Page 1

2007

MIC

FADER START

HEAD PHONES

VIDEO INPUT

USB

DVD

CH 1

VIDEO

EX

CH 4

MIC OFF ON

TALK

OVER

MIN

DVD/LINE PHONO

MAX

VIDEO

VIDEO

S-VIDEO

EX

VIDEO TRIM

MIC 1

MIC1

LEVEL

MIC2

LEVEL

HI

LOW

CH1

AUDIO INPUT

AUDIO TRIM

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

+9

MID

+6-26

HI

+6-26

LOW

CUE

CROSS FADER

ASSIGN

PROFESSIONAL SOUND&VISION MIXER

BA

SVM-1000

+6-26

10

9

8

7

6

5

4

3

2

1

0

A THRU B

1

VIDEO INPUT

DVD

MIN

DVD LINE DIGITAL

MAX

VIDEO

S-VIDEO

VIDEO TRIM

AUDIO INPUT

AUDIO TRIM

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

+9

MID

+6-26

HI

+6-26

LOW

CUE

CROSS FADER

ASSIGN

+6-26

10

9

8

7

6

5

4

3

2

1

0

A THRU B

2

VIDEO INPUT

DVD

MIN

DVD LINE DIGITAL

MAX

VIDEO

S-VIDEO

VIDEO TRIM

AUDIO INPUT

CH SELECT

AUDIO TRIM

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

+9

MID

+6-26

HI

+6-26

LOW

CUE

CROSS FADER

ASSIGN

+6-26

10

9

8

7

6

5

4

3

2

1

0

CROSS FADER CURVE SD CARD

A THRU B

3

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

VIDEO INPUT

DVD

MIN

LINE PHONO

MAX

VIDEO

VIDEO

S-VIDEO

VIDEO TRIM

AUDIO INPUT

AUDIO TRIM

dBLR

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

+9

BOOTH MONITOR

0

MID

+6-26

HI

+6-26

LOW

CUE

CROSS FADER

ASSIGN

+6-26

BALANCE

MASTER

RL

CUE

10

9

8

7

6

5

4

3

2

1

0

CH FADER CURVE

VIDEO

MASTER LEVEL

WHITEBLACK

MONO STEREO

A THRU B

4

EX

0

0

0

+12

-12

+12-12

CH2

CH3

CH4

MONOSPLIT STEREO

MIXING

PHONES

MASTER

CUE

LEVEL

AUDIO MASTER LEVEL

0

TIME/

PARAMETER

LEVEL/

DEPTH

EFFECT

CUE

VIDEO FX

PATTERN/

TEXT BANK

MAXMIN

FADER

AV SYNC

VIDEO

SOLO MODE

JPEG

VIEWER

ON/OFF

SET UP

VIDEO EQ

MASTER

MONITOR

SET UP

UTILITY

EFFECT

ON/OFF

2

4

5

6

7

SVM-1000

For details, refer to "Important Check Points for good servicing".

SOUND & VISION MIXER

SVM-1000

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

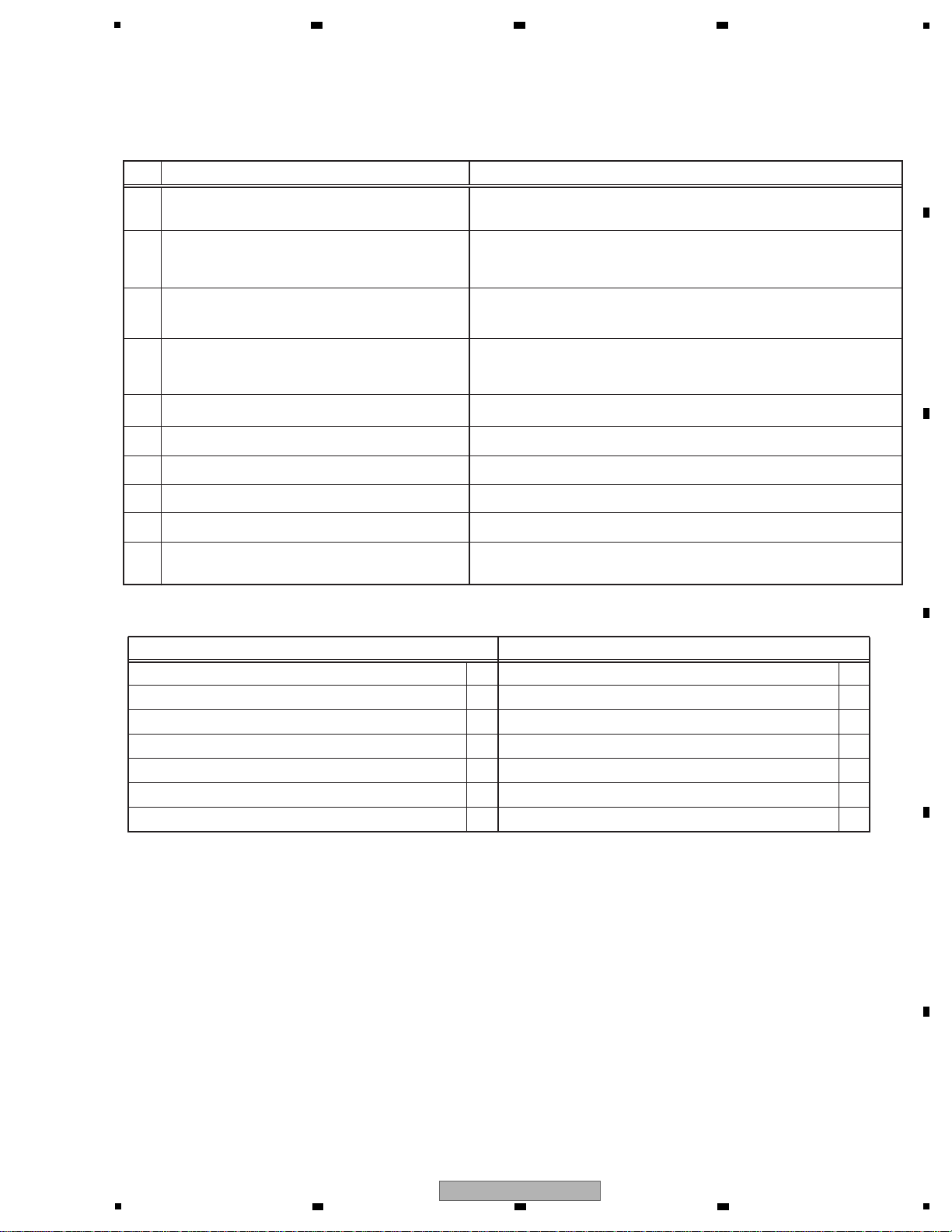

Model Type Power Requirement Remarks

SVM-1000 KUCXJ AC 120 V

SVM-1000 WYXJ5 AC 220 V to 240 V

SVM-1000 TLXJ AC 110 V to 240 V

ORDER NO .

RRV3678

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

T-ZZR DEC.

2007 Printed in Japan

Page 2

1

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

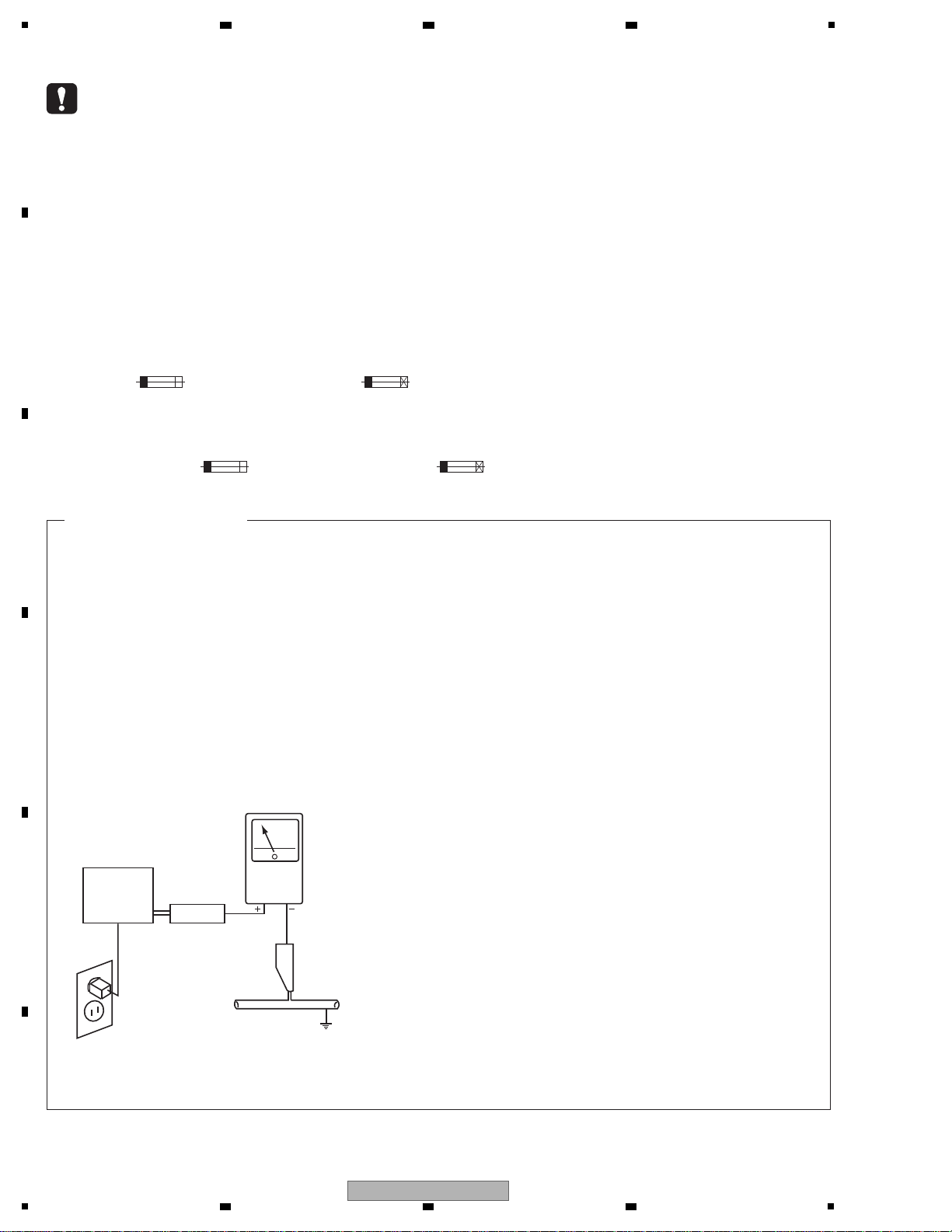

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

SVM-1000

Page 3

5

6 7 8

(FOR USA MODEL ONLY)

This product contains mercury. Disposal of this material may be regulated due to environmental considerations.

For disposal or recycling information, please contact your local authorities or the Electronics Industries

Alliance: www.eiae.org.

The backlighting lamp of LCD in this equipment contains mercury. Disposal of this material may be

regulated due to environmental considerations according to Local, State or Federal Laws. For disposal

or recycling information, please contact your local authorities or the Electronics Industries

Alliance: www.eiae.org

A

B

C

D

E

F

SVM-1000

5

6 7 8

3

Page 4

1

2 3 4

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product saf ety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment b y

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety .

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise .

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity . (Refer to the e xample)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws .

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires , scratches, melting, etc. on the coating of the pow er cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages .

If you find a damaged power cord, please exchange it with a suitab le one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the po wer cord if necessary .

a Safe en vironment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prev ent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

T o k eep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues , and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping scre ws

T o protect products from damages or f ailures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follo w this method especially if it is specified in this manual.

F

4

1

SVM-1000

2 3 4

Page 5

5

6 7 8

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................7

1.1 NOTES ON SOLDERING......................................................... .......................................... ........................7

2. SPECIFICATIONS.............................................................................................................................................7

2.1 ACCESSORIES..........................................................................................................................................7

2.2 SPECIFICATIONS ......................................................................................................................................8

2.3 PANEL FACILITIES........................................................ .......................................... ...................................9

3. BASIC ITEMS FOR SERVICE........................................................................................................................13

3.1 CHECK POINTS AFTER SERVICING .................................................................... .................................13

3.2 PCB LOCATION ..................................................................................... ..................................................14

4. BLOCK DIAGRAM..........................................................................................................................................16

4.1 OVERALL WIRING DIAGRAM ......................................... .......................................... ..............................16

4.2 AUDIO BLOCK DIAGRAM............................................................................................... .........................18

4.3 VIDEO BLOCK DIAGRAM.................................. ... .......................................... .........................................20

4.4 FUNCTION BLOCK DIAGRAM ................................................................................................................22

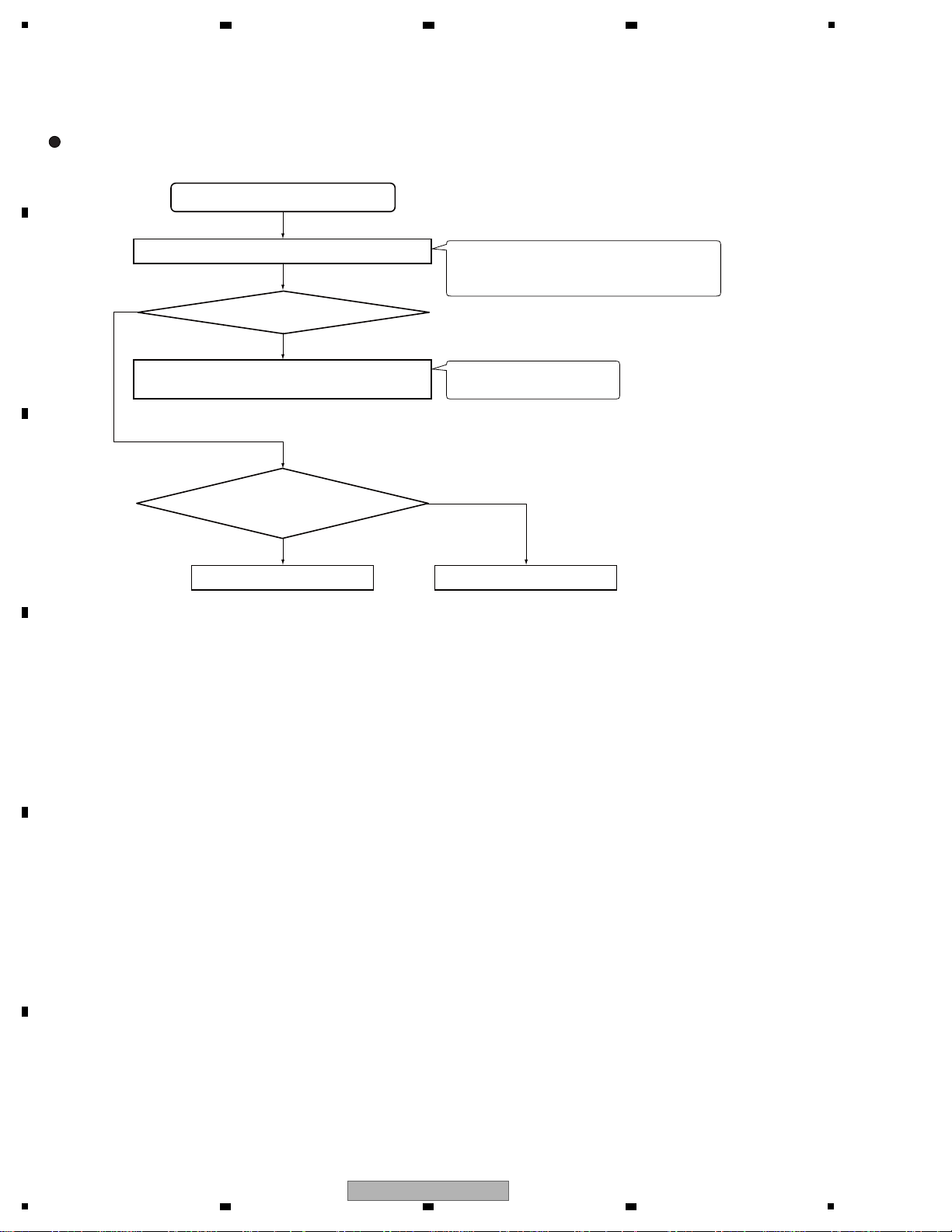

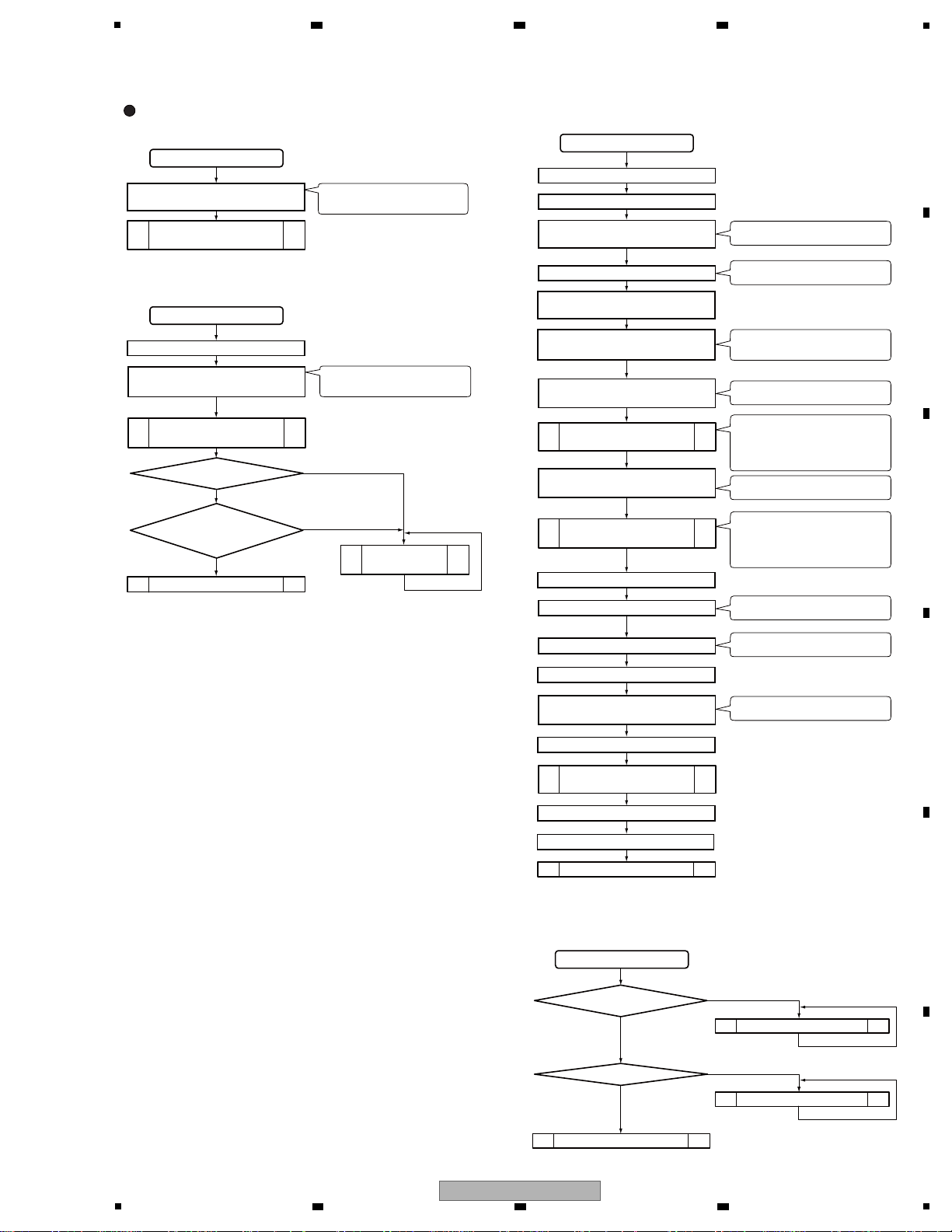

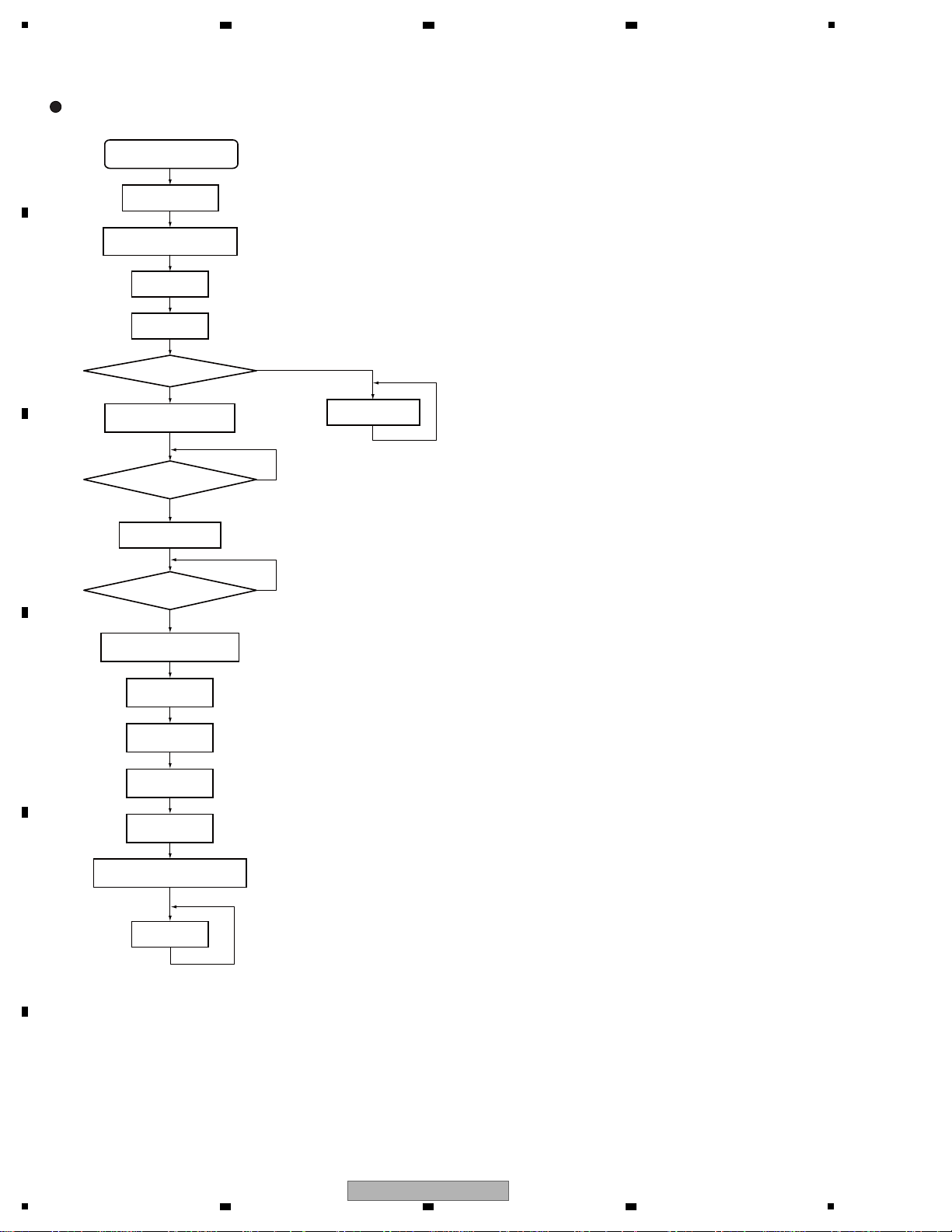

5. DIAGNOSIS....................................................................................................................................................24

5.1 DIAGNOSIS FLOW.......................................................................................... .........................................24

5.2 POWER ON SEQUENCE............................................................................. ............................................25

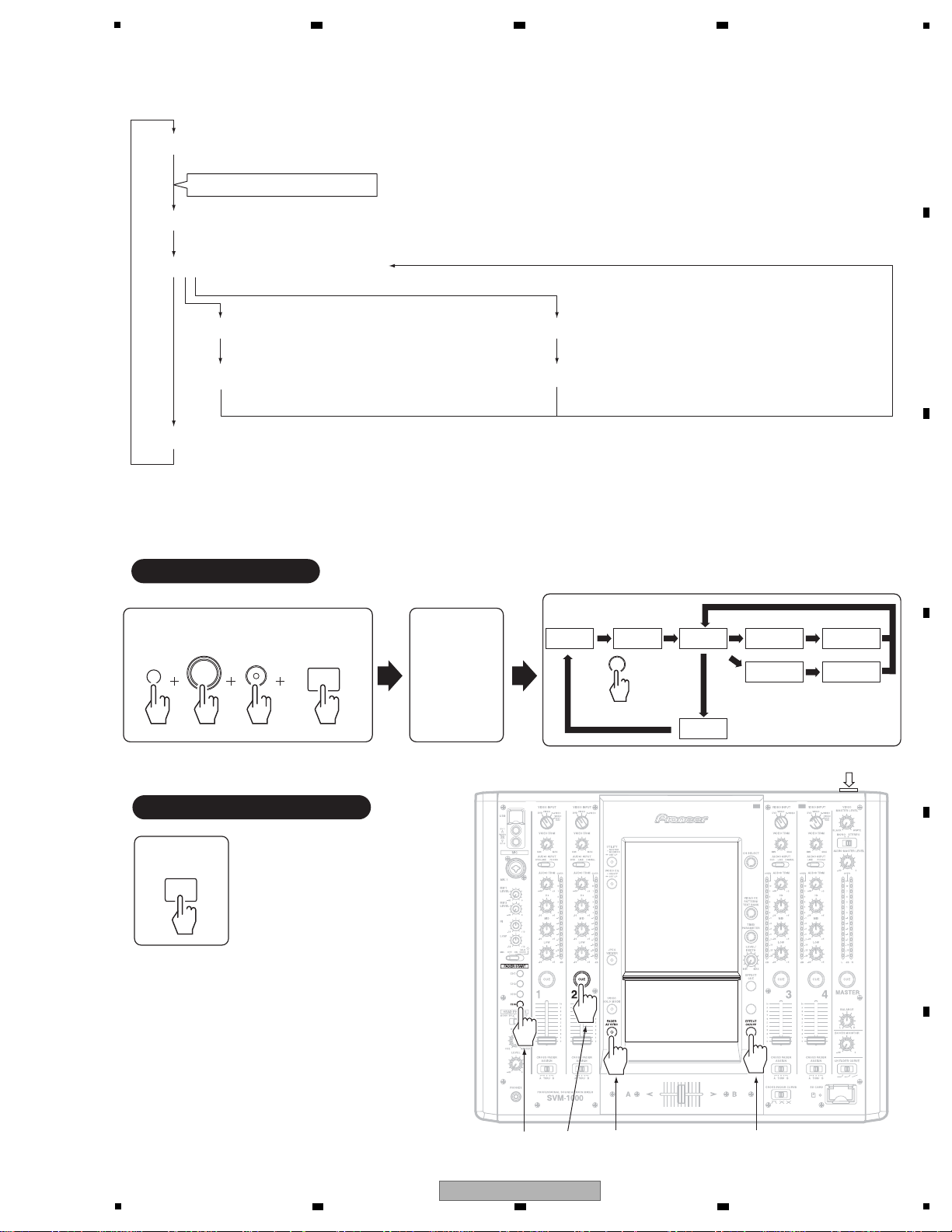

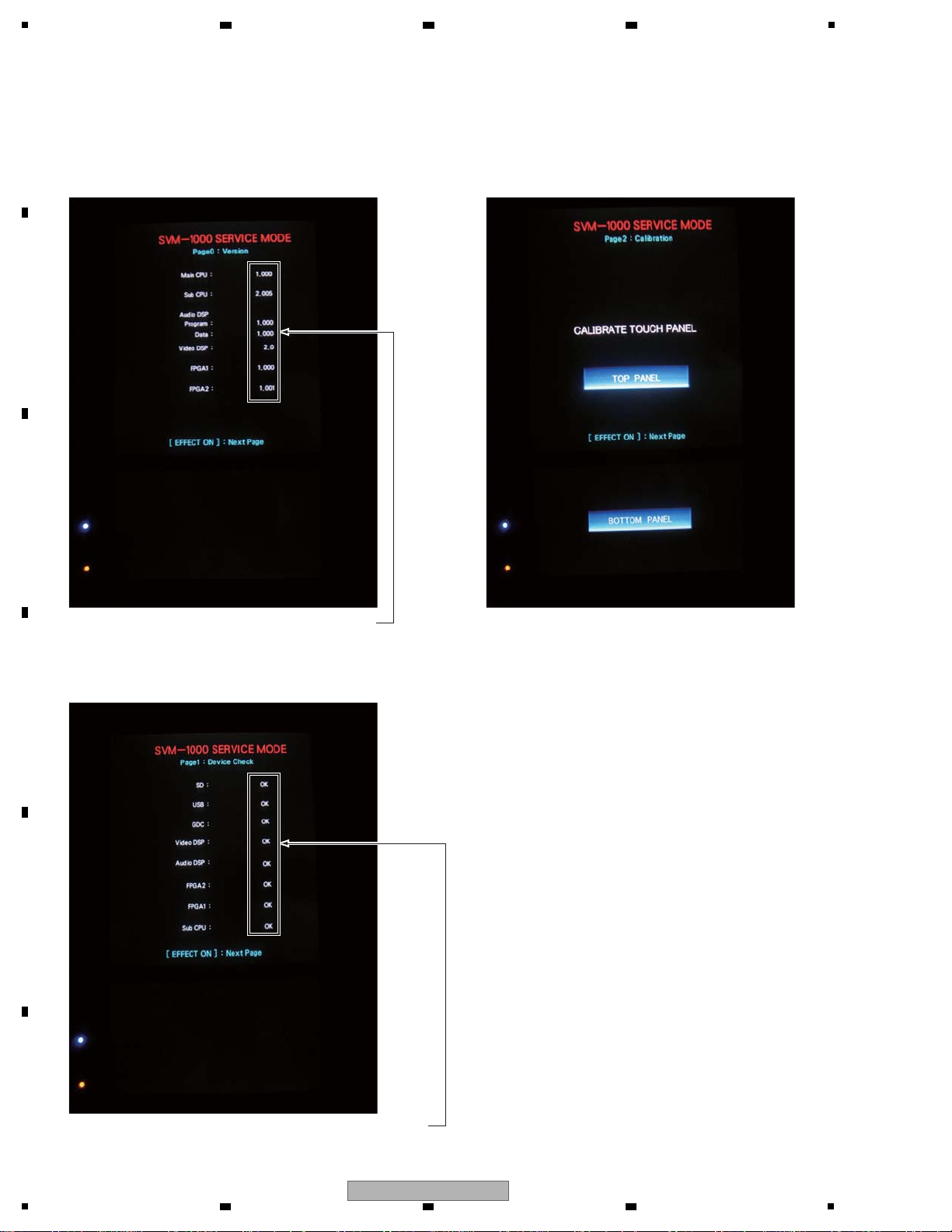

6. SERVICE MODE.............................................................................................................................................27

6.1 LIST OF PAGES IN SERVICE MODE.............................. .......................................... ..............................27

6.2 SERVICE MODE........................................................... ... .......................................... ..............................27

6.3 SERVICE MODE IDENTIFICATION .........................................................................................................28

6.4 LIST OF PAGES IN TEST MODO ............................................................................................ ................33

6.5 TEST MODE.......................................................... .. .......................................... .......................................34

6.6 TEST MODE IDENTIFICATION................................................................................................................35

6.7 HOW T O USB DOWNLOAD................................................................... ... ...............................................41

6.8 NOTES ON VARIOUS SETTINGS WHEN THE UNIT ARE REPLACED............................................... ..43

7. DISASSEMBLY ...............................................................................................................................................44

8. EACH SETTING AND ADJUSTMENT............................................................................................................55

9. EXPLODED VIEWS AND PARTS LIST...........................................................................................................56

1 PACKING SECTION........................................................................................................... ......................56

9.

9.2 EXTERIOR SECTION .................................................................................. ............................................58

9.3 BOTTOM SECTION................................................. .......................................... .......................................60

9.4 OPERATION PANEL SECTION............................................................................................. ...................62

9.5 LCD PANEL SECTION ..................................................... .......................................... ..............................64

10. SCHEMATIC DIAGRAM............................................. .. ................................................ ... ... ...........................66

10.1 AUD1 ASSY (1/5)...................................................................................................................................66

10.2 AUD1 ASSY (2/5)...................................................................................................................................68

10.3 AUD1 ASSY (3/5)...................................................................................................................................70

10.4 AUD1 ASSY (4/5)...................................................................................................................................72

10.5 AUD1 ASSY (5/5)...................................................................................................................................74

10.6 AUD2 ASSY (1/5)...................................................................................................................................76

10.7 AUD2 ASSY (2/5)...................................................................................................................................78

10.8 AUD2 ASSY (3/5)...................................................................................................................................80

10.9 AUD2 ASSY (4/5)...................................................................................................................................82

10.10 A

10.11 VIO1 ASSY...........................................................................................................................................86

10.12 MJCK, VIN3 and VIO2 ASSYS.............................................................................................................88

10.13 MAIN ASSY (1/9). .................................................................................................................................90

10.14 MAIN ASSY (2/9). .................................................................................................................................94

10.15 MAIN ASSY (3/9). .................................................................................................................................98

10.16 MAIN ASSY (4/9). ...............................................................................................................................102

10.17 MAIN ASSY (5/9). ...............................................................................................................................106

10.18 MAIN ASSY (6/9). ...............................................................................................................................110

10.19 MAIN ASSY (7/9). ...............................................................................................................................114

10.20 MAIN ASSY (8/9). ...............................................................................................................................118

10.21 MA

10.22 SCPU ASSY (1/2)...............................................................................................................................126

10.23 SCPU ASSY (2/2)...............................................................................................................................130

10.24 CTL1 ASSY ........................................................................................................................................134

10.25 CTL2A ASSY......................................................................................................................................136

10.26 CTL2B, CFD1, CFD2, CFD3 and CFD4 ASSYS................................................................................138

10.27 INVT ASSY.........................................................................................................................................140

10.28 CTL3R ASSY......................................................................................................................................142

UD2 ASSY (5/5) .................................................................................................................................84

IN ASSY (9/9)................................................................................................................................122

A

B

C

D

E

F

SVM-1000

5

6 7 8

5

Page 6

1

2 3 4

10.29 CTL3LB ASSY...................................................................................................................................144

10.30 CTL3LA, CRFD and DIO2 ASSYS.....................................................................................................146

10.31 DIO1 ASSY (1/2)................................................................................................................................148

10.32 DIO1 ASSY (2/2)................................................................................................................................150

A

10.33 MIDI ASSY......................................................................................................................................... 152

10.34 SDIO ASSY........................................................................................................................................ 154

10.35 USB1 and USB2 ASSYS ...................................................................................................................156

10.36 HAMP ASSY......................................................................................................................................158

10.37 MJCK and ACSW ASSYS.................................................................................................................. 160

10.38 PDIV ASSY........................................................................................................................................162

10.39 REG and ILMR ASSYS...................................................................................................................... 164

10.40 ILML ASSY ........................................................................................................................................ 166

10.41 POWER SUPPLY UNIT......................................................................................................................168

10.42 VOLTAGES......................................................................................................................................... 170

10.43 WAVEFORMS....................................................................................................................................173

11. PCB CONNECTION DIAGRAM................................................................................................................. 186

B

11.1 AUD1 and MJCK ASSYS..........................................................................................................

11.2 AUD2 ASSY......................................................................................................................................... 190

11.3 VIO1 and VIO2 ASSYS........................................................................................................................ 194

11.4 MAIN ASSY ......................................................................................................................................... 198

11.5 SCPU and CRFD ASSYS....................................................................................................................202

11.6 CTL1, CFD1 and CFD2 ASSYS...........................................................................................................206

11.7 CTL2A, CFD3, CFD4 and CTL2B ASSYS........................................................................................... 210

11.8 INVT, CTL3R, CTL3LB and CTL3LA ASSYS....................................................................................... 214

11.9 DIO2, SDIO, USB1 and USB2 ASSYS................................................................................................ 218

11.10 DIO1 and MIDI ASSYS...................................................................................................................... 220

11.11 ACSW, PDIV and REG ASSYS ......................................................................................................... 224

C

11.12 VIN3, ILMR and ILML A

SSYS ...........................................................................................................226

11.13 HAMP and HJCK ASSYS..................................................................................................................228

12. PCB PARTS LIST....................................................................................................................................... 230

........... 186

D

E

F

6

1

2 3 4

SVM-1000

Page 7

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 °C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 °C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

• Operating Instructions

(KUCXJ: DRB1421)

(WYXJ5: DRB1422)

(TLXJ: DRB1423)

Accessories

• Power Cord

(KUCXJ : DDG1028)

(WYXJ5 : ADG7062)

(TLXJ : ADG7062)

• Warranty Card

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

2. SPECIFICATIONS

2.1 ACCESSORIES

C

D

E

5

SVM-1000

6 7 8

F

7

Page 8

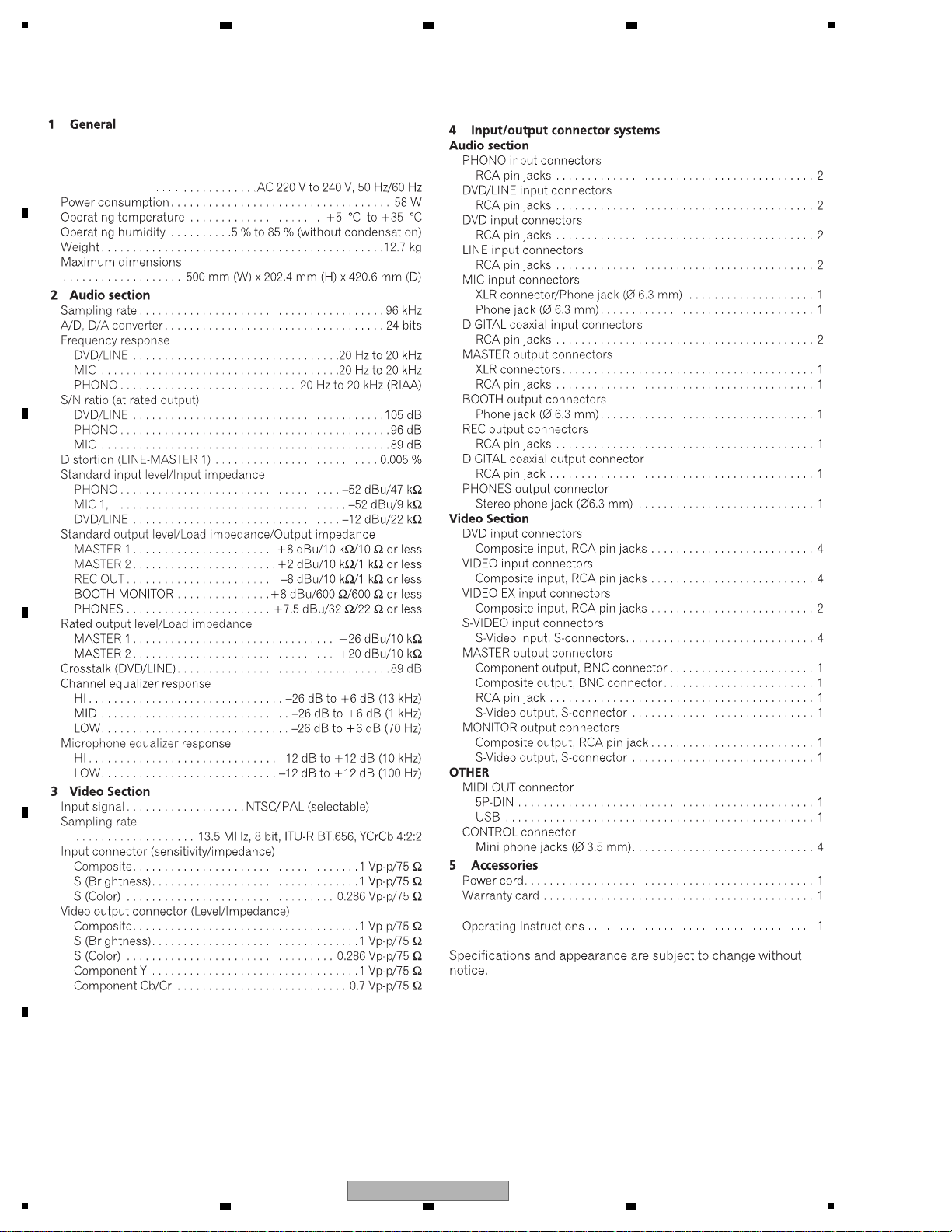

1

Power source

KUCXJ model

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC 120 V, 60 Hz

TLXJ model . . . . . . . . . . . . . . . . . . AC 110 V to 240 V, 50 Hz/60 Hz

WYXJ5 model

(Except SVM-1000/TLXJ)

2 3 4

2.2 SPECIFICATIONS

A

B

C

D

E

F

8

1

2 3 4

SVM-1000

Page 9

5

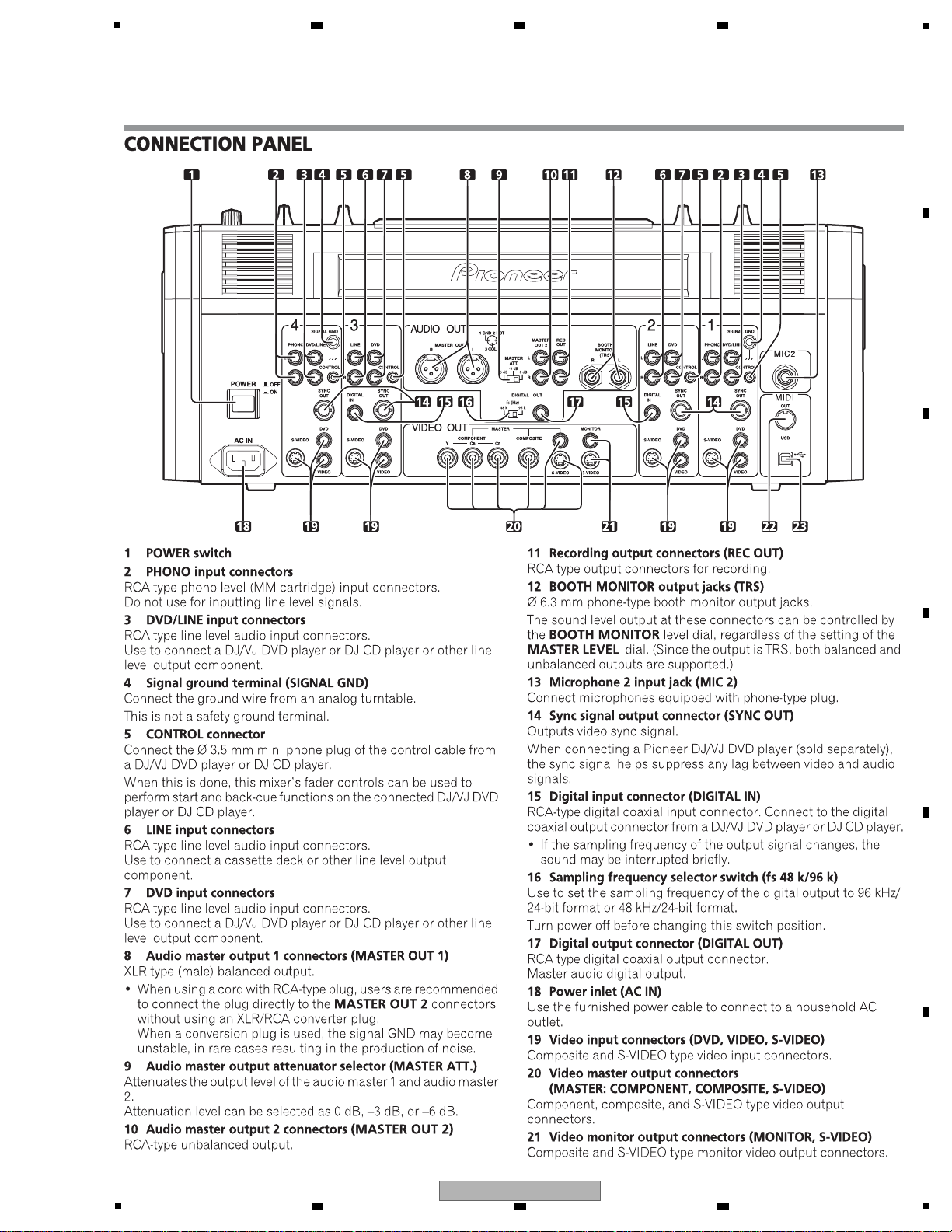

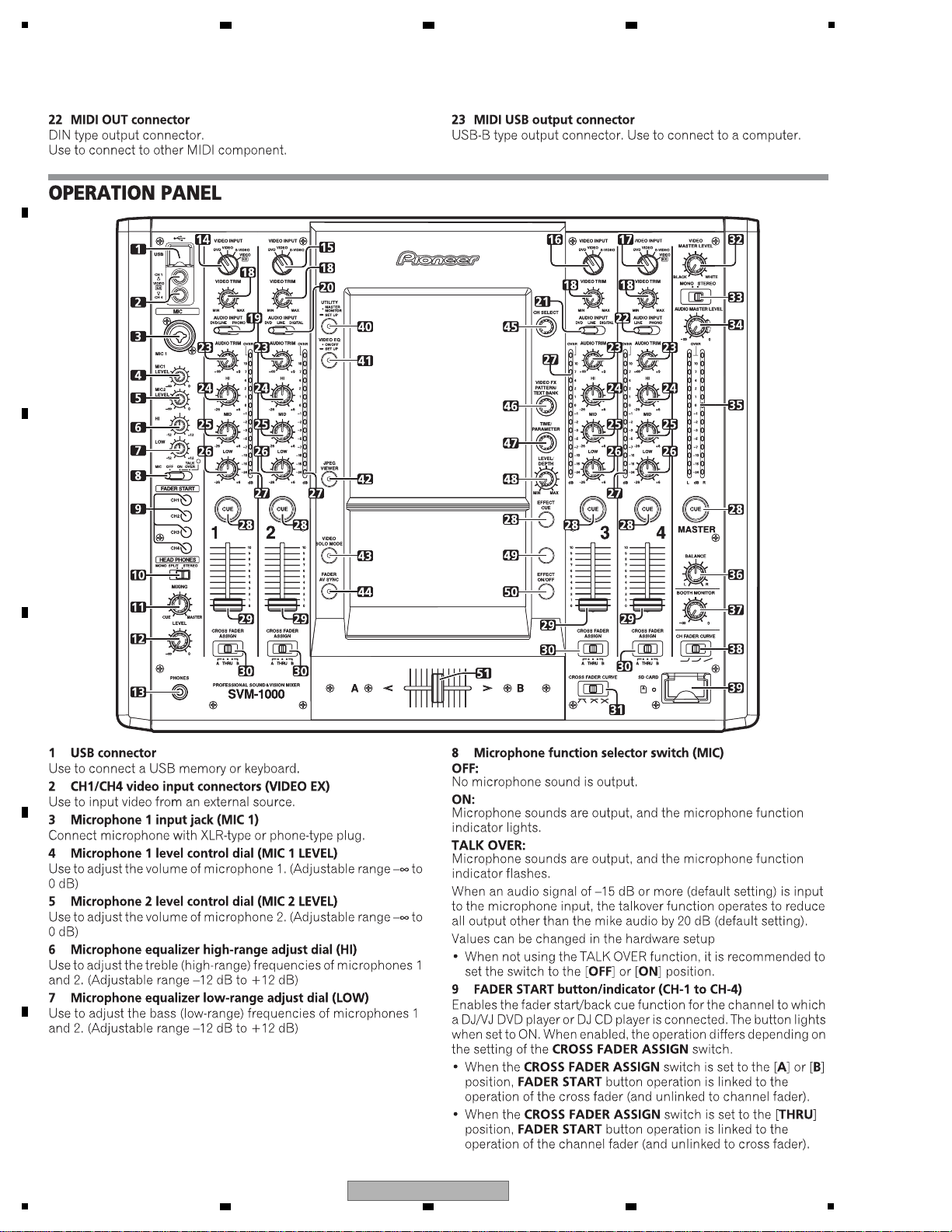

2.3 PANEL FACILITIES

6 7 8

A

B

C

D

E

F

SVM-1000

5

6 7 8

9

Page 10

1

A

B

2 3 4

C

D

E

F

10

1

2 3 4

SVM-1000

Page 11

5

6 7 8

A

B

C

D

E

F

SVM-1000

5

6 7 8

11

Page 12

1

A

B

2 3 4

C

D

E

F

12

1

2 3 4

SVM-1000

Page 13

5

6 7 8

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

To ensure the quality of the product after repair, check the recommended items shown below:

Item to be checkedProceduresNo.

A

Check if all the symptoms pointed out by the customer

1

have been addressed.

Check the analog audio inputs. (Make connections for

2

analog audio signals with a DVD player.)

Check the digital audio inputs. (Make connections for

3

digital audio signals with a DVD player.)

Check the video outputs.

4

(Make connections with a DVD player.)

5

Check the buttons.

6

Check the exterior section.10

The symptoms in question must not be reproduced.

Audio and operations must be normal.

Check the output of Audio Master Out connector 1 from all input connectors.

Check the outputs of the all output connectors from the CH1 input connector.

Audio for each channel and operations must be normal.

Input digital signals to CH2 and CH3 and check if the output signals from

the digital output connectors are normal.

Audio for each channel and operations must be normal.

Check the output of the Video Master Out connectors from all input connectors.

Check the outputs of the all output connectors from the CH1 input connector.

Video and operations must be normal.

Audio must be normal, without noise.Check the audio from headphone output.

Operate the buttons of the main unit, and check it operate normally.

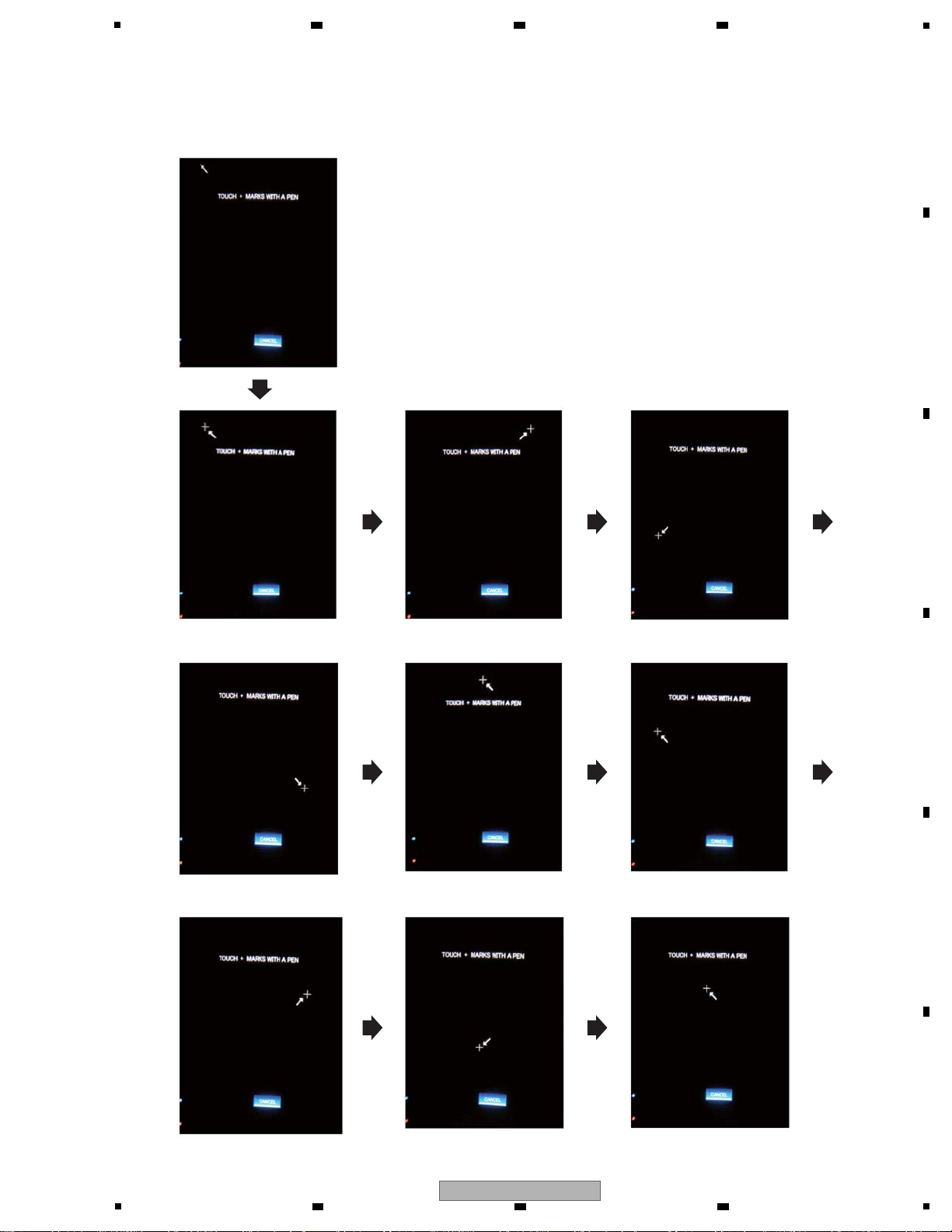

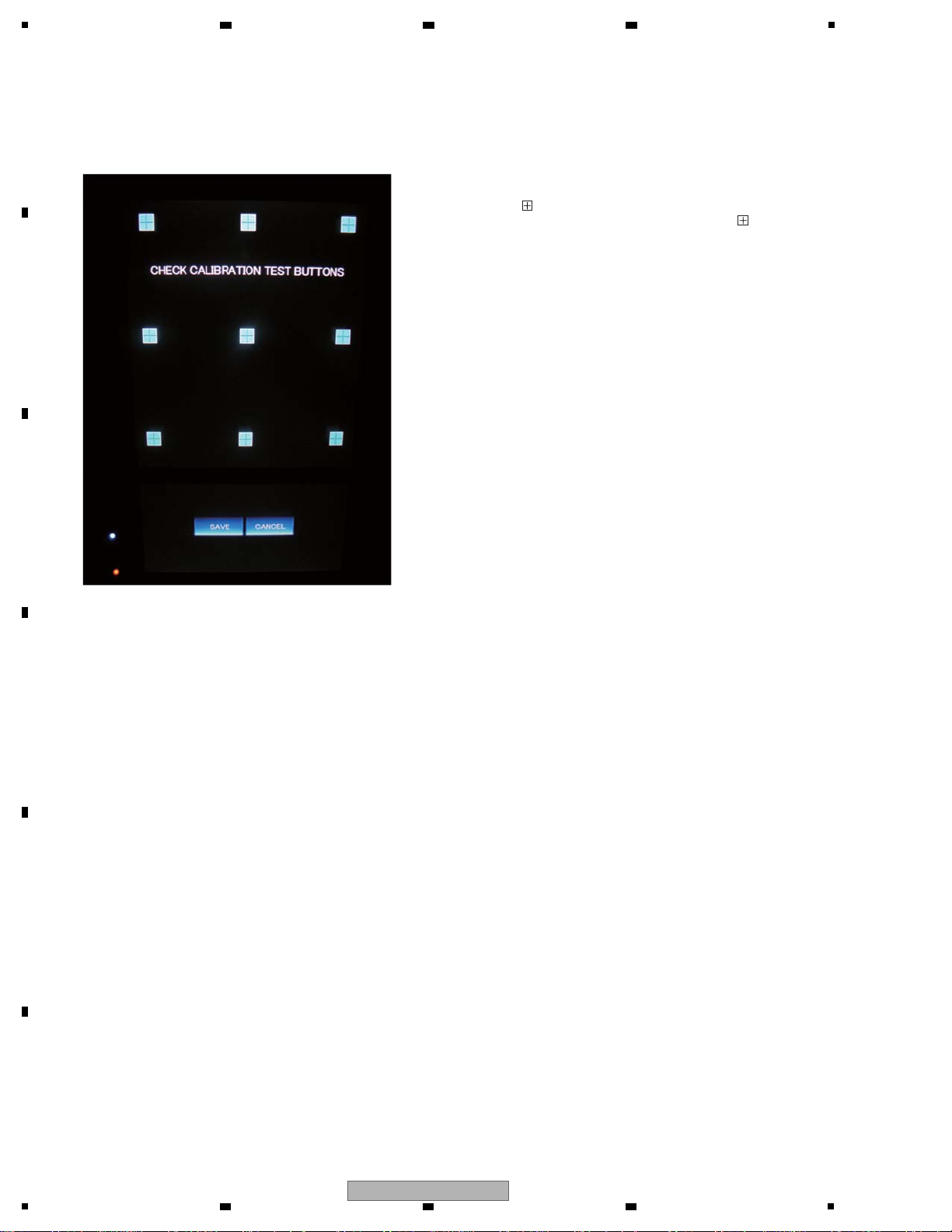

Calibration must be terminated.Check the touch panel.7

The video system must be appropriately set for the destination.Check the System Setting.8

The content of utility setup must be the same as before the repair.Check the contents of utility setup.9

Check for any scratches or dirt that have been made or attached on

the exterior section after receiving the product for repair.

See the table below for the items to be checked regarding video and audio:

Item to be checked regarding video Item to be checked regarding audio

Block noise

Horizontal noise

Dot noise

Disturbed image (video jumpiness)

Too dark

Too bright

Mottled color

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

B

C

D

E

F

SVM-1000

5

6 7 8

13

Page 14

1

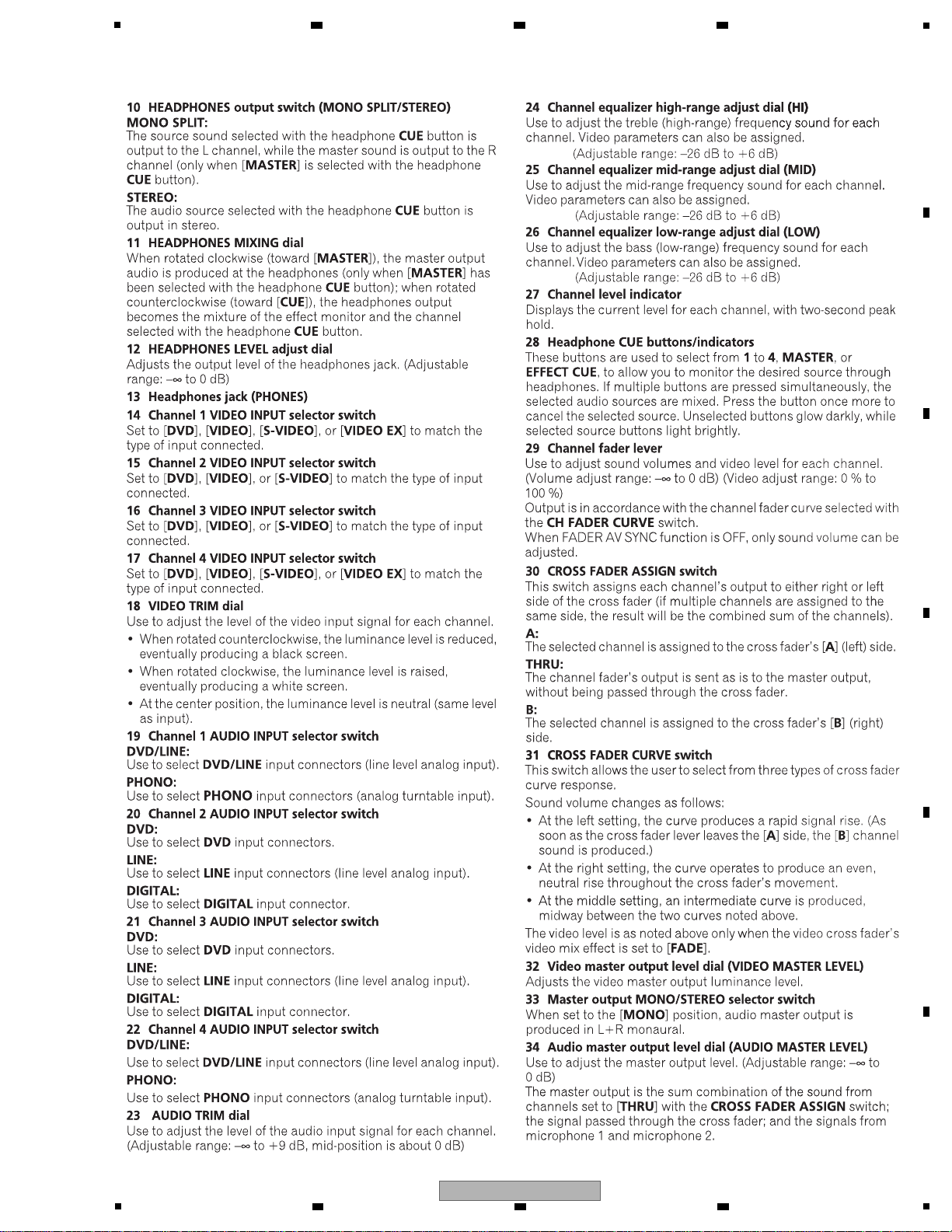

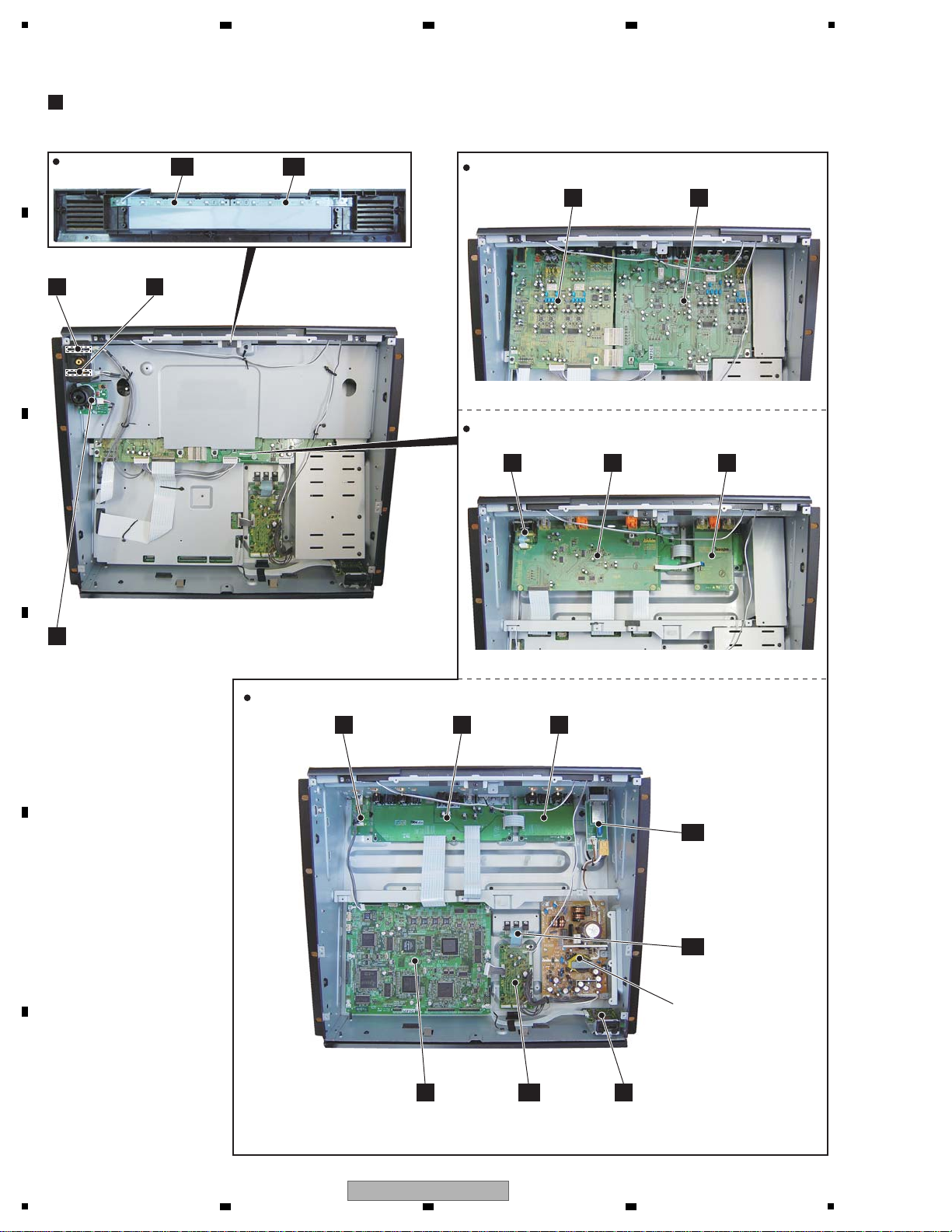

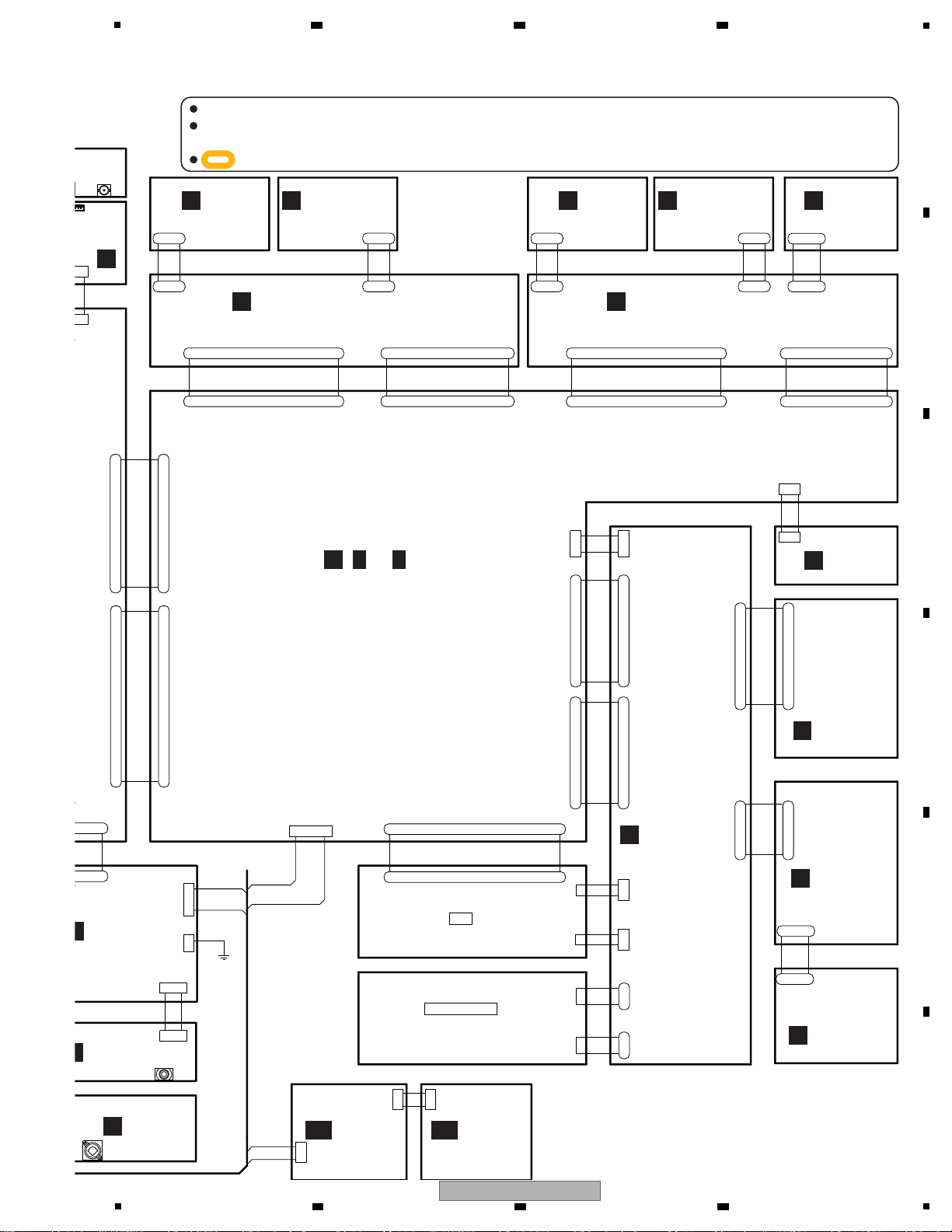

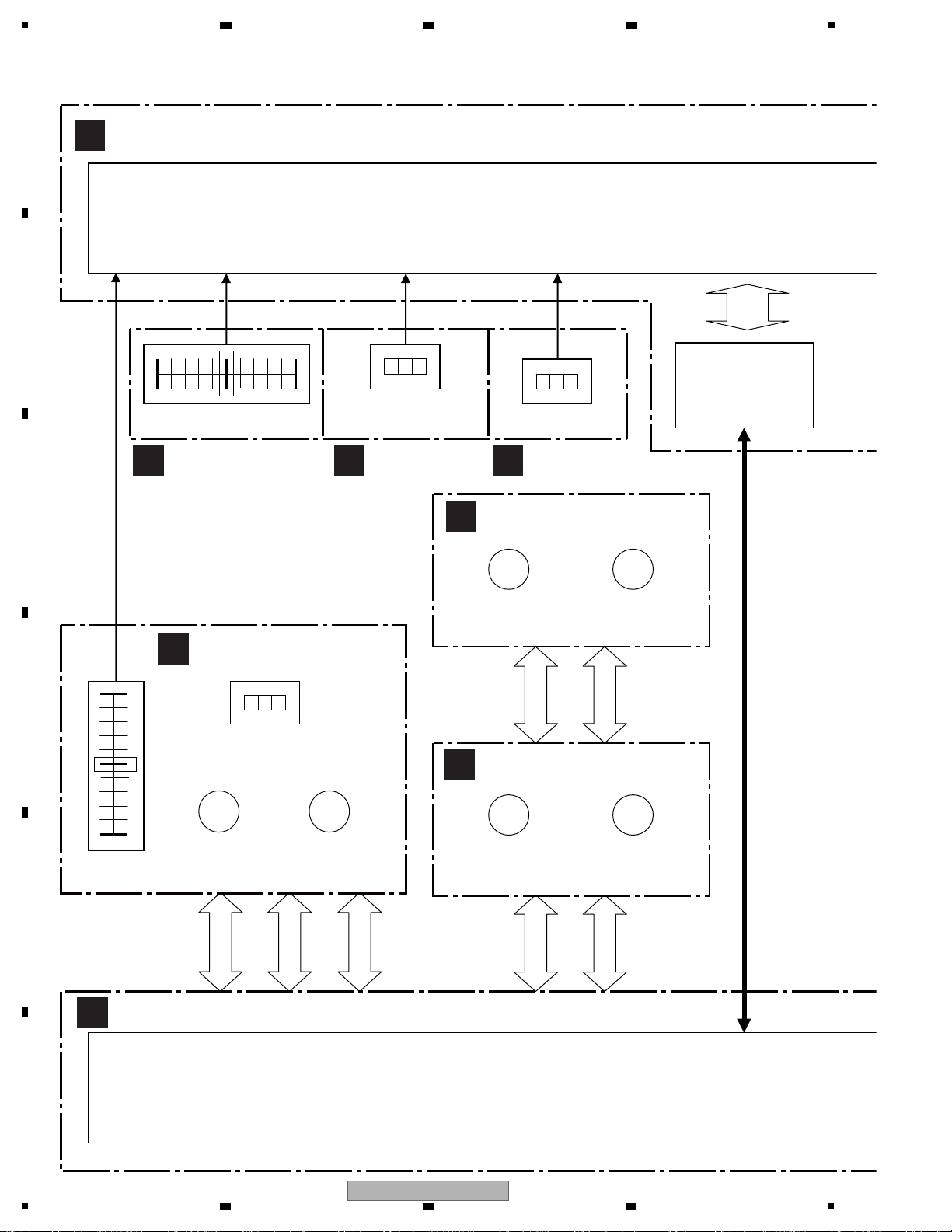

3.2 PCB LOCATION

Main Section

A

2 3 4

B

C

Front view

USB2 ASSY

Z

AG

VIN3 ASSY

E

ILML ASSY

ILMR ASSY

AF

3F

2F

MIDI ASSY

W

AUD1 ASSY

A

DIO1 ASSY

V

AUD2 ASSY

B

U

DIO2 ASSY

MJCK ASSY

D

1F

D

E

USB1 ASSY

Y

VIO1 ASSY

C

VIO2 ASSY

F

ACSW ASSY

AC

REG ASSY

AE

POWER SUPPLY UNIT

MAIN ASSY

G

F

14

1

2 3 4

SVM-1000

PDIV ASSY

AD

SDIO ASSY

X

Page 15

5

6 7 8

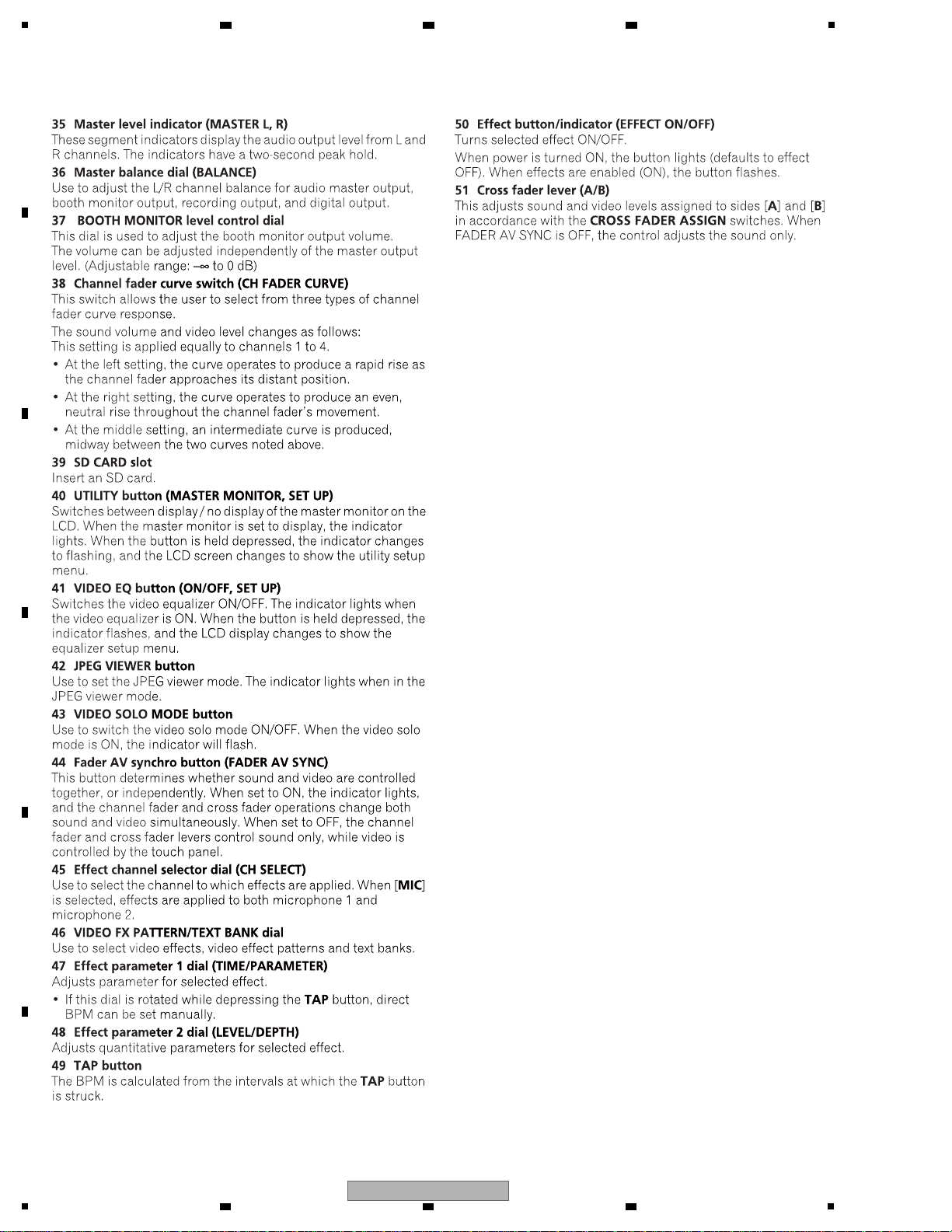

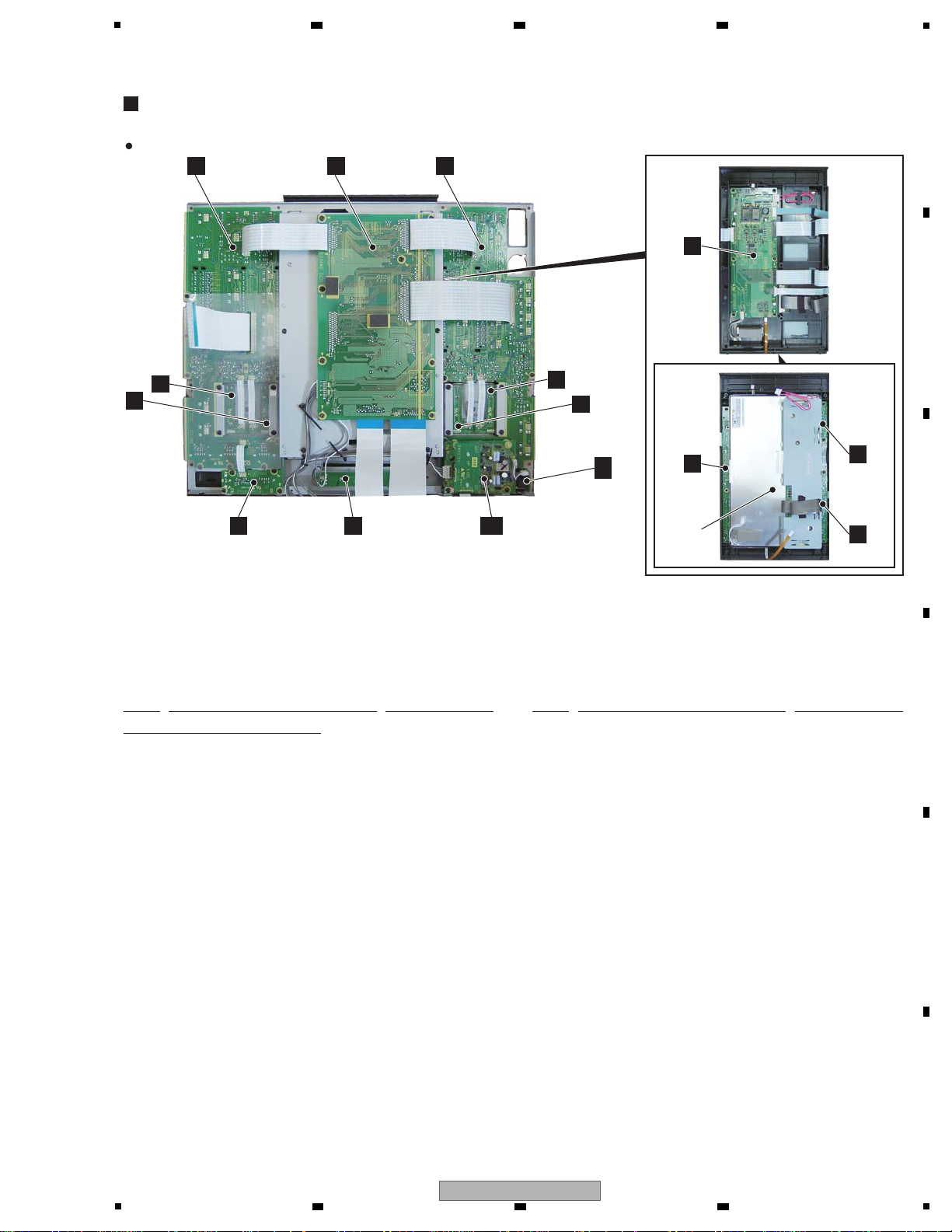

Operation Panel Section

Bottom view

CTL2A ASSY

J

CFD4 ASSY

CFD3 ASSY

O

N

CTL2B ASSY

K

SCPU ASSY

H

CRFD ASSY

T

CTL1 ASSY

I

HAMP ASSY

AA

CFD1 ASSY

L

CFD2 ASSY

M

HJCK ASSY

AB

INVT ASSY

P

CTL3R ASSY

Q

LCD Panel

CTL3LA

ASSY

S

CTL3LB

ASSY

R

A

B

C

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

1..MAIN ASSY DWX2715

NSP 1..SCIV ASSY DWM2302

2..SCPU ASSY DWX2706

2..INVT ASSY DWX2717

NSP 1..AUDI ASSY DWM2303

2..AUD1 ASSY DWX2718

2..DIO2 ASSY DWX2719

2..USB1 ASSY DWX2727

NSP 1..AUIL ASSY DWM2304

2..AUD2 ASSY DWX2721

2..ILMR ASSY DWX2722

2..ILML ASSY DWX2723

NSP 1..DIHP ASSY DWM2305

2..USB2 ASSY DWX2720

2..DIO1 ASSY DWX2724

2..PDIV ASSY DWX2725

2..HAMP ASSY DWX2726

2..SDIO ASSY DWX2728

2..MIDI ASSY DWX2751

2..REG ASSY DWX2767

2..COVER PCB DWX2793

NSP 1..CTVI ASSY DWM2306

2..CTL1 ASSY DWX2729

2..CTL3R ASSY DWX2730

2..VIO1 ASSY DWX2731

2..VIO2 ASSY DWX2732

2..VIN3 ASSY DWX2733

2..HJCK ASSY DWX2734

NSP 1..CTFD ASSY DWM2307

2..CTL2A ASSY DWX2735

2..CTL2B ASSY DWX2736

2..ACSW ASSY DWX2737

2..MJCK ASSY DWX2738

2..CRFD ASSY DWX2739

2..CFD1 ASSY DWX2740

2..CFD2 ASSY DWX2741

2..CFD3 ASSY DWX2742

2..CFD4 ASSY DWX2743

2..CTL3LA ASSY DWX2744

2..CTL3LB ASSY DWX2745

> 1..POWER SUPPLY UNIT DWR1440

> 1..LCD Panel CWX3405

D

E

F

SVM-1000

5

6 7 8

15

Page 16

1

3

MIC2

7

CH3

VIDEO SYNC

OUT

19

5

1

4

3

OUT DDEN

12

6

5

CN1016

AKM1277-

11

12

FADER_ST_4+

24

V+5D

1

8

3

17

GNDD

12

16

MUTE_OFF1

1

MUTE_OFF

13

CBV_CH1_1

GNDA

DIGI_4896_OUT

15

6

INPUT_SEL4

16

5

RST_HP

2

GNDD

1

GNDA

GNDD

13

GNDA

GPO_CH1START

2

+5V_USB1

7

CBV_CH1_2

GNDA

MAIN_YOUT

7

1

MUTE_OFF2

14

20

26

POWER SUPPLY

UNIT (DWR1440)

29

10

V-15

CH2

VIDEO

INPUT

GNDA

2

GNDD

7

GNDD

MASTER_DATA

4

3

96K_3

R

32

14

GNDA

MMCMD

L

15

DKP3792-

PH

4PIN

MIC_DATA

5

MIC_DATA

8

14

VR_CS_INPUT1

6

12

GNDA

+5V_USB1

GNDD

35

19

GNDA

TO SCPU

VR_CS0

30

CN5009

S7B-EH

ATT

24

16

GNDA

5

SDDAT3

7

16

VR_CS_INPUT2

1

8

5

2

CN7401

CKS4999-

12

6

12

33

9

GNDD

G

14

SWPS

16

SUB_S_YOUT

RSD_AAD

13

1

6

9

7

1

V-BB

G

GNDD

LRCK

+5V_USB2

MAIN_CROUT

DOUT_DATA

GNDA

22

GNDD

VR_SIR_SCK

2

MAIN_MIC_HOT

7

11

5

5

MASTER_DATA

10

VR_CS4

Y_CH3_1

MAIN_MIC_COLD

LRCK

37

GNDD

CH3

VIDEO

INPUT

12

LINE

GNDD

1

Y_CH4_1

GNDD

2

1

DIR_CS2

GNDD

TOP PANEL

CH4_DATA

13

SUB_VOUT

CLK24M_3

L

DSP_RST

4

GNDA

CN4011

DKN1512-

33

4

22

HP_DATA

22

BOOTH

MONITOR

(TRS)

8

96K_2

V-BB

GNDD

GNDD

24

CN8005

VKN1193-

FADER_ST_3+

GNDA

HP_DATA

12

LINE

GNDA

9

V+15

22

DIGITAL

IN

2

6

19

3

XCARDIN

GNDD

8

1

GNDA

26

DIGI_4896_OUT

CN5005

PLUG 19PIN

VKN1775-

22

GNDA

21

6

2

XCARDIN

CN1007

AKM1275-

GNDD

9

GNDD

1

GNDD

9

V+8

13

12

5

GNDD

17

CN1009

VKN1428-

11

L

34

DOUT_DATA

3

R

7

7

13

31

GNDD

LINE

XRESET

10

VR_DATA

17

6

28

1

6

8

15

GNDA

CN8202

S6B-PH-K-S

19

7

13

19

14

OUT DDT11

7

DIGITAL

OUT

V+12

10

DKP3791-

PH 6PIN

SHIELD

1

3

V+3R3

FPGA_TX

11

1

7

14

REC OUT

COMPONENT

2

GNDD

CBV_CH3_1

7

17

CN202

B15B-PH-K-S

CH3

AUDIO

CN6501

DKN1480-

XMMCD

GNDA

19

24

20

1

7

3

DVD

11

9

GNDA

CBV_CH4_2

CBV_CH4_3

V+5

2

CN7403

B4B-PH-K-S

5

MCK

4

CH3_DATA

8

29

CH2

MASTER OUT1

28

2

4

1

GNDD

8

VR_CS2

21

GNDD

GNDD

GNDD

24

1

GNDA

96K_2

CH3_DIGI_INPUT

Y_CH4_1

29

DIR_CS1

V+15A

CLK24M_2

GNDD

GNDA

5

GNDA

GNDA

OUT DDT9

VR_CLK

MAIN_S_DC

31

6

MUTE_OFF

4

D-_USB1

CN1012

VKN1434-

CBV_CH4_3

2

GNDD

11

11

5

TP1_YAD

151413

DDD1384-

1mm FFC 17PIN

REVERSE

13

GPO_CH4START

24

VR_CS_INPUT4

4

1

37

32

CN8651

B4B-PH-K-S

6

GNDA

16

GNDA

TP1_XV

GNDA

3

L

V+5D

VIDEO

SYNC

OUT

GNDD

2

C_CH1_1

GNDA

10

32

D+_USB1

9

2

GNDA

GNDD

SYNC_OUT

21

N

7

TO ILMR

RST_SRC

PF15PP-S17

C_CH3_1

10

1

PHON

17

PF07EE-D12

16

GNDD

V+5D

C_CH1_1

7

GND5

HP L

V+15

GNDA

3

SUB_S_YOUT

13

23

GNDA

4

V+5A

14

8

17

D+_USB1

GLED

GNDA

1

6

GNDD

29

12

OUT DDT10

7

7

27

GNDD

15

21

7

GNDD

2

GNDD

13

DDD1375-

1mm FFC 34PIN

REVERSE

6M_3

TO AUD2

1

16

3

23

1

2

CN1017

AKM1280-

V+15B

REC_DATA

33

GNDD

VR_CS5

3

V-BB

9

GNDD

GNDD

6

CONT

SDPOWER

SUB_S_DC

GNDA

MIDI_TX

7

CH1

AUDIO

GNDA

24

30

C_CH4_1

11

BOOTH_MUTE

12

GNDD

CH1_FADER

36

VR_CLK

DVD

7

1

19

MONITOR

5

34

GNDD

CH3_DATA

PF02EE-D32

18

CBV_CH2_1

21

1

1

12

18

8

24

GNDA

GNDD

MCK

24

9

DDD1381-

1mm FFC 30PIN

REVERSE

5

11

MAIN_CBOUT

27

GNDD

28

FROM PDIV

GNDA

OUT DDT13

GPO_CH3START

31

9

3

2

GNDD

GNDA

CN4016

RECEPTACLE 19PIN

19R-1.25FJ

19

22

40

C_CH2_1

1

5

SDWP

CH3_DIGI_INPUT

GNDA

20

5

GNDA

V-15

SDDAT3

5

12

GNDD

2

17

V+5D

MUTE_OFF1

GNDD

15

CN9157

B2B-EH

10

CN4014

S8B-EH

9

CN5004

PLUG 19PIN

VKN1775-

10

OUT DDT4

GNDD

GNDD

VR_SIR_RX

GNDA

17

5

12

MAIN_S_DC

VR_SIR_TX

1

C_CH2_1

GNDD

KUC DDG1028-

CBV_CH1_2

3

GNDFL

GNDA

6

C_CH4_1

MAIN_VOUT

S-VIDEO

GNDA

GNDA

CN8551

AKM1276-

CN7705

VKN1193-

V+5D

3

22

VR_CS3

5

V-15

JJ BDG1048-

29

14

CH4_DATA

CONT

23

GND15

4

3

CN

B2B

1

WY TL ADG7062-

3

GNDD

4

26

GND5

GNDD

GNDD

GND5

27

EFFECT_ON

CN4002

B3B-PH-K-S

GNDA

MASTER

GNDA

1

13

DIT_CS1

FADER_ST_1-

2

VR_SIR_TX

17

MUTE_OFF2

V+5D

V3R3

27

V+3R3DREF

CBV_CH3_2

18

CN1008

VKN1417-

CRS_FADER

CN4010

DKN1511-

MAIN_S_YOUT

15

S-VIDEO

13

SUB_S_COUT

R

OUT DDT12

25

7

7

5

4

GNDD

20GNDD

GNDD

INPUT_SEL3

8

FPGA_SCLK

7

GNDD

PWRFL(+15)

CN8301

VKN1305-

GNDD

3

4

6

V+15A

GNDA

MIDI_TX

MAIN_S_COUT

9

18

9

CBV_CH4_1

GNDA

CLK24M_3

22

11

VR_MUTE

CN9151

B5B-PH-K-S

2

CH3_DIGI_IN

INPUT_SEL3

GNDA

2

CN3

52492

30

SUB_CPU_BUSY

2

3

9

4

15

28

INPUT_SEL4

ATT

3

JH9201

51048-0400

3

!

GNDD

L

DDD1376-

1mm FFC 17PIN

REVERSE

JUMPER

9PIN

CH1

GNDA

6

8

CONT

10

17

AC INLET ASSY

!

8

GREF1

GNDA

GNDA

V+5D

BOOTH_DATA

4

OUT DDT3

REAR PANEL

17

GNDD

7

25

4

GNDA

GNDA

GNDA

CH2_DATA

INSEL1

L

Y_CH3_1

DDD1377 1mm FFC

12PIN

REVERSE

SD CARD

4

20

2

CH4

VIDEO SYNC

OUT

3

15

CH1_FADER

V+5A

GNDA

CH2_DIGI_IN

GNDA

GNDA

16

N

GNDD

7

BCK

GPO_CH1STOP

5

2

8

GNDD

17

15

23

12

18

GNDA

7

29

GNDD

GNDD

1

13

GNDFL

GNDD

GNDD

PF05EE-D37

GNDA

32

18

22

5

9

25

25

17

GNDA

29

GNDA

4

GNDD

CN1010

VKN1438-

GNDD

28

19

10

CH1_DATA

GPO_CH3STOP

R

GNDA

OUT DDT7

6

OUT DDT15

9

V+5A

19

8

15

VR_CS_MASTER

18

CN1004

VKN1444-

18

13

D-_USB1

FADER_ST_4-

10

MMCMD

32

MIDI_TX

6M_3

MCK

13

INSEL1

GNDD

GNDA

28

CN1006

AKM1276-

PF08EE-

D17

FADER_ST_4-

Y_CH2_1

5

GNDA

GNDD

INPUT_SEL4

GNDD

REC_DATA

6

1

4

4

15

5

14

V-15

9

21

C_CH3_1

24

VLED(+5)

PWRFL(+15)

GNDA

15

MAIN_YOUT

13

13

V+5

CH2

SUB_S_DC

33

TAP_SW

GNDD

2

5

Y

FSYNC

10

GNDD

12

25

6

OUT DDT1

8

V3R3

5

CBV_CH4_2

FADER_ST_2-

CBV_CH3_1

PHONO

8

8

10

3

20

GNDA

15

32

VMUTE

18

19

PF05PP-

D20

22

8

17

OUT DDT14

8

7

12

16

GNDA

BCK

INSEL2

GNDD

GNDD

3

15

7

19

GNDA

GPO_CH2STOP

GNDD

GNDD

2

GNDD

GNDA

FADER_ST_4+

MUTE_OFF2

8

3

CH1_FADER

GNDD

GNDD

BOARD TO BOARD

19PIN

9

GNDD

INSEL3

VLED(+5)

26

3

NEUTRAL

96K_1

30

FADER_ST_3+

GNDA

4

D+_USB2

CBV_CH3_1

11

PHONO

INSEL4

L

39

SDDAT0

SDDAT2

DDD1378-

1mm FFC 24PIN

REVERSE

DCLKO

23

9

CN9152

B15B-PH-K-S

DDD1379-

1mm FFC 34PIN

CBV_CH3_2

2

CBV_CH3_2

N

V+5

SYNC_OUT

DIT_CS1_X

9

4

28

GNDD

23

V3R3

V+5D

V+5D

GNDA

GREF1

23

MAIN_CROUT

8

GND5

17

4

27

VMUTE

4

CN8601

AKM1290-

GNDD

CN

S5

6

BCK

6

GNDD

DIGI_4896_IN

OUT DDT8

GNDD

VR_MUTE

10

5

7

8

L

21

BOOTH_DATA

CBV_CH3_2

GNDA

34

CH2_DATA

V+5D

27

DIGI_4896_IN

DSP_RST

8

GNDD

SDPOWER

CN8701

S3B-PH-K-S

2

GNDD

Y_CH1_1

12

GNDD

GNDD

GNDD

6

9

V+5D

R

WA ADG7105-

5

10

12

30

GNDA

25

VR_CS3

3

GNDA

LINE

4

AC POWER CORD

V+12

VR_CS1

INSEL3

CN8251

VKN1374-

16

1

18

15

5

!

6

5

13

3

GNDD

WYTL WA DKP3762-

1

CH4_DATA

38

CH3_DATA

8

13

19

17

CBV_CH4_2

!

1

7

GNDA

5

V3R3

3

6

34

34

CBV_CH1_3

2

R

GNDA

!

26

GNDA

9

4

CN1001

VKN1434-

9

!

14

3

CBV_CH4_3

19

GNDD

9

GPO_CH2START

19

3

17

2

27

GNDD

31

VR_MUTE

CH4_FADER

14

9

CBV_CH1_3

V-15

GNDD

V+15D

CN1002

VKN1416-

GNDD

CN4015

RECEPTACLE 19PIN

19R-1.25FJ

XRESET

CN7706

VKN2004-

4

VR_DATA

18

V+15

3

12

COMPOSITE

27

GNDD

7

GNDA

GNDA

34

16

VR_CS_INPUT3

2

18

20

3

DIR_CS2

27

GNDA

1

JUMPER

4PIN

GNDD

JH9151

51048-0900

DSP_RST

4

GNDD

2

24

3

MASTER_MUTE_OFF

4

GNDA

GNDD

11

8

GNDA

10

INPUT_SEL3

VSYNC

14

GNDD

4

GNDA

10

6M_1

12

DKP3794-

PH 3PIN

SHIELD

INPUT_SEL2

6

20

GNDD

GNDD

1

3

SYNC_OUTPUT

RST_SRC

11

8

10

11

V+BB

26

20

3

11

OUT DDT5

CN9154

B5B-EH

4

6

2

SDWP

3

5

CN1015

VKN1421-

CBV_CH3_1

16

26

16

10

HP L

GNDD

9

CH1

VIDEO

INPUT

8

6

V+8D

11

15

V+5A

6

14

MIDI OUT

OUT DDT6

26

REC_DATAREC_DATA

R

2

GNDD

V3R3

GNDHP

GNDA

5

CLK24M_2

25

36

GNDA

GNDD

2

20

5

GNDD

V-15

D-_USB2

FADER_ST_4-

GNDA

4

C_CH3_1

12

1

6

SDDAT2

4

28

26

GNDA

1

MAIN_S_COUT

VR_CS4

7

DDD13811mm FFC

13PIN

13

V+15D

VR_CS4

4

31

1

CBV_CH2_2

GNDD

INPUT_SEL1

9

GNDD

GNDD

CBV_CH2_2

23

4

18

2

GNDD

3

18

4

12

Y_CH4_1

23

14

GNDD

VR_SIR_RX

22

11

DKP3799-

2PIN

33

CBV_CH4_2

5

DDD1388-

1mm FFC

5PIN

REVERSE

8

4

3

VR_CLK

GNDD

GNDD

30

CN6503

52147-0410

GNDD

GNDA

V+BB

GNDD

1

5

V+3R3DREF

1

GNDA

AC POWER CORD

6

FADER_ST_1+

CN6

52492

29

30

FADER_ST_3-

GNDD

10

CH3_FADER

MIC1

16

4

VR_SIR_SCK

GNDA

AC INLET ASSY

3

23

VR_MUTE

8

PF07EE-D12

18

3

VR_DATA

KUC JJ DKP3761-

29

15

GNDD

10

27

3

2

38

5

GNDD

JH9501

51048-0900

5

CN1003

VKN1438-

18

20

3

GNDD

1

16

4

6

4

11

3

15

10

V+15B

GNDA

30

6

CN9101

2-178496-4

PF08EE-D30

D+_USB2

C_CH3_1

6

CBV_CH4_3

J9101

(BOARD-IN)

14

MAIN_MIC_HOT

FADER_ST_3-

17

TP1_YV

CLK24M_1

CH2

AUDIO

GLED

6M_2

C_CH4_1

4

CONT

Y_CH2_1

12

16

SUB_CPU_RST

GNDA

14

5

V+5

CH4_DATA

1

1

D-_USB2

5

GNDA

ATT

CBV_CH2_1

6M_2

CN201

B5B-PH-K-S

31

1

2

28

+5V_USB2

4

GNDD

12

13

USB B

1

Y_CH1_1

GNDD

16

3

CH4

AUDIO

INSEL2

2

MASTER

OUT2

GNDD

CH1

VIDEO

INPUT

GNDD

CN6502

VKN1374-

GNDA

GNDD

V+BB

8

11

23

25

33

Cb

2

FADER_ST_2+

3

13

GNDA

35

2

7

MUTE_OFF

VR_CS5

MASTER_DATA

GNDD

TO HAMP

GNDD

11

V+5D

CH2_FADER

CH3_DATA

MMCLK

14

1

11

GNDD

6

21

4

CH1_DATA

VR_CLK

GNDA

25

XRESET

!

FPGA_RX

CH4

VIDEO

INPUT

21

GNDD

2

2

GNDA

2

11

14

ATT

16

MAIN_MIC_COLD

SUB_S_COUT

VR_MUTE

USB A

2

3

OUT DDT2

9

GNDD

GNDD

4

CH3_DIGI_IN

3

GNDA

CN5006

S8B-EH

12

CN9156

B8B-EH

10

GPO_CH4STOP

14

Y_CH3_1

MAIN_CBOUT

GNDA

SDDAT1

L

GNDD

LRCK

6

8

Y_CH4_1

96K_3

4

5

2

5

20

MIDI_TX

GNDA

BOARD TO BOARD

19PIN

GNDA

23

BOOTH_MUTE

15

11

GNDD

30

16

2

21

V+5D

GNDD

14

5

GNDA

11

V+5D

4

VR_CS3

4

10

XMMCD

1

GNDD

4

V+5A

V+8D

26

11

FADER_ST_3+

FADER_ST_4+

24

MMCLK

GNDD

MAIN_S_YOUT

SUB_CPU_INT

SYNC_OUTPUT

17

GNDREF

DDD1382-

1mm FFC 30PIN

MUTE_OFF1

15

GNDD

VIDEO

SYNC

OUT

3

15

GNDHP

4

DDD1383-

1mm FFC 40PIN

C_CH4_1

2

CN9155

B9B-PH-K-S

GND15

OUT DDT0

PF05PP

-S15

MASTER_DATA

GNDA

10

CBV_CH1_1

GNDD

GNDD

GNDA

V+8

FADER_ST_3-

L

10

GND15

29

8

VR_DATA

GNDA

28

GNDA

MAIN_VOUT

PF09PP-

D05

SDDAT1

21

CN9153

B7B-EH

RST_HP

2

1

INL101

B2P3-VH

INSEL4

DIR_CS1

GNDA

17

GNDA

CH3

DIGITAL

IN

GNDD

GNDD

Cr

GND15

11

GNDD

1

2

22

2

9

CBV_CH4_1

VMUTE

40

39

GNDREF

1

CH4

VIDEO

INPUT

7

GNDA

BROWN

1

V+15B

GNDD

9

GNDD

TP1_XAD

VR_CS5

5

25

WHITE

Y_CH3_1

1

V-15

6

SDDAT0

CN7707

VKN1200-

CH2_DIGI_IN

GNDA

19

6

21

V+15B

GNDD

LIVE

5

GNDD

SUB_VOUT

VR_CS_MIC

30

13

14

2

3

GNDD

CN101

Y

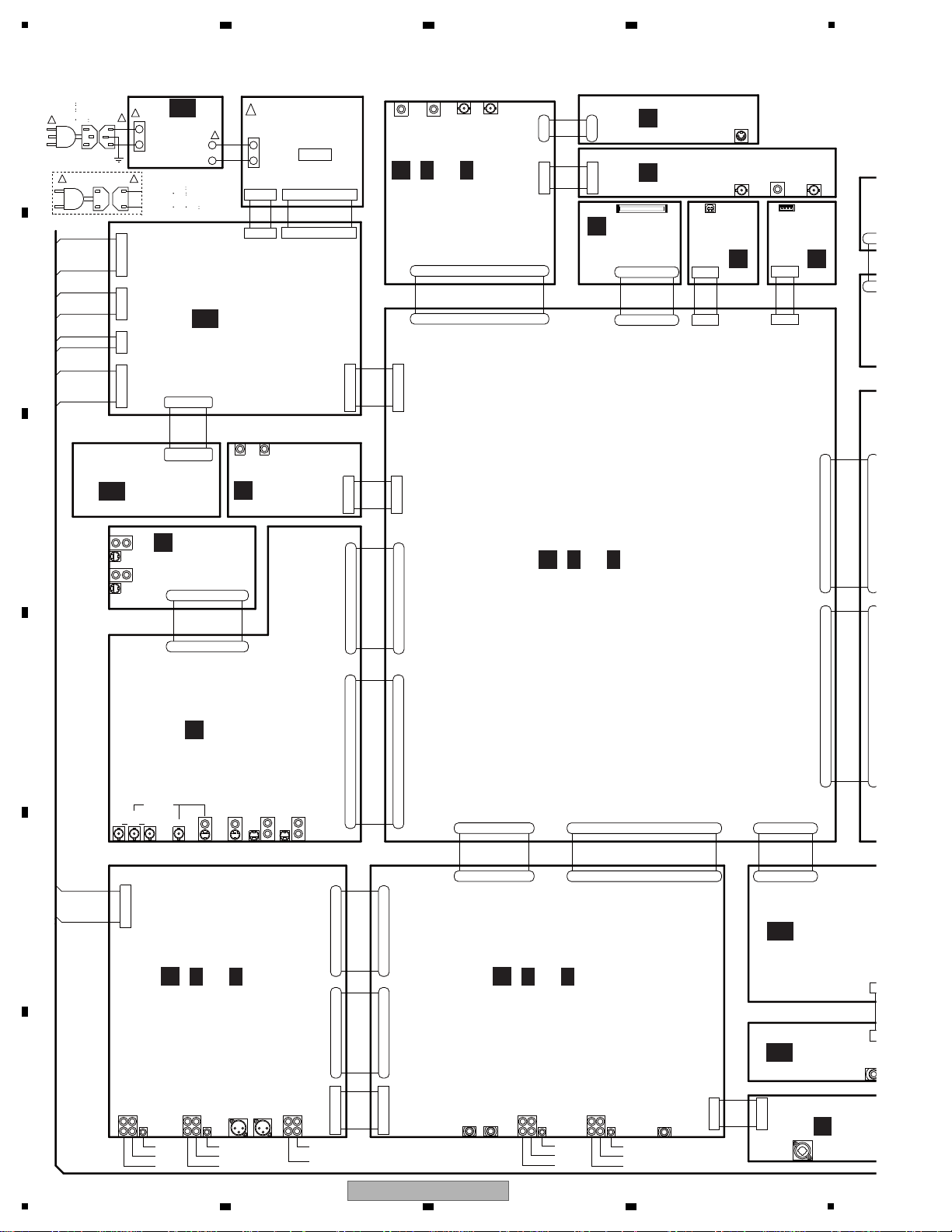

USB1 ASSY

(DWX2727)

D

HAMP ASSY

(DWX2726)

HJCK ASSY

(DWX2734)

MJCK A

(DWX27

Z

USB2 ASSY

(DWX2720)

B B( 1/5- 5/5)

B

AUD2 ASSY

(DWX2721)

A A( 1/5- 5/5)

A

AUD1 ASSY

(DWX2718)

G G( 1/9- 9/9)

G

MAIN ASSY

(DWX2715)

V V( 1/2- 2/2)

V

DIO1 ASSY

(DWX2724)

AA

AB

C

VIO1 ASSY

(DWX2731)

F

VIO2 ASSY

(DWX2732)

E

VIN3 ASSY

(DWX2733)

W

MIDI ASSY

(DWX2751)

U

DIO2 ASSY

(DWX2719)

X

SDIO ASSY

(DWX2728)

REG ASSY

(DWX2767)

AE

PDIV ASSY

(DWX2725)

AD

ACSW ASSY

(DWX2737)

AC

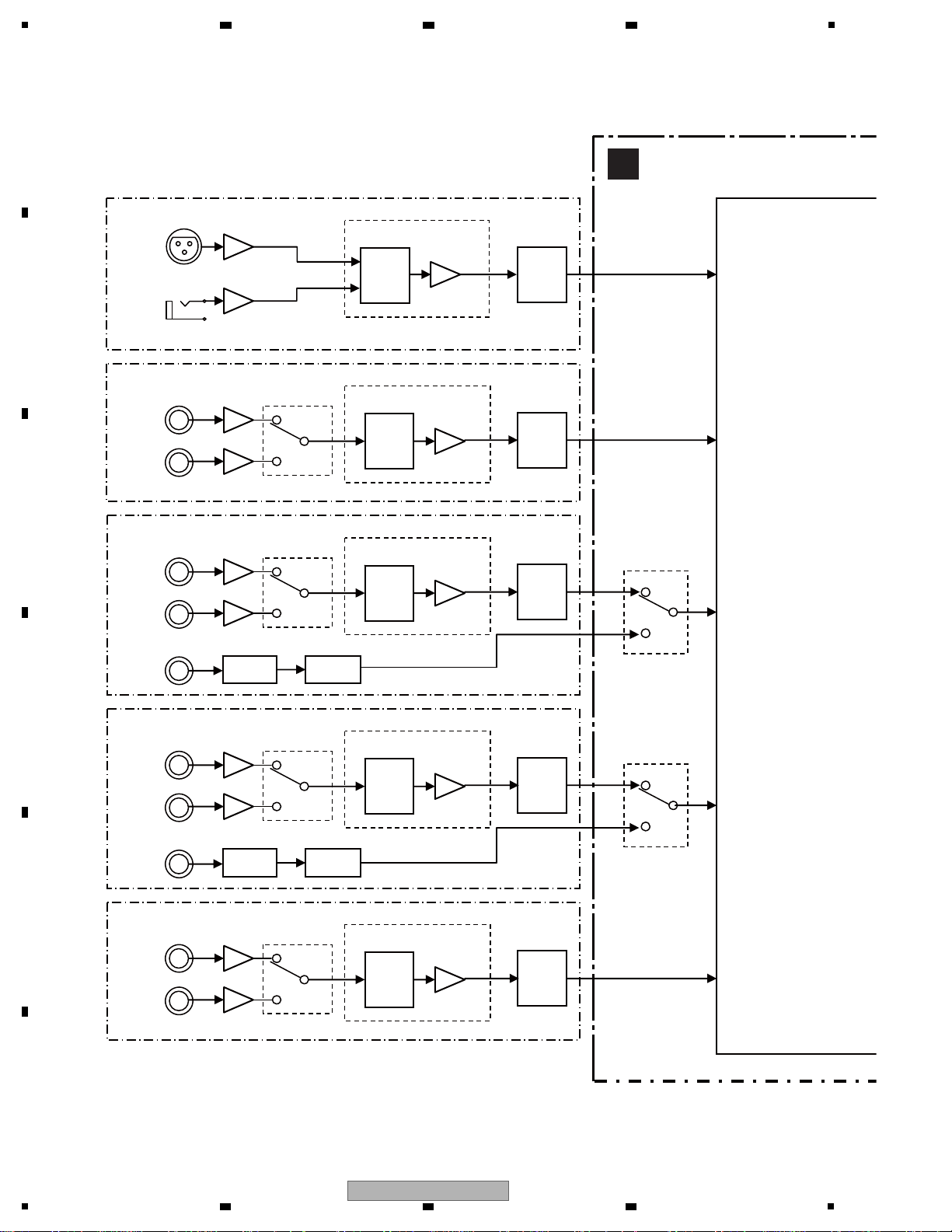

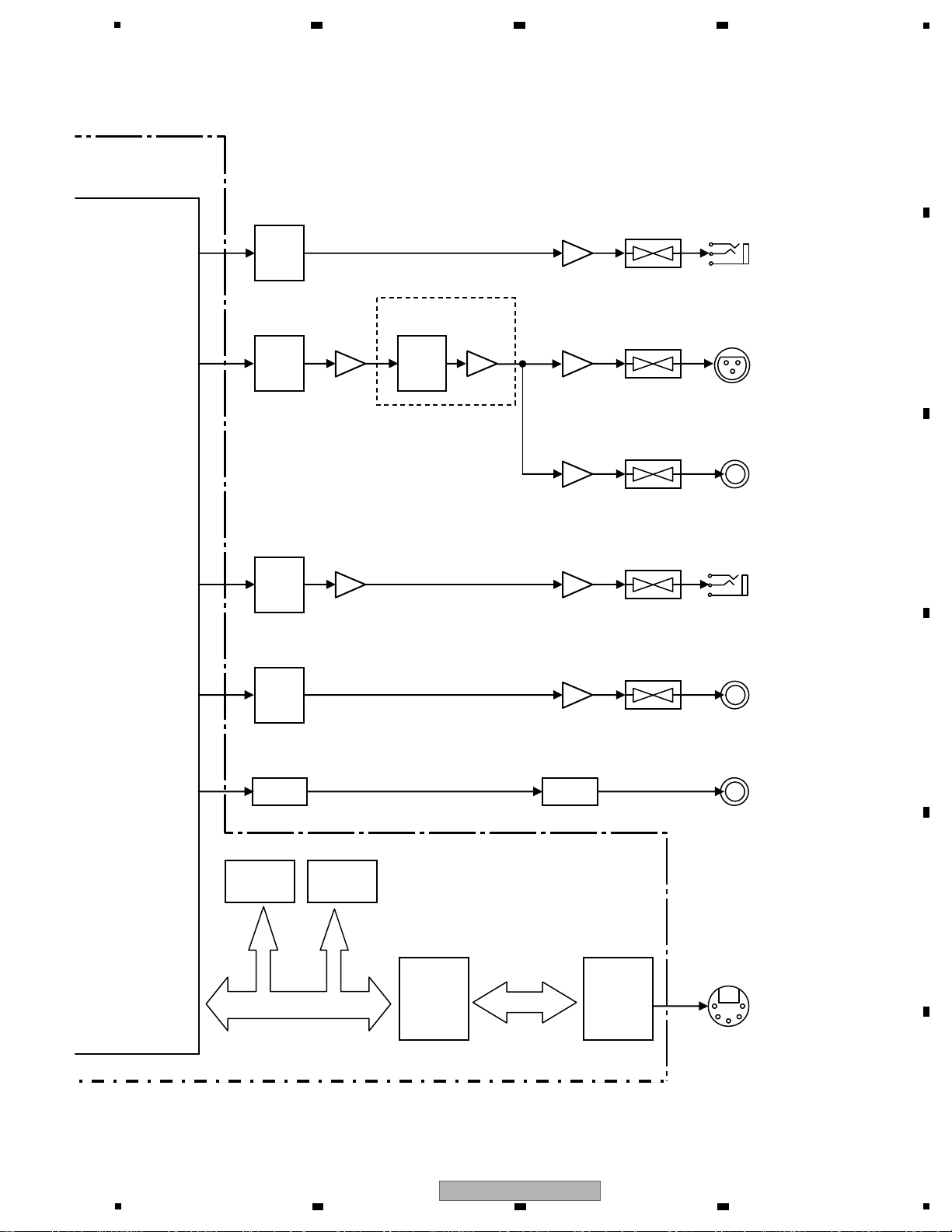

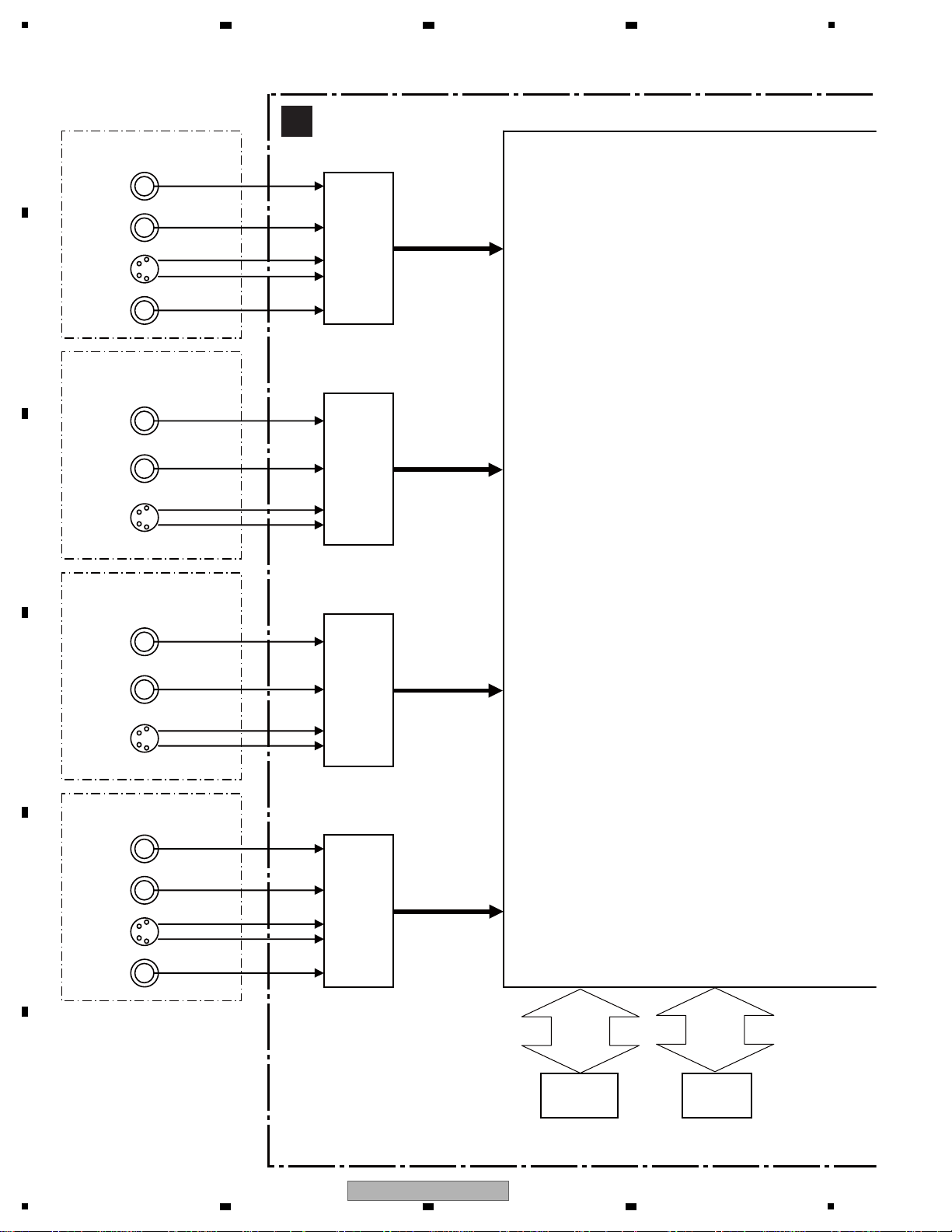

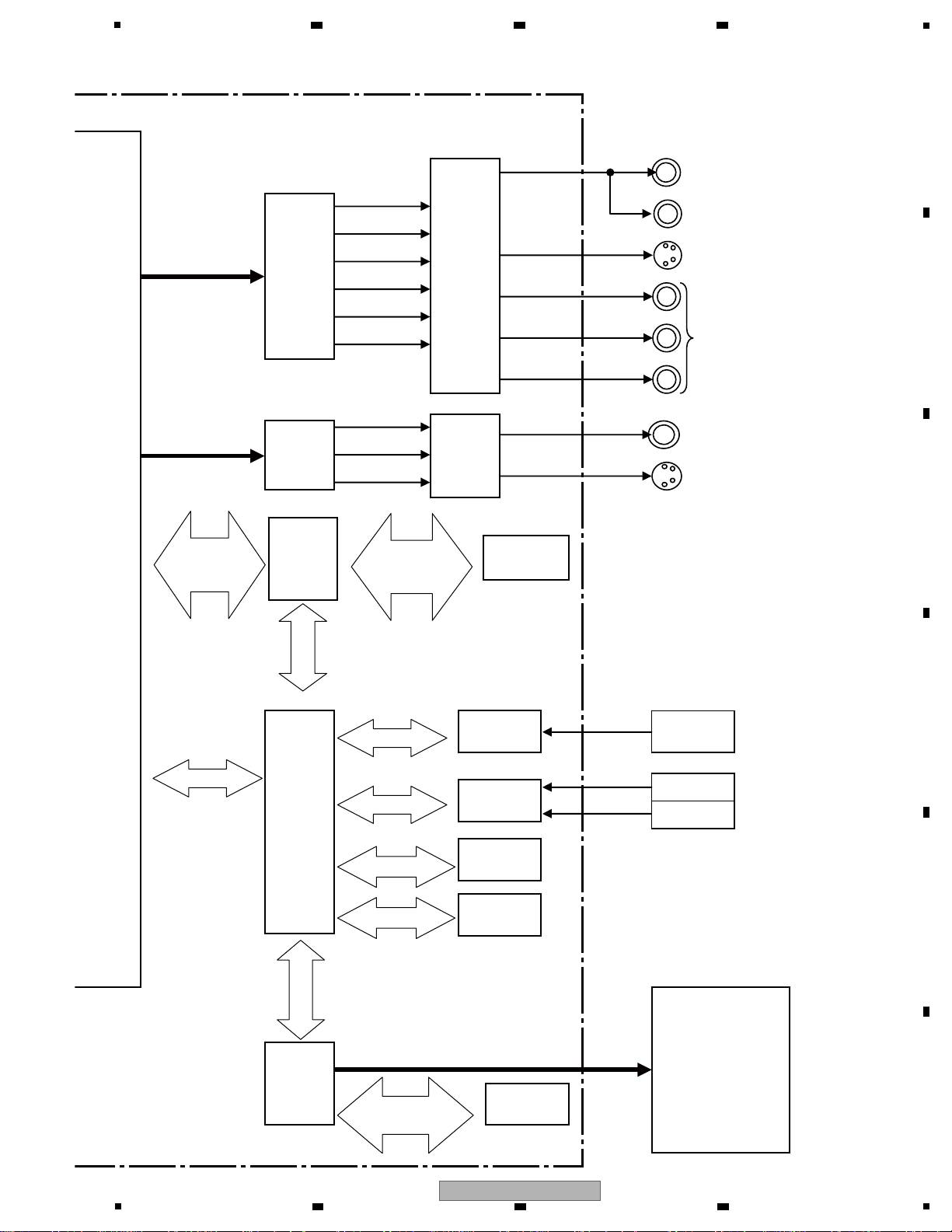

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

16

1

2 3 4

2 3 4

SVM-1000

Page 17

SW_MAT0

CH3

VIDEO SYNC

OUT

GND

19

14

14

7

22

G5

TOUCH PANEL

20

FFC

4P

4

3

OUT DDEN

29

HP_R

GLED

10

20

CH3_FADER

SW_SCAN4

19

2

V3R3REF1

8

3

23

6

20

17

DDD1385-

1mm FFC 24PIN

REVERSE

GREF1

1

19

CN9001

B2B-EH

GNDD

MUTE_OFF

V3R3

33

4L

3

MIL

SW_MAT5

21

RST_HP

R2

2

11

12

3VT

20

26

1

LED-10

V3R3REF1

2

INSEL1

SW_MAT0

V3R3REF2

19

GREF1

3AT

18

14

26

25

GNDD

1

10

2

17

V3R3REF1

V3R3

18

2

5

40

G4

TP1_XAD

BOTTOM

T_LEDD0A

22

31

2

T_LEDD0

GREF1

V3R3REF1

GNDD

B4

14

16

G2

CH4_FADER

SUB_CPU_INT

6

9

DKP3792-

PH

4PIN

9

5

28

EFF_CH_S0

8

LEDD12B

11

FIL_S1

TP1_XV

V3R3REF1

24

GNDD

6

35

DDD1389-

1.25mm FFC 28PIN

REVERSE

OUT DDT8

LEDD6A

TOP

2

30

1

4

GREF1

7

LEFT

16

V3R3REF1

CN7401

CKS4999-

31

ISNEL1

5

GNDHP

16

GREF1

2

20

23

SW_MAT6

CN3013

52492-2820

2

25

24

GNDHP

SW_SCAN3

GNDD

13

GREF1

TAP_SW

GREF2

SW_SCAN3

T_LEDD2

23

T_LEDD5

3

LED-0

FROM PDIV

14

2

14

6

TAP_SW

23

9

CH2_FADER

7

13

GREF1

11

1

2

37

2

GREF1

LED-6

V3R3REF1

CRS_FADER

18

10

17

18

35

10

SW_MAT4

26

LED-6

19

TOP PANEL

SW_SCAN3

_

2

4

5

V+15D

GNDD

LED-8

B1

22

PF05EE-D37

HP_DATA

10

17

23

SW_MAT2

10

13

T_LEDD0A

DDD1394-

1.25mm FFC

5PIN

REVERSE

1M

HP_DATA

SW_SCAN7

28

16

9

15

22

2

5

V3R3

2

22

GNDD

MAB

TIME_1

LED-4

22

21

LEDD9A

6

GNDD

CN6008

9610S-04B

26

CN1007

AKM1275-

B0

36

GNDD

LEDD14B

R4

TIME_1

BO

30

UP SIDE

TOUCH PANEL

G5

VLED(+5V)

5

2VT

13

12

34

6

25

8

SW7

GNDD

SW_MAT2

PWRFL(+15)

TP2_XV

34

GREF1

11

7

13

GNDD

5

GNDHP_L

5

12

GREF1

23

CLK

24

SMIC_TRIM

SW_MAT3

CN8751

S3B-PH-K-S

2

27

16

U/D

LEDD7B

8

19

CH3_FADER

B4

CN7101

52492-3620

1L

OUT DDT11

GNDD

LEDD7B

CH2_FADER

INSEL4

LEDD11B

FPGA_TX

1

14

LEDD3B

5

20

17

TIME_0

VLED(+5)

28

V3R3

G3

14

27

LEDD3B

19

HPL

23

7

17

LED-10

1

4 SW_MAT2

9

SW3

LCD_SW

CN7403

B4B-PH-K-S

15

10

INSEL4

5

LEDD5A

LED-7

18

OUT DDT15

29

SUB_CPU_BUSY

28

G0

OUT DDT3

GNDD

T_LEDD4

GNDD

19

8

15

10

2M

GLED

5

3

FIL_S1

SW1

28

HIGH VOLTAGE

V3R3

28

9

8

DCLK0

GNDD

3

LEDD11A

4

GND

13

16

OUT DDT9

6

LED0A

MUTE_OFF

EFFECT_ON

1012

GNDD

4

GND15

T_LEDD0A

GREF1

TP1_YAD

19

6

LEDD14B

GNDD

16

7

18

1

17

SW_MAT5

FL_PWR_H1

SW_SCAN3

6

8

HS

LEDD0B

37

CN8651

B4B-PH-K-S

B0

21

GNDD

FIL_S1

TP1_XV

3

INSEL2

20

DDD1390-

1.25mm FFC 36PIN

REVERSE

GNDHP_R

R5

SW_MAT5

SW_MAT5

8

36

V3R3REF1

SW4

14

MIC_TRIM

2

GNDD

16

1

20

G4

LEDD9B

27

28

GREF1

10

PHONES

1

GREF2

3

GNDD

GNDD

HP_L

GLED

GREF1

LEDD5B

3

23

GLED

1VT

10

LEDD6B

5

OUT DDEN

1

29

2L

OUT DDT10

9

INSEL2

GNDD

12

R0

GNDD

VLED(+5V)

SMIC_TRIM

LED-10

23

GNDD

18

CN6001

CKS3836-

GNDFL

GNDD

V3R3

GNDD

OUT DDT12

10

TP2_YV

SW2

3

23

16

OUT DDT4

1H

LEDD11B

1

VLED(+5V)

V3R3

11

33

3

4

2

4

13

5

8

13

2

21

CN3004

52147-0610

LED-2

6

19

CN6002

VKN1814-

16

24

2

12

13

6

LEDD14B

5

CN8452

52492-0620

HSYNC

V+15D

1

SW_SCAN4

12

1

LEDD9B

CH1_FADER

36

7

3

SW_MAT2

13

1

38

5

18

SW_MAT5

T_LEDD5A

14

2

V3R3REF2

25

1

21

22

36

SW7

12

LED-3

DCLKO

V3R3

8 GNDD

CN8951

52492-0520

SW5

DEPTH

GNDD

DIM_DUTY

24

1

GNDD

4

3

TP2_XAD

23

GNDD

(DSX1074)

HPM

GLED

18

OUT DDT13

11

SW_MAT0

SW2

LEDD1A

SW_SCAN4

GNDD

26

3

GNDFL

LEDD9B

14

22

40

22

23

V3R3

2

6

16

LEDD11A

GNDD

LEDD8B

14

35

4

CN3005

S8B-EH

LEDD8A

22

SW_MAT2

19

LEDD1B

GREF1

DIM_DUTY

SW_MAT0

SW4

LEDD13A

33

OUT DDT1

GNDD

TP1_YV

3

29

TP2_YV

4

LEDD6A

OUT DDT4

GNDD

30

V3R3

OUT DDT6

SW_MAT1

1

17

R1

4

GLED

LED-4

V3R3REF1

TP2_XV

21

GNDD

24

8

33

GNDD

GNDD

5

SW_MAT0

T_LEDD1A

29

DEPTH

GND

28

1

GNDD

6

EFFECT_ON

1

LEDD13B

CN7402

B2B-PH-K-S

20

CN3011

52492-3620

1

SW_MAT4

SW_MAT5

13

27

27

EFFECT_ON

GNDD

DKP3797PH

2PIN

SW_MAT0

CH4_FADER

36

SW_MAT3

4AT

1M

5

R1

SW3

V3R3REF1

G2

VSYNC

GLED

1

DDD1395-

0.5mm FFC 40PIN

12

3

4H

28

V3R3REF1

SW_MAT2

SW_SCAN4

LEDD2A

V3R3REF1

4H

3

CH3_FADER

7

GNDHP_R

SW6

27

V+3R3DREF

18

LEDD2B

LEDD8B

26

INSEL3

LEDD9A

CRS_FADER

15

EFFECT_ON

4M

TP1_XV

R0

2

OUT DDT12

7

11

GNDFL

33

GNDD

20

PF08EE-D30

OUT DDT14

GREF2

GNDD

GREF1

2

2

LCD_SW

VDD

TIME_0

GNDFL

FPGA_SCLK

T_LEDD1A

OUT DDT11

3

6

FIL_S1

9

V+5D

1

GND

4

9

4

FL_PWR_L1

_

GREF1

2

1

12

7

CN3006

DKN1480-

CN3007

52492-3620

SW_MAT0

3

28

T_LEDD2A

CH4_FADER

22

TP1_XAD

21

3

11

CH1_FADER

LED2A

6

3

CN8501

VKN1282-

7

1

R5

21

8

9

GREF1

6

40

2

OUT DDT3

B5

TIME_0

24

VDD

ERSE

VML

PF02EED32

CH1_FADER

15

12

T_LEDD4A

7

TAP_SW

LED-1

SW_MAT1

SW_MAT4

GNDD

PWRFL(+15)

TP1_XV

24

3H

11

8

GND

TIME_1

GNDD

14

23

EFF_CH_S0

29

GNDD

LEDD12B

LEDD4A

2

1

4

CH3_FADER

GNDD

23

SW_MAT2

GNDD

32

LEDD2A

8

LED-2

9

32

1AT

34

12

15

32

LED-8

6

1

11

10

PWRFL(+15)

3

LED-3

OUT DDT7

OUT DDT15

39

T_LEDD2A

5

4

LEDD12A

18

21

MAL

FL_PWR_L2

GNDFL

1004

21

5

18

CN3010

VKN1428-

DDD1392-

1.25mm FFC 36PIN

DDD1387-

1mm FFC

11PIN

GNDD

3

CN6005

52151-0610

LEDD3A

INSEL1

4

V3R3REF1

30

2

2H

28

3

19

1

GREF2

10

4

3H14

5

19

4

32

30

15

DE

LEDD5A

21

24

4

24

TP1_YAD

OUT DDT2

6

13

V3R3REF2

32

T_LEDD5A

13

TAP_SW

LED-1

3

8

FSYNC

24

SW_SCAN4

GLED

25

OUT DDT1

GND

5

6

LED3A

CN6007

CKS4428-

1

HERNESS

2PIN

SW_MAT5

GREF1

32

DDD1391-

1.25mm FFC 24PIN

18

1

B3

SW_MAT3

OUT DDT14

7

CH4_FADER

17

EFF_CH_S0

GND15

CH2_FADER

35

INSEL2

27

3

SW_SCAN7

3M

CRS_FADER

7

GNDD

LEDD0A

GNDD

ISNEL1

TP1_YAD

DDD1394-

1.25mm FFC

5PIN

REVERSE

R2

V3R3REF1

CH1_FADER

V3R3

12

GNDD

GNDD

INSEL3

V3R3

33

EFF_CH_S1

30

V3R3REF2

27

LED0A

13

16

LEDD7A

D+_USB2

7

31

LED-10

TOP

39

36

OUT DDT5

3L

DCLKO

23

3

4

21

21

GREF1

4

GLED

GNDD

G1

CN6804

52492-0520

5

15

CH1_FADER

VS

LEDD7A

TP2_YAD

FIL_S0

MAB

TIME_0

CN6003

VKN1814-

LOW VOLTAGE

9

3

35

CN6004

VKN1303-

1

22

18

GREF2

1VT

GREF1

3VT

T_LEDD15

SW_MAT3

OUT DDT9

U/D

2

GND

T_LEDD1

CN8401

52492-0620

17

CN7105

52492-0620

2

CN8601

AKM1290-

CN7402

S5B-EH

T_LEDD3A

5

OUT DDT8

5

5

SW_MAT4

21

VLED(+5)

15

13

GNDD

13

LEDD1A

20

6

LED-4

22

V3R3REF1

12

LEDD14A

LEFT

GNDD

LED0A

EFF_CH_S1

3

T_LEDD15A

GREF1

2

GREF1

12

9

GREF1

GNDD

GNDHP_L

VSYNC

5

VDD

T_LEDD5A

4

GNDD

11

SW_MAT0

DDD1394-

1.25mm FFC

5PIN

REVERSE

LED-3

MIH

17

LED1A

2

15

4

3

V+15D

LEDD14A

LED1A

GREF2

9

LED-3

1L

4

CN6801

52492-2820

MIC_TRIM

38

LEDD8A

8

LED-0

23

4

11

34

3

10

LEDD3A

22

FPGA_SCLK

VLED(+5V)

GNDFL

5

4L

17

3

EFF_CH_S0

17

34

7

6

EFFECT_ON

GNDD

1

21

GLED

26

20

GNDD

9

20

4

LED-10

4AT

15

B5

9

CN6006

CKS3192-

V3R3REF2

19

1

GNDD

27

FROM PDIV

13

SW_MAT5

31

GNDD

GNDD

CH4_FADER

3AT

1

TP1_XAD

7

VML

2

6

SW_MAT0

002

416-

33

LED-9

LEDD12A

24

GREF1

18

1

15

GREF1

LED-9

SW_SCAN4

LEDD10B

12

1

3M

22

3

SW_MAT2

TP2_XAD

27

L/R

6

GNDD

EFFECT_ON

GREF2

16

V3R3REF2

25

V-15A

VR_MUTE

4

11

17

SW_SCAN3

8

GNDD

11

PF02EE-

D32

20

24

RIGHT

SW032

2

4

34

17

4

17

GREF1

V3R3REF2

VSYNC

VLED(+5V)

V3R3REF1

LCD

4

GNDD

4

2

10

SW_MAT6

10

TP1_YV

11

1

3

20

B1

GNDD

4

HPL

21

19

TP1_YV

MIH

SW1

T_LEDD3

LED-3

14

11

8

37

GND

22

11

OUT DDT5

4

SW_MAT6

SW_MAT4

SW_MAT4

5

DEPTH

G3

16

SW_SCAN3

26

SW_MAT6

38

HP_L

V3R3REF1

LEDD4B

GNDD

6

2VT

G0

11

15

SW6

2

LEDD0A

19

INSEL3

OUT DDT6

LEDD4A

PWRFL(+15)

SW_SCAN4

4

GLED

2

GNDD

7

VLED(+5V)

2

SW_MAT1

GNDD

25

3

36

37

17

2

39

LEDD1B

OUT DDT10

1

2

3

1

FFC

4P

GREF1

3

TP1_YAD

29

1AT

EFF_CH_S1

6

25

VLED(+5V)

28

8

26

3

2AT

35

6

CN7103

52492-0520

22

CH4_FADER

10

26

CN3012

52492-2420

PWRFL(+15)

17

24

20

GNDD

9

2M

12

18

LEDD10A

2

GNDD

10

4VT

18

10

T_LEDD15A

LEDD5B

21

HPM

DDD1385-

1mm FFC 24PIN

REVERSE

3

19

LED-4

GNDD

36

8

8

TAP_SW

9

GNDD

V3R3REF1

30

2H

GNDD

15

CN3001

DKN1481-

HP_R

DOWN SIDE

TOUCH PANEL

V3R3REF1

11

7

GNDD

1

32

CN8451

CKS3825-

1

V+3R3DREF

GREF1

21

GNDD

6

CN6802

52492-3620

GNDD

PF03PP-D15

INSEL4

4

GNDD

10

CH3_FADER

8

MIC1

2

GNDD

TP2_YAD

12

LED1A

SW_MAT3

8

19

V3R3REF2

12

GND

HERNESS

2PIN

MIL

GREF1

FL_PWR_H2

19

4VT

25

CN8351

52492-0620

38

5

PWRFL(+15)

SW_MAT1

5

(CWX3405)

20

3

T_LEDD15A

4

SW_SCAN4

B2

LEDD14B

22

SW_MAT2

LEDD2B

LEDD4B

12

GNDD

GREF1

GNDD

D+_USB2

16

GNDFL

7

L/R

CN7104

52492-0520

GNDD

TP1_YV

SW_MAT3

GNDD

15

1

CN7102

52492-2420

INSEL2

15

34

DDD1393-

1.25mm FFC

6PIN

REVERSE

1

CH2_FADER

LED-7

SUB_CPU_RST

3

26

T_LEDD0A

DDD1393-

1.25mm FFC

6PIN

REVERSE

3

1

LEDD0B

_

FSYNC

5

7

15

CH2_FADER

B3

1

EFF_CH_S1

14

31

1

14

9

4

4

29

GNDD

SW_MAT0

2

9

5

4

2

GNDD

T_LEDD5A

16

CN3002

CKS5075-

3

11

16

GREF1

25

GREF1

OUT DDEN

15

7

33

10

CN9051

B2B-EH

30

CN3008

VKN1428-

13

VDD

35

CN8851

52492-0520

GNDD

FPGA_TX

23

DDD1386-

1mm FFC 22PIN

REVERSE

12

T_LEDD5A

GNDD

21

26

13

CH2_FADER

31

LEDD10B

GND

GNDD

CN6009

9610S-04B

GND15

FPGA_RX

19

GND

8

LED4A

TAP_SW

GREF1

CN9002

B2B-EH

LEDD13B

CRS_FADER

BOTTOM

11

4

14

CN3009

S3B-PH-K-S

10

GND

VR_MUTE

GLED

7

USB A

GREF2

17

DDD1394-

1.25mm FFC

5PIN

REVERSE

PWRFL(+15)

OUT DDT2

V3R3REF1

3

GNDD

27

9

SW_MAT5

2

14

29

G1

12

LEDD6B

GNDD

SW_MAT5

T_LEDD3A

16

PF04PPD05

2

4

GREF1

LEDD10B

22

RIGHT

11

15

20

FIL_S0

23

2

LEDD13A

FROM PDIV

11

30

FIL_S0

20

2

GLED

SW5

GNDD

14

JUMPER

6PIN

REVERSE

11

13

DEPTH

1

9

SW_MAT2

GNDFL

T_LEDD4A

4

OUT DDT7

3

GNDD

24

SUB_CPU_RST

1

9

4M

V+15A

SUB_CPU_INT

B2

GNDREF

9

LED-3

5

DDD1382-

1mm FFC 30PIN

OUT DDT13

INSEL3

LED-10

GLED

CH3_FADER

27

SW0

5

DDD1383-

1mm FFC 40PIN

T_LEDD0A

R4

OUT DDT0

3L

CN8901

52492-0520

BO

10

5

3

GNDA

16

4

24

18

GNDD

1

R3

24

PWRFL(+15)

31

24

LEDD9B

22

1H

RST_HP

31

MAL

GNDD

INSEL4

GREF1

5

VLED(+5V)

R3

17

T_LEDD0A

20

5

21

6

7

16

15

18

TIME_1

34

7

29

5

40

39

18

GNDREF

35

GNDD

GREF1

2AT

2L

FIL_S0

2

FPGA_RX

8

6

TP1_XAD

25

25

LEDD10A

OUT DDT0

1

30

10

12

CH1_FADER

LEDD10B

GNDA

CN8801

52492-0520

CN6803

52492-0520

D

HAMP ASSY

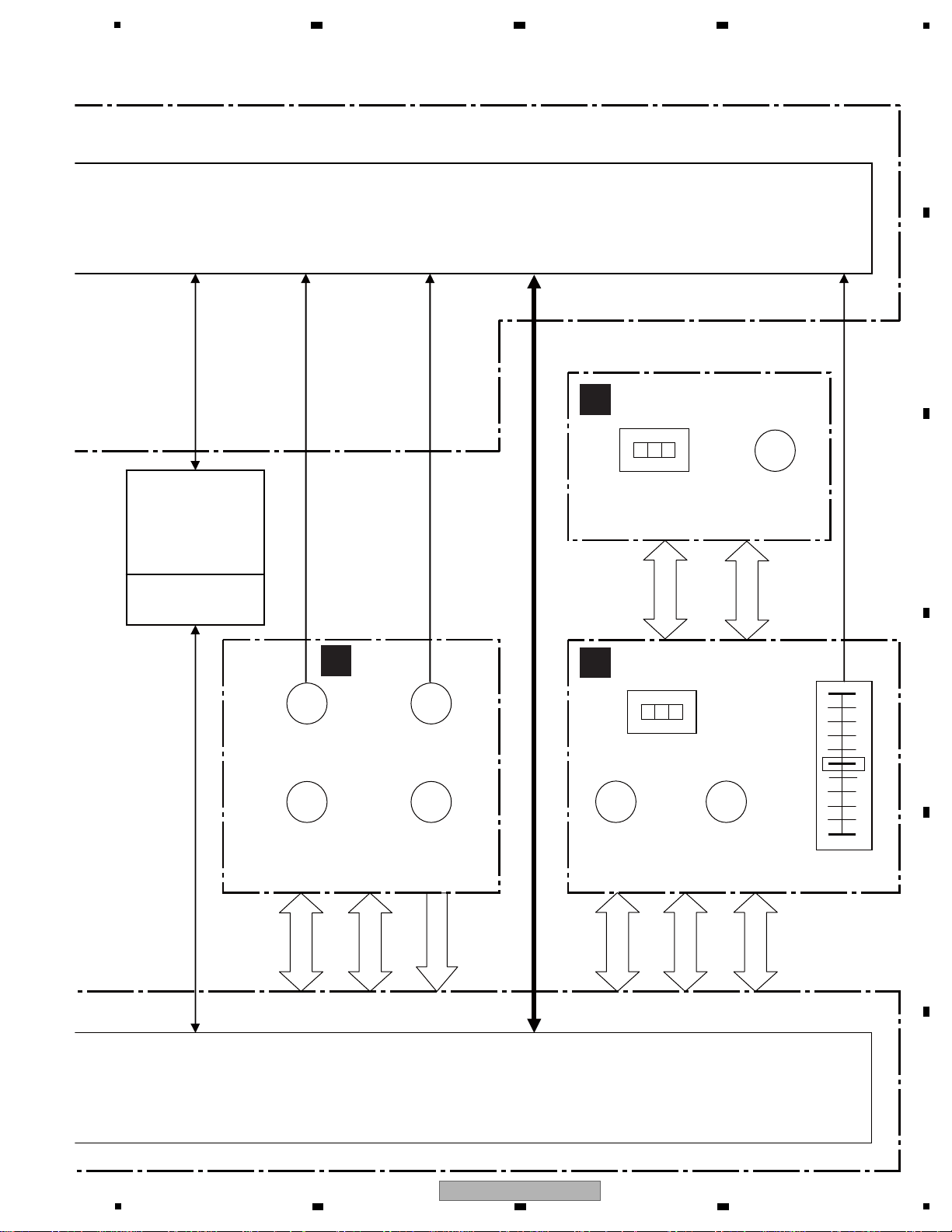

(DWX2726)

HJCK ASSY

(DWX2734)

MJCK ASSY

(DWX2738)

Z

H H( 1/2- 2/2)

H

SCPU ASSY

(DWX2716)

ILMR ASSY

(DWX2722)

AF

ILML ASSY

(DWX2723)

AG

L

CFD1 ASSY

(DWX2740)

M

CFD2 ASSY

(DWX2741)

N

CFD3 ASSY

(DWX2742)

O

CFD4 ASSY

(DWX2743)

K

CTL2B ASSY

(DWX2736)

I

CTL1 ASSY

(DWX2729)

J

CTL2A ASSY

(DWX2735)

T

CRFD ASSY

(DWX2739)

P

INVT ASSY

(DWX2717)

R

CTL3LB ASSY

(DWX2745)

Q

CTL3R ASSY

(DWX2730)

S

CTL3LA ASSY

(DWX2744)

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

: The power supply is shown with the marked box.

5

6 7 8

5

SVM-1000

6 7 8

A

B

C

D

E

F

17

Page 18

1

MIC1, 2

CH1

MIC

D-TRIM

IC4001

IC4003

IC4004

IC4009

MIC1

IC4001

147

MIC2

CH1

D-TRIM

IC4017

DVD

IC4012

IC4011

IC4020

IC4021

RY4001

IC4032

IC1083

IC4026

IC4035

IC4036

RY4002

IC5032

IC5041

IC5042

RY5003

IC5047