Page 1

Please compl ete this information and retain this manual

ENGLISH

Installation & Operation Manual

D

E

I

F

I

T

R

E

C

D

E

S

I

G

N

C IRE T IF ED

IMPORTANT FOR FUTURE REFEREN CE

for the life of t he equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

REDUCED OIL VOL UME

FRYING SYSTEM

Covering

Models

SSHLV14, SSHLV184 SERIES

L20-407 rev. 2 (12/14)

Page 2

TO THE PURCHASER, OWNER AND STORE MANAGER

WARNING

thoroughly before installi ng, ope ra t ion, servicing this appliance.

Please review these warnings prior to posting them in a prominent location for reference.

Post in a prominent location the instructi ons t o be follow e d in the

event that an operator smells gas. Obtai n thi s i nf ormat ion from

your local gas supplier.

DO NOT store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other applia nc e.

Do not spray aerosols in the vicinity of this a pplia nc e whe n it is

in operation.

Improper installation, adjustment, operation, alteration, service

or maintenance can cause property damage , injury or death.

Read the installation, operati ng a nd maint e na nc e instr uc t ions

Installation, maintenance and repairs should be performed by a

Pitco Authorized Service and Parts ( AS AP) c ompany te c hnic ian

or other qualified personnel. Installation, maintenance or repairs

by an unauthorized and unqualified per s onnel will voi d the

warranty.

Installation and all connections must be made according to

local codes in force. In the absence of local code s i n Nort h

America, the installation must conform with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas and

Propane Installation Code CSA B149.1 as applicable. In

Australia, the appliance must ins talled in compliance with

AS/NZS 5601.

During the warranty period if a customer el ect s to use a nonoriginal part or modifies an origi nal part purchased from Pitco

and/or its Authorized Service and Parts (ASAP) companies, this

warranty will be void. In addition, Pit c o and its affiliates will not

be liable for any claims, damages or expenses i ncurr e d by the

customer which arises directly or indirectly, in whole or in part,

due to the installation of any modified par t and/or re c ei v e d from

an unauthorized service center.

This appliance, when installed, must be ele c tr ic al ly grounded in

accordance with local codes, or in the abse nc e of local c odes,

with the National Electrical Code, ANSI /NFPA 70, or the Canadian

Electric al Code, CS A C22.2 , a s applicable and the hose must

comply with AS/NZS 1869 and be class B or D.

Adequate means must be provided to LIMIT the movement or thi s

appliance without depending on the gas or elec tri c al cor d

connection. Single appliances e quippe d wi t h le gs must be

stabilized by installing anc hor s traps . All a ppliances equipped

with casters must be stabilized by insta lling restraining chains.

An appliance equipped with casters and a fle xi ble ga s line must

be connected to the gas supply with a quick disconne c t devi c e.

In North America this quick disconnect must c ompl y wit h ANSI

Z24.41. In Australia, the quick disconnec t m us t compl y wit h AS

4627.

DO NOT alter or remove structural materi al on the appliance to

accommodate placement under a ventilation hood.

If the appliance is equipped with a power cord and it is damaged,

it must be replaced by a Pitco Authorized Servic e and Part s

(ASAP) company technician, or a similarly qualified person in

order to avoid a hazard.

The power supply must be disconnected before ser vi ci ng,

maintaining or cleaning this applianc e .

The appliance is NOT jet stream approved. DO NOT clean the

appliance with a water jet.

DO NOT attempt to move this appliance or transfer hot liquids

from one container to another when the unit is at operati ng

temperature or filled with hot liquids. Serious personal injury

could result if skin comes in contact with the hot surfaces or

liquids.

DO NOT use an open flame to check for gas leaks!

ii L20-407 rev.2 (12/14)

TO THE PURCHASER

FOR YOUR PROTECTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DO NOT sit or stand on this appliance. The applia nce’s fr ont

panel, tank, splash back, tank cover, wor kshelf, drain board is

not a step. Serious injury could result from sli pping, falling or

contact with hot liquids.

NEVER use the appliance as a step for cleaning or accessing the

ventilation hood. Serious injur y could re s ult fr om slips, trips or

from contacting hot liquids.

The oil/shortening level shoul d NOT fall bel ow the minimum

indicated level line at any time. The use of old shorte ning c an be

dangerous as it will have a reduced flash point and be more

prone to surge boiling.

The contents of the crumb catch and/or filt er pan of any filter

system must be emptied into a fireproof contai ner at the end of

the frying operation each day. Some food particles can

spontaneously combust into flames if l eft soaki ng in c er tain

oil/shortening materials.

Completely shut the appliance down whe n shor tening/oil is being

drained from the appliance. This will prev e nt the appliance from

heating up during the draining and filli ng proc e ss. Serious injury

can occur.

This appliance is intended for indoor use onl y.

DO NOT operate appliance unless all panels and acces s cov er s

are attached correctly.

It is recommended that this appliance be inspected by a qualifie d

service technician for proper perfor m a nc e and oper ation on a

yearly basis.

There is an open flame inside this appliance. The unit m ay get

hot enough to set nearby materials on fire. Ke e p the area around

the appliance free from combustible s.

DO NOT supply the appliance with a gas that is not indicate d on

the data plate. If you need to convert the applianc e to anothe r

type of fuel, contact your dealer.

If gas flow to appliance is interrupted, or pilots extinguish, wait 5

minutes before attempting to relight t he pil ot t o all ow any

residual gas in appliance to dissi pate .

Ensure that the appliance can get enough air to keep the fla me

burning correctly. If the flame is starved for air, it can give off a

dangerous carbon monoxide gas. Carbon m onoxi de is a clear

odorless gas that can cause suffocation.

Never add oil to the appliance when it is at operati ng

temperature. Splashing hot oil can caus e seve re injuries.

Never add water to hot oil. Violent boiling can occur c a usi ng

severe injury.

This appliance is intended for profess ional use only and should

be operated by fully trained and qualifi e d personne l.

. To avoid splashing of hot liquid when installed, this fryer must

be restrained either in the manner of install a ti on, or wi t h

adequate ties to prevent tipping.

In North America, gas appliances equippe d wi t h casters must

be installed with connectors that comply with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69.CSA

6.16 Latest Edition. This connection s hould include a quick

disconnect device that complies wi t h the Sta ndar d f or Quick

Disconnect Devices for Use With Gas Fuel ANSI Z21.4 1. CSA

6.9 Latest Edition. In Australia, an appliance equipped with

casters and a flexible gas line must be connected to the gas

supply with a quick disconnect device tha t compli e s wit h AS

4627 and a restraining cable. The restraining cable must not

exceed 80% of the length of the flexible gas line.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Page 3

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

THEORY OF OPERATION ................................................................................................................................. 5

1.

2. INSTALLATION ................................................................................................................................................ 6

2.1. CHECKING AND UNPACKING YOUR NEW APPLIANCE .................................................................................... 6

2.2. INSTALLATION CLEARANCES .......................................................................................................................... 6

2.3. LEVELING THE FRYER – LEGS/CASTERS ........................................................................................................... 7

2.4. GAS CONNECTION .......................................................................................................................................... 8

2.5. QUICK DISCONNECT CONNECTION ................................................................................................................ 8

2.6. FUEL SUPPLY LINE LEAK AND PRESSURE TESTING .......................................................................................... 8

2.7. INSTALLATION SETUP ........................................................................................................................................... 8

2.8. ELECTRICAL CONNECTIONS ............................................................................................................................ 9

2.9. VENTILATION AND FIRE SAFETY SYSTEMS ...................................................................................................... 9

2.10. INSPECTION ............................................................................................................................................. 10

2.11. INITIAL ADJUSTMENTS ............................................................................................................................. 11

2.11.1. FILLING THE APPLIANCE ....................................................................................................................... 11

2.11.2. LIGHTING INSTRUCTIONS ..................................................................................................................... 11

2.11.3. PILOT FLAME ADJUSTMENT ................................................................................................................. 12

2.11.4. MAIN BURNER SYSTEM ADJUSTMENT ................................................................................................. 12

2.12. INITIAL CLEANING .................................................................................................................................... 13

3. OPERATION .................................................................................................................................................. 14

3.1. OPERATIONAL FEATURES ............................................................................................................................. 14

3.2. BASIC OPERATIONAL FEATURES ............................................................................................................................ 15

3.3. FILLING THE FRY POT .................................................................................................................................... 16

3.4. FILLING THE TANK WITH LIQUID SHORTENING ............................................................................................ 16

4. APPLIANCE START UP ................................................................................................................................... 17

4.1. COOKING ...................................................................................................................................................... 18

4.2. COOKING TIPS .................................................................................................................................................. 18

5. COMPUTER CONTROLLER OPERATION ......................................................................................................... 19

5.1. TO TURN THE APPLIANCE ON: ............................................................................................................................. 19

5.2. TO TURN THE APPLIANCE OFF: ............................................................................................................................ 19

5.3. TO START A COOK: ............................................................................................................................................ 19

5.4. TO CANCEL A COOK: .......................................................................................................................................... 19

5.5. TO VIEW ACTUAL AND SET TEMPERATURES: ........................................................................................................... 19

5.6. TO VIEW CURRENT SETTINGS FOR COOK, SHAKE, AND HOLD TIMES: ............................................................................ 20

5.7. TO PERFORM A BOIL OUT OPERATION: .................................................................................................................. 20

5.7.1. Automatic Boil Entry (Water Detection): ............................................................................................. 20

5.7.2. Manual Boil Entry: ............................................................................................................................... 20

5.8. TO ENTER PROGRAMMING LEVEL 1 (FOR THE STORE MANAGER): .............................................................................. 21

5.9. TO SET COOK TEMPERATURE: ............................................................................................................................. 21

5.10. TO CHANGE A PRODUCT KEY–COOK, SHAKE, HOLD, AND HOLD PRE-ALARM TIMES: ................................................. 21

5.10.1. Cook Time ............................................................................................................................................ 21

5.10.2. Shake Time ........................................................................................................................................... 21

5.10.3. Hold Time ............................................................................................................................................. 21

5.10.4. Hold Pre-Alarm..................................................................................................................................... 22

5.11. TO EXIT LEVEL 1 PROGRAMMING: .................................................................................................................... 22

5.12. TO ENTER PROGRAMMING LEVEL 2 (FOR THE STORE MANAGER) ........................................................................... 22

5.13. FAHRENHEIT OR CELSIUS DISPLAY: ................................................................................................................... 22

5.14. PASSWORD CHANGE OR REQUIRED? ................................................................................................................ 22

5.15. BEEPER VOLUME AND TONE: .......................................................................................................................... 23

5.16. LANGUAGE SELECTION: .................................................................................................................................. 23

5.17. MELT CYCLE TYPE: ........................................................................................................................................ 23

5.18. RECOVERY TEST VALUE: ................................................................................................................................. 23

L20-407 rev. 2 (12/14) 3

Page 4

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

CONTROL OR TIMER: (LEFT SIDE OF DUAL OR SINGLE VAT) ................................................................................... 23

5.19.

5.20. CONTROL OR TIMER: (RIGHT SIDE OF DUAL VAT) ................................................................................................ 24

5.21. OTHER DISPLAYS: ..................................................................................................................................... 24

5.22. COMPUTER SHUTDOWN ............................................................................................................................. 24

5.23. FLUSH HOSE OPERATION (IF EQUIPPED) ...................................................................................................... 24

6. BASKET LIFT OPERATION .............................................................................................................................. 25

7. PUSH BUTTON OIL TOP OFF SYSTEM ............................................................................................................ 25

8. AUTOMATIC OIL TOP SYSTEM (OPTION) ...................................................................................................... 25

9. QUICK STRAIN FILTERING “FILTER SOON” LIGHT FLASHING .......................................................................... 26

10. COOK COUNTER ADJUSTMENT ................................................................................................................. 26

11. APPLIANCE SHUTDOWN ........................................................................................................................... 27

11.1. STANDBY MODE ....................................................................................................................................... 27

11.2. COMPLETE SHUTDOWN ........................................................................................................................... 27

12. PREVENTATIVE MAINTENANCE ................................................................................................................ 27

12.1. DAILY PREVENTATIVE MAINTENANCE ..................................................................................................... 27

12.1.1. FILTERING DAILY cleaning .................................................................................................................... 27

12.1.2. REPLACING THE FILTER MEDIA (if equipped) ....................................................................................... 28

12.1.3. APPLIANCE INSPECTION ....................................................................................................................... 29

12.1.4. CLEANING THE COOK TANK ................................................................................................................. 29

12.1.5. CLEANING THE CABINET ...................................................................................................................... 29

12.1.6. FILTER CLEANING (If Equipped) ............................................................................................................ 29

12.2. WEEKLY PREVENTATIVE MAINTENANCE .................................................................................................. 30

12.3. MONTHLY PREVENTATIVE MAINTENANCE .............................................................................................. 30

12.3.1. BOIL OUT PROCEDURE ......................................................................................................................... 30

12.3.2. TEMPERATURE CHECK ......................................................................................................................... 31

12.4. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION .................................................... 32

12.4.1. Safety Evaluation ................................................................................................................................. 32

12.4.2. Mechanical Inspection ......................................................................................................................... 32

12.4.3. Temperature Control System ............................................................................................................... 32

12.4.4. Filter System (If Equipped) ................................................................................................................... 32

12.4.5. GAS COMBUSTION SYSTEM ................................................................................................................. 33

12.5. VENTILATION HOOD ................................................................................................................................ 33

13. TROUBLESHOOTING ................................................................................................................................. 34

13.1. POWER FAILURE ....................................................................................................................................... 34

13.2. HIGH TEMPERATURE LIMIT SWITCH ........................................................................................................ 34

13.3. DRAIN VALVE INTERLOCK ......................................................................................................................... 34

13.4. SELF CLEANING BURNER SYSTEM (NOT ON ALL MODELS) .............................................................................. 35

13.5. RESETTING THE SELF CLEANING BURNER SYSTEM TEMPERATURE LIMIT SWITCH ................................................... 35

13.6. TROUBLESHOOTING CHARTS ................................................................................................................... 36

13.6.1. Fryer Troubleshooting Chart ................................................................................................................ 36

13.6.2. Filter troubleshooting chart (if equipped) ............................................................................................ 36

13.6.3. COMPUTER & DIGITAL CONTROLLER DISPLAYS (IF EQUIPPED) ........................................................... 37

4

L20-407 rev.2 (12/14)

Page 5

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

1. THEORY OF OPERATION

The Pitco Low (or reduced) Oil Volume fryer works very similarly to the Pitco standard

SG/SSH fryer.

The Low Oil Volume Fryer has a reduced cold zone to significantly reduce oil usage and

extend oil life. This smaller zone may require more frequent filtering depending on the

product being fried.

Upon turning the fryer on, the high limit closes the (side on) safety relay which stays

closed until the fryer is turned off. If the oil temperature exceeds 450 deg F, the high

limit opens and prevents further operation until the cooking oil has reached a safe

cooking temperature . This pl aces a minimum duty cycle on the safety (side on) relay to

insure its proper operation when needed. The “heat demand” relay o pens and clos es on

demand from the primary control to maintain the desired cooki ng temperature. When

the “heat demand” relay closes, it energizes the main burners in the fry pot. Near the

fryer pot heat tubes, the temperature probe and high limit can be found. The

temperature probe provides a signal to the primary control, sensing the oil temperature

in the fry pot.

The fryer is equipped w it h a manual “ADD OIL” button that can transfer fresh oil from a

JIB (Jug in Box) located under the fryer or a bulk oil management system. The operator

can use the manual “ADD OIL” button as needed to replenish any oil consumed in the

cooking process. It is recommended that oil only be added when the fry pot is at the

desired temperature, and that the “ADD OIL” button not be used to fil l an empty fry pot

from the JIB.

Optional Automatic Top Off: If equipped, the fryer (only when operating at desired

temperature) senses the oil level and replenishes consumed oil only between cook

cycles. There are no progr amming opti ons for the operator or servi ce techni ci an, the

control functions like any other Pitco electric fryer computer control. The “ADD OIL”

switch (described above) is present with Auto Top Off.

L20-407 rev. 2 (12/14) 5

Page 6

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

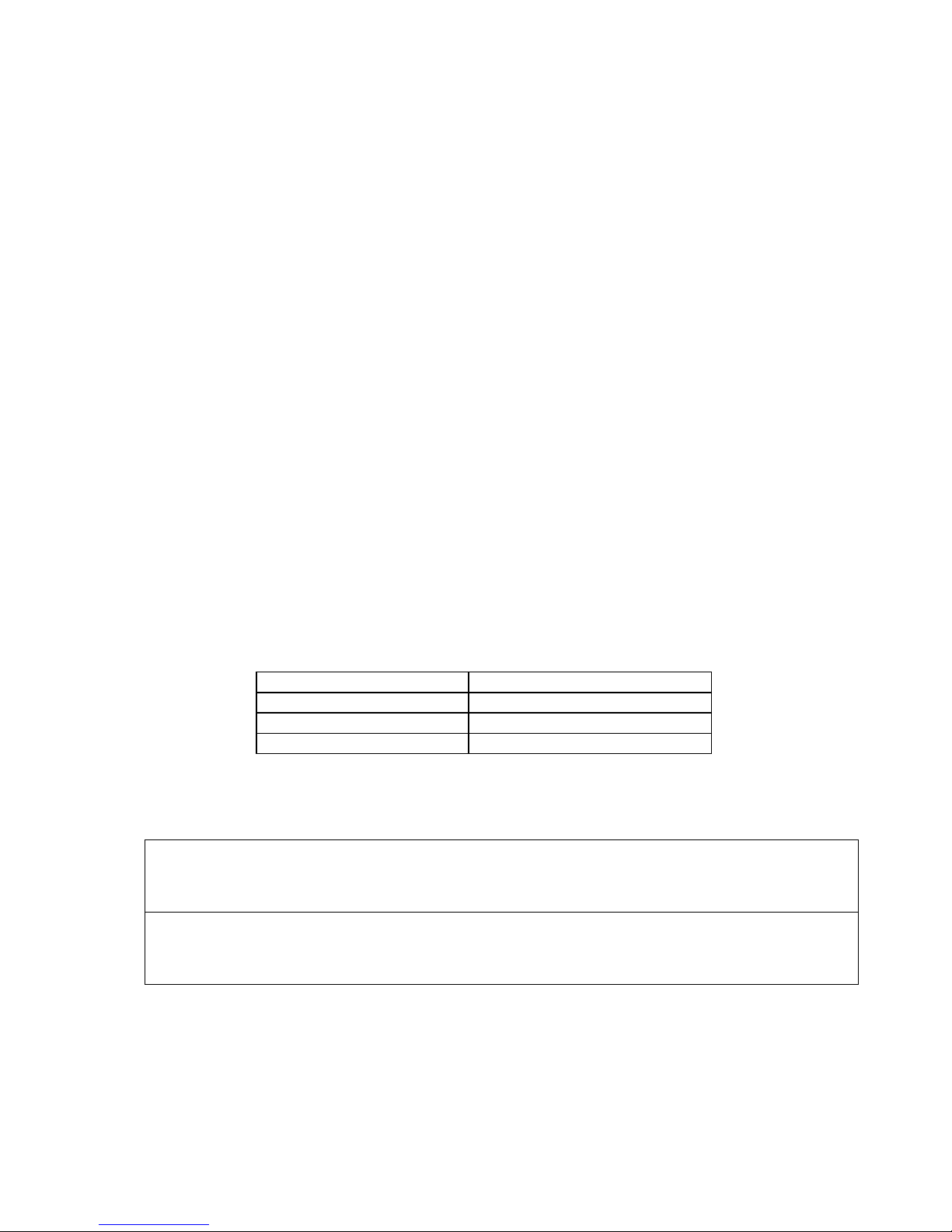

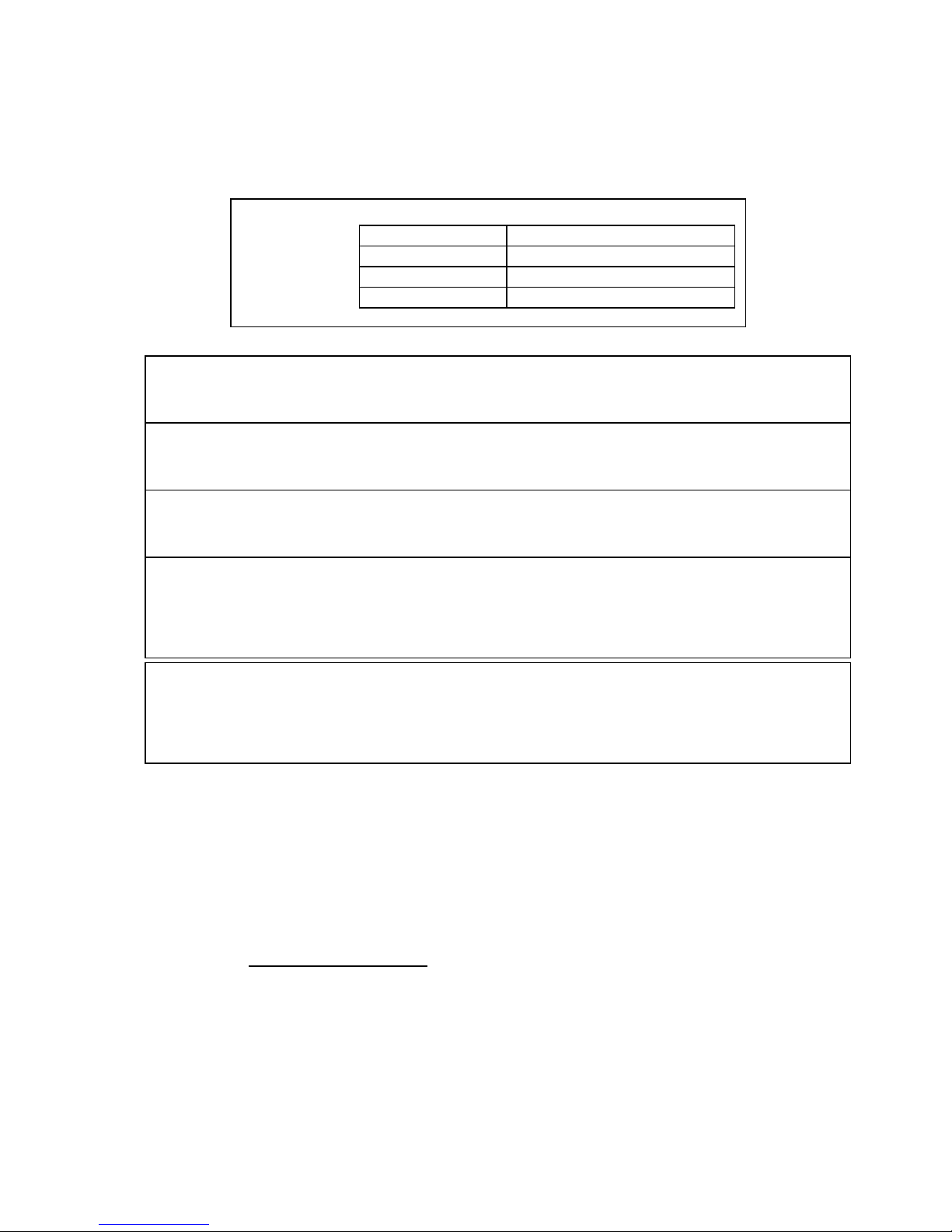

Combustible Construction

Non Combustible Construction

Inches (centimeters)

Inches (centimeters)

Back

6.0" (15.2cm)

0.0" (0.0cm)

Sides

6.0" (15.2cm)

0.0" (0.0cm)

Counter

6.0" (15.2cm)

6.0" (15.2cm)

Floor

9” (22.86 cm)

9” (22.86 cm)

WARNING

meet the minimum clearance requirements specified in this manual.

WARNING

causing hot oil to be ejected from the fryer, and creating a burn hazard.

2. INSTALLATION

2.1. CHECKING AND UNPACKING YOUR NEW APPLIANCE

Your new Pitco appliance has been carefully packed into one crate. Every effort has been made to

ensure that it is delivered to you in perfect condition. Pitco does not assume responsibility for damage

or loss incurred in transit.

1. Upon Delivery, inspect for visible shipping damage in the presence of the trucking operator. If

something appears damaged, file a claim for damages regardless of extent.

2. Unpack and inspect unit for damage. Contact the shipper within 15 days and file a concealed

damage claim; the shipper is only responsible for concealed damage for 15 days after delivery.

3. Remove the unit from the shipping pallet:

a: Remove the filter pan, and JIB pan from unit before attempting to

dismount the unit from the shipping base.

4. Do not allow the full weight of the unit to rest on the legs or caster when removing the appliance

from the shipping pallet. The casters can be bent or damaged if too much weight or force is

applied to them from improper handling.

5. Check the packing list enclosed with your appliance to ensure that you have received all the parts

to the appliance. If you are missing any parts, contact the dealer from whom the appliance was

purchased.

6. Using the front cover of this manual, record the following for warranty service or future reference:

1. Your Pitco model number. 2. Fryer serial numbers (Found on the inner door of each fryer).

3. The date purchased from your dealer invoice.

Once you have completed the above, the appliance is ready to be installed.

2.2. INSTALLATION CLEARANCES

The clearances shown below are for combustible and non-combustible installations and will allow for

safe and proper operation of your appliance.

In addition to the above clearances there must also be at least 30 inches (76.2cm) of aisle space in

front of the unit.

DO NOT obstruct the flow of ventilation air openings around the appliance. Adequate clearance

around the appliance is necessary for servicing and proper component ventilation. Ensure that you

DO NOT install this appliance next to a water cooker, or use in any way in which water can come in

contact with the hot oil. Splash over of water into hot oil may result in a steam eruption, potentially

6

L20-407 rev.2 (12/14)

Page 7

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

CAUTION

WARNING

WARNING

injury could result.

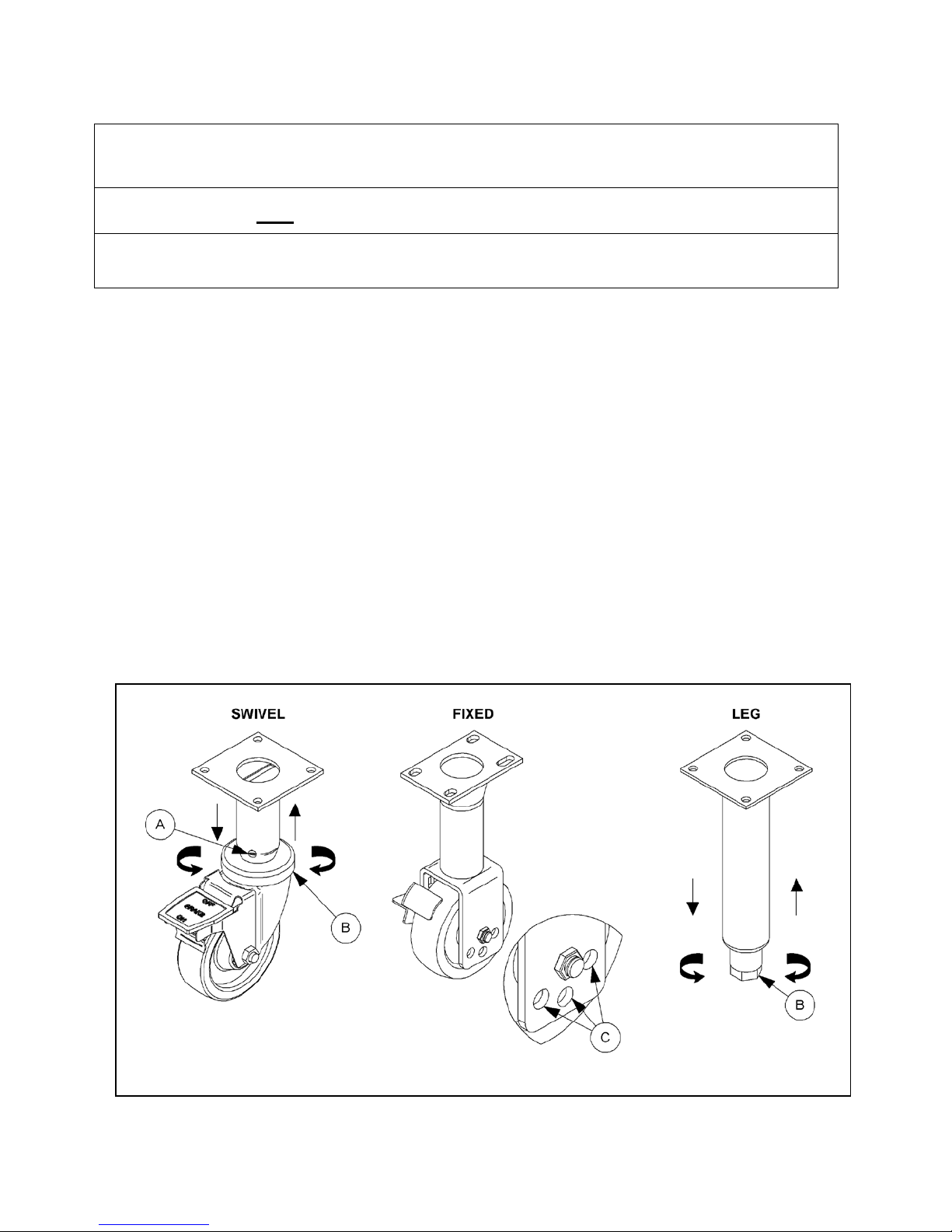

2.3. LEVELING THE FRYER – LEGS/CASTERS

To prevent equipment damage and/or personal injury, do not tilt the appliance onto any two of its

casters or legs, or pull the appliance by the splash back.

This appliance must be installed with the legs or casters provided by the manufacturer.

DO NOT perform leveling procedure when appliance is in operation or full of hot liquids. Serious

When you receive your appliance it is complete ly assembled with legs or optional casters. This

appliance must be installed with legs or casters; it cannot be curb mounted, or sealed to a base.

Curb mounting will seriously inhibi t th is appliance’s ability to effect proper component ventilation.

The supplied legs or casters provide the necessary height to meet sanitation requirements and

assure adequate air supply for electrical component ventilation. To level the fryer, us e the

following procedure.

Required tools: Large pair of water pump pliers, Medium flat blade screwdriver, level 12” long max.

1 Position appliance in final installed location.

2 Apply level across front, and then the left and right side of unit, determine lowest point, and

distance to level.

3 Add the distance determined in step 2 to caster or leg on the lowest corner of appliance.

a. Swivel casters- loosen 2 set screws (A)

b. Legs and swivel casters-. Adjust the height of the leg / caster by turning adjustment collar/

foot (B) with water pump pliers until desired change in height is achieved.

c. Swivel casters only: Retighten set screws (A).

d. Fixed casters- Adjust hei gh t by moving wheel and axle to alternate holes in wheel bracket

higher or lower as needed. Refer to Figure 3C “FIXED” type caster.

4 Adjust remaining casters or legs as needed to insure the appliance is supported evenly at each

caster/leg contact point.

Figure 3 Caster and leg types

L20-407 rev. 2 (12/14) 7

Page 8

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

dealer you purchased it from.

NOTICE

2.4. GAS CONNECTION

Your gas appliance will give you peak performance when the gas supply line is of sufficient size to

provide the correct gas pressure. The gas line must be installed to meet the local building codes or

National Fuel Gas Code ANSI Z223.1 Latest Edition. In Canada, install the appliance in accordance

with CAN/CGA-B149.1 or .2 and local codes. In Australia, install the appli anc e in acc ordanc e with

AS/NZS 5601. Gas line sizing requirements can be determined by your local gas company or, in

North America, by referring to the National Fuel Gas Code, Appendix C, Table C-4 (for natural gas)

and Table C-16 (for propane). The gas line needs to be large enough to supply the necessary amount

of fuel to all appliances without losing pressure to any appliance. A properly sized and installed gas

line will deliver a supply pressure between 7.0” W.C. (17.4mbars, 1.74kPa) and 10.0”W.C.

(24.9mbars, 2.49kPa) natural gas or between 11.0”W.C. (27.4mbars, 2.74kPa) and 13.0” W.C.

(32.4mbars, 3.25kPa) for propane to all appliances connected to the supply line, operating

simultaneously at full demand. The pressure at the gas valve shall not exceed ½ PSI.

The gas supply connection to this appliance is located in the rear of the appliance approximately

10-1/2” (26.7 cm) from the floor of the appliance when legs are used.

Each appliance is equipped to operate on one certain fuel type. The type of fuel with which the

appliance is intended to operate is stamped on the data plate, which is attached to the inside of the

door.

NEVER supply the appliance with a gas other than the one that is indicated on the data

plate. Using the incorrect gas type will cause improper operation and could result in serious

injury or death. If you need to convert the appliance to another type of fuel, contact the

NEVER use an adapter to make a smaller gas supply line fit the appliance connection. This

may not allow proper gas flow for optimum burner operation, resulting in poor performance

and improper operation.

2.5. QUICK DISCONNECT CONNECTION

In North America, gas appliances equipped with casters must be installed with connectors that

comply with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69.CSA 6.16

Latest Edition. This connection should include a quick disconnect device that complies with the

Standard for Quick Disconnect Devices for Use With Gas Fuel Appliances ANSI Z21.41.CSA 6.9

Latest Edition. In Australia, an appliance equipped with casters and a flexible gas line must be

connected to the gas supply with a quick disconnect device that complies with AS 4627 and a

restraining cable. The restraining cable must not exceed 80% of the length of the flexible gas line.

The restraining device should be attached to the appliance at the back panel.

2.6. FUEL SUPPLY LINE LEAK AND PRESSURE TESTING

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be

tested at a pressure greater than ½ PISG (3.45 kPa, 34.5 mbar), insure that that appliance is

disconnected from the fuel line. If the fuel line is to be tested at a pressure equal to or less than ½

PSIG (3.45 kPa, 34.5 mbar), the appliance can be connected during the test, but the unit’s gas

valve must be shut. Test all gas line connections for leaks with a solution of soap and water when

pressure applied.

2.7. INSTALLATION SETUP

The installation of this appliance MUST conform to local codes. In the absence of local codes in

North America, the installation must conform with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or the Natural Gas and Propane Installation Code CSA B149.1 as applicable. In

Australia, the appliance must installed in compliance with AS/NZS 5601 (current revision)

8

L20-407 rev.2 (12/14)

Page 9

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

CAUTION

the warranty.

WARNING

specified on the data plate located on the inside of the appliance door.

WARNING

on the data plate. Electrical connection should be performed by qualified personnel.

WARNING

local codes. In all other cases, re fer to local and national codes and regulations.

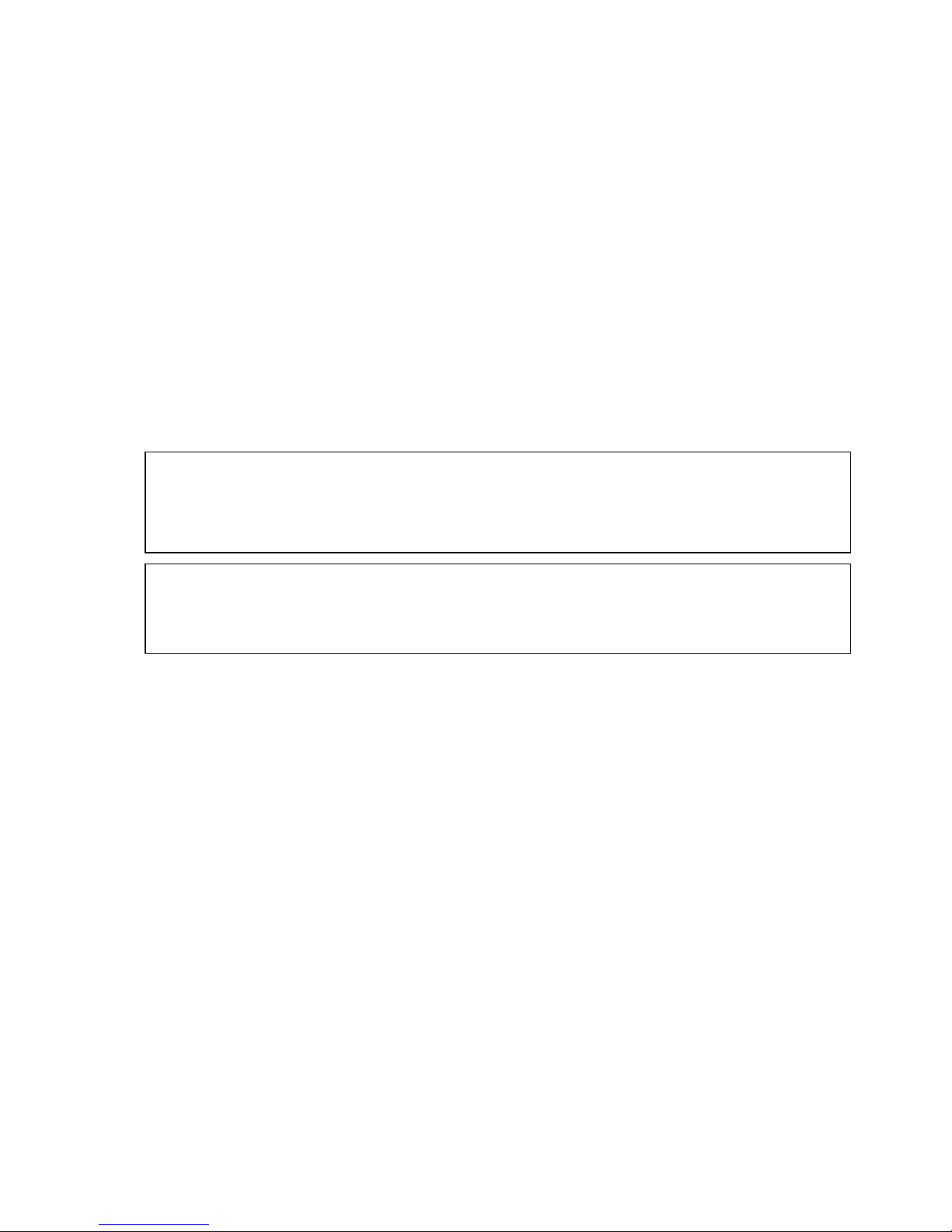

North America

International

Input Voltage

120 VAC, 50/60 Hz

220, 230 or 240 VAC 50/60 Hz

Current per unit

1.0 Amp

0.5 Amps

Filter Current

7.5 Amp

4.2 Amps

Heat Tape

0.4 Amp

0.2 Amps

WARNING

should be plugged into a properly grounded three-prong receptacle.

2.8. ELECTRICAL CONNECTIONS

It is advised that this power supply be plugged into a wall receptacle that is controlled by the

ventilation control. This will prevent the appliance from being operated without the ventilator on. If

your appliance requires an electrical connection, the power requirements are listed below.

A full version of the wiring diagram can be found adhered to the inner door(s) of the appliance.

Connecting the appliance to the wrong power supply may damage the appliance and void

This appliance must be connected to a power supply having the same voltage and p hase as

DO NOT attempt to connect the appliance to an electrical supply other than that indicated

The electrical connection used by this appliance must comply with local codes. In the

United States if there are no local codes that apply, refer to the National Electrical Code

(NEC), ANSI/NFPA 70 for installation in the US. In Canada, refer to CSA Standard C22.2 and

If your appliance is equipped with an oil proof, electrical supply cord with a three-prong

safety plug. This is to protect oper ators from electrical shock hazard in the event of an

equipment malfunction. DO NOT cut or remove the grounding (third) prong from this plug; it

2.9. VENTILATION AND FIRE SAFETY SYSTEMS

Your new appliance must have proper ventilation to function safely and properly. Exhaust gas

temperatures can reach as high as 1100 °F (593 °C). Therefore, it is very important to install a fire

safety system. Your ventilation system should be designed to allow for easy cleaning. Frequent

cleaning and proper maintenance of the ventilation system and the appliance will reduce the chances

of fire. Ventilation and fire safety systems must comply to local and national codes for US and

Canada. Refer to ANSI 83.11 for a list of reference documents that will provide guidance on

ventilation and fire safety systems. For installations in U.S. and Canada, additional information can

be obtained from CSA International, 8501 East Pleasant Valley Road, Cleveland, OH, 44131 or visit

their website at www.csa-international.org

. In Australia the ventilation system must comply with

AS/NZS 5601.0.

It is essential that the appliance be operated only when adequate ventilation is provided. Your

ventilation hood should be properly maintained. A qualified installation professional should ensure that

the hood is operating properly in conjunction with the appliance. Inadequate ventilation may not

properly evacuate appliance all emissions. Excessive or unbalanced ventilation may cause drafts,

which could interfere with proper operation of the pilot and burners. Leave at least 18 inches (47cm) of

open space between the flue of the appliance and the intake of the exhaust hood.

L20-407 rev. 2 (12/14) 9

Page 10

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

WARNING

WARNING

under the fire safety system are adequately protected.

Ensure that your ventilation system does not cause a down draft at the appliance’s flue

opening. A down draft will not allow the appliance to exhaust properly and will cause

overheating, which may cause permanent damage. Damage caused by down drafts will not

be covered by the warranty. NEVER allow anythin g to ob struct the flow of combustibles or

ventilation exiting the applianc e. NEVER place anything on top of the flue area, or block the

flue in any way. Never place a grease condensing drip pan over the flue opening.

NEVER connect the ventilation blower or hood directly to the flue of this appliance. The

resulting increased flow of air thr o ug h th e combustion system will cause improper

operation, poor temperature recovery, poor ignition and could extinguish the pilot.

Replacing or adding appliances under a pre -existing fire safety system may require

modifications to the system. ALWAYS contact a professional who is qualified in installing,

designing and maintaining your fire safety system to assure that any appliances located

For Australia, the fryer must be installed in accordance with AS/NZS 5601, local authority and any other

relevant statutory regulations. Flexible hose (if used) must comply with AS/NZS 1869 Class B or D, be of

appropriate internal diameter, be kept as short as possible (not exceed 1.2 meters), must not be kinked

and not be in contact with a hot surface. A chain must be fitted to restrict the fryer movement to no more

than 80% of the hose length.

2.10. INSPECTION

Before you begin filling and adjusting the app lianc e, p er f orm the following visual checks:

After the appliance is in its permanent location, check the levelness. Any additional leveling that

is necessary can be performed as previously described.

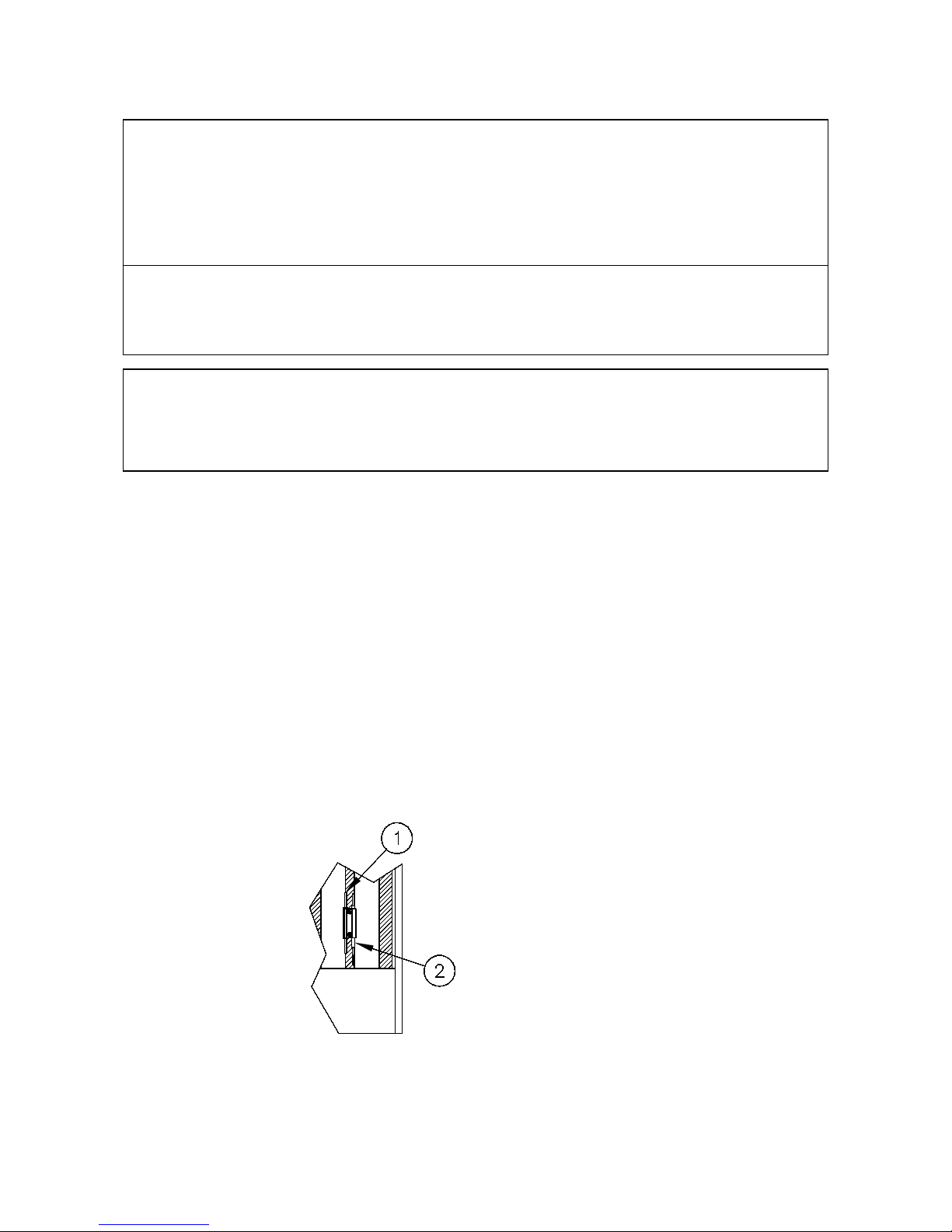

Ensure that the sensing probe and high temperature limit bulb are in place and secure. Check

the high limit bulb mounting screws to ensure that they are tight.

Review the installation portion of this manual and ensure that all steps have been followed and

executed properly.

1) Probe

2) High Tempe r ature Limit

10 L20-407 rev.2 (12/14)

Page 11

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

ON

OFF

PUSH BLUE HANLDE IN

WARNING

CAUTION

WARNING

set near by materials on fire. Keep the area around the appliance free from combustibles.

2.11. INITIAL ADJUSTMENTS

After your appliance has been properly installed as described in the installation section of this

manual, it will need to be adjusted to ensure that it will perform as designed. A qualified person must

perform these adjustments.

To perform these adjustments the following tools will be needed:

Manometer

Digital Thermometer (Temperature Probe)

DC Microammeter

DC Voltmeter

2.11.1. FILLING THE APPLIANCE

Refer to the following procedure to fill the cook tank prior to

operation.

1. Ensure that the drain valve is closed.

2. Fill the tank with oil/shortening until the oil/shortening

reaches the level line(s). Never let the oil/s hor t eni ng leve l

go below the MIN LEVEL mark stamped on the tank.

Oil/shortening must completely cover the heat tubes at all times while appliance is on.

This appliance is not designed for cooking with water. Fill with oil/shortening only.

During operation there is an open flame ins ide this appliance. The unit may get hot enough to

2.11.2. LIGHTING INSTRUCTIONS

There is nothing to manually light on the SSHLV system. Pilot ignition is performed and controlled

by the electronic ignition system. Refer to the following instructions to light the appliance.

1. Open the gas supply valves to the appliance.

2. Turn the gas valve knob to the ON position.

3. Turn the controller on.

*

Press the

*

4. The main burners will light and be controlled by the computer.

Note: If your appliance has a self cleaning burner system, the burners may make a

popping sound immediately after the main bur ners light during startup. This noise during

startup is part of the normal operation of the self cleaning burner system and should NOT

continue during normal cooking & idle periods. (SCB Only)

button to turn the COMPUTER on.

L20-407 rev. 2 (12/14) 11

Page 12

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

OFF

ON

WARNING

Do not store flammable materials in or near this appliance. Do not spray aerosols in the

vicinity of this appliance while it is in op eration. Contact a qualified service person or the

factory, using the information on the back of this manual, if the appliance produces unusual

odor, yellow tipping flames or is not per forming as per the original installation.

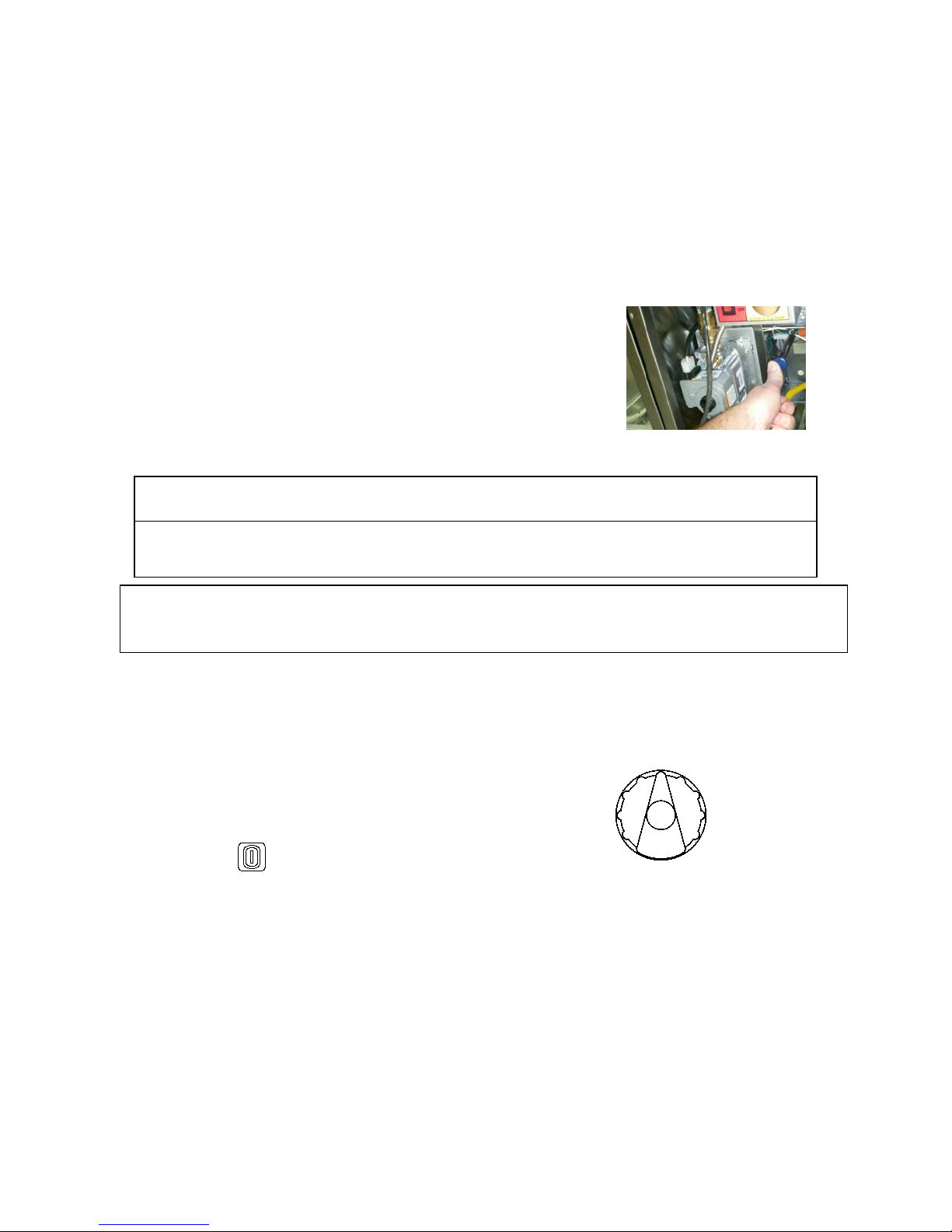

2.11.3. PILOT FLAME ADJUSTMENT

Perform this procedure with the pilot lit.

Note: This procedure requires the use of a DC microam m eter.

1. Connect the DC microammeter between the flame

sensor terminal and the flame sensor lead. Observe

proper polarity: if the meter needle goes below 0,

reverse the leads. The current reading must be 1.0 µA

or greater, (0.15 µA or greater for CE units).

2. Adjust the current reading to the required level by

adjusting the pilot flame. Remove the pilot adj ustment

screw cap to expose the pilot adjustment screw.

Turning the pilot adjustment screw clockwise will

decrease the size of the pilot flame and flame sense

current. Turning the pilot adjus tm ent scr ew

counterclockwise will increase the pilot flame size and

the flame sense current.

3. Rotate the screw in the direction needed to achieve a

reading of 1.0 µA or greater, (0.15 µA or greater for CE

units).

Note: Allow 3 to 5 minutes between flame adjustments

to allow the reading to stabilize.

4. Once the pilot flame has been adjusted properly,

replace the pilot adjustment screw cap screw and

remove the microammeter.

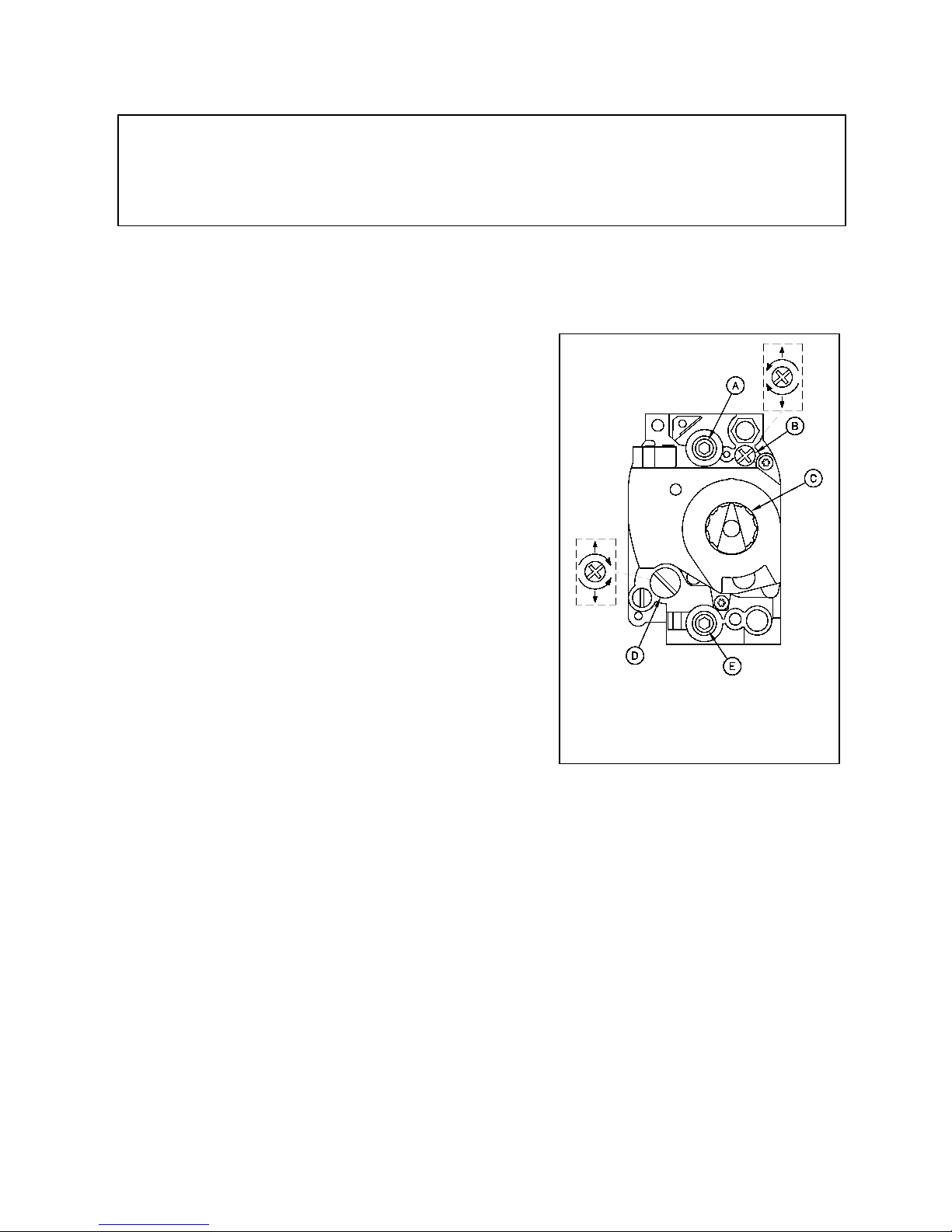

2.11.4. MAIN BURNER SYSTEM ADJUSTMENT

For the main burners to operate the gas supply valve must be open and the main power button

on the computer must be pressed. The main burners receive gas from the main gas supply

through the thermostatically controlled valve. When the oil temperature drops below the preset

temperature the gas control valve opens.

The main burners must be adjusted to deliver optimum flame. Refer to the following procedure to

adjust the main burners.

1. Ensure that the main gas valve is shut off, remove the manifold pressure tap plug and

connect an accurate pressure gauge (range of 0-16 “W.C. (39.85mbar, 3.98kPa) in 0.1”

(.25mbar, .02kPa) increments) or manometer.

2. Turn on this and all appliances connected to the gas supply line and light their main burners.

The pressure reading of the installed pressure gauge should not drop from the required

installation pressure. Any loss of pressure indicates inadequate supply line installation,

which will cause poor performance of all appliances during peak usage.

3. The installed pressure gauge should be the same, ±0.1” W.C. (.25mbar, .02kPa), as that

marked on the data plate on the inside door of the appliance. If the pressure is correct, go to

step 6, if it is not, adjust the pressure as outlined in step 4.

A) Burner Pressure Tap

B) Pilot Adjustment Screw Cap

C) ON/OFF Knob

D) Burner Pressure Adjustment Screw Cap

E) Inlet Pressure Tap

12

L20-407 rev.2 (12/14)

Page 13

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

CAUTION

and cleaning of this appliance.

WARNING

when disposing of water. The water is extremely hot and can cause severe injuries.

CAUTION

go below the heat tubes.

WARNING

time the cleaner remains on the food contact surfaces.

To adjust the pressure, remove the regulator adjustment screw cap and, with a flat head

screwdriver, adjust the regulat or sc rew unt il the prop er burner pressure is reached. Turning

the screw clockwise will increase the burner pressure. Turning the screw counterclockwise

will decrease the burner pressure.

4. When the pressure is correct, replace the regulator adjustment screw cover.

5. Turn off the ALL appliances, shut the main gas valve to your Pitco appliance and remove the

pressure gauge. Apply pipe joint compound to the manifold pressure tap plug and reinstall it.

Be careful not to disturb the probe and high temperature limit during operation

2.12. INITIAL CLEANING

When your appliance is shipped, many of its parts are covered with a thin coat of oil for protection.

Before the appliance is ready for cooking all transit material must be removed and the appliance must

be cleaned. This will remove the oil coating and any foreign matter that may have accumulated during

storage and shipment. Refer to the following procedure to clean the appliance.

Wear protective gloves and clothing when clea ning and draining the appliance and

DO NOT leave the appliance unattended during cleaning. Never let the liquid level

1. Read the “operation” section of this manual prior to filling or operating the appliance.

2. The following steps should be followed using a grease dissolving commercial cleaner.

Use a commercial grade cleaner formulated to effectively clean and sanitize food

contact surfaces. Read the directions and precautionary statements before use.

Particular attention must be paid to the concentration of cleaner and the length of

3. Following the manufacturer’s directions, clean the tank interior and all other food contact

surfaces.

4. When cleaning is complete, rinse the inside of the tank thoroughly with cool water. Continue

to rinse the tank until the cleaner has been completely and thoroughly rinsed from the tank.

5. Using a clean dry cloth, wipe out all of the water.

6. Repeat the previous steps to clean the bread and batter station or filter pan if equipped.

If the appliance can’t be adjusted to operate properly contact a qualified service person or contact the

factory using the contact information on the back of this manual.

L20-407 rev. 2 (12/14) 13

Page 14

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

securing the fryer in place are not used.

3. OPERATION

An operator’s manual for your appliance’s specific control type should be included with this manual.

Refer to that manual prior to operating this appliance.

Before operating the fryer, check that tipping restraints or other features to prevent tipping are

installed and mechanically sound. Splashing of hot liquid may occur if adequate means of

3.1. OPERATIONAL FEATURES

The diagram below outlines some of the key operational components of your appliance. Refer to the

following sections of this manual to learn more about these features.

14 L20-407 rev.2 (12/14)

Page 15

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

3.2. BASIC OPERATIONAL FEATURES

1. Basket Hanger - Holds fry baskets while draining or between loads. Lifts off for easy cleaning.

2. Fry pot oil top off supply jug- Supplied by others, provides on board storage for fresh cooking oil.

3. Oil Top Off Switch (OPTIONAL) - Replenishes oil in frypot.

4. JIB (Jug in Box) Status Light (YELLOW)- Indicates oil jug is nearing empty.

5. Filter Return Switch - controls the frypot return valve, and starts filter pump to filter or refill frypots.

6. Drain Valve Handle (Blue) - Pull to drain frypot. Push in close drain valve.

7. Filter Pan Cover - Easily slides out for cleaning.

8. Filter Pan Assembly - Holds oil during frypot cleaning and filtering. Contains filter pick up assembly,

and pick up tube

9. Cooking Computer - Controls frypot temperature, and provides cook time tracking.

10. Filter Soon Indicator (RED) - Based on cooking loads, lights to indicate a frypot should be filtered.

11. Cook Load Counter Selector - Used to establish filtering frequency.

12. Gas Valve Shut off Knob- closes gas off safely at end of day.

13. Filter Motor Thermal Overload Reset button (RED) - Press to reset. SEE WARNING BELOW

14. Drain Outlet – Swings out to ease shortening disposal.

15. Pump Strainer - Prevents debris from jamming filter pump if filter paper rips or is installed poorly.

16. Filter Pump Circuit Breaker- Protects pump motor from over current. SEE WARNING BELOW

17. Frypot High Limit Reset Button ( Shown on page 37 ) - Press to reset

Resetting either the filter pump circuit breaker (item 16), or the filter pump motor thermal

overload (item 13) may cause unexpected hot oil discharge if a refill switch or flush hose valve ( if

equipped) is left in the ON position. Always check that the filter return switches (ite m 5), or the

flush hose valves ( if equipped) are OFF before resetting the breaker or thermal overload.

L20-407 rev. 2 (12/14) 15

Page 16

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

conditions

WARNING

Overtopping may create hazards such as burns or slippery floors.

WARNING

THE PUSH BUTTON TOP OFF SYSTEM IS NOT INTENDED TO FILL FRY POTS.

CAUTION

CAUTION

WARNING

Oil must completely cover the heating tubes at all times while appliance is on.

3.3. FILLING THE FRY POT

Only use shortening that is liquid at room temperature in this appliance.

This appliance is NOT designed for cooking with water. Fill with oil or shortening only.

This appliance is not designed for use with solid shortening. Using solid shortening will

cause the filter pump and oil lines to become plugged, and require professional service

3.4. FILLING THE TANK WITH LIQUID SHORTENING

To fill the tank with liquid shortening, refer to the following procedure.

FRY POT OIL CAPACITY: SSHLV14 = 30 lbs (13.6 kg)

SSHLV14T = 17 lbs (6.8 kg)

It is recommended that high quality liquid frying oils be used for longest oil life.

WARNING

personnel to fix.

1. Verify that the tank interior is clean and free of any construction debris.

2. Rinse the tank and drain line with a small amount of clean cooking oil.

3. Ensure that the drain valve is closed.

4. Fill the tank to the “MIN” level mark. The oil will expand when heated up, raising the level to

OIL LEVEL line.

5. After the cooking oil is at operating temperature, add oil to the frypots as needed to obtain the

desired operating level.

Replace shortening that is smoking, or foam s when cooking. Old shortenings have reduced

flash point, and are prone to surge boiling. Using old shortening may create dangerous

Do not overload the fry baskets, or allow the oil level to exceed the MAX line while cooking. Wet

product, or too much oil in the frypot can lead to surge boiling, and over topping the frypot.

This appliance is NOT designed for cooking with water. Severe equipment damage will occur if

16 L20-407 rev.2 (12/14)

a fryer is used as a water bath for rethermalizi n g foods.

Page 17

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

WARNING

void your warranty.

WARNING

WARNING

4. APPLIANCE START UP

Refer to the following procedure to start the appliance prior to operation.

1. Ensure that the drain valve is closed.

2. Fill the cook tank with oil/shortening. (See section 3.3 “Filling the Cook Tank”)

3. Light the appliance. (See “Lighting Instructions” section)

4. Turn the controller on. Press the

Note: If your appliance has a self cleaning burner system, the burners may make a

popping sound immediately after the main bur ners light during startup. This noise

during startup is part of the normal operation of the self cleaning burner system and

should NOT continue during normal cooking & idle periods. (SCB Only)

5. The appliance is now on and heating the oil/shortening in the cook tank.

NEVER operate the appliance with an empty fry tank. It will void the warranty.

Oil/shortening level should NOT be allowed to fall below the minimum indicated level line at any

time. Dry firing of the fry tank will shorten tank service life and will void your warranty.

Oil level should NOT be allowed to fall below the minimum indicated level line at any time. Dry firing

of the elements may cause a fire, and can shorten element service life. Evidence of dry firing will

Keep the oil temperature in the fryer to a maximum of 190°C (374°F). Higher temperatures will cause

rapid breakdown of the oil and give you no faster cooking. At 205°C (401°F) to 210°C (410°F) the life of

the oil is only one third of its life at 190°C (374°F). In addition, increased decomposition causes the oil

to smoke badly even if the temperature is lowered to 190°C (374°F) again. High temperatures give you

no advantage, cost you money and increase the fire danger.

Mantenere la temperatura dell’olio nella friggitrice fino a un massimo di 190°C. Temperature maggiori

causano un rapido degrado dell’olio, senza tuttavia eseguire una cottura più rapida. Da 205°C a 210°C

la durata dell’olio è inferiore di un terzo rispetto a quella a 190°C. Inoltre, l’accresciuta decomposizione

comporta una forte emissione di fumo, anche se la temperatura viene riportata di nuovo a 190°C. Le

alte temperature non prevedono vantaggi, sono antieconomiche e aumentano il rischio d’incendio.

Διατηρείτε τη θερμοκρασία λαδιού στη φριτέζα μέχρι 190 βαθμούς Κελσίου. Υψηλότερες θερμοκρασίες

θα αλλάξουν τη σύνθεση του λαδιού πολύ σύντομα και δεν ψήνετε γρηγορότερα. Η δυναμικότητα του

λαδιού στους 205-210 βαθμούς Κελσίου είναι μόνο το ένα τρίτο της δυναμικότητάς του στους 190

βαθμούς Κελσίου. Επιπλέον η αυξημένη αποσύνθεση του λαδιού, σε θερμοκρασίες πάνω από 190

βαθμούς Κελσίου, κάνει το λάδι να καπνίζει άσχημα κι αν ακόμη κατεβάσετε τη θερμοκρασία κατόπιν

πάλι στους 190 βαθμούς Κελσίου. Οι υψηλές θερμοκρασίες δε σας παρέχουν κανένα πλεονέκτημα, σας

κοστίζει περισσότερα χρήματα και αυξάνουν τον κίνδυνο πυρκαγιάς.

button to turn the controller on.

OIL TEMPERATURE

TEMPERATURE DEL L ’O LIO

ΘΕΡΜ ΟΚΡΑΣΙ Α ΛΑΔΙΟΥ

L20-407 rev. 2 (12/14) 17

Page 18

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

Typical French Fry Cook Times

Fry Thickness

350F

360F

370F

(177C)

(182C)

(188C)

Thin

2:45

2:30

2:15

medium

3:45

3:30

3:15

Thick

4:15

4:00

3:45

WARNING

4.1. COOKING

To ensure the quality of the food you cook in this appliance, follow the preparation instructions from

the food manufacturer. When the applianc e is not in us e, the oil should be cooled and covered to

prevent contamination.

Dry fired heat tubes are extremely hot, will shorten its service life and will void your warra nty.

4.2. COOKING TIPS

Always follow the food manufacturer’s directions.

The lower the oil temperature, the longer the cooking time and the greater the fat absorption.

NEVER overfill fryer baskets. Overfilling can result

in soggy, greasy product.

When removing baskets from the cook tank, shake

gently to remove excess oil.

Never leave a basket over the fryer. The heat from

the cook tank will continue to cook the product.

Oil/shortening quality can effect product quality.

Keep salt and water away from the oil/shortening to

maintain its life. Oil/shortening filtration removes

crumbs from the oil which will also extend its life.

This table is for reference only. Please refer

to the product manufacturer’s specifications to

determine exact cook temperatures and

18

L20-407 rev.2 (12/14)

Page 19

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

5. COMPUTER CONTROLLER OPERATION

5.1. TO TURN THE APPLIANCE ON:

If power is applied to the appliance, the displays will show [OFF]. Press the [I/O] key.

Displays will show one of the normal displays: [HEATING]; [MELTING]

[SOLID]/[LIQUID]; or [READY]. Some messages may show in both left and right

displays. Wait for the appliance to heat up to the [READY] condition before cooking.

5.2. TO TURN THE APPLIANCE OFF:

Press the [I/O] key. Display will momentarily show the software version number and then

[OFF][OFF]. Use the Left [I/O] key for left side and Right [I/O] key for the right of dual vat

control 60126802. Either key may be used on the single vat controller.

5.3. TO START A COOK:

When displays are showing [READY] the appliance has reached set temperature and is

ready to cook. Press the desired product key, and place product into the vat. The

indicator above the product key will flash to indicate the cook timer is running. In the

example above, product 4 is cooking with 2 minutes and 28 seconds remaining. The right

side display has no running cook timers, and shows [READY].

Multiple cooks may run together. While cooks are running, the displays will always show the cook with

the least time remaining. Longer running cooks will flash their indicators at a slower rate. Cook time

remaining on these keys may be checked by momentarily pressing the product key.

5.4. TO CANCEL A COOK:

Press and hold the product key to cancel a running cook. If no other cooks are pending, controller

displays will return to [READY].

5.5. TO V IEW ACTUAL AN D SET TEMPERATURES:

To view the actual vat temperature, press the thermometer key. The display will show

[ACT nnnF] or [ACT nnnC], where nnn is the current vat temperature. After a few

moments, the display will return to [READY], [MELT ], or [HEATING] when no cooks are

running, or, [CKn mm:ss] for any cooks still running.

To view the set temperature, press the thermometer key twice. The display will

show [SET nnnF] or [SET nnnC], where nnn is the current set temperature. After a

few moments, the display will return to [READY], [MELT ], or [HEATING] , or,

[CKn mm:ss] for a cook still running.

L20-407 rev. 2 (12/14) 19

Page 20

INSTALLATION & OPERATIONAL SGLV MANUAL

5.6. TO VIEW CURRENT SETTINGS FOR COOK, SHAKE, AND HOLD

TIMES:

To view the current settings for any product key, press the clock key, followed by

the desired product key.

The display will show [CKn mm:ss], followed by [SHn mm:ss], then [HDn mm:ss]. Where “n” is the key

number, and “mm:ss” are the current settings for time. After a few moments, the display will return to

[READY], [MELT ], or [HEATING] , or, [CKn mm:ss] for a cook still running.

Typical displays using key 4 as an example:

Key 4 set for 3 minutes and 28 seconds cook time.

Key 4 Shake Time is set for 2 minutes and :00 seconds before the

end of the Cook.

Key 4 Hold Time in set for 10:00 minutes.

In a few moments, the display will return to [READY]

5.7. TO PERFORM A BOIL OUT OPERATION:

Normal maintenance of a fryer requires regular tank cleaning. This

process involves draining the vat of oil and filling with water .

Cleaning solution is added, and the control is set to the boil out mode by one of the following methods:

5.7.1. AUTOMATIC BOIL ENTRY (WATER DETECTION):

After filling an empty vat with water, turn the applianc e O n. Heat will be applied to the vat

warming the water. This control will detect the presence of water by temperatures not rising

above the boiling point of water; 212°F (100°C). After a time at this temperature, displays will

show:

Heat will be disabled until the operator responds to this prompt. Pressing the [0] key is a YES

response to the boil prompt. If pressed, display will show:

Heat will maintain vat temperature at 185°F (85°C) for cleaning as long as the control remains on.

To exit boil mode control must be turned off.

Warning: Pressing any other key at the [PRESS 0 ] [TO BOIL ] prompt is regarded by the control

as a NO response. With this response, the control will app l y heat to the vat as if oil were pres ent

in the vat. With water in the vat, a rolling boil will result. This will cause undesirable foam over

conditions, and steam burn hazards to operators performing cleaning operations.

5.7.2. MANUAL BOIL ENTRY:

After filling an empty vat with water, turn the applianc e on.

Press the thermometer key and enter key sequence [2], [1],

[2]. If control is set to display in the Celsius scale, press [1],

[0], [0] keys to manually enter boil mode. The display will

show [ BOIL ] to indicate entry into boil mode.

To exit boil mode, control must be turned off.

20

L20-407 rev.2 (12/14)

Page 21

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

Level 1 & 2 Password

5.8. TO ENTER PROGRAMMING LEVEL 1 (FOR THE STORE MANAGER):

Note: The factory default setting for this control does not require an operator password to be entered.

However, the operator password requirement and value may be changed in (See section 4.12 “To Enter

Programming Level 2” (For the Store Manager). This text assumes the operator password is disabled.

Entry of a password when NOT required will not interfere with the programming process.

With no cook timers running, displays will show one of the following displays: [HEATING], [MELT]

[LIQUID (or SOLID)], or [READY].

Press the [P] program key. Left display will show

[PROGRAM]. Right display will be blank.

Enter password 6684 using the product keys as numeric

keypad for entry.

Display still shows [PROGRAM].

From the [PROGRAM] display, continue with this section or go to section 3.

5.9. TO SET COOK TEMPERATURE:

Press “P” key then press the thermometer key once for Single Vat (left side of Dual Vat) or

press key twice for Dual Vat (right side of Dual Vat).

The display will show [SET xxxF] [TEMP] or [SET xxxC] [TEMP], where “xxx” is the temperature

setting. Use the product keys for numeric entry to adjust the current setting. Press the [P] key

to save setting. Display now shows [PROGRAM]. To exit here, press [P] again, or continue.

5.10. TO CHANGE A PRODUCT KEY–COOK, SHAKE, HOLD, AND HOLD PRE-ALARM TIMES:

For each product key, Cook, Shake, Hold, and Hold P re-alarm times are set in this section. With display

showing [PROGRAM], continue with the following section for each product key to change.

5.10.1. COOK TIME

Cook Time may be set for each product key. To deactivate any product key enter a zero value

for cook time.

Press the [Clock] key. Display will show [SELECT] [PRODUCT]. Press the desired product key

to change.

The display is now showing [nCK mm:ss] [TIME] where “n” is the key number,

“CK” means Cook, and “mm:ss” is minutes and seconds. Use the product

keys for numeric entry to adjust the current setting. Press the [Clock] key to

save cook time and continue setup for this product key.

5.10.2. SHAKE TIME

Shake time is an alarm that sounds during Cook Time to prompt operators to shake the basket.

Default for this value is zero, meaning the Shake Time is inactive. To use Shake Time, time value

must be a non-zero value, and must be set to a value less than cook time.

Display shows [nSH mm:ss] [TIME] where “n” is the key number, “SH” means

Shake, and “mm:ss” is time in minutes and seconds.

Use the product keys for numeric entry to adjust the current setting. Press the

[Clock] key to save shake time and continue setup for this product key.

Note: Cook Time minus DisplayShake Time = Shake Value Entry, Example: 3:00 cook time with a

2:00 shake time, the value you enter would be 1:00 minute.

5.10.3. HOLD TIME

Cooked product may stand in holding bins for a period of time. This timer produces an alarm to

inform operators to discard old product and start a new cook. Default for this

value is zero, meaning the Hold Time is inactive.

Display is showing [nHD mm:ss] [TIME], where “n” is the key number, “HD

means HOLD, and “mm:ss” is minutes and seconds.

Use the product keys for numeric entry to adjust the current setting. Press the [Clock] key to

save hold time and continue setup for this product key.

L20-407 rev. 2 (12/14) 21

Page 22

INSTALLATION & OPERATIONAL SGLV MANUAL

5.10.4. HOLD PRE-ALARM

Hold Pre-Alarm is a timer setting that is used to warn operators that the Hold Time is about to

expire. To use Hold Pre-Alarm, time value must be a non-zero value, and must be set to a value

less than Hold Time. Default value is zero, meaning the Hold Pre-Alarm is inactive.

Display is showing [nPA mm:ss] [TIME] where “n” is the key number, PA means Pre-Alarm, and

“mm:ss” is minutes and seconds.

Use the product keys for numeric entry to adjust the current setting.

Press the [Clock] key to save cook time and continue setup for this product key.

Note: Value entered for Hold pre-alarm time is the hold time minus the prealarm time. Example: 15:00 hold time with a 5:00 prealarm time, the value you

enter would be 10:00 minutes.

Display will again return to [SELECT] [TIME]. Repeat steps from 1 to make changes to any other

product keys or continue.

5.11. TO EXIT LEVEL 1 PROGRAMMING:

Display shows [SELE CT] [TIME]. Continue to make changes or exit here in next step.

Press the [P] key.

Display shows [PROGRAM].

To exit Level 1 programming, press the [P] key again.

Displays will show [HEATING], [MELT] [LIQUID (or SOLID)], or [READY].

5.12. TO ENTER PROGRAMMING LEVEL 2 (FOR THE STORE MANAGER)

The display must show [PROGRAM] from (See section 4.8 “To Enter Programming

Level 1” (For the Store Manager). to change these options. When the product key

[0] is pressed, the display will show [SELECT] [OPTIONS]. Indicator lights above

product keys will illuminate to represent options that may be changed. Each option

listed below uses the product key [0] to toggle or scroll through available choices in

the display. When the correct value is displayed, press the [P] key to save choice. The display

will again return

to [PROGRAM] for another option selection.

5.13. FAHRENHEIT OR CELSIUS DISPLAY:

The Controller will display temperatures in the Fahrenheit or Celsius scales. The

default scale is °F. With display showing [PROGRAM], press the prod uc t k e y [0].

Display shows [SELECT] [OPTIONS].

Press product key 1, display shows [DEGREE n] [F OR C], where “n” is the current

setting.

Use the product key [0] to scroll through choices (F or C). Press [P] key to save choice.

Display shows [PROGRAM].

5.14. PASSWORD CHANGE OR REQUIRED?

With factory settings, an operator password is not required to enter programming Levels 1 and 2.

The password may be activated or changed in this section.

With display showing [PROGRAM], press the product key [0]. Display will show

[SELECT] [OPTIONS].

Press product key 2, display shows [SET PASS] [NEW PASS]. Use the product key

[0] to scroll through choices [NO PASS] or [PASS REQ]. Press [P] key to save

choice.

If [NO PASS] is selected Display returns to [PROGRAM].

If [PASS REQ]. is selected, display will show [PASSnnnn] [NEW PASS] to prompt for new

password. Displayed value “nnnn” is the current password. Use the product keys for

numeric entry to change password. Press [P] key to save choice. Display shows

[PROGRAM].

Note: The factory default password (6684) will always work even if a different password is selected

above.

22

L20-407 rev.2 (12/14)

Page 23

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

5.15. BEEPER VOLUME AND TONE:

Volume and Tone of the beeper alar m may be changed in this sec tion. Volume ranges are 1,2 and 3,

where 3 is the loudest setting.

With display showing [PROGRAM], press the product key [0].

Display will show [SELECT] [OPTIONS]. Press product key 3, display shows

[VOLUME n] [BEEPER]. Use the produc t key [0] to scroll through choices (n= 1,2,3,

or T). Beeper volume will change as each selection is made.

If “T” is selected an additio nal displ ay is s hown, [T ONE n] [BEE PER]. Us e the pr oduct

key [0] to scroll through choices (n= 1,2,3). Beeper tone will change as each selection is made.

Press [P] key to save choice. Display shows [PROGRAM].

5.16. L ANGUAGE SELECTION :

With display showing [PROGRAM], press the product key [0].

Display shows [SELECT] [OPTIONS].

Press product key 4, display shows [ENGLISH] [LANGUAGE].

Use the product key [0] to scroll through choices (ENGLISH, ESPANOL, FRANCAIS,

DEUTSCH, HOLLAND).

Press [P] key to save choice. Display shows [PROGRAM].

5.17. MELT CYCLE TYPE:

This adjustment allows selection of the melt cycle type, or, disabling the melt cycle requirement when

starting the appliance from a cold start.

With display showing [PROGRAM], press the product key [0].

Display will show [SELECT] [OPTIONS].

Press product key 5, display shows [LIQUID], the default setting.

Use the product key [0] to scroll through choices (liquid, solid, no melt).

Press [P] key to save choice. Display will again return to [PROGRAM].

5.18. RECOVERY TEST VALUE:

This controller maintains a record of heat up times for the appliance. A

poorly running appliance will have increased recovery times stored in

this display. There is no selection done here, just the display of

recovery time values.

With display showing [PROGRAM], press the product key [0].

Display shows [SELECT] [OPTIONS].

Press product key 6; display will show [RECOVERY] [TEST].

Press the product key [0]. Display will show [FnnnLyyy], where nnn is

the factory recovery value, and yyy is the last warm up recovery value.

After recording these values, press the [P] key. Display returns to

[PROGRAM].

5.19. CONTROL OR TIMER: (LEFT SIDE OF DUAL OR SINGLE VAT)

With display showing [PROGRAM], press the product key [0].

Display shows [SELECT] [OPTIONS].

Press product key 7; display will show [CONTROL].

Use the product key [0] to scroll through choices (Control, Timer).

Press [P] key to save choice. Display shows [PROGRAM].

Note: If timer is selected, heat control outputs are disabled, leaving only the timer

functions active. Do not make this selection on SSHLV fryer models.

L20-407 rev. 2 (12/14) 23

Page 24

INSTALLATION & OPERATIONAL SGLV MANUAL

5.20. CONTROL OR TIMER: (RIGHT SIDE OF DUAL VAT)

Note: This key has no function of single vat controls.

With display showing [PROGRAM], press the product key [0].

Display shows [SELECT] [OPTIONS].

Press product key 8; display will show [CONTROL].

Use the product key [0] to scroll through choices (Control, Timer).

Press [P] key to save choice. Display shows [PROGRAM].

Note: If timer is selected, heat control outputs are disabled, leaving only the timer

functions active. Do not make this selection on Solstice fryer models.

5.21. OTHER DISPLAYS:

[PROBE OP] [OPEN]

Open probe detection is standard on all Pitco controls. If probe is detected open, normal heating and

cooking activities are suspended.

[HIGH TMP] [HIGH TMP]

This display warns operators that the vat temperature has exceeded set temperature by 40°F (22°C), or

an absolute maximum of 410°F (210°C). This display does not show the status of the mechanical high

limit switch.

[DRAINING] [TURN OFF]

This message indicates that the drain valve has been opened, the vat is assumed to be empty by the

controller. Normal heat control activities are suspended. To restore to normal operation, close the drain

value. Display will show [TURN OFF] [TURN OFF].

Turn controller off, and refill the vat. Continue with normal operations at (See section 4.6).

[HEAT] [FAILURE] OR [IGNITION] [FAILURE]

This message indicates that the heating system failed to respond. Typically, the high temperature limit

switch has tripped and is in need of resetting. In the case on gas fired appliances, this message will

display if the pilot fails to light or is detected marginal by the ignition module.

[SYSTEM] [FAILURE]

This message indicates a shorted probe. If probe is detected as a short circuit normal heating and

cooking activities are suspended.

5.22. COMPUTER SHUTDOWN

Press and hold the computer control

appliance shutdown instructions.

5.23. FLUSH HOSE OPERATION (IF EQUIPPED)

The cooker tank can be rinsed cleaned by using a filter flush hose (if equipped). Refer to the

following procedure to operate the filter flush hose.

1. Turn the appliance OFF.

2. Pull the blue drain handle down to drain oil/shortening from the cooker tank into the filter pan.

3. Connect the filter flush hose to the quick connecting fitting.

4. Point the filter hose nozzle outlet into the cooker tank.

5. Pull the yellow handle to turn the pump on and allow oil/shortening to flow through the flush

hose.

6. To refill the tank, lift the blue drain handle up.

7. When the tank has completed filling, push the yellow handle to deactivate the pump.

button to turn the fryer OFF. Refer to section 6.5 for complete

24

L20-407 rev.2 (12/14)

Page 25

INSTALLATION & OPERATIONAL SSHLV SERIES MANUAL

LOW BOTTLE LIGHT

FRYPOT TOP OFF SWITCH

6. BASKET LIFT OPERATION

If the appliance is equipped with basket lifts, place the basket onto the basket lift prior to starting

the timer(s). The basket(s) will be lowered into the cook tank when a product key is pressed. At

the end of the preset cooking time, the basket lift will raise the basket out of the cook tank.

7. PUSH BUTTON OIL TOP OFF SYS TEM

Refer to the following procedure to perform easy cooking oil

replenishment.

It is not intended for filling the frypot.

(If yellow light comes on for LOW OIL BOTTLE it indicates that

oil jug is getting low.)

1. TOP OFF LOW FRYPOT. Press and hold switch to

replenish frypot oil as needed.

2. Remove oil jug from oil jug holding compartment provided

(except on Solofilters) Insert cap assembly hose until cap

rests on edge of jug. Return to cabinet.

8. AUTOMATIC OIL TOP SYSTEM (OPTION)

Pitco offers the “Automatic Oil Level Control” option (Auto-Top Off) to maintain the optimal oil level in your

Pitco fryer. This optional system minimizes the need for the operators attention during busy cooking

hours. The system maintains oil levels in the frying vat by adding small amounts of fresh oil when

appropriate. Replenishment oil is drawn from a Jug In Box (JIB) located in one of the cabinets in a

multiple vat build. Alternately, the JIB can be remotely located within nine feet of the fryer. The system

can also accommodate a bulk oil system.

The Oil Level Driver Board (OLDB) works with the Filter Control Board (FCB) to

maintain proper cooking oil levels. An optional “Manual Fill Switch” to allow

operators to add fresh oil at their discretion can also be supplied.