Page 1

P

R

H

O

I

N

M

G

D

N

J

U

O

O

G

S

• XR-A670

STEREO CD CASSETTE DECK RECEIVER

XR-A670

XR-A370

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

MYXJ AC220-230V

NVXJ AC230V

KUCXJ AC120V

XR-A670 XR-A370

Model

Power Requirement

Remarks

ORDER NO.

RRV2188

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..14

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

................................................

.....................................................

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 1999

.......................................

.................

...........................

32

47

57

2

4

7. GENERAL INFORMATION

7.1 DIAGNOSIS

...................................................

7.1.1 DISASSEMBLY

7.2 PARTS

7.2.1 IC

7.2.2 DISPLAY

...........................................................

.............................................................

..................................................

8. PANEL FACILITIES AND SPECIFICATIONS

..................................

67

67

........................................

67

70

70

72

.......

74

T – IZK SEPT. 1999 Printed in Japan

Page 2

XR-A670, XR-A370

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

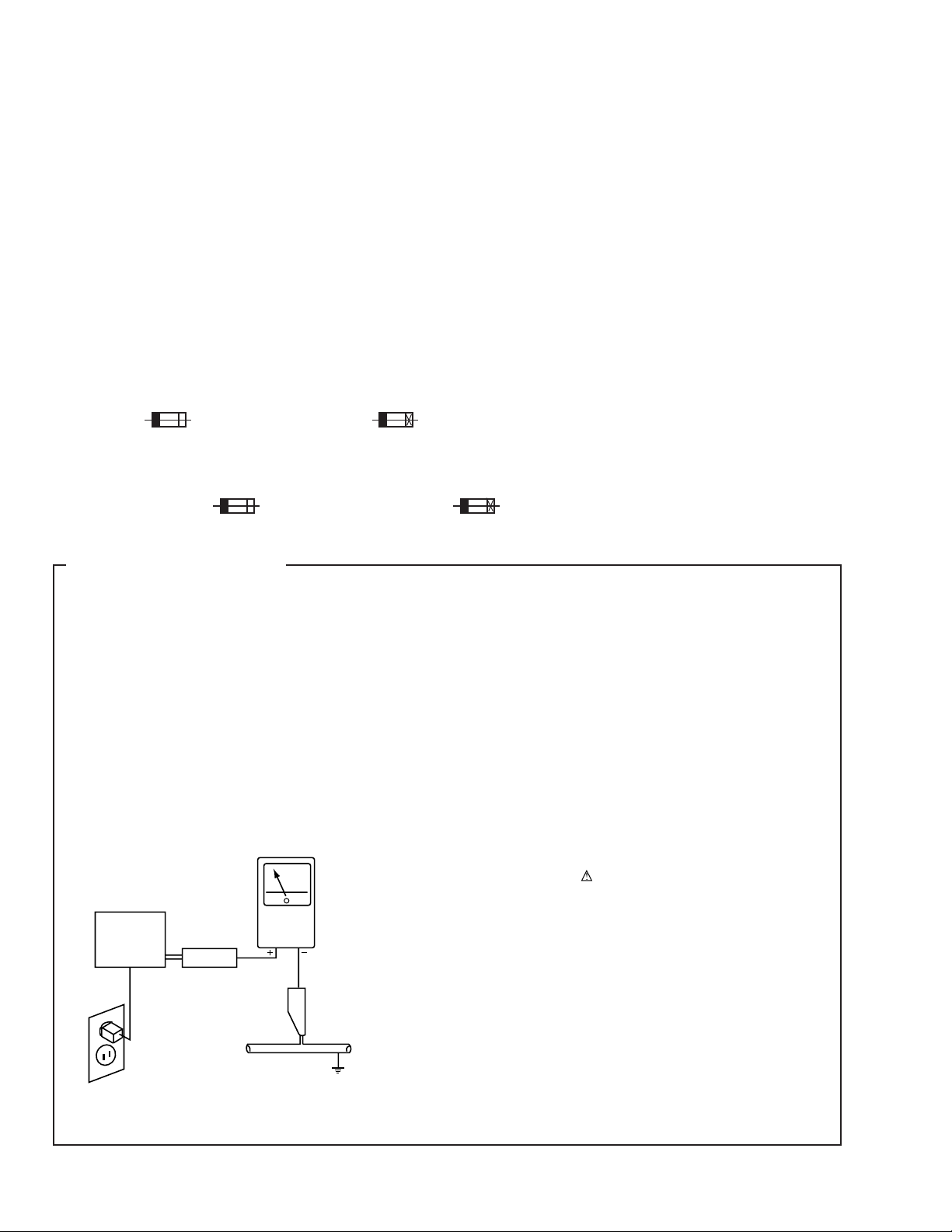

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

XR-A670, XR-A370

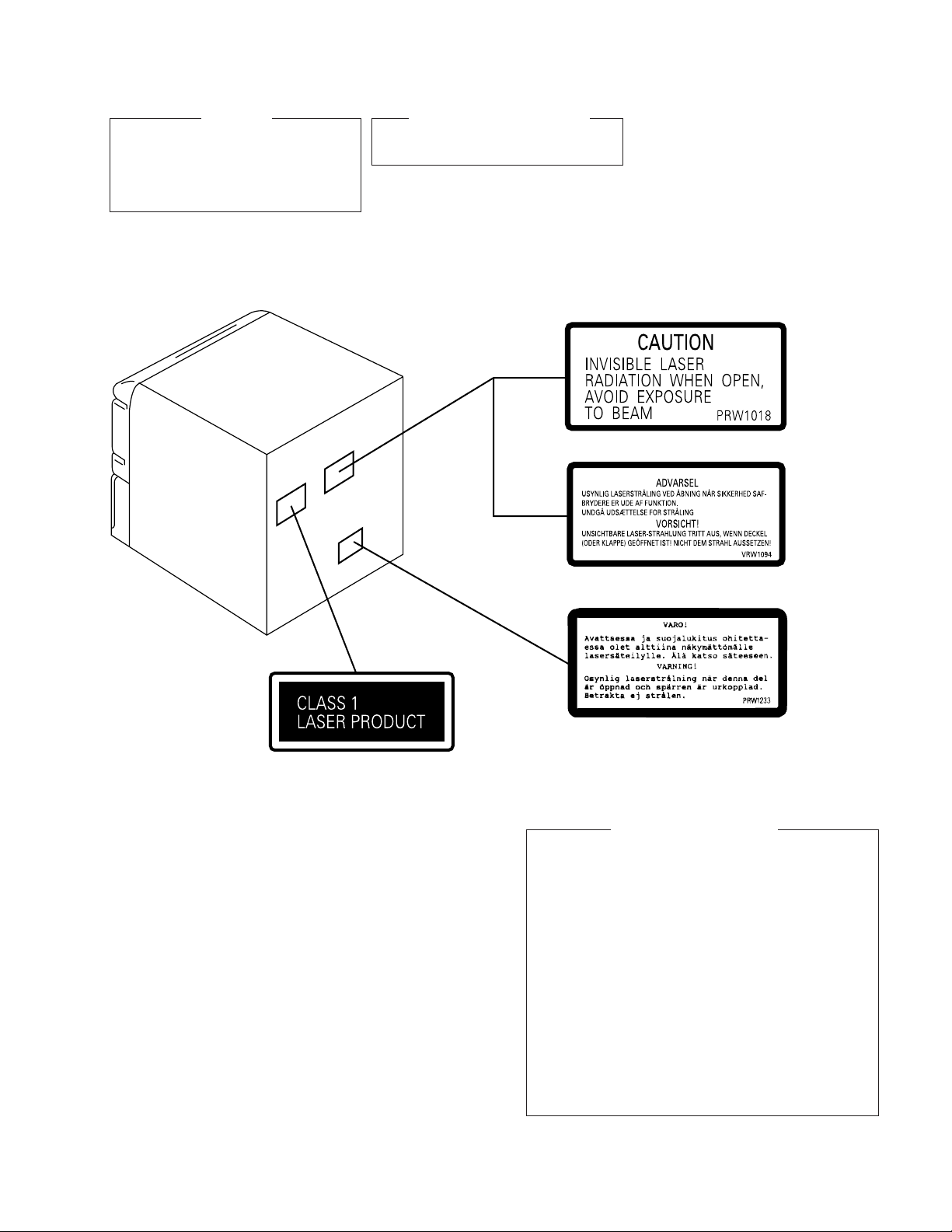

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 780 nm to 785 nm

LABEL CHECK (For MYXJ and NVXJ Types)

NVXJ Type

MYXJ Type

Printed on the Rear Panel

MYXJ Type

Additional Laser Caution

1.Laser Interlock Mechanism

The position of the switch (S9501) for detecting loading

state is detected by the system microprocessor, and

the design prevents laser diode oscillation when the

switch (S9501) is pressed physically.

Thus, the interlock will no longer function if the switch (S9501)

is released physically and deliberatery.

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of

CXA1821M (IC8101) on the CD ASSY mounted on the

$M Loading Mechanism assembly is connected to GND,

or else the terminals of Q8101 are shorted to each other

(fault condition).

2.When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class

1 laser beam.

∗

: Refer to page 66.

3

Page 4

XR-A670, XR-A370

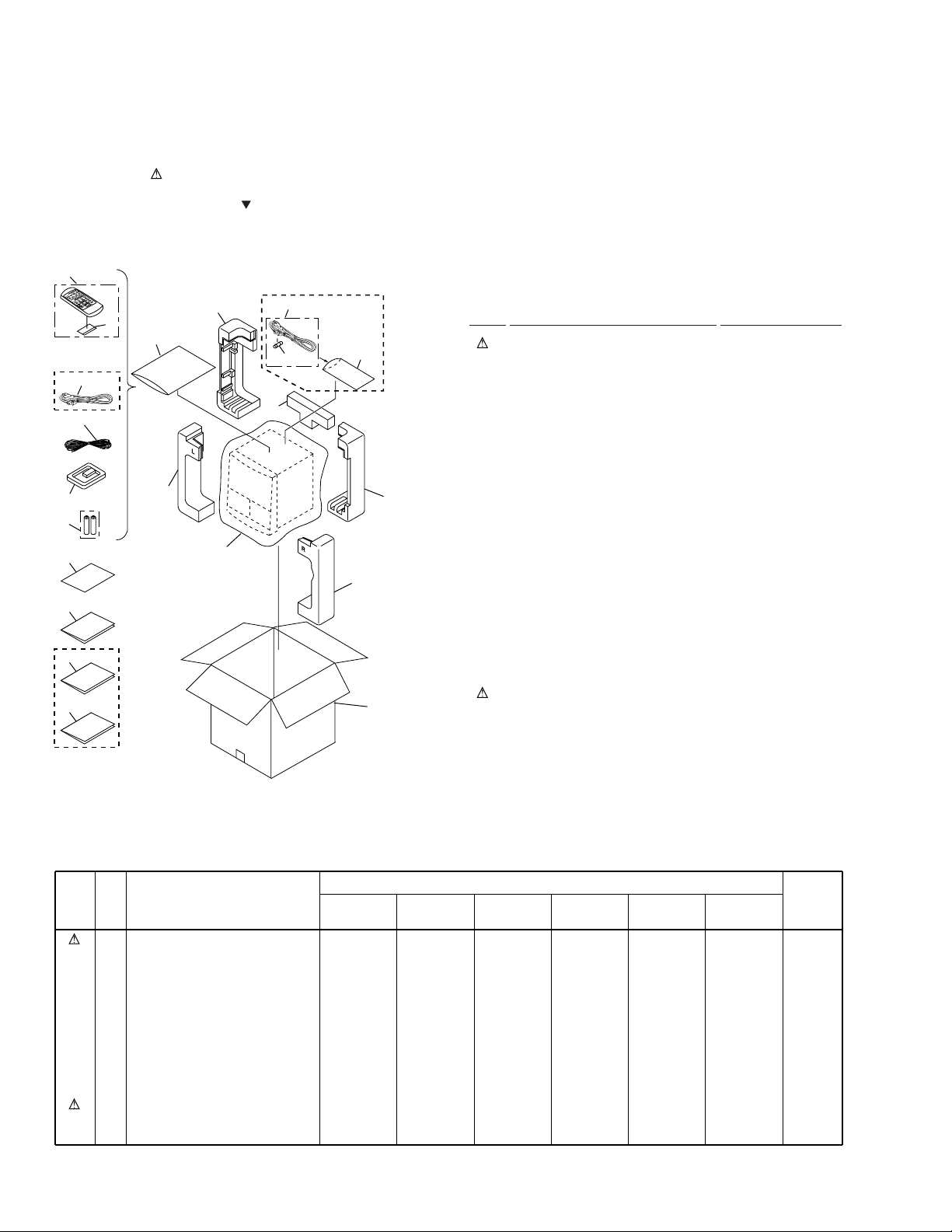

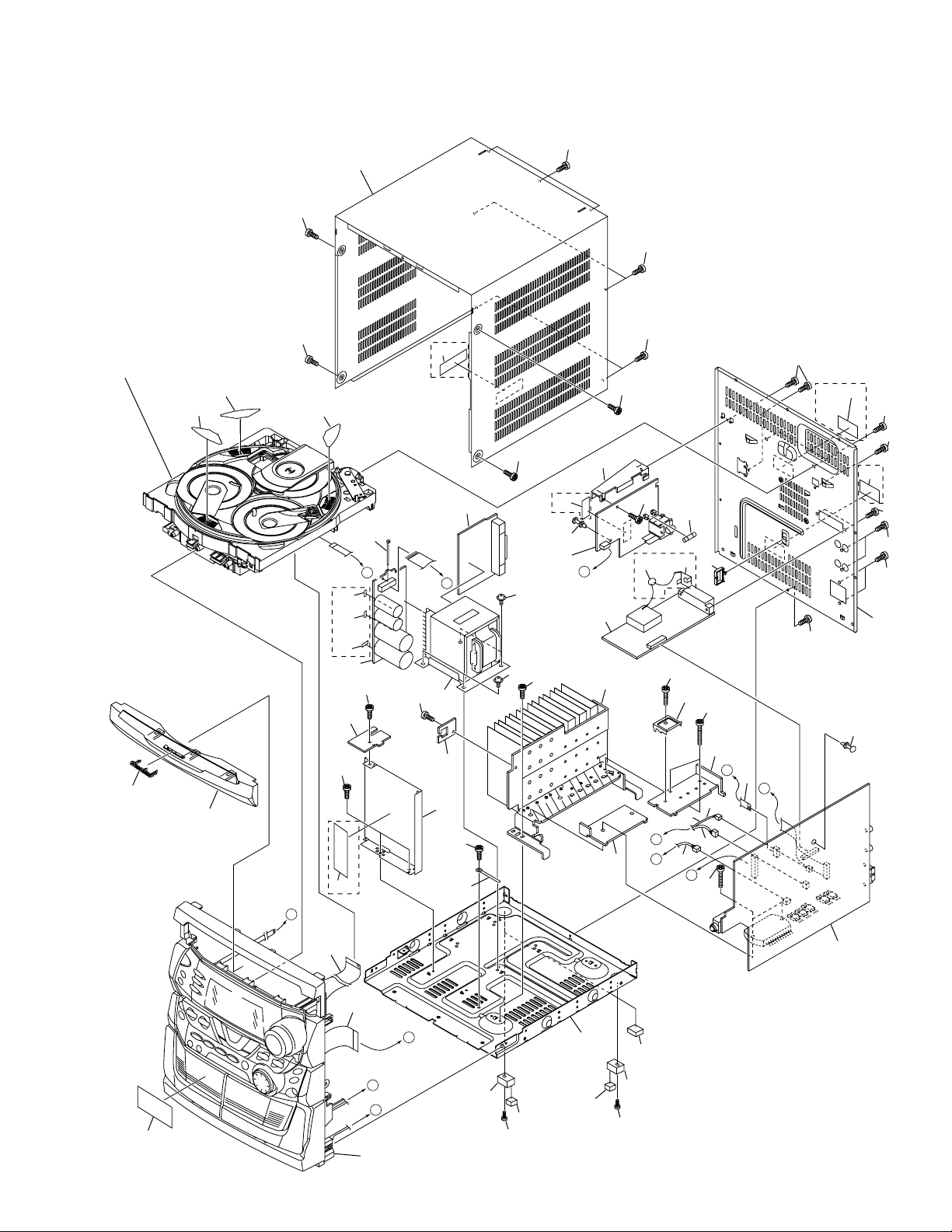

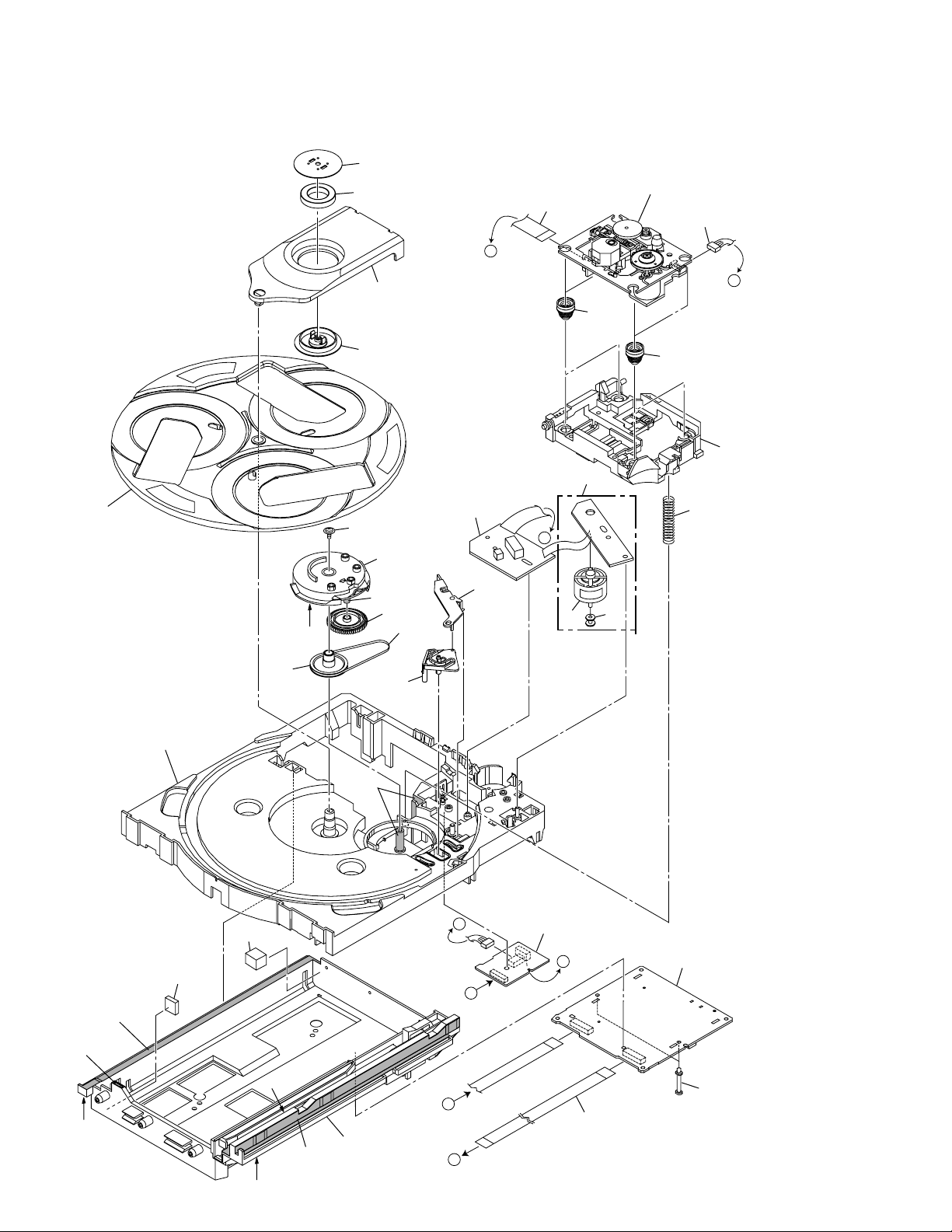

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

4

S

L

E

E

P

.B

POWER

A

S

S

D

I

S

P

L

A

Y

A

U

X

Except

NVXJ Type

3

6

11

13

14

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

V

K

O

A

L

R

A

O

K

E

S

D

F

IS

C

C

P

D

C

IS

L

C

E

A

R

D

P

IS

G

C

M

R

E

P

E

A

T

R

A

N

D

O

M

STATION

R

E

M

O

T

E

C

O

N

T

M

R

O

O

L

N

U

O

N

IT

C

U

B

-X

A

N

R

0

D

2

5

9(1/2)

1

5

12

17

18

1

2

16

8(1/2)

NVXJ Type

Only

9(2/2)

7

8(2/2)

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Power Cord See Contrast table (2)

2 FM Antenna See Contrast table (2)

3 AM Loop Antenna XTB3001

4 Remote Control Unit XZN3067

(CU-XR060)

5 Battery Cover XZN3065

NSP 6 Dry Cell Battery (R6P, AA) VEM-013

7 Packing Sheet AHG7049

8 Front Pad XHA3013

9 Rear Pad XHA3014

10 Packing Case See Contrast table (2)

NSP 11 Warranty Card See Contrast table (2)

12 Polyethylene Bag Z21-038

(0.03 × 230 × 340)

13 Operating Instructions See Contrast table (2)

(English/French)

14 Operating Instructions See Contrast table (2)

(Italian/Dutch/German)

15 Operating Instructions See Contrast table (2)

(Portuguese/Swedish/Spanish)

16 Sub Pad XHA3017

15

10

NSP 18 Polyethylene Bag See Contrast table (2)

XR-A670/MYXJ and

XR-A370/MYXJ Only

(2) CONTRAST TABLE

XR-A670/MYXJ, NVXJ, KUCXJ, XR-A370/MYXJ, NVXJ and KUCXJ are constructed the same except for the following :

Part No.

17 Fuse (T5A) See Contrast table (2)

Mark No. Symbol and Description

1

Power Cord

2

FM Antenna

10

NSP

NSP

Packing Case

11

Warranty Card

13

Operating Instructions

(English/French)

14

Operating Instructions

(Italian/Dutch/German)

15

Operating Instructions

(Portuguese/Swedish/Spanish)

17

Fuse (T5A)

18

Polyethylene Bag

XR-A670

/MYXJ

ADG1154

ADH7005

XHD3090

ARY7022

XRE3023

XRC3014

XRC3015

Not used

Not used

XR-A670

/NVXJ

ADG1156

ADH7005

XHD3090

ARY7022

XRE3023

Not used

Not used

AEK7001

AHG7033

XR-A670

/KUCXJ

ADG7022

ADH7004

XHD3091

ARY7033

XRE3024

Not used

Not used

Not used

Not used

XR-A370

/MYXJ

ADG1154

ADH7005

XHD3081

ARY7022

XRE3023

XRC3014

XRC3015

Not used

Not used

XR-A370

/NVXJ

ADG1156

ADH7005

XHD3081

ARY7022

XRE3023

Not used

Not used

AEK7001

AHG7033

XR-A370

/KUCXJ

ADG7022

ADH7004

XHD3082

ARY7033

XRE3024

Not used

Not used

Not used

Not used

Remarks

4

Page 5

B

C

D

A

A

B

C

D

E

E

F

F

Refer to

"2.3 FRONT PANEL SECTION".

Refer to

"2.4 $M MECHANISM CD-2".

6

30

30

30

21

2

7

4

51

50

50

51

51

54

54

8

25

53

28

26

31

20

46

14

18

17

16

15

3

11

35

5

1

48

48

48

49

55

55

37

38 or 44

55

55

55

55

49

49

48

49

41

40

42

45

KUCXJ

Type

Only

Except

NVXJ

Type

XR-A670

Only

KUCXJ Type

Only

Except

KUCXJ

Type

Except

KUCXJ Type

MYXJ

Type

Only

24

29

52

52

47

27

9

32

12

43

13

33

34

36

22

23

19

39

56

50

56

50

57

57

Note :

Attatch on the same numbers × three.

Note :

Hook Tray cap on top of loading

tray and then insert the bottom

three hooks.

10

52

2.2 EXTERIOR SECTION

XR-A670, XR-A370

5

Page 6

XR-A670, XR-A370

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 AF Assy See Contrast table (2)

2 PRIMARY Assy See Contrast table (2)

3 SUB TRANS Assy See Contrast table (2)

4 SECONDARY Assy See Contrast table (2)

5 FM/AM TUNER Module See Contrast table (2)

NSP 6 $M Mechanism CD-2 See Contrast table (2)

7 Power Transformer See Contrast table (2)

8 Fuse (FU1) See Contrast table (2)

NSP 9 Fuse Caution Label See Contrast table (2)

10 Card Spacer XEC3008

11 Card Spacer XEC3011

12 25P 120 Flexible Cable/60V XDD3034

(AF CN5101 ↔ DISPLAY CN5503)

13 19P 190 Flexible Cable/30V XDD3038

(CD CN8201 ↔ DISPLAY CN5501)

14 08P 230 Flexible Cable/30V XDD3039

(AF CN1052 ↔ CD CN8204)

15 Connector Assy 5P See Contrast table (2)

(AF CN2301, CN2302 ↔ DECK)

16 Connector Assy 3P XDE3021

(AF CN2303 ↔ DECK)

17 Connector Assy 3P See Contrast table (2)

(AF CN2301 ↔ DECK)

18 Connector Assy 2P See Contrast table (2)

(AF CN2302 ↔ DECK)

NSP 19 Chassis XNA3004

20 Rear Panel See Contrast table (2)

21 Bonnet Case See Contrast table (2)

22 Tray Cap See Contrast table (2)

23 Pioneer Badge XAM3001

24 Heat Sink See Contrast table (2)

25 PCB Bracket XMR3007

26 Earth Plate See Contrast table (2)

27 Shield Plate XNG3017

28 Wire Clip A XEC3003

29 Sub Heat Sink B XNH3012

30 Disc Label XAX3127

31 Ceramic Capacitor See Contrast table (2)

32 Cord Clamper RNH-184

NSP 33 Support Assy XWZ3205

NSP 34 Cable Holder XWZ3206

NSP 35 Fuse Card See Contrast table (2)

36 Binder ZCA-SKB90BK

37 Caution Label HE See Contrast table (2)

38 Caution Label See Contrast table (2)

39 Cushion Leg B XEB3009

40 ICP Label See Contrast table (2)

41 ICP Label See Contrast table (2)

42 ICP Label See Contrast table (2)

NSP 43 Getter See Contrast table (2)

44 Caution Label See Contrast table (2)

45 65 Label See Contrast table (2)

NSP 46 Sub Heat Sink A XNH3011

NSP 47 FET Bracket XNG3016

48 Screw BPZ30P080FZK

49 Screw VBT30P080FZK

50 Screw BBZ30P060FMC

51 Screw BBZ30P080FMC

52 Screw BBZ30P180FMC

53 Screw BPZ30P080FMC

54 Screw ASZ40P060FMC

55 Screw BPZ30P100FZK

56 Cushion Leg A XEB3008

57 Leg XMR3012

6

Page 7

XR-A670, XR-A370

(2) CONTRAST TABLE

XR-A670/MYXJ, NVXJ, KUCXJ, XR-A370/MYXJ, NVXJ and KUCXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

1

AF Assy

2

PRIMARY Assy

3

SUB TRANS Assy

4

SECONDARY Assy

5

FM/AM TUNER Module

XR-A670

/MYXJ

XWZ3200

XWZ3213

XWZ3208

XWZ3221

AXQ7068

XR-A670

/NVXJ

XWZ3200

XWZ3213

XWZ3208

XWZ3221

AXQ7068

XR-A670

/KUCXJ

XWZ3199

XWZ3224

XWZ3227

XWZ3221

AXQ7065

XR-A370

/MYXJ

XWZ3197

XWZ3225

XWZ3228

XWZ3220

AXQ7068

XR-A370

/NVXJ

XWZ3197

XWZ3225

XWZ3228

XWZ3220

AXQ7068

XR-A370

/KUCXJ

XWZ3196

XWZ3224

XWZ3227

XWZ3220

AXQ7065

Remarks

NSP

NSP

NSP

NSP

6

$M Mechanism CD-2

7

Power Transformer

8

Fuse (FU1 : T5A)

8

Fuse (FU1 : 5A)

8

Fuse (FU1 : 6.3A)

8

Fuse (FU1 : T4A)

9

Fuse Caution Label

15

Connector Assy 5P

17

Connector Assy 3P

18

Connector Assy 2P

20

Rear Panel

21

Bonnet Case

22

Tray Cap

24

Heat Sink

26

Earth Plate

31

Ceramic Capacitor

35

Fuse Card

37

Caution Label HE

38

Caution Label

40

ICP Label

41

ICP Label

42

ICP Label

43

Getter

44

Caution Label

45

65 Label

XXA3012

XTS3031

AEK1061

Not used

Not used

Not used

Not used

XDE3020

Not used

Not used

XNC3039

XZN3098

XAK3091

XNH3010

XNG3015

CKPUYB102K50

AAX7098

PRW1233

VRW1094

XAX3121

XAX3153

XAX3158

XAX3142

Not used

Not used

XXA3012

XTS3031

AEK1061

Not used

Not used

Not used

Not used

XDE3020

Not used

Not used

XNC3039

XZN3098

XAK3091

XNH3010

XNG3015

CKPUYB102K50

Not used

Not used

Not used

XAX3121

XAX3153

XAX3158

XAX3142

PRW1018

Not used

XXA3012

XTS3032

Not used

Not used

REK1085

Not used

XAX3157

XDE3020

Not used

Not used

XNC3040

XZN3098

XAK3091

XNH3010

Not used

Not used

AAX2374

Not used

Not used

XAX3121

XAX3153

XAX3158

XAX3143

Not used

ORW1069

XXA3009

XTS3016

Not used

Not used

Not used

AEK1060

Not used

XDE3020

Not used

Not used

XNC3034

XZN3097

XAK3085

XNH3009

XNG3015

CKPUYB102K50

Not used

PRW1233

VRW1094

Not used

Not used

Not used

XAX3137

Not used

Not used

XXA3009

XTS3016

Not used

Not used

Not used

AEK1060

Not used

XDE3020

Not used

Not used

XNC3034

XZN3097

XAK3085

XNH3009

XNG3015

CKPUYB102K50

Not used

Not used

Not used

Not used

Not used

Not used

XAX3137

PRW1018

Not used

XXA3009

XTS3017

Not used

REK1083

Not used

Not used

XAX3122

Not used

XDE3022

XDE3023

XNC3035

XZN3098

XAK3091

XNH3009

Not used

Not used

AAX7097

Not used

Not used

Not used

Not used

Not used

XAX3138

Not used

ORW1069

7

Page 8

XR-A670, XR-A370

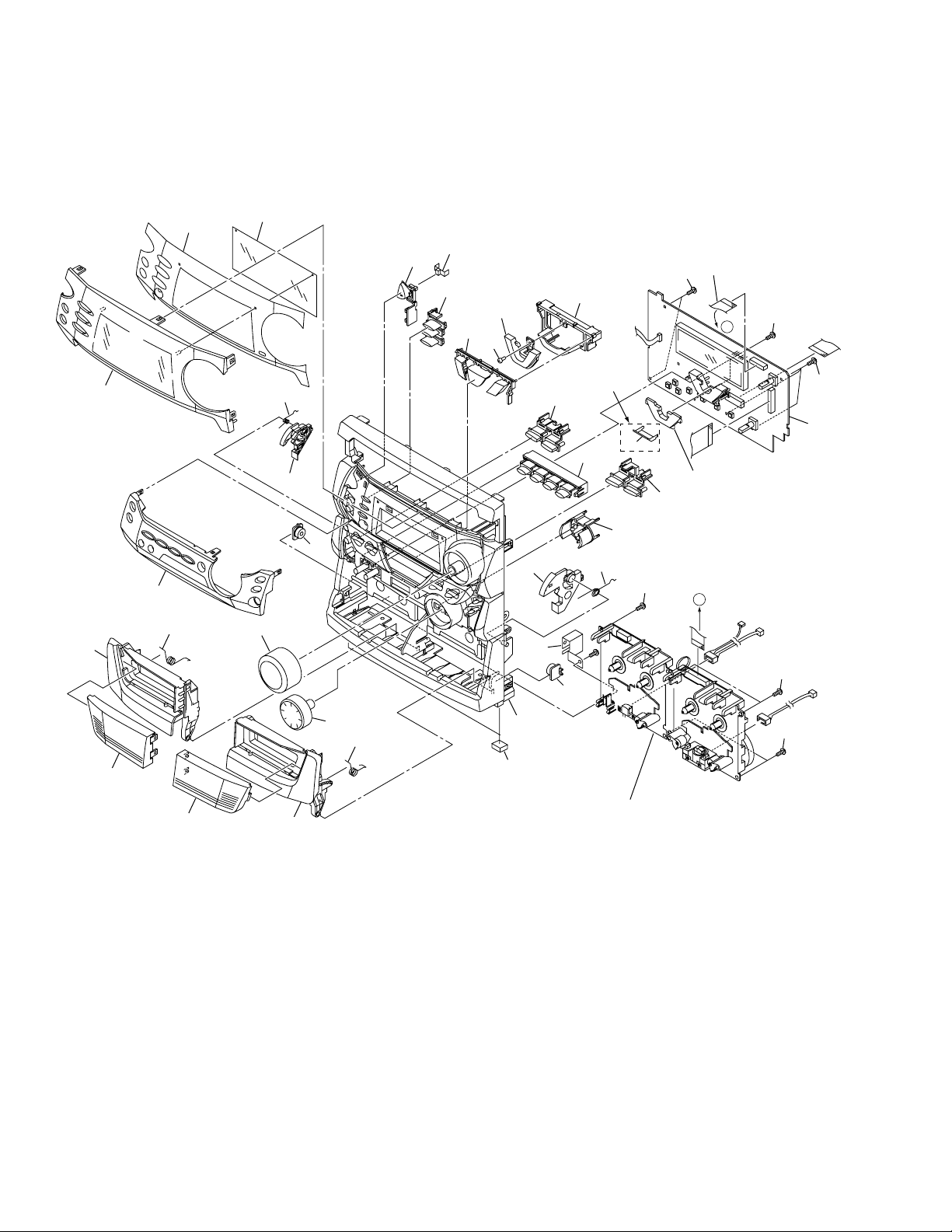

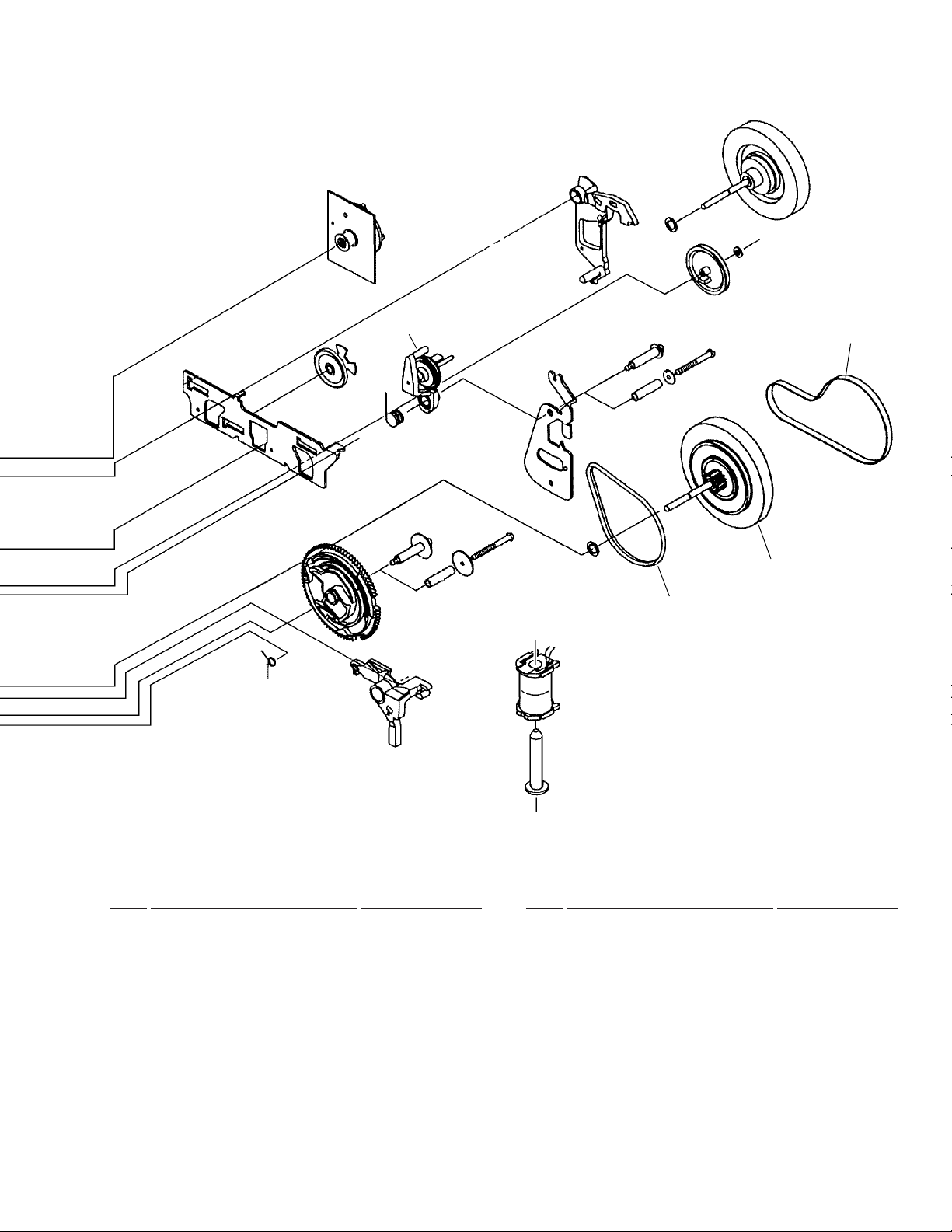

2.3 FRONT PANEL SECTION

32

17

30

11

15

31

24

25

18

13

38

4

9

6

10

14

XR-A670

Only

22

20

23

27

5

38

3

6

26

35 or 36

38

16 or 34

A

38

A

38

1

38

19

7

28

29

33

12

21

8

37

2

Refer to

"2.6 MECHANISM UNIT".

38

8

Page 9

XR-A670, XR-A370

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 DISPLAY Assy See Contrast table (2)

2 Mechanism Unit See Contrast table (2)

3 Earth Plate B XNG3023

4 Ratch Spring_L ABH7130

5 Ratch Spring_R ABH7131

6 Damper Assy AXA7052

7 Door Spring_L XBH3001

8 Door Spring_R XBH3002

9 Ratch Mold_L XMR3001

10 Ratch Mold_R XMR3002

11 Volume Knob See Contrast table (2)

12 JOG Knob See Contrast table (2)

13 V Button A See Contrast table (2)

14 V Button B See Contrast table (2)

15 FL Filter XAK3089

16 LT Conductor See Contrast table (2)

17 Display Panel See Contrast table (2)

18 V Lens XAK3117

19 FL Cover See Contrast table (2)

20 LED Cover See Contrast table (2)

21 Front Panel See Contrast table (2)

22 Function Button A XZN3087

23 S.C. Button XZN3080

24 POWER Button See Contrast table (2)

25 CD Button XZN3079

26 Function Button B XZN3102

27 JOG Lens XZN3082

28 Deck Lens L XZN3077

29 Deck Lens R XZN3078

30 Sub Panel XZN3093

31 ST Lens XZN3101

32 Deck Door_L See Contrast table (2)

33 Deck Door_R See Contrast table (2)

34 V Cap See Contrast table (2)

35 17P 180 Flexible Cable/60V See Contrast table (2)

(DISPLAY CN2903 ↔ DECK CN2905)

36 15P 180 Flexible Cable/60V See Contrast table (2)

(DISPLAY CN2903 ↔ DECK CN2905)

37 Cushion Leg A XEB3008

38 Screw BPZ30P080FMC

(2) CONTRAST TABLE

XR-A670/MYXJ, NVXJ, KUCXJ, XR-A370/MYXJ, NVXJ and KUCXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

1

DISPLAY Assy

2

Mechanism Unit

11

Volume Knob

12

JOG Knob

13

V Button A

XR-A670

/MYXJ

XWZ3215

XYM3010

XAA3013

XAA3014

XAD3034

XR-A670

/NVXJ

XWZ3215

XYM3010

XAA3013

XAA3014

XAD3034

XR-A670

/KUCXJ

XWZ3214

XYM3010

XAA3013

XAA3014

XAD3034

XR-A370

/MYXJ

XWZ3210

XYM3010

XAA3011

XAA3012

XAD3025

XR-A370

/NVXJ

XWZ3210

XYM3010

XAA3011

XAA3012

XAD3025

XR-A370

/KUCXJ

XWZ3209

XYM3008

XAA3013

XAA3014

XAD3034

Remarks

14

V Button B

16

LT Conductor

17

Display Panel

19

FL Cover

20

LED Cover

21

Front Panel

24

POWER Button

30

Sub Panel

32

Deck Door_L

33

Deck Door_R

34

V Cap

35

17P 180 Flexible Cable/60V

36

15P 180 Flexible Cable/60V

XAD3039

XAK3090

XAK3112

XAK3124

XMR3009

XMB3023

XAD3027

XAK3105

XAN3015

XAN3016

Not used

XDD3032

Not used

XAD3039

XAK3090

XAK3112

XAK3124

XMR3009

XMB3023

XAD3027

XAK3105

XAN3015

XAN3016

Not used

XDD3032

Not used

XAD3039

XAK3090

XAK3113

XAK3088

XMR3009

XMB3023

XAD3033

XAK3106

XAN3015

XAN3016

Not used

XDD3032

Not used

XAD3038

Not used

XAK3078

XAK3124

Not used

XMB3022

XAD3022

XAK3079

XAN3013

XAN3014

XAK3083

XDD3032

Not used

XAD3038

Not used

XAK3078

XAK3124

Not used

XMB3022

XAD3022

XAK3079

XAN3013

XAN3014

XAK3083

XDD3032

Not used

XAD3039

Not used

XAK3108

XAK3088

Not used

XMB3023

XAD3027

XAK3080

XAN3019

XAN3016

XAK3083

Not used

XDD3033

9

Page 10

XR-A670, XR-A370

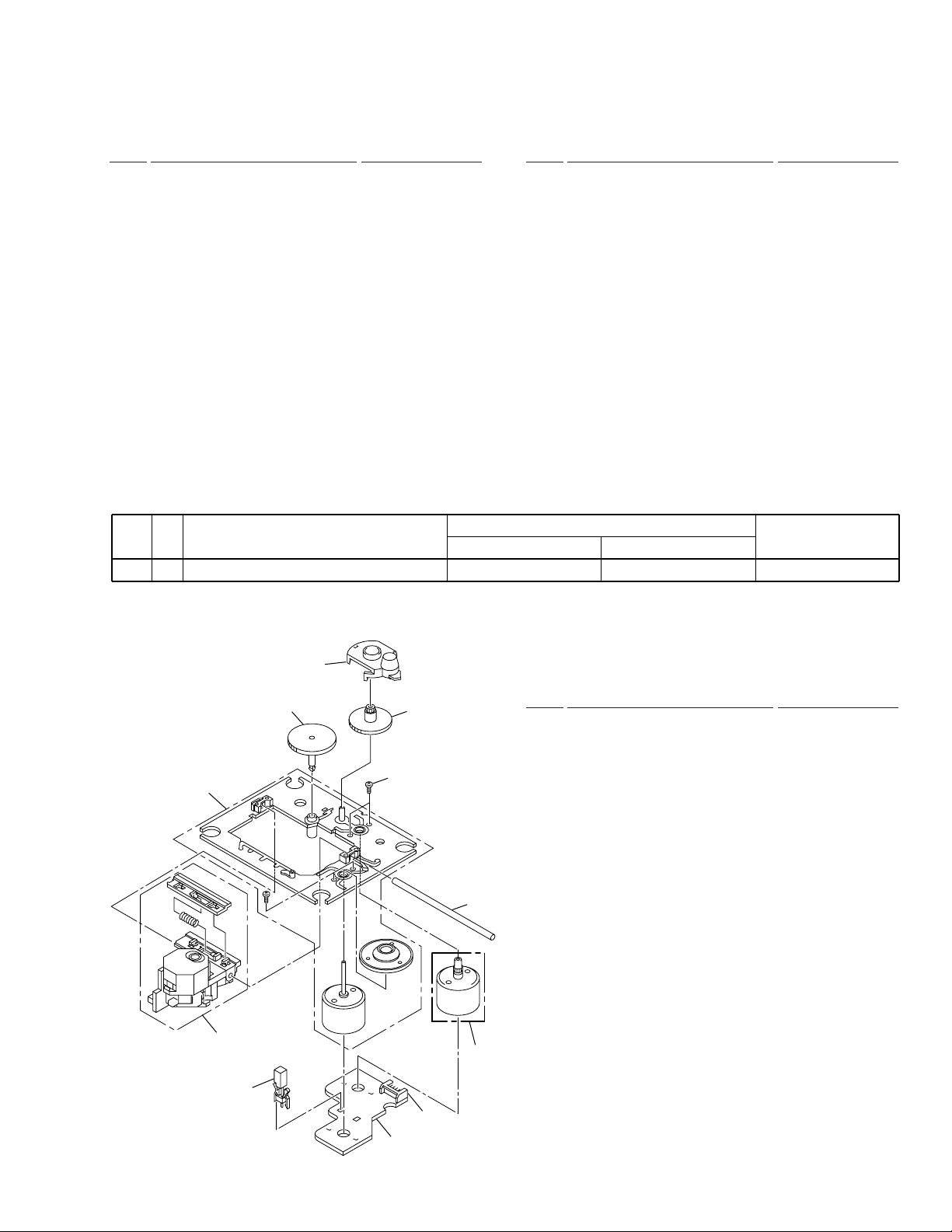

2.4 $M MECHANISM CD-2

12

29

26

8

7

A

14

13

2

15

19

29

18

6

21

C

27

Refer to

"2.5 SERVO MECHANISM ASSY".

25

22

D

24

23

11

1

5

28

29

29

29

10

30

32

29

16

29

17

29

D

B

A

9

B

4

C

31

3

20

10

29

Page 11

(1) $M MECHANISM CD-2 PARTS LIST

(2) CONTRAST TABLE

$M Mechanism CD-2 (XXA3012) and (XXA3009) are constructed the same except for the following :

Mark No. Symbol and Description

Part No.

Remarks

XXA3012 (XR-A670) XXA3009 (XR-A370)

3 CD Assy XWZ3233 XWZ3229

XR-A670, XR-A370

Mark No. Description Part No.

1 MOTOR Assy XWZ3230

2 SW Assy XWZ3231

3 CD Assy See Contrast table (2)

4 TRADE Assy XWZ3232

5 Servo Spring ABH7126

6 Belt AEB7072

7 Clamp Magnet AMF7001

8 Yoke ANB7216

9 Mecha Base XNW3011

10 Loading Tray XNW3002

11 Traverse Base XNW3006

12 Rotary Tray ANW7124

13 Clamper XNW3007

14 Clamper Holder XNW3004

15 Main Cam ANW7093

Mark No. Description Part No.

16 Gear Pulley ANW7094

17 Lock Lever ANW7095

18 Planet Gear ANW7096

19 Actuator ANW7097

20 Mini Card Spacer AEC7143

21 16P 200 Flexible Cable/60V XDD3036

22 Connector Assy (6P) ADE7010

23 Float Rubber A AEB7063

24 Float Rubber B AEB7066

25 Servo Mechanism Assy XXA3010

26 Screw IPZ30P080FMC

27 Carriage Motor VXM1033

28 Motor Pulley PNW1634

29 Ha Narl GEM1016

30 Cushion Rubber XEB3005

31 11P 185 Flexible Cable/30V XDD3037

32 Cushion Rubber XEB3007

2.5 SERVO MECHANISM ASSY

No supplied part

4

1

14

9

5

SERVO MECHANISM ASSY PARTS LIST

•

Mark No. Description Part No.

NSP 1 Motor Chassis Assy • • • • •

NSP 5 Screw +P2*3 • • • • •

3

2

2 Motor Gear Assy X-2625-769-(1)

3 Sled Shaft 2-626-908-(01)

4 Gear (A)(S) 2-625-188-(02)

6 Leaf Switch 1-572-085-(11)

7 Motor(6p)(S)PCB 1-639-678-(12)

8 Connector Pin 6p 1-564-722-(11)

9 Gear(B)(RP) 2-627-003-(01)

10 • • • • •

11 • • • • •

12 • • • • •

13 • • • • •

14 KSS-213C(Pick-up) 8-848-483-(05)

6

8

7

11

Page 12

XR-A670, XR-A370

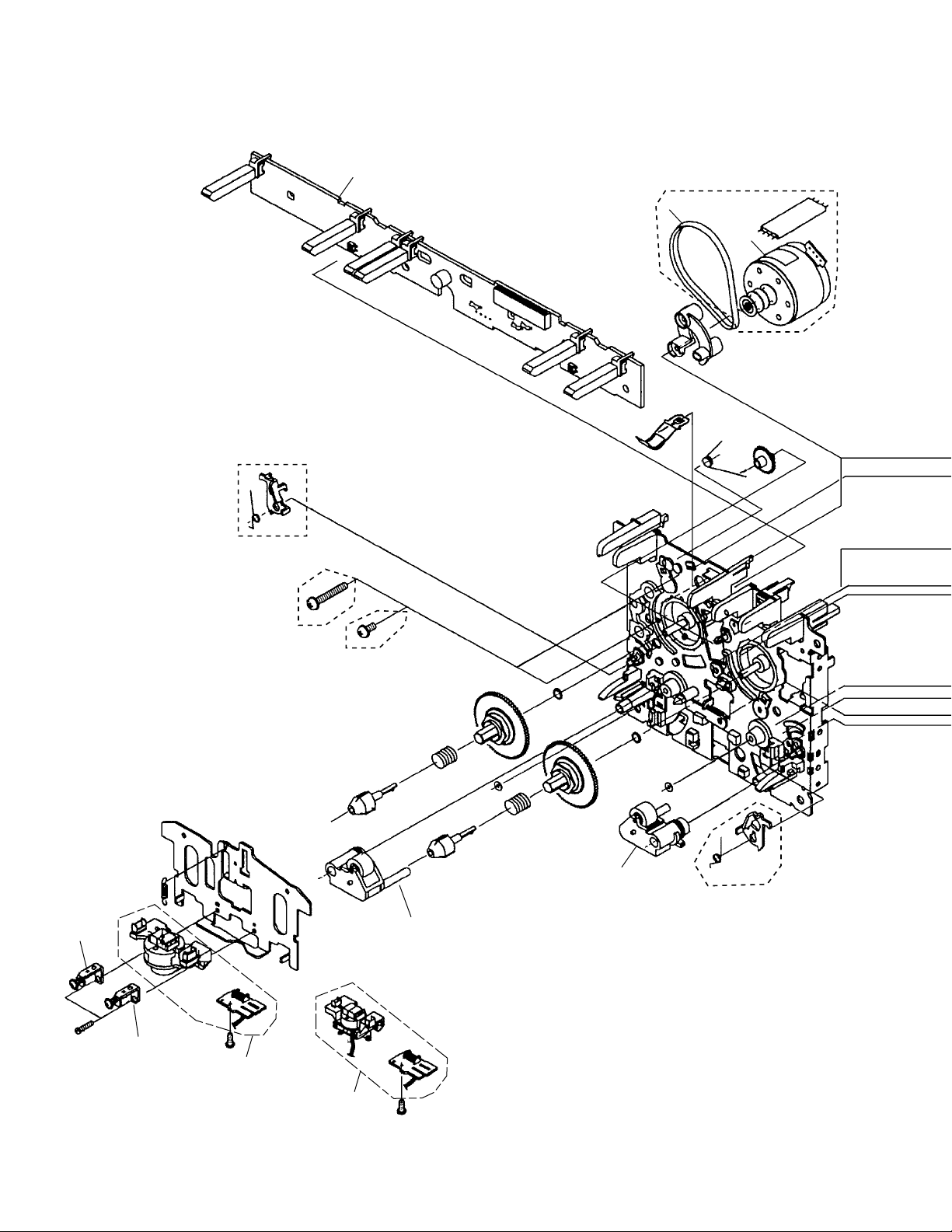

2.6 MECHANISM UNIT

Mech. Ι

Only

Mech. Ι

Mech. ΙΙ

4

Only

Mech. ΙΙ

Only

7

2

12

Mech. ΙΙ

13

Mech. ΙΙ

9

Mech. ΙΙ

Only

10

1

2

Mech. Ι

12

Page 13

XR-A670, XR-A370

5

8

11

6

MECHANISM UNIT PARTS LIST

•

(XYM3010)

Mark No. Description Part No.

1 Plate HD BLK (Mech. ΙΙ) F513-847

2 Plate HD BLK (Mech. Ι) F513-846

3 Motor Main BLK (Mech. ΙΙ only) F525-329

4 PCB Control BLK F567-630

5 Clutch Assy BLK F522-049

6 Main Belt FF19N-11

7 Joint Belt 113 (Mech. ΙΙ only) FF19P-11

8 Clutch Assy BLK (Mech. Ι) FR25B-11

8 Clutch Assy BLK (Mech. ΙΙ) FR24Y-11

9 Roller Pinch BLK R F514-129

10 Roller Pinch BLK L F514-130

11 F/R Belt FF19S-11

12 Plate Base BLK F512-127

13 Plate Base BLK F512-128

MECHANISM UNIT PARTS LIST

•

(XYM3008 : XR-A370/KUCXJ)

Mark No. Description Part No.

1 Plate HD BLK (Mech. ΙΙ) F513-848

2 Plate HD BLK (Mech. Ι) F513-846

3 Motor Main BLK (Mech. ΙΙ only) F525-329

4 PCB Control BLK F567-631

5 Clutch Assy BLK F522-049

6 Main Belt FF19N-11

7 Joint Belt 113 (Mech. ΙΙ only) F19N-11

8 Clutch Assy BLK (Mech. Ι) FR25B-11

8 Clutch Assy BLK (Mech. ΙΙ) FR24Y-11

9 Roller Pinch BLK R (Mech. ΙΙ) F514-131

10 Roller Pinch BLK L (Mech. ΙΙ) F514-130

11 F/R Belt FF19S-11

12 Plate Base BLK F512-127

13 Plate Base BLK F512-128

13

Page 14

1

23

XR-A670, XR-A370

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

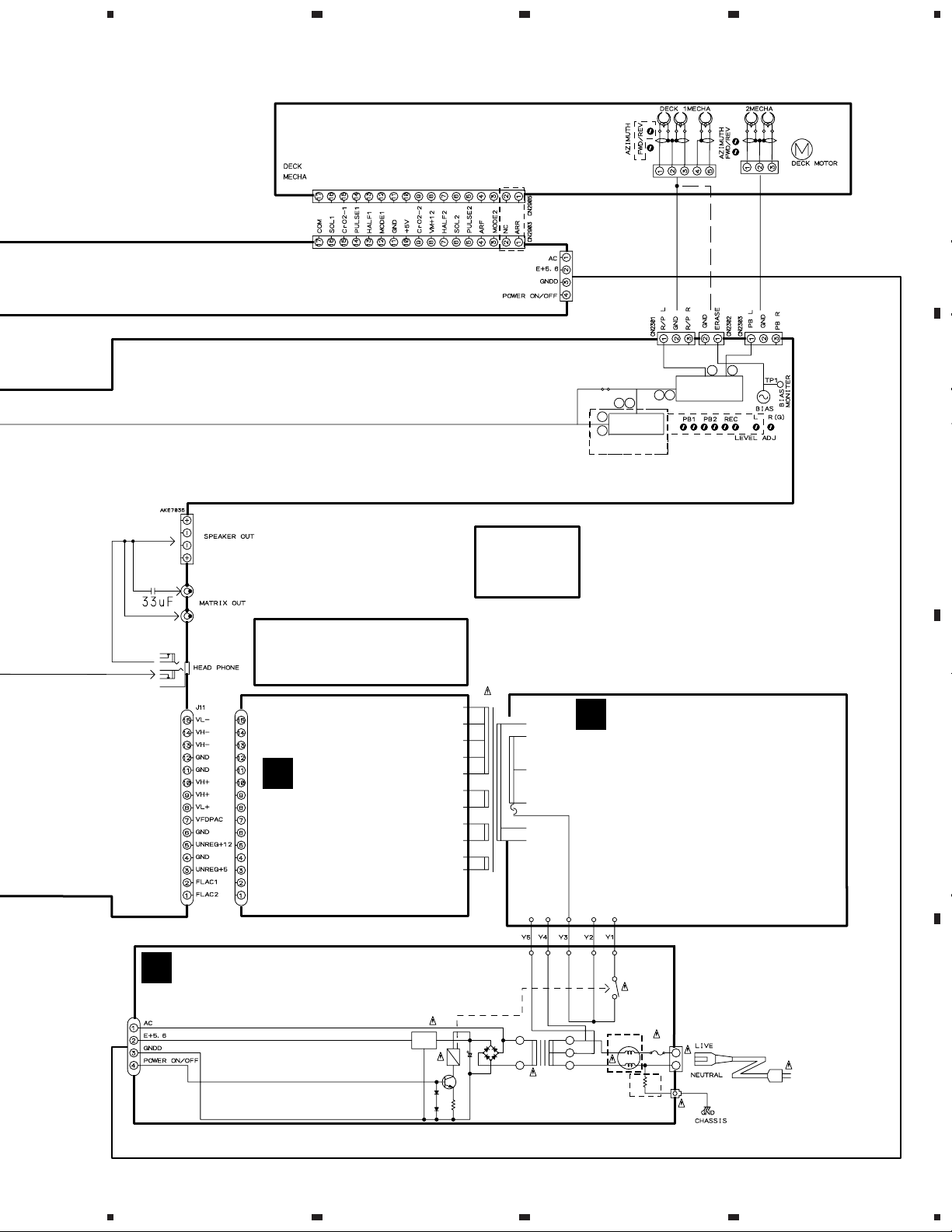

3.1 BLOCK DIAGRAM and OVERALL WIRING DIAGRAM

4

V5621

A

J

DISPLAY ASSY

(XR-A670/MYXJ, NVXJ : XWZ3215)

(XR-A670/KUCXJ : XWZ3214)

(XR-A370/MYXJ, NVXJ : XWZ3210)

PDC057A

System Control

(XR-A370/KUCXJ : XWZ3209)

B

IC3001

LC75394NED

17

E-VOL IC

58 55

AA

33

16

21

FL TUBE

29

IC5501

81 82

83

84

IC3101

BA4558F-HT

62 71 1014

AMP

S5951

S5952

STK407-100B (XR-A670)

STK407-070B (XR-A370)

5901

SR

IC3301

Power AMP

67

FM/AM TUNER MODULE

(MYXJ, NVXJ : AXQ7068)

IC3501, IC3502

BA4558F-HT

AB

FM/AM TUNER MODULE

Godzilla Amp

3517

(KUCXJ : AXQ7065)

CN6201

MYXJ, NVXJ

TYPES

C

ONLY

IC5751

BU1923F

RDS IC

4

16

F

AF ASSY

F 1/3- F 3/3

(XR-A670/MYXJ, NVXJ : XWZ3200)

JA3001

(XR-A670/KUCXJ : XWZ3199)

(XR-A370/MYXJ, NVXJ : XWZ3197)

(XR-A370/KUCXJ : XWZ3196)

B

CD ASSY

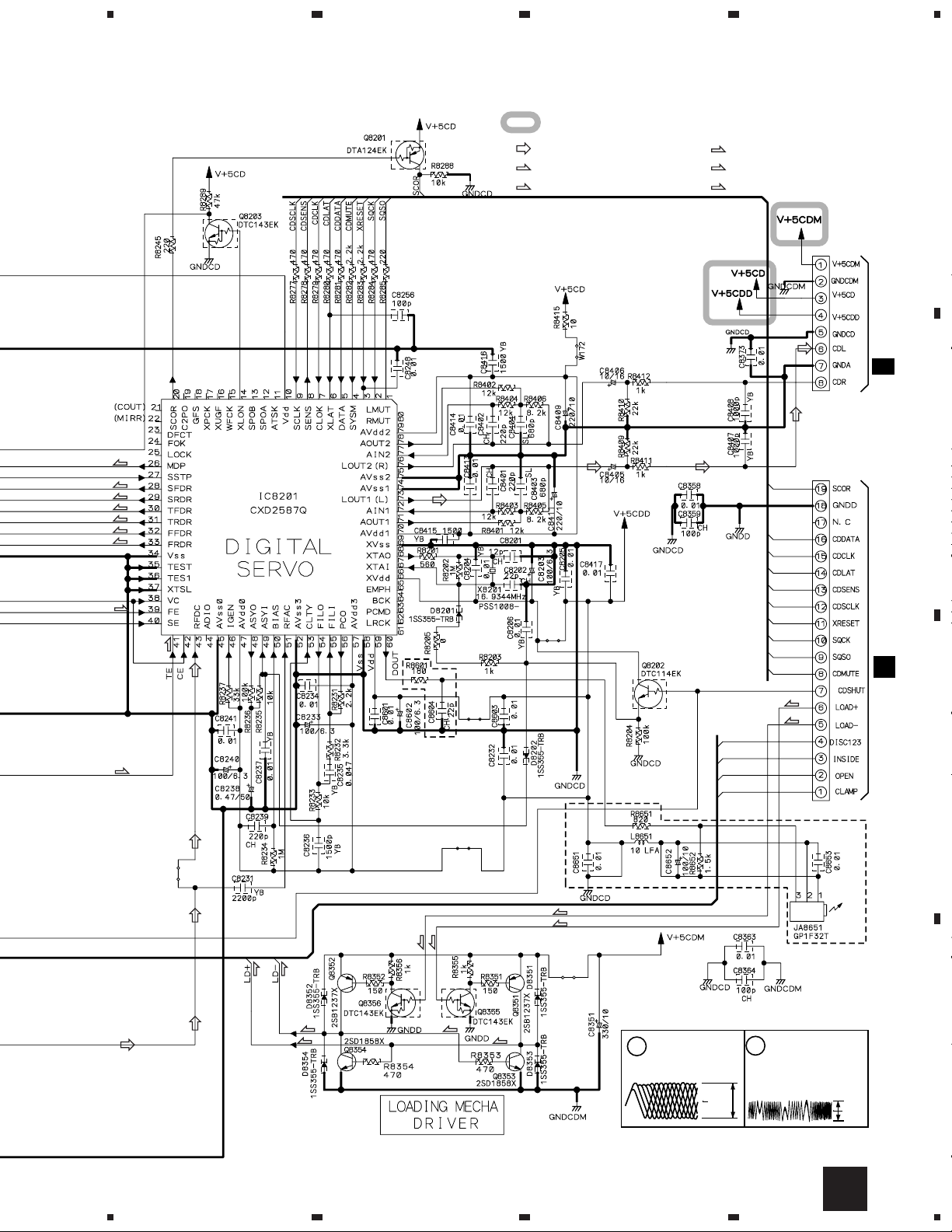

IC8201

CXD2587Q

DIGITAL

SERVO

D

IC8101

CXA1821M

RF AMP

IC8301

BA5970FP

DRIVER

XR-A670

ONLY

SERVO MECHANISM ASSY

(XXA3010)

TRADE ASSY

E

14

1234

(XWZ3232)

(XR-A670 : XWZ3233)

JA8651

(XR-A370 : XWZ3229)

D

SW ASSY

(XWZ3231)

C

MOTOR ASSY

(XWZ3230)

Page 15

5

678

XR-A670, XR-A370

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

A

CN3331

JA3441

CN3991

SUPPORT

ASSY

CN11

G

SECONDARY ASSY

(XR-A670 : XWZ3221)

(XR-A370 : XWZ3220)

EXCEPT

XR-A370

/KUCXJ

J81

16

Dolby IC

1

IC2201

HA12136AF

XR-A670

ONLY

IC2301

HA12211NT

89

CABLE

HOLDER

ASSY

T1

POWER TRANSFORMER

(XR-A670/MYXJ, NVXJ : XTS3031)

(XR-A670/KUCXJ : XTS3032)

(XR-A370/MYXJ, NVXJ : XTS3016)

(XR-A370/KUCXJ : XTS3017)

H

PRIMARY ASSY

(XR-A670/MYXJ, NVXJ : XWZ3213)

(XR-A670/KUCXJ, XR-A370/KUCXJ

: XWZ3224)

(XR-A370/MYXJ, NVXJ : XWZ3225)

2627

2 8

REC PB IC

B

C

CN81

SUB TRANS ASSY

I

(XR-A670/MYXJ, NVXJ : XWZ3208)

(XR-A670/KUCXJ, XR-A370/KUCXJ : XWZ3227)

(XR-A370/MYXJ, NVXJ : XWZ3228)

IC81

NJM7805FA

5

RY81

Q81

6

MYXJ, NVXJ

TYPES

ONLY

L1

T2

KUCXJ TYPE

ONLY

FU1

AN1

MYXJ, NVXJ :

50/60Hz AC220-230V

KUCXJ :

60Hz AC120V

D

AC POWER CORD

MYXJ : ADG1154

NVXJ : ADG1156

KUCXJ : ADG7022

15

7

8

Page 16

1

23

XR-A670, XR-A370

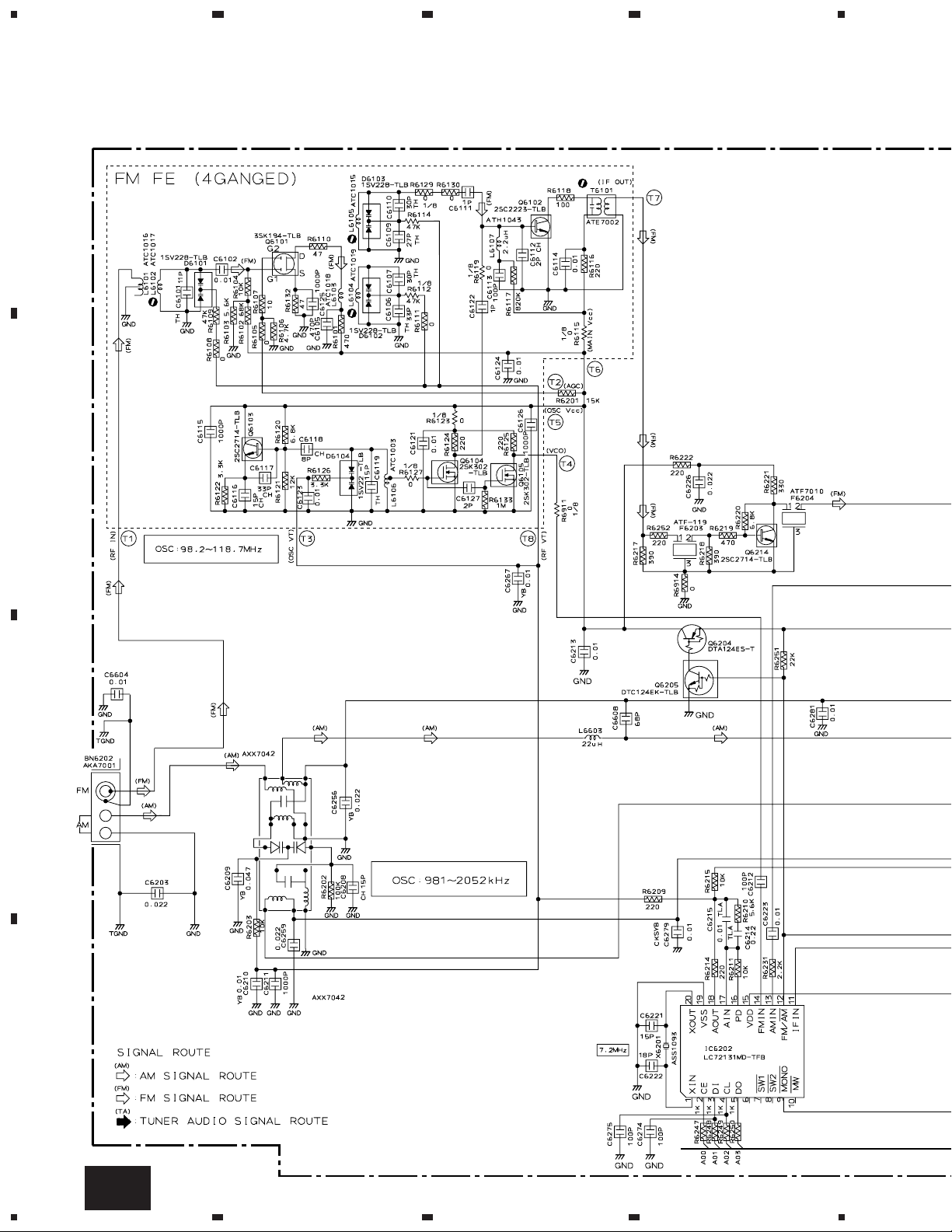

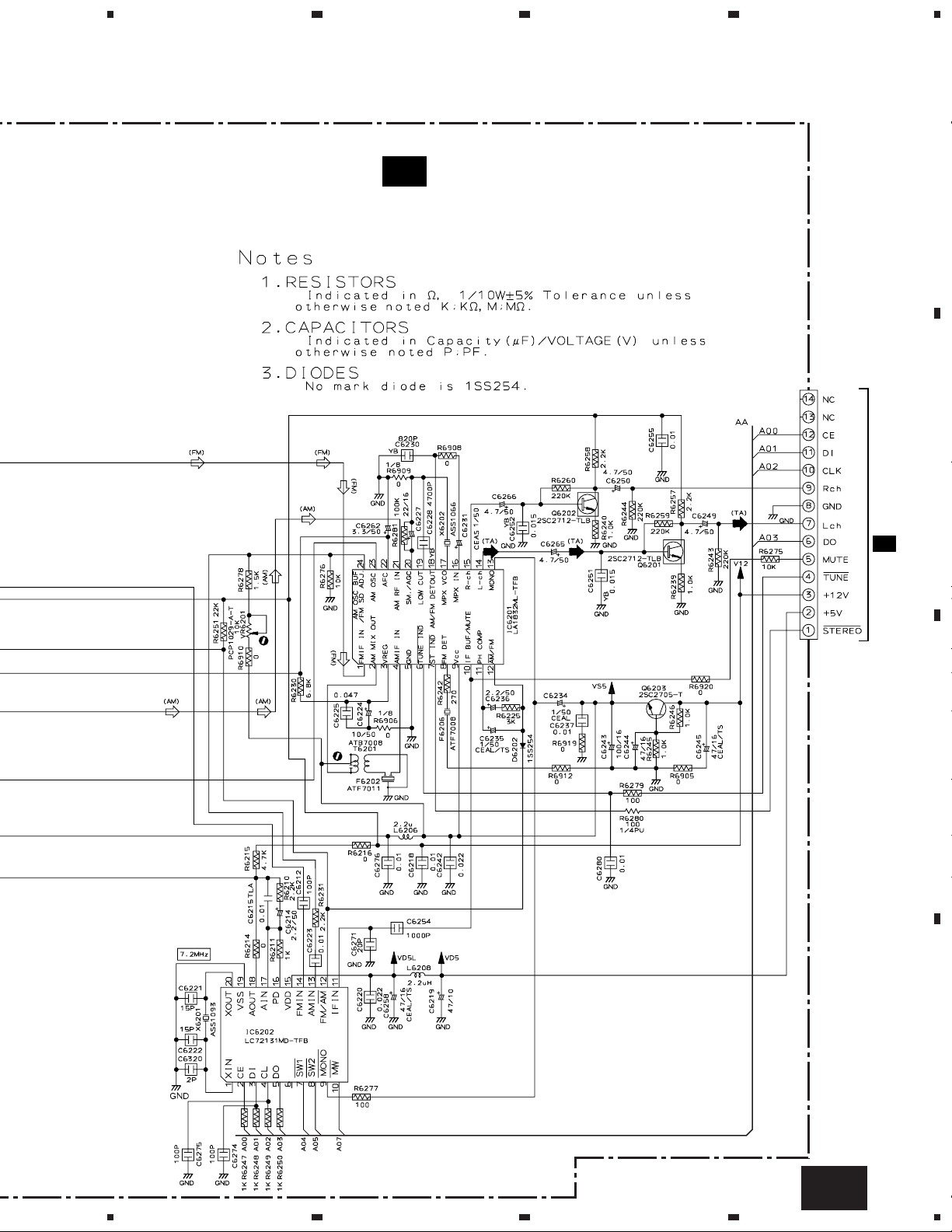

3.2 FM/AM TUNER MODULE (For MYXJ and NVXJ Types)

A

MIX AMP

RF AMP

OSC

B

4

BUFFER

IF AMP

FM +B SW

C

AM RF TUNING BLOCK

D

16

AA

1234

PLL

Page 17

5

678

XR-A670, XR-A370

A

FM/AM TUNER MODULE

AA

(AXQ7068)

B

AF AMP

REGULATOR

CN3051

2/3

F

AF AMP

CN6201

KP200IA14L

C

D

AA

5

6

7

8

17

Page 18

1

23

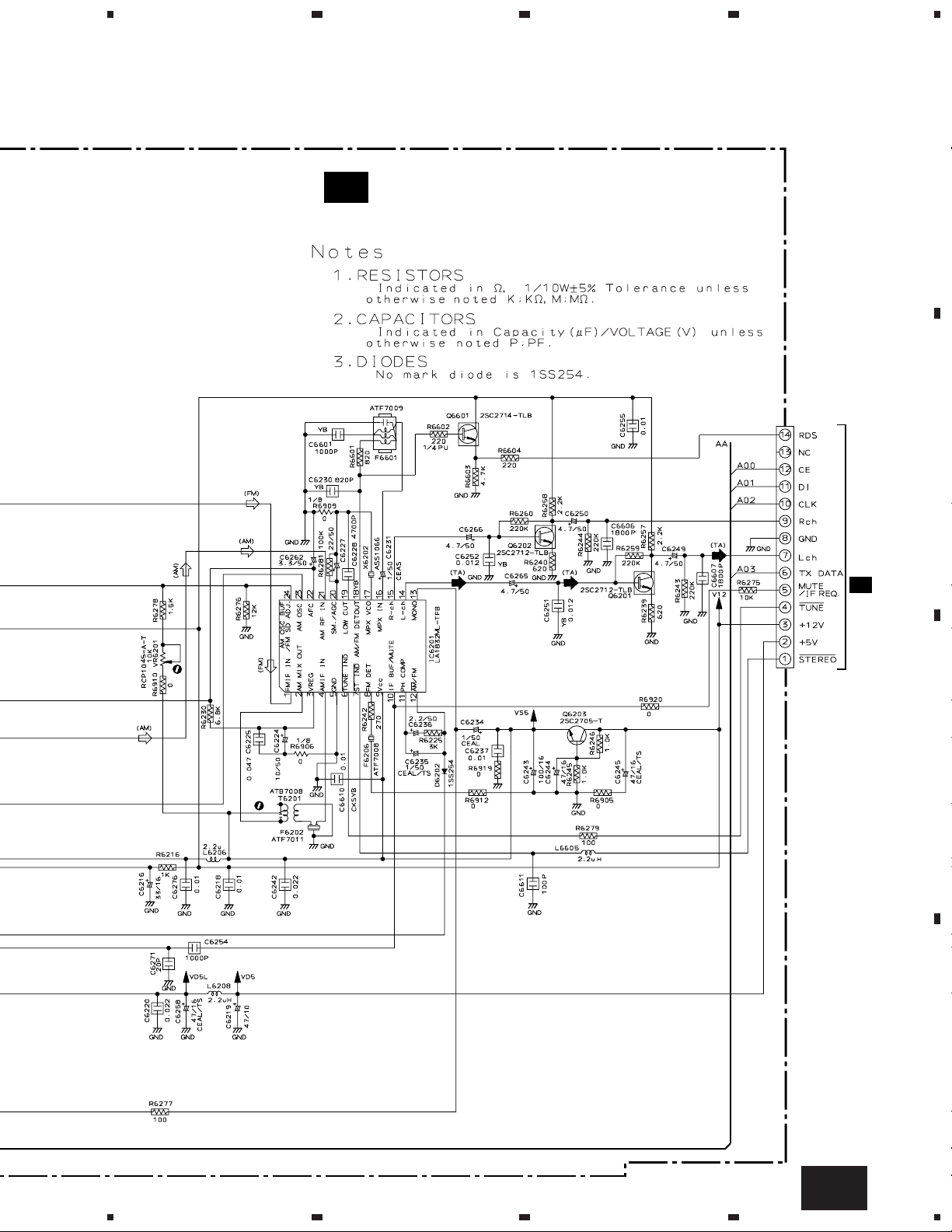

XR-A670, XR-A370

3.3 FM/AM TUNER MODULE (For KUCXJ Type)

4

A

B

RF AMP

1T378A

OSC

1T378A

MIX AMP

BUFFER

IF AMP

FM +B SW

C

MW RF TUNING BLOCK

AKX7041

D

18

AB

1234

Page 19

5

678

XR-A670, XR-A370

FM/AM TUNER MODULE

AB

(AXQ7065)

AF AMP

A

B

CN3051

2/3F

AF AMP

PLL

REGULATOR

CN6201

KP200IA14L

C

D

AB

5

6

7

8

19

Page 20

1

23

XR-A670, XR-A370

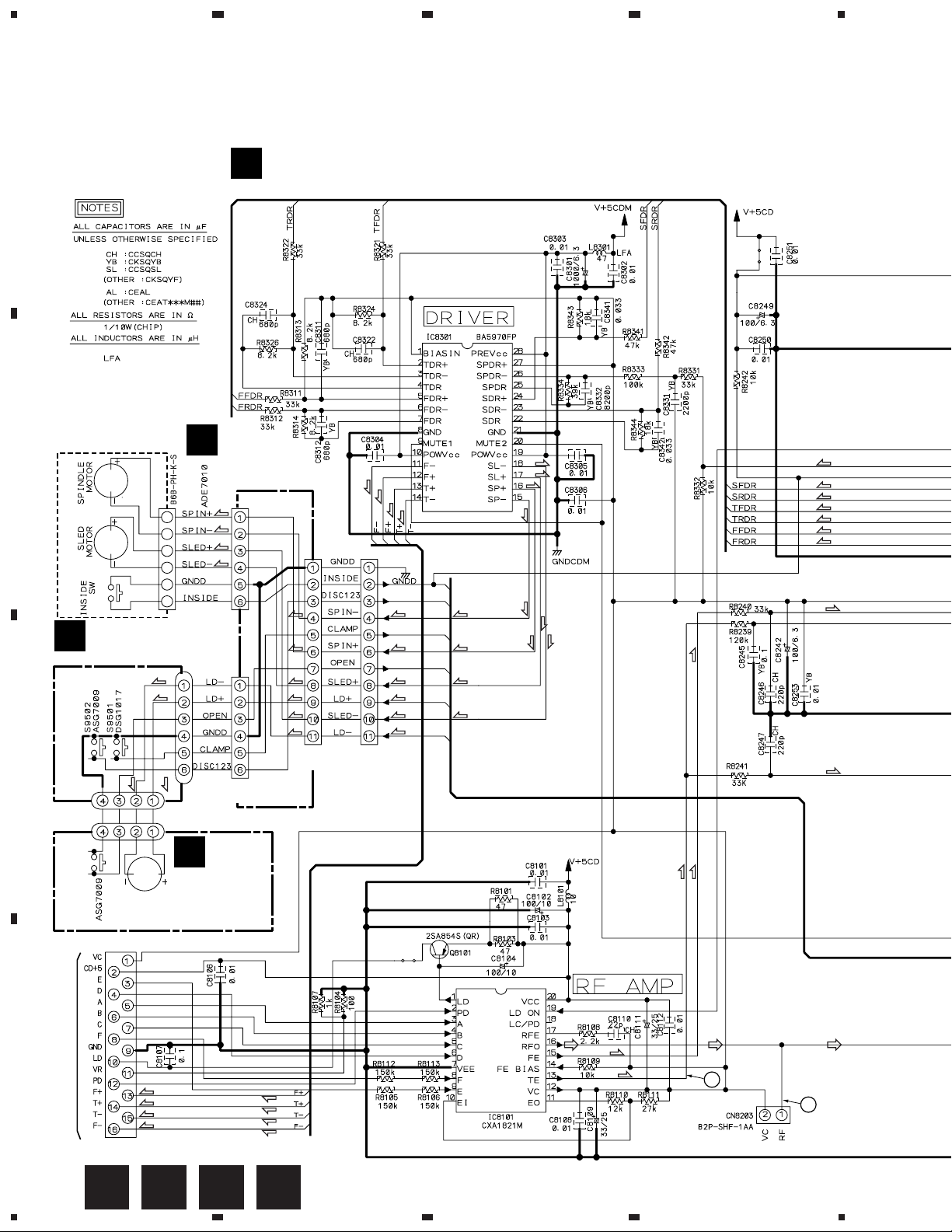

3.4 CD, MOTOR, SW and TRADE ASSYS

4

A

CD ASSY (XR-A670 : XWZ3233)

B

(XR-A370 : XWZ3229)

TRADE

E

B

SERVO MECHANISM ASSY

SW ASSY

D

ASSY

(XWZ3232)

CN9001

(S)

S6B-PH-K-S

(S)

(C)

(C)

(S)

(S)

(F)

(F)

(T)

(T)

(S)

(S)

(S)

(S)

(C)

(C)

(S)

(S)(S)

(C)

(C)

(S)

(S)

(C)

(C)

(T)

(T)

(F)

(F)

(F)

(XWZ3231)

J9501

D20PWY0610E

(C)(L)

(L)

(L) (L)

(C)

(L)

(C)

(C)

(L)

(C)

(C)

(F)

CN9002

C

(L)

(L)

J9502

D20PWW0405E

CN9501

52147-0610

SLW11R-1C7

CN8002

SLW11R-1C7

(T)

C

CARRIAGE

S9503

VXM1033

D

SERVO MECHANISM ASSY

CN8101

SLW16R-1C7

20

B C D E

1234

MOTOR

(F)

(T)

(T)

(F)

ASSY

(XWZ3230)

(CD)

(F)

(T)

(F)

(T)

(T)

(F)

MOTOR

(F)

(T)

(CD)(CD)

2

1

Page 21

5

678

XR-A670, XR-A370

: The power supply is shown with the marked box.

(CD)

: CD AUDIO SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SPINDLE MOTOR ROUTE

(C)

: CARRIAGE MOTOR ROUTE

(L)

: LOADING MOTOR ROUTE

CN8204

52044-0845

A

CN1052

(CD)

2/3

F

(CD)

(S)

(C)

(C)

(T)

(T)

(F)

(F)

(F)

(T)

(CD)

(CD)(CD)

CN8201

52045-1945

B

CN5501

J

(CD)

(L)

(L)

XR-A670

(T)

(CD)(CD)(CD)

ONLY

(L)

(L)

C

XR-A670

(L)

(L)

ONLY

(CD)

(L)

(L)

Note: The encircled numbers

denote measuring point in the

(L) (L)

(L) (L)

5

6

schematic diagram.

CN8203- Pin 1 :

1

PLAY MODE (RF)

H : 500nsec/div

7

1.8Vp-p

VREF

IC8101- Pin 13 :

2

TEST MODE,

Tracking Open(TRER)

H : 5msec/div

1.0Vp-p

VREF

B

8

D

21

Page 22

1

XR-A670, XR-A370

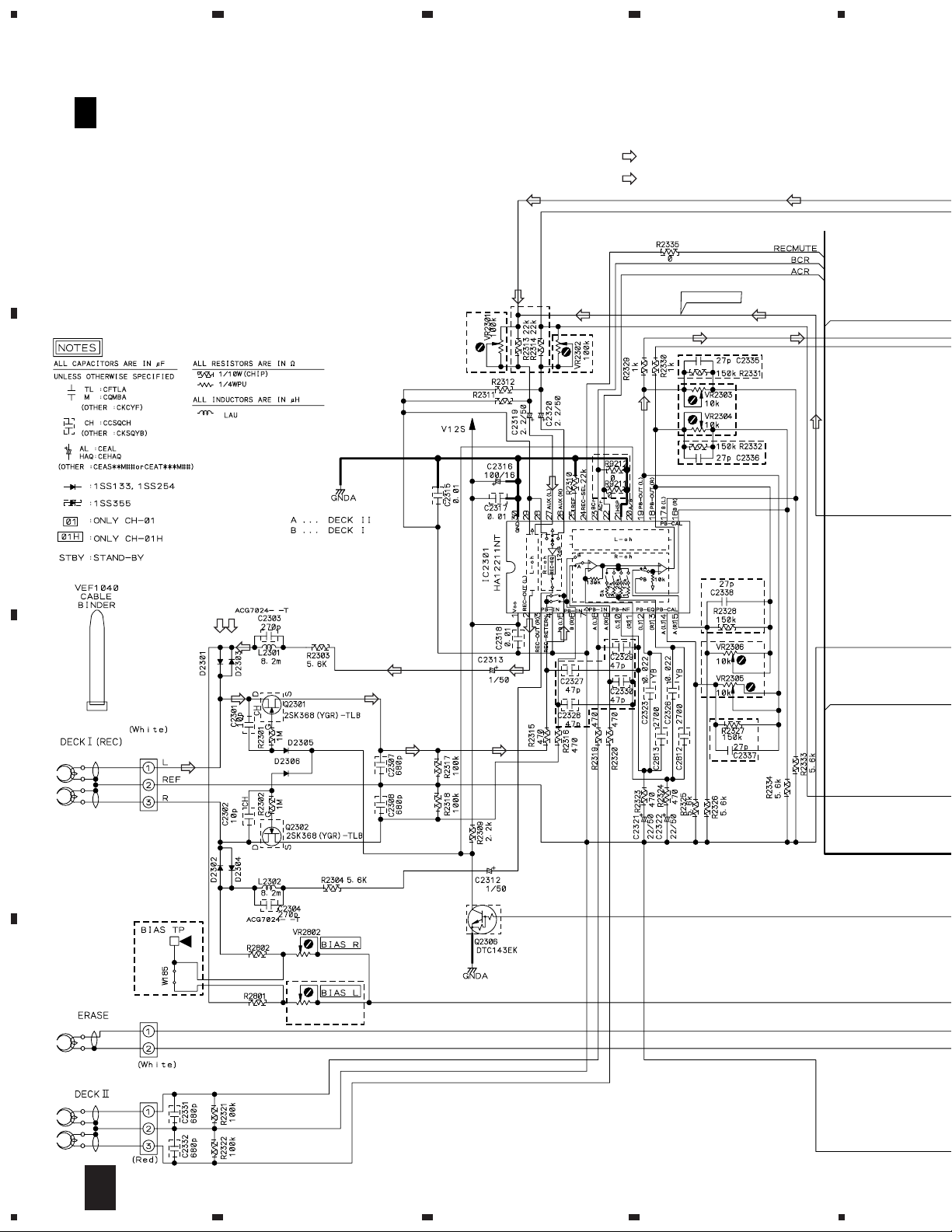

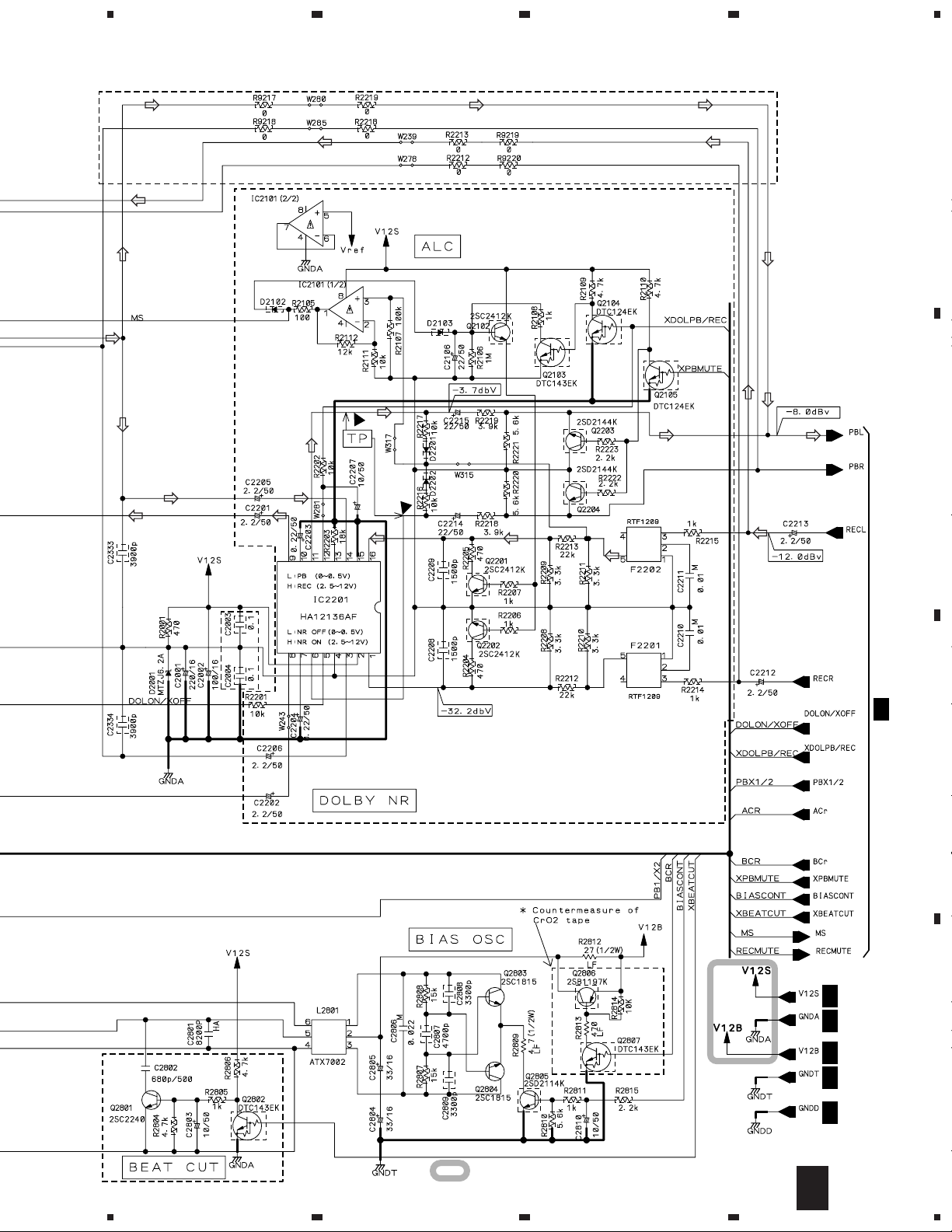

3.5 AF ASSY (1/3)

23

4

F 1/3

A

B

AF ASSY

(XR-A670/MYXJ, NVXJ : XWZ3200)

(XR-A670/KUCXJ : XWZ3199)

(XR-A370/MYXJ, NVXJ : XWZ3197)

(XR-A370/KUCXJ : XWZ3196)

R2311, R2312 :

22k (XR-A670)

39k (XR-A370)

XR-A670

ONLY

(REC)

XR-A370

ONLY

XR-A670

ONLY

(REC)

(PB)

: DECK PB SIGNAL ROUTE

(REC)

: DECK REC SIGNAL ROUTE

–3.7XR-A670

(PB) (PB)

(PB)

XR-A370

ONLY

XR-A370 ONLY

XR-A370

ONLY

(REC)(REC)

XR-A370

ONLY

XR-A670

ONLY

(REC)(REC)

(REC)

(REC)

(REC)

(REC)

(REC)

D2301-D2306 : 1SS133

(PB) (PB)

(PB) (PB)

CN2301

B3B-PH-K-S

XR-A370

ONLY

CN2302

B2B-PH-K-S

(PB)

33k (XR-A670)

47k (XR-A370)

33k (XR-A670)

47k (XR-A370)

220k (VCP1164): XR-A670

100k (VCP1162): XR-A370

VR2801

220k

XR-A670

ONLY

C

(REC)

MYXJ, NVXJ

TYPES ONLY

(REC)

(PB)

XR-A670 ONLY

XR-A370

ONLY

D

22

F

CN2303

B3B-PH-K-R

1/3

1234

Page 23

5

678

XR-A670, XR-A370

(PB) (PB) (PB)

(PB)

(REC)

XR-A670

(PB)

(PB)

ONLY

(PB) (PB)

BA4558F-HT

(REC)(REC)

BA4558F-HT

(PB)

(PB)

(REC)

1SS355

(REC)

(PB)

XR-A370

ONLY

(REC)(REC)

A

(PB)(PB)

(REC)

(PB)

B

(REC)

XR-A670/

MYXJ, NVXJ

ONLY

XR-A670

ONLY

(REC)

3/3

F

2/3,3/3

F

F

2/3

C

3/3

F

XR-A670

ONLY

XR-A670

ONLY

5

6

: The power supply is shown with the marked box.

7

F

3/3

F

2/3

F

1/3

8

23

D

Page 24

1

XR-A670, XR-A370

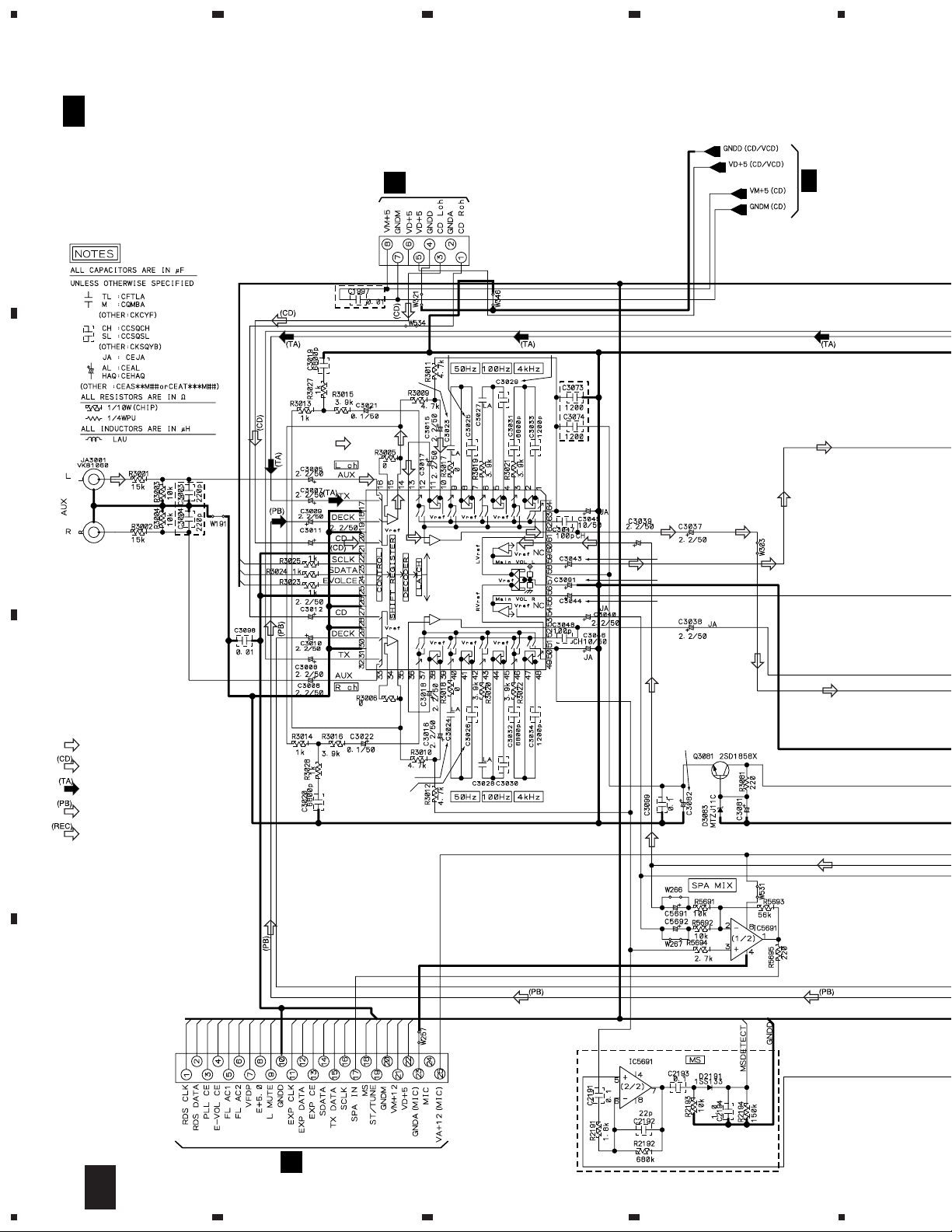

3.6 AF ASSY (2/3)

F 2/3

AF ASSY

A

B

(XR-A670/MYXJ, NVXJ : XWZ3200)

(XR-A670/KUCXJ : XWZ3199)

(XR-A370/MYXJ, NVXJ : XWZ3197)

(XR-A370/KUCXJ : XWZ3196)

MYXJ,

NVXJ

TYPES ONLY

23

CN8204

B

CN1052

52045-0845

MYXJ,

NVXJ

TYPES ONLY

0.056 (MYXJ,NVXJ)

0.027 (KUCXJ)

MYXJ,

NVXJ

TYPES

ONLY

0.56 (MYXJ,NVXJ)

0.47 (KUCXJ)

0.1 (MYXJ,NVXJ)

0.068 (KUCXJ)

0.33

4

3/3

F

0.47/50

IC300

LC75394NED

0.47/50

: AUDIO SIGNAL ROUTE

0.33

0.056 (MYXJ,NVXJ)

0.027 (KUCXJ)

C

: CD AUDIO SIGNAL ROUTE

: TUNER AUDIO SIGNAL ROUTE

: DECK PB SIGNAL ROUTE

: DECK REC SIGNAL ROUTE

0.56 (MYXJ,NVXJ)

0.47 (KUCXJ)

0.1 (MYXJ,NVXJ)

0.068 (KUCXJ)

0.47/50 (MYXJ,NVXJ)

2.2/50 (KUCXJ)

2.2/50 (MYXJ,NVXJ)

10/50 (KUCXJ)

0.47/50 (MYXJ,NVXJ)

2.2/50 (KUCXJ)

0.47/50 (MYXJ,NVXJ)

2.2/50 (KUCXJ)

4.7/50 (MYXJ,NVXJ)

10/50 (KUCXJ)

BA4558F-HT

CN5102

D

CN5503

J

24

F

2/3

52045-2545

XR-A670

ONLY

BA4558F-HT

1234

Page 25

5

CN6201 (MYXJ, NVXJ TYPES)

AA

CN6201 (KUCXJ TYPE)

AB

678

XR-A670, XR-A370

CN3051

KM200IB14

MYXJ, NVXJ

TYPES

ONLY

MYXJ, NVXJ

TYPES ONLY

3.9k (MYXJ,NVXJ)

4.7k (KUCXJ)

3.9k (MYXJ,NVXJ)

4.7k (KUCXJ)

MYXJ, NVXJ

TYPES ONLY

MYXJ, NVXJ

TYPES ONLY

BA4558F-HT (1/2)

BA4558F-HT (1/2)

MYXJ, NVXJ TYPES ONLY

F

3/3

F

A

3/3

B

3/3

F

1/3,3/3

F

3/3

3/3

F

3/3

F

2/3

8

F

25

XR-A670

ONLY

3/3

F

1/3

F

5

6

7

F

C

D

Page 26

1

23

XR-A670, XR-A370

3.7 AF (3/3) and SECONDARY ASSYS

A

R3515,R3516,R3517,R3518

1.5k (MYXJ, NVXJ)

1.2k (KUCXJ)

2/3

F

B

IRF9540G (XR-A670)

IRFI9Z34G (XR-A370)

2/3

F

IRF540G

(XR-A670)

IRFIZ34G

(XR-A370)

1SR139-100

D3302

1SR139-100

MYXJ, NVXJ

TYPES

ONLY

56k

56k

BA4558F-HT (1/2)

4

STK407-100B (XR-A670)

STK407-070B (XR-A370)

1k (MYXJ, NVXJ)

0 (KUCXJ)

MYXJ, NVXJ

TYPES

ONLY

56k (MYXJ, NVXJ)

68k (KUCXJ)

BA4558F-HT (1/2)

47k (XR-A670)

39k (XR-A370/MYXJ, NVXJ)

47k (XR-A370/KUXJ)

BA4558F-HT (2/2)

2/3

F

1/3, 2/3

F

2/3

F

2/3

C

F

F

F

2/3

2/3

XR-A370/KUCXJ

ONLY

EXCEPT

XR-A370/KUCXJ

BA4558F-HT (2/2)

1/3

F

2/3

F

D

2/3

F

: The power supply is shown with the marked box.

26

3/3

F

1234

Page 27

5

678

XR-A670, XR-A370

F 3/3

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

AF ASSY

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 4911.25 MFD, BY LITTELFUSE INK.

FOR IC71 (AEK7010).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491003 MFD, BY LITTELFUSE INK.

FOR IC41 (AEK7050).

(XR-A670/MYXJ, NVXJ : XWZ3200)

(XR-A670/KUCXJ : XWZ3199)

(XR-A370/MYXJ, NVXJ : XWZ3197)

(XR-A370/KUCXJ : XWZ3196)

: AUDIO SIGNAL ROUTE

100 (MYXJ, NVXJ)

10 (KUCXJ)

820

100 (MYXJ, NVXJ)

10 (KUCXJ)

KUCXJ TYPE

ONLY

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

MYXJ, NVXJ

TYPES ONLY

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491004 MFD, BY LITTELFUSE INK.

FOR IC31 (AEK7053: XR-A670).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491003 MFD, BY LITTELFUSE INK.

FOR IC31 (AEK7050: XR-A370).

CN3331

AKE7001

MYXJ, NVXJ

TYPES ONLY

JA3441

VKB1060

XR-A670

ONLY

A

B

8.2k (XR-A670)

5.6k (XR-A370)

MYXJ, NVXJ

TYPES ONLY

CN11

KPE15

4700/80 (XCH3001 : XR-A670)

3300/63 (AXH7071 : XR-A370)

S1WB(A)60SBD (XR-A670)

S1WB(A)60SD (XR-A370)

S1WB(A)60SBD (XR-A670)

S1WB(A)60SD (XR-A370)

J11

D15A15-350-2651

SECONDARY ASSY (XR-A670 : XWZ3221)

G

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491010F MFD, BY LITTELFUSE INK.

FOR IC11 AND IC12 (AEK7068: XR-A670).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491007 MFD, BY LITTELFUSE INK.

FOR IC11 AND IC12 (AEK7047: XR-A370).

PHONES

CN3991

AKN-056

1.25A

AEK7021 (7A) : XR-A670

AEK7019 (5A) : XR-A370

AEK7021 (7A) : XR-A670

AEK7019 (5A) : XR-A370

AEK7053 (4A) : XR-A670

AEK7050 (3A) : XR-A370

AEK7068 (10A) : XR-A670

AEK7047 (7A) : XR-A370

T1

POWER TRANSFORMER

(XR-A370 : XWZ3220)

CAUTION : FOR CONTINUED PROTECTION AGAINST

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491007 MFD, BY LITTELFUSE INK.

FOR IC21 AND IC22 (AEK7021: XR-A670).

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491005 MFD, BY LITTELFUSE INK.

FOR IC21 AND IC22 (AEK7019: XR-A370).

C

D

3/3

F

5

6

7

G

8

27

Page 28

1

23

XR-A670, XR-A370

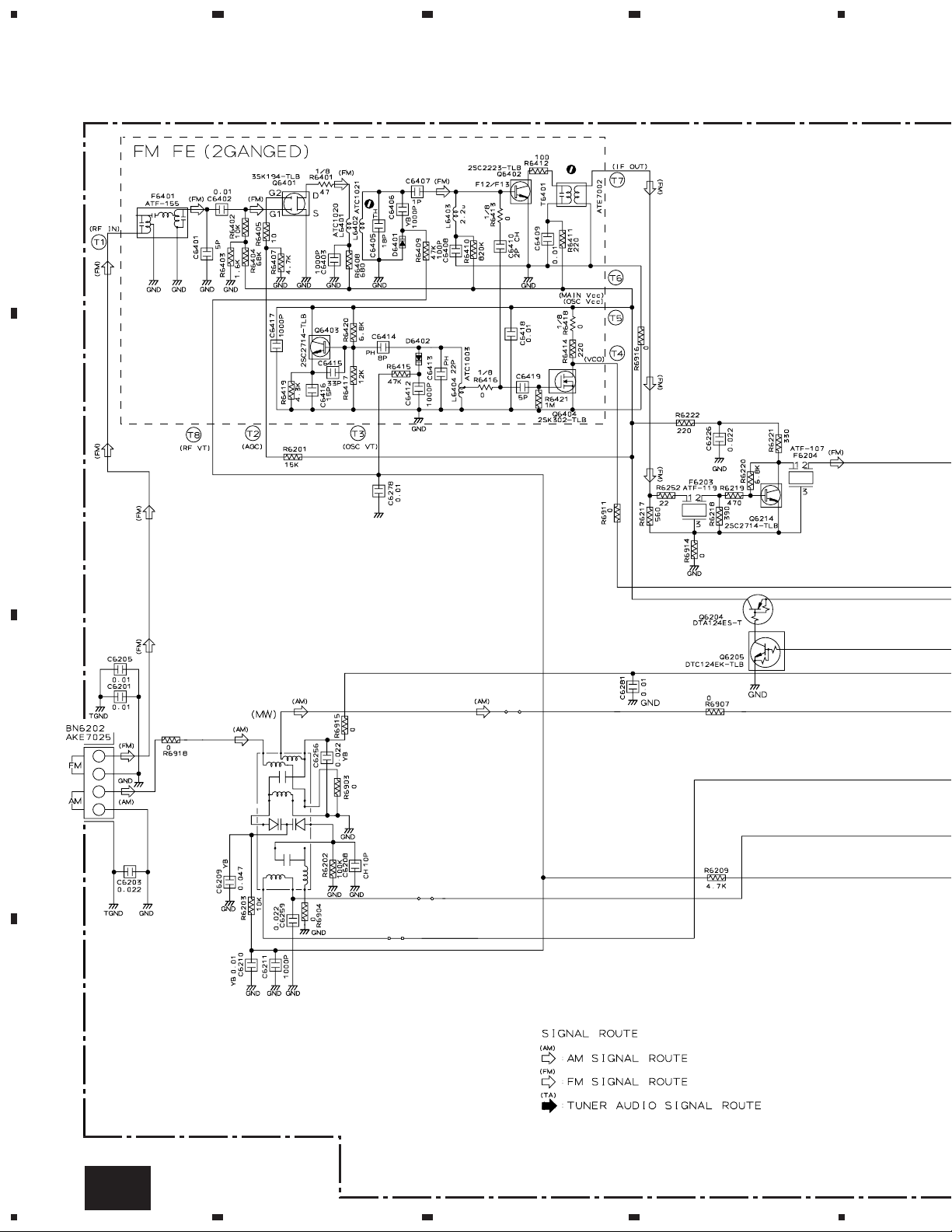

3.8 PRIMARY and SUB TRANS ASSYS

A

4

XR-A670/

MYXJ, NVXJ

ONLY

120

B

10

230

120

XR-A670/

MYXJ, NVXJ

ONLY

(XR-A370/

MYXJ, NVXJ)

(KUCXJ)

XR-A670/

MYXJ, NVXJ

ONLY

EXCEPT

XR-A670/

MYXJ, NVXJ

XR-A670/

MYXJ, NVXJ

ONLY

EXCEPT

XR-A670/

MYXJ, NVXJ

EXCEPT

XR-A670/

MYXJ, NVXJ

T1 POWER TRANSFORMER

C

J81

J

CN81

52147-0410

NJM7805FA

S1WB(A)60-4062

D

28

H I

1234

Page 29

5

678

XR-A670, XR-A370

A

PRIMARY ASSY

H

(XR-A670/MYXJ, NVXJ : XWZ3213)

(XR-A670/KUCXJ, XR-A370/KUCXJ : XWZ3224)

(XR-A370/MYXJ, NVXJ : XWZ3225)

B

MYXJ, NVXJ TYPES

KUXJ TYPE

• NOTE FOR FUSE REPLACEMENT

CAUTION -

MYXJ, NVXJ

TYPES ONLY

L1

ATF1136 (XR-A670)

XTF3001 (XR-A370)

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

FU1

XR-A670/MYXJ, NVXJ :

AEK1061 (T5A)

XR-A670/KUCXJ :

REK1085 (6.3A)

XR-A370/MYXJ, NVXJ :

AEK1060 (T4A)

XR-A370/KUCXJ :

REK1083 (5A)

I

SUB TRANS ASSY

(XR-A670/MYXJ, NVXJ : XWZ3208)

(XR-A670/KUCXJ, XR-A370/KUCXJ

: XWZ3227)

(XR-A370/MYXJ, NVXJ : XWZ3228)

AN1

AN1

XKP3041 (MYXJ, NVXJ)

XKP3042 (KUCXJ)

KUCXJ

TYPE

ONLY

C

D

H I

5

6

7

8

29

Page 30

1

XR-A670, XR-A370

3.9 DISPLAY ASSY

A

B

23

DISPLAY ASSY

J

(XR-A670/MYXJ, NVXJ : XWZ3215)

(XR-A670/KUCXJ : XWZ3214)

(XR-A370/MYXJ, NVXJ : XWZ3210)

(XR-A370/KUCXJ : XWZ3209)

4

6Mz

C

MYXJ, NVXJ

XR-A670

ONLY

XR-A670

ONLY

XR-A670

ONLY

D

300 (XR-A670)

390 (XR-A370)

TYPES ONLY

XR-A670

ONLY

KUCXJ

TYPE ONLY

SYSTEM CONTROL

30

J

1234

Page 31

5

678

XR-A670, XR-A370

J81

D20PYY0425E

I

CN81

CN8201

B

KUCXJ TYPE

ONLY

CN5501

52492-1920

CN5503

52045-2545

XR-A670

ONLY

F

2/3

CN5102

52045-1745 (OTHERS)

52045-1545 (XR-A370/KUCXJ)

DECK MECHA

CN2903

EXCEPT

XR-A370

/KUCXJ

A

B

1SS181

1SS181

KUCXJ TYPE

ONLY

S5911-S5917, S5919-S5936 : XSG3001

MYXJ, NVXJ

TYPES ONLY

XR-A670 ONLY

C

S5911 : DISC 1

S5912 : DISC 2

S5913 : DISC 3

S5914 : STANDBY/ON (POWER)

S5915 : DISC CHANGE

S5916 : OPEN/CLOSE

S5917 : 2 NR ON/OFF

5

6

S5919 : CD

S5920 : AUX •

S5921 : TUNING + ¡ • ¢

S5922 : STOP/ST.MEMORY 7

S5923 : PLAY/PAUSE 2 3

S5924 : TUNING – 4 • 1

S5925 : TUNER/BAND

S5926 : TAPEΙ/ΙΙ

S5927 : FREQ/STATION

S5928 : REC/STOP

S5929 : PRESET

S5930 : ASES/COPY

S5931 : EQUALIZER

S5932 : ZOOM SURROUND

7

S5933 : P.BASS (DEMO)

S5934 : SET

S5935 : DISPLAY

S5936 : TIMER/CLOCK ADJ

S5951 : VOLUME

S5952 : SOUND MORPHING JOG

J

8

D

31

Page 32

1

23

XR-A670, XR-A370

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

A

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGS

DGGSS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

4.1 FM/AM TUNER MODULE (For MYXJ and NVXJ Types)

B

FM/AM TUNER MODULE

AA

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

CN3051

F

4

SIDE A

C

Q6204 Q6203

FM/AM TUNER MODULE

AA

VR6201

SIDE B

D

32

AA

Q6101

Q6501

Q6102 - Q6105 Q6205

Q6214

Q6601

Q6202

IC6202

Q6201

IC6201

(ANP7160-B)

1234

Page 33

1

234

4.2 FM/AM TUNER MODULE (For KUCXJ Type)

FM/AM TUNER MODULE

AB

CN3051

F

XR-A670, XR-A370

A

B

FM/AM TUNER MODULE

AB

Q6204

SIDE A

VR6201

Q6203

C

(ANP7159-B)

Q6306

Q6304

Q6401

Q6402

Q6303Q6302 Q6301

Q6214

Q6403

Q6404

Q6205

Q6202 Q6201

IC6202

IC6201

D

SIDE B

AB

1

2

3

4

33

Page 34

1

23

XR-A670, XR-A370

4.3 CD, MOTOR, SW and TRADE ASSYS

CD ASSY

B

A

B

4

IC8201

Q8351

Q8353

IC8301 IC8101

Q8354

Q8352

SERVO

MECHANISM

ASSY

C

CN5501

F

J

SW ASSY

D

Q8101

CN1052

TRADE

E

ASSY

SERVO

MECHANISM

D

SIDE A

34

B C D E

1234

(XNP3023-B)

ASSY

MOTOR

C

ASSY

Page 35

Q8021

Q8024Q8404

Q8401Q8203 Q8403

1

234

XR-A670, XR-A370

CD ASSY

B

A

Q8356

D

Q8202

Q8355

SW

ASSY

TRADE

E

ASSY

B

C

MOTOR

C

D

ASSY

SIDE B

B C D E

1

2

3

(XNP3023-B)

35

4

Page 36

1

X

0

2

2

XR-A670, XR-A370

4.4 AF ASSY

23

4

A

AF ASSY

F

MECHANISM

UNIT Ι

CN6201 (MYXJ, NV

AA

CN6201 (KUCXJ)

AB

B

CN11

G

C

D

VR2302 VR

VR2802 VR

36

Q2801Q2084Q2083Q71Q54Q3081

Q3351Q3352IC42IC51IC32

F

1234

IC33

Page 37

5

678

XR-A670, XR-A370

YXJ, NVXJ)

UCXJ)

CN8204

B

A

J

CN5503

B

VR2302 VR2301

VR2802 VR2801

MECHANISM

UNIT Ι

MECHANISM

UNIT ΙΙ

VR2303-VR2306

IC2301

IC3301IC33023351

(XNP3022-B)

Q52

Q51

SIDE A

C

D

F

5

6

7

8

37

Page 38

1

AF ASSY

F

(XNP3022-B)

IC5891 Q53 Q3621 Q2301 IC2101 Q21

IC5892 Q3605-Q3608 Q2302 Q2204 Q2203

Q2802 Q2306 Q3601 Q3603 Q3314 Q3313 IC2201

Q3312 Q3311

Q3503 IC3502 IC3501

SIDE B

XR-A670, XR-A370

A

B

23

4

C

D

38

F

1234

Page 39

5

678

XR-A670, XR-A370

A

B

IC2101 Q2102 Q2201 Q2202 Q5751 Q5752 IC5691 IC3001

Q2204 Q2203 Q2103 IC5751 IC3951 Q3501 Q3502 IC3101

3313 Q2104 Q2801 Q2803-Q2807 Q56 Q55IC2201

Q3312 Q3311 Q3351-Q3354 Q71

5

6

Q31

7

F

8

C

D

39

Page 40

1

23

XR-A670, XR-A370

4.5 SECONDARY and PRIMARY ASSYS

A

H

Y5

Y4

Y3

B

I

4

PRIMARY ASSY

Y2

Y1

POWER TRANSFORMER

SECONDARY ASSY

G

C

T1

F

J11

D

SIDE A

40

G H

IC71 IC41 IC31 IC22 IC21 IC11 IC12

(XNP3021-B)

1234

Page 41

1

PRIMARY ASSY

H

234

XR-A670, XR-A370

A

B

SECONDARY ASSY

G

(XNP3021-B)

C

D

SIDE B

G H

1

2

3

4

41

Page 42

1

XR-A670, XR-A370

4.6 DISPLAY ASSY

A

J

B

23

DISPLAY ASSY

4

I

CN81

C

D

42

J

1234

IC3901

Page 43

5

678

XR-A670, XR-A370

A

MECHANISM UNIT

F

CN5102

B

CN8201

B

C

(XNP3021-B)

IC3931

D

SIDE A

J

5

6

7

8

43

Page 44

1

DISPLAY ASSY

J

(XNP3021-B)

Q2903 Q2910 Q2901 Q5501 IC5501

Q2911 Q5622 Q5502

Q2904

Q2907

Q5601-Q5603

SIDE B

XR-A670, XR-A370

A

B

23

4

C

D

44

J

1234

Page 45

5

678

XR-A670, XR-A370

A

B

IC5501 Q5615-Q5620 Q5613 Q5801 Q5821 Q5604

Q5606

5

6

7

J

8

C

D

45

Page 46

1

XR-A670, XR-A370

4.7 SUB TRANS ASSY

A

23

SUB TRANS ASSY

I

4

IC81

B

Q82

IC82

Q81

LIVE

J81

J

AC IN

NEUTRAL

(XNP3021-B)

SIDE A

Y5Y4Y2Y1 Y3

H

SUB TRANS ASSY

C

I

D

(XNP3021-B)

SIDE B

46

I

1234

Page 47

XR-A670, XR-A370

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 103→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 .....................................................................................RN2H

1 Ω→1R0 .....................................................................................RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

LIST OF WHOLE PCB ASSEMBLIES

Mark Symbol and Description

FM/AM TUNER MODULE

NSP

$M SERVO MECHA ASSY

CD ASSY

MOTOR ASSY

SW ASSY

TRADE ASSY

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Part No.

XR-A670 XR-A370

MYXJ NVXJ KUCXJ MYXJ NVXJ KUCXJ

AXQ7068

XWX3008

XWZ3233

XWZ3230

XWZ3231

XWZ3232

AXQ7068

XWX3008

XWZ3233

XWZ3230

XWZ3231

XWZ3232

AXQ7065

XWX3008

XWZ3233

XWZ3230

XWZ3231

XWZ3232

AXQ7068

XWX3007

XWZ3229

XWZ3230

XWZ3231

XWZ3232

AXQ7068

XWX3007

XWZ3229

XWZ3230

XWZ3231

XWZ3232

K

K

Remarks

AXQ7065

XWX3007

XWZ3229

XWZ3230

XWZ3231

XWZ3232

MAIN ASSY

AF ASSY

COMPLEX ASSY

SECONDARY ASSY

PRIMARY ASSY

SUB TRANS ASSY

DISPLAY ASSY

XWM3101

XWZ3200

XWM3114

XWZ3221

XWZ3213

XWZ3208

XWZ3215

XWM3101

XWZ3200

XWM3114

XWZ3221

XWZ3213

XWZ3208

XWZ3215

XWM3100

XWZ3199

XWM3113

XWZ3221

XWZ3224

XWZ3227

XWZ3214

CONTRAST OF PCB ASSEMBLIES

CD ASSY

B

XWZ3233 and XWZ3229 are constructed the same except for the following :

Mark Symbol and Description

L8651

C8604

C8651, C8653

C8652

R8601

R8651

R8652

JA8651 Optical Link Out

XWZ3233 XWZ3229

LFA100J

CCSQCH220J50

CKSQYF103Z50

CEAT101M10

RS1/10S181J

RS1/10S821J

RS1/10S152J

GP1F32T

XWM3098

XWZ3197

XWM3109

XWZ3220

XWZ3225

XWZ3228

XWZ3210

Part No.

XWM3098

XWZ3197

XWM3109

XWZ3220

XWZ3225

XWZ3228

XWZ3210

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

XWM3097

XWZ3196

XWM3108

XWZ3220

XWZ3224

XWZ3227

XWZ3209

Remarks

47

Page 48

XR-A670, XR-A370

Mark No. Description Part No.

AF ASSY (for XR-A670)

F

Mark No. Description Part No.

XWZ3200 and XWZ3119 are constructed the same except for the following :

Mark Symbol and Description

IC5751

Q5751

Q5752

L3333, L3334

L3991

L5751

C1997

C2003, C2004

C2327-C2330, C3101, C3102, C3321, C3322

C3003, C3004

C3023, C3024

C3025, C3026

C3029, C3030

C3043, C3044

C3051, C3052

C3073, C3074

C3081

C3082

C3091

C3335-C3338

XWZ3200 XWZ3199

BU1923F

2SA1037K

DTC124EK

ATH-133

Not used

LAU1R0J

CKSQYB103K50

CKSQYB104K25

CCSQCH470J50

CKSQYB221K50

CFTLA564J50

CKSQYB104K25

CKSQYB563K25

CEATR47M50

CKSQYB472K50

CKSQYB122K50

CEAT4R7M50

CEATR47M50

CEAT2R2M50

CKSQYF104Z50

Part No.

Remarks

Not used

Not used

Not used

Not used

LAU4R7J

Not used

Not used

Not used

Not used

Not used

CFTLA474J50

CKSQYB683K25

CKSQYB273K50

CEAT2R2M50

Not used

Not used

CEAT100M50

CEAT2R2M50

CEAT100M50

Not used

C3345, C3346

C5751, C5752, C5755

C5753

C5754

C5756

C5757

C5758

R3101, R3102

R3315, R3316

R3317, R3318

R3323, R3324

R3333, R3334

R3335, R3336

R3515-R3518

R5751

R5752

R5753

R5754

X5751 Crystal Resonator (4.332MHz)

ACG7021 (0.01µF)

CCSQCH270J50

CKSQYB102K50

CEAT330M16

CCSQCH561J50

CCSQCH271J50

CEAT100M50

RS1/10S392J

RS1/10S563J

RD1/4PU563J

RS1/10S102J

RD1/4LMF101J

RS1/10S100J

RS1/10S152J

RS1/10S223J

RS1/10S222J

RS1/10S101J

RS1/10S102J

ASS7004

Not used

Not used

Not used

Not used

Not used

Not used

Not used

RS1/10S472J

RS1/10S683J

RD1/4PU683J

RS1/10S0R0J

RD1/4LMF100J

Not used

RS1/10S122J

Not used

Not used

Not used

Not used

Not used

48

Page 49

XR-A670, XR-A370

Mark No. Description Part No.

AF ASSY (for XR-A370)

F

Mark No. Description Part No.

XWZ3197 and XWZ3196 are constructed the same except for the following :

Mark Symbol and Description

IC5751

Q5751

Q5752

L101

L3333, L3334

L3991

L5751

C1997

C2327-C2330, C3101, C3102, C3321, C3322

C3003, C3004

C3023, C3024

C3025, C3026

C3029, C3030

C3043, C3044

C3051, C3052

C3073, C3074

C3081

C3082

C3091

C3335-C3338

XWZ3197 XWZ3196

BU1923F

2SA1037K

DTC124EK

VTH1024

ATH-133

Not used

LAU1R0J

CKSQYB103K50

CCSQCH470J50

CKSQYB221K50

CFTLA564J50

CKSQYB104K25

CKSQYB563K25

CEATR47M50

CKSQYB472K50

CKSQYB122K50

CEAT4R7M50

CEATR47M50

CEAT2R2M50

CKSQYF104Z50

Part No.

Remarks

Not used

Not used

Not used

Not used

Not used

LAU4R7J

Not used

Not used

Not used

Not used

CFTLA474J50

CKSQYB683K25

CKSQYB273K50

CEAT2R2M50

Not used

Not used

CEAT100M50

CEAT2R2M50

CEAT100M50

Not used

C3345, C3346

C5751, C5752

C5753

C5754

C5755

C5756

C5757

C5758

R3101, R3102

R3315, R3316

R3317, R3318

R3323, R3324

R3333, R3334

R3335, R3336

R3509

R3515-R3518

R5751

R5752

R5753

R5754

X5751 Crystal Resonator (4.332MHz)

ACG7021 (0.01µF)

CCSQCH270J50

CKSQYB102K50

CEAT330M16

CCSQCH270J50

CCSQCH561J50

CCSQCH271J50

CEAT100M50

RS1/10S392J

RS1/10S563J

RD1/4PU563J

RS1/10S102J

RD1/4LMF101J

RS1/10S100J

RS1/10S393J

RS1/10S152J

RS1/10S223J

RS1/10S222J

RS1/10S101J

RS1/10S102J

ASS7004

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

RS1/10S472J

RS1/10S683J

RD1/4PU683J

RS1/10S0R0J

RD1/4LMF100J

Not used

RS1/10S473J

RS1/10S122J

Not used

Not used

Not used

Not used

Not used

49

Page 50

XR-A670, XR-A370

Mark No. Description Part No.

SECONDARY ASSY

G

Mark No. Description Part No.

XWZ3221 and XWZ3220 are constructed the same except for the following :

Mark Symbol and Description

IC11, IC12

IC21, IC22

IC31

D31, D41

C11, C12

PRIMARY ASSY

H

XWZ3221 XWZ3220

AEK7068 (10A)

AEK7021 (7A)

AEK7053 (4A)

S1WB(A)60BSD

XCH3001 (4700µF/80V)

Part No.

XWZ3213, XWZ3224 and XWZ3225 are constructed the same except for the following :

Mark Symbol and Description

NSP

Y4 Jumper Wire

NSP

Y5 Jumper Wire

SUB TRANS ASSY

I

XWZ3213 XWZ3224 XWZ3225

XDX3009

Not used

Part No.

Not used

XDX3011

XWZ3208, XWZ3227 and XWZ3228 are constructed the same except for the following :

Mark Symbol and Description

L1 Line Filter

R1 (2.2MΩ, 1/2W)

AN1 1P AC INLET

XWZ3208 XWZ3227 XWZ3228

ATF1136

Not used

XKP3041

Part No.

Not used

RCN1080

XKP3042

Remarks

AEK7047 7A)

AEK7019 (5A)

AEK7050 (3A)

S1WB(A)60SD

ACH7071 (3300µF/63V)

Remarks

XDX3009

Not used

Remarks

XTF3001

Not used

XKP3041

DISPLAY ASSY

J

XWZ3215, XWZ3214, XWZ3210 and XWZ3209 are constructed the same except for the following :

Mark Symbol and Description

Q5610-Q5613

D5561, D5562

D5593

D5594-D5596

D5597

D5608

D5613-D5616

D5617, D5618

D5651

C5503

R5502

R5505

R5604

R5605, R5606

R5607-R5610

R5702, R5704

CN2903 17P FFC Connector

CN2903 15P FFC Connector

LED Holder

XWZ3215 XWZ3214 XWZ3210

DTC143EK

1SS181

1SS133

1SS133

Not used

NSPBF50S-8451

MBG5064X

SLP7118C51H

MTZJ5.6A

CKSQYF473Z50

RS1/10S471J

RS1/10S102J

RD1/4PU391J

RD1/4PU301J

RS1/10S221J

Not used

52045-1745

Not used

XMR3006

DTC143EK

1SS181

1SS133

Not used

1SS355

NSPBF50S-8451

MBG5064X

SLP7118C51H

MTZJ5.6A

CKSQYF473Z50

RS1/10S471J

Not used

RD1/4PU391J

RD1/4PU301J

RS1/10S221J

RS1/10S223J

52045-1745

Not used

XMR3006

Part No.

Not used

Not used

Not used

1SS133

Not used

Not used

Not used

Not used

Not used

Not used

Not used

RS1/10S102J

Not used

RD1/4PU391J

Not used

Not used

52045-1745

Not used

Not used

XWZ3209

Not used

Not used

Not used

Not used

1SS355

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

RD1/4PU391J

Not used

RS1/10S223J

Not used

52045-1545

Not used

Remarks

50

Page 51

XR-A670, XR-A370

Mark No. Description Part No.

Mark No. Description Part No.

PCB PARTS LIST FOR XR-A670/MYXJ UNLESS OTHERWISE NOTED

FM/AM TUNER MODULE (AXQ7068)

AA

SEMICONDUCTORS

IC6201 LA1832ML

IC6202 LC72131MD

Q6102 2SC2223

Q6203 2SC2705

Q6201,Q6202 2SC2712

Q6103,Q6214,Q6601 2SC2714

Q6104,Q6105 2SK302

Q6101 3SK194

Q6204 DTA124ES

Q6205 DTC124EK

D6202 1SS254

D6101-D6104 1SV228

COILS AND FILTERS

L6106 FM COIL ATC1003

L6105 FM RF COIL ATC1015

L6101 FM ANTENNA COIL ATC1016

L6102 FM ANTENNA COIL ATC1017

L6103 FM RF DRIVE COIL ATC1018

L6104 FM RF TUNING COIL ATC1019

F6203 FM CERAMIC FILTER ATF-119

F6206 FM CERAMIC DISCLI. ATF7008

F6601 ANTI BIRDY FILTER ATF7009

F6204 FM CERAMIC FILTER ATF7010

F6202 AM CERAMIC FILTER ATF7011

L6107 CHIP COIL ATH1043

L6603 LAU220J

L6206,L6208,L6605 LAU2R2J

TRANSFORMERS

T6201 ATB7008

T6101 ATE7002

CAPACITORS

C6113,C6212,C6274,C6275,C6611 CCSQCH101J50

C6116,C6208,C6221 CCSQCH150J50

C6222 CCSQCH180J50

C6271 CCSQCH200J50

C6117 CCSQCH330J50

C6608 CCSQCH680J50

C6118 CCSQCH8R0D50

C6111,C6122 CCSQCK1R0C50

C6112,C6127 CCSQCK2R0C50

C6105 CCSQSL471J50

C6101 CCSQTH110J50

C6119 CCSQTH150J50

C6109 CCSQTH270J50

C6107,C6110 CCSQTH300J50

C6106 CCSQTH330J50

C6234,C6235 CEAL1R0M50

C6245 CEAL470M16

C6224 CEAS100M50

C6243 CEAS101M16

C6231 CEAS1R0M50

C6227 CEAS220M16

C6236 CEAS2R2M50

C6216 CEAS330M16

C6262 CEAS3R3M50

C6219 CEAS470M10

RESISTORS

OTHERS

FM/AM TUNER MODULE (AXQ7065)

SEMICONDUCTORS

COILS AND FILTERS

C6244 CEAS470M16

C6249,C6250,C6265,C6266 CEAS4R7M50

C6258 CEJA470M16

C6215 CFTLA103J50

C6214 CFTLA224J50

C6115,C6125,C6126,C6211,C6254 CKSQYB102K50

C6601 CKSQYB102K50

C6102,C6114,C6121,C6123,C6124 CKSQYB103K50

C6210,C6213,C6237,C6267,C6276 CKSQYB103K50

C6279,C6281,C6604 CKSQYB103K50

C6251,C6252 CKSQYB123K50

C6606,C6607 CKSQYB182K50

C6203,C6259 CKSQYB223K50

C6228 CKSQYB472K50

C6209 CKSQYB473K50

C6230 CKSQYB821K50

C6218,C6223,C6255 CKSQYF103Z50

C6220,C6226,C6242,C6256 CKSQYF223Z50

C6225 CKSQYF473Z50

C6610 CKSYB103K50

R6602 RD1/4PU221J

R6115,R6119,R6123,R6127,R6129 RS1/8S0R0J

R6906,R6909,R6911 RS1/8S0R0J

R6112 RS1/8S473J

VR6201 (10kΩ) RCP1045

Other Resistors RS1/10S J

BN6202 2P ANTENNA TERMINAL AKA7001

X6202 CERAMIC RESONATOR ASS1066

(456kHz)

X6201 CRYSTAL RESONATOR ASS1093

(7.2000MHz)

CN6201 14P SOCKET KP200IA14L

AB

IC6201 LA1832ML

IC6202 LC72131MD

Q6402 2SC2223

Q6203 2SC2705

Q6201,Q6202 2SC2712

Q6214,Q6403 2SC2714

Q6404 2SK302

Q6401 3SK194

Q6204 DTA124ES

Q6205 DTC124EK

D6202 1SS254

D6401,D6402 1T378A

L6404 FM COIL ATC1003

L6401 FM RF COIL ATC1020

L6402 FM RF COIL ATC1021

F6204 FM CERAMIC FILTER ATF-107

F6203 FM CERAMIC FILTER ATF-119

51

Page 52

XR-A670, XR-A370

Mark No. Description Part No.

F6401 FM BAND PASS FILTER ATF-155

F6206 FM CERAMIC DISCLI. ATF7008

F6202 AM CERAMIC FILTER ATF7011

L6206,L6208,L6403 LAU2R2J

TRANSFORMERS

T6201 ATB7008

T6401 ATE7002

CAPACITORS

C6208 CCSQCH100D50

C6212,C6274,C6275,C6408 CCSQCH101J50

C6412 CCSQCH102J50

C6221,C6222,C6416 CCSQCH150J50

C6271 CCSQCH200J50

C6415 CCSQCH330J50

C6406 CCSQCH331J50

C6401,C6419 CCSQCH5R0C50

C6407 CCSQCK1R0C50

C6410 CCSQCK2R0C50

C6413 CCSQRH180J50

C6414 CCSQRH8R0D50

C6405 CCSQTH150J50

C6234,C6235 CEAL1R0M50

C6245 CEAL470M16

C6224 CEAT100M50

C6243 CEAT101M16

C6231 CEAT1R0M50

C6227 CEAT220M25

C6214,C6236 CEAT2R2M50

C6262 CEAT3R3M50

C6219 CEAT470M10

C6244 CEAT470M16

C6249,C6250,C6265,C6266 CEAT4R7M50

C6258 CEJA470M16

C6215 CFTLA103J50

C6211,C6254,C6403,C6417 CKSQYB102K50

C6201,C6205,C6210,C6237,C6276 CKSQYB103K50

C6278,C6280,C6281,C6402,C6409 CKSQYB103K50

C6418 CKSQYB103K50

C6251,C6252 CKSQYB153K50

C6203,C6259 CKSQYB223K50

C6228 CKSQYB472K50

C6209 CKSQYB473K50

C6230 CKSQYB821K50

C6218,C6223,C6255 CKSQYF103Z50

C6220,C6226,C6242,C6256 CKSQYF223Z50

C6225 CKSQYF473Z50

Mark No. Description Part No.

CD ASSY

B

SEMICONDUCTORS

IC8301 BA5970FP

IC8101 CXA1821M

IC8201 CXD2587Q

Q8101 2SA854S

Q8351,Q8352 2SB1237X

Q8353,Q8354 2SD1858X

Q8201 DTA124EK

Q8202 DTC114EK

Q8203,Q8355,Q8356 DTC143EK

D8201,D8202,D8351-D8354 1SS355

COILS

L8101,L8651 LFA100J

L8301 LFA470J

CAPACITORS

C8256,C8359,C8364 CCSQCH101J50

C8201 CCSQCH120J50

C8110,C8202,C8604 CCSQCH220J50

C8239,C8246,C8247,C8401,C8402 CCSQCH221J50

C8322,C8324 CCSQCH681J50

C8403,C8404 CCSQSL681J50

C8405,C8406 CEAT100M50

C8102,C8104,C8652 CEAT101M10

C8203,C8233,C8240,C8242,C8249 CEAT101M6R3

C8602 CEAT101M6R3

C8301 CEAT102M6R3

C8409,C8411 CEAT221M10

C8109,C8111 CEAT330M25

C8351 CEAT331M10

C8238 CEATR47M50

C8407,C8408 CKSQYB102K50

C8204-C8206,C8237,C8253,C8373 CKSQYB103K50

C8107,C8245 CKSQYB104K25

C8236,C8415,C8416 CKSQYB152K50

C8231,C8331 CKSQYB222K50

C8341,C8342 CKSQYB333K50

C8235 CKSQYB473K50

C8311,C8312 CKSQYB681K50

C8332 CKSQYB822K50

C8101,C8103,C8106,C8108,C8112 CKSQYF103Z50

C8232,C8234,C8241,C8248 CKSQYF103Z50

C8250,C8251,C8302-C8306,C8358 CKSQYF103Z50

C8363,C8413,C8414,C8417,C8601 CKSQYF103Z50

C8603,C8651,C8653 CKSQYF103Z50

RESISTORS

R6280 RD1/4PU101J

R6413,R6416,R6418,R6906,R6909 RS1/8S0R0J

R6401 RS1/8S470J

VR6201 (10kΩ) PCP1029

Other Resistors RS1/10S J

OTHERS

BN6202 4P ANTENNA TERMINAL AKE7051

X6202 CERAMIC RESONATOR ASS1066

X6201 CRYSTAL RESONATOR ASS1093

CN6201 14P SOCKET KP200IA14L

52

(456kHz)

(7.2000MHz)

RESISTORS

All Resistors RS1/10S J

OTHERS

CN8204 8P FFC CONNECTOR 52044-0845

CN8201 19P FFC CONNECTOR 52045-1945

CN8203 2P TOP POST B2P-SHF-1AA

JA8651 OPTICAL LINK OUT GP1F32T

CN8002 FFC CONNECTOR (11P) SLW11R-1C7

CN8101 FFC CONNECTOR (16P) SLW16R-1C7

X8201 CRYSTAL RESONATOR PSS1008

(16.9344MHz)

Page 53

XR-A670, XR-A370

Mark No. Description Part No.

MOTOR ASSY

C

SWITCH

S9503 ASG7009

OTHERS

J9502 JUMPER WIRE 4P D20PWW0405E

SW ASSY

D

MOTOR PULLEY PNW1634

CARRIAGE MOTOR VXM1033

SWITCHES

S9502 ASG7009

S9501 DSG1017

OTHERS

J9501 JUMPER WIRE 6P D20PWY0610E

TRADE ASSY

E

OTHERS

CN9501 6P JUMPER CONNECTOR 52147-0610

CN9001 KR CONNECTOR S6B-PH-K-S

CN9002 FFC CONNECTOR (11P) SLW11R-1C7

Mark No. Description Part No.

D73 1SS133

D2102,D2103,D2201,D2202,D3051 1SS355

D63,D64 1SS355

D3355,D3356 20E2-FC

D3083 MTZJ11C

D61 MTZJ12C

D35,D36 MTZJ15C

D3359,D3360 MTZJ18B

D74 MTZJ33C

D3363,D3364 MTZJ39C

D2001 MTZJ6.2A

D48 MTZJ6.8C

D3357,D3358 MTZJ7.5C

D75 MTZJ8.2B

D51,D52 S5688G

D71,D72 S5688G

COILS AND FILTERS

L3331-L3334 AF CHOKE COIL ATH-133

L2801 OSC COIL ATX7002

L5751 LAU1R0J

L2301,L2302 LTA822J

F2201,F2202 MPX FILTER RTF1209

L101 FERRITE BEAD VTH1024

RELAY

RY3601 ASR7008

AF ASSY (XWZ3200)

F

SEMICONDUCTORS

IC2101,IC3101,IC3501,IC3502 BA4558F-HT

IC42 NJM7805FA

IC32 NJM7812FA

IC3301 STK407-100B

Q71 2SA1837

Q31 2SD2012

Q3352 IRF540A

Q3351 IRF9540A

D3301,D3302 1SR139-100

IC5691 BA4558F-HT

IC5751 BU1923F

IC5891,IC5892 BU4094BCF

IC2201 HA12136AF

IC2301 HA12211NT

IC3001 LC75394NED

Q3354,Q3601,Q3621,Q5751 2SA1037K

Q2806 2SB1197K

Q2803,Q2804 2SC1815

Q2801 2SC2240

Q2102,Q2201,Q2202,Q3353,Q3603 2SC2412K

Q3605-Q3608 2SC2412K

Q3081 2SD1858X

Q2203,Q2204,Q2805,Q3311,Q3312 2SD2114K

Q2301,Q2302,Q3501,Q3502 2SK368

Q3313,Q3503 DTA124EK

Q2104,Q2105,Q3314,Q5752 DTC124EK

Q2103,Q2306,Q2802,Q2807 DTC143EK

D2191,D2301-D2306,D3351-D3354 1SS133

D3361,D3362,D3601,D3603,D3604 1SS133

D3621,D3622,D3625,D3626,D46 1SS133

CAPACITORS

C3345,C3346 (0.01µF) ACG7021

C2303,C2304 (270pF) ACG7024

C2301,C2302 CCSQCH100D50

C3047,C3048 CCSQCH101J50

C2192 CCSQCH220J50

C5751,C5752,C5755 CCSQCH270J50

C5757 CCSQCH271J50

C2327-C2330,C3101,C3102 CCSQCH470J50

C3321,C3322 CCSQCH470J50

C5756 CCSQCH561J50

C3319,C3320 CCSQCJ3R0C50

C3311,C3312,C3507,C3508 CEANL1R0M50

C3317,C3318 CEANP220M35

C3621 CEANP2R2M2A

C3313,C3314 CEANP2R2M50

C3441 CEANP330M2A

C3602 CEAT100M2A

C2207,C2803,C2810,C3045 CEAT100M50

C3105,C3106,C33,C35,C43 CEAT100M50

C5758 CEAT100M50

C2002,C2316 CEAT101M16

C71 CEAT101M2A

C3303,C3304 CEAT101M50

C2312,C2313,C3506 CEAT1R0M50

C2106,C2214,C2215,C2321,C2322 CEAT220M50

C72 CEAT220M50

C2001,C3601 CEAT221M16

C41 CEAT222M25

C31 CEAT222M35

C2201,C2202,C2205,C2206 CEAT2R2M50

53

Page 54

XR-A670, XR-A370

Mark No. Description Part No.

C2212,C2213,C2319,C2320 CEAT2R2M50

C3005-C3010,C3015-C3018,C3037 CEAT2R2M50

C3039,C3091 CEAT2R2M50

C2804,C2805,C5754 CEAT330M16

C3501,C3502,C3509,C3510 CEAT470M25

C3081 CEAT4R7M50

C3021,C3022 CEATR10M50

C2203,C2204 CEATR22M50

C3011,C3012,C3043,C3044,C3082 CEATR47M50

C3325 CEATR47M50

C3046 CEJA100M50

C3038,C3040 CEJA2R2M50

C3027,C3028 CFTLA334J50

C3023,C3024 CFTLA564J50

C2802 CKCYB681K2H

C5753,C5892 CKSQYB102K50

C1997,C2315,C2317,C2318,C3053 CKSQYB103K50

C3098 CKSQYB103K50

C2003,C2004,C2191,C2193 CKSQYB104K25

C3025,C3026,C3099,C5891 CKSQYB104K25

C2194 CKSQYB105K10

C3033,C3034,C3073,C3074 CKSQYB122K50

C2208,C2209 CKSQYB152K50

C3003,C3004 CKSQYB221K50

C3315,C3316 CKSQYB222K50

C2323,C2326 CKSQYB223K50

C2812,C2813 CKSQYB272K50

C2808,C2809 CKSQYB332K50

C2333,C2334 CKSQYB392K50

C2807,C3051,C3052 CKSQYB472K50

C3029,C3030 CKSQYB563K25

C2307,C2308,C2331,C2332 CKSQYB681K50

C3019,C3020,C3031,C3032 CKSQYB682K50

C3503,C3504 CKSQYB682K50

C3331-C3333,C3335-C3338 CKSQYF104Z50

C2801 CQHA822J2A

C2210,C2211 CQMBA103J50

C2806 CQMBA223J50

RESISTORS

R2812 RD1/2LMF270J

R2813 RD1/2LMF471J

R2809 RD1/2LMF4R7J

R3333,R3334 RD1/4LMF101J

R3353,R3354 RD1/4PU101J

R61 RD1/4PU102J

R73 RD1/4PU103J

R3081 RD1/4PU221J

R3317,R3318 RD1/4PU563J

R72 RD1/4PU822J

R3991,R3992 RS2LMF331J

R3601,R3602 RS3LMFR22J

VR2303-VR2306 (10kΩ) VCP1156

VR2301,VR2302 (100kΩ) VCP1162

VR2801,VR2802 (220kΩ) VCP1164

Other Resistors RS1/10S J

OTHERS

15P CABLE HOLDER 51063-1505

CN1052 8P FFC CONNECTOR 52045-0845

CN5102 25P FFC CONNECTOR 52045-2545

CN3331 4P SPEAKER TERMINAL AKE7001

CN3991 HEADPHONE JACK AKN-056

Mark No. Description Part No.

CN2302 KR CONNECTOR B2B-PH-K-S

CN2303 KR CONNECTOR B3B-PH-K-R

CN2301 KR CONNECTOR 3P B3B-PH-K-S

J11 JUMPER WIRE D15A15-350-2651

CN3051 14P PLUG KM200IB14

X5751 CRYSTAL RESONATOR ASS7004

AF ASSY (XWZ3197)

JA3001,JA3441 2P PIN JACK VKB1060

F

PCB BINDER VEF1040

(4.332MHz)

SEMICONDUCTORS

IC3101,IC3501,IC3502 BA4558F-HT

IC5751 BU1923F

IC42 NJM7805FA

IC32 NJM7812FA

IC3301 STK407-070B

Q71 2SA1837

Q31 2SD2012

Q3351 IRFI9Z34G

Q3352 IRFIZ34G

D3301,D3302 1SR139-100

D3355,D3356 20E2-FC

D71,D72 S5688G

IC5691 BA4558F-HT

IC5891 BU4094BCF

IC2301 HA12211NT

IC3001 LC75394NED

Q3354,Q3601,Q3621,Q5751 2SA1037K

Q2803,Q2804 2SC1815

Q3353,Q3603,Q3605-Q3608 2SC2412K

Q3081 2SD1858X

Q2805,Q3311,Q3312 2SD2114K

Q2301,Q2302,Q3501,Q3502 2SK368

Q3313,Q3503 DTA124EK

Q3314,Q5752 DTC124EK

Q2306 DTC143EK

D2301-D2306,D3351-D3354 1SS133

D3361,D3362,D3601,D3603,D3604 1SS133

D3621,D3622,D3625,D3626,D46 1SS133

D73 1SS133

D3051,D63,D64 1SS355

D3083 MTZJ11C

D61 MTZJ12C

D35,D36 MTZJ15C

D3359,D3360 MTZJ18B

D74 MTZJ33C

D3363,D3364 MTZJ39C

D2001 MTZJ6.2A

D48 MTZJ6.8C

D3357,D3358 MTZJ7.5C

D75 MTZJ8.2B

D51,D52 S5688G

COILS

L3331-L3334 AF CHOKE COIL ATH-133

L2801 OSC COIL ATX7002

L5751 LAU1R0J

L2301,L2302 LTA822J

L101 FERRITE BEAD VTH1024

54

Page 55

XR-A670, XR-A370