DISPLAY

P.BASS SKIP ON A.TRACK D.VOL A.VOL DIG ANA [ 32 44 48 ]RDM ALL RPT-1SFC

CD 2 CD 3 CDR

1st TRACK

CD CD

REC

DIGITAL OUT

RECORDING

CDR

SPC

(DEMO)

CD—RW

REC

FINALIZE

–TUNING+

1

¡

FM/AM TAPE

6

7

P.BASS

P

U

ERASE

N

U

O

EACH

D

0

TRACK NO.

WRITE(MANUAL) AUTO/MANUAL

CD1

CD2

CD3

STEREO MONO TUNED

PGM

12

PHONO

E

T

N

E

J

D

A

K

C

O

L

C

/

R

E

M

I

T

PHONES

STEREO CD/CD-R RECEIVER XR-MR7

LINE

CD 1

3COMPACT DISC MULTI CHANGER

S

4

.

T

.

–

DIRECT REC SELECT

FINALIZE

S

R

.

M

T

E

.

N

+

U

¢

/

M

ALL 1 TRACK

O

CD1

CDR CDR CDR

ANALOG DIGITAL

-–

+-–+

¶ 6 7

REC LEVEL REC LEVEL

COMPACT DISC DIGITAL RECORDER

LINE2 IN LINE2 OUTOPTICAL

CD

1

0

2

0

3

0

MULTI JOG VOLUME

STANDBY/ON

STEREO CD / CD-R RECEIVER

XR-MR7

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KU/CA AC120V

MY AC220-230V

Model

XR-MR7

Power Requirement Remarks

ORDER NO.

RRV2250

¶ This product is a system(s) component.

Be sure to connect it to the prescribed system component(s), otherwise damage may result.

Component Model Service manual Remarks

STEREO CD/CD-R RECEIVER XR-MR7 RRV2250 This manual.

SPEAKER SYSTEM S-MR7 RRV2248

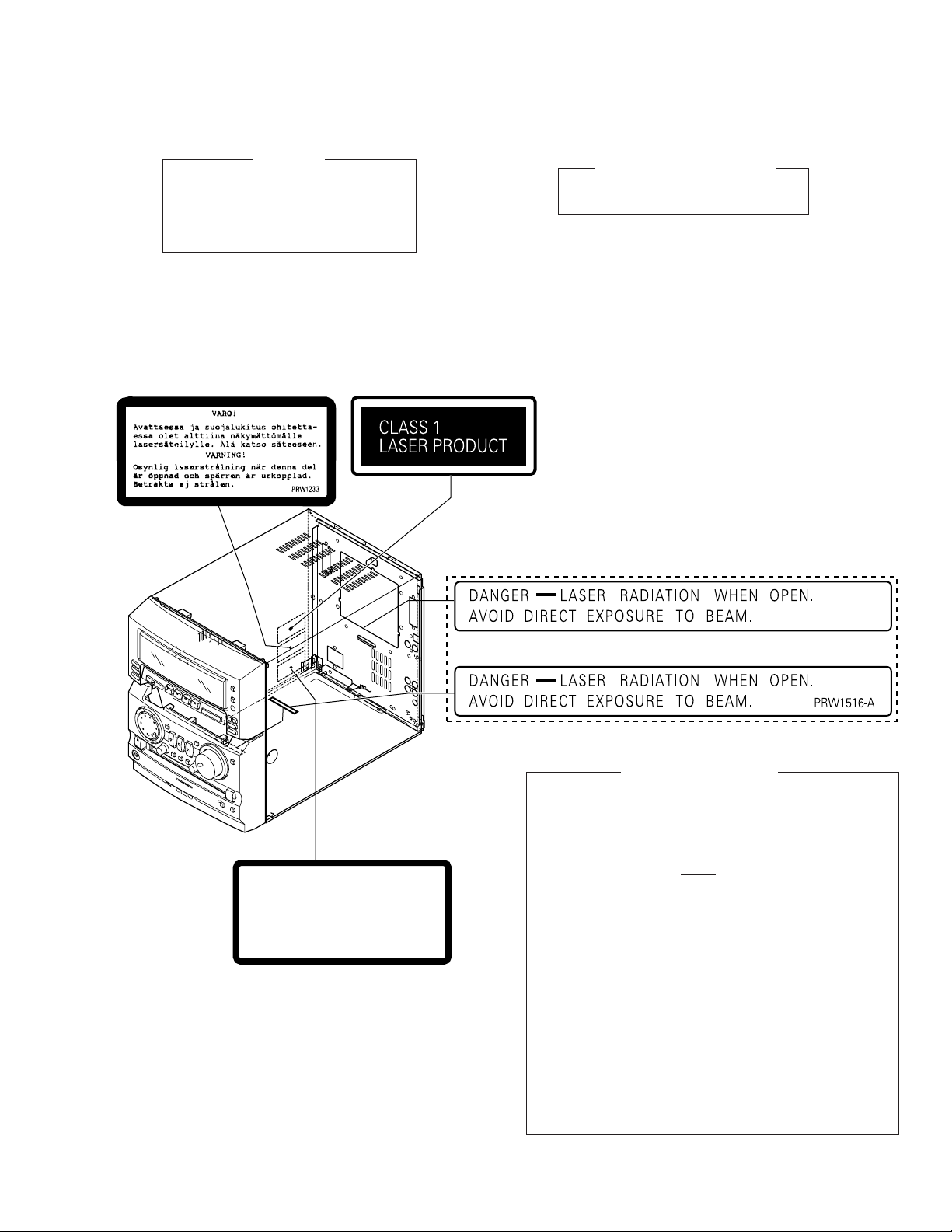

FOR U.S. MODELS

NECESSARY INFORMATION FOR DHHS

RULES MARKED ON THE REAR BASE AND ON

THE TOP OF CD MECHANISM AS BELOW.

DANGER – LASER RADIA TION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

.......................................

.................

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..14

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

................................................

.....................................................

...........................

50

71

81

2

4

7. GENERAL INFORMATION

7.1 DIAGNOSIS

...................................................

7.1.1 DISASSEMBLY

7.1.2 SEQUNCE AFTER THE POWER ON

7.2 PARTS

7.2.1 IC

7.2.2 DISPLAY

.........................................................

...........................................................

................................................

8. PANEL FACILITIES AND SPECIFICATIONS

..................................

........................................

......

.....

91

91

91

96

100

100

103

104

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 1999

T – ZZR DEC. 1999 Printed in Japan

XR-MR7

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

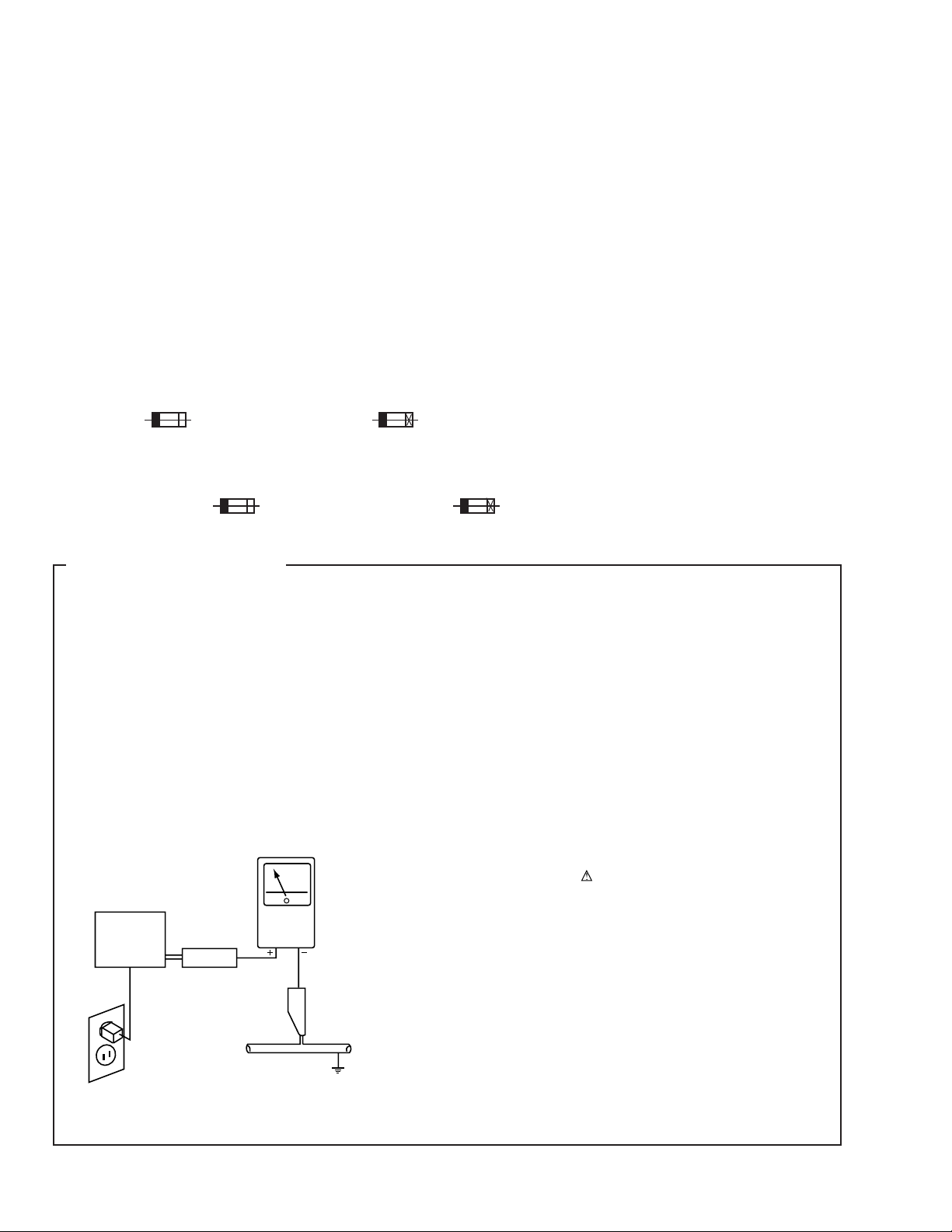

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

XR-MR7

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS ΙΙΙ b.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

LABEL CHECK

MY Type

IMPORTANT

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 23 mW

WAVELENGTH: 778 – 787 nm

MY Type

VRW-328

KU/CA Type

Printed on Rear Panel

USYNLIG LASERSTRÅLING VED ÅBNING NÅR SIKKERHED SAFBRYDERE ER UDE AF FUNKTION.

UNDGÅ UDSÆTTELSE FOR STRÅLING

UNSICHTBARE LASER-STRAHLUNG TRITT AUS, WENN DECKEL

(ODER KLAPPE) GEÖFFNET IST! NICHT DEM STRAHL AUSSETZEN!

ADVARSEL

VORSICHT!

VRW1094

MY Type

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) on the SERVO

MECHANISM Assy for detecting loading state is detected

by the system microprocessor, and the design prevents

laser diode oscillation when the switch (S601) is not on

CLMP terminal side (CLMP signal is OFF or high level.).

Thus, the interlock will no longer function if the switch

(S601) is deliberately set to CLMP terminal side (low

level).

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

CD-R PICKUP is connected to GND, or pin 19 is

connected to low level (ON), or else the terminals of Q101

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism

block removed and turned over, close viewing of the

objective lens with the naked eye will cause exposure to a

Class 1 laser beam.

∗ Refer to page 84.

3

XR-MR7

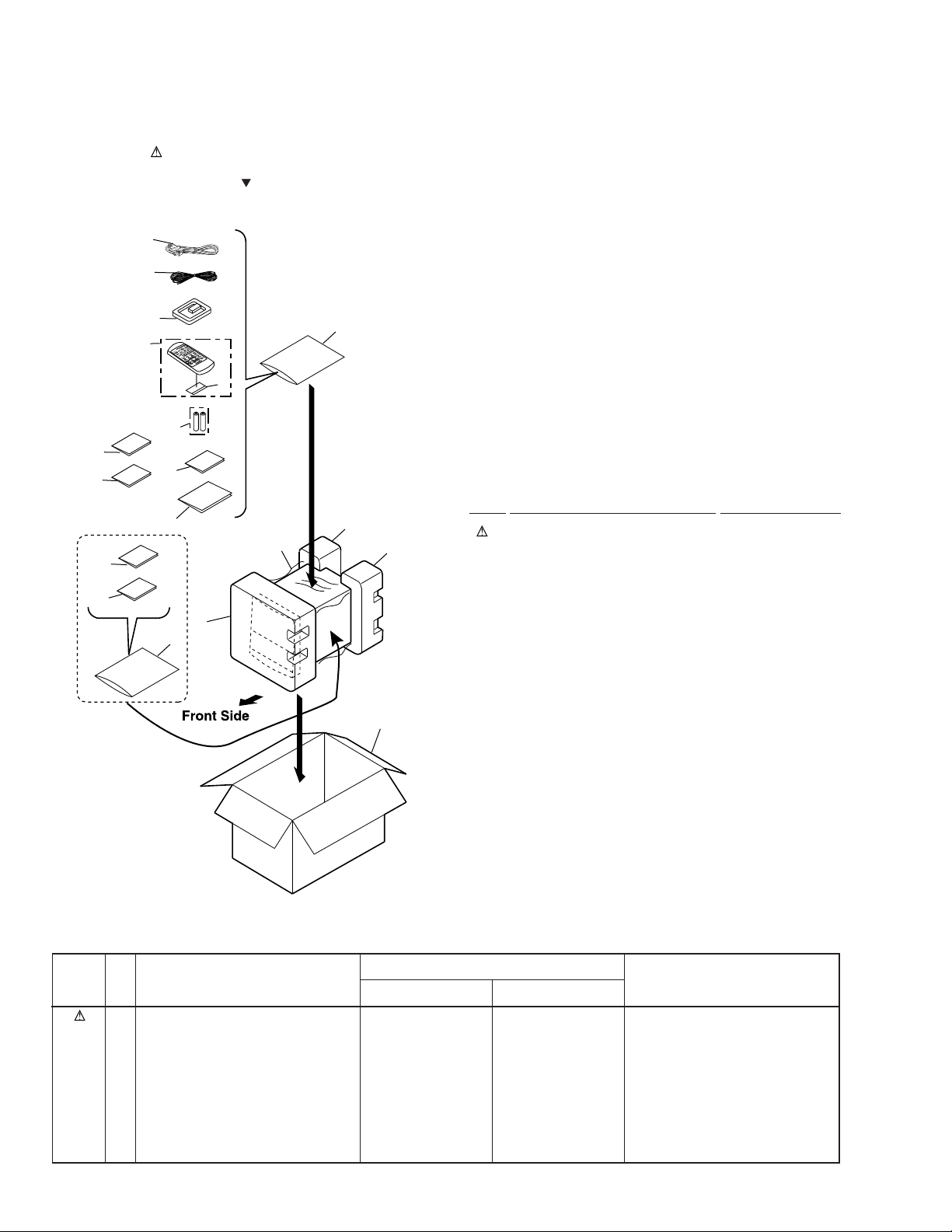

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

2.1 PACKING

1

2

14

15

MY:Only

16

17

3

V

K

O

A

L

R

A

O

K

E

4

S

DISC DISC DISC

F

S

C

L

E

E

P

P

.B

POWER

C

A

L

S

E

S

A

R

D

IS

P

P

L

A

G

Y

M

A

U

X

R

E

P

E

A

T

R

A

N

D

O

M

S

T

A

T

REMOTE CONTROL UNIT CU-XR025

IO

N

M

O

N

O

B

A

N

D

12

5

6

13

(1) PACKING PARTS LIST

Mark No. Description Part No.

11

7

8

12

9 (1/2)

9(2/2)

10

1 Power Cord See Contrast table (2)

2 FM Antenna See Contrast table (2)

3 AM Loop Antenna ATB7009

4 Remote Control Unit AXD7241

(CU-XR059)

5 Battery Cover AZA7378

NSP 6 Dry Cell Battery (R6P, AA) VEM-013

7 Packing Sheet AHG7003

8 Front Pad AHA7281

9 Rear Pad LR AHA7282

10 Packing Case See Contrast table (2)

NSP 11 Warranty Card See Contrast table (2)

12 Polyethylene Bag Z21-038

(0.03 x 230 x 340)

13 Operating Instructions See Contrast table (2)

(English)

14 Operating Instructions See Contrast table (2)

(English/French)

15 Operating Instructions See Contrast table (2)

(German/Italian)

16 Operating Instructions See Contrast table (2)

(Dutch/Swedish)

17 Operating Instructions See Contrast table (2)

(2) CONTRAST TABLE

(Portuguese/Spanish)

XR-MR7/MY and /KU/CA are constructed the same except for the following:

Mark

No.

Symbol and Description

MY type KU/CA type

1 Power Cord ADG1127 ADG7021

2 FM Antenna ADH7005 ADH7004

10 Packing Case AHD7849 AHD7848

NSP 11 Warranty Card ARY7022 ARY7033

13 Operating Instructions (E) Not used ARB7213

14 Operating Instructions (E/F) ARE7238 Not used

15 Operating Instructions (G/I) ARE7239 Not used

16 Operating Instructions (D/S) ARC7290 Not used

17 Operating Instructions (P/Sp) ARC7291 Not used

4

Part No.

Remarks

A

D

D

B

C

A

R

R

M

K

I

S

G

H

G

F

E

O

P

Q

E

H

F

J

K

L

M

N

N

B

Q

P

O

S

L

I

C

J

74

71

MY Type

Only

MY Type

Only

44

3

4

61

1

41

42

29

39

37

20

52

52

52

52

52

52

52

53

53

53

51

51

51

51

51

29

51

51

67

76

43

45

48

45

45

25

26

47

5

9

38

38

10

6

7

49

66

65

70

69

77

8

63

64

31

27

28

37

60

60

15

50

73

51

19

52

52

53

75

55

53

52

2

30

13

13

13

13

36

33

21

35

12

17

21

18

34

14

16

52

51

22

29

23

24

32

51

40

51

58

59

57

65

58

59

56

62

Refer to "2.6 3CD MICROCHANGER MECHA "

Refer to "2.3 FRONT PANEL SECTION"

Refer to "2.4 CD-R CORE ASSY (1/2)

2.5 CD-R CORE ASSY (2/2) "

11

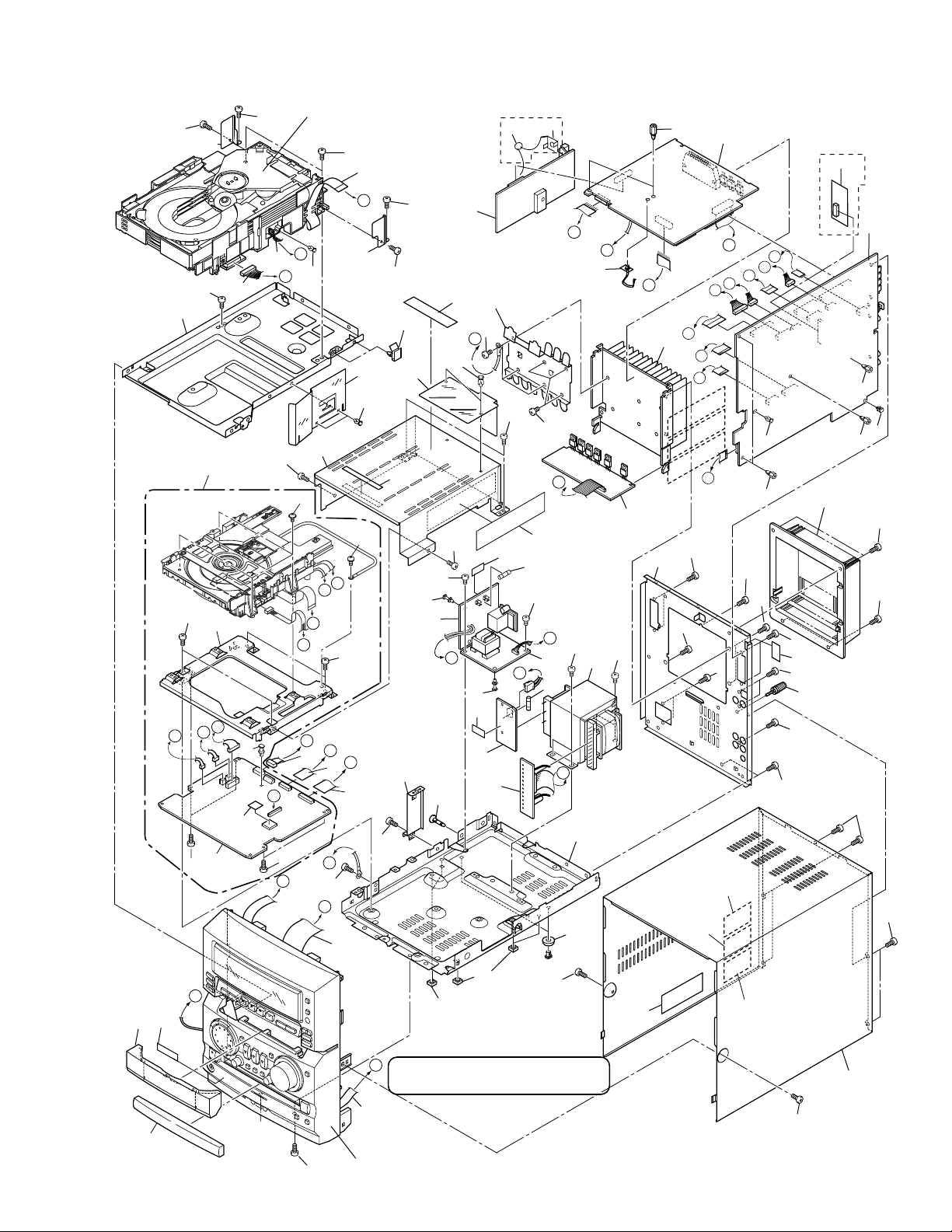

2.2 EXTERIOR SECTION

XR-MR7

5

XR-MR7

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 2 CD-R CORE ASSY PXA1625

1 FM/AM TUNER Module See Contrast table (2)

3 AF ASSY See Contrast table (2)

4 AMP ASSY See Contrast table (2)

5 REG ASSY AWU7468

6 SECONDARY ASSY AWU7451

7 PRIMARY ASSY See Contrast table (2)

8 SUBTRANS ASSY See Contrast table (2)

9 AC IN/OUT ASSY See Contrast table (2)

10 Power Transformer See Contrast table (2)

11 Fuse (FU 2 : ) See Contrast table (2)

12 6P Connector Assy ADE7055

13 Screw BBZ30P080FCC

NSP 14 3CD MICROCHANGER MECH AXA7077

15 27P FFC/30V ADD7203

(DIS CN5601 ↔ AF CN5501)

16 16P FFC/60V ADD7178

(AF CN1101 ↔ 3CD MECHA)

17 21P FFC/60V ADD7200

(AF CN7701 ↔ CDR CN501)

18 15P FFC/60V ADD7201

(AF CN7702 ↔ CDR CN301)

19 9P FFC/60V ADD7205

(AF CN3201 ↔ FRO. CN5403)

20 Fuse (FU 1 : ) See Contrast table (2)

21 Screw BBT30P080FCC

22 2mm Connector ASSY 6P ADE7051

(AF CN1301 ↔ 3CD CN8002)

23 Connector ASSY 11P PG11KK-G20

(AF CN1302 ↔ 3CD CN8003)

NSP 24 Mini Clamper VEC1597

NSP 25 Heat Sink ANH7115

26 Heat Plate ANG7266

NSP 27 Chassis ANA7101

28 Leg Assy AEC7248

29 Pla Rivet DEC1704

30 Tray Panel (CD-R) AAK7712

NSP 31 PCB Holder PNW2029

32 Flexible Holder AEC7252

33 CD-R CORE ASSY PYY1273

34 Radiator Sheet PEB1305

NSP 35 PCB Spacer AEC1371

NSP 36 Mecha Base PNB1613

37 PCB Spacer (3x12) AEC1372

38 Screw IBZ40P060FCC

39 Shield Case ANG7272

40 Side Stay ANG7261

41 CD Stay ANG7259

42 CD Sheet AEC7253

43 Rivet (PLASTIC: 3x4.5) RBM–003

44 Tapping Card Spacer AEC7098

45 Card Spacer AEC7214

NSP 46 PCB Spacer AEC7254

47 Rear Panel R See Contrast table (2)

48 Rear Cover AMR7310

49 Bonnet Case R AZN7824

50 Tray Panel (CD) See Contrast table (2)

51 Screw BBZ30P060FCC

52 Screw BBZ30P080FNI

53 Screw BBZ30P080FZK

54 Screw BPZ30P060FMC

55 Terminal Screw AKE- 031

56 Supporter Plate L ANG7290

57 Supporter Plate R ANG7291

58 Screw IPZ30P060FMC

59 Screw PBZ30P120FMC

60 Spacer R AEB7189

61 Tapping Card Spacer AEC7262

62 Harness Lifter DEC1262

63 Fuse Label See Contrast table (2)

64 Fuse Label See Contrast table (2)

65 65 Label See Contrast table (2)

66 Fuse Caution Label See Contrast table (2)

NSP 67 Laser Caution Label See Contrast table (2)

68 Disc Caution Label See Contrast table (2)

69 Caution Label HE See Contrast table (2)

70 Caution Label See Contrast table (2)

71 Ceramic Capacitor See Contrast table (2)

72 Cord Clamper RNH-184

NSP 73 Getter See Contrast table (2)

74 Earth Plate See Contrast table (2)

75 Speaker Caution Label ARW7080

76 LEGATO ASSY See Contrast table (2)

77 Caution Label (F) See Contrast table (2)

6

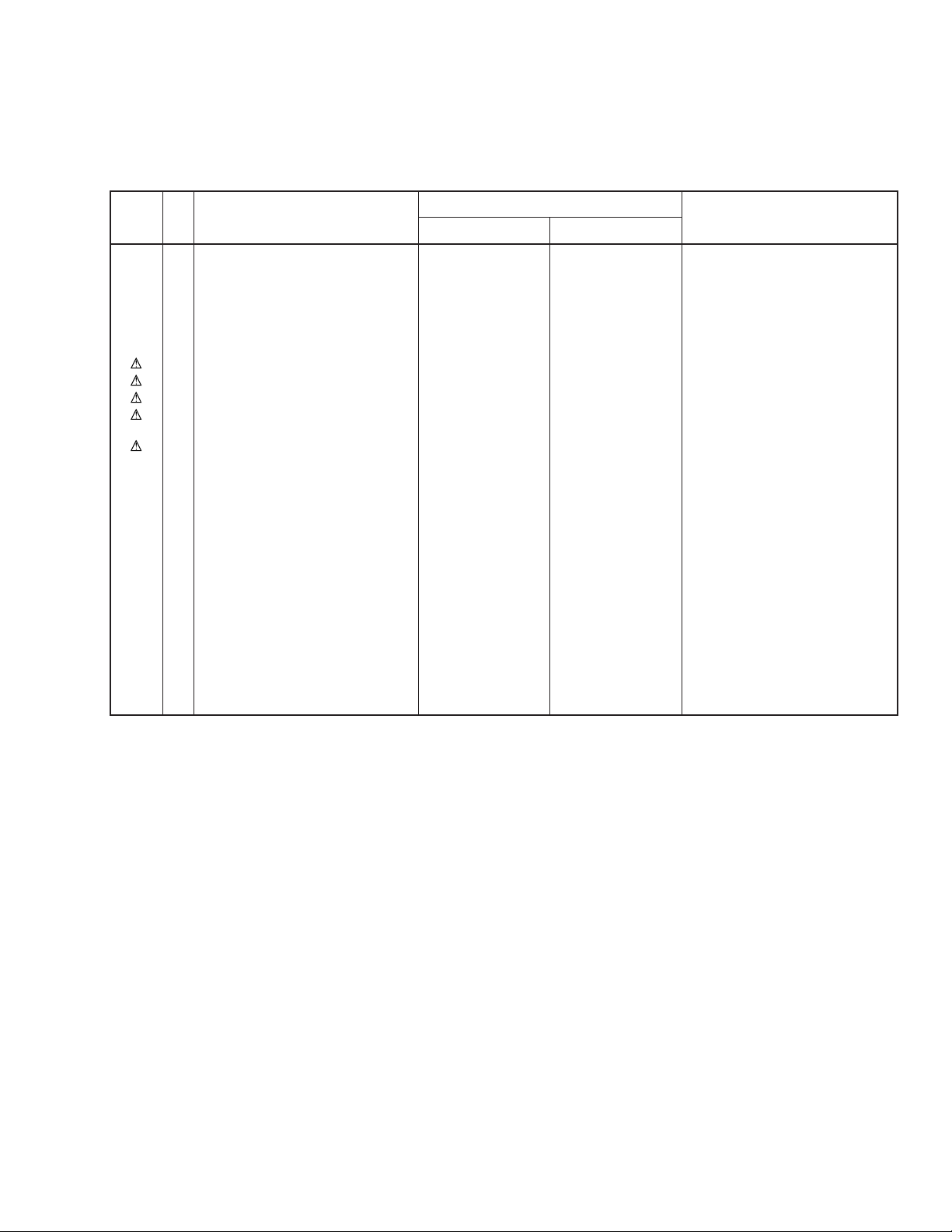

(2) CONTRAST TABLE

XR-MR7/MY and /KU/CA are constructed the same except for the following:

Mark

No.

1 FM/AM TUNER Module AXQ7068 AXQ7065

3 AF ASSY AWU7460 AWU7448

4 AMP ASSY AWU7464 AWU7555

7 PRIMARY ASSY AWU7469 AWU7457

8 SUBTRANS ASSY AWU7471 AWU7459

9 AC IN/OUT ASSY AWU7470 AWU7458

10 Power Transformer ATS7271 ATS7272

11 Fuse (FU 2 : 4A/125V) Not used REK1082

11 Fuse (FU 2 : T2AL250V) AEK1057 Not used

20 Fuse (FU 1 : 5A/125V) Not used REK1083

20 Fuse (FU 1 : T2.5AL250V) AEK1058 Not used

47 Rear Panel R ANC7880 ANC7879

50 Tray Panel (CD) AAK7746 AAK7715

NSP 63 Fuse Label AAX1581 AAX1419

NSP 64 Fuse Label AAX1580 AAX1194

Symbol and Description

MY type KU/CA type

Part No.

XR-MR7

Remarks

65 65 Label Not used ARW7050

NSP 67 Laser Caution Label Not used PRW1516

66 Fuse Caution Label Not used ARW7081

68 Disc Caution Label Not used PRW1532

69 Caution Label HE PRW1233 Not used

70 Caution Label VRW1094 Not used

71 Ceramic Capacitor CKPUYB102K50 Not used

73 Getter ARW7086 ARW7077

74 Earth Plate XNG3015 Not used

76 LEGATO ASSY AWU7525 Not used

77 Caution Label (F) VRW–328 Not used

7

XR-MR7

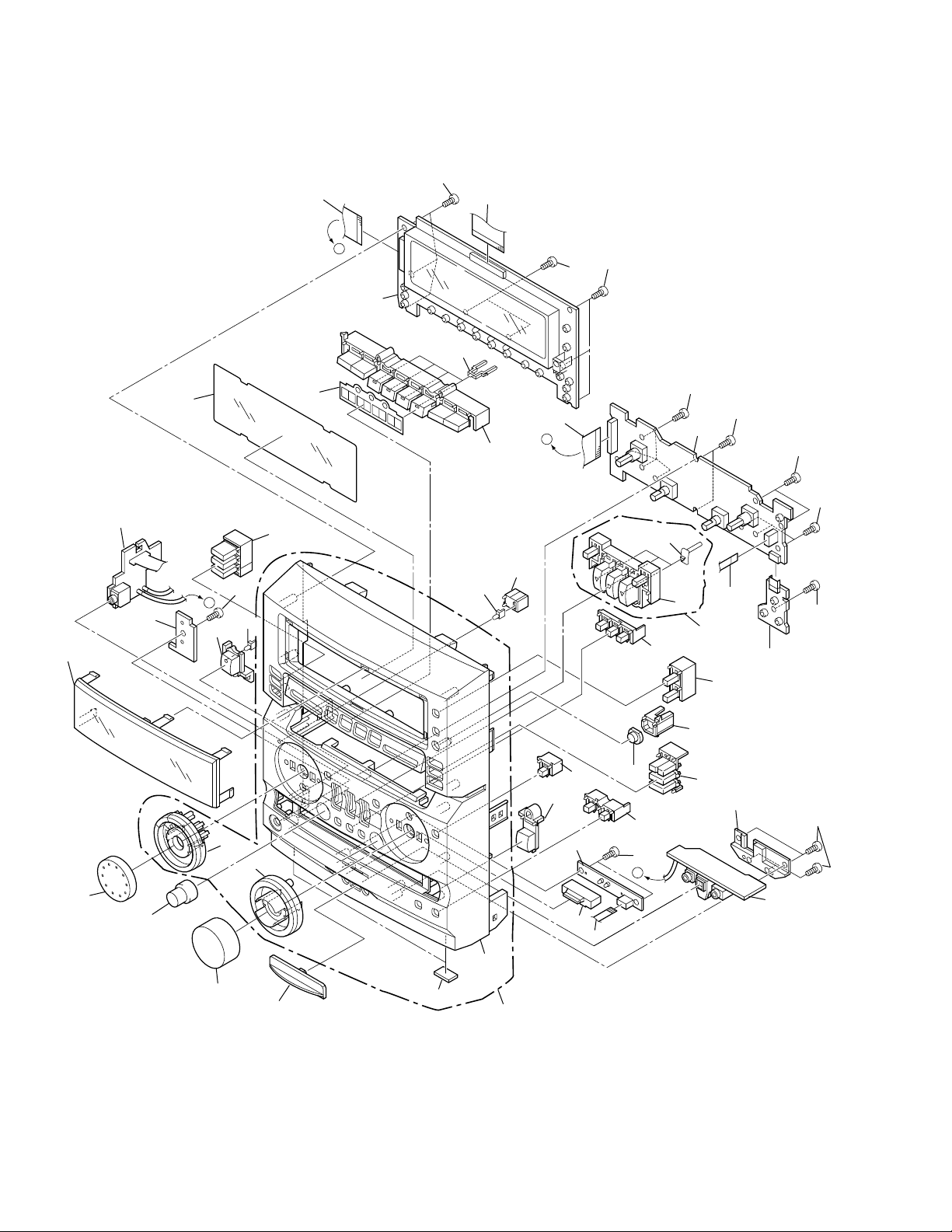

2.3 FRONT PANEL SECTION

5

27

6

23

1

PCB Cutting

Parts

21

B

19(4/4)

27

11

16 (1/2)

29

A

2

14

13(1/2)

17

A

12(2/2)

27

27

27

5

35

22

12(1/2)

27

3

27

27

31

27

20

30

15

25

33

24

13(2/2)

36

18

19(1/4)

27

B

16 (2/2)

Front Panel Cutting Parts

27

4

19(3/4)

19(2/4)

9

8

26

34

7

28

32

10

8

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

1 H.P ASSY AWU7453

2 DISPLAY ASSY AWU7461

3 SW JOG ASSY AWU7466

4 FRONT LINE ASSY See Contrast table (2)

5 21P FFC/60V ADD7202

6 27P FFC/60V ADD7203

7 Rubber Sheet AEB1111

8 VOL Ring R AAB7219

9 Button RE AAD7559

10 Function Lens PNW2796

XR-MR7

NSP 11 Indicate Lens AAK7085

NSP 22 Button RF AAD7560

NSP 26 Front Panel RK AMB7690

NSP 35 Button Lens MRF AAK7691

12 Button RD AAD7554

13 Button RB AAD7553

14 Button Lens MRB AAK7690

15 Button RA AAD7557

16 Button RC AAD7558

17 LED Lens PNW2745

18 Receiv Lens AAK7586

19 Button RG ASSY AXG7087

20 Button RF ASSY AXG7086

21 FL Plate AAK7718

23 Display Window R AAK7710

24 VOL Knob R AAB7218

25 Jog Knob R AAB7217

27 Screw BPZ30P080FZK

28 Front Panel RK ASSY AXG7091

29 Shield Sheet R AED7041

30 CDR SW ASSY AWU7517

31 5P FFC/60V ADD7204

32 CDR LED ASSY AWU7467

33 Knob R AAB7216

34 Cap AAK7713

(2) CONTRAST TABLE

XR-MR7/MY and /KU/CA are constructed the same except for the following:

Mark

No.

Symbol and Description

MY type KU/CA type

4 FRONT LINE ASSY AWU7450 AWU7438

Part No.

Remarks

9

XR-MR7

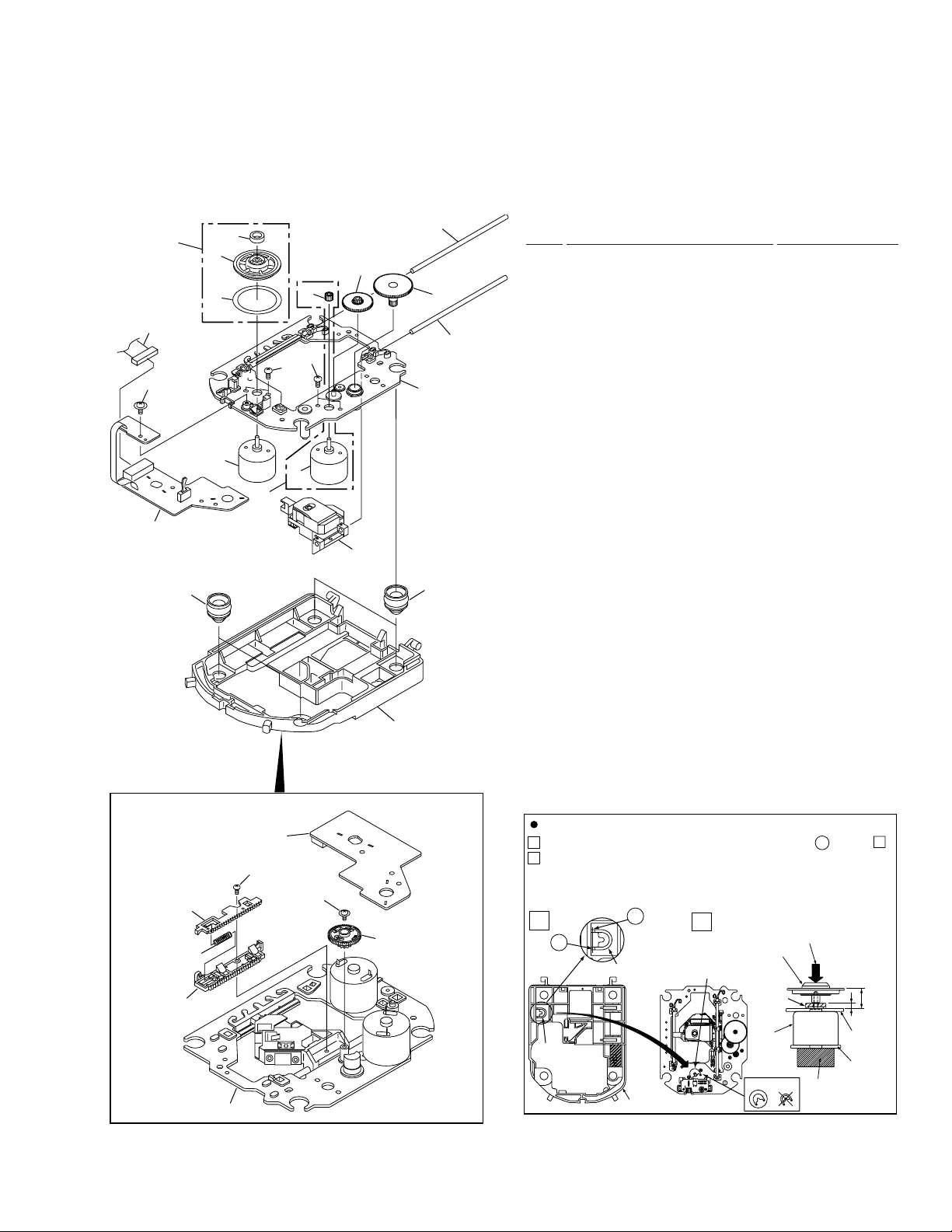

2.4 CD-R CORE ASSY (1/2)

• Bottom View

A

18

13

1

20

9

12

7

26

25

Refer to

"2.5 CD-R CORE ASSY (2/2)"

23

31

24

19

5

28

26

29

5

30

5

6

21

4

17

8

CD-R CORE ASSY(1/2) PARTS LIST

•

3

A

2

11

16

15

27

22

14

10

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 LOADING A Assy PWZ3760

NSP 2 LOADING B Assy PWZ3761

3 Connector Assy PG02KK-E15

(LOADING B CN551 ↔ LOADING A CN502)

4 DC Motor (LOADING) PXM1027

5 Screw DBA1006

6 Motor Pulley PNW1634

7 Screw VBA1055

8 Tray Stopper Spring VBH1277

9 Rubber Belt VEB1260

10 Loading Base VNL1844

11 Tray VNL1731

12 Gear Pulley VNL1733

13 Loading Gear VNL1734

14 Drive Gear VNL1735

15 Drive Cam VNL1736

16 Lock Plate VNL1820

NSP 28 Earth Lead Unit PDF1200

17 Tray Stopper VNL1739

18 Connector Assy PF03KK-E37

(LOADING A CN501 ↔ CD-R CORE CN451)

19 Screw BBZ26P040FMC

20 Screw Z39-019

21 Loading Motor Assy VXX2505

22 Binder PEC-107

23 Clamper Plate VNE2068

24 Bridge VNE2069

25 Clamper VNL1738

26 Screw IPZ26P060FMC

27 32P Flexible Cable / 30V PDD1195

(CD-R Pickup ↔ CD-R CORE CN101)

29 Tray Holder PNM1341

30 Stopper DNH2076

31 Spacer PNM1334

10

2.5 CD-R CORE ASSY (2/2)

25

17

22

1

20

15

23

9

23

3

7

2

26

4

10

21

16

XR-MR7

CD-R CORE ASSY(2/2) PARTS LIST

•

19

11

18

5

Mark No. Description Part No.

NSP 1 SERVO MECHANISM Assy PWZ3759

2 DC Motor Assy (SPINDLE) PEA1235

NSP 3 DC Motor (CARRIAGE) PXM1042

4 Float Rubber A AEB7063

5 Float Rubber B AEB7066

NSP 6 Rack Spring DBH1285

NSP 7 Reflection Sheet PNM1325

8 Servo Base PNW2853

9 Pinion Gear PNW2854

10 Gear A PNW2855

11 Gear B PNW2856

12 Gear C PNW2857

13 Rack PNW2858

14 Rack Stopper PNW2859

NSP 15 Disc Table PNW2860

16 Carriage Base S PNW2874

17 Connector Assy PG09KK-E17

(SERVO MECHANISM CN601↔CD-R CORE CN452)

18 Guide Bar VLL1488

19 Sub Guide Bar VLL1489

NSP 20 Magnet VYM1024

21 CD-R Pickup PEA1351

22 Screw Z39-018

23 Screw PMZ20P030FMC

24 Screw JGZ17P030FMC

• Bottom View

SERVO MECHANISM

ASSY

14

6

13

Carriage Base S

24

22

12

25 Disc Table Assy PEA1349

26 Carriage Motor Assy PEA1350

8

How to Install the Disc Table

Use nippers or other tool to cut the two sections marked A in figure 1 .

1

While supporting the spindle motor shaft with the stopper, put spacer on

2

top of the carriage base, and stick the disc table on top (takes about 9kg

pressure). Take off the spacer.

1

A

Spacer

A

Spacer

Servo Base

2

Spacer setting

Position

Disc table Assy

(Pressure of about 9kg)

Spacer

Spindle

motor

OK NG

Stopper

11mm

2.8mm

Carriage

Base

PCB

11

XR-MR7

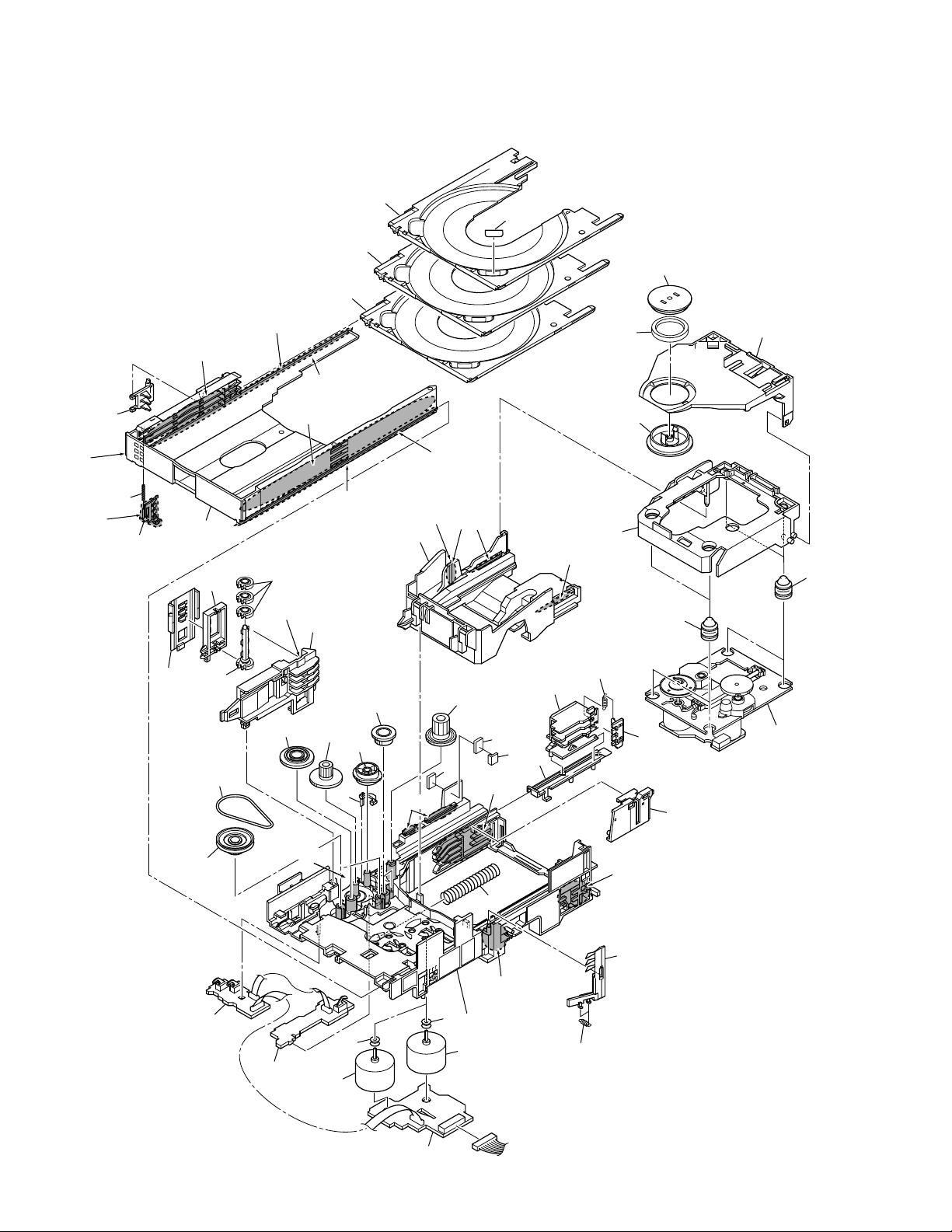

2.6 3CD MICROCHANGER MECHANISM

*1 : Floil (PN-397)

*2 : Dyefree (ME-413A)

*2

(No.36 Sub Tray Part)

38

*2

(Gutter)

*2

(Inside Gutter)

*2

(Bottom Gutter)

36

36

36

37

30

29

28

31

*2

(Left Front

Under Gutter)

35

*2

(Whole)

34

42

15

33

41

18

39

40

*1

(Gutter)

14

*1

(Column)

*2

(Bottom Gutter)

19

12

13

17

16

*1

(Boss)

32

*1

(Gutter)

*2

(Gutter)

*1

(Gutter)

11

43

43

*1

(Rail)

8

44

23

*1

(Gutter)

20

27

22

*1

(Inside Rail)

21

26

(Black)

25

(Blue)

4

24

12

9

*1

(Inside Rail)

2

7

3

5

7

6

5

1

10

3CD MICROCHANGER MECHANISM PARTS LIST

•

Mark No. Description Part No.

1 MOTOR UNIT AWU7431

2 LOADING UNIT AWU7432

3 SELECT UNIT AWU7433

4 PICK–UP UNIT KSM213CCM

5 Slider Motor VXM1033

6 Mecha Base ANW7129

7 Motor Pulley PNW1634

8 Lift Spring ABH7173

9 Home Lever ANW7153

10 HL Spring ABH7182

11 Extended Gear A ANW7138

12 Gear A ANW7136

13 Extended Gear B ANW7139

14 Gear B ANW7137

15 Gear Pully ANW7135

16 Select Lever ANW7143

17 EV Camgear ANW7140

18 Belt AEB7159

19 Elevator Base ANW7132

20 Tray Guide ANW7150

XR-MR7

21 TG Stopper ANW7151

22 TG Spring ABH7175

23 Cam Plate ANW7147

24 Lock Lever ANW7148

25 Float Rubber A (Blue) AEB7063

26 Float Rubber B (Black) AEB7066

27 Float Base ANW7130

28 Clamper Holder ANW7152

29 Yoke ANG7257

30 Clamper Magnet AMF7001

31 Clamper SO XNW3007

32 Swing Base ANW7131

33 Main Tray ANW7133

34 Lock Plate ANW7144

35 Lock Plate Spring ABH7174

36 SUB Tray ANW7134

37 Tray Label ARW7070

38 Stopper Arm ANW7145

39 gear Shaft ANW7142

40 Loading Gear ANW7141

41 Elevator ANW7146

NSP 43 MB Spacer AEC7259

NSP 44 MB3 Spacer AEC7263

42 Elevator Cover ANW7149

13

1

23

XR-MR7

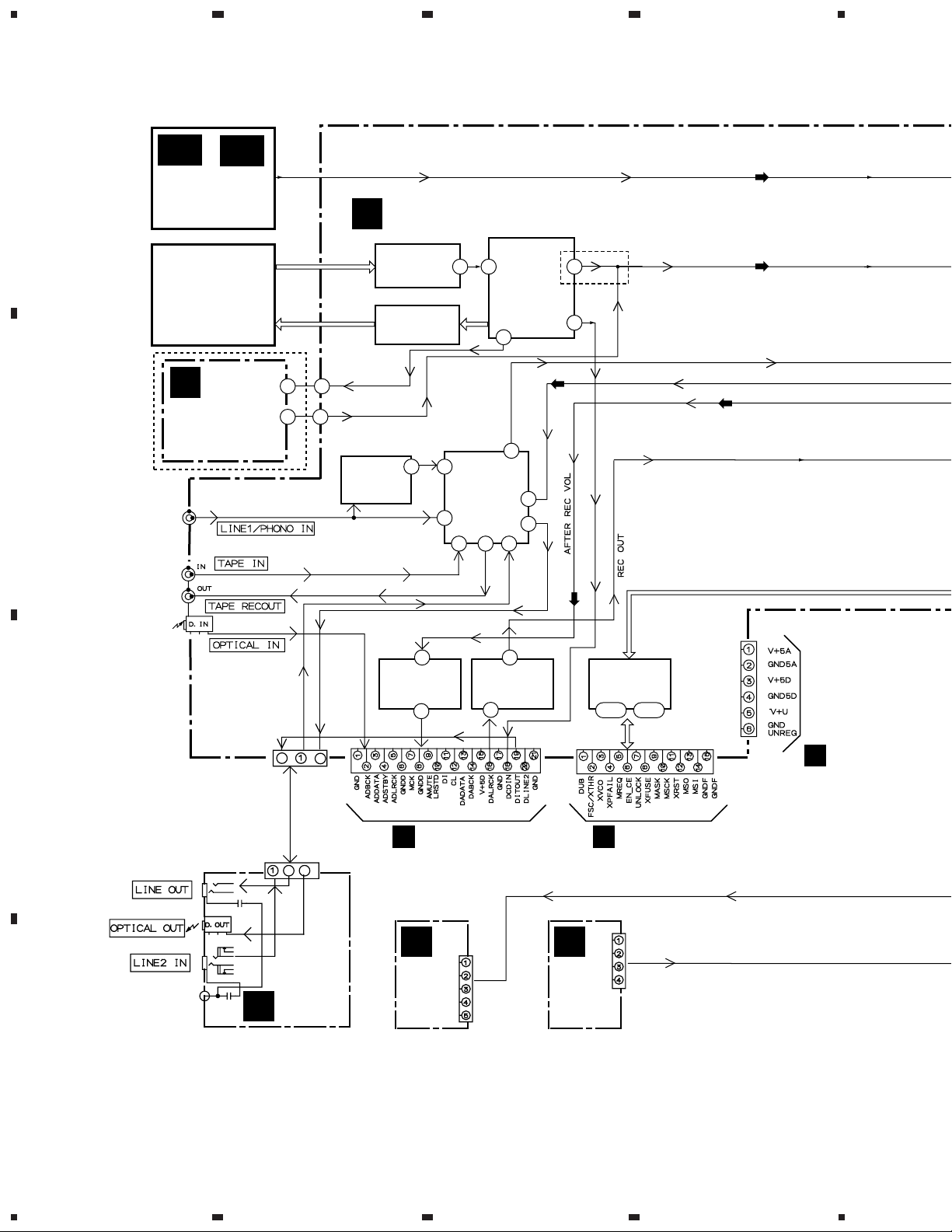

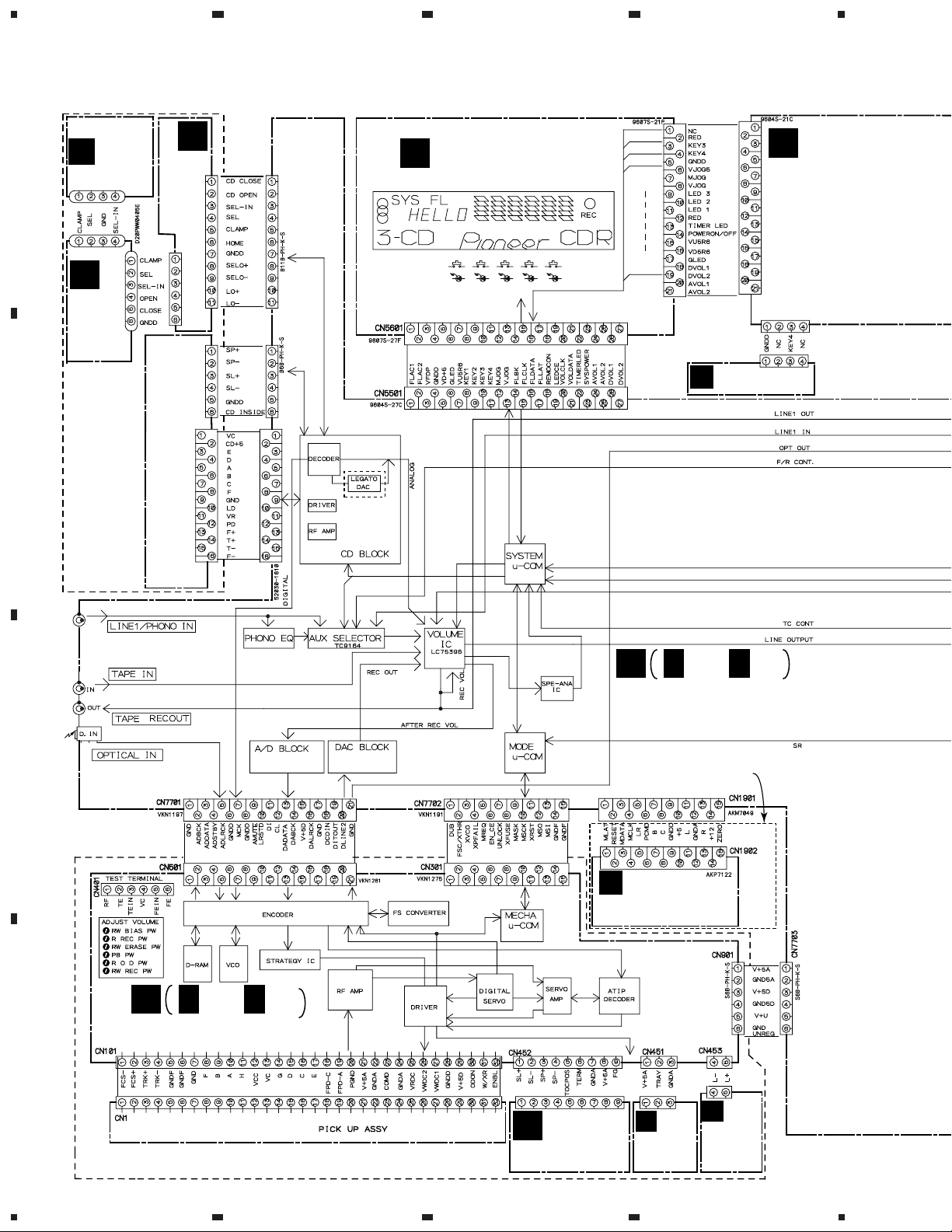

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM (1/2)

4

A

AA

AB

(TX)

FM/AM TUNER

Module

3CD MICRO

CHANGER

MECHA.

(AXA7077)

LEGATO

V

ASSY

(AWU7525)

MY : Only

B

LINE IN

TAPE PLAY

TAPE REC

IC1901

(PE8001A)

D/A Converter

6 6

11 11

AF ASSY

I

(CXA2570N)

RF Amp.

(M56788FP)

IC3131

(UPC4570G2)

PHONO EQ

IC1101

IC1301

Driver

1

23 72

43

IC1201

(CXD2587Q)

Servo Decoder

62

7

2

IC3101

(TC9164AF)

SIGNAL

SELECTOR

3

4 5

13

11

10

KU/CA:Only

60

(REC)

(REC)

CD ANALOG OUT

CD DIGITAL OUT

(CD)

(REC)

DIGITAL IN

(OPTICAL)

CN3201

C

CN5403

9

5

9

5

FRONT

LINE

ASSY

O

D

1

IC7301

(PMC1800-1)

A / D BLOCK

15

CD-R CORE

B

ASSY : CN501

N

CDR

LED

ASSY

16

IC7401

(PE8001A)

D / A BLOCK

2

CN5962

CN7701

M

CDR

SW

ASSY

IC7501

(PE5113B)

MODE µCOM

11-13 44-46

CD-R CORE

B

ASSY : CN301

CN5954

CN7702

CN7703

CD-R ASSY : CN901

B

14

1234

5

678

XR-MR7

(REC)

CN5952

TX

53

CD

55

CDR

54 31

LINE

51

49

(REC)

L

Rotary

Encoder

Rotary

Encoder

CD-R

30, 50

IC3151

(BA4558F-HT)

BUFFER

1 3

SW JOG ASSY

S5966

JOG

S5965

VOL

S5969

DVOL

S5970

AVOL

: AUDIO SIGNAL ROUTE

IC3031

(LC75396NE)

Input Selector, SFC, E-VR

GEQ

IC3081

(M62457AFP)

Spectram Analyzer IC

E-VR

34

8

AD

28

CN3102

CN521

SPEAKER

TERMINAL

CDR

CD

AMP

IC5501

(PD5545A)

System Control

Microcomputer

MICOM +5V

CN3001

CN3002

AMP

J

IC3301

(STK407-040B)

Power Amp.

14

24

AMP ASSY

RY3601

7

DC DET.

Overload DET.

CN3101

CN3902

Phones

P

J3901

HP ASSY

Speaker

CN2551

System

Connector

(CT-J7)

CN5502

Flash

Microcomputer

ROM

Write

BZ5501

Buzzer

A

B

C

CN5953

K

Key Input

DISPLAY ASSY

(BU2092F)

LED Driver

V5601

(AAV7073)

FL TUBE (included Driver)

5

IC5801

PRIMARY ASSY

REG ASSY

U

SECONDARY ASSY

S

Power Supply

Block

Power

Transformer

T

SUBTRANS ASSY

Q

ACINOUT ASSY

R

RY11

FU1

CN1

AC OUTLET

MY : Only

AC INLET

D

Standby

Power Supply

Block

Standby

Transformer

15

6

7

8

1

23

XR-MR7

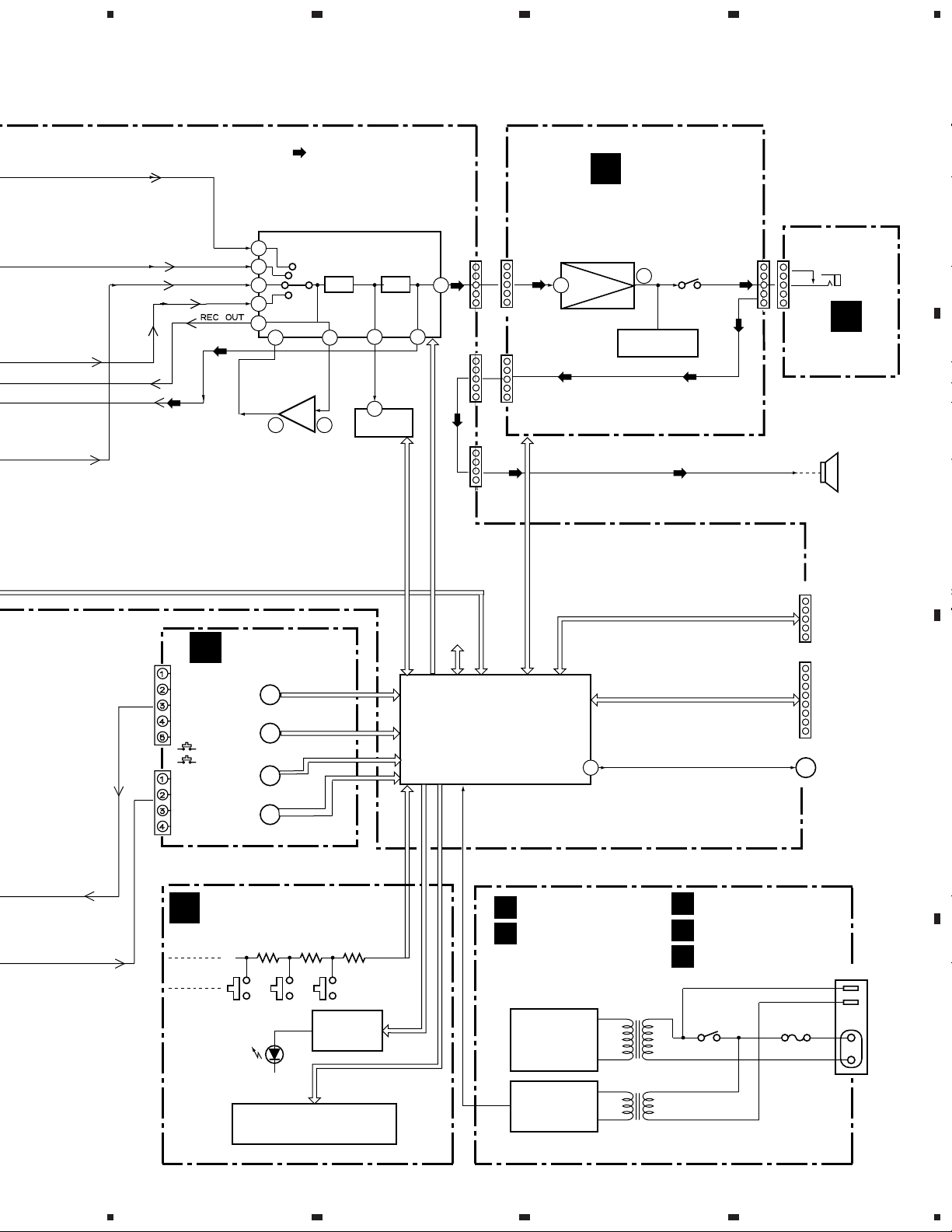

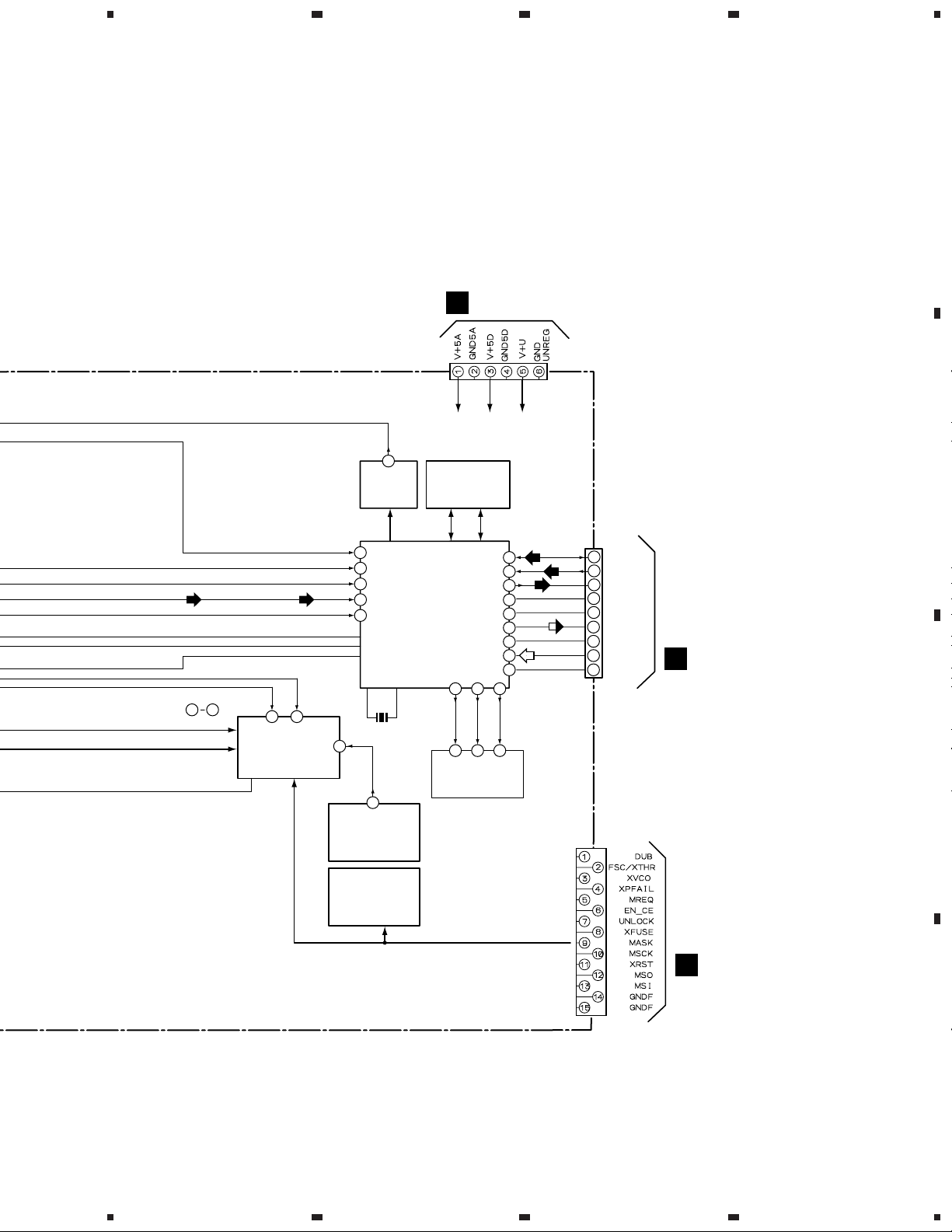

3.2 BLOCK DIAGRAM (2/2 : CD-R)

4

A

Disc (CD, CD-R, CD-RW)

B

PICKUP

PEA1351

CD-R

CN1 CN101

A

10

B

9

C

16

D

15

E

17

F

8

G

14

H

11

FCS+

4

FCS–

1

TRK+

3

TRK–

2

SIGNAL ROUTE

(REC)

: REC SIGNAL (after A/D)

(PB)

(PB)

: PB OUT (before D/A)

(CD)

: DIGITAL CN INPUT

(LI2)

: DIGITAL LINE 2

(DO)

: DIGITAL OUT

: RF SIGNAL ROUTE

CD-R CORE

ASSY

B

RF AMP CIRCUIT

A–D

A

10

B

9

16

15

17

8

14

11

4

1

3

2

A–H

C

D

E

F

G

H

IC181

NJM2137M

6 1

76

73

71 68

RFDC

HF

17.2872MHz

19

IC101

AK8563

RF PROCESSOR

58

11

10

29

46

WRF

FE

TE

RFAC

RFWBL

IC251-IC254

RUNNING OPC

CIRCUIT

BLOCK

RFOPC

AOUT

IC431

PDK041A

STRATEGY

CONTROL IC

CXD2585Q

CD DECODER

RFDC

43

FE

39

TE

41

RFAC

50

IC401

34.5744MHz

4

17.2872MHz

6

CDLRCK

65

CDBCK

67

CDDATA

66

CDTX

64

LD CONTROL

CIRCUIT

SERVO MECHANISM

C

ASSY

PC651

C

NJL5803K-F1

FG

M

DC MOTOR

ASSY

(SPINDLE)

PEA1235

M

CARRIAGE MOTOR

ASSY (SLIDER)

PEA1350

LOADING B

E

ASSY

CN601

9

3

4

1

2

CN452

FG

SPDL

SL

FG

9

FCS+

3

SPDL

4

2

1

SL

FCS–

TRK+

TRK–

SPDL

L

34

35

IC451

32

M56788FP

31

TRK DRIVER

12

FCS DRIVER

13

SLD DRIVER

SPDL DRIVER

9

10

LOADING DRIVER

14

15

TE

HF

RFWBL

29

IC201

---

PA9007A

SERVO AMP IC

38

19

FG

IC351

PDJ014A

ATIP

DECODER IC

32 37

39 40

AD0-AD7

Address

CN551

M

LOADING

MOTOR

ASSY

VXX2505

1

LLL

2

CN453

4

5

D

16

1234

5

43 36

AD0-AD7

Address

17.2872MHz

CDLRCK

CDBCK

CDDATA

CDTX

AOUT

RFOPC

61 60

IC301

PE5109A

MECHANISM

CONTROL µCOM.

34.5744MHz

7

IC561

BA7082F

VCO IC

76

46

45

44

EFM ENCODER IC

47

X501

16.9344MHz

59

3

IC302

TK11041M-1

TEMPERATURE

SENSOR IC

678

XR-MR7

A

AF ASSY : CN7703

I

CN901

V+ 5D

2

1

48

1

48

30

36

33

35

DIRDATA

V+ U

(DO)

(LI2)

(PB)

(REC)

(CD)

CN301

20

18

19

16

14

13

5

3

2

CN501

DLINE2

DCDIN

DITOUT

DALRCK

DABCK

DADATA

ADLRCK

ADDATA

ADBCK

B

AF ASSY : CN7701

I

C

V+ 5A

IC503

LH64256CK-70

D-RAM

Address Data

IC501

LC89585

15 16 17

DIRBCK

DIRLRCK

2 4 43

IC502

AD1893JST

Fs CONVERTER

IC303

PYY1196

(BR93LC46AF)

EEPROM

AF ASSY : CN7702

I

D

17

5

6

7

8

1

XR-MR7

23

4

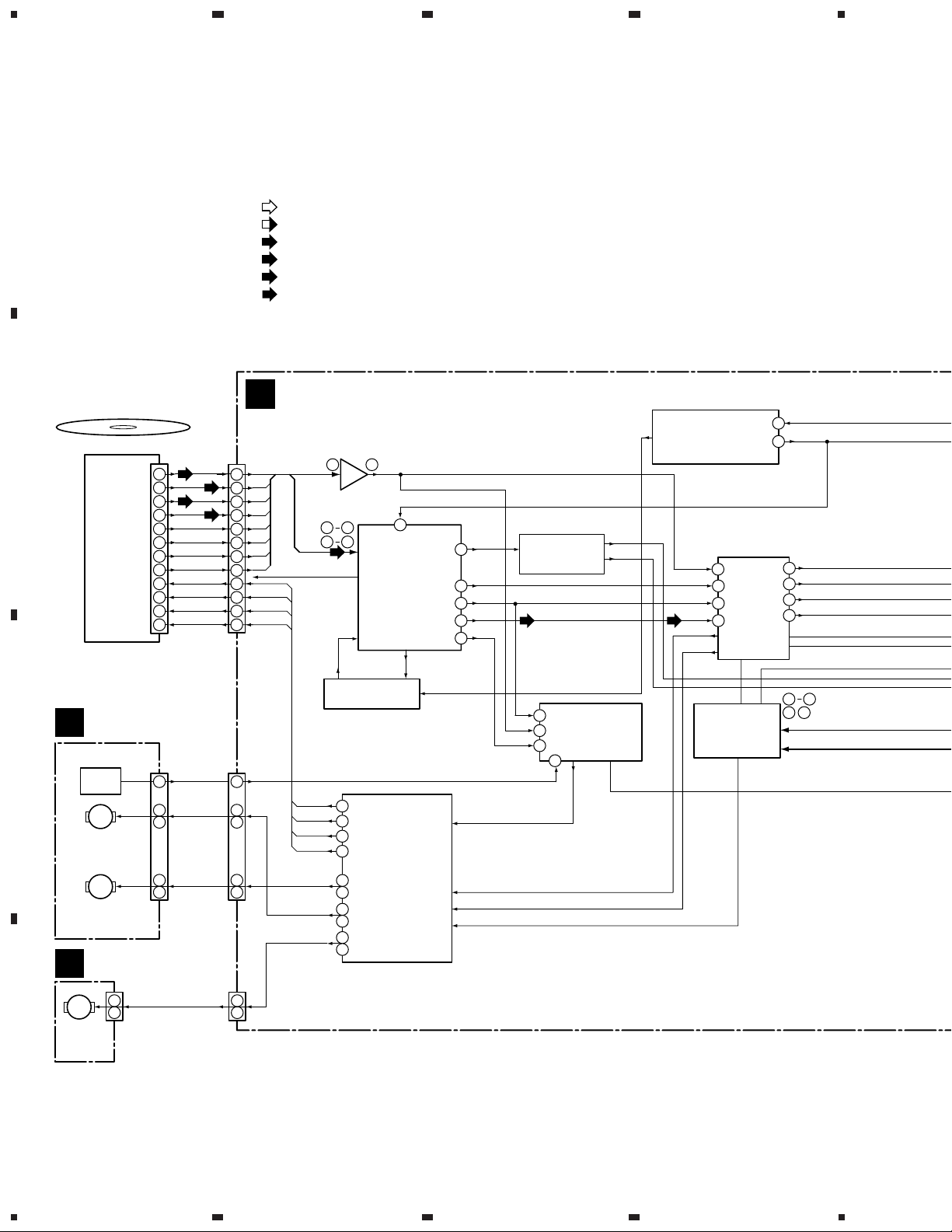

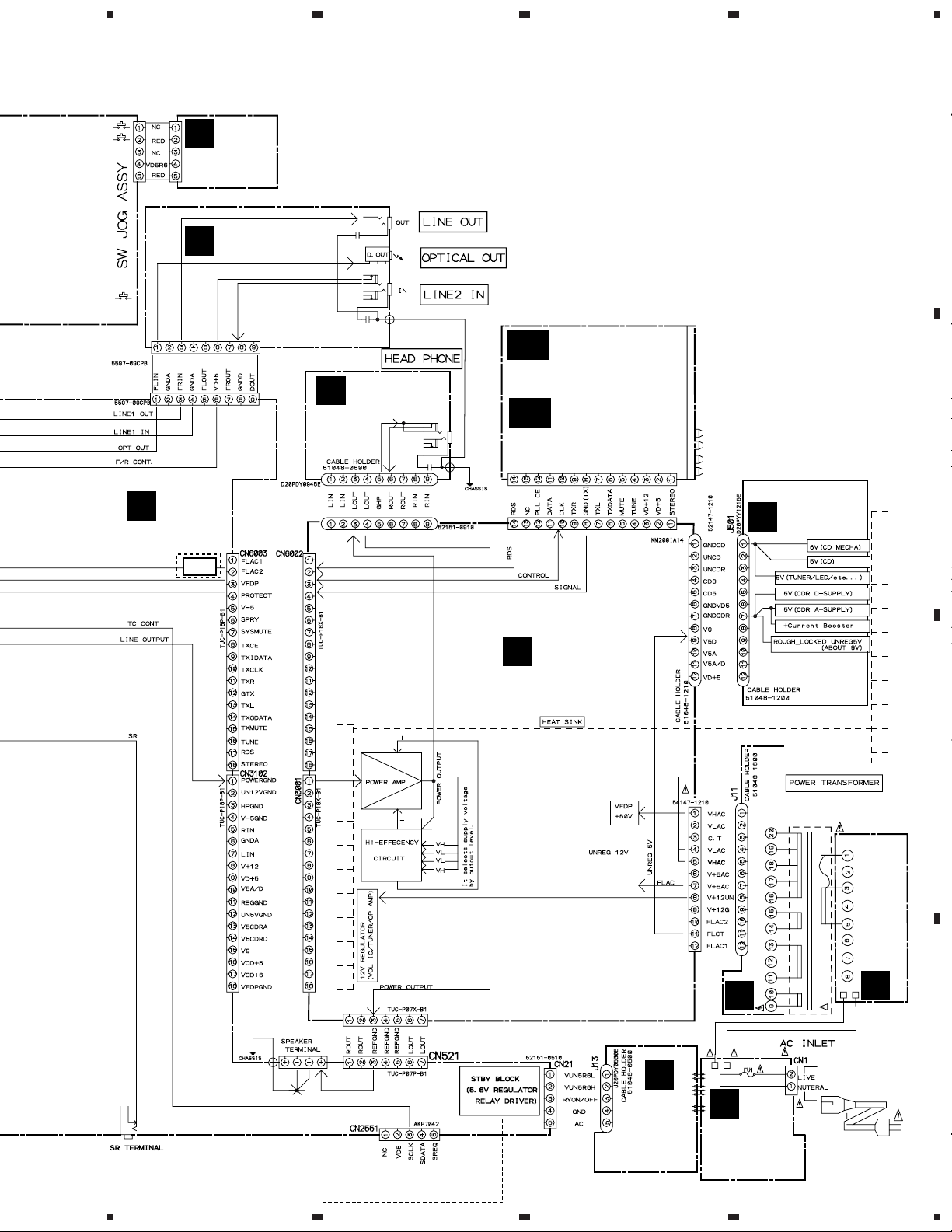

3.3 OVERALL WIRING DIAGRAM

SELECT

UNIT

A

F

(AWU7433)

J8502

G

J8503

CN8501

H

(AWU7431)

MOTOR UNIT

CN8003

CN1302

PG11KK-G20

DISPLAY ASSY

K

(AWU7461)

CN5901

UNIT

LOADING

(AWU7432)

B

MECHA

(AXA 7077)

CN8002

PICKU UNIT

(KSM213CCM)

ADE7051

CN1301

ADD7178

ADD7203

MY:Only

CN5951

ADD7202

CN5953

CN5954

CDR SW ASSY

M

(AWU7517)

L

(AWU7466)

SW JOG ASSY

3 CD MICRO CHANGER

CN1101

I 1/4- I 4/4

I

AF ASSY

(XR-MR7/MY : AWU7460)

(XR-MR7/KU/CA : AWU7448)

MY:LEGATO

C

ADD7200

KU/CA:NORMAL

ADD7201

XR-MR7/MY Only

V

LEGATO ASSY

(AWU7525)

B 1/5- B 5/5

B

CD-R CORE ASSY

(PYY1273)

D

PDD1195

CD-R

(PEA1351)

C

(PWZ3759)

SERVO

MECHA

CN601

CN501

D

LOADING

A ASSY

(PWZ3760)

E

ADE7055

CN551

B ASSY

LOADING

(PWZ3761)

18

1234

5

678

XR-MR7

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

CN5952

CN5403

CN3201

ADD7204

I

CN5962

N

(AWU7467)

O

ADD7205

AF ASSY

MY:Only

RDS

CDR LED

ASSY

FRONT LINE

ASSY

(MY : AWU7450)

FRONT LINE

ASSY

(KU/CA : AWU7438)

P

J3901

H. P ASSY

(AWU7453)

CN3101

FM/AM TUNER

AA

AB

MODULE

(MY : AXQ7068)

FM/AM TUNER

MODULE

(KU/CA : AXQ7065)

CN6201

CN6001

CN5001

REGULATOR

ASSY

U

(AWU7468)

A

B

AMP ASSY

J

(MY : AWU7464)

(KU/CA : AWU7555)

T1

CN11

S

CN3002

Q

SUB TRANS

ASSY

(MY : AWU7471)

(KU/CA:AWU7459)

SYSTEM CONNECTOR

FOR CT-J7

5

6

XR-MR7/MY Only

7

R

AC IN/OUT

ASSY

(MY:AWU7470)

(KU/CA:AWU7458)

(MY : ATS7271)

(KU/CA : ATS7272)

PRIMAR ASSY

(MY : AWU7469)

SECONDARY ASSY(AWU7451)

T

MY :

50/60Hz AC220-230V

KU/CA :

60Hz AC120V

AC POWER CORD

MY : ADG1127

KU/CA : ADG7021

19

8

C

(KU/CA : AWU7457)

D

1

23

XR-MR7

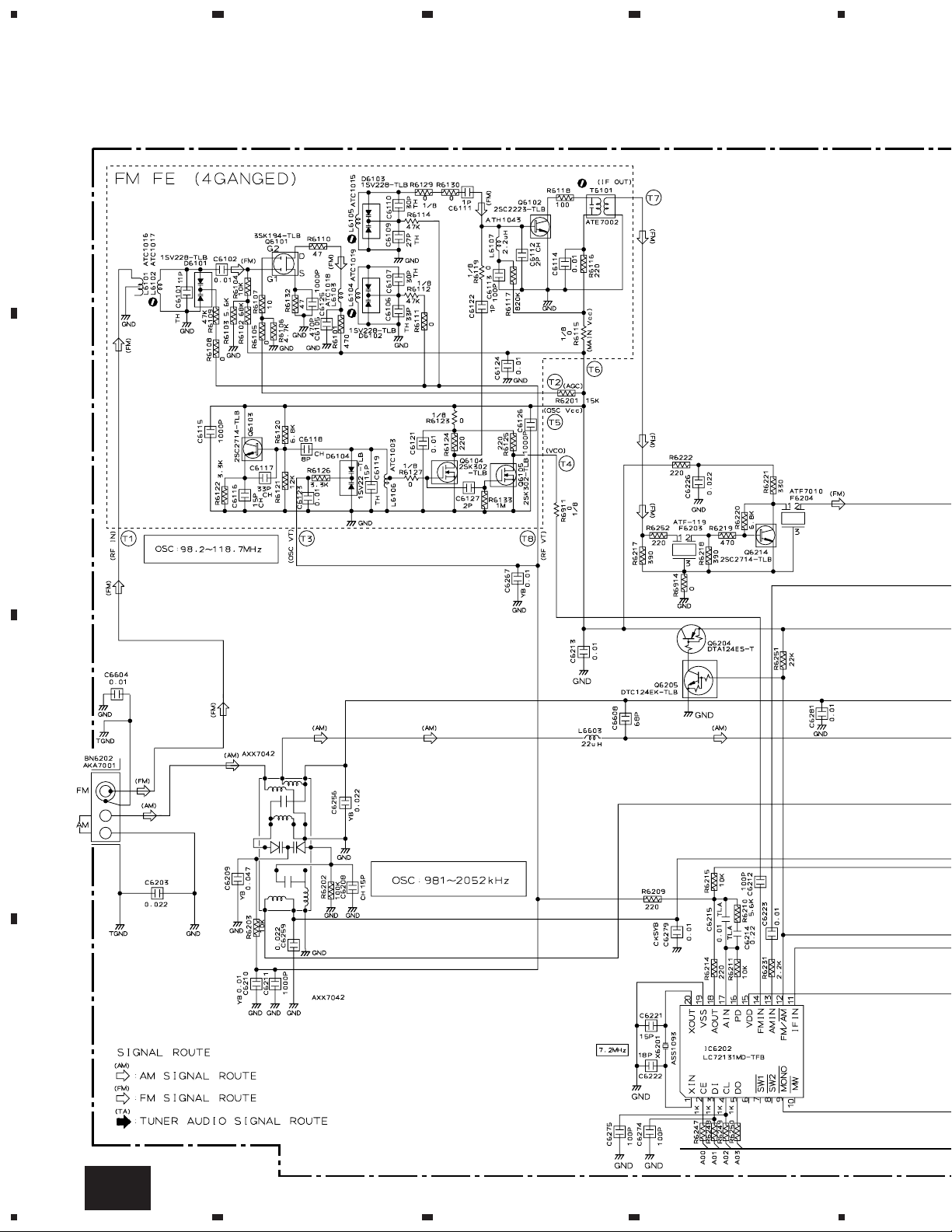

3.4 FM/AM TUNER MODULE (For MY Type)

A

RF AMP

OSC

B

4

MIX AMP

BUFFER

IF AMP

FM +B SW

C

AM RF TUNING BLOCK

D

20

AA

1234

PLL

5

678

XR-MR7

A

FM/AM TUNER MODULE

AA

(AXQ7068)

B

AF AMP

REGULATOR

CN6001

J

AF AMP

CN6201

KP200IA14L

C

D

AA

5

6

7

8

21

1

23

XR-MR7

3.5 FM/AM TUNER MODULE (For KU/CA Type)

4

A

B

RF AMP

1T378A

OSC

1T378A

MIX AMP

BUFFER

IF AMP

FM +B SW

C

MW RF TUNING BLOCK

AKX7041

D

22

AB

1234

5

678

XR-MR7

FM/AM TUNER MODULE

AB

(AXQ7065)

AF AMP

A

B

CN6001

J

AF AMP

PLL

REGULATOR

CN6201

KP200IA14L

C

D

AB

5

6

7

8

23

1

XR-MR7

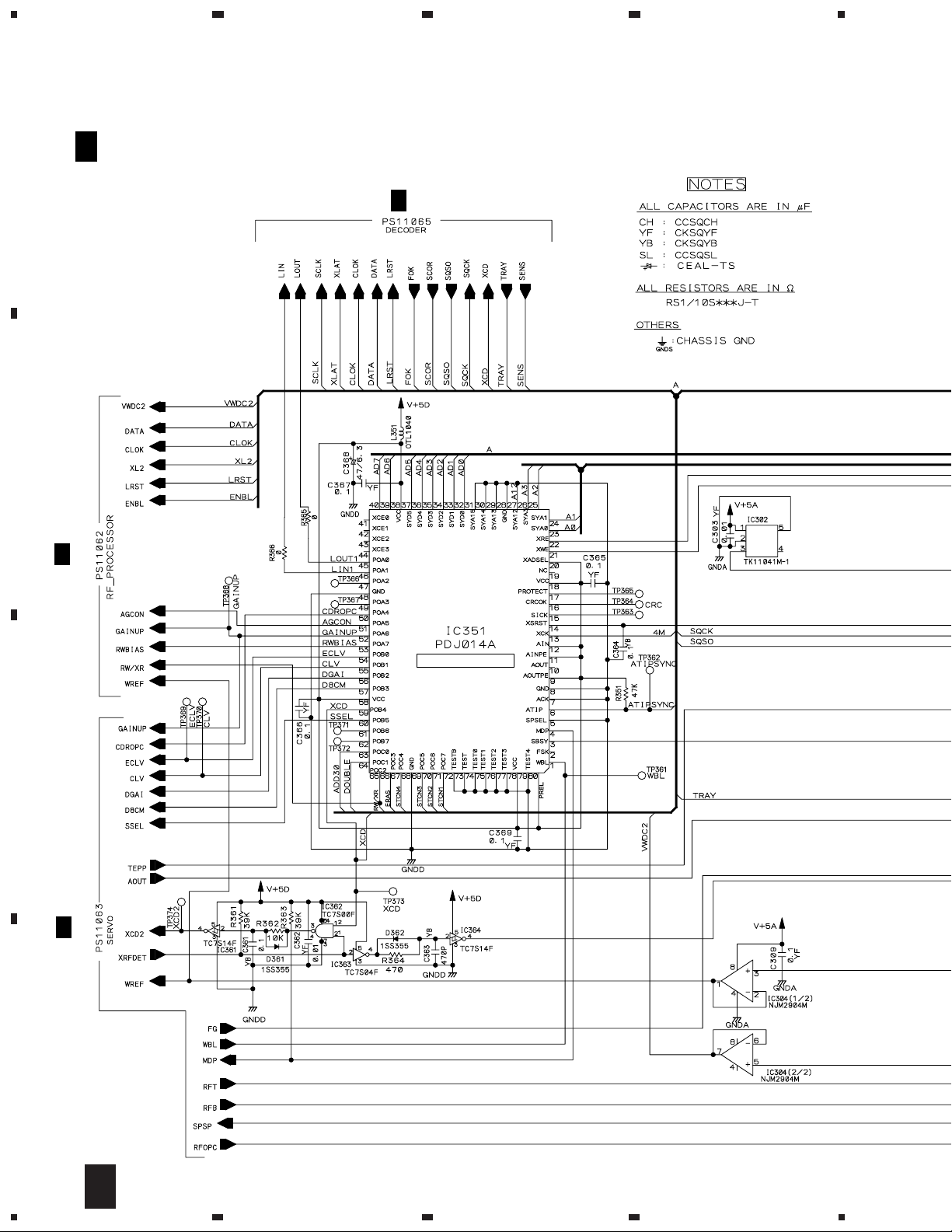

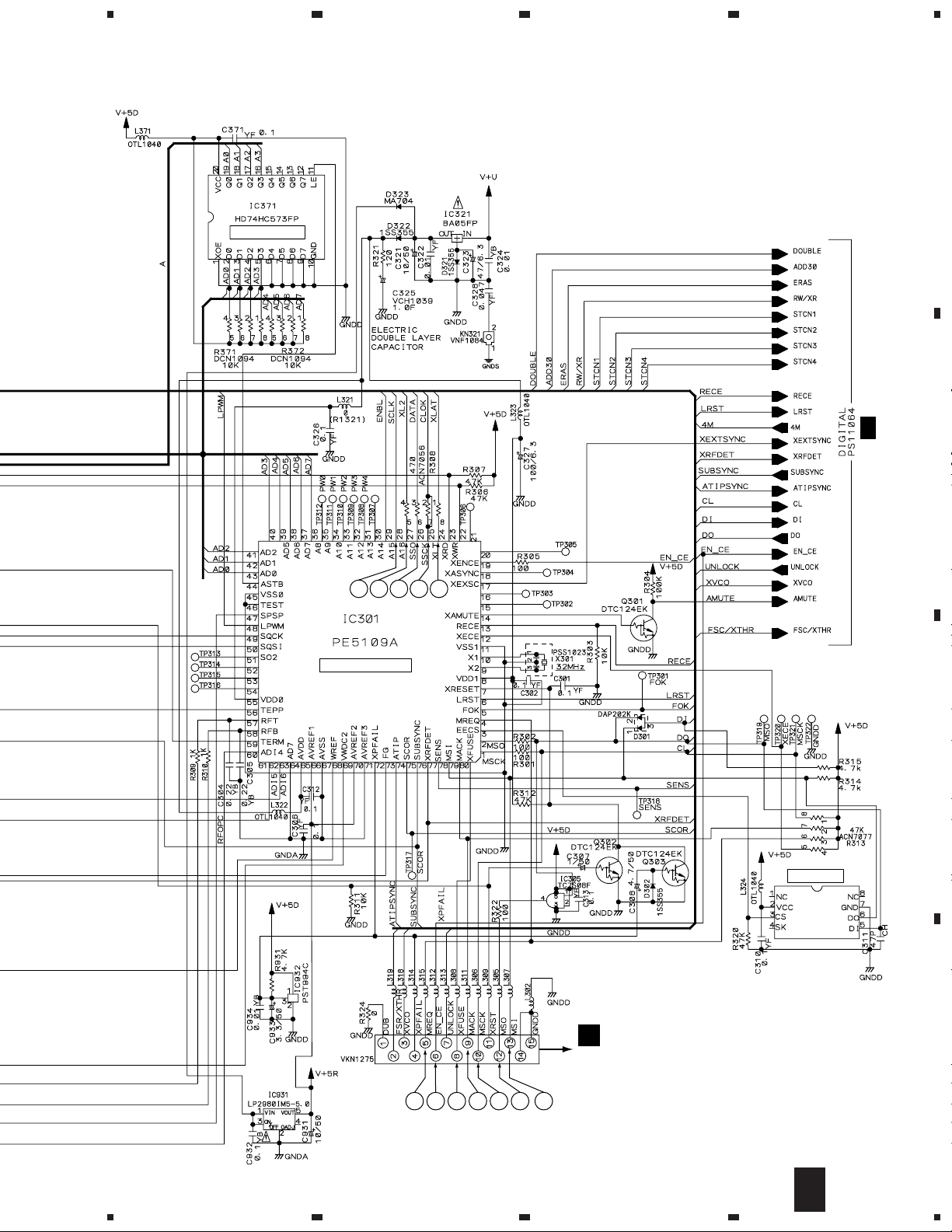

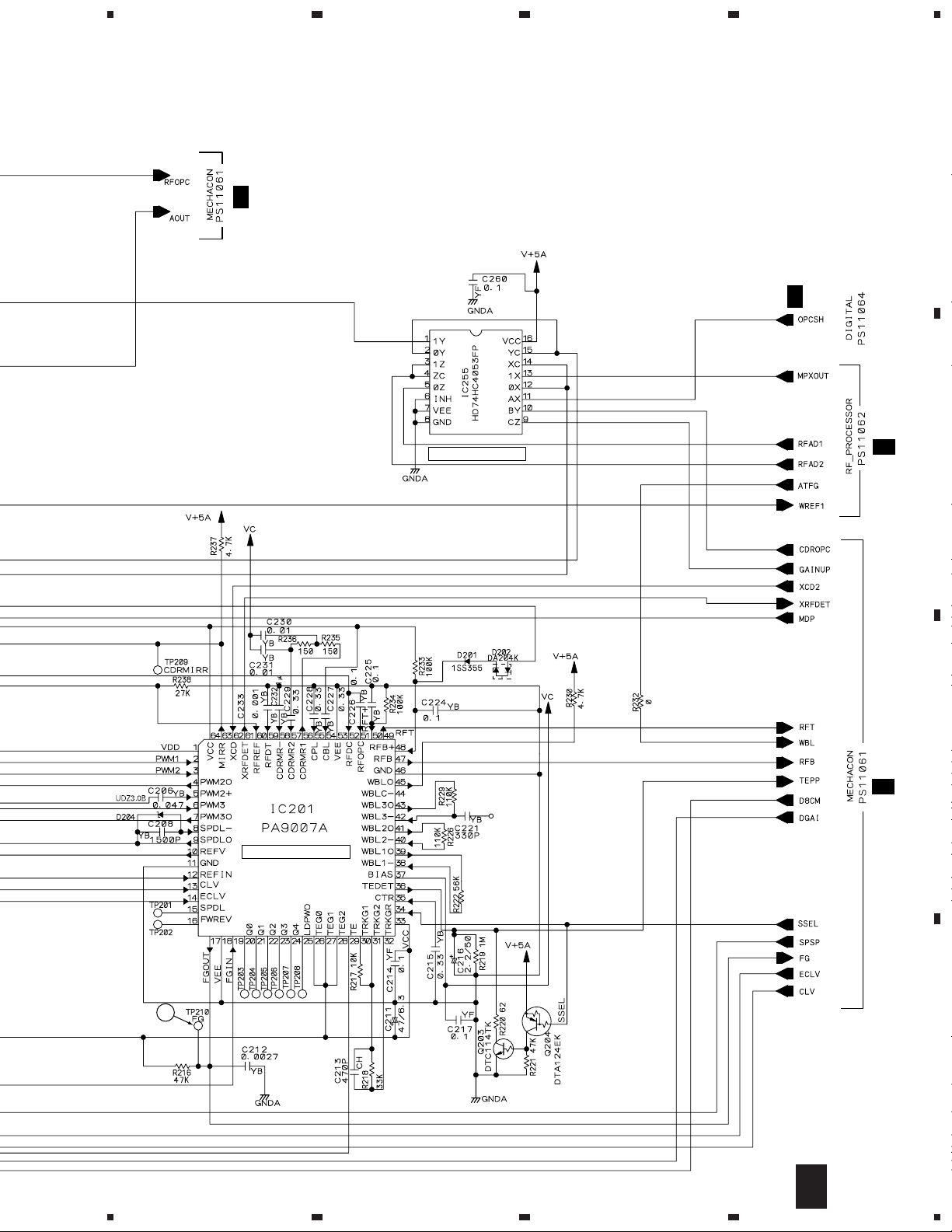

3.6 CD-R CORE ASSY (1/5)

23

4

CD-R CORE ASSY (PYY1273)

1/5

• MECHA. CONTROL µCOM BLOCK

B

5/5

B

B

2/5

A

B

ATIP DECODER

C

3/5

B

D

24

1/5

B

1234

5

8 bit LATCH

678

XR-MR7

A

4/5

B

B

8 9 10 11 12

MECHA µ-COM

CN301

L302,L305-L309,

L311-L315,L318,L319 :OTL1040

I

CN7702

EEPROM

IC303

PYY1196

(BR93LC46F)

C

D

1 2 3 4 5 6 7

1/5

5

6

7

B

8

25

1

23

XR-MR7

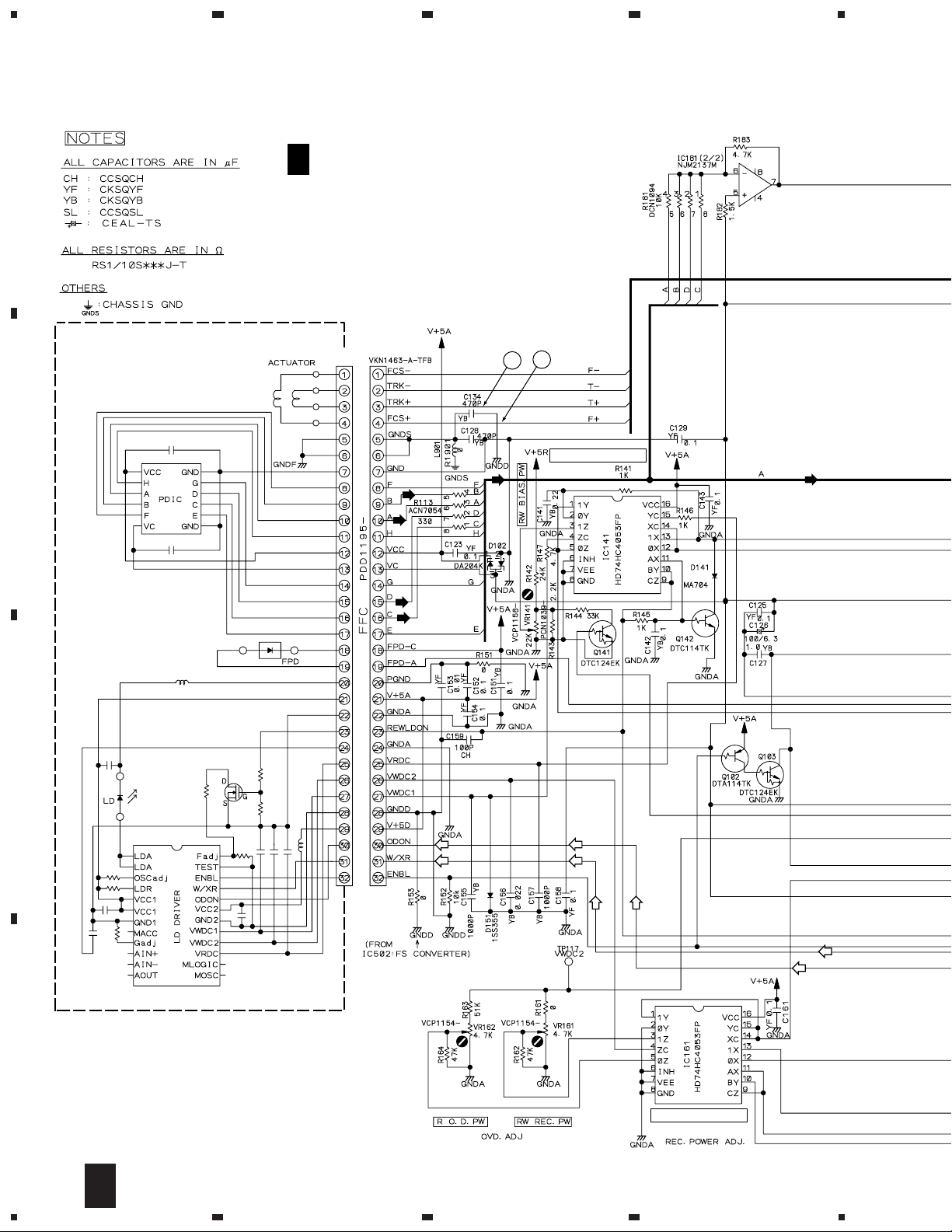

3.7 CD-R CORE ASSY(2/5) and CD-R PICKUP

4

A

B

CD-R PICKUP

(PEA1351)

B

CD-R CORE ASSY (PYY1273)

2/5

• RF PROCESSOR BLOCK

CN101

CN1

7

8

MULTI PLEXER

C

(REC)

(REC)

D

26

2/5

B

1234

(REC)

(REC)

(REC)

(REC)

MULTI PLEXER

(REC)

(REC)

4

CN102

3

5

678

XR-MR7

: RF SIGNAL ROUTE

(REC)

: AUDIO SIGNAL ROUTE (REC)

3/5

B

1

2

5

B

3/5

A

B

(REC)

(REC)

RF PROCESSOR

(REC)

6

(REC)

(REC)

(REC)

B

B

B

3/5

C

1/5

4/5

D

2/5

B

5

6

7

8

27

1

XR-MR7

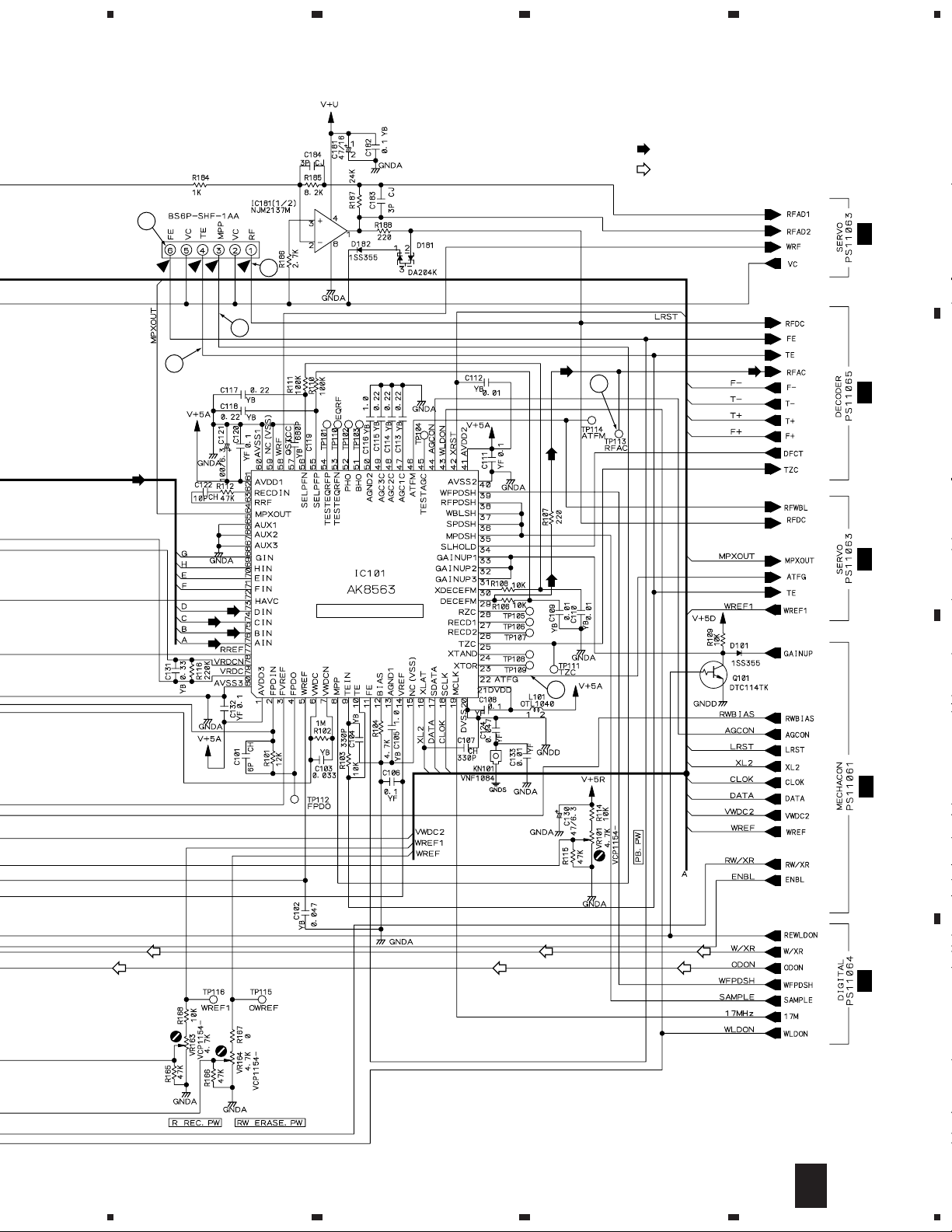

3.8 CD-R CORE ASSY (3/5)

23

4

B

A

B

CD-R CORE ASSY (PYY1273)

3/5

• SERVO BLOCK

2/5

B

1/5

B

2

5/5

B

C

2/5

B

D

28

3/5

B

1234

5

678

XR-MR7

A

1/5

B

4/5

B

2/5

MULTI PLEXER

B

B

C

1/5

B

CDR SERVO AMP

1

D

3/5

B

5

6

7

8

29

1

M

XR-MR7

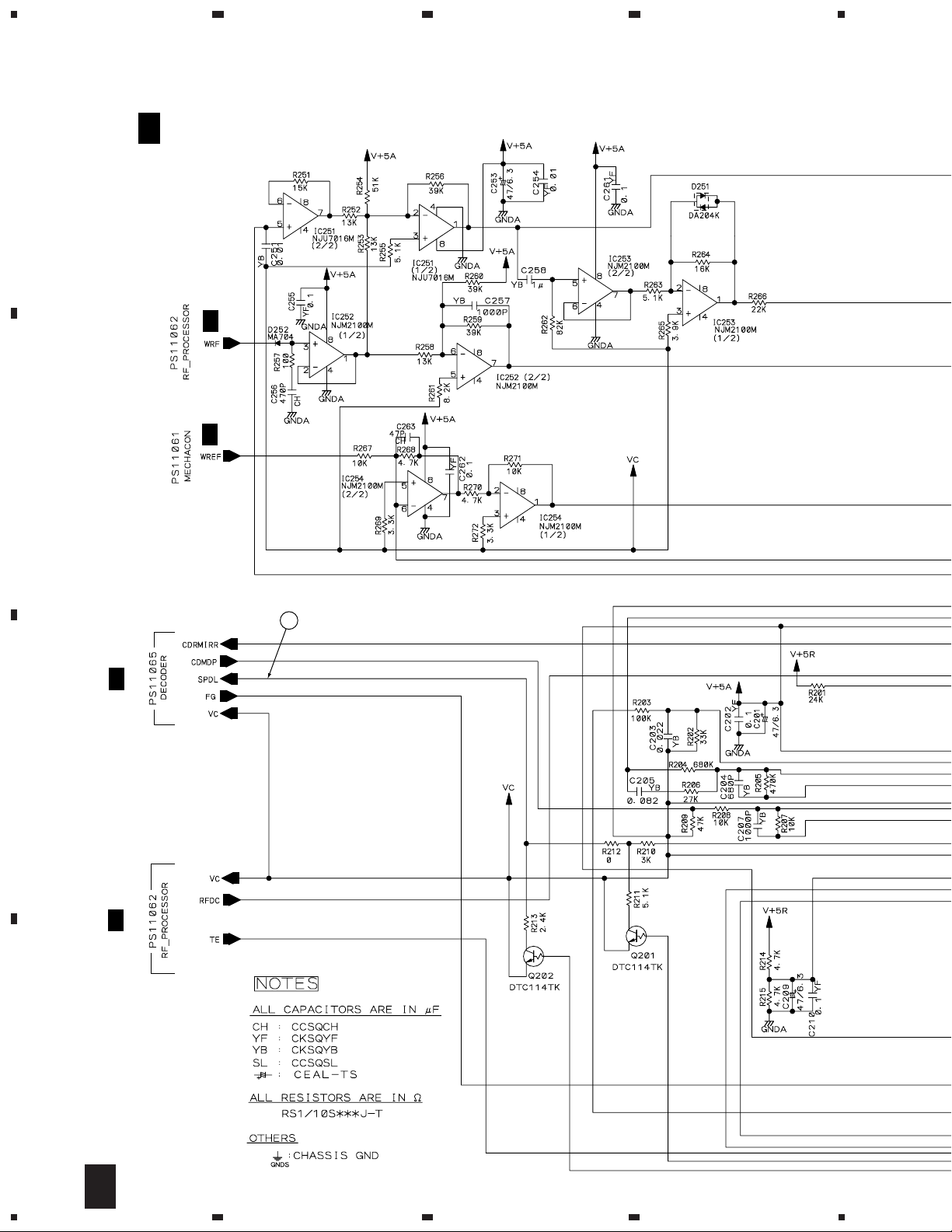

3.9 CD-R CORE ASSY (4/5)

23

4

A

3/5

B

B

B

CD-R CORE ASSY (PYY1273)

4/5

• DIGITAL BLOCK

(REC)

D-RA

VCO

(REC)

13

EFM ENCODER IC

2/5

B

C

D

(REC)

(REC)

(REC)

17

(REC)

18

(REC)

15

16

14

(REC)

(REC)

STRATEGY

CONTROL

(REC)

(DI1)

(DI2)

30

1/5

4/5

B

1234

B

D-RAM

5

678

XR-MR7

: AUDIO SIGNAL ROUTE

(REC)

: REC SIGNAL (after A/D)

(PB)

: PB OUT (before D/A)

(DI1)

: DIGITAL INPUT1

(DI2)

: DIGITAL INPUT2

(DO)

: DIGITAL OUT

: The power supply is shown with the marked box.

A

(DO)

16.9344MHz

(REC)

FS CONVERTER

(PB)

(DO)

(REC)

(PB)

(REC)

(PB)

(REC)

VCO

B

CN501

(REC)

(REC)

(PB)

(DI1)

(D0)

(DI2)

(PB)(PB)

1

2

3

4

12

5

6

7

8

9

10

11

C

I

CN7701

B

5/5

MULTI PLEXER

5

6

L511-L513,L515-L518,

L522,L524,L526 : OTL1040

F510,F514,F520

F521,F527 : VTH1097

7

B

4/5

8

D

31

1

23

4

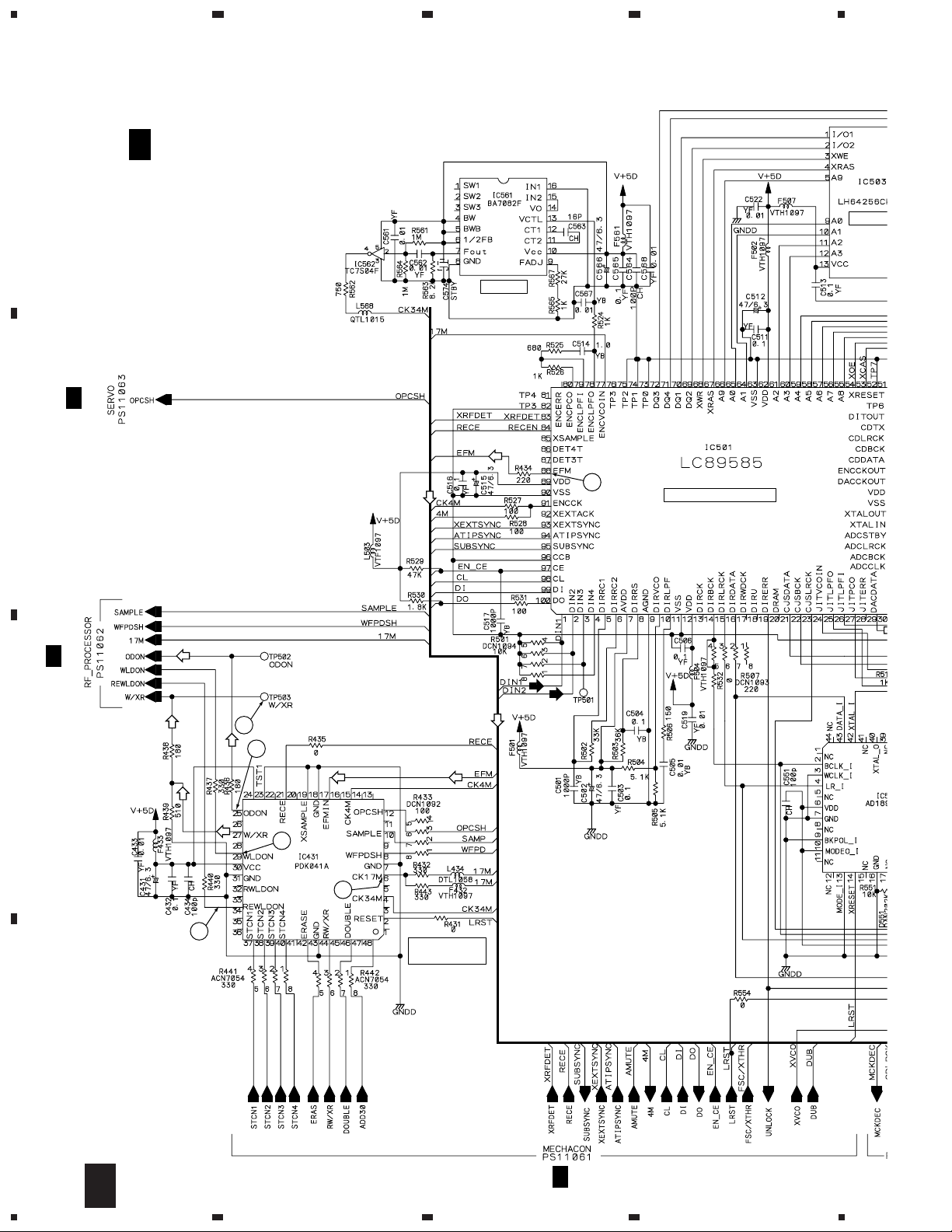

XR-MR7

3.10 CD-R CORE ASSY(5/5), SERVO MECHANISM, LOADING A and LOADING

B ASSYS

A

3/5

B

B

CN453

CN451

CN452

1 2

B

CD-R CORE ASSY (PYY1273)

5/5

• DECODER BLOCK

5ch ACTUATOR DRIVER

3

C

CN501

S501

LOADING A

D

ASSY (PWZ3760)

LOADING B

E

ASSY (PWZ3761)

CN551

CARRIAGE MOTOR

ASSY (SLIDER)

CN601

D

PEA1350

DC MOTOR ASSY

(SPINDLE)

PEA1235

S601

SERVO MECHANISM

C

ASSY (PWZ3759)

LOADING MOTOR

ASSY

VXX2505

PC651

NJL5803K-F1

J601

B

2/5

32

5/5

B

1234

C

D

E

5

678

XR-MR7

2/5

B

B

5

4

A

1/5

B

CD DECODER

CN901

4/5

B

CN7703

I

C

: RF SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

: The power supply is shown with the marked box.

5

6

D

5/5

B

7

8

33

XR-MR7

VOLTAGES and WAVEFORMS

CD-R CORE ASSY

1/5

B

Media Pickup Position

12cm Inner 0V 0V

12cm Outer 5V 0V

CD

8cm Inner 0V 0V

8cm Outer 5V 0V

12cm Inner 5V 0V

CD-R

CD-RW

12cm Outer 5V 0V

8cm Inner 0V 5V

8cm Outer 5V 5V

at FS = 44 kHz

(at FS Converter through)

FSR/XTHR

(CN301-pin 2)

at DIGITAL LOCK at DIGITAL UNLOCK

XVCO

(CN301-pin3)

UNLOCK

(CN301-pin7)

XPFAIL

(CN301-pin4)

XRST

(CN301-pin11)

0V 5V

0V 5V

0V 5V

5V

5V

DGAI

(IC351-pin56)

D8CM

(IC351-pin57)

Others

−

−

Note :

The encircled numbers denote measuring point in the schematic diagram.

1/5

CD-R CORE ASSY

B

CN301 - pin 5 (MREQ)

1

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 6 (EN_CE)

2

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 8 (XFUSE)

3

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 13 (MSI)

7

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 28 (SCLK)

8

V: 2V/div. H: 2µsec/div.

(Disck Loading)

IC301 - pin 27 (XL2)

9

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CD-R CORE ASSY

3/5

B

Operating

Mode

CLV

(IC201-pin13)

ECLV

(IC201-pin14)

STOP 0V 0V

CAV 0V 5V

CLV 5V 0V

ECLV 5V 5V

CD-R CORE ASSY

4/5

B

A/D Converter used

ADSTBY

(CN501-pin4)

AMUTE

(CN501-pin9)

LRSTD

(CN501-pin10)

at Analog REC Pause

or REC

0V 5V

at MUTE ON

(Audio Signal Not Output)

5V 0V

5V −

Others

at MUTE OFF

(Audio Signal Output)

CN301 - pin 9 (MACK)

4

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 10 (MSCK)

5

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN301 - pin 12 (MSO)

6

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 26 (DATA)

10

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 25 (CLOK)

11

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 24 (XLAT)

12

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

34

XR-MR7

CD-R CORE ASSY CD-R CORE ASSY

2/5

B

CN102 - pin 1 (RF)

1

V: 20mV/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN102 - pin 3 (MPP)

2

V: 10mV/div.(10 : 1) H: 2msec/div.

(PLAY)

CN102 - pin 4 (TE)

3

V: 5mV/div.(10 : 1) H: 2msec/div.

(PLAY)

TP113 (RFAC)

5

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(PLAY)

IC101 - pin 22 (ATFG)

6

V: 0.2V/div. H: 20µsec/div.

(REC)

CN101 - pin 3 (TRK +)

7

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

3/5

B

TP210 (FG)

1

V: 0.2V/div.(10 : 1) H: 1msec/div.

(PLAY)

Foot of R212 (SPDL)

2

V: 20mV/div. H: 2msec/div.

(PLAY)

CN102 - pin 6 (FE)

4

V: 5mV/div.(10 : 1) H: 2msec/div.

(PLAY)

CN101 - pin 4 (FCS +)

8

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

35

XR-MR7

CD-R CORE ASSY CD-R CORE ASSY

4/5

B

CN501 - pin 2 (ADBCK)

1

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 3 (ADDATA)

2

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC)

CN501 - pin 5 (ADLRCK)

3

V: 0.2V/div.(10 : 1) H: 10µsec/div.

(STOP)

CN501 - pin 14 (DABCK)

7

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 16 (DALRCK)

8

V: 0.2V/div.(10 : 1) H: 10µsec/div.

(STOP)

CN501 - pin 18 (DIN1)

9

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC_OPTICAL)

IC501 - pin 88 (EFM)

13

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(REC)

IC431 - pin 6 (17M)

14

V: 0.2V/div.(10 : 1) H: 50msec/div.

(REC)

IC431 - pin 25 (ODON)

15

V: 0.2V/div.(10 : 1) H: 0.1µsec/div.

(REC)

5/5

B

CN452 - pin 2 (SL +)

1

V: 0.2V/div.(10 : 1) H: 5msec/div.

(PLAY)

CN452 - pin 3 (SP +)

2

V: 0.2V/div.(10 : 1) H: 5msec/div.

(PLAY)

CN452 - pin 9 (FG)

3

V: 0.2V/div.(10 : 1) H: 1msec/div.

CN501 - pin 7 (MCK)

4

V: 0.1V/div.(10 : 1) H: 50msec/div.

(STOP)

CN501 - pin 12 (CL)

5

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(STOP)

CN501 - pin 13 (DADATA)

6

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN501 - pin 19 (DITOUT)

10

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 20 (DIN2)

11

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC_Coaxial)

CN501 - pin 11 (DI)

12

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC431 - pin 29 (WLDON)

16

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

IC431 - pin 34 (REWLDON)

17

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

TP503 (W/XR)

18

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

IC401 - pin 25 (MDP)

4

V: 0.2V/div.(10 : 1) H: 5µsec/div.

(PLAY)

IC401 - pin 25 (MDP)

4

V: 0.2V/div.(10 : 1) H: 5µsec/div.

(REC)

IC401 - pin 20 (MIRR)

5

V: 0.2V/div.(10 : 1) H: 20µsec/div.

(REC_CD-RW)

36

1

234

3.10 MOTOR, LOADING, SELECT and PICKUP UNITS

SELECT UNIT

F

(AWU7433)

MOTOR UNIT (AWU7431)

H

J101

J101

XR-MR7

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SPINDLE SERVO LOOP LINE

(C)

: CARRIAGE SERVO LOOP LINE

(L)

: LOADING SERVO LOOP LINE

CN101

S11B-PH-K-S

A

CN1302

2/4

I

B

LOADING UNIT (AWU7432)

G

PICKUP UNIT

(KSM213CCM)

J102

J102

(S)

(S)

(S)

(S)

(C)

(C)

(L)

(L)

CN1301

(L)

(L)

(C)

(C)

2/4

I

C

CN1101

2/4

I

(F)

(T)

(F)

1

2

3

(F)

(T)

(T)(T)

(F)

F

G

H

4

D

37

1

23

XR-MR7

3.11 AF (1/4) and H.P ASSYS

4

C3205

470p

A

(L1)

LINE1 / PHONO IN

KU/CA :220p

MY : 330 p

C3203

KU/CA :220p

MY : 330 p

(REC)

(L1)

470p

C3204

470p

(L2)

R3299

(REC)

(L1)

(REC)

µ

470p

C3206

B

CN5403

O

4.952V

(Lin)

(Lin)

(L1)

(L2)

(CD-R) (CD-R)

(TX)

(CD)

(REC)

11.738V

Separator

(Lin) (Lin)

(REC)

(Lin)

(TX)

(REC)

(CD)

(CD)

-5.667V

10.132V

4.954V

C

(CD)

(TX) (TX)

(CD)

-5.673V

(REC)(REC)

(TX)

1.226V

(REC)(REC)

(TX)

16.242V

I 3/4

0.615V

-0.002V

D

(CD-R) (CD-R) (CD-R)

8.165V

-0.002V

5.532V

38

I

I 3/4

1/4

Q

J13

1234

5

SIGNAL ROUTE

(CD)

: CD AUDIO SIGNAL

(L1)

: LINE 1 SIGNAL

(L2)

: LINE 2 SIGNAL

(MAIN)

: MAIN OUT SIGNAL

678

XR-MR7

(CDR)

: CD-R AUDIO SIGNAL

(TX)

: TUNER AUDIO SIGNAL

(Lin)

: LINE IN SIGNAL

(REC)

: RECORDING SIGNAL

I 1/4

AF ASSY(1/4)

(MY : AWU7460)

(KU/CA : AWU7448)

I 4/4

A

(Lin)

(TX)

(CD-R)

10.216V

(REC)

10.977V

(CD)

11.739V

(REC)

(REC)

(1/2)

(REC)

(REC)

(REC)

(REC)(REC)

I 4/4

MY:Only

To CT-J7

B

MY:Only

(MAIN)

MY:Only

(MAIN)

-5.674V

(TX)

CN6002

J

J

CN3002

(MAIN)

(MAIN)

(MAIN)

C

(2/2)

(MAIN)

(MAIN) (MAIN)

J

(REC)(REC)

O

J5401

D

(TX)

(MAIN)

(MAIN)

CN3101

4.954V

11.742V

CN3001

J

L501

4.940V

VTL1094

4.913V

P

4.953V

8.775V

4.939V

H.P ASSY

(AWU7453)

5.948V

: The power supply is shown with the marked box.

1/4

I

5

6

7

P

8

39

1

XR-MR7

3.12 AF (2/4) and LEGATO ASSYS

A

B

23

5.948V

4.868V

(SM)

(SM)

(SM)(SM)

(SM)

(CM)

4

4.888V

(SM)

(CM)

(CM)

(TS)

(TS)

(FS)

(FS)

2.444V

(F)

(CM)

(CM)

(F)

5.681V

4.889V

1.629mV

0.087V

IC1101- Pin 16 :

2

TEST MODE,

Tracking Open (TRER)

H : 5msec/div

VC : IC1101- Pin22

2.44V

(CD)

To CD MECHA.

C

(L)

(S)

(C)

To CD MECHA.

5.948V

1.0Vp-p

VC

(CD)

(T)

(CD)

(F)

(T)

(T)

2

(T)

1

D

40

To P.U Assy

2/4

I

(F)

(T)

(T)

(F)

IC1101- Pin 13:

1

PLAY MODE (RF)

H : 500nsec/div

1.0Vp-p

VC

(F)

1234

5

678

XR-MR7

I 2/4

KU/CA:Only

(SM)

(CM)

(CM)

(TS)

(TS)

(FS)

(FS)

(F)

100p

2.120V

(PC)

4.870V

KU/CA:Only

MY:Only

4.885V

AF ASSY(2/4)

(MY : AWU7460)

(KU/CA : AWU7448)

4.885V

4.881V

MY:Only

W267

KU/CA:Only

W268

KU/CA:Only

(CD)

(CD)

I 4/4

4.936V

11.740V

(D)(D)

MY:Only

(CD)

–5.673V

A

I 1/4

B

(T)

(T)

(CD)

(CD)

LEGATO ASSY

V

MY:Only

4.887V

0.163V

MY:Only

4.633V

SIGNAL ROUTE

(CD)

: CD AUDIO SIGNAL ROUTE

(FS)

: FOCUS SERVO LOOP LINE

(TS)

: TRACKING SERVO LOOP LINE

(AWU7525)

0.164V

(SM)

(CM)

(LM)

4.847V

4.885V

(CD)

: SPINDLE MOTOR ROUTE

: CARRIAGE MOTOR ROUTE

: LOADING MOTOR ROUTE

(PC)

MY:Only

C

(CD)

(PC)

6.142V

(CD)

D

: The power supply is shown

with the marked box.

2/4

5

6

7

I

V

8

41

1

XR-MR7

3.13 AF ASSY (3/4)

23

4

I 3/4

A

6.247V

AF ASSY(3/4)

(MY : AWU7460)

(KU/CA : AWU7448)

6.247V

6.247V

11.735V

(CDR)(CDR)

(CDR)(CDR)

4.934V

R7406

KU/CA:220

R7407,R7408

KU/CA : 0

MY:100

KU/CA:PCM1716E

MY:PE8001A

KU/CA:STBY

MY:100

C7412

MY:100p

4.935V

4.760V

(CDR)(CDR)

17.25mV

B

3.365mV

I 1/4

4.932V

(REC) (REC)

4.688V

2.096V

(REC)

100p

4.908V

C

(REC)

2.09V

4.688V

2.096V

R7305

2.99V

VTL1096

MY:1.8k

KU/CA:560

D

42

3/4

I

1234

5

678

XR-MR7

SIGNAL ROUTE

(CDR)

: CD-R AUDIO SIGNAL

(REC)

: RECORDING SIGNAL

V+5D

4.951V

4.939V

R7492

KU/CA:330

MY : 1.8k

4.939V

R7451

KU/CA:560

MY : 0

17.40mV

4.585V

57.75mV

2.167V

VTL1096

L7454

2.002V

16.10mV

A

I 4/4

VTL1096

CN501

B

B

VTL1105

470

I 1/4

C

CN301

B

VTL1096

4.906V

4.949V

CN901

8.781V

B

D

I 1/4

3/4

I

5

6

7

8

43

1

23

XR-MR7

3.14 AF (4/4), FRONT LINE, CDR SW and CDR LED ASSYS

A

I 1/4

4.633V

5.525V

4.632V

4

B

4.952V

5.505V

FRONT LINE ASSY

O

(MY:AWU7450, KU/CA:AWU7438)

C

(L2)

L5409

L5404

VTL1096

220p

VTL1096

220p

C5413

L5407

1000p

VTL1096

(L2)

(L2)

(L2)

(REC)

I 1/4

CN3201

P

1000p

J5401

DB011ND0

D

44

4/4

I

1234

C5414

L5406

VTL1096

L5408

L5405

(REC)

VTL1096

O

VTL1096

220p220p

(REC)

SIGNAL ROUTE

(L2)

: LINE 2 SIGNAL

(REC)

: RECORDING SIGNAL

5

678

XR-MR7

AC:7.704V

I 4/4

4.632V

AF ASSY(4/4)

(MY : AWU7460)

(KU/CA : AWU7448)

4.707V

5.051V

5.524V

MY:Only

A

37.30V

CN5601

K

B

M

: The power supply is shown

with the marked box.

5

CDR SW ASSY

(AWU7517)

L

CN5953

6

CDR LED ASSY

N

(AWU7467)

7

CN5952

L

I

4/4

M

N

8

C

D

45

A

1

23

4

XR-MR7

3.15 AMP, REG, SECONDARY, PRIMARY, SUBTRANS and AC IN/OUT ASSYS

23.083V

100p

MY:Only

(MAIN)

100p

-23.035V

-39.32V

39.41V

39.44V

(MAIN)

-39.39V

B

C

AKP1121 (MY)

AKP1122 (KU/CA)

D

VNF1084

KU/CA

TYPE

Only

POWER

TRANSFORMER

(MY:AWU7469)

PRIMARY ASSY

(KU/CA:AWU7457)

T

FU 2

KU/CA : AEK1082 4A/125V

MY : AEK1057 T2.0AL250V

FU 2

CN1

MY :

TYPE

Only

AKP1034

AC IN/OUT

R

(KU/CA:AWU7458)

ASSY

(MY:AWU7470)

SECONDARY

S

ASSY

(AWU7451)

FU 1

ATT7064 (MY)

ATT7063 (KU/CA)

L 1

ATF–151

SUB TRANS

Q

ASSY

(MY:AWU7471)

(KU/CA:AWU7459)

4.899V

FU 1

MY : AEK1058 T2.5AL250V

KU/CA : AEK1083 5A/125V

6.69V

(MAIN)

36.97V

6.69V

21.68V

14.65V

CN21

I

CAUTION : FOR CONTINUED PROTECTION AGAINST

11.76V

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491004 FOR IC14, 4910007 FOR

IC15, IC18, IC19 MFD. BY LITTELFUSE INC.

(MAIN)

46

Q

1234

RJ

S

T

(MAIN)

5

678

XR-MR7

SIGNAL ROUTE

(MAIN)

: MAIN OUT SIGNAL

(TX)

: TUNER AUDIO SIGNAL

R6099

KU/CA:1.2k

MY : 0

–5.675V

A

J

AMP ASSY

(MY : AWU7464)

(KU/CA : AWU7555)

(MAIN)

(MAIN)

(MAIN)

CN6201 (MY TYPE)

AA

CN6201 (KU/CA TYPE)

AB

(TX)

(TX)

(MAIN)

4.944V

4.898V

(MAIN)

14.58V

4.96V

(MAIN)

14.58V

4.97V

(MAIN)

(TX) (TX)

(MAIN)

(MAIN)

12.32V

11.738V

4.94V

37.23V

37.29V

11.742V

4.954V

4.915V

4.954V

8.777V

I

CN6003

I

CN3102

B

C

14.63V

14.63V

4.95V

5.95V

14.56V

REGULATOR

U

ASSY

(AWU7468)

: The power supply is shown with the marked box.

• NOTE FOR FUSE REPLACEMENT

CAUTION -

5

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

6

4.95V

8.73V

(MAIN)

P

J3901

7

4.898V

4.94V

(MAIN)

5.948V

I

CN521

J U

8

D

47

1

XR-MR7

3.16 DISPLAY and SW JOG ASSYS

DISPLAY ASSY

A

B

K

(AWU7461)

23

36.6V

4

4.96V

C

CN5501

I

4.95V

D

48

K

1234

DISPLAY ASSY

S5901 : 1 0

S5902 : 2 0

S5903 : 3 0

S5904 : LINE1/PHONO

S5905 : LINE2

S5906 : 1

S5907 : 2

S5908 : 3

CD

CD SELECT

S5909 : CD-R

S5914 : FM/AM

S5915 : TAPE

S5916 : 1 (–)

S5917 : 7 (STOP)

S5918 : 6 (PLAY/PAUSE)

S5919 : ¡ (+)

S5920 : SFC (DEMO)

S5921 : DISPLAY

5

678

XR-MR7

A

SW JOG ASSY

L

(AWU7466)

B

POWER REC

REC/PLAY

ALL 1-TRACK RENTAL

C

SW & JOG ASSY

S5951 : TIMER/CLO.

S5952 : ENTER

S5953 : MENU

S5954 : FINALIZE

S5955 : ERASE

S5956 : P.BASS

S5957 : REC STOP

5

S5959 : RENTAL

S5960 : 1–TRACK

S5961 : ALL

S5962 : REC PLAY

S5963 : REC

S5964 : STANDBY/ON

S5965 : VOLUME JOG

6

CN5962

N

S5966 : MULTI JOG

S5969 : DIGTAL VOL

S5970 : ANALOG VOL

CN5954

M

K

7

L

8

49

D

1

23

XR-MR7

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

A

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGS

DGGSS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

4.1 FM/AM TUNER MODULE ( For MY Type )

FM/AM TUNER MODULE

B

AA

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

CN6001

J

4

SIDE A

C

Q6204 Q6203

FM/AM TUNER MODULE

AA

VR6201

SIDE B

D

50

AA

Q6101

Q6501

Q6102 - Q6105 Q6205

Q6214

Q6601

Q6202

IC6202

Q6201

IC6201

(ANP7160-B)

1234

1

234

XR-MR7

4.2 FM/AM TUNER MODULE (For KU/CA Type)

FM/AM TUNER MODULE

AB

Q6204

CN6001

J

A

B

VR6201

Q6203

FM/AM TUNER MODULE

AB

Q6306

Q6304

Q6401

SIDE A

Q6402

Q6303Q6302 Q6301

Q6214

Q6403

Q6404

Q6205

Q6202 Q6201

IC6202

C

(ANP7159-B)

IC6201

D

SIDE B

AB

1

2

3

4

51

1

23

4

XR-MR7

4.2 CD-R CORE ASSY SIDE A

A

CD-R CORE ASSY

B

• This PCB is a four-layered board.

E

CN551

D

CN501

C

CN601

I

CN7703

B

I

CN7702

To

C

CD-R

PICKUP

I

CN7701

(PNP1465-B)

VR164

VR161 VR141 VR162 VR163 VR101

IC361-IC364 IC303 IC302 IC305IC931-IC933

D

IC351 IC371 IC301 IC304 IC503Q301

Q302 Q303 Q402 Q401 IC401 IC501 IC507 IC506IC352

IC451 IC201 IC502 IC509Q203 Q203IC251-IC254

Q201 IC101 Q142 IC562 IC431

52

B

1234

1

234

XR-MR7

SIDE B

CD-R CORE ASSY

B

• This PCB is a four-layered board.

A

B

Q551 Q202 IC255

IC505 IC508 IC181

Q102 IC561 IC141 IC161

Q103 Q141

1

2

C

(PNP1465-B)

D

B

3

4

53

1

XR-MR7

4.3 SERVO MECHA, LOADING A and LOADING B ASSYS

A

23

4

CARRIAGE

MOTOR

M

B

SPINDLE

MOTOR

SERVO

C

MECHANISM

ASSY

M

CN452

B

D

LOADING A

ASSY

SERVO

C

MECHANISM

ASSY

LOADING A

D

ASSY

C

CN451

B

LOADING B

LOADING B

E

ASSY

SIDE A SIDE B

D

54

C

D

1234

E

LOADING

MOTOR

M

B

CN453

(PNP1447-C)

E

ASSY

1

4.4 SELECT UNIT, LOADING UNIT and MOTOR UNIT

234

XR-MR7

SELECT

F

UNIT

A

B

MOTOR

H

UNIT

M

CN1302

I

M

LOADING

G

UNIT

(ANP7314-B)

C

(ANP7314-B)

(ANP7314-B)

SIDE A

D

1

2

3

F

G

H

4

55

XR-MR7

M

4.5 AF ASSY

A

B

1

AF ASSY

I

23

CN3002

J

B

CN901

CN3001

J

4

CD MECHA

CD

J13

Q

CN1902

V

C

D

56

I

1234

1

234

XR-MR7

CD MECHA

HA

CN6002

J

CD MECHA

CN5601

K

Q1342

Q1346

Q1341 Q1345

Q1101

IC21

Q21

Q22

SIDE A

A

B

B

1

CN501

B

CN301

C

CN5403

O

D

(ANP7320-D)

57

I

2

3

4

A

B

1

XR-MR7

AF ASSY

I

23

4

C

D

58

I

1234

1

234

XR-MR7

SIDE B

A

Q5752 Q5751 Q3125

Q1343 Q1346

Q1342

IC5751

Q1344 Q1341

Q1345

Q5501 Q1406

Q5505

IC1301

Q1405

IC1101

Q22 Q21

B

IC5501

Q5502

IC1201

Q1403

Q1402

Q1402

IC3131

Q1203

Q5503

Q1401

Q3143

Q7304

IC7502

IC7401

IC3031

IC7301

IC7501

Q4602

Q1404

Q1901

Q3142

Q5504

Q3141

Q3144

Q7510Q7509 Q1911Q1201

IC3101

IC3031

Q3122

IC3151

Q3121

Q4601

C

Q7231

Q7502 Q7232

IC7231

Q7236 Q7237

IC3081

D

(ANP7320-D)

59

I

1

2

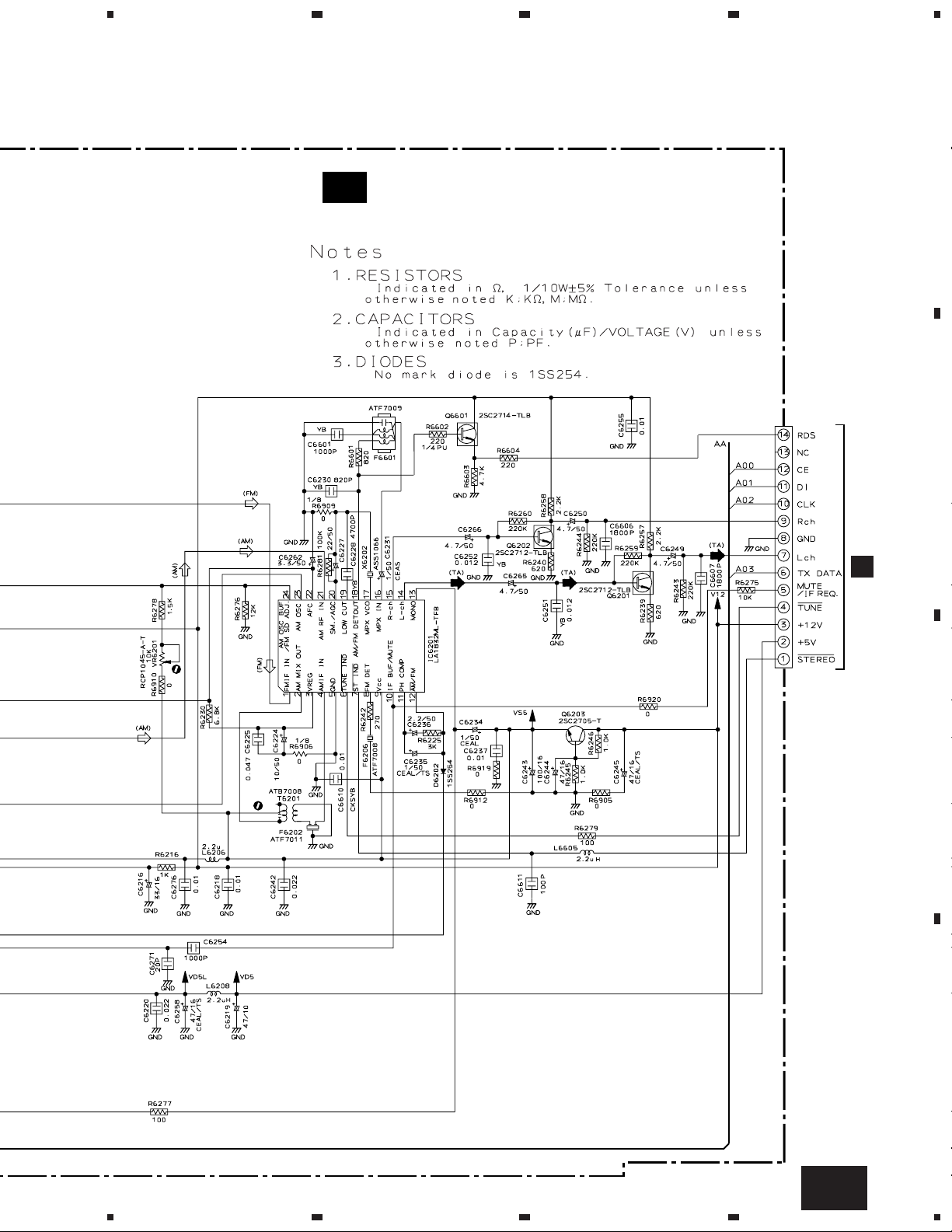

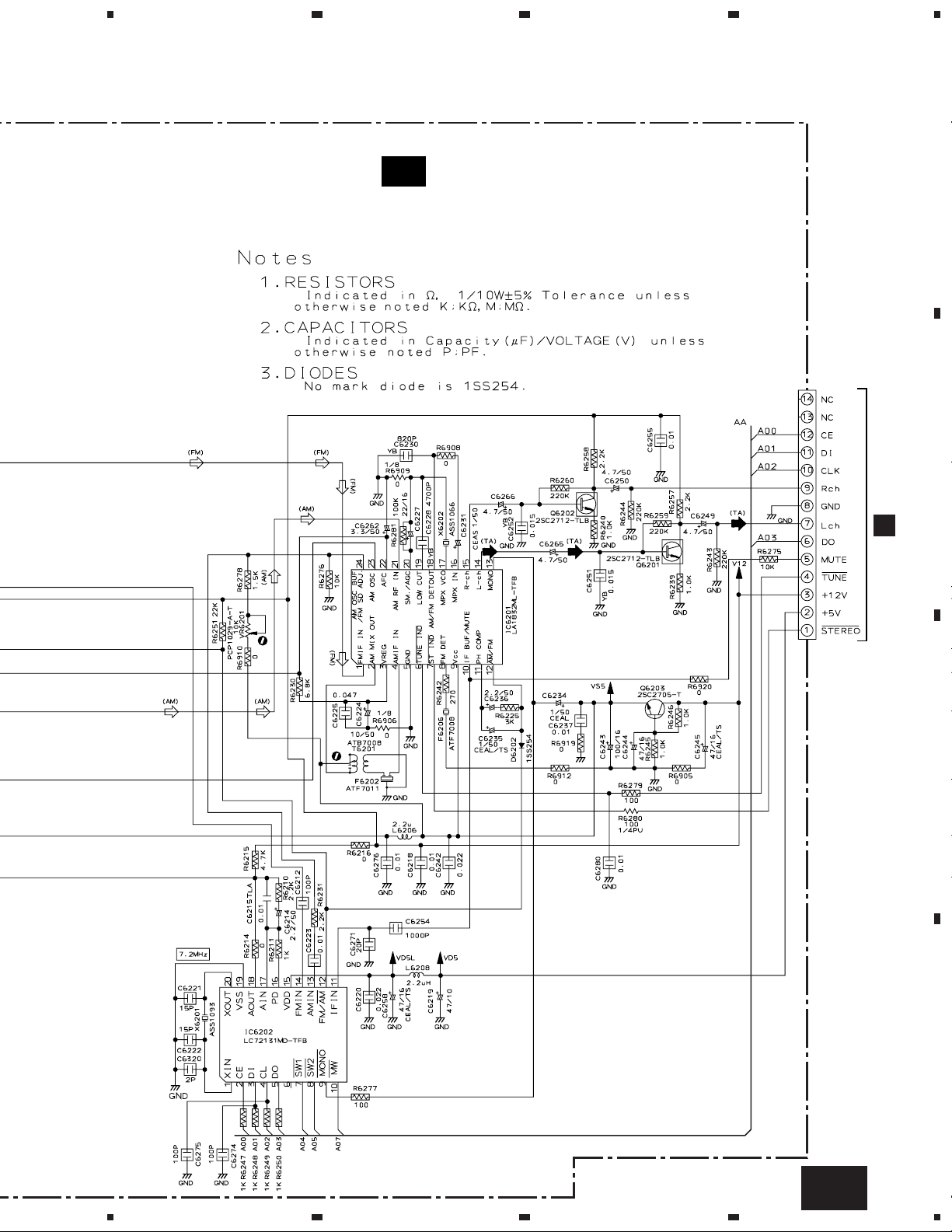

3

4

1

23

XR-MR7

4.6 AMP, H.P and REGULATOR ASSYS

4

A

J

AMP ASSY

B

CN6201 (MY)

AA

CN6201 (KU/CA)

AB

C

IC3301

Q301

Q302

60

IC5003

J

1234

D

S

J11

I

IC12

IC301

CN521

IC5001 Q5001

CN3102

I

IC15

I

(ANP7321-D)

CN6003

1

234

XR-MR7

SIDE A

H.P ASSY

P

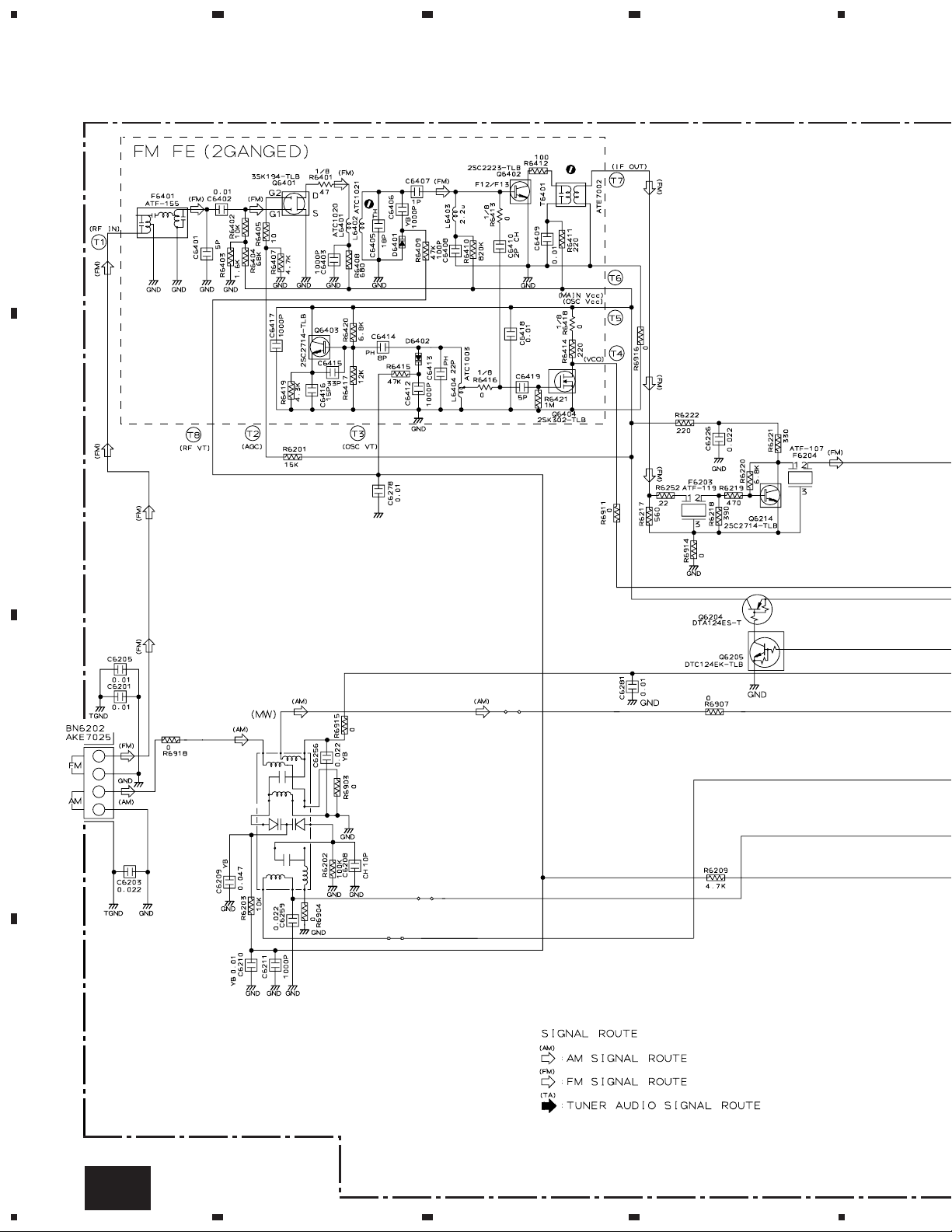

REGULATOR ASSY

U

IC503 IC502 IC501 IC504 IC505 Q502 Q501

O

J5401

To GND Chassis

(ANP7320-D)

A

B

C

(ANP7320-D)

D

P

1

2

3

U

4

61

1

REGULATOR ASSY

U

H.P ASSY

P

(ANP7320-D)

(ANP7320-D)

XR-MR7

23

4

A

B

SIDE B

C

D

62

P

U

1234

J

AMP ASSY

1

234

XR-MR7

SIDE B

A

B

C

(ANP7321-D)

Q5001

Q3612

1

Q322

IC5001

2

Q320

Q324 Q323

Q3611

Q3608

Q3605 Q3606 Q3607

3

Q3610

Q3609

Q3303

Q3302

Q3301

Q303

Q304

IC3301 Q301

Q302

IC5003

J

4

D

63

1

23

XR-MR7

4.7 AC IN/OUT, SUBTRANS, PRIMARY and SECONDARY ASSYS

AC IN/OUT

R

A

B

ASSY

AC IN AC OUT

SUBTRANS

Q

ASSY

4

SIDE A

I

CN21

(ANP7321-D)

PRIMARY

T

(ANP7321-D)

ASSY

C

(ANP7321-D)

POWER TRANSFORMER

SECONDARY

S

ASSY

D

64

Q

R

1234

S

T

IC19

IC18

J

IC14

CN11

(ANP7320-D)

1

234

XR-MR7

SIDE B

SUBTRANS

Q

ASSY

PRIMARY

T

ASSY

(ANP7321-D)

AC IN/OUT

R

ASSY

A

B

(ANP7321-D)

SECONDARY

S

ASSY

1

C

(ANP7321-D)

(ANP7320-D)

Q

2

3

R

S

T

4

65

D

1

23

4

XR-MR7

4.8 DISPLAY ASSY SIDE A

A

DISPLAY

K

CN5951

L

ASSY

B

Q5601

CN5501

I

C

D

(ANP7321-D)

66

K

1234

1

234

XR-MR7

SIDE B

DISPLAY

K

ASSY

A

Q5603

IC5602

B

IC5601

Q5602

IC5801

(ANP7321-D)

C

D

K

67

1

2

3

4

1

23

4

XR-MR7

4.9 SW JOG, CDR SW and CDR LED ASSYS SIDE A

A

SW JOG ASSY

L

CDR LED ASSY

N

(ANP7320-D)

B

CDR SW ASSY

M

(ANP7320-D)

C

D

68

(ANP7321-D)

L

M N

1234

CN5901

K

1

234

XR-MR7

SIDE B

SW JOG ASSY

L

CDR LED ASSY

N

CDR SW ASSY

M

A

(ANP7320-D)

B

Q5951

Q5952

(ANP7321-D)

(ANP7320-D)

C

D

1

2

3

L

M N

4

69

1

23

XR-MR7

4.10 FRONT LINE and LEGATO ASSYS

4

FRONT LINE ASSY

A

B

O

I

CN3201

(ANP7320-D)

FRONT LINE ASSY

O

Q3123

Q3124

LEGATO ASSY : MY Only

V

C

I

CN1901

D

(ANP7320-D)

LEGATO ASSY : MY Only

V

IC1902

IC1901

70

SIDE A

O

V

1234

SIDE B

Mark No. Description Part No.Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

7 LIST OF WHOLE PCB ASSEMBLIES

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 .....................................................................................RN2H R 5 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

1 Ω→1R0 .....................................................................................RS1P

1 R 0

XR-MR7

K

Mark

FM/AM TUNER MODULE AXQ7068 AXQ7065

CD-R CORE ASSY RYY1273 RYY1273

NSP MECHANISM ASSY PWX1570 PWX1570

NSP SERVO MECHANISM ASSY PWZ3759 PWZ3759

NSP LOADING A ASSY PWZ3760 PWZ3760

NSP LOADING B ASSY PWZ3761 PWZ3761

NSP 3CD UNIT AWM7473 AWM7473

MOTOR UNIT AWU7431 AWU7431

LOADING UNIT AWU7432 AWU7432

NSP SELECT UNIT AWU7433 AWU7433

NSP MAIN ASSY AWM7479 AWM7477

AF ASSY AWU7460 AWU7448

FRONT LINE ASSY AWU7450 AWU7438

H.P ASSY AWU7453 AWU7453

SECONDARY ASSY AWU7451 AWU7451

NSP CDR LED ASSY AWU7467 AWU7467

CDR SW ASSY AWU7517 AWU7517

LEGATO ASSY AWU7525 Not used

NSP COMPLEX ASSY AWM7480 AWM7478

AMP ASSY AWU7464 AWU7555

REG ASSY AWU7468 AWU7468

PRIMARY ASSY AWU7469 AWU7457

SUB TRANS ASSY AWU7471 AWU7459

AC IN/OUT ASSY AWU7470 AWU7458

DISPLAY ASSY AWU7461 AWU7461

SW JOG ASSY AWU7466 AWU7466

MY Type KU/CA Type

Part No.

RemarksSymbol and Description

71

XR-MR7

Mark No. Description Part No.Mark No. Description Part No.

7 CONTRAST OF PCB ASSEMBLIES

AF ASSY

I

AWU7460 and AWU7448 are constructed the same except for the following :

Mark Symbol and Description

IC5751

IC7401

Q1201,Q1911

Q1403,Q1404

Q1901

AWU7460 AWU7448

BU1923F

PE8001A

2SC2412K

Not used

DTA124EK

Part No.

Remarks

Not used

PCM1716E

Not used

DTA124EK

Not used

Q4601

Q5751

Q5752

L5751

C22

C1107

C1201,C1202

C1204

C2551- C2553,C7412

C3015

C3101- C3104

C3126,C3127

C3335- C3340

C3345- C3346

C4601

C5751, C5752

C5753,C5755

C5754

C5756

C5757

C5758

D5506

R1201

R1202

R1205

R1286,R1287

R1420,R1951,R3991,R5754,R5755

R1931

R2551- R2553

R2554

2SA1037K(RS)

2SA1037K

DTC143EK

LAU1R0J

CEAT470M25

CKSQYB103K50

Not used

CCSQCH101J50

CCSQCH101J50

CKSQYB473K25

CCSQCH331J50

CEAT2R2M50

CKSQYB104K25

ACG7041

CKSQYB104K25

CCSQCH270J50

CKSQYB103K50

CEAT330M16

CKSQYB561K50

CCSQCH271J50

CEAT100M50

1SS133

Not used

Not used

RS1/10S103J

Not used

RS1/10S0R0

RS1/10S103J

RS1/10S221J

RS1/10S472J

2SA1037K(QR)

Not used

Not used

Not used

CEAT470M35

CKSQYB104K25

CCSQCH150J50

Not uaed

Not used

CKSQYB104K25

CCSQCH221J50

CEAT100M50

Not used

Not used

CKSQYB103K50

Not used

Not used

Not used

Not used

Not uesd

Not used

Not used

RS1/10S331J

RS1/10S105J

Not used

RS1/10S221J

Not used

Not used

Not used

Not used

72

R3335- R3338

R5751

R5752

R5753

R5960

R5961

R7305

R7406- R7408

R7451

R7492

CN1901

CN2551

X1201 Crystal Resonator (16.9344MHz)

X5751 Crystal Resonator (4.332MHz)

RD1/10S100J

RS1/10S223J

RD1/10S222J

RS1/10S101J

RS1/10S473J

Not used

RS1/10S182J

RS1/10S101J

RS1/10S0R0J

RS1/10S182J

AKM7049

AKP7042

Not used

ASS7004

Not used

Not used

Not used

Not used

Not used

RS1/10S473J

RS1/10S561J

RS1/10S0R0J

RS1/10S561J

RS1/10S331J

Not used

Not used

PSS1008

Not used

Mark No. Description Part No.Mark No. Description Part No.

AC IN/OUT ASSY

R

AWU7470 and AWU7458 are constructed the same except for the following :

Mark Symbol and Description

CN 01

CN02

SUB TRANS ASSY

Q

AWU7471 and AWU7459 are constructed the same except for the following :

Mark Symbol and Description

KN01

R01

T02

AWU7470 AWU7458

AKP1121

AKP1034

AW7471 AWU7459

Not used

Not used

ATT7064

Part No.

Part No.

XR-MR7

Remarks

AKP1122

Not used

Remarks

VNF1084

RCN1080

ATT7063

AMP ASSY

J

AWU7464 and AWU7555 are constructed the same except for the following :

Mark Symbol and Description

Q304

Q320

C3305

C3317

R6099

FRONT LINE ASSY

O

AWU7450 and AWU74638are constructed the same except for the following :

Mark Symbol and Description

CN5403 52045-0945 HLEM9S-1

PRIMARY ASSY

T

AWU7464 AWU7555

2SA1037K (RS)

2SA1037K (RS)

CCSQCH101J50

CCSQCH101J50

RS1/10S0RJ

AWU7450 AWU7438

Part No.

2SA1037K(QR)

2SA1037K (QR)

Not used

Not used

RS1/10S1R2J

Part No.

Although AWU7469 and AWU7457 are different in part number, they consist of the same components.

Remarks

Remarks

73

XR-MR7

Mark No. Description Part No.Mark No. Description Part No.

PCB PARTS LIST FOR XR-MR7/MY UNLESS OTHERWISE NOTED

FM/AM TUNER MODULE (AXQ7068)

AA

SEMICONDUCTORS

IC6201 LA1832ML

IC6202 LC72131MD

Q6102 2SC2223

Q6203 2SC2705

Q6201,Q6202 2SC2712

Q6103,Q6214,Q6601 2SC2714

Q6104,Q6105 2SK302

Q6101 3SK194

Q6204 DTA124ES

Q6205 DTC124EK

D6202 1SS254

D6101-D6104 1SV228

C6244 CEAS470M16

C6249,C6250,C6265,C6266 CEAS4R7M50

C6258 CEJA470M16

C6215 CFTLA103J50

C6214 CFTLA224J50

C6115,C6125,C6126,C6211,C6254CKSQYB102K50

C6601 CKSQYB102K50

C6102,C6114,C6121,C6123,C6124CKSQYB103K50

C6210,C6213,C6237,C6267,C6276CKSQYB103K50

C6279,C6281,C6604 CKSQYB103K50

C6251,C6252 CKSQYB123K50

C6606,C6607 CKSQYB182K50

C6203,C6259 CKSQYB223K50

C6228 CKSQYB472K50

C6209 CKSQYB473K50

COILS AND FILTERS

L6106 FM COIL ATC1003

L6105 FM RF COIL ATC1015

L6101 FM ANTENNA COIL ATC1016

L6102 FM ANTENNA COIL ATC1017

L6103 FM RF DRIVE COIL ATC1018

L6104 FM RF TUNING COIL ATC1019

F6203 FM CERAMIC FILTER ATF-119

F6206 FM CERAMIC DISCLI. ATF7008

F6601 ANTI BIRDY FILTER ATF7009

F6204 FM CERAMIC FILTER ATF7010

F6202 AM CERAMIC FILTER ATF7011

L6107 CHIP COIL ATH1043

L6603 LAU220J

L6206,L6208,L6605 LAU2R2J

TRANSFORMERS

T6201 ATB7008

T6101 ATE7002

CAPACITORS

C6113,C6212,C6274,C6275,C6611CCSQCH101J50

C6116,C6208,C6221 CCSQCH150J50

C6222 CCSQCH180J50

C6271 CCSQCH200J50

C6117 CCSQCH330J50

C6608 CCSQCH680J50

C6118 CCSQCH8R0D50

C6111,C6122 CCSQCK1R0C50

C6112,C6127 CCSQCK2R0C50

C6105 CCSQSL471J50

C6101 CCSQTH110J50