Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

ENGLISH

Exploded Parts Manual

SSPG Gas Pasta Cooker

L22-383 Rev 0 (9/13)

Page 2

Exploded Parts-SSPG Gas Model

TO THE PURCHASER, OWNER AND

STORE MANAGER

Please review these warnings prior to

posting them in a prominent location for

reference

TO THE PURCHASER

Post in a prominent location the instructions to be followed in the

event that an operator smells gas. Obtain this information from your

local gas supplier.

WARNING

DO NOT store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

WARNING

Improper installation, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this

appliance.

WARNING

Installation, maintenance and repairs should be performed by a Pitco

Authorized Service and Parts (ASAP) company technician or other

qualified personnel. Installation, maintenance or repairs by an

unauthorized and unqualified personnel will void the warranty.

WARNING

Installation and all connections must be made according to national

and local regulations and codes in force.

WARNING

During the warranty period if a customer elects to use a non-original

part or modifies an original part purchased from Pitco and/or its

Authorized Service and Parts (ASAP) companies, this warranty will be

void. In addition, Pitco and its affiliates will not be liable for any

claims, damages or expenses incurred by the customer which arises

directly or indirectly, in whole or in part, due to the installation of any

modified part and/or received from an unauthorized service center.

WARNING

This appliance, when installed, must be electrically grounded in

accordance with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.2, as applicable.

WARNING

Adequate means must be provided to LIMIT the movement or this

appliance without depending on the gas or electrical cord connection.

Single appliances equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with casters must be

stabilized by installing restraining chains.

WARNING

An appliance equipped with casters and a flexible gas line must be

connected to the gas supply with a quick disconnect device. This

quick disconnect must comply with ANSI Z24.41.

WARNING

DO NOT alter or remove structural material on the appliance to

accommodate placement under a ventilation hood.

WARNING

This appliance is intended for professional use only and should be

operated by fully trained and qualified personnel.

WARNING

If the appliance is equipped with a power cord and it is damaged, it

must be replaced by a Pitco Authorized Service and Parts (ASAP)

company technician, or a similarly qualified person in order to avoid a

hazard.

WARNING

The power supply must be disconnected before servicing, maintaining

or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT clean the

appliance with a water jet.

L22-383 Rev 0 (09/13)

WARNING

DO NOT attempt to move this appliance or transfer hot liquids from

one container to another when the unit is at operating temperature or

filled with hot liquids. Serious personal injury could result if skin comes

in contact with the hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s front panel,

tank, splash back, tank cover, workshelf, drain board is not a step.

Serious injury could result from slipping, falling or contact with hot

liquids.

WARNING

NEVER use the appliance as a step for cleaning or accessing the

ventilation hood. Serious injury could result from slips, trips or from

contacting hot liquids.

WARNING

The water level should be maintained at the level line. DO NOT turn

the appliance on until the heat tubes are fully covered with water at all

times. Serious injury could result from hot steam vapors off the heat

tubes.

WARNING

If overflow drain is not equipped or if overflow drain stop is used, do

not leave appliance unattended while filling with water. Over filling the

appliance can cause serious injuries and damage the equipment.

WARNING

Completely shut the appliance down when the water is being drained

from the appliance. This will prevent the appliance from heating up

during the draining and filling process. Serious injury can occur.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and access covers are

attached correctly.

WARNING

It is recommended that this appliance be inspected by a qualified

service technician for proper performance and operation on a yearly

basis.

WARNING

There is an open flame inside this appliance. The unit may get hot

enough to set nearby materials on fire. Keep the area around the

appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas that is not indicated on the

data plate. If you need to convert the appliance to another type of fuel,

contact your dealer.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots extinguish, wait 5

minutes before attempting to relight the pilot to allow any residual gas

in appliance to dissipate.

WARNING

Ensure that the appliance can get enough air to keep the flame

burning correctly. If the flame is starved for air, it can give off a

dangerous carbon monoxide gas. Carbon monoxide is a clear

odorless gas that can cause suffocation.

Page 3

Exploded Parts-SSPG Gas Model

NOTICE

IN THE EVENT OF PROBLEMS OR QUESTIONS ABOUT YOUR ORDER, CONTACT THE PITCO FRIALATOR FACTORY AT (603)

225-6684.

IN THE EVENT OF PROBLEMS OR QUESTIONS ABOUT YOUR EQUIPMENT, CONTACT THE PITCO FRIALATOR AUTHORIZED

SERVICE AND PARTS REPRESENTATIVE (ASAP) COVERING YOUR AREA, OR CONTACT PITCO AT THE NUMBER LISTED

ABOVE.

MAILING ADDRESS

PITCO FRIALATOR

P. O. BOX 501

CONCORD, NH 03302-0501

SHIPPING ADDRESS

PITCO FRIALATOR

10 FERRY STREET

CONCORD, NH 03301

TABLE OF CONTENTS

A) TANK & FLUE ................................................................................................................................................4

TANK & FLUE EXPLODED PARTS LIST/VIEW ........................................................................................................................... 4

B) BURNER ASSEMBLY ....................................................................................................................................5

BURNER ASSEMBLY EXPLODED PARTS LIST/VIEW.................................................................................................................. 5

C) GAS TRAIN ....................................................................................................................................................6

GAS TRAIN DRAWING PARTS LIST ......................................................................................................................................... 6

D) GAS CONVERSION KITS ..............................................................................................................................7

GAS CONVERSION KITS QUICK REFERENCE .......................................................................................................................... 7

E) STANDARD CABINET DRAWING .................................................................................................................8

STANDARD CABINET DRAWING LIST ...................................................................................................................................... 8

STANDARD CABINET PARTS DRAWING ................................................................................................................................... 9

F) ACCESSORIES ............................................................................................................................................10

ACCESSORIES DRAWING PARTS .......................................................................................................................................... 10

L22-383 Rev 0 (9/13)

3

Page 4

Exploded Parts-SSPG Gas Model

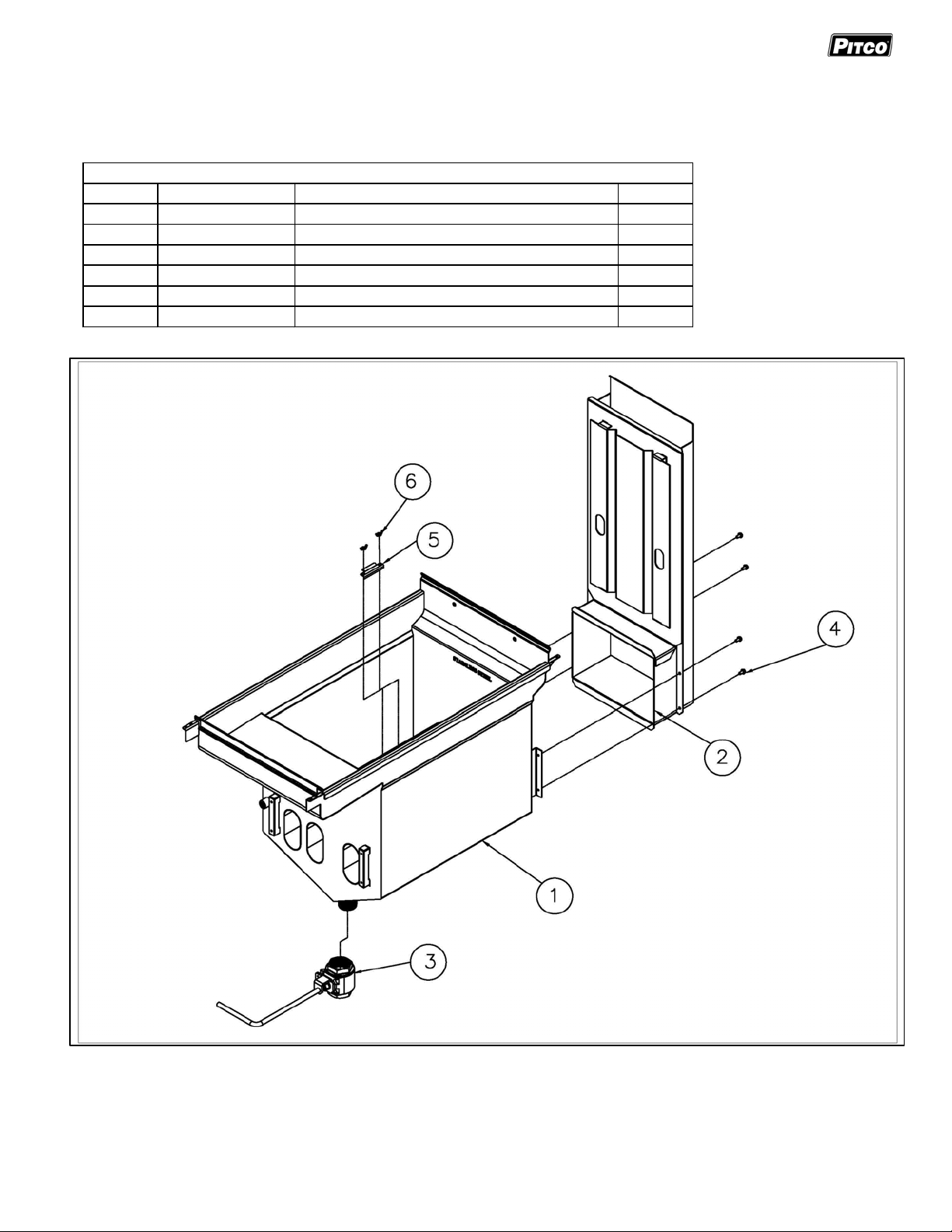

A) TANK & FLUE

Tank & Flue Exploded Parts List/View

ITEM NO. PART NO. DESCRIPTION QTY

1 B3330702 TANK, WELDMENT 1

2 B3505601 FLUE, WELDMENT 1

3 60148604 VALVE, BALL 1. 250" FULL PORT STAINLESS 1

4 PP10023 SC REW , 10-24 X .375 SELF TAPPING 4

5 A1402202 CLAMP, BULB LIMIT 316 SS 1

6 PP10568 NUT, WING 10-24 SS 2

BOM TABLE

4

L22-383 Rev 0 (9/13)

Page 5

Exploded Parts-SSPG Gas Model

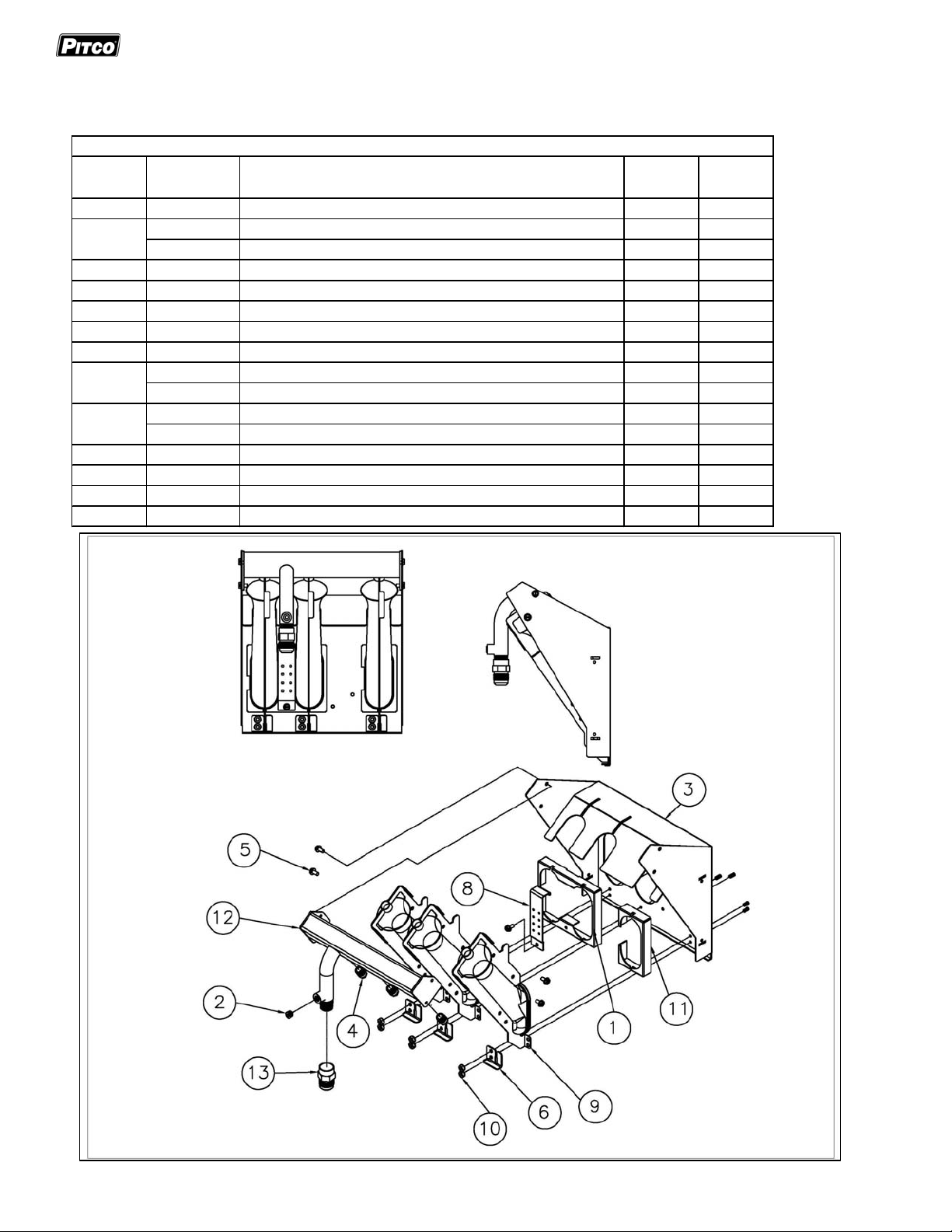

B) BURNER ASSEMBLY

Burner Assembly Exploded Parts List/View

ITEM NO. PART NO. DESCRIPTION

1 A8042301 PIPING, BURNE R BRACKET 1 1

2

3 B8046301 PIPING, BURNE R MANIFOLD WE LDMENT 1 1

4 60127501 FITTING, ADAPTER MALE FLARE X .500 FPT 1 1

5 60129701 FITTING, BURNER 3 3

6 N/A 1/8 NPT 3/16 HEX SOCKET HEAD PLUG 1 1

7 A8031601 PIPING, CROSSOVER 1 1

8

9

10 PP10023 SCREW , 10-24 X .375 SELF TAPPING HEX HD SLTD 5 5

11 PP10174 STUD, WELD FLANGED 10-24 UNC X 375 8 8

12 P0092300 NUT, HEX KEP 10-24 ZN 6 6

13 A8043201 PIPING, BURNER RETAI NER BRACK ET 3 4

B8041901 PIPING, BURNE R INCONEL 601 S CREEN 3 B8046101 PIPING, BURNE R INCONEL 20X20 SCREEN - 3

A803171 PI P ING, BURNER SHIEL D LH 1 A8034901 PIPING, BURNE R LP SHIELD LH - 1

A8031801 PIPING, BURNE R SHI ELD 1 A8034905 PIPING, BURNE R LP SHIELD - 1

BOM TABLE

NAT

QTY

LP

QTY

L22-383 Rev 0 (9/13)

5

Page 6

Exploded Parts-SSPG Gas Model

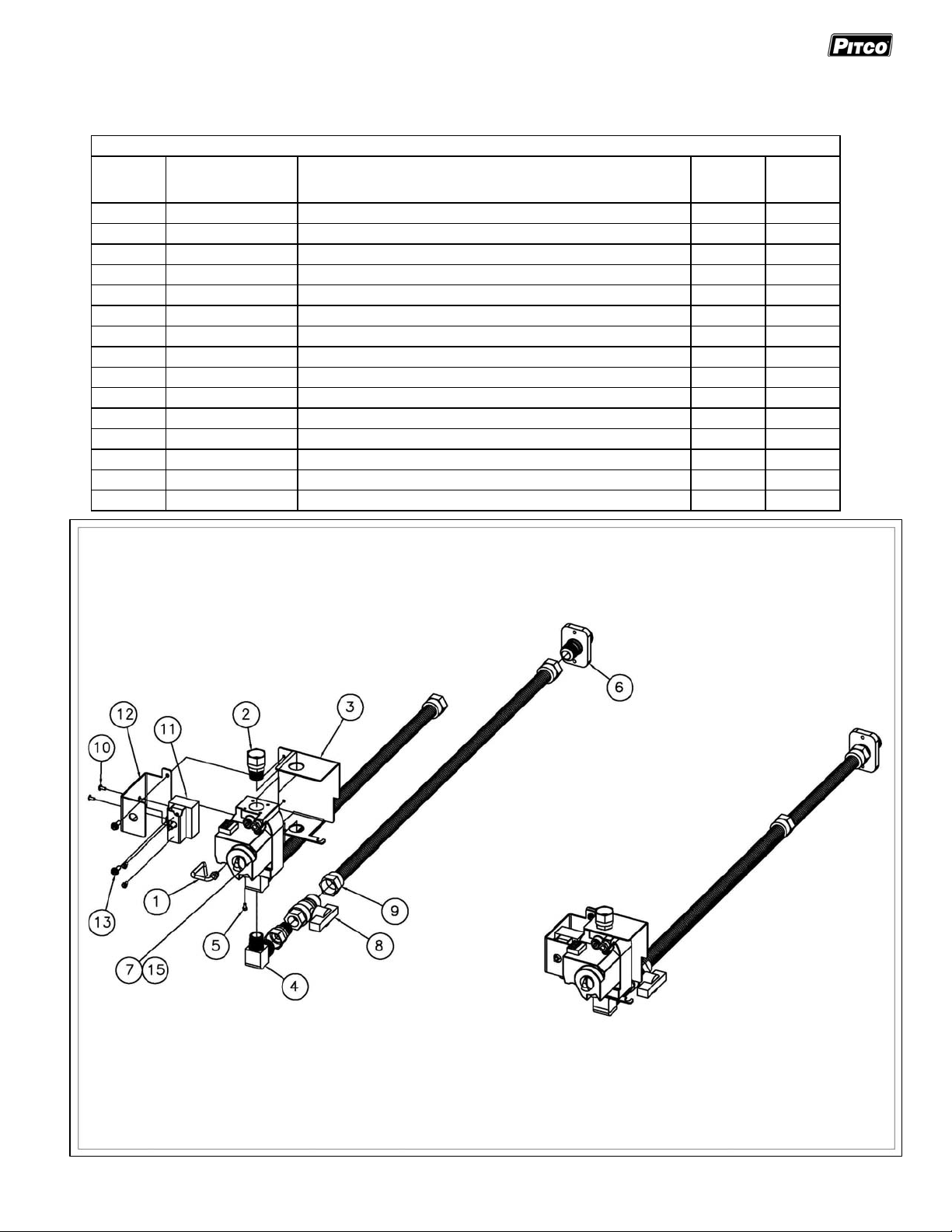

C) GAS TRAIN

Gas Train Drawing Parts List

ITEM NO. PART NO. D ESCRIPTION

1 60125901 TUBE, VENT GAS VALVE 1 1

2 60127601 FITT ING, APAPTER FEMALE SWIVEL X 500 NPT 2 2

3 A8043501 PIPING,VALVE SHIELD HE PASTA 1 1

4 60127401 FITTING,ELBOW MALE FLARE X MALE PIPE THREAD 2 1

5 P0007300 SCREW , 8-32 X . 250 HEX HEAD SLOTTED ZN 3 3

6 A8029105 COUPLING, GAS SUPPLY SHORT 1 1

7 60113501 VALVE, GAS VR8204 24V FAST NAT 1 8 60128101 VALVE, GAS SUPPLY SHUTOFF 1

9 6012816 TUBING, FLEXI B LE WITH FITTINGS 28 GAS 1 1

10 PP10687 SCREW, 6-32 X 313 THRUSS HEAD PHILLIPS ZN 2 2

11 PP10803 SWITCH, HI-LI MIT 250F LB117-026 1 1

12 A8043601 BRACKET, HI LIMIT PSG 1 1

13 P0075400 SCREW, 10- 24 X .500 SELF TAPPING 2 2

14 B6745502 WI RING, HI-LIMIT 24VAC (NOT SHOW N) 1 1

15 60113502 VAVLE, GAS VR8204 24V FAST LP - 1

BOM TABLE

NAT 24V

QTY

LP 24V

QTY

1

6

L22-383 Rev 0 (9/13)

Page 7

Exploded Parts-SSPG Gas Model

D) GAS CONVERSION KITS

Gas Conversion Kits Quick Reference

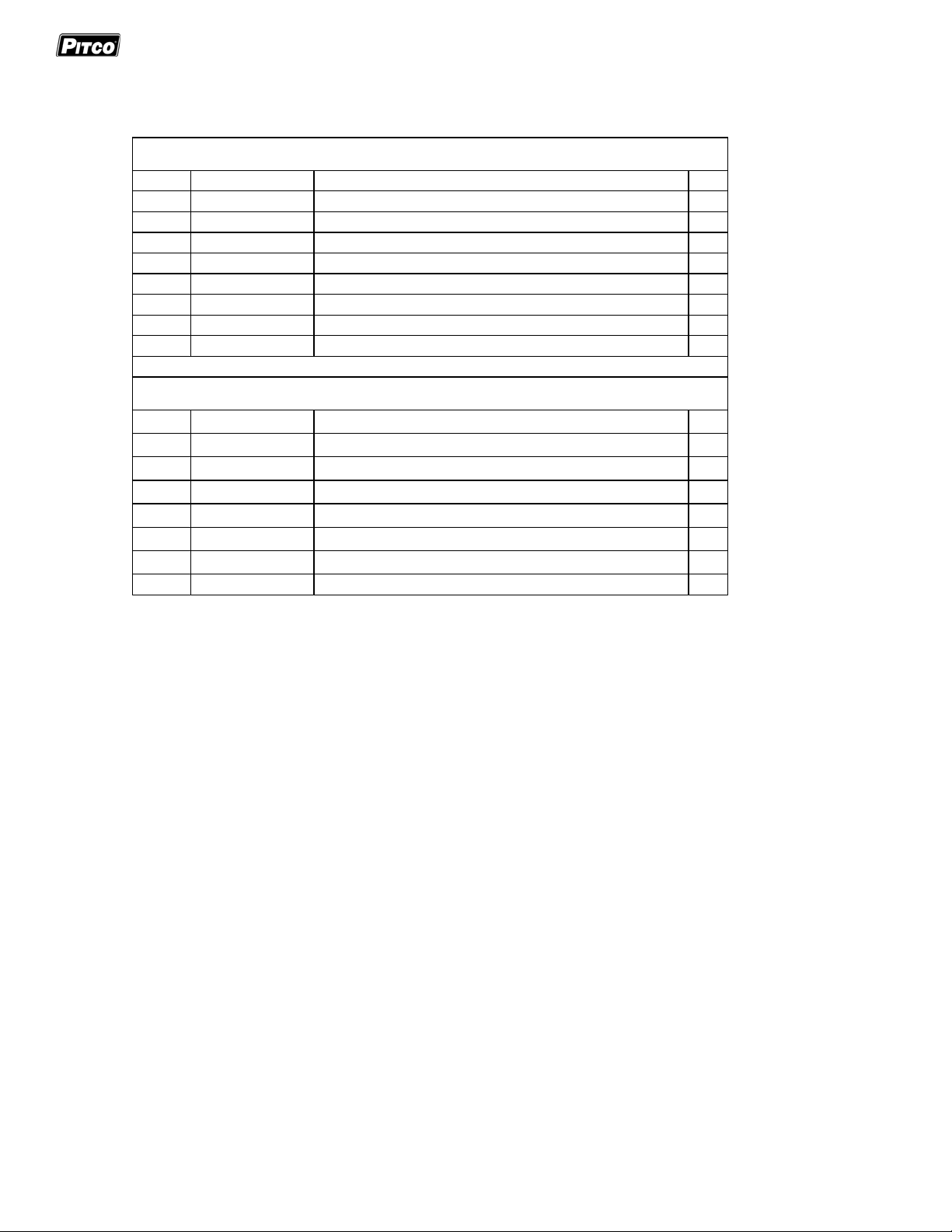

ITEM # PART # PART DESCRIPTION QTY

1 B8043250-C PG,CO N V S SPG NAT TO LP

2908 -0 940 502 ORF,P IL OT RNR TUBE # 68 1

P6071665 ORF,SPUD LP .016[0.40] 1

PP10426 LBL, GAS NOTICE CVRSN LP 1

PP11141 VLV,CONV KIT VR8204 NAT TO LP 1

A8034905 PG,COLLAR BNR LP ST MG,SGH 2

B8046101 PG,BNR INC 600,20X20 SCRN 2

P6071353 ORIFI CE #53 2

ITEM # PART # PART DESCRIPTION QTY

1 B8043251-C

2908 -0 940 501 ORF,P IL OT RNR TUBE # 52 1

P6071666 ORF,SPUD NAT .022[0.55] 1

PP10427 LBL, GAS NOTICE CVRSN NAT 1

PP11319 VLV,CONV KIT VR8204 LP TO NAT 1

A8031801 PG,BNR SHLD SG14T* 2

P6071342 ORIFI CE #42 2

NATURAL TO LP

LP TO NATURAL

PG,CONV SSPG LP TO NAT

L22-383 Rev 0 (9/13)

7

Page 8

Exploded Parts-SSPG Gas Model

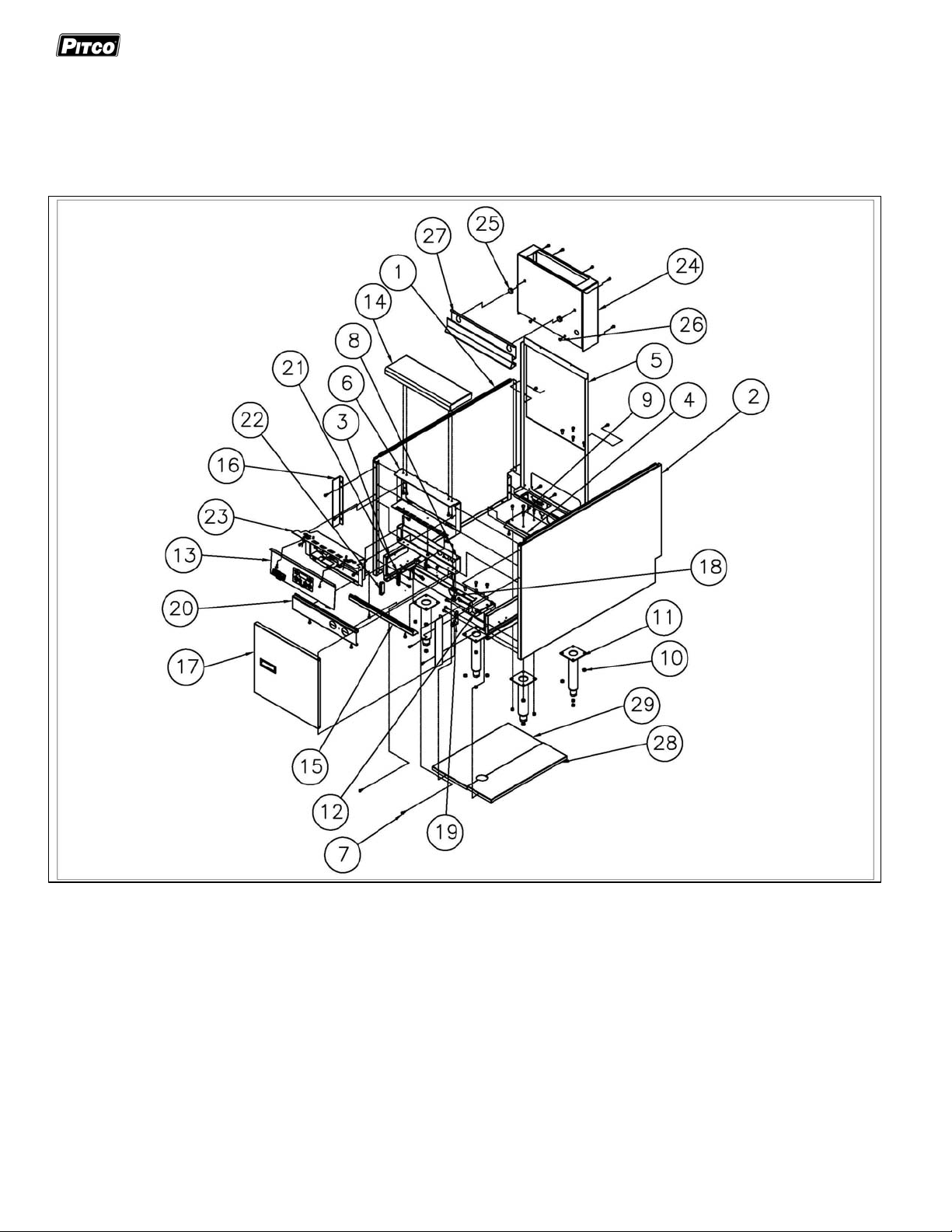

E) Standard Cabinet Drawing

Standard Cabinet Drawing List

ITEM

NO.

PART NO. DESCRIP TION QTY

1 A153 7002 CABINET SIDE, LH HE PASTA GAS 1

2 A153 7004 CABINET SIDE, RH HE PASTA GAS 1

3 A153 7102 CABINET SIDE, SUPPORT HE PAST A MOD 2

4 A1638202 CABINET BACK,BOTTOM HE PASTA 14 1

5 A163 8101 CABINET BA CK, T OP SSPG14 1

6 A185 3201 CABINET, SPACER HE PASTA 14 1

7 P0075400 SCREW, 10-24 X .500 SELF TAPPING 58

8 A185 3601 CABINET, SPACER SOLSTI CE GA S PASTA 14 1

9 P0020600 SCREW, .250-20 X .625 HEX HEAD ZN 16

10 P0093300 NU T, H EX KEP .250-20 ZN 16

11 60132401 LEG, ADJUSTABLE 9" POWDER COATED 4

12 A1234301 CABI NET BOTT OM BRACE, FRONT 1

13 B3636 203 FRONT PAN EL, BEZEL ASSEMBLY COMPACT DIGIT AL 1

14 B3636501 FRONT PANEL,TOP DECK WELDMNT 1

15 A3679002 FRONT PAN EL, BOTTOM HE PASTA 1

16 A3678802 FRONT PANEL, END CAP 2

17 B2304 616 DOOR, ASSEMBLY 1

18 B3802 401 HINGE, WELDMEN T UPPER RH 1

19 B3801801 HINGE, WELDMENT LOWER RH 1

20 A3679102 FRONT PANEL, LOWER SSPG14 T&S MX VLV 1

21 A1847002 CLIP, BRACKET MAGNET CA T CH 1

22 P6071300 CATCH, MAGNET STANDARD 1

23 B2006 102 CONTROL BOX ASSEMBLY 1

24 A4110902 SPLASH BACK, HE PASTA T&S 1

25 60132001 TANK, STUD SPLASH BACK SCREW ON 2

26 60125801 SCREW, 10-24 X .375 THRUSS HEAD SLOTTED SST 2

27 A1108002 BASKET H ANGER, HEMMED HE PASTA 1

28 A1236502 CA BINET, BOTTOM SH ELF HE PASTA RH 1

29 A1236504 CABINET, BOTTOM SHELF HE PA ST A LH 1

BOM TABLE

8

L22-383 Rev 0 (9/13)

Page 9

Exploded Parts-SSPG Gas Model

Standard Cabinet Parts Drawing

L22-383 Rev 0 (9/13)

9

Page 10

Exploded Parts-SSPG Gas Model

F) ACCESSORIES

Accessories Drawing Parts

ITEM # PART # PART DESCRIPTION

1 A3305701 CLEAN-OUT ROD

2 PP10730 BRUSH,NYL FRYER-CLNR STR 416T

3 60132401 9" LEG

4 B 392102 9" LEG SET OF 4 WITH HARDW ARE (NOT SHOWN)

5 60115301 9" LEG WI TH BOTTOM BOLT FLANGE ADJUSTABLE (NOT SHOWN)

6 PP10814 9" CASTER NON-LOCKING

7 PP10815 9" CASTER LOCKING

8 B3901504 9" CASTER SET OF 4 (2 LOCKING, 2 NON-LOCKING) (NOT SHOW N)

9 A1108001 BASKET HANGER, HEMMED HE PASTA

10 B 4510101 W R/G,RACK PASTA BSKT PG14D,PPG

11 B 4510001 W R/G,BSKT PST RND 4-7/8 REG

12 B 4512702 W R/G,BSKT PST LG BULK FINE MSH

13 B 4509901 W R/G,BSKT PST RND 6-1/2 REG

14 B 4510202 W R/G,BSKT PST SM BULK FINE MSH

15A B9010006 SET IND SERV BSKTS W/RACK

15B P6071998 IND SERVING BASKET

16 B 4509801 OBLONG BASKET

10

L22-383 Rev 0 (9/13)

Page 11

NOTES

L22-383 Rev 0 (9/13) 11

Page 12

Exploded Parts-SSPG Gas Model

p

In the event of problems with or questions

about your order, please contact the Pitco

Frialatorfactoryat

(603) 225-6684 World Wide

www.

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

itco.com

SHIPPINGADDRESS–10FERRYST.,CONCORD,NH03301

In the event of problem s with or questions

about your equipment, please contact the

Pitco Frialator Authorized Service and

Parts representative (ASA P) covering your

area, or contact Pitco at the numbers

to the left.

listed

12

L22-383 Rev 0 (9/13)

Loading...

Loading...