Page 1

XR-A660

STEREO CD CASSETTE DECK RECEIVER

XR-A660

XR-A550

XR-A330

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

DBDXJ – AC110-127V/220-230V/240V With the voltage selector

DLXJ/NC – AC110-127V/220-230V/240V With the voltage selector

DXJ/NC – AC110-127V/220-230V/240V With the voltage selector

DXJ – – AC110-127V/220-230V/240V With the voltage selector

XR-A660 XR-A550 XR-A330 the following method.

Model

Power Requirement

The Voltage can be converted by

ORDER NO.

RRV2006

CONTENTS

1. SAFETY INFORMATION ...................................... 2

2. EXPLODED VIEWS AND PARTS LIST................ 3

3. SCHEMATIC DIAGRAM ..................................... 16

4. PCB CONNECTION DIAGRAM.......................... 32

5. PCB PARTS LIST ............................................... 44

6. ADJUSTMENT .................................................... 52

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

PIONEER ELECTRONIC CORPORATION 1998

7. GENERAL INFORMATION ............................... 61

7.1 PARTS ......................................................... 61

7.1.1 IC ......................................................... 61

7.1.2 DISPLAY.............................................. 68

7.2 DISASSEMBLY ........................................... 72

7.3 BLOCK DIAGRAM....................................... 76

8. PANEL FACILITIES AND SPECIFICATIONS.... 78

T – IZK AUG. 1998 Printed in Japan

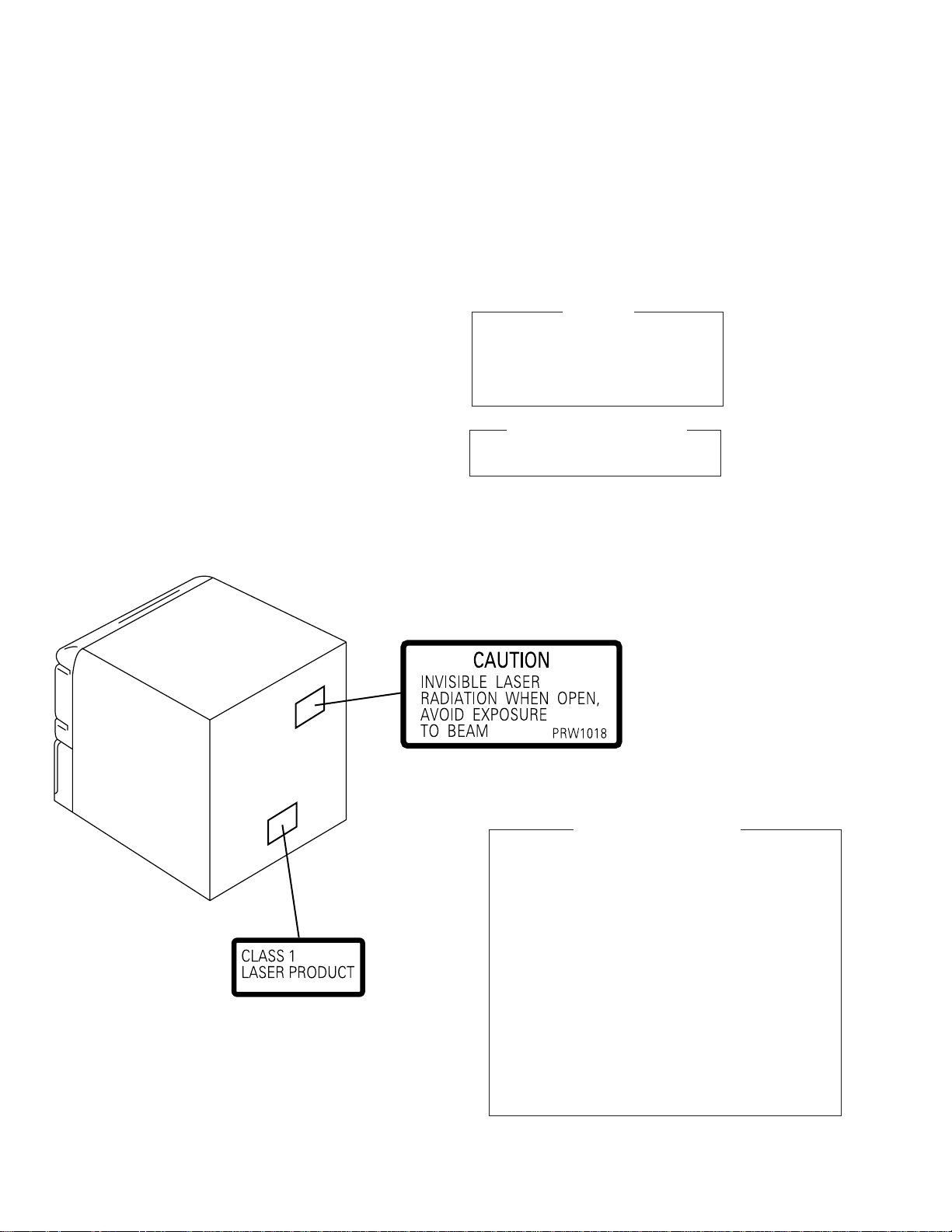

Page 2

XR-A660, XR-A550, XR-A330

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

LABEL CHECK (For DLXJ/NC types)

THIS PIONEER APPARATUS CONTAINS

IMPORTANT

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 1.3 mW

WAVELENGTH: 790 nm ± 25 nm

Additional Laser Caution

1.Laser Interlock Mechanism

The position of the switch (S8501) for detecting loading

state is detected by the system microprocessor, and

the design prevents laser diode oscillation when the

switch (S8501) is pressed physically.

Thus, the interlock will no longer function if the switch (S8501)

is released physically and deliberatery.

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 62 of

LA9240ML (IC8101) on the CD ASSY mounted on the

Printed on the Rear Panel

2

$M Loading Mechanism assembly is connected to GND,

or else the terminals of Q8101 are shorted to each other

(fault condition).

2.When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class

1 laser beam.

∗

: Refer to page 60.

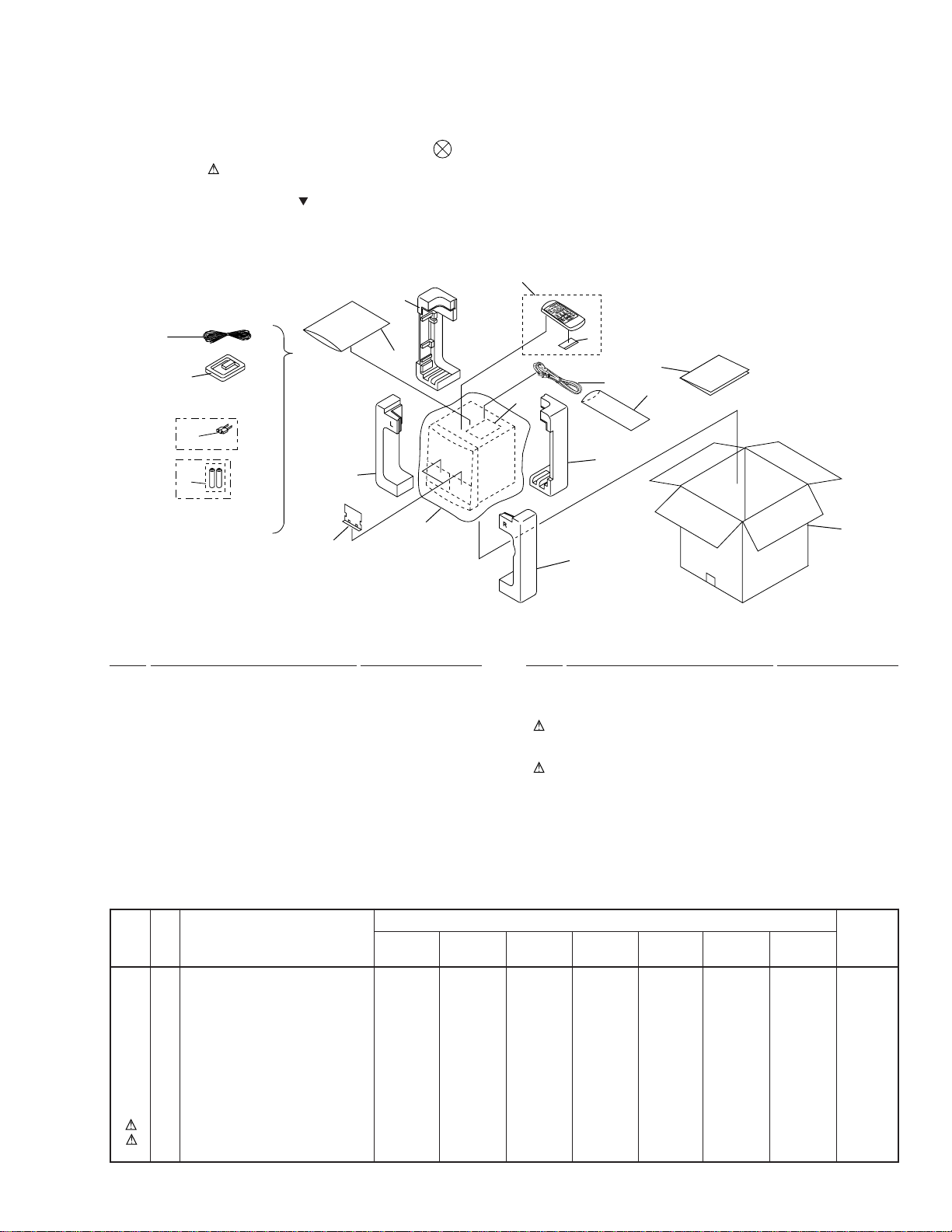

Page 3

XR-A660, XR-A550, XR-A330

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" and can not be supplied.

•

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

2.1 PACKING

1

3

DXJ/NC and DXJ

Types Only

12

6

Except

DXJ/NC Type

8(1/2)

16

9(1/2)

4

VOL

K

A

R

A

O

K

E

S

DISC DISC DISC

F

S

C

L

E

E

P

P

.B

POWER

CLEAR

A

S

S

D

IS

P

PGM

L

A

Y

AU

X

R

E

P

E

A

T

R

A

N

D

O

M

STATIO

REMOTE CONTROL UNIT CU-XR025

N

MONOBAND

5

7

15

13

2

14

9(2/2)

11

10

8(2/2)

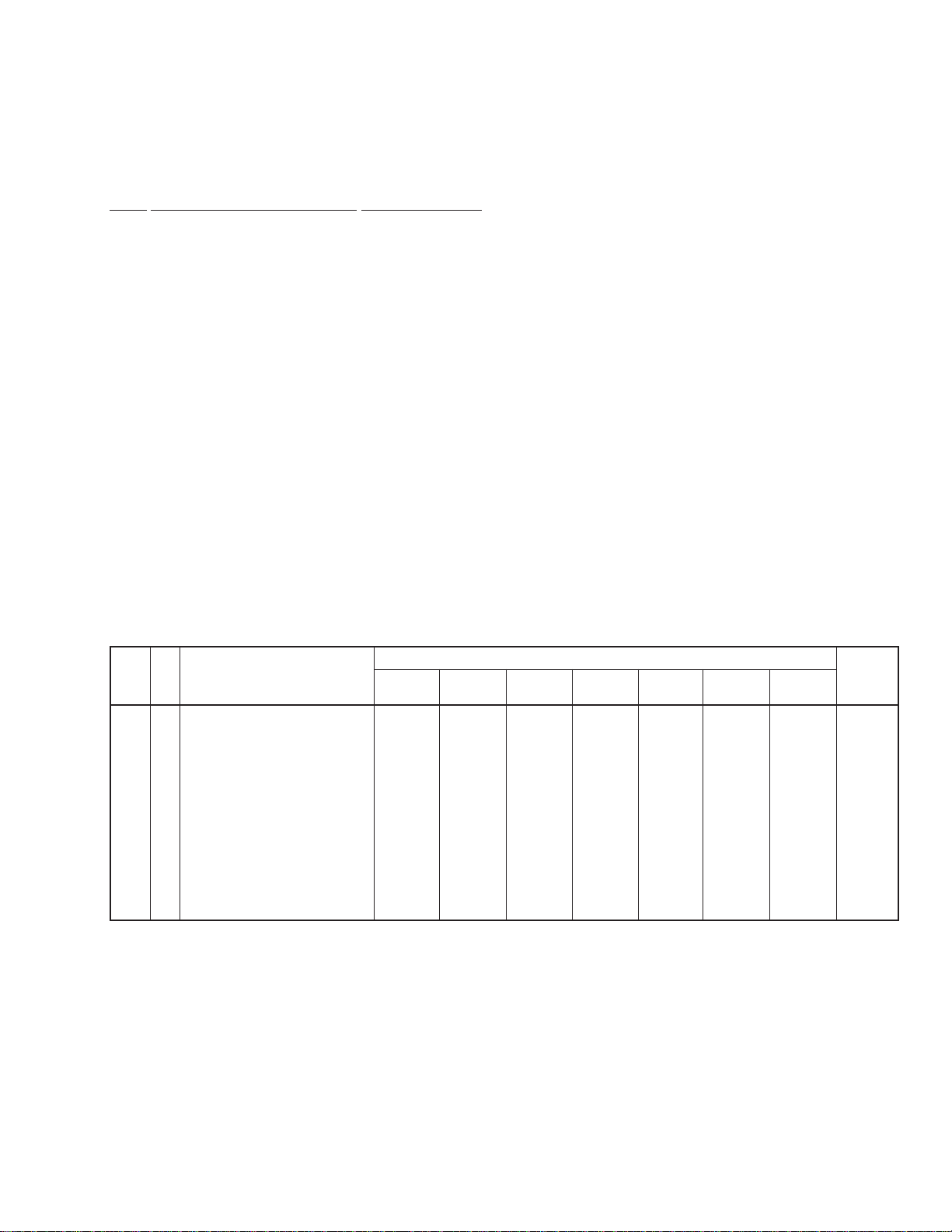

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 FM Antenna ADH7004

2 Operating Instructions See Contrast table (2)

3 AM Loop Antenna XTB3001

4 Remote Control Unit XZN3006

(CU-XR048)

5 Battery Cover AZA7204

NSP 6 Dry Cell Battery (R6P, AA) See Contrast table (2)

7 Catalog Bag Z21-038

(0.03 × 230 × 340)

8 Front Pad XHA3003

Mark No. Description Part No.

9 Rear Pad XHA3004

10 Packing Case See Contrast table (2)

11 Packing Sheet AHG7049

12 Power-cord Plug See Contrast table (2)

Conversion Adapter

13 Power Cord See Contrast table (2)

14 Polyethylene Bag AHG7033

NSP 15 Caution Card XAX3130

NSP 16 Door Spacer XHG3002

(2) CONTRAST TABLE

XR-A660/DBDXJ, DLXJ/NC, DXJ/NC, XR-A550/DXJ, XR-A330/DBDXJ, DLXJ/NC and DXJ/NC are constructed the

same except for the following :

.oNtraP

kraM.oNnoitpircseDdnalobmyS

2snoitcurtsnIgnitarepOdesutoNdesutoN0103ERXdesutoNdesutoNdesutoN0103ERX

)eseugutroP/hsinapS/hsilgnE(

2snoitcurtsnIgnitarepO1103ERXdesutoNdesutoN1103ERX1103ERXdesutoNdesutoN

)esenihC/hsinapS/hsilgnE(

2snoitcurtsnIgnitarepOdesutoN9003ERXdesutoNdesutoNdesutoN9003ERXdesutoN

)esenihC/naissuR/hsilgnE(

066A-RX

JXDBD/

066A-RX

CN/JXLD/

066A-RX

CN/JXD/

055A-RX

JXD/

033A-RX

JXDBD/

033A-RX

CN/JXLD/

033A-RX

CN/JXD/

skrameR

PSN6 )AA,P6R(yrettaBlleCyrD310-MEV310-MEVdesutoN310-MEV310-MEV310-MEVdesutoN

01esaCgnikcaP1403DHX2303DHX2303DHX6303DHX8503DHX5303DHX5303DHX

21

retpadAnoisrevnoCgulPdroc-rewoP

desutoNdesutoN7001XKV7001XKVdesutoNdesutoN7001XKV

31droCrewoP8511GDA4511GDA4511GDA4511GDA8511GDA4511GDA4511GDA

3

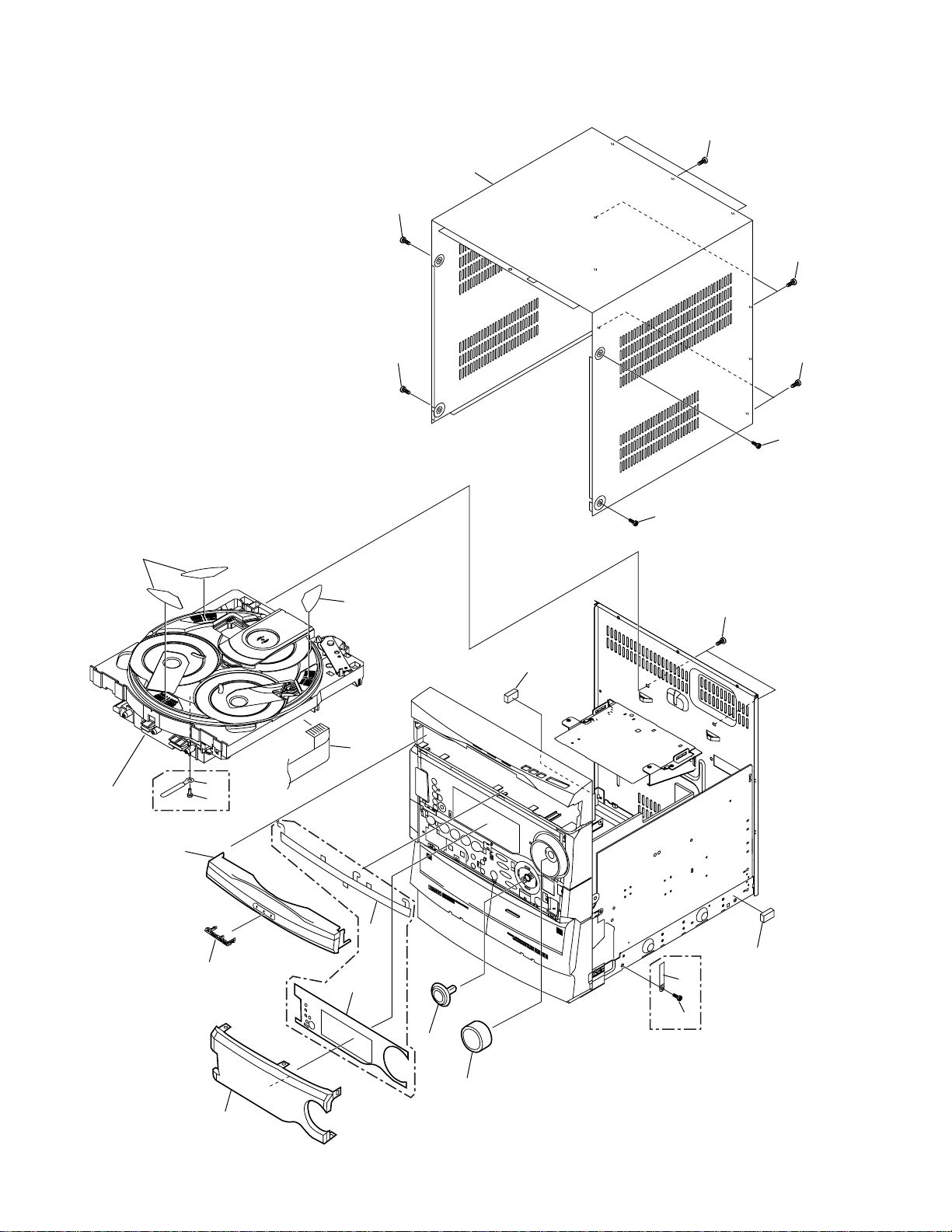

Page 4

XR-A660, XR-A550, XR-A330

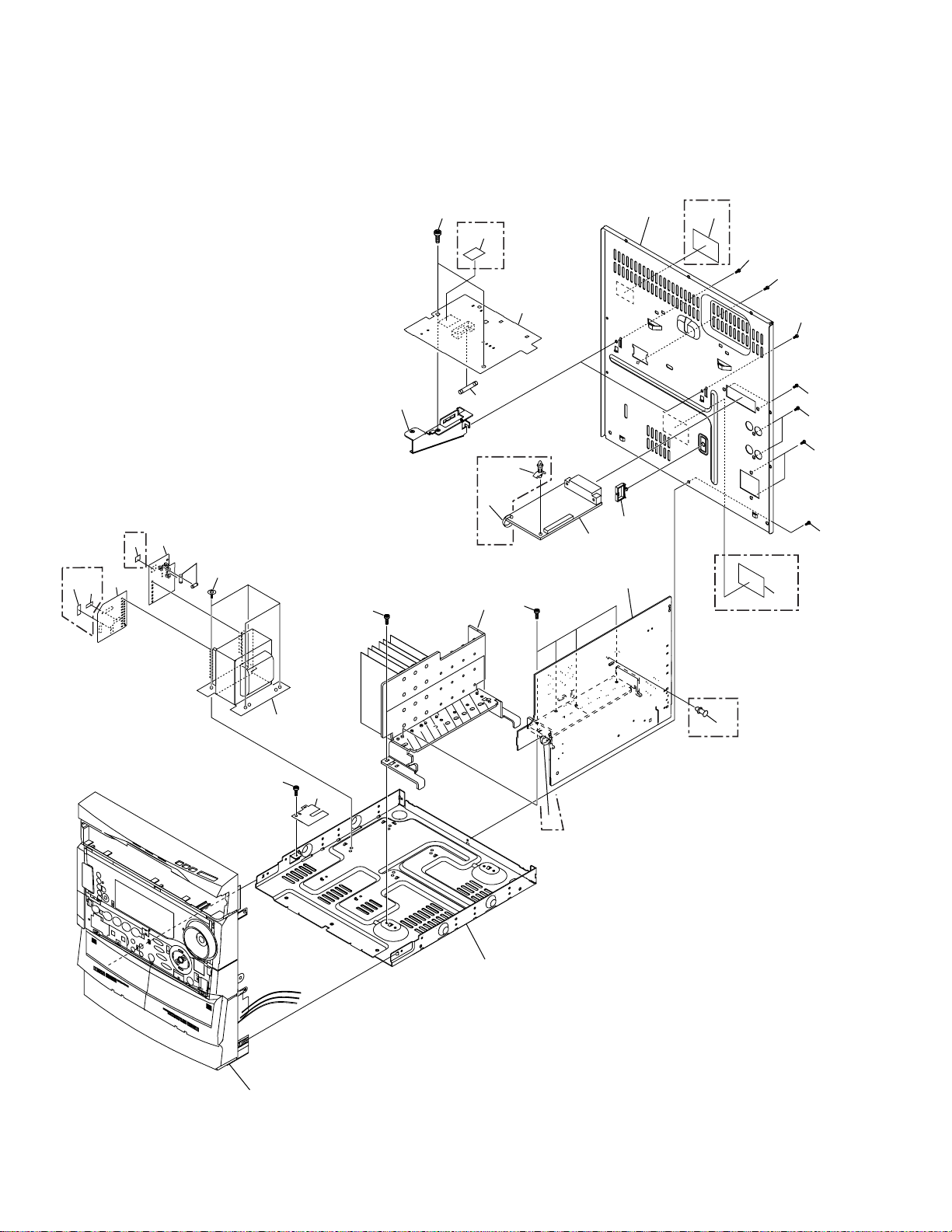

2.2 EXTERIOR (1/2)

Note :

Hook Tray cap on top of loading tray and then

insert the bottom three hooks.

Note :

Attatch on the same numbers × three.

12

11

15

8

9

15

11

9

11

17

10

18

XR-A550,

XR-A330

only

2

Refer to

"2.5 $M MECHANISM CD".

6

12

9

19

1

4

19

5

13, 14

16

11

XR-A660 only

3

7

XR-A660 only

4

Page 5

(1) EXTERIOR (1/2) PARTS LIST

Mark No. Description Part No.

XR-A660, XR-A550, XR-A330

NSP 2 $M Mechanism CD XXA3005

NSP 17 Cord Stopper See Contrast table (2)

1 20P F.F.C/30V XDD3017

3 Volume Knob See Contrast table (2)

4 FL Cover A See Contrast table (2)

5 FL Cover B See Contrast table (2)

6 Tray Cap See Contrast table (2)

7 Display Panel See Contrast table (2)

8 Bonnet Case See Contrast table (2)

9 Screw BPZ30P100FZK

10 Pioneer Badge AZN3049

11 Screw VBZ30P080FZK

12 Disc Label XAX3127

13 Jog Knob Assy See Contrast table (2)

14 Jog Knob See Contrast table (2)

15 Screw BCZ30P060FZK

16 Cord Clamper See Contrast table (2)

18 Push Rivet See Contrast table (2)

19 Cushion Rubber XEB3002

(2) CONTRAST TABLE

XR-A660/DBDXJ, DLXJ/NC, DXJ/NC, XR-A550/DXJ, XR-A330/DBDXJ, DLXJ/NC and DXJ/NC are constructed the

same except for the following :

.oNtraP

kraM.oNnoitpircseDdnalobmyS

3bonKemuloV5003AAX5003AAX5003AAX7003AAX7003AAX7003AAX7003AAX

4ArevoCLF6203KAX6203KAX6203KAXdesutoNdesutoNdesutoNdesutoN

5BrevoCLF6303KAX6303KAX6303KAXdesutoNdesutoNdesutoNdesutoN

6paCyarT7403NZX7403NZX7403NZX8403NZX8403NZX8403NZX8403NZX

7lenaPyalpsiD0203KAX0203KAX0203KAX0503KAX0303KAX0303KAX0303KAX

066A-RX

JXDBD/

066A-RX

CN/JXLD/

066A-RX

CN/JXD/

055A-RX

JXD/

033A-RX

JXDBD/

033A-RX

CN/JXLD/

033A-RX

CN/JXD/

skrameR

8esaCtennoB9303NZX9303NZX9303NZX5403NZX5403NZX5403NZX5403NZX

31yssAbonKgoJ3203GXX3203GXX3203GXXdesutoNdesutoNdesutoNdesutoN

41bonKgoJdesutoNdesutoNdesutoN8003AAX8003AAX8003AAX8003AAX

61repmalCdroC481-HNR481-HNR481-HNRdesutoNdesutoNdesutoNdesutoN

PSN71reppotSdroCdesutoNdesutoNdesutoN8211FND8211FND8211FND8211FND

81teviRhsuPdesutoNdesutoNdesutoN8317CEA8317CEA8317CEA8317CEA

5

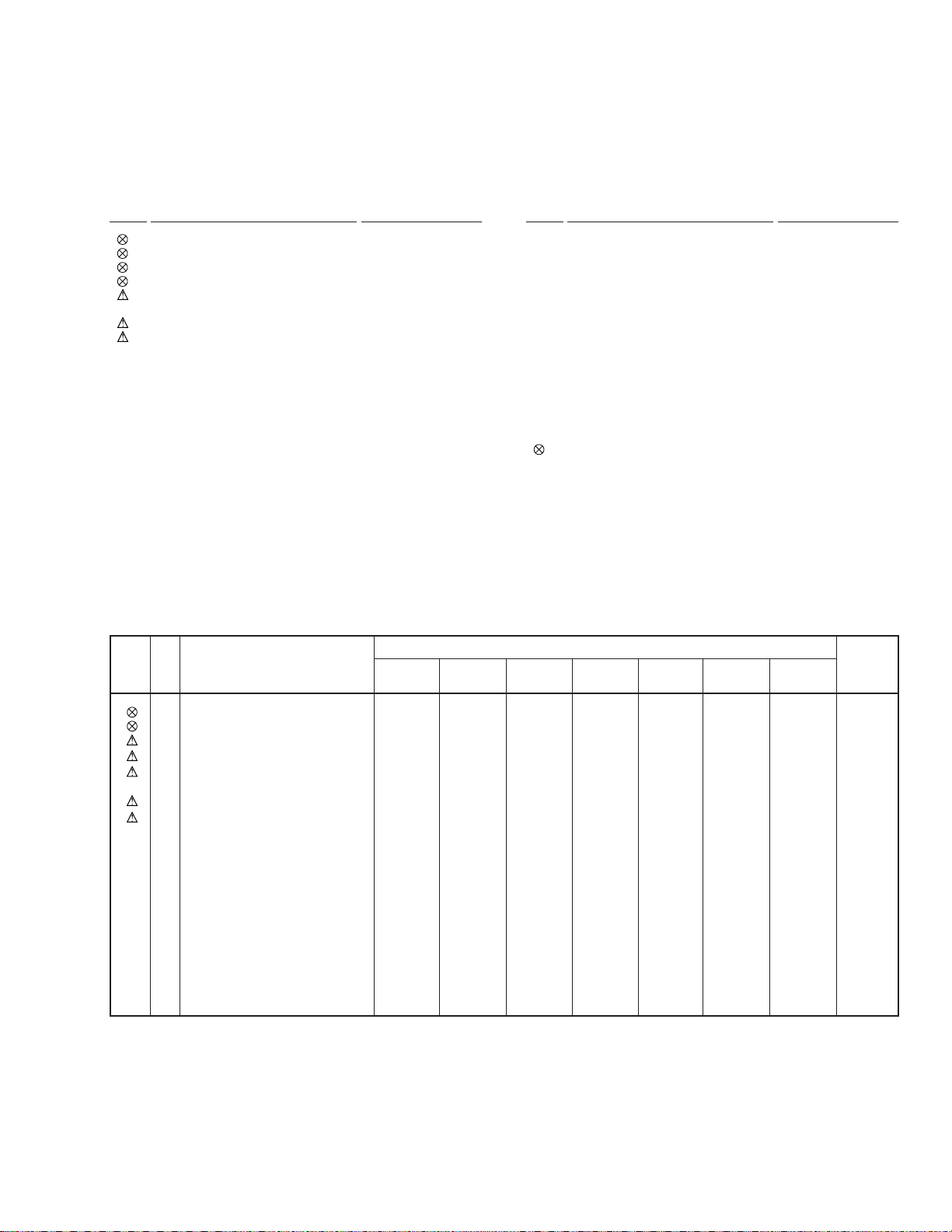

Page 6

XR-A660, XR-A550, XR-A330

2.3 EXTERIOR (2/2)

19

31

XR-A660,

XR-A550

only

DLXJ/NC Type only

15

25

19

24

XR-A660,

XR-A550

only

28

27

29

11

XR-A550,

XR-A330

only

3

30

2

6

21

19

5

19

17

7

13

32

22

14

4

1

19

Except

DLXJ/NC Type

33

XR-A550,

XR-A330

only

19

24

24

24

19

26

22

XR-A660

only

8

Refer to

"2.4 FRONT PANEL SECTION".

6

Page 7

(1) EXTERIOR (2/2) PARTS LIST

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

1 AF Assy See Contrast table (2)

2 SECONDARY Assy See Contrast table (2)

3 PRIMARY Assy XWZ3048

4 FM/AM TUNER MODULE AXQ7065

5 T1 Power Transformer See Contrast table (2)

6 FU2, FU3 Fuse See Contrast table (2)

7 FU1 Fuse See Contrast table (2)

NSP 8 Chassis XNA3001

9 • • • • •

10 • • • • •

11 PCB Bracket XNG3006

12 • • • • •

13 Heat Sink See Contrast table (2)

14 Wire Clip XEC3002

15 Rear Panel See Contrast table (2)

Mark No. Description Part No.

16 • • • • •

NSP 17 SUPPORT Assy XNP3008

18 • • • • •

19 Screw VBZ30P080FZK

20 • • • • •

21 Screw ASZ40P060FMC

22 Binder ZCA-SKB90BK

23 • • • • •

24 Screw BPZ30P100FZK

25 Caution Label See Contrast table (2)

NSP 26 Name Label See Contrast table (2)

27 ICP Label See Contrast table (2)

28 ICP Label See Contrast table (2)

29 SUB TRANS Assy XWZ3049

NSP 30 Fuse Card See Contrast table (2)

NSP 31 Fuse Card See Contrast table (2)

32 Locking Spacer See Contrast table (2)

33 Card Spacer See Contrast table (2)

(2) CONTRAST TABLE

XR-A660/DBDXJ, DLXJ/NC, DXJ/NC, XR-A550/DXJ, XR-A330/DBDXJ, DLXJ/NC and DXJ/NC are constructed the

same except for the following :

.oNtraP

kraM.oNnoitpircseDdnalobmyS

1yssAFA3803ZWX3803ZWX3803ZWX4703ZWX5403ZWX5403ZWX5403ZWX

2yssAYRADNOCES4803ZWX4803ZWX4803ZWX4803ZWX6403ZWX6403ZWX6403ZWX

5remrofsnarTrewoP1T5103STX5103STX5103STX5103STX2103STX2103STX2103STX

6)A2T(esuF3UF,2UF7501KEA7501KEA7501KEA7501KEAdesutoNdesutoNdesutoN

6)A6.1T(esuF3UF,2UFdesutoNdesutoNdesutoNdesutoN6501KEA6501KEA6501KEA

066A-RX

JXDBD/

066A-RX

CN/JXLD/

066A-RX

CN/JXD/

055A-RX

JXD/

033A-RX

JXDBD/

033A-RX

CN/JXLD/

033A-RX

CN/JXD/

skrameR

7)A4T(esuF1UF0601KEA0601KEA0601KEA0601KEAdesutoNdesutoNdesutoN

7)A51.3T(esuF1UFdesutoNdesutoNdesutoNdesutoN9501KEA9501KEA9501KEA

31kniStaeH2003HNX2003HNX2003HNX2003HNX3003HNX3003HNX3003HNX

51lenaPraeR7103CNX1003CNX7103CNX8103CNX8103CNX4003CNX8103CNX

52lebaLnoituaCdesutoN8101WRPdesutoNdesutoNdesutoN8101WRPdesutoN

PSN62lebaLemaN3003LAXdesutoNdesutoN5203LAX8103LAXdesutoNdesutoN

72lebaLPCI0213XAX0213XAX0213XAX0213XAXdesutoNdesutoNdesutoN

82lebaLPCI1213XAX1213XAX1213XAX1213XAXdesutoNdesutoNdesutoN

PSN03draCesuF7532XAA7532XAA7532XAA7532XAAdesutoNdesutoNdesutoN

PSN13draCesuF9907XAA9907XAA9907XAA9907XAAdesutoNdesutoNdesutoN

23recapSgnikcoLdesutoNdesutoNdesutoN9003CEX9003CEX9003CEX9003CEX

33recapSdraCdesutoNdesutoNdesutoN8003CEX8003CEX8003CEX8003CEX

7

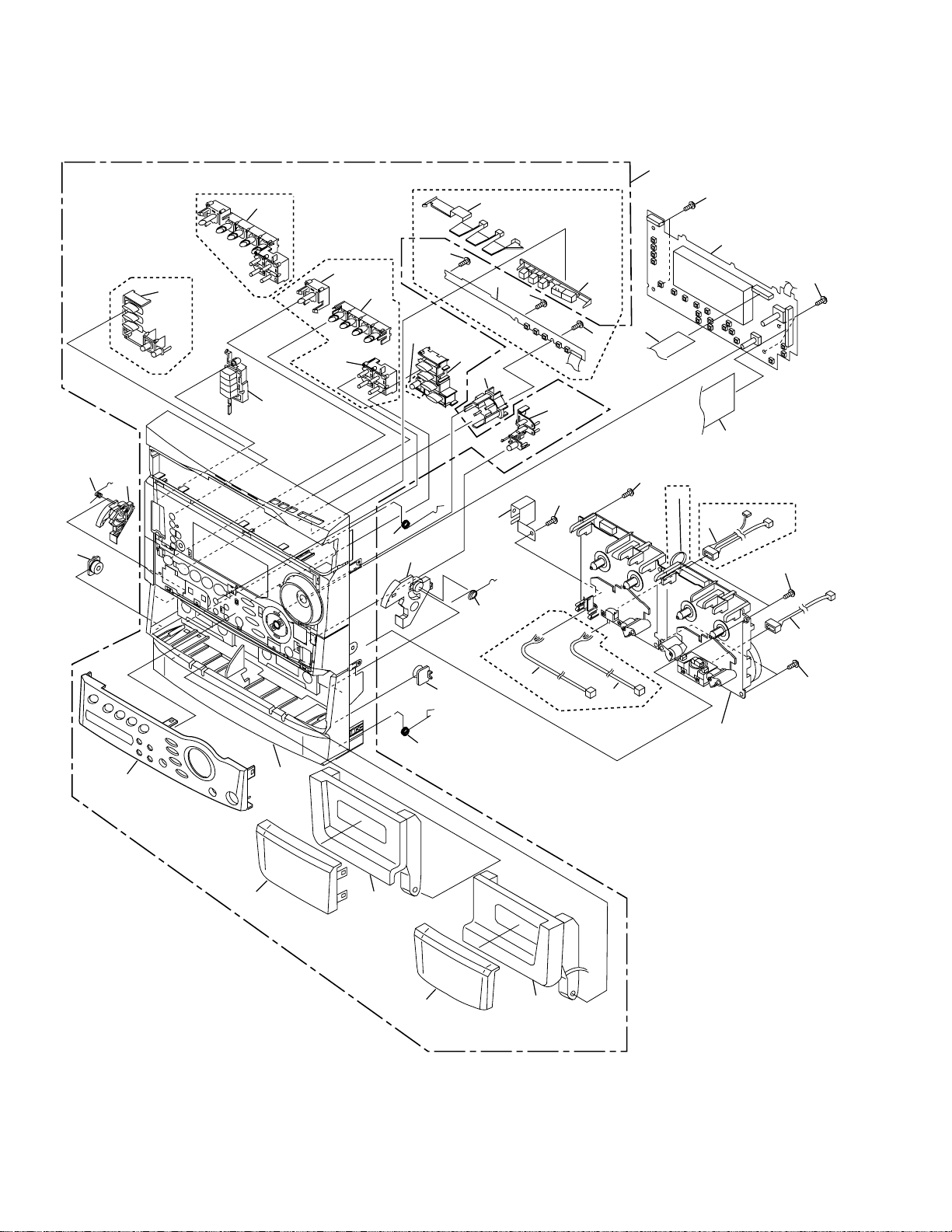

Page 8

XR-A660, XR-A550, XR-A330

2.4 FRONT PANEL SECTION

21

15

XR-A550,

XR-A330 only

25

18

XR-A550,

XR-A330 only

34

24

XR-A660 only

34(1/2)

34(2/2)

35

13

19

XR-A660 only

17

XR-A660

only

36

29

16

26

20

23

17

1

17

17

9

37

17

25

17

7

XR-A550,

17

XR-A330 only

38

8

XR-A660 only

10

2

17

33

27

32

30

28

14

21

4

5

XR-A550,

XR-A330 only

31

12

Refer to "2.7 and 2.8

MECHANISM UNIT".

17

8

Page 9

(1) FRONT PANEL SECTION PARTS LIST

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

1 DISPLAY Assy See Contrast table (2)

2 CD SW LED Assy See Contrast table (2)

3 • • • • •

4 Connector Assy 2P See Contrast table (2)

5 Connector Assy 4P See Contrast table (2)

6 • • • • •

7 Flexible Cable 19P See Contrast table (2)

8 Flexible Cable 38P XDD3004

9 Connector Assy 3P XDE3001

10 Connector Assy 5P See Contrast table (2)

11 • • • • •

12 Mechanism Unit See Contrast table (2)

13 Door Spring L XBH3001

14 Door Spring R XBH3002

15 Latch Spring L ABH7130

16 Latch Spring R ABH7131

17 Screw BPZ30P100FZK

18 Latch Mold L XMR3001

19 Latch Mold R XMR3002

20 GND Plate B XNG3005

Mark No. Description Part No.

21 Damper Assy AXA7052

22 • • • • •

NSP 23 Front Panel Assy See Contrast table (2)

24 Function Button See Contrast table (2)

25 CD Button See Contrast table (2)

26 CD Lens See Contrast table (2)

27 Deck Lens L XZN3035

28 Deck Lens R XZN3036

29 Jog Lens See Contrast table (2)

30 Door Pocket L See Contrast table (2)

31 Door Pocket R See Contrast table (2)

32 Front Panel See Contrast table (2)

33 Sub Panel A See Contrast table (2)

34 Power Button See Contrast table (2)

35 Play Button See Contrast table (2)

36 S.C. Button See Contrast table (2)

37 TIMER Button See Contrast table (2)

38 Binder See Contrast table (2)

(2) CONTRAST TABLE

XR-A660/DBDXJ, DLXJ/NC, DXJ/NC, XR-A550/DXJ, XR-A330/DBDXJ, DLXJ/NC and DXJ/NC are constructed the

same except for the following :

.oNtraP

kraM.oNnoitpircseDdnalobmyS

1yssAYALPSID5803ZWX5803ZWX5803ZWX7403ZWX7403ZWX7403ZWX7403ZWX

2yssADELWSDC6803ZWX6803ZWX6803ZWXdesutoNdesutoNdesutoNdesutoN

4P2yssArotcennoCdesutoNdesutoNdesutoN4003EDX4003EDX4003EDX4003EDX

5P4yssArotcennoCdesutoNdesutoNdesutoN3003EDX3003EDX3003EDX3003EDX

7P91elbaCelbixelF9003DDX9003DDX9003DDXdesutoNdesutoNdesutoNdesutoN

066A-RX

JXDBD/

066A-RX

CN/JXLD/

066A-RX

CN/JXD/

055A-RX

JXD/

033A-RX

JXDBD/

033A-RX

CN/JXLD/

033A-RX

CN/JXD/

skrameR

7P71elbaCelbixelFdesutoNdesutoNdesutoN0103DDX0103DDX0103DDX0103DDX

01P5yssArotcennoC2003EDX2003EDX2003EDXdesutoNdesutoNdesutoNdesutoN

21tinUmsinahceM3003MYX3003MYX3003MYX2003MYX2003MYX2003MYX2003MYX

PSN32yssAlenaPtnorF4103GXX4103GXX4103GXX1103GXX1103GXX1103GXX1103GXX

42nottuBnoitcnuF0203NZX0203NZX0203NZX1203NZX1203NZX1203NZX1203NZX

52nottuBDC8103NZX8103NZX8103NZX9103NZX9103NZX9103NZX9103NZX

62sneLDC7303NZX7303NZX7303NZXdesutoNdesutoNdesutoNdesutoN

92sneLgoJ5203KAX5203KAX5203KAXdesutoNdesutoNdesutoNdesutoN

03LtekcoProoD3103NZX3103NZX3103NZX4103NZX4103NZX4103NZX4103NZX

13RtekcoProoD5103NZX5103NZX5103NZX6103NZX6103NZX6103NZX6103NZX

23lenaPtnorF1103NZX1103NZX1103NZX2103NZX2103NZX2103NZX2103NZX

33lenaPbuS1303NZX1303NZX1303NZX3303NZX3303NZX3303NZX3303NZX

43nottuBrewoP2203NZX2203NZX2203NZX3203NZX3203NZX3203NZX3203NZX

53nottuByalP4203NZX4203NZX4203NZXdesutoNdesutoNdesutoNdesutoN

63nottuB.C.S5203NZX5203NZX5203NZX7203NZX7203NZX7203NZX7203NZX

73nottuBREMIT9203NZX9203NZX9203NZX0303NZX0303NZX0303NZX0303NZX

83redniBdesutoNdesutoNdesutoN

KB09BKS-ACZKB09BKS-ACZKB09BKS-ACZKB09BKS-ACZ

9

Page 10

XR-A660, XR-A550, XR-A330

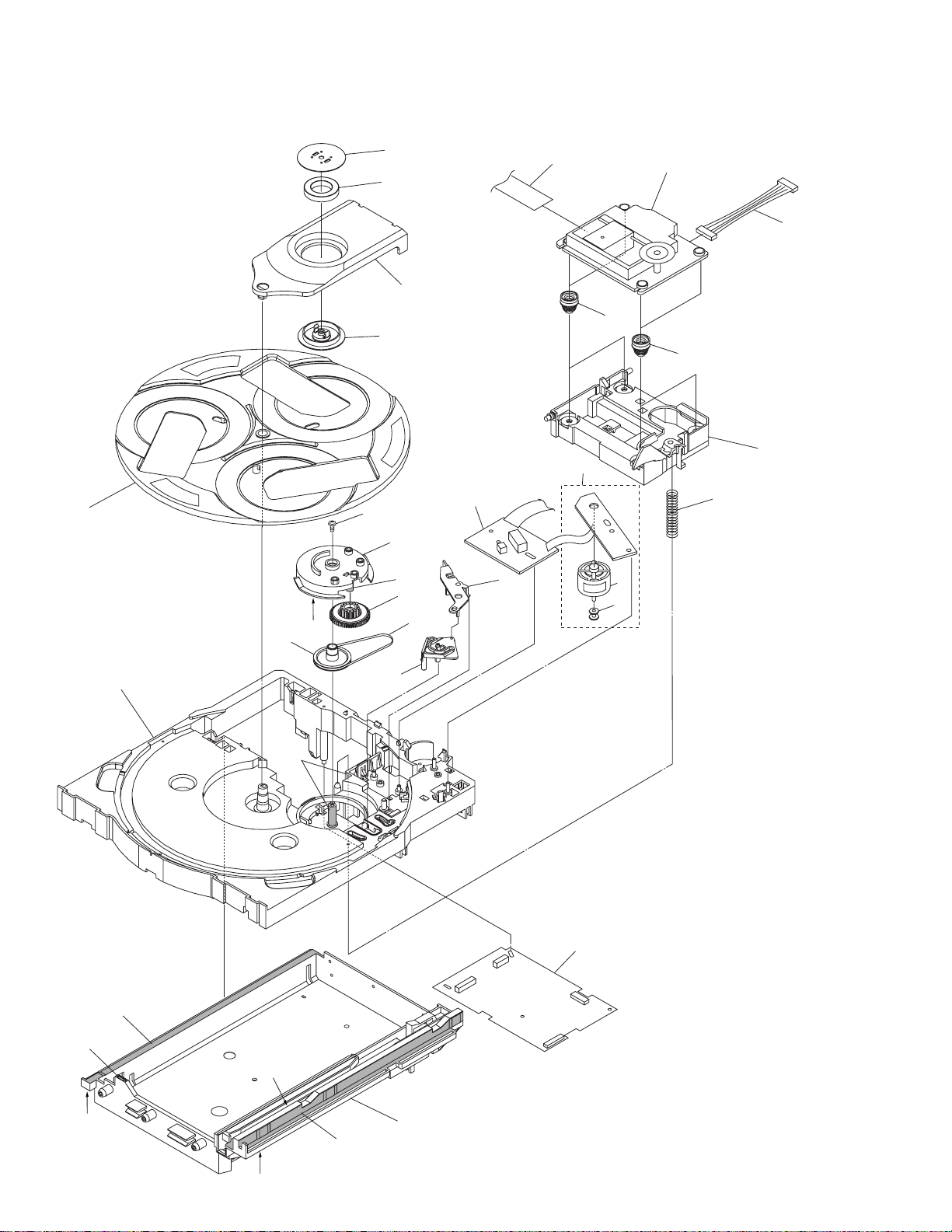

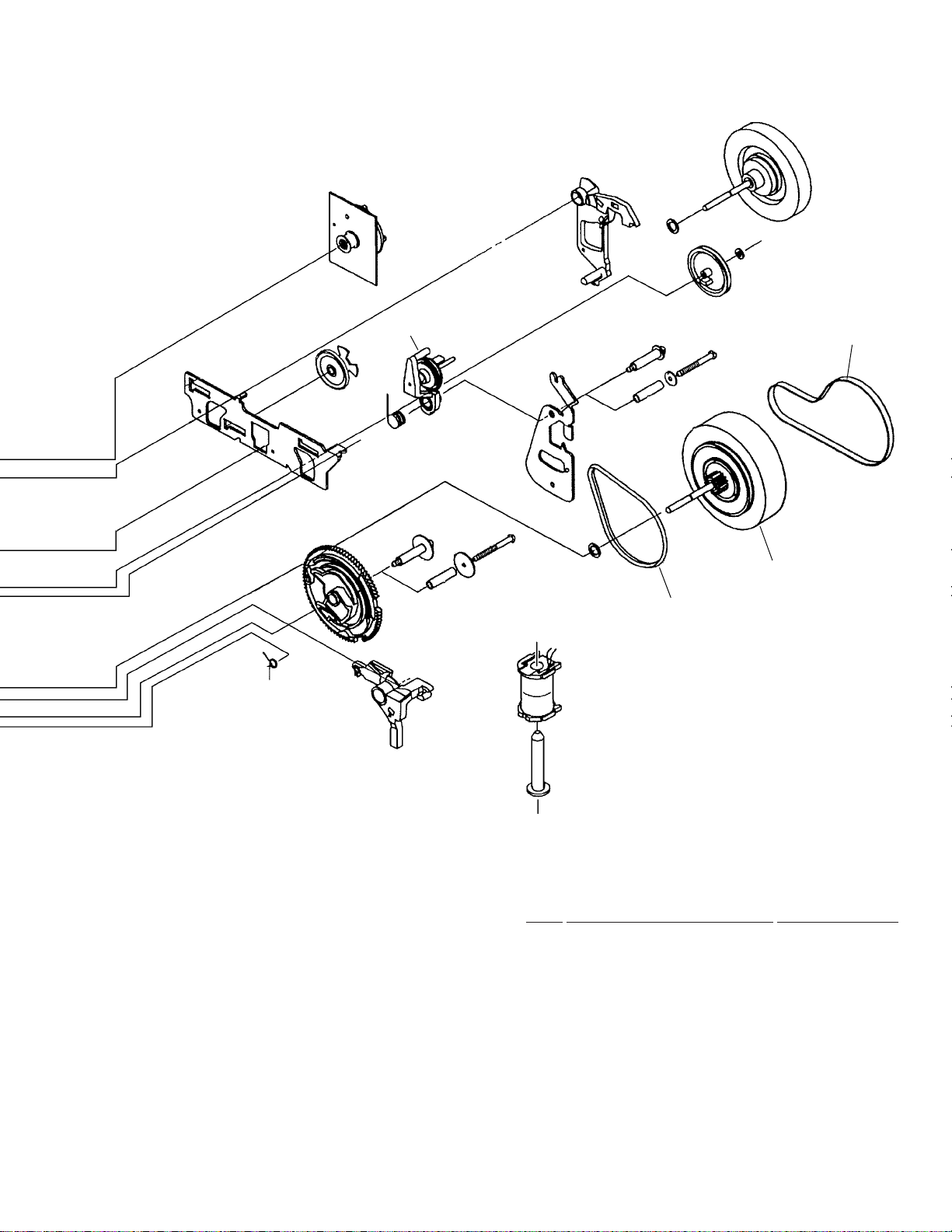

2.5 $M MECHANISM CD

13

8

21

7

14

1

Refer to "2.6 SERVO MECHANISM ASSY".

25

22

24

23

11

12

10

16

29

29

26

17

15

29

18

2

19

6

27

28

3

5

10

29

29

29

29

9

29

29

Page 11

$M MECHANISM CD PARTS LIST

•

Mark No. Description Part No.

1 MOTOR Assy AWZ8428

NSP 2 SW Assy AWZ8429

3 CD Assy AWZ3050

4 • • • • •

5 Servo Spring ABH7126

6 Belt AEB7072

7 Clamp Magnet AMF7001

8 Yoke ANB7067

9 Mecha Base ANW7125

10 Loading Tray ANW7088

11 Servo Base ANW7089

12 Rotary Tray ANW7113

13 Clamper ANW7091

14 Clamper Holder ANW7092

15 Main Cam ANW7093

16 Gear Pully ANW7094

17 Lock Lever ANW7095

18 Planet Gear ANW7096

19 Actuater ANW7097

20 • • • • •

XR-A660, XR-A550, XR-A330

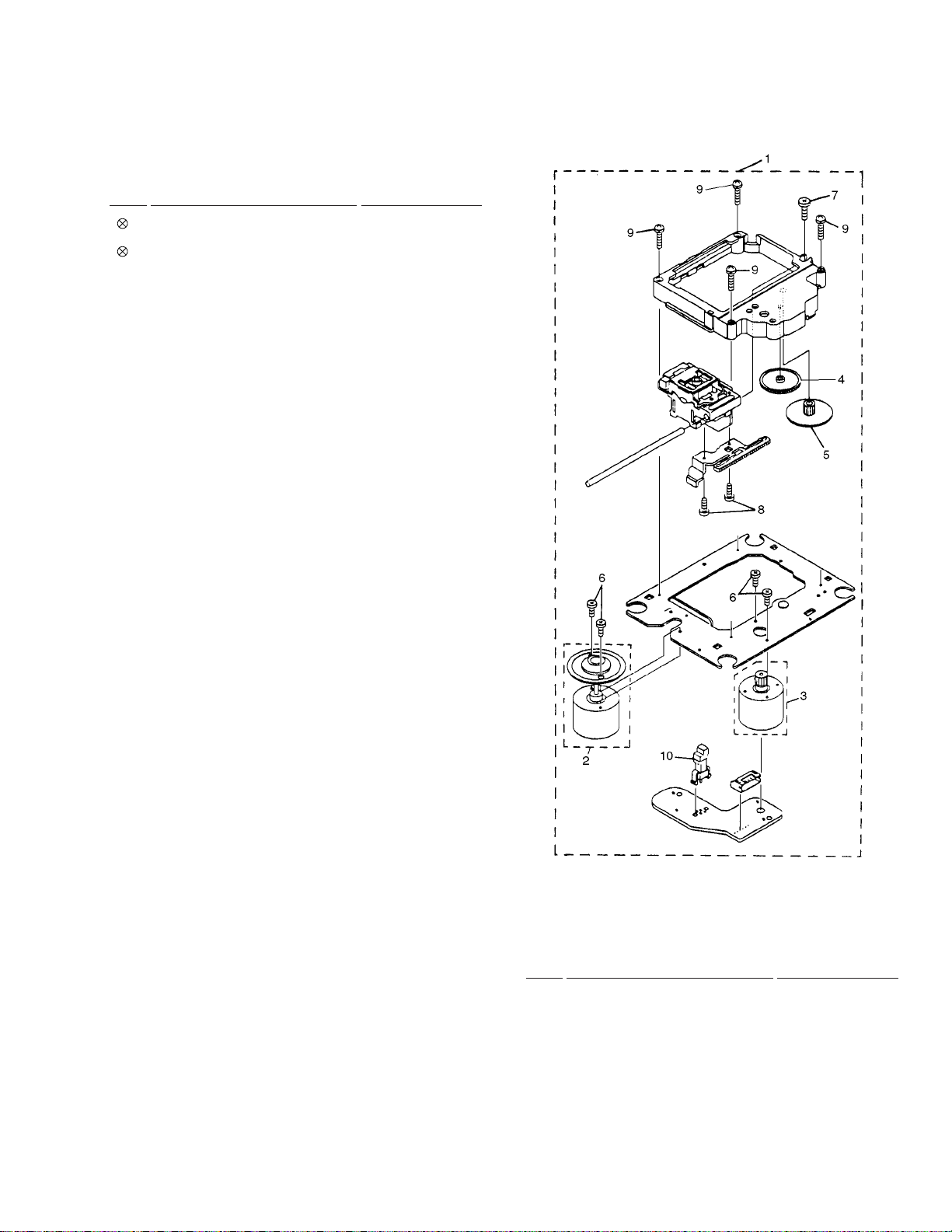

2.6 SERVO MECHANISM ASSY

21 15P F.F.C/30V ADD7038

22 Connector Assy (6P) ADE7010

23 Float Rubber A AEB7063

24 Float Rubber B AEB7066

25 Servo Mechanism Assy AXA7039

26 Screw IPZ30P080FMC

27 Carriage Motor VXM1033

28 Motor Pulley PNW1634

29 Ha Narl GEM1016

SERVO MECHANISM ASSY PARTS LIST

•

Mark No. Description Part No.

1 Servo Mechanism AXA7039

2 SPINDLE MOTOR Assy AEA7009

3 SLEAD MOTOR Assy AEA7010

4 Gear A AEA7013

5 Gear B AEA7014

6 Screw AEA7015

7 Screw AEA7016

8 Screw AEA7017

9 Screw AEA7018

10 Leaf Switch AEA7011

11

Page 12

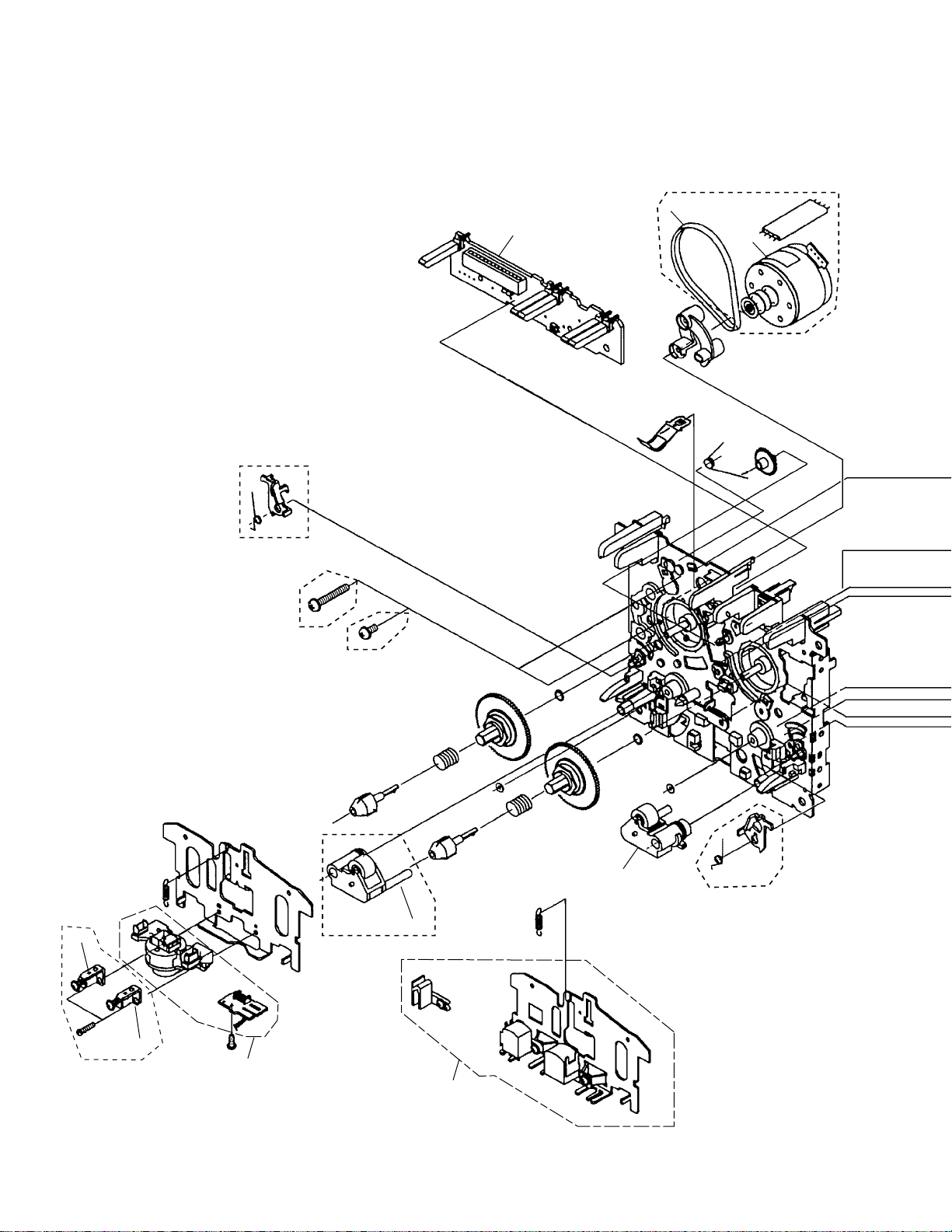

XR-A660, XR-A550, XR-A330

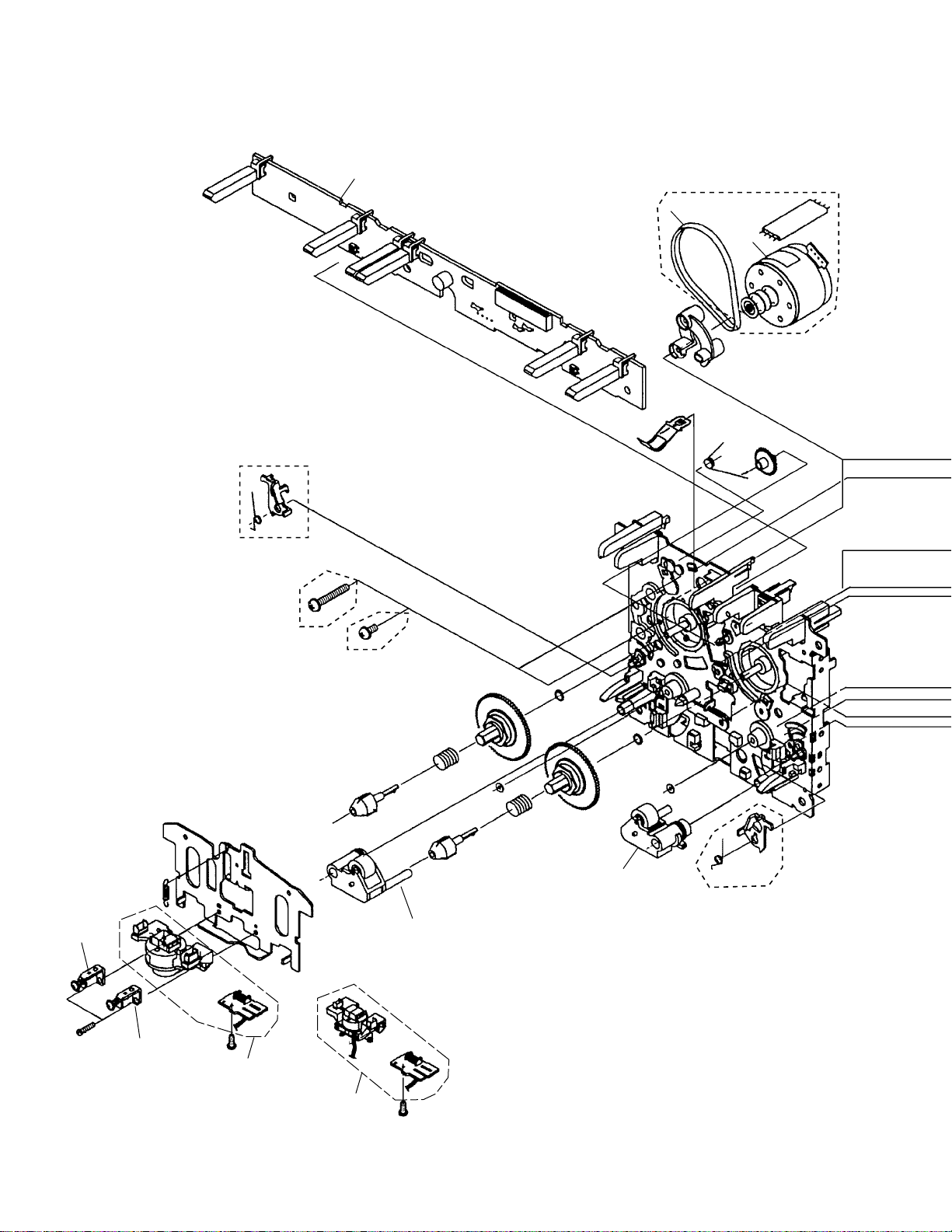

2.7 MECHANISM UNIT (XR-A660)

Mech. ΙΙ

Only

Mech. Ι

4

Mech. Ι

Only

Mech. Ι

Only

7

2

12

Mech. Ι

13

Mech. ΙΙ

9

Mech. Ι

Only

10

1

1

Mech. ΙΙ

12

Page 13

XR-A660, XR-A550, XR-A330

5

8

11

6

MECHANISM UNIT PARTS LIST

•

Mark No. Description Part No.

1 Plate HD BLK (Mech. Ι) F513-811

1 Plate HD BLK (Mech. ΙΙ) F513-819

2 Motor Main BLK (Mech. Ι only) F525-324

3 • • • • •

4 PCB Control BLK (Mech. Ι only) F567-621

5 Clutch Assy BLK F522-037

6 Main Belt FF17G-31

7 Joint Belt 113 (Mech. Ι only) FF19D-21

8 Clutch Assy BLK F522-045

9 Roller Pinch BLK R F514-129

10 Roller Pinch BLK L F514-130

11 F/R Belt FF18W-12

12 Plate Base BLK F512-127

13 Plate Base BLK F512-128

13

Page 14

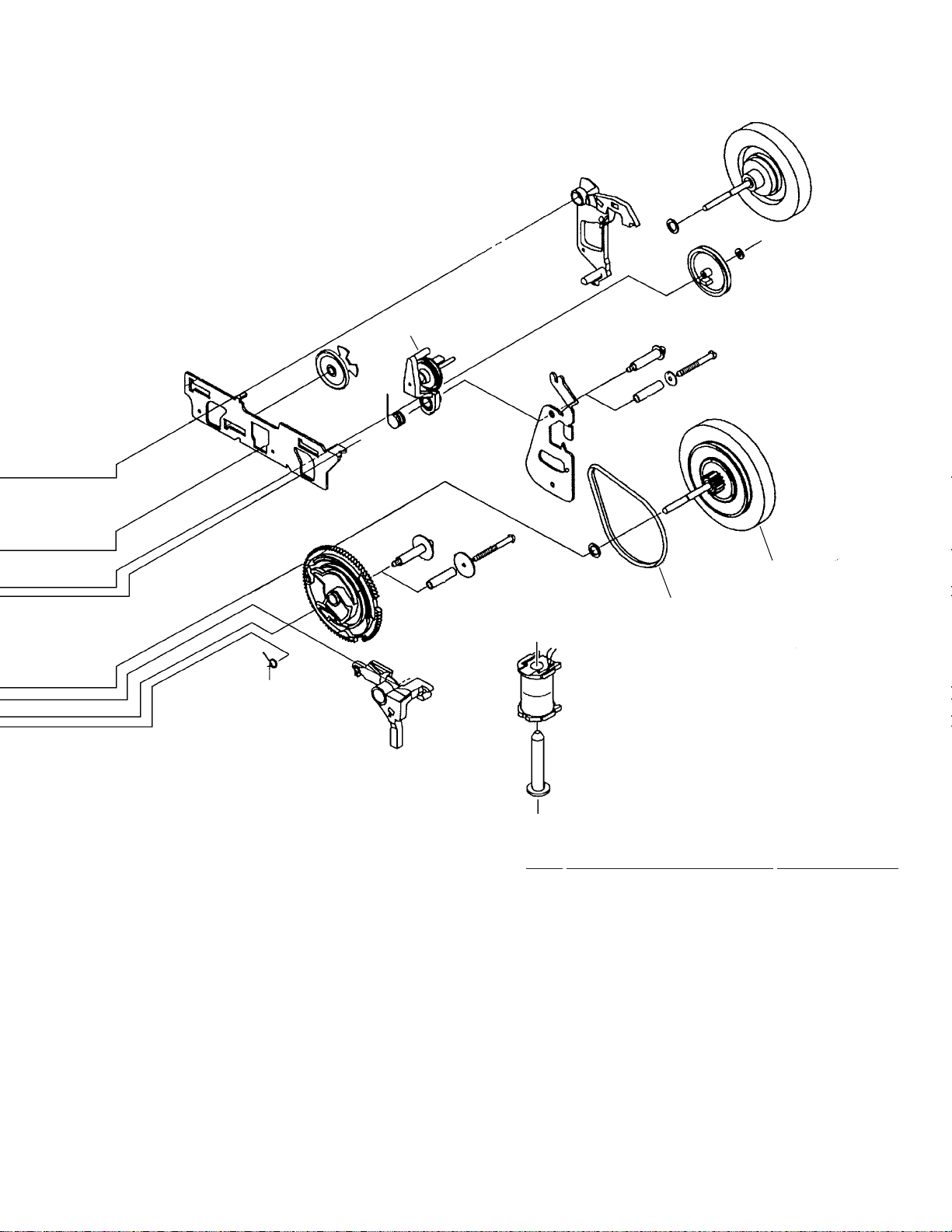

XR-A660, XR-A550, XR-A330

2.8 MECHANISM UNIT (XR-A550 and XR-A330)

4

Mech. ΙΙ

Only

Mech. Ι

Only

Mech. Ι

Only

6

2

12

Mech. Ι

Mech. Ι

Mech. ΙΙ

9

Mech. Ι

Only

10

Mech. Ι

Only

Mech. Ι Only

14

13

1

1

Mech. ΙΙ

Page 15

XR-A660, XR-A550, XR-A330

5

8

11

MECHANISM UNIT PARTS LIST

•

Mark No. Description Part No.

1 Plate HD BLK (Mech. Ι) F513-811

1 Plate HD BLK (Mech. ΙΙ) F513-825

2 Motor Main BLK (Mech. Ι only) F525-324

3 • • • • •

4 PCB Control BLK (Mech. Ι only) F567-622

5 Clutch Assy BLK F522-037

6 Main Belt (Mech. Ι only) FF17G-31

7 • • • • •

8 Clutch Assy BLK (Mech. Ι) F522-045

8 Clutch Assy BLK (Mech. ΙΙ) F522-038

9 Roller Pinch BLK R (Mech. Ι) F514-129

9 Roller Pinch BLK R (Mech. ΙΙ) F514-131

10 Roller Pinch BLK L (Mech. Ι only) F514-130

11 F/R Belt FF18W-12

12 Plate Base BLK (Mech. Ι only) F512-127

13 Plate Base BLK (Mech. Ι only) F512-128

15

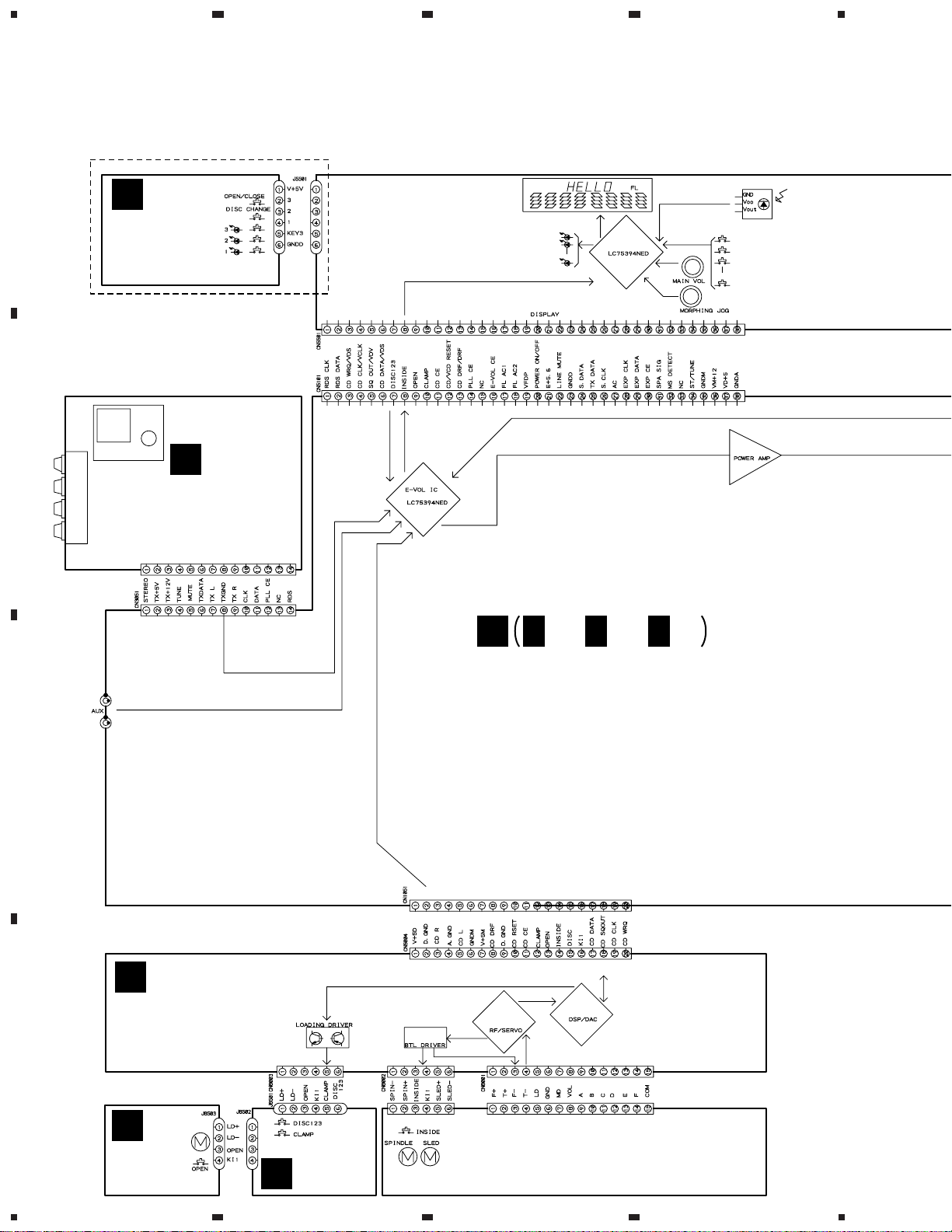

Page 16

1

XR-A660, XR-A550, XR-A330

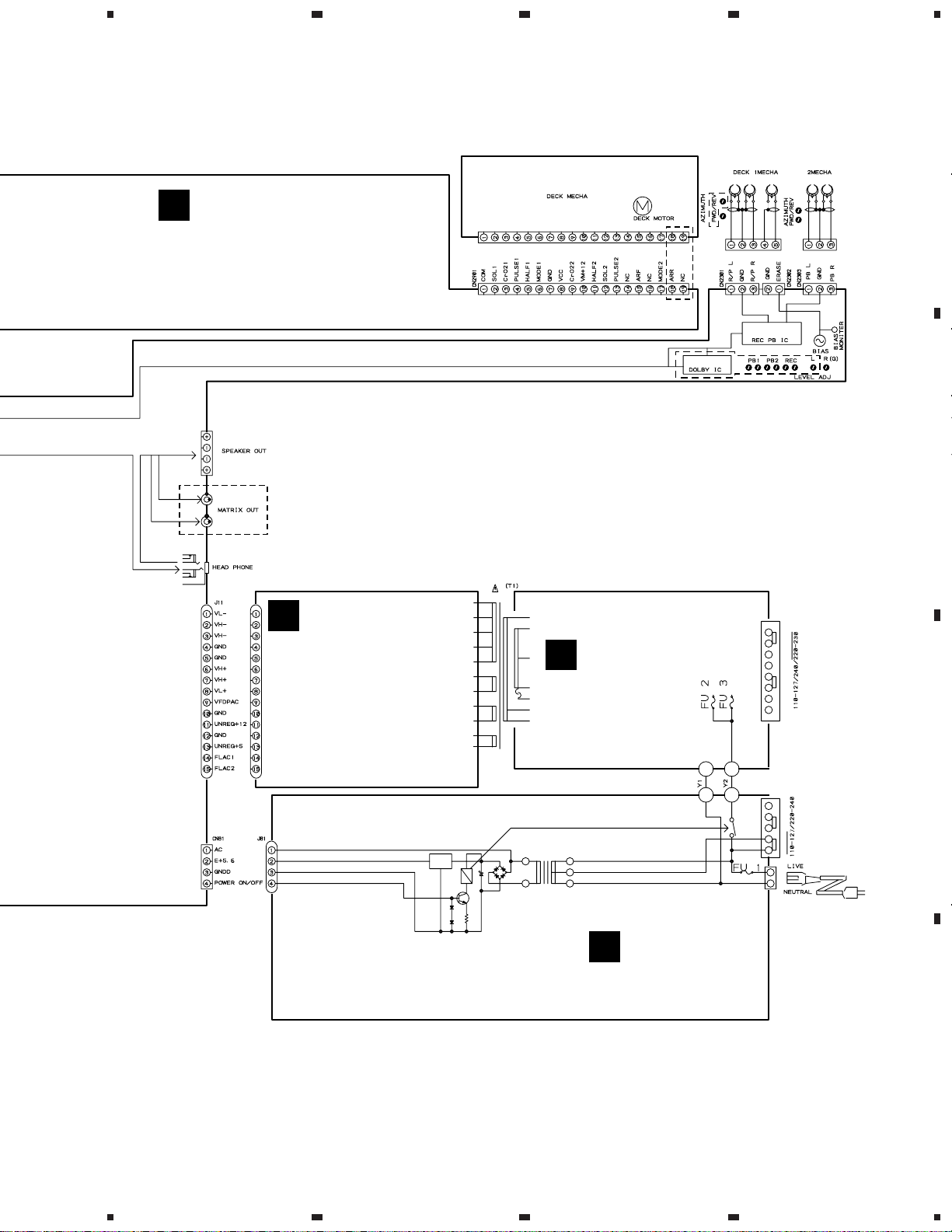

3. SCHEMATIC DIAGRAM

3.1 OVERALL WIRING DIAGRAM

A

J

CD SW LED

ASSY

(XWZ3086)

XR-A660 ONLY

23

4

B

C

A

FM/AM TUNER

MODULE

(AXQ7065)

CN6201

E

E

AF ASSY

(XR-A660 : XWZ3083)

(XR-A550 : XWZ3074)

(XR-A330 : XWZ3045)

E E

1/3, 3/3

2/3,

B

CD ASSY

(XWZ3050)

D

CARRIAGE

C

16

MOTOR

ASSY

(AWZ8428)

1234

SW ASSY

D

(AWZ8429)

SERVO MECHANISM ASSY

(AXA7039)

Page 17

5

678

XR-A660, XR-A550, XR-A330

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

I

DISPLAY ASSY

(XR-A660 : XWZ3085)

(XR-A550, XR-A330 : XWZ3047)

XR-A660 ONLY

XR-A660 ONLY

AEK7071

XR-A660 ONLY

A

B

F

SECONDARY

ASSY

(XR-A660, XR-A550

: XWZ3084)

(XR-A330 : XWZ3046)

G

PRIMARY ASSY

(XWZ3048)

C

H

SUB TRANS ASSY

(XWZ3049)

D

17

5

6

7

8

Page 18

1

RF AMP

1T378A

1T378A

MIX AMP

BUFFER

IF AMP

FM +B SW

MW RF TUNING BLOCK

AKX7041

OSC

FM/AM TUNER MODULE

(AXQ7065)

XR-A660, XR-A550, XR-A330

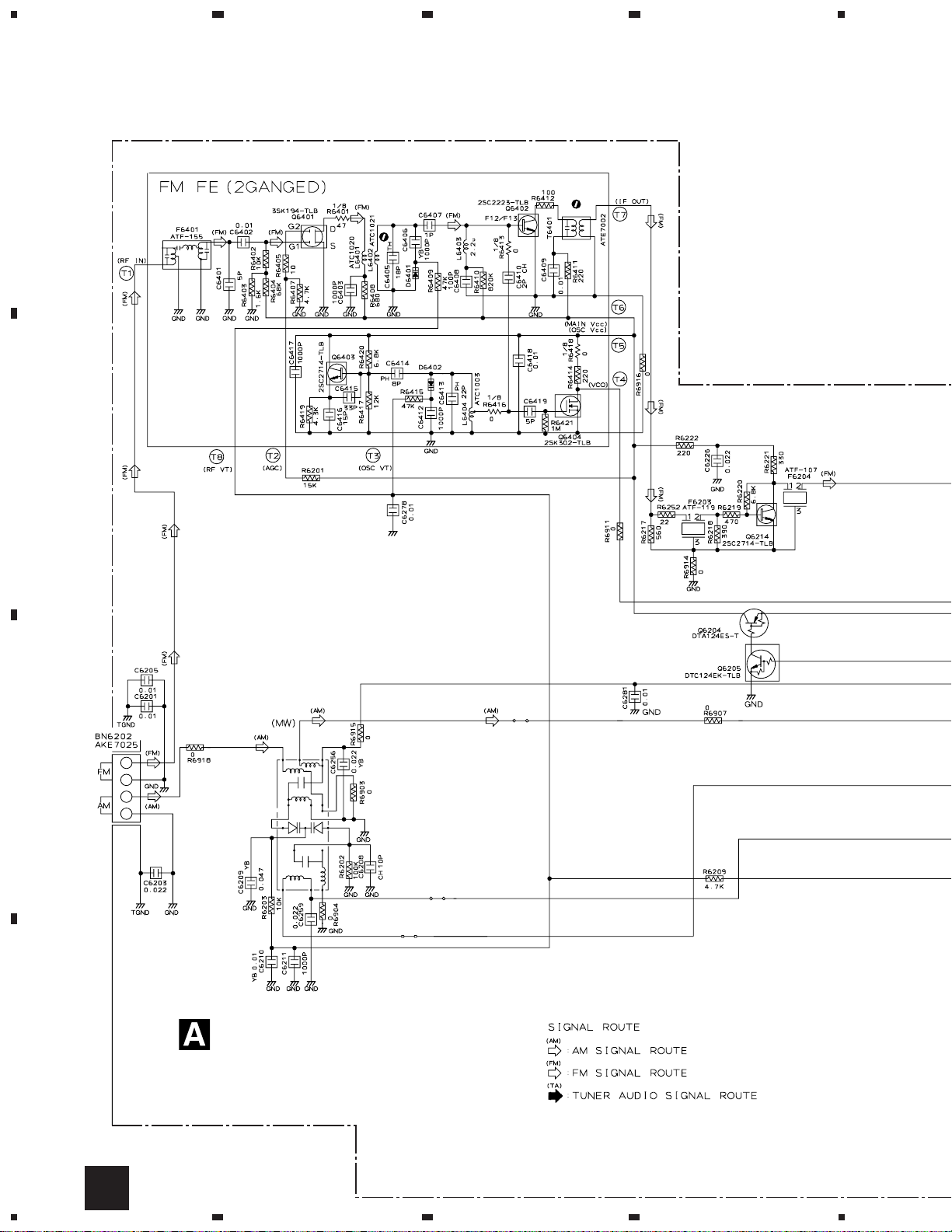

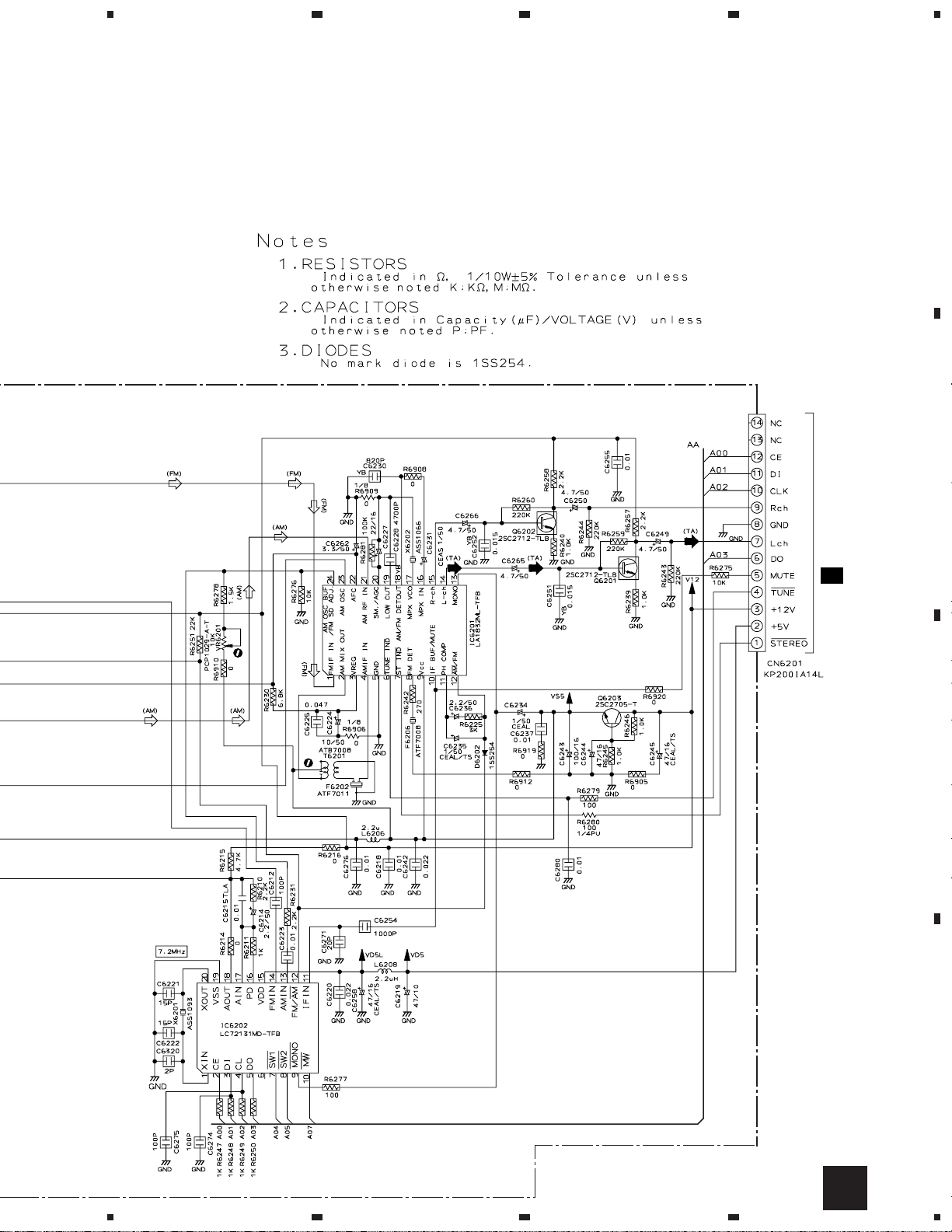

3.2 FM/AM TUNER MODULE

A

23

4

B

C

D

18

A

1234

Page 19

5

678

XR-A660, XR-A550, XR-A330

A

B

AF AMP

AF AMP

REGULATOR

CN3051

2/3E

C

PLL

D

A

5

6

7

8

19

Page 20

1

23

XR-A660, XR-A550, XR-A330

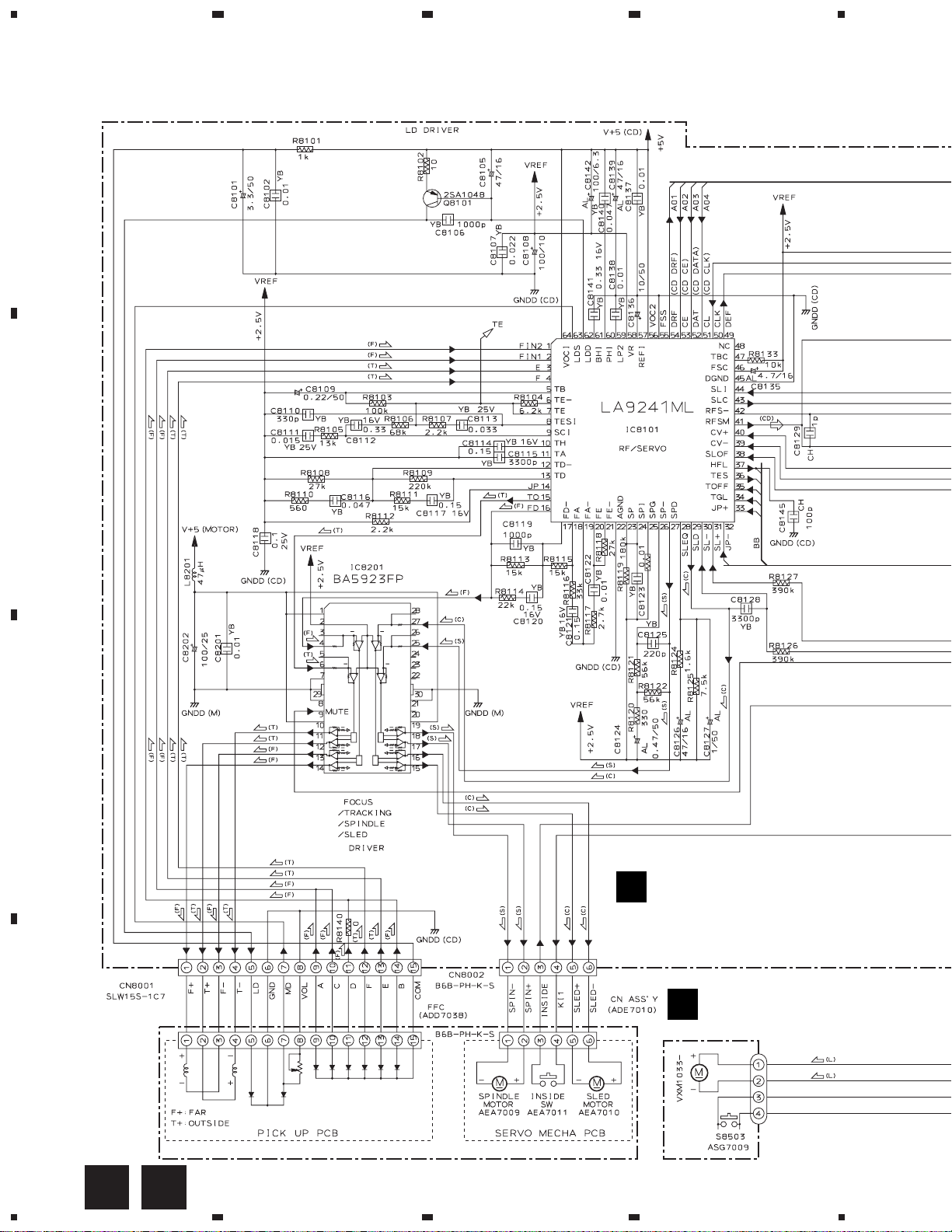

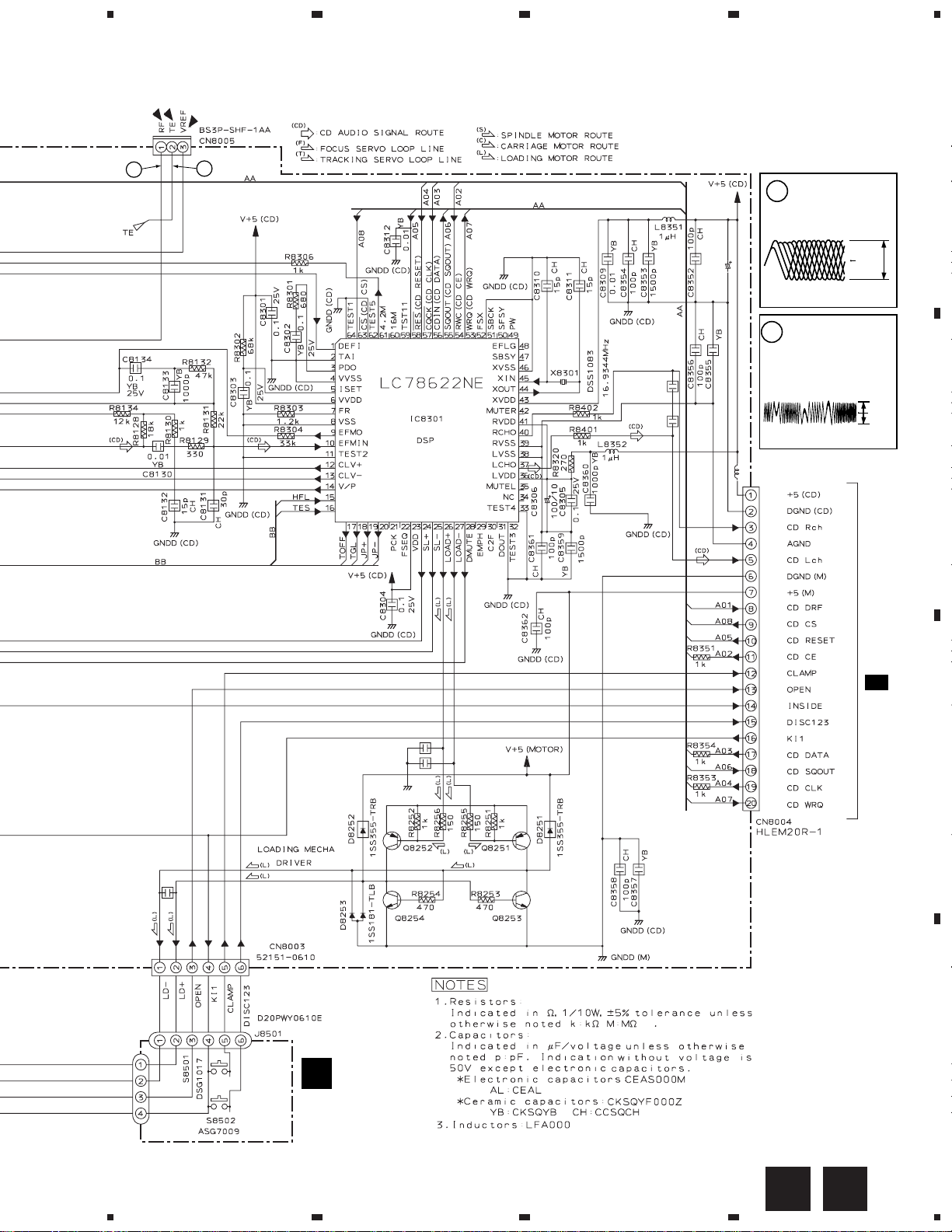

3.3 CD, MOTOR and SW ASSEMBLIES

A

B

4

56k

R8123

C

B

CD ASSY

(XWZ3050)

MOTOR ASSY

C

(AWZ8428)

CARRIAGE MOTOR

D

20

B C

J8502

SERVO MECHANISM ASSY AXA7039

1234

D20PWW0405E

Page 21

5

678

XR-A660, XR-A550, XR-A330

Note: The encircled numbers

denote measuring point in the

1

2

schematic diagram.

CN8005- Pin 1 :

1

PLAY MODE (RF)

H : 500nsec/div

1.8Vp-p

A

C8308

1000p

C8307

1000p

YB

YB

C8371

100/10

0.047

CN8005- Pin 2 :

2

TEST MODE,

Tracking Open(TRER)

H : 5msec/div

VREF:CN8005- Pin3

L8371 47µH

VREF

1.0Vp-p

VREF

B

CN1051

2/3E

J8502

C8257

0.1

C8256 0.1

C8255 0.1

2SB1237X 2SB1237X

2SD1858X

0.047

2SD1858X

C

D

D

SW ASSY

(AWZ8429)

B D

5

6

7

8

21

Page 22

1

23

XR-A660, XR-A550, XR-A330

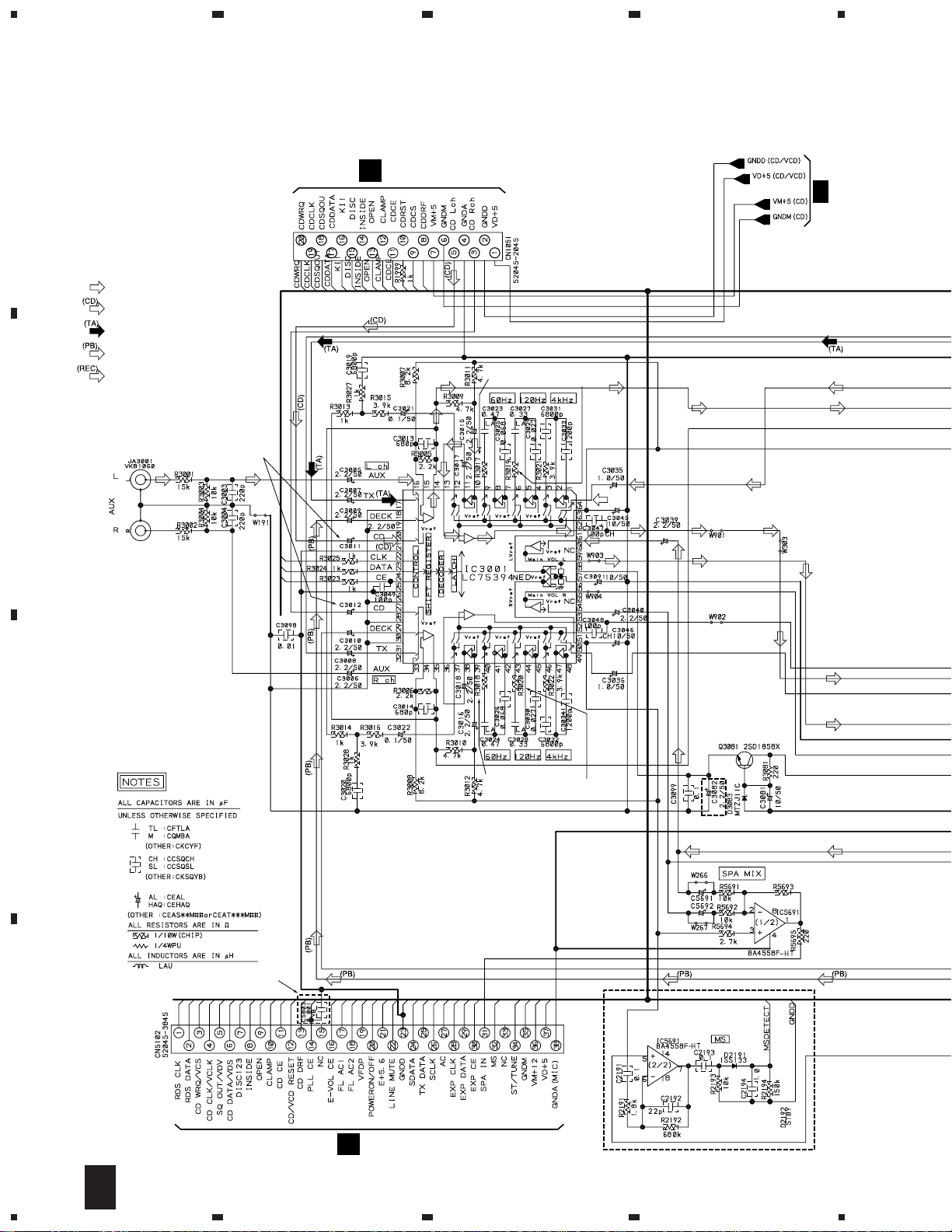

3.4 AF ASSY (1/3)

4

A

E

AF ASSY

1/3

(XR-A660 : XWZ3083)

(XR-A550 : XWZ3074)

(XR-A330 : XWZ3045)

XR-A660

ONLY

22k(XR-A660)

39k(XR-A550,A330)

B

: DECK PB SIGNAL ROUTE

: DECK REC SIGNAL ROUTE

XR-A550,A330

ONLY

XR-A660

ONLY

C2335 27p

C2336 27p

XR-A550,A330

ONLY

XR-A660

ONLY

XR-A550,A330

ONLY

C2337 27p

XR-A550,A330

ONLY

XR-A660

ONLY

680p(XR-A660)

1000p(XRA550,A330)

C

XR-A550,A330

ONLY

D

33k(XR-A660)

47k(XRA550,A330)

220k(XR-A660)

100k(XRA550,A330)

XR-A660

ONLY

0.022(XR-A660)

0.027(XRA550,A330)

C2338 27p

XR-A550,A330

ONLY

22

1/3

E

1234

Page 23

XR-A550,A330

ONLY

5

XR-A550,A330

ONLY

678

XR-A660, XR-A550, XR-A330

A

XR-A550,A330

ONLY

XR-A550,A330

ONLY

XR-A550,A330

ONLY

E

2/3

B

XR-A550,A330

ONLY

22k(XR-A660)

0(XR-A550,A330)

22k(XR-A660)

0(XR-A550,A330)

XR-A550,A330

ONLY

XR-A660 ONLY

E

C

2/3

3/3

E

D

2/3

E

XR-A660

ONLY

1/3

E

5

6

7

8

23

Page 24

1

23

XR-A660, XR-A550, XR-A330

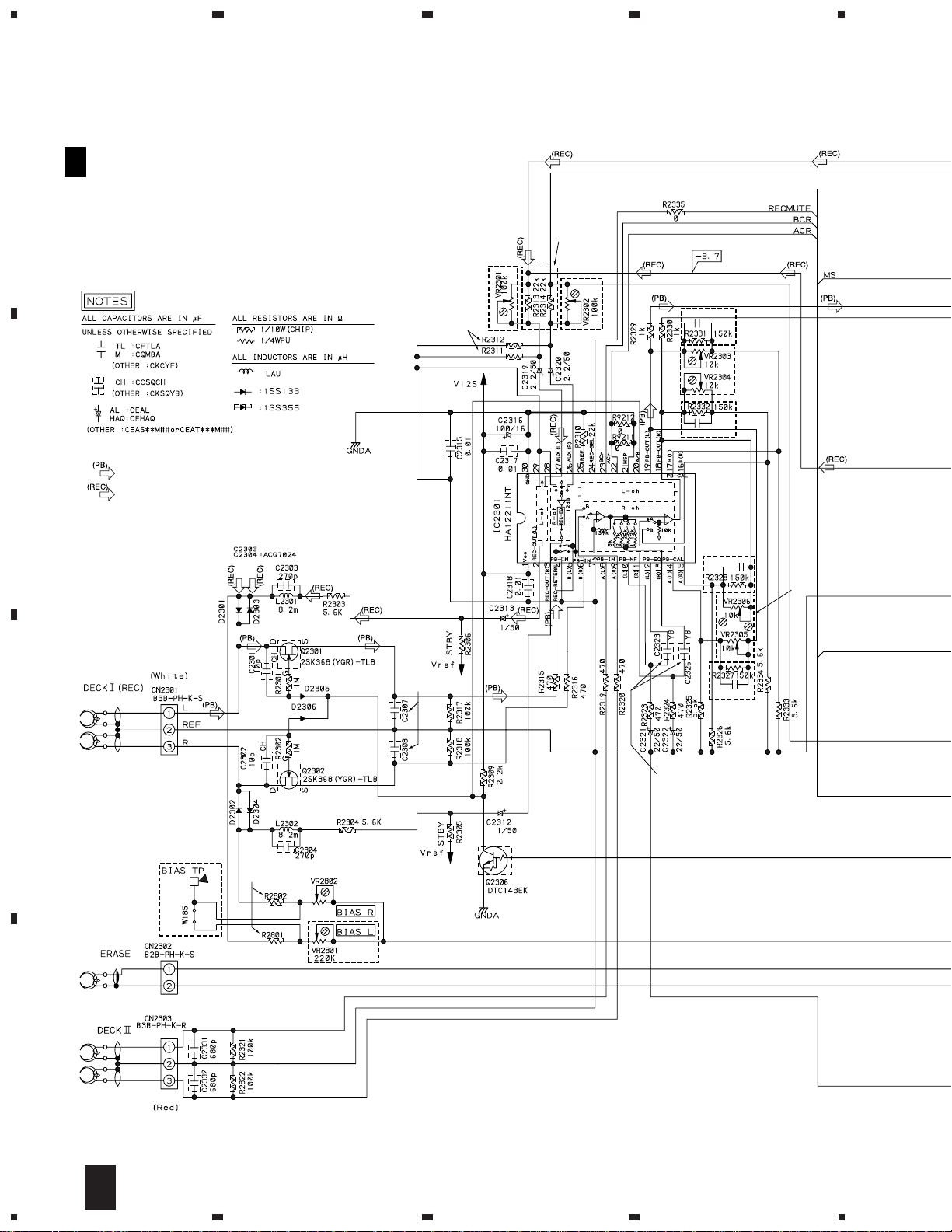

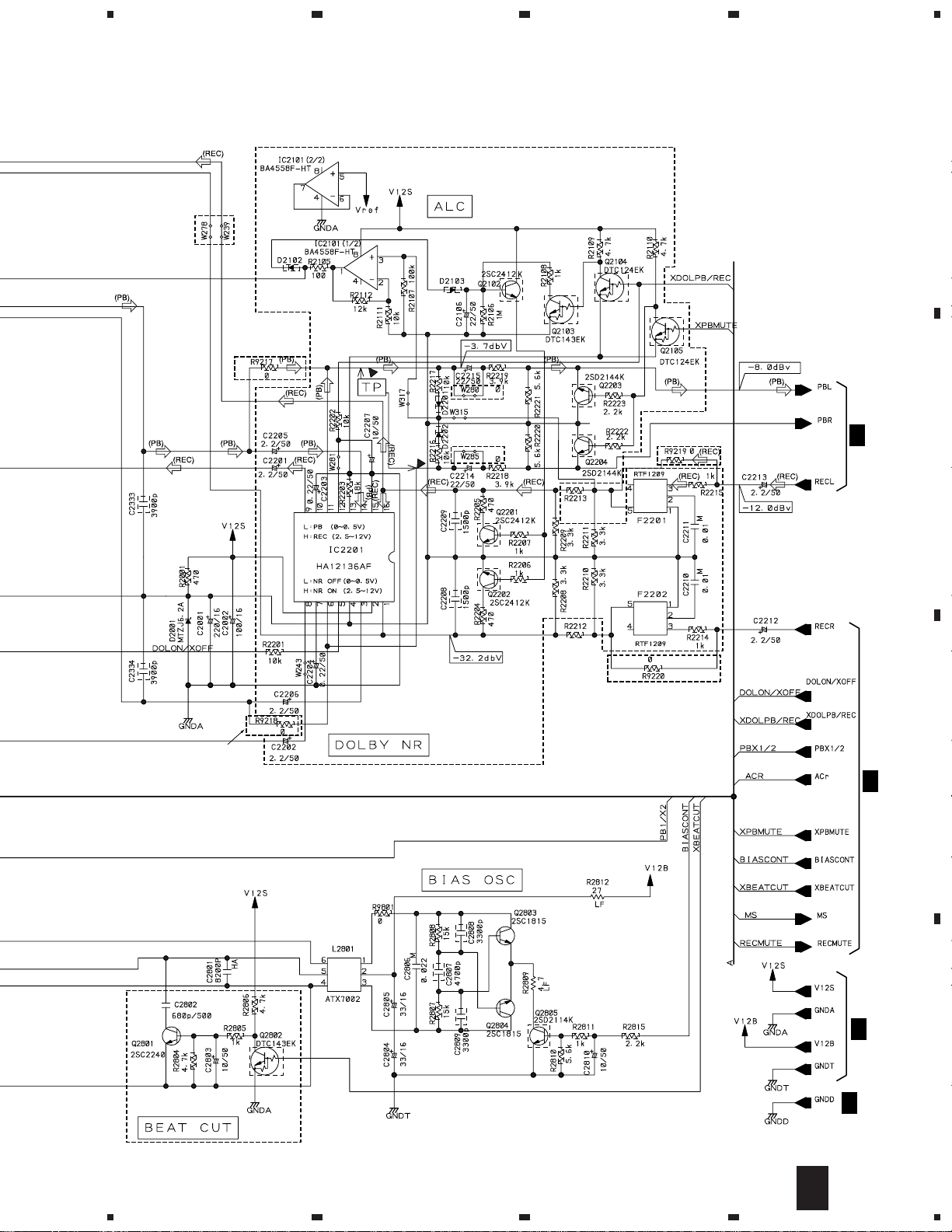

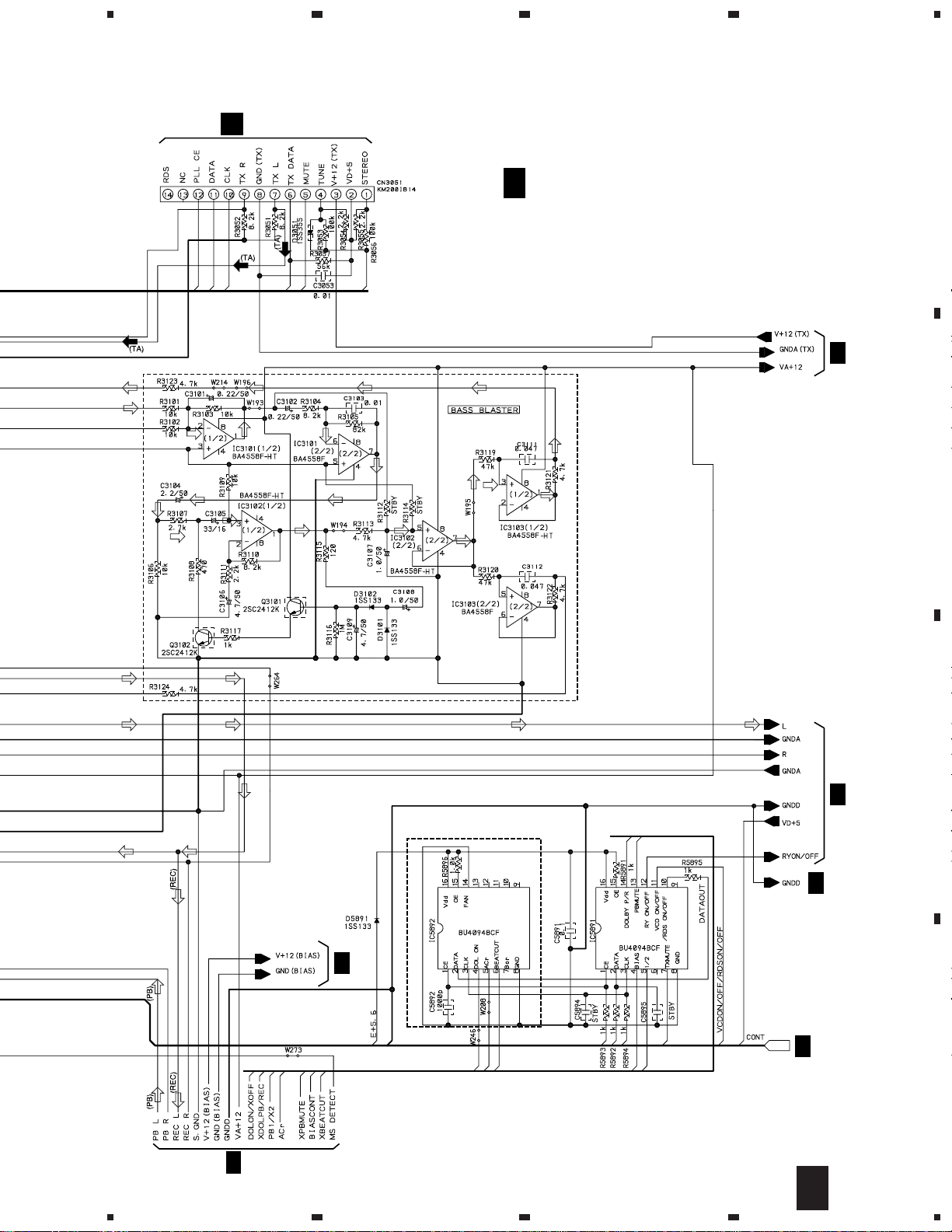

3.5 AF ASSY (2/3)

4

A

: AUDIO SIGNAL ROUTE

: CD AUDIO SIGNAL ROUTE

: TUNER AUDIO SIGNAL ROUTE

: DECK PB SIGNAL ROUTE

: DECK REC SIGNAL ROUTE

2.2/50(XR-A660,A550)

B

0.47/50(XR-A330)

B

CN8004

6.8k(XR-A660,A550)

0k(XR-A330)

6.8k(XR-A660,A550)

3.9k(XR-A330)

E

3/3

C

XR-A660

ONLY

D

CN5501

I

24

2/3

E

1234

6.8k(XR-A660,A550)

0k(XR-A330)

6.8k(XR-A660,A550)

3.9k(XR-A330)

XR-A660

ONLY

XR-A330 ONLY

2.7k(XR-A660)

56k(XR-A550,A330)

Page 25

5

A

CN6201

678

XR-A660, XR-A550, XR-A330

A

AF ASSY

2/3

E

(XR-A660 : XWZ3083)

(XR-A550 : XWZ3074)

(XR-A330 : XWZ3045)

3/3

E

XR-A660

ONLY

B

C

3/3

E

XR-A660

ONLY

1/3

E

3/3

E

3/3

E

D

1/3

E

2/3

E

5

6

7

8

25

Page 26

1

23

XR-A660, XR-A550, XR-A330

3.6 AF (3/3) and SECONDARY ASSEMBLIES

A

2/3

E

B

IC3301

STK407-070B(XR-A660,A550)

STK407-050B(XR-A330)

4

2/3

E

1/3

E

C

2/3

E

1/3

E

2/3

D

E

26

2/3

E

3/3

E

1234

Page 27

5

678

XR-A660, XR-A550, XR-A330

E

AF ASSY

3/3

(XR-A660 : XWZ3083)

(XR-A550 : XWZ3074)

(XR-A330 : XWZ3045)

: AUDIO SIGNAL ROUTE

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 4911.25 MFD, BY LITTELFUSE INK.

FOR IC71 (AEK7010).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491003 MFD, BY LITTELFUSE INK.

FOR IC31 AND IC41 (AEK7015).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491007 MFD, BY LITTELFUSE INK.

FOR IC11 AND IC12 (AEK7021: XR-A660).

12k(XR-A660,A550)

15k(XR-A330)

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION

CAUTION

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491005 MFD, BY LITTELFUSE INK.

FOR IC21 AND IC22 (AEK7046: XR-A660).

: FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491005 MFD, BY LITTELFUSE INK.

FOR IC11 AND IC12

: FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491004 MFD, BY LITTELFUSE INK.

FOR IC21 AND IC22

(AEK7019: XR-A550, XR-A330).

(AEK7053: XR-A550, XR-A330).

SPEAKER

XR-A660 ONLY

A

B

2SA965(XR-A660,A550)

2SA1837(XR-A330)

XR-A660,A550

ONLY

100/100(XR-A660,A550)

220/63(XR-A330)

5.6k(XR-A660,A550)

2.2k(XR-A330)

XR-A330

ONLY

820(XR-A660,A550)

1.5k(XR-A330)

J81

H

3300/50(XR-A660,A550)

2200/50(XR-A330)

IC11, IC12

AEK7021(XR-A660,A550)

AEK7019(XR-A330)

IC21, IC22

AEK7046(XR-A660,A550)

AEK7053(XR-A330)

SECONDARY ASSY

F

(XR-A660,XR-A550 : XWZ3084)

(XR-A330 : XWZ3046)

C

T1

POWER TRANSFORMER

D

3/3

E

5

6

7

F

8

27

Page 28

1

23

XR-A660, XR-A550, XR-A330

3.7 PRIMARY and SUB TRANS ASSEMBLIES

A

PRIMARY ASSY

G

(XWZ3048)

4

H5 H6

B

XR-A660, XR-A550 : AEK1057 (T2A)

XR-A330 : AEK1056 (T1.6A)

POWER TRANSFORMER

C

AKR7001

H3 H4

SUB TRANS ASSY

H

(XWZ3049)

CN81

3/3

E

D

28

G H

1234

Page 29

5

678

XR-A660, XR-A550, XR-A330

A

B

10000pF/AC250V

C

XR-A660, XR-A550 : AEK1060 (T4A)

XR-A330 : AEK1059 (T3.15A)

D

G H

5

6

7

8

29

Page 30

1

23

XR-A660, XR-A550, XR-A330

3.8 DISPLAY and CD SW LED ASSEMBLIES

A

B

DISPLAY ASSY

S5911 : DISPLAY

S5912 : TIMER

S5913 : ENTER

S5914 : P. BASS

S5915 : ZOOM SURROUND

S5916 : BASS BLASTER

S5917 : EQUALIZER

S5918 : PRESET

S5919 : STANDBY/ON

S5920 : TUNING - 1 4

S5921 : TUNING + ¡ ¢

S5922 : STOP

S5923 : PLAY/PAUSE

S5924 : REC/STOP

S5925 : FREQ/STATION

S5926 : DOLBY NR ON/OFF

S5927 : ASES/COPY

S5928 : AUX

S5929 : TAPE Ι/ΙΙ

S5930 : TUNER/BAND

S5931 : CD

S5932 : DISC 1 SELECT

S5933 : DISC 2 SELECT

S5934 : DISC 3 SELECT

S5935 : DISC CHANGE

S5936 : OPEN/CLOSE

DISPLAY ASSY

I

(XR-A660 : XWZ3085)

(XR-A550,XR-A330 : XWZ3047)

SLP3118C51H

XR-A660

ONLY

XR-A660

ONLY

4

XR-A550,A330

ONLY

1k(XR-A660)

0(XR-A550,A330)

C

D

XR-A660

ONLY

XR-A550,

A330

ONLY

1SS181

V5621 FL TUBE

XAV3004(XR-A660)

XAV3003(XR-A550,A330)

30

I

1234

Page 31

5

678

XR-A660, XR-A550, XR-A330

XR-A660 ONLY

SLP9118C51H(XR-A660)

SLP7118C51H(XR-A550,A330)

XR-A660

ONLY

CN5501

52045-3845

XR-A660

ONLY

E

2/3

CN5101

1SS183

HLEM19S-1(XR-A660)

HLEM17S-1(XR-A550,A330)

DECK MECH

XR-A660

ONLY

A

B

1SS181 1SS181

5

XR-A550,

A330

ONLY

XR-A660 ONLY

6

CD SW LED ASSY

J

(XWZ3086)

7

XR-A660 ONLY

XR-A550,

XR-A330

ONLY

S5937 : OPEN/CLOSE

S5938 : DISC CHANGE

S5939 : DISC 3 SELECT

S5940 : DISC 2 SELECT

S5941 : DISC 1 SELECT

JI

8

C

D

31

Page 32

XR-A660, XR-A550, XR-A330

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGS

DGGSS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

32

Page 33

1

4.1 FM/AM TUNER MODULE

FM/AM TUNER MODULE

A

234

XR-A660, XR-A550, XR-A330

A

CN3051

E

SIDE A

B

FM/AM TUNER MODULE

A

Q6204

VR6201

Q6203

SIDE B

C

IC6201

1

IC6202

Q6202Q6201

Q6205

2

Q6403

Q6404

Q6303 Q6302Q6301

Q6214

Q6402

Q6401

3

Q6304

Q6306

(ANP7159-B)

A

4

D

33

Page 34

1

23

XR-A660, XR-A550, XR-A330

4.2 CD, MOTOR and SW ASSEMBLIES

A

MOTOR

C

ASSY

B

SERVO

MECHANISM

ASSY

SW ASSY

D

LOADING

MOTOR

M

4

Q8101

PICKUP

ASSY

C

Q8254

Q8252

Q8251

E

CB

CN1051

D

CD ASSY

B

(ANP7144-E)

D

SIDE A

34

1234

Q8253

Page 35

1

234

XR-A660, XR-A550, XR-A330

SW ASSY

MOTOR ASSY

C

D

A

B

IC8201

IC8101

IC8301

C

D

CD ASSY

B

1

2

(ANP7144-E)

3

SIDE B

CB

D

4

35

Page 36

1

E

AF ASSY

H

J81

CN6201

A

MECHANISM

UNIT

F

J11

VR2302

VR2802

VR230

VR280

Q2801Q2804Q2803Q3081 Q71

Q3351Q31 IC32 IC51 IC42 Q3352

XR-A660, XR-A550, XR-A330

4.3 AF ASSY

A

23

4

B

C

D

36

SIDE A

E

1234

Page 37

5

678

XR-A660, XR-A550, XR-A330

1

B

CN8004

I

CN5501

A

B

VR2802

1 IC3301

VR2301

VR2801

VR2303VR2302

IC2301

VR2306

MECHANISM

UNIT

MECHANISM

UNIT

(XNP3008-C)

Q52

Q51

C

D

E

5

6

7

8

37

Page 38

1

1

2

XR-A660, XR-A550, XR-A330

A

B

23

E

AF ASSY

4

C

(XNP3008-C)

D

SIDE B

38

E

1234

IC5891 IC2101

IC5892 Q3605 Q3608

Q2802 Q2306 Q2105 Q3601

Q53

IC3301

Q2301 Q2204 Q2203 Q

Q3603 Q2302

Q3314 Q3313 Q3312 Q33

IC2201

Page 39

5

678

XR-A660, XR-A550, XR-A330

A

B

IC2101 Q2201Q2202 Q5751 Q5752

2204 Q2203 Q2103 IC5751

IC2201

Q3312 Q3311 Q3351 Q3352

Q3353 Q3354 Q3101 Q3102

IC42 IC51 IC32 Q31

5

IC5691 IC3001

IC3951 IC3101 IC3103

Q2805 Q2807

C

D

E

6

7

8

39

Page 40

1

23

XR-A660, XR-A550, XR-A330

4.4 SECONDARY and PRIMARY ASSEMBLIES

A

F

SECONDARY ASSY

B

E

J11

IC71

IC11

IC12

IC21

IC22

4

IC31

IC41

(XNP3008-C)

POWER TRANSFORMER (T1)

C

NL

Y1

H

Y2

(XNP3012-B)

D

G

PRIMARY ASSY

SIDE A

40

F

G

1234

Page 41

1

4.5 SUB TRANS ASSY

234

XR-A660, XR-A550, XR-A330

E

CN81

Y2

H

SUB TRANS ASSY

A

B

G

Y1

AC IN

C

LIVE

NEUTRAL

(XNP3012-B)

D

SIDE A

H

1

2

3

4

41

Page 42

1

23

XR-A660, XR-A550, XR-A330

4.6 DISPLAY and CD SW LED ASSEMBLIES

A

E

CN5101

MECHANISM

UNIT

B

4

I

DISPLAY

ASSY

C

J

CD SW LED

ASSY

(XNP3012-B)

D

SIDE A

42

I

J

1234

Page 43

Q2903

Q2901

Q2906

Q2908

Q2907

1

I

DISPLAY

ASSY

234

XR-A660, XR-A550, XR-A330

A

B

Q5605

IC5601

Q2904

IC5501

Q2910

Q2911

Q5801

Q5502

Q5501

Q5821

IC5631

C

J

CD SW LED

ASSY

Q5606

Q5601

Q5604

IC3901

IC3931

(XNP3012-B)

D

SIDE B

JI

1

2

3

4

43

Page 44

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:

LIST OF HOLE PCB ASSEMBLIES

Parts marked by "NSP" and can not be supplied.

•

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

1

→ 561 ........................................................RD1/4PU 5 6 1 J

3

→ 473 ........................................................RD1/4PU 4 7 3 J

0.5 Ω→R50 .....................................................................................RN2H

1 Ω→1R0 ..................................................................................... RS1P 1 R 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

kraMnoitpircseDdnalobmyS

ELUDOMRENUTMA/MF

PSN

PSN

YSSADC

YSSAROTOM

YSSAWS

YSSADRAOBOVRESM$

Mark No. Description Part No.

R 5 0

.oNtraP

066A-RX055A-RX033A-RX

,JXDBD

,CN/JXLD

JXD

CN/JXD

5607QXA

2003XWX

0503ZWX

8248ZWA

9248ZWA

5607QXA

2003XWX

0503ZWX

8248ZWA

9248ZWA

,JXDBD

,CN/JXLD

CN/JXD

5607QXA

2003XWX

0503ZWX

8248ZWA

9248ZWA

K

skrameR

PSN

PSN

YSSANIAM

YSSAFA

YSSAYRADNOCES

YSSAXELPMOC

YSSAYRAMIRP

YSSASNARTBUS

YSSAYALPSID

YSSADELWSDC

Mark No. Description Part No.

FM/AM TUNER MODULE

A

SEMICONDUCTORS

IC6201 LA1832ML

IC6202 LC72131MD

Q6402 2SC2223

Q6203 2SC2705

Q6201,Q6202 2SC2712

Q6214,Q6403 2SC2714

Q6404 2SK302

Q6401 3SK194

Q6204 DTA124ES

Q6205 DTC124EK

D6202 1SS254

D6401,D6402 1T378A

COILS AND FILTERS

L6404 FM COIL ATC1003

L6401 FM RF COIL ATC1020

L6402 FM RF COIL ATC1021

F6204 FM CERAMIC FILTER ATF-107

F6203 FM CERAMIC FILTER ATF-119

8403MWX

3803ZWX

4803ZWX

9403MWX

8403ZWX

9403ZWX

5803ZWX

6803ZWX

3403MWX

4703ZWX

4803ZWX

4403MWX

8403ZWX

9403ZWX

7403ZWX

desutoN

0303MWX

5403ZWX

6403ZWX

1303MWX

8403ZWX

9403ZWX

7403ZWX

desutoN

Mark No. Description Part No.

F6401 FM BAND PASS FILTER ATF-155

F6206 FM CERAMIC DISCRIMINATOR ATF7008

F6202 AM CERAMIC FILTER ATF7011

L6206,L6208,L6403 LAU2R2J

TRANSFORMERS

T6201 AM IF TRANS. ATB7008

T6401 FM CONNECT TRANS. ATE7002

CAPACITORS

C6208 CCSQCH100D50

C6212,C6274,C6275,C6408 CCSQCH101J50

C6412 CCSQCH102J50

C6221,C6222,C6416 CCSQCH150J50

C6271 CCSQCH200J50

C6415 CCSQCH330J50

C6406 CCSQCH331J50

C6401,C6419 CCSQCH5R0C50

C6407 CCSQCK1R0C50

C6410 CCSQCK2R0C50

44

Page 45

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

C6413 CCSQRH180J50

C6414 CCSQRH8R0D50

C6405 CCSQTH150J50

C6234,C6235 CEAL1R0M50

C6245 CEAL470M16

C6224 CEAT100M50

C6243 CEAT101M16

C6231 CEAT1R0M50

C6227 CEAT220M25

C6214,C6236 CEAT2R2M50

C6262 CEAT3R3M50

C6219 CEAT470M10

C6244 CEAT470M16

C6249,C6250,C6265,C6266 CEAT4R7M50

C6258 CEJA470M16

C6215 CFTLA103J50

C6211,C6254,C6403,C6417 CKSQYB102K50

C6201,C6205,C6210,C6237,C6276 CKSQYB103K50

C6278,C6280,C6281,C6402,C6409 CKSQYB103K50

C6418 CKSQYB103K50

C6251,C6252 CKSQYB153K50

C6203,C6259 CKSQYB223K50

C6228 CKSQYB472K50

C6209 CKSQYB473K50

C6230 CKSQYB821K50

C6218,C6223,C6255 CKSQYF103Z50

C6220,C6226,C6242,C6256 CKSQYF223Z50

C6225 CKSQYF473Z50

RESISTORS

R6280 RD1/4PU101J

R6413,R6416,R6418,R6906,R6909 RS1/8S0R0J

R6401 RS1/8S470J

VR6201 (10kΩ) PCP1029

Other Resistors RS1/10S J

Mark No. Description Part No.

CAPACITORS

C8145,C8352,C8354,C8356,C8358 CCSQCH101J50

C8361,C8362 CCSQCH101J50

C8132,C8310,C8311 CCSQCH150J50

C8131 CCSQCH300J50

C8129 CCSQCK1R0C50

C8142 CEAL101M6R3

C8127 CEAL1R0M50

C8126,C8139 CEAL470M16

C8135 CEAL4R7M16

C8124 CEALR47M50

C8136 CEAT100M50

C8108,C8306,C8371 CEAT101M10

C8202 CEAT101M25

C8101 CEAT3R3M50

C8105 CEAT470M16

C8109 CEATR22M50

C8106,C8119,C8133,C8307,C8308 CKSQYB102K50

C8360 CKSQYB102K50

C8102,C8122,C8123,C8130 CKSQYB103K50

C8137,C8138,C8201,C8309,C8312 CKSQYB103K50

C8134,C8302,C8303 CKSQYB104K25

C8353,C8359 CKSQYB152K50

C8111 CKSQYB153K25

C8114,C8117,C8120,C8121 CKSQYB154K16

C8125 CKSQYB221K50

C8107 CKSQYB223K50

C8110 CKSQYB331K50

C8115,C8128 CKSQYB332K50

C8113 CKSQYB333K25

C8112,C8141 CKSQYB334K16

C8116,C8140,C8355,C8357 CKSQYB473K50

C8118,C8255-C8257,C8301 CKSQYF104Z25

C8304,C8305 CKSQYF104Z25

OTHERS

BN6202 4P ANTENNA TERMINAL AKE7025

X6202 CERAMIC RESONATOR ASS1066

X6201 CRYSTAL RESONATOR ASS1093

CN6201 14P SOCKET KP200IA14L

CD ASSY

B

(456kHz)

(7.2000MHz)

MW RF TUNING BLOCK AXX7041

SEMICONDUCTORS

IC8201 BA5923FP

IC8101 LA9241ML

IC8301 LC78622NE

Q8101 2SA1048

Q8251,Q8252 2SB1237X

Q8253,Q8254 2SD1858X

D8253 1SS181

D8251,D8252 1SS355

COILS

L8351,L8352 LFA1R0K

L8201,L8371 LFA470J

RESISTORS

All Resistors RS1/10S J

OTHERS

X8301 CERAMIC RESONATOR DSS1083

CN8003 6P JUMPER CONNECTOR 52151-0610

CN8002 KR CONNECTOR B6B-PH-K-S

CN8005 3P SIDE POST BS3P-SHF-1AA

CN8004 FFC CONNECTOR 20P HLEM20R-1

CN8001 FFC CONNECTOR SLW15S-1C7

MOTOR ASSY

C

(16.9344MHz)

SWITCH

S8503 ASG7009

OTHERS

J8502 JUMPER WIRE 4P D20PWW0405E

MOTOR PULLEY PNW1634

CARRIAGE MOTOR VXM1033

45

Page 46

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

SW ASSY

D

SWITCHES

S8502 ASG7009

S8501 DSG1017

OTHERS

J8501 JUMPER WIRE 6P D20PWY0610E

AF ASSY (XWZ3083)

E

SEMICONDUCTORS

IC2101,IC3101-IC3103,IC5691 BA4558F-HT

IC5891,IC5892 BU4094BCF

IC2201 HA12136AF

IC2301 HA12211NT

IC3001 LC75394NED

IC42 NJM7805FA

IC32 NJM7812FA

IC3301 STK407-070B

Q71 2SA965

Q31 2SD2012

Q3351 IRFI9Z34G

Q3352 IRFIZ34G

D3301,D3302 1SR139-100

D3355,D3356 20E2-FC

D71,D72 S5688G

Q3354,Q3601,Q3621 2SA1037K

Q2803,Q2804 2SC1815

Q2801 2SC2240

Q2102,Q2201,Q2202,Q3101,Q3102 2SC2412K

Q3353,Q3603,Q3605-Q3608 2SC2412K

Q3081 2SD1858X

Q2203,Q2204,Q2805,Q3311,Q3312 2SD2114K

Q2301,Q2302 2SK368

Q3313 DTA124EK

Q2104,Q2105,Q3314 DTC124EK

Q2103,Q2306,Q2802 DTC143EK

D2191,D2301-D2306,D3101,D3102 1SS133

D3351-D3354,D3361,D3362,D3601 1SS133

D3603,D3604,D3621,D3622 1SS133

D3625,D3626,D5891,D73 1SS133

D2102,D2103,D2201,D2202,D3051 1SS355

D3357,D3358 MTZJ10C

D3083 MTZJ11C

D35,D36 MTZJ15C

D3359,D3360 MTZJ18B

D74 MTZJ33C

D3363,D3364 MTZJ39C

D2001 MTZJ6.2A

D48 MTZJ6.8C

D75 MTZJ8.2B

COILS AND FILTERS

L3331,L3332 AF CHOKE COIL ATH-133

L2801 OSCILLATION COIL ATX7002

L3991 LAU4R7J

L2301,L2302 LTA822J

F2201,F2202 MPX FILTER RTF1209

Mark No. Description Part No.

RELAY

RY3601 ASR7008

CAPACITORS

C2303,C2304 (270pF) ACG7024

C2301,C2302 CCSQCH100D50

C3047,C3048 CCSQCH101J50

C2192 CCSQCH220J50

C3319,C3320 CCSQCH3R0C50

C3317,C3318 CEANP220M35

C3621 CEANP2R2M2A

C3313,C3314 CEANP2R2M50

C2207,C2803,C2810,C3045,C3081 CEAT100M50

C3091,C33,C35,C3602,C43 CEAT100M50

C2002,C2316 CEAT101M16

C71 CEAT101M2A

C3303,C3304 CEAT101M50

C2312,C2313,C3035,C3107,C32 CEAT1R0M50

C3311,C3312,C42,C3108 CEAT1R0M50

C2106,C2214,C2215,C2321,C2322 CEAT220M50

C72 CEAT220M50

C2001,C3601 CEAT221M16

C41 CEAT222M25

C31 CEAT222M35

C2201,C2202,C2205,C2206 CEAT2R2M50

C2212,C2213,C2319,C2320 CEAT2R2M50

C3005-C3012,C3015-C3018,C3039 CEAT2R2M50

C3104 CEAT2R2M50

C2804,C2805,C3105 CEAT330M16

C3106,C3109 CEAT4R7M50

C3021,C3022 CEATR10M50

C2203,C2204,C3101,C3102 CEATR22M50

C3325 CEATR47M50

C3046 CEJA100M50

C3036 CEJA1R0M50

C3040 CEJA2R2M50

C3027,C3028 CFTLA334J50

C3023,C3024 CFTLA474J50

C2802 CKCYB681K2H

C5803,C5892 CKSQYB102K50

C2315,C2317,C2318,C3053,C3098 CKSQYB103K50

C3103 CKSQYB103K50

C2191,C2193,C3099,C5891 CKSQYB104K25

C2194 CKSQYB105K10

C3033,C3034 CKSQYB122K50

C2208,C2209 CKSQYB152K50

C3315,C3316 CKSQYB222K50

C2323,C2326 CKSQYB223K50

C3029,C3030 CKSQYB273K50

C2808,C2809 CKSQYB332K50

C2333,C2334 CKSQYB392K50

C2807 CKSQYB472K50

C3111,C3112 CKSQYB473K25

C2307,C2308,C2331,C2332 CKSQYB681K50

C3013,C3014 CKSQYB681K50

C3019,C3020,C3031,C3032 CKSQYB682K50

C3025,C3026 CKSQYB683K25

C3331-C3333 CKSQYF104Z50

C2801 CQHA822J2A

C2210,C2211 CQMBA103J50

C2806 CQMBA223J50

46

Page 47

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

RESISTORS

R2812 RD1/2LMF270J

R2809 RD1/2LMF4R7J

R72 RD1/2PM562J

R3333,R3334 RD1/4LMF100J

R3353,R3354 RD1/4PU101J

R73 RD1/4PU103J

R3081 RD1/4PU221J

R3991,R3992 RS2LMF331J

R3317,R3318 RD1/4PU683J

R3601,R3602 RS3LMFR22J

VR2303-VR2306 (10kΩ) VCP1156

VR2301,VR2302 (100kΩ) VCP1162

VR2801,VR2802 (220kΩ) VCP1164

Other Resistors RS1/10S J

OTHERS

CN1051 20P FFC CONNECTOR 52045-2045

CN5102 38P FFC CONNECTOR 52045-3845

CN81 4P JUMPER CONNECTOR 52147-0410

CN3331 4P SPEAKER TERMINAL AKE7001

CN2302 KR CONNECTOR B2B-PH-K-S

CN2303 KR CONNECTOR B3B-PH-K-R

CN2301 KR CONNECTOR 3P B3B-PH-K-S

CN3051 14P PLUG KM200IB14

JA3001,JA3441 2P PIN JACK VKB1060

CN3991 HEADPHONE JACK XKN3001

AF ASSY (XWZ3074)

E

15P CABLE HOLDER 51063-1505

SEMICONDUCTORS

IC5691 BA4558F-HT

IC5891 BU4094BCF

IC2301 HA12211NT

IC42 NJM7805FA

IC3001 LC75394NED

Mark No. Description Part No.

D3359,D3360 MTZJ18B

D74 MTZJ33C

D3363,D3364 MTZJ39C

D2001 MTZJ6.2A

D48 MTZJ6.8C

D75 MTZJ8.2B

D71 S5688G

D72 S5688G

COILS

L3331,L3332 AF CHOKE COIL ATH-133

L2801 OSCILLATION COIL ATX7002

L3991 LAU4R7J

L2301,L2302 LTA822J

RELAY

RY3601 ASR7008

CAPACITORS

C2303,C2304 (270pF) ACG7024

C2301,C2302 CCSQCH100D50

C3047,C3048 CCSQCH101J50

C3319,C3320 CCSQCH3R0C50

C3317,C3318 CEANP220M35

C3621 CEANP2R2M2A

C3313,C3314 CEANP2R2M50

C2810,C3045,C3046,C3081,C3091 CEAT100M50

C33,C35,C3602,C43 CEAT100M50

C2002,C2316 CEAT101M16

C71 CEAT101M2A

C3303,C3304 CEAT101M50

C2312,C2313,C32,C3311,C3312 CEAT1R0M50

C42 CEAT1R0M50

C2321,C2322,C72 CEAT220M50

C2001,C3601 CEAT221M16

C41 CEAT222M25

C31 CEAT222M35

C2212,C2213,C2319,C2320 CEAT2R2M50

C3005-C3012,C3015-C3018 CEAT2R2M50

IC32 NJM7812FA

IC3301 STK407-070B

Q3354,Q3601,Q3621 2SA1037K

Q71 2SA965

Q2803,Q2804 2SC1815

Q3353,Q3603,Q3605-Q3608 2SC2412K

Q3081 2SD1858X

Q31 2SD2012

Q2805,Q3311,Q3312 2SD2114K

Q2301,Q2302 2SK368

Q3313 DTA124EK

Q3314 DTC124EK

Q2306 DTC143EK

Q3351 IRFI9Z34G

Q3352 IRFIZ34G

D3301,D3302 1SR139-100

D2301-D2306,D3351-D3354 1SS133

D3361,D3362,D3601,D3603,D3604 1SS133

D3621,D3622,D3625,D3626,D5891 1SS133

D73 1SS133

D3051 1SS355

D3355,D3356 20E2-FC

D3357,D3358 MTZJ10C

D3083 MTZJ11C

D35,D36 MTZJ15C

C3039,C3040 CEAT2R2M50

C2804,C2805 CEAT330M16

C3021,C3022 CEATR10M50

C3325 CEATR47M50

C3027,C3028 CFTLA334J50

C3023,C3024 CFTLA474J50

C2307,C2308 CKSQYB102K50

C2315,C2317,C2318,C3053,C3098 CKSQYB103K50

C3099,C5891 CKSQYB104K25

C3033,C3034 CKSQYB122K50

C3315,C3316 CKSQYB222K50

C2323,C2326,C3029,C3030 CKSQYB273K50

C2808,C2809 CKSQYB332K50

C2333,C2334 CKSQYB392K50

C2807 CKSQYB472K50

C2331,C2332,C3013,C3014 CKSQYB681K50

C3019,C3020,C3031,C3032 CKSQYB682K50

C3025,C3026 CKSQYB683K25

C3331-C3333 CKSQYF104Z50

C2801 CQHA822J2A

C2806 CQMBA223J50

C2325-C2338 CCCCH270J50

47

Page 48

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

RESISTORS

R2812 RD1/2LMF270J

R2809 RD1/2LMF4R7J

R72 RD1/2PM562J

R3333,R3334 RD1/4LMF100J

R3353,R3354 RD1/4PU101J

R73 RD1/4PU103J

R3081 RD1/4PU221J

R3317,R3318 RD1/4PU683J

R3991,R3992 RS2LMF331J

R3601,R3602 RS3LMFR22J

VR2802 (100kΩ) VCP1162

Other Resistors RS1/10S J

OTHERS

15P CABLE HOLDER 51063-1505

CN1051 20P FFC CONNECTOR 52045-2045

CN5102 38P FFC CONNECTOR 52045-3845

CN81 4P JUMPER CONNECTOR 52147-0410

CN3331 4P SPEAKER TERMINAL AKE7001

CN2302 KR CONNECTOR B2B-PH-K-S

CN2303 KR CONNECTOR B3B-PH-K-R

CN2301 KR CONNECTOR 3P B3B-PH-K-S

CN3051 14P PLUG KM200IB14

JA3001 2P PIN JACK VKB1060

CN3991 HEADPHONE JACK XKN3001

Mark No. Description Part No.

D3359,D3360 MTZJ18B

D74 MTZJ33C

D3363,D3364 MTZJ39C

D2001 MTZJ6.2A

D48 MTZJ6.8C

D75 MTZJ8.2B

D72 S5688G

D76 S5688G

COILS

L3331,L3332 AF CHOKE COIL ATH-133

L2801 OSCILLATION COIL ATX7002

L3991 LAU4R7J

L2301,L2302 LTA822J

RELAY

RY3601 ASR7008

CAPACITORS

C2303,C2304 (270pF) ACG7024

C2301,C2302 CCSQCH100D50

C3047,C3048 CCSQCH101J50

C3319,C3320 CCSQCH3R0C50

C3317,C3318 CEANP220M35

C3621 CEANP2R2M2A

C3313,C3314 CEANP2R2M50

C2810,C3045,C3081,C3091 CEAT100M50

C33,C35,C3602,C43 CEAT100M50

C2002,C2316 CEAT101M16

AF ASSY (XWZ3045)

E

SEMICONDUCTORS

IC5691 BA4558F-HT

IC5891 BU4094BCF

IC2301 HA12211NT

IC42 NJM7805FA

IC32 NJM7812FA

IC3301 STK407-050B

Q71 2SA1837

Q31 2SD2012

Q3351 IRFI9Z34G

Q3352 IRFIZ34G

D3301,D3302 1SR139-100

D3355,D3356 20E2-FC

IC3001 LC75394NED

Q3354,Q3601,Q3621 2SA1037K

Q2803,Q2804 2SC1815

Q3353,Q3603,Q3605-Q3608 2SC2412K

Q3081 2SD1858X

Q2805,Q3311,Q3312 2SD2114K

Q2301,Q2302 2SK368

Q3313 DTA124EK

Q3314 DTC124EK

Q2306 DTC143EK

D2301-D2306,D3351-D3354 1SS133

D3361,D3362,D3601,D3603,D3604 1SS133

D3621,D3622,D3625,D3626,D5891 1SS133

D73 1SS133

D3051 1SS355

D3357,D3358 MTZJ10C

D3083 MTZJ11C

D35,D36 MTZJ15C

C73 CEAT100M2A

C3303,C3304 CEAT101M50

C2312,C2313,C32,C3311,C3312 CEAT1R0M50

C42 CEAT1R0M50

C2321,C2322,C72 CEAT220M50

C2001,C3601 CEAT221M16

C71 CEAT221M63

C41 CEAT222M25

C31 CEAT222M35

C2212,C2213,C2319,C2320 CEAT2R2M50

C3005-C3010,C3015-C3018 CEAT2R2M50

C3039,C3082 CEAT2R2M50

C2804,C2805 CEAT330M16

C3021,C3022 CEATR10M50

C3011,C3012,C3325 CEATR47M50

C3046 CEJA100M50

C3040 CEJA2R2M50

C3027,C3028 CFTLA334J50

C3023,C3024 CFTLA474J50

C2307,C2308 CKSQYB102K50

C2315,C2317,C2318,C3053,C3098 CKSQYB103K50

C3099,C5891 CKSQYB104K25

C3033,C3034 CKSQYB122K50

C3315,C3316 CKSQYB222K50

C2323,C2326,C3029,C3030 CKSQYB273K50

C2808,C2809 CKSQYB332K50

C2333,C2334 CKSQYB392K50

C2807 CKSQYB472K50

C2331,C2332,C3013,C3014 CKSQYB681K50

C3019,C3020,C3031,C3032 CKSQYB682K50

C3025,C3026 CKSQYB683K25

C3331-C3333 CKSQYF104Z50

C2801 CQHA822J2A

C2806 CQMBA223J50

C2335-C2338 CCCCH270J50

48

Page 49

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

RESISTORS

R72 RD1/2PM222J

R2812 RD1/2LMF270J

R2809 RD1/2LMF4R7J

R3333,R3334 RD1/4LMF100J

R3353,R3354 RD1/4PU101J

R73 RD1/4PU103J

R3081 RD1/4PU221J

R3317,R3318 RD1/4PU683J

R3991,R3992 RS2LMF331J

R3601,R3602 RS2LMFR22J

VR2802 (100kΩ) VCP1162

Other Resistors RS1/10S J

OTHERS

15P CABLE HOLDER 51063-1505

CN1051 20P FFC CONNECTOR 52045-2045

CN5102 38P FFC CONNECTOR 52045-3845

CN81 4P JUMPER CONNECTOR 52147-0410

CN3331 4P SPEAKER TERMINAL AKE7001

CN2302 KR CONNECTOR B2B-PH-K-S

CN2303 KR CONNECTOR B3B-PH-K-R

CN2301 KR CONNECTOR 3P B3B-PH-K-S

CN3051 14P PLUG KM200IB14

JA3001 2P PIN JACK VKB1060

CN3991 HEADPHONE JACK XKN3001

Mark No. Description Part No.

PRIMARY ASSY

G

SWITCH

S1 AKX7006

CAPACITOR

C3 (10000pF/AC250V) ACG7020

OTHERS

H3-H6 FUSE CLIP AKR7001

SUB TRANS ASSY

H

SEMICONDUCTORS

IC81 NJM7805FA

D81-D84 S5688G

Q81 2SD1859X

D85,D88-D90 1SS133

TRANSFORMER

T2 ATT7027

SWITCH AND RELAY

S2 AKX7004

RY81 ASR7018

SECONDARY ASSY

F

(1) CONTRAST TABLE

XWZ3084 and XWZ3046 are constructed the same except

for the following :

Mark Symbol and Description

IC11,IC12 PROTECTOR AEK7021 AEK7019

IC21,IC22 PROTECTOR AEK7046 AEK7053

C21,C22 CEAT332M50 CEAT222M50

Part No.

XWZ3084 XWZ3046

(7A) (5A)

(5A) (4A)

Remarks

(2) PARTS LIST FOR XWZ3084

SEMICONDUCTORS

IC71 (1.25A) AEK7010

IC31,IC41 (3A) AEK7015

IC11,IC12 (7A) AEK7021

IC21,IC22 (5A) AEK7046

D11,D21 GBU4DL-5303

D31-D34,D41-D44 S5688G

CAPACITORS

C11,C12 (220µF/63V) ACH7071

C21,C22 CEAT332M50

OTHERS

J11 JUMPER WIRE D15A15-350-2651

15P CABLE HOLDER 51063-1505

CAPACITORS

C82 CEAT102M25

C83 CEAT100M50

RESISTORS

All Resistors RD1/4PU J

OTHERS

AN1 1P AC INLET BKP1046

DISPLAY ASSY (XWZ3085)

H1,H2 FUSE CLIP AKR7001

J81 JUMPER WIRE 4P D20PYY0425E

I

4P CABLE HOLDER 51048-0400

SEMICONDUCTORS

IC5631 BA3835F

IC5601 BU2092F

IC5501 PDC048A

Q5501 2SA1037K

Q2903,Q2906,Q2908 2SB1132

Q5604,Q5801 2SC2412K

Q2910,Q2911 DTA124EK

Q5606 DTC124EK

Q2901,Q2904,Q2907,Q5502,Q5603 DTC143EK

Q5821 DTC143EK

D5593,D5811 1SS133

D5551-D5554,D5563-D5568 1SS181

D2901-D2903,D5569,D5570,D5626 1SS355

D5901 1SS355

D5612 BR5064X

49

Page 50

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

D5608-D5611 MBG5064X

D5613-D5616 MPG5064X

D5617-D5620 SLP3118C51H

D5603-D5607,D5621 SLP9118C51H

COIL

L5811 LAU220J

SWITCHES

S5951 ASX7004

S5952 ASX7017

S5911-S5931 XSG3001

CAPACITORS

C5812 (0.047F/5.5V) ACH1246

C5601 CCSQSL151J50

C5821 CEJA100M16

C5803 CEJA1R0M50

C5510,C5811,C5814 CEJA470M16

C5804 CKSQYB102K50

C5995,C5996 CKSQYB103K50

C5816,C5997-C5999 CKSQYB104K25

C5509,C5951-C5954 CKSQYB471K50

C5506-C5508 CKSQYB472K50

C5602,C5631-C5634,C5901 CKSQYF104Z50

C5503,C5504,C5813,C5822 CKSQYF473Z50

RESISTORS

R5529 (470Ω) ACN7056

R5554,R5561,R5562 (1.5kΩ) ACN7062

R5558,R5563,R5564 (47kΩ) ACN7077

R5508 RA11T104J

R5506 RA7T104J

R2907,R2909,R2910,R5611,R5919 RD1/4PU102J

R5915 RD1/4PU181J

R5925 RD1/4PU331J

R5605,R5606,R5612,R5613,R5926 RD1/4PU561J

R2902,R5604,R5607-R5610 RD1/4PU681J

R5927 RD1/4PU821J

R2911-R2913,R5567 RS1/8S0R0J

R5702 RS1/8S223J

R5614 RS1/8S331J

R2905 RS1/8S681J

Other Resistors RS1/10S J

OTHERS

X5501 CERAMIC RESONATOR RSS1050

(6MHz)

CN2901 19P FFC CONNECTOR 52045-1945

CN5501 38P FFC CONNECTOR 52045-3845

X5901 REMOTE RECEIVER UNIT GP1U28X

V5621 FL TUBE XAV3004

2902 FL HOLDER XNG3008

Mark No. Description Part No.

DISPLAY ASSY (XWZ3047)

I

SEMICONDUCTORS

IC5501 PDC048A

Q5501 2SA1037K

Q2903,Q2906,Q2908 2SB1132

Q5604,Q5801 2SC2412K

Q2910,Q2911 DTA124EK

Q5606 DTC124EK

Q2901,Q2904,Q2907,Q5502 DTC143EK

Q5601-Q5603,Q5605,Q5821 DTC143EK

D5631,D5811 1SS133

D5551-D5554,D5563-D5568 1SS181

D2901-D2903,D5569,D5570,D5626 1SS355

D5901 1SS355

D5602 SLP3118C51H

D5603 SLP7118C51H

D5601,D5604,D5621 SLP9118C51H

COIL

L5811 LAU220J

SWITCHES

S5951 ASX7004

S5952 ASX7017

S5911-S5915,S5917-S5925 XSG3001

S5927-S5936 XSG3001

CAPACITORS

C5812 (0.047F/5.5V) ACH1246

C5821 CEJA100M16

C5803 CEJA1R0M50

C5510,C5811,C5814 CEJA470M16

C5804 CKSQYB102K50

C5995,C5996 CKSQYB103K50

C5816,C5997-C5999 CKSQYB104K25

C5509,C5951-C5954 CKSQYB471K50

C5506-C5508 CKSQYB472K50

C5634,C5901 CKSQYF104Z50

C5625 CKSQYF224Z25

C5503,C5504,C5813,C5822 CKSQYF473Z50

RESISTORS

R5529 (470Ω) ACN7056

R5554,R5561,R5562 (1.5Ω) ACN7062

R5558,R5563,R5564 (47kΩ) ACN7077

R5508 RA11T104J

R5506 RA7T104J

R2907,R2909,R2910,R5919 RD1/4PU102J

R5915 RD1/4PU181J

R5925 RD1/4PU331J

R5926 RD1/4PU561J

R2902 RD1/4PU681J

R5927 RD1/4PU821J

R2911-R2913,R5567 RS1/8S0R0J

R5702 RS1/8S223J

R5614 RS1/8S331J

R2905 RS1/8S681J

50

Other Resistors RS1/10S J

Page 51

XR-A660, XR-A550, XR-A330

Mark No. Description Part No.

OTHERS

X5501 CERAMIC RESONATOR RSS1050

CN2901 17P FFC CONNECTOR 52045-1745

CN5501 38P FFC CONNECTOR 52045-3845

X5901 REMOTE RECEIVER UNIT GP1U28X

5631 FL HOLDER VNF1096

V5621 FL TUBE XAV3003

CD SW LED ASSY

J

(6MHz)

SEMICONDUCTORS

D5623 SLP3118C51H

D5624 SLP7118C51H

D5622 SLP9118C51H

SWITCHES

S5937-S5941 XSG3001

RESISTORS

All Resistors RS1/10S J

OTHERS

J5501 JUMPER WIRE D20PWW0615E

Mark No. Description Part No.

51

Page 52

XR-A660, XR-A550, XR-A330

6. ADJUSTMENT

6.1 TUNER SECTION

FM Tuner Section

Set the mode selector to FM BAND.

•

Connect the wiring as shown in Fig. 1.

•

petS

.oN

1

2

:etoN

tnemtsujdA

eltiT

dnEtnorF

ytivitisneS

.DNIDENUT

leveLgnithgiL

AM Tuner Section

Set the mode selector to AM BAND.

•

Connect the wiring as shown in Fig. 1.

•

petS

.oN

1

(etoN ∗ .zHk0001ebdluohsseicneuqerf,petszHk01gnisuaeraehtroF:)1

tnemtsujdA

eltiT

dnEtnorF

ytivitisneS

,zHk1(GSMF ± ).vedzHk57

ycneuqerF

)zHM(

8903-0zHM89

8981 ± 2zHM891026RV

.stnemtsujdaekamnehtdna,tsrifrehto

ycneuqerF

)zHk(

(999 ∗ )154-53(zHk999 ∗ )11026T

Bd( µ )m/V

Bd( µ )V

noitpeceR

leveL

).doM%03,zH004(GSMA

leveL

ycneuqerF

yalpsiD

noitpeceR

ycneuqerF

yalpsiD

tnemtsujdA

noitacoL

2046L

1046T

.puthgilot

tnemtsujdA

noitacoL

snoitacificepS

-1026CIehtneewtebegatlovCDehttahtostsujdA

.levelmumixamtasemocebDNGdna02nip

strats.DNIDENUTforotacidniehttahtostsujdA

hcaehtiwtcatnocotnimehtgnirb,mehtneewtebpagasierehtfI.2046Ldna1046Lneewtebpagonsierehterusekam,gnitsujdaerofeB

snoitacificepS

-1026CIehtneewtebegatlovCDehttahtostsujdA

.levelmumixamtasemocebDNGdna02nip

AM

antenna

terminal

FM

antenna

terminal

AM SG

MPX SG FM SG

Center

FM75Ω antenna terminal

Fig. 1 AM and FM Adjustment Wiring Diagram

FM/AM TUNER MODULE

SIDE A

YELLOW BLACK

AXX7041

60cm

T6401

Center

Loop antenna

AM antenna terminal

PRODUCT

T6201

DC

Voltmeter

IC6201

Pin 20

VR6201

52

L6401

L6402

Fig. 2 Adjustment Point

Page 53

6.2 CASSETTE DECK SECTION

6.2.1 For XR-A660

Adjustment points and test points are shown in Fig.3, Fig.5 and Fig.7.

•

Mechanical Adjustment

Test tape: NCT-111 (3kHz, 30min).

•

1. Tape Speed Adjustment

.oNedoMepaTtseT

1

kceD I

YALP

111-TCN

)zHk3:kcabyalP(

gnitsujdA

stnioP

noRV.JDA

ETTESSAC

)3.giF(AHCEM

AF Assy

)yssAFA(

XR-A660, XR-A550, XR-A330

tnemerusaeM

stnioP

TSETEPAT

)hcR(TNIOP

Front Side

zH0003semoceb ± rettulf&wowtahtmrifnoC.zH02

Tape Speed

ADJ. VR

erudecorPtnemtsujdAskrameR

gnidaerehttahtostsujdadnaWSYALPehtsserP

mrifnoc,noitceridesreverehtni(%3.0wolebsilevel

zH0003nihtiwsignidaerehttaht ± .)zH06

Cassette

Mechanism

Section

(Side View)

Fig.3 Tape Speed ADJ. Point

Electrical Adjustment

Check the following before starting.

(1) Confirm that the tape speed adjustment has been completed.

(2) Clean the heads and demagnetize them using a head eraser.

(3) Set the measurement level to 0 dBV = 1 Vrms.

(4) Use the specified tape for adjustment. Use the labeled (A)

side of the test tape.

STD-331E : For playback check

STD-632 : Normal blank tape

(5) Provide yourself with the following measuring devides:

AC millivoltmeter

•

Low-frequency oscillator

•

Attenuator

•

Oscilloscope

•

(6) Adjust both right and left channels unless otherwise specified.

(7) Turn the DOLBY NR switch off unless otherwize specified.

(8) Warm up the unit for several minutes before adjustment.

In particular, be sure to warm up the unit in the REC/PLAY

mode for 3 to 5 minutes before starting recording/playback

frequency characteristics adjustment.

(9) Always follow the indicated adjustment order.

Otherwise, a complete adjustment may not be achieved.

Playback Adjustment (Decks I and II)

(1) Head Azimuth Adjustment

(2) Playback Level Adjustment

Recording Adjustment (Deck I)

(1) Bias Oscillation Frequency Adjustment

(2) Recording Bias Adjustment

(3) Recording Level Adjustment.

(4) ALC Operation Check

* As the reference recording level is 250nwb/m for STD-331E, the

recording level will be higher by 4 dB for STD-331B (160nwb/m).

When adjusting, pay carefull attention to the type of tape used.

Dolby noise reduction manufactured under license from Dolby

Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol are trademarks of Dolby

Laboratories Licensing Corporation.

53

Page 54

XR-A660, XR-A550, XR-A330

0 dB

30s

315Hz

Playback Adjustment

(1) Head Azimuth Adjustment

Do not switch between forward and reverse operation with the screwdriver inserted.

•

petSedoM

1YALP

0 dB: 315 Hz, 250 nwb/m

30s 30s 30s 10s 10s ......................................................................................................... 10s

12.5

6.3kHz 10kHz 315Hz 14kHz

kHz

10kHz

8kHz 4kHz 2kHz

Fig. 4 STD-331E Test Tape

/langiStupnI

epaTtseT

epattsetE133-DTS

,zHk01:kcabyalP(

)Bd02-

kceD I

kceD II

stnioPgnitsujdA

htumizadaeH

tnemtsujda

)5.giF(wercs

6.3

kHz

stnioP

)yssAFA(

500Hz250Hz125

1kHz

tnemerusaeM

TSETEPAT

)hcR,L(TNIOP

tnemtsujdA

eulaV

kcabyalp.xaM

levellangis

Hz

63Hz 40Hz

skrameR

–20 dB

otdnobnocilisylppa,tnemtsujdaretfA

.wercstnemtsujdahtumizadaeheht

(2) Playback Level Adjustment

Since this adjustment determines playback Dolby NR level, perform it carefully.

•

petSedoM

1YALP

E133-DTS

epattset

/langiStupnI

epaTtseT

kceD I

)Bd0,zH513:kcabyalP(

kceD II

stnioPgnitsujdA

)hcL(3032RV

)hcR(4032RV

)hcL(5032RV

)hcR(6032RV

tnemerusaeM

stnioP

TSETEPAT

)hcR,L(TNIOP

)yssAFA(

tnemtsujdA

eulaV

VBd7.3–

skrameR

PLAY BACK

250

3dB

10k

3dB 4dB

12.5k

RECORDING

250

3dB

10k

3dB 5dB

12.5k

REV Azimuth Adjustment Screw

Fig. 5 Head Azimuth Adjustment Screw

54

FWD Azimuth Adjustment Screw

Fig. 6 Frequency Characteristics

Page 55

XR-A660, XR-A550, XR-A330

Recording Adjustment

(1) Bias Oscillation Frequency Adjustment

petSedoM

1CER

/langiStupnI

epaTtseT

236-DTSehtdaoL

ehttesdnaepattset

.edomgnidrocer

kceD II

KCED I

stnioPgnitsujdA

1082L

)yssAFA(

(2) Recording Bias Adjustment

Since this adjustment affects recording bias, prevent distortion from increasing due to underbias.

•

petSedoMepaTtseT/langiStupnIstnioPgnitsujdA

1CER

2

CER →

YALP

.XUAotrotceles

.slangiszHk01

ehtotlangiszH513atupnI

tupniehttesdnalanimretXUA

dnazH513ehtkcabyalp/drocer

)wolebetoNehtees(

Note : Set the 10kHz input signal level to the same value as the 315Hz input signal level of step 1.

kceD II

KCED I levellangistupnI

dnaepattset236-DTSehtdaoL

kceD II

KCED I

tnemerusaeM

stnioP

A

neewteB

7.giFnitniop

± .zHk2

.DNGdna

)hcL(1082RV

)hcR(2082RV

eulaV

noitallicsO

stnioP

TSETEPAT

)yssAFA(

TSETEPAT

)yssAFA(

tnemtsujdA

otycneuqerf

zHk0.501eb

.zHk3ot2

tnemerusaeM

)hcR,L(TNIOP

)hcR,L(TNIOP

skrameR

ruofrofnottubPOTS/CERehtfI

DNATSnisirewopehtelihwsdnoces

esaercedlliwycneuqerfeht,edomYB

eulaVtnemtsujdAskrameR

VBd7.32–

levelkcabyalplitnutnemtsujdataepeR

0nihtiwsilangiszHk01ehtfo ± Bd5.0

.langiszH513ehtfotahtmorf

(3) Recording Level Adjustment

petSedoMepaTtseT/langiStupnIstnioPgnitsujdA

1CER

2

CER →

YALP

.XUAotrotceles

.langis

ehtotlangiszH513atupnI

tupniehttesdnalanimretXUA

dnaepattset236-DTSehtdaoL

zH513ehtkcabyalp/drocer

(4) ALC Operation Check

petSedoMepaTtseT/langiStupnIstnioPgnitsujdA

1

2

/CER

ESUAP

.XUAotrotceles

ehtotlangiszH513atupnI

tupniehttesdnalanimretXUA

kceD II

kceD II

KCED I

KCED I

tnemerusaeM

stnioP

levellangistupnI

)hcL(1032RV

)hcR(2032RV

levellangistupnI

ehtevodaBd01+levelaotteS

.1petstaleveltupni

TSETEPAT

)hcR,L(TNIOP

)yssAFA(

TSETEPAT

)hcR,L(TNIOP

)yssAFA(

tnemerusaeM

stnioP

TSETEPAT

TNIOP

)hcR,L(

)yssAFA(

VBd2.8–

2.2– ± .VBd5.2

eulaVtnemtsujdAskrameR

VBd7.7–

dnakcabyalp,gnidrocertaepeR

ehtfolevelkcabyalplitnutnemtsujda

.VBd7.7–semoceblangiszH513

eulaVtnemtsujdAskrameR

signidaerehttahtmrifnoC

55

Page 56

XR-A660, XR-A550, XR-A330

AF ASSY

SIDE A

L2801

A

VR2302

VR2802

TAPE TEST

POINT

L ch R ch

VR2301

VR2801

VR2303 VR2305

VR2304

VR2306

FRONT

56

Fig.7 Adjustment and Measurement Points

Page 57

6.2.2 For XR-A550 and XR-A330

Adjustment points and test points are shown in Fig.8, Fig.10 and Fig.11.

•

Mechanical Adjustment

Test tape: NCT-111 (3kHz, 30min).

•

1. Tape Speed Adjustment

.oNedoMepaTtseT

1

kceD I

YALP

111-TCN

)zHk3:kcabyalP(

gnitsujdA

stnioP

noRV.JDA

ETTESSAC

)8.giF(AHCEM

AF Assy

stnioP

TSETEPAT

)yssAFA(

)hcR(TNIOP

tnemerusaeM

Front Side

XR-A660, XR-A550, XR-A330

erudecorPtnemtsujdAskrameR

gnidaerehttahtostsujdadnaWSYALPehtsserP

zH0003semoceb ± rettulf&wowtahtmrifnoC.zH02

mrifnoc,noitceridesreverehtni(%3.0wolebsilevel

zH0003nihtiwsignidaerehttaht ± .)zH06

Tape Speed

ADJ. VR

Cassette

Mechanism

Section

(Side View)

Fig.8 Tape Speed ADJ. Point

Electrical Adjustment

Check the following before starting.

(1) Confirm that the tape speed adjustment has been completed.

(2) Clean the heads and demagnetize them using a head eraser.

(3) Set the measurement level to 0 dBV = 1 Vrms.

(4) Use the specified tape for adjustment. Use the labeled (A)

side of the test tape.

STD-331E : For playback check

STD-632 : Normal blank tape

(5) Provide yourself with the following measuring devides:

AC voltmeter (Noisemeter : filter off)

•

AC millivoltmeter

•

Low-frequency oscillator

•

Attenuator

•

Oscilloscope

•

(6) Adjust both right and left channels unless otherwise specified.

0 dB

30s

315Hz

0 dB: 315 Hz, 250 nwb/m

30s 30s 30s 10s 10s ......................................................................................................... 10s

6.3kHz 10kHz 315Hz 14kHz

12.5

kHz

(7) Warm up the unit for several minutes before adjustment.

In particular, be sure to warm up the unit in the REC/PLAY

mode for 3 to 5 minutes before starting recording/playback

frequency characteristics adjustment.

(8) Always follow the indicated adjustment order.

Otherwise, a complete adjustment may not be achieved.

Playback Adjustment (Decks I and II)

(1) Head Azimuth Adjustment

Recording Adjustment (Deck I)

(1) Bias Oscillation Frequency Adjustment

(2) Recording Bias Adjustment

* As the reference recording level is 250nwb/m for STD-331E, the

recording level will be higher by 4 dB for STD-331B (160nwb/m).

When adjusting, pay carefull attention to the type of tape used.

10kHz

6.3

8kHz 4kHz 2kHz

kHz

500Hz250Hz125

1kHz

Hz

–20 dB

63Hz 40Hz

Fig. 9 STD-331E Test Tape

57

Page 58

XR-A660, XR-A550, XR-A330

REV Azimuth Adjustment Screw

FWD Azimuth Adjustment Screw

Fig. 10 Head Azimuth Adjustment Screw

Playback Adjustment

(1) Head Azimuth Adjustment

Do not switch between forward and reverse operation with the screwdriver inserted.

•

petSedoM

1YALP

)Bd02-

/langiStupnI

epaTtseT

epattsetE133-DTS

,zHk01:kcabyalP(

kceD I

kceD II

stnioPgnitsujdA

htumizadaeH

tnemtsujda

)01.giF(wercs

stnioP

TSETEPAT

)yssAFA(

Recording Adjustment

(1) Bias Oscillation Frequency Adjustment

petSedoM

1CER

/langiStupnI

epaTtseT

236-DTSehtdaoL

ehttesdnaepattset

.edomgnidrocer

kceD II

KCED I

stnioPgnitsujdA

1082L

)yssAFA(

stnioP

A

neewteB

.DNGdna

tnemerusaeM

)hcR,L(TNIOP

tnemerusaeM

11.giFnitniop

± .zHk2

tnemtsujdA

eulaV

kcabyalp.xaM

levellangis

tnemtsujdA

eulaV

noitallicsO

otycneuqerf

zHk0.501eb

skrameR

otdnobnocilisylppa,tnemtsujdaretfA

.wercstnemtsujdahtumizadaeheht

skrameR

(2) Recording Bias Adjustment

Since this adjustment affects recording bias, prevent distortion from increasing due to underbias.

•

petSedoMepaTtseT/langiStupnIstnioPgnitsujdA

1CER

2

)langisoN(drocer

CER →

YALP

B

dnaepattset236-DTSehtdaoL

.epattset236-DTSehtdaoL

zHk01dnazH513ehtdroceR

leveltupniVBd52-taslangis

.kcabyalpdna)tniopkcehc(

IkceD

kceD II

KCED I

Note : No connecting to BIAS TP POINT at Step 2 REC→PLAY.

58

2082RV

)yssAFA(

2082RV

)yssAFA(

)yssAFA(

)yssAFA(

tnemerusaeM

stnioP

TNIOPPTSAIB

TSETEPAT

)hcR,L(TNIOP

V72–V42

.langiszH513

eulaVtnemtsujdAskrameR

litnutnemtsujdataepeR

ehtfolevelkcabyalp

0nihtiwsilangiszHk01 ±

ehtfotahtmorfBd0.1

Page 59

XR-A660, XR-A550, XR-A330

FRONT

AF ASSY

SIDE B

TAPE TEST

POINT

R ch

VR2301

L ch

VR2802

VR2302

B

(VR is nothing)

L2801

BIAS TP POINT

A

Fig.11 Adjustment and Measurement Points

59

Page 60

XR-A660, XR-A550, XR-A330

6.3 TEST MODE

NOTE: There is no information to be shown in this CD adjustment.

How to Start/Cancel Test Mode

TEST MODE : ON

TEST DISC: YEDS-7

STANDBY/ON

TEST MODE : PLAY

TEST DISC: YEDS-7

Pickup

outwards

Move

inwards

TEST MODE : STOP CANCEL

REC/

STOP

CD

Function CD

REC/

STOP

Laser diode: LIGHTS UP

Focus servo: CLOSE

CD TEST

Short Point

"TEST 4"

Spindle motor: START

Spindle servo: CLOSE

PLAY/

PAUSE

CD TEST

Short Point

PLAY/

PAUSE

CLOSE OPEN

Tracking servo:

STOP all operations.

Test Point

DISPLAY ASSY

STANDBY/ON

SIDE B

Bottom Side

CD TEST

60

Page 61

XR-A660, XR-A550, XR-A330

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

HA12136AF (AF ASSY : IC2201)

• Dolby B Type NR System IC

Pin Function

•

.oNemaNniPnoitcnuF.oNemaNniPnoitcnuF

1NICERtupni)edocnE(gnidroceR9TUOCERtuptuo)edocnE(gnidroceR

2V

CC

3NIBPtupni)edoceD(kcabyalP11TUOBPtuptuo)edoceD(kcabyalP

4ferVegatlovecnerefeR21BP/CER

5FFO/NORN

6TUOBPtuptuo)edoceD(kcabyalP41NIBPtupni)edoceD(kcabyalP

7TEDrotcetedlevelehtrofniptnatsnocemiT51DNGdnuorG

8TUOCERtuptuo)edocnE(gnidroceR61NICERtupni)edocnE(gnidroceR

ylppusrewoP01TEDrotcetedlevelehtrofniptnatsnocemiT

FFO/NORNrofniplortnocedoM

FFORN:"L",NORN:"H"

31SAIBsretlifevitcaehtrofniptupnitnerrucecnerefeR

)edoceD/edocnE(BP/CERrofniplortnocedoM

)edoceD(BP:"L",)edocnE(CER:"H"

HA12211NT (AF ASSY : IC2301)

• REC Equalizer and PB Equalizer System IC

Block Diagram

•

REC IN

GND