Page 1

ORDER No.AD0109126C8

Portable MD Recorder

SJ-MR220

MD unit: RAE1640Z-M Mechanism Series

Colour

(S)...................Silver Type

(W)..................White Type [(GH) area only.]

Areas

EB...................Great Britain.

EG...................Europe.

GCS................Singapore, Malaysia.

GH...................Hong Kong.

1

Page 2

SPECIFICATIONS

Audio

System:

Laser:

Sampling frequency:

Coding:

No. of channels:

Frequency response:

Wow and flutter:

General

Input terminal

OPT/LINE IN jack

Impedance:

Input level:

MIC jack

Impedance:

Input level:

Output terminal

Output Jack:

Power output:

Power supply

Specifications

MiniDisc digital audio system

Semiconductor laser (=780 nm)

44.1 kHz

Adaptive Transform Acoustic Coding

(ATRAC / ATRAC3)

2 (left and right, stereo)

1 (monaural)

20 Hz-20 kHz (+0 dB, -8dB)

Below measurable limit

22k

SENS H: 178mV

SENS L: 500mV

600

SENS H: 0.4mV

SENS L: 2.5mV

Phones, 22

3.5 mW+3.5 mW

2

Page 3

Rechargeable battery:

Battery:

AC adaptor:

Dimensions (WxHxD)

Cabinet dimensions:

incl.projecting parts:

Weight:

Play time

(When used in hold mode, at 25°C, on a flat, stable surface)

Battery type:Play timeRecord time

Rechargeable

Normal:

LP2:

LP4:

Panasonic alkaline

Normal:

LP2:

LP4:

Both together

Normal

LP2:

LP4:

DC 1.2V

(included rechargeable battery)

DC 1.5V (One LR6, AA, UM-3 battery)

DC 1.8V (included AC adaptor)

78.2x71.6x16.0

mm

80.4x74.1x18.3

mm

115 g (with

battery)

88 g (without battery)

About 11.5 hoursAbout 5.5 hours

About 15 hoursAbout 8 hours

About 17 hoursAbout 9.5 hours

About 42 hoursAbout 19 hours

About 54 hoursAbout 26 hours

About 62 hoursAbout 34 hours

About 54 hoursAbout 25 hours

About 71 hoursAbout 34 hours

About 82 hoursAbout 44 hours

Notes:

- The play time may be less depending on the operating

conditions.

- Specifications are subject to charge without notice. Weight

and dimensions are approximate.

2001 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

3

Page 4

1. Accessories

- Rechargeable battery................................ .............1pc.

(RP-BP62EYD)

- External battery case...............................................1pc.

(RFA1537-S2)

- Carrying case.........................................................1pc.

(RFC0069-H)

- Stereo earphones..................................................1pc.

(L0BAB0000162)

- Connection cable..................................................1pc.

(K2KA39B00001)

For EB area

- AC adaptor.............................................................1pc.

(RFEA003B-S)

For EG, GCS areas

- AC adaptor.............................................................1pc.

(N0JCAD000001)

For GH area

- AC adaptor.............................................................1pc.

(RFEA004H-S)

- Wired remote control.............................................1pc.

(N2QCBD000012)

For EB, EG, GCS areas

- Wired remote control............................................1pc.

(N2QCBD000013)

2. Precation of Laser Diode

4

Page 5

3. Operating Instructions

4. Handling Precautions for Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference

caused by static electricity of clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

5

Page 6

4.1. Handling the traverse deck (optical pickup)

1. The traverse deck (optical pickup) is an extremely high-precision

construction and must not be subjected to impact, excessive

vibration, or other types of rough handling.

2. In order to prevent static electricity damage to the laser diode, use a

short pin or similar tool to short the optical pickup’s flexible circuit

boards after they have been disconnected from the main circuit

board. (as shown in Fig. 1)

3. Handle the flexible circuit boards with care; excessive force could

cause them to be broken.

4. Do not turn the pre-set variable resistor (for adjustment of the laser

power); it has been adjusted at the factory.

(as shown in Fig. 2)

Fig. 1

Fig. 2

4.2. Grounding for electrostatic breakdown prevention

6

Page 7

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from

your body. (as shown in Fig. 3)

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where

the traverse deck (optical pickup) is placed, and ground the sheet.

(as shown in Fig. 4)

Caution

The static electricity of your clothes will not be grounded through the

wrist strap.

So, take care not to let your clothes touch the traverse deck (optical

pickup).

Fig. 3

Fig. 4

5. Operation Checks and Component Replacement

Procedures

- This section describes procedures for checking the operation of the

major printed circuit boards and replacing the main components.

7

Page 8

- For reassembly after operation checks or replacement, reverse the

respective procedures. Special reassembly procedures are

described only when required.

- After replacing the main components (optical pickup or traverse

motor, etc.) of mechanism unit block, change to the adjust mode,

and then perform the “ROM/RAM auto-adjustment”.

5.1. Checking for the main P.C.B.

- Check the main P.C.B. (A side) as shown below.

8

Page 9

[Checking for the main P.C.B. (B side)]

- Each parts on main P.C.B. (B side) can not be checkesd directly,

however, for the checking of main component parts on P.C.B., refer

to the “Checking procedures of main components parts on the main

P.C.B. (B side).

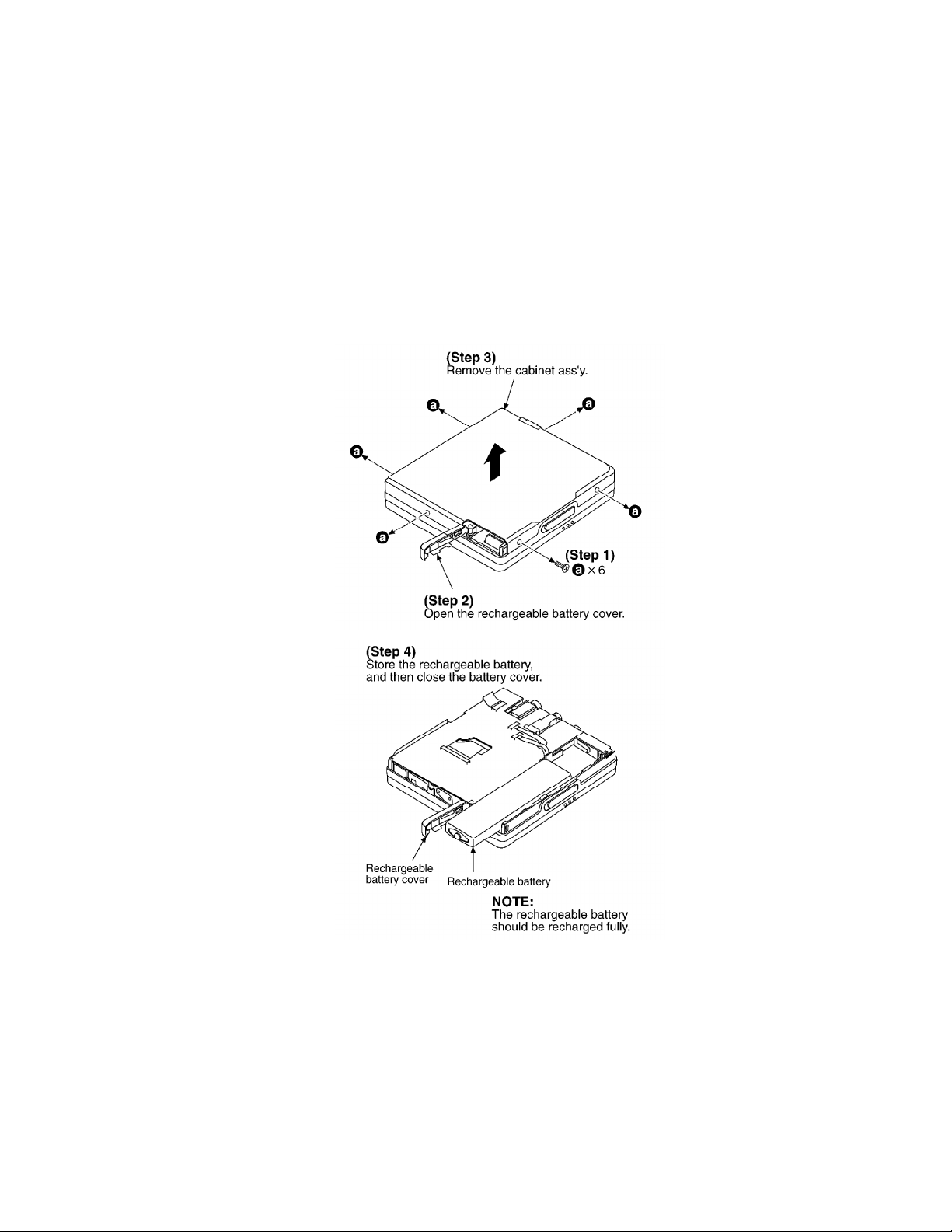

5.2. Replacement for the intermediate cabinet

- Follow the (Step 1) - (Step 3) of item 5.1.

9

Page 10

5.3. Replacement for the open knob and lock unit

- Follow the (Step 1) - (Step 3) of item 5.1.

- Follow the (Step 1) - (Step 3) of item 5.2.

5.4. Replacement for the traverse motor

- Follow the (Step 1) - (Step 3) of item 5.1.

10

Page 11

11

Page 12

5.5. Replacement for the LCD

- Follow the (Step 1) - (Step 3) of item 5.1.

- Follow the (Step 1) - (Step 3) of item 5.2.

12

Page 13

13

Page 14

5.6. Replacement for the lift motor

- Follow the (Step 1) - (Step 3) of item 5.1.

- Follow the (Step 1) - (Step 3) of item 5.2.

- Follow the (Step 1) of item 5.5.

14

Page 15

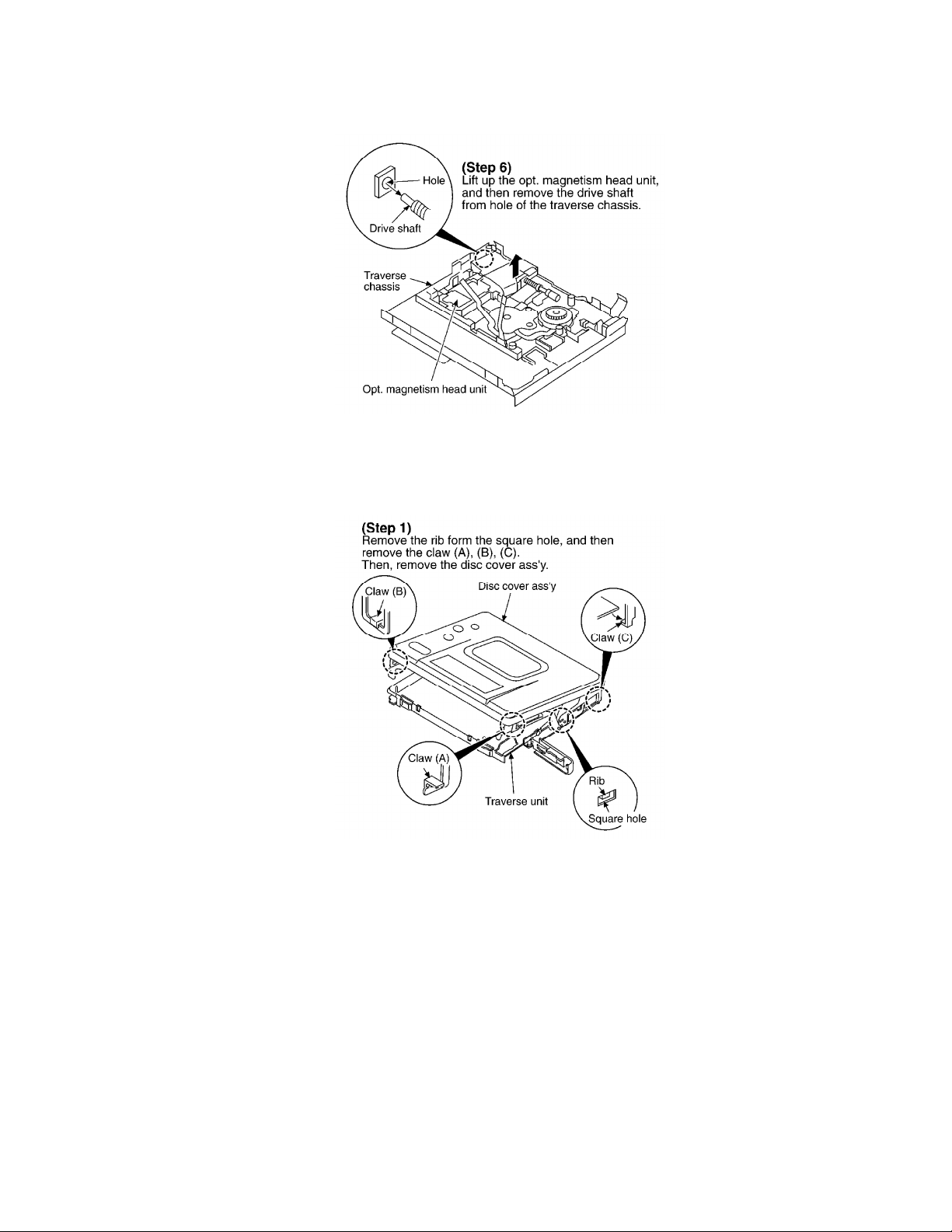

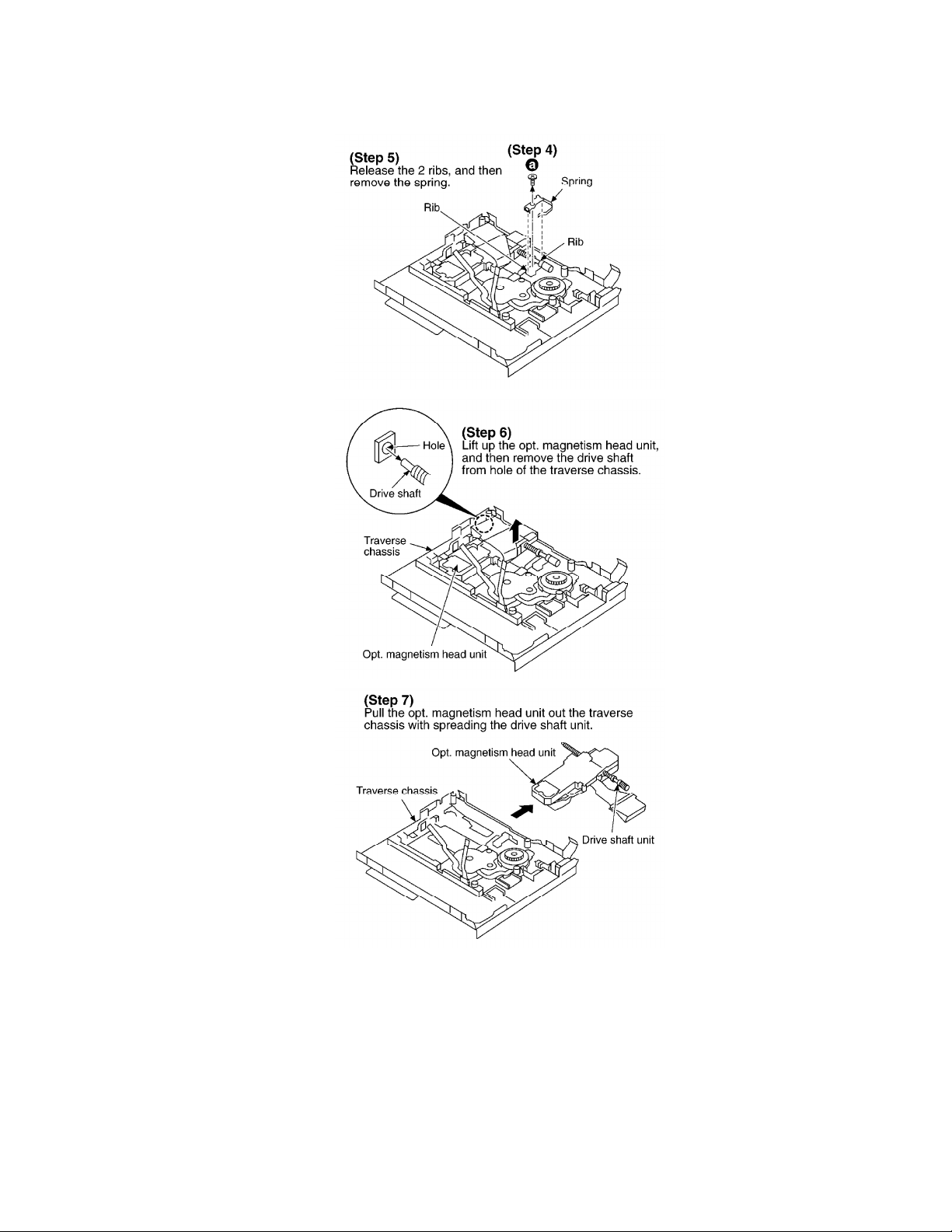

5.7. Replacement for the optical pickup

- Follow the (Step 1) - (Step 3) of item 5.1.

- Follow the (Step 1) - (Step 3) of item 5.2.

- Follow the (Step 1) - (Step 4) of item 5.4.

- Follow the (Step 1) of item 5.5.

15

Page 16

16

Page 17

5.8. Replacement for the spindle motor

- Follow the (Step 1) - (Step 3) of item 5.1.

- Follow the (Step 1) - (Step 4) of item 5.4.

6. Measurements and Adjsutments

Note:

After replacing the main components (optical pickup or traverse motor, etc.) of mechanism unit

block, change to the adjust mode, and then perform the “laser power adjustment”, “off-set autoadjustment” and “playback-only disc/magneto-optical disc auto-adjustment”.

6.1. Instruments to prepare

1. Playback-only disc (Test disc RFKV0006)

17

Page 18

2. Commercially available recordable disc (fully recorded with music)

(magneto-optical disc)

3. Laser power meter (LE8010 or compatible meter)

4. Remote controller

Note:

For use of MD cartridge type laser power meter, remove the intermediate cabinet before perform

the laser power adjustment (as for the method of disassembly, refer to “5. Operation checks and

main component replacement procedures”.).

6.2. Laser power adjustment, Playback-only disc/magneto-optical disc

auto- adjustment

6.2.1. Enter the adjustment mode

1. Set the battery and connect the remote controller.

2. Turn off the power, and switch main unit’s HOLD switch off.

3. Press the buttons of the remote controller in order from 1 to 4 [ for

(EB, EG, GCS) areas, refer to Fig. 5. For (GH) area , refer to Fig. 6.]

Fig. 5

Fig. 6

18

Page 19

4. When the adjustment mode is activated, “T0E1” or “T0E2” will be

displayed on the LCD of remote controller and unit [(EB, EG, GCS)

areas are displayed only unit]. After “T0E1” or “T0E2” is displayed,

select the desired adjustment item with the button or button

of the remote controller. (If it is not displayed, perform the

procedures written above again.)

Adjustment mode

Adjustment mode Display

Laser power adjustment T0**

Off-set automatic adjustment T1**

Magneto-optical disc automatic adjustment T2**

Playback-only disc automatic adjustment T3**

Automatic adjustment value check T4**

EFM jitter meajurement T5**

REC jitter meajurement T6**

Area setting T7**

Open T8**

Error rate measurement (double velocity) T9**

Open TA**

ROM collection check sum TB**

DRAM check TC**

Reliability test TD**

Tilt measurement (disc middle speed) TE**

PWB inspection (audio test) TF**

*In the display of T0** ~ TF** shown above, you must adjust T0**, T1**, T2** and T3**. You must

perform the adjustment by observing the order T0** T1** T2** T3**.

19

Page 20

6.2.2. Laser Power Adjustment

Adjust each laser power: read power for reading (play) and write power for writing (record).

6.2.2.1. Set the Unit to the Adjustment Mode

Cautions

About handling the optical pickup and the magnetic head.

- The optical pickup and the magnetic head are structured precisely;

therefore, they are very fragile. Be careful not to touch them with the

edge of the laser power meter. Do not touch the lens.

- The sensor of the laser power meter is a very fine part. Be careful not

to touch it to the optical pickup lens.

- Do not loosen or remove the magnetic head installing screw.

- The focus point of the laser reaches to 356°F. Therefore, avoid

adjusting using laser power for a long time because the sensor of

the laser power meter may be burned.

- Do not allow the write power to even momentarily reach or exceed

6mW. Doing so will result in damage to the optical pickup.

- Do not set the unit to the laser power adjustment mode with the MD

loaded. Doing so may result in damage to the MD.

- Laser diode in the optical pickup may be destroyed by the

staticelectricity generated in your clothes or body. Be especially

careful with the static electricity.

6.2.2.2. Adjustment Procedure

1. Have “T0**” indicated on display, and move the optical pickup to the

most inside (only when a MD cartridge type laser power meter is

used).

2. Set the laser power meter.

[For use of stick type laser power meter.]

2-1 Uncover the laser power meter (refer to Fig. 7).

2-2 Locate the sensor of the laser power meter right over above the

optical pickup (horizontally at a level of the disc position). (as

shown in Fig. 8)

[For use of MD cartridge type laser power meter.]

2-1 Set the laser power meter and close the disc cover, fix it with

tape as not to open. (refer to Fig. 9).

20

Page 21

Fig. 7

Fig. 8

Fig. 9

3. Press the PLAY key of the remote controller (“T0**” changes to “LD”

of the LCD).

4. Press the key of the remote controller (“LD” changes to “LP” of

the LCD).

5. Perform the read power adjustment. Set the light power at 600 W±

10% by using VOL+, VOL- , EQ and PLAY MODE keys of the remote

controller. In the laser power adjustment, EQ and PLAY MODE keys

change every 8 steps for VOL+ and VOL- keys change 1 step.

Note:

EQ and PLAY MODE keys are applied for only (GH) area. For other areas, those keys are not

applied. Perform with only VOL+ and VOL- keys.

Caution:

21

Page 22

Proceeding on to the subsequent adjustment procedure with the

read power exceeding 600 W±10% will result in damage to the

optical pickup.

6. Press the key of the remote controller (“LP” changes to “RLDA”

in the LCD).

Specified range (read power): 600 W±10% or lower

7. Perfome the light power adjustment. Set the light power at 5.7mW

by using VOL+, VOL-, EQ and PLAY MODE keys of the remote

controller. If at this time the voltage between TP406 and TP407 is

85mA or higher, it is conceivable that the optical pickup is defective.

Specified range (light power): 5.7mW

Caution:

Do not allow the write power to even momentarily reach or exceed 5

mW. Doing so will result in damage to the optical pickup.

8. Press the key of the remote controller (“RLDA” changes to “LP”

on the LDC. At this time, the data is written to EEPROM.).

9. Press the PLAY key on the remote controller (“LP” changes to “T0*

*” on the LCD.).

10. Remove the laser power meter. Laser power adjustment is

finished.

6.2.3. Off-set automatic adjustment

1. After laser power adjustment performed, press the key of the

remote controller and make “T1**” display on the LCD .

2. Make the optical pickup move to center.

3. Press the PLAY key of remote controller without insert disc (change

the display of the LCD to “1FADJ” , adjustment will be started.).

4. Press the PLAY key of the remote controller (change the display of

the LCD to “T1**” , off-set automatic adjustment will be finished.).

6.2.4. Magneto-optical disc automatically adjustment

1. Have “T2**” indicated on display, and move the optical pickup to

around the center.

22

Page 23

2. Set the full-recorded magneto-optical disc with the prevention erase

situation.

3. Press the PLAY key of the remote controller (“T2**” changes to

“1AADJ” on the LCD, adjustment is started.).

4. If it has been finished normally, “1ADDJ” changes to “00OK” or

“10OK” on LCD. If it is abnormally, it changes to “10NG”.

5. Press the PLAY key (“00OK” or “10OK” or ”10NG” changes to “T3*

*”, magneto-optical disc adjusment is finished.).

Note:

If it is displayed “10NG”, check the “Troubleshooting Procedures” in the order.

6.2.5. Playback-only disc automatically adjustment

1. Have “T3**” indicated on display, and move the optical pickup to

around center.

2. Set the playback-only disc.

3. Press the PLAY key of the remote controller (“T3**” changes to

“10ADJ” on the LCD, adjusment is started.).

4. If it has been finished normally, “10ADJ” changes to “00OK” (or

“10OK”) on LCD. If it is abnormally, it changes to “10NG”.

5. Press the PLAY key (“00OK” or “10OK” or “10NG” changes to “T3*

*”, playback-only disc adjustment is finished.).

Note:

If it is displayed “10NG”, check the “Troubleshooting Procedures” in the order.

6.2.6. How to get out the adjustment mode

Remove the battery when you finish the adjustment mode.

6.3. Checking the main unit's keys

Note:

“T KJP1” and “T KJP2” are displayed only (GH) area. Other areas are not display them.

23

Page 24

1. Set the battery and connect the remote controller.

2. Turn off the power. Then, with the main unit’s HOLD switch at OFF,

press the VOL+, VOL-, , and buttons on the remote

controller within two seconds. (as shown in Fig. 5 or Fig. 6)

3. When entering the main unit’s key check mode, “KEY JP1” or “KEY

JP2” will be displayed on the LCD of main unit and “T KJP1” or “T

KJP2” will be displayed on the LCD of remote controller. (If it is not

displayed, perform the procedures written above again.)

4. Confirm the display of LCD by pressing any keys on the main unit.

There is no order to press the keys.

Mian unit’s keys LCD display positions and letters

HOLD OFF 1st. 2nd. letters are AA

REC PAUSE 3rd. 4th. letters are BB

EDIT 5th. 6th. letters are CC

STOP 7th. 8th. letters are DD

PLAY 9th. 10th. letters are EE

5. Remote controller’s LCD [(GH) area only] lights “T ” and main

unit’s LCD lights all when you can detect all keys.

6. Perform below voltage check about the keys come under if you

cannot detect the key.

Main unit’s keys Check points ON OFF

HOLD

REC PAUSE IC501 3pin 0.12V 2.2V

EDIT IC501 3pin 1.96V 2.2V

STOP IC501 3pin 1.05V 2.2V

PLAY IC501 3pin 0V 2.2V

TP403

0V 2.2V

7. When the keys are ready for detection, press the PLAY key of the

remote control.

8. Pressing each key mounted to the main body, make sure of

displayed three letters (4th ~ 6th letters) on the right side of the

24

Page 25

remote control. / Keys to be pressed are not in order. / When the 3

keys apportioned to the respective letters as shown below are all

OK, “0” is displayed.

Display position Main unit’s keys

4th. letter

5th. letter Flat pad middle rank 3 keys

6th. letter Flat pad upper rank 3 keys

Flat pad lower rank 3 keys

9. Upon detection of all keys, “000” is shown on the right side of LCD

of the remote control [(GH) area only].

10. Perform below voltage check about the keys come under if you

cannot detect the key.

Main unit’s keys Check points ON OFF

Flat pad (*1) IC501 65~67pin 2.2V 0V

11. Remove the battery when you exit from this mode.

Note:

Refer to “12. Printed Circuit Board and Wiring Connection Diagram” for the test points.

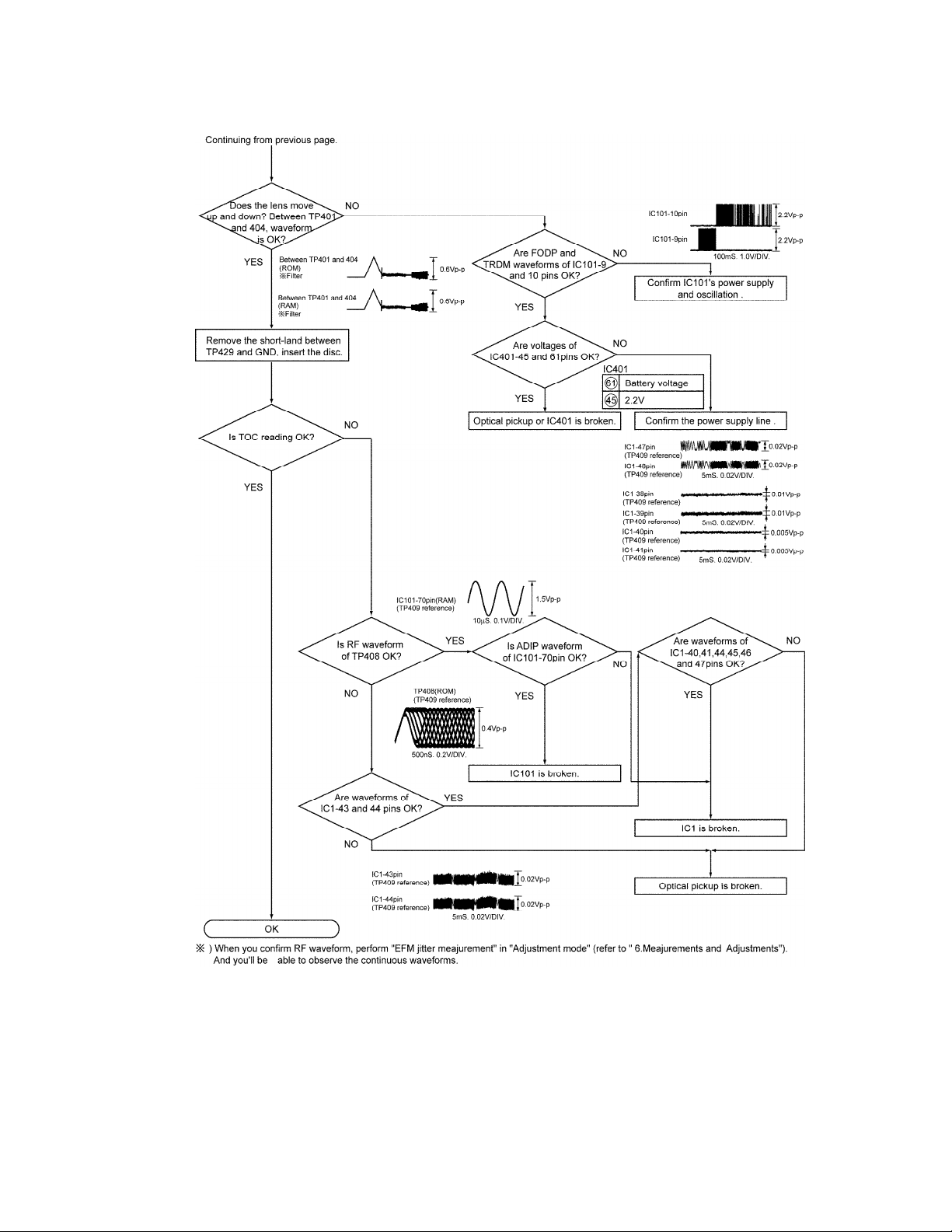

7. Troubleshooting Guide

252627282930313233

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

8. Checking Procedures of Main Components Parts on

the Main P.C.B. (B side)

As it cannot meajure the mechanism side of MAIN P.C.B. directly, refer to the table shown below

for the criterion in the time of repairing or checking.

34

Page 35

Circuit

measure

TP137

voltage

check

TP137

IC304.

form

FPC

solder

and

is

the

form

supply

and

and

is

IC401.

form

check

IC701

solder,

unusual

IC701.

form

check

perihperal

No.

IC304

IC901

IC601

Part No. Function Symptom Check point Result and

C0DBAGZ00006

C0GBE000003

C0FBAJ000008

DC-DC converter

/ 3.5V / Power

IC for magnetic

head driver

control

Optical head lift

motor drive

A/D

CONVERTER

Recording is

impracticable.

Recording is

impracticable.

Magnetic head

fails to descend.

Optical input

permits recording,

but line input does

not.

MIC recording is

impracticable.

Confirm the

voltage of IC902

(pin 14) or (TP137)

Confirm the

voltage of IC501

(pin 74)

Confirm the

motor drive wave

form of TP145,146,

147 and 148 (CN901

pins 1,2,3 and 4).

Make sure of

IC101 (pin 27) input

wave form (during

MIC/LINE input

time).

If voltage at

normal and

IC501 is unusual,

IC501 and switch

periphery.

If voltage at

unusual, replace

If drive wave

normal, check

condition of

around lift motor,

nothing unusual

found, replace

motor.

If drive wave

unusual, check

voltage of IC401

peripheral solder,

nothing unusual

found, replace

If input wave

IC601 is unusual,

supply voltage of

and peripheral

and if nothing

found, replace

If input wave

IC601 is normal,

IC601 and

circuit.

9. Display of Self-Diagnostic Function

This model is equipped with a self-diagnosis function and shows, when necessary, the following

indication in the LCD section of the set.

35

Page 36

“F15”---This indication appears when the Down switch fails to turn ON since the magnetic head

fails to move up/down normally (Due to trouble of the magnetic head or trouble of the magnetic

head up/down motor) or the magnetic head P.C.B. is out of position or a foreign matter has mixed

in or for some other reason.

In such a case, check the peripheral parts of the magnetic head, repair or replace defective parts

with normal ones.

10. Schematic Diagram Notes

10.1. Schemtic Diagram Notes

This schematic diagram may be modified at any time with the development of new technology.

Notes:

S1

S2-1

S2-2

S801

S802

S803

S804

S806

Magnetic head up switch (M.HEAD UP)

:

Open/close det. switch (OPEN/CLOSE)

:

PROTECT det. switch

:

Play / record / pause / operation on /

:

character type button ( , CHARA)

Recording pause / operation on / LP

:

recording switch (REC , LP MODE)

:

Stop / operation off / edit cancel button ( ,

OPR OFF)

Enterling edit mode, completing edit,

:

changing track ,mark mode switch (EDIT,

MARK MODE)

Hold swithc in “OFF” position. (HOLD )

:

- Indicated voltage values are the standard values for the unit

measured by the DC electronic circuit tester (high-impedance) with

the chassis taken as standard. Therefore, there may exist some

36

Page 37

errors in the voltage values, depending on the internal impedance of

the DC circuit tester.

No mark: MD STOP

( ): MD play [1kHz, L+R, 0dB]

Important safety notice:

Components identified by mark have special characteristics important for safety.

Furthermore, special parts which have purpose of fire-retardant (resistors), high-quality sound

(capacitors), low-noise (resistors), etc. are used. When replacing any of components, be sure to

use only manufacture's specified parts shown in the parts list.

Caution!

IC and LSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

Cover the parts boxes made of plastics with aluminum foil.

Ground the soldering iron.

Put a conductive mat on the work table.

Do not touch the legs of IC or LSI with the fingers directly.

Voltage and signal line

: Positive voltage line

: Playback signal line

: Recording signal “digital” line

: Recording signal “analog” line

: Mic signal line

10.2. Type Illustration of IC's, Transistors and Diodes

11. Schematic Diagram

12. Printed Circuit Board Diagram

13. Block Diagram

14. Wiring Connection Diagram

15. Terminal Function of IC's

15.1. IC1 (AN22010A-VF) : RF AMP

37

Page 38

Pin

output

terminal

No.

Mark I/O

Function

Division

1

LDO O Laser amp output terminal

2

LD IN I Laser amp reverse input

terminal

3 APCPD I Photo diode light quantity

det. input terminal

4

APC REF I APC amp reference voltage

input terminal

5

ARFO O RF amp. output terminal

6 NC — Not used, open

7

EQ IN I EQ input terminal

8

CRF

AGC

— RFAGC capacitor

connection terminal

(Connected to GND

through capacitor)

9

OUT RF O EFM signal output terminal

10

11

NC — Not used, open

PEAK

EFM bright side det. output

O

terminal

12

GND — GND terminal

13 BOTM O EFM dark side det. output

terminal

14

CEA I 3T envelope det. capacitor

connection terminal

(Connected to power

supply through capacitor)

15

MON3T O AS/3TMON signal output

terminal

16 CC O C signal dark side det. /

amplifier output terminal

17 DD

D signal dark side det. /

O

amplifier output terminal

18

V

CC

I Power supply terminal (+

3V)

19

BB GAIN

O B signal I/V converter

output terminal

20 AA

A signal I/V converter

O

output terminal

21 FF2 O F2 signal I/V converter

output terminal

22 FF1 O F1 signal I/V converter

38

Page 39

output

terminal

Pin

No.

23,24 NC

25

26 NC

Mark I/O

Function

Division

Not used, open

—

ADIP O ADIP signal output terminal

Not used, open

—

27 NREC I REC/PLAY select signal

input terminal

28 RFSWHL

Reflect H/L select signal

I

input terminal

29 RFSWPG

Pit / group select signal

O

output terminal

30 GND

31 NC

32

MONIOFF

GND terminal

—

Not used, open

—

3TMON circuit control

I

signal input terminal

33 CLT2

ADIP BPF select signal

I

input terminal

34 LDON

ACP circuit control signal

I

input terminal

35

NRFSTBY

I Standby control signal

input terminal

36

TEMP O Temperature sensor amp

output terminal

37

TEMP IN I Temperature sensor amp

input terminal

38

39

F1 I F1 signal input terminal

F2 I F2 signal input terminal

40 A I Main beam A signal input

terminal

41 B

I Main beam B signal input

terminal

42

VREF I Reference voltage input

terminal

43

44

45

RF2 I RF2 signal input terminal

RF1 I RF1 signal input terminal

CENVD I D signal det. capacitor

input terminal

46

CENVC I Beam E signal detection

capacitor input terminal

47 D I

Main beam D signal input

terminal

39

Page 40

Pin

No.

48

Mark I/O

Division

C

I

Function

Main beam C signal input

terminal

15.2. IC101 (M66621ARG) : ATRAC ENCORDER/DECORDER, SERVO

SIGNAL PROCESSOR

Pin

No.

10 FODP O Focus (+) drive signal

11 TRDM O Tracking (-) drive signal

12 TRDP O Tracking (+) drive signal

13 DVDD0 — Power supply input

14 LDON O LD lighting control signal

15 TVDM/

Mark I/O

Division

1 TS0 I Test input terminal (Not

used, connected to GND)

2 APCD O Laser power setting PWM

output terminal

3 RFSWPG O Pit / group setting signal

output terminal

4 RFSWHL O High / low reflection

setting signal output

terminal

5 CLV2 O High speed select signal

output terminal

6 REFM O EFM signal output terminal

7 SPDM O Spindle (-) drive signal

output terminal

8 SPDP O Spindle (+) drive signal

output terminal

9 FODM O Focus (-) drive signal

output terminal

output terminal

output terminal

output terminal

terminal ( For digital circuit)

output terminal

O Traverse (-) drive signal /

STPO0

stepper drive signal 0

output terminal

Function

40

Page 41

Pin

No.

16 TVDP/

Mark I/O

Division

STPO1

Function

O Traverse (+) drive signal /

stepper drive signal 1

output terminal

17 SBCK/

STPO2

O Sub code Q clock for

resistor / stepper drive

signal 2 output terminal

18 SUBC/

STPI0

19 BLKCK/

STI1

I Sub code Q / stepper

status 0 input terminal

I Sub code block clock

signal / stepper status 1

input terminal

20 NCLDCK

/

STPI2

I Sub code flame clock

signal / stepper status 2

input terminal

21 NREC O REC / PLAY select signal

output terminal

22 DRVSEL I Driver mode select input

terminal

23 DATA/FG I CD data / FG input terminal

24

BCK I CD bit clock input terminal

25 LRCK I CD word clock input

terminal

26 FS384 O External ADC / DAC clock

output terminal

27 SDAR I Audio data input terminal

28 SDAP O Audio data output terminal

29 SWS O Word clock output terminal

30 SCL O Bit clock output terminal

31 RX2 I Digital audio interface 2

input terminal

32 RX1 I Digital audio interface 1

input terminal

33 TX O Digital audio interface

output terminal

34 DVDD1 — Power supply terminal

35 DVSS1 — GND terminal

36 SGSYNC O Frame synchronous signal

output terminal

37 MDISY O Leader synchronous signal

output terminal

41

Page 42

Pin

No.

Mark I/O

Division

Function

38 SCTSY O ADIP synchronous noise

output terminal

39 SSDR O System control read data

output terminal

40 SSDW I System control write data

input terminal

41 SSCK I System sift clock signal

input terminal

42 SELAD I System control address

signal select input terminal

43 MONI1 O Monitor 1 output terminal

(Not used, open)

44 MONI2 O Monitor 2 output terminal

(Not used, open)

45 MONI3 O Monitor 3 output terminal

(Not used, open)

46 NRST I Hardware reset signal

input terminal

47

PWMVSS

— GND terminal

48 ADACR O Audio Rch output terminal

49 ADACL O Audio Lch output terminal

50

PWMVDD

— Power supply terminal

51 AVSS0 — GND terminal

52 PEAK I Servo A/D converter input

terminal

53 BOTM I Servo A/D converter input

terminal

54 OSC I Servo A/D converter input

terminal

55 MON3T I Servo A/D converter input

terminal

56 VREF1 I Reference voltage input

terminal

57 FF2 I Servo A/D converter input

terminal

58 FF1 I Servo A/D converter input

terminal

59 AVDD0 — Power supply terminal

60 DD I Servo A/D converter input

terminal

42

Page 43

Pin

No.

Mark I/O

Division

Function

61 CC I Servo A/D converter input

terminal

62 BB I Servo A/D converter input

terminal

63 AA I Servo A/D converter input

terminal

64 AVSS1 — GND terminal

65 PEFMS I EFM signal input terminal

66 PEFM1 O EFM data slice roop filter 1

output terminal

67 EFMIL O EFM data slice roop filter 2

output terminal

68

EFMPLLF

O Filter for EFMPLL output

terminal

69 EFMIREF I Reference voltege for

EFMPLL setting input

terminal

70 ADIP I ADIP signal input terminal

71 AVDD1 — Power supply terminal

72 MONI0 O Monitor 0 output terminal

73 RAD11 O Address for DRAM 11

output terminal

74 RAD10 O Address for DRAM 10

output terminal

75 RAD9 O Address for DRAM 9 output

terminal

76 RAD8 O Address for DRAM 8 output

terminal

77 RAD7 O Address for DRAM 7 output

terminal

78 RAD6 O Address for DRAM 6 output

terminal

79 DVSS2 — Connected to GND

80 RAD5 O Address for DRAM 5 output

terminal

81 RAD4 O Address for DRAM 4 output

terminal

82 RAD3 O Address for DRAM 3 output

terminal

43

Page 44

Pin

No.

83 RAD2 O Address for DRAM 2 output

84 RAD1 O Address for DRAM 1 output

85 DVDD2 I Power supply input

86 RAD0 O Address for DRAM 0 output

87 RDT3 I/O Data for DRAM 3 input /

88 IVDD1 — Power supply for I/O pad

89 RDT2 I/O Data for DRAM 2 input /

90 RDT1 I/O Data for DRAM 1 input /

91 RDT0 I/O Data for DRAM 0 input /

92 NRAS O Load address strobe for

93 NCAS O Calam address strobe for

94 NEW O Write enable signal for

95 TS2 I Test input terminal (Not

96 DVSS0 — GND terminal

97 XO O Crystal oscillator output

98 XI I Crystal oscillator input

99 IVDD0 — Power supply for I/O pad

100 TS1 I Test input terminal (Not

Mark I/O

Division

Function

terminal

terminal

terminal

terminal

output terminal

output terminal

output terminal

output terminal

DRAM signal output

terminal

DRAM signal output

terminal

DRAM output terminal

used, connected to GND)

terminal (F=16.9344MHz)

terminal (F=16.9344MHz)

used, connected to GND)

15.3. IC401 (C0GBZ0000006) : FOCUS/TRACKING COIL, TRAVERSE

MOTOR DRIVE, SPINDLE MOTOR DRIVE, ROTARY DETECTOR

44

Page 45

Pin

No.

Mark I/O

Division

Function

1 IN 1R I H bridge 1 reverse input

terminal

2 IN 2F I H bridge 2 forward input

terminal

3 IN 2R I H bridge 2 reverse input

terminal

4 STALL I Standby input terminal

5 STHB I H1, H2 bridge mute input

terminal

6 SP VM1 I Half bridge 1 input terminal

7 SP U

OUT

O Spindle motor coil (U)

output terminal

8 SP PG1 — GND terminal

9 NC —

10 SP V

OUT

Not used, open

O Spindle motor coil (V)

output terminal

11 SP VM2 I Half bridge input terminal

12 SP W

OUT

O Spindle motor coil (W)

output terminal

13 SP PG2 — GND terminal

14 PWVM I Power supply terminal

15 PWOUT O Hlaf bridge 1 output

terminal / (Not used, open)

16 PWPG — GND terminal

17 PWIN1 — GND terminal

18 SP U IN I Roter position detect

comparater (U) input

terminal

19 SP V IN I Roter position detect

comparater (V) input

terminal

20 SPWIN I Roter position detect

comparater(W) input

terminal

21 SPCOM I Spindle motor coil center

input terminal

22 RIB —

Connected to GND through

resistor

23 CST — Connected to GND through

capacitor

45

Page 46

capacitor

Pin

No.

Mark I/O

Division

Function

24 CSL1 I Slope capacitor connection

terminal (connected to

GND through capacitor)

25 CSL2 I Slope capacitor connection

terminal (connected to

GND through capacitor)

26 FG O Speed pulse output

terminal

27 BRK- I Brake comparater- input

terminal

28 BRK+ I Brake comparater+ input

terminal

29 ASGND — GND terminal

30 SGND — GND terminal

31 S1 I Stepping decorder 1 input

terminal

32 S2 I Stepping decorder 2 input

terminal

33 S3 I Stepping decorder 3 input

terminal

34 BEMFU O Step detect comparater (U)

output terminal

35 BEMFV O Step detect comparater (V)

output terminal

36 BEMFW O Step detect comparater (W)

output terminal

37 SLCOM I Step motor coil center

input terminal

38 SLPG2 — GND terminal

39 SLWOUT O Stepping motor (W) output

terminal

40 SLVM2 I Power supply terminal

41 SLVOUT O Stepping motor (V) output

terminal

42 SLPG1 — GND termial

43 SLUOUT O Stepping motor (U) output

terminal

44 SLVM1 I Power supply terminal

45 VCC2 I Power supply terminal

46 VCC1 I Power supply terminal

46

Page 47

Pin

No.

47 VG O Charge pump output

48 C2M — Charge pump capacitor 2(-)

49 C2P — Charge pump capacitor 2(+)

50 C1M — Charge pump capacitor 1(-)

51 C1P — Charge pump capacitor 1(+)

52 EXTCLK I Not used, open

53 NC — Not used, open

54 H2 PG2 — GND terminal

55 H2 R

56 H2 VM I Power supply terminal

57 H2 F

58 H2 PG1 — GND terminal

59 H1 PG2 — GND terminal

60 H1 R

61 H1 VM I Power supply terminal

62 H1 F

63 H1 PG1 — GND terminal

64 IN 1F I H bridge 1 forward input

Mark I/O

Division

O H bridge 2 reverse output

OUT

O H bridge 2 forward output

OUT

O H bridge 1 reverse output

OUT

O H bridge 1 forward output

OUT

Function

terminal

connect terminal

connect terminal

connect terminal

connect terminal

terminal

terminal

terminal

terminal

terminal

15.4. IC501 (MN101C61GAB) : SYSTEM CONTROL

47

Page 48

Pin

No.

Mark I/O

Division

Function

1 VREF- I Reference voltage input

terminal

2 REM

KEY

I Remote cont. key input

terminal

3 KEY IN1 I Unit key1 input terminal

4 TEMP I Temperature sensor input

terminal

5 BATT1 I Battery voltage det. input

terminal

6 LDPADJ I LDP input terminal

7 DOCTOR O Doctor mode input terminal

8 OUTC O Charge pump output

terminal (Not used, open)

9 NC — Not used, open

10 VREF+ I Reference voltage input

terminal

11 V

DD

I Power supply terminal

12 OSC2 I System clock input

terminal (f=10.02MHz)

13 OSC1 O System clock output

terminal (f=10.02MHz)

14 VSS — GND terminal

15 XI I Sub clock input terminal

(Not used, connected to

GND)

16 XO O Sub clock output terminal

(Not used, open)

17 MMOD — Memory mode select input

terminal (Connected to

GND)

18 REM

DATA

19 LINK

O LCD driver data output

terminal

I Link serial input terminal

RXD

20 NC — Not used, open

21 SSDW O MSP/MDA interface writing

data output terminal

22 SSDR I MSP/MDA interface reading

data input terminal

48

Page 49

Pin

No.

Mark I/O

Division

Function

23 SSCLK O MSP/MDA interface data

forward clock output

terminal

24 BUZZER O Buzzer output trminal

25 RST I Reset signal input terminal

26 SELAD O MSP/MDA interface

address signal output

terminal

27 ATRAC

CNT

O ATRAC contorl output

terminal (“H”:NORMAL, “L”

:HiFi)

28 LCD STB O LCD driver strobe signal

output terminal

29 MIC

SENSE

O MIC sensitivity select

output terminal

30 EFMON O Magnetic head EFM drive

output terminal

31

OPENSW

I Disc cover open/close

switch det. input terminal

(“H”:open, “L”:close)

32 WAKEUP I Micro computer wake up

signal input terminal

33 SCTSY I ADIP/sub A synchronize

signal from IC101 input

terminal

34 CFSYNC I MDA synchronize signal

from IC101 input trminal

(11.6ms pulse)

35 MDISY I Leader synchronize signal

from IC101 input terminal

36 LCD

DATA

O LCD driver data output

terminal

37 NC — Not used, open

38 LCD CK I LCD driver clock input

terminal

39

CHARGE1

O Recharging control output

terminal

40 EEPCS O EEPROM chip select

output terminal

41 EEPCK O EEPROM clock output

terminal

49

Page 50

Pin

No.

42

Mark I/O

EEPDATA0

Function

Division

O EEPROM data output

terminal

43

EEPDATAI

O EEPROM data input

terminal

44

AKMCDT1

O Analog input PGA A/D

converter interface data

output terminal

45 AKMCSN O Analog input PGA A/D

converter interface chip

select output terminal

46

AKMCCLK

O Analog input PGA A/D

converter interface clock

output terminal

47 AKMPDN O Analog input PGA A/D

converter interface reset

output terminal

48 EL ON I EL display control input

terminal

49 DC IN

WAKEUP

I DC IN wake up input

terminal

50 LCDCNT O LCD power cont. output

terminal (“H” : ON)

51

MONIOFF

O 3T monitor OFF output

terminal (“H : OFF)

52 MUTEA O Analog mute A output

terminal

53 MUTEB O Analog mute B output

terminal

54 NC — Not used, open

55 DEBUG1 O Micro computer debug

output terminal

56 DEBUG2 O Micro computer debug

output terminal

57 MHEAD

UP

58

PROTECT

I Magnetic head down input

terminal

I Erase prevention switch

input terminal

59 HOLD

SW

60

DCINDET

I HOLD switch input

terminal (“H”:OFF, “L”:ON)

I DC IN det. input terminal

50

Page 51

Pin

No.

61 MIC DET I Mic det. input terminal

62 INSEL I INPUT select det. input

63 FPOUT1 O Flat pad A output terminal

64 FPOUT2 O Flat pad B output terminal

65 FP IN1 I Flat pad 1 input terminal

66 FP IN2 I Flat pad 2 input terminal

67 FP IN3 I Flat pad 3 input terminal

68 LOAD0 O Magnetic head movement

69 LOAD1 O Magnetic head movement

70 MIC/LINE O MIC/LINE select output

71 HFON1 I HF module ON 1 input

72

73 RFCNT O RF power supply control

74

75 PWRCNT O Power supply control

76 FPOUT3 O Flat pad output terminal

77 PC O 4ch driver standby output

78 STBY2 O FD/TR coil power supply

79

80 MSP

Mark I/O

RECCNT2

RECCNT1

NRFSTBY

RST

Function

Division

terminal

control 0 output terminal

control 1 output terminal

terminal

terminal

O REC control 2 output

terminal

output terminal

O REC control 1 output

terminal

output terminal

terminal

control output terminal

O RF amp standby output

terminal

O MSP reset output terminal

16. Caution in Use of Rechargeable Battery Ass'y

- Take Rechargeable Battery Ass’y out of Battery Carrying Case and

use it.

- Be sure to carry Rechargeable Battery Carrying Case. If not, it may

51

Page 52

either heat or ignite by shorting with a metal. (as shown in Fig. 10)

Fig. 10

17. Replacement Parts List

Notes:

*Important safety notice: / Components identified by mark have special characteristics

important for safety. / Funrthermore, special parts which have purposes of fire-retardant

(resistors), high-quality sound (capacitors), low-noise (resistors), etc. are used. / When replacing

any of components, be sure to use only manufacture’s specified parts shown in the parts list. / *

Warning: This product uses a laser diode. Refer to caution statements.

*ACHTUNG:Die lasereinheit nicht zerlegen.Die lasereinheit darf nur gegen einc vom hersteller

spezifizierte einheit ausgetauscht werden.

*Capacity values are in microfarads (uF) unless specified otherwise, P=Pico-farads (pF) F=Farads

(F) / *Resistance values are in ohms, unless specified otherwise, 1K=1,000 (OHM), 1M=1,000K

(OHM)

*The marking <RTL> indicates that the Retention Time is limited for this item. After the

discontinuation of this assembly in production, the item will continue to be available for a specific

period of time. The retention period of availability is dependant on the type of assembly , and in

accordance with the laws governing part and product retention. After the end of this period, the

assembly will no longer be available.

*"<IA>"-“<IC>” marks in Remarks indicate languages of instruction manuals.

[<IA>:English/Spanish/French/German/Netherlands/Swedish/Italian/Danish/Polish,<IB>:

English,<IC>:English/Chinese]

52

Page 53

Ref. No. Part No. Part Name & Description Pcs Remarks

1 L5DCAEC00001 LCD 1

2 RJB2434A OPERATION FPC 1

3 RGP0875-1Q1 LCD HOLDER 1 (W)

3 RGP0875-Q1 LCD HOLDER 1 (S)

4 RGU2014-D1 OPERATION BUTTON 1 (W)

4 RGU2014-S1 OPERATION BUTTON 1 (S)

5 RHQ0083-S SCREW 6

6 RMZ0580 INSULATION SHEET 1

7 RXM0075-2 LINK UNIT 1

8 RYF0596-S DISC COVER ASS’Y 1 (S)

8 RYF0596-W DISC COVER ASS’Y 1 (W)

8-1 RGV0284-S REC KNOB 1

8-2 RGV0286-S HOLD KNOB 1

8-3 RMA1469 REC LEVER 1

9 RYK1125-S INTERMEDIATE CABI.ASS’Y 1 (S)

9 RYK1125-1S INTERMEDIATE CABI.ASS’Y 1 (W)

9-1 RGV0285-S1 OPEN KNOB 1

10 XQN14+B2FC SCREW 1

11 RYK1124A-S CABINET ASS’Y 1 (EB)(EG)

11 RYK1124B-S CABINET ASS’Y 1 (GH)(S)

11 RYK1124B-W CABINET ASS’Y 1 (GH)(W)

11 RYK1124C-S CABINET ASS’Y 1 (GCS)

12 RHD14094-S SCREW 6

13 RKK0151-S RECHARGEABLE BATT.COVER 1 (S)

13 RKK0151-W RECHARGEABLE BATT.COVER 1 (W)

14 RHD14080 SCREW 1

15 BRL1A1CWD LIFT LEVER 1

16 RDG0482-1 REDUCTION GEAR 1

17 RHW06001 WASHER 1

18 RMB0650 EJECT SPRING 1

19 RMC0232 SPRING 1

20 RML0586-3 LIFTER 1

21 RML0587-3 LINK 1

22 RMM0230 EJECT ROD A 1

23 RMQ0958-3 ARM 1

24 RXG0050 TRANSFER GEAR 1

25 RXK0318 HOLDER UNIT 1

26 RXM0071 EJECT ROD B 1

28 RDG0510 INTERMEDIATE GEAR 1

29 RHD14078 SCREW 1

30 RHW11011 WASHER 1

31 RMC0437 SPRING 1

32 BRL1A1CWF TRAVERSE MOTOR 1

33 K0L2LF000001 SWITCH(S2) 1

34 REM0096 SPINDLE MOTOR 1

35 RHD14067 SCREW 8

36 RHD14082 SCREW 1

37 RMA1364-2 HOLDER ANGLE 1

38 RMK0496 TRAVERSE CHASSIS 1

53

Page 54

Ref. No. Part No. Part Name & Description Pcs Remarks

39 RMX0156-1 STOPPER RUBBER 2

40 RMZ0592 INSULATION SHEET 1

41 XQN14+B4FC SCREW 1

42 XQN14+C12FZ SCREW 2

43 RXJ0030 DRIVE SHAFT UNIT 1

44 RFKQMR220S OPT MAGNETISM HEAD UNIT 1

45 RJC99039-1 R.BATTERY TERMINAL(+) 1

46 RJR0195-2 BATTERY SHAFT 1

A1 RP-BP62EYD RECHARGEABLE BATT. ASSY 1

A1-1 RFA0475-Q RECHARGEABLE BATT.CASE 1

A2 RFA1537-S2 EXTERNAL BATTERY CASE 1

A3 RFC0069-H CARRYING CASE 1

A4 RFEA003B-S AC ADAPTOR 1

A4 N0JCAD000001 AC ADAPTOR 1

A4 RFEA004H-S AC ADAPTOR 1

A5 N2QCBD000013 WIRED REMOTE CONTROL 1 (EB)(EG)(GCS)

A5 N2QCBD000012 WIRED REMOTE CONTROL 1 (GH)

A5-1 RFKY0004 REMOTE CONT.CLIP ASS’Y 1 (GH)

A5-2 RFKY0003 REMOTE CONT.FRONT PANEL 1 (GH)

A6 L0BAB0000162 STEREO EARPHONES 1

A7 RQT6074-B INSTRUCTION MANUAL 1 (EB)<IB>

A7 RQT6073-E INSTRUCTION MANUAL 1 (EG)<IA>

A7 RQT6075-G INSTRUCTION MANUAL 1 (GH)(GCS)<IC>

A8 K2KA39B00001 CONNECTION CABLE 1

A9 RQCB0169 SERVICE CENTER LIST 1

(EB)

(EG)(GCS)

(GH)

C1 ECUVNA224KBV 10V 0.22U 1 F1H1A224A028

C2 ECUVNA105ZFV 10V 1U 1 F1H1A105A030

C3 ECUVNC104ZFN 16V 0.1U 1 F1J1C104A081

C4 ECUE1E472KBQ 25V 4700P 1 F1G1E4720004

C5 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C20,21 ECUVNA224KBV 10V 0.22U 2 F1H1A224A028

C30 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C31 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C34 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C35 F5A421040001 4V 0.1U 1

C50 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C51 ECUE1H102KBQ 50V 1000P 1 F1G1H102A457

C52 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C53 ECUVNJ474KBV 6.3V 0.47U 1 F1H0J474A002

C101 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C102 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C103 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C104 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C105 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C106 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C107 RCST0EX227RE 2.5V 220U 1 F3G0E2270001

C109,10 ECUE1H100DCQ 50V 10P 2 F1G1H100A420

C111 ECUE1H470JCQ 50V 47P 1 F1G1H470A422

54

Page 55

C111

ECUE1H470JCQ

50V

47P1F1G1H470A422

55

Page 56

Ref. No. Part No. Part Name & Description Pcs Remarks

C112 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C120 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C121 ECUE1C223KBQ 16V 0.022U 1 F1G1C223A044

C122 ECUVNA224KBV 10V 0.22U 1 F1H1A224A028

C123 ECUE1E681KBQ 25V 680P 1

C130 ECUE1E472KBQ 25V 4700P 1 F1G1E4720004

C140 ECUE1C103KBQ 16V 0.01U 1

C201 F1J0J4750010 6.3V 4.7U 1

C202 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C203 F1J0J4750010 6.3V 4.7U 1

C204 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C205 RCST0GZ226RG 4V 22U 1 F3E0G226A002

C206 F5A421040001 4V 0.1U 1

C207 ECUE1H331KBQ 50V 330P 1 F1G1H331A402

C208 F1J0J4750010 6.3V 4.7U 1

C211,12 ECUVNJ105KBV 6.3V 1U 2 F1H0J105A002

C213,14 ECUE1H102KBQ 50V 1000P 2 F1G1H102A457

C215,16 RCST0EX227RE 2.5V 220U 2 F3G0E2270001

C220 ECUE1H101KBQ 50V 100P 1

C222 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C223 ECUE1C103KBQ 16V 0.01U 1

C301 RCST0EC397RE 2.5V 390U 1 F3H0J397A012

C302 RCST0JX107RG 6.3V 100U 1 F3G0J1070002

C303 F3Z0G107A003 4V 100U 1

C304 RCST0JY226RG 6.3V 22U 1 F3F0J2260002

C305 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C306 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C308-10 ECUENA104KBQ 10V 0.1U 3 F1G1A104A014

C312 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C313 ECUE1C103KBQ 16V 0.01U 1

C316 F1J0J1060001 6.3V 10U 1

C317 F1J0J4750005 6.3V 4.7U 1

C318 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C401 F1J0J4750010 6.3V 4.7U 1

C402 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C403 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C404 F5A421040001 4V 0.1U 1

C411 RCST0GZ226RG 4V 22U 1 F3E0G226A002

C412-14 ECUE1H222KBQ 50V 2200P 3 F1G1H222A457

C415-17 ECUENC333KBQ 16V 0.033U 3 F1G1C333A004

C418 ECUVNJ334KBV 6.3V 0.33U 1 F1H0J334A002

C419,20 ECUENA104KBQ 10V 0.1U 2 F1G1A104A014

C501 RCST0GZ226RG 4V 22U 1 F3E0G226A002

C502 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C503 ECUE1C103KBQ 16V 0.01U 1

C505 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C510 ECUVNJ474KBV 6.3V 0.47U 1 F1H0J474A002

C511 ECUE1H101KBQ 50V 100P 1

C513 ECUE1C103KBQ 16V 0.01U 1

C516 F1H0J2250003 50V 2.2U 1

56

Page 57

Ref. No. Part No. Part Name & Description Pcs Remarks

C601 F1J0J4750005 6.3V 4.7U 1

C602 ECUE1C103KBQ 16V 0.01U 1

C603 F1J0J4750005 6.3V 4.7U 1

C605 RCST0GZ156RG 4V 15U 1 F3E0G156A002

C606 ECUVNJ105KBV 6.3V 1U 1 F1H0J105A002

C607,08 ECUE1H102KBQ 50V 1000P 2 F1G1H102A457

C611,12 ECUVNJ105KBV 6.3V 1U 2 F1H0J105A002

C701 RCST0JY226RG 6.3V 22U 1 F3F0J2260002

C702 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C704 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C711 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C713,14 ECUVNJ105KBV 6.3V 1U 2 F1H0J105A002

C720-22 ECUENA104KBQ 10V 0.1U 3 F1G1A104A014

C723,24 ECUE1H102KBQ 50V 1000P 2 F1G1H102A457

C725,26 F1J0J4750010 6.3V 4.7U 2

C727,28 RCST0GZ106RG 4V 10U 2 F3E0G106A002

C801 ECUENC333KBQ 16V 0.033U 1 F1G1C333A004

C802 ECUE1E472KBQ 25V 4700P 1 F1G1E4720004

C803 ECUE1C103KBQ 16V 0.01U 1

C806 ECUE1C103KBQ 16V 0.01U 1

C901 RCST0GZ226RG 4V 22U 1 F3E0G226A002

C902 ECUVNA224KBV 10V 0.22U 1 F1H1A224A028

C903 ECUENA473KBQ 10V 0.047U 1 F1G1A473A014

C904 ECUVNA224KBV 10V 0.22U 1 F1H1A224A028

C905-07 ECUE1E472KBQ 25V 4700P 3 F1G1E4720004

C908 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C909 ECUE1C103KBQ 16V 0.01U 1

C911 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C912 RCST0GZ106RG 4V 10U 1 F3E0G106A002

C913 ECUENA104KBQ 10V 0.1U 1 F1G1A104A014

C914 ECUE1H150JCQ 50V 15P 1

C915 ECUENA473KBQ 10V 0.047U 1 F1G1A473A014

CN1 K1MN21B00045 CONNECTOR(21P) 1

CN2 K1MN06B00069 CONNECTOR(6P) 1

CN3 K1MN04B00034 CONNECTOR(4P) 1

CN403,04 K1MN04B00034 CONNECTOR(4P) 2

CN701 K1MN13B00043 CONNECTOR(13P) 1

CN901 K1MN10B00064 CONNECTOR(10P) 1

CP801 K1MN13B00042 CONNECTOR(13P) 1

CP802 K1MN07B00053 CONNECTOR(7P) 1

CP803 K1MN06B00082 CONNECTOR(6P) 1

D101 MA2YD2100L DIODE 1

D301 MA2S111TX DIODE 1 MA2S11100L

D303 B0JCMB000001 DIODE 1

D304 MA2YD2100L DIODE 1

D305 MA2Z74800L DIODE 1

D911 MA133TX DIODE 1 MA3S13300L

57

Page 58

Ref. No. Part No. Part Name & Description Pcs Remarks

D912,13 ZHCS1006TA DIODE 2 B0JCLG000001

IC1 AN22010A-VF IC 1

IC101 MN66621ARG IC 1

IC102 C3ABMB000026 IC 1

IC201 TA2131FL IC 1 C1BB00000516

IC301 NJU7015RTE1 IC 1 C0ABHA000012

IC302 C0DBAFZ00020 IC 1 C0DBAFZ00017

IC303 XC6367A151MR IC 1 C0DBAFZ00012

IC304 C0DBAGZ00006 IC 1

IC305 C0CBCAC00006 IC 1

IC401 C0GBZ0000006 IC 1

IC501 MN101C61GAB IC 1

IC502 C3EBCG000052 IC 1

IC503 C0EBC0000035 IC 1

IC601 C0FBAJ000008 IC 1

IC701 C1BB00000609 IC 1

IC901 C0GBE0000003 IC 1

IC902 C0JBAZ001767 IC 1

IC903 B1MBBDA00002 IC 1

IC904 B1MBBLA00001 IC 1

JK201 RJJ36TK06-C JACK,HEADPHONE 1 K2HC106E0002

JK301 K2EA2A000001 JACK,DC IN 1

JK701 RJJ38TW01-H JACK,OPT/LINE 1 B3MBZ0000002

JK702 K2HC103E0016 JACK,MIC 1

L1 RLQP1R0KT2-Y COIL 1 G1C1R0K00005

L101 RLQP100MT-W COIL 1 G1C100M00016

L201,02 RLBV601V-W COIL 2 J0JCC0000059

L203 G1C100Z00011 COIL 1

L301 G1A220D00002 COIL 1

L302 G1A150D00002 COIL 1

L303 ELJEA470KF COIL 1

L305 RLM9Z006T-D COIL 1 J0LC00000008

L411 ELJEA470KF COIL 1

L501 RLQP100MT-W COIL 1 G1C100M00016

L710-12 RLBV601V-W COIL 3 J0JCC0000059

L721,22 RLBV601V-W COIL 2 J0JCC0000059

P1 RPK1649 PACKING CASE 1 (EB)(EG)(GCS)

P1 RPK1702 PACKING CASE 1 (GH)(S)

P1 RPK1662 PACKING CASE 1 (GH)(W)

P2 RPQ0991 PAD 1

P3 RPF0257-1 PROTECTION BAG 1

PCB1 REP3036A-M REC.HEAD P.C.B. 1 (RTL)

PCB2 REP3203A-M MAIN P.C.B. 1 (RTL)

PCB3 REP3204A-S OPERATION P.C.B. 1 (RTL)

58

Page 59

Ref. No. Part No. Part Name & Description Pcs Remarks

Q1 2SB1295-6-TB TRANSISTOR 1 B1ADKB000001

Q101 B1CDGD000001 TRANSISTOR 1

Q202 2SB1295-6-TB TRANSISTOR 1 B1ADKB000001

Q203 B1ABDF000001 TRANSISTOR 1

Q301 B1ABDF000001 TRANSISTOR 1

Q302 B1CFHD000005 TRANSISTOR 1

Q303 XP4601TX TRANSISTOR 1 XP0460100L

Q304 B1CFNC000001 TRANSISTOR 1

Q305 B1CHMC000001 TRANSISTOR 1

Q306,07 B1CFNC000001 TRANSISTOR 2

Q308 2SB1462STX TRANSISTOR 1 2SB14620SL

Q311 2SD1979 TRANSISTOR 1

Q312 B1CHMC000001 TRANSISTOR 1

Q313 B1CHHD000003 TRANSISTOR 1

Q314 DTC144EETL TRANSISTOR 1 B1GBCFNN0001

Q701 XP4601TX TRANSISTOR 1 XP0460100L

Q702 DTC144TETL TRANSISTOR 1 B1GBCFNA0001

Q703 2SB1462STX TRANSISTOR 1 2SB14620SL

Q901 DTC144EETL TRANSISTOR 1 B1GBCFNN0001

Q911 DTC144EETL TRANSISTOR 1 B1GBCFNN0001

R1 ERJ2GEJ472X 1/4W 4.7K 1 ERJ2RMJ472X

R2 ERJ2GEJ272X 1/4W 2.7K 1 ERJ2RMJ272X

R3 ERJ2GEJ1R5X 1/4W 1.5 1

R4 ERJ2GEJ472X 1/4W 4.7K 1 ERJ2RMJ472X

R5 ERJ2GEJ271X 1/4W 270 1 ERJ2RMJ271X

R6 ERJ2GEJ150X 1/4W 15 1

R7 ERJ2GEJ474X 1/4W 470K 1 ERJ2RMJ474X

R11 ERJ2GEJ222X 1/4W 2.2K 1 ERJ2RMJ222X

R41 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R42 ERJ2GEJ473X 1/4W 47K 1 ERJ2RMJ473X

R101 ERJ2GEJ105X 1/4W 1M 1 D0GA105JA001

R103 ERJ2GEJ100X 1/4W 10 1 ERJ2RMJ100X

R104 ERJ2GEJ221X 1/4W 220 1 ERJ2RMJ221X

R110 ERJ2GEJ470X 1/4W 47 1 ERJ2RMJ470X

R111 EXB24V470JX 47~2 1

R112 ERJ2GEJ470X 1/4W 47 1 ERJ2RMJ470X

R120 ERJ2GEJ123X 1/4W 12K 1

R121,22 ERJ2GEJ333X 1/4W 33K 2 ERJ2RMJ333X

R123 ERJ2GEJ221X 1/4W 220 1 ERJ2RMJ221X

R130 ERJ2GEJ222X 1/4W 2.2K 1 ERJ2RMJ222X

R201 ERJ2GEJ221X 1/4W 220 1 ERJ2RMJ221X

R202 ERJ2GEJ471X 1/4W 470 1 ERJ2RMJ471X

R203 ERJ2GED273X 1/4W 27K 1 ERJ2RHD273X

R204 EXB24V103JX 10K~2 1

R205 ERJ2GEJ104X 1/4W 100K 1 ERJ2RMJ104X

R206 EXB24V103JX 10K~2 1

R207 EXB24V392JX 1/16W 3.9K 1

R208 EXB24V225JX 1/16W 2.2M 1

R209 EXB24V100JX 1/16W 10 1

59

Page 60

Ref. No. Part No. Part Name & Description Pcs Remarks

R210 EXB24V221JX 1/4W 220 1

R301 EXB24V334JX 1/16W 330K 1

R302 EXB24V104JX 1/4W 100K 1

R303 ERJ2RHD823X 1/4W 82K 1

R304 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R305 ERJ2GEJ101X 1/4W 100 1 ERJ2RMJ101X

R306 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R307 ERJ2GEJ474X 1/4W 470K 1 ERJ2RMJ474X

R308 EXB24V474JX 1/16W 470K 1

R309 ERJ2GEJ394X 1/4W 390K 1 ERJ2RMJ394X

R310 ERJ2GED333X 1/4W 33K 1 ERJ2RHD333X

R311 ERJ2GED104X 1/4W 100K 1 D0HA104ZA002

R312 ERJ3GEYJ335V 1/16W 3.3M 1

R313 EXB24V104JX 1/4W 100K 1

R314 ERJ2GEJ154X 1/4W 150K 1 ERJ2RMJ154X

R315 ERJ2GED104X 1/4W 100K 1 D0HA104ZA002

R316 ERJ2GEJ104X 1/4W 100K 1 ERJ2RMJ104X

R317 ERJ6RSJR10V 1/10W 0.1 1

R318 ERJ2GED105X 1/4W 1M 1 ERJ2RKD105X

R320 ERJ2GEJ474X 1/4W 470K 1 ERJ2RMJ474X

R321 ERJ2GEJ394X 1/4W 390K 1 ERJ2RMJ394X

R322 ERJ2GEJ225X 1/4W 2.2M 1 ERJ2RMJ225X

R323 ERJ2GEJ105X 1/4W 1M 1 D0GA105JA001

R324 ERJ2GEJ474X 1/4W 470K 1 ERJ2RMJ474X

R326 ERJ2GEJ221X 1/4W 220 1 ERJ2RMJ221X

R401 EXB24V473JX 1/16W 47K 1

R411 ERJ2GEJ471X 1/4W 470 1 ERJ2RMJ471X

R412 ERJ2GEJ682X 1/4W 6.8K 1 ERJ2RMJ682X

R431 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R501 EXB24V473JX 1/16W 47K 1

R502-04 EXB24V334JX 1/16W 330K 3

R505,06 EXB24V104JX 1/4W 100K 2

R507,08 EXB24V224JX 1/4W 220K 2

R509 ERJ2GEJ223X 1/4W 22K 1 ERJ2RMJ223X

R510 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R511 ERJ2GEJ224X 1/4W 220K 1 ERJ2RMJ224X

R512 ERJ2GEJ221X 1/4W 220 1 ERJ2RMJ221X

R513 ERJ2GEJ104X 1/4W 100K 1 ERJ2RMJ104X

R601 ERJ2GEJ4R7X 1/4W 4.7 1 ERJ2RMJ4R7X

R701 ERJ2GEJ101X 1/4W 100 1 ERJ2RMJ101X

R702 ERJ2GEJ184X 1/4W 180K 1 ERJ2RMJ184X

R703 EXB24V104JX 1/4W 100K 1

R704 ERJ2GEJ334X 1/4W 330K 1 ERJ2RMJ334X

R705 ERJ2GEJ473X 1/4W 47K 1 ERJ2RMJ473X

R706 EXB24V182JX 1.8K~2 1

R707 EXB24V223JX 1/4W 22K 1

R708 EXB24V182JX 1.8K~2 1

R710 ERJ2GEJ472X 1/4W 4.7K 1 ERJ2RMJ472X

R711 ERJ2GEJ471X 1/4W 470 1 ERJ2RMJ471X

R712 ERJ2GEJ104X 1/4W 100K 1 ERJ2RMJ104X

60

Page 61

Ref. No. Part No. Part Name & Description Pcs Remarks

R713 ERJ2GEJ101X 1/4W 100 1 ERJ2RMJ101X

R714 ERJ2GEJ103X 1/4W 10K 1 ERJ2RMJ103X

R715 EXB24V104JX 1/4W 100K 1

R801 ERJ2GEJ122X 1/4W 1.2K 1 ERJ2RMJ122X

R802 ERJ2GEJ563X 1/4W 56K 1

R803 ERJ2GEJ683X 1/4W 68K 1 ERJ2RMJ683X

R807 ERJ2GEJ333X 1/4W 33K 1 ERJ2RMJ333X

R808 ERJ2GEJ513X 1/4W 51K 1 ERJ2RMJ513X

R901 ERJ2GEJ682X 1/4W 6.8K 1 ERJ2RMJ682X

R902 ERJ2GEJ153X 1/4W 15K 1 ERJ2RMJ153X

R903 ERJ2GEJ182X 1/4W 1.8K 1 ERJ2RMJ182X

R904 ERJ2GEJ471X 1/4W 470 1 ERJ2RMJ471X

R905 ERJ2GEJ102X 1/4W 1K 1 ERJ2RMJ102X

R911 EXB24V473JX 1/16W 47K 1

R912 ERJ2GEJ6R8X 1/4W 6.8 1

S1 ABC1111P SW,MAGNETIC HEAD 1 K0L1BA000050

S801 RSG0051-P SW,PLAY/PAUSE,CHARA 1

S802 K0F111A00335 SW,REC,LP MODE 1

S803 RSG0051-P SW,STOP,OPR/OFF 1

S804 RSG0051-P SW,EDIT/MARK MODE 1

S806 K0D112A00114 SW,HOLD 1

TH40 D4CC11030009 THERMISTORS 1

TH901 D4CC11030009 THERMISTORS 1

X101 H0J169500011 OSCILLATOR 1

X501 H2D100500004 OSCILLATOR 1

Z301 RJH9212-1 BATT.CONNECTOR TERMINAL 1 K4BC02E00007

18. Cabinet Parts Location

61

Page 62

19. Packaging

62

Page 63

Printed in Japan (H010900000) KA/HH

63

Loading...

Loading...