Page 1

6th

Product Training

Guide

Generation Plasma

Models

Technical Training Department

1925 E. Dominguez Street

Long Beach, CA 90810

Page 2

Page 3

Contents

Plasma Model List…………………………4 PCB Locations………………………..…29

G5 And G6 System Comparison………..5 Operation Status Panel LED’s………..30

Overall Block Diagram………………….6~7 Power Down LED (Red Flashing)….....31

HD Digital Assembly Block……………..8 Power Down Defective Points…...…32~33

Y – Drive Block………………………...….9 3 Times Power Down Flashing……....34

X – Drive Block……………………….…..10 8 Times Power Down Flashing……....35

Differences – G5 & G6 Drive…….....11~13 Shutdown Block (Blue Flashing)…....36

X & Y Board Differences – G5 & G6….14 Audio Board Caution……………….….37

Power Supply Map – X & Y Drive…..…15 Operation Without Media Receiver…..38

Scan A & B Block…………………….….16 Power On With No Panel Drive……….39

Scan IC – 43 Inch Models……………18~19 Adjustments……………………….….40~46

Scan IC – 50 Inch Models…………...20~21 How To Clear The History……………..47

Address Circuit Blocks – G6…….…22~25 Panel Factory Mode……………….….48~56

Audio Assembly …………………..…26~27 Disassembly…………………………...57~60

Power Supply Unit…………………..….28 RS232 Connection………………..……61

Page 4

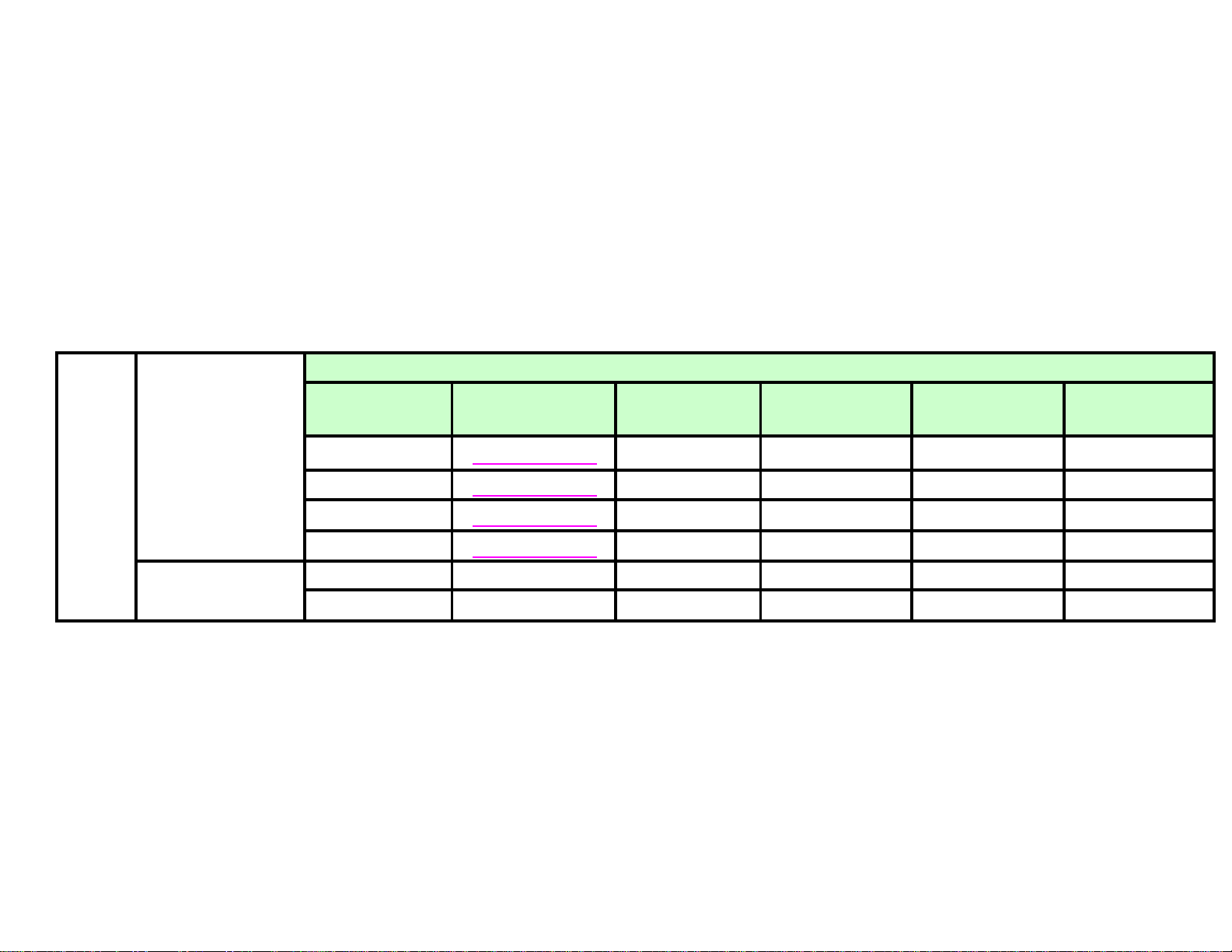

PLASMA MODEL LIS

T

y

4

Consumer Models

G6

Regular Model

Elite Model

Type Model #

43" System PDP4360HD

43" System

50" System

50" System

43" System

50" System

PDP4361HD

PDP5060HD

PDP5061HD

PRO930HD

PRO1130HD

Media

receiver

PDPR06U PDP436PU PDPS37LR PDKTS10

PDPR06U PDP436PU PDPS37LR PDKTS11

PDPR06U PDP506PU PDPS38LR PDKTS10

PDPR06U PDP506PU PDPS38LR PDKTS10

PROR06U

PROR06U

Plasma

Speakers

Displa

PRO436PU PDPS35LR

PRO506PU PDPS36LR

Table top

stand

PDK1013

PDK1013

Page 5

L

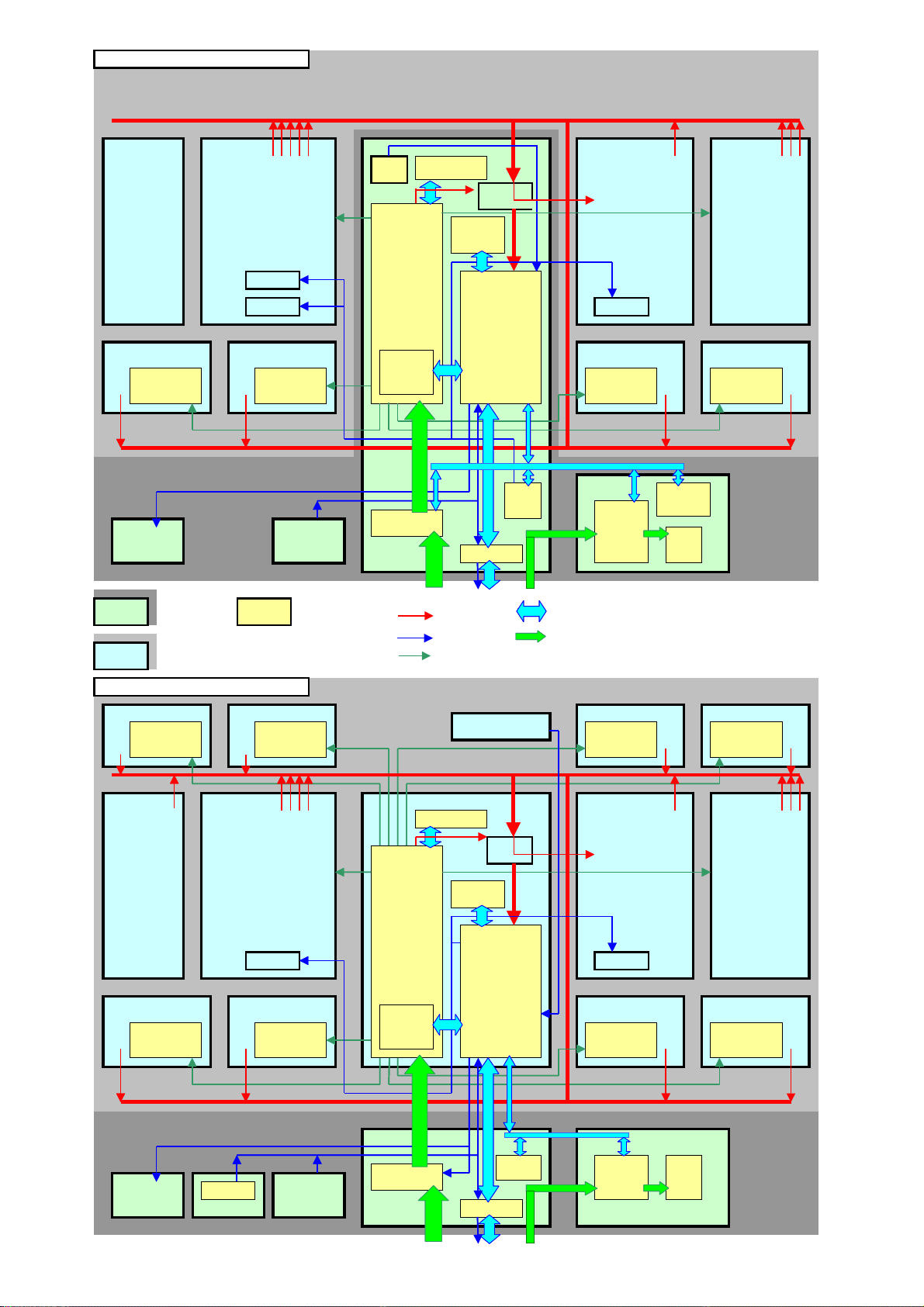

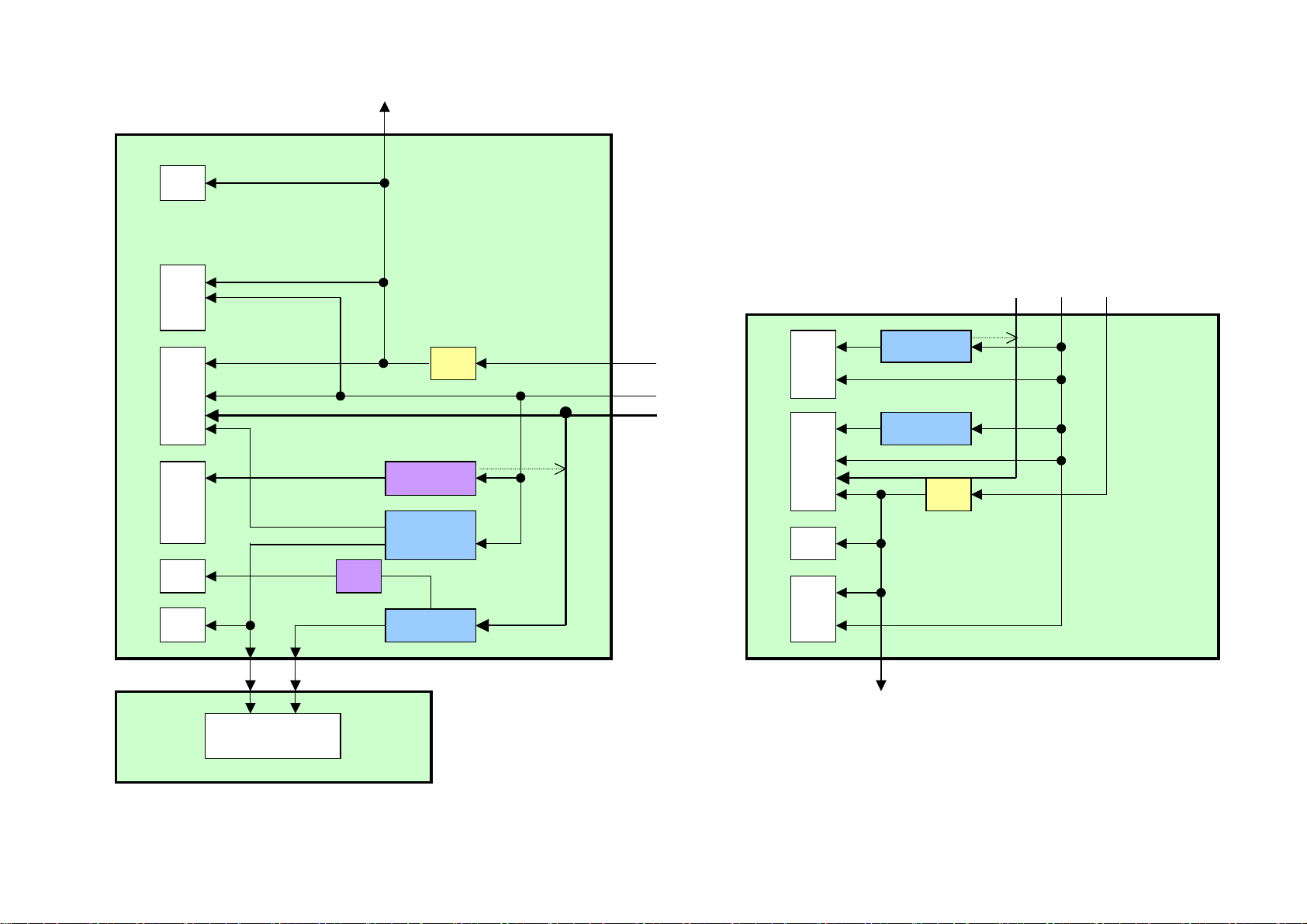

G5 & G6 System Diagram

PD

PD

PD

PD

AND ci

it

PD

Discrimination

PDPDPD

PD

Diff

Main Devi

Protecti

by models

( Power Down )

LOGIC singal

Video / Audio signal

C

t

Vid

l

R

PDPDPD

PD

PDPDPD

PD

AND

PD判別

PDPDPD

PD

5

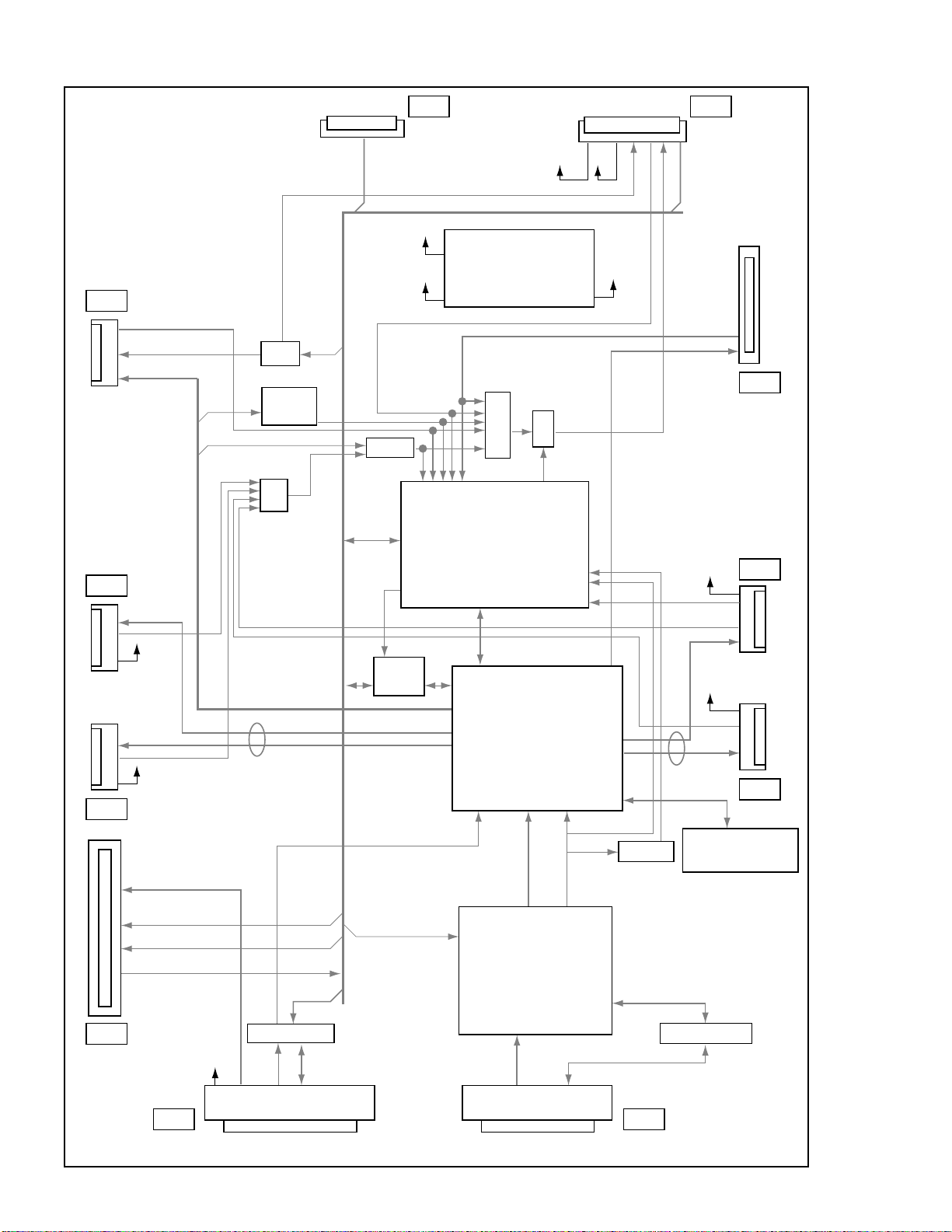

G6 HD MODEL

SCAN Y DRIVE HD DIGITA

TEMP

SENSOR

IC3301

FLASH ROM

rcu

Power Supply

IC3156

EEPROM

V RST

V OFFSET V SUS

ADRES ADRES ADRES ADRES

LVDS

RECEIVER

LVDS

RECEIVER

LED IR

IC3401

SEQUENCE

PROCESSOR

CPU

IC3001

DVI Receiver

IC5201

MODULE

Ucom

BUFF

IC3157

DAC

LVDS

RECEIVER

HD AUDIO

IC3753

VOLUME

IC3754

BACK UP

EEPROM

IC3751

AMP

X DRIVE

LVDS

RECEIVER

erent Assy

ommon use Assy

o all of models

ce

on circuit lineSerial communication line

eo sequnce signa

G4/G5 HD MODEL

ADRES ADRES ADRES ADRES

LVDS

RECEIVER

LVDS

RECEIVER

TEMP SENSO

LVDS

RECEIVER

SCAN Y DRIVE DIGITAL PS X DRIVE

FLASH ROM

EEPROM

SEQUENCE

PROCESSOR

V OFFSET V SUS

ADRES ADRES ADRES ADRES

LVDS

RECEIVER

LVDS

RECEIVER

CPU

DAC

MODULE

Ucom

LVDS

RECEIVER

LVDS

RECEIVER

LVDS

RECEIVER

BACKUP

KEYSCAN

DVI Receiver

LED KEY IR

PANEL I/F HD AUDIO

EEPROM

BUFF

VOLUME AMP

Page 6

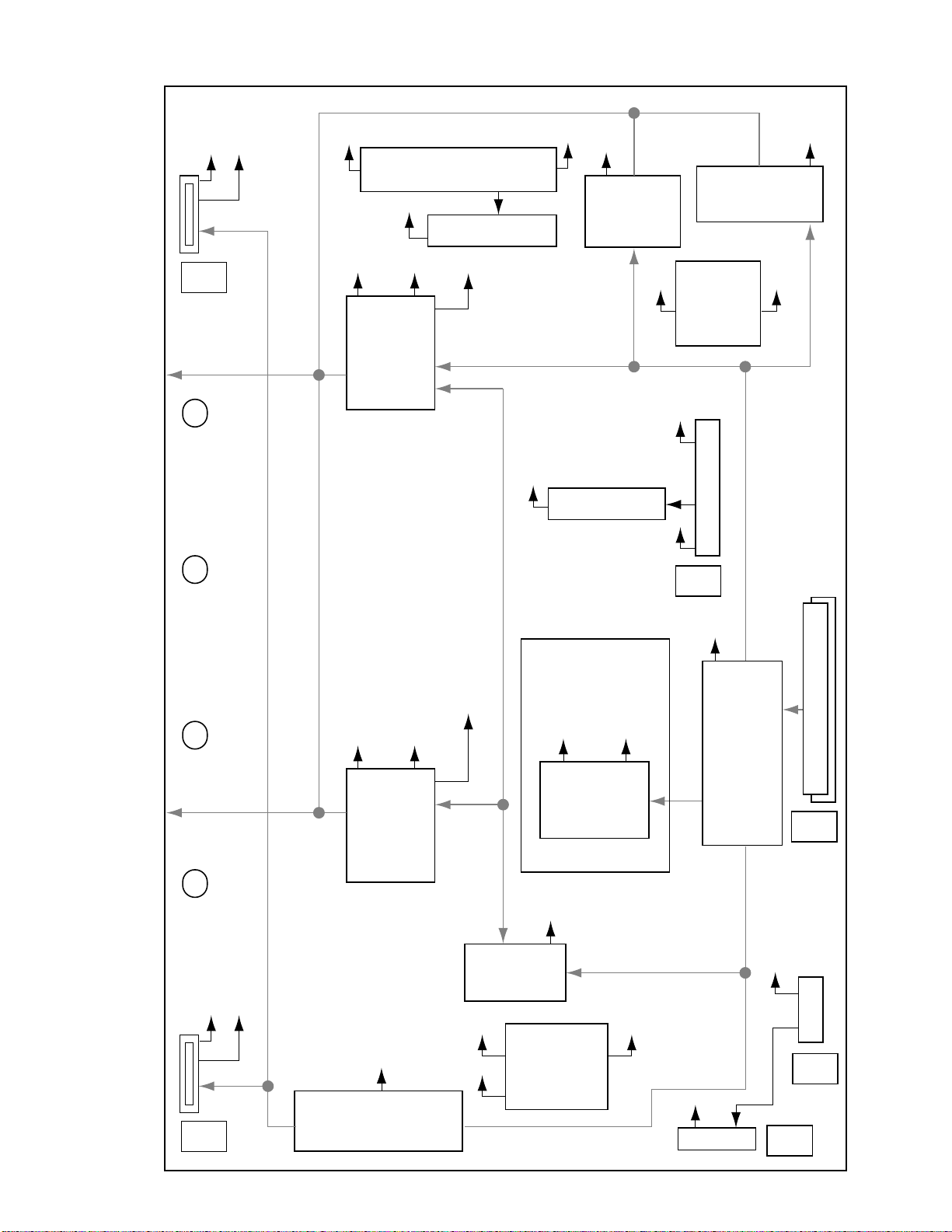

50 SCAN B ASSY

6

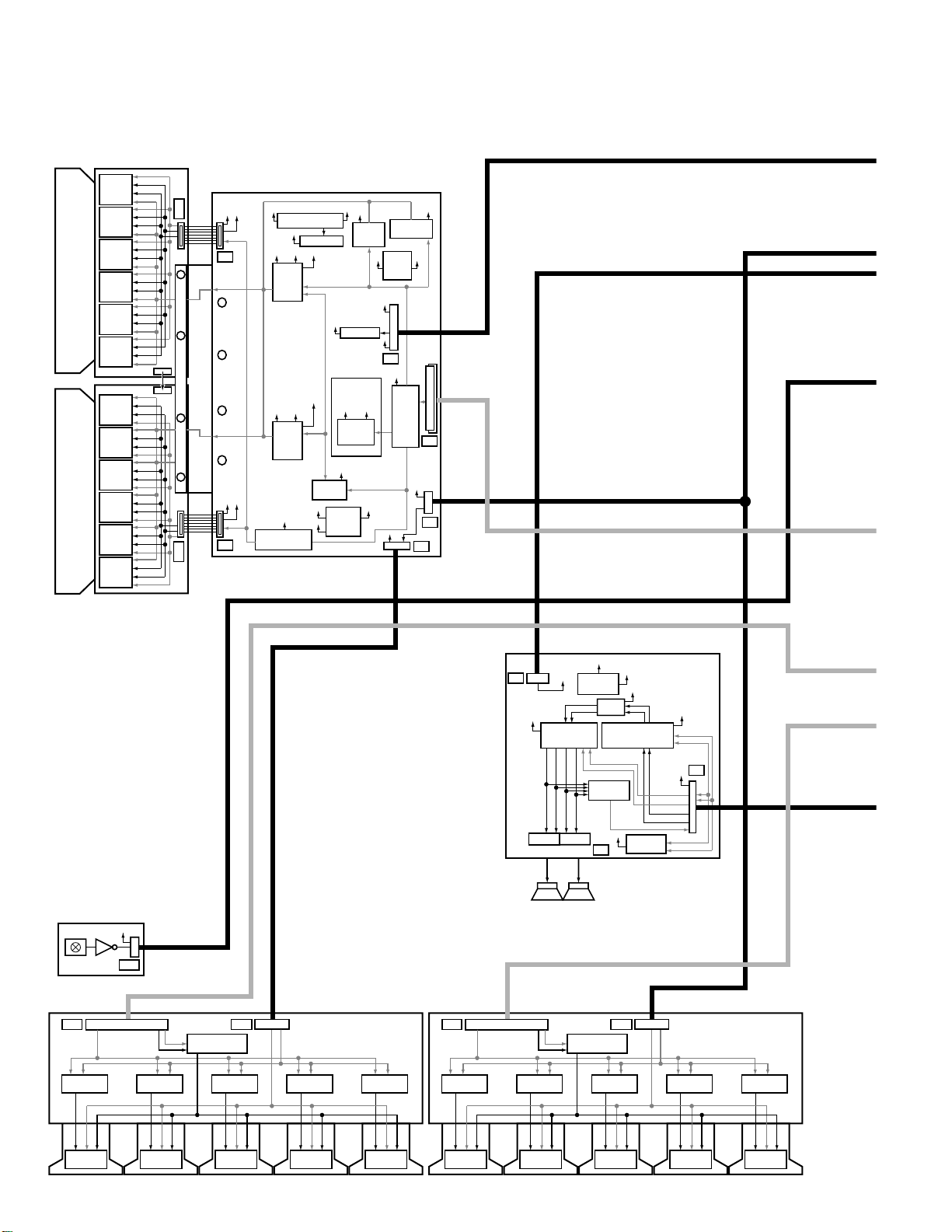

OVERALL BLOCK DIAGRAM

(UPPER)

Scan Signal

VH

IC2801

IC5V

Scan IC

PSUS

PSUS

IC5V

VH

Scan Signal

SB1

SA1

IC2802

Scan IC

IC2803

Scan IC

IC2804

Scan IC

IC2805

Scan IC

IC2806

Scan IC

CN2802

CN2702

IC2701

Scan IC

IC2702

Scan IC

IC2703

Scan IC

IC2704

Scan IC

IC2705

Scan IC

IC2706

Scan IC

Serial Data

50 SCAN A ASSY

(LOWER)

50 Y DRIVE ASSY

PSUS

PSUS

VH

IC5V

IC5V

VH VSUS

VH DC/DC Conv.

Vprst

Vprst Reg.

+5V +16.5V

VSUS

IC2252

Mask

Mod.

VSUS

+5V

+16.5V

IC2253

Mask

Mod.

IC5V

IC5V

Photo Coupler

VF

Block

SUSOUT

Soft-D

Block

IC5V/VF

VH

Y2

Y3

Vprst

+5V

Regulator

Resonance

Block

+5V

IC2101

DK Mod.

+16.5V

DC/DC

Conv.

Scan Signal

+ Reset

Block

VOFS

VSUS

+6.5V

+16.5V

+16.5V

+16.5V

+5V

VOFS

DC/DC

Conv.

Y4

+5V

Logic

Block

VOFS

Offset

Block

+16.5V

Drive Signal

+5V

60V

Y6

Y1

Y5

HD AUDIO ASSY

+16.5V

A2

+16.5V

+16.5V

IC3751

Power Amp IC

R_OUT +

R_OUT –

L_OUT +

L_OUT –

Left

Right

SP TERMINAL

IC3752

Regulator

Buffer

WOW + Volume IC

DC Detect

Block

+3.3V

A3

+9.0V

+9.0V

IC3753

IC3754

EEP ROM

+3.3V

A_Mute

A_STBY_B

R_Audio

L_Audio

A_NG_B

+9.0V

SCL

SDA

SDA

SCL

A1

HD IR ASSY

IR Receive unit

STB3.3V

U1681

AD1 AD2

Resonance

IC1555

Driver IC

V+8V

Block

V+ADR5

RE1

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

IC1501

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CLK/LE/HBLK/LBLK

CN1502

V+5V

(PEE002A-K) (PEE002A-K)

R/G/B

50 ADDRESS

V+60V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Driver IC

Block

V+ADR1

IC1551

SPEAKERS

V+8V

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

IC1501

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CLK/LE/HBLK/LBLK

AD1 AD2

Resonance

CN1502

R/G/B

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

Page 7

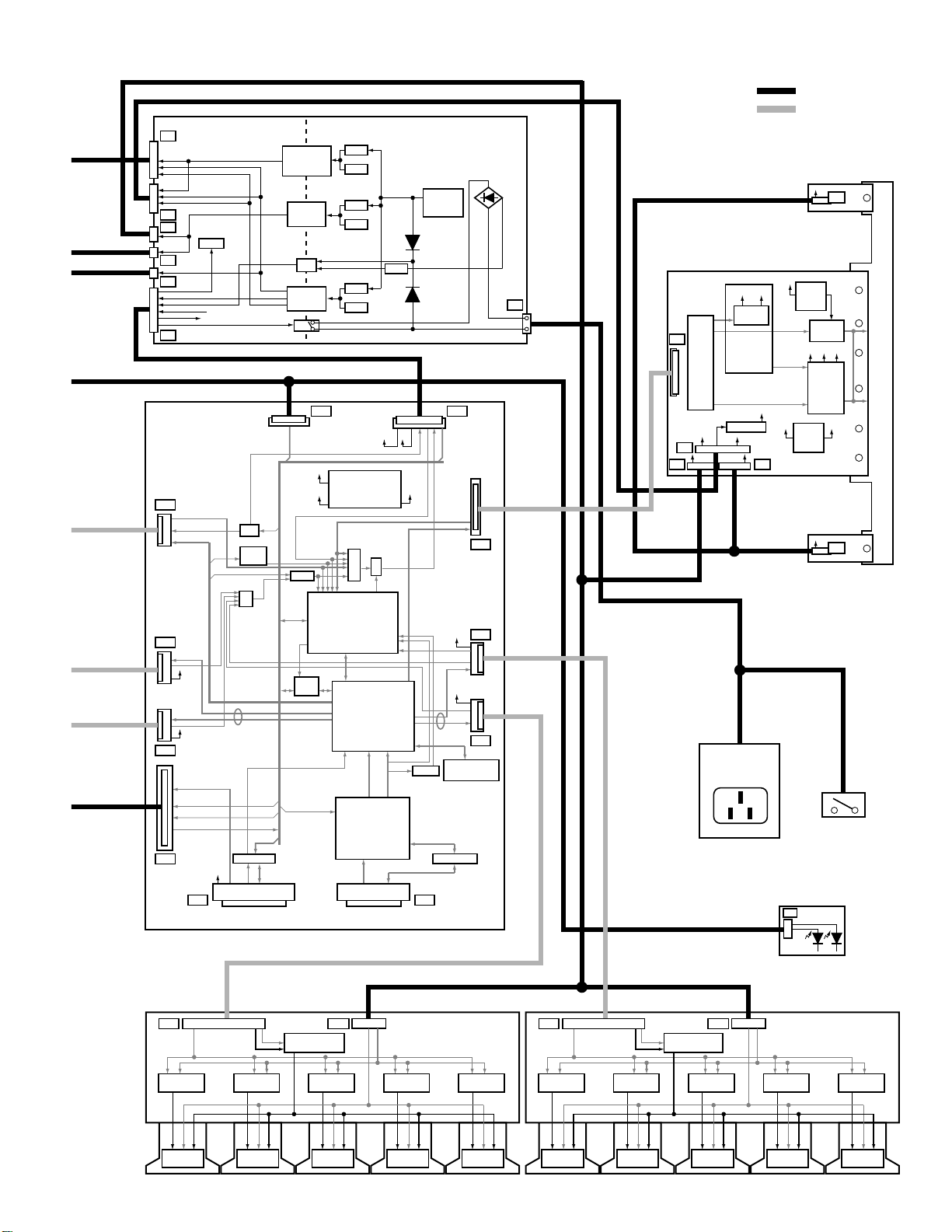

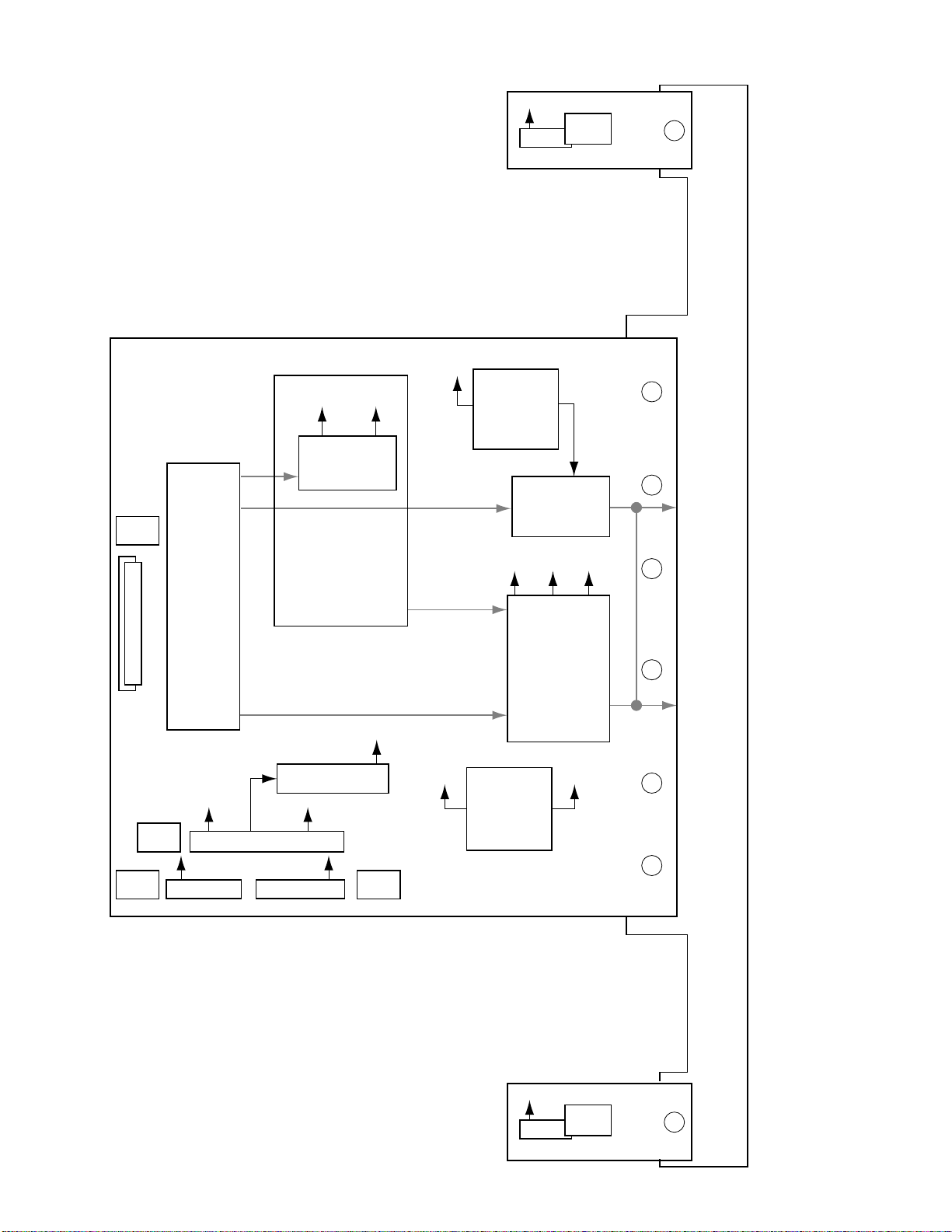

P1

7

P2

P7

+60V

P6

P5

RELAY

+16.5V

VSUS_ADJ

STA3.3V

SECONDARY PRIMARY

VSUS

+16.5V

+6.5V

VSUS_CONT

IC202

+8V

PS_PD

EXT_PD

P4

LED_R

LED_B

REM

SCAN_PD

YDRIVE_PD

YSUSTN_PD

YDD_CNV_PD

D10

SCN5V_PD

Vofs_ADJ,VYPRST_ADJ

SCAN

YSUS

DAC

Pulse

Width

OR

SCL,

SCA

ADR_PD1

D5

V+8V

V+8V

LVDS

D6

AUDIO L

AUDIO R

SCL, SDA

A_MUTE,A_STBY_B

A_NG

V+3V STB

Bus Buffer

REM

STB_MT

D3

D2 D1

HD DIGITAL ASSY

Switching

RY102

Q703

Q704

Switching

Switching

Q901

Q902

Switching

Switching

Q501

Q502

Switching

IC101

Switching

T702

T902

T101

T502

D4 D11

V+8V

V+3V ACT

Vsus_ADJ

V+3V_D

DC-DC Converter

V+1V_D

PS_PWDN

SQ_PD

Mask

UART

SW

SCL, SDA

Module

(AXY1116)

OR

IC3151

(M30620FCPGP)

Module Ucom

IC3401

(PEG122C-K)

Sequence

Processor

FIELD

IC3001

TMDS Receiver

TMDS

DVI CONNECTORMDR CONNECTOR

PD

PD_MUTE

VD

HD

DCLK, DERA, GA, BA

POWER SUPPLY

UNIT

IC3301

NEUTRAL

D9

D8

D7

D103

LIVE

+390V

V+8V

DDC

PFC Q101

D109

D107, D108

XSUS

PSIZE

H DET

Q102

Q103

RELAY,

PD_TRIGGER

AC_DET,

DRF

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

V+8V

V+8V

LVDS

Flash Memory

Bus Buffer

: Wire haerness

: FFC

SUS CLAMP 1

ASSY

VSUS

CL1

50 X DRIVE ASSY

+16.5V

+5V

P3

+16.5V

DK Mod.

IC1101

X1

Logic

Block

Drive Signal

+5V

+6.5V

+5V

Regulator

VSUS

VSUS

+16.5V

X2

X4 X3

VRN

DC/DC

Conv.

– Reset

Block

+5V

+16.5V

SUS OUT

IC1202

Mask

Mod.

+16.5V VF

15V

DC/DC

Conv.

VSUS

VRN

VSUS

PSUS

CL2

SUS CLAMP 2

ASSY

POWER SW

AC INLET

HD LED ASSY

L1

V+8V

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

IC1501

LVDS Receiver

AD1 AD2

Resonance

CN1502

(PEE002A-K) (PEE002A-K)

Resonance

Block

V+ADR3

CLK/LE/HBLK/LBLK

R/G/B

IC1553

Driver IC

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

CN1501

AD1 AD2

V+8V

CN/P DN/P CLKN/P

Resonance

Block

V+ADR5

IC1555

Driver IC

AN/P BN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

LVDS Receiver

IC1501

Resonance

Block

V+ADR3

CLK/LE/HBLK/LBLK

IC1553

Driver IC

CN1502

R/G/B

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

Page 8

D4 D11

8

HD DIGITAL ASSY

Input from

Power Supply

SCAN_PD

YDRIVE_PD

D10

YSUSTN_PD

YDD_CNV_PD

SCN5V_PD

Vofs_ADJ,VYPRST_ADJ

SCAN

YSUS

D5

DAC

Pulse

Width

OR

LED_R

LED_B

REM

SCL,

SCA

ADR_PD1

V+3V_D

V+1V_D

PS_PWDN

SQ_PD

Mask

V+3V ACT

Vsus_ADJ

DC-DC Converter

Module

(AXY1116)

OR

IC3151

(M30620FCPGP)

Module Ucom

V+8V

PD

PD_MUTE

V+8V

XSUS

PSIZE

RELAY,

PD_TRIGGER

AC_DET,

DRF

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

V+8V

D9

D8

V+8V

V+8V

D6

AUDIO L

AUDIO R

SCL, SDA

A_MUTE,A_STBY_B

A_NG

D3

V+3V STB

LVDS

Bus Buffer

REM

STB_MT

UART

SW

SCL, SDA

(PEG122C-K)

Sequence Processor

FIELD

RA, GA, BA

TMDS Receiver

TMDS

IC3401

IC3001

VD

HD

DCLK, DE

DDC

H DET

V+8V

LVDS

D7

IC3301

Flash Memory

Bus Buffer

D2

D1

DVI CONNECTORMDR CONNECTOR

Page 9

VH

9

50 Y DRIVE ASSY

130 Volt

200 Volt

Voltage Plus Reset

Note:

VH 130V

and

VSUS 200V

will be the

same for

43 and 50

inch sets.

IC5V

VH VSUS

VH DC/DC Conv.

Vprst

Vprst Reg.

Vprst

+ Reset

Block

VOFS

Offset

Block

Y2

PSUS

+5V +16.5V

IC2252

Mask

Mod.

+16.5V

+5V

VSUS

VSUS

+5V

SUSOUT

Regulator

Resonance

Block

+5V

+16.5V

VOFS

VSUS

+6.5V

+16.5V

VOFS

DC/DC

Conv.

Y4

+5V

+16.5V

Drive Signal

Logic

Block

PSUS

VH

Y3

IC5V

IC2253

Mask

Mod.

IC5V

Photo Coupler

Block

IC5V

VF

Soft-D

Block

+16.5V

IC5V/VF

DC/DC

Conv.

Scan Signal

IC2101

DK Mod.

+16.5V

+5V

Y1

+5V

Y5

60V

Y6

Page 10

50 X DRIVE, SUS CLAMP 1 and SUS CLAMP 2 ASSYS

10

New

New

From Power Supply

180 Volt

43 & 50

inch sets.

50 X DRIVE ASSY

X1

+16.5V

IC1101

DK Mod.

SUS CLAMP 1

+5V

+16.5V

ASSY

VSUS

VRN

DC/DC

Conv.

CL1

VRN

– Reset

Block

Logic

Block

Drive Signal

+5V

+6.5V

+16.5V

Regulator

VSUS

X2

+5V

VSUS

X4 X3

+16.5V

SUS OUT

+16.5V VF

15V

DC/DC

Conv.

+5V

IC1202

Mask

Mod.

VSUS

PSUS

SUS CLAMP 2

ASSY

VSUS

CL2

Page 11

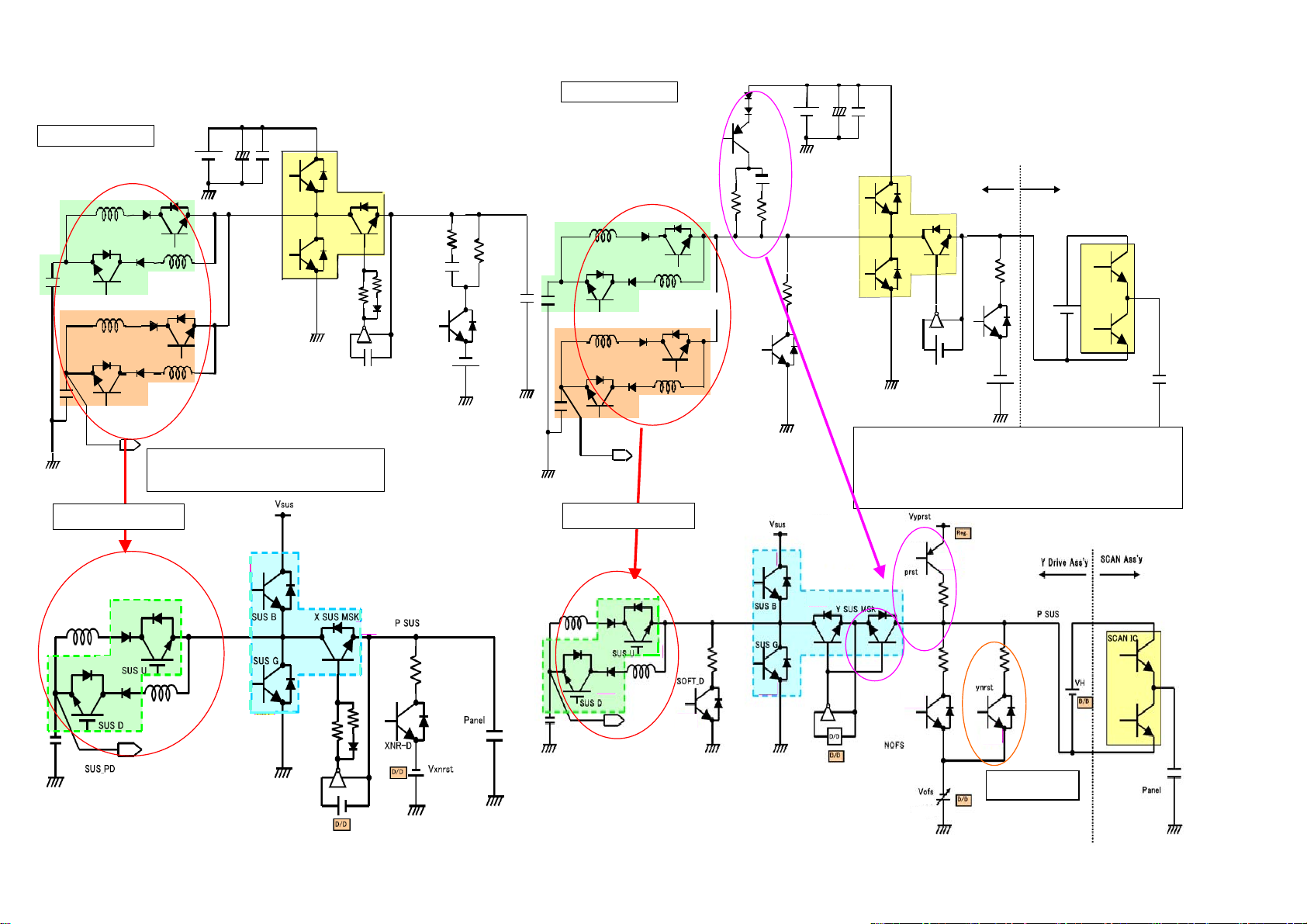

Outline of Differences between G5 and G6 Drive Circuits

11

1. Y Drive Reset Pulse

G5: 3 times reset pulses --> G6: 1time reset pulse

Purpose: Due to improve the black level.

Because Plus Reset voltage on Y Drive Assy is larger than the VSUS voltage,

a power regulator for the Plus Reset was added and Mask Circuit was changed to two ways.

Minus reset circuit was also added on Y Drive Assy

2. X & Y Drive Resonance circuit

G5: Discrete & double resonance circuit --> G6: Module IC, single resonance circuit

Purpose: Due to cost down

3. X Drive MASK Module IC

G5: Using 2 ICs --> G6 : Using 1 IC

Purpose: Due to cost down

Because Sustain pulse was slightly changed, SUS-Clamp boards were added.

4. Change of SCAN IC

Purpose: To reduce cost.

5G 6G

50" Panasonic

43" TI SN755866PZP SN755870PZT

AN16021AA AN16025A

Page 12

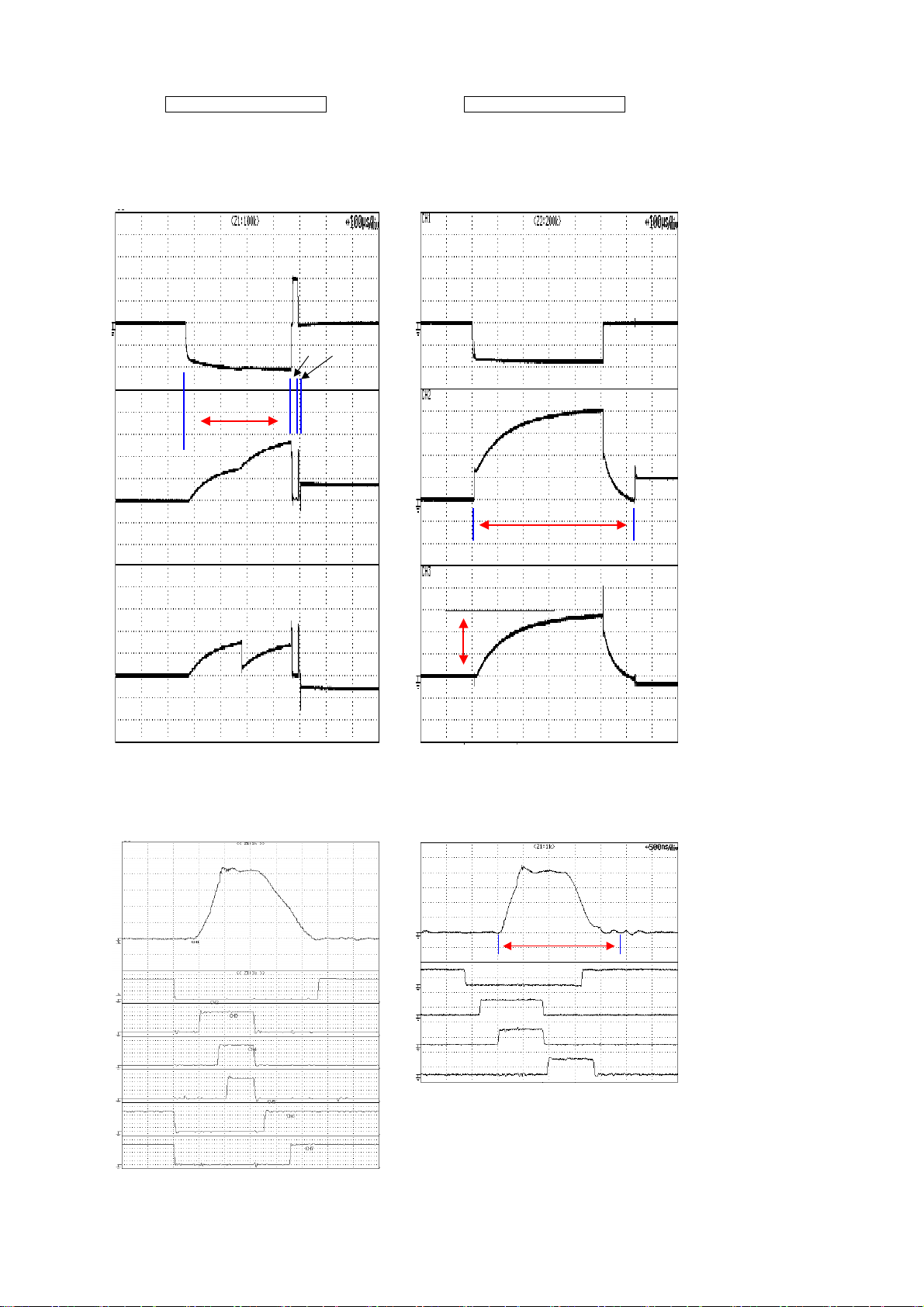

Difference of waveform between G5 and G6

)

P

N

e

12

VPRST

Can be

up to

350V

G5 G6

Reset waveform

3 times reset → 1 time reset (Improve dark brightness

Reset voltage of Y drive (Plus voltage) U

Reset voltage of X drive (Minus voltage) DOW

XPSUS XPSUS

②③

100V/DIV 100V/DIV

SCAN out

①

SCAN out

①

YPSUS

Sustain waveform

2 step resonance → 1 step resonanc

Vsus voltage LESS

Sustain pulse cycle SHORTER

SUS-G

SUS-U1

SUS-U2

SUS-B

100V/DIV

100V/DIV

YPSUS

PSUSPSUS

Pulse width of G5

SUS-G

SUS-U

SUS-B

SUS-D

SUS-D2

SUS-D1

Page 13

Comparison Drive Assy between G5 and G6

13

(Block diagram)

X Drive Assy for G5

Vsus

SUS D2

223V

SUS B

SUS G

SUS U2

2nd Resonance

MASK Module

X SUS MSK

RN D

P SUS

Y Drive Assy for G5

Panel

SUS D2

SUS U2

2nd Resonance

共振2段目

PR-U

SOFT_D

Vsus

434:215V

504:223V

SUS B

SUS G

MASK Module

Y SUS MSK

Y Drive A ss'ySCAN Ass'y

Y Drive Ass'y

P SUS

P SUS

130V

SCAN IC

VH

SUS U1

1st Resonance

SUS D1

中点電位検出回路へ(既定電圧幅

より上がっても下がってもPD)

2 Step Resonance→1 Step Resonance

Discreet Structure→DK Module

X Drive Assy for G6

Resonance Module

( DK Module)

X Mask Module

Vrn

-230V

SUS U1

SUS D1

共振1段目

1st Resonance

To detecting midpoint voltage

PD should occur if this voltage is over or

below from specified value.

Y Drive Assy for G6

DK Module

To detecting midpoint

voltage circuit

Plus reset voltage G5: VSUS → G6:Reserved power

supply

Since the value of Plus Reset Voltage became beyond the

value of VSUS, Plus Reset connect to PSUS and SUSMSK

became two-way.

Y Mask Module

VF

Vofs

Vofs

-30V

-30V

~-52V

~-52V

Panel

Added circuit

for Minus Reset

Page 14

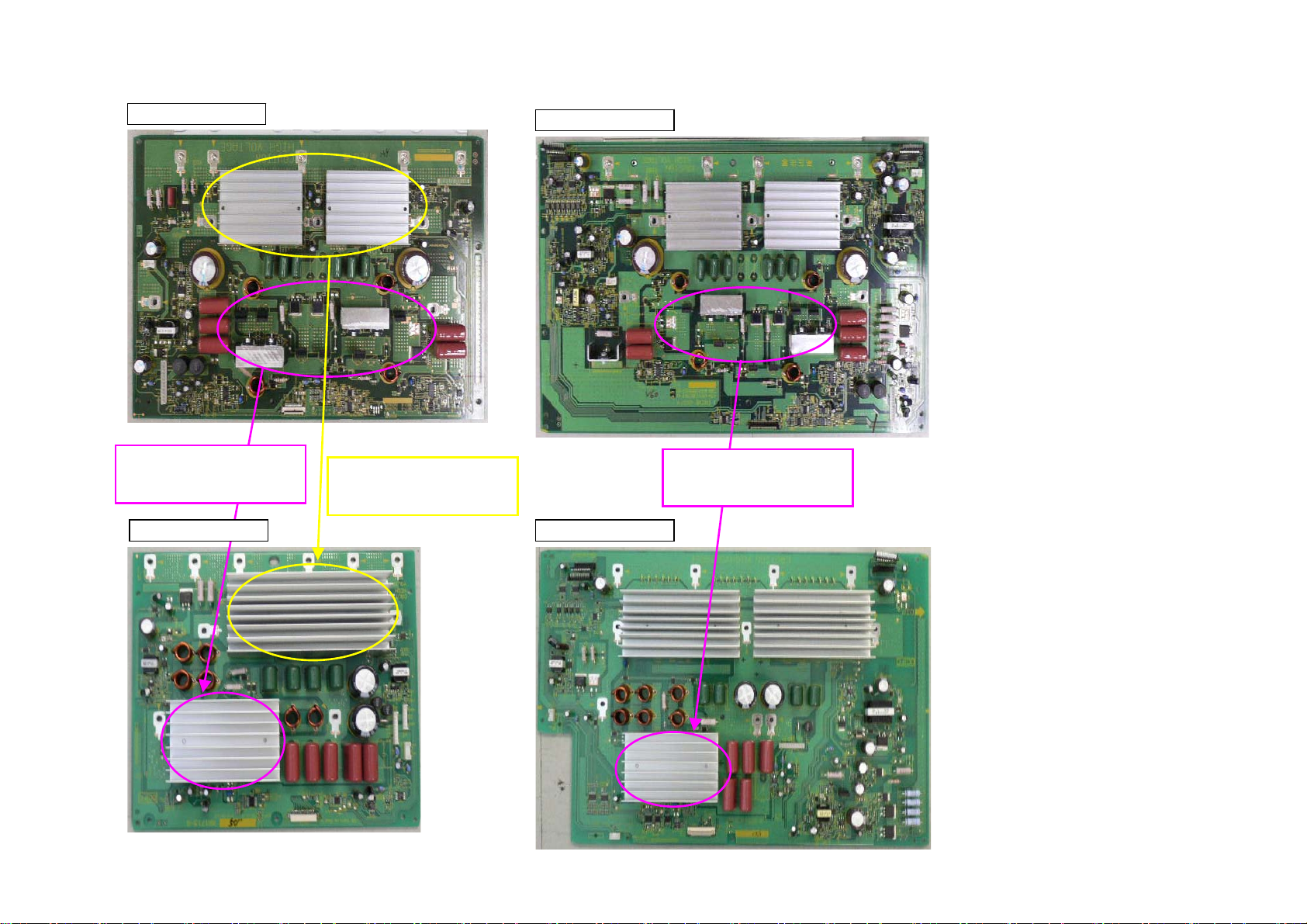

Board Differences between G5 and G6

14

G5 X Drive Assy

G5 :Discrete circuit

G6: DK Module IC

G6 X Drive Assy

G5 : Two Mask Module ICs

G6: One Mask Module IC

G5 Y Drive Assy

G5 :Discrete circuit

G6: DK Module IC

G6 Y Drive Assy

Page 15

Power Supply map of X and Y Drive ASSY

to Add

'y

f

ly

f

ly

Y Dri

X Dri

Note:to Add

'y

e

A

N

15

200v

Voltage level Depends on Panel.

ress Ass

Logic

DK

Mod.

Mask

Mod.

Ofset

Reset

Scan

Logic

ve Assy

Vprst

5.0V

VOFS

VF

IC5V

VPRST

Reg.

VH

5.0V 6.5V

5V

Reg.I

16.5V

VSUS

VOFS

DC/DC Conv.

IC5V

DC/DC Conv.

VH

DC/DC Conv.

rom P Supp

Reset

Mask

Mod.

Logic

DK

Mod.

ve Assy

VRN

VRN

DC/DC Conv.

15V

DC/DC Conv.

5.0V

5V

Reg.

rom P Supp

VSUS 16.5V 6.5V

Scan Assy

Scan IC

ress Ass

DC/DC converter, for VOFS, and regulator of VPRST ar

controlled by Electric Volume.

lthough, basically, each DC/DC converter for VOFS and VR

is inputted 16.5V, as Vcc, they are not active if VSUS is below 100V

Page 16

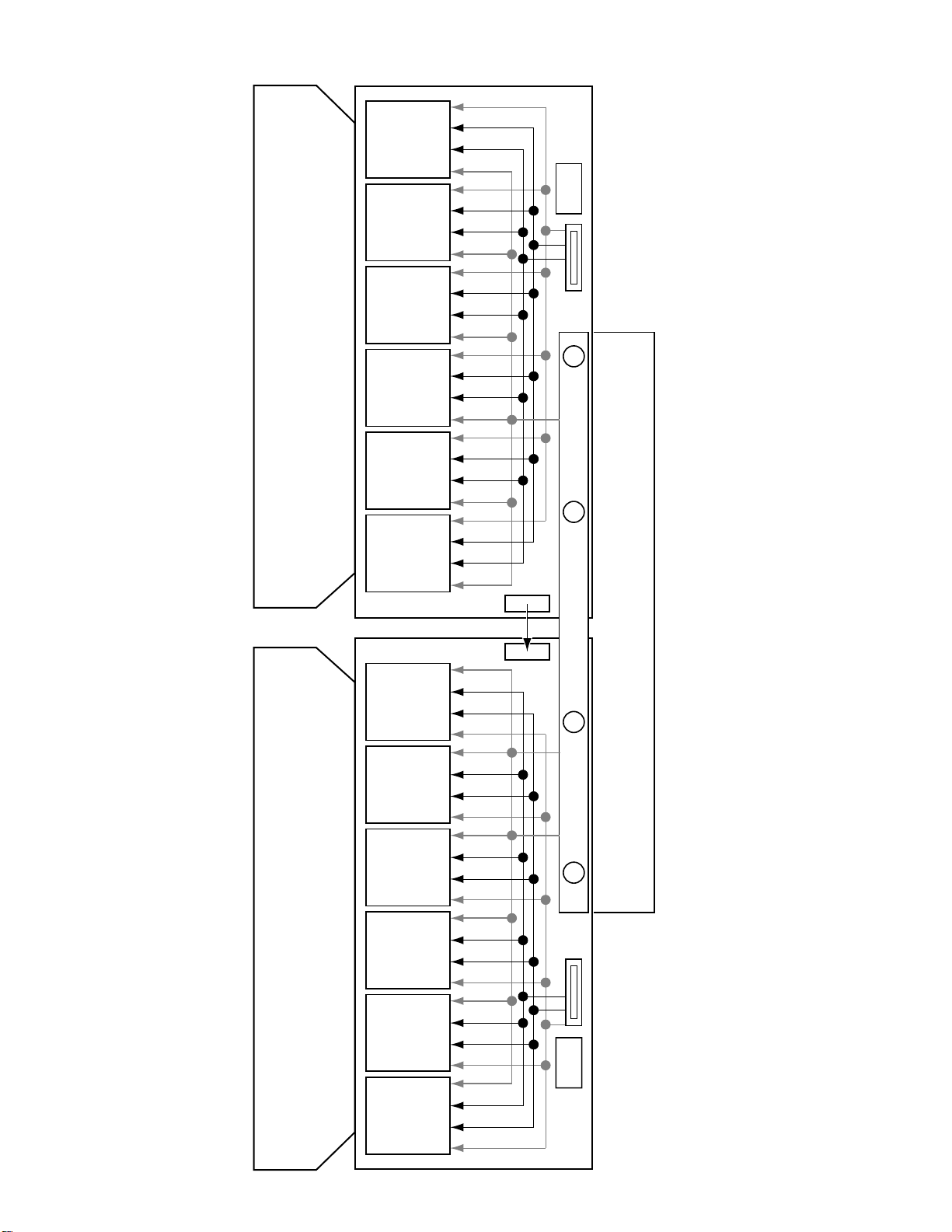

50 SCAN A and B ASSYS

16

IC2801

Scan IC

IC2802

Scan IC

IC2803

Scan IC

IC2804

Scan IC

IC2805

Scan IC

IC2806

Scan IC

Scan Signal

VH

IC5V

PSUS

50 SCAN B ASSY

(UPPER)

SB1

IC2701

Scan IC

IC2702

Scan IC

IC2703

Scan IC

IC2704

Scan IC

IC2705

Scan IC

CN2802

Serial Data

CN2702

IC2706

Scan IC

PSUS

IC5V

VH

Scan Signal

SA1

50 SCAN A ASSY

(LOWER)

Page 17

Blank Page

Page 18

SCAN IC - 43 Inch Models

18

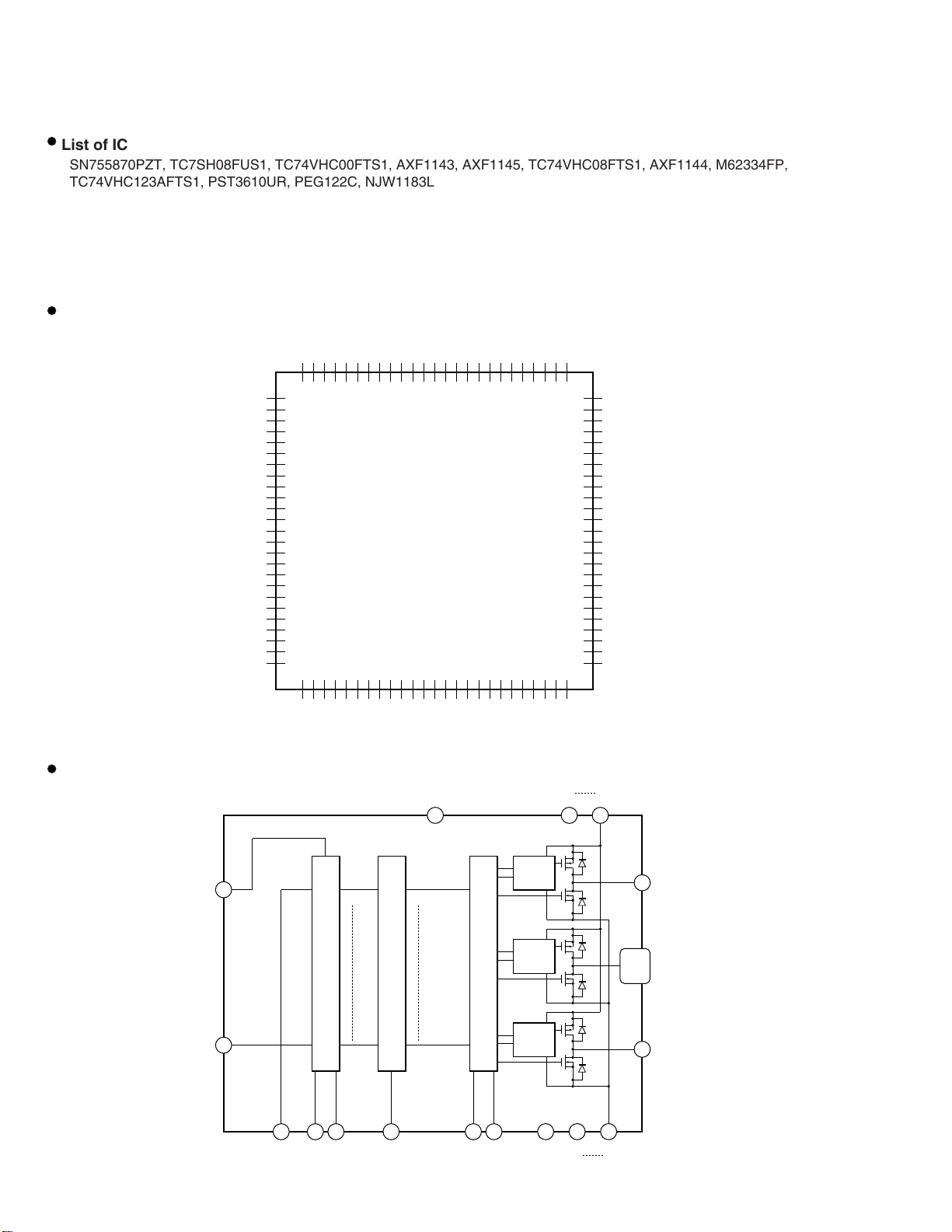

List of IC

SN755870PZT, TC7SH08FUS1, TC74VHC00FTS1, AXF1143, AXF1145, TC74VHC08FTS1, AXF1144, M62334FP,

TC74VHC123AFTS1, PST3610UR, PEG122C, NJW1183L

SN755870PZT (43 SCAN A ASSY : IC2701 - IC2706)

(43 SCAN B ASSY : IC2801 - IC2806)

• Plasma Display Panel IC

Pin Arrangement (Top view)

OUT2100

OUT199

N.C.98

VDDH97

VDDH96

N.C.95

GND194

GND193

CLR92

SI91

OC290

OC189

VDD88

LAT87

CLK86

SO85

DIR84

GND183

GND182

N.C.81

VDDH80

VDDH79

N.C.78

OUT6477

OUT6376

Block Diagram

1OUT3

2OUT4

3OUT5

4OUT6

5OUT7

6OUT8

7OUT9

8OUT10

9OUT11

10OUT12

11OUT13

12OUT14

13OUT15

14OUT16

15OUT17

16OUT18

17OUT19

18OUT20

19OUT21

20OUT22

21OUT23

22OUT24

23OUT25

24OUT26

25OUT27

26OUT28

27OUT29

28OUT30

29OUT31

30OUT32

31N.C.

32VDDH

33VDDH

34N.C.

35GND1

36GND1

37GND1

38N.C.

DD

V

88

39GND2

40GND1

41GND1

42N.C.

43VDDH

44VDDH

45N.C.

46OUT33

47OUT34

48OUT35

49OUT36

50OUT37

VDDH

DDH

V

OUT6275

OUT6174

OUT6073

OUT5972

OUT5871

OUT5770

OUT5669

OUT5568

OUT5467

OUT5366

OUT5265

OUT5164

OUT5063

OUT4962

OUT4861

OUT4760

OUT4659

OUT4558

OUT4457

OUT4356

OUT4255

OUT4154

OUT4053

OUT3952

OUT3851

SO

GND2

DK

DA

DK

DA

DK

DA

GND1

46-76,

GND1

99

1-30,

100

77

OUT1

OUT2 - OUT63

OUT64

Level

Shift

91

SI

64-bit Shift Register

85

DIR

9284

CLR

86

CLK

Data

64-bit Latch

Data

87

LAT

OC1

Circuit

Level

Shift

Circuit

Output Control Circuit

Level

Shift

Circuit

9089

OC2

Page 19

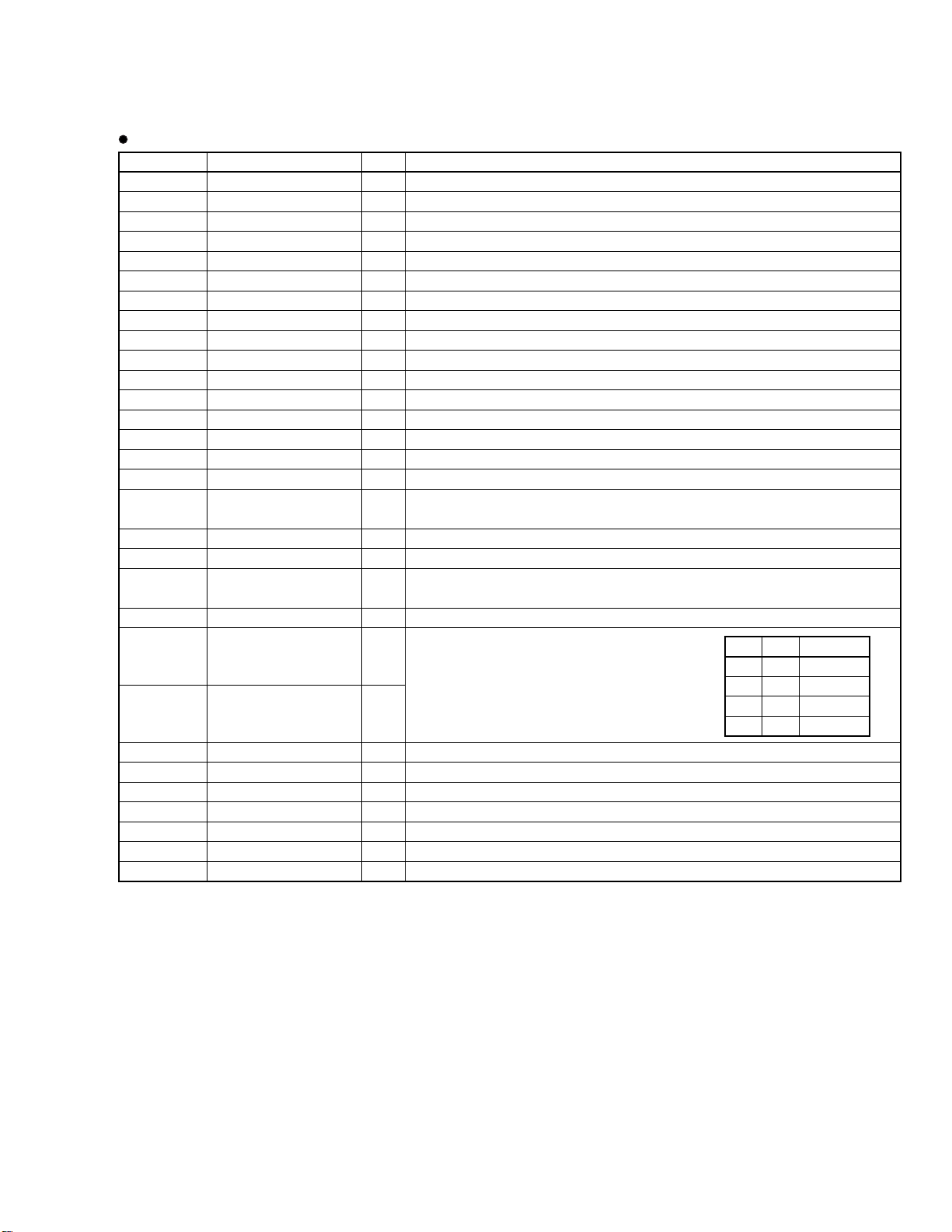

Pin Function

19

No. Pin Name I/O Pin Function

1 - 30 OUT3 - OUT32 O High-voltage push-pull output

31 N.C. − Not connected

32 - 33 V

34 N.C. − Not connected

35 - 37 GND1 − Ground

38 N.C. − Not connected

39 GND2 − Ground

40 - 41 GND1 − Ground

42 N.C. − Not connected

43 - 44 V

45 N.C. − Not connected

46 - 77 OUT33 - OUT64 O High-voltage push-pull output

78 N.C. − Not connected

79 - 80 V

81 N.C. − Not connected

82 - 83 GND1 − Ground

84 DIR I

85 SO I/O Serial data input / output

86 CLK I Serial clock input Fetch SI or SO data to shift register by CLK rise edge

87 LAT I

88 V

DDH − High-voltage circuit supply

DDH − High-voltage circuit supply

DDH − High-voltage circuit supply

Setup of shift register shift direction

L = Shift into reverse (SO → SI) H = Shift forward (SI → SO)

LAT data input

L = Transfer shift register data to output latch H = Hold data to output latch

DD − Logic supply

89 OC1 I

Output control

Control output according to the right

truth value table

90 OC2 I

OC1 OC2 OUT

LLALL Hi-Z

LH DATA

HL ALL L

HH ALL H

91 SI I/O Serial data input / output

92 CLR I All output reset CLR pin : L → Normal operation CLR pin : H → All output High

93 - 94 GND1 − Ground

95 N.C. − Not connected

96 - 97 V

DDH − High-voltage circuit supply

98 N.C. − Not connected

99 - 100 OUT1 - OUT2 O High-voltage push-pull output

Page 20

SCAN IC - 50 Inch Models

20

•

List of IC

AN16025A, TC7SH08FUS1, TC74VHC00FTS1, AXF1140, AXF1142, TC74VHC08FTS1, AXF1141, M62334FP,

TC74VHC123AFTS1, PST3610UR, PEG122C, NJW1183L

AN16025A (50 SCAN A ASSY : IC2701 - IC2706)

(50 SCAN B ASSY : IC2801 - IC2806)

• Plasma Display Panel IC

Pin Arrangement (Top view)

OUT2100

OUT199

N.C.98

VDDH97

VDDH96

N.C.95

GND194

GND193

CLR92

SI91

OC290

OC189

VDD88

LAT87

CLK86

SO85

DIR84

GND183

GND182

N.C.81

VDDH80

VDDH79

N.C.78

OUT6477

OUT6376

Block Diagram

1OUT3

2OUT4

3OUT5

4OUT6

5OUT7

6OUT8

7OUT9

8OUT10

9OUT11

10OUT12

11OUT13

12OUT14

13OUT15

14OUT16

15OUT17

16OUT18

17OUT19

18OUT20

19OUT21

20OUT22

21OUT23

22OUT24

23OUT25

24OUT26

25OUT27

26OUT28

27OUT29

28OUT30

29OUT31

30OUT32

31N.C.

32VDDH

33VDDH

34N.C.

35GND1

36GND1

37GND1

38N.C.

DD

V

88

39GND2

40GND1

41GND1

42N.C.

43VDDH

44VDDH

45N.C.

46OUT33

47OUT34

48OUT35

49OUT36

50OUT37

VDDH

DDH

V

OUT6275

OUT6174

OUT6073

OUT5972

OUT5871

OUT5770

OUT5669

OUT5568

OUT5467

OUT5366

OUT5265

OUT5164

OUT5063

OUT4962

OUT4861

OUT4760

OUT4659

OUT4558

OUT4457

OUT4356

OUT4255

OUT4154

OUT4053

OUT3952

OUT3851

SO

GND2

DK

DA

DK

DA

DK

DA

GND1

46-76,

GND1

99

1-30,

100

77

OUT1

OUT2 - OUT63

OUT64

Level

Shift

91

SI

64-bit Shift Register

85

DIR

9284

CLR

86

CLK

Data

64-bit Latch

Data

87

LAT

OC1

Circuit

Level

Shift

Circuit

Output Control Circuit

Level

Shift

Circuit

9089

OC2

Page 21

Pin Function

21

No. Pin Name I/O Pin Function

1 - 30 OUT3 - OUT32 O High-voltage push-pull output

31 N.C. − Not connected

32 - 33 V

34 N.C. − Not connected

35 - 37 GND1 − Ground

38 N.C. − Not connected

39 GND2 − Ground

40 - 41 GND1 − Ground

42 N.C. − Not connected

43 - 44 V

45 N.C. − Not connected

46 - 77 OUT33 - OUT64 O High-voltage push-pull output

78 N.C. − Not connected

79 - 80 V

81 N.C. − Not connected

82 - 83 GND1 − Ground

84 DIR I

85 SO I/O Serial data input / output

86 CLK I Serial clock input Fetch SI or SO data to shift register by CLK rise edge

87 LAT I

88 V

DDH − High-voltage circuit supply

DDH − High-voltage circuit supply

DDH − High-voltage circuit supply

Setup of shift register shift direction

L = Shift into reverse (SO → SI) H = Shift forward (SI → SO)

LAT data input

L = Transfer shift register data to output latch H = Hold data to output latch

DD − Logic supply

89 OC1 I

Output control

Control output according to the right

truth value table

90 OC2 I

OC1 OC2 OUT

LLALL Hi-Z

LH DATA

HL ALL L

HH ALL H

91 SI I/O Serial data input / output

92 CLR I All output reset CLR pin : L → Normal operation CLR pin : H → All output High

93 - 94 GND1 − Ground

95 N.C. − Not connected

96 - 97 V

DDH − High-voltage circuit supply

98 N.C. − Not connected

99 - 100 OUT1 - OUT2 O High-voltage push-pull output

Page 22

Simplified Circuit of G6 ADDRESS

22

ADR B

ADR U

ADR OUT

Detective

circuit

ACTIVE HIGH

Vadr

60V

ADR D

ADR Module

(TCP)

Panel

<<Feature of G6 address>> <<Change from G5>>

Single addressing drive Vadr 61V to 60V

Old: 8 PCB (Top side and bottom side) 9V to 8V

New: 4 PCB (Bottom side) 2 connector of Power and Signal

Add TCP heat sink FFC LVDS transmission 3.3V 8V

New TCP (Address IC's) Cord 60V/5V

Clock frequency:102.5MHz PD circuit

Double edge clock Old: Detecting over current

New: Watching voltage

ADR PD

Page 23

pp

Simplified Address System Drawing for G6

23

5V

(Power for TCP)

Y-Drive

60V

X-Drive

FFC LVDS transmission

3.3V(Power for LVDS receiver)

8V(Power for FET, in address resonance)

Digital

Assy

60V

5V

(Power for TCP)

Address

Note: 60V(power for Address) and 5V(power for TCP) are supplied through X and Y Drive Assy.

The signal of LVDS, 3.3V(power for LVDS receiver) and 8V(power for FET, address resonance)

are su

lied through Digital Assy.

Address

Address

Address

Page 24

50 ADDRESS ASSY

24

AD1 AD2

V+8V

Resonance

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

IC1554

Driver IC

Block

V+ADR4

V+3V

IC1501

(PEE002A-K)

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CN1502

V+60VV+5V

Resonance

CLK/LE/HBLK/LBLK

R/G/B

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

Page 25

Block diagram of Address circuit of 43 inch PDP

25

DRIVER IC

IC1552

V+ADR1

RESONANCE

BLOCK

V+60V

V+5V

DRIVER IC

IC1553

DRIVER IC

IC1501

LVDS RECEI

VER

IC1554

CLK / LE / HBLK / LBLK

R/G/B

DRIVER IC

IC1555

V+ADR5

RESONANCE

BLOCK

V+8V

AD2

CN1502

V+3V

AN/P BN/P

CN/P DN/P CLKN/P

AD1

CN1501

Page 26

HD AUDIO Assy and other Assy

A

A

Y

Y

Y

y

t

y

y

y

y

26

- Differences between G4 / G5 and G6 2005.07.28

Content G4 /G5 AUDIO Assy G6 AUDIO Assy MEMO

1. Change of Surround IC and NJM2195L + BD3869AS NJW1183L SRS IC and VOL IC are changed one chip IC

VOL IC (IC3753) due to cost down

2. Change of IC control NJW2195L ⇒ Port control NJW1183L ⇒ IIC Using only IIC control

BD3869AS ⇒ IIC control

3. Change of SP terminal AKE1060-

4. Change of AUDIO assembly

construction + SP TERMINAL ASS'

5. EEP ROM for Backup On HD PANEL IF ASS'

- Differences between 43 inch and 50 inch : None

- Audio output during Service Factory mode: None

UDIO AMP ASS'Y HD AUDIO ASS'

KE1061- G5: Under-Angle type

G6: Straight-Angle type

One board construction due to cost down

On HD AUDIO ASS'YDue to deletion of PANEL IF Ass

- Other small assemblies:

* LED Assy Change of LED color during Power On ( Green --> Blue )

* IR Assy IR unit was changed to G4 IR uni

* TEMP SENSOR Ass

* KEY Ass

KEY TERMINAL Ass

( No circuit change )

Move to DIGITAL VIDEO Ass

Deleted

( Move to front panel of Media Receiver )

Page 27

A2

27

+16.5V

HD AUDIO ASSY

+16.5V

+16.5V

IC3752

Regulator

+9.0V

+9.0V

Buffer

+9.0V

R_OUT +

Right

IC3751

Power Amp IC

R_OUT –

L_OUT +

SP TERMINAL

L_OUT –

Left

DC Detect

Block

A3

WOW + Volume IC

+3.3V

IC3753

EEP ROM

IC3754

SCL

SDA

+3.3V

A_Mute

A_STBY_B

R_Audio

L_Audio

A_NG_B

SDA

SCL

A2

SPEAKERS

Page 28

P1

28

200v

To Address

P2

P7

+60V

VSUS

+16.5V

+6.5V

VSUS_CONT

IC202

POWER SUPPLY UNIT

SECONDARY PRIMARY

Switching

T702

T902

Q703

Q704

Switching

Switching

Q901

Q902

Switching

+390V

PFC Q101

Q102

Q103

D109

D103

P6

P5

RELAY

P4

+16.5V

VSUS_ADJ

+8V

STA3.3V

PS_PD

EXT_PD

T502

T101

RY102

Switching

Q501

Q502

Switching

IC101

Switching

D107, D108

P3

NEUTRAL

LIVE

Page 29

GENERAL INFORMATION

29

PCB LOCATION

SUS CLAMP 1 Assy

50 Y DRIVE Assy50 SCAN B Assy

POWER SUPPLY Unit

50 X DRIVE Assy

50 SCAN A Assy

50 ADDRESS Assy50 ADDRESS Assy 50 ADDRESS Assy 50 ADDRESS Assy

HD LED

Assy

HD AUDIO Assy HD DIGITAL Assy SUS CLAMP 2 AssyHD IR Assy

Page 30

DIAGNOSIS OF SHUTDOWN/POWER-DOWN INDICATED BY LEDS

30

(RED LED)

(BLUE LED)

Deleted

• Operation statuses as indicated by LEDs On The Panel

Status LED Pattern

Standby

Power ON

AC Power OFF of

one side

System cable

disconnection

Power-down

Shutdown

No backup copy

Lit in Red1

Lit in Blue2

Red flashes

3

(1000ms)

Red and

blue flash

4

(1000ms)

Red flashes

5

(500+2500ms)

Blue flashes

6

(500+2500ms)

Lit in Red and

7

blue flashes

(200ms)

Blue

Red

Blue

Red

Blue

Red

1000ms

Blue

1000ms

Red

Blue

Once

Red

500ms

Blue

500ms

Red

Once Twice

200ms

Blue

Red

: Lit in Red LED

: Lit in Blue LED

Twice

• PD (power-down) count

1 Not used

2 POWER SUPPLY Unit

3 SCAN Assy

4 5V power supply for SCAN

5 Y-DRIVE

6 DCDC for Y drive

7 Y-SUS

8 ADDRESS Assy

9 X-DRIVE

10 DCDC for X drive

11 X-SUS

12 Not used

13 Sequence drive stop

14 Not used

15 UNKNOWN

Note:

• When a shutdown occurs, a warning will be issued by the

Media Receiver and displayed, then the power will be shut off.

• When a shutdown or power-down occurs on the Panel side,

the Media Receiver will enter Standby mode (the red LED

will light).

1000ms

n times

n times

2.5s

2.5s

Once

Once

• SD (shut down) count

1 SEQUENCE PROCESSOR (SQ_IC)

2 MDU-IIC

3 RST2 abnormality

4 Panel high temperature

5 Speaker short-circuit *

* When a jumper (J110) between the HD AUDIO Assy and

the HD DIGITAL Assy is disconnected, the SD LED

flashes in this manner.

Page 31

Y Drive PD system(6G)

31

(Power Down System - RED Flashing LED on Panel)

130v

VH

IC5V

Detection of

SCAN Upper

connection

Detection of

SCAN Lower

connection

VOFS

VPrst

UVP

Detection

UVP

Detection

Voltage

Detection

Deletion of 16.5 V detection circuit (YDRIVE_PD)

Voltage

Detection

Voltage

Detection

SCAN_PD

( 3 times PD )

SCN5V_PD

( 4 times PD )

( 5 times PD )

Y_DD_PD

( 6 times PD )

Middle-point

Voltage of

resonance

Comparison

to standard

( Sustain )

X Drive PD system(6G)

16.5V

VRN

VF15V

voltage

OCP

detection

Deletion of this

detection circuit

UVP

Detection

UVP

Detection

YSUS_PD

( 7 times PD )

XDRIVE_PD

( 9 times PD )

Only detecting

disconnection

of FFC

XDD_PD

( 10 times PD )

Middle-point

Voltage of

resonance

( Sustain )

Comparison

to standard

voltage

XSUS_PD

( 11 times PD )

NOTE UVP: Under Voltage Protection, OCP: Over Current Protection

Page 32

Power Down diagnosis ( defective points)

T

32

(RED FLASHING LED)

Number of PD circuit in Reason for PD

Blinking operation

2 times POWER P SUPPLY Ass'y

3 times

4 times

6 times

7 times Y-SUS Y DRIVE Ass'y

8 times

9 times X-DRIVE X DRIVE Ass'y CN1201

10 times X-DCDC

SCAN

SCN-5V

Y-DCDC Y DRIVE Ass'y

ADRS ADDRESS Ass'y

Defective PBC Assy

SCAN Ass'y

Y DRIVE Ass'y

SCAN Ass'y

Y DRIVE Ass'y IC5V DC/DC Q2605,R2647

X DRIVE Ass'y

(Power-down) Point to be Checked Possible Defective Part Remark

SCAN IC SCAN IC VH-GNDH

VH UVP

Detection of cable detection CN2001, CN2350

Detection of cable detection

IC5V UVP

VOFS UVP

Vprst UVP Vprst Regulator Q2531,Q2532,IC2535

PD cuased by dtection of

Sustain middle-point voltage

Address Power Down

Detection of cable detection

VRN UVP

PD cuased by dtection of

Sustain middle-point voltage

DDRESS RESONANCE BLOCKD1634

Y SUS BLOCK IC2252,IC2253

VH DC/DC IC2502,L2501

CN2401, CN2402

SCAN IC SCAN IC

VOFS DC/DC Q2606,R2619,R2620

Y SUS BLOCK IC2252,IC2253,Q2280,Q2281

Y RESONANCE BLOCK IC2101

Y SUS BLOCK Q2221

VRN DC/DC Q1323,R1332,R1333

X SUS BLOCK Q1272

X RESONANCE BLOCK IC110111 times X-SUS X DRIVE Ass'y

VSUS-SUSOUT, SUSOUTSUSGND

MSKS-SUSOUT

V+ADR-GND_ADR

CN1501

OVP : OVER VOLTAGE PROTEC

UVP : UNDER VOLTAGE PROTECT

Page 33

Assumed symptom from PD mode

33

Blinking PD circuit Check portion Main symptom Remarks

2 Power PD Power Supply

Scan Ass'y Short between VH and GNDH, Scan IC PD with panel briefly flashing

Malfunction of DC/DC converter, for VH PD with panel briefly flashing

Short between VSUS, SUSOUT, or SUSGND, Mask

3 SCAN PD

4 IC5V PD

5 Y-DRIVE PD Delete detection circuit

6 Y DCDC PD Y Drive Assy

7

8 Address PD Address Assy

9 X-DRIVE PD X Drive Assy

10

11 X SUS PD X Drive Assy

X DCDC PD X Drive Assy

Y Drive Assy

X Drive Assy

SCAN Ass'y Short between IC5V and GNDH, Scan IC

Y Drive Assy

Y Drive AssyY SUS PD

Module

Disconnect connector between Y Drive and Power

Supply, or Digital Assy.

Short between VSUS, SUSOUT, or SUSGND, Mask

Module

Disconnect bridge connector, between Scan Assy and

Y Drive,

R2352 open (16.5V line resistor) PD without panel flashing

Malfunction of DC/DC converter, for IC5V

Short between PSUS and MSKS, Mask Module

Short between MSKS and SUSOUT, Mask Module PD with panel briefly flashing

Malfunction of DC/DC converter, for VOFS

Malfunction of Regulator of Vprst

Malfunction of DK module

Control signal line problem

Disconnect Flexible cable, between Digital Assy and X

Drive

Disconnect connector between X Drive and Power

Supply

Malfunction of DC/DC converter, for VRN

R1204 open (16.5V line resistor) PD without panel flashing

Malfunction of DK module

Control signal line problem

PD without panel flashing

PD without panel flashing

PD without panel flashing

Page 34

Diagnosis method for 3 times flashing PD

34

Diagnose 3 times flashing PD according to the steps below

1. Visual check with Power off condition

2. Impedance check with power off condition

3. Voltage check with power on condition

Actual diagnosis methods are as follows

1. Visual check with Power off condition

Check the all of connectors and FFC on Y Drive Assy whether completely connected

2. Impedance check with power off condition

i ) Impedance check between Vsus - SUSGND on Power Supply Assy

If the impedance is several hundreds k ohm or over -> go to step " ii "

If the impedance is short circuit -> Remove P1 and P2 connectors and check impedance

between Vsus - SUSGND on X Drive and Y Drive Assy.

Vsus - SUSGND impedance check on X and Y Drive Assy with no Vsus cables

If the impedance on X Drive Assy is short circuit → Replace X Drive Assy

Vsus-SUSOUT or SUSOUT-SUSGND are short circuit : Defective of X MASK module IC

Other than above : defective of other devices

Follow check steps below.

If the impedance on Y Drive Assy is short circuit → Replace Y Drive Assy

Vsus-SUSOUT or SUSOUT-SUSGND are short circuit : Defective of Y MASK module IC

Other than above : defective of other devices

If the impedance on Power Supply Assy is short circuit → Replace Power Supply Assy

NOTE: Because some capacitors have voltage, it seems impedance is short just after

measuring of impedance by multimeter.

Actually if no short circuit , the impedance is soon going up.

ii ) Impedance check between VH - PSUS on Y DRIVE Assy

If the impedance is several M ohm or over -> go to step 3

If the impedance is short circuit -> Remove bridge connectors between Y Drive Assy and Scan A or

B Assy and check it again at Y drive, Scan A and Scan B Assy.

Short circuit on Scan A Assy -> Scan IC on Scan A Assy is defective

Short circuit on Scan B Assy -> Scan IC on Scan B Assy is defective

Short circuit on Y Drive Assy -> Defective of Y Drive Assy

3. Voltage check with power on condition before PD is working

Vsus voltage is not going up to around 200 V -> Defective of Power Supply Assy

VH voltage is not going up to around 130 V -> Defective of DC-DC converter on Y Drive Assy

4. Check of Power Down detection circuit

If there is no problem step 1, 2, and 3, both of VH voltage and VSUS voltage are normal, but PD

circuit is working. Therefore PD detection circuit has problem.

-> Replace Y Drive Assy : because detection circuits for 3 times PD are on Y Drive Assy

Page 35

The list of possible defective parts

A

A

35

(Address PD : Red LED blinks 8 times)

Parts# and mark

50 inch 43 inch

HAT1110R

Q1614 etc. Q1609 etc.

UDZS15(B)

D1605 etc. D1620 etc.

EP05FA20

D1634 etc. D1608 etc.

CH1405

C1602 etc. C1602 etc.

2SA1163

Q1613 Q1612

RN1901

Q1612 Q1615

disconnecting connector

CH1422

Description

FET

Zener Diode

Diode

φ10 Chemical

Condenser

Transistor

Digital Transistor

FFC disconnecting connector

Defective mode

Short or Open between

D(Drain) and S(Source)

Short or Open

Short or Open

Short

Short or Open

Short or Open

Page 36

・

B

Q

p

.

36

lock diagram of the shutdown signal

Note:

The figures ① - ⑤ indicate the

number of times the LED flashes

when sutdown occurs in the

corres

onding route

HD DIGITAL ASSY

HD AUDIO ASSY

D3

A2

IC3504

AMP

IC3754

EEPROM

IC3753

VOLUME IC

A_NG

⑤

IC3157

DAC IC

IC3001

DVI REIVER

・Diagnosis of shutdown

TXD_SQ

RXD_SQ

CLK_SQ

BUSY S

②

SCL

SDA

CE_SQ

IC3401

sequence

processor

①

IC5201

Module Ucom

RST2

③

IC3303

OR

②

E_SCL

E_SDA

TEMP1

IC3302

3.3V-RST

IC3304

1.2V-RST

IC3156

EEPROM

④

TEMP SENSOR

IC3158

Number of

flashes

1 time

2 tim es

3 tim es

4 times

5 tim es

SD Cirsuit in Operation Defective Assy Reason for Shutdown

Communication fai lure of IC3401

Communication fai lure

of the driving processor

Communication fai lure

of the IICline (C heck the

SD subcategory on the

Factory Menu.)

Power failure of the

drivi ng proc es sor

(RST2)

Abnormally hig h

temperature of the pa n el

Audi o f a ilure

HD DIGITAL

HD DIGITAL

HD AUDIO

HD DIGITAL

POWER SUPPLY the 8-V power supply is not activated.

HD AUDIO Defective AMP IC HD AUDIO ASSY IC3751

HD AUDIO Disconnection of connectors A1- P5

Writing failur e of IC3401

Communicatio n fai lure of the EEPROM

(for retaining 4-Kbyte of data)

Communication error of DAC IC MODULE UCOM BLOC

Communication error of DVI Re ceiver IC TMDS RX BLOC

Communicatio n fai lure of the EEPROM

(for retaining 4-Kbyte of data)

Disconnection of connectors A2-D3

Defective volume IC HD AUDIO ASSY IC3753

Defective DC-DC converter DIGITAL DD CON BLOCKU3601

Defective RST IC PANEL FLASH BL OCK IC3302-IC3304

Defective IC3401 SQ ASIC BLOCK IC3401

Abnormally high temperature of the panel Ambient temperature

Grounding fault of speaker out puts

Point to be checked

SQ ASIC BLOCK,

PANEL FLASH BLOC

MODULE UCOM BLOCK IC3156

K IC3001

PANEL IF BL OCK IC3754

Defective Part

IC3401, IC3301

K

K IC3157

Possidle

Remarks

Check if versi on data can be

read,using the

"GS1"command,after the

power is turned on again.

Check if the connectors are

disconn ec te d or are not

connecte d secu r el

Check if 3.3-V and 1.5-V

power supplies are activated.

Check if the 8-V power is

supplied at Pin 1 of the D11

connector.

The pane l wil l be shutdown i

the senso r de tec ts temperature

of 75℃ or higher (for the

PDP-436P/-506P

Check if the speaker cables

are in contact with the

chassis,etc.

Check if connectors are

disconn ent ed or are not

connecte d secu r ely.

y.

).

f

Page 37

- Attention point for repair

37

Since G6 Audio IC is BLT type of Power IC as same as G4 and G5 Audio IC,

both of speaker outputs ( plus and minus ) always have about 7 V DC.

Therefore do not short between speaker minus and GND like the following figure.

Otherwise Power IC or a measuring equipment may have damege.

CH1 CH2

Both of SP OUT+ and -

have about 7V

Measuring

point

GND

LA4625

Example of error measurement

( GND and SP OUT " - " are shorted onto measuring instrument. )

- Assumed Power Down and Shut Dowon caused by AUDIO Assy

Cable becomes disconnected ( A2<-> D3) or IIC communication

error including VOL IC defective.

Cable becomes disconneced ( A1<-> P5 ) or working DC

detection circuit at SP output.

Short circuit between Power line (16.5 V ) - GND

( In case of power on operation during the problem has occurred )

Short circuit between Power line (16.5 V ) - GND

( During normal operation )

Short circuit between power line (+3.3V_D)- GND

( During normal operation )

Short circuit between power line (+3.3V_D)- GND

( In case of power on operation during the problem has occurred )

+

-

Number of PD / SDMain reason of PD or SD

SD (Blue 2 times )

SD (Blue 5 times )

PD (Red 2 times )

PD (Red 4 times )

PD ( Red 13 times)

SD ( Blue 3 times )

NOTE: The above number of PD and SD are not always the reasons in the above lis

t

Page 38

OPERATION WHEN THE MEDIA RECEIVER IS NOT CONNECTED

38

As the connection conditions of the system cables (MDR cable, DVI cable) are usually detected, if no connection, such as cable

disconnection, is detected, a warning indication (alternate flashing of the red and blue areas) is displayed on the mask screen, and the red

and blue LEDs flash alternately. Then after about 30 seconds, the power is automatically turned off.

BlueBlue

Alternate flashing at intervals of about 1 second

To operate the panel without the Media Receiver, there are the following two ways:

1. Operation-without-the-Media-Receiver mode

Input the "SYS S00" RS232C command. The status of the LEDs changes to that in normal operation mode.

Note: Turning the AC switch to OFF then ON also maintains this mode. However, once the unit is connected with the Media Receiver using

the System cable, this mode is automatically canceled.

2. DVI mode

Turn the unit on while DVI SG signals are being input with only the DVI connecter connected. After a warning is displayed for about 5

seconds, the unit is ready to display the screen of the input signal. (Blue LED lit)

Notes: • Although the output from XGA (43 inch) and WXGA (50 inch) can be input to the unit, this is not a mode open to general users.

(With some signals, errors such as power-down may occur.)

REDREDRED

Page 39

POWER ON/OFF FUNCTION FOR THE LARGE-SIGNAL SYSTEM

39

Note: This will shut down the 200v (VSUS Supply to the X & Y Drive assy's)

and shut down the 60v line to the Address assy's.

Function: To prevent a power-down from being generated, operation of only the digital-signal processing and audio circuits

are enabled, and power is not supplied to the panel driving system (large-signal system).

Usages: 1. In a case where a check is required of signals' being correctly output to the driving systems during a repair, etc.

2. In a case where diagnosis is required for judging whether the power to the large-signal system or small-signal

system has been down when a power-down occurred

3. In a case where rewriting of the microcomputer is required

Methods: 1. Short-circuit the points (see Fig. 4 below) on the face and on the reverse side of the HD DIGITAL Assy.

2. Issue the "DRV S00" RS-232C command. (Command for turning the function off: DRV S01)

Notes: • When the power to the large-signal system is off, as the PD signal is muted, power-downs other than PS_PD are

not activated.

• As soon as the clips are removed while the power to the large-signal system is off, a power-down will occur.

Be sure to turn the power off before removing the clips.

• While this function is activated with RS-232C commands, it is possible to issue "DRV S01" (for turning the

function off) while the power is on. However, as it may damage the unit, turn the power off before issuing the

"DRV S01" command.

• Although the "DRV S00/S01" RS-232C commands are valid during Standby mode, once the main power is

turned off, the unit will return to "DRV S01."

Position of DRIVE OFF

Short-circuit the face and the

reverse side, using clips, etc.

Note: It is recommended to use clips like

those shown here rather than alligator clips,

because alligator clips may not reach the

copper foil of the board.

Page 40

ADJUSTMENT

40

1. At shipment, the unit is adjusted to its best conditions. Normally, it is not necessary to readjust even if an assembly is replaced. If the

adjustment is shifted or if it becomes necessary to readjust because of part replacement, etc., perform the adjustment as described below.

2. Any value changed in Service/Factory mode will be stored in memory as soon as it is changed. Before readjustment, take note of the

original values for reference in case you need to restore the original settings.

3. Use a stable AC power supply.

ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED

When any of the following assemblies is replaced

POWER SUPPLY Unit No adjustment required

DIGITAL VIDEO Assy

50 X DRIVE Assy No adjustment required

50 Y DRIVE Assy No adjustment required

Service Panel

Other assemblies

Writing of backup data is required.

Refer to the "BACKUP WHEN THE MAIN UNIT IS

ADJUSTED. "

Refer to the "6.3 METHOD FOR REPLACING THE SERVICE

PANEL ASSY."

No adjustment required

When any part in the following assemblies is replaced

POWER SUPPLY Unit

DIGITAL VIDEO Assy No adjustment required

50 X DRIVE Assy

The assembly must be replaced as a unit, and no part

replacement is allowed.

No adjustment required

50 Y DRIVE Assy

Other assemblies No adjustment required

No adjustment required

Page 41

METHOD FOR REPLACING THE SERVICE PANEL ASSY

41

When the Panel Assy is replaced with one for service, the following adjustments are required:

Adjustments of Vofs voltage and Vyprst voltage

Enter the reference adjustment values for the Vofs voltage and Vyprst voltage that are written on the label attached to the

panel for service.

Note: Enter the values, using an RS-232C command or the Factory Menu.

AWU∗∗∗∗

Vofs = 35V Vyprst = 270V

Hour Meter HSpace

AWU∗∗∗∗

Vofs = 35V Vyprst = 270V

Hour Meter H1520

(Rear of the Panel)

Write in the value for the hour

meter when the Panel is

Using an RS-232C command

replaced (ex. 1520H).

Enter a "PFY" command with Factory mode ON.

Convert the adjustment voltage values written on the label attached at the rear of the Panel to an input command, referring to

the conversion chart. (See the next page.)

• Reference adjustment of the Vofs voltage: Ex. "Vofs = 35" → (Check the conversion chart.) Enter "VOF112."

• Reference adjustment of the Vyprst voltage: Ex. 50-inch "Vyprst = 170 V" → (Check the conversion chart.) Enter "VRP055."

(Note that the conversion charts for 50-inch and 43-inch Panels are different.)

Using the Factory Menu

1

5

10

15

16

15 10 15 20 25 30 32

A.PNEL

AJ(+)PNEL–1AD

V–D1 1 1160 –NTV HJ–S6FACT

L/1[BT60VS

]

1

5

10

15

16

Select the main item "PANEL FACT." by pressing the MUTE key then enter Panel Factory mode by pressing the SET key.

Using the 5/∞ keys, select "PANEL-1 ADJ" then press the SET key to enter the next lower nested layer.

Select "VOL-OFFSET" or "VOL RST P" then enter a command value converted from the voltage value, using the 2/3 keys.

15 10 15 20 25 30 32

A.PNEL

AJPNEL–1AD

O <=>VLRSTP

V–D1 1 1160 –NTV HJ–S6FACT

L/1[BT60VS

5:0 8

]

Clearing data on various histories of the Panel, such as those on the hour meter

• It is necessary to clear the data on the hour meter, etc. to match them to the actual driving hours of the Panel.

• It is also necessary to clear the data on SD and PD, because the accumulated power-on time when a shutdown or powerdown occurred is recorded.

Note: Clear the values, using an RS-232C command or the Factory Menu.

There are two types of hour meters. Do not take the MR hour meter for the hour meter.

Using an RS-232C command

To acquire the accumulated power-on time of the product itself, use the "GS2" RS-232C command. (See "6.5 Outline of

Commands.")

1 To clear the data on the hour meter (for the Panel) : CHM

2 To clear the data on the pulse meter : CPM

3 To clear the data on the SD history : CSD

4 To clear the data on the PD history : CPD

Using the Factory Menu

1

5

10

15

16

15 10 15 20 25 30 32

A.PNEL

T+EC. ( )

V–D1 1 1160 –NTV HJ–S6FACT

L/1[BT60VS

]

1

5

10

15

16

In Panel Factory mode, select "ETC" with the 5/∞ keys then press the SET key. Select "HR-MTR INFO" with the 5/∞ keys.

Select "CLEAR" with the 2/3 keys then press and hold the SET key for 5 seconds. (The menu automatically returns to the item "ETC".)

In the same manner, clear the data by selecting the subcategory items "PM/B1-B5," "PD INFO," and "SD INFO" under "ETC."

15 10 15 20 25 30 32

A.PNEL

TEC.

RO.<=>H- TMR NIF

V–D1 1 1160 –NTV HJ–S6FACT

L/1[BT60VS

O:N

]

Page 42

<Conversion charts for electronic VRs:Conversion chart for the Vofs>

42

Conversion chart for the Vofs

(Commands vs. common voltage values for the 50-inch and 43-inch models)

Command

VOF000 14.09 VOF056 24.55 VOF112 35.01 VOF168 45.47 VOF224 55.93

VOF001 14.28 VOF057 24.74 VOF113 35.20 VOF169 45.66 VOF225 56.12

VOF002 14.46 VOF058 24.92 VOF114 35.38 VOF170 45.85 VOF226 56.31

VOF003 14.65 VOF059 25.11 VOF115 35.57 VOF171 46.03 VOF227 56.49

VOF004 14.84 VOF060 25.30 VOF116 35.76 VOF172 46.22 VOF228 56.68

VOF005 15.02 VOF061 25.48 VOF117 35.95 VOF173 46.41 VOF229 56.87

VOF006 15.21 VOF062 25.67 VOF118 36.13 VOF174 46.59 VOF230 57.05

VOF007 15.40 VOF063 25.86 VOF119 36.32 VOF175 46.78 VOF231 57.24

VOF008 15.58 VOF064 26.04 VOF120 36.51 VOF176 46.97 VOF232 57.43

VOF009 15.77 VOF065 26.23 VOF121 36.69 VOF177 47.15 VOF233 57.61

VOF010 15.96 VOF066 26.42 VOF122 36.88 VOF178 47.34 VOF234 57.80

VOF011 16.14 VOF067 26.61 VOF123 37.07 VOF179 47.53 VOF235 57.99

VOF012 16.33 VOF068 26.79 VOF124 37.25 VOF180 47.71 VOF236 58.17

VOF013 16.52 VOF069 26.98 VOF125 37.44 VOF181 47.90 VOF237 58.36

VOF014 16.70 VOF070 27.17 VOF126 37.63 VOF182 48.09 VOF238 58.55

VOF015 16.89 VOF071 27.35 VOF127 37.81 VOF183 48.27 VOF239 58.73

VOF016 17.08 VOF072 27.54 VOF128 38.00 VOF184 48.46 VOF240 58.92

VOF017 17.27 VOF073 27.73 VOF129 38.19 VOF185 48.65 VOF241 59.11

VOF018 17.45 VOF074 27.91 VOF130 38.37 VOF186 48.83 VOF242 59.30

VOF019 17.64 VOF075 28.10 VOF131 38.56 VOF187 49.02 VOF243 59.48

VOF020 17.83 VOF076 28.29 VOF132 38.75 VOF188 49.21 VOF244 59.67

VOF021 18.01 VOF077 28.47 VOF133 38.93 VOF189 49.39 VOF245 59.86

VOF022 18.20 VOF078 28.66 VOF134 39.12 VOF190 49.58 VOF246 60.04

VOF023 18.39 VOF079 28.85 VOF135 39.31 VOF191 49.77 VOF247 60.23

VOF024 18.57 VOF080 29.03 VOF136 39.49 VOF192 49.96 VOF248 60.42

VOF025 18.76 VOF081 29.22 VOF137 39.68 VOF193 50.14 VOF249 60.60

VOF026 18.95 VOF082 29.41 VOF138 39.87 VOF194 50.33 VOF250 60.79

VOF027 19.13 VOF083 29.59 VOF139 40.05 VOF195 50.52 VOF251 60.98

VOF028 19.32 VOF084 29.78 VOF140 40.24 VOF196 50.70 VOF252 61.16

VOF029 19.51 VOF085 29.97 VOF141 40.43 VOF197 50.89 VOF253 61.35

VOF030 19.69 VOF086 30.15 VOF142 40.62 VOF198 51.08 VOF254 61.54

VOF031 19.88 VOF087 30.34 VOF143 40.80 VOF199 51.26 VOF255 61.72

VOF032 20.07 VOF088 30.53 VOF144 40.99 VOF200 51.45

VOF033 20.25 VOF089 30.71 VOF145 41.18 VOF201 51.64

VOF034 20.44 VOF090 30.90 VOF146 41.36 VOF202 51.82

VOF035 20.63 VOF091 31.09 VOF147 41.55 VOF203 52.01

VOF036 20.81 VOF092 31.28 VOF148 41.74 VOF204 52.20

VOF037 21.00 VOF093 31.46 VOF149 41.92 VOF205 52.38

VOF038 21.19 VOF094 31.65 VOF150 42.11 VOF206 52.57

VOF039 21.37 VOF095 31.84 VOF151 42.30 VOF207 52.76

VOF040 21.56 VOF096 32.02 VOF152 42.48 VOF208 52.94

VOF041 21.75 VOF097 32.21 VOF153 42.67 VOF209 53.13

VOF042 21.94 VOF098 32.40 VOF154 42.86 VOF210 53.32

VOF043 22.12 VOF099 32.58 VOF155 43.04 VOF211 53.50

VOF044 22.31 VOF100 32.77 VOF156 43.23 VOF212 53.69

VOF045 22.50 VOF101 32.96 VOF157 43.42 VOF213 53.88

VOF046 22.68 VOF102 33.14 VOF158 43.60 VOF214 54.06

VOF047 22.87 VOF103 33.33 VOF159 43.79 VOF215 54.25

VOF048 23.06 VOF104 33.52 VOF160 43.98 VOF216 54.44

VOF049 23.24 VOF105 33.70 VOF161 44.16 VOF217 54.63

VOF050 23.43 VOF106 33.89 VOF162 44.35 VOF218 54.81

VOF051 23.62 VOF107 34.08 VOF163 44.54 VOF219 55.00

VOF052 23.80 VOF108 34.26 VOF164 44.72 VOF220 55.19

VOF053 23.99 VOF109 34.45 VOF165 44.91 VOF221 55.37

VOF054 24.18 VOF110 34.64 VOF166 45.10 VOF222 55.56

VOF055 24.36 VOF111 34.82 VOF167 45.29 VOF223 55.75

Voltage value[V]

for common sizes

Common

Voltage value[V]

for common sizes

Common

Voltage value[V]

for common sizes

Command

Voltage value[V]

for common sizes

Command

Voltage value[V]

for common sizes

Page 43

43

<Conversion charts for electronic VRs:Conversion chart for the Vyprst>

Common

VRP000

VRP001

VRP002

VRP003

VRP004

VRP005

VRP006

VRP007

VRP008

VRP009

VRP010

VRP011

VRP012

VRP013

VRP014

VRP015

VRP016

VRP017

VRP018

VRP019

VRP020

VRP021

VRP022

VRP023

VRP024

VRP025

VRP026

VRP027

VRP028

VRP029

VRP030

VRP031

VRP032

VRP033

VRP034

VRP035

VRP036

VRP037

VRP038

VRP039

VRP040

VRP041

VRP042

VRP043

VRP044

VRP045

VRP046

VRP047

VRP048

VRP049

VRP050

VRP051

VRP052

VRP053

VRP054

VRP055

Conversion chart for the Vyprst

(Commands vs. voltage values for the 50-inch and 43-inch models)1/2

voltage[V]5

0-inch

modele

246.3 236.3

246.7 236.7

247.1 237.1

247.6 237.6

248.0 238.0

248.4 238.4

248.9 238.9

249.3 239.3

249.7 239.7

250.2 240.2

250.6 240.6

251.0 241.0

251.5 241.5

251.9 241.9

252.4 242.4

252.8 242.8

253.2 243.2

253.7 243.7

254.1 244.1

254.5 244.5

255.0 245.0

255.4 245.4

255.8 245.8

256.3 246.3

256.7 246.7

257.1 247.1

257.6 247.6

258.0 248.0

258.4 248.4

258.9 248.9

259.3 249.3

259.7 249.7

260.2 250.2

260.6 250.6

261.0 251.0

261.5 251.5

261.9 251.9

262.3 252.3

262.8 252.8

263.2 253.2

263.6 253.6

264.1 254.1

264.5 254.5

264.9 254.9

265.4 255.4

265.8 255.8

266.3 256.3

266.7 256.7

267.1 257.1

267.6 257.6

268.0 258.0

268.4 258.4

268.9 258.9

269.3 259.3

269.7 259.7

270.2 260.2

voltage[V]4

3-inch

modele

Common

VRP056

VRP057

VRP058

VRP059

VRP060

VRP061

VRP062

VRP063

VRP064

VRP065

VRP066

VRP067

VRP068

VRP069

VRP070

VRP071

VRP072

VRP073

VRP074

VRP075

VRP076

VRP077

VRP078

VRP079

VRP080

VRP081

VRP082

VRP083

VRP084

VRP085

VRP087

VRP088

VRP089

VRP090

VRP091

VRP092

VRP093

VRP094

VRP095

VRP096

VRP097

VRP098

VRP099

VRP100

VRP101

VRP102

VRP103

VRP104

VRP105

VRP106

VRP107

VRP108

VRP109

VRP110

VRP111

VRP112

voltage[V]5

0-inch

modele

270.6 260.6

271.0 261.0

271.5 261.5

271.9 261.9

272.3 262.3

272.8 262.8

273.2 263.2

273.6 263.6

274.1 264.1

274.5 264.5

274.9 264.9

275.4 265.4

275.8 265.8

276.2 266.2

276.7 266.7

277.1 267.1

277.5 267.5

278.0 268.0

278.4 268.4

278.9 268.9

279.3 269.3

279.7 269.7

280.2 270.2

280.6 270.6

281.0 271.0

281.5 271.5

281.9 271.9

282.3 272.3

282.8 272.8

283.2 273.2

284.1 274.1

284.5 274.5

284.9 274.9

285.4 275.4

285.8 275.8

286.2 276.2

286.7 276.7

287.1 277.1

287.5 277.5

288.0 278.0

288.4 278.4

288.8 278.8

289.3 279.3

289.7 279.7

290.1 280.1

290.6 280.6

291.0 281.0

291.4 281.4

291.9 281.9

292.3 282.3

292.8 282.8

293.2 283.2

293.6 283.6

294.1 284.1

294.5 284.5

294.9 284.9

voltage[V]4

3-inch

modele

Common

VRP113

VRP114

VRP115

VRP116

VRP117

VRP118

VRP119

VRP120

VRP121

VRP122

VRP123

VRP124

VRP125

VRP126

VRP127

VRP128

VRP129

VRP130

VRP131

VRP132

VRP133

VRP134

VRP135

VRP136

VRP137

VRP138

VRP139

VRP140

VRP141

VRP142

VRP143

VRP144

VRP145

VRP146

VRP147

VRP148

VRP149

VRP150

VRP151

VRP152

VRP153

VRP154

VRP155

VRP156

VRP157

VRP158

VRP159

VRP160

VRP161

VRP162

VRP163

VRP164

VRP165

VRP166

VRP167

VRP168

voltage[V]50-

inch modele

295.4 285.4

295.8 285.8

296.2 286.2

296.7 286.7

297.1 287.1

297.5 287.5

298.0 288.0

298.4 288.4

298.8 288.8

299.3 289.3

299.7 289.7

300.1 290.1

300.6 290.6

301.0 291.0

301.4 291.4

301.9 291.9

302.3 292.3

302.7 292.7

303.2 293.2

303.6 293.6

304.0 294.0

304.5 294.5

304.9 294.9

305.3 295.3

305.8 295.8

306.2 296.2

306.7 296.7

307.1 297.1

307.5 297.5

308.0 298.0

308.4 298.4

308.8 298.8

309.3 299.3

309.7 299.7

310.1 300.1

310.6 300.6

311.0 301.0

311.4 301.4

311.9 301.9

312.3 302.3

312.7 302.7

313.2 303.2

313.6 303.6

314.0 304.0

314.5 304.5

314.9 304.9

315.3 305.3

315.8 305.8

316.2 306.2

316.6 306.6

317.1 307.1

317.5 307.5

317.9 307.9

318.4 308.4

318.8 308.8

319.2 309.2

voltage[V]43-

inch modele

Page 44

Conversion chart for the Vyprst (Commands vs. voltage

44

values for the 50-inch and 43-inch models)2/2

Common

VRP169

VRP170

VRP171

VRP172

VRP173

VRP174

VRP175

VRP176

VRP177

VRP178

VRP179

VRP180

VRP181

VRP182

VRP183

VRP184

VRP185

VRP186

VRP187

VRP188

VRP189

VRP190

VRP191

VRP192

VRP193

VRP194

VRP195

VRP196

VRP197

VRP198

VRP199

VRP200

VRP201

VRP202

VRP203

VRP204

VRP205

VRP206

VRP207

VRP208

VRP209

VRP210

VRP211

VRP212

VRP213

VRP214

VRP215

VRP216

VRP217

VRP218

VRP219

VRP220

VRP221

VRP222

VRP223

VRP224

voltage[V]50-

inch modele

319.7 309.7

320.1 310.1

320.6 310.6

321.0 311.0

321.4 311.4

321.9 311.9

322.3 312.3

322.7 312.7

323.2 313.2

323.6 313.6

324.0 314.0

324.5 314.5

324.9 314.9

325.3 315.3

325.8 315.8

326.2 316.2

326.6 316.6

327.1 317.1

327.5 317.5

327.9 317.9

328.4 318.4

328.8 318.8

329.2 319.2

329.7 319.7

330.1 320.1

330.5 320.5

331.0 321.0

331.4 321.4

331.8 321.8

332.3 322.3

332.7 322.7

333.2 323.2

333.6 323.6

334.0 324.0

334.5 324.5

334.9 324.9

335.3 325.3

335.8 325.8

336.2 326.2

336.6 326.6

337.1 327.1

337.5 327.5

337.9 327.9

338.4 328.4

338.8 328.8

339.2 329.2

339.7 329.7

340.1 330.1

340.5 330.5

341.0 331.0

341.4 331.4

341.8 331.8

342.3 332.3

342.7 332.7

343.1 333.1

343.6 333.6

voltage[V]43-

inch modele

Common

VRP225

VRP226

VRP227

VRP228

VRP229

VRP230

VRP231

VRP232

VRP233

VRP234

VRP235

VRP236

VRP237

VRP238

VRP239

VRP240

VRP241

VRP242

VRP243

VRP244

VRP245

VRP246

VRP247

VRP248

VRP249

VRP250

VRP251

VRP252

VRP253

VRP254

VRP255

voltage[V]50-

inch modele

344.0 334.0

344.4 334.4

344.9 334.9

345.3 335.3

345.7 335.7

346.2 336.2

346.6 336.6

347.1 337.1

347.5 337.5

347.9 337.9

348.4 338.4

348.8 338.8

349.2 339.2

349.7 339.7

350.1 340.1

350.5 340.5

351.0 341.0

351.4 341.4

351.8 341.8

352.3 342.3

352.7 342.7

353.1 343.1

353.6 343.6

354.0 344.0

354.4 344.4

354.9 344.9

355.3 345.3

355.7 345.7

356.2 346.2

356.6 346.6

357.0 347.0

voltage[V]43-

inch modele

Page 45

BACKUP WHEN THE MAIN UNIT IS ADJUSTED

45

Outline

Adjustment data set at the factory are stored in the EEPROM (IC****/4K) on the HD DIGITAL Assy. Those adjustment data are

automatically backed up in the EEPROM (backup EEPROM: IC****) on the HD AUDIO Assy. Therefore, even if the HD DIGITAL Assy

is replaced, the adjustment data can be restored by copying the backup data, which enables you to omit newly performing adjustments on

the main unit.

Data to be backed up

• Voltage margin adjustment values

• Data on the hour meter

• Upper limit of power-adjustment value

• Data on the pulse meter

• Panel WB adjustment values

• Serial number

• Drive waveform adjustment values

• Data of the P-ON counter

• PD/SD histories

How to copy the backup data

1. When the HD DIGITAL Assy is replaced with that for service (normal servicing)

(In a case where no data are on the DIG. EEP, and backup data have been adjusted)

Command: "BCP" (Effective during FAY)

Factory Menu

PANEL INFORMATION

∞ (down)

• • •

∞ (down)

ETC. (+)

[set]

BACKUP DATA: NO OPRT

>> (right)

BACKUP DATA: TRANSFER

[set] (Press and hold for 5 seconds.)

2. In a case where a HD DIGITAL Assy that was mounted on another unit is to be reused as a service part.

Command: "FAJ" (Effective during FAY)

Factory Menu: PANEL FACT => ETC => DIGITAL EEPROM: DELETE

PANEL INFORMATION

∞ (down)

• • •

∞ (down)

ETC. (+)

[set]

BACKUP DATA: NO OPRT

∞ (down)

DIGITAL EEPROM: NO OPRT

>> (right)

DIGITAL EEPROM: REPAIR

[set] (Press and hold for 5 seconds.)

• If this command is not executed, the red LED lights, and the blue LED flashes,

to warn you that copying of the backup adjustment data for the main unit failed.

• If both the HD DIGITAL Assy and HD AUDIO Assy are to be replaced, first replace

the HD AUDIO Assy and set the unit to Standby mode. Then replace the HD

DIGITAL Assy.

• If the HD DIGITAL Assy of Unit 1 is mounted to be reused in Unit 2 to be

repaired, and Unit 2 enters Standby mode, the adjustment data and histories

stored in Unit 1 are erased, and those of Unit 2 are copied. Once overwritten,

the original data will not be restored. After the Assy is replaced, be sure to enter

Factory mode, using the remote control unit for servicing, and perform the

procedures described herein. Or, before mounting an Assy to be reused as a

service Assy, perform these procedures then mount it on the product to be

repaired.

Page 46

3. In a case where the HD DIGITAL Assy is replaced with one for servicing because of a defective EEPROM on the original Assy and

46

manual adjustments are to be performed (in a case where no data are stored in the HD DIGITAL Assy or as backup, and input

adjustment data are to be applied as adjustment data for the main unit)

Command: "UAJ" (Effective during FAY)

Factory Menu

PANEL INFORMATION

∞ (down)

• • •

∞ (down)

ETC. (+)

[set]

BACKUP DATA: NO OPRT

∞ (down)

DIGITAL EEPROM: NO OPRT

>> (right)

DIGITAL EEPROM: REPAIR

[set] (Press and hold for 5 seconds.)

• If the HD DIGITAL Assy with which adjustment data for the main unit have been copied is mounted,

the above procedures are not necessary after manual adjustment.

(The indication "DIGITAL EEPROM: REPAIR" will not be displayed.)

Page 47

HOW TO CLEAR THE HISTORY

47

Clearing data on various histories when the HD DIGITAL Assy is replaced

Other than adjustment data for the main unit, data to be backed up include the accumulated power-on time and a history of defective parts,

which are data updated and stored in memory. Among those data, some are required to be cleared when the HD DIGITAL Assy is replaced

for servicing, as shown below:

Type of servicing

Item Backed-up data

Hour meter Accumulated display To be cleared Not to be cleared

Point where an SD

SD history

PD history

Pulse meter

Accumulated number

of power-ons

Notes:

1: With the PDP-506P/436P and subsequent models, because various compensation functions use pulse-meter data for calculating

compensation values, if related Assys are replaced, data on various histories must be cleared.

2: To clear data using RS-232C commands, after entering Factory mode (by sending FAY or PFY), issue a corresponding command.

Otherwise, the command will not be executed.

occurred and data on the

hour meter

Point where a PD

occurred and data on the

hour meter

Accumulated number of

pulses of the Panel (5

blocks)

Accumulated number of

RELAY_ONs

Panel

replacement

To be cleared Not to be cleared

To be cleared Not to be cleared

To be cleared

(essential)

Not to be

cleared

Replacement of the

power-supply block

Not to be cleared

To be cleared

(essential)

Others

Not to be

cleared

Not to be

cleared

Not to be

cleared

Not to be

cleared

Not to be

cleared

RS-232C

command

CHM

CSD

CPD

CPM

CPC

How to clear the history for each item on the Factory Menu

Start point of Panel Factory

PANEL INFORMATION

∞ (down)

• • •

∞ (down)

ETC. (+)

[set]

BACKUP DATA

∞ (down)

DIGITAL EEPROM

∞ (down)

Clearing the PD history

PD INFO: NO OPRT

∞ (down)

>> (right)

PD INFO: CLEAR

[set] (Press and hold for 5 seconds.)

Clearing the SD history

Clearing the data on the

hour meter

Clearing the data on the

pulse meter

Clearing the data on the

number of power-ons

SD INFO: NO OPRT

∞ (down)

HR-MTR INFO: NO OPRT

∞ (down)

PM/B1-BS INFO: NO OPRT

∞ (down)

P COUNT INFO: NO OPRT P COUNT INFO: CLEAR

>> (right)

>> (right)

>> (right)

>> (right)

SD INFO: CLEAR

[set] (Press and hold for 5 seconds.)

HR-MTR INFO: CLEAR

[set] (Press and hold for 5 seconds.)

PM/B1-BS INFO: CLEAR

[set] (Press and hold for 5 seconds.)

[set] (Press and hold for 5 seconds.)

Page 48

OVERVIEW OF PANEL FACTORY MODE

48

Top screen of the Factory Menu

MR INFORMATION

< MUTE > key

FUNC. CHECK

< MUTE > key

COMMON ADJ.

< MUTE > key

PANEL FACTORY

< SET > key

If a Panel of Generation 6 is connected,

1

5

10

15

16

15 10 15 20 25 30 32

AREA

A.PNEL

1

APNEL NIFORAM

2

3

OMDULE –01 MS0S1

4

ESQ–PGR–01MA

5

QS–DTV–520W

6

QS–DTP–520W

7

8

ESRIAL ___ ____________

9

A

IDG.E PEADJSUTDE

B

ABCKUP NO ADT !A

C

D

E

I–N1 5 2060 –RGB HE–S6FACT

TION

0A2

1024 x 672

Note: With this model, the structure of Factory mode has been changed, and all items related to the Panel are

gathered into PANEL FACTORY mode.

"6" is indicated here.

Page 49

7 Configuration of Panel Factory mode

49

No.

1 PANEL INFORMATION

2 PANEL WORKS

3 POWER DOWN

4 SHUT DOWN

5 PANEL-1 ADJ (+)

5-1 X-SUS B <=> 120 to 136 Equivalent to XSB

5-2 Y-SUS B <=> 120 to 136 Equivalent to YSB

5-3 Y-SUSTAIL T <=> 120 to 136 Equivalent to YTG

5-4 Y-SUSTAIL W <=> 120 to 136 Equivalent to YTW

5-5 XY-RST W <=> 120 to 136 Equivalent to RSW

5-6 VOL SUS <=> 000 to 255 Equivalent to VSU

5-7 VOL OFFSET <=> 000 to 255 Equivalent to VOF

5-8 VOL RST P <=> 000 to 255 Equivalent to VRP

5-9 SUS FREQ. <=> MODE1 to MODE8 Equivalent to SFR

6 PANEL-2 ADJ (+)

6-1 R-HIGH <=> 000 to 511 Equivalent to PRH

6-2 G-HIGH <=> 000 to 511 Equivalent to PGH

6-3 B-HIGH <=> 000 to 511 Equivalent to PBH

6-4 R-LOW <=> 000 to 999 Equivalent to PRL

6-5 G-LOW <=> 000 to 999 Equivalent to PGL

6-6 B-LOW <=> 000 to 999 Equivalent to PBL

6-7 ABL <=> 000 to 255 Equivalent to ABL

7 PANEL REVISE

7-1 R-LEVEL <=> LV-0 to LV-7 Equivalent to RRL

7-2 G-LEVEL <=> LV-0 to LV-7 Equivalent to RGL