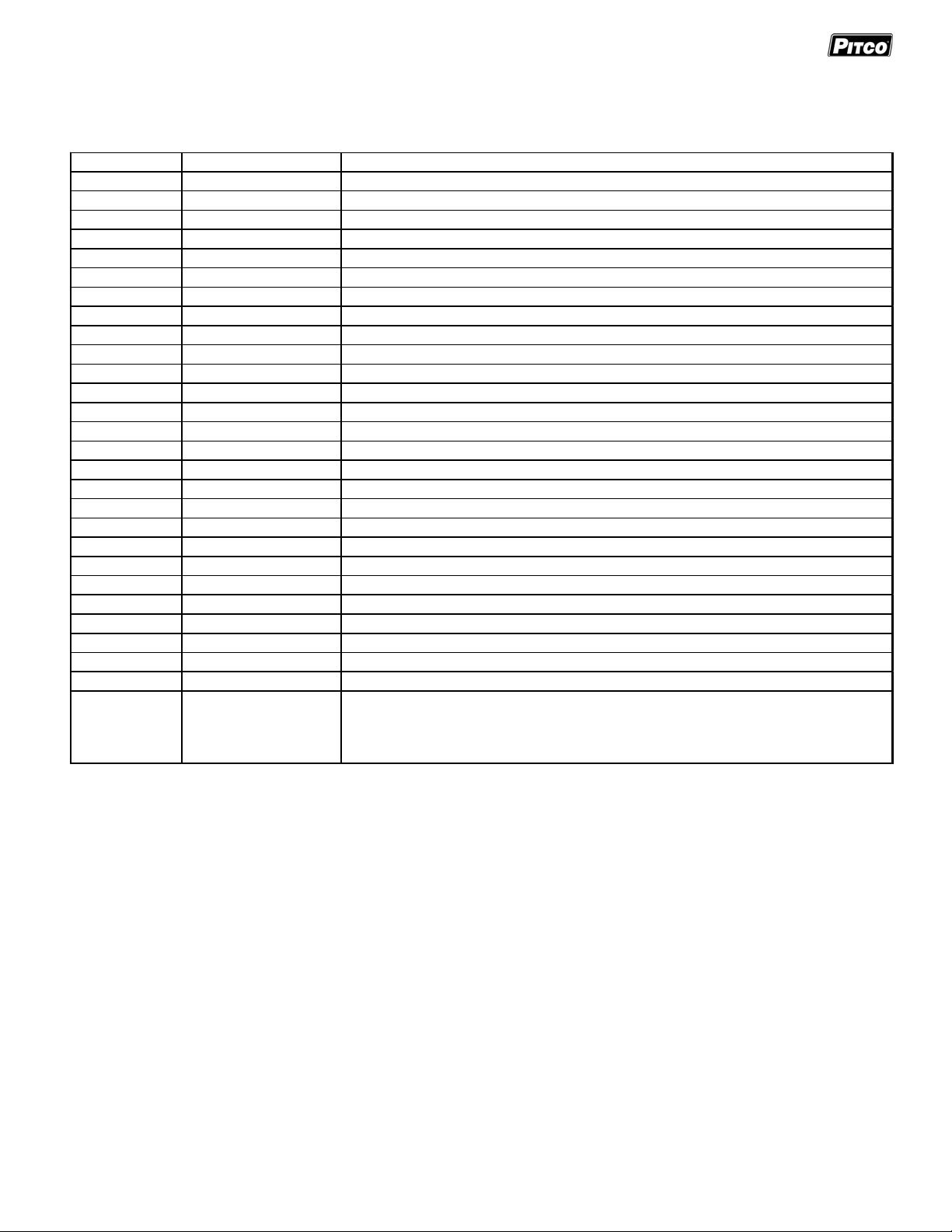

Accessories Drawing Parts

ITEM # PART # PART DESCRIPTION

1 A3301001 CLEAN-OUT ROD

2 PP10056 CLEANING BRUSH NYLON

3 A2510101 DRAIN EXTENSION

4 CONTACT PITCO FRONT WORKSHELF

5 CONTACT PITCO SIDE WORKSEHELVE/DRAINBOARD

6 CONTACT PITCO REAR WORKSHELF

7 CONTACT PITCO REAR WORKSHELF INSERT

8 CONTACT PITCO SPLASH GUARD SIDE

9 60132401 9" LEG

B3900704 9" LEG SET OF 4 WITH HARDWARE

60115301 9" LEG WITH BOTTOM BOLT FLANGE ADJUSTABLE

10 PP10814 9" CASTER NON-LOCKING

B3901504 9" CASTER SET OF 4 (2 LOCKING, 2 NON-LOCKING)

B3902302 9" RIGID CASTER NON-LOCKING

11 PP10815 9" CASTER LOCKING

B3902304 9" RIGID CASTER LOCKING

12 P6072145 TWIN BASKET

P6072146 TWIN BASKET FINE MESH

P6072147 TRIPLE BASKET SG14, SG14R

P6072143 SQUARE BULK BASKET FRONT HANDLE

P6072144 SQUARE BULK BASKET FINE MESH FRONT HANDLE

13 P6073148 TUBE RACK

A4500201 TUBE SCREEN

B7425301-C FISH GRID SG14

14 A1842302-C CABINET BACK

15 B2101518-C TANK COVER ASSEMBLY

16 A3340601-C TANK BACK STANDOFF SG14

14

L22-382 Rev 1 (8/14)

Page 15

Exploded Parts-VF35 Gas Model

Accessories Drawing Parts List

L22-382 Rev 1 (8/14)

15

Page 16

p

In the event of problems with or questions

about your order, please contact the Pitco

Frialatorfactoryat

(603) 225-6684 World Wide

www.

itco.com

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPINGADDRESS–10FERRYST.,CONCORD,NH03301

L22-382 Rev 1 (8/14)

In the event of problem s with or questions

about your equipment, please contact the

Pitco Frialator Authorized Service and

Parts representative (ASA P) covering your

area, or contact Pitco at the numbers

to the left.

listed

Loading...

Loading...