Pioneer XR-A880 Service Manual

• XR-A880

STEREO CD CASSETTE DECK RECEIVER

XR-A880

XR-A770

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KUCXJ AC120V

YPWXJ AC240V

XR-A880 XR-A770

Model

Power Requirement Remarks

ORDER NO.

RRV2065

CONTENTS

1. SAFETY INFORMATION ...................................... 2

2. EXPLODED VIEWS AND PARTS LIST................ 4

3. SCHEMATIC DIAGRAM ..................................... 16

4. PCB CONNECTION DIAGRAM.......................... 34

5. PCB PARTS LIST ............................................... 49

6. ADJUSTMENT .................................................... 57

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER ELECTRONIC CORPORATION 1998

7. GENERAL INFORMATION ............................... 63

7.1 PARTS ......................................................... 63

7.1.1 IC ......................................................... 63

7.1.2 DISPLAY.............................................. 69

7.2 DISASSEMBLY ........................................... 71

7.3 BLOCK DIAGRAM....................................... 74

8. PANEL FACILITIES AND SPECIFICATIONS.... 76

T – ZZK DEC. 1998 Printed in Japan

XR-A880, XR-A770

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty . If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

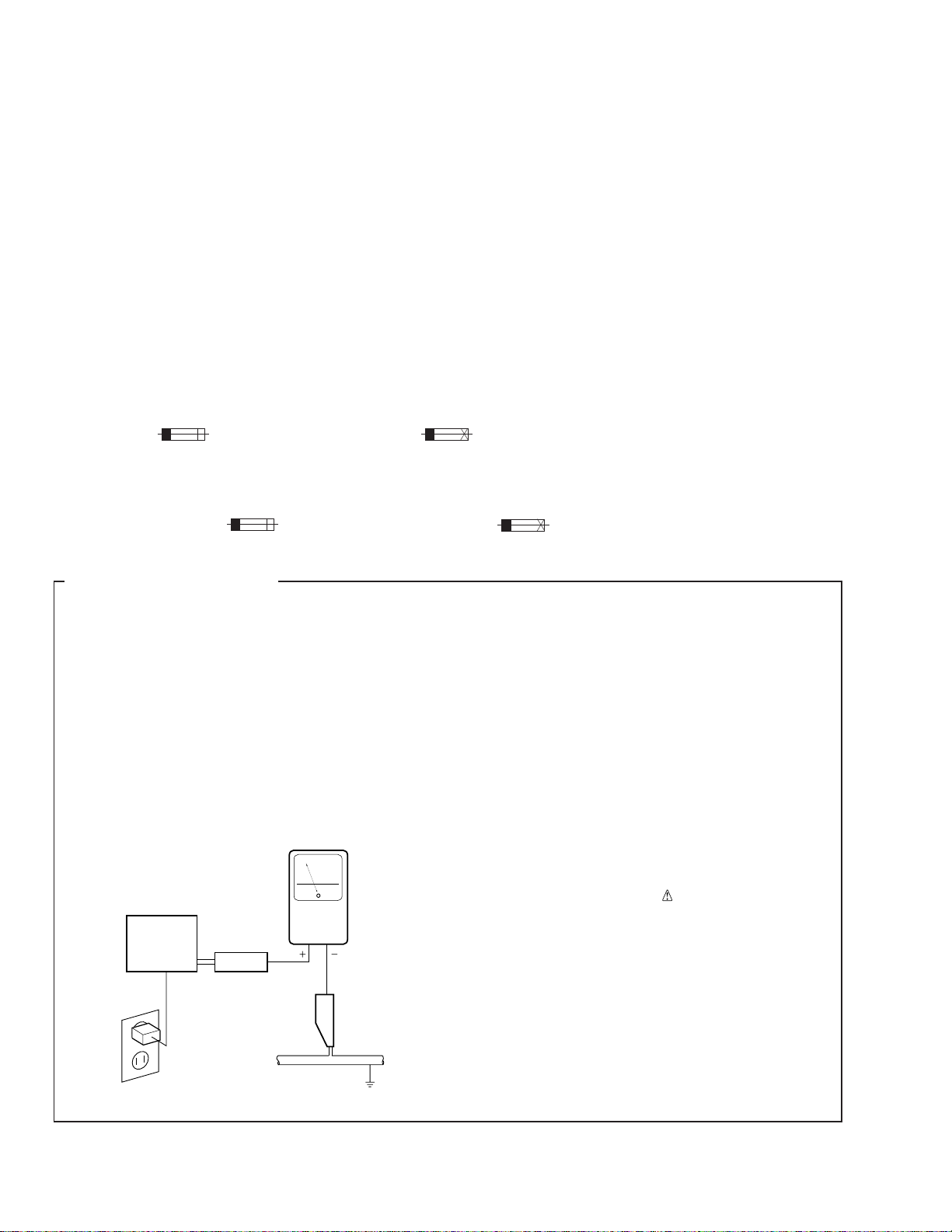

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

Leakage

current

tester

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

2

LABEL CHECK (for YPWXJ type)

XR-A880, XR-A770

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 1.3 mW

WAVELENGTH: 790 nm ± 25 nm

IMPORTANT

Printed on the Rear Panel

Additional Laser Caution

1.Laser Interlock Mechanism

The position of the switch (S8501) for detecting loading

state is detected by the system microprocessor, and

the design prevents laser diode oscillation when the

switch (S8501) is pressed physically.

Thus, the interlock will no longer function if the switch (S8501)

is released physically and deliberatery.

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 62 of

LA9240ML (IC8101) on the CD ASSY mounted on the

$M Loading Mechanism assembly is connected to GND,

or else the terminals of Q8101 are shorted to each other

(fault condition).

2.When the cover is opened, close viewing of the

objective lens with the naked eye will cause exposure

to a Class 1 laser beam.

∗

: Refer to page 62.

3

XR-A880, XR-A770

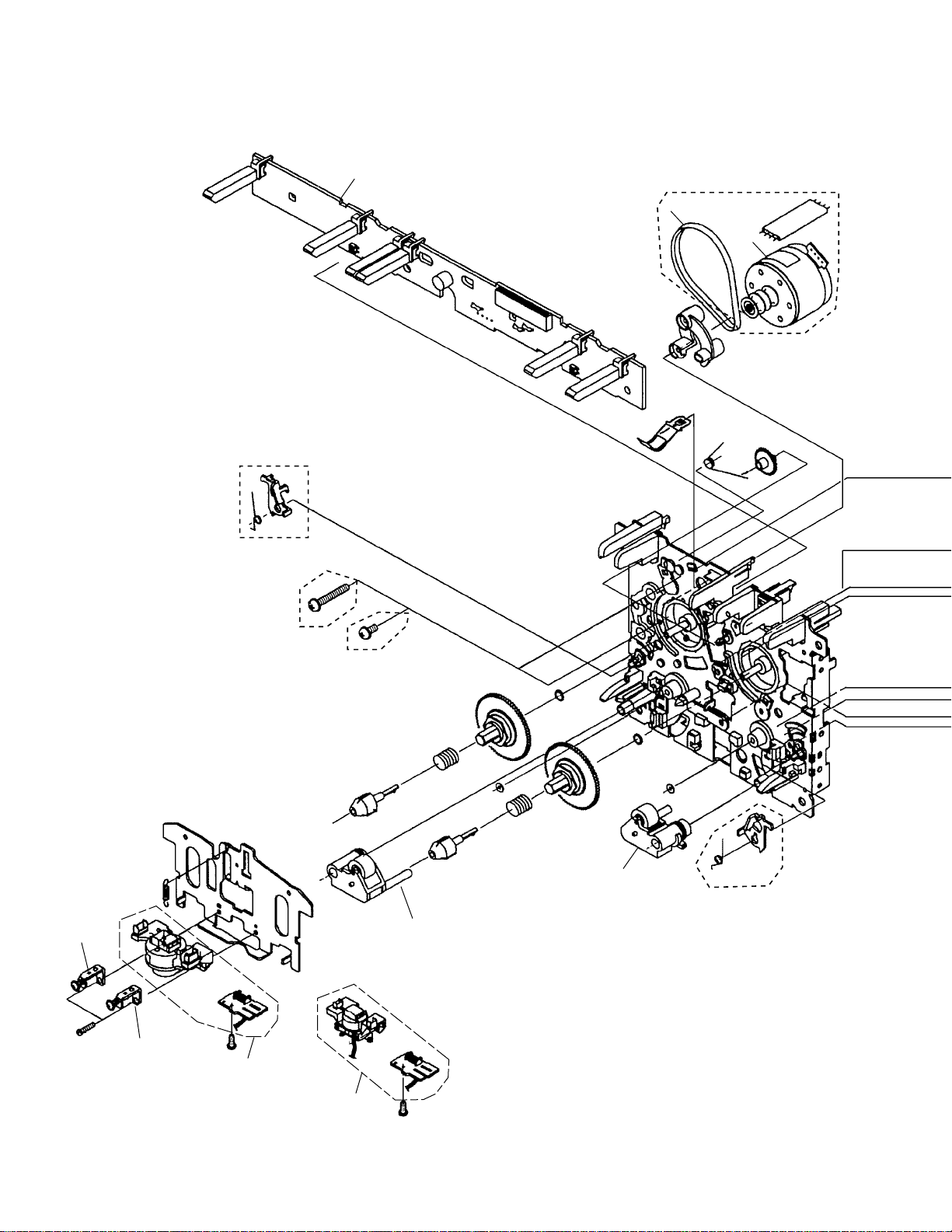

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" and can not be supplied.

•

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

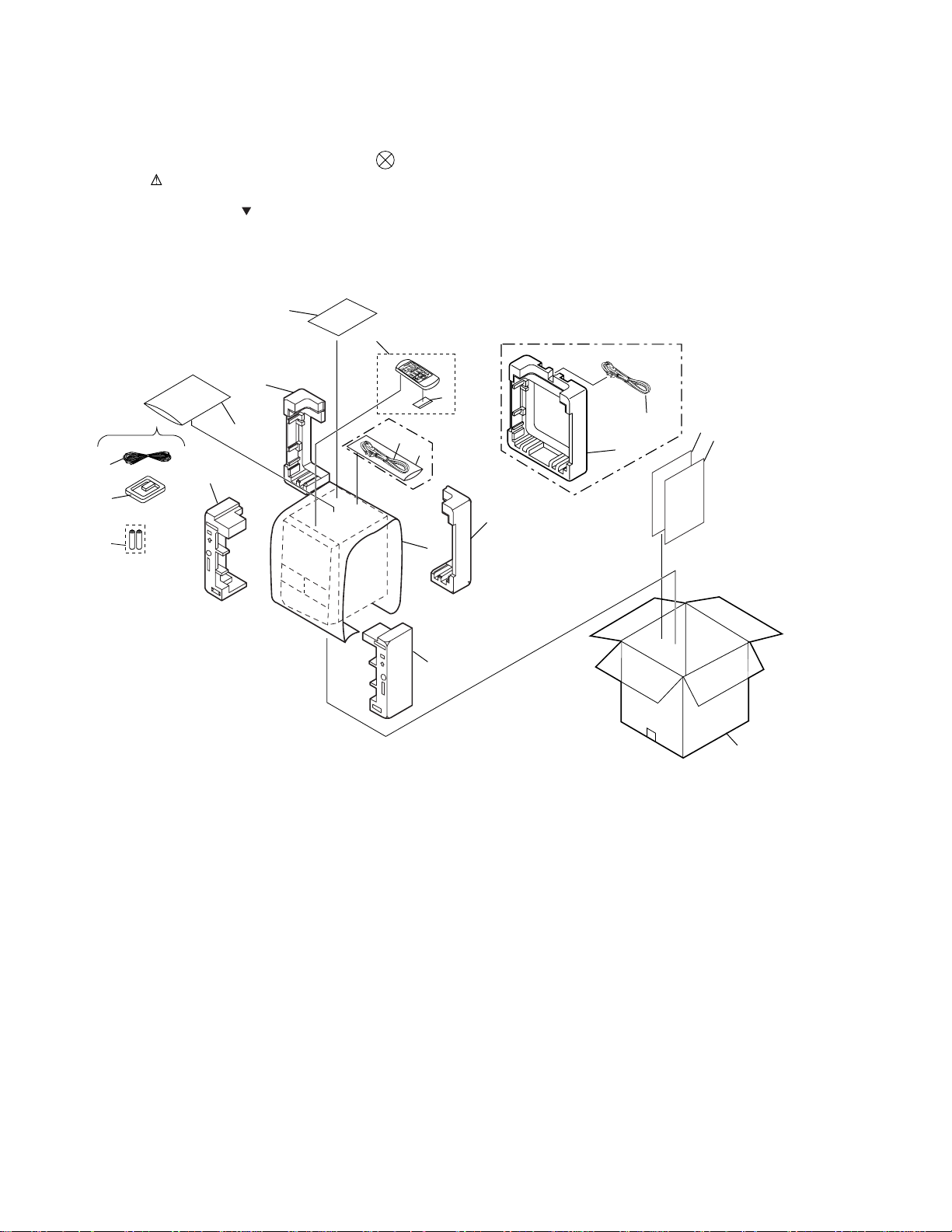

2.1 PACKING

1

3

6

8(1/2)

KUCXJ

Type Only

9(1/2)

7

12

4

VOL

K

A

R

A

O

K

E

S

DISC DISC DISC

F

S

C

L

E

E

P

P

.B

POWER

CLEAR

A

S

S

D

IS

P

PGM

LA

Y

A

U

X

R

E

P

E

A

T

R

A

N

D

O

M

ST

ATIO

REMOTE CONTROL UNIT CU-XR025

N

MONOBAND

YPWXJ Type Only

5

13

14

KUCXJ

13

9

2

15

Type Only

9(2/2)

KUCXJ

11

Type Only

8(2/2)

10

4

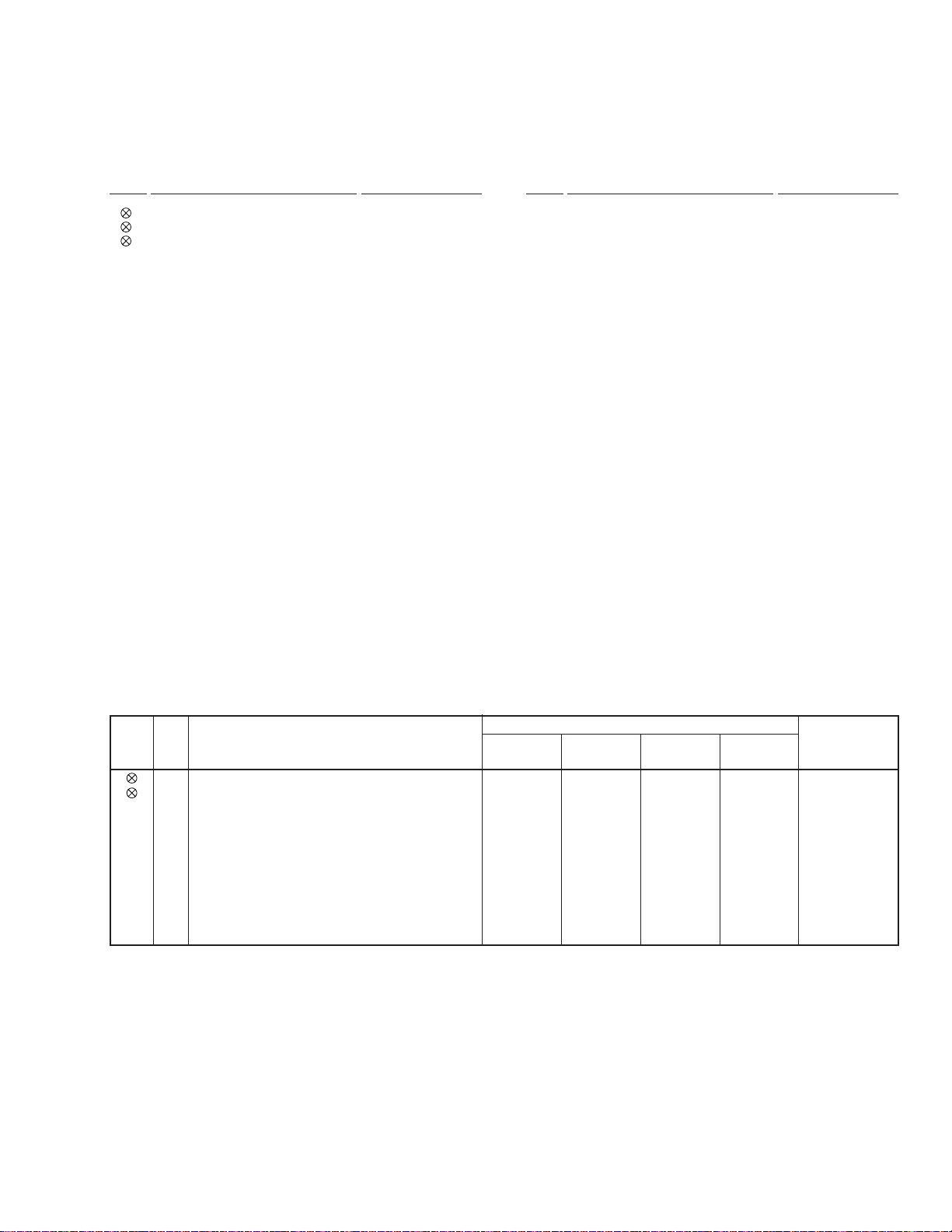

(1) PACKING PARTS LIST

Mark No. Description Part No.

XR-A880, XR-A770

Mark No. Description Part No.

1 FM Antenna ADH7004

2 Operating Instructions XRE3012

(English/French)

3 AM Loop Antenna XTB3001

4 Remote Control Unit See Contrast table (2)

5 Battery Cover AZA7204

NSP 6 Dry Cell Battery (R6P, AA) VEM-013

7 Polyethylene Bag Z21-038

(0.03 × 230 × 340)

8 Front Pad See Contrast table (2)

9 Rear Pad See Contrast table (2)

10 Packing Case See Contrast table (2)

NSP 12 Warranty Card See Contrast table (2)

13 Power Cord See Contrast table (2)

NSP 14 Polyethylene Bag See Contrast table (2)

11 Packing Sheet AHG7049

15 Operating Instructions See Contrast table (2)

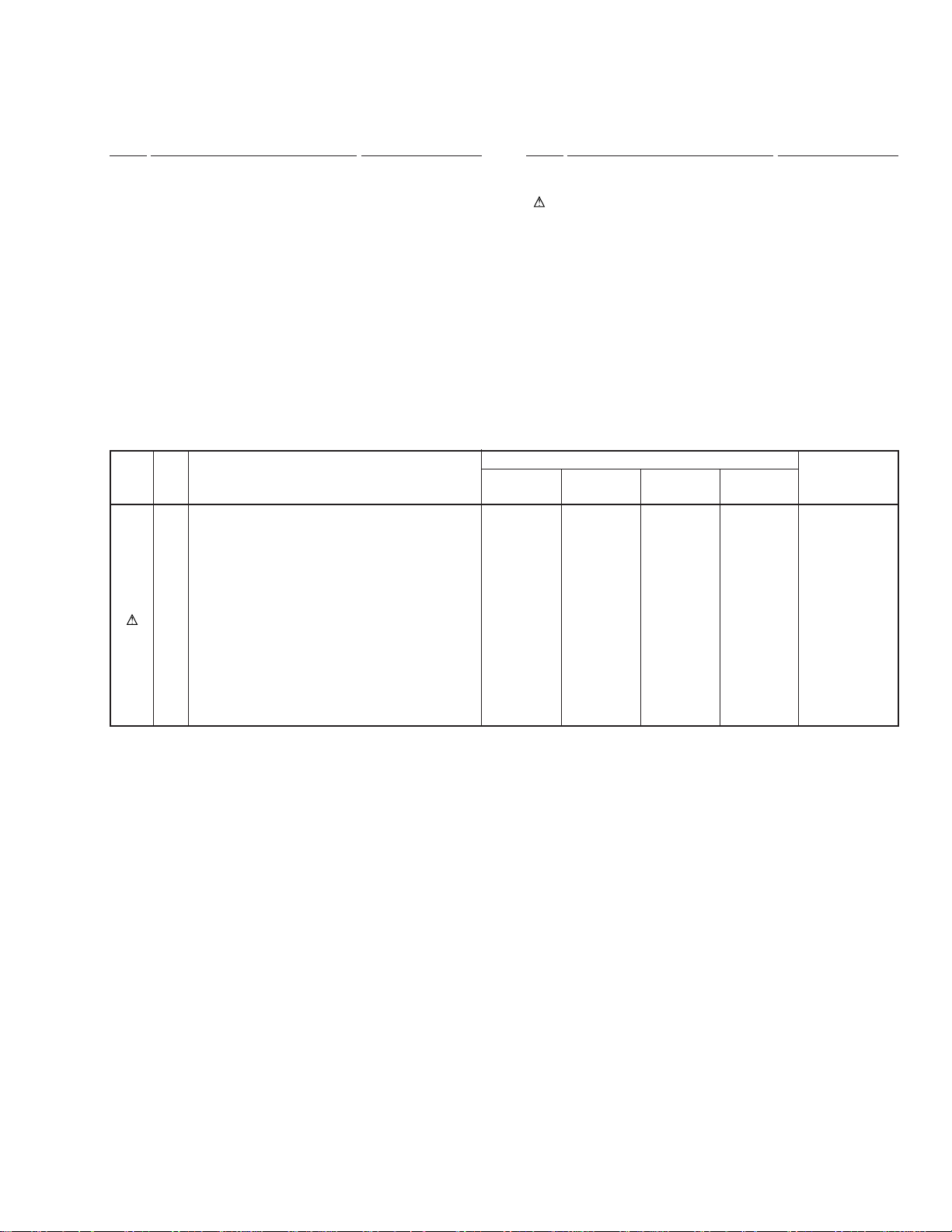

(2) CONTRAST TABLE

XR-A880/KUCXJ, YPWXJ, XR-A770/KUCXJ and YPWXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

XR-A880 XR-A880 XR-A770 XR-A770

/KUCXJ /YPWXJ /KUCXJ /YPWXJ

4 Remote Control Unit (CU-XR050) XZN3008 XZN3008 Not used Not used

4 Remote Control Unit (CU-XR049) Not used Not used XZN3007 XZN3007

8 Front Pad XHA3005 XHA3009 XHA3005 XHA3009

9 Rear Pad XHA3006 XHA3010 XHA3006 XHA3010

10 Packing Case XHD3072 XHD3052 XHD3049 XHD3048

NSP 12 Warranty Card ARY7023 ARY7027 ARY7023 ARY7027

13 Power Cord ADG7022 ADG1160 ADG7022 ADG1160

NSP 14 Polyethylene Bag AHG7033 Not used AHG7033 Not used

15 Operating Instructions (English/French/German/ Not used Not used XRE3016 XRE3016

Italian/Dutch/Swedish/Spanish/Portuguese/Chinese)

Remarks

15 Operating Instructions (English/French/Spanish/ XRE3018 XRE3018 Not used Not used

Portuguese/Chinese)

5

XR-A880, XR-A770

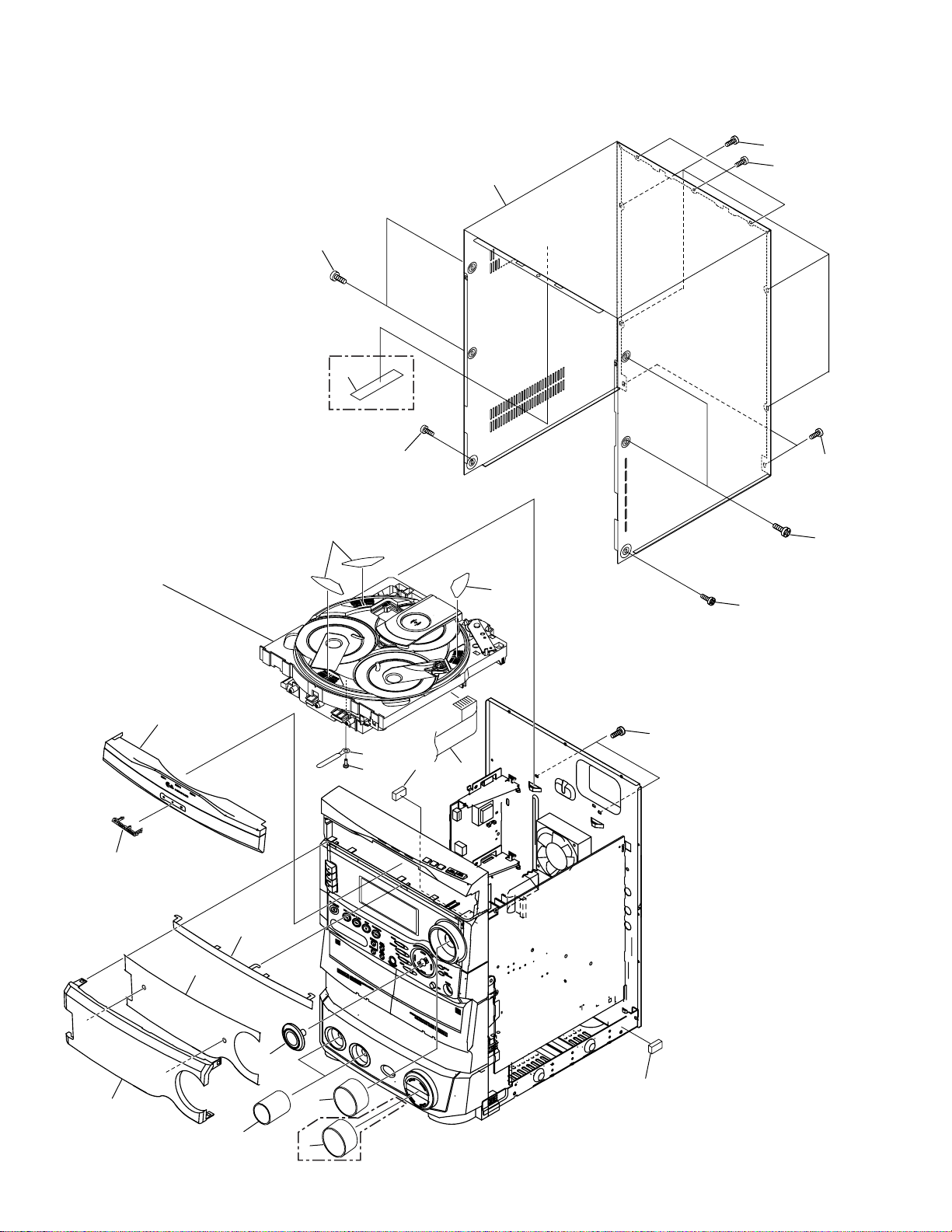

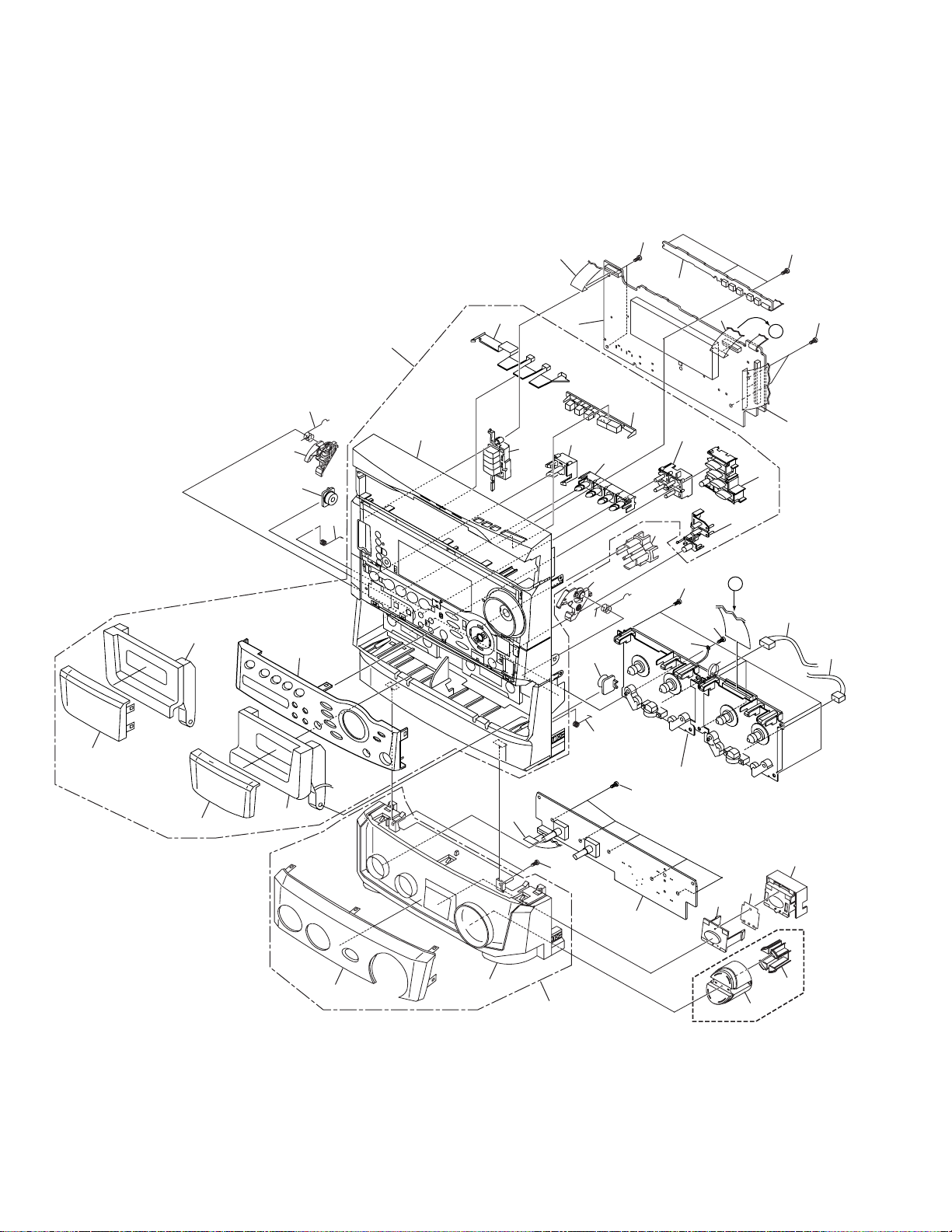

2.2 EXTERIOR (1/2)

9

19

KUCXJ Type only

15

8

15

Note :

Hook Tray cap on top of loading tray and then

insert the bottom three hooks.

Note :

Attatch on the same numbers × three.

Refer to

"2.5 $M MECHANISM CD".

2

6

10

12

16

17

11

18

11

9

12

11

9

1

4

5

13

7

14

3

3

XR-A770 Only

18

6

(1) EXTERIOR (1/2) PARTS LIST

Mark No. Description Part No.

XR-A880, XR-A770

NSP 2 $M Mechanism CD XXA3006

NSP 16 Cord Stopper DNF1128

1 22P F.F.C/30V XDD3018

3 Volume Knob XAA3005

4 FL Cover A XAK3026

5 FL Cover B XAK3036

6 Tray Cap XZN3047

7 Display Panel See Contrast table (2)

8 Bonnet Case XZN3040

9 Screw BPZ30P100FZK

10 Pioneer Badge XZN3049

11 Screw VBT30P080FZK

12 Disc Label XAX3127

13 Jog Knob Assy XXG3023

14 Bass Knob XAB3005

15 Screw BCZ30P080FZK

17 Push Rivet AEC7138

18 Cushion Rubber XEB3002

19 65 Label See Contrast table (2)

(2) CONTRAST TABLE

XR-A880/KUCXJ, YPWXJ, XR-A770/KUCXJ and YPWXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

7 Display Panel XAK3065 XAK3029 XAK3060 XAK3028

19 65 Label ORW1069 Not used ORW1069 Not used

XR-A880 XR-A880 XR-A770 XR-A770

/KUCXJ /YPWXJ /KUCXJ /YPWXJ

Remarks

7

XR-A880, XR-A770

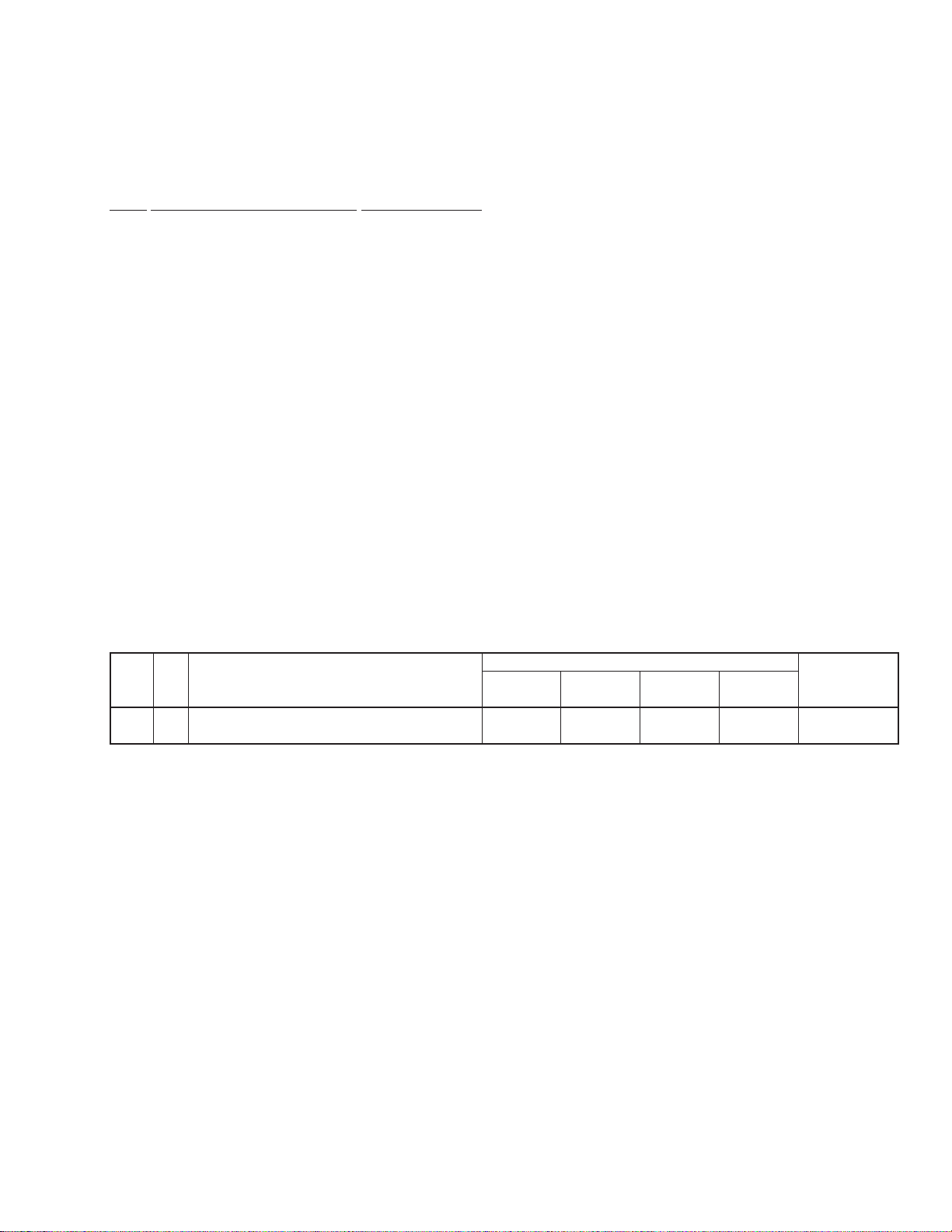

2.3 EXTERIOR (2/2)

13

19

27

27

32

35

16

31

37

XR-A880

ONLY

18

1

20

19

36

19

d

c

b

b

b

c

a

b

b

c

a

a

b

a

a

b

c

a

a

38

28

aa

41

42

a

b

c

A

d

40

30

34

b

33

28

19

3

2

21

19

15

19

24

11

19

YPWXJ

Type only

25

24

24

24

24

24

19

24

24

XR-A770

only

XR-A880

only

29

7

11

9

5

22

39

10

19

17

22

4

14

26

19

8

A

Refer to

"2.4 FRONT PANEL SECTION".

8

(1) EXTERIOR (2/2) PARTS LIST

XR-A880, XR-A770

Mark No. Description Part No.

1 AF Assy See Contrast table (2)

2 SECONDARY Assy XWZ3137

3 PRIMARY Assy See Contrast table (2)

4 FM/AM TUNER MODULE AXQ7065

5 Power Transformer (T1) See Contrast table (2)

6 • • • • •

7 Fuse (FU1) See Contrast table (2)

NSP 8 Chassis XNA3001

9 DC Fan Motor AXM7003

10 Fan Plate ANG7153

11 PCB Bracket XNG3006

12 • • • • •

13 Heat Sink XNH3004

14 Wire Clip A XEC3003

15 Rear Panel See Contrast table (2)

16 Cord Stopper DNF1128

NSP 17 SUPPORT Assy XNP3009

18 Screw BBZ30P140FMC

19 Screw VBZ30P080FZK

NSP 20 Tweeter Cover See Contrast table (2)

Mark No. Description Part No.

21 Screw ASZ40P060FMC

22 Binder ZCA-SKB90BK

23 • • • • •

24 Screw BPZ30P100FZK

25 Screw BBZ30P300FMC

26 Caution Label See Contrast table (2)

27 Screw BBZ30P060FMC

28 Screw IBZ30P135FMC

29 SUB TRANS Assy See Contrast table (2)

30 REAR AMP Assy See Contrast table (2)

31 TRADE Assy See Contrast table (2)

32 PRO LOGIC Assy See Contrast table (2)

33 H.S.Bracket XNG3007

34 FET Bracket XNG3009

35 H.S.Support XNG3014

36 Wire Clip B XEC3004

37 PCB Spacer B See Contrast table (2)

38 Mica Sheet XEE3002

39 Locking Spacer XEC3009

40 Card Spacer XEC3008

41 Push Rivet See Contrast table (2)

42 Shield Plate See Contrast table (2)

(2) CONTRAST TABLE

XR-A880/KUCXJ, YPWXJ, XR-A770/KUCXJ and YPWXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

XR-A880 XR-A880 XR-A770 XR-A770

/KUCXJ /YPWXJ /KUCXJ /YPWXJ

1 AF Assy XWZ3134 XWZ3134 XWZ3114 XWZ3114

3 PRIMARY Assy XWZ3118 XWZ3115 XWZ3118 XWZ3115

5 Power Transformer (T1 : AC120V) XTS3029 Not used XTS3029 Not used

5 Power Transformer (T1 : AC240V) Not used XTS3018 Not used XTS3018

7 Fuse (FU1 : 6.3A) REK1085 Not used REK1085 Not used

7 Fuse (FU1 : T4A) Not used AEK1060 Not used AEK1060

15 Rear Panel XNC3026 XNC3013 XNC3011 XNC3025

NSP 20 Tweeter Cover Not used Not used XAK3069 XAK3069

26 Caution Label Not used PRW1018 Not used PRW1018

29 SUB TRANS Assy XWZ3119 XWZ3116 XWZ3119 XWZ3116

30 REAR AMP Assy XWZ3195 XWZ3195 XWZ3194 XWZ3194

31 TRADE Assy XWZ3140 XWZ3140 Not used Not used

32 PRO LOGIC Assy XWZ3133 XWZ3133 Not used Not used

37 PCB Spacer B XEC3005 XEC3005 Not used Not used

41 Push Rivet AEC7069 AEC7069 Not used Not used

42 Shield Plate XNK3004 XNK3004 Not used Not used

Remarks

9

XR-A880, XR-A770

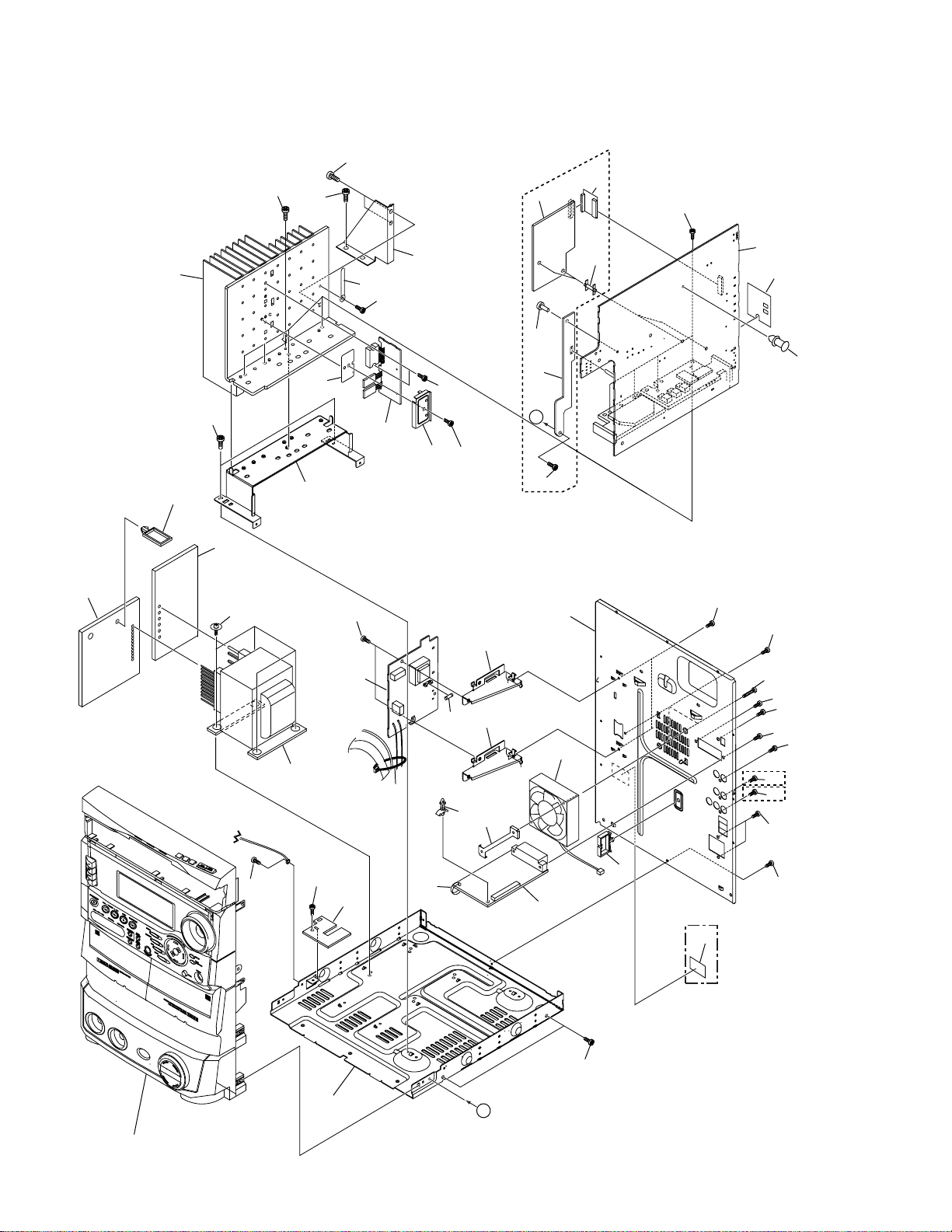

2.4 FRONT PANEL SECTION

30

18

21

33

15

13

23

32

26

24

6

34(1/2)

17

2

34(2/2)

17

17

5

7

37

A

46

1

25

35

20

19

16

21

17

17

A

8

36

10

9

27

28

31

44

45

14

12

Refer to

17

6

17

43

"2.7 MECHANISM UNIT".

38

40

42

3

39

41

XR-A880ONLY

10

XR-A880, XR-A770

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 DISPLAY Assy See Contrast table (2)

2 CD SW LED Assy XWZ3131

3 SUB DISPLAY Assy See Contrast table (2)

4 • • • • •

NSP 5 Cord With Plug DE007VE0

6 Flexible Cable 14P XDD3011

7 Flexible Cable 19P XDD3009

8 Flexible Cable 38P XDD3004

9 Connector Assy 3P XDE3013

10 Connector Assy 5P XDE3014

11 • • • • •

12 Mechanism Unit XYM3003

13 Door Spring L XBH3001

14 Door Spring R XBH3002

15 Latch Spring L ABH7130

16 Latch Spring R ABH7131

17 Screw BPZ30P100FZK

18 Latch Mold L XMR3001

19 Latch Mold R XMR3002

NSP 20 Jog Lens XAK3025

21 Damper Assy AXA7052

22 • • • • •

NSP 23 Front Panel Assy See Contrast table (2)

24 Function Button XZN3020

25 CD Button XZN3018

26 CD Lens XZN3037

27 Deck Lens L XZN3035

28 Deck Lens R XZN3036

29 • • • • •

30 Door Pocket L XZN3013

31 Door Pocket R XZN3015

32 Front Panel A XZN3011

33 Sub Panel A See Contrast table (2)

34 Power Button XZN3022

35 Play Button XZN3024

36 S.C. Button XZN3025

37 TIMER Button XZN3029

38 Sub Buttun XAD3012

39 Dolby Lens See Contrast table (2)

40 Diffusion Sheet XAK3035

41 Dolby Panel See Contrast table (2)

42 Button Lens See Contrast table (2)

NSP 43 Front Panel Assy B See Contrast table (2)

44 Sub Panel B See Contrast table (2)

45 Front Panel B See Contrast table (2)

46 Binder ZCA-SKB90BK

(2) CONTRAST TABLE

XR-A880/KUCXJ, YPWXJ, XR-A770/KUCXJ and YPWXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

XR-A880 XR-A880 XR-A770 XR-A770

/KUCXJ /YPWXJ /KUCXJ /YPWXJ

1 DISPLAY Assy XWZ3135 XWZ3142 XWZ3117 XWZ3143

NSP 23 Front Panel Assy XXG3014 XXG3014 XXG3017 XXG3017

NSP 43 Front Panel Assy B XXG3027 XXG3027 XXG3026 XXG3026

3 SUB DISPLAY Assy XWZ3132 XWZ3132 XWZ3112 XWZ3112

33 Sub Panel A XZN3031 XZN3031 XZN3044 XZN3044

39 Dolby Lens XAK3034 XAK3034 Not used Not used

41 Dolby Panel XAK3042 XAK3042 Not used Not used

42 Button Lens XAK3044 XAK3044 XAK3043 XAK3043

44 Sub Panel B XZN3053 XZN3053 XZN3052 XZN3052

45 Front Panel B XZN3051 XZN3051 XZN3050 XZN3050

Remarks

11

XR-A880, XR-A770

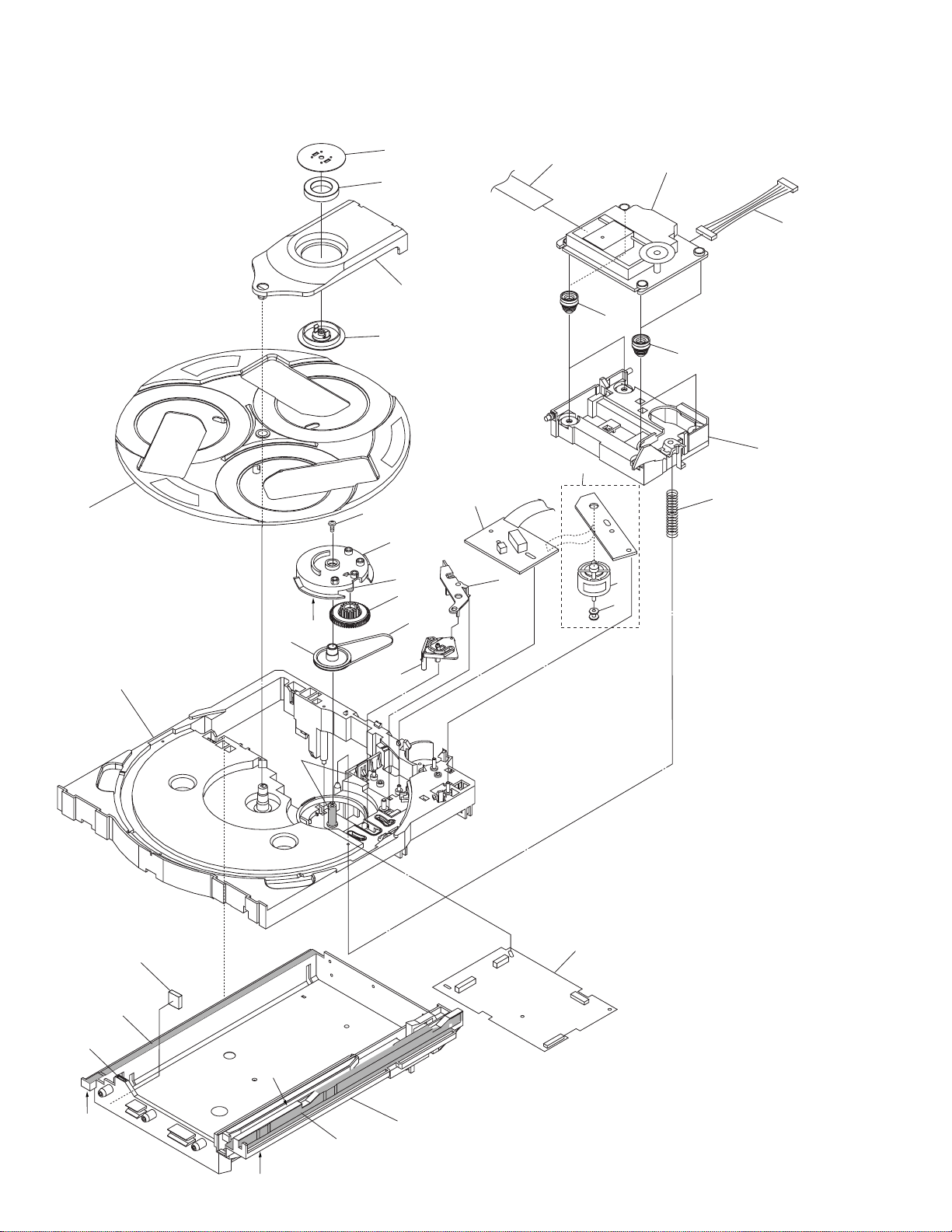

2.5 $M MECHANISM CD

13

8

21

7

14

1

Refer to "2.6 SERVO MECHANISM ASSY".

25

22

24

23

11

12

10

30

16

29

29

26

17

15

29

18

2

19

6

27

28

3

5

12

29

29

29

29

9

29

29

XR-A880, XR-A770

2.6 SERVO MECHANISM ASSY

$M MECHANISM CD PARTS LIST

•

Mark No. Description Part No.

1 MOTOR Assy AWZ8428

NSP 2 SW Assy AWZ8429

3 CD Assy AWZ3141

4 • • • • •

5 Servo Spring ABH7126

6 Belt AEB7072

7 Clamp Magnet AMF7001

8 Yoke ANB7067

9 Mecha Base ANW7125

10 Loading Tray ANW7088

11 Servo Base ANW7089

12 Rotary Tray ANW7113

13 Clamper ANW7091

14 Clamper Holder ANW7092

15 Main Cam ANW7093

16 Gear Pully ANW7094

17 Lock Lever ANW7095

18 Planet Gear ANW7096

19 Actuater ANW7097

20 • • • • •

21 15P F.F.C/30V ADD7038

22 Connector Assy (6P) ADE7010

23 Float Rubber A AEB7063

24 Float Rubber B AEB7066

25 Servo Mechanism Assy AXA7039

1

9

9

9

8

6

7

9

4

5

26 Screw IPZ30P080FMC

27 Carriage Motor VXM1033

28 Motor Pulley PNW1634

29 Ha Narl GEM1016

30 Cushion Rubber XEB3003

3

10

2

SERVO MECHANISM ASSY PARTS LIST

•

Mark No. Description Part No.

1 Servo Mechanism AXA7039

2 SPINDLE MOTOR Assy AEA7009

3 SLEAD MOTOR Assy AEA7010

4 Gear A AEA7013

5 Gear B AEA7014

6 Screw AEA7015

7 Screw AEA7016

8 Screw AEA7017

9 Screw AEA7018

10 Leaf Switch AEA7011

13

XR-A880, XR-A770

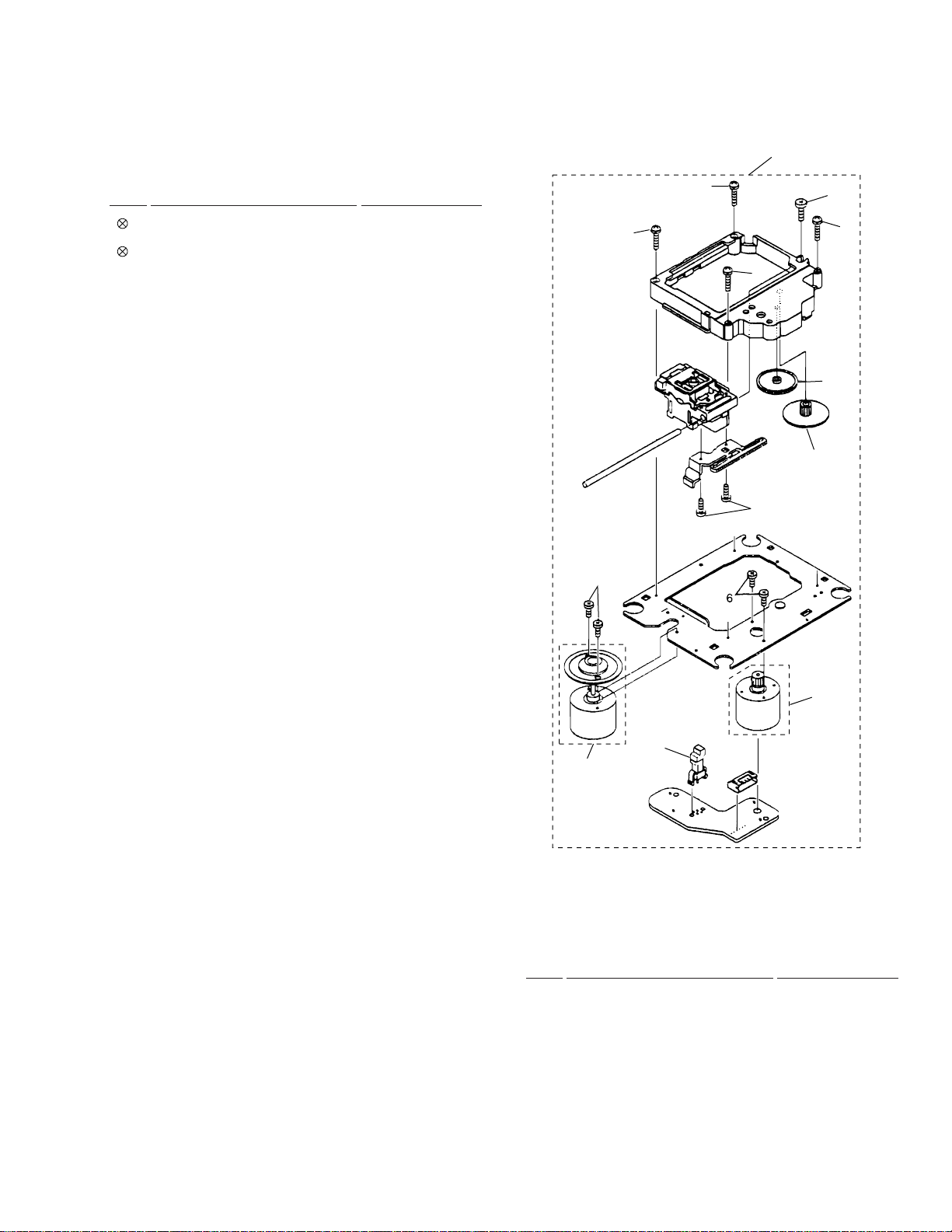

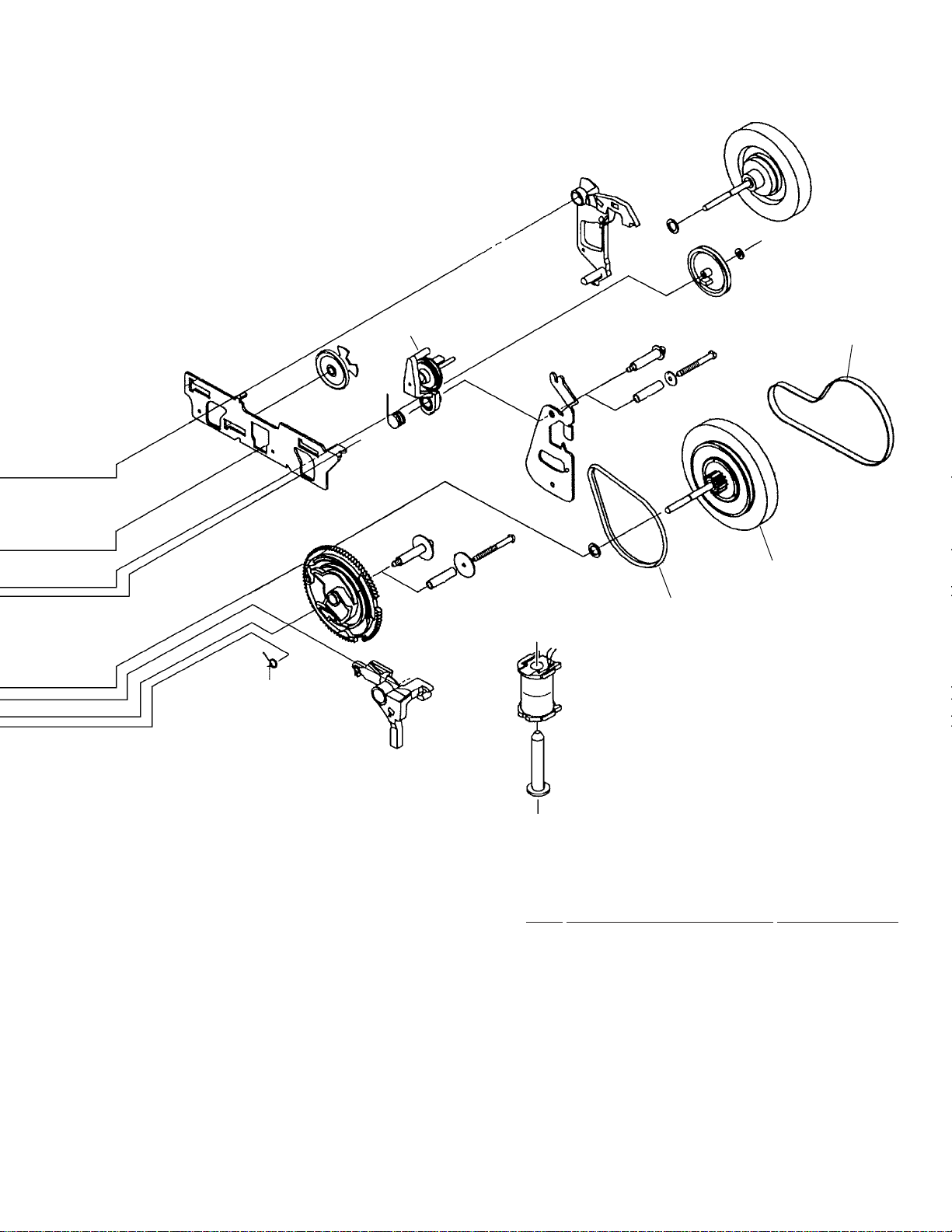

2.7 MECHANISM UNIT

Mech. Ι

Only

Mech. ΙΙ

4

Mech. ΙΙ

Only

7

3

12

Mech. Ι

13

Mech. Ι

9

Mech. ΙΙ

Only

10

1

2

Mech. ΙΙ

14

XR-A880, XR-A770

5

8

11

6

MECHANISM UNIT PARTS LIST

•

Mark No. Description Part No.

1 Plate HD BLK (Mech. Ι) F513-819

2 Plate HD BLK (Mech. ΙΙ) F513-811

3 Motor Main BLK (Mech. ΙΙ only) F525-324

4 PCB Control BLK F567-621

5 Clutch Assy BLK F522-037

6 Main Belt FF17G-31

7 Joint Belt 113 (Mech. ΙΙ only) FF19D-21

8 Clutch Assy BLK F522-045

9 Roller Pinch BLK R F514-129

10 Roller Pinch BLK L F514-130

11 F/R Belt FF18W-12

12 Plate Base BLK F512-127

13 Plate Base BLK F512-128

15

1

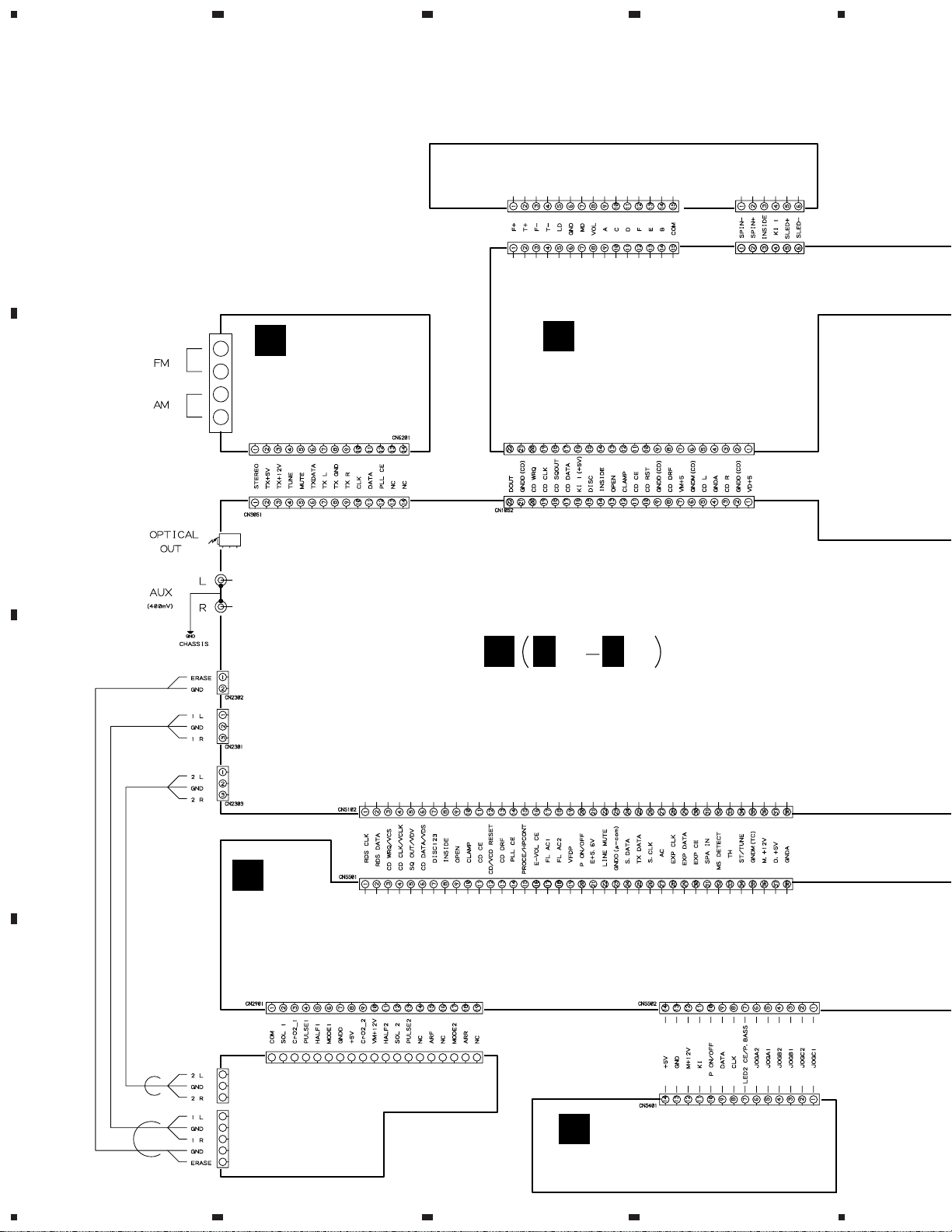

1/3

AF ASSY

(XR-A880 : XWZ3134)

(XR-A770 : XWZ3114)

DISPLAY ASSY

(XR-A880/KUCXJ : XWZ3135) (XR-A770/KUCXJ : XWZ3117)

(XR-A880/YPWXJ : XWZ3142) (XR-A770/YPWXJ : XWZ3143)

SERVO MECHANISM ASSY (AXA7039)

E

CD ASSY(XWZ3141)

CN8001 CN8002

DECK MECHA

B

I

SUB DISPLAY ASSY

(XR-A880 : XWZ3132)

(XR-A770 : XWZ3112)

K

FM/AM

TUNER MODULE

(AXQ7065)

A

E

3/3

E

XR-A880, XR-A770

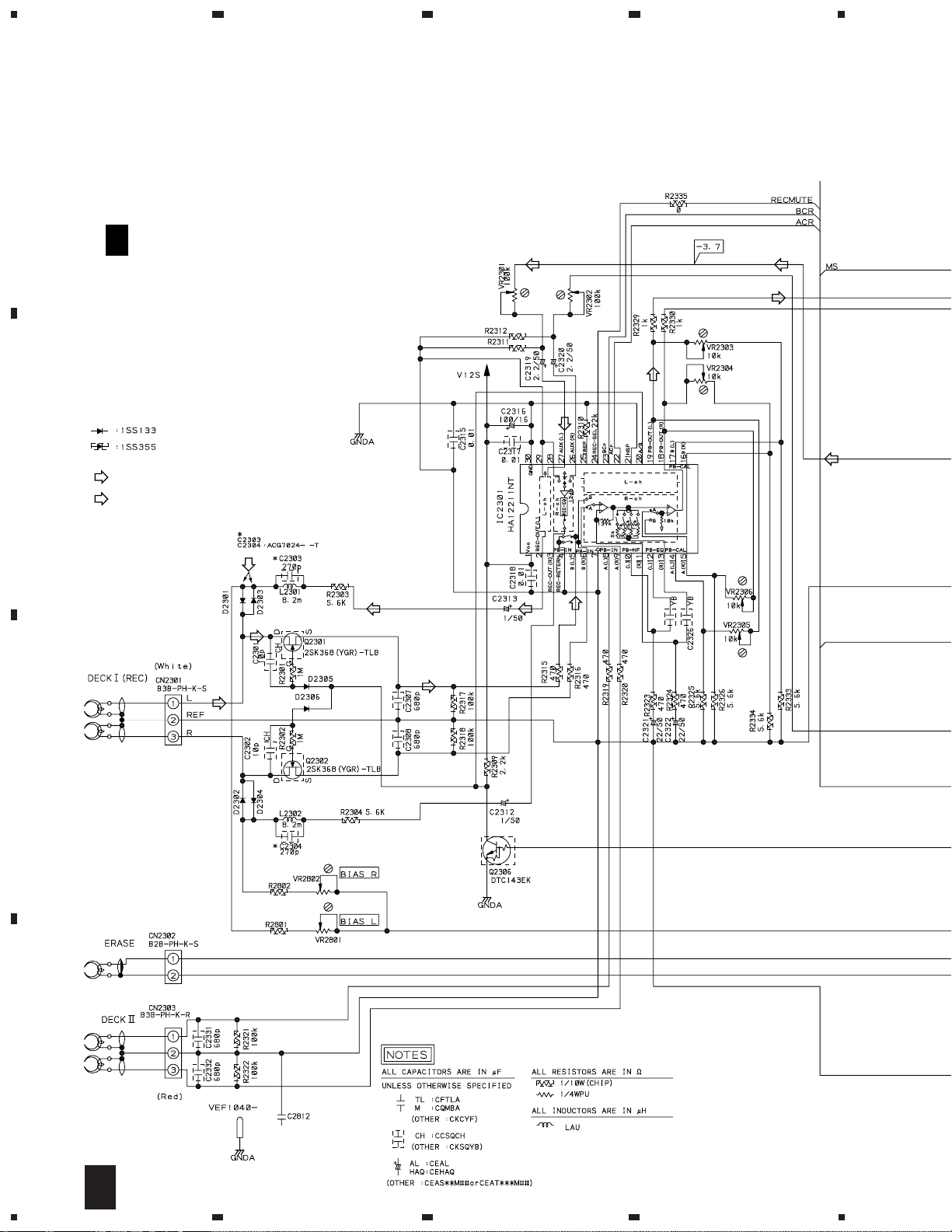

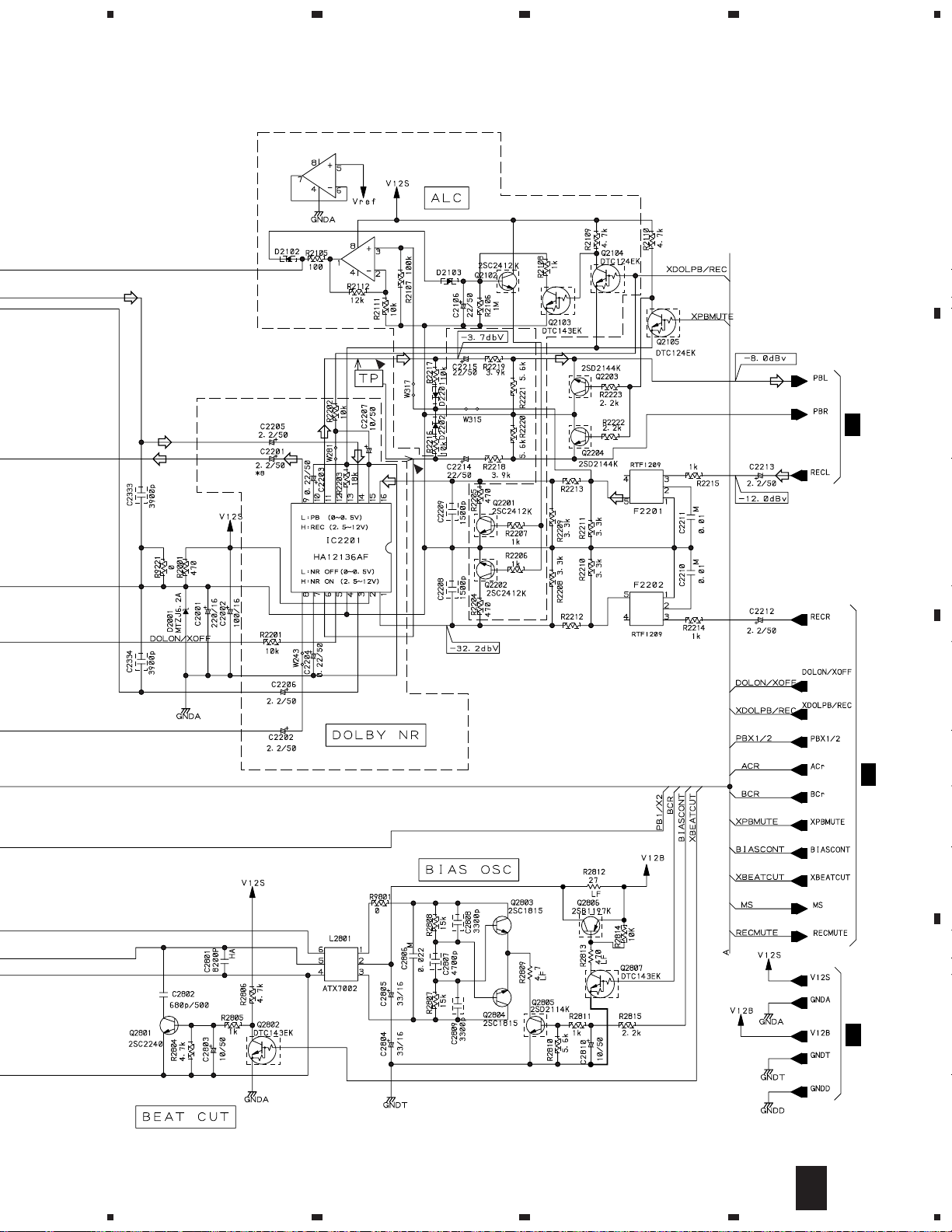

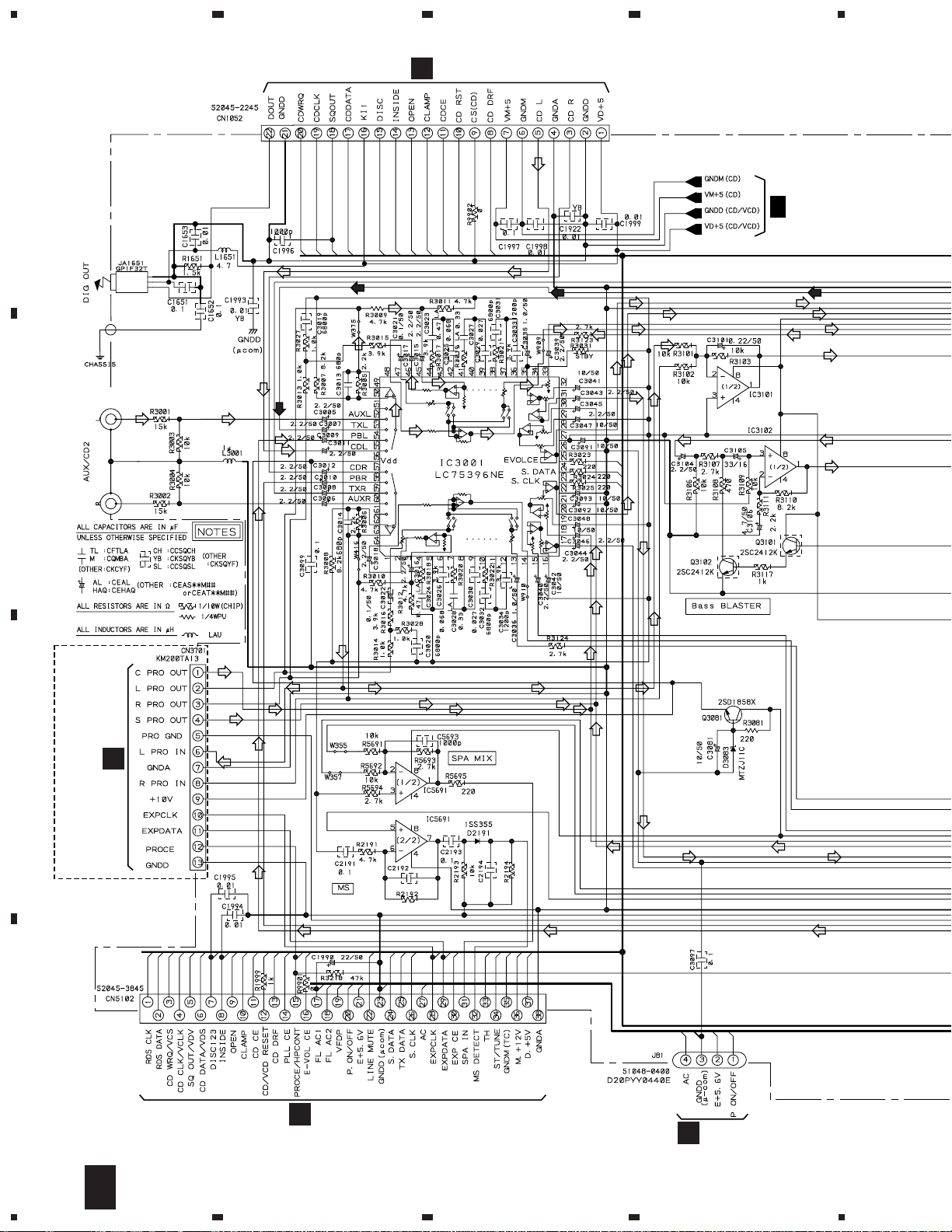

3. SCHEMATIC DIAGRAM

3.1 OVERALL WIRING DIAGRAM

A

23

4

B

C

D

16

1234

5

678

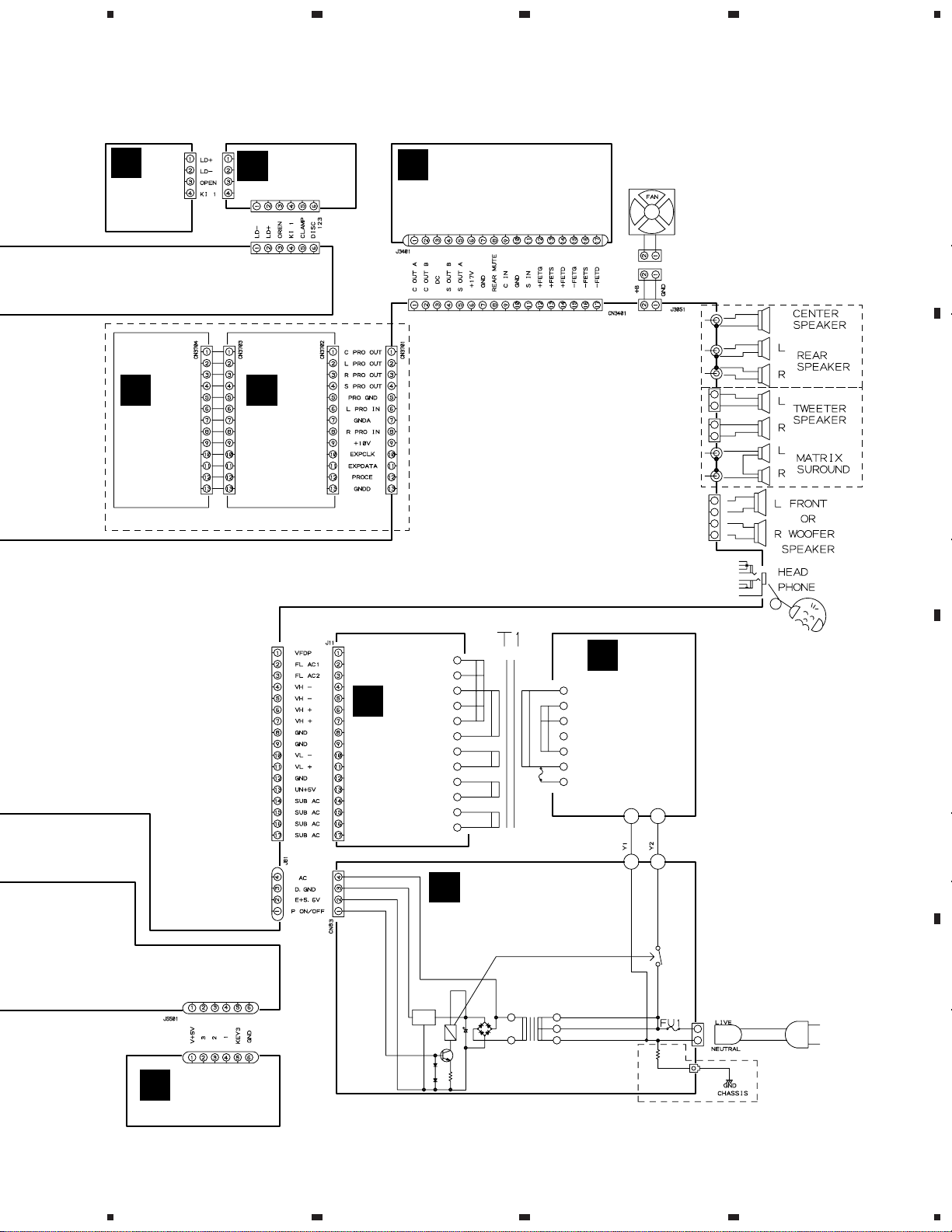

XR-A880, XR-A770

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

C

MOTOR

ASSY

(AWZ8428)

N

PRO

LOGIC

ASSY

(XWZ3133)

XR-A880 ONLY

SW ASSY

D

(AWZ8429)

CN8003

M

TRADE

ASSY

(XWZ3140)

REAR AMP ASSY

L

(XR-A880:XWZ3195)

(XR-A770:XWZ3194)

A

XR-A880

B

XR-A770

(XR-A880)

(XR-A770)

CD SW LED

J

ASSY

(XWZ3131)

F

SECONDARY

ASSY

(XWZ3137)

H

(KUCXJ TYPE : XWZ3119)

(YPWXJ TYPE : XWZ3116)

PRIMARY

ASSY

(KUCXJ TYPE

: XWZ3118)

(YPWXJ TYPE

: XWZ3115)

SUB TRANS ASSY

YPWXJ TYPE

KUCXJ TYPE

G

C

D

KUCXJ

TYPE

ONLY

17

5

6

7

8

1

RF AMP

1T378A

1T378A

MIX AMP

BUFFER

IF AMP

FM +B SW

MW RF TUNING BLOCK

AKX7041

OSC

FM/AM TUNER MODULE

(AXQ7065)

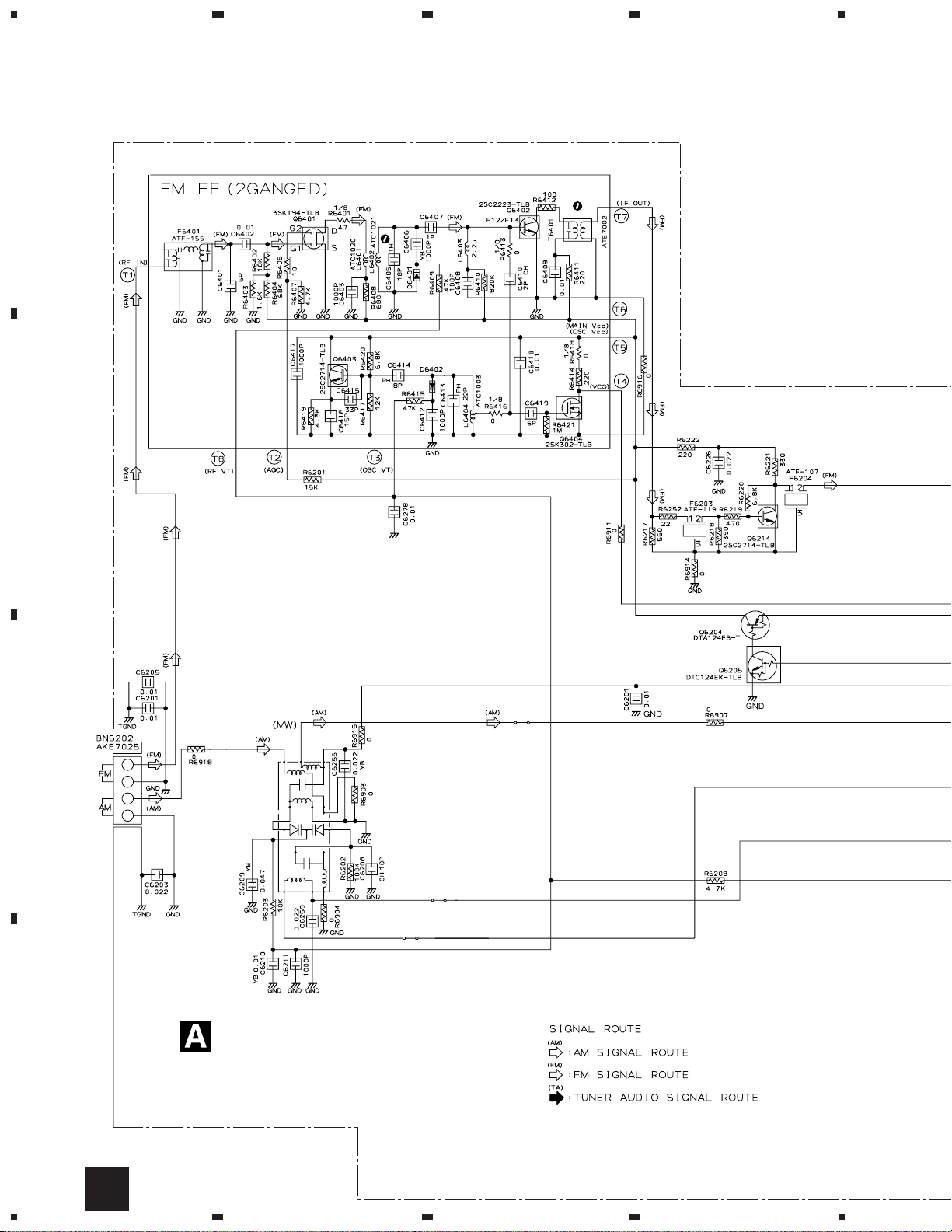

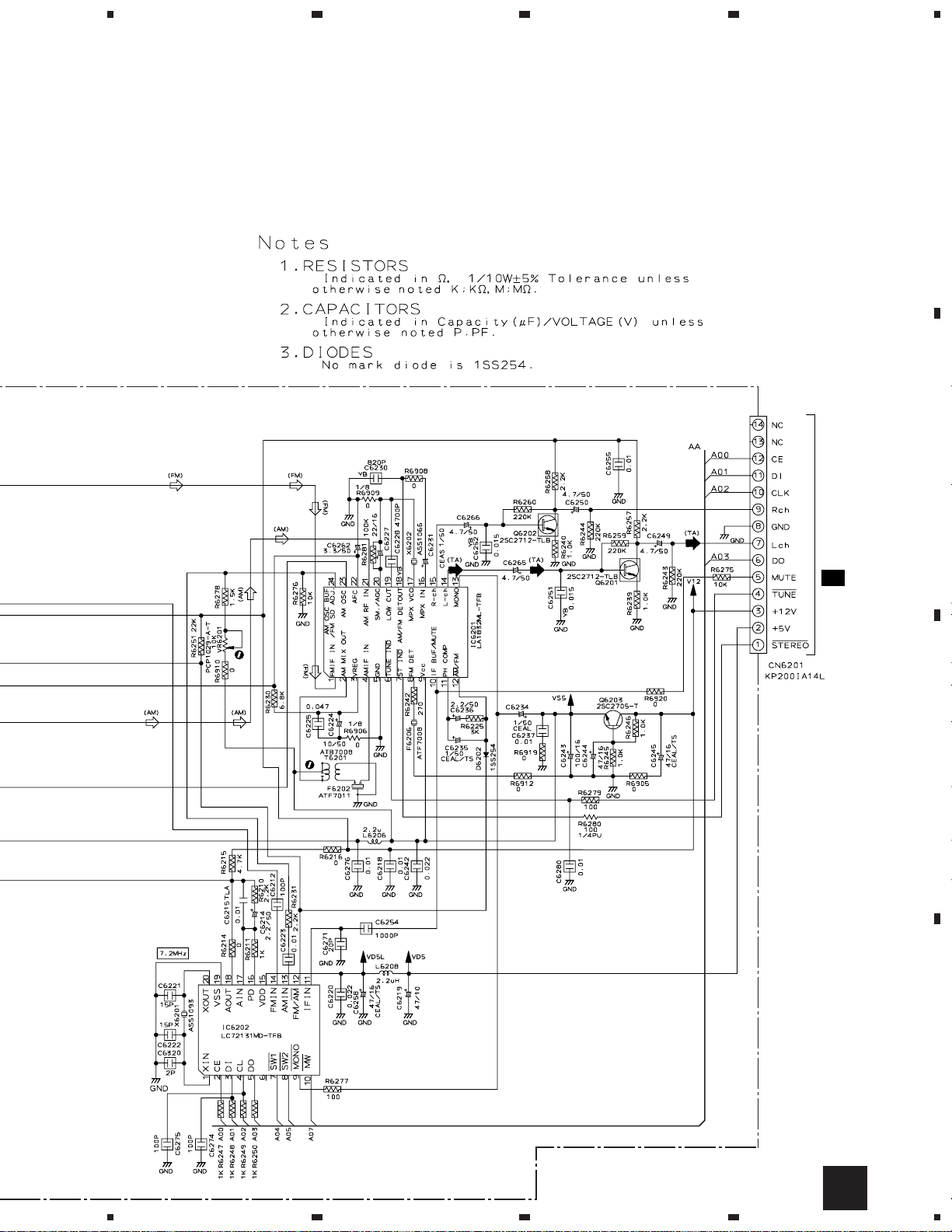

XR-A880, XR-A770

3.2 FM/AM TUNER MODULE

A

23

4

B

C

D

18

A

1234

5

678

XR-A880, XR-A770

A

B

AF AMP

AF AMP

REGULATOR

CN3051

2/3E

C

PLL

D

A

5

6

7

8

19

1

23

XR-A880, XR-A770

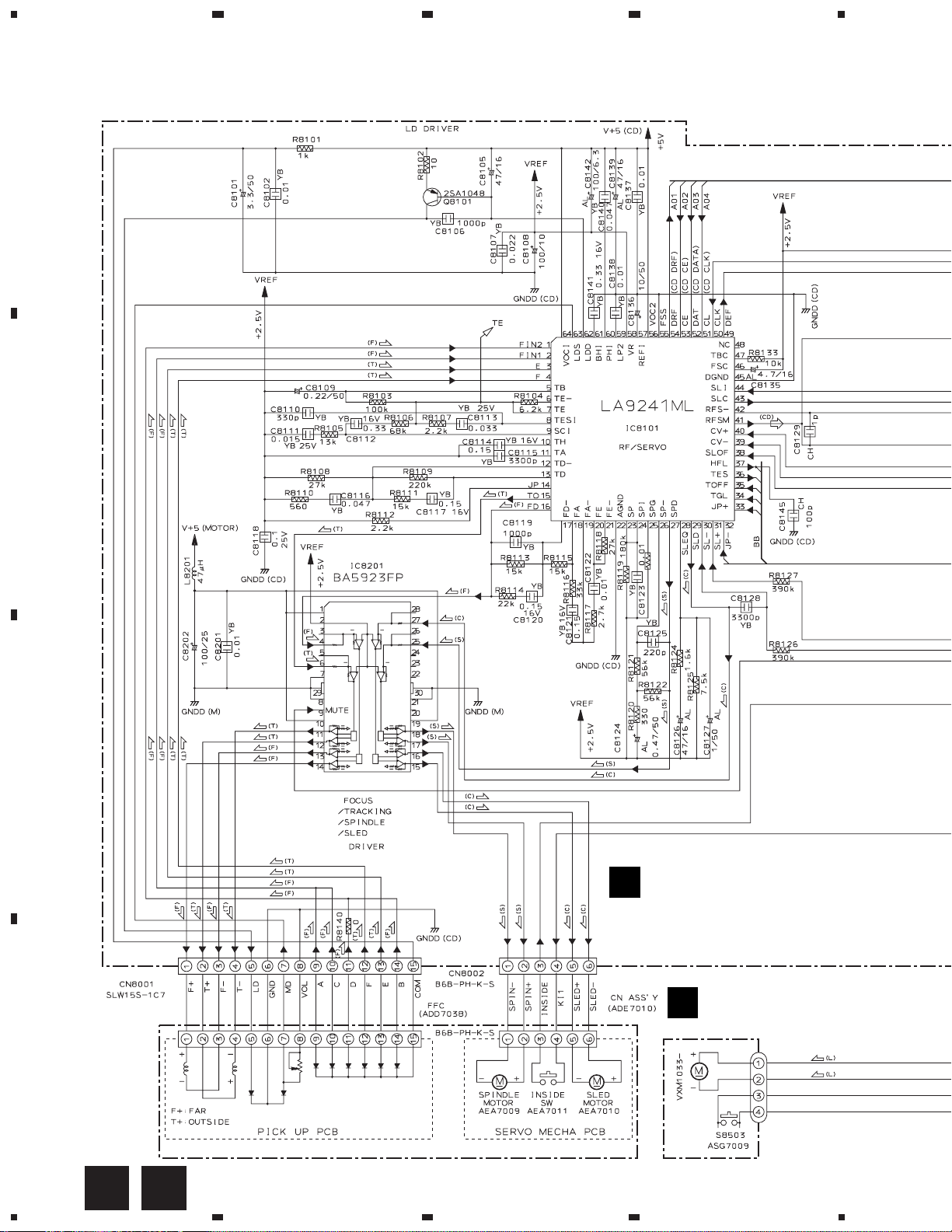

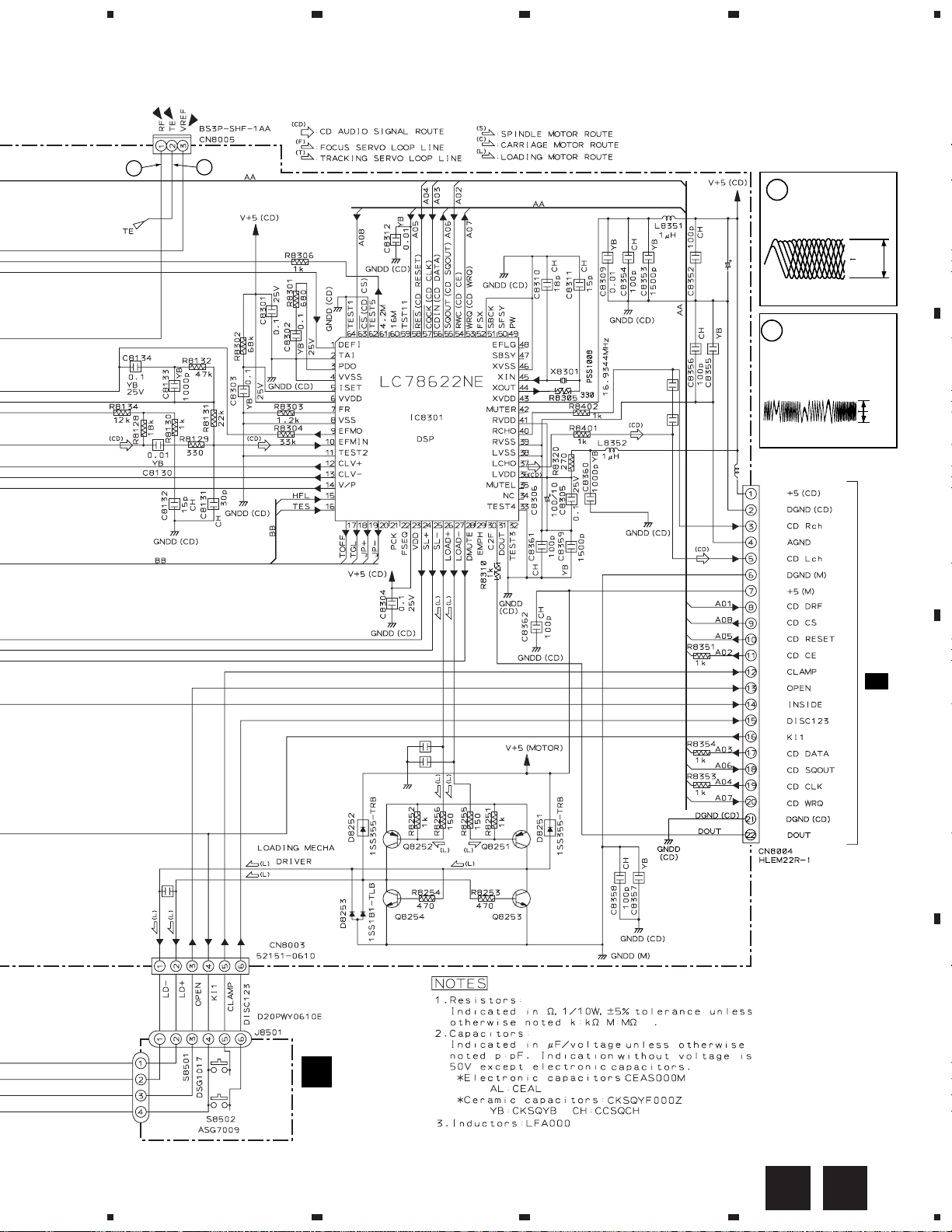

3.3 CD, MOTOR and SW ASSEMBLIES

A

B

4

56k

R8123

C

CD ASSY

B

(XWZ3141)

MOTOR ASSY

C

(AWZ8428)

CARRIAGE MOTOR

D

20

B C

J8502

SERVO MECHANISM ASSY AXA7039

1234

D20PWW0405E

5

678

XR-A880, XR-A770

Note: The encircled numbers

denote measuring point in the

1

2

schematic diagram.

CN8005- Pin 1 :

1

PLAY MODE (RF)

H : 500nsec/div

1.8Vp-p

A

C8308

1000p

C8307

1000p

YB

YB

C8371

100/10

0.047

CN8005- Pin 2 :

2

TEST MODE,

Tracking Open(TRER)

H : 5msec/div

VREF:CN8005- Pin3

L8371 47µH

VREF

1.0Vp-p

VREF

B

CN1052

2/3

E

J8502

C8257

0.1

C8256 0.1

D

C8255 0.1

2SB1237X 2SB1237X

2SD1858X

0.047

2SD1858X

C

D

SW ASSY

(AWZ8429)

B D

5

6

7

8

21

1

XR-A880, XR-A770

3.4 AF ASSY (1/3)

A

E

1/3

AF ASSY

(XR-A880 : XWZ3134)

(XR-A770 : XWZ3114)

B

(PB)

: DECK PB SIGNAL ROUTE

(REC)

: DECK REC SIGNAL ROUTE

23

(REC) (REC)

22k

22k

(PB)

(REC)

4

(PB)

(REC)

(REC)

(REC)

(PB)

(PB)

(PB)

C

220k

33k

33k

220k

(PB)

(REC)

0.022

C2323

0.022

D

0.01

22

1/3

E

1234

5

678

XR-A880, XR-A770

IC2101(2/2)

BA4558F–HT

A

(PB)

(PB)

(REC)

IC2101(1/2)

BA4558F–HT

(REC)

(PB)

(PB) (PB)

(PB)

(REC)

22k

22k

(REC)

(PB)

(REC)

E

2/3

B

2/3

E

2/3

E

1/3

E

5

6

7

8

23

C

D

1

XR-A880, XR-A770

3.5 AF ASSY (2/3)

23

CN8004

B

4

A

(TA)

XR-A770:XKB3002

XR-A880:VKB1060

B

(CD)

(TA)

(PB)

(CD)

(PB)

(CD)

(CD)(CD)

(TA)

R3019,R3020

XR-A880 : 1.8k

XR-A770 : 3.9k

(C)

(S/T)

(S/T)

(F/W)

(C) (C)

(F/W)

(C)

(B)

3/3

E

(S/T)(S/T)

BA4558F-HT

(B)

(TA)

(C)

(B)(B)

(B)

(B)

(B)

C

D

M

CN3702

XR-A880 ONLY

(C)

(S)

(PRO)

(PB) (PB)

(C)

(PRO)

(PB)

(PRO/B)

(B)

100k

(C)

BA4558F-HT

BA4558F-HT

22p

(S/T)

(C)

(B)

(S)(S)

(C)

(T)

1

180k

(T)

(B) (B)

(B)

(F/W)

(F/W) (F/W)

(T)

(PB)(PB)

24

CN5501

I

CN83

H

2/3

E

1234

Loading...

Loading...