Page 1

ORDER NO.

RRV3337

SPEAKER SYSTEM

S-1EX XTW/E

NOTE

As this speaker system weighs approx. 66 kg, be sure to have two people work on it. If this

speaker system will be turned on its side for servicing, lay it on a piece of soft cloth, etc., to

protect the cabinet from being scratched.

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained to

properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the

warranty. If you are not qualified to perform the repair of this product properly and safely, you should not risk

trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

CONTENTS

1. PARTS LIST

2. FOR PRECAUTION OF REASSEMBLY AND DISASSEMBLY

3. SCHEMATIC DIAGRAM

...............................................................................................

4. JIG

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

..................................................................................

....

.............................................................

T – ZZS FEB. 2006 Printed in Japan

2

8

11

12

Page 2

1

23

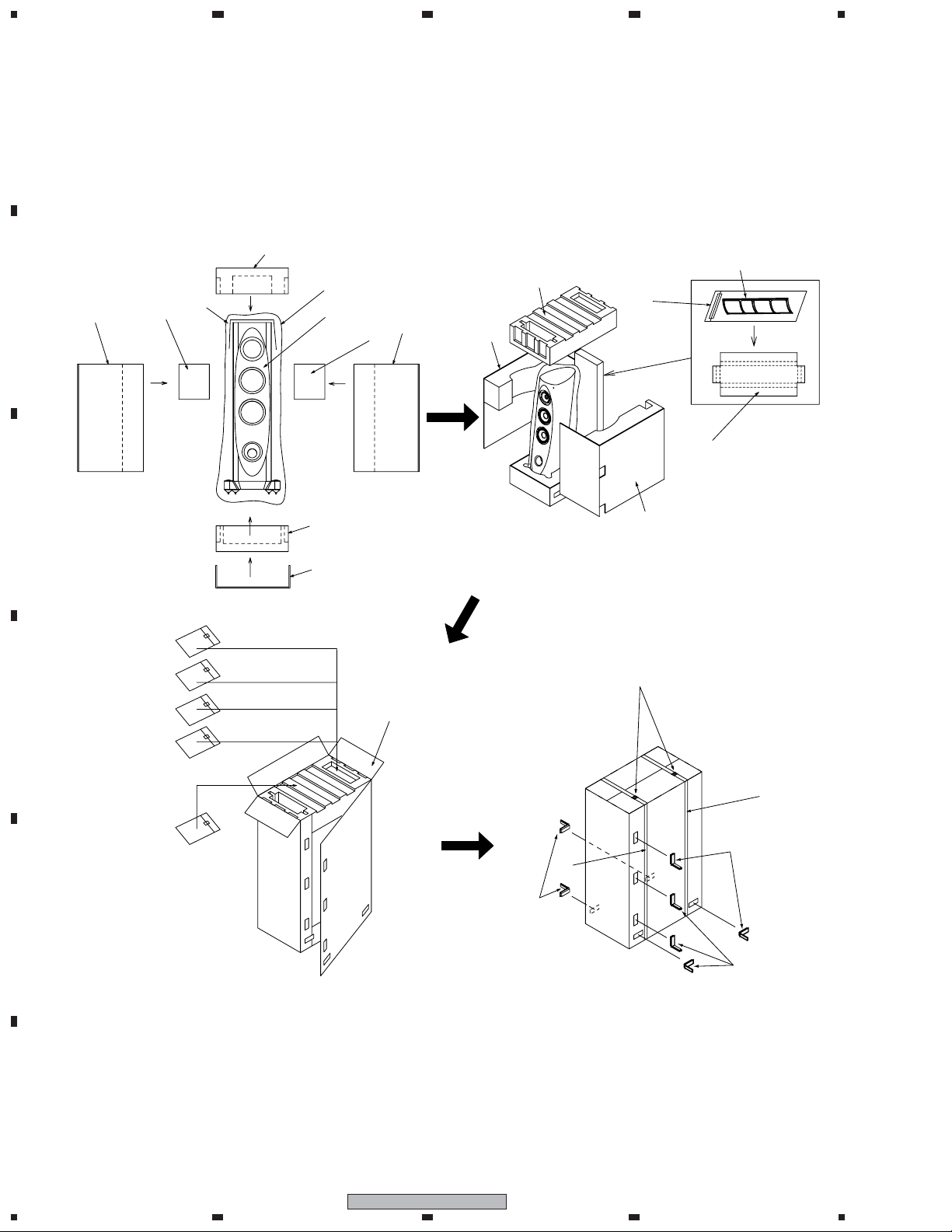

1. PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

A

1.1 PACKING

÷ The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

4

1

10

B

C

D

6

8

4

19

15

17

18

Speaker system

2

3

5

11

6

(6)

(1)

9

(6)

14

32

7

16

12

13

12

E

F

2

1234

S-1EX

13

13

Page 3

1

234

PACKING Parts List

Mark No. Description Part No. Mark No. Description Part No.

1 Top Protector SHA6081

2 Middle Protector (R) SHA6082

3 Bottom Protector SHA6083

4 Middle Protector (L) SHA6090

5 Packing Case (bottom) SHB6032

NSP 15 Accessory Set SME6034

Spike Bases SBG6003

Nuts (for spike) SBA6057

Hex Wrench SEX6002

Polyethylene Bag S0 SHL1412

A

6 Protector (middle) SHB6033

7 Protector (grille) SHB6034

8 Protection sheet SHC1843

9 Protection sheet SHC6037

10 Protection sheet SHC6040

11 Packing Case SHG6207

NSP 12 PP Band SHX6001

13 Joint for Packing Case SNK6124

NSP 14 Stopper (for PP band) SNK6127

NSP 16 Accessory Set SME3716

Operating Instructions SRD1310

(English, French, Spanish,

Simp-Chinese, Trad-Chinese)

Polyethylene Bag S2 SHL1265

NSP 17 Accessory Set SME6036

Fastening Screws (for grille) SLH6013

Finishing Screws (for grille) SLH6014

Polyethylene Bag S0 SHL1259

NSP 18 Accessory Set SME6037

Screw (for metal catch) BMZ40P120FTB

Metal Catch FRNH-028

Polyethylene Bag S0 SHL1259

NSP 19 Accessory Sset (for grille holes) SME6047

Caps (for grille holes) SEC2068

Polyethylene Bag S0 SHL1259

NSP Label Serial SRW1112

B

C

D

E

F

S-1EX

1

2

3

4

3

Page 4

1

23

4

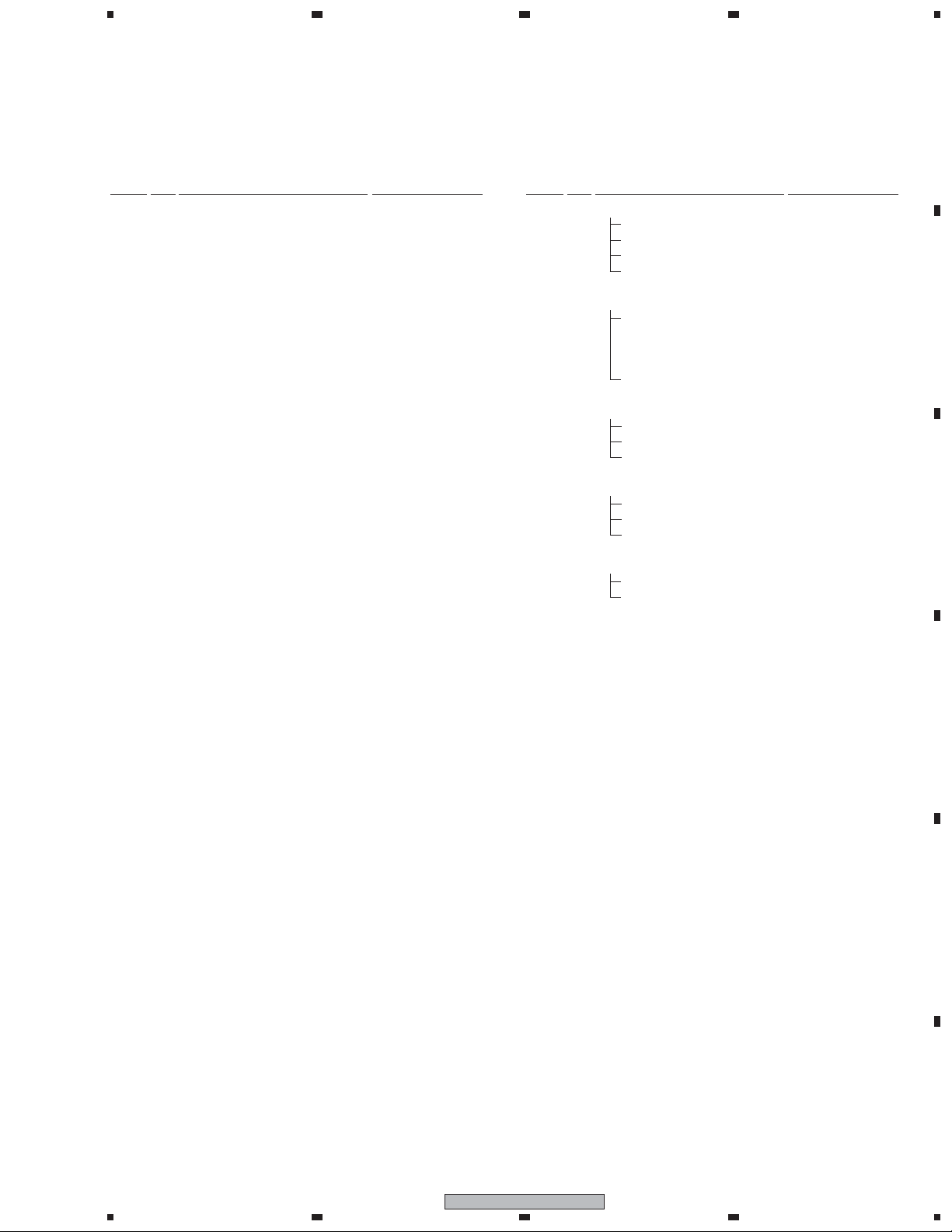

1.2 SPEAKER SYSTEM

A

31

B

C

68

71

(x6 /unit)

46

47

A

(40)

A-A' Sectional view

TW

MID

Connect the cords with

black tape to the tweeter.

Connect the cords with

white tape to the

midrange.

73 (x4)

A'

40

(Long

cords)

47

67

72 (x8)

D

(Short

cords)

Upper side for the

HPF input terminals

Lower side for the

E

44 (x4)

LPF input terminals

39

60 (x4)

65 (x4)

70

(x8)

63

45

(x4)

64

F

4

1234

: Refer to the adhesive points on page 9

S-1EX

(x6)

74

69

(x16)

42

(x4)

66

Page 5

1

∅3

∅4

∅8.3

2.530

4.2 max.

4.2 max.

Screw (SBA1260)

4.9 max.

4.9 max.

75

3.1

∅10.3

∅5

∅3.6

Screw (SBA1262)

234

SPEAKER SYSTEM Parts List

Mark No. Description Part No.

NSP 31 Cabinet SMM2026

NSP

39 Network ASSY (low pass) SWN1758

40 Network ASSY (high pass) SWN1759

42 Spike

44 Spike Cover (for spike (top)) SEB6012

45 Rubber Ring

NSP 46 Gasket (for MID/TW) SEC2031

NSP 47 Gasket (for WF) SEC2032

NSP 60 Gasket (cabinet-input terminals) SEC2065

NSP 63 Wood Base SMS6017

NSP Acoustic Absorbent SMT1312

NSP Acoustic Absorbent SMT1313

NSP Acoustic Absorbent SMT1314

NSP Acoustic Absorbent SMT1315

NSP Acoustic Absorbent SMT1316

NSP Acoustic Absorbent SMT1318

NSP Acoustic Absorbent SMT1320

NSP Acoustic Absorbent SMT1329

64 Bottom Spike

65 Spike (top) SNH6011

66 Bottom Spike SNH6017

Fung Nut M4 (for grille, metal catch)

(height adjustment screw)

(vibration deadening)

(inside the chamber and baffle board corner)

(under the duct, back board, behind the duct)

(chamber, side board)

(around the duct board)

(duct board side/upper roll)

(black, behind the duct)

(chamber/holes, input terminals)

(inside chamber/top)

(spike bottom)

SBN1066

SBA6044

SEB6013

SNH6010

A

Screw (SBA1225)

B

C

5

∅8.5

4

(4.6)

∅3

∅4

35

Screw (SBA1261)

∅3

∅4

40

2.5

∅8.3

4.2 max.

4.2 max.

D

67 Speaker (WF) B18IU60-52H

68 Speaker (MID/TW) A14GR55-52DX

69 Screw (bottom spike - base) BKC50P300FTB

70 Screw (spike top - base) BMZ40P400FTB

71 Hexagon Socket Screw SBA1225

(for WF, MID/TW)

72 Screw (for NW assy) SBA1260

73 Screw (for closure panel) SBA1261

74 Screw (base - cabinet) SBA1262

E

F

1

2

S-1EX

3

4

5

Page 6

1

23

4

51

A

Specification for attaching the

packing for the Bottom spike

57

56

5

52

55

(x22)

52

48

59

5

5

50

58

49

B

Specification for attaching the

packing for the Spike (top)

Specification for attaching the

packing for the base (top side)

5

54

53

Specification for attaching the

packing for the base (bottom side)

37

C

Specification for attaching the

packing for the Bottom spike

43

D

The direction of the cord

holes must be vertical.

62

E

77

75

61

The direction of the cord

holes must be vertical.

41

43

36

38

34

35

76

33

Front View Back View

No.32 Grille

F

6

1234

S-1EX

Page 7

1

234

SPEAKER SYSTEM Parts List

Mark No. Description Part No.

32 Grille SMG6093

33 Badge FRAM-048

34 Packing SEC6060

NSP 35 Grille ASSY SMG6094

NSP 36 Fung Nut SBN6019

NSP 37 Grille Frame SMC6002

NSP 38 Punching Net SNH6013

NSP 41 Sticker SAN3871

43 Cord SDS1192

NSP 48 Gasket (for spike (top)) SEC2043

NSP 49 Gasket (for spike (top)) SEC2044

NSP 50 Gasket (for spike (top)) SEC2045

NSP 51 Gasket (for bottom spike) SEC2046

NSP 52 Gasket (for bottom spike) SEC2047

NSP 53 Gasket (for bottom spike) SEC2048

NSP 54 Gasket (for bottom spike) SEC2049

NSP 55 Gasket (for screw holes) SEC2050

A

B

C

NSP 56 Gasket (base top) SEC2051

NSP 57 Gasket (base top) SEC2052

NSP 58 Gasket (base top) SEC2053

NSP 59 Gasket (for spike (top)) SEC2055

61 Input Terminal (Red) SKX6027

62 Input Terminal (Black) SKX6028

NSP 75 Model Label SAN3790

NSP 76 Country Label SAN3782

NSP 77 Label Serial SRW1111

D

E

F

S-1EX

1

2

3

4

7

Page 8

1

23

2. FOR PRECAUTION OF REASSEMBLY AND DISASSEMBLY

2.1 GRILLE

A

B

How to disassemble

1 Loosen the finishing screws. Then remove the grille.

Finishing Screws

Note 1:

You may remove the fastening screws if they impede

disassembly.

How to reassemble

1 Insert the supplied fastening screws into the screw holes at

the four corners of the speaker front.

Fastening Screws

2 Place the grille with the badge located at the lower part,

aligning the 4 holes of the grille with the fastening screws

inserted in Step 1.

3 Tighten the supplied finishing screws into the fastening

screws to secure the grille.

Finishing Screws

4

C

Note 2:

Do not use a flathead screwdriver or a hexagonal wrench to

tighten the screws. Securing the screws too tightly may

damage the cabinet.

2.2 SPEAKER UNIT

For better audio quality, the receptacle terminals and terminal fittings of the speaker unit are soldered.

Two people are required for servicing of this speaker unit: one to hold the removed unit and another to

solder.

Tools to be used

• Hexagonal wrench (4 mm): GGK1024

D

• Soldering gun: GGK1069

• Lead-free solder: GYP1006

• The woofer is attached to the baffle board with 6

hexagon-socket screws from the outside.

When disassembling, remove all these screws, pull out the

woofer, then remove the solder to disconnect the cords.

When reattaching, after connecting the cords, solder the

terminals for the woofer then place the woofer so that the

terminal board comes to the lower side.

Upper side

E

Te r minal size: Extra large

: White with Black line

White tape

Upper woofer

Long cord

Te r minal size: Large

: White

• The midrange and tweeter are integrated into a coaxial

unit. This coaxial-unit speaker is attached to the baffle

board with 6 hexagon-socket screws from the outside.

When disassembling, remove all these screws, pull out

the coaxial-unit speaker, then remove the solder to

disconnect the cords.

When reattaching, connect the cord with black tape to the

tweeter and the cord with white tape to the midrange then

solder the terminals. Place the coaxial unit so that the

terminal board of the midrange comes to the lower side

then turn it counterclockwise slightly to secure it.

: White with Black line

Upper side

Terminal board

of the tweeter

Te r minal size:

Large

Te r minal size:

Small

Black tape

: White

Upper side

Te r minal size: Extra large

: White with Black line

White tape

Coaxial unit

Te r minal size:

Extra large

: White with Black line

White tape

Lower woofer

Short cord

F

8

Te r minal size: Large

: White

S-1EX

1234

Terminal board

of the midrange

Te r minal size:

Large

: White

Page 9

1

234

2.3 NETWORK ASSY

Before removing the Network Assy, remove the grille and each speaker unit then disconnect the cords from the

speaker unit.

• For removal/reattachment of the Network Assy for the woofer: Only the woofer must be removed.

• For removal/reattachment of the Network Assy for the midrange/tweeter: Removal of all the units is required.

A

2.3.1 Network Assy for the Woofers

• The Network Assy for the woofers is located inside the

back board behind the lower woofer and secured with

4 screws.

(1) Remove the acoustic absorbent pads at the input

terminals. (See Figs. 2-5 to 2-8.)

(2) Remove the 2 nuts that secure the round connectors

from the lower input terminals.

(See Fig. 2-1. Tool: Box wrench, 14 mm/GGH-002)

(3) Remove the 4 screws that secure the Network Assy

then pull the Assy out through the hole where the

woofer was attached. (See Fig. 2-2.)

(4) When reattaching, pass the Network Assy through the

hole where the lower woofer was attached then secure

it in place with the 4 screws. (See Fig. 2-2.)

(5) Among the 3 pairs of cords from the Network Assy,

connect the cords with black tape to the lower input

terminals and secure them with the nuts.

(See Fig. 2-1. Tool: Box wrench, 14 mm/GGH-002)

(6) Apply adhesive to the secured nuts.

(Adhesive: DIABOND black/GYL-014)

(7) Reinstall the acoustic absorbent pads at the input

terminals. (See Figs. 2-5 to 2-8.)

(8) Among the 3 pairs of cords from the Network Assy,

connect and solder the remaining 2 pairs of cords

with white tape to the woofer and reattach the woofer

in the cabinet.

Apply adhesive.

+: White with Black line

From the Network Assy

for the midrange/tweeter

From the Network Assy

for the woofers

-: White

Apply adhesive.

2.3.2 Network Assy for the midrange /

tweeter

• The Network Assy for the midrange/tweeter is attached to

the inside of the left side board behind the upper woofer,

using 4 screws.

(1) Remove the acoustic absorbent pads at the input

terminals, inside and at the rear of the chamber, and

behind the chamber.

(See Figs. 2-5 to 2-8 and 2-9 to 2-11.)

(2) Remove the 2 nuts that secure the round connectors

from the upper input terminals.

(See Fig. 2-1. Tool: Box wrench, 14 mm/GGH-002)

(3) Remove the 4 screws that secure the closure panel

inside the chamber, remove the 4 screws that secure

the Network Assy, and pull the Network Assy out

through the hole where the woofer was attached.

(See Figs. 2-3 and 2-4. Tool: Screwdriver/GGK1012)

(4) When reattaching, pass the Network Assy through the

hole where the upper woofer was attached and secure

it in place using the 4 screws.

(See Fig. 2-3. Tool: Screwdriver/GGK1012)

(5) Among the cords from the Network Assy, connect the

cords with the round connectors to the upper input

terminals and secure them with the nuts.

(See Fig. 2-1. Tool: Box wrench, 14 mm/GGH-002)

(6) Apply adhesive to the secured nuts.

(Adhesive: DIABOND black/GYL-014)

(7) Pass the 2 pairs of cords from the closure panel

through behind the chamber then secure the closure

panel from inside the chamber, using the 4 screws.

(See Fig. 2-4.)

(8) Reinstall the acoustic absorbent pads at the input

terminals, inside and rear of the chamber, and behind

the chamber.

(See Figs. 2-5 to 2-8 and 2-9 to 2-11.)

(9) Connect and solder the cords to the coaxial-unit

speaker and reattach it in the cabinet.

B

C

D

Fig. 2-1: Input terminals (inside the cabinet)

Upper side

Bottom side

: Screws : Screws

Fig. 2-2: Specifications for attaching

the Network Assy for the woofers

1

Upper side

Bottom side

Fig. 2-3: Specifications for attaching the

Network Assy for the midrange/tweeter

S-1EX

2

Closure panel

: Screws

Chamber

Fig. 2-4: Specifications for attaching the

closure panel (cross-sectional view of the

coaxial-unit speaker)

3

4

E

F

9

Page 10

1

23

2.3.3 Removal/Reattachment of Acoustic absorbent pads

Removal/reattachment of acoustic absorbent pads is necessary before or after removal/reattachment of the Network Assy.

A

Note:

When reattaching the Network Assy for the midrange/tweeter, before reattaching the closure panel, be sure to remove the

acoustic absorbent pads located behind the chamber. (See Fig. 2-11.) If the closure panel pinches an acoustic absorbent

pad when it is secured, air leakage may occur, which may result in poor performance of this speaker system.

1. Acoustic absorbent pads around the input terminals 2. Acoustic absorbent pads inside the chamber for

4

the midrange/tweeter

1 Remove this acoustic absorbent

pad. When reattaching, roll it

and push it in under the rein-

B

(Adhesive: DIABOND black/GYL-014)

forcing plate.

As only this acoustic absorbent

pad must be fixed with adhesive,

before pushing it in, apply

adhesive to the side board of the

cabinet.

Fig. 2-9: After the midrange/tweeter is removed (1)

1 Remove this acoustic absorbent pad.

When reattaching, lay it along the

upper board inside the chamber.

2 Remove this acoustic absorbent pad

When reattaching, place it along the

surface inside the chamber so that it

forms a U shape.

Fig. 2-5: After the lower woofer is removed (1)

2 Remove this acoustic absorbent

pad. When reattaching, push it

in along the lower surface of the

C

reinforcing plate.

Fold the remaining part of the

pad toward the bottom board

side so that it forms an L shape.

The cords from the input

terminals must be pulled out

from the upper side of the

acoustic absorbent pad.

Fig. 2-10: After the midrange/tweeter is removed (2)

3 Remove this acoustic absorbent

pad from the closure panel section.

When reattaching, fold it in half

lengthwise and push it in.

Fig. 2-6: After the lower woofer is removed (2)

3. Acoustic absorbent pads around the Network Assy

3 Remove this acoustic

D

absorbent pad.

When reattaching, fold it in

half lengthwise and push it

in.

Fig. 2-7: After the lower woofer is removed (3)

E

In this state, remove or

reattach the Network Assy.

for the midrange/tweeter

4 Do not remove the acoustic

absorbent pads around the Network

midrange/tweeter

Assy for

Remove the 2 rolled acoustic

absorbent pads stuffed behind the

space of the chamber for

.

/tweeter

Insert your hand in the direction of

the arrow to remove.

Removal/reattachment of the

Network Assy for the midrange/

tweeter and of the closure panel

must be done in this state.

Fig. 2-11: After the upper woofer is removed

When reattaching, lay one acoustic absorbent pad on another and

roll them, and make 2 rolls of acoustic absorbent pads.

Place one roll lengthwise, push it into the front of the top board

of the cabinet, then push another beneath of the first one.

.

midrange

Fig. 2-8: After the lower woofer is removed (4)

F

10

S-1EX

1234

Page 11

1

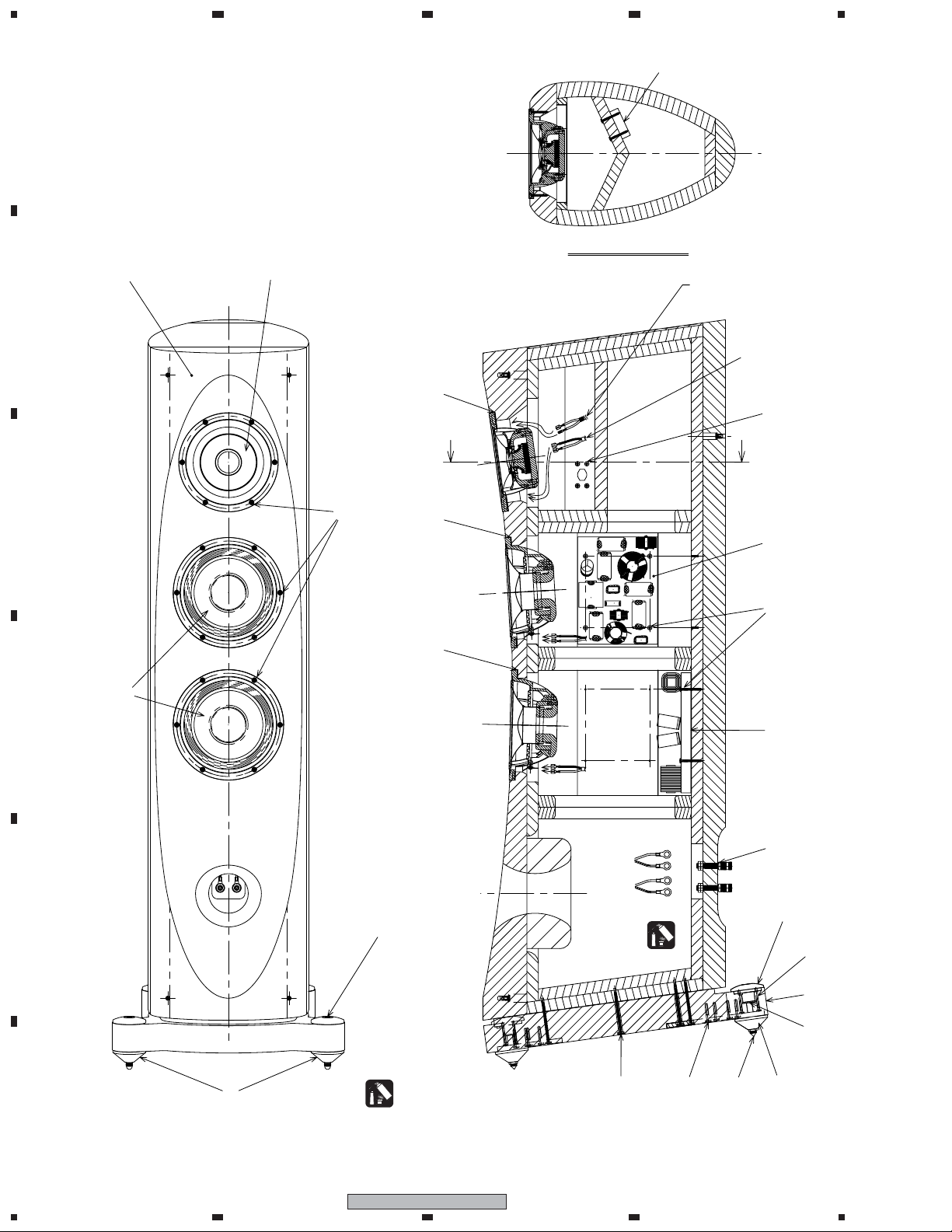

3. SCHEMATIC DIAGRAM

NETWORK ASSY (SWN1758)

234

A

White

with Black line

INPUT

White

White

with Black line

INPUT

White

L1

3.9mH

C1

68µF/100V

NETWORK ASSY (SWN1759)

C1

2.7µF/250V

C4

47µF/250V

R3

0.47Ω/10w

0.3mH

COIL

L1

0.82mH

L3

COIL

0.8mH

C2

12µF/250V

R3

2.2Ω/10w

C5

C3

L2

COIL

L2

2.2mH

C2

68µF/100V

22µF/250V

R1

3Ω/10w

1.2mH

COIL

15µF/250V

White

with Black line

WOOFER

White

White

with Black line

B

WOOFER

White

White

with Black line

C

TWEETER

White

C6

68µF/100V

L4

C7

14µF/250V

L5

0.82mH

COIL

C8

15µF/250V

White

with Black line

D

MIDRANGE

White

E

F

S-1EX

1

2

3

4

11

Page 12

A

1

4. JIG

7 Jigs list to be used

Jig Name Part No. Remarks

Phillips screwdriver (large) stubby

type

23

GGK1012

For removal/reattachment of the Network Assy for

the midrange unit and the tweeter

4

Soldering gun

Lead-free solder

B

Hexagonal wrench (4mm)

Box wrench (14 mm)

GGK1069

GYP1006

GGK1024

GGH-002

For removal/reattachment of the speaker unit

For removal/reattachment of the speaker unit

For removal/reattachment of the speaker unit

For removal/reattachment of the Network Assy

7 Adhesives list to be used

Adhesive Name Part No. Remarks

DIABOND (Black) (DB-1600WB) GYL-014 For removal/reattachment of the Network Assy

C

D

E

F

12

1234

S-1EX

Loading...

Loading...