Pioneer PRO-700HD Service Manual

ORDER NO.

ORDER NO.

ARP3013

PROJECTION MONITOR RECEIVER

PRO-700HD

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KUXC/CA AC120V

Model

PRO-700HD

• The PRO-700HD service manual is composed of ORDER NO. ARP3013 and

ORDER NO. ARP3024. Use these two manuals as one set. For other details,

refer to the separate manual (ORDER NO.ARP3024).

Power Requirement

Remarks

CONTENTS

1. SAFETY INFORMATION ...................................... 2

2. EXPLODED VIEWS AND PARTS LIST................ 5

3. SCHEMATIC DIAGRAM ..................................... 22

4. PCB CONNECTION DIAGRAM........................ 111

5. PCB PARTS LIST ............................................. 159

6. ADJUSTMENT .................................................. 178

7. GENERAL INFORMATION .............................. 214

7.1 WIRING DIAGRAMS ................................. 214

7.2 IC ............................................................... 215

7.3 BLOCK DIAGRAM..................................... 266

8. PANEL FACILITIES AND SPECIFICATIONS.. 272

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER ELECTRONIC CORPORATION 1998

O- SZG DEC. 1998 Printed in Japan

ORDER NO.

ARP3013

ORDER NO.

ARP3024

PRO-700HD

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained to

properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the

warranty. If you are not qualified to perform the repair of this product properly and safely, you should not

risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

Health & safety code section 25249.6—Proposition 65

NOTES

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces de

remplacement doivent avoir la même désignation.

1.1 SAFETY PRECAUTIONS

NOTlCE: Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis or picture

tube.

The following precautions should be observed:

1. Do not install, remove, or handle the picture tube in any

manner unless shatterproof goggles are worn. People

not so equipped should be kept away while picture tubes

are handled.

Keep picture tube away from the body while handling.

2. When service is required, even though the PROJECTION MONITOR RECEIVER an isolation transformer

should be inserted between power line and the set in

safety before any service is performed.

3. When replacing a chassis in the set, all the protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

4. When service is required, observe the original lead

dress.

Extra precaution should be taken to assure correct lead

dress in the high voltage circuitry area.

5. Always use the manufacturer’s replacement components. Especially critical components as indicated on the

circuit diagram should not be replaced by other

manufacture’s.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

6. Before returning a serviced set to the customer, the service technician must thoroughly test the unit to be certain

that it is completely safe to operate without danger of

electrical shock, and be sure that no protective device

built into the set by the manufacturer has become defective, or inadvertently defeated during servicing.

Therefore, the following checks should be performed for the

continued protection of the customer and service technician.

Leakage Current Cold Check

With the AC plug removed from 120V AC 60Hz source,

place a jumper across the two plug prongs. Turn the AC

power switch on. Using an insulation tester (DC 500V), connect one lead to the jumpered AC plug and touch the other

lead to each exposed metal part (input/output terminals,

screwheads, metal overlays, control shafts, etc.), particularly any exposed metal part having a return path to the

chassis. Exposed metal parts having a return path to the

chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

2

PRO-700HD

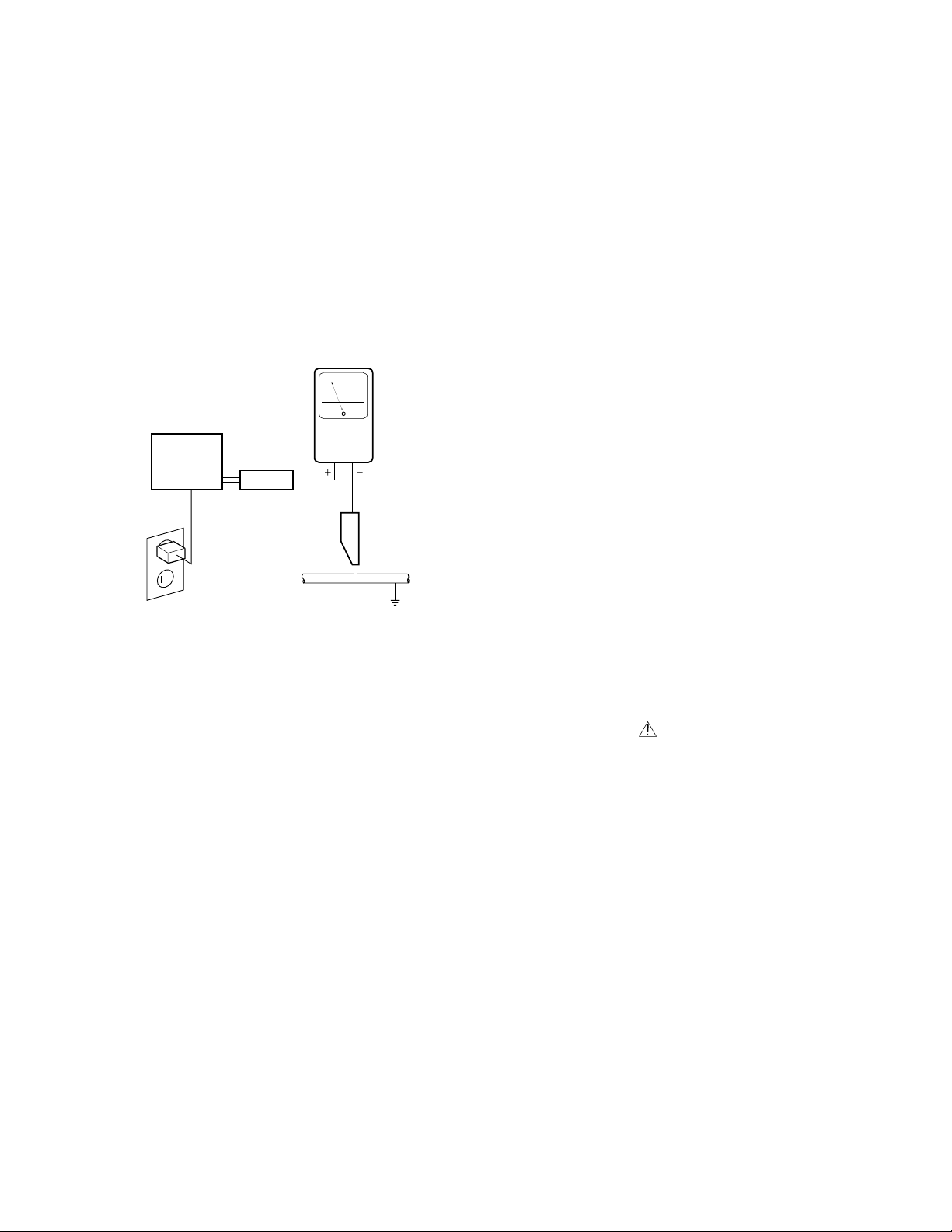

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC 60Hz outlet (

do not use an isolation transformer for this check). Turn the

AC power switch on.

Using a “Leakage Current Tester (Simpson Model 229

equivalent )”, measure for current from all exposed metal

parts of the cabinet ( input/output terminals, screwheads,

metal overlays, control shaft, etc. ), particularly any exposed

metal part having a return path to the chassis, to a known

earth ground (water pipe, conduit, etc.). Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

2-wire cord

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS OUTLINED

ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED BEFORE RETURNING THE SET

TO THE CUSTOMER.

High V oltage

This set is provided with a X-ray protection for clearly indicating that voltage has increased in excess of a predetermined value. Comply with all notes described in this Service

Manual regarding this hold down circuit when servicing, so

that this X-ray protection may correctly by operated.

Serviceman W arning

In the status of the black picture ( video muting is being applied ) when no signal is input, high voltage of this set during

operation is less than 30.5kV. In case any component having some relation to the high voltage is replaced, confirm

that the high voltage is lower than 30.5kV in the status of the

black picture when no signal is input.

To measure H.V. use a high impedance H.V. meter.

Connect ( – ) to earth and ( + ) to the FBT anode cable connector.

(Refer to page 214)

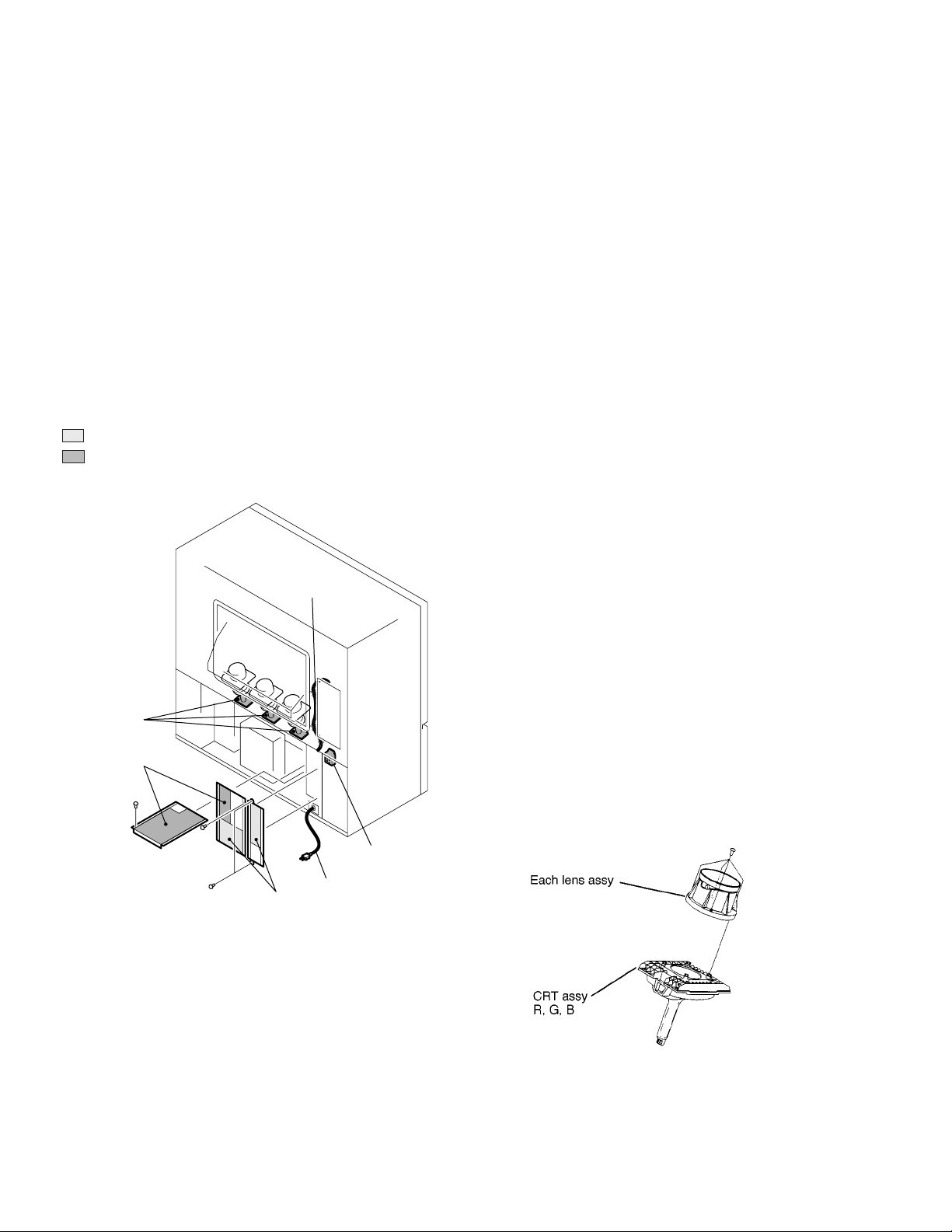

X-radiation

TUBE: The primary source of X-radiation in this set is the

picture tube.

For continued X-radiation protection, the replacement tube

must be the same type as the original, PIONEER approved

type.

The picture tube (the CRT assy R, G, B ) use in this set

holds complete guarantee against X-ray radiation when the

X-ray is sealed (See page 4). Accordingly, when the current

in flowing to the picture tube (CRT assy R, G, B) be sure to

perform it by putting the tube into X-ray sealed applied state.

Avoid absolutely to flow the current to the picture tube (CRT

assy R, G, B) itself. Moreover, when the voltage of the high

voltage circuit becomes abnormally a little higher, the picture tube radiates X-rays. Accordingly, when servicing the

high voltage circuit be sure to replace as an assembly with

the DEFLECTION SERVICE assy in the manner in which

has been adjusted to perform normal operation.

1.2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded by

them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics

are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, X-radiation, or

other hazards.

Product Safety is continuously under review and new instructions are issued from time to time. For the latest information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

3

PRO-700HD

1.3 CHARGED SECTION, HIGH VOLTAGE GENERATING POINT

AND X-RAY PROTECTION

7 Charged section

The circuit in which the commercial AC power is used as it

is without passing through the power supply transformer. If

the charged section is touched, there is a risk of electric

shock. In addition, the measuring equipment can be damaged if it is connected to the GND of the charged section

and the GND of the non-charged section while connecting

the set directly to the commercial AC power supply. In this

case, be sure to connect the set via an insulated transformer

and supply the current.

7 Charged section

(Power supply primary side)

1. The primary side of the AC IN assy

2. AC power cord

3. The primary side of the POWER SUPPLY assy

4. AC power cord for DTV STB

: Part is the charged section.

: Part is the high voltage generating

points other than the charged section.

AC power cord for

DTV STB

High Voltage

generating point

High Voltage

generating point

7 High voltage generating point

The place where voltage is 100V is generated.

1.Charged seciton

DEFLECTION assy

(including FBT) (30.5kV, 1.2kV, 210V,135V)

2. POWER SUPPLY assy (135V)

3. R. CRT DRIVE assy (10.5kV, 210V)

4. G. CRT DRIVE assy (10.5kV, 210V)

5. B. CRT DRIVE assy (10.5kV, 210V)

6. CRT assy R (CRT service assy R) (30.5kV)

7. CRT assy G (CRT service assy G) (30.5kV)

8. CRT assy B (CRT service assy B) (30.5kV)

9. Focus variable resistor(VR1) (10.5kV)

10. Deflection yokes (L1, L2 and L3) Approx. (1100V at peak)

7 X-ray protection

• Regarding the parts which are relative to radiation of Xrays (There is the danger to radiate X-ray from the individual CRT assy R, G, B), there are notifications of caution in the individual schematic diagrams. Be sure to read

them for safety’s sake.

• The component parts for X-ray protection are as follows :

When the current flows to the CRT assy R, G, B, be sure

to perform it with these parts being attached. Protection

from the X-ray radiation is maintained in the state in which

these parts have been installed to the CRT assy. R, G, B.

Accordingly, never supply current only to the CRT assy R,

G, B.

Moreover, the anode voltage of the CRT assy R, G, B

should always be kept not higher than the predetermined

value (in the minimum brightness and picture state when

non signal input is less than 30.5kV). Be sure to drive the

CRT assy R, G, B by using a completely functional DEFLECTION assy which have been adjusted completely in

the combined state. (When the voltage abnormally becomes high, the X-ray protection circuit will operate.)

1.CRT assy R, G, B (Do not dismantle CRT assemblies un-

der any circumastances)

2.Each Lens assy

High Voltage

generating point

AC Power cord

Charged section

Fig. 1 Charged section and high voltage generating point

4

Fig. 2 Component parts for X-ray protection

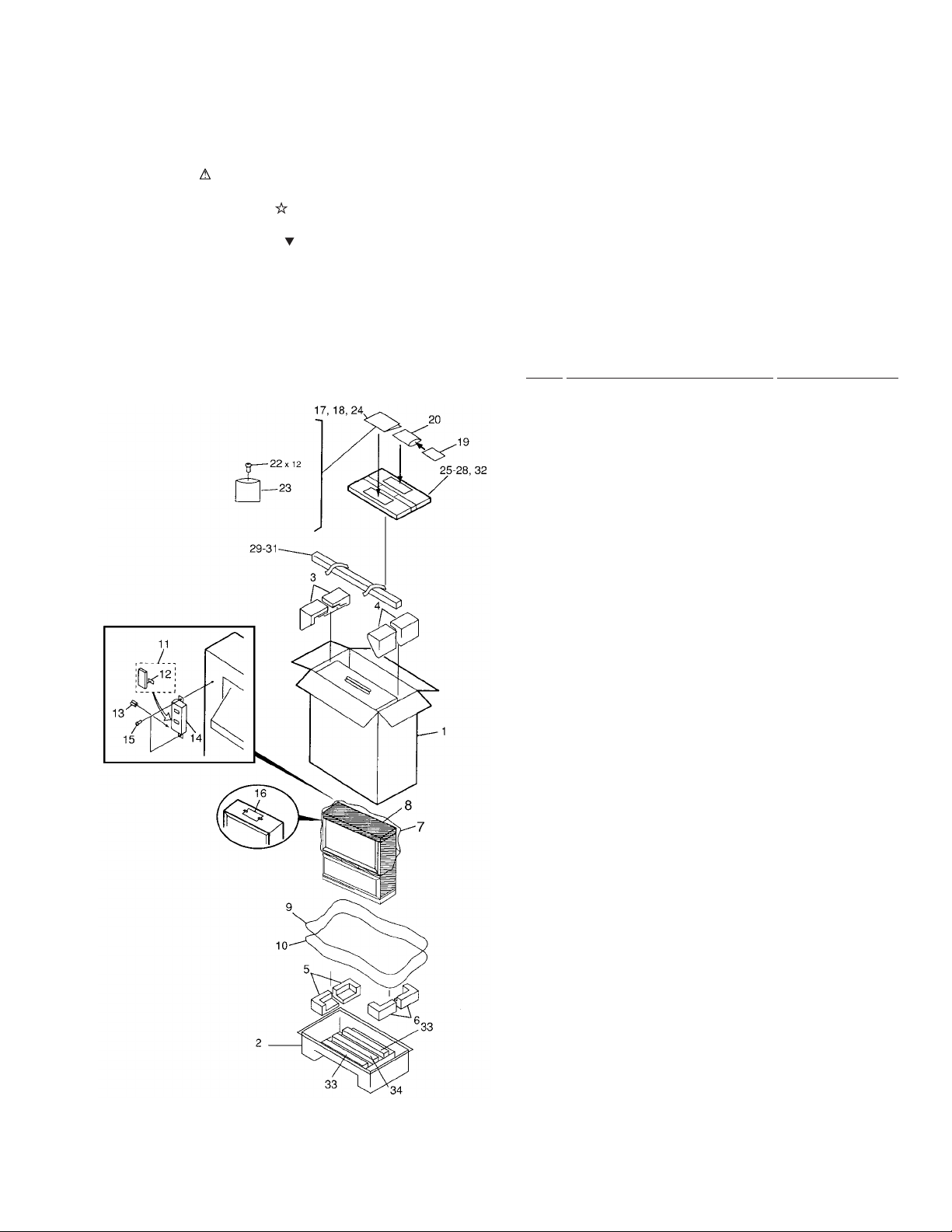

2. EXPLODED VIEWS AND PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Parts marked by are important parts which relate in X-rays radiation.

•

If any of these parts need to be replaced, always replace with specified parts.

Screws adjacent to mark on the product are used for disassembly.

•

PRO-700HD

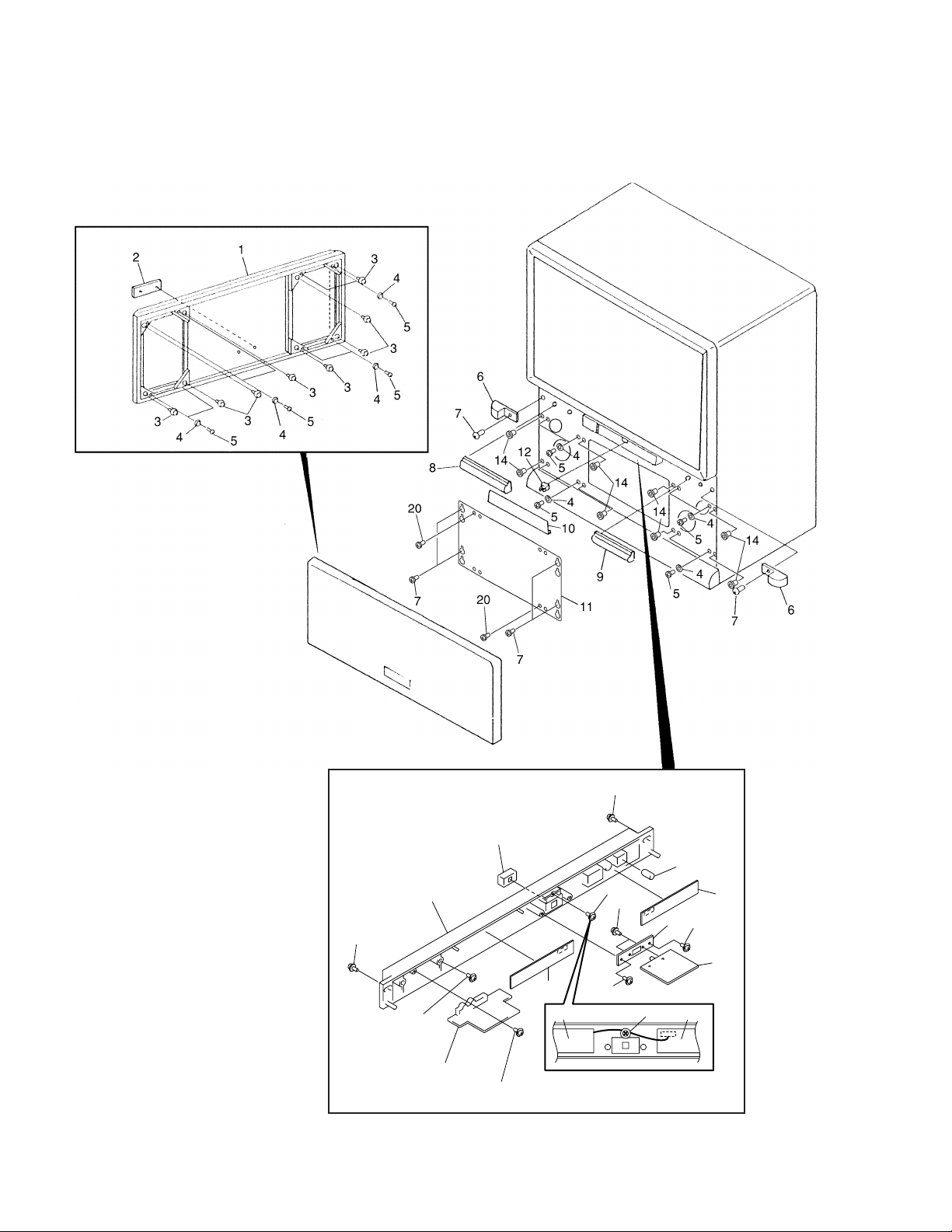

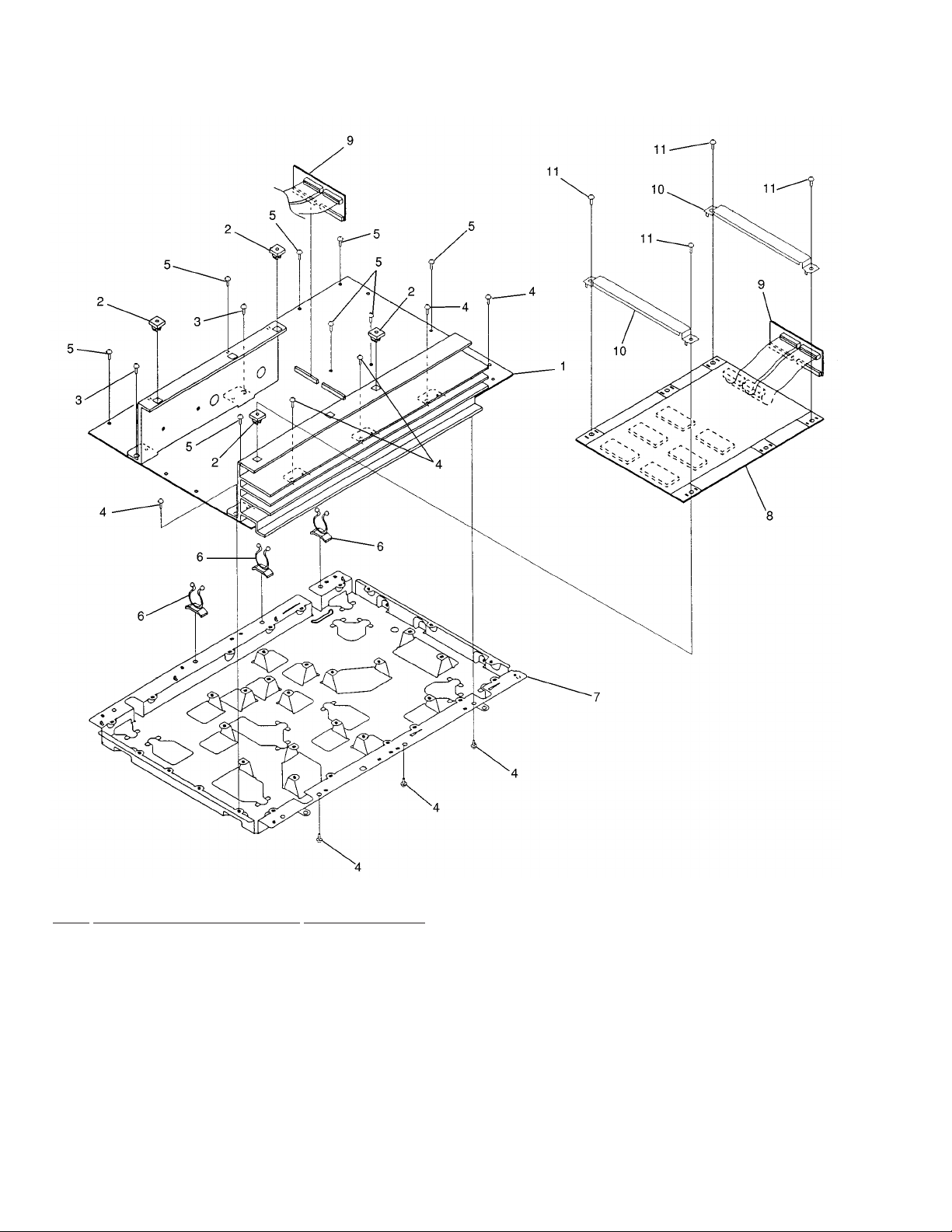

2.1 PACKING

• PACKING PARTS LIST

Mark No. Description Part No.

1 Upper Carton 64W AHD2994

2 Under Carton 64W AHD2995

3 Upper Pad L AHA2222

4 Upper Pad R AHA2223

5 Under Pad L AHA2224

6 Under Pad R AHA2225

NSP 7 Vinyl Sheet 64W Upper AHG1288

NSP 8 Packing Sheet 60 AHG1230

NSP 9 Packing Sheet 64 Under AHG1290

10 Vinyl Sheet 64W Under AHG1289

11 Remote Control Unit AXD1438

(CU-SD105)

12 Battery Cover AZN2401

NSP 13 Alkarine Dry Cell Battery AEX1018

(LR6,AA)

14 CU Packing Case AHC1032

15 Special Screw ABA1239

16 CONV. Attention Card ARM1151

17 Operating Instructions ARB1519

(English)

NSP 18 Caution Card ARM1057

NSP 19 Warranty Card EL ARY1026

NSP 20 Poly Bag AHG1285

21 ...........

22 Special Screw ABA1226

(Panel Frame Attaching Screw)

NSP 23 Wrapper Bag AHG1076

NSP 24 Literature Bag AHG1222

25 Panel Case 64W AHB1202

NSP 26 Vinyl Sheet 64W (for Panel) AHG1286

27 Protective Screen AAK2729

28 Acrylic Caution Card ARH1160

29 Frame Cover H AAP1593

30 Frame Cover V AAP1594

31 Panel Frame H AND1163

32 Panel Frame V AND1164

NSP 33 Under Cushion A AHA2228

NSP 34 Under Cushion B AHA2229

Note : As for accessory parts of part No. 22, 27 and 29 to 32, refer

to page 7.

5

PRO-700HD

2.2 FRONT VIEW (1/2)

7

15

26

13

7

19

16

17

16

22

23

21

24

25

24

18

2519 22

6

(1) FRONT VIEW (1/2) PARTS LIST

Mark No. Description Part No.

1 Grille 64 AMM2936

2 Badge AAM1081

NSP 3 Catcher A ANZ-241

4 Magic Tape AEC1394

5 Screw ABA1271

6 Side Cover AMR3107

7 Special Screw ABA1240

8 Side Panel Assy L (64W) AMB2627

9 Side Panel Assy R (64W) AMB2635

10 Door Assy AAN1444

11 Blind Plate AMM2933

12 Cather F2M AEC1609

13 Front Panel Assy AMB2625

14 Catch B ANZ-242

15 Power Knob AAD4102

16 Screw ABZ40P080FZK

17 FRONT INPUT Assy AWZ6339

18 POWER SW Assy AWZ6341

19 FRONT CONTROL Assy AWZ6337

20 Screw ABA1239

PRO-700HD

NSP 21 Switch Holder ANG2313

22 Screw ABA1269

23 Screw AMZ30P060FZK

24 Screw APZ30P080FZK

25 LED DPO Assy AWZ6338

26 LED Lens AAK2730

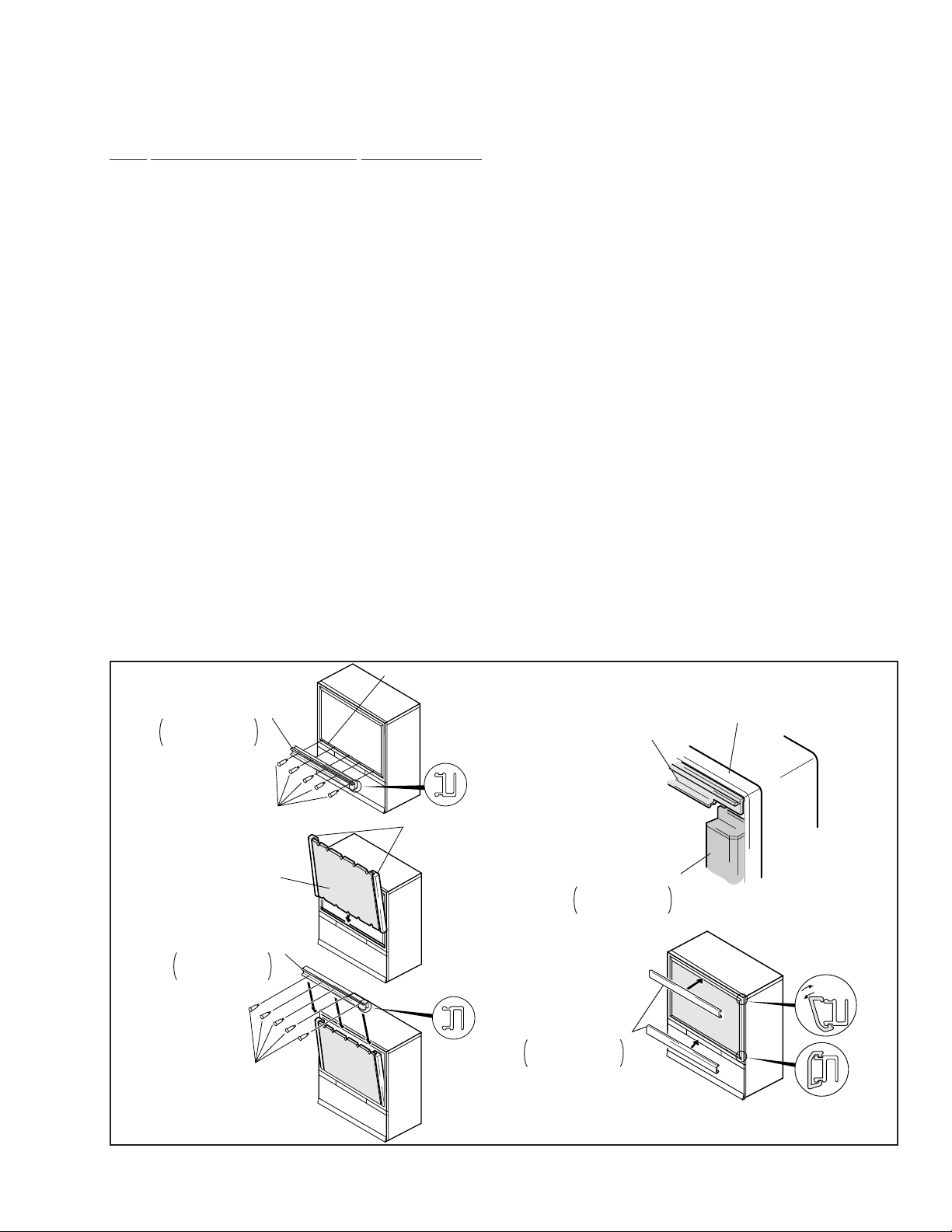

• Accessory Parts

Panel frame

31 Panel Frame H

AND1163

22 Panel Frame Attaching Screw

(ABA1226)

27 Protective screen

(AAK2729)

Panel frame

31 Panel Frame H

AND1163

Screen frame

Side view

32 Panel Frame V

(AND1164)

Upper panel frame

Side frame cover

30 Frame Cover V

AAP1594

Screen frame

Upper frame cover

Remove

Attach

22 Panel Frame Attaching Screw

(ABA1226)

Side view

Frame Cover

29 Frame Cover H

AAP1593

Lower frame cover

7

PRO-700HD

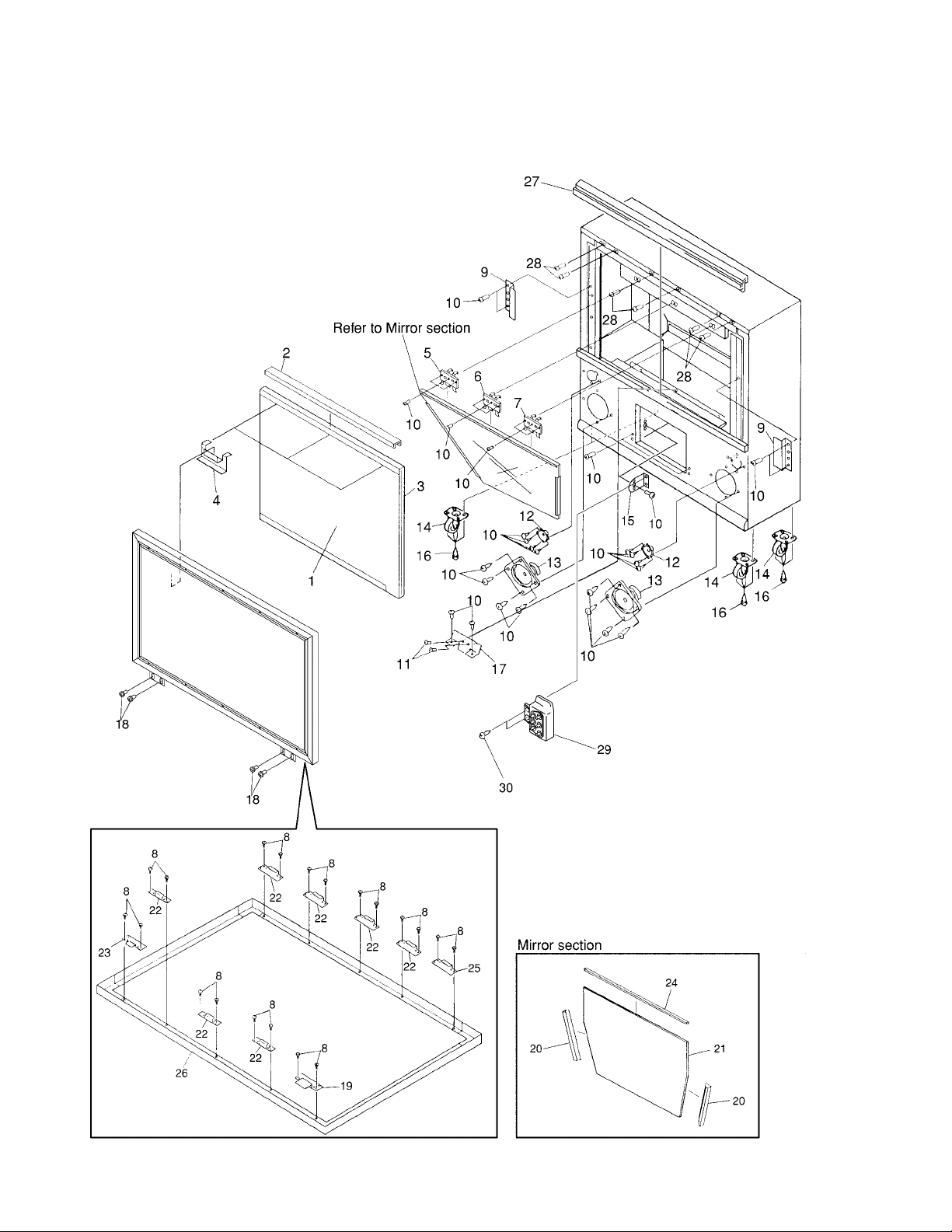

2.3 FRONT VIEW (2/2)

8

(1) FRONT VIEW (2/2) PARTS LIST

Mark No. Description Part No.

1 Lenticular Sheet AMR3115

2 Screen Holder Top 64 ANG2312

3 Fresnel 64W AMR3116

NSP 4 Upper Cabinet Metal ANG2000

NSP 5 Mirror Upper Stay L ANG2004

NSP 6 Mirror Upper Stay C ANG2006

NSP 7 Mirror Upper Stay R ANG2005

NSP 8 Screw BYC35P160FMC

NSP 9 Screen Side Fitting ANG1993

10 Special Screw ABA1240

11 Screw ACZ40P080FMC

12 Speaker 66 (Tweeter) D66AP45-56L

13 Cone Speaker APV1048

14 Caster AMR2547

NSP 15 VR Holder ANG1956

16 Special Screw SBA-140

NSP 17 CRT Front Holder ANG2118

18 Screw M5 ABA1189

NSP 19 Under Screen Metal B ANG2009

20 Mirror Frame V 64W ANG2315

PRO-700HD

21 Mirror 64 AMR3113

NSP 22 Upper Screen Metal B ANG2002

NSP 23 Under Screen Metal A ANG2003

24 Mirror Frame H 64 W ANG2314

NSP 25 Upper Screen Metal A ANG2001

26 Screen Frame Assy 64W AAP1592

27 Screen Holder Low 64W AAP1601

28 Screw BYC35P160FZK

29 Focus VR (VR1) ACX1096

30 Screw BBZ30P080FZK

9

PRO-700HD

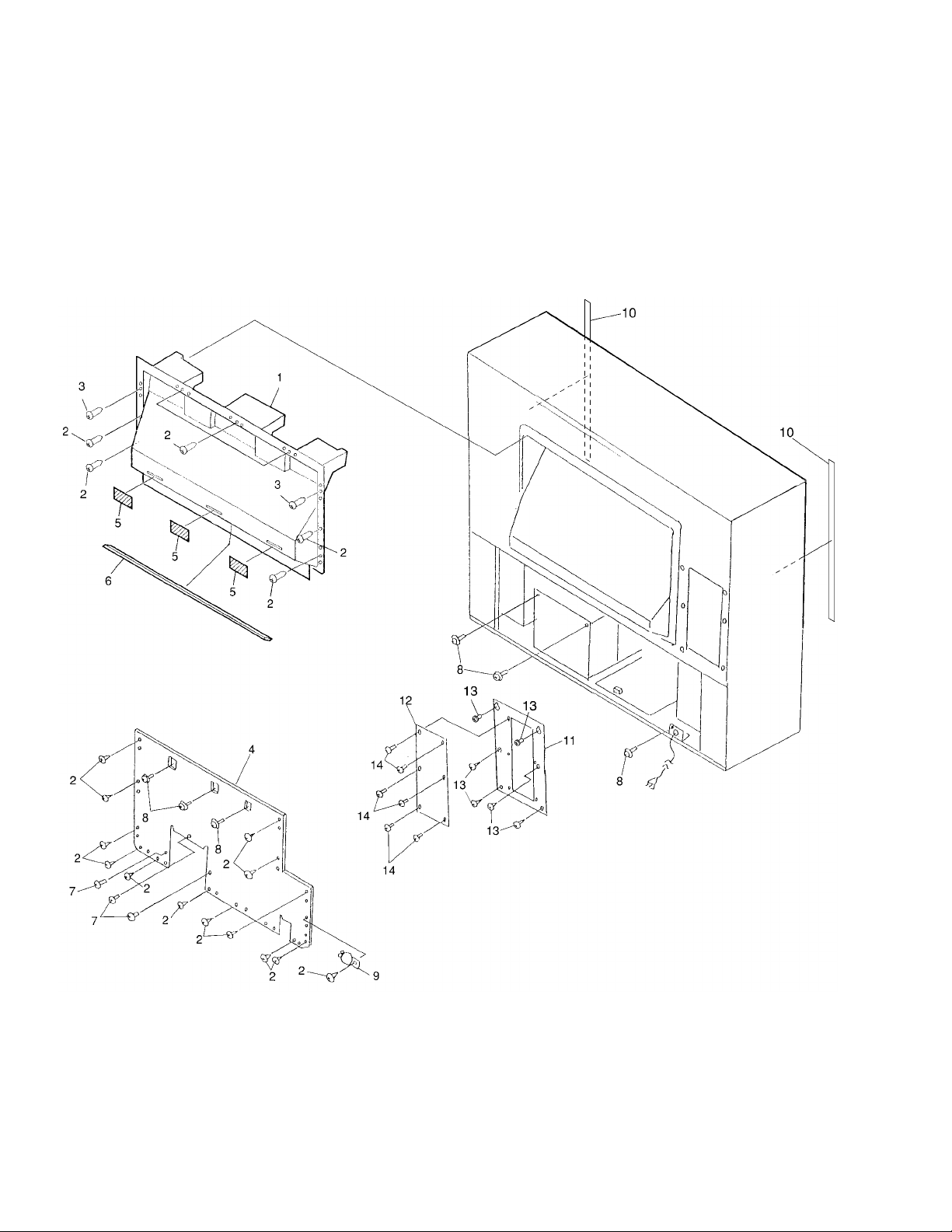

2.4 REAR VIEW (1/2)

10

(1) REAR VIEW (1/2) PARTS LIST

Mark No. Description Part No.

1 Mirror Case 51 AME2296

2 Screw ABA1240

3 Screw PYC40T140FZB

4 Rear Cover AMM2929

5 Blind Sheet AEC1622

6 Mirror Case Coshion AEC1627

7 Screw ABZ30P100FZK

8 Screw ABA1269

NSP 9 Cabinet Wire Holder AEC1263

10 Screen Cushion 64 AEC1778

11 Rear Cover (DTV) Assy ANE1577

12 Rear Cover Sheet AMR3135

13 Screw PMB40P160FZB

14 Screw BCZ30P080FZK

15

PRO-700HD

11

PRO-700HD

2.5 REAR VIEW (2/2)

12

37

44

13

44

41

39

36

42

40

32

24

35

(1) REAR VIEW (2/2) PARTS LIST

Mark No. Description Part No.

1 CRT Service Assy 64B AWY1415

2 CRT Service Assy G AWY1413

3 CRT Service Assy 64R AWY1414

4 Lens Assy AMR3121

5 Screw FBT40P120FZK

6 Screw ABA1168

7 Screw AMZ40P080FZK

NSP 8 CRT Front Frame ANA1541

NSP 9 CRT Rear Frame ANA1542

10 Screw ACZ40P080FMC

NSP 11 CRT Front Holder ANG2118

NSP 12 CRT Rear Holder ANG2119

13 Screw ABA1240

14 Cord Holder AEC1257

NSP 15 Tube Label AAX2497

16 Rivet AEC-441

NSP 17 CRT Stand Holder R ANA1497

NSP 18 CRT Stand Holder L ANA1496

19 Screw PMB50P250FZB

20 Special Screw ABA1121

PRO-700HD

Mark No. Description Part No.

OTHERS

1P Lead Wire (J3) ADX2231

1P Lead Wire (J4) ADX2232

1P Lead Wire (J5) ADX2233

1P Lead Wire (J6) ADX2289

1P Lead Wire (J7) ADX2290

1P Lead Wire (J8) ADX2291

4P Housing Wire (J2) ADX2484

Wire Harness A (J10) ADX2485

Wire Harness B (J11) ADX2487

NSP 21 Back Cover Panel AMM2939

22 Back Cover Cushion AEC1779

23 Screw ABA1241

NSP 24 Cabinet Wire Holder AEC1263

25 Screw ABA1210

NSP 26 Fixing Metal ANG1958

27 SR Assy AWZ6340

NSP 28 Tray AMR2563

NSP 29 Solder Warning Label AAX2672

NSP 30 Warning Label (KC) AAX1797

NSP 31 AC Cord Holder A ANG2307

NSP 32 Bind Holder AEC1785

33 Ferrite Core ATX1033

34 AC Power Cord ADG1180

NSP 35 AC Cord Holder B ANG2311

36 Wire Harness C (J14) ADX2491

37 AC Power Cord B ADG1181

38 Screw BBZ30P080FZK

39 Screw ABA1271

40 Ferrite Core ATX1031

NSP 41 Nylon Clamp 18N AEC1789

42 Nylon Binder AEC-093

43 1P Lead Wire (J1) ADX2505

44 Screw PMB40P250FZB

13

PRO-700HD

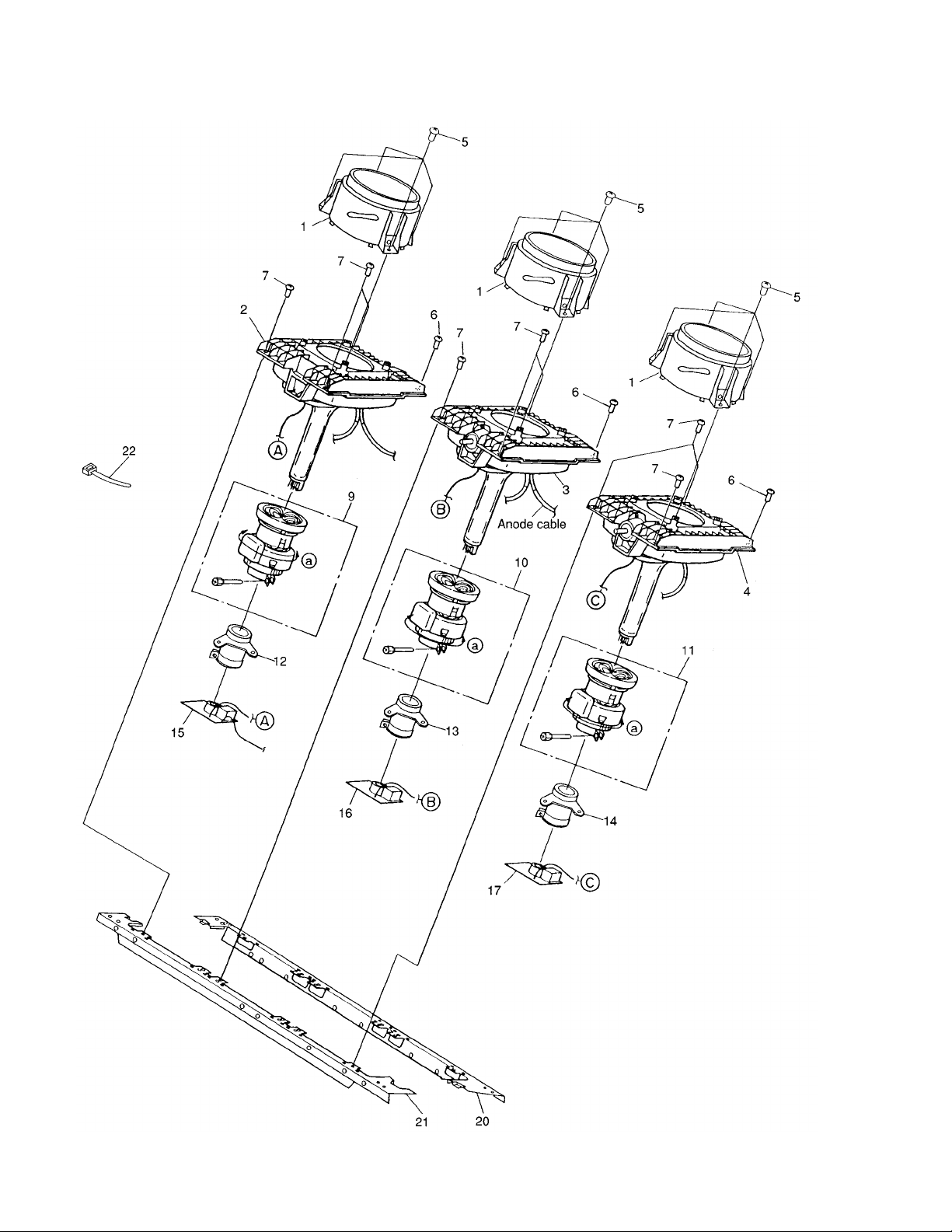

2.6 CRT BLOCK

14

(1) CRT BLOCK PARTS LIST

Mark No. Description Part No.

1 Lens Assy AMR3121

2 CRT Service Assy 64R AWY1414

3 CRT Service Assy G AWY1413

4 CRT Service Assy 64B AWY1415

5 Screw AMZ40P080FZK

6 Screw FBT40P120FZK

7 Screw ABA1168

8 ...........

9 Deflection Yoke (L1) ATL1136

10 Deflection Yoke (L2) ATL1136

11 Deflection Yoke (L3) ATL1136

12 VM Coil (L4) ATL1137

13 VM Coil (L5) ATL1137

14 VM Coil (L6) ATL1137

15 R.CRT DRIVE Assy AWZ6344

16 G. CRT DRIVE Assy AWZ6345

17 B. CRT DRIVE Assy AWZ6346

18 ............

19 ............

NSP 20 CRT Rear Frame 62 ANA1542

PRO-700HD

NSP 21 CRT Front Frame 62 ANA1541

22 Nylon Binder AEC-093

15

PRO-700HD

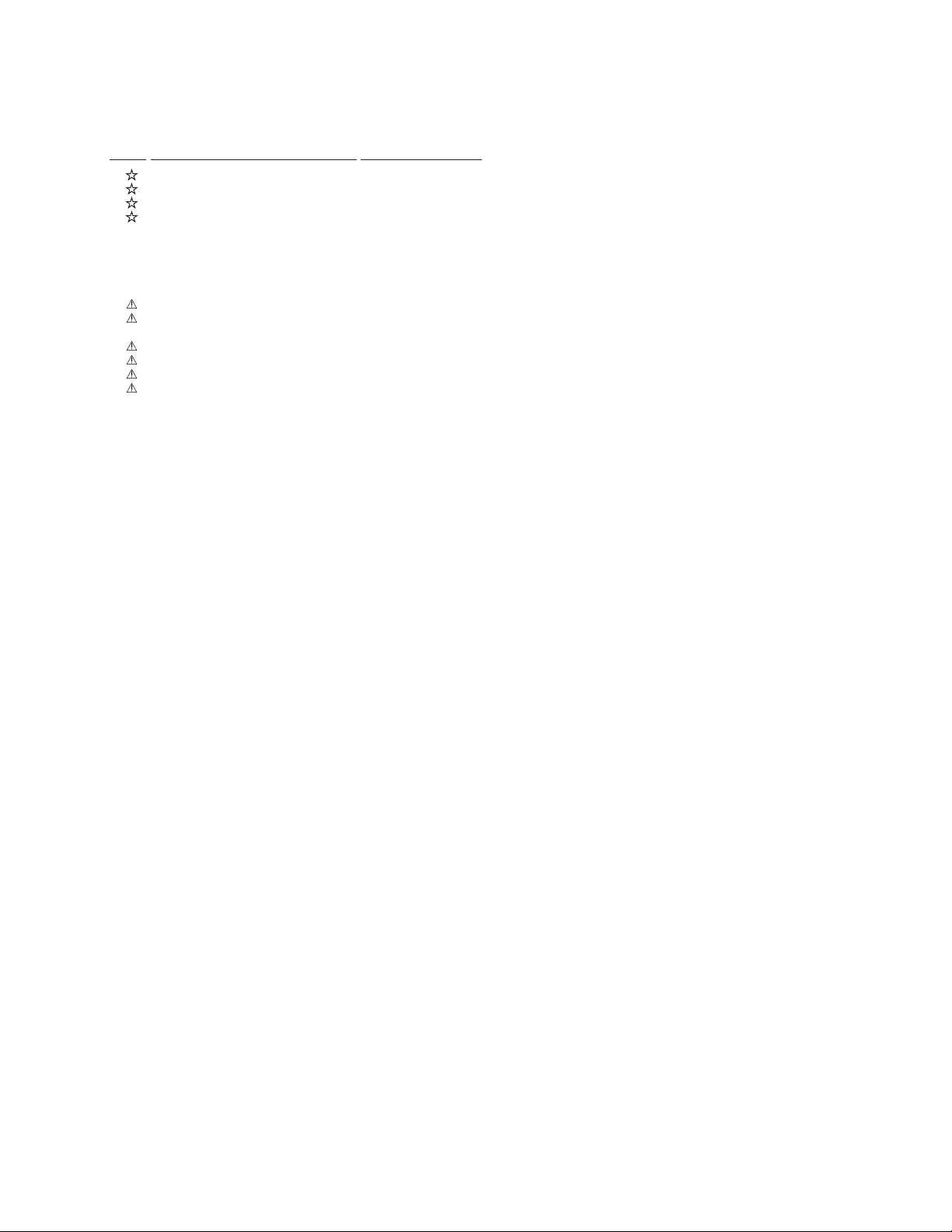

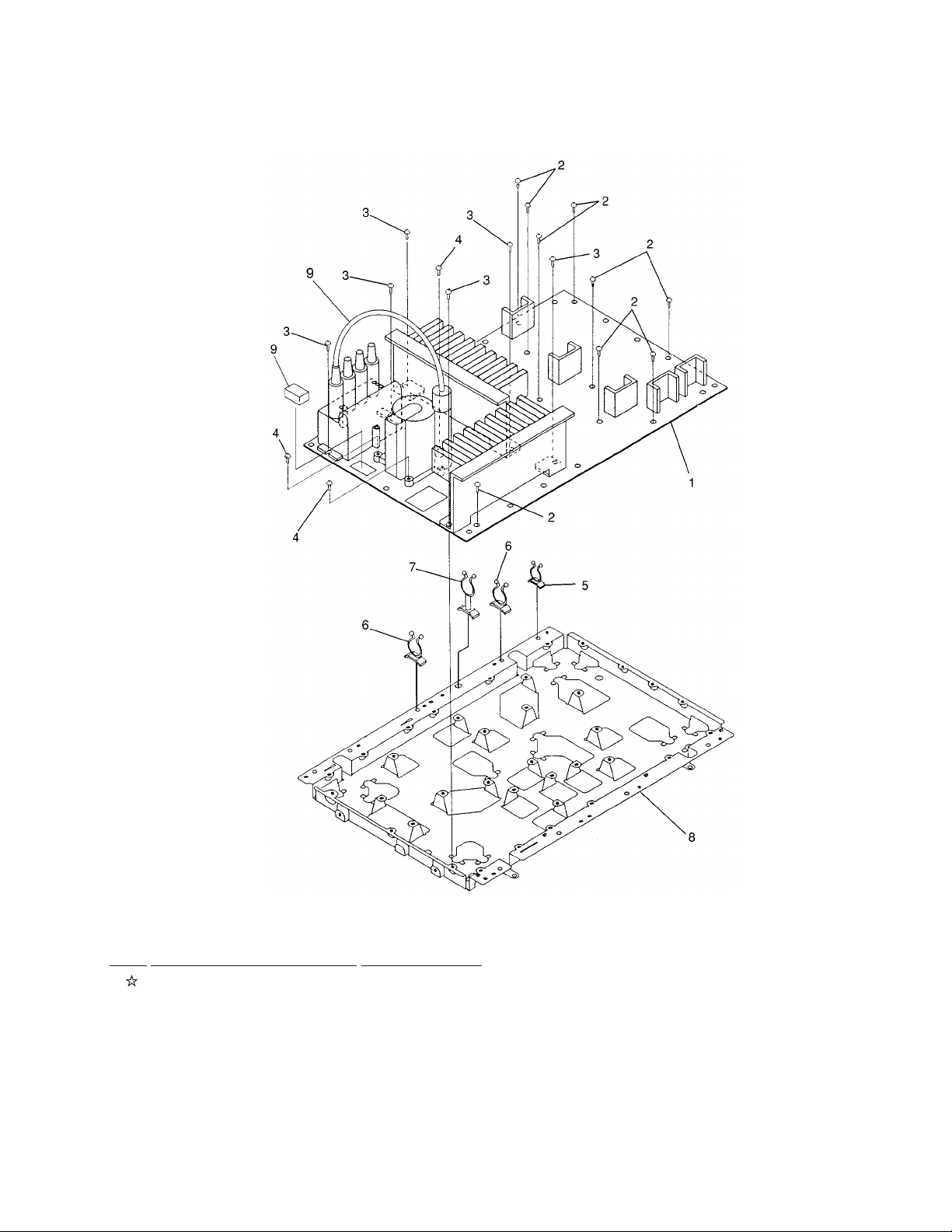

2.7 VIDEO BLOCK

Refer to

“2.8 SIGNAL ASSY BLOCK”

Refer to

“2.8 SIGNAL ASSY BLOCK”

Refer to

“2.8 SIGNAL ASSY BLOCK”

(1) VIDEO BLOCK PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 Video Chassis ANA1584

2 VIDEO Assy AWV1716

3 AV / IO Assy AWV1714

4 Rear Panel ANC2321

5 ...........

6 ...........

7 Nut ABN-087

8 Screw BBZ30P080FZK

9 Screw BBZ30P080FCU

10 TUNER u-COM Assy AWV1715

16

11 SIGNAL Assy AWV1717

12 SUB VIDEO Assy AWV1718

13 RF Switch AXF1098

14 Washer WAXOF160N100

NSP 15 Lead Clamper M AEC1611

NSP 16 Cable Clip AEP-214

NSP 17 PCB Side Holder ANG2305

18 SR BNC Assy AWZ6342

19 Screw BCZ30P080FZK

20 4P Housing Wire (J13) ADX2490

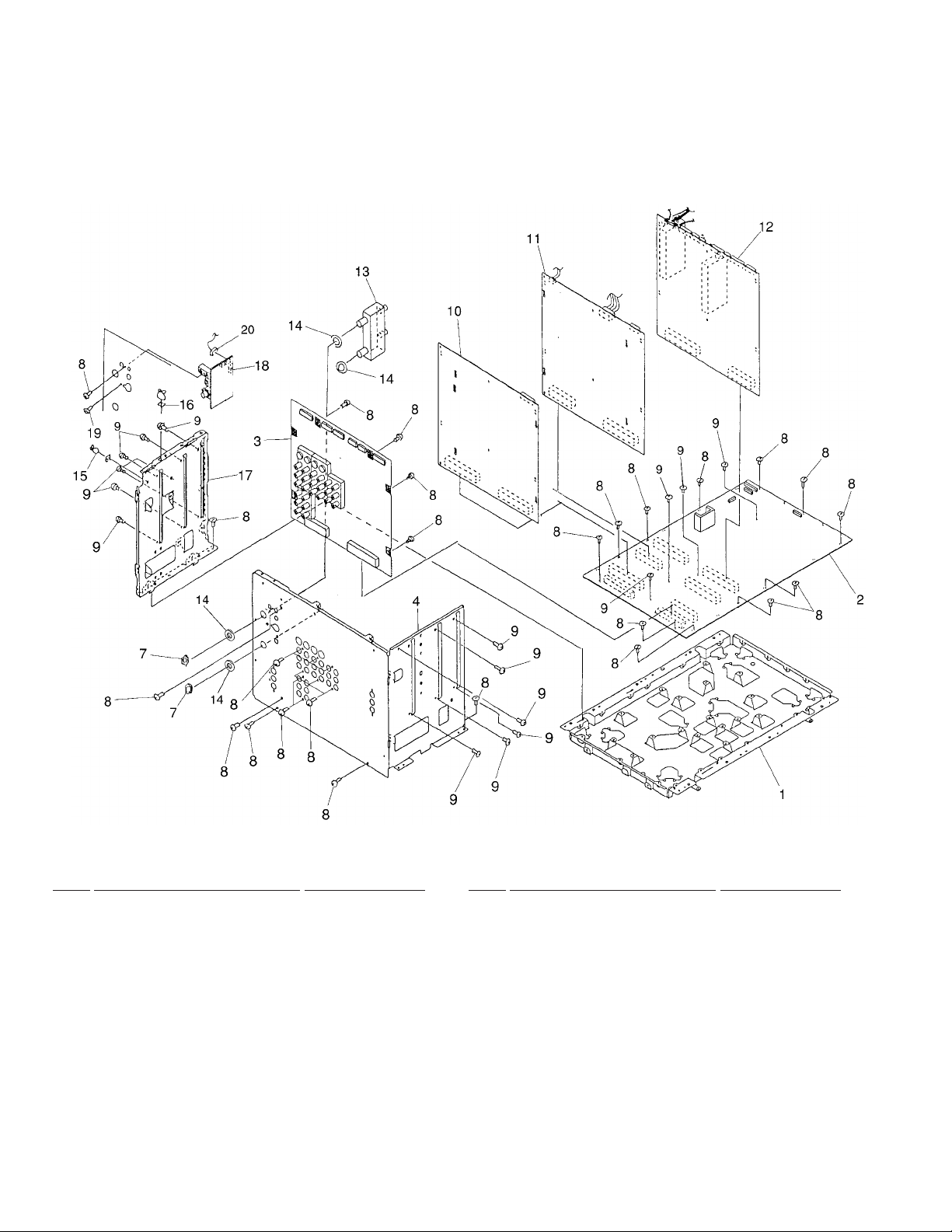

2.8 SIGNAL ASSY BLOCK

PRO-700HD

(1) SIGNAL ASSY BLOCK PARTS LIST

Mark No. Description Part No.

1 Shield Cover ANK1562

NSP 2 PCB Sub-Frame ANG2304

NSP 3 Lead Clamper M AEC1611

4 SUB VIDEO Assy AWV1718

5 Screw BBZ30P080FCU

NSP 6 Analog Shield B ANK1537

7 SIGNAL Assy AWV1717

8 TUNER u-COM Assy AWV1715

NSP 9 Cable Clip D3M AEC1783

10 Screw ABZ30P080FCU

Mark No. Description Part No.

11 Shield Front Cover B ANK1592

12 Shield Rear Cover B ANK1596

13 Shield Front Cover A ANK1591

17

PRO-700HD

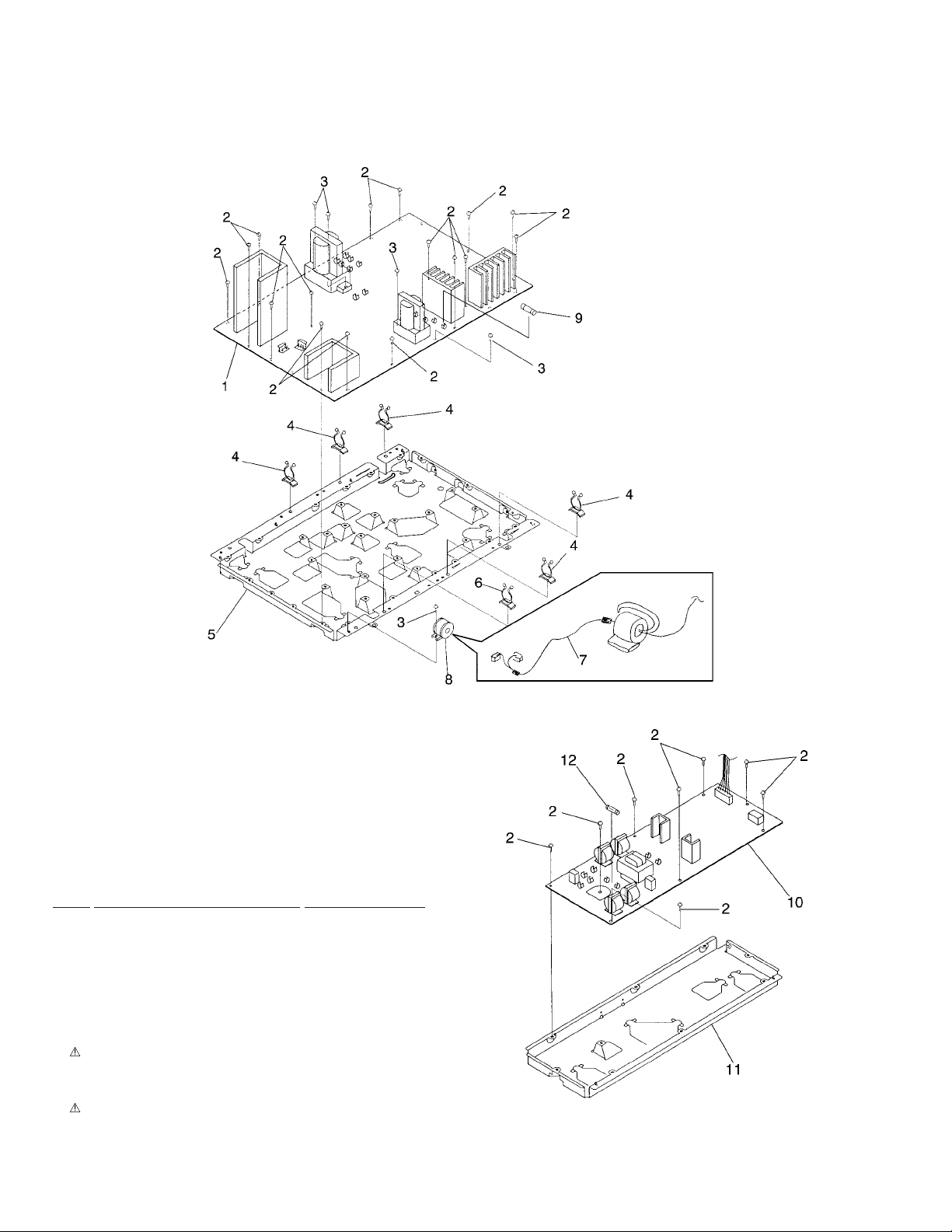

2.9 AMP BLOCK

(1) AMP BLOCK PARTS LIST

Mark No. Description Part No.

1 AMP Assy AWV1712

2 Grommet AEC1418

3 Special Screw ABA1099

4 Screw ABZ30P100FZK

5 Screw BBZ30P080FZK

NSP 6 Cable Clip D3M AEC1783

NSP 7 AMP Chassis ANA1585

NSP 10 Head Sink Holder ANG2306

18

8 CONVER . DAC Assy AWZ6333

9 CONNECTOR Assy AWZ6335

11 Screw VPZ40P120FZK

12

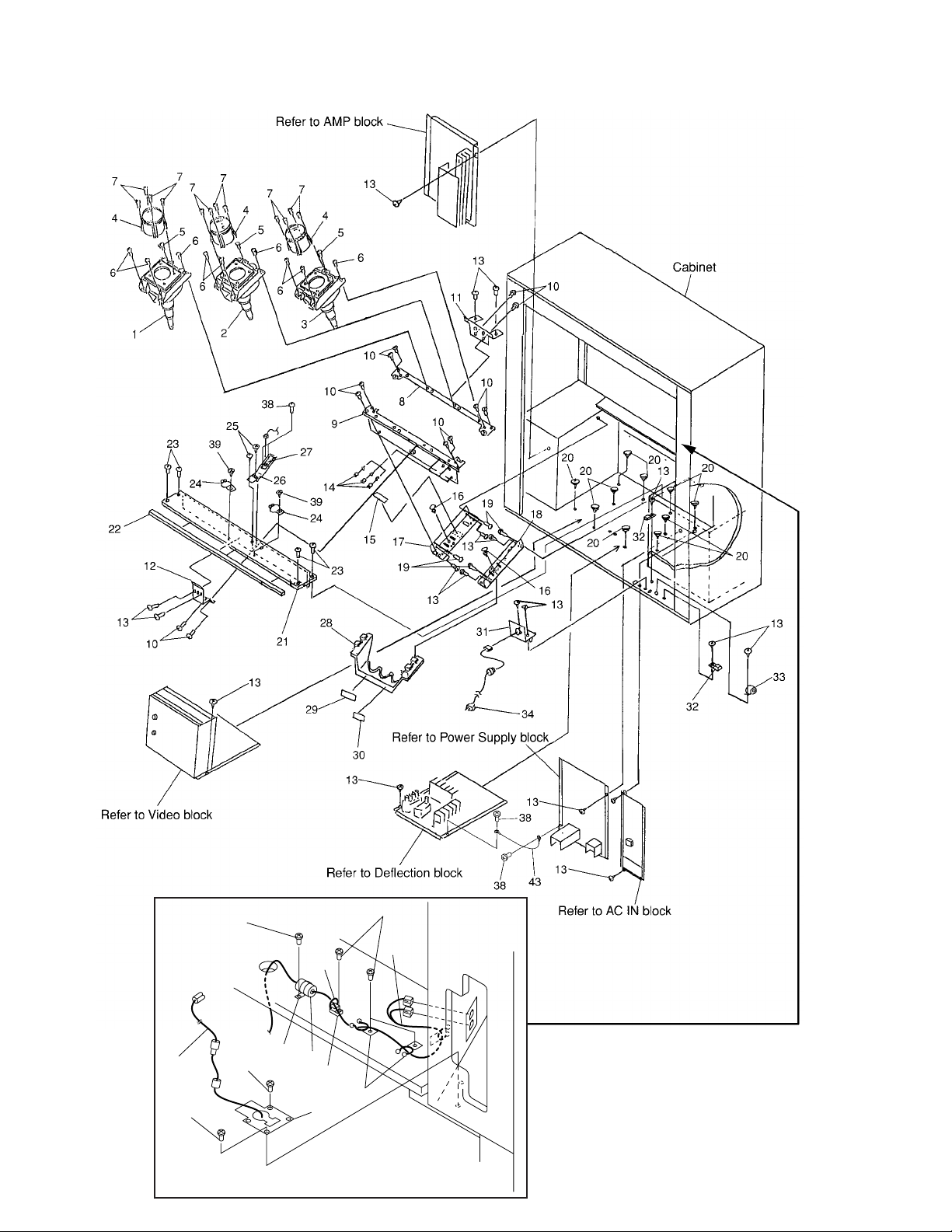

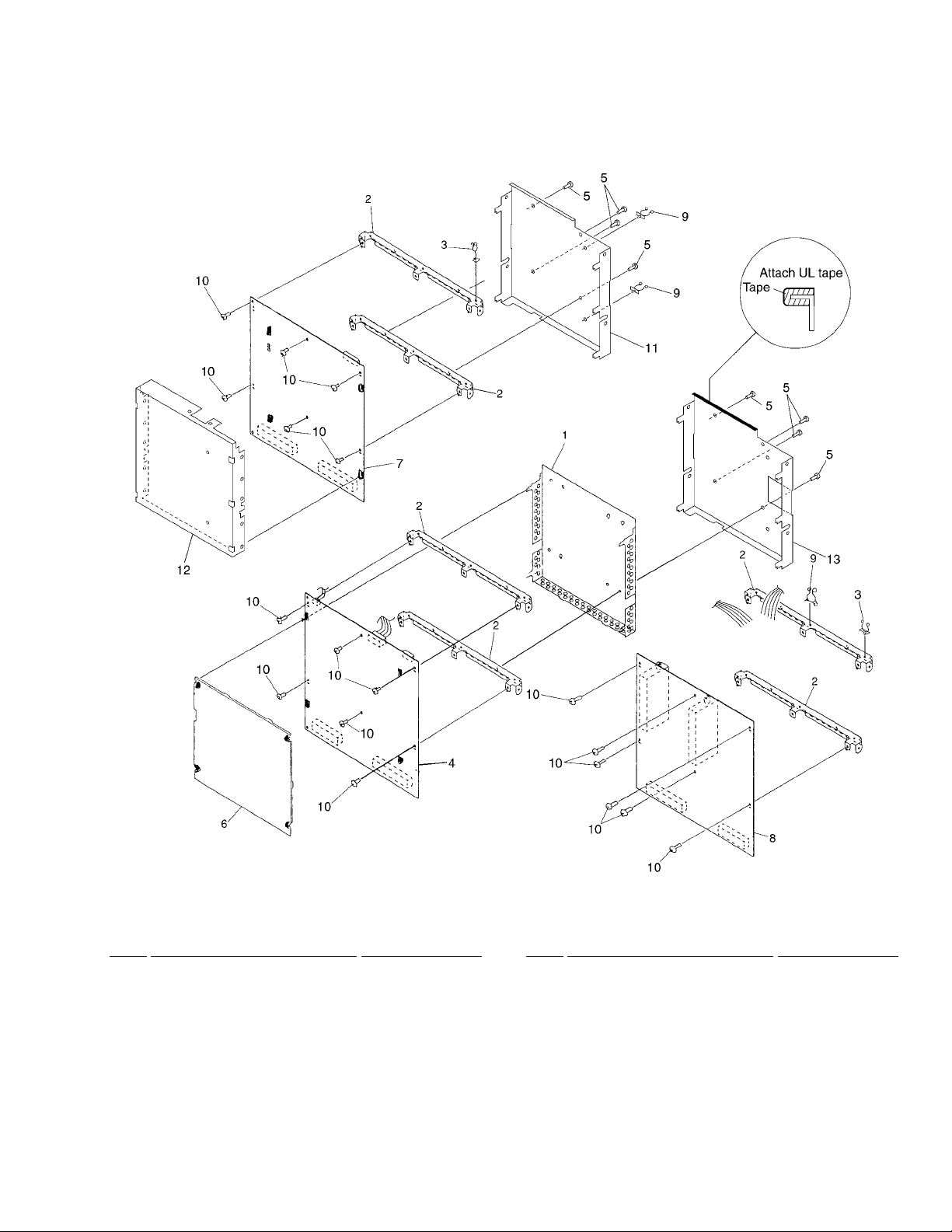

2.10 DEFLECTION BLOCK

PRO-700HD

(1) DEFLECTION BLOCK PARTS LIST

Mark No. Description Part No.

1 DEFLECTION SERVICE AWV1731

Assy

2 Screw BBZ30P080FZK

3 Screw ABZ30P100FZK

4 Screw VBZ30P200FMC

NSP 5 Cable Clip D3S AEC1782

NSP 6 Cable Clip D3M AEC1783

NSP 7 Cable CliP AEC1325

NSP 8 DF Chassis ANA1583

9 Shield Case ANK1510

19

PRO-700HD

2.11 POWER SUPPLY / AC IN BLOCK

Power Supply Bkock

AC IN Block

(1) POWER SUPPLY / AC IN BLOCK PARTS LIST

Mark No. Description Part No.

1 POWER SUPPLY Assy AWV1710

2 Screw BBZ30P080FZK

NSP 4 Cable Clip D3S AEC1782

NSP 5 PS Chassis ANA1582

NSP 6 Cable Clip D3M AEC1783

NSP 11 LF Chassis ANA1586

3 Screw ABZ30P100FZK

7 Wire Harness D (J15) ADX2489

8 Ferrite Core ATX1033

9 Fuse (6.3A/125V) REK1085

10 AC IN Assy AWZ6353

12 Fuse (500mA/125V) AEK1010

20

PRO-700HD

21

1234

1

PRO-700HD

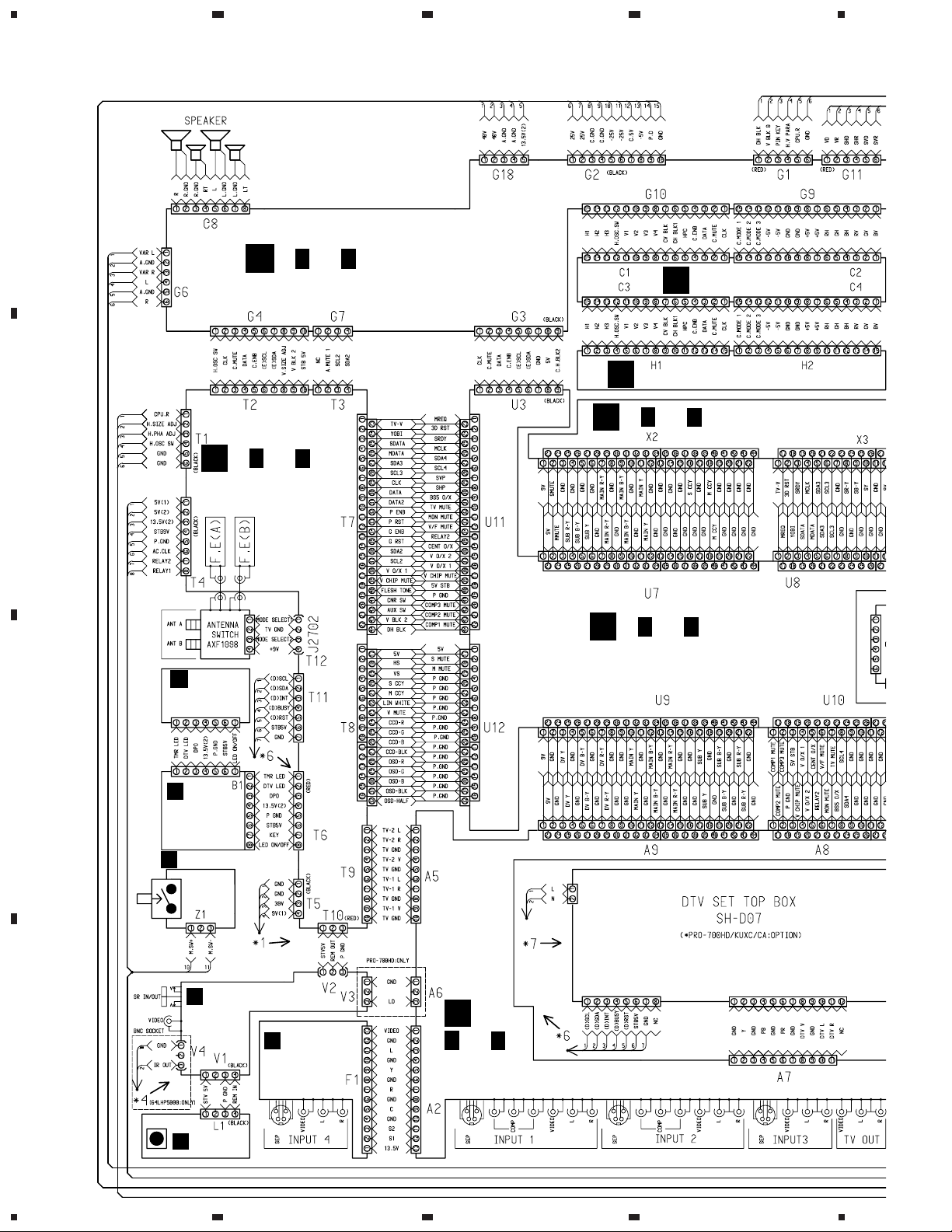

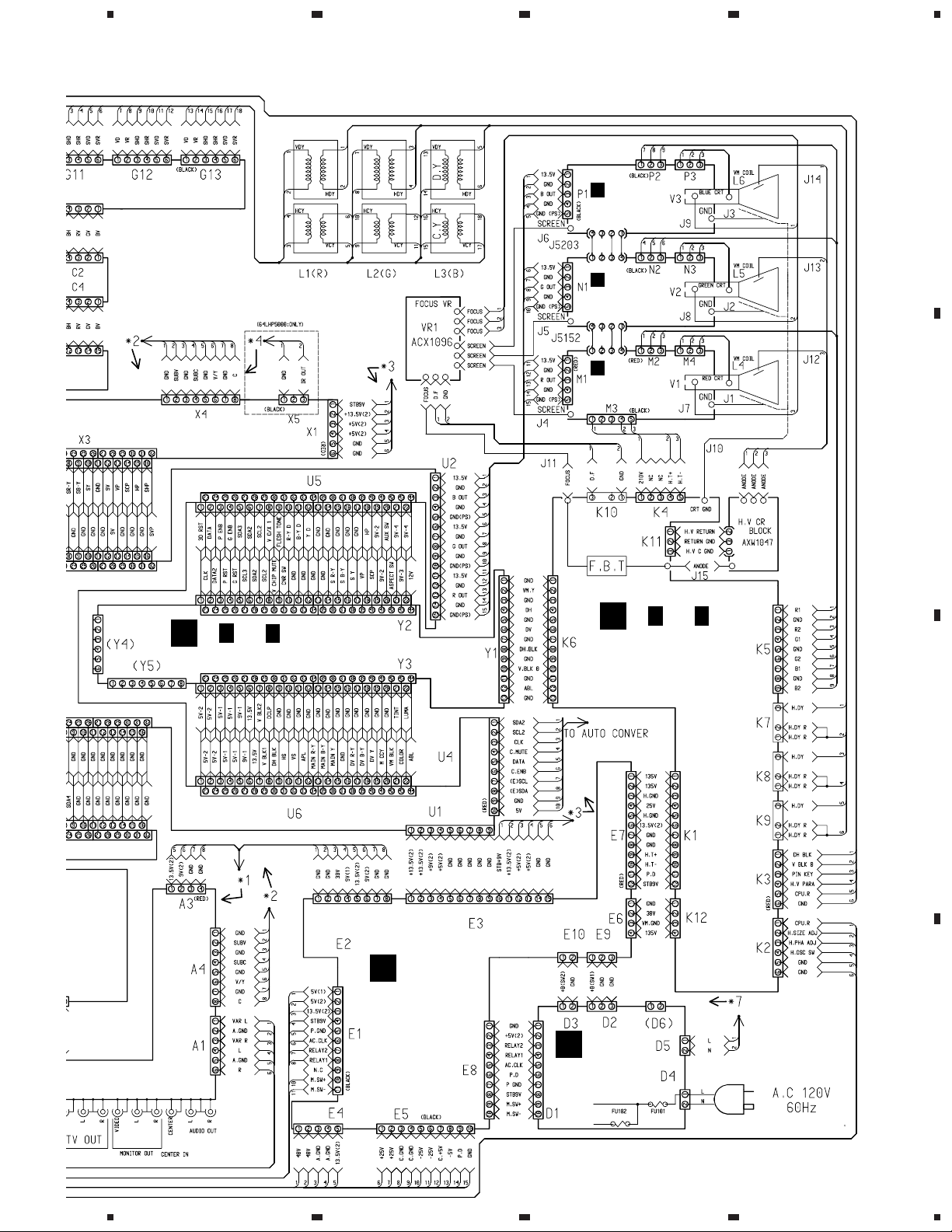

3. SCHEMATIC DIAGRAM 3.1. OVERALL CONNECTION DIAGRAM

A

1/3E3/3

( - )

E

AMP ASSY (AWV1712)

E

CONNECTOR ASSY

G

(AWZ6335)

CONVER.DAC ASSY (AWZ6333)

F

1/8D 8/8D

( - )

D

1/3A 3/3A

( - )

B

C

A

TUNER u-COM ASSY

(AWV1715)

K

LED DPO ASSY

(AWZ6338)

1/2B 2/2B

( - )

B

VIDEO ASSY

(AWV1716)

SIGNAL ASSY (AWV

J

FRONT

CONTROL ASSY

(AWZ6337)

POWER SW ASSY

L

(AWZ6341)

SR BNC ASSY

H

(AWZ6342)

N

FRONT INPUT

I

ASSY

D

Not Used

SR ASSY

M

(AWZ6340)

22

1234

(AWZ6339)

1/3N 3/3N

( - )

AV I/O ASSY

(AWV1714)

5678

3

PRO-700HD

A

R

B CRT DRIVE ASSY

(AWZ6346)

Q

G CRT DRIVE ASSY

Not Used

(AWZ6345)

33)

AWV1717)

( - )

C

1/5C 5/5C

SUB VIDEO ASSY (AWV1718)

P

R CRT DRIVE ASSY

(AWZ6344)

1/3S 3/3S

( - )

S

DEFLECTION

SERVICE ASSY

B

(AWV1731)

C

T

POWER

SUPPLY ASSY

(AWV1710)

O

AC IN ASSY

(AWZ6353)

4A 125V

56

7

D

10A 250V

23

8

1234

7

P

N

PRO-700HD

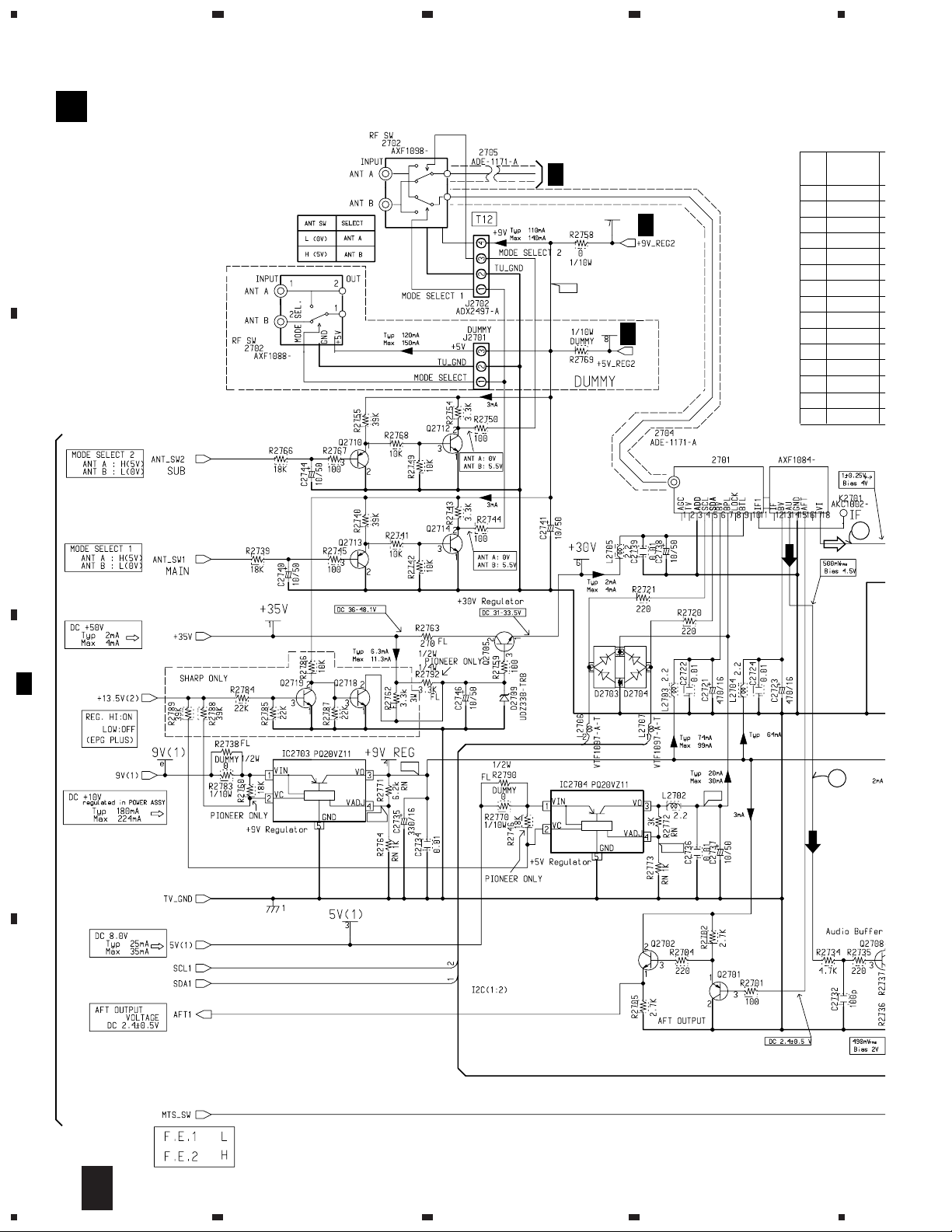

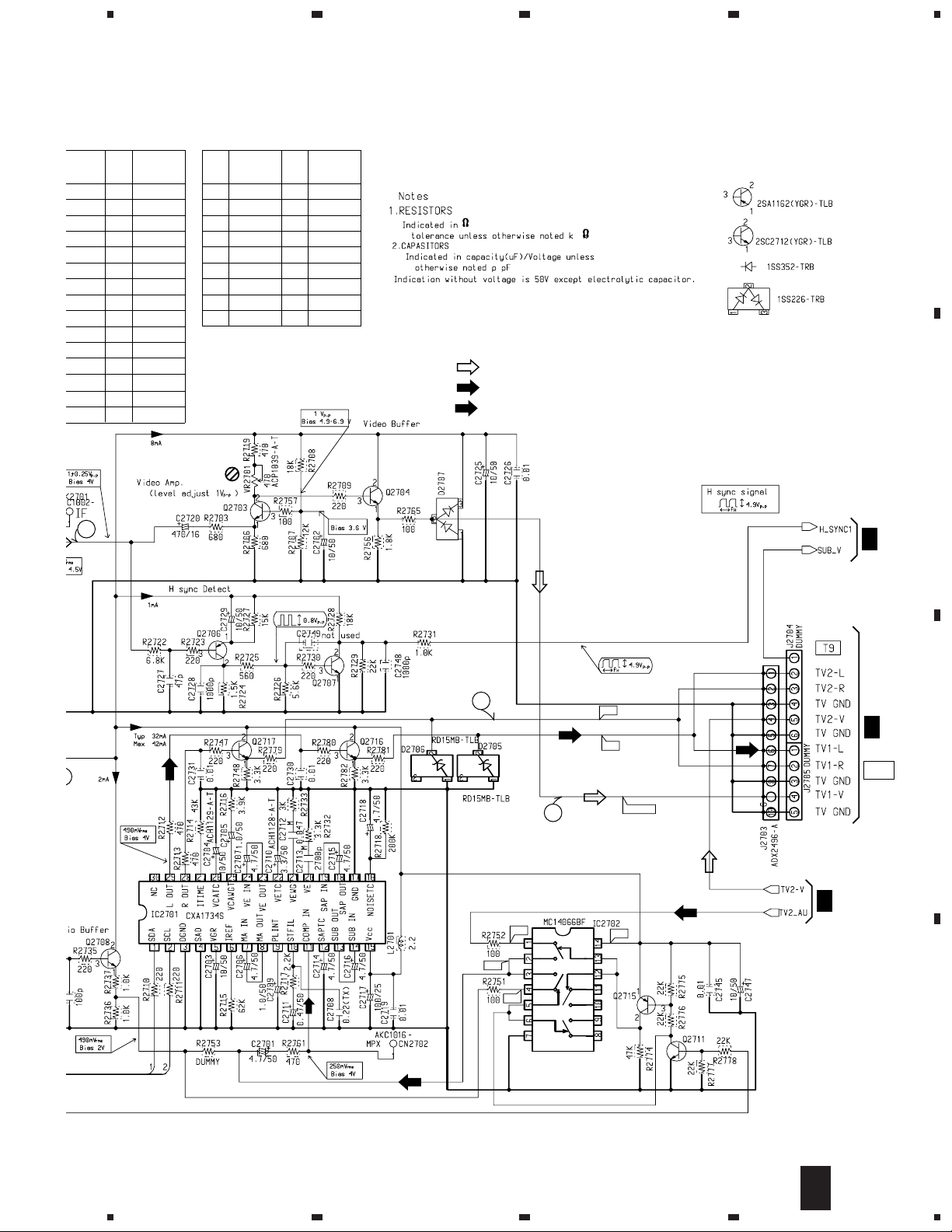

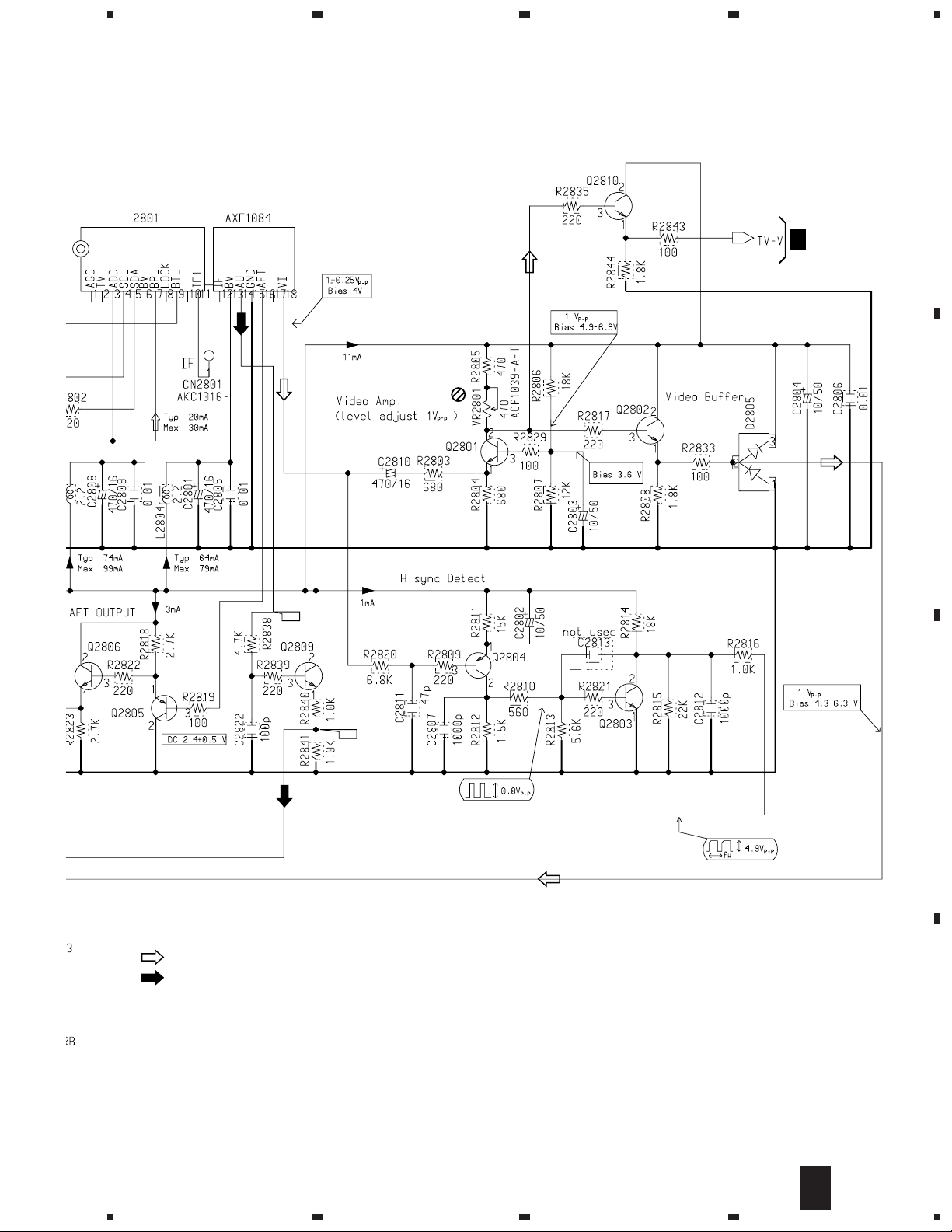

3.2 TUNER u-COM ASSY (1/3)

TUNER u-COM ASSY (1/3) (AWV1715)

A

• TUNER 1 BLOCK

A

B

A

2/3

9.0

Not used

A

A

2/3

2/3

IC2701 (CXA1

Pin

Voltage

No.

[V]

1

–

2

–

3

0

4

0

5

1.3

6

1.3

7

3.9

8

3.9

9

3.3

10

3.6

11

4.0

12

1.3

13

3.6

14

3.6

15

9.0

(C)

Not used

3/3

A

C

9.0

5.0

1.25

1.25

1

3

(C)

D

24

A 1/3

1234

5678

PRO-700HD

(CXA1734S)

Pin

oltage

No.

[V]

–

16

–

17

0

18

0

19

1.3

20

1.3

21

3.9

22

3.9

23

3.3

24

3.6

25

4.0

26

1.3

27

3.6

28

3.6

29

9.0

30

1

Voltage

[V]

2.9

0

3.6

3.6

3.5

4.0

1.7

4.0

3.9

3.9

1.8

1.3

4.0

4.0

–

FRONT END

M2701 (M2801)

Pin

Voltage

No.

[V]

7.0

1

1.0

2

0*

3

–

4

–

5

9.0

6

5.0

7

–

8

33

9

*M2801 [5V]

Pin

No.

10

11

12

13

14

15

16

17

18

Voltage

[V]

–

–

–

9.0

4.7

0

3.0

–

4.7

SIGNAL ROUTE

: Video Signal Route (TV1,TV2)

: Audio Signal Route (TV1.L,TV2.L)

(C)

: Composite Audio Signal Route

A

A

B

3/3

4

2

2.0

2.0

2.0

(C)

3.4

3.4

(TV1)

4.3‘6.3

IC2701:

MTS DECODER

9.0

1/3

N

CN6002

A5

(TV2)

(C)

A

2/3

C

D

56

A 1/3

7

8

25

1234

PRO-700HD

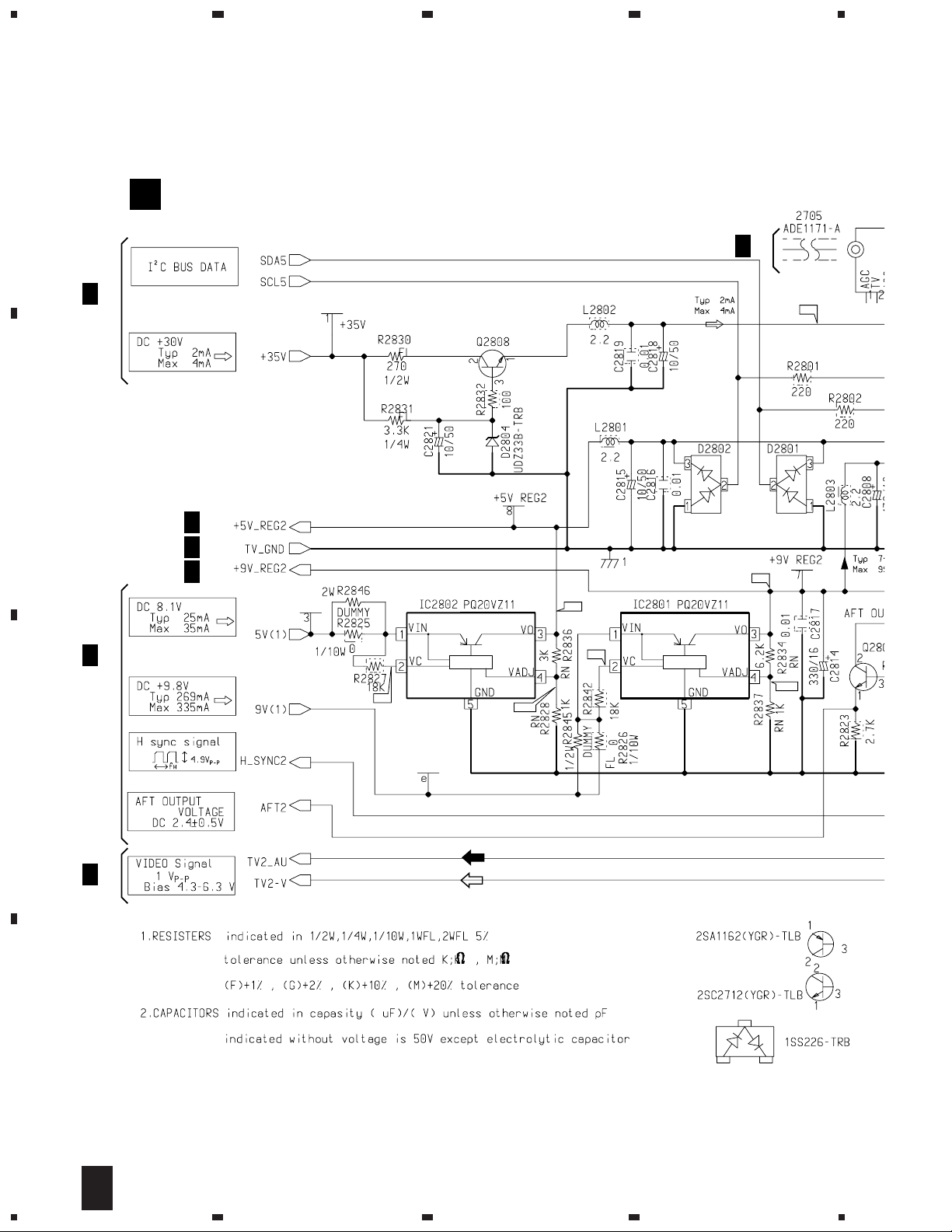

3.3 TUNER u-COM ASSY (2/3)

A

TUNER u-COM ASSY(2/3) (AWV1715)

A

• TUNER 2 BLOCK

3/3

A

B

A

1/3

33

1/3

A

3/3

A

1/3

A

5

3/3

A

4. 7

C

1/3

A

1.25

(C)

(TV2)

5

9

1.25

D

26

A 2/3

1234

5678

PRO-700HD

A

3/3

A

(TV2)

(C)

(TV2)

(TV2)

B

4.5

2

(C)

SIGNAL ROUTE

(TV2)

: Video Signal Route (TV2)

(C)

: Composite Audio Signal Route

C

56

D

A 2/3

7

8

27

1234

2

PRO-700HD

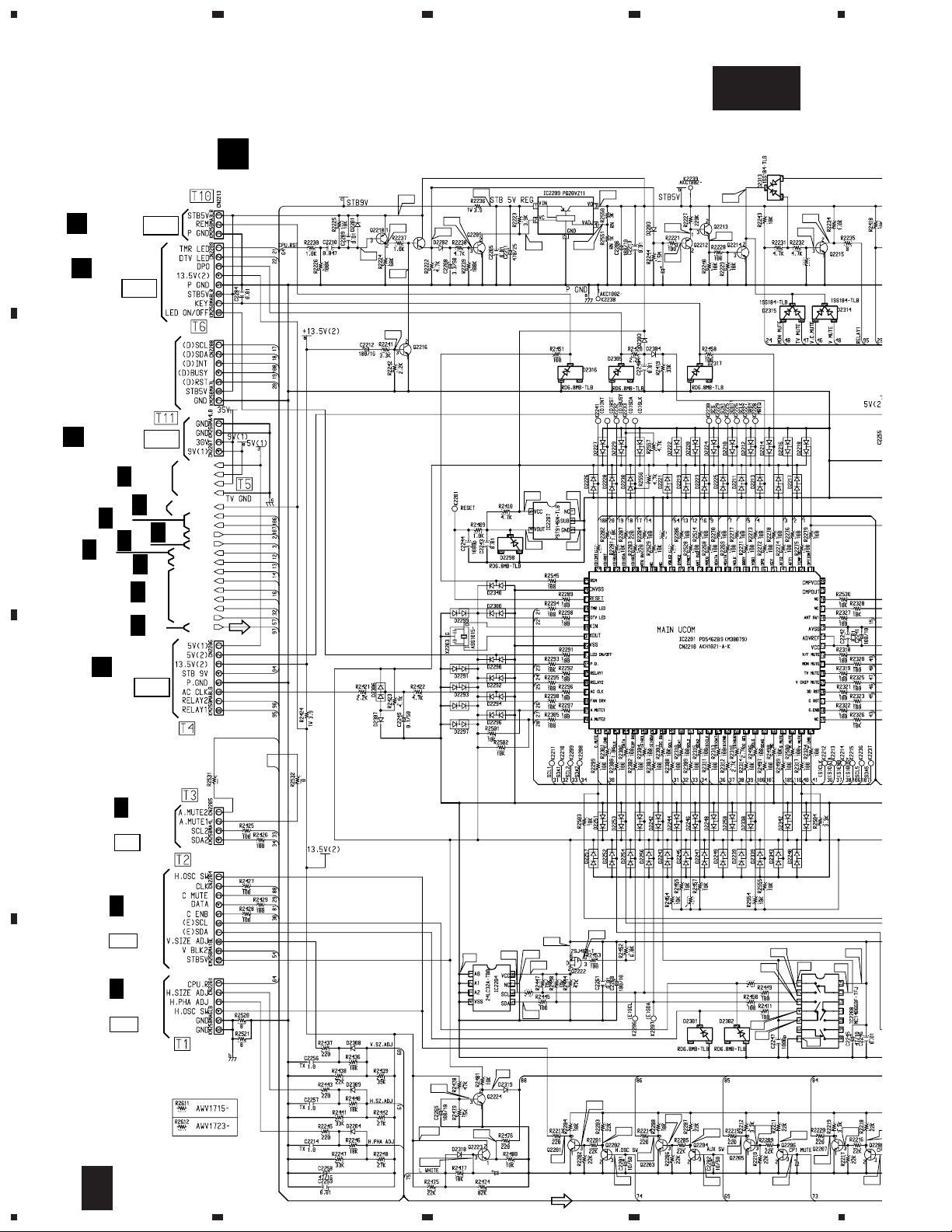

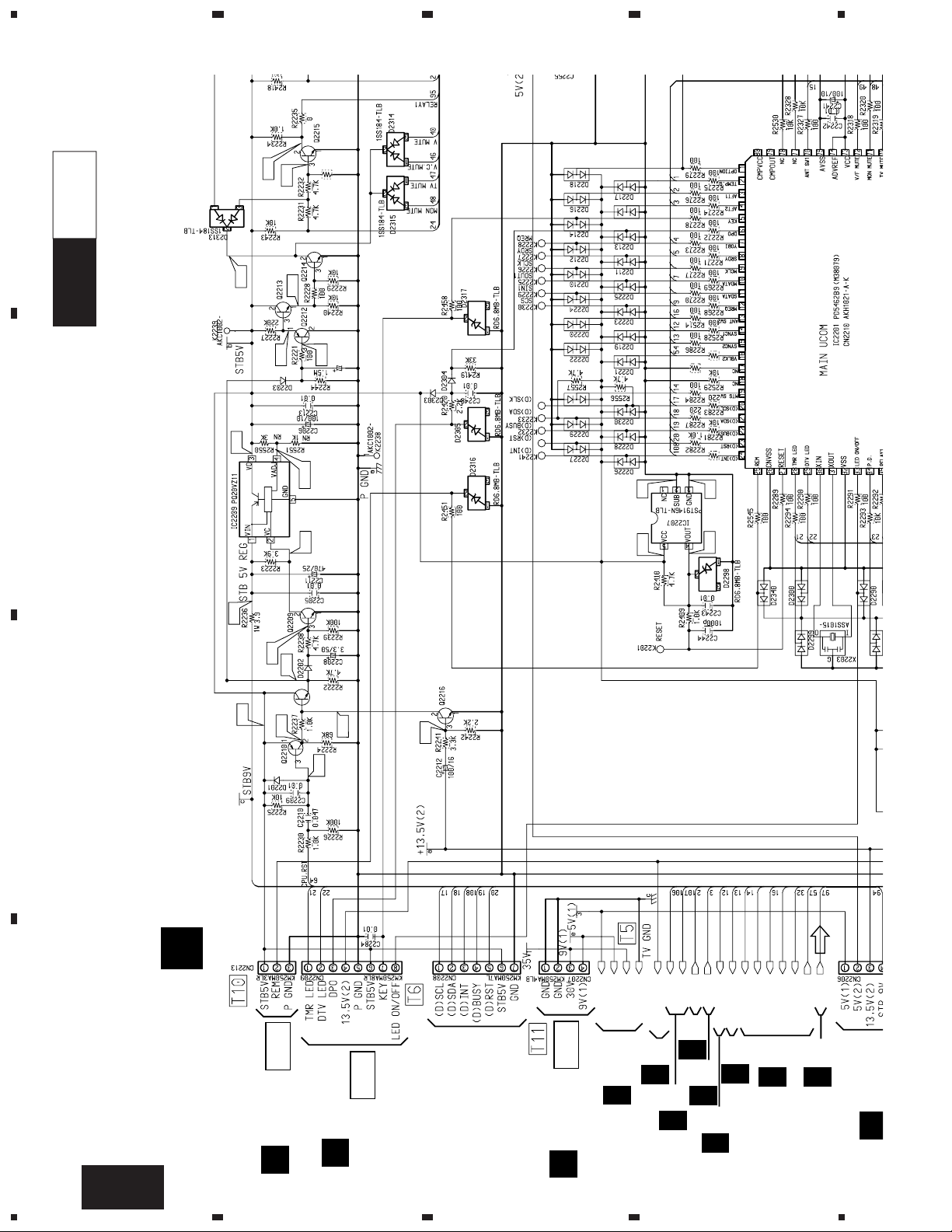

3.4 TUNER u-COM ASSY (3/3)

A-a

3/3

A

J5024

H

J

CN5001

V2

TUNER u-COM ASSY (3/3) (AWV1715)

A

• µ-COM BLOCK

5

0

5

0

9.1

0

0

7.5

1.25

5

0.7

0.1

4.7/50

C2207

0.1

2.8

R2233

0

15K

0.1

B1

0

DTV SET

TOP BOX

SH-DO7

CN209

T

B

A

1/3

A

1/3,2/3

A

A

2/3

2/3

A

A

A

A

E2

1/3

A

2/3

1/3

2/3

TV_GND

+13.5V(2)

1/3

H_SYNC1

H_SYNC2

MTS_SW1

ANT_SW1

ANT_SW2

5V(1)

9V(1)

35V

SCL5

SAA5

AFT1

AFT2

SCL1

SDA1

SUB_V

TV_V

IC2207:

RESET

5

5

D2331

0

0

D2215

CN210

T

EI

2827

C

2/2

E

CN1205

0

D2255

D2241

G7

1/2

E

CN908

G4

0

1/3

S

CN308

K2

D

0.6

28

A 3/3

13. 5

10. 4

1234

9. 8

C2264

1.0/50

0

4. 3

5

R2446

100

5

0

0. 1

5

0. 7

2. 8

0

5

0. 7

2. 8

0

5

5

0

5

R2412

100

0

0

0. 7

0

2. 8

5

5

0

0

0. 7

0

5

5678

A-b

3.9

0

8. 1

3/3

5

1. 25

A-aA-a A-b A-b

R2382

D2274

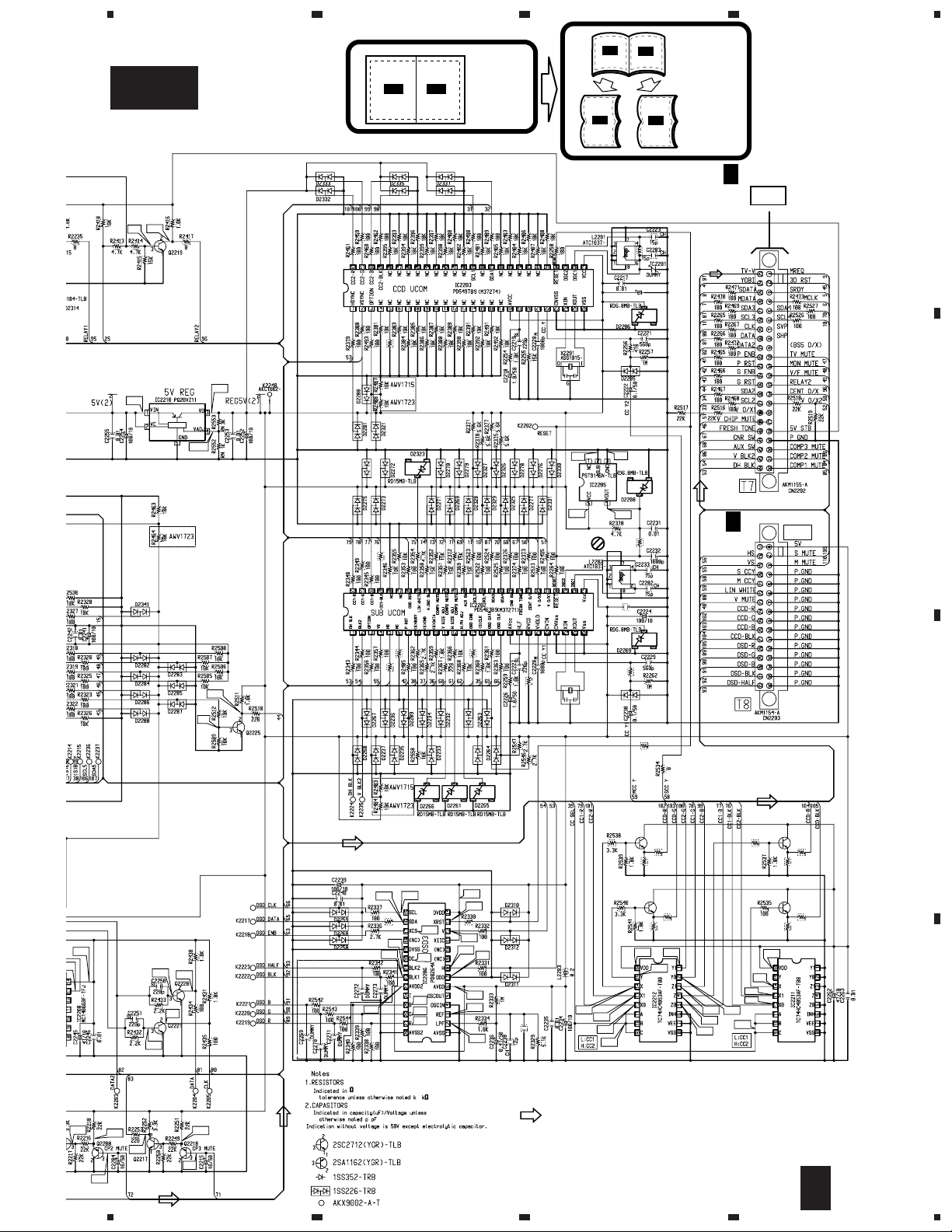

PRO-700HD

Large size

SCH diagram

A-aA-a

A-a A-a

A-b A-b

A-b A-b

Guide page

Detailed page

A

CN5605

2/2

B

D2336D2334

C2216

100/10

10K

IC2205:

RESET

0

0

U11

B

5

5

Not use

100

R2347

10K

R2486

100

R2358

5

0

5

5

R2335

100

4. 3

5

0

0. 2

4. 7

4. 7

0. 2

0

0

0

5

0

0

0

1.1

D2238

1K

0.2

R2364

5

0.5

D2262

5

5

0.6

2.7K

15K

R2260

0

0

0

C2237

CH

39p

1.0K

R2263

C2225

0.01

470

R2261

D2207

0

R2573

Q2227

R2564

100

470

R2563

Q2226

R2562

100

470

R2561

5

0

0

0

0

2/2

CN5604

B

U12

C

Q2228

R2536

R2566

3.3K

100

470

R2565

Q2229

R2568

100

2.2K

R2567

5

0

0

0

0

0

0

0

0

D

SIGNAL ROUTE

0. 7

2. 8

1. 7

5

0. 6

0

Note: As for voltages of IC2201, IC2202 and IC2203

refer to page 108.

56

: Video Signal Route

7

A 3/3

8

29

PRO-700HD

T

CN210

A

1234

3/3

2.8

0

15K

R2233

D2215

A-b

0.1

0.1

A-a

1.25

7.5

0.1

4.7/50

C2207

0

D2331

0

RESET

IC2207:

0

5

0

5

3/3

B

9.1

0.7

5

0

0

5

0

C

TUNER u-COM ASSY (3/3) (AWV1715)

• µ-COM BLOCK

5

A

35V

5V(1)

9V(1)

TV_GND

D

V2

B1

E2

1/3,2/3

A

SH-DO7

TOP BOX

CN209

T

30

A-a

J5024

H

CN5001

J

DTV SET

3/3

1234

SCL5

SAA5

+13.5V(2)

1/3

A

2/3

A

AFT1

AFT2

1/3

A

2/3

A

H_SYNC1

H_SYNC2

MTS_SW1

2/3

A

1/3

A

SCL1

SDA1

ANT_SW1

SUB_V

ANT_SW2

1/3

A

TV_V

2/3

A

Loading...

Loading...