Pioneer SXSW-515 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

ORDER NO.

RRV3562

SX-SW515

AUDIO MULTI-CHANNEL RECEIVER SUBWOOFER

SX-SW515

SX-SW570

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

SX-SW515 WYXCN5 AC 220 V to 240 V

SX-SW570 KUCXCN AC 120 V

For details, refer to "Important Check Points for Good Servicing".

T-AZV MAR. 2007 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

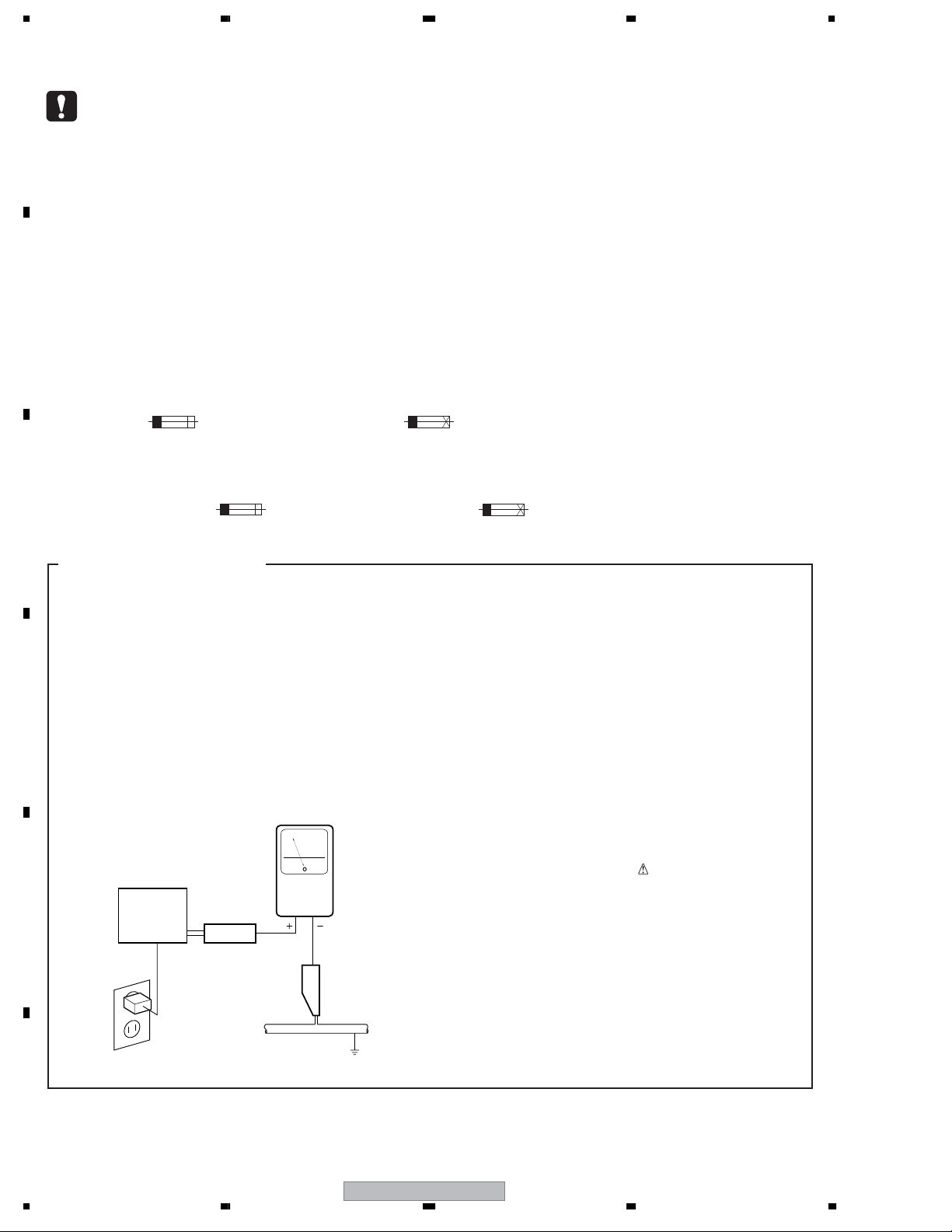

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

SX-SW515

5678

Important Check Points for Good Servicing

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

SX-SW515

E

F

3

7

8

1234

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

Important Check Points for Good Servicing......................................................................................................... 3

CONTENTS......................................................................................................................................................... 4

A

1. SERVICE PRECAUTIONS ............................................................................................................................... 5

2. SPECIFICATIONS ............................................................................................................................................ 6

2.1 ACCESSORIES ......................................................................................................................................... 6

2.2 SPECIFICATIONS...................................................................................................................................... 6

2.3 PANEL FACILITIES.................................................................................................................................... 7

3. BASIC ITEMS FOR SERVICING .................................................................................................................... 11

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 11

3.2 PCB LOCATIONS .................................................................................................................................... 12

3.3 JIGS LIST ................................................................................................................................................ 13

4. BLOCK DIAGRAM.......................................................................................................................................... 14

4.1 OVERALL BLOCK DIAGRAM.................................................................................................................. 14

5. DIAGNOSIS.................................................................................................................................................... 16

B

5.1 CIRCUIT DESCRIPTION......................................................................................................................... 16

5.1.1 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION .................................................................... 16

5.1.2 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER............... 17

5.1.3 CONDITIONS FOR SWITCHING THE ROTATION SPEED OF THE FAN ........................................ 18

6. SERVICE MODE ............................................................................................................................................ 19

6.1 SERVICE TEST MODE............................................................................................................................ 19

7. DISASSEMBLY............................................................................................................................................... 22

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 25

8.1 ADJUSTMENT......................................................................................................................................... 25

9. EXPLODED VIEWS AND PARTS LIST .......................................................................................................... 26

C

D

9.1 PACKING SECTION ................................................................................................................................ 26

9.2 EXTERIOR SECTION.............................................................................................................................. 28

9.3 DISPLAY UNIT ......................................................................................................................................... 30

10. SCHEMATIC DIAGRAM ............................................................................................................................... 32

10.1 MAIN ASSY (1/5) ................................................................................................................................... 32

10.2 MAIN ASSY (2/5) ................................................................................................................................... 34

10.3 MAIN ASSY (3/5) ................................................................................................................................... 36

10.4 MAIN ASSY (4/5) ................................................................................................................................... 38

10.5 MAIN ASSY (5/5) ................................................................................................................................... 40

10.6 AC INLET, CONNECT and FL ASSYS .................................................................................................. 42

10.7 JACK TX ASSY ...................................................................................................................................... 44

10.8 POWER SUPPLY UNIT.......................................................................................................................... 46

10.9 WAVEFORMS ........................................................................................................................................ 48

11. PCB CONNECTION DIAGRAM ................................................................................................................... 49

11.1 MAIN ASSY ........................................................................................................................................... 50

11.2 AC INLET............................................................................................................................................... 54

11.3 CONNECT ASSY................................................................................................................................... 55

11.4 FL ASSY ................................................................................................................................................ 56

11.5 JACK TX ASSY ...................................................................................................................................... 58

11.6 POWER SUPPLY UNIT.......................................................................................................................... 60

11.7 DISPLAY ................................................................................................................................................ 62

12. PCB PARTS LIST ......................................................................................................................................... 63

E

F

4

1234

SX-SW515

SYSTEM

CONNECTOR

SPEAKERS

DVD/DVR 2

(OPTICAL)

CENTER

SURROUND

DVD/DVR 1

(COAXIAL)

DIGITAL

AUDIO INPUT

FM

UNBAL75

AM

LOOP ANTENNA

ANALOG

DIGITAL

(OPTICAL)

RL

R

L

FRONT

RL

CONTROL

OUTSUB WOOFER

USE ONLY WITH

DISPLAY UNIT

5678

1. SERVICE PRECAUTIONS

CAUTION

• Ask users to bring both subwoofer and the display unit together when servicing.

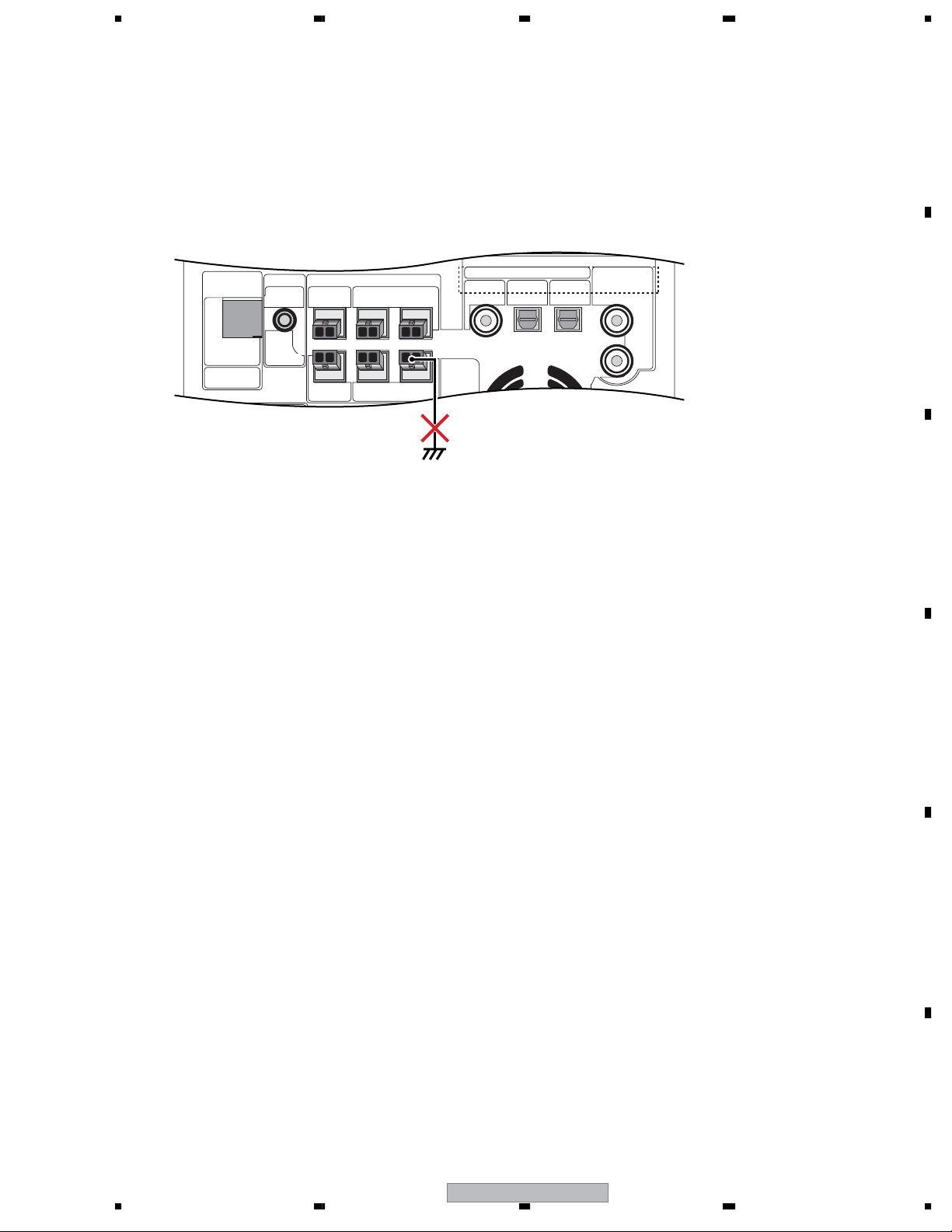

NOTES ON BTL DRIVE

As a signal to drive the BTL is output from the negative speaker terminal, DO NOT short-circuit between the

negative speaker terminal and ground, such as the chassis.

Do not short-circuit between the plus speaker terminal and ground, such as the chassis, too.

SW515/WY SW570/KUC

DVD/DVR1 DVD

DVD/DVR2 DTV

DIGITAL PC/GAME

ANALOG AUX

Negative Speaker Terminal

Do not short-circuit

Ground (Chassis)

A

B

NOTES ON SOLDERING

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

C

D

E

SX-SW515

56

F

5

7

8

1234

2. SPECIFICATIONS

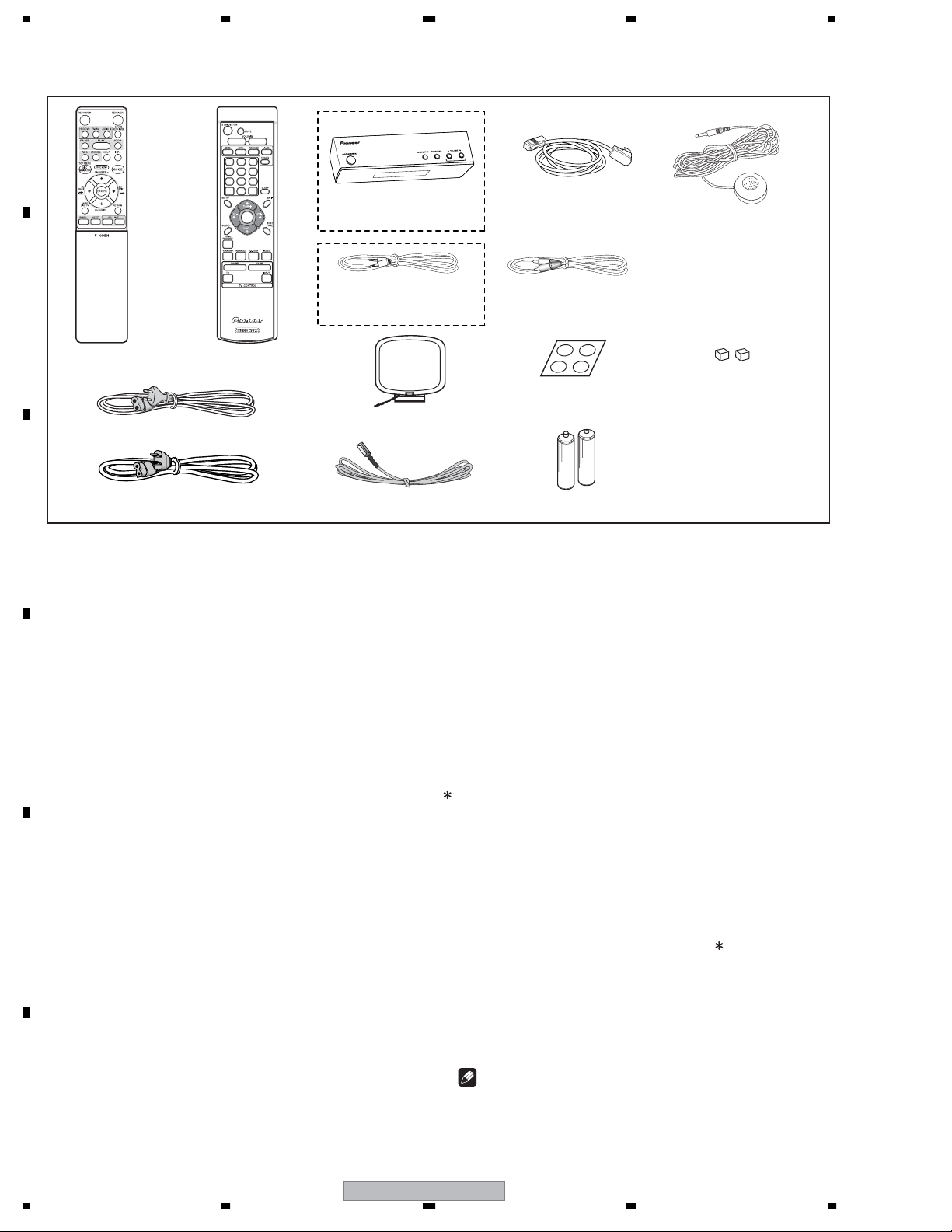

2.1 ACCESSORIES

A

Display unit

(AXX7246)

Display cable (ADE7122)

Microphone

(for Auto MCACC setup)

(APM7006)

B

Remote control

(SX-SW515 : AXD7482)

Power cord (WYXCN5 : ADG1154)

C

Power cord (KUCXCN : ADG7022)

Remote control

(SX-SW570 : AXD7485)

WYXCN5 only

AM loop antenna

(ATB7013)

2.2 SPECIFICATIONS

• Amplifier section

SW515/WY

RMS Power Output:

Front, Center, Surround. . . . . . . . . . . . . 100 W per channel

Subwoofer. . . . . . . . . . . .100 W (100 Hz, 10 % T.H.D., 4 Ω)

SW570/KUC

FTC Power Output:

Front, Center, Surround. . . . . . . . . . . . . 25 W per channel

D

(200 Hz to 20 kHz, 1 % T.H.D., 4 Ω)

Subwoofer . . . . . 30 W (45 Hz to 200 Hz, 10 % T.H.D., 4 Ω)

• FM tuner section

Frequency range. . . . . . . . . . . . . . . . . . 87.5 MHz to 108 MHz

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 Ω, unbalanced

• AM tuner section

Frequency range. . . . . . . SW515/WY

SW570/KUC

Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Loop antenna

• Subwoofer section

Enclosure. . . . . . . . . . . . . . . . . . . . . . . . Bass-reflex floor type

E

System . . . . . . . . . . . . . . . . . . . . . . . . . . 16 cm 1-way system

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 cm cone type

Nominal impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Ω

Frequency range. . . . . . . . . . . . . . . . . . . . . . 25 Hz to 1.0 kHz

Maximum Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . 100 W

• Miscellaneous

SW515/WY

Power requirements. . . . . . . AC 220 V to 240 V, 50 Hz/60 Hz

Power consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 W

Power consumption in standby. . . . . . . . . . . . . . . . . . . . 0.3 W

Dimensions. . . . . . . 200 mm (W) x 375 mm (H) x 438 mm (D)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 kg

F

(1 kHz, 10 % T.H.D., 4 Ω)

: 531 kHz to 1602 kHz

: 530 kHz to 1700 kHz

Control cable

(ADE7114)

FM wire antenna

(ADH7030)

Coaxial cable (ADE7115)

Non-skid pads (large)

(AEB7383)

Dry cell batteries

AA/R6P

Spacers

(AEB7382)

SW570/KUC

Power requirements. . . . . . . . . . . . . . . . . . . . AC 120 V/60 Hz

Power consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 W

Power consumption in standby. . . . . . . . . . . . . . . . . . . . 0.2 W

Dimensions. . . . . 7-7/8 in. (W) x 14-3/4 in. (H) x 16-7/8 in. (D)

200 mm (W) x 375 mm (H) x 438 mm (D)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 lb 14 oz/9.0 kg

• Accessories

Remote control

Display unit

AA/R6 dry cell batteries (to confirm operation)

Coaxial cable

Control cable

Display cable

AM loop antenna

FM wire antenna

Microphone (for Auto MCACC setup)

Power cord

Non-skid pads (large)

Spacers

Warranty card

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Instructions

SW515/WY only

Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

“DTS” and “DTS Digital Surround” are registered

trademarks of DTS, Inc.

Note

Specifications and design subject to possible

modification without notice, due to improvements.

6

1234

SX-SW515

5678

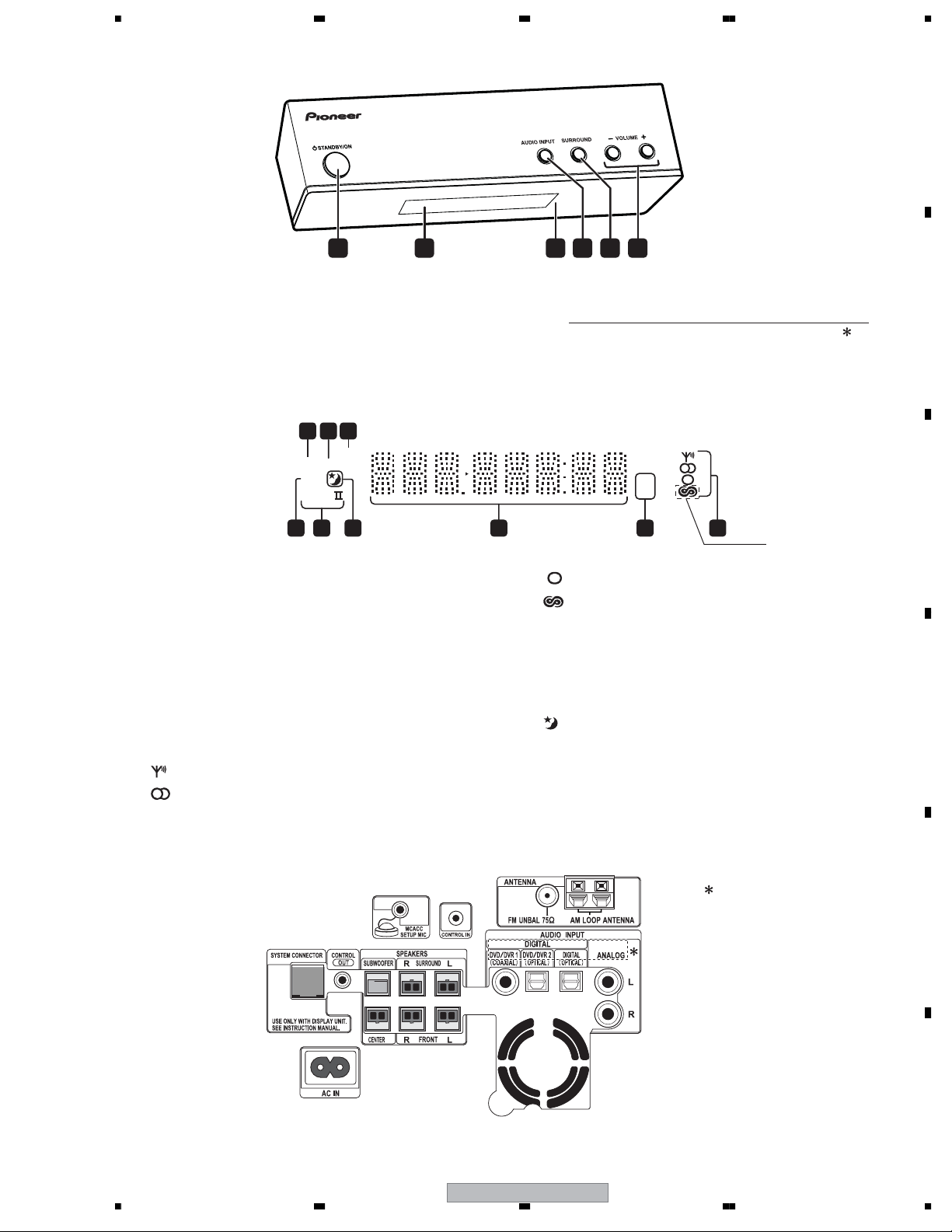

2.3 PANEL FACILITIES

Display unit

A

1 3 62

1 STANDBY/ON

Press to switch the system on/into standby.

2 Front panel display

See below for details.

3 IR remote sensor

Display

2 3

1

SOUND

DTS F.SURR.

2

D

2

PL

789

1 DTS

Lights during playback of a DTS source.

2 F.SURR.

Lights when one of the Front Stage Surround

Advance listening modes is selected.

SURR.

Lights when one of the Advanced Surround listening

modes is selected.

3 SOUND

Lights when Sound Retriever is active.

4 Tuner indicators

– Lights when a broadcast is being received.

– Lights when a stereo FM broadcast is being

received in auto stereo mode.

4 5

4 AUDIO INPUT

Press repeatedly to select one of the external audio

inputs (DVD/DVR1, DVD/DVR2, DIGITAL or ANALOG).

5 SURROUND

Use to select a Surround mode.

6 VOLUME buttons

Use to adjust the volume.

kHz

MHz

6

– Lights when FM mono reception is selected.

– Lights when in one of the RDS display or search

modes.

5 kHz / MHz

Indicates the frequency unit shown in the character

display (kHz for AM, MHz for FM).

6 Character display

7

Lights when sleep timer is active.

2

PL II

8

Lights during Dolby Pro Logic II decoding.

9

2

D

Lights during playback of a Dolby Digital source.

5 4

SW515/WY only

B

C

D

Rear Panel (Receiver subwoofer)

56

SX-SW515

SW515/WY SW570/KUC

DVD/DVR1 DVD

DVD/DVR2 DTV

DIGITAL PC/GAME

ANALOG AUX

7

8

E

F

7

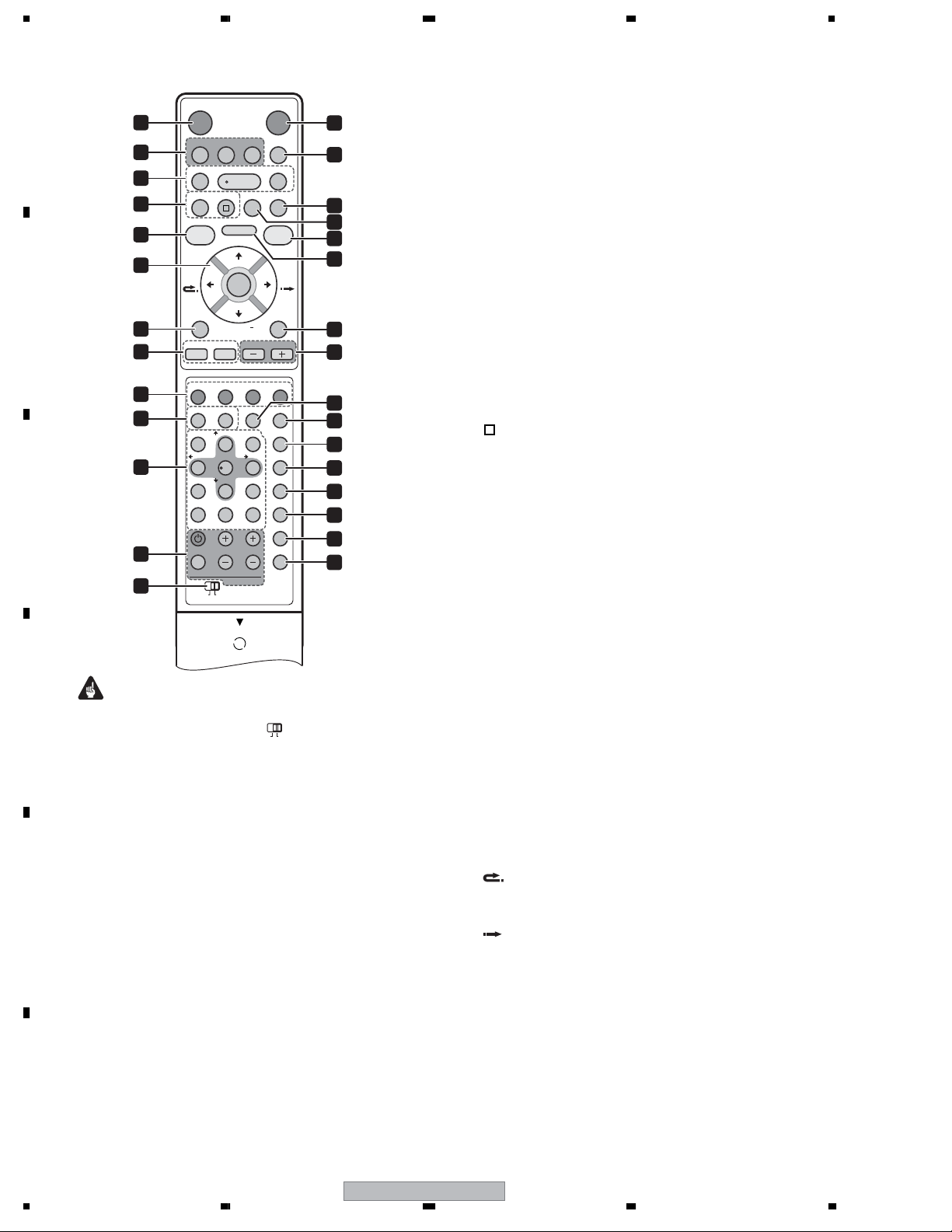

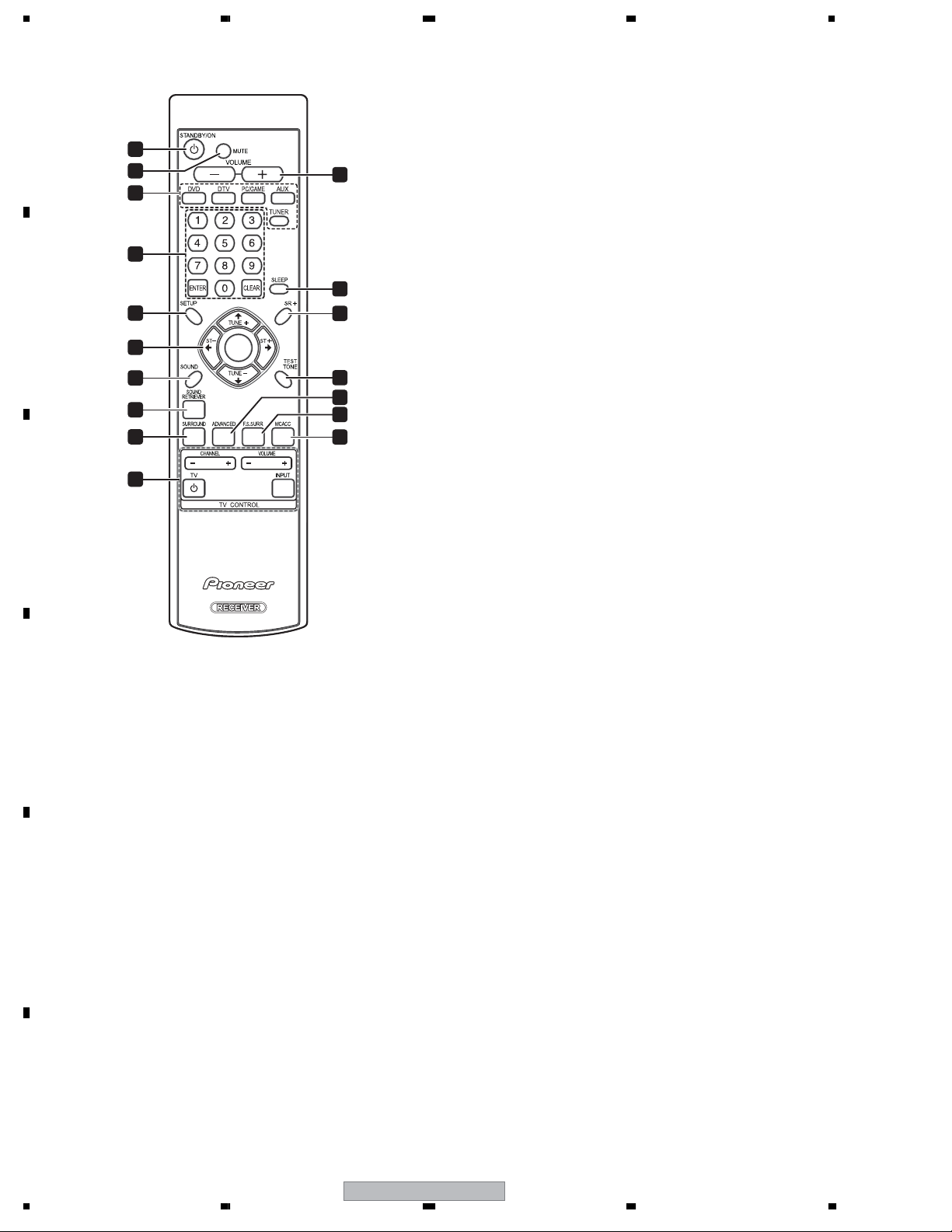

Remote control

SX-SW515/WYXCN5

A

B

C

1234

4 SOUND RETRIEVER

Press to restore CD quality sound to compressed audio

sources.

5 Playback controls

PAUSE

Press to pause playback or recording.

PLAY

Press to start playback.

STOP

Press to stop playback.

6 Recording controls

REC

Press to start recording. Press repeatedly to set the

recording time in blocks of 30 mins.

When the red action button is visible in a GUIDE

TM

Plus+

screen, use for One-Button-Record.

STOP REC

Press to stop recording.

7 INFO

Press to see additional information for the highlighted

item in GUIDE Plus+

TM

.

8 HELP

Press for help on how to use the current GUI screen.

9 DISC NAVIGATOR / TOP MENU

Press to display the Disc Navigator screen, or the top

menu if a DVD-Video or finalized DVD-R/RW (Video) disc

is loaded.

1

3

5

6

9

12

13

15

17

19

22

27

29

RECORDER

RECEIVER

SOUND

HDD/DVD

PAUS E PLAY STO P

REC

TOP MENU

NAVIGATOR

CM

BACK

PAUS E

LIVE TV

PREV NEXT

//

SETUP

/ ST

F. S . S URR TEST TONE

SURROUND

SLEEP CLEAR

INPUT

AUDIO IN

FM/AM

STOP REC

HOME MENU

DISC

123

-

456

789

CHANNEL

CHANNEL

/

TUNE

ENTER

/

TUNE

ENTER

+

-

+

VOLUME

TIMER REC

+

SR

/ ST

SOUNDADVANCED

ONE TOUCH COPY

+

0

VOLUMECHANNEL

MCACC

TV CONTROL

SUBMAIN

OPEN

RETRIEVER

INFOHELP

GUIDE

CM

SKIP

RETURN

PLAY MODEANGLESUBTITLEAUDIO

REC MODE

MENU

VIDEO IN

TV / DVD

JUKEBOX

DISPLAY

RDS DISP

2

4

7

8

10

11

14

16

18

20

21

23

24

25

26

28

Important

D

• Functions printed in green on the remote control are

accessed by switching the MAIN/SUB switch

SUBMAIN

to SUB.

1 RECORDER

Press to switch the recorder on or into standby.

2 RECEIVER

Press to switch the receiver subwoofer on or into standby.

3 Input select buttons

HDD/DVD

E

Press to select the hard disk (HDD) or DVD for

recording and playback. The receiver subwoofer's

audio input is also switched to DVD/DVR1.

FM/AM

Press to select the built-in radio tuner.

AUDIO INPUT

Press repeatedly to select one of the receiver

subwoofer's audio inputs (DVD/DVR1

DIGITAL or ANALOG).

1

, DVD/DVR2,

10 GUIDE

Press to display the GUIDE Plus+

TM

screen; press again

to exit.

11 HOME MENU

Press to display the Home Menu, from which you can

navigate many functions of the system.

12

»/«/|/\

(cursor buttons) and ENTER

Use to navigate all HDD/DVD recorder on-screen

displays. Press ENTER to select the currently

highlighted option.

CHANNEL +/–

Press to change the channel of the built-in TV tuner.

CM BACK (commercial back)

Press repeatedly to skip progressively backward

through the video playing.

CM SKIP (commercial skip)

Press repeatedly to skip progressively forward

through the video playing.

13 PAUSE LIVE TV

Press to start recording the current TV channel, but with

playback paused, effectively pausing the broadcast.

F

8

SX-SW515

1234

5678

14 RETURN

Press to go back one level in the on-screen menu or

display.

15 PREV / NEXT

Press to skip to the previous or next title/chapter/track/

folder; or to display the previous or next menu page.

When GUIDE Plus+™ is displayed, use to display the

previous/next page.

16 VOLUME +/–

Use to adjust the volume.

17 GUIDE Plus+™ Action buttons

When in the GUIDE Plus+™ system, these buttons

act as the Red, Green, Yellow and Blue Action

buttons (the functions of these buttons change

according to the GUIDE Plus+™ Area).

AUDIO

Press to change the audio language or channel.

(When the recorder is stopped, press to change the

tuner audio.)

SUBTITLE

Press to display/change the subtitles included in

multilingual DVD-Video discs.

ANGLE

Press to switch camera angles on discs with multiangle scenes.

PLAY MODE

Press to change the play mode (search, repeat,

programme play, etc.).

18 TIMER REC

Press to set a timer recording from the GUIDE Plus+™

system.

19 /

Press to start reverse or forward scanning. Press

again to change the speed.

/, /

While paused, press and hold to start slow-motion

playback. Press repeatedly to change the playback

speed.

While paused, press to advance a single frame in

either direction.

When GUIDE Plus+™ is displayed, use to display the

previous/next day.

20 REC MODE

Press repeatedly to change the recording mode (picture

quality).

2122ONE TOUCH COPY

Press to start One Touch Copy of the currently playing

title to DVD or the HDD.

Number buttons

Use the number buttons for track/chapter/title

selection; channel selection, and so on.

»/«/|/\ (cursor buttons) and ENTER

Use to control receiver functions.

SETUP

Use to access the menu system for surround sound

setup, tuner settings and so on .

SR+

Use to setup the SR+ features and to select the SR+

mode.

F.S.SURR

Use to select a Front Stage Surround Advance mode.

TEST TONE

Use to output the test tone (for speaker setup).

SURROUND

Use to select a Surround mode.

SLEEP

Press to set the sleep timer.

ADVANCED

Use to select a Pioneer original surround mode .

SOUND

Press to access the sound menu, from which you can

adjust bass and treble, etc.

CLEAR

Press to clear an entry and start again.

23 MENU

Press to display the disc menu if a DVD-Video, finalized

DVD-R/-RW (Video mode) or finalized DVD+R/+RW disc

is loaded.

When in the GUIDE Plus+™ system, use to jump directly

to the Menu bar.

24 VIDEO IN

Press to change the HDD/DVD recorder input to use for

recording.

25 TV/DVD

Press to switch between 'TV mode', in which you get the

picture and sound from the TV's tuner, and 'DVD mode',

in which you get picture and sound from the system's tuner

(or an external input).

26

JUKEBOX

Press to display the Jukebox screen of the HDD/DVD

recorder, from where you can copy music to the HDD for

playback.

27

TV CONTROL

After setting up, use these controls to control your TV.

MCACC

Starts the Auto MCACC setup.

28

DISPLAY

Displays/changes the on-screen information displays.

RDS DISP

Changes RDS displays.

29 MAIN/SUB

Change from MAIN to SUB to access the green functions/

commands on the remote.

Note

Specifications and design subject to possible

modification without notice, due to improvements.

Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

“DTS” and “DTS Digital Surround” are registered

trademarks of DTS, Inc.

A

B

C

D

E

F

56

SX-SW515

9

7

8

Remote control

SX-SW570/KUCXCN

A

1234

5 Number buttons, CLEAR and ENTER

Use the number buttons for entering radio stations

directly, and so on.

Use CLEAR to clear an entry and start again.

1

2

4

3

Use ENTER to confirm an entry.

6 SLEEP

Press to set the sleep timer.

7 SETUP

5

Use to access the menu system for surround sound

setup, tuner settings and so on.

B

C

1 STANDBY/ON

D

Press to switch the recorder subwoofer on or into

7

9

10

12

13

17

standby.

23 MUTE

Press to mute all audio from the speakers. Press again

to cancel and restore the sound.

11

14

15

16

6

8

8 SR+

Use to setup the SR+ features and to select the SR+

mode.

9

»/«/|/\

(cursor buttons) and ENTER

Use to navigate the receiver subwoofer menus.

10 SOUND

Press to access the sound menu, from which you can

adjust bass and treble, etc.

11 TEST TONE

Use to output the test tone (for speaker setup).

12 SOUND RETRIEVER

Press to restore CD quality sound to compressed stereo

audio sources.

13 SURROUND

Use to select a Surround mode.

14 ADVANCED

Use to select a Pioneer original surround mode.

15 F.S.SURR

Use to select a Front Stage Surround Advance mode.

16 MCACC

Starts the Auto MCACC setup.

17 TV CONTROL

After setting up, use these controls to control your TV.

VOLUME +/–

Use to adjust the volume.

4 Input select buttons

E

DVD - Press to select the DVD input.

DTV - Press to select the DTV input.

PC/GAME

(PC/GAME) input.

AUX

- Press to select the auxilliary (AUX) input.

TUNER

F

10

1234

-

Press to select the PC/game console

- Press to select the built-in radio tuner.

SX-SW515

5678

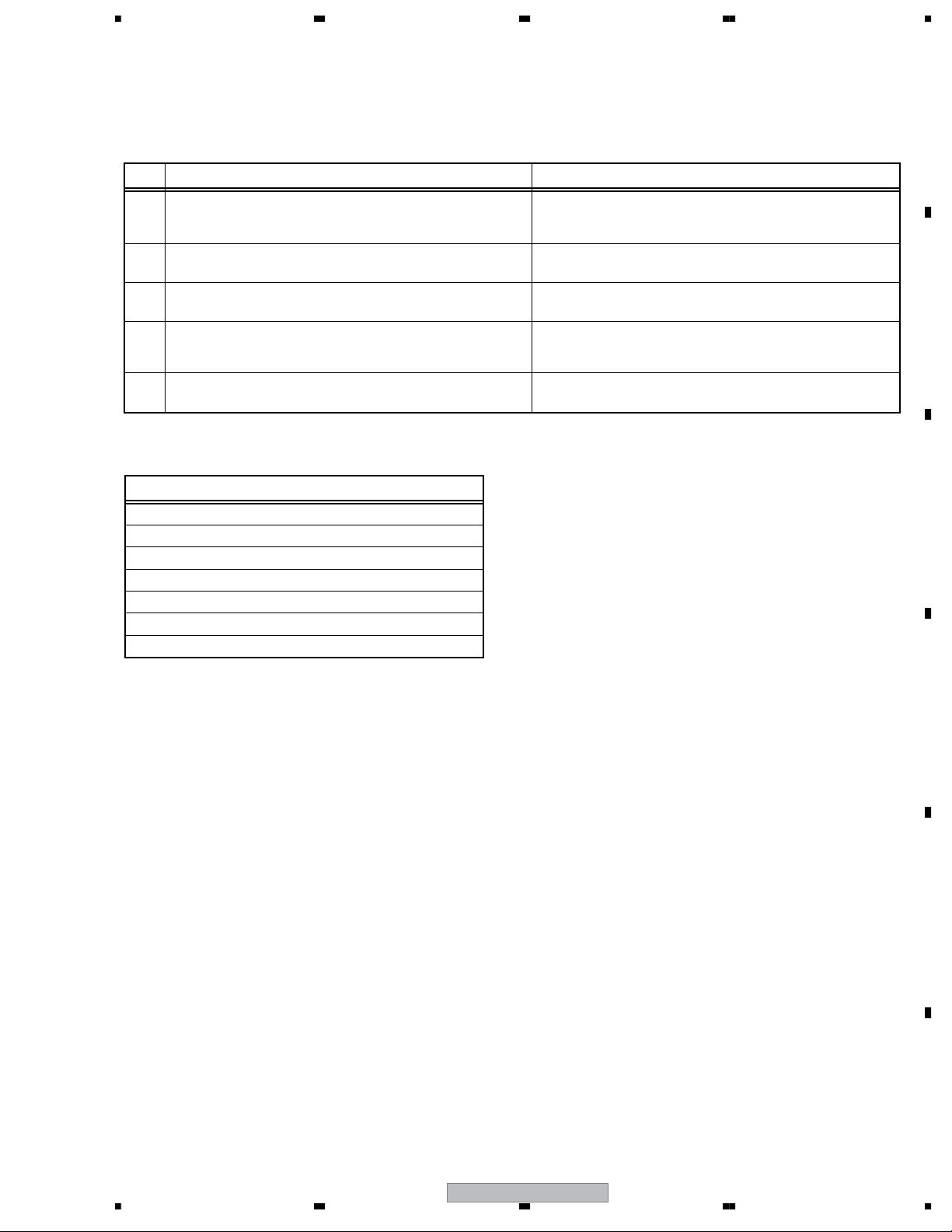

3. BASIC ITEMS FOR SERVICING

3.1 CHECK POINTS AFTER SERVICING

Check points after servicing (Subwoofer receiver)

To keep the product quality after servicing, confirm recommended check points shown below.

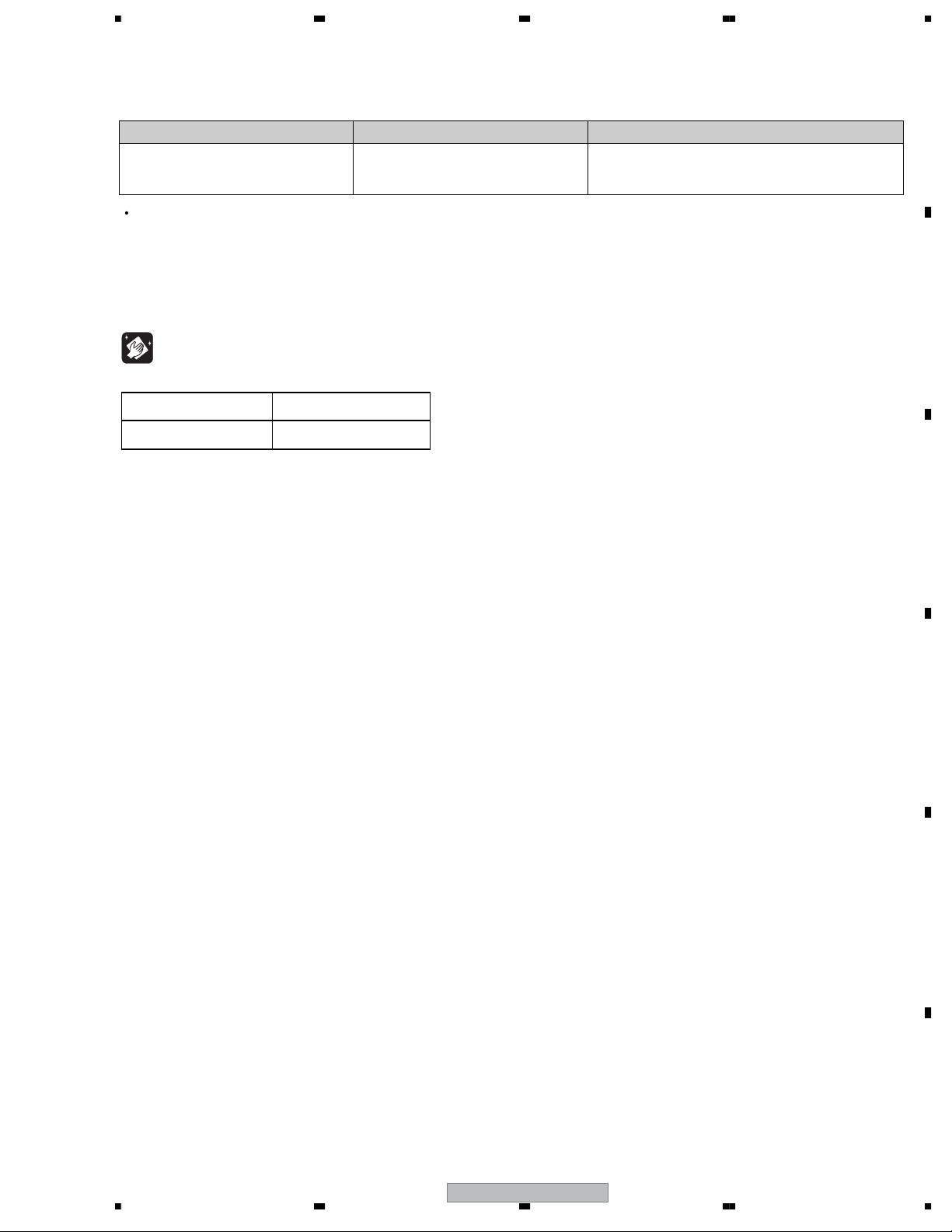

No. Procedure Check points

Confirm whether the customer complain has been solved. If the

1

customer complain occurs with the particular source, such as

Dolby Digital, DTS and AAC, input it for the operation check.

Check the analog audio playback.

2

(Make the analog connections with a DVD player.)

Check the digital audio playback.

3

(Make the digital connections with a DVD player.)

Check surround playback.

(Select Surround mode and check the multichannel operations

4

via the DSP circuit.)

Check the appearance of the product. No scratches or dirt on its appearance after receiving it for

5

See the table below for the items to be checked regarding audio:

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

The customer complain must not be reappeared.

Audio and operations must be normal.

Each channel audio and operations must be normal.

Each channel audio and operations must be normal.

Each channel audio and operations must be normal.

service.

A

B

C

D

E

F

56

SX-SW515

11

7

8

1234

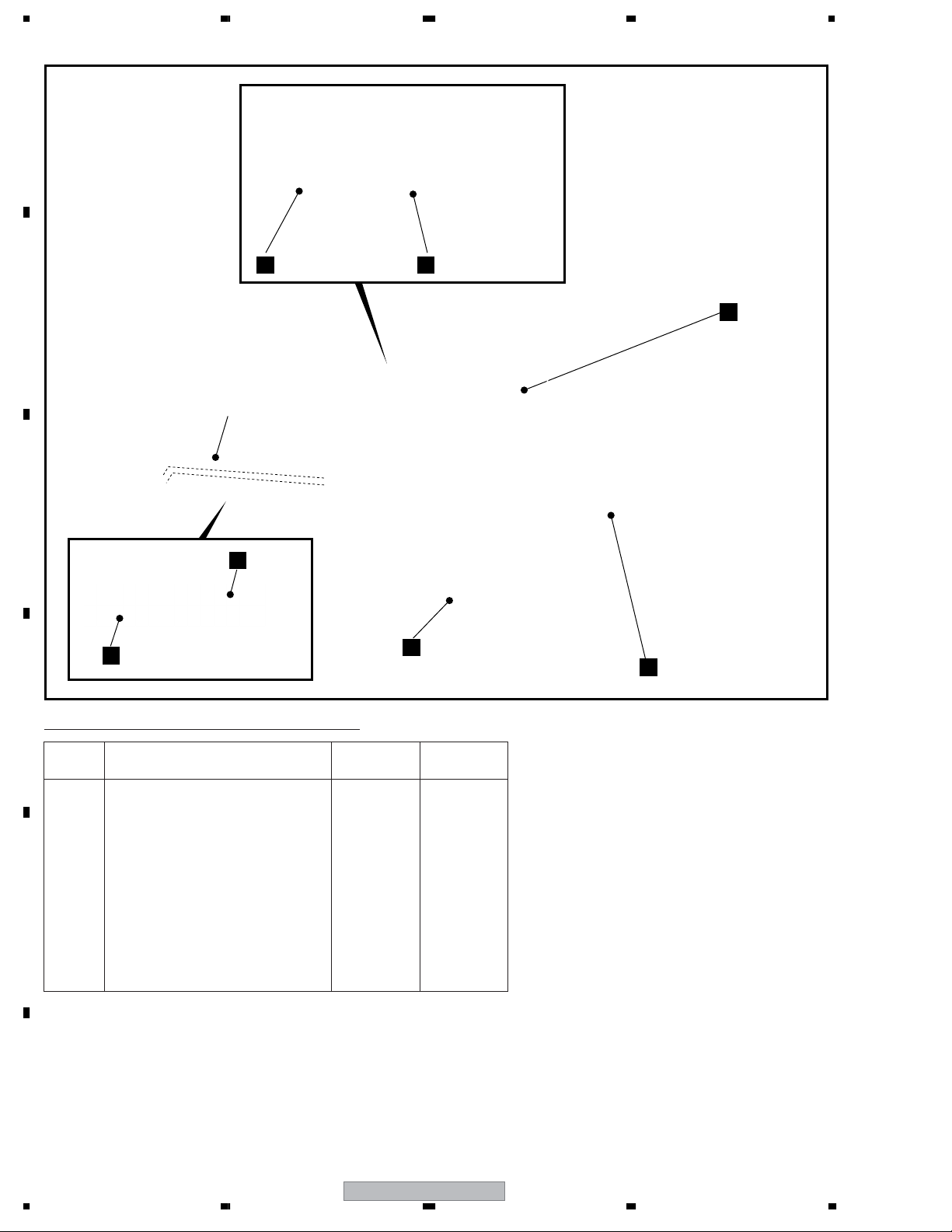

3.2 PCB LOCATIONS

A

>

B

C

D

LIST OF

FM/AM TUNER Unit

G

DISPLAY Unit

FL Assy

D

CONNECT Assy

C

WHOLE PCB ASSEMBLIES

AC INLET Assy

B

JACK TX Assy

E

A

POWER SUPPLY Unit

F

MAIN Assy

Mark Symbol and Description

1..MAIN Assy AWK8000 AWK8002

1..DISPLAY ASSY AWM8078 Not used

NSP 1..DISPLAY ASSY Not used AWM8079

2..FL Assy AWU8294 AWU8294

2..CONNECT Assy AWU8295 AWU8295

NSP 2..AC INLET Assy AWU8296 AWU8297

E

F

1..JACK TX Assy AWX8707 AWX8708

1..POWER SUPPLY Unit AWR7043 AWR7044

1..FM/AM TUNER Unit AXX7248 AXX7250

12

1234

SX-SW515/

WYXCN5

SX-SW515

SX-SW570/

KUCXCN

5678

3.3 JIGS LIST

7 Jigs list

Name Jig No. Remarks

Speaker Cable with terminal SDS1174 (FL/WHITE)

SDS1175 (FR/RED), SDS1176 (SL/BLUE)

SDS1177 (SR/GRAY), SDS1178 (C/GREEN)

For checking audio at the SP terminal

Compatibility of the display unit

If you have product jig of SX-SW77 series or SX-SW404 series, it is able to use the display unit of these models

for this model.

7 CLEANING

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Fans Cleaning paper : GED-008

A

B

C

D

E

F

56

SX-SW515

13

7

8

1234

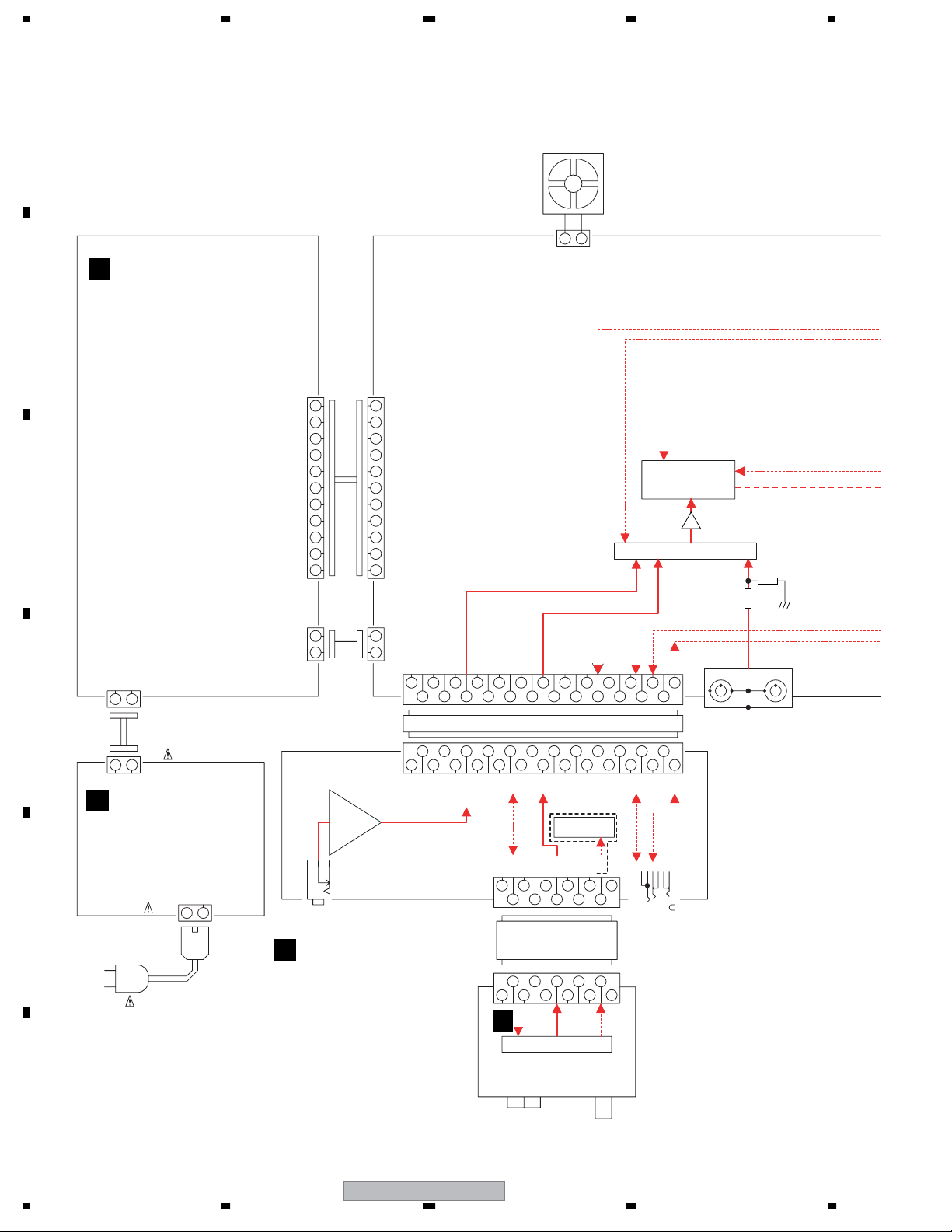

4. BLOCK DIAGRAM

4.1 OVERALL BLOCK DIAGRAM

A

POWER SUPPLY UNIT

F

B

FAN

VXM1121

CN5602

2

1

B2B-PH-K-S

FAN+

GNDF

(AWR7043 : SX-SW515/WYXCN5)

(AWR7044 : SX-SW570/KUCXCN)

C

LIVE

NEUTRAL

21

B2P3S-VH

B11B-PH-K-S

VSF+12

VS+12

BEAT CUT

VE+5

GNDD

VS+3R3

POWER CONT

GNDD

FL DC-

FL DC+

VFDP

B2P-VH

GND

+B

1

2

3

4

5

6

7

8

9

10

11

ADX7508

1

2

ADX7507

D

ADX7510

CN1

21

B2P3S-VH

AC INLET ASSY

B

3

(AWU8296 : SX-SW515/WYXCN5)

(AWU8297 : SX-SW570/KUCXCN)

RKN1004

LIVE

NEUTRAL

AN1

E

/WYXCN5 : XKP3084

/KUCXCN : XKP3085

AC CORD

21

JA3901

MCACC

MIC IN

JACK TX ASSY

E

(AWX8707 : SX-SW515/WYXCN5)

(AWX8708 : SX-SW570/KUCXCN)

AMP

CN1001

B11B-PH-K-S

1

2

3

4

5

6

7

8

9

10

11

CN3201

B2P-VH

1

2

CN3002

9604S-25C

7

7

341

5

2

6

2219201718 161514

232425

SL

VREF

GNDDSRGNDD

GNDD

MICOUT

9

13

121110

8

25pin FFC

ADD7539

12

1321 745

DI

CE

DO

TXL

CLK

VS+12

WY only

CE

GND

CLKDIDO

135

9604S-11C

CN5701

24 10

11pin FFC

ADD7538

123457

6

17 2119

11109

TXR

GNDD

GNDD

RDS

LC72725KM

TXR

+9V

TXL

7119

810

18 22161514

8

RDSPOW

RDSDATA

2

4

RDS

VSM

119

14

20

6

VS+5

RDSCLK

GND

IC3003

A/D Converter

9, 10

IC3001

TC4052BFN

24

31

TXD

RXD

RMC_SWR

2861

7

356

JA5401

SR+

(SR IN)

3

AK5358ET

2

3

4

2523

2

RMC

VE+5

4

Q3003

Tr

BUFFER

Input Selector

3001

AKB7143

CN5801

9607S-25F

XKN3015

11

9

2

-7dB

Analog Input

MCLK

G

TUNER MODULE

(AXX7248 : SX-SW515/WYXCN5)

(AXX7250 : SX-SW570/KUCXCN)

F

14

1234

SX-SW515

5678

A

MAIN ASSY

A

(AWK8000 : SX-SW515/WYXCN5)

TX&RDS

IC951

5V -> 3V

TC74VHC08FTS1

IC5501

PDC155A

u-COM

(AWK8002 : SX-SW570/KUCXCN)

FL&KEY

IR

B

14

IC601

13

DIR

AK4117VF

35

8

IC4602

TC74VHC00FTS1

SelectorDigital

25

JA4603

GP1FAV51RKBF

Digital Input

DIGITAL DVD/DVR2 DVD/DVR1

(OPT) (COAX)(OPT)

FL ASSY

D

STANDBY/ON

FL Tube

JA4602

GP1FAV51RKBF

(AWU8294)

IR

4,12

VKB1159

JA4601

VOL+VOL-

SELECTOR

12

MCLK

MCLK

SURROUNDINPUT

FL Driver

73

DSPC56371AF180

1

JA5951

RKN1004

SR OUT

DSPIC801

XKP3074 XKP3063

CN5901 CN5651

GNDD

FLDATA

FLCS

FLCK

VE+5

FLDC-

KEY1

CN5902 CN5653

VFDP

GNDD

FLDC+

KEY2

GNDD

REMOCON

VE+5

XKP3074 XKP3063

5, 6, 7

29, 30, 31

1

2

3

4

5

6

7

1

2

3

4

5

6

7

IC3101

PWM Processor

TAS5508BPAG

63

52, 50 47, 45 43, 41

IC3401

TAS5142DDV

36 28

AKE7120

-

CN3211

6

4

2

6

4

2

Power IC

FILTER FILTER

SW C

7

5

3

1

7

5

3

1

IC3301

TAS5142DDV

36 28

FILTER FILTER

-+-

+

CONNECT

C

ASSY

(AWU8295)

SR FR SL

8, 188, 188, 18

Power IC

IC3201

TAS5142DDV

36 28

FILTER FILTER

-+-+-

CN5652

AKP7131

7

11

8

9

10

12

Power IC

+FL+

1

5

243

6

IR

10

675

4123

ADE7122

8

9

1.GNDD

2.GNDD

3.VFDP

4.KEY2

5.FLDATA

6.REMOCON

7.XFLCS

8.FLCK

9.VE+5

10.KEY1

11.F+

12.F-

AKP7131

CN5601

1112

C

D

E

ANALOG AUDIO SIGNAL

DIGITAL or PWM AUDIO SIGNAL

COMMUNICATION LINE

SX-SW515

56

F

15

7

8

1234

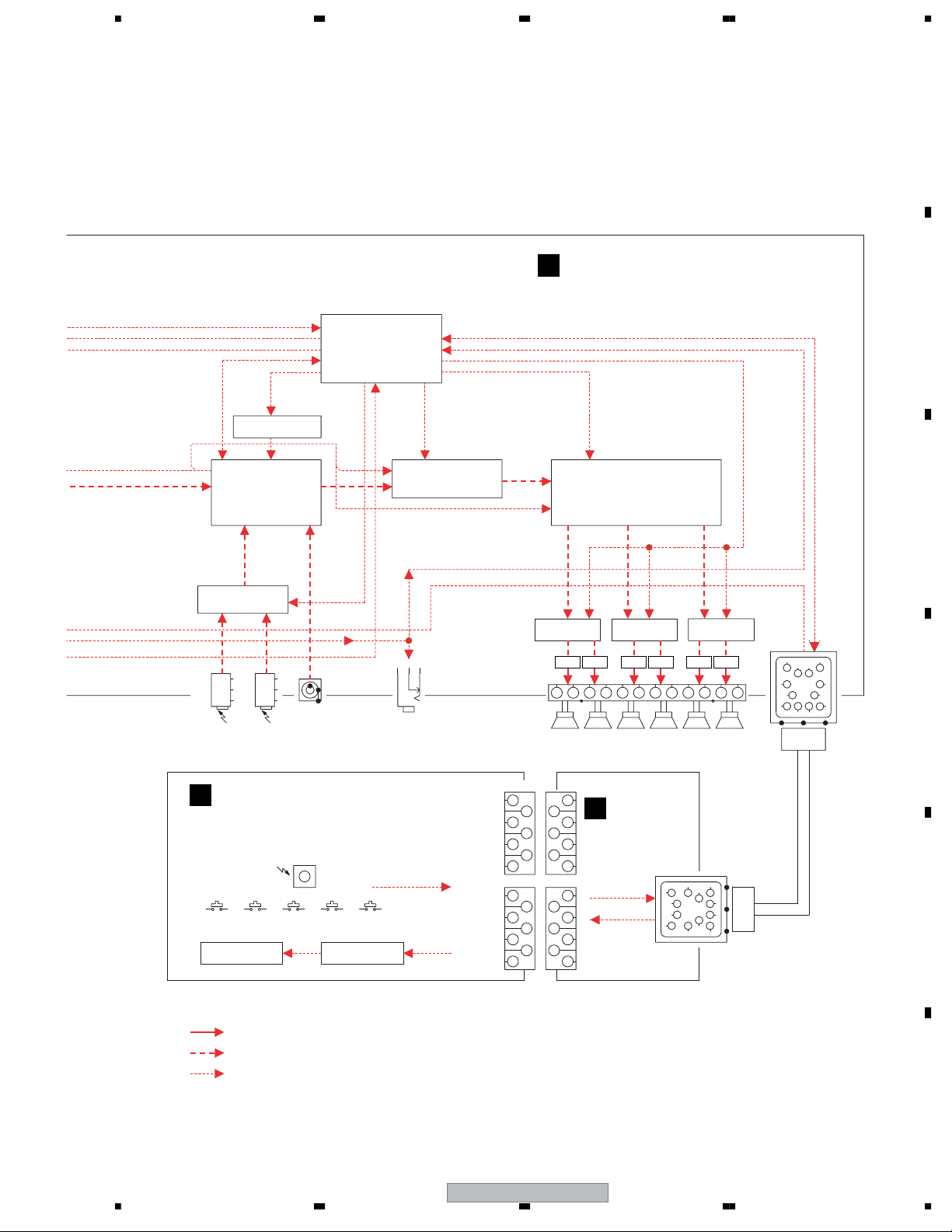

5. DIAGNOSIS

5.1 CIRCUIT DESCRIPTION

5.1.1 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION

A

3.3V

30.5V

0V

To UCOM

XSD

XOTW

0V

*1

*2

TAS5142DDV

B

C

PCM Signal

From DSP

TAS5508BPAG

Filter

and

Volume

PCM → PWM

IC3101 IC3201, IC3301, IC3401

PWM Processor section

Timing

Control

Protection

*1 XSD : /SD (5pin)

*2 XOTW : /OTW (2pin)

Power Stage section

Gate

Drive

Gate

Drive

Output LPF section

PWM Processor section

The PCM signals output from the DSP are input to this section, and their volume and sound quality are digitally adjusted.

At the output stage, after conversion from PCM to PWM, the signals are output to the Power stage.

0V

0V

Power Stage section

In this section, timing is controlled so that the MOSFETs on the high and low sides will not be turned on simultaneously.

The voltage of the PWM signals are raised to drive the gates of the MOSFET, and the PWM signals to drive the speakers

are output from the MOSFET at the output stage. Detection and protection functions against short-circuiting of the output

signals and temperature exceeding the standard value are also provided.

D

If the detection and protection work, the ports of the power stage ICs become the following state.

Power Stage ICs No. Protection Enable State

IC3201 /SD (5pin) ⇒ L

IC3301

IC3401 /OTW (2pin) ⇒ L

Output LPF section

The carrier elements, high-frequency signals that are unnecessary for these speakers, are eliminated. The signals passed

through the LPF will become sine-wave signals, as shown in the figure above.

E

F

16

1234

SX-SW515

5678

5.1.2 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER

The protection circuits for the Digital Amplifier are activated, following the specifications shown below. The error indication on

the FL display shows the reason a protection circuit was activated.

Upon diagnosis of the Digital Amplifier, refer to the specifications for the protection circuits here and the overview of the Digital

Amplifier circuitry.

1. Overview

The system microcomputer monitors the ports for shutdown requests (Pin 5 : /SD) and the ports for abnormal-temperature

detection (Pin 2 : /OTW) of the Power Stage ICs (IC3201, IC3301, and IC3401). As soon as any abnormality is detected, it

shuts the unit down.

To notify the user of the possibility of a too high a volume, when the unit is turned on the next time, the volume level will be set

to 0, and an error message will be displayed on the FL display.

A

2. Ports on the system microcomputer to be used for detection

Pin 77: SHUTDOWN

Low voltage at this pin means overcurrent at the Power Stage ICs or that the power supply voltage for the gate

drive for the Power Stage ICs (= GVDD, Pins 1, 22, 23, and 24), i.e., VS+12 is less than 10 V.

Pin 79: XOTW

Low voltage at this pin means the temperature at the Power Stage ICs exceeded 125°C.

Note: As one Power Stage IC is provided with two channels, three Power Stage ICs (in total 6 channels) are mounted in

this unit. For abnormality detection, the unit implements a logical OR operation regarding these three ICs.

Therefore, which IC is abnormal cannot be known directly. To find which IC is abnormal, it is required to check

whether abnormality detection is activated or not with the abnormality detection port of each IC open (by

temporarily removing a series resistor (IC3201:R3201, R3202, IC3301:R3301, R3302, IC3401:R3401, R3402) ).

3. Detection timing

Start : Detection starts 500 ms after the PWRCONT port (Pin 84) of the system microcomputer becomes active by your

pressing the STANDBY/ON key.

Finish : When the STANDBY/ON key is pressed again (when the power-off process starts).

4. Operation of the protection circuits

The following three protection circuits are activated when the conditions shown below are met:

B

C

D

Overcurrent detection: Indication on the FL display: OC ERROR

Conditions: If the SHUTDOWN ports, which are monitored every 10 ms, become low 7 times in succession.

Abnormal temperature detection 1: Indication on the FL display: OVERTEMP

Conditions: If the XOTW ports, which are monitored every 10 ms, become low in succession for one minute.

Abnormal temperature detection 2: Indication on the FL display: OVERTEMP

(Prerequisite: The XOTW ports, which are monitored every 10 ms, become low three times in succession.)

Conditions: The above prerequisite is upheld, and the conditions for an overcurrent detection are met.

5. Process when the protection circuits are activated

The unit is shut down within 30 ms after abnormality detection then the volume level is set to 0. The unit can be turned on

immediately after the shutdown.

56

SX-SW515

7

8

E

F

17

1234

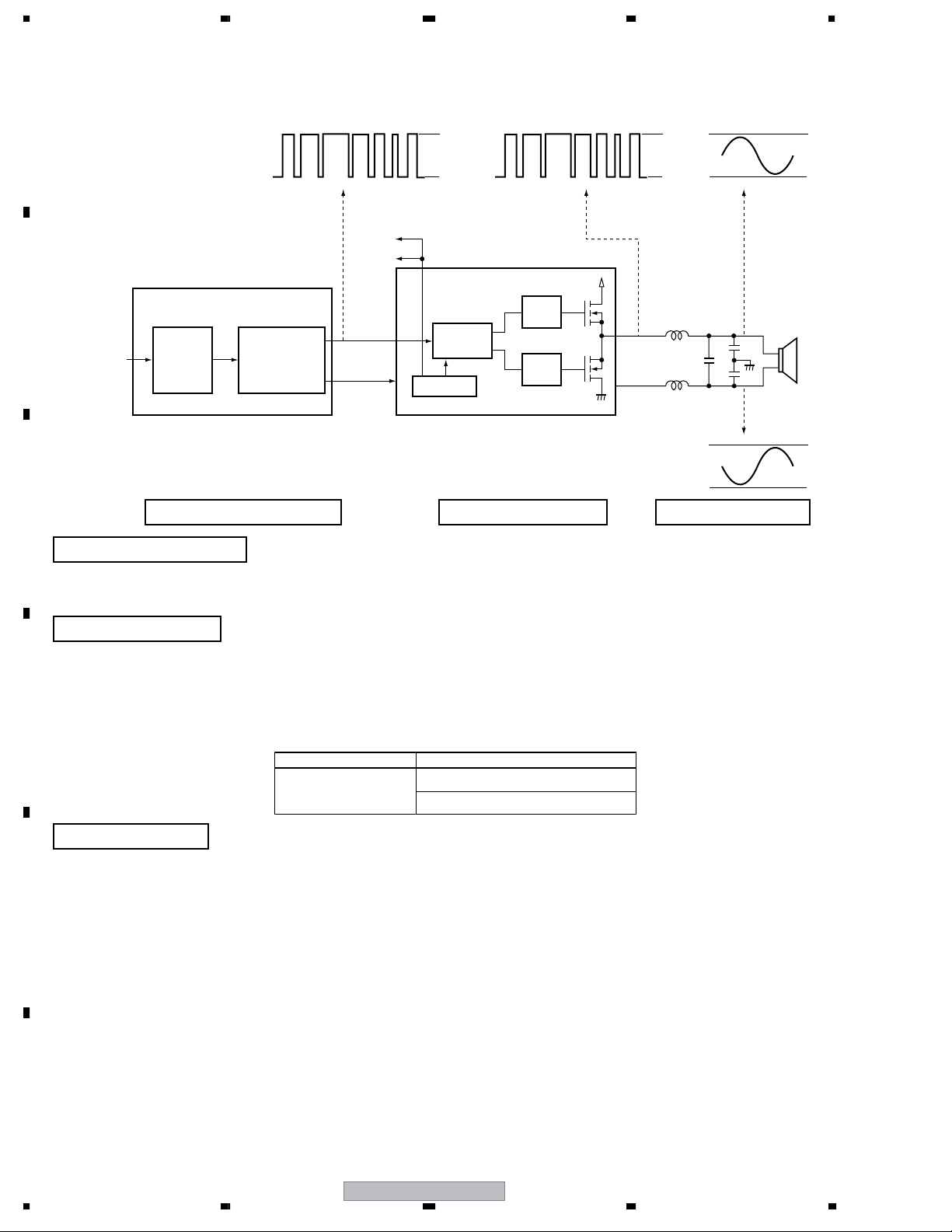

5.1.3 CONDITIONS FOR SWITCHING THE ROTATION SPEED OF THE FAN

A fan is provided with this unit. Its rotation speed can be switched between low and high under the following conditions.

A

1. Conditions for switching the rotation speed from low to high

In a case where an audio signal is input and the main volume becomes VOL 20 or more

• The rotation speed is not switched to high immediately after the main volume becomes VOL 20 but with a delay of 30 seconds.

• If a digital audio signal is not input, the rotation speed is not switched to high even if the main volume becomes VOL 20 or more.

• If the function is ANALOG IN (AUX), even if there is no audio signal input, 30 seconds after the main volume becomes VOL 20 or

more, the rotation speed is switched to high.

2. Conditions for switching the rotation speed from high to low

B

• If the main volume becomes less than VOL 20

• During muting

• If a digital audio signal is not input

• If DIR IC has gone to an unlocking state, such as during function selection or surround selection

Note: The rotation speed is immediately switched to low when one of the above conditions is met.

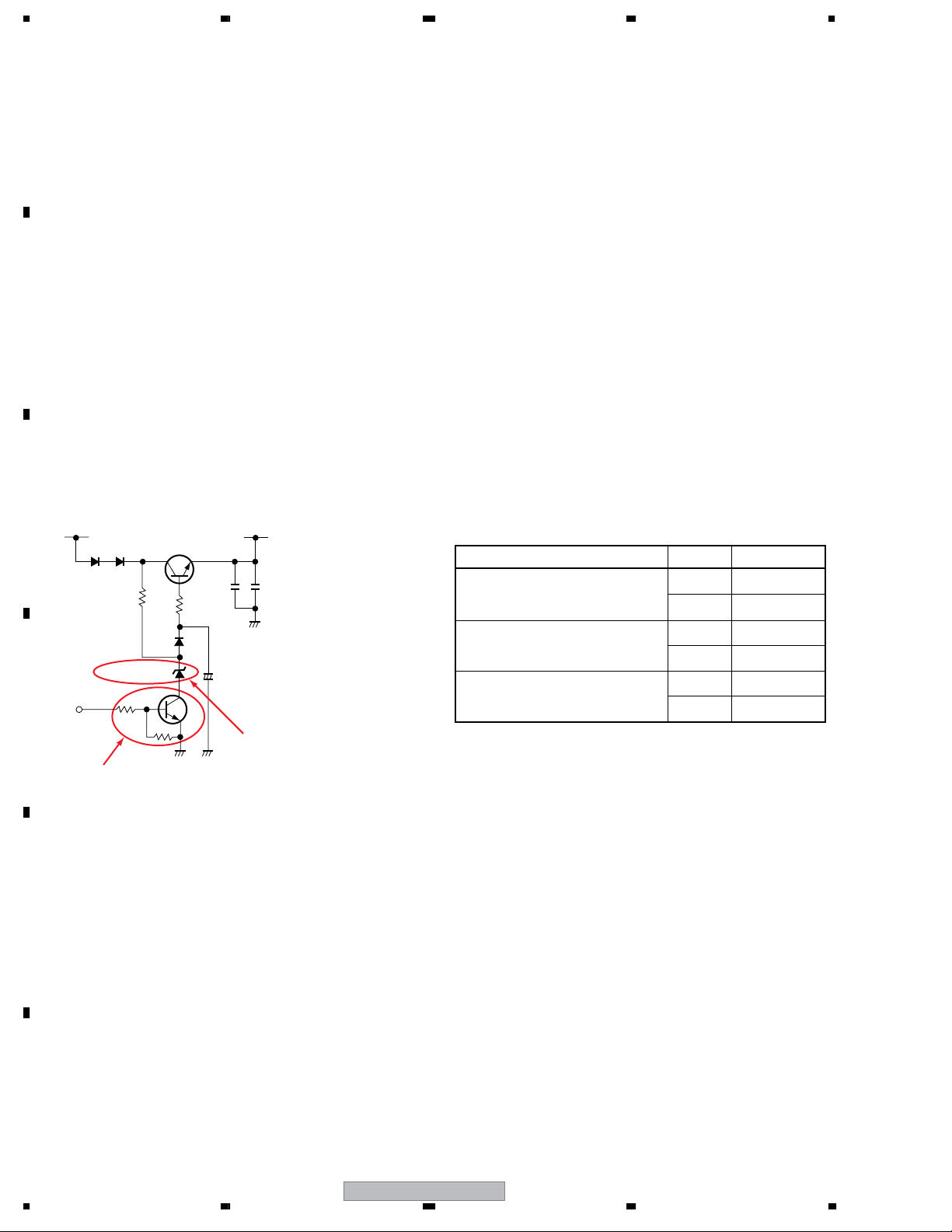

3. Fan drive circuit and drive voltage

The fan drive circuit and the drive voltages at low/high rotation speed are shown below:

C

VSF+12

UDZS8R2(B)

D

Transistor for switching

the drive voltage between

7 V and 12 V

1k

2SD1858X

10→220

VSFAN

0.1 x 2

+

10/50

Zener diode for output

voltage stability (7 V)

Low speed, no digital stream signal

(except when the function setting is

ANALOG IN)

Low speed, with audio input,

with VOL 19 or less

High speed, with VOL 20 or more

Note: The above voltage values are references.

They differ from product to product.

Power Voltage (V)

VSF+12 12.9

VSFAN 7.1

VSF+12 14.3

VSFAN 7.2

VSF+12 14.2

VSFAN 11.3

E

F

18

1234

SX-SW515

5678

6. SERVICE MODE

6.1 SERVICE TEST MODE

1. Conditions During Service Test Mode

• During Service Test mode, the unit will not be shut down for an emergency even if one of the failures mentioned below

occurs.

• After the unit has been shut down in Normal mode for an emergency upon detection of one of the failures mentioned below,

you can turn it on immediately, without waiting for one minute, in Service Test mode.

2. How to enter Service Test mode

• Immediately after the power is turned off (within 5 seconds after the "-OFF-" indication goes dark), simultaneously hold the

AUDIO INPUT and STANDBY/ON keys on the Display unit pressed for more than 3 seconds.

• Service Test mode can also be entered in either of the following ways:

1. Connect the power cord to the wall outlet with the STEST port (microcomputer terminal IC5501: 43-pin) at High (5 V).

(See "Service Test mode connecting point".)

2. Connect the power cord to the wall outlet while holding both the AUDIO INPUT and STANDBY/ON keys on the Display

unit pressed.

Note: If the power cord was disconnected immediately before, be sure to wait at least one minute before turning on the

power in the manner mentioned above. Otherwise, the unit may not operate properly.

3. How to quit Service Test mode, and conditions for quitting

• To quit Service Test mode, press STANDBY/ON key and turn the power off.

• When Service Test mode is quit, only data on failure in RAM will be initialized, and data on user settings in RAM will not be

initialized.

4. Indications on the FL display when Service Test mode is entered

• The function setting will be COAXIAL input.

• The indication on the FL display when Service Test mode is entered will differ depending on whether the unit was shut down

normally or with an abnormality detected, as shown below:

• Advanced Surround mode will become 5-channel STEREO (X-STEREO) so that multichannel output can be obtained.

A

B

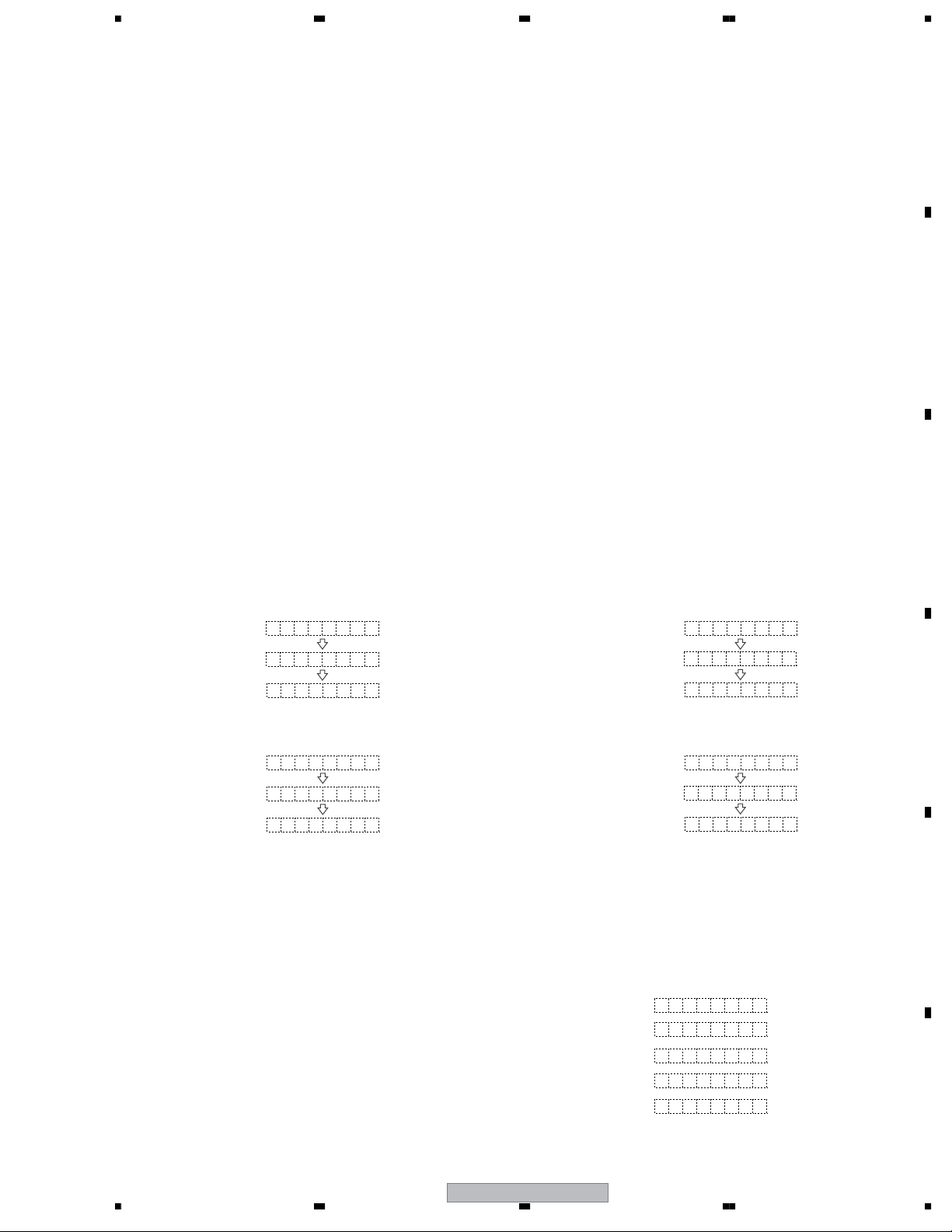

C

[After a normal power-off]

FL display

FL display

FL display

[After a shutdown caused by an EEPROM failure]

FL display

FL display

FL display

P O W E R O N

V O L 0

O AC VS E R

E E P E R R

V O L 0

O AC VS E R

[After a shutdown caused by over current detection]

FL display

FL display

FL display

[After a shutdown caused by high-temperature detection]

FL display

FL display

FL display

O C E RR R O

V O L 0

O AC VS E R

O V E R PT E M

V O L 0

O AC VS E R

5. Operations during Service Test Mode

• Basically, operations in Service Test mode are the same as in Normal mode. However, to indicate that the unit is in Service

Test mode, the following are displayed when the functions are changed:

[Functions]

TUNER

DVD/DVR1

DVD/DVR2

DIGITAL

ANALOG

• SX-SW570/KUC• SX-SW515/WY

TUNER

DVD

DTV

PC/GAME

AUX

[FL display]

T X S E R V

O A S E R

C

P 1 S E R VO

2 S E R

O

P

N A S E R

A

V

V

V

D

E

F

56

SX-SW515

19

7

8

e

1234

6. Failures

• Depending on the types of errors, one of the following error messages will be displayed when the unit is turned on:

E E P E R R

A

1. Breakage or short-circuiting of the communication line to the EEPROM can be suspected.

2. A failure in the EEPROM can be suspected.

O C E RR R O

• If "OC ERROR" is not displayed when the unit is turned on in Normal mode, short-circuiting of the speaker terminals

can be suspected.

• If "OC ERROR" is displayed again when the unit is turned on in Normal mode, the following causes can be suspected:

1. One or more of the ICs among the three digital amplifier ICs (IC3201, IC3301, and IC3401: TAS5142DDV) on the

MAIN Assy is in failure.

2. The line between one of the above digital amplifier ICs and the speaker terminals is short-circuited.

3. The SHUTDOWN line from one of the above digital amplifier ICs to the system-control IC (PDC155A) is short-circuited

by grounding or is broken.

B

C

4. The voltage at VS+12 is low (less than 10 V).

5. (In a case when an error claimed by the customer could not be duplicated) The customer let the volume of the

speakers increase when two poles of the speaker cable had been short-circuited.

6. (In a case when an error claimed by the customer could not be duplicated) The customer let the conductor of the

speaker cable touch the chassis of the main unit.

O V E R PT E M

• If "OVERTEMP" is not displayed when the unit is turned on in Normal mode, the unit is normal.

(It might be caused by a temporary temperature rise.)

• If "OVERTEMP" is displayed again when the unit is turned on in Normal mode, the following causes can be suspected:

1. One or more of the ICs among the three digital amplifier ICs (IC3201, IC3301, and IC3401: TAS5142DDV) on the

MAIN Assy is in failure.

2. The XOTW line from one of the above digital amplifier ICs to the system-control IC (PDC155A) is short-circuited by

grounding or is broken.

3. Inappropriate installation of the heat sink (loose screws, failure to apply silicon grease, etc.)

7. DSP error display

• Each time the SOUND key on the remote control unit is pressed while the power is on in Service Test mode, the DSP error

display and the normal display are alternately switched.

FL display

D

Example)

DIR ERR

DSP ERR

HREQ ERR

DSP NG

E

DMUTE ON

NO ERR

(The source is 88.2/96kHz.)

NO ERR

(The source is not 88.2/96kHz.)

O O O O - U M 9

The name of an error is displayed by four characters.

D I E R - U M

D S E R - U M

H R E Q - U M

D S N G - U M

D M U T - M

D S O K - 9

D S O K -

96k (This character is displayed while the source is 88.2 or 96kHz PCM.)

DSP MUTE (This character is displayed while DSPMUTE is active.)

DIR UNLOCK (This character is displayed while DIR is UNLOCK.)

Data cannot be received from DIR. → DIR is assumed to be in failure.

Data cannot be received from DSP. → Communication between DIR and DSP

is in failure. → DSP is assumed to be in failure.

No value is returned from HREQ. → DSP is assumed to be in failure.

There are DSP error data. → Communication between DIR and DSP is in failur

→ DSP is assumed to be in failure.

DECMUTE is always activated. → Communication between DIR and DSP is in

failure. → DSP is assumed to be in failure.

96-kHz source data are being played back. (No abnormality)

No abnormality

• DSP error message mode

Press the "SOUND" key in Service Test mode, to select the mode that DSP error messages are displayed.

Press the "SOUND" key again to return to the normal test mode display.

For this reason, the usual function of "SOUND" does not work in the Service Test mode.

F

20

1234

SX-SW515

5678

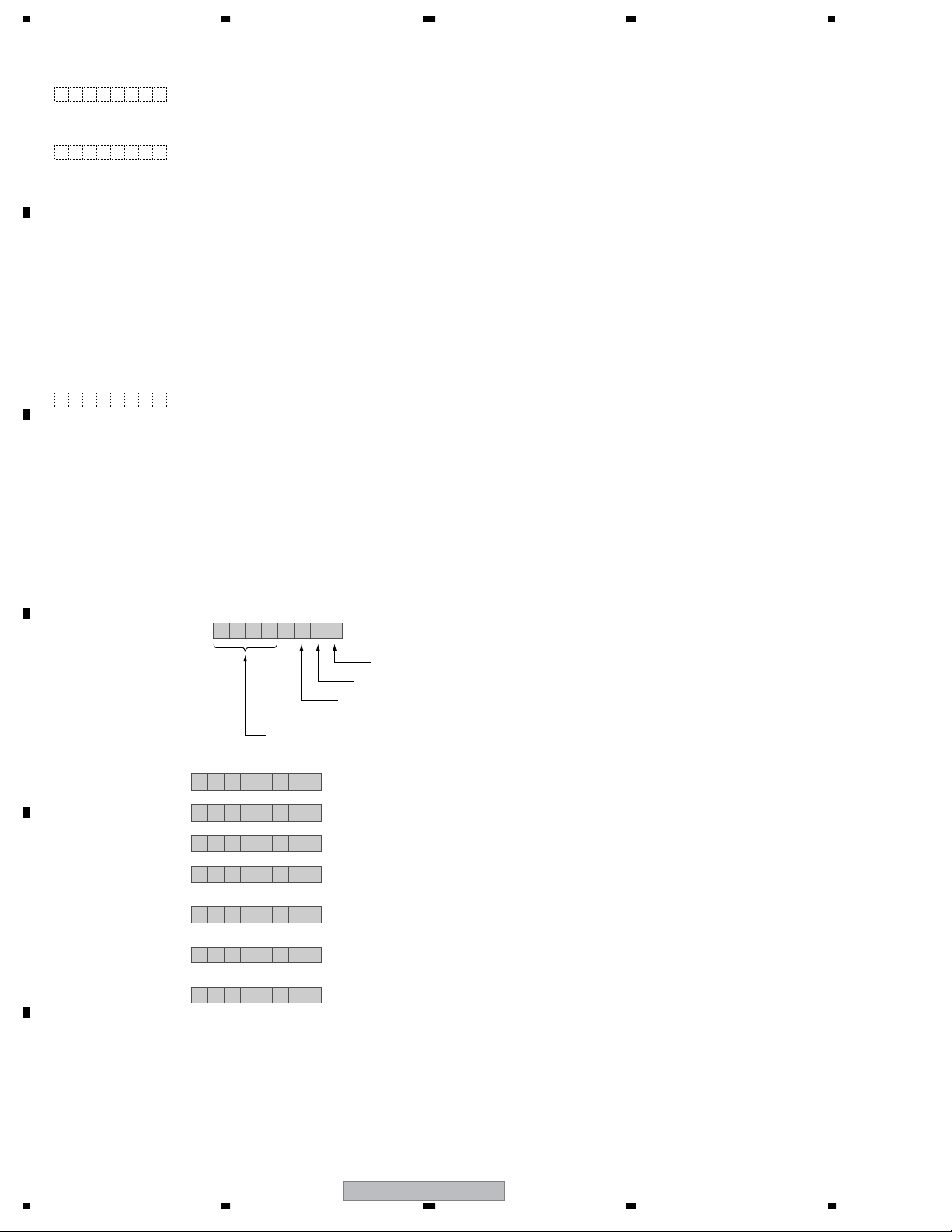

8. Accumulated power-on time display and speaker setting display

• You can check the accumulated power-on time and speaker settings by holding the AUDIO INPUT key on the Display unit

pressed for more than 8 seconds while the power is on in Service Test mode. While the key is held pressed, the

accumulated power-on time indication and speaker-setting indication are alternately displayed for 3 seconds each.

Speaker-setting display

Accumulated power-on time display

• Power-on time is always counted while the power is on, regardless of unit's functions and operations.

However, it is not counted during Standby mode.

• The maximum countable power-on time is 255H59M (255 hours 59 minutes). The indication will not advance beyond that.

• The accumulated power-on time basically cannot be cleared.

S M A L L

At intervals of 3 seconds

1 0 H 3 0 M

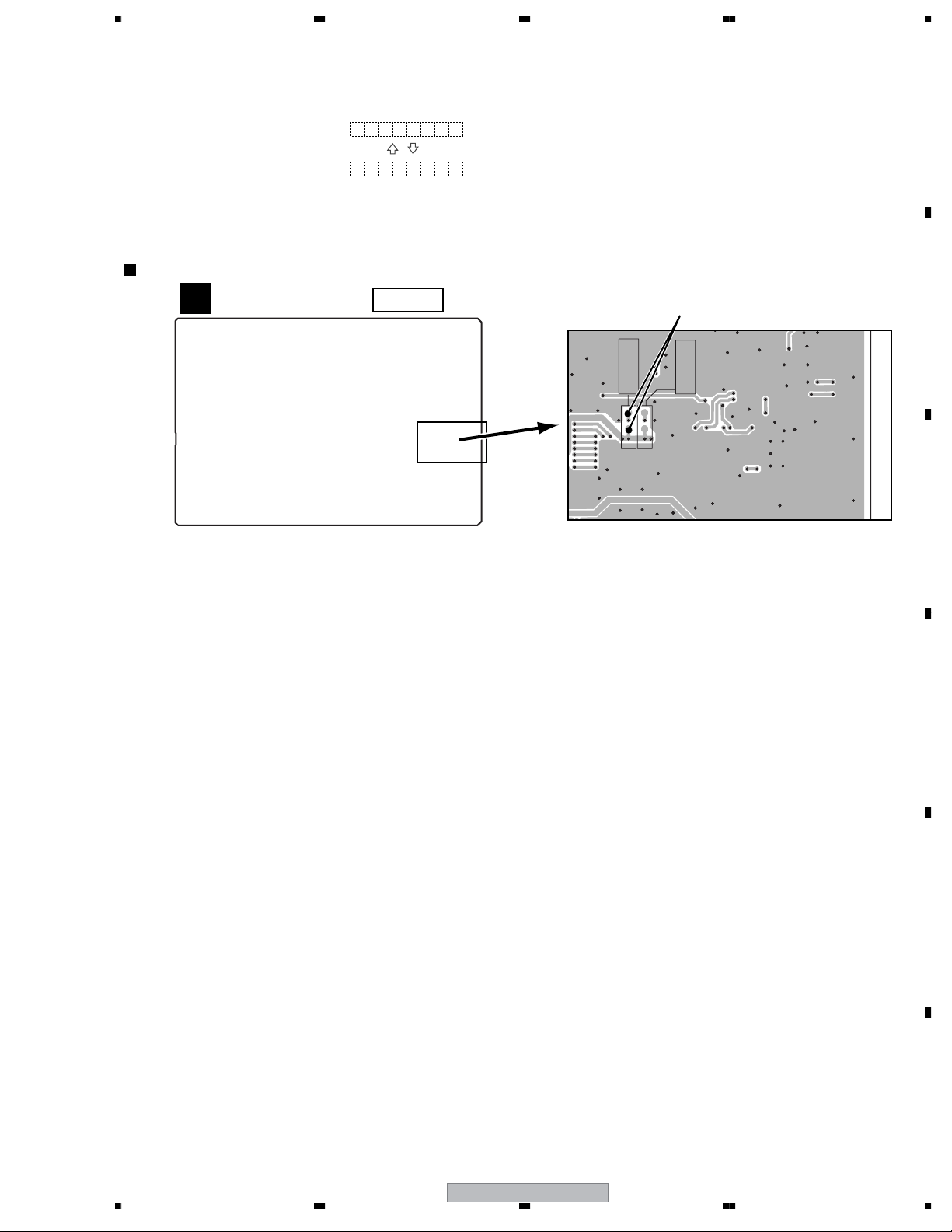

Service Test Mode connecting point

A

MAIN ASSY

A

SIDE B

Connecting point

S TEST

U TEST

B

C

D

56

SX-SW515

E

F

21

7

8

Loading...

Loading...