Pioneer PLL-1000 Service manual

FS

Eefticec%anual

LINEAR MOTOR ARM

STEREO

TURNTABLE

PL-L1cI0(f

()rrrorueEr{

MODEL

PL-LIOOO

COMES

IN

THREE VERSIONS

DISTINGUISHED

AS

FOLLOWS:

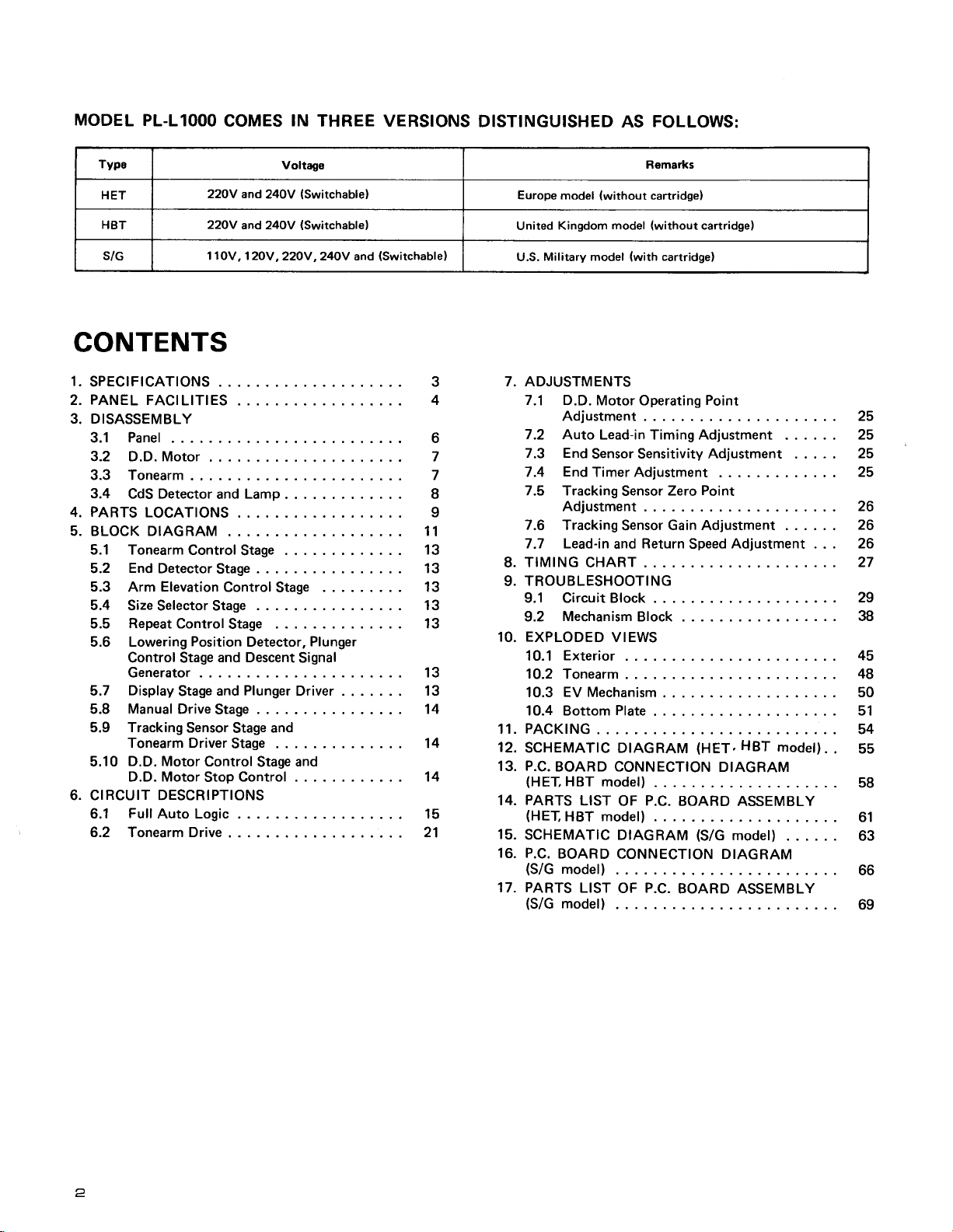

t

Type

HET

HBT 22OY

s/G 1lOV. 12OV,

22OV and

240V

and 24OV

CONTENTS

1.

SPECIFICATIONS

PANEL

2.

3. DISASSEMBLY

3.1

3.2 D.D. Motor

3.3 Tonearm

3.4

4. PARTS

5. BLOCK DIAGRAM

5.1 Tonearm

5.2

5.3

5.4

5.5 Repeat Control

5.6 Lowering

5.7

5.8

5.9 Tracking

5.10

6. CIRCUIT DESCRIPTIONS

6.1

6.2 Tonearm Drive

FACILITIES

Panel

.

CdS Detector

LOCATIONS

Control

End

Detector

Elevation

Arm

Size Selector Stage

Position

Control Stage

Generator

Display

Manual

Tonearm Driver

D.D.

D.D. Motor

Full

Stage

Drive

Sensor

Motor Control

Auto Logic .

Lamp

and

Stage

Stage

Control

Stage

and Descent

Plunger

and

Stage

Stage

Stage

Control

Stop

.

.

.

Detector,

and

Stage

Voltage

(Switchablel

(Switchablel

22OV,24OV and

.

Stage

Plunger

Signal

Driver .

and

(Switchablel

3

4

6

7

7

I

I

11

13

13

13

13

13

13

13

14

14

14

15

21

Europe

United

Military model

U.S.

7. ADJUSTMENTS

7.1 D.D.

7.2

7.3 End

7.4

7.5 Tracking

7.6

7.7 Lead-in

TIMING

8.

TROUBLESHOOTING

9.

9.1 Circuit Block .

9.2 Mechanism Block .

10. EXPLODED

10.1

10.2

10.3

10.4 Bottom

11.PACK|NG....

12.

SCHEMATTC DTAGRAM

P.C.

13.

(HET,

PARTS

14.

(HET,

15.

SCHEMATIC DIAGRAM

16. P.C.

(S/G

17. PARTS

(S/G

(without

model

Kingdom

Adjustment

Auto Lead-in Timing Adjustment

End

Adjustment

Tracking

Exterior

Tonearm

EV

BOARD CONNECTION

BOARD

model)

model)

model

(with

Motor Operating

Sensor Sensitivity

Timer

Adjustment

Sensor

Sensor

Return

and

CHART

VIEWS

Mechanism

Plate

HBT model)

LIST

HBT model)

OF

CONNECTION DIAGRAM

LIST

OF

Remarks

cartridge)

(without

.

P.C.

P.C.

cartridgel

cartridge)

Point

Adjustment

Point

Zero

Gain Adjustment . . . . .

Adjustment . . .

Speed

(HET,HBT

DIAGRAM

BOARD

BOARD ASSEMBLY

(S/c

ASSEMBLY

model)

modet).

.

25

25

25

25

26

26

26

27

3:

45

48

50

51

54

55

58

61

63

t

l

a

e

\

PL-L1

clclcl

Fr

)

ftr,

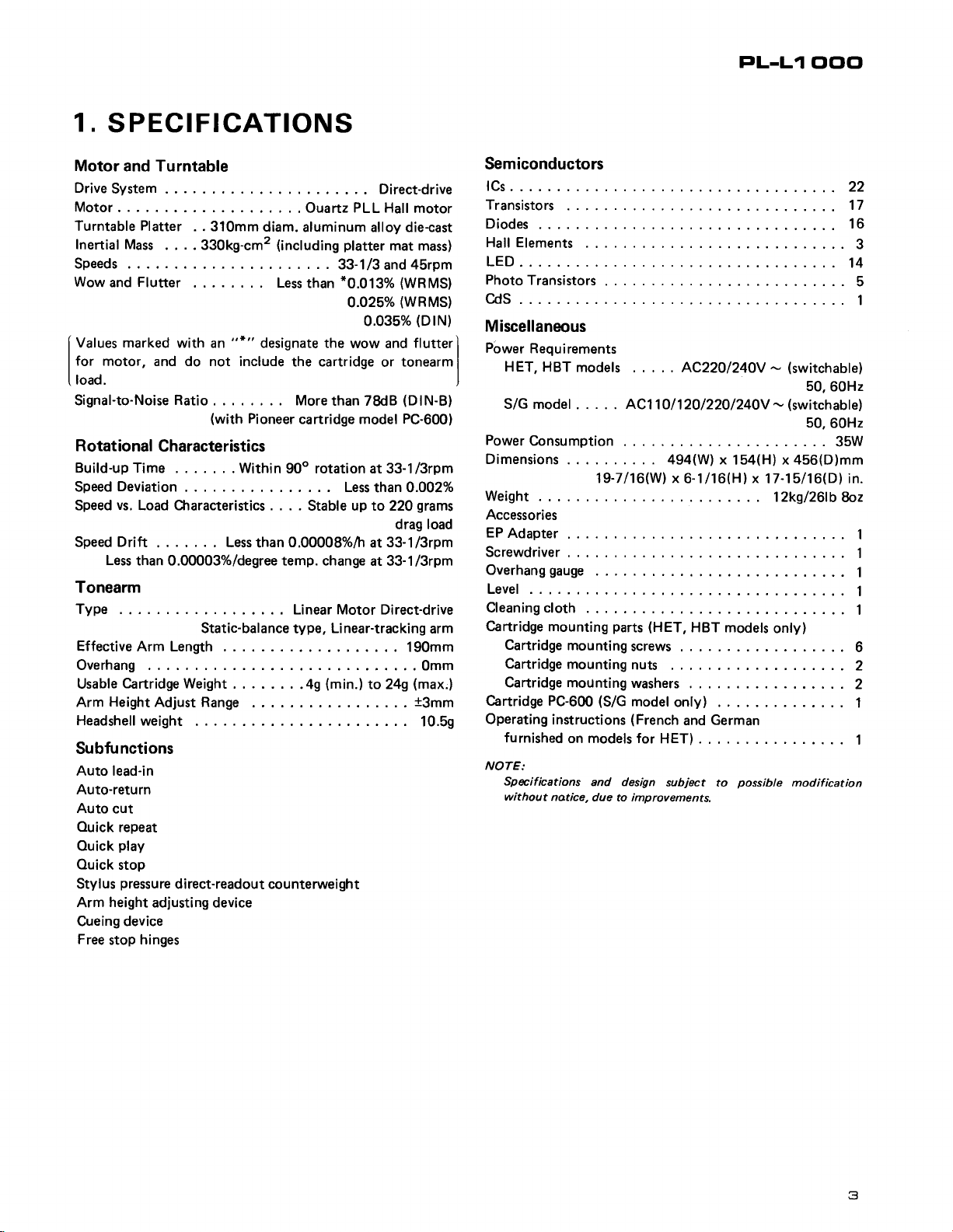

1.

SPECIFICATIONS

Motor and Turntable

DriveSystem

Motor.

Turntable

Inertial

Speeds

Wow

Values marked

for

load.

Signal-to-Noise

Rotational

Build-up Time

Speed

Speed

Speed

Platter

Mass

Flutter

and

motor, and do not include

. . 31Omm

. . . . 330kg-cm2

with an

Ratio

(with

Characteristics

.

Deviation

vs.

Load Characteristics . . . .

Drift .

Less

than 0.00003%/degree temp. change

.

. .

. Less

....OuartzPLLHall

diam.

aluminum alloy die-cast

(including

Less than

"*"

designate the

the cartridge

More

Pioneer

Within

.

cartridge model

90o rotation at 33-1/3rpm

Stable up to 220

0.00008o/o/h

than

Tonearm

Type .

Static-balance

EffectiveArmLength

Overhang

Cartridge Weight

Usable

Height

Arm

Headshell

Adjust Range

weight

.. LinearMotorDirect-drive

type,

. .

.49

Subfunctions

Auto lead-in

Auto-return

Auto

cut

Ouick

repeat

play

Ouick

Ouick

stop

pressu

us

Styl

height

Arm

Cueing device

Free

stop

re

d i rect-readout counterwei

adjusting device

hinges

.. Direct-drive

motor

platter

mat mass)

.

33-1/3

*0.013%

o.o25Yo

0.035%

wow and

than 78dB

Less

Linear-tracking

(min.)

ght

45rpm

and

(WRMS)

(WRMS)

(DtN)

flutter

tonearm

or

(DlN-B)

PC-600)

than O.OO2TI

grams

drag

33-1/3rpm

at

at 33-1/3rpm

....190mm

....0mm

(max,)

to 249

t3mm

. .

10.5g

load

arm

Semiconductors

fCs...

Transistors

Diodes 16

Hall Elements

LED.

.

PhotoTransistors.

...

cds..

Miscellaneous

j

Power

Requirements

I

HET,

HBT

models . . . AC22O/24OV

S/G model

PowerConsumption

Dimensions

Weight

Accessories

EP

Adapter

Screwdriver

Overhanggauge.

Level .

Cleaningcloth.

Cartridge

Cartridge PC-600

Operating

NOTE:

mounting

Cartridgemountingscrews

Cartridgemountingnuts

Cartridgemountingwashers

instructions

furnished

Specif

without

on models for

ications

natice,

ACl

. .

19-7116(W) x

(S/G

and design

due to improvements.

parts

model

(French

10/

12O/22O/24OY

494(W)

6-1116(Hlx 17-15/16(D) in.

(HET,

HBT models

onty) .

and

HET)

subject

x 154(H) x 456(D)mm

German

to

-

-

12kg/261b fbz

only)

possibte

(switchable)

(switchable)

.......

.......

modif ication

22

17

....3

14

..... 5

1

50,60H2

50,60H2

..35W

1

1

......1

1

1

...6

...2

2

1

1

t

T

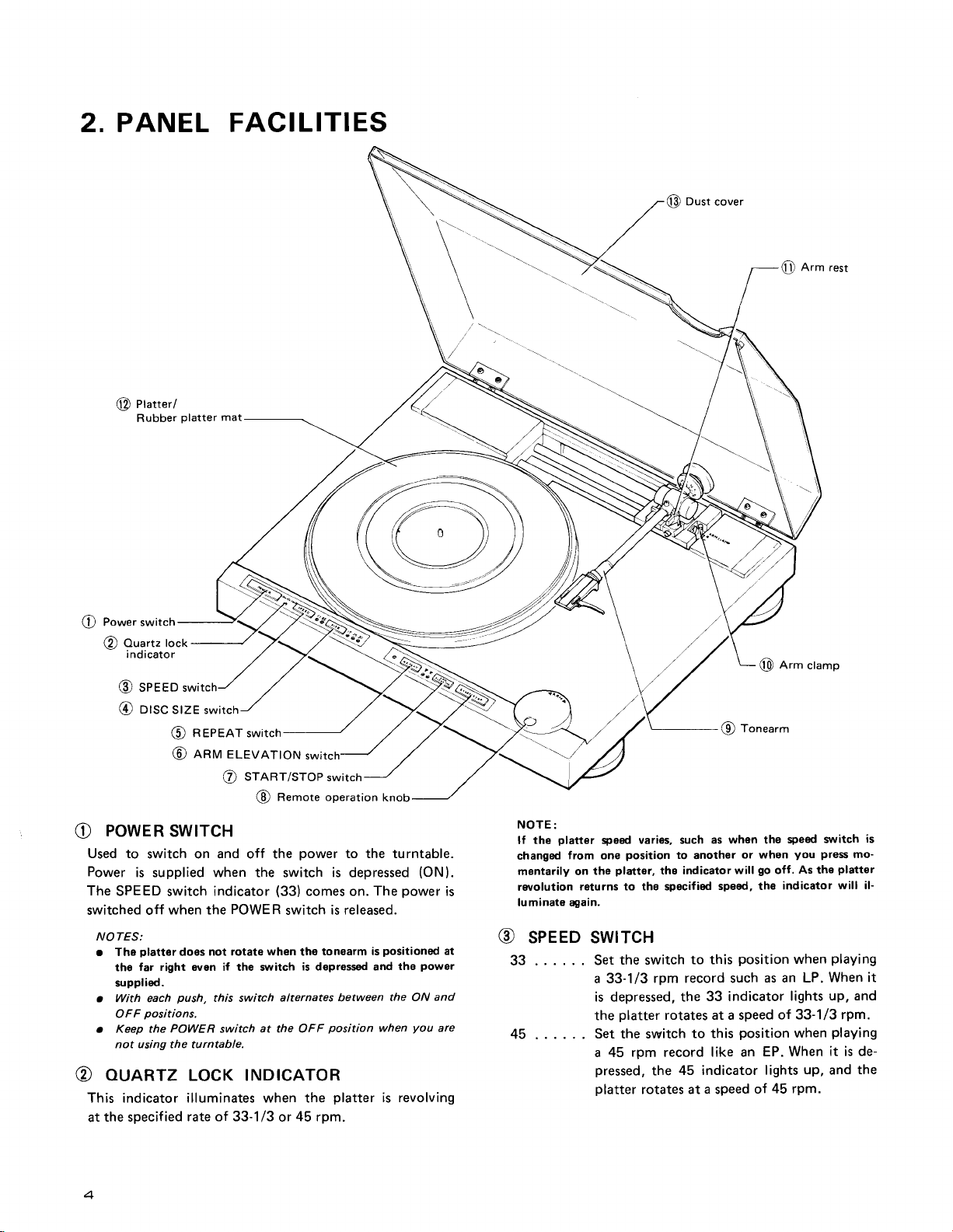

2. PANEL FACILITI

ES

@

Dust

cove.

Arm rest

@

I

a

/t\

Power switch

v

ouartz lock

@

indicator

seeeo

@

otsc slZE switch

@

(!)

R EPEAT switch

(O

ARM

ELEVATION

srnnr/sroP

@

Remote operation

@

POWER

e

Used to

Power

The

SPEED

switched off

SWTTCH

switch on and off the

is supplied when the switch is depressed

indicator

switch

when the

(33)

POWER

switch

NOTES:

platter

r The

the

supplied.

. With each

OFF

Keep the

.

not using the turntable.

euARTz LocK rNDrcAToR

@

doos not rotate

far right oven if the sl,lritch

push,

POWER

this switch

switch

positions.

when

alternates between

at the OFF

This indicator illuminates when the

the specif

at

ied rate of 33-1/3

45 rpm.

or

swi

switch

power

to the turntable.

comes on.

The

is released.

tonearm is

tho

is depressed and

position

platter

knob

(ON).

power

is

positioned

the ON

when

the

powgr

you

at

and

are

is revolving

NOTE:

platter

the

lf

changed

mantarily on

ro/olution

luminate again.

@

33 .

from one

the

returns to the specified

sPEED swrrcH

. . . . . Set

a 33-1/3

is depressed, the

the

45 . . . . . .

Set the switch

a 45

speed varies, such

position

platter,

the

to

ths indicatorwill

switch

rpm record such

platter

pressed,

platter

rotates at a speed

rpm

record

45 indicator

the

rotates at a speed

A-

I onearm

19,

as when the

another

to this

or when

go

sped, the

position

33 indicator

to this

position

like an

of

Arm

ctamp

@

speed s:witch

you press

As the

off.

indicator

when

as an LP.

lights

of 33-1/3

when

EP. When

up,

lights

45 rpm.

is

mo-

platter

will il-

playing

When it

up, and

rpm.

playing

it is de-

the

and

t

r)-

V

a

\.

PL-L1

Clclc'

t

n

n'

t,

I

Drsc

@

Selects the

ord

12"30

10"25

7"17

o

Used

stance,

switch for

the

sets it

o When

will

30cm

you

srzE

swrrcH

switch that

want

.

. . . For

.

to

17cm

to the

always

and the

hear

to

For

. .

30cm

25cm

ForlTcmrecords

. .

select

the record

when

the

the

25cm

position.

30cm

power

the

be

corresponding

set

NOTE:

This

sruitch

will

(auto

moving

REPEAT

@

Press

this switch for

cator

will light up,

(refer

to

Press

this

off and the repeat

not work if

lead-in,

swtrcH

page

12 for further

switch

again

auto-return,

play

NOTE:

This

slitch

will

(auto-return,

moving

enru ELEVATIoN

@

Use this

form

When

descend

arm

switch to

manual

the DOWN

and

rise.

will

ternately every

not

auto

interrupt

play.

position

when the

These

time the

NOTES:

r When

in

r This

moving

o When

nisrn is

sranr/srop

O

Press

this

tate,

the tonearm

edge

of

lf

this

POWER

th€

position.

the UP

switch

will not

(auto

the switch

actuated

switch

the record

switch

lead-in,

is at UP,

and so there

for

auto

will

and

pressed

is

automatically return

ter will stop rotating

cut).

NOTE:

This

moving

saritch

(auto

will

not work if depressed

lead-in).

corresponds

auto

play

operation.

for

records

records

size

when

30cm

indicator

position,

Depressing

and

the switch

position.

switch is

for

turned

records

light

depressed

auto

cut).

play.

repeat

When

and the record

details

release

to

function

work if depressed

cut).

it.

will be released.

swtrcH

play

temporarily

is depressed

position

UP

is

two operations

switch is

switch is

work if depressed

auto-return.

pressed.

set to

ON, the tonearm will

auto cutl.

tho auto-return

will be no

swtrcH

play.

automatically

play

will begin

during

to the

arm clamp

play

and

platter

The

play,

will be

to

the size

of the

depressed. For

lights

up,

depress

depress

it

again

once

ON, the

with

will

come

when

will be

turntable

a diameter

on.

the tonearm

pressed

the indi-

played

on repeat

The indicator

wh6n

the ton€arm is

or

the tonearm

depressed

will

be

when

auto-roturn.

the tone-

performed

th€ tonearm is

cancelling

will start

move

over

(auto

lead-in).

the

tonearm

position,

the

suspended

when the tonearm

rec-

in-

the

for

more

of

again

play).

go

will

per-

to

will

al-

start

mecha-

to ro-

to the

will

plat-

(auto

is

@ REMoTE

Used

Rotate

Rotate

NOTE:

Whon the

cut and

remote

ToNEARM

@

The

force

low

The tonearm

remotely

is

the motor

the

turned to the

NOTE:

When

be

at tho

member

@ ARM

Used

To

secure

down

turntable,

released

anru

@

This secures

rotate

clamp.

switch

and

secure

NOTE:

When

pipe

(

!

pIRIIER/RUBBER

@

When

turntable,

speed.

also

absorbs external

ousr

@

Keep

or changing

cords

straight

cabinet.

opERATtoN

when

moving

counterclockwise

clockwise

auto-return,

operation

to move

arm elevation

the tonearm

is released

tonearm function

to the cartridge.

the

stylus

to trace

can

be

with

the remote

switch

platter

and when

rotates

and it

arm clamp

the POWER

moved

by either

OFF

to

manual

position,

set the POWER

cLAMp

to

secure

the

tonearm.

the

tonearm,

on

the

secure

when

clamp.

the tonearm

the clamp

REsr

the

tonearm

the

arm rest

When

to UP

the

the arm elevation

cannot be

position.

l

the tonearm

the

The

playing

not

(

!

)

pipe.

secured. Make

platter

rubber

and

is moved

platter

vibration,

covER

this closed

during

up,

unless

records.

record

this

dust cover

This

play.

KNoB

the tonearm

to move

the tonearm

switch is

and th6 knob

is

to apply

maintbin

the record

operated

operation

stops

position.

switch

or remote

this

may result

move

When

is raised.

pipe.

counterclockwise

a

then rotate

sritch is

will

start

mat

operating

serves

When fully

the

DOWN

at

does

not move

the correct

this value

grooves

manually

knob.

it moves

when

is

at OFF,

operation.

in damage

switch

to ON when

to

it

the

you

do

not

in

this

way.

When

record,

set

the

at DOWN

sure this

sl,tritch is

pLATTER

power

and

rotating

stabilizes

the controls

keep

to

can

be

by remote

tonearm

to

rotated.

to

right.

the

or auto lead-in,

even

precisely

accurately.

your

with

lt

is coupled

across

to

the record,

the tonearm

the ton€arm

lf it

so

right

and

then

intend

to use

The

tonearm

playing

and

release

the

arm

arm rest

(l

ttre

l,

set to tho UP

clockwise

MAT

is

supplied

at

the

set rotation

the records

or

tonearm,

dust

off

of

opened

removed

and

from

control.

the left.

auto

when

the

tracking

and

al-

hand

or

to

is re-

cannot

forced

is

always re-

moving

it.

push

the

is

a record,

the

elevation

tonearm

to

the

and

the re-

pulled

the

DISASSEMBLY

3.

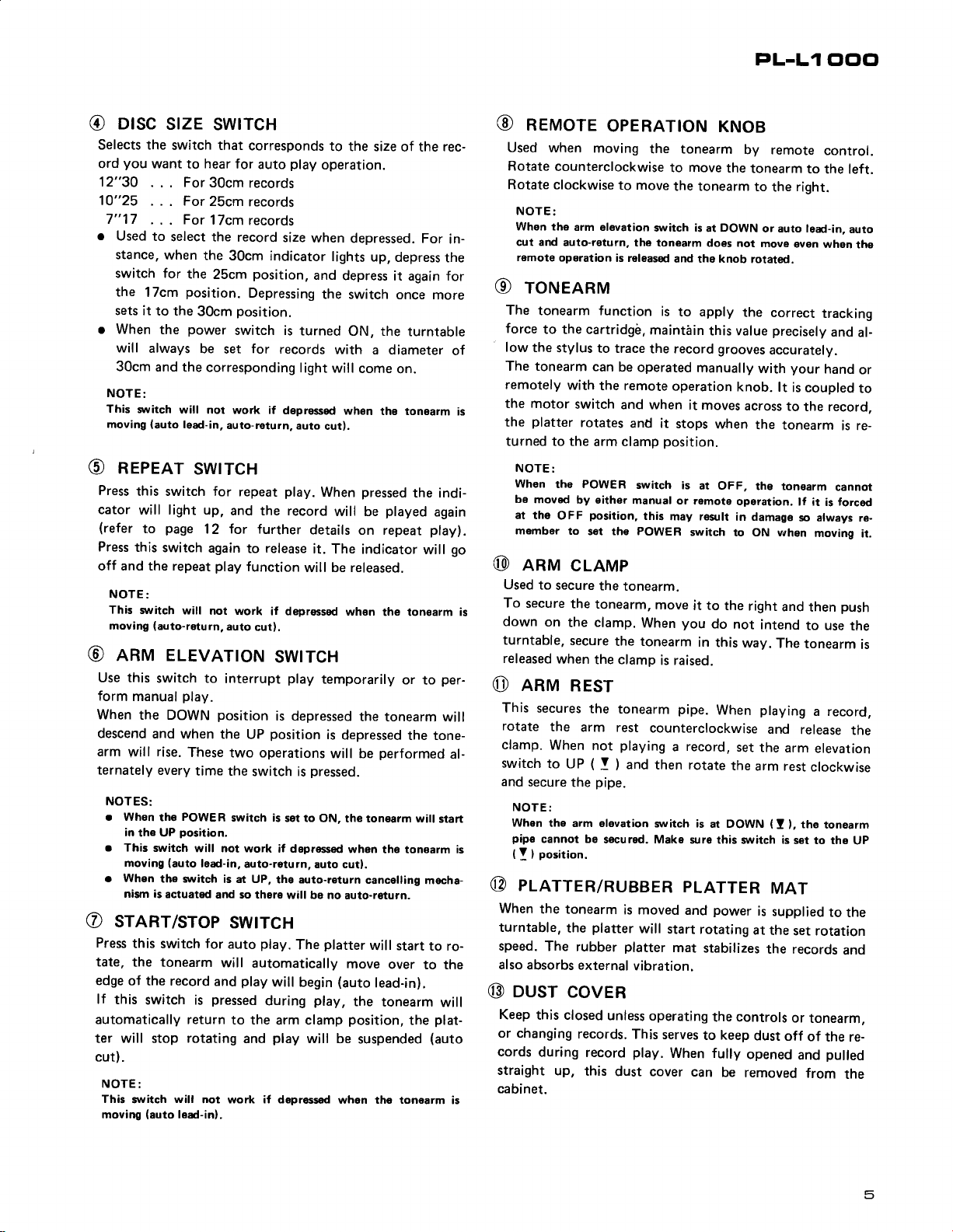

3.1 PANEL

1.

Remove

2.

Remove

3.

Shift

4.

Lift

nectors

the

the

the 4

insulator

the

top

tonearm

panel

from

the

cover.

across

up,

printed

and

mounting

to the

center-

disconnect

circuit

screws.

the

board

B con_

below.

Top

cover

I

)

a

Fis.

3-1

Ei

FL-LI

Oclcl

t

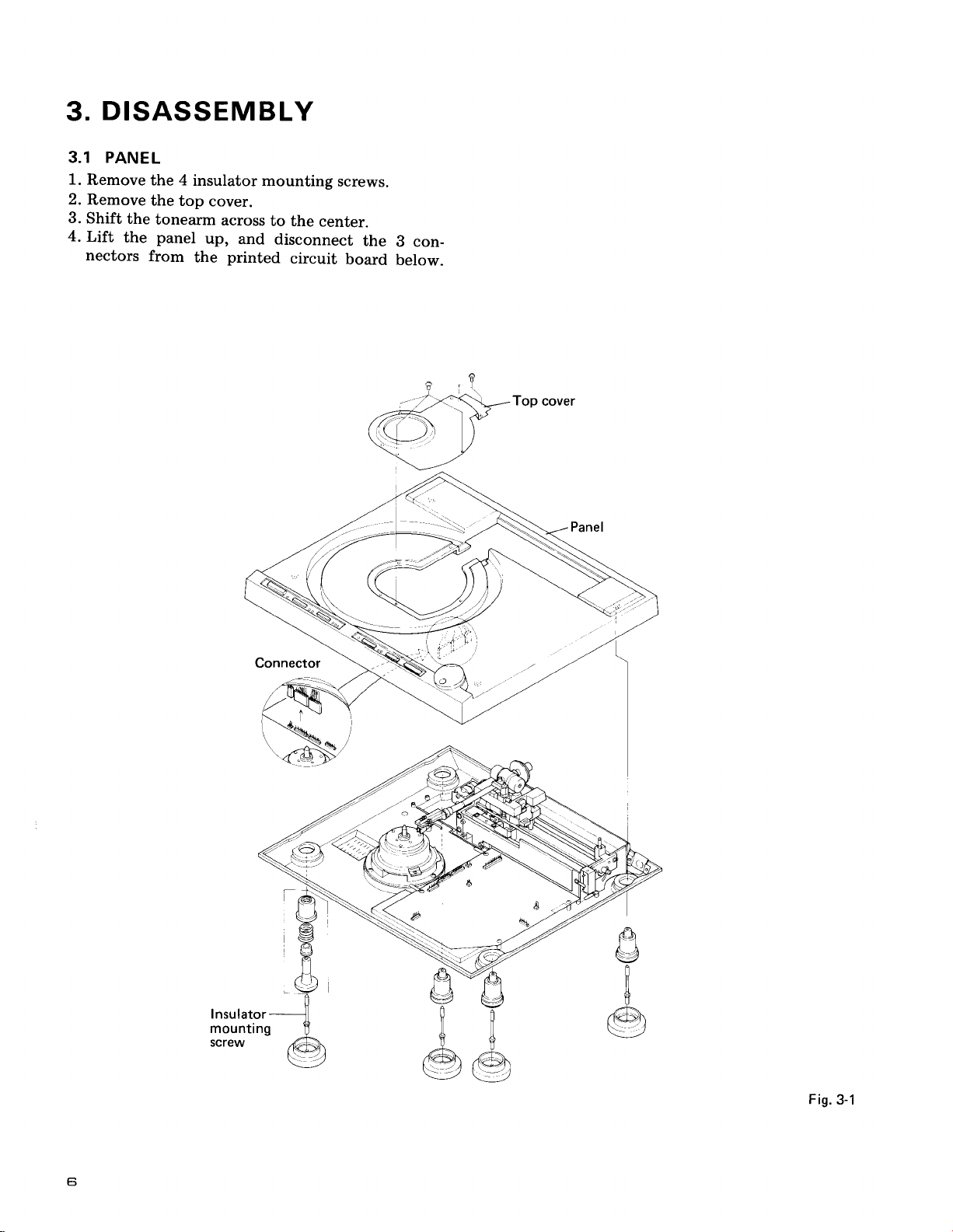

3.2 D.D

1.

Remove the 3 D.D motor

2. Disconnect

)

MOTOR

the D.D

securing screws.

motor connector.

l"

Fis.

3-2

pull-

by

both rails

by

at

a

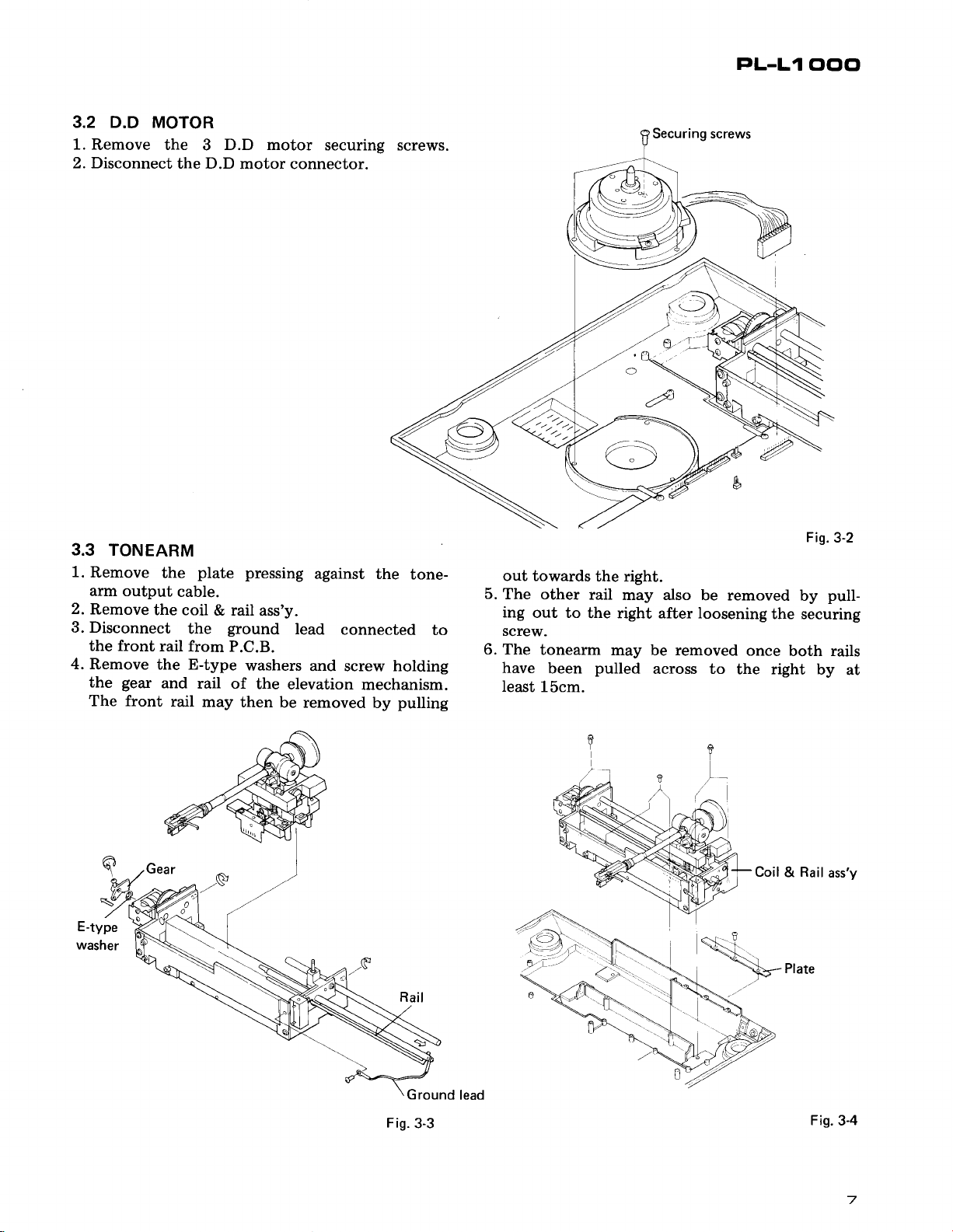

3.3

TONEARM

1.

Remove

arm output

2.

Remove

3. Disconnect

the front

4.

Remove the E-type

the

The front

gear

the

cable.

the coil

the

rail from

and

rail

plate

& rail

ground

P.C.B.

rail of

may

pressing

ass'y.

washers

the

elevation

then

be removed

against the

lead

connected

and screw holding

mechanism.

pulling

by

tone-

to

out towards

5.

The other

ing

out to

screw.

6. The

have

least

tonearm

15cm.

the right.

rail

may also

the right after loosening

may be removed

been

pulled

across to

be removed

the securing

once

the right

E

!t

E-type

washer

Ground

Fig.

3-3

lead

Coil & Rail

Fig.3-4

ass'y

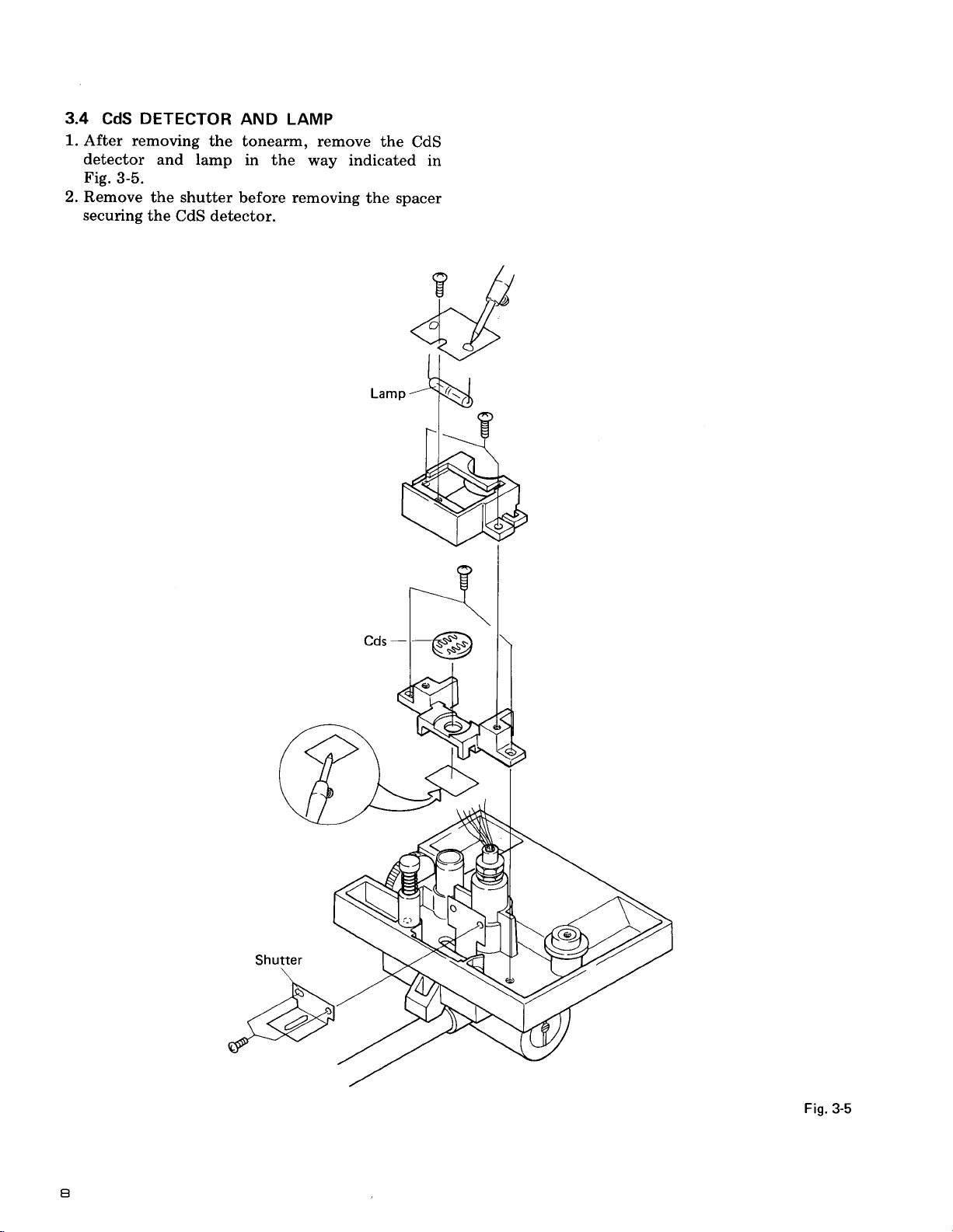

3.4

1.

After removing

detector

Fig.

2. Remove

securing

DETECTOR

CdS

and lamp

3-5.

the shutter

the CdS detector.

AND LAMP

the tonearm, remove

in the

before removing

way indicated

the spacer

the

CdS

in

utter

Sh

\

@

)

I

Fig.

3-5

a

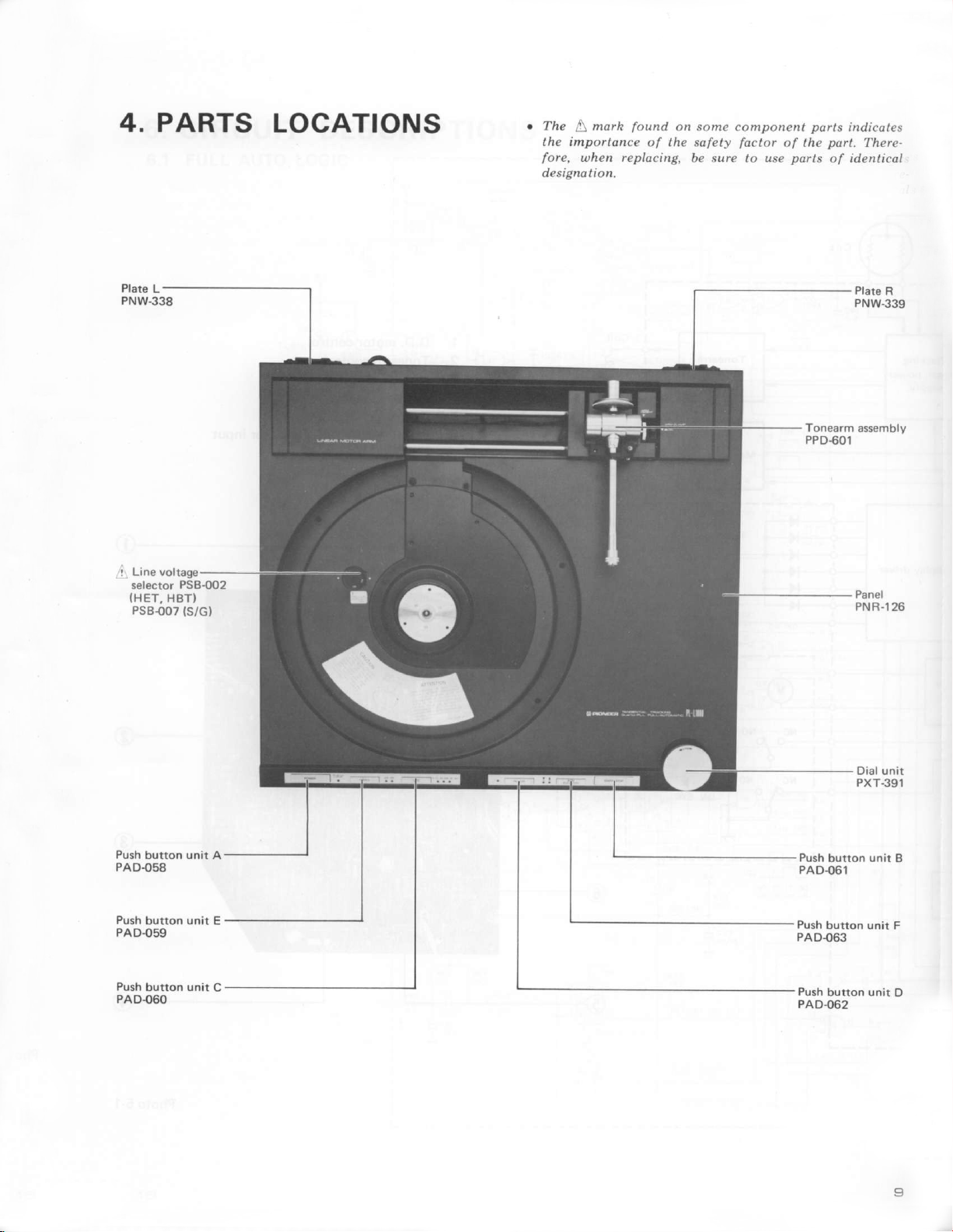

4. PARTS

LOCATIONS

o

The

Ihe importance

fore,

designation.

morh

l\

@hen

otr some component

found

of the sately

replacing,

be sure Io use

lactor

parts

of the

parts

itldicates

parl.

There-

of id.enlical

t

ri

Push

button

PAD-058

unir

Tonearm

PPD€01

A

Push

PAD-061

assembly

PNR.I26

Dial unit

PXT.391

button

unit

B

Push button unit

PAD{60

C

al

tcotes

lhere

'ntlcal

BtE R

rw-339

PL-LI Clclc'

nel

\tR.l26

ialunit

xT-391

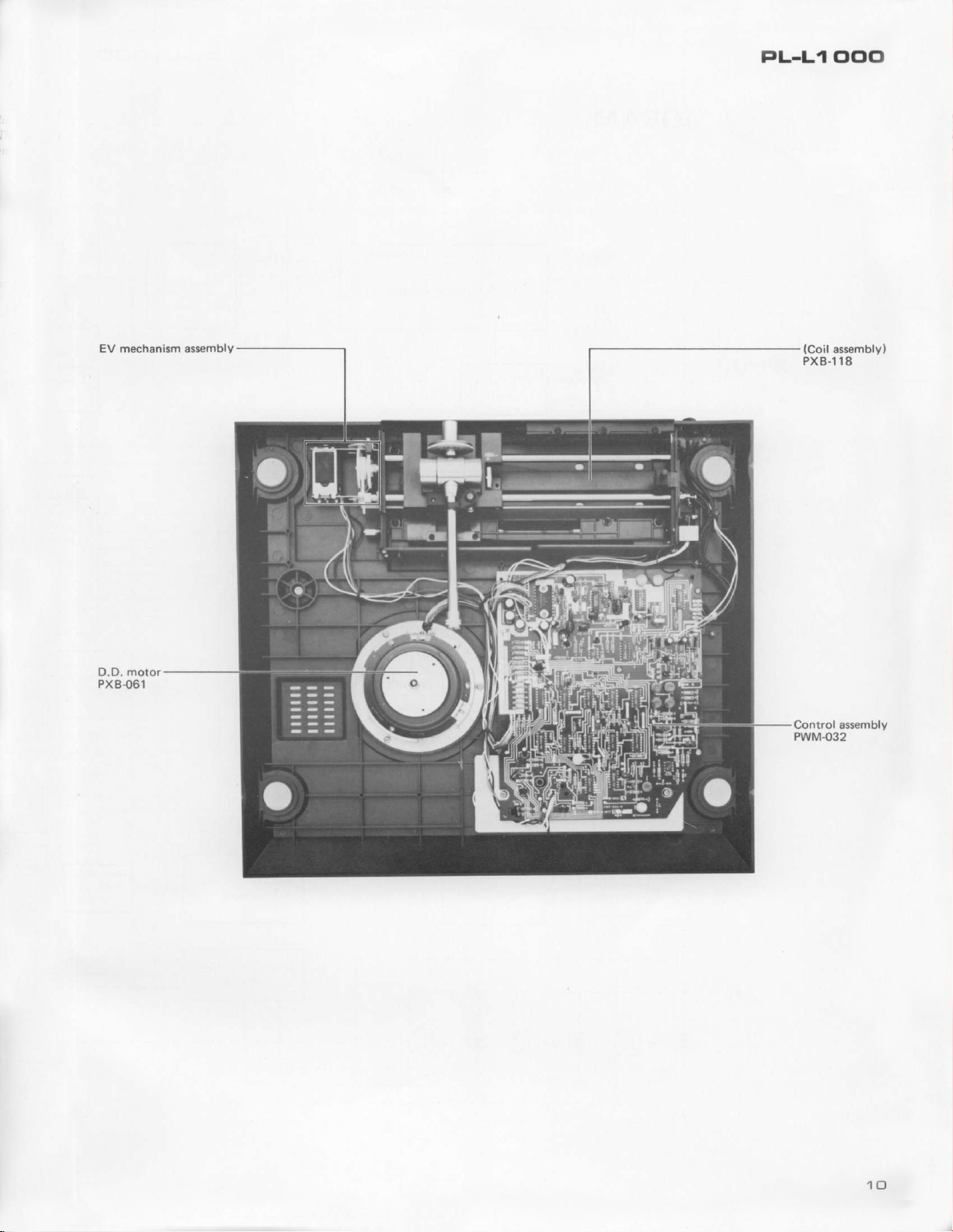

EV mechanism assembly

motor

D.D.

PX

B-061

(Coil

assembly)

PXB{ 18

Controlassembly

PWM{32

PL-L1

oclcl

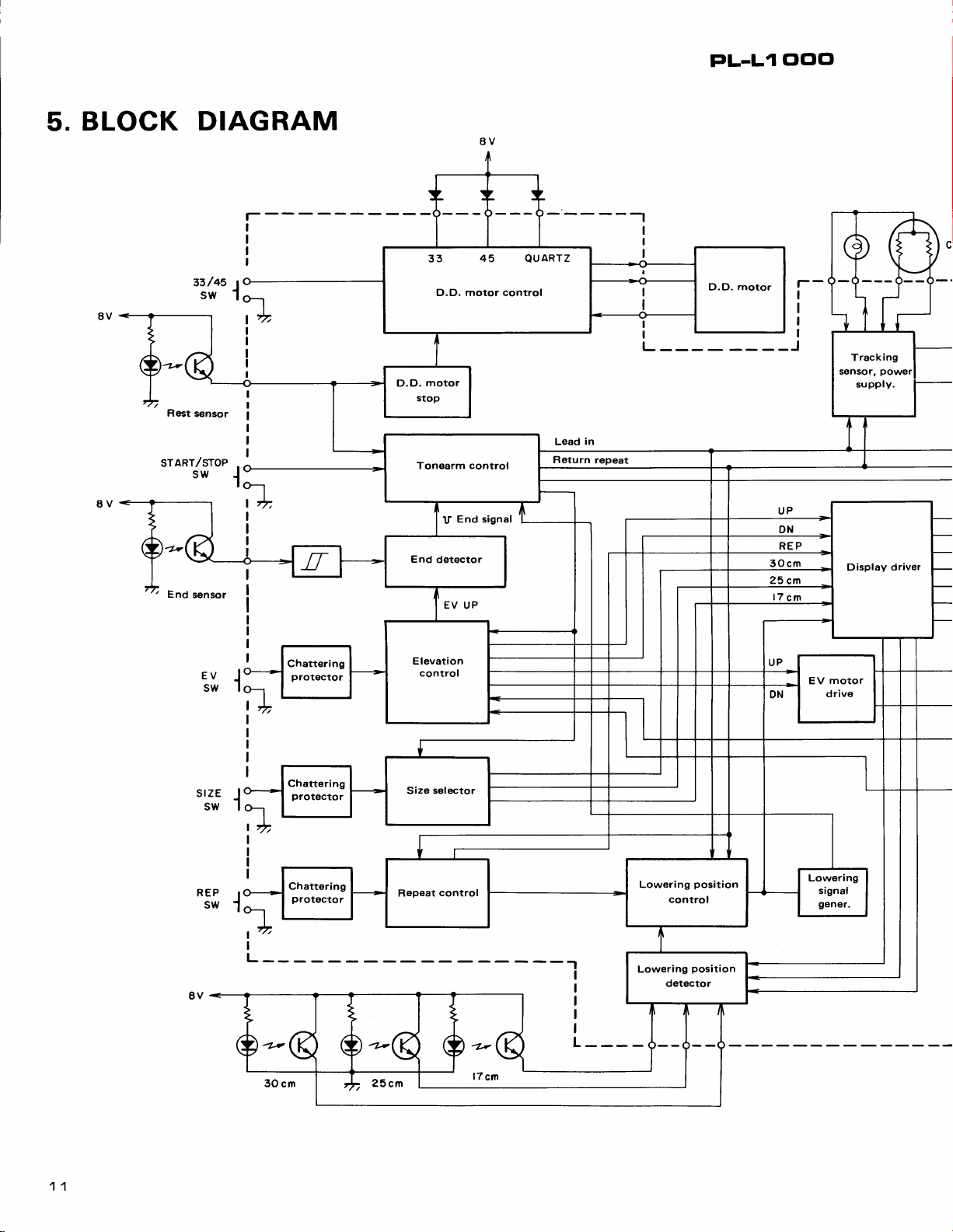

BLOCK

5.

DIAGRAM

Rest sensor

33

D.D. motor

End signal

|If

45

QUARTZ

control

Lead

-l

I

I

I

in

driver

Display

End

sensor

REP

sw

1q

177

I

L-_

____l

Lowering

I

position

control

11

30

cm

rooo

I

,lr-

Ji

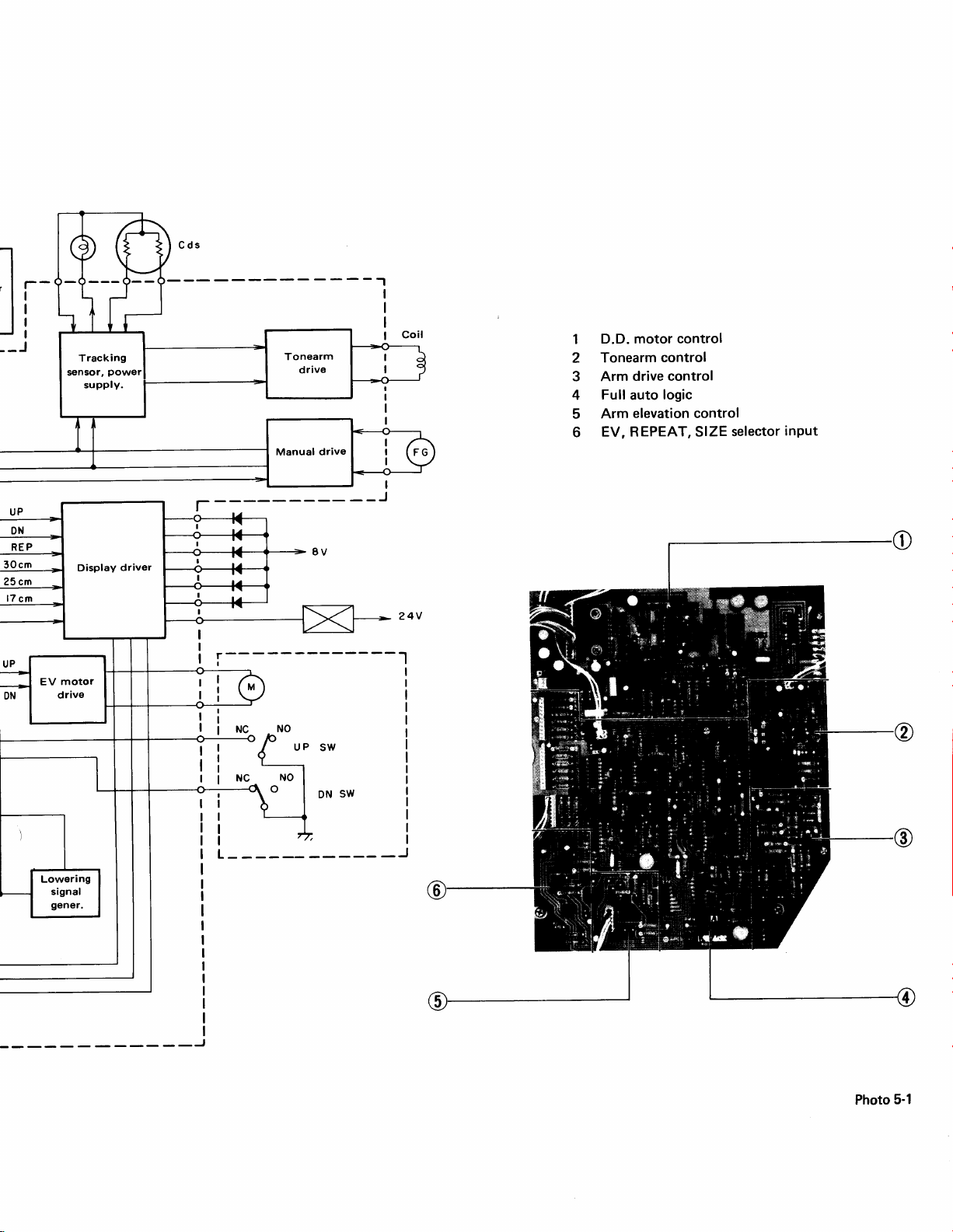

Cds

?

$-€

rl f;

Tracking

power

sensor,

supPlY.

Tonearm

drive

Manual

drive

I

I

I

uoll

I

l<

l'

I

I

I

I

i€

D.D. motor

1

Tonearm

2

Arm

3

Full

4

Arm

5

EV, REPEAT, SIZE

6

control

drive control

logic

auto

elevation control

control

selector

input

Photo

5-1

I

BLOCK

5.1

a.

DIAGRAM

TONEARM

Lead-in

Lead-in

Return

b. When

"AUTO

either

AUTO

set

to

the

drive.

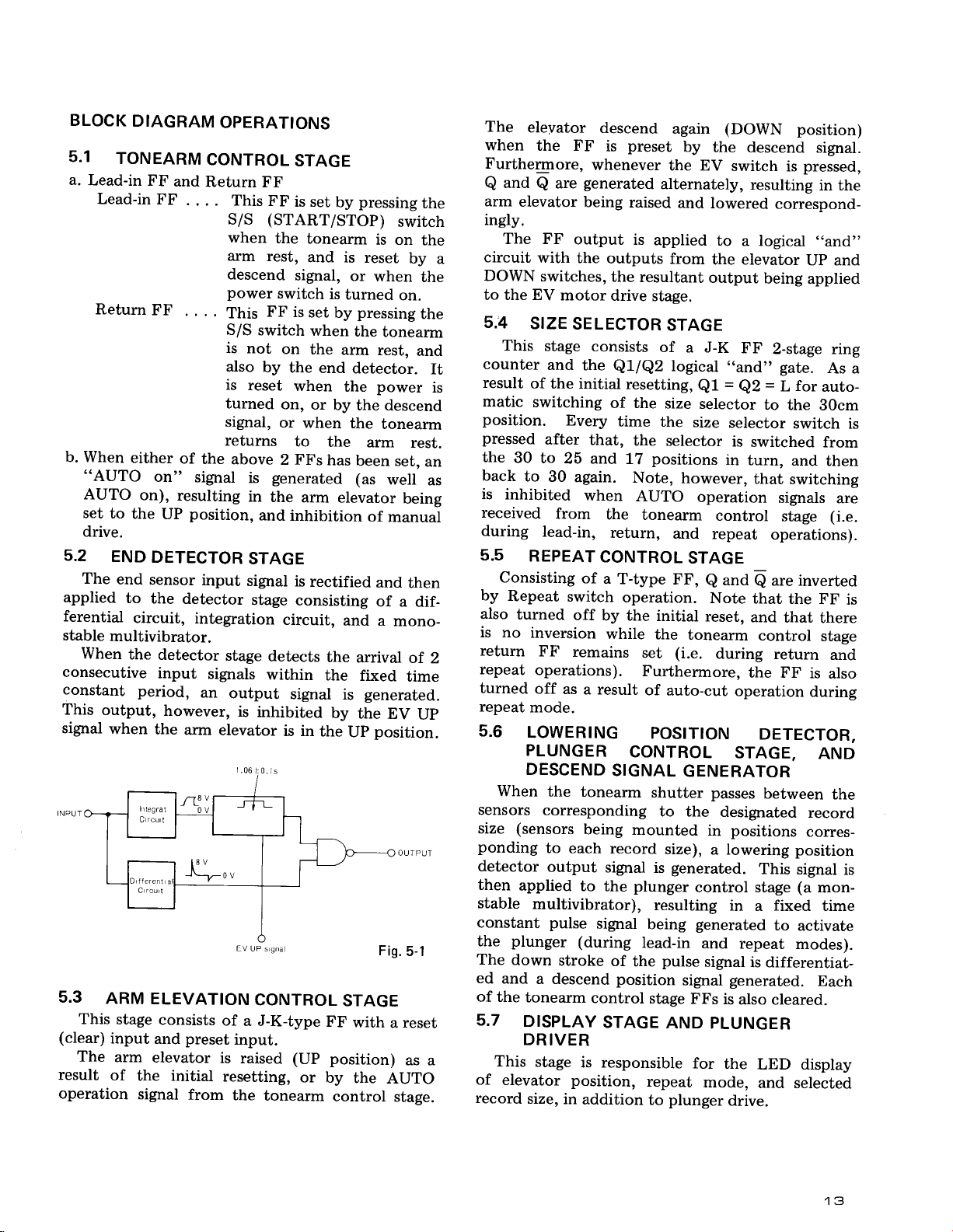

5.2

applied

ferential

stable

END

The

end

to

circuit,

multivibrator.

When

the

consecutive

constant

This

signal

5.3

This

(clear)

The

result

operation

period,

output,

when

ARM

stage

input

arm

of

the initial

signal

OPERATIONS

CONTROL

FF

and

Return

FF

.

. . . This

FF

. .

. .

of

the

on"

signal

on),

resulting

position,

UP

DETECTOR

sensor

the

input

detector

integration

detector

input

signals

an

however,

the

arm

elevator

ELEVATION

consists

preset

and

elevator

is raised (Up position)

from

FF

FF

(START/STOP)

S/S

when

arm

the

rest,

descend

power

This

S/S

is not

also

is

turned

signal,

switch

FF

switch

by

reset

or

on

the

on,

returns

above

2

generated

is

in

the

and

inhibition

STAGE

signal

stage

circuit,

stage

detects

within

output

is

signal

inhibited

is in

qna

EV

up s

CONTROL

of

a J-K-type

input.

resetting,

the

tonearm

STAGE

is set

pressing

by

tonearm

and

is reset

signal,

is

when

when

to

FFs

is

set

by

when

the

end

or

by

the

has

or

turned

pressing

the

arm

detector.

the

the descend

the

been

(as

arm

elevator

is

rectified

consisting

and

the

arrival

the

fixed

is

by

the

the

Up

STAGE

FF

with a reset

or

by

the

control

the

switch

is on

the

by

when

the

on.

the

tonearm

rest,

and

It

power

is

tonearm

arm

rest.

ser,

an

well

as

being

of

manual

and

then

of

a dif-

a

mono-

of

2

time

generated.

EV

Up

position.

OUTPUI

Fig.

5_1

as a

AUTO

stage.

The

when

Furthermore,

Q

arm

ingly.

a

circuit

DOWN

to the EV

s.iA

counter

result

matic

position.

pressed

the

back

is inhibited

received

during

5.5

Consisting

by

also

is no

return

repeat

turned

repeat

5.6

When

sensors

size

ponding

detector

then

stable

constant pulse

the

The

ed

of the

5.7

This

of

record

eleyator

the FF

descend

preset

is

whenever

and

Q

elevator

The FF

with

SIZE

This

of

switching

30

to

generated

are

being

output

the

switches,

motor

SELECTOR

stage

and

consists

the

the initial

Every

after

that,

to

25 and

30

again.

outputs

the

drive

QUQ2

resetting,

of the

time

17

when

from

lead-in,

REPEAT

Repeat

turned

inversion

FF

the

return,

CONTROL

of

a

T-type

switch

off

by the

while

remains

operation.

operations).

off

as

a result

mode.

LOWERING

PLUNGER

DESCEND

SIGNAL

the tonearm

corresponding

(sensors

applied

being

to each

output

to the

record

signal

multivibrator),

signal

plunger

down

and

tonearm

DISPLAY

(during

stroke

of

a descend position

control

STAGE

DRIVER

stage

is responsible

elevator position,

size,

in

addition

again

by

the

the

EV

alternately,

raised

and

is

applied

from

resultant

lowered

the elevator

output

stage.

STAGE

of

a J-K

logical

Ql

size

selector

the

size

the

selector

positions

Note,

AUTO

however,

operation

tonearm

and

repeat

STAGE

FF,

e

Note

initial

the

set

reset,

tonearm

(i.e.

Furthermore.

of

auto-cut

POSITION

CONTROL

GENERATOR

shutter passes

to the

mounted

is

plunger

in

size),

a lowering position

generated.

control stage

resulting

being

lead-in

the

generated

pulse

and

signal

signal

stage

FFs

AND

PLUNGER

for

repeat

to

mode,

plunger

(DOWN

descend

switch

is

resulting

correspond-

to

a logical

being

FF

2-stage ring

,,and,'

=

Q2

gate.

=

L

to the

selector

is

switched

in turn,

that

signals

control

stage

operations).

and

are inverted

Q

that

the FF

and

that

control

during

return

the FF

operation

DETECTOR,

STAGE,

between

designated

positions

This

in

a fixed time

to

repeat

is differentiat-

generated.

is

also

cleared.

the

LED display

and selected

drive.

position)

signal.

pressed,

in the

,,and"

Up

and

applied

As a

for

auto-

B0cm

switch

from

and

then

switching

are

(i.e.

is

there

stage

and

is

also

during

AND

the

record

corres-

signal

is

(a

mon-

activate

modes).

Each

is

5.8

By

motol

sensol

f,onea.

opera

is DC

return

5.9

Thr

CdS

voltag

ment.

the

d

par

to

the

to

EITOT

sensor

./.

7

V

\

r

PL-L1 000

5.8

motor

sensor

tonearm

operation

is

retum,

5.9

MANUAL

By

amplifying

mounted

stage

to

is inhibited,

DOWN

during

and repeat).

TRACKING

TONEARM

The

tracking

CdS element,

voltage

ment.

the

to

the

elror

sensor

differences

These output signals are then

driver

pass

tonearm

stage

a current

(i.e.

to avoid

in

outputs).

DRIVE

the

in

balance

be

moved

auto

SENSOR

DRIVER

sensor

and

where

through

such

STAGE

input

the

to

locate

power generator

the

stage,

the

tracking

is upset, permitting

back

and

forth.

however,

operation

when

modes

STAGE

the elevator

(lead-in,

AND

STAGE

(consisting

stage

shutter)

generates

of lamp,

*

in response to tonearm

applied to

they

are

amplified,

a way

the

the drive

as to eliminate

generation

coil

of

to drive

tracking

tracking

the

Such

and

move-

and

5.10

The

motor

MOTOR CONTROL

D.D.

MOTOR

D.D.

phono

when

motor stop control stage stops the

the rest sensor detects

STOP CONTROL

of the tonearm back on

the tonearm

will continue to

stage

employs 3 specially designed

PA2OA4,

remains

off

rotate. The

PD1003. These control stages also

and

the

the arm rest, the motor

STAGE AND

rest.

arm

phono

motor control

ICs - PA2005,

the

As

presence

long as

include the speed selector, speed indicator, and

qtartz

lock indicator circuits.

-

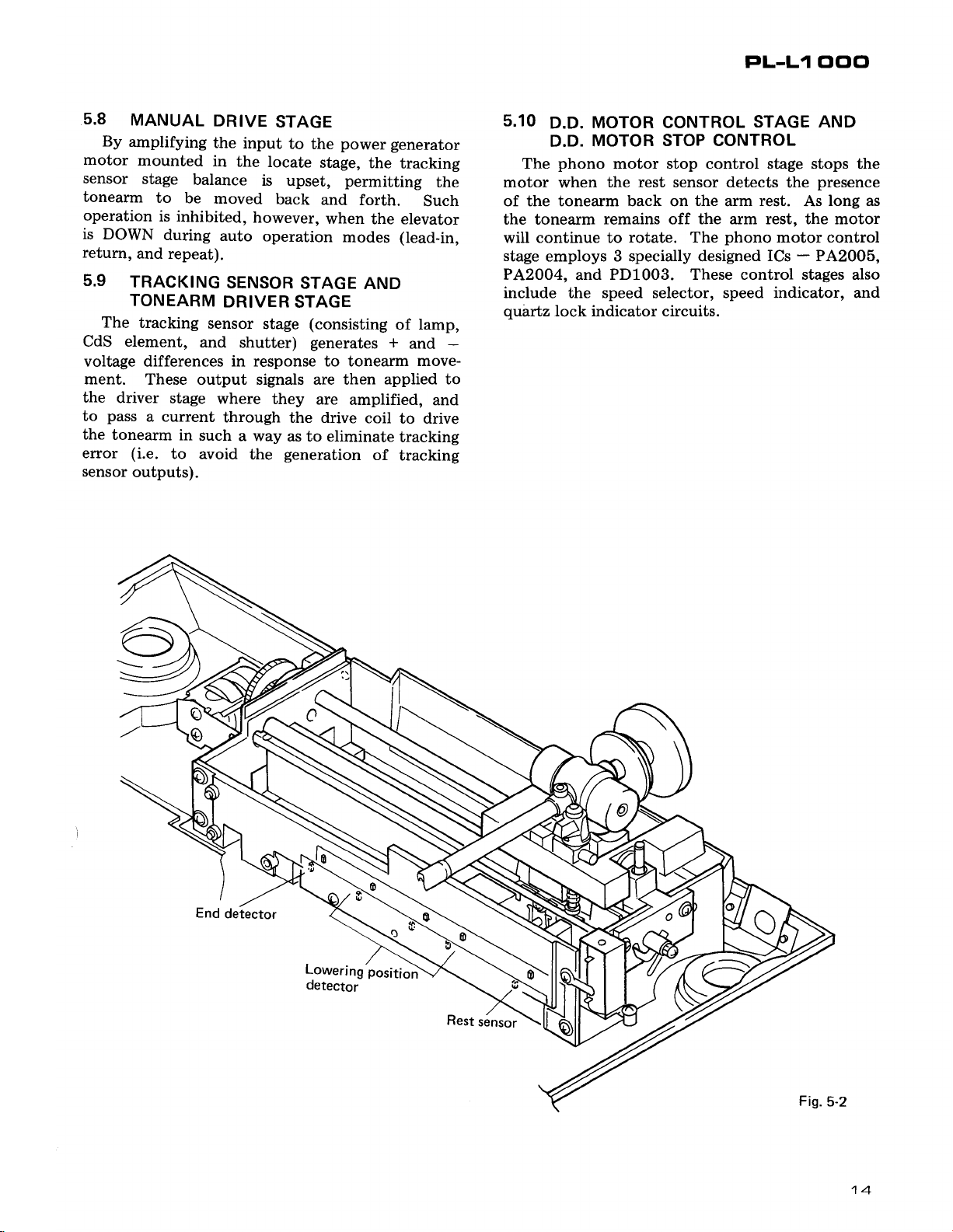

End

detector

Lowering

detector

positioi

Rest

sensor

Fis.

5-2

PL-L1

c,Clc'

€i.

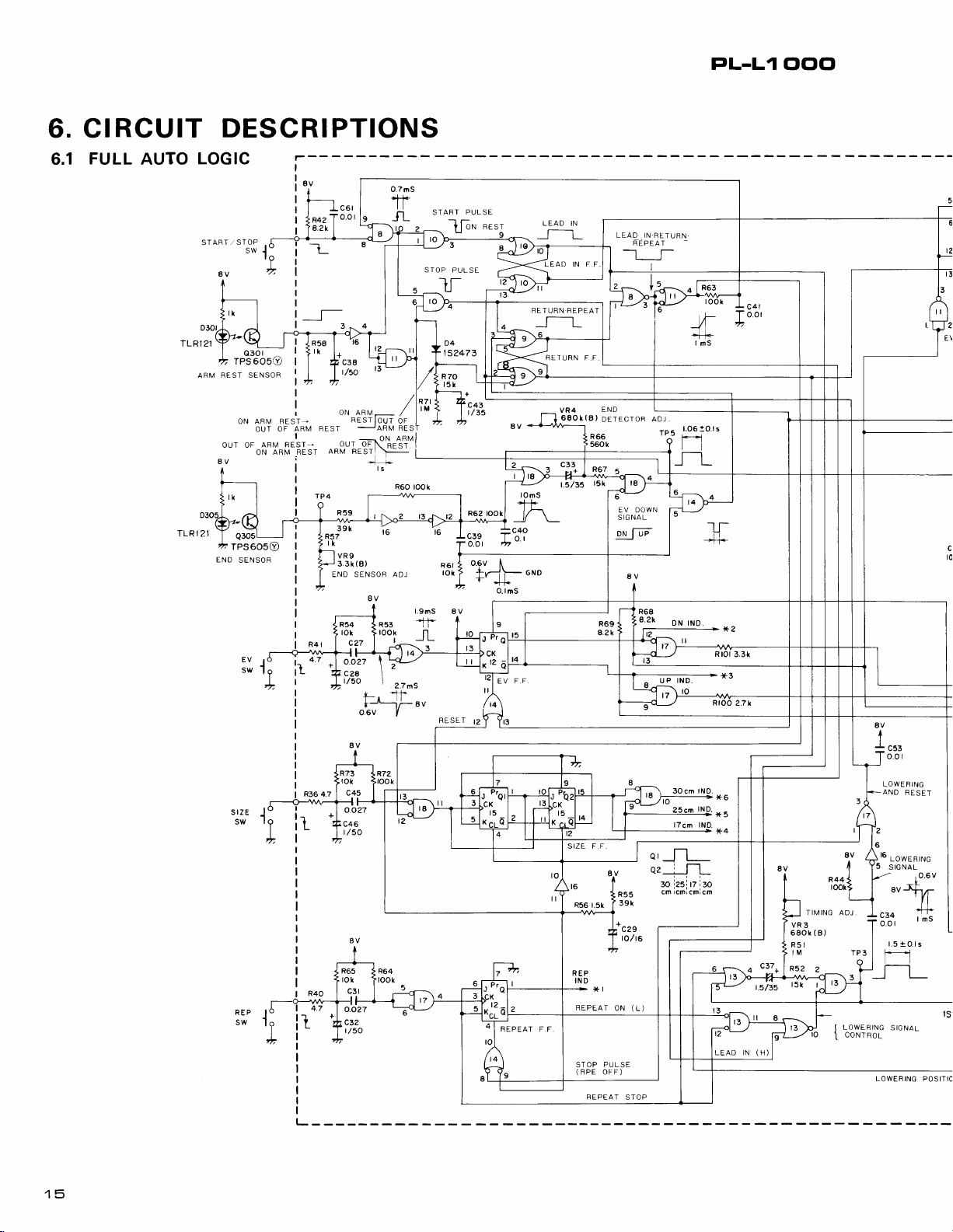

CIRCUIT

FULL

6.1

AUTO

DESCRIPTIONS

LOGIC

O.7nS

-rt

g

fL

|

o30

TPS60S0

REST SENSOF

ARM

8V

END

r

ON

OUT

Q3O5L--

t

TPS6050

SENSOF

AFM RESTOUT

ARM REST-,

OF

ON

I

ARM

OF

I

ARM REST

c38

t/5o

oN ARM-

RESTIoUT

JARM

REST

orr

*xot.tltl

aRv nEStl

-t

R59

,urtt'

rk

VR9

3.3k(8)

END SENSOF ADJ

8V

R54

rok

c27

ocizz \ y-,

c?a

t/5o

l#

fr__..iFuu

o.6v

rok

c45

o.o?7

c46

t/50

8V

R65

tok

-lt-

7

o.o2'

ic3?

t/50

r3

/lazt

/

l'u

oF

I

REST

!

ts

R60

took

io

\

I

e.zrs

I

STAFTJULSE

Lolr

STOP

PULSE

*es-t

Ir

lK.liJ_-r\_

c3s

+i"9

'

-

,,

o.ol

o.gv

I

fy--j l-

-r

oruo

'l+

O.lnS

REPEAT F.F

RETURN

VR4

680I(B)

t.S/3S

16

q55

REPEAT

F.F.

END

DETECTOF

R66

560k

t5k

BV

1.51

LEAD

--t__f-

|

{nss

ssr

|

ON

IN.FETURN

REPEAT

ADJ

TP5

a._fl-L

.o

cmicm cmicm

(L)

.

jasl

rz

iro

R rOl

3.3k

LEAD IN

(H)

TII\,4ING ADJ

VR3

680k

R5l

IM

R52

(B)

?

rL0wERrNG

I

8V

:J---r_

CONTR0L

A

I

I

o.o

LOWERING

AND

FESET

16

r-owEntruc

IG NAL

S

:"t

r 's

3:"1

1.5!Ols

fi

StcNAL

BEPEAT

STOP

1

clclcl

t

I

IN

LEAD

REPEAT

ST0P

ra)

@

TO AFM

DRIVE SECTION

rc

I

g1_-_/

bl J

to

L.owERlNc

coNTROr

1

8V

I

I

I

o.o

LOWEF

ING

AND

FESET

16

loweRtnc

5

srcNAL

:"t

r 's

3.t"t,

+

1.5

O.l s

fi

'_r-L_

srcNAL

LOWERING

c47

to/t6

,o.r1?

POSITION SIGNA.

l(l

x?

.t€

*4

.n5

,(6

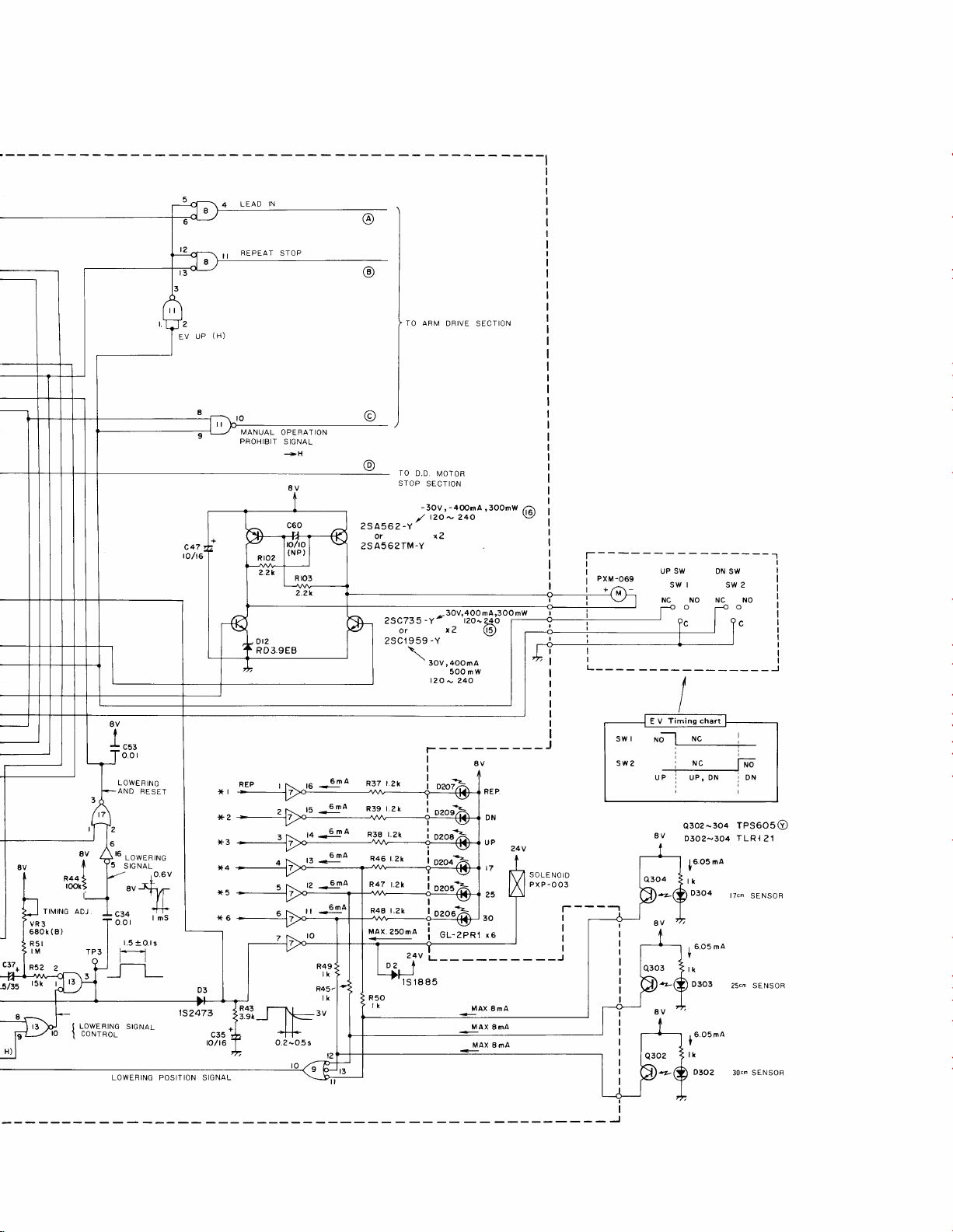

MANUAL

PROHIBIT

3

+

i

OPERATION

SIGNAL

+H

.^

15

r+

,u

ra

rr

-tga

-9i1A

6mA

6mA

tto

6mA

o

6)

TO

D.D.

STOP

SECTION

-3ov,-4ooma,3oomw

y' tzoN

-Y

2S 456

2

or x?

A562 TM-Y

2S

-Y-

25c735

orx?(9

-Y

25C1959

\

3OV,4OOmA

l?Q

I

r.2k

t.zl

D?

lsr885

I

I

I

I

R37 t.2k

R39

R38 r.2k

R46 r.2k

R47

MAx.25Oma

MOTOR

24o

3OV,4OO

-

5OOmW

* 24O

0209

ol_zeRt

mA,3OO mw

tzo-zAo

REP

DN

UP

t7

?5

30

,e

MAX

8mA

MAX

MAx

8mA

8mA

r;\

\9

l.

SOLE

PXP-OO3

PXM-069

UP

ON

SW

swt swz

SW

NC NO NC NO

I

I

l1

rl

L---

_____J

swl

sw2

-30a

NO

ID

-- --]

r

Q303

Q3O2

8V

8V

<L

+4.

Q302

D3O2-3Oa

t

tk

1

tk

t

tk

16.05

0304

6.05 ma

D3O3

6.O5mA

|

0302

rPS60so

TLRI

nA

lTcm

25cm SENSOB

30cn SENSOR

21

SENSOR

*

Number

x

LdenotesLlevel.

*

HdenotesHlevel-

*

EV

denotes

elevator

elevator

The

Full

following

Tonearm

(1)

End

(2)

Elevation

(3)

(4) Record size selector

(5)

Repeat control

6.1.1 TONEARM

1.

When the

. . .

. the

by

C29lF-55 to IC16,-+ICI7,->IC9,

. . . . the

if the

commence

moved

2. When

with

*

*

*

*

(8)

Pin

(10)

Pin

appears

lead-in

being

switched

Once

pin

(3)

pin

in

L level,

operation).

(13)

Pin

resulting

H level,

raised

(

Pin

ing in

STOP

(in

order

set

when the

the

same

H

level

Hence,

elevator

ing

inhibited.

parenthesis

in

arm

elevator,

is in

is

in the

Auto

5 main

detector

lead-in

the initial reset

phono

the

the

tonearm

of IC8

of

at

FF

pin

(10)

of IC8

(8)

thereby inhibiting

of IC14

in

and the

to the

of IC11

)

the inhibition

switch

to

time,

to inhibit

the relevant

raised,

UP

DOWN

Logic section

stages.

control

control

power

START/STOP

IC8 is

pin

being set

of

pin

UP

stage

stage

stage

stage

CONTROL

switch

FF

motor

tonearm is

rotate

to

away.

on

is

switched

switched

(3)

to H level).

of

IC10

is switched

IC1L

is

(12)

elevator

position.

is switched

inputs

prevent

tonearm leaves

pin (12)

switching

and record

are

the IC

UP denotes

position,

position.

stage

STAGE

is

turned

and retum FF

signal

will remain

on the arm rest,

if it has

switch is

the arm

to L level.

to H level,

of

IC10,

(and

pin (10)

is switched

to L level,

being likewise

manual

also switched

of IC12

being

of

any further

after a delay

the return FF from

of

IC18 is

of

FFs

size

pin

while DN

is

made up

on

. . .

are

(passed

and

stationary

alreadv been

then

rest,

resulting

of

IC10

to H level,

switched

drive

to L level,

being switched

consequently

to H level,

of about lms

the

arm rest).

switched

the size selector.

are set,

selector switch-

numbers.

that

arm

that

of the

.

reset

from

IC10).

but

pressed

and

this

in

the

also

resulting

to

(locate

to

result-

START/

being

At

to

the arm

(11-)

Pin

transferred

properly

is

switch is switched

pin

in

pin (4)

This IC8

resulting

VRb and R99 via

drops

ference

through

czrlrier.

The

the record.

When

in front

will

Pin

and

serves

brator incorporated

generation

This is

presetting

arm.

The

in

turn attracts

plate.

The carrier

ing

index

TP3

later,

and R44

which is

clear

The

selector

at the

As

a further

level,

R43 and

discharge

is

maintained

forced

has

retumed

of IC10

to

in the

(5)

of IC8

of IC8

pin

in

a current being

below

is

the

carrier is

the carrier reaches

of the

block the light

(13)

of IC9 is

pin

(10)

as a trigger for

of an H level

applied to

the

TPB H

to a stop

is switched

the

elevator

been

level signal

plate.

the signal being

provide

to

passed

FFs

switching

same time.

the charge

the IC7

period

back

eompleted.

to DOWN

is switched

pin (6)

UP

to the NO

being

switched

(4)

H level

R93.

potential

the

amplified

coil to subsequently

thus shifted

(Assume

30cm

of

of IC9 switched

EV

FF for

the

continues

when the swing

back

via

and

stop the

UP, locate

inhibition

result

held

base resistance.

(0.3

in

the attracted

(by

a spring)

position

PL-L1 clc'cl

to L, and

of ICS.

position,

switched to L level,

to H level.

signal

size selector

position,

the 30cm sensor.

thereby

the monostable

in IC13,

TP3

is used

plunger

to L level

the tonearm

IC1-7, IC9

of TPB

by

to

The elevator

Once the elevator

the UP detector

position,

then turns

passed

If

and a current

a

to move further,

differentiated

potential

the

at TP10,

across towards

set to

position

the carrier

switched to L level,

to H level.

resulting

signal

and

C35

0.5 sec.)

of r = 2.2 sec.

pin

lowering

to drive IC7,

raise

and

pin

descend

and IC10

carrier drive

inhibition,

are dlso cancelled

being

switched

is

discharged via

position,

once

the discharge

for

start of

this is

resulting

and

on,

Q7

from

VR8 to

at TP8

the dif-

passed

drive the

30cm).

about

(9)

20mm

shutter

This

multivi-

in the

of lCL2,

of

the tone-

and

index

the

com-

strikes

2.2 seconds

During

the

is thereby

by

C34

signal

current.

and

to

plunger

but is

play.

the

size

this

to

L

l

3. START/STOP

is not

on

x

(8)

Pin

*

The IC8

pin (4)

retum FF to be set.

*

This then

and inhibition of size selector switching, S/S

switch input after a delay

*

The L level

red

ing inversion of the repeat

the

pin (4)

the repeat FF. The

circuit referred to above

time

ployed

*

In a similar fashion to the lead-in operation,

the L

once the elevator has been completely

is converted into an H

resulting in

however, the TP10

TP8

retumed towards the arm rest.

x

When the shutter

beam during the

is switched to H level, but since the

has been switched off,

at H level,

monostable multivator.

t

Once the carrier reaches the arm

the rest sensor transfers

pin (3)

being switched to L

motor.

+

When

the charge stored on C43

the return

on

circuit). During this

pressed

4. End detector

*

When

switched to L level by the end detector, and the

retum FF

steps are the same as during normal

mode.

*

When the repeat mode is on, the retum

again

operation. However, when the shutter

across the size sensor, the

of IC8 is switched

pin (10)

of IC10 being

pins (5)

to

pin (4)

IC10

of IC12 via

for

the

in clearing this FF.

level

potential,

of IC16, resulting in

pin (11)

(1)

pin

against the

the

set in the same way for normal return

switch

the arm rest

results in the elevator being raised,

signal on

and

L level change is transferred to

generation

signal appearing at

being turned on. In this case,

Q8

resulting in the

retum

thereby

of IC11 is switched to L

FF

being cleared after

of IC9 is reduced to 1/2Vcc

operation

repeat mode is

is consequently set. Subsequent

pressed

to L level.

change to H

changed to L

pin (9)

(6)

of 1C72, thereby

pin (8)

purpose

is

of

signal

potential

cuts

across

motion,

pin (1)

preventing

and L level signal to

level to stop the

is discharged via R71,

period,

arm rest.

when tonearm

level results in

level for the

of 1ms, and locate.

of IC9 is transfer-

inhibit-

FF.

Furthermore,

of IC14 to clear

of the 1ms delay

permit

to

the time

pin

at

drops below the

the sensor

operation

pin (11)

the cauier

pin

off,

plunger

sufficient

pulse

(9)

pin

(11)

carrier being

pin (10)

repeat mode

of IC13 will be

position,

rest

of

potential

the

remains

(3)

of IC9 is

is activated

em-

of IC9

raised,

of IC8,

light

of IC9

of the

IC11

phono

level,

(delay

return

FF is

cuts

(TP3

generation

way as during

lowered for recommencement

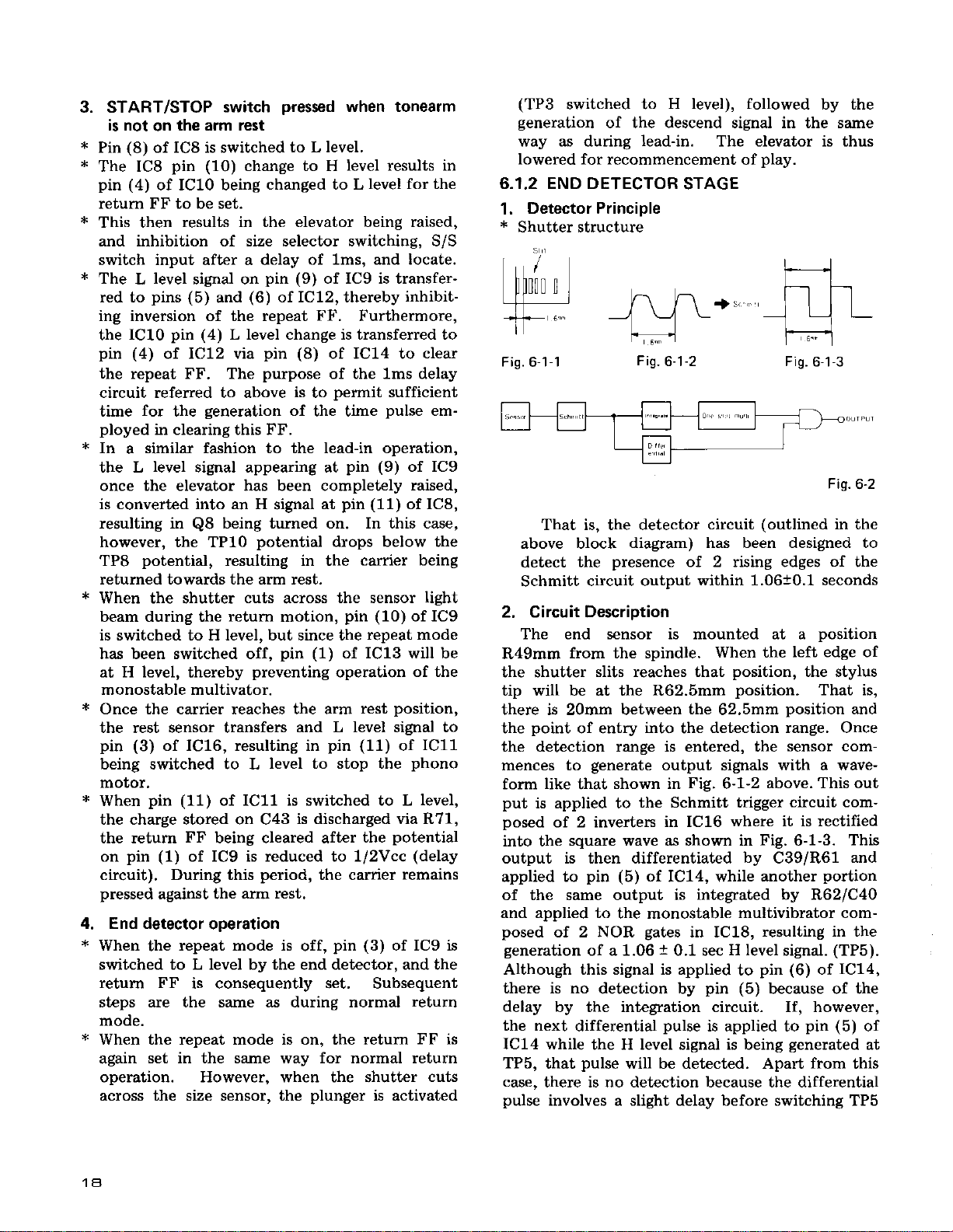

6.1.2 END DETECTOR

1.

*

Shutter structure

hhnin n

ff"" " I

.IE;

switched to

of the descend signal in the same

Detector Principle

-r\4'

i

Fis.6-1-1

That is, the detector

above block

detect the

Schmitt

2, Circuit Description

The end sensor is mounted at a

R49mm

the shutter

tip will be at the R62.5mm

there is 20mm between

point

the

the detection range is entered, the

mences to

like

form

put

is applied to

posed

into the

output is then differentiated

applied to

of the same output is

and applied to

posed

generation

Although this signal is applied

there is no

delay

the next

IC14 while

TP5,

case,

pulse

of 2 inverters

of 2 NOR

by the integration circuit. If, however,

that

there is no detection because the differential

involves a slight delay before switching TP5

presence

circuit output

from the spindle.

slits reaches that

of entry

generate

shown in

that

square wave as shown in

pin (5)

the monostable

of a 1.06 1 0.1 sec

detection by

differential

the H level signal is being

pulse

H level), followed

lead-in.

The elevator is thus

play.

of

STAGE

-l-Ll-

#E

Fig.

6-1-2 Fis.6-1-3

circuit

diagram) has been designed to

of 2 rising edges

within 1.0610.1 seconds

the

into

output signals with a wave-

the Schmitt trigger

of

gates

will be detected. Apart

detection range. Once

the

Fig.

in IC16

IC14, while

integrated by

in IC18,

pin (5)

pulse

is applied to

(outlined

When the

position,

position.

62.5mm

above. This out

6-1-2

where it is rectified

Fig.

by

C39/R61

another

multivibrator com-

resulting in the

H level

pin

to

because of the

by the

[1

Fis.

6-2

in the

of

the

position

left edge of

the stylus

That is,

position

sensor com-

clcuit com-

6-1-3.

signal.

(6)

pin (5)

generated

and

This

and

portion

R62|C4O

(TPb).

IC14,

of

from

this

.Jl

q

of

at

FL-L1

clclcl

to H level.

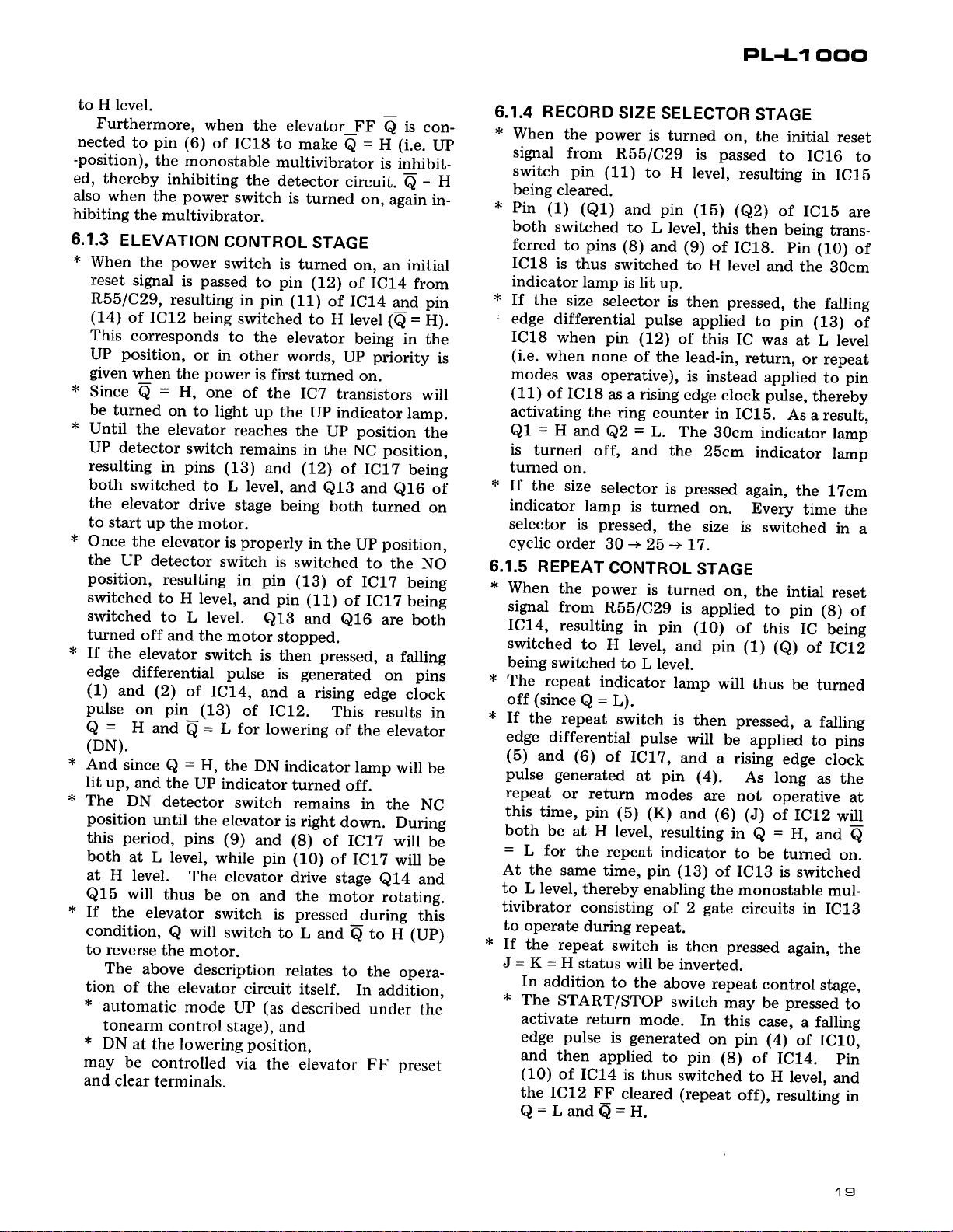

Furthermore,

nected

-position),

ed,

also

hibiting

6.1.3

x

*

x

x

x

*

lit

x

The

x

to

tion

*

*

may

and

to

thereby

when

ELEVATION

When

reset

sigrral

R551C29,

(14)

of IC12

This

corresponds

position,

UP

given

when

Since

be

turned

Until

UP

detector

resulting

both

switched

the

elevator

to start

Once

the

the

UP detector

position,

switched

switched

turned

If

the

edge

differential

(1)

and

pulse

=

H

Q

(DN).

And

since

up,

DN

position

period,

this

both

at

at

H level.

will

Q15

If

the

condition,

reverse

The

of

automatic

tonearm

DN

at the lowering

be

clear

when

pin

(6)

of

the monostable

inhibiting

power

the

the

multivibrator.

CONTROL

power

the

resulting

the

=

Q

on

the

elevator

in

up

the motor.

elevator

resulting

to H

to

off

and

elevator

(2)

pin

on

and

Q

and

the

detector

until

L level,

thus

elevator

Q

the

above

the

control

controlled

terminals.

switch

passed

is

being

or in

power

H,

one

to light

switch

pins

(13)

to L level,

drive

is

switch

level,

L level.

the

switch

of

lCL4,

(13)

=

L for

Q

=

H,

the DN

UP indicator

the

elevator

pins

(9)

while

The

elevator

be

switch

will

switch

motor.

description

elevator

mode

the elevator

IC18

to

multivibrator

the

detector

switch

is turned

pin (12)

to

pin

in

switched

to

the

elevator

other

reaches

stage

in

motor

pulse

switch

on

UP

stage),

via

words,

is

first

of the

up

the

remains

and

being

properly

is

pin

pin

and

Q1B

stopped.

is

then

is

and

of IC12.

lowering

indicator

is right

and

pin

and

is

to

relates

circuit

(as

and

position,

the

FF

make

Q

circuit.

is

tumed

STAGE

on,

of IC14

(11)

of IC14

to H

level (Q

being

Up

turned

ICZ

transistors

Up

indicator

the

in

(I2)

and

in

switched

(18)

(11)

and

generated

a rising

turned

remains

(8)

(10)

drive

the

pressed

L and

itself.

described

elevator FF

position

Up

the

NC

of IC1Z

e13

both

the

Up

of

of

e16

pressed,

This

of

the

lamp

off.

down.

of

IC1T

of IC1?

stage

motor

Q

to the

In

Q

=

H

is

inhibit_

on,

again

an

and

priority

on.

position,

and

e16

turned

position,

to

the NO

IC1?

IC1Z

are

a falling

on

edge

results

elevator

will

in

the

During

will

will

e14

rotating.

during

to

H

addition,

under

is

con-

(i.e.

Up

=

Q

in-

initial

from

pin

=

H).

in

the

will

lamp.

the

being

of

on

being

being

both

pins

clock

in

be

NC

be

be

and

this

(Up)

opera_

the

preset

H

is

6.1.4

x

*

*

*

6.1.5

*

*

x

x

RECORD

When

signal

switch pin

being

Pin

both

ferred

IC18

indicator

If

'

edge

IC18

(i.e.

modes

(11)

activating

Q1

is

turned

If

indicator

selector

cyclic

When

signal

ICI4,

switched

being

The

off(sinceQ=L).

If

edge

(5)

pulse

repeat

this

both

=

At

to

tivibrator

to

If

= K =

J

x

the

from

cleared.

(1) (Q1)

switched

to

is

thus

the

size

differential pulse

when

when

was

of

IC18

=

H

and

turned

on.

the size

is

order

REPEAT

the

from

resulting

switched

repeat

the

repeat

differential

(6)

and

generated

or return

time, pin

be

at H

L for

the same

L level,

operate

the

In

The

activate

edge pulse

and

(10)

the

Q=LandQ=H.

the

repeat

H

status

addition

START/STOP

then

of

IC12

SIZE

power

pins

lamp

none

operative),

the

off,

selector

lamp

pressed,

power

to H

indicator

thereby

consisting

during

return

applied

IC14

FF

is

P"55lC29

(11)

to

and

to

(8)

switched

is lit

selector

pin

(12)

of the lead-in,

as a rising

ring

=

Q2

and

is

-->

30

25

CONTROL

is

R55/C29

in

level,

to

L level.

switch

pulse

of

lCL7,

at

modes

(5)

(K)

level,

repeat

pin

time,

enabling

repeat.

switch

will

to the

mode.

generated

is

is

thus

cleared (repeat

SELECTOR

turned

H level,

pin

L level,

and

up.

is

counter

L. The

the

is

turned

the

->

turned

pin

and

lamp

is

pin

resulting

indicator

of

is

be inverted.

above

switch

to

on,

passed

is

(15)

this

(9)

of

to

H level

pressed,

then

applied

of

this

is

instead

edge

clock

in IC1b.

BOcm

2bcm

pressed

on.

size

L7.

STAGE

on,

is

applied

(10)

pin

will

then

will

be

and

a rising

(4).

are

(6)

and

in

(13)

of IC13

the monostable

gate

2

pressed

then

repeat

may

In

this case,

on

pin

(S)

switched

STAGE

the

initial

to

IC16

resulting

(e2)

then being

IC18.

to

IC

was

return,

indicator

indicator

again,

Every

is

switched

the

of

this

(1)

thus

pressed,

applied

As long

not

(J)

e

to

be

circuits

control

be

pin

of

to H

off), resulting

in

of rClb

pin

(10)

and

the

the falling

pin

(18)

at

L level

or repeat

applied

pulse,

to

thereby

As

a result,

the

time

intial

pin

(g)

IC

(e)

of.

be

turned

a falling

to

edge

as

operative

of

IC12

-

H,

and

turned

is switched

in IC1B

again,

stage,

pressed

a falling

(4)

of IC10,

ICL

.

level,

reset

IClb

are

transBOcm

pin

to

lamp

lamp

17cm

the

in

reset

of

being

lCL2

pins

clock

the

at

will

Q

on.

mul-

the

to

pin

and

in

to

of

of

a

*

When the

repeat mode),

level, this being

terminals

any inversion.

ing

of the

retum

pin

FF

(9)

is set

(during

IC9 is switched to

of

return or

transferred to the J and

repeat FF,

thereby

inhibit-

L

K

I,

TONEARM

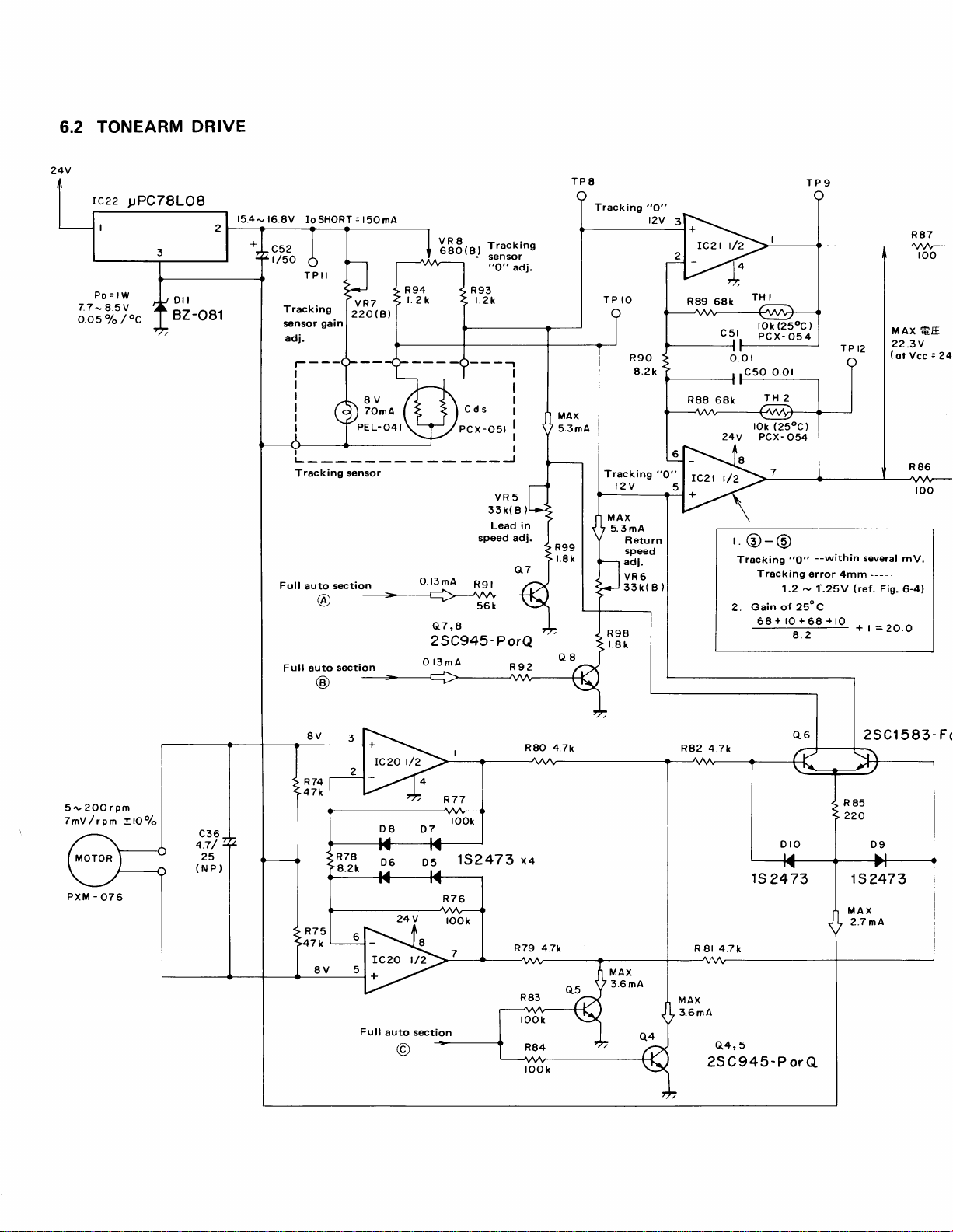

6.2

DRIVE

24V

tczz

Po:lW

-

7.7

8.5V

Q.o1o/o

!PC78LOB

oC

/

15.4

-

16

8V Io SHORT : t

TPII

Tracking

gain

sensor

adi.

Full

Full auto

auto

section

sectaon

50 mA

8V

TOmA

PEL-

04

EEBr',

R93

I

o'13mA

25C945-PorQ

l3mA

o

IJ;:j;"'

"O"

t.?k

Lead

speed adj.

R9l

Rgz

adj.

TP8

Tracking

"O"

t?v

3

TP9

rc?t t/2

R89

RgB

MAX

5.3mA

t?v

"O"

5

rczt t/2

Tracking

in

tl.Bh

o:

TH I

68k

cq,.

, .c50

6Bk

tok

?4v

|

@-@

Tracking

Tracking

Gain of 25oC

?.

68+tO+68+tO

t?!',l33Tl

0.ol

TH

2

(250c)

PCX-

O54

"9" --within

error 4mm

1.2 - 1'.25V

4.2

MAX

22.3V

(otVcc:24

several

-----

(ref.

Fig.

+t=2O.O

€E

mV.

6-4)

5,v 2OO

7mY

rom

/

-

PXM

076

rpm

l9o/o

ltj

D6

TC20 t/2

Full

auto section

24t!

D5

took

152473 xq

R79 47r

R80 4.7k

MAX

3.6 mA

q4

R82 4.7k

ts

R

4.7k

81

MAX

3.6mA

Q4,5

25C945-PorQ

2473

25Cl

15

MAX

2.7 mA

?47 3

583-

Fr

TP

I?

--within

error 4mm

,1'.25V (ref.

several

+

2S Cl583

1S?473

MAX

2.7 mA

MAX

?2.3V

(ot

mV.

--

--Fig.6-4)

t=20.o

roc

€E

Vcc

| | uAx

=

?4Y

I

-

For

G

I

to/35

ceg

3OOmA

(

250

t?5A671-Bor C \

\

esclo6l

t25A816-OorY \-^

\

zS

Cl

-Borc)

c 16?6- o orY

x

)

Coil Ass'y

PXB-II8

R=73t5rl

(or

25('C)

TPlO

@

volt

R

2 or

^'

Fis.

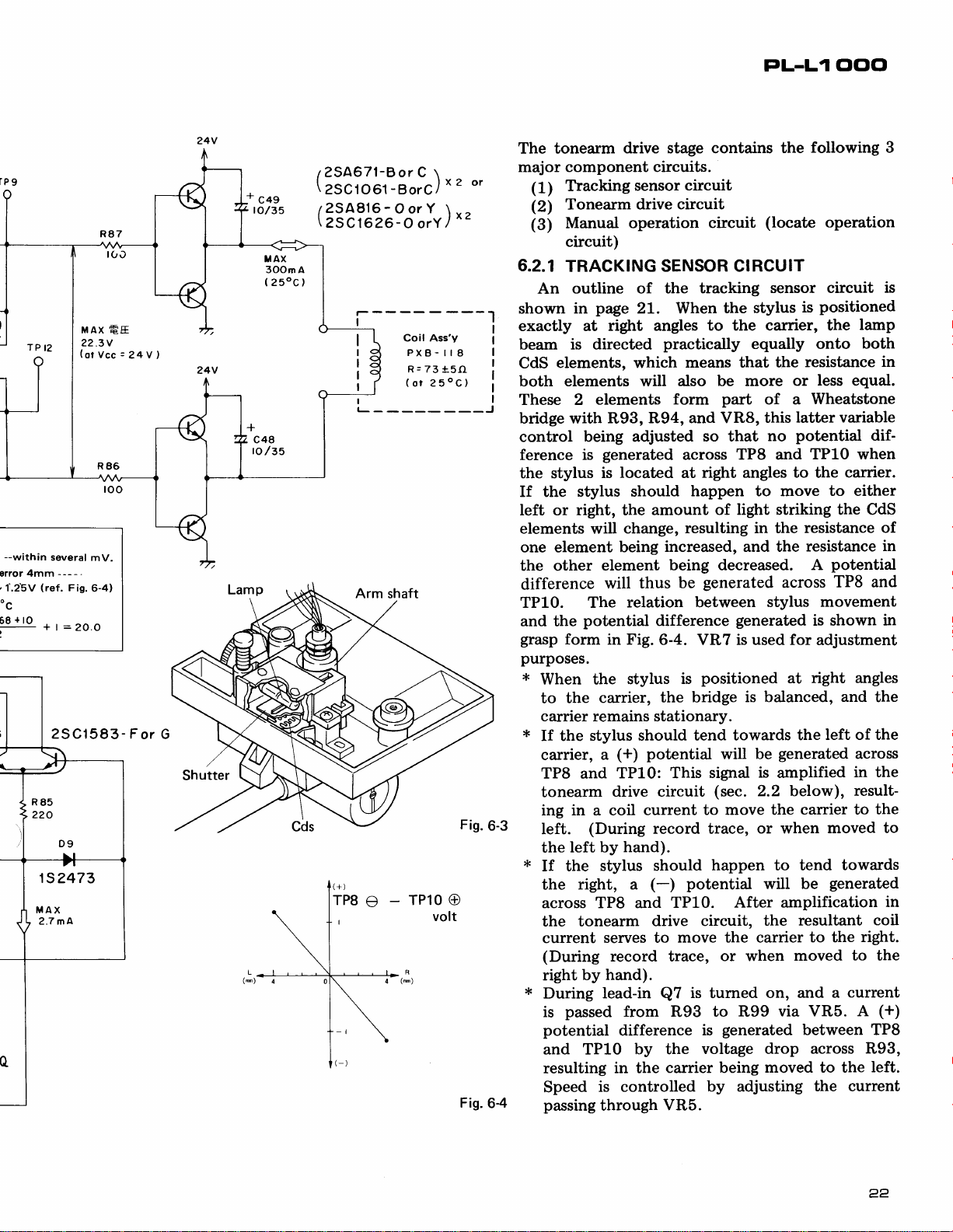

The tonearm

major

component circuits.

Tlacking

(1)

Tonearm drive

(2)

Manual operation

(3)

circuit)

6.2.1

shown

TRACKING SENSOR CIRCUIT

outline of the

An

in

exactly at

beam

CdS

both

is directed

elements, which

elements will

These 2

bridge with R93,

control

ference

being adjusted

is

the stylus

If the stylus

left or right, the

elements will

one element being

the other

difference

TP10. The

and the

grasp

potential

form in Fig.

purposes.

i<

When the

the

to

carrier remains stationary.

*

If the

ca"rrier,

TP8 and

tonearm

ing in a coil

Ieft.

left by

the

*

If the

right,

the

across TP8 and

the tonearm

current

(During

by

right

{€

During

pumsed

is

potential

and TP10

resulting

Speed

6-4

passing

drive stage contains

sensor

circuit

circuit

page

21. When

right angles

practically

means that

also be more

elements

form

R94, and VR8,

generated

located

is

should

across

at

happen to move

amount of

change,

resulting in the

increased, and the

element

will

being decreased.

be

thus

relation between

difference

6-4.

VR?

stylus

carrier,

stylus should

(+)

a

is

the bridge

tend towards

potential

TP10: This

drive circuit

current to

(During

record trace,

hand).

stylus should

potential

(-)

a

TP10.

drive

serves to

move the carrier

record trace,

hand).

lead-in

from

Q7

R93

is

difference

by the

in the

carrier being

is controlled

through

VR5.

FL-L1

the

the

(locate

sensor circuit

stylus

circuit

tracking

to the carrier, the

ClClCl

following 3

operation

positioned

is

lamp

equally onto

resistance

the

less

or

part

of a

latter variable

this

potential

so that

no

TP8 and

right angles to the

equal.

Wheatstone

TP10 when

carrier.

to either

light striking the CdS

resistance of

resistance

potential

A

generated

stylus

generated

is used for

positioned

is balanced,

will be

(sec.

is

2.2 below),

signal

move the

or when

across

generated

amplified

TP8 and

movement

is shown

adjustment

right angles

at

and

left of the

the

carrier to

moved to

across

in the

result-

happen to tend towards

will be

generated

After amplification

resultant

circuit,

the

to the

or when

turned

to R99

is

on, and

via VR5.

generated

voltage drop

moved

between TP8

to

current

a

A

across R93,

moved to the

by adjusting

the current

is

both

in

dif-

in

in

the

the

in

coil

right.

the

(+)

left.

Loading...

Loading...